Page 1

Page 2

3

Sartorius

Research Series

Electronic Semi-Micro and

Analytical Balances

Installation and Operating Instructions

WRC 6001-e94013

Page 3

2

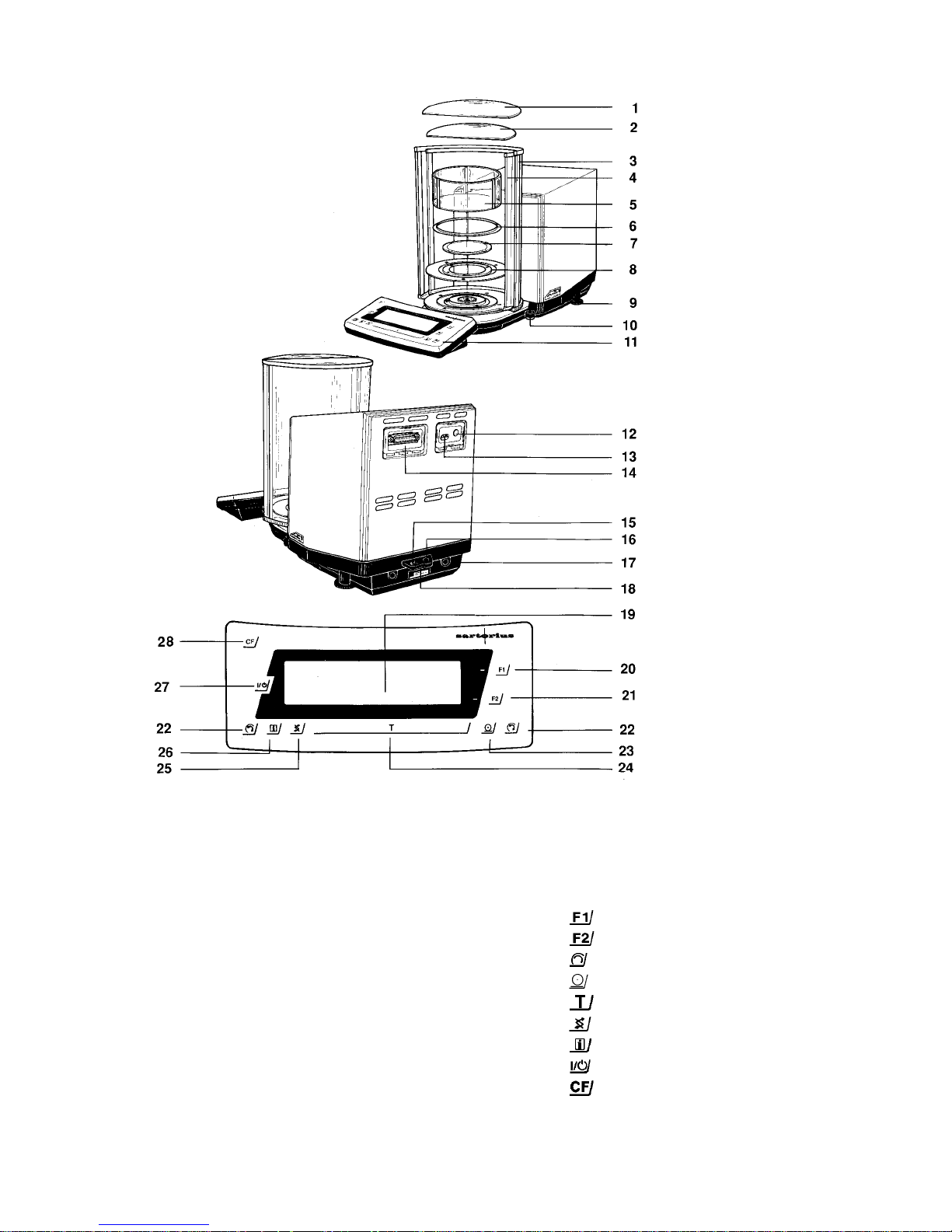

1 Large draft shield cover

2 Small draft shield cover

3 Exterior draft shield element, semi cylindrical

(can be moved by hand)

4 Interior draft shield door, semi cylindrical (can be

moved by motor control or by hand)

5 Interior weighing chamber draft shield (depending

on the balance model)

6 Protective ring

7 Weighing pan

8 Shield disk

9 Levelling food

10 Level indicator

11 Display unit

12 AC jack

13 Menu access switch

14 Data interface port

15 Terminal for connecting an equipotential bonding

conductor

16 Lug for attaching the antitheft locking device

17 Metrological label (only *D1-Models)

18 Manufacturer's label

19 Weight and Information display

20

- function key

21

- function key

22

- draft shield function key

23

- Print key (data transfer)

24

- Tare control

25

- toggle key

26

- Info key

27

- ON/Off key

28

- key

Page 4

3

Contents

Page

Warranty 4

Storage and Shipping Conditions 5

Transporting the Balance 5

Equipment Supplied 6

Installation instructions 7

Ambient Conditions 7

Getting Started 8

Adjusting the Exterior Draft 8

Adjusting the Swivel-Mounted Display Unit 8

Connecting the Balance to Line Voltage 9

Safety Precautions 10

Information on Radio-Frequency Interference 10

Connecting Electronic Devices (Peripherals) 10

Information on Weighing

Electro statically Charged Samples 11

Levelling the Balance Listing the Level Indicator 11

How to Operate the Balance 12

Turning the Display On and Off (Standby Mode) 13

Self-Test 13

Important Note for Automatic

Operation with a Robot 13

Opening and Closing the Draft Shield Door 14

Weighing 16

Taring 16

Weighing Range Structure 17

Weighing in the IQ-Mode ™ 18

(Load-Dependent Readability)

Mass Unit Conversion by Toggling 19

Page

Calibration and Linearization 20

Fully Automatic Calibratio n 21

Internal Calibration 22

External! Calibration 23

Calibration Test 24

Internal Linearization 25

For additional functions if you want to

do more than "just weigh," see

"Part III: Balance Operating Menu" and

"Part IV! Application Programs"

Data Interface 26

Interfacing Devices with the Balance 27

Below- Balance Weighing 28

How to Fasten the Antitheft

Locking Device 28

Troubleshooting Guide 29

Care and Maintenance 30

Cleaning the Balance H ousing

and the Draft Shield 30

Cleaning the Weighing Chamber 30

Safety Inspection 31

Safety Certificate 32

Page 5

4

With this Sartorius Balance, you have acquired a high-quality electronic weig hing

instrument that will ease your daily workload.

Please read these Installation and operating instructions carefully before you begin to operate your new balance.

In "Part l: Installation and Operating Instructions," it is assumed that you are using the factory-set menu codes.

Warranty

Do not miss out o n the benefits of our full warranty.

Please complete the warranty registration card, indicating the date of Installation,

and return the card to your Sartorius Office or dealer.

Page 6

5

Storage and Shipping Conditions

Allowable sto rage temperature: +5 °C. ..+40 °C

+41 °F...+104 °F

The packaging has been designed to ensure that the balance will not be damaged

even if it is dropped from a height of 80 cm (about 32 inches).

After unpacking the balance, please check it immediately for any visible damage

as a result of rough h and 1during shipment.

lf this is the case, proceed as directed in the section entitled "Safety inspection."

Save all parts of the packaging and the box for your balance to avoid damage

during transportation. You may ship your balance only in the complete original

Standard packaging supplied. Before you pack your balance, unplug all connected cables to prevent damage.

Do not expose the balance unnecessarily to extreme temperatures, moisture,

shocks, blows or vi brat Ions.

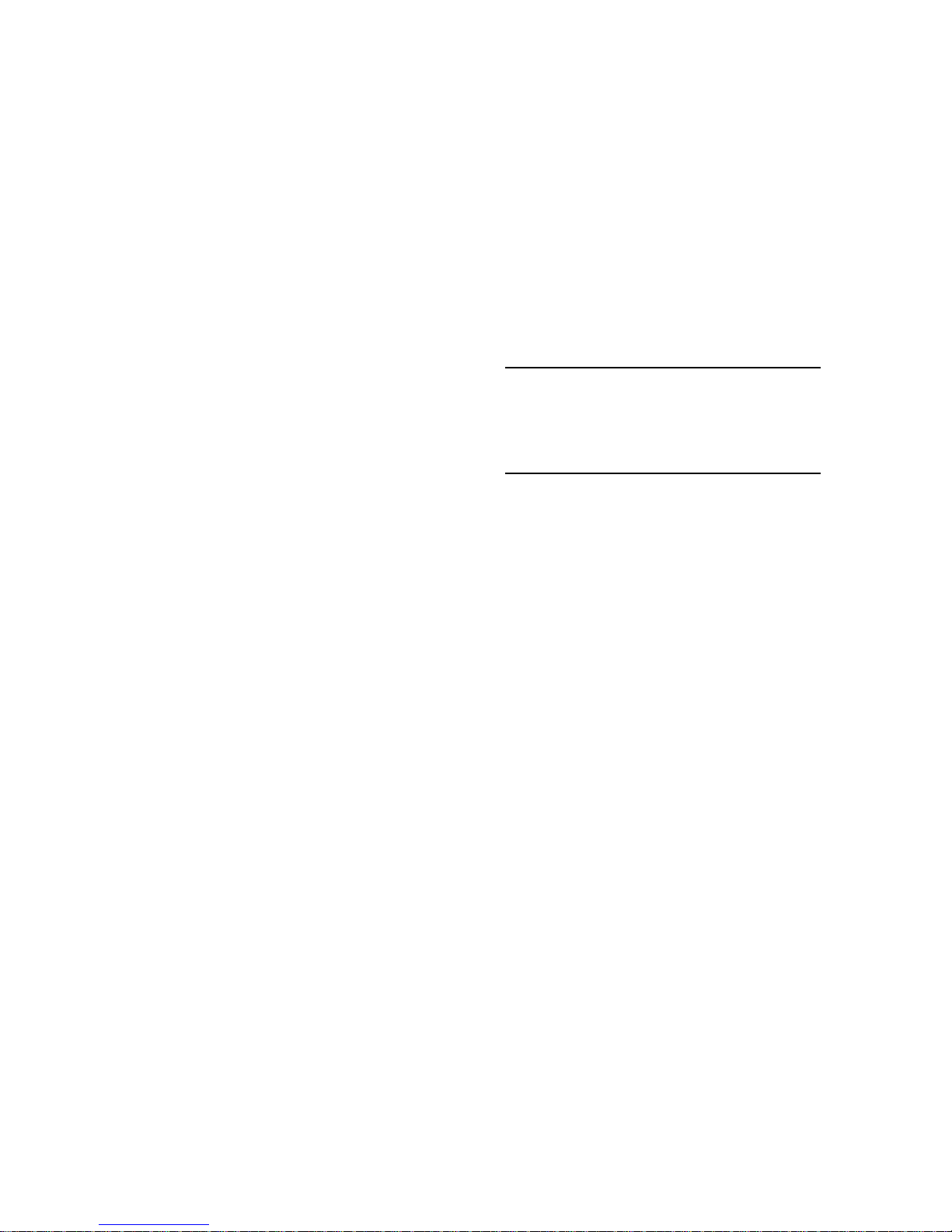

Transporting the Balance

To transport the balance, lift it by the housing base using both hands.

Do not lift it by the display unit or by the draft shield!

Page 7

6

Equipment Supplied

The equipment supplied includes the components listed below:

—

Balance

—

Power supply

—

Weighing pan

—

Shield disk

—

Protective ring

—

Interior weighing chamber draft shield

(depending on the balance model)

—

2 draft shield covers

—

Dust cover for the draft shield and balance housing

—

Dust cover for the display unit

Page 8

7

Installation Instructions

Ambient Conditions

Unfavourable ambient conditions may affect the weight readouts.

