Page 1

Installation Instructions

Sartorius Explosion-protected Weigh Cells

Models WZA...-NX

98648-020-60

Page 2

Contents User Information

Warnings and Safety Precautions

User Information ............... 2

Warnings and Safety Precautions . . 2

General View of the Equipment .... 4

Installation ................... 5

Storage and Shipping Conditions ... 5

Incoming Inspection ............. 5

Equipment Supplied ............. 5

Ambient Conditions ............. 5

Components Attached

to the Load Receptor ............ 5

Connecting an Optional Display

and Control Unit ............... 5

Conditions for Installation ........ 6

Connecting an Equipotential

Bonding Conductor ............. 7

Connecting the Weigh Cell

to AC Power ................... 7

Leveling the Load Receptor ........ 8

Leveling the Weigh Cell .......... 9

Operation

Notes on Analytical Weighing ......10

Below-Cell Weighing ............11

Factory Settings ................12

Parameter Settings (Overview) ......14

RS-232 Interface Port ...........17

Pin Assignment Chart ............24

Troubleshooting Guide ...........25

Overview .....................26

Specifications ..................26

Dimensions (Scale Drawings) .......27

Accessories (Options) ............30

EC / EU Declaration of Conformity . . 31

FCC Supplier’s Declaration

of Conformity ..................33

EC-Type Examination Certificate

(FM Approvals) .................34

IECEx Certificate of Conformity ....37

Safety Instructions ..............41

Verification of the Intrinsic Safety ...42

Form: Return delivery ............48

Declaration about decontamination

2

. . 49

Warning / Danger Symbols

These notes identify hazards

which have a high probability of

physical injury if not avoided.

Explanation of Symbols

The following symbols are used in these

− Texts that use this mark are lists

Conventions for these Instructions:

The figures in these instructions are based

About These Instructions.

resulting in death or serious

These notes identify hazards that

can result in moderate or mild

injuries if not avoided.

These notes identify hazards

associated with the risk of

material damage.

This symbol identifies useful

information and tips.

instructions:

t indicates required steps.

y describes what happens after you have

performed a particular step

on “standard” scales. On scales verified

for use in legal metrology, some displays and

from the figures.

cant for operation, the differences will

be explained in the text.

t Please read these instructions carefully

and completely before putting the

equipment into operation for the first

time. Observe the safety instructions.

t These instructions are an important part

of the product. Keep these instructions

in a safe place. If you give the device to

others to use, give them these instructions too.

t If these instructions are lost, please

contact Sartorius for a replacement or

download the latest manual from our

website: www.sartorius.com

reports may deviate slightly

Where this is signifi-

System Description

− The product is comprised of two

components:

− Compact weigh cell that can be affixed

to a smooth, even surface

− Electronics module

− These compact weigh cells can be used

to determine weights within restricted

space.

− The weigh cells have been developed for

− Installation in measuring devices and

production machinery

− High-precision weighing within limited

space

− Precise weight determination on active

production lines

Safety Precautions

− The weigh cell meets the requirements

for Group II, Category 2 equipment in

accordance with EC Directive 94/9/EC

and bears the designation h II 2G Ex

ib IIC T4 Gb and II 2D Ex ib IIIB T80°C

Db in accordance with FM EC typeexamination certificate FM 15ATEX0013X.

− Furthermore, the weigh cell meets

the EC Directives for electromagnetic

compatibility (see the Declaration of

Conformity). Improper use or handling,

however, can result in damage and/or

injury.

− The weigh cell may be used in Zone 1,

2, 21 or 22 hazardous areas or Class 1,

Division 1 or 2 hazardous locations (gas

and dust explosion hazards). Please

make sure the currently valid regulations and guidelines for installing

equipment in the hazardous areas/locations listed above (e.g., EN60079-14)

are strictly observed. Whether the

equipment can be used in a given area

containing potentially explosive agents

must be checked on a case-by-case

basis.

− That way you will prevent damage to

the device.

− These installation instructions describe

only the technological specifications of

the weigh cell and the conditions that

must be observed during installation.

− Read these installation instructions

thoroughly before using your weigh

cell. The weigh cell can be operated

indoors or outdoors.

Any incoming inspection, alterations to the equipment or instal-

lation work that does not conform to the instructions in this manual will

result in forfeiture of all claims under the

manufacturer’s warranty.

If you use electrical equipment

in installations and under ambi-

ent conditions requiring higher

safety standards, you must comply with

the provisions as specified in the applicable

regulations for installation in your country.

t Have the equipment inspected at

appropriate intervals for correct functioning and safety by a trained technician.

Page 3

Always make sure the weigh cell

is disconnected from AC power

before performing any installation, cleaning, maintenance or repair work.

If the equipment housing is opened by

anyone other than persons authorized by

Sartorius, all claims under the manufacturer’s warranty are forfeited. Use only original Sartorius spare parts.

Disconnecting equipotential

bonding conductors is not per-

mitted.

If you see any indication that

the weigh cell cannot be oper-

ated safely (for example, due to

damage), turn off the unit and lock it in a

secure place so that it cannot be used for

the time being. Observe the relevant safety

precautions and inform personnel as

required.

The casing on all connecting

cables, as well as the casing on

wires inside the equipment

housing, is made of PVC. Chemicals that

corrode these materials must be kept away

from these cables.

Make sure the weighing instru-

ment is not exposed to sub-

stances that release chlorine ions

at the place of use. If such exposure

cannot be ruled out, the operator is

responsible for establishing and observing

appropriate safety precautions, to

be checked at regular intervals for continued effectiveness.

The weigh cell may be used and

operated by qualified personnel

only. The permissible use of the

equipment is defined by the equipment

specifications and the relevant safety regulations. Operating the weigh cell beyond

the specifications listed in the typeapproval certificate is not permitted, and

is considered use of the equipment for

other than its intended purpose. All restrictions listed in the type-examination certificate must be strictly observed.

t Once the weigh cell has been installed,

it must be checked to ensure:

− Observance of the guidelines and stand-

ards for using electrical equipment

− Electromagnetic compatibility of the

entire device

− Compliance with mandatory safety reg-

ulations.

− Installation in a Zone 1, 2, 21 or 22

hazardous area or Class 1, Division 1 or

2 hazardous location must be performed by a trained technician who is

familiar with the assembly and operation of the equipment, as well as with

the procedure for putting the system

into operation. Furthermore, the trained

technician must have the required qualifications and must be familiar with the

relevant guidelines and regulations.

If you need assistance, contact the

system installer, your Sartorius dealer or

the Sartorius Service Center.

Any installation work that does not

conform to the instructions in this

manual will result in forfeiture of

all claims under the manufacturer’s

warranty. Be sure to observe all restrictions listed in the type-examination

certificate. Operating the weigh cell

beyond the limits imposed by these

restrictions is not permitted and is considered use of the equipment for other

than its intended purpose.

Always make sure the weigh cell

is disconnected from AC power

before performing any installa-

tion, cleaning, maintenance or repair work.

The electronics module and the

optional YAC01NX display and

control unit may not be opened.

The weigh cell may be opened only by

authorized service technicians who have

been trained by Sartorius and who follow

Sartorius’ standard operating procedures

for maintenance and repair work.

Avoid interchanging weigh cells

and electronics modules.

Connect the parts that fit

together, ensuring that the serial numbers

match.

Be sure to unplug the system

from AC power before connecting or disconnecting any cables.

If you are using the optional

YAC01NX display and control

unit, it must be installed a way

that limits the risk of mechanical damage.

Never open the display and

control unit.

If there is visible damage to the

components: disconnect the

equipment from AC power and

replace the weigh cell along with the electronics module.

If you use cables purchased from

another manufacturer in the

non-hazardous area/location,

check the pin assignments. Before connecting the cable to Sartorius equipment,

check the pin assignments in the cable

against those specified by Sartorius and

disconnect any wires that are assigned

differently. The operator shall be solely

responsible for any damage or injuries that

occur when using cables not supplied by

Sartorius. On request, Sartorius will provide

information on the minimum operating

specifications (in accordance with the

Standards for defined immunity to interference).

When using the weigh cell in

hazardous areas/locations, make

sure there is no current or voltage in the equipment before connecting or

disconnecting current-carrying cables to or

from the weigh cell. Disconnect the weigh

cell from AC power before connecting or

disconnecting cables.

Avoid exposing the weigh cell to static

electricity.

All components of the system

must be grounded, including

any draft shields used. Be sure

to connect an equipotential bonding

conductor.

Do not expose the weigh cell

unnecessarily to extreme tem-

peratures, aggressive chemical

vapors, moisture, temperature fluctuations

or vibrations. The permissible operating

temperature range during operation is

+5°C to +40°C.

− If any problems arise with the weigh

cell that require service, please contact

your local Sartorius dealer.

Hotline

§ If you have technical questions about

the construction, specifications or

installation of this weigh cell, just call

or fax your local Sartorius office.

