Page 1

Operating Instructions

Sartorius LMA110S Moisture Analyzer

Model Mark 3 LTE

Electronic Moisture Analyzer

98040-699-09 Rev. D

Page 2

Contents

Contents 2

Introduction 3

Intended Use 3

Descriptions and Symbols 3

Warning and Safety Information 4

Sample Pans 6

Safety Precautions 7

Getting Started 8

Storage and Shipping Conditions 8

Unpacking the Moisture Analyzer 8

Instructions for Recycling the Packaging 9

Equipment Supplied

General Views of the Moisture Analyzer 10

Assembly 12

Choosing a Suitable Location 13

Connecting the Moisture Analyzer

to AC Power 13

Leveling the Moisture Analyzer 14

Operating Design 15

Keypad 15

Display Modes 17

Menu Structure 19

Data Output 20

LED Status Lights 20

Operating the Moisture Analyzer 21

Standby Screen 21

Standby Temperature with a

New Program 22

Default Drying Program 23

Recalling a Program 24

Testing a Sample 25

Setup Menu 28

Setting the Device Parameters in

Program Manage Menu 28

Edit Current Program 29

Table: Program Settings 30

Units 31

Factors 32

Temperature 1 and 2 33

Time 1 and 2 34

Slope 34

Target Limits 39

Test Mode 40

Program Name 41

Create a New Program 42

Delete Program 42

Sort Programs 42

Configuring the Printout 43

Print Current Program 43

Print Program List 43

Print All Programs 43

Data Log 44

Device Information 45

Modify Operators 46

Graphing 47

Results Printout Format 48

Setting the Time and Date 51

Communication Ports 52

Pin Assignment Chart 52

Serial Command List 53

Conserve Mode 60

Security 61

Activate and Deactivate Security 61

Setup Security Access 62

Clear Data Log 63

Clear Operators 63

Restore Factory Defaults 64

Manage Program Storage 64

Transfer Programs 66

Audio, Video and Language 67

Audio Adjustments 67

Video Contrast Adjustment 68

Video Color Scheme 68

Service 69

System 69

Calibration | Adjustment Functions 70

Calibrate Balance 70

Heater Adjustment 73

Adjust Temperature 73

Verify Temperature 73

Concentration Mode 77

Multi-module Mode 78

Cleaning 80

Dispoal 81

Specifications 82

Accessories (Options) 83

Regulatory Compliance 84

2

Page 3

3

Introduction

Thank you for choosing the Sartorius

Mark 3 LTE moisture analyzer, the international version of the field-proven Mark

3 from Sartorius. This analyzer is a modular analytical instrument that can be configured to meet various performance

requirements. Each analyzer consists of

two parts, a control module and a heater

module. The control module is comprised

of a keypad, a display and a printer

(optional) with the appropriate electronics. The heater module consists of the

electronic balance and heating cavity. Up

to two heater modules may be interfaced

with a single control module. On initial

power-up, the control module will automatically detect how many heater modules have been connected and are powered on. If more than one heater module

is detected, the analyzer will run in the

Multi-module mode.

The Mark 3 LTE moisture analyzer is used

as a quick and reliable means of determining the moisture content in various

samples by the principle of loss on

drying.

Key features of the Mark 3 LTE include:

§ Sample heating with infrared quartz tubes

§ Precision electronic balance for accurate

weighing and continuous weight monitoring during analysis

§ Quarter VGA screen for easy viewing

§ Large storage of methods for easy recall

of frequently used drying procedures

§ Modular system for add-on capability

of multiple heater modules

Please take the time to read these

Operating Instructions to learn the safe

operation of this analyzer. The Mark 3

LTE has many features that will be

described and can be of benefit to your

moisture testing program.

The Operating Instructions contain

guidance in the form of descriptions,

charts, software flow charts, and

pictorial diagrams:

§ Key names are presented in bold:

Start|Stop

§ Safety symbols indicate notes or caution

of risks as detailed below.

Descriptions and Symbols

Important safety related instructions

are highlighted visually throughout the

Operating Instructions with a description:

Danger

Warning of a possible danger that may

lead to a serious injury.

Caution

Warning of a possible danger that may

result in minor injury or damage.

Note

Important guideline on how to use the

moisture analyzer correctly.

Instrument labels

Caution:

!

Read manual before operating

Danger:

Electrical hazard

Caution:

Hot surface

Page 4

Warning and Safety Information

This moisture analyzer complies

with the European Council Directives as well as international regulations and standards for electrical

equipment, electromagnetic compatibility, and the stipulated safety

requirements. Improper use or

handling, however, can result in

damage and/or injury.

Read these operating instructions

thoroughly before using your moisture analyzer to prevent damage to

the equipment. Keep these instructions in a safe place.

Follow the instructions below to

ensure safe and trouble-free operation of your moisture analyzer:

!

Use the moisture analyzer only

for performing moisture analysis of

samples. Any improper use of the

analyzer can endanger persons and

may result in damage to the analyzer or other material assets.

!

Samples or containers (e.g., beakers

or graduated flasks) that are too

large or bulky to permit complete

closure of the sample chamber

hood must not be placed in the

analyzer.

!

Do not use this moisture analyzer

in a hazardous area/location; operate it only under the ambient conditions specified in these instructions.

– The moisture analyzer may be

operated only by qualified persons

who are familiar with the properties

of the sample to be analyzed.

!

Class A Warning

Warning: This is a class A product.

In a domestic environment this

product may cause radio interference in which case the user may

be required to take adequate

measures.

4

Page 5

!

Make sure before getting started

that the voltage rating printed on

the manufacturer‘s label is identical

to your local line voltage (see the

section on “Connecting the Moisture Analyzer to AC Power” in the

chapter entitled “Getting Started”)

– The analyzer comes with a power

supply that has a grounding conductor

– The only way to switch the power

off completely is to unplug the

power cord.

– Position the power cable so that it

cannot touch any hot areas of the

moisture analyzer.

– Use only extension cords that meet

the applicable standards and have

a protective grounding conductor.

– Disconnecting the ground conduc-

tor is prohibited.

– Connect only Sartorius accessories

and options, as these are optimally

designed for use with your moisture analyzer.

– Protect the moisture analyzer from

contact with liquid.

– If there is visible damage to the

moisture analyzer or power cord:

unplug the equipment and lock it

in a secure place to ensure that it

cannot be used for the time being.

!

Clean your moisture analyzer

according to the cleaning instructions only (see “Cleaning”).

Do not open the analyzer housing.

If the seal is broken, this will result in

forfeiture of all claims under the manufacturer’s warranty.

In case you have any problems with

your moisture analyzer:

$ contact your local Sartorius office,

dealer or service center

Warning: Severe Burns!

– When setting up the moisture analyzer,

leave enough space to prevent heat

from building up and to keep your

analyzer from overheating:

– leave 20 cm (about 8 inches) around

the moisture analyzer

– 1 m (3 ft.) above the device

– Do not put any flammable substances

on, under or near the moisture analyzer,

because the area around the heating

unit will heat up.

– Be careful when removing the sample

from the chamber: the sample itself, the

heater module and the sample pan used

can still be extremely hot.

– Do not remove the heater module unit

during operation: the heating element

and its protective glass panels can get

extremely hot!

– Prevent excess heat build-up around the

analyzer.

5

Page 6

Hazards for persons or equipment

posed by using specific samples:

Fire Explosion

– Flammable or explosive substances

– Substances that contain solvents

– Substances that release flammable or

explosive gases or vapors during the

drying process

In some cases, it is possible to operate

the moisture analyzer in an enclosed

nitrogen atmosphere to prevent the

vapor released during drying from

coming in contact with oxygen in the

surrounding atmosphere. Check on a

case-to-case basis whether this method

can be used, because installation of the

analyzer in too small an enclosed space

can affect its functions (for instance

through excessive heat build-up within

the analyzer). When in doubt, perform

a risk analysis.

The user shall be liable and responsible

for any damage that arises in connection with this moisture analyzer.

Poisoning Caustic burns

– Substances containing toxic or caustic

or corrosive substances: These may

be dried only under a fume hood.

The value for the “lower toxic limit” in

a work area must not be exceeded.

Corrosion:

– Substances that release aggressive

vapors during the heating process

(such as acids): In this case we recommend that you work with small sample

quantities. Otherwise, vapors can condense on cold housing parts and cause

corrosion.

The user shall be liable and responsible

for any damage that arises in connection with this moisture analyzer.

– Sample Pans (Delivered with the

Analyzer):

The reusable metal pans are not

made of stainless steel. For this reason,

they are not resistant to corrosion.

These pans can be used only for powder

and granules (e.g. plastics) with very

low moisture content.

If the moisture content is higher, the

disposable aluminium pans (90 mm

diameter) must be used (see chapter

“Accessories”).

6

Page 7

Caution

Do not touch the metal surfaces inside

the drying chamber while removing

or placing a sample in the analyzer since

the surfaces are very hot.

Do not touch the heater hood ventilation area at any time because this area

can be hot during and after a test.

§ Do not test flammable or toxic

materials.

§ Use the analyzer in a fume hood if the

samples emit fumes which could be

harmful.

§ Know where the fire extinguisher is

located. Use only an extinguisher rated

for use with electrical fires.

§ Keep the analyzer clean. Always unplug

the analyzer and cool it thoroughly

before cleaning or performing service.

§ Do not block the ventilation areas of

the heating chamber.

§ If necessary, press the Start|Stop key

during a test to stop the test.

§ Locate the analyzer away from

flammable materials.

§ If liquid is spilled into the analyzer,

unplug the Heating Module from the

electrical supply immediately.

§ Analyzer is suitable for continuous

operation

Safety Precautions

Danger

Use of this product in a manner

not specified by the manufacturer

may impair any safety protection

provided by the equipment!

Every attempt has been made to

make this analyzer safe and easy to

use. However, like any laboratory

instrument respect must be given

to the operation of the analyzer

due to environmental conditions,

the nature of the samples being

tested and of the chemicals which

might be near the analyzer.

To avoid personal injury or damage

to the analyzer, please observe the

following precautions:

Read all instructions in the Operating Instructions prior to operating

your analyzer.

Warning

Control module contains 3V Lithium

Battery. Please dispose of in accordance with local regulations and

conventions.

