Operating Manual

PMA.Evolution | PMA.HD

EVO1X | LAB1X

Paint-mixing Scales for Use in Potentially Explosive Atmospheres

98648-020-50

Operating Manual EVO1X | LAB1X 3

Contents

Contents

1 About This Document.......................................4

1.1 Scope....................................................4

1.2 Symbols Used ...........................................4

1.3 User Information........................................4

2 Safety

........................................................5

2.1 General Safety Instructions.............................5

2.2 Installation Instructions ................................6

2.3 Intended Use............................................7

3 Device Overview

.............................................8

3.1 Front View ..............................................8

3.2 Rear View ...............................................9

3.3 Ex-link Converter/AC Adapter .........................10

3.4 Operating and Display Elements.......................11

3.5 Menu List ..............................................13

4 Installation

.................................................17

4.1 Unpacking and Equipment Supplied...................17

4.2 Selecting a Setup Location ............................17

4.3 Installing the Scale.....................................18

4.4 Supply Voltage.........................................18

4.4.1 AC Adapter Assembly (Optional) ..............18

4.4.2 Connecting the Scale..........................20

4.5 Anti-theft Locking Device .............................22

5 Commissioning

.............................................23

5.1 Leveling ................................................23

5.2 Warm-up Time.........................................23

6 Operation

...................................................24

6.1 Switching the Device On/Off ..........................24

6.2 Locking the Keypad/Weight Display ...................24

6.3 Zeroing/Taring .........................................24

6.4 Calibration/Adjustment................................24

6.4.1 Calibration.....................................25

6.5 Weighing...............................................25

6.5.1 Weighing with One Decimal Place ............25

6.5.2 Weighing with Two Decimal Places

(Not for Verified Models)......................26

6.6 Applications............................................26

6.6.1 Calculation by a Factor........................26

6.6.2 Weighing Using the Recalculation Function ..27

6.7 Menu Settings .........................................29

6.7.1 Accessing the SETUP Menu....................29

6.7.2 Configuring the Main Menu Settings . . . . . . . . .29

7 Care and Maintenance

....................................33

7.1 Cleaning................................................33

7.2 Maintenance ...........................................33

8 Malfunctions

...............................................34

9 Storage

.....................................................35

10 Disposal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

11 Serial Number Coding

.....................................36

12 Technical Data

..............................................37

12.1 General Data ...........................................37

12.2 Model-specific Data ...................................38

12.3 Verified Models with EC Type Approval Certificate:

Model-specific Technical Data.........................38

12.4 Device Dimensions .....................................39

12.4.1 Model EVO1X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

12.4.2 Model LAB1X ..................................39

12.5 USB Port (PC Connection) .............................39

12.5.1 Purpose ........................................39

12.5.2 Installing the Software Driver.................40

13 Accessories

..................................................41

14 Sartorius Service

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

15 Conformity & Licenses

.....................................42

15.1 EU Declaration of Conformity .........................42

4 Operating Manual EVO1X | LAB1X

About This Document

1 About This Document

1.1 Scope

This operating manual applies to paint-mixing scale models:

− EVO1X

− LAB1X

1.2 Symbols Used

Denoting instructions and direct hazard warnings, all especially important

statements to be observed in these installation instructions will be marked as

follows:

This symbol denotes a possible danger with medium risk of death or (severe) injury

if not avoided.

This symbol denotes a possible danger with a low risk of moderate or minor injury

if not avoided.

This symbol denotes a danger with low risk that could result in property damage

if not avoided.

This symbol

− is an indication of a function or setting on the device

− is an indication that caution should be exercised while working

− identifies useful information.

This symbol provides information for the sale of scales verified for use in legal

metrology.

In the following, the term “verified” is used to mean “verified for use in legal

metrology” or “conformity-assessed.”

The following symbols are also used:

− Text that follows this symbol is a list.

t Text that follows this symbol describes activities which are to be performed in

the specified order.

y Text that follows this symbol describes the result of an action.

1.3 User Information

The illustrations in these instructions are based on the PMA.Evolution (EVO1X) model.

Operating Manual EVO1X | LAB1X 5

Safety

2 Safety

2.1 General Safety Instructions

− The scale and the ex-link converter meet the relevant legal provisions and

applicable standards (see the corresponding certificates in Chapter 15,

page 42).

− Nevertheless, improper use or handling can result in damage and/or injury.

Any improper use or operation of the scale or of the ex-link converter, i.e., that is

not consistent with the instructions, will result in forfeiture of all claims under

the manufacturer's warranty.

− Personnel need to have read and understood these installation instructions,

including the safety instructions.

− In the event of use in systems and under ambient conditions with higher safety

requirements, you must observe the requirements and provisions applicable in

your country.

− Always keep the equipment and scale freely accessible.

Ensure that the voltage rating printed on the AC adapter (optional) is identical to

your local mains voltage.

The IP protection rating of the scale and the ex-link converter YCO14-Z/YCO14-Y is

IP40 as per EN 60529. The devices must be handled carefully according to the IP

protection rating. The environment must be suitably secured.

Use within the scope of validity of the European ATEX Directive:

− In accordance with Directive 2014/34/EU, the model in the EVO1X | LAB1X series

is a category 2 device, suitable for use in Zone 1 potentially explosive areas.

− The ex-link converter YCO14-Z is only suitable for installation as an associated

electrical apparatus with the following ID code outside of the potentially

explosive area.

− The ex-link converter YCO14-Y is an associated electrical apparatus that can be

used in Zone 2.

− Refer to the EU Type Examination Certificates in Chapter 15, page 42 for the

device ID codes. Please observe the safety instructions in drawing 2023040 in

Chapter 15, page 42.

Use in Canada and the USA:

The intrinsically safe scales in the EVO1X | LAB1X model series are suitable for use in

Class I, Division 1 and Class I, Zone 1. The ex-link converter YCO14-Y can be used in

Class I, Division 2 and Class I, Zone 2.

Please observe Certificates of Conformity FM16US0226X and FM16CA0124X as well

as Control Drawing 2021459 in Chapter 15, page 42.

Use in Australia/New Zealand:

Please observe IECEx Certificate of Conformity IECEx FME 14.0008X and Safety

Instructions 2023040 in Chapter 15, page 42.

6 Operating Manual EVO1X | LAB1X

Safety

2.2 Installation Instructions

Do not operate the scale if its housing, the ex-link converter, or the AC adapter

including all connections are damaged.

Immediately disconnect the damaged device from the power.

Do not expose the scale, the ex-link converter, the AC adapter, or the accessories

supplied by Sartorius to extreme temperatures, aggressive chemical vapors, moisture,

shocks, vibrations, or strong electromagnetic fields. Observe the conditions of

operation described in the Specifications.

The connection cables between the devices as well as the casing on the wires inside

the device housing are made of PVC. Chemicals that corrode this material must be

kept away from these cables.

The operator shall be solely responsible for any modifications to the equipment and

for connecting any cables or equipment not supplied by Sartorius. Information on

operational quality is available upon request from Sartorius.

Only use original Sartorius accessories!

Note the IP protection rating of the scale, the ex-link converter, and the AC adapter.

Do not allow liquid penetration. The protection rating specifies the suitability of

equipment for various environmental conditions (moisture, foreign bodies).

Before cleaning the AC adapter, ex-link converter, or the scale:

Disconnect all devices from the power supply.

The scale and ex-link converter may only be opened by personnel trained by

Sartorius with the power disconnected.

Do not open the AC adapter.

Avoid generating static electricity on the glass panel of the touch screen and plastic

casing. The equipotential bonding conductor of the devices must be connected

properly, according to commonly accepted technical standards.

Only clean the device as stipulated in the cleaning instructions.

Take care that the glass panel of the touch screen is not damaged (e.g., by falling

objects, impact, or extreme pressure).

If the glass panel is damaged, disconnect the device from the power supply

immediately.

The surface of the touch screen should not be touched with pointed, sharp, hard, or

rough objects. You should only use the touch pen provided or your fingertips. Do not

use parts of clothing (e.g., sleeves) or sponges for cleaning because these can scratch

the surface (e.g., due to rivets or buttons in the sleeve, or sand in the sponge).

The device must be protected from unnecessarily extreme temperatures, aggressive

chemical vapors, moisture, shocks, and vibrations. Note the connection data (see

EC Type Examination Certificates for the device and/or the safety instructions,

drawing no. 2023040).

Operating Manual EVO1X | LAB1X 7

Safety

Warnings Concerning Installation and Operation:

The equipment must only be used indoors. Avoid generating static electricity on glass

and plastic parts. Connect the scale and the ex-link converter to the equipotential

bonding conductor using a suitable low-resistance method. All electrical circuits are

grounded and electrically connected to the metal parts of the devices.

− The installation must be checked for correct function and safety by trained and

qualified personnel at appropriate intervals (e.g., checking the cables for

damage).

− Operating personnel must be trained to recognize faulty operating states and to

be able to initiate the necessary safety measures (e.g., disconnecting the ex-link

converter from the power supply).

Lay the cables where they pose no risk of causing someone to trip.

Danger of Scale Damage!

Never close a paint can using a hammer while it is still on the weighing pan.

When closing, place the paint can on a firm, stable surface.

Observe the additional safety precautions and hazard warnings in subsequent

chapters.

2.3 Intended Use

This scale is only intended for mixing colors and paints. The scale is connected

to the ex-link converter only using the link cable supplied. The scale and ex-link

converter may only be used in potentially explosive areas in accordance with Safety

Instructions 2023040 in Chapter 15, page 42. Appropriate containers must be used

for loading each type of material.

The scale can be operated via the keypad as a stand-alone device or using

application software (e.g., a paint-mixing program from a paint manufacturer)

installed on a connected PC. The PC is connected to the ex-link converter via a

USB cable.

