Page 1

Operating Instructions | Betriebsanleitung

Sartocheck® 4 plus Filter tester | Filter tester MultiUnit

Filter Integrity Tester | Filterintegritäts-Testgerät

1000025369

Page 2

2 Contents

Contents | Inhalt

English .............................................. Page 3

Deutsch ............................................. Seite 94

Page 3

1. Contents

1. Contents ........................................2

1.1 Contents ....................................3

1.2 FCC ......................................5

2. Overview and Proper Use .........................6

2.1 Overview .....................................6

2.2 Proper Use ...................................6

2.3 Technical Specifications ........................7

2.3.1 Dimensions and Weight ..................7

2.3.2 Connection Data .......................7

2.3.3 Pneumatics ............................7

2.3.4 Test Media .............................7

2.3.5 Product-specific Data ...................8

2.3.6 Test Methods ...........................9

2.3.7 General Data ...........................9

3. Safety ..........................................10

3.1 Notes | Warnings | Descriptions .................10

3.1.1 Manufacturer’s ID Label .................10

3.2 Installed Safety Equipment .....................11

3.3 Safety Precautions ............................11

3.4 Operator’s Obligations .........................12

3.5 Safety Tests and Inspections Carried Out by

the Manufacturer at the Facilities ................12

4. General Warnings ................................13

4.1 Hazards ......................................13

4.2 Operating Personnel and Service

and Maintenance Personnel .....................13

4.3 Installation of Replacement Parts ................14

4.4 Shutdown Procedure ..........................14

5. Installation ......................................15

5.1 Equipment Supplied ...........................15

5.2 Receipt of Delivery ............................15

5.3 Installation Instructions ........................16

5.3.1 Ambient Conditions and Conditions

at the Place of Installation ................16

5.3.2 Transport and Unpacking the Equipment ....16

5.4 Connections .................................17

5.4.1 Front Panel and Back Panel ..............17

5.4.2 Left and Right Panels ....................17

5.4.3 Left and Right Panels Sartocheck® 4

MultiUnit ..............................18

5.5 Connections with Internal Pressure Sensor .........18

5.6 Connections with External Pressure Sensor .........20

5.6.1 Inserting Paper Roll and Ribbon Cartridge . . .21

5.6.2 Sartocheck® 4 MultiUnit ..................22

6. Function ........................................23

6.1 General Functional Description .................23

6.2 Test Programs ................................23

6.3 Managing the Test Results .....................24

6.4 Function Test ................................24

6.5 Cleaning ....................................24

6.6 User Interrupt ...............................24

6.7 Self-Test for Broken Conductors and

Short-Circuiting ..............................24

6.8 Calibration ..................................24

6.9 Internal Pressure Sensor .......................24

6.10 Pressure Gauge Function .......................24

6.11 Cleaning | Drying .............................24

6.12 Safety Functions ..............................24

6.13 Software Update .............................25

6.14 Serial Number ................................25

7. Operation .......................................26

7.1 Switching on the Unit .........................26

7.1.1 Operating Elements .....................26

7.2 Switching the Unit ON and OFF .................28

7.2.1 Running a Test .........................29

7.2.2 Switching Off the Unit ..................29

7.2.3 Switching Off the Unit in the Event

of a Power Failure ......................29

7.3 Tests ........................................29

7.3.1 Test Parameters ........................29

7.3.2 Test Methods ..........................30

7.3.3 Programming Tests (F2 – Main Menu) .....30

7.4 Diffusion Test ................................31

7.5 Bubble Point Test .............................35

7.6 Customer-Specific BP .........................36

7.7 Diffusion and Bubble Point Test (Combined Test) . . .36

7.8 Water Intrusion Test | Water Flow Test . . . . . . . . . . .37

7.9 Pressure Drop Test ............................38

7.10 Multipoint Diffusion Test ......................38

7.11 Customer-Specific Multipoint Diffusion Test ......39

7.12 Volume Measurement .........................39

7.13 Plate Holder Test .............................40

7.14 Installed Bag Test .............................41

7.15 Program Database (F4 – Main Menu) ............42

7.15.1 Loading Test Program from Internal

Memory (F1) ...........................43

7.15.2 Uploading Test Program from SD card (F2) . .43

7.15.3 Saving Backup to SD card (F4) ............45

7.15.4 Loading Backup from SD card (F6) .........46

7.15.5 Deleting PLC Programs (F8). . . . . . . . . . . . . . .47

7.16 Visualize (F3 – Main Menu) ....................47

Contents 3

Page 4

4 Contents

7.17 Results Database (F5 – Main Menu) ...........47

7.18 Special Functions (F6 – Main Menu) ...........49

7.18.1 Function Test MU (F1) ................49

7.18.2 Function Test TU (F2) .................50

7.18.3 Cleaning (F3) . . . . . . . . . . . . . . . . . . . . . . . .50

7.18.4 Drying (F4) .........................52

7.18.5 Pressure Gauge Function (F5) ..........52

7.18.6 Modify Own Password (F6) ............53

7.19 Service (F7 – Main Menu) ....................53

7.19.1 Load Program from TU (F1-Service) .....54

7.19.1.1 External reference volume .....55

7.19.1.2 Network Settings .............56

7.19.1.3 Test Unit Address Allocation ....57

7.19.2 Hardware Configuration (F2-Service) ....58

7.19.3 Calibration|Adjustment (F3-Service) . . . .62

7.19.3.1 Calibration and Adjustment of

the Internal Pressure Sensor . . . .63

7.19.3.2 Calibration and Adjustment

of the External Pressure Sensor

Input .......................65

7.19.4 User Data Management (F4-Service) . . . .66

7.20 Using the Barcode Scanners (optional) .........67

8. Maintenance | Servicing ........................68

8.1 Maintenance ..............................68

8.1.1 Exchanging the Fine-wire Fuses ........68

8.1.2 Sartorius Stedim Biotech Service Menu . .68

8.2 Cleaning .................................68

9. Troubleshooting ................................69

9.1 Disposal and repair instructions ..............69

9.2 Troubleshooting ...........................69

10. Emergencies ...................................80

11. Information and Instructions on Disposal

and Repairs ...................................80

12. Appendix ......................................81

12.1 Detailed Test Description ....................81

12.1.1 Diffusion Test

(Only valid for the

Sartocheck

®

4 plus Filter tester) ........81

12.1.2 Bubble Point Test

(Only valid for the

Sartocheck® 4 plus Filter tester) ........82

12.1.3 Pressure Drop Test ...................83

12.1.4 Plate Holder Test .....................83

13. Electronic Data Transfer via Network Connection ..84

13.1 Network Concept ..........................84

13.2 FTP Server Requirements ....................85

13.2.1 How to Configure Your FTP Server ......85

14. PLC Control ...................................86

14.1 Digital Inputs ..............................86

14.1.1 START Input .........................86

14.1.2 PROG Input .........................86

14.1.3 STOP Input ..........................86

14.2 Digital Output .............................86

14.2.1 POWER on ..........................86

14.2.2 TEST RUNNING ......................86

14.2.3 ERROR .............................86

14.2.4 TEST OK ............................86

14.2.5 TEST not OK .........................86

14.2.6 External Valve 1. . . . . . . . . . . . . . . . . . . . . .86

14.2.7 External Valve 2. . . . . . . . . . . . . . . . . . . . . .86

14.3 Pin Layout ................................87

14.4 Examples .................................88

14.5 Outlets ...................................91

15. Index .........................................92

Page 5

1.2 FCC Note:

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined

by turning the equipment off and on, the user is encouraged to try to correct the

interference using one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment to an outlet on a circuit different from that

to which the receiver is connected.

– Consult the dealer or an experienced radio | TV technician for help.

Shielded Cables

Connections between the devices and peripherials must be made using shielded

cables in order to maintain compliance with FCC radio frequency emission limits.

Modifications

Any modifications made to this device that are not approved by Sartorius Stedim

Biotech GmbH may void the authority granted to the user by the FCC to operate

this equipment.

This instruction manual is based on screen shots from software version 3.1.3.

It is also valid for later software versions.

Translation

When the unit is supplied to countries in the EEA, the operating instructions must be

translated into the language or languages of the country of use. If any discrepancies

arise in the translated text, the original German operating instructions shall form the

basis for clearer interpretation or the manufacturer must be contacted.

Copyright

Reproduction, dissemination, transfer by any means and other use is not permitted

without the prior written consent of Sartorius Stedim Biotech GmbH. Offenders will

be liable for damages. All rights reserved.

