Operating Instructions

Sartorius PMA.Power

Model PMA35001-X

Electronic Paint-mixing Scale for Use

in Potentially Explosive Atmospheres

1000025334

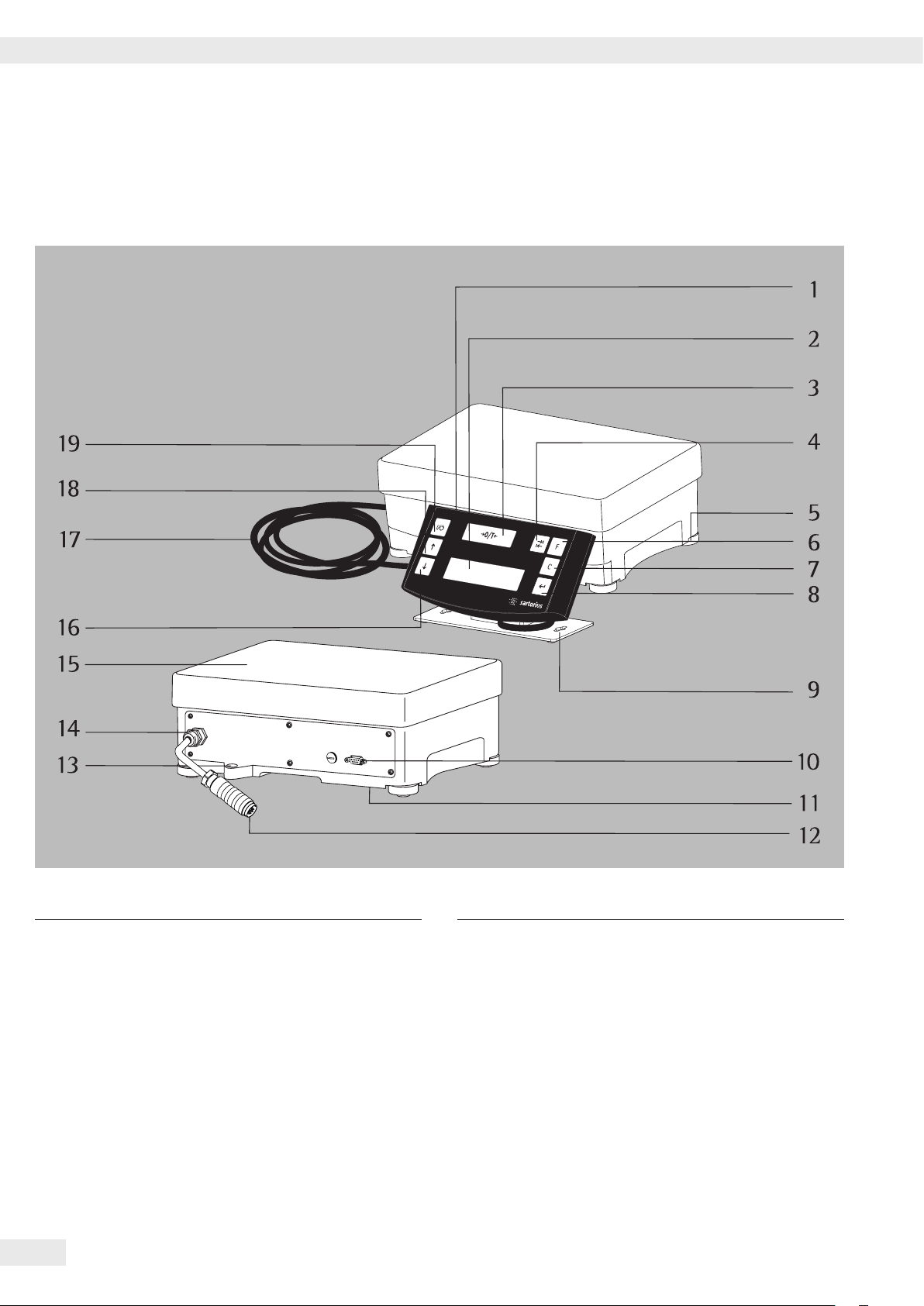

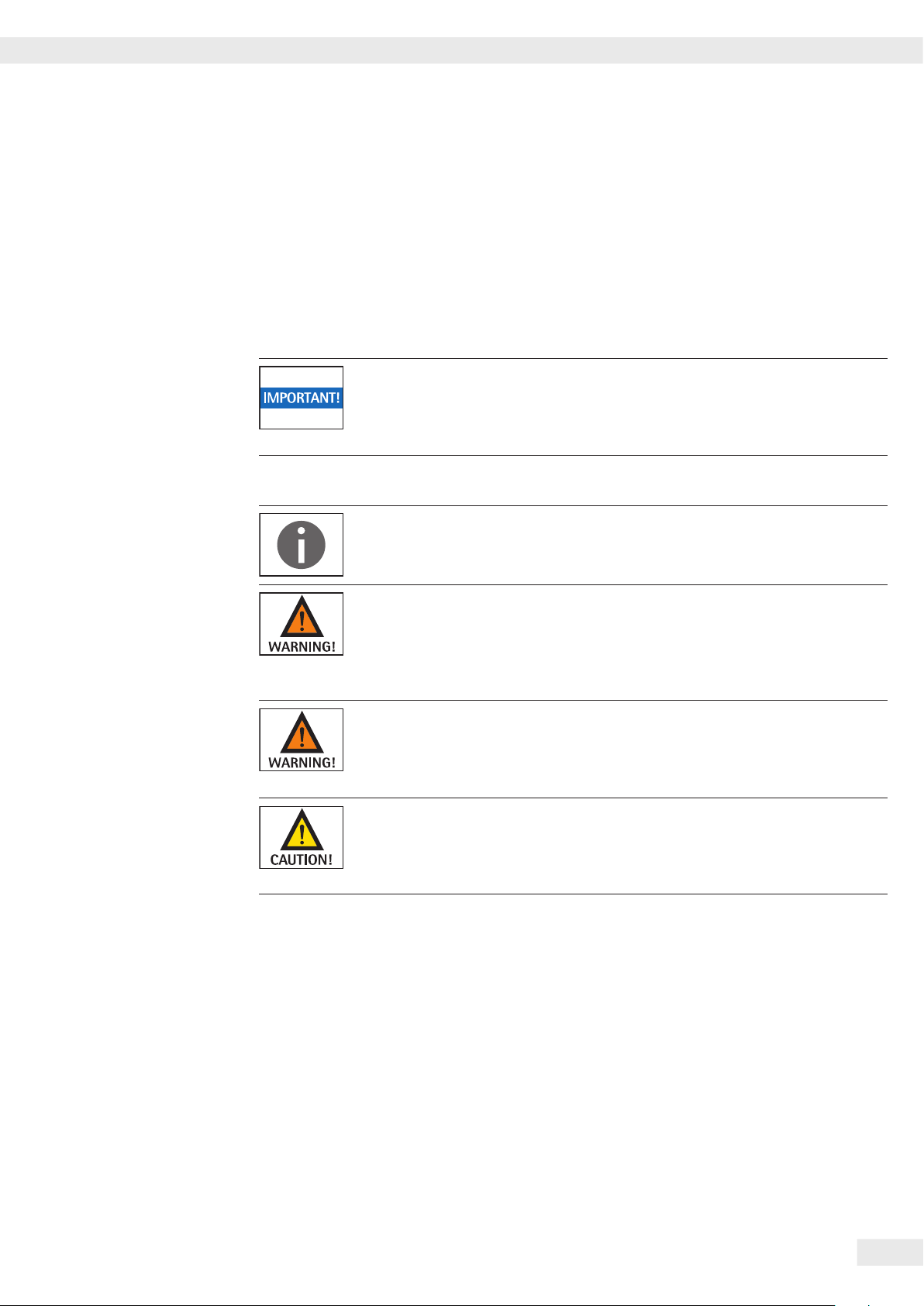

General View of the Equipment

General View of the Equipment

Item Description

Display and control unit

2 Display

3 U key (Zeroing/Taring)

4 I toggle key depending on the menu setting:

You can configure the PMA35001 menu to enable

toggling between grams (g) and parts per pound (p).

