Page 1

85030-511-58

Technical data and operating instructions

Vivaspin® 500 µl and 2 ml

Vivaspin® 500 and 2 10K devices for in vitro diagnostic use

Vivaspin

®

500 and 2 3K, 5K, 30K, 50K, 100K, 300K, 1000K and 0.2 µm

devices for research use only; not for use in diagnostic procedures

For French, Italian, and Spanish manuals, please go to

www.sartorius.com/en/product-family/product-family-detail/m-centrisart-i/

Page 2

2 |

Vivaspin® 500 µl and 2 ml – Introduction

Storage conditions|shelf life

Vivaspin

®

ultrafiltration spin columns

should be stored at 15 – 30°C. The devices

should be used before the expiry date

printed on the box.

Introduction

Vivaspin

®

Concentrators are disposable

ultrafiltration devices for the concentration

of biological samples. Vivaspin

®

500 is suitable for sample volumes of 100–500 µl and

the Vivaspin

®

2 can handle samples up to

2 ml. Vivaspin

®

2 can effectively be used in

either swing bucket or fixed angle rotor

accepting 15 ml centrifuge tubes.

The patented vertical membrane design

and thin channel filtration chamber

(US 5,647,990) minimises membrane fouling

and provides high speed concentrations,

even with particle laden solutions.

Vivaspin

®

500 can be used in a benchtop

fixed angle rotor, accepting 2.2 ml

centrifuge tubes.

C

The Vivaspin® 500 & 2 product line includes

9 different cutoffs (Molecular Weight Cutoff,

MWCO):

– Vivaspin

®

500 & 2 3K device: 3,000 MWCO

– Vivaspin

®

500 & 2 5K device: 5,000 MWCO

– Vivaspin

®

500 & 2 10K device:

10,000 MWCO

– Vivaspin

®

500 & 2 30K device:

30,000 MWCO

– Vivaspin

®

500 & 2 50K device:

50,000 MWCO

– Vivaspin

®

500 & 2 100K device:

100,000 MWCO

– Vivaspin

®

500 & 2 100K device:

300,000 MWCO

– Vivaspin

®

500 & 2 100K device:

1000,000 MWCO

– Vivaspin

®

500 & 2 100K device: 0.2 µm

Vivaspin

®

500 & 2 10K filter devices are for

in vitro diagnostic use and can be used to

concentrate serum, urine, cerebrospinal

fluid, and other body fluids prior to analysis.

Vivaspin

®

500 & 2 3K, 5K, 30K, 50K, 100K,

300K, 1.000K and 0.2 µm filter devices are

for research use only and not for use in

diagnostic procedures. The Vivaspin

®

500 &

2 devices are supplied non-sterile and are for

single use only.

Page 3

| 3

Vivaspin® 2

The Vivaspin

®

2 is specifically designed with

low internal surface and membrane area in

order to achieve superior recoveries from

very dilute solutions.

Another feature of the Vivaspin

®

2 is the

choice of directly pipetting the concentrate

from the dead stop pocket built into the

bottom of the concentrator, or alternatively

reverse spinning the concentrate into the

recovery cap.

Membrane Alternatives

In addition to the proven high flux

polyethersulfone (PES) membrane range

which is recommended with most solutions,

Vivaspin

®

2 is additionally offered with

cellulose triacetate (CTA) and Hydrosart

®

.

CTA is particularly recommended when

high recovery of the filtrate solution is of

primary importance. Hydrosart

®

is a stabilised

cellulose based membrane that has been

optimised for the biotechnological industry.

The Hydrosart

®

membrane is a stable polymer

that features a broad pH range. Hydrosart

®

is also extremely hydrophilic, making it

non-protein binding, virtually non-foul,

and has extremely high flux. Hydrosart

®

is

available in 5k, 10k, and 30k molecular

weight cutoffs.

Please note that membrane behaviour largely

depends on the specific characteristics of the

solution being processed. Sartorius Stedim

Biotech recommends that users experiment

with alternative membranes in seeking to

optimise their process performance.

Equipment Required

1. Centrifuge with swing bucket of fixed

angle (minimum 25°) rotor.

Device Carrier Required

Vivaspin

®

500 2.2 ml/11 mm d

Vivaspin

®

2 15 ml/17 mm d

2. Pipettes for sample delivery and removal.

For maximum recovery a thin gel loader type

is recommended.

