Page 1

Application Instructions | Applikationshinweise

Sartorius WZA25-NC

98648-018-08

Page 2

English – page 2

Deutsch – Seite 9

2

Page 3

Contents 1. General

1. General . . . . . . . . . . . . . . . . . . 3

1.1 Intended Use . . . . . . . . . . . . . . 3

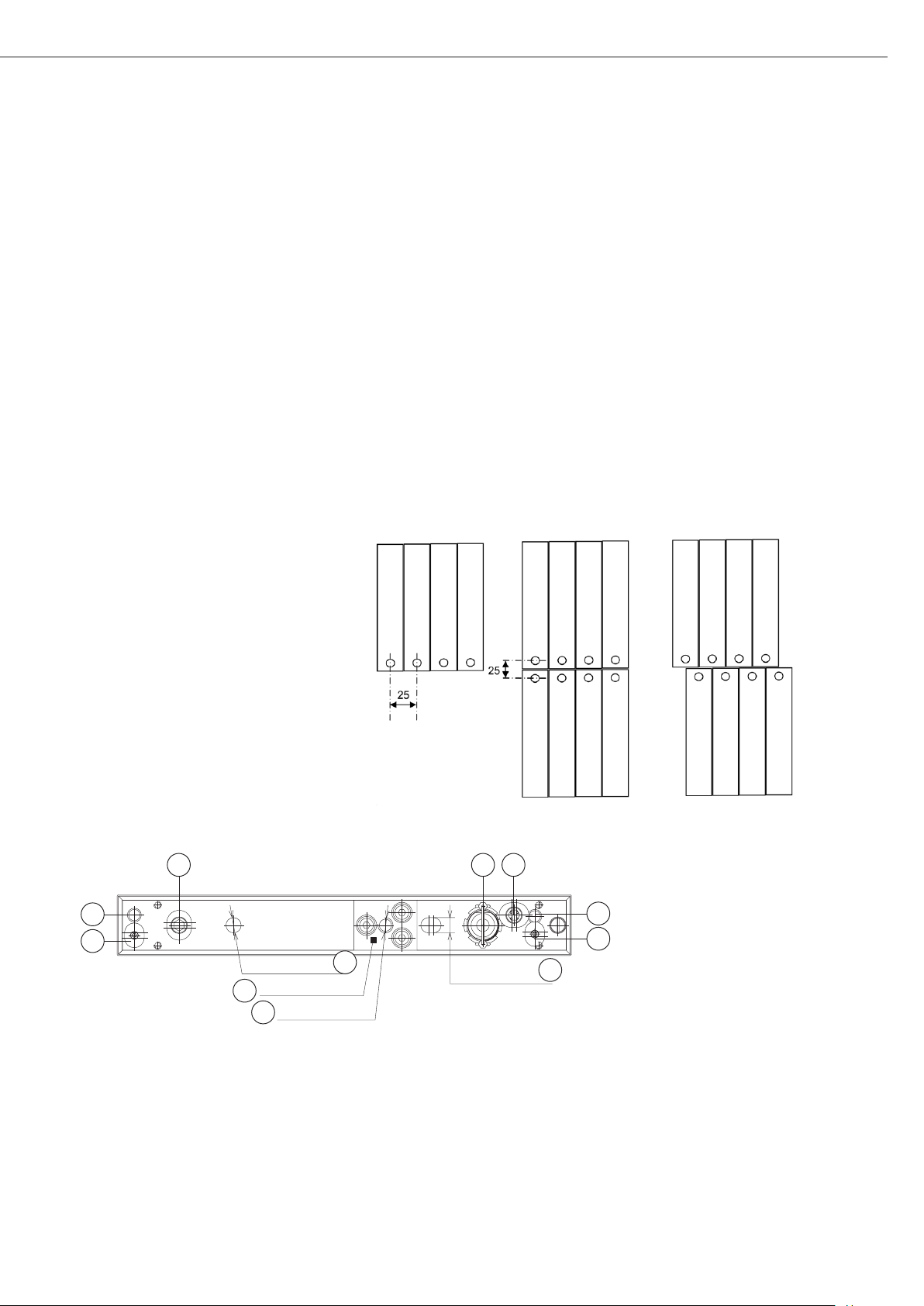

1.2. Connections. . . . . . . . . . . . . . . 3

1.3. Securing the Weigh Cell ......3

2. Transducer................4

3. IP Protection ..............5

4. Internal Calibration......... 6

5. Cooling Air Operation ....... 6

6. Enclosure.................7

7. Interconnection

of Multiple Cells ...........8

7.1 Interconnection

of Pneumatic Functions ...... 8

7.2 Interconnection

of Electronic Functions.......8

8. Optimal Operating Point..... 8

These application instructions are

a supplement to the accompanying

installation instructions. The application

instructions address particular features

of the WZA25-NC.

Please read the accompanying installa-

tion instructions carefully.

1.1 Intended Use

The WZA25-NC weigh cell was devel-

oped for automatic weighing facilities

and metering units in the pharmaceutical industry in particular.