8 Operating Manual EVO1X | LAB1X

Device Overview

3 Device Overview

3.1 Front View

3

2

1

Item Designation

1 Operating and display elements (see also Chapter 3.4, page 11)

2 Support column

3 Weighing pan

Operating Manual EVO1X | LAB1X 9

Device Overview

3.2 Rear View

4

3

2

67

1

2

8

9

5

8

10

Item Designation

1 RJ-45 socket for link cable

2 Cable holders

3 Support column

4 Link cable (blue)

5 Ex-link converter

6 Anti-theft locking device

7 Grounding terminal for equipotential bonding

8 Leveling feet (PMA.HD and verified models only)

9 Leveling (PMA.HD and verified models only)

10 Menu access switch

10 Operating Manual EVO1X | LAB1X

Device Overview

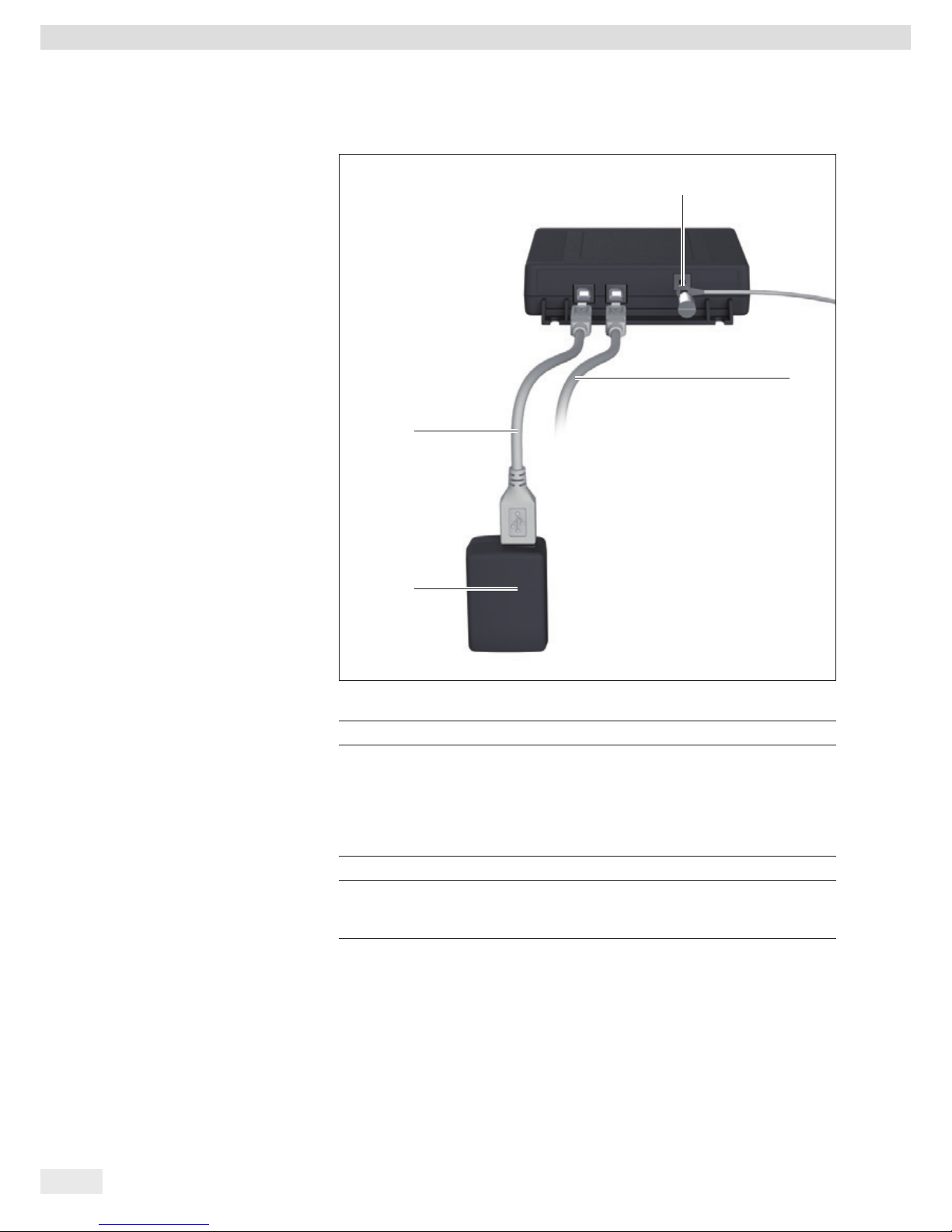

3.3 Ex-link Converter/AC Adapter

3

4

2

1

Item Designation

1 Grounding terminal for equipotential bonding

2 USB cable for connecting to PC or notebook. If the ex-link converter

YCO14-Y is in Zone 2 or Division 2 as per the Safety Instructions or Control

Drawing (Chapter 15, page 42) and the USB cable does not have an intrinsically safe electrical circuit with protection rating Ex ic or an NIFW electrical

circuit (for Division 2), the cable must be secured against disconnection

(see Chapter “4.4.2 Connecting the Scale,” page 20).

3 AC adapter (optional); only outside of the potentially explosive area

4 USB cable for power supply via the AC adapter (optional)

The AC adapter is only approved for the ex-link converter power supply if

the ex-link converter is installed outside of the potentially explosive area.

Operating Manual EVO1X | LAB1X 11

Device Overview

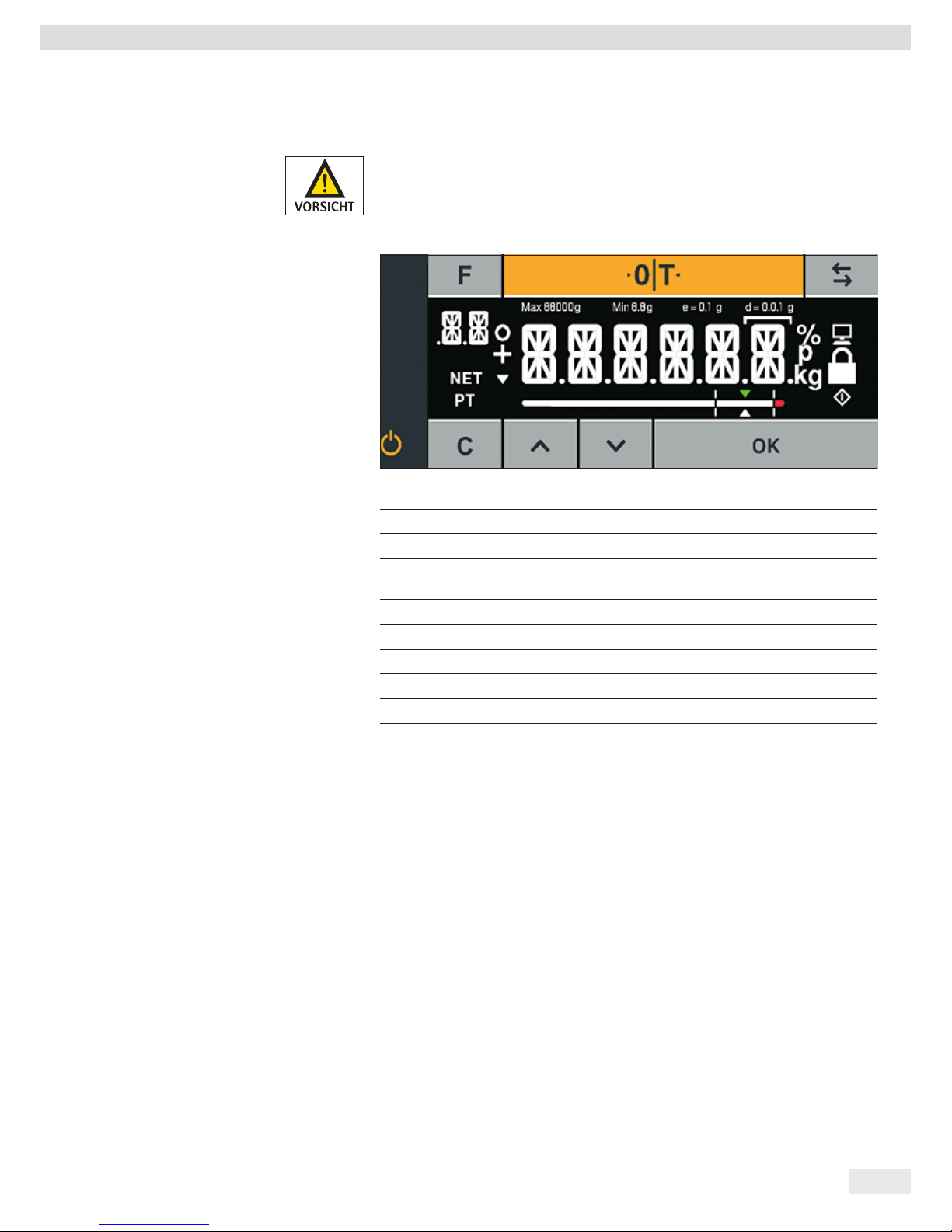

3.4 Operating and Display Elements

Sharp or pointed instruments (such as ballpoint pens) can damage the device!

− The touch screen should only be operated by lightly pressing it using the tips of

your fingers.

Key Function

$

Factor key for paint-mixing applications

&

Zeroing/taring

Z

Toggle key: Toggles the decimal places and/or unit

Depends on the menu setting

j

On/standby

§

Clear key/display of correction factor for paint-mixing applications

O

Up

P

Down

!

ENTER key/MEM key for paint-mixing applications

12 Operating Manual EVO1X | LAB1X

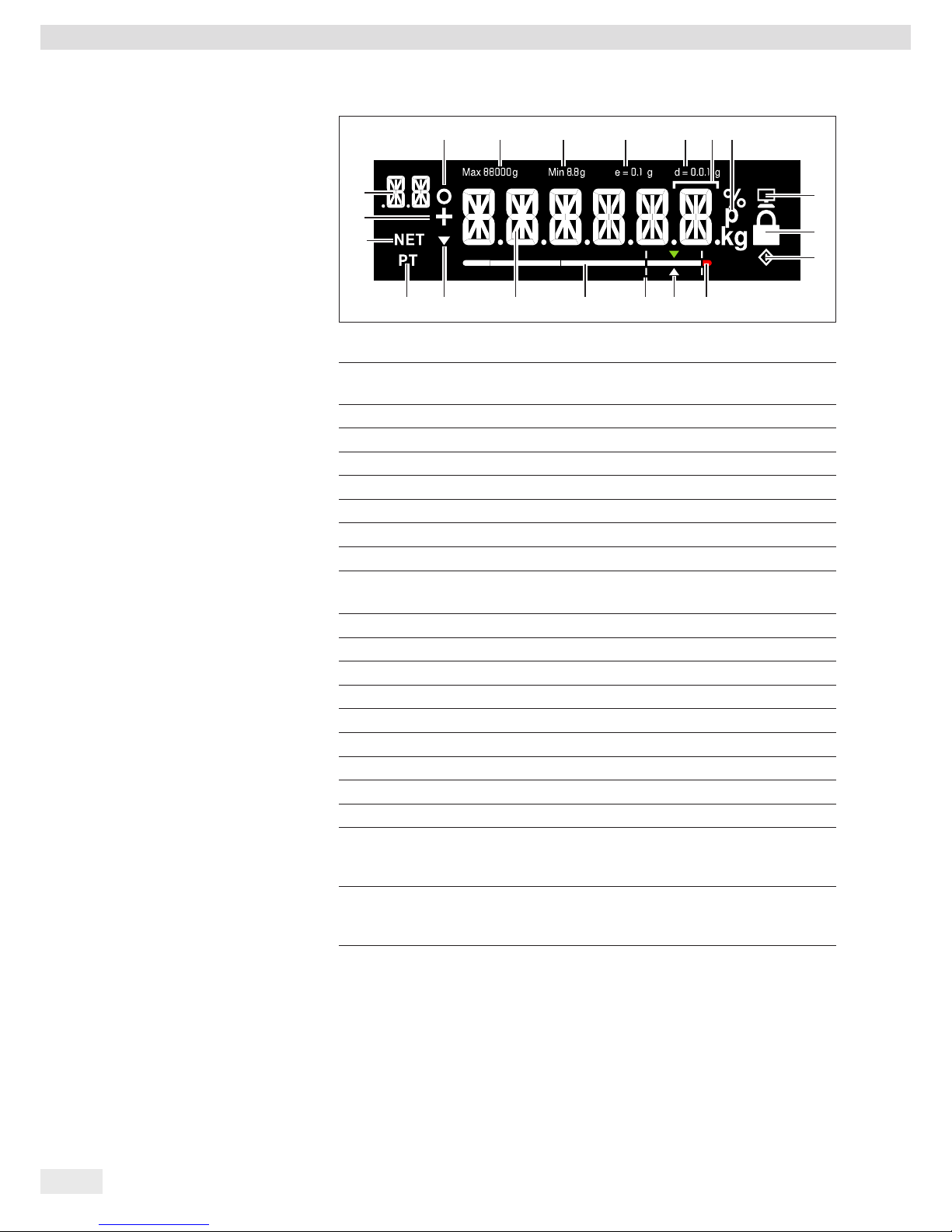

Device Overview

Item Function

1 Activated function in the menu list (see Chapter 3.5, page 13)

Symbols for zero range (verified models only)

