Sartorius LP Models Operating Instructions Manual

1

Getting Started

Sartorius Master

pro

Series

LP Models

Electronic Precision Balances

Operating Instructions

98648-006-26

2

Intended Use

The Master

pro

Series from Sartorius

offers precision balances with

capacities ranging from 1 to 64 kg

for measurement of mass. A broad

range of special performance

features make the Master

pro

balances

ideal for use as measuring and test

equipment in ISO or GLP quality

management systems. These features

include:

– Fully automatic self-calibrating

and adjustment function, isoCAL

(time- and temperature-dependent)

– reproTEST for quick determination

of the standard deviation to check

the reproducibility of results

– ISO/GLP-compliant recording

capability for printouts

– Password-protected menu lock

Master

pro

balances meet the highest

requirements on the accuracy and

reliability of weighing results through

the following features:

– Efficient filtering-out of vibration

– Stable and reproducible results

– Excellent readability under any

lighting conditions

– Rugged, durable weighing system

Master

pro

balances save

work and speed up simple routine

applications through:

– Ultrafast response times

– Built-in applications

(counting, animal weighing,

weighing in percent, etc.)

– Automatic initialization when you

switch on the balance

– Easy input of alphanumeric

sample, lot and balance IDs

– Flexible, easy-to-use display and

control unit

– Connectivity for control through

an on-line computer

Contents

Intended Use .............................2

Contents .................................. 2

Warnings and

Safety Precautions ..................... 2

Operating Design ...................... 3

Getting Started ......................... 5

Configuring the Balance

Setting the Language ............. 10

’Info’ Display ........................ 10

Entering User Data (Input) ....... 11

Setting Parameters (Menu) ...... 14

Operating the Balance

Basic Weighing Function........ 21

Calibration/Adjustment .......... 24

ReproTEST ........................... 30

Application Programs

Toggle between

Weight Units ........................ 31

Counting ............................. 33

Weighing in Percent .............. 36

Net-Total Formulation ............. 40

Animal Weighing.................. 42

Checkweighing .................... 46

Recalculation ........................ 51

Data Output Functions ............ 56

Pin Assignment Chart ............. 68

Cabling Diagram .................. 69

Additional Functions .............. 70

MP8 Interface Emulation ......... 72

Error Codes ............................ 73

Care and Maintenance............. 75

Instructions for Recycling .......... 76

Overview

General Views

of the Balances ..................... 77

Description of the Keys ........... 80

Menu Structure ..................... 81

Specifications ....................... 82

Accessories (Options)............. 88

Declaration of Conformity ....... 90

EC Type-Approval Certificates .. 93

Plates and Markings .............. 96

Index .................................. 97

Appendix

Entering the User Password

Warnings and

Safety Precautions

This balance has been constructed

in accordance with the European

Directives as well as international

regulations and standards for

operation of electrical equipment,

electromagnetic compatibility, and

stipulated safety requirements.

Improper use or handling, however,

can result in damage and/or injury.

Read these operating instructions

thoroughly before using your

balance to prevent damage to the

equipment. Keep these instructions

in a safe place.

Follow the instructions below

to ensure safe and trouble-free

operation of your balance:

! Do not use this balance

in a hazardous area/location

! Make sure that the voltage rating

printed on the AC adapter is

identical to your local line voltage

– The only way to switch the power

off completely is to disconnect the

AC adapter

– Type of protection for the housing:

– LP64001S, LP34001S,

LP16001S, LP34001P and

LP34000 meet IP44

requirements

– Additional balances with a

readabilty ≥ 1 mg comply

with IP54

– AC adapters meet IP20

requirements

– Protect the AC adapter from

contact with liquid

– Connect only Sartorius accesso-

ries and options, as these are

optimally designed for use with

your Master

pro

balance

When cleaning your balance,

make sure that no liquid enters the

balance housing; use only

a slightly moistened cloth to clean

the balance.

Do not open the balance housing.

If the seal is broken, this will result in

forfeiture of all claims under the

manufacturer’s warranty.

In case you have any problems with

your balance:

k contact your local Sartorius

office, dealer or service center

3

Getting Started

Operating Design

The balances in the Master

pro

Series consist of a weighing cell

and a display and control unit.

In addition to the choice of power

supply (via AC adapter or external

rechargeable battery pack), your

balance also has an interface port

for connecting a printer, computer or

universal remote control switch.

The display and control unit and the

weighing cell can be set up

separately. Operation of Master

pro

balances follows a uniform

“philosophy” which is described in

this manual.

Keys

The functions used most often

are assigned to their own specific

keys. There are additional

keys for assignment of other (multiple)

functions, in some cases

dependent on the current operating

status (so-called “soft keys”).

Each key is described in detail in

the chapter entitled “Overview.”

Normal Operation

In the operating mode, these four

keys function as c, q, w and

v keys.

Setup Mode

In the setup mode, these keys

take on the function of arrow keys

(x y Y X).

Soft Key Mode

The ‘soft key’ functions depend on

the current operating status; the

current function is indicated in the

text line of the display. In this

example, the soft keys are used to

access Info, Menu and Input

functions.

info--menu--input

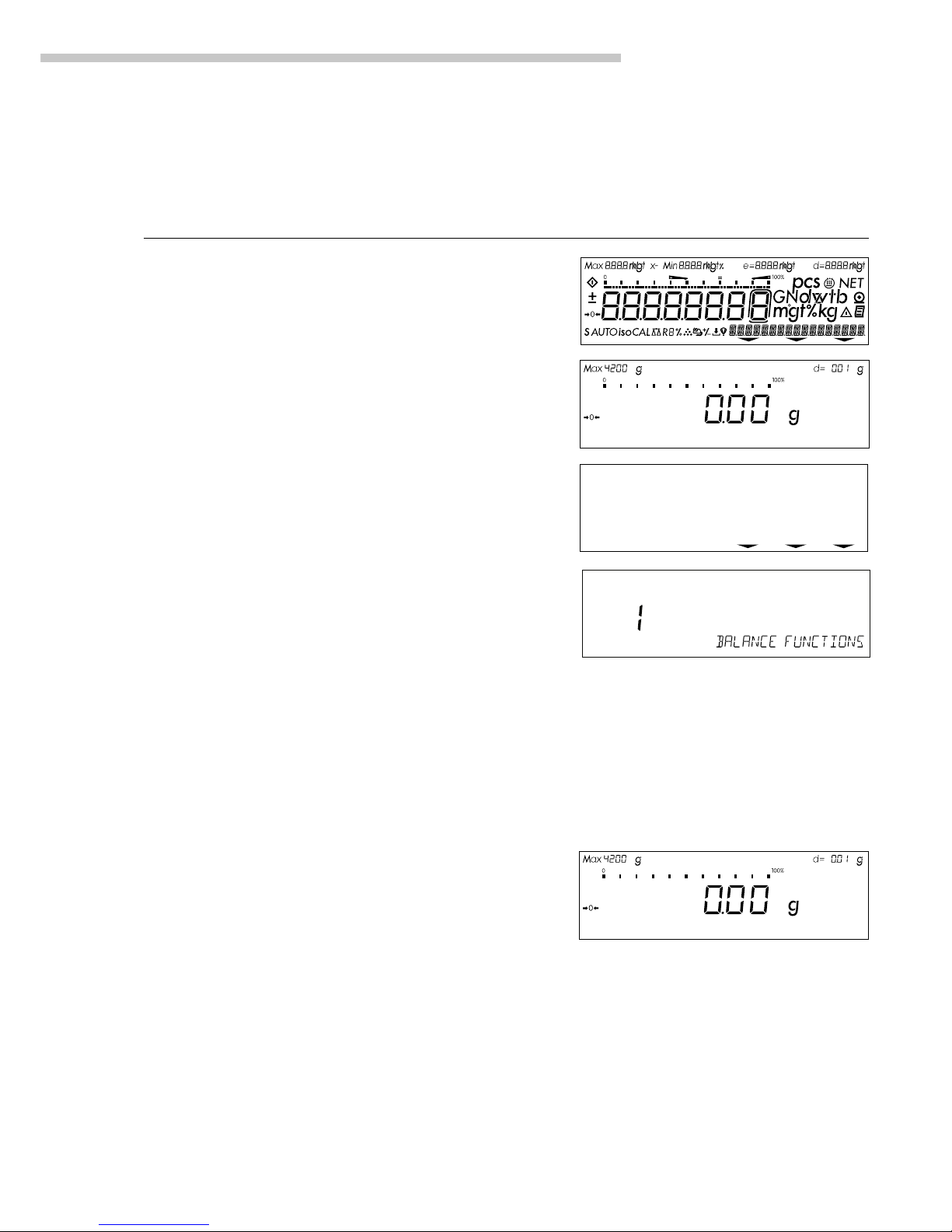

Display

The display is divided into six

sections:

– Line for metrological data:

Metrological specifications of the

weighing platform.

Max ...g d=...g

Display during use as a legal

measuring instrument:

Max ...g Min ...g e=...g d=...g

– Bar graph: Display in percent of

the weight on the balance relative

to the maximum capacity and for

over/under checkweighing

– Measured value line:

Display of weight readout or

alphanumeric input

Important Note Concerning

Verified Balances Approved for

Use as Legal Measuring

Instruments in the EU*:

For verified balances that have

a verification scale interval “e”

which is greater than the scale

interval “d,” the last digit on the

display is bordered.

– Weight unit display:

Weight unit, other unit of measure,

operating information

The G symbol indicates nonverified weight values.

– Symbol display:

Indicates operating status;

application selected

– Text line: Prompts for operator

guidance, soft key designations

See the “Data Output” section

in the chapter entitled “Operating

the Balance” for a detailed

description of the information

displayed in each of these sections.

* including the Signatories of

the Agreement on the European

Economic Area

Operating Design

4

Input

Numeric Input

To enter numbers:

Press the 1 2 … 0 . keys

To store numbers entered:

Press the soft key

To interrupt/cancel numeric input:

Press c

Alphabetic Input

To enter letters:

First press the a key, then press

a letter soft key (Y or y)

repeatedly until the desired letter

or special character is displayed in

the text line

To store a word entered:

Press the soft key

To interrupt/cancel alphabetic input:

Press c

Configuring Balance Operating

Parameters

To set parameter options for

configuring your balance, you can

select the desired parameters from

a list. The lists of parameter options

comprise a menu, which has

three levels.

For configuration functions:

Press the M key; then press the

menu soft key

To move within a menu level:

Press Y or y

To change to another menu level:

Press x or X

To confirm the selected parameter

setting in the 3rd menu level:

Press X

“o” indicates the currently set

parameter

Additional information is displayed

in the text line. See the chapter

entitled “Configuring the Balance”

for a detailed description of all

parameter settings.

To save setting and exit menu:

Press M

To interrupt the parameter setting

process without saving changes:

Press e

Data Output

Your Master

pro

balance is equipped

with a data interface for connecting

your choice of the following:

– Printer

– Peripheral device (e.g., computer)

– Universal remote control switch

Printer

You can configure the print

functions to meet your individual

requirements by selecting the

corresponding menu code.

You can have printouts generated

automatically, or by pressing p;

dependent on or independent of the

stability or time parameters; with

or without IDs; and as standard or

ISO/GLP-compliant printouts.

ISO: International Organization

for Standardization

GLP: Good Laboratory Practice

See the section on “Data Output

Functions” in the chapter entitled

“Operating the Balance” for

a detailed description of data output

options.

Interface Port

Instead of a printer, you may choose

to connect a different peripheral

device, e.g. a computer (PC). With

an on-line PC you can control both

the weighing cell and the display

unit of the Master

pro

balance.

Request messages are sent

via the interface to initiate functions

in the weighing cell and in the

display unit. Some of the functions

generate response messages.

See the section on “Data Output

Functions” in the chapter

entitled “Operating the Balance”

for a detailed description of the

interface port.

Error Codes

If you press a key that has no

function, or which is blocked

at a certain point in an application

program, this error is indicated

as follows:

– a double-beep is sounded as an

acoustic signal, and

– where necessary, a message is

displayed for 2 seconds in the text

line, after which the text line

returns to the previous display.

The response to an operator error

is identical in all models of the

Master

pro

series. See the chapter

entitled “Error Codes” for a detailed

description.

Storing Settings

Storing Parameter Settings

The settings configured are

stored in the balance’s non-volatile

memory. The most recent

parameter settings are active when

you switch on the balance.

Saving Parameter Settings

You can assign passwords

in order to block access to the

“Menu” and “Input” functions.

5

Getting Started

Getting Started

Warranty

Do not miss out on the benefits of our

full warranty. Complete the warranty

registration card, indicating the date

of installation, and return the card

to your Sartorius office or dealer.

Storage and Shipping

Conditions

Allowable storage temperature:

0 °C …+40 °C (+32°F …+104°F)

The packaging has been designed

to ensure that the balance will not be

damaged even if it is dropped from

a height of 80 centimeters (about

31 inches). Do not expose the

balance to extreme temperatures,

blows, shocks, vibration or moisture.

Unpacking the Balance

● After unpacking the balance,

check it immediately for any

visible damage as a result of

rough handling during shipment.

k If this is the case, proceed

as directed in the section on

“Safety Inspection” in the chapter

entitled “Care and Maintenance.”

It is a good idea to save the box

and all parts of the packaging until

you have successfully installed your

balance. Only the original packaging provides the best protection

for shipment. Before packing your

balance, unplug all connected cables

to prevent damage. The cardboard

strips between the display and

control unit and the weighing

platform are part of the protective

packaging for shipment!