Contents 5

Page 6

2. Overview and Proper Use 2. Overview and Proper Use

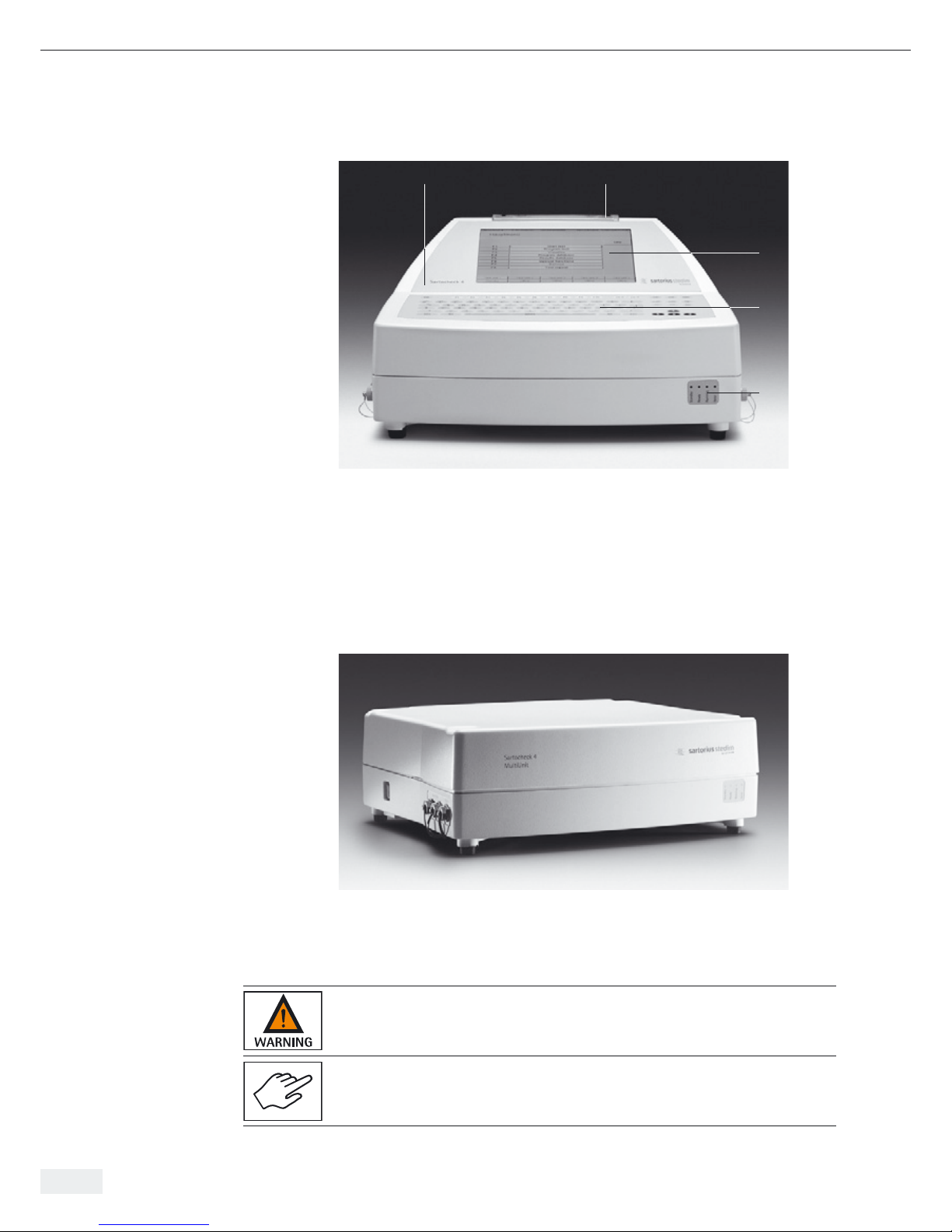

2.1 Overview: Sartocheck® 4 plus

Filter tester

Fig. 2-1 | Overview

Picture of Sartocheck® 4 plus Filter tester

1 Housing

2 Printer

3 Touch screen

4 Keypad

5 Indicator lights

Overview: Sartocheck® 4 plus Filter tester MultiUnit

Fig. 2-2 | Overview

2.2 Proper Use Sartocheck® 4 plus Filter tester is a filter integrity tester. It was exclusively developed,

constructed and built for the industrial and commercial purpose of conducting filter

tests in pharmaceutical and biotechnological production and laboratory operations.

The unit is not intended for use in or with explosive atmospheres!

The system is exclusively designed for the purpose defined above. Any other

application above or beyond this or any modifications to the unit without the

written permission of the manufacturer is not considered proper use.

12

3

4

5

6 Overview and Proper Use

Page 7

Sartorius Stedim Biotech GmbH cannot assume liability if Sartocheck® 4 plus test

units are subjected to improper use or improper operation. Sartorius Stedim Biotech

is not liable for any damages resulting therefrom. The operator bears the sole risk.

Proper use also includes compliance with operating, inspection and maintenance

conditions prescribed by the manufacturer. Non-compliance with the warnings in

the operating instructions and installation instructions, in particular, constitutes

improper use of the equipment. Only EMC-tested control leads and accessories may

be used. Units may only be returned in their original boxes or appropriate secure

packaging. No liability can be accepted for transport damage.

2.3 Technical Specifications

2.3.1 Dimensions and Weight Sartocheck

®

4 plus Filter tester

Length: 460 mm

Width: 390 mm

Height: 245 mm

Weight: 15 kg

Packing Weight: 2.7 kg

Sartocheck

®

4 plus Filter tester MultiUnit

Length: 460 mm

Width: 390 mm

Height: 150 mm

Weight: 13 kg

Packing Weight: 2.7 kg

2.3.2 Connection Data Sartocheck

®

4 plus Filter tester | Sartocheck® 4 plus Filter tester MultiUnit

Power requirements

Operating voltage: 100-240 V/±10%

Number of phases: 1 Ph/N

Neutral conductor: Loadable N (in the Appendix)

Grounding conductor: Separate SL (yellow-green) (in the Appendix)

Frequency: 47-63 Hz

Protection rating: IP 44

Installation: According to VDE regulations

Permissible voltage fluctuation: ± 10% from normal value

Maximum operating pressure: 10 bar g

Operating pressure: min. 4 bar g

Maximum power input: 74 Watt

Internal limit pressure: 10 bar g

2.3.3 Pneumatics Sartocheck

®

4 plus Filter tester | Sartocheck® 4 plus Filter tester MultiUnit

Required compressed air 4–9 bar g

Water, oil and particle free

2.3.4 Test Media Sartocheck

®

4 plus Filter tester | Sartocheck® 4 plus Filter tester MultiUnit

Test gas: Compressed air, dehydrated and deoiled

Wetting fluid: Water or as described with the process validation

documents for the filter cartridge to be tested

Overview and Proper Use 7

Page 8

8 Overview and Proper Use

2.3.5 Product-specific Data Manual input range upstream system volume 01) –150000 ml

Measuring Ranges

– Test pressure: 100–8000 mbar g

– Pressure drop: 1–2000 mbar

– Max. measurable volume: 150 L

– Diffusion: 0.1–3000 ml/min

– Water intrusion: 0.1–999 ml/10 min

– Water flow: 0.01–99.9 ml/min

– Bubble point: 100–8000 mbar

Measuring Accuracy

– Pressure ± 0.1% | ± 9.5 mbar full scale

– Pressure drop ± 1 mbar

– Net volume measurement ± 4%

– Diffusion ± 5%

– Water intrusion ± 5%

– Bubble point ± 50 mbar

Operating Conditions

– Room temperature +15°C to +35°C

– Rel. humidity 10-80%

Touch screen (Sartocheck

®

4 plus Filter tester only)

– Size 10.4“

– Color 256 colors

Interface Port for Data Output

– Serial port TU RS232| RS485

– Serial port MU RS232 (Sartocheck® 4 plus

Filter tester only)

– PLC port binary signals 12 pins

– Network Connection RJ45

Selectable languages:

English, German, French, Spanish, Italian

1)

When 0 is input, the upstream system volume is measured. Volume input and volume measurement are

not applicable for bag testing.

Page 9

Overview and Proper Use 9

2.3.6 Test Methods Test method Without ext. ref. tank With ext. ref. tank

Press. drop test All filter systems up to Not applicable

net volume of 150 L

Diffusion test

Cartridge systems up to Cartridge systems up

net volume of 14 L net volume of 150 L

Bubble point test Small systems and cartridge Small systems and cartridge

systems up to net volume systems up to net volume

of 14 L of 150 L

Multipoint diffusion Cartridge systems up to –

test net volume of 14 L

Diffusion and Cartridge systems up to Cartridge systems up to

bubble point test net volume of 14 L net volume of 150 L

(complete test)

Intrusion test, Cartridge systems up to –

water flow test net volume of 14 L

2.3.7 General Data Ambient conditions

Ambient temperature: +5 up to +35°C

Noise level: < 70 dB (A)

Humidity: 95% at 25°C

The unit should be set up under ambient conditions that produce no negative

effects during operation and processing, e.g. from contaminated airflows,

metallic dust or fluids from leaks, condensation, aerosols or widely changing

temperature conditions.

Page 10

3. Safety 3. Safety

Operating instructions are binding;

designated by a “book”.

Warnings

are designated by a “Hazard” triangle.

Electrical Hazards

are designated by the symbol to the left.

Notes

are designated by a “Hand”.

Grounding Conductor Connection

is designated by this symbol at the connection sites.

Mandatory Instructions

for handling electrical plug connections.

3.1.1 Manufacturer’s ID Label

Fig. 3-1 | Manufacturer’s ID Label Sartocheck® 4 plus Filter tester

Fig. 3-2 | Manufacturer’s ID Label Sartocheck

®

4 Filter tester MultiUnit

10 Safety

3.1 Notes | Warnings |

Descriptions

Page 11

The information given in these operating instructions applies to Sartocheck® 4 plus

Filter tester, Order no. 26288---FT and Sartocheck® 4 Filter tester MultiUnit,

Order no. 26288---FM.

The manufacturer’s label is affixed to the rear panel of the unit.

Important: if you have any questions

Always have the following information ready:

– Model

– Version

– Serial number

Having the right information readily available will ensure correct and quick

processing.

3.2 Installed Safety Equipment The installed safety equipment must be inspected at regular test intervals

(d = daily, w = weekly, m = monthly). The test methods used are: S = sight inspection,

F = functional testing.

The unit has the following safety equipment installed:

Line Disconnector

The unit is disconnected from the mains voltage by switching off the unit or when

the unit is unplugged from the wall outlet (mains supply).

Housing

All unit-specific components are shielded against external influences by a plastic

housing. It is strictly forbidden to disengage or dismantle the safety equipment.

The function of this safety equipment must be inspected and tested according to the

instructions given in the Chapter “Maintenance”.

The operator is responsible for instructing the operating personnel and

service and maintenance personnel about the meaning and the function

of the safety equipment.

These operating instructions are an integral part of the unit and must be available to

operating personnel and service and maintenance personnel at all times.

The safety precautions and warnings contained herein must be observed.

3.3 Safety Precautions The operator must

(to be carried out by – instruct their operating and servicing personnel in the use of the filter cartridge

the operator) housing’s safety devices and

– ensure that the safety precautions are complied with.

– prevent unauthorized persons (not operating and servicing personnel) from

accessing the filter cartridge housing danger zone.

These operating instructions must be kept in a safe place for future reference.

The frequency of inspections and checks must be observed.

The work described in these operating instructions is explained in such a way that it

can be understood by trained workers and qualified technicians.

Safety 11

Test

Interval Method

m S/F

Test

Interval Method

m S

Page 12

12 Safety

Definitions Adapted from EN 60204-1:

Trained Worker

A person familiarized with and, if applicable, trained in their particular duties by

a qualified technician and instructed about the potential dangers in the event of

improper conduct and on the necessary safety devices and safety precautions.