For the address, please visit our Internet

website at: www.sartorius. com

3

Page 4

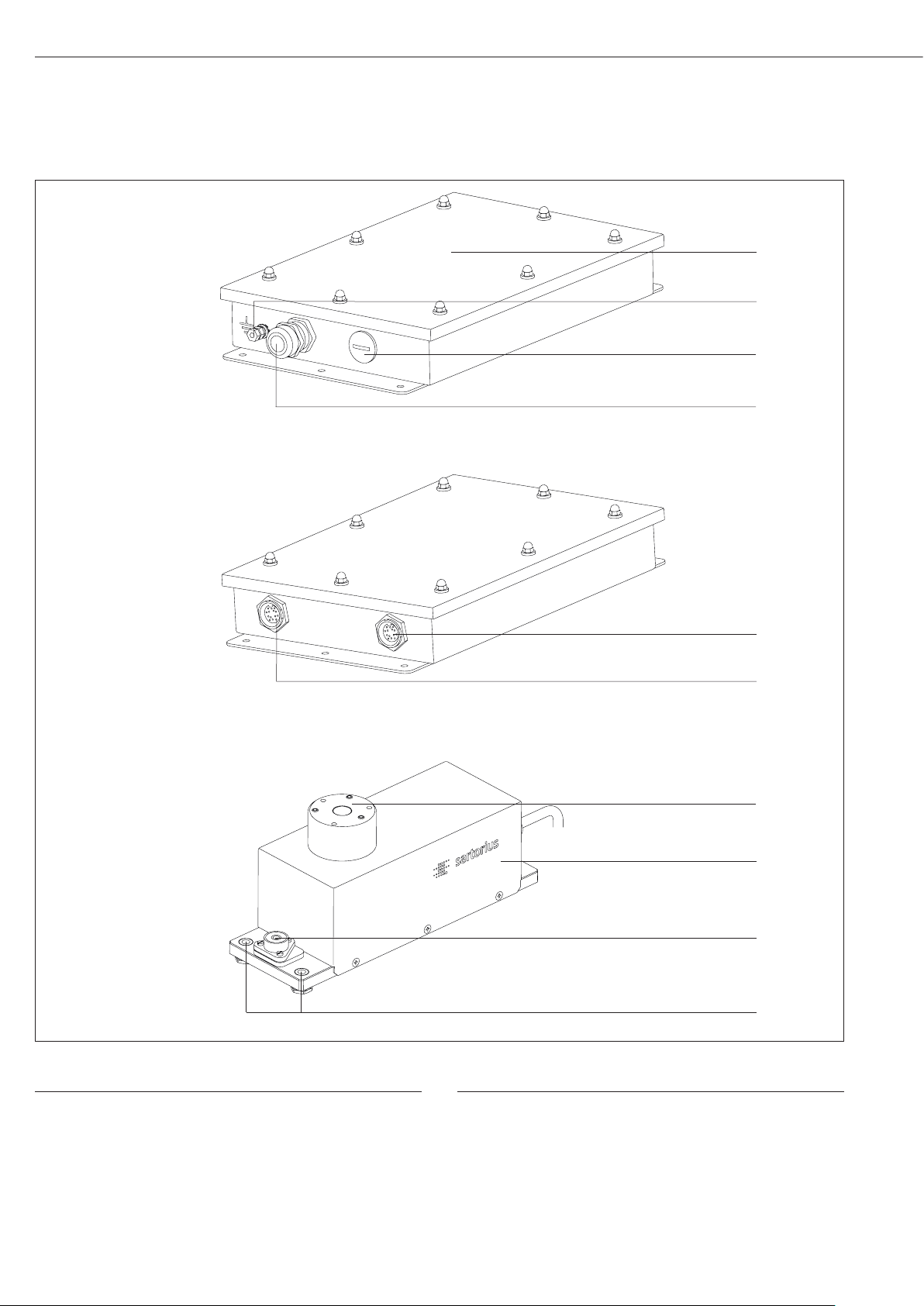

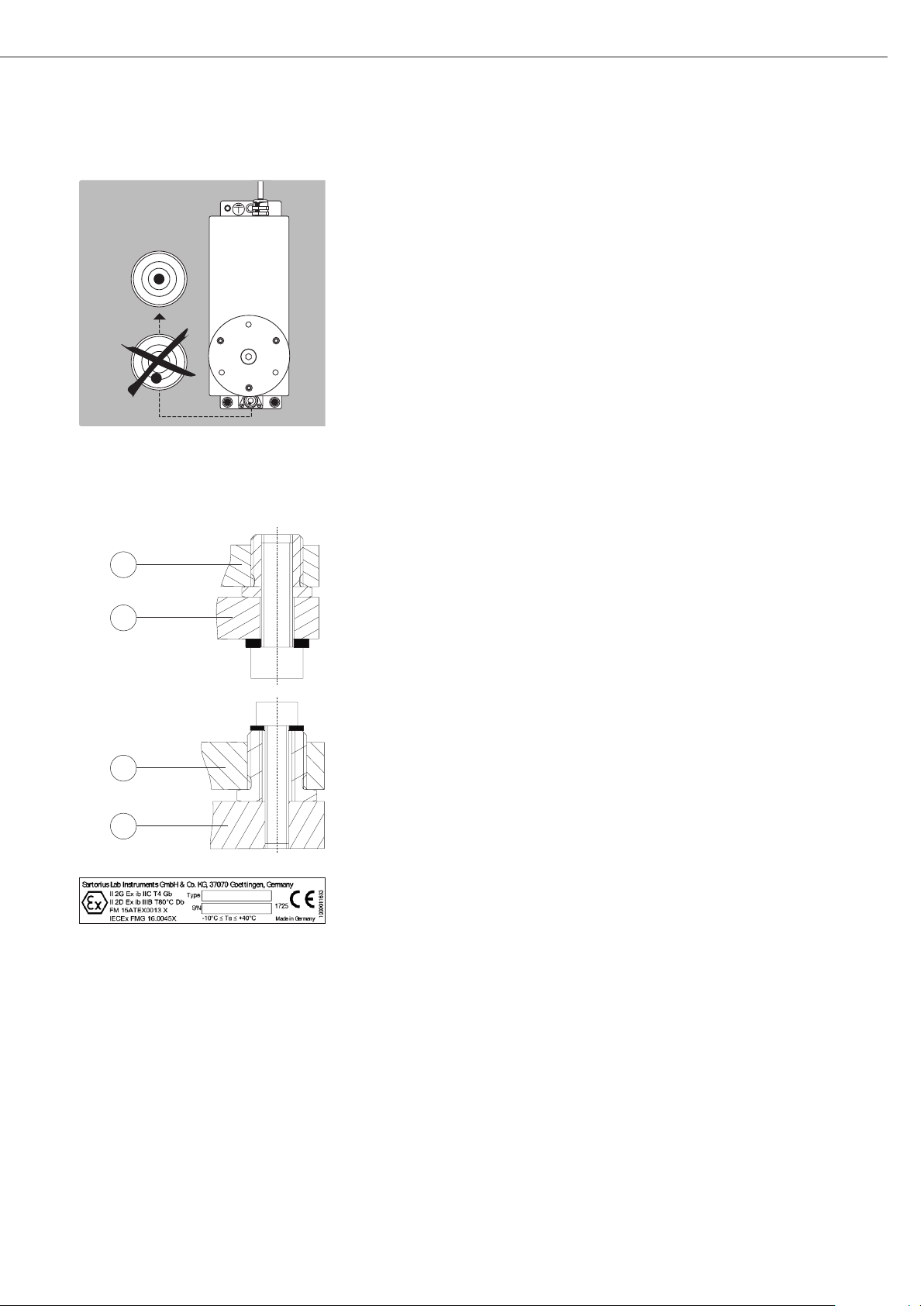

General View of the Equipment

1

2

3

4

Pos. Designation

1 Electronics module

2 Read these installation instructions thoroughly before using

your weigh cell.

3 Socket for connecting an optional display and control unit

4 Connection for weigh cell

5 Connection for optional Zener barrier

5

6

7

8

9

10

Pos. Designation

6 DC jack

7 Load receptor

8 Weigh cell

9 Level indicator

10 Threaded hole (M6) for mounting the weigh cell

4

Page 5

Installation

The weigh cells are available in various

versions. If you have ordered special

options, the weigh cells are equipped

with the specified features at the factory.

Storage and Shipping Conditions

– Once the equipment has been removed

from the packaging, it may lose accuracy if subjected to strong vibration.

Excessively strong vibration may compromise the safety of the equipment.

– Do not expose the equipment unneces-

sarily to extreme temperatures, moisture, shocks or vibration.

$ It is a good idea to save the box and all

parts of the packaging until you have

successfully installed your equipment.

Only the original packaging provides

the best protection for shipment.

$ Before packing your equipment, unplug

all connected cables to prevent damage.

$ Do not expose the equipment to

gravitational acceleration in excess of

0 300 m/s

ment is installed on the load receptor

that enables it to withstand this force).

Incoming Inspection

The customer shall inspect the product

and packaging immediately upon delivery for proper functioning, completeness, and absence of defects. This is to

be performed in an incoming inspection

within 10 days of delivery of the product. The incoming inspection must take

place before the equipment is installed.

Any obvious defects, errors, or incorrect

delivery must be reported in writing.

Defects detected at a later date must

be reported in writing immediately

upon detection.

Be sure to perform the following as part

of the incoming inspection:

– We recommend performing a repeata-

bility test using an auxiliary draft shield

to make sure the weigh cells were not

damaged in transport. You can use the

“Sartorius CAS-Suite” software or the

optional YAC01NX display and control

unit as an aid for this test.

2

(unless additional equip-

Equipment Supplied

– Weigh cell

– Electronics module

– Installation instructions (this document)

– Special accessories as listed on the bill

of delivery, if ordered, or in accordance

with specific arrangement.

Ambient Conditions

The equipment is designed to provide

reliable results under normal ambient

conditions. If you have any questions

or difficulties when developing your

weighing system, please contact the

specialists at Sartorius. When designing

and setting up your weighing system,

please observe the following so that

you will be able to work with added

speed and accuracy:

– Avoid exposing the equipment to the

effects of extremely high temperatures;

for example, caused by other electronic

components, heaters or direct sunlight.

– Protect the equipment from drafts that

come from open windows or doors.

– Avoid exposing the equipment to exces-

sive vibrations during weighing; for

example, caused by motors or valves.

– Protect the equipment from aggressive

chemical vapors.

Switch the system to the standby mode

when not in use.

Conditioning the Equipment:

Moisture in the air can condense on the

surface of a cold weighing instrument

or other device whenever it is moved

to a substantially warmer place. If you

transfer the equipment to a warmer

area, make sure to condition it for

about 2 hours at room temperature,

leaving it unplugged from AC power.

Components Attached to the Load

Receptor

– Components that are attached to the

load receptor can adversely affect the

way the weigh cell functions. The user

is responsible for how the series is used

and the specifications achieved for the

entire system. Your specifications may

differ from those listed in the section

entitled “Specifications.”

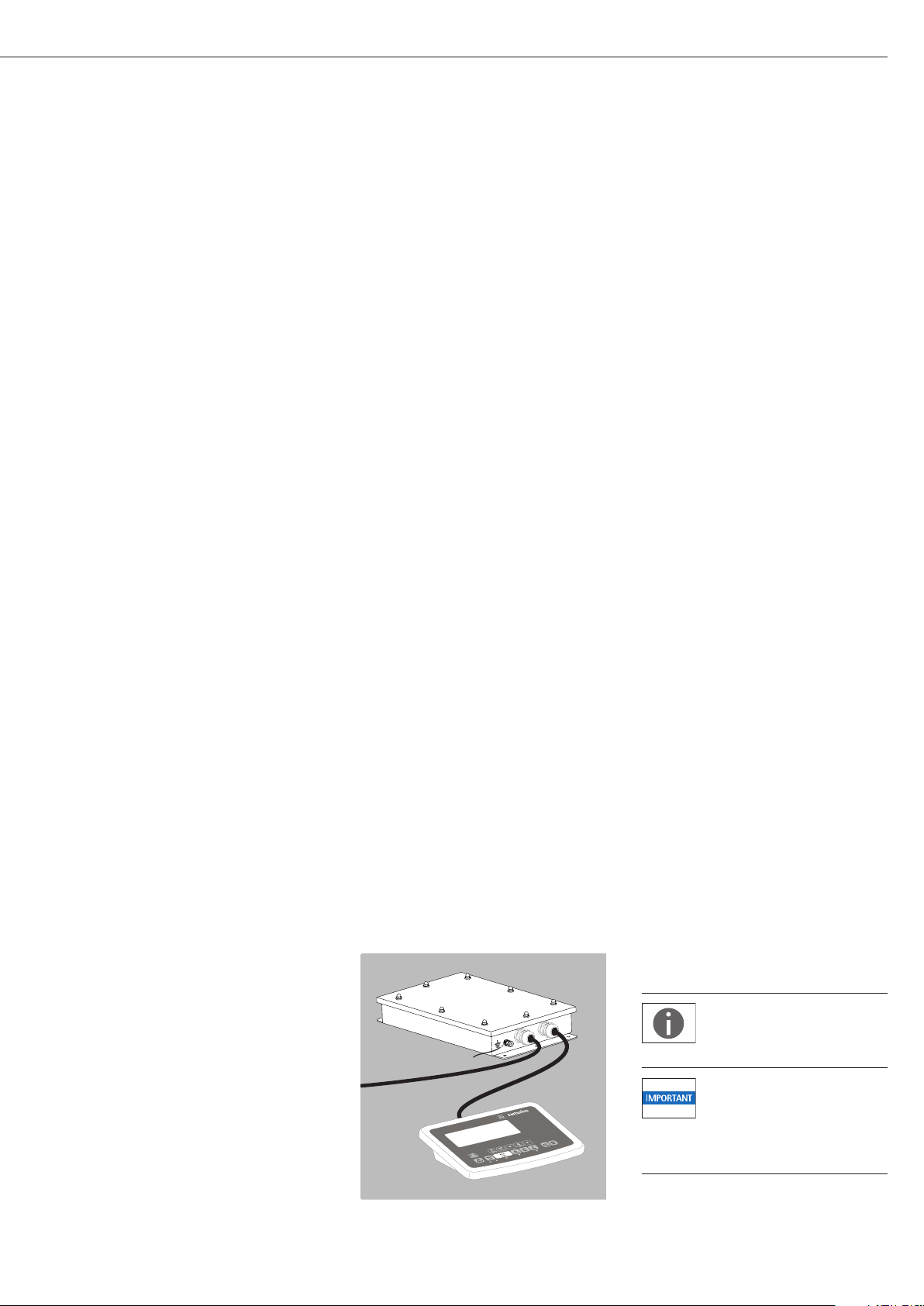

Connecting an Optional YAC01NX Display and Control Unit

The display and control unit can

only be connected if specified

directly at the time the order is

placed.

Protect the YAC01NX display

and control unit from mechani-

cal damage. If you discover that

the equipment has been damaged, disconnect it from AC power and remove it from

service.

5

Page 6

YPSC01-Z ..

Conditions for Installation

Before putting the equipment into operation, it is important to

make sure that the power cord on the associated power supply is

correctly connected to the power outlet (mains supply). All equipment must be connected to the equipotential bonding conductor

by connecting the grounding cable (not included in delivery) to the

grounding terminals provided for this purpose on each device.

The dimensions of the grounding cable are specified in national

regulations for electrical installations. Installation must be performed by a trained technician in accordance with national regulations and acknowledged technological standards.

Use only cabling and extensions approved by Sartorius, as these are

made in accordance with the restrictions on permissible cable lengths

imposed by both the capacitance and inductivity values and the

requirements for electromagnetic compatibility (see the EC TypeExamination Certificate).

Before putting the weighing system into operation for the first

time, make sure there is no hazard of explosion present at the place

of installation. If there is any indication that the equipment does

not function properly (e.g., display remains blank or is not backlit)

due to damage during transport:

– disconnect the equipment from power and

– notify your nearest Sartorius Service Center.

The weigh cell specifications for Ui, Li, Pi, Ta, temperature class,

Ci, and Li are listed in the EC type-examination certificate.

This certificate also specifies the display and control unit models

that can be used with these weigh cells.

The explosion-protected weighing system must be installed in

accordance with acknowledged rules of engineering. These include

national and international laws and regulations (such as VbF,

EX-RL, DIN EN 60079-14, DIN VDE 0166, DIN VDE 0100, DIN VDE

0101, and DIN VDE 0800).

In particular, the conditions described under Item 17 of the KEMA

EC type-examination certificate, “Special Conditions for Safe Use,”

must be observed. Furthermore, national regulations for accident

prevention and environmental protection must be observed at all

times.

Before you operate your weigh cell in a hazardous area/location,

it must be inspected either by a certified electrician or under the

guidance and supervision of a certified electrician to make sure that

the weigh cell complies with the applicable regulations. Determine

whether your weigh cell must be reported to the technical inspection authorities (such as the trade board) in your country. The system

must also be inspected during operation. The system should be

inspected at intervals which allow for early detection of the faults

that occur as a result of normal wear and tear, so that they can

be corrected before damage is caused. In any case, inspection must

be performed at least every 3 years. Other conditions and standards

that regulate the installation and operation of the equipment and

are applicable in your country must be met as well. When performing inspections, generally acknowledged rules of engineering relevant to these conditions must also be applied. If the unit housing

is opened by anyone other than persons authorized by Sartorius,

or if the equipment is installed or operated incorrectly, this will

result in forfeiture of the approval for use in the stated hazardous

area(s)/location(s) and of all claims under the manufacturer’s

warranty.

