Page 1

98648-012-08

Operation Manual

Sartorius Basic Meter PB-11

Page 2

Page 3

3

Contents

4 General View

6 Warning and Safety Information

7 Installing and Maintaining Electrodes

9 Standardizing for pH Measurement

13 Using Setup

15 Standardizing for Millivolt Measurement

18 Understanding pH Theory

19 Temperature Compensation

20 Measuring pH

21 Troubleshooting

23 Meter Specifications

24 Accessories

25 C Declaration of Conformity

Page 4

4

General View

1 Setup button:

Press to clear buffers,

review electrode

calibration or select new

autorecognized buffers

2 Mode button:

Press to toggle between

pH and mV mode

3 Standardize button:

Press to enter each buffer

4 Enter button:

Press to select menu

item options

5 Measuring icon

6 Temperature

7 Mode

8 Result

9 Prompts

10 Buffer icons

11 Icon: standardization

(calibration of the meter)

in process

12 Stability icon

13 Standardizing icon

14 Standardization result

Front View

Display

1

2

3

4

1.68

4.01 6.86

9.18

12.46

S1

S2 S3

32

1

%/¡C

Auto

Man

Set

Clear

OK

Error

1234567810101213

Sal

TDS

%DO

mg/L

S/cm cm ion

rel

mV pH

m

µ

K

M

°C

S

13

12

11

10

14

5

6

7

8

9

1

2

3

Page 5

5

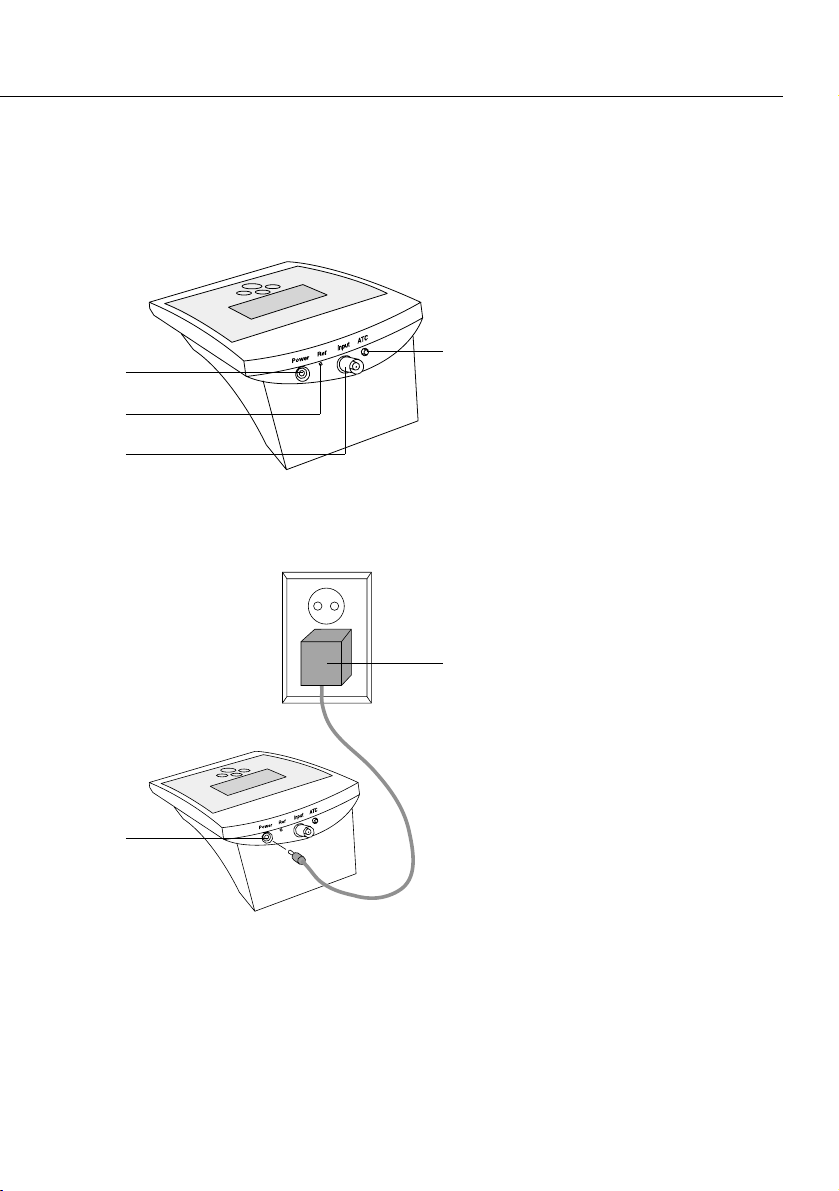

1 Power cable connector

2 Reference electrode

connector (used with

separate reference

electrodes)

3 BNC electrode connector

4 Temperature compensation

probe connector

5 AC adapter

Rear View

Connecting to a Power Source

1

2

3

4

1

5

Page 6

6

Warning and Safety Information

For safety and operating reasons, only authorized

service technicians may open the Basic Meter PB-11

housing. Therefore, only authorized technicians may

repair or perform maintenance on this pH meter.

