Sartorius QC64EDE-S, QC7CCE-D, QC7CCE-S0CE, QC34EDE-S0CE, QC64EDE-S0CE Operating Instructions Manual

...

This document courtesy of:

Data Weighing Systems, Inc.

Contact Us

For immediate assistance call

1-800-750-6842

98648-009-86

Sartorius QC Models

Electronic Scale

Operating Instructions for Standard QC Models and

QC Models Verifiable for Use in Legal Metrology

Industrial

Weighing Technology

Contents

Page

General View of the Scale 1– 0

Installation Instructions 1– 5

Zone 2/Class I, Division 2

Hazardous Areas/Locations 1– 8

Setting Up the Scale

– QC7 Models 1–10

– QC34 and QC64 Models 1–12

Mounting Options for the

Display Unit 1–14

Getting Started

Transport Locking Device 1–22

Using the Scale in

Legal Metrology 1–23

Connecting the Scale to

AC Power 1–24

Safety Precautions 1–26

Connecting Electronic

Peripheral Devices 1–27

Leveling the Scale Using

the Level Indicator 1–28

Declaration of Conformity 1–29

CE Marking 1–30

EC Type-Approval Certificate 1–33

Operating the Scale 1–35

Simple Weighing 1–36

Calibration/Adjustment 1–37

Data Interface

Connecting Electronic

Peripheral Devices 1–39

Interfacing Devices

with the Scale 1–40

Page

Care and Maintenance 1–42

Cleaning 1–42

Safety Inspection 1–43

Scale Operating Menu 2– 1

Changing Menu Code Settings 2– 1

Accessing the Menu 2– 2

Undoing All Menu Code

Changes – Reset Function 2– 3

Scale Operating Parameters 2– 4

Adapting the Scale

to Ambient Conditions 2– 4

Standard Weighing and

Manual Filling 2– 4

Stability Range 2– 4

Stability Symbol Delay 2– 5

Tare Parameter 2– 5

Auto Zero Function 2– 5

Calibration/Adjustment

and Linearization Functions

Using the e/o Key 2– 6

Simple Counting 2– 6

Weight Units 2– 7

Interface Parameter Settings

Baud Rate 2– 8

Parity 2– 8

Number of Stop Bits 2– 8

Handshake Mode 2– 8

Troubleshooting Guide 1–41

0–0

0–1

Page

Utilities for Printouts

or Data Transfer

Data Output Parameter 2– 9

Auto Print 2– 9

Data Output at

Defined Intervals 2–10

Data ID Codes 2–11

Automatic Output of the

Tare Memory Data 2–11

Printout/Record Configuration 2–12

Data Record Output 2–13

Additional Functions:

Menu Access Function 2–16

Beep Tone (Acoustic Signal) 2–16

Blocking the Keys 2–16

Blocking the Number Keys 2–16

Universal Switch for

Remote Control 2–17

Power-On Mode 2–17

Display Backlighting 2–18

Automatic Shutoff

(Battery Saver) 2–18

Undoing All Menu Code

Changes – Reset Function 2–19

Application Programs 3– 1

General Description

of the Data Interface 4– 1

Basic Program 4–10

Synchronization and

Data Output Parameters 4–13

Interface Parameter Settings 4–16

Cabling Diagram 4–19

Page

Specifications 5– 1

Accessories (Options) 5– 9

Index 6– 1

Supplement:

Brief Instructions

Card for insertion under the

dust cover

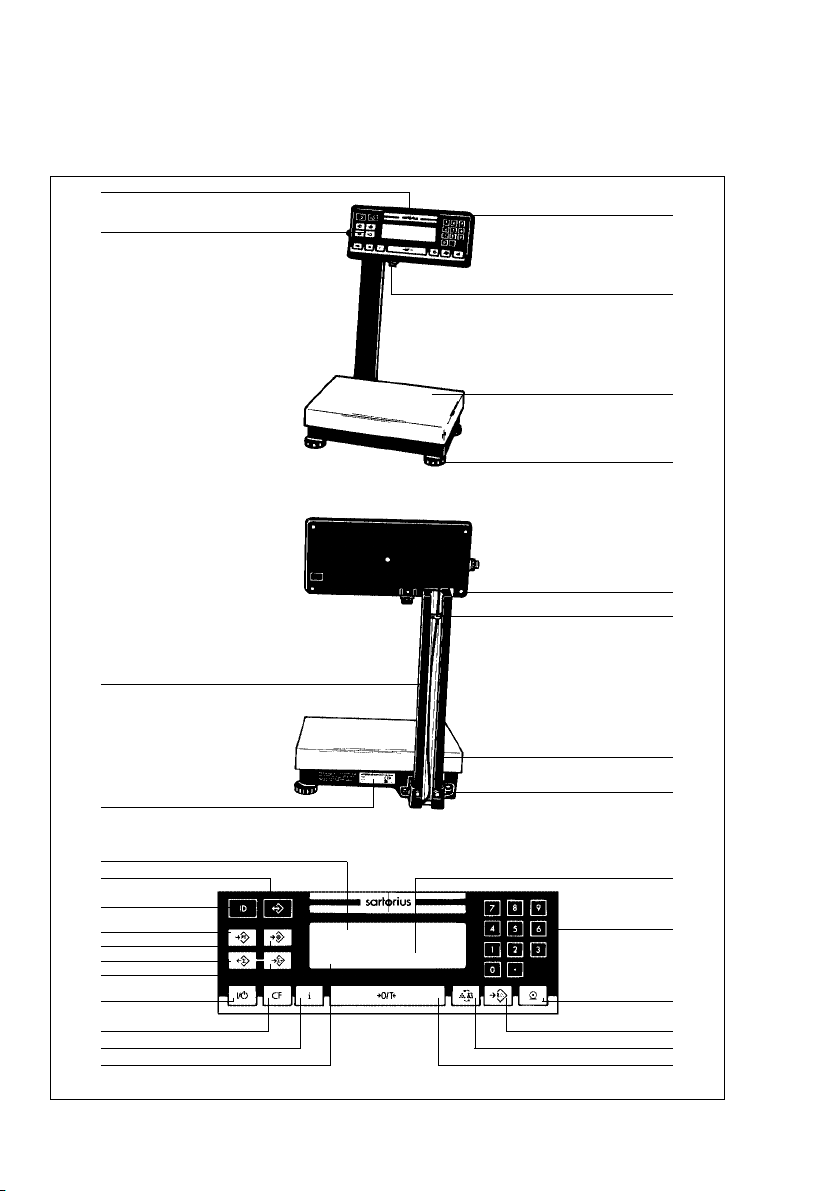

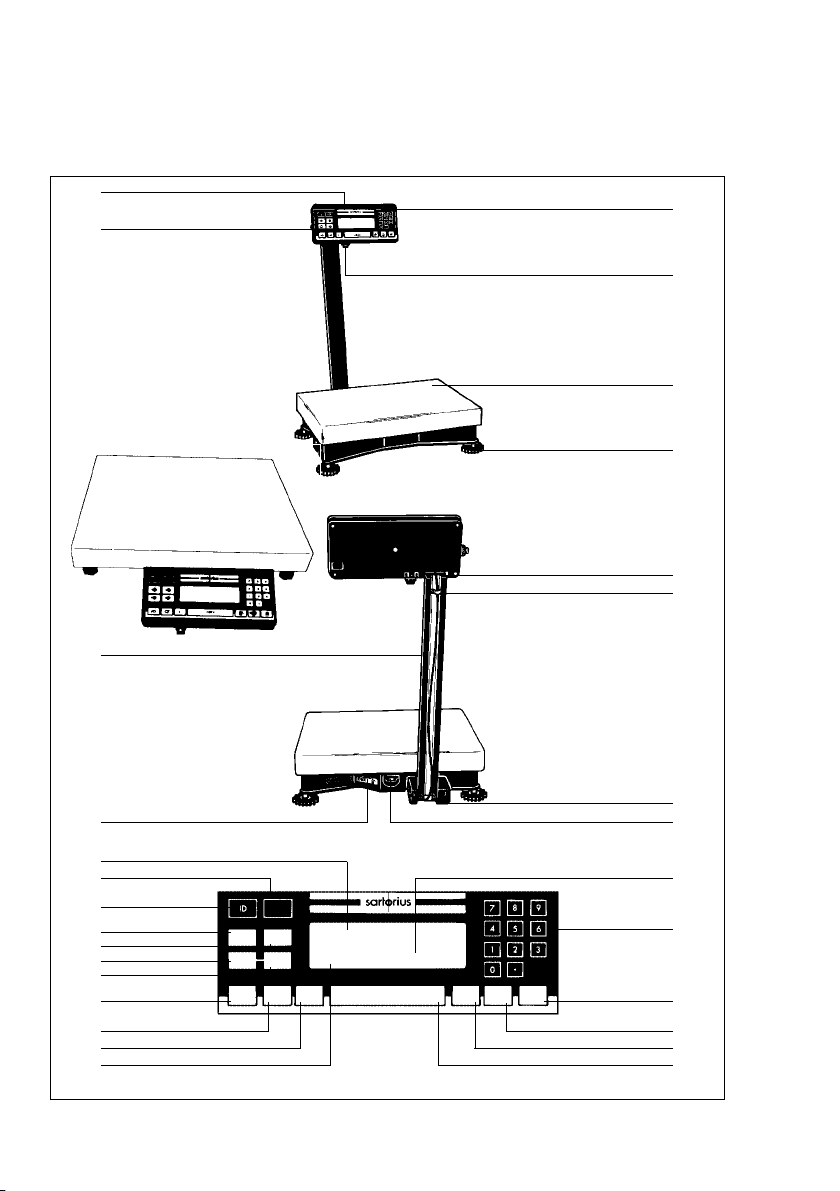

QC 7 Models

Note: This illustration shows only the -L0CE model with raised display

29

28

1

2

3

4

5

6

1–0

27

26

25

24

23

22

21

20

19

18

17

16

15

7

8

9

10

11

12

13

14

1–1

No. Designation

1 Display unit

2 Power socket

3 Load plate

4 Leveling foot

5 Retainers for the display unit

6 Clip

7 Fastening screws for the

support arm

8 Level indicator

9 Display

10 0 –9 and . number keys

11 p/p Print key (data output)

12 u/w Start key for

counting mode

13 g/W Key for toggling

between weighing/counting

applications, between reference

sample quantity and average

piece weight, or for toggling

weight units for all models

except QC34EDE-L0CE and

QC64EDE-L0CE

14 =/z Tare key – Zero/tare

No. Designation

15 Display for application programs

16 i/i Info key

17 c/c CF key

18 e/o On/Off

19 S/a Totalization memory –

add

20 s/r Data output – total

21 z/T Start checkweighing

mode

22 o/t Store value in tare

memory

23 d/d Store ID for individual

output values

24 r/s Memory (recall/store)

25 Bar graph (linear range indicator)

26 Manufacturer’s label

27 Support arm

28 Threaded cap on the interface port

29 ID label

(only for scales verified for use in

legal metrology)

Note: The keypad overlay shown here is the version for use in Europe.

QC 34 and QC 64 Models

29

28

27

1

2

3

4

5

6

1–2

26

25

24

23

22

21

20

19

18

17

16

15

RECALL/

STORE

PRESET

PRESET

TARE

TARGET

ACCUM.

ACCUM.

RECALL

+

ON/OFF CLEAR INFO

COUNT/

WEIGHT

AV.PIECE

WEIGHT

7

8

9

10

PRINTZERO/TARE

11

12

13

14

1–3

No. Designation

1 Display unit

2 Power socket

3 Load plate

4 Leveling foot

5 Retainers for the display unit

6 Clip

7 Fastening screws for the

support arm

8 Level indicator

9 Display

10 0 –9 and . number keys

11 p/p Print key (data output)

12 u/w Start key for

counting mode

13 g/W Key for toggling

between weighing/counting

applications, between reference

sample quantity and average

piece weight, or for toggling

between weight units for all

models except QC34EDE-L0CE

and QC64EDE-L0CE

14 =/z Tare key – Zero/tare

No. Designation

15 Display for application programs

16 i/i Info key

17 c/c CF key

18 e/o On/off

19 S/a Totalization memory –

add

20 s/r Data output – total

21 z/T Start checkweighing

mode

22 o/t Store value in tare

memory

23 d/d Store ID for individual

output values

24 r/s Memory (recall/store)

25 Bar graph (linear range indicator)

26 Manufacturer’s label

27 Support arm

28 Threaded cap on the interface port

29 ID label

(only for scales verified for use in

legal metrology)

Note: The keypad overlay shown here is the version for use with -0UR models

in the US.

!

Important Note to Users

Make sure to carefully read and follow sections

marked with this symbol – they contain important

safety instructions.

If you turn off the scale while it is running on power

supplied by the battery pack and the external AC

adapter YRB06Z is not plugged in for recharging,

make sure to turn off the battery pack as well.

Note:

(For QC 34 and QC 64 models only)

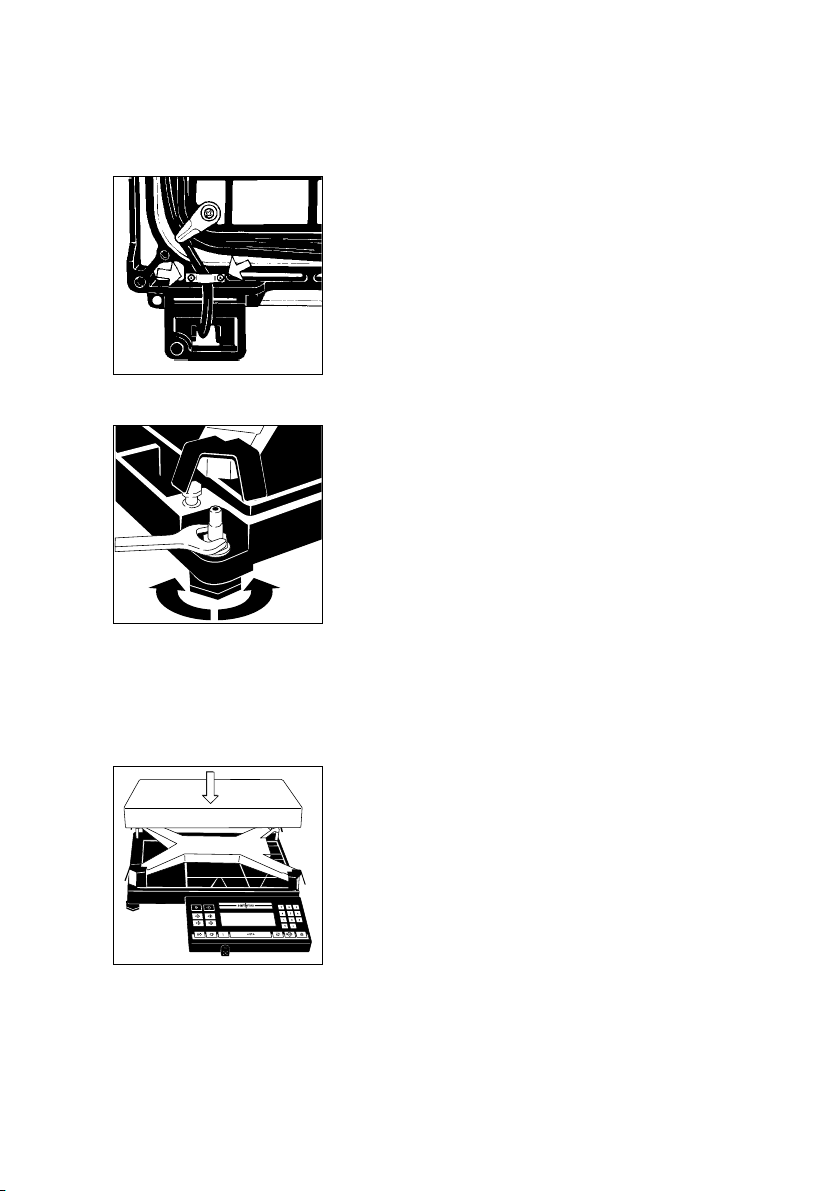

Transport Locking Device

Do not remove the transport locking device until the

scale is set up at the place of installation. Remove the

load plate.

The transport locking devices (yellow) are located on

the short sides of the scale.

Remove the transport locking devices (unfasten

them using an Allen wrench) before initially operating

the scale.

1–4

Verification Mark (Seal)

The law requires that a verified scale be sealed

with a verification mark. The verification marks

(seals) on a verified QC scale indicate that this scale

may only be opened and serviced by authorized

technicians, to ensure reliable and trouble-free

operation and to avoid forfeiture of the warranty

coverage. If a verification mark (seal) is damaged,

please observe the national laws and regulations

in effect at the place of installation.

