Sartorius QC64EDE-S, QC7CCE-D, QC7CCE-S0CE, QC34EDE-S0CE, QC64EDE-S0CE Operating Instructions Manual

...Page 1

This document courtesy of:

Data Weighing Systems, Inc.

Contact Us

For immediate assistance call

1-800-750-6842

Page 2

98648-009-86

Sartorius QC Models

Electronic Scale

Operating Instructions for Standard QC Models and

QC Models Verifiable for Use in Legal Metrology

Industrial

Weighing Technology

Page 3

Contents

Page

General View of the Scale 1– 0

Installation Instructions 1– 5

Zone 2/Class I, Division 2

Hazardous Areas/Locations 1– 8

Setting Up the Scale

– QC7 Models 1–10

– QC34 and QC64 Models 1–12

Mounting Options for the

Display Unit 1–14

Getting Started

Transport Locking Device 1–22

Using the Scale in

Legal Metrology 1–23

Connecting the Scale to

AC Power 1–24

Safety Precautions 1–26

Connecting Electronic

Peripheral Devices 1–27

Leveling the Scale Using

the Level Indicator 1–28

Declaration of Conformity 1–29

CE Marking 1–30

EC Type-Approval Certificate 1–33

Operating the Scale 1–35

Simple Weighing 1–36

Calibration/Adjustment 1–37

Data Interface

Connecting Electronic

Peripheral Devices 1–39

Interfacing Devices

with the Scale 1–40

Page

Care and Maintenance 1–42

Cleaning 1–42

Safety Inspection 1–43

Scale Operating Menu 2– 1

Changing Menu Code Settings 2– 1

Accessing the Menu 2– 2

Undoing All Menu Code

Changes – Reset Function 2– 3

Scale Operating Parameters 2– 4

Adapting the Scale

to Ambient Conditions 2– 4

Standard Weighing and

Manual Filling 2– 4

Stability Range 2– 4

Stability Symbol Delay 2– 5

Tare Parameter 2– 5

Auto Zero Function 2– 5

Calibration/Adjustment

and Linearization Functions

Using the e/o Key 2– 6

Simple Counting 2– 6

Weight Units 2– 7

Interface Parameter Settings

Baud Rate 2– 8

Parity 2– 8

Number of Stop Bits 2– 8

Handshake Mode 2– 8

Troubleshooting Guide 1–41

0–0

Page 4

0–1

Page

Utilities for Printouts

or Data Transfer

Data Output Parameter 2– 9

Auto Print 2– 9

Data Output at

Defined Intervals 2–10

Data ID Codes 2–11

Automatic Output of the

Tare Memory Data 2–11

Printout/Record Configuration 2–12

Data Record Output 2–13

Additional Functions:

Menu Access Function 2–16

Beep Tone (Acoustic Signal) 2–16

Blocking the Keys 2–16

Blocking the Number Keys 2–16

Universal Switch for

Remote Control 2–17

Power-On Mode 2–17

Display Backlighting 2–18

Automatic Shutoff

(Battery Saver) 2–18

Undoing All Menu Code

Changes – Reset Function 2–19

Application Programs 3– 1

General Description

of the Data Interface 4– 1

Basic Program 4–10

Synchronization and

Data Output Parameters 4–13

Interface Parameter Settings 4–16

Cabling Diagram 4–19

Page

Specifications 5– 1

Accessories (Options) 5– 9

Index 6– 1

Supplement:

Brief Instructions

Card for insertion under the

dust cover

Page 5

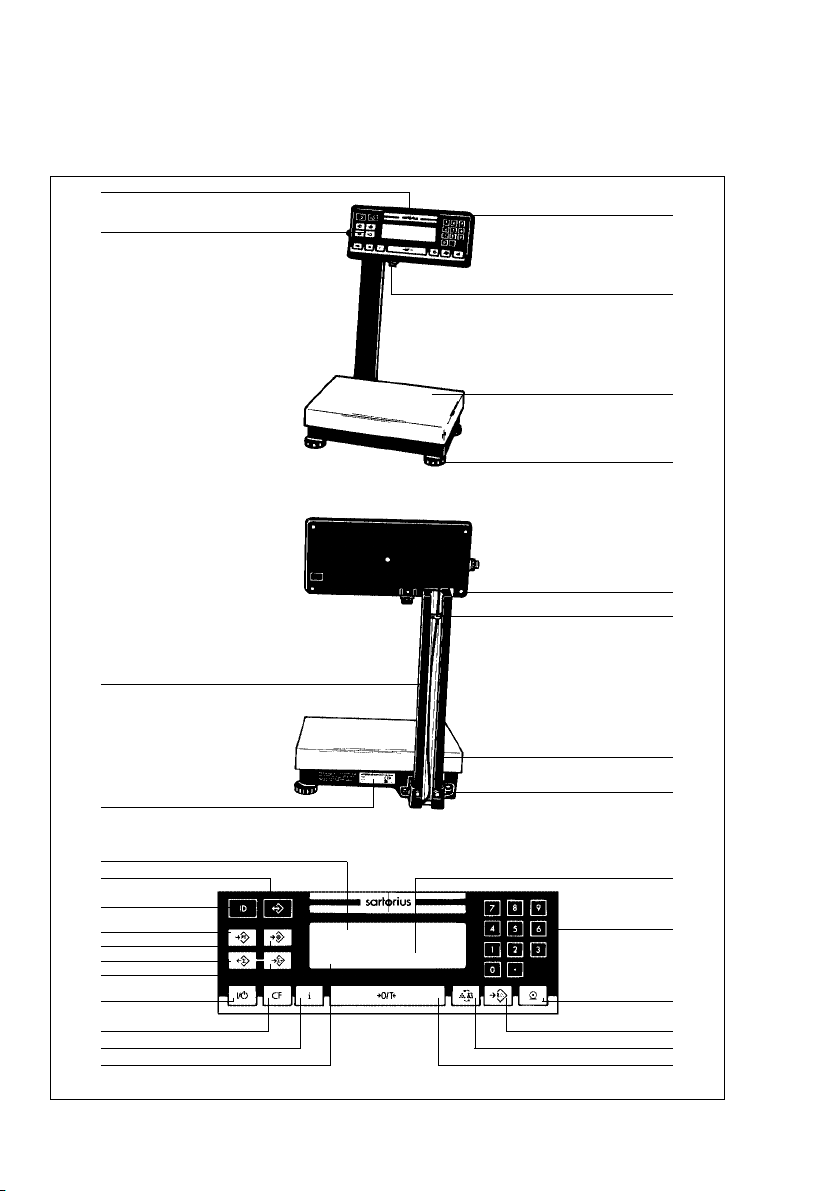

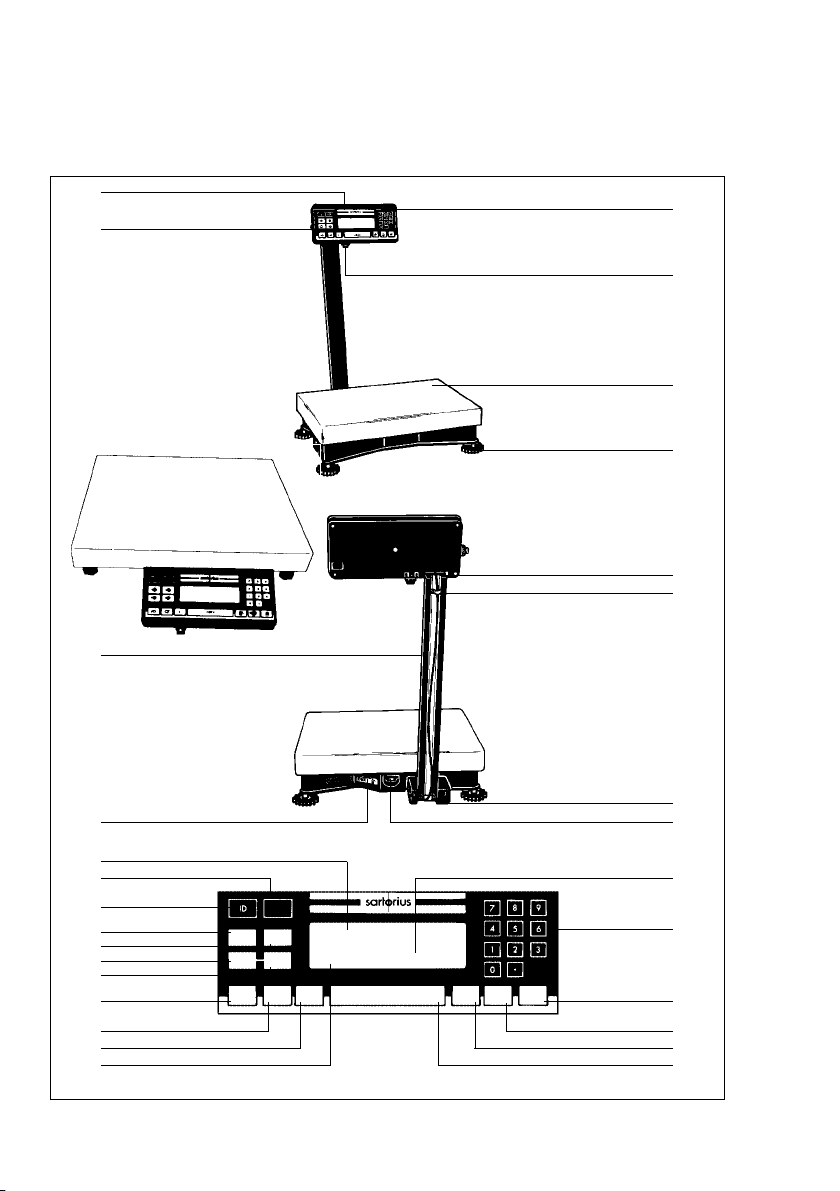

QC 7 Models

Note: This illustration shows only the -L0CE model with raised display

29

28

1

2

3

4

5

6

1–0

27

26

25

24

23

22

21

20

19

18

17

16

15

7

8

9

10

11

12

13

14

Page 6

1–1

No. Designation

1 Display unit

2 Power socket

3 Load plate

4 Leveling foot

5 Retainers for the display unit

6 Clip

7 Fastening screws for the

support arm

8 Level indicator

9 Display

10 0 –9 and . number keys

11 p/p Print key (data output)

12 u/w Start key for

counting mode

13 g/W Key for toggling

between weighing/counting

applications, between reference

sample quantity and average

piece weight, or for toggling

weight units for all models

except QC34EDE-L0CE and

QC64EDE-L0CE

14 =/z Tare key – Zero/tare

No. Designation

15 Display for application programs

16 i/i Info key

17 c/c CF key

18 e/o On/Off

19 S/a Totalization memory –

add

20 s/r Data output – total

21 z/T Start checkweighing

mode

22 o/t Store value in tare

memory

23 d/d Store ID for individual

output values

24 r/s Memory (recall/store)

25 Bar graph (linear range indicator)

26 Manufacturer’s label

27 Support arm

28 Threaded cap on the interface port

29 ID label

(only for scales verified for use in

legal metrology)

Note: The keypad overlay shown here is the version for use in Europe.

Page 7

QC 34 and QC 64 Models

29

28

27

1

2

3

4

5

6

1–2

26

25

24

23

22

21

20

19

18

17

16

15

RECALL/

STORE

PRESET

PRESET

TARE

TARGET

ACCUM.

ACCUM.

RECALL

+

ON/OFF CLEAR INFO

COUNT/

WEIGHT

AV.PIECE

WEIGHT

7

8

9

10

PRINTZERO/TARE

11

12

13

14

Page 8

1–3

No. Designation

1 Display unit

2 Power socket

3 Load plate

4 Leveling foot

5 Retainers for the display unit

6 Clip

7 Fastening screws for the

support arm

8 Level indicator

9 Display

10 0 –9 and . number keys

11 p/p Print key (data output)

12 u/w Start key for

counting mode

13 g/W Key for toggling

between weighing/counting

applications, between reference

sample quantity and average

piece weight, or for toggling

between weight units for all

models except QC34EDE-L0CE

and QC64EDE-L0CE

14 =/z Tare key – Zero/tare

No. Designation

15 Display for application programs

16 i/i Info key

17 c/c CF key

18 e/o On/off

19 S/a Totalization memory –

add

20 s/r Data output – total

21 z/T Start checkweighing

mode

22 o/t Store value in tare

memory

23 d/d Store ID for individual

output values

24 r/s Memory (recall/store)

25 Bar graph (linear range indicator)

26 Manufacturer’s label

27 Support arm

28 Threaded cap on the interface port

29 ID label

(only for scales verified for use in

legal metrology)

Note: The keypad overlay shown here is the version for use with -0UR models

in the US.

Page 9

!

Important Note to Users

Make sure to carefully read and follow sections

marked with this symbol – they contain important

safety instructions.