Any tampering with the pH meter or negligent or

intentional damage to this equipment will void any

warranty claims against the manufacturer.

If liquid gets into the pH meter, unplug it from AC

power (mains supply) and have an authorized service

technician check the pH meter.

If you do not plan to use this pH meter for a relatively

long period, please disconnect it from AC power.

For safety reasons, use this equipment only for the

application described in this operation manual.

Make sure that the buffers used for standardizing

have exactly the same values that are stored.

Page 7

7

Installing and Maintaining Electrodes

1. Remove the protective end cover from the electrode.

2. Before first use of your electrode, or whenever

the electrode is dry, soak overnight in a standard

solution or KCI solution.

3. Remove the shorting cap on the pH meter connector.

Install the electrode by plugging the BNC and ATC

connectors into the jacks on the rear panel.

Page 8

8

4. Option: Install an ion selective electrode by removing

the BNC shorting cap and plugging the BNC connector

(twist-lock) into the BNC jack. If a combination

electrode is not available, plug the separate reference

electrode into the ref pin.

5. Clean the electrode between each measurement with

distilled water or deionized water, or part of the next

solution to be measured.

6. Store glass pH electrodes in KCI solution or electrode

filling solution. Make sure the liquid level of the

internal filling solution is always a few centimeters

higher than that of the measurement solution.

Reference

Electrode

ISE

Page 9

9

Standardizing for pH Measurement

Because electrodes vary in their response, you

must standardize (calibrate) your pH meter and

electrode to compensate for electrode variation.

The more frequently you standardize, the more

accurate your measurements. Standardize daily,

or more often, for accurate results.

This pH meter allows automatic standardization

using up to three buffers. Press the Standardize

button again to delete all the standardization data

stored up to that point. The pH meter performs

automatic temperature compensation.

1. Immerse electrode in a buffer solution. Stir gently.

Allow the electrode to reach a stable value.

2. Press the Mode button until your digital display

indicates pH mode. This button toggles between

pH and mV modes.

Page 10

10

3. Clear existing buffers when doing a new 2- or

3-point standardization. Use the Setup button.

Also use the Setup button to select the individual

sets of buffers. (See page 13.)

4. Press Standardize. The meter recognizes the buffer

and flashes a buffer icon. When the signal is stable,

the buffer is entered. By pressing ENTER you can

also enter the current buffer directly.

5. The meter displays the slope of the electrode as

100.0%. On entering a second or third buffer,

the meter performs a diagnostic check on the

electrode and displays the slope. (See step 7 ff.)

[Standardize]

Page 11

11

6. To enter a second buffer, place the electrode in

the second buffer solution, stir, allow time for the

electrode to stabilize, and press Standardize again.

The meter recognizes the buffer and displays the

first and second buffer values.

7. Next, the meter performs a diagnostic test of

the electrode. The display indicates either Good

Electrode (“OK”) or Electrode Error (“Error”).

The meter also displays the slope of the electrode.

8. Error indicates that your electrode or the buffer

is not working properly, or a wrong set of buffers

has been selected. The electrode response must be

between 90 and 105% slope. (See Troubleshooting,

on page 21.) Press Enter to clear the Error, then

try re-entering the buffer as described in step 6.

9. To set a third standard, place the electrode in the

third buffer solution, stir, allow to stabilize, and

press Standardize. The results will be the same

as in steps 6 and 7, except the display will show

three buffer values.

[Standardize]

[Standardize]

Page 12

12

10. After entering three buffers, the Standardizing

icon goes out and the Measuring icon appears

on the display to indicate that the meter returns

to Measuring operation.

! Note:

The meter continually adjusts for temperature.

Therefore, buffers may vary slightly from the

nominal values because of temperature.

11. Standardize your pH meter using at least two

buffers with pH values bracketing the expected pH

of your samples. Stirring with a magnetic stir bar

provides faster electrode response.

Page 13

13

Using Setup

The Setup button lets you clear all the standardization data that you have entered, review calibration

information, or select the buffer set that you want.