6

Page 7

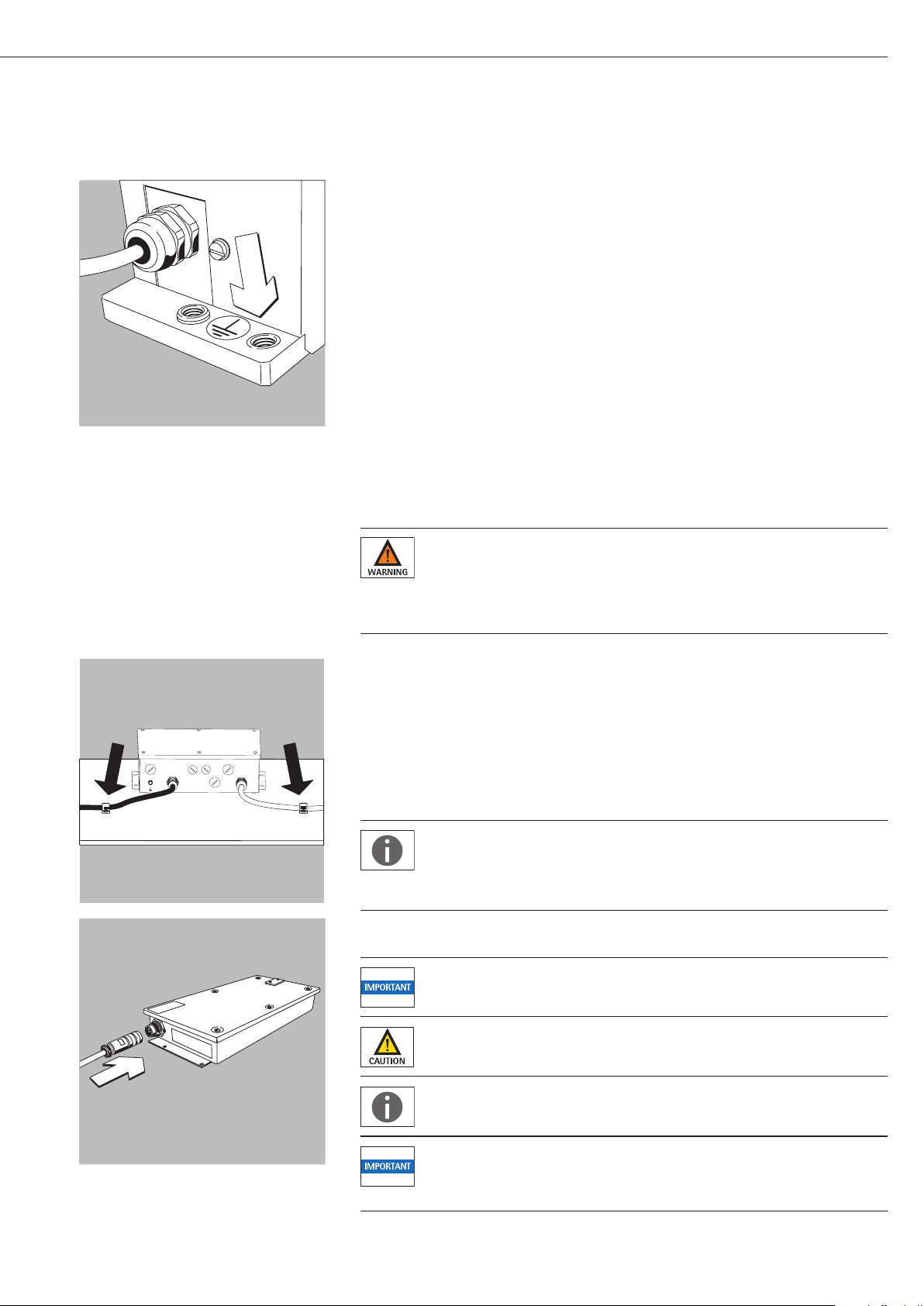

t Connecting an Equipotential Bonding Conductor (Grounding)

− If the weigh cell is in a hazardous area/location, it must be grounded (i.e., an equipoten-

tial bonding conductor must be connected). This connection should be made by

a trained technician. The weigh cell is equipped with a connector for the grounding conductor. The position is marked by the symbol shown here, indicating the grounding connection.

Use a stainless steel screw (M6 thread) to connect the grounding conductor.

We recommend using a tooth lock washer to prevent the screw from coming loose.

The wire used for the grounding conductor should have a cross-sectional diameter of at

least 4 mm

2

, with a suitable ring lug attached.

The grounding cable must be installed in such a way that it is not under mechanical

stress and so the screw will not become loose. Connect all equipment, including peripheral devices, to the equipotential bonding conductor.

Connecting the Weigh Cell to AC Power

t Before putting the weigh cell into operation, make sure that the power cable is

correctly connected to the electrical outlet; it is especially important to make sure

the grounding cable is attached to the housing of the power supply. All devices used

must be connected to the equipotential bonding conductor via the retainers provided on

each device. Installation must be carried out by a certified electrician according to the

valid standards of technology.

Before putting the equipment into operation for the first time, make sure that the

area of installation is not hazardous. If the equipment shows any signs of mal-

function as a result of damage during shipment (display remains blank, display

not backlit even with a weight readout, weight value not repeatable, readout does not

stabilize, etc.), disconnect the equipment from AC power and contact a Sartorius service

technician.

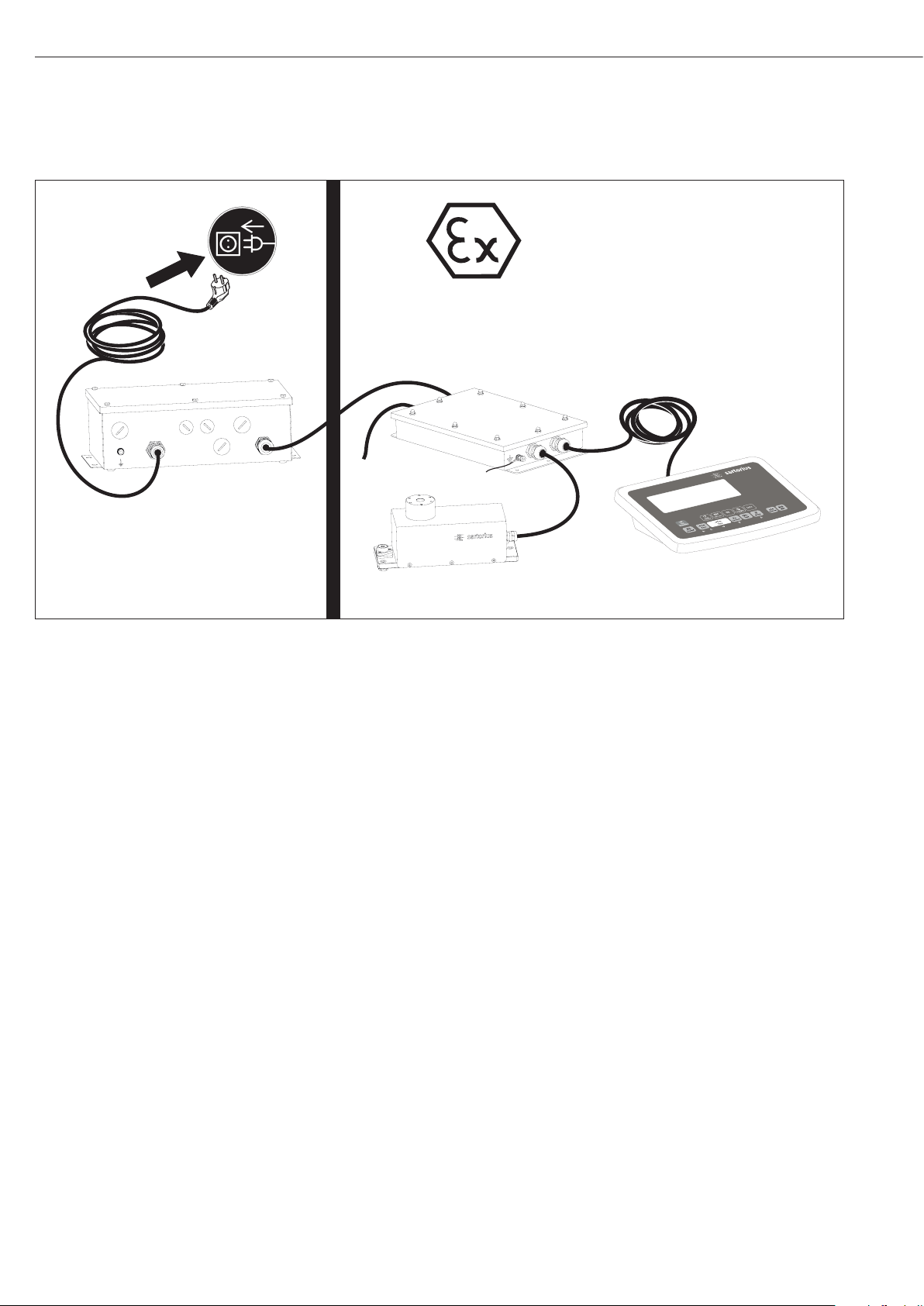

t YPSC01-X: flameproof power supply:

− Lay both cables in a manner that is secure and protected.

− Flexible installation of cables with threaded fasteners can be carried out on request.

t Check the voltage rating and the plug design.

− If they do not match the rating or standard you use, contact your Sartorius office or dealer.

− Use only original Sartorius power supplies:

− YPC01-Z... (for use outside hazardous areas/locations)

− YPC01-X (for use within hazardous areas/locations)

To operate the weigh cell in a hazardous area or location, please comply with the

following:

– Currently valid standards and regulations for installation of explosion-protected

equipment in such areas

–

Installations in Zone 1 must be carried out and checked by a certified electrician.

t Plug the female connector of the blue intrinsically safe power supply cable into the

socket on the weigh cell. Secure this connection by tightening the knurled collar.

Be sure to connect the power supply to the electronics module before plugging

the equipment in to AC power.

Install the power cable so that it is protected from damage.

The intrinsically safe connector for the power cable (primary side) is not part of

the standard equipment supplied (open cable ends).

Connecting Electronic Peripheral Devices

Make absolutely sure to unplug the weigh cell from AC power before you connect

or disconnect a peripheral device (display and control unit or PC) to or from the

interface port.

7

Page 8

Warmup Time

The amount of warmup time required depends in part on the system in which the

weigh cell is installed. To deliver exact results, the weigh cell must warm up for at

least 30 minutes after it is connected to power for the first time. Only after this

time will the device have reached the required operating temperature.

Leveling the Load Receptor and User-Specific Transducer

t Remove the (S1) screw.

t Use the (S2) screws to radially position and level the load receptor (minor height adjust-

ment also possible).

t Attach the (S1) screw to affix the load receptor and tighten it as indicated in the table

below listing the torque values.

t Attach any user-specific transducer to the threaded fastener (S3) on the load receptor and

tighten it as indicated in the table below: Maximum load on load receptor.

t The user-specific transducer must be rigid and securely connected to the load receptor.

R

G

G = Load

R = Distance from the center of the pan

M

= G . R

eck

Maximum load on load receptor:

Model M

eck

S1 S2 S3

WZA623-NX 2.5 Nm 1 Nm 1 Nm 2 Nm

WZA6202-NX 6 Nm 4 Nm 2 Nm 4 Nm

If the load is not centered on the load receptor, the corner load moment M

exceeded, since this could lead to a defect in the weigh cell.

may not be

eck

The force “G” is comprised of the weight of the sample and the non-centric load on the

weigh cell.

The load receptors should be constructed so that they are stiff and cannot be bent or

twisted.

Example: What is the maximum permissible length of the cantilever

(on WZA623-NX in this instance)?

It is assumed that the load is connected to a cantilever that has a uniform width.

The cantilever utilizes the necessary preload of 600 grams on the WZA623-NX.

M

~ 1 R + G

eck Arm

M

= R + G

eck Last

= 6.1 N

M

= M

eck

= R (1 + G

R

(1 G

= ———————————

eck Arm

M

eck

Arm

Last

Arm

+ M

+ G

Arm

eck Last

+ G

Last

)

Last

)

R = 2.5 Nm / 12 N = 0.2 m

R = 0.2 m

G

= 9.81 m/s2 + 0.6 kg

Arm

= 5.9 N

G

= 9.81 m/s2 + 0.62 kg

Last

The maximum length that the cantilever

can be without destroying the system is

200mm. As a result of handling, other

moments can occur, which must be taken

into consideration. In general, we recommended testing first because there can

be undesired repercussions. Drafts can

influence results as well.