2 Maximum weighing range

3 Minimum load Min (verified models only)

4 Verification scale intervals (verified models only)

5 Readability of the scale (scale interval d)

6 Weight unit and stability indicator

7 Communication with the PC

8 Activate “LOCK” function, or function activated

9

l symbol: Indicates that an internal process is in progress

For verified models: Indicates an invalid weight value

10 Tolerance range has been exceeded

11 Target value for bar graph

12 Tolerance range

13 Bar graph: Scaled display showing capacity usage (in percent)

14 Fourteen segment display

15 Trend display

16 Info on weight entry via application keypad (preset tare)

17 Net value

18 Plus (or minus) sign of the weight

19 Display:

− SETUP level

− Component/factor for paint-mixing applications

20

In verified mode for devices where e ≠ d: The frame indicates a scale

interval (standard scale interval d is smaller than verification scale

interval e)

19

18

17

16 15 14 13 12 10

7

8

9

11

1 2 3 4 5 20 6

Operating Manual EVO1X | LAB1X 13

Device Overview

3.5 Menu List

The “o” in the active column indicates the activated function in the respective menu.

Level 1 Level 2 Level 3 Active Level 4 Function CODE

SETUP

1.

| - - - -

SCALE

1.1

| | - - -

AMBIEN.

Installation site 1.1.1

| | |- - - -

V.STABL.

Very stable ambient conditions 1.1.1.1

| | |- - - - o

STABLE

Stable ambient conditions 1.1.1.2

| | |- - - -

UNSTAB.

Unstable ambient conditions 1.1.1.3

| | |- - - -

V.UNSTB.

Very unstable ambient conditions 1.1.1.4

| | - - -

FILTER

Application filter 1.1.2

| | |- - - -

FIN.RD.

Final readout 1.1.2.1

| | |- - - - o

FILL.WT.

Filling weight 1.1.2.2

| | - - -

STAB.RG.

Stability range/stability 1.1.3

| | |- - - -

1/2-DIG.

1/2 digit/good 1.1.3.2

| | |- - - -

1-DIG.

1 digit/normal 1.1.3.3

| | |- - - - o

2-DIG.

2 digits/sufficient 1.1.3.4

| | |- - - -

4-DIG.

4 digits/low 1.1.3.5

| | - - -

AUTOZ.

Automatic zero/drift correction 1.1.6

| | |- - - -

ON

On 1.1.6.1

| | |- - - - o

OFF

Off 1.1.6.2

| | - - -

WT.UNIT

Weight units 1.1.7

| | |- - - - o

GRAMS

Grams 1.1.7.2

| | |- - - -

PT.P.LB

Parts per pound

1

) 1.1.7.14

| | - - -

DSP.DEC.

Accuracy

1

) 1.1.8

| | |- - - - o

ALL

Show all decimal places 1.1.8.1

| | |- - - -

POLYR.

Multi-interval lab 1.1.8.13

| | - - -

CAL.ADJ.

Calibration/adjustment 1.1.9

| | |- - - - o

CAL.EXT.

External calibration/adjustment with default weight 1.1.9.1

| | |- - - -

LOCKED

CAL key/command locked 1.1.9.10

|

APP.PRG.

1.3

| | - - -

UNIT 2

2nd unit

1

) 1.3.1

| | |- - - - o

GRAMS

Grams 1.3.1.2

| | |- - - -

PT.P.LB

Parts per pound 1.3.1.14

| | - - -

DEC 2

Accuracy 2nd unit

1

) 1.3.2

| | |- - - -

ALL

Show all decimal places 1.3.2.1

| | |- - - - o

POLYR.

Multi-interval lab 1.3.2.13

| | - - -

TOGGLE

Toggle key on/off

1

) 1.3.3

| |- - - - o

OFF

Toggle key off 1.3.3.1

| |- - - -

ON

Toggle key on 1.3.3.2

|

Continued on next page

1

) Not available on scales verified for use in legal metrology

14 Operating Manual EVO1X | LAB1X

Device Overview

Level 1 Level 2 Level 3 Active Level 4 Function CODE

(SETUP)

| - - -

REC.MOD.

Recalculation 1.3.4

| | |- - - - o

TOTAL

Gross weight 1.3.4.1

| | |- - - -

INDIV.

Individual 1.3.4.2

|

GEN.SRV.

1.9

| | - - -

MEN.RES.

Menu reset 1.9.1

| | |- - - -

DEFAUL.

Load default menu 1.9.1.1

| | |- - - - o

NO

Stand-by 1.9.1.2

| |

DEVICE

2.

| - - - -

EXTRAS

2.1

| | - - -

MENU

Menu 2.1.1

| | | - - - - o

ENABLE

Menu can be edited 2.1.1.1

| | | - - - -

RD.ONLY.

Menu read only 2.1.1.2

| | - - -

KEYS

Key function enabled/locked 2.1.3

| | | - - - - o

ENABLE

Keypad enabled 2.1.3.1

| | | - - - -

LOCKED

Keypad locked 2.1.3.2

| | - - -

BACKLT.

Background light 2.1.4

| | | - - - -

10 PCT.

2.1.4.1

| | | - - - -

20 PCT.

2.1.4.2

| | | - - - -

30 PCT.

2.1.4.3

| | | - - - -

40 PCT.

2.1.4.4

| | | - - - -

50 PCT.

2.1.4.5

| | | - - - -

60 PCT.

2.1.4.6

| | | - - - - o

70 PCT.

2.1.4.7

| | |- - - -

80 PCT.

2.1.4.8

| | | - - - -

90 PCT.

2.1.4.9

| | | - - - -

100 PCT.

2.1.4.10

| | - - -

BARGR.

Bar graph on/off 2.1.5

| | |- - - -

OFF

Display without bar graph 2.1.5.1

| | |- - - - o

ON

Display with bar graph 2.1.5.2

| | - - -

ON.MODE

Switch-on behavior 2.1.6

| | |- - - - o

ON/STB.

On/standby 2.1.6.3

| | |- - - -

AUTO.ON

Automatic on 2.1.6.4

| | - - -

LOCK

Lock weight display 2.1.9

| | |- - - - o

OFF

Display on 2.1.9.1

| | |- - - -

ON

Display off 2.1.9.2

| | - - -

BAR.MOD

Bar graph mode 2.1.10

| | | - - - - o

NORMAL

Normal width 2.1.10.1

| | | - - - -

WIDE

Extra wide 2.1.10.2

| |

Continued on next page

Operating Manual EVO1X | LAB1X 15

Device Overview

Level 1 Level 2 Level 3 Active Level 4 Function CODE

(DEVICE) INTERF.

2.2

| | - - -

PROT.

Data transfer protocol 2.2.1

| | |- - - - o

SBI

SBI protocol 2.2.1.1

| | |- - - -

XBPI

XBPI protocol 2.2.1.2

| | - - -

BAUD

Baud rate 2.2.2

| | |- - - -

600

600 baud 2.2.2.3

| | |- - - -

1200

1200 baud 2.2.2.4

| | |- - - - o

2400

2400 baud 2.2.2.5

| | |- - - -

4800

4800 baud 2.2.2.6

| | |- - - -

9600

9600 baud 2.2.2.7

| | |- - - -

19200

19200 baud 2.2.2.8

| | |- - - -

38400

38400 baud 2.2.2.9

| | |- - - -

57600

57600 baud 2.2.2.10

| | - - -

PARITY

Parity bit 2.2.3

| | |- - - - o

ODD

Odd 2.2.3.3

| | |- - - -

EVEN

Even 2.2.3.4

| | |- - - -

NONE

No parity check 2.2.3.5

| | - - -

STOPBT.

Number of stop bits 2.2.4

| | |- - - - o

1 BIT

2.2.4.1

| | |- - - -

2 BITS

2.2.4.2

| | - - -

HANDSH.

Type of handshake 2.2.5

| | |- - - -

SOFTW.

Software handshake (X-On/X-Off) 2.2.5.1

| | |- - - -

HARDW.

Hardware handshake (RTS/CTS) 2.2.5.2

| | |- - - - o

NONE

No handshake 2.2.5.3

| | - - -

DATABT.

Number of data bits 2.2.6

| |- - - - o

7 BITS

7 data bits 2.2.6.1

| |- - - -

8 BITS

8 data bits 2.2.6.2

COMMUN.

Communication parameters 3.

| - - - -

SBI

SBI communication parameter 3.1

| | - - -

MAN.AUT.

Output 3.1.1

| | | - - - -

MAN.W/O

Print individual value without stability 3.1.1.1

| | | - - - -

MAN.W/

Print individual value after stability 3.1.1.2

| | | - - - - o

AUT.W/O

Print automatically without stability 3.1.1.4

| | | - - - -

AUT.W/

Print automatically after stability 3.1.1.5

| |

| | - - -

CANCEL

Cancel automatic output 3.1.2

| | | - - - - o

OFF

Cancellation not possible 3.1.2.1

| | | - - - -

ON

Cancel by pressing Print key 3.1.2.2

| | - - -

FORMAT

3.1.3

| | | - - - - o

16 CHR.

3.1.3.1

| | | - - - -

22 CHR.

3.1.3.2

Continued on next page

16 Operating Manual EVO1X | LAB1X

Device Overview

Level 1 Level 2 Level 3 Active Level 4 Function CODE

INPUT

4.

| - - - -

PASSWD.

Password 4.1.

| | - - -

NEW PW

Change/enter password 4.1.1

|

INFO

Information 5.

| - - - -

VER.NO.

Version number (firmware) 5.1

| - - - -

SER.NO.

Serial number 5.2

| - - - -

MODEL

Model designation 5.3

| - - - -

TYPE

Name/type information 5.4

| - - - -

INTRO

Intro text (if available) 5.5

|

LANG.

Language selection 6.

| - - - -

D

German 6.1

| - - - -

UK/US

o English 6.2

| - - - -

F

French 6.4

| - - - -

I

Italian 6.5

| - - - -

E

Spanish 6.6

| - - - -

NL

Dutch 6.7

| - - - -

P/BR

Portuguese 6.8

| - - - -

PL

Polish 6.9

| - - - -

TR

Turkish 6.10

| - - - -

PYC

Russian/Cyrillic 6.11

| - - - -

SLO

Slovenian 6.12

| - - - -

SRB

Serbian 6.13

| - - - -

CODES

Number codes 6.25

Operating Manual EVO1X | LAB1X 17

Installation

4 Installation

4.1 Unpacking and Equipment Supplied

t Open the packaging, making sure to remove all parts carefully.

t After unpacking the device, check it immediately for any external damage.

t If you detect any damage, proceed as directed in Chapter “7 Care and

Maintenance,” page 33.

t Save the box and all parts of the packaging for any future transport. All cables

should be unplugged when transporting.