LP balances with a capacity ≥ 16 kg

– Balance with display and

control unit

– AC adapter

– Weighing pan

Installation Instructions

The Sartorius Master

pro

balances

are designed to provide reliable

weighing results under normal

ambient conditions in the laboratory

and in industry. When choosing

a location to set up your balance,

observe the following so that you will

be able to work with added speed

and accuracy:

– Set up the balance on a stable,

even surface

– Avoid placing the balance

in close proximity to a heater or

otherwise exposing the balance to

heat or direct sunlight

– Protect the balance from

drafts that come from open

windows or doors

– Avoid exposing the balance

to extreme vibrations during

weighing

– Protect the balance from aggres-

sive chemical vapors

– Do not expose the balance

to extreme moisture

Conditioning the Balance

Moisture in the air can condense

on the surfaces of a cold balance

whenever it is brought into a substantially warmer place. If you transfer

the balance to a warmer area, make

sure to condition it for about 2 hours

at room temperature, leaving it

unplugged from AC power.

Afterwards, if you keep the balance

connected to AC power, the

continuous positive difference in

temperature between the inside

of the balance and the outside will

practically rule out the effects

of moisture condensation.

Equipment Supplied

The equipment supplied includes the

components listed below:

LP balances with a readability of 1 mg

– Balance with display and

control unit

– AC adapter

– Dust cover

– Shield disk

– Pan support

– Weighing pan

– Glass draft shield cylinder

– Draft shield cover

LP8200S, LP8200P, LP 6200S,

LP 4200S, LP 2200S, LP 820, LP 420,

LP 2200P, LP 5200P

– Balance with display and

control unit

– AC adapter

– Dust cover

– Pan draft shield

– Weighing pan

LP 12000S, LP 6200,

LP 4200, LP 2200, LP 12000P

– Balance with display and

control unit

– AC adapter

– Dust cover

– Weighing pan

Important Note Concerning

Verified Balances Approved for

Use as Legal Measuring Instruments in the EU*:

Provided that an official seal is

required for the verified balance,

a control seal is affixed to the

balance. This seal will be irreparably damaged if you attempt to

remove it. If the seal is broken,

the validity of the verification will

become void, and you must have

your balance re-verified.

* including the Signatories

of the Agreement on the European

Economic Area

6

Setting Up the Balance

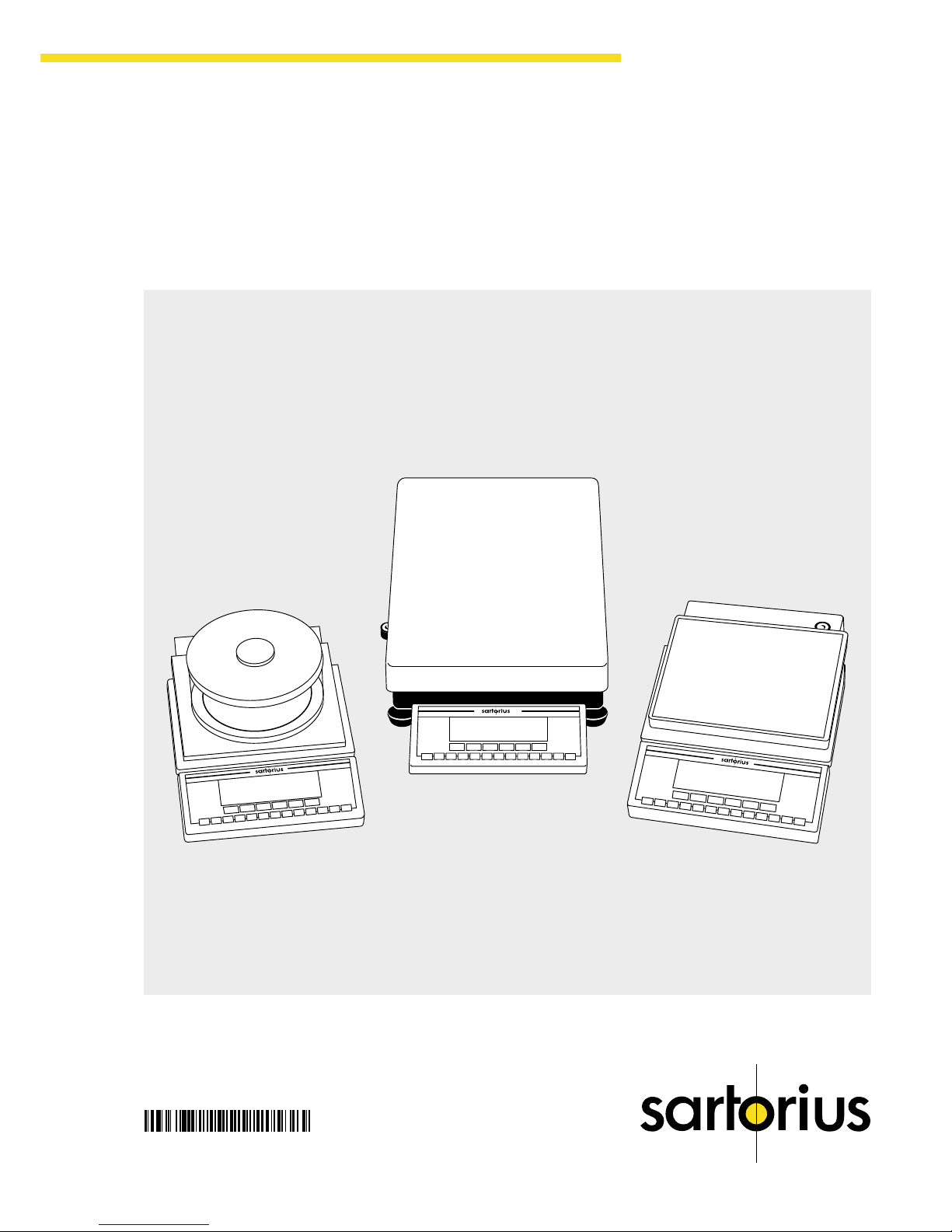

Preparing Balances with a Round Glass Draft Shield

● Place the components listed below on the balance in the order given:

– Dust cover

– Shield disk; turn counter-clockwise until it stops and is secured

– Pan support

– Weighing pan

– Glass draft shield cylinder

– Draft shield cover

Preparing Balances with a Rectangular Weighing Pan

and a Weighing Capacity ≤ 12 k g

● Place the components listed below on the balance in the order given:

– Dust cover

– Pan draft shield (depending on the model)

– Weighing pan

Preparing Balances with a Rectangular Weighing Pan

and a Weighing Capacity ≥16 kg

● Place the weighing pan on the balance

7

Getting Started

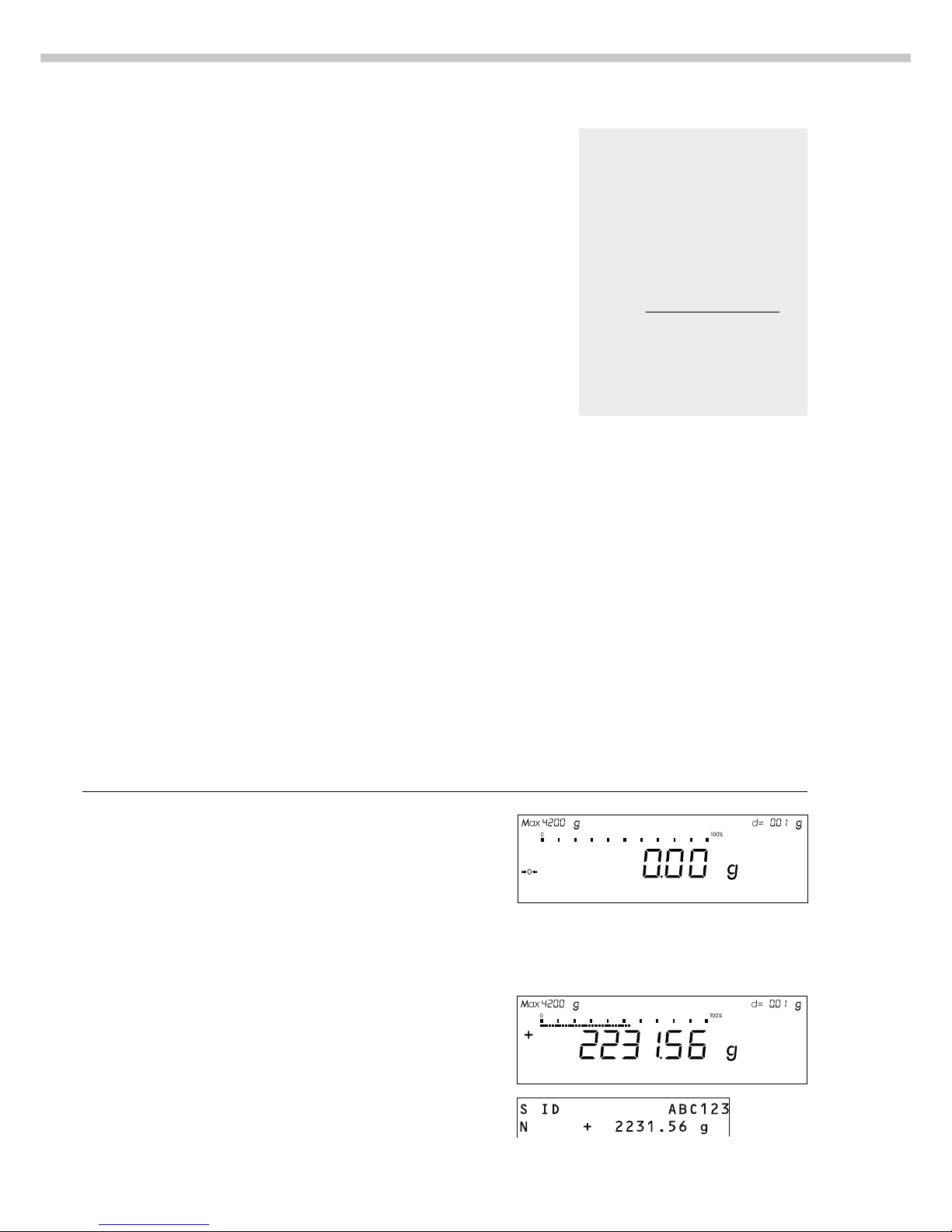

Separate Operation of the Display Unit

● Turn the balance upside down and lay it on a padded surface

to avoid damage to the weighing system.

● Use a screwdriver to remove the 2 screws from the display unit retainer

● Remove the display unit

> Cable lengths

– LP balances with a weighing capacity ≤ 12 kg: 55 cm

– LP balances with a weighing capacity ≥ 16 kg: 80 cm

k See the chapter entitled “Accessories” for information on longer cables

k If you wish to use a longer cable, it must be installed by an authorized

Sartorius service technician

Options for Mounting the Display Unit for a Balance with

a Weighing Capacity ≥ 16 kg

The display unit can be mounted as follows:

– on the short side of the weighing cell (factory mounting)

– on the back (long side) of the of the weighing cell

● Turn the weighing cell over

● Remove the fastening screws from the display unit retainer

● Remove the fastening screws from the plate that covers the cable raceway

(channel) and remove the plate

● Fasten the display unit retainer onto the back of the weighing

cell with the 2 Allen screws

● Thread the cable through the raceway and replace the cover plate

8

Connecting the Balance to AC Power

● Check the voltage rating and the plug design

– If they do not match the rating or standard you use,

contact your Sartorius office or dealer

Use only

– Original Sartorius AC adapters

– AC adapters with a registered approval rating from

a national testing laboratory

k To use a main feeder cable from the ceiling or to mount a CEE plug,

you will have to make arrangements inside your facilities to have this

equipment installed

k See the “Accessories” for information on using an IP65-protected

industrial AC adapter or an external rechargeable battery pack with

your balance

● Insert the right-angle plug into the jack and tighten the screws

● Then plug the AC adapter into a wall outlet (mains)

Safety Precautions

The AC adapter rated to Class 2 can be plugged into any wall outlet

without requiring any additional safety precautions. The ground or

earth terminal is connected to the balance housing, which can be additionally

grounded, if required. The data interface is also electrically connected

to the balance housing (ground).

Information on Radio Frequency Interference

Warning!

This equipment generates, uses and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction manual, may cause

interference to radio communications. It has been tested and found to comply

with the limits for a Class A computing device pursuant to Subpart J of Part 15

of FCC Rules, which are designed to provide reasonable protection against

such interference, when operated in a commercial environment. Operation of

this equipment in a residential area is likely to cause interference, in which

case the user, at his own expense, will be required to take whatever measures

may be required to correct the interference.

Connecting Electronic Peripheral Devices

● Make absolutely sure to unplug the balance from AC power

before you connect or disconnect a peripheral device (printer or PC)

to or from the interface port.

Warmup Time

To deliver exact results, the balance must warm up for at least 30 minutes

after initial connection to AC power or after a relatively long power outage.

Only after this time will the balance have reached the required operating

temperature.

Using Verified Balances as Legal Measuring Instruments in the EU*

The balance must warm up for at least 24 hours after initial connection

to AC power.