If you turn off the scale while it is running on power

supplied by the battery pack and the external AC

adapter YRB06Z is not plugged in for recharging,

make sure to turn off the battery pack as well.

Note:

(For QC 34 and QC 64 models only)

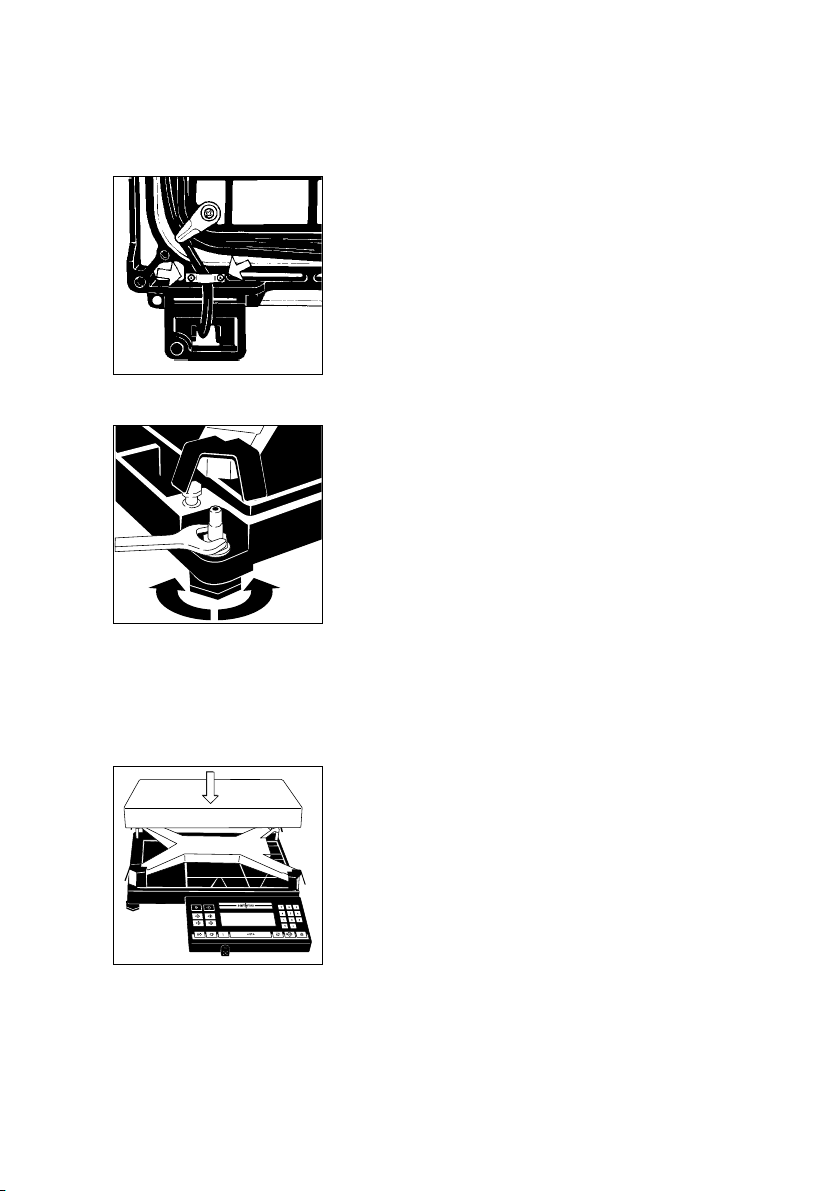

Transport Locking Device

Do not remove the transport locking device until the

scale is set up at the place of installation. Remove the

load plate.

The transport locking devices (yellow) are located on

the short sides of the scale.

Remove the transport locking devices (unfasten

them using an Allen wrench) before initially operating

the scale.

1–4

Verification Mark (Seal)

The law requires that a verified scale be sealed

with a verification mark. The verification marks

(seals) on a verified QC scale indicate that this scale

may only be opened and serviced by authorized

technicians, to ensure reliable and trouble-free

operation and to avoid forfeiture of the warranty

coverage. If a verification mark (seal) is damaged,

please observe the national laws and regulations

in effect at the place of installation.

Page 10

Installation Instructions

Please read these installation and operating

instructions carefully before you begin operating your

new scale.

Intended Use

The QC series counting scales are ideal for use in

production and in warehouse management. They are

designed primarily for counting parts of identical

weight and for the related applications: totalizing,

checkweighing, documentation, counting and

for storing data on articles weighed. You can connect

a PC (for remote operation of your scale or for

integration into a warehouse management system)

or any of a variety of accessory devices to the data

interface port of the scale (see the section entitled

“Accessories (Options)”).

If you are interested in using your Sartorius QC scale

for any other purpose, please contact your Sartorius

Service Center. Sartorius does not accept any liability

connected with the use of their scales for other than

their intended purposes.

Warranty

Do not miss out on the benefits of our full warranty.

Please complete the warranty registration card,

indicating the date of installation, and return the card

to your Sartorius office or dealer.

1–5

Page 11

Storage and Shipping Conditions

Allowable storage temperature: –40°C...+70°C

–40°F...+158°F

The packaging has been designed to ensure that

the scale will not be damaged even if it is dropped

from a height of up to 80 cm (about 31inches).

After unpacking the scale, please check it immediately

for any visible damage as a result of rough handling

during shipment.

If this is the case, proceed as directed in the section

entitled “Safety Inspection.”

Save the box and all parts of the packaging for any

future shipment of your scale. Before packing your

scale, unplug all cables to prevent damage. Replace

the screw cap (28) on the data interface port.

To ensure your scale’s long service life:

Do not expose the scale unnecessarily to extreme

temperatures, moisture, blows, shocks or vibration.

Note:

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant

to Part 15 of the FCC rules. These limits are designed

to provide reasonable protection against harmful

interference when the equipment is operated in a

commercial environment. This equipment generates,

uses and can radiate radio frequency energy and,

if not installed and used in accordance with the

instruction manual, may cause harmful interference

to radio communications. Operation of this

equipment in a residential area is likely to cause

harmful interference in which case the user will be

required to correct the interference at his own

expense. Changes or modifications not expressly

approved by Sartorius AG could void the user’s

authority to operate the equipment.

1–6

Page 12

Installation

Ambient Conditions

Sartorius QC scales are designed to provide reliable

weighing and counting results under normal ambient

conditions encountered in industrial environments.

When choosing a location to set up your scale,

observe the following so that you will be able to work

with added speed and accuracy:

–

Set up the scale on an even, stable surface (table or floor)

– Avoid extreme heat radiation from heaters

or direct sunlight

– Protect the scale from drafts that come through open

doors and windows

– Avoid areas that may subject the scale to extreme

vibrations during weighing

– Protect the scale from aggressive chemical vapors

The scale may not be used in hazardous

areas/locations where there is danger of explosion.

Do not expose the scale to extreme moisture over long

periods of time. Moisture in the air can condense on

the surfaces of a cold scale whenever it is brought to

a substantially warmer place. If you transfer the scale to

a warmer area, make sure to condition it for about 2 hours

at room temperature, leaving it unplugged from AC

power. Afterwards, if you keep the scale connected to

AC power, the constant positive difference in

temperature between the inside of the scale and the

outside will practically rule out moisture condensation.

Note for QC Models Verifiable for Use in Legal Metrology:

The scale can be adapted to your individual requirements through simple changes to code settings in the

scale operating menu. For more information, see the

section entitled “Scale Operating Menu.”

Preparing the Scale for Verification as a Legal

Measuring Instrument in the EU*:

After initially connecting the scale to the power

supply (or after a relatively long power outage),

allow the scale to warm up for at least 24 hours.

1–7

°C

Page 13

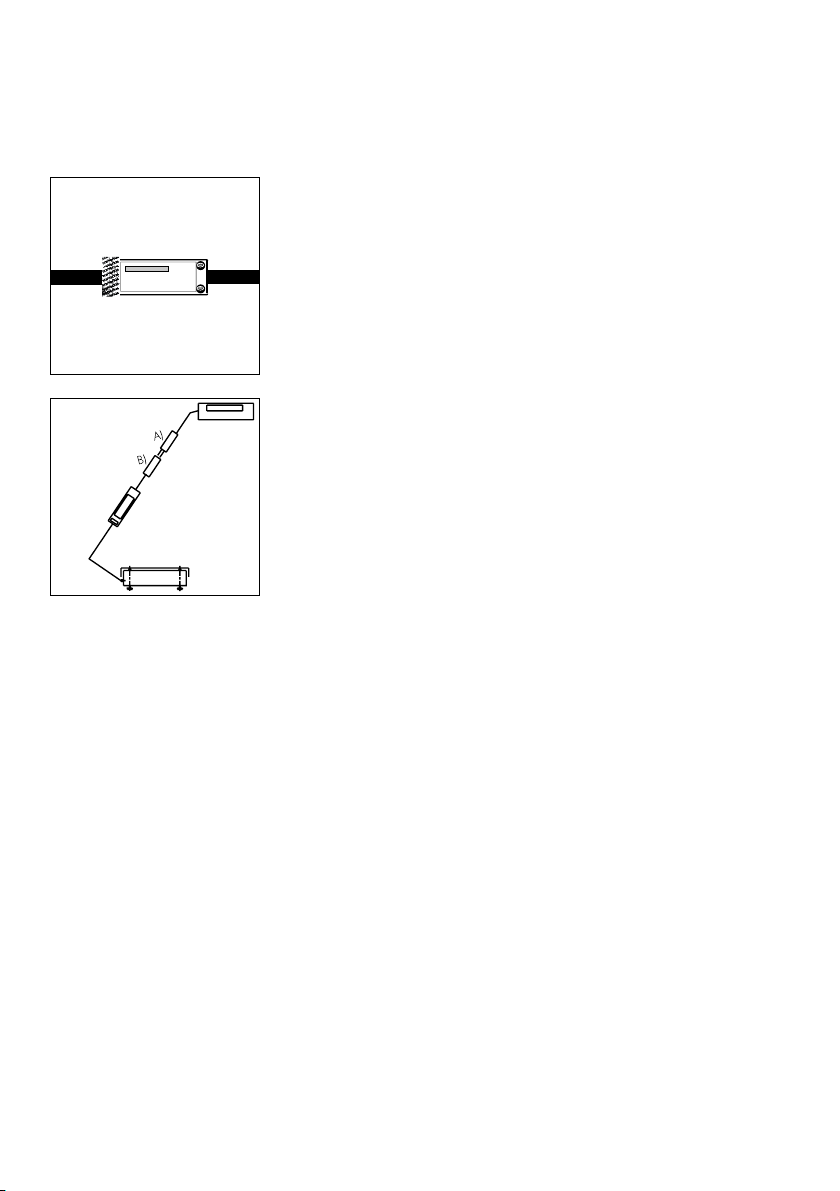

Check the serial number on the display unit of the QC

scale against the number on the tag ofthe scale cable.

Plug connector A into connector B.

Zone 2/Class I,Division 2 Hazardous Areas/Locations

You may operate the scale in a Zone 2 hazardous

area in Europe or in a Class I, Div. 2 hazardous

location (in the U.S. and Canada).

In this case, you must comply with the national electrical code and applicable safety regulations of your

country (in Germany, according to DIN VDE 0165).

For information on the legal regulations currently

applicable in your country, please ask your Sartorius

office or dealer.

To install the power supply, please read the instructions

in the section entitled “Getting Started.”

If you operate the scale in a Zone 2/Class I, Div. 2

hazardous area/location, you will need to observe

the installation conditions as described for the QC

display unit in the section entitled “Getting Started.”

The QC scale may not be operated in Zone 0,1, 20,

21 or22 hazardous areas/locations, as it does not

have an EX approval certificate for these areas.

1–8

* = including the Signatories of the Agreement on the

European Economic Area

Page 14

Any tampering with the QC equipment by anyone,

other than authorized by Sartorius service

technicians, will result in forfeiture of all claims under

the manufacturer’s warranty!

Fastening an Antitheft Locking Device

QC 7 Model:

To protect the scale from theft, attach it in a secure

location using the lug located at the back of the scale.

QC 34 and QC 64 Models:

Thread a commercially available bicycle lock through

one of the fins in the lower housing of the scale.

The QC scale along with an ING2 power supply

is suitable for use in the following hazardous area

within the European Community:

Zone 2, Group II, temperature class T4 according to

EN 60079-14

In countries other than Germany, the QC scale

may not be used in a Zone 2/Class I, Div. 2

hazardous area/location unless approval for use

in such hazardous areas has been granted by

the local authorities.

