Sartorius

TS 6100B, TS 12

Electronic Over/Under Scales

Installation and Operating Instructions

98648-001-40

2

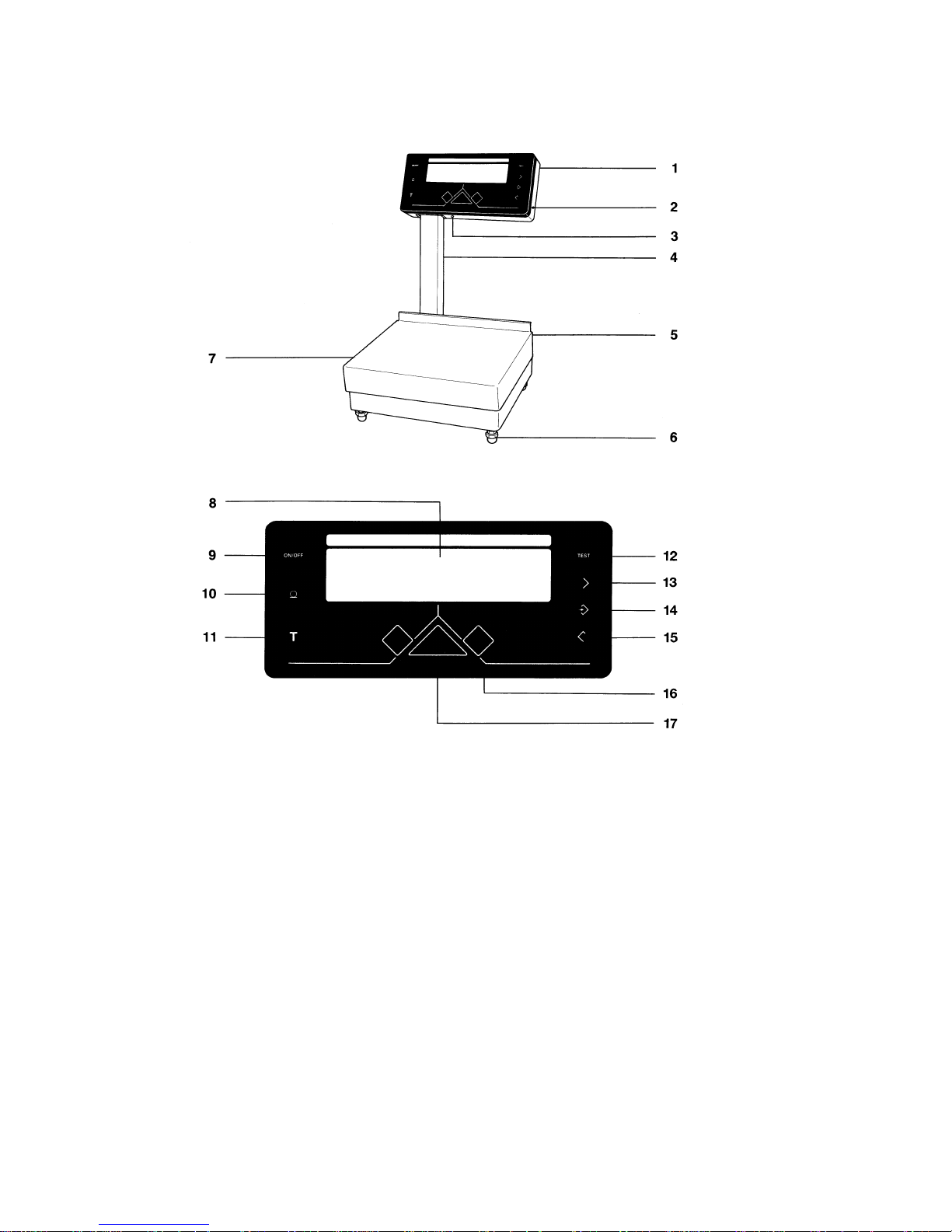

1

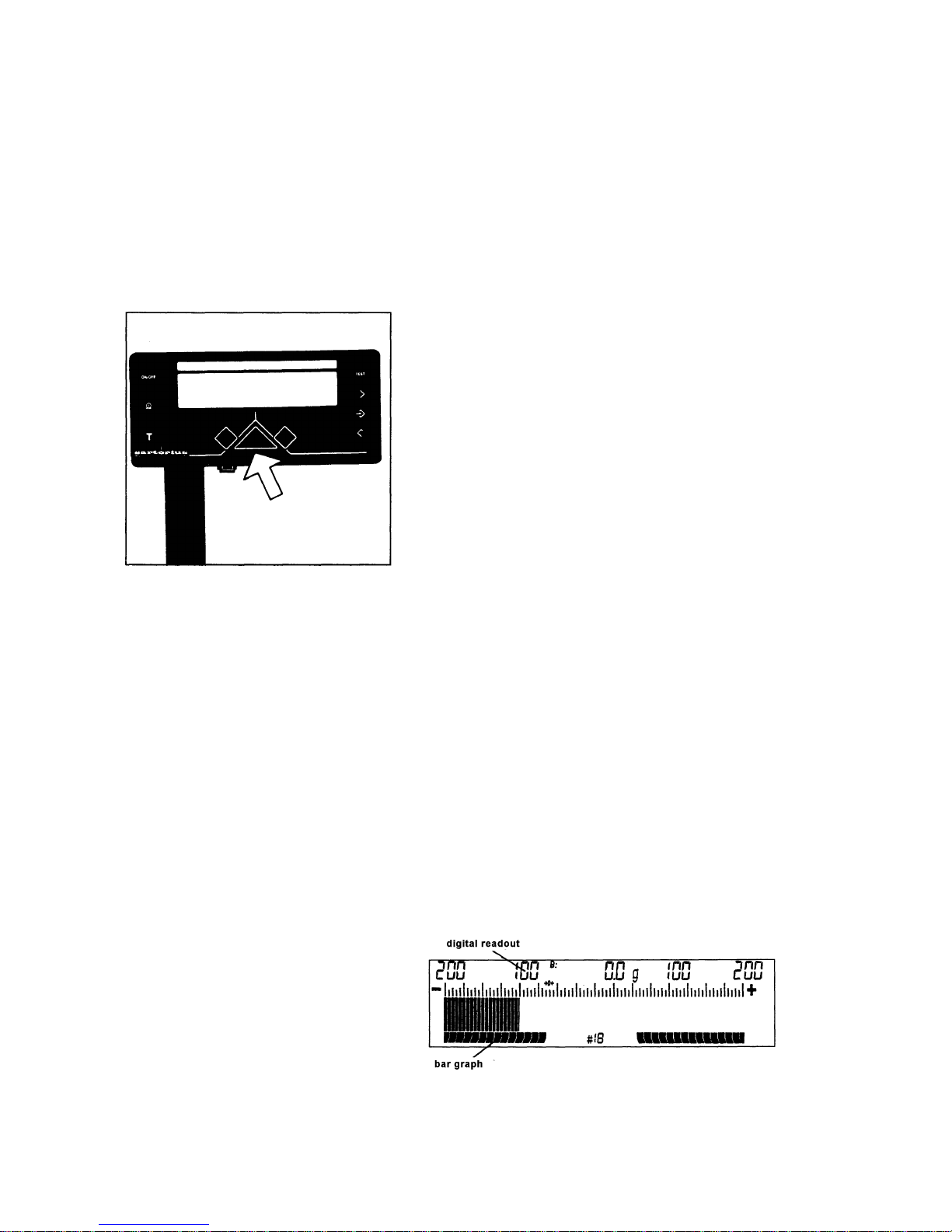

Display head

2

Lock

3

Jack for AC power

4

Support arm

5

Weighing platform

6

Leveling foot

7

Analog range indicator/weight display

8

ON/OFF key

9

PRINT key

10

Tare key (for zeroing the display)

11

Test key (full-segment display test)

12

Increase key

13

Set key

14

Decrease key

15

RED/GREEN/YELLOW indicators

3

Contents

Page

About the Product (Warranty)

4

Storage and Shipping Conditions 5

Equipment Supplied

6

Installation Instructions

6

Startup

7

Connecting the Scale to AC Power 7

Connecting Electronic Devices

(Peripherals) 8

Safety Precautions 8

How to Operate the Scale

9

Turning the Display On and Off 9

Taring 9

Weighing 9

Over/Under Checkweighing 11

Product ID Numbers and

Product Data

14

Changing the Product ID Number 15

Changing the Target Weight 16

Changing the Scale Divisions

in the Display 18

Changing the "Under" Limit 19

Changing the "Over" Limit 20

Calibration

21

Scale Operating Program

23

Factory Settings 24

How to Access the

Scale Operating Program 24

List of Parameters 26

Mounting Instructions

30

Changing the Display Mounting 30

How to Install the Interface Gable

Changing the Scale Housing Cover 31

Interface Description (Option)

32

General Specifications 32

Data Output Format 32

Data Output Parameters 33

Interfacing Devices with the Scale 33

Pin Assignment 34

Options and Accessories

35

Specifications

36

Troubleshooting Guide

37

Care and Maintenance

38

Cleaning 38

Safety Inspection 38

4

About the Product (Warranty)

With this Sartorius Scale you have acquired a high-quality

electronic weighing Instrument that will ease your daily

workload.

Please read these installation and operating instructions

carefully before operating your new scale.

Pursuant to the German Directive for the

Implementation of Regulations for Prevention of

Accidents "Elektrische Anlagen und

Betriebsmittel (VBG 4)" [Electrical Installations

and Equipment] of April 1986, it is hereby

certified that the equipment delivered, "Electronic

Over/Under Scale, model TS 6100B or TS 12," is

manufactured and tested in compliance with the

following DIN/VDE regulations:

DIN IEC 348/VDE 0411

Safety requirements for electronic measuring

apparatus

DIN IEC 380/VDE 0806

Safety of electrically energized Office machines

DIN IEC 601/VDE 0750

Safety of medical electrical equipment

and with Article 10 of the Low Voltage Directive

73/23/EEC issued on February 19, 1973, by the

European Community.

