Page 1

Operating Instructions

Sartorius Moisture Analyzer

Model MA160

Electronic Moisture Analyzer

98648-019-98

Page 2

Contents

Contents

User Information ....................................... 3

Safety Information

General View of the Equipment

Startup

................................................ 8

Transporting the Analyzer

Basic Principles

Operating the Moisture Analyzer

..................................... 4

......................... 7

............................. 12

........................................ 13

...................... 20

Switching the Analyzer On and Off (Standby) .......... 20

Setting the Language ................................ 21

Operating Concept .................................. 22

Menu .............................................. 23

Entering Numbers on the Number Pad ................ 24

Entering Text and Characters ......................... 24

Scrolling in the Display .............................. 25

System Settings (Setup Menu)

......................... 26

Opening the Menu and Changing the Settings ......... 26

List of Available Settings ............................. 27

Performance Test

..................................... 52

Starting the Performance Test ........................ 52

Performance Test Measurement Not

Successfully Completed .............................. 54

Performance Test Successfully Completed ............. 54

Calibration and Adjustment

............................ 55

Weighing ........................................... 58

ISO/GLP-compliant Printout

USB Interface

......................................... 61

........................... 59

Communication with Peripheral Devices. . . . . . . . . . . . . . . 61

Interface Specification ............................... 64

Error Messages

Shipping the Analyzer

Care and Maintenance

Disposal

Specifications

........................................ 66

................................. 68

................................ 70

............................................... 74

......................................... 75

Moisture Analysis

..................................... 36

Viewing and Changing Method Parameters ............ 36

Performing the Moisture Analysis ..................... 38

Creating and Managing Methods ..................... 42

Accessories

Analyzer Dimensions

............................................ 76

................................... 77

Declaration of Conformity

............................. 78

2

Operating Instructions Moisture Analyzer MA160

Page 3

User Information

User Information

Warning/Danger Symbols Used in these Instructions:

These notes identify hazards which have a high probability of resulting in death

or serious physical injury if not avoided.

These notes identify hazards that can result in moderate or mild injuries if not

avoided.

These notes identify hazards associated with the risk of material damage.

Explanation of Symbols

The following symbols are used in this manual:

Useful information and tips

Hot surface: Warning – Risk of severe burns!

Note regarding device operation

When individual buttons are displayed, they should be pressed.

The following symbols are used in these instructions:

t Indicates a required action

y Describes what happens after you have performed a particular step

Perform steps in the specified order:

1. First action

2. Second action

3. …

– Indicates an item in a list

Application Advice/Technical Support

Addresses for applications advice and technical support can be found on

the website at: http://www.sartorius.com

Operating Instructions Moisture Analyzer MA160

3

Page 4

Safety Information

Safety Information

Guidelines and General Information

– The analyzer complies with EU Directives and standards, among other

regulations, for electrical safety and electromagnetic compatibility*. Improper

use or handling can, however, result in damage to objects injury. Any improper

use or operation of the analyzer that is not consistent with the instructions

will result in forfeiture of all claims under the manufacturer’s warranty.

– Personnel need to have read and understood these installation instructions,

including the safety instructions.

– In the event of use in systems and ambient conditions which have greater

safety requirements, you must observe the requirements and provisions

applicable in your country.

– Always keep the equipment and analyzer freely accessible.

Any improper installation of the analyzer that is not consistent with the

instructions will result in forfeiture of all claims under the manufacturer’s

warranty.

* = see “Specifications”

Danger of Explosion!

The analyzer must not be operated in potentially explosive atmospheres. Materials

liable to catch fire or explode may not be used as samples for moisture analysis.

Danger of severe personal injury or property damage due to faulty analyzer

Danger of Electric Shock!

Before initial startup, ensure that the voltage rating printed on the manufacturer’s

ID label of the analyzer matches the voltage of the local AC power.

Installation Instructions

components! Do not operate the analyzer if the housing or power supply cable,

including any connections, is damaged. Immediately disconnect the damaged

analyzer from the power by pulling the plug.

The analyzer has a power supply cable with a protective grounding conductor.

Only standard-compliant extension cords with protective grounding conductors are

permitted for use with the analyzer.

Do not expose the analyzer, its power supply cable, or accessories supplied by

Sartorius to extreme temperatures, aggressive chemical vapors, moisture, shock,

vibrations, or strong electromagnetic fields.

Observe the conditions of operation described in the Specifications.

4

Operating Instructions Moisture Analyzer MA160

The operator shall be solely responsible for any modifications to the equipment

and for connecting any cables or equipment not supplied by Sartorius.

Information on operational quality is available upon request from Sartorius.

Only use original Sartorius accessories!

Page 5

Safety Information

Before cleaning the analyzer: Unplug the power supply cable from the socket.

Position the power cable so that it cannot touch the hot surfaces of the analyzer

– Flammable or explosive substances

– If in doubt, carry out a careful risk analysis.

Note the IP protection class of the analyzer! Do not allow liquid penetration.

The protection class specifies the suitability of equipment for various environmental

conditions (moisture, foreign bodies).

and is not a trip hazard. Disconnecting the grounding conductor is prohibited.

The device may only be opened by specialized personnel trained by Sartorius.

Danger due to Fire or Explosion!

– Substances containing solvents

– Substances that release flammable or explosive gases or vapors during the drying

process: When working with these types of samples, use a drying temperature

that is low enough to prevent a fire or explosion from occurring.

– Wear safety glasses.

– Always work with small sample quantities.

Never leave the analyzer unattended in these cases.

No modifications are permitted to the analyzer.

The device may only be opened by specialized personnel trained by Sartorius.

Symbols Used on the Device

When setting up the moisture analyzer, leave enough space to prevent heat from

building up and to keep the analyzer from overheating:

– 1m above the analyzer

– 20cm around the analyzer

The vent above the sample must not be covered or modified in any other way.

During operation do not open the hood, because the heating unit may be very hot.

Do not put any flammable substances on, under, or near the moisture analyzer

because the area around the heating unit will heat up.

Be careful when removing the sample: The sample itself, the heating unit, and the

sample pans may still be extremely hot.

Observe the additional safety and danger information in the following chapters.

Operating Instructions Moisture Analyzer MA160

5

Page 6

Safety Information

Personal Protective Equipment

When operating the analyzer, suitable protective equipment must be worn

in order to minimize dangers to health.

– During work, always wear the protective equipment needed for the task

at hand.

– Follow any instructions posted in the work area pertaining to personal

protective equipment.

Wear the following personal protective gear during all work:

Protective Clothing

Wear a laboratory coat. This lab coat protects the user from hazards due to

the dangerous substances or is prescribed for your process.

Safety Glasses

Wear safety glasses to protect yourself from liquid spray and splashes, and

substances escaping under high pressure.

Safety Gloves

Wear suitable safety gloves when handling chemicals or hazardous substances.

Check that the gloves are not worn and do not have any holes or tears before

putting them on.

Intended Use

The moisture analyzer can be used for quick and reliable determination of the

moisture content of materials of liquid, pasty, and solid substances using the

thermogravimetric method. Only use the analyzer for this purpose. Any other use

outside the limits of the technical specifications is not permitted.

Moisture analysis applications must be optimized by the user in accordance with

local regulations.

Appropriate containers must be used for each type of sample material.

All other applications are not considered the intended use. If the equipment is used

in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

6

Operating Instructions Moisture Analyzer MA160

Page 7

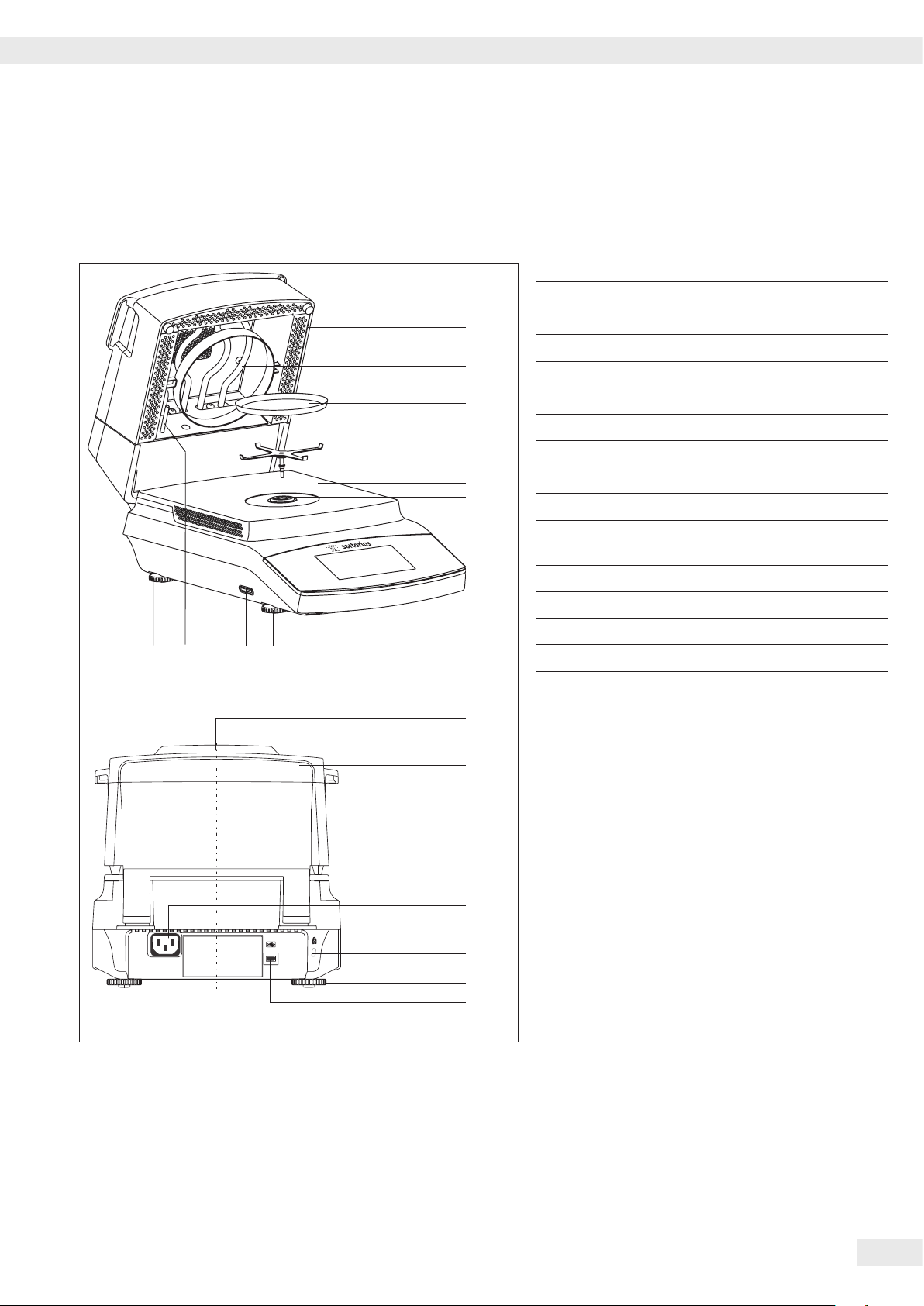

General View of the Equipment

General View of the Equipment

Item Name and Function

1 Heating module

2 Heating element

1

3 Disposable sample pan

2

4 Pan support

5 Sample chamber bottom

3

6 Locking socket (bayonet)

4

7 Process status light

8 Unlocking handle for heating module

5

6

9 Power socket for country-specific power cable

10 Fastening point for an optional Kensington

key lock

11 Leveling feet

12 USB port for mini AB

13 Display and control unit (touch screen)

1311141511

10

11

12

14 SD card slot

15 Temperature sensor

7

8

9

Operating Instructions Moisture Analyzer MA160

7

Page 8

Startup

Startup

Unpacking and Equipment Supplied

t Open the packaging, making sure to remove all parts carefully.

t After unpacking the analyzer, check it immediately for any external damage.

– If you detect any damage, proceed as directed in “Care and Maintenance.”

– Save the box and all parts of the packaging for any future transport. During

shipment, please do not leave cables plugged in!

The following parts are included in the equipment supplied:

– Moisture analyzer

– Country-specific power cable

– Pan support

– Protective cover for the control panel

– 80 disposable aluminum sample pans

– Sample forceps

Choosing a Location

t Select the proper setup location:

An optimal location guarantees accuracy and reliability. Ensure that the following

ambient conditions are met:

– Set up the analyzer on a stable, even surface that is not exposed to vibrations

(e.g., weighing stone).

– Maintain free access to the analyzer at all times.

– Make sure to choose a place where excessive heat cannot build up.

– Leave enough space between it and materials that are affected by heat.

Choose a location that is not subject to the following negative influences:

– Heat (heater or direct sunlight)

– Drafts from open windows, AC systems, and doors

– Extreme vibrations during measurement

– Heavy traffic areas (personnel)

– Extreme humidity

– Electromagnetic fields

Acclimatization

Condensation from humidity can form on the surfaces of a cold device when it is

brought into a substantially warmer area. You should therefore let a device that has

been disconnected from its power source acclimatize for approximately 2 hours

before reconnecting it to the power.