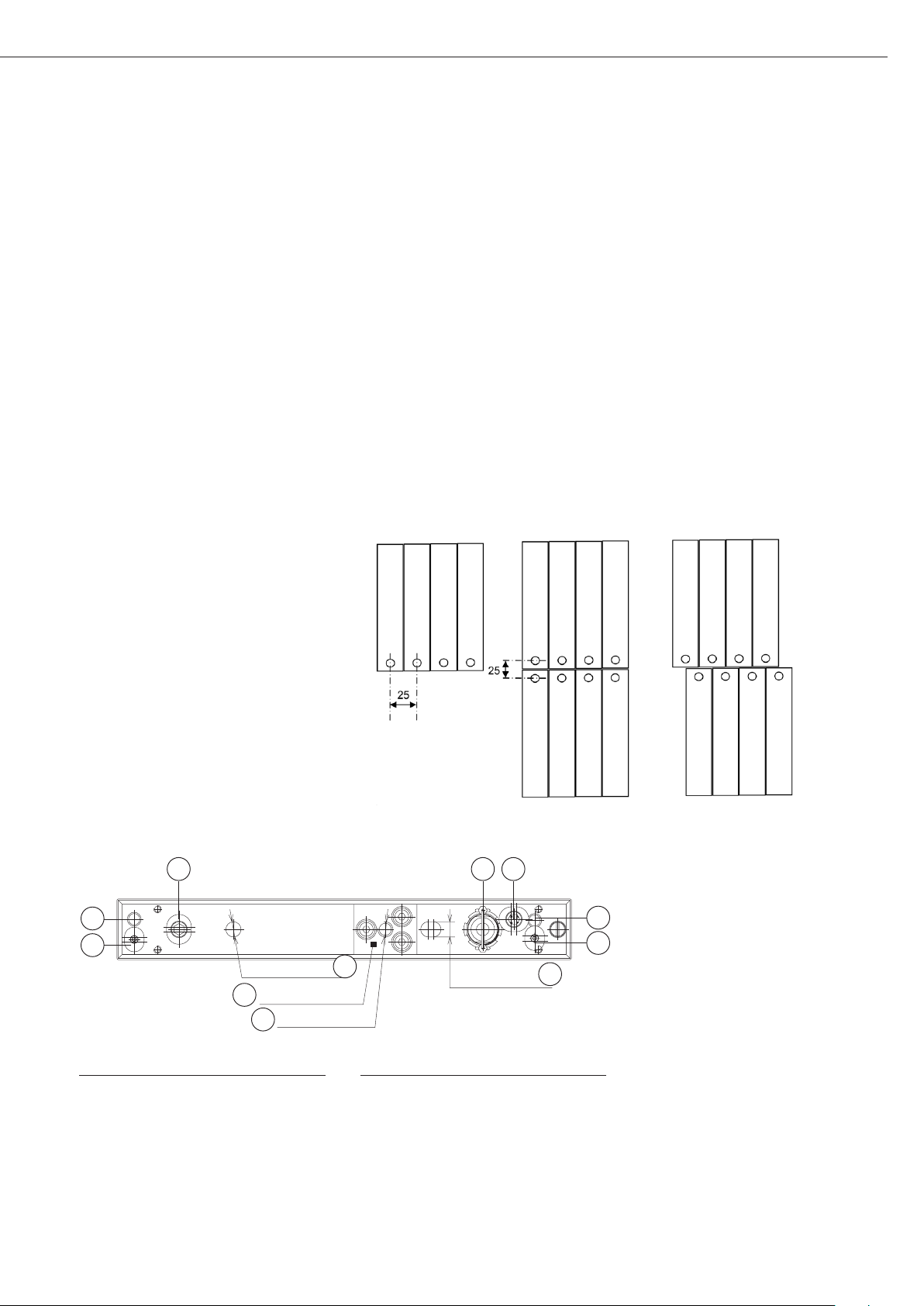

Multiple cells can be interconnected

in a row, 25 mm apart from each other.

It is also possible to interconnect them

in two rows, where a 25-mm distance

can be achieved.

Using special measures, a protection

rating of IP68 can be achieved when

the system using the weigh cell is being

cleaned. This function also has a pneumatic drive, which easily enables the

interconnection of multiple cells (see

Section „Interconnection of Multiple

Cells“).

The cells have a built-in calibration

weight, which can be used to check

that the cells are functioning properly

or to readjust the sensitivity of the cells.

1.2 Connections

8 5 9

10

6

d 6 H8; 6 deep

Mounting surface

1

M6; 6 deep

2

6 and 7 are sintered filters.

Pos. Description

Mounting surface

Threaded hole for mounting

Positioning holes

Electrical connection

Pressure inlet weight circuit

6 bar, d 3 mm

All dimensions are given in millimeters

3

6 H8; 6 deep

Pos. Description

Pressure inlet closing mechanism

6 bar, d 3 mm

Air inlet for rinsing cycle < 50 mbar

Air outlet for rinsing cycle

< 50 mbar

Pressure outlet for and

1.3 Securing the Weigh Cell

Secure the weigh cell at low tension to

the mounting surface 1 (second Figure)

with an M6 screw. Observe the maximum screw installation depth.

10

Use the positioning holes 3 and 4 to

align the weigh cell exactly.

7

Use the M6 fixing screw to connect to

4

the device ground in order to divert

electrostatic charges.

