Page 1

Sartorius Balance

Service Manual

MC 5

Page 2

Contents Page

Exploded-View Diagram 1 ......................................................................................................................... 4

Exploded-View Diagram 2 ......................................................................................................................... 6

Exploded-View Diagram 3 ......................................................................................................................... 8

Exploded-View Diagram 4 ....................................................................................................................... 10

Exploded-View Diagram 5 ....................................................................................................................... 12

Additional Service Tools and Equipment ................................................................................................. 14

Accompanying Literature......................................................................................................................... 14

General Information................................................................................................................................. 15

Installation Instructions............................................................................................................................ 16

Application Programs ........................................................................................................... ...................17

Key Functions ......................................................................................................................................... 18

Display Overview..................................................................................................................................... 18

Accessing the Balance Operating Menu and Setting Menu Codes ......................................................... 19

Displaying the Hardware and Software Version of the MC5 Microbalance ............................................. 20

Displaying the Model Name and the Serial Number................................................................................ 20

Activating the BPI Mode.......................................................................................................................... 21

Standard Service Tools and Equipment - Repair Policy.......................................................................... 22

Adjustment Data Sheet ........................................................................................................................... 22

Adjusting the Microbalance ..................................................................................................................... 23

Adjustment Sequence ............................................................................................................................. 23

Reproducibility......................................................................................................................................... 24

Null Indicator ........................................................................................................................................... 25

Checking the Null Indicator ..................................................................................................................... 25

Preload .................................................................................................................................................... 25

Checking and Adjusting the Preload ....................................................................................................... 25

Checking and Adjusting the Overload Stops ........................................................................................... 25

Indifferent Equilibrium.............................................................................................................................. 26

Checking the Indifferent Equilibrium (Tilt)................................................................................................ 26

Adjusting the Indifferent Equilibrium ........................................................................................................ 26

Off-Center Load (Eccentricity)................................................................................................................. 27

Checking the Off-Center Loading Tolerances ......................................................................................... 27

Adjusting the Off-Center Loading Tolerances ......................................................................................... 27

3-Point Coarse Adjustment ..................................................................................................................... 27

5-Point Fine Adjustment ..........................................................................................................................27

Linearity................................................................................................................................................... 28

External Linearization .............................................................................................................................. 28

Checking the Linearity............................................................................................................................. 28

Adjusting the Linearity ............................................................................................................................. 29

External Calibration ................................................................................................................................. 30

Overwriting the Internal Linearity Weight................................................................................................. 31

Overwriting the Internal Calibration Weight ............................................................................................. 32

Internal Calibration ........................................................................................................... ....................... 33

Internal Self-Calibrating Function ............................................................................................................ 33

Page 3

Description of the Microbalance .............................................................................................................. 34

Electronics............................................................................................................................................... 35

Main PCB (Exchanging) .......................................................................................................................... 35

Analog PCB (Exchanging)....................................................................................................................... 35

System PCB (Exchanging; Null Indicator Interface) ................................................................................ 35

Data Output PCB .................................................................................................................................... 35

Weight Servomotor PCB ......................................................................................................................... 35

Draft Shield PCB ..................................................................................................................................... 35

System Connector PCB ..........................................................................................................................35

Power-On Routine and Error Messages.................................................................................................. 36

Error Messages....................................................................................................................................... 36

Draft Shield ............................................................................................................................................. 38

Cleaning the Draft Shield......................................................................................................................... 38

Disassembling the Draft Shield Base Unit....................................................................................... ........ 38

Disassembling the Draft Shield Bearing .................................................................................................. 39

Checking and Adjusting the Draft Shield Bearing.................................................................................... 39

Overview of the Balance Operating Program .......................................................................................... 40