Installation Instructions

Please read these installation and operating

instructions carefully before you begin operating your

new scale.

Intended Use

The QC series counting scales are ideal for use in

production and in warehouse management. They are

designed primarily for counting parts of identical

weight and for the related applications: totalizing,

checkweighing, documentation, counting and

for storing data on articles weighed. You can connect

a PC (for remote operation of your scale or for

integration into a warehouse management system)

or any of a variety of accessory devices to the data

interface port of the scale (see the section entitled

“Accessories (Options)”).

If you are interested in using your Sartorius QC scale

for any other purpose, please contact your Sartorius

Service Center. Sartorius does not accept any liability

connected with the use of their scales for other than

their intended purposes.

Warranty

Do not miss out on the benefits of our full warranty.

Please complete the warranty registration card,

indicating the date of installation, and return the card

to your Sartorius office or dealer.

1–5

Storage and Shipping Conditions

Allowable storage temperature: –40°C...+70°C

–40°F...+158°F

The packaging has been designed to ensure that

the scale will not be damaged even if it is dropped

from a height of up to 80 cm (about 31inches).

After unpacking the scale, please check it immediately

for any visible damage as a result of rough handling

during shipment.

If this is the case, proceed as directed in the section

entitled “Safety Inspection.”

Save the box and all parts of the packaging for any

future shipment of your scale. Before packing your

scale, unplug all cables to prevent damage. Replace

the screw cap (28) on the data interface port.

To ensure your scale’s long service life:

Do not expose the scale unnecessarily to extreme

temperatures, moisture, blows, shocks or vibration.

Note:

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant

to Part 15 of the FCC rules. These limits are designed

to provide reasonable protection against harmful

interference when the equipment is operated in a

commercial environment. This equipment generates,

uses and can radiate radio frequency energy and,

if not installed and used in accordance with the

instruction manual, may cause harmful interference

to radio communications. Operation of this

equipment in a residential area is likely to cause

harmful interference in which case the user will be

required to correct the interference at his own

expense. Changes or modifications not expressly

approved by Sartorius AG could void the user’s

authority to operate the equipment.

1–6

Installation

Ambient Conditions

Sartorius QC scales are designed to provide reliable

weighing and counting results under normal ambient

conditions encountered in industrial environments.

When choosing a location to set up your scale,

observe the following so that you will be able to work

with added speed and accuracy:

–

Set up the scale on an even, stable surface (table or floor)

– Avoid extreme heat radiation from heaters

or direct sunlight

– Protect the scale from drafts that come through open

doors and windows

– Avoid areas that may subject the scale to extreme

vibrations during weighing

– Protect the scale from aggressive chemical vapors

The scale may not be used in hazardous

areas/locations where there is danger of explosion.

Do not expose the scale to extreme moisture over long

periods of time. Moisture in the air can condense on

the surfaces of a cold scale whenever it is brought to

a substantially warmer place. If you transfer the scale to

a warmer area, make sure to condition it for about 2 hours

at room temperature, leaving it unplugged from AC

power. Afterwards, if you keep the scale connected to

AC power, the constant positive difference in

temperature between the inside of the scale and the

outside will practically rule out moisture condensation.

Note for QC Models Verifiable for Use in Legal Metrology:

The scale can be adapted to your individual requirements through simple changes to code settings in the

scale operating menu. For more information, see the

section entitled “Scale Operating Menu.”

Preparing the Scale for Verification as a Legal

Measuring Instrument in the EU*:

After initially connecting the scale to the power

supply (or after a relatively long power outage),

allow the scale to warm up for at least 24 hours.

1–7

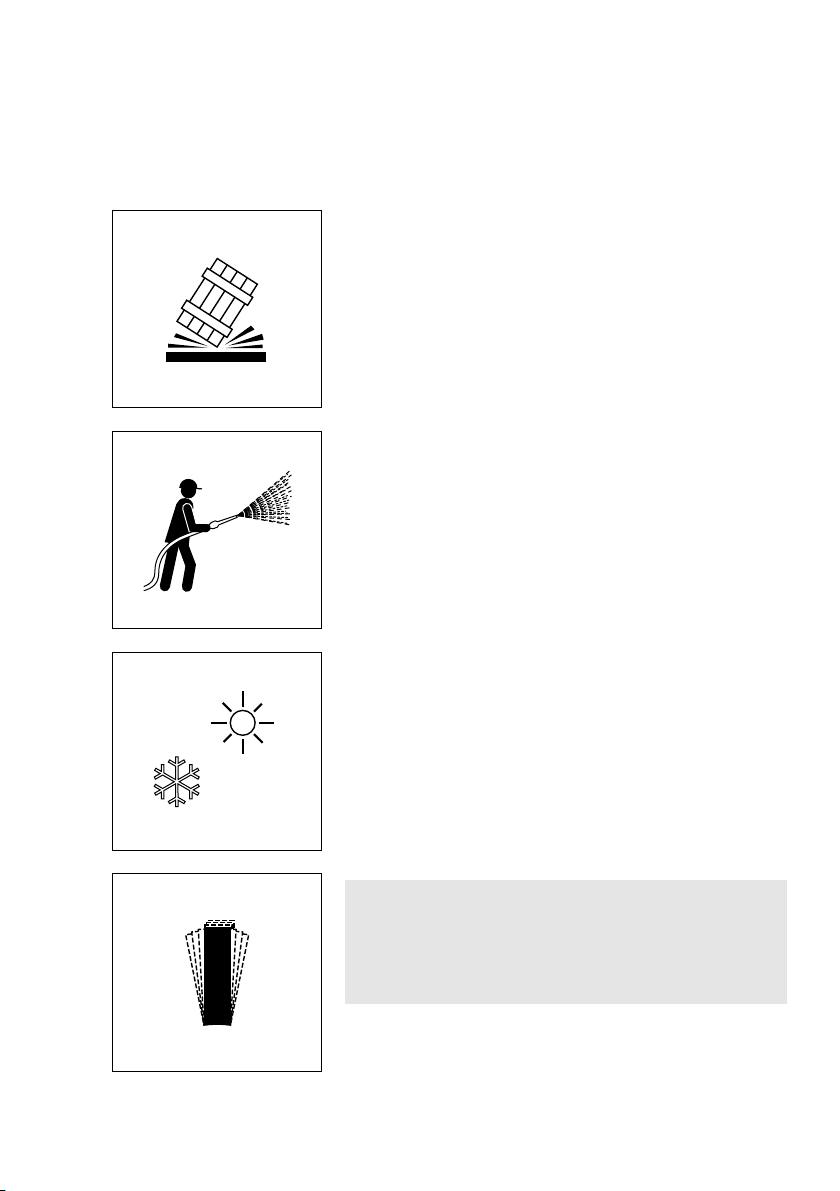

°C

Check the serial number on the display unit of the QC

scale against the number on the tag ofthe scale cable.

Plug connector A into connector B.

Zone 2/Class I,Division 2 Hazardous Areas/Locations

You may operate the scale in a Zone 2 hazardous

area in Europe or in a Class I, Div. 2 hazardous

location (in the U.S. and Canada).

In this case, you must comply with the national electrical code and applicable safety regulations of your

country (in Germany, according to DIN VDE 0165).

For information on the legal regulations currently

applicable in your country, please ask your Sartorius

office or dealer.

To install the power supply, please read the instructions

in the section entitled “Getting Started.”

If you operate the scale in a Zone 2/Class I, Div. 2

hazardous area/location, you will need to observe

the installation conditions as described for the QC

display unit in the section entitled “Getting Started.”

The QC scale may not be operated in Zone 0,1, 20,

21 or22 hazardous areas/locations, as it does not

have an EX approval certificate for these areas.

1–8

* = including the Signatories of the Agreement on the

European Economic Area

Any tampering with the QC equipment by anyone,

other than authorized by Sartorius service

technicians, will result in forfeiture of all claims under

the manufacturer’s warranty!

