Sartorius LE1003S, LE1003P, LE324S, LE623S, LE6202S Operating Instructions Manual

...

Operating Instructions

Sartorius Expert Series

LE Models

Electronic Micro-, Analytical and Precision Balances

98648-011-40

Contents

3 Warnings and Safety

Precautions

4 Getting Started

5 Installation

13 Operation

13 Overview of Display and

Operating Elements

14 Basic Weighing Function

16 Below-Balance Weighing

18 Calibration and Adjustment

23 Configuration

23 Printing the Parameter Settings

24 Setting the Parameters

(Menu Codes)

25 Parameter Settings (Overview)

30 Setting IDs, Time, Date and

Display Brightness

33 Application Programs

34 Net-total Formulation

38 Counting

38 Reference Balance/Scale

for Counting

41 Weighing in Percent

43 Animal Weighing/Averaging

45 Toggling between Weight Units

46 Generating a Printout

48 ISO/GLP-compliant

Printout/Record

50 Interface Port

54 Data Input Format

57 Pin Assignment Charts

58 Cabling Diagram

59 Troubleshooting Guide

61 Care and Maintenance

63 Instructions for Recycling

64 Overview

64 Specifications

73 Accessories (Options)

76 Declarations of Conformity

79 EC Type-approval Certificate

80 Plates and Markings

2

Warnings and Safety Precautions

Safety Instructions

§ Please read these operating instructions

carefully before using your balance to

prevent damage to the equipment.

! Do not use this equipment in hazardous

areas/locations.

! The balance housing may be opened

only by Sartorius service technicians

who have been trained at the factory.

! Make sure you disconnect the balance

from power before connecting or disconnecting peripheral devices to or

from the balance.

! If you operate the equipment under

ambient conditions that require higher

safety standards, you must comply with

the installation regulations applicable in

your country.

When cleaning your balance, make

sure that no liquid enters the balance

housing; use only a slightly moistened

cloth to clean the balance.

Installation

! Make sure the voltage rating printed on

the AC adapter is identical to your local

line voltage.

– Proceed with extreme caution when

using pre-wired RS-232 connecting

cables, as the pin assignments may not

be compatible with Sartorius equipment.

Check all pin assignments against the

cabling diagrams and disconnect any

lines that do not match.

! If there is visible damage to the equip-

ment or power cord, disconnect the

equipment from power and lock it in a

secure place to ensure that it cannot be

used for the time being.

– Connect only Sartorius accessories and

options, as these are optimally designed

for use with your balance. The operator

shall be responsible for any modifications to Sartorius equipment and for

any connection of cables or equipment

not supplied by Sartorius and must

check and, if necessary, correct these

modifications and connections. On

request, Sartorius will be happy to provide information on operating specifications (in accordance with the Standards

for defined immunity to interference).

$ Do not open the balance. If the seal is

broken, this will result in forfeiture of

all claims under the manufacturer's

warranty.

$ If you have any problems with your bal-

ance, please contact your local

Sartorius office, dealer or service center.

IP Rating:

Industrial protection ratings for the

housing:

– LE34001S, LE34001P and LE16001S

models meet IP44 requirements

– Other models with readabilities > 10 mg

meet IP53 requirements

– Models with readabilities < 1 mg meet

IP32 requirements

– The AC adapters meet IP20 require-

ments

3

Getting Started

Storage and Shipping Conditions

– Do not expose the balance to extreme

temperatures, moisture, shocks, blows

or vibration.

Unpacking the Balance

§ After unpacking the equipment, please

check it immediately for any external

damage

$ If damage is evident, refer to the

instructions under “Safety Inspection"

in the chapter entitled “Care and

Maintenance."

$ Save the box and all parts of the

packaging for any future transport.

Disconnect all cables before packing

the balance for shipping!

