Page 1

Sartorius Micro

M 500 P

Installation and Operating Instructions

98648-000-73

Page 2

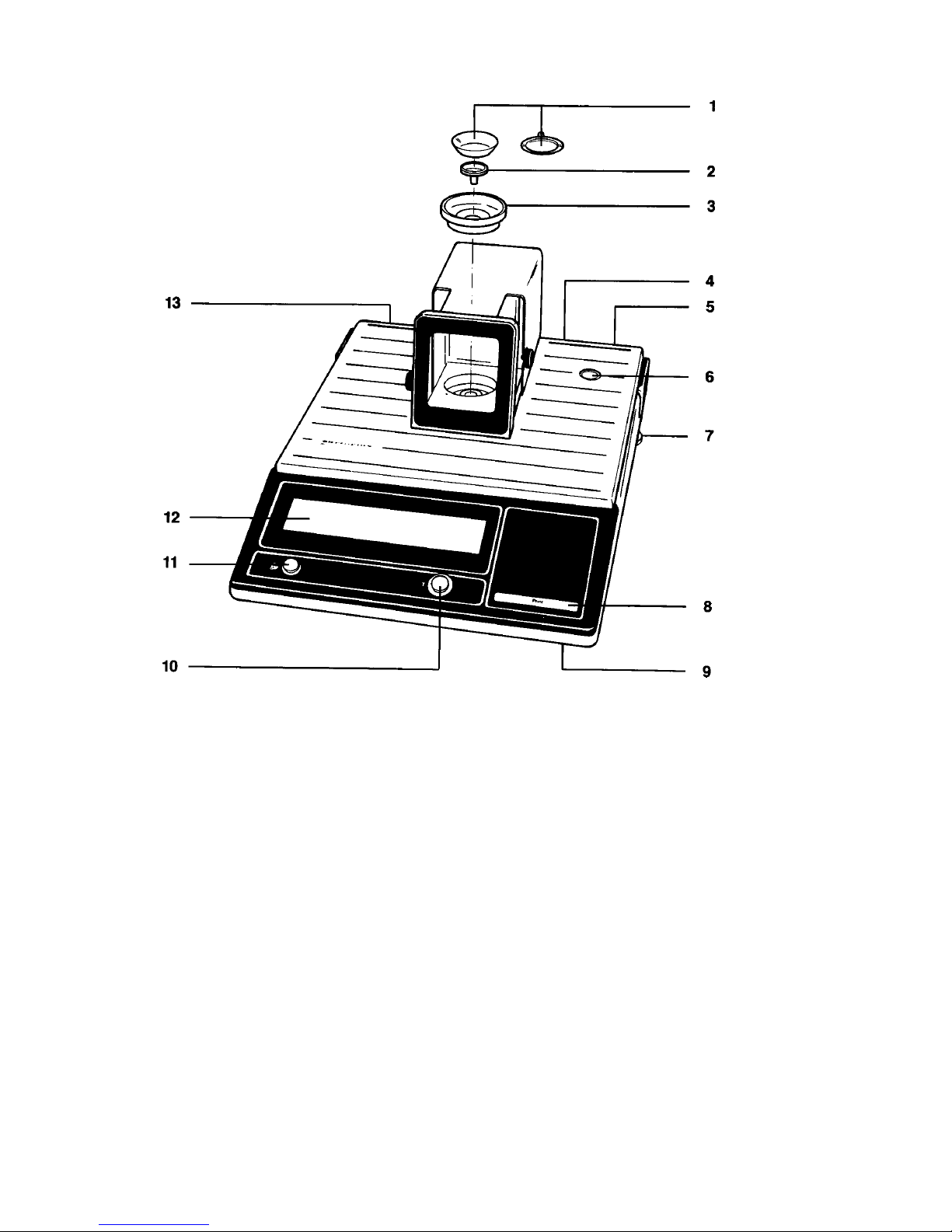

2

1

Weighing pans

2

Pan support

3

Interior draft shield

4

Interface

5

Power receptacle

6

Level indicator

7

Leveling foot

8

Print control

9

Menu access switch

10

Tare control

11

ON/OFF button

12

Weight display

13

Manufacturer's label

Page 3

3

Contents

Page

About the Product

(Warranty) 4

Storage and Shipping Conditions 5

Equipment Supplied

6

How to Handle Your Microbalance

7

Installation Instructions

8

Ambient Conditions 8

Connecting Electronic Devices (Peripherals) 8

Startup

9

Connecting the Balance to Line Power 9

Voltage Selection 9

Safety Precautions 11

Leveling the Balance using the Level Indicator 11

Operation

12

Weight Display 12

Turning the Display On and Off 13

Self-Test 13

Weighing 13

Taring 13

Calibration

14

Balance Operating Program

15

How to Access the Menu of the

Balance Operating Program 15

How to Read a Program Menu Code (List Mode) 15

How to Change a Program Menu Code

(Change Mode) 16

Menu of the Balance Operating Program 17

Troubleshooting Guide

18

Accessories

19

Care and Maintenance

20

Cleaning 20

Safety Inspection 20

Data Interface

21

Specifications

22

Page 4

4

About the Product (Warranty)

With this Sartorius Balance you have acquired a high-quality

electronic weighing Instrument that will ease your daily workload.

Please read these Installation and operating instructions carefully before operating your new balance.

Pursuant to the German Directive for the Implementation

of Regulations for Prevention of Accidents "Elektrische

Anlagen und Betriebsmittel (VBG 4)" [Electrical

Installations and Equipment] of April 1986, it is hereby

certified that the equipment delivered, "Electronic

Microbalance, model M 500 P," is manufactured and

tested in compliance with the following DIN/VDE

regulations

DIN IEC 348/VDE 0411 Safety requirements for

electronic measuring apparatus

DIN IEC 380/VDE 0806 Safety of

electrically energized Office

machines

DIN IEC 601/VDE 0750 Safety of medical electrical

equipment

and Article 10 of the Low Voltage Directive (73/23/EEC)

issued on February 19, 1973 by the European

Community. When you use electrical equipment in

installations and under ambient conditions requiring

higher safety Standards, you must comply with the

provisions as specified in the applicable regulations for

installation in your country.

Page 5

5

Storage and Shipping Conditions