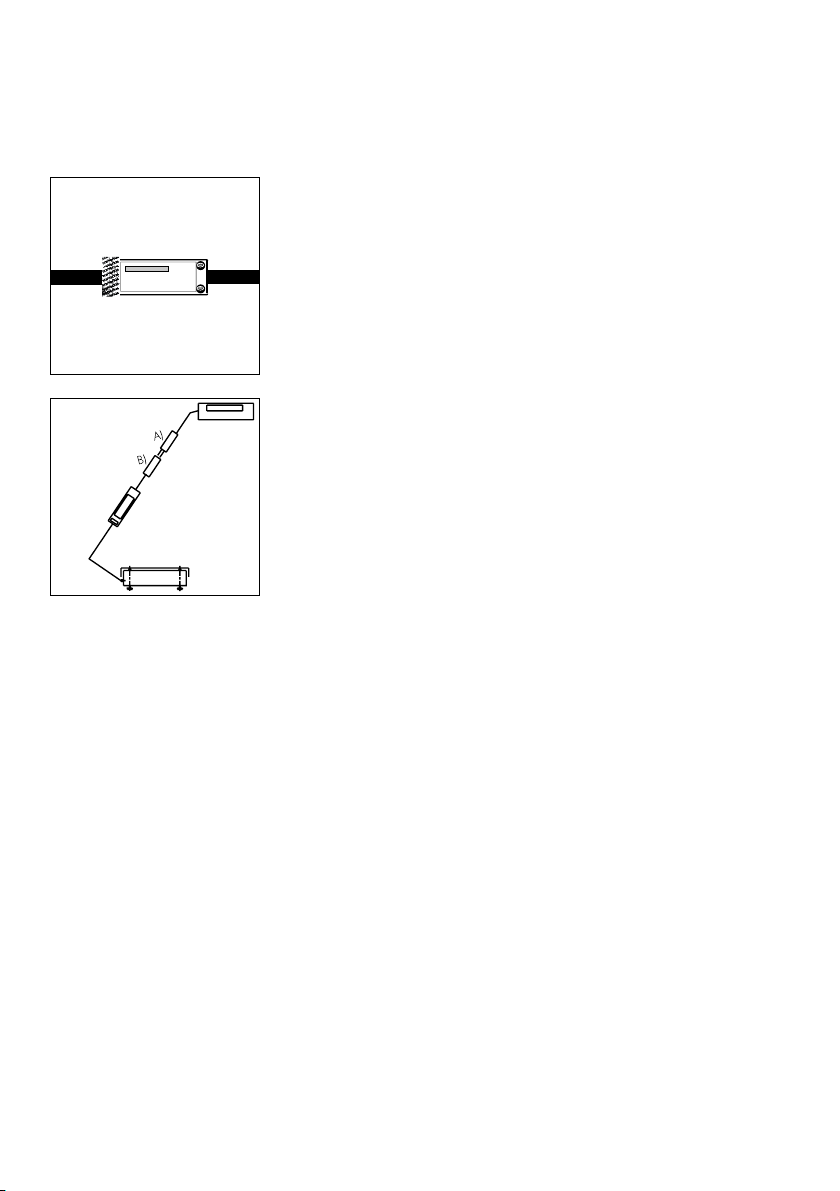

Fastening an Antitheft Locking Device

QC 7 Model:

To protect the scale from theft, attach it in a secure

location using the lug located at the back of the scale.

QC 34 and QC 64 Models:

Thread a commercially available bicycle lock through

one of the fins in the lower housing of the scale.

The QC scale along with an ING2 power supply

is suitable for use in the following hazardous area

within the European Community:

Zone 2, Group II, temperature class T4 according to

EN 60079-14

In countries other than Germany, the QC scale

may not be used in a Zone 2/Class I, Div. 2

hazardous area/location unless approval for use

in such hazardous areas has been granted by

the local authorities.

Pursuant to the German Directive for the

Implementation of Regulations for Prevention of

Accidents “Elektrische Anlagen und Betriebsmittel”

(VBG 4) (Electrical Installations and Equipment) of

April,1986, and in conjunction with Article 10

of the Low Voltage Directive 72/23/EEC issued on

February 19,1973, by the European Community,

it is hereby certified that the equipment delivered,

the QC scale and accessories, has been

manufactured and tested in compliance with the

following DIN/VDE regulations:

DIN EN 60950

DIN EN 61010

1–9

Setting Up the Scale

– QC 7 Models:

Carefully unpack the scale and accessories.

Mounting the Display Unit on a Table or Wall

(optional; order no. YDH01TS)

– Remove the retainers (5) from the support arm

– Remove the display unit

1–10

– Unfasten the screws on the display unit (7) and

remove the retainers.

– Slide the clips (6) which hold down the cable in

the raceway (channel) up and out of the support arm;

then remove the cable from the raceway.

– Remove the support arm.

– Then slide the clips back onto the support arm.

– Fasten the display unit holder to the display unit

using the retainers (5)

– Unfasten the retaining plate from the back

of the scale

– Unwind the cable as far as required and then

refasten the retaining plate

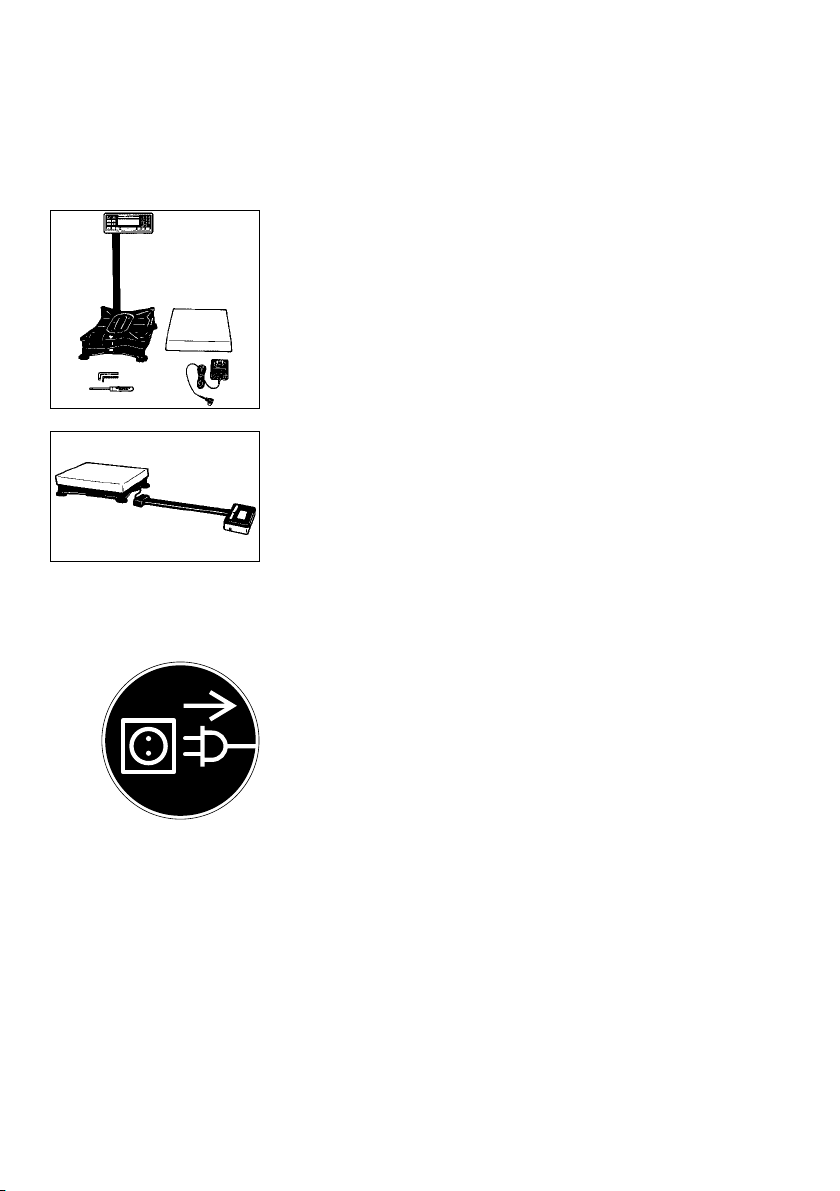

Leveling the Scale Using the Level Indicator

§ Level the scale using the level indicator as a guide.

$ Extend the leveling feet (turn clockwise)

to raise the scale

$ Retract the levelling feet (turn counterclockwise) to

lower the scale.

§ When the air bubble is exactly centered, use the

open-end wrench (spanner) to tighten the locknuts.

Important Note:

If you install the scale on a cart or trolley, it is sufficient

to level the scale once. Scales used as legal measuring

instruments are not allowed to be installed on a cart

or trolley!