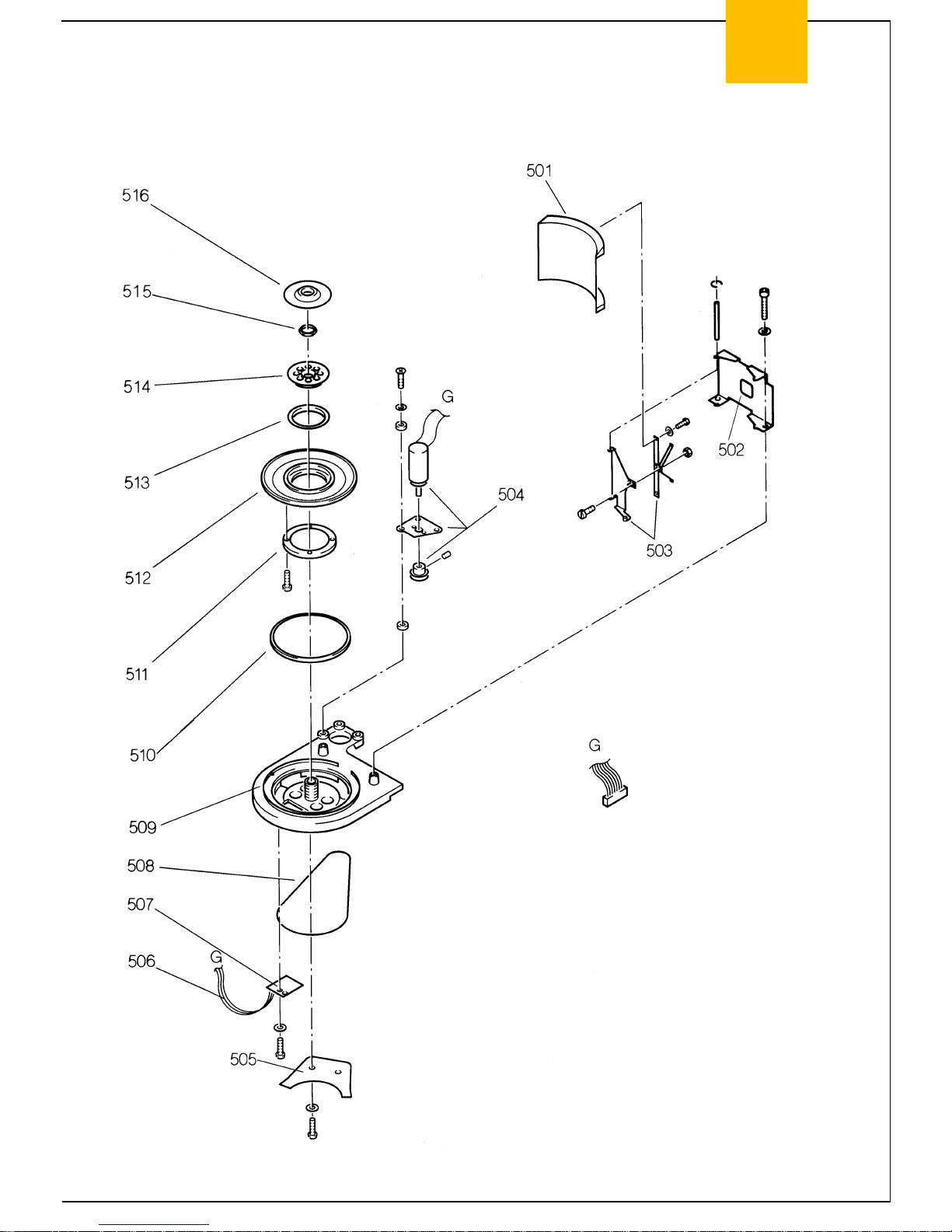

Page 4

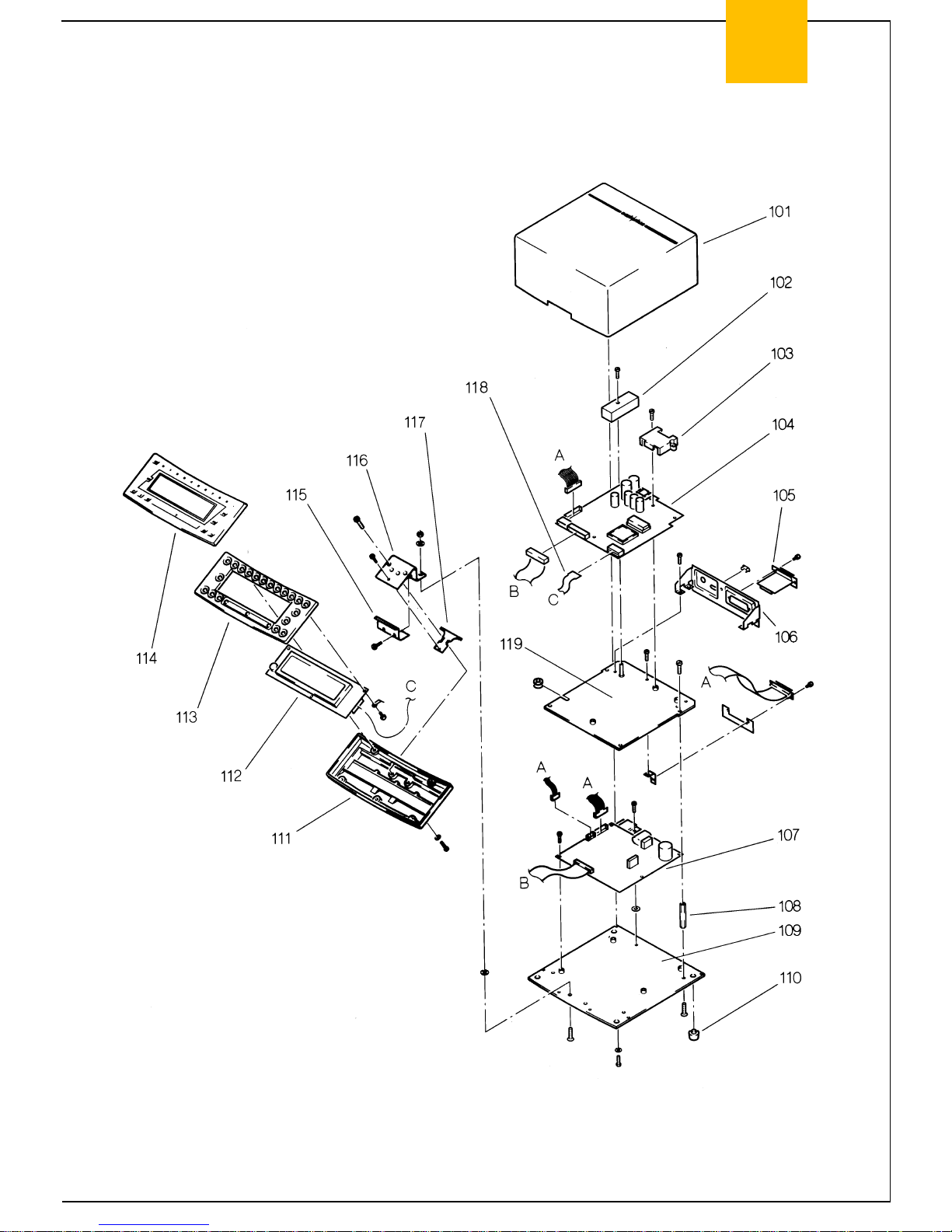

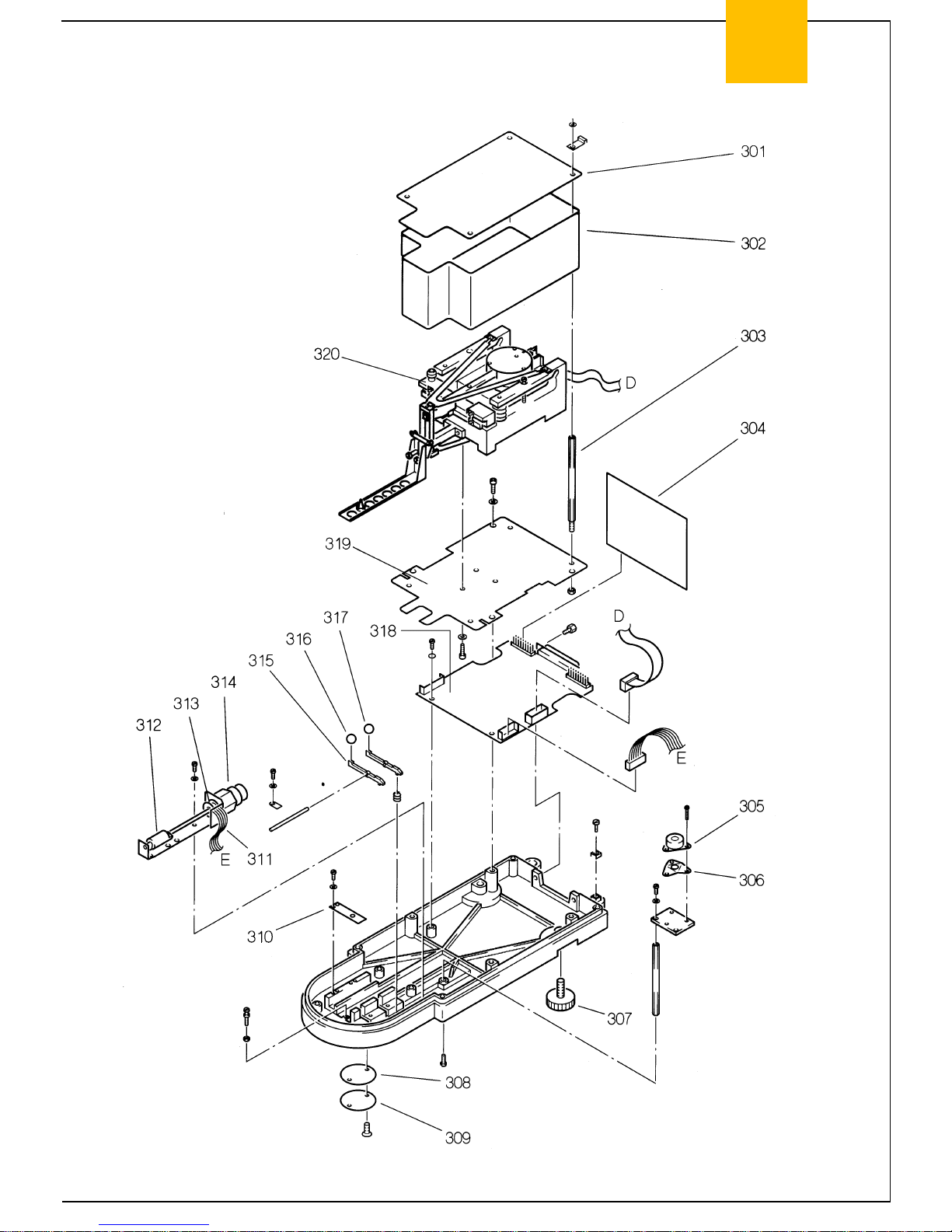

4 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Exploded - View Diagram 1

Page 5

Stand 1/94 SARTORIUS MC 5 Balance 5

MC 5

Index Designation

101 Top part of housing

102 Shielded enclosure

103 Guide

104 Main printed circuit (PCB)

105 Data output port (interface card)

106 Bracket

107 Analog PCB

108 Space rod

109 Ground plate

110 Leveling foot

111 Display housing

112 Display PCB module

113 Frame for switch pad

114 Switch pad

115 Angular cover plate

116 Holder

117 Cover plate

118 Mylar-backed strip conductor cable

119 Plate

Page 6

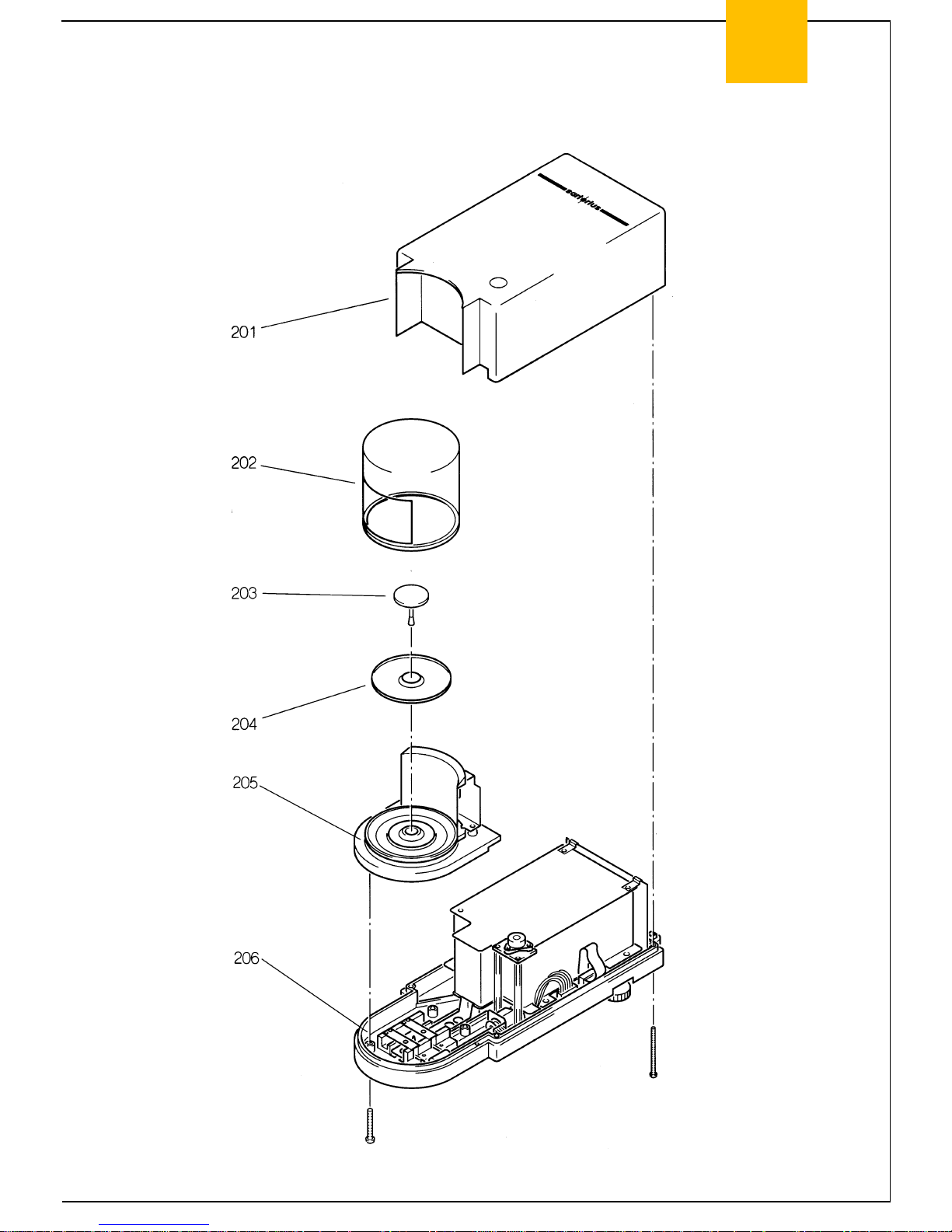

6 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Exploded - View Diagram 2

Page 7

Stand 1/94 SARTORIUS MC 5 Balance 7

MC 5

Index Designation

201 Top part of housing

202 Draft shield

203 Weighing pan

204 Protective shield plate

205 Disassembling the Draft Shield Base

206 Groundtub

Page 8

8 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Exploded - View Diagram 3

Page 9

Stand 1/94 SARTORIUS MC 5 Balance 9

MC 5

Index Designation

301 Cover plate

302 Enclosure frame

303 Space rod

304 System PCB

305 Level indicator

306 Leaf spring fastener

307 Leveling foot

308 Gasket

309 Disk

310 Retaining plate

311 Weight servomotor PCB with system sensor cable

312 Eccentric cam

313 Code disk

314 Drive (servomotor)

315 Lever

316/17 Ball

318 System connector PCB

319 System Disk

320 System

Page 10

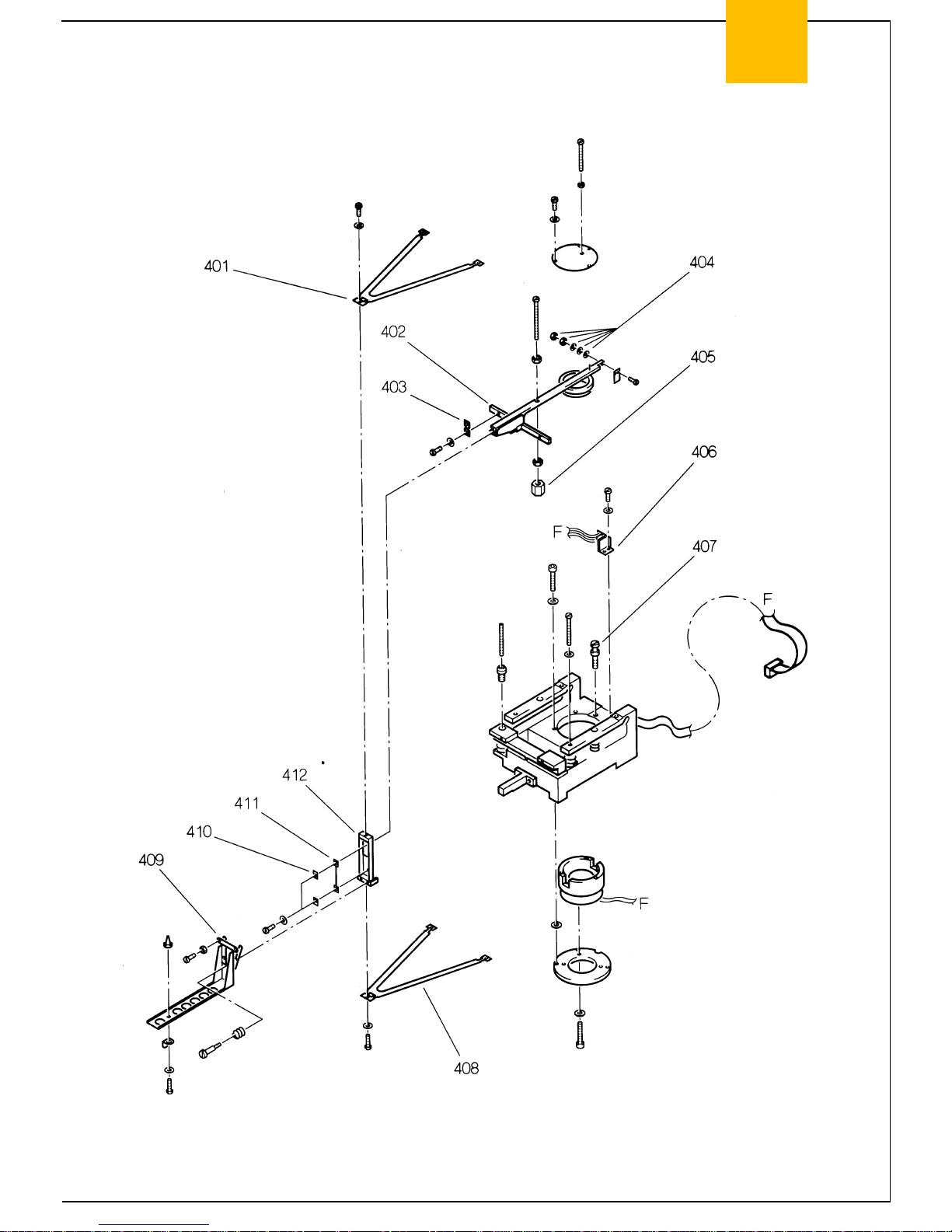

10 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Exploded - View Diagram 4

Page 11

Stand 1/94 SARTORIUS MC 5 Balance 11

MC 5

Index Designation

401/08 Guides

402 Lever, factory premounted

403 Leaf spring

404 Preload weights

405 Indifferent equilibrium weight

406 Null indicator subassembly, complete

407 Screw with special thread

409 Cantilever, complete

410 Clamping plate

411 Linkage flexure

412 Linkage

Page 12

12 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Exploded - View Diagram 5

Page 13

Stand 1/94 SARTORIUS MC 5 Balance 13

MC 5

Index Designation

501 Curved panel for draft shield

502 Drive

503 Lever

504 Sensor cable (attached to draft shield PCB)

505 0-ring

506 Bearing ring

507 Centering ring

508 Support disk for bearing shell

509 Bearing shell

510 Thrust ring

511 Nut

512 Cover plate

Page 14

14 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Additional Service Tools and Equipment

To service and repair the microbalance, set it up in a clean, stable work area that is free of vibrations and

drafts, and use the appropriate tools.

In addition to your regular tools, you will need the following special tools to work on the SARTORIUS

MC5 Microbalances:

No. of Units/Set Designation Order No.

1 Digital voltmeter, 4 ½ digits (e.g., Beckmann) 6738-62

1 2-channel oscilloscope, 20 MHz

1 Constant voltage source (e.g., Analogic AN 3100)

Weights and weight sets required:

1 E1 weight set if a PSION or a PC CAS prg. is not available

1 E2 weight set if a PSION or a PC CAS prg. is not available 6713-001

1 Weight, 1 g, E1

1 Weight, 5 g, E1

Caution!