7

Page 8

Getting Started

Thank you for choosing the Sartorius

LMA110S moisture analyzer. The

LMA110S is a modular analytical instrument designed to be configured to meet

various performance requirements. Each

analyzer consists of two parts, a control

module and a heater module. The control module contains the keypad, display and a printer (optional) with the

appropriate electronics. The heater

module consists of an electronic balance and heating cavity. Up to two

heater modules may be interfaced with

a single control module. On initial

power-up, the control module will

automatically detect how many heater

modules have been connected and are

powered on. If more than one heater

module is detected, the analyzer will

run in the multi-module mode.

Storage and Shipping Conditions

Allowable storage temperature:

–10 to +50°C

–14°F to +122°F

Allowable shipping temperature:

–40 to +70°C

–40°F...+158°F

Unpacking the Moisture Analyzer

The moisture analyzer is delivered in

a set of two custom-made boxes specifically designed for this precision instrument to provide optimum protection

during transportation.

Note

Retain the original packaging in order

to ship the analyzer if it needs to be

transported or stored at some future

time.

8

Page 9

Follow the instructions carefully when

unpacking the analyzer:

§ Unpack the analyzer carefully and

gently.

§ Remove all the contents of the carton.

Check carefully to make sure you have

removed all accessory items.

§ The LMA110S consists of two modules,

a control module and a heater module.

Up to two heater modules

may be connected to a single control

module.

§ Inspect each module for physical damage and report any damage immediately

to Sartorius or the distributor that you

purchased the analyzer from.

§ Verify that you have received the

following accessories:

Instructions for Recycling

the Packaging

To ensure adequate protection for safe

shipment, your moisture analyzer has

been packaged to the extent necessary

using environmentally friendly materials. After successful installation of the

moisture analyzer, you should return

this packaging for recycling because

it is a valuable source of secondary raw

material. For information on recycling

options, including recycling of old

weighing equipment, contact your

municipal waste disposal center or local

recycling depot.

Equipment Supplied

– Inter-module cable

– Power module cable

– Pan support

– Pan shield

– Power cord

– Tweezers

– Sample pans

– Operating instructions manual

9

Page 10

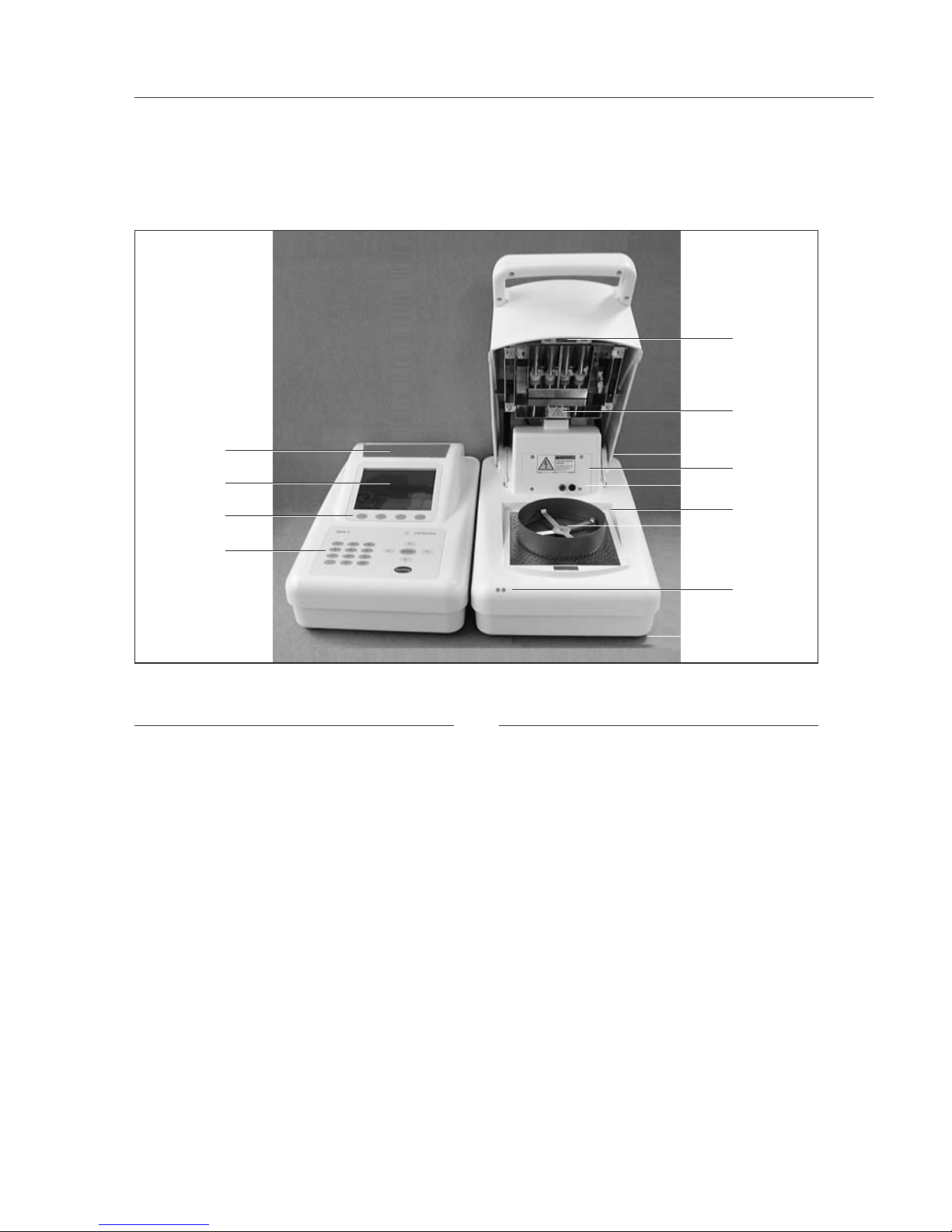

General Views of the Moisture Analyzer

No. Designation

Heater Module

1 Pan shield

2 Pan support

3 Cylindrical quartz heating tubes

4 RTD temperature sensor

5 Heater adjustment tool connector

6 LED status lights

7 Service panel, heaters & RTD

temperature sensor

8 Level vial

9 Adjustable leveling feet

10 Inter-module cable receptacle

11 Main power switch

12 Main cord receptacle

13 Fuse 1 (250 V~5A T)

14 Fuse 2 (250 V~5A T)

15 Module power cable receptacle

No. Designation

Control Module

16 Storage Bin

17 VGA display

18 Soft keys and display overlay

19 Keypad

20 Inter-module cable receptacle

21 Module power cable receptacle

22 Ethernet socket: only for Sartorius

Service

23 USB socket: only for Sartorius

Service

Cables and Power cord

24 Serial connector

25 Inter-module cable

27 Main power cord

10

16

17

18

19

4

3

8

7

5

1

2

6

9

Page 11

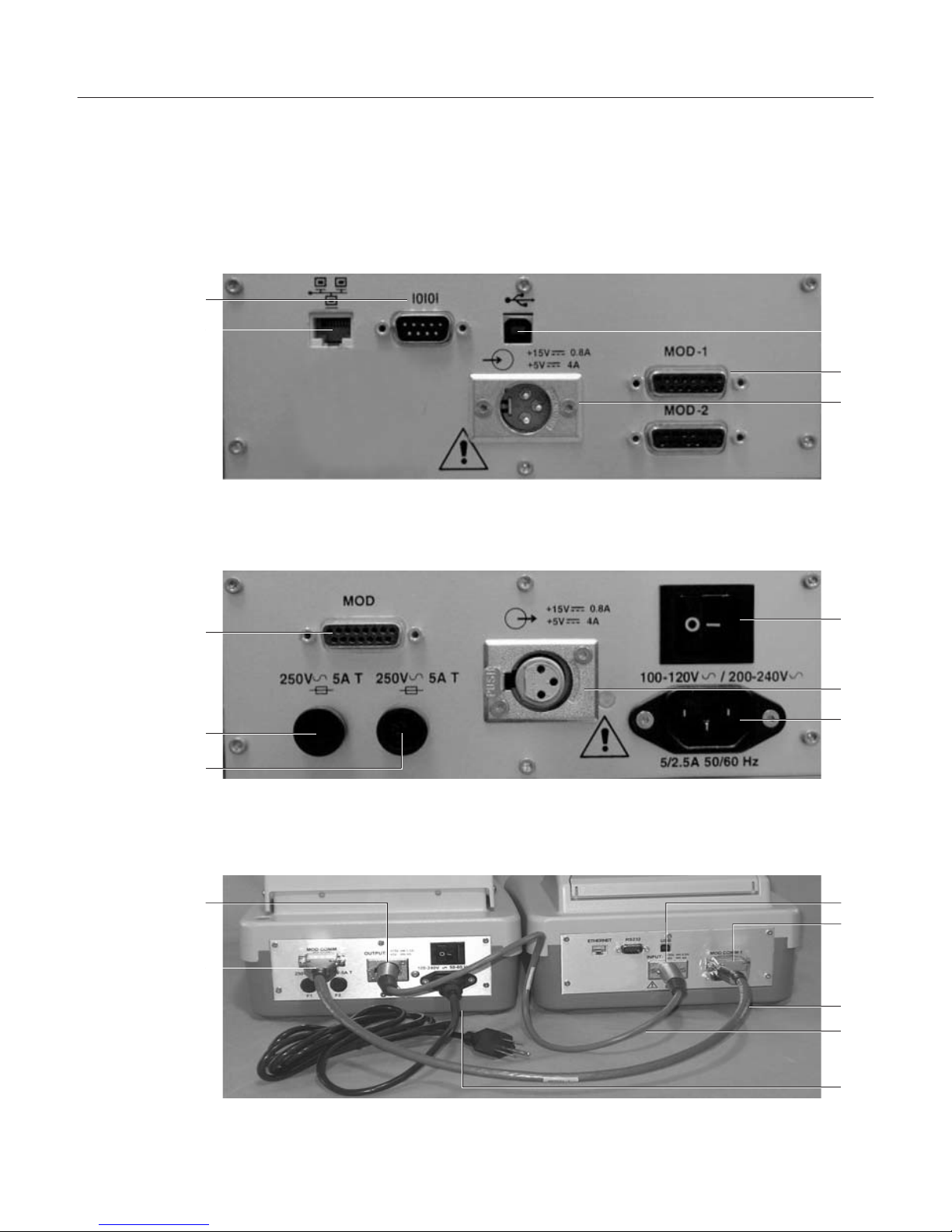

Control Module Connector Panel

Heater Module Connector Panel

Cables Connected to Control and Heater Modules

11

23

20

21

11

15

12

21

20

25

26

27

24

22

10

13

14

15

10

Page 12

Assembly

The analyzer does not come fully

assembled. The control and heater

modules are placed next to each other

and may be placed on either side of

each other. Assemble the modules and

individual components in the following

order:

1. Open the heater hood using the handle

and install the pan shield so that the

center hole fits over the center ring of

the cavity base plate.