The following parts are included in the equipment supplied:

Model Name PMA.Evolution PMA.HD

Large weighing pan: d 233 mm

x –

Small weighing pan: d 180 mm

– x

USB cable x x

Ex-link converter x x

Potential equalization cable x x

Link cable from converter to scale x x

Installation instructions x x

4.2 Selecting a Setup Location

Select the right setup location:

− Set up the device on a stable, even surface that is not exposed to vibrations.

− Maintain free access to the device at all times.

Choose a location that is not subject to the following negative influences:

− Heat (heater or direct sunlight)

− Drafts from open windows, AC systems, and doors

− Extreme vibrations during weighing

− Heavy “traffic areas” (personnel)

Acclimatization

Condensation from humidity can form on the surfaces of a cold device when it

is brought into a warm area. You should therefore let a device that has been

disconnected from its power source acclimatize for approximately 2 hours before

reconnecting it to the supply voltage.

Seal on Scales Verified for Use in Legal Metrology:

Legislation requires that a seal be affixed to verified scales. On Sartorius devices, this

seal takes the form of a sticker with the “Sartorius” logo. If the seal is removed, the

validity of verification will become void and you must have your scale re-verified.

The verification supplied here is for verified weighing instruments for use in the EEA.

Please keep it in a safe place.

18 Operating Manual EVO1X | LAB1X

Installation

4.3 Installing the Scale

The scale must be disconnected from the power supply for all assembly work.

Placing the Weighing Pan onto the Scale

t Place the weighing pan onto the scale from above.

4.4 Supply Voltage

The scale is connected to the power supply via a PC/notebook or using the optional

AC adapter YPS06-USB (see Chapter “13 Accessories,” page 41), which is supplied

with mains adapters for use in various countries.

Power supply via the AC adapter is only required:

− When no PC or notebook is available.

− In exceptional cases, when the output power of the USB interface of the PC or

notebook is not sufficient.

The assembly is described in the following.

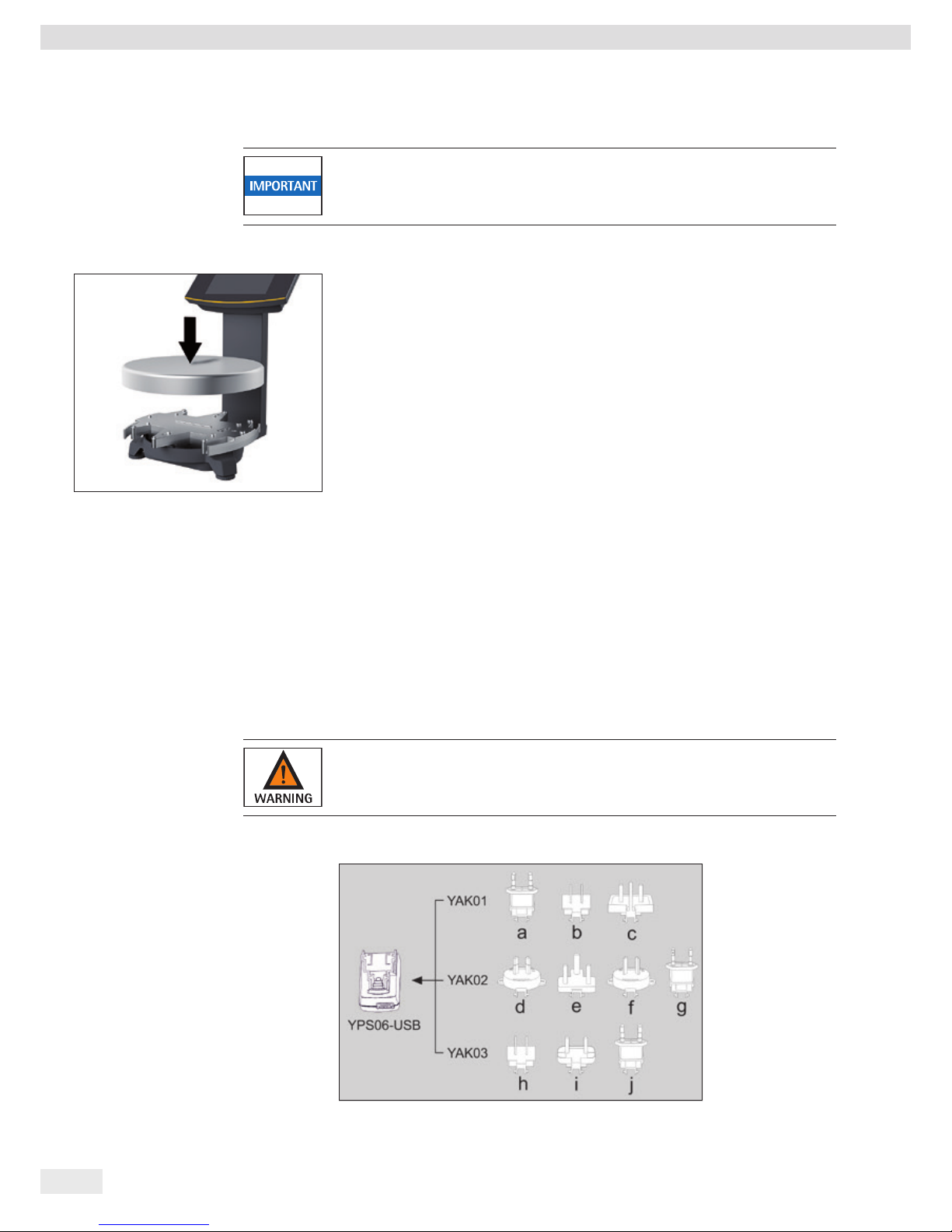

4.4.1 AC Adapter Assembly (Optional)

Using the wrong mains adapter may cause a fatal electric shock and damage

the equipment.

Never plug the mains adapter into the socket when it is disconnected from the

AC adapter (danger of electric shock).

t Use the right mains adapter for your mains power supply.

Operating Manual EVO1X | LAB1X 19

Installation

Mains Adapter Set YAK01

Bag Region/Country

a) transparent Europe/EU (except United Kingdom)

b) blue USA

c) yellow United Kingdom

Mains Adapter Set YAK02

d) red Australia

e) turquoise South Africa

f) white Argentina

g) pink Brazil

Mains Adapter Set YAK03

h) light brown China

i) black India

j) green Korea

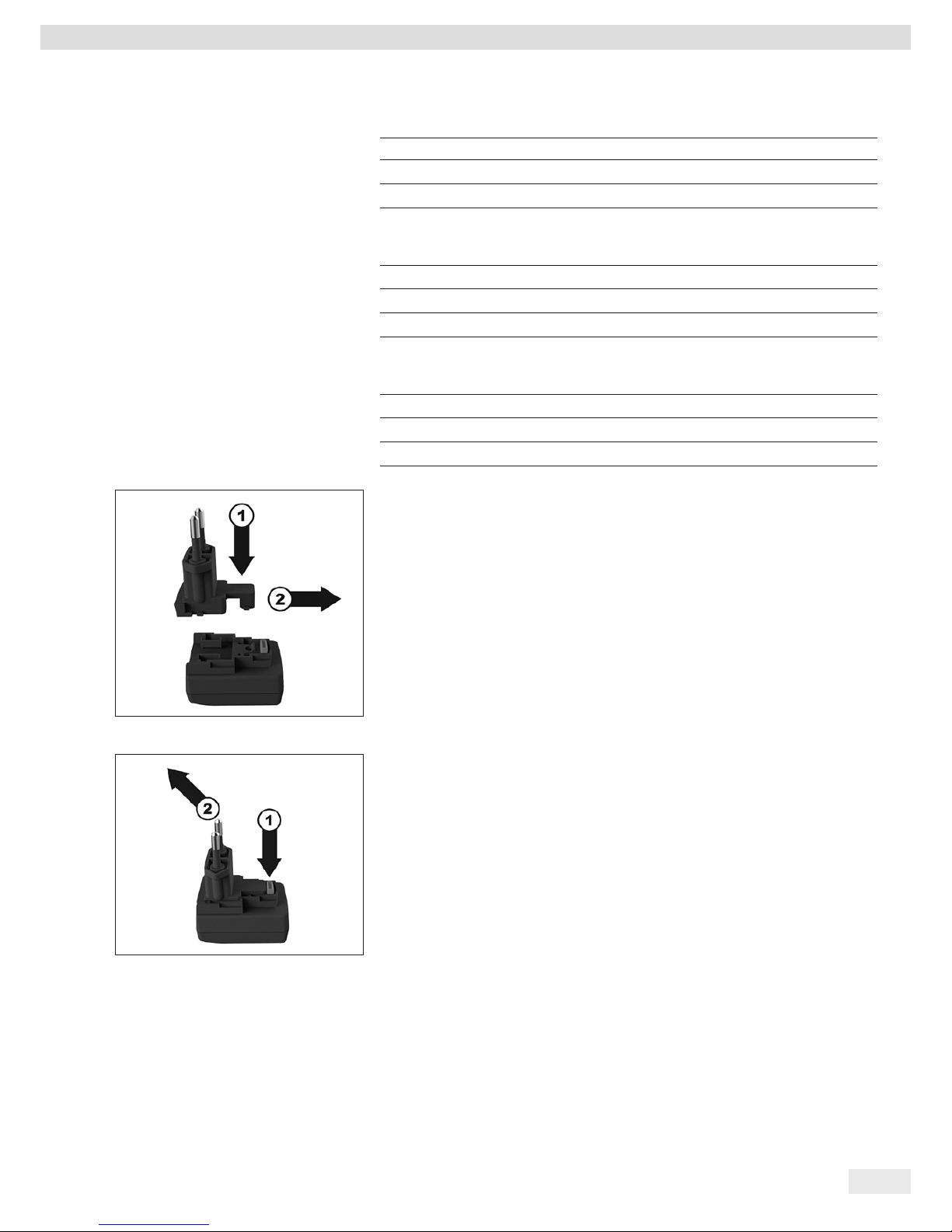

t Push (1) and slide (2) the mains adapter required for your power supply into the

opening of the AC adapter module.

When doing this, the mains adapter needs to lock into position.

Removing/Replacing the Mains Adapter

t Unlock (1) and then remove (2) the mains adapter.

Power Connection/Safety Precautions

− Only use original Sartorius AC adapters.

The AC adapter has an IP rating of IP40 in accordance with EN60529 / IEC60529.

− Make sure that the voltage rating printed on this unit matches the voltage at the

place of installation.

− If the stated supply voltage or the plug design of the AC adapter does not

comply with your country's standard then please inform your nearest Sartorius

representative.

− The power must be connected in accordance with the regulations applicable in

your country.