3

Page 4

d

d

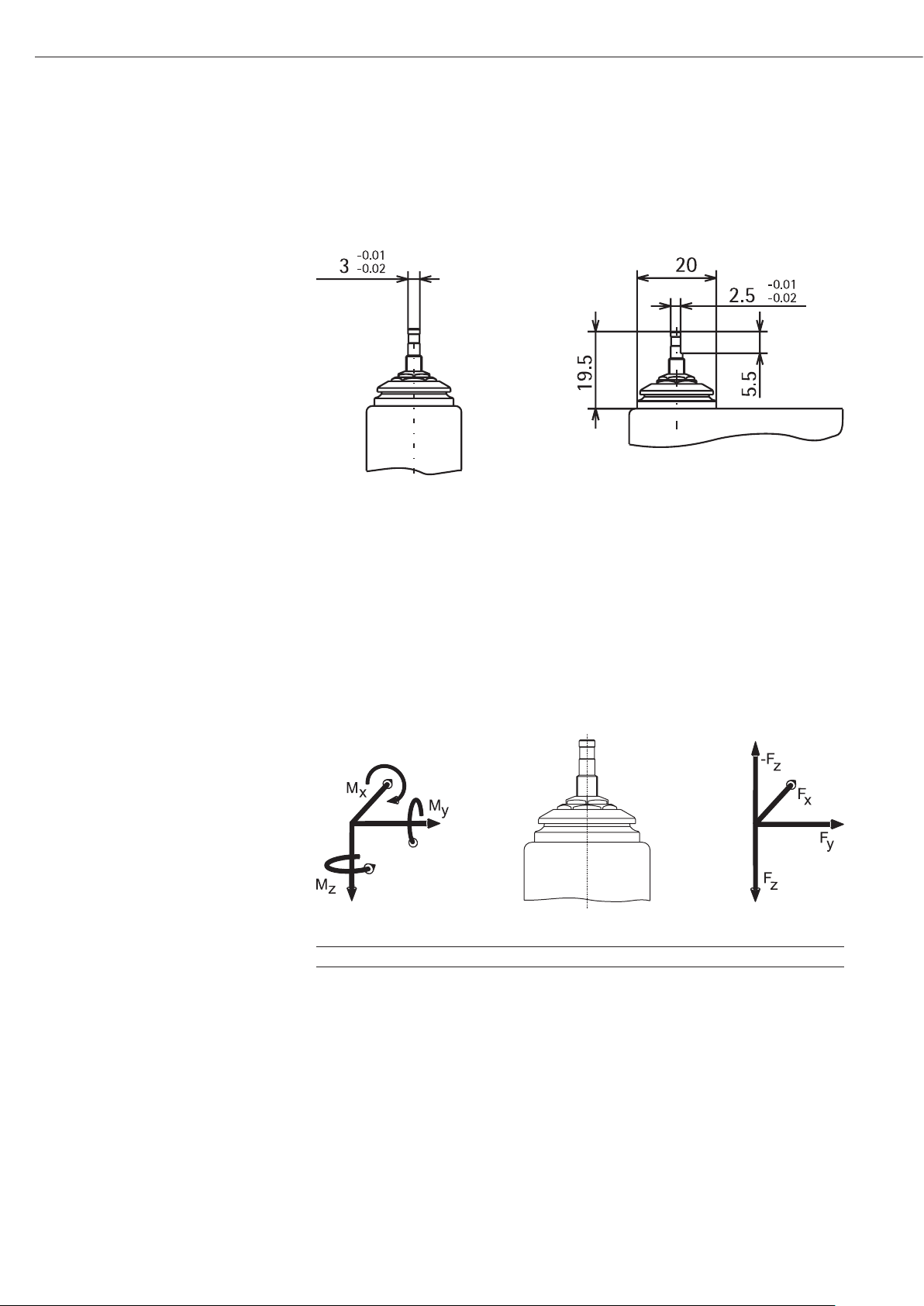

2. Transducer

The weigh cell is equipped with a partially beveled cylindrical stud (see Figure) for securing a

transducer at the customer‘s premises. The beveling (2.5 mm) serves to secure the transducer

in a specified direction of rotation.

The transducer can be installed on this stud using clamps, for example. The transducer

should consist of conductive, non-magnetic material in order to minimize electrostatic and

magnetic interference. The transducer must weigh 5 g ± 0.1 g, so that the full weighing

capacity of 20 g can be achieved. It must be smaller than 10 g in order to use the internal

calibration function. Remove the transducer when transporting the weigh cell.

The stud is overload protected. Do not exceed the maximum forces and torque. The stud

may bend due to the effects of forces or torque.

Bending can occur if torque is greater than 2 mNm for a 5 g transducer.