§ Place the load plate on the scale base

1–11

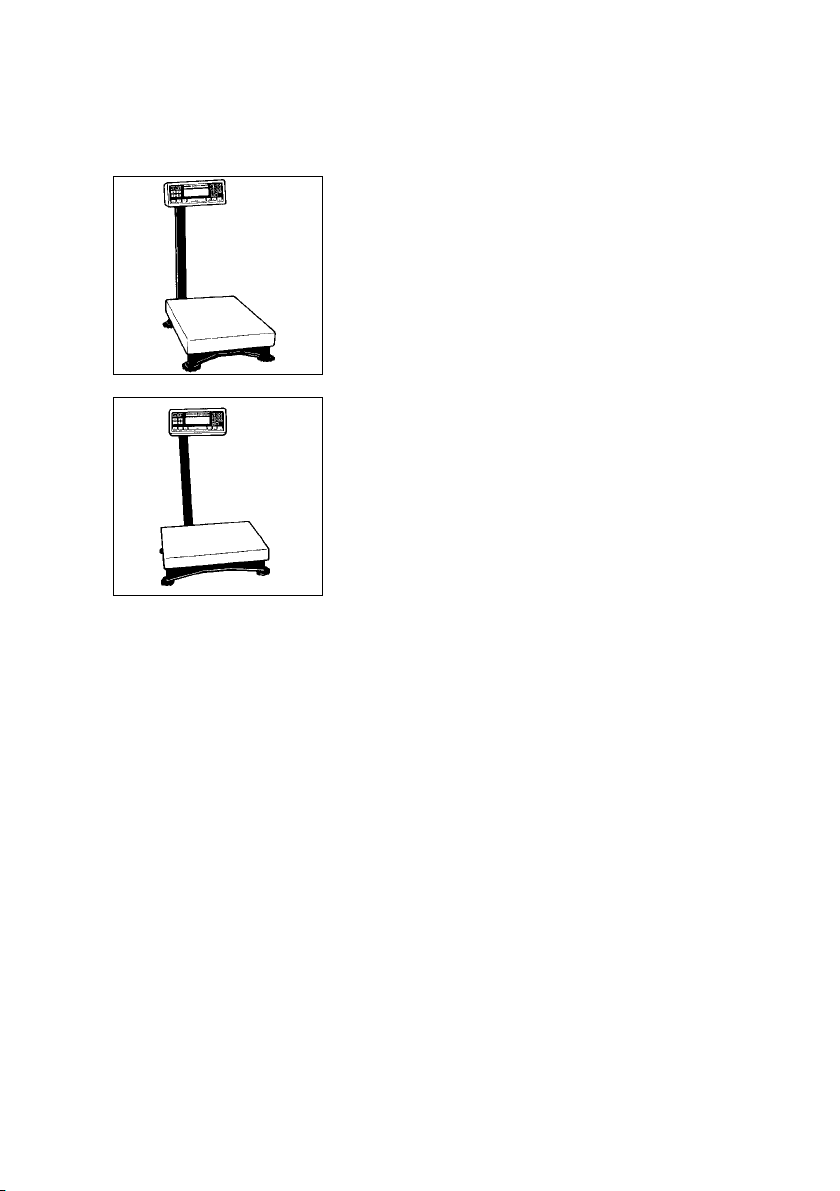

– QC 34 and QC 64 Models:

Carefully unpack the scale and accessories.

Place the scale on a table and lay the support arm

and display unit next to it.

! Always secure the transport locking devices before

any transport of your scale. Unplug the scale

from AC power and remove the load plate from the

scale before changing the display mounting.

1–12

Mounting Options for the Display Unit

Note:

The following display mounting options apply

to QC 34 and QC 64 models only.

The display unit can be mounted as follows:

– on the short side of the scale (see page 1–14)

– on the back (long side) of the scale (see page 1–16)

– as a remote display unit (see page1–19 ); only

possible with the display holder which is available

as an option.

1–13

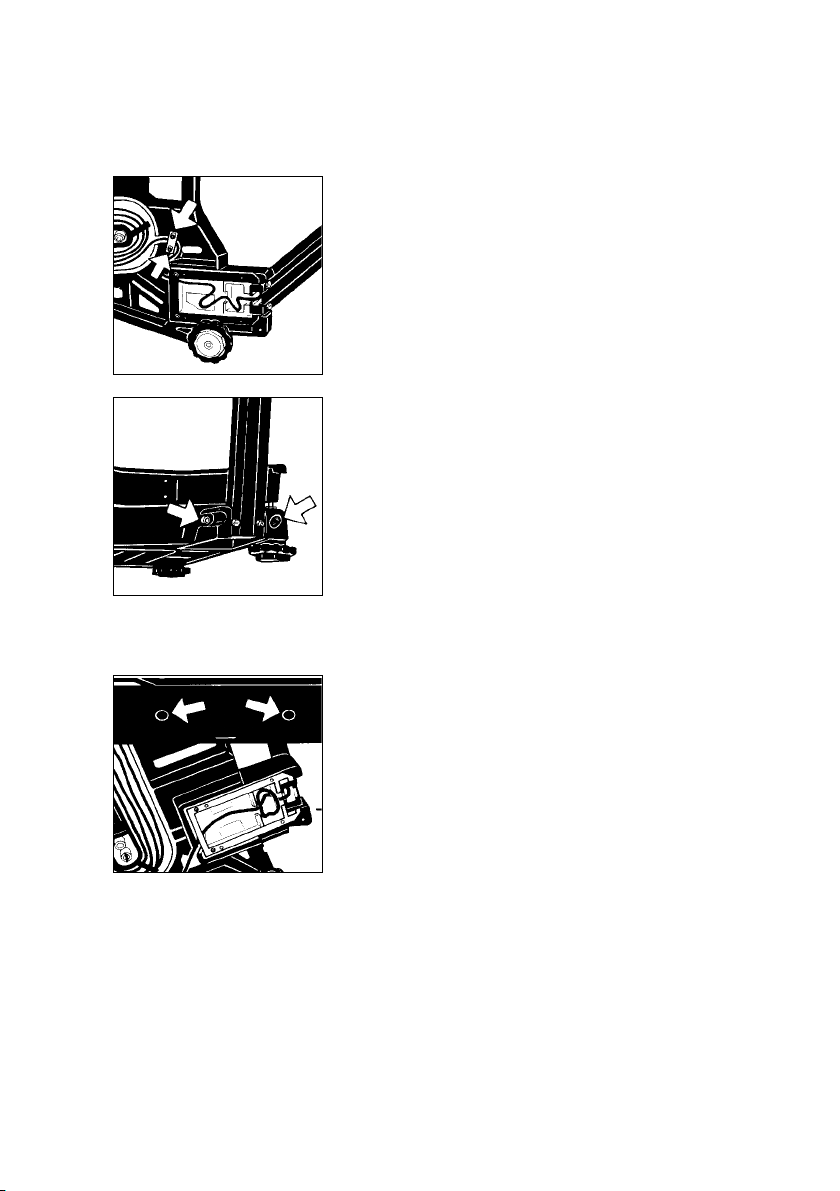

Mounting the Raised Display Unit on the Short Side

of the Scale

First, decide whether you want to mount the display on

the short side or on the back (long side) of the scale.

! Please follow the instructions given on page1–12

before you begin to change the display mounting.

Fasten the support arm to the base.

Note:

Use the center row of threaded drill holes when

inserting the screws.

Slide the clips into position to keep the cable from

slipping out of the raceway (channel).