When you use electrical equipment in

installations and under ambient conditions

requiring higher safety Standards, you must

comply with the provisions as specified in the

applicable regulations for installation in your

country.

5

Do not miss out on the benefits of our full warranty.

Please complete the warranty registration card,

indicating the date of installation, and return the

card to your Sartorius dealer.

Storage and Shipping Conditions

Storage temperature: -40°C... +70°C

-40°F... 158°F

After unpacking the scale, please check it immediately for

any visible damage as a result of rough handling during

shipment.

lf this is the case, proceed as directed in the section

entitled "Safety Inspection."

Save all parts of the packaging and the box because

you may need to ship your scale.

Before you pack your scale to ship it, unplug all

connected cables to prevent damage.

Do not expose the scale unnecessarily to extreme temperatures, moisture, shocks, blows or vibrations.

6

Equipment Supplied

The equipment supplied includes the following components:

— Scale

— Weighing platform

— Power supply

— Key

— Set of brief instructions

— Instruction manual entitled "Installation and Oper-

ating Instructions"

Installations Instructions

Your Sartorius Scale will provide accurate readouts even

when it is exposed to unfavorable conditions.

However, exposure to intensive heat radiation, vibrations

and drafts may affect the weighing accuracy and should

be avoided äs much as possible.

You can adapt the scale to your requirements simply

by changing the menu code settings in the scale

operating program.

For more information, see pages 23 through 29.

7

Startup

Place the weighing platform

(5)

on the scale.

Connecting the Scale to AC Power

The scale is energized by an external power supply.

Make sure that the voltage rating printed on this unit is

identical to your local voltage rating.

lf the voltage specified on the label or the plug design of

the power supply does not match the rating or Standard

you use, please contact your Sartorius Office or dealer.

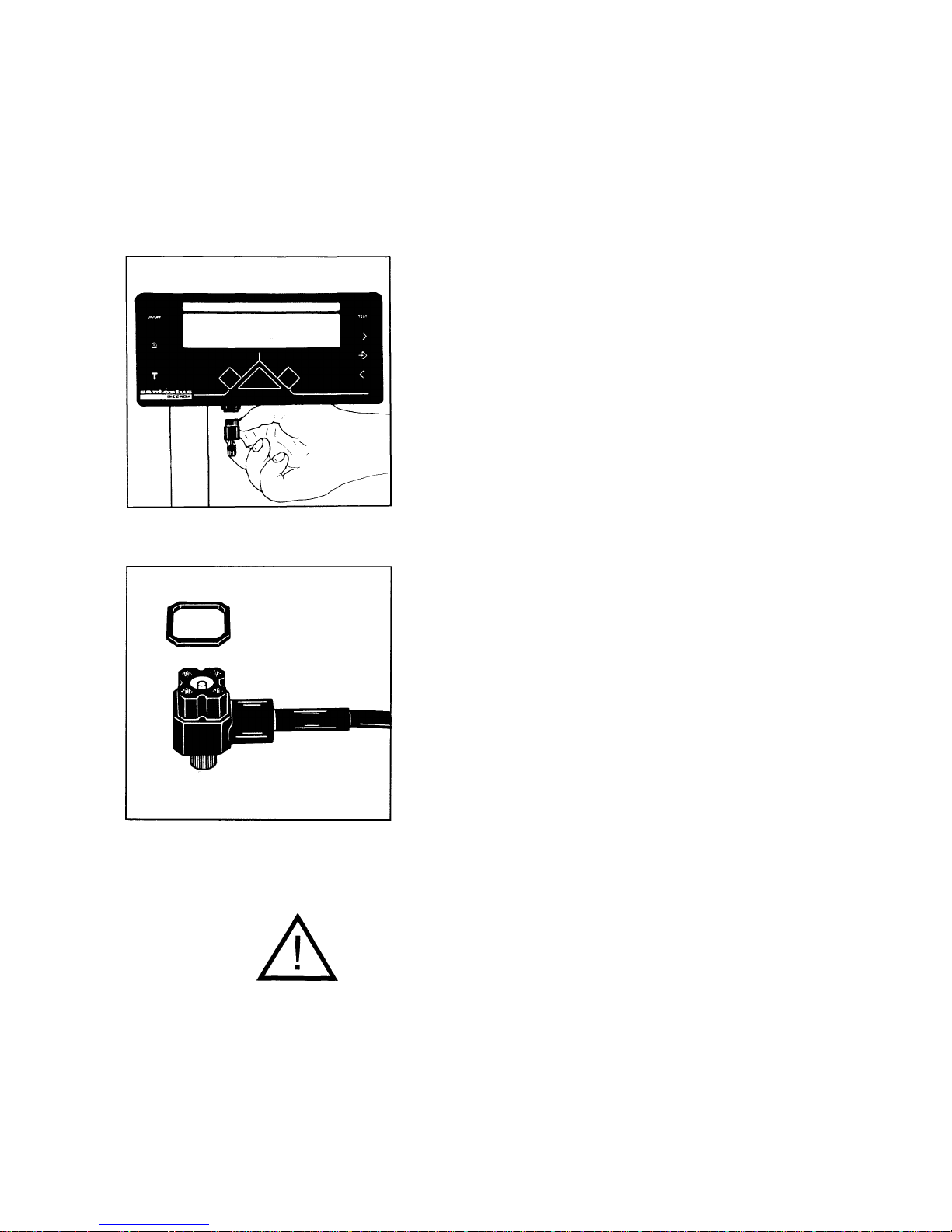

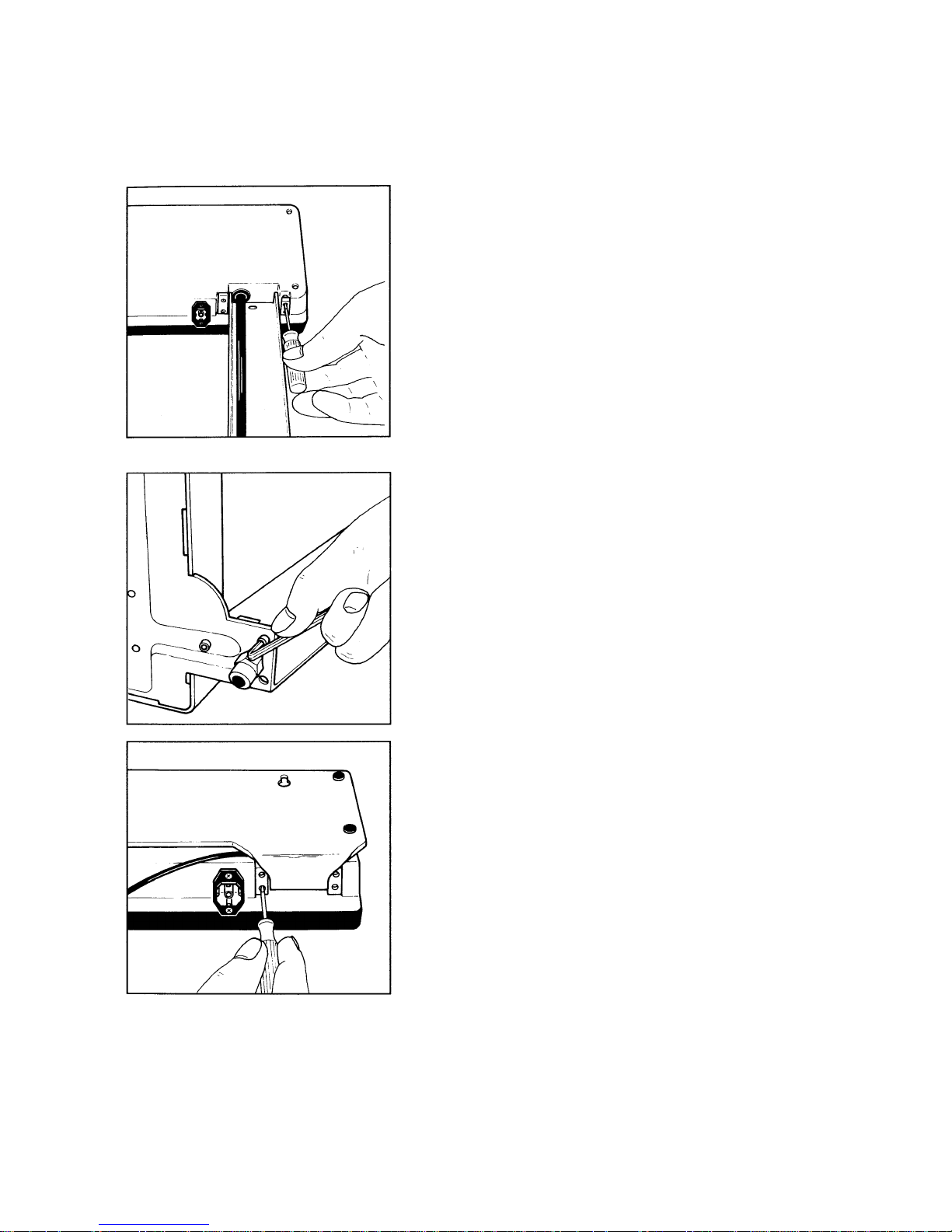

Insert the right-angle plug of the power supply in the AC

jack as shown in the picture on the left. Tighten the screw

by hand.

The IP 65 protection rating is guaranteed only if a

rubber gasket is instalied and the plug is securely

connected to form a leak-tight seal.

Then plug the power supply into a wall outlet.

Important Note:

Only use original Sartorius Power Supplies identified by

the Sartorius label. Use of power supplies from other

manufacturers, even if these units have a registered

approval rating from a national testing laboratory, requires

the consent of a certified Sartorius service technician.

8

Connecting Electronic Devices (Peripherals)

Make sure to unplug the power supply from the wall outlet

or from the scale before you connect or disconnect a

peripheral device (printer or PC) to or from the interface

port (Option).