Page 4

4 |

Operation

1. Select the most appropriate membrane

for your sample. For maximum recovery

select a MWCO at least 50% smaller than

the molecular size of the species of interest.

2. Fill concentrator with up to maximum

volumes shown in table 1. (Ensure lid is fully

seated).

3. Insert assembled concentrator into

centrifuge (when fixed angle rotors are

used, angle concentrator so that the

printed window faces upwards|outwards).

4. Centrifuge at speeds recommended

in table 2, taking care not to exceed the

maximum g force indicated by membrane

type and MWCO.

5. Once the desired concentration is

achieved, (see tables 3a & 3b for guide

to concentration times), remove assembly

and recover sample from the bottom of

the concentrate pocket with a pipette.

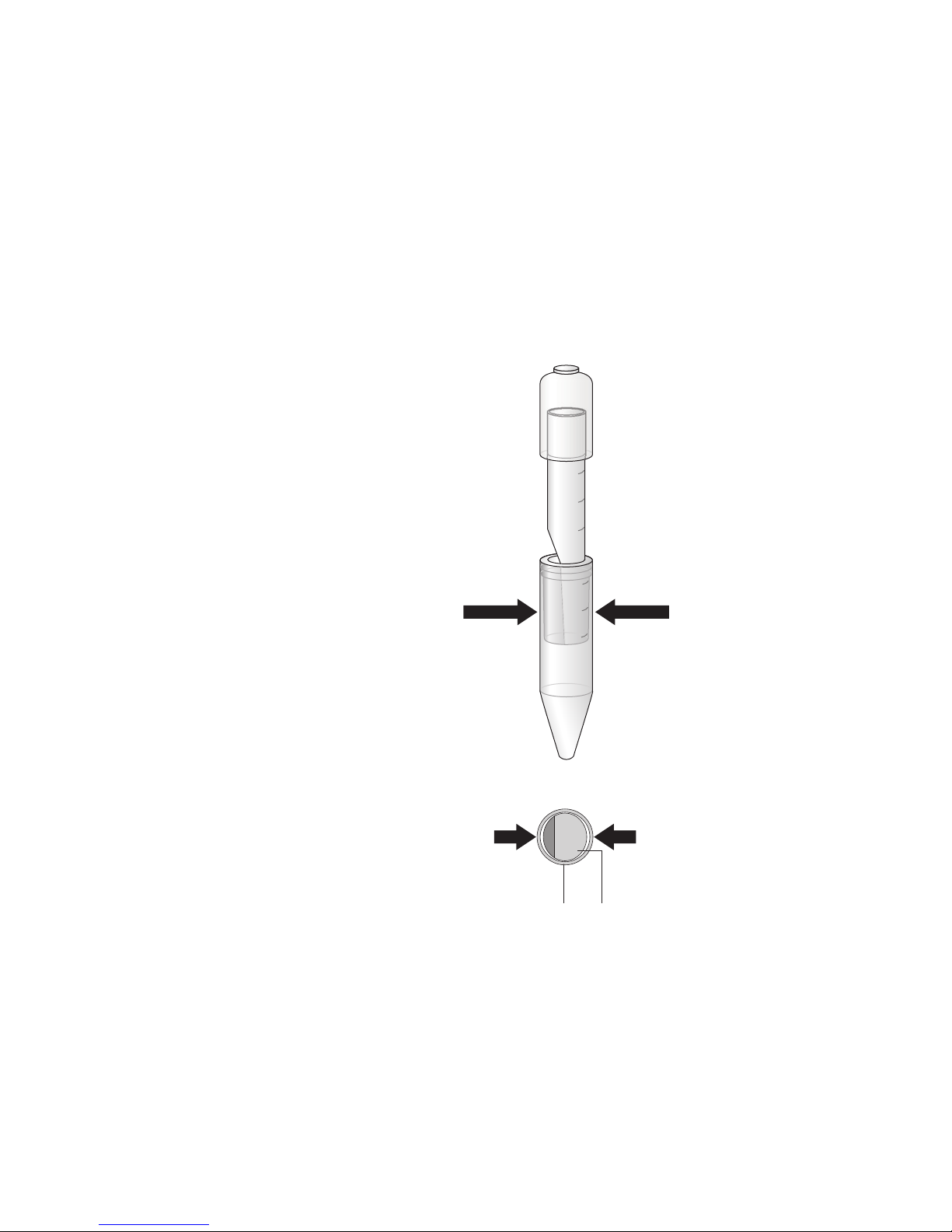

Removing the Vivaspin

®

2 body from

the filtrate tube

The sleeve (seen from the end) is oval in

cross section. The tube is round in cross

section to give a tight fit to the sleeve. To

release the tube from the sleeve, you must

pinch the tube – to press it into an oval

shape – before removing it with a twisting

action.