Allowable storage temperature range: -40°C...+70°C

-40°F... 158°F

The packaging of the balance has been designed to ensure that

the balance will not be damaged even if it is dropped from a

height of 80 cm (about 32 inches).

After unpacking the balance, please check it immediately for

any visible damage as a result of rough handling during shipment. If this is the case, proceed as directed in the section entitled "Safety Inspection."

Save all parts of the packaging and the box for shipping

your balance to prevent any damage during transportation.

In addition, please disconnect all connecting cables (e.g.

the plug on the power supply) to avoid damaging them.

Do not expose the balance unnecessarily to extreme temperatures, moisture, shocks, blows or vibrations.

Page 6

6

Equipment Supplied

The equipment supplied consists of the components pictured on

the left:

— balance

— draft shield

— portable power supply

— dust cover

The kit of Standard accessories contains the following:

1 Standard weighing pan

1 special pan for weighing filaments

1 pan support

1 interior draft shield

1 calibration weight, 500 mg (accuracy class: E2)

1 brush

1 pair of forceps

1 chamois

Page 7

7

How to Handle Your Microbalance

Before you Start weighing, please observe the

following:

After plugging your balance into a wall outlet, make sure to allow for >2 hours' warmup.

Working with a microbalance requires a steady hand and a

smooth, uninterrupted technique.

Use forceps or other suitable Utensils to load your sample on

the pan.

Do a few trial weighing procedures before you begin with actual

weighing of your sample.

lf the weighing chamber has not been opened for a relatively

long period, it may have a temperature which is different from

that of the balance's surrounding environment. Therefore, as

soon as you open the weighing chamber, a change in the temperature will inevitably occur. This change in temperature may

show up as a change in the weight readout. In this case, we

recommend that before you begin with an actual repetitive

weighing procedure you open and dose the weighing chamber

at the same rate as you will be doing during such a procedure.

Carefully place you sample on the pan and, if necessary, remove it along with the pan. After the weighing chamber is

closed, the weight readout, as a rule, will stabilize after 30 sec.

at the latest.

The accuracy of the resulting weight readouts will increase as

the degree of consistency is increased for successive weighing

procedures.