8

Operating Instructions Moisture Analyzer MA160

Page 9

Startup

Setting Up the Analyzer

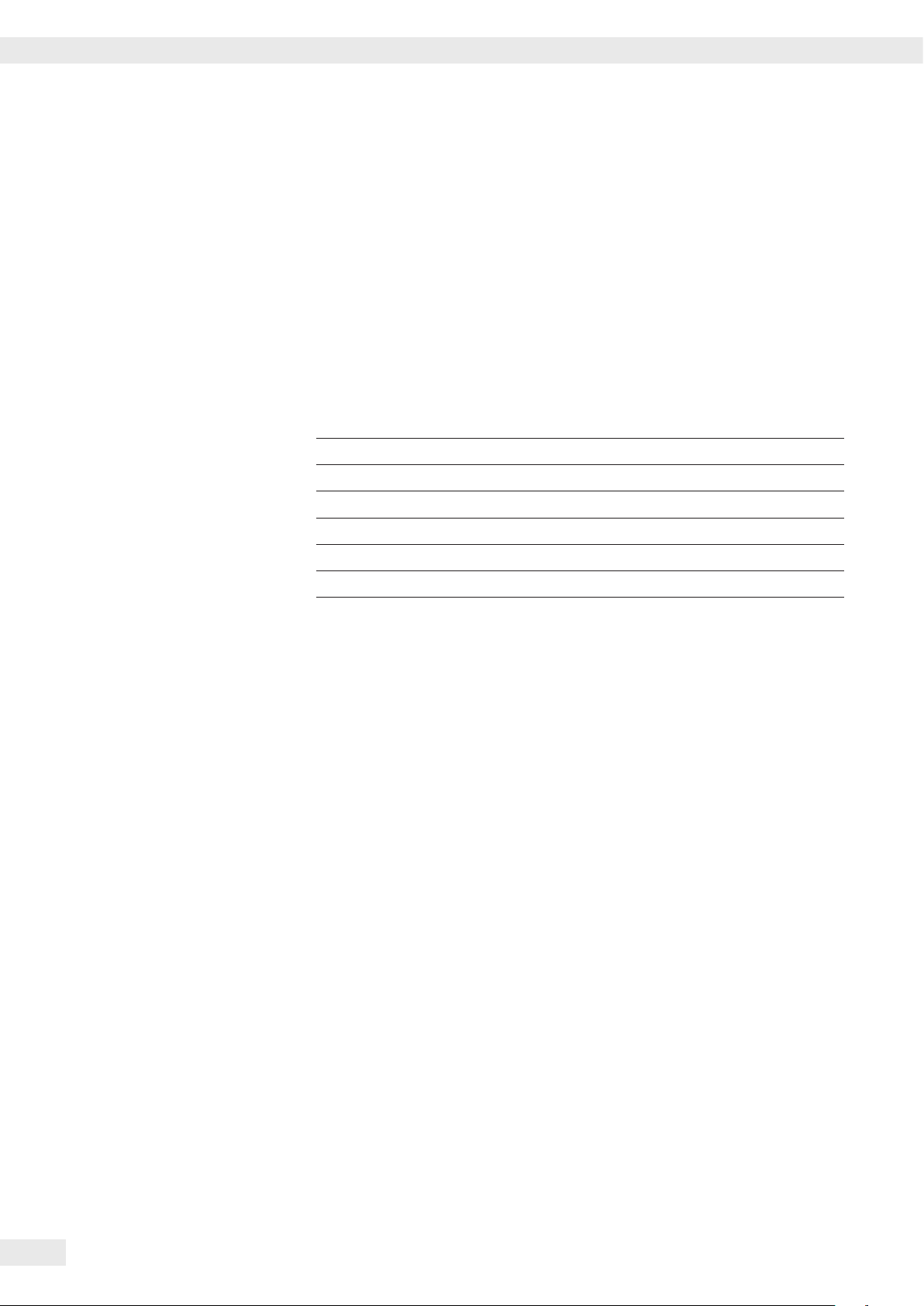

t Assemble the parts in the following order:

– Pan support

– Disposable sample pan

– The protective cover over the control panel is pre-assembled at the factory.

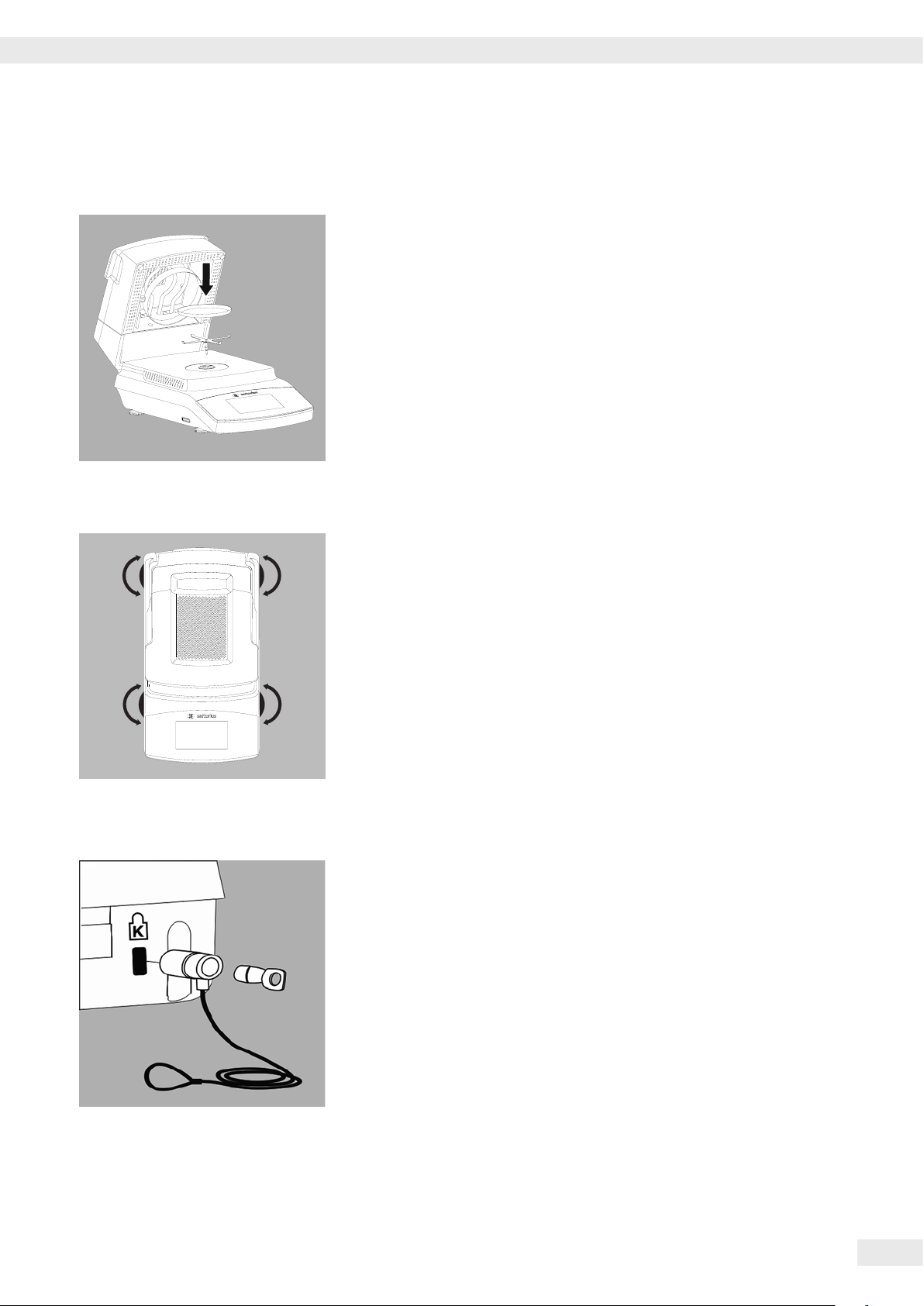

Compensating for Unevenness of the Setup Surface

t Twist the leveling feet until any slight unevenness in the setup surface is

rectified and the analyzer is stable.

Anti-theft Locking Device

– To protect against theft, the analyzer has a fastening point for a security lock

if required.

t A Kensington key lock can be installed at the fastening point on the back of

the analyzer if required.

Operating Instructions Moisture Analyzer MA160

9

Page 10

Startup

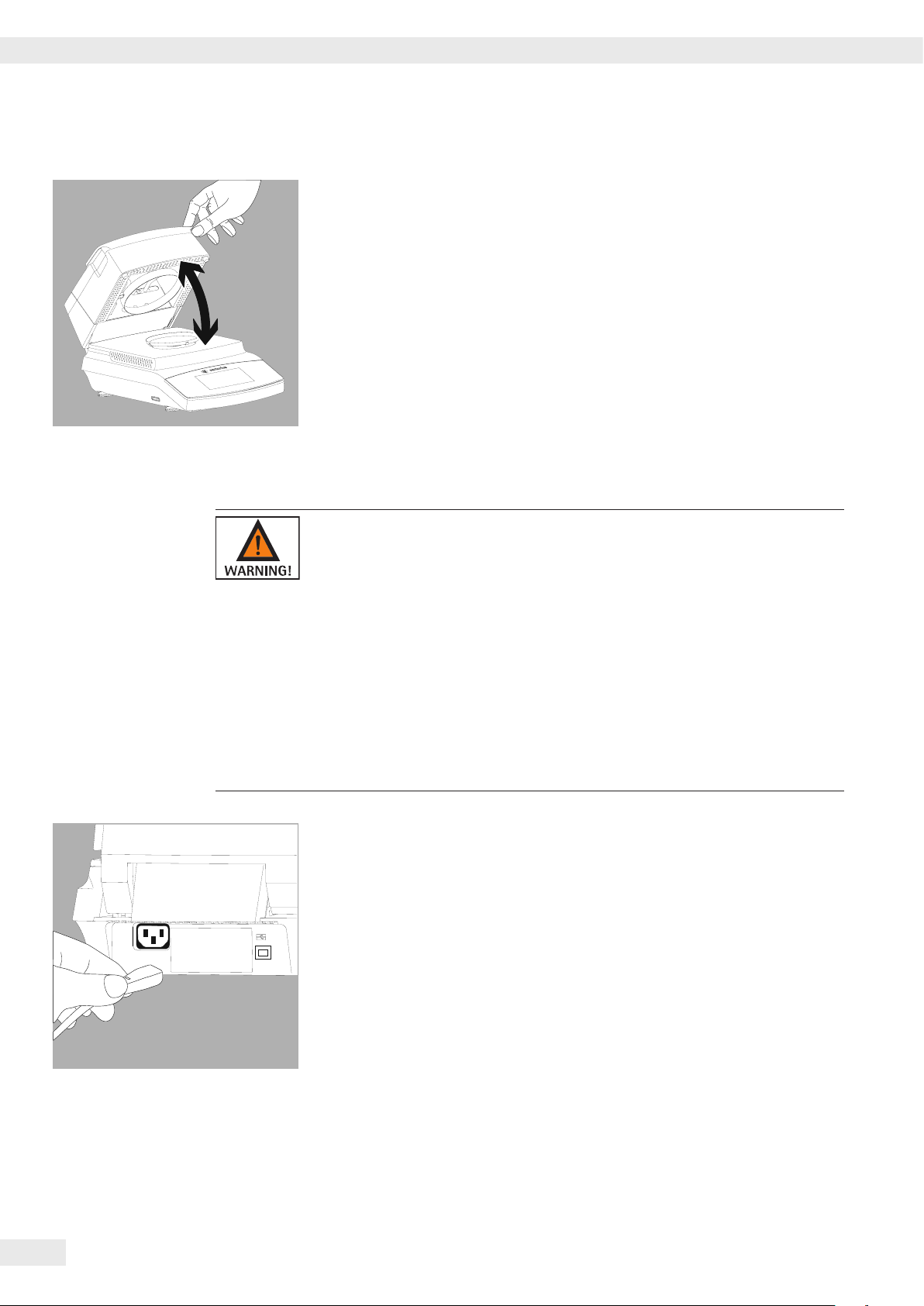

Opening and Closing the Sample Chamber

t Open or close the sample chamber by hand. Always open the heating module

fully.

Power Connection (Power Supply)

Connecting the Analyzer to AC Power

– Using the wrong power cables may cause fatal electric shock and damage

the equipment.

– Never plug the power cable into the socket when it is disconnected from the

analyzer (danger of electrical shock).

– Only connect the analyzer to an AC socket with a protective grounding

conductor.

– Only standard-compliant extension cords with protective grounding conductors

are permitted for use with the analyzer.

– Intentionally disconnecting the analyzer from the protective grounding

conductor is not permitted.

t Check the plug design of the power cable.

If the plug design of the power cable does not comply with your country’s

standard, please inform the nearest Sartorius representative or your dealer.

The power must be connected in accordance with the regulations applicable

in your country. In order to connect the equipment to the power supply

(protection class 1), use a correctly installed wall outlet with a protective

grounding conductor (PE) and a fuse of a maximum 16 A. The power plug or

another suitable disconnecting device for the power must be easily accessible

so that the analyzer can be disconnected from the AC power supply in the

event of an emergency.

10

t Connect the analyzer to the AC power.

t Position the cable so that it cannot be damaged or hinder the measurement

process.

Safety Precautions

If you use an electrical outlet that does not have a protective grounding

conductor, ensure that an equivalent protective conductor is installed by a

certified electrician (as specified in the applicable regulations for installation in

your country). The protective effect must not be negated by using an extension

cord without a protective grounding conductor.

Operating Instructions Moisture Analyzer MA160

Page 11

Startup

0

30

Power Cable Versions

Item No. Region/Country

69 00900 Europe/EU (except the UK, Denmark, Italy, and Switzerland)

69 00901 USA, Canada, and Japan

69 00902 South Africa

69 00905 Australia, New Zealand

69 71945 UK

69 71972 Brazil

69 71973 India

69 71975 Israel

69 71976 Italy

69 71977 Argentina

69 71978 China

69 71979 Switzerland

69 71980 Denmark

Note:

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following

measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which

the receiver

– Consult the dealer or an experienced radio/TV technician for help

Warm-up Time

To return precise results, the analyzer must warm up for at least 30 minutes after

initial connection to the power supply. Only after this time will the analyzer have

reached the required operating temperature.