8

Page 9

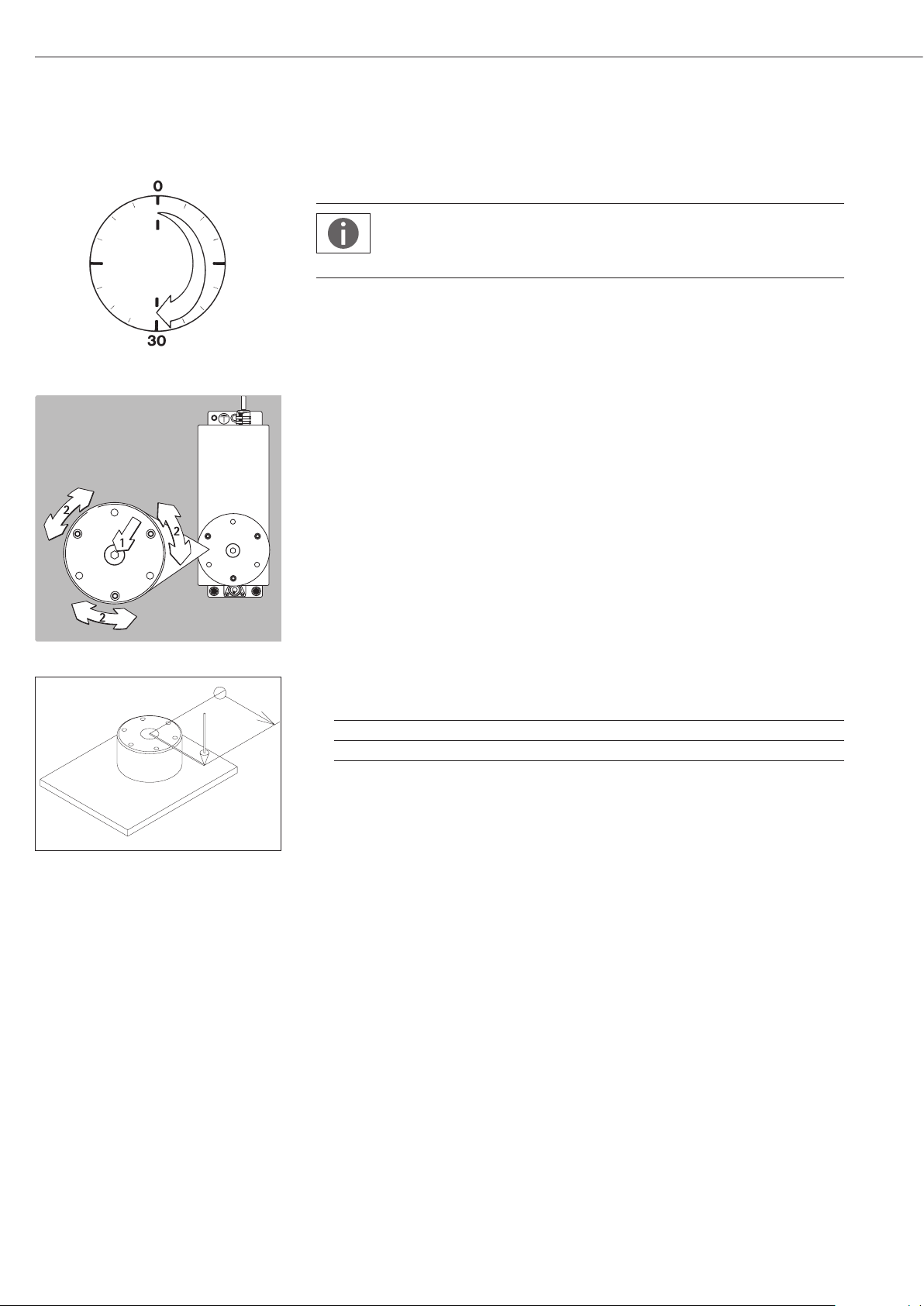

Leveling the Weigh Cell in a Portable Weighing System (Leveling Feet Optional)

Purpose:

– To compensate for uneven areas at the place of installation

– To ensure that the weigh cell is placed in a perfectly horizontal position for consistently

reproducible weighing results

– Always level the weigh cell again any time after it has been moved to a different location.

§ Adjust the leveling feet until the air bubble is centered within the circle on the level

indicator.

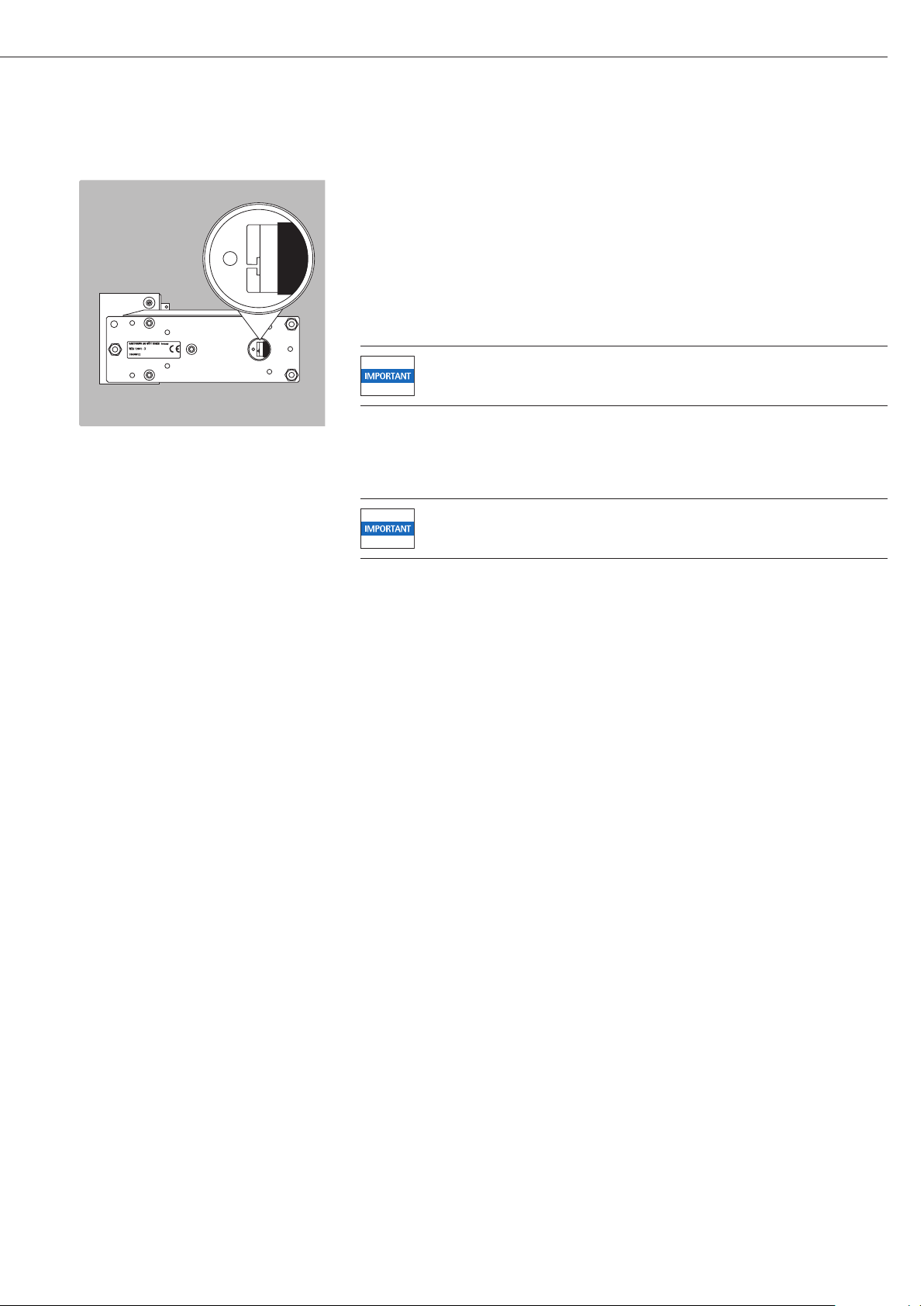

Permanently Installed Weigh Cells

– Adjust the weigh cell after it has been installed in the system in its permanent location

(see next page).

The weigh cell must be leveled again any time the location or position of the weighing

system is changed.

– For optimum operation, install the weigh cell in a horizontal position.

1

1) Bottom plate of the weighing cell

2) Fastening frame of the system

2

1

§ Fastening with M6 screws:

Connection to the threaded fasteners on the weigh cell (1): torque: 2.5 Nm

§ Fastening with M4 screws:

Connection to the threaded fasteners of a user-specific frame (2).

2

Device-Specific Information: Coding of the Serial Number

The year that the device was manufactured is coded in the serial number.

The format is as follows:

YMM x x x x x

Y Year

3 2014–2020 6 2035–2041

4 2021–2027 7 2042–2048

5 2028–2034 8 2049–2055

9 2056–2062

Each number in the Y column represents a group of seven years during which the device

was manufactured. Within each group of years, the months of the year (M M) advance

chronologically from 13 upwards.

Year: 2015 2016 2017 ...

MM: 25-36 37-48 49-60 ...

Example:

328xxxxx (April 2015)

xxxxx is a consecutive number that is counted upward after being reset each month.

9

Page 10

Operation

Notes on Analytical

Weighing with Weigh Cells

Handling of Samples and Containers

Samples should be acclimatized to the

temperature of the weigh cell to avoid

negative effects on results, such as

measurement errors and fluctuations

caused by air buoyancy resulting from

convection currents across the surface

of the sample.

These negative effects increase as the

volume and/or surface area of the sample increases. For this reason, the size of

the container should be appropriate for

the sample.

Samples and containers should not be

touched by the operator’s hands, as the

hygroscopic effect of fingerprints and

the effect of the hand’s temperature

can influence the measurement results.

Samples must be applied very carefully,

whether manually (using forceps) or

automatically (by a robot or filling

system).

When designing a draft shield device,

steps must be taken to keep the

increase in temperature within the

weighing chamber to a minimum

(e.g., using a bypass).

Weighing Electrostatically Charged

Samples or Containers

If a sample or container is electrostatically charged, significant errors may

result during weighing. Materials with

low conductivity, such as glass, plastic

or filters, are particularly susceptible to

static electricity (resulting, e.g., from

friction) because the weighing pan can

discharge the static electricity only very

slowly.

The result is a force action between

the charge on the sample and the permanently installed parts of the weigh

cell. This causes the readout to fluctuate constantly.

Ionization can be applied to make the

air around the sample conductive. This

allows the charge to be compensated

through the air, or discharged through

the ground (grounded).

The area around the weigh cell can

also contain charges that negatively

affect the accuracy of weighing results.

Appropriate steps taken in the design

of a draft shield device can counteract

such effects. In the process, be sure to

install devices that are suitable for use

in the particular hazardous zones.

Weighing Magnetic or Magnetizable

Samples

For technical reasons, the use of magnetizable materials in the manufacture

of weigh cells is unavoidable, primarily

because the operating principle of highresolution weigh cells is based on

compensation of the load through

magnetic forces.

When weighing magnetic or magnetizable samples or containers, interaction

between the sample or container and

certain parts inside the weigh cell may

have a distorting effect on the weighing

results.

To keep such effects to a minimum,

we recommend increasing the distance

between the sample/container and the

weighing system using a non-magnetic

material. The force is reduced quadratically with the increase in distance.

Magnetizable or magnetized samples

and the weigh cell itself interact with

magnetic fields and magnetizable or

magnetized parts in the area surrounding the weighing system. The system

can be shielded from external magnetic

fields to some extent using (soft magnetic) plates.

10

Calibration/Adjustment

Calibration/adjustment can be per-

formed as follows:

– Using control commands sent by the

CAS-Suite configuration software from

Sartorius, installed on a computer

(see page 18 for the commands)

or

− Using the optional YAC01NX display

and control unit

Page 11

Below-Cell Weighing

A port for a below-cell weighing hanger is located on the bottom of the weigh cell.

t Remove the cover plate.

− Threaded fastener for hook: M3

Overload protection

− Standard feature on the WZA623-NX model

Models WZA6202-NX:

No overload protection provided

t Carefully install the special hook: maximum torque: 0.75 Nm

− If necessary, install a shield for protection against drafts.

Protection rating: only IP22 is provided when the cover plate for the below-cell

weighing port has been removed.

11

Page 12

Factory Settings (Setup)

Purpose

− The weigh cell is configured at the fac-

tory. The factory settings can be

adapted to individual requirements by

editing the “Setup” menu.

Features

Parameters are combined into the

following groups

(1st menu level):

1. Setup: Balance parameters

2. Device parameters

3. Data output

4. Application program

5. Input

6. Information

7. Language setting

1

)

Factory Settings for the Parameters

Factory-set configurations are marked

with “o.” Customer-specific settings

can be configured on request.

Preparation

The following operating menu

functions can be carried out using

the Sartorius CAS-Suite configuration

software installed on a PC:

– Read

– Change

– Print

– Save

or

With one of the optional YAC01NX

control units

1

) Detailed instructions on the available

application programs can be found

in the operating instructions for the

Cubis Series, MSE Models, which can be

downloaded online:

Go to www.sartorius.com –

Service Center ➝ Downloads.