5 Leveling foot

6 K factor key for paint-mixing applications

7 c key (Clear) and [REC] key

for paint-mixing applications

8 L [ENTER] key and [MEM] key for paint-mixing

applications

2 Operating Instructions PMA 35001-X

Item Description

9 Mounting bracket for display and control unit

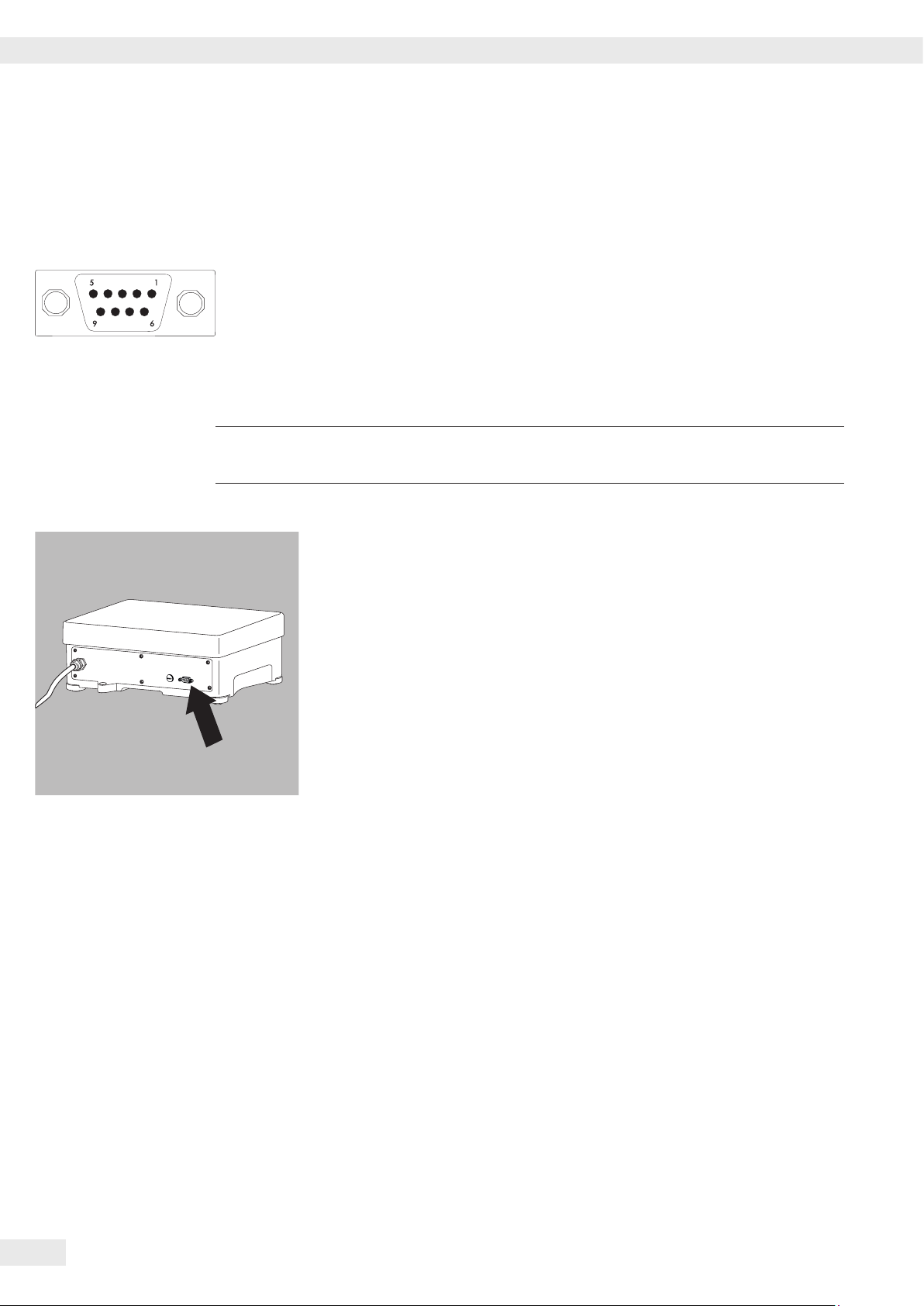

10 Interface (D-SUB socket, 9-pin)

11 Grounding terminal

12 Adapter cable for the AC adapter

13 Level indicator

14 Cable connection

15 Load plate

16 S key: down

17 Power supply and data cable for the display and

control unit

18 R key: up

19 Q key (on/standby)

Contents

Contents

General View of the Equipment ..................................... 2

Contents ...................................................... 3

User Information ................................................ 4

Intended Use ................................................... 5

Safety Instructions .............................................. 5

Getting Started ................................................. 8

Equipment Supplied .......................................... 8

Installation ................................................. 8

Operation ..................................................... 12

Applications ................................................... 13

Calibration .................................................... 16

Menu Setting .................................................. 17

Error Messages .................................................22

Care and Maintenance ............................................ 23

Disposal ...................................................... 25

Interface Port .................................................. 26

Specifications .................................................. 27

Accessories .................................................... 28

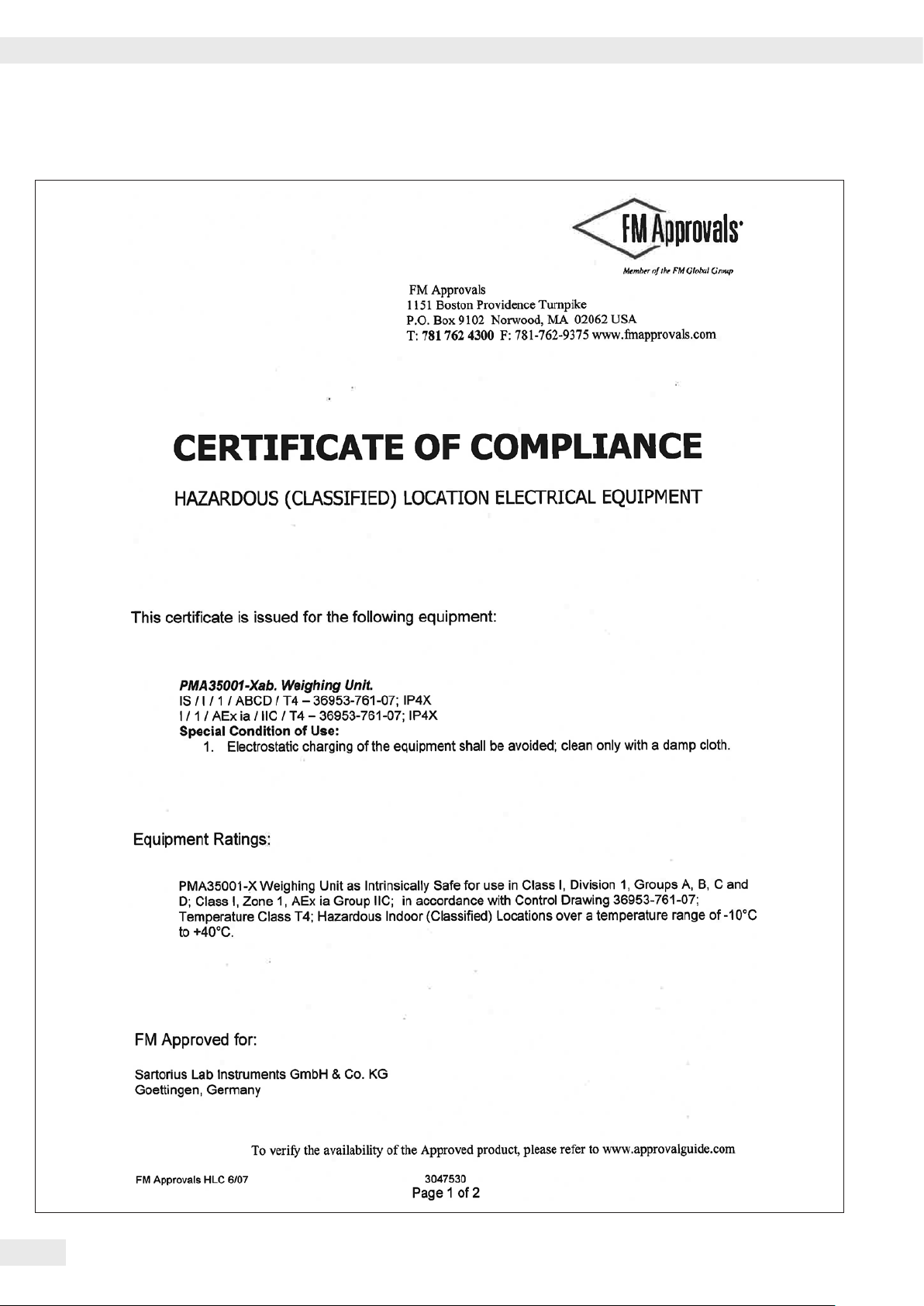

Documents

EC Declaration of Conformity ..................................29

Safety Instructions ...........................................31

Certification: CE Type Test ..................................... 32

Verification of Intrinsic Safety, English ............................ 35

Certificate of Compliance ......................................40

Operating Instructions PMA 35001-X 3

User Information

User Information

About these Installation Instructions

t Please read these installation instructions carefully before putting the

equipment into operation for the first time.

t Make sure to follow the safety instructions.

t Keep these installation instructions in a safe place that is easily accessible to

allpersonnel who operate this equipment.

t If these instructions are lost, please contact Sartorius for a replacement or

download the latest manual from our website, www.sartorius.com.

Warning/Danger Symbols

Warning/danger symbols used in these instructions:

This symbol identifies hazards which have a high probability of resulting in

death or serious physical injury if not avoided.

This symbol identifies hazards that can result in moderate or mild injuries if not

avoided.

These notes identify hazards associated with the risk of material damage.

This symbol identifies useful information and tips.

Explanation of Symbols

The following symbols are used in these instructions:

t Indicates a required action

4 Operating Instructions PMA 35001-X

y Describes what happens after you have performed a particular step

1. Perform steps in the specified order

2.

– Indicates an item in a list

Intended Usage

Intended Usage

The PMA35001-X is a scale designed for use in paint-mixing applications. The

scale can be operated via the keypad as a stand-alone device or using application

software (such as a paint-mixing program from a paint manufacturer) installed on

a connected PC.

If you wish to create your own application software, Sartorius can supply the

required drivers for Windows operating systems.

Make sure to read and store these installation instructions carefully before

installing and operating your paint-mixing scale.

Safety Instructions

This device meets stipulated safety requirements. Improper use or handling,

however, can result in damage and/or injury. The manufacturer is not responsible

for any damage caused by non-compliance with warnings or safety instructions.

– The requirements pertaining to applicable installation regulations must be

followed when using electrical equipment in systems and environmental

conditions with increased safety requirements.

Use of the paint-mixing scale is not permitted in legal metrology or in medical

areas or hazardous areas containing dust or explosive materials.

– The intrinsically safecolor-mixing scale has been manufactured in accordance

with the European standards of CENELEC (see “EC Type Examination

Certificate" in the appendix).

The color-mixing scale can be used with intrinsically safe Sartorius accessories

in Zone 1 areas. (see: “Verification of Intrinsic Safety", cert. no: 36953-761-60).

Operating Instructions PMA 35001-X 5

Safety Instructions

The IP protection rating of the color-mixing scale in accordance with EN 60529 is

IP 43.

The device must be handled carefully in accordance with the IP protection rating.

The environment must be suitably secured.

The color-mixing scale meets all requirements for electromagnetic compatibility

(EMC). Interference stronger than the maximum values specified in the standards

(see Declarations of Conformity) should be avoided.

The casing on all connection cables as well as the casing on the wires inside the

equipment housing are made of PVC. Chemicals that corrode this material must

bekept away from these cables.

None of the components of the color-mixing scale should be exposed to ambient

temperatures outside the range of 0°C to 40°C during operation. Sufficient

ventilation must be provided, in order to avoid excessive build-up of heat.

The equipment must only be used indoors. Avoid generating static electricity

onglass and plastic parts. The color-mixing scale must be connected to the

equipotential bonding conductor using a suitable low resistance method.

All electrical circuits are earthed and electrically connected to the metal parts of

the device.

– The scale must be checked for correct function and safety by a trained and

qualified person at appropriate intervals (e.g. checking the cable for damage).

– Operating personnel must be trained to recognize faulty operating states and to

be able to initiate the necessary safety measures.

Proceed with extreme caution when using pre-wired connection cables purchased

from other manufacturers, as the pin assignments may not be compatible with

Sartorius equipment.

Only use cables and cable lengths approved by Sartorius.

– The operator is solely responsible when using cables not supplied by Sartorius.

The scale should only be opened by trained personnel with the power

disconnected. Danger to life: do not touch conductive parts of the power supply

wiring!

6 Operating Instructions PMA 35001-X

The scale must be installed and operated in a way that ensures that the control

unit cannot be damaged (e.g., by falling objects).

If the control unit is damaged, disconnect the device from the power supply

immediately.

A defective device may only be repaired by trained service technicians in

accordance with Sartorius guidelines. Only original replacement parts should be

used. Always ensure that the equipment is disconnected from AC power before

performing any maintenance, cleaning, or repair work.

If the equipment is opened by anyone other than persons authorized by Sartorius,

all claims under the manufacturer's warranty are forfeited. If necessary, speak to

your dealer or the Sartorius Service Center.

Safety Instructions

Ex Zone 1 (Category 2 Equipment)

– In accordance with Directive 94/9/EC, the PMA35000-X model is a category 2

device, suitable for use in Zone 1 potentially explosive areas.

EC Type Examination Certificates: DEKRA 12ATEX0180 X ID code: II 2 G Ex ia

IIC T4 Gb

The scale may only be connected to supply voltages of 90 V to 264 V at a

frequency of 48–62 Hz.

If the device is used in Zone 1 potentially explosive areas outside the Federal

Republic of Germany, the relevant national electrical codes and safety regulations

must be observed. Ask the dealer or Sartorius Service Center about the guidelines

that apply in their country.

The following points must be followed:

This scale should only be opened by trained personnel with the power

disconnected.

The device is intended to be installed exclusively in locations that offer sufficient

protection against the penetration of solid foreign bodies or water. The safety of

the equipment is compromised by foreign bodies and water.

The terminal must be protected against damage and direct or indirect penetration

of water and foreign bodies (< 1 mm diameter).

Avoid generating static electricity on the front panel and plastic casing.

The equipotential bonding conductor of the devices must be connected properly,

according to commonly accepted technical standards.

Only clean the device as stipulated in the cleaning instructions.

The device must be protected from unnecessarily extreme temperatures, aggressive

chemical vapors, moisture, shocks, and vibrations. Note the connection data

(seeEC Type Examination Certificate of the device and/or the safety instructions,

drawing no. 36953-760-16).

Operating Instructions PMA 35001-X 7

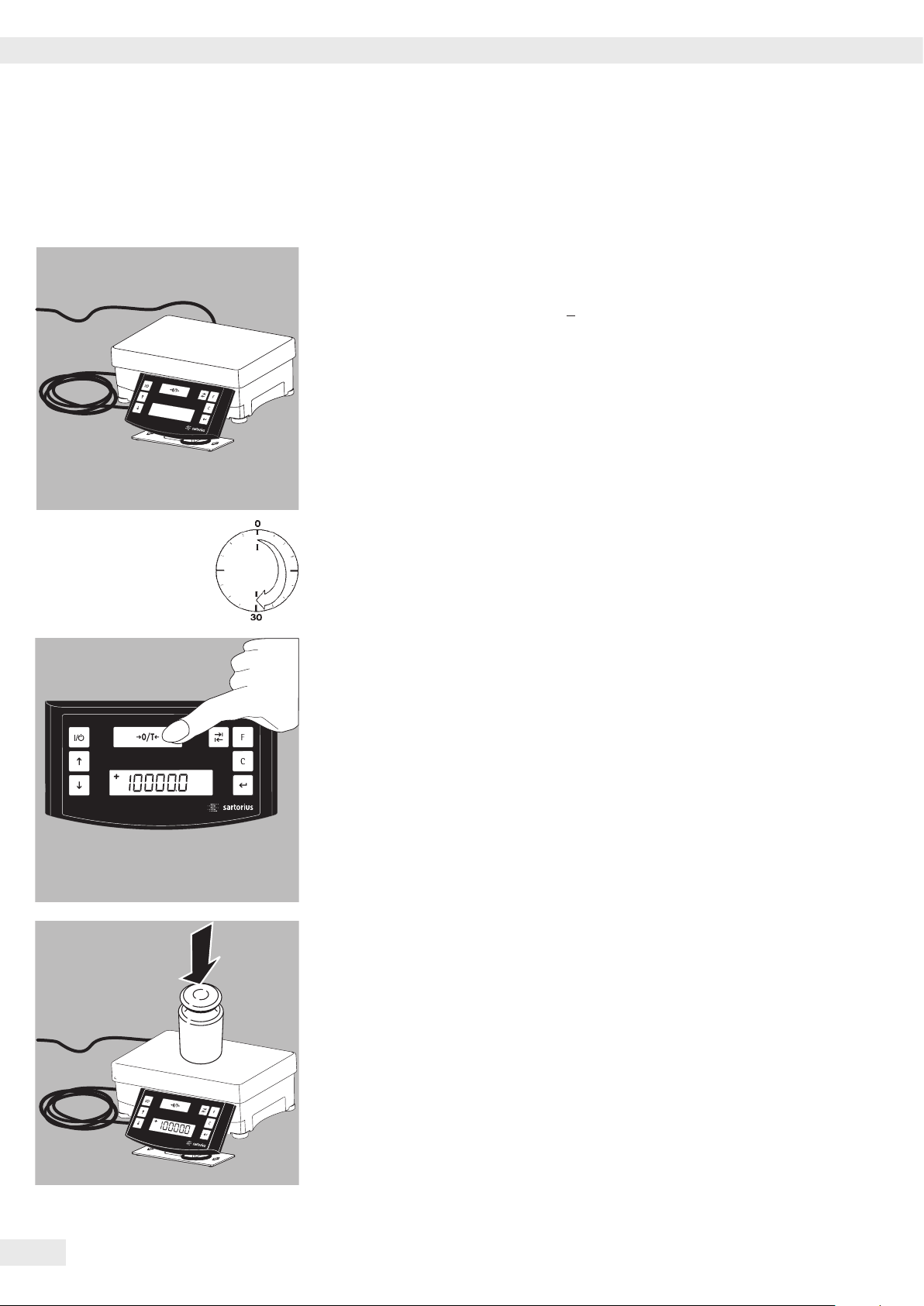

Commissioning

°C

Commissioning

Equipment Supplied

t Unpack the scale carefully.