1–14

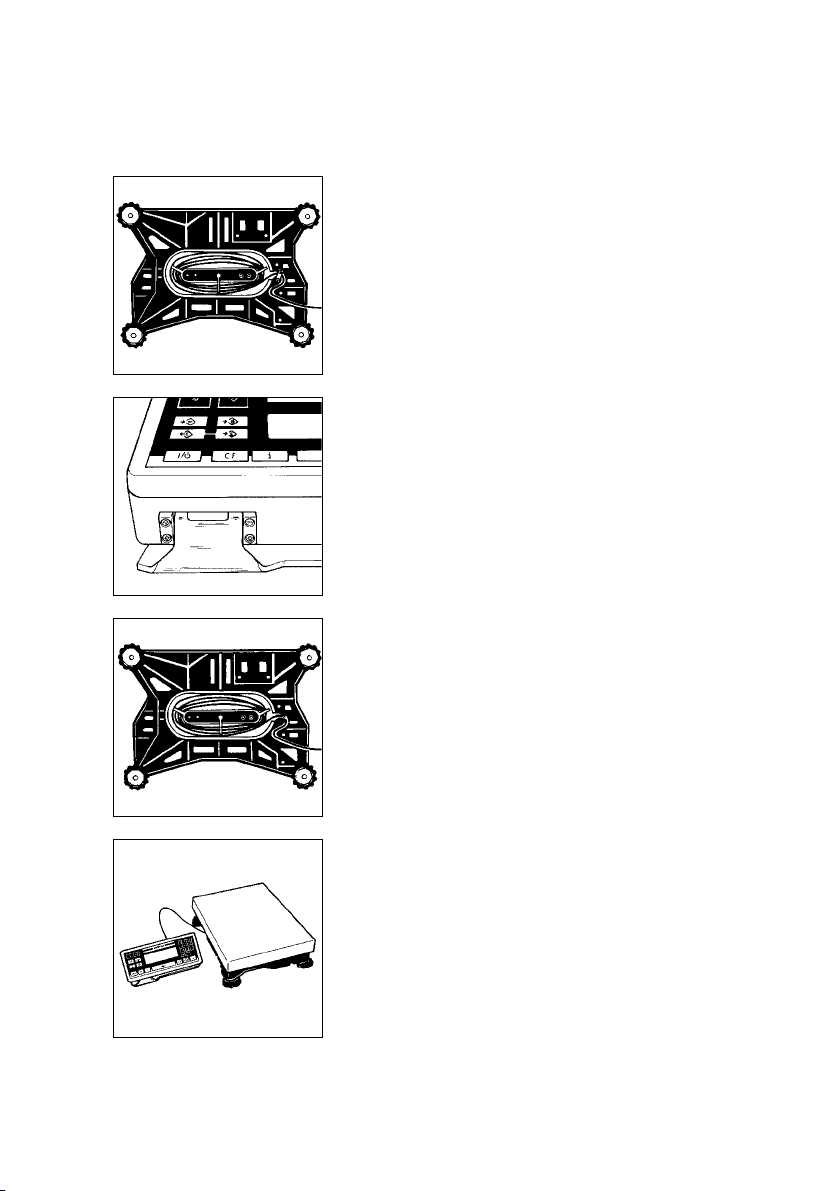

Scale with the display unit mounted on the short side.

Scale with the display unit mounted on the back

(long side).

Note:

The cable routing will have to be changed, depending

on the position of the display unit.

1–15

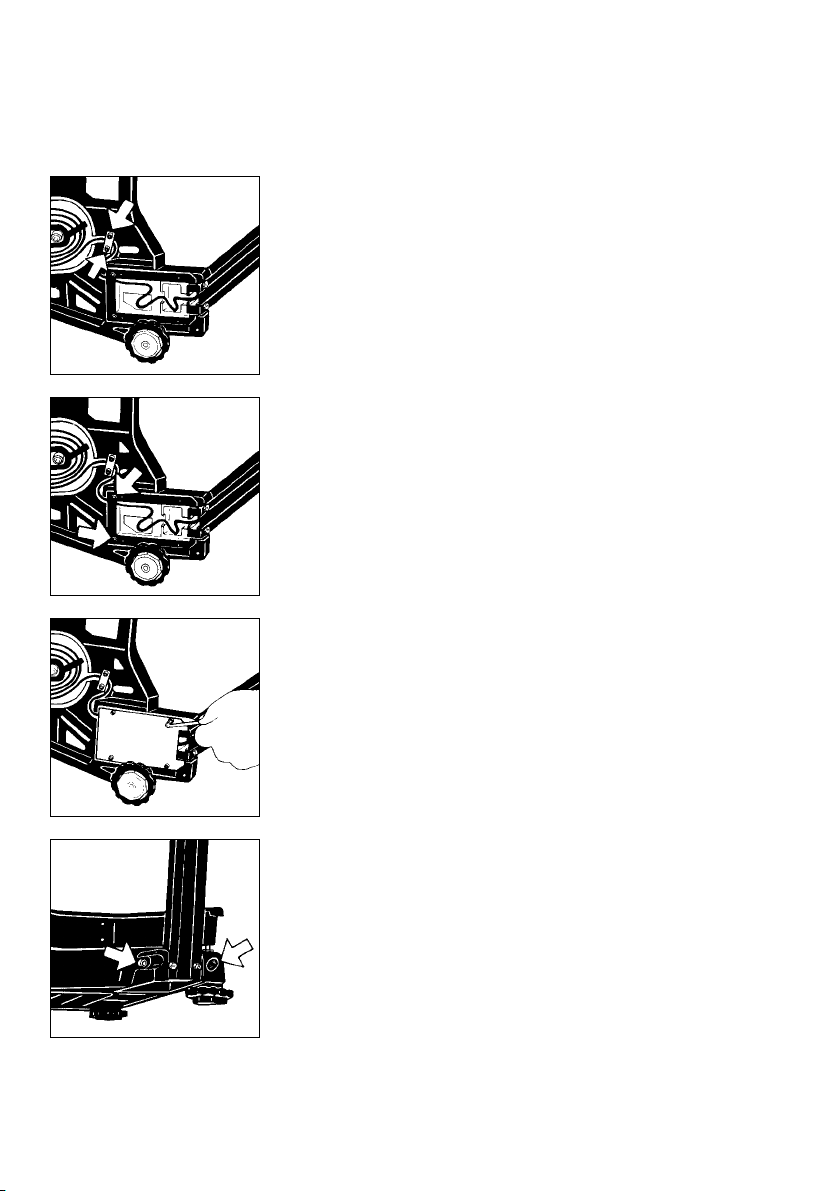

Mounting the Raised Display Unit on the Long Side

of the Scale

Please be careful that the scale does not fall over

when disassembling and mounting the parts as

described here and in the following steps. Follow the

instructions given on page1–12 before you begin

to change the display mounting.

Lay the scale on its side to disassemble and mount the

display unit.

Unfasten the Allen screws on the base plate

and remove the base plate.

1–16

Remove the fastening screws.

Remove the screws on the retainer plate.

Then set the scale back upright.

Remove the screws on the base (7).

Lay the support arm along with the base and the

display unit on a table.

Remove the plugs from the long side of the scale

(insert them in the holes on the short side). Loosely

attach the display unit with the support arm and base

to the long side of the scale with the Allen screws.

Lay the scale on its side again.

Thread the cable through the raceway.

1–17

Refasten the retainer plate for the cable.

Refasten the frame with the fastening screws.

Refasten the base plate.

1–18

Set the scale back upright and tighten the Allen screws

on the base.

Follow these steps if you need to change the display

mounting again.