2. Next, place the stem of the pan support

through the center ring of the base

plate and into the hole of pan receiver.

3. Remove the foam from the heater

chamber.

4. Connect the power module cable

between the control module and the

heater module, observing the pin orientation.

5. Connect the inter-module cable

between the control module (MOD

COMM 1 connector) and the heater

module, observing the connector orientation.

6. If multiple heater modules are used,

install the additional inter-module

cables from each heater module to the

control module inter-module cable

receptacle (MOD COMM 1-2). Refer to

the chapter in this manual on multimode operation for instructions specific

to operating multiple heater modules.

12

Page 13

Choosing a Suitable Location

In order to ensure that the analyzer

functions properly, select a location that

meets the following requirements:

§ Permissible ambient environment

– Temperature:

+15 to +40°C (59°F to 104°F)

– Relative humidity:

10 – 85%, non-condensing

– Altitude:

0 to 2,000 meters (0 to ~6562 ft)

§ The analyzer is intended for indoor use.

§ Place the analyzer on a rigid, horizontal

surface, preferably free of vibration.

§ Avoid drafts and excessive temperature

fluctuation.

§ Locate the analyzer away from

flammable materials.

Connecting the Moisture Analyzer

to AC Power

This Class I Equipment (grounded

type) analyzer contains a universal

self-adjusting power supply rated to

100-120/200-250V~5/2.5A 50/60 Hz.

Check that this voltage matches your

local line voltage. If your voltage is not

within this rating, do not connect the

power cord to the power supply.

Danger

! The analyzer may only be operated

using the original power cord supplied.

Please do not use it with an extension

cord. The wall socket must be grounded.

The AC Power mains supply fluctuations

are not to exceed +/–10% of the nominal supply voltage. The (Over Voltage)

Category II for transient over voltages

is EN 61010-1. The pollution Degree 2

is supplied EN 61010-1. The analyzer

is rated to Normal Protection (not

protected against harmful ingress of

moisture).

§ Insert the power cord that with the

analyzer into the power input receptacle

on the back of the heater module.

§ Then plug the power cord into a wall

socket.

§ Turn the analyzer on by moving the

power switch on the back of the analyzer

to the On position. The analyzer will

briefly proceed through a self-diagnostic

routine and then display the standby

screen. It will automatically enter a

warm-up period as noted on the screen.

Should the analyzer display any warnings, consult the troubleshooting section of this manual, or call Sartorius.

13

Page 14

Leveling the Moisture Analyzer

In order to function properly, the heater

module should be horizontal. The heater

module has a level vial. You can tell

when the analyzer is level by checking

whether the bubble is centered in the

vial.

§ Check that all four feet are in the fully

inserted position.

§ Observing the level vial, rotate one foot

at a time to level.

Adjust control module so that it does

not rock.

Note

The heater module must be re-leveled

each time the analyzer is moved.

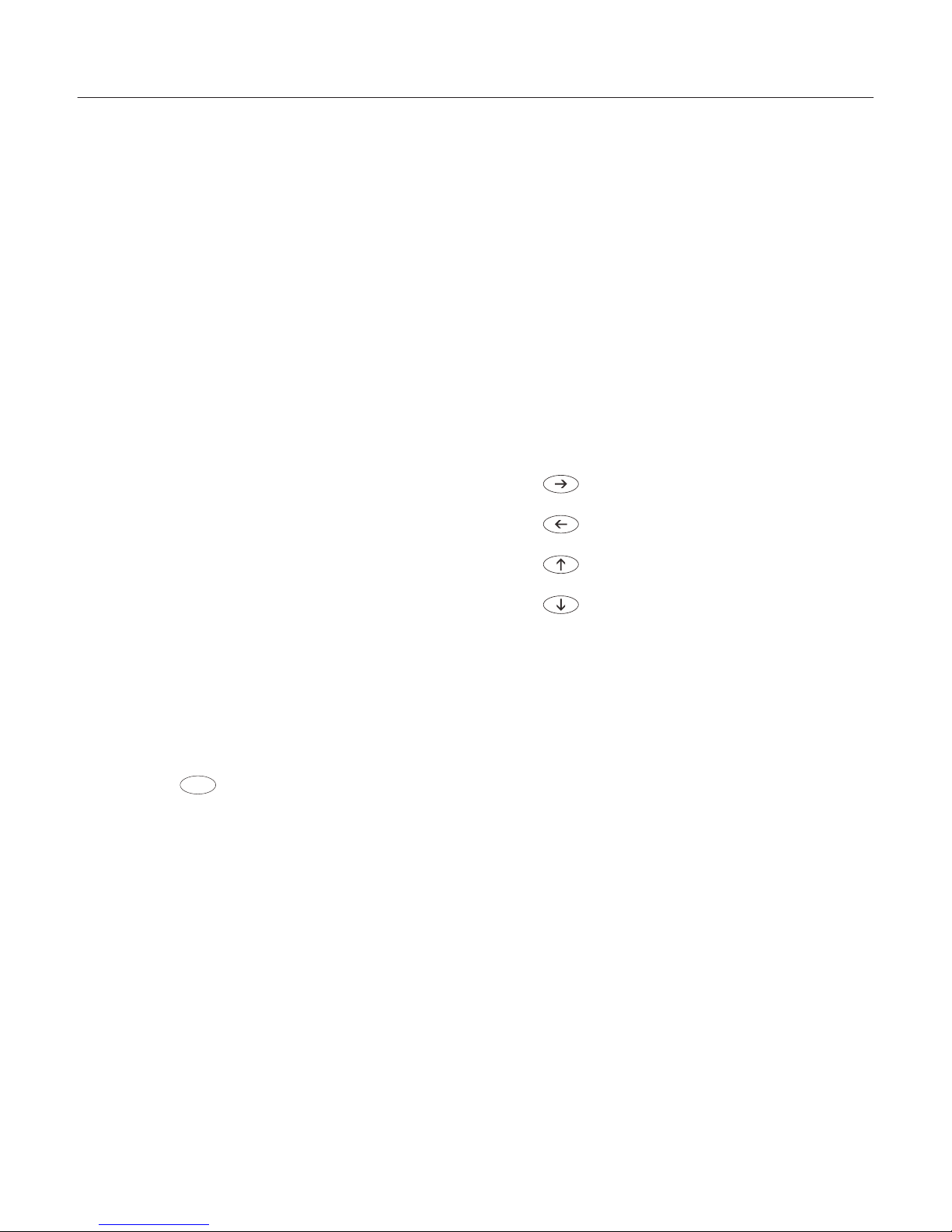

LMA110S Keypad

Warm-up

To enable the analyzer to function

optimally, plug it in and leave it powered on for a minimum of 15 minutes.

The analyzer is preprogrammed to alert

the operator that the device is in the

warm-up period. It is best to allow the

analyzer to complete this warm-up

period before testing samples; however,

this may be overridden by pressing the

Enter key.

14

Numeric

keys

Soft keys

Navigational

keys

Page 15

Operating Design

The Mark 3 LTE analyzer is operated

through the keypad in conjunction

with the quarter VGA screen. The

Mark 3 LTE is preprogrammed with

operational and setup software that

enables the analyzer to be custom

configured to meet the particular

needs of the application, environment or user ability.

Keypad

The analyzer has two membrane

type keypads: the main keypad and

a second that also serves to sealed

the display. The keypad consists of

three dedicated keys, numeric keys,

navigational keys and soft keys.

The following is a description of

each of the key functions:

Dedicated keys:

Each key has a particular function.

Pressing the key once will initiate the

desired action.

Initiates the testing of a sample

Stops a test in progress

u Press to finalize the entry of

a numeric value

– Selects the highlighted menu

selection in a list

– From the Standby screen will print

the last result

Start|Stop

Numeric and Decimal Point Keys

Numbers from 0 to 9 and the decimal point are pressed either to enter

a specific numeric value or to make

a selection from a list of menu

choices preceded by a number.

Navigational Keys

Four keys are intended to move the

highlighted cursor on the screen in

a particular direction.

Moves the cursor to the right

Moves the cursor to the left

Moves the cursor up

Moves the cursor down

15

Page 16

Soft keys:

The functionality of these keys will

change depending on what is on the

display. A label on the display just

above the key will describe the key

function at the moment.

Some examples of the soft keys are

as follows:

Prints various items corresponding to

the menu selection

Toggles a highlighted selection

between on and off

Used to select a drying program from

the Program menu

Access to all setup parameters from

the Setup menu.

Setup

Recall

On/off

Print

Used to select an operator. Name will

be printed on the results printout.

Display will return to the previous

menu.

Display will return to the Standby

menu.

Deletes the single highlighted

character when entering alphanumeric program names and operators.

Sets analyzer to the weighing mode.