The scale comprises the following components:

– Scale

– Load plate – Display and control unit

t After unpacking the equipment, check immediately for any visible external

damage. If you detect any damage, proceed as directed in the “Safety

Inspections" chapter (page 23).

Installation

The color-mixing scale is authorized for use in Zone 1 potentially explosive areas

(see documents).

Make absolutely sure that the device is unplugged from the power supply

before connecting/disconnecting data transfer or control lines.

Installation Location

Choose a suitable location where the power supply will not be

exposed to drafts, heat radiation, moisture, or vibrations.

8 Operating Instructions PMA 35001-X

Installation

Setup Instructions

The following ambient conditions must be avoided when selecting the installation

location so you can work with extra speed and accuracy:

– Uneven installation location

– Drafts

– Extreme moisture or chemical vapors

– Extreme heat (e.g. avoid placing the terminal/control panel in close proximity to

a heater or exposing it to direct sunlight). Do not set up the device in a control

cabinet or in any other poorly ventilated location.

– Extreme vibrations

Follow all warnings and safety precautions.

– Before startup, make sure that the power cable is properly connected to the

power supply. In particular, the protective conductor must be connected to the

housing of the AC adapter. Connect all devices to the potential equalization

using a ground connection cable (not included) via the equipotential bonding

conductor terminals

Make sure that the cable gage conforms with national specifications.

Installation must be carried out properly by trained personnel and according to

commonly accepted technical standards.

– Only cables and cable lengths approved by Sartorius should be used, which

takeaccount of the limitations of the cable lengths due to the capacity and

inductance values (see appendix on EC Type Examination Certificate) and the

EMC behavior.

– The system should only be operated for the first time when it is certain that the

area is not potentially explosive.

– If deviations are evident during startup due to transport damage (no display,

nobacklighting, etc.), the system should be disconnected from the power

supply and service professionals should be contacted.

Make absolutely sure that the device is unplugged from the power supply

before connecting/disconnecting data transfer or control lines.

This explosion-protected color-mixing scale should be set up according to

commonly accepted technical standards. The applicable national electrical

codesand safety regulations for your particular country must be observed.

– Before commissioning the color-mixing system in potentially explosive areas, a

check must be carried out by or under the supervision of a qualified electrician

to ensure that the system is in good working order.

on the device.

Check whether or not the competent authorities (e.g. industrial supervisory board)

need to be informed. It is also necessary to carry out inspections of the system

during operation. Inspection intervals should be such that any significant defects

that may occur can be identified in good time. Inspections should be carried out

atleast once every three years. The applicable requirements and guidelines should

also be observed during operation.

Operating Instructions PMA 35001-X 9

Setup Instructions

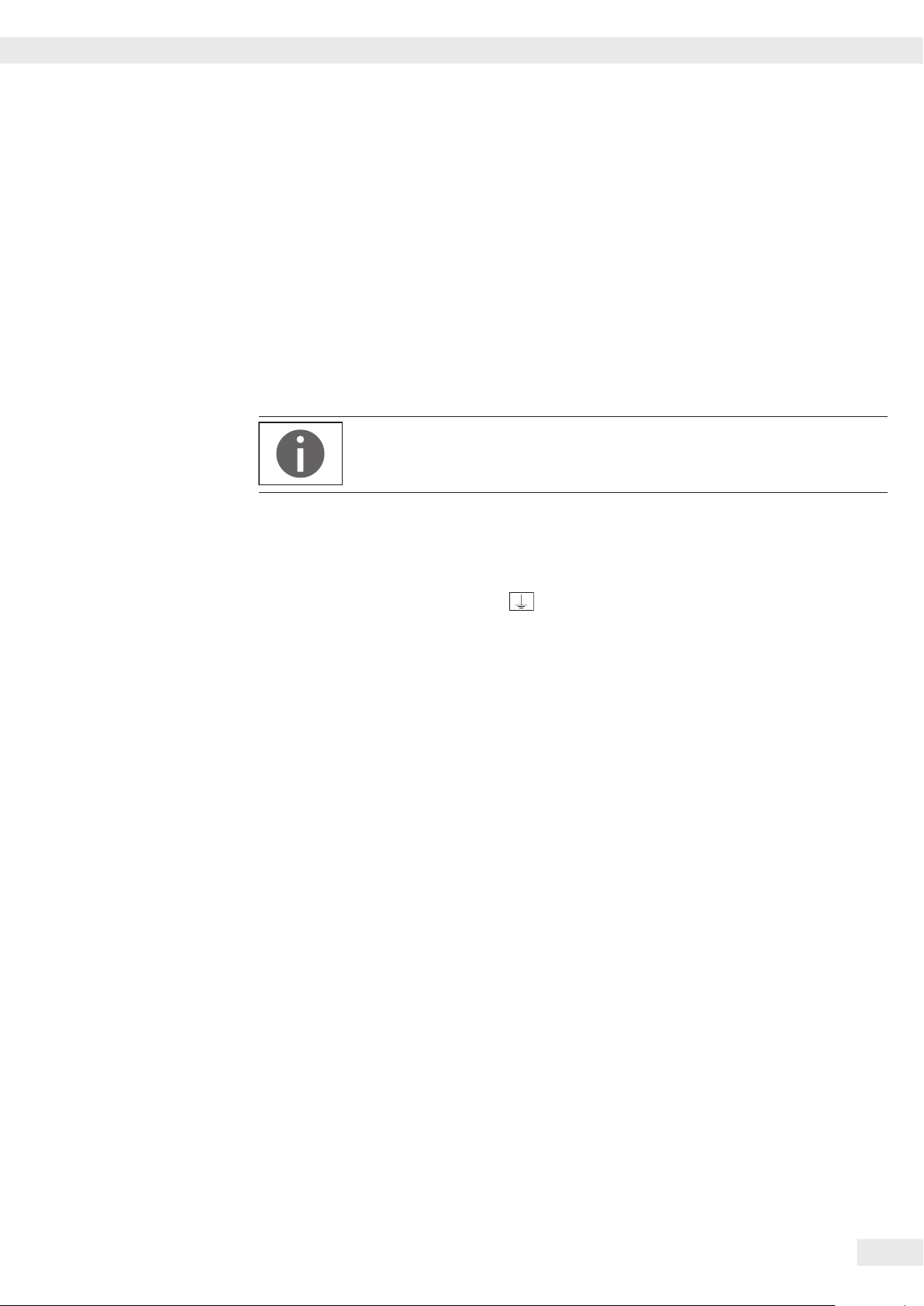

Connect the equipotential bonding connector:

Establish a low resistance connection with the color-mixing scale using a suitable

grounding cable with a gage of at least 4 mm2 (not included) via the equipotential

bonding conductor connections (PA) on the devices.

Installation must be carried out properly by trained personnel and according to

commonly accepted technical standards.

If deviations due to transport damage are evident during startup (e.g. no display,

no backlighting), the system should be disconnected from the power supply and

service professionals should be contacted.