Page 8

8

Installation Instructions

Ambient Conditions

Microbalances are highly precise and very sensitive measuring

Instruments. Therefore, please choose a suitable place to set

up your balance. lt should not be exposed to the following:

- Heat radiation

- Aggressive/corrosive substances

- Vibrations

- Drafts

Use a balance table or a wall console (see "Accessories") to set

up your balance.

Do not expose the balance to extreme moisture over long periods. Moisture in the air can condense on the surfaces of the

balance whenever a cold balance is brought to a substantially

warmer place.

lf you need to transfer the balance to a warmer area, make sure

to condition it for a few hours at room temperature. The best

way to prevent moisture condensation is to leave the balance

connected to line power. The components used in the balance

are rated to at least class KSF according to DIN 40040.

Your Sartorius Balance will provide accurate readouts even

when it is exposed to unfavorable ambient conditions.

You can adapt the balance to your requirements simply by

changing the menu code settings in the balance operating program.

For this purpose, read pages 14 through 16

Connecting Electronic Devices (Peripherals)

Always unplug the power supply before you connect or disconnect devices to or from the interface ports.

Page 9

9

Startup

Install components

(3 - 1)

in the weighing chamber.

Connecting the Balance to Line Power

Your balance is powered by a portable power supply unit. Use a

screwdriver to adjust the voltage selector on the power supply

unit to the setting of your local line voltage (either 115 or 230

volts).

Voltage Selection

Make sure that the voltage rating printed on this unit is identical

to your local line voltage rating.

Write the new voltage setting on the manufacturer's label.

lf the voltage rating specified on the power supply or the plug

design does not match the rating or Standard you use, please

contact your Sartorius dealer.

Important Note

Only use original Sartorius power supplies identified by the Sartorius label. Use of power supplies made by other manufacturers, even if these power supplies have a registered approval

rating from a national testing laboratory, requires the consent of

a certified Sartorius technician.

Plug the cord line into the power receptacle. Secure the

connection by tightening the knurled collar. Now plug the power

supply unit into a wall outlet.

Page 10

10

Safety Precautions

The power supply rated to Class 2 (double insulated) can be

plugged into a wall outlet without taking any additional safety

precautions. The pole of each Output voltage is connected to

the balance housing which can be grounded for Operation.

The interface (see "Interfacing Devices" on page 19 in addition)

is also electrically connected to the balance housing (ground).

Leveling the Balance using the Level Indicator

At the point of use, level the balance using the leveling feet

(7)

so that the air bubble is centered within the circle of the level indicator

(6)

.

Page 11

11

Operation

The weight display shows the following special

messages for your information:

BUSY

The balance processor is still busy processing a function and

will not accept any other commands to perform functions at this

time.

STANDBY

The display has been turned off with the ON/OFF key and the

balance is now in the ready-to-operate mode so that it does not

require warmup.

POWER OFF

The balance was disconnected from line power (reconnection to

line power after the balance was unplugged; power failure or

outage).

CAL

The calibration function has been activated.

Page 12

12

Turning the Display On and Off

Press the ON/OFF button

(11)

to turn the display on or off. You

can also turn it on by pressing the tare control

(10)

.

After the balance is connected to line power, the weight display

will go out whenever you turn off the power with the ON/OFF

key. The electronic circuits remain energized (indicated by

STANDBY).

Self-Test

After the power is turned on, a test of all essential electronic circuits is automatically run.

The display readout "0.000 mg" at the end of the self-test indicated that it has been successfully completed.

Weighing

At this point, place your sample on the pan

(1)

to determine the

weight. Read off the weight in the display

(12)

once the weight

unit symbol (in this case "g") appears. The weight readout is

stable a few seconds afterwards, as a rule.

Taring

lf you wish to use a Container of if the weight display does not

indicate "0.000" mg, press the tare control to zero the display.

This means the balance is ready to operate without requiring

warmup the next time you turn it on.

Page 13

13

Calibration

Unload the balance. When the display reads zero, press the

tare control

(10)

for at least three seconds until the calibration

weight appears in the weight display.

Center the calibration weight (see Accessory Kit) on the pan

and dose the weighing chamber.

The weight unit symbol

"mg"

will now appear in the weight display. An acoustic Signal indicates the end of the calibration procedure.

You can block the calibration function – see "Balance Operating

Program." This function is accessible whenever the balance operating program is unlocked by the menu access switch.