Do not attempt to repair mechanical system; return microbalances with mechanical defects to our

International Service Headquarters in Goettingen, Germany.

To repair SARTORIUS MC5 Microbalances, considerable experience, completion of the

microbalance service course in Goettingen, Germany, and all special tools are required. Repair

attempts by non-authorized persons must therefore be avoided. Repair of balances by anyone other

than an authorized SARTORIUS service technician will result in the loss of all warranty coverage.

Accompanying Literature

The Sartorius Micro Instruction Manual, publ. no. WMC6011-e93091, contains these sections:

Installation Instructions

How to Operate the Balance

Balance Operating Menu

Application Programs

Interface Description

Specifications

Page 15

Stand 1/94 SARTORIUS MC 5 Balance 15

MC 5

11

12

13

7

5

8

9

10

7 1

17 2

3

16

4

15 5

6

14

General Information

The MC5 microbalance consists of a weighing cell and a display unit.

1 Draft shield 11 Male connector on display unit

2 Weighing cell 12 Data interface port

3 Level indicator

4 Weighing pan 13 AC jack

5 Leveling foot 14 Menu access switch

6 Protective shield plate

7 Manufacturer’s label (on the underside of the balance) 15 Key pad

8 Lug for attaching an anti-theft locking device 16 Metrological ID label ("stamp-/type

approved“ models: verified for trade)

9 Male connector on weighing cell 17 Display unit

10 Terminal for equipotential bonding conductor

Page 16

16 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Installation Instructions

Important Note:

1. Use only the 7.5 DC

power supply, order no. 6971172 EURO or

order no.6971173 US/CDN

Do not use any other type of power supply or AC adapter;

otherwise this could cause problems with instability or drift!

2. Position the equipment to provide the required access for

operation.

Place the weighing cell on the left or the right of the display unit.

3. Mount the draft shield so that the periphery engages the

projected rim.

4. Attach the cable so that both units are directly connected without

the cable being kinked.

5. Level the weighing cell using the level indicator.

Page 17

Stand 1/94 SARTORIUS MC 5 Balance 17

MC 5

6. ERROR 235:

The display unit and the weighing cell constitute a single unit, as

programmed by the software. If you connect a display unit or

weighing cell of a different MC5 microbalance, you will obtain

the error message ERROR 235.

7. After initial installation, a power failure or opening the weighing

cell, allow the microbalance unit to warm up for at least 5-6

hours.

8. Whenever possible, use certified E1 weights.

Observe the weight tolerances when adjusting the microbalance

and overwriting the internal linearity or calibration weights.

(A 5g Class E1 weight has a tolerance of ±15µg)

(A 5g Class E2 weight has a tolerance of ±50µg)

9. You should set up the weighing cell on a sturdy balance table

that has a stone slab surface. Avoid exposing the microbalance

to extreme ambient conditions: heat radiation - temperature

fluctuations - drafts - vibrations - chemically aggressive

environments - high humidity. The microbalance is not allowed

to be operated in hazardous areas/locations.