Safety Precautions

The power supply rated to Class 2 (double insulation) can

be plugged into a wall outlet without taking any additional

safety precautions. The pole (ground) of the Output

voltage is connected to the scale housing (metallic parts),

which can be grounded for Operation.

The interface (see "Interfacing Devices" on page 33 in

addition) is also electrically connected to the scale housing (ground).

9

How to Operate the Scale

After initially connecting the scale to line power, allow

for at least 30 minutes' warmup.

Turning the Display On and Off

Press the ON/OFF key

(8)

to turn the display on or off.

Self-Test

After the scale is turned on, an automatic self-test of the

scale's electronic circuitry is performed. During this test,

all segments briefly appear in the display (full-segment

display test).

lt ends with the readout of all set parameters.

Taring

lf you wish to use a Container of if the weight display does

not indicate "

0.0 g/0 g

" (or the equivalent with the weight

unit of your choice), press the tare key before weighing.

10

The zero symbol (with arrows)

->0<-

in the weight display

shows that the scale has been exactly tared so the display

reads

"0"

.

Weighing

Place your sample on the weighing platform

(5)

to determine the weight.

Read off the weight indicated in the display

(7)

as soon as

the motion detection symbol "~" above the plus/minus

sign disappears.

In addition to grams, this scale gives you a variety of

other menu-definable weight unit options.

Select the weight unit you desire from the fable on

page 26 and change the code in the scale operating

program (for this purpose, see pages 23 through 29).

Auto Zero

This scale has an automatic zero tracking function, known

as "Auto Zero" (can be turned off by menu code - see

"Scale Operating Program").

Any changes off zero <± 0.5 digit per second will be set to

zero automatically.

11

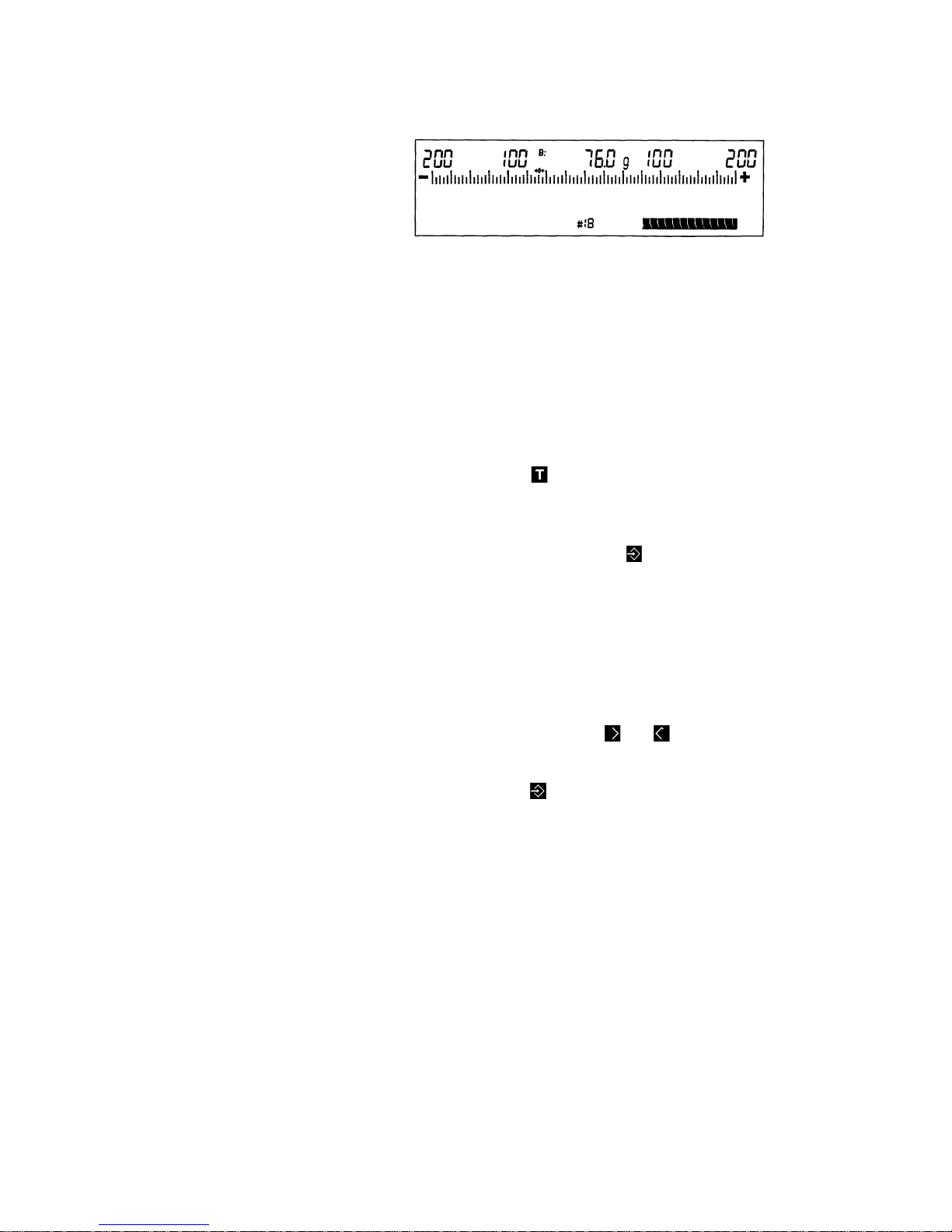

Over/Under Checkweighing

Over/under checkweighing allows you to sort and classify

products according to preset limits.

"Classification" means sorting samples based on their

weight into classes with defined weight ranges.

RED/GREEN/YELLOW Indicators

The RED/GREEN/YELLOW indicators are convenient

visual aids.

When you weigh the object to be checked, one of these

color-coded indicators will light up to indicate the Status of

the sample as follows:

RED

= the sample is underweight

GREEN

= the sample is o.k. and within the

preselected tolerance range

Yellow

= the sample is overweight

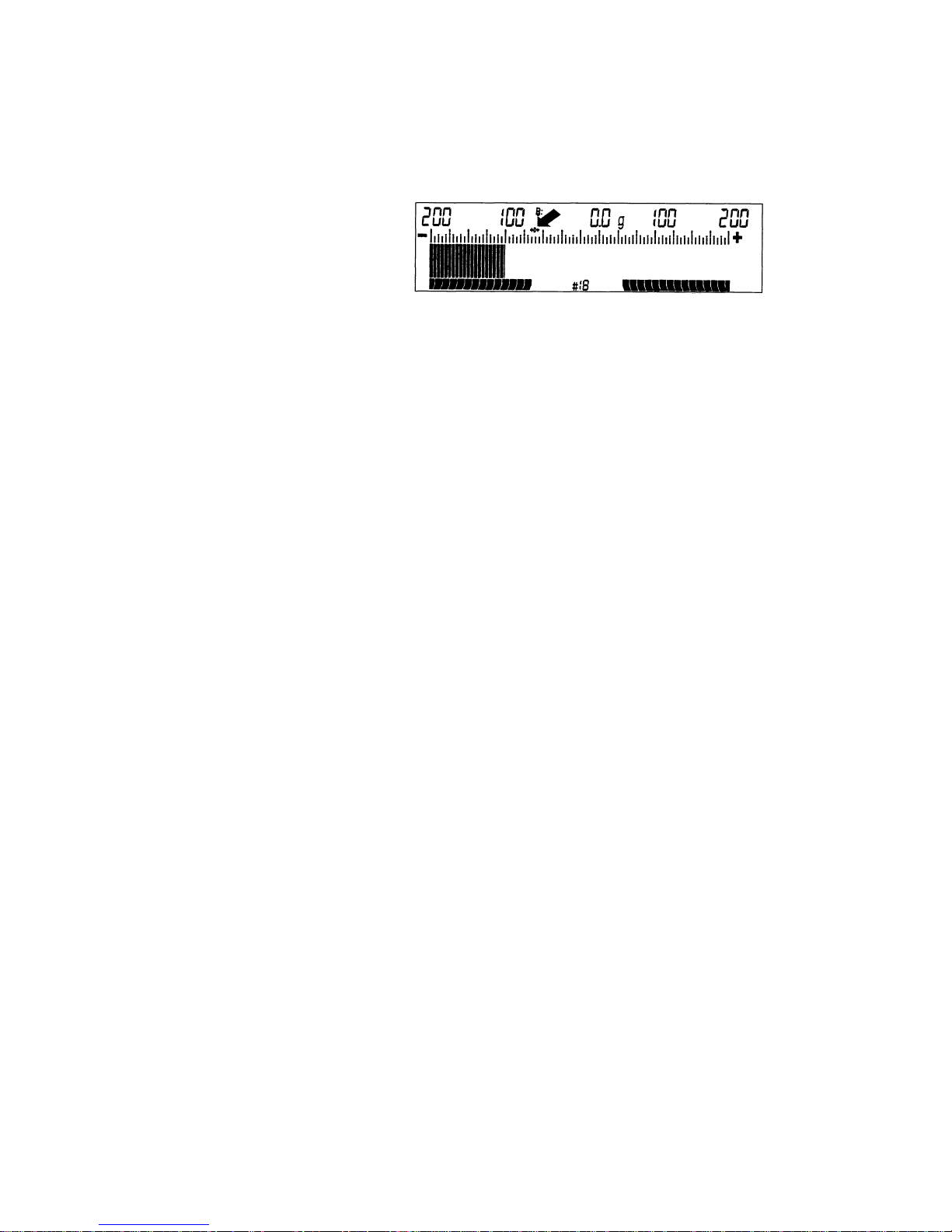

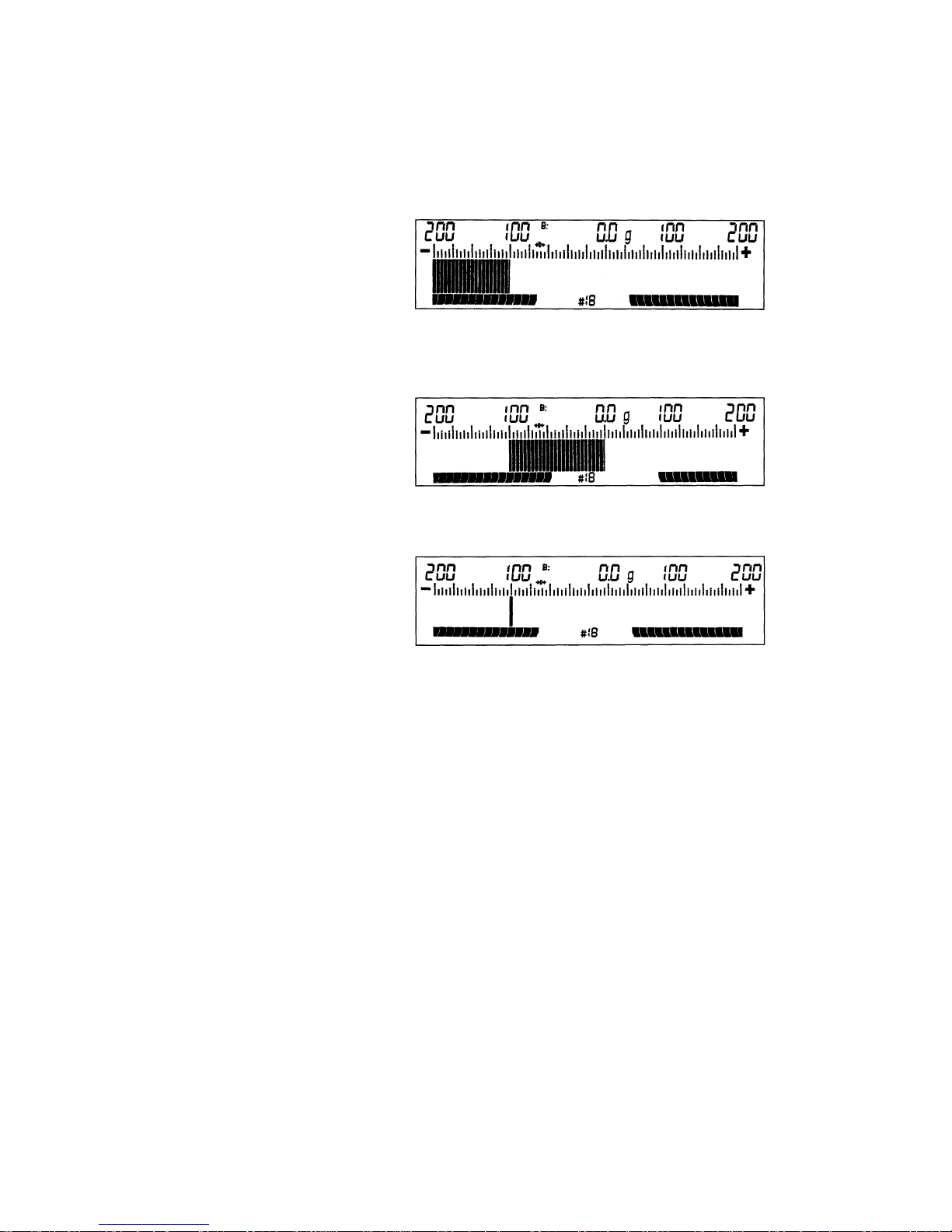

Wide Range Analog Indicator (Bar Graph)

At the same time, the wide range analog indicator, a bar

graph, gives you additional information on your sample.

The digital readout shows you the difference of the weight

of your sample from the target weight (depending on the

menu code set in the scale operating program) and the

bar graph helps you weigh-in accurately.

In addition, you can define the mode of this wide band

analog indicator to best meet your requirements.

12

For example, for a target weight of 100 g, you can choose

between

— a continuous bar graph that travels from the left to the

right (for determination of a sample weight)

— a bar graph with a zero point = target weight

(for determination of the difference in weight)

— and a "traveling marker."

The bar graph mentioned above can be shown in the

following user-selectable application modes for the weight

display. Depending on your choice of the display mode,

set the appropriate menu code in the scale operating

program (see pages 23 through 29).

13

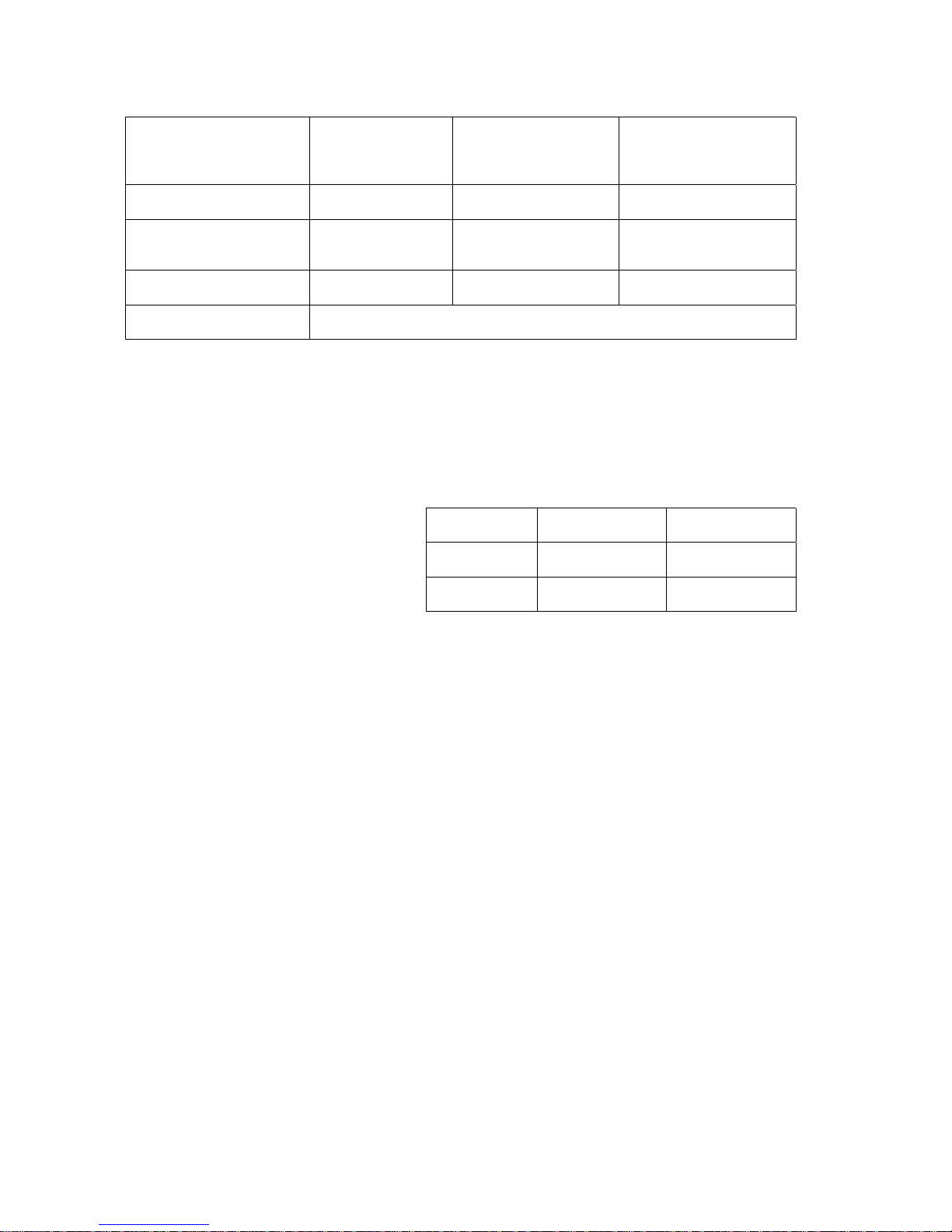

Without digital

weight readout

code:

3 2

With net weight

readout

code:

3 3

With readout of

the difference

in weight

code:

3 4

Continues bar graph

code:

9 6

X X X

Bar graph with

zero point = target weight

code:

9 7

X X X

Traveling marker

code:

9 5

X X X

No bar graph digital weight readout only

code:

3 1

The resolution of the display scale range depends on the

parameter you have selected.

Starting from the target weight, the over and under range

that can be displayed in either direction as follows:

Weight unit

in »g«

Weight unit

in »kg«

TS 6100 B

± 20 g, ± 40 g,

± 80 g, ± 200 g

± 400 g, ± 800 g,

± 2 kg

TS 12

± 40 g, ± 80 g,

± 200 g

± 400 g, ± 800 g,

± 2 kg, ± 4 kg

14

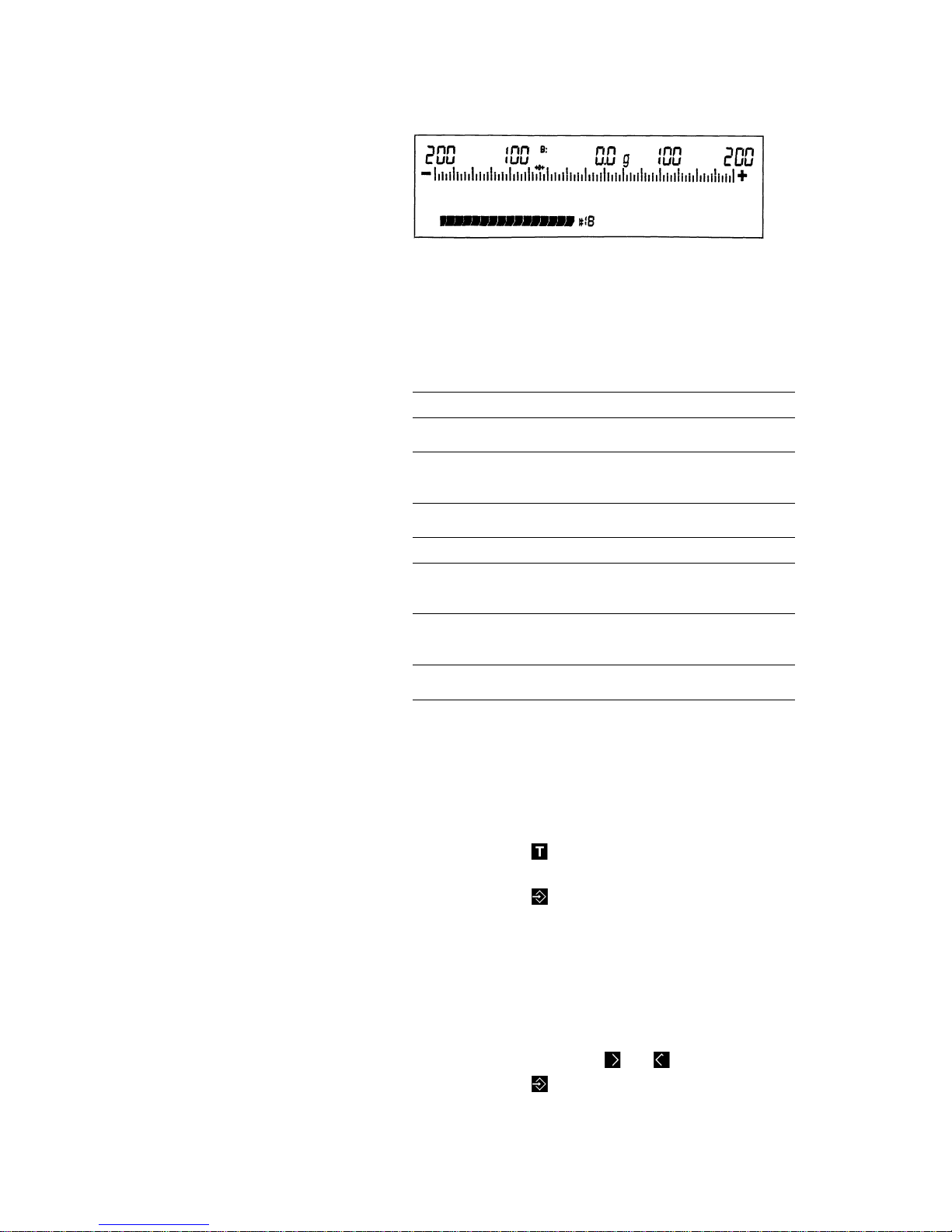

Product ID Numbers and

Product Data

Retrieving the desired Product ID Number

Press the

key

(8)

to turn the scale on.

The product ID number that is selected at the moment will

be displayed in the lower half of the weight display

(7)

.

To retrieve the desired product numbers, use keys

(12)

and

(14)

.

Changing Product Data

You can change and store the following for 12 different

products:

— the product ID number (1...12)

— the target weight

— the scale divisions in the display

— the lower and

— the upper tolerance limits.

These data are stored in a non-volatile memory so you do

not have to worry about a power outage.

The new product data are then available under the corresponding product ID numbers.

15

How to activate a product data function:

Press the

key

(8)

to turn the scale on.

Clear the weighing platform.

With the scale turned off, hold down the

key

(13)

and

briefly press the

key

(8)

.

When the readout is displayed, release the

key

(13)

.

Changing the Product ID Number

First select the product ID number you wish to assign to a

sample.

Caution:

Please keep in mind that all data stored under this ID

number will be deleted if you change the ID number.

The # symbol will flash in front of the product number

selected.

Use the

key to increase the number or the key to

decrease the number;

press the key labeled

to store the selected number.

The program will automatically change to the next parameter.

16

Changing the Target Weight

The target weight depends on the menu code setting in

the scale operating program.

You can enter the target weight either by storing the

weight of a sample on the platform or by numeric entry.

The following menu codes can be set in the scale operating program:

Code

1 1 1

Only target weight by loading sample; retain

same setting for over/under tolerance limits

1 1 2

Target weight by loading sample;

over/under limits by loading underweight and

overweight samples

1 1 3

Target weight by loading sample;over/under

limits by numeric entries using keys

1 1 4

Not assigned

1 1 5

Only target weight by numeric entry using

keys; retain same setting for over/under

tolerance limits

1 1 6

Target weight by numeric entry using keys;

over/under limits by loading underweight and

overweight samples

1 1 7

Target weight by numeric entry using keys;

over/under limits by numeric entries using keys

At the factory, we have set

code 1 1 3

.

lf necessary, you can change this setting. To do so,

please read pages 23 through 29.

17

How to enter a target weight using a sample on the

weighing platform:

— Clear the weighing platform

— Press the

key to tare the scale

— Place your sample on the platform (if you do not

place a sample on the weighing platform, the previous weight will be stored)

— Press the

key to store the weight.

Entering a numeric value for the target weight:

Five digits appear in the display - the last digit flashes.

— Press the

key to select the digit you wish to

change.

— Press the

key to change the flashing digit.

— To store the target weight you have entered,

press the

key. The program will automatically

change to the next parameter (scale divisions in

the display).

The error message "E3" will appear if:

—

the value of the target weight is negative, or

—

the value entered is too large.

18

Changing the Scale Divisions in the Display

lf you do not wish to change the tolerance limits, it is not

necessary to change the scale divisions

(codes 1 1 5, 1 1 1). In this case, the scale will skip the

following steps.

The user-definable scale divisions in the display allow you

to spot off-weights easily.

Depending on the expected off-weights of the samples to

be checkweighed, you can expand the analog display by

selecting a lower number of the scale divisions.

Possible settings:

Weight unit

in »g±

Weight unit

in »kg±

TS 6100 B

± 20 g, ± 40 g,

± 80 g, ± 200 g

± 400 g, ± 800 g,

± 2 kg

TS 12

± 40 g, ± 80 g,

± 200 g

± 400 g, ± 800 g,

± 2 kg, ± 4 k g

Press the keys labeled

or each time to increase or

decrease the scale division settings.

To store a setting, press the key labeled

; the program

will automatically change to the next parameter (tolerance

limits).

19

Changing the "Under" Limit

Depending on the menu code setting in the scale operating program, you can enter the under limit either by storing the weight of a sample on the platform or by numerical

entry.

The following menu codes can be set in the scale operating program:

Code

1 1 1

Target weight by loading sample; retain same

setting for over/under tolerance limits

1 1 2

Target weight by loading sample;

over/under limits by loading underweight and

overweight samples

1 1 3

Target weight by loading sample; over/under

limits by numeric entries using keys

1 1 4

Not assigned

1 1 5

Target weight by numeric entry using keys;

retain same setting for over/under tolerance

limits

1 1 6

Target weight by numeric entry using keys;

over/under limits by loading underweight and

overweight samples

1 1 7

Target weight by numeric entry using keys;

over/under limits by numeric entries using keys

How to enter the under limit using an

underweight sample:

— Clear the weighing platform

— Press the

key to tare the scale

— Place the sample on the platform and

— Press the

key to store the weight.

How to enter a numeric value for the under limit:

The analog range for the under limit will flash.

Starting with the limit previously set, enter the "under" limit

as a deviation from the target weight.

— Use the keys labeled

and to enter the limit.

— Press the

key to store the numeric underweight you have just entered; the program will

automatically change to the next parameter.

20

Changing the “Over” Limit

Depending on the menu code setting in the scale operating program, you can enter the over limit in one of two

ways: either by storing the weight of a sample on the

platform or by a numeric entry (see "Changing the Under

Limit").

How to enter an over limit using an overweight sample:

— Clear the weighing platform

— Press the

key to tare the scale

— Place your sample on the platform (at this point,

load the target weight and the tolerance weight to

obtain an overweight sample) and

— store the weight with the

key.

How to enter a numeric value for an over limit:

The analog range for the over limit will flash.

Starting with the limit previously set, enter the over limit as

a deviation from the target weight.

— Use the keys labeled

and to change the

value.

— To store the "over" weight you have just entered,

press the

key.

This completes the entry of product data; the program will

automatically change to the weighing mode.

21

Calibration

This is only possible with an accurate calibration weight:

(see "Accessories")