Press

here

Press

here

Tube Sleeve

Page 5

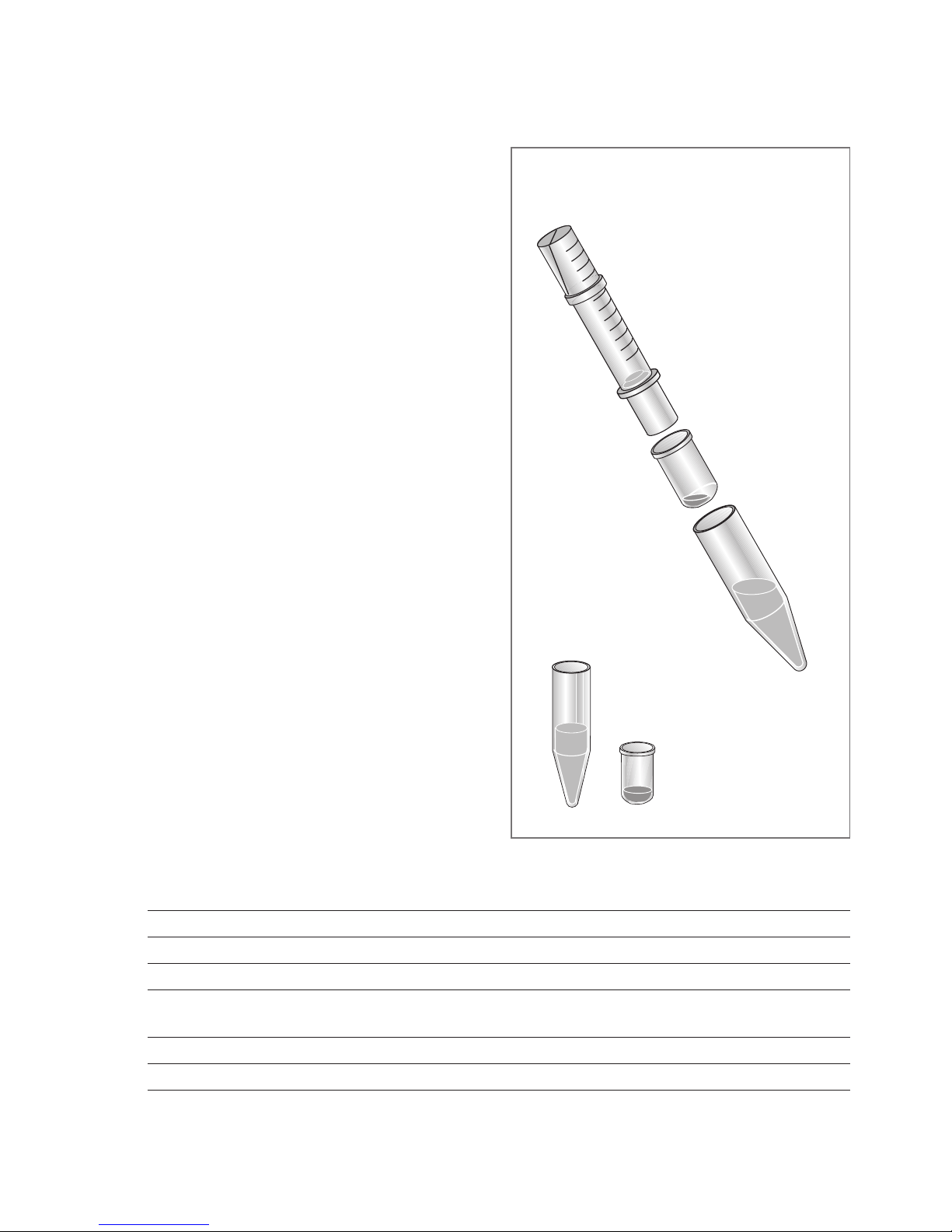

Reverse spin with Vivaspin® 2

Depending on user preference and need

for sample storage, the concentrate can be

reverse spun into the concentrate recovery

cap (when fixed angle rotors are used, angle

concentrator so that the printed window

faces upwards|outwards). In this procedure

remove filtrate tube, invert the concentrator

body, insert concentrate recovery cap into

filtrate tube and then spin at up to 3,000 g

for 2 minutes.

