Sartorius Vivaflow 50,Vivaflow 50R,Vivaflow 200 Directions For Use Manual

85030-519-25

Directions for Use

Vivaflow 50 | 50R | 200

2 |

Contents

Vivaflow 50 3

Single Module 3

Linked Modules 4

Diafiltration|Desalting 5

Concentration 6

Recovery 6

System Components 7

Technical Specifications 7

Performance Characteristics 8

Ordering Information 9

Chemical Compatibility 10

Vivaflow 50R and Vivaflow 200 11

Operation of Single Module 11

Operation of Two Modules 12 – 13

Diafiltration|Desalting 14

Concentration 14

Recovery 14

Technical Specifications 15

Cleaning 16

Storage 16

Performance Characteristics 17 – 18

Ordering Information 19 – 20

Chemical Compatibility 21

| 3

Vivaflow 50

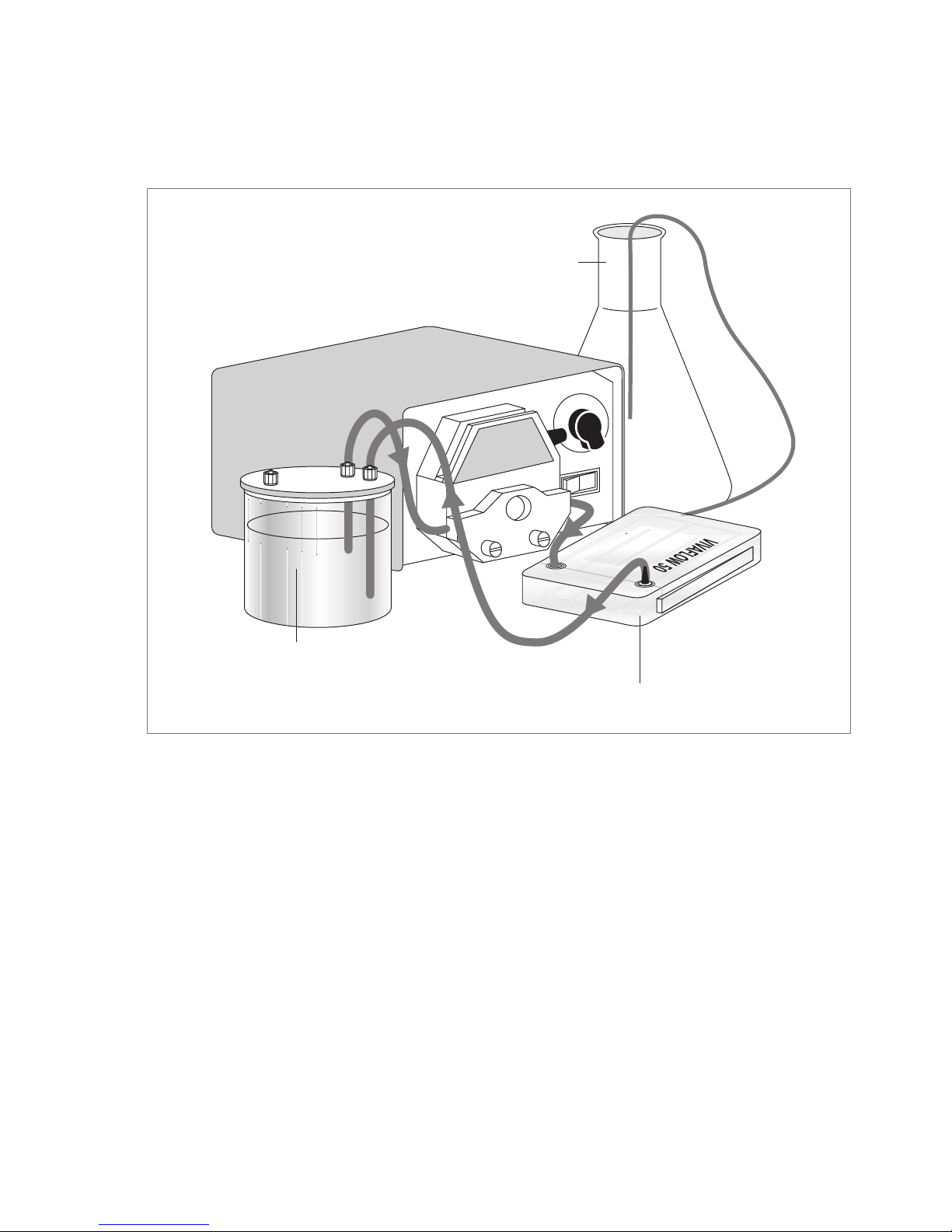

Single module

1. Set up the system as illustrated in

Diagram 1. Note the positioning of the

flow restrictor on the return line.

