Page 1

Operating Instructions

Sartorius Cubis Series

Electronic Semimicro, Micro, Precision and Analytical Balances

MSE Models

1000025315

Page 2

Contents

Contents

Notes on Using these Instructions � � � � � � � � � � � � � � � � 3

Safety Instructions ���������������������������� 4

Intended Use �������������������������������� 6

General View of the Equipment ���������������� 7

Getting Started ������������������������������ 9

Unpacking the Equipment ��������������������� 9

Setup Instructions ��������������������������� 9

Assembly ��������������������������������� 11

Transporting the Balance ��������������������� 17

Storage and Shipping Conditions ���������������� 17

Power Connection ��������������������������� 18

Warm-up Time ����������������������������� 19

Anti-theft Locking Device ��������������������� 20

Modification Options ������������������������ 21

Preparing Below-Cell Weighing ����������������� 26

Using the Cable Opening in the

Analytical Balance Draft shield� � � � � � � � � � � � � � � � � � 28

Operation ����������������������������������� 29

Display and Control Panel ��������������������� 29

Basic Weighing Function ���������������������� 30

Leveling the Balance with the Inclination Sensor ���� 31

Turning the Ionizer On/Off (Optional) ������������ 31

Calibration and Adjustment �������������������� 33

Configuration (Operating Menu) ����������������� 36

Key Functions during Configuration ������������� 36

Menu Navigation Example: Setting the Language ��� 36

Menu Structure (Overview) �������������������� 37

Parameter Settings: Overview ������������������ 38

Application Programs �������������������������� 45

Density Determination ������������������������ 45

Counting ��������������������������������� 48

Weighing in Percent ������������������������� 50

Calculation �������������������������������� 52

Animal Weighing/Averaging ������������������� 54

Net-total Formulation ������������������������ 56

Totalizing ��������������������������������� 58

Mass Unit Conversion ������������������������ 60

ISO/GLP-compliant Print-out �������������������� 62

Data Interfaces� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 63

Error Codes ��������������������������������� 75

Care and Maintenance

(Packing the Balance for Shipping) �������������� 76

Transporting the Balance ����������������������� 80

Disposal ������������������������������������ 86

Specifications �������������������������������� 87

Dimensions (Balance Drawings) ����������������� 100

Accessories (Options) ������������������������� 108

EC / EU Declaration of Conformity ��������������� 110

FCC Supplier’s Declaration of Conformity ��������� 111

CSA Certificate of Compliance ������������������ 112

EC Type Approval Certificate ������������������� 115

Plates and Markings �������������������������� 116

The enclosed CD-ROM contains the

h

operating instructions as a PDF file�

To read and print the file, you require

the program Acrobat Reader, which

you can download for free from the

Adobe website (www�adobe�com)�

Software drivers for configuration of

SB interfaces can also be downloaded

from the internet:

http://www�ftdichip�com/FTDrivers�htm

The “installation guides" for these

drivers can be found here:

http://www�ftdichip�com/Documents/

InstallGuides�htm

2 Cubis MSE Operating Instructions

Page 3

Notes on Using these Instructions

t Please read these instructions carefully and completely before using the device�

t Read the Safety Instructions carefully�

t These instructions are part of the product� Keep them in a safe and easily

accessible location�

t If the instructions should be lost or misplaced, please contact Sartorius

for a replacement or download the latest version from our website:

www�sartorius�com

Symbols and Signs

The following symbols are used in this manual:

Danger of explosion

1

Potential danger of physical injury or death

Notes on Using these Instructions

Danger of electrical shock

2

Danger of physical injury or death

Warning of potential physical injury,

3

Health risk or risk of property damage

Useful information and tips

h

Notes on use in legal metrology within the scope of validity of

Council Directive 2014/31/EU for instruments for which the conformity assessment

procedure has been carried out (verified instruments)�

Note regarding device operation

Explanation of Symbols

The following symbols are used in these instructions:

t Indicates a required action

y Describes what happens after you have performed a particular step

1�, Perform steps in the specified order

2�

– Indicates an item in a list

Technical advice / Hotline:

h

Phone: +49�551�308�4440

Fax: +49�551�308�4449

Cubis MSE Operating Instructions 3

Page 4

Safety Instructions

Safety Instructions

This device complies with European Council Directives as well as international regulations and standards for electrical

equipment, electromagnetic compatibility, and the stipulated safety requirements� Improper use or handling can,

however, result in damage and/or injury�

This device should only be operated by trained personnel�

Operators must read these installation instructions, particularly the safety information, and must be familiar with the

operation of the equipment� The operator is required to supplement these safety precautions as appropriate�

The operating personnel must be provided with the appropriate training�

The requirements pertaining to applicable installation regulations must be followed when using electrical equipment

in systems and environmental conditions with increased safety requirements� Relevant laws, standards, regulations,

guidelines and environmental protection laws valid in your country must be observed�

Always keep the equipment and balance freely accessible�

Any installation work or balance operation that does not conform to the instructions will result in forfeiture of all

claims under the manufacturer's warranty�

Danger of Explosion!

Do not use this equipment in hazardous areas in which explosive materials are present�

1

Danger of Electrical Shock!

If the device is not used in accordance with the instructions, this can affect the product liability for the device�

3

Make sure that the voltage rating printed on the AC adapter is identical to your local line voltage� The wall outlet must

2

2

2

2

2

have a protective grounding conductor� The operating instructions included with the AC adapter must be followed�

Do not switch on the equipment if the AC adapter or power cord are damaged� If the balance, the AC adapter or

any of the cables are damaged, disconnect the equipment from the power supply and secure it so that it cannot be

turned on�

Chemicals (e�g� gases or liquids) that can corrode and damage the inside or outside of the balance, AC adapter, power cable or

peripherals must be kept away from the equipment�

Do not operate the balance unless the housing and the display are undamaged and the housing is closed so that

inadvertent contact with parts inside the equipment is not possible� Make sure that no liquids penetrate the balance

and do not allow conductive parts to touch the balance�

Note on Installation:

The operator shall be solely responsible for any modifications to the equipment

and for connecting any cables or equipment not supplied by Sartorius�

Information on operational quality is available upon request from Sartorius�

You should only use peripherals and options supplied by Sartorius�

Protection Class of the Balance Housing

3

4 Cubis MSE Operating Instructions

– Models with a readability of ≥10 mg and 0�1 mg: These models fulfill the requirements of protection class IP54�

The IP protection only applies to the balance housing and not to the AC adapter�

– The IP protection is only guaranteed when the weighing pan is mounted�

– The IP protection is restricted if the data interfaces are used�

Retain the cover cap for the data output� When the data output is not in use, reapply the cover cap to protect it

against vapors, moisture, and dust or dirt�

Page 5

Safety Instructions

Note on cable quality:

3

3

3

3

CE conformity is only guaranteed with well shielded cables�

The shielding braid of the cable must be made of metal with at least 80% coverage and also covered with metal foil

as much as possible�

The shielding on both sides on the full metal or metalized connector casing, as well as on the casing inlet, must be

high-frequency compliant and have a flat design�

You can only turn off power to the device by pulling the plug or disconnecting the power cord, or by unscrewing the four-

pin plug at the DC supply cable for the balance�

Only use a lightly-moistened cloth for cleaning� See “Care and Maintenance" for cleaning the device� Do not

compromise the IP protection of the balance�

Do not open the balance housing� If the seal is broken, this will result in forfeiture of all claims under the

manufacturer’s warranty� The device may only be opened by specialized personnel trained by Sartorius�

Disconnect the balance from the wall outlet prior to moving the device�

3

Avoid condensation damage to the device� When the balance is turned on,

3

Hazards at the Place of Installation and During Operation

3

3

3

3

3

condensation build-up is not possible� If the device is moved from a cool environment to a warm environment, you

must allow the device to acclimatize for approx� 2 hours before connecting to the power supply�

Avoid generating static electricity and establish potential equalization� A 10 kOhm ground is used when connecting

the balance to the power supply�

Disconnecting the ground conductor is not permitted�

Models with a separate electronics module (e� g� MSE6�6/3�6/2�7 225S/P and 125P): Do not replace the electronics

module�

Replacing with, e� g� models of the ME/SE series will damage the device�

Exercise caution to avoid glass breakage�

There is a danger of lacerations or cuts caused by sharp edges on glass or metal (contact springs), particularly when

removing or replacing the glass draft shield panels; during cleaning; if a glass sample container breaks, or when

modifying the balance hardware configuration�

Make sure all equipment operators have received proper instructions when working with hazardous or toxic materials�

Failure to follow correct handling procedures can result in breakage of parts or spillage of liquids or other substances�

Make sure the necessary protective clothing or equipment is worn, such as protective gloves, clothing, eyewear� All safety

regulations applicable in the laboratory must be observed�

Exercise caution to avoid squeezing or crushing fingers when

– Operating the electronic draft shield

– Removing or installing the panels

– Adjusting the display

Do not expose the device to aggressive chemical vapors or to unnecessarily extreme temperatures, moisture, shocks,

3

3

or vibration�

The device should be setup in areas away from equipment or devices that have strong magnetic properties�

Extreme electromagnetic fields from electrical lines should also be avoided�

Cubis MSE Operating Instructions 5

Page 6

Safety Instructions

Use69719

87

1

2

3

4

5

6

7

8

9

11

12

13

14

15

16

17

18

19

7

1

3

20

10

10

Intended Use

Cubis models are high-resolution balances� They were specially

developed for exact determination of material mass in liquid,

paste, powder or solid form�

Appropriate containers must be used for each type of sample

material�

Specific models cover specific weighing ranges: see

“Specifications�"