Desalting|Buffer Exchange

1. Concentrate sample to desired level.

2. Empty filtrate container.

3. Refill concentrator with an appropriate

solvent.

4. Concentrate the sample again and repeat

the process until the concentration of

contaminating microsolute is sufficiently

reduced. Typically 3 wash cycles will remove

99% of initial salt content.

| 5

Vivaspin® 2 Reverse Spin

Filtrate and

concentrate

can be sealed

for storage.

Concentrate

recovery cap

Concentrate

Position with printed

window upwards|outwards

Concentrator body

Filtrate tube

Filtrate

Equipment required Vivaspin® 500 Vivaspin® 2

Centrifuge

Rotor type Fixed angle Swing bucket or Fixed angle

Minimum rotor angle 40° 25°

Rotor cavity To fit 2.2 ml (11 mm) To fit 15 ml (17 mm)

conical bottom tubes conical bottom tubes

Concentrate recovery

Pipette type Fixed or variable volume Fixed or variable volume

Recommended tip Thin gel loader type Thin gel loader type

Page 6

6 |

Technical Specifications

Table 1: Technical specifications

Vivaspin

®

500 Vivaspin® 2

Concentrator capacity

Swing bucket rotor do not use 3 ml

Fixed angle rotor 500 µl 2 ml

Dimensions

Total length 50 mm 126 mm

Width 11 mm 17 mm

Active membrane area 0.5 cm

2

1.2 cm

2

Hold-up volume, <5 µl <10 µl

membrane and support

Dead stop volume* 5 µl 8 µl

Materials of construction

Body Polycarbonate Polycarbonate

Filtrate vessel Polypropylene Polycarbonate

Membrane Polyethersulfone PES, CTA, HY

Table 2: Recommended Spin Speed (x g)

Device Vivaspin

®

500 Vivaspin® 2

Membrane Fixed angle Fixed angle Swing bucket

3–50,000 PES 12,000 8,000 4,000

>100,000 PES 12,000 8,000 4,000

5–20,000 CTA – 8,000 4,000

Hydrosart

®

– 8,000 4,000

* Dead stop volume as designed in moulding tool. This volume may vary depending on

sample, sample concentration, operation temperature and centrifuge rotor.

Page 7

Usage Tips

1. Flow Rate

Filtration rate is affected by several parameters, including MWCO, porosity, sample concentration, viscosity, centrifugal force and

temperature. Expect significantly longer spin

times for starting solutions with over 5% solids. When operating at 4°C, flow rates are

approximately 1.5 times slower than at 25°C.

Viscous solutions such as 50% glycerine will

take up to 5 times longer to concentrate

than samples in a predominantly buffer

solution.

2. Pre-rinsing

Membranes fitted to Vivaspin

®

concentrators

contain trace amounts of Glycerine and

Sodium azide. Should these interfere with

analysis they can be removed by rinsing fill

volume of buffer solution or deionised water

through the concentrator. Decant filtrate

and concentrate before processing sample

solution. If you do not want to use the

pre-rinsed device immediately, store it in the

refrigerator with buffer or water covering

the membrane surface. Please do not allow

the membrane to dry out.

3. Sanitization of Polyethersulfone

Membranes

Vivaspin

®

devices should not be autoclaved

as high temperatures will substantially

increase membrane MWCO. To sanitize, use

a 70% ethanol solution or sanitizing gas

mixture.

4. Chemical Compatibility

Vivaspin

®

concentrators are designed for use

with biological fluids and aqueous solutions.