Operating Instructions Moisture Analyzer MA160

11

Page 12

Transporting the Analyzer

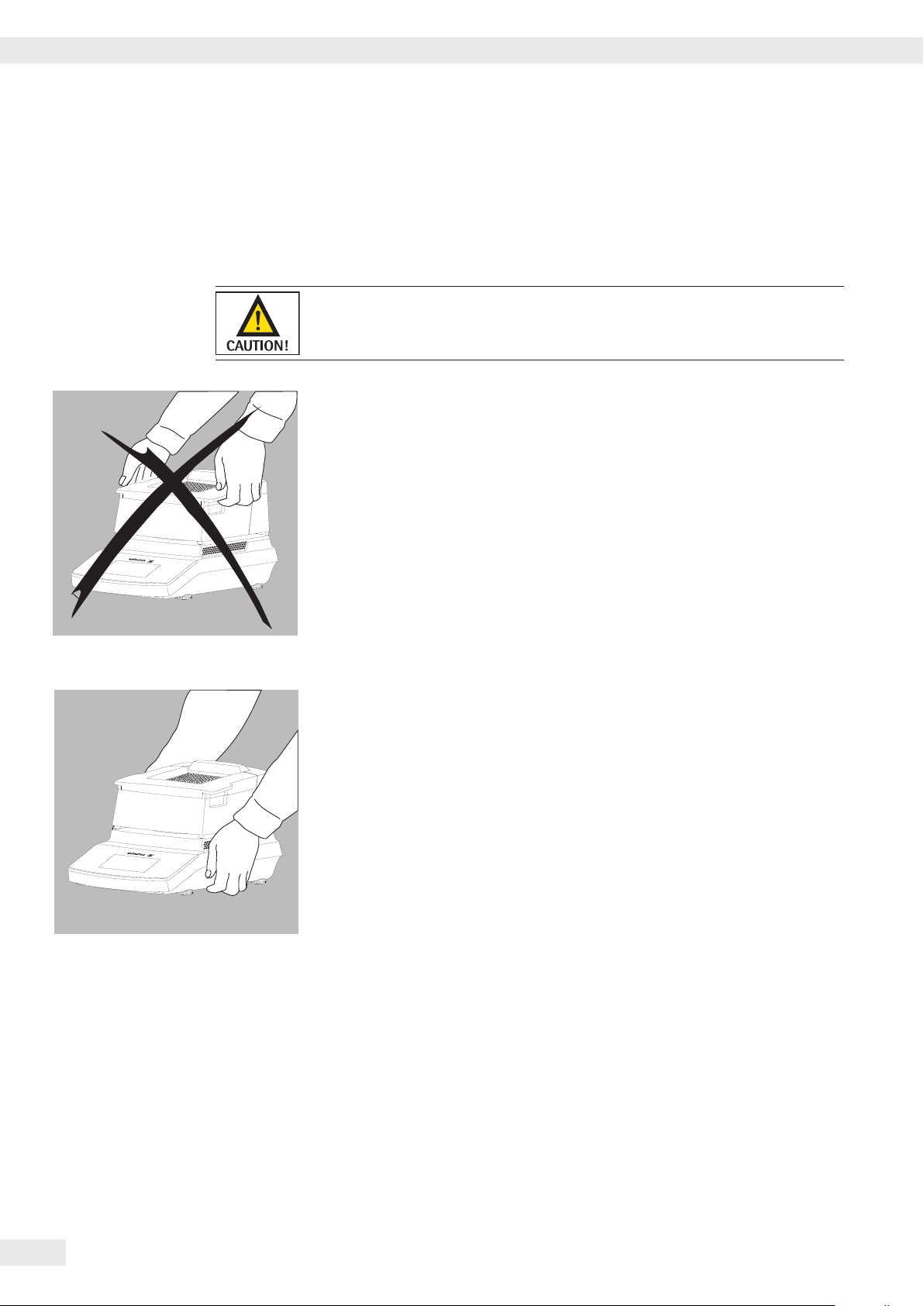

Transporting the Analyzer

Moving the Analyzer in the Lab

Avoid shocks and vibrations:

t Never lift and carry the analyzer by its heating module.

t Hold the analyzer under the housing, lift it up carefully, and carry it to its new

location.

12

Operating Instructions Moisture Analyzer MA160

Page 13

Basic Principles

Basic Principles

Purpose

The moisture analyzer can be used for quick and reliable determination of the

moisture content of materials of liquid, pasty, and solid substances using the

thermogravimetric method.

Material

The moisture of a material is often mistakenly equated to its water content. In fact,

the moisture of a material includes all of the volatile components which are emitted

when the sample is heated, irrespective of the type of material. Among such volatile

substances are:

– Water

– Fats

– Oils

– Alcohols

– Organic solvents

– Flavorings

– Volatile components, products of decomposition (when a sample is overheated)

There are many methods for determining the moisture content of a substance.

Basically, these methods can be divided into two categories:

When absolute methods are used, the moisture content is directly determined

(for example, as a weight loss registered during the drying routine). These methods

include oven drying, infrared drying, and microwave drying. All three of these

methods are thermogravimetric.

When deductive methods are used, the moisture content is indirectly determined.

A physical property related to the moisture in the substance is measured (e.g.,

absorption of electromagnetic rays). These methods include Karl Fischer titration,

infrared spectroscopy, microwave spectroscopy, etc.

Thermogravimetry is the process of determining the loss of mass that occurs when

a substance is heated. In this process, the sample is weighed before and after being

heated, and the difference between the two weights is calculated.

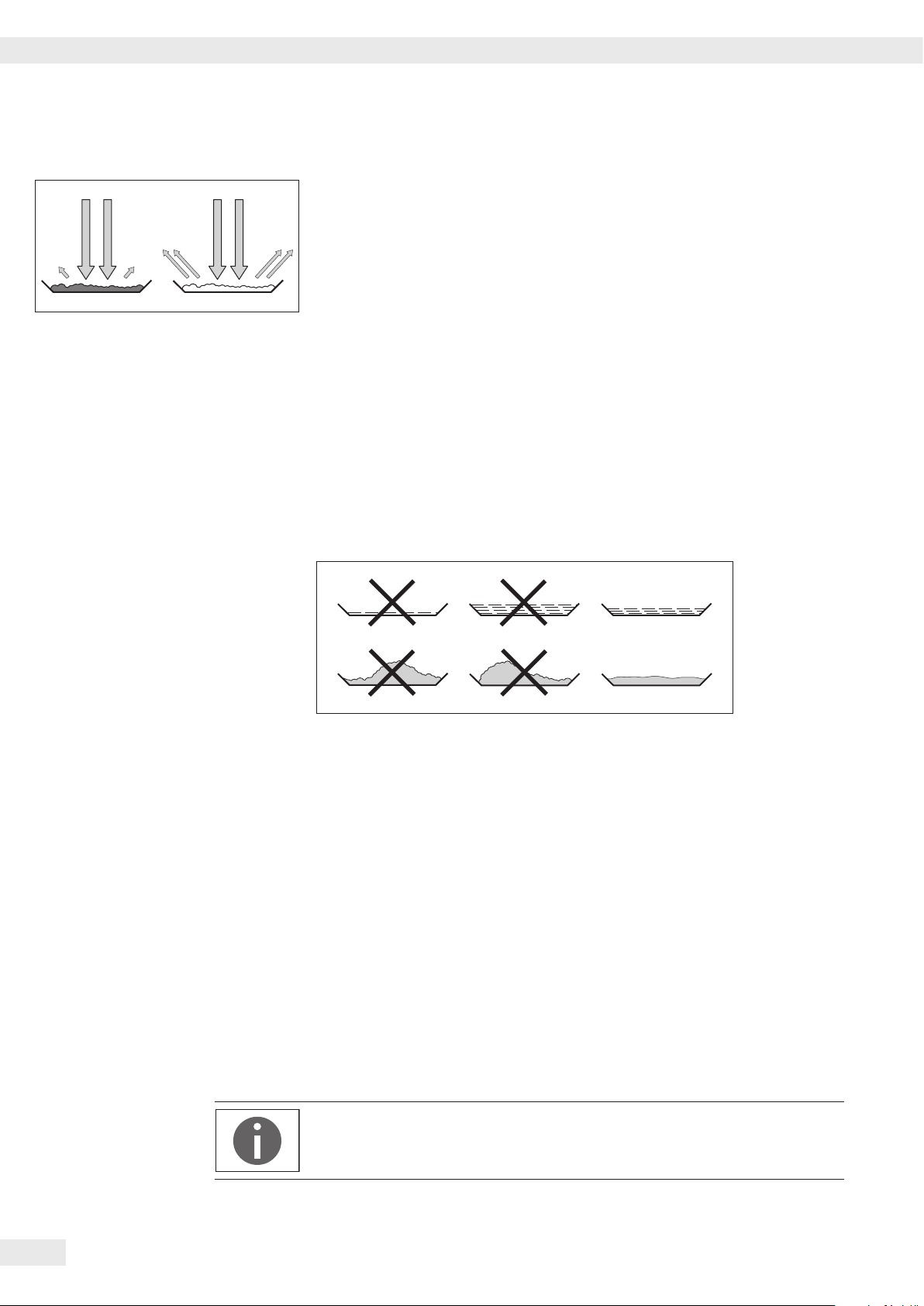

In a conventional drying oven, circulating hot air warms the sample from the

outside to the inside. Efficiency is lost during drying because as the moisture

evaporates, it cools the sample surface.

By contrast, infrared rays (IR rays) penetrate a sample without being impeded.

Having reached the interior of a sample, they are converted into heat energy.

IR-Strahlung

Wärmeenergie

Substanz

Operating Instructions Moisture Analyzer MA160

13

Page 14

Basic Principles

A small part of the IR rays is reflected from the surface of the substance.

The number of reflected IR rays depends to a great extent on whether the

substance is light or dark in color.

– Dark substance – low reflection

– Light substance – high reflection

How the rays penetrate the sample depends on the permeability of the sample.

If the degree of light-transmitting capacity is low, the rays can penetrate only the

uppermost layers of the sample. The heat conductivity of the sample dictates the

degree to which the heat can be transmitted to the underlying layers. The higher

the conductivity, the faster and more uniformly the substance is heated.

The substance should be applied to the sample pan in a thin, even layer. A height of

approximately 2–5 mm for 5–15 g substance weight has proved to be ideal.

Otherwise, the sample will not be dried completely or the analysis time will be

unnecessarily extended, a crust/skin will form on the surface of the sample or the

sample will scorch, and the analysis results obtained will not be reproducible (and

hence cannot be used).

While preparing substances for measurement, no processes may be used that

generate heat. The heat generated may result in a loss of moisture prior to the

measurement.

Perform initial analysis of a new substance to test how the IR rays are absorbed by

the sample and converted into heat. A printout of the intermediate values of the

drying process provides information on this at an early stage.

Experience has shown that the temperature setting selected for infrared drying is

usually lower than the temperature setting used when working with a drying oven.

In many cases, the fully automatic switch-off mode will meet your requirements.

If the final result is higher or lower than expected, try varying the temperature

setting before resorting to a different switch-off criterion.

When analyzing the samples that lose their moisture only very slowly or when

operating a cold moisture analyzer, the fully automatic mode may end the drying

routine too early since no analyzable progress in the drying routine can be

detected. In this case, preheat the moisture analyzer for two to three minutes

before starting the drying routine, or select a different switch-off criterion.

The Application Guide for the Sartorius Moisture Analyzer provides you with

important information on the use of your moisture analyzer.

14

Operating Instructions Moisture Analyzer MA160

Page 15

Basic Principles

Preparation

Before drying a sample, you must carry out the following preparations:

– Adjust against the existing measurement system

– Prepare the sample

– Set the drying program parameters

Adjusting against an Existing Measurement System

A moisture analysis method often replaces another drying method (such as oven

drying method) because it is simple to use and requires shorter analysis time. In this

case, you should adapt this method to that of the moisture analyzer in order to

obtain values comparable to those yielded by your standard reference method.

Perform parallel measurements:

t Take a fresh sample and divide it in half

t Determine the moisture content of the first half using your standard method of

analysis

t Determine the moisture content of the second half using the following settings:

– Fully automatic mode for the switch-off criterion

– Lower temperature settings than for the oven drying method

– Temperature setting for organic substances: 80–100°C

– Temperature setting for inorganic substances: 140–160°C

If the result of the second analysis does not correspond to that of the first:

1. First, repeat the analysis using a different temperature setting

2. Then use the semi-automatic mode for the switch-off criterion (for example with

a different loss rate per 24 s)

Change the switch-off criterion if required:

– Increase end-point recognition: Set the parameter to 2 mg/24 s or 1 mg/24 s

– Decrease end-point recognition: Set the parameter to 10 mg/24 s or 20 mg/24 s

Preparing the Sample

Select a sample:

t Select a representative part of the whole substance as a sample.

– Choose a representative number of individual samples for quality control

– Choose enough samples to indicate a trend for in-process control

t If required, homogenize the product before a sample is taken by:

– Mixing or stirring

– Taking several samples from different areas of the product

– Taking several samples at defined intervals

t Take only one sample at a time for a given analysis and prepare it as quickly as

possible. In this way, it will not lose or gain moisture as a result of the ambient

conditions.

t If several samples need to be taken simultaneously, the samples must be sealed

in airtight containers to ensure that the storage conditions do not alter the state

or condition of the samples:

– Warm or highly volatile substances lose their moisture very quickly.

– If you store the samples in a container, the moisture can condense on the walls

of the container.

– If the container is too big and not filled completely, the sample can exchange its

moisture with the air remaining in the container.

t Mix the condensed moisture back in with a sample if necessary.

Operating Instructions Moisture Analyzer MA160

15

Page 16

Basic Principles

Prepare the sample:

t When crushing a sample, avoid any contact with heat.

Heat results in moisture loss.

t Crush the sample using:

– Pestle

– Lab mill

If the sample is liquid containing solids, use one of the following tools:

– Glass stirrer

– Spoon

– Magnetic stirrer

t Use an appropriate tool for grinding the sample.

Use a disposable sample pan:

t Use only Sartorius disposable sample pans (inner diameter of 92 mm). Reusing

sample pans leads to poor repeatability of results:

– After cleaning, sample residues can still remain on the pan.

