Sartorius MW1,MW2,Midrics 1,Midrics 2 Operating Instructions Manual

Operating Instructions

Sartorius Midrics®1| Midrics®2

Models MW1 | MW2

Complete Scales

98648-014-94

Midrics®1 and 2 are rugged complete

scales for the demanding area of daily

quality control. They meet the highest

requirements placed on the accuracy

and reliability of weighing results:

– in the food industry

– in the pharmaceutical industry

– in the chemical industry

– in the electronics and metal-working

industries

Midrics

®

complete scales are:

– Rugged and durable

(stainless steel housing)

– Easy to clean and disinfect

– Easy to operate, thanks to:

– large, backlit display segments

– large keys with positive click action

– Independent of the weighing platform

location

– Equipped with a range of interfaces

for flexible use

– Password-protected from unauthorized

changes in the operating menu

Additional characteristics (Midrics

®

2):

– Input functions for tare values

through numeric keypad

– Option for 4 alphanumeric lines

to identify samples

– Fast response times

– Designation of weight values with up

to 4 lines of alphanumeric text

– Built-in application programs for:

– Counting

– Neutral measurement

– Weighing in percent

– Averaging

– Checkweighing

– Classification

– Net-total formulation

– Totalizing

– Automatic initialization when the

Midrics is switched on

– Automatic taring when the first load

is placed on the weighing platform

– Optional remote control using an

external computer

Symbols

The following symbols are used

in these instructions:

§ denotes general operating instructions

$ indicates instructions for exceptional

cases

> describes the outcome of an

operating step

!indicates a hazard

Intended Use

2

2 Intended Use

4 Warnings and Safety Precautions

4 Getting Started

4 Unpacking the Midrics

4 Equipment Supplied

4 Installation

4 Conditioning the Scale

5 Connecting the Scale to AC Power

6 Leveling the Weighing Platform

6 Operating Limits

7 General View of the Equipment

7 Display and Keypad

7 Back Panel

7 Weighing Platform

8 Operating Design

8 Keypad

8 Keypad Input

9 Input Through the Digital

Control Port

10 Measured Value Display

10 Display of Measured and

Calculated Values

11 Saving Data in Weighing Mode

12 Operating Menu Navigation

12 Error Codes

12 Data Output

12 Saving Data

13 Configuration

13 Setting the Language

14 Entering or Changing the Password

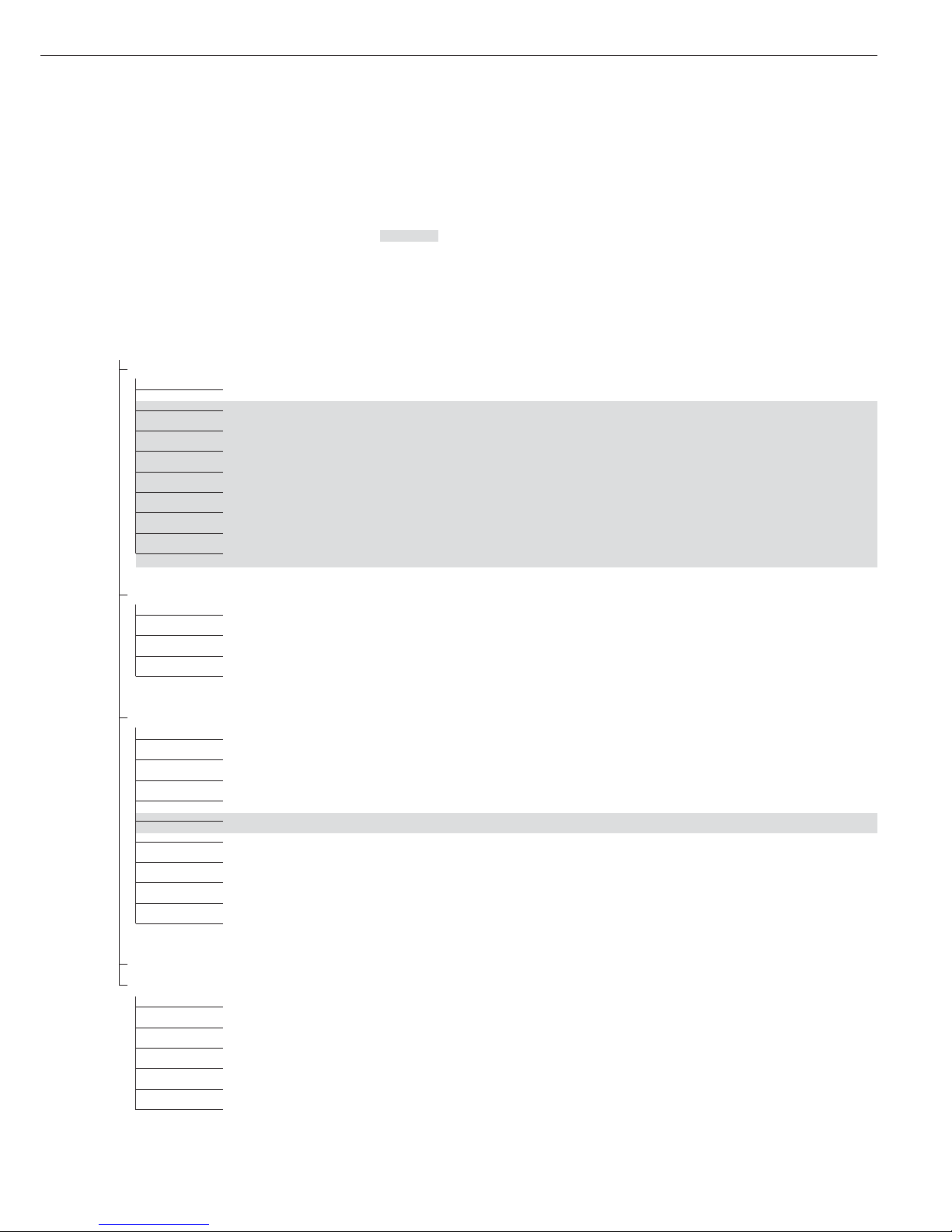

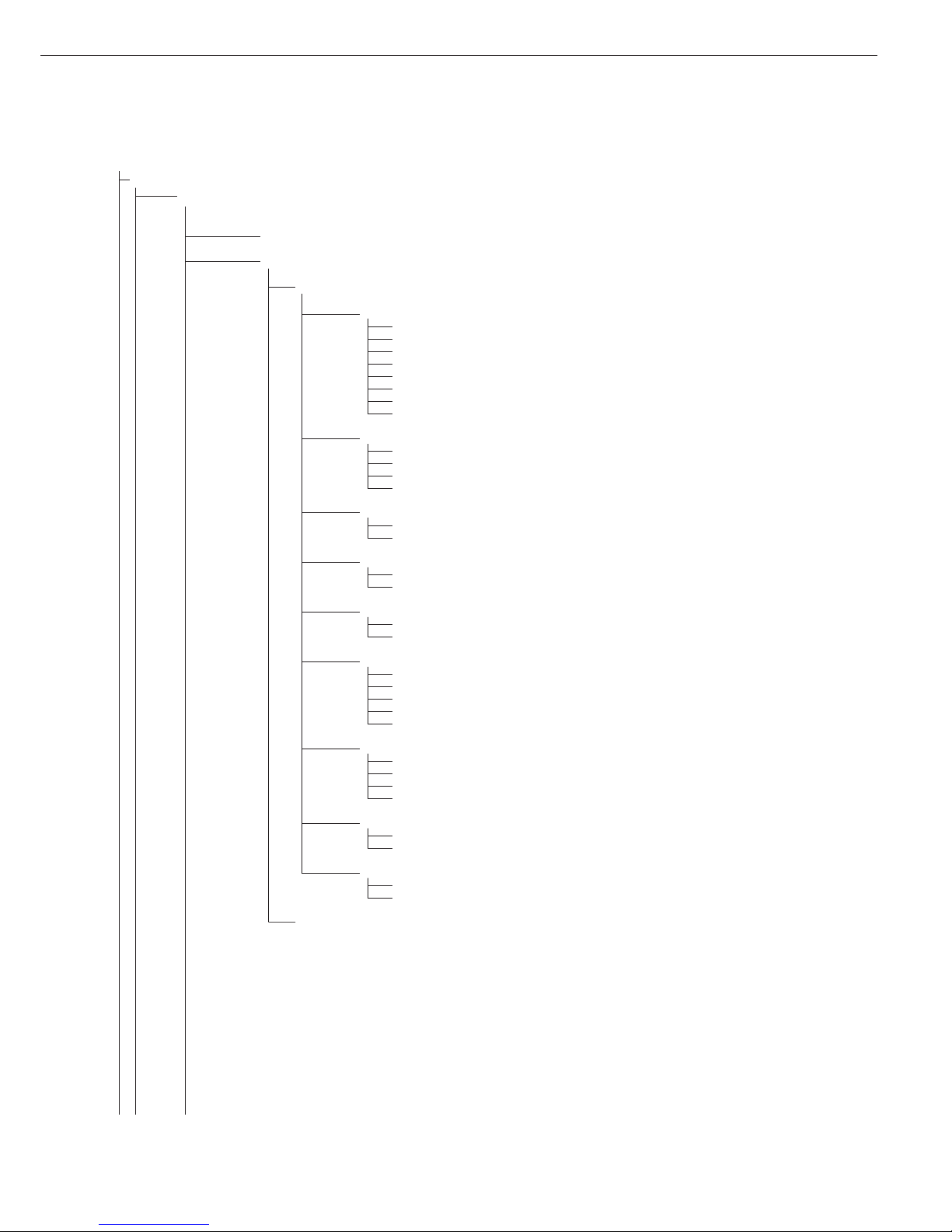

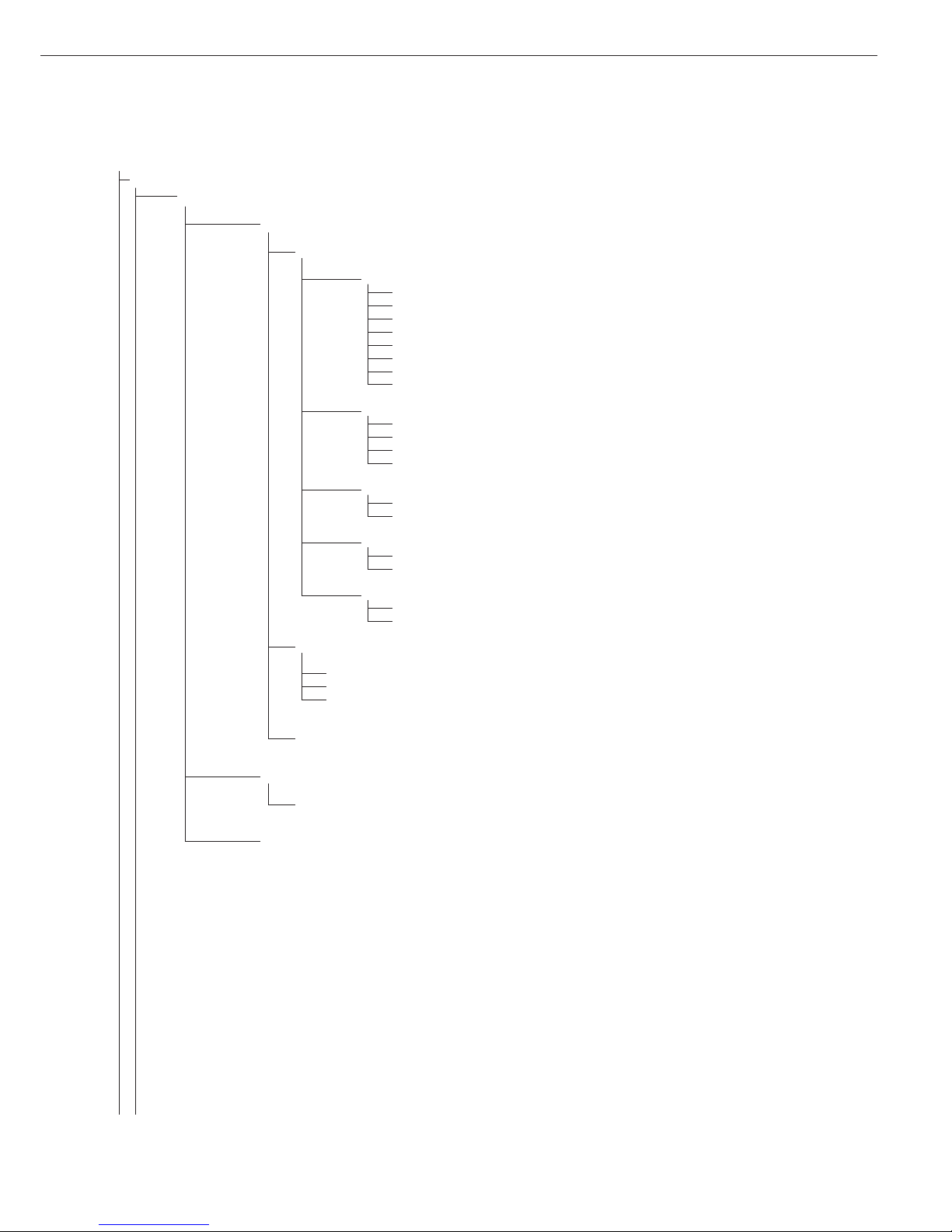

15 Operating Menu Overview

32 Operation

32 Basic Weighing Function

32 Weighing W

32 Device Parameters

33 Tare Function in Weighing

34 Numeric Input for Weighing

35 Weighing with Variable Tare Values

36 Calibration and adjustment

38 Data ID Codes

40 Application Programs

41 Counting

44 Neutral Measurement

47 Averaging

50 Weighing in Percent

53 Checkweighing

56 Classification

59 Totalizing

62 Net-total Formulation

65 Configuring Printouts

66 Configuring the Data Interface

as a Printer Port

66 Configuring the Layout

67 GMP-compliant Printouts

68 Sample Printouts

71 Interface Port (Optional)

71 COM1

71 UniCOM

71 External Keyboard Functions

(Computer Keyboard)

72 Error Codes

73 Care and Maintenance

73 Instructions for Recycling

74 Overview

74 Common Specifications

74 Model-specific Specifications

75 Dimensions

76 Accessories

80 Declarations of Conformity

83 EC Type-Approval Certificate

84 Test Certificate

85 Plates and Markings

87 Index

Appendix

General Password

Contents

3

Safety Information

§ To prevent damage to the equipment,

please read these operating instructions

carefully before using your scale.

!Do not use this equipment in hazardous

areas. If you use electrical equipment in

installations and under ambient conditions subject to stricter safety standards

than those described in this manual,

make sure you comply with the provisions specified in the applicable regulations for installation in your country.

!Disconnect the equipment from

the power supply before connecting or

disconnecting peripheral devices.

!The display and control unit may

be opened only by trained service

technicians.

!If there is visible damage to the equip-

ment or power cord, turn off the power

and disconnect the equipment from

AC power immediately. Lock the equipment in a secure place to ensure that

it cannot be used for the time being.

!If the equipment is exposed to excessive

electromagnetic interference, it can

affect the value displayed. Once the

disturbance has ceased, the instrument

can be used again in accordance with

its intended purpose.

Installation

!Always wear gloves, safety boots

and protective clothing when lifting

the load plate with suction lifting

equipment.

Warning: Danger of personal injury!

This work must be carried out

by authorized and properly trained

personnel.

– Weighing platforms with dimensions

of 1 + 1 m or larger are provided with

suspension supports. Do not stand

beneath the weighing platform/load

plate when it is being transported or

lifted with a crane. Always comply

with the applicable safety regulations.

Make sure to avoid damaging the

junction box or the load cells during

transport.

– The operator shall be solely responsible

for installation and testing of any

modifications to Sartorius equipment,

including connection of cables or

equipment not supplied by Sartorius.

– Contact Sartorius for detailed operating

specifications in accordance with the

applicable standards for immunity

to interference.

If Option L8 (24-volt module) for connection to low-voltage sources is used,

be sure to comply with the requirements for safety extra low voltage

(SELV) and protective extra low voltage

(PELV).

– Do not expose the equipment

to aggressive chemical vapors or to

extreme temperatures, moisture,

shocks, or vibration.

– Clean your Midrics scale only in accor-

dance with the cleaning instructions

(see “Care and Maintenance").

IP Rating

Industrial protection ratings for the

housing:

– Models MW1P/MW2P are rated to IP65

– Models MW1S/MW2S:

– Display and control unit: IP65

– Weighing platform: IP67

– The IP65 protection rating for the

display and control unit is ensured only

if the rubber gasket is installed and

all connections are fastened securely

(including the caps on unused sockets).

Weighing platforms must be installed

and tested by a certified technician.

– If you install an interface port after

setting up your display and control

unit, keep the protective cap in a safe

place for future use. The cap protects

the interface connector from vapors,

moisture and dust or dirt.

Use in Legal Metrology

– If the scale is to be verified, make sure

to observe the applicable regulations

regarding verification.

– If any of the verification seals are dam-

aged, make sure to observe the national

regulations and standards applicable

in your country in such cases.

In some countries, the equipment

must be re-verified.

The complete scale is available in

various versions. If you have ordered

special options, the display and control

unit is equipped with the required

features at the factory.

Storage and Shipping Conditions

– Allowable storage temperature:

10°C to +40°C (+14°F to 104°F)

– Once the equipment has been removed

from the packaging, it may lose accuracy

if subjected to strong vibration.

Excessively strong vibration may compromise the safety of the equipment.

– Do not expose the equipment unneces-

sarily to aggressive chemical vapors

or to extreme temperatures, moisture,

shocks, or vibration.

Unpacking the Equipment

§ After unpacking the equipment,

please check it immediately for any

external damage.

$ If you detect any damage, proceed

as directed in the chapter entitled

“Care and Maintenance," under

“Safety Inspection."

$ Save the box and all parts of the

packaging for any future transport.

Unplug all connected cables before

packing the equipment.

Equipment Supplied

– Complete scale

– Operating instructions (this manual)

– Special accessories as listed on the bill

of delivery, if ordered

Installation

Choose a location that is not subject

to the following negative influences:

– Heat (heater or direct sunlight)

– Drafts from open windows or doors

– Excessive vibration during weighing

– Excessive moisture

Conditioning the Scale

Moisture in the air can condense on

cold surfaces whenever the equipment is

moved to a substantially warmer place.

To avoid the effects of condensation,

condition the scale for about 2 hours at

room temperature, leaving it unplugged

from AC power.

Equipment Not in Use

Switch off the equipment when not

in use.

Warnings and Safety Precautions Getting Started

4

Connecting the Scale to AC Power

§ Check the voltage rating and the plug design.