Model Max. torque Screwing torque Max. force opposite to Max. forces

M

WZA25-NC 0.1 Nm 0.5 Nm 2 N 2 N

, My, Mz direction of load (-Fz) Fx, Fy, F

x

z

4

Page 5

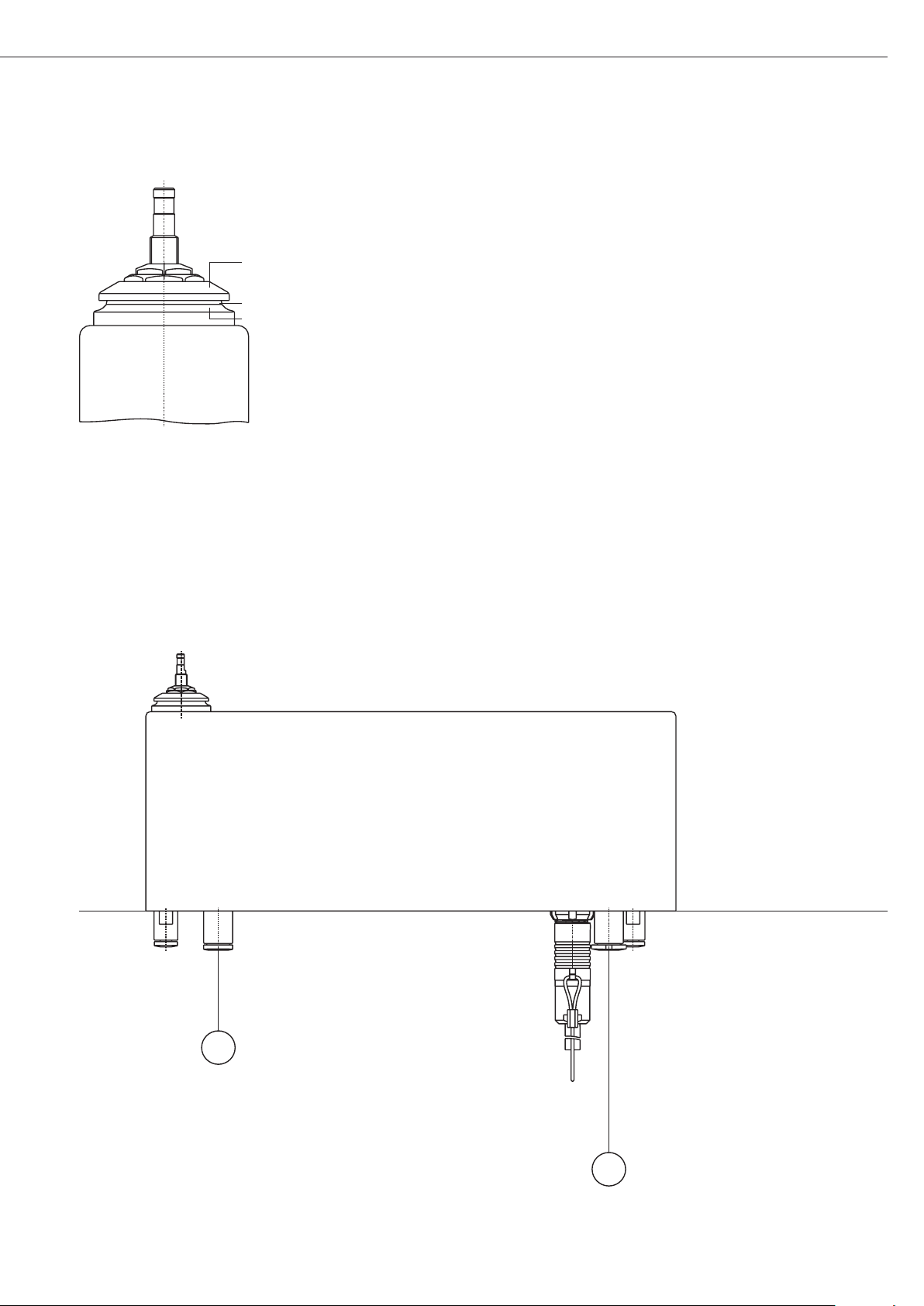

8

9

Shield plate

Gap

Seal ring

3. IP Protection

The cell has a rating of IP44 in normal weighing mode. This protection rating is only valid

when there is a gap between the shield plate and the seal ring.

The gap is sealed by applying the pressure inlet (7) at 6 bar. A closing mechanism is set

in the space, which pulls the stud and shield plate against the seal ring. Observe a distance

of approx. 1 mm between the transducer and the rest of the equipment. In this position,

the cell does not provide a weight value; instead it displays the error message, “H.”

After the closing mechanism is opened, the weigh cell requires some time to restabilize.

The connection side of the weigh cell can be sealed by placing a seal between the lower

edge of the weigh cell housing and the mounting plate. Use as soft a sealing material as

possible (e.g., Sili-Rex silicone foam round cords from Rexio GmbH Co. KG, Westerrönfeld,

Germany) in order to minimize the force on the cell housing. This process causes the plug

and pressure outlet to be outside of the contamination and cleaning area (process side).

The connection side has a rating of IP44.

Cleaning

Apply overpressure to ensure that cleaning fluid does not penetrate the weigh cell.

To do so, apply an overpressure of max. 50 mbar through overpressure inlets 8 and 9 to the

weigh cell interior (use dry filtered oil-free and particle-free air only).

Once cleaning is successfully complete, the closing mechanism can be opened, and air can

continue to be blown into the cell. The air exits through the gap and dries the area after

cleaning.

Process side

Connection side

5

Page 6

4. Internal Calibration

8 5 9

5. Cooling Air Operation

The weigh cell has a built-in calibration

weight, which can be used to check that

the cell is functioning properly or to readjust the sensitivity of the cell. The built-in

calibration weight has a mass of approx.

10 g. It is calibrated at the factory.

The calibration value is entered in the

data record as the “user-defined weight“

and should not be overwritten (except

when recalibration occurs). Use the Public

CAS software tool to enter the calibration

weight.

The weigh cell is calibrated/adjusted in

the same way as it would be using a

user-defined weight. The menu is pre-set

accordingly (1.1.9.3 and 1.1.10.1).

Calibration is triggered via interface

command Esc f1_ when the weigh cell has

nothing on it (see installation instructions).

Upon triggering the calibration, 6 bar must

be applied to the pressure inlet for the

weight circuit

exceeded. Then switch off the pressure.

until the value has been

The weigh cell must not exceed an internal temperature of 60°C during cleaning.

Monitor the internal temperature when the cell is being cleaned with hot cleaning agents.

Monitoring can be done via the following XBPI commands:

XBPI Commands: Temperature Sensor

For in-depth information concerning Sartorius xBPI-functions refer to manual “Sartorius

– Description of Protocols and Functions in the Weighing Platform Interface”

Read Temperature

Fct.No. Input Output

076H Unsigned 1 Float5 (xBPI command response)

Input parameter Unsigned 1 (1) relates to existing sensor (only sensor 1)

Bit Explanation (if bit =1)

0 Sensor 1

Example

Function XBPI-Command Response

Read Temperature Len, 01, 09, 76, 21, 00, Chk Len, 41, 35, float5, Chk

example: 06:01 09 76 21 example:

00:A7 08:41 35 41 CE 05 E0 00:72

→ internal Temperature = 25.753°C

Len = Numbers of bytes to follow, including the checksum

Chk = Checksum of the entire message including the “length” byte; Module 256 – sum of

all preceding bytes(*)

(*) for comprehensive information refer to manual “Sartorius – Description of Protocols

and Functions in the Weighing Platform Interface”

Please note:

– The temperature sensor is not individually calibrated - it is good to measure temperature

differences of some degrees.

– The temperature sensor is thermally connected to a massive metallic part - it is much

slower than the air temperature.