Therefore, choose a suitable place to set u p your balance. lt should not be exposed to the following:

—

Extreme heat radiation

—

Drafts

—

Extreme- vibrations

—

Aggressive chemical atmospheres

Set up your balance on a sturdy fable or on a wall console (see "Accessories" in

"Part l): Product Data Sheet").

Do not expose the balance to extreme moisture over long pe rio d s. Mo isture in the

air can condense on the surfaces of a cold balance whenever it is brought to a

substantially warmer place. lf you transfer the balance to a warmer area, make

sure to condition it for about 2 hours at room temperature, leaving it unplugged.

Afterwards, if you keep the balance connected to AC power, the continuous positive difference in temperature between the inside of the balance and the outside

will practically rule out the effects of moisture condensation.

You can adapt the balance to your specific requirements and to the ambient conditions simply by changing the code settings in the balance operating menu. For

more information, t urn to "Part III: Balance Operating Menu."

Page 9

8

Getting Started

Place the components listed below inside the weighing chamber one at a time in

the Order given:

- shield disk (8)

- weighing pan (7)

- protective ring (6)

- interior weighing chamber draft shield (depending on the balance model) (5)

Place the small draft shield cover (2) on top of the semi cylindrical interior draft

shield door (4).

Adjusting the Exterior Draft Shield Element

The draft shield consists of two semi cylindrical dements, one of which functions as

a door. Turn the exterior draft shield element (3) by the riffled part on the bottom

to the position you desire, That way, you will have the opening located exactly

where it is most convenient for you. When adjusting the exterior element, be sure

to shield the weighing chamber from you r breath and the warmth of your hands

(see diagram on the left in addition).

Depending on your application, you can define the menu code so that the inferior

draft shield door (4) is opened by motor or by hand (see pp. 14).

Adjusting the Swivel-Mounted Display Unit

Move the swivel-mounted display unit (11) around the base of the draft shield to

adjust it to the position you desire (+/- 85°).

Page 10

9

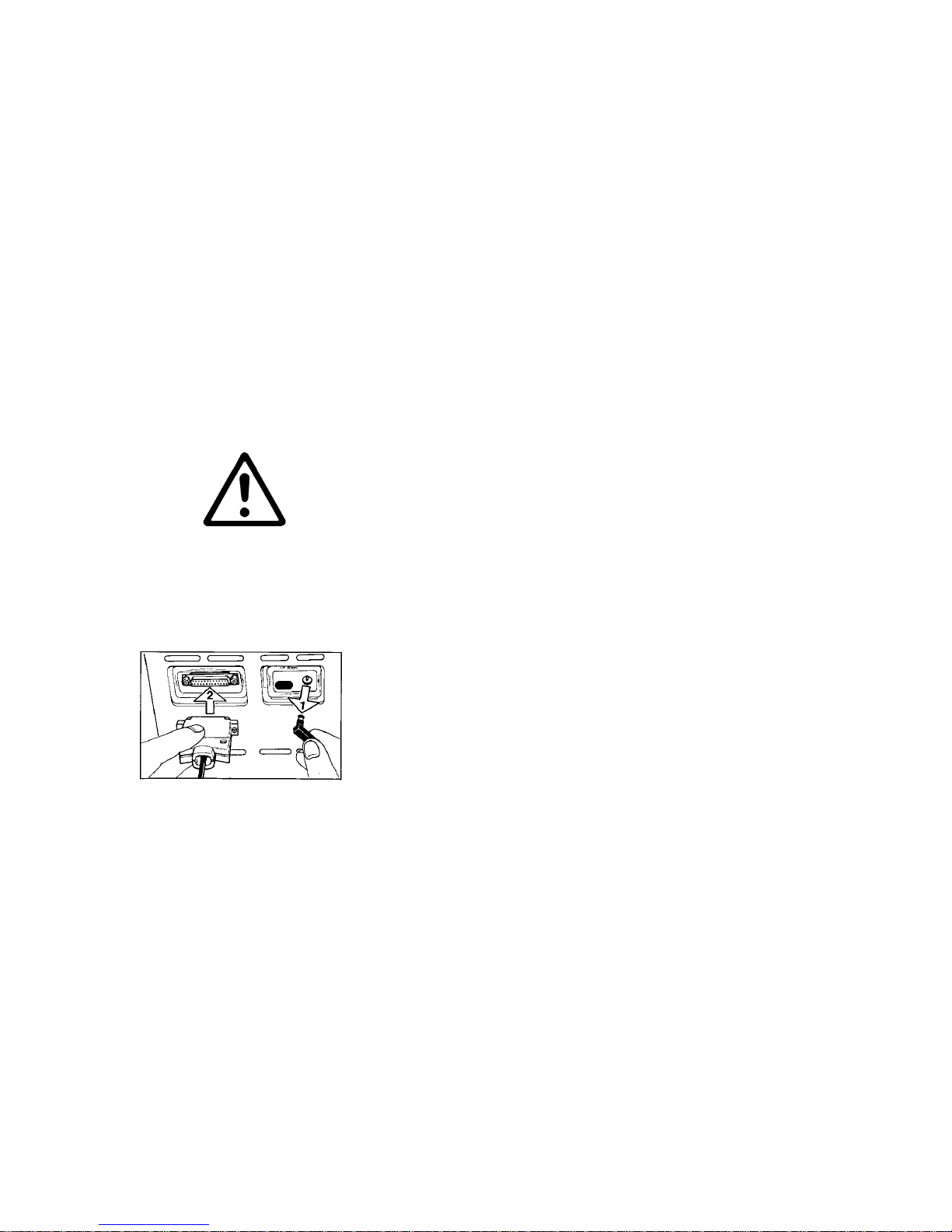

Connecting the Balance to Line Voltage

The balance is energized by a power supply. Make sure that the voltage rating

printed o n this unit is identical to your local line voltage .

lf the voltage specified on the label or the plug design of the power supply does

not match the rating or Standard you use, please contact your Sartorius Office or

dealer.

The power supply is suitable for installation as stationary equipment. To use a

main feeder cable from the ceiling or to mount a CEE plug, you will have to make

arrangements inside your facilities for installation of such cable equipment by a

certified electrician.

Important Note

Use only original Sartorius Power Supplies identified by the Sartorius label. Use of

power supplies from other manufacturers, even if these units have an approval

identification marking from a national testing laboratory, requires the consent of

an authorized Sartorius service technician.

To operate your balance using an external rechargeable battery, pack, see "Accessories" in "Part II: Product Data Sheet.".

Detailed information on additional options for powering the balance is available

in our Service Information bulletin, no. 15/88 (fore example, using local! extralow voltage).

Plug the cord of the power supply into the AC jack on the balance, Then insert the

plug of the power supply in a wall outlet.

Page 11

10

Safety Precautions

The power supply rated to Class 2 can be plugged into a wall outlet without taking any additional safety precautions. The pole of the Output voltage is connected

to the balance housing, which ca n b e grounded for Operation.

The interface (see "Interfacing Devices" on page 28 in addition) is also electrically

connected to the balance housing (ground).

Information on Rad io-Frequency Interfere nce:

Warning!

This equipment generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause interference to radio communications.

It has been tested and found to comply with the limits for a class A computing device pursuant to Subpart J of Part 15 of FCC rules, which are designed to provide

reasonable. protection against such interference, when operated in a commercial

environment Operation of this equipment in a residential area is likely to cause interference, in which case the user at this own expense will be required .to take

whatever measures may be required to correct the interference.

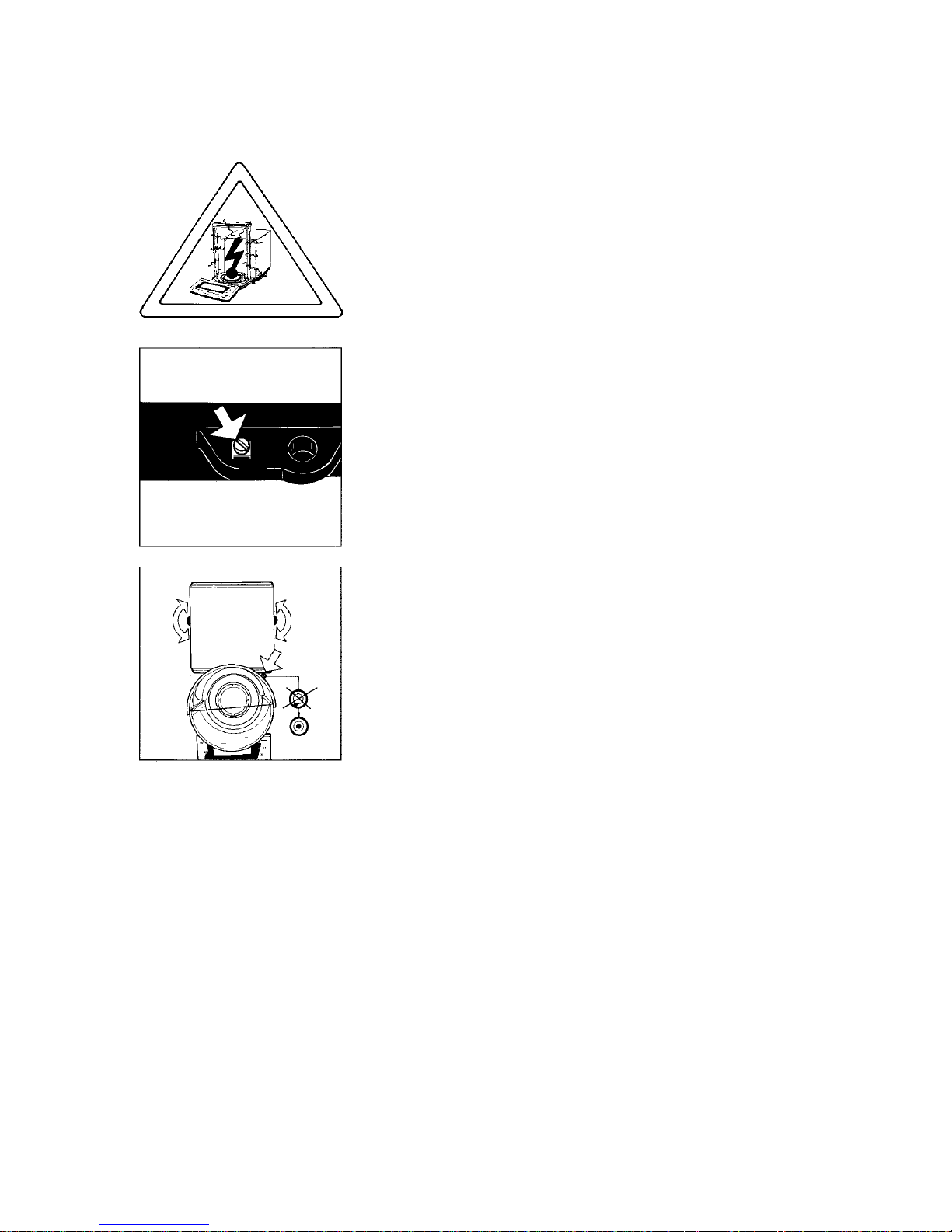

Connecting Electronic Devices (Peripherals)

Make sure to unplug the balance from the power

supply before you connect or disconnect a

peripheral device (printer or PC) to or from the

interface port. Safety Precautions

Page 12

11

Information on Weighing Electro statically Charged Samples

Problems with static electricity can occur in environments with low humidity. To

avoid these problems when you use your balance in such an area, wipe down the

entire draft shield on both the inside and outside with a commercially available

antistatic agent. In addition, the glass draft shield interior has a conductive coating.

There is a terminal (15) for connecting an equipote ntial g ro unding conductor to

the frame (housing) on the rear side of the balance. This is used for additionally

grounding a peripheral device connected to the balance (for example, a vibrating

spatula). The terminal is designed for single grounding wires up to .25" Standard

gauge or 6 mm

2

- and for .18" Standard gauge or 4 mm2 stranded wires.

lf you need to use electro statically charged glass or plastic Container s with a relatively large diamet er, you should utilize our antist a t ic pan (155 mm – see "Acce s sories" in "Part II: Product Data Sheet").

