Sartorius MCE2.7S M, MCE6.6S M, MCE10.6S M, MCE3.6P M, MCE2.7S F Operating Instructions Manual

...Page 1

Operating Instructions

Original Operating Instructions

Cubis®

MCE Models

Micro Balances

1000047964

Page 2

Page 3

Contents

Contents

1 About these Instructions............................ 5

1.1 Scope ....................................... 5

1.2 Symbols Used................................. 5

1.2.1 Warnings in Operating Instructions........ 5

1.2.2 Other Symbols ......................... 5

1.3 Target Groups................................. 6

2 Safety Instructions ................................. 7

2.1 Intended Use ................................. 7

2.2 Personnel Qualification......................... 7

2.3 Significance of these Instructions ................ 7

2.4 Proper Working Order of the Device.............. 8

2.5 Symbols on the Device ......................... 8

2.6 Electrical Equipment ........................... 8

2.6.1 Damage to the Electrical Equipment

of the Device .......................... 8

2.6.2 Working on the Device’s Electrical

Equipment............................. 8

2.6.3 AC Adapter and Power Supply Cable....... 8

2.7 Conduct in an Emergency....................... 8

2.8 Accessories, Consumables, and Spare Parts ........ 9

2.9 Personal Protective Equipment .................. 9

2.10 Glass Breakage................................ 9

3 Device Description ................................10

3.1 Device Overview .............................10

3.2 Draft Shield .................................11

3.3 Weighing Pan and Associated Components ....... 12

3.4 Connections and Components on the Backside

of the Weighing Module.......................12

3.5 Connections on the Control Unit................ 13

3.6 Connections and Components on the Electronics

Module .....................................13

3.7 Displays on Weighing Module (Only for

Microbalance) ...............................14

3.8 Motorized Draft Shield ........................14

3.8.1 Sensor Area........................... 14

3.8.2 Operating Elements for the Draft Shield...14

3.9 Conformity-assessed Devices ................... 14

3.10 Symbols on the Device ........................15

4 Operating Concept................................16

4.1 Operating Display in Weighing Mode ............16

4.2 Operating Display in the Menu .................17

4.3 Buttons and Keys on the Operating Display....... 17

4.4 Displays in the Operating Display ...............18

4.5 Menu Structure ..............................20

4.5.1 Overview of the Device Settings Menu ....20

4.6 Navigating the Menus.........................24

5 Installation....................................... 26

5.1 Scope of Delivery............................. 26

5.2 Selecting an Installation Site ................... 26

5.3 Unpacking the Device .........................27

5.4 Preparing Below-cell Weighing ................. 27

5.5 Installing a Microbalance with Glass Draft Shield.. 29

5.5.1 Positioning the Weighing Pan and

Associated Components ................29

5.6 Installing a Filter Microbalance with a Metal Ring

Draft Shield .................................30

5.6.1 Inserting a Filter Pan or Weighing Pan

and Associated Components.............30

5.6.2 Optimizing a Filter Weighing Pan

with a Metal Ring Draft Shield for Left-

handed Users .........................31

5.7 Connecting the Electronics Module .............31

5.8 Acclimatization ..............................31

6 Getting Started................................... 32

6.1 Connecting Electronic Components .............32

6.2 Installing the AC Adapter ......................32

6.3 Connecting the Power Supply ..................32

7 System Settings................................... 33

7.1 Performing System Settings....................33

7.2 Switching Off the isoCAL Function ..............33

7.3 Parameter List ...............................34

7.3.1 Parameters in the “Setup” Main Menu ....34

7.3.2 Parameters in the “Device” Main Menu....36

7.3.3 Parameters in the “Data Output”

Main Menu ...........................41

7.3.4 Parameters in the “Applications”

Main Menu ...........................42

7.3.5

7.3.6

7.3.7 Parameters in the “Unit 1”, “Unit 2”,

8 Operation ........................................ 46

8.1 Switching the Device On and Off ...............46

8.2 Leveling the Device ...........................46

8.3 Opening and Closing the Motorized Draft Shield

(Only for Devices with a Motorized Draft Shield) ..47

8.3.1 Defining the Opening Width.............47

8.4 Preparing Weighings.......................... 48

8.5 Weighing ...................................48

8.6 Overview of Calibration, Adjustment, and

Linearization ................................48

8.7 Adjusting with the isoCAL Function .............49

8.8 Internally Calibrating and Adjusting the Device ...50

8.9 Externally Calibrating and Adjusting the Device

(Not for Conformity-assessed Models) ...........51

8.10 Printing Results ..............................53

8.11 Weighing and Printing with ID Marking..........53

8.12 Running Applications (Examples) ...............54

8.12.1 Executing the “Toggle Between Weight

8.12.2 Running the “Statistics” Application ......54

Parameters in the “Input” Main Menu

Parameters in the “Language” Main Menu

“Unit 3”, and “Unit 4” Application Menus.. 45

Units” Function........................54

.....44

..45

Cubis® MCE Operating Instructions 3

Page 4

Contents

9 Cleaning and Maintenance.........................56

9.1 Preparing the Device..........................56

9.2 Cleaning the Device ..........................56

9.3 Assembling and Connecting the Device ..........57

9.4 Maintenance Schedule ........................57

9.5 Performing a Software Update .................58

10 Malfunctions ..................................... 59

10.1 Status Messages.............................. 59

10.2 Warning Messages............................59

10.3 Troubleshooting..............................61

11 Decommissioning .................................62

11.1 Decommissioning the Device ...................62

12 Transport ........................................62

12.1 Transporting the Device .......................62

13 Storage and Shipping .............................63

13.1 Storage .....................................63

13.2 Returning Device and Parts ....................63

14 Disposal..........................................64

14.1 Information on Decontamination . . . . . . . . . . . . . . . 64

14.2 Dispose of Device and Parts ....................64

14.2.1 Information on Disposal ................64

14.2.2 Disposal.............................. 64

15 Technical Data.................................... 65

15.1 Dimensions and Weight .......................65

15.1.1 Microbalance .........................65

15.2 Power Supply ................................65

15.2.1 Device ...............................65

15.2.2 Power Supply Unit .....................65

15.2.3 Safety of Electrical Equipment........... 66

15.2.4 Electromagnetic Compatibility........... 66

15.3 Materials.................................... 66

15.4 Integrated Clock .............................66

15.5 Backup Battery ..............................66

15.6 Ambient Conditions ..........................67

15.6.1 Installation Site .......................67

15.6.2 Ambient Temperature for the isoCAL

Function .............................67

15.6.3 Protection Class .......................67

15.7 Metrological Data ............................68

15.7.1 Models MCE2.7S | MCE10.6S | MCA6.6S |

MCA3.6P .............................68

15.8 Recommended Calibration Weight ..............69

15.9 isoCAL Function ..............................69

15.10 Interfaces ...................................69

15.10.1 Specifications for the COM-RS232

Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

15.10.2 Specifications for the USB-A Interface.... 69

15.10.3 Specifications for the USB-B Interface ....69

16 Accessories.......................................70

16.1 Accessories .................................. 70

16.1.1 Printers and Communication ............70

16.1.2 Displays and Input / Output Elements .....70

16.1.3 Hardware and Software for Pipette

Calibration ...........................71

16.1.4 Filter Balance and Antistatic Accessories ..71

16.1.5 Weighing Tables .......................71

16.1.6 Weighing Accessories ..................71

17 Sartorius Service..................................72

18 Conformity & Certificates..........................72

18.1 EU Declaration of Conformity ..................72

18.2 Certificate of Compliance...................... 74

18.3 FCC Supplier’s Declaration of Conformity ........76

4 Cubis® MCE Operating Instructions

Page 5

About these Instructions

1 About these Instructions

1.1 Scope

These instructions are part of the device. These instructions apply to the device in the

following versions:

Device Model

Ultramicrobalances and microbalances

with a motorized draft shield

Filter ultramicrobalances and

microbalances

1.2 Symbols Used

MCE10.6S...-M | MCE2.7S...-M |

MCE3.6P...-M | MCE6.6S...-M

MCE10.6S...-F | MCE2.7S...-F |

MCE6.6S...-F

1.2.1 Warnings in Operating Instructions

WARNING

Denotes a danger with the risk that death or severe injury may result if it is not

avoided.

CAUTION

Denotes a hazard that may result in moderate or minor injury if it is not avoided.

NOTICE

Denotes a danger with the risk that property damage may result if it is not avoided.

1.2.2 Other Symbols

t

y Result: Describes the result of the actions carried out.

[ ] Text inside brackets refers to control and display items.

[ ] Text inside brackets indicates status, warning, and error messages.

Required action: Describes actions which must be carried out.

Indicates information for legal metrology for conformity-assessed

(verified) devices. Conformity-assessed devices are also referred to as

“verified” in these instructions.

Figures on the Operating Display

The figures on the operating display of the device may deviate from those in these

instructions.

Cubis® MCE Operating Instructions 5

Page 6

About these Instructions

1.3 Target Groups

These instructions are addressed to the following target groups. The target groups

must possess the specified knowledge.

Target group Knowledge and responsibilities

User The user is familiar with the operation of the device and the

associated work processes. They understand the hazards which may

arise when working with the device and know how to prevent them.

They have been trained in the operation of the device.

The training is carried out by the operating engineer / laboratory

manager or the operator of the device.

Operator The operator of the device is responsible for compliance with safety

requirements and workplace safety regulations.

The operator must ensure that all persons who work with the device

have access to the relevant information and are trained in working

with the device.

6 Cubis® MCE Operating Instructions

Page 7

Safety Instructions

2 Safety Instructions

2.1 Intended Use

The device is a high-resolution balance, which can be used in laboratories. The device

was developed for the accurate determination of the mass of materials in liquid,

paste, powder, or solid form.

Appropriate containers must be used for loading each type of material. The device

can be used in stand-alone operation or can be operated on a PC.

The device is exclusively designed for use according to these instructions. Any further

use beyond this is considered improper.

If the device is not used properly: The protective systems of the device may be

impaired. This can lead to unforeseeable personal injury or property damage.

Operating Conditions for the Device

Do not use the device in potentially explosive environments. The device may only be

used indoors.

The device may only be used with the equipment and under the operating conditions

described in the Technical Data section of these instructions.

Modifications to the Device

You may not modify or repair the device or make any technical changes. Any retrofitting or technical changes to the device are only permitted with prior written

permission from Sartorius.

2.2 Personnel Qualification

All persons working on the device must possess the necessary knowledge and

responsibilities (see Chapter “1.3 Target Groups”, page 6).

If no qualifications are indicated for the actions described in these instructions:

The actions described are addressed to the “User” target group.

If individual actions must be carried out by other target groups or by

Sartorius Service personnel: The qualification required will be indicated in the

description of the action.

2.3 Significance of these Instructions

Failure to follow the instructions in this manual can have serious consequences, e.g.,

exposure of individuals to electrical, mechanical, or chemical hazards.

t Before working with the device: Read the instructions carefully and completely.

t If these instructions are lost: Request a replacement or download the latest

version from the Sartorius website (www.sartorius.com).

t Ensure that the information contained in these instructions is available to all

individuals working on the device.

Cubis® MCE Operating Instructions 7

Page 8

Safety Instructions

2.4 Proper Working Order of the Device

A damaged device or worn parts may lead to malfunctions or cause hazards which

are difficult to recognize.

t Only operate the device when it is safe and in perfect working order.

t Have any malfunctions or damage repaired immediately by Sartorius Service.

2.5 Symbols on the Device

All symbols appearing on the device, such as warnings and safety labels, must be

legible.

t Do not conceal, remove, or modify the symbols.

t Replace the symbols if they become illegible.

2.6 Electrical Equipment

2.6.1 Damage to the Electrical Equipment of the Device

Damage to the electrical equipment of the device, e.g. damage to the insulation, can

be life-threatening. Contact with parts under voltage represents a direct danger to

life.

t If the device’s electrical equipment is defective, disconnect the device from the

power supply and contact Sartorius Service.

t Keep live parts away from moisture. Moisture can cause short circuits.

2.6.2 Working on the Device’s Electrical Equipment

Only Sartorius Service personnel may work on or modify the electrical equipment of

the device. The device may only be opened by Sartorius Service personnel.

2.6.3 AC Adapter and Power Supply Cable

Serious injury can result, e.g. from electric shocks, if an unsuitable and inadequately

dimensioned power supply cable or unsuitable power supply is used.

t Only use the original power supply cable and power supply.

t If the power supply or power supply cable must be replaced: Contact Sartorius

Service. Do not repair or modify the power supply or power supply cable.

2.7 Conduct in an Emergency

If there is immediate danger of personal injury or if there is a risk of damage to

the device, e.g., due to malfunctions or dangerous situations, the device must be

immediately taken out of operation.

t Disconnect the device from the power supply cable by disconnecting the power

supply cable.

t Malfunctions should be remedied by Sartorius Service.

8 Cubis® MCE Operating Instructions

Page 9

Safety Instructions

2.8 Accessories, Consumables, and Spare Parts

The use of unsuitable accessories, consumables, and spare parts can affect the

functionality and safety of the device and have the following consequences:

− Risk of injury to persons

− Damage to the device

− Malfunction of the device

− Device failure

t Only use approved accessories, consumables, and spare parts supplied by

Sartorius. Information on operational quality is available upon request from

Sartorius.

t Only use accessories, consumables, and spare parts that are in proper working

order.