Model Calibration weight Order number

TS 6100 B 5000 g 707213

TS 12 10000 g 707218

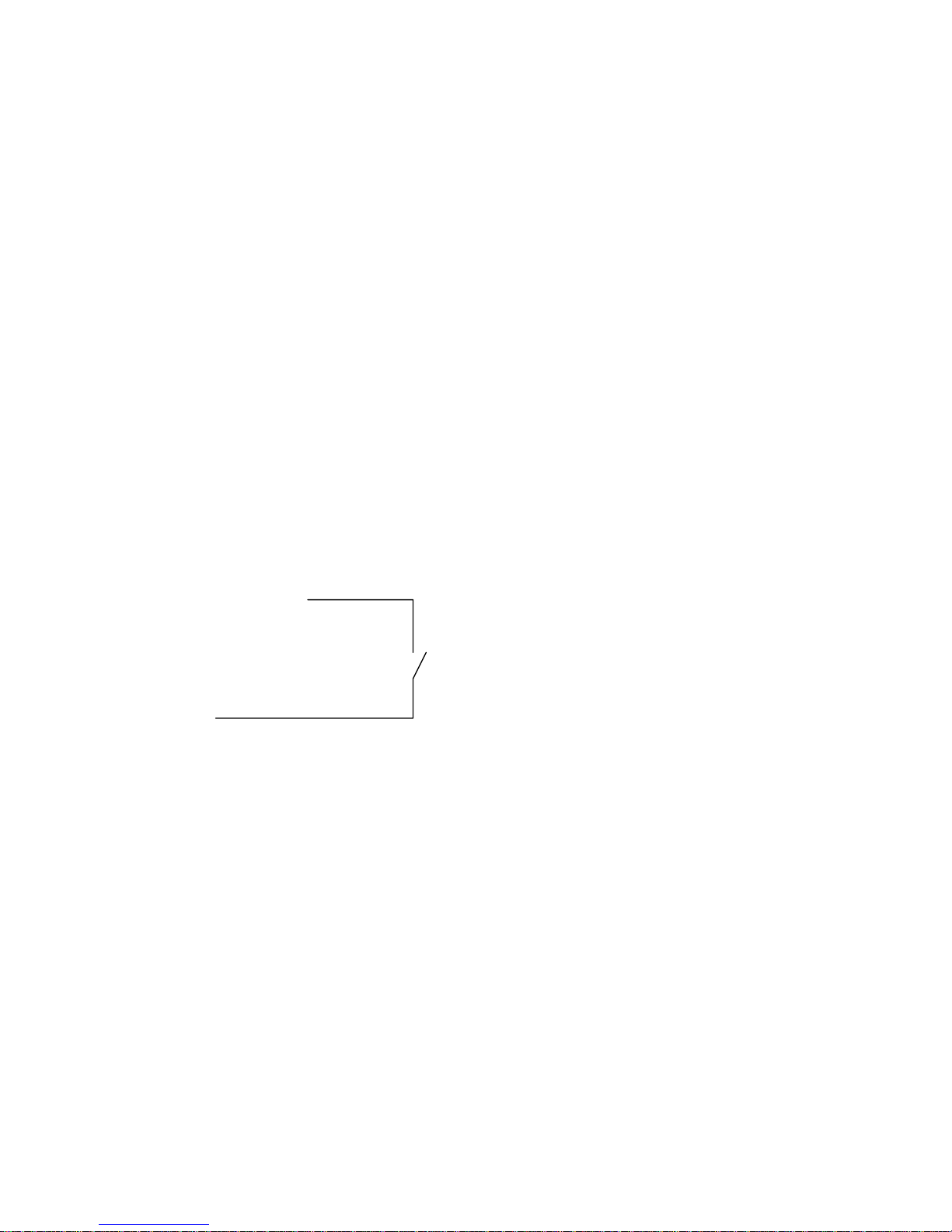

How to activate the calibration function:

Insert the

in the side of the display head.

Unload the weighing platform.

With the scale turned off, hold down the

key and

briefly press the

key

(8)

.

Once the readout appears, release the

key.

lf

->0<-

does not appear below "DEF," tare the scale.

22

Then press the

key - the calibration weight will appear,

i.e.:

Center the calibration weight on the weighing platform.

lf "+" appears in front of the weight readout, the calibration

weight is too light. lf "–" is displayed, the weight is too

heavy.

The plus/minus sign disappears if the calibration weight is

accepted and an acoustic Signal indicates the end of the

calibration procedure.

The "+" symbol reappears at this time, also.

23

Scale Operating Program

In order to access the scale operating program, you will

need the

.

The scale operating program enables you to change the

menu code settings for the weight unit, the individual

operating parameters for the scale, the display mode,

Update rate and the data output parameter, including the

parameter for the application mode.

At the factory, we have set the codes for the scale operating program so you do not need to make any changes if

you only want to use the "over/under check weighing"

mode under normal ambient conditions.

Any changes to the menu codes in the scale operating program will affect how the products are weighed.

To familiarize yourself with all of the performance capabilities this scale offers, why not try out a few menu code

settings that sound interesting to you?

After all, you can always change them back to the original

settings.

Use the "

codes

" to select the desired function in the

menu of the scale operating program.

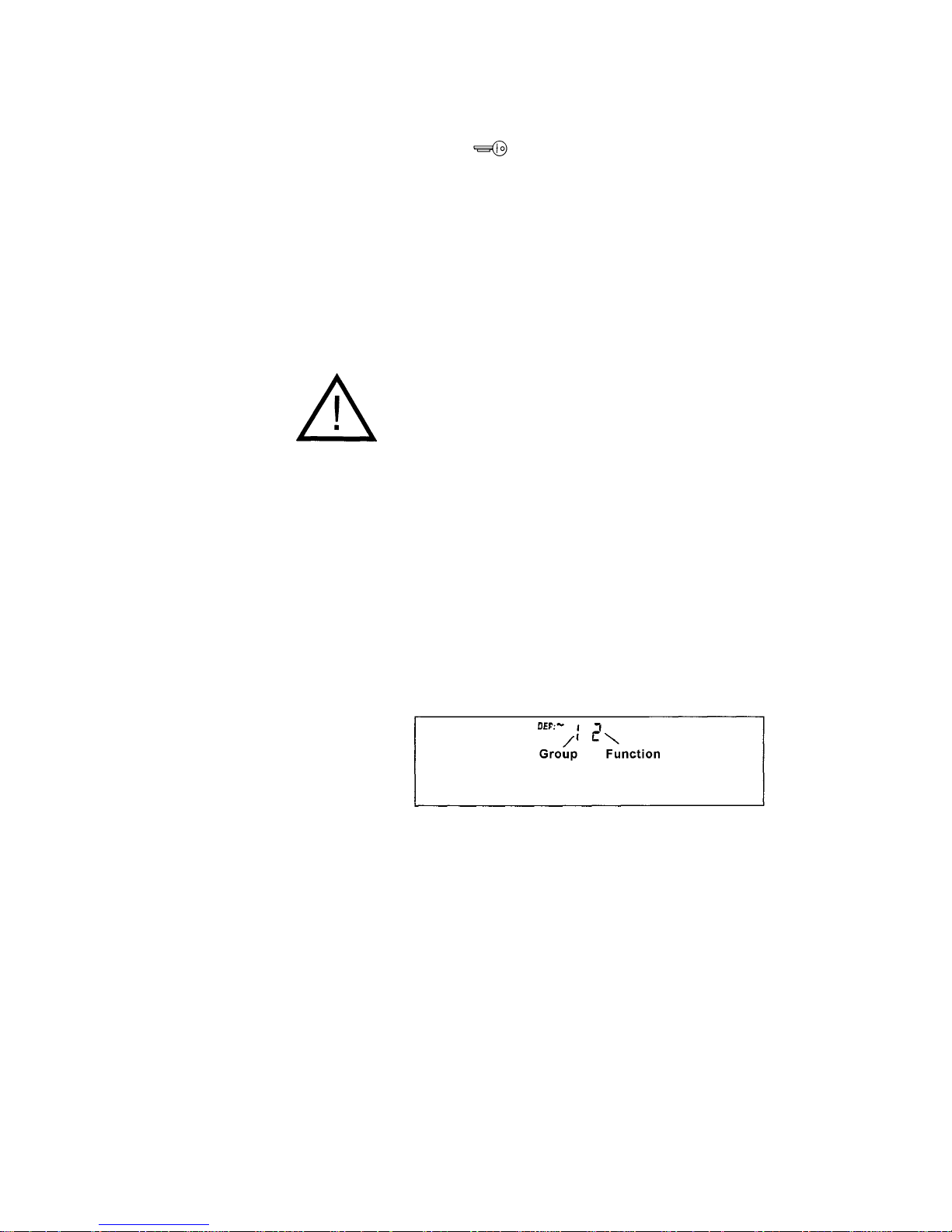

Each code consists of a left-hand number for the function

group and a right-hand number for a function within a

group.

24

Factory Settings

Code

1 — 1 7 — 2

2 — 2 8 — 2

3 — 3 9 — 14

4 — 1 10 — 1

5 — 5 11 — 3

6 — 2 12 — 2

How to Access the Scale Operating Program

Insert the

in the lock located on the side of the

display head.

With the scale turned off, hold down the

key and briefly

press the

key

(8)

.

25

After the readout appears, release the

key.

To check a menu code setting, select the desired function

group using the

or key.

Press the

key to access a particular function.

Now the numeric code for the function will be displayed.

The function setting is identified by the symbol "~" that

appears after "

DEF

."

Use the keys labeled

and to select the desired

function.

Use the

key to confirm the setting; the code will then

disappear.

Now you can select the next function group.

Remove the key after you have finished entering the

desired codes and

only a function group

is displayed.

By doing so, you will leave the scale operating program

and the code changes will be saved at the same time.

lf you turn off the scale using the ON/OFF key while

the scale operating program is accessed, none of the

code changes will be stored.

The following pages will give you a list of the functions in

the scale operating program.