Levelling the Balance Using the Level Indicator

At the point of use, level the balance using the levelling feet (9) so t hat the air

bubble is centered within the circle of the level indicator (10).

To level the balance .using the level Indicator as a guide:

Extend the levelling feet (turn clockwise) to lift the balance.

Retract the feet (turn counter clockwise) to lower the balance.

Page 13

12

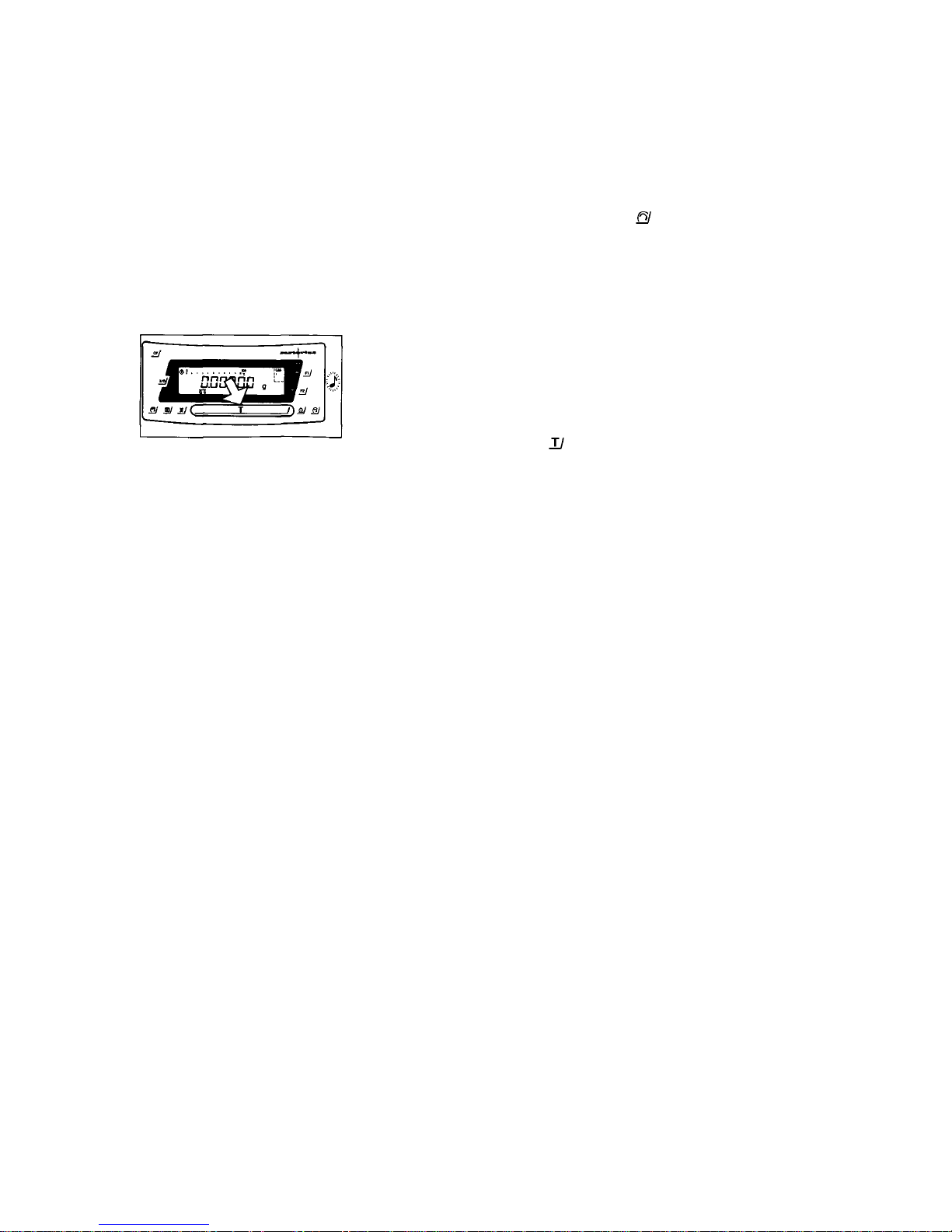

How to Operate the Balance

After initially connecting the balance to line power (or after a relatively

long power outage), allow for at least 2 hours' warmup.

Working with the Research Series Balance requires a smooth, uninterrupted technique.

The weight display shows the following special codes for your information:

OFF

The balance was disconnects from line power (power failure or outage; the balance was reconnected to line power).

0 (standby)

The display has been turned off by the

key (27), and the balance is now in the

ready-to-operate mode and does not require warmup.

(busy)

Once you turn on the balance, the

symbol is displayed until you press a key.

During Operation, this symbol indicates that the balance processor is still busy

processing s function and will not accept any other commands to perform functions at this time.

CAL

I

The balance has internal calibration weights and can be calibrated with the

key (for the "Quick-CAL” function, see also page 22).

, R1 or R2

The number in the R code identifies the particular weighing range you have selected.

Symbol for the application selected (in this case, the weighing mode and toggling

among the weighing ranges).

Page 14

13

Important Note

lf the

symbol flashes, this means that the balance wants to self-calibrate. You

do not need to interrupt your weighing procedure, because the balance will wait

until it detects that you have stopped weighing for one complete minute.

Afterwards, the balance will perform fully automatic infernal calibration. The

symbol will flash until the balance Starts this fully automatic procedure on its own

or until you activate one of the calibration functions by pressing a key (see p p.

22).

Turning the Display On and Off (Standby Mode)

Press the

key (27) to turn the display on or off.

Self-Test

After the balance has been turned on, an automatic self-test of the balance's electronic circuitry is performed, and the draft shield closes automatically.

It ends with a readout of "0.00000 g" or "0.0000 g" ( depending on your b a lance model or the display mode selected).

Important Note for Automatic Operation with a Robot

To be on the safe side for automatic Operation of the -balance with a robot, you

should turn off the full y a utomatic draft shield functi on (see "Part III: Balance Op erating Menu"). Otherwise, if a power outage occurs and the balance is automatically restarted, the robot arm may accidentally hit the draft shield as it is closing.

Page 15

14

Opening and Closing the Draft Shield Door

If you are loading small objects, open the draft shield

only as far as is absolutely necessary for your

application. This reduces the amount of draft so

your balance will stabilize faster than it normally

would when the draft shield is wide-open.

You have several options for operating the interior draft shield door (4):

– Semi-Automatic Mode (Aperture Angle s 170°) –

Press one of the keys labeled

(22) to have the draft shield door opened or

closed by motor.

The interior draft shield door moves slowly the first time it is opene d after connecting the balance to AC power.

– Semi-Automatic with an Aperture Angle of 10° to 140° –

By a "self-teaching function," the draft shield door can "learn" to open automatically to a user-define d aperture angle from 10° to 140°:

To define this angle, move the interior draft shield door (4) to the desire d Po sitio n.

Page 16

15

Press the

key (22] to have the draft shield door closed by motor.

While closing, the door moves slowly. The previously adjusted aperture angle is

stored in the process.

Now if you press the

key (22) again, the draft shield door will open at a faster

speed to the Position you selected.

You can load and remove a tare container with a diameter exceeding the aperture angle, without having to change the stored aperture setting. To do

so, press the

key (22) for approx. 2 seconds.

This will cause the draft shield door to open automatically as far as it will go

(170°).

You can always change the aperture angle by manually adjusting the position of

the draft shield door.

lf you want the draft shield door (4) to open completely (170° C) after you p re s s

the

key, just open the door manually as far as it will go.

Important Note

The aperture angle remains stored even after you have turned off the display u

sing the

key.

A stored aperture setting will not be erased until you unplug the balance from AC

current.

– Manual Mode –

Of course, you can also open and dose the draft shield door (4) by hand.

Page 17

16

Weighing

Place your sample on the weighing pan (7) to determine the weight, and dose the

draft shield door (for example, by pressing the

key (22). Do not read off the

weight indicated in the display (18) until the weight unit (in this case “g” or a different unit selected - see "Part III: Balance Operating Menu"} appears as the stability symbol.

Taring

lf you wish to use a Container or if the weight display does not indicate

0.00000 g or 0.0000 g (depe n d i ng on the particular bal a n ce model you are us ing, or on the display mode selected), zero the display before You weigh.

To do so, press the tare control

(24).

During taring, you can have the fully automatic draft shield function either on or

off. To shorten work procedures; and make them easier, you should have this fully

automatic function o n active Status. In this case, after you press the tare control,

the draft shield door will dose, the balance will be tared, and the draft shield door

will re-open.

For more information on turning this function on or off b y menu code, refer to

"Part III: Balance Operating Menu."

Page 18

1

7

Weighing Range Structure

SuperRange - "SingleWide-Range Balance"

(identified by S in the model designation RC...S)

SuperRange models have an extraordinarily high resolution, i.e., the weighing

range has a resolution ranging u p to a few million digits. There is one level of

fine readability for the entire weighing range [for example: 0.01 mg).

DualRange

(identified by D in the model designation RC...D)

2 weighing ranges;

a fine range and a Standard range

The balance automatically)' switches from the fine range which is 10 times more

accurate (for example:

52 g capacity - readability of 0.01 mg) to the Standard range (for Instance:

210 g capacity -01 mg readability} when the balance is loaded beyond the fine

range limit (>52 g). The weight readout is displayed with the readabil ity o f the

Standard range until you tare in the fine range (loa d <52 g).

PolyRange

(identified by P in the model designation RC...P).

-Wide weighing range with multiple levels of accuracy

In the PolyRange balance, the weighing range is divided into as many as 3

ranges, each with a different readability. In the various ranges, the readability

will adjust so that the last numeral of a 'weight readout is displayed with a resolution of 1, 2 or 5 digits.

After you press the tare control (24), you will obtain the highest possible resolution, even when the balance is loaded.