Weighing System: The MC5 features a weighing system that is specially designed

for this microbalance, has a weighing capacity of 5 g with a

readability that is accurate to 1 µg over the entire range, and

does not require any internal tare weights. The weighing system

allows direct weight compensation.

The total resolution is 5 million digits.

Electronic Circuitry: The MC1 electronic circuitry has been adapted for this

microbalance (similar to the RC electronic circuitry).

Application Programs: Mass unit conversion by toggling between units; „EUREKA“ air

buoyancy correction program; differential weighing and

backweighing; diameter determination; tare memory / net-total;

weighing in percent; over/under checkweighing (classification,

filling); parts counting; GLP / GMP records/printouts

Built-in Interface Port: RS-232 C-S / V24-V28, RS-423 /V 10; 7-bit; even, mark, odd or

space parity; transmission speed: 150...19,200 baud; 1 or 2

stop bits; software/hardware handshake

Page 18

18 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Key Functions:

on/off key

deletes or interrupts program runs and confirms that a changed menu code has been stored

key - displays/outputs info and stored values

tare control - zeros the display

weighing range toggle key

print key

function key for activating the first program application or calibration functions

function key for activating the second program application

draft shield function key - open toward the >> left <<

draft shield function key - open toward the >> right <<

View of the Display and Keypad:

0 - 9 keys (numeric keys)

. decimal point

Page 19

Stand 1/94 SARTORIUS MC 5 Balance 19

MC 5

Accessing the Balance Operating Menu and Setting Menu Codes

- Using the key, turn the balance off and back on again.

- While all segments are displayed, press the key.

- If >> -L- << is displayed, change to >> -C- << using the menu

access key to unlock the menu.

- To select the desired number, press

the key to increase or

the key to decrease the number.

- To select the desired place - left - center - right - press

the key to move to the left

the key to move to the right.

- Press the key to confirm the code

entered; a >> ° << appears after the code.

For example, to assign >> 2-1-4° << to the key

(see „Balance Operating Menu“ in the instruction manual),

set >> 9-1° << to reset all parameters to the factory settings

(default settings).

- To store the code, exit the program by pressing the key.

- Reset the menu access switch back to "locked“ indicated by

>> -L- <<.“

- If you do not want to save changes to the menu codes, exit from

the menu by pressing

the key.

Page 20

20 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Displaying the Hardware and Software Version of the MC5

Microbalance

- Turn the microbalance off and back on again using the key.

- While all segments are displayed, briefly

press the key.

- The display shown on the left will appear for approx. 3 sec.

- The first two numbers show the hardware generation; the last

two, the software version.

- The balance will then return to its standard weight display mode.

Displaying the Model Name and Serial Number

- Turn the microbalance off and back on again using the key.

- While all segments are displayed, briefly press

the key.

- Model Name:

- Mod MC5 appears in the display shown on the left.

- Press the key.

- Serial Number:

- The serial number of the particular MC5 microbalance is

indicated in the display shown on the left.

- Then press the key, and the balance will return to the

standard weight display mode.

Page 21

Stand 1/94 SARTORIUS MC 5 Balance 21

MC 5

Activating the BPI Mode

To be able to work with the PSION server or the PC CAS program, change the communications protocol

for the interface to the BPI mode = Binary Protocol Interface, e.g., for linearization or diagnosis.

- Unplug the power supply and open the balance housing (Index

10).

- Plug the power supply back into the microbalance, and turn on

the microbalance using the key. mc-t-on.tif key. Wait for the

microbalance to complete the self-test; i.e., until 0.000mg is

displayed.

- Afterwards, plug the red jumper (short-circuit connector

located on the digital PCB 104) into the BPI position as shown

on the left.

- This closes a 12-volt circuit to the MC1 processor, which

disables the EEPROM’s write-protect status.

- The full-segment display test will run in regular cycles.

- Wait for at least 3 cycles, after which the balance will be in the

BPI mode.

- Afterwards, plug the jumper back into its original SBI position.

The balance will automatically revert to the standard weighing

mode.

Important Note:

- Turn off the microbalance using the key.

- Disconnect the microbalance from AC power.

- Close the balance housing.

- Plug the microbalance back into AC power and turn it on using

the key.

- Now the microbalance is ready to work with the MC1 server or

the CAS program for PCs in the BPI mode.

- After operating the microbalance with the PSION server or using

the PC CAS program, make sure to reset the interface mode by

software command to SBI = Sartorius Balance Interface:

PSION = Close

PC CAS = Log off

Otherwise, peripheral devices will not run on the microbalance’s

RS-232 interface port (ERR 30 will appear).

Page 22

22 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Standard Service Tools and Equipment - Repair Policy

For diagnosis, adjustment or PCB exchange, you will need the following:

PSION server with the repair Datapack version 4.0 or Datapack version 4.2

or higher, as well as PC CAS program version 7.1 or higher.

Do not attempt to repair mechanical subassemblies; return

microbalances with mechanical defects to our International Service

Headquarters in Goettingen, Germany.

To obtain special authorization to repair mechanical defects, you are required

to have completed an intensive training course in Goettingen, Germany.

Until July, 1994, you are required to obtain special permission from the WSV

International Service Support Dept. to perform such repair work.

ADJUSTMENT DATA SHEET

for MC5 Microbalances

Balance Model MC5

Capacity /

range level

5 g

Readability 0.001mg

Reproducibility <=± 0.001mg

Linearity <=± 0.004mg

Calibration

weight

5 g / E1

Off-center

test weight

5 g

ø = 8mm

Off-center

test area

at the edge

of the pan

off-center

tolerance

<=± 0.007mg

Preload

test weight

0 g

Preload

voltage

-450...-550mV

Page 23

Stand 1/94 SARTORIUS MC 5 Balance 23

MC 5

Adjusting the Microbalance

Preparation:

Set up the microbalance on a stable surface, such as a balance

table with a stone slab. Level the weighing cell using the level

indicator, and allow the microbalance to warm up for at least 6

hours.

Avoid exposing the microbalance to extreme ambient conditions:

heat radiation - temperature fluctuations - drafts - vibrations chemically aggressive environments - high humidity.

The microbalance is not allowed to be operated in hazardous

areas/locations.

Adjustment Sequence

Check and, only if absolutely necessary, adjust the following:

1. Reproducibility

2. Null indicator

3. Preload

4. Indifferent equilibrium

5. Off-center load

6. External linearity

7. External calibration

8. Internal linearity weight (overwrite)

9. Internal calibration weight (overwrite)

Page 24

24 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Reproducibility

Checking the Reproducibility:

- Before you check the reproducibility, be sure to observe the

following:

a. The conditions specified on page 22 of this Service Manual must

be met.

b. Make sure that code >> 1-6-1 << for Auto Zero has been set (for

instructions, see the section entitled „Accessing the Balance

Operating Menu and Setting Menu Codes“ on page 19 of this

manual).

To check the reproducibility, change the load on the pan 10 times using a 5g weight as described in the

following:

- Use the long anti-magnetic forceps.

- Unload the weighing pan. Close the draft shield by pressing

. After approx. 10 sec., 0.000mg will be displayed.

- Load 5g weight. Close the draft shield; once the readout has

stabilized, write it down.

- Remove the weight. Close the draft shield; once the readout

has stabilized, write it down.

- Repeat this test 10 times.

You can connect a printer, model YDP 02, to the microbalance in order to print out the values displayed

instead of writing them down.

If the standard deviation is >= 1 , you have to check and clean the weighing cell.

If the reproducibility error cannot be eliminated by cleaning the weighing cell, the weighing system is

defective, and the microbalance must be returned to the factory in Goettingen, Germany.

Page 25

Stand 1/94 SARTORIUS MC 5 Balance 25

MC 5

Null Indicator

Checking the Null Indicator:

The null indicator has to be re-adjusted only if the lever does

not stabilize symmetrically between the two beam overload

stops. It is unlikely that the null indicator subassembly will

become mis-aligned on its own.

Checking and Adjusting the Overload Stops:

The upper and lower stops must be adjusted so that the lever

can stabilize symmetrically between them.

When the lever has stabilized, you can measure approx. - 6V at

pin 6 of IC 303 (null indicator output) on the system PCB.

When you move the lever toward the upper and lower stops, the

voltage reading on the digital voltmeter should change by

approx. ± 1 V.

To adjust the beam overload stops, slightly turn the stop screw

as follows:

- lower stop - adjust the screw located between the null

indicator and the magnet cover

- upper stop - adjust the screw located on the rear section of

the magnet cover

Adjust the catch pin of the lever in the magnet cover so that the

lever can move freely.

A build-up of dirt on the coil or foreign objects on the null

indicator will cause the balance readouts to be non-reproducible.

Make sure that the stops are clean (no dirt film); if

necessary, use alcohol to clean them.

Preload

Checking the Preload:

With the weighing pan in place, the microbalance, when

unloaded, must generate a voltage reading of - 500mV ±50mV

on the digital voltmeter; at maximum load, it must generate

approx. 6.35V (unidirectional control circuit).

Adjusting the Preload:

Allow the beam to stabilize.

The preload weights (M 1.4 nuts and washers) are secured by

thescrew fastener which is located on top of the null indicator

flag.You can change the preload voltage by adding or removing

the washers.

Page 26

26 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Indifferent Equilibrium

Checking the Indifferent Equilibrium (Tilt):

- Required only after you have worked on the weighing system

Purpose: Slight tilting of the weighing system must not cause the display to vary by more than ± 5 d !