Equipment Supplied

– Balance

– Weighing pan

– AC adapter

– Dust cover

Additional equipment for models

with readabilities < 0.1 mg and LE…-DS

models:

– Electronics box

(models LE26P, LE225D only)

– Draft shield with base plate

– Shield ring

Additional equipment for models with

a readability of 1mg:

– Draft shield with shield plate

– Weighing pan receptor

– Base plate

Installation

Choose a location that is not subject

to the following negative influences:

– Heat (heater or direct sunlight)

– Drafts from open windows and doors

– Extreme vibrations during weighing

– Excessive moisture

Conditioning the Balance

Moisture in the air can condense on

the surfaces of a cold balance whenever

it is brought into a substantially warmer

place. If you transfer the balance to

a warmer area, make sure to condition

it for about 2 hours at room tempera-

ture, leaving it unplugged from AC

power.

Seal on Balances Verified for Use in

Legal Metrology in the EU*:

EU legislation requires that a control

seal be affixed to verified balances

of accuracy class K. The control seal

consists of a sticker with the “Sartorius"

logo. If the seal is broken, the verifica-

tion becomes null and void and the bal-

ance must be re-verified.

* Including the Signatories of the Agree-

ment on the European Economic Area

4

Installation

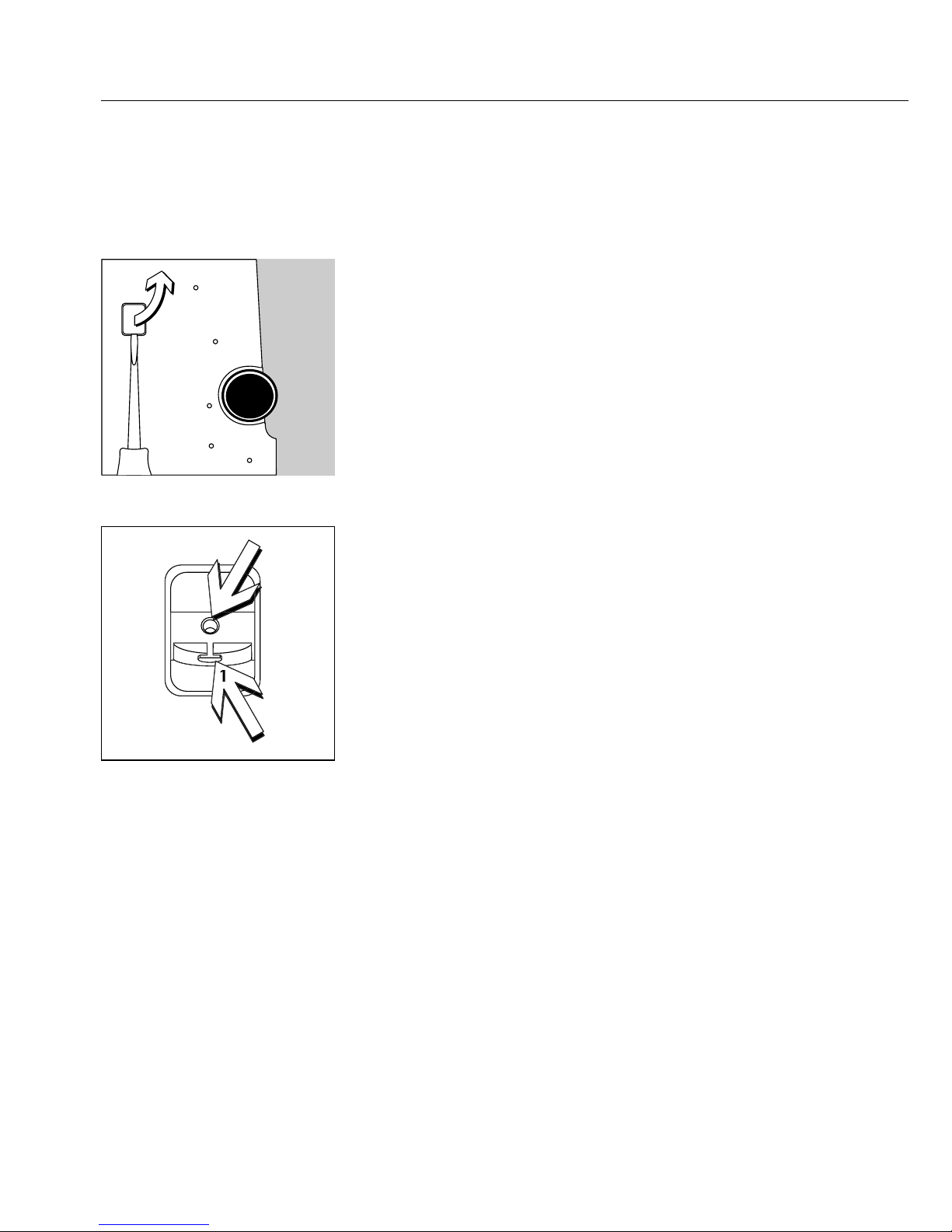

Balances with an Analytical Draft Shield

!Check the sliding lock device on the back of the

draft shield; make sure it is in the “open" position

(to the right).

§ Position the draft shield carefully on the balance

§ Secure the draft shield by pressing lightly on the

draft shield base and moving the sliding lock device

to the left

§ Place components inside the chamber in the

following order:

– Base plate

– Shield ring

– Pan support (not with model LE225D)

– Weighing pan

5

Connecting Model LE26P, LE225D(-0CE) to the

Electronics Box

– Plug the male connector on the cable into the

female connector on the electronics box

!Do not exchange the balance or electronics box with

a component of a different balance!

Balances with a 3-Sided Draft Shield

§ Place draft shield on the balance with the cover

opening in front on the right

§ Turn the draft shield clockwise until it is firmly in

position

§ Place components inside the chamber in the

following order:

– Base plate

– Weighing pan receptor

– Weighing pan

$ To access the weighing chamber from the side,

remove side panels as desired

6

1

2

7

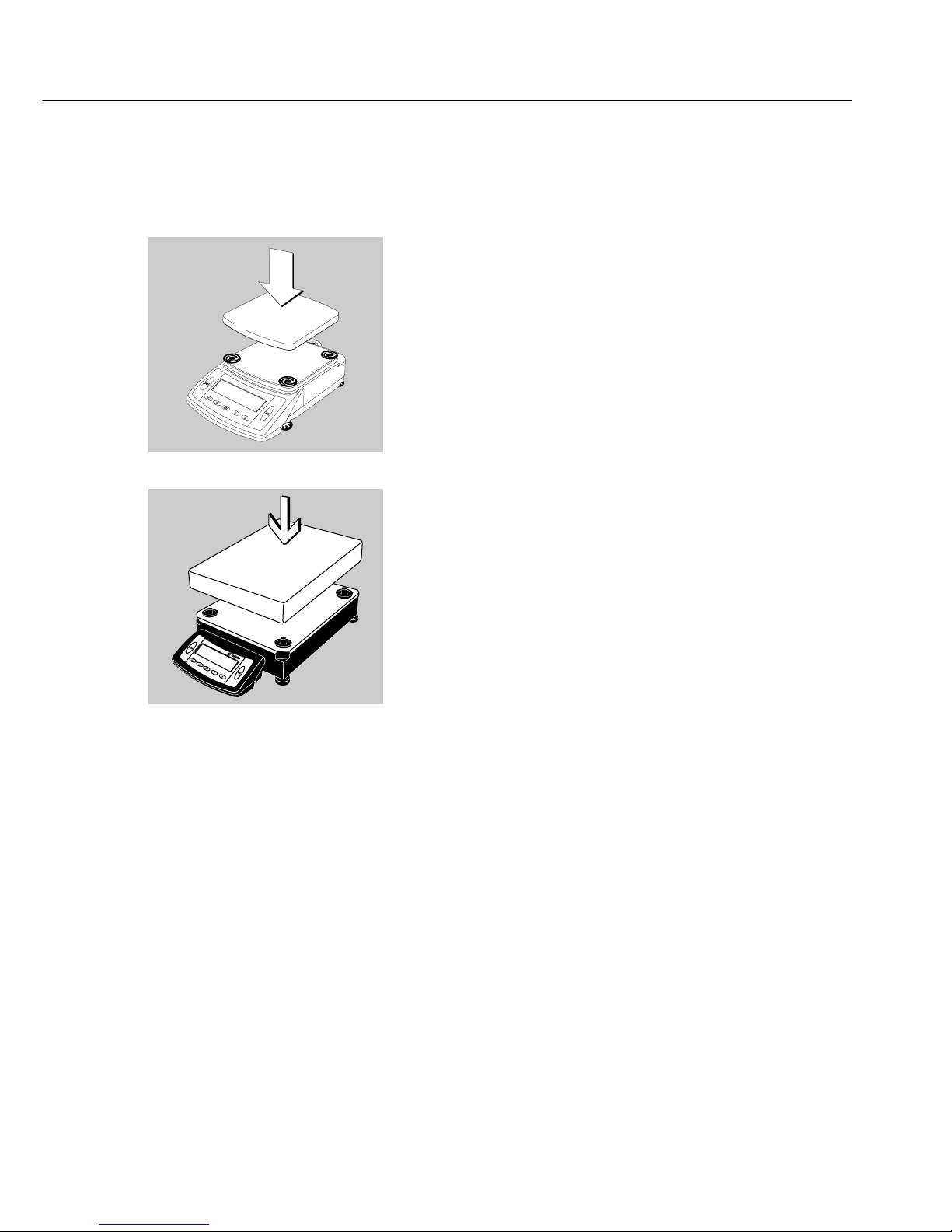

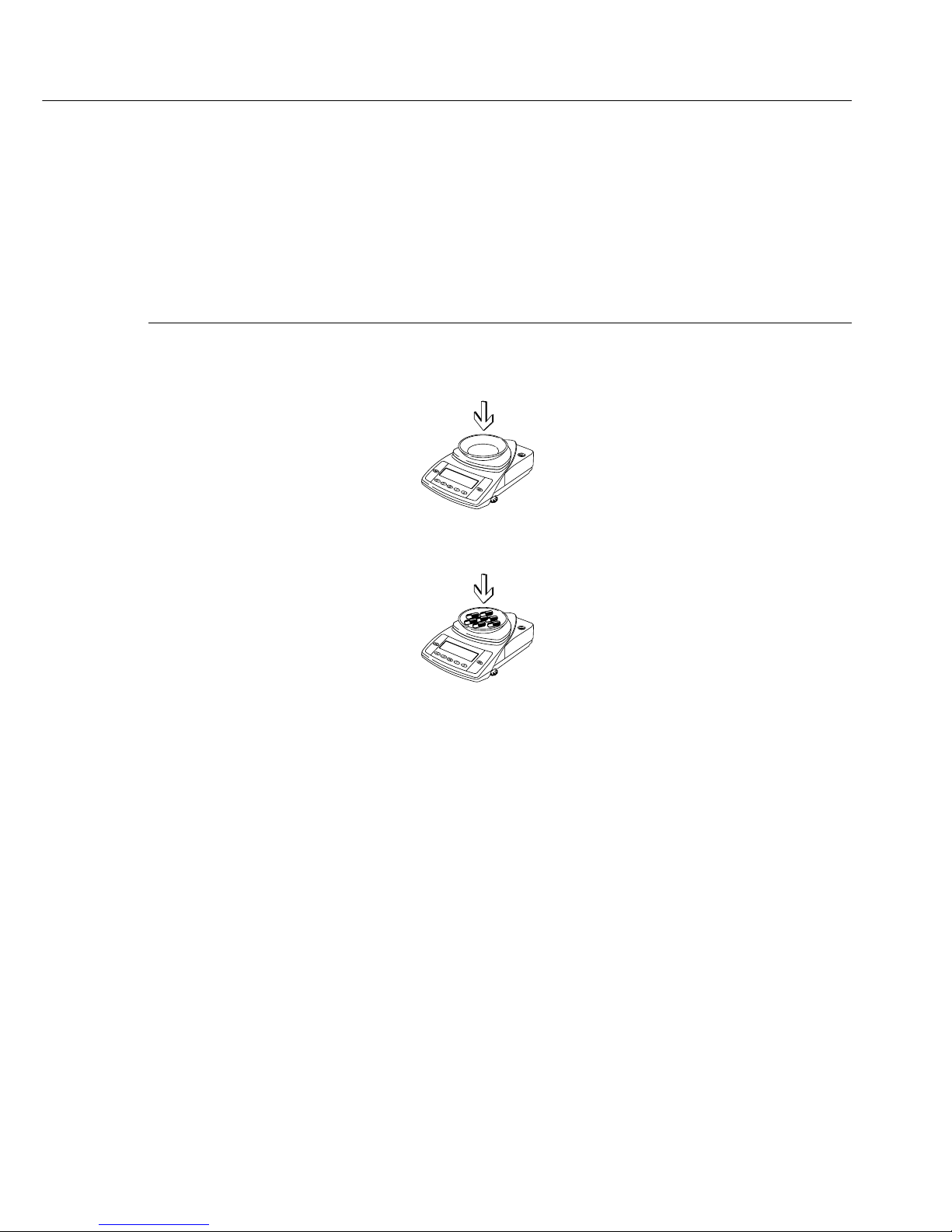

Balances with a Rectangular Weighing Pan and

a Weighing Capacity up to 10 kg

§ Place the weighing pan on the balance

Balances with a Rectangular Weighing Pan and a

Weighing Capacity over 10 kg

§ Place the weighing pan on the balance

8

Connecting the Balance

to AC Power/Safety Precautions

$ Use only original Sartorius equipment.

The AC adaptor meets the requirements of IP20 in

accordance with EN 60529.

$ For AC adapters with higher protection

ratings or for an external rechargeable

battery pack, please see “Accessories."