Make sure to calibrate the balance each time you exchange

the Standard pan for the one for weighing filaments and

vice versa to rule out any effects caused by the inevitable

differences in weights of the pans.

Page 14

14

Balance Operating Program

The balance operating program lets your adapt your balance to

various ambient conditions and application requirements. At the

factory, we have set the codes for a Standard program, which is

protected by a locking function to prevent accidental changes.

How to Access the Menu of the Balance Operating Program

With the display turned off (

STANDBY

state), hold down the

tare control and press the ON/OFF button.

Release the tare control as soon as

"CH5"

is displayed.

lf

"L"

appears in the display, this Stands for the list mode. In

this mode, you can read a menu code setting, but you cannot

change it.

How to Read a Program Menu Code (List Mode)

Press the tare control each time after the desired digit in the

hundreds, tens and units place is displayed.

The

"o"

symbol indicates the actual menu code setting.

How to return to the weighing mode:

Press the tare control each time a

"0"

appears in the numerical

sequence (first, second and third digits).

Page 15

15

How to Change a Program Menu Code (Change Mode)

Slide the menu access switch in the direction of the arrow (the

menu access switch is located under a protective cap on the

front right of your balance).

"C"

will appear in the display (indicating the change mode).

Press the tare control each time the numeral desired appears in

the hundreds, tens, and ones place, respectively.

The

"o"

symbol that appears indicates the actual setting.

How to return to the weighing mode:

Slide the menu access switch back to its original setting.

"L"

will now be displayed.

Press the tare control each time a

"0"

appears in the numerical

sequence.

lf you have changed a menu code, it will be stored as soon as

the display returns to the weighing mode.

Page 16

16

List of the programmable Menu Code Settings

C 1 3 1

Page Line Word

Balance Operating program

(active Parameters)

Code

Ambient Conditions

Code

Tare Parameter

C 1 1 1

Very stable

C 2 1 1

Without stability

C 1 1 2

Stable

At stability

c 1 1 3

Unstable

C 1 1 4

Very unstable

Auto Zero

C 1 5 1

ON

Code

Stability Range

C 1 5 2

OFF

C 1 2 1

0,25 digit

C 1 2 2

0,5 digit

Calibration

C 1 2 3

1 digit

C 1 6 1

Accessible

C 1 2 4

2 digits

C 1 6 2

Access blocked

C 1 2 5

4 digits

C 1 2 6

8 digits

Special Information

C 1 2 7

16 digits

Code

Program Lock

C 1 2 8

32 digits

C 4 1 1

OFF

C 1 2 9

64 digits

C 4 1 2

ON

Code

Display Format

Code

Acoustic Signal

C 1 3 1

Last decimal ON

C 4 3 1

ON

C 1 3 2

Last decimal OFF

C 4 3 2

OFF

C 1 3 3

Last decimal at stability

C 1 3 4

All decimals at stability

Additional Parameters for the data Output format at the interface port and for calculation programs are

available on request.-Please refer to the “Accessories."

Page 17

17

Troubleshooting Guide

Problem ... Causes ... Remedy

No segments appear in the weight

display

(12)

- No line current available

- The power supply is not plugged

in

- Check power supply

- Plug in power supply

Weight display only shows

"L"

or

"CH 2"

- The weighing pan

(1)

or the pan

support

(2)

is not in place

- Position the pan and pan support

Weight display shows

"H"

- Sample exceeds weighing range - Unload the weighing pan

The weight readout changes

constantly or the special message

"BUSY"

does not go out in the

weight display

- The air bubble of the level

indicator is not within the circle

- Unstable ambient conditions

- Too much vibration or balance

exposed to drafts

- The doors of the weighing

chamber are not completely

closed

- Sample does not have a stable

weight

- level balance

- Set up balance in another area

- Access the menu to adjust the

proper code for the particular

type of weighing environment

- Close the doors of the weighing

chamber

The weight readout is obviously

wrong

- The balance has not been

calibrated

- The balance has not been tared

before weighing)

- The air bubble of the level

indicator is not with in the circle

- Calibrate the balance

- Tare before weighing

- Level the balance

Page 18

18

Accessories (Options)