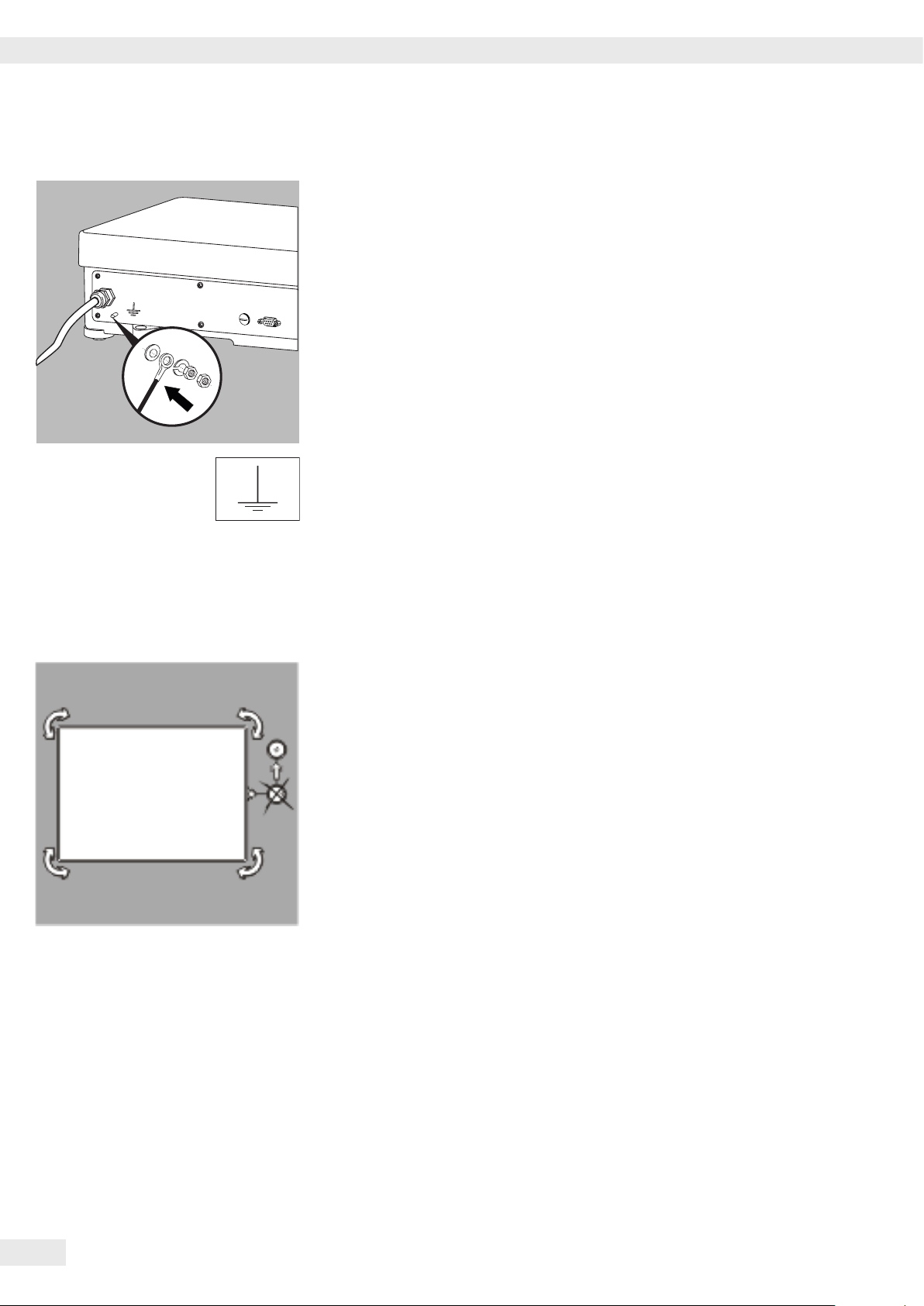

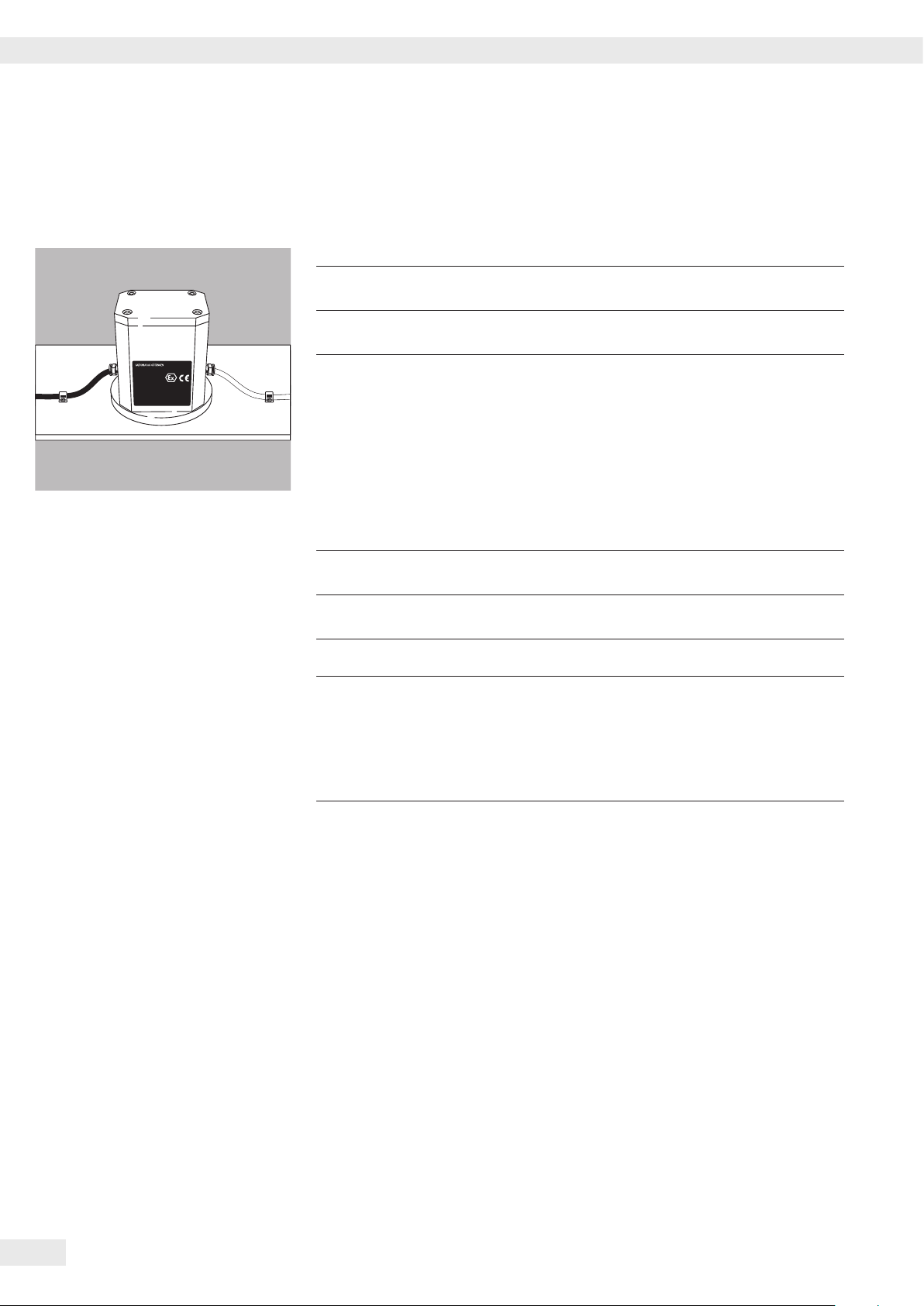

Leveling the Weighing Platform

Purpose:

– To compensate for unevenness at the place of installation

– To ensure that the equipment is placed in a perfectly horizontal position for

consistently reproducible weighing results. Always level the weighing platform

again any time after it has been moved to a different location.

t Level the weighing platform using the four leveling feet. Turn the feet until the

air bubble is centered in the level indicator.

t Ensure that all leveling feet are resting securely on the work surface.

y Each of the leveling feet must support an equal load.

y Adjusting the leveling feet:

To raise the weighing platform, extend the leveling feet (turn counterclockwise). To lower the weighing platform, retract the leveling feet (turn clockwise).

10 Operating Instructions PMA 35001-X

Installation

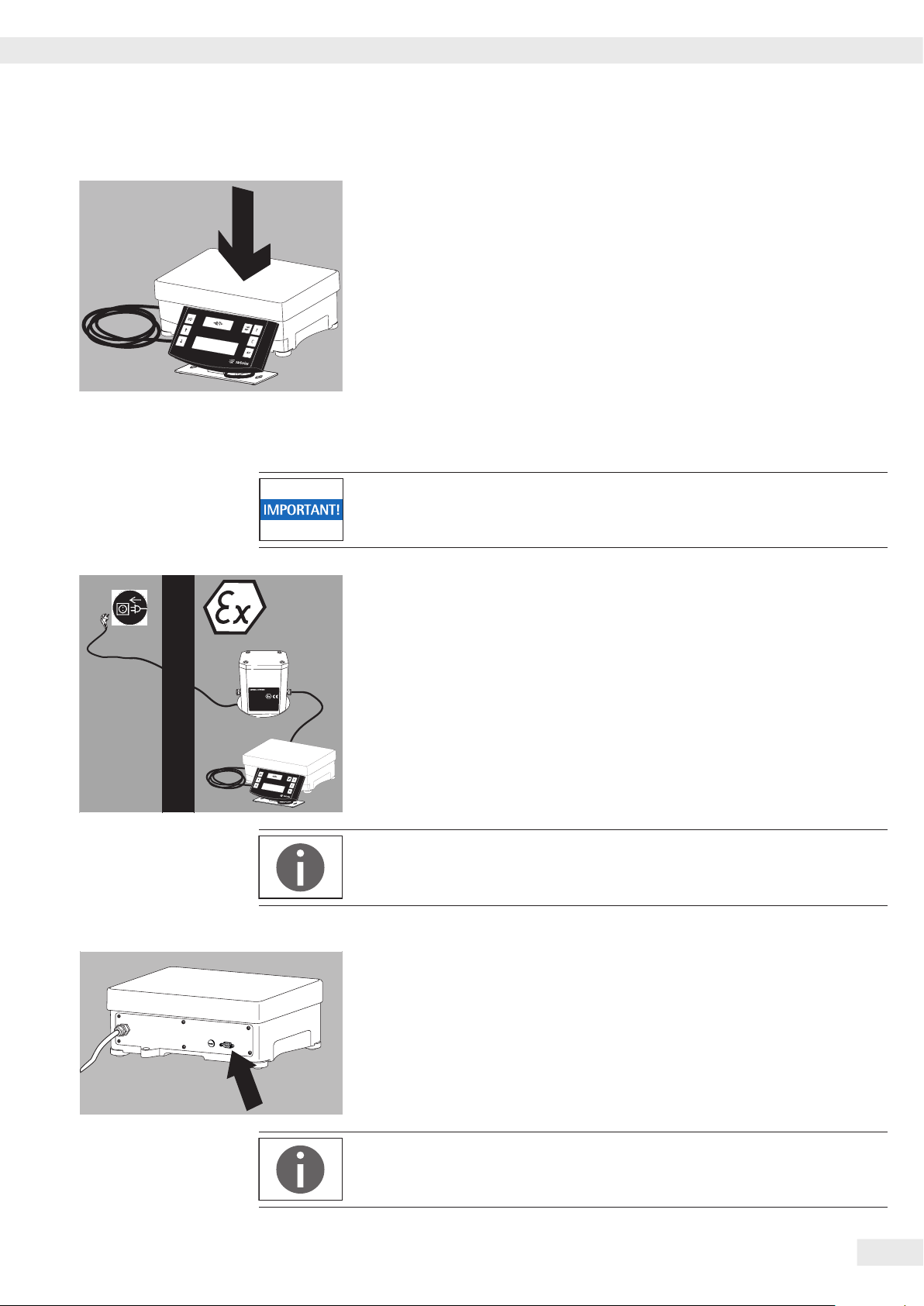

t Place the weighing pan on the balance.

Connecting the Device to AC Power

Power is supplied via a Sartorius AC adapter. Make sure that the voltage rating

printed on this unit matches the voltage at the place of installation.

If the stated supply voltage or the plug design of the power cord does not comply

with the standard you use, please inform your nearest Sartorius representative or

your supplier. Use only original Sartorius adapters: A list of permitted models can

be found in the Accessories (Options) chapter on page 28. The use of cables from

other manufacturers, even if these units have a registered approval rating from

anational testing laboratory, requires the consent of a qualified technician.

When operating the scale in Zone 1 potentially explosive areas, follow the

current standards and regulations for the installation of devices in Zone 1.

In order to connect the equipment to the power supply, use a correctly installed

wall outlet with a protective grounding conductor (PE) and a fuse of a maximum

16 A.

t Connection of the power supply outside of the potentially explosive

atmosphere or mechanically secured (refer to “Safety Information" documents).

t Plug the power cord on the Sartorius AC adapter into the wall outlet (mains).

Observe all warnings and safety precautions.

See also: “Safety Instructions” documents.

Connection of Peripheral Devices:

When installing the device in potentially explosive atmospheres of Zone 1,

connectors may only be plugged in or disconnected in a currentless/dead-voltage

state.

Disconnect the scale from the power line before connecting peripheral devices

(printer, PC) to the interface port of the device.

t When connecting peripheral devices (printer, PC) to the scale's interface port,

make sure that the screws on the data plug are securely tightened.

Observe all warnings and safety precautions.

See also: “Safety Instructions” documents.

Operating Instructions PMA 35001-X 11

Operation

Operation

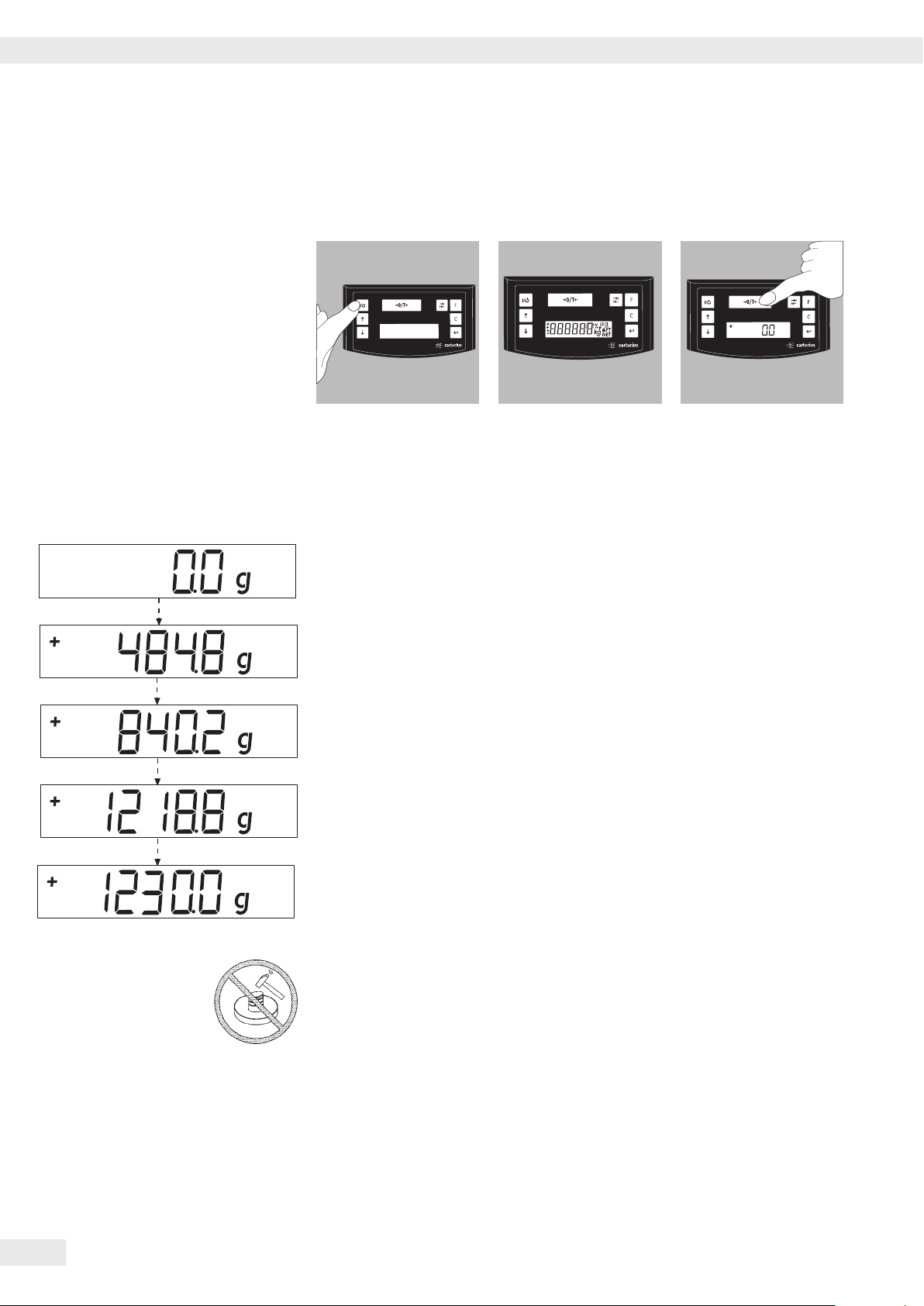

Press the Q key to turn

on the scale.

Weighing

Place an empty paint can on the load plate.

Press the U key (Zero/Tare) (3).

The display shows “0.0 g.” Pour the first component of your formula into the can

and read off the weight when the stability symbol (in this example) “g" is displayed.

Add the other components up to the desired weight (formula).

Remove the filled paint can from the load plate.

Once the scale has been

turned on, it will run an

automatic self-test. This

ends when the display

shows 0.0 g.

If a different value is

displayed: Tare the

scale using the U

key (Zero/Tare).

12 Operating Instructions PMA 35001-X

Never use a hammer to close a paint can while is it still on the load plate, as this

will damage the weighing system.

The weighing system will get damaged!