$ The scale is powered through the pre-installed power cord. The power supply is built into

display and control unit, which can be operated with a supply voltage of 100V to 240V.

Make sure that the voltage rating printed on the manufacturer's ID label is identical

to that of your local line voltage. If the voltage specified on the label or the plug design

of the AC adapter do not match the rating or standard you use, please contact your

Sartorius office or dealer.

The power connection must be made in accordance with the regulations applicable in

your country.

§ To power a device of protection class 1, plug the power cord into an electrical outlet

(mains supply) that is properly installed with a protective grounding conductor

(protective earth = PE). The power plug or a different, suitable disconnecting device for

the power must be easily accessible.

!NOTE: This equipment has been tested and found to comply with the limits pursuant to

part 15 of FCC Rules. These limits are designed to provide reasonable protection against

harmful interference. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with these instructions, may cause

harmful interference to radio communications. For information on the specific limits and

class of this equipment, please refer to the Declaration of Conformity. Depending on the

particular class, you are either required or requested to correct the interference. If you

have a Class A digital device, you need to comply with the FCC statement as follows:

“Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his own expense."

If you have a Class B digital device, please read and follow the FCC information

given below:

“[...]However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help."

Before you operate this equipment, check which FCC class (Class A or Class B)

it has according to the Declaration of Conformity included. Be sure to observe the

information of this Declaration.

Safety Precautions

If you use an electrical outlet that does not have a protective grounding conductor,

make sure to have an equivalent protective conductor installed by a certified electrician

as specified in the applicable regulations for installation in your country. Make sure

the protective grounding effect is not neutralized by use of an extension cord that lacks

a protective grounding conductor.

Warmup Time

To deliver exact results, the scale must warm up for at least 30 minutes after initial

connection to AC power or after a relatively long power outage. Only after this time will

the scale have reached the required operating temperature.

Using Equipment Verified as a Legal Measuring Instrument in the EU:

$ Allow the equipment to warm up for at least 6 hours after initial connection to

AC power.

5

Leveling the Weighing Platform (Verified Models Only)

Purpose:

– To compensate for uneven areas at the place of installation

– To ensure that the equipment is placed in a perfectly horizontal position

for consistently reproducible weighing results

Always level the weighing platform again any time after it has been moved

to a different location.

§ Level the weighing platform using the four leveling feet.

Turn the feet until the air bubble is centered in the level indicator.

§ Check to ensure that all leveling feet rest securely on the work surface.

> Each of the leveling feet must support an equal load.

§ Loosen the locknuts on the leveling feet using an open-end wrench (spanner).

> Adjusting the leveling feet:

To raise the weighing platform, extend the leveling feet (turn counterclockwise).

To lower the weighing platform, retract the leveling feet (turn clockwise).

§ After leveling the weighing platform, tighten the lock nuts as follows:

Small platforms (1 load cell): tighten the locknuts against the platform frame

Large platforms (4 load cells): tighten the locknuts against the platform foot

Operating Limits

Never exceed the maximum capacity of the weighing platform.

The maximum loading capacities of the weighing platforms in this series are listed in

the table below, and depend on the position of the load on the platform:

Model Width (mm) Length (mm) Center* Side Corner

DC 240 320 50 35 20

ED 300 400 130 85 45

FE 400 500 300 200 100

GF 500 650 600 400 200

IG 600 800 450 300 150

II 800 800 1200 800 400

LI 800 1000 900 600 300

LL 1000 1000 4500 3000 1500

NL 1000 1250 4500 3000 1500

NN 1250 1250 4500 3000 1500

RN 1250 1500 4500 3000 1500

RR 1500 1500 4500 3000 1500

WR 1500 2000 4500 3000 1500

* overload capacity of the platform

Getting Started

6

Display and Keypad

1 Display

(for details, see the chapter entitled

“Operating Design")

2 On/standby key

3 Zero key

4 Tare key

5 Function key (e.g., toggle between

gross and net values)

6 Print key (data output)

7 ID key

(for entering product information)

8 Numeric keypad

9 Info key (for viewing ID codes

and manual tare values)

10 Toggle key

(function depends on application)

11 OK key

(function depends on application)

12 Reference value key

(function depends on application)

13 Clear-function key

(function depends on application)

Back Panel of Display and Control Unit

14 Connector for weighing platform

15 Menu access switch

16 Optional:

Second interface (UniCOM)

17 Optional:

RS-232C interface (COM1)

18 Ground terminal

(equipotential bonding)

19 Power cord

Weighing Platform

20 Load plate

21 Level indicator (verified models only)

22 Leveling feet

General View of the Equipment

7

6

5

10

9

14

8

7

11

12

13

1

2

3

4

Midrics 1

Midrics 2

Midrics

display and

control unit

Midrics

weighing platform

19

18

17

14

15

16

21

20

22

6

5

1

2

3

4

Keys

Operation of the Midrics

®

1 or Midrics

®

2 scale involves just a few keys.

These keys have one function during

measurement and another during

configuration. Some of the keys have

one function when pressed briefly

and another activated by pressing

and holding the key for longer than

2 seconds.

If a key is inactive, this is indicated

as follows when it is pressed:

– The error code “———-” is displayed

for 2 seconds. The display then returns

to the previous screen content.

Configure the operating menu for

the desired application program first

(printer settings, etc.). Then you can

begin weighing.

Input

Keypad Input

Labeled Keys

Some keys have a second function,

activated by pressing and holding

the key for at least 2 seconds.

Whether a function is available

depends on the operating state

and menu settings.

e On/standby

(in standby mode,

OFF is displayed).

( – Zero the scale

– Cancel calibration/adjustment

) – Tare the scale

k Toggle between 1

st

and 2ndweight

unit, or gross and net values,

or normal and 10-fold higher

resolution, depending on operating

menu settings

p – To print: press briefly

(< two seconds).

Midrics 2 only:

d ID key for entering product

information

Midrics 2 only:

I View application data or manual

tare values, depending on the key

pressed subsequently (e.g., ))

Midrics 2 only:

w Toggle between display modes

within an application program

Midrics 2 only:

O Save a value or start an application

program.

Midrics 2 only:

r Modify a reference value

Midrics 2 only:

c – Quit an application or delete

an input character

Midrics 2 only:

0, 1, 2 … 9

Enter numbers, letters and other

characters

Operating Design

8

Operating elements: Midrics®2

Numeric Input Through the Keypad

(Midrics 2 only)

§ To enter numbers (one digit at a time):

Press 0, 1, 2 …9

§ To save input:

press the required key (e.g., )

to save manual tare input)

§ To delete a digit:

Press c

Loading a Tare Value from

the Weighing Platform

You can store the weight on

the weighing platform; for example,

as a tare weight, by pressing

the ) key

Input Through the

Digital Input Port

You can connect a remote hand switch

or foot switch to the input control line,

for use with all application programs.

Assign one of the following functions

to this switch in the operating menu,

under “

Control IO/ -> Control

input":

CTRL IO

CTRL INP

8

8.4 Universal IN

…

…

…

CTRL OUT

For a detailed list of menu items, please see

the chapter entitled “Configuration."