* including the Signatories of the Agreement on the European Economic Area

9

Getting Started

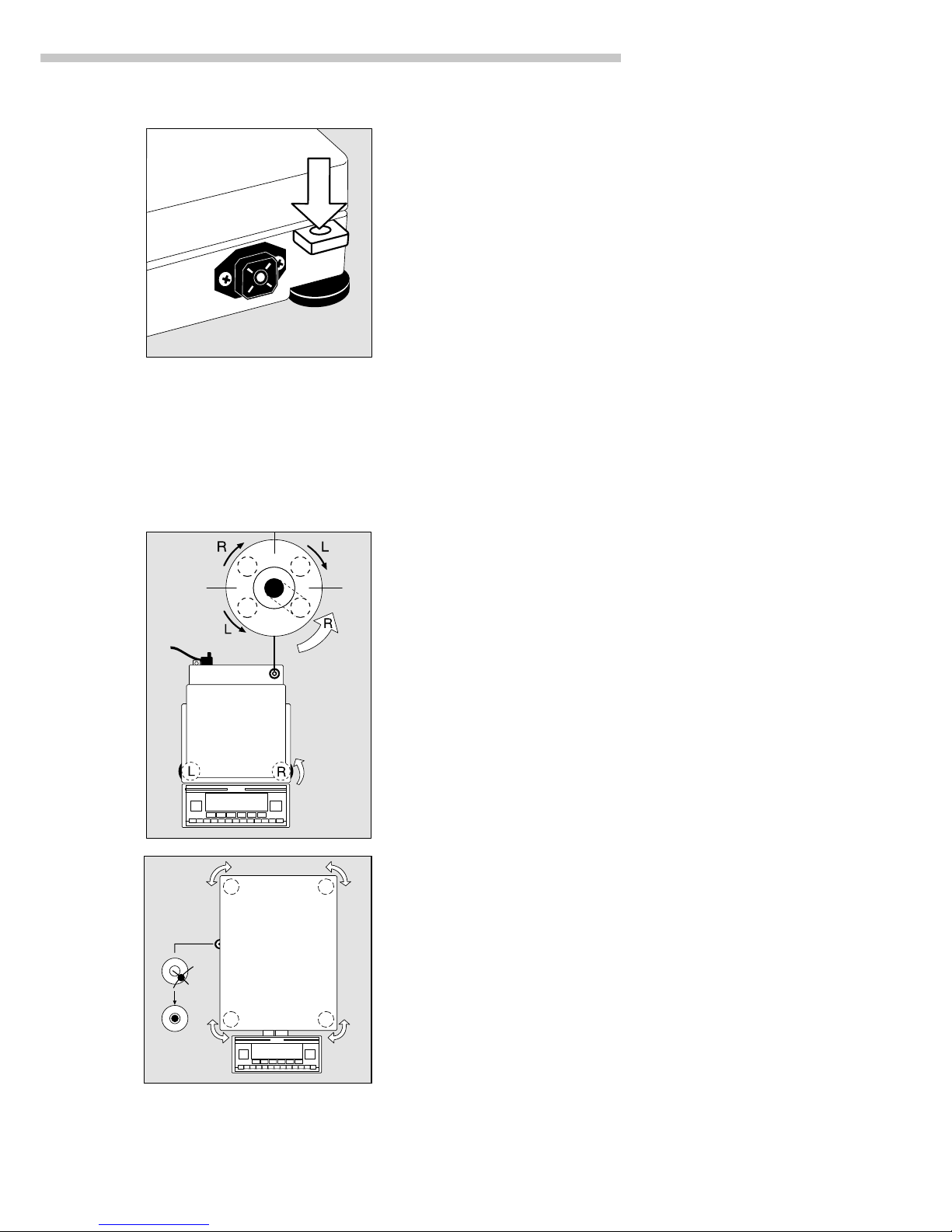

Fastening an Antitheft Locking Device:

Balances with a Weighing Capacity of 12 kg

To fasten an antitheft locking device, use the lug located

on the rear panel of the balance.

● Secure the balance at the place of installation, e.g.,

with a chain or a lock.

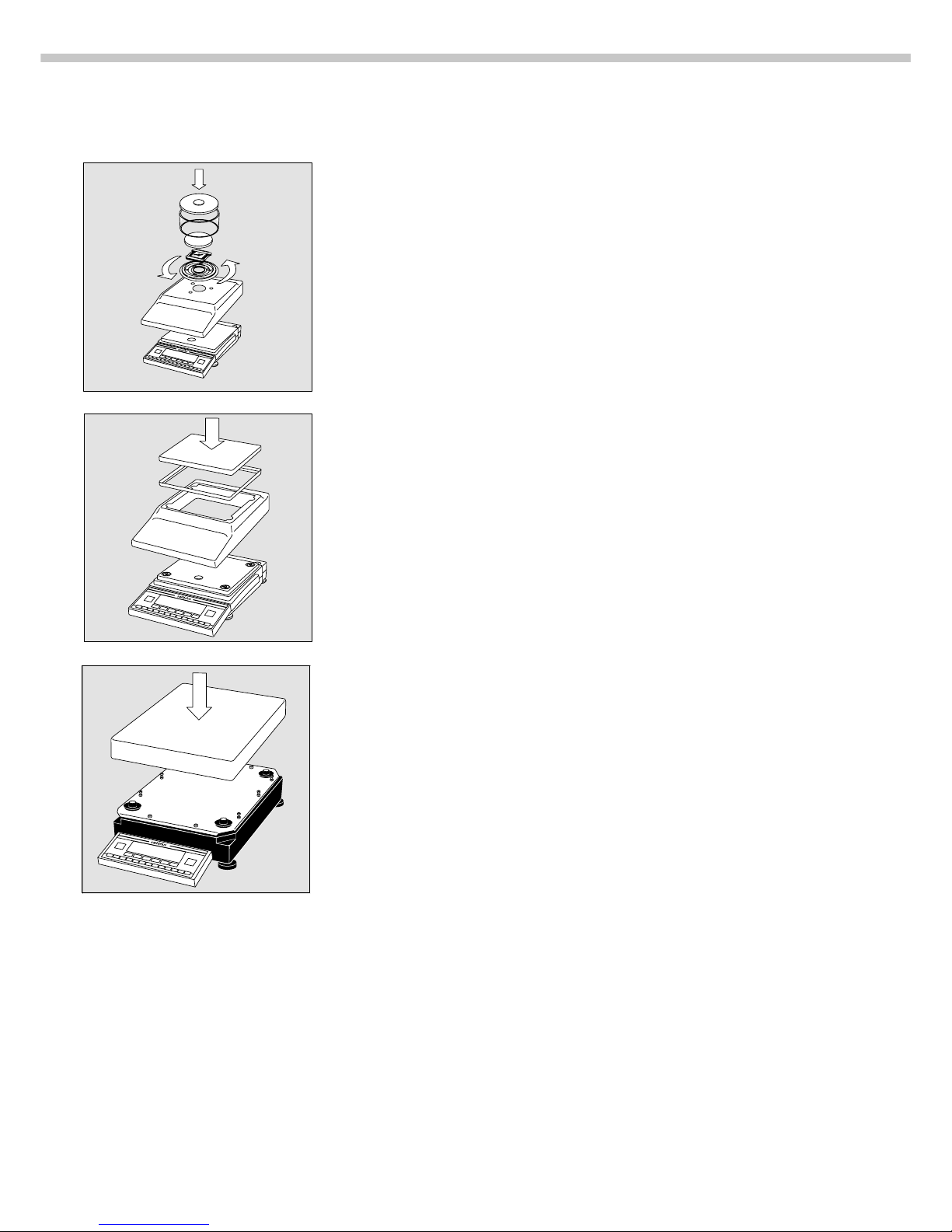

Leveling the Balance

Purpose:

– To compensate for unevenness at the place of installation

– To achieve perfectly horizontal positioning of the balance

for consistent reproducibility

Always level the balance again any time after it has been moved.

Leveling Balances with a Weighing Capacity ≤12 k g

Only the 2 front feet are used for leveling.

● Retract the 2 rear feet

● Turn the 2 front feet as shown in the diagram until the air bubble

is centered within the circle of the level indicator

> Several leveling steps are usually required.

● For weighing heavy samples:

Extend the 2 rear feet until they touch the surface on which the

balance rests

Leveling Balances with a Weighing Capacity ≥16 kg

● Adjust the four leveling feet until the air bubble is centered

within the circle of the level indicator

10

Configuring the Balance

Purpose

You can configure your Master

pro

balance to meet individual

requirements by entering user data

and setting parameters in the Setup

menu. You can also configure the

display to show balance-specific

information (such as the serial no.).