Dry, oil-free, filtered cooling air can be directed through the cell if the temperature

of the cleaning agent is greater than 60°C (inlet connection 8, outlet connection 9).

The pressure within the cell cannot exceed 50 mbar, and the air volume cannot exceed

1500 liters per hour. Cooling air can also be used to return the cell to an operating

temperature more quickly once the cell has been successfully cleaned. After cleaning,

allow the cooling air to flow in, keeping the closing mechanism of the shield plate open

(no pressure to connection 7). This process dries the area around the seal.

Cooling results greatly depend on how the weigh cell is installed and therefore must be

determined by testing it on site.

10

10

6

d 6 H8; 6 deep

Mounting surface

1

M6; 6 deep

2

3

6 H8; 6 deep

4

7

6

Page 7

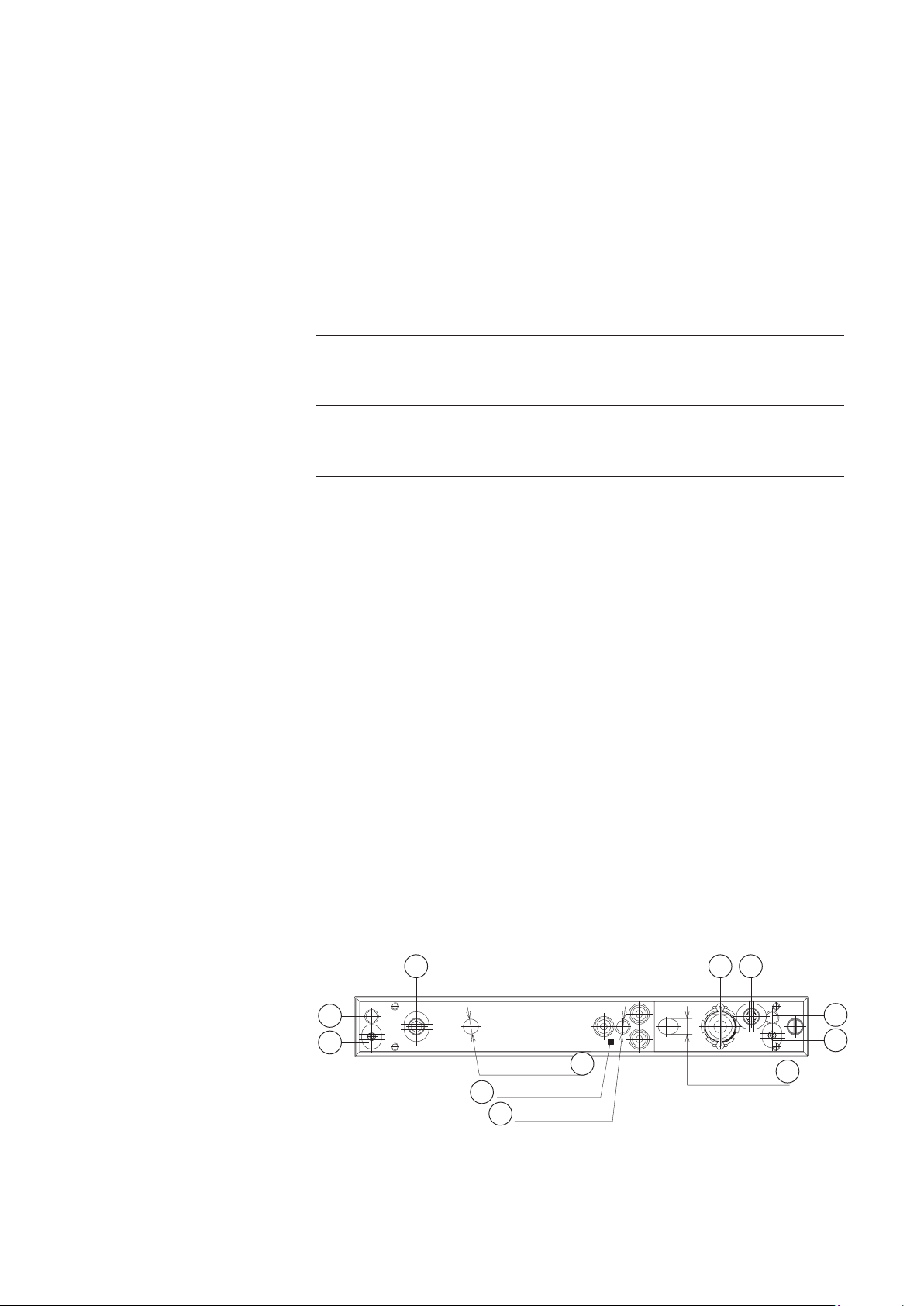

6. User-Specific Housing

One or more weigh cells can be equipped with an additional

housing for their protection or to make cleaning easier.

This housing should be made of non-magnetic materials.

Stud

Lock nut

Shield plate

Sealing plate

To seal the weigh cell(s) in an IP-compliant way, complete the

following steps:

– Remove the weighing pan.

– Loosen the lock nut of the shield plate using the supplied tools.

Ensure that the lock nut is unscrewed evenly, to avoid transfer-

ring torque to the stud.

– Unscrew the lock nut and shield plate from the stud.

– Unscrew the sealing plate using the supplied tools.

– Unscrew the coupling nut located under the sealing plate.

– Attach the housing with a drill hole with a diameter of 11 mm

and a maximum thickness of 2.5 mm.

– Reattach the parts in a reverse order to the way they were

removed.

– Set the gap between the shield plate and sealing plate to approx.

1 mm. (Use a thickness gauge.)

Housing

7

Page 8

7. Interconnection of Multiple Cells

8. Optimal Operating Point

7.1 Interconnection of Pneumatic Functions

The pressure inlets for triggering calibration (6) or the closing

mechanism (7) can be interconnected using T-pieces and controlled

via one valve.