– Residues from cleaning agents can evaporate during the next moisture

analysis.

– Scratches and grooves made during cleaning result in damage that forms

points of attack for hot, rising air produced during the drying process (more

pronounced buoyancy).

16

Operating Instructions Moisture Analyzer MA160

Page 17

Basic Principles

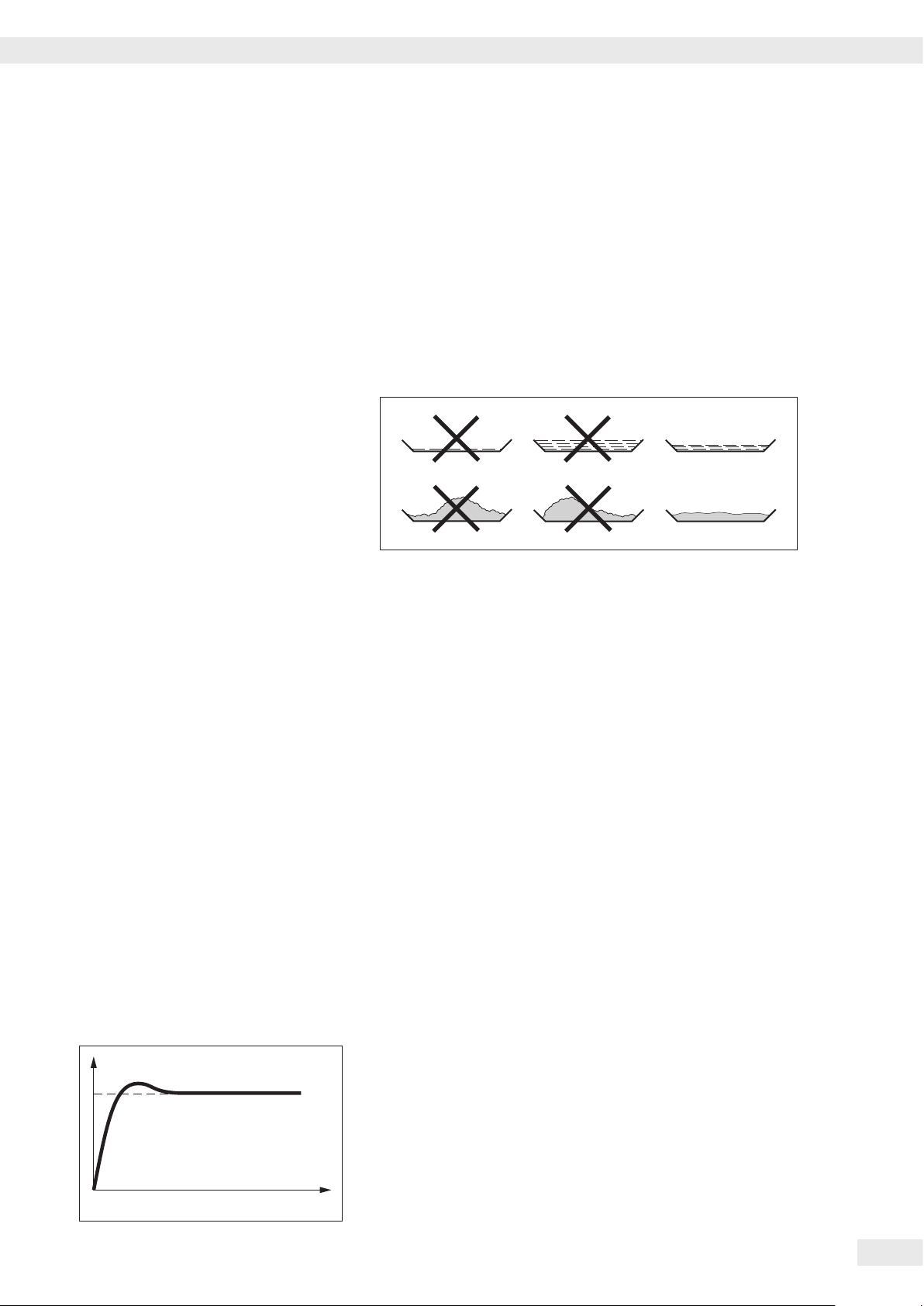

Apply the sample to the sample pan:

t Apply the sample to the sample pan in a thin, even layer (height: 2 to 5 mm,

weight: 5 to15 g); otherwise:

– A sample applied unevenly will result in a nonuniform distribution of heat

– A sample will not be dried completely

– The analysis time will be unnecessarily extended

– The sample will burn or a crust/skin will form on its surface as a result of a

very thick layer

– The crust makes it difficult or impossible for moisture to escape from the

sample during the drying process

– An uncertain and unknown quantity of moisture will remain in the sample

t

Apply liquid samples, pasty samples, or samples that can melt to a glass-fiber

filter (order no. 6906940); this provides the following benefits:

– Uniform distribution due to the capillary effect

– Liquids are prevented from beading together and forming drops

– With larger surfaces, the moisture can evaporate faster

– Colorless/transparent samples do not reflect

– Considerably more convenient than the “sea-sand method”

When drying samples containing sugar, a crust or skin can form and seal the

surface. A glass-fiber filter is particularly useful in such cases. The moisture can

evaporate downwards through the surface of the filter. Crust/skin formation can be

prevented or limited by placing the glass-fiber filter on top of the sample.

t Cover solid, heat-sensitive samples with a glass-fiber filter (order no. 6906940);

this provides the following benefits:

– Gentle heating, because the sample surface is shielded from excessive heat

– Higher temperature setting can be selected

– Uniformity of the sample surface

– Fast evaporation of the moisture

– Excellent repeatability for samples containing fat

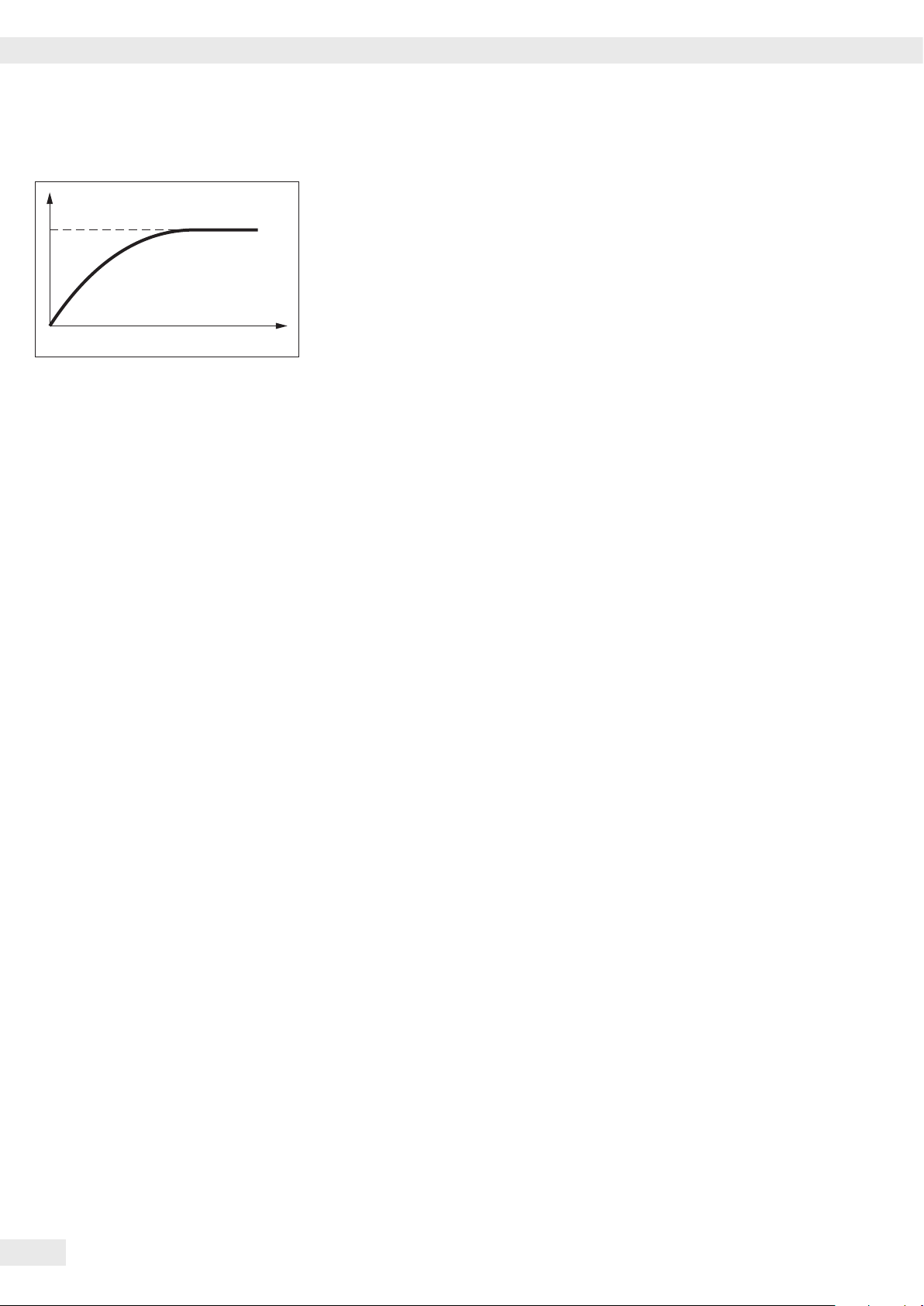

Heating Programs

Two heating programs are available for performing moisture analysis of a

substance:

– Standard drying

– Delicate drying

T [°C]

Standardtrocknung

t [s]

Standard drying:

For standard drying, you need to enter the final temperature. The final temperature

is reached using an overshoot if necessary. The maximum set temperature is 160°C.

Operating Instructions Moisture Analyzer MA160

17

Page 18

Basic Principles

T [°C]

Delicate drying:

For delicate drying, you need to enter the final temperature. The maximum set

temperature is 160°C. The target temperature is reached more slowly and the

measurement time is extended. Delicate drying is recommended for sensitive

samples.

Standardtrocknung

t [s]

Standby Temperature

Temperature set to defined value when the sample chamber is closed.

Heating only occurs when the analyzer is in a measurement cycle. The standby

temperature is not the same as the measurement temperature.

The “Timeout Standby Temp.” can be set to 1 to 24 hours and is preset to 2 hours.

To change the setting, see Chapter “System Settings (Setup Menu)”.

Initial Weight

The target weight (as a guide for applying a sample to the analyzer – not as a

starting condition) can be entered by the user. The tolerance range can be freely

selected, e.g., ± 0.5 g.

Print Lines

When print lines are activated (1 or 2 lines with 20 characters each), additional

information about the method, entered by the user, appears on the report and

printout.

Filter

The user has the option of selecting between 0, 1, or 2 filters. During taring a

message appears indicating that the configured number of filters must be placed

with the sample pan for taring.

Target Value

The user can enter a target value with a tolerance range. During analysis a progress

bar appears, indicating the progress of the measurement. At the end of the analysis,

you can see whether the value is within the tolerance range.

18

Operating Instructions Moisture Analyzer MA160

Page 19

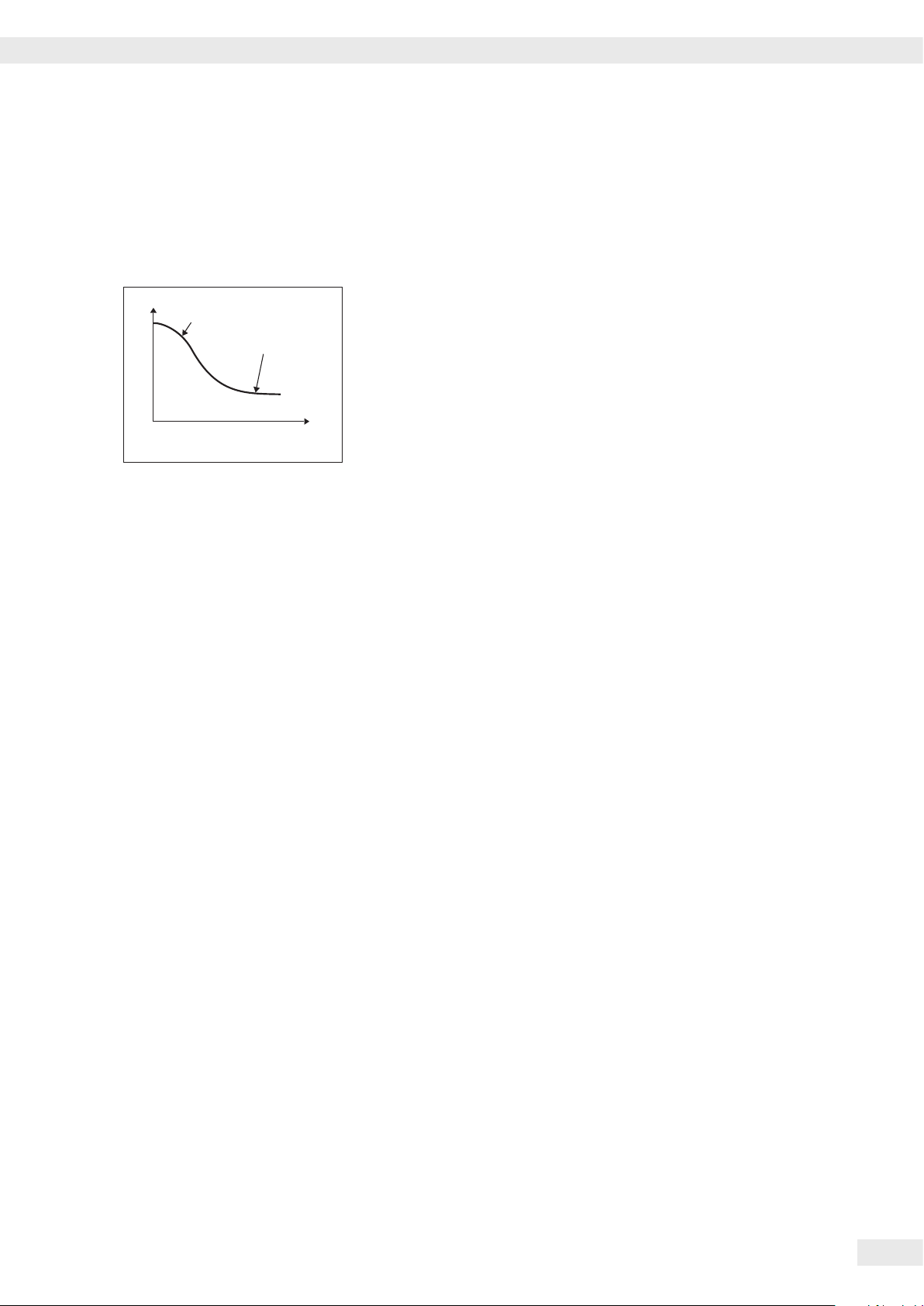

Weight

Moisture (steam)

Autom. stopping

Basic Principles

Starting the Analysis

– After closing the hood:

If the initial weight condition is met, the analyzer prompts you to close the

hood. The start weight is accepted as soon as the sample chamber is closed.