Pursuant to the German Directive for the

Implementation of Regulations for Prevention of

Accidents “Elektrische Anlagen und Betriebsmittel”

(VBG 4) (Electrical Installations and Equipment) of

April,1986, and in conjunction with Article 10

of the Low Voltage Directive 72/23/EEC issued on

February 19,1973, by the European Community,

it is hereby certified that the equipment delivered,

the QC scale and accessories, has been

manufactured and tested in compliance with the

following DIN/VDE regulations:

DIN EN 60950

DIN EN 61010

1–9

Page 15

Setting Up the Scale

– QC 7 Models:

Carefully unpack the scale and accessories.

Mounting the Display Unit on a Table or Wall

(optional; order no. YDH01TS)

– Remove the retainers (5) from the support arm

– Remove the display unit

1–10

– Unfasten the screws on the display unit (7) and

remove the retainers.

– Slide the clips (6) which hold down the cable in

the raceway (channel) up and out of the support arm;

then remove the cable from the raceway.

– Remove the support arm.

– Then slide the clips back onto the support arm.

– Fasten the display unit holder to the display unit

using the retainers (5)

Page 16

– Unfasten the retaining plate from the back

of the scale

– Unwind the cable as far as required and then

refasten the retaining plate

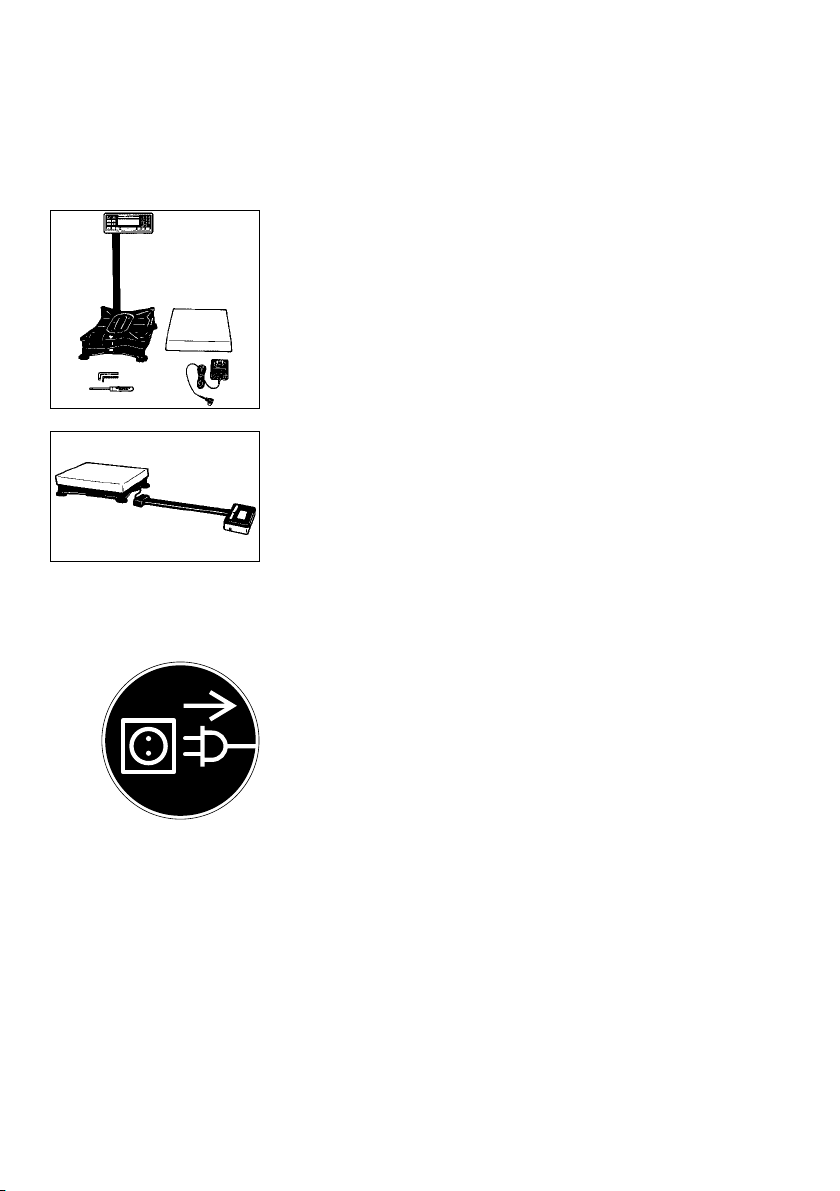

Leveling the Scale Using the Level Indicator

§ Level the scale using the level indicator as a guide.

$ Extend the leveling feet (turn clockwise)

to raise the scale

$ Retract the levelling feet (turn counterclockwise) to

lower the scale.

§ When the air bubble is exactly centered, use the

open-end wrench (spanner) to tighten the locknuts.

Important Note:

If you install the scale on a cart or trolley, it is sufficient

to level the scale once. Scales used as legal measuring

instruments are not allowed to be installed on a cart

or trolley!

§ Place the load plate on the scale base

1–11

Page 17

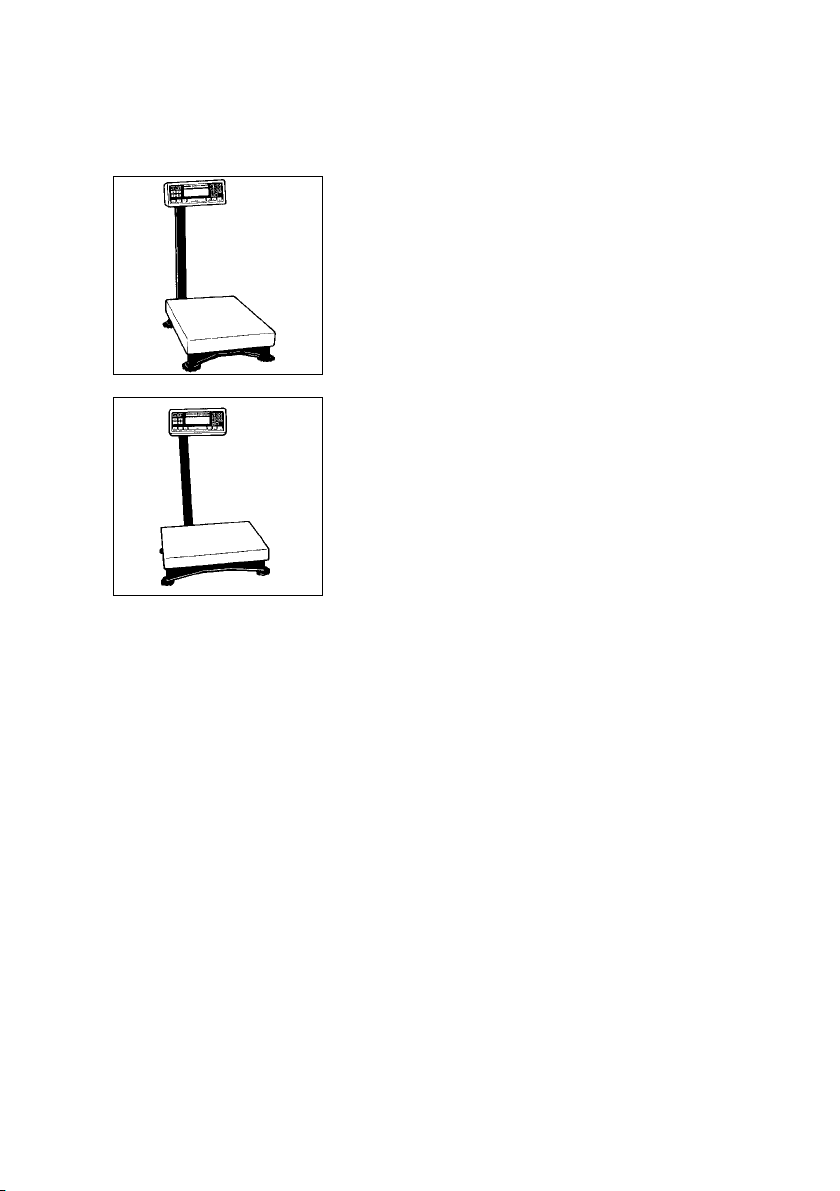

– QC 34 and QC 64 Models:

Carefully unpack the scale and accessories.

Place the scale on a table and lay the support arm

and display unit next to it.

! Always secure the transport locking devices before

any transport of your scale. Unplug the scale

from AC power and remove the load plate from the

scale before changing the display mounting.

1–12

Page 18

Mounting Options for the Display Unit

Note:

The following display mounting options apply

to QC 34 and QC 64 models only.

The display unit can be mounted as follows:

– on the short side of the scale (see page 1–14)

– on the back (long side) of the scale (see page 1–16)

– as a remote display unit (see page1–19 ); only

possible with the display holder which is available

as an option.

1–13

Page 19

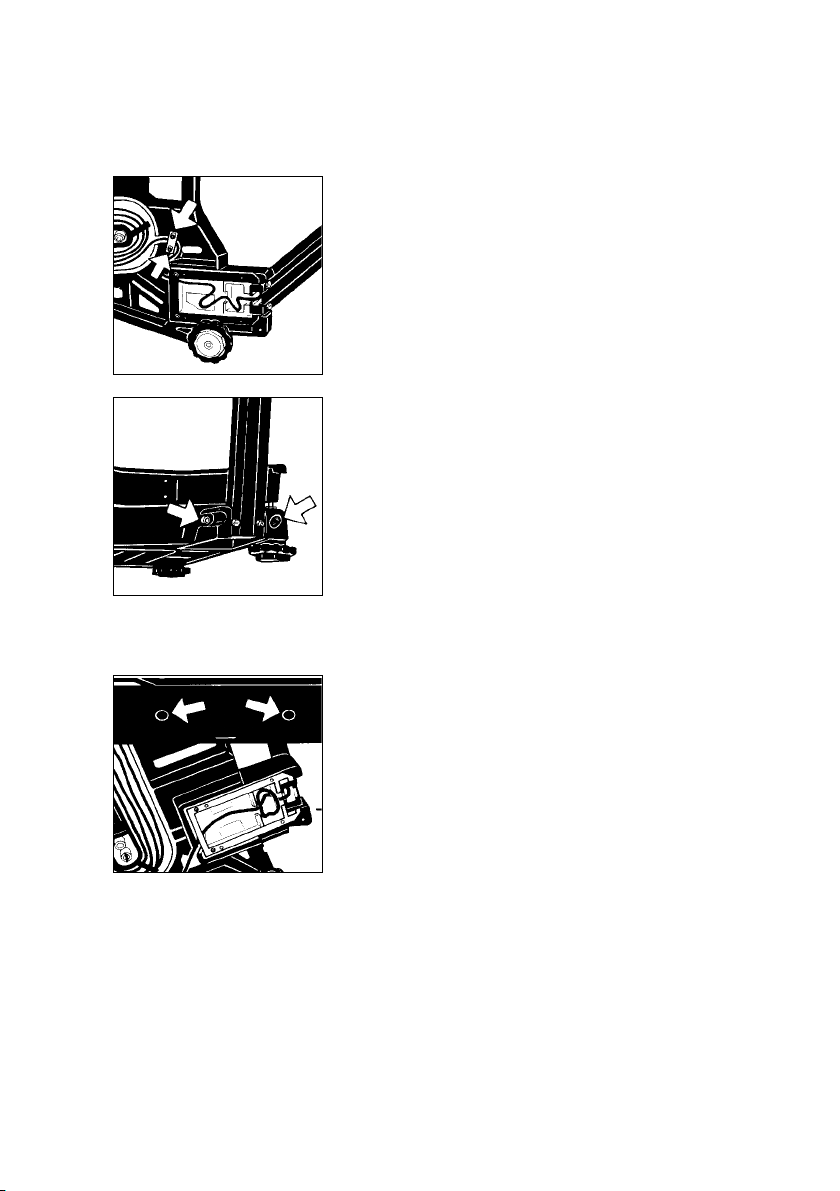

Mounting the Raised Display Unit on the Short Side

of the Scale

First, decide whether you want to mount the display on

the short side or on the back (long side) of the scale.

! Please follow the instructions given on page1–12

before you begin to change the display mounting.

Fasten the support arm to the base.

Note:

Use the center row of threaded drill holes when

inserting the screws.

Slide the clips into position to keep the cable from

slipping out of the raceway (channel).