2.9 Personal Protective Equipment

Personal protective equipment protects against risks arising from the samples used.

t If the workplace or the measurement process in which the device is being used

requires personal protective equipment: Wear personal protective equipment.

2.10 Glass Breakage

Glass components can break if they fall or are handled incorrectly. Glass fragments

can cause cuts.

t Only lift the device by its base, not by the draft shield.

t When lifting and transporting, ensure that no personnel or objects are in the

way.

Cubis® MCE Operating Instructions 9

Page 10

Device Description

3 Device Description

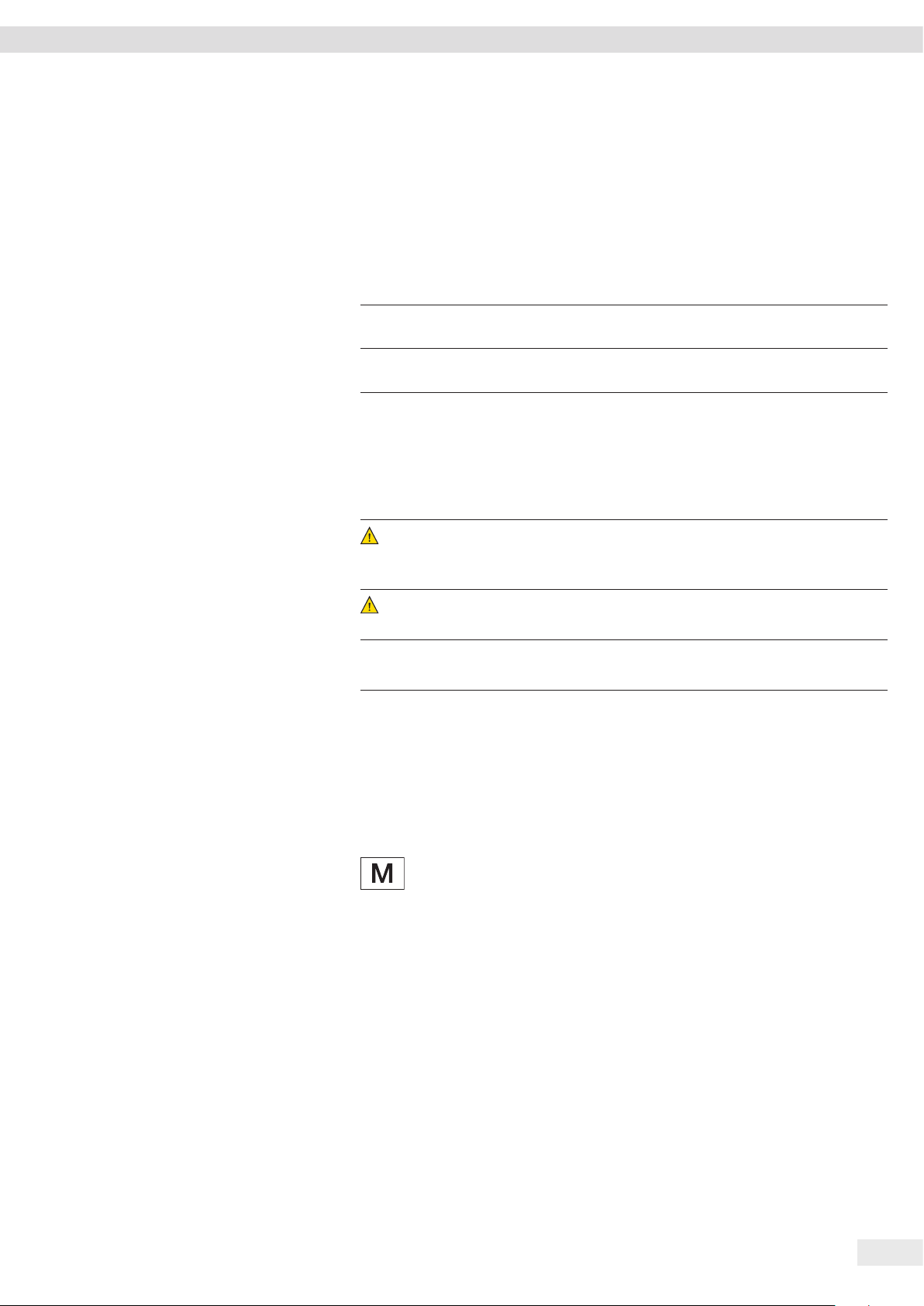

3.1 Device Overview

7

1

2

3

6

Fig. 1: Microbalance with glass draft shield and electronics module (example)

Pos. Designation Description

1 Leveling foot Motorically adjustable

2 Manufacturer’s ID label Not depicted

3 Electronics module

4 Operating display Touchscreen

5 Control unit

6 Weighing module

7 Weighing chamber

4

5

10 Cubis® MCE Operating Instructions

Page 11

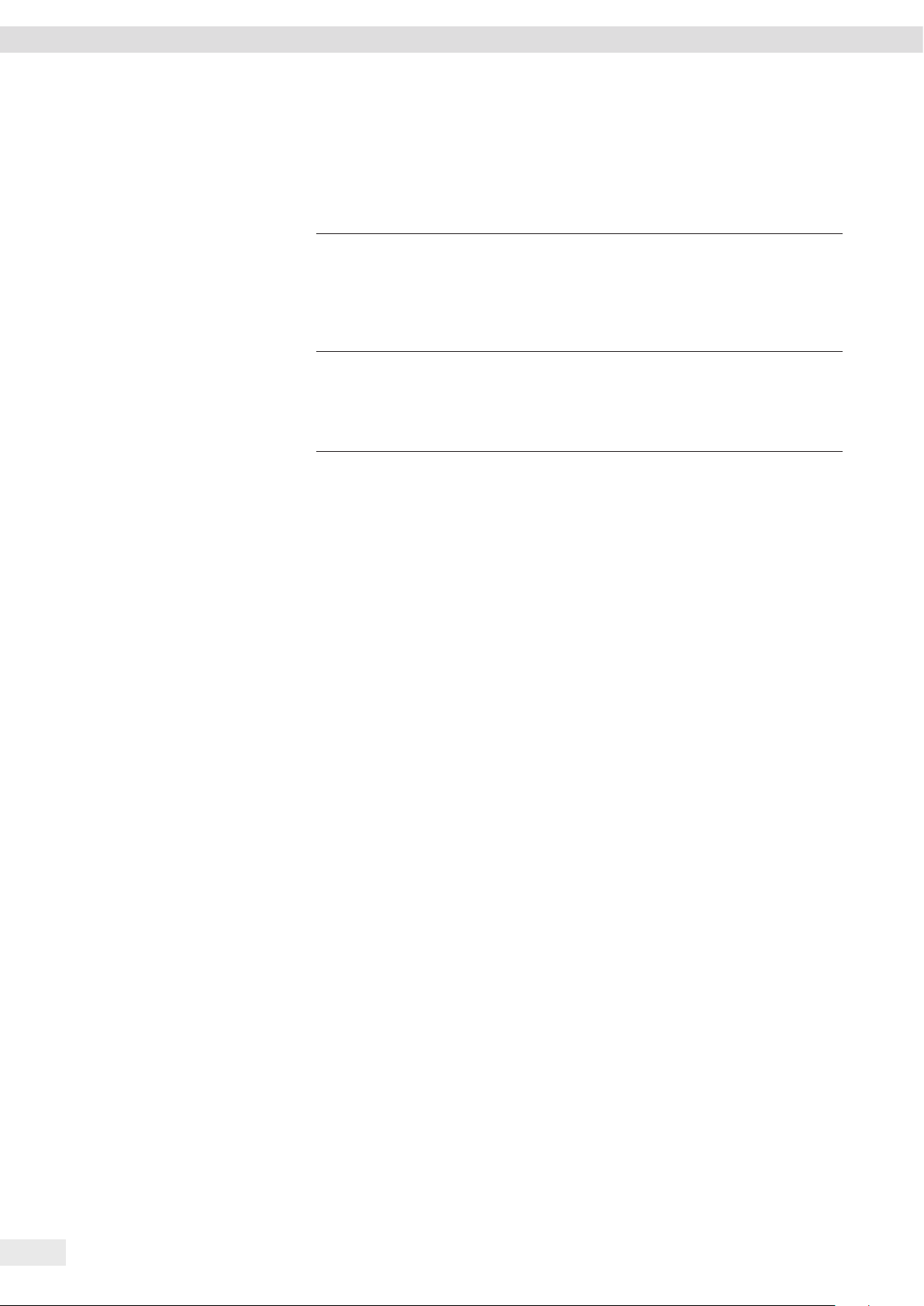

3.2 Draft Shield

3

Device Description

4

1

2

Fig. 2: Microbalance with motorized glass draft shield and filter microbalance with manual metal ring draft shield (example)

Pos. Designation Description

1 Metal ring draft shield cover Made from metal, with handle, can be removed.

2 Metal ring draft shield Consists of 2 metal rings that have been placed into each other with a side opening,

can be rotated manually.

3 Glass draft shield Made from glass, with side opening, motorized rotation. Can be removed.

4 Sensor window For the motion sensor, controls opening and closing of the motorized glass draft

shield

Cubis® MCE Operating Instructions 11

Page 12

Device Description

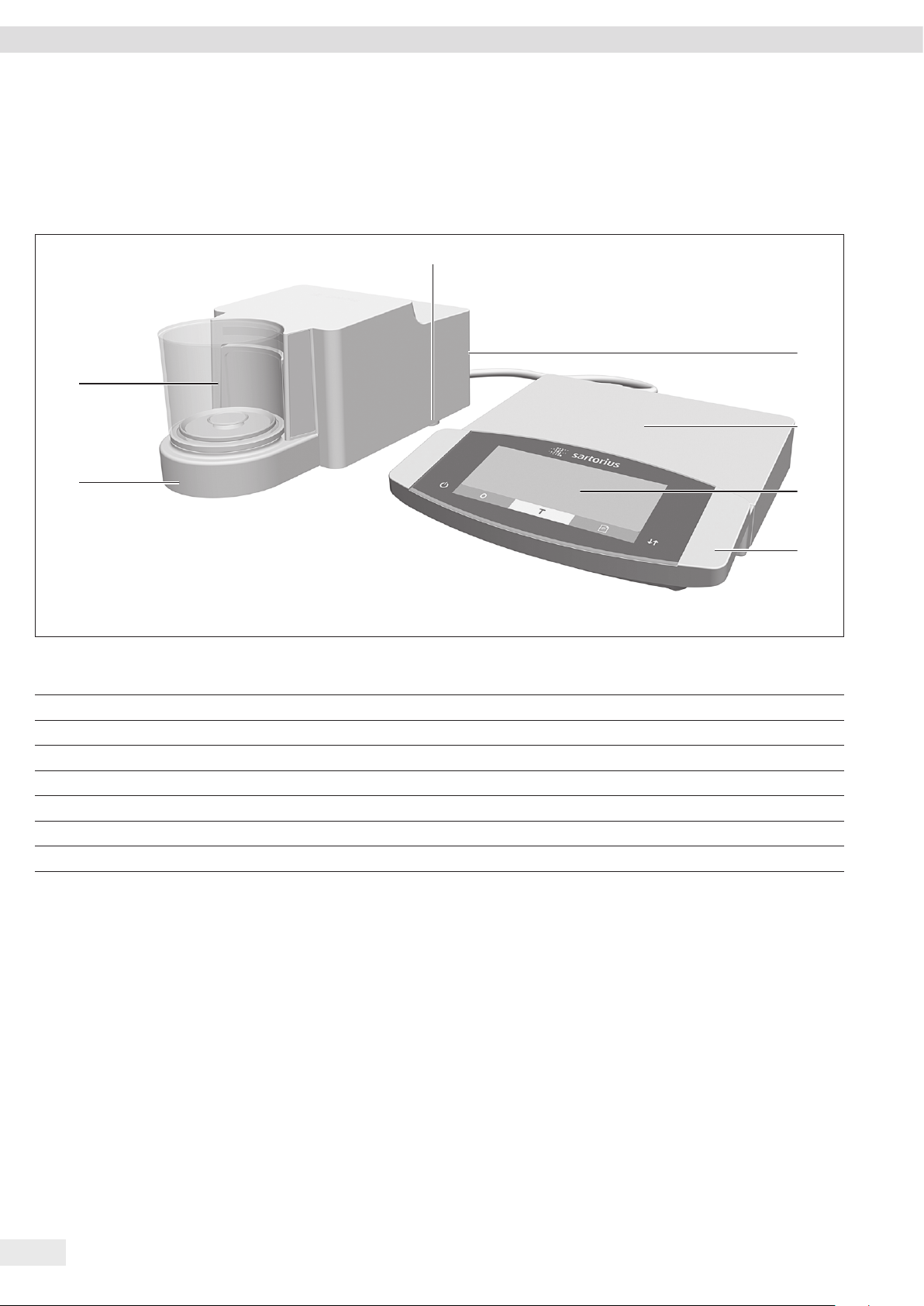

3.3 Weighing Pan and Associated Components

6

1

5

2

2

3

4

Fig. 3: Microbalance with glass draft shield and filter microbalance with metal ring draft shield (example)