End of Analysis

– Fully automatic:

The analysis ends as soon as the weight loss per 24 s is below an automatically

detected threshold.

– Semi-automatic, absolute:

The analysis ends as soon as the weight loss per the set interval is lower than a

user-defined threshold (set in milligrams). The weight loss is entered by the user.

Time

– Semi-automatic, percentage:

The analysis ends as soon as the weight loss in percent is lower than a userdefined threshold (set in percent). The percentage is entered by the user.

– Time

The analysis ends as soon as the specified time has elapsed.

– Manual:

Switch off using the END key. The maximum analysis duration is 24 hours.

Operating Instructions Moisture Analyzer MA160

19

Page 20

Operating the Moisture Analyzer

Operating the Moisture Analyzer

Switching the Analyzer On and Off (Standby)

Wednesday, April 2, 2014 16:50

Moisture in %M

Start new measurement

Standard

Standard

Coffee creamer

Oats

Washing powder

Starch

105 °C

End autom.

105 °C

Fully automatic

100 °C

Fully automatic

80 °C

Fully automatic

85 °C

2 mg/24 sec

80 °C

2 mg/24 sec

y The main screen appears after the moisture analyzer has been switched on.

– The default language for the display text is English.

– You can change the language (see “Setting the Language” on page 21).

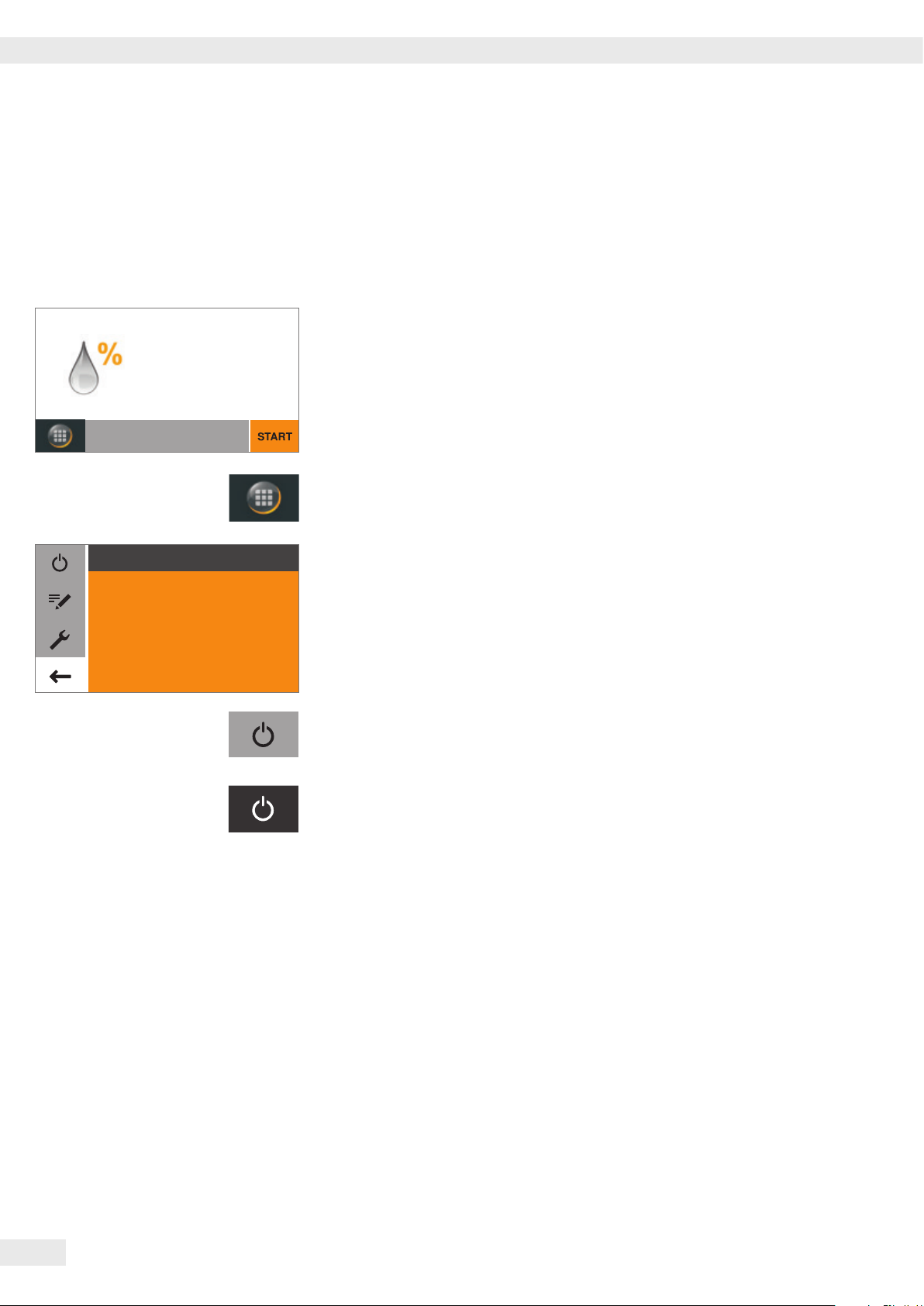

t To switch the moisture analyzer to standby, select the menu key at the bottom

left of the main screen on the display.

y The menu is displayed.

t Select the

j button in the menu.

y The moisture analyzer switches to standby mode.

t To switch the moisture analyzer on again: Select j on the display.

The moisture analyzer starts in the method most recently used before the

analyzer was last switched off.

20

Operating Instructions Moisture Analyzer MA160

Page 21

Operating the Moisture Analyzer

Setting the Language

The default language for the display text is English.

To change the language, proceed as follows:

t Select the menu key at the bottom left of the main screen on the display.

Standard

Coffee creamer

Oats

Washing powder

Starch

Settings

Language

Date and Time

Device information

Calibration/Adjustment

Language

English

Deutsch

105 °C

Fully automatic

100 °C

Fully automatic

80 °C

Fully automatic

85 °C

2 mg/24 sec

80 °C

2 mg/24 sec

y The menu is displayed.

t Select the

i (Setup) button in the menu.

y The Settings window appears.

t Select Language or the top entry in the list.

y The Language settings window appears.

t Select the desired language, such as Deutsch (German).

t Select l to confirm.

y The display changes directly to the desired language.

t Select o to return to the menu.

Français

Operating Instructions Moisture Analyzer MA160

21

Page 22

Operating the Moisture Analyzer

Operating Concept

This section explains the operating options available to you so that you can

familiarize yourself with the moisture analyzer.

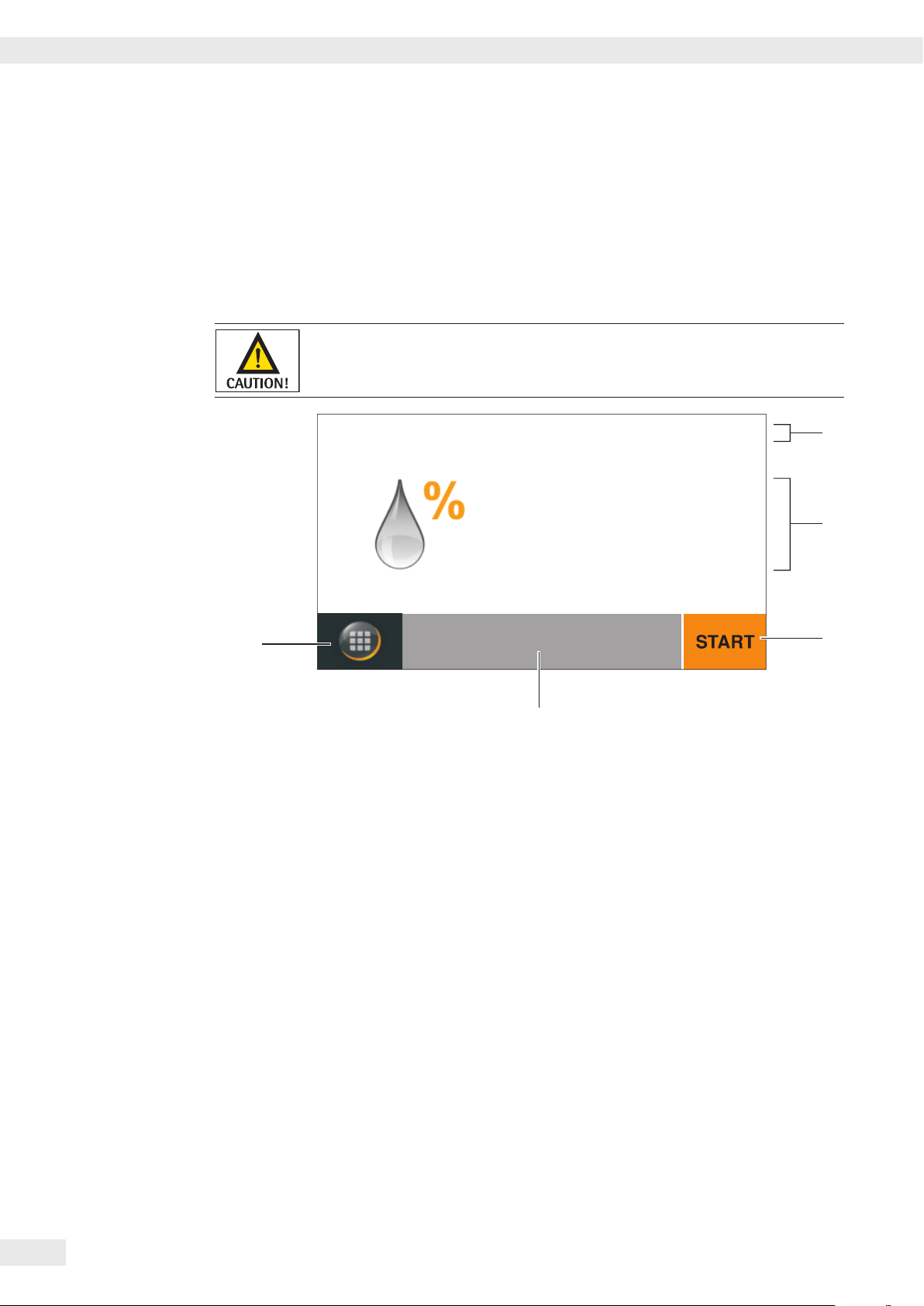

Operating and Display Elements

Sharp or pointed objects (such as ballpoint pens) can damage the device.

– The touch screen should only be operated by lightly pressing it using the tips of

your fingers. You can also operate the touch screen when wearing lab gloves.

Wednesday, April 2, 2014 16:50

1

Moisture in %M

Start new measurement

5

Standard

4

105 °C

End autom.

1 Current date and time

2 Selected result display for the method

3 Operate method, such as start moisture analysis

4 View settings for the selected method

5 Menu: Switch to the menu or method selection

2

3

22

Operating Instructions Moisture Analyzer MA160

Page 23

Operating the Moisture Analyzer

1

Menu

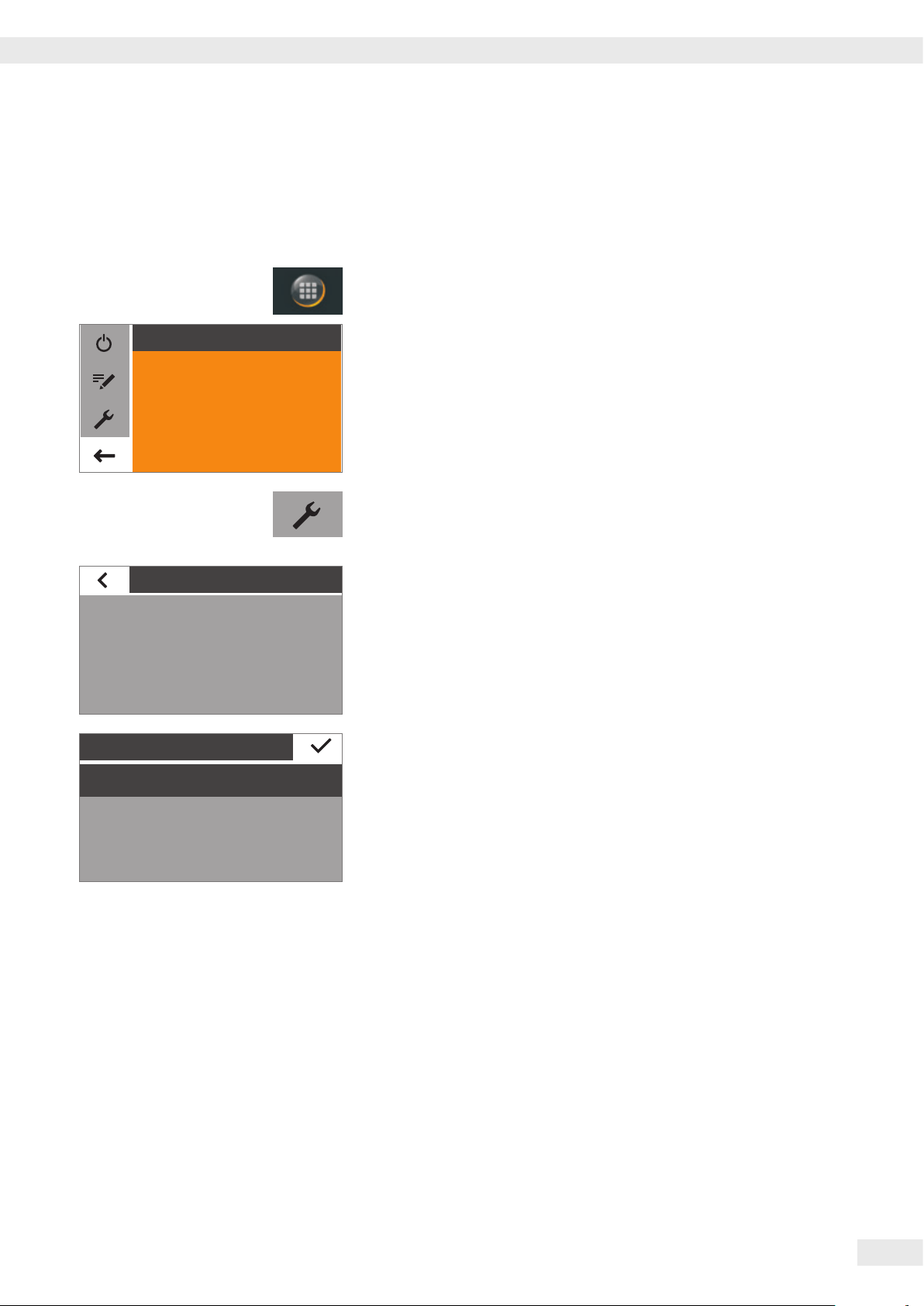

All methods and settings for the moisture analyzer can be accessed via the menu.