1–14

Page 20

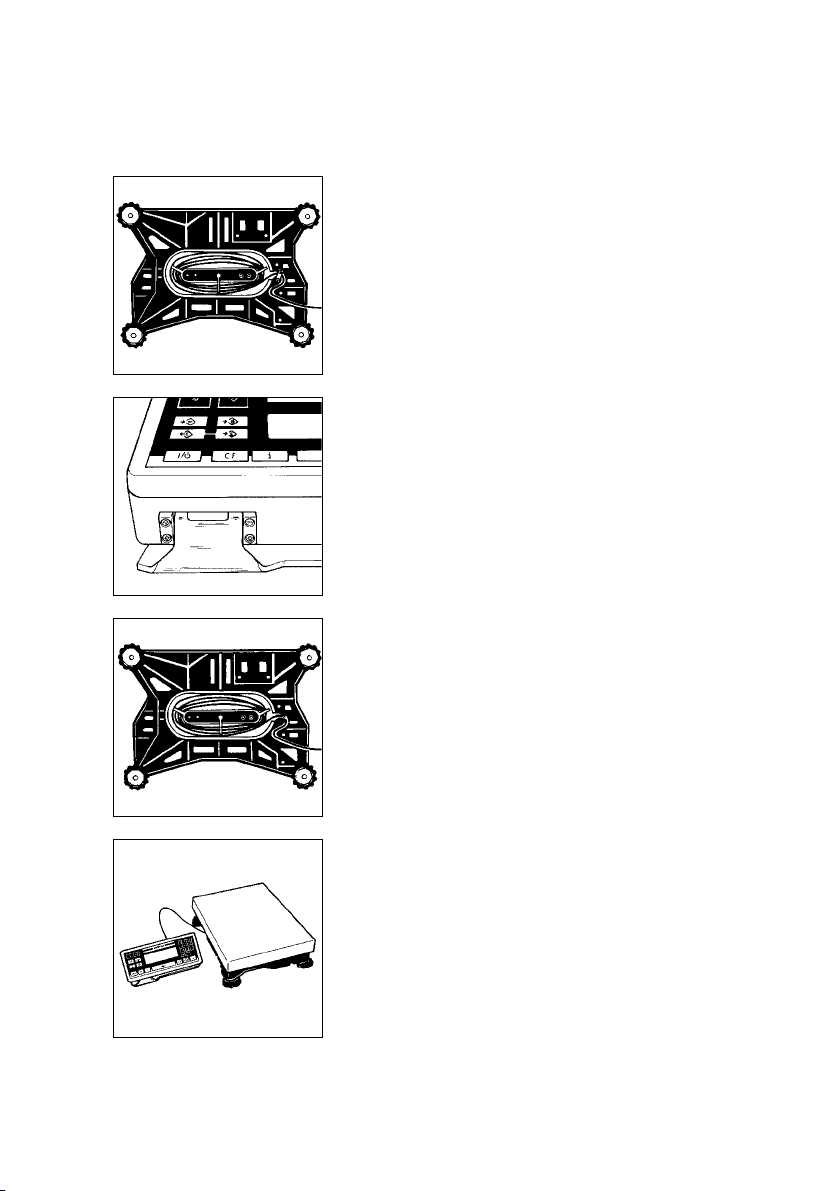

Scale with the display unit mounted on the short side.

Scale with the display unit mounted on the back

(long side).

Note:

The cable routing will have to be changed, depending

on the position of the display unit.

1–15

Page 21

Mounting the Raised Display Unit on the Long Side

of the Scale

Please be careful that the scale does not fall over

when disassembling and mounting the parts as

described here and in the following steps. Follow the

instructions given on page1–12 before you begin

to change the display mounting.

Lay the scale on its side to disassemble and mount the

display unit.

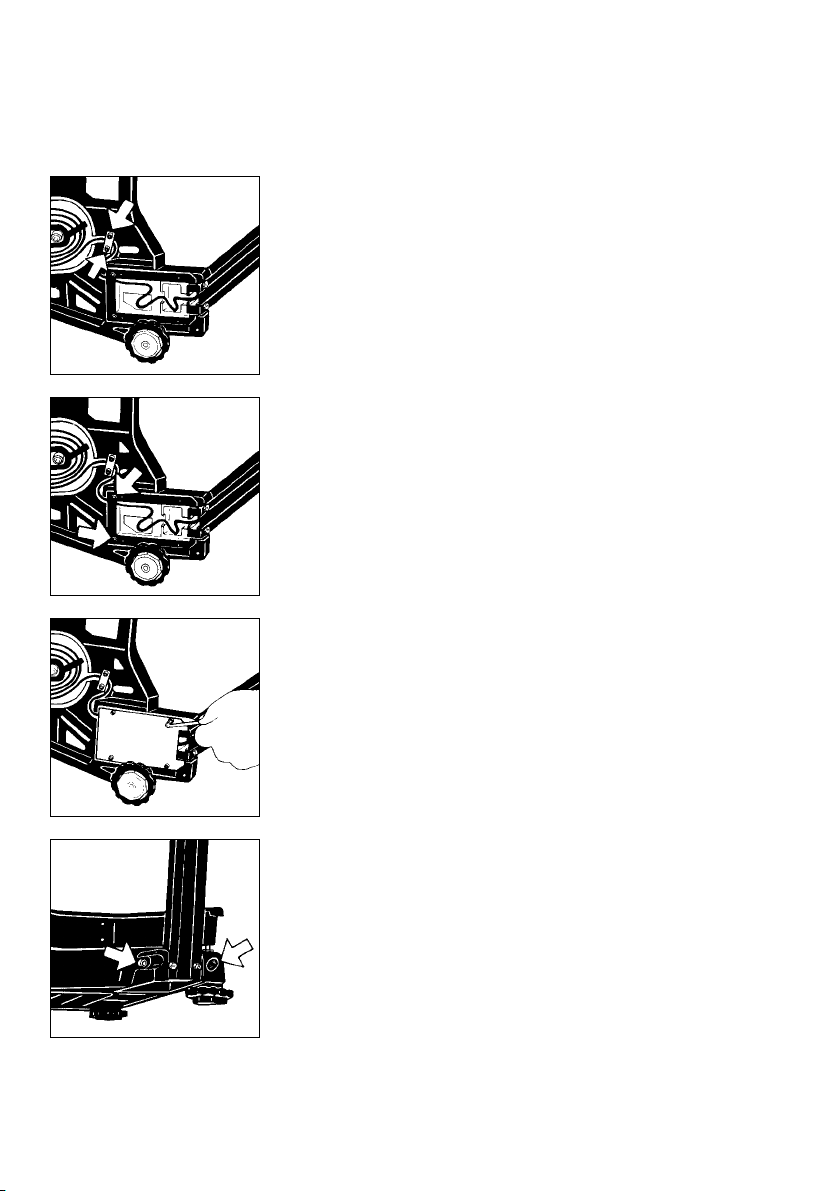

Unfasten the Allen screws on the base plate

and remove the base plate.

1–16

Remove the fastening screws.

Page 22

Remove the screws on the retainer plate.

Then set the scale back upright.

Remove the screws on the base (7).

Lay the support arm along with the base and the

display unit on a table.

Remove the plugs from the long side of the scale

(insert them in the holes on the short side). Loosely

attach the display unit with the support arm and base

to the long side of the scale with the Allen screws.

Lay the scale on its side again.

Thread the cable through the raceway.

1–17

Page 23

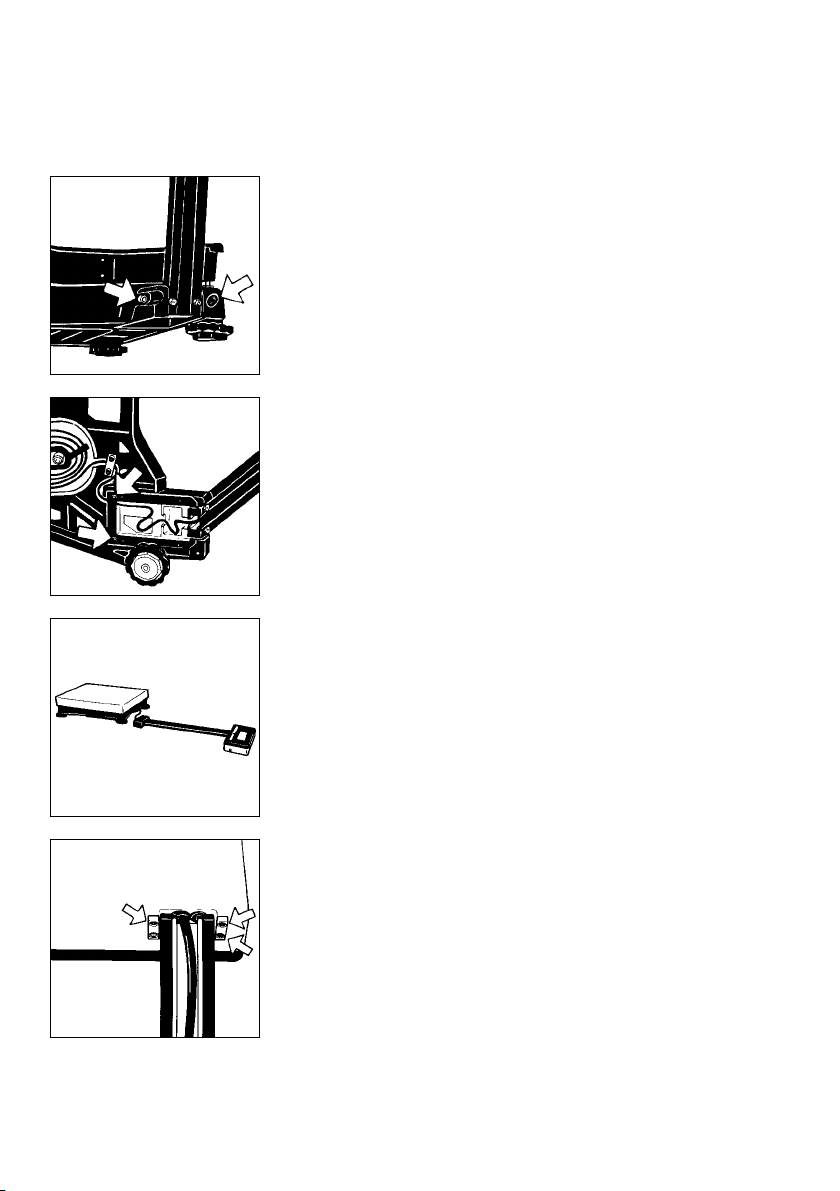

Refasten the retainer plate for the cable.

Refasten the frame with the fastening screws.

Refasten the base plate.

1–18

Set the scale back upright and tighten the Allen screws

on the base.

Follow these steps if you need to change the display

mounting again.