Qualified Technician

A person who, by virtue of their technical training, know-how, experience and

knowledge of relevant standards, is able to assess the work assigned to them

and identify potential dangers.

3.4 Operator’s Obligations

In the European Economic Area (EEA), the laws to nationally implement Council

Directive (89/391/EEC), as well as the corresponding individual Directives and specifically including Council Directive (89/655/EEC) concerning the minimum safety and

health requirements for the use of work equipment by workers during labor, must be

observed and complied with in their respectively valid versions.

In Germany, the Operational Safety Regulation dated October 2002 must be

observed (regulation transposing the above-mentioned Directives into national law).

The operator must obtain a local operating permit and follow the regulations and

restrictions set forth therein.

Additionally, the operator must comply with the local rules and

regulations for:

– The safety of the personnel (accident prevention regulations)

– The safety of the work equipment (protective gear and equipment and

maintenance)

– Product disposal (Waste Management Act)

– Material disposal (Waste Management Act)

– Cleaning (cleaning agents and disposal) and the environmental rules

and regulations.

3.5 Safety Tests and Inspections 1. Measurement of airborne noise

Carried Out by the 2. Testing and inspection according to DIN EN 61010-1

Manufacturer at the Facilities

Page 13

General Warnings 13

4. General Warnings 4. General Warnings

4.1 Hazards The safety systems and safety notes described in these operating instructions should

be complied with accordingly.

Keep the work area of the Bag tester free of objects during operation so that

unimpeded access is possible at all times.

Before any installation, servicing or repair work is carried out, make sure you

are aware of the electrical hazards!

Unplug the equipment from the wall outlet (mains supply) before opening it!

Observe the required operating conditions, especially with regard to the temperature

of the medium. It is transmitted to the components. Touching components or contact

with the medium can result in burns or scalding.

In order for the Sartocheck® 4 plus Filter tester to be EMC compliant, the original

Ethernet cable must be used.

4.2 Operating Personnel and Operating personnel and service and maintenance personnel are persons who are

Service and Maintenance responsible for the transport, installation, operation, equipping, maintenance and

Personnel cleaning as well as troubleshooting on the unit.

1. The unit may only be operated by trained and authorized persons in accordance

with operating instructions that have been issued by the operator.

2. The responsibilities for operation of the unit must be clearly set down and

observed so that no ambiguities arise with respect to safety.

3. The safety precautions and warnings given in the operating instructions must be

complied with when carrying out any work (operation, maintenance, repairs etc.).

4. The operator shall never work in any way that could impair the safety of the

unit or him | herself or others.

5. It is the responsibility of the operator to ensure that only authorized persons

work on the unit.

6. It is the responsibility of the operator to report immediately any changes

occurring on or to the unit to the operating company.

7. It is the responsibility of the operator to ensure that the unit is only operated

in perfect working condition.

Page 14

4.3 Installation of Please note that replacement parts and Replacement Parts accessories that not have

been supplied by Sartorius Stedim Biotech GmbH have not been tested and approved

by Sartorius Stedim Biotech GmbH. The installation of and|or the use of such

products can therefore have a negative effect on the design properties of the unit as

constructed.

Sartorius Stedim Biotech GmbH is not liable for any damages resulting from the use

of non-original parts or non-original accessory parts.

Standard parts can be purchased from specialized dealers.

4.4 Shutdown Procedure

The following shutdown procedure must be followed before any cleaning,

servicing or repair work is carried out.

1. Line disconnect

Turn off the main switch by pulling out the AC adapter of the mains supply.

2. Compressed air supply

Turn off the compressed air supply and vent system.

Personnel may suffer physical injuries or fatalities if this procedure is not followed!

14 General Warnings

Page 15

5. Installation 5. Installation

5.1 Equipment Supplied

Fig. 5-1 | Sartocheck® 4 plus Filter tester

The equipment supplied with the Sartocheck® 4 plus Filter tester includes:

1. Sartocheck® 4 plus Filter tester, Order no. 26288---FT

2. Operating instructions and technical documents

3. Accessories (not shown in the picture)

– Tubing “Inlet” with compressed air filter (I.D. = 6 mm) Order no.: 18104

– Tubing “Outlet” (I.D. = 4 mm) Order no.: 18103

– Spare ink ribbon cartridge Order no.: 6982141

– Spare roll of printer paper Order no.: 6982142

– Country-specific power cord

The equipment supplied with the Sartocheck® 4 Filter tester MultiUnit includes:

1. Sartocheck® 4 Filter tester MultiUnit, Order no. 26288---FM

2. Operating instructions and technical documents

3. Accessories (not shown in the picture)

– Tubing “Inlet” with compressed air filter (I.D. = 6 mm) Order no.: 18104

– Tubing “Outlet” (I.D. = 4 mm) Order no.: 18103

– Country-specific power cord

– Connecting cable Sartocheck

®

4 plus Filter tester MultiUnit and

Sartocheck® 4 plus Bag tester MultiUnit, Order no.: 1ZE---0010

5.2 Receipt of Delivery Incoming inspection:

– Check the shipment for damage!

– Check the shipment against the delivery note to ensure that it is complete!

Complaints

If the shipment was damaged during transit:

– Immediately contact the carrier!

– Keep the packaging material (in case the carrier wants to inspect it or

the shipment has to be returned to us)

If the shipment is not complete:

– Immediately contact Sartorius Stedim Biotech GmbH or the Customer Service

Department in your country!

If the delivery has other defects:

– Immediately contact Sartorius Stedim Biotech GmbH or the Customer Service

Department in your country!

Operating Instructions | Betriebsanleitung

Sartocheck® 4 plus Filter tester | Filter tester MultiUnit

Filter Integrity Tester | Filterintegritäts-Testgerät

85032-536-78

1 2

Installation 15

Page 16

Packaging for Return Shipment

Use the original packaging and original packaging material as far as possible.

If the original packaging and original packaging material are

no longer available:

– Commission a packaging company with specialized technicians.

– Pack the unit in a shipping container in such a way that mechanical

damage is prevented.

If you have any questions about packaging and transport securing devices,

please contact Sartorius Stedim Biotech GmbH.

Check the equipment supplied against the delivery note. Please report incomplete

deliveries immediately to the shipping carrier or the supplier.

Interim Storage

The external packaging of the unit and its spare and replacement parts is designed

for a storage period of three months from delivery.

Units kept in interim storage must be stored in a closed, dry room at temperatures

from +5°C to max. +50°C.

5.3 Installation Instructions

5.3.1 Ambient Conditions Select a place of installation that meets the following conditions:

and Conditions at the Place t No relatively high temperature or exposure to heat or sun

of Installation t No strong drafts

t No aggressive chemical environments

t No strong vibrations

t No dust

t No major humidity effects

5.3.2 Transporting and The unit and its accessories are packaged according to the national custom and

Unpacking the Equipment protected against impacts. To avoid damaging the equipment, please comply with

the following notes and instructions:

t Please observe the Technical Specifications in Chapter 3!

t Please observe the weight. For transport to the unpacking site, use a floor

truck if appropriate.

t

To prevent the unit from slipping, it should always be carried or lifted by two people.

t To open the packaging, remove the unit and place it on a workbench

or table intended for that purpose.

t The workbench or table must be level and able to bear the appropriate load.

Allow sufficient space around the workbench or table for the operator to work.

t Unpack the accessories and technical documents and put them in a safe place.

t Moisture in the air can condense on the surfaces of a cold unit whenever it is

brought into a substantially warmer place. If you transfer the unit to a warmer

area, make sure to condition it for about 2 hours at room temperature, leaving it

plugged into AC power. The positive temperature differential between the inside

of the unit and the ambient environment essentially protects the unit against

humidity and moisture.

Open the packaging carefully. It is a good idea to save the packaging material

(in case the carrier wants to inspect it or the shipment has to be returned).

Dispose of packaging materials in compliance with prevailing environmental

safety regulations.

16 Installation

Page 17

5.4 Connections Before starting up the unit; make sure that the unit is stable and secure.

Check all pneumatic and electrical connections on the unit.