20 Operating Manual EVO1X | LAB1X

Installation

4.4.2 Connecting the Scale

Connecting the Scale

t Insert the link cable plug into the RJ-45 socket on the back of the display.

Laying the Link Cable

t Lay the link cable (blue) through the cable holders on the back of the scale.

t Connect the link cable to the ex-link converter.

Connecting the Grounding Cable

This explosion-protected system should be set up according to commonly accepted

technical standards. The applicable national electrical code and safety regulations for

your particular country must be observed.

Before commissioning the scale, a check must be carried out by or under the

supervision of a qualified electrician to ensure that the system is in good working

order.

Check whether or not the competent authorities (e.g., industrial supervisory board)

need to be informed. It is also necessary to carry out inspections of the system

during operation.

Inspection intervals should be such that any significant defects that may occur can

be identified in good time. Inspections should be carried out at least once every

three years. The applicable requirements and guidelines should also be observed

during operation.

Establish a low-resistance connection from the scale and the ex-link converter

YCO14-Z to a customer-supplied equipotential bonding conductor connection

via the equipotential bonding conductor connections (PA) on the device using a

suitable grounding cable with a gage of at least 4 mm

2

.

Installation must be carried out properly by trained personnel and according to

commonly accepted technical standards. The system should only be operated for

the first time when it is certain that the area is not potentially explosive.

Operating Manual EVO1X | LAB1X 21

Installation

If deviations are evident during startup due to transport damage (e.g., no display,

no backlighting), disconnect the scale from the power supply and contact Sartorius

Service.

Connect the scale to the equipotential bonding conductor using an equipotential

bonding cable with a gage of at least 4 mm².

t Connect the cable lug of the equipotential bonding cable to the grounding

terminal of the scale.

t Connect the equipotential bonding cable to the customer-supplied equipotential

bonding conductor.

Connect the ex-link converter to the equipotential bonding conductor using another

equipotential bonding cable with a gage of at least 4 mm².

t Connect the cable lug of the equipotential bonding cable to the grounding

terminal of the ex-link converter.

t Connect the equipotential bonding cable to the customer-supplied equipotential

bonding conductor.

Connecting a PC/Notebook

t Insert a USB cable (1) into the right-hand socket on the ex-link converter and

connect the cable to a PC or notebook. If the ex-link converter YCO-Y is being

used and installed in Zone 2 or Division 2 potentially explosive areas and the

USB cable (1) does not have an intrinsically safe electrical circuit, the cable must

be secured against disconnection. Refer to the Control Drawing and Safety

Instructions (Chapter 15, page 42) as well as the following illustrations.

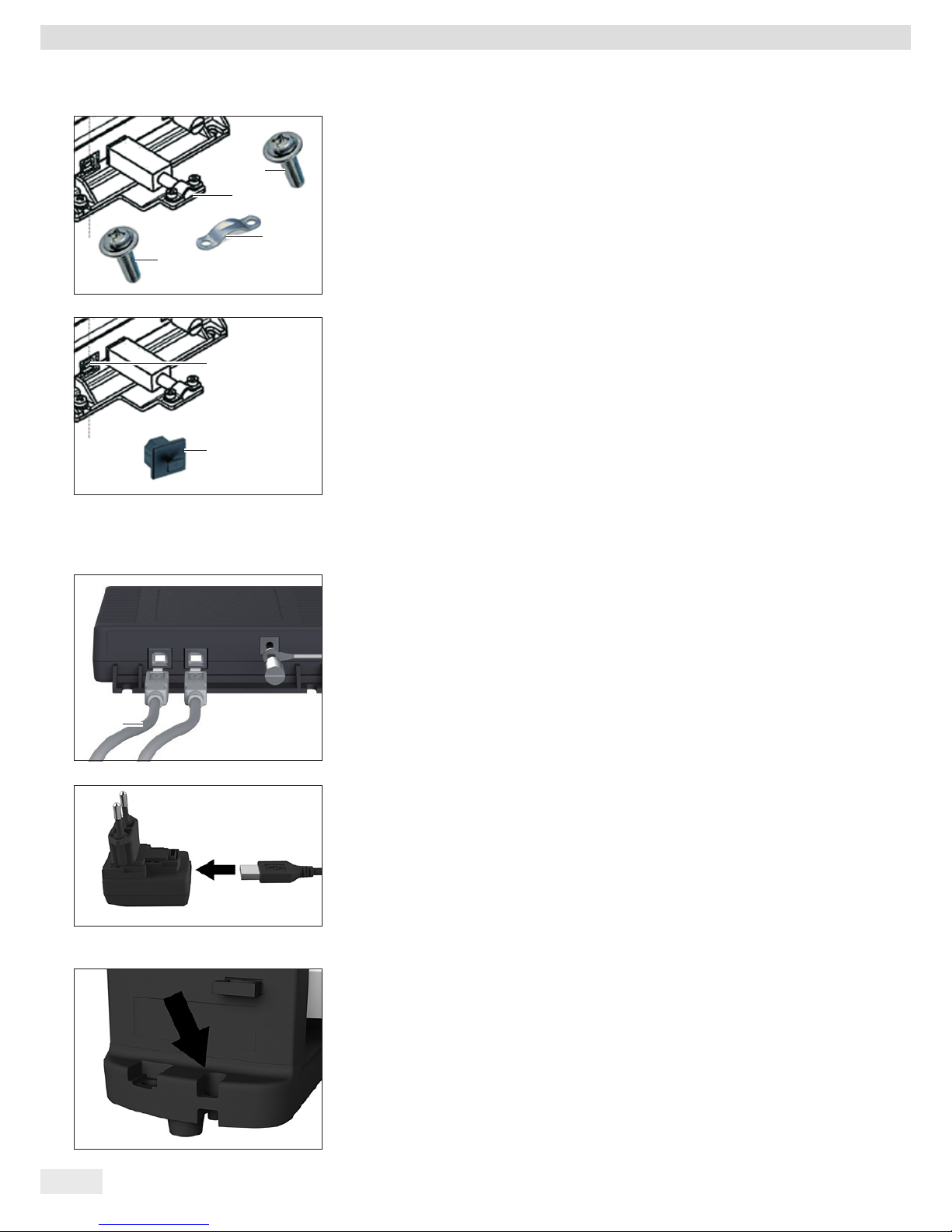

t Fasten the strain relief YSR01 to the converter (1) using the two screws (2).

1

1

2

2

22 Operating Manual EVO1X | LAB1X

Installation

t Attach the USB cable to the strain relief (3) using the clamp (1) and the two

screws (2).

t Use the protective cap (2) to seal up the left-hand USB port (1).

Connecting the AC Adapter (Optional); not for YCO14-Y when Installed in

Zone 2 or Division 2 Potentially Explosive Areas

t Insert an additional USB cable (2) into the ex-link converter.

t Insert the USB cable into the YPS06-USB AC adapter.

t Plug the AC adapter into a wall outlet (supply voltage).

t Insert the USB cable into the YPS06-USB AC adapter.

t Plug the AC adapter into a wall outlet (supply voltage).

4.5 Anti-theft Locking Device

t If required, secure the scale at the back.

2

1

2

3

2

1

2

Operating Manual EVO1X | LAB1X 23

Commissioning

5 Commissioning

5.1 Leveling

Leveling for PMA.HD and Verified Models

Leveling the scale compensates for slant or unevenness at the place of installation.

The scale must be perfectly horizontal to ensure consistent, reproducible weighing

results.

The scale needs to be re-leveled and then adjusted each time its setup location is

changed.

t Turn the two leveling feet as shown in the illustration until the air bubble is

centered within the circle of the level indicator.

− Air bubble at “12 o'clock:” Turn both feet clockwise.

− Air bubble at “3 o'clock:” Turn the left foot clockwise and the right foot

counterclockwise.

− Air bubble at “6 o'clock:” Turn both feet counterclockwise.

− Air bubble at “9 o'clock:” Turn the left foot counterclockwise and the right

foot clockwise.

5.2 Warm-up Time

To ensure accurate results are delivered, the scale must warm up for at least

30 minutes after initial connection to the power supply. Only then will the device

have reached the required operating temperature.

Using a Scale Verified for Use in Legal Metrology:

− Ensure that there is a warm-up time of at least 24 hours after initial connection

to the power supply.

12*

9*

6*

* Clock

0

30

24 Operating Manual EVO1X | LAB1X

Operation

6 Operation

6.1 Switching the Device On/Off

Switching On

t Briefly press the j key (on/standby).

y An automatic self-test runs. This ends when the display shows 0.0 g.

t If another value is displayed: Set the scale to zero via the 0 key.

Switching Off

t Press and hold the j key for several seconds (on/standby).

y The scale switches to standby mode.

6.2 Locking the Keypad/Weight Display

Locking

t Briefly press the j key (on/standby) to lock the keypad and turn off the weight

display.

y The padlock symbol H flashes for several seconds.

t Press the padlock symbol H while flashing to activate the lock.

y The keypad/weight display is locked and the padlock symbol lights up continually.

Unlocking

t Press the padlock symbol H to deactivate the lock.

t Enter the password (if set) (see Chapter 6.7.2.6, page 31).

y The lock is deactivated.

6.3 Zeroing/Taring

t Briefly press the 0 key.

6.4 Calibration/Adjustment

The scale needs to be re-leveled and then adjusted each time its setup location is

changed.

Warm-up Time

To ensure accurate results are delivered, the scale must warm up for at least

30 minutes after initial connection to the power supply.

Only then will the device have reached the required operating temperature.

t Wait approx. 30 minutes after connecting the scale to the power supply before

adjusting the scale and weighing.

Using a Scale Verified for Use in Legal Metrology:

− Ensure that there is a warm-up time of at least 24 hours after initial connection

to the power supply.

0

30

Operating Manual EVO1X | LAB1X 25

Operation

6.4.1 Calibration

External Calibration/Adjustment for Verified Scales

Scales for use in legal metrology must be externally calibrated before being verified

at the location of use.

− When the scale is used in legal metrology, external calibration is locked as

follows:

− The menu access switch is locked

− The menu access switch cap is sealed

t Press the 0 key for approx. 2 seconds.

y The preset calibration weight appears in the display (e.g., 5000 g)

t If required, select a different calibration weight via the O / P keys.

t Confirm the displayed calibration weight via the ! key.

y CAL.EXT. appears on the display with the negative calibration weight.

t Center the calibration weight on the weighing pan.

y The calibration is performed. The calibration is complete when CAL.DON appears

in the display.

t Remove the calibration weight from the weighing pan.

6.5 Weighing

Using a Verified Balance in Legal Metrology:

The Type-Approval Certificate for verified scales is only valid for non-automatic

weighing instruments. For automatic operation with or without additional integrated

equipment, please follow the applicable national regulations for the installation

location.

− The temperature range (°C) listed on the ID label should not be exceeded during

operation.

Example:

K +10–+30°C

6.5.1 Weighing with One Decimal Place

t Place the empty paint can on the weighing pan.

t Briefly press the 0 key to zero.

y The display shows “0.0 g.”

t Add the first component “484.8 g.”

t Read off the weight when the stability symbol (in this example) “g” is displayed.

t Add the other components until the desired weight (formula) is reached.

t Remove the filled paint can from the weighing pan.