Cubis models are designed specially for use in research,

education and day-to-day laboratory tasks in science and

industry�

They are designed to be used exclusively indoors�

Cubis models can be operated as standalone, connected to a

PC, or on a network�

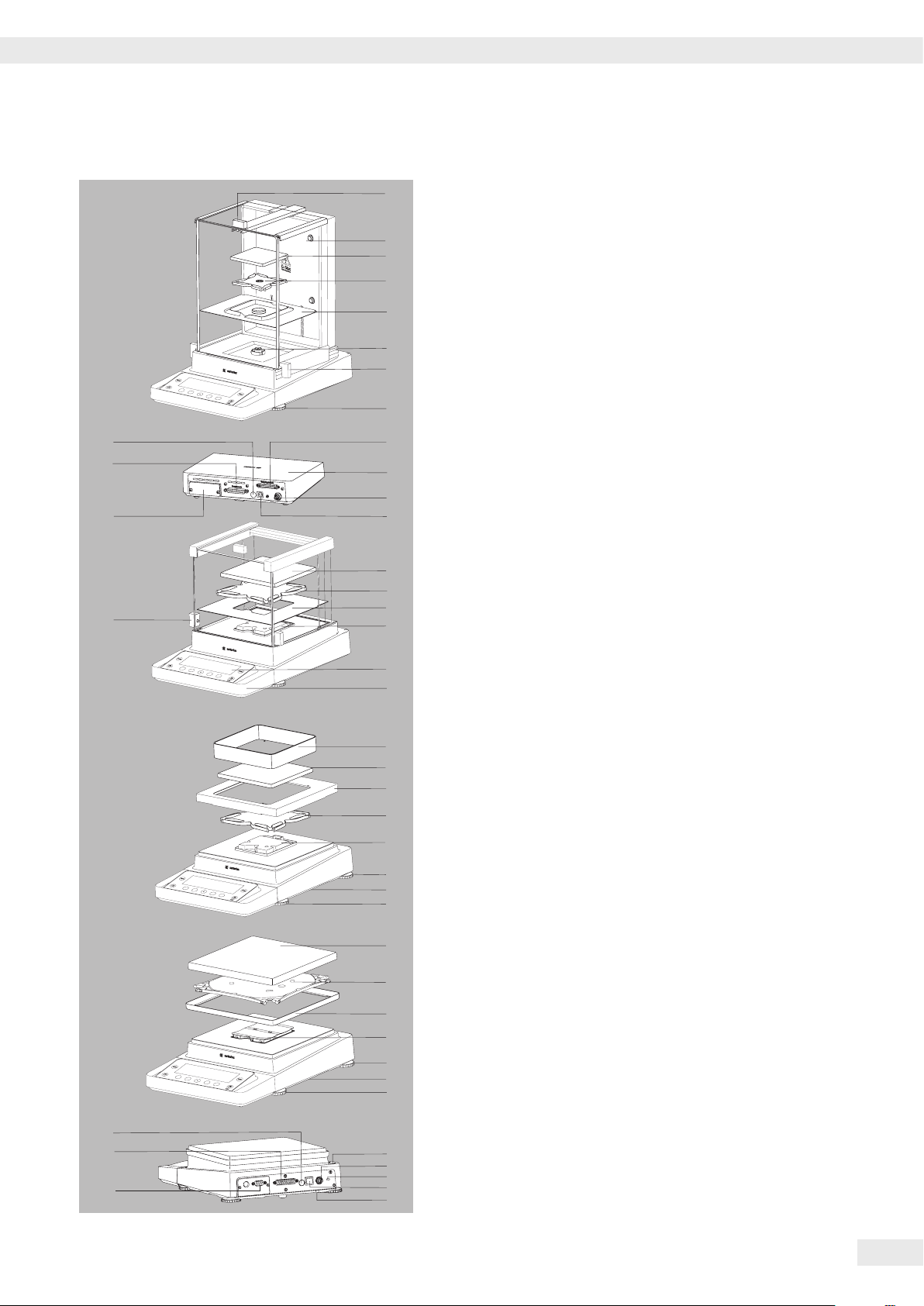

General View of the Equipment and Equipment Supplied

Balances with a readability of ≤ 1 µg

Pos� Description

1 Weighing pan

2 Filter weighing pan d 50 mm

3 Internal draft shield (for MSx2�7S-F only)

4 Optional weighing pan d 75 mm

5 Shield disk

6 Optional filter weighing pan d 90 mm

7 Shield plate

8 Level indicator

9 Leveling foot

10 MSE2�7�� model: bush

11 Draft shield cover

6 Cubis MSE Operating Instructions

Pos� Description

12 Female connector for weigh cell

13 DC jack

14 Display and control unit

15 Serial communications port (PERIPHERALS)

16 Slot for optional interfaces, e� g� 9-pin data output or Bluetooth�

PS2 socket has no function�

17 Lug for attaching antitheft locking device

18 Equipotential bonding conductor terminal

19 Equipotential bonding conductor terminal

20 Draft shield

Not shown: AC adapter, USB cable

Page 7

General View of the Equipment and Equipment Supplied

9

10

22

3

4

5

5

6

6

12

12

10

10

13

13

6

11

11

4

3

3

14

15

16

17

18

19

20

21

4

23

24

14

16

19

20

21

1

2

3

4

5

6

7

8

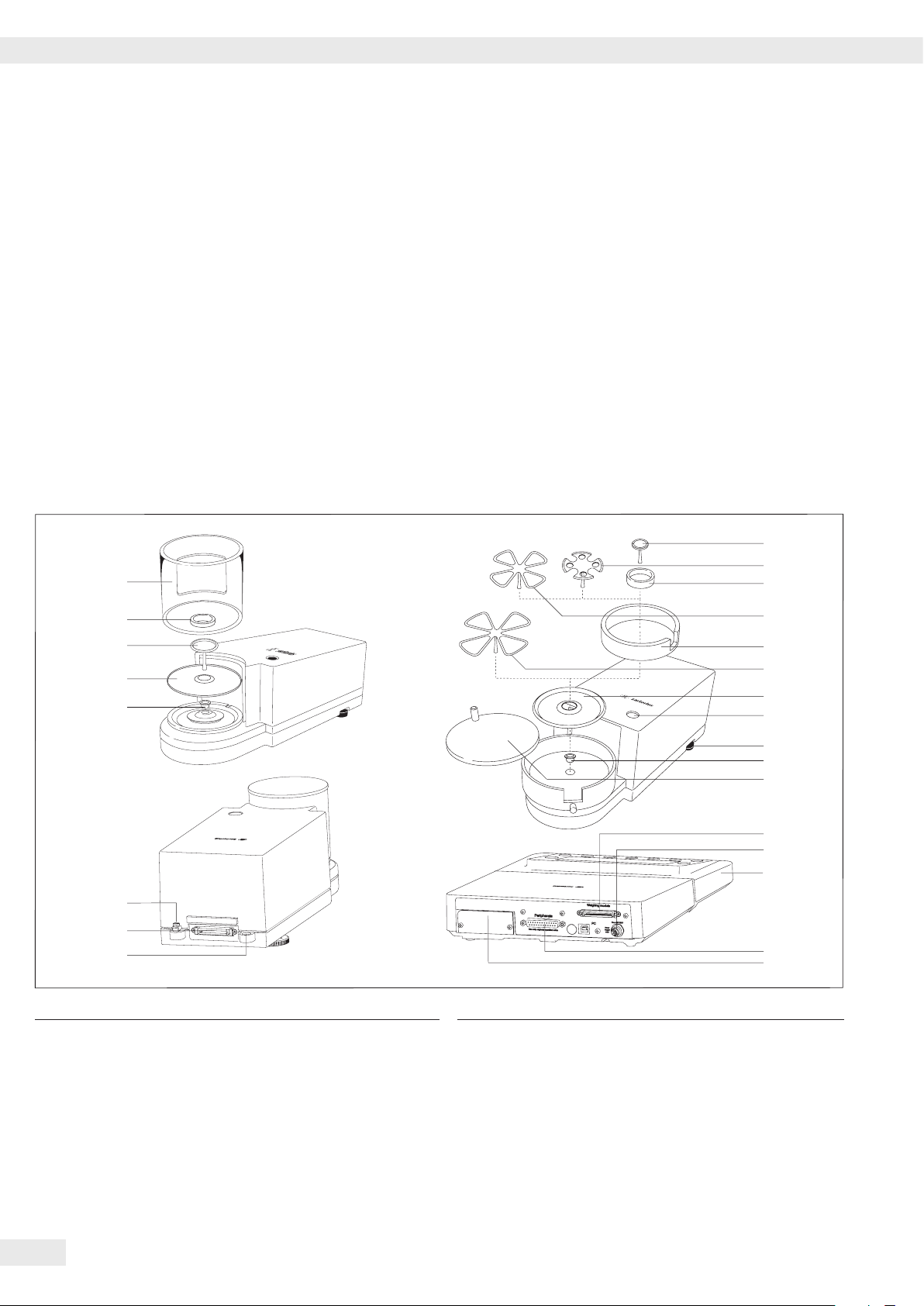

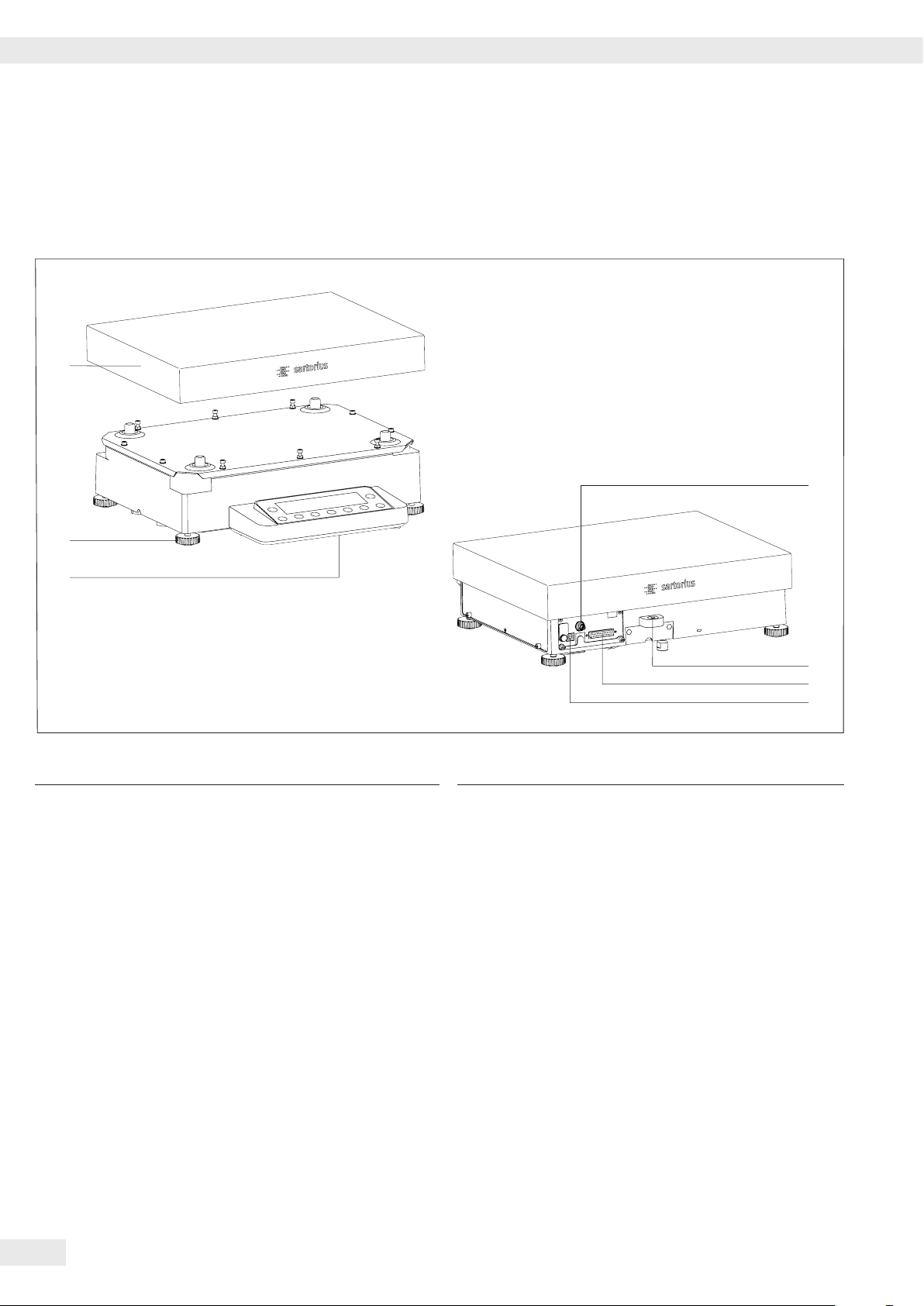

General View of the Equipment

and Equipment Supplied

Item Description

Analytical and precision balances with a weighing range of up to 15 kg

1 Upper sliding draft shield panel/Handle

2 Back panel

3 Weighing pan

4 Pan support (not for MSx225���/MSx125��� models)

5 Shield plate

6 Pan retainer

7 Right sliding panel/Handle

8 Leveling foot

9 Display

10 Display and control unit

11 Draft shield/Shield disk (only for models with a readability of

1 mg and 10 mg)

12 Below-cell weighing port

(on the bottom of the balance)

13 Leveling foot

14 Level indicator

15 Power socket

16 Slot for attaching an

anti-theft locking device

17 USB socket for a PC connection

18 Below-cell weighing hook

19 Slot for optional interfaces,

e�g�, 9-pin data output (as shown) or Bluetooth�

PS2 socket has no function�

20 Communication port (PERIPHERALS) for accessories

21 Menu access switch

22 Left sliding panel/handle

23 Semi-microbalances: Female connector for weigh cell

24 Semi-microbalances: Electronics module

(for MSx225���/MSx125��� models)

Not shown:

– AC adapter

– USB cable

– Operating instructions

– In-use cover over the display unit

– Dust cover (only for balances with a draft shield)

– In-use cover for housing (only for models with a readability of

19 mg/100 mg and a weighing capacity of <14 kg)

Cubis MSE Operating Instructions 7

Page 8

General View of the Equipment and Equipment Supplied

1

3

4

5

7

2

6

Equipment Supplied and General View of the Equipment

Balances with a weighing range of 20 kg or more

Pos� Bezeichnung

1 DC jack

2 Leveling foot

3 Level indicator

4 Serial communications port (PERIPHERALS)

Pos� Bezeichnung

5 USB interface for PC connection

6 Display and control unit

7 Weighing pan

Not shown: AC adapter, USB cable

8 Cubis MSE Operating Instructions

Page 9

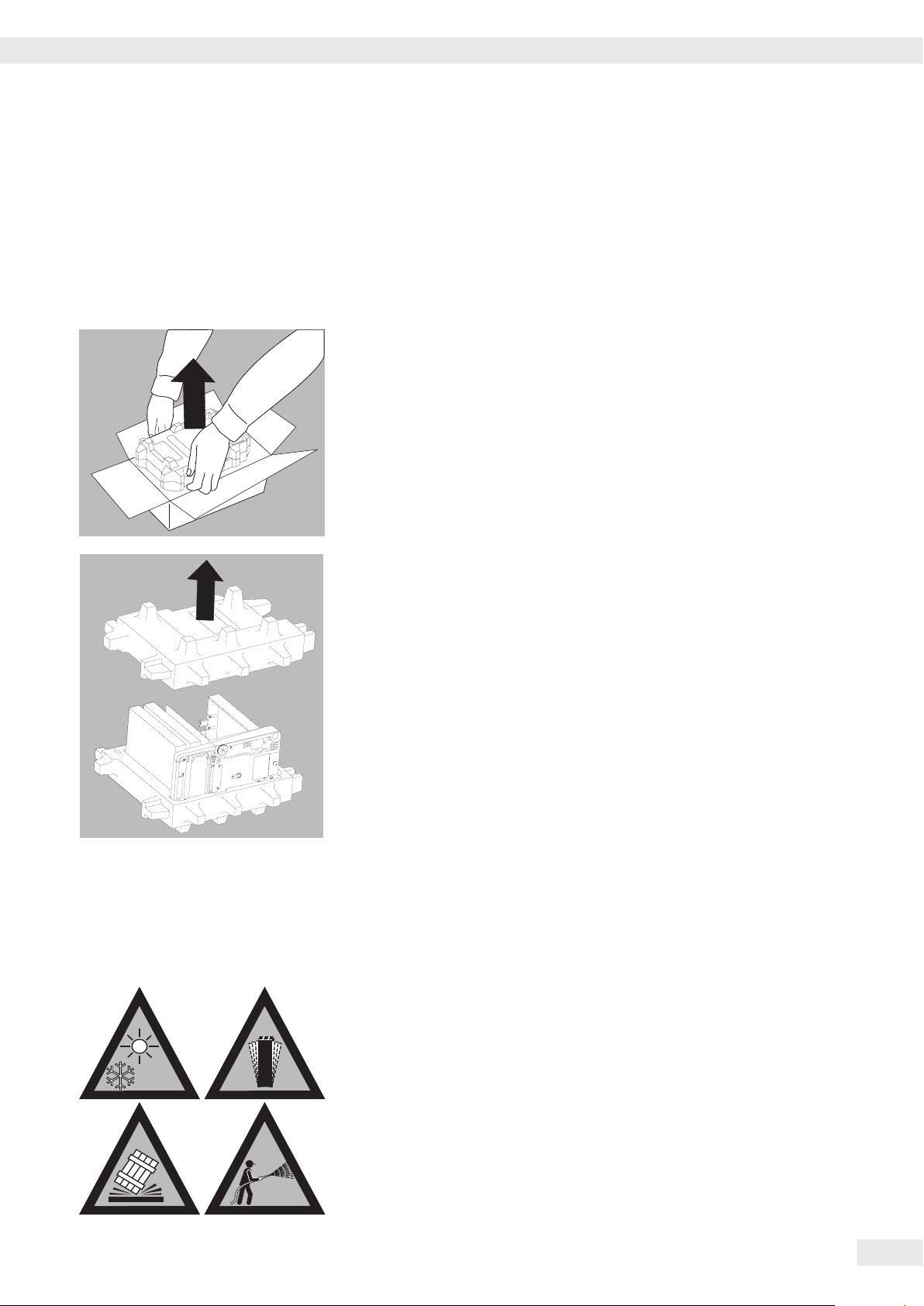

Getting Started

°C

Getting Started

Unpacking the Equipment

t Open the packaging at the top�

t Use both hands to lift the balance, with the packaging, out of the cardboard

box�

t Place the packaging with the balance on the floor�

t Remove the top part of the packaging�

Installation Instructions

t Select the proper setup location:

– Set up the device on a stable, even surface that is not exposed to vibrations

(e�g� weighing stone)�

– Place the device in a location with enough free space around it so that

excessive heat cannot build up�

– Maintain free access to the device at all times�

Choose a location that is not subject to the following negative influences:

– Heat (heater or direct sunlight)

– Drafts from open windows, AC systems and doors

– Extreme vibrations during weighing

– Excessive moisture

Acclimatization

Condensation from humidity can form on the surfaces of a cold device when it is

brought into a substantially warmer area�

To avoid the effects of condensation, condition the balance for about two hours at

room temperature, leaving it unplugged from the power supply�

Carefully read all warnings and safety precautions in the respective section of this