t To access the menu, select the menu key at the bottom left of the display.

y The menu opens.

5

Standard

Coffee creamer

4

Oats

3

2

1 List of available methods

2 Back: Activate last used method again

3 Setup menu: Open system settings (see page 26)

4 Method management: Change parameters and create new methods

5 Switch moisture analyzer to standby mode

Washing powder

Starch

105 °C

Fully automatic

100 °C

Fully automatic

80 °C

Fully automatic

85 °C

Semi-automatic

80 °C

Semi-automatic

Operating Instructions Moisture Analyzer MA160

23

Page 24

Operating the Moisture Analyzer

jkl_

Temperature

123

456

789

0000105

°C

C

0

Ke

qwer tzuiop

asdfgh

yxcvbnm- /

123

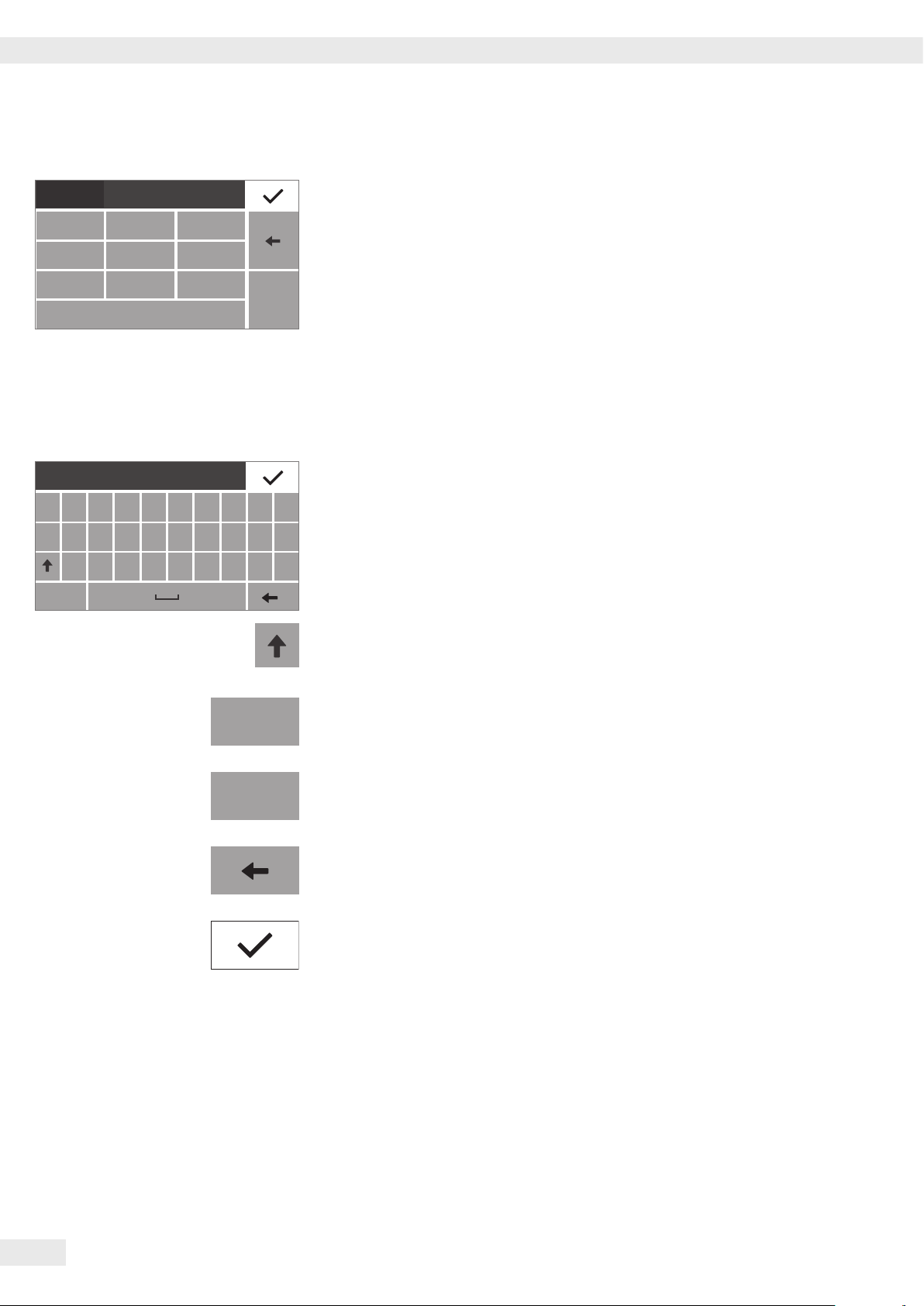

Entering Numbers on the Number Pad

You can enter numeric values in the method parameters or system settings (such as

heating temperature). A number pad appears on the display, which is always used in

the same way.

t To enter numbers, select the desired numbers one after the other.

y The entered numbers appear at the top of the display.

t To correct the last entered number, select p.

y The number is deleted. Then enter the correct number.

t To clear the entire entered value, select C.

t To confirm the entry, select l.

Entering Text and Characters

A keyboard will appear when you have to enter text and characters.

t Select the individual characters one after the other. The entered text appears

at the top of the display. If you hold down a character for longer, the special

versions of that character (umlauts, accent marks) and special characters appear.

t Use the Shift key to switch the keyboard display between uppercase and

lowercase letters.

123

ABC

t Use the 123 key to switch the keyboard display from letters to numbers.

t Use the ABC key to switch the keyboard display from numbers to letters.

t Use the back arrow key to delete the last character.

t The

l key ends the process and saves character input.

24

Operating Instructions Moisture Analyzer MA160

Page 25

Operating the Moisture Analyzer

Date and time

Scrolling in the Display

If more than one entry is available, you can scroll up and down through the display

to select the desired entry.

Settings

Device information

Calibration/Adjustment

Printout

Signals

Settings

Calibration/Adjustment

Printout

Signals

Display brightness

t To scroll, place your finger on the display and drag it slowly either up or down.

y The entries on the display move in the corresponding direction. While you are

scrolling, a gray scroll bar appears on the right of the display, indicating where

you are in the list of options.

t Tap the desired entry to select it.

Operating Instructions Moisture Analyzer MA160

25

Page 26

System Settings (Setup Menu)

Date and time

System Settings (Setup Menu)

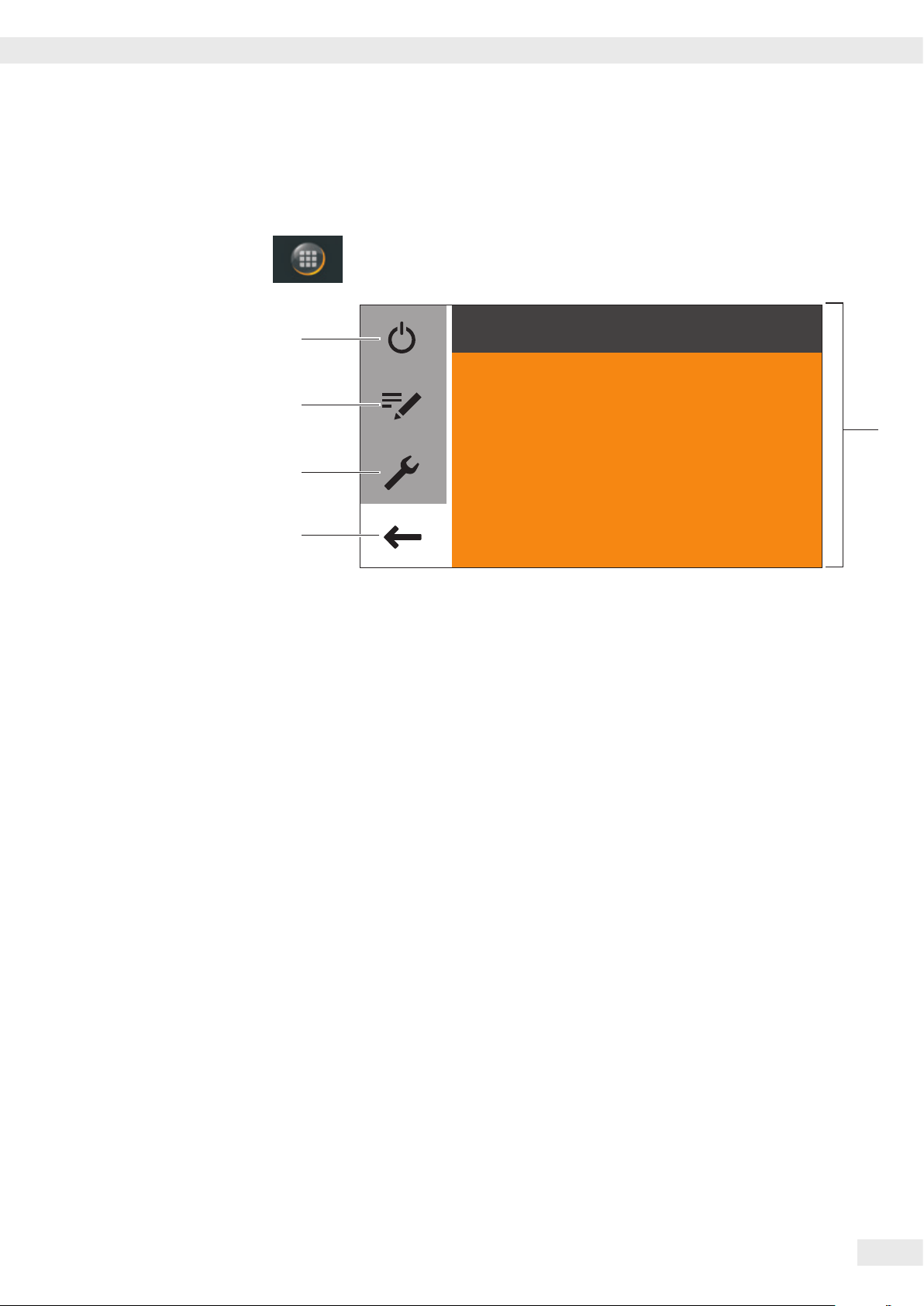

The Settings (Setup) menu contains all basic settings for the moisture analyzer.

Opening the Menu and Changing the Settings

t Select the menu key on the main screen.

Standard

Coffee creamer

Oats

Washing powder

Starch

Settings

Language

Date and Time

Device information

Calibration/Adjustment

Settings

Device information

Calibration/Adjustment

Printout

Signals

105 °C

Fully automatic

100 °C

Fully automatic

80 °C

Fully automatic

85 °C

2 mg/24 sec

80 °C

2 mg/24 sec

y The menu is displayed.

t Select the i (Setup) key in the menu.

y The Settings (Setup) menu appears.

t To scroll, place your finger on the display and drag it slowly either up or down.

y The entries on the display move in the corresponding direction. While you are

scrolling, a gray scroll bar appears on the right of the display, indicating where

you are in the list of options.

t Select a setting and make the desired change. Information about the available

settings can be found from page 26.

t Select l to confirm your changes.

26

Operating Instructions Moisture Analyzer MA160

t Select ; to return to the menu. The changed settings are active when you reach

the first level of the menu again.

Page 27

List of Available Settings

This section contains information about all of the basic settings on the moisture

analyzer, which can be defined in the Settings menu.

Language

System Settings (Setup Menu)

Language

The language of the display text can be set here. English is set as the default

language on the moisture analyzer (see “Setting the Language” on page 21).

English

The following languages are available:

Deutsch

Français

– English

– German

– French

– Spanish

– Italian

– Japanese

– Russian

– Chinese

– Polish

– Portuguese

– Turkish

Date and Time

Date and time

Date

Date format

Time

Time format

The date, time, and display format can be set here.

Under Date:

t To set the date, select t, enter the current date and confirm with l.

Under Date format:

t Select how the date is displayed and printed out.

– DD-MMM-YYYY:

The date is displayed in the order of day, month, then year.