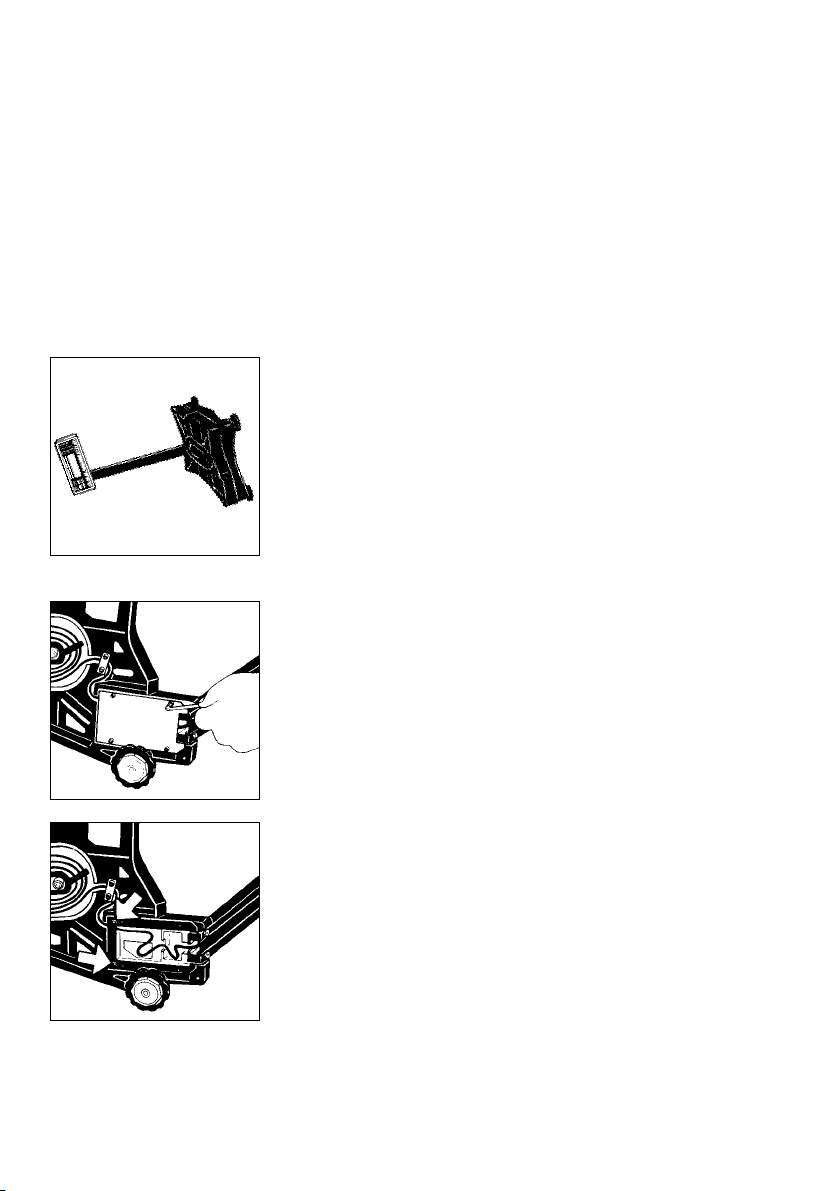

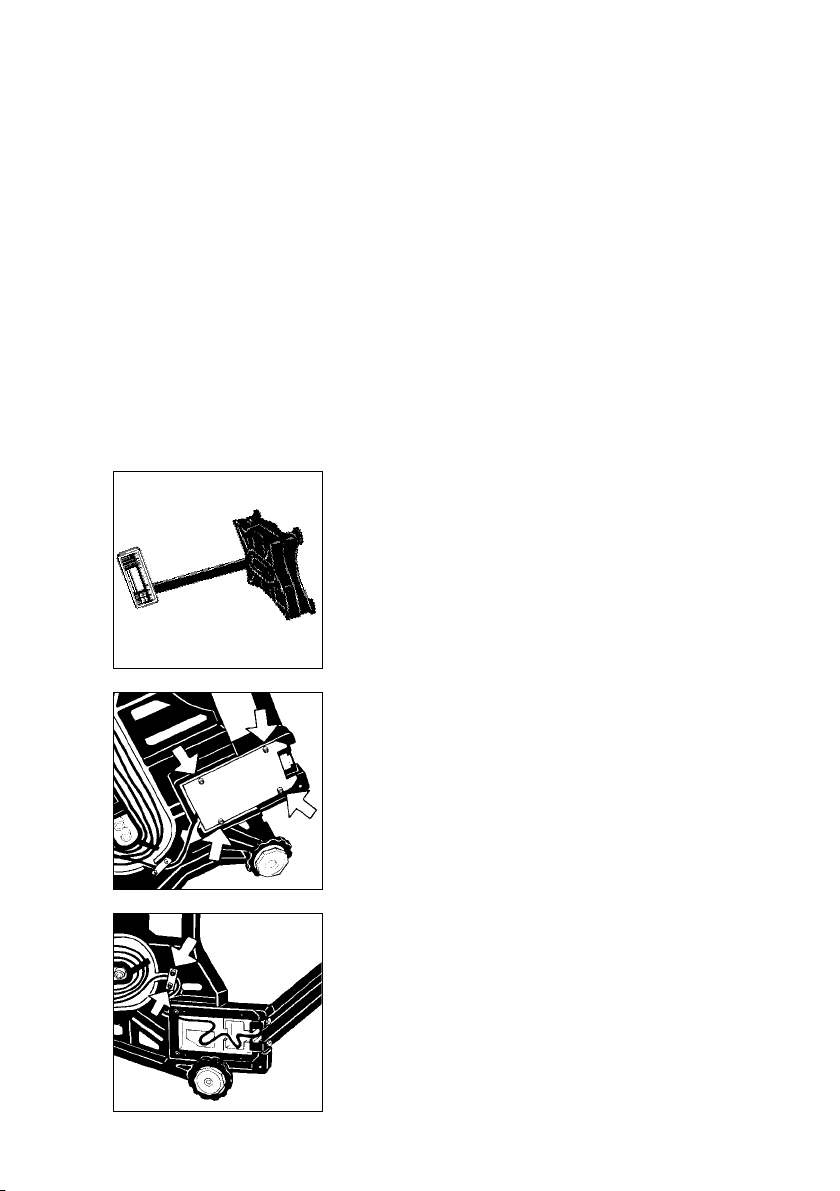

Mounting the Remote Display Unit (Option)

(only possible with the optional display holder;

order no. YDH01TS)

Note:

You can also mount the display as a remote unit

for the QC 7 model.

!

Please be careful that the scale does not fall over

when disassembling and mounting the parts as

described here and in the following steps. Follow the

instructions given on page1–12 before you begin to

change the display mounting.

Lay the scale on its side to disassemble and mount

the parts.

Unfasten the Allen screws on the base plate

and remove it.

Remove the screws on the retainer plate.

1–19

Remove the screws on the base (7) (see diagram

on the left).

Then set the scale back upright.

Remove the fastening screws.

Lay the support arm along with the base and the

display unit on a table.

1–20

Unfasten the screws on the display unit (5) and remove

the retainers.

Slide the clips which hold down the cable in the

raceway up and out of the support arm.

Unwind the cable as far as required.

Mount the display unit on the display holder using the

retainers you previously removed.

Now refasten the retainer plate for the cable.

Set the scale back upright.

1–21

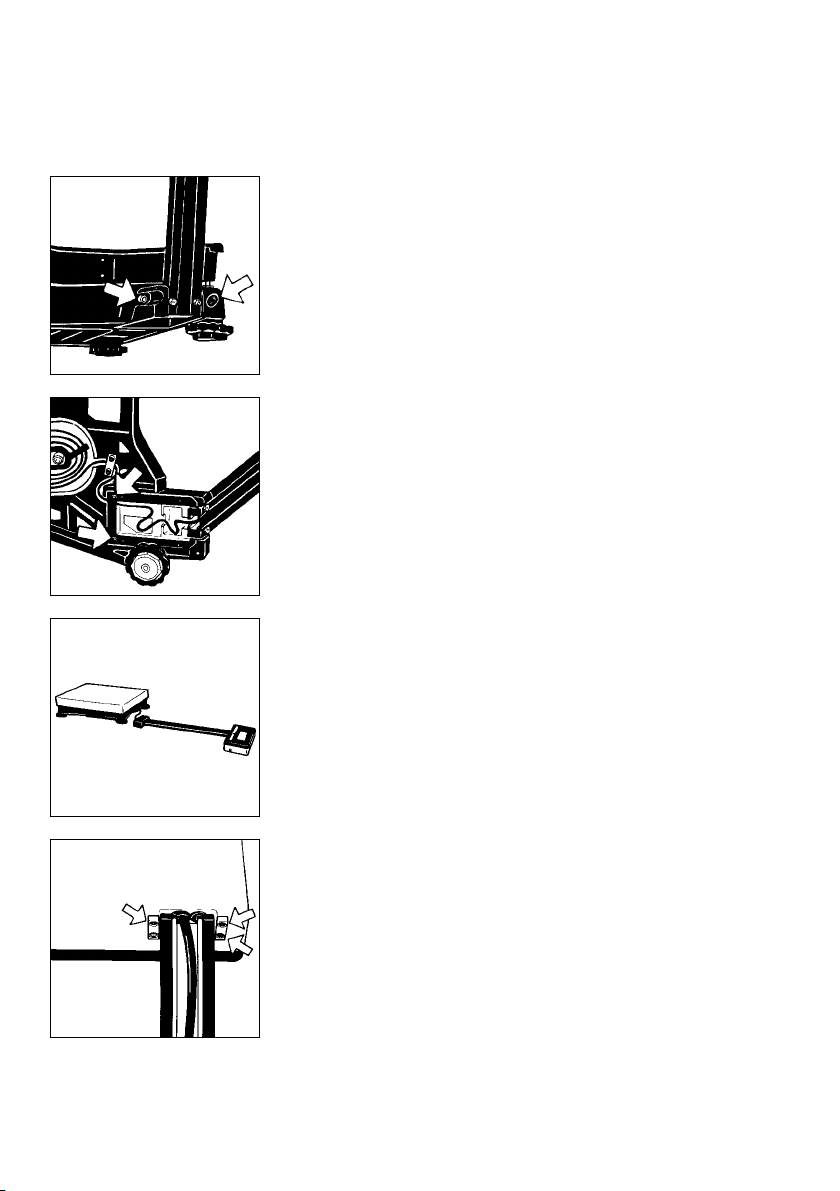

Getting Started

Set the load plate (3) on the scale.