For chemical compatibility details, refer to

table 4.

| 7

Page 8

8 |

Performance Characteristics

Table 3a: Typical Performance Characteristics Vivaspin® 500

Time to concentrate up Concentrate

to 30x [min.] at 20°C recovery %

Start volume 500 µl 500 µl

Aprotinin 0.25 mg/ml (6,500 MW)

3,000 MWCO PES 30 96%

BSA 1.0 mg/ml (66,000 MW)

5,000 MWCO PES 15 96%

10,000 MWCO PES 5 96%

30,000 MWCO PES 5 95%

IgG 0.25 mg/ml (160,000 MW)

30,000 MWCO PES 10 96%

50,000 MWCO PES 10 96%

100,000 MWCO PES 10 96%

Page 9

Table 3b: Typical Performance Characteristics Vivaspin® 2

Time to concentrate up Concentrate

to 30x [min.] at 20°C recovery %

Start volume 2 ml 2 ml

Insulin chain A 0.1 mg/ml (2,535 MW)

2,000 MWCO Hydrosart

®

35 95%

Aprotinin 0.25 mg/ml (6,500 MW)

3,000 MWCO PES 50 96%

BSA 1.0 mg/ml (66,000 MW)

5,000 MWCO PES 12 98%

5,000 MWCO CTA 50 96%

5,000 MWCO Hydrosart

®

22 98%

10,000 MWCO PES 8 98%

10,000 MWCO CTA 10 96%

10,000 MWCO Hydrosart

®

12 98%

20,000 MWCO CTA 5 96%

30,000 MWCO PES 8 97%

30,000 MWCO Hydrosart

®

5 97%

IgG 0.25 mg/ml (160,000 MW)

20,000 MWCO CTA 6 97%

30,000 MWCO PES 10 96%

50,000 MWCO PES 10 96%

100,000 MWCO PES 8 95%

| 9

Page 10

10 |

Chemical Compatibility

Table 4: Chemical Compatibility (2hr contact time)

Solutions PES CTA HY

Compatible pH range pH 1–9 pH 4–8 pH 1–9

Acetic Acid (25.0%) OK NO OK

Acetone (10.0%) NO NO NO

Acetonitrile (10.0%) NO NO NO

Ammonium Hydroxide (5.0%) ? OK OK

Ammonium Sulphate (saturated) OK ? ?

Benzene (100%) NO NO NO

n-Butanol (70%) ? NO ?

Chloroform (1.0%) NO NO NO

Dimethyl Formamide (10.0%) ? NO NO

Dimethyl Sulfoxide (5.0%) OK NO NO

Ethanol (70.0%) OK OK OK

Ethyl Acetate (100%) NO NO NO

Formaldehyde (30%) OK OK OK

Formic Acid (5.0%) OK ? OK

Glycerine (70%) OK OK OK

Guanidine HCI (6 M) OK ? OK

Hydrocarbons, aromatic NO NO NO

Hydrocarbons, chlorinated NO NO NO

Hydrochloric Acid (1 M) OK NO OK

Imidazole (300 mM) OK NO ?

Isopropanol (70%) OK OK OK

Lactic Acid (5.0%) OK NO OK

Mercaptoethanol (1.0 M) NO NO OK

Methanol (60%) ? ? OK

Nitric Acid (10.0%) OK NO NO

Page 11

Solutions PES CTA HY

Compatible pH range pH 1–9 pH 4–8 pH 1–9

Phenol (1.0%) ? ? NO

Phosphate Buffer (1.0 M) OK OK OK

Polyethylene Glycol (10%) OK ? ?

Pyridine (100%) NO NO NO

Sodium Carbonate (20%) OK NO ?

Sodium Deoxycholate (5.0%) OK ? ?

Sodium Dodecylsulfate (0.1 M) OK OK OK

Sodium Hydroxide (2.5 M) NO NO NO

Sodium Hypochlorite (200 ppm) OK NO NO

Sodium Nitrate (1.0%) OK ? OK

Sulfamic Acid (5.0%) OK NO ?

Tetrahydrofuran (5.0%) NO NO NO

Toluene (1.0%) NO NO NO

Trifluoroacetic Acid (10%) OK NO OK

Tween

®

* 20 (0.1%) OK OK OK

Triton

®

** X-100 (0.1%) OK OK OK

Urea (8 M) OK ? OK

OK = Acceptable ? = Questionable NO = Not recommended

* Triton

®

is a registered trademark of Union Carbide Corp.

** Tween

®

is a registered trademark of ICI Americas Inc.

| 11

Page 12

12 |

Ordering Information

Ordering Tips

– Choose a membrane pore size at least

50% smaller than the size of the

molecule to be retained.