Page 24

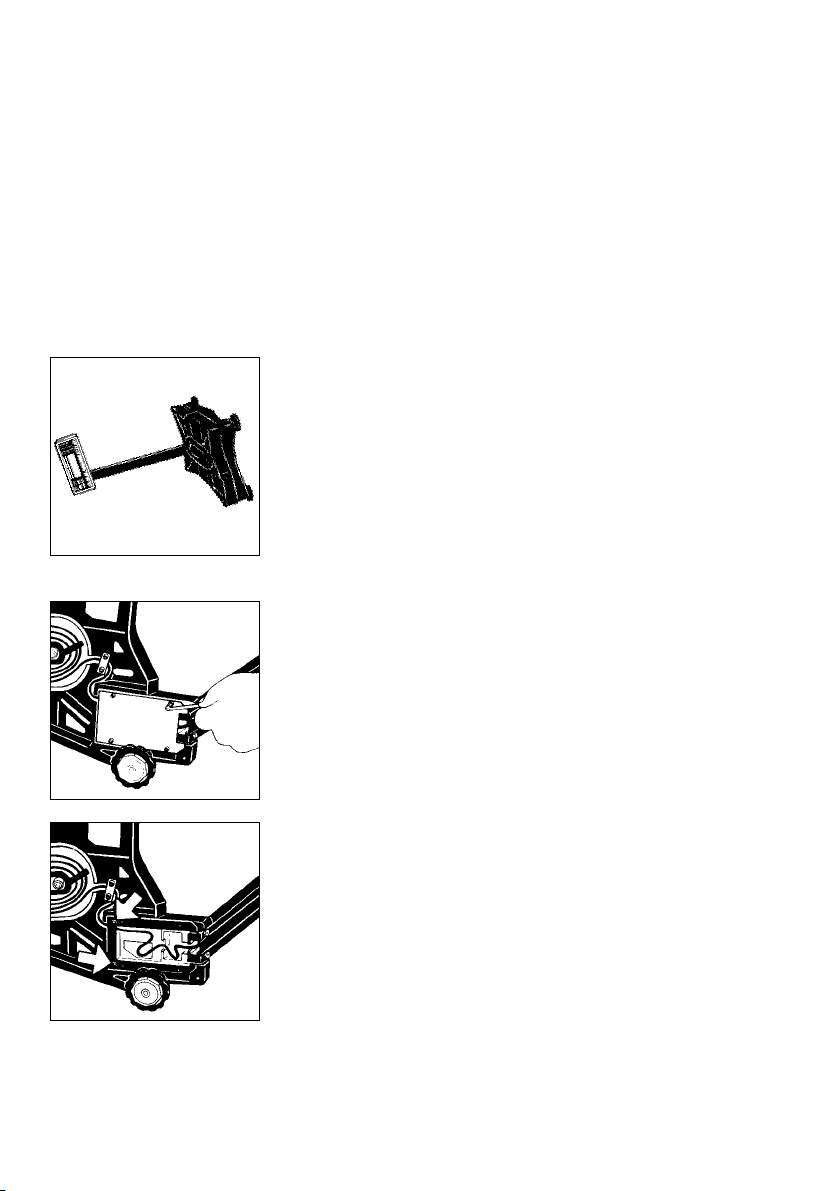

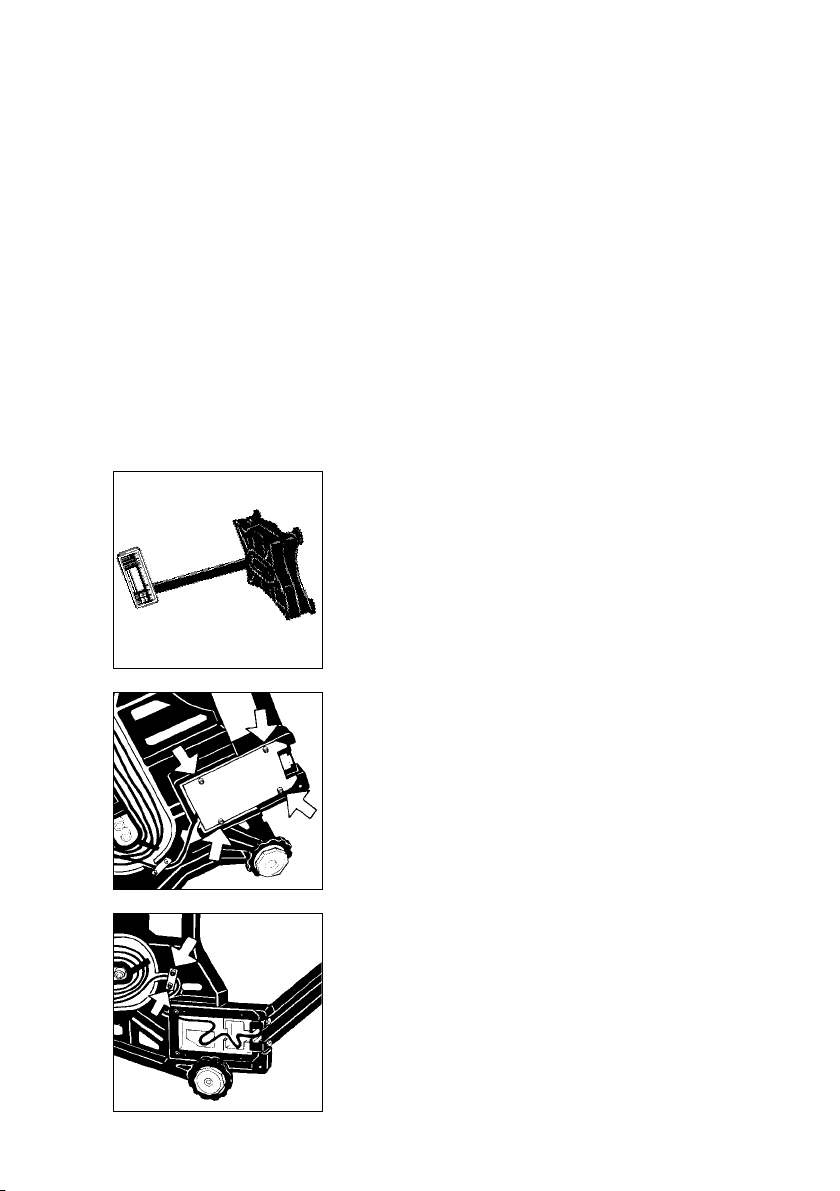

Mounting the Remote Display Unit (Option)

(only possible with the optional display holder;

order no. YDH01TS)

Note:

You can also mount the display as a remote unit

for the QC 7 model.

!

Please be careful that the scale does not fall over

when disassembling and mounting the parts as

described here and in the following steps. Follow the

instructions given on page1–12 before you begin to

change the display mounting.

Lay the scale on its side to disassemble and mount

the parts.

Unfasten the Allen screws on the base plate

and remove it.

Remove the screws on the retainer plate.

1–19

Page 25

Remove the screws on the base (7) (see diagram

on the left).

Then set the scale back upright.

Remove the fastening screws.

Lay the support arm along with the base and the

display unit on a table.

1–20

Unfasten the screws on the display unit (5) and remove

the retainers.

Slide the clips which hold down the cable in the

raceway up and out of the support arm.

Page 26

Unwind the cable as far as required.

Mount the display unit on the display holder using the

retainers you previously removed.

Now refasten the retainer plate for the cable.

Set the scale back upright.

1–21

Page 27

Getting Started

Set the load plate (3) on the scale.

Note:

(For QC 34 and QC 64 models only)

Transport Locking Device

Set up the scale at the place of installation and remove

the load plate. The transport locking devices (yellow)

are located on the short sides of the scale.

Remove the transport locking devices (unfasten

them using an Allen wrench) before initially operating

the scale.

1–22

!

Verification Mark (Seal)

The law requires that a verified scale be sealed

with a verification mark. The verification marks (seals)

on a verified QC scale indicate that this scale

may only be opened and serviced by authorized

technicians, to ensure reliable and trouble-free

operation and to avoid forfeiture of the warranty

coverage. If a verification mark (seal) is damaged,

please observe the national laws and regulations

in effect at the place of installation.

Save the box and all parts of the packaging for any

future shipment of your scale.

Place the load plate on the scale.

Level the scale at the place of installation using the

leveling feet.

Page 28

Using the Scale in Legal Metrology

(QC-...0CE Models)

* = Pursuant to Directive No. 90/384/EEC on non-automatic weighing instruments

Approved Auxiliary Measuring Devices

When using the load plate as a legal measuring instrument in the EU, you may

connect to it only auxiliary measuring devices that have been approved for

legal metrology. Metrologically relevant auxiliary devices, such as printers,

additional display units, etc., must be type-approved for this purpose and marked

by a green metrology sticker imprinted with a black “M.” The auxiliary device

must be verified in conjunction with the weighing instrument. If the auxiliary device

is connected at a later date to a weighing instrument that has already been used

in legal metrology, the responsible weights and measures office must be informed

of the addition of the auxiliary device. The auxiliary device can be used in legal

metrology, however, as soon as it has been properly connected if it has

the green metrology sticker with a black “M.”

Since the type-approval certificate for verification applies to non-automatic

weighing instruments only, you must comply with your country’s national

regulations that apply to the place of installation of your weighing instrument for

automatic operation with or without auxiliary devices installed.

To Be Filled Out by the Service Representative Authorized to Perform the

Initial Verification*:

Verified on (date):

The verification is valid for the following scale location:

Company/Name:

Serial no.:

Address:

City/Post code:

Country:

or Zone:

As a weighing instrument, the QC is not allowed to be used for weighing goods

intended for direct sale to the public, nor may it be used as a legal measuring

instrument until it has been initially verified by Sartorius. If the scale is moved, it

must be verified again at its new location. In this case, the scale must be

verified and stamp-approved at the new location by your local weights and

measures office.

1–23

Page 29

Connecting the Scale to AC Power

The scale is powered by an AC adapter supplied with the scale. Make sure that

the voltage rating printed on this unit is identical to that of your local line voltage.

If the voltage specified on the label or the plug design of the AC adapter do not

match the rating or standard you use, please contact your Sartorius office or dealer.

When you use the scale and associated equipment, you must comply with the

national electrical code and applicable safety regulations of your country.

If you use the QC scale in a Zone 2/Class I, Div. 2 hazardous area/location,

make sure to comply with the valid standards and regulations of your country,

applicable to the installation of equipment in a Zone 2/Class I, Div. 2 hazardous

area/location, e.g. in Germany with ElexV from 27.02.1980 (BGBI. I, P.214).

Only authorized technicians are allowed to install the equipment

in a Zone 2/Class I, Div. 2 hazardous area/location.

The female plug of the power cable must be securely fastened to the male socket

on the QC display unit. On the other end of the power cable,

– either an explosion-proof plug-and-socket connection must be installed

– or the plug must be detached from the power cable and the power cable

securely connected to a suitable junction box.

(Wiring Diagrams for Connecting the Scale

to the AC power in Zone 2/Class I, Div. 2 Hazardous Areas/Locations)

Brown (live (L))

Blue (neutral (N))

Yellow/green (grounding conductor)

Hook up the scale to the power supply in conformance with the installation

requirements of your country.

1–24

Page 30

The IP 65-protected ING-2 no. 69 71899 AC adapter

is completely encapsulated and can be installed as a

stationary unit. To use a main feeder cable from the

ceiling or to mount a CEE plug, you will have to make

arrangements.

The IP 65 protection rating is ensured only if the square

rubber gasket is installed and the plug is connected

securely to form a hak-tight seal.

Ensure IP protection (Tighten the screw).

IP65 Protection (Painted Models) or IP67 Protection

(Stainless Steel FEP-I, IGP-I, FES-I and IGS-I Models)

The weighing platform is dusth-tight and washdownresistant in conformity with the IP65 or IP67 protection

rating, depending on the model.

Legend to Protection Ratings

First digit: rating 6 indicates resistance to penetration

by dust particles of a specified size. Second digit:

rating 5 indicates resistance to splashes of water,

as well as washdown-resistance. Rating 7 indicates

resistance to penetration by water during 30 minute

immersion up to a depth of 1meter (apporoximately

31/4feet).

IP65 or IP67 protections is only guaranteed if:

– the junction box seal was installed by a qualified

technician, and

– the connecting cables and cable glands were

installed and connected by a qualified technician.

1–25

Page 31

!

Use only original Sartorius AC adapters. Use of AC

adapters from other manufacturers, even if these units

have a registered approval rating from a national

testing laboratory, requires the approval of an

authorized Sartorius service technician.

To operate the scale using an external rechargeable

battery pack, see the section entitled “Accessories

(Options)”.

First insert the right-angle plug into the jack on the scale

as shown (2) and tighten the screw.

The IP 65 protection rating is ensured only if the square

rubber gasket is installed and the plug

is connected securely to form a leak-tight seal.

Installation within Safe Areas:

Plug the AC adapter into a wall outlet (mains).

Note:

Thread the AC adapter cable through the channel

(raceway) on the support arm (27).

Slide the clips (6) into position to keep the cable from

slipping out of the raceway.

1–26

Safety Precautions

The AC adapter, rated to Class 2 (double insulation)

can be plugged into any wall outlet without taking any

additional safety precautions. The pole of the output

voltage is connected to the scale housing, which can

be grounded for operation.

The interface is also electrically connected to the

scale housing (ground) (see also “Data Interface” on

page1–39).

Page 32

Connecting Electronic Peripheral Devices

Make absolutely sure to unplug the scale from the

power supply before you connect or disconnect

a peripheral device (e.g. printer, PC, etc.) to or from

the interface port.

Adjusting the Display Unit

Adjust the display unit to the position desired.

If you use the QC scale in a Zone 2/Class I, Div. 2

hazardous area/location, the QC equipment must

be completely disconnected from AC power before

you connect or disconnect any cables to or from

the equipment. The same applies to all accessories

operated with the system.