Page 19

18

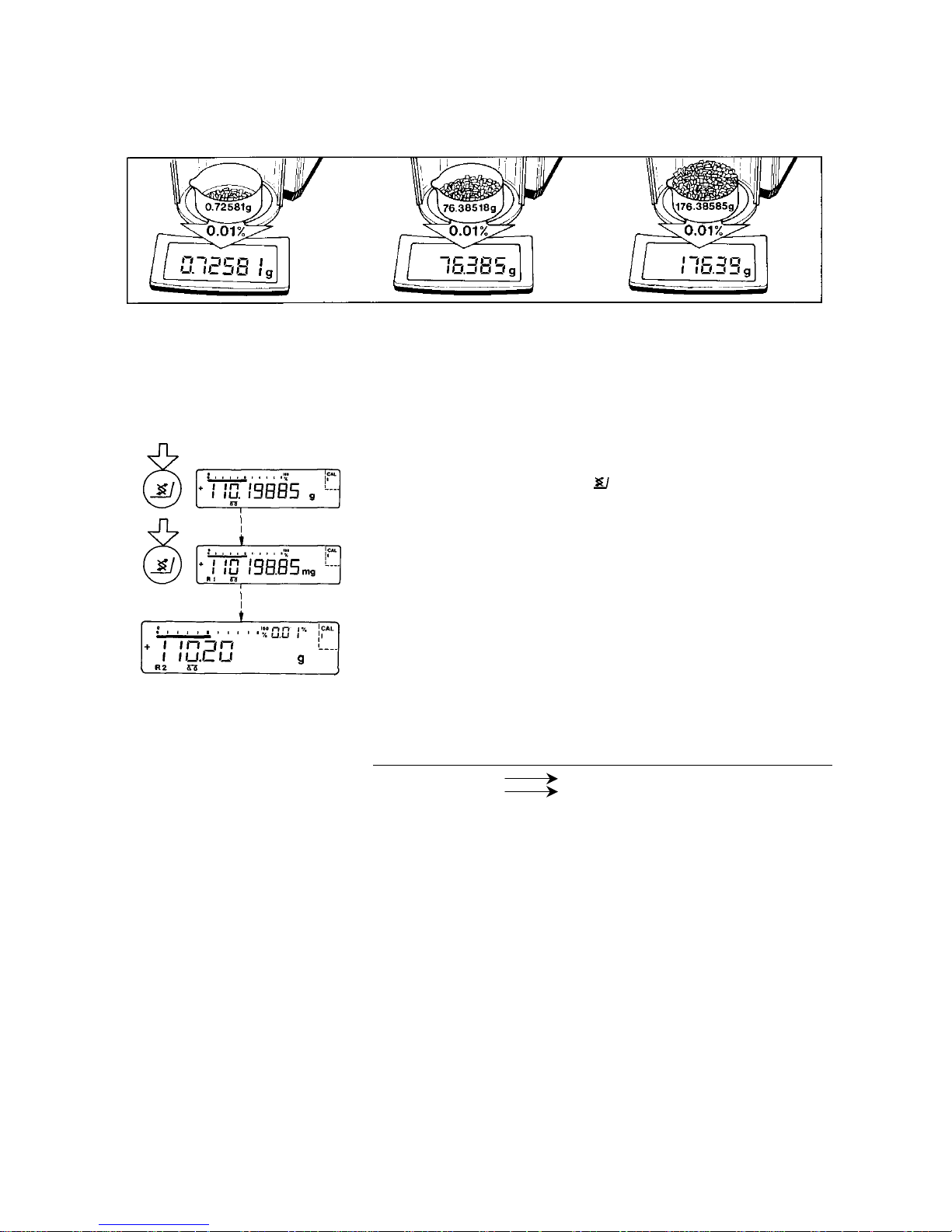

Weighing in the IQ-Mode™

(Load-Dependent Readability)

In the IQ-Mode™ (IQ = Intelligently quick), weighing is done with a loaddependent readability of 0.01 % (for different settings, see "Part III: Bal a nce Operating Menu') throughout the entire weighing range of the balance. The display

resolution of the l a st digit changes in increments of 1, 2, 5, 10, 20, etc. in proportion 1o the weight of a sample.

Oftentimes, a display accuracy of 10 milligrams is sufficient for a load of approx.

110 g. In this case. it makes s ense to select weighing range R 1 with an accuracy

of 0.01 o/a by pressing the toggle key

(25).

While you are filling u p to a target weight. it is certainly easier to work with a

target of 110.20 g than with an absolutely accurate readout of 110.1S885 g.

By selecting the IQ-Mode™ for automatic adaption of the display accuracy, you

will obtain stable weight readouts even faster.

In daily laboratory routines, analyses must often be performed with a certain accuracy. The IQ-Mode™ meets this requirement - on a semi-microbalance, it gives

you the full accuracy of all 5 decimal places for initial sample weights below 1 g;

whereas for heavier samples (of 100 g o r more), it provides lower readability

which is sufficient:

Initial sample weight readout

Below 1 g

Above 100 g

0,98756 g

123,13 g

Page 20

19

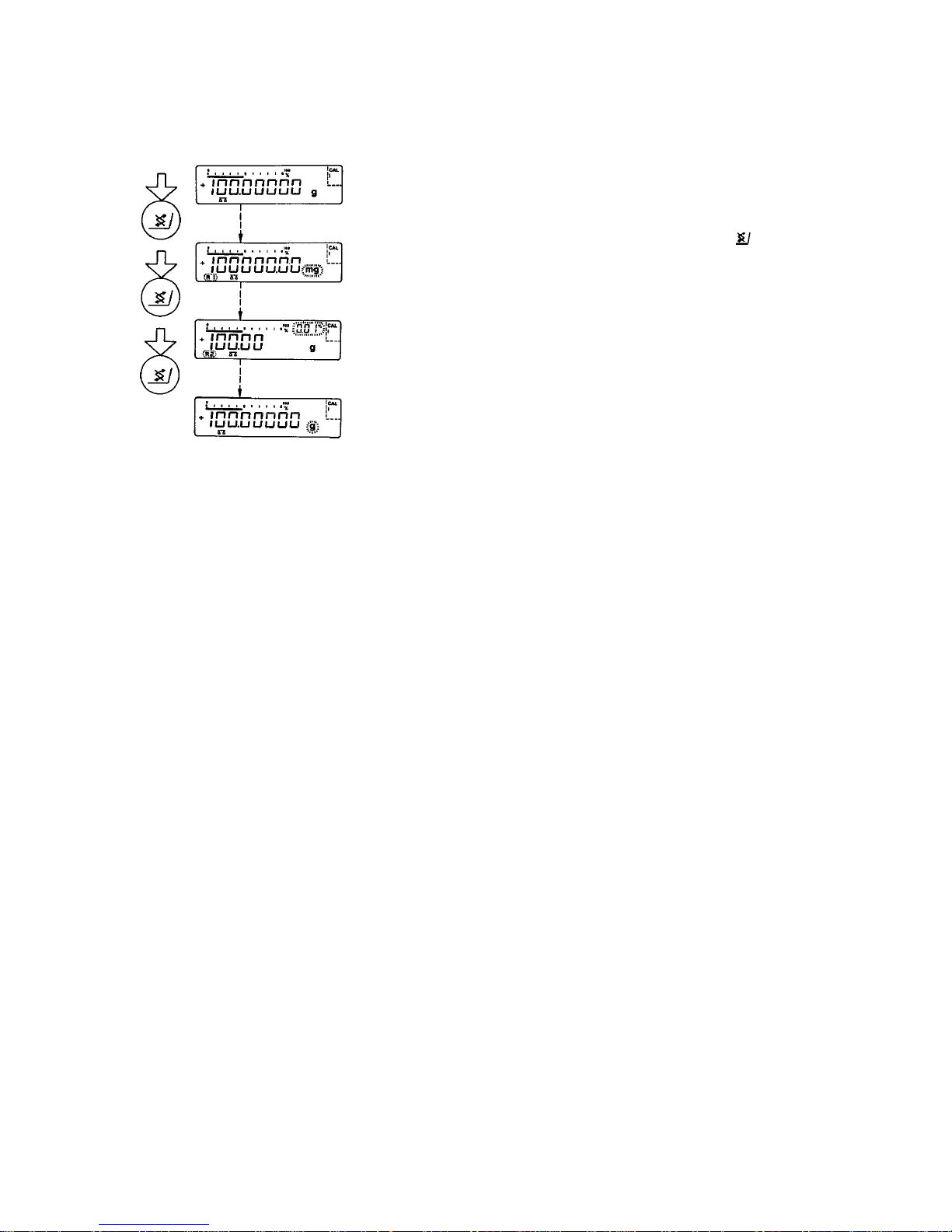

Mass Unit Conversion by Toggling

You can have the weight displayed in grams or milligrams.

To select the three weighing ranges one after the other, press the

toggle key

(25] each time.

In addition to grams and milligrams, this balance gives you a wide variety of

other menu-definable international weight unit options. For more information, refer to "Part III: Balance Operating Menu."

Page 21

20

Calibration and Linearization

During calibration, the balance is adapted to changes in ambient conditions.

You should recalibrate your balance each lime you set it up in a different area or

when the ambient conditions change (fore example, temperature or barometric

pressure). When these conditions are constant, the balance should be calibrated

once a day. To meet the highest requirements for accurate weighing, we recommend that you calibrate the balance before each weighing series.

Make sure that the draft shield is closed before calibration or linearization Starts.

You can abort any calibration or linearization procedure by pressing the

key (28),

The balance offers you various calibration and linearization functions. The function you select is indicated in the display by one of the following special codes;

»CALI« The balance has built-in calibration weights and can be calibrated

with the

key (“Quick-CAL" - see page 22)

»CALI« The calibration or linearization function is activated

»C.I.« Internal calibration

»C.t.« Calibration test

»L.I.« Linearisieren intern

»C.E.« Eternal calibration

Page 22

21

Fully Automatic Calibration

lf the

symbol flashes, this means that the balance wants to self--calibrate. You

do not need 1o interrupt your weighing procedure, because the balance will wait

until it detects that you have stopped weighing for one complete minute.

Afterwards, the balance will perform fully automatic internal calibration.

During this procedure, the draft shield should be closed 1o ensure that calibration

is done correctly.

The symbol will flash until the balance Starts this fully automatic procedure on its

own o r until you activate one of the calibration functions by pressing a key (sees

next page).

The balance can perform fully automatic internal calibration two hour after it has

been connected to line power or once the temperature has changed by ±1.5 degrees since the last calibration process. Independently of these factors, the balance can perform a fully automatic calibration after four hours at the latest.

To turn off the fully automatic calibration function by menu code, refer to "Part III:

Balance Operating Menu."

In the fully automatic mode, the draft shield closes after

or the tare control is

pressed.

Page 23

22

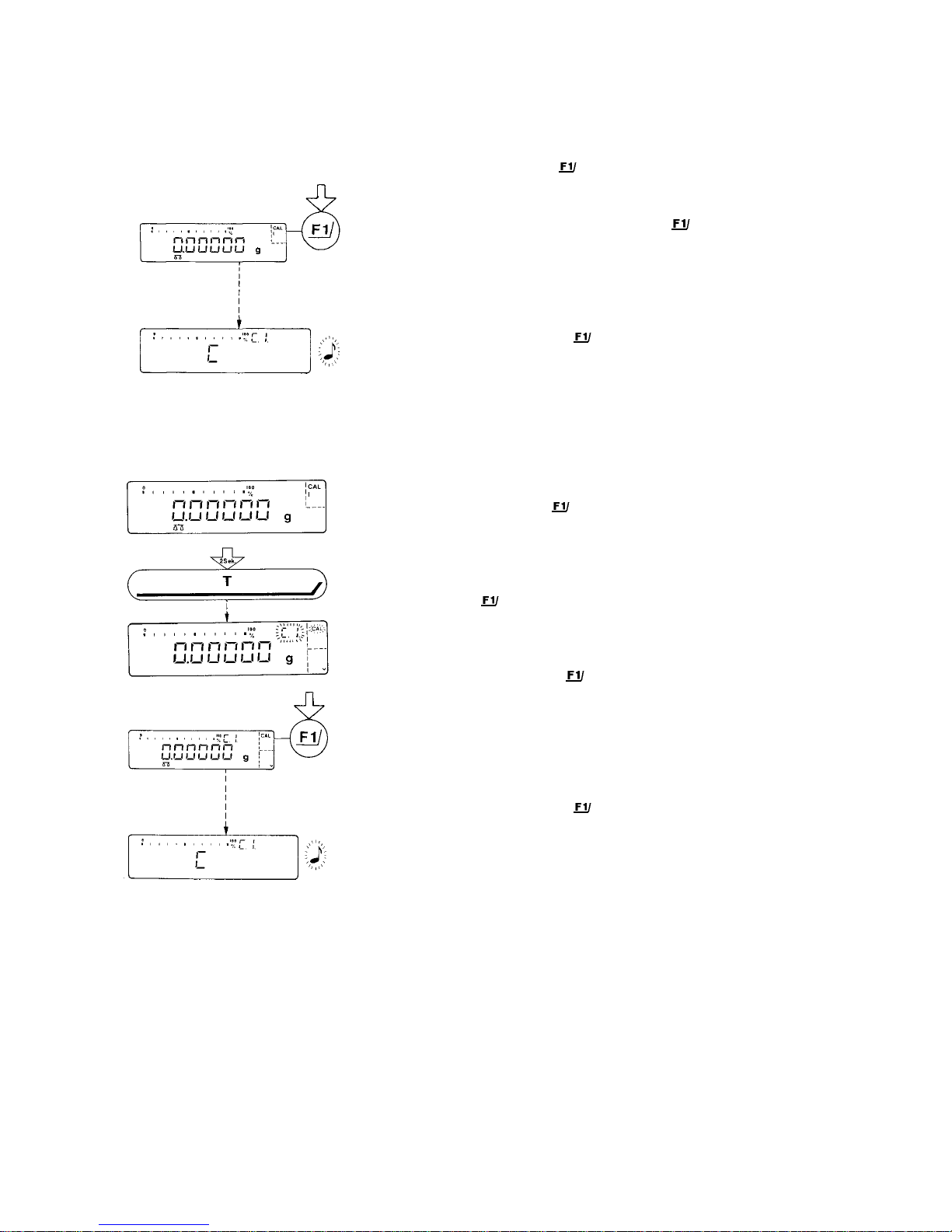

INTERNAL CALIBRATION

Quick-CAL Function using the

key:

Unload the pan, close the draft shield and tare.