9

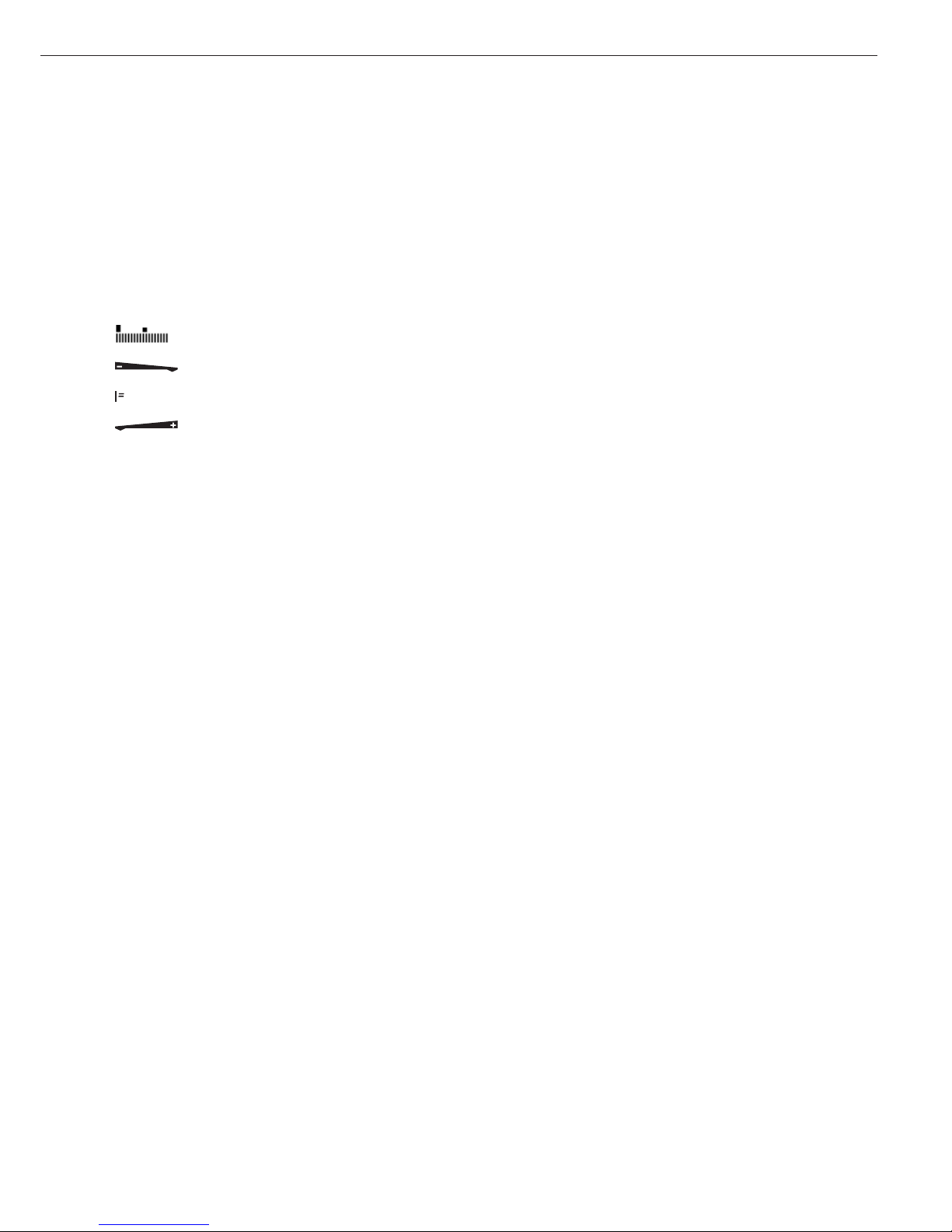

Display in Weighing Mode

The illustration above shows all display

segments and the symbols and other

elements used during normal weighing

operation.

1. Bar graph

– Shows the percentage of the

weighing platform's capacity that

is “used up" by the load on the

scale (gross value), or

– Shows the measured value in

relation to a target value

(with the Checkweighing or

Classification application)

2. Printing in progress

3. Display of the range on multiple-range

instruments

4. Indicates a net or gross value in

the main display (when data is stored

in tare memory)

5. Identifies the value on the main

display as calculated (value not valid

in legal metrology)

6. Battery symbol showing status of

rechargeable battery (empty outline

indicates battery is drained)

7. GMP-compliant printing in progress

(optional; with interface and “clock"

options)

8. Weight unit of the value displayed

9. Numeric display; e.g., showing

reference value (Midrics 2 only)

Midrics 2:

10. Symbol indicating data transfer:

– Interface initialized

– Flashes during data transfer

11. Symbols for reference updating

(Midrics 2 only)

– Auto: Depending on the weight

value, a reaction is triggered

in the application

– Opt: Automatic reference

updating has been performed

(Counting application)

12. Weight value or calculated value

(main display)

13. Application symbols for Midrics 2

applications:

A Counting

B Weighing in Percent

V Averaging (Animal Weighing)

H Checkweighing

W Classification

L Totalizing

R Net-total Formulation

Checkweighing:

Batching to a target value

Verified models only:

14. The “zero-setting" symbol is displayed

after the active scale or weighing

platform has been zeroed

15. Stability symbol

16. Plus or minus sign for the value

displayed

17. Busy symbol; indicates that an internal

process is in progress

There are two display modes:

– Normal operation (weighing mode)

– Operating menu (for configuration)

Weighing Mode: Display

of Measured and Calculated

Values (Main Display)

Application, printing and battery

symbols:

The application symbol indicates

the selected program; for example:

A Counting application symbol

S Printing mode active

T GMP printing mode active

The battery symbol b indicates

the charge level of the external

rechargeable battery.

Operating Design

10

13

4

5

6

7

8

9

1011

12

13

14

16

15

17

2

Bar graph

The bar graph shows the percentage of the

weighing platform's capacity that is “used

up" by the load on the scale (gross value).

0% Lower limit

100% Upper limit

The following symbols indicate tolerance

levels for Checkweighing:

Bar graph with 10% markings

Minimum in Checkweighing

Target in Checkweighing

Maximum

Plus/minus sign:

+ or - for weight value or calculated

value,

o when the weighing platform

is zeroed or tared.

Measured value/result line

This field shows weight values and

calculated values (alphanumeric characters)

Unit and stability

When the weighing system reaches

stability, the weight unit or the unit for

a calculated value is displayed here.

Tare in memory, calculated values:

The following symbols may be displayed

here:

a Calculated value (not valid in

legal-for-trade applications)

NET Net value

(gross weight minus tare)

B/G Gross value

(net value plus tare)

Data in tare memory, calculated values,

designation of the active weighing

platform

pt Identification of manual tare

input when viewing tare

information

Saving Data in Weighing Mode

All of the application parameters

saved (e.g., reference values) remain in

memory and are still available after

– the Midrics has been switched off

and back on again, or

– you return to the originally selected

application from a second one (e.g.,

when you switch from Averaging back

to Counting, all parameters saved

for Counting are available)

11

Operating Menu Navigation

The keys below the readout let you

navigate the menu and define parameters

for configuration.

Opening the Menu

Press the e key to switch the Midrics

off and then on again; while all segments

are displayed, press the ) key briefly.

Navigating the Menu

( Close the active submenu and

return to the next higher menu level

(“back")

) – Press briefly:

Select and save a menu item

– Press and hold (> 2 seconds):

Exit the menu

k Show the next item on the same

menu level (the display scrolls

through all items in series)

p Print the menu settings starting

from the current position, or print

Info data

Alphanumeric Input in the Menu

( – Press briefly:

Activate character to the left

of the current character

(when first character is active:

exit input mode without saving

changes)

– Press and hold (> 2 seconds):

Exit input mode without saving

changes

) – Press briefly:

Confirm currently active character

and move cursor 1 position to

the right (after the last character:

save input)

– Press and hold (> 2 sec ):

Save current input and display

the menu item

k – Cursor in first position,

no characters entered yet:

Delete character(s) and enter 0

– Change the displayed character;

scroll forward (sequence:

0 through 9, decimal point,

minus sign, A to Z, space)

p – Cursor in first position,

no characters entered yet: Delete

entire string and enter a space

– Change the displayed character;

scroll backwards (sequence:

space, Z to A, minus sign, decimal

point, 9 through 0)

Numeric input in Midrics 2 operating

menu:

Enter values (date and time, etc.) using

the 10-key numeric keypad

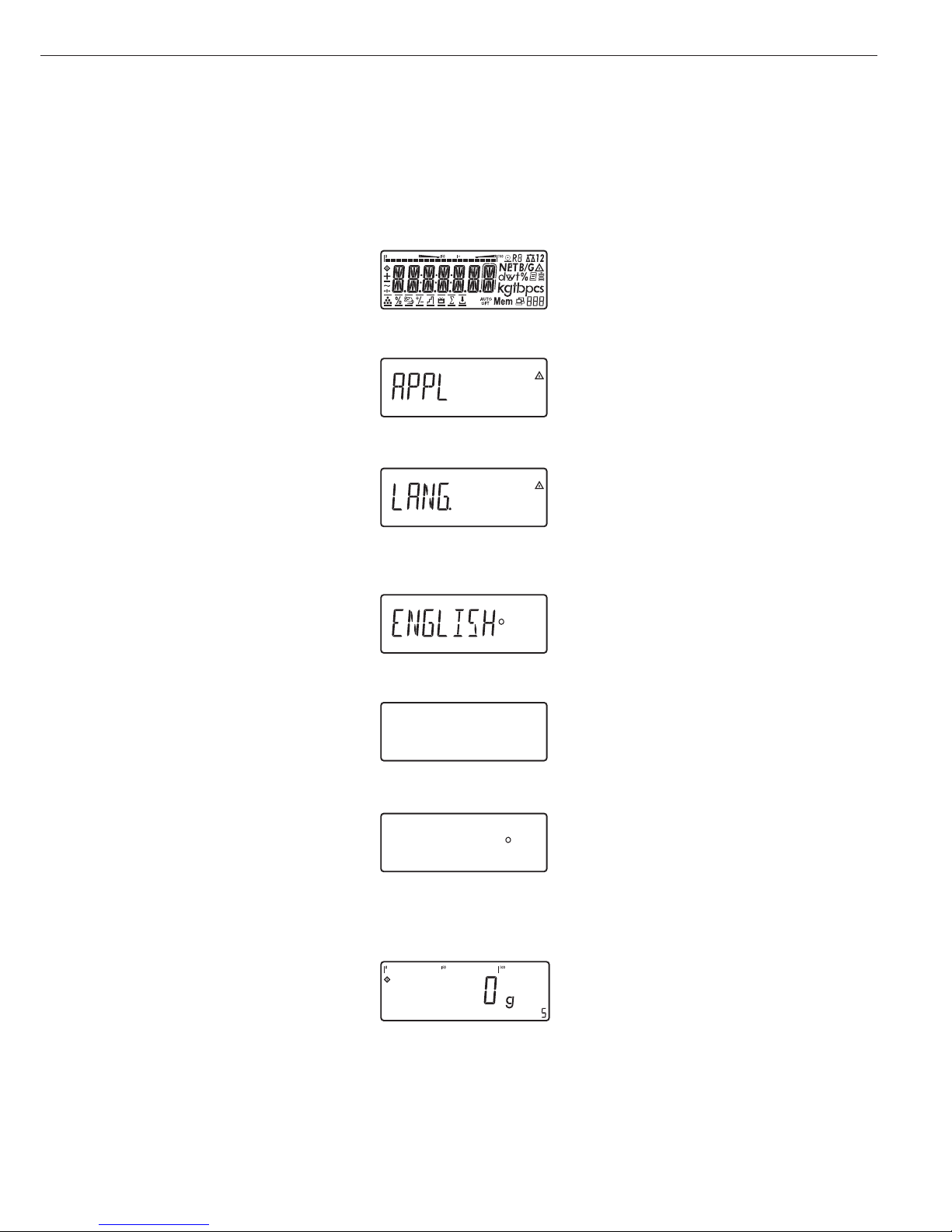

Display of Menu Settings

The illustrations above show examples

of the main display during menu

configuration.