You can escape the setup mode at any time by

pressing pH/mV.

1. Press Setup once to clear all buffers you have

entered. If you are sure you want to clear the

buffers, press Enter. The meter clears all buffers

and returns to Measuring.

2. Press Setup again to show electrode performance,

slope and the first and second calibration points.

The two buffer values will also be displayed.

3. Pressing Setup again shows the electrode slope

between the second and third buffers (if three

buffers have been entered) and shows the second

and third buffer icons.

[Setup]

[Enter]

2+ [Setup]

Page 14

14

4. Press Setup again to display a Set Buffers icon

and to display the first buffer set icons.

5. Press Enter to select the set of buffers shown on

the display or Press Setup again to toggle between

the existing sets of buffers.

6. Press Enter to select the displayed buffer set that

contains the buffer you want to use. Press Setup

again, or press the Mode button at any time to

return to Measuring.

!Note:

You may select buffers from different sets.

[Setup] or

[Enter]

[Setup]

Page 15

15

Standardizing for

Millivolt Measurement

(Relative Millivolt)

You will normally use millivolt measurements for

determining ion concentration and for measuring

redox potential (also called ORP, oxidation reduction

potential).

You will use an ion selective electrode (ISE),

combined with a reference electrode, to measure ion

concentration. The ISE senses the ion concentration

and responds with a millivolt potential. The millivolt

readings are then used to determine ion concentrations (on the basis of a previously entered

calibration curve).

You will normally use a redox/ORP electrode to

measure redox potential (ORP). ORP measurements

indicate the oxidizing or reducing capability of a

solution. You can use ORP values to monitor or

control solutions requiring a set amount of oxidants

or reductants.

1. Immerse electrode in a standard solution.

Page 16

16

2. Press Mode until your digital display indicates

mV mode.

3. Press Standardize to enter an mV standard and

read relative mV.

4. When the signal becomes stable, or when you

press Enter, the current absolute mV value (offset)

becomes zero relative millivolts.

[Mode]

[Standardize]

Page 17

17

5. To clear an mV offset and return to absolute

millivolt mode, press Setup. The meter displays

a flashing Clear icon, and shows the current

relative millivolt offset.

6. To clear the previous mV offset, press Enter.

You then return to absolute mV mode.

[Setup]

[Enter]

Page 18

18

Understanding pH Theory

Defining pH

The measurement of pH plays an important

role in identifying and controlling acidity

and alkalinity levels for industry and

research. pH is a measure of the acidity

or alkalinity of a solution and can be

represented by this equation:

pH = -log [H

+

]

with [H

+

] representing the concentration

of hydrogen ions in the solution. pH is

sometimes referred to as the power of the

hydrogen ion in a solution.

By using a pH meter, you can determine

exact pH levels of solutions. For example,

rather than say that lemon juice is quite

acidic, you can say that lemon juice has

a pH of 2.4. An exact pH value can be

used to control or measure acidity levels

for manufacturing processes or for basic

research.

pH values generally range from 0 to14,

with a pH of 7 being the neutral point,

or the value of pure water. pH values

greater than 7 represent increasing

alkalinity, whereas pH values below 7

represent increasing acidity (Figure 1).

pH

0 Strong Acid

1

2 Lemon Juice

3

4 Tomato Juice

5 Coffee

6

Neutral 7 Pure Water

8 Baking Soda

9

(sodium hydrogen carbonate)

10

11

12 Ammonia

13

14 Strong Base

more acidicmore basic

Figure 1.

pH scale showing

the relative acidity

or basicity of some

common substances.

Page 19

19

Temperature Compensation

!Note: Automatic temperature compensation

only functions properly if a temperature probe

is connected.

Temperature compensation influences the results

in two different ways:

1. pH values of the buffers change as a function

of temperature.

Each buffer varies as a function of the temperature of the respective solution. Typically, these

values are indicated on the buffer label. The

values detailed in the table below apply to most

technical buffers.

If standardization is performed in the pH mode,

the pH value is adapted to the nominal value of

the current temperature.

For example, if the buffer has a nominal pH of

7.00 at a temperature of 25°C, the meter will

standardize the buffer to 7.02 instead of 7.00 at

a temperature of 20°C.

2. Electrode slope changes as a function of

temperature.

Theoretically, the change of voltage per pH unit

is approx. 59.16 mV at 25°C. However, this mV

per pH unit changes as a function of temperature.

The meter compensates for these changes by

taking into account the temperature dependency

of the Nernst factor when calculating pH values.