When the balance displays a zero readout, press the

key (20).

"C" will now be displayed. The built-in calibration weights are internal~ applied

by servomotor and removed at the end of calibration.

lf external interference affects the calibration procedure, you may obtain a brief

display of the e rror message "Err 02. "

In this case, tare and then press the

key again when a zero readout appears.

An acoustic Signal indicates the end of calibration.

Internal Calibration Using the Tare Control:

Calibrate the balance using the tare control if an application program (such as the

tare memory) is assigned to the

key by menu code in the balance operating

menu (see Parts III a nd IV).

Press the tare control (24) for at least 2 seconds until "C.l." and "CAL” are displayed (next to the

key).

Unload the pan, make sure the draft shield is closed, and tare. When the balance

displays a zero readout, press the

key (20).

“C" will now be displayed. The built-in calibration weights are internal by applied

by servomotor and removed at the end of calibration.

If external interference affects the calibration procedure, you may obtain a brief

display of the e rror message "Err 02. "

In this case, tare and then press the

key again when a zero readout appears.

An acoustic signal indicates the end of calibration.

Page 24

23

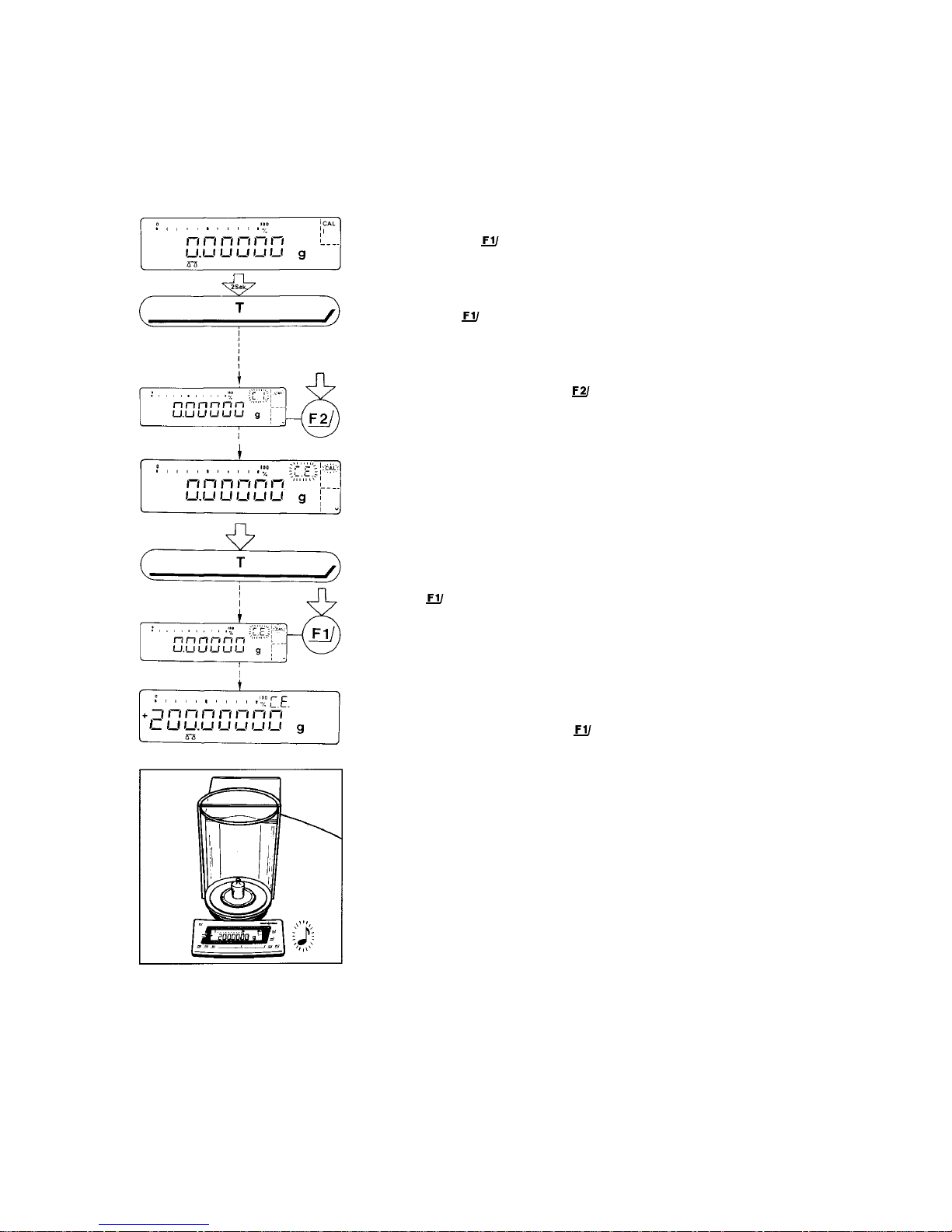

EXTERNAL CALIBRATION

Use only calibration weights that have tolerances equal or better than those of accuracy class E2 (for 200 g -> ±0. 3 mg).

Press the tare control (24) for a1 least 2 seconds until "C.l." and “CAL” are displayed (next to the

key).

Important Note

lf you press the

key (20) when "C.l." is displayed, this will activate the internal

calibration function.

For "external calibration" press the

key (21) until "C.E." is displayed.

“C.E.” Stands for "external calibration."

Unload the balance, make sure the draft shield is closed, and tare.

Press the

key (20) when a zero readout is displayed. Afterwards, the calibra-

tion weight readout will be indicated.

lf external interference affects the calibration procedure, you may obtain a brief

display of the e rror message "Err 02. "

In this case, tare and then press the

key again when a zero readout appears.

Center the calibration weight on the weighing pan and dose the draft shield door.

An acoustic Signal indicates the end of calibration.

Page 25

24

CALIBRATION TEST

Rather substantial changes In barometric pressure and temperature may affect t

he display response of these highly accurate Research Series balances.

To ensure that you obtain the full accuracy of these balances, even when you use

the entire weighing range, we have implemented a calibra tion lest function. It will

help you decide whether o r not you need to recalibrate your balance (for example, to maintain the same accuracy during long-term weighing series).

Press the tare control (24) for at least 2 seconds until "C.l." and "CAL" are displayed (next to the

key).

Select the calibration test by pressing the

key (21) twice until "C.t." is dis-

played.

Unload the balance, make sure the draft shield is closed and tare.

"C.t." Stands for “calibration fest.”

When the balance displays a zero readout, press the

key (20). The built-in

calibration weights are now internal by applied by servomotor.

Afterwards, the deviation of the momentary weight readout from the target weight

(displayed in grams only) is indicated.

lf external interference affects the calibration test procedure, you may obtain a

brief display of the error message " E R R 02."

In this case, tare and then press the

key again when a zero readout appears.

Important Note

The balance should be recalibrated if the deviation of the readout from zero exceeds the tolerance of the calibration weights used (accuracy class E2 ± 0.3mg).

-key (20): The balance automatically calibrated

(see also page 21).)

or

-key (21): Quits the calibration test

An acoustic Signal indicates the end of the calibration test.

Page 26

25

INTERNAL LINEARIZATION

Press the tare control {24) for at least 2 seconds until "C.l." and “CAL” are displayed (next to the

key).

Select "internal linearization" by p re s s ing the

key (21} three times until "L.l."

is displayed.

Unload the balance, make sure the draft shield is closed and tare.

"L.l." Stands for "internal linearization."

When a zero readout is displayed, press the

key (20). “C” will now be indicated. The built-in weights are internally applied one after the other by the Servomotor, and the weighing range is automatically liberalized.

lf external interference affects the linearization procedure, you may obtain a brief

display of the e rror message "Err 02. "

In this case, tare and then press the

key again when a zero readout appears.

An acoustic signal indicates the end of linearization.

Important Note

The balance automatically self-calibrates after each internal linearization procedure.

Page 27

26

Data Interface

lf you wish to record weight data using a Sartorius Data Printer or process them

using "Data Control," plug the printer connector into the interface port (14} of the

balance. You do not need to adjust any settings!

Remove the protective cap from the data interface port.

Caution!

Make sure to unplug the balance from the power supply before you connect or

disconnect a peripheral device (printer or PC) to or from the interface port.

To print data on hard copy or Output them on the

screen o1 an on-line Computer, press the

key (23).

For information o n s pecial data output Parameters, se-e "Utilities" under "Pa rt III:

Balance Operating Menu."

During data Output, you can have the fully automatic draft shield function either

on or off.

To shorten work procedures and make them easier, you should have this fully

automatic function on active Status. In this case, after you press

key, the draft

shield door will dose, the balance will output data, and the draft shield door will

re-open.

For more information on turning this fully automatic draft shield function on or off

by menu code, refe r t o "Part III: Balance Opera ting Menu."

Page 28

2

7

Interfacing Devices with the Balance

Please note that the interface port is electrically connected lo the protective

grounding conductor of the balance housing. The interface cables supplied as

Standard equipment are shielded, and both ends of each cable are electrically

connected to the connector cases. This co nnection may result in interference

caused by ground loops o r by transient currents if you have grounded the hous ing or connected the protective grounding conductor for line power. If necessary

connect an equipotent bonding conductor to the balance

Page 29

28

Below-Balance Weighing

A port for a below-balance weighing hanger is available on the bottom of the

balance.

To fasten the hanger, open the below-balan c e por t by r emov i ng t h e tw o scr ews on

the bottom of the balance and detaching the closing plate.

Now you can attach a sample using a Suspension wire, for example.

Common applications for below-balance weighing include specific gravity determination or immersing a sample in a special atmosphere (medium for reaction).

You can also use the M2 thread to attach a sample.

Important Note

When you use such below-balance weighing hangers, you must install a shield to

eliminate drafts..

How to Fasten the Antitheft Locking Device

To fasten the antitheft locking device, use the lug (16) located on the rear panel of

the balance.

At the place of installation, secure your balance with the lock.

Page 30

29

Troubleshooting Guide

Problem … Causes … Solution

No segments appear in the weight

display (19)

—

No line power available

—

The power supply is not plugged in

—

Check power supply

—

Plug in the power supply

The display shows “Err 54” or ”L”

—

The weighing pan (7) is not in place

—

Position the pan

The display shows ”H”

—

The load exceeds the capacity of the

balance

—

Unload the balance

The display (19) briefly shows

”Err 02”

—

The key (20) was not pressed when the

display indicated a zero readout during

calibration

—

The balance is loaded

—

Press the tare control and re-press

the

key

—

Unload the balance

The display (19) briefly shows

”Err 03” or ”Err 04”

—

The balance is in the warmup phase

—

The weighing System is affected by drafts

or vibrations

—

After plugging the balance into line

power, allow for at least 2 hours'

warmup

—

Set up the balance in another area

The special code “C” does not go

out in the weight display

—

The balance is not ready to calibrate or is

in the warmup phase

—

The weighing system is affected by drafts or

vibrations

—

The draft shield door is not closed

—

The port for the below-balance weighing

hanger is open

—

After plugging in the balance using

the power supply, allow for at least 2

hours' warmup

—

Access the menu to select the correct

code for the weighing enviro nment

(see Part III)

—

Check draft shield function and dose

door

Fasten the closing plate to dose the port

for below balance weighing

The special code does not go

out in the weight display (19)

—

None of the keys has been pressed after the

balance was turned on

—

Press a key

The weight readout changes

constantly

—

Unstable ambient conditions

—

Too much Vibration or the balance is

exposed to a draft

—

The door of the draft shield is not

completely closed

—

A draft shield cover is not in place

—

A foreign object is caught between the pan

and the bottom of the weighing chamber

—

The port for the below-balance weighing

hanger is open

—

The sample does not have a stable weight

(absorbs moisture or evaporates)

—

Set up the balance in another area

—

Access the menu to select the correct

code for the weighing enviro nment

(see Part III)

—

Close the draft shield door

—

Position the draft shield cover

—

Remove foreign object

—

Fasten the plate to dose the port for

below-balance weighing

The weight readout is obviously

wrong

—

The balance is not calibrated

—

The balance was not tared

before weighing

—

The air bubble in the level indicator (10) is

not within the circle

—

Calibrate (see pp. 20-25)

—

Tare before weighing

—

Level the balance (see page 11)

Page 31

30

Care and Maintenance

Before cleaning the balance, unplug the power supply from the wall outlet.