Weigh

Delete

Users

16

Page 17

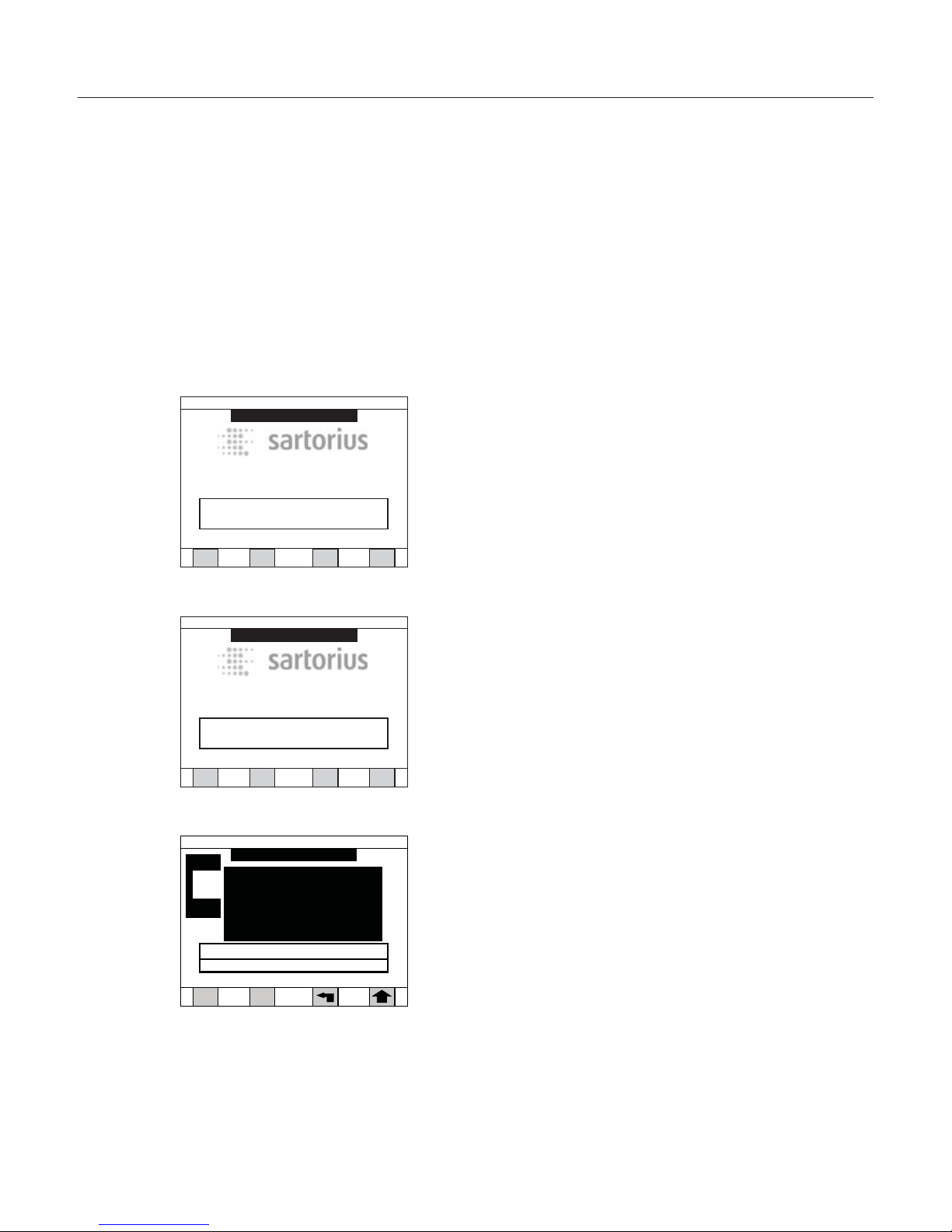

Display Modes

The large quarter VGA display is designed to make

operation and setting up the analyzer easy through

of detailed information in clear descriptions, choices

or menus. The analyzer will display information in

several different formats as described below:

Warm-up:

This mode is entered whenever the analyzer is powered on. The warm-up period ensures that the analyzer is properly conditioned before testing is begun.

During warm-up the screen will be mostly blank.

Standby (or Test Done):

In this mode the analyzer is in an ideal status.

This is the period between testing samples.

The temperature of the chamber is controlled to a

particular level based on the Standby temperature

set for the last test performed. The screen will display

the program name, date and time, temperature and

the last result, if a test has been run.

Test:

This mode is entered when the Start|Stop key

is pressed to initiate a test. The screen is similar in

design to the Standby mode but also includes

prompts to guide the operator through the steps

of adding a sample, entering an ID, if desired, and

displaying the result when the test is completed.

Default

05/01/2011 02:14 PM

WARMIN G UP

Ver. 1.00.00

Mark 3 LTE Moisture Analyzer

Recall

Setup

Weigh

Users

Press ENTER to override warm up

Default

05/01/2011 02:14 PM

WARMIN G UP

Ver. 1.00.00

Mark 3 LTE Moisture Analyzer

Recall

Setup

Weigh

Users

Press ENTER to override warm up

Add sample to pan

DRY MILK POWDER

05/01/2011 02:14 PM

Module 1

0.000

g

Zero

{ }

0%

Standby

Current

60

57

17

Page 18

Graph:

The graph mode can be entered during or after

a test to show a graph of the weight versus time,

temperature versus time, or result versus time.

Data Log:

The data log mode is used for reviewing past

samples that have been tested. The log of samples

can be sorted, or samples can be manually selected

to perform statistical calculations.

18

Temperature / time

DRY MILK POWD ER

05/01/2011 02:14 PM

Print Result

210

30

0.5 1.0 1.5 2.0 2.5 3.0

3.5 4.0 4.5 5.0 min

25.67 %

View Data Log

Down Up

Top

Dry milk power 05/01/2011 02:10

3.45%M 6.7min 672001

Dry milk power 05/01/2011 02:02

3.50%M 6.8min 672002

Dry milk power 05/01/2011 01:53

3.47%M 7.0min 672003

05/01/2011

02:18 PM

Page 19

Menu Structure

The Mark 3 LTE set up software is structured

according to a series of menus. The Setup menu lists

several topics of instrument setup. By drilling down

into these topics, sub-menus will allow specific

choices to be selected. See the Setup section for

details.

How to navigate in the menu structure:

§ To select a menu and to drill down to more specific

information:

– Press the preceding number key of this listing or

– Use the navigational arrow keys to highlight the

desired listing first, then press the Enter key

§ To return to a preceding menu level, press the arrow

soft key. Subsequent presses will return you to the

Standby screen.

§ To return to the Standby screen, press the bent

arrow if one is available from that screen. To choose

a specific selection option or to enter a value:

A selection can be made by:

– Pressing the preceding number key of this listing,

or

– Using the navigational arrow keys to highlight the

desired listing first, then press the Enter key.

§ How to make a numeric input:

– Use the numeric keypad to enter a value fist, then

press the Enter key.

19

1)Program manage

2)Data log

3)Modify operators

4)Results printout format

5)Time and date

6)Communication ports

7)Conserve mode

8)Security

9)Audio & video

0)Module port scan

. ) Service

Setup Menu

05/01/2011 02:18 PM

Page 20

Data Output

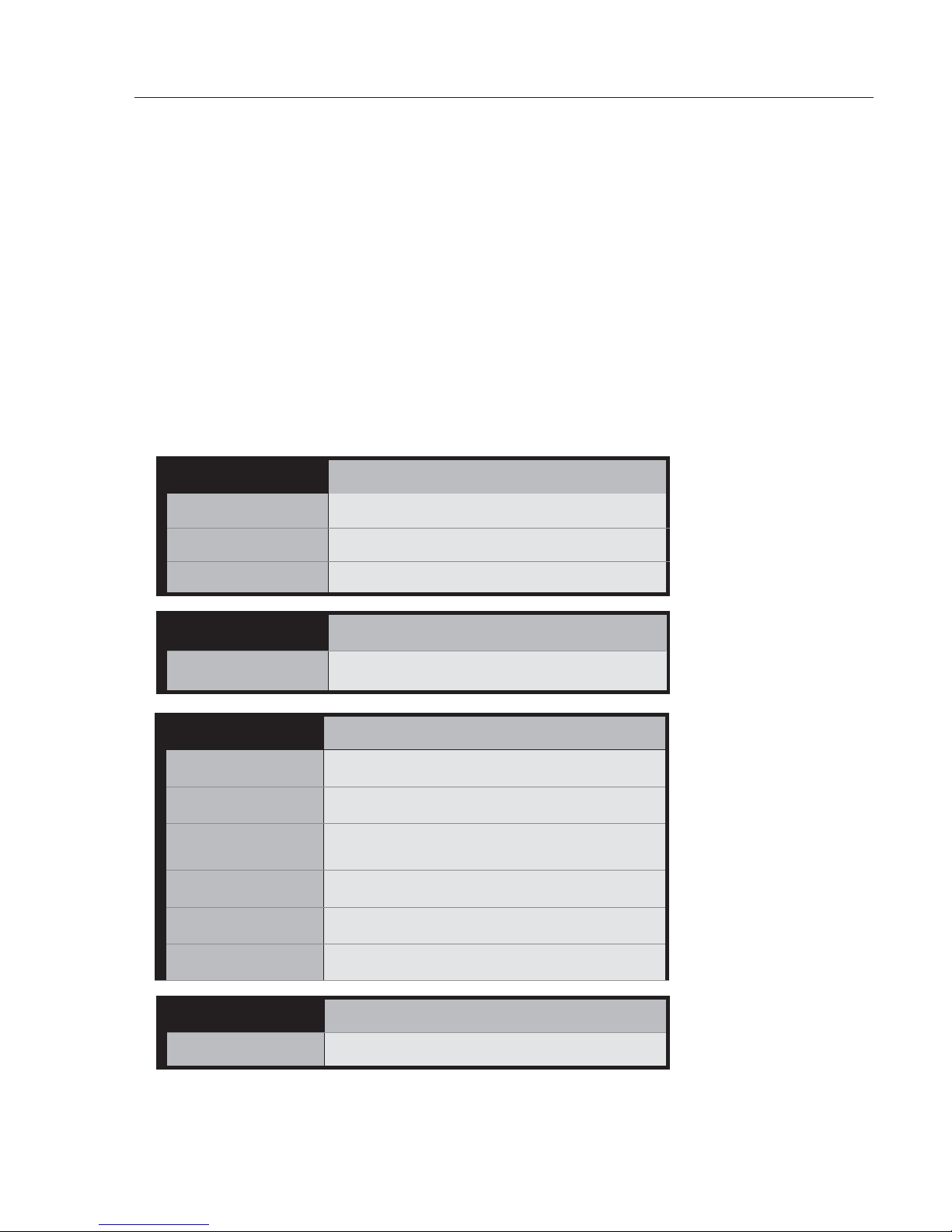

LED Status Lights

The Mark 3 LTE heater module has two

LED lights on the front left corner that

visually indicate the status of the analyzer. The left LED shows the status of

the balance. The right LED indicates the

status of the heating function.

Each LED may have three colors:

red, green or amber. Red is generally

associated with a warning state and

shows that corrective action must be

taken. Green is generally associated with

a positive condition, indicating you can

proceed. Yellow generally indicates

a transitional period or that the test

is in progress.

20

Warmup

Balance LED

Heater LED

Warming up

Rapidly ashing RED Rapidly ashing RED

Ready to test

Steady GREEN Steady GREEN

Heater in conserve mode

Steady GREEN Steady YELLOW

Standby

Balance LED Heater LED

Sample in chamber

heating cavity (chamber)

Flashing YELLOW Flashing GREEN

Test mode Balance LED

Heater LED

Test in progress Steady YELLOW

Steady YELLOW

Test done

Flashing YELLOW Flashing GREEN

Sample loading

Below target

Flashing GREEN

Steady GREEN

Within target Flashing YELLOW

Steady GREEN

Above target Flashing RED

Steady GREEN

Diagnostics Balance LED

Heater LED

Failed diagnostics

Flashing RED

Flashing RED

Page 21

The Mark 3 LTE Moisture Analyzer is designed to

test moisture content in a large variety of materials

including powders, pastes and liquids. The performance of the analyzer is dependent upon selecting

optimum drying analysis conditions for your specific

sample type. Sartorius will support you in finding

the set of testing parameters (referred to as a program) you need for your specific tests. On request,

we will provide a chart of the parameters and test

results we have compiled by testing samples in our

laboratory and comparing the results to those

obtained by reference methods.