1–27

Page 33

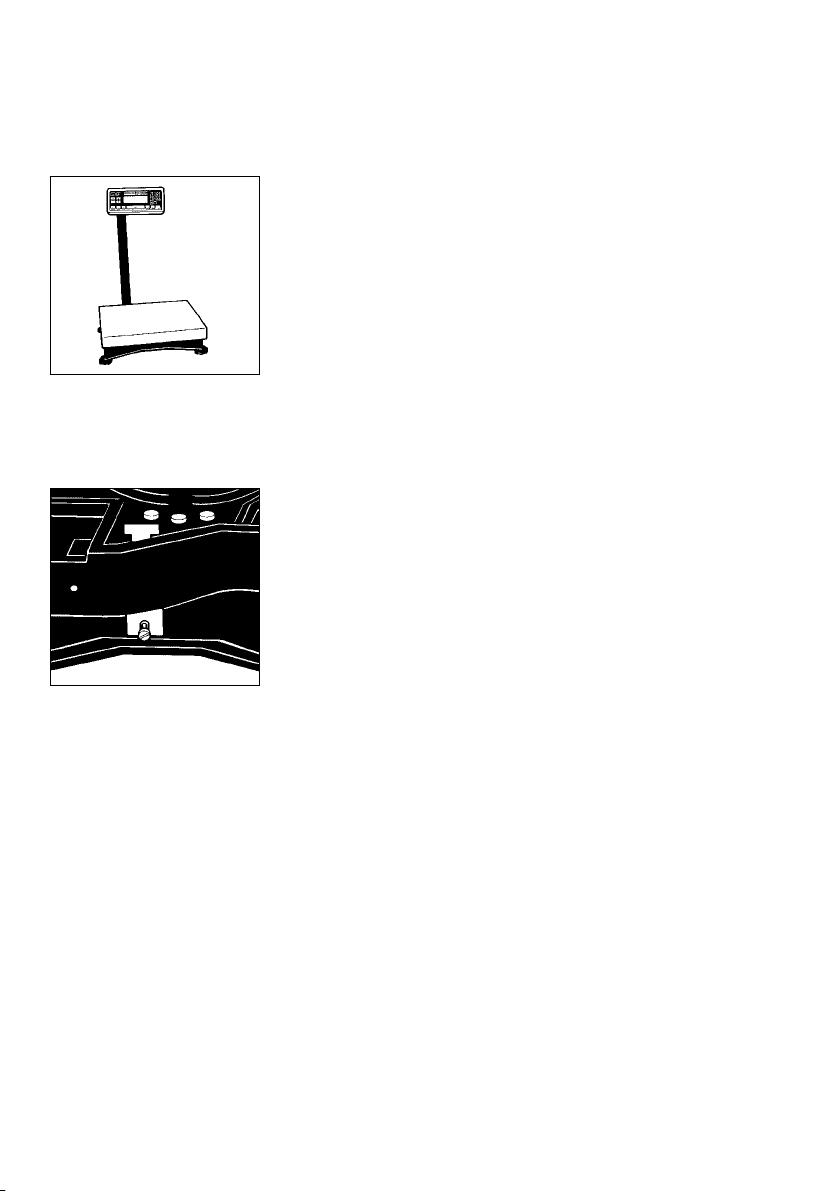

Leveling the Scale Using the Level Indicator

At the place of installation, level the scale using the

leveling feet (4) as follows, so that the air bubble is

centered within the circle of the level indicator (8).

Then check to make sure that all four feet are resting

on the surface of the benchtop (stability test).

Extend leveling feet (turn clockwise) to raise the scale.

Retract leveling feet (turn counterclockwise) to lower

the scale.

Note:

When installing the scale on a transportable cart,

a single setting is sufficient.

Equipment used as a legal weighing instrument is not

allowed to be installed on a ramp.

Installing a Drive-on Ramp

(For the models FEP-I, IGP-I, FES-I und IGS-I)

The drive-on ramp must be installed and put into

operation by a trained Sartorius dealer or service

technician.

See the table in the “Accessories” list to order the

drive-on ramp suited for use with your weighing

platform.

1–28

Page 34

Declaration of Conformity

CE Marking of Sartorius Devices

In 1985, the Council of the European Community approved a resolution

concerninga new approach to the technical harmonization and standardization

of national regulations. The organization for monitoring compliance with the

directives and standards concerning C marking is governed in the individual

EU Member States through the implementation of the EC Directives adopted

by the respective national laws.

Sartorius complies with the EC Directives and European Standards in order to

supply its customers with weighing instruments that feature the latest advanced

technology and provide many years of trouble-free service.

The C mark may be affixed only to weighing instruments and associated

equipment that comply with the applicable Directive(s):

Council Directive 89/336/EEC “Electromagnetic Compatibility (EMC)«

This Directive regulates the use of equipment that can cause electromagnetic

interference or whose functioning can be influenced by such interference:

The safety requirements are

– limitation of emissions

– defined immunity to interference

The Declaration of Conformity is included in this manual.

For further information concerning C marking on Sartorius equipment,

please request the corresponding brochure available under publication no.

WYD6056-p98023.

Important Note:

Additional instruction manual(s) that belong to these Operating Instructions:

Guide to Verification of Weighing Instruments with the YCO01IS-0CE or

YCO02IS-0CE.

Please carefully read, complete and file this Guide

1–29

Page 35

C Marking

The C marking affixed to the equipment indicates that the equipment meets the

requirements of the following Directive(s):

Council Directive 89/336/EEC “Electromagnetic compatibility (EMC)”

This Directive regulates the use of equipment that can cause electromagnetic

interference or whose functioning can be influenced by such interference.

Applicable European Standards:

Limitation EN 50081-1 Residential, commercial and

of emissions light industry

EN 50081-2 Industrial environment

Defined immunity EN 50082-1 Residential, commercial and

to interference light industry

EN 50082-2 Industrial environment

Important Note:

The operator shall be responsible for any modifications to Sartorius equipment

and for any connections of cables or equipment not supplied by Sartorius and must

check and, if necessary, correct these modifications and connections.

On request, Sartorius will provide information on the minimum operating

specifications (in accordance with the Standards listed above for defined immunity

to interference).

Council Directive 73/23/EEC

“Electrical equipment designed for use within certain voltage limits”

Applicable European Standards:

EN 60950 Safety of information technology equipment including

electrical business equipment

EN 61010 Safety requirements for electrical equipment for measurement,

control and laboratory use

Part 1: General requirements

If you use electrical equipment in installations and under ambient conditions

requiring higher safety standards, you must comply with the provisions as specified

in the applicable regulations for installation in your country.

1–30

Page 36

Weighing Instruments for Use in Legal Metrology:

Council Directive 90/384/EEC

“Non-Automatic Weighing Instruments”

This Directive regulates/the determination of mass in

legal metrology.

For the respective Declaration of Conformity for

weighing instruments that have been verified by

SARTORIUS for use as legal measuring instruments

and that have an EC Type-Approval Certificate,

see the next page.

This Directive also regulates the performance of the

EC verification by the manufacturer, provided that an

EC Type-Approval Certificate has been issued and

the manufacturer has been accredited by an officer of

a Notified Body registered at the Commission of the

European Community for performing such verification.

The legal basis allowing Sartorius to perform EC

verification is constituted by the EC Council Directive

No. 90/384/EEC on non-automatic weighing

instruments that has been in effect since January 1,

1993, in the Internal Market as well as by the

Certificate of Accreditation of the Sartorius AG

Quality Management System issued by the Metrology

Department of the Regional Administration Office of

Lower Saxony, Germany (“Niedersächsisches

Landesverwaltungsamt – Eichwesen”) on February

15, 1993.

For information on the C mark on Sartorius

equipment and legal regulations currently applicable

in your country, and to obtain the names of the

persons to contact, please ask your local Sartorius

office, dealer or service center.

1–31

Page 37

Declaration of Type Conformity

1–32

Page 38

1–33

EC Type-Approval Certificate

Page 39

“EC Verification” –

a Service Offered by Sartorius

Our service technicians authorized to perform the

verification* of your weighing instruments that

are acceptable for legal metrological verification can

inspect and verify the metrological specifications

at the place of installation within the Member States

of the European Union and the Signatories of the

European Economic Area.

“New Installation” Service

Initial verification is covered in our “New Installation”

service package. In addition to initial verification, this

package provides you with a series of important

services which will guarantee you optimal results in

working with your weighing instrument:

− Installation

− Startup

− Inspection

− Training

− Initial verification

Subsequent Verifications within the

European Countries

1–34

The validity of the verification will become void in

accordance with the national regulations of the

country in which the weighing instrument is used. For

information on verification and legal regulations

currently applicable in your country, and to obtain the

names of persons to contact, please ask your local

Sartorius office, dealer or service center.

* in accordance with the accreditation certificate

issued to Sartorius AG

Page 40

Operating the Scale

Turning the Scale On and Off

Press the e/o key (18) to turn the display on

and off.

Self-Test

When the scale is switched on, an automatic self-test

of the scale’s electronic circuitry is performed.

At the end of the self-test, a zero readout is displayed.

This means that the scale is ready for use.

If an error is found during the self-test, the display

reads: “Err xx”.

Note:

If the “Err xx” error code is displayed, see the

“Troubleshooting Guide” in this manual.

For verified scales QC 7CCE-S0CE and

QC 64EDE-S0CE, which have a verification scale

interval “e” that is greater than the scale interval “d,”

the last digit on the display is bordered.

The display shows the following special codes

for your information:

OFF*

displayed in the upper right corner indicates that the

scale was disconnected from AC power (scale

reconnected to AC power or power outage longer

than 3 seconds).

O* displayed in the lower left corner means Stand-by

The display has been turned off by pressing e/o

(18), or the scale shut itself off automatically (see Scale

Operating Menu). The scale is now in the ready-tooperate mode and does not need to warm up.

* depends on the “Power-On Mode” setting in the

scale operating menu

O

OFF

1–35

▼

Page 41

b

b means Busy

Once you turn on the scale, the b symbol is

displayed until you press a key. During operation, this

symbol indicates that the scale is still busy processing

a function and will not accept another command to

perform any other functions at this time.

Important Note Concerning Scales Verifiable for Use

as Legal Measuring Instruments:

A weight readout can be displayed in grams “g”

or kilograms “kg” (depends on model).

In addition to grams and kilograms, you can also

weigh in other international weight units on all

standard scales. See the “Scale Operating Menu”

in Part 2 of this manual.

For verified scales QC 7CCE-S0CE and

QC 64EDE-S0CE, which have a verification scale

interval “e” that is greater than the scale interval “d”,

the last digit on the display is bordered.

Taring

A weight can be determined with accuracy only from

a defined zero point. Press the =/z key (14) to

zero the weight display. You can tare within the

▼

entire weighing range of the scale.

1–36

Simple Weighing

Place your sample on the load plate (3) to determine

the weight. Read off the weight indicated on the

display only after the weight unit “g” or “kg” appears

as the stability symbol.

Page 42

Calibration/Adjustment

“Calibration” technically means to determine the

difference between the scale readout and the actual

weight on the platform to determine the accuracy.

Adjustment means to bring a scale to the level

of accuracy required for its use.

Note:

For 0CE-series scales, the calibration function is sealed

and locked after verification.

You must adjust or calibrate your new scale at the

place of installation after each warmup period and

before the first measurement. You must also re-adjust

or recalibrate your scale each time you set it up

in a different area or when the ambient conditions

change (especially the temperature).

Menu code: 1 9 1*

Use only calibration weights with an accuracy equal

to or better than the readability of your scale.

You can find an overview of the calibration weight

sets available in the section entitled “Accessories

(Options).” You need an exact calibration weight.

Type QC7CCE-S QC34EDE-S QC64EDE-S

Weight (g) 1x5,000 1x10,000 2 x10,000

Accuracy

class F1 F1 F1

* = factory setting

1–37

Page 43

When a zero readout is displayed, press the

=/z key (14). This starts calibration. The

▼

calibration weight is displayed in grams.

Errors or interference at the start of the calibration

routine are indicated by the error code “Err 02.”

If this is the case, tare and press the =/z key

again when a zero readout appears.

Center the calibration weight on the load plate.

The scale then calibrates automatically. At the end of

calibration, the calibration weight readout and the

stability symbol “g” or “kg” are displayed.

Blocking the Calibration Functions

You can block the calibration functions by setting

code 1 9 7.

1–38

Page 44

Data Interface

If you wish to record weighing data using a Sartorius

Data Printer, plug the YCC01-0016M3 data cable

into the interface port (28) of the scale. You do not

need to adjust any settings!

Connecting Electronic Peripheral Devices

Make absolutely sure to unplug the scale from AC

power before you connect or disconnect a peripheral

device (printer or PC) to or from the interface port.

The IP 65 protection rating is ensured only if

the square rubber gasket is installed and the plug is

connected securely to form a leakproof seal.

Unscrew the protective cap (28) that covers the data

interface port.

Note:

Keep the protective cap in a safe place where it will

not get lost!

– Plug the connector into the interface port

– Secure the connector with the screw ring

1–39

Page 45

Note:

If you use the QC scale in a Zone 2/Class I, Div. 2

hazardous area/location, the QC equipment

must be completely disconnected from AC power

before you connect or disconnect any cables

to or from the equipment. The same applies to all

accessories operated with the system.

Press the p/p key (11) to output data.

For information on data output parameters and data

ID codes, see the section entitled “Utilities for Printouts

or Data Transfer.” For details on the data interface

(such as the data output or input format, pin

assignment, etc.), see Part 4, “General Description of

the Data Interface.”

Interfacing Devices with the Scale

Please note that the interface port is electrically

connected to the protective grounding conductor of the

scale housing. The interface cables supplied as

standard equipment are shielded and both ends of

each cable are electrically connected to the connector

cases. This connection may result in interference

caused by ground loops or by transient currents if you

have grounded the housing or connected the

protective grounding conductor for line power.

If necessary, connect an equipotential bonding

conductor to the scale.