manual�

Cubis MSE Operating Instructions 9

Page 10

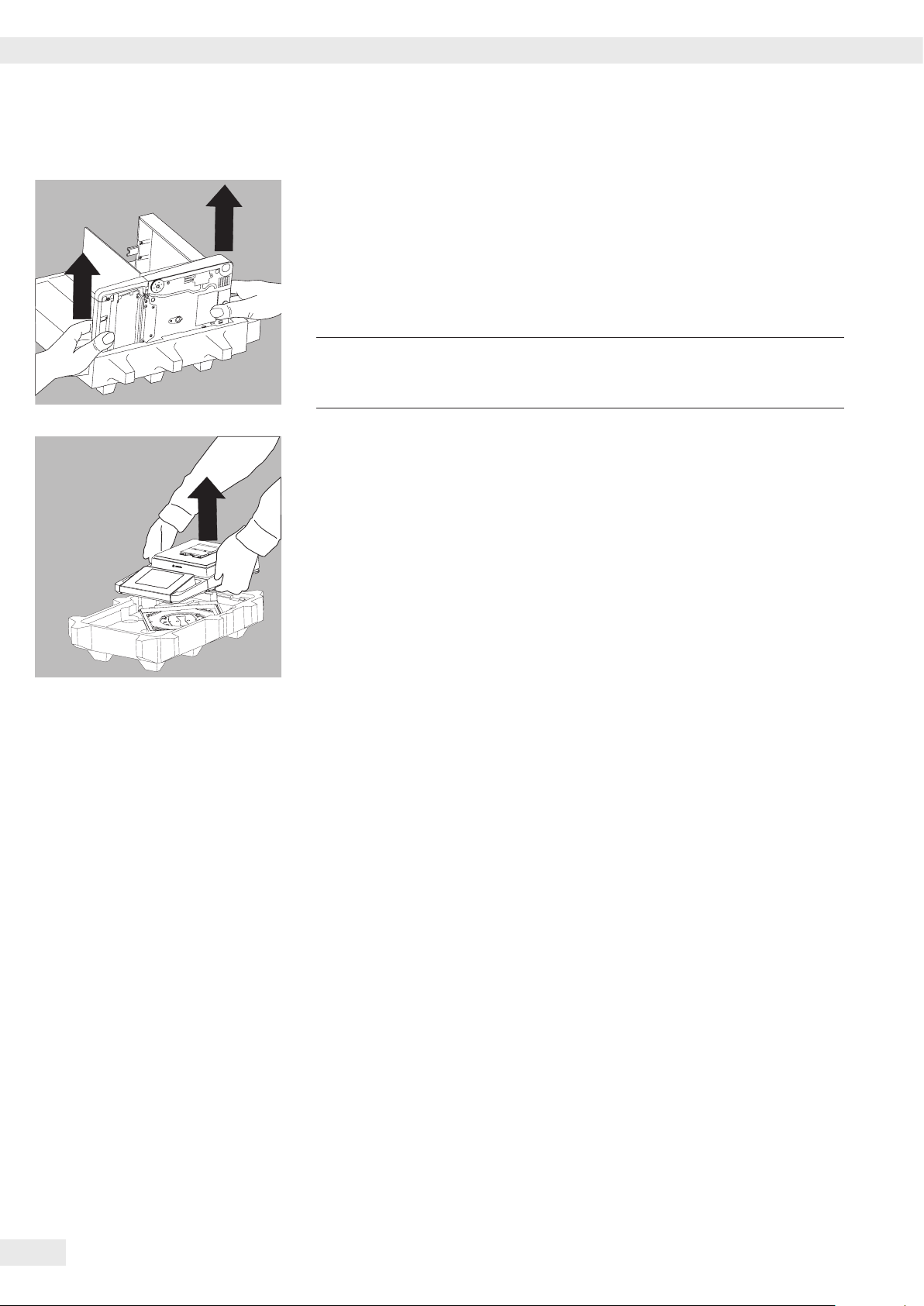

Getting Started

Balance with Draft Shield

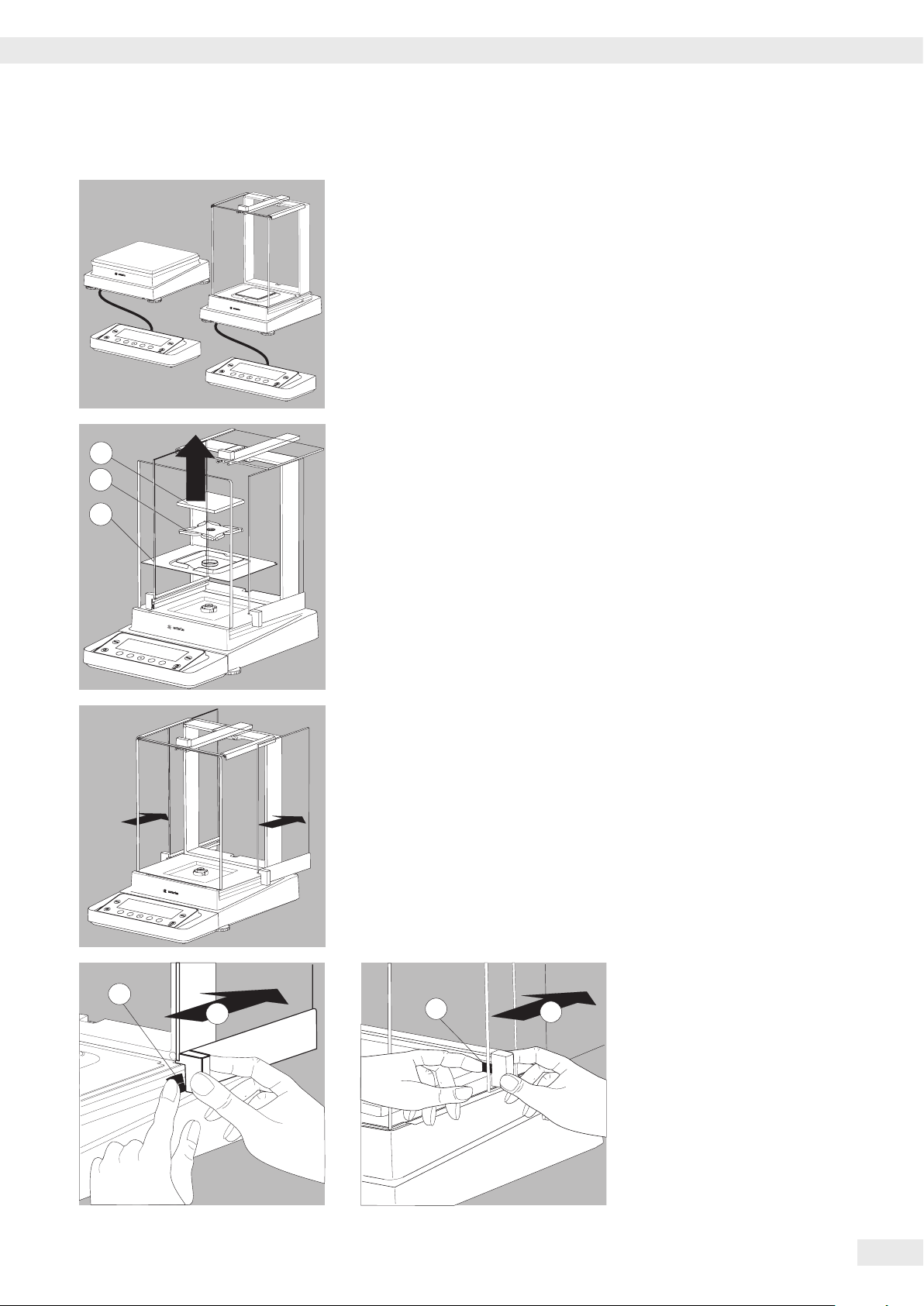

t Remove the packages (containing draft shield panels, weighing pan, pan

support, AC adapter, etc�) from the lower packaging and place them to one

side�

t Use both hands to lift the balance out of the packaging�

Exercise caution to avoid glass breakage�

3

t Place the balance on an even surface�

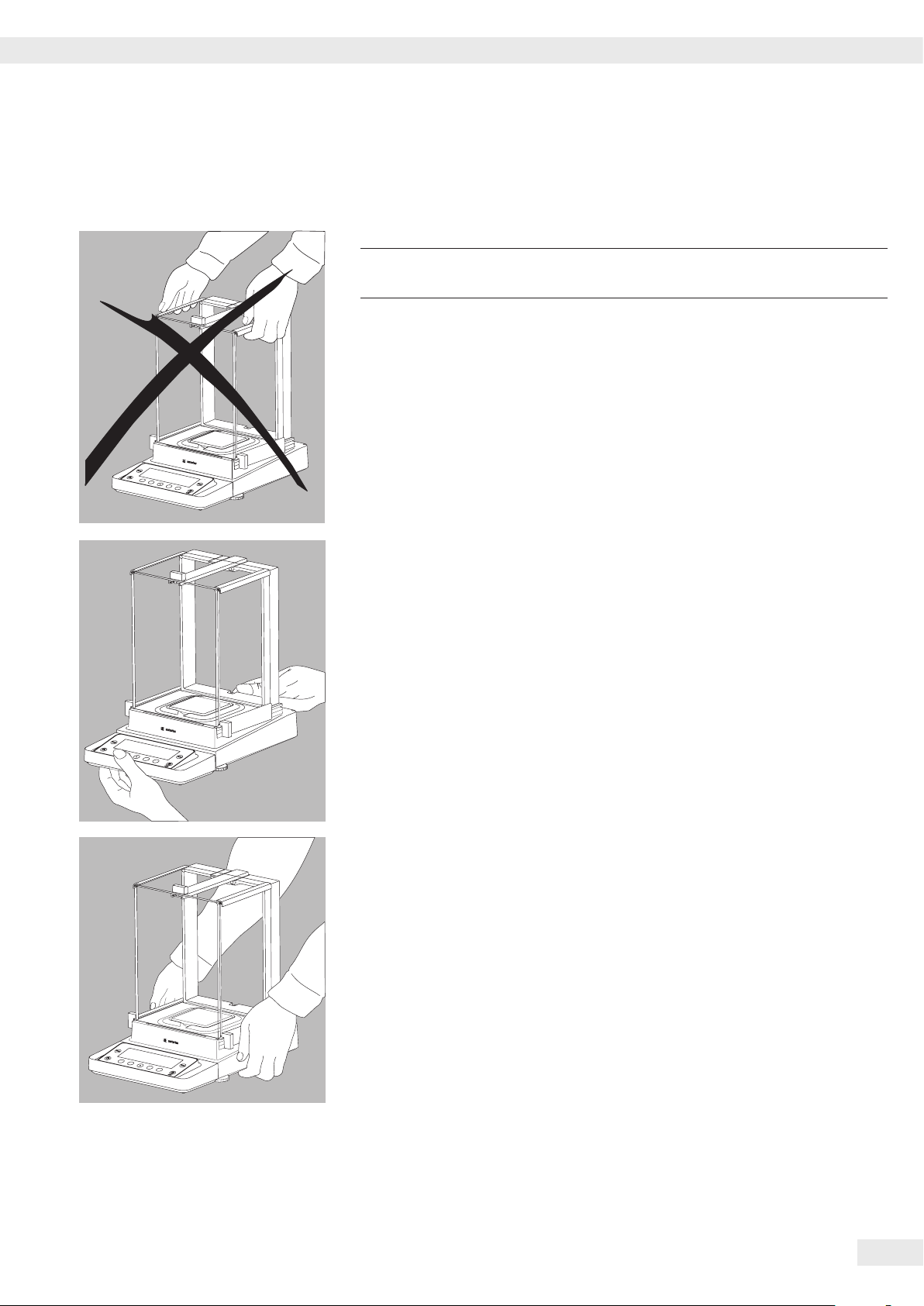

Never lift the equipment by the draft shield panels to remove it from the

packaging�

Balance with No Draft Shield

t Use both hands to remove the model without a draft shield from the

packaging�

t Remove the AC adapter and the balance parts from the packaging�

10 Cubis MSE Operating Instructions

Page 11

Getting Started

Assembly

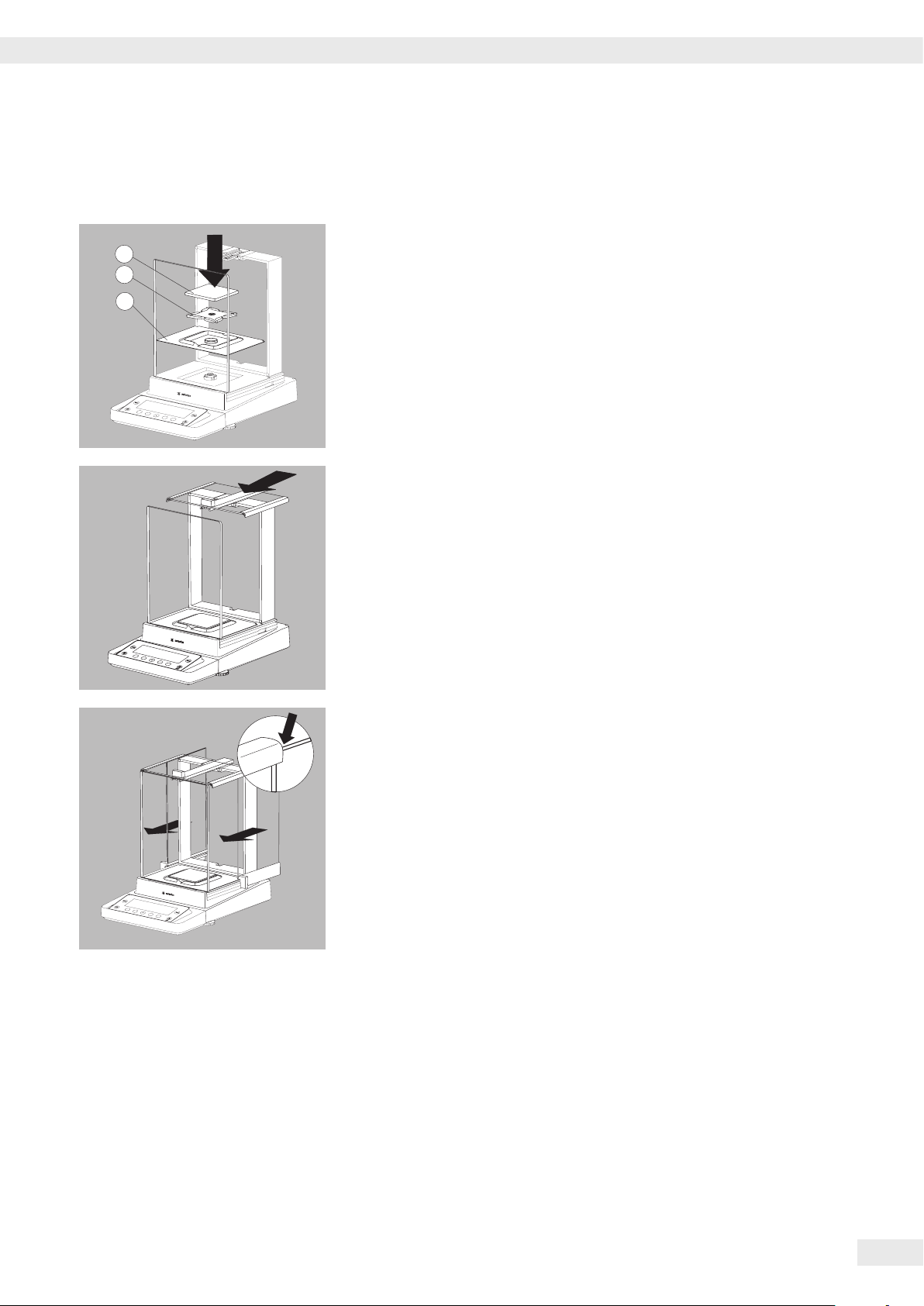

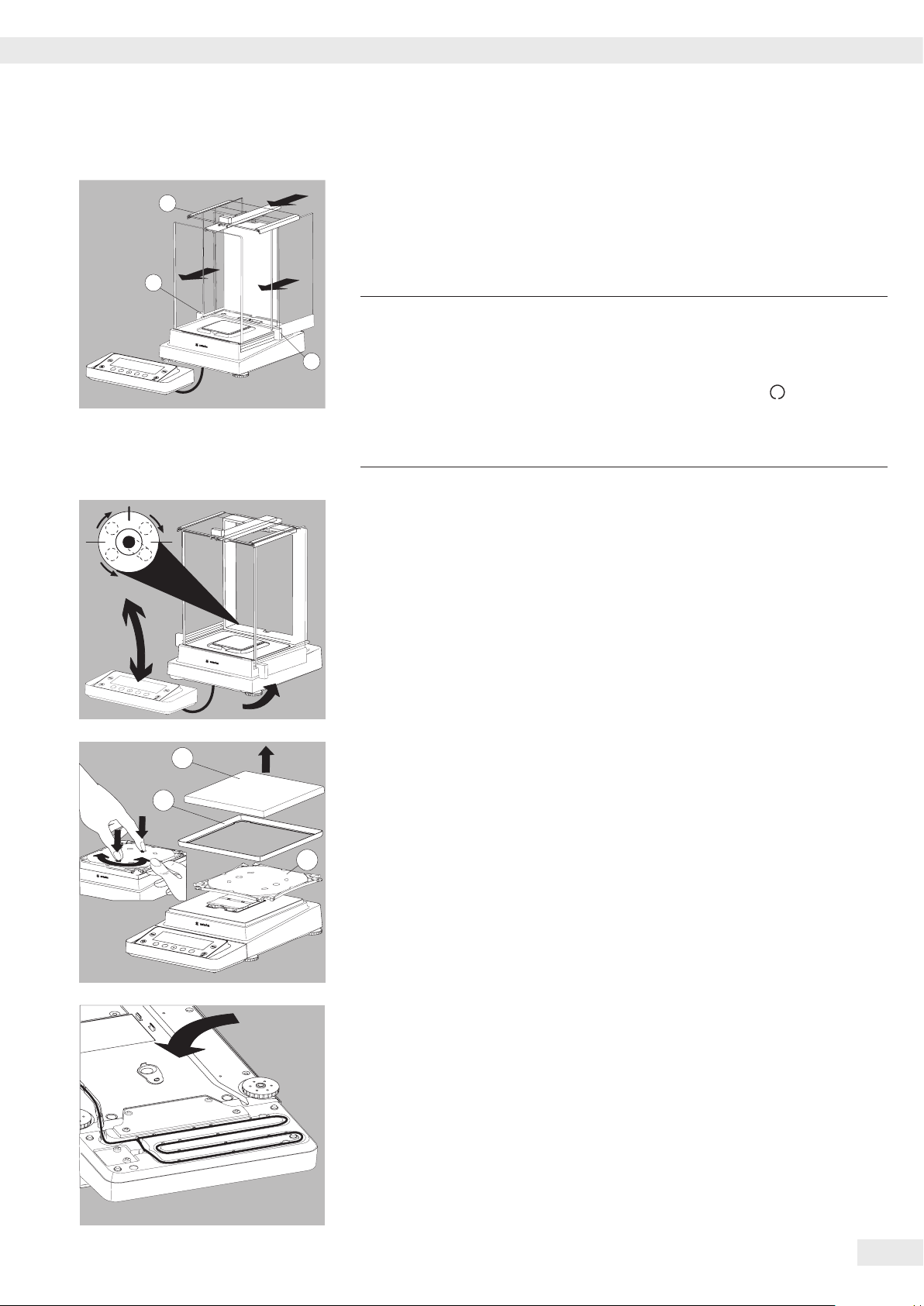

Installing the Analytical Draft Shield Labeled DA, DI, and DU

3

2

1

Assembling the Balance

t Fit parts onto the balance as shown in the picture�

1. Shield plate

2. Pan support (not for MSx225���/MSx125��� models)

3. Weighing pan

t Slide the upper draft shield panel into the guide rails from the rear�

t Slide the left and right draft shield panels into the guide rails from the rear�

Make sure the panels are within the upper and lower guide rails�

t Slide the panels in until they engage�

1. Right draft shield panel

2. Left draft shield panel

y This completes the balance assembly�

Cubis MSE Operating Instructions 11

Page 12

3

2

1

3

2

1

Getting Started

Installing the Draft Shield Labeled DE for Milligram Balances

Assembling the Balance

t Fit parts onto the balance as shown in the picture�

1. Shield plate

2. Pan support

3. Weighing pan

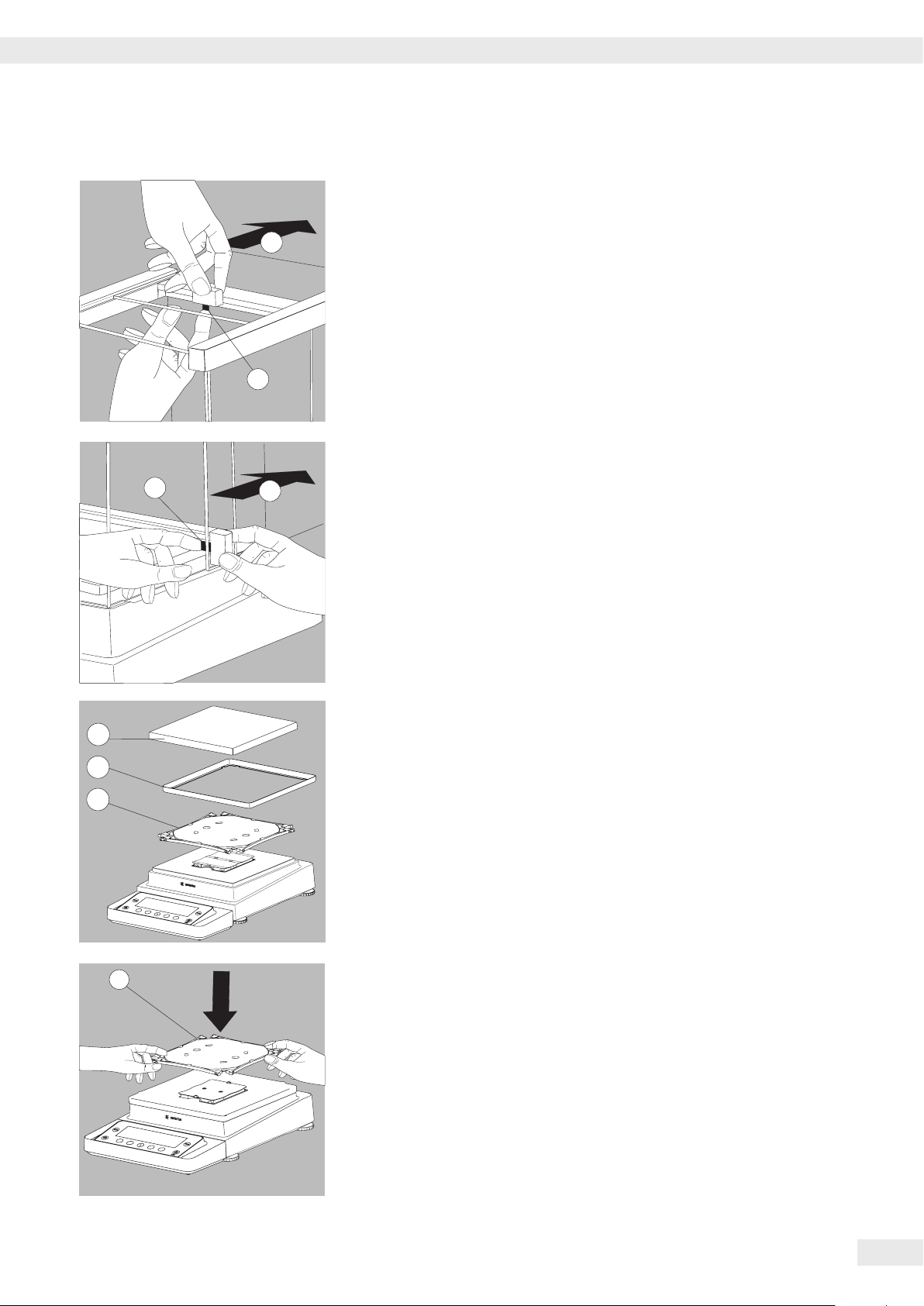

Assembly of Milligram Balances without Glass Draft Shield (DR Option):

Balance Assembly

4

3

2

1

t Fit all components listed below onto the balance in the order given:

1. Pan support (see also next section)

2. Shield plate

3. Weighing pan

4. Draft shield frame

t First insert the shield plate�

t Make sure the pin on the pan support is facing toward the front, and slide it

under the clip on the pan retainer�

1. Insert the pan support�

t After inserting the pan support, press it down against the shield plate so that it

lies flat�

3

2. Press down the pan support�

Exercise caution to avoid pinching or crushing fingers�

12 Cubis MSE Operating Instructions

t Place the weighing pan on the pan support�

3. Weighing pan

Page 13

Getting Started

2

1

2

1

t Slide the upper draft shield panel into the guide rails from the rear while

pressing the locking tab�

t Slide the side draft shield panel into the guide rails from the rear while pressing

the locking tab�

y This completes the balance assembly�

t Remove the panel again if necessary

1. Press on the locking tab�

2. Remove the panel again if necessary

t Place the panel in the storage slot at the back of the balance�

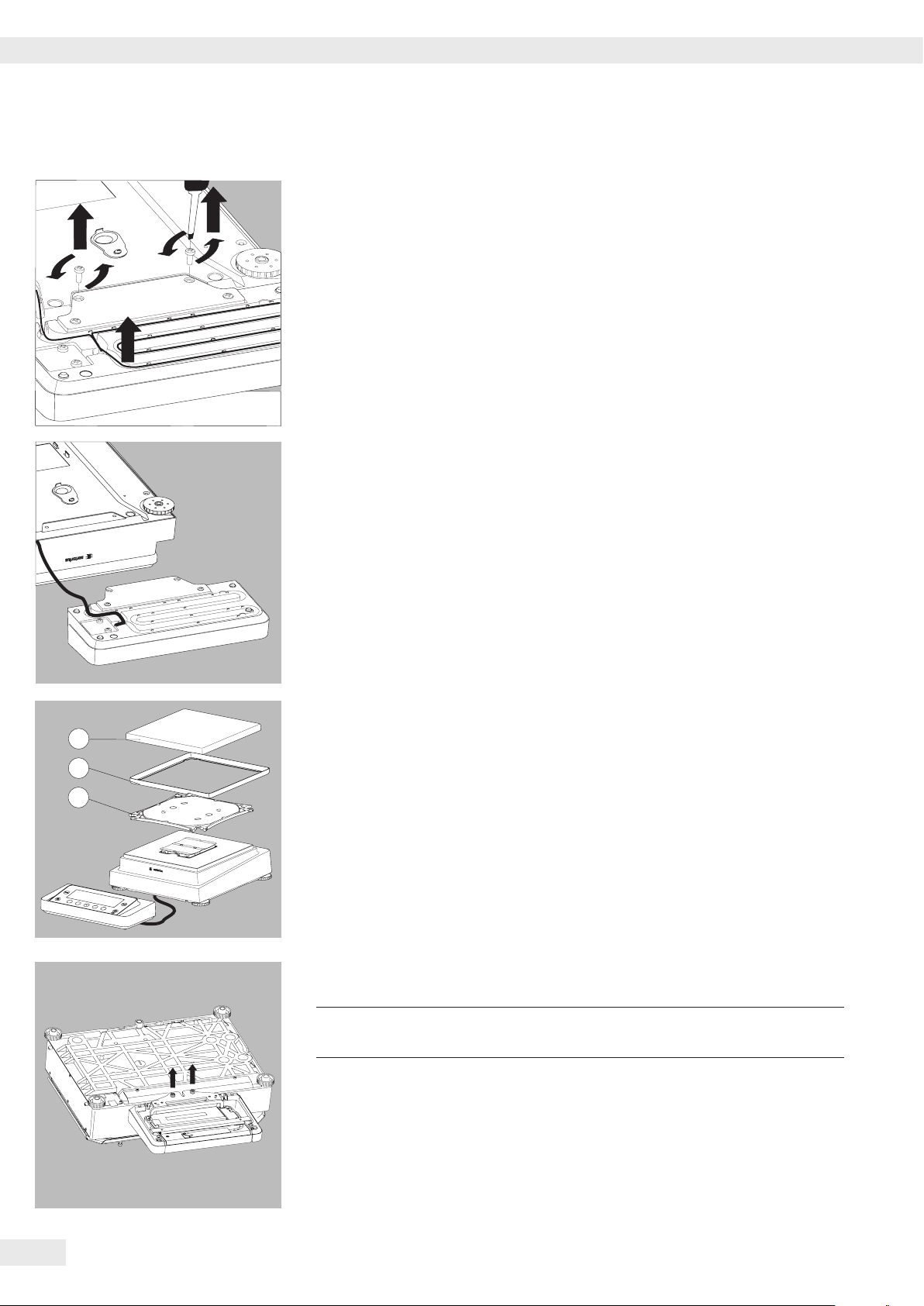

Assembly for Precision Balances without Draft Shield with a Weighing Range

3

2

1

up to 15 kg

t Fit parts onto the balance as shown in the picture�

1. Pan support

2. Shield plate/Draft shield

3. Weighing pan

1

t Place the pan support diagonally and press down lightly�

1. Pan support

Cubis MSE Operating Instructions 13

Page 14

Getting Started

3

t Carefully turn the pan support clockwise until the two buttons engage�

The pan support is now attached�

t 2. Insert the shield plate/draft shield�

t 3. Place the weighing pan on the pan support�

2

y This completes the balance assembly�

Models with a Weighing Range from 20 kg Upwards:

t Place the weighing pan on the balance�

14 Cubis MSE Operating Instructions

Page 15

Getting Started

MSE225…, MSx125:

MSE6�6S/3�6P/2�7S:

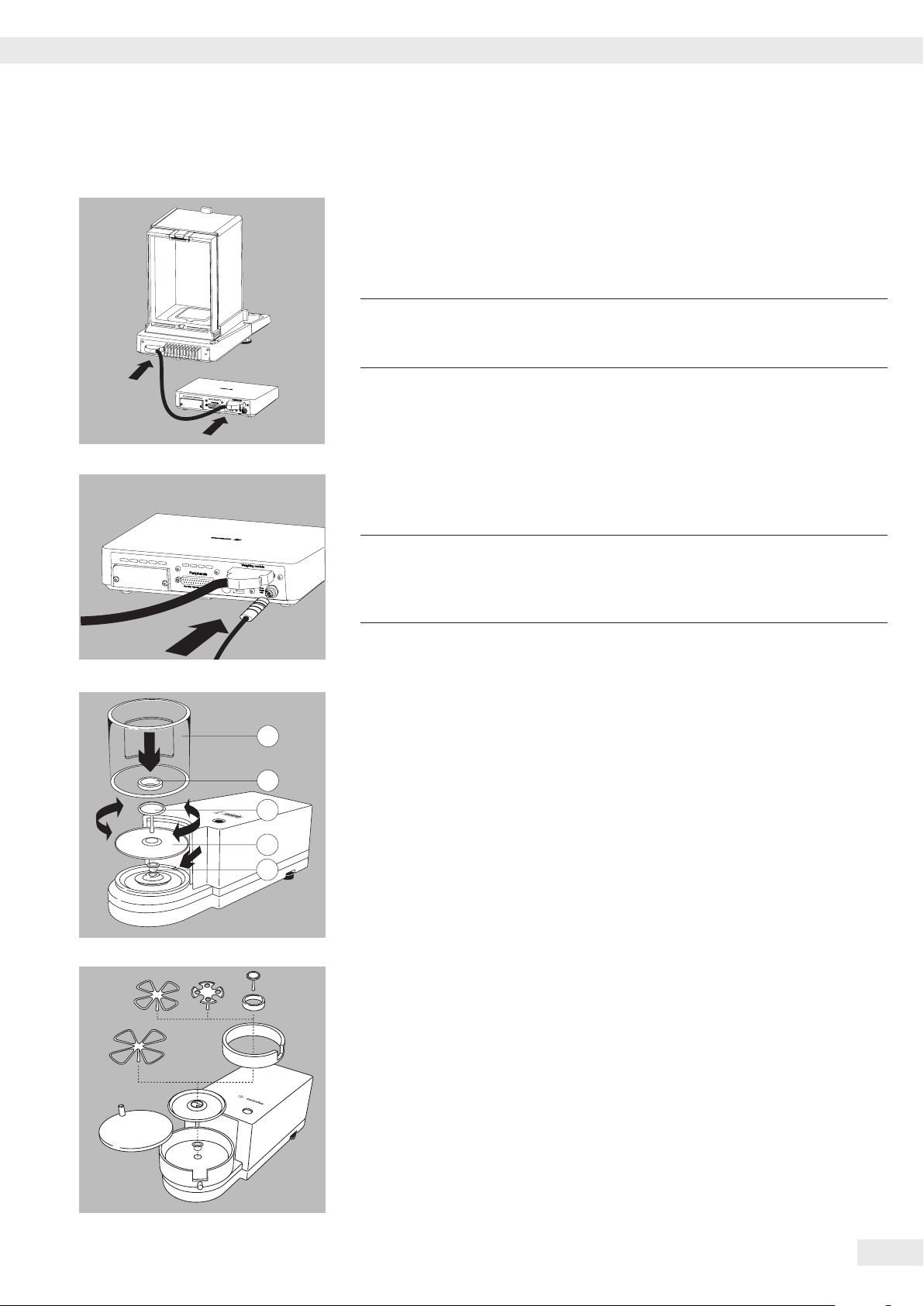

Connecting the Weigh Cell to the Electronics Module/Evaluation Unit

t Connect the weigh cell and electronics module using the connection cable�

Make sure that the connectors click into place so that both ends are securely

connected�

Please check the plug contacts to ensure a proper connection�

3

t Connecting the Weigh Cell to the Evaluation Unit

3

There should be no tension on the connection cable�

We therefore recommend placing the device close to the wall�

Make sure that the connectors click into place so that the connection is secure�

Models with a separate electronics module (e�g� MSE6�6/3�6/2�7),

MSE225S/P and MSE125P: Do not replace the electronics module�

Replacing them with models from the ME/SE series, for example, can

damage the device�

MSE6�6S/3�6P/2�7S:

MSE6�6S-F/2�7S-F:

Microbalances (Models MSE6.6S/3.6P/2.7S):

Placing Components on the Weigh Cell

t Install the following parts in the order listed:

5

1� MSE2,7S models: bush

4

3

2

1

2� Shield plate

3� Weighing pan

Note: After inserting the weighing pan, turn it slightly to the left and right,

while pressing it down lightly�

4� Internal draft shield (for MSE2�7S only)

5� Draft shield: Center the hole over the pan (see arrows)

Filter Balances (Models MSE6.6S-F/2.7S-F):

Placing Components on the Weigh Cell

t Place the components listed below inside the weigh cell in the order given:

1� MSE2,7S-F models: female connector

2� Shield plate

3� Internal draft shield

4� Filter weighing pan d 50 mm or weighing pan

(optional filter weighing pan d 75 mm or d 90 mm)

Note: After inserting the pan, turn it slightly to the left and right,

while pressing it down lightly�

5� Draft shield cover

!

Tip: Turn the balance off and then on again after replacing the pan during

operation�

Cubis MSE Operating Instructions 15

Page 16

Getting Started

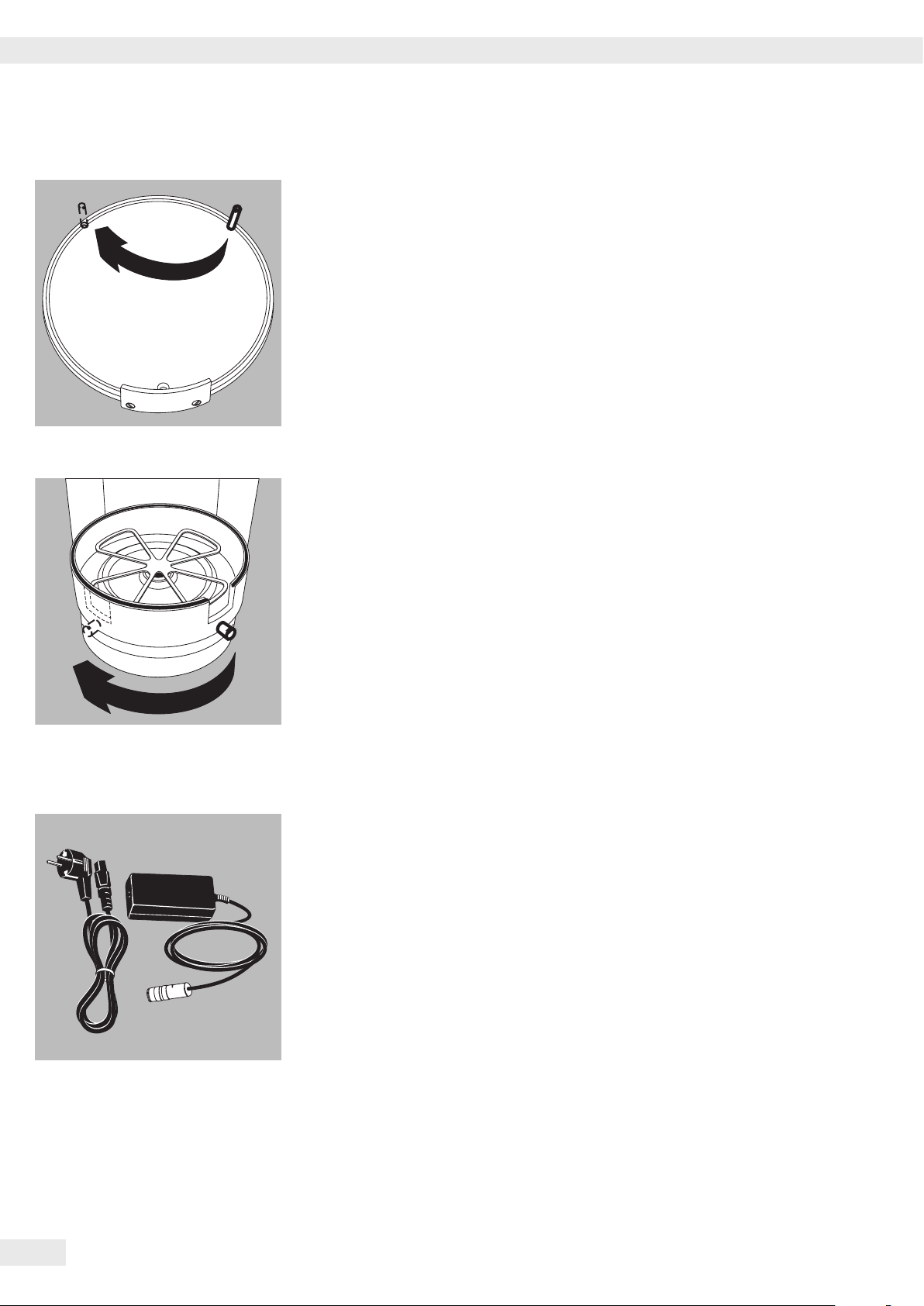

Setting up a filter weighing pan for left-handed users:

t Remove the draft shield cover

t Unscrew the pin and move from the right to the left side

t Turn draft shield parts approx� 90 degrees to the left (loosen knurled screw)

Power Connection

t Check the voltage rating and plug design�

– Make sure that the voltage rating printed on the manufacturer’s ID label is

identical to that of your local line voltage�

– If the stated supply voltage or the plug design of the power cord does not

comply with your country’s standard, please inform the nearest Sartorius

representative or your dealer�

– The power connection must be made in accordance with the regulations

applicable in your country�

– In order to connect the equipment to the power supply (protection class 1), use

a suitable, correctly installed wall outlet with a protective grounding conductor

(PE) and a fuse of a maximum 16 A�

– If a main feeder from the ceiling is required or if installation of a CEE plug is

necessary, these must be carried out by a qualified electrician�

– Only use original Sartorius AC adapters�

16 Cubis MSE Operating Instructions

Page 17

Transporting the Balance

Transporting the Device over Short Distances

Exercise caution to avoid glass breakage�

3

Never lift and carry the balance by its draft shield�

Getting Started

t Carry as shown in the illustration�

or

t Carry as shown in the illustration�

Storage and Shipping Conditions

– Permitted storage and shipping temperature: -10 to +60 °C

– Unpacked devices can lose their precision if subject to extreme vibrations�

– Excessive vibrations may compromise the safety of the equipment�

Save the packaging for any future storage or shipment of the balance�

Only the original packaging provides optimum protection for the equipment�

– Follow all warnings and safety precautions�

– Follow the instructions in the chapter: “Transporting the Balance�"

Cubis MSE Operating Instructions 17

Page 18

Getting Started

2

1

Analytical and precision balances:

1. Plug the DC supply cable of the AC adapter into the power socket of the

balance and tighten the threaded fitting�

Balances with a readability of ≤ 0�01 mg

1. Plug the DC supply cable of the AC adapter into the power socket of the

electronics module and tighten the threaded fitting�

2. Plug the other end of the power cord into the AC adapter�

3. Insert the AC adapter power plug into the wall outlet�

y The balance is now ready to use�

Safety Precautions

The output line of the adapter has a terminal (GND) connected to the metal

housing of the balance� The data port is also galvanically linked to the balance

housing (GND)�

18 Cubis MSE Operating Instructions

Page 19

Getting Started

93

R

L

L

L

R

R

12

2

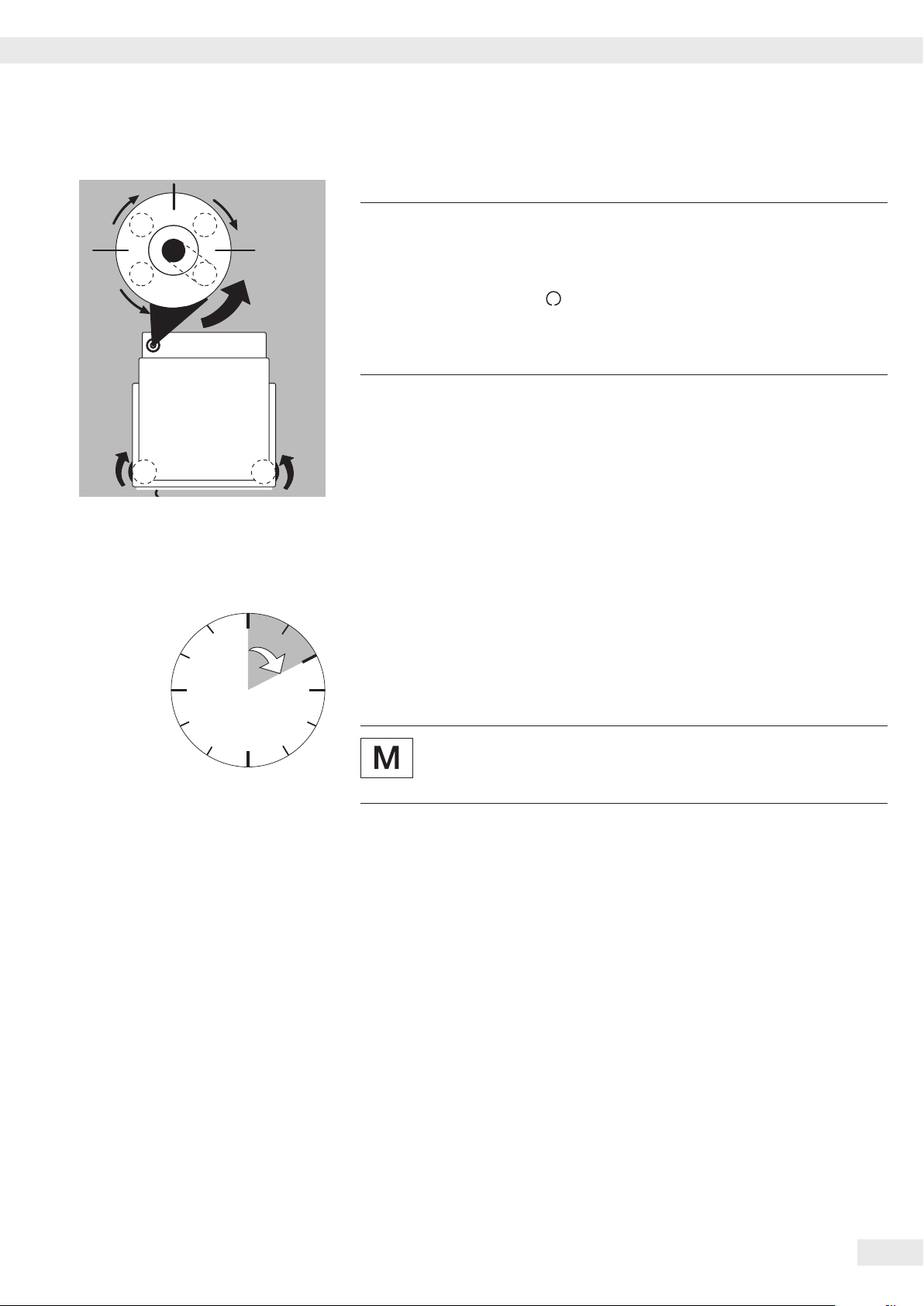

Leveling the Balance, Setting the Level Indicator

Leveling the balance compensates for slant or unevenness at the place

h

Leveling the Balance Manually

t The balance is leveled using both front leveling feet�

t Screw in both back leveling feet (only for models with back leveling feet)�

t Turn the two front feet as shown in the illustration until the air bubble is

y Normally, several leveling steps are required�

t Screw out both back leveling feet until they touch the setup surface

Warm-up Time

y In order to deliver the precise results described in the Technical Specifications,

of installation� The balance must be perfectly horizontal to ensure

consistent, reproducible weighing results� All models are equipped with

an electronic tilt angle detection feature� If the balance is not level,

a warning symbol is shown on the display� Push-button automatic

leveling is available on models with motorized leveling feet� For models

with manual leveling feet, please follow the instructions on the display:

see “Leveling the Balance with the Inclination Sensor�"

centered within the circle of the level indicator�

(only for models with back leveling feet)�

the balance must warm up for at least 30 minutes after initial connection to

the power supply� Only after this time will the device have reached the required

operating temperature�

6

When a verified balance used in legal metrology (legal-for-trade

applications) is connected to the power, it must warm up for at least

two hours before operation�

Cubis MSE Operating Instructions 19

Page 20

Getting Started

Connecting Electronic Devices (Peripherals)

t Make absolutely sure that the device is unplugged from the power supply

before connecting/disconnecting any peripheral device (printer, scanner, PC) to

or from the data port�

A device connected to the power supply should never be opened�

3

Anti-theft Locking Device (Accessory)

Balances with a readability of ≤ 0�01 mg

t An anti-theft locking device can be installed to the back of the balance if

required�

Balances with a readability of ≤ 1 µg

To fasten an antitheft locking device, use the lug located on the back of the weigh

cell�

20 Cubis MSE Operating Instructions

Page 21

Getting Started

2

1

2

1

Modification Options

Setting Up the Display and Control Unit at the Place of Use

The display and control unit can be removed for all models to enable the operator

to customize the work space�

Removing the Retainer with the Display and Control Unit

1

2

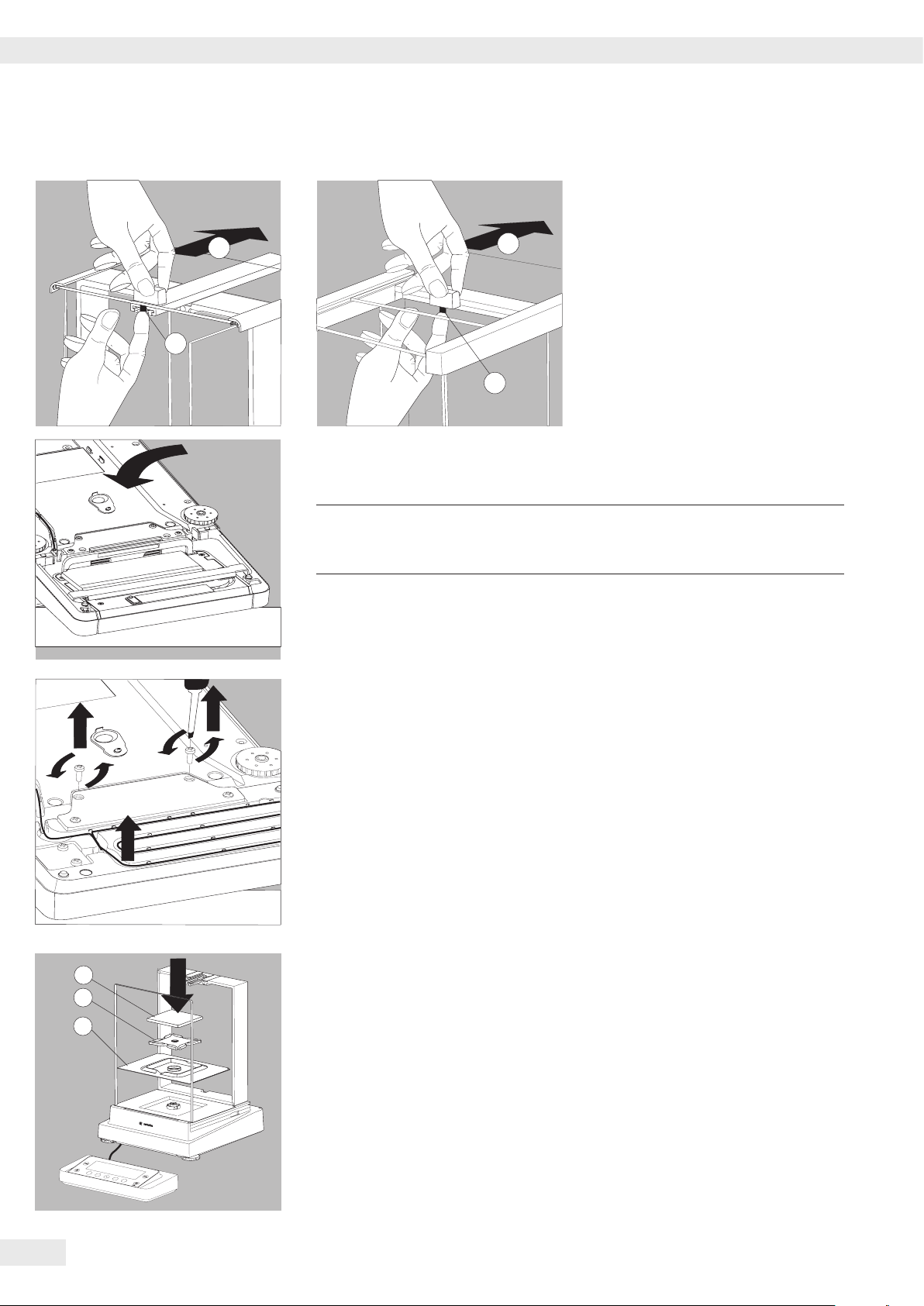

t Remove all items (such as weights) from the draft shield�

3

t Carefully remove all parts as shown in the illustration�

1. Weighing pan

2. Pan support (not for MSE225… MSE125… models)

3. Shield plate/Draft shield

t Keep all parts in a safe place�

t Remove the panels (right and left)�

Models with the analytical draft shield:

1. Press on the locking tab�

2. Remove the panel�

Models with the milligram draft shield:

1. Press on the locking tab�

2. Remove the panel�

t Keep all parts in a safe place�

Cubis MSE Operating Instructions 21

Page 22

Getting Started

2

1

2

1

t Remove the upper draft shield panel�

Models with the analytical draft shield

(left illustration)�

1. Press on the locking tab�

2. Remove the panel�

Models with the milligram draft shield

(right figure):

1. Press on the locking tab�

2. Remove the panel�

t Keep all parts in a safe place�

t Turn over the balance and place it on a soft surface�

3

t Use a 2�5 mm Allen wrench to remove the two screws from the display and

t Remove the display and re-insert both screws back into their holes�

t Lengthen the cable and position the display and control unit as desired�

t Turn the balance over and place it on an even surface�

3

2

1

t Carefully place all parts on the balance:

1. Shield plate/Draft shield

2. Pan support (not for MSE225… /MSE125… models)

3. Weighing pan

Exercise caution to avoid breaking the glass on models with a draft

shield�

control unit retainer bracket�

22 Cubis MSE Operating Instructions

Page 23

Getting Started

1

1. Upper draft shield panel

2. Right draft shield panel

3. Left draft shield panel

t Replace the upper and side shield panel�

3

t Level the balance�

Leveling the balance compensates for slant or unevenness at the place

h

2

of installation� The balance must be perfectly horizontal to ensure

consistent, reproducible weighing results� All models are equipped with

an electronic tilt angle detection feature�

If the balance is not level, a warning symbol is shown on the display�

The display shows a graphical representation of a level indicator and text

prompts that guide the user through the leveling process: see “Leveling

the Balance with the Inclination Sensor�"

R

L

t The balance is leveled using both front leveling feet�

t Screw in both back leveling feet (only for models with back leveling feet)�

L

t Turn the two front feet as shown in the illustration until the air bubble is

centered within the circle of the level indicator�

y Normally, several leveling steps are required�

R

1

2

t Screw out both back leveling feet until they touch the setup surface

(only for models with back leveling feet)�

Removing the Display and Control Unit from Precision Balances

without a Draft Shield and with a Weighing Range of up to 15 kg

t Carefully remove all parts as shown in the illustration�

1. Weighing pan

3

2. Shield plate/Draft shield

3. Pan support

t Keep all parts in a safe place�

t Turn over the balance and place it on a soft surface�

Cubis MSE Operating Instructions 23

Page 24

Getting Started

2

1

3

t Remove the two retaining screws�

t Remove the display and re-insert both screws back into their holes�

t Carefully pull the cable connected between the display and control unit from

the retainer�

t Determine the required cable length�

t Return the balance to an upright position and fit the parts onto the balance�

1. Attach the pan support�

2. Shield disk (only for models with a readability of 10 mg)

3. Weighing pan

t Level the balance�

Removing the Display and Control Unit from Models with a Weighing Range

of 20 kg or more

Remove the weighing pan before unscrewing the control unit so that

3

t Turn over the balance so that the pan side is facing down�

t Remove the two fixing screws using a screwdriver�

t Remove the control unit and re-insert both screws into their holes�

t Carefully remove the connection cable from its holder�

y Long connection cables should only be installed by a Sartorius technician�

the weighing pan does not fall and cause injury�

24 Cubis MSE Operating Instructions

Page 25

Getting Started

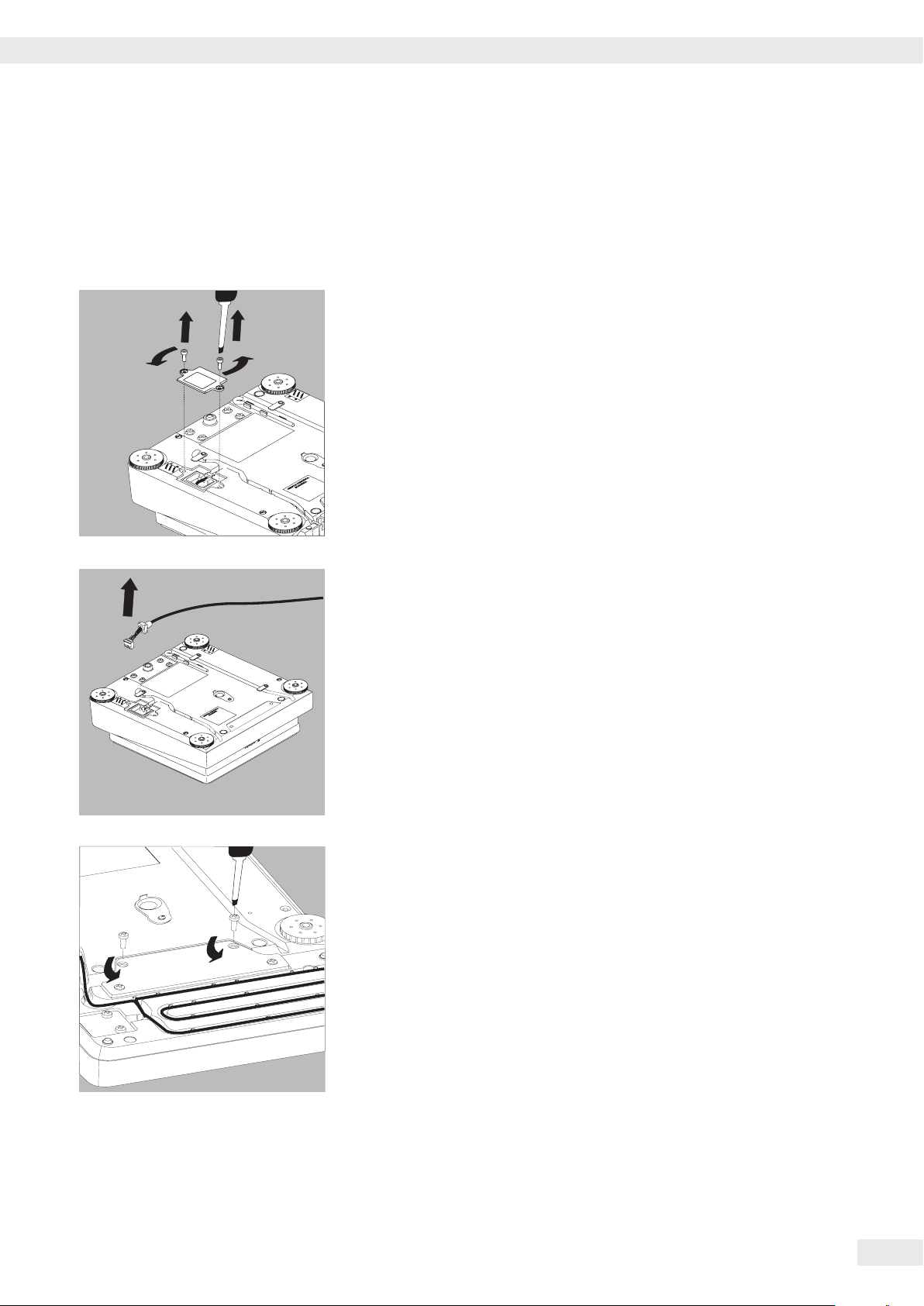

Semi-microbalances: Attaching the Display and Control Unit to the Electronics

Module (MSE225..., MSE125... models)

The display and control unit can also be attached to the electronics module if

required for operation�

t Turn over the balance and place it on a soft surface�

Remove the connection cable from the cable channel:

t Remove two screws from beneath the weigh cell and detach the plate�

t Remove the connection cable plug�

t Then reattach the plate to the slot�

t Remove the display and control unit from the weigh cell:

Remove two retaining screws�

t Remove the display and control unit�

Cubis MSE Operating Instructions 25

Page 26

Getting Started

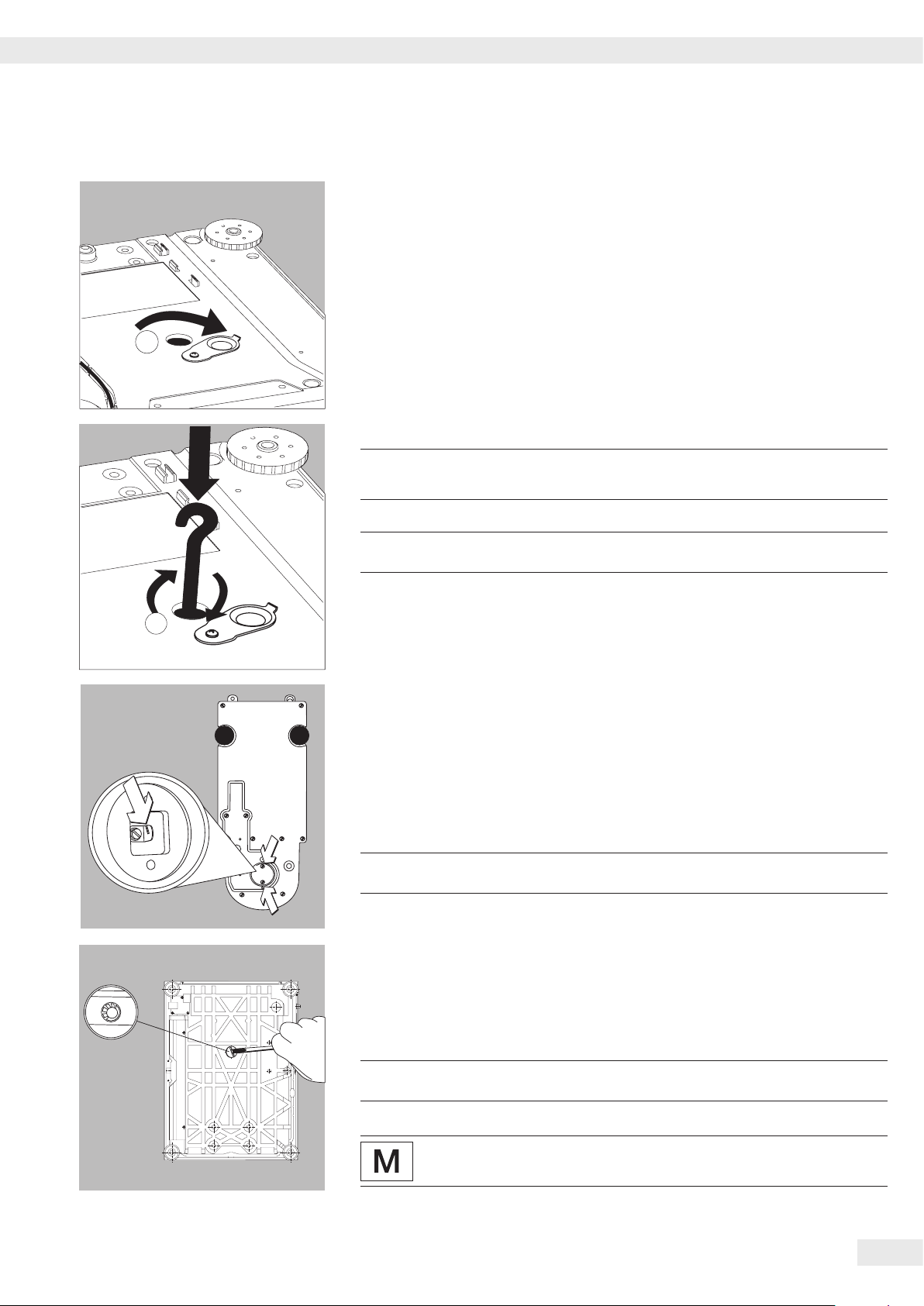

t Attach the display and control unit to the electronics module:

Reattach the two retaining screws�

Open the slot for the connection cable on the electronics module:

t Remove the screws from beneath the electronics module and detach the plate�

Connect the display and control unit to the electronics module:

t Plug in the connection cable�

t Then reattach the plate to the slot�

t Slide the cable that sticks out into the cable channel�

Preparing Below-Cell Weighing

Balances with a readability of ≥ 0,01 mg:

1

A port for a below-cell weighing hook is located on the bottom of the balance�

Analysis and Precision Balances with a Weighing Range up to 15 kg:

1. Remove the hook for below-cell weighing from the clip on the bottom of the

balance�

26 Cubis MSE Operating Instructions

Page 27

Getting Started

2. Push the cover of the below-cell weighing port to one side�

2

3. Carefully screw on the below-cell weighing hook�

Do not screw it in too tightly, as this could damage the thread

3

or the balance�

Install a draft protection shield�

h

t Attach the sample (e�g�, using a suspension wire) to the hook�

3

4. When weighing has been completed, unscrew the hook and return it to the clip�

t Close the cover of the below-cell weighing port�

Balances with a readability of ≤ 1 µg

t Remove both screws from beneath the weigh cell and detach the cover plate�

t Attach a wire, for example, to the sample and hang it on the notched hook�

Install a draft protection shield�

h

Balances with a Weighing Range of 20 kg or more:

t Use a suitable screwdriver to unscrew the cover plate from the bottom of the

balance�

t Request the hook directly from Sartorius� The hook is available as an accessory�

Install a draft protection shield�

h

The below-cell weighing port may not be opened or used on balances

used for legal metrology�

Cubis MSE Operating Instructions 27

Page 28

Getting Started

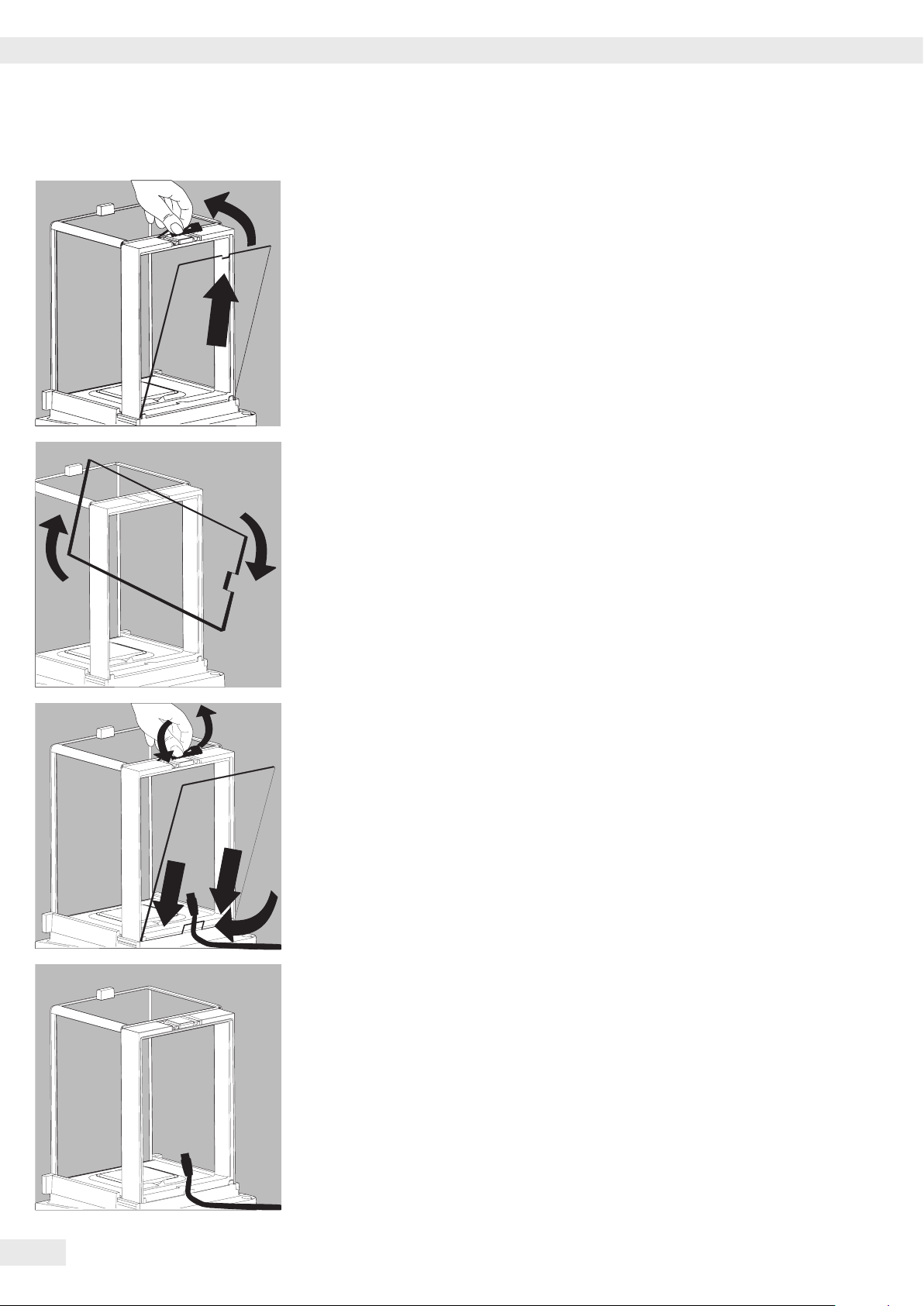

Using the Cable Opening of the

Manual Analytical Balance Draft Shield

Models with a manual analytical draft shield have an opening for passing a cable

(for example, for a temperature sensor) through to the interior of the weighing

chamber�

1. Lift the locking tab on the rear panel of the analytical draft shield�

2. Lift the panel out of the draft shield�

t Turn the panel clockwise 180° so that the opening is at the bottom�

t Install the desired sensor�

t Insert the panel in the guide rail�

t Lift the locking tab and gently press the panel into position�

t Press the locking tab down and close it�

t You can now begin weighing�

28 Cubis MSE Operating Instructions

Page 29

Operation

Operation

22

21

3

20

19

18

17

16

15

14

13

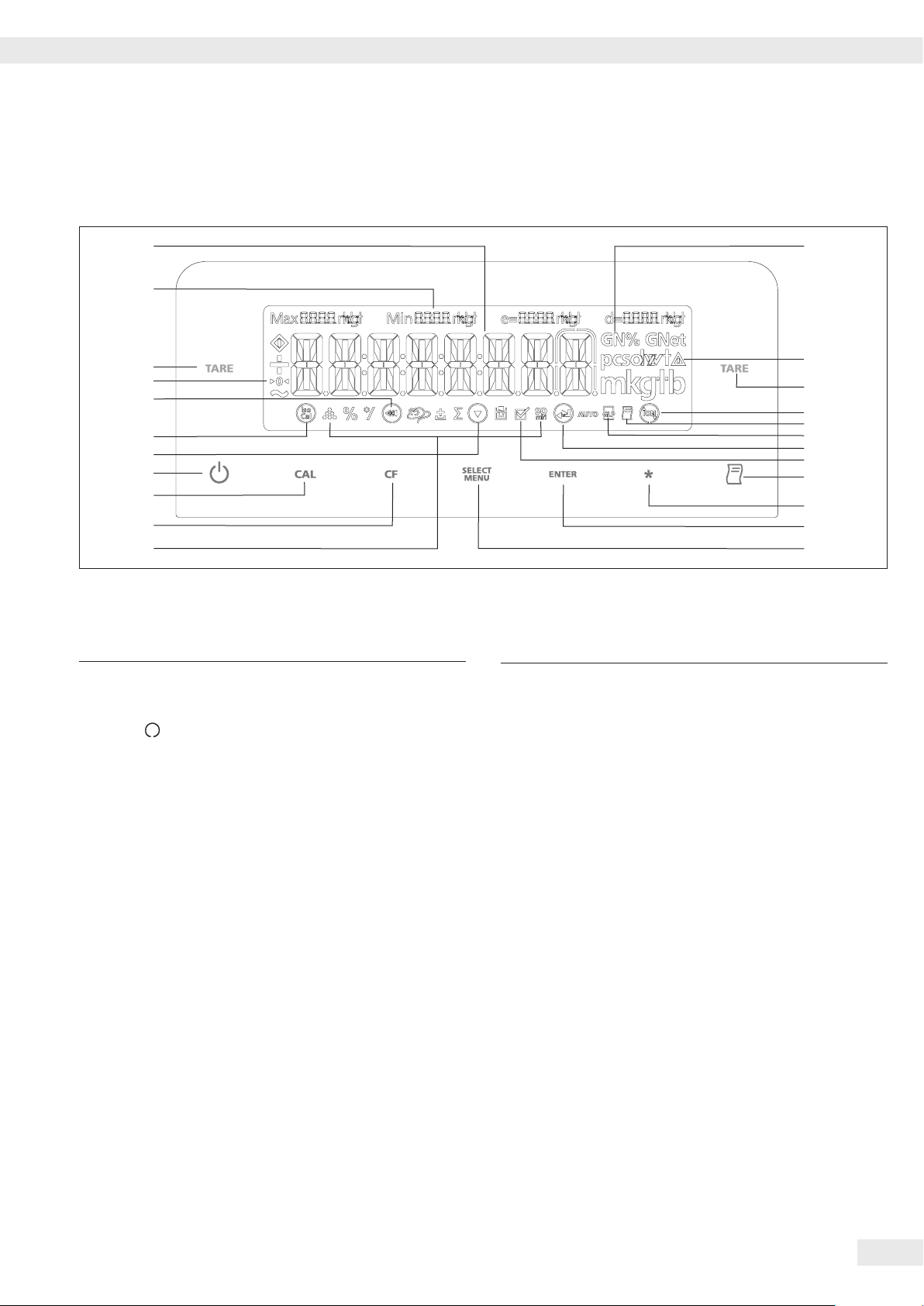

Overview of Display and Control Panel

Position Description

1 Weight units

2 Calculated-value indicator: not a weight value

3 Tare

4

5 Symbol for “Printing mode active"

6 Symbol for “GLP printing mode active"

8 Symbol for “Application program active"

9 Data output: Press this key to send readout values

10 Level balance, open/close draft shield or turn on/

11 Start an application program

12 Select an application program | Access the menu

13 Symbols for an active application

symbol flashes: Balance is not level, leveling

is required; n: open/close draft shield using key

*; m: ionizer active

to the built-in data interfaces�

off ionizer

(Z, L, V, +, /, u, o)

1

2

3

4

5

6

7

8

9

10

11

12

Position Description

14 Clear Function

This key is generally used to cancel functions:

– Quit application program

– Cancel calibration/adjustment routine |

Exit the menu

– GLP-compliant printout

15 Start the calibration process

16 On/off Key

18 Display: “isoCAL:" Calibration/adjustment function

20 Symbols for zero range (verified models only)

21 Metrological Data

22 Weight value displayed in selected weight unit

Symbol:

19 tt Exit the menu

19 t Select previous menu level

17 q Select menu item

7 u Select next item in current menu level

7↵ Confirm menu item

Cubis MSE Operating Instructions 29

Page 30

Operation

Basic Weighing Function

Features

– Tare the balance

– Print weight value

Using a verified balance in legal metrology:

The Type-Approval Certificate for verified balances is only valid for non-automatic

weighing instruments�

For automatic operation with or without additional, integrated equipment, please

follow the applicable national regulations for the installation location�

§ Before use in legal metrology, the balance should be adjusted via the internal

motorized calibration weight at the installation location:

see the “Calibration and Adjustment" section in this chapter�

$

The temperature range (°C) listed on the ID label should not be exceeded during

operation�

Example:

MSX

K

+10/+30°C

+5°C/+40°C isoCAL

Preparation

§ Turn balance on: Press the A key

§ Level the balance if required

§ Tare the balance if necessary: Press the J key

$ If necessary, change the configuration settings: see “Configuration"

$ If desired, load the factory settings: see “Configuration"

Additional functions:

$ Turn balance off: Press the A key

Quick Guide: First Weighing

Step Press key Display/Printout

1� Turn balance on A 0.0 g

Self-test runs�

Then the balance performs an automatic initial tare�

2� Place container on weighing pan (in this example : 11�5 g)� + 11.5 g

Close the draft shield (if available)�

3� Tare the balance J 0.0 g

The balance is tared and the displayed value is zero�

4� If required, open the draft shield and carefully place the sample in

the container on the weighing pan - in this example : 132 g� + 132.0 g

Close the draft shield (if available)� You can read the measured value

as soon as the weight value stops changing and the unit is displayed�

5� Print weight value P N + 132.0 g

30 Cubis MSE Operating Instructions

Page 31

Operation

Level the Balance (Q-Level)

It is essential for exact weighing results that the balance is absolutely level� The

front leveling feet can be used to level out small tilts in the floor� An integrated

sensor detects the alignment of the balance and triggers a warning message when

leveling is required� When “ " flashes on the display, you must level the balance�

Leveling with the inclination sensor:

Step Press key Display

1�

2� Fully screw in both back leveling feet

3� Directional arrow on the right of TURN:

Directional arrow on the left of TURN:

flashes on the display: flashes

Start leveling� * SCREW IN

(depends on the model) and confirm� * TURN

Turn right leveling foot� TURN

Turn left leveling foot� TURN

Directional arrow : Turn the respective leveling

foot to the right until the

directional arrow disappears�

Directional arrow : Turn the respective leveling

foot to the left until the

directional arrow disappears� SCREW OUT

4� Screw out both back leveling feet

(depends on the model) until they

touch the setup surface� * 0.0g

Leveling the balance with motorized leveling feet (optional):

t To start the leveling function, press the * key� flashes

y You can continue when the balance displays a weight value�

Each time the balance is leveled, the balance must be calibrated/adjusted

3

(see Calibrating/Adjusting the Balance)�

Turning the ionizer on/off (optional)

Purpose: The electrostatically charged weighing sample is neutralized as much as

possible in the air flow of the ionizer�

If your balance is equipped with an ionizer module, you can use the * key to

turn the ionizer on/off�

Preparation

t Set the intensity of the ionization in the menu�

Menu setting: extras: device: ionisat.: *Off, Soft intensity, Normal

intensity

or Strong intensity

AUT.LEV

Cubis MSE Operating Instructions 31

Page 32

Operation

Opening and closing the motorized draft shield (optional)

*

h

If your balance is equipped with a motorized draft shield, you can use the * key

to open and close the draft shield doors�

Models with the analytical draft shield:

The * key can be set, for example, so that it opens and closes the right and

top door (for right-handed people)� The opening width (entirely or partially) of the

sliding panels can also be defined� You can configure these settings manually on

the draft shield itself (see next section “Learning Function" below)�

Assigning Opening Functions to the * Key (Learning Function)

The balance must be turned on�

t Close all draft shield doors�

t Manually operate the door you want to assign to the * key: Push the right

door open as far as you want it to opened (entirely or partially)�

t Press the * key�

y The door will close again� Now you have configured the * key so that, when

pressed, it opens or closes the right door�

t Proceed in the same way to configure the left door�

Using the same method, you can assign the upper door to this key� You can also

configure one key to move both doors by manually opening both doors during

setup before pressing the * key�

Models with a rotation draft shield (MSx6.6S/3.6P/2.7S):

100°

t Set the opening width: manually select the desired opening angle

t 1) Open to the previously selected opening angle:

Press the * key

2) Close: Press the * key

0°

260°

180°

32 Cubis MSE Operating Instructions

Page 33

Operation

Calibration and Adjustment

Purpose

Adjustment is the correction of the difference between the measured value

displayed and the true weight of a sample, or the reduction of the difference to an

allowable level within maximum permissible error limits�

Using a verified balance in legal metrology:

Before use in legal metrology, the “internal calibration" function should be carried

out at the installation location�

Features

The adjustment procedure should only be started when

– The balance is unloaded

– The balance is tared

– The weighing signal is stable

– The sensitivity of the balance can be corrected a max� of 2%�

– Adjustment with a Sartorius density determination kit YDK… is possible�

– Balances with motorized leveling feet are leveled automatically prior to each

new calibration/adjustment (menu setting: device: extras: level: auto.)