- Unload the weighing pan and tare the microbalance.

- Level the microbalance using the level indicator and tare.

- Tare the microbalance. Then check the „front-to-back“ level.

- Tilt the microbalance so that the level indicator shows and write down the value displayed.

- Re-level the microbalance so that the circle in the level indicator returns to the original centered

position.

- Tare the microbalance. Then check the „right-to-left“ level.

- Tilt the microbalance so that the level indicator shows and write down the value displayed.

- Re-level the microbalance so that the circle in the level indicator returns to the original centered

position.

The values displayed must be within the tolerances ( ±5d ).

Adjusting the Indifferent Equilibrium:

As a rule, this is hardly ever necessary.

--> All microbalances are adjusted at the factory. Any substantial variation is due to a deeper

underlying cause. In this case, you should return the microbalance to the factory in Goettingen,

Germany, whenever possible.

- You can adjust the indifferent equilibrium on the „right-to-left“ level

through the closed cover (see diagram on the left) by using the set

screw 5 on the system support.

- Check the indifferent equilibrium by following the procedure described

above.

- Adjust the equilibrium by turning the set screw.

- Read off the display and repeat this procedure until the readout is

within the tolerances (± 5d).

Caution! Always use the special tool to lock the lever beam first before loosening the indifferent

equilibrium weight on the lever in order to adjust it.

Therefore, the weight cannot be adjusted without using the appropriate tool!

- Check the „front-to-back“ indifferent equilibrium by following the procedure described above.

- Read off the display and repeat this procedure until the readout is within the tolerances listed below:

Zero point error ±0.000005g

Sensitivity error for 5g ±0.000005g

- If the "!front-to-back“ indifferent equilibrium is out of tolerance, return the microbalance to Sartorius

Service Headquarters in Goettingen, Germany.

Page 27

Stand 1/94 SARTORIUS MC 5 Balance 27

MC 5

Off-Center Load (Eccentricity)

Checking the Off-Center Loading Tolerances (Eccentricity Test):

Check the off-center loading toleranzes ("corner load“/eccentric

loading error) at the 5 points shown in the diagram on the left.

Off-center test weight: 5g ø: approx. 8mm

Off-center test area: up to the edge of the weighing pan

Off-center tolerances: ± 0.007mg

If the values measured are out-of-tolerance, re-adjust the off-center

load.

Important Note:

If the off-center loading errors exceed the tolerances, check

the weighing system very carefully (reproducibility / visual

inspection).

Excessive off-center loading errors (> 500 d) indicate that the

weighing system is defective.

In this case, return the microbalance to the factory in

Goettingen, Germany.

Adjusting the Off-Center Loading Tolerances:

Before you begin to make this adjustment, remove the housing

cover from the weighing system.

Adjust the off-center loading tolerances in two steps:

- 3 Point (Coarse Adjustment):

For errors of approx. 50d to approx. 500d.

For coarse adjustment, use the set screws marked 3 and 4.

- 5 Point (Fine Adjustment):

For errors up to approx. 50d.

For fine adjustment, use the set screws marked 1 and 2. Adjust

them by only one complete turn at the most.

For the 1st step, measure the off-center loading error at 3 points.

Following coarse adjustment, measure the off-center loading error

at 5 points and perform fine adjustment, if necessary ( see top

diagram).

Page 28

28 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Linearity

External Linearization

Note: Linearization can be done in 3 different ways:

1. as described in this service manual

2. using the PSION server or

3. using the CAS program written for personal computers and laptops

However, you should use only the PSION server or the CAS program written for PCs and laptops to

check and adjust the linearity of this microbalance.

Checking the Linearity:

- (The values displayed for a 1g test weight at various points along the weighing range must be equal

± 4d).

- When unloaded, the microbalance must display 0.000mg; if not, press the key.

- Place a 1g weight (test weight) on the weighing pan, close the draft shield, and write down the value

displayed.

- Remove the 1g weight from the pan.

- Place an approx. 1g weight on the pan to generate a load, close the draft shield, and press the

key.

- Add the test weight to the pan, close the draft shield, wait for the readout to stabilize, and write down

the readout.

- Remove the test weight from the pan.

- Now add another 1g weight to the pan to generate a preload of approx. 2g, close the draft shield, and

press the .

- Then place the test weight on the pan, close the draft shield, and write down the value displayed.

- Remove the test weight from the pan.

- Next, add another 1g weight to the pan to generate a preload of approx. 3g, close the draft shield, and

press the .

- Then place the test weight(s) on the pan, close the draft shield, and write down the value displayed.

- Remove the test weight(s) from the weighing pan.

- Next, place another 1g weight on the pan to generate a preload of approx. 4g, close the draft shield,

and press the key.

- Then place the test weight on the pan, close the draft shield, and write down the value displayed.

- Remove the weights (preload and test weights).

Important Note:

- The differences in the absolute values displayed may not exceed the tolerances given in the

"Adjustment Data Sheet“ (see page 22).

Important Note:

The linearity tolerance listed in the Adjustment Data Sheet is the average of 10 individual weighing

operations. Because of the spread of the measured values, the allowable variation in the linearity for

an individual weighing operation is approximately 2 times higher.

If the deviations are greater than the allowable tolerances, you will need to adjust the linearity.

Page 29

Stand 1/94 SARTORIUS MC 5 Balance 29

MC 5

Adjusting the Linearity:

Important Note:

Whenever possible, linearize the microbalance only by using the PSION server or the Sartorius CAS

program written for personal computers and laptops.

- Set menu code >> 1-12-1 << - external linearization accessible on the microbalance (see page 40 of the "Overview of the

Balance Operating Program“ aand page 19 "Accessing the

Balance Operating Menu").

- When the display shows 0.000 mg, hold down the key for

more than 3 sec. You will see the display shown on the left.

- Use the key to „scroll“ through the menu until >> L.E. <<

appears in the upper right-hand corner.

- Tare the microbalance using the key and press the key

to activate the linearization routine.

- The first linearity weight is now displayed.

- If necessary, use the numeric keys to enter a new, accurate

weight 5.0000xx (see Weight Certificate to enter the correct

value).

Important Note:

The microbalance will accept only a weight that is within a tolerance of approx. 2% of the factoryprogrammed linearity. You can set the microbalance for greater linearity variations only using the PSION

server (approx. 8% of the factory-programmed linearity) or the CAS program for PCs and laptops (in this

case, the linearity is adjustable from 0 to 100% of the factory-programmed value).

- Open the draft shield.

- Center the required weight on the pan and close the draft shield.

- After the weight has been accepted, the next linearity weight will

be displayed.

- Center the required weight on the pan and close the draft shield.

- Follow the same procedure outlined above to have all linearity

points recalled and the new weights accepted and stored by the

microbalance.

- At the end, you will be prompted to unload the microbalance.

- After the zero point has been stored, the microbalance will return

to the standard weighing mode.

- Now check the linearity again.

- At the end of the linearization routine, reset the menu code to

>> 1-12-2 << (external linearization - access denied).

For directions on how to overwrite the internal linearity weight, see page 31.

Page 30

30 SARTORIUS MC 5 Balance Stand 1/94

MC 5

External Calibration

Important: External calibration should be done only in exceptional cases

because calibration using internal weights is more accurate, as a rule. In

addition, the weights used to calibrate the microbalance at the factory in

Goettingen usually have a higher accuracy than do the external weights

normally available.

If you opt for external calibration, use external calibration weights with tolerances that are equal to or

better than accuracy class E2 (± 0.050mg for 5g) or E1 (± 0.015mg for 5g).

Note:

External calibration can be done in 3 different ways:

1. as described in this service manual

2. using the PSION server or

3. using the CAS program for personal computers and laptops

Important Note:

The microbalance will accept only a weight that is within a tolerance of approx. 2% of the factoryprogrammed value. You can set the microbalance for greater variations only using the PSION server

(approx. 50% of the factory-programmed calibration weight) or the CAS program written for PCs and

laptops (in this case, the calibration weight is adjustable from 0 to 100% of the factory-programmed

value).

However, you should use only the PSION server or the CAS program for PCs and laptops to check and

adjust the calibration weight of this microbalance.

- Unload the pan and press the key (ERR 02 see page 36).

- When the display shows 0.000000g, hold down the key for

more than 3 sec. You will see the display shown on the left.

- As soon as >> C.I. << appears, continue to press the

key until >> C.E. << is displayed.

- Tare the microbalance using the key and press the key

to activate the external calibration routine.

- The calibration weight is now displayed.

- If necessary, use the numeric keys to enter a new, accurate

weight 5.0000xx (see Weight Certificate to enter the correct

value).

- Center the required weight (5g) on the pan and close the draft

shield.

- After the calibration weight has been stored, the microbalance

will return to the standard weighing mode.

Page 31

Stand 1/94 SARTORIUS MC 5 Balance 31

MC 5

Overwriting the Internal Linearity Weight

Caution!

Do not overwrite the internal linearity weight for the sensitivity unless you have done the

following: run the three internal linearization and calibration routines and then take 3 readings

using a Sartorius external test weight (see Calibration Certificate for weights). Calculate the

average for these 3 test readings first, then calculate the allowable deviation range as follows: add

this average to the uncertainty of the test weight ±2 times the standard deviation of the

microbalance ± 4µg. If the average exceeds the allowable deviation, overwrite the linearity weight.