Overpressure can be applied to multiple cells by interconnecting

the sealing air inlets (8) and (9) of multiple cells using the

appropriate T-pieces. The maximum overpressure of 50 mbar must

not be exceeded during this process.

During cooling air operation, the air must be evenly distributed

among all connected cells, and the maximum overpressure must

not be exceeded. Use the appropriate dimensions for inlet and

outlet cross-sections and distributions.

7.2 Interconnection of Electronic Functions

The electricity supply inlets can be interconnected to an adaptor

with the appropriate power capacity. Ensure that the shields of the

data output cable are placed only on one side of the E-box and

that the signal lines are galvanically separated.

Multiple cells can be connected to a computer via several RS-232

interfaces or via a terminal server (e.g., multiple-port NPort Server

from Moxa).

When a weighing system is accelerated in the direction of the

weighing axis, acceleration forces of effective seismic masses occur,

which show in the measuring signal as interference.

By filtering the signal, the effect of this interference on the measurement result is reduced. The size of the effective seismic masses

depends on the mass distribution on the measurement system and

the size of the mass on the stud. The measurement system used in

the WZA25-NC has a shape and size that has minimal influence,

if the system weighs 15 g (transducer and object being weighed).

This operating point is also optimal in terms of sensitivity drifts and

should be strived for every time the weighing system is operated.

8

Page 9

Befestigungsfläche

6 H8; 6 tief

d 6 H8; 6 tief

M6; 6 tief

10

6

8 5 9

10

7

3

1

2

4

Inhalt

1. Allgemeine Hinweise

1. Allgemeine Hinweise . . . . . . . 9

1.1 Verwendungszweck . . . . . . . . 9

1.2. Anschlüsse . . . . . . . . . . . . . . . 9

1.3. Befestigung der Wägezelle . . . 9

2. Lastaufnahme ............ 10

3. IP- Schutz ...............11

4. interne Justierung......... 12

5. Kühlluftbetrieb ........... 12

6. Umgehäuse . . . . . . . . . . . . . . 13

7. Zusammenschalten

mehrerer Zellen........... 14

7.1 Zusammenschalten der

pneumatischen Funktionen .. 14

7.2 Zusammenschalten der

elektronischen Funktionen ...14

8. Optimaler Arbeitspunkt..... 14

Diese Applikationshinweise stellen eine

Ergänzung der beiliegenden Installationsanleitung dar. Die Applikationshinweise gehen speziell auf die Besonderheiten der WZA25-NC ein.

Bitte lesen sie sich aufmerksam die

oben genannte Installationsanleitung

durch.

1.1 Verwendungszweck

Die Wägezelle WZA25-NC wurde für

automatische Wägeanlagen und Dosiereinrichtungen insbesondere in der

Pharmaindustrie entwickelt.

Mehrere Zellen können in einer Linie

mit 25 mm Abstand zusammengeschaltet werden. Es sind natürlich auch

2 Reihen die wiederum einen Abstand

von 25 mm haben können möglich.

Durch besondere Maßnahmen kann

während des Reinigungsprozesses

der Anlage in der die Zelle eingesetzt

wurde, ein Schutzgrad IP68 hergestellt

werden. Diese Funktion verfügt auch

über einen Druckluftantrieb, der auf

einfache Weise die Zusammenschaltung

mehrerer Zellen erlaubt (siehe Kapitel

»Zusammen schalten mehrer Wägezellen«).

Die Zellen verfügen über ein einge-

bautes Justiergewicht mit dem die

ordnungsgemäße Funktion überprüft

werden kann bzw. die Empfindlichkeit

der Zelle nachjustiert werden kann.

1.2 Anschlüsse

6 und 7 sind Sinterfilter

Pos. Bezeichnung

Befestigungsfläche

Befestigungsgewinde

Positionierlöcher

Elektrische Verbindung

Druckeingang-Gewichtsschaltung

6 bar, d 3 mm

Alle Angaben in Millimetern

Pos. Bezeichnung

Druckeingang-Verschlussmecha-

Lufteintritt Spüllauf < 50 mbar,

Luftaustritt Spüllauf < 50 mbar,

Druckausgang für und

nismus 6 bar, d 3 mm

d 6 mm

d 6 mm

1.3 Befestigung der Wägezelle

Die Wägezelle spannungsarm auf

der Auflagefläche 1 (Bild 2) mit einer

Schraube M6 befestigen. Die maximale

Einschraubtiefe beachten. Für eine

exakte Ausrichtung dienen die Positionierlöcher 3 und 4.

Die Verbindung zur Gerätemasse für die

Ableitung elektrostatischer Ladungen

erfolgt über die Befestigungsschraube

M6.

9

Page 10

d

d

2. Lastaufnahme

Für die Befestigung eines kundenseitigen Lastaufnehmers ist an der Wägezelle ein teilweise

abgeflachter zylindrischer Zapfen vorgesehen (siehe Bild). Die Abflachung (2,5 mm) dient

einer in Drehrichtung definierten Befestigung des Lastaufnehmers.

Auf diesen Zapfen kann der Lastaufnehmer z.B. durch Klemmung angebracht werden.

Der Lastaufnehmer sollte aus leitfähigem, unmagnetischem Material bestehen um elektrostatische und magnetische Einflüsse zu minimieren. Das Gewicht des Lastaufnehmers muss

5 g ± 0,1 g betragen, damit der volle Wägebereich von 20 g zur Verfügung steht. Er muss

kleiner als 10 g sein, um die interne Justierung nutzen zu können. Bei einem Transport der

Zelle den Lastaufnehmer entfernen.

Der Zapfen ist überlastgesichert. Die maximalen Kräfte und Momente nicht überschreiten.