Applications

Applications

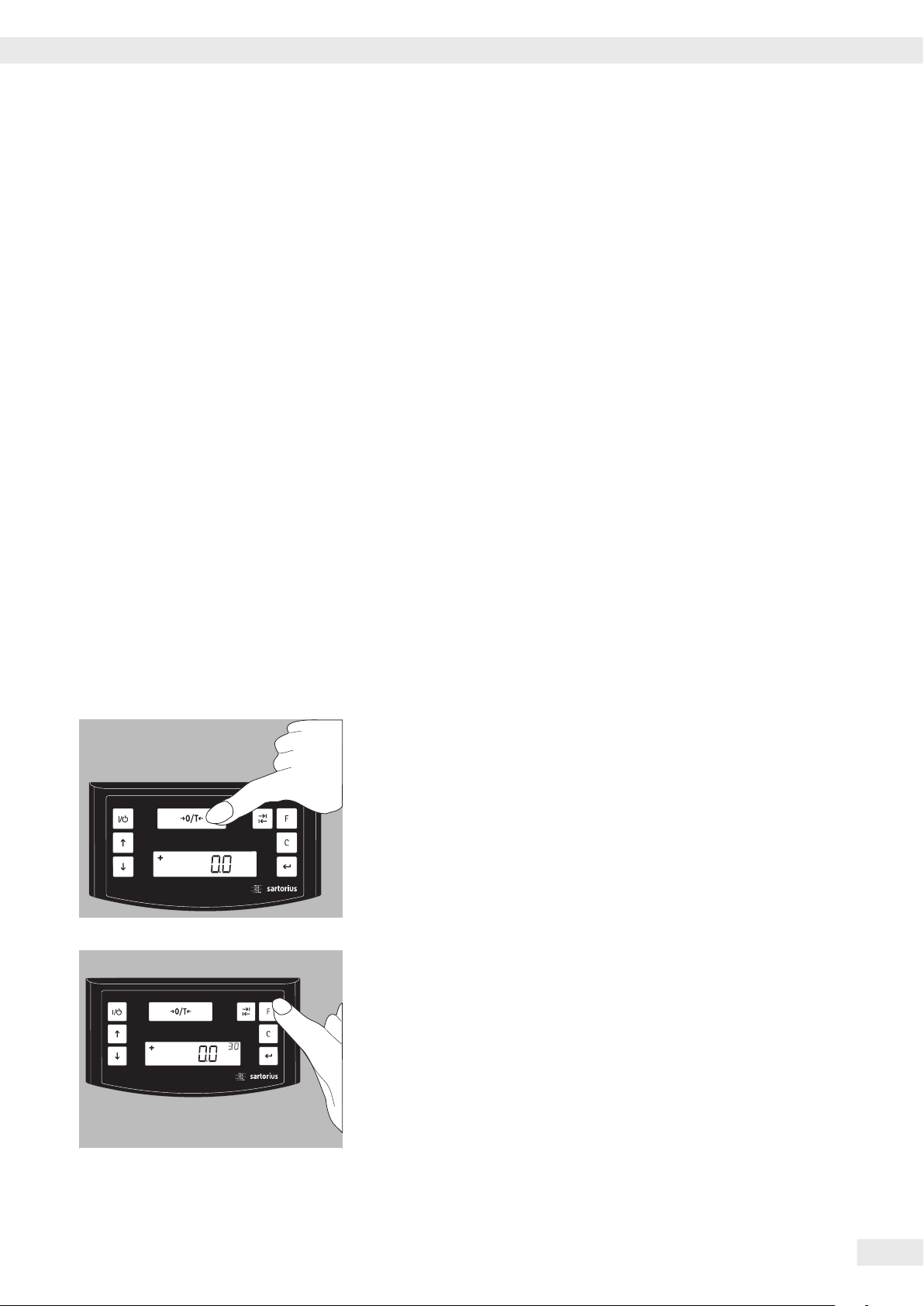

Formulation Mode (Calculation by a Factor)

This mode enables you to weigh in amounts that are smaller or larger than that of

your basic formula for a specific paint color (e.g. 250 ml of a 1 l formula). Press the

K factor key to select the desired factor (quantity):

By pressing the R key: up

or S key: down

the value can

be modified – in 0.1 increments for factors of 1.0 to 6.0

or – in 0.01 increments for a factor of up to 1.0.

Note:

A flashing n arrow on the display indicates that the weight value displayed is not

valid in legal metrology (i.e. not legal for trade).

Example:

As you pour in the components of your formula, the weight is displayed in “g.”

Let'ssuppose you want to weigh out 3 kg of a 1kg basic formula, and you don't

want to have to manually recalculate the individual components of the formula.

The basic formula for 1 kg is:

250 g 1st component

+ 250 g 2nd component

+ 500 g 3rd component

Total: 1000 g

1. Place the empty container on the load plate and tare the scale.

2. Press the F factor key repeatedly to set the factor to “3.0" for this example.

Operating Instructions PMA 35001-X 13

Applications

3. A “3.0" appears next to the weight readout.

4. Slowly pour in the first “250 g" of component until the display shows “250 g.”

5. Pour in the second “250 g" component until “500 g" is displayed.

6. Pour in the last “500 g" component until “1000 g" is displayed.

This concludes the recalculation example. According to the display, exactly

1000 g was poured in, but the paint in the container weighs 3 kg in accordance

with the factor you selected.

The procedure is the same for any other conversion factor.

Weighing Using the Recalculation Mode

Let's suppose that you poured in too much of one color component for a given

formula (in this example, a 4-component recipe).

This example further assumes that you previously poured in all of the other

amounts exactly according to each of the values you entered and saved by pressing

the L key [MEM]. Press the S key to start the recalculation program; “C" flashes

on the display. Press the S key to correct the value so that it matches the amount

specified in the formula. Press the L key [MEM]; the scale returns to component 1

and automatically calculates the amount to be added for each of the components

that were already poured. The display shows the amounts required to correct the

formula up to the point at which the overpour occurred.

After the correction has been completed, you can continue filling the remaining

components. The same factor is used.

Note:

You can correct overpours as often as needed.

Keep in mind that the total quantity of paint at the conclusion of filling increases

each time you correct a component. Press the c key to check how much the

correction factor for the total quantity will be. “C" stands for “Correction factor."

14 Operating Instructions PMA 35001-X

An n arrow on the display indicates that the weight value displayed is not valid in

legal metrology (i.e. not legal for trade).

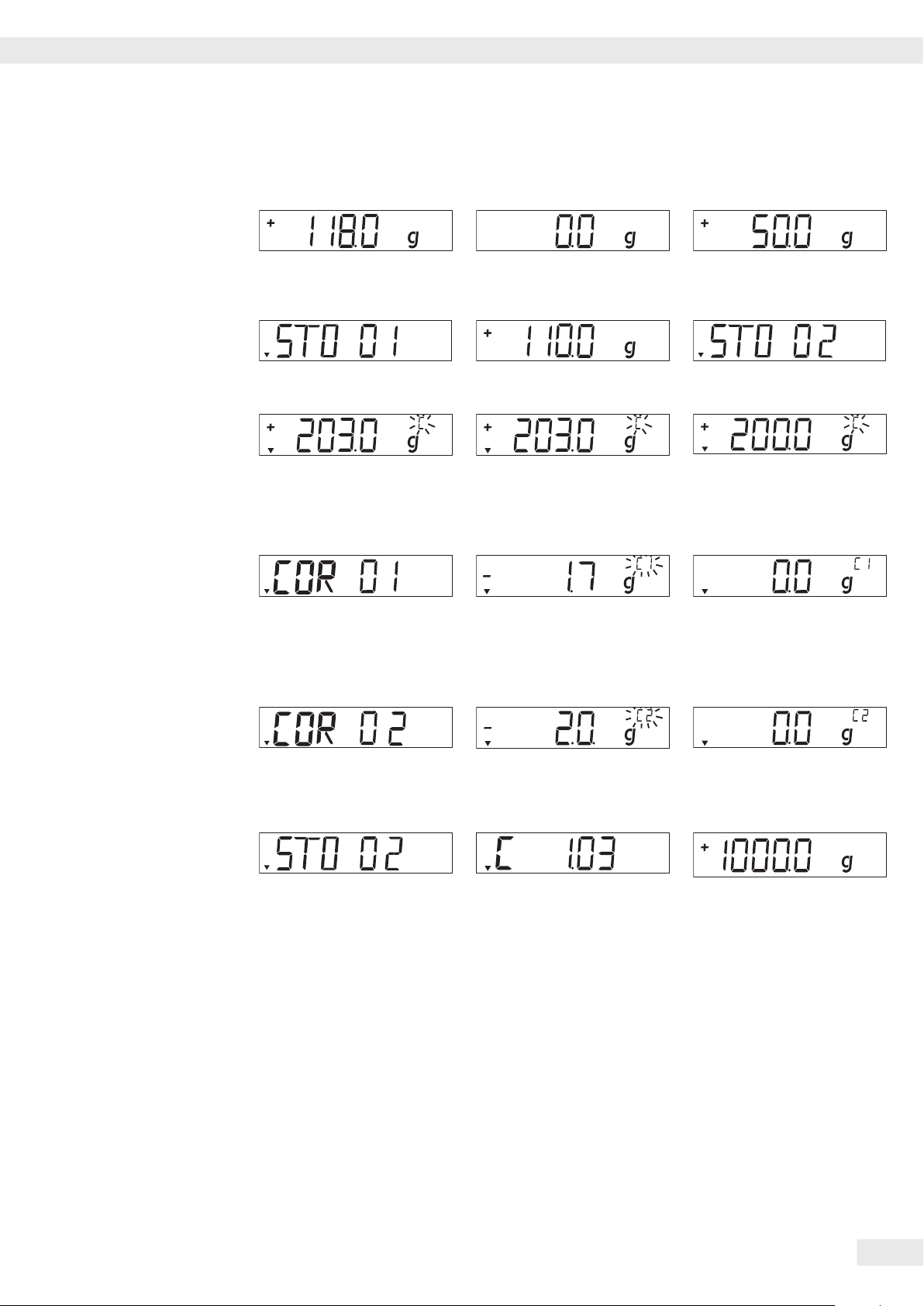

Example (Cumulative Weighing)

Applications

1. Center an empty paint can

on the load plate.

+ 118.0 g

4. Press the L key [MEM]

STO 01

7. Add the third component

+ 203.0 g

Oops! You poured in too

much. The correct value for

the formula is 200.0 g.

10. Press the L key [MEM]

COR 01

2. Press the U key

(Zero/Tare).

0.0 g

5. Add the second component

+ 110.0 g

8. PPress the S key to start

the recalculation mode.

A »C« (“Correction”) flashes

on the display.

11. Add the required amount of

the first component. “C1”

appears on the display.

–1.7 g.

3. Add first component.

+ 50.0 g

6. Press the L key [MEM]

STO 02

9. Press the S key repeatedly

to correct the value.

+ 200.0 g

12. Add until value reaches

0.0 g.

0.0 g

13. Press the L key [MEM]

COR 02

16. Press the L key [MEM].

The scale returns to the

formulation program. »C«

is no longer displayed.

+ 200.0 g.

14. Add the required amount

of the second component.

“C2” appears on the display.

2.0 g

17. Press the c key (7) [REC]

to view the factor by which

the total weight will exceed

the original target.

(C = “Correction;”

in this example, 1.03).

(Total weight = original

target + correction factor)

15. Add until value reaches

0.0 g.

0.0 g

18. Add fourth component

+1000.0 g

This concludes the

recalculation example.

Operating Instructions PMA 35001-X 15

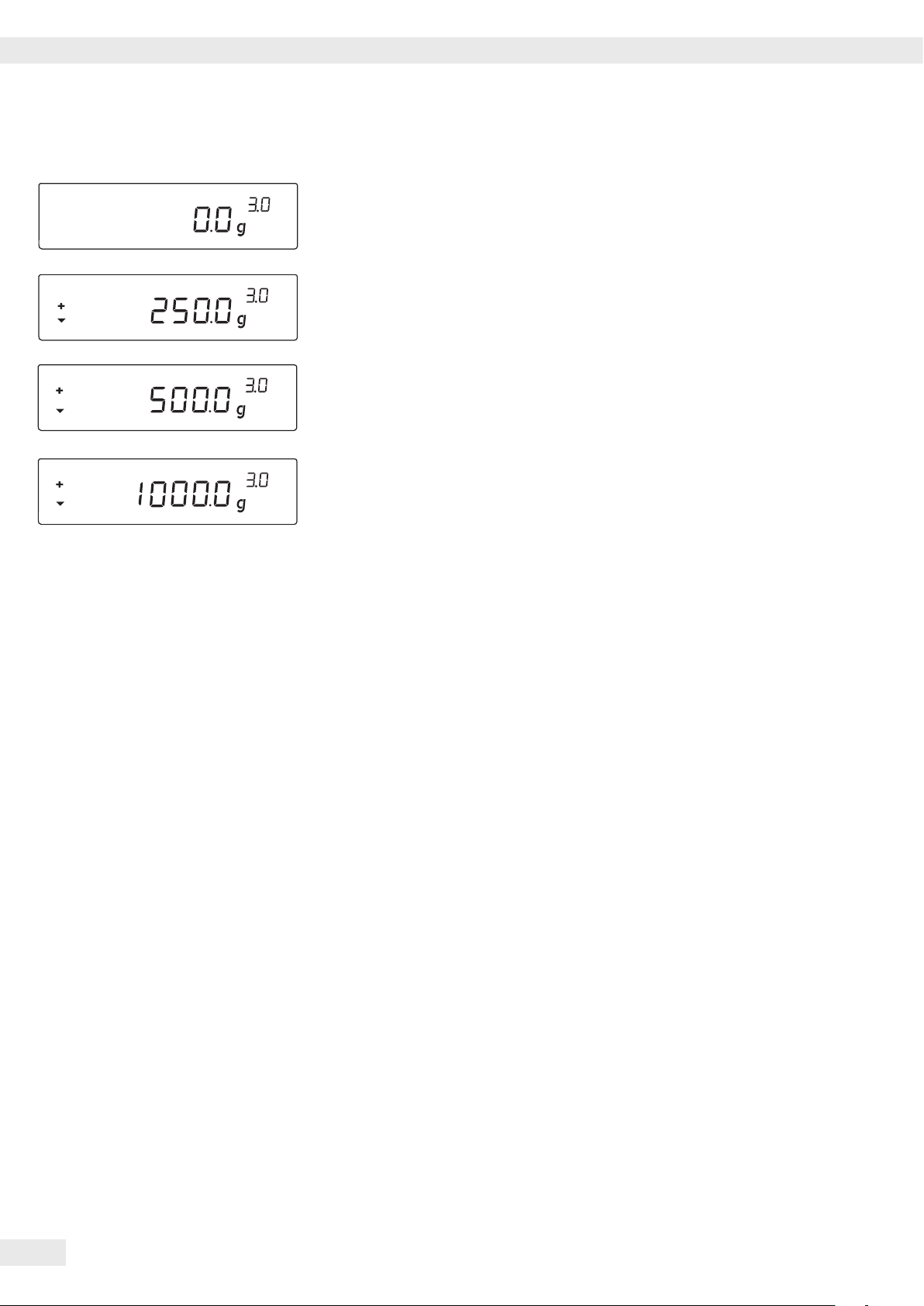

Adjustment

Adjustment

You can calibrate/adjust the scale by pressing the U key (Zero/Tare).