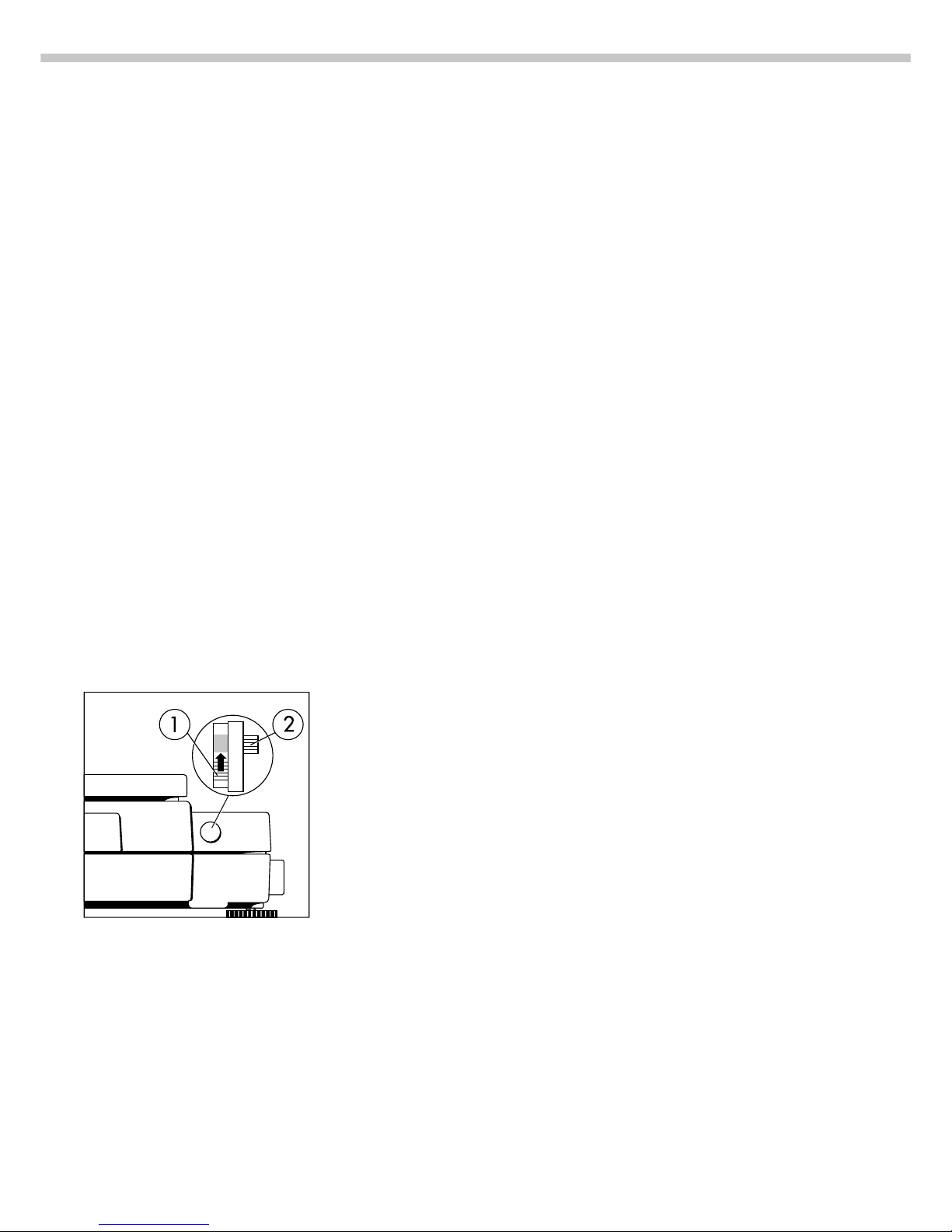

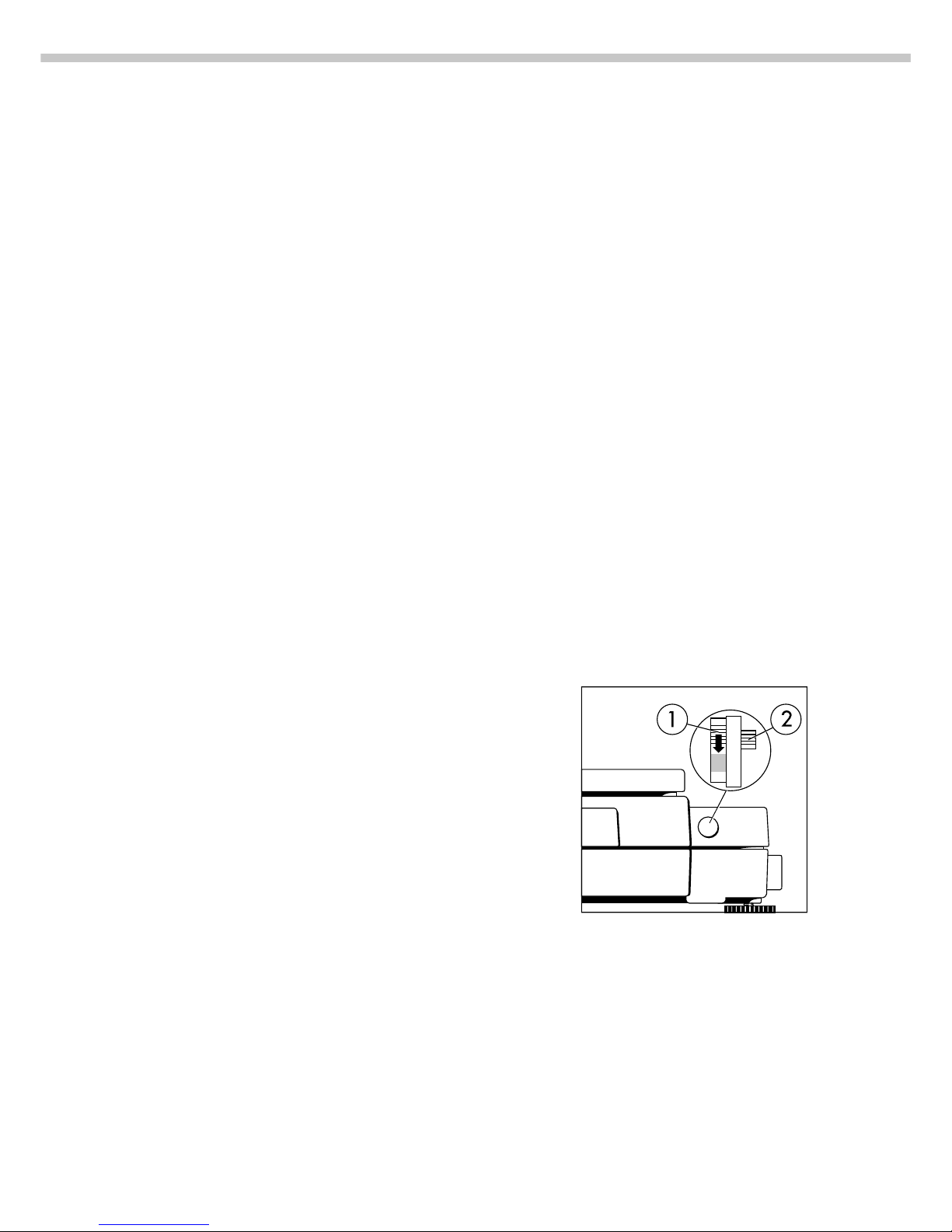

Setting the Function Switch for Using

the Balance in Legal Metrology

To use the balance in legal

metrology, the following functions

must be activated by setting the

switch as described below:

– Display: Verification scale interval e;

lower weighing range limit:

Min

– External calibration/adjustment:

Blocked

– MP8 interface emulation active

Preparation

● Remove the covering plate from the

back of the balance housing

● Move switch 1 in the direction of

the arrow

> Switch up:

external calibration blocked

Switch down:

external calibration accessible

> Note:

Do not move Switch 2

Setting the Language

Available Features

You can choose from 5 languages

for the information display:

1German

2 English (factory setting)

3 English with U.S. date/time

format

4 French

5 Italian

6 Spanish

Selecting the Language

● Enter the corresponding number

● Press M

’Info’ Display

Purpose

To have information about the

equipment displayed.

Features

You can have the following

information displayed:

– Program version number

for the display and control unit

– Program version

for the weighing cell

– Balance model

– Serial number of the weighing cell

Display Balance Information

● Select the Setup menu:

Press M

● Select information:

Press the info soft key q

> Readout in measured value line:

Version number of the display and

control unit (see also “Data Output

Functions,” pages 56–57, in the

chapter entitled “Operating the

Balance”)

k Select next item of information:

Press Y

> Readout in measured value line:

Next information

k Select previous information:

Press y

> Readout in measured value line:

Previous information

k Print information: Press p

> Printout (example)

Mod. LP6200S

Ser. no. 60406906

Ver. no. 01-30-13

Software version

(display and control unit)

Ver. no. 00-20-07

Software version

(weighing platform)

● Exit the Setup menu:

Press M

> Balance returns to previous status

11

Configuring the Balance

Entering User Data (Input)

Purpose

To display, input or change user

data. You can block access to these

data by assigning a password.

Features

You can display, input or change

the following user data:

– Workstation number* for the

balance: ID (balance ID; max.

20 characters)**

– Weighing series number, to

designate a series or lot:

L ID (lot ID; max. 20 characters)**

– Weight set number for calibration/

adjustment: W ID (weight ID;

max. 14 characters)**

– Exact weight value for calibra-

tion/adjustment of the balance

(see the section on “Calibration/

Adjustment,” starting on page 24

in the chapter entitled “Operating

the Balance; in particular refer

to page 27)

– Password for access to the Setup

menu: Input and Setup:

Menu (max. 8 characters)**

*** Only in conjunction with

ISO/GLP-compliant printouts

(see the section on “Setting

Parameters” in the chapter

entitled “Configuring the

Balance;” under menu code

number 8 10 x).

** A decimal point is displayed

together with its preceding digit

or character; it does, however,

count as a separate character.

This also applies when you

enter S ID and NUM as well

as to data entered via the

interface.

*** To delete user password:

Enter a decimal point using the

. key and confirm

Factory Settings

Password: No designation

If no password has been assigned,

anyone can access the “Setup:

Input” and “Setup: Menu” functions

without entering a password.

If you assign a password and then

forget what the word is, you can use

the General Password (see Appendix)

to access these menus.

Preparation

Display existing user data

● Select the Setup program:

Press M

> The soft keys Info, Menu and

Input are displayed in the text

line

● Select the user data input function:

Press the Input softkey v

> The password prompt is displayed

k If access is blocked by

a password: enter the password

using the alphanumeric input keys

● Display user data:

Press the enter passw.

soft key v

> The last 8 digits of a workstation/

balance number (ID no.), if

any ID is assigned, are displayed

in the measured value line

Enter/Change Password

● Select the Setup menu:

Press M

> The soft keys Info, Menu and

Input are displayed in the text

line

● Select the user data input function:

Press the Input soft key v

If you have already assigned

a password:

> The password prompt is displayed

k Enter the password

k Press the enter passw.

soft key v

● Write down the password here:

Password = .............................

If you no longer remember the

password assigned:

k Enter the General Password

(see Appendix)

k Press the enter passw.

soft key v

> The last 8 digits of a workstation/

balance number (ID no.), if any ID

is assigned, are displayed in the

measured value line

● Select password setting: Press y

> Password is displayed

in the text line

> If a password exists, it is now

displayed in the measured value

line

● New password: Enter the letters/

numbers for the new password

(8 characters max.)**

The password “none” means that

no password is stored.***

● Confirm input: Press X

● Exit the Setup menu:

Press M

> Restart the application

12

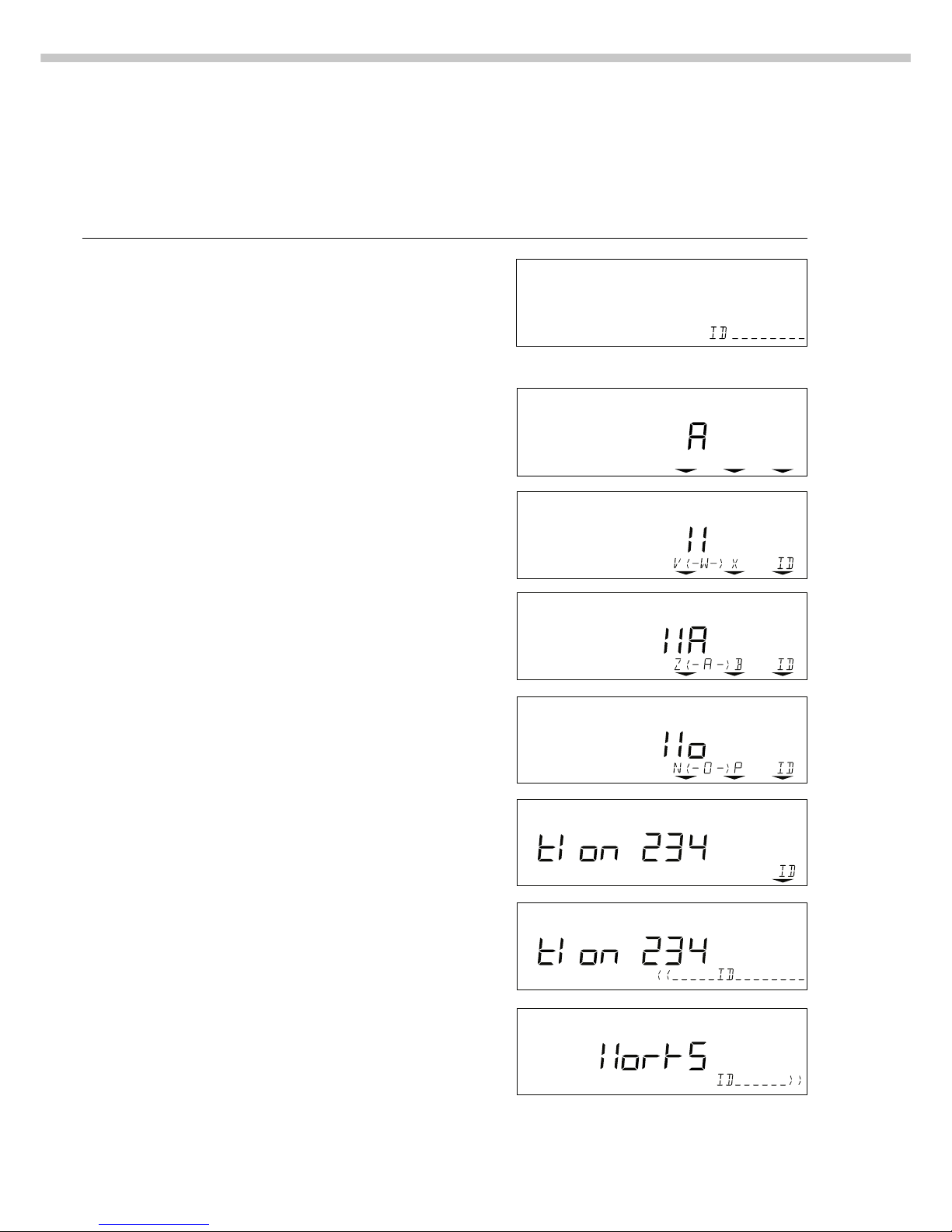

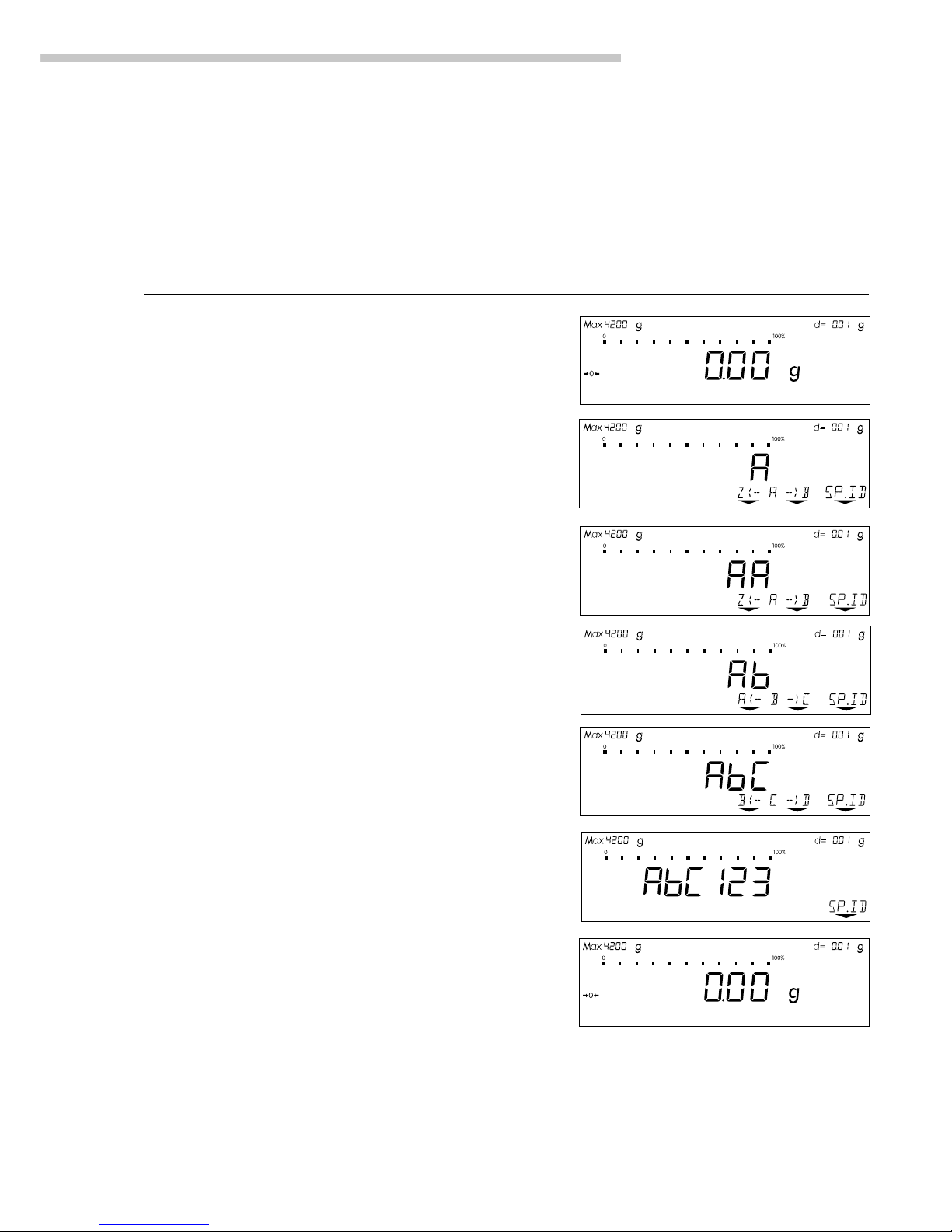

Practical Example

Enter “Workstation 234” as Balance ID; Display and Print Other User Data

Step Key (or instruction) Display/Output

1. Select Setup menu, then Input; see Preparation

Display balance workstation ID (in

this example: no ID number exists)