Cleaning the Balance Housing and the Draft Shield

Please do not use any aggressive cleaning agents (solvents or similar agents]. Instead, use a piece of lint-free cloth which has been wet with a mild detergent.

Clean the semi cylindrical elements of the draft shield with a commercially available glass cleaning agent.

Make sure that no liquid enters the balance housing.

After cleaning, wipe down the balance with a soft, dry piece of cloth.

Cleaning the Weighing Chamber

Keep the draft shield base plate from becoming too dirty:

Carefully remove spilled powder from the weighing chamber by using a small

vacuum cleaner (such as a small car vacuum cleaner with a mini-hose attached).

Afterwards, remove the weighing pan (7] and the shield disk (8) from the weighing chamber.

Vacuum out the remaining powder from the weighing chamber using the same

equipment described above.

Do not clean the weighing chamber by blowing off powder from the parts!

To remove liquid spills, use blotting paper.

Page 32

31

Safety Inspection

lf there is any indication that safe Operation of the balance is no longer warranted. turn off the power and unplug the balance from the power supply immediately. Lock the balance and the power supply in a secure place lo ensure that

they cannot be used for the time being.

Safe Operation of the equipment is no longer ensured when

—

there is visible damage 1o the power supply

—

the power supply no Ionger functions properly

—

the power supply has been stored for relatively Ion g periods under unfavourable conditions

In this case, notify your nearest Sartorius Service Center or the International Service Support Department based in Goettingen, Germany. Only service technicians

who have access to the required maintenance manuals are allowed to perform

maintenance and repair work on the equipment.

We recommend that the balance together with the power supply be inspected by

a qualified Sartorius service technician according to the following checklist;

—

Insulation resistance >7 megohms measured with a constant voltage of at

least 500 V at a 500 kohm l oad

—

Equivalent leakage current <0.05 mA measured by a property calibrated

multimeter

The duration and number of measurements should be determined by a qualified

Sartorius service technician according to the particular ambient and operational!

conditions for the power supply.

Such inspection should be done at least once a year.

Page 33

32

Safety Certificate

The electrical and electronic components used in the balance are rated to at least

Class KSF according to DIN 40040.

Pursuant to the German Directive for the Implementation of Regulations fo

r

Prevention of Accidents "Elektrische Anlagen und Betriebsmittel (VBG 4)"

(Electrical Installations and Equipment] of April 1986, in conjunction with

Article 10 of the Low-Voltage Directive 73/23/EEC issued on February IS,

1973, by the European Comm unity it is hereby certified hat the equipment

delivered, "Electronic Semi-Microbalance or Analytical Balance of the RC

Series," is manufactured and tested in compliance with the following

DIN/VDE regulations:

DIN IEC 348/VDE 0411

Safety requirements for electronic measuring apparatus

DIN IEC 380/VDE 0806

Safety of electrically energized office machines

DIN IEC 601/VDE 0750

Safety of medical electrical equipment

When you use electrical equipment in installations and under ambient

conditions requiring higher safety Standards, you must comply with the

provisions as specified in the applicable regulations for Installation in your

country.

Page 34

Page 35

Sartorius AG

B 37070 Göttingen

P Weender Landstraße 94–108, 37075 Göttingen

T (0551) 308-0, F (0551) 308-3289

Internet: http://www.sartorius.com

Copyright by Sartorius AG, Göttingen, Deutschland.

All rights reserved. No part of this publication may be

printed or translated in any form or by any means without

the prior written permission of Sartorius AG.

Sartorius AG reserves the right to make change to the

technology, features, specification and design of the equipment

without notice.

Page 36

Sartorius

Research Series

Product Data Sheet

WRC 6002-e93042

Page 37

Dimensions (Scale Drawings)

2

Page 38

Specifications

Model RC 210S RC 210P RC 210D RC 250S

Weighing range structure SuperRange PolyRange DualRange SuperRange

Capacity/weighing range levels g 210 60 / 110 / 210 52 / 210 250

Readability mg 0.01 0.01 / 0.02 / 0.05 0.01 / 0.1 0.1

Tare range (by subtraction) g -210 -210 -210 -250

Reproducibility (standard deviation)*

for weighing range

mg

g

≤

±0.015 ±0.02 ±0.03

0-50 50-100 100-210

≤

±0.02 /0.04/0.05

≤

±0.02 /0.1

≤

±0.1

Linearity mg

≤

±0.12

≤

±0.15

≤

±0.03/0.2

≤

±0.2

Linearity within 5 g mg ≤ ±0.02

≤

±0.02

≤

±0.02

Response time (typical) s

≤

10

≤

10

≤

10

≤

2.5

Response time in the IQ-Mode (0.01 %) s 2.5 2.5 2.5 1.5

Adaption to ambient conditions and application requirements 4 optimized filter levels

Display update (depends on the filter level selected) s 0.2 – 0.4 (selectable)

Allowable ambient temperature range for operation

o

C +5 … +40

Operating temperature range

o

C +10 … +30

Sensitivity drift within + 10 … + 30o C /oC

≤

±1 ·

10-6

Moisture-proof rating acc. to D IN 40040 Class F, non-condensing

Pan size mm Ø 90 / 3.5”

Weighing chamber (Ø x H), approx. mm 166 x 248/ 6.5 x 9.8”

Net weight, approx. kg 12 26.4 lbs

AC power source/power requirements V~ power supply. 230 or 115. +15 % . . . –20 %

Frequency Hz 48 – 60

Power consumption incl. power supply, approx. VA max.: 28; average: 16

Selectable weight units g, kg, ct, lb, oz, ozt, tlh, tls, tlt, gr, dwt and mg

Applications programs

mass unit conversion, tare memory, net total, weighing in percent,

over/under checkweighing (classification and filling), counting

Automatic zero tracking function (can be turned off by menu code) standard feature

Built-in interface

RS 232 C-S/V24-V28, RS 423/V10; 7-bit; parity;: even, mark, odd, spa c e;

transmission rates: 150 … 19,200 baud; 1 or 2 stop bits; software/hardware handshake

Standard features/equipment supplied

Dust cover x x x x

Power supply x x x x

Attachment for below-balance weighing x x x x

Interior weighing chamber draft shield x x x x

Built-in automatic calibration available on request

*

= standard deviation of the reproducibilit y according to DIN 1319, Part 3

3

Page 39

Accessories (Options)

Data Printer YDP02-0DV1

with date/time

and statistics functions

Print speed

approx. lines/sec. 1.5

Printer housing (WxDxH)

in mm 150x138x43

in inches 5.9x5.4x1.7

Data Control terminal 73822 C &

with built-in printer, LCD and

set of programs

Replace & with one

of the codes below:

2086 for statistics

2126 for specific gravity/density

External rechargeable

batterypack YRB02Z

hours of Operation: approx. 10;

rechargeable by power supply

(detailed information on additional

options for powering the balance

is available in our Service

Information bulletin 15/88)

BalanceReaderSof tw a re YAK 10 PC-0002

for collecting data that are transmitted by your

Sartorius Balance to a commercially available

personal Computer. These data are read into

spreadsheets and stored. The stored spreadsheets

can be further processed using commercially

available Standard Software (Excel, Lotus 1-2-3,

etc.). This applications kit includes the following

Software and equipment:

– - 3

1/2

" and 5

1/4

program diskettes

– program description

– interface cable

– adapter (25-pin to 9-pin)

4

Page 40

Density determination kit YDK 01

Draft shield cover

with pipette opening YDS 01 RC

Antistatic pan YWP 01

Weighing bowls

Stainless steel bowl, 20 g 6003

Glass bowl , 20 g 6015

Stainless steel bowl

with pouring spout, 300 ml 6407

Foot switch with T-connector

and three functions YPE 01 RC

for opening/closing the draft shield,

taring and printing

Universal remote - control switch

with menu-code definable print,

tare, F1/F2 key or open/close

draft shield function

Foot switch 7223

Foot switch with T-connector YPE 01 Z

Hand switch 7226

T-connector 7258

Antivibration balance fable YWT 01

Wall console 6804

Vibrating spatula 6025

Forceps 6708-62

Dust brush 6708-02

Carrying case YDB01RC

Dust cover 6960RC01

5

Page 41

Sartorius AG

B 37070 Göttingen

P Weender Landstraße 94–108, 37075 Göttingen

T (0551) 308-0, F (0551) 308-3289

Internet: http://www.sartorius.com

Copyright by Sartorius AG, Göttingen, Deutschland.

All rights reserved. No part of this publication may be

printed or translated in any form or by any means without

the prior written permission of Sartorius AG.

Sartorius AG reserves the right to make change to the

technology, features, specification and design of the equipment

without notice.

Page 42

Sartorius

Research Series

Balance Operating Menu

WRC 6003-e93042

Page 43

2

Overview of the Balance Operating Menu

Page

How to Access the Menu 3

Examples for Changing Menu Code Settings 6

How to Undo All Menu Code Changes: Reset Function 9

Balance Operating Parameters 11

How to Adapt the Balance to Ambient Conditions 11

Standard Weighing Mode - Manual Filling Mode 11

Stability Range 11

Stability Symbol Delay 12

Tare Parameter 12

Auto Zero Function 12

Weighing in Three Range s 13

How to Select the Number of Ranges 13

Weight Units 13

IQ-Mode™ 15

Display Modes 16

Final Readout Mode "- -" 16

Last Numeral Blanked When the Load Changes 16

Display Accuracy 16

PolyRange Function 16

Calibration and Linearization Functions 17

Utilities for Printouts or Data Transfer 20

Data l D Codes 21

Additional Functions 22

Menu Access Function 22

Beep Tone (Acoustic Signal) 22

Blocking the Keys 22

Analog Display: Bar Graph/Marker 23

Power-On Mode 23

Display Backlighting 23

Fully Automatic Draft Shield Function 24

Display Accuracy with the Draft Shield Automatically Opened or Manually Adjusted 24

IQ-Mode™ with the Draft Shield Automatically Opened or Manually Adjusted 25

GLP/GMP Printout or Reco rd 26

Setting the ID No./Time/Date 31

Reset Function 32

Brief Instructions fo r Setting a Menu Code 33

Quick-Reference Guide to All Menu Code Settings 34

Page 44

3

How to Access the Menu

The Sartorius MC1 Balance can do much more than "just weigh."

It can "think" in various units of measure, adapt to unfavourable conditions and process weight data for a variety of

applications.

In the operating menu, you can define how your balance will adapt to ambient conditions and also how it will work to meet

your special requirements.

For your convenience, the m enu codes have been factory-set so that you do not have to make any changes if yo u want to "just

weigh," and if your balance will be operated under normal ambient conditions.

To select specific functions, you will need to set the respective menu code.