Calibration weight: 10000 g; precision: +2%.

Always allow approximately 30 minutes for the scale to warm up after connecting it

to AC power and before performing calibration/adjustment.

Press and hold the U key (Zero/Tare) for 2 seconds; “10000" is displayed.

Release the key.

Center the calibration weight on the load plate. Adjustment is performed

automatically.

Remove the calibration weight.

16 Operating Instructions PMA 35001-X

Menu Settings

Menu Settings

Accessing the SETUP Menu

Example:

Menu Item: Adapting the Scale to the Installation Point

t Hold down the L key [ENTER] for approximately 2 seconds; “SETUP" is

displayed (level one).

t Use the RS keys to select the desired menu item for level one.

t Press the L key [ENTER] to select the next menu level (level two).

t Call up the desired menu item in level two.

Use the RS keys to select the desired menu item.

t Use the L key [ENTER] to select the next menu level (level three).

t The third level menu is displayed. Use the RS keys to select the desired menu

item.

t Press the L key [ENTER] to select the next menu level (level four).

t Call up the desired menu item in level four. Use the RS keys to select the

desired menu item.

(This concludes the example.)

t Press the L key [ENTER]; “o" is displayed, indicating that this new item is set.

t Press the c key (Clear) repeatedly to exit the menu.

Note:

Contact your local Sartorius office for a detailed list of the menu codes.

Operating Instructions PMA 35001-X 17

Menu Settings

Configuring the Main Menu Settings

Hold down the L key [ENTER] for approximately 2 seconds; “SETUP” is displayed (level 1).

Level 1

SETUP

Language Setting

Level 1 Level Setting

LANGUAGE Press the R key to select LANGUAGE

Press the L key [ENTER]

o GERMAN Press the RS keys to select a language

ENGLISH Press the L key [ENTER];

FRENCH o indicates the active setting

ITALIAN Press the c key (Clear) repeatedly to exit

etc. the menu

Default Unit: Standard and Grams/Parts per Pound

The default setting that is active when the scale is switched on can be found under

“SETUP > SCALE > UNIT” and SETUP>SCALE>SET:

Level 1 Level 2 Level 3 Level 4 Setting

SETUP Press the L key [ENTER]

SCALE Press the L key [ENTER]

UNIT Use the RS keys to select e.g. “SET”

GRAMS Press the L key [ENTER]

KG

o PT./PD. Use the RS keys toselect e.g. “STANDARD”

SET Press the L key [ENTER]; o indicates

o STANDARD the new code is set

Press the c key (Clear) repeatedly

to exit the menu

I Activating the Toggle Key

When the toggle key I (6) is active, you can use it to toggle the weight unit between grams

and parts per pound or to toggle between the decimal places. The unit is toggled each time the key is

pressed.

Level 1 Level 2 Level 3 Level 4 Setting

SETUP Press the L key [ENTER]

APPLICATION Use the RS keys to select “APPLICATION”

Press the L key [ENTER]

TOGGLE Use the RS keys to select “TOGGLE”

OFF Press the L key [ENTER]

o ON Use the RS keys to select “ON”

Press the L key [ENTER]; o indicates

the active setting

Press the c key (Clear) repeatedly

to exit the menu

18 Operating Instructions PMA 35001-X

Menu Settings

I Configuring the Toggle Key Function

Pressing the toggle key I toggles the scale between the default unit (see previous page) and the unit

defined as follows under SETUP > APPLICATION > UNIT.

Level 1 Level 2 Level 3 Level 4 Setting

SETUP Press the L key [ENTER]

APPLICATION Use the RS keys to select

“APPLICATION”

UNIT Press the L key [ENTER], press S to

select “UNIT” and press L [ENTER] to

confirm.

o PT./PD. Use the RS keys to select the desired

unit; e.g., “GRAMS”

GRAMS Press the L key [ENTER]; o indicates

the active setting

Press the c key (Clear)

Activating the “LOCK” Function

The LOCK function protects the scale from unauthorized use. When this function is active, the scale

readout shows weight values only when there is active communication between the scale and a PC.

If communication is interrupted, the readout goes blank and the display shows a padlock symbol. The

LOCK function is activated under “Extras.”

Level 1 Level 2 Level 3 Level 4

SETUP Press the L key [ENTER]

EXTRAS Use the RS keys to select “EXTRAS”

Press the L key [ENTER]

LOCK Use the RS keys to select “LOCK”

Press the L key [ENTER]

OFF Use the RS keys to select ON and

o ON press L to confirm

Press the c key (Clear) repeatedly to exit

the menu.

Operating Instructions PMA 35001-X 19

Menu Settings

Configuring Password Protection

In addition to the LOCK function, you can configure password protection for additional security.

With this feature, the LOCK function can be deactivated only by entering the valid password.

The password is numeric and can have up to 6 digits. Use the RS keys to select the digits

(0 through 9) for your password. The password is hidden on the display; only dashes (“------”) are

shown. The first dash flashes to prompt input. Press the RS keys to select the desired digit (0 to 9)

and then press the L key [ENTER]. The digit is stored and the second dash flashes on the display.

Repeat the input procedure as described for the first digit. To store a space as a character in the

password, press the L key [ENTER] while the corresponding dash is flashing.

Once all 6 characters have been stored, press the L key [ENTER] to enter the password.

Note:

Keep a copy of your password in a safe place.

The LOCK function can be deactivated only with this password.

Level 1 Level 2 Level 3 Setting

INPUT Use the RS keys to select “INPUT”

PASSWORD Press the L key [ENTER]

Press the L key [ENTER]

PW.NEW Use the RS keys to select “PW.NEW”

-------- Enter the password and press the

L key [ENTER]

Press the c key (Clear) repeatedly to exit

the menu

Changing the Password

To define a new password, the existing password must first be entered correctly under “PASSWORD.”

“PW.OLD” prompts this input. Once the old password is entered correctly, the “PW.NEW” prompt is

shown automatically. Enter the new password or press L at each position to confirm.

The display shows spaces.

Note:

Entering 6 spaces deletes the password, which deactivates the password function.

Level 1 Level 2 Level 3 Setting

INPUT Use the RS keys to select “INPUT”

PASSWORD Press the L key [ENTER]

PW.OLD Press the L key [ENTER]

-------- Enter the old password

PW.NEW After the old password has been entered

correctly, “PW.NEW” is displayed.

-------- Enter the desired password and press

the L key [ENTER]

Press the c key (Clear) repeatedly to exit

the menu

20 Operating Instructions PMA 35001-X

Menu Settings

Configuring the Text Length (“LONG” or “SHORT”)

You can define the length of the operator guidance texts shown on the display.

Level 1 Level 2 Level 3 Level 4 Setting

SETUP Press the L key [ENTER]

EXTRAS Use the RS keys to select “EXTRAS”

Press the L key [ENTER]

TEXTS Use the RS keys to select “TEXTS”

Press the L key [ENTER]

LONG Use the RS keys to select “SHORT”

o SHORT and press L to confirm

Press the c key (Clear) repeatedly

to exit the menu

Resetting the Scale (“RESET”)

You can restore the factory settings on the scale.

Note:

If you have activated the password function, this feature is password-protected.

Level 1 Level 2 Level 3 Level 4 Setting

SETUP Press the L key [ENTER]

RESET Use the RS keys to select “RESET”

Press the L key [ENTER]

MENU Use the RS keys to select “MENU”

Press the L key [ENTER]

YES Use the RS keys to select “YES”

o NO Press the L key; factory settings are

restored and “MENU” is displayed

Press the c key (Clear) repeatedly

to exit the menu

Code Settings

Select the “CODES” setting to have menu items identified by numeric codes (1.1.1.1.) rather than texts.

Level 1 Level 2 Setting

LANGUAGE Press the R key to select “LANGUAGE”

Press the L key [ENTER]

GERMAN Use the RS keys to select “CODES”

etc. Press the L key [ENTER]; o indicates

o CODES the active setting

Press the c key (Clear) repeatedly

to exit the menu

Note:

Contact your local Sartorius office for a detailed list of the menu codes.

Operating Instructions PMA 35001-X 21

Error Codes

Error Codes

Problem Cause Remedy

No segments appear

onthe weight display

The weight readout

shows “Low"

The weight readout

shows “High"

The weight readout

changes constantly

The weight readout is

obviously incorrect

No weight value is

shown and the padlock

symbol

is displayed

– No AC power is

available

– No load plate on the

scale

– Weighing capacity

exceeded

– The setup location

isunstable

– Excessive vibration

ordraft

– The sample is not

stable

– Scale not tared before

weighing

– Communication

between scale and PC

has been interrupted,

activating the LOCK

function

– Check the AC power

supply

– Position the load plate

– Unload the scale

– Change the setup location

– Make the necessary

adjustment via the scale

operating menu

(see “Menu Settings")

– Tare before weighing

– Access the menu to make

the necessary adjustment

and switch off the LOCK

function

– Check the connection

22 Operating Instructions PMA 35001-X

Care and Maintenance

Care and Maintenance

Service

Regular servicing by a Sartorius technician will ensure continued functional safety.

Sartorius offers its customers service contracts with regular maintenance intervals

ranging from 1 month to 2 years.

The maintenance interval depends on operating conditions and requirements.

Repairs

Disconnect defective equipment from power supply immediately.

Repair work must be performed only by authorized Sartorius service technicians

using original replacement parts. Repairs performed by untrained persons may

result in considerable hazards for the user.

Safety Inspections

Safe operation of the device is no longer ensured when:

– the device has visible damage or is no longer working;

– it has been stored for a relatively long time under unfavorable conditions.

In this case, notify the Sartorius Service Center. Maintenance and repair work

mayonly be performed by authorized service technicians who have access to the

required maintenance manuals and instructions and have attended relevant service

training courses. If you are sending your scale to be repaired:

t remove as much paint residue as possible and disconnect all cables before

sending, in order to avoid any further damage;

t enclose a description of the error.

Cleaning

Prevent moisture from penetrating the interior.

Do not use aggressive cleaning agents. Never use concentrated acids,

alkalisolutions or pure alcohol to clean the equipment.

Spraying the device with water or blowing it with compressed air is not

permissible.

t Turn off the device before cleaning the control unit, since touching the screen

could trigger unwanted inputs.

t Use a damp, lint-free cloth to clean the device.

Operating Instructions PMA 35001-X 23

Care and Maintenance

Do not apply any cleaning agents to ID labels or printed surfaces.

Corrosive Environment

t Remove all traces of corrosive substances from the device on a regular basis.

Storage and Shipping Conditions

– Permissible storage temperature: -10 °C … +60 °C

24 Operating Instructions PMA 35001-X

Disposal

Disposal

The packaging is made of environmentally friendly materials that can be used as

secondary raw materials. If you no longer require the packaging, you can dispose

ofit free of charge in Germany through the Vfw dual system (contract number

D-59101-2009-1129). Otherwise you should dispose of the material in accordance

with the waste disposal regulations that are applicable in your area. The device,

including its accessories and batteries, should not be disposed of as household

waste. It should instead be recycled as electric/electronic equipment. For more

information regarding disposal and recycling, please contact our local service

representatives. Our partners listed on the following website will also be able to

provide assistance within the EU:

1) Go to http://www.sartorius.com.

2) Select the “Services" tab.

3) Then select “Disposal Information.”