Example: (for a single test point):

- Conventional mass of the test weight listed on the Calibration Certificate: 2g + 0.022mg ±12µg

(±12µg is the uncertainty of the test weight)

- Standard deviation of the microbalance: ±1µg

- Allowable deviation: ±18µg

- The average of the values measured can range from 2.000004g to 2.000040g.

If the average of the values measured is greater, you are allowed to overwrite the internal linearity weight.

In this case, the attainable adjustment accuracy is approx. ± (the worst uncertainty of the weight used

+ 6µg).

Important Note:

If you need to overwrite the internal linearity weight on this microbalance, use only the PSION server or

the CAS program for PCs and laptops.

Procedure for Overwriting the Internal Linearity Weight:

Both the external linearizatio >> L.E. << and calibration >> C.E. << routines must be correctly

carried out before you begin with this procedure.

- Make sure that the menu code >> 1-13-1 << - internal

linearization accessible - has been set on the microbalance

(see page 40 of the „Overview of the Balance Operating Program“ for a list of the linearization menu codes).

- If you need to change the code, unlock the menu access switch

located on the rear panel of the microbalance.

- Then turn the microbalance off and back on again using the

key.

- While all segments are displayed (full-segment test), briefly

press the key.

- >> C.C. << or >> C.L. << now appears above the weight

readout in the upper right-hand corner.

- Press the key until >> C.L. << is displayed.

- Press to tare the microbalance first, then press to

activate the linearization routine for overwriting. >> C << will now

appear.

Page 32

32 SARTORIUS MC 5 Balance Stand 1/94

MC 5

- The internal linearity weights are now loaded and unloaded in

sequence by the servomotor. In the process, the weight value is

stored in the EEPROM of the microbalance processor.

Afterwards, the microbalance returns to the standard weighing

mode.

- At the end of the linearization routine, reset the menu code to

>> 1-13-2 << and lock the menu access switch.

Overwriting the Internal Calibration Weight

Caution!

Do not overwrite the internal calibration weight unless you have done the following: run the

internal linearization and calibration routines and then take 10 readings using a Sartorius external

test weight (see Calibration Certificate for weights). Calculate the average for these 10 test

readings first, then calculate the allowable deviation range as follows: add this average to the

uncertainty of the test weight ± the standard deviation of the microbalance ± 4µg. If the average

exceeds the allowable deviation, overwrite the internal calibration weight.

Example:

- Conventional mass of the test weight listed on the Calibration Certificate: 5g + 0.022mg

±15µg (±15µg is the uncertainty of the test weight)

- Standard deviation of the microbalance: ±1µg

- Allowable deviation: ±20µg

- The average of the values measured can range from 5.000002g to 5.000042g.

If the average of the values measured is greater, you are allowed to overwrite the internal calibration

weight.

In this case, the attainable calibration accuracy is approx. ± (the worst uncertainty of the weight used

+ 6 µg).

Important Note:

If you need to overwrite the internal calibration weight on this microbalance, use only the PSION server or

the CAS program for PCs and laptops.

Procedure for Overwriting the Internal Calibration Weight:

Important note: The microbalance must be accurately calibrated using a external >> E1 << weight set

or, better yet, using the PSION server before you begin with this procedure.

- Make sure that the menu code >> 1-10-1 << - internal calibration

accessible - has been set on the microbalance (see page 40 of

the "Overview of the Balance Operating Program“).

- If you need to change the code, unlock the menu access switch.

It is accessible when you remove the cap next to the AC jack on

the rear panel of the microbalance.

Page 33

Stand 1/94 SARTORIUS MC 5 Balance 33

MC 5

- Then turn the microbalance off and back on again using the

key.

- While all segments are displayed (full-segment test), briefly

press the key.

- >> C.C.<< or >> C.L.<< now appears above the weight readout.

- Press the key until >> C.C. << is displayed.

- Press to tare the microbalance first, then press to

activate the calibration routine.

The internal calibration weights are now loaded and removed in

sequence by the servomotor. In the process, the weight stored

in the EEPROM of the microbalance is overwritten by the weight

currently displayed. Afterwards, the microbalance returns to the

standard weighing mode.

- At the end of the calibration routine, reset the menu code to

>> 1-10-2 << and lock the menu access switch.

Internal Calibration:

- Make sure that the menu code >> 1-10-1 <<

- internal calibration accessible - has been set on the

microbalance.

- As soon as the readout has stabilized, press the key.

- Confirm by pressing the key, and >> C.I. << will be

displayed.

- The internal calibration weights are now loaded and unloaded in

sequence by the servomotor. In the process, the weight value is

stored in the EEPROM of the microbalance processor.

Afterwards, the microbalance returns to the standard weighing

mode.

- At the end of the internal calibration routine, reset the menu

code to >> 1-10-2 << and lock the menu access switch.

Internal Self-Calibrating Function:

- To activate the internal self-calibrating function (ISOcal), check

that menu code >> 1-15-3 << has been set.

- When the microbalance wants to self-calibrate, a balance

symbol will flash on the display, and the microbalance will then

perform automatic internal calibration.

- If a printer is connected to the microbalance, a record of this

process will be printed on hard copy (for GLP/GMP compliance),

depending on the menu code setting (see page 2-31 in the MC5

instruction manual).

Page 34

34 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Description of the Microbalance:

The MC5 consists of two major units:

a. Weighing Cell

Located inside the weighing cell are the mechanical coil/beam

system, the servomotor subassembly for internal weight

application, the draft shield drive and bearing system, including the

following:

System connector PCB

(See page 8 Exploded-view diagram 3.....No.318)

System PCB

(see page 8 Exploded-view diagram 3.....No.304)

Weight servomotor PCB

(see page 8 Exploded-view diagram 3.....No.311)

Null indicator PCB

(see page 10 Exploded-view diagram 4.....No.406)

Draft shield PCB

(see page 12 Exploded-view diagram 5.....No.504)

b. Display Unit

The display unit houses the following components:

Main PCB

(see page 4 Exploded-view diagram 1.....No.104)

Analog PCB

(see page 4 Exploded-view diagram 1.....No.107)

Data output PCB

(see page 4 Exploded-view diagram 1.....No.105)

The LCD of the display unit is attached to the following:

Display PCB module

(see page 4 Exploded-view diagram 1.....No.111)

Page 35

Stand 1/94 SARTORIUS MC 5 Balance 35

MC 5

Electronics: The microbalance’s electronics consist of 9 printed-circuit

boards (PCBs) that have various functions depending on the

type of components mounted:

1. The main PCB contains the following:

Power supply, microcomputer, motor control subassembly,

menu switch and EEPROM IC106 for: menu functions,

adjustment, calibration, linearization, vibration filter settings,

temperature compensation for drift (creep), and codes relevant

to manufacturing operations.

To exchange this board, see item 4 of this section.

2. The following components are mounted on the analog PCB:

low-pass filter, temperature-compensating circuit, reference

voltage circuit, and the A / D converter, including the EEPROM

IC208 with the components for temperature compensation and

the temperature-compensating sensor.

To exchange this board, see item 4 of this section.

3. Located on the system PCB is an amplifier circuit for the null

indicator and the temperature sensor as well as the system

EEPROM IC107 with the serial number of the microbalance.

To exchange this board, see item 4 of this section.

Important Note:

4. Before exchanging a PCB mentioned in items 1-3, make sure to

save all EEPROM data by downloading them onto a PSION

server, PC or laptop!

5. The RS-232 port driver is on the data output PCB.

6. Photoelectric barriers are mounted on the servomotor PCB for

the internal weight and the draft shield PCB.

7. One transmitter diode and two receiver diodes are located on

the null indicator PCB.

8. The multicontact connectors listed below are mounted on the

system connector PCB:

A 20-pin connector is routed from the null indicator/interface

PCB, connector St. 22/23. (The connectors are abbreviated in

German as „St.“ below):

St.21 25-pin To computing (display) unit

St.28 10-pin To null indicator/system PCB

St.27 7-pin To weight servomotor PCB

St.29 9-pin To draft shield PCB

Display Module: Similar to the MC1 technology on RC models; with numeric key functions from 0...9.

Page 36

36 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Power-On Routine and Error Messages

Once your have turned on the balance using the key, " 0.000 mg “ is displayed. This indicates that

the balance is ready to operate.

Error Messages

On the MC 5, error messages are indicated by a code number.

All codes for operating errors, including errors in the sequence of a function, have two-digit numbers.

Error codes for hardware errors have three-digit numbers.

The error codes enable you to identify the type of operating error.

Display Meaning Reason/Solution

Err 01 Display format overflow The weighing system is overloaded.

Err 02 Zero point error at the start Re-tare;

of the CAL routine check system.

Err 04 Control error during Check system for stability.

multiple calibration mode

Err 06 Internal calibration weight Check system. Return the microbalance

defective or not available to the factory, if necessary.

Err 10 1st tare memory disabled The tare functions are

when a value is stored in interlocked. Clear tare

2nd tare memory memory to enable the CF/ tare key.

Err 11 Attempt to store an invalid The readout was negative,

number in tare memoryfor example - check sample.

using TAR -F1/

Err 20 The ></ key was pressed For instance, you forgot

before an application to store a reference

program was initialized percentage for weighing in percent.

Err 21 Reference percentage or Code 2 3 1 is selected in the balance

reference piece count setting operating menu. Change this code

disabled, or this application to 2 3 2 or 2 3 3.

does not have a parameter mode

Err 22 Reference cannot be stored The weight is too light or

for weighing in percent or counting no sample is on the pan.