– Usually choose Polyethersulfone

membranes for fastest concentrations.

– Usually choose Cellulose Triacetate for

Protein Removal|Ultrafiltrate recovery.

– Usually choose Hydrosart

®

membranes

for highest recovery with Ig fractions.

Vivaspin® 500 Polyethersulfone Qty per box Prod. no.

3,000 MWCO 25 VS0191

3,000 MWCO 100 VS0192

5,000 MWCO 25 VS0111

5,000 MWCO 100 VS0112

10,000 MWCO 25 VS0101

10,000 MWCO 100 VS0102

30,000 MWCO 25 VS0121

30,000 MWCO 100 VS0122

50,000 MWCO 25 VS0131

50,000 MWCO 100 VS0132

100,000 MWCO 25 VS0141

100,000 MWCO 100 VS0142

300,000 MWCO 25 VS0151

300,000 MWCO 100 VS0152

1,000,000 MWCO 25 VS0161

1,000,000 MWCO 100 VS0162

0.2 µm 25 VS0171

0.2 µm 100 VS0172

Starter pack (5 of each 5 k, 10 k, 30 k, 50 k, 100 k) 25 VS01S1

Page 13

Vivaspin® 2 Polyethersulfone Qty per box Prod. no.

3,000 MWCO 25 VS0291

3,000 MWCO 100 VS0292

5,000 MWCO 25 VS0211

5,000 MWCO 100 VS0212

10,000 MWCO 25 VS0201

10,000 MWCO 100 VS0202

30,000 MWCO 25 VS0221

30,000 MWCO 100 VS0222

50,000 MWCO 25 VS0231

50,000 MWCO 100 VS0232

100,000 MWCO 25 VS0241

100,000 MWCO 100 VS0242

300,000 MWCO 25 VS0251

300,000 MWCO 100 VS0252

1,000,000 MWCO 25 VS0261

1,000,000 MWCO 100 VS0262

0.2 µm 25 VS0271

0.2 µm 100 VS0272

Starter pack (5 of each 5 k, 10 k, 30 k, 50 k, 100 k) 25 VS02S1

| 13

Page 14

Vivaspin® 2 Cellulose triacetate Qty per box Prod. no.

5,000 MWCO 25 VS02U1

5,000 MWCO 100 VS02U2

10,000 MWCO 25 VS02V1

10,000 MWCO 100 VS02V2

20,000 MWCO 25 VS02X1

20,000 MWCO 100 VS02X2

Vivaspin

®

2 Hydrosart® Qty per box Prod. no.

2,000 MWCO 25 VS02H91

2,000 MWCO 100 VS02H92

5,000 MWCO 25 VS02H11

5,000 MWCO 100 VS02H12

10,000 MWCO 25 VS02H01

10,000 MWCO 100 VS02H02

30,000 MWCO 25 VS02H21

30,000 MWCO 100 VS02H22

In Vitro Diagnostic Product Labeling

The following tabe defines the symbols found on Vivaspin

®

500 & 2 10K device labels.

Symbol SymbolDefinition Definition

In vitro diagnostic medical device

Catalogue number

Do not reuse

Use by

Batch code

Date of manufacture

Manufacturer

Temperature limitation

Non-sterile product

CE conformity marking

14 |

Page 15

Made in UK

Sartorius Stedim Lab Ltd

Sperry Way

Stonehouse Park

Gloucestershire

GL10 3UT, UK

www.sartorius-stedim.com

Copyright by

Sartorius Lab Instruments

GmbH & Co. KG, Goettingen,

Germany.

All rights reserved. No part

of this publication may

be reprinted or translated in

any form or by any means

without the prior written

permission of Sartorius Lab

Instruments GmbH & Co. KG.

The status of the information,

specifications and illustrations

in this manual is indicated

by the date given below.

Sartorius Lab Instruments

GmbH & Co. KG reserves the

right to make changes to the

technology, features,

specifications and design of the

equipment without notice.

Status:

September 2018,

Sartorius Lab Instruments

GmbH & Co. KG,

Goettingen, Germany

Specifications subject to change without

notice. Copyright Sartorius Stedim Biotech

GmbH. Printed in the EU on paper

bleached without chlorine.

Publication No.: SLU6093-e180910

Ver. 09 | 2018

Loading...

Loading...