1–40

Page 46

Troubleshooting Guide

Problem Causes Solution

No segments – No AC power is available – Check the AC power

appear in the weight supply

display (1) – The AC adapter is not – Plug in the AC adapter

plugged in

The weight display – The load exceeds the – Unload the scale

shows “H” capacity of the scale

The weight display – The load plate (3) – Position the platform

shows “L” or “Err 54” is not in place

The weight display – The display did not show – Press the =/z

briefly shows “Err 02” a zero readout when the key (14); then press the

=/z key (14) =/z key again

was pressed to calibrate and hold it until

the calibration weight

is displayed

– The scale is loaded – Unload the scale

The special code “b” – None of the keys has – Press a key

remains displayed been pressed since the

scale was turned on

The weight readout – Unstable ambient conditions – Set up the scale

changes constantly in another area

– Too much vibration, or the – Access the menu to

scale is exposed to a draft select the correct code

for the weighing

environment (e.g.11 4)

The scale cannot – There is a foreign object – Remove the foreign

be stabilized between the load plate object

and the scale housing

The weight readout – The scale is not calibrated – Calibrate the scale

is obviously wrong (see page1–36)

– The scale was not tared – Tare before weighing

before weighing

– The air bubble of the – Level the scale

level indicator (8) is not (see page1–27)

within the circle

1–41

Page 47

Care and Maintenance

Service

Regular servicing by a Sartorius service technician

will extend the service life of your scale and

ensure its continued weighing accuracy. Sartorius can

offer you service contracts, with your choice of

regular maintenance intervals ranging from 1 month

to 2 years.

Cleaning

Before cleaning the scale, unplug the AC adapter

from the wall outlet.

Please do not use any aggressive cleaning agents

(solvents or similar agents). Instead, use a piece

of cloth which has been wet with a mild detergent

(soap). Make sure that no liquid enters the scale

housing. After cleaning, wipe the scale down with

a soft, dry piece of cloth.

1–42

Note:

If the water that you use to clean the scale is too hot or

cold, the difference in temperature between the water

and the scale can cause condensation within the

scale (according to EN 60529 on IP65 protection).

This condensation may cause the scale to malfunction!

Page 48

Safety Inspection

If there is any indication that safe operation of the

scale with the AC adapter is no longer warranted,

turn off the power and disconnect the equipment from

AC power immediately. Lock the equipment in

a secure place to ensure that it cannot be used for the

time being.

Safe operation is no longer ensured when

– there is visible damage to the AC adapter

– the AC adapter no longer functions properly

– the AC adapter has been stored for a relatively

long period under unfavorable conditions.

Instructions for Recycling the Packaging

To ensure safe shipment, your scale has been

packaged using environmentally friendly materials.

After successful installation of the equipment, you

should return this packaging for recycling.

For information on recycling old weighing equipment,

consult your communal or municipal waste disposal

center or local recycling depot.

1–43

Page 49

Scale Operating Menu

Changing Settings in the Scale Operating Menu

In the operating menu, you can define how your scale will adapt to ambient

conditions and also how it will work to meet your special requirements.

The factory settings of the scale operating menu are identified by an “*”. You can

select the functions not identified by an “*” by setting the respective menu codes.

You can find the codes in the section entitled “Scale Operating Parameters” which

starts on page 2 - 4. If you need to change any of the factory settings, we

recommend that you enter these changes along with the date in the column headed

by “Changes.”

The keys have special functions for setting

menu codes:

u/w (12) = Increases a number by one with

each press (the numbers change

in cycles)

=/z (14) = Confirms a code setting; stores a

code setting and exits the menu

p/p (11) = Moves to the next of the three

numbers of a code

(1st – 2nd –3rd – 1st – etc.)

Now try changing a code to adapt your scale

to a special power-on mode. The code for “Automatic

power-on” is 8 5 4.

Changing Menu Code Settings

To select specific functions, you will need to change

the respective menu code.

There are three steps to changing a code:

– Accessing the menu

– Setting the code

– Confirming and storing the code

2–1

Page 50

Accessing the Menu

– Press e/o (18) to turn off the scale.

Turn the scale back on.

– While all segments are displayed, briefly hold

down the =/z key (14).

C

▼

– Release when “1” (“–C–”) is displayed.

Note:

If you use the scale as a legal measuring instrument,

the “external calibration” function is blocked.

Only menu items that are permitted for scale

▼

operation in legal metrology can be read and

changed by the user!

– Press u/w (12) until “8” appears.

▼

– Press p/p until the 2nd number of the

code appears.

▼

▼

– Press u/w until “5” appears

– Press p/p until the 3rd number appears

(when you move to this number, the previously set

menu code will appear).

▼

▼

– Press u/w to select “4.”

– Confirming Code Changes

Press =/z (14 ) to confirm the code you have

just set (this is indicated by the “o” after the code).

Note:

▼

– To store the new menu code setting, press

=/z (14) for more than two seconds until the

self-test function starts.

2–2

Page 51

Important Note:

Changes to the code settings are not stored if you

turn off the scale by pressing e/o while selecting

the code numbers or before saving a setting.

The current menu setting in the scale operating menu

is identified by a small, superscript “o” after the last

number. When you access the operating menu,

the previously set code will be displayed after you

have selected the right-hand number, which means the

entire menu code setting is displayed. This makes it

easy for you to check the previously set codes.

If you want to change several menu code settings,

you do not have to press =/z (14) after each

change to exit the scale operating menu. You can

also confirm individual settings.

Undoing All Menu Code Changes – Reset Function

The reset function lets you undo all menu code

changes, which means you will obtain the original

factory-set menu codes identified here by an “*”.

To use this function, select code 9 – – 1°.

For information on confirming and storing menu code

settings see the previous page.

2–3

Page 52

Scale Operating Parameters

Adapting the Scale to Ambient Conditions

The scale can be adapted to the prevailing ambient conditions at the place

of installation.

Code Changes

Very stable conditions 1 1 1

Stable conditions 1 1 2 *

Unstable conditions 1 1 3

Very unstable conditions 1 1 4

Standard Weighing Mode – Manual Filling Mode

You can optimally adapt your scale to meet either of these requirements.

In the manual filling mode, the display compensates for fluctuations of the load

on the scale, giving you especially fast and stable readouts.

Code Changes

Standard weighing mode 1 2 1 *

Manual filling mode 1 2 2

(e.g. if you need to package screws in certain quantities)

Stability Range

The stability symbol will remain displayed in the case of a weight variation +/–.

Code Changes

0.25 digit 1 3 1

0.5 digit 1 3 2 ***

1 digit1) 133

2 digits1) 1 3 4 * (**)

4 digits2) 135

8 digits2) 136

* Settings for standard models

** Settings for QC 7CCE-S0CE and QC 64EDE-S0CE models

*** Settings for QC 7-,34-,64- L0CE and QC 34EDE-S0CE models

1

) blocked for all verifiable models of accuracy class m.

2

) blocked for all verifiable models

2–4

Page 53

Stability Symbol Delay

This setting allows your scale to compensate for individual interfering factors

which slowly subside. You will not need to make any changes in this code setting,

as a rule.

Code Changes

No delay 1 4 1

Short delay 1 4 2 *

Long delay 1 4 3

Extremely long delay 1 4 4

Tare Parameter

You can define when the scale will perform the taring operation.

Code Changes

At any time1)151

Not until the readout is stable 1 5 2 *

Auto-Zero Function

When this zero tracking function is activated, any changes off the zero readout

that are equal to a defined fraction of digits per second are automatically tared.

If the deviation is less than the defined fraction, the internal taring function of

the scale will be initiated (e.g. 0.5 digit per second). In other words, it ensures

a stable zero.

Code Changes

Auto-Zero on 1 6 1 *

Auto-Zero off 1 6 2

1

) blocked for all verifiable models

*= factory setting

2–5

Page 54

Calibration/Adjustment and Linearization Functions Using the =/z Key

(hold down key for more than 2 seconds)

Important Note:

For verifiable scales used as legal measuring instruments the menu access switch is

blocked and sealed. The external calibration is not permitted.

External Calibration and/or Linearization

The weights to be placed on the scale for linearization are indicated in the display

one after the other, in increasing order.

Calibration/adjustment and linearization Code Changes

External calibration 1 9 1 *

External linearization 1 9 5

Adjustment/calibration function blocked 1 9 7 **

* = factory setting

** = blocked for all veryfiable models

2–6

Page 55

Weight Units

Note:

For verified scales approved for use as legal measuring instruments all weight units

except g/kg are blocked.

Code*** Symbol Conversation factor Code Changes

1g =

User-definable unit *** 1. 1 7 1

Grams g 1. 1 7 2 *

Kilograms kg 0.001 1 7 3 **

Carats ct 5. 1 7 4

Pounds 14 /lb 0.0022046226 1 7 5

Ounces oz 0.035273962 1 7 6

Troy ounces ozt 0.032150747 1 7 7

Hong Kong taels 8 tlh 0.02671725 1 7 8

Singapore taels 9 tls 0.02646063 1 7 9

Taiwanese taels 10 tlt 0.02666666 1 7 10

Grains GN 15.43235835 1 7 11

Pennyweights dwt 0.643014931 1 7 12

Parts per pound o 1.1287667712 1 7 14

Chinese taels 15 tlc 0.02645547175 1 7 15

Mommes 16 m 0.2667 1 7 16

Austrian carats 17 k 5. 1 7 17

Tola 18 tol 0.0857333381 1 7 18

Baht 19 bat 0.06578947436 1 7 19

Mesghal 20 MS 0.217 1 7 20

* = factory setting

** = factory setting for QC 34/QC 64EDE scales and scales verifiable for use

as legal measuring instruments (QC 34EDE-L0CE and QC 64EDE-L0CE)

*** = some of the unit symbols printed on hard copy or output on a computer

screen will differ from the way they are shown on the scale display.

2–7

Page 56

Interface Parameter Settings

Baud Rate Code Changes

150 baud 5 1 1

300 baud 5 1 2

600 baud 5 1 3

1,200 baud 5 1 4 *

2,400 baud 5 1 5

4,800 baud 5 1 6

9,600 baud 5 1 7

19,200 baud 5 1 8

Parity Code Changes Mark 5 2 1 Space 5 2 2 Odd 5 2 3 * Even 5 2 4

Number of Stop Bits Code Changes 1 stop bit 5 3 1 * 2 stop bits 5 3 2

Handshake Mode Code Changes Software handshake 5 4 1 Hardware handshake with 2 characters after CTS 5 4 2 * Hardware handshake with 1 character after CTS 5 4 3

* = factory setting

2–8

Page 57

Utilities for Printouts or Data Transfer

Sartorius QC scales come standard with an interface.

You can plug a Sartorius printer or a computer into this interface port. In addition,

you can choose to have data output from your scale to this on-line device either

automatically or by pressing the p/p key.

The scale operating menu lets you define the various parameters for data output.

For information on the data formats and for interfacing a computer or a different

peripheral device, see Part 4, “General Description of the Data Interface.”

Data Output Parameter

This parameter is coupled with the stability parameter; stability = stable readout

or no motion is detected.

Print on request = data is output only when the p/p key is pressed

or a software command is received

Auto print = continuous, automatic data output

Code Changes

Print on request regardless of stability 6 1 1

Print on request after stability, with storage of the function 6 1 2 *

Print on request after stability, without storage of the function 6 1 3

Auto print regardless of stability 6 1 4

Auto print at stability 6 1 5

Auto Print

You can stop and start automatic data output (auto print function) by pressing

the p/p key (11). To avoid operating errors or to ensure that the data will be

output continuously in the automatic mode, you can block this function.

Start/stop auto print using the Code Changes

p/p key 6 2 1

Auto print not stoppable 6 2 2 *

* = factory setting

2–9

Page 58

Data Output at Defined Intervals

You can reduce the volume of data in the “auto print” mode by defining the

interval at which data will be output automatically. This auto print interval is based

on the number of display updates.

Auto print interval Code Changes

1 display update 6 3 1 *

2 display updates 6 3 2

5 display updates1) 633

10 display updates1) 634

20 display updates1) 635

50 display updates1) 636

100 display updates1) 637

Automatic Taring after Data Output

You can have the scale tare automatically (=/z key function) after one of the

following keys is pressed:

Code Changes

No function 6 4 1 *

Automatic taring after pressing the p/p key 6 4 2

Automatic taring after pressing the S/a key 6 4 6

Automatic Output of the Application Parameters

You can have the application parameters and results printed out or transferred to an

on-line computer (e.g. checkweighing limits, tare memory, etc.) automatically when

the application is activated.

Code Changes

Off 711*

On 712

1

) blocked for all verifiable models

* = factory setting

2–10

Page 59

Data ID Codes

To help you identify weights, piece counts, percentages, etc., a code letter is

printed or displayed in front of these values.

If you set the code for “without data ID code,” only net weights, results in percent

and counting results will be output. You will find the data ID codes for a particular

application program listed in the corresponding description. The ID code

increases the data output format for each weight readout from16 to 22 characters.