Note:

(For QC 34 and QC 64 models only)

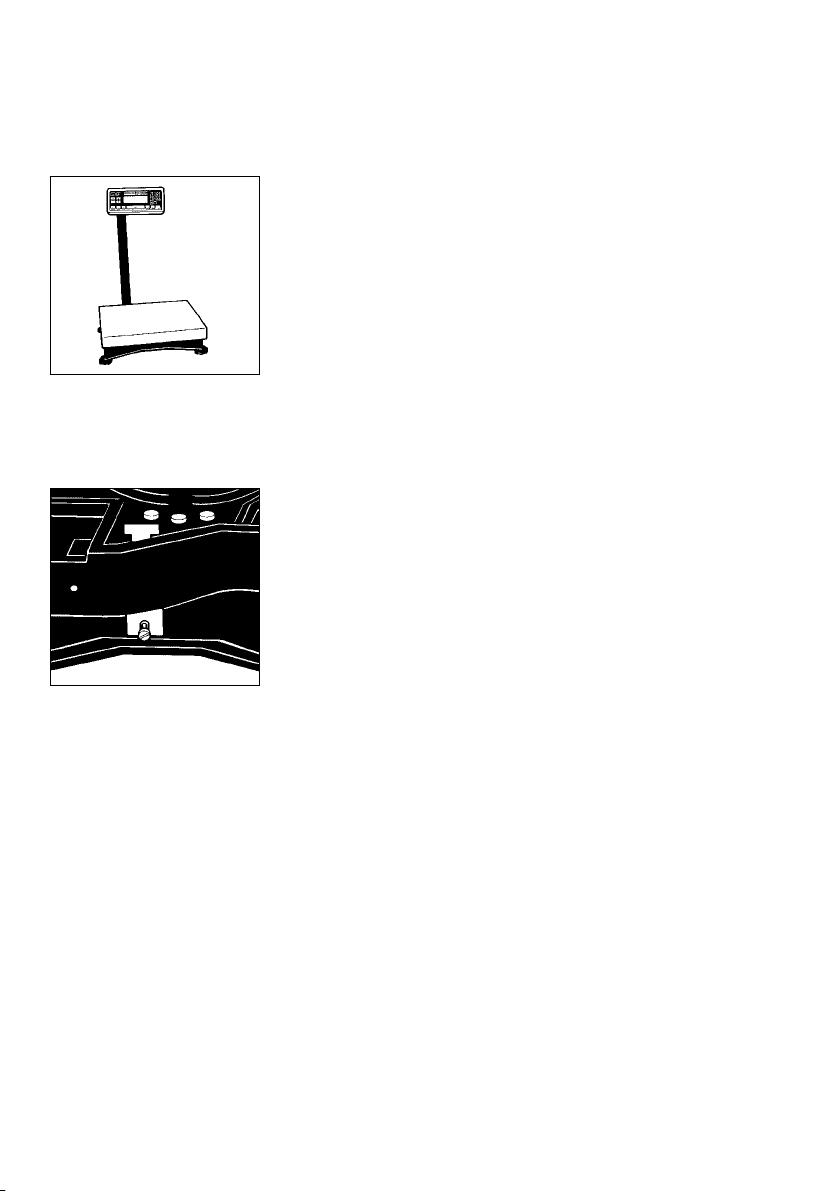

Transport Locking Device

Set up the scale at the place of installation and remove

the load plate. The transport locking devices (yellow)

are located on the short sides of the scale.

Remove the transport locking devices (unfasten

them using an Allen wrench) before initially operating

the scale.

1–22

!

Verification Mark (Seal)

The law requires that a verified scale be sealed

with a verification mark. The verification marks (seals)

on a verified QC scale indicate that this scale

may only be opened and serviced by authorized

technicians, to ensure reliable and trouble-free

operation and to avoid forfeiture of the warranty

coverage. If a verification mark (seal) is damaged,

please observe the national laws and regulations

in effect at the place of installation.

Save the box and all parts of the packaging for any

future shipment of your scale.

Place the load plate on the scale.

Level the scale at the place of installation using the

leveling feet.

Using the Scale in Legal Metrology

(QC-...0CE Models)

* = Pursuant to Directive No. 90/384/EEC on non-automatic weighing instruments

Approved Auxiliary Measuring Devices

When using the load plate as a legal measuring instrument in the EU, you may

connect to it only auxiliary measuring devices that have been approved for

legal metrology. Metrologically relevant auxiliary devices, such as printers,

additional display units, etc., must be type-approved for this purpose and marked

by a green metrology sticker imprinted with a black “M.” The auxiliary device

must be verified in conjunction with the weighing instrument. If the auxiliary device

is connected at a later date to a weighing instrument that has already been used

in legal metrology, the responsible weights and measures office must be informed

of the addition of the auxiliary device. The auxiliary device can be used in legal

metrology, however, as soon as it has been properly connected if it has

the green metrology sticker with a black “M.”

Since the type-approval certificate for verification applies to non-automatic

weighing instruments only, you must comply with your country’s national

regulations that apply to the place of installation of your weighing instrument for

automatic operation with or without auxiliary devices installed.

To Be Filled Out by the Service Representative Authorized to Perform the

Initial Verification*:

Verified on (date):

The verification is valid for the following scale location:

Company/Name:

Serial no.:

Address:

City/Post code:

Country:

or Zone:

As a weighing instrument, the QC is not allowed to be used for weighing goods

intended for direct sale to the public, nor may it be used as a legal measuring

instrument until it has been initially verified by Sartorius. If the scale is moved, it

must be verified again at its new location. In this case, the scale must be

verified and stamp-approved at the new location by your local weights and

measures office.

1–23

Connecting the Scale to AC Power

The scale is powered by an AC adapter supplied with the scale. Make sure that

the voltage rating printed on this unit is identical to that of your local line voltage.

If the voltage specified on the label or the plug design of the AC adapter do not

match the rating or standard you use, please contact your Sartorius office or dealer.

When you use the scale and associated equipment, you must comply with the

national electrical code and applicable safety regulations of your country.

If you use the QC scale in a Zone 2/Class I, Div. 2 hazardous area/location,

make sure to comply with the valid standards and regulations of your country,

applicable to the installation of equipment in a Zone 2/Class I, Div. 2 hazardous

area/location, e.g. in Germany with ElexV from 27.02.1980 (BGBI. I, P.214).

Only authorized technicians are allowed to install the equipment

in a Zone 2/Class I, Div. 2 hazardous area/location.

The female plug of the power cable must be securely fastened to the male socket

on the QC display unit. On the other end of the power cable,

– either an explosion-proof plug-and-socket connection must be installed

– or the plug must be detached from the power cable and the power cable

securely connected to a suitable junction box.

(Wiring Diagrams for Connecting the Scale

to the AC power in Zone 2/Class I, Div. 2 Hazardous Areas/Locations)

Brown (live (L))

Blue (neutral (N))

Yellow/green (grounding conductor)

Hook up the scale to the power supply in conformance with the installation

requirements of your country.

1–24

The IP 65-protected ING-2 no. 69 71899 AC adapter

is completely encapsulated and can be installed as a

stationary unit. To use a main feeder cable from the

ceiling or to mount a CEE plug, you will have to make

arrangements.

The IP 65 protection rating is ensured only if the square

rubber gasket is installed and the plug is connected

securely to form a hak-tight seal.

Ensure IP protection (Tighten the screw).

IP65 Protection (Painted Models) or IP67 Protection

(Stainless Steel FEP-I, IGP-I, FES-I and IGS-I Models)

The weighing platform is dusth-tight and washdownresistant in conformity with the IP65 or IP67 protection

rating, depending on the model.

Legend to Protection Ratings

First digit: rating 6 indicates resistance to penetration

by dust particles of a specified size. Second digit:

rating 5 indicates resistance to splashes of water,

as well as washdown-resistance. Rating 7 indicates

resistance to penetration by water during 30 minute

immersion up to a depth of 1meter (apporoximately

31/4feet).

IP65 or IP67 protections is only guaranteed if:

– the junction box seal was installed by a qualified

technician, and

– the connecting cables and cable glands were

installed and connected by a qualified technician.

1–25

Loading...

Loading...