4) Addresses for the local Sartorius disposal contacts can be found in the PDF files

available for download on this page.

Sartorius will not take back equipment contaminated with hazardous materials

(ABC contamination) – either for repair or disposal.

Detailed information, including service addresses for returning your device for

repair or disposal, can be found on our website (www.sartorius.com) or requested

from a Sartorius Service Center.

Serial Number Coding

The manufacture date of this device is encoded in the serial number.

The format is as follows: YMM x x x x x

Y Year

1 2000–2006

2 2007-2013

3 2014–2020, etc.

The Y column indicates the year group, which covers a period of 7 years.

Withineach year group, the months (M M) are counted up from 13.

Year: 2013 2014 2015 2016 2017 etc.

MM: 85-96 13-24 25-36 37-48 49-60 etc.

Example: 288xxxxx (April 2013). “xxxxx" is a consecutive number, increasing

by one every month.

Operating Instructions PMA 35001-X 25

Interface Port

!

Interface Port

Pin assignment

9-pin data output (socket):

Pin 2: (RXD) Receive data

Pin 3: (TXD) Transmit data

Pin 4: (DTR) Data terminal ready

Pin 5: (GND) Ground

Pin 6: not used.

Pin 8: Clear to send (CTS)

Make sure to observe the safety instructions.

t Remove the protective cover from the interface port.

Keep the protective cover in a safe place.

y Replace the interface cover when storing or shipping the scale.

26 Operating Instructions PMA 35001-X

Specifications

Specifications

Model PMA 35001-X

Weighing Capacity g 35000

Readability g 0.1

Tare range (subtractive) g -35000

Linearity g ≤±0,2

Stability range (configurable in menu) Digit 0.25 to 4

Humidity class F non-condensing

Permissible ambient operating temperature range °C 0 to +40

IP protection IP 43, in accordance with EN60529/IEC60529

Load plate dimensions mm 350 + 240

Scale housing (WxDxH) mm 350 + 243 + 132,5

Net weight, approx. kg 11.4

External calibration weight kg 10 (accuracy class F2 or better)

Interface RS232

Format 7-bit ASCII, 1 start bit, 1 or 2 stop bits

Parity Even, odd, none

Transmission rates 1200 to 38,400 bps

Handshake Software or hardware

Power consumption VA Average: 8, max. 16

Mains Connection V 100 – 240 V ~

Voltage frequency Hz 50 – 60

Device ID (explosion protection) II 2G Ex ia IIC T4 Gb

DEKRA 12ATEX0180 X The terminal/control panel is

suitable for use in potentially explosive areas in

accordance with Directive 94/9/EC

Zone1 (devices in category 2)

Ambient conditions

Environment For indoor use only

Ambient temperature: Storage and shipping -10 °C … +60 °C

Ambient temperature: Operation 0 °C … +40 °C

Highest relative humidity: 80 % for temperatures up to 31 °C, decreasing linearly up to

50 % relative humidity for 40 °C

Safety of electrical equipment

Electromagnetic compatibility

Defined immunity to interference:

Limitation of emissions:

as per EN 61010-1:2010

Safety requirements for electrical equipment for

measurement, control, and laboratory use — Part 1:

Generalrequirements

as per EN 61326-1:2006

Electrical equipment for measurement, control, and laboratory use — EMC requirements — Part 1: General requirements

Industrial areas

Class B: Suitable for use in residential areas and areas that

are directly connected to a low voltage network

Operating Instructions PMA 35001-X 27

Accessories

Accessories

AC adapters

ATEX certified for Europe:

AC adapter for use inside of potentially explosive area

ATEX certified for Europe:

AC adapter for use outside of potentially explosive area

FM certified for the USA:

AC adapter for use inside of potentially explosive area

FM certified for the USA and Canada:

AC adapter for use outside of potentially explosive area

CSA certified for Canada:

AC adapter for use inside of potentially explosive area

Safety barrier

Data communication cable with integrated

energy limiting unit for direct communication (RS232) from

thePC to a Sartorius scale in potentially explosive atmosphere

xx = different cable lengths available (8m, 15m, 30m)

YPSC01-X

YPSC01-Z

YPS02-XUR

YPS02-ZKR

YPS02-XKR

YELU01-ZMxx

In-use dust cover

Data communication cable (2 m) YCC01-0047M2

YDC01PMA

28 Operating Instructions PMA 35001-X

EC Declaration of Conformity

Operating Instructions PMA 35001-X 29

ECDeclaration of Conformity

30 Operating Instructions PMA 35001-X

Safety Instructions

1) The equipment must be installed, operated, maintained and repaired by a qualified technician in compliance

with applicable laws, rules and regulations, ordinances and standards. In particular, be sure to conform to the

European Standards EN 60079-14 (Explosive atmospheres – Part 14: Electrical installations design, selection

and erection). For more information see „Verification of Intrinsic Safety“ 36953-761-60 (ATEX) and „Control

Drawing“ 36953-761-07 (for use in the USA and in Canada).

Installation, maintenance, cleaning and repair work may only take place with all power disconnected from the

equipment. Do not plug in or disconnect the cable in potentially explosive atmospheres.

2) Be sure to follow the installation, operating, maintenance and servicing instructions given in the manuals

supplied.

3) The equipment shall be installed in such a way that it is protected against the entry of solid foreign objects or

water capable of impairing the safety of the apparatus. Reduce the risk of mechanical damage to a minimum.

4) The equipment must be powered by a suitable certified/approved power supply/battery pack with intrinsically

safe circuits as described in the certificate of this equipment.

5) Exposure to UV radiation is not allowed! Avoid exposure to direct sunlight.

6) The connecting cables of the display unit must be protected against damage and stress caused by strain.

7) Prior to opening the equipment, disconnect the power supply or make sure that there is no potentially

explosive atmosphere or any other explosion hazard in the surrounding area!

8) The data cables connected to the equipment are considered as intrinsically safe circuits. The connection is

secured against accidental disconnection and may only be plugged in or disconnected when the power is

switched completely off. Check the correct function of the data transfer before you use the equipment in a

hazardous location.

9) If the equipment is not operating properly, unplug it immediately from the line power (mains supply) and

secure it against any further use!

10) All metal parts must be electrically connected to the terminal for the equipotential bonding conductor (PA).

The equipment operator must to connect a lead with a gauge of at least 4 mm² (cross section) to the PA

terminal located on the side of the housing (indicated by the ground symbol). The low resistance of this

connection to the PA busbar must be checked when the system is installed at the intended place of use. Ensure

that the connection cannot be unplugged by pulling on the grounding cable. The shielding of the connecting

cables may only be used for grounding when no impermissible difference in voltage is generated and the

shielding is able to conduct the equipotential current.

11) Avoid generating static electricity. Use only a damp cloth to wipe down the equipment. The equipment

operator shall be responsible for preventing any risks caused by static electricity.

12) Keep chemicals and other agents, which can corrode the housing seals and cable sheaths, away from the

equipment. These agents include oil, grease, benzene, acetone and ozone. If you are not sure about the safety

of a certain substance, please contact the manufacturer.

13) Use equipment only in the temperature ranges indicated. Avoid exposing the equipment to inadmissible

sources of heat or cold. Avoid heat build-up and ensure that the equipment has sufficient ventilation.

14) The equipment operator is responsible for any non-Sartorius cables used.

15) Check the EX approval marking (particularly the group for gases and temperature code) on all equipment in

the hazardous area before operation to ensure that the equipment is permitted to be operated in this area.

16) At reasonable intervals, have your equipment installation checked for proper functioning and safety by a

trained and certified technician.

17) If your equipment needs to be repaired, use only original spare parts supplied by the manufacturer!

18) Any tampering with the equipment by anyone, other than repair work done by authorized Sartorius service

technicians, will result in the loss of EX conformity and in the forfeiture of all claims under the manufacturer's

warranty. Only authorized specialists may open the equipment.

19) Modifications, including those to be carried out by Sartorius employees, may be permitted only after express

written authorization has been obtained from Sartorius.

2012-10-18

Dr. D. Klausgrete

Safety Instructions

36953-761-16

Operating Instructions PMA 35001-X 31

PMA35001-X..

Revision 00

Sheet of

1

1

EC Verification

32 Operating Instructions PMA 35001-X

EC Verification

Operating Instructions PMA 35001-X 33

EC Verification

34 Operating Instructions PMA 35001-X

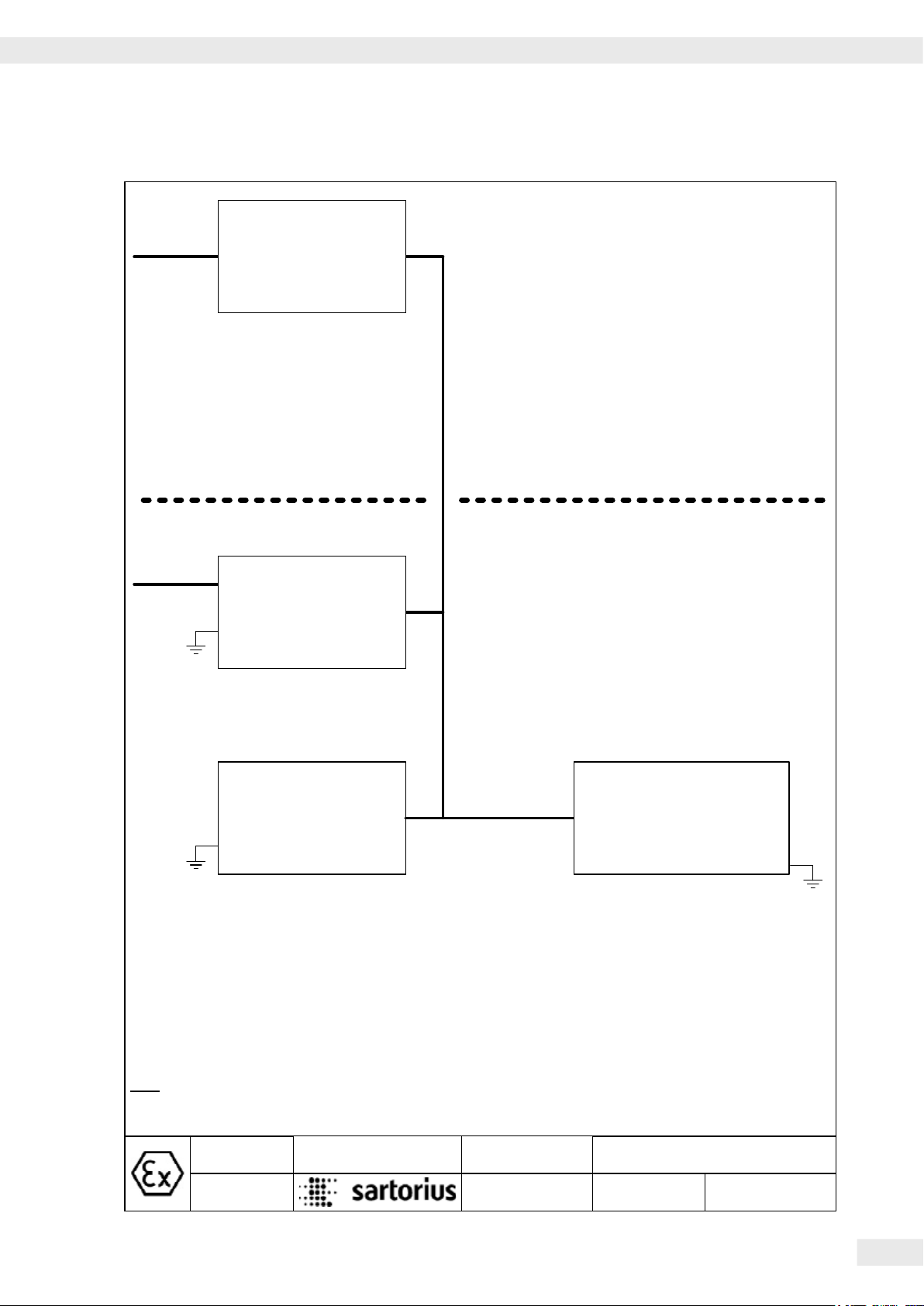

Verification of Intrinsic Safety

Mains cable

Mains cable

1)

Power supply

(100-240 Vac)

II (2) G [EEx ib] IIC

II (1) D

YPS02-Z.R

1)

YPS02-X.R

Power supply

2)

(100-240 Vac)

II 2 G EEx d [ib] IIC T4

II 1 D T135°C IP65

YPS02-X.. /YPS02-Z..:

Circuit Uo Io Po Co Lo

V_1 12.6 V 133 mA 1.46 W 1 µF 300 µH

V_2 12.6 V 133 mA 1.46 W 1 µF 300 µH

V_3 8.6 V 187 mA 1.51 W 4 µF 300 µH

V_4 12.6 V 150 mA 1.68 W 1 µF 300 µH

YRB02-X:

Circuit Uo Io Po Co Lo

V_1 12.6 V 133 mA 1.43 W 0.5 µF 300 µH

V_2 12.6 V 133 mA 1.43 W 0.5 µF 300 µH

V_3 8.6 V 186 mA 1.49 W 0.8 µF 200 µH

V_4 12.6 V 150 mA 1.65 W 0.5 µF 300 µH

Non-Hazardous Area

Hazardous Area

Alternative

connections

Sartorius cable; permanently mounted on the

power supply / explosion-protected (EX)

rechargeable battery pack; cable can be flexibly

installed; max. length: 50m

Zone 1

Gas: IIC T4

YRB02-X

EX battery pack

II 2 G EEx e m [ib]IIC T4

2)

II 1 D IP6X T80°C

Note:

1: For circuits with Vs< 375V

2: Bus bar

Dr. D. Klausgrete

2013-05-02

PMA35001-X..