26

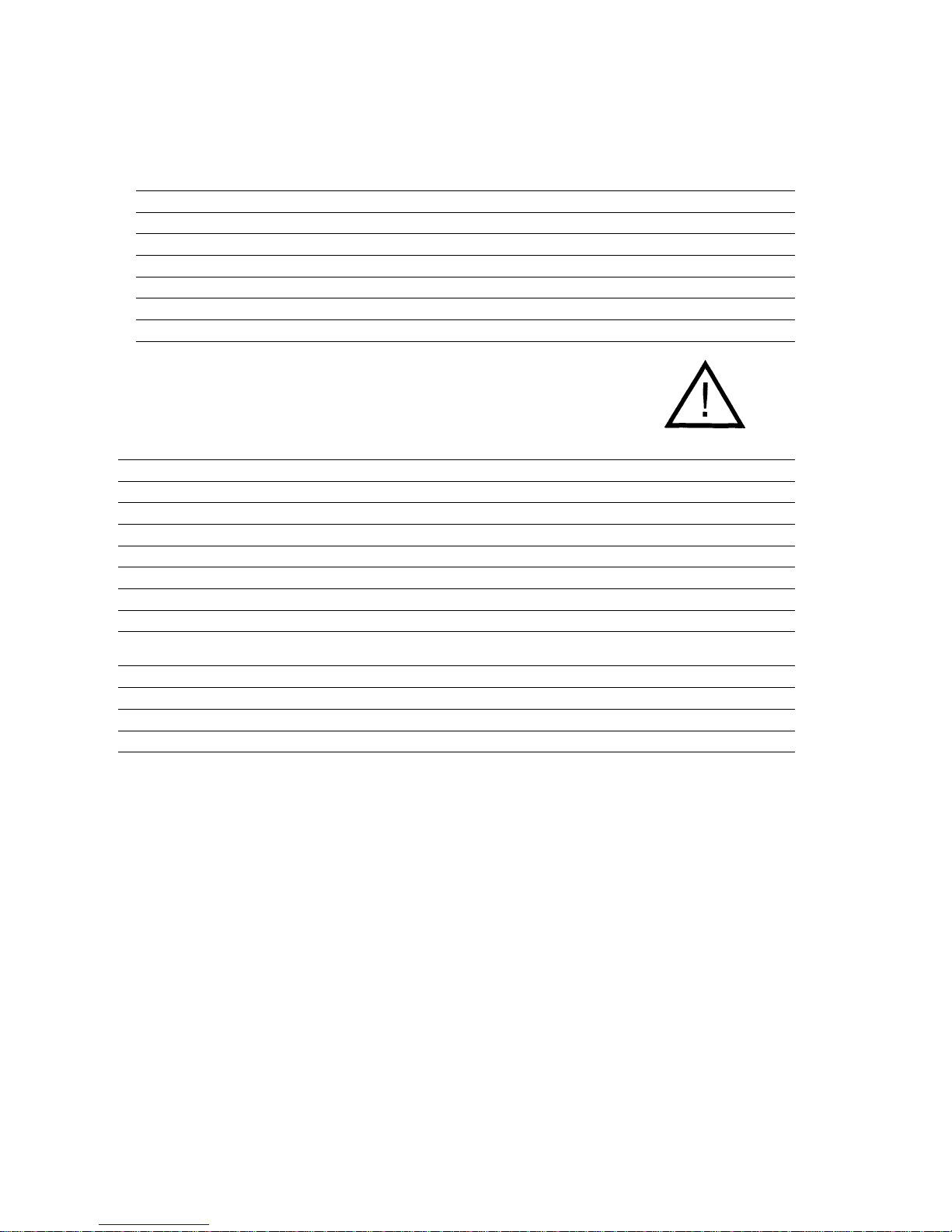

List of the Programmable menu Code Settings

“*” = Factory setting

Code Weight units

1 1* Grams g

1 2 Kilograms kg

1 3 Pounds lb

1 4 Ounces oz

1 5 Troy ounces ozt

1 6 grams

«0»

lf you change between grams and kilograms, the product weights

stored will remain valid, but not if you change the code to other weight units.

Code Acoustic Signal

2 1 Off

2 2* On

Code Application Mode for Weight Display

3 1 Digital weight readout only (weighing mode)

3 2 Over/under application without digital weight readout

3 3* Over/under application with net weight readout

3 4 Over/under application with readout of the difference in weight

(weight displayed = difference from the target weight)

Code Ambient Conditions

4 1* Stable (100 ms display update)

4 2 Stable to unstable (200 ms display update)

27

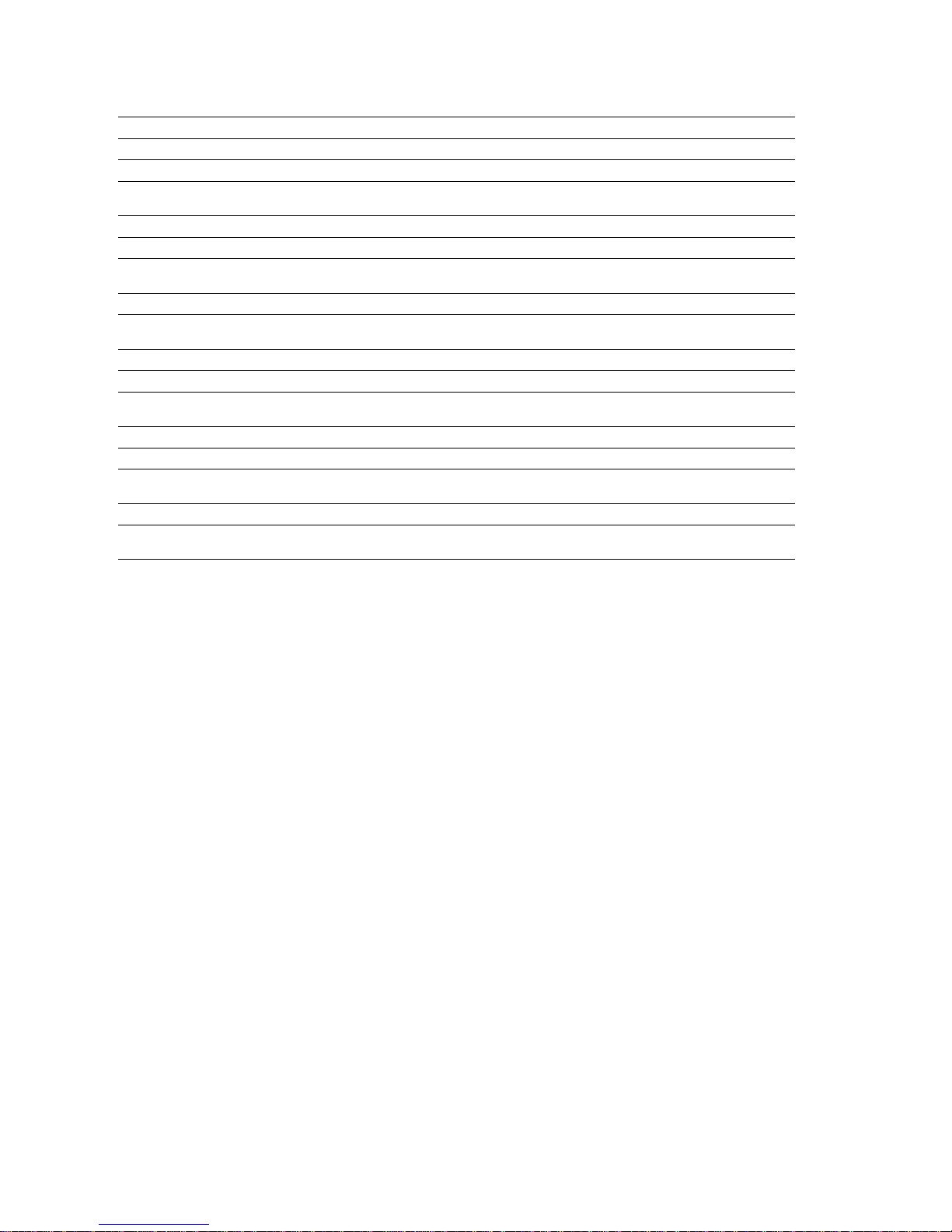

Code Stability Range

5 1 0,25 digit

5 2 0,5 digit

5 3 1 digit

5 4 2 digits

5 5* 4 digits

5 6 8 digits

5 7 16 digits

5 8 32 digits

The motion detection symbol "~" will appear only if a change in weight beyond the

defined number of digits is detected.

Code Tare Parameter (Zeroing the Display)

6 1 Without stability control

(the tare command is immediately executed)

6 2* At stability

(the tare command is stored until the scale has stabilized and is then executed)

Code Auto-Zero

7 1 Off

7 2* On

The scale features an automatic zero tracking function, known as "Auto Zero.

When this function is on, changes off zero ≤ 0.5 of a digit per second are set to zero

automatically after the display is zeroed with the tare key.

28

Code Data Output Parameter Printout

8 1 Single print when key is pressed, regardless of stability Actual weight

8 2* Single print when key is pressed and readout is stable Actual weight

8 3 Single print when key is pressed and weight readout is

stable & within the display range

Actual weight

8 4 Auto print regardless of stability Actual weight

8 5 Auto print when readout is stable Actual weight

8 6 Auto print when the weight readout is in the display

scale range and stable

Actual weight

8 7 Single print activated by load when readout is stable Actual weight

8 8 Single print activated by load when readout is stable and

within the display scale range

Actual weight

8 9 Single print when key is pressed, regardless of stability Weight difference

8 10 Single print when key is pressed and readout is stable Weight difference

8 11 Single print when key is pressed and readout is

stable & within the display scale range

Weight difference

8 12 Auto print regardless of stability Weight difference

8 13 Auto print when readout is stable Weight difference

8 14 Auto print when readout is stable and within display

scale range

Weight difference

8 15 Single print activated by load when readout is stable Weight difference

8 16 Single print activated by load when readout is

stable & within the display scale range

Weight difference

Single print = Output of an individual weight

Auto print = Automatic, continuous output of weights

(can be stopped and started by pressing the print key)

Stability; stable = The motion detection symbol is not displayed

Display scale range = Analog display of the weighing range with user-definable

scale divisions

Activated by load = An individual value is output automatically when a load is on

the platform and the scale has stabilized.

This procedure may be repeated once the weight is removed from the platform.