2. Vivaflow membranes contain trace

amounts of glycerine and sodium azide.

To remove these chemicals and to check

the security of the tube connections,

it is recommended to rinse the module,

and to test the system at full pressure

before introducing the sample.

3. Place 500 ml deionised water in a suitable

reservoir. The Vivaflow sample|diafiltration reservoir (prod. no. VFA006) is

recommended.

4. Pump liquid through the system to purge

any air pockets. The recirculation rate

should be in the range 200–400 ml/min,

and suitable flow should exit the filtrate

line. If used, the pressure indicator (prod.

no. VFA020), should read approximately

2.5 bar.

5. Allow 400 ml to pass into the filtrate

vessel. Check for any leakage at tubing

connection points. Drain the system

and empty or replace the filtrate vessel,

(see recovery section). The system is now

ready for use.

Filtrate vessel

Sample|diafiltration

reservoir (VFA006)

Pink flow restrictor

Designed for single use only. Anything else constitutes improper use.

Diagram 1: Vivaflow 50 set up

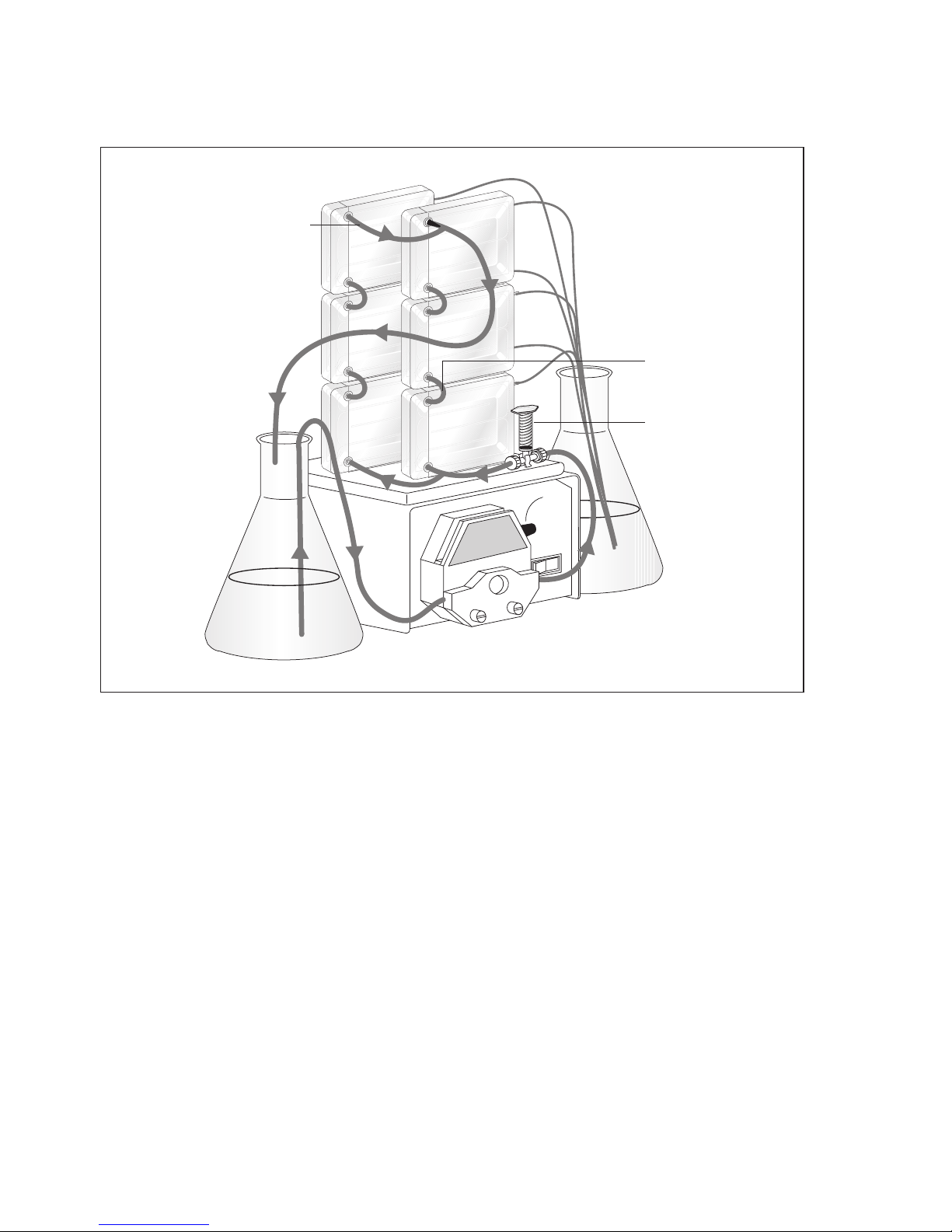

Linked modules

1. Set up the system as illustrated in

Diagram 2. Link the required number of

modules by sliding the tongue and groove

edges together. Note the positioning of

the flow restrictor on the return line.

2. Use series interconnectors, (prod. no.

VFA031), to connect a single row of

modules. Detailed ordering information

for system components to be found of

page 7, Diagram 4.

3. In addition, use T-connectors, (prod. no.

VFA030), to connect two rows of modules

in parallel.

4. The flow path of the system can be configured to suit the membrane|sample

combination. Most solutions are better

suited by modules connected in parallel.

Very low viscosity solutions favour modules connected only in series. Rinse the

system as detailed under single module

operation.