Standard buffers:

pH 4.00 pH 7.00 pH 10.00

0°C 4.005 7.13 10.34

5°C 4.003 7.10 10.26

10°C 4.001 7.07 10.19

15°C 4.002 7.05 10.12

20°C 4.003 7.02 10.06

25°C 4.008 7.00 10.00

30°C 4.010 6.99 9.94

35°C 4.020 6.98 9.90

40°C 4.030 6.97 9.85

50°C 4.061 6.97 9.78

Page 20

20

Measuring pH

To measure pH with a conventional glass pH electrode, the

meter uses a pH-sensing glass

bulb that is sensitive to hydrogen

ions. The potential developed at

the glass membrane is directly

related to the pH of the solution.

The glass electrode is paired

with a reference electrode

which completes the electrical

measuring circuit and provides

a stable reference point. These

two electrodes are joined to

create a combination electrode.

The combination glass electrode

is connected to the pH meter

which reads the voltage, converts

it to pH units, and displays the

result.

Reference

Electrode

Porous

Junction

(Diaphragm)

pH Sensor

Temperature sensor

with automatic temperature

compensation (ATC)

Page 21

21

Troubleshooting

1. If the signal from the electrode is out of range, the

display will show “——”. This may happen when the

electrode is not immersed in a solution.

2. The meter will display Error when it detects an

error in electrode response. During standardization,

the message indicates that the electrode is less than

90% or more than 105% of the correct response.

The Error message can indicate either a bad electrode

or bad buffer(s).

3. If the meter detects an error in the temperature

measurement, the display shows “—-°C.” If you do

not use a temperature probe, the meter uses the

standard temperature (25°C).

Page 22

22

4. To test the pH electrode, place it in a good

pH 7 buffer. Press pH/mV to use the mV

mode, and note the millivolt reading.

Repeat for either a pH 4 or pH 10 buffer.

The electrode signals must be within the

limits shown below (when temperature is

approx. 25°C).

5. To test the meter for correct operation, install

the BNC (input) shorting cap. Press pH/mV to

select the mV mode, and note the mV reading.

If the meter reads 0 ± 0.3 mV, it is measuring

correctly. Note that a long-term drift of

0.1 mV/month since last calibration is

specified.

Electrode Test

pH=7 0 ± 30 mV

pH=4 169 to 186 mV

more than pH 7

pH=10 159 to 185 mV

less than pH 7

ATC

Input

Ref

Power

Page 23

23

Meter Specifications

pH –2.00 bis +20.00

Readability 0.01

Accuracy ± 0.01

mV –1800.0 to 1800.0 mV

Readability 0.1 mV

Accuracy ± 0.2 mV (0.05% if <– 400 mV/>+ 400 mV)

Temperature range –5.0 to +105.0°C

Readability 0.1°C

Accuracy ± 0.2°C

Calibration points Maximum 3 buffers

Automatic buffer recognition 16 buffers

2; 4; 7; 10; 12

1; 3; 6; 8; 10; 13

1.68; 4.0; 6.86; 9.18; 12.46

Automatic temperature compensation

Automatic electrode slope correction

between 90–105% of the theoretical slope

Page 24

24

Accessories

Order No.

pH combination electrodes:

– Plastic body with built-in temperature sensor, KCI liquid-filled PY-P10

– Glass body with built-in temperature sensor KCI liquid-filled,

platinum junction PY-P11

– Plastic body with built-in temperature sensor, gel-filled PY-P12

– Plastic body, gel-filled PY-P20

– Glass body, KCI liquid-filled, platinum junction PY-P21

Temperature Probe PY-T01

Other pH electrodes and sensors for special measuring conditions

including ion selective electrodes and redox electrodes are also

available on request.

Page 25

25

Page 26

26

Page 27

Page 28

Printed in Germany on paper that has

been bleached without any use of chlorine

W1A000 BasicMeter PB11 · KT

Publication No.: WPB6004-e04032

Sartorius AG

Weender Landstrasse 94–108

37075 Goettingen, Germany

Phone +49.551.308.0

Fax +49.551.308.3289

www.sartorius.com

Copyright by Sartorius AG,

Goettingen, Germany.

All rights reserved. No part

of this publication may

be reprinted or translated in

any form or by any means

without the prior written

permission of Sartorius AG.

The status of the information,

specifications and illustrations

in this manual is indicated

by the date given below.

Sartorius AG reserves the

right to make changes to the

technology, features,

specifications and design of the

equipment without notice.

Status:

March 2004, Sartorius AG,

Goettingen, Germany

Loading...

Loading...