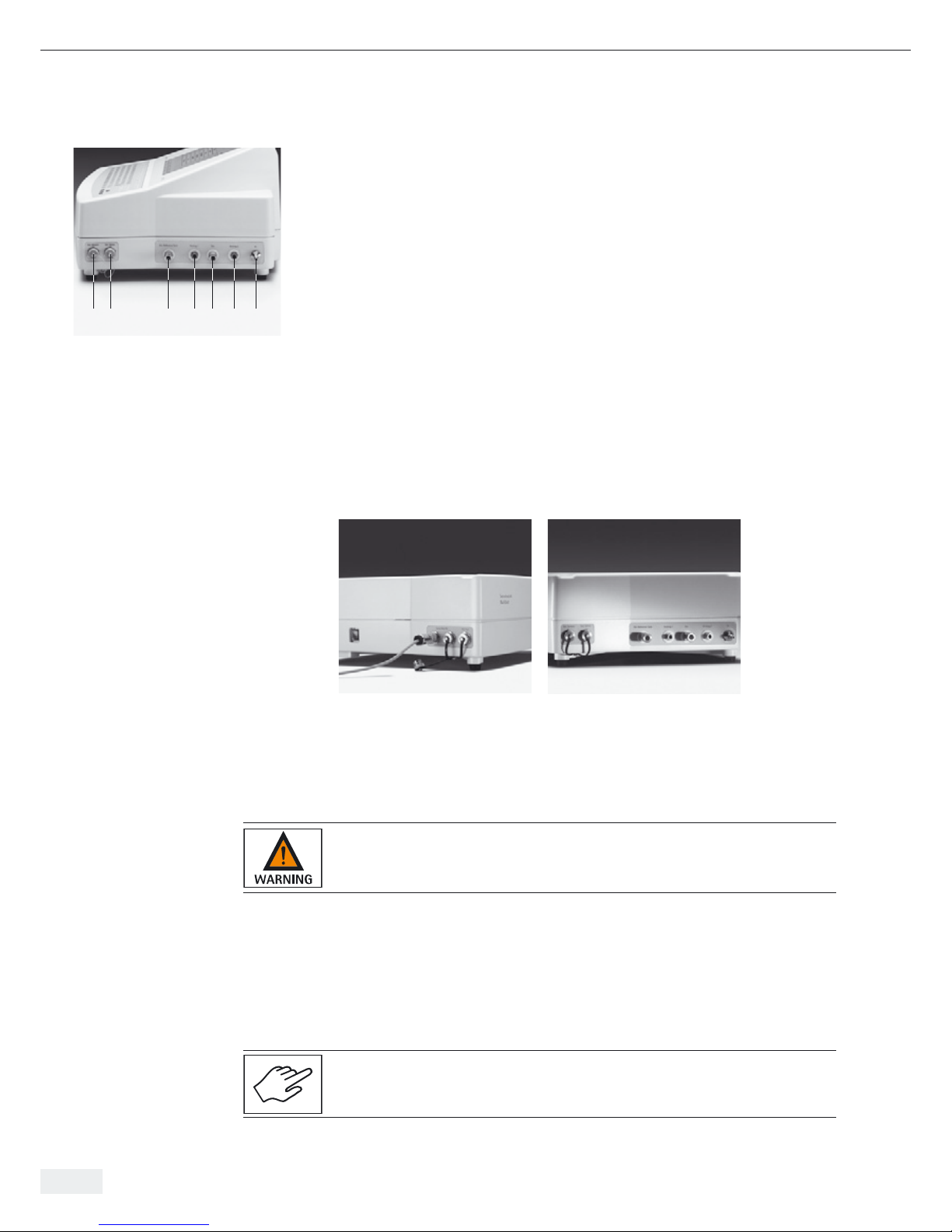

5.4.1 Front Panel and Back Panel The following displays are located on the front panel:

1 Standby

Is lit up when Sartocheck

®

4 plus Filter tester is ready for operations, but not

currently running any test program. (Blinking LED)

2 Ready

Lights up when the result of the filter test is ready. (LED lit)

3 Running

Is lit up when a test is currently running. (LED lit)

4 Error

Lights up when the test unit has identified an error and cancelled the test.

(LED lit)

The following connection ports are located on the back panel:

1 Housing ventilator

The unit is equipped with a ventilator that ensures that Sartocheck® 4 plus

Filter tester is kept at a constant temperature.

2 Serial port MU (Management Unit)

This port is used for connecting accessories (e.g. barcode scanner).

3 AC adapter

Power plug for connecting the power cord to mains supply.

4 Fuses

Fine-wire fuses between unit and mains supply.

5 Network Connection

RJ45

5.4.2 Left and Right Panels

Sartocheck® 4 plus Filter tester Located on the left panel:

1 Main power switch

Switch on the power with the main power switch.

2 SD Card Reader

The SD card reader is designed for standard SD cards for inputting and

storing data.

3 Serial port TU (test unit)

Port for connecting additional test units (Multiunits).

4 PLC Port

Port for connecting PLC controller signal input and output.

1 2 3 4

Fig. 5-2 | Front Panel

14

3

2

5

Fig. 5-3 | Back Panel

1 2 3 4

Fig. 5-4 | Left panel

Installation 17

Page 18

Located on the right panel:

1 Ext. sensors

Port for connecting an external pressure sensor.

2 Ext. valves

Port for connecting external valves.

3 Ext. reference tank

Quick connector for external reference tank.

4 Venting 1

Quick connector for Venting 1.

5 OUT

Quick connector for test tubing.

6 Venting 2

Quick connector for Venting 2.

7 IN

Quick connector for compressed air supply.

5.4.3 Left and Right Panels

Sartocheck

®

4 Filter tester MultiUnit

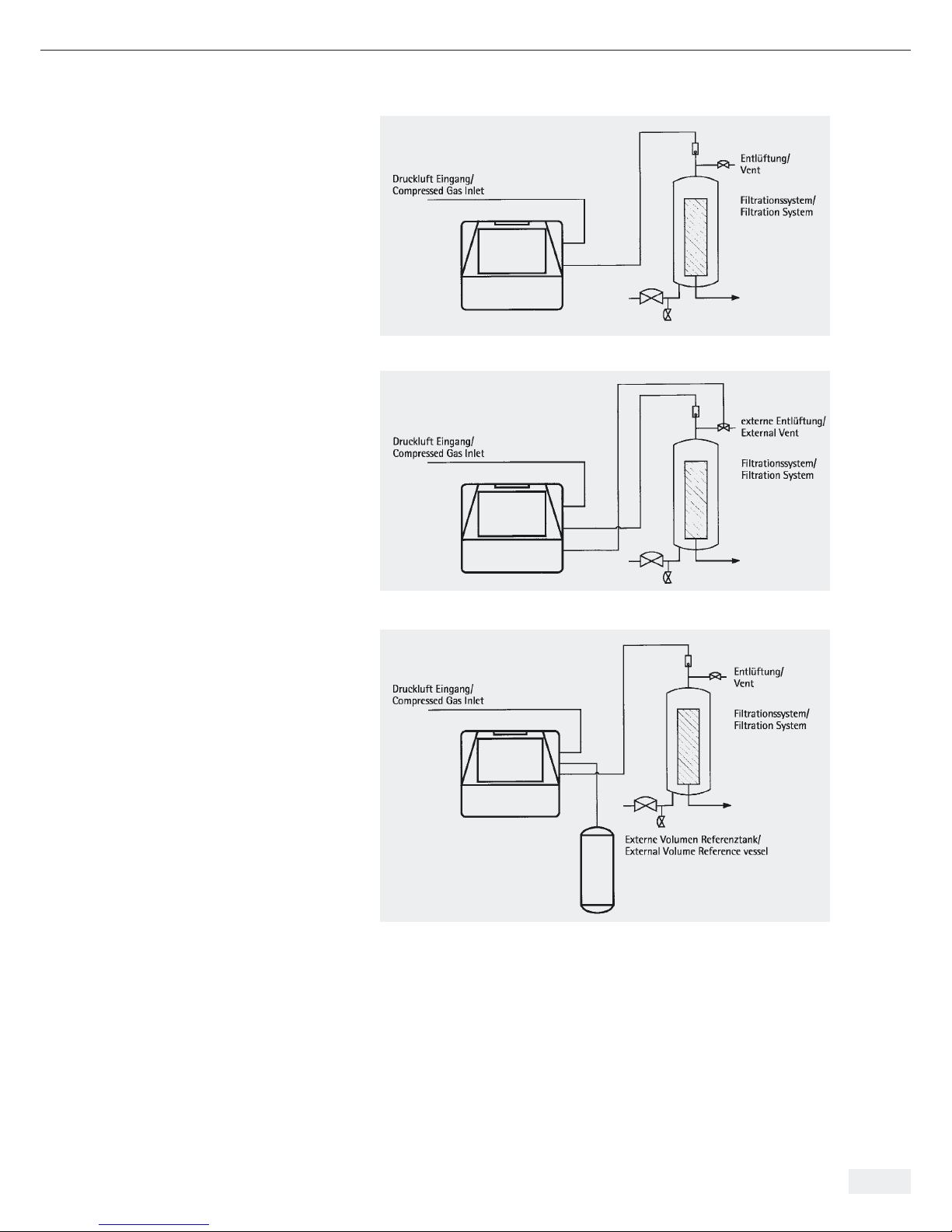

5.5 Pneumatic Connections Sartocheck® 4 plus can be operated with an internal pressure sensor and with

different ports for connecting tubing. The ports for connecting tubing, for both

the Sartocheck® 4 plus and Sartocheck® 4 MultiUnit, are illustrated in Fig. 5-8,

Fig. 5-9 and Fig. 5-10.

Do not connect Sartocheck® 4 plus Bag tester to pressurized or high temperature systems! Wait until the whole system is at room pressure and temperature!

Inlet Pressure During Operation with Internal Pressure Sensor

The minimum operating pressure required depends on the test method selected,

but should be at least:

> 4000 mbar and > 500 mbar above the test pressure or above the max. B.P. entered.

Sartocheck® 4 plus automatically detects the operating pressure during the function

test before starting each test and during the whole test sequence.

Check to make sure that all inlet and outlet pressure tubing is connected properly,

that all electrical connections have been correctly installed, and that the paper roll

as well as the ribbon cartridge have been inserted.

1 2 3 4 5 6 7

Fig. 5-5 | Right panel

Fig. 5-6 | Left panel Fig. 5-7 | Right panel

18 Installation

Page 19

Installation 19

Fig. 5-8 | Connection with internal pressure sensor

Fig. 5-9 | Connection with internal pressure sensor and external vent

Fig. 5-10 | Connection with internal pressure sensor and external volume reference tank

Sartocheck 4 plus

Sartocheck 4 plus

Sartocheck 4 plus

Page 20

5.6 Connections with Sartocheck® 4 plus can be operated with an external pressure sensor and with

External Pressure Sensor different ports for connecting tubing. The ports for connecting tubing, for both the

Sartocheck

®

4 plus and Sartocheck® 4 MultiUnit, are illustrated in Fig. 5-11, Fig. 5-12

and Fig. 5-13.

Check to make sure that all inlet and outlet pressure tubing is connected properly,

that all electrical connections have been correctly installed, and that the paper roll

as well as the ribbon cartridge have been inserted.