4 |

T-connector

Interconnector

Pressure

indicator

Diagram 2: Setting up multiple Vivaflow 50 cassettes

| 5

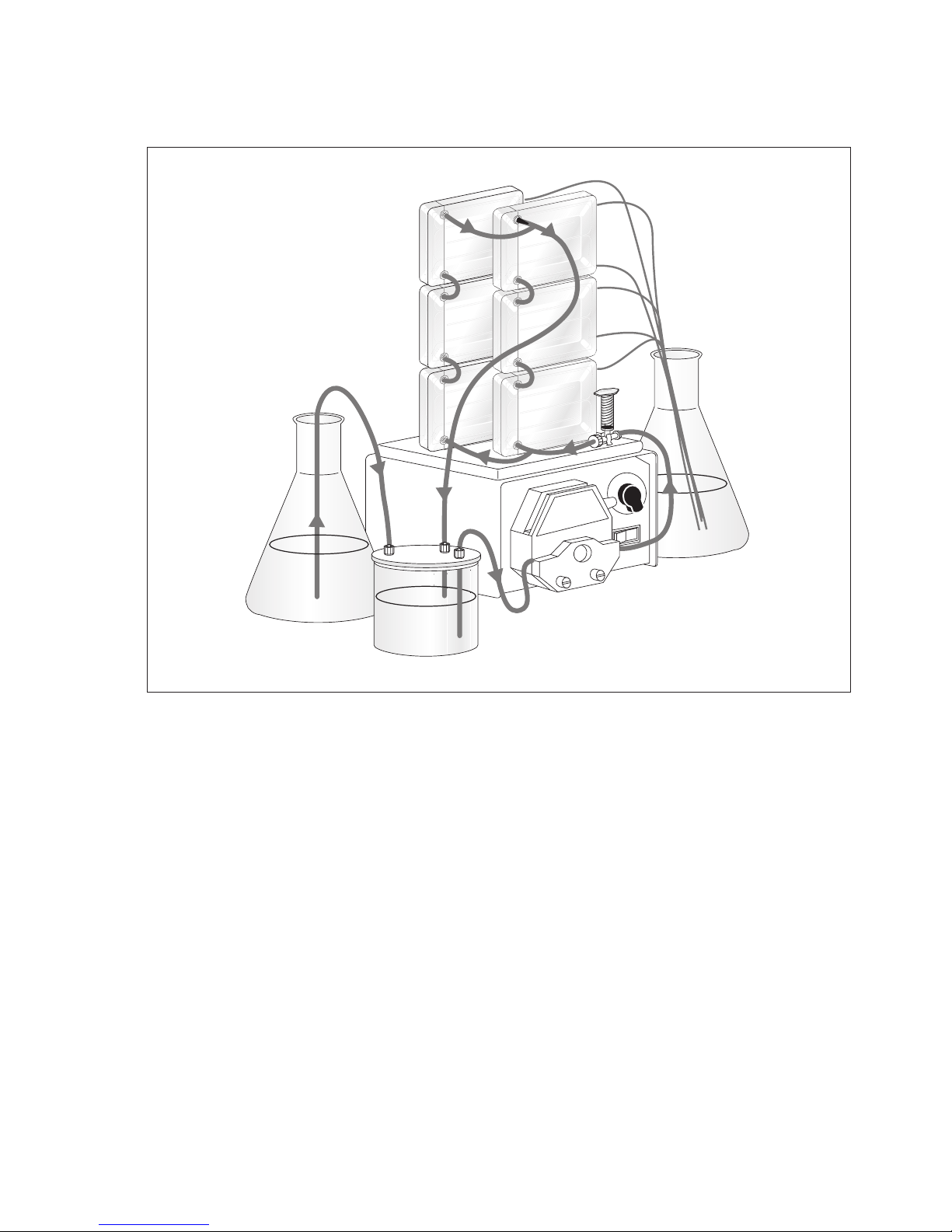

Diafiltration|Desalting

1. Set up the system as illustrated in

Diagram 3 for linked modules. If only

one module is required, connect it in

place of the linked modules.

2. Rinse the system as detailed previously.

3. Either place the solution to be purified in

the 500 ml sample|diafiltration reservoir

(prod. no. VFA006), or concentrate a

larger volume to 500 ml or less so that it

is fully contained in the 500 ml reservoir.

Ensure the reservoir lid is firmly closed.

4. Fill a large feed reservoir with exchange

solvent and pump sample through the

system as for concentration.

5. As the volume in the 500 ml reservoir

decreases, the vacuum created draws

exchange solvent through the feed line

from the larger reservoir. Over 99%

solvent exchange can be accomplished

with an exchange volume approximately

5 times the volume of the sample.

Diagram 3: Buffer exchange | diafiltration with Vivaflow 50

6 |

Concentration

1. Fill the feed reservoir with sample solution. When initial volumes larger than

500 ml are required, place 500 ml in

the sample|diafiltration reservoir, the

remaining volume in another suitable container and connect the vessels

as detailed in the diafiltration section.

Alternatively, use a larger container for

the entire sample volume and immerse

the feed and return lines directly into

the liquid.