12

Page 13

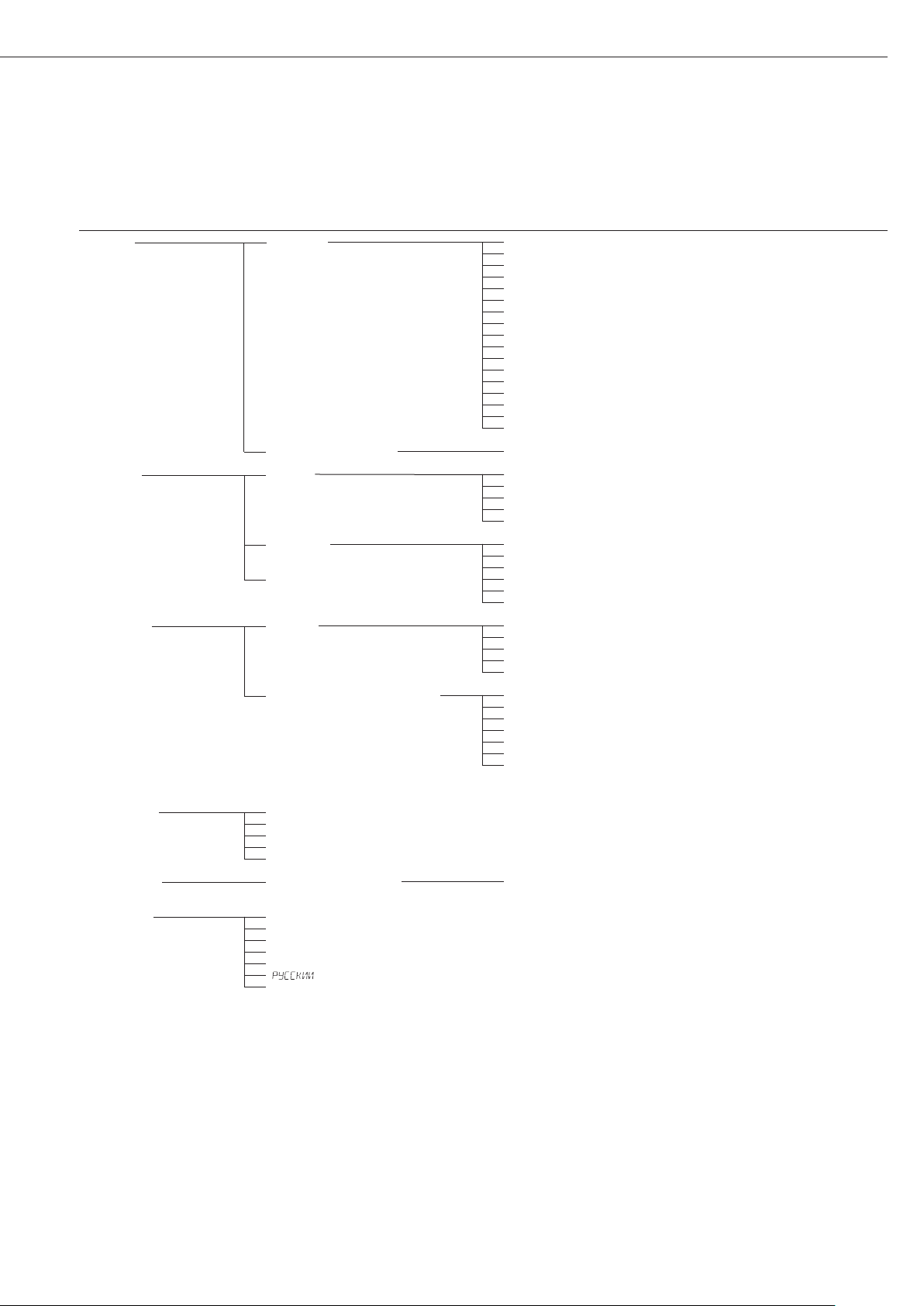

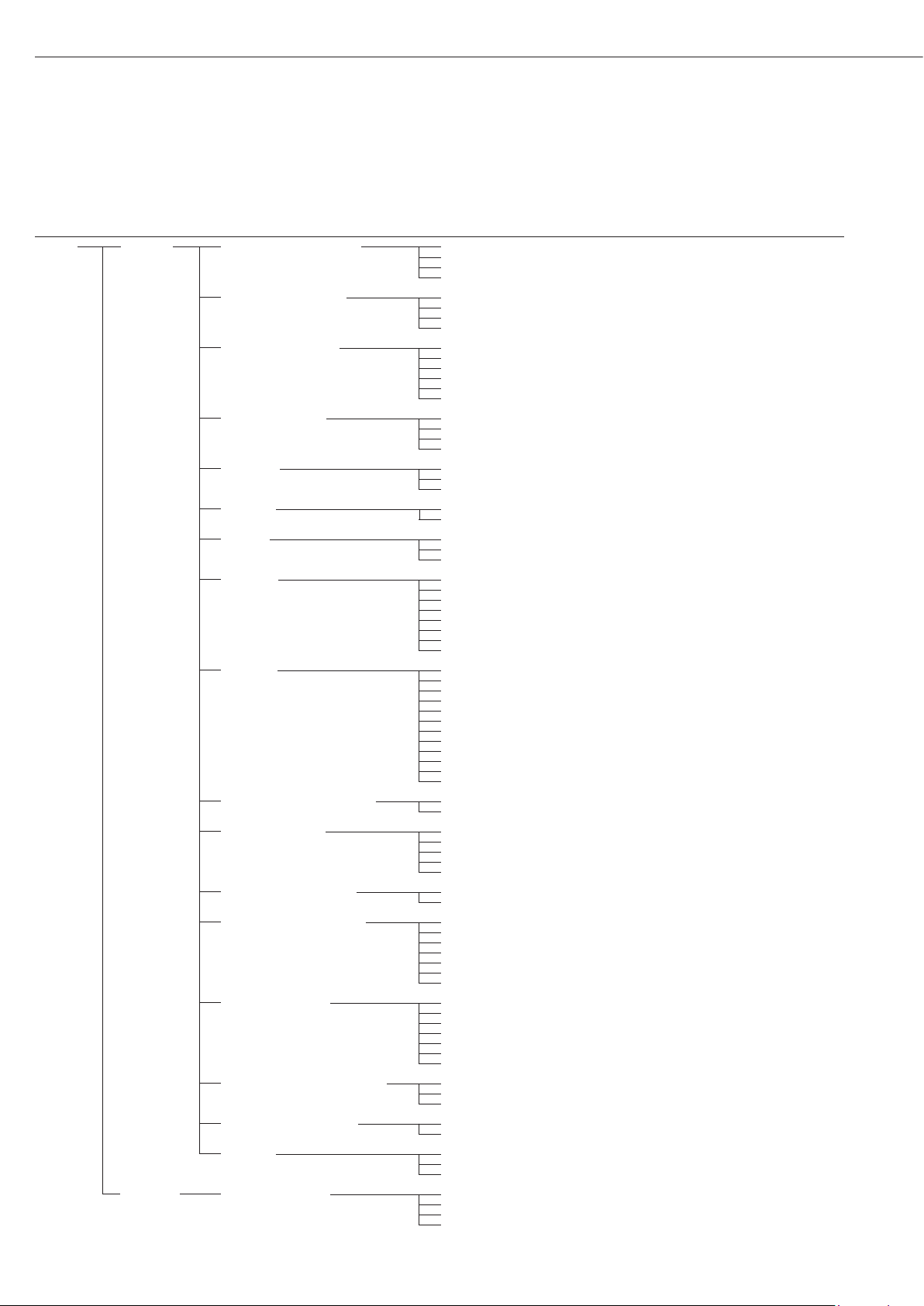

Menu Structure (Overview)

Level 1 Level 2 Level 3 Menu level info

1) Setup Bal.Scal. Ambient Ambient conditions 1. 1. 1.

(Weigh cell functions) app.filt. Application filter 1. 1. 2.

Stab.rng. Stability range 1. 1. 3.

Stab.dly Stability delay 1. 1. 4.

Taring Taring

Autozer. Auto zero 1. 1. 6.

Wt.Unit Basic weight unit 1. 1. 7.

Display Display accuracy

Cal./adj. Function of the C key 1. 1. 9.

Cal.routine Calibration/adjustment routine 1. 1. 10.

Zerorng. Zero range 1. 1. 11.

Zero.on Zero at power on 1. 1. 12.

On.tare Tare/zero at power on 1. 1. 13.

Cyc.rate Output rate 1. 1. 14.

isocal Auto calibration/adjustment 1. 1. 15.

EXT.Cal. External adjustment 1. 1. 16.

cal.unit Weight unit for calibration

gen.serv. General service men.reset Factory settings 1. 9. 1.

2) Device extras menu Menu read only/can edit 2. 1. 1.

(Additional functions) Signal Acoustic signal 2. 1. 2.

Keys (Keypad) 2. 1. 3.

Ext.Key External switch function 2. 1. 4.

Onmode Power-on mode 2. 1. 6.

Peripher. dat.rec. Communication mode 2. 2. 1./2. 3. 1.

(25-pin “Peripherals” interface) Baud Baud rate 2. 2. 2./2. 3. 2.

parity Parity 2. 2. 3./2. 3. 3.

pc-usb (USB port “PC”) Stopbit Number of stop bits 2. 2. 4./2. 3. 4.

Handshk. Handshake mode 2. 2. 5./2. 3. 5.

databit Number of data bits 2. 2. 6./2. 3. 6.

3) Dataout com.sbi com.out Communications output 3. 1. 1.

(Data output) (PC communication) Stop Stop automatic output 3. 1. 2.

Aut.Cycl. Time-dependent automatic data output 3. 1. 3.

Format (Line format) 3. 1. 4.

Auto.Tare Auto taring after data output 3. 1. 5.

Print.para Parameters for printing Res. Print resolution (manual/automatic) 3. 2. 1.

Format Line format for printout 3. 2. 2.

Prt.Init. Printout of appl. parameters 3. 2. 3.

GLP ISO/GLP-compliant printout 3. 2. 4.

tar./prt. Tare bal./scale after ind. print 3. 2. 5.

time: 12h/24h 3. 2. 6.

date Date format 3. 2. 7.

4) Applic.ation programs

5) Input Input ID. ID input; max. 7 characters 5. 1.

Date Set date 5. 2.

Time Set time 5. 3.

Password Password entry (for service) 5. 4.

Cal.wt. Enter weight value 5. 5.

6) Information Version, Ser.no., model, Display of software version, serial no., model 6. 1. to 6. 6.

lobs, kdcvers, DR.Shield, if OPT.MOD

7) Language English English (factory setting) 7. 1.

Deutsch German 7. 2.

franc. French 7. 3.

ital. Italian 7. 4.

Espanol Spanish 7. 5.

Polski Polish 7. 7.

1

)

Russian 7. 6.

1

) 1. 1. 5.

1

) 1. 1. 8.

1

) 1. 1. 17.

1

) Detailed instructions on the available application programs can be found in the operating instructions for the „Signum series,“ which can be downloaded online:

Go to www.sartorius.com – Service Center Downloads.