Fig. 5-11 | Connection with external pressure sensor and manual valves

Fig. 5-12 | Connection with external pressure sensor and external valves

Sartocheck 4 plus

Sartocheck 4 plus

20 Installation

Page 21

Installation 21

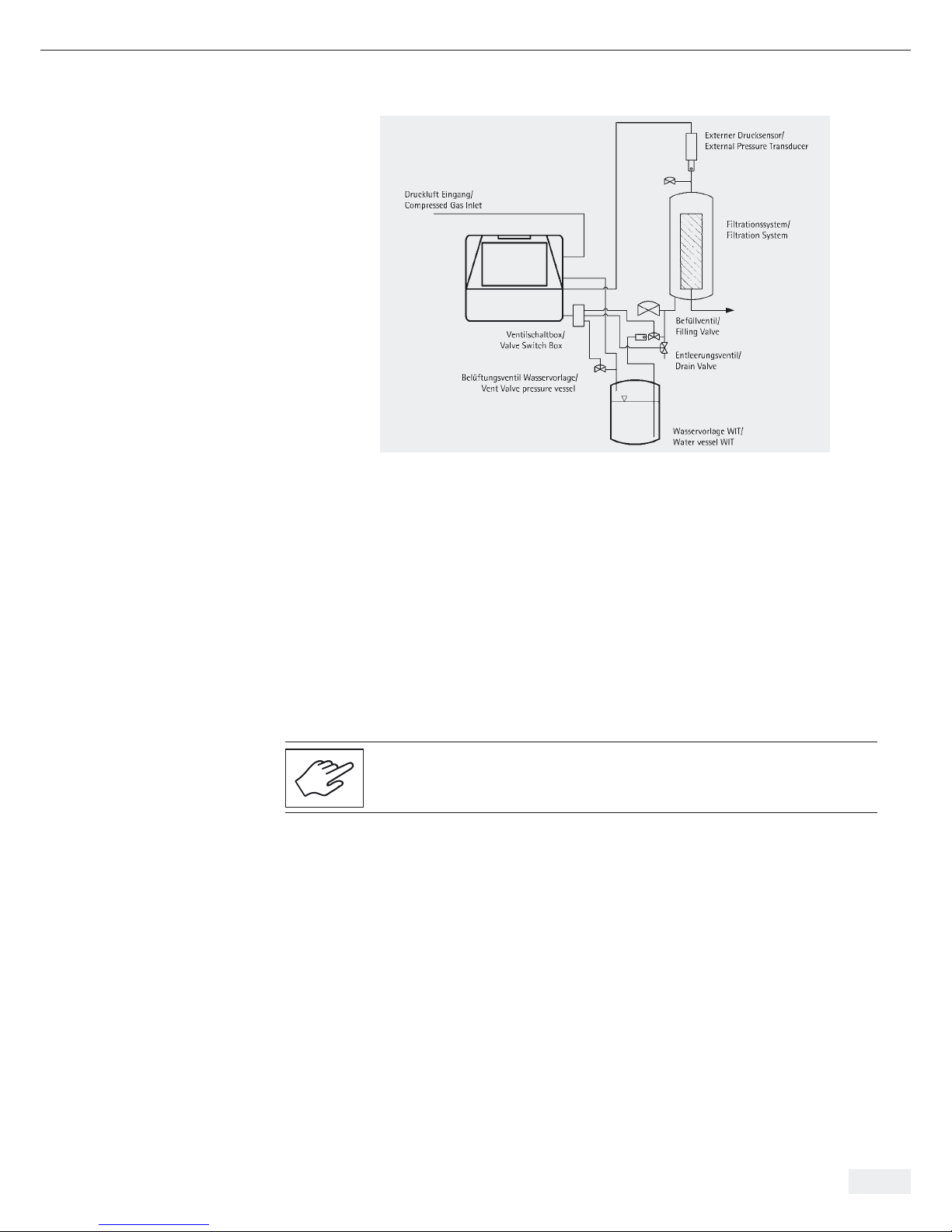

Fig. 5-13 | Connection with external pressure sensor for WIT

5.6.1 Inserting Paper Roll To insert or change the paper roll, lift the cover off the paper feed. Pull the feed

Ribbon Cartridge mechanism out of the assembly and push the cover to the left and lift it out

of its attachments. Now lift the paper feed mechanism out of the Sartocheck® 4 plus

housing.

Insert a new paper roll into the paper slot and slide the paper feed mechanism back

into the housing. Thread the end of the paper through the slot of the paper feed.

Make a final check to ensure that the feed mechanism is locked in place.

Close the printer cover and secure the splashguard. Check to make sure that the

splashguard is locked in place.

To change the ribbon cartridge (when the feed mechanism is pulled outwards)

lift the previously installed cartridge out of the paper feed and insert a new one.

Apply slight pressure to lock the cartridge in.

Sartocheck 4 plus

Page 22

22 Installation

5.6.2 Sartocheck® 4 plus Sartocheck® 4 Bag tester MultiUnits are connected to the Sartocheck® 4 plus Filter

Filter tester MultiUnits tester MultiUnit or to the Sartocheck® 4 plus Bag tester via the serial port TU

connection ports. Different ways of connecting are shown below in Fig. 5-14 to 5-17.

The location of the Sartocheck

®

4 Bag tester MultiUnits, relative to the Sartocheck®

4 plus Filter tester or to the Sartocheck® 4 plus Filter tester MultiUnit, will determine

which method is best suited for the application.

Fig. 5-14 | Serial connection to a Bag tester

Fig. 5-15 | Serial connection to a Filter tester

Page 23

Function 23

6. Function 6. Function

Fig. 6-1 | Overview

Picture of Sartocheck® 4 plus Filter tester

1 Housing

2 Printer

3 Touch screen

4 Keypad

5 Indicator lights

6.1 General Functional Description Sartocheck® 4 plus Filter tester is a qualifiable filter integrity testing unit, consisting

of a data management unit, a test unit and up to four additional Filter tester

MultiUnits or Bag tester MultiUnits.

The test unit is a mechanically, pneumatically and electrically closed functional unit.

A test unit cannot be operated directly by the user, but is 100% controlled by the

data management unit via an internal RS 485 interface. With the help of its electrical

and pneumatic peripheral devices, the data management unit performs the actual

filter tests along with a series of other additional functions.

Bag Test

The main purpose of Sartocheck® 4 plus Bag tester is to test single use bags and

single use bioreactors according to the pressure drop method.

Filter Integrity Test

The main purpose of Sartocheck® 4 plus Filter tester is to test the integrity

of membrane filters according to various methods.

6.2 Test Programs In the test program, the procedural steps and the parameters are set down for either

the bag test or for the filter integrity test.

A programmed test program can be loaded into the test unit and the test will be run

independently.

– Load a test program

– Run a test program

The test unit runs through the previously loaded test program, in other words,

it carries out the test and saves the result in non-volatile memory. The data management unit monitors the progress of the bag test or the filter integrity test, i.e. it reads

in the current data in order to present them to the user.

12

3

4

5

Page 24

24 Function

6.3 Managing the Test Results Sartocheck® 4 plus Filter tester processes the measured raw data (the test results),

which means that the unit values are converted and numbers transformed into text.

6.4 Function Test With the function test, the user is able to interactively test the functionality

of pneumatic components. The proportional valves are not explicitly, but rather

implicitly tested in this context.

6.5 Cleaning Sartocheck

®

4 plus Filter tester starts the procedure for cleaning and flushing the

internal lines and the volume reference tank.

6.6 User Interrupt The user can interrupt any test on Sartocheck

®

4 plus Filter tester by pressing the

[STOP] button. Pressing the [arrow upwards] and [STOP] buttons simultaneously

will interrupt tests on all Sartocheck® 4 plus Filter tester MultiUnits or

Sartocheck® 4 Bag tester MultiUnits connected to the Sartocheck® 4 plus Filter tester,

as well as any test running on the Sartocheck

®

4 plus Filter tester unit.

6.7 Self-Test for Broken While controlling the valves and sensors, the Sartocheck® 4 plus Filter tester

Conductors and Short-Circuiting hardware can check whether there are any broken conductors or short-circuits.

6.8 Calibration The calibration function is designed to calibrate the internal pressure sensor with

the help of more accurate reference measuring equipment, and if necessary, adjust it.

The sensor has a monitored calibration date.

An adjustment routine automatically follows the test. The test can also be activated

separately. Sartocheck® 4 plus Filter tester saves the raw data for the calibration

record in permanent memory.

The operator can use the following sensor type for determining the reference

pressure:

t Relative pressure sensor:

The measured reference pressures relate to the ambient pressure. The ambient

pressure must be known or measured with additional reference measuring

equipment.

6.9 Internal Pressure Sensor Sartocheck® 4 plus Filter tester sets 8 pressure values and compares them with

the internal pressure sensor and the pressure values measured on the reference

measuring instrument (connected to the “OUT” connector) to calculate scale

and linearization.

6.10 Pressure Gauge Function When in the pressure gauge function, Sartocheck

®

4 plus Filter tester acts like

a digital pressure measuring device.

6.11 Cleaning | Drying Through the pneumatic connectors, Sartocheck

®

4 plus Filter tester is able to

flush almost all internal volumes. It is the responsibility of the user to use original

Sartocheck® equipment only (Cleaning Kit type 26288---CK”).

6.12 Safety Functions t As one of its technical options, Sartocheck® 4 plus Filter tester runs the test step

Initialization | Security Status in the event of a power failure. Basically, what this

step does is close the compressed air supply and the block valve to the test set-up.

t Sartocheck® 4 plus Filter tester is not responsible for ensuring whether the

pressure supplied to the system being tested is too high. This means that the

user must make sure that the programmed pressure cannot damage the system

being tested.

Page 25

Function 25

6.13 Software Update The operating software on Sartocheck® 4 plus Filter tester is updated with a

corresponding program run with an external PC|laptop. The Management Unit

may be updated with an SD card. Since the configuration data are localized in

a battery-backed RAM, they remain unchanged during any software update.

6.14 Serial Number Every unit bears its own unique serial number. The serial number may not be changed

during a software update.

t The serial number is entered for the first time during production of the unit.

t If the PCB has to be replaced during repairs that may arise later,

the unit must be assigned the exact same serial number that is imprinted

on the manufacturer’s label.

Page 26

26 Function

7. Operation 7. Operation

7.1 Switching On the Unit

Fig. 7-1 | Overview

Picture of Sartocheck

®

4 plus Filter tester

1 Housing

2 Printer

3 Touch screen

4 Keypad

5 Indicator lights

7.1.1 Operating Elements

Fig. 7-2 | Display and control panel

The display and control panel features the following operating elements:

1 Esc

Press this key to cancel the current procedure.

2 F1-F 10

Function keys F1-F10 correspond to the function types displayed on touch screen.

3 Log on

Press this key to switch on the log-on screen.

4 Log off

Press this key to log the current user off.

12

3

4

5

8 109 12

11

13

7

654321

Page 27

Function 27

5 Start

Press this key to start a test.

6 Stop

Press this key to stop a running test.

7 Paper

This key advances the paper in the internal printer.