– MMM-DD-YYYY:

The date is displayed in the order of month, day, then year.

– YYYY-MM-DD (ISO):

The date is displayed in the order of year, month, then day.

(The time is always displayed in 24-hour format with this setting.)

Under Time:

t To set the time, select t, enter the current time and confirm with l.

Under Time format:

t Select how the time is displayed and printed out.

– 24h:

The time is displayed in 24-hour format. (This is the only available setting

when the date is set to ISO format.)

– 12h (AM/PM)

The time is displayed in 12-hour format. The hours before noon are

displayed with AM and the hours after noon are displayed with PM.

Operating Instructions Moisture Analyzer MA160

27

Page 28

System Settings (Setup Menu)

Device Information

The manufacturer, model, serial number and software version of the moisture

Device information

Manufacturer: Sartorius

Model: MA160

Serial number: 0000021087

Version BAC: 00-53-01.01 CN:1701

Version APC: 01-80-01.01 CN:0000

Version DOC: 07-40-95.02 CN:0000

analyzer are displayed here.

Calibration/Adjustment

Calibration/Adjustment

Performance test

Weighing system adjustment

Calibration report

The settings for calibration and adjustment of the moisture analyzer can be defined

here.

Under Performance Test:

Test functions for different temperature ranges are available here. You can only use

these functions with the ReproEasy pad (accessory).

Under Weighing system adjustment:

t Select the option of your choice.

– CAL-Extern: Carry out calibration with an external calibration weight

(see Chapter “Calibration/Adjustment”).

– Weighing only: Use the weighing function to use the moisture analyzer

as a simple lab balance (see Chapter “Calibration/Adjustment”, section

“Weighing”).

Under Calibration report:

The most recent calibration reports are sorted here by date. Up to 99 calibration

and adjustment entries are saved per day. Calibration reports older than 30 days are

deleted.

Printout

You can configure the settings for printing and data output here. Some of

Printout

Printout measurement

Printout and Report Format

User-defined

the settings depend on the configuration of the USB interface (see Chapter “USB

Interface”).

Printout measurement:

Under

t Select the settings for printing out the results on the connected lab printer.

– Printout measurement: The printout can be activated and deactivated

during the measurement here.

– Intermed. results: If the printout is activated, you can also activate the

output of intermediate values during the measurement here.

– Interval [sec]: Enter the desired interval in seconds for the output of the

intermediate results.

Under Printout and Report Format:

t Configure all settings for the output format.

– Result only: Only the result of the moisture analysis is output.

– With GLP and method parameters: The GLP data and parameters used for

the moisture analysis are also output.

– User-defined: Activate the “User-defined” menu item.

Under User-defined:

t Select the data for output individually and confirm with l.

28

Operating Instructions Moisture Analyzer MA160

Page 29

Signals

System Settings (Setup Menu)

Signals

Touch signals

Acoustic signal

Status light

The key tones, acoustic signals, and process status light can be switched on and off

here.

The following settings are available for each signal:

– On: The signal is activated.

– Off: The signal is deactivated.

Display Brightness

Display brightness

Bright

Medium

Eco mode

The brightness of the display can be set here.

The following brightness levels are available:

– Bright

– Medium

– Eco mode: Energy-saving mode (factory setting): The brightness is reduced

after 2 min. of inactivity. To reactivate the normal brightness: Touch the

screen. During measurement and during the results display, eco mode is

deactivated.

Identifiers

Identifier

Device ID

Batch ID Function

Sample ID Function

The identifiers for the printout can be defined here.

– The Device ID identifier is entered here once. The device ID can be a maximum

of 14 characters long.

– The Batch ID and Sample ID functions can be activated here. The user must

then enter the batch and sample IDs before each measurement routine. Batch

and sample IDs cannot exceed 20 characters.

Under Device ID:

The device identifier (ID) is printed on the GLP report in the header.

t To set the device ID, select Device ID, enter the desired device ID and

confirm with l.

Under Batch ID Function:

The batch ID (L ID) is queried once at the beginning of the measurement routine.

t If you wish to print the batch ID, activate this option.

Under Sample ID Function:

The sample identifier (S ID) can be activated for each printout by selecting the g

button.

t If you wish to print the sample ID, activate this option.

To enter and delete numbers and text, e.g., for the sample ID,

see “Entering Text and Characters” on page 24.

Operating Instructions Moisture Analyzer MA160

29

Page 30

System Settings (Setup Menu)

Info

Model Number MA160

Serial Number 0000000000

Version Balance 00-53-99.98 CN:1701

Version Display 01-80-99.38 CN:0000!

Version Heater 07-40-95.00 CN:0000

Identifier

Set Device ID

Batch ID

Sample ID

Batch ID function OFF

Anzahl Filter 1

Measurement

Start weight +0.809g

Start date 2014-05-06

Measurement time 00:09 min

Start time 10:21

Result 0.25 %M

Final weight +0.807g

Status Measurement canceled

Methods

Methods

You can define the sort order of the created methods in the menu and export the

created methods to or import them from an SD card.

Sort order

Export

Import

Under Sort order:

t Select the desired sort order of the methods in the menu.

– Last used: Sort by frequency of use. The most recently used methods are

– A-Z: Alphabetical sorting in ascending order.

– Z-A: Alphabetical sorting in descending order.

Under Export:

Export all existing methods to the SD card.

Under Import:

Import methods from the SD card. All of the methods on the analyzer are

overwritten in this case.

Results

Results

Overview

Export

Delete

The analysis results can be viewed, exported, or deleted here.

Under Overview:

The saved results can be viewed or printed by date here.

t Select the desired entry.

t To print the displayed result, select a.

Under Export:

t Select this option to export the results. The data is exported in XML format.

Under Delete:

t Select this option to delete all saved results.

You are prompted to confirm.

t To delete the results, select YES.

at the top.

Viewing Exported Data

You can open the data exported to the SD card as XML files with a browser and

RESULT

30

Operating Instructions Moisture Analyzer MA160

view it there. The file is then displayed in table format in the browser (see figure on

the left).

Page 31

Timeout Standby Temp.

System Settings (Setup Menu)

Timeout standby temp.

2

1

3

The timeout for the standby temperature can be set here.

t To set the time, select t, enter the desired time and confirm with l (entry in

hours from 1 h to 24 h).

USB Interface

USB port

Device / Protocol

RS232 Configuration

Decimal separator

Keyboard emulation

The settings for the data transfer to a peripheral device (such as a PC or printer) can

be defined here.

Depending on the cable and peripheral device connected to the moisture analyzer,

various options are available in the menu. The moisture analyzer automatically

detects the type of connection.

Sartorius order no.:

1)

Mini-B

YCC04-D09

Type-A

PC-SBI

PC spreadsheet format

PC text format

Off

USB Host

(Master)

Device / Protocol

PC spreadsheet format

PC - SBI

PC text format

Off

Printer equipment

2)

Mini-A Type-B

3)

Mini-A

supplied

Sartorius order no.:

YCC03-D09

RS 232

9-pin

Printer YDP30,

YDP40

Off

Printer YDP20-0CE

USB-RS 232 SBI

Off

There are several ways to connect the device via USB:

1) Connection to a PC via USB Cable (Mini-B to USB A)

Under Device/Protocol:

t Select the data format for the transfer to the PC.

– PC - SBI: Driver for PC required (CDC Virtual Com Port). The data is sent

via SBI protocol using a virtual serial interface. Additional information can

be found in Chapter “USB Interface”, section “Direct Transfer of Data (PC)”.

– PC spreadsheet format: The analyzer transmits the data via keyboard

command (keyboard emulation) to the currently opened application on the

PC in spreadsheet format.

– PC text format: The analyzer transmits the data via keyboard command

(keyboard emulation) to the currently opened application on the PC in text

format.

– Off: Data transmission is deactivated.

USB Device

(Slave)

Serial device

with 9-pin

SUB-D plug

Operating Instructions Moisture Analyzer MA160

31

Page 32

System Settings (Setup Menu)

Under Decimal separator (also available when “PC spreadsheet format” has been

selected):

– Decimal point (default setting): The number value is transmitted with a

decimal point to the PC program (example: 99.963 g).

– Decimal comma: The value is transmitted with a decimal comma to the PC

program (example: 99,963 g).

Under Keyboard emulation (also available when “PC spreadsheet format” or

“PC text format” has been selected):

– Universal (Num Lock on) (default setting): Data is sent as special keyboard

characters in ASCII format (ALT + number pad).

Requirement: Numbers lock must be turned on on the PC keyboard.

– English (USA): Data is sent according to a keyboard set to English (USA).

Requirement: For PC applications, such as MS Excel, the keyboard must be set

to English (USA).

You can find more information in Chapter “USB Interface”.

2) Connection to Sartorius Lab Printer via the Supplied Printer Cable

Under Device/Protocol:

t Select the desired setting for the connection to the printer.

– YDP30/YDP40: The connected printer is detected automatically and the

connection is established.

– Off: The connection to the printer is deactivated.

3) Connection to a Serial Printer or Another External Serial Device via a 9-pin

Serial Interface (USB Mini-A to RS-232)

Under Device/Protocol:

t Select the desired setting for the connection to the device.

– Printer YDP20-0CE

– USB-RS232 SBI

– Off: The connection is deactivated.

t Printer YDP20-0CE

Set the printer to the default setting: 1200 baud, 7 bits, odd parity,

1 stop bit, CTS/RTS handshake

32

Under RS232 Configuration:

This option can be selected if under Device/Protocol the setting USB-RS232 SBI

has been selected.

t Select the desired setting for the RS-232 interface.

– Baudrate: 600 to 19,200 (default setting: 9600)

– Databits: 7 bits or 8 bits (default setting: 8 bits)

– Parity: Odd, even, or none (default setting: odd)

– Stopbits: 1 bit or 2 bits (default setting: 1 bit)

– Handshake: Software (XON, XOFF), hardware (CTS, RTS), or off

[default setting: hardware (CTS, RTS)]

Operating Instructions Moisture Analyzer MA160

Page 33

Data Backup

System Settings (Setup Menu)

Data backup

Export settings

Import settings

This function can be used to create a data backup of all settings. An SD card must

be inserted for this function.

t Select the desired option and follow the instructions that appear on the display.

y During the export and import, the process is shown on the display.

Export settings

File: 1 of 1

CONFIG\

SETTINGS

y If the data backup is canceled, the menu appears again.

Import settings

File: 1 of 1

CONFIG\

SETTINGS

Protected Mode

Protected mode

Set password

Password

Please input new password twice.

The moisture analyzer is equipped with password protection to ensure that only

authorized persons can make changes to the system settings.

t To define a password, select Set password.

t Select t.

Operating Instructions Moisture Analyzer MA160

33

Page 34

System Settings (Setup Menu)

Passw. 1

12

45

78

0

Passw. 2

12

45

78

0

Password

Device has password protection.

t Enter a number as the password.

If you have made a mistake, you can correct your entry:

3

– k button: Delete individual characters in reverse order.

– C button: Delete all characters.

6

9

C

t Enter the same password again to check your entry.

t Confirm with l.

3

6

9

C

y The message “Device has password protection.” appears.

y The new password is only active once you have returned to the first level of the

menu.

Protected mode

Modify password

Delete password

t To change the password, select Change password.

t Enter the desired password and confirm with l.

t To delete the password, select Reset password and confirm with YES.

If you have forgotten the password, contact the Sartorius Service Center.

Service Mode/Service Access

This function is used by the Sartorius Service Center and can only be accessed by

Service access

Access code: xxxxxx

authorized service technicians.

34

Operating Instructions Moisture Analyzer MA160

Page 35

Restoring All Settings

All settings can be reset to the factory settings here.

t When the security prompt appears, select Yes, reset and confirm with l.

The moisture analyzer is reset and restarts.

System Settings (Setup Menu)

Operating Instructions Moisture Analyzer MA160

35

Page 36

Moisture Analysis

Moisture in %M

Start new measurement

Standard

End autom.

105 °C

Wednesday, April 2, 2014 16:50

Moisture Analysis

Purpose: The moisture analyzer can be used to determine the moisture content of liquid,

pasty, or solid samples.

Accessories: Depending on the consistency of the sample, one or two filters are recommended in

order to distribute the sample optimally in the sample pan.

– Liquid sample: Tare one filter with the sample pan, then distribute the sample

drop by drop onto the filter.

– Pasty sample: Tare two filters with the sample pan, then place the sample

between the two filters and press together evenly.

– Solid sample: Distribute the granulated sample evenly onto the sample pan

without a filter. Use one or two filters for solid samples that liquefy at high

temperatures or contain fat or sugar, in order to prevent crusting.

Danger of poisoning or caustic burns!

Substances that contain poisonous or caustic ingredients may produce poisonous

gases when dried, which can cause irritation (to the eyes, skin, or airways) or nausea

and lead to serious injury or death.

– These samples must only be dried in a laboratory hood.

Standard

Heating program Standard drying

105 °C

End Fully automatic

Initial weight Off

Result display Moisture in %M

Target value Off

Standby temperature Off

Number of filters 0

Print lines Off

Corrosion due to aggressive vapors!

Substances that emit aggressive vapors when heated may cause condensation to

form on cooler housing parts and lead to corrosion.

– Use small sample quantities of these substances.

Viewing and Changing Method Parameters

Before starting the moisture analysis, you can view the current parameters and

change them if necessary.

– You can predefine up to 100 separate methods. You can change and save the

parameters for each method to suit your requirements.

The most important parameters (method name, temperature, switch-off criterion)

are displayed.

t To check additional parameters, select the gray button at the bottom of the

main screen on the display.

y A summary of the current parameters is displayed.

If a lab printer is connected, you can print out the method parameters:

t Select the print symbol.

y The parameters are printed out.

t Select l to close the display.

t To change the parameters, select the menu key at the bottom left of the main

36

Operating Instructions Moisture Analyzer MA160

screen on the display.