3

4

Pos. Designation Description

1 Filter weighing pan

2 Shield plate

3 Connector For models MCE2.7S...F only

4 Pan retainer

5 Internal draft shield For models MCE2.7S...F only

6 Weighing pan

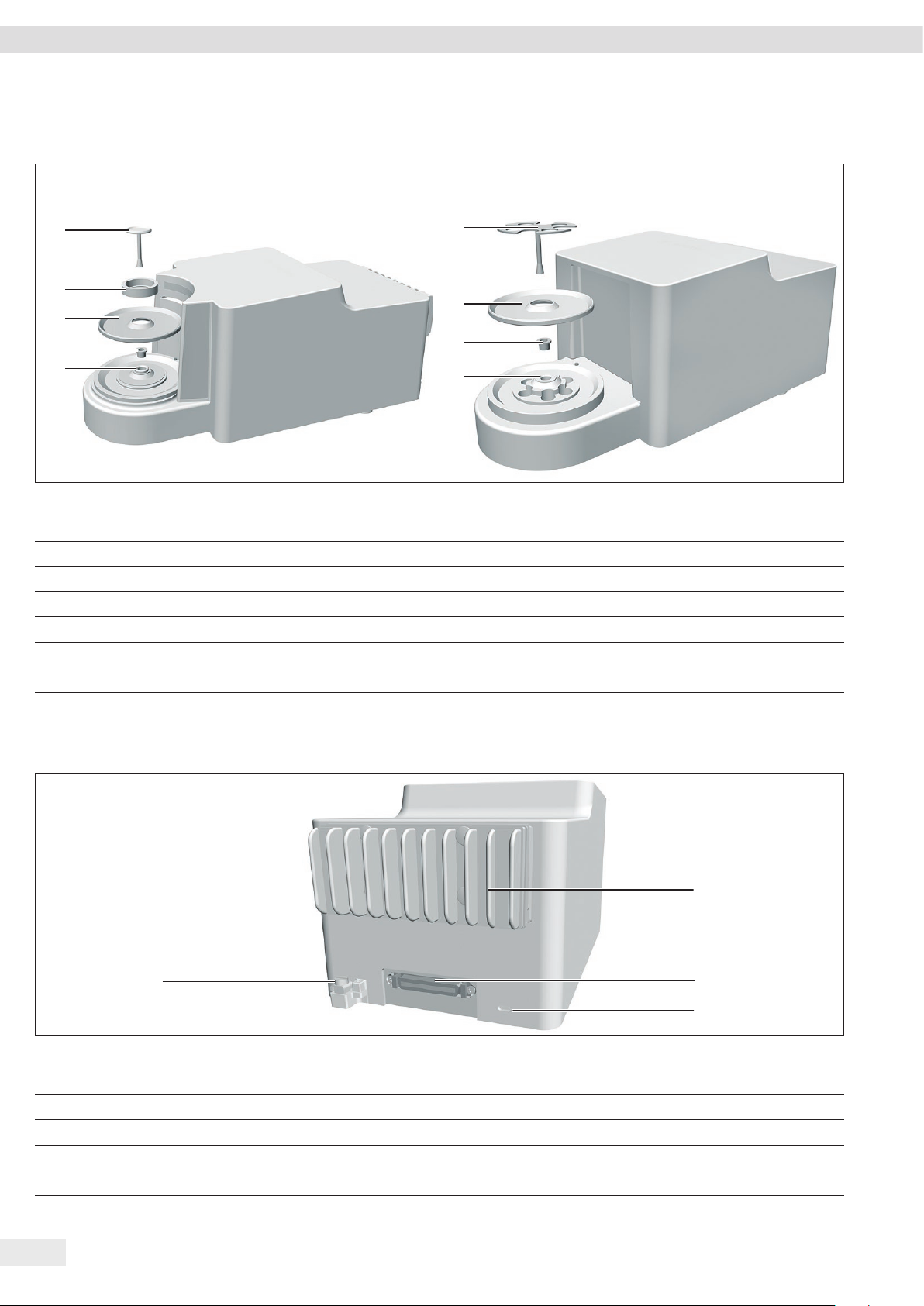

3.4 Connections and Components on the Backside of the Weighing Module

4

Fig. 4: Connections on the weighing module of the microbalance and filter microbalance (example)

Pos. Designation Description

1 Cooling fins For models MCE2.7S...F only

2 Electronics module connection For connecting the electronics module to the weighing module

3 Slot For the anti-theft device

4 Connection clamp For connection of a potential equalization

1

2

3

12 Cubis® MCE Operating Instructions

Page 13

Device Description

3.5 Connections on the Control Unit

Fig. 5: Connections on the control unit

Pos. Designation Description

1 USB connection Concealed, no function, for Sartorius Service only

1

3.6 Connections and Components on the Electronics Module

1 2 3 4 5

Fig. 6: Connections on the electronics module

Pos. Designation Description

1 On key Switches the device on from standby mode.

2 USB-A connection For printers and for software updates via a USB mass storage device

3 USB-B connection For connection to a PC

4 COM-RS232 connection 9-pin, for connection to a PC or PLC

5 Access switch Protects the device from changes to the device settings. Is sealed for conformity-

assessed devices.

6 Peripheral connection For connecting Sartorius accessories.

7 Weighing module connection For connecting the electronics module to the weighing module

8 Power supply For connection to the power supply

6

7

8

Cubis® MCE Operating Instructions 13

Page 14

Device Description

3.7 Displays on Weighing Module (Only for Microbalance)

1

Fig. 7: Displays on the weighing module (example)

Pos. Designation Description

1 LED strip Used for lighting of weighing chamber. The intensity of the

lighting can be adjusted in the menu. When the control unit

displays an error message: The LED strip is illuminated in

orange.

3.8 Motorized Draft Shield

3.8.1 Sensor Area

The device has a motion sensor that opens the draft shield automatically as soon as

a motion is detected within the sensor area. Following that the draft shield will be

automatically closed again. The operation is optimized for left- and right-handed

users due to the motion sensor.

The motion sensor sensitivity can be adjusted in steps (see Chapter “Parameters in

the “Motion Sensors” Submenu”, page 38)

3.8.2 Operating Elements for the Draft Shield

The draft shield can be opened and closed via the [Change] key. Operation via the

[Change] key enables the opening and closing of the draft shield as well as the

activation and deactivation of the motion sensor.

3.9 Conformity-assessed Devices

Some settings of conformity-assessed models are protected against user changes,

e.g. external calibration for devices in accuracy class II. This measure is intended to

ensure the suitability of the devices for use in legal metrology.

14 Cubis® MCE Operating Instructions

Page 15

Device Description

3.10 Symbols on the Device

1

Fig. 8: ID label on the device (example)

Pos. Designation Description

1 Manufacturer’s ID label Displays the metrological data of the device.

Symbol Meaning

During operation, parts in the device may be live. Only electricians

may have access to and work on these parts, such as for maintenance and repairs.

Cubis® MCE Operating Instructions 15

Page 16

Operating Concept

4 Operating Concept

4.1 Operating Display in Weighing Mode

21

3

6

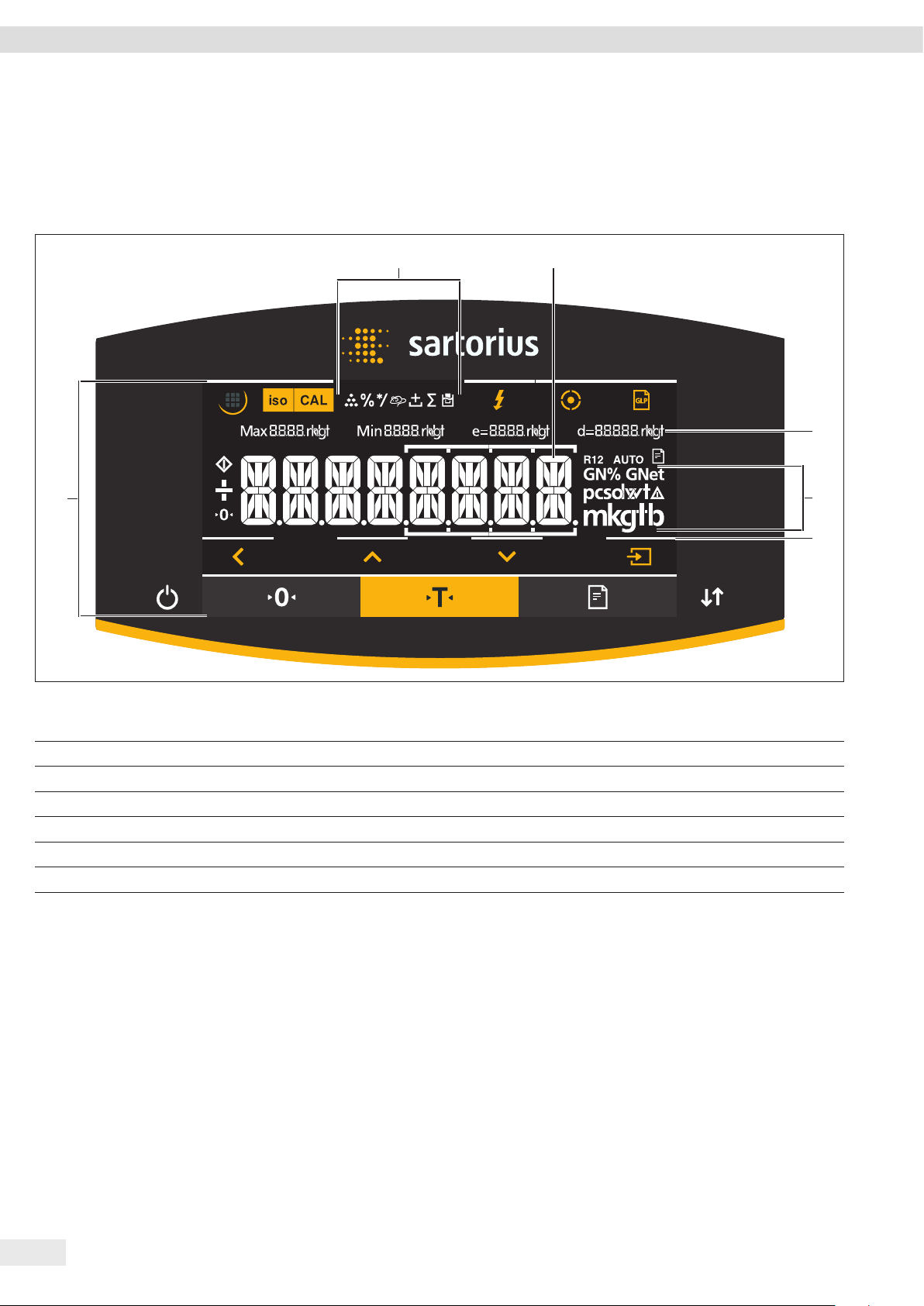

Fig. 1: Operating display in weighing mode (example)