2. Pump liquid through the system. The

recirculation rate should be in the range

200–400 ml/min, and suitable flow

should exit the filtrate line. If used, the

pressure indicator, (prod. no. VFA020),

should read approximately 2.5 bar.

3. Concentrate the sample to the desired

volume.

!

Warning: Do not run the same section of

tubing through the pump head for longer

than six hours, over use of tubing will

result in significant pressure drop and

ultimately, failure.

4. When the desired volume has been

reached, reduce the recirculation rate

to 20–40 ml/min and recirculate the

concentrated sample for 1–2 minutes to

maximise recovery.

Recovery

1. Disconnect the feed line from the lid

of the 500 ml reservoir or when using

a different container, remove the feed

line from the sample.

2. Pump residual system volume back into

the reservoir|container. (When parallel

modules are used with viscous solutions,

ensure that all modules are empty by

pinching the tubing between each of

the stacks of modules in turn).

3. For a more complete sample recovery

rinse approximately 5–10 ml per module

of water or sample buffer through the

system, and recover as before.

| 7

Table 1: Technical Specifications

Dimensions

Overall L|H|W 107|84|25 mm

Channel W|H 15 mm|0.3 mm

Active membrane area 50 cm

2

Hold up volume (module) 1.5 ml

Min recirculation volume < 10 ml

Non recoverable hold-up < 0.5 ml

Operating Conditions

Pump flow 200–400 ml/min

Maximum pressure 3 bar (45 psi)