8 PC keypad

Is used for inputting and starting processes.

9 Home

When this key is pressed, programming is cancelled without saving. The former

test is reinstated and the user is automatically taken back to the Main Menu.

10 End

Press this key to jump to the end of the input line when entering parameters

and data.

11 Page up

Press this key to scroll a page back in the service menu guidance.

12 Page down (toggle key)

Press this key to scroll to the next service menu window.

13 All Test Stop

Pressing the [Ç] and [STOP] buttons simultaneously will stop all running tests

on all MultiUnits, as well as any running test on the Sartocheck

®

4 plus Filter

tester unit.

Both the keypad and the touch screen can be used to operate Switching Sartocheck®

4 plus Filter tester. These two options can also be combined.

Individual menu items can be selected Sartocheck® 4 plus Filter tester with function

keys, on the keypad or by pressing the touch screen. Selection from lists is done by

entering the line number or by direct selection on the touch screen.

All dialog boxes are set up so that the operator can tell by the color which part

of the touch screen can be operated, which are the input boxes and which areas are

for information only. Function keys and other keys that can be pressed on the

screen and on the keypad are highlighted in yellow.

Input boxes are white. Non-changeable information boxes or function keys

that have already been activated are highlighted in gray. Selected dialog boxes are

colored blue. Warnings and error messages appear in red.

Page 28

28 Operation

7.2 Switching the Unit If you want to switch the unit on, proceed as follows:

ON and OFF

Before you switch on the power supply and the compressed air, compare the

connection data for the unit (see the Chapter 01 Technical Specifications) with

the data for the mains current and the compressed air supply.

Connect Sartocheck® 4 plus Filter tester to the mains supply by plugging the power

cord into the wall outlet, install all tubing connections. The unit is now ready for

operation.

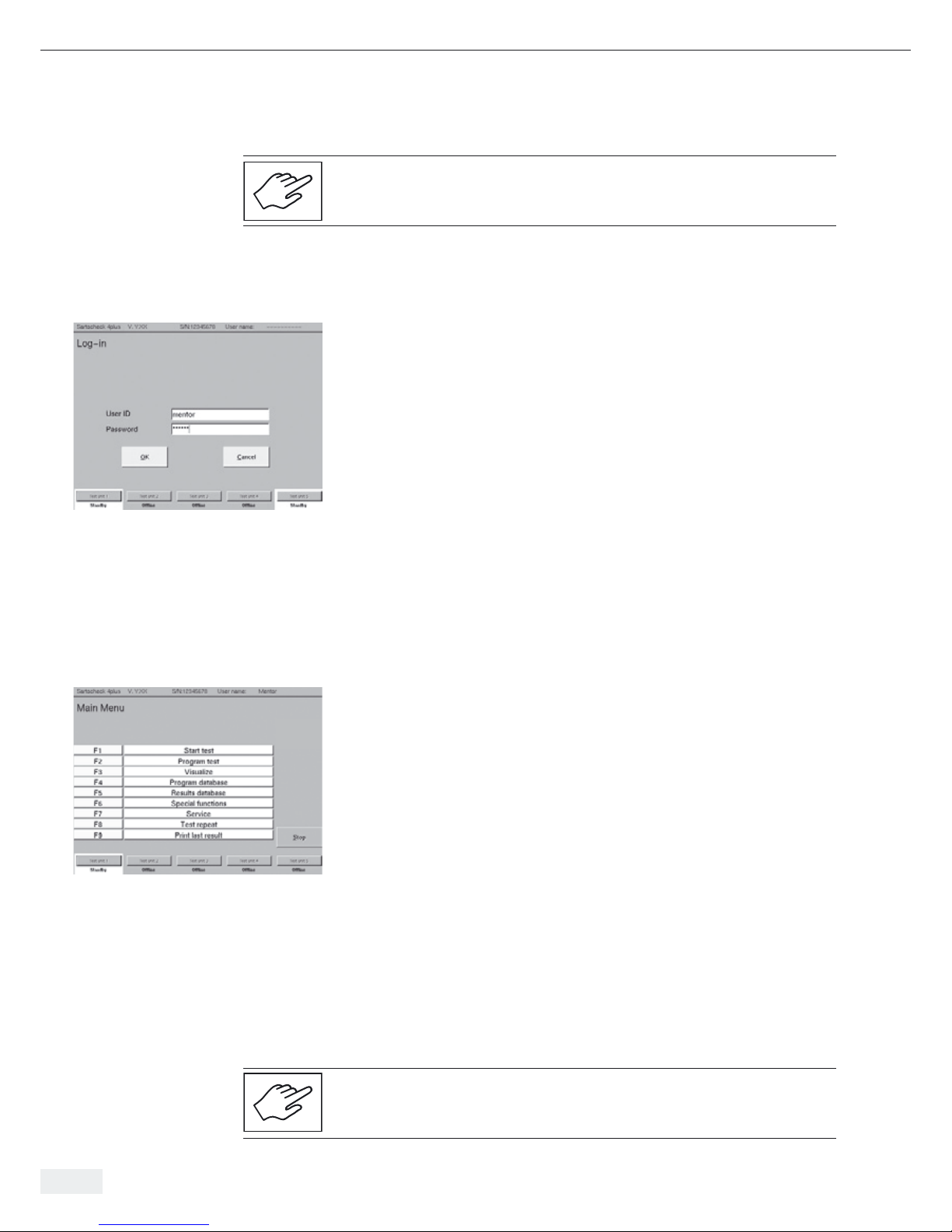

Login menu

User ID: Enter operator’s name

Password: Enter operator’s password

OK: Confirm correct entry

Cancel: Delete entry

Important Note: When Sartocheck® 4 plus Filter tester is delivered it is factory

set for the following user:

Name: mentor

Password: mentor

Operators must log-in before activating the Main Menu.

The operator logs in by pressing the “Login” key on the keypad. After pressing the

“Login” key, the user will be asked for their name and password. When both are

entered correctly, the keypad and touch screen are released for use. When the operator stops working with Sartocheck

®

4 plus Filter tester, they must always log out by

pressing the “Logout” key. Sartocheck® 4 plus Filter tester is then blocked for further

operation until another operator logs in.

Information line with model, version, system number and user name.

Menu display: Main Menu

F1-F8: Select the function menus with the function keys

Selects the function menus

Functional unit selected and operational status.

The Main Menu appears.

t Before starting a test, allow the unit to warm up for about 20–30 min.

For shut-down times < 30 min and constant ambient temperatures, the warm-up

phase can be shortened accordingly. For more information about the tests, see

Chapter 7.3 ff.

t Program the data for the test routine.

t The Sartocheck® 4 plus Filter tester ready for operation (by the logged-in user).

t Start the test.

Only service technicians or trained personal may install connections and start up

the unit!

Fig. 7-3 | Login menu

Fig. 7-4 | Main Menu

Page 29

Operation 29

7.2.1 Running a Test Run the test according to the test procedure that you selected and programmed.

7.2.2 Switching Off the Unit When switching off the unit, proceed as follows:

t Run the test to the end.

t Close the compressed air supply at the compressed air supply port.

t Run the log-off function.

t Turn off the main power switch.

7.2.3 Switching Off the Unit in In the event of a power failure, all valves will be switched to a secure state.

the Event of a Power Failure This guarantees that the system being tested is vented. The ongoing test is cancelled.

No test result will be available.

Loss of Compressed Air

In the event that the compressed air supply stops, the test is automatically

cancelled and an error message appears. “Target pressure not reached”. The system

is vented automatically. When the supply of compressed air resumes, the unit must

be restarted and the test repeated.

7.3 Tests

7.3.1 Test Parameters To obtain reliable and reproducible test results, observe the following:

t Run the test at room temperature (approx. 15–30°C), whenever possible.

t During a test run, always avoid any temperature changes.

t The upstream side of the system must be absolutely leak-free

t Do not connect the tester to pressurized systems.

t For filter testing: If you wish to use other types of compressed gas and| or wet-

ting fluids not specified by Sartorius Stedim Biotech, consult your local Sartorius

Stedim Biotech office or Sartorius Stedim Biotech GmbH in Germany.)

t For the Water Intrusion Test, the surface tension of the water must be

> 70 dyn/cm.

t Always enter correct test parameters. Incorrect test parameters will lead to

incorrect test results or erroneous evaluations.

Calibration

The Sartocheck 4 plus Filter tester should be re-calibrated at least once a year,

twice being preferable.

Page 30

30 Operation

7.3.2 Test Methods With the Sartocheck® 4 plus Filter tester, you can directly select a particular test

method. This greatly simplifies programming the data for a test, since only the

parameters that are relevant for the selected test are displayed.

You can select any of the following test methods:

Test methods

1 Diffusion test

2 Bubble point test (Standard and Customer specific)

3 Diffusion and bubble point test

4 Water intrusion test

5 Pressure drop test

6 Multipoint diffusion test (Standard and Customer specific)

7 Volume measurement

8 Plate holder test

9 Installed bag test

System Venting

At the end of each test, after a power failure or after switching off the unit during

a test, the system is automatically vented.

7.3.3 Programming Tests The Sartocheck® 4 plus Filter tester cannot perform bag tests.

(F2 – Main Menu) Nevertheless it is possible to program bag tests due to the fact that additional Bag

tester MultiUnits may be connected to the Filer tester. The test parameters for the

individual tests are entered and selected on Sartocheck

®

4 plus Filter tester by using

the keypad or the touch screen. The Main Menu is the starting point for programming. The following example uses a diffusion test to illustrate how to program

data for tests and run test sequences (F2 – Main Menu). The programming and test

sequences are identical for the other test types.

Before we start programming, we would like to explain a few important keys

and|or touch commands.

The Sartocheck® displays are set up with yellow buttons located on the right side

of the screen. These buttons always have the same functions:

Main Menu: The program jumps back to the Main Menu (see Fig. 7-5)

Page Up: the program scrolls to the previous page of the screen

Page Down: the program scrolls to the next page of the screen

List Up: Whenever a list is displayed on the screen, use LIST UP

to scroll up the list

List Down: Whenever a list is displayed on the screen, use LIST DOWN

to scroll down the list

Enter: Confirms the selected function, action or entry.