Alternative

connections

PMA35001-X..

II 2 G Ex ia IIC T4 Gb

2)

Circuit Ui Ii Pi Ci Li

V_1 12.6 V 133 mA 1.46 W 188 nF 0 mH

V_2 12.6 V 133 mA 1.46 W 3 nF 0 mH

V_3 8.6 V 187 mA 1.51 W 391 nF 0 mH

V_4 12.6 V 150 mA 1.68 W 223 nF 82 µH

Power Supply

36953-761-60

Verification of Intrinsic Safety

Revision 00

Page 5of

1

Operating Instructions PMA 35001-X 35

Verification of Intrinsic Safety

Mains cable

1)

2)

II (2) GD [Ex ib] IIC

Any suitable intrinsically

2)

safe Sartorius Equipment

YPSC01-Z

Power supply

(100-240 Vac)

A)

B)

Alternative

connection

YPSC01-X /YPSC01-Z:

Circuit Uo Io Po Co Lo

V_1 12.6 V 115 mA 1.45 W 0.5 µF 350 µH

V_2 12.6 V 115 mA 1.45 W 0.5 µF 350 µH

V_3 8.6 V 168 mA 1.45 W 0.88 µF 350 µH

V_4 12.6 V 134 mA 1.68 W 0.5 µF 350 µH

V_5* 8.6 V 168 mA 1.45 W 0.88 µF 350 µH

*: not used

Sartorius cable; permanently

mounted on the power supply;

cable can be flexibly installed;

max. length: 50m

Non-Hazardous Area

Hazardous Area

Zone 1

Gas: IIC T4

YPSC01-X

B)

Power supply (100-240 Vac)

II 2 G Ex e mb[ib] IIC T4

II 1D (2)G Ex tD A20 [ib]IIC

2)

Note:

1: For circuits with Vs< 375V

2: Bus bar

A: Connection to main printed circuit board (PCB) 1 in YPSC01-.

B: Connection to main PCB 2 in YPSC01-.

IP6X T130°C

Dr. D. Klausgrete

2013-05-02

PMA35001-X..

A)

Alternative

connections

Circuit Ui Ii Pi Ci Li

V_1 12.6 V 133 mA 1.46 W 188 nF 0 mH

V_2 12.6 V 133 mA 1.46 W 3 nF 0 mH

V_3 8.6 V 187 mA 1.51 W 391 nF 0 mH

V_4 12.6 V 150 mA 1.68 W 223 nF 82 µH

Power Supply

36953-761-60

PMA35001-X..

II 2 G Ex ia IIC T4 Gb

Verification of Intrinsic Safety

Revision 00

Page 5of

2

2)

36 Operating Instructions PMA 35001-X

Verification of Intrinsic Safety

YDI05-Z.. interface converter

II (2) GD [EEx ib] IIC or

Z966 Zener barrier

4)

in YDI02-Z..: II (2) G [EEx ib] IIC or

YCO01-Y interface converter

II (2) GD [EEx ib] IIC or

II 3 (2)GD EEx nR[ib]IIC T4

YDI05-Z..

Uo 12.4 V* Ui 12.6 V*

Io 260 mA*** Ii any

Po 800 mW Pi any

Co 1.24 µF* Ci 0

Lo 400 µH* Li 0

Lo/Ro 44 µH/

YCO01-Y

Uo 11.8 V* Ui 12.6 V*

Io 123 mA*** Ii 131 mA

Po 361 mW Pi any

Co 1.5 µF* Ci 0.5 nF

Lo 2 mH* Li 0.8 µH

Lo/Ro 98 µH/

2)

24.8 V** 25.2 V**

112 nF**

400 µH**

* / 22 µH/ **

2)

23.6V** 25.2 V**

129 nF**

2 mH**

* / 98µH/ **

1)

Z966

Uo 12 V*

Io 82 mA /164 mA

Po 0.24 W / 0.48 W

Co 1.41 µF*

Lo 5.52 mH

Lo/Ro 147 µH/

pins A/J/K/N and M

24 V**

125 nF**

57 µH/

8)

8)

1.38 mH

Non-Hazardous Area

Hazardous Area

8)

8)

Zone 1

Gas: IIC T4

RS232 data interface

(pins A/J/K/N and M)

Ui 12.6 V Uo 12.6 V

Ii 85 mA Io 28 mA

Pi 270 mW Po 88 mW

Ci 3 nF Co 1.15 µF

Li 0 Lo 50 mH

FC/FCA/IS.......-.X..

1)

3)

6-wire standard cable, up to 0.5mm² stranded wire, with max.

250nF/km, 750µH/km and minimum 34ohm/km has 22µH/

ohm. However, the length of the cable (flexibly installed) is

limited to under 25m by the RS-232 specifications. 6-wire

cable, type PR6136 (Lmax = 1.1mH/km; Cmax = 220nF/km;

Rmin = 26 ohms/km: 43µH/ohm): under 25m (see above).

scale / weighing

platform

(see remark 5 on page 3)

Note:

1: Per circuit

2: Combined circuits

3: Not all models can be used in zones 20,21,22

4: BAS01ATEX7005; II (1) GD [EEx ia] IIC

5: Both channels connected on Z966

*: Versus GND; **: Between the lines; ***: Resistively limited

Alternative

connection

PMA35001-X..

II 2 G Ex ia IIC T4 Gb

2)

RS232 data interface

Ui 12.6 V* / 25,2V** Uo 10 V* / 20V**

Ii 328 mA*** Io 101 mA***

Pi any Po 253 mW

Ci 2.2 nF* / 0.5nF** Co 3 µF* / 217nF**

Li 0 mH Lo 3 mH

COM1

Lo/Ro 140 µH/

Dr. D. Klausgrete

2013-05-02

PMA35001-X.. RS232 Data Interface

36953-761-60

Operating Instructions PMA 35001-X 37

Verification of Intrinsic Safety

Revision 00

Page 5of

3

Verification of Intrinsic Safety

YDI05-Z.. interface converter

II (2) GD [EEx ib] IIC or

Z966 Zener barrier

4)

in YDI02-Z..: II (2) G [EEx ib] IIC

or

YCO01-Y interface converter

II (2) GD [EEx ib] IIC or

II 3 (2)GD EEx nR[ib]IIC T4

Data cable:

Recommended: Sartorius cable

YCC485-X with approx.

10µH/ohm and 120pF/m (wire/wire)

up to 1000m flexibly installed.

5) 2)

RS485 data interface

Uo 7.2 V Ui 12.6 V

Io 127 mA* Ii 1.5 A*

Po 0.273 W Pi 2.5 W

Co 11.3 µF Ci 0

Lo 2 mH Li 2 µH

Lo/Ro 118 µH/ohm

(UNICOM. LV2)

YDI05-Z..

2) 3)

Uo 12.4 V* Ui 12.6 V*

24.8V** 25.2

V**

Io 130 mA*** Ii any

Po 400 mW Pi any

Co 1.24 µF* Ci 0

112nF**

Lo 0.4 mH* Li 0

0.4 mH**

Lo/Ro 44 µH/

YCO01-Y

* / 22 µH/ **

2)

Uo 7.2 V* Ui 12.6 V*

8.0 V** 25.2 V**

Io 207 mA*** Ii 1.5 A

Po 330 mW Pi 2.5 W

Co 13.5 µF* Ci 1 nF

8.4 µF**

Lo 0.7 mH* Li 1.6 µH

0.7 mH**

Lo/Ro 36 µH/

* / 36µH/ **

Zone 1

Gas: IIC T4

Z9661)pins A/J/K/N and M

Uo 12 V*

24V**

Io 82 mA /164mA

Po 0.24 W / 0.48W

Co 1.41 µF*

125nF**

Lo 5.52 mH

1.38mH

Lo/Ro 147 µH/

57 µH/

Non-Hazardous Area

Hazardous Area

PMA35001-X..

6)

6)

6)

6)

RS485 data interface

8.2 V

3)

4)

Uo 7.2 V

Io 168 mA* Ii 1.5 A*

Po 0.25 W Pi 2.5 W

Co 13 µF

Co 7.6 µF

3)

4)

5) 2)

(LV4)

Ui 12.6 V

Ci 300 nF

Ci 100 nF

Up to 7 additional

CIXS3 or

SIWS… / ISXS...

3)

4)

Lo 0.8 mH Li 0 mH

Lo/Ro 118 µH/ohm

Note:

1: Per circuit

2: Combined circuits

3: Only two RS232 connections are used on the YDI05-Z

4: BAS01ATEX7005; II (1) GD [EEx ia] IIC

5: Data for CIXS3

6: Both channels connected on Z966

*: Versus GND; **: Between the lines; ***: Resistively limited

Dr. D. Klausgrete

2013-05-02

PMA35001-X.. RS485 Data Interface

36953-761-60

II 2 G Ex ia IIC T4 Gb

3)

RS485 data interface

Ui see below Uo 5.2 V

Ii see bwlow Io 210 mA***

Pi any Po 263 mW

Ci 260 nF Co 60 µF

Li 0 mH Lo 600 µH

Ui ±12.4V 12.0V 7.2V

Ii 130 mA*** 164mA*** any

2)

Lo/Ro 125 µH/

Verification of Intrinsic Safety

Revision 00

Page 5of

4

38 Operating Instructions PMA 35001-X

Verification of Intrinsic Safety

YDI05-Z

(Option A25)

Interface converter

II (2) GD [EEx ib] IIC

Alternative

connection

YCO01-Y

Interface converter

RS422 data interface of YDI05-Z

Uo 6.0 V *

Io 172 mA (linear) Ii 0.2 A

Po 0.5 W Pi 2.3 W

Co 12 µF *

Co 17.7 µF

Lo 0.7 mH Li 2 µH

RS422 data interface of YCO01-Y

Uo 7.2 V* Ui 12.6 V*

Io 207 mA*** Ii 1.5 A

Po 330 mW Pi 2.5 W

Co 13.5 µF* Ci 1 nF

Lo 0.7 mH* Li 1.6 µH

Lo/Ro 36 µH/

)

6.8 V **

8.0 V** 25.2 V**

8.4 µF**

0.7 mH**

)

)

**)

*/ 36µH/ *

Ui 12.6 V *

Ci 28 µF *

Ci 200 nF **

2)

25.2 V **

2)

Non-Hazardous Area

)

)

)

)

Cable:

For a standard cable (e.g., type

LiYCY with max. 250nF/km (wire

versus wire or wire versus

shield), max. 750µH/km and at

least 34 ohms/km (e.g. 0.5mm²

stranded wire), this yields Lo/Ro

= 22 µH/ohm

the flexibly installed cable: 330m

RS422 data interface

Uo 5,2 V Ui 8.6 V

Io 290 mA Ii 210 mA

Po 496 mW Pi 0.5 W

Co 60 µF Ci 0.5 µF

Lo 300 µH Li 0 mH

Lo/Ro 50 µH/

Note:

1: Per circuit

2: Combined circuits

*: Versus GND; **: Between the lines; ***: Resistively limited

Permitted length of

2)

(COM1)

Hazardous Area

Zone 1

Gas: IIC T4

PMA35001-X..

II 2 G Ex ia IIC T4 Gb

Dr. D. Klausgrete

2013-05-02

PMA35001-X.. RS422 Data Interface

36953-761-60

Operating Instructions PMA 35001-X 39

Verification of Intrinsic Safety

Revision 00

Page 5of

5

Certificate of Compliance

40 Operating Instructions PMA 35001-X

Certificate of Compliance

Operating Instructions PMA 35001-X 41

Certificate of Compliance

42 Operating Instructions PMA 35001-X

Certificate of Compliance

Operating Instructions PMA 35001-X 43

Last updated:

The information and figures contained in these

instructions correspond to the version date

specified below.

Sartorius reserves the right to make changes

to the technology, features, specifications and

design of the equipment without notice.

Masculine or feminine forms are used to

facilitate legibility in these instructions and

always simultaneously denote the other

gender as well.

Copyright notice:

This instruction manual, including all of its

components, is protected by copyright.

Any use beyond the limits of the copyright law

is not permitted without our approval.

This applies in particular to reprinting,

translation and editing irrespective of the type

of media used.

© Sartorius Germany

Sartorius Lab Instruments GmbH & Co. KG

Otto-Brenner-Strasse 20

37079 Goettingen, Germany

Phone:

+49.551.308.0

Fax:

www.sartorius.com

+49.551.308.3289

04 | 2016

Printed in the EU on paper bleached

without chlorine. | W

Publication No.: WPM6074-e160403

Loading...

Loading...