Pos. Designation Description

1 Symbols for the selected application

2 Weight value display In the selected basic unit.

3 Metrological data

4 Weight units Shows the selected basic unit, e.g. grams, [g].

5 Visual touch-feedback Visual note on an active button or key.

6 Operating and display area

4

5

16 Cubis® MCE Operating Instructions

Page 17

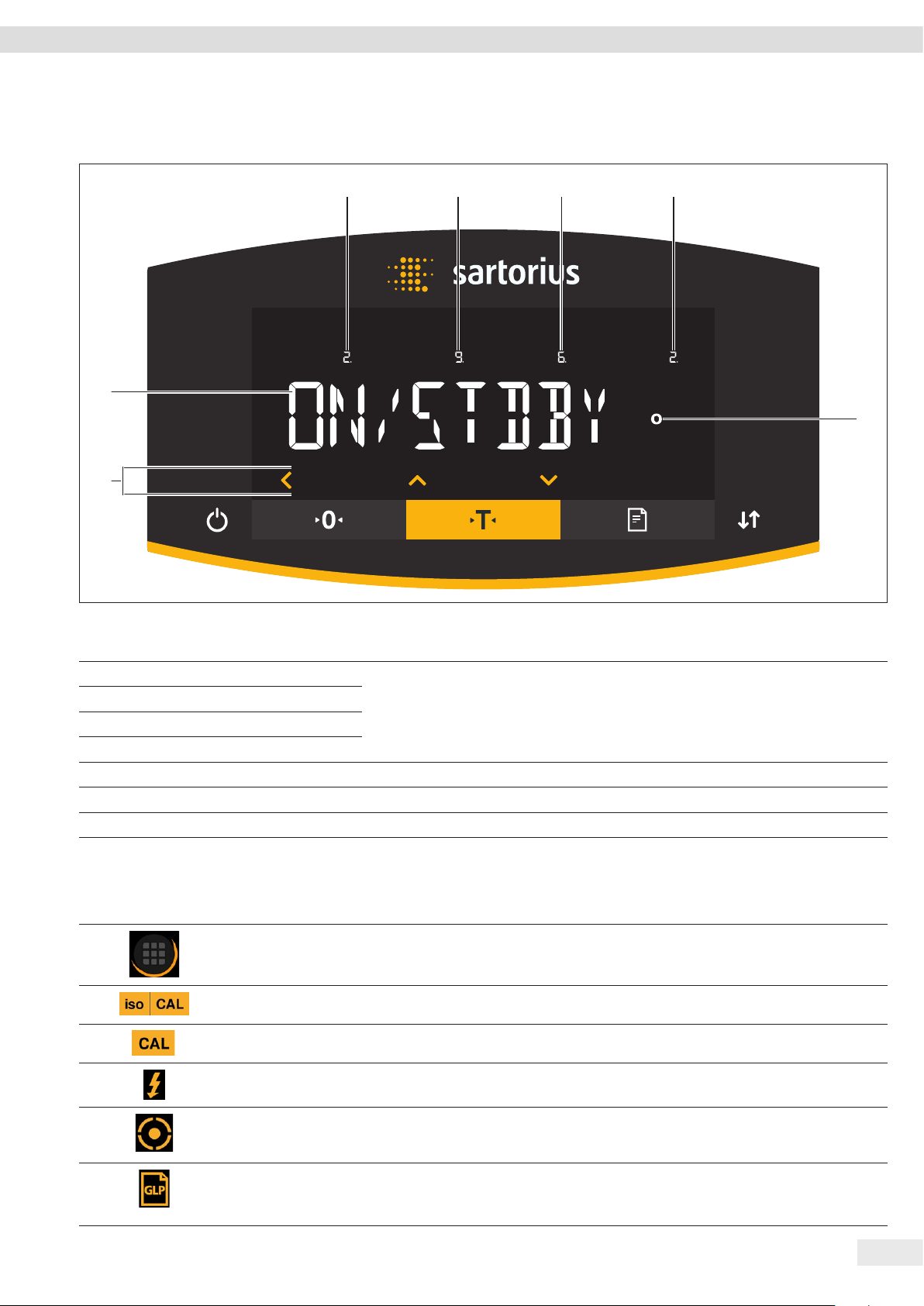

4.2 Operating Display in the Menu

1 2 3 4

7

6

Operating Concept

5

Fig. 2: Operating display in the menu (example)

Pos. Designation Description

1 Position in the 1st menu level Shows the position of the displayed menu or configuration value in up to 4 menu

2 Position in the 2nd menu level

levels.

3 Position in the 3rd menu level

4 Position in the 4th menu level

5 [Computed values] display Note on the set menu item

6 Operating area

7 Name of the menu or setting

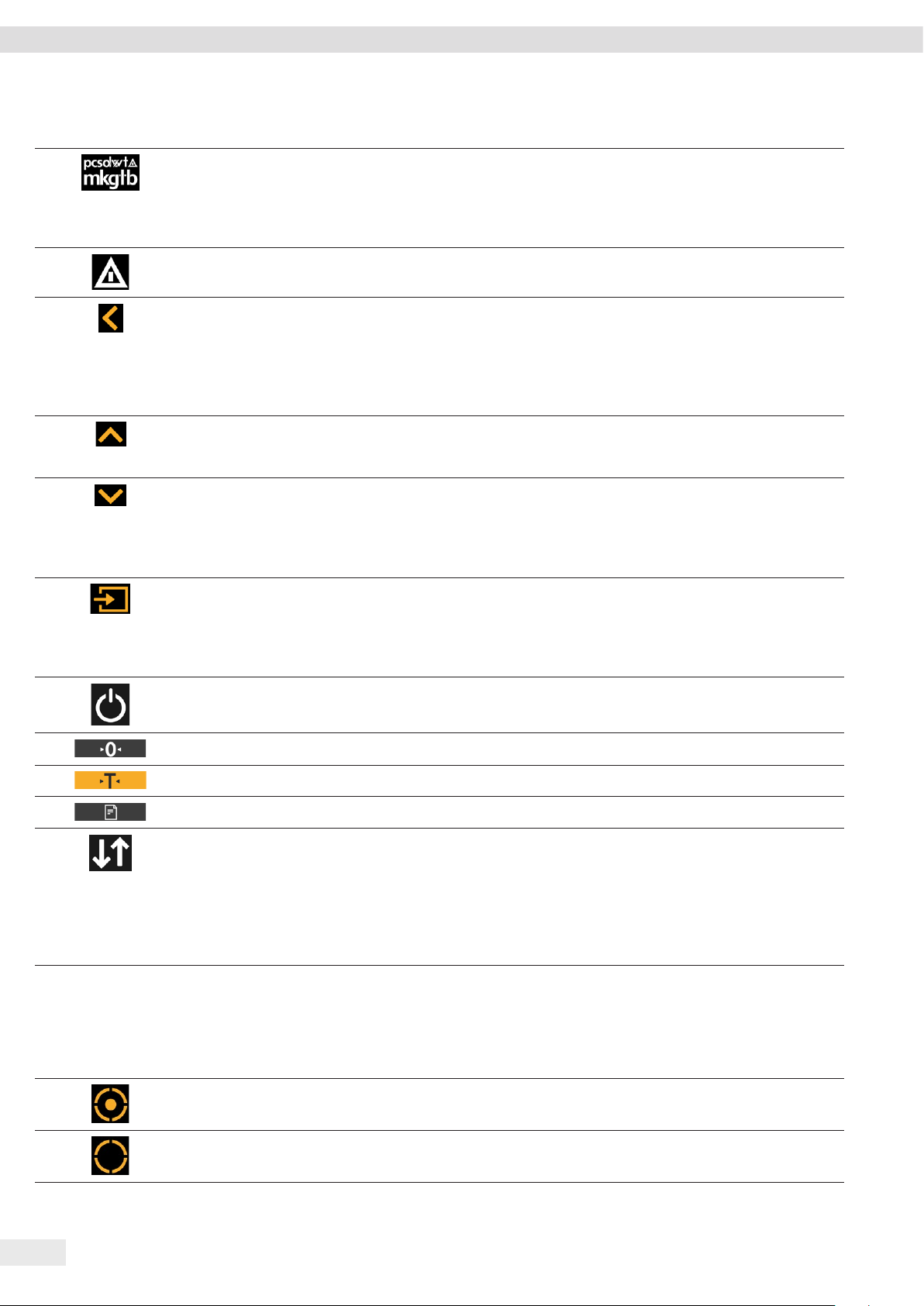

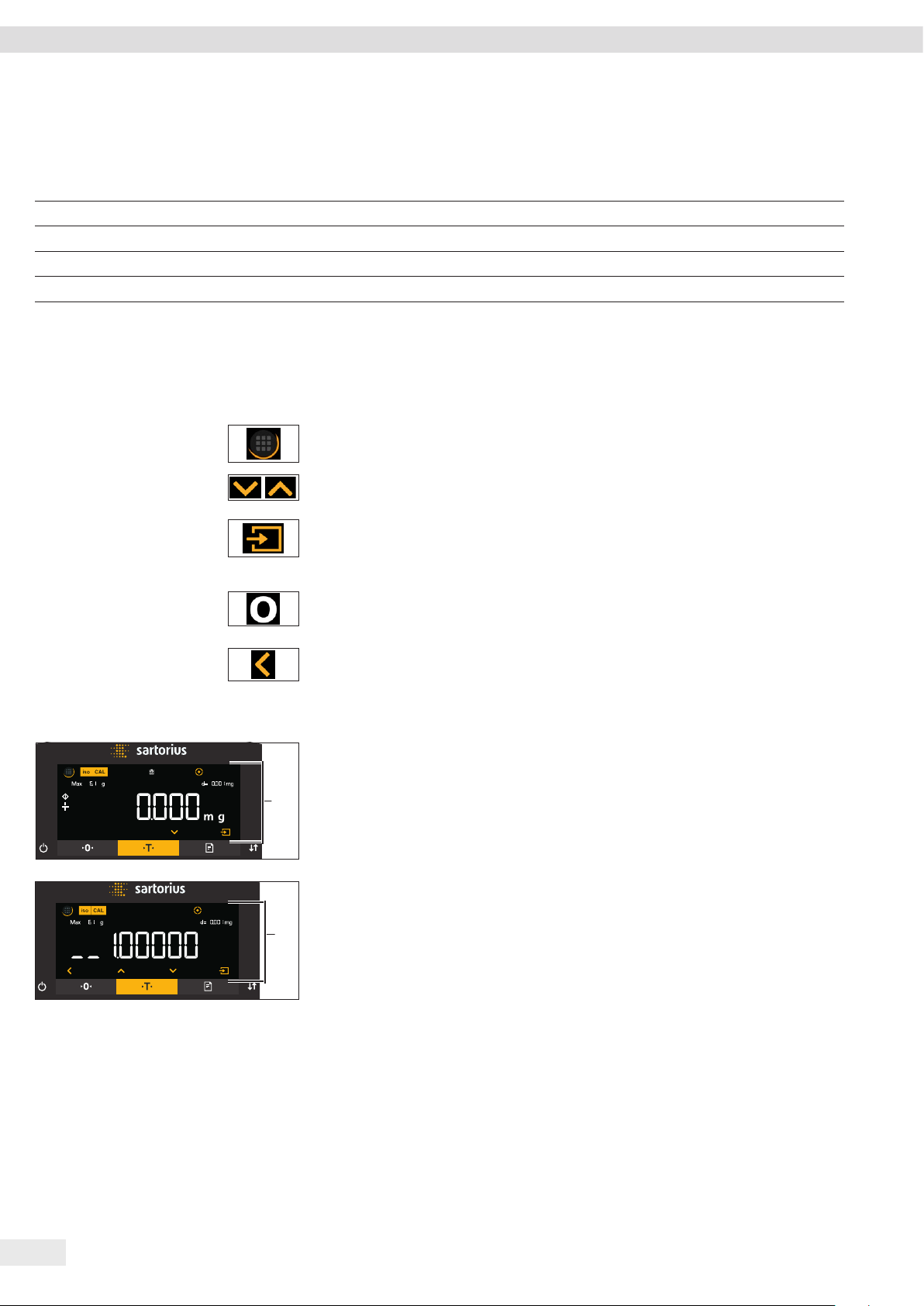

4.3 Buttons and Keys on the Operating Display

Pos. Symbol Designation Description

1

2

3

[Menu] button When the button is pressed: The settings menu opens.

If the button is held down: It switches to version display.

[isoCAL] button Starts the isoCAL function.

[Adjust] button Starts the set calibration and adjustment function.

4

5

6

[Ionizer] button Starts an ionization process.

[Leveling] button Starts a leveling process.

[GLP] button − Exits the GLP printout and starts printing the GLP footer.

− If the “Net-total”, “Totalizing”, or “Statistics” application is active: Prints and

deletes the saved values and exits the application.

Cubis® MCE Operating Instructions 17

Page 18

Operating Concept

Pos. Symbol Designation Description

7

8

[Toggle between weight

units] button

[Invalid weight value]

button

If the “Toggle between weight units” function is active:

− If the button is held down: Accesses the “Toggle between weight units” function

menu.

− When the button is pressed: Switches between the basic unit display and up to

4 other units.

If a fault exists in the weighing module: Indicates the cause of this fault.

9

10

11

12

13

14

[Back] button − In the menu:

− When the button is pressed: Returns to the previous display.

− If the button is held down: Saves the menu settings.

− When entering digits: Selects the previous digit position.

− For an active application: Exits the application and deletes the set reference

value.

[Up] button − In the menu: Scrolls through the menu levels or the available configuration

values.

− When entering digits: Increases the displayed value.

[Down] button − In the menu: Scrolls through the menu levels or the available configuration

values.

− When entering digits: Decreases the displayed value.

− In the main display of an active application: Accesses the display to set the

reference values.

[Confirm] button − In the menu: Accesses the displayed menu level or confirms the displayed

configuration value.

− When entering digits: Selects the next digit position.

− In the main display of an active application: Starts the application process and

saves the set reference value.

[On / Off] key If the key is briefly pressed: Switches the operating display on.

If the key is held down: Switches the operating display off.

[Zero] key Zeros the device.

15

16

17

[Tare] key Starts taring.

[Print] key Exports the readouts to the integrated data interfaces.

[Change] key − For models with a motorized draft shield: Opens or closes the doors on the draft

shield.

− For models without a motorized draft shield, if the “Toggle between weight

units” function is active:

− If the key is briefly pressed: Switches between the set weight units.

− If the key is held down: Accesses the “Toggle between weight units”

function menu.