Following confirmation, the yellow key turns gray

Fig. 7-5 | Main Menu

Page 31

Operation 31

Programming Tests

Select the programs in the menu “Programming tests: Program selection”. You can

select existing programs by entering the line numbers or by selecting them directly

on the touch screen. The selected line is highlighted in blue. Scroll back and forth

in the program selection list with List DOWN|UP. Confirm the selected program line

by pressing Enter. The Enter key turns gray. If you would like to correct the program

memory location, select a new line number or highlight the new line directly on

the touch screen.

Re-confirm by pressing Enter. Press PAGE DOWN to scroll to the next page.

The diffusion test is used as an example.

If the optional Barcode Scanner is used for programming, please compare chapter

7.18 on page 49).

Optional Parameters for Detection of Disconnected Filters

In case of a disconnected filter (housing), an integrity test can be successfully

performed because the test-evaluating parameters (e.g. BP

min

, Diff

max

) are fulfilled.

To avoid such situations, it is possible to define four additional parameters.

A non-standard test (compare fig. 7-8) must be chosen to get access to these

parameters. As soon as at least one of these listed parameters are not fulfilled, a

warning message is displayed | printed. The following parameters can be defined:

Min. limits: Parameters can be activated | deactivated

The parameters can be activated / deactivated.

If deactivated the here below described limits will have no impact

on the test sequence.

Min. DIF/WIT/WFT: A minimal diffusion rate can be defined.

This parameter is valid for diffusion test, WIT and WFT.

If the measured value falls below this limit a warning message

will be printed at the end of the test together with the test

evaluation. It is then responsibility of the of the quality assurance

to decide if the test is conforming or not.

The test evaluation of the Sartocheck 4 plus remains “passed”.

Min. Flow BPT: A minimum flow rate can be defined for the Bubble Point Test.

This value represents the minimum flow that must be

measured at BP

max

.

If the measured value falls below this limit a warning message

will be printed at the end of the test together with the test

evaluation. It is then responsibility of the quality assurance to

decide if the test is conforming or not.

The test evaluation of the Sartocheck 4 plus remains “passed”.

Min. Volume: A minimal net volume can be defined. A net volume measure-

ment below this value will abort the test. An error message will

be printed.

Max. Volume: A maximal net volume can be defined. A net volume measure-

ment above this value will abort the test. An error message will

be printed.

Fig. 7-6 | Programming tests: Program selection

Fig. 7-6b | Optional parameters

Page 32

32 Operation

7.4 Diffusion Test When pressure is applied to the upstream side of a wet filter, a diffuse gas stream

starts to flow through the filter membrane after a short time. Diffusion is dependent

on the effective filter surface area. The diffusion test is not suitable for testing disk

filter systems. However, the diffusion test is a very well suited test method for the

integrity testing of medium-sized and larger filter cartridge systems starting from

approx. 150 cm

2

. The diffusion value refers to a test pressure, which means there is

a direct correlation to the actual retention behavior of the filter (for a more detailed

description, see Chapter 12, Appendix).

In the menu “Programming tests: Program selection”, the test type is selected.

– Select test type (standard test or user-defined test)

In the menu “Test parameters: External connections,” decisions about external

connections and the configuration are entered. The function keys are used here to

enter the appropriate settings. The following external connections and parameters

must be configured for all tests:

– Standard test (Yes|No)

– External pressure sensor (Yes|No)

– External valves (Yes | No)

The parameters for the standard test are defined in the configured Service Menu.

Unlike the defaults (standard values), the values can be individually adjusted.

For the diffusion test, you have the following options:

Pressure unit: mbar|psi|hPa

Automatic test mode: No| Yes

Enter parameters for the diffusion test

Test pressure: from 100 – 8000 mbar

Stabilization time: in min.

Test time: in min.

Max. diff.: in ml/min

Net volume: in ml

In the menu “Test parameters: Diffusion test,“ the parameters for the diffusion test

are entered with or without net volume measurement.

For tests with volume measurements:

– Test pressure

– Stabilization time

– Test time

– Max. diffusion

When conducting tests without volume measurement, net volume should

be entered separately.

The test parameter data can be found in the validation documents of the respective

filter cartridge.

Locks

The locks are activated for the test parameters (default). After entering with the

Shift + F keys, the programmer can lock the data to prevent any changes.

The dialog boxes are then highlighted in gray. The user can no longer change

the entered data.

Fig. 7-7 | Programming tests: Program selection

Fig. 7-8 | Test parameters: External connections

Fig. 7-9 | Test parameters: Diffusion test

Page 33

Operation 33

Enter record data 1 (up to 32 characters per field)

Company: Company name

Building: Building name; house number

Department: Identification of the department

Manufact. site: Production sector

Product: Product name

Product lot: Batch number

Filter: Filter size

Filter lot: Number of the filter batch

Locks

After entering with the Shift + F keys, the programmer can lock the data

to prevent any changes. The dialog boxes are then highlighted in gray.

The user can no longer change the entered data. The relevant record data are

entered in the menu “Test program: Record data 1.”

Entry of record data 2

Filter line: Name of filter line

Housing: Type of housing

Wetting medium: Type of wetting medium

Test gas: Type of test gas

Water quality: Data on water quality

Comment: Name of operational process

Comment 2: Enter test-relevant remarks

Comment 3: Enter test-relevant remarks

Start the Test Program

Save:

After confirmation, the data are saved

The menu “Test program: Start” lists the options for that test start.

Once the programming is finished, the test can be started.

Choose the test unit on which to perform the integrity test.

Only test units that are currently available will be selectable.

Fig. 7-10 | Test program: Record data 1

Fig. 7-11 | Test program: Record data 2

Fig. 7-12 | Test program: Start

Fig. 7-13 | Test unit selection

Page 34

34 Operation

The test sequence is structured as follows:

Pressurization

Sartocheck

®

4 plus Filter tester adjusts the pressure to the pre-programmed test

pressure.

After a short waiting period during which the system is tested for major leakage,

the program goes into the stabilization phase.

Stabilization Phase

During the stabilization phase, the test pressure is adjusted to the exact desired

value. Fluctuations in test pressure occur as a result of cartridge compaction and

temperature variations created by the different filter housing temperatures and

the downstream air flowing in from the compressed air supply.

These fluctuations in test pressure are compensated for during stabilization.

About half of the stabilization time is utilized to carry out volume measurement

(when volume measurement is selected).

Test Phase

In the test phase, the system is in a closed state. The pressure drop resulting from

diffusion is measured over the test time entered.

Volume Measurement

A clock is shown during the volume measurement.

Fig. 7-14 | Test: Start

Fig. 7-15 | Stabilization

Fig. 7-16 | Volume measurement

Page 35

Operation 35

Volume Measurement

The volume is displayed in ml.

In the test phase, the current diffusion value is displayed as a graph and additionally

as a numerical value. The graph is designed so that the limit is drawn as a red line.

If the actual value is below this, the integrity of the filter is proven.

7.5 Bubble Point Test In wet membranes, the wetting liquid is held inside the porous structure by capillary

force. This force increases as the pore size decreases. A specific gas pressure

dependent on the pore size of the membrane is necessary to force out the liquid

from the pores. This pressure is generally designated as the “Bubble Point,” or

B.P. for short. It generally indicates the largest pores of a filter since liquid is first

expelled from them. Hence, it follows that the B.P. of a filter depends both on the

filter material (the contact angle varies from material to material) and, in particular,

on the surface tension of the wetting fluid. Low surface tensions, as are present

in organic solvents, detergents and emulsifiers yield low B.P.’s.

Since the surface tension also depends on the temperature, different wetting

fluid temperatures will also yield different B.P.’s. The Bubble Point Test is especially

suitable for checking the integrity of disc filter systems.

(For a more detailed description, see Chapter 12, Appendix).

Test parameters: Bubble Point Test

Enter the parameters: BP Min. in mbar

BP Max. in mbar

System test class: e.g. standard

Net volume: Enter or measure, if Enter: Volume in ml

Recommendation for test-class selection:

Small Systems: disc filters, mini cartridges, capsules up to 5“

Standard Systems: 10‘‘–20‘‘ filter cartridges and capsules

Special Systems: 30“ and small multiple cartridge systems

For bigger systems please use the customer specific BP Test.

Please contact Sartorius Stedim Biotech if specific settings are needed.

Fig. 7-17 | Volume Measurement

Fig. 7-18 | Test Phase

Fig. 7-19 | Test parameters: Bubble Point Test

Page 36

36 Operation

7.6 Customer-Specific BP The normal bubble point test (as previously described) uses a standard set-up of

parameters to cover most of applications. However, some applications in which the

wetting fluid differs considerably from water (e.g. oily or viscous products) or in

which the filtration area is large (multi-round housings), bubble point detection can

be optimized using the customer-specific bubble point test.

Please ask for Sartorius Stedim Biotech support to program the optimal parameters.

Test parameters: customer-specific BP

Start factor: Enter the factor

Prestabilization: in sec.

Stability by phase: in sec.

Phase test: in sec.

A1 Criterion : in ml/min

A2 Criterion : in ml/min

7.7 Diffusion and Bubble Point This test method is a combination of the diffusion and the B.P. tests and is

Test (Combined Test) predominantly used to check the integrity of membrane filters.

Test parameters: Diffusion and Bubble Point Test

Test pressure: in mbar

Stabilization time: in min.

Test time: in min.

Max. diffusion: in ml/min.

Min BP: in mbar

Max BP: in mbar

Net volume: Enter or measure, if Enter: Volume in ml

Fig. 7-20 | Test parameters: Customer-specific BP

Fig. 7-21 | Test parameters: Diffusion + BP Test

Page 37

Operation 37

7.8 Water Intrusion Test | This test method is used exclusively to test hydrophobic gas filter elements.

Water Flow Test The test sequence of this test method is the same as that of the Diffusion Test.

However, the Water Intrusion Test differs from the latter test in that the hydrophobic

filter element in the filter housing is flooded upstream with water to blind the filter

so that when a pressure gradient is applied, the water volume intruding into and

diffusing through the hydrophobic filter matrix per unit of time is calculated

from the pressure drop, instead of the gas stream diffusing through the membrane

as in the Diffusion Test.