29

Code Analog Display/Backlighting

9 1 Marker Backlighting off

9 2 Bar graph for sample weight Backlighting off

9 3 Bar graph for weight difference Backlighting off

9 4 Not assigned

9 5 Marker Backlighting on

9 6 Bar graph for sample weight Backlighting on

9 7 Bar graph for weight difference Backlighting on

9 8 Not assigned

9 9 Marker Backlighting off, LED on

9 10 Bar graph for sample weight Backlighting off, LED on

9 11 Bar graph for weight difference Backlighting off, LED on

9 12 Not assigned

9 13 Marker Backlighting on

9 14* Bar graph for sample weight Backlighting on, LED on

9 15 Bar graph for weight difference Backlighting on, LED on

Code Product Selection Mode

10 1* Only with inserted key

10 2 Without key

Code Entry Mode for the Target Weight and Limits

11 1 Target weight by loading sample; retain same setting

for over/under tolerance limits

11 2 Target weight by loading sample; over/under limits by loading underweight

and overweight samples

11 3* Target weight by loading sample; over/under limits by numeric

entries using keys

11 4 Not assigned

11 5 Target weight by numeric entry using keys; retain same setting for

over/under tolerance limits

11 6 Target weight by numeric entry using keys; over/under limits by loading

underweight and overweight samples

11 7 Target weight by numeric entry using keys; over/under limits by numeric

entries using keys

Code RED/GREEN/YELLOW Indicators

12 1

"RED" off when load approx. <5% of the target weight,

weight readout at stability

12 2*

"RED" on when load approx. <5% of the target weight,

weight readout regardless of stability

12 3

"RED" off when load approx. <5% of the target weight,

weight readout at stability

12 4

"RED" on when load approx. <5% of the target weight, LED only when readout

weight readout at stability is stable

30

Mounting Instructions

Changing the Display Mounting

(Raised Display to Remote Display)

— Loosen the cable clamp on the support arm

— Remove the retainer bars for the support arm

from the display head

— Dismount the display head

— Remove the three screws from the support arm

base plate

— Dismount the support arm

— Use the retainer bars to fasten the holder to the

display head

How to Install the Interface Cable

The interface cable should be installed only by a

certified electrician.

Ask for separate instructions describing how to install the

interface cable.

31

Changing the Scale Housing Cover

— Remove the weighing platform

— Unscrew the 4 platform support disks

— Gently pull the left and right sides of the scale

housing cover outward and lift it off

— Place a new housing cover on the scale base,

making sure that both sides snap in audibly

— Refasten the four platform support disks

using the screws

— Reposition the weighing platform

32

Interface Description (Option)

lf you wish to record weight data using the Sartorius Data Printer, just plug the printer

connector Mo the interface port of the scale. You do not need to adjust any settings!

(You can also interface your scale with a Computer.)

General Specifications

Type of interface Serial point-to-point connector

Operating mode Asynchronous, simplex

Standard V24-V28, RS232 C-S

Handshake lines Clear to Send (CTS)

Data Terminal Ready (DTR)

Initialization External or automatic print command depending

of the interface on the code selected (8 1 to 8 16)

Character coding 7-bit ASCII

Transmission rate 1,200 baud

Parity Odd

Synchronization 1 Start bit, 1 stop bit

Additional port lines for 4, for upper/lower limits,

over/under checkweighing tolerance range and target

Data Output Format

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

H H - - - -

+

-

- - Z Z Z Z Z Z Z _ X X X CR LF

1st and 2nd characters: Weight difference or net weight

3rd to 6th characters: Space

7th character: Plus or minus signor space

8th and 9th characters: Space

10th to 16th characters: Digit, space or decimal point

17th character: Space

18th to 20th characters: Letter or space

21st character: Carriage Return

22nd character: Line Feed

33

Data Output Parameters

(Codes

8 1

to

8 16

)

Data can be transferred to the output port depending on

the particular stability state of the weighing system (stability parameter: stable readouts).

You can choose to have data transferred regardless of

stability or only when the readout is stable.

lf you opt to have data transferred only when the weighing

system has stabilized, an output command will remain

stored until the system has stabilized.

For the auto print setting (automatic data output), weight

data are transferred continuously the moment you turn on

the power. lf you have additionally selected the stability

parameter for this Option, only data for stable readouts

will be output. To stop and start automatic data transfer,

press the print key.

Each signal received by the RxD line will initiate data

transfer (external data request).

Interfacing Devices with the Scale (RS Interface)

Make sure that the interface port is electrically connected

to the scale housing. The interface cable supplied as an

optional accessory is shielded and must be installed so

that the interface end is electrically connected to the

housing. This electrical connection may result in interference caused by ground loops or by transient currents if

you have grounded the housing or connected the protective grounding conductor for AC power. lf necessary,

connect an equipotential bonding conductor to the scale.

34

Pin Assignment for the Interface

Female Interface Connector:

25-position D-submini DB25S with screw lock hardware for the cable gland

Male Connector Required:

25-pin D-submini DB25S with integrated shielded cable clamp assembly (Amp type 826 982-1) and

fastening screws (male screws for female screw lock, Amp type 164 868-1)

Pin Assignment

Designations Direction Standard Level

Pin 1: Protective Ground

Pin 2: Data Output (TxD) Output RS323

Pin 3: Data lnput (RxD) lnput RS232

Pin 4: Not Connected

Pin 5: Clear to Send (CTS) lnput RS232

Pin 6: Not Connected

Pin 7: Internal Ground

Pin 8: Internal Ground

Pin 9: Not Connected

Pin 10: Not Connected Print/Tare*)

Pin 11: +12 V Output (50 mA max.)

Pin 12: Reset —| Output TTL

Pin 13: +5 V Output (50 mA max.)

Pin 14: Internal Ground

Pin 15: lnput open Collector

Pin 16: Low Signal Output LS-TTL

Pin 17: OK Signal Output LS-TTL

Pin 18: High Signal Output LS-TTL

Pin 19: Set Signal Output LS-TTL

Pin 20: Data Terminal Ready (DTR) Output RS232

Pin 21: Not Connected

Pin 22: Not Connected

Pin 23: Not Connected

Pin 24: Not Connected

Pin 25: +5 V Output (50 mA max.)

*) Print or tare (have this parameter implemented or changed by a Sartorius service technician)

35

Options and Accessories

Options

Interface

YDO 01 TS

(for connecting a data printer or a PC)

Display holder

YDH 01 TS

for benchtop or wall mounting

Spacer feet

YAS 01 TS- 00

for lifting the scale by about 8 cm (3") 000 V 001

Spare scale housing cover 69 T 00001

Accessories

Data printer

with date/time YDP 02-0DV1

& statistics functions

Print speed approx. lines/sec. 1.5

Printer housing (W x D x H)

in mm 150x138x43

in inches 5.9x5.4x1.7

Calibration weight

for TS 6100 B 707213

Calibration weight

for TS 12 707218

36

Specifications

Model

TS 6100B TS 12

Capacity g 6,100 12,100

Readability g 0.5 1

Tare range (by subtraction) g -6,100 -12,100

Standard deviation g

≤ ± 0.5 ≤ ± 1

Max. linearity g

≤ ± 0.5 ≤ ± 1

Stabilization time (typical) s 1.1

Display Update

– when the readout stabilizes

(depends on the filter level

selected)

– when the load changes

s

s

0.1/0.2

0.1

Adaptation to application requirements

and ambient conditions

By selection of one of 2 optimized filter levels

Stability range d 0.25 ... 32 (selectable)

Ambient temperature range K 273 — 313 (0oC...+40oC) (32oF … 104oF)

Moisture-proof rating acc. to DIN 40040 Class F, non-condensing

Dust and water protection rating in

conformance with DIN 40050/IEC529

IP65

Sensitivity drift within 10...30°C /oC

≤±2.5 ∙ 10

-6

Platform size

mm

in.

260 x 210

10.2 x 8.4

Scale housing (W x D x H)

mm

in.

260 x 295 x 110/450

10.2 x 11.6 x 4.3/17.7

Net weight, approx.

kg

~lb

6.5

14.3

Power requirements

(voltage + frequency)

115 or 230 depending on the type

of power supply used; 50-60 Hz

Allowable voltage fluctuation -20% ... +15%

Power consumption (typ.) VA 14

37

Troubleshooting Guide

Problem … Causes … Solution

No segments appear in the weight

display

(7)

- No AC power available

- The power supply is not plugged

in

- Check AC power supply

- Plug in power supply

Display shows

“L”

- The weighing platform

(5)

is not in

place

- Position the platform

Display shows

“H”

- The load exceeds the capacity of

the scale

- Unload the scale

The weight readout changes

constantly

- Unstable ambient conditions

- Too much Vibration or the scale is

exposed to a draft

- Set up the scale in another area

- Access the menu to select the

proper code for the particular type

of weighing environment

Display shows

“EO”

- The platform was not empty

during calibration

- Clear weighing platform and

repeat calibration procedure

The weight readout is obviously

wrong

- The scale has not been calibrated

- The scale has not been tared

before weighing

- Calibrate the scale

- Tare before weighing

38

Care and Maintenance

Clearing

Wash down the scale with cleaning agents that you

commonly use in the food industry.

Important Note:

Featuring the IP 65 protection rating (approximately

equivalent to NEMA 4), the scale is dust-tight and

washdown-resistant. See the "Test Mark Award Certificate" issued by the TÜV, the German Association

for Technical Inspection.

Safety Inspection

lf there is any indication that safe Operation of the scale

with the power supply is no longer warranted, turn off the

power and unplug the scale from the power supply immediately. Lock the scale in a secure place to ensure that it

cannot be used for the time being.

In this case, notify your nearest Sartorius Service Center

or the International Technical Support Group based in

Goettingen, Germany. Only Sartorius service technicians

who are authorized by Sartorius and have the proper

manuals are allowed to perform maintenance and repair

work on the scale.

Safe Operation of the scale with the power supply is no

longer ensured when

— there is visible damage to the power supply

— the power supply no longer functions properly

We recommend that the scale and power supply be

inspected according to the following checklist by a qualified Sartorius service technician:

— Leakage current <0.05 mA measured by a prop-

erly calibrated multimeter

— Insulation resistance >7 megohms measured with

a constant voltage of at least 500 V at a 500

kohm load.

The duration and number of measurements should be

determined by a qualified Sartorius service technician

according to the particular ambient and operational conditions. However, such inspection should be done at least

once a year.

Sartorius AG

B 37070 Göttingen

P Weender Landstraße 94–108, 37075 Göttingen

T (0551) 308-0, F (0551) 308-3289

Internet: http://www.sartorius.com

Copyright by Sartorius AG, Göttingen, Deutschland.

All rights reserved. No part of this publication may be

printed or translated in any form or by any means without

the prior written permission of Sartorius AG.

Sartorius AG reserves the right to make change to the

technology, features, specification and design of the equipment

without notice.

Loading...

Loading...