Maximum temperature 60˚C

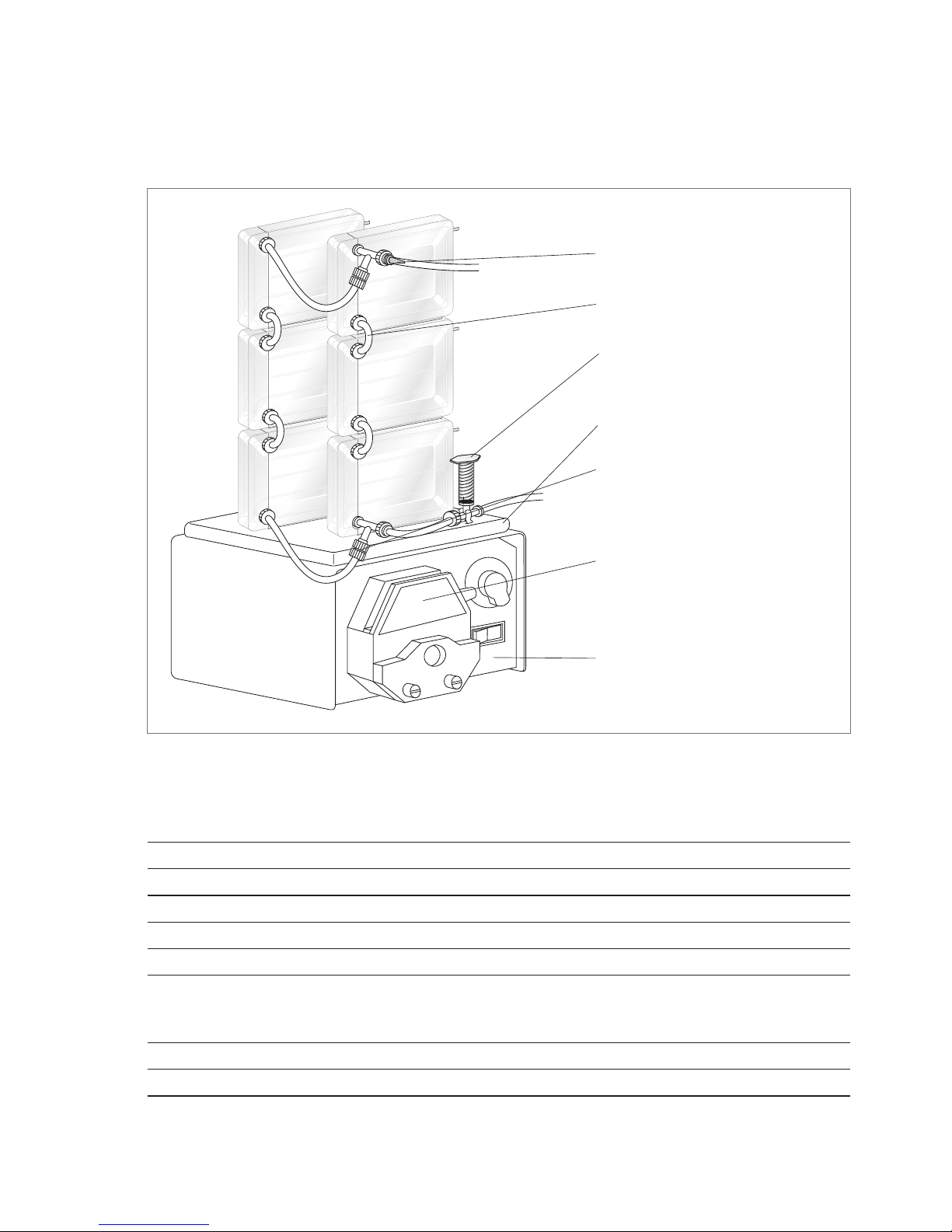

Inconnectors (Prod. No. VFA031)

Pink flow restrictor on

the return line

T-Connectors for running 2 stacks

(Prod. No. VFA030)

Pressure Indicator

(Prod. No. VFA020)

Masterflex easy load pump head

(Prod. No. VFA012)

Stand (Prod. No. VFA016)

Masterflex pump

CE 230V – US 115V

(Prod. No. VFP001|VFP002)

System Components

Diagram 4: System componets for setting up multiple Vivaflow 50 units

Materials of Construction

Main housing Polycarbonate

Flow channel TPX (PMP)

Membrane support TPX (PMP)

Seals and O rings Silicone

Pressure indicator Polypropylene, SS Spring,

Flow restrictor Polypropylene

Fittings Nylon

Tubing PVC (medical grade)

Table 2: Performance characteristics

Time to concentrate up to 20x (min.) at 3 bar

inlet pressure, 20°C

Single Three Solute Recovery %

Device Devices

250 ml Start 1 L Start Direct 10 ml rinse

Vol. min. Vol. min.

BSA 1.0 mg/ml (66,000 MW)

5,000 MWCO PES 34 49 96% > 99%

10,000 MWCO PES 22 32 94% > 99%

30,000 MWCO PES 22 32 92% 99%

50,000 MWCO PES 20 29 92% 98%

γ Globulins 1.0 mg/ml

100,000 MWCO PES 43 62 92% 98%

100,000 MWCO RC 40 58 92% 98%

100,000 MWCO Hydrosart 40 58 92% 98%

Yeast 1.0 mg/ml (S.Cerevisiae)

0.2 µm PES 33 47 92% 98%

8 |

Loading...

Loading...