1 Selected menu item on the text

level (e.g. printer, for configuring

the connected printer)

2 Menu history (indicates the highest

menu level)

3 Indication that there are other

submenus

4 Highest level in numeric menu

5 Second level in numeric menu

6 Third level in numeric menu

Errors

– If a key is inactive, “-------" or

“No function" is displayed briefly

(2 seconds)

– Temporary errors are displayed for

2 seconds in the measured value/result

line (e.g.,

Inf 09); fatal errors are

displayed steadily (e.g.,

Err 101) until

the Midrics is reset (switched off and

then on again).

For a detailed description,

see “Error Codes" on page 89.

Data Output

Printer

You can connect two strip or label

printers to the Midrics 1 or Midrics 2

and have printouts generated at the

press of a key or automatically. You can

also configure separate summarized

printouts, and print a list of the active

menu settings. See “Configuring

Printouts" on page 82 for details.

Backup

Application parameters (such as

reference values) are saved when you

change application programs or switch

off the Midrics. You can assign a password to prevent unauthorized users

from changing settings in the “Device

parameters" menu under:

Setup

Password

See also pages 14 and 31.

Operating Design

12

Display of menu settings: Text menu (example) Display of menu settings: Numeric menu (example)

You can configure the Midrics scale

by selecting parameters in the operating

menu. The parameters are combined

in the following groups (this is the

highest menu level):

– Application parameters

– Fn key function

– Device parameters (“

Setup")

– Device-specific information (“

Info")

– Language

When the scale is used in legal

metrology, not all parameters can

be accessed.

Factory-set parameters are identified

by an asterisk (“*") in the list starting

on page 16.

You can choose from six language

settings for the display of information:

– German

– English (factory setting)

– English with U.S. date/time format

– French

– Italian

– Spanish

Printing parameter settings:

§ Open the operating menu and

press the p key

Scope of printout:

Depends on the active menu level

Setting the Language

Setting the Language

Example: Selecting “U.S. Mode" for the language

e

Switch on the scale

)

While all segments are lit,

press the ) key

The first item in the main menu is shown:

APPL

k

Switch to the LANG. menu item

(press k repeatedly until

LANG.

is shown)

)

Select LANG. to open the submenu

for setting the language

The currently active language setting

is shown

k

Press k repeatedly until U.S. Mode

is displayed

)

Confirm this menu item

(

Exit this menu level and configure

other settings as desired, or

)

(press and hold) Exit the operating menu

Configuration

13

U.S. Mode

U.S. Mode

Entering or Changing the Password

Example:

Assign a password (in this example,

AB2) to protect the application program settings APPL

and the device parameters SETUP from unauthorized changes

e

1. Switch on the scale

)

2. While all segments are lit,

press the ) key

The first item in the main

menu is shown:

APPL

k

3. Select the SETUP menu item

(press k repeatedly until

SETUP is displayed)

)

4. Open the SETUP menu

k

5. Select the PASSWORD menu

item (press k repeatedly

until

PASSWORD is displayed)

)

6. Open the PASSWORD menu

p, p

7. Enter the first character

using the p and k keys

(in this example:

A)

)

8. Save the character

p, p, p

9. Enter the second character

using the p and k keys

(in this example:

B)

)

10. Save the character

k, k, k

, 11. Enter the third character

using the p and k keys

(in this example:

2)

)

12. Save the password

(

13. Exit this menu level

to configure other menu

settings, or

)

14. Exit the operating menu

(press and hold the ) key)

To modify or delete a password:

Overwrite the old password

with the new password, or enter

a space as the password and

press ) to confirm

14

1stlevel 2ndlevel Function

display display

Menu

appl Select and configure application programs

W Basic weighing function

Z Counting

Z nm_ Neutral Measurement

V Averaging (animal weighing)

O Checkweighing

W Classification

L Weighing in percent

R Net-total formulation

L Totalizing

Fn-Key Define the function of the k key

off No function

gro net Gross/net toggling

2.unit Toggle between weight units

res 10 10-fold increased resolution

Setup Adapt Midrics to user requirements

wp1 Settings for weighing instrument on WP1

com1 Settings for the RS-232 interface

UNICOM Settings for the optional second interface

ctrl 10 Assign a function to the control inputs/outputs

barcode Set the bar code scanner function

prtprot Configure the printout

Utilit Operating parameters

time Set the time

Date Set the date

password Enter a password to protect menu settings

Info View device-specific information (service date, serial number, etc.)

Lang Select language for calibration, adjustment and GMP printouts

deutsch German

english English

u.s. mode English with U.S. date/time format

franc. French

ital. Italian

espanol Spanish

Operating Menu Overview

You can configure the Midrics to meet

individual requirements by entering

user data and setting selected parameters

in the operating menu.

Menu levels are identified by texts, and numeric codes identify the individual settings.

= Setting/function available on Midrics 2 only

15

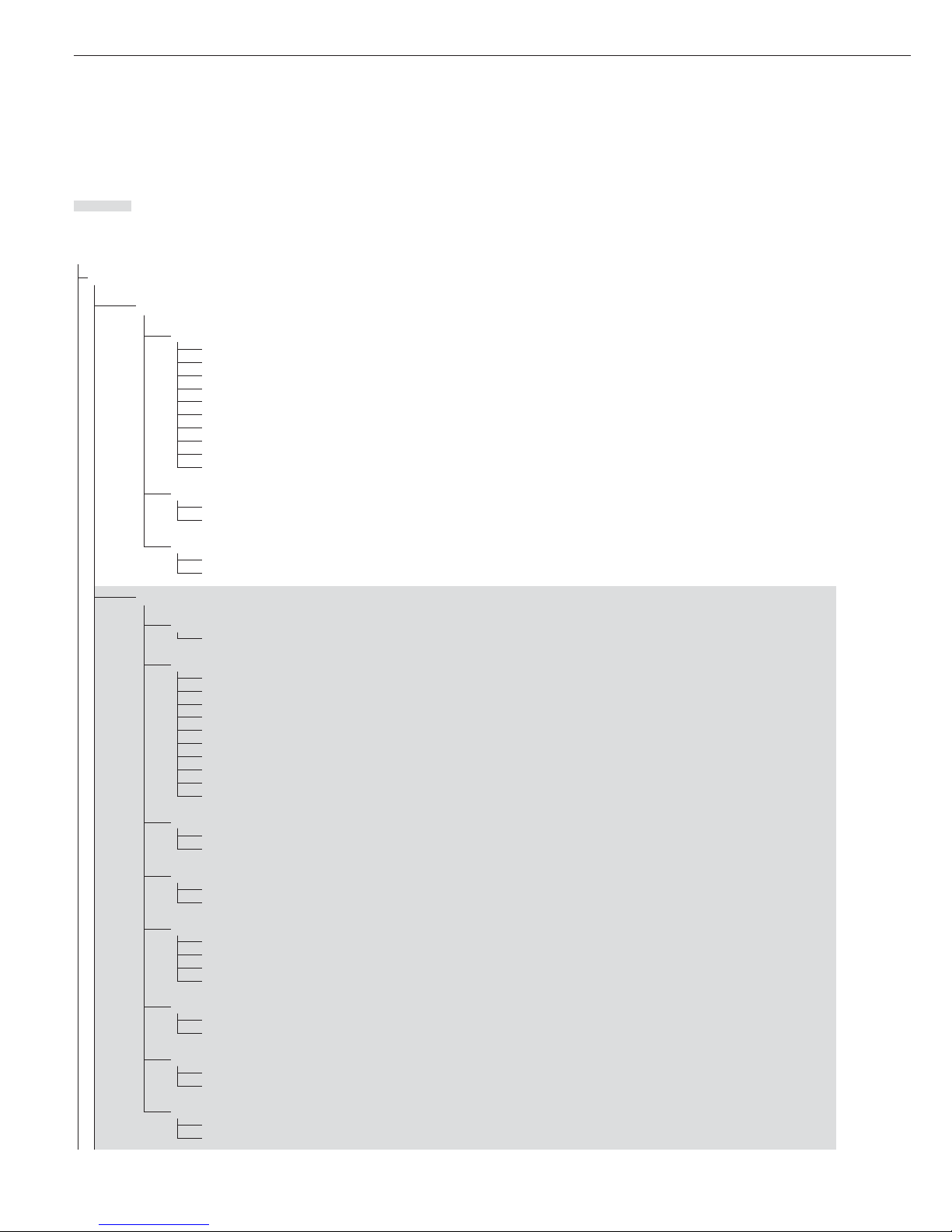

Operating Menu

= Setting/function available on Midrics 2 only

* Factory setting

Menu

appl Application Programs

W

Basic weighing function

3.5. Minimum load for automatic taring and automatic printing

3.5.1* 1 digit

3.5.2 2 digits

3.5.3 5 digits

3.5.4 10 digits

3.5.5 20 digits

3.5.6 50 digits

3.5.7 100 digits

3.5.8 200 digits

3.5.9 500 digits

3.5.10 1000 digits

3.7. Automatic taring: first weight tared

3.7.1* Off

3.7.2 On

9.1. Factory settings for all application programs

9.1.1 Yes

9.1.2* No

Z Counting

3.5. Minimum load for automatic taring and automatic printing

Numeric menu as for Weighing

3.6. Minimum load for initialization

3.6.1* 1 digit

3.6.2 2 digits

3.6.3 5 digits

3.6.4 10 digits

3.6.5 20 digits

3.6.6 50 digits

3.6.7 100 digits

3.6.8 200 digits

3.6.9 500 digits

3.6.10 1000 digits

3.7. Automatic taring: first weight tared

3.7.1* Off

3.7.2 On

3.8. Start application and load most recent application data when the Midrics is switched on

3.8.1 Automatic (on)

3.8.2* Manual (off)