If our chart of applications shows a drying program

that is not already programmed into your analyzer,

you may do this yourself by following the instructions under Setup in this manual.

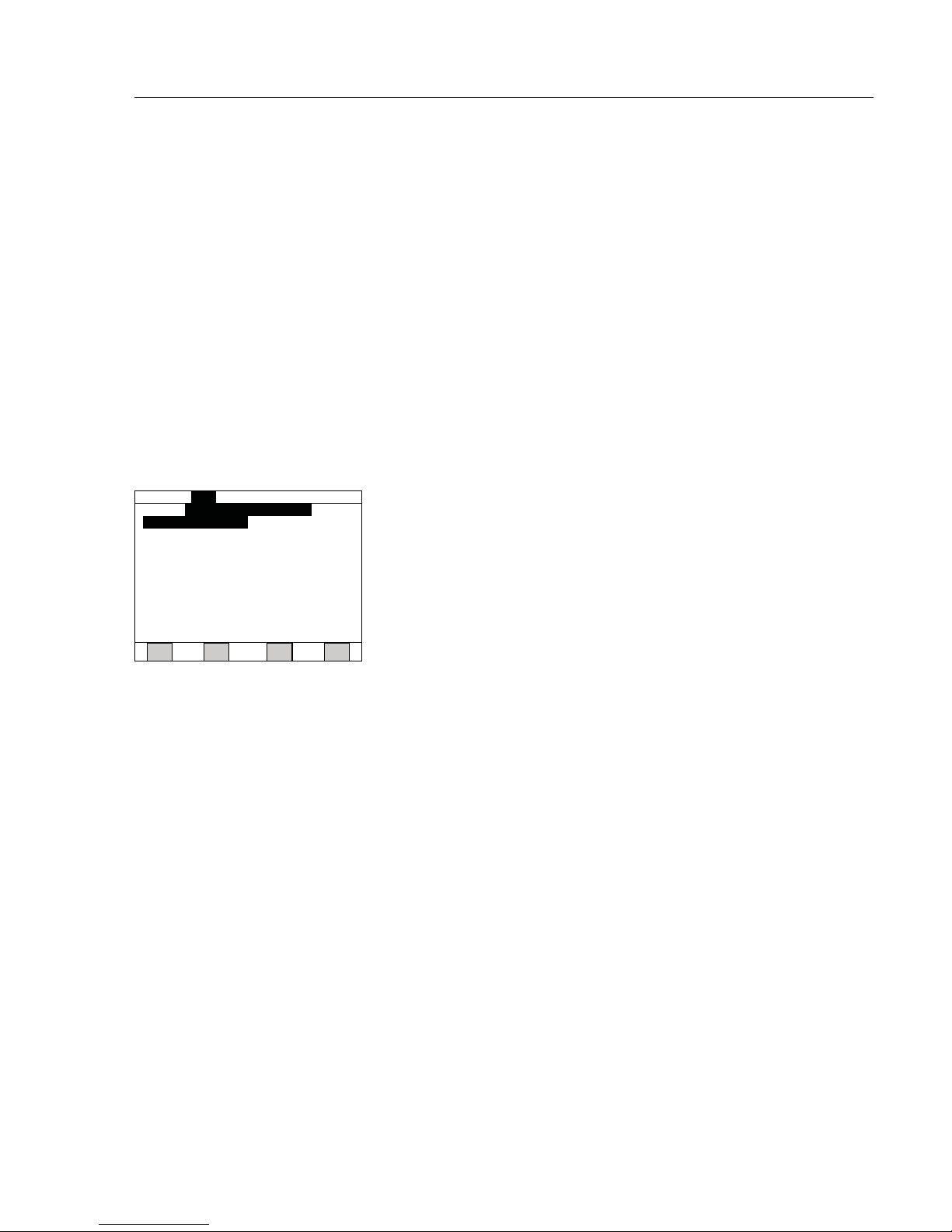

Standby Screen

During warm-up, your analyzer will enter the Standby mode and the Standby screen will be displayed.

It is from the Standby (or Test Done) screen that all

functions of operating the analyzer, including testing samples and setting parameters, take place.

The standby screen shows the following

information:

§ Program name

§ Time and date

§ Standby temperature and actual temperature

§ Various soft keys for options that are available

depending on the security setup options engaged

§ Warnings that will need to be addressed before

testing

21

Operating

the Moisture Analyzer

DRY MILK POWDER

Standby

Recall Setup

Weigh Users

Press START key to begin test

Standby

Current

60

59

05/01/2011 02:18 PM

Ver. 1.00.00

Mark 3 LTE Moisture Analyzer

Page 22

Functions available from the Standby screen:

§ Press Start|Stop key to initiate a test

§ Press Recall soft key to change the program to

be used for testing a sample

§ Press User soft key to select an operator name

(feature must be turned on in Setup)

§ Press Setup soft key to enter the Setup menu in

order to make all parameter changes

§ Press Graph soft key to display a graph

§ Press Weigh soft key to use as a balance

Standby-Temperature

!

with a New Program

When creating a new program, the standby

temperature setting from the previous drying

program is used automatically by the analyzer.

Example:

You have created a new program for drying

a temperature-sensitive sample at low temperature. The analyzer uses the standby temperature, e.g. 165°C, from the previous program.

You must call up the standby temperature

parameter and change the temperature value.

If you forget performing this setting, your analyzer is always too hot before starting the test.

22

Page 23

Default Drying Program

Your analyzer is delivered with a default drying program. The drying program contains all the specific

parameters to test a sample including temperature,

endpoint, unit of measure, standby temperature,

etc. You will notice if you are in the default program

or a specific material program by the program name

at the top left of the display.

23

Program name: Default

Temp1=105C

Time1=Off

Temp2=Off, Time2=Off

Slope=0.050%/1 minute, Actual

Start delay=0 second

Standby temp=60C, Ideal weight=5g, Lock=Off

Target limits=Off

Mode=Standard

Page 24

Recalling a Program

Drying programs are stored for easy access at a later

time. This eliminates the need to change parameters

for frequently tested samples. Up to 60 drying programs can be stored. Creating and storing a program

is described under Developing a Drying Program.

To recall a stored program, perform the following

steps:

1. From the Standby screen, press the RECALL soft key.

The screen will change to the first page of stored

programs as show below.

2. To display programs on the next pages, press the

Down soft key.

3. Press the number(s) key followed by the Enter key

for the number that precedes the program name.

As an alternative, use the arrow keys to highlight the

desired program name, then press Enter. The display

will change to the Standby screen with the new

program in the top left corner. This program will be

used for the next test. If a blank program is entered,

the analyzer will use the last valid program that

was entered.

Note

As a shortcut, it is not necessary to have the desired

program listed on the display to recall it. Simply

enter the desired number from your memory on the

first page and press the Enter key.

24

11)

2) Whey Protein 12)

)3

1 )3

)4

1

)

4

)5

1

)

5

)6

1

)6

)71 )7

)8

1

)

8

)91

)9

)0

2

)01

Programs

Program #:

Down

1)

Dry Milk Powder

Up

_

Top

05/01/2011 02:18 PM

Page 25

Testing a Sample

A test can only be initiated from the Standby or Test

Done screen. The program that will be used is shown

in the upper left corner.

To test a sample, perform the following:

1) Open the hood of the heater module using the

handle on the front of the analyzer.

Caution

The heater hood will be hot during testing and the

standby mode.

Only touch the heater hood by the handle.

2) Place one pan onto the pan support and close the

heater hood.

3) From the Standby screen, press the Start|Stop key.

The display will change to the test mode as shown

on the left. The balance will automatically tare and

show zero weight on the screen.

Note

If you forgot to place the pan onto the balance

ahead of time, you may open the heater hood now,

add the pan, close the heater hood and manually

tare by pressing the Zero soft key.

25

DRY MILK POWDER

Standby

Recall Setup

Weigh Users

Press START key to begin test

Standby

Current

60

59

05/01/2011 02:18 PM

Ver. 1.00.00

Mark 3 LTE Moisture Analyzer

Sampling

DRY MILK POWDER

Module 1

0.000

g

Zero

{ }

0%

Standby

Current

60

57

05/01/2011 02:19 PM

Page 26

4. At the “Add sample to pan” prompt, open the heater

hood and begin adding sample to the pan. A bar

graph on the display will guide the operator to place

the correct amount of sample as set by the ideal

weight parameter of the drying program. Continue

adding sample until the beeper sounds, indicating

that the sample amount is within 10% of the ideal

weight. The exact weight is also displayed on the

screen.

5. At the “Close heater hood” prompt, close the heater

hood. The balance will capture the initial weight of

the sample “Sampling” and then show that the test

is in progress. The display will change to show current information including the elapsed time and the

current percentage weight loss in the units as specified in the drying program.

Note

To stop the test in progress, press the Start|Stop key.

The optional printer will begin to print as the test

begins. Printout information can be selected in

Setup menu under Printer.

At the end of the test the display will show “Test

Done.” The result will stay on the screen as well as

be printed. The analyzer will enter the Standby

mode until the next test is initiated.

26

Dry Milk Powder

Test in Progress

0.01

% Moisture

Elapsed time: 00.10

Graph

Press STOP key to stop test

Temp 1

Current

105

71

05/01/2011 02:18 PM

Press START key to begin test

Dry Milk Powder

Test Done

3.47 % Moisture

Result time: 7.0 min

ID: 126399.1

Target: Pass

Recall Setup

Graph User

Warning: Sample on pan

Standby

Current

105

105

05/01/2011 02:18 PM

Page 27

The display will prompt you, the

operator to remove the sample

before the next sample can be tested. Open the hood and carefully

remove this sample using tweezers,

and while the hood is open, add

the sample pan for the next sample

to be tested.

Caution

!

The sample is hot during and after

the test. Remove the sample with

care by using the tweezers provided

with the analyzer. Do not touch

any internal part of the heating

chamber or pan shield as they will

be very hot.

Press the Start|Stop key to begin the

next test using the same program.