2. Enter the first letter of the balance a 13th through 20th digits of ID displayed

workstation ID

3. Set the letter “W” y repeatedly, until the W

is in the middle

4. Enter the next letter of the balance a

workstation ID

5. Select the letter “o” Y repeatedly

6. Repeat steps 4 and 5 with a x X

the appropriate letters (display

“longer” values: see “Data Output

Functions” on page 57)

7. Store balance workstation ID ID soft key (X)

8. Display the 5th through 12th digits x

of the balance workstation ID

IDz(- a -)b

13

Configuring the Balance

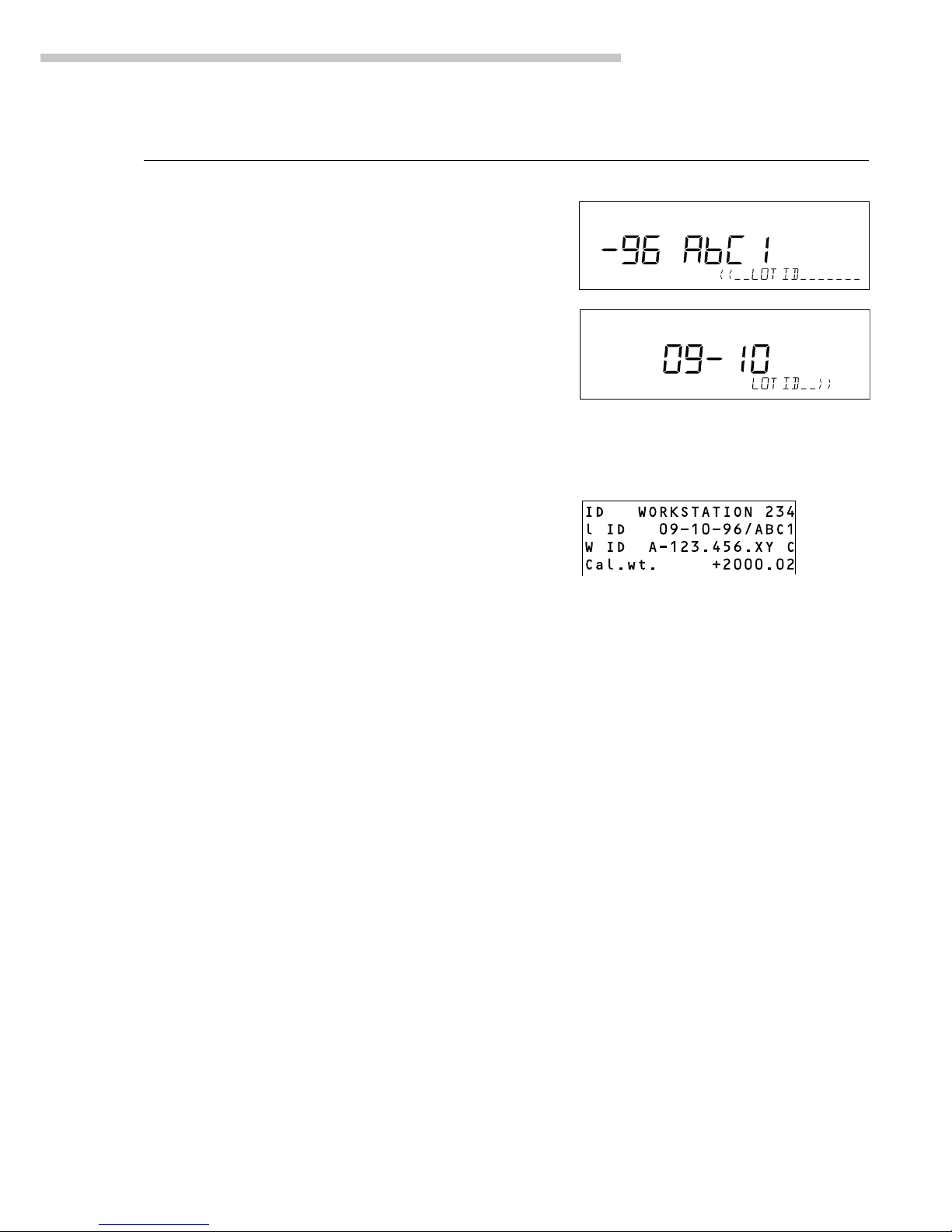

Step Key (or instruction) Display/Output

9. Display lot number Y 13th through 20th digits displayed

(In this example: 09-10-96/ABC1)

10. Display 5th through x

12th digits of lot no.

11. Display other user data xyYX

– Weight set no.

– Exact calibration weight

– Password

12. Print user data (example) p

13. Exit “Setup: Input” M

14

Setting Parameters (Menu)

Purpose

To configure the balance; i.e.,

adapt the balance to individual

requirements by choosing from

a list of parameter options in

a menu. You can block access

to this menu by assigning

a password.

Features

The parameter options are

divided into the following groups

(1st menu level):

1 Balance functions

2 Application programs

3 Application parameters

4 +/– parameter

(for over/under checkweighing)

5 Interface parameters

6 Print for weighing (print weights)

7 Print for application program

(print app. data)

8 Additional functions

9 Reset menu

Factory Settings

The factory-set configurations

are marked with an “o” in the list

starting on page 16

Preparation

● Select the Setup menu:

Press M

> The Info, Menu and Input soft

keys are displayed in the text line

● Select the parameter menu:

Menu soft key w

> Password prompt is displayed

● Enter password using the alpha-

numeric input keys

● Confirm password entered:

enter passw. soft key v

> Measured value line:

1 (1st menu level)

> Text line: Balance functions

k Select the next group: Press Y

k Select the next submenu

within a group (2nd menu level):

Press X

k Select previous group: Press y

k Return to next higher menu level:

Press x

Additional Functions

● Exit the menu: Press M

> Restart the application

● Print parameter settings:

– When the 3rd menu level

is selected: Press p

> Printout (example)

4 2 Auto print +/ 2 Off

– When the 2nd menu level

is selected: Press p

> Printout (example)

4 Parameter +/-

------------------4 2 Auto print +/ 2 Off

4 3 +/- ctrl ports

1 Within ctrl r

– When the 1st menu level

is displayed: Press p

> Prints all of the menu parameters

that are currently set

15

Configuring the Balance

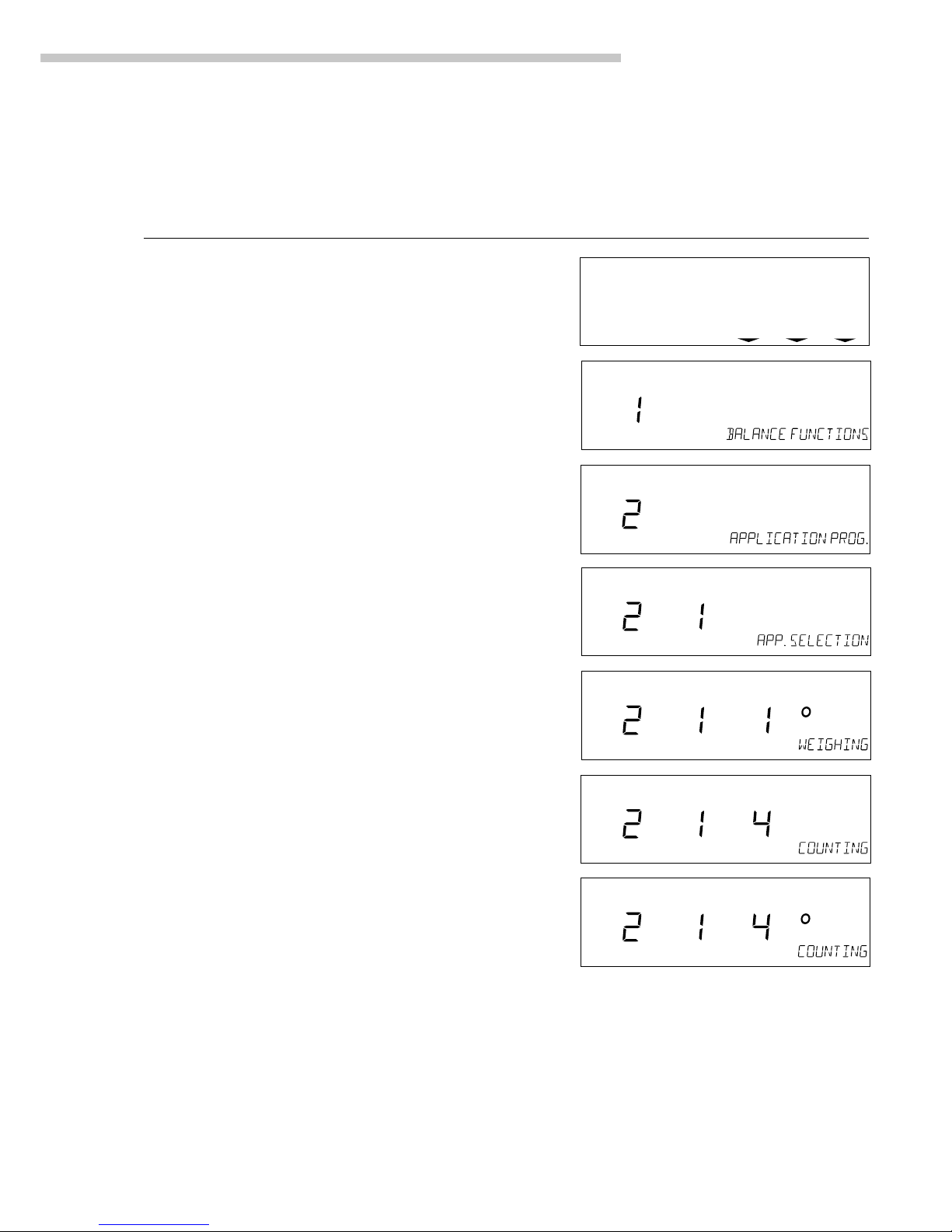

Practical Example

Select the Counting Application Program

Step Key (or instruction) Display/Output

1. Select Setup menu M

2. Select Balance Functions Menu soft key w

group code (Menu)

3. Select the Application Y

Prog. group

4. Confirm Application Program X

(2nd menu level)

5. Confirm App. Selection X

(3rd menu level shows current

setting; in this case: weighing)