4.4 Displays in the Operating Display

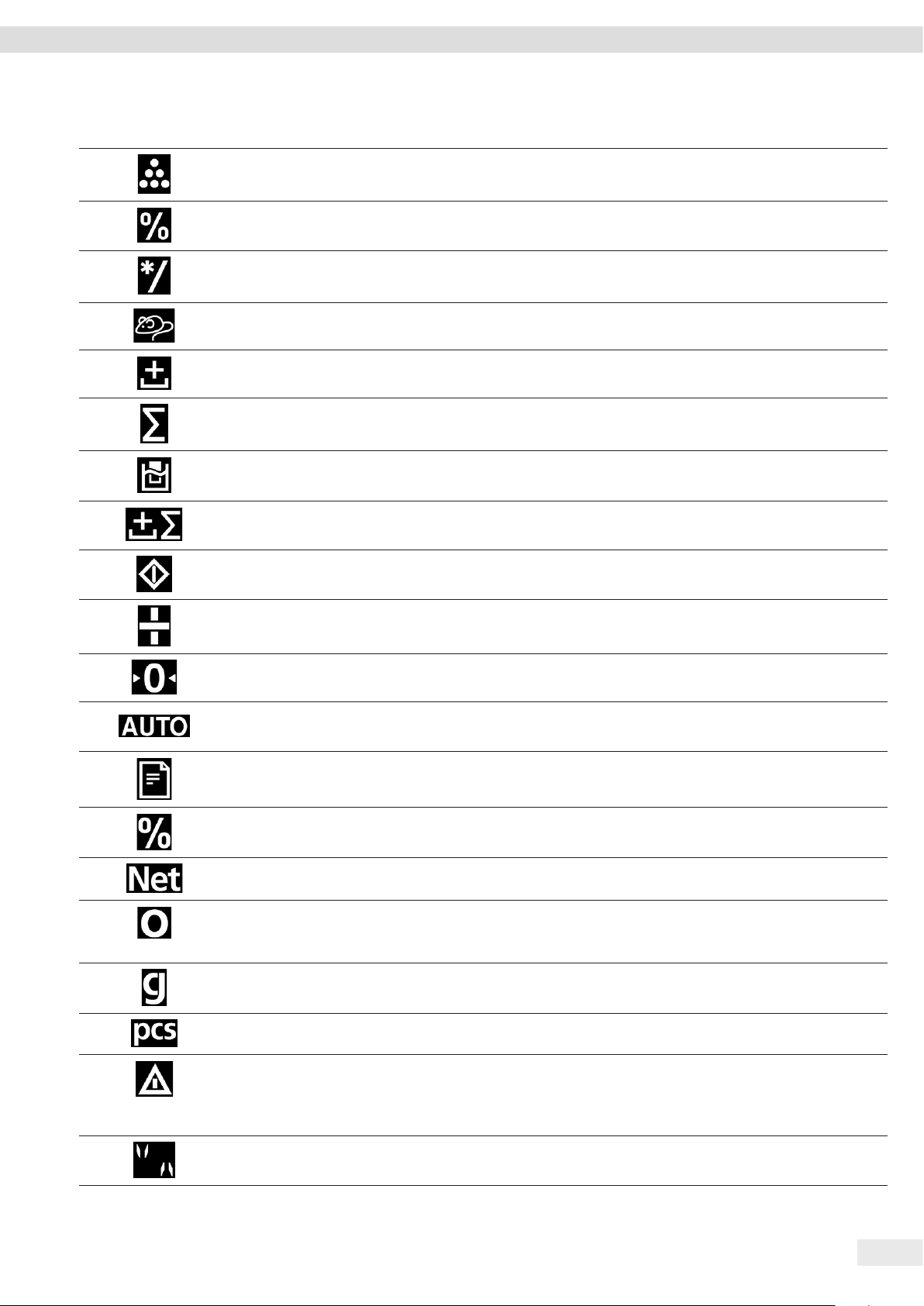

Pos. Symbol Designation Description

1

2

[Leveling] display − Indicates that the device is leveled.

− If the center circle is flashing: Indicates that the device is not leveled.

[Leveling] display Flashes while the device is leveling.

18 Cubis® MCE Operating Instructions

Page 19

Pos. Symbol Designation Description

3

[Counting] display Indicates that the “Counting” application is selected.

Operating Concept

4

5

6

7

8

9

10

11

12

[Weighing in percent]

Indicates that the “Weighing in percent” application is selected.

display

[Calculation] display Indicates that the “Calculation” application is selected.

[Animal weighing]

Indicates that the “Animal weighing” application is selected.

display

[Net-total] display Indicates that the “Net-total” application is selected.

[Totalizing] display Indicates that the “Totalizing” application is selected.

[Density determination]

Indicates that the “Density determination” application is selected.

display

[Statistics] display Indicates that the “Statistics” application is selected.

[Busy] display Indicates that the device is processing a command.

[Sign] display Indicates whether the value being displayed is positive or negative.

13

14

15

16

17

18

19

20

21

22

[Zero] display For some conformity-assessed devices: Indicates that the device has been zeroed.

[AUTO] display Indicates that the “Animal weighing” application starts automatically.

[Data output] display Indicates that the data output is active.

[Percent] display Indicates that a percentage value is being displayed.

[Net] display Indicates that a net value is being displayed.

[Computed value]

display

− In the menu: Identifies the selected configuration value.

− If the “Calculation” or “Density determination” application is active: Indicates

that a calculated value is being displayed.

[Unit symbol] display Indicates the set weight unit, e.g. [g] for “grams”.

[Quantity] Indicates that a quantity is being displayed.

[Invalid weight value]

display

− Indicates that the display does not contain a weight value, rather it is the

calculated result of an application, e.g. for the “Totalizing” application.

− For conformity-assessed devices: Indicates a fault. The cause of this fault is

displayed after pressing the [Change] key.

[Directional arrows]

display

If leveling with the inclination sensor is active: Displays the direction of rotation of

the leveling foot.

Cubis® MCE Operating Instructions 19

Page 20

Operating Concept

4.5 Menu Structure

4.5.1 Overview of the Device Settings Menu

t Navigating in Menus (see Chapter 4.6, page 24).

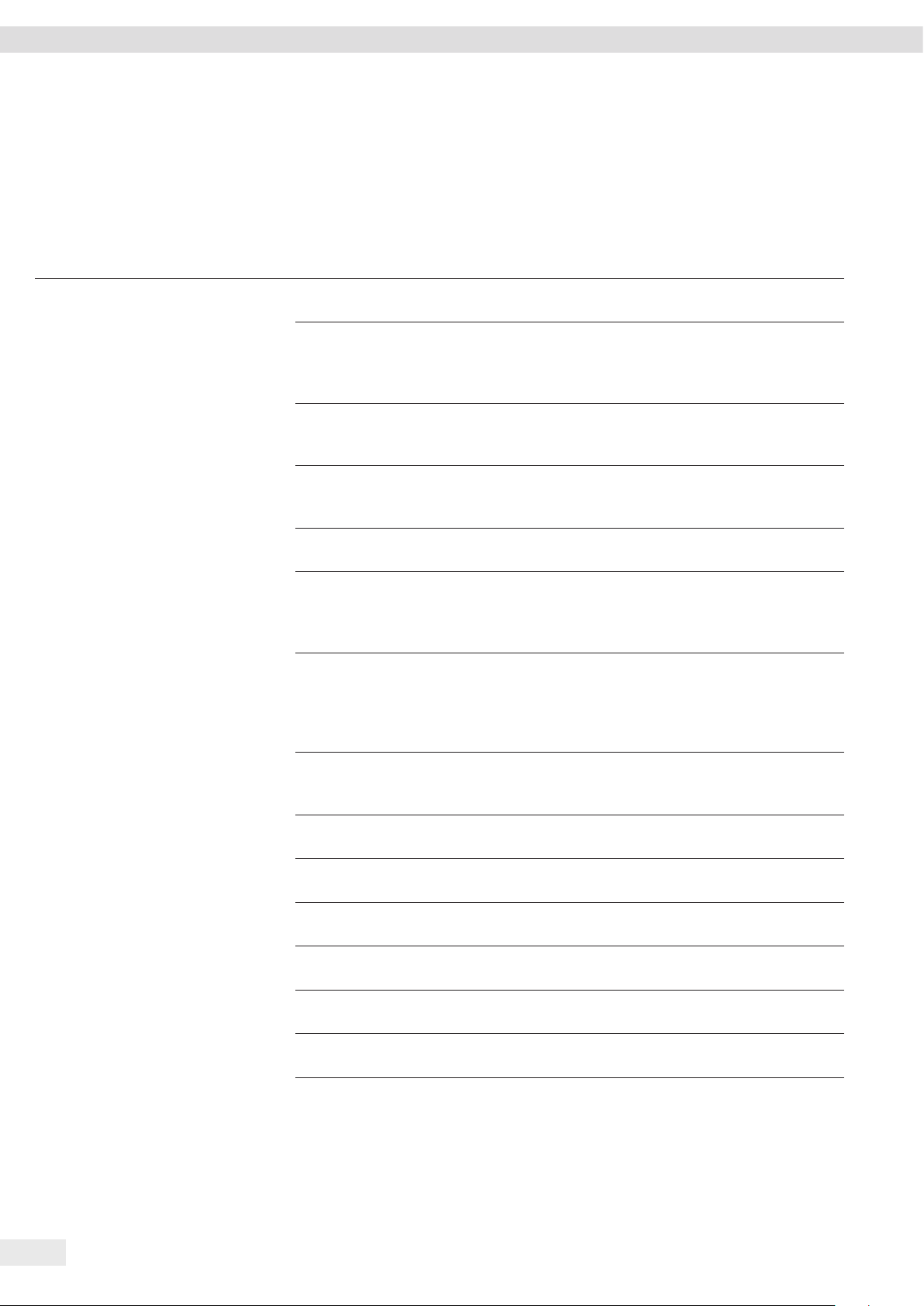

Level 1 Level 2 Level 3 Description | Reference

SETUP BALANCE AMBIENT

“Ambient conditions”

APP FILT.

“Application filter”

STABIL.

“Stability range”

ST.DEL.

“Stability delay”

ZERO/TAR.

“Zeroing and taring”

AUTOZER.

“Auto zero”

UNIT Define the weight unit, e.g. grams, kilograms, pounds.

DISP.DIG. Define whether all decimal places are displayed. A lower

CAL./ADJ.

“Adjust”

CAL.SEQ.

“Calibration sequence”

ZERORNGE

“Zero range”

INI.ZERO.R

“Zero at power on”

ON Z/T

Tare / zero at power on

CYC.RATE

“Output rate”

Enter the ambient conditions at the device’s installation

site.

Equalize the load deviations in the display. The load

deviations occur between the complete placement of the

sample on the weighing pan and reaching the final result

display.

Define the accuracy of the stability range. If the weight

unit symbol appears, the weight readout is stable within

the range indicated by the stability range

Define the duration of the stability delay. The stability

delay is used to bridge residual fluctuations in the vibration

of the device in order to display reliable results.

Define the trigger for zeroing and taring.

Activate / deactivate automatic control of the zero display.

The deviations of a set fraction of scale intervals per

second starting from the display zero point are

automatically zeroed.

Depending on the country-specific model version, not all

weight units listed may be available. Some weight units

may be blocked from use in conformity-assessed devices,

depending on national verification laws.

display accuracy enables a faster display. The setting option

is not available on conformity-assessed devices.

Define the function of the [Adjust] button.

Define the sequence of the “Calibrate and adjust” function.

Define the zero range of the device.

Define the zero range when switching on the device.

Activate / deactivate automatic taring when starting the

device.

Determine the data output rate.

20 Cubis® MCE Operating Instructions

Page 21

Operating Concept

Level 1 Level 2 Level 3 Description | Reference

ISOCAL Configure the isoCAL function.

EXT.CAL.

“External adjustment”

CAL.UNIT

Configure the function “External calibration and

adjustment”.

Define the weight unit for the calibration weight.

“Calibration weight unit”

GEN.SERV.

“General services”

DEVICE RS232

MEN.RESET

Reset the menu to factory settings.

“Menu reset”

DAT.REC. Set the communication protocol for the connected device.

“COM-RS232, 9-pin”

BAUD Set the baud rate for the connected device.

PARITY Set the parity for the connected device.

STOPBIT Set the number of stop bits.

HANDSHK. Set the handshake between the balance and the device.

DATABIT Set the number of data bits.

PC-USB

DAT.REC. Set the communication protocol for the connected PC.

“USB-B (Device/

Slave)”

BAUD Set the baud rate for the connected PC.

PARITY Set the parity for the connected PC.

STOPBIT Set the number of stop bits.

HANDSHK. Set the handshake between the device and the connected

PC.

DATABIT Set the number of data bits.

USB

“USB-A (Host/Master)”

D.SHIELD

DEV.USED

Display the device connected via USB-A.

“Device in use”

CONTROL Activate / deactivate the motorized draft shield.

“Draft shield”

Only for devices with

a motorized draft

shield.

INT.ADJ. Define the function of the draft shield when starting an

internal adjustment.

SEN.L.MOT. Set the sensitivity of the left motion sensor.

ACT.L.MOT. Define the action for the left motion sensor.

SEN.R.MOT. Set the sensitivity of the right motion sensor.

ACT.S.MOT. Define the action for right motion sensor.

LIGHTING Set the brightness of the lighting of the draft shield.

LEVELING

“Leveling”

LEVEL Define the settings for the integrated inclination sensor.

START Define the trigger for automatic leveling.