Note

The analyzer balance must be calibrated

before putting the unit into routine

service. See the section on Calibrate

Balance in this manual.

27

Page 28

Setup Menu

All settings for to the Mark 3 LTE, including changing of instrument options and program parameters,

are selected in the Setup menu. Each subject is listed

on the Setup menu screen.

To enter the Setup menu:

§ From the Standby screen, press the Setup soft key to

display the Setup Menu screen.

Note

Pressing the arrow soft key from the Setup menu or

any submenu will always take you back one level.

Setting the Device Parameters

in the Program Manage Menu

The Program Manage Menu provides access to all

setup functions associated with creating, editing, or

managing sample drying programs.

To enter the Program Manage Menu:

§ From the Setup menu screen, press the 1 key

or highlight “Program manage”, using the navigation keys and press Enter.

28

1)Program manage

2)Data log

3)Modify operators

4)Results printout format

5)Time and date

6)Communication ports

7)Conserve mode

8)Security

9) Audio & video

0) Module port scan

.

) Service

Setup Menu

05/01/2011 02:31 PM

Page 29

Edit Current Program

All parameters associated with a currently stored

drying program can be edited and re-stored or

changed without re-storing. The program to be

edited will be in the top left corner of the display.

If this is not the program you wish to edit, then

it must first be recalled.

To edit a current program:

§ From the Program manage menu, press the 1 key to

display the Program Menu screen.

All the parameters of the drying program are

displayed on this screen for the program named in

the top left corner. To make a change to any of the

parameters, enter the submenu for that topic.

A complete list of all variables for each parameter

is shown on the next page.

To edit a current program without storing:

§ Make the change, then press the arrow key to return

one level.

§ Alternatively make the change, then press the bent

arrow key to return to the Standby screen. On the

Standby screen, the warning will show that the

changes have not been saved.

To save an edited program:

§ Make changes, then press the Save soft key to

return to the Standby screen.

29

Default

Program Manage Menu

1)Edit current program

2)Create new program

3)Delete program

4)Sort programs (alphabetize)

5)Sort programs (fill in blanks)

6)Print current program

7)Print program list

8)Print all programs

05/01/2011

02:18 PM

1) Unit Moisture (0.00%)

2) Temp 1 105C, std, Time 1 O

3) Temp 2 O, Time 2 O

4) Slope 0.05%/1min, actual

5) Start delay 0 sec

6) Standby temp 60C, Equilibrate O

7) Ideal weight 5g, lock O

8) Target limits O

9) Mode Standard

0) Program name Default

Press Save soft key to save changes.

Program Menu

Default

05/01/2011 02:18 PM

Print

Save

Page 30

Table: Program Settings

Screen Parameter Variables Explanation

Units Units Moisture Initial wt. – final wt. / Initial wt. + 100

Solids Final wt. / Initial wt. + 100

Volatiles Initial wt. – final wt. / Initial wt. + 100

Moisture/dry Initial wt. – final wt. / Final wt. + 100

mg/l Final wt. + 1000 / volume in mL

Weight Initial wt. – final wt.

Result display Decimal place 0.01% or 0.001%

Factors Scale factor Factored result = (result + scale factor) + offset

Offset Factored result = (result + scale factor) + offset

Temperature 1 Temperature Maximum 210°C Set temperature or Off

Time 10.0 – 99.9 minutes Set time or Off

Temperature 2 Temperature Maximum 210°C Set temperature or Off

Time 20.0 – 99.9 minutes Set time or Off

Slope % Initial weight 0.01 – 9.99 Weight variable of endpoint criteria

Window of time 0.1 – 99.9 minutes Time variable of endpoint criteria

Calculation Actual slope Slope criteria met for endpoint

Calc 1 Calculated endpoint

Calc 2 Calculated endpoint

Calc 3 Calculated endpoint

Start delay Start delay 0 - 9 seconds Delay before starting test

Mode Mark 2 Simulates Mark 2 start delay

LMA110S LMA110S start delay

Standby temp. Standby temp. Maximum 165°C Set temperature between tests

Ideal weight Ideal weight 0.1 – 99.0 g Set ideal sample weight for test

Percent 1 – 10% Set tolerance of ideal weight

Ideal weight Lock On or Off Set ideal weight lock strict (On) or Off

Target limit Target limit Upper limit Set upper limit of result tolerance

Lower limit Set lower limit of result tolerance

Turn limits Off Turns target limit feature Off

Mode Mode Standard Standard test mode

Concentration Corrects a result for sample volume

30

Page 31

Units

The analyzer will calculate the test result in a variety

of units of measure, depending on your specific

application. This menu also provides access to the

advanced options associated with units: displayed

readability and correlation factors.

To change the unit of measure:

§ Press the 1 key from the Program Menu to display

the Units menu. The current unit will be shown.

§ Press a number key for the new unit of choice.

§ Note that there is an advanced option indicated by

Factor on the soft key. To change this feature, see

“Factors.”

§ When all the parameters for units have been

changed, then press the arrow soft key to accept

the changes. The display will return to the Program

Menu.

31

Current units: Moisture

1)Moisture

2)Solids

3)Volatiles

4)Moisture/dry

5) Weight

Units

Default

Factors: active

05/01/2011 02:24 PM

Factor

Page 32

Factors

The analyzer has a feature for entering a scale or

offset factor to adjust the result to a more accurate

value. Only under special circumstances will either of

the factors ever be used.

To set or change factors:

§ Press the 1 key for Units to display the Units screen.

§ Press the Factor soft key. The display will change to

the Factors screen.

§ Press the 1 or 2 key to display either the scale factor

or offset screen.

§ Enter the desired value and press the Enter key

to return to the Factors screen.

§ Press the Arrow soft key to return to the Units

screen.

(result) · (scale) + offset

32

Current units: Moisture

1)Moisture

2)Solids

3)Volatiles

4)Moisture/dry

5) Weight

Units

Default

Factors: active

05/01/2011 02:24 PM

Factor

Factors

Default

1) Set scale factor: 1.000

2) Set offset: 0.000

Enter the scale and offset

to apply to the result calculation:

(Result)*(Factor) + Offset

05/01/2011 02:21 PM

Page 33

Temperature 1 and 2

The analyzer will dry the sample at one or two

temperatures set in one degree of Celsius increments. A second temperature is optional and is normally set to Off. See the Applications section for a

description of when to use a second temperature for

two-step drying.

To set or change Temperature 1 or Temperature 2:

§ Press the 2 or 3 key for Temp 1 or Temp 2,

respectively. The display will change to the Temp 1

or Temp 2 screen. The current temperature will be

shown.

§ Using the numeric keys, type in the desired temperature and press Enter.

§ Note that there are some advanced options indicated

by Ramp and Time 1 (or 2) on the soft keys. To

change these features see, “Time 1 and 2.”

§ When all the parameters for Temperature 1 or 2

have been changed, press the Enter again or the

Arrow key to accept the changes. The display will

return to the Program Menu.

33

Temperature: 105 C

Max. Temperature: 210 C

Time: 99.9 minutes

Temperature 1

Default

| C

Clear

Time

05/01/2011 02:21 PM

Page 34

34

Time 1 and 2

Each the Temperature 1 and 2 setting

can have a set period of time. Time 1 or

2 is the time during which the sample

will be dried at each temperature before

advancing to the next temperature.

Once the time for the last temperature

has elapsed, the test will terminate

unless a slope endpoint has been turned

On. If Temperature 2 is set, then at the

end of Time 1, the analyzer will ramp to

Temperature 2.

To set or change Time 1 or 2:

§ Press the Time 1 or Time 2 soft key to

display the Time 1 or Time 2 screen.

§ Use the numeric keys type in the desired

temperature, then press the Enter key.

The display will return to the Temperature 1 or 2 screen.

Slope

The slope function provides an automatic endpoint for the test. The slope

function consists of two variables:

window of time and percent of initial

weight (%IW) change. During the test,

the weight change of the sample is continuously monitored within a moving

window of time. When the loss of

weight within the window is less than

the initial weight percentage set, the

slope criteria has been met. The final

weight is taken and calculation is

performed to end the test. This slope

is referred to as “actual slope” because

the endpoint is actually achieved.

Tim

e

W

e

i

g

h

t

% of I.W.

W

indow of time

End of test (Endpoint)

W

Page 35

To set or change slope:

§ Press the 4 key from the Program Menu to display

the Slope screen. The current initial weight percentage is shown.

§ Use the numeric keys type in the desired %IW, then

press the Enter key.

§ Note that there are some advanced options indicated by Time and Calc on the soft keys. To change

these features, see “Windows of Time” or “Calculation Endpoint.”

§ When all the parameters for Slope have been

changed, press the Enter again or the Arrow key to

return to the Program menu.

Window of Time

To set or change window of time:

§ Press the Time soft key to display the Window of

time screen.

§ Use the numeric keys to type in the desired window

of time, then press the Enter key. The display will

return to the Slope screen.

Endpoint Calculation

There are three additional advanced slope settings

called Calc 1, Calc 2 and Calc 3, which are algorithms that calculate the endpoint prior to achieving

the actual slope. These will provide more rapid

results on some samples; however, the success of the

Calc mode varies from case to case.

To set or change Calc endpoint:

§ Press the Calc soft key to display the Calc menu.

§ Press a number key to select the desired calculation

setting. The display will return to the Slope screen.

§ If developing a method, check the correlation of

each Calc mode starting with Calc 1 to the actual

endpoint result.

35

Enter percent of initial weight: 0.05

Range: 0.00 to 9.99%

Enter 0.00 to turn off slope

Time: 1.0 Minute

Calculation: Actual

Slope

Default

| %

Time

New

Calc

05/01/2011 02:24 PM

Page 36

Start Delay

The start delay is a time in seconds that can be set

to ensure that a good initial weight is taken at the

beginning of the test.

To set or change start delay:

§ Press the 5 key from the Program Menu to display

the Start delay screen. The current start delay is

shown.

§ Use the numeric keys to type in the desired %IW,

then press the Enter key.

§ Note the mode: Mark 2 or LMA110S. If in the Mark 2

mode, start delay will simulate the previous Mark 2

analyzer. Press the Mode soft key to toggle between

Mark 2 and LMA110S.

§ Press the Enter key again or the Arrow soft key to

return to the Program Menu.

Standby Temperature

The standby temperature is the temperature that

the analyzer chamber will be controlled to at the

end of a test or prior to a test when a new program

is recalled.

To set or change standby temperature:

§ Press the 6 key from the Program Menu to display

the standby temperature screen. The current standby

temperature is shown.