ID code for data output Code Changes

Without 7 2 1

With 7 2 2 *

Automatic Output of the Tare Memory Data

If you have assigned the o/t key (22) to the tare memory, the following

values will be output automatically:

Code Changes

Last net value (individual value N1) 7 3 1 *

Tare memory data (tare balancing memory) 7 3 2

This function only works in conjunction with the code setting 7 1 2 – “Automatic

Output of the Application Parameters.”

* = factory setting

2–11

Page 60

Printout/Record Configuration

The printout/record can be configured to meet your special requirements.

Depending on the menu code settings you select, you can have the weighing data

output from your scale to a Sartorius printer (e.g. the YDP 03-0CE) or to an on-line

computer. The data that is output also depends on the code settings.

The printout/record can have the following lines:

The ID code designates:

08-JAN-97 15:38:32 Current date and time, taken from the printer

(with YDP 03-0CE only)

Maier and Co. First header line – manufacturer/company

name, saved in non-volatile memory

(up to 20 characters)

Wiesbaden Second header line – enter data of your

choice, saved in non-volatile memory

(up to 20 characters)

ArtNo.12345678901234 Third header line – 6 characters –,

saved in non-volatile memory

Fourth header line – a field for entering

additional identification data

(up to14 characters)

nRef + 10 pcs Reference sample quantity (piece count)*

wRef +9.4880 g Reference weight*

n+22 Current components – only with “Totalizing”*

N1 +4744.0 g Current net value

T1 + 56.0 g Tare memory*

B +4800.0 g Current gross value*

Qnt + 500 pcs Current piece count*

Selectable line-feed (0 to 3 lines)

* These values are only output if you have selected the respective application

(only with YDP 03-0CE printer)

2–12

Page 61

Data Record Output

You can have the printout/record output automatically, or by pressing the

p/p key (as often as you like), depending on the menu code selected

(see following pages).

Output Date, Time and Number Entered

For additional documentation, you can enter up to14 characters (fourth header

line) through the number pad (keys 0–9), for example to record article, order,

customer or batch numbers. Information entered through the number pad (keys

0–9) is saved by pressing the ID key and automatically output with the

printout/record. These entries can be overwritten at any time.

You can assign a fixed identification (third header line) of up to 6 characters

to precede the14-character identifier described above. This ID can be entered

through an on-line computer, or by a Sartorius service technician. The on-line

computer can also receive data from the scale. By connecting a printer, you can

print the data received in the computer. These data are saved in non-volatile

memory. For more information, see the section entitled “Interface Description.”

You can choose between two printers:

Industrial printer YDP01IS-0CE

Data printer YDP03-0CE

2–13

Page 62

Data output with data and time

The data output ID is different for each printer.

“Data Printer” can output the article no. (ID) with the date and time.

The industrial printer only prints the article no. (ID).

You can vary the data on the printout by changing the respective menu settings:

Code YDP03-0CE Printer YDP01IS-0CE Printer

7 4 1 No output No output

7 4 2 Output date/time Form feed only

7 4 3 Output article no. (ID) Output article no. (ID)

7 4 4* Output date/time Output article no. (ID)

and article no. (ID) and form feed

Printout/Record Header (Your Company Name)

You can enter information in the first and second header lines to identify the

data that is output by your scale. This information can be entered through an online computer, or by a Sartorius service technician. The on-line computer can

also receive data from the scale. By connecting a printer, you can print the data

received in the computer. These data are saved in non-volatile memory. They are

printed out together with each data output. For more information, see the section

entitled “General Description of the Data Interface”.

Output of1st and 2nd headers Code Changes

No output 7 5 1

Output first header only 7 5 2

Output second header only 7 5 3

Output both headers 7 5 4 *

*= factory setting

2–14

Page 63

Output of “wRef” and “nRef”

Automatic output of the average piece weight, “wRef,” and the reference sample

quantity, “nRef”:

Your scale calculates the average piece weight from the number of parts loaded

and the weight of the pieces; the calculation begins when you press the u/w

key. This value can be output to a printer, depending on the code setting selected.

Output of “wRef” and “nRef” Code Changes

No output 7 6 1

Reference sample quantity “nRef”762

Average piece weight “wRef”763

Piece count “nRef” and piece weight “wRef”764*

Output of Net-/Tare-/Gross Weights/Counting Result

Depending on the settings for tare memory and the counting application,

the following data can be output to an on-line printer.

Output Code Changes

Output net weight or counting result 7 7 1

Output net weight and piece count 7 7 2

Output net weight/tare compensation/

gross weight or counting result 7 7 3

Output net weight/tare compensation/

gross weight and counting result 7 7 4 *

Line Feed

You can configure your printer to add a line feed automatically at the end

of a printout (1to 3 lines). This means you can tear off the printout as soon as it is

output, without having to press the line feed key on your printer.

Line feed Code Changes

No line feed 7 8 1

Line feed – 1 line 7 8 2

Line feed – 2 lines 7 8 3

Line feed – 3 lines 7 8 4 *

*= factory setting

2–15

Page 64

Additional Functions

Menu Access Function

You can define the function of the menu access switch by setting the code for the

scale operating menu to “accessible.” In this setting –C– (change) will be displayed

on your scale whenever you access the menu. This means that you can change the

menu codes any time regardless of the setting of the menu access switch.

Access to the scale operating menu Code Changes

Accessible: “–C–” on the display 8 1 1 * (**)

* factory setting for standard devices

** menu items not shown in scales of accuracy classes K and l

Beep Tone (Acoustic Signal)

If you wish, you can turn off the beep tone (acoustic signal).

Acoustic signal Code Changes

On 821*

Off 822

Blocking the Keys

You can block all of the keys on the scale (except the e/o key).

Key functions Code Changes

Accessible 8 3 1 *

Blocked 8 3 2

Note:

The keys can also be blocked by a control command given through the interface;

see “Data Input Formats” in the section entitled “General Description of the

Data Interface.”

Blocking the Number Keys

You can also block the number keys by setting the respective code.

Number keys 0–9 Code Changes

Blocked 2 5 1

Accessible 2 5 2 *

* = factory setting

2–16

Page 65

Universal Switch for Remote Control

You can connect an external universal switch to the interface of your scale for

remote control of certain functions listed below. Set the appropriate menu code

to define the function of this switch.

External key pad function Code Changes

p/p key (11) Data output 8 4 1 *

=/z key (14) Zero/tare 8 4 2

g/W key (13) Toggle between weighing/

counting or between ref./pc.ct 8 4 3

o/t key (22) Store in tare memory 8 4 4

u/w key (12) Start counting 8 4 5

z/T key (21) Start checkweighing 8 4 6

S/a key (19) Add to totalizing memory 8 4 7

Block all keys 8 4 8

Power-On Mode for QC Scales

The power-on mode can be set to meet your individual requirements. Your scale

recognizes the power source (line power or battery pack).

* = factory setting

2–17

Settings under Menu Code 8-5-x

Code 8-5-1 Code 8-5-2 Code 8-5-3 Code 8-5-4

Scale plugged in Scale plugged in Scale plugged in Scale plugged in

e/o key

e/o key e/o key

e/o key e/o key e/o key

Stand-by I

(only the e/o key

is active; electronics

are off)

Stand-by II

(only the e/o key

is active; electronics

are on, display not lit)

Scale in ready-to-

operate mode

When using a battery

pack, you can

also choose settings

8-6-3 and 8-7-1

Page 66

Display Backlighting

Depending on your individual workplace requirements, you can turn the display

backlighting on or off.

Display backlighting Code Changes

On 861

Off 862

Automatic shut-off after 2 minutes 8 6 3 *

If you select “Automatic shut-off after 2 minutes,” the display will shut off

automatically after 2 minutes. If the displayed weight value does not change after

1minute, the “b” symbol flashes on the display. This automatic shut-off feature

will help you save electricity (and money!) After a second minute passes with

no change in the display, the scale shuts down completely. You can use this

advantage especially in battery operation. When you are ready to resume work

with your scale, lightly touch the scale load plate.

Automatic Shut-Off With Code 8 5 2, or When Using the Battery Pack

When using batteries with your scale, the automatic shut-off feature should be

switched on – it saves you electricity and money, plus you can work longer

with your scale before having to recharge the batteries. If the displayed weight

value does not change after 1 minute, the “b” symbol flashes on the display.

After a second minute passes with no change in the display, the scale shuts down

completely.

When you are ready to resume work with your scale, press e/o key to turn it

back on.

Automatic shut-off of the scale Code Changes

On 871

Off 872*

*= factory setting

2–18

Page 67

Undoing All Menu Code Changes – Reset Function

This function enables you to reset all menu codes back to the original factory

settings, which are identified by an “*” in this manual. This can be very useful,

for instance when you are not sure what changes have been made in the

code settings.

Reset function Code Changes

On (active) 9––1

Off 9––2 *

Connecting the YDP01IS-0CE Printer to a QC Scale

You can connect a QC scale to a YDP01IS-0CE industrial printer rather than the

YDP03-0CE printer via the cable supplied. You should make the following

changes in the code settings of your QC scale:

Function Code Changes

9,600 baud 5 1 7

Space parity 5 2 2

2 stop bits 5 3 2

Handshake: 2 characters 5 4 2

Printout product no.: ID and line feed 7 4 4 *

Note:

The date/time printout is available only with the YDP03-0CE printer.

You can also print labels on the QC scale with the YDP01IS-0CE printer

(without bar code printout).

*= factory setting

2–19

Page 68

Application Programs

In addition to the weighing functions, your scale offers a variety of application

programs for use in the rough world of everyday industrial tasks. The description of

the application programs is divided into several parts. To aid you in making

optimal use of these programs, your scale’s display will show helpful symbols and

abbreviations.

This manual contains simple working examples for each of the basic application

program modes. The settings required to run the program and to generate

documentation are given in a code table at the beginning of each example.

Your Sartorius scale can help you in counting parts, totalizing values, checking or

storing the weight of parts or of a piece count.

With these functions, your Sartorius QC counting scale can help to ease your

daily workload. The scale is set at the factory so that as a rule you do not need to

make any changes. If you have special requirements, or if you wish to use the

additional functions available in the application programs, you can change the

appropriate settings in the scale operating menu accordingly.

The procedure for setting codes is described in detail in Part 2.

Additional settings for running a particular program and displaying or printing

the data on hardcopy are listed in a table of codes before each practical example.

For your convenience, we have indicated the factory-set codes with an “*“.

One thing you should do when you want to set codes for a different program,

or when someone else has already operated the scale, is:

Select the reset function (code 9 – – 1°) to change all menu codes back to the

original factory settings.

Note:

When using verified scales as legal measuring instruments, the external

calibration function is blocked by menu code!

3–1

Page 69

Insertable Instruction Cards for the Dust Cover

In the pocket at the back of this manual, you will find a sheet of instruction

cards for various applications. Detach the cards of your choice and insert them in

the pockets provided in the dust cover. These cards will make it easy for you to

operate the scale.

Display Dust Cover:

Counting:Key Functions:

ON/OFF

Start counting

Weighing/Counting

Zero/Tare

Info

Clear function

Tare scale

(if the display does not

show “0”)

Place10 pieces in the

container

Start count

Counting Control

Display

(Suggested example)

Main Display of the QC Counting Scale:

3–2

Bar graph

Application display

Program display Special information

Main

display

Page 70

Programs (Applications)

Counting (page 3–4)

Counting using your choice of reference piece count or reference weight.

Tare Memory (page 3–13)

Storing weighed values or numeric-key input of a weight with simultaneous

subtraction of the stored value from the displayed value (subtraction of container

weight).

Totalizing (page 3–15)

Summation of weighed values and piece counts (breaking bulk and portioning).

Over/Under Checkweighing (page 3–20)

Check net value or difference of weighed or counting values with visual support

(filling guide) using analog display, e.g. for counting parts.

Individual Data ID Code (ID), C*, NUM (page 3–29)

Individual14-digit entry of work order, article, customer, position or batch numbers.

Optional 6-digit ID, e.g. for entry of “Article No:”.

Memory (page 3–31)

User-definable assignment of and access to 25 memory modules for tare weights,

part weights or target values.

Please note:

A number entered manually without a decimal point is always a piece count!

A number entered manually with a decimal point is always a weight value!

3–3

Page 71

Counting

Counting u/w key Code 2 1 4*

Symbol displayed: P

The counting program allows automatic conversion of weights into piece counts

based on a reference sample quantity and weight. A weight readout is stored as

a reference sample quantity (factory setting: 10 pcs = pieces).

General Functions in the Counting Program

Function/Application Entry Mode User Data

Guide Output

Display ID

Clear the counting c/c key + CF –

application function u/w key

Display information: i/i key + reF –

reference sample u/w key

quantity “nRef”or average

piece weight “wRef”

Data output: i/i key + nRef

reference sample quantity p/p key + reF wRef

“nRef” or average u/w key

piece weight “wRef”