Cubis® MCE Operating Instructions 21

Page 22

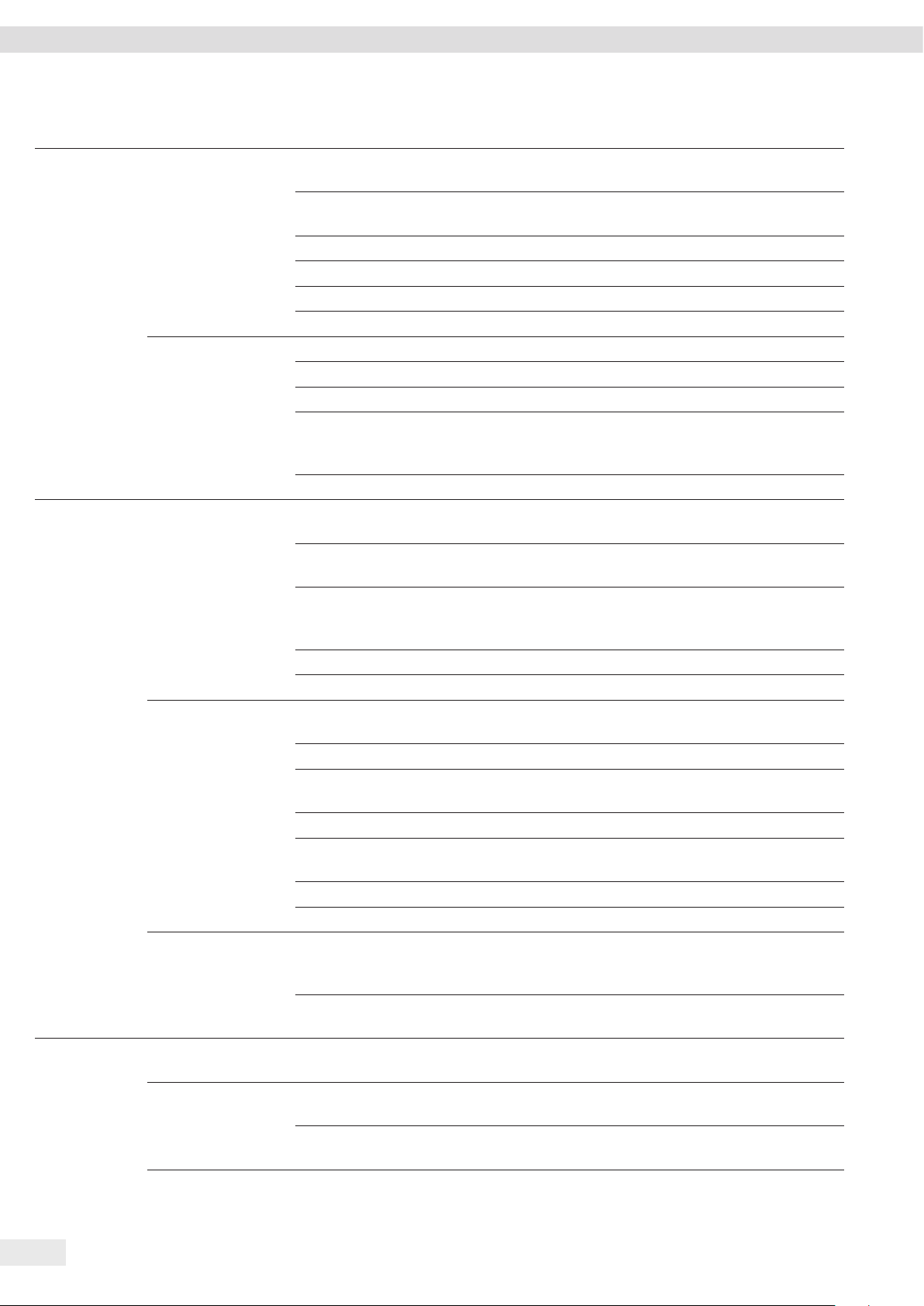

Operating Concept

Level 1 Level 2 Level 3 Description | Reference

MOTION.S.

CONTROL Activate / deactivate the motion sensor.

“Motion sensor”

NUM.GEST.

Define the number of possible gestures.

“Number”

LEFT CMD. Define the function for the left gesture.

RIGHT.CMD. Define the function for the right gesture.

UP.CMD. Define the function for the up gesture.

DOWN.CMD. Define the function for the down gesture.

EXTRAS MENU Lock or unlock the menu’s configuration parameters.

SIGNAL Set or deactivate the acoustic signal.

KEYS Activate / deactivate the key lock.

ON MODE

“Switch-on and

Configure the device’s switch-on and switch-off options,

e.g. switch between standby mode and operating mode.

switch-off options”

LIGHTING Activate / deactivate the lighting for the operating display.

DATA.OUTP.

“Data output”

COM. SBI

“SBI communication”

COM.OUTP. Configure the automatic data output.

STOP.AUTO Define whether the automatic data output can be stopped

and started with the [Print] key.

AUTO.CYCL.

“Time-dependent

interval”

− Define an interval for the automatic data output.

− Define whether data output takes place after an

interval with or without balance stability.

FORMAT Define the data output format (characters per line).

AUTO.TARE Activate / deactivate automatic taring after the printout.

PRNT.PARA.

“Printout settings”

ACTIVATE

“Triggers”

Define whether a printout is triggered via a software

command or using the [Print] key.

FORMAT Define the format for the printout (characters per line).

PRT.INIT.

Define the settings for printer initialization.

“Initializing”

GLP Define the settings for the GLP printout.

TAR./PRT.

“Tare / print”

Activate / deactivate automatic taring after every print

process.

TIME Define the time format.

DATE Define the date display format.

PC.DIRECT

DEC.SEPAR. Define the decimal separator character.

Direct transfer of data

(PC)

OUTP.FORM. Define the output format for the data exchange between

the balance and the PC.

APPLIC.

“Applications”

WEIGH

(Factory setting)

UNIT Activate / deactivate the “Toggle between weight units”

function for all applications.

COUNT RESOLUT. Define the resolution of the weight value for the

“Counting” application.

REF.UPDT.

“Reference updating”

Activate / deactivate automatic reference updating for the

“Counting” application.

22 Cubis® MCE Operating Instructions

Page 23

Operating Concept

Level 1 Level 2 Level 3 Description | Reference

PERCENT

“Weighing in percent”

NET-TOTL.

“Net-total”

TOTAL

“Totalizing”

ANIMALW.

“Animal weighing”

DEC.PLCS

“Decimal places”

COMP.PRT.

“Component printout”

COMP.PRT.

“Component printout”

ACTIVITY

“Animal activity”

Define the number of decimal places for the “Weighing in

percent” application.

Activate / deactivate the component printout for the “Nettotal” application.

Activate / deactivate the component printout for the

“Totalizing” application.

Define the level of activity of the sample for the “Animal

weighing” application.

START Define the trigger for starting the animal weighing.

CALC.

“Calculation”

DENSITY

“Density

METHOD Define the method of calculation for the “Calculation”

application.

DEC.PLCS

“Decimal places”

DEC.PLCS

“Decimal places”

Define the number of decimal places for the “Calculation”

application.

Define the number of decimal places for the “Density

determination” application.

determination”

STATIST.

“Statistics”

COMP.PRT.

“Component printout”

TAR./STAT.

“Tare/statistics”

Activate / deactivate the component printout for the

“Statistics” application.

Activate / deactivate automatic taring for the “Statistics”

application.

UPDATE Start a firmware update. The menu is only available if a

USB mass storage device is connected.

INPUT ID NO. Save the entered ID number for the device.

LOT ID Activate / deactivate the prompt of the lot ID number

before every data output.

DATE Set the date.

TIME Set the time.

USER.PASS. Set the user password.

DEL.PASS. Delete the user password. The menu is only available if a

user password is set.

SERV.PASS. Activate the service mode.

CAL.WT.

Define the value of the external user calibration weight.

“Calibration weight”

INFO

“Device

VERSION

“Version number”

Display the software version number.

information”

SER. NO.

Display the device’s serial number.

“Serial number”

MODEL Display the device’s model ID.

APC VER. Display the version of the APC processor.

BAC VER. Display the version of the BAC processor.

MCU VER. Display the version of the MCU processor.

WPC VER.

Display the draft shield software version.

“Draft shield version”

LANGUAGE Change the menu language.

Cubis® MCE Operating Instructions 23

Page 24

Operating Concept

Overview of the “Toggle between weight units” Function

t Navigating in Menus (see Chapter 4.6, page 24).

Level 1 Description

Unit 1 Define the displayed weight unit and the resolution for the 1st convertible unit.

Unit 2 Define the displayed weight unit and the resolution for the 2nd convertible unit.

Unit 3 Define the displayed weight unit and the resolution for the 3rd convertible unit.

Unit 4 Define the displayed weight unit and the resolution for the 4th convertible unit.

4.6 Navigating the Menus

Procedure

t To access the settings menu: Press the [Menu] button.

t To scroll through all menus in the same level: Press the [Up] or [Down] button.

t To switch to the displayed menu level: Press the [Confirm] button on the keypad.

t To scroll through the configuration values: Press the [Up] or [Down] button.

t To select the configuration value shown in the display or the displayed

application: Press the [Confirm] button on the keypad.

y The [Value] display identifies the selected configuration value or the selected

application.

t To return to the next higher menu level: Press the [Back] button.

t To exit the settings menu: In the main menu level, press the [Back] button.

t If the start display (1) of a selected application is displayed:

t To start the application without changing the preset reference value: Press

the [Confirm] button on the keypad.

1

t To change a reference value before starting the application, e.g. density value,

divisor or reference quantity: Press the [Up] button.

y The reference value display is shown for the selected application.

t If a reference value with decimal places needs to be selected in the reference

value display (1) of a selected application, e.g. “Density determination” or

1

“Calculation” applications:

y The selected digit position flashes.

t Use the [Up] or [Down] button to change the value for the selected digit

position.

t If a digit position other than the last digit position is selected: Press the

[Confirm] button to select the next digit position.

t If a digit position other than the first digit position is selected: Press the

[Back] button to select the previous digit position.

t If the last digit position is selected: Press the [Confirm] button to save the

displayed reference value and start the application process.

t If the first digit position is selected: Press the [Back] button to delete the

displayed reference value and return to the application’s status display.

24 Cubis® MCE Operating Instructions

Page 25

Operating Concept

t If an integer reference value needs to be selected in the reference value display

(1) of a selected application, e.g. “Weighing in percent” or “Animal weighing”

1

applications:

t Press the [Up] or [Down] button. This increases or decreases the reference

value by 1.

t Hold down the [Up] or [Down] button. This increases or decreases the

reference value by 10.

t To start the application: Press the [Confirm] button on the keypad.

t To delete the displayed reference value and return to the application’s status

display: Press the [Back] button.

t If the results display (1) of a selected application is displayed:

t To switch between the application results display and the set reference value

1

display: Press the [Up] or [Down] button.

t To exit the results, display and delete the set reference value and the result of

the application: Press the [Back] button.

Cubis® MCE Operating Instructions 25

Page 26

Installation

5 Installation

5.1 Scope of Delivery

Item Quantity

Device 1

Weighing pan 1

For filter ultramicrobalances and microbalances: Filter weighing pan 1

For model MCA2.7S…: Shield disk 1

For model MCA2.7S…: Internal draft shield 1

Shield plate 1

Pan support 1

Power supply unit 1

Country-specific power supply cable with test seal 1

USB connection cable 1

In-use dust cover for control unit 1

In-use dust cover for the weighing module 1

Electronics module with power supply cable 1

Connection cable for electronics module 1

5.2 Selecting an Installation Site

Procedure

t Ensure that the following conditions are met at the installation site:

Condition Features

Ambient conditions Suitability tested (see Chapter “15.6 Ambient

Conditions”, page 67)

Setup surface Stable, even surface that is not exposed to

vibrations

Not directly against a wall

Sufficiently dimensioned for the device and the

peripheral devices (device space requirements see

Chapter “15.1 Dimensions and Weight”, page 65;

peripheral device space requirements see instructions for the peripheral devices, e.g. printer)

Sufficient load-bearing capacity for the device

and the peripheral devices even when full (device

weight see Chapter “15.1 Dimensions and Weight”,

page 65; weight of the peripheral devices see

instructions for the peripheral devices, e.g. printer)

Access Barrier-free

26 Cubis® MCE Operating Instructions

Page 27

Installation

5.3 Unpacking the Device

Procedure

t Lift the device in the Styrofoam padding out of the packaging.

t Place the device in the Styrofoam padding on its side.

t Lift the Styrofoam padding off the device.

t NOTICE Glass breakage due to the incorrect handling of the device! Only lift the

device by its base.

t Place the device on its base.

t Keep all parts of the original packaging, e.g. to return the device.

5.4 Preparing Below-cell Weighing

The device can be configured for below-balance weighing. Samples can be

suspended for weighing using below-balance weighing, e.g. samples, which do not

fit on the weighing pan.

For below-balance weighing, the cover plate must be removed and the device set up

on a weighing table with recess.

In legal metrology:

− Do not use the below-cell weighing equipment.

− Do not open the cover of the below-cell weighing equipment.

Tool: 1 Torx Allen key, T20

Material: 1 soft support base

1 draft protection shield

1 weighing table with recess

Requirements

− The draft shield has not been mounted.