§ Use the numeric keys to type in the desired standby

temperature, press the Enter key.

§ When all the parameters for slope have been

changed, press the Enter key again or Arrow key to

return to the Program Menu.

36

Enter standby temp: 60 C

Maximum temperature 165 C

Standby Temperature

Default

| C

Clear

05/01/2011 02:31 PM

Page 37

Ideal Weight

The ideal weight is the amount of sample in grams

that should be used for the test as prompted with

a bar graph and beeper in the Test mode.

To set or change the ideal weight:

§ Press the 7 key from the Program Menu to display

the Ideal Weight screen. The current ideal weight

is shown.

§ Use the numeric keys to type in the desired ideal

weight then press the Enter key.

§ Note that there are some advanced options indicated by Lock and % on the soft keys. To change these

features, see “Ideal Weight Percent Limit” and “Ideal

Weight Lock.”

§ When all the parameters for slope have been

changed, press the Enter key again or the Arrow key

to return to the Program Menu.

37

Enter ideal weight: 5.0 g

Range: 0.1 –39.0 g

Ideal weight percent: 10%

Lock: Off

Ideal weight

Default

| g

Lock

Clear

%

05/01/2011 02:24 PM

Page 38

38

Ideal Weight Percent Limit

The ideal weight limit is a tolerance

range for the ideal weight in percent

that the sample weight must be in.

Example: If the ideal weight is 10 grams,

and the target limit is 10%, then an

acceptable sample weight is between

9 and 11 grams.

To set or change the Ideal weight percent limit:

§ Press the % soft key to display the Ideal

weight percent screen.

§ Use the numeric keys to type in the

desired time, press the Enter key. The

display will return to the Ideal Weight

screen.

Ideal Weight Lock

When activated, the ideal weight lock

prevents the use of any other sample

weight other than the one that is within

the target limits. If the lock is not activated, when in the test mode, the target

weight guide is still shown but any

sample weight can be used for the test.

To set or change ideal weight lock:

§ Press the Lock soft key to toggle On or

Off on the Ideal Weight screen.

Page 39

Target Limits

The Target limit Menu provides a statistical process

control (SPC) feature that can be set to identify

when a tested sample is within or outside the desirable limits selected. If this feature is activated, a Pass

or Fail will be displayed after each test, indicating

the sample is within or outside the set limits; this

will also appear on the printout.

To turn the Target Limits feature on and to enter

limits:

§ Press the 8 key from the Program Menu to display

the Target Limits screen. The current target limits

are shown.

§ Press the On|Off soft key to toggle target limits: On

§ Press the 1 key to set the upper limit.

§ Press the 2 key to set the lower limit.

When all the parameters for target limits have been

changed, press the Arrow key to accept the changes.

The display will return to the Program Menu.

39

1. Upper Limit 100.00% Moisture

2. Lower Limit 0.00% Moisture

Target Limits Menu

Default

On/off

05/01/2011 02:24 PM

Page 40

40

Test Mode

This feature provides a few special test

modes for specific applications:

§ Standard: normal test mode where a

sample is placed directly onto the pan

or pan with sample pads to take a direct

weight of the initial weight.

§ Concentrate: used for determining total

suspended solids in low solid samples.

The sample solids are first concentrated

onto a filter pad placed in a vacuum

apparatus. During the test mode, the

operator will then be prompted to enter

the number of milliliters of sample that

was filtered. Results are displayed in

mg/l. See details in the chapter on

Concentration Mode in this manual.

To change the test mode:

§ Press the 9 key from the Program Menu

to display the Mode screen.

§ Press the number key for the mode of

choice. The display will return to the

Program Menu.

Page 41

Program Name

Each program is stored by a unique program name.

Your analyzer may be preprogrammed with a default

set of programs or a set customized for your

company. Program names can be alphanumeric

and have some characters.

To change or set the program name:

§ Press the 0 key from the Program Menu to display

the Program Name screen.

§ Use the navigational arrow keys, up and down,

to enter letters, symbols or a space at the cursor.

Pressing the up arrow key first shows a space, then

scrolls through the alphabet starting with “A”

forward, followed by symbols. Pressing the

down arrow scrolls through the symbols followed

by letters in backwards order. To change to lower

case letters, press the Lower soft key.

§ After selecting the first character, press the navigational arrow right key to move to the cursor to the

next character space and repeat the process.

§ The navigational arrow left key moves the cursor

left.

§ When finished entering the program name, press the

Enter key to return to the Program Manage menu

Menu.

41

Program name: Default

Enter numbers with keypad

Program Name

Default

Lower

Clear

Delete

05/01/2011 02:24 PM

Page 42

42

Create a New Program

The analyzer will store 60 drying programs. New programs can be created

and stored for routine usage. All drying

program parameters are set as described

in “Edit Current Program” on page 30.

When creating a new program, the

parameters will be used of the last program to be recalled.

Note

When creating a new program, you will

edit the last program to be recalled and

shown on the Program Menu screen.

However, you will need to give it a new

program name for storing. Therefore,

first choose a program that is most similar to your new program to minimize

the amount of changes to make.

To create a new program:

§ From the Program Manage menu press

the 2 key for “Create new program” to

display the Program Menu screen.

§ The program name will be labeled

“New.” Change program to your desired

name.

§ Finish making changes to all program

parameters as desired.

§ Press the Save key to store the new

program in the first available blank

program slot.

Note

Programs will be saved when downloading a new software version.

Delete Program

At times you may want to delete

a drying program that you will no

longer need.

To delete a program:

§ From the Program Manage menu, press

the 3 key to go to the Delete screen

showing the list of programs.

§ Type in the number of the program you

want to delete or move the highlight

with the navigation arrow keys and

press the Enter key. The screen will

return to the Program Manage menu.

Sort Programs

Programs can be sorted in two ways

to make them easier to view when

recalling programs:

§ Alphabetical: sorts by alphabetical order

starting with characters, numbers and

then letters.

§ Fill in the blank: removes all the blank

program positions and places programs

in the storage positions starting at 1 in

the same order as before the sort.

To sort programs:

§ From the Program Manage menu, press

the 4 or 5 key. The display will change,

indicating that the analyzer is sorting.

When finished, the display will return to

the Program Manage menu screen.

Page 43

Configuring the Printout

Print Current Program

To print the parameters of the current

program as shown in the top left corner

of the Program Manage menu screen:

§ From the Program Manage menu, press

the 6 key. The current program will be

printed.

Print Program List

To print the entire list of programs:

§ From the Program Manage menu, press

the 7 key. The list of programs will be

printed.

Print All Programs

To print all programs with parameters:

§ From the Program Manage menu, press

the 8 key. The list of programs with

parameters will be printed.

43

Page 44

Data Log

The analyzer will store the last 999 test results.

Results can easily be sorted, viewed on the display or

printed. In addition, you can perform statistical

analysis on sorted or selected results for viewing or

printing. Sorted data may be also downloaded.

Note

The default setting for the data log is Off.

To store data to the data log, it must be turned On

first. Results in the data log are saved when dowd

loading a new software version.

To enter the data log:

§ From the Standby screen, press the Setup soft key to

display the Setup menu screen.

§ Press the 2 key or highlight “Data log” and press the

Enter key to display the Data Log menu.

To enable data to enter the data log:

§ From the Data Log menu, press the On|Off soft key

to toggle data log to On.

To prevent data from entering the data log:

§ From the Data Log menu, press the On|Off soft key

to toggle data log to Off.

To view data log results:

§ From the Data Log menu, press the

1 key to display the data log.

§ Use the soft keys to move through the data:

Up Moves to more recent data

Down Moves to older data

To manually select data log results to form a group:

§ From the Data Log menu, press the 5 key to display

the data log selection screen. The last group selected

is still retained.

44

1)View data log

2)Statistics

3)Select by date range

4)Select by module

5)Select data points

n

O :gol at

aD

Number of points in log:495

Data log menu

05/01/2011 02:43 PM

On/Off

Page 45

§ Toggle the Select All or Clear All soft

key to select or deselect all data in order

to define a known starting point.

§ Use the navigation keys to scroll

through the data: right arrow to page

down, left arrow to page up.

§ Highlight a test result and press the

Enter key to show STAT. Continue for

all desired results to form the group.

To print the data group:

§ From the data log selection screen,

press the Print Stat soft key to print the

selected group results.

To print the entire data log:

§ From the data log selection screen,

press the Print All soft key to print all

the data log results.

To print statistics for a group:

§ After selecting a group from the data

log selection screen, press the Arrow

soft key to return to the Data Log menu

while retaining the group.

§ From the Data Log menu, press the 2

key to view statistics of the selected

results. The display will show statistics

including the average, standard deviation, relative standard deviation, the

highest value and the lowest value.

§ To print the statistics, press the Print

soft key. Use the Arrow soft key to

return to the Data Log menu.

To select by date range:

§ From the Data Log menu screen, press

the 3 key for Select by date range to go

to the Select data range screen.

§ Press the 1 key and set a start date

§ Press the 2 key and set an end date

§ Press the Arrow soft key to sort the

data log for this date range.

All data in the data log tested on and

between these dates will be retained as

a group. The display will return to the

Data Log menu screen. From here you

can perform statistics on the group by

pressing the 2 key for Statistics, or view

selected data by pressing the 5 key for

Select data points. All data in this group

will be displayed when you press STAT.

From here you may print this group by

pressing the Print soft key.

45

Page 46

Modify Operators

our analyzer may be programmed with a custom list

of operators specific for your company.

Operators can be alphanumeric and contain various

characters.

To change or set operator names:

§ Press the 3 key from the Setup menu to display the

current list of operators.

§ Use the arrow soft keys, then press Enter for any

operator slot to display the alphanumeric entry

screen. You may also press the Edit soft key for the

highlighted name.

§ Enter the desired name, then press the Enter key to

return to the Set Users/Operators Menu.

§ Line 20 is a blank line that cannot be edited.

§ When finished, press the Arrow soft key to return to

the Setup menu.

Note

To enable the use of Operators and to have the

operator name on the result printout, Operator must

first be activated in the Results Printout Format

menu. When Operator is activated, then the User

soft key will be available from the Standby menu to

select an operator from the list of operators.

Note

Operator names will be deleted when downloading

a new version of software.

46

•

•

•

••

••

•

•

••

••

••

••

••

Operator setup

Edit Clear

•

05/01/2011 02:24 PM

Page 47

Graphing

Your analyzer is able to display and

print a graph of the current or last test.