6. Select the Counting program Y Y

7. Confirm selection X

of Counting program

8. Set other parameters, if desired x y Y X

9. Save settings and exit menu M

info--menu--input

16

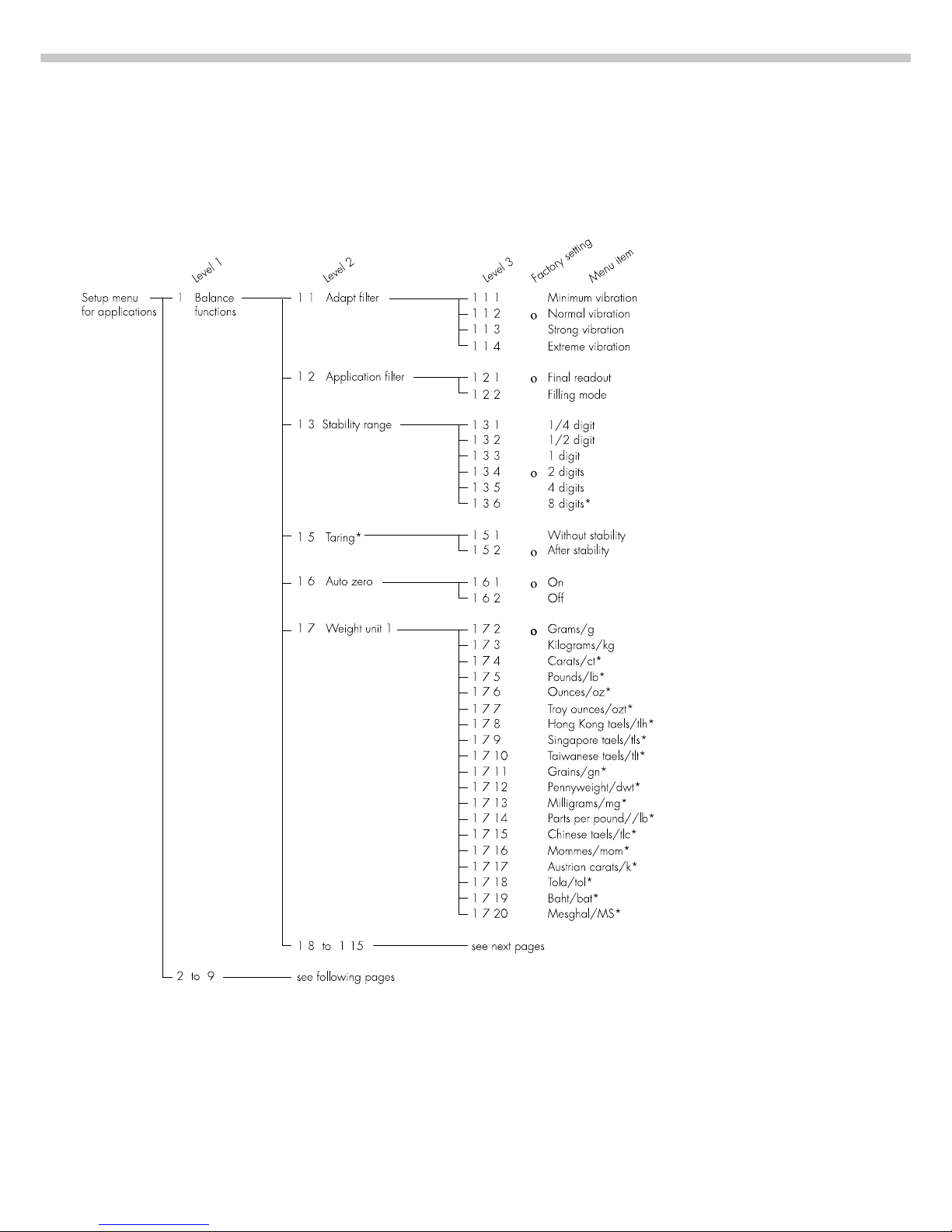

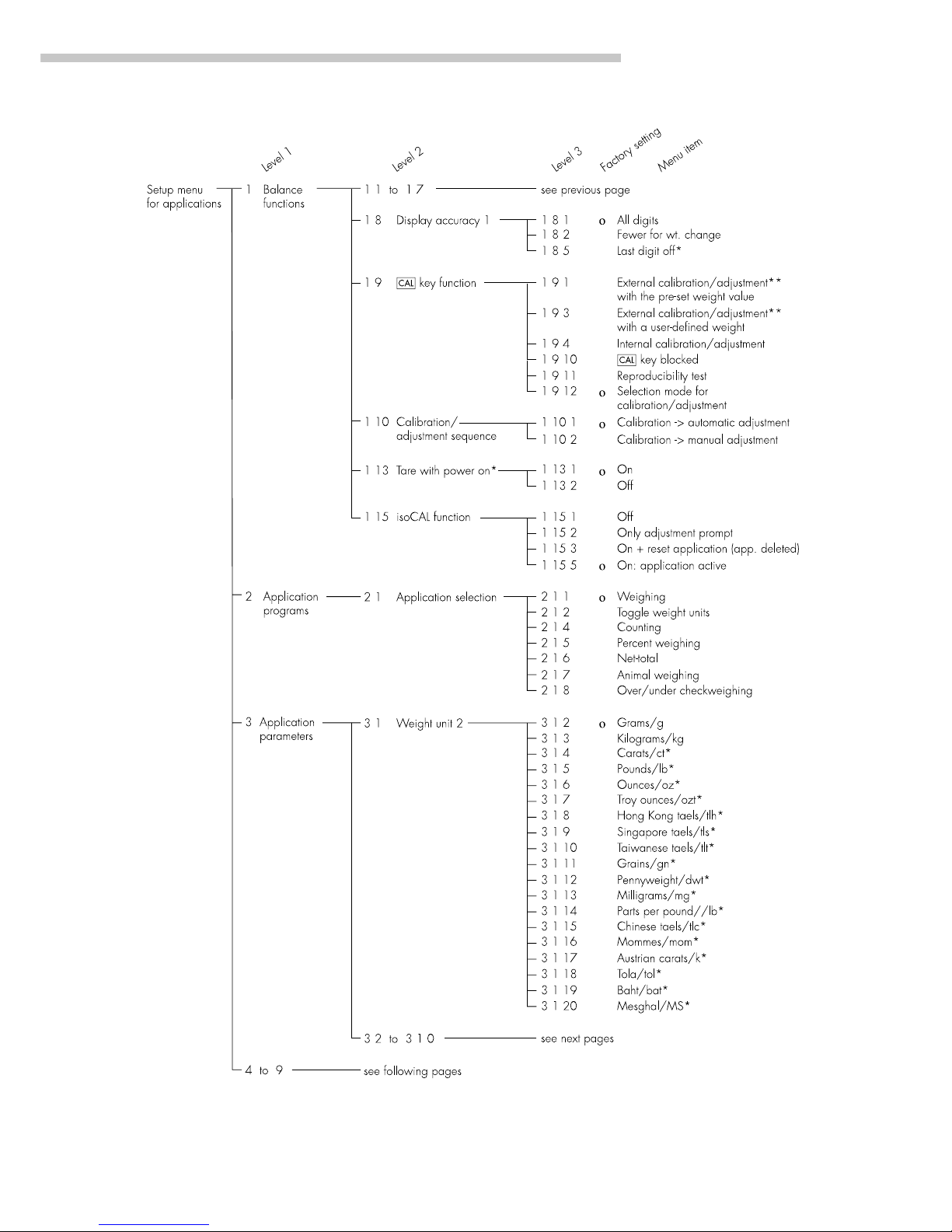

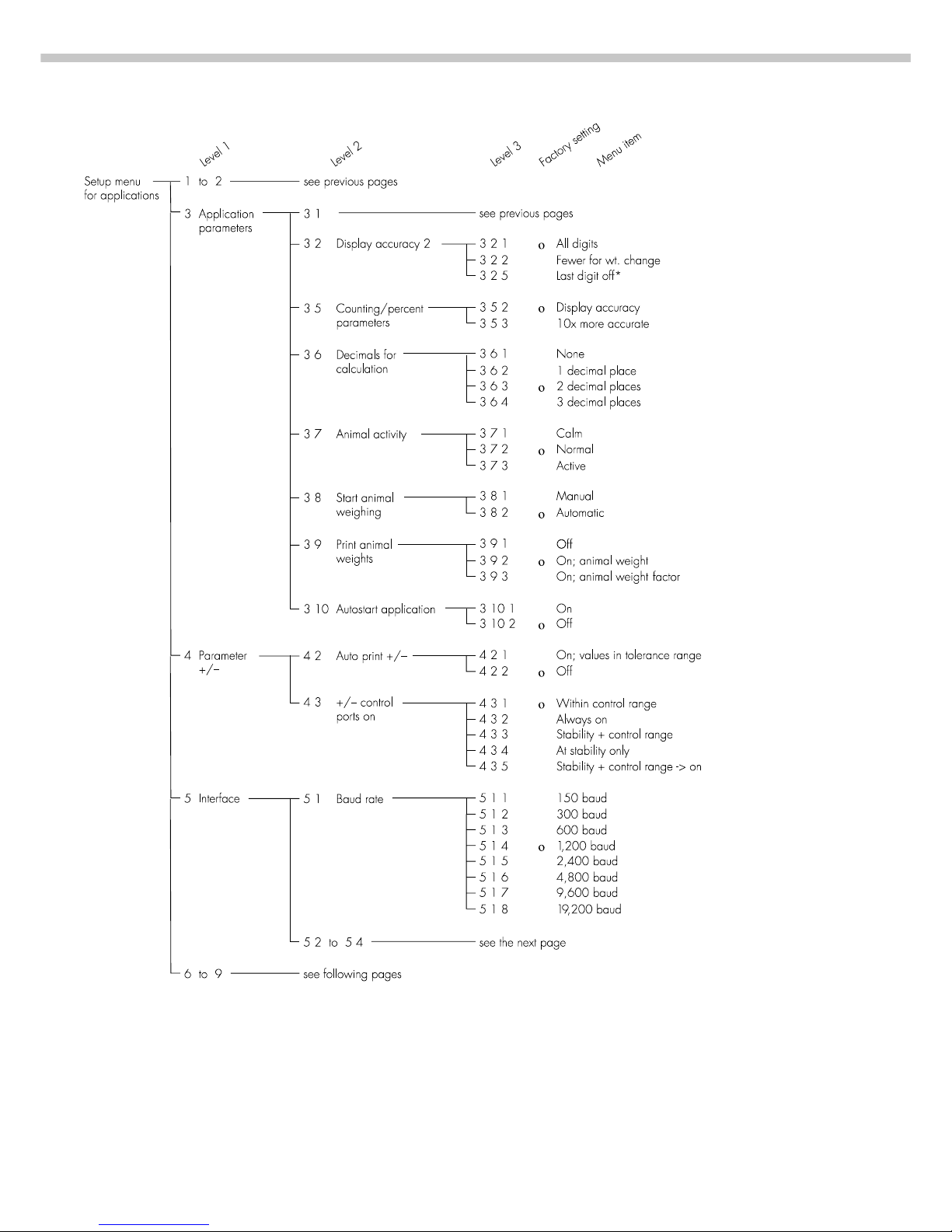

Setup Parameters (Overview)

o Factory setting

√ User setting

* = setting not applicable in balances verified for use in legal metrology

17

Configuring the Balance

* = setting not applicable in balances verified for use in legal metrology

** = for balances of accuracy class K, only calibration (not adjustment) can be performed with a user-defined weight

18

* = setting not applicable in balances verified for use in legal metrology

19

Configuring the Balance

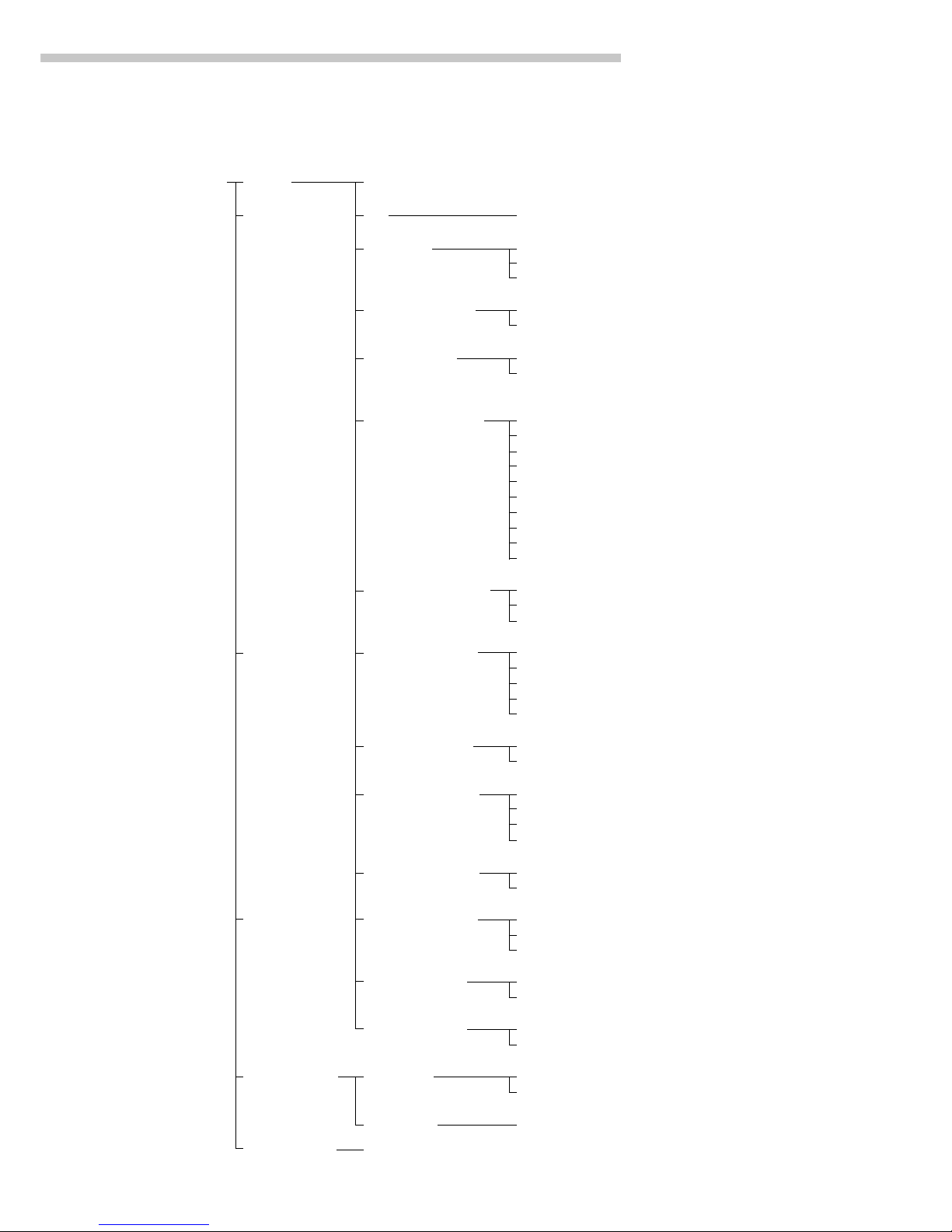

Setup menu 1 to 4 see previous pages

for applications

5 Interface 5 1 see previous page

5 2 Parity 5 2 2 Space

5 2 3 ο Odd

5 2 4 Even

5 3 No. of stop bits 5 3 1 ο 1 stop bit

5 3 2 2 stop bits

5 4 Handshake 5 4 1 Software handshake

mode 5 4 3 ο Hardware handshake,

1 character after CTS

5 5 Communication 5 5 1 ο SBI

mode 5 5 2 xBPI

5 5 4 YDP01IS

5 5 5 YDP02

5 5 6 YDP03

5 5 7 YDP01IS Label printer

5 5 10 YDP02IS

5 5 11 YDP02IS Label printer

5 5 14 YDP04IS

5 5 15 YDP04IS Label printer

5 6 Network address 5 6 1 ο Address 0

5 6 x Addresses 1 to 30

5 6 32 Address 31

6 Print for 6 1 Print manual/ 6 1 1 Manual without stability parameter

weighing automatic 6 1 2 ο Manual with stability parameter

6 1 4 Auto print without stability parameter

6 1 5 Auto print at stability

6 1 6 Auto print after weight change**

6 2 Stop auto print 6 2 1 Use p key

6 2 2 ο Not possible

6 3 Time-dependent 6 3 1 1 display update

auto print 6 3 2 2 display updates

6 3 4 10 display updates*

6 3 7 100 display updates*

6 4 Print -> 6 4 1 ο Off

autotare 6 4 2 On

7 Print for 7 1 Print application 7 1 1 ο Off

application parameters 7 1 2 All parameters

7 1 3 Only main parameters

7 2 Line format 7 2 1 For raw data

7 2 2 ο For other applications/GLP

7 3 Print net total 7 3 1 ο Auto print net

7 3 2 Auto print tare

8 Extra functions 8 1 Menu 8 1 1 ο Parameter settings alterable

8 1 2 Parameter settings readable

8 2 to 8 10 see next page

9 Balance menu see next page

Level 1

Level 2

Level 3

Factory setting

Menu item

* = setting not applicable in balances verified for use in legal metrology

** = Auto print if change in weight >10 d and has stable readout; function enabled when load <5 d

20

* = not in balance models with a weighing capacity ≥16 kg.