13

Page 14

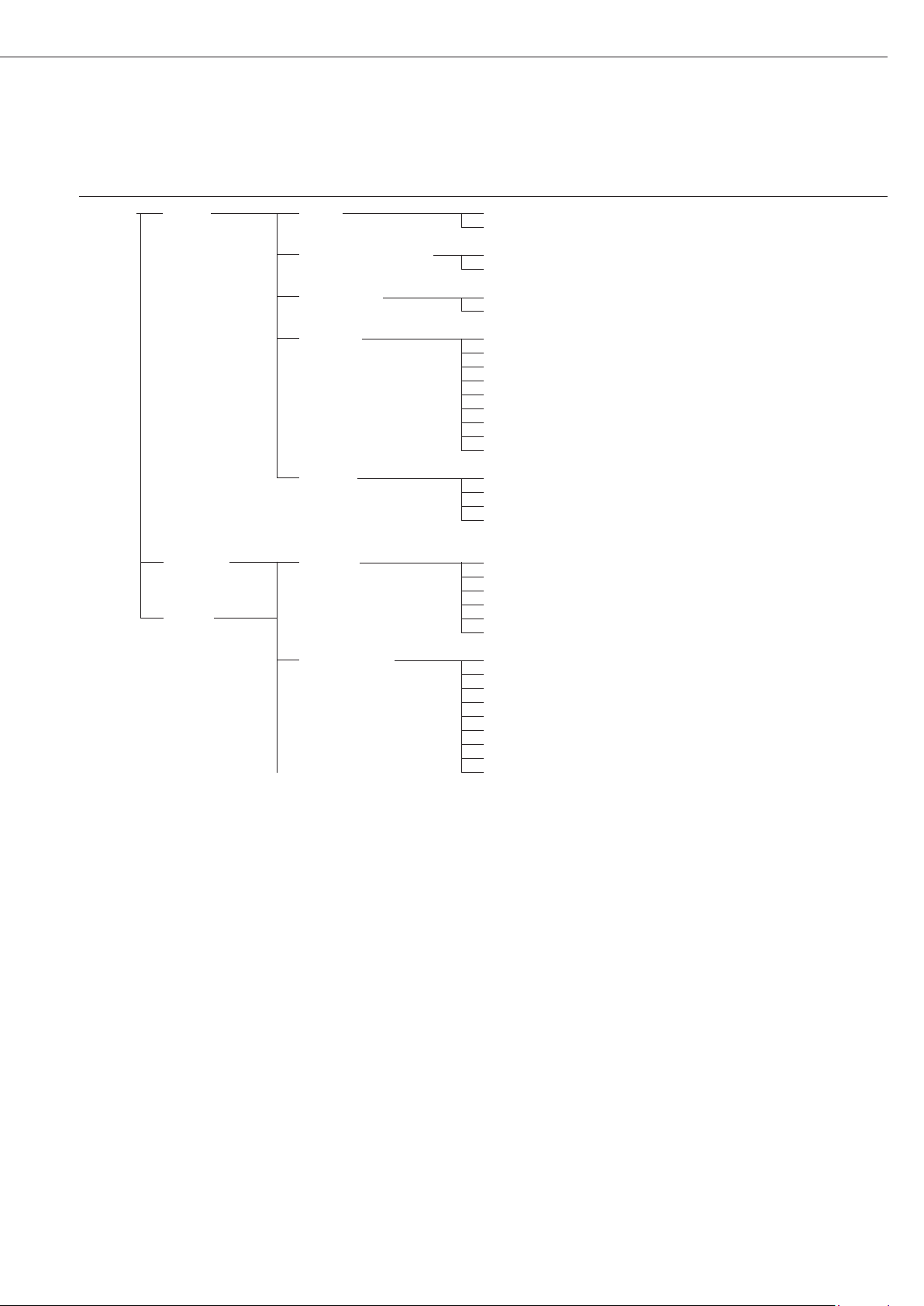

Parameter Settings: Overview

ο = factory setting;√ = user-defined setting

Info about

Level 1 Level 2 Level 3 Level 4 menu level

1) Setup Bal.Scal. Ambient Ambient conditions V.Stable Very stable 1. 1.1. 1

Balance (filter adjustment) ο Stable Stable 1. 1.1. 2

parameters unstabl Unstable 1. 1.1. 3

v.unstbl. Very unstable 1. 1.1. 4

App.Filt. Application filter ο Final.rd. Final readout mode 1. 1.2. 1

Filling Filling mode 1. 1.2. 2

Reduc. Reduced 1. 1.2. 3

Off Off 1. 1.2. 4

Stab.rng. Stability range Max.acc. Maximum accuracy (1⁄4 digit) 1. 1.3. 1

V.acc. Very accurate (1⁄2 digit) 1. 1.3. 2

Acc. Accurate (1 digit) 1. 1.3. 3

ο Fast Fast (2 digits) 1. 1.3. 4

V.fast Very fast (4 digits) 1. 1.3. 5

Max.fast Maximum speed (8 digits) 1. 1.3. 6

St.del. Stability delay No No delay 1. 1.4. 1

ο Short Short delay 1. 1.4. 2

Averg. Average delay 1. 1.4. 3

Long Long delay 1. 1.4. 4

Tare Tare wiostb. Without stability 1. 1.5. 1

ο Wistb. After stability 1. 1.5. 2

Atstab. At stability 1. 1.5. 3

Aut.zero ο on Automatic zeroing on 1. 1.6. 1

Auto zero off Automatic zeroing off 1. 1.6. 2

WT.UNIT For list of units, see 1. 1.7. 1

Basic weight unit “Toggling between weight units” to

1. 1.7.24

Disp.dig. ο all Display all digits 1. 1.8. 1

Display accuracy lp.on.off Last digit after load change 1. 1.8. 2

Increment of measured values one level lower 1. 1.8. 3

Increment of measured values two levels lower 1. 1.8. 4

Increment of measured values three levels lower 1. 1.8. 5

Incrm.1 Last digit single increment 1. 1.8. 6

Minus 1 Reduced by one digit 1. 1. 8. 7

Resolution by a factor of 10 1. 1. 8.14

Cal./Adj. EXT.Cal. External calibr./adjustment with factory-set weight 1. 1.9. 1

Function of C key cal.e.usr. External calibr./adjustment with user-defined weight 1. 1.9. 3

ο cal.int. Internal calibr./adjustment 1. 1.9. 4

lin.int. Internal linearization (on analytical balances only) 1. 1.9. 5

lin.ext. External linearization with factory-set weights 1. 1.9. 6

lin.usr. External linearization with user-defined weights 1. 1.9. 7

set.prel. Set the preload 1. 1.9. 8

clr.prel. Delete the preload 1. 1.9. 9

blocked C locked 1. 1.9.10

Select Select 1. 1.9.12

set.ext.w. Determine ext. calibration weight for cal.e.usr 1. 1.9.17

Determine internal weight 1. 1.9.18

Cal./Adj. Calibration/adjustment ο Sequence Sequence adjustment 1. 1.10. 1

CAL/adj. Adjustment as needed 1. 1.10. 2

Zerorng. Zero range 1perc. 1 percent of max. load 1. 1.11. 1

ο 2perc. 2 percent of max. load 1. 1.11. 2

5perc. 5 percent of max. load 1. 1.11. 3

10perc. 10 percent 1. 1.11. 4

default (factory-set) 1. 1.11. 5

init.zero Zero at power on ο default (factory-set) 1. 1.12. 1

2perc. Initial zero 2 percent 1. 1.12. 2

On. Tare Tare/zero at power on ο On Init. tare/zero on 1. 1.13. 1

Off Init. tare/zero off 1. 1.13. 2

5perc. 5 percent 1. 1.13. 3

10perc. 10 percent 1. 1.13. 4

20perc. 20 percent 1. 1.13. 5

50perc. 50 percent 1. 1.13. 3

100perc. 100 percent 1. 1.13. 7

cyc.rate Output rate ο normal Normal output 1. 1.14. 1

highvar. High var. output 1. 1.14. 2

slow Slow output 1. 1.14. 3

medium Medium output 1. 1.14. 4

fast Fast output 1. 1.14. 5

veryfast Very fast output 1. 1.14. 6

maximum Max. output 1. 1.14. 7

ISOcal Auto calibration/adjustment ο Off Auto cal./adj. off 1. 1.15. 1

Note Info 1. 1.15. 2

On Auto cal./adj. on 1. 1.15. 3

Ext.cal. External calibration ο free Unlocked 1. 1.16. 1

locked Locked 1. 1.16. 2

cal.unit ο Gram Grams 1. 1.17. 1

Unit for calibration weight Kilogr. Kilograms 1. 1.17. 2

Userdef. User-defined unit (factory setting: pounds) 1. 1.17. 4

gen.serv. men.Reset Menu reset Yes Restore factory settings 1. 9. 1. 1

General service (factory settings) ο No Do not restore factory settings 1. 9. 1. 2

Standard Standard settings 1. 9. 1. 3

Verifiable Verifiable settings 1. 9. 1. 4

14

Page 15

Level 1 Level 2 Level 3 Level 4 Menu level info

2) Device extras menu ο canedit Can edit 2. 1. 1. 1

(Additional Rd.only Read only 2. 1. 1. 2

functions)

Signal Acoustic signal off Acoustic signal off 2. 1. 2. 1

ο on Acoustic signal on 2. 1. 2. 2

Keys Keypad ο free Unlocked 2. 1. 3. 1

locked Locked 2. 1. 3. 2

Ext.Key ο Print P key (print) 2. 1. 4. 1

External switch function Z/Tare J key (tare) 2. 1. 4. 2

cal. C key (calibrate) 2. 1. 4. 3

cf F key (go back/exit) 2. 1. 4. 5

enter V key (enter) 2. 1. 4. 6

Dr.shield Draft shield 2. 1. 4. 9

Ionizer Ionizer 2. 1. 4. 10

appl. Application key 2. 1. 4. 11

Asterisk * key 2. 1. 4. 12

onmode off/on/sb Off/On/Standby 2. 1. 6. 1

Power-on mode off/on/SO Off/On/Auto shut-off 2. 1. 6. 2

on/sb On/Standby 2. 1. 6. 3

ο AutoOn Auto on 2. 1. 6. 4

Periphery:/PC USB:

Peripher. dat.rec. ο SBI (ASCII) 2. 2. 1. 1/2. 3. 1. 1

(25-pin “Peri- Operating mode XBPI 2. 2. 1. 2/2. 3. 1. 2

pherals” interface) Rem.displ. Remote display 2. 2. 1. 4/2. 3. 1. 4

uni.Print Universal printer 2. 2. 1. 7/2. 3. 1. 7

pc usb lab.print (Parameters for YDP10 printer) 2. 2. 1. 8/2. 3. 1. 8

(USB port for PC) OFF Interface off 2. 2. 1.10/2. 3. 1.10

Baud Baud rate 600 2. 2. 2. 3/2. 3. 2. 3

ο 1200 2. 2. 2. 4/2. 3. 2. 4

2400 2. 2. 2. 5/2. 3. 2. 5

4800 2. 2. 2. 6/2. 3. 2. 6

9600 2. 2. 2. 7/2. 3. 2. 7

19200 1) 2. 2. 2. 8/2. 3. 2. 8

38400 1) 2. 2. 2. 9/2. 3. 2. 9

57600 1) 2. 2. 2.10/2. 3. 2.10

115200 1) 2. 2. 2.11/2. 3. 2.11

1

) Only one of the two interfaces can be used.

15

Page 16

Level 1 Level 2 Level 3 Level 4 Menu level info

Periphery:/PC USB:

2) Device peripher. Parity ο Odd Odd parity 2. 2. 3. 3/2. 3. 3. 3

pc usb Parity Even Even parity 2. 2. 3. 4/2. 3. 3. 4

None No parity 2. 2. 3. 5/2. 3. 3. 5

StopBit ο 1Stop 1 stop bit 2. 2. 4. 1/2. 3. 4. 1

Number of stop bits 2Stop 2 stop bits 2. 2. 4. 2/2. 3. 4. 2

Handshk. Softw. Software 2. 2. 5. 1/2. 3. 5. 1

Handshake mode ο Hardw. Hardware 2. 2. 5. 2/2. 3. 5. 2

# None No handshake 2. 2. 5. 3/2. 3. 5. 3

DataBit 7Bits 7 data bits 2. 2. 6. 1/2. 3. 6. 1

Number of data bits ο 8Bits 8 data bits 2. 2. 6. 2/2. 3. 6. 2

3) dataout Comm.SBI COM. Output in.wio Without stability 3. 1. 1. 1

Data PC Manual/automatic ο IN. After After stability 3. 1. 1. 2

output communication IN.at At stability 3. 1. 1. 3

Auto.wio Auto without stability 3. 1. 1. 4

Aut.With Auto with stability 3. 1. 1. 5

Stop ο off Auto output off 3. 1. 2. 1

Auto output on Auto output on 3. 1. 2. 2

Aut.Cycl. ο Every 3. 1. 3. 1

Time-dependent automatic data output 2ndvalue 3. 1. 3. 2

Format Line format ο 16chars (digit not identified) 3. 1. 4. 1

22chars (digit identified) 3. 1. 4. 2

Extr.line (date, time, and weight value) 3. 1. 4. 4

Auto.Tare ο Off Auto tare off 3. 1. 5. 1

Auto taring after data output On Auto tare on 3. 1. 5. 2

Print.para res.olution Manual without Manual without stability 3. 2. 1. 1

Parameters (manual/auto) ο man.after Manual after stability 3. 2. 1. 2

for printing man.at Manual at stability 3. 2. 1. 3

auto.lc Auto at load change 3. 2. 1. 6

Format Line format for printout 16chars (digit not identified) 3. 2. 2. 1

ο 22chars (digit identified) 3. 2. 2. 2

Extr.line (date, time, and weight value) 3. 2. 2. 4

Prt.Init. Printout off Printout off 3. 2. 3. 1

of application parameters ο all Print all parameters 3. 2. 3. 2

Mainpar. Print main parameters 3. 2. 3. 3

GLP ISO/GLP- ο off Printout off 3. 2. 4. 1

compliant printout cal.adj. For calibration/adjustment only 3. 2. 4. 2

Always Printout always on 3. 2. 4. 3

tar./prt. ο off Taring off 3. 2. 5. 1

Tare bal./scale after individual print on Taring on 3. 2. 5. 2

Time ο 24h 24 h display 3. 2. 6. 1

12h 12 h display (AM/PM) 3. 2. 6. 2

Date ο dd.mmm.yy Date format 3. 2. 7. 1

mmm.dd.yy Date format 3. 2. 7. 2

# = Factory setting for “PC-USB” interface

16

Page 17

RS-232 Interface Port

Purpose

The weigh cells are equipped with

a data interface for connection to

a computer or other peripheral device.

Computer

You can connect a computer to alter,

start or monitor weigh cell functions.

Features

Type of interface: Serial interface

Operating mode: Full duplex

Standard: RS-232

Transmission rates: 600 to 115,200 baud

Parity: Space, odd, even

Character format: Start bit, 7-bit ASCII, parity 1 or 2 stop bits

Handshake mode: For 2-wire interface: software (XON/XOFF)

For 4-wire interface: hardware (CTS/DTR)

Operating mode: SBI (ASCII), XBPI*

* XBPI operating mode:

Always with 9600 baud, 8-bit, parity odd, 1 stop bit.