3.9. Resolution for calculation of reference value

3.9.1* Display resolution

3.9.2 Display resolution + 1 decimal place

3.9.3 Display resolution + 2 decimal places

3.9.4 Internal resolution

3.11. Parameter for saving weight values (“storage parameter")

3.11.1* At stability

3.11.2 At increased stability

3.12. Reference sample updating (“APW update")

3.12.1 Off

3.12.3* Automatic

9.1. Factory settings for all application programs

9.1.1 Yes

9.1.2* No

16

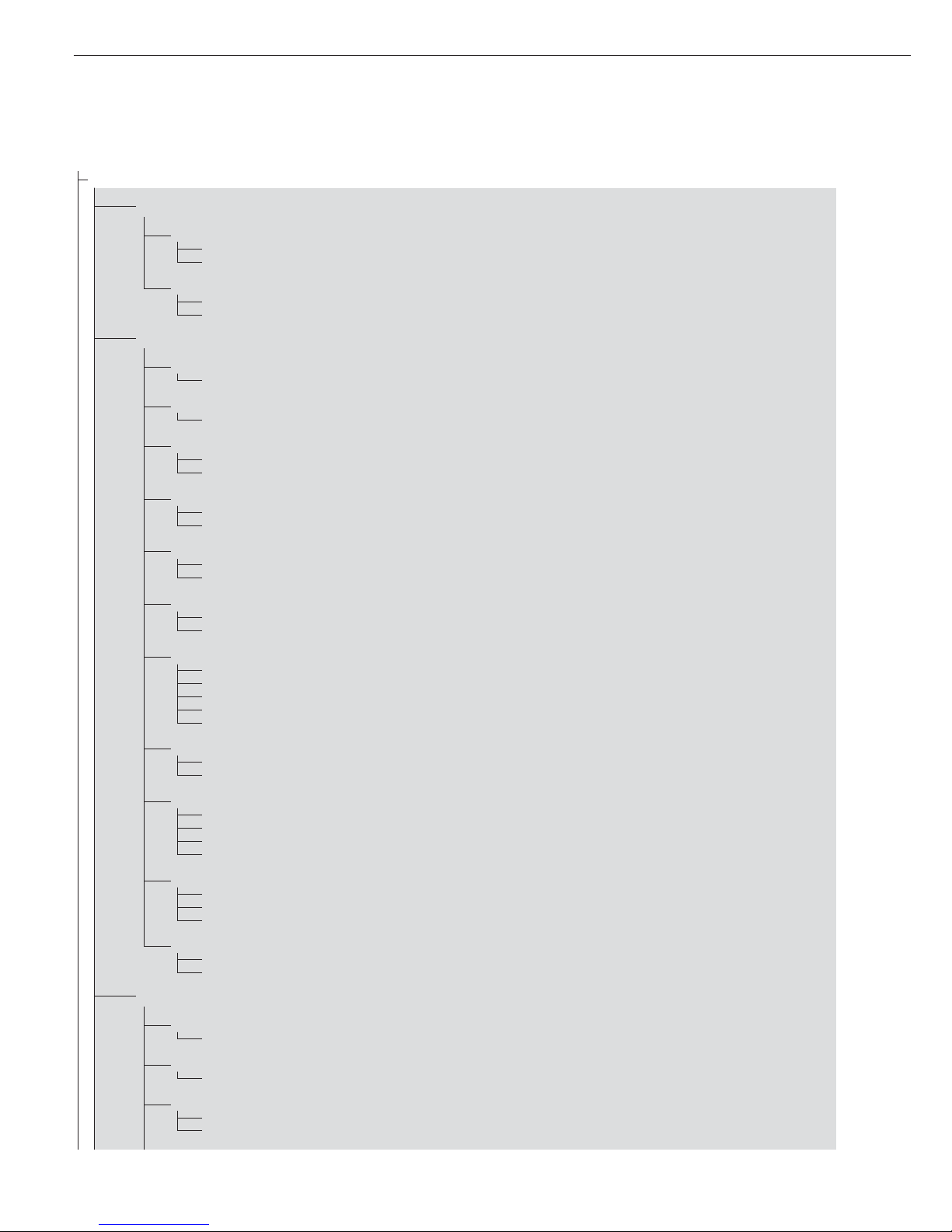

appl

Z nm

Neutral Measurement

3.5. Minimum load for automatic taring and automatic printing

Numeric menu as for Weighing

3.6. Minimum load for initialization

Numeric menu as for Counting

3.7. Automatic taring: first weight tared

3.7.1* Off

3.7.2 On

3.8. Start application and load most recent application data when the Midrics is switched on

3.8.1 Automatic (on)

3.8.2* Manual (off)

3.9. Resolution for calculation of reference value

3.9.1* Display resolution

3.9.2 Display resolution + 1 decimal place

3.9.3 Display resolution + 2 decimal places

3.9.4 Internal resolution

3.10. Decimal places in displayed result

3.10.1* None

3.10.2 1 decimal place

3.10.3 2 decimal places

3.10.4 3 decimal places

3.11. Parameter for saving weight values

3.11.1* At stability

3.11.2 At increased stability

9.1. Factory settings for all application programs

9.1.1 Yes

9.1.2* No

V Averaging (Animal Weighing)

3.5. Minimum load for automatic taring and automatic printing

Numeric menu as for Weighing

3.6. Minimum load for automatic start

Numeric menu as for Counting

3.7. Automatic taring: first weight tared

3.7.1* Off

3.7.2 On

3.8. Start application and load most recent application data when the Midrics is switched on

3.8.1 Automatic (on)

3.8.2* Manual (off)

3.18. Start of averaging routine

3.18.1* Manual

3.18.2 Automatic

3.19. Animal activity

3.19.1 0.1% of the animal/object

3.19.2* 0.2% of the animal/object

3.19.3 0.5% of the animal/object

3.19.4 1% of the animal/object

3.19.5 2% of the animal/object

3.19.6 5% of the animal/object

3.19.7 10% of the animal/object

3.19.8 20% of the animal/object

3.19.9 50% of the animal/object

3.19.10 100 % of the animal/object

3.20. Automatic printout of results

3.20.1* Off

3.20.2 On

17

appl

V

Averaging (Animal Weighing)

3.21. Static display of result after load removed

3.21.1* Display is static until unload threshold reached

3.21.2 Display is static until c is pressed

9.1. Factory settings for all application programs

9.1.1 Yes

9.1.2* No

O Checkweighing

3.5. Minimum load for automatic taring and automatic printing

Numeric menu as for Weighing

3.6. Minimum load for initialization

Numeric menu as for Counting

3.7. Automatic taring: first weight tared

3.7.1* Off

3.7.2 On

3.8. Start application and load most recent application data when the Midrics is switched on

3.8.1 Automatic (on)

3.8.2* Manual (off)