21

Operating the Balance

Operating the Balance

Basic Weighing Function

Purpose

The basic weighing function

is always accessible and can be

used alone or in combination with

an application program (Toggle

between Weight Units, Counting,

Weighing in Percent, etc.).

Features

– Taring the balance

– Assigning IDs to weights

– Printing weights

– Printing ID codes for weights

Factory Settings

Tare: After stability (1 5 2)

Print manual/automatic:

Manual after stability (6 1 2)

Line format for printout:

For other applications/GLP (7 2 2)

Alphanumeric input of a weight ID:

Keys unblocked (8 3 1)

Below-Balance Weighing

A port for a below-balance

weighing hanger is located on the

bottom of the balance.

Balances with a weighing capacity

>12 kg:

● Open cover plate (1) on the

bottom of the balance

1

● Attach the sample (e.g., using a

suspension wire) to the hook (2).

2

k If necessary, install a shield for

protection against drafts

Balances with a weighing capacity

≥ 16 kg:

● Use a screwdriver to open

the cover plate on the bottom

of the balance

● Attach the hook ordered directly

from Sartorius

Important Note Concerning

Verified Balances Approved

for Use as Legal Measuring

Instruments in the EU*:

The below-balance weighing port

may not be opened or used when

an approved balance is being

operated as a legal measuring

instrument.

Preparation

● Turn on the balance: Press e

> All display segments light up

briefly

k To change configurations:

see the chapter entitled

“Configuring the Balance”

k To load factory-set configurations:

see “Configuring the Balance,”

parameter 9 1

k To tare the balance: Press t

> The U symbol is displayed

when the balance is zeroed

or tared (only on balances verified

for use in legal metrology)

Using Verified Balances

Approved for Use as Legal

Measuring Instruments in the EU*:

The type-approval certificate for

verification applies only to nonautomatic weighing instruments;

for automatic operation with

or without auxiliary measuring

devices, you must comply

with the regulations of your

country applicable to the place

of installation of your balance.

$ The temperature range

indicated on the verification ID

label must not be exceeded

during operation

* including the Signatories

of the Agreement on the European

Economic Area

22

ID for weight value (if desired):

● Select the parameters

“Line format” and “For other

app./GLP” from the

Setup menu: Press M

● Select mode:

Press the menu soft key

● Set parameter 7 2 2: See the

chapter entitled “Configuring the

Balance”

● Exit the Setup menu:

Press M

Additional Functions

In addition to the functions:

– alphanumeric input,

– taring

(not during alphanumeric input),

– printing,

you can also access

the following functions from the

weighing application:

– calibration

(not during alphanumeric input),

– setup,

– turning off the balance.

Calibration

● Press q

> See the section on “Calibration/

Adjustment” for further instructions.

Setup Menu

● Press M

> See the chapter entitled

“Configuring the Balance” for

further instructions.

Turning Off the Balance

● Press e

> The balance shuts off

> The display goes blank

Important Note Concerning

Verified Balances of Accuracy

Class k:

To avoid measuring errors, the

respective air density must be

allowed for. The following

formula is used to calculate the

mass of the sample:

1 – ρ

L

/8000 kg m

–3

m= n

w

1 – ρL/ρ

m = mass of the sample

nw= weight readout

ρ

L

= air density during weighing

ρ = density of the sample

Practical Examples

Example W1: Simple Weighing

Step Key (or instruction) Display/Output

1. If necessary, tare the balance t

(U symbol: balance is tared,

– verified balances only)

2. Enter sample ID see Example W2

3. Determine sample weight Place sample on balance

(Example)

4. Print weight p

23

Operating the Balance

Example W2

Enter “ABC123” as a sample ID

Note:

– The sample ID generally applies to one weighing operation only

– The ID is deleted after data output

Step Key (or instruction) Display/Output

Initial status (balance unloaded)

(ID can also be entered while balance

is loaded)

1. Enter the letter “A” a

2. Select and enter the letter “B” a

Softkey B (Key Y)

3. Select and enter the letter “C” a Softkey . .

(Key Y Y)

4. Enter the numbers “1,” “2” and “3” 1 2 3

5. Store the ID Press the SP.ID soft key v

(max. 20 characters)

– The next printout will include this ID

24

For service technicians only:

External Calibration in Verified

Balances of Accuracy Class K

– External calibration is blocked

when the balance is used in

legal metrology

> External calibration can only

be released after removing the

verification control seal, in which

case the validity of the erification

becomes void and the balance

must be re-verified

– External calibration can now

be performed

Factory Settings

Calibration/adjustment mode:

Selection mode (1 9 12)

Calibration/adjustment sequence:

Adjustment automatically follows

calibration in a single operation

(1 10 1)

Automatic initiation of calibration/

adjustment (isoCAL function):

isoCAL on (1 15 5)

ISO/GLP printout: off (8 10 1)

Adjustment can be performed

– automatically following calibration

(1 10 1); or

– if desired, the adjustment

operation can be started manually after calibration (1 10 2)

You can also configure whether

the calibration mode

– will be activated according

to the specific setting (by setting

1 9 1, 1 9 3 or 1 9 4), or

– can be selected by the user after

pressing the q key (1 9 12).

You can have the balance

automatically display an adjustment

prompt after a certain time interval

has elapsed since the last

calibration/adjustment or when

the ambient temperature changes by

a defined amount.

You can also configure the balance

to perform calibration and

adjustment automatically (isoCAL)

when the pre-set time and/or

temperature limit is reached

(1 15 3 and 1 15 5).

You can have the calibration/

adjustment results documented in

a ISO/GLP-compliant printout.

Releasing Access to External

Calibration in Verified Balances

of Accuracy Class k

§ Remove the covering plate from

the back of the balance housing

§ Move Switch 1 in the direction

of the arrow

> Switch down:

external calibration accessible

Switch up:

external calibration blocked

> Note:

Do not move Switch 2

Calibration/Adjustment

Purpose

Calibration is the determination

of the difference between the

weight readout and the true weight

(mass) of a sample. Calibration

does not entail making any changes

within the balance.

Adjustment is the correction of this

difference between the measured

value displayed and the true

weight (mass) of the sample, or the

reduction the difference to an

allowable level within the maximum

permissible error limits.

Available Features

Your balance can be calibrated

externally (menu item 1 9 1 or1 9 3)

or internally (1 9 4).

External calibration can

be performed

– with the pre-set weight value

(1 9 1), or

– with a user-defined weight value

(1 9 3)

* including the Signatories of the

Agreement on the European

Economic Area

25

Operating the Balance

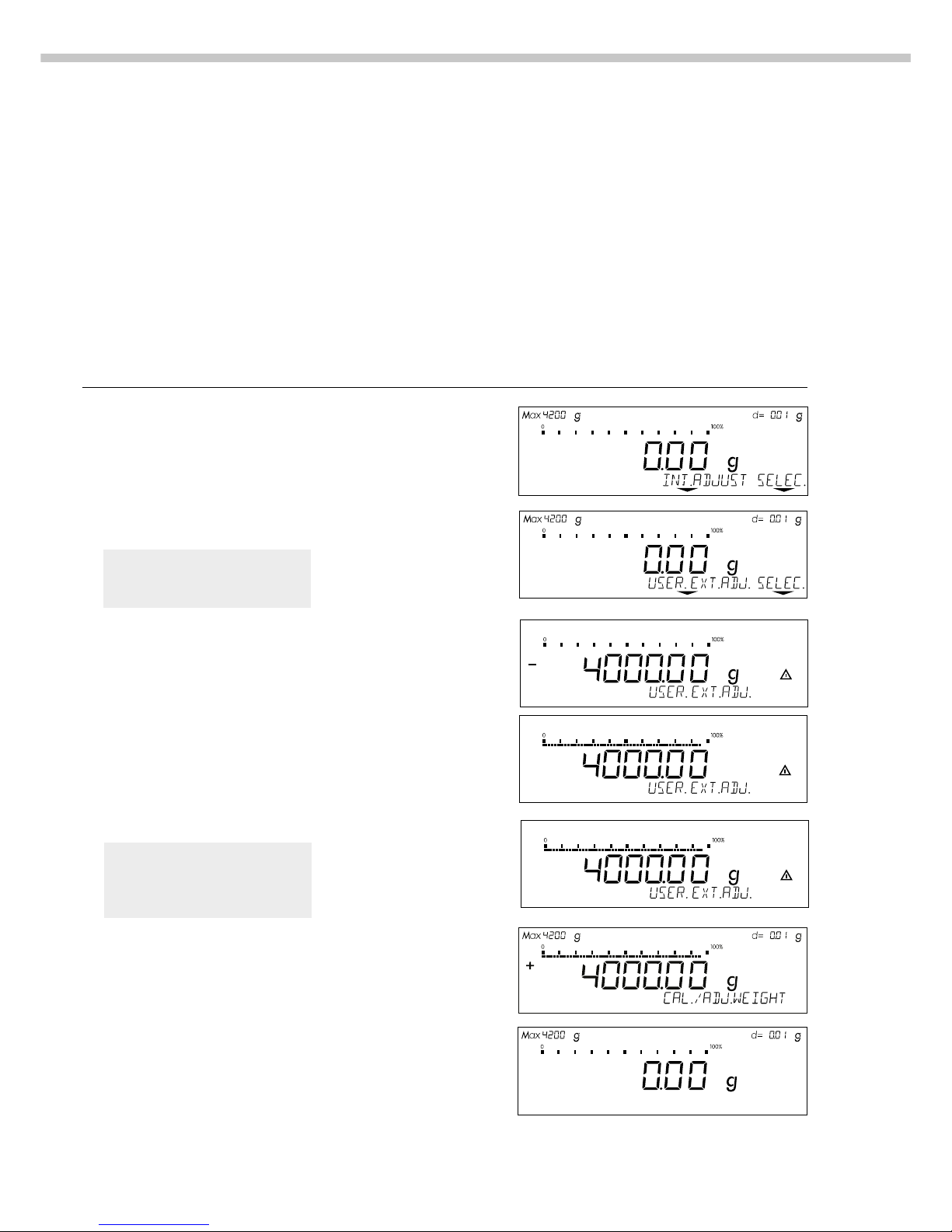

Preparation

Configure Parameters for Calibration and Adjustment

Step Key (or instruction) Display/Output

1. Turn on the balance e

2. Select the Setup menu M

3. Select the Balance Functions menu menu soft key w

4. Set parameters for:

– Calibration key function 1 9

– Calibration/adjustment

sequence 1 10

– isoCAL self-calibrating and

adjustment function 1 15

See the chapter entitled “Setup” x y Y X

5. Exit the Setup menu M

info--menu--input

26

Configure External Calibration and Automatic Adjustment of the Balance in Selection Mode

Step Key (or instruction) Display/Output

1. Select the calibration function q

2. Select external calibration/ Press the selec.

adjustment mode soft key three times v

(for balances of accuracy

class K, only “external

adjustment” is possible)

3. Confirm external calibration/ Press the

adjustment mode user. ext.adj. soft key q

4. Place the calibration weight Place weight on balance

on the balance (e.g., 4000.00 g)

Minus sign –: Weight too low

Plus sign +: Weight too high

No plus/minus sign: Weight o.k.

This is displayed after calibration:

(on verified balances, the

display shows the difference

between the weight readout

and the actual weight value)

This is displayed after adjustment:

5. Unload the balance Remove weight(s)

Selecting the Calibration/

Adjustment Parameter

The setting 1 9 12 must be selected

in the Setup menu.

You can configure the balance

so that after selecting a calibration

procedure by pressing the q key,

you can choose among the following

calibration/adjustment modes:

– External calibration/adjustment

with the pre-set weight value

(Def. Ext. Adj.)

– External calibration with

a user-defined weight value

(user. ext.adj.)