There are numerous additional commands for communicating with the weigh cell.

Please contact Sartorius for more information about their operation.

Protocols

For data exchange, the interfaces are configured with the following protocols:

– Printer output

– SBI (Sartorius Balance Interface): Sartorius standard protocol for output to a PC or control

unit. This simple ASCII-based protocol allows you to use ESC commands from your PC to

control the basic weighing functions.

– xBPI (eXtended Balance Processor Interface, also known as X-Bus): Binary protocol with

extended scope of commands. This protocol lets you control numerous weighing functions. For further information on this, please contact Sartorius. To use the protocols,

application software must be installed on the PC.

Synchronization

During data communication between balance and PC, messages consisting of ASCII or

binary characters are transmitted via the interface. For error-free data exchange, parameters for baud rate, parity, handshake mode, and character format must be identical for

both units. You can configure the respective settings in System Settings (menu).

In addition to these settings, data output for the balance can also be made dependent on

several conditions that are defined in the individual tasks. These conditions are described

under each of the tasks.

17

Page 18

Data Output

You can define the data output parameter so that output is activated either when a print

command is received or automatically synchronized with the display or at defined intervals

(see application programs and autoprint settings).

Data Output following Print Command The print command can be transmitted by pressing the P key or by a software command (EscP).

Automatic Data Output In Autoprint mode, data is output to the data interface port without an extra print

command. You can have synchronized data output automatically at defined display update

intervals, with or without the stability parameter. The interval time depends on the balance

operating status and balance type.

If the automatic data output is activated in the Device Configuration, it starts immediately

after the balance is turned on. You can also configure whether the automatic data output

can be stopped and started with the P key.

Data Output Formats

You can output the values displayed in the line for measured values and weight units with or

without an ID code. Configure this output parameter in the Device Parameters menu (Menu

> Device parameters > Configure data output > Line format).

Example: Output without Identification + 253 pcs 16 characters are printed

Example: Output with Identification Qnt + 253 pcs 22 characters are printed

Data Output Format with 16 Characters

Display segments that are not activated are output as spaces.

The type of character that can be output depends on the character‘s position:

Position 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

+ A A A A A A A * E E E CR LF

or – . . . . . . . * * *

or * * * * * * * * *

18

*: Space CR: Carriage return

A: Displayed characters LF: Line feed

E: Unit characters . : Decimal point

Special Outputs

Position 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

* * * * * * * * * * * * * * CR LF

or H i g h

or L o w

or C a l . E x t .

*: Space High: Overload

Cal. Ext.: Adjustment, external Low: Underweight

Error Message

Position 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

E r r * # # # * * * * CR LF

A P P . E R R

D I S . E R R

P R T . E R R

*: Space # # #: Error code

1

)For cause and solution, please refer to the “Troubleshooting Guide”

1)

* * * * CR LF

1)

* * * * CR LF

1)

* * * * CR LF

Page 19

Example: Output of the weight value + 123.56 g

Position 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

+ * * * 1 2 3 . 5 6 * g * * CR LF

Position 1: Plus or minus sign or space

Position 2: Space

Positions 3 – 10: Weight value with decimal point; leading zeros are output as spaces.

Position 11: Space

Position 12 – 14: Characters for unit of measure or space

Position 15: Carriage return

Position 16: Line feed

Data Output Format with 22 Characters

When data is output with an ID code, the 6-character code precedes the 16-character string described above.

These six characters identify the subsequent value.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

K K K K K K + * A A A A A A A A * E E E CR LF

* * * * * – . . . . . . . . * * *

* * * * * * * * *

K: ID code character E: Unit characters

*: Space CR: Carriage return

A: Displayed characters LF: Line feed

Example:

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

N + 1 2 3 . 5 6 * g * * CR LF

SBI Setting:

In the “SBI” setting (menu code 1. 5. 6. 1), the non-verified display digit is not automatically identified.

Please take the corresponding measures or adjust the settings on the peripheral device.

Special Outputs

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

S t a t * * * * * * * * * * * * * * * * CR LF

H i g h

L o w

C a l . E x t .

*: Space High: Overload

Cal. Ext.: Adjustment, external Low: Underweight

Error Message

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

S t a t * * * * * E R R * # # # * * * * CR LF

S t a t * * * * * A P P . E R R

S t a t * * * * * D I S . E R R

S t a t * * * * * P R T . E R R

1)

* * * * CR LF

1)

* * * * CR LF

1)

* * * * CR LF

*: Space # # #: Error code

1

) For cause and solution, please refer to the “Troubleshooting Guide”

Data Output Rates – Values per Second

Ambient Conditions (filter adjustment) XBPI / SBI “Autoprint”

Very stable (1.1.1.1) 20 20

Stable (1.1.1.2) 10 10

Unstable (1.1.1.3) 5 5

Very unstable (1.1.1.4) 2.5 2.5

19

Page 20

Data Input (Compatibility with Current Weigh Cells)

SBI Commands (Data Input Format)

The computer connected via the data port can send control commands to the balance to

control balance and application program functions.

These control commands may have different formats and contain up to 20 characters. Each

of these characters must be sent based on the setup configuration for data transmission.

Formats for Control Commands (Syntax)

Format 1: Esc ! CR LF

Format 2: Esc ! # _ CR LF

Esc: Escape

!: Command character

#: Number

&: Parameter (number or letter)

_: Underscore (ASCII: 95)

CR: Carriage return (optional)

LF: Line feed (optional)

Examples:

Format 1: Esc P

Format 2: Esc x1_

20

Page 21

Overview of SBI Commands

Format Comment Action/Function Note

1 ESC P Print at the interface sending the print request

1 ESC T “TARE” key; taring and zeroing

1 ESC K Filter “Very stable conditions”

1 ESC L Filter “Stable conditions”

1 ESC M Filter “Unstable conditions”

1 ESC N Filter “Very unstable conditions”

1 ESC O Lock keypad

1 ESC Q Acoustic signal

1 ESC R Unlock keypad

1 ESC S Restart

1 ESC Z Internal adjustment According to menu settings;

1 ESC U Taring

1 ESC V Zeroing

1 ESC Z External adjustment According to menu settings;

with standard weight 1/2 step increments

2 ESC f0_ S key

2 ESC f1_ Start adjustment

2 ESC f2_ V key

2 ESC kP_ Print as with “PRINT” key

2 ESC s3_ F key: Go back, exit, cancel

2 ESC x1_ ESC x1_ Print model

2 ESC x2_ Print serial no.

2 ESC x3_ Print software version

According to menu settings; with/without stability

1/2 step increments

(e.g., at multiple interfaces)

21

Page 22

Example:

“Calibration/Adjustment” Function via RS-232 Interface

Purpose

Adjustment is the correction of the difference between the measured value displayed and

the true weight of a sample, or the reduction of the difference to an allowable level within

maximum permissible error limits.

Features

The adjustment routine should only be started when

– The weigh cell is not loaded

– The weigh cell is tared

– The weighing signal is stable

– The sensitivity of the balance can be corrected by max. 2%.

If these criteria are not met, error message “Err 02” appears.

Error message “Err02”:

– Note ambient conditions

– Weigh cell needs stability

– If necessary, change the balance parameter settings:

Select Ambient conditions menu item 1.1.1.4 (very unstable) or execute interface

command ESC N

Adjustment can be made using different weight units:

CAL.Unit > Gram, Kilogr.

Internal Calibration

In the menu, the item Cal./adj. > cal.int. must be set.

The weigh cell housing has a built-in motorized calibration weight.

§ Select calibration/adjustment: Command ESC Z

> The internal calibration weight is loaded automatically

> The balance is adjusted/calibrated

> The internal calibration weight is removed

22

Page 23

Internal Calibration/Adjustment

External Calibration

Configuration:

SETUP > Bal.scal. > CAL./adj. > Cal.Int.

The weigh cell housing has a built-in motorized calibration/

adjustment weight.

§ Select calibration: Command ESC Z

> The internal calibration weight is automatically loaded

> The balance is calibrated

> When the setup is configured to “Calibration and adjustment in

one,” the balance will be adjusted automatically

> The internal calibration weight is removed

Performing Calibration and Adjustment Routines

The following settings can be configured:

– Always perform calibration and adjustment in one routine

(factory setting)

– After calibration, the user has the option to quit the routine

without correction or to adjust the balance.

If no deviations are found during calibration, the calibration/

adjustment routine can be exited after the calibration is completed.

Two keys are now active:

– Start the adjustment: Command ESC f1_

– Exit the routine: Command ESC f3_

Step Execute interface Display/

command Output

1. Tare balance ESC T 0.0000 g

Configuration:

SETUP > Bal.scal. > CAL./adj. > Ext.Cal.

The balance has a factory-set calibration weight value

(see“Specifications”).

Step Execute interface Display/

command Output

1. Tare balance ESC T 0.0000 g

2. Start adjustment routine ESC W Ext.cal.

Once you store the zero point,

a prompt for the required

calibration weight flashes

on the display. - 50.0000 g

3. Place displayed calibration 50.0000 g

weight on balance (in this

example: 50 g).

Weight too low:

a minus sign “-” is shown

Weight too high:

a plus sign “+” is shown

The display stops flashing

as soon as the weight value

is within the defined limit.

4. Adjustment carried out; Cal.end

adjustment weight is

displayed + 50.0000 g

2. Start adjustment routine ESC Z CAL.Int.

The internal calibration weight

is loaded automatically. CAL.RUN.

3. Adjustment carried out CAL.end

4. Internal weight is removed

from balance 0.0000 g

5. Remove the adjustment 50.0000 g

weight

23

Page 24

Pin Assignment Chart

Female Interface Connector:

14-contact round connector with screw

lock hardware

Pin Assignment

14-contact: 12-contact:

Electronics module of the weigh cell YDI05-Z... Zener barrier

14-contact 12-contact RS-232 signal RS-485 signal

round round (SBI and xBPI) (xBPI)

connector connector

G A

3

) Control output “heavier” Control output “heavier”

K B Data output (T+D) R+D – T+D – N

J C Data input (R+D) R+D – T+ D – P

N D Data terminal ready (DTR) –

M E Signal ground Signal ground

F G

3

) Control output “lighter” Control output “lighter”

A H Clear to Send (CTS) –

E J

O – Universal switch function

D L

3

) Control output “equal” Control output “equal”

3

) Control output “set” Control output “set”

2

) Universal switch function2)

Provide a low-resistance connection between shield and connector casing.

1

) RS-485 interface available on request

2

) For details, see “External Remote Switch” under “Additional Functions”

3

) Control output available only for YDI03-Z

1

)

24

Only electrical equipment with a maximum voltage rating Um of 250 V is permitted

to be connected to the Zener barrier. The voltage rating UZ of this Zener barrier is

12 V.

Cabling Diagram (Connecting Cable for PC)

YCC01-09ISM5 adapter cable, round, DB9-PC

Diagram for interfacing a computer via a Zener barrier to the weigh cell using the RS-232C/

V24 standard and cables up to 15 m long.

Warning When Using Prewired Connecting Cables:

Cables purchased from other manufacturers often have incorrect pin assignments

for use with Sartorius weighing instruments. Be sure to check the pin assignment

against the chart below before connecting the cable, and disconnect any lines marked

“Internally Connected.” Failure to do so may damage or even completely destroy your weigh

cell and/or peripheral device.

Page 25

Troubleshooting Guide

Error codes are displayed for about 2 seconds. The program then returns automatically to the previous mode.

Display Cause Solution

high or Err 55 Weighing capacity exceeded Unload the weighing pan

low or Err 54 Contact between load plate and environment; Weighing pan must not be in contact

load on weighing pan too light with surrounding parts

App.err. Cannot save data: Increase weight

Load on weighing pan too light or

no sample on pan while application is active

dis.err. Data output not compatible with output format Set the correct output format in the menu

prt.err. Data interface for printout locked Reset menu factory settings

or

Contact your local Sartorius Service Center

err 02 Calibration parameter not met,

e.g.:

– Unstable Correct the setup conditions

– Tare Calibrate only when zero is displayed

– Load on weighing pan Unload the balance/scale

err 10 “Tare” function is locked for Clear the tare memory to unlock the “Tare” function

active application program

“Net total” application program;

only one tare function can be used at a time

err 11 Tare memory not allowed Carry out “Tare” function

err 03 Zero point error at the end of calibration

err 06 Int. calibration weight faulty or not available Service

err 08 <> Zero range Error during zeroing (value outside 2%) Change process

err 09 < 0 not allowed Error during taring (tare value <0) Change process

err 19 Preload is too high The preload to be applied is too high Change the preload value

err 30 Balance/scale is in BPI mode Use service tool and built-in “Close” function

err 50 or 53 TC converter failure Service

err 241 Checksum error Service

err 243 Checksum error Carry out menu reset

err 245 or 247 Checksum error Calibrate/adjust balance/scale

err 249 Checksum error Service

Weight readout changes constantly Unstable ambient conditions Change setup location

(excessive vibration or draft) Adjust Setup configuration

Foreign body between weighing pan Remove foreign body

and housing

The weight readout is obviously wrong Balance/scale not calibrated/adjusted Adjust

Balance/scale not tared before weighing Tare

Weight data not output via the Initial connection of an optional 1) Move the lock switch back and forth

serial interface (err 294). YAC01…display and control unit (position see page 3 ff.).