If these settings are not made, the error message “Err 02" appears�

Adjustment can be made using different weight units:

CAL.UNIT - grams, Kilogr (not for verified models)

– You can also configure the mass comparator to perform calibration/adjustment

automatically (isoCAL), when the preset time or temperature limit has been

exceeded�

External calibration for verified balances of accuracy class K

– When the balance is used in legal metrology, external calibration is blocked

as follows:

– The menu access switch is locked

– The menu access switch cap is sealed

To block calibration/adjustment:

– Select Cal./Adj. - Blocked

– Close the menu access switch on the back of the balance

Calibration and adjustment results can be printed in an ISO/GLP-compliant

printout: settings and printout templates are listed starting on page 62�

Application parameters are deleted after calibration/adjustment�

Internal Calibration

In the operating menu, select Cal./Adj. -Cal.Int.�

The balance housing has a built-in motorized calibration weight�

§ Select Calibration/Adjustment: Press the C key

> The internal calibration weight is loaded automatically

> The balance is adjusted

> The internal calibration weight is removed

Cubis MSE Operating Instructions 33

Page 34

Operation

isoCAL*: automatic calibration and adjustment

In the operating menu, select isocal-on�

The balance will automatically display a flashing “isoCAL" character whenever the

ambient temperature has changed since the last calibration|adjustment or a time

interval has been exceeded�

The balance wants to perform an automatic adjustment�

The automatic internal calibration and adjustment prompt is activated when the

following conditions have been met

– Temperature change or time interval is higher than listed in the table below

– The load has not changed within the last 2 minutes

– The balance has not been operated within the last 2 minutes

– The load may not exceed 2% of the maximum capacity�

The following appears when the requirements are met

1� The “isoCal" symbol flashes

2� CAL�INT� appears in the measured value line

In the Setup menu, you can configure the balance so that it displays an adjustment

prompt, but does not perform the calibration and adjustment functions

automatically� (menu item NOTE)�

isoCAL is turned off on verified models:

the balance can only be used for legal-for-trade applications within a limited

temperature range�

– Balance of accuracy class k: +15°C to +25°C

– Balance of accuracy class �: +10°C to +30°C

The fully automatic adjustment function is triggered by the following criteria:

Model When the After

temperature a time

changes by interval of

MSE6�6…, MSE3�6P, MSE2�7…, MSE225S,

MSE225P, MSE125P, MSE324S,

MSE224S, MSE324P, MSE124S, MSE3203P,

MSE2203S, MSE2203P, MSE1203P 1�5 °C 4 h

MSE623S, MSE623P, MSE323S, MSE10202S,

MSE8202S, MSE6202P, MSE4202S,

MSE70201S, MSE36201S, MSE36201P,

MSE20201S, MSE70200S, MSE36200S 2 °C 6 h

MSE2202S, MSE1202P 4 °C 12 h

MSE8201S, MSE5201S 4 °C 24 h

These criteria are also set on the corresponding verified models (models

MSE…-0CE)�

34 Cubis MSE Operating Instructions

Page 35

Operation

Internal Calibration/Adjustment

Configuration:

SETUP - Bal.Scal- CAL./ADJ. - Cal.Int.

The balance housing has a built-in calibration/adjustment

weight�

§ Select Calibration/Adjustment: (CAL) key

> The internal calibration weight is automatically loaded

> The balance is calibrated

> When the setup is configured to “Calibration and

adjustment in one,” the balance will be adjusted

automatically

> The internal calibration weight is removed

Performing Calibration and Adjustment Routines

The following settings can be configured:

– Always perform calibration and adjustment in one

routine (factory setting)

– After calibration, the user has the option to quit the

routine without correction or to adjust the balance

If no deviations are found during calibration, the calibration/

adjustment routine can be exited after the calibration is

completed�

Two keys are now active:

– The (CAL) key for initiating the adjustment routine

– The (CF) key for exiting the routine

External Calibration

Configuration:

SETUP - Bal.Scal- CAL./ADJ. - Cal.Ext.

The balance has a factory-set calibration weight value (see

“Specifications”)�

Step Key Display/

Printout

1� Tare the balance J 0.0 g

2� Start the calibration process C CAL.ext.

Once you store the zero - 5000.0 g

point, the display prompts

for the required calibration

weight (flashing display)�

3� Place displayed calibration 5000.0 g

weight on balance (in this

example: 5000 g)�

Weight too low:

a minus sign “-" is shown

Weight too high:

a plus sign “+" is shown

The display stops flashing

as soon as the weight value

is within the defined limit�

Step Key Display/

Printout

1� Tare the balance J 0.0 g

2� Start the calibration process C CAL.Int.

Internal weight is CAL.RUN.

applied automatically

3� Calibration/Adjustment CAL.end

executed

4� The internal weight is

removed 0.0 g

4� Calibration/Adjustment Cal.end

executed; then the calibration

weight value is displayed +5000.0 g

5� Remove calibration weight 0.0 g

Cubis MSE Operating Instructions 35

Page 36

Configuration (Operating Menu)

Configuration (Operating Menu)

You can configure the balance; i�e�, adapt it to individual requirements�

Functions of the Keys in the Menu:

Symbol displayed Key Function

q S Scroll through menu items

u V Select next item on current menu level

(use right cursor to scroll through up to

4menu levels)

↵ V Confirm menu item

F (Press Save settings and exit menu from

and hold) any position

tt F Save settings and exit menu

t F Select previous menu level (left cursor)

2. 3. 1. 1 Indicates menu level

Menu Navigation

Example: Setting the Language

Step Press key Display/Printout

1� Open the menu: S Hold Applic.

Display the 1st menu item

in the weighing mode

2� Scroll upward within the Press repeatedly Input

menu level; S ���

After the last menu code, the first

code is displayed again (scroll) language

3� Select next menu level Press repeatedly english

(scrolls to the right) V

5� Change setting: S English

Select the menu item by

scrolling up

6� Confirm setting; V English

“o” indicates the menu item

you have set

o

o

36 Cubis MSE Operating Instructions

7� Go back to the previous menu F Language

level (from menu level 4)

$ If required, select further menu items S, V

8� Save setting Press repeatedly

and exit the menu F

> Restart your application 0.0 g

Page 37

Configuration (Operating Menu)

Menu Structure (Overview)

Level 1 Level 2 Level 3 Info about Menu Level

1) Setup Bal.Scal. Ambientconditions 1� 1� 1�

Balance parameters App.Filt. Application filter 1� 1� 2�

Stab.Rng. Stability range 1� 1� 3�

STABILDLY� Stability delay 1� 1� 4�

Tare

AutoZer. Auto zero 1� 1� 6�

Wt.Unit Basic weight unit 1� 1� 7�

DISP.DIG. Display accuracy

Cal./ADJ. Function of the C key 1� 1� 9�

Cal.routine 1� 1� 10�

Zero rng. Zero range 1� 1� 11�

INIT.ZERO Zero at Power On 1� 1� 12�

ON TARE Tare/zero at Power On 1� 1� 13�

CYC.rate Output rate 1� 1� 14�

ISOCAL Autom� calibration/adjustment 1� 1� 15�

EXT.Cal. External adjustment 1� 1� 16�

Cal.Unit Weight unit for calibration

GEN.SERV. General Service MEN.RESET Factory settings 1� 9� 1�

2) DEVICE extras Menu Menu read only/can edit 2� 1� 1�

(Additional functions) Signal Acoustic Signal 2� 1� 2�

Keys (Keypad) 2� 1� 3�

Ext.Key External switch function 2� 1� 4�

On Mode Power-on mode 2� 1� 6�

DR.SHIELD 2� 1� 9�

RE.DR.SH Resolution, draft shield open 2� 1� 10�

IONIZER 2� 1� 11�

LEVEL 2� 1� 12�

LEVELING 2� 1� 13�

PERIPHER. DAT.REC. Communication mode 2� 2� 1�/2� 3� 1�

(25-pin “Peripherals” interface) Baudrate 2� 2� 2�/2� 3� 2�

parity Parity 2� 2� 3�/2� 3� 3�

pc-usb (USB port “PC”) Stopbit Number of stop bits 2� 2� 4�/2� 3� 4�

Handshk. Handshake mode 2� 2� 5�/2� 3� 5�

Databit Number of data bits 2� 2� 6�/2� 3� 6�

3) DATA OUT COM.SBI Communications output 3� 1� 1�

(data output (PC communication) Stop automatic output 3� 1� 2�

Aut.Cycl. Time-dependent automatic data output 3� 1� 3�

Format (Line format) 3� 1� 4�

Auto.Tare Autom� taring after data output 3� 1� 5�

PRINT.PARA for printing RES.olution (manual/automatic) 3� 2� 1�

Format Line format for printout 3� 2� 2�

Prt.Init. Printout of appl� parameters 3� 2� 3�

GLP ISO/GLP-compliant printout 3� 2� 4�

tar./prt. Tare bal�/scale after ind� print 3� 2� 5�

time: 12h/24h 3� 2� 6�

date format 3� 2� 7�

4) Applic. Application programs Weigh 4� 1�

Unit Toggle 4� 2�

Counting resolut. 4� 3� 1�

Ref.Updt.Automatic Reference updating 4� 3� 2�

percentweighing Dec.Plcs Decimal places 4� 4� 1�

net.tot. Net total Comp.Prt. Printout of components 4� 5� 1�

Total Totalizing Comp.Prt. Printout of components 4� 6� 1�

AnimalW. Animal weighing Activty. Animal activity 4� 7� 1�

start 4� 7� 2�

Calc. Calculation Method (Operator) 4� 8� 1�

Dec.Plcs Decimal places 4� 8� 2�

Density determination Dec.Plcs Decimal places 4� 9� 1�

5) Input Input ID. ID input; max� 7 characters 5� 1�

Date Set date 5� 2�

Time Set time 5� 3�

password Password entry (for Service) 5� 4�

Cal.wt.. Enter weight value 5� 5�

6) InFoInformation Version, Ser. nr. , model,

lobs, kdc vers, DR.Shield, if OPT�MOD

7) Language English (factory setting) 7� 1�

(Language) Deutsch (German) 7� 2�

franc.çais (French) 7� 3�

ital.iano (Italian) 7� 4�

Espanol (Spanish) 7� 5�

Polski (Polish) 7� 7�

(Russian) 7� 6�

8) opt.MOD (optional interface) 8� 1� to 8� 6�

1

) Not available on balances verified for use in legal metrology

1

) 1� 1� 5�

1

) 1� 1� 8�

1

) 1� 1� 17�

Display software version, serial no�, model

6� 1� to 6� 6�

Cubis MSE Operating Instructions 37

Page 38

Configuration (Operating Menu)

Parameter Settings: Overview

ο = Factory setting√ = User-defined setting

Info about

Level 1 Level 2 Level 3 Level 4 Menu Level

1) Setup BAL.SCAL. AMBIENT conditions (adapt filter) V.Stable Very stable 1� 1�1� 1

Balance ο STABLE 1� 1�1� 2

parameters UNSTABL 1� 1�1� 3

V.UNSTBL. Very unstable 1� 1�1� 4

App.Filt. Application filter ο FINAL.RD. Final readout mode 1� 1�2� 1

Filling Filling mode 1� 1�2� 2

REDUC. Reduced 1� 1�2� 3

OFF 1� 1�2� 4

Stab.Rng. Stability range Max. ACC. Maximum accuracy 1� 1�3� 1

V.ACC. 1� 1�3� 2

ο ACC. 1� 1�3� 3

FAST 1� 1�3� 4

V.FAST. 1� 1�3� 5

Max.FAST

ST.DEL� Delay No 1� 1�4� 1

ο Short 1� 1�4� 2

AVERG. 1� 1�4� 3

LONG 1� 1�4� 4

Tare

ο WISTB.After stability 1� 1�5� 2

ATSTAB. At stability 1� 1�5� 3

Aut.zero Off 1� 1�6� 1

Auto zero ο on 1� 1� 6� 2

WT.UNIT For list of units, see 1� 1�7� 1

Basic weight unit “Toggling Between Weight Units” to

1� 1�7�24

DISP.DIG.

Display accuracy lp.on.off (last digit after load change) 1� 1�8� 2

DIV.1 1 interval 1� 1�8� 6

Minus 1 Reduced by 1 digit 1� 1� 8� 7

Cal./ADJ. EXT.CAL. External calibration with standard weight

Function of C key e.cal.usr. External calibr�/adjustment with user-defined weight

ο Cal.Int. Internal calibration 1� 1�9� 4

Int.lin. Internal linearization (on analytical balances only) 1� 1�9� 5

Set.Prel. Setting the Preload 1� 1�9� 8

Del.Prel. Clearing the Preload 1� 1�9� 9

blocked C Blocked 1� 1�9�10

Select 1� 1�9�12

set.ext.w. Determine ext� calibration weight for e.cal.usr. 1� 1�9�17

Cal.adj.ON ο Sequence adjustment 1� 1�10� 1

CAL.ADJ. Adjustment as needed 1� 1�10� 2

Zero rng. Zero range 1 perc.ent 1� 1�11� 1

ο 2 perc.ent 1� 1�11� 2

INIT.ZERO Zero at Power On ο default Factory setting 1� 1�12� 1

2 perc.ent 1� 1�12� 2

On Tare Tare/zero at power on ο ON 1� 1�13� 1

OFF 1� 1�13� 2

CYC.rate Output rate ο normal 1� 1�14� 1

highvar. 1� 1�14� 2

slow 1� 1�14� 3

medium 1� 1�14� 4

fast 1� 1�14� 5

veryfast 1� 1�14� 6

maximum 1� 1�14� 7

ISOcal Autom� calibration/adjustment Off 1� 1�15� 1

Note 1� 1�15� 2

ο On 1� 1�15� 3

To.w.linearization (for analytical balances only) 1� 1�15� 4

EXT.Cal. External calibration

Locked (blocked) 1� 1�16� 2

cal.unit

for calibration weight Kilogr. Kilograms 1� 1�17� 2

USERDEF. (factory setting: pound) 1� 1�17� 4

GEN.SERV. men.Reset Menu reset Yes Restore fcty� settings 1� 9� 1� 1

General servicing (Factory Settings) ο no Do not restore settings 1� 9� 1� 2

Standard

Verifiable

38 Cubis MSE Operating Instructions

1

) WIOSTB.W/o stability 1� 1�5� 1

1

) ο All 1� 1�8� 1

1

) ο Free 1� 1�16� 1

1

) ο Gram 1� 1�17� 1

1

) 1� 1�3� 6

2

) 1� 1�9� 1

1

) 1� 9� 1� 3

1

) 1� 9� 1� 4

1

) Not available on balances verified for use in legal metrology

2

) Not available on balances for use in legal metrology of accuracy class K

2

) 1� 1�9� 3

Page 39

Configuration (Operating Menu)

Level 1 Level 2 Level 3 Level 4 Info about Menu Level

2) device extras menu CAN EDIT 2� 1� 1� 1

(Additional Rd. Only Read only 2� 1� 1� 2

functions)

Signal Acoustic Signal off 2� 1� 2� 1

ο on 2� 1� 2� 2

Keys (Keypad) ο Free 2� 1� 3� 1

Locked 2� 1� 3� 2

ext.key ο Print key P 2� 1� 4� 1

External switch function Z/Tara key J 2� 1� 4� 2

cal. key C 2� 1� 4� 3

cf key F 2� 1� 4� 5

enter key V 2� 1� 4� 6

DR.SHIELD 2� 1� 4� 9

Ionizer 2� 1� 4� 10

appl. key 2� 1� 4� 11

Asterisk key * 2� 1� 4� 12

on mode ο off/on/sb off/on/standby 2� 1� 6� 1

Power-on mode off/on/so off/on/autom� shut-off 2� 1� 6� 2

on/sb On/Standby 2� 1� 6� 3

Auto On Auto on 2� 1� 6� 4

DR.SHIELD ο Off 2� 1� 9� 1

on/ion: Ionizer is turned on

when closing the draft shield 2� 1� 9� 2

Cl/Co: Close →Execute command 2� 1� 9� 3

Locked (blocked) 2� 1� 9� 4

Locked (blocked) 2� 1� 9� 5

Res.dr.sh (Weight ο All All decimal places 2� 1�10� 1

resolution when door is open) REDUC.ed 2� 1�10� 2

IONIZER ο Off 2� 1�11� 1

Intensity Weak 2� 1�11� 2

Medium 2� 1�11� 3

Strong 2� 1�11� 4

Level Off 2� 1�12� 1

ο Note to 2� 1�12� 2

Err.msg. Error message 2� 1�12� 3

LEVELING ο key (manual start) 2� 1�13� 1

auto. Auto� before cali�/adjustment 2� 1�13� 2

Periphery:/PC USB:

peripher Dat.rec. # SBI (ASCII) 1) 2� 2� 1� 1 / 2� 3� 1� 1

Uni.print.