1. The Water Intrusion Rate: Indicates the rate calculated from the pressure drop,

test time and upstream volume (analogous to the calculation of diffusion).

2. The Water Flow Rate: Indicates the rate related to the water flow in the

membrane (Water Intrusion converted to “Water Flow”).

The Water Intrusion Test is suitable for all hydrophobic systems of approx. 1000cm

2

filtration area and larger, all the way to process-scale systems.

(For a more detailed description, see Chapter 12, Appendix)

Test parameters: Water Intrusion Test

Test pressure: in mbar

Stabil. time 1: in min.

Stabil. time 2: in min.

Test time: in min.

Max. WIT: in ml/min

Auto filling: Yes| No

Net volume: Enter or measure, if Enter: Volume in ml

Remark:

Stab 1 is the stabilization time before Netvolume determination. This time is needed

to compact the filter system and therefore to avoid misinterpretation.

Stab 1 should not be less than 3 min.

Stab 2 is the stabilization time before the water-intrusion (water-flow) measurement. The stab 2 value is available in the validation guide of the filter cartridges.

The standard value is 10 min.

Fig. 7-22 | Test parameters: Water Intrusion Test

Page 38

38 Operation

7.9 Pressure Drop Test The Pressure Drop Test is based on the change in pressure within a filter system

connected upstream. This change is caused by the diffusive gas stream flowing

through a wet membrane at a given test pressure (see “Diffusion Test”).

The pressure drop measured in the process can be used as a direct measure of the

filter system’s integrity, provided that the upstream volume of the system is constant

and known. For this reason, a Pressure Drop Test is recommended mainly to leak-test

empty housings and pressure vessels with a known volume.

We additionally recommend that you carry out the following Pressure Drop Test to

check for major leakages. (For a more detailed description, see Chapter 12, Appendix).

Pressure Drop Test

Test pressure: 3000 mbar

Stabilization time: 3 min

Test time: 3 min

Pressure drop: max. 3 mbar

Test parameters: Pressure Drop

Test pressure: in mbar

Stabilization time: in min.

Test time: in min.

Max. pressure drop: in mbar

7.10 Multipoint Diffusion Test The Multipoint Diffusion Test is based on the dependence of the diffusive gas

flow to the actual test pressure. Starting at a given minimum pressure, the test

pressure is increased step by step up to the maximum value, or the bubble point,

and the diffusion is measured for each pressure increment. All values are output

by Sartocheck

®

4 plus in the form of a pressure|diffusion curve and a data table.

The slope of the curve allows changes in the filter material to be identified before

the next filtration run so that by comparing the curves obtained at the beginning of

the filter’s use, any defects can be detected before they can spoil an actual filtration

run. The Multipoint Diffusion Test is thus suitable as an additional test method for

verifying integrity test results.

Test parameters: Multipoint Diffusion Test

Min. test press.: in mbar

Max. test press.: in mbar

Pressure incr.: e.g. in 100 mbar increments

Test class: e.g. Standard

Net volume: Enter or measure, if Enter: Volume in ml

Fig. 7-23 | Test parameters: Pressure Drop Test

Fig. 7-24 | Test parameters: Multipoint Diffusion Test

Page 39

Operation 39

7.11 Customer-Specific The normal Multipoint Diffusion Test does not determine a pass or fail result.

Multipoint Diffusion Test This Customer-Specific Multipoint Diffusion Test allows the user to enter a maximum

diffusion limit line. Up to eight (8) points can be used to define this limit line

(pressure vs. diffusion). During test execution the actual measured diffusion will

be compared to this limit line to determine a pass or fail result.

7.12 Volume Measurement This test method measures the net volume of the system (e.g. filter housing).

The Sartocheck

®

4 plus Filter tester uses its internal or external reference tank

pressurized to the programmed pressure to determine the unknown volume. This is

not an integrity test. Rather, this test enables net volume validation of vent filter

installation for water intrusion tests using an external pressure sensor, for instance.

Please ask for Sartorius Stedim Biotech support before performing any net volume

validation.

Enter test parameters: Volume Measurement

Test pressure: in mbar

Stabilization time: in min.

Fig. 7-25 | Limit line parameters

Fig. 7-26 | Test parameters: Volume Measurement

Page 40

40 Operation

7.13 Plate Holder Test This test sequence may be programmed on the Sartocheck 4 plus Filter tester but

may only be performed if a Bag tester MultiUnit is connected. The test sequence

is designed for leak testing of 2 dimensional bags (e.g. Flexboy) being maintained

between 2 metal plates during the test e.g. using the FlexAct BT trolley equipped with

fleeces. The test sequence is based on the change in pressure within the bag system

including connected tubes.

The pressure drop measured in the process can be used as a direct measure of the bag

set-up leak tightness and absence of pinholes or similar defects, provided that the

upstream volume of the system is constant.

Enter parameters for the plate holder test

Test pressure: from 3–300 mbar

Stabilization time: 10-3600 seconds.

Test time: 10-3600 seconds

Max. pressure drop: 1-programmed test pressure

Please verify the test parameters for the bag being tested. Applying too high a test

pressure may jeopardize the integrity of the bag.

Since the viscosity of the remaining liquid may influence the leak rate of an eventual

pinhole, please do not mix up pre-use test values with specifically validated post-use

values.

This test can also be used for testing vessels as long as they resist the applied

pressure.

Enter record data 1 (up to 32 characters per field)

Company: Company name

Building: Building name; house number

Department: Identification of the department

Manufact. site: Production sector

Product: Product name

Product lot: Batch number

Bag type: E.g. Flexboy 50L

Bag lot: Number of the bag batch

Locks

After entering with the Shift + F keys, the programmer can lock the data to prevent

any changes. The dialog boxes are then highlighted in gray. The user can no longer

change the entered data. The relevant record data are entered in the menu

“Test program: Record data 1.”

Entry of record data 2

Nom. bag volume: Nominal volume of the bag

Test gas: Type of gas

Comment: Name of operational process

Comment 2: Enter test-relevant remarks

Comment 3: Enter test-relevant remarks

Fig. 7-27 | Test parameters for plate holder test

Fig. 7-28 | Data log group 1

Fig. 7-29 | Data log group 2

Page 41

Operation 41

7.14 Installed bag Test This test sequence may be programmed on the Sartocheck 4 plus Filter tester but

may only be performed if a Bag tester MultiUnit is connected. The test sequence is

designed for leak testing of 3 dimensional bags (e.g. STR Cultibags) being installed in

the appropriate STR holder equipped with fleeces.

The test sequence is based on the change in pressure within the bag system including

connected tubes and vent filters.

The pressure drop measured in the process can be used as a direct measure of the

bag set-up leak tightness and absence of flaws or similar defects, provided that the

upstream volume of the system is constant.

Enter parameters for the plate holder test

Test pressure: from 3–50 mbar

Stabilization time: 1-1080 minutes.

Test time: 1-1080 minutes

Max. pressure drop: 1-programmed test pressure

Filling time: 1-1080 minutes

Please verify the test parameters for the bag being tested. Applying too high a test

pressure may jeopardize the integrity of the bag.

Since the viscosity of remaining liquid may influence the leak rate of an eventual

flaw, please do not mix up pre-use test values with specifically validated post-use

values.

This test can also be used for testing vessels as long as they resist the applied

pressure.

Enter record data 1 (up to 32 characters per field)

Company: Company name

Building: Building name; house number

Department: Identification of the department

Manufact. site: Production sector

Product: Product name

Product lot: Batch number

Bag type: E.g. STR Cultibag 1000L

Bag lot: Number of the bag batch

Locks

After entering with the Shift + F keys, the programmer can lock the data to prevent

any changes. The dialog boxes are then highlighted in gray. The user can no longer

change the entered data. The relevant record data are entered in the menu

“Test program: Record data 1.”

Entry of record data 2

Nom. bag volume: Nominal volume of the bag

Test gas: Type of gas

Comment: Name of operational process

Comment 2: Enter test-relevant remarks

Comment 3: Enter test-relevant remarks

Fig. 7-30 | Test parameters for installed bag test

Page 42

42 Operation

7.15 Program Database All test programs created are saved in the program database.

(F4 – Main Menu) Sartocheck® 4 plus Filter tester features the option to archive 250 user-programmable

test programs in its internal database. The program data in the program item “Program database (F4)” can be managed.

The following functions can be selected:

F1: Load test programs from internal memory

This will display all programs inside the Sartocheck

®

4 plus Filter tester

F2: Upload test programs from SD card

This gives the possibility to install new programs in the Sartocheck® 4 plus

Filter tester (e.g. transfer from one Sartocheck

®

4 plus to another)

F3: Upload test program from network

Allows uploading test programs from the network, eventually previously

downloaded from another Sartocheck® 4 plus, if the if FTP directory is identical

for both Sartocheck

®

s.

F4: Save backup to SD card

Saves a full copy of the programs set-up to an SD card

F5: Save backup to network

Saves a full copy of the programs set-up to the network

F6: Load backup from SD card

Restores a copy of test programs set-up from an SD card

(this will overwrite the existing programs)

F7: Load backup from network

Restores a copy of test programs set-up from the network

(this will overwrite the existing programs)

F8: Delete PLC programs

With F4 and F5, the test programs are stored in backup format.

This applies to the entire program database only. Individual programs cannot

be stored in backup format.

Fig. 7-31 | Program database

Page 43

Operation 43

7.15.1 Loading Test Program from When loading test programs from internal memory, all test programs are displayed

Internal Memory (F1) in the program selection list. You can highlight the programs by entering the list

number or using the touch screen. There is an entry line “From ## to ##”above the

program list. In this line, you can highlight test program blocks.

Confirm your selection by pressing enter.

The highlighting can be removed with the button “Undo marking”.

The highlighted test program is displayed above the function keys F1-F4.

When test program blocks are highlighted, you can scroll through the selection

list with LIST UP|DOWN.

You can select the following functions:

F1: View

Display the parameters predefined in the test program along with

previously defined record data.

F2: Print

Print out the test program on the internal printer

F3: Save parameters to SD card

Save the test program to an SD card

F4: Save to network

Save the test program to the FTP server

F5: Save as program PLC 1

Save the selected program to memory location PLC 1