− The weighing pan and the associated components have not been set up.

Procedure

t Turn the device on its side and place it on the soft support base.

Cubis® MCE Operating Instructions 27

Page 28

Installation

2

t Unscrew both screws (2) from beneath the weighing module with the 1 Torx

Allen key.

1

t Lift out the cover plate (1).

t Install a draft protection shield.

3

t Set up the device on the weighing table with recess. The hook for below-balance

weighing (3) may not touch the weighing table.

t Install the draft protection shield.

t To cover the below-balance weighing equipment after weighing:

t Insert cover plate and screw on with both screws.

t Place the device back on the device base on a level surface.

28 Cubis® MCE Operating Instructions

Page 29

Installation

5.5 Installing a Microbalance with Glass Draft Shield

5.5.1 Positioning the Weighing Pan and Associated Components

Procedure

t For a device with a connector: Place the connector (2) on the base of the

weighing chamber.

t Place the shield plate (1) on the base of the weighing chamber.

1

2

t Place the weighing pan (1) through the opening in the weighing chamber into

the pan retainer.

t To mount the weighing pan: Turn the weighing pan slightly while pressing down

lightly.

1

t For devices with an internal draft shield: Place the internal draft shield on a

shield plate.

t Center and insert glass draft shield with recess (1) above the snap-in peg (2).

1

2

Cubis® MCE Operating Instructions 29

Page 30

Installation

5.6 Installing a Filter Microbalance with a Metal Ring Draft Shield

5.6.1 Inserting a Filter Pan or Weighing Pan and Associated Components

Procedure

t For a device with a connector: Place the connector on the base of the weighing

chamber.

t Place the shield plate (2) on the base of the weighing chamber.

t Place the draft shield (1) on the base of the weighing chamber. The inner metal

1

2

ring of the draft shield must be inserted into the outer metal ring.

t Turn the opening of the draft shield in the direction of the arrows.

t To mount the draft shield: Turn the screw (2).

1

2

1

t Place the filter pan (1) or the weighing pan through the opening in the shield

plate on the pan retainer.

t BEWARE The filter pan or weighing pan can be damaged due to improper

assembly. To mount the inserted filter pan or weighing pan: Screw in the filter

pan or weighing pan with slight pressure to make correctly position it in the pan

retainer.

t Insert the pin (1) in the draft shield cover into the recess of the draft shield and

screw on draft shield cover onto draft shield.

30 Cubis® MCE Operating Instructions

Page 31

Installation

5.6.2 Optimizing a Filter Weighing Pan with a Metal Ring Draft Shield for Left-handed Users

Requirements

The metal ring draft shield has been mounted.

Procedure

t Lift the draft shield cover from the draft shield and turn.

t Unscrew bearing pin (1) from the underside of the draft shield cover and screw

1

into the opening of the opposite side.

t Place the wind shield cover on wind shield.

t Loosen screw (1) on draft shield and turn draft shield in the direction of the

arrows by 90°.

t Retighten the screw.

1

5.7 Connecting the Electronics Module

Procedure

t Connect the connection cable to the electronics module’s weighing module

connection.

t Connect the other end of the connection cable to the weighing module

electronics module connection.

t To lock the connection cable: Lock the plugs of the connection cable onto both

connections with two clicks in each case.

t NOTICE Damage to the device due to incorrect connection!

t Check the correct fit of the plug contacts.

t There should be no tension on the connection cable, e.g. do not install

directly against a wall.

5.8 Acclimatization

When a cold device is brought into a warmer area: The temperature difference can

lead to condensation of humidity in the device (moisture formation). Moisture in the

device can lead to malfunctions.

t Allow the device to acclimatize for approx. 2 hours at the installation site.

Ensure that the device is disconnected from the power supply during that time.

Cubis® MCE Operating Instructions 31

Page 32

Getting Started

6 Getting Started

6.1 Connecting Electronic Components

Procedure

t NOTICE Improper connection may damage the device! If the device is connected

using electronic components, e.g. printer, PC: The device must be disconnected

from the power supply. Ensure that the device is disconnected from the power

supply.

t Connect the device using electronic components (see electronic components

instructions).

6.2 Installing the AC Adapter

Procedure

t Plug the DC supply cable of the AC adapter into the electronics module’s “power

supply” connection socket and tighten the threaded fitting.

t Connect the power supply cable to the AC adapter connection.

6.3 Connecting the Power Supply

Procedure

t

WARNING Severe injuries caused by using a defective power supply cable!

Check the power supply cable for damage, e.g., cracks in the insulation.

t If required: Contact Sartorius Service.

t Check whether the country-specific power plug matches the power connections

at the installation site.

t If required: Contact Sartorius Service.

t NOTICE Damage to the device due to excessive input voltage! Check whether the

voltage specifications on the AC adapter match those of the power supply at the

installation site.

t If the input voltage is too high: Do not connect the device to the power

supply.

t Contact Sartorius Service.

t Connect the mains plug of the power supply cable to the wall outlet at

the installation site.

y The [BOOTING] display appears in the operating display.

y The device performs a self-test.

y The device performs an initial tare function.

32 Cubis® MCE Operating Instructions

Page 33

System Settings

7 System Settings

7.1 Performing System Settings

Default settings can be adjusted for the device and the applications in order to align

with the ambient conditions and individual operating requirements.

The following settings are necessary to operate the device together with connected

components:

− Set up the communication of the connected devices

− Set up additional components

The following settings are recommended to set up the device:

− Set the menu language

− Set the behavior of the isoCAL function

− Set the behavior of the motorized draft shield (only for devices with a motorized

draft shield)

Procedure

t Press the [Menu] button.

t Open the desired settings menu.

t To adjust settings: Open the desired main menu and submenu.

t Select and confirm the desired configuration value (configuration values, see

Chapter “7.3 Parameter List”, page 34).

t Exit the menu.

y If settings have been adjusted in the “SETUP”, “DEVICE”, “DATA.OUTP.” or

“APPLIC.” menu: The [BOOTING] display appears in the operating display and the

device restarts.

7.2 Switching Off the isoCAL Function

If the isoCAL function is switched off for a conformity-assessed device, the device

can only be used for legal-for-trade applications in restricted temperature ranges

(see Chapter “15.6.2 Ambient Temperature for the isoCAL Function”, page 67). The

isoCAL function cannot be switched off for all model versions.

Procedure

t In the “SETUP” / “BALANCE” menu, for the “ISOCAL” parameter, select the “OFF”

configuration value.

Cubis® MCE Operating Instructions 33

Page 34

System Settings

7.3 Parameter List

7.3.1 Parameters in the “Setup” Main Menu

Parameters in the “Balance” Submenu

Parameters Setting values Explanation

AMBIENT V.STABLE Sets the ambient conditions to “very stable”: Activates a fast change in the weight values

in the event of a load change with a high output rate.

Recommended for the following work environment:

− Very stable table near the wall

− Closed and calm room

STABLE* Sets the ambient conditions to “stable”.

Recommended for the following work environment:

− Stable table

− Slight movement in the room

− Slight draft

UNSTABL. Sets the ambient conditions to “unstable”: Activates the delayed change in weight values

with a reduced output rate.

Recommended for the following work environment:

− Simple office desk

− Room with moving machinery or personnel

− Slight air movement

V.UNSTBL. Sets the ambient conditions to “very unstable”: Activates a significantly delayed change

in the weight values and long wait for stability with a further reduction in the output

rate.

Recommended for the following work environment:

− Noticeable and slow floor vibrations

− Noticeable building vibrations

− Weighed goods moved

− Very strong air movements

APP FILT. FINAL.RD.* Activates a filter that enables a fast change in the display for very fast load changes.

Display changes with minimal load changes (in the digit range) occur more slowly.

FILLING Activates a filter that enables a very fast change in the display with minimal load

changes (e.g. when filling containers).

REDUC. Activates a weak but fast filter that always behaves in the same way for load changes

(e.g. when filling automated systems).

OFF Deactivates the active application filter.

STABIL. MAX ACC. Sets the stability to “maximum accuracy”.

V. ACC. Sets the stability to “very accurate”.

ACC.* Sets the stability to “accurate”.

FAST Sets the stability to “fast”.

V. FAST Sets the stability to “very fast”.

MAX.SPEED Sets the stability to “maximum speed”.

ST.DEL. NONE Sets the stability delay to “none”: The stability symbol is displayed after the stability

criterion is reached.

SHORT* Sets the stability delay to “short”: The stability symbol only appears after a short delay in

order to provide a reliable result despite fluctuations.

* Factory setting

34 Cubis® MCE Operating Instructions

Page 35

System Settings

Parameters Setting values Explanation

MEDIUM Sets the stability delay to “medium”: The stability symbol only appears after a longer

delay in order to provide a reliable result in case of higher fluctuations.

LONG Sets the stability delay to “long”: The stability symbol only appears after a long delay in

order to balance out major instability.

ZERO/TAR. W/O STB. Without stability: The function of the [Zero] or [Tare] key is executed immediately once

the key is pressed.

W/ STAB.* With stability: The function of the [Zero] or [Tare] key is only executed after stability is

achieved.

AT STAB. At stability: The function of the [Zero] or [Tare] key is executed if stability exists when

the key is pressed.

AUTOZER. ON* Activates automatic zeroing. The display is automatically set to zero in case of a

deviation of 0 less than (X).

OFF Deactivates automatic zeroing. Zeroing must be triggered with the [Zero] key.

UNIT The availability of units may depend on national legislation and is therefore country-

specific.

GRAMS* The device displays the weight in grams.

KILOGR. The device displays the weight in kilograms (not for semi-microbalances).

CARATS The device displays the weight in carats.

POUNDS The device displays the weight in pounds (not for semi-microbalances).

OUNCES The device displays the weight in ounces.

TROY OZ. The device displays the weight in troy ounces.

HKTAEL The device displays the weight in taels (Hong Kong).

SNGTAEL The device displays the weight in taels (Singapore).

TWNTAEL The device displays the weight in taels (Taiwan).

GRAINS The device displays the weight in grains.

PENYWT. The device displays the weight in pennyweights.

MILLIGR. The device displays the weight in milligrams.

CHINATAEL The device displays the weight in taels (China).

MOMMES The device displays the weight in mommes.

TOLA The device displays the weight in tolas.

BAHT The device displays the weight in baht.

MESGHAL The device displays the weight in mesghals.

NEWTON The device displays the weight in newtons.

DISP.DIG. ALL* “Show all decimal places”: All decimal places are shown in the display. Not available on

conformity-assessed devices.

LP.ON/OFF “Reduced by 1 decimal place for load change”:

The last decimal place on the display is switched off until stability is achieved.

DIVIS. 1 “Last decimal place of the 1st division”: The last decimal place always shows the 1st

division.

MINUS 1 “Last decimal place off”: The last decimal place is switched off.

* Factory setting

Cubis® MCE Operating Instructions 35

Page 36

System Settings

Parameters Setting values Explanation

CAL./ADJ. EXT.CAL. The [Adjust] button starts an external calibration with the preset calibration weight.

E.CAL.USR. The [Adjust] button starts an external calibration with the user-defined calibration

weight value.

INT.CAL.* The [Adjust] button starts an internal calibration.

INT.LIN. The [Adjust] button linearizes the balance with the integrated weight (not for precision

balance)

CAL.SEQ. ADJUST* Calibration and adjustment is one routine.

CAL.-ADJ. Adjustment must be started or exited manually after calibration with the [Adjust]

button.

ON Z/T ON* Activates the initial taring / zeroing. The device is tared or zeroed after it is switched on.

OFF Deactivates the initial taring / zeroing: After it is switched on, the device shows the value

before it was last switched off.

ISOCAL OFF Switches the isoCAL function off.

NOTE TO The [isoCAL] button flashes if the balance needs to be adjusted. The isoCAL function

must be manually triggered with the [Adjust] button.

ON* Activates the isoCAL function. The device is automatically adjusted as soon as a trigger

starts the isoCAL function.

ON W/LIN.

(only for semi-

Activates the isoCAL and linearization function. The device is automatically adjusted and

then linearized as soon as a trigger starts the isoCAL function.

microbalances

and analytical

balances)

CAL.UNIT GRAMS* Changes the calibration weight unit to grams.

KILOGR. Changes the calibration weight unit to kilograms.

* Factory setting

Parameters in the “General Services” Submenu

Parameters Setting values Explanation

MEN.RESET YES Resets the system settings to the factory default settings.

NO* Deactivates the option of resetting the device menu.

* Factory setting

7.3.2 Parameters in the “Device” Main Menu

Parameters in the “Extras” Submenu

Parameters Setting values Explanation

MENU EDITABLE* Activates write access: The menu parameters can be changed.

RD.ONLY Activates read access: The menu parameters cannot be changed.

SIGNAL OFF Switches the acoustic signal off.

QUIET Sets the volume of the acoustic signal to “quiet”.

MEDIUM* Sets the volume of the acoustic signal to “medium”.

LOUD Sets the volume of the acoustic signal to “loud”.

KEYS UNLOCKED* Deactivates the key lock.

LOCKED Activates the key lock.