Der Zapfen kann sich beim Einwirken von Kräften oder Momenten neigen.

Mit einer Neigung ist ab einem Moment von 2 mNm bei einem 5 g Lastaufnehmer zu

rechnen.

Modell Max. Momente Schraubmomente Max. Kraft entgegen Max. Kräfte

M

WZA25-NC 0,1 Nm 0,5 Nm 2 N 2 N

, My, Mz der Lastrichtung (-Fz) Fx, Fy, F

x

z

10

Page 11

8

9

Schirmplatte

Spalt

Dichtungsring

3. IP- Schutz

Die Zelle hat im normalen Wägebetrieb IP44. Dieser Schutzgrad ist bedingt durch einen

Spalt zwischen der Schirmplatte und dem Dichtungsring.

Der Spalt wird abgedichtet durch Beaufschlagung des Druckeinganges (7) mit 6 bar. Dadurch

wird ein Verschlussmechanismus in Gang gesetzt, der den Zapfen mit der Schirmplatte

gegen den Dichtungsring zieht. Den Hub von ca. 1 mm beachten bei der Konstruktion des

Lastaufnehmers und seiner Umgebung. Die Zelle liefert in dieser Stellung keine Wägewerte,

sondern die Fehlermeldung „H“.

Nach Öffnen des Verschlussmechanismus benötigt die Wägezelle einige Zeit um sich wieder

zu stabilisieren.

Die Abdichtung der Anschlussseite der Wägezelle kann durch eine Dichtung zwischen der

Unterkante des Wägezellengehäuses und der Montageplatte erfolgen. Ein möglichst weiches

Dichtungsmaterial (z.B. Sili-Rex Silikonschaum-Rundschnüre der Firma Rexio GmbH Co. KG,

Westerrönfeld) verwenden, um die Kraft auf das Zellengehäuse klein zu halten. Durch diese

Maßnahme liegen der Stecker und die Druckausgänge außerhalb des Verschmutzungs- und

Reinigungsbereiches (Prozessseite). Die Anschlussseite hat IP44.

Reinigung

Einen Überdruck realisieren zur Sicherheit gegen eindringende Reinigungsflüssigkeit.

Dazu den Innenraum der Wägezelle über die Überdruckeingänge 8 und 9 mit einem Überdruck von maximal 50 mbar versorgen (nur trockene gefilterte öl- und partikelfreie Luft

verwenden).

Nach erfolgter Reinigung kann der Verschlussmechanismus geöffnet werden und weiterhin

Luft in die Zelle geblasen werden. Die Luft tritt am Spalt aus und trocknet anhängige

Tropfen.

Prozessseite

Anschlussseite

11

Page 12

4. Interne Justierung

Befestigungsfläche

6 H8; 6 tief

d 6 H8; 6 tief

M6; 6 tief

10

6

8 5 9

10

7

3

1

2

4

5. Kühlluftbetrieb

Die Wägezelle verfügt über ein eingebautes

Justiergewicht mit dem die ordnungsgemäße Funktion überprüft werden kann

bzw. die Empfindlichkeit der Zelle nachjustiert werden kann. Das eingebaute Kalibriergewicht hat eine Masse von ca. 10 g.

Es ist werksseitig kalibriert. Der Kalibrierwert ist als „Anwendergewicht“ im

Datensatz eingetragen und sollte nicht

überschrieben werden (außer bei einer

Neu kalibrierung). Zum Eintragen das

Software-Tool Public CAS verwenden.

Eine Justierung/ Kalibrierung erfolgt

wie eine Justierung/ Kalibrierung mit

Anwendergewicht. Das Menü ist entsprechend voreingestellt (1.1.9.3. und

1.1.10.1.).

Das Justieren wird bei entlasteter Wägezelle

über einen Schnittstellenbefehl Esc f1_ ausgelöst (siehe auch Installationsanleitung).

Nach Anforderung des Justiergewichtes

muss der Druckeingang für die Gewichtsschaltung

werden bis der Wert übernommen wurde.

Danach den Druck abschalten.

mit 6 bar beaufschlagt

Ü

Die Wägezelle darf bei der Reinigung maximal eine Innentemperatur von 60°C haben.

Die Innentemperatur überwachen, wenn die Zelle mit wärmeren Reinigungsmedien

behandelt wird.

Das kann über folgende XBPI Befehle geschehen:

XBPI-Befehle: Temperatursensor

Ausführliche Informationen zu Sartorius xBPI-Funktionen siehe Sartorius-Anleitung

„XBPI-Protokoll- und Funktionsbeschreibung der Wägeplattformen“.

Temperatur lesen

Fkt.-Nr. Eingang Ausgang

076H Unsigned 1 Float5 (xBPI-Befehlsantwort)

Der Eingangsparameter Unsigned 1 (1) bezieht sich auf den vorhandenen Sensor

(nur Sensor 1)

Bit Erklärung (wenn Bit =1)

0 Sensor 1

Beispiel:

Funktion XBPI-Befehl Antwort

Temperatur lesen Len, 01, 09, 76, 21, 00, Chk Len, 41, 35, float5, Chk

Beispiel: 06:01 09 76 21 Beispiel:

00:A7 08:41 35 41 CE 05 E0 00:72

→ Innentemperatur = 25,753°C

Len = Anzahl der folgenden Bytes einschließlich Checksumme

Chk = Checksumme des gesamten Telegramm einschließlich des Längenbytes;

Modul 256 – Summe aller vorhergehenden Bytes (*)

(*) ausführliche Informationen siehe Sartorius-Anleitung „XBPI-Protokoll- und Funktionsbeschreibung der Wägeplattformen“

Bitte beachten!