4.2. Checkweighing range

4.2.1* 30 to 170%

4.2.2 10% to infinity

4.3. Activate control line for “Set” as:

4.3.1* “Set” output

4.3.2 Ready to operate (for process control systems)

4.4. Activation of outputs

4.4.1 Off

4.4.2 Always active

4.4.3 Active at stability

4.4.4* Active within checkweighing range

4.4.5 Active at stability within the checkweighing range

4.5. Parameter input

4.5.1* Min, max, target

4.5.2 Only target with percent limits

4.6. Automatic printing

4.6.1* Off

4.6.2 On

4.6.3 Only values within tolerance

4.6.4 Only values outside tolerance

4.7. Checkweighing toward zero

4.7.1* Off

4.7.2 On

4.7.3 On

9.1. Factory settings for all application programs

9.1.1 Yes

9.1.2* No

W Classification

3.5. Minimum load for automatic taring and automatic printing

Numeric menu as for Weighing

3.6. Minimum load for initialization

Numeric menu as for Counting

3.7. Automatic taring: first weight tared

3.7.1* Off

3.7.2 On

18

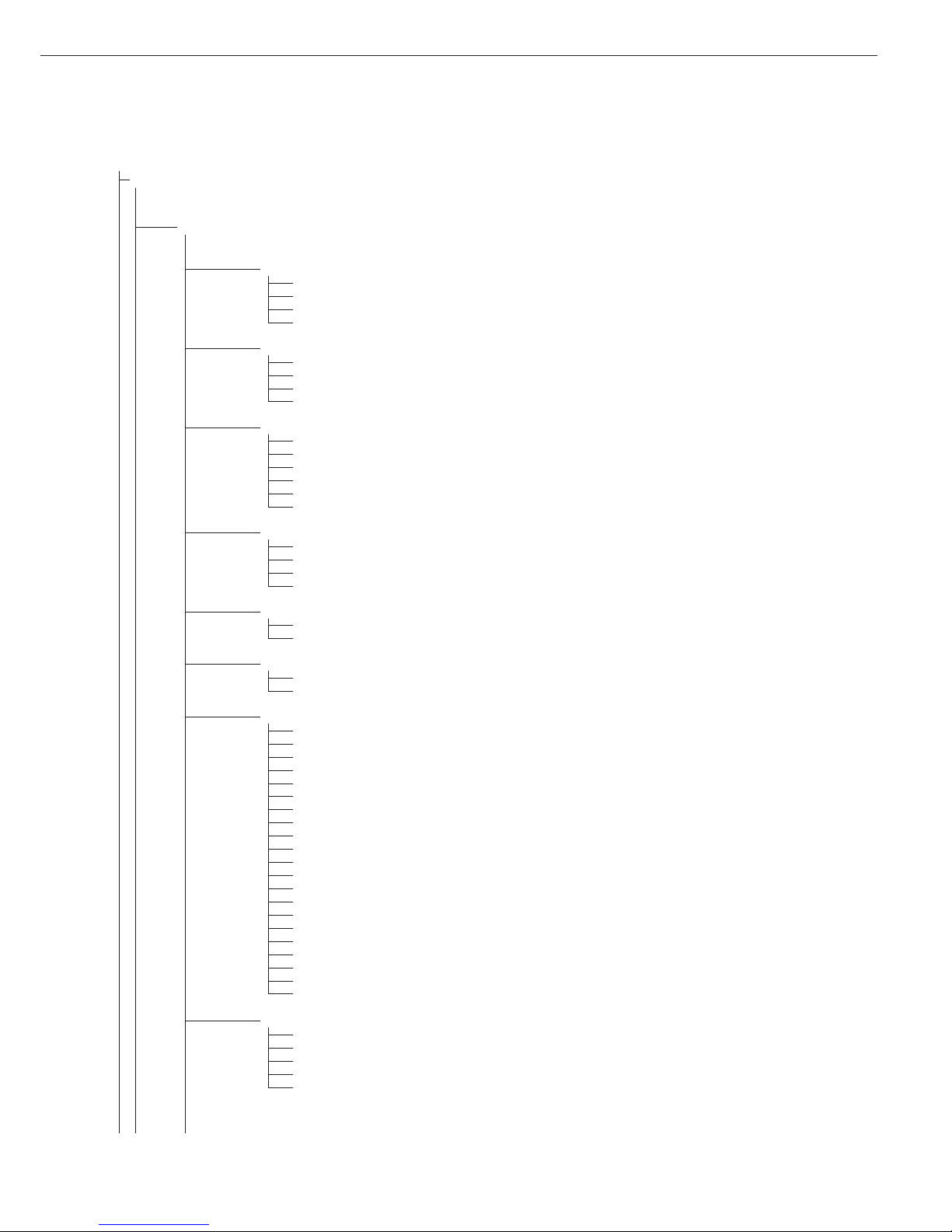

appl

W Classification

3.8. Start application and load most recent application data when the Midrics is switched on

3.8.1 Automatic (on)

3.8.2* Manual (off)

4.3. Activate control line for “Set” as:

4.3.1* “Set” output

4.3.2 Ready to operate (for process control systems)

4.7. Activation of outputs

4.7.1 Off

4.7.2 Always active

4.7.3* Active at stability

4.8. Number of classes

4.8.1* 3 classes

4.8.2 5 classes

4.9. Parameter input

4.9.1* Weight values

4.9.2 Percentage

4.10. Automatic printing

4.10.1* Off

4.10.2 On

9.1. Factory settings for all application programs

9.1.1 Yes

9.1.2* No

L Weighing in Percent

3.5. Minimum load for automatic taring and automatic printing

Numeric menu as for Weighing

3.6. Minimum load for initialization

Numeric menu as for Counting

3.7. Automatic taring: first weight tared

3.7.1* Off

3.7.2 On

3.8. Start application and load most recent application data when the Midrics is switched on

3.8.1 Automatic (on)

3.8.2* Manual (off)

3.9. Resolution for calculation of reference value

3.9.1* Display resolution

3.9.2 Display resolution + 1 decimal place

3.9.3 Display resolution + 2 decimal places

3.9.4 Internal resolution

3.10. Decimal places in displayed result

3.10.1* None

3.10.2 1 decimal place

3.10.3 2 decimal places

3.10.4 3 decimal places

3.11. Parameter for saving weight values

3.11.1* At stability

3.11.2 At increased stability

3.15. Display

3.15.1* Residue

3.15.2 Loss

9.1. Factory settings for all application programs

9.1.1 Yes

9.1.2* No

19

appl

R

Net-total Formulation (2ndTare Memory)

3.5. Minimum load for automatic taring and automatic printing

Numeric menu as for Weighing

3.6. Minimum load for automatically saving/transferring values

Numeric menu as for Counting

3.7. Automatic taring: first weight tared

3.7.1* Off

3.7.2 On

3.17. Printout when value is saved in totalizing memory

3.17.1 Automatic printout of results off

3.17.2* Generate printout with complete standard configuration each time O is pressed

3.17.3 Generate printout with complete standard configuration only the first time O is pressed

9.1. Factory settings for all application programs

9.1.1 Yes

9.1.2* No

L Totalizing

3.5. Minimum load for automatic taring and automatic printing

Numeric menu as for Weighing

3.6. Minimum load for automatically saving/transferring values

Numeric menu as for Counting

3.7. Automatic taring: first weight tared

3.7.1* Off

3.7.2 On

3.8. Start application and load most recent application data when the Midrics is switched on

3.8.1 Automatic (on)

3.8.2* Manual (off)

3.16. Values saved automatically

3.16.1* Off

3.16.2 On

3.17. Individual component data printed when value is added to totalizing memory

3.17.1 Automatic printout of results off

3.17.2* Individual printout of a totalizing item when O is pressed

3.17.3 Components of transaction printed when O is pressed

9.1. Factory settings for all application programs

9.1.1 Yes

9.1.2* No

off Disabled

fn-key k Key Assignment

off * No k key function

gro net Gross/net toggling

2. unit Show 2ndWeight unit

res 10 10-fold increased resolution Display: max. 5 seconds

20

Setup Device Parameters

Password prompt displayed if a password is configured

wp-1

1

Weighing platform 1

(Display designation of this menu level: 1)

1.1. Adapt weighing instrument to ambient conditions (adapt filter)

1.1.1 Very stable conditions

1.1.2* Stable conditions

1.1.3 Unstable conditions

1.1.4 Very unstable conditions

1.2. Application filter

1.2.1* Final readout

1.2.2 Filling mode

1.2.3 Low filtering

1.2.4 Without filtering

1.3. Stability range

1.3.1 4 digit

1.3.2 1 digit

1.3.3 1 digit

1)

1.3.4* 2 digits

1)

1.3.5 4 digits

1)

1.3.6 8 digits

1)

1.4. Stability symbol delay

1.4.1 No delay

1.4.2* Short delay

1.4.3 Average delay

1.4.4 Long delay

1.5. Taring

1)

1.5.1 Without stability

1.5.2* After stability

1.6. Auto zero

1.6.1* On

1.6.2 Off

1.7. Weight Unit 1

2)

1.7.1 Grams / o

1.7.2 Grams / g

1.7.3 Kilograms / kg

1.7.4 Carats / ct

1)

1.7.5 Pounds / lb

1)

1.7.6 Ounces / oz

1)

1.7.7 Troy ounces / ozt

1)

1.7.8 Hong Kong taels / tlh

1)

1.7.9 Singapore taels / tls

1)

1.7.10 Taiwanese taels / tlt

1)

1.7.11 Grains /GN

1)

1.7.12 Pennyweights / dwt

1)

1.7.14 Parts per pound / lb

1)

1.7.15 Chinese taels / tlc

1)

1.7.16 Mommes / mom

1)

1.7.17 Austrian carats / k

1)

1.7.18 Tola / tol

1)

1.7.19 Baht / bat

1)

1.7.20 Mesghal / MS

1)

1.7.21 Tons / t

1.7.22 Pounds: ounces

1)

1.8. Display accuracy 1

1)

1.8.1* All digits

1.8.2 Reduced by 1 decimal place for load change

1.8.14 10-fold increased resolution

1.8.15 Resolution increased by 2 scale intervals (e.g., 5 g to 1 g)

1.8.16 Resolution increased by 1 scale interval

(e.g., from 2 g to 1 g or from 10 g to 5 g)

1)

Not available on instruments verified for use in legal metrology

2)

Depends on weighing platform model

21

Setup

wp-1

1

1.9. Calibration and adjustment

1.9.1* External calibration/adjustment; default weight

1.9.3 External calibration/adjustment; weight can be selected under menu item 1.18.1

1.9.10 No function when you press and hold ) > 2 sec

1.10. Calibration/adjustment sequence

1.10.1 Calibration with automatic adjustment

1.10.2* Calibration with adjustment triggered manually

1.11. Zero-setting range

1.11.1 1 percent/max. cap.

1.11.2* 2 percent/max.cap.

1.12. Initial zero-setting range

1.12.2 2 percent/max. cap.

1.12.3 5 percent/max.cap. (setting depends on model)

1.12.4* 10 percent/max.cap.