Err 23 Value cannot be stored No sample is on the pan or

for any particular application program the readout is negative.

Err 30 The print key was pressed Connect printer.

in the BPI mode; no printer on-line

Err 50 Converter error (TC range) Check system or return microbalance to the

factory in Goettingen.

Err 53 Temperature sensor circuit failure Check temperaturecompensating sensor or

return microbalance to the factory in Goettingen.

Err 54 Balance converter value below Check system.

the minimum limit Beam at lower stop.

Page 37

Stand 1/94 SARTORIUS MC 5 Balance 37

MC 5

Err 55 Balance converter value below

the maximum limit Beam at upper stop.

Err 62 Pressing the F1/ key is Follow correct operating

momentarily not allowed procedure.

Err 63 Pressing the F2/ key is not Follow correct operating

allowed procedure.

Err 64 Numeric entry is not allowed Follow correct operating procedure.

Err 70 Incorrect numeric entry Enter new value that is appropriate for the

microbalance’s weighing capacity/range levels.

Hardware Errors

Hardware error codes are displayed as long as the error persists. During this time, the error code is

output via the data interface port.

Err 210 Defective AOC interface Replace the PCB.

Err 220 EPROM checksum error Using the ON/OFF key, turn the microbalance

off, then back on again;

you may need to exchange the PCB.

Err 230 RAM read/write error Using the ON/OFF key, turn the microbalance

off, then back on again;

you may need to exchange the PCB.

Err 234 Checksum error in the battery-backed Leave microbalance plugged into AC current

RAM; rechargeable battery for approx. 12 hours to recharge battery.

completely drained or defective

Err 235 Display unit and weighing cell do not match

Err 237 EEPROM checksum error, Activate >>external linearization<< function

linearity range

Err 239 EEPROM checksum error Determine the

>>internal linearization weight<<

Err 241 EEPROM checksum error, Incorrrect software programming;

permanent area contact the International Service Support Dept.

for help.

Err 243 EEPROM checksum error, Turn microbalance off and back on;

menu area change menu access switch setting to

"Change“ and access menu.

Change code and exit from the menu using CF.

Err 247 EEPROM checksum error, Run calibration routine

calibration range by setting the appropriate

calibration menu code.

Err 249 EPROM checksum error, Determine the internal

calibration weight calibration weight.

Err 253 Checksum error, Run the air density

air density determination program.

Page 38

38 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Draft Shield

Cleaning the Draft Shield

- Turn off the microbalance.

- Unplug the microbalance from line power.

- Remove the glass draft shield (202), the weighing pan (203), and

shield plate (204), including, if necessary, the cover plate (516) by

turning it by hand toward the left.

- Now the support disk (512) and the curved panel (501) are accessible

for cleaning.

- Use only a commercially available detergent or dishwashing liquid

heated to max. 95° Celsius to clean the draft shield (202).

- Afterwards, re-assemble the draft shield following the steps above in

reverse order.

- Place the glass draft shield on the base without tilting it so that the

periphery engages the protective rim.

Disassembling the Draft Shield Base Unit

- Turn off the microbalance.

- Unplug the microbalance from line power.

- Remove the glass draft shield, (202), the weighing pan (203), and the

shield plate (204).

- Carefully invert the weighing cell so that it rests on the top part of the

housing (201).

- Remove the 4 fastening screws (A) to detach the top part of the

housing (201).

- Remove the 4 fastening screws (B) to detach the draft shield base unit

(205).

- Holding the draft shield base unit (205) in place, turn the weighing

system right side up so that it rests on the leveling feet (307).

- Disconnect the sensor cable (506) from the plug that is located on the

left side of the system, and lift off the draft shield base unit (205).

- Now you can disassemble the draft shield bearing (see exploded-view

drawing 5 on page 12).

- Afterwards, re-assemble the draft shield bearing by following the steps

above in the reverse order.

- Important note: Make sure to insert the sensor cable (506) through

the slot of the system holding plate (319) without pinching the cable.

- Allow the microbalance to warm up briefly (wait approx. 30 minutes)

so that it will be ready to operate again.

Page 39

Stand 1/94 SARTORIUS MC 5 Balance 39

MC 5

Disassembling the Draft Shield Bearing

- Disassemble the draft shield base unit from the weighing system (see

"Disassembling the Draft Shield Base Unit“ on page 38).

- Remove the V-belt (508) from the drive (504).

- Detach the cover plate (516), the 14mm locknut (515) and the thrust

ring (514), and remove the support disk (512).

- Now you can exchange the bearing ring ((510) and the bearing shell

(513).

- It is important that the ball side of the bearing thrust ring (510) and the flat side of the bearing

shell (513) face upward.

- Position the support disk (512) on the adapter, which must be

centered with respect to the curved draft shield panel. Turn the disk

slightly until it rests completely flat. Press-fit the V-belt (508) in the

groove of the support disk (512).

- Unscrew the thrust ring (514) just until it has sufficient clearance.

Then place the V-belt (508) on the drive (504).

- Now attach the locknut (515) to the thrust ring (514). Hold the thrust

ring in place while tightening the locknut (515).

- Turn the support disk (512) by hand. If you hear a scraping sound

when you turn the disk, or if it is difficult to turn, slightly loosen the

thrust ring. In rare cases, you may need to adjust the sensor PCB

(507).

- Assemble the complete draft shield by following the steps listed above in the reverse order.

- Important note: Make sure to insert the sensor cable (506) through the slot in the system holding plate

(319) and plug in the connector. Check that none of the cables is jammed.

- Allow the microbalance to warm up briefly (wait approx. 30 minutes) so that it will be ready to operate

again.

Checking and Adjusting the Draft Shield Bearing

- Press the key.

If the draft shield does not open easily, slightly loosen the thrust ring

(514).

If the draft shield closes beyond the normal position, slightly retighten

the thrust ring (514).

To do so, hold the thrust ring in place while tightening the locknut

(515).

- Check that the speed of the draft shield movement is the same for

each direction.

- If this is not the case, you need only to remove the top part of the

housing (201) - see "Disassembling the Draft Shield Base Unit“) and

the screw on the right (502a) or on the left (502b); slightly move back

the angular retainers (502) of the curved panel (501); and retighten

the screw.

- Check the functioning of the draft shield movement again as described

above; if necessary, re-adjust.

- Close the weighing system by following the steps above in the reverse

order.

- Attach the cover plate (516), and mount the shield plate (204), the

weighing pan (203) and the draft shield (202).

- Allow the microbalance to warm up briefly (wait approx. 30 minutes) so that it will be ready to operate

again.

Page 40

40 SARTORIUS MC 5 Balance Stand 1/94

MC 5

Overview of the Balance Operating Program

1 Balance Operation

1 Ambient Conditions

1-1-1 Very stable (shortest response time)

1-1-2 Stable (short response time)

1-1-3 Unstable (long response time)

1-1-4 Very unstable (longest response time)

2 Application Filter

1-2-1 Standard weighing

1-2-2 Filling

3 Stability Range

1-3-1 0,25 digit

1-3-2 0,5 digit

1-3-3 1 digit

1-3-4 2 digits

1-3-5 4 digits

1-3-6 8 digits

4 Stability Symbol Delay

1-4-1 None delay

1-4-2 Short delay

1-4-3 Long delay

1-4-4 Extremely long delay

5 Tare Parameter

1-5-1 At any time

1-5-2 After stability

6 Auto - Zero Function

1-6-1 Auto - Zero on

1-6-2 Auto - Zero off

1st Range

7 Weight Units

1-7-1 o Selectable unit

1-7-2 g Grams

1-7-3 o Kilograms

1-7-4 ct Carats

1-7-5 lb Pounds

1-7-6 oz Ounces

1-7-7 ozt Troy ounces

1-7-8 tl Hon Kong taels

1-7-9 tl Singapore taels

1-7-10 tl Taiwanese taels

1-7-11 gr Grains

1-7-12 dwt Pennyweights

1-7-13 mg Milligrams

1-7-14 o Parts/pound

1-7-15 tl Chinese taels

1-7-16 m Mommes

Page 41

Stand 1/94 SARTORIUS MC 5 Balance 41

MC 5

1 Balance Operation

1-7-17 o Carats

1-7-18 t Tola

1-7-19 b Baht

1-7-20 m Mesghal

8 Display Mode Selection

1-8-1 Highest accuracy

1-8-2 Last numeral blanked when load changes

1-8-3 Rounding factor 2

1-8-4 Rounding factor 5

1-8-5 Rounding factor 10

1-8-6 1.0 % display accuracy

1-8-7 0.5 % display accuracy

1-8-8 0.2 % display accuracy

1-8-9 0.1 % display accuracy

1-8-10 0.05 % display accuracy

1-8-11 0.02 % display accuracy

1-8-12 0.01 % display accuracy

1-8-13 PolyRange function

9 External Calibration

1-9-1 Accessible

1-9-2 Access denied

10 Internal Calibration

1-10-1 Accessible

1-10-2 Access denied (key)