* Factory setting

36 Cubis® MCE Operating Instructions

Page 37

System Settings

Parameters Setting values Explanation

ON MODE ON/STDBY* The [On / Off] key switches between on / standby.

ON/OFF The [On / Off] key switches between on / off.

AUTO ON Changes the function of the [On / Off] key: The device no longer switches off or to

standby mode, instead it starts a boot process.

LIGHTING OFF Deactivates the lighting on the operating display.

ON* Activates the lighting on the operating display.

* Factory setting

Parameters in the “Draft Shield” Submenu (Only for Devices with a Motorized Draft Shield)

Parameters Setting values Explanation

CONTROL OFF Deactivates the motorized draft shield.

ON* Activates the motorized draft shield.

INT.ADJ. NONE The draft shield does not perform an action if an internal calibration / adjustment

starts.

CLOSE* Draft shield closes if an internal calibration / adjustment starts.

SEN.L.MOT. OFF* Deactivates the left motion sensor of the gesture control for the draft shield.

LOW Sets the sensitivity of the left motion sensor of the gesture control to “low”.

MEDIUM* Sets the sensitivity of the left motion sensor of the gesture control to “medium”.

HIGH Sets the sensitivity of the left motion sensor of the gesture control to “high”

ACT.L.MOT. OWN SITE* The own (left) site of the draft shield is controlled by the left motion sensor of the

gesture control.

OPPOSITE The opposite (right) site of the draft shield is controlled by the left motion sensor of

the gesture control.

SEN.R.MOT. OFF Deactivates the right motion sensor of the gesture control for the draft shield.

LOW Sets the sensitivity of the right motion sensor of the gesture control to “low”.

MEDIUM* Sets the sensitivity of the right motion sensor of the gesture control to “medium”.

HIGH Sets the sensitivity of the right motion sensor of the gesture control to “high”

ACT.S.MOT. OWN SITE* The own (right) site of the draft shield is controlled by the right motion sensor of the

gesture control.

OPPOSITE The opposite (left) site of the draft shield is controlled by the right motion sensor of

the gesture control.

LIGHTING OFF Deactivates the lighting on the draft shield.

DARK Sets the brightness of the lighting of the draft shield to “dark”.

MEDIUM* Sets the brightness of the lighting of the draft shield to “medium”.

BRIGHT Sets the brightness of the lighting of the draft shield to “bright”.

* Factory setting

Cubis® MCE Operating Instructions 37

Page 38

System Settings

Parameters in the “Leveling” Submenu

Parameters Setting values Explanation

LEVEL OFF The device does not display messages on the status of the level.

NOTE* The [LEVELING] display flashes if the device needs to be leveled.

ERR.MSG. The [LEVEL.ERR.] message appears in the operating display if the device has not been

leveled.

START KEY Sets the trigger for leveling to “key”: Leveling must be started manually by pressing

the [Leveling] button.

AUTO* Sets the trigger for leveling to “automatic”: The device automatically performs a

leveling function using the integrated sensor before every internal

calibration / adjustment.

* Factory setting

Parameters in the “Motion Sensors” Submenu

Parameters Setting values Explanation

CONTROL OFF Deactivates the motion sensor: No gestures are recognized.

ON* Activates the motion sensor.

NUM.GEST. 2 GESTUR.* Activates the control of functions with 2 gestures. Gestures: Left, right

4 GESTUR. Activates the control of functions with 4 gestures. Gestures: Left, right, top, bottom

LEFT CMD. PRINT* Left command of the gesture control corresponds to the [Print] key.

ZERO Left command of the gesture control corresponds to the [Zero] key.

TARE Left command of the gesture control corresponds to the [Tare] key.

D.SHIELD Left command of the gesture control corresponds to the [Change] key.

OPEN LFT. Left command of the gesture control opens the left draft shield panel.

OPEN RT. Left command of the gesture control opens the right draft shield panel.

OPEN TOP Left command of the gesture control opens the upper draft shield panel.

CLOSE DS. Left command of the gesture control closes the entire draft shield.

NONE No function is assigned to the left command of the gesture control.

RIGHT.CMD. PRINT* Right command of the gesture control corresponds to the [Print] key.

ZERO Right command of the gesture control corresponds to the [Zero] key.

TARE Right command of the gesture control corresponds to the [Tare] key.

D.SHIELD Right command of the gesture control corresponds to the [Change] key.

OPEN LFT. Right command of the gesture control opens the left draft shield panel.

OPEN RT. Right command of the gesture control opens the right draft shield panel.

OPEN TOP Right command of the gesture control opens the upper draft shield panel.

CLOSE DS. Right command of the gesture control closes the entire draft shield.

NONE No function is assigned to the right command of the gesture control.

UP.CMD. PRINT* Upper command of the gesture control corresponds to the [Print] key.

ZERO Upper command of the gesture control corresponds to the [Zero] key.

TARE Upper command of the gesture control corresponds to the [Tare] key.

D.SHIELD Upper command of the gesture control corresponds to the [Change] key.

OPEN LFT. Upper command of the gesture control opens the left draft shield panel.

OPEN RT. Upper command of the gesture control opens the right draft shield panel.

OPEN TOP Upper command of the gesture control opens the upper draft shield panel.

CLOSE DS. Upper command of the gesture control closes the entire draft shield.

NONE No function is assigned to the upper command of the gesture control.

* Factory setting

38 Cubis® MCE Operating Instructions

Page 39

System Settings

Parameters Setting values Explanation

DOWN.CMD. PRINT* Lower command of the gesture control corresponds to the [Print] key.

ZERO Lower command of the gesture control corresponds to the [Zero] key.

TARE Lower command of the gesture control corresponds to the [Tare] key.

D.SHIELD Lower command of the gesture control corresponds to the [Change] key.

OPEN LFT. Lower command of the gesture control opens the left draft shield panel.

OPEN RT. Lower command of the gesture control opens the right draft shield panel.

OPEN TOP Lower command of the gesture control opens the upper draft shield panel.

CLOSE DS. Lower command of the gesture control closes the entire draft shield.

NONE No function is assigned to the lower command of the gesture control.

* Factory setting

Parameters in the “COM-RS232” Submenu

Parameters Setting values Explanations

DAT.REC. SBI.WEIGH. Enables a faster SBI communication, only for software commands to the weighing

module.

XBPI Extended range of commands to control numerous balance functions with binary

protocol for direct communication with the weighing module.

SBI* Enables SBI communication. The data is output to a PC or control unit. Enables the

use of ESC commands from a PC to control the basic balance functions with ASCII

protocol.

OFF Deactivates the automatic data output.

BAUD 600 Sets the baud rate to 600 baud.

1200 Sets the baud rate to 1200 baud.

2400 Sets the baud rate to 2400 baud.

4800 Sets the baud rate to 4800 baud.

9600* Sets the baud rate to 9600 baud.

19200 Sets the baud rate to 19200 baud.

38400 Sets the baud rate to 38400 baud.

57600 Sets the baud rate to 57600 baud.

115200 Sets the baud rate to 115200 baud.

PARITY ODD* Applies an odd parity.

EVEN Applies an even parity.

NONE Does not apply a parity.

STOPBIT 1 BIT* Sets the number of stop bits to 1.

2 BITS Sets the number of stop bits to 2.

HANDSHK. SOFTWARE Sets the handshake protocol to software handshake.

HARDWARE* Sets the handshake protocol to hardware handshake.

NONE Does not set a handshake protocol.

DATABIT 7 BITS Sets the number of data bits to 7.

8 BITS* Sets the number of data bits to 8.

* Factory setting

Cubis® MCE Operating Instructions 39

Page 40

System Settings

Parameters in the “PC-USB” Submenu

Parameters Setting values Explanations

DAT.REC. SBI.WEIGH. Enables a faster SBI communication, only for software commands to the weighing

module.

XBPI Extended range of commands to control numerous balance functions with binary

protocol.

SBI* Enables SBI communication. The data is output to a PC or control unit. Enables the

use of ESC commands from a PC to control the basic balance functions with ASCII

protocol.

PC.SPREAD. Enables data output to a spreadsheet program via a direct PC connection.

PC.TEXT Enables a direct PC connection to be established to a text processing program.

OFF Deactivates the data output.

BAUD 600 Sets the baud rate to 600 baud.

1200 Sets the baud rate to 1200 baud.

2400 Sets the baud rate to 2400 baud.

4800 Sets the baud rate to 4800 baud.

9600* Sets the baud rate to 9600 baud.

19200 Sets the baud rate to 19200 baud.

38400 Sets the baud rate to 38400 baud.

57600 Sets the baud rate to 57600 baud.

115200 Sets the baud rate to 115200 baud.

PARITY ODD* Applies an odd parity.

EVEN Applies an even parity.

NONE Does not apply a parity.

STOPBIT 1 BIT* Sets the number of stop bits to 1.

2 BITS Sets the number of stop bits to 2.

HANDSHK. SOFTWARE Sets the handshake protocol to software handshake.

HARDWARE Sets the handshake protocol to hardware handshake.

NONE* Does not set a handshake protocol.

DATABIT 7 BITS Sets the number of data bits to 7.

8 BITS* Sets the number of data bits to 8.

* Factory setting

Parameters in the “USB” Submenu

Parameters Setting values Explanation

DEV.USED NONE* Indicates that no device connection is detected at the USB port.

[Device Designation] Displays the designation of the devices connected to the USB port.

* Factory setting

40 Cubis® MCE Operating Instructions

Page 41

System Settings

7.3.3 Parameters in the “Data Output” Main Menu

Parameters in the “SBI Communication” Submenu

Parameters Setting values Explanations

COM. OUTP. IND.NO* Starts the data output after pressing the key or software command as an individual

value without stability.

IND.AFTER Starts the data output after pressing the key or software command as an individual

value without stability.

IND.AT Starts the data output after pressing the key or software command as an individual

value at stability.

AUTO W/O Activates the automatic data output without stability.

AUTO W/ Activates the automatic data output after stability.

STOP.AUTO OFF* Deactivates the option to abort the automatic data output.

ON

The automatic data output is aborted by pressing the [PRINT] key or a software command.

AUTO.CYCL. EACH VAL* Starts the automatic data output with a cycle after each value.

2. VALUE Starts the automatic data output with a cycle after every 2nd value.

FORMAT 16 CHARS 16 characters per line are data output.

22 CHARS Data output provides 22 characters per line (16 characters for the measured values

and 6 characters for identifiers).

EXTR.LINE Data output provides an additional line with the date, time, and weight value.

AUTO.TARE OFF* Deactivates automatic taring after data output.

ON The device automatically tares after data output.

* Factory setting

Parameters in the “Settings for Printouts” Submenu

Parameters Setting values Explanation

RESOLUT. MAN. NO Manual without stability: Print process can be started manually at any time.

MAN.AFTER* Manual after stability: After pressing the [Print] key, the print command is only

executed once stability is achieved.

MAN.AT Manual at stability: Print process can be started manually when stability is achieved.

AUTO.LC Automatically at load change: Print process starts after every load change.

FORMAT 22 CHARS* Printer output prints 22 characters per line (16 characters for the measured values

and 6 characters for identifiers)

EXTR.LINE Printer output prints an additional line with the date, time, and weight value.

PRINT.INIT OFF Deactivates the output of the application parameters.

ALL* Print command prints all parameters.

MAIN PAR. Print command only prints the main parameters.

GLP OFF* Deactivates the GLP printout.

CAL.-ADJ. Activates the GLP printout for all calibration and adjustment processes.

ALWAYS The GLP printout is always switched on. All printouts contain a GLP header and a

GLP footer.

TAR./PRT. OFF* Deactivates automatic taring after printer output.

ON Automatically tares the device after every printout.

TIME 24H Sets the time to 24-hour mode.

12H Sets the time to 12-hour mode (AM / PM).

DATE DD.MMM.YY* Sets the date display format to DD.MMM.YY

MMM.DD.YY Sets the date display format to MMM.DD.YY

* Factory setting

Cubis® MCE Operating Instructions 41

Page 42

System Settings

Parameters in the “PC Direct Transfer” Submenu

Parameters Setting values Explanations

DEC.SEPAR. DEC.POINT* Sets a point as a decimal separator.

DEC.COMMA Sets a comma as a decimal separator.

OUTP.FORM. TEXT+NUM.* Exports text and numbers.

ONLY NUM. Only exports numbers.

* Factory setting

7.3.4 Parameters in the “Applications” Main Menu

Parameters in the “Weighing” Submenu

Parameters Setting values Explanation

UNIT ON* Activates the “Toggle between weight units” function.

OFF Deactivates the “Toggle between weight units” function.

* Factory setting

Parameters in the “Counting” Submenu

Parameters Setting values Explanation

RESOLUT. DISP.ACC.* Sets the resolution to “display resolution”. The “Counting” application is started with

the displayed value.

10-FOLD Sets the resolution to 10-times more accurate than “display resolution”.

100-FOLD Sets the resolution to 100-times more accurate than “display resolution”.

REF.UPDT. OFF* Deactivates automatic reference sample updating.

AUTO Activates the automatic reference sample updating.

* Factory setting

Parameters in the “Weighing in Percent” Submenu

Parameters Setting values Explanation