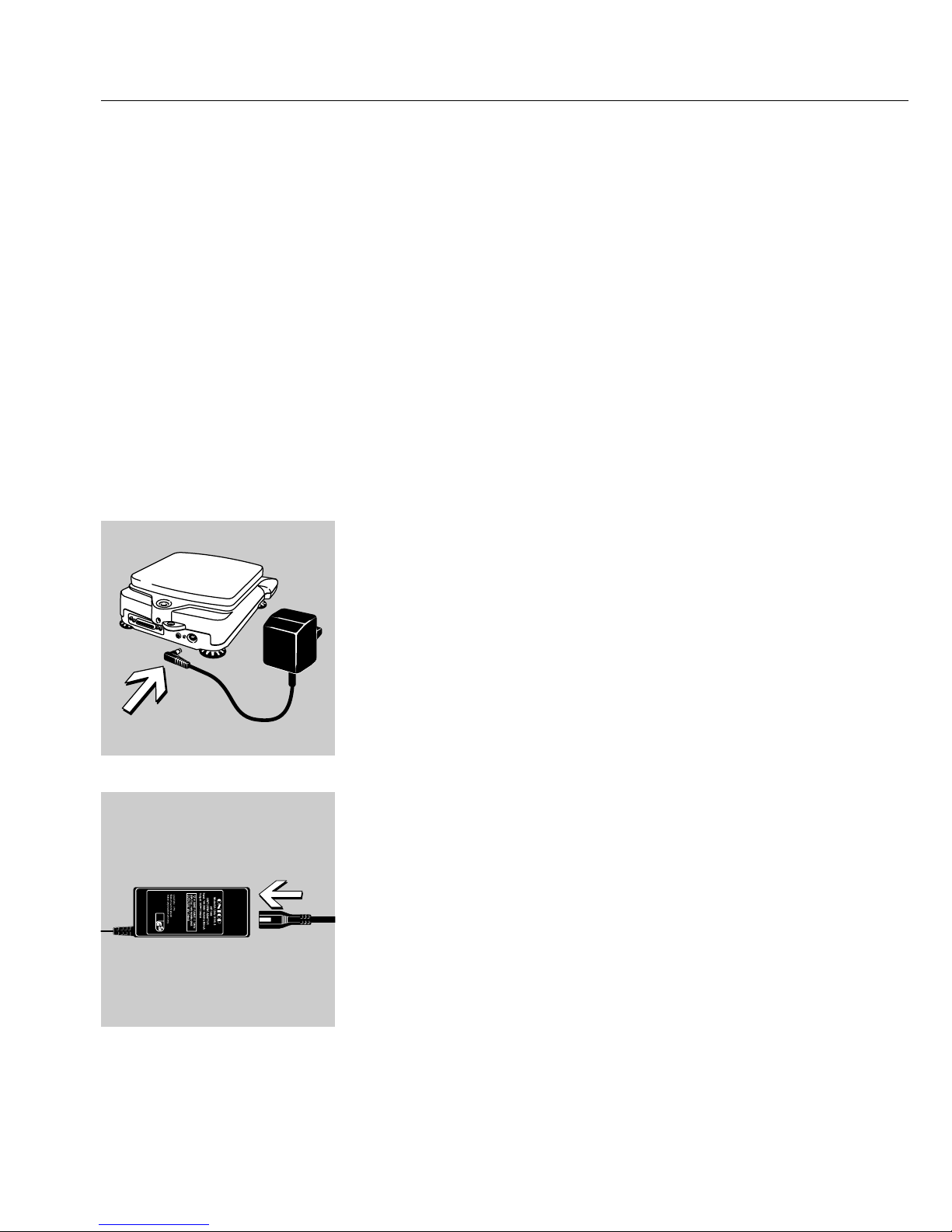

LE26P, LE225D:

§ Insert the right-angle plug from the AC adapter into

the jack on the electronics box.

All Other Balances with a Weighing

Capacity up to 10 kg:

§ Insert the right-angle plug from the AC adapter into

the jack on the balance.

Connect the power cord to the AC adapter (on balances with weighing capacities up to 10 kg)

$ Use an original Sartorius AC adapter

with a wide input voltage range (100 to 240 V~),

order no. 6971966, and replaceable

power cord:

6900900 (Europe)

6900901 (US/CDN)

6971945 (UK)

6900905 (AUS)

6900902 (ZA)