This code tells the microcomputer inside the balance what it has to do to meet your requirements.

Here is a short example to help you understand how to set a menu code.

Just take a look at the picture below.

See the apple on one of the trees?

Now if you want to explain to somebody where this apple is located, you could number the trees, the main branches and the

small branches according to a certain pattern.

Then you could describe the location like this: the apple is on tree no. 3, main branch no. 1 and small branch no. 4. To express

this as a menu code, you'd say: 3 1 4.

Now that’s easy enough, isn't it?

Page 45

4

The areas where certain code settings are found in the balance/scale operating menu are designated similarly to the way in

which the location of the apple is pinpointed.

Going back to our example, tree no. 3:

The apple is located exactly where the unit symbol "ct" is on our menu "tree."

On main branch no. 1, you'll f ind all weight units for the seco nd weighing range which you select with the toggle key

. On

small branch no..4, carats - "ct" is defined

as the weight unit - so your code will be 3 1 4.

The weight unit "g" for grams is on the same tree (3) and the same main branch (1 ), but on small branch no. 2.

Therefore, the code for grams is 3 1 2.

The code for pounds (lb) is 3 1 5, and so on.

(For a list of codes, see "Overview of the Weight Units," column for the "2nd range," on page 14.)

At this point, you'll probably want to know how to change the menu codes stored in your balance.

Go right ahead and try to change a few of the menu code settings. That’s the best way to familiarize yourself with the

performance capabilities and the versatility of the microcomputer in your Sartorius Balance.

Don't worry!

Even if you've selected the "wildest" codes and totally thrown off all the code settings you need, all you have to do is press a

key to set things straight again.

Your balance will work just like it did when it left the factory - with the original factory-set menu codes.

There are three Steps to changing a code:

- access the menu

- set a code

- confirm and store this code

To set a code, use the four keys which are defined on the display as arrow points to indicate the direction.

Function Key

Go back

Go forward

increase

Decrease

Page 46

5

Now for a little hands-on practice!

It's your turn to try a setting - how abo ut cha ng ing the weight unit in the second weighing ra nge (use

to select this range)

from grams to carats (et), Code: 3 1 4. (In our example, the 1

st

weighing range " " will remain unchanged.)

The balance operating menu is protected against accidental changes. That’s why you'll need to "unlock" it:

Change from the Status readout

to

-L- Stands for "list" for checking menu code settings, and

-C- Stands for "change" for selecting a different menu code.

In the following directions, we've included diagrams to show you what you actually see on the display and which key you need

to press, for example:

The text next to the diagrams tells you how to carry out each Step

Page 47

6

Examples for Changing Menu Code Settings

How to set code 3 1 4 for "ct" in the second weighing range

- Turn off the balance

- Turn it back on

- While all segments are displayed, briefly press the tare control

- If -L- is displayed, unlock the menu access switch

- Remove the protective cap located to the left of the AC jack o n the re ar pane l

of the balance, and move the switch in the direction of the arrow

- Change the left-hand number to “3”

- Move to the middle number

- Now move from "1" to the right-hand number (Whe n yo u m o ve to the right-

hand number, the previously set numeric code will appear.)

- Change the right-hand numbe r to “4”

- Confirm the code setting

Important Note:

You must press the tare control

in order to .confirm the code you have just set:

This is indicated by the "o" after the code.

- Press

to store your menu code setting

Page 48

7

That’s all there is to it!

Now, if you press the

key, you can read the weight in carats "ct":

Of course, you'll be in the IQ-Mode™, with a load-dependent readability of

0.01%, as defined by the factory-set menu code.

You say you don't like it?

You'd rather weigh in the unit "ct" with the highest possible accuracy down to the

last digit?

No problem!

Just set the appropriate code:

3 2 1. (You'll find this code listed under "Display Modes" on page 16.)

How to set code 3 2 1 for full resolution in the second weighing range

- Turn off the balance

- Turn it back on

- While all segments are displayed, briefly press the tare control

- Change the left-hand number to “3”

- Move to the middle number

- Change the middle number to “2”

- Move from "2" to the rig ht-ha nd number (When you move to the rig ht-ha nd

number, the previously set numeric code will appear.)

- Change the right-hand numbe r to “1”

Page 49

8

- Confirm the code setting

Important Note:

You must press the tare control

in order to .confirm the code you have just set:

This is indicated by the "o" after the code.

- Press

to store your menu code setting

Now you can read the weight in "ct" accurately down to the last digit.

Congratulations! You've just finished the two examples we've given to help familiarize you with how to use the code setting function.

Remember, the keys labelled

, , , , and have special functions

in this mode:

and = Move to the le ft and right, re spe ctive ly

and = Respectively increase and decrease a number by one

= Confirms a code setting

= Stores a code setting and leaves the menu

n the application programs, the

and keys will have other f unctio ns deter-

mined by the program that you have selected.

The particular function assigned is always shown on the display next to each key

for easy identification.

Before you begin to look for different menu codes in the description of the application programs, you should try out the reset function to undo all changes in order

to see how it works.

Page 50

9

How to Undo All Menu Code Changes - Reset Function

The reset function lets you undo all menu code changes, which means that you will obtain the original factory-set menu codes

so that your balance will operate according

to them. To use this function, you will need to select code 9 - - 1.

How to set code: 9 – – 1

- Turn off the balance

- Turn it back on

- While all segments are displayed, briefly press the tare control (

)

- Change the left-hand number to “9”

- Move to the middle number

For this code, the middle number is skipped.

Instead, you will always obtain the right-hand number.

- Change the number to “1”

- Confirm the code setting

Important Note:

You must press the tare control (

)to confirm the code you have just set:

This is indicated by the "o" after the code.

- Press “

” to store your menu code setting

All menu code settings are now the ones which were originally set at the factory.

Page 51

10

Note:

The actual menu code setting in the balance operating menu is identified by a small "o" after the last number. When you

access the operating menu, the previously set numeric code will be displayed after you select the left and the middle numbers,

which means the entire menu code setting is displayed. This makes it easy for you to check the m e nu code se ttings.

Please do not forget to relock the balance operating menu. The "-L-" indicates that it is currently locked:

You can lock the menu anytime you wish once you have accessed it. However, it is best if you wait until you have changed the

last code setting.

To use the locking function, make sure code 8 1 2 is set in the balance operating menu.

If code 8 1 1 is set, the menu access switch will not l ock.

In this case, "-C-" will be displayed whenever you access the menu:

The lists on the next pages give just a small sampling of the code options available for the balance operating menu. These

options involve Standard balance Operation, utilities for printouts or data transfer, and additional functions.

lf you would like to change several menu code settings, you do not have to press

/ after each change to leave the balance

operating menu.

For your convenience, we've indicated all factory code settings with an "*."

You'll find information on the application programs in "Part IV."

A quick-reference guide listing all menu code options for the "Standard" operating parameters of the balance is given in the

section starting on page 34. This guide also provides space for you to enter any changes to the menu codes.

Page 52

11

Balance Operating Parameters

How to Adapt the Balance to Ambient Conditions

To adapt your balance to ambient conditions, you may need to change the response time (see the Product Data Sheet).

Code

Very stable conditions 1 1 1

Stable conditions * 1 1 2

Unstable conditions 1 1 3

Very unstable conditions 1 1 4

Standard Weighing Mode - Manual Filling Mode

You can optimally adapt your balance to meet either of these requirements.

In the manual filling mode, the display compensates for fluctuations of the load on the balance so that you obtain a steadier

readout.

Code

Standard weighing mode * 1 2 1

Manual filling mode 1 2 2

Stability Range

The stability range in digits works together with the stability symbol (unit symbol).

When the stability symbol is displayed, the weight readout is stable within the defined range.

Readout is stable within ± Code

0,25 digit ** 1 3 1

0,5 digit 1 3 2

1 digit 1 3 3

2 digits * 1 3 4

4 digits 1 3 5

8 digits 1 3 6

* = Factory setting

** = Setting not available for balances with 0.01 mg readability

Page 53

12

Stability Symbol Del a y

This setting allows your balance to compensate for individual interfering factors which slowly subside, such as turbulent air

currents generated within the weighing chamber.

Code

No delay 1 4 1

Short delay * 1 4 2

long delay 1 4 3

Extremely long delay 1 4 4

Tare Parameter

You can define when the balance will perform the taring Operation:

Code

At any time 1 5 1

not until the readout is stable * 1 5 2

Auto Zero Function

When this zero tracking function is activated, any changes off of the zero readout that are equal to a defined fraction of digits

per second are automatically tared. In other words, it ensures a stable zero.

Code

Auto Zero on * 1 6 1

Auto Zero off 1 6 2

* = Factory setting

Page 54

13

Weighing in Three Ranges

The toggle key

lets you switch back and forth among three weighing ranges.

lf the menu code is set for three ranges, press the

key each time to toggle to a different range.

How to Select the Number of Ranges

Code

Block the key 2 1 1

Two weighing ranges 2 1 2

Three weighing ranges * 2 1 3

lf two or three weighing ranges are defined by menu code, the ID displayed for the particu lar r ange ju st selected will ch an ge as

follows:

ID displayed

1

st

range 2nd range 3rd range

Two weighing ranges R1 R2

Three weighing ranges – – – **) R1 R2

Weight Units

The "initial weight unit" is the unit in which your balance will weigh the moment you turn it on. This unit is defined in the 1

st

range.

You can select a different unit for each weighing range by setting the appropriate menu codes.

Important Note:

You can select almost any weight unit; however, this may entail a loss of resolution, since the number of places which can be

displayed is limited (e.g., if you select "kilograms.")

* = Factory setting

**) The weighing range available when the balance is on is identified only by the scale symbol.

Page 55

14

Overview of the Weight Units:

Symbol Code

1

st

range 2nd range 3rd range

Grams o 1 7 1 3 1 1 3 3 1

Grams g *1 7 2 *3 1 2 3 3 2

Kilograms kg 1 7 3 3 1 3 3 3 3

Carats ct 1 7 4 3 1 4 3 3 4

Pounds lb 1 7 5 3 1 5 3 3 5

Ounces oz 1 7 6 3 1 6 3 3 6

Troy ounces ozt 1 7 7 3 1 7 3 3 7

Hong Kong taels tl 1 7 8 3 1 8 3 3 8

Singapore taels tl 1 7 9 3 1 9 3 3 9

Taiwanese taels tl 1 7 10 3 1 10 3 3 10

Grains gr 1 7 11 3 1 11 3 3 11

Pennyweights dwt 1 7 12 3 1 12 3 3 12

Milligrams mg 1 7 13 3 1 13 *3 3 13

Codes 1 7 1, 3 1 1 and 3 3 1 are reserved for programming special units to meet the needs of customized applications. The

Standard, factory-set unit is grams.

In the display, you will see "o" as the stability symbol for a stable readout, just as for kilograms.

Some unit Symbols printed on hardcopy or output on a Computer screen will differ from the way they are shown on the

balance display:

This applies to code numbers ending with 3 = kg

6 = tlh

9 = tls

10 = tlt

* = Factory setting

Page 56

15

IQ-Mode™

(Load-dependent readability)

In the IQ-mode™, weighing is done with a menu-definable, load-dependent readability throughout the entire weighing range

of your balance. In the process, the display resolution of the last weight digit changes in increments of 1, 2, 5, 10, 20, etc., in

proportion to the weight of the sample.

Oftentimes, a display accuracy of 10 milligrams is sufficient for a relatively heavy load.

In this case, it makes sense to select the 2nd weighing range (identified as "R 1" for 3 ranges) with an accuracy of 0.01 % - a

touch of the toggle key

is all it takes. In the second weighing range (codes 3 2 1 through 3 2 13), a load-dependent

readability of 0.01% has been factory-set.

While you're filling up to a target weight, it is certa i nly easier to work with a target of 110.20 g than with an abs olutely

accurate readout of 110.19885 g.

By selecting this function for automatic adaption of the display accuracy, you will obtain stable weight readouts even faster.