Page 37

Moisture Analysis

Standard

Coffee creamer

Oats

Washing powder

Starch

105 °C

Fully automatic

100 °C

Fully automatic

80 °C

Fully automatic

85 °C

2 mg/24 sec

80 °C

2 mg/24 sec

y The menu is displayed.

t Select the M button in the menu.

t Select the desired method in the method menu.

Heating program

End

Initial weight

Result display

Heating program

End

Initial weight

Result display

Customize parameters

Standard drying

105 °C

Fully automatic

Off

Moisture in %M

Customize parameters

Standard drying

105 °C

Fully automatic

Off

Moisture in %M

y The current method parameters are displayed.

t Select the parameter you wish to change, such as “Heating program.”

Heating program

Type Temperature [°C]

Standard drying

Gentle drying

110

85

125

t Set the parameters to suit your requirements.

Select t if necessary and enter the desired values (see section “Entering

Numbers on the Number Pad” in Chapter “Operating the Moisture Analyzer”).

t Select l to confirm.

Operating Instructions Moisture Analyzer MA160

37

Page 38

Moisture Analysis

0

D

Initial weight Off

Result display

Target value

Standby temperature

Number of filters

Customize parameters

Moisture in %M

Off

Off

Save changes

Temperature: 110 °C

Initial weight: On

Target value: On

Wednesday, April 2, 2014 16:50

Moisture in %M

Start new measurement

Standard

105 °C

End autom.

t Scroll through the list if necessary and change further parameters.

t When you are finished making changes, select o.

y The changed method parameters are displayed.

t Select the desired option:

– Make further changes: Select <. This takes you back to the list of

parameters.

– Reject changes: Select NO.

– Save changes: Select YES.

NOYES

y The menu is displayed.

t To return to the main screen, select k.

Performing the Moisture Analysis

When all parameters have been set to suit your requirements, you can start the

moisture analysis.

Observe the following instructions in order to ensure successful measurement:

– Wear gloves for each measurement, so that the liquid in the sample is not

influenced by handling.

– Remove the sample directly from the process or keep it in an airtight and

watertight container until measurement.

– Ensure that the sample is representative for the product and is homogeneous

(shake, stir, or mix before measurement).

– If using a filter or filters, store the filters in airtight and watertight packaging.

t Select START on the main screen or open the hood.

If you selected START on the main screen:

38

Open hood

0.000 g

Operating Instructions Moisture Analyzer MA160

t Open the hood now.

y The next step is displayed when the hood is opened.

Page 39

Moisture Analysis

D

D

;

;

;

Place pan and two filters,

close hood for taring

t Place an empty sample pan on the analyzer, along with one or two filters if

necessary.

The number of filters depends on how many filters are set in the parameters for

+ 4.000 g

the current method.

t Close the hood.

y The moisture analyzer tares automatically.

Open hood

0.000 g

Fill in sample

- 0.000 g

t Open the hood.

t Place the sample on the sample pan or filter(s).

Fill in sample

+ 1.929 g

2.000

Close hood to start

y If you have activated the “Initial weight” option in the method parameters,

a target value display appears.

t Add the sample to the sample pan slowly. When the sample quantity reaches

the preset range, the target value display turns green.

t Close the hood.

y The moisture analysis starts automatically.

+ 1.929 g

2.000

During the measurement, the process status light on the analyzer flashes,

if the light has not been switched off in the menu.

Operating Instructions Moisture Analyzer MA160

39

Page 40

Moisture Analysis

n

n

y The current measurement value and progress are shown on the display during

the moisture analysis.

Standard

Standard

i

Measurement completed

65.00 %M

67.50 %M

67.00 %M

+

11:18 min

67.53 %M

67.50 %M

09:41 min

110 °C

End autom.

09:41 min

110 °C

End autom.

– If a target value is set, the measurement process is displayed as a bar diagram.

The target value is marked and tolerance limits are displayed.

– If no target value is set, the measurement process is displayed as a curve

diagram.

The following information is also shown on the display:

– Information bar at the top right: measurement time expired

– Function bar below: method name, target temperature, switch-off criterion

t To cancel the moisture analysis before it is finished: Select <.

y When the moisture analysis is finished, the moisture content of the sample is

shown on the display.

The process status light on the analyzer flashes three times and then goes out.

– If a target value is set, the moisture content is displayed as a bar diagram.

– Bar is green: Result is within the tolerance limits.

– Bar is red: Result is not within the tolerance limits.

– Bar is orange: Measurement was canceled.

Standard

i

Measurement completed

Standard

110 °C

End autom.

85.15 %M

110 °C

End autom.

OK New

11:18 min

OK New

– If no target value is set, the moisture content is displayed as a curve diagram.

t Select the desired option:

– to perform another moisture analysis using this method:

Select NEW.

– To view the report and print it out if desired: Select n.

– To exit the measurement: Select OK.

40

Operating Instructions Moisture Analyzer MA160

Page 41

Printing Out the Analysis Report

a

If a lab printer is connected, you can print out the result of the moisture analysis.

Moisture Analysis

The settings for the analysis report can be configured in the system settings

t Select a.

y The analysis report is printed out.

(see section “Printout” in Chapter “System Settings”).

Further information and an example of an analysis report can be found in

Chapter “ISO/GLP-compliant Printout”.

Removing a Sample

Danger of burns due to hot sample pan!

The sample and sample pan may be very hot.

– Do not touch the sample pan.

– Use sample forceps (included in delivery) to remove the sample.

Remove sample

Remove the old sample from the sample

chamber.

y When you have exited the measurement by selecting OK, you can remove the

sample from the moisture analyzer.

t Open the hood.

t Remove the sample pan from the moisture analyzer using sample forceps.

t Close the hood.

t Allow the sample to cool down and dispose of it properly.

Operating Instructions Moisture Analyzer MA160

41

Page 42

Moisture Analysis

Creating and Managing Methods

You can predefine up to 100 separate methods. You can change and save the

parameters for each method to suit your requirements.

A wizard for creating new methods is provided to guide you through the process

step by step. You can create methods manually or import them from an SD card.

Opening the Method Menu

t Select the menu key at the bottom left of the main screen on the display.

Standard

Coffee creamer

Oats

Washing powder

Starch

105 °C

Fully automatic

100 °C

Fully automatic

80 °C

Fully automatic

85 °C

2 mg/24 sec

80 °C

2 mg/24 sec

y The menu is displayed.

The list displays all available methods.

t Select the M button in the menu.

+

Standard

Wood glue

Coffee creamer

Oats

Washing powder

105 °C

Fully automatic

110 °C

Fully automatic

100 °C

Fully automatic

80 °C

Fully automatic

85 °C

2 mg/24 sec

y The method menu appears.

This menu shows all created methods. Unavailable methods are marked in the

method menu with a H symbol.

t To leave the method menu: Select k.

Creating a New Method with the Wizard

To create a new method quickly and ensure that all relevant parameters have

been included, use the wizard: The wizard prompts you to configure all relevant

parameters, provides a practical range of options, and prevents you entering

implausible data.

42

t Select + in the method menu.

New method

Manual input

Assistant

Import

Operating Instructions Moisture Analyzer MA160

t Select Assistant.

Page 43

Moisture Analysis

qwer tzuiop

asdfgh jkl_

yxcvbnm- /

123

Ke

;

;

Method name

Enter name for new method

y The wizard appears.

First enter a name for the new method.

t Select t.

t Enter the desired name.

t Select l to confirm.

Result display

Select result display mode

In the next step, define how the result will be displayed:

t Select t.

Result display

Moisture in %M

Dry weight in %S

Atro in %M/S

Target value

Enter target value and tolerance for

moisture portion of this sample

t Select the desired option:

– Moisture in %M (% Moisture)

– Dry weight in %S (% Solids)

– Atro in %M/S (% Moisture/Solids)

t Select l to confirm.

y Then enter the target value and tolerance.

t Select t.

Operating Instructions Moisture Analyzer MA160

43

Page 44

Moisture Analysis

;

;

Target value

Target value [%M] +/- [%M]

2.00

50.00

90.00

Sample consistency

Enter consistency data of sample

Sample consistency

solid

fluid

pasty

0.20

0.10

0.50

t Select the desired target value and tolerance or press t and enter the values

using the keyboard.

t Select l to confirm.

y Then enter the sample consistency.

t Select t.

t Select the desired option:

– solid

– fluid

– pasty

t Select l to confirm.

Sample type

Sample type

Specify sample type

organic

inorganic

unknown

y In the last step, enter the sample type.

t Select t.

t Select the desired option:

– organic

– inorganic

– unknown

t Select l to confirm.

44

Operating Instructions Moisture Analyzer MA160

Page 45

Moisture Analysis

jkl_

y The method can then be tested.

Test the method

Method successfully created.

Would you like to test the method now?

Temperature: 105 °C

t Select the desired option:

– To test the method with the suggested temperature: Select YES. Moisture

analysis is then carried out with the set parameters (see „Performing the

Moisture Analysis“ on page 38).

– To save the method without testing: Select NO and then o to return to the

NOYES

+

Standard

Ketchup

Wood glue

Coffee creamer

Oats

105 °C

Fully automatic

110 °C

Fully automatic

110 °C

Fully automatic

100 °C

Fully automatic

80 °C

Fully automatic

y The newly defined method now appears in the method menu. It is not available

method menu.

yet and therefore marked with an H symbol.

Creating a New Method Manually

To define each parameter for a method yourself, create the method manually:

t Select + in the method menu.

New method

Manual input

Assistant

Import

Method name

Enter name for new method

Ke

qwer tzuiop

asdfgh

t Select Manual input.

y First enter a name for the new method.

t Select t.

t Enter the desired name.

t Select l to confirm.

yxcvbnm- /

123

Operating Instructions Moisture Analyzer MA160

45

Page 46

Moisture Analysis

New method

Method name Ketchup

Heating program

End

Initial weight

New method

Method name Ketchup

Heating program

End

Initial weight

Save new method

Method name: Ketchup

Type: Standard drying

Temperature: 110 °C

End: Fully automatic

Initial weight: Off

Standard drying

105 °C

Fully automatic

Off

Standard drying

105 °C

Fully automatic

Off

y The new method is created and displayed with the default parameters.

t Select the parameters you wish to change and configure the desired settings.

t Scroll through the list if necessary and change further parameters.

t Select l to confirm.

y The parameters of the new method are displayed.

You can scroll through the list to view all parameters.

t Select the desired option:

– To change further parameters: Select <. This takes you back to the list of

parameters.

– To discard the new method: Select NO.

NOYES

– To save the new method: Select YES.

+

Standard

Ketchup

Wood glue

Coffee creamer

Oats

105 °C

Fully automatic

110 °C

Fully automatic

110 °C

Fully automatic

100 °C

Fully automatic

80 °C

Fully automatic

y The newly defined method now appears in the method menu. It is not available

yet and therefore marked with an H symbol.

46

Operating Instructions Moisture Analyzer MA160

Page 47

Moisture Analysis

Importing Methods from an SD Card

You can import a new method from an SD memory card.

t Insert the SD card containing the desired method into the SD card slot on the

analyzer.

t Push the SD card into the slot as far as it will go.

To remove the card, press it against the resistance in the direction of the slot so

that the card springs out.

t Select + in the method menu.

New method

Method name Coffee

Heating program

End

Initial weight

New method

Manual input

Assistant

Import

Import

Grain coffee

Coffee

Cocoa powder

Potato flakes

Standard drying

85 °C

Fully automatic

Off

t Select Import.

y The list of methods on the SD card is displayed.

t Select the desired method from the list.

y The method is imported as a new method.

y The parameters of the method are displayed.

If the moisture analyzer’s memory already contains a method with the same

name, a message appears, indicating that the imported method must be

renamed.

t To accept the imported method, select l.

Save new method

Method name: Coffee

Type: Standard drying

Temperature: 85 °C

End: Fully automatic

Initial weight: Off

y The parameters of the new method are displayed.

t To save the method, select YES.

y The imported method now appears in the method menu.

NOYES

Operating Instructions Moisture Analyzer MA160

47

Page 48

Moisture Analysis

Testing Methods

Evaluation

Result is within the tolerance range

Result: 85.15 %M

Target value: 85.00 %M

Tolerance range: 84.50 %M - 85.50 %M

Are you satisfied with this result?

y If the target value and initial weight options are activated, the measurement/

method is evaluated and the result of the evaluation is displayed.

t Select the desired option:

– If you are satisfied with the result, select YES. You can then unlock the

method.

– If you are not satisfied with the result: Select NO and run the test again.

NOYES

t Select the desired option:

Test the method

Method successfully created.

Would you like to test the method now?

Temperature: 105 °C

– To test the method with the suggested temperature: Select YES. Moisture

analysis is then carried out with the set parameters (see „Performing the

Moisture Analysis“ on page 38).

– To save the method without testing: Select NO and then o to return to the

method menu.

NOYES

Unlocking Methods

+

Standard

Ketchup

Wood glue

Coffee creamer

Oats

105 °C

Fully automatic

110 °C

Fully automatic

110 °C

Fully automatic

100 °C

Fully automatic

80 °C

Fully automatic

Methods must be unlocked (available) before they can be used.

Unavailable (locked) methods are marked in the method menu with an H symbol.

t Select the method you wish to unlock.

Method name Ketchup

Heating program

End

Initial weight

Customize parameters

Customize parameters

Print

Test

Release

Delete

Standard drying

110 °C

Fully automatic

Off

y The parameters of the method are displayed.

t Scroll all the way to the bottom.

t Select Release.

48

Operating Instructions Moisture Analyzer MA160

Page 49

Moisture Analysis

t Select RELEASE to confirm.

Release method

Would you really like to release the

“Ketchup” method?

RELEASE

+

Standard

Ketchup

Wood glue

Coffee creamer

Oats

105 °C

Automatic

110 °C

Automatic

110 °C

Automatic

100 °C

Automatic

80 °C

Automatic

y The unlocked method is then displayed in the method menu without an H