Danger of Scale Damage!

Never close a paint can using a hammer while it is still on the weighing pan.

t When closing the paint can, place it on a firm, stable surface.

0.0

484.8

840.2

1218.8

1230.0

26 Operating Manual EVO1X | LAB1X

Operation

6.5.2 Weighing with Two Decimal Places (Not for Verified Models)

A menu setting is required for weighing with two decimal places (see

Chapter “6.7.2.4 Activating the Toggle Key (Not for Verified Models),” page 30).

t Place the empty paint can on the weighing pan.

t Briefly press the 0 key to zero.

y The display shows “0.0 g.”

t Press the toggle key Z.

y The display shows “0.00 g.”

t Add the first component “205.50 g.”

t Read off the weight when the stability symbol (in this example) “g” is displayed.

t Add the other components until the desired weight (formula) is reached.

t Remove the filled paint can from the weighing pan.

When the scale is tared and the second decimal place with a resolution of 0.05 g is

activated via the toggle key Z, weighing up to 999.95 g with two decimal places

can be performed.

Values over 999.95 g can only be weighed using one decimal place.

Danger of Scale Damage!

Never close a paint can using a hammer while it is still on the weighing pan.

t When closing the paint can, place it on a firm, stable surface.

6.6 Applications

Note for Scales for Use in Legal Metrology:

All application programs can be selected on scales verified for use in legal metrology.

Computed values can be marked using the following characters:

− Percent = %

− Computed values = o, l symbol

6.6.1 Calculation by a Factor

This function enables you to weigh in amounts that are smaller or larger than that

of your basic formula for a specific paint color (e.g., 250 ml of a 1 l formula).

The factors (amounts) can be set via the factor key $ and O / P in a range of

0.1 to 6.0.

The following factors can be set directly via the factor key $:

0.25 0.5 0.75 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0.

Using the keys O (up) and P (down), the factor can be changed

− in the range 0.10 to 1.0 in increments of 0.01

− in the range 1.0 to 6.0 in increments of 0.1

0.0

0.00

205.50

213.50

593.85

1414.2

Operating Manual EVO1X | LAB1X 27

Operation

Factor Calculation Example

As you add the components of your formula, the weight is displayed in “g.”

For models verified for use in legal metrology, the displayed value is marked with

a l symbol to indicate computed values.

Suppose you want to weigh 250 ml for a basic formula that has a total of 1 l, and

you don't want to have to manually recalculate the individual components of the

formula.

The basic formula for 1 liter:

250 g 1st component

+ 250 g 2nd component

+ 500 g 3rd component

Total: 1000 g

t Place the empty container on the weighing pan.

t Briefly press the 0 key to tare.

t Press the factor key $ several times until the factor “.25” is displayed below the

factor key.

t Slowly add the first component “250 g” of the formula until the display shows

“250 g.”

t Add the second color component “250 g” until the display shows “500 g.”

t Add the third component “500 g” until the display shows “1000 g.”

This concludes the calculation example. According to the display, exactly 1000 g was

poured in, but the container actually only contains 250 g by weight in accordance

with the factor you selected.

The procedure is the same for any other conversion factor.

6.6.2 Weighing Using the Recalculation Function

Let's suppose that you poured in too much of one color component for a given

formula (in this example, a 4-component recipe).

This example further assumes that you previously poured in all of the other amounts

exactly according to each of the values you entered and saved them by pressing the

MEM key !.

t Press the P key to start the recalculation program.

y “C” flashes on the display.

t Correct the value using the O / P keys to match the specified formula value.

t Press the MEM key !.

y The scale automatically calculates the amount to be added for each of the

components that were already poured in. The display shows the amounts required

to correct the formula up to the point at which the overpour occurred.

t After the correction has been completed, you can continue filling the remaining

components.

You can correct overpours as often as needed, as long as the total weight of the

formula does not exceed the scale's maximum weight.

Keep in mind that the total quantity of paint (liter) at the conclusion of filling

increases each time you correct a component. Press the § key to display the

correction factor of the fill quantity. “C” = correction factor

0.0

250.0

500.0

1000.0

.25

.25

.25

.25

28 Operating Manual EVO1X | LAB1X

Operation

Recalculation Example (Gross Weight)

For models verified for use in legal metrology, the displayed value is marked with a

l symbol to indicate computed values.

t Place the empty container on the weighing pan.

y The scale shows the weight of the empty paint can.

t Briefly press the 0 key to tare.

t Slowly add the first component (50 g) of the formula until the display shows

“50 g.”

t Briefly press the ! key to save the value.

y “STO 01” appears on the display, the first value is saved.

y ”02” appears in the top left of the display (second color component).

t Add the second color component (60 g) until the display shows “110 g.”

t Briefly press the ! key to save the value.

y “STO 02” appears on the display, the second value is saved.

y “03” appears in the top left of the display (third color component).

t Add the third color component (90 g) until the display shows “200 g.”

Oops! You poured in too much (203 g). The correct value for the formula is

200.0 g.

t Press the P key.

y The recalculation is started. “c” flashes in the top left of the display.

t Press the P key until the correct weight value “200 g” is displayed.

t Briefly press the ! key to confirm the corrected value.

y ”C0R 01” flashes briefly on the display (correction of the first color component).

y ”C1” appears in the top left of the display with the weight value to be corrected

“- 1.7 g.”

t Add 1.7 g of the first color component until the display shows “0.0 g” or the bar

graph stops below the green arrow.

t Confirm the correction for the first color component by pressing the ! key.

y ”C0R 02” flashes briefly on the display (correction of the second color

component).

y ”C2” appears in the top left of the display with the weight value to be corrected

“- 2.0 g.”

t Add 2.0 g of the second color component until the display shows “0.0 g” or the

bar graph stops below the green arrow.

y ”STO 02” appears on the display, the second (corrected) value is saved.

y You are automatically returned to the formulation program.

y ”04” appears in the top left of the display (fourth color component).

t Press the § key to check the amount of the total weight.

y The correction factor “C 1.03” appears on the display for several seconds.

Total weight = weight of specified formula x correction factor.

y ”04” appears again in the top left of the display after the correction factor is

displayed (fourth color component).

t Add additional color components of the formula as described above.

This concludes the calculation example.

118.0

0.0

50.0

STO 01

02

110.0

STO 02

03

203.0

200.0

C

COR 01

C1

1.7

C1

0.0

COR 02

C2

2.0

C2

0.0

STO 02

04

1000.0

C 1.03

04

1000.0

Operating Manual EVO1X | LAB1X 29

Operation

6.7 Menu Settings

6.7.1 Accessing the SETUP Menu

Accessing the SETUP menu and settings is described in the following using “Adapting

the scale to ambient conditions” as an example (SETUP -> SCALE -> AMBIEN.):

t Press the ! key for approx. 2 seconds.

y Level 1 of the SETUP menu is displayed.

t Select the SETUP menu item of the first level using the O / P keys.

t Press the ! key.

y Level 2 of the SETUP menu is displayed.

t Select the SCALE menu item of the second level using the O / P keys.

t Press the ! key.

y Level 3 of the SETUP menu is displayed.

t Select the AMBIEN. menu item of the third level using the O / P keys.

t Press the ! key.

y Level 4 of the SETUP menu is displayed.

t Select the desired setting using the O / P keys.

t Press the ! key.

y The setting is applied; “o” appears on the display.

(This concludes the example.)

t Press the § key several times to exit the menu.

A detailed list of possible settings can be found in Chapter “3.5 Menu List,”

page 13.

6.7.2 Configuring the Main Menu Settings

6.7.2.1 Accessing the Setup Menu

t Press and hold the ! key for approx. 2 sec.

y SETUP (level 1) appears on the display.

30 Operating Manual EVO1X | LAB1X

Operation

6.7.2.2 Language Setting

Level 1 Level 2

LANG.

t Press O, select LANG.

t Press !

D

o German

t Press O / P, select language

UK/US

English

t Press !, “o” appears.

F

French y The desired setting is applied.

I

Italian

t Press § several times to exit the menu

etc.

6.7.2.3 Standard Default Settings (0.1 g)/Polyrange (0.05 g/0.1 g) and Grams/Parts per Pound. (Not for Verified Models)

The default settings which are active when the scale is switched on can be found under “SETUP > SCALE > WT.UNIT” and “SETUP >

SCALE > DSP.DEC.:”

t Access the Setup menu (see Chapter 6.7.2.1, page 29).

Level 1 Level 2 Level 3 Level 4

SETUP

t Press !

| - - -

SCALE

t Press !

| - - -

WT.UNIT

Units

t Press O / P, e.g., select DSP.DEC.

| |- - - o

GRAMS

t Press !

| |- - -

PT.P.LB

t Press O / P, e.g., select ALL

| - - -

DSP.DEC.

Accuracy

t Press !, “o” appears

|- - - o

ALL

y The new code is set.

|- - -

POLYR.

t Press § several times to exit the menu

6.7.2.4 Activating the Toggle Key (Not for Verified Models)

When the toggle key Z is active, you can use it to toggle the unit between, e.g., grams, parts per pound, or the decimal place.

The unit and/or decimal place is toggled when the key is pressed:

t Access the Setup menu (see Chapter 6.7.2.1, page 29).

Level 1 Level 2 Level 3 Level 4

SETUP

t Press !

| - - -

APP.PRG.

t Press O / P, select APP.PRG.

| - - -

TOGGLE

t Press !

|- - - o

ON

t Press O / P, select ON

|- - -

OFF

t Press !, “o” appears.

y Toggle key Z is activated.

t Press § several times to exit the menu

Configuring the Toggle Key Z Function

Pressing the toggle key Z toggles the scale between the default settings (see Chapter 6.7.2.3, page 30) and settings defined in

“SETUP > APP.PRG. > UNIT” and “SETUP > APP.PRG. > DSP.DEC.”

t Access the Setup menu (see Chapter 6.7.2.1, page 29).

Operating Manual EVO1X | LAB1X 31

Operation

Level 1 Level 2 Level 3 Level 4

SETUP

t Press !

| - - -

APP.PRG.

t Press O / P, select APP.PRG.

| - - -

UNIT 2

t Press !, press O / P, select UNIT 2

| |- - - o

GRAMS

t Press !, press O / P, select setting (e.g., GRAMS)

| |- - -

PT.P.LB

t Press !, “o” appears indicating the desired setting is applied.

| - - -

DEC 2

t Press §

|- - -

ALL

t Press O / P, select DEC 2

|- - - o

POLYR.

t Press !, press O / P, select setting

t Press !, “o” appears indicating the desired setting is applied.

t Press § several times to exit the menu

6.7.2.5 Activating the “LOCK” Function

The “LOCK” function protects the scale from unauthorized use. When this function is active, the scale readout shows weight values

only when there is active communication between the scale and a connected PC. If communication is interrupted, the readout

goes blank and the display shows a padlock symbol. Activation of the LOCK function is configured under “EXTRAS.”

t Access the Setup menu (see Chapter 6.7.2.1, page 29).