2) Switch power off and then on again.

Check installation conditions; observe warm-up time;

repeat calibration

If any other errors occur, contact your local Sartorius Service Center.

Web address: http://www.sartorius.com

25

Page 26

Overview

Specifications

Standard specifications User-specific

modifications

Model WZA623-NX WZA6202-NX

Weighing capacity g 620 6,200

Readability g 0.001 0.01

Necessary preload onpan support g 600 0

Tare range (subtractive) g 100% of the maximum capacity

1

Repeatability (standard deviation)

Linearity <±g 0.002 0.02

1

Response time

) s < 1.5 < 2

Adaptation to ambient conditions By selection of 1 of 4 optimized filter levels

Display update (factory

setting, depends on filter level selected) s 0.1 – 0.4

Fast display update

(with menu code setting 1 14 2) s 0.02 – 0.1

Operating temperature range °C +10…+30 °C

Allowable ambient operating temperature °C +5…+40 °C

Sensitivity driftwithin +10… +30°C <±/K 2 · 10

External calibration weight g 200 (E2) 2000 (E2)

(of at least accuracy class)

Material:

– Weigh cell: Stainless steel (load receptor: chemically nickel-plated aluminum)

– Electronics module: Stainless steel aluminum/Stainless steel

Net weight, approx. kg 2.0 2.8

AC power source, power supply AC adapter 90 Vac (min.) to 264 Vac (max.)

Frequency 48 – 60 Hz

Power consumption 25 VA

Built-in interface RS-232C-S/V24-V28; 7-bit; parity: even, mark, odd, or space;

transmission rates 150 to 19,200 baud, 1 or 2 stop bits, software/hardware

handshake

IP protection rating of the weigh cell IP44

) <±g 0.001 0.01

–6

2 · 10

–6

1

) = depends on system design

26

Page 27

Overview

Dimensions (Balance Drawings)

Electronics module:

All dimensions shown in millimeters.

27

Page 28

Dimensions (Balance Drawings)

Weigh cell model: WZA623-NX

All dimensions shown in millimeters.

28

Page 29

Weigh cell model: WZA12001-NX

All dimensions are given in millimeters.

29

Page 30

Accessories

Product Order No.

Display and control unit with cable (2.5 m) for connection

to enclosed electronics module (factory installed) YAC01NX

Configuration software for settings,

calibration/adjustment and setting the preload Sartorius CAS-Suite

AC adapters

AC adapter for use outside of the hazardous area

(110…240 V, cable length: 20 m) YPSC01-Z..

! Install the cable so that it is protected from damage.

Connect the terminal of the housing to a terminal

for equipotential bonding or a grounding conductor.

AC adapter for use within the hazardous area

(110…240 V, cable length: 6 m) YPSC01-Z..

! Install the cable so that it is protected from damage.

Connect the terminal of the housing to a terminal

for equipotential bonding or a grounding conductor.

Electrical accessories

RS-232 Zener barrier for connecting accessories YDI05-Z

in the non-hazardous area/location; e.g., printer/PC, with option

RS-232 cable for PC/laptop with 9-contacts. Cable length: 5 m + M52

Cable length between electronics module and Zener barrier: 20 m + M56

! Install the cable so that it is protected from damage.

Connect the terminal of the housing to a terminal for equipotential

bonding or a grounding conductor.

Additional options and accessories available upon request

30

Page 31

31

Page 32

32

Page 33

FCC

upplier’s Declaration of Conformity

S

Device type Digital weighing unit

Model WZA6202-NX, WZA623-NX

P

arty issuing Supplier’s Declaration of Conformity /

R

esponsible Party – U.S. Contact Information

Sartorius Corporation

5 Orville Dr Suite 200

11716 Bohemia, NY

USA

Telephone: +1.631.254.4249

F

CC Compliance Statement

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

I

nformation to the user

Note: This equipment has been tested and found to comply with the limits for a c

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

lass B

Connections between the device and peripherals must be made using shielded cables in order

to maintain compliance with FCC radio frequency emission limits.

Any modifications made to this device that are not approved by Sartorius may void the

authority granted to the user by the FCC to operate this equipment.

___________________________________________________________________________________________

Doc: 2417130-00 SLI18FCC044-00.en 1 / 1 PMF: 2032658 OP-113_fo1_2015.10.12

33

Page 34

1

EC-TYPE EXAMINATION CERTIFICATE

2

Equipment or Protective systems intended for use in Potentially

Explosive Atmospheres - Directive 94/9/EC

3

EC-Type Examination Certificate No: FM15ATEX0013X

4

Equipment or protective system:

(Type Reference and Name)

5

Name of Applicant: Sartorius Lab Instruments GmbH & Co. KG

6

Address of Applicant: Weender Landstrasse 94 - 108

7 This equipment or protective system and any acceptable variation thereto is specified in the schedule to this

certificate and documents therein referred to.

8 FM Approvals Ltd, notified body number 1725 in accordance with Article 9 of Directive 94/9/EC of 23 March

1994, certifies that this equipment has been found to comply with the Essential Health and Safety Requirements

relating to the design and construction of equipment intended for use in potentially explosive atmospheres given

in Annex II to the Directive.

The examination and test results are recorded in confidential report number:

9 Compliance with the Essential Health and Safety Requirements, with the exception of those identified in item 15

of the schedule to this certificate, has been assessed by compliance with the following documents:

10 If the sign ‘X’ is placed after the certificate number, it indicates that the equipment is subject to specific

conditions of use specified in the schedule to this certificate.

11 This EC-Type Examination certificate relates only to the design, examination and tests of the specified

equipment or protective system in accordance to the directive 94/9/EC. Further requirements of the Directive

apply to the manufacturing process and supply of this equipment or protective system. These are not covered by

this certificate.

12 The marking of the equipment or protective system shall include:

II 2 G Ex ib IIC T4 Gb

II 2 D Ex ib IIIB T80 °C Db -10°C ≤ Ta ≤ +40°C

EN 60079-0:2012, EN 60079-11:2012 and EN 60529:1992+ A2:2013

WZAab-NXc Intrinsically Safe Digital Weighing Unit

Goettingen 37075

Germany

st

3053244 dated 21

May 2015

34

Mick Gower

Certification Manager, FM Approvals Ltd.

Issue date: 27

THIS CERTIFICATE MAY ONLY BE REPRODUCED IN ITS ENTIRETY AND WITHOUT CHANGE

FM Approvals Ltd. 1 Windsor Dials, Windsor, Berkshire, UK. SL4 1RS

T: +44 (0) 1753 750 000 F: +44 (0) 1753 868 700 E-mail: atex@fmapprovals.com www.fmapprovals.com

F ATEX 020 (Apr/14) Page 1 of 3

th

May 2015

Page 35

SCHEDULE

to EC-Type Examination Certificate No. FM15ATEX0013X

13

Description of Equipment or Protective System:

The WZAab-NXc Intrinsically Safe Digital Weighing Unit is used for weighing small amounts of weights

but with high accuracy. Additional data transfer can be made by an intrinsically safe RS232, RS485 or

RS422 data output board with and without digital I/O signals. As an option all models can be equipped

with a display unit.

The intrinsically safe digital weighing unit series WZAab-NXc consists of a weighing cell, an electronic

box and optionally a display unit. The WZAab-NXc is suitable for use in hazardous areas Zone 1 with

gas group IIC and temperature class T4 and for use in hazardous areas Zone 21 group IIIB. The

maximum surface temperature for dusts is 80°C.

WZAab -NXc Intrinsically Safe Digital Weighing Unit

-10°C ≤ Ta ≤ +40°C

a = up to four numbers denoting the maximum load

b = one number for number of digits behind the decimal point

c = up to four letters and/or numbers or blank

Electrical Parameters:

Connections to the DC Supply Connector

Circuit Ui Ii Pi Ci Li

V_1 12.6 V 133 mA 1.46 W 188 nF 0.0 mH

V_2 12.6 V 133 mA 1.46 W 3 nF 0.0 mH

V_3 8.6 V 187 mA 1.51 W 391 nF 0.0 mH

V_4 12.6 V 150 mA 1.68 W 223 nF 0.1 mH

The WZAab-NXc Digital weighing unit may be powered by the Sartorius Ex-Battery Pack YRB02-X

(KEMA 03ATEX2137X) or by the Sartorius power supply type YPS02-X.. (KEMA 98ATEX0892 X),

YPS02-Z.. (KEMA 98ATEX0611 X), YPSC01-X or YPSC01-Z (KEMA 08 ATEX 0044) or by any other

suitable power supply with EC-TYPE EXAMINATION CERTIFICATE.

Connections to the Data Adapter Board (COM1)

Circuit Ui Ii Pi Ci Li

RS232 12.6 V*/25.2 V** 328 mA*** any 2.2 nF*/0.5nF** 0 mH

RS422 8.6 V 210 mA 0.5 W 0.5 μF 0 mH

RS485 See Table 1 See Table 1 any 260nF 0 mH

Digital I/O 8.6 V any any 0 μF 0 mH

*: versus ground; **: between the lines; ***: resistively limited

Table 1: For the RS485 communication

Ui

Ii

Rmin

RS485 (Rmin = Ui / Ii is the minimum output resistance of the combined circuits of the associated

apparatus connected to the WZAab-NXc)

THIS CERTIFICATE MAY ONLY BE REPRODUCED IN ITS ENTIRETY AND WITHOUT CHANGE

FM Approvals Ltd. 1 Windsor Dials, Windsor, Berkshire, UK. SL4 1RS

T: +44 (0) 1753 750 000 F: +44 (0) 1753 868 700 E-mail: atex@fmapprovals.com www.fmapprovals.com

F ATEX 020 (Apr/14) Page 2 of 3

±12.4 V 12 V 7.2 V

130 mA*** 164 mA*** any

95.4 Ω 73.2 Ω any

35

Page 36

SCHEDULE

to EC-Type Examination Certificate No. FM15ATEX0013X

Output parameters (COM1)

Circuit Uo Io Po Co Lo Lo/Ro

RS232 10.0 V*/20.0V** 101 mA*** 253 mW 3 μF*/217nF** 3 mH 140μH/Ω

RS422 5.2 V 290 mA 496 mW 60 μF 300 μH 50μH/Ω

RS485 5.2 V 210 mA*** 263 mW 60 μF 600 μH 125 μH/Ω

Digital I/O 6.0 V 45 mA*** 67 mW 40 μF 20 mH 530 μH/Ω

*: versus ground; **: between the lines; ***: resistively limited

14

Specific Conditions of Use:

1. The front panel (of the optionally used display unit) of the intrinsically safe digital weighing unit WZAab-

2. The cables between the electronic box and weighing cell and between the electronic box and display unit

3. Electrostatic charges shall be avoided. Use only a damp cloth to wipe down the equipment.

15

Essential Health and Safety Requirements:

The relevant EHSRs that have not been addressed by the standards listed in this certificate have been identified

and assessed in the confidential report identified in item 8.

16

Test and Assessment Procedure and Conditions:

This EC-Type Examination Certificate is the result of testing of a sample of the product submitted, in

accordance with the provisions of the relevant specific standard(s), and assessment of supporting

documentation. It does not imply an assessment of the whole production.

Whilst this certificate may be used in support of a manufacturer’s claim for CE Marking, FM Approvals Ltd

accepts no responsibility for the compliance of the equipment against all applicable Directives in all

applications.

This Certificate has been issued in accordance with FM Approvals Ltd’s ATEX Certification Scheme.

NXc is non-metallic and shall not be used where UV light or radiation may impinge on the enclosure.

must be permanently installed and protected against damages.

36

17

Schedule Drawings

A list of the significant parts of the technical documentation is annexed to this certificate and a copy has

been kept by the Notified Body.

18

Certificate History

Details of the supplements to this certificate are described below:

Date Description

27th May 2015 Original Issue.

THIS CERTIFICATE MAY ONLY BE REPRODUCED IN ITS ENTIRETY AND WITHOUT CHANGE

FM Approvals Ltd. 1 Windsor Dials, Windsor, Berkshire, UK. SL4 1RS

T: +44 (0) 1753 750 000 F: +44 (0) 1753 868 700 E-mail: atex@fmapprovals.com www.fmapprovals.com

F ATEX 020 (Apr/14) Page 3 of 3

Page 37

3738394041

Page 38

Page 39

Page 40

Page 41

1) Install the equipment in compliance with applicable laws, rules and regulations, ordinances and standards. In

particular, be sure to conform to the European Standards EN 60079-14 (Explosive atmospheres – Part 14:

Electrical installations design, selection and erection). For more information see „Verification of Intrinsic Safety“

2020665.

2) Be sure to follow the installation, operating, maintenance and servicing instructions given in the manuals

supplied.