In daily laboratory routines, analyses must often be performed with a certain level of accuracy. The IQ-Mode™ meets this

requirement - on a semi-microbalance, it gives you all 5 decimal places for initial sample weights below 1 g; whereas for

heavier samples of 100 g or more, it provides pro p ortionally lower readability which is usually sufficient:

Initial sample weight Readout (for a code setting of 0.01 %)

Below 1 g Æ 0.98756 g

Above 100 g Æ 123.13 g

This mode for adapting the display accuracy enables you to weigh with constant proportional precision between 1 % and

0.01% over the entire weighing range of your balance. The particular accuracy you choose is indicated in the top right corner

of the application display field.

Select the load-dependent display accuracy independently for each of the three weighing rang es.

Code

Load-dependent display accuracy

1

st

range 2nd range 3rd range

1.0 % 1 8 6 3 2 6 3 4 6

0.5 % 1 8 7 3 2 7 3 4 7

0.2 % 1 8 8 3 2 8 3 4 8

0.1 % 1 8 9 3 2 9 3 4 9

0.05 % 1 8 10 3 2 10 3 4 10

0.02 % 1 8 11 3 2 11 3 4 11

0.01 % 1 8 12 *3 2 12 3 4 12

* = Factory setting

Page 57

16

Display Modes

You can select the display mode that best meets your individual requirements.

The menu code settings for all weighing ranges are l i s ted on the next page.

Final Readout Mode "- -"

lf you are only interested in the final readout, you can select this mode by setting code 2 5 1. A special symbol "- -" will be

displayed in any weighing range until the final stable readout appears in digits. For the Standard readout mode, set code

2 5 2 (all readouts in digits).

Readout mode Code

Special symbol “ – – “ for unstable readings when load changes 2 5 1

Standard digital readout mode * 2 5 2

Last Numeral Blanked When the Load Changes

As the load on your balance changes, the display resolution is reduced by a factor of 10 so that you will obtain a faster and

more stable readout.

In the process, the last numeral is blanked until the load stabilizes. Once the load stabilizes, the readout is shown again with

the full display accuracy, which means the

last numeral is displayed.

Display Accuracy t

You can define the level of accuracy by changing the displ a y increments, also called "scale intervals" (of the l a st numeral). The

display increments p ossible are as follows: 1, 2, 5, 10, 20, 50, etc.

Starting with the basic increments of a weight unit, the display accuracy can be reduced by as many as three levels so that you

will obtain a faster readout with reduced display accuracy.

To make this concept easier to understand, the three levels are designated as "rounding factors" in the tables summarizing the

various menu code settings.

PolyRange Function (application for "single-range" balances)

The PolyRange function divides a single weighing range into as many as 3 ranges, each with a different readability. In the

various ranges, the readability will adjust so that the last numeral of a readout Ts displayed with a resolution of 2 or 5

increments. The PolyRange function makes filling easier because the readability becomes slightly coarser as the load increases

and you will not immediately lose an entire place of readability. Press the tare control at any range level to restore the full

resolution of the first range, even when the balance is loaded.

Code

Display mode

1st range 2nd range 3rd range

Highest possible accuracy 1 8 1 3 2 1 3 4 1

Last number bla n ked when load changes *1 8 2 3 2 2 *3 4 2

Rounding factor 2 1 8 3 3 2 3 3 4 3

Rounding factor 5 1 8 4 3 2 4 3 4 4

Rounding factor 10 1 8 5 3 2 5 3 4 5

PolyRange function** 1 8 13 3 2 13 3 4 13

* = Factory setting

** = Only available for balances with the weighing range structure "SuperRange"

Page 58

1

7

Calibration und Linearization Functions

Select the appropriate menu code to define the access Status for each of the following calibration and linearization functions,

which are activated by holding down the tare control

for a few seconds:

– External calibration C.E.

– Internal calibration C.I.

– Calibration fest C.t.

– Internal linearization L.I.

– External linearization L.E.

However, if the menu access switch is unlocked ("acce ssibl e " Status indicated by -c- after you have accessed the balance

operating menu), the "external calibration" function will be accessible even though you have set the menu code 1 9 2 for

"access denied."

External calibration Code

Accessible * 1 9 1

Access denied 1 9 2

Internal calibration Code

Accessible * 1 10 1

Access denied 1 10 2

Calibration test Code

Accessible * 1 11 1

Access denied 1 11 2

External linearization

The linearization weights to be loaded are displayed on the balance one after the other in increasing order.

External linearization Code

Accessible * 1 12 1

Access denied 1 12 2

Internal linearization Code

Accessible * 1 13 1

Access denied 1 13 2

* = Factory setting

Page 59

18

Multiple Calibration Mode

The calibration accuracy can be increased. The calibration values calculated from the average of the individual calibration

procedures. You can use the "multiple calibration mode" for both infernal and external calibration. The number of calibration

procedures is indicated in the 3rd place of the application display field (e.g., "C 1 5”).

Important Note:

lf "Err 04" is briefly displayed, the calibration va lues deviate too much from one another. This means the calibration value

measured is not stored, and the calibration procedure will be repeated.

Multiple calibration mode Code

Off * 1 14 1

On 1 14 2

Fully Automatic Calibration and Linearization

Automatic calibration and linearization Code

Off 1 15 1

Off (with calibration Status ) * 1 15 2

Fully automatic calibration on * 1 15 3

Fully automatic calibration and linearization on 1 15 4

Wait Interval until Fully Automatic Calibration Starts

Code

1 minute after stabil i ty * 8 9 1

2 minutes after stability 8 9 2

* = Factory setting

* = The symbol "

" flashes in the display until you press the appropriate key to activate one of the calibration functions.

Page 60

19

Quick CAL with

You can activate the "internal calibration" function anytime by a touch of the

key (factory setting).

That’s why we call it "Quick CAL" for short.

You can also set a different menu code to change the function of the

key from "internal calibration" to "calibration test."

Both functions are accessib le even if you select co de 1 10 2 or 1 11 2, respectively.

Function of the

key Code

Access denied 2 2 1

Internal calibration * 2 2 5

Calibration test 2 2 6

* = Factory setting

Page 61

20

Utilities for Printouts or Data Transfer

Sartorius MC1 Balances come Standard with an interface.

You can plug a Sartorius Printer or a Computer into this interface port to print data on hard copy or transfer them to your

Computer. Moreover, you can choose to Output data from your balance to this on-line device either automatically or by

pressing the print key on the balance.

The balance operating menu lets you define the various parameters for data output.

For information on the data formats and for interfacing a Computer or a different peripheral device, see "Part V: Interface

Description."

Data Output Parameter

This parameter is coupled with or without the stability parameter = stable readout or no motion is detected

Print on request = data is output only when the print key is pressed or a Software command is received

Auto print = continuities. automatic data output

Code

Print on request regardless of stability 6 1 1

Print on request after stability with storage of the function * 6 1 2

Print on request after stability without storage of the function 6 1 3

Auto print regardless of stability 6 1 4

Auto print at stability 6 1 5

Automatic Data Output

You can stop and Start automatic data output by pressing the print key. To avoid operating errors or to ensure that data will be

output continuously in the automatic mode, you can block this function

Code

Start/stop auto print using the print key 6 2 1

Auto print not stoppable * 6 2 2

* = Factory setting

Page 62

21

Data Output at Defined Intervals

You can reduce the volume of data in the "auto print" mode by defining the interval at which data will be Output automatically .

This auto print interval is based on the number of times the display is updated.

Auto print interval Code

1 display update * 6 3 1

2 display updates 6 3 2

5 display updates 6 3 3

10 display updates 6 3 4

20 display updates 6 3 5

50 display updates 6 3 6

100 display updates 6 3 7

Automatic Taring after Data Output

This convenient setting lets you checkweigh a series of samples or products without having to unload the balance after each

weighing Operation.

This means less work for you:

– the sample remains on the pan after the weight readout has been printed or transferred to an on-line Computer

– the balance is tared automatically after the weight readout has been printed or transferred to an on-line Computer

– you simply load the next sample or part

Automatic taring after data output Code

Data output without automatic taring * 6 4 1

Data output with automatic taring 6 4 2

Data ID Codes

To help you identify weights, piece counts, percentages, etc., a code letter is printed or displayed in front of these values.

For example, an "N" printed or displayed before a weight value identifies it as a net weight. You will find the data ID codes of

a particular application program listed in the corresponding description. This ID code increases the data Output format from

16 to 22 characters for each weight readout.

ID code for data output Code

Without * 7 2 1

With 7 2 2

* = Factory setting

Page 63

22

Additional Functions

A number of additional menu codes enable you to assign or deny access to various functions.

Menu Access Function

You can define the function of the menu access switch by setting the code for the balance operating menu to "accessible." In

this setting, "-C-" will be displayed on your balance whenever you access the menu.

This means that you can change the menu codes at any time regardless of the setting the menu access switch.

Access to the balance operating menu Code

Accessible 8 1 1

depends on setting of menu access switch * 8 1 2

Beep Tone (Acoustic Signal)

lf you wish, you can turn off the beep tone (i.e., "acoustic Signal").

Acoustic signal Code

On * 8 2 1

Off 8 2 2

Blocking the Keys

You can block all keys on the balance (except for

).

Key function Code

Accessible * 8 3 1

Blocked 8 3 2

* = Factory setting

Page 64

23

Analog Display: Bar Graph/Marker

In the factory setting, the analog display works as a bar graph: By changing the menu code, you can turn the analog display

completely off or have it appear as a marker.

When the marker is selected, two individual Segments will move within the display scale range to indicate the loading Status of

your balance.

Analog display Code

Off 8 5 1

Bar graph * 8 5 2

Marker 8 5 3

Power-On Mode

Depending on the operating mode, - line current, battery Operation or continuous Operation -, you can change the power-on

mode of your balance.

The factory setting is: (power) off Æ on ÅÆ standby.

In the setting "toggle between on and standby," the balance power will turn back on automatically after a power failure has

occurred, or after you have disconnected your balance temporarily from line current.

In the setting "automatic power-on," the balance will turn back on automatically after a power failure has occurred; after the

balance has been disconnected from line current; or after the

key has been pressed. In this setting, the balance can no

longer be turned off by the

key.

Power-on mode Code

(power) off Æ on Æ standby * 8 6 1

on Æ standby 8 6 2

Automatic power-on 8 6 3

Display Backlighting

Depending on your individual workplace requirements, you can turn the display backlighting on or off accordingly:

Display backlighting Code

On * 8 8 1

Off 8 8 2

* = Factory setting

Page 65

24

Fully Automatic Draft Shield Function

You can define the fully automatic draft shield function to meet the most diverse requirements in o rder to sho rten work

procedures and make them easier. After you have pressed a function key (or after a control command has been received – see

"Part V: Interface Description"), the draft shield will dose automatically and the balance will then perform th e par ticu lar function

activated by the key. lf code 8 11 2 or 8 11 3 is set, the draft shield will open once the function selected has been performed.

In code setting 8 11 4 or 8 11 5, the last numeral is displayed when a balance with 0.01 mg readability is turned on.

To be on the safe side for automatic Operation of the balance with a robot, you should turn off the fully automatic draft shield

function (code 8 11 1). Otherwise, if a power outage occurs and the balance is automatically restarted (e.g., code 8 6 3 or 8 6

4), the robot arm may accidentally hit the draft shield as it is closing.

The draft shield operates automatically for the following functions:

— powering on the balance (

key)

— taring once the balance has stabilized (tare control

)

— printing on request after stability (

key)

— starting the calibration function (

key)

— using the tare memory once the balance has stabilized (

key) - see also "Part IV: Application Programs"

— storing weights during over/under checkweighing (

key) - see also "Part IV: Application Programs"

— storing weights while weighing in percent and counting (

key) - see also "Part IV: Application Programs"

Automatic draft shield function Code

Off 8 11 1