Level 1 Level 2 Level 3 Level 4

DEVICE

t Press O / P, select DEVICE, press !

| - - -

EXTRAS

t Press O / P, select EXTRAS, press !

| - - -

LOCK

t Press O / P, select LOCK, press !

|- - - o

ON

t Press O / P, select ON

|- - -

OFF

t Press !, “o” appears,

y The “LOCK” function

is activated.

t Press § several times to exit the menu

6.7.2.6 Password Prompt

In addition to the “LOCK” function, you can also configure password protection for additional security.

With this feature, the “LOCK” function can only be deactivated by entering the password you configure.

Entering the Password

When the password prompt appears, the numbers 1 2 3 4 5 6 appear on the display.

You can switch to the numbers 7 8 9 0 and back again via the O / P keys.

t Enter the password by entering the individual numbers on the display.

y When you enter the correct password, the “LOCK” function will be deactivated.

32 Operating Manual EVO1X | LAB1X

Operation

Changing the Password

The password is numeric and can have up to 6 digits. Entering 6 spaces deletes the password, which deactivates the password

function. This restores the device to its original setting (scale is not password-protected).

t Access the Setup menu (see Chapter 6.7.2.1, page 29).

Level 1 Level 2 Level 3

INPUT

t Press O / P, select INPUT, press !

| - - -

PASSWD.

t Press O / P, select PASSWD., press !

| - - -

OLD PW

| - - | - - | - - | - - | - - | - - | - - -

y When an old password is active, OLD PW appears briefly so that you can enter the old password.

y The display shows: “_ _ _ _ _ _ .”

y The first line flashes.

t Make the following inputs:

− O / P keys: Selects numbers 0 to 9.

− §: Go back to the previous number.

− !: Confirm entry or go to the next number.

t Repeat to enter the remaining numbers.

y If you make an incorrect entry, NOT OK appears. Press ! and reenter the old password.

NEW PW y When you make a correct entry, NEW PW appears briefly so that you can enter the new pass-

word.

y The display shows: “_ _ _ _ _ _ .”

y The first line flashes.

t Make the following inputs:

− O / P keys: Selects numbers 0 to 9.

− §: Go back to the previous number.

− You can enter spaces to delete the number/password.

− !: Confirm entry or go to the next number.

t Repeat to enter the remaining numbers.

y The password has been changed.

t Press § several times to exit the menu.

6.7.2.7 Resetting the Scale: “RESET”

If required, you can restore the scale to its factory settings.

Note:

If you have activated the password function, this feature is password-protected.

t Access the Setup menu (see Chapter 6.7.2.1, page 29).

Level 1 Level 2 Level 3 Level 4

SETUP

t Press O / P, select SETUP, press !

| - - -

GEN.SRV.

t Press O / P, select GEN.SRV., press !

| - - -

MEN.RES.

t Press O / P, select MEN.RES., press !

|- - -

DEFAUL.

t Press O / P, select DEFAUL.

|- - - o

NO

t Press !, “o” appears,

y The factory settings are loaded.

t Press § several times to exit the menu

Operating Manual EVO1X | LAB1X 33

Care and Maintenance

7 Care and Maintenance

7.1 Cleaning

Electrical Hazard from Voltage or Current

Disconnect the AC adapter (if connected) from the mains. Unplug any connected

data cables from the ex-link converter. Never open the scale, the AC adapter, or

the ex-link converter. The parts contained in these cannot be cleaned, repaired or

replaced by the user.

− Make sure that no liquid or dust gets into the scale, the AC adapter, or the

ex-link converter.

− Only use soft brushes and cloths for cleaning.

− Never use cleaning accessories or agents that contain abrasive components or

ingredients (e.g., scouring cream, steel wool),

which can ultimately damage the equipment.

Do not clean the following parts with acetone or aggressive cleaning agents:

mains socket, data interface, labels, and all other plastic parts.

Cleaning the Control Panel

t Turn off the device before cleaning the control panel since touching the screen

could trigger unwanted inputs.

Cleaning the Device Housing

t Clean the device.

t Use a soft cloth to dry the device.

7.2 Maintenance

Electrical Hazard from Voltage or Current

Repair work on the (optional) AC adapter must only be carried out by trained service

technicians. Contact Sartorius Service for professional repairs (see Chapter 15.1,

page 42).

To ensure the continued accuracy of your scale, we recommend scheduling regular

servicing at least once a year.

Sartorius Service offers different service contracts with maintenance intervals that

are tailored to your needs.

A calibration certificate should always be issued as part of every maintenance

session.

Safety inspections of the AC adapter and its connections must be performed at

appropriate intervals by a qualified electrician (e.g., every 2 years).

34 Operating Manual EVO1X | LAB1X

Malfunctions

8 Malfunctions

Problem Cause Remedy

No segments appear

on the weight display

− No AC power is available − Check power supply

The weight readout

shows “LOW”

− No weighing pan on the

scale

− Position the weighing

pan

The weight readout

shows “HIGH”

− Weighing capacity

exceeded

− Unload the scale

The weight readout

changes constantly

− Unstable ambient

conditions

− Excessive vibration or

draft

− Weighing pan is being

affected at some point

by outside influences

− Set up scale in

another area

− Adjust the scale

settings (see Chapter “3.5 Menu List,”

page 13)

The weight readout is

obviously incorrect

− The sample is not stable

− Scale not tared before

weighing

− Tare before weighing

No weight value is shown

and the padlock symbol

H is displayed

− PC connection to the

scale has been interrupted, activating the

“LOCK” function

− Manual “LOCK”

function is active

− Access the scale

operating menu to

make the necessary

adjustment and switch

off the “LOCK”

function

− Check the connection

− Switch off the manual

“LOCK” function

Operating Manual EVO1X | LAB1X 35

Storage

9 Storage

If the device is not set up immediately after delivery, or will not be used temporarily,

the ambient conditions listed in Chapter “12 Technical Data,” page 37 must be

observed for storage.

Only store the device in dry buildings and do not leave the device outdoors.

In case of improper storage, no liability will be assumed for resulting damage.

10 Disposal

Packaging

The packaging consists of environmentally friendly materials that can be used as

secondary raw materials. The packaging is to be taken to a local waste disposal site

if no longer required.

Device

The device, including accessories and empty non-rechargeable and rechargeable

batteries, does not belong in your regular household waste; this device is

manufactured from high-grade materials which can be recycled and reused.

European Directive 2002/96/EC (WEEE) requires that electrical and electronic

equipment be separated from normal household waste so that it may then be

recycled. The crossed-out waste bin symbol indicates that separate collection is

required.

In Germany and several other countries, Sartorius itself assumes responsibility for

the return and legally compliant disposal of its electrical and electronic products.

These products may not be placed with household waste or be brought to collection

centers run by local public disposal operations – not even by small commercial

operators. Please contact Sartorius Service.

In countries that are not members of the European Economic Area (EEA) or where no

Sartorius subsidiaries or dealerships are located, please contact your local authorities

or a commercial disposal operator.

Prior to disposal and/or scrapping of the device, any batteries should be removed

and disposed of at a local collection point.

Sartorius will not take back devices contaminated with hazardous materials

(ABC contamination) – either for repair or disposal.

Addresses for Disposal

Detailed information with service addresses for the disposal of your device can be

found on our website (www.sartorius.com).

Serial Number Coding

36 Operating Manual EVO1X | LAB1X

11 Serial Number Coding

Sartorius Lab Instruments GmbH & Co. KG

37070 Goettingen, Germany

CA: Ex ia IS CL I, Div 1, GP C,D T4

Zone 1, Ex ib IIB T4

USA: IS CL I, Div 1, GP C,D T4

CL I, Zone 1, AEx ib IIB T4

1000011682

0°C Ta +40°C

产品型号:

产品名称:卓逸PMA

1725

Made in Germany

II 2G Ex ib IIB T4 Gb

FM 14ATEX0085X

IECEx FME 14.0008X

PCEC CE16.2058X

For installation and maintenance see control drawing

2021459. Pour installation et maintenance voir le No

2021459 du diagramme de contrôle.

安装和维护请参见安全说明 2021459。

The manufacture date of this device is encoded in the serial number. The format is as

follows:

YMM x x x x x

Y Year

3 2014-2020

4 2021-2027

5 2028-2034, etc.

The Y column indicates the year group, which covers a period of 7 years. Within each

year group, the months (M M) are counted up from 13.

Year: 2015 2016 2017 2018 2019 ...

MM: 25-36 37-48 49-60 61-72 73-84 ...

Example:

328xxxxx (April 2015). “xxxxx” is a consecutive number, increasing by one every

month.

Operating Manual EVO1X | LAB1X 37

Technical Data

12 Technical Data

12.1 General Data

Specification Unit Value

Scale

Supply voltage Only via USB port or Sartorius AC adapter YPS06-USB

Input voltage V

DC

+4.5–5.0

Power consumption W 2.0 (typically)

Further data IP40 in accordance with EN 60529/IEC 60529

Ambient conditions

The specifications apply under the following ambient conditions:

Environment For indoor use only

Ambient temperature* °C +10 to +30

Operational capability °C Guaranteed between +5 and +40

Storage and shipping °C -10 to +60

Relative humidity ** % 15 to 80 for temperatures up to 30°C non-condensing, decreasing linearly

to 50% relative humidity at 40°C

Ex-link converter interface connection USB, type B

Electromagnetic compatibility In accordance with EN 61326-1/IEC 61326-1 Electrical equipment for

measurement, control and laboratory use – EMC requirements – Part 1:

General Requirements

Interference resistance Basic requirements

Transient emissions Class B

Suitable for use in residential areas and areas that are connected to a low

voltage network that also supplies residential buildings.

Verified scales in accordance with EU requirements comply with the

requirements of Council Directive 2014/31/EU with EN 45501:2015 and

OIML R76:2006.

* For verified scales in accordance with EU requirements, refer to the

information on the scale.

** For verified scales in accordance with EU requirements, the legal

regulations apply.

Available application programs Recalculation, factor calculation, formula

AC adapter YPS06-USB

USB power plug (5 V/900 mA) Type FW7712 (manufacturer's certificate)

Primary 100–240 V~, -10%/+10%, 50–60 Hz, 0.125 A

Secondary 5 V

DC

, ± 5%, 900 mA (max.)

Further data Protection class II

IP40 in accordance with EN 60529/IEC 60529

Ex-link converter YCO14-Z, YCO14-Y

Further data IP40 in accordance with EN 60529/IEC 60529

38 Operating Manual EVO1X | LAB1X

Technical Data

12.2 Model-specific Data

Specification Unit Value Value

Model name PMA.Evolution PMA.HD

EVO1X LAB1X

Weighing capacity g 7500/999.95 2200

Readability g 0.1/0.05 0.01/0.1

Tare range (subtractive) g -7500 -2200

External adjustment weight /

accuracy class

kg 1, 2, 5 /

F2 or better

1, 2 /

F1 or better

Size of weighing pan

d mm

233 180

Net weight kg 2.4 2.3

12.3 Verified Models with EC Type Approval Certificate:

Model-specific Technical Data

Specification Unit Value

Model name PMA.Evolution EVO1X

Accuracy class

�

Type PMA-EV

Weighing capacity max. g 7500

Scale interval d g 0.1

Verification scale interval e g 1

Temperature range +10°C–+30°C

Tare equalization range (subtractive)

< 100% from max. weighing capacity

Specification Unit Value

Model name PMA.HD, LAB1X

Accuracy class

l

Type PMA-HD

Weighing capacity max. g 2200

Scale interval d g 1

Verification scale interval e g 1

Temperature range +10°C–+40°C

Tare equalization range (subtractive)

< 100% from max. weighing capacity

Operating Manual EVO1X | LAB1X 39

Technical Data

12.4 Device Dimensions

12.4.1 Model EVO1X

12.4.2 Model LAB1X

12.5 USB Port (PC Connection)

12.5.1 Purpose

This device can be connected to a PC via the USB port.