Data printer with

date/time and statistics functions

YDP 02-0DV1

Print speed approx. lines/sec

1,5

Printer housing (W x D x H)

in mm

in inches

150 x 138 x 43

5.5 x 5.4 x 1.7

Tare foot switch 7252

Integrable „“Data Input“ keyboard YDI 02 M

for determination of the diameter – **DZ4

Carrying case YDB 01 M

Antitheft locking device 6087

Antivibration balance table 6801

Extension with 2 drawers for

balance table

6802

Wall console 6804

Digital/analog converter YDA 01 Z

IEC converter 7253 16

BCD parallel converter 7253 18

Dust cover 6960 M150

Page 19

19

Care and Maintenance

Cleaning

Please do not use any aggressive cleaning agents (solvents or

similar agents). Instead, use a piece of cloth wet with a mild detergent to clean the balance.

Make sure that no liquid enters the balance housing.

After cleaning, wipe down the balance with a soft, dry piece of

cloth.

Safety Inspection

lf there is any indication that safe Operation of the balance is

no longer warranted, turn off the power and unplug the balance

immediately. Lock the equipment in a secure place to ensure

that it cannot be used for the time being.

In this case, notify the Sartorius Technical Services Dept. or Division. Only certified Sartorius service technicians who have the

proper manuals are allowed to perform maintenance and repair

work on the balance.

Safe Operation of the balance with the power supply is no

longer ensured when

— there is visible damage to the power supply

— the power supply no longer functions properly

— the power supply has been stored for relatively long periods

under unfavorable conditions

— the power supply has been exposed to rough handling dur-

ing shipment

We recommend that the balance with the power supply be inspected according to the following checklist by a qualified Sartorius Service technician:

— Leakage current <0.05 mA measured by a properly cali-

brated multimeter

— Insulation resistance >7 M

Ω

measured with a constant volt-

age of at least 500 V at a 500 k

Ω

load

The duration and number of measurements should be determined by a qualified Sartorius service technician according to

the particular ambient and operational conditions. However,

such inspection must be done at least once a year.

Page 20

20

Data Interface

See the "Interface Description for Sartorius Balances and

Scales" enclosed.

Interfacing Devices with the Balance (RS Interface)

Make sure that the interface port is electrically connected to the

protective grounding conductor of the balance housing. The

cabling supplied as accessory components is shielded and

electrically connected on both ends to the cases of the

connectors. This electrical connection may result in interference

caused by cables scraping the floor or by transient currents

ifyou have grounded the housing or connected the protective

grounding conductor for line power. lf necessary, connect an

equipotential bonding conductor to the balance.

Page 21

21

Specifications

Model M 500 P

Capacity / weighing range mg 52/102/202/510

Readability mg 0,002/0,005/0,01/0,02

Tare range (by subtraction) mg 510

Standard deviation mg

≤±0,004/0,005/0,01/0,02

Max. linearity mg

≤±0,004/0,01/0,02/0,04

Stabilization time (typical) s 8

Display update s 0,1 – 0,8 (selectable)

Adaption to ambient conditions

and application requirements

By selection of 1 of 4 optimized filter levels

Stability range d 0,25 ... 64 (selectable)

Ambient temperature range

o

C +15 to +30

Sensitivity drift within 290 … 300 K /K

≤± 1∙10

-5

Pan size mm

mm

28 Ø (standard pan)

28 Ø (special pan for weighing filaments)

Balance housing (W x D x H) mm 219 x 291 x 135

Weighing chamber (W x D x H) mm 54 x 53 x 50

Net weight, approx. kg 547

Netzspannung, Frequenz 50-60 Hz

115 oder 230 V entsprechend verwendetem Netzteil

Leistungsaufnahme VA 7,2 (typisch)

Schnittstelle

RS 232 C/V24 – 28, RS 423/V10; 7-bit;

parity: even, mark, odd, space;

Übertragungsgeschwindigkeit 150 ... 9600 Baud

Page 22

Sartorius AG

B 37070 Göttingen

P Weender Landstraße 94–108, 37075 Göttingen

T (0551) 308-0, F (0551) 308-3289

Internet: http://www.sartorius.com

Copyright by Sartorius AG, Göttingen, Deutschland.

All rights reserved. No part of this publication may be

printed or translated in any form or by any means without

the prior written permission of Sartorius AG.

Sartorius AG reserves the right to make change to the

technology, features, specification and design of the equipment

without notice.

Loading...

Loading...