– Internal calibration (int. adjust)

– Reproducibility test (reprotest)

When making your selection,

the available modes

are displayed in cycles; i.e.,

after reprotest, def. ext.adj.

is displayed again

27

Operating the Balance

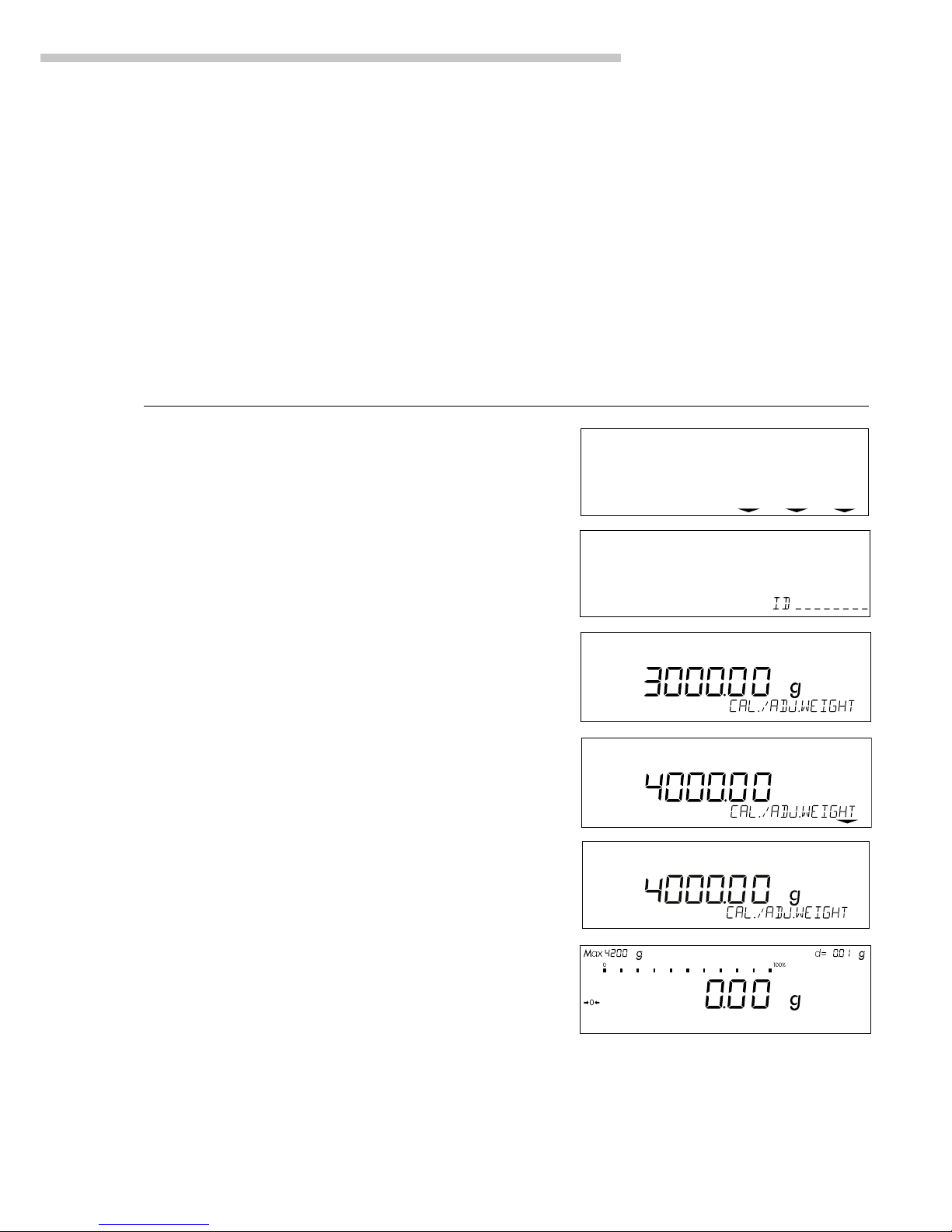

External Calibration/Adjustment*

with a User-Defined Weight

First set either 1 9 3 or selection

mode (1 9 12) in the menu.

You can define a weight for

calibration/adjustment.

External calibration/adjustment must

be performed with weights that are

traceable to a national standard and

that have error limits which are at

least 1/3 of the required tolerance

of the display accuracy.

The balance has a factory-set weight

value (see “Specifications”).

Define the Calibration Weight

Step Key (or instruction) Display/Output

1. Select the Setup menu M

2. Access the Input Mode Input soft key v

3. Select input for calibration Y Y Y

weight (currently 3000.00 g)

4. Enter calibration weight 4 0 0 0 . 0

(e.g., 4000.00 g) 0

5. Save weight … weight soft key v

6. Exit the Setup menu M

* = for verified balances of accuracy class K, only external calibration is possible

info--menu--input

To reset a user-defined calibration/

adjustment weight to the original

factory setting, enter the factory-set

weight value manually (see

“Specifications”) or set menu code

1 9 1 in the Setup menu.

28

Internal Calibration/Adjustment

The menu code setting 1 9 4 must be

selected in the Setup menu.

Inside the balance housing is a builtin, motorized calibration weight.

The internal calibration/adjustment

sequence is as follows:

● Select the calibration function:

Press q

> The internal calibration weight

is applied automatically

> The balance is calibrated

> If the setting for “Calibration

automatically followed by

adjustment” (1 10 1) is selected

in the Setup menu, the balance is

now automatically adjusted

> The internal calibration weight

is removed

Calibration and Adjustment Sequence

In the Setup menu, you can configure

the balance so that:

– calibration is always followed

automatically by adjustment

(cal. -> auto adjust, 1 10 1), or

– you have the choice of ending

the sequence or starting adjustment after calibration

(cal. -> man. adjust, 1 10 2).

If no deviation is determined during

calibration, or the deviation is within

the tolerance limits dictated by the

degree of accuracy you require, it is

not necessary to adjust the balance.

In this case, you can end the

calibration/adjustment sequence

after calibration. There are 2 soft

keys active at this point:

– ext. adjust or int. adjust

to start adjustment

– end to end the sequence

29

Operating the Balance

isoCAL:

Automatic Calibration and Adjustment

Either 1 15 3 or 1 15 5 must be

selected in the Setup menu.

The “isoCAL” display automatically

begins flashing if the ambient

temperature has changed in relation

to the temperature at the time

of the last calibration/adjustment,

or after a defined time interval

has elapsed. The balance is telling

you that it wants to self-calibrate

and adjust.

This adjustment prompt is activated

when:

– The change in temperature

or the elapsed time interval is

greater than that shown

in the table below

– The balance status does not

correspond to Setup configurations

– No number or letter input is active

– The load on the pan has not been

changed within the last 2 minutes

– The balance has not been

operated within the last 2 minutes

– The weight on the pan must be

no more than 2% at the most of

the maximum capacity of the

balance

When these requirements are met,

the following symbols are displayed:

– C in the measured value line

–

isoCAL

in the symbol display

– G in the weight unit display

If the balance is not operated and

the load is not changed, internal

calibration and adjustment starts after

15 seconds have elapsed.

In the Setup menu, you can

configure the balance so that after

calibration and adjustment

– the application program

must be restarted

(On + reset app. 1 15 3), or

– the application program

resumes where it left off

(isoCAL on, 1 15 5)

Fully automatic adjustment is initiated under the following conditions:

Model When the temperature After a time

changes by interval of

LP 3200D, LP 1200S 1.5 Kelvin 4 h

LP8200S, LP8200P, 2 Kelvin 6 h

LP 620S, LP 620P, LP 6200S,

LP 4200S, LP 5200P, LP 220S

LP 2200S, LP 2200P, 4 Kelvin 12 h

LP 34001P, LP 34001S, LP 64001S

LP 820, LP 420, LP 16001S, 4 Kelvin 24 h

LP 12000S, LP 12000P,

LP 6200, LP 4200, LP 2200,

LP 34000

These values are also set in the corresponding verified or verifiable balances

(LP models with the -0CE designation).

In the Setup menu, you can also

configure the balance so that it

displays an adjustment prompt,

but does not perform the calibration/

functions automatically

(Only adj. prompt, 1 15 2)

Function in Verified Balances:

Automatic calibration is also

performed outside of the limited

temperature range if you set menu

code 1 15 1, “isoCAL function: off”

or code 1 15 2, “only at adjustment

prompt” in the Setup menu.

To generally deactivate automatic

calibration in balances with

a weighing capacity ≤12 kg:

– After the balance has been

modified by the Sartorius

Service Center

> Afterwards, the balance

can only be used for legal

metrology within the

temperature range allowed

by law

Limited temperature range:

– For balances of accuracy

class k: +15°C to +25°C

(59°F to 77°F)

– For balances of accuracy

class K: +10°C to +30°C

(50°F to 86°F)

Extended temperature range:

–0°C to +40°C

(32°F to 104°F)

Deactivating the “isoCAL”

30

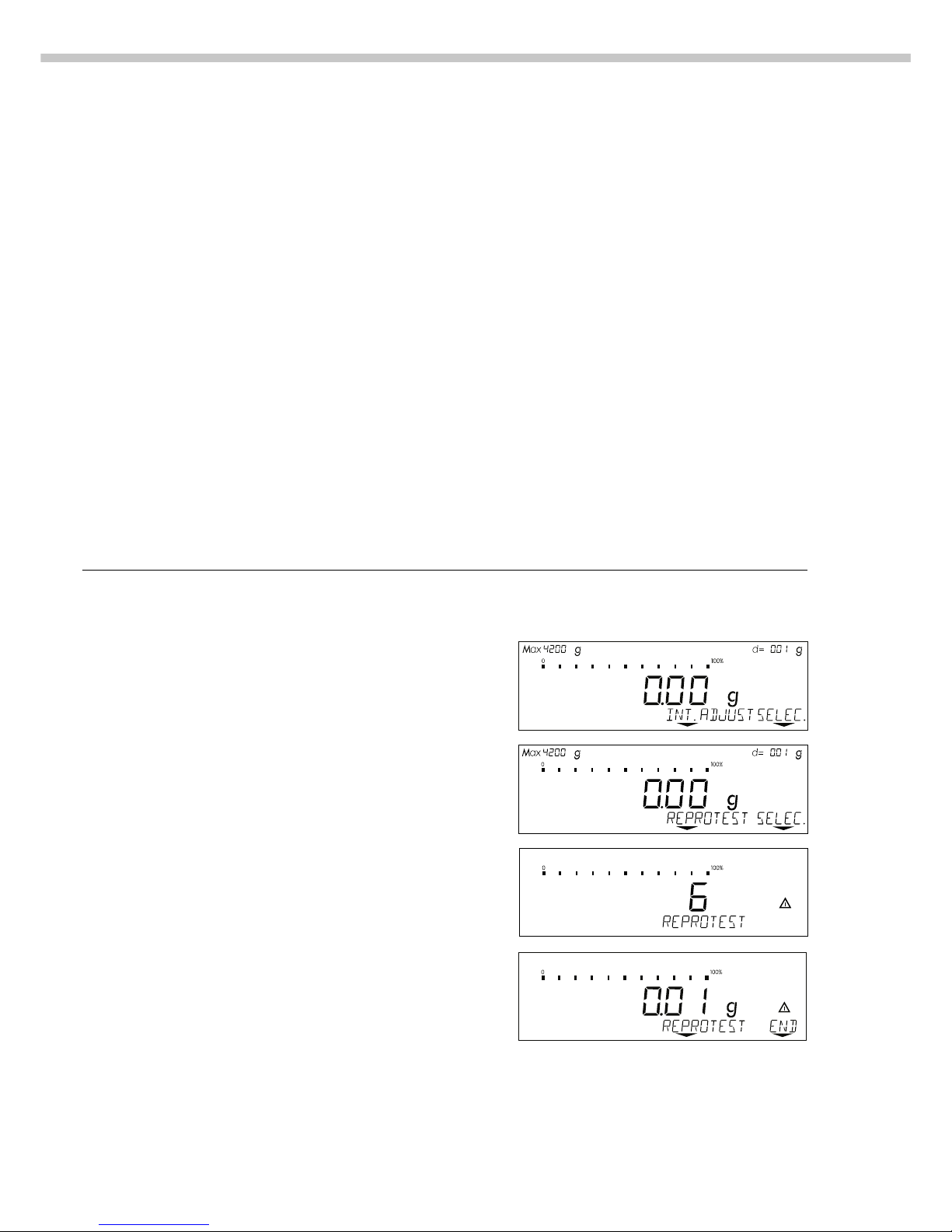

Check the Reproducibility of the Balance

Step Key (or instruction) Display/Output

1. If parameter 1 9 11 is set

(reproTEST), proceed with step 4.

2. Access the Selection Mode for q

calibration/adjustment

3. Select reproTEST selec. soft key v

4. Start reproTEST q

Number of measurements

is displayed

6 measurements will now

be performed

The standard deviation is displayed

5. End reproTEST End soft key v

or restart reproTEST reprotest soft key

Determination of the

Repeatability (reproTEST)

Definition

Repeatability (reproducibility) is the

ability of the balance to display

identical readouts when it is loaded

several times with the same weight

under constant ambient conditions.

The standard deviation for a given

number of measurements is used to

quantify the repeatability.

Purpose

The “reproTEST” function automatically calculates the repeatability of

results (based on 6 individual

measurements). In this way, the

balance determines one of the most

important quantities in relation to

the place of installation. The results

are displayed with the balance’s

accuracy.

Preparation

● Turn on the balance:

Press e

> All display segments light up

briefly

● Select reproTEST in the Setup

menu: Press M

● Select Menu:

Press w (menu softkey)

● Select either 1 9 11 (reproTEST)

or 1 9 12 (selection mode):

See “Configuring the Balance.”

● Exit the Setup menu:

Press M

Loading...

Loading...