pc-usb ο lab.print

(25-pin “Peripherals”

interface)

Rem.displ. 2� 2� 1� 4 / 2� 3� 1� 4

(USB port “PC”)

OFF 2� 2� 1�10 / 2� 3� 1�10

Operating mode XBPI 2� 2� 1� 2 / 2� 3� 1� 2

Universal printer

(parameters for YDP10 printer)

2� 2� 1� 7 / 2� 3� 1� 7

2� 2� 1� 8 / 2� 3� 1� 8

Baudrate 600 2� 2� 2� 3 / 2� 3� 2� 3

1200 2� 2� 2� 4 / 2� 3� 2� 4

2400 2� 2� 2� 5 / 2� 3� 2� 5

4800 2� 2� 2� 6 / 2� 3� 2� 6

ο 9600 2� 2� 2� 7 / 2� 3� 2� 7

19200 2� 2� 2� 8 / 2� 3� 2� 8

38400 2� 2� 2� 9 / 2� 3� 2� 9

57600 2� 2� 2�10 / 2� 3� 2�10

115200 2� 2� 2�11 / 2� 3� 2�11

1

) Note concerning verified balances/scales as legal measuring instruments in the EU*: In the “SBI” setting, the non-verified display digit is not automatically

identified�

Please take the corresponding measures or adjust the settings on the peripheral device (see also “Interfaces”)�

Cubis MSE Operating Instructions 39

Page 40

Configuration (Operating Menu)

Info about

Level 1 Level 2 Level 3 Level 4 Menu Level

Periphery:/PC USB:

2) device peripher Parity ο Odd 2� 2� 3� 3 / 2� 3� 3� 3

pc-usb Parity Even 2� 2� 3� 4 / 2� 3� 3� 4

None 2� 2� 3� 5 / 2� 3� 3� 5

StopBit ο 1 Stop 2� 2� 4� 1 / 2� 3� 4� 1

Numberofstopbits 2 bits 2� 2� 4� 2 / 2� 3� 4� 2

Handshk. Softw.are 2� 2� 5� 1 / 2� 3� 5� 1

Handshake mode ο Hardw.are 2� 2� 5� 2 / 2� 3� 5� 2

# None 2� 2� 5� 3 / 2� 3� 5� 3

DataBit 7 Bits 2� 2� 6� 1 / 2� 3� 6� 1

Numberofdatabits ο 8 Bits 2� 2� 6� 2 / 2� 3� 6� 2

3) data out comm.SBI COM. Output ο IN.WIO Stability 3� 1� 1� 1

(data (computer (manual/automatic) IN.AFTER Stability 3� 1� 1� 2

output) communication) IN.AT Stability 3� 1� 1� 3

Auto.WIO Auto w/o stability 3� 1� 1� 4

Aut.With Stability 3� 1� 1� 5

Stop ο Off 3� 1� 2� 1

Auto output on 3� 1� 2� 2

Auto.CYCL. ο Every 3� 1� 3� 1

Time-dependent automatic data output 2ndValue 3� 1� 3� 2

Format (Line format) 16 chars (digit is not identified) 3� 1� 4� 1

ο 22 chars (digit is identified) 3� 1� 4� 2

Extr.line (date, time and weight value) 3� 1� 4� 4

Auto.tare ο Off 3� 1� 5� 1

Autom� taring after data output on 3� 1� 5� 2

PRINT.PARA RES. Manual without Stability 3� 2� 1� 1

for printing (manual/autom�) ο man.after. Stability 3� 2� 1� 2

man.at Stability 3� 2� 1� 3

auto.lc (autom� at load change) 3� 2� 1� 6

Format Line format 16 chars (digit is not identified) 3� 2� 2� 1

for printout ο 22 chars (digit is identified) 3� 2� 2� 2

Extr.line (date, time and weight value) 3� 2� 2� 4

Prt.Init.

application parameters ο all Parameters 3� 2� 3� 2

mainpar. Main parameters 3� 2� 3� 3

GLP ISO/GLP-compliant printout ο Off 3� 2� 4� 1

cal.adj. For calibration/adjustment only 3� 2� 4� 2

Always on 3� 2� 4� 3

Printout

of off 3� 2� 3� 1

tar./prt. ο off 3� 2� 5� 1

Tare bal�/scale after ind� print on 3� 2� 5� 2

Time ο 24h display 3� 2� 6� 1

12h display “AM/PM” 3� 2� 6� 2

Date ο dd.mmm.yy format 3� 2� 7� 1

mmm.dd.yy format 3� 2� 7� 2

# = Factory setting for “PC-USB” interface

40 Cubis MSE Operating Instructions

Page 41

Configuration (Operating Menu)

Info for

Level 1 Level 2 Level 3 Level 4 Menu level

4) App- WEIGH. 4� 1�

lic. Unit Toggle 4� 2�

Application

programs

Counting resolut. ο Disp.dig. Display accuracy 4� 3� 1� 1

10 fold 10 times > disp� 4� 3� 1� 2

100 fold 10 times > disp� 4� 3� 1� 3

Ref.Updt. Auto� ο off 4� 3� 2� 1

Reference updating autom.atically 4� 3� 2� 2

percent dec.plcs. None No decimal places 4� 4� 1� 1

Weighing Decimal places ο 1 dec.pl. 1 decimal place 4� 4� 1� 2

in Percent 2 Dec.Pl. 2 decimal places 4� 4� 1� 3

3 Dec.Pl. 3 decimal places 4� 4� 1� 4

net.tot. comp.prt. off 4� 5� 1� 1

Net-total Component printout ο On 4� 5� 1� 2

Formulation

Total comp.prt. off 4� 6� 1� 1

Totalizing Component printout ο On 4� 6� 1� 2

AnimalW. activty. calm (fluct�: 2% of test obj�) 4� 7� 1� 1

Animal Animal activity ο active (fluct�: 5% of test obj�) 4� 7� 1� 2

Weighing v.active (fluct�: 20% of test obj�) 4� 7� 1� 3

start manual 4� 7� 2� 1

ο auto 4� 7� 2� 2

Calc. Method (Operator) ο Mul. Multiplier 4� 8� 1� 1

Calculation div. Divisor 4� 8� 1� 2

Dec.plcs none No decimal places 4� 8� 2� 1

Decimal places ο 1 dec.pl. 1 decimal place 4� 8� 2� 2

2 Dec.Pl. 2 decimal places 4� 8� 2� 3

3 Dec.Pl. 3 decimal places 4� 8� 2� 4

Density dec.plcs none No decimal places 4� 9� 1� 1

determination Decimal places ο 1 dec.pl. 1 decimal place 4� 9� 1� 2

2 Dec.Pl. 2 decimal places 4� 9� 1� 3

3 Dec.Pl. 3 decimal places 4� 9� 1� 4

1

) Not available on balances verified for use in legal metrology

Cubis MSE Operating Instructions 41

Page 42

Configuration (Operating Menu)

Input: ID number, date and time

Info about

Level 1 Level 2 Level 3 Menu Level

5) Input ID. ID input, max� 7 characters 5� 1�

Input Possible characters: 0-9, A-Z,

dash|hyphen and space

DATE Set date 5� 2�

Time Set time 5� 3�

password Password entry (for Service) 5� 4�

cal.wt. Enter weight value 5� 5�

Depending on the setting of the “Print PRINT�PARA – DATE” menu item, the date

is displayed in the following format:

Format Display: Date

DD�MMM�YY

MMM�DD�YY

Depending on the setting of the “Print PRINT�PARA – TIME” menu item, the time is

displayed in the following format:

Time Display: Time

24h mode

12h mode

42 Cubis MSE Operating Instructions

Page 43

Configuration (Operating Menu)

Level 1 Level 2 Level 3 Level 4 Info about Menu Level

Device-specific information

6) InFo Ver. no. Displays the software version 00-39-13 6� 1�

Info

Ser. no. Displays the serial number 10801234 6� 2�

(to toggle between the upper/lower part of the display:

press the S key)

Model Displays the model ID mse8201s 6� 3�

(to toggle between the upper, middle and lower part of the display:

Press the S key)

lobs Displays the software version Rel.19.03 6�4�1�

kDc vers Displays the software version Rel.10.02 6�6�1�

DR.SHIELD Displays the software version 00-00-00 6�6�1�

Menu display: Selecting languages or codes

7)

Language

(Language) Deutsch (German) 7� 2�

franc.çais (French) 7� 3�

ital.iano (Italian) 7� 4�

Espanol (Spanish) 7� 5�

(Russian) 7� 6�

Polski (Polish) 7� 7�

English (factory setting) 7� 1�

Interface Options

8) opt.MOD: Dat.rec. SBI (ASCII) 1) 8� 1� 1

9-pin or 25-pin interface Operating mode uni.print universal printer 8� 1� 7

ο lab.print (: parameters for YDP10 printer) 8� 1� 8

OFF 8� 1�10

Baudrate 1200 8� 2� 3

2400 8� 2� 5

4800 8� 2� 6

ο 9600 8� 2� 7

19200 8� 2� 8

38400 8� 2� 9

57600 8� 2�10

115200 8� 2�11

Parity ο Odd 2� 3� 1

Parity Even 2� 3� 2

None 2� 3� 3

StopBit ο 1 Stop 2� 4� 1

Numberofstopbits 2 Bits 2� 4� 2

Handshk. Softw.are 2� 5� 1

Handshake mode ο Hardw.are 2� 5� 2

None 2� 5� 3

DataBit 7 Bits 2� 6� 1

Numberofdatabits ο 8 Bits 2� 6� 2

or

8) opt.MOD: Dat.rec. SBI (ASCII) 1) 8� 1� 1

Bluetooth Operating mode uni.print universal printer 8� 1� 2

ο lab.print (: parameters for YDP10 BT printer) 8� 1� 3

OFF 8� 1� 4

Find 8� 2�

ser. no. 10801234 8� 3� 1

(serial number)

Model YDP10BT 8� 4� 1

(e� g� printer ID)

1

) Note concerning verified balances/scales as legal measuring instruments in the EU*: In the “SBI” setting, the non-verified display digit is not automatically

identified�

Please take the corresponding measures or adjust the settings on the peripheral device (see also “Interfaces”)�

Cubis MSE Operating Instructions 43

Page 44

Configuration (Operating Menu)

Setting the ID number, date and time

Step Press key Display

1� Starting the Menu: S Hold Applic.

1� Display menu level

2� Select “Input” S Input

ID no.:

3� Select input for ID 2x V ID.

4� Set or change ID number – S 3-------

With auto key repeat: S Press and hold

5� Moving within the 7-digit number V or 3-aBC12

Move ID no� F

6� Save at the V ID.

last position of the ID no�

Date:

7� Select and confirm “Date” S, V 08.feb.09

8� Change setting – S 10.feb.09

With auto key repeat: S Press and hold

9� Change position between V or 10.feb.09

the day/month/year

10� Save setting at “Year” position V date

Time:

11� Select “Time” S, V 10.46.23

12� Change setting – S 11.46.23

With auto key repeat: S Press and hold

13� Change position between V or 11.46.32

hour/minute/second

14� Set seconds to “zero” S 11.47.00

44 Cubis MSE Operating Instructions

15� Save setting at “Second” position V time

16� Save settings and exit menu Press repeatedly

F

> Restart your application 0.0 g

Page 45

Application Programs

Application Programs

All application programs can be selected on models

verified for use in legal metrology�

Verified values can be marked using the following

characters:

– Percent = %

– Piece count (Counting) = pcs

– Computed values = o, G

Density Determination

Display symbol: u

Purpose

This application program can be used to determine the

density of solid materials according to the buoyancy method�

Features

The density of liquid (g/cm3) can be set for a corresponding

temperature via the S key� See the next page for a table

on water density values� Factory setting is 1 g/cm3�

The following formula is used:

Density of sample =

Weight in air

————————————————————————

(weight in air – weight in water)

The liquid density is displayed briefly when you start the

density calculation�

Positive and negative weight values can be applied for the

sample in the air and water� The value in water, however,

must be less than the value in the air; otherwise, this will

trigger an error message�

The results can be displayed with 0 to 3 decimal places:

See the chapter entitled “Configuration�” Not part

of the scope of delivery: sample holder and suspension

wire�

Preparation

§ Select the “Density Determination” application in the

menu:

See “Configuration”

§ Configuring parameters:

•Density of liquid

Applic. Application programs

Density Density determination

DEC.PLCS Number of decimal places

none No dec� places

o 1 dec pl. 1 decimal place

2 dec pl. 2 decimal places

3 dec pl. 3 decimal places

Note on using 3 decimal places:

Using three decimal places for density can result in a high

measurement error rate because corrections to the air density

and the density calculation sets are not taken into account,

for example�

o= Factory settings

Cubis MSE Operating Instructions 45

Page 46

Application Programs

Density determination printout

RhoFl 0.99823 o : Liquid density (g/cm3)

Wa + 20.0 g : Weight in air

Wfl + 15.0 g : Weight in liquid

Rho 4.0 o : Result: Density of sample

Table:

Density values of H2O at temperature T (in °C)

T/°C 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

10. 0�99973 0�99972 0�99971 0�99970 0�99969 0�99968 0�99967 0�99966 0�99965 0�99964

11. 0�99963 0�99962 0�99961 0�99960 0�99959 0�99958 0�99957 0�99956 0�99955 0�99954

12. 0�99953 0�99951 0�99950 0�99949 0�99948 0�99947 0�99946 0�99944 0�99943 0�99942

13. 0�99941 0�99939 0�99938 0�99937 0�99935 0�99934 0�99933 0�99931 0�99930 0�99929

14. 0�99927 0�99926 0�99924 0�99923 0�99922 0�99920 0�99919 0�99917 0�99916 0�99914

15. 0�99913 0�99911 0�99910 0�99908 0�99907 0�99905 0�99904 0�99902 0�99900 0�99899

16. 0�99897 0�99896 0�99894 0�99892 0�99891 0�99889 0�99887 0�99885 0�99884 0�99882

17. 0�99880 0�99879 0�99877 0�99875 0�99873 0�99871 0�99870 0�99868 0�99866 0�99864

18. 0�99862 0�99860 0�99859 0�99857 0�99855 0�99853 0�99851 0�99849 0�99847 0�99845

19. 0�99843 0�99841 0�99839 0�99837 0�99835 0�99833 0�99831 0�99829 0�99827 0�99825

20. 0�99823 0�99821 0�99819 0�99817 0�99815 0�99813 0�99811 0�99808 0�99806 0�99804

21. 0�99802 0�99800 0�99798 0�99795 0�99793 0�99791 0�99789 0�99786 0�99784 0�99782

22. 0�99780 0�99777 0�99775 0�99773 0�99771 0�99768 0�99766 0�99764 0�99761 0�99759

23. 0�99756 0�99754 0�99752 0�99749 0�99747 0�99744 0�99742 0�99740 0�99737 0�99735

24. 0�99732 0�99730 0�99727 0�99725 0�99722 0�99720 0�99717 0�99715 0�99712 0�99710

25. 0�99707 0�99704 0�99702 0�99699 0�99697 0�99694 0�99691 0�99689 0�99686 0�99684

26. 0�99681 0�99678 0�99676 0�99673 0�99670 0�99668 0�99665 0�99662 0�99659 0�99657

27. 0�99654 0�99651 0�99648 0�99646 0�99643 0�99640 0�99637 0�99634 0�99632 0�99629

28. 0�99626 0�99623 0�99620 0�99617 0�99614 0�99612 0�99609 0�99606 0�99603 0�99600

29. 0�99597 0�99594 0�99591 0�99588 0�99585 0�99582 0�99579 0�99576 0�99573 0�99570

30. 0�99567 0�99564 0�99561 0�99558 0�99555 0�99552 0�99549 0�99546 0�99543 0�99540

46 Cubis MSE Operating Instructions

Page 47

Application Programs

Parameter configuration: Applic. - Density - dec.plcs. -1 dec.pl.

Example: Determining the density of a solid sample� The density at 20�0 degrees Celsius is 0�99823 g/cm3�

Step Press key Display/Printout

1� Attach sample holder and suspension wire

2� Tare the balance J 0.0 g

3� Change density of buoyancy liquid S _1.00000

4� Set density value (in this example: 0�99823)

Enter numerals in increments of 1 or: Repeatedly press S, press

and hold the V key _0.99823

5� Set the density value and start the application� V

The current density value will be saved in protected

memory until the setting is changed�

6� Confirm “air” display V air

7� Determining the weight of the sample in air:

Place sample on the balance + 20.0 g

8� Save weight in air V

9� Remove sample from the balance water

10� Determining weight value in liquid:

Place sample in basket

11� Confirm “water” display V 0.0 g

12� Place sample in liquid + 15.0 g

13� Save weight value in liquid, display and print results V

+ 4.0

o

RhoFl 0.99823 o

Wa + 20.0 g

Wfl + 15.0 g

14� Delete results F Rho 4.0 o

15� Repeat as needed, starting from Step 5

Cubis MSE Operating Instructions 47

Page 48

Application Programs

Counting

Display symbol: Z

Purpose

With the Counting application, you can determine the

number of parts which each have approximately equal

weight� First the weight of a manually-determined number

of parts is calculated and then the individual weight is

determined from this (reference)�

The total number of the unknown number of parts is then