Three styles of graphs are available:

– Percent|time

– Weight|time

– Temperature|time

To view the percent|time graph during

a test:

§ From the Test in Progress screen,

press the Graph soft key. The display

will show the Result|Time graph.

The graph automatically updates and

scales until the test is completed.

When the test has been completed it

will automatically scale one more time.

To view the weight|time graph during

a test:

§ From the Percent|Time graph, press the

Weight soft key.

To view the Temperature|Time graph

during a test:

§ From either the Percent|Time or

Weight|Time graphs, press the Temp

soft key.

To return to the Percent|Time graph:

§ From either the Weight|Time or

Temp|Time graphs, press the % (result)

soft key.

To return to the Test in Progress screen

during a test:

§ From any graph screen, press the

Test soft key.

To view a graph from the Test Done

or Standby screen after a test is completed:

§ Prior to running a new test, press the

Graph soft key.

To print any graph:

After the test is completed, from the

Test Done screen, press the Print soft

key while displaying any of the three

graphs.

47

Page 48

Results Printout Format

The printout format is used with the internal printer

(optional) or the serial communications port.

The printout format may be customized by choosing

the specific content regarding the analyzer or your

testing conditions that may be important to your

testing program. The default printout format is

shown below:

To change the printout format:

§ From the Setup Menu screen press the 4 key or

highlight Results Printout format using the navigation keys and press Enter to display the Results

Printout menu.

48

Results Printout Menu

On/Off

05/01/2011 02:44 PM

1.Header

2.Analzyer Info

3.Operator

4.Sample number

5.Calibration Info

6.Program name

7.Program info

8.Interval print

9.Weight info

0.Signature line

On

On

Off

Off

Off

On

On

Off

On

Off

LMP110S Moisture Analyzer

Module 1: M30604026

Program 1: Default

UNITS: Moisture

MODE: Standard START DELAY: 0 sec M2

TEMP1: 105C, Std TIME1: Off

TEMP2: Off TIME2: Off

SLOPE: Window: 1.0 %IW: 0.05 Actual

STANDBY: 60C

IDEAL WT: 5.0 grams LOCK: Off

RESULT on 05/15/2011 at 10:24 AM

Elapsed time: 07:13

52.46 %M

Initial Weight = 5.167 grams

Final Weight = 2.456 grams

Weight Loss = 2.711 grams

Page 49

49

§ Press the number key corresponding to the content

to be added to the Result Printout format.

§ The following content is either On or Off:

Analyzer info Operator

Calibration info Program name

Program info Weight info

Signature line

§ The following content requires a selection or input:

Header

Sample number

Interval print

A complete printout format is shown to the left:

Header line 1

Header line 2

Header line 3

LMA110S Moisture Analyzer

Module 1: M30604026

Operator: John Smith

Sample ID: 1

Calibration external: 06/01/2011 09:00 AM

Last temp cal: 05/13/2011 08:20 AM

Program 1: Titon X

UNITS: Moisture FACTOR: 1.00, 0.00

MODE: Standard START DELAY: 9 sec M2

TEMP1: 105C, Std TIME1: Off

TEMP2: Off TIME2: Off

SLOPE: Window: 1.0 %IW: 0.05 Actual

STANDBY: 60C

IDEAL WT: 5.0 grams LOCK: Off

TARGETS: MIN: 45.00 MAX: 55.00

Time Temp Weight Data Units

- - - - - - - - - - - - - - - - - - - - - - - - - -

- - - -

0:00 61C 5.167 0.00 %M

RESULT on 06/15/2011 at 10:24 AM

Elapsed time: 07:13

52.46 %M

Target: PASS

Initial Weight = 5.167 grams

Final Weight = 2.456 grams

Weight Loss = 2.711 grams

Signature:

Page 50

50

To edit or change header lines:

§ From the Results Printout menu press the 1 key.

§ From the Header screen press the number key 1, 2

or 3 to edit or change any of the three header lines.

§ Press the Enter key when finished editing each

header line.

§ Press the Enter key from the Header screen to return

to the Results Printout menu.

To select a sample number format:

§ From the Results Printout menu press the 4 key to

display the Sample Number screen.

§ Press the number for the format desired.

The display will return to the Results Printout menu

screen. (If Numeric Increment is selected you will be

prompted to enter a starting number before returning to the Results Printout menu screen.)

To set a print interval:

§ From the Results Printout menu, press the 8 key.

§ Select an interval in seconds. The screen will return

to the Results Printout menu.

1.Header line 1

2.Header line 2

3.Header line 3

Header

05/01/2011 02:24 PM

Header line 1

Lower

Symbol

Sartorius

Clear

all

A

Clear

one

05/01/2011 02:39 PM

Select sample number: Off

1.Numeric

2.Numeric increment ( 1 )

3.Batch

Sample Number

05/01/2011 02:39 PM

Page 51

51

Setting the Time and Date

The time and date along with the date format will

need to be set to your local time on setup. The date

will automatically roll to the next year. The analyzer

will set the day of the week automatically.

To set the time and date (and format):

§ From the Setup Menu screen, press the 5 key or

highlight Time and Date using the navigation keys

and press Enter to display the Time and Date screen.

To set the time:

§ From the Time and Date screen, press the 1 key for

Set time.

§ At the Time screen, press the Format soft key to

select the 12- or 24-hour clock.

§ Use the numeric keys to type in the local time.

§ If you want to use the 12-hour clock, press the

AM|PM soft key to select AM or PM.

§ Press the Enter key to return to the Time and Date

screen.

To set the date:

§ From the Time and Date screen, press the 2 key for

Set date.

§ At the Date screen, press the Format soft key to

select format.

§ Use the numeric keys to type in the date. The day is

automatically shown.

§ Press the Enter soft key to return to the Time and

Date screen.

1. Set time 02:14 PM

2. Set date 05/01/2011

Day: Monday

Time and Date

05/01/2011 02:24 PM

Page 52

52

Communication Ports

The LMA110S offers four unique modes

to communicate to other Sartorius

moisture analyzers, a PC, with a network or to the optional internal printer.

§ Serial – Transfer programs between

moisture analyzers (LMA110S [Mark 3]

or Mark 2) or interface with a PC

§ USB – For Sartorius Service only

§ Ethernet – connect to a network

To set up serial communications to

match peripheral device:

§ From the Setup Menu screen, press the

6 key or highlight the Communication

Ports menu using the navigation keys

and press the Enter key.

§ Press the 1 key for Serial Port to display

the Serial Port menu screen.

§ Press the 1 key or On|Off soft key to

toggle the serial port On.

§ Press the 2 key for Select baud rate and

then the appropriate key to select either

300, 1200, 2400, 4800, 9600, 19200,

57600, or 115200. The screen will

return to the Serial Port menu screen.

§ Press the 3 key for Set up serial port to

make final selections:

– 8, no parity, 1 stop bit

– 7, even parity, 1 stop bit

– 7, odd parity, 1 stop bit

§ Finally, press the 4 key to toggle CTS

On or Off.

To turn the optional internal printer

Off, press the 4 key from the Communication Ports menu, or highlight Printer

On and toggle the On|Off soft key to

display Printer Off.

Note

To download or upload drying programs from another Sartorius product

(Mark 3, Mark 2, Omni 1) refer to

operating instructions Transfer

Programs on page 61.

Serial Command Set

Through specific serial commands

entered via a personal computer interfaced to the LMA110S, all setup and

operational functions of the analyzer

can be performed from the computer.

For a complete set of serial commands,

please contact Sartorius.

Pin Assignment Chart

Pin Configuration of 9 pin DE-9S

Pin Remark

1 Shorted with pins 4 and 6

2 TxD (out)

3 RxD (in)

4 Shorted with pins 1 and 6

5 GND

(tied to shell and digital ground)

6 Shorted with pins 1 and 4

7CTS

8RTS

9 No connection

Page 53

Serial Command List

Command Format Limit Description Response Format Range

Test Setting Commands

SET UNITS MOISTURE UNITS MOISTURE

SOLIDS UNITS SOLIDS

VOLATILES UNITS VOLATILES

MOISTURE/DRY UNITS MOISTURE/DRY

WEIGHT UNITS WEIGHT

SET TEMP1 + Float (0-210) 0=OFF TEMP1 x 25-210C

SET TEMP2 + Float (0-210) 0=OFF TEMP2 x 25-210C

SET TIME1 xx.x Float (0-99.9) 0=OFF TIME1 xx.x 0=99.9 minutes, 0=OFF

SET TIME2 xx.x Float (0-99.9) 0=OFF TIME2 xx.x 0=99.9 minutes, 0=OFF

SET FACTOR x.xxx Float FACTOR x.xxx

SET OFFSET x.xxx Float OFFSET x.xxx

SET PLACES x Integer (2 or 3) PLACES x 2,3

SET SLOPE x.xxx Float (0.0 - 9.99) SLOPE x.xxx 0-9.99%, 0=OFF

SET SLOPETIME x.xx Float (0.1 - 99.99) SLOPETIME x.xx 0-9.99 minutes, 0=OFF

SET CALC ACTUAL “ACTUAL”/”CALC1”/

”CALC2”/”CALC3” CALC ACTUAL

CALC1 CALC CALC1

CALC2 CALC CALC2

CALC3 CALC CALC3

SET DELAY x Integer (0 - 9) DELAY x 0-9 sec

SET STANDBY x Integer (<165) STANDBY x 25-165C

SET IDEALWEIGHT xx.x Float (0.1 - 99.0) IDEALWEIGHT xx.x 0-99 grams

SET IDEAL PERCENT xx.x Float (0.1 - 10.0) IDEAL PERCENT xx.x 1-10

SET IDEALLOCK ON “ON”/”OFF” IDEALLOCK ON

OFF IDEALLOCK OFF

SET TARGETUPPER xxx.x Float (0 - 100.0) TARGETUPPER xxx.x 0-100

SET TARGETLOWER xxx.x Float (0 - 100.0) TARGETLOWER xxx.x 0-100

SET TARGETLIMIT ON “ON”/”OFF” TARGETLIMIT ON

OFF TARGETLIMIT OFF

SET MODE STANDARD “STANDARD”/

”CONCENTRATION” MODE STANDARD

CONCENTRATION MODE CONCENTRATION

SET PROGRAMNAME string String PROGRAMNAME string Max: 15 characters

GET TEMP1 Float (0-210) 0=OFF TEMP1 x

GET TEMP2 Float (0-210) 0=OFF TEMP2 x

53

Page 54