– Der Temperatursensor ist nicht einzeln kalibriert. Daher sollten Temperaturdifferenzen

von einigen Grad festgestellt werden.

– Der Temperatursensor ist thermisch mit einem massiven Metallteil verbunden.

Er ist erheblich langsamer als die Lufttemperatur.

Bei einer Reinigungsmitteltemperatur über 60°C kann trockene, ölfreie gefilterte Kühlluft

durch die Zelle geleitet werden (Eingang Anschluss 8, Ausgang Anschluss 9). Der Druck

innerhalb der Zelle darf 50 mbar und die Luftmenge 1500l/Stunde nicht übersteigen.

Die Kühlluft kann auch verwendet werden um nach erfolgter Reinigung die Zelle

schneller wieder auf Betriebstemperatur zu bringen. Nach einer Reinigung die Kühlluft

einströmen lassen und dabei den Verschlussmechanismus der Schirmplatte geöffnet

halten (kein Druck auf Anschluss 7). Dadurch wird der Bereich um die Dichtung

getrocknet. Das Ergebnis der Kühlung hängt stark von der Einbausituation ab und ist

daher durch eigene Untersuchungen zu ermitteln.

12

Page 13

6. Anwenderspezifisches Gehäuse

Eine oder auch mehrere Wägezellen können zu ihrem Schutz

bzw. zur weiteren Verbesserung der Reinigungssituation mit

einem zusätzlichen Gehäuse versehen werden.

Dieses Gehäuse sollte aus unmagnetischem Material bestehen.

Zapfen

Kontermutter

Schirmplatte

Dichtplatte

Zur IP-gerechten Abdichtung wird wie folgt vorgegangen:

– Waagschale entfernen

– Kontermutter von Schirmplatte mit Hilfe der mitgelieferten

Werkzeuge lösen.

Dabei ist auf gleichzeitiges gegensinniges Verdrehen zu achten,

um keine Momente auf den Zapfen zu übertragen.

– Kontermutter und Schirmplatte vom Zapfen abschrauben.

– Dichtplatte mit Hilfe des mitgelieferten Werkzeuges abschrau-

ben.

– Die unter der Dichtplatte befindliche Überwurfmutter abschrau-

ben.

– Gehäuse mit Bohrung Durchmesser 11 mm und maximaler Dicke

2,5 mm aufsetzen.

– In umgekehrter Reihenfolge Teile wieder montieren.

– Den Spalt zwischen Schirmplatte und Dichtplatte auf ca. 1 mm

einstellen.

(Fühllehre verwenden)

Gehäuse

13

Page 14

7. Zusammenschalten mehrer Wägezellen

8. Optimaler Arbeitspunkt

7.1 Zusammenschalten der pneumatischen Funktionen

Die Druckeingänge für die Auslösung der Justierfunktion (6) bzw.

des Verschlussmechanismus (7) können über T- Stücke zusammengeschaltet und über ein gemeinsames Ventil angesteuert werden.

Die Herstellung eines Überdrucks in mehreren Zelle kann über das

Zusammenschalten der Spühllufteingänge (8) und (9) mehrer Zellen

über entsprechende T- Stücke erfolgen. Der maximale Überdruck

von 50 mbar darf dabei nicht überschritten werden.

Bei Kühlluftbetrieb ist auf eine gleichmäßige Verteilung der Luft auf

alle angeschlossenen Zellen, sowie auf den maximalen Überdruck

in den Zellen zu achten. Die Querschnitte der Zu- und Ableitungen

und die Verteilungen bitte hierzu entsprechend dimensionieren.

7.2 Zusammenschalten der elektronischen Funktionen

Die Stromversorgungseingänge können an einem entsprechend

leistungsfähigem Netzteil zusammengeschaltet werden. Bitte

beachten Sie, dass die Schirme der Datenausgangskabel nur einseitig auf der E-Boxseite aufgelegt sind und die Signalleitungen

galvanisch getrennt sind.

Datenseitig können mehrere Zellen an einen Rechner mit

mehreren RS232 Schnittstellen oder über einen Terminalserver

(z.B. 4, 8, …-fach NPortserver der Fa. Moxa) angeschlossen werden.

Bei Beschleunigungen eines Wägesystems in Richtung der Wägeachse treten Beschleunigungskräfte der wirksamen seismischen

Massen auf, die in das Messsignal als Störungen eingehen.

Durch die Signalfilterung wird der Einfluss dieser Störungen auf

das Messergebnis reduziert. Die Größe der wirksamen seismischen

Masse hängt von der Masseverteilung am Messsystem ab und

ist abhängig von der Größe der Masse am Zapfen. Das in der

WZA25-NC verwendete Messsystem ist so dimensioniert, dass der

Einfluss bei einer Masse von 15 g (Lastaufnahme und Wägegut) ein

Minimum hat. Dieser Arbeitspunkt ist auch bezüglich der Empfindlichkeitsdriften optimal und sollte angestrebt werden.

14

Page 15

Page 16

Sartorius Weighing Technology GmbH

Weender Landstrasse 94–108

37075 Goettingen, Germany

Phone +49.551.308.0

Fax +49.551.308.3289

www.sartorius.com

Copyright by Sartorius,

Goettingen, Germany.

All rights reserved. No part

of this publication may

be reprinted or translated in

any form or by any means

without the prior written

permission of Sartorius.

The status of the information,

specifications and illustrations

in this manual is indicated

by the date given below.

Sartorius reserves the

right to make changes to the

technology, features, specifications

and design of the equipment

without notice.

Status:

June 2013,

Sartorius Weighing Technology GmbH

Goettingen, Germany

Printed in Germany on paper that has been

bleached without any use of chlorine

W_WZA25-NC_Applikationshinw · KT

Publication No.: WWZ6010-a13064

Loading...

Loading...