1.13. Tare/zero at power on

1.13.1* On

1.13.2 Off, load previous tare value

1.13.3 Only zero at power on

1.15. Calibration prompt

1.15.1* Off

1.15.2 Calibration prompt (W) flashes on the display

1.16. External calibration/adjustment

1)

1.16.1* Accessible

1.16.2

2)

Blocked

1.17. Calibration weight unit

1.17.1 Grams

1.17.2* Kilograms

1.17.3 Tons

1.17.4 Pounds

1)

1.18. Enter calibration weight

1.18.1 External user-defined weight (enter value; e.g.: 10,000 kg)

3.1. Weight unit 2

3)

3.1.1 Grams / o

3.1.2 Grams / g

3.1.3* Kilograms / kg

3.1.4 Carats /ct

1)

3.1.5 Pounds /lb

1)

3.1.6 Ounces /oz

1)

3.1.7 Troy ounces / ozt

1)

3.1.8 Hong Kong taels / tlh

1)

3.1.9 Singapore taels / tls

1)

3.1.10 Taiwanese taels / tlt

1)

3.1.11 Grains / GN

1)

3.1.12 Pennyweights / dwt

1)

3.1.14 Parts per pound / lb

1)

3.1.15 Chinese taels / tlc

1)

3.1.16 Mommes / mom

1)

3.1.17 Austrian carats /k

1)

3.1.18 Tola / tol

1)

3.1.19 Baht / bat

1)

3.1.20 Mesghal / MS

1)

3.1.21 Tons / t

3.1.22 Pounds:ounces

1)

3.2. Display accuracy 2

1)

3.2.1* All digits

3.2.2 Reduced by 1 decimal place for load change

3.2.14 10-fold increased resolution

3.2.15 Resolution increased by 2 scale intervals (e.g., 5 g to 1 g)

3.2.16 Resolution increased by 1 scale interval (e.g., 2 g to 1 g or from 10 g to 5 g)

3.3. Weight unit 3

3)

(settings as for 3.1, “Weight unit 2”)

3.4. Display accuracy

3)

(settings as for 3.2, “Display accuracy 2”)

9.1. Restore factory settings in WP1 numeric menu

9.1.1 Yes

9.1.2* No

1)

= Not available on instruments verified for use in legal metrology

2)

= Factory setting on instrument verified for use in legal metrology

3)

= Menu depends on weighing platform model

22

Setup

Com1

2

Interface port 1 (optional)

(Display designation of this menu level: 2)

off

*

Off

datProt Data protocol

sbi

*

SBI: standard version

5.1. Baud rate

5.1.1 150 baud

5.1.2 300 baud

5.1.3 600 baud

5.1.4* 1200 baud

5.1.5 2400 baud

5.1.6 4800 baud

5.1.7 9600 baud

5.1.8 19,200 baud

5.2. Parity

5.2.2 Space

2)

5.2.3 Odd

5.2.4 Even

5.2.5 None

3)

5.3. Number of stop bits

5.3.1* 1 stop bit

5.3.2 2 stop bits

5.4. Handshake mode

5.4.1 Software handshake

5.4.3* Hardware handshake, 1 character after CTS

5.6. Number of data bits

5.6.1* 7 data bits

5.6.2 8 data bits

6.1. Data output: manual/automatic

6.1.1 Manual without stability

6.1.2* Manual after stability

6.1.4 Automatic without stability

6.1.5 Automatic with stability

6.1.7 Protocol for computer (PC)

6.3. Time-dependent automatic data output

6.3.1* 1 display update

6.3.2 2 display updates

6.3.4 10 display updates

6.3.7 100 display updates

7.2. Data output: line format for printout

7.2.1 For raw data: 16 characters

7.2.2* For other applications: 22 characters

9.1. Restore factory settings in numeric menu COM1: SBI

9.1.1 Yes

9.1.2* No

xbpi-232 XBPI-232

1)

Menu depends on weighing platform model

2)

not with setting 5.6.2 (8 bits)

3)

not with setting 5.6.1 (7 bits)

23

Setup

Com1

2

datProt

SMA SMA interface function

5.1. Baud rate

5.1.1 150 baud

5.1.2 300 baud

5.1.3 600 baud

5.1.4 1200 baud

5.1.5 2400 baud

5.1.6 4800 baud

5.1.7* 9600 baud

5.1.8 19,200 baud

5.2. through 5.6.

Numeric menu as for SBI

Printer Printer configuration

YDP01IS YDP01IS

line

*

Strip printer

label Label printer

lab ff Label printer with manual feed

YDP02 YDP02 variants

5.1. Baud rate

5.1.4* 1200 baud

5.1.5 2400 baud

5.1.6 4800 baud

5.1.7 9600 baud

5.2. Parity

5.2.2 Space

5.2.3* Odd

5.2.4 Even

5.3. Number of stop bits

5.2.2 Space

5.3.1* 1 stop bit

5.3.2 2 stop bits

5.4. Handshake mode

5.4.1 Software handshake

5.4.3* Hardware handshake, 1 character after CTS

YDP03 YDP03-0CE

5.1. Baud rate

5.1.4* 1200 baud

5.1.5 2400 baud

5.1.6 4800 baud

5.1.7 9600 baud

5.1.8 19,200 baud

5.2. through 5.4.

Numeric menu as for COM02

YDP02IS YDP02IS

line

*

Strip printer

label Label printer

24

Setup

Com1

2

Printer

Uni-pri Universal interface

5.1. Baud rate

5.1.1 150 baud

5.1.2 300 baud

5.1.3 600 baud

5.1.4 1200 baud

5.1.5 2400 baud

5.1.6 4800 baud

5.1.7* 9600 baud

5.1.8 19,200 baud

5.2. Parity

5.2.2 Space

1)

5.2.3 Odd

5.2.4 Even

5.2.5* None

2)

5.3. Number of stop bits

5.3.1* 1 stop bit

5.3.2 2 stop bits

5.4. Handshake mode

5.4.1* Software handshake

5.4.3 Hardware handshake, 1 character after CTS

5.6. Number of data bits

5.6.1 7 data bits

5.6.2* 8 data bits

YDP04IS

*

YDP04IS

line

*

Strip printer

label Label printer

lab ff Label printer with manual feed

yam01is YAM01IS as electronic memory for print data

Memory Verifiable data memory

yam01is YAM01IS external data memory

Off Disabled

1)

not with setting 5.6.2 (8 bit)

2)

not with setting 5.6.1 (7 bits)

25

Setup

unicom

3

Interface port 2 (Optional)

(Display designation of this menu level: 3)

off

*

Off

datprot Data protocol

sbi

*

SBI: standard version

5.1. through 9.1.

Numeric menu as for COM1

bpi-232 XBPI-232

bpi-485 XBPI-485

0 to 31 Network address: From 0 to 31 inclusive

sma SMA interface function

5.1. through 5.6.

Numeric menu as for COM1

ETHER

src-ip Source IP: 192.168.0.1*

src.name Source name (16 characters maximum)

lis.port Listen on port: 49155*

supnet Subnet mask:255.255.255.0*

gate-ip Gateway IP: 0.0.0.0*

dest-ip Destination IP: 0.0.0.0*

dest.por Destination port: 49155*

Protocol TCP*

UDP

Mode SBI (server)* 6.1. Manual output/automatic

6.1.1 Manual without stability

6.1.2 * Manual after stability

6.1.4 Automatic without stability

6.1.5 Automatic with stability

6.1.7 Data record for computer printout

7.2. Data output: line format for printout

7.2.1 For raw data: 16 characters

7.2.2* For other apps.: 22 characters

SBI-C/S (client) 6.1. Manual output/automatic

6.1.1 Manual without stability

6.1.2 * Manual after stability

6.1.4 Automatic without stability

6.1.5 Automatic with stability

6.1.7 Data record for computer printout

XBPI 6.3. Time-dependent automatic

data output

SMA 6.3.1 * 1 display update

Modbus/TCP 6.3.2 2 2 display updates

6.3.4 10 10 display updates

6.3.7 100 100 display updates

7.2. Data output: line format for printout

7.2.1 For raw data: 16 characters

7.2.2* For other apps.: 22 characters

26

Setup

uniCom1

3

Second interface (optional)

Printer Printer configuration

YDP01IS YDP01IS

line

*

Strip printer

label Label printer

lab ff Label printer with manual feed

YDP02 YDP02

5.1. through 5.4.

Numeric menu as for COM1

YDP03 YDP03-0CE

5.1. through 5.4.

Numeric menu as for COM1

YDP02IS YDP02IS

line

*

Strip printer

label Label printer

Uni-pri Universal interface

5.1. through 5.6.

Numeric menu as for COM1

YDP04IS

*

YDP04IS

line

*

Strip printer

label Label printer

lab ff Label printer with manual feed

yam01is YAM01IS as electronic memory for print data

Analog Analog data output port for PLC operation

8.12. Analog output: value

8.12.1* Net value

8.12.2 Gross value

8.13. Analog output: error indicator

8.13.1* High level (20 mA)

8.13.2 Low level (0/4 mA). When menu is open or during calibration:

0/4 mA on this interface.

8.14. Analog output: mode

8.14.1*

1)

Zero to maximum capacity

8.14.2 Minimum/maximum values

8.15. Analog output: min./max.

8.15.1

2)

Min. (0/4 mA) input in kg

8.15.2 Max. (20 mA) input in kg

Memory Verifiable data memory

yam01is YAM01IS external data memory

1)

When setting 8.14.1 is active, analog data output only works for XBPI weighing instruments

2)

not with setting 8.14.1

27

Loading...

Loading...