A virtual serial interface (virtual COM port, VCP) is set up on the PC as a device type

via the USB port. This virtual serial interface is identified and operated by the

application program.

The xBPI and SBI protocols can be transmitted via the virtual serial interface.

40 Operating Manual EVO1X | LAB1X

Technical Data

12.5.2 Installing the Software Driver

12.5.2.1 Installing the Software Driver (Windows Update)

t Connect the scale to the USB port of the computer (see Chapter “4.4.2

Connecting the Scale,” page 20).

y Windows will detect the scale connected to the USB port as a device.

If the device is being connected for the first time, the Windows Installation

Wizard will run automatically.

t Follow the instructions that appear.

t To complete the installation, click on Finish.

y The virtual interface is now ready for operation.

12.5.2.2 Installing the Software Driver (via CD)

t Ensure that the scale is not connected to the PC.

t Insert the supplied CD into the PC.

t If the Installation Wizard does not start automatically after you insert the CD,

then manually start driver installation via Setup.bat located on the CD.

t Follow the instructions that appear.

t To complete the installation, click on Finish.

y The virtual interface is now ready for operation.

t Connect the scale to the USB port of the computer (see Chapter “4.4.2

Connecting the Scale,” page 20).

Windows

®

usually adds the virtual port in the position following your highestnumbered COM port.

Example:

For a PC with up to 4 COM ports, the new virtual port would then be COM5

(see Device Manager).

12.5.2.3 Installation Instructions for Windows XP

®

and Above

Changing the Port Number

If you use the USB interface with programs that limit the number of COM port

designations (e.g., only COM1, 2, 3, 4), you may have to assign one of these port

numbers to the new virtual port.

t Open the setting for the USB serial port in the Windows

®

Control Panel:

− START > My Computer > Control Panel

− System > Hardware > Device Manager

t Open the Connections submenu.

t Double-click on USB Serial Port.

t Select Port Settings > Advanced.

Use the “COM Port Number” button to change the port number.

Uninstalling the Driver

You can uninstall the software driver for the USB port via the Device Manager

(only if the scale is connected):

t Use the right mouse button to click on the respective port.

t Then select “uninstall” from the context menu that appears.

Operating Manual EVO1X | LAB1X 41

Accessories

13 Accessories

Accessories Order Number

AC adapter (5 V/900 mA) YPS06-USB

USB connection cable YCC01-0040M5

Mains adapter set for YPS06-USB YAK01

− USA and Japan

− Europe/EU

− United Kingdom

Mains adapter set for YPS06-USB YAK02

− Australia

− South Africa

− Argentina

− Brazil

Mains adapter set for YPS06-USB YAK03

− India

− Korea

− China

Ex-link converter

YCO14-Z

Ex-link converter

YCO14-Y

Link cable

from converter to scale, 10 m

YCC01-0052M10

from converter to scale, 20 m

YCC01-0052M20

from converter to scale, 30 m

YCC01-0052M30

Equipotential bonding cable, 2 m

YCC01-X046M2

In-use dust cover

for control panel, pack of 10 YDC03PMA10

for support column, PMA.Evolution, pack of 10 YDC03PMA-CO10

for weighing pan, PMA.Evolution, pack of 10 YDC03PMA-WP10

Calibration weights

for PMA.Evolution:

− 5 kg, accuracy class F2

YCW654-AC-00

− 2 kg, accuracy class F2

YCW624-AC-00

− 1 kg, accuracy class F2

YCW614-AC-00

for PMA.HD:

− 2 kg, accuracy class F1

YCW623-AC-00

− 1 kg, accuracy class F1

YCW613-AC-00

42 Operating Manual EVO1X | LAB1X

Sartorius Service

14 Sartorius Service

Sartorius Service is at your disposal for queries regarding the device. For information

about the service addresses, services provided or to contact a local representative,

please visit the Sartorius website (www.sartorius.com).

15 Conformity & Licenses

15.1 EU Declaration of Conformity

The attached Declaration of Conformity hereby confirms compliance of the device

with the directives cited.

The declaration of conformity supplied here is for conformity-assessed (verified)

weighing instruments for use in the EEA.

Please keep it in a safe place.

Operating Manual EVO1X | LAB1X 43

Conformity & Licenses

44 Operating Manual EVO1X | LAB1X

Conformity & Licenses

Operating Manual EVO1X | LAB1X 45

Conformity & Licenses

S

S

S

MD

MD

K

Schilder und Marken / Plates and Markings / Plaques et

marques / Placas y Marcas / Etichette e Sigilli

Typ Waage / Type weighing instrument / Type d’instrument de pesage / Tipo del instrumento de

pesaje / Tipo di strumento per pesare: PMA-EV, PMA-HD

EG Baumusterprüfbescheinigung / EC type-examination certificate / Certificat d’examen UE de

type / Certificado de examen UE de tipo / Certificato di esame UE del tipo : UK3066

46 Operating Manual EVO1X | LAB1X

Conformity & Licenses

Schale / Pan / Plateau de pesée / Plato de pesaje / Piatto di pesata

Unterschale / Subpan / Plateau inférieur / Plato inferior / Piatto inferiore

Libelle / Bubble level / Nivelle sphérique / Nivel de burbuja / Livella

Segmentiertes LCD-Display / Segmented LCD display / Afficheur à segments (LCD) / Visualizador de

segmentos (LCD) / Visualizzatore a segmenti (LCD)

LCD Graphik-Display / LCD graphic display / Afficheur graphique (LCD) / Visualizador gráfica (LCD) /

Visualizzatore grafico (LCD)

Grundplatte / Base plate / Plaque de montage / Placa base / Piastra di base

Wägesystem / Weighing system / Système de pesée / Sistema pesador / Sistema di pesatura

Auswerteelektronik / Evaluation electronics / Dispositif de détection électronique / Electrónica de

evaluación / Elettronica per la valutazione

Anzeigeeinrichtung / Indicating device / Dispositif indicateur / Dispositivo indicador / Dispositivo di

visualizzazione

Metrologische Daten Max, Min, e und wenn vorhanden d / Metrological data Max, Min, e and if

existent d / Données métrologiques : Max, Min, e et, si disponible, d / Datos metrológicos: Máx, Mín,

e y d, si está disponible / Dati metrologici: Max, Min, e, e d se disponibile

Sicherungsstempel (selbstklebende Marke oder Plombe) / Protective mark (self-adhesive mark or

seal) / Marque de protection (marque ou sceau autocollant) / Sello de seguridad (marca

autoadhesiva o precinto) / Sigillo di protezione (bollino autoadesivo o piombo)

Kennzeichnungsschild mit CE-Zeichen / Descriptive plate with CE-sign / Plaque d’identification avec

marque CE de conformité / Placa de características con la marca CE / Etichetta d'identificazione con

marchio CE

Programmverriegelungsschalter / Menu access switch / Commutateur d’accès au menu / Interruptor

de bloqueo de programa / Commutatore di accesso al menu

gesperrt / locked / verrouillé / bloqueado / bloccato

offen / open / ouvert / abierto / aperto

1

2

3

4

5

6

7

8

9

MD

S

K

Operating Manual EVO1X | LAB1X 47

Conformity & Licenses

2023040

Safety Instructions

2015-10-10

Dr. D. Klausgrete

Revision 01

EVO1X.....-..... / LAB1X.....-..... + YC014-.

Sheet of

1 2

Hazardous Area

Zone 1, Group IIB, T4

Non-Hazardous Area

3)

USB

3)

Sartorius Cable Type

YCC01-0052Mxx

4)

SARTORIUS

Model

EVO1X.....-.....

or

LAB1X.....-.....

+5V Power supply

(optional); e.g.

Sartorius Model

YPS06-USB or

YPS07-USB

3)

3)

Sartorius Cable Type

YCC01-0052Mxx

4)

SARTORIUS

Model

YCO14-Y

SARTORIUS

Model

EVO1X.....-.....

or

LAB1X.....-.....

Hazardous Area

Zone 2, Group IIB, T4

SARTORIUS

Model

YCO14-Y

or

YCO14-Z

5)

7)

2)

2)

Ambient temperature range:

0°C .... +40°C (+32°F .... + 104°F)

3)

USB

3)

Sartorius Cable Type

YCC01-0052Mxx

4)

SARTORIUS

Model

YCO14-Y

SARTORIUS

Model

EVO1X.....-.....

or

LAB1X.....-.....

USB

6)

7)

8)

48 Operating Manual EVO1X | LAB1X

Conformity & Licenses

2023040

Safety Instructions

2015-10-10

Dr. D. Klausgrete

Revision 01

EVO1X.....-..... / LAB1X.....-..... + YC014-.

Sheet of

2 2

These safety instructions apply to the installation, operation, maintenance and repair of the equipment

Be sure to follow the installation, operating, maintenance and servicing instructions given in the manuals supplied.

1) Install the equipment in compliance with applicable laws, rules and regulations, ordinances and standards. For

ATEX: In particular, be sure to conform to the European Standards EN 60079-14 (Explosive atmospheres – Part

14: Electrical installations design, selection and erection). Be sure to follow the installation, operating,

maintenance and servicing instructions given in the manuals supplied.

2) No connection to any device that uses or generates in excess of 250Vrms or 250Vdc.

3) All metal parts must be electrically connected to the terminal for the equipotential bonding conductor (PA).

The equipment operator is obligated to connect a lead with a gauge of at least 4 mm² (cross section) to the PA

terminal located on the housing of the Ex-Link converter and scale. The low resistance of this connection to

the PA bus bar must be checked when the system is installed at the intended place of use. The shielding of the

connecting cables may only be used for grounding when no impermissible difference in voltage is generated

and, if necessary, the shielding is able to conduct the equipotential current.

4) Only the Sartorius cable type YCC01-0052Mxx (XX = 10 for 10m, 20 for 20m; 30 for 30m) may be used.

Maximum cable length: 100ft (30.5m). The data cable connected to the scale (weighing unit) is considered as

intrinsically safe circuit. Check the correct function of the data transfer before you use the equipment in a

hazardous location. The equipment operator is responsible for any non-Sartorius cables used.

5) If the Ex-Link Converter YCO14-Y is installed in Zone 2, the installation must be done in such a way that the

pollution degree 2 of the YCO04-Y board is guaranteed.

6) If the Ex-Link Converter YCO14-Y is installed in Zone 2, it must be connected via an USB cable to a apparatus