11 Sensitivity Test

1-11-1 Accessible

1-11-2 Access denied

12 External Linearization

1-12-1 Accessible

1-12-2 Access denied

13 Internal Linearization

1-13-1 Accessible

1-13-2 Access denied

14 Multiple Calibration Mode

1-14-1 Off

1-14-2 On

15 Auto - Calibr. and

Linearization

1-15-1 Off

1-15-2 Cal. status only

1-15-3 On

1-15-4 Auto-cal. + lin.on

16 Air Density Determination

1-16-1 Accessible

Page 42

42 SARTORIUS MC 5 Balance Stand 1/94

MC 5

2st Applications

2-1-1 No application

2-1-2 2 weighing ranges

2-1-3 3 weighing ranges

2-1-4 Counting

2-1-5 Weighing in percent

2-1-6 Backweighing

2-1-7 Diameter determination

2-1-8 Air buoyancy correction

2 F1 - Key Applications

2-2-1 No function

2-2-2 Tare memory

2-2-3 Over/under - net weight

2-2-4 Over/under - difference in weight

2-2-5 Intern. calibration

2-2-6 Calibration test

3 Parameter Mode

2-3-1 Access denied

2-3-2 In cycles (table)

2-3-3 In increments of 1

4 Clear Function with CF

2-4-1 Clear all keys

2-4-2 Clear F1 -> F2

2-4-3 Clear F1 or F2

5 Numeric Keys

2-5-1 Access denied

2-5-2 Accessible without +/- sign

2-5-3 Accessible with +/- sign

Page 43

Stand 1/94 SARTORIUS MC 5 Balance 43

MC 5

2st Range

3 Para. 1st Application

1 Weight Units

3-1-1 o Selectable unit

3-1-2 g Grams

3-1-3 o Kilograms

3-1-4 ct Carats

3-1-5 lb Pounds

3-1-6 oz Ounces

3-1-7 ozt Troy ounces

3-1-8 tl Hong Kong taels

3-1-9 tl Singapure taels

3-1-10 tl Taiwanese taels

3-1-11 gr Grains

3-1-12 dwt Pennyweights

3-1-13 mg Milligrams

3-1-14 o Parts/pound

3-1-15 tl Chinese taels

3-1-16 m Mommes

3-1-17 o Carats

3-1-18 t Tola

3-1-19 b Baht

3-1-20 m Mesghal

2 Display Mode Selection

3-2-1 Highest accuracy

3-2-1 Last numeral blanked when load changes

3-2-1 Rounding factor 2

3-2-1 Rounding factor 5

3-2-1 Rounding factor 10

3-2-1 1 % display accuracy

3-2-1 0.5 % display accuracy

3-2-1 0.2 % display accuracy

3-2-1 0.1 % display accuracy

3-2-1 0.05 % display accuracy

3-2-1 0.02 % display accuracy

3-2-1 0.01 % display accuracy

3-2-1 PolyRange function

Page 44

44 SARTORIUS MC 5 Balance Stand 1/94

MC 5

3st Range

3 Para. 1st Application

3 Weight Units

3-3-1 o Selectable unit

3-3-2 g Grams

3-3-3 o Kilograms

3-3-4 ct Carats

3-3-5 lb Pounds

3-3-6 oz Ounces

3-3-7 ozt Troy ounces

3-3-8 tl Hong Kong taels

3-3-9 tl Singapore taels

3-3-10 tl Taiwanese taels

3-3-11 gr Grains

3-3-12 dwt Pennyweights

3-3-13 mg Milligrams

3-3-14 o Parts/pound

3-3-15 tl Chinese taels

3-3-16 m Mommes

3-3-17 o Carats

3-3-18 t Tola

3-3-19 b Baht

3-3-20 m Mesghal

4 Display Mode Selection

3-4-1 Highest accuracy

3-4-2 Last numeral blanked when load changes

3-4-3 Rounding factor 2

3-4-4 Rounding factor 5

3-4-5 Rounding factor 10

3-4-6 1 % display accuracy

3-4-7 0.5 % display accuracy

3-4-8 0.2 % display accuracy

3-4-9 0.1 % display accuracy

3-4-10 0.05 % display accuracy

3-4-11 0.02 % display accuracy

3-4-12 0.01 % display accuracy

3-4-13 PolyRange function

5 Readout in Percent

3-5-1 Without decimal

3-5-2 1 decimal

3-5-4 2 decimals

3-5-4 3 decimals

Page 45

Stand 1/94 SARTORIUS MC 5 Balance 45

MC 5

3 Para. 1st Application

6 Backw.: Weighing Sequence

3-6-1 Individual weighing

3-6-2 Consec. indiv. weighing

3-6-3 Combined weighing

7 Backw.: Tara Weighing

3-7-1 Off

3-7-2 On

8 Backw.: 1st Calculated Value

3-8-1 Residue in grams

3-8-2 Residue in percent

3-8-3 Difference in grams

3-8-4 Difference in percent

9 Backw.: 2nd Calculated Value

3-9-1 Residue in grams

3-9-2 Residue in percent

3-9-3 Difference in grams

3-9-4 Difference in percent

4 Para. 2st Application

1 Over / Under Tolerance Limits

4-1-1 ± 0.1 %

4-1-2 ± 0.2 %

4-1-3 ± 0.5 %

4-1-4 ± 1.0 %

4-1-5 ± 1.5 %

4-1-6 ± 2.0%

4-1-7 ± 2.5 %

4-1-8 ± 3.0 %

4-1-9 ± 5.0 %

4-1-10 ± 10.0 %

2 Auto Output of OK Values

4-2-1 Off

4-2-2 On

3 Activation of Port Lines

4-3-1 Within checkweighing range

4-3-2 Always on

4-3-3 At stability + in ch. range

4-3-4 At stability

Page 46

46 SARTORIUS MC 5 Balance Stand 1/94

MC 5

5 Interface Parameters

1 Baud Rate

5-1-1 150 baud

5-1-2 300 baud

5-1-3 600 baud

5-1-4 1200 baud

5-1-5 2400 baud

5-1-6 4800 baud

5-1-7 9600 baud

5-1-8 19200 baud

2 Parity

5-2-1 Mark parity

5-2-2 Space parity

5-2-3 Odd parity

5-2-4 Even parity

3 Number of Stop Bits

5-3-1 1 stop bit

5-3-2 2 stop bits

4 Handshake Mode

5-4-1 Software

5-4-2 Hardware 2 characters after CTS

5-4-3 Hardware 1 character after CTS

6 Utilities

1 Data Output Parameter

6-1-1 Without stability

6-1-2 After stability

6-1-3 At stability

6-1-4 Auto print w/out stability

6-1-5 Auto print after stability

2 Auto Data Output

6-2-1 Stop with key

6-2-2 Not stoppable

3 Print Interval after

6-3-1 1 display update

6-3-2 2 display updates

6-3-3 5 display updates

6-3-4 10 display updates

6-3-5 20 display updates

6-3-6 50 display updates

6-3-7 100 display updates

4 Auto Tare after Data Output

6-4-1 off

6-4-2 on

Page 47

Stand 1/94 SARTORIUS MC 5 Balance 47

MC 5

7 Recording Printing Applications

1 Automatic Output of Parameters

7-1-1 Off

7-1-2 All Parameters

7-1-3 Main parameters only

2 Data Output Format

7-2-1 Without data ID code

7-2-2 With data ID code

3 Auto Tare Output / Printing

7-3-1 Last net weight

7-3-2 Total tare weight

4 Backweighing Rec. w/ Data Time

7-4-1 Off

7-4-2 Date only

7-4-3 Time only

7-4-4 Date and time

5 Backw. Rec. w / Tare_ Net weight

7-5-1 Off

7-5-2 Tare weight only

7-5-3 Net weight only

7-5-4 Tare and net weight

6 Backw. Rec. w / Residue

7-6-1 Off

7-6-2 Residue in g

7-6-3 Residue in %

7-6-4 Residue in g + %

7 Backw. Rec. w / Difference

7-6-1 Off

7-6-2 Difference in g

7-6-3 Difference in %

7-6-4 Difference in g + %

Page 48

48 SARTORIUS MC 5 Balance Stand 1/94

MC 5

8 Additional Functions

1 Access to Menu

8-1-1 Accessible

8-1-2 Readable

2 Acoustic Signal

8-2-1 On

8-2-2 Off

3 Key Functions

8-3-1 Accessible

8-3-2 Blocked

4 Universal - Switch

8-4-1 Print

8-4-2 Tare

8-4-3 Function 1 key

8-4-4 Function 2 key

8-4-5 Open/close draft shield

5 Power-On Mode

8-5-1 Off - on - standby

8-5-2 Off - on (battery op.)

8-5-3 On - standby

8-5-4 Auto. power on (remote control)

6 Display Backlighting

8-6-1 On

8-6-2 Off

8-6-3 Auto - off

7 Interface Port - Function

8-7-1 Data output

8-7-2 Data input

8 Auto Draft Shield

8-8-1 Off

8-8-2 Shut - function - open

8-8-3 Shut - delay - function - open

8-8-4 Shut - function

8-8-5 Shut - delay - function

9 Display Accuracy w. / Draft

Shield Auto Open. / Man. Adjus.

8-9-1 Highest accuracy

8-9-2 Rounding factor 2

8-9-3 Rounding factor 5

8-9-4 Rounding factor 10

8-9-5 Rounding factor 20

8-9-6 Rounding factor 50

8-9-7 Rounding factor 100

Page 49

Stand 1/94 SARTORIUS MC 5 Balance 49

MC 5

8 Additional Functions

10 GLP / GMP Printout / Record

8-10-1 Off

8-10-2 Only for cal. functions

8-10-3 Always on

9 Reset Function

9-1-1 Active

9-1-2 Off

Loading...

Loading...