9

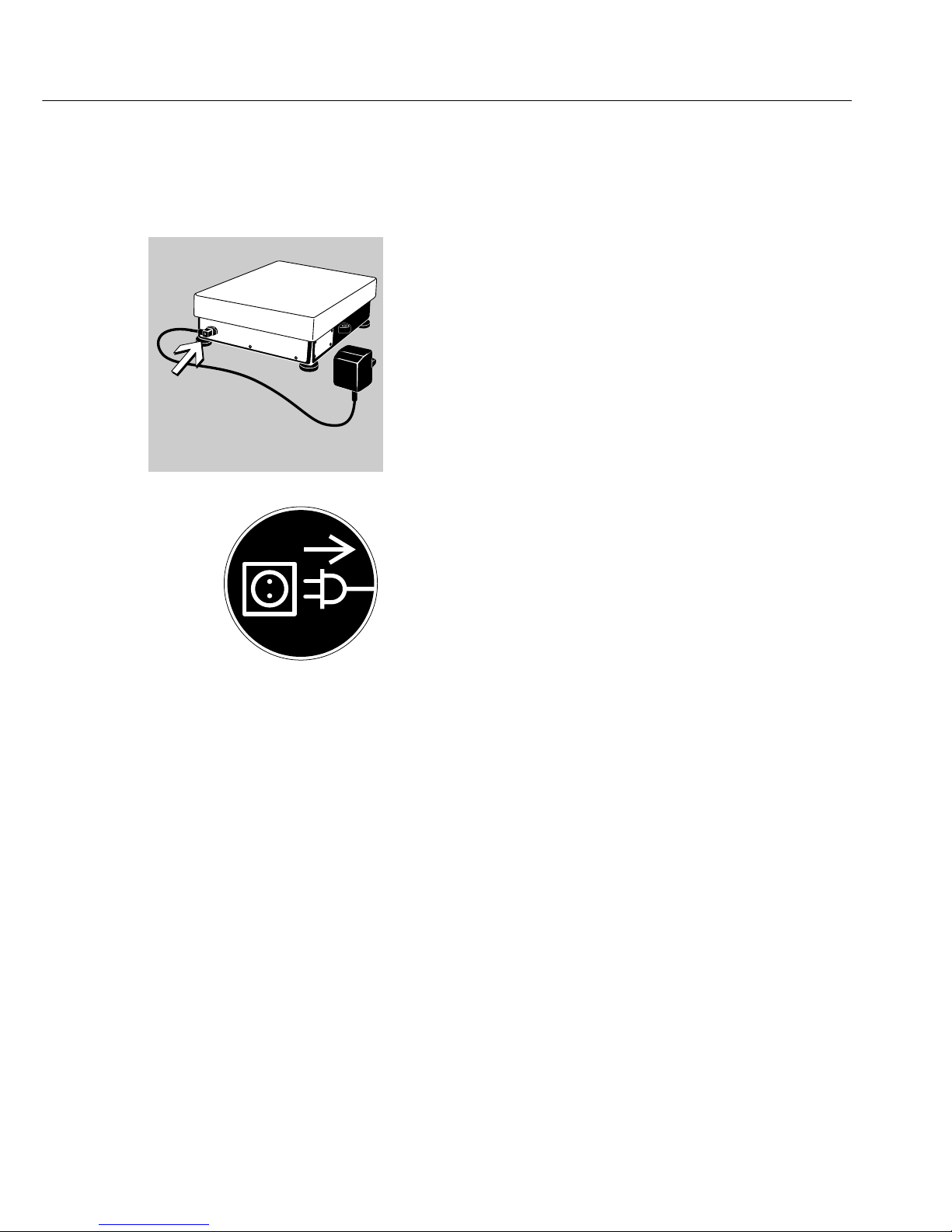

Balances with a Weighing Capacity over 10 kg:

● Insert the right-angle plug into the jack and tighten

the screw.

Safety Precautions

Plug-in AC Adapter:

The AC adapter rated to Class 2 can be plugged

into any wall outlet without additional safety

precautions.

Benchtop AC Adapter 6971966:

The AC adapter rated to Class 1 can be plugged into

any wall outlet without additional safety precautions.

The ground terminal is connected to the balance

housing, which can be additionally grounded for

operation. The data interface is also electrically

connected to the balance housing (ground).

Note:

This equipment has been tested and found to

comply with the limits pursuant to part 15 of FCC

Rules. These limits are designed to provide reasonable protection against harmful interference. This

equipment generates, uses and can radiate radio

frequency energy and, if not installed and used

in accordance with these instructions, may cause

harmful interference to radio communications.

For information on the specific limits and class of

this equipment, please refer to the Declaration

of Conformity. Depending on the particular class,

you are either required or requested to correct the

interference.

If you have a Class A digital device, you need

to comply with the FCC statements as follows:

“Operation of this equipment in a residential area

is likely to cause harmful interference in which case

the user will be required to correct the interference

at his own expense.”

If you have a Class B digital device, please read and

follow the FCC information given below:

However, there is no guarantee that interference

will not occur in a particular installation. If this

equipment does cause harmful interference to radio

or television reception, which can be determined

by turning the equipment off and on, the user is

encouraged to try to correct the interference by

one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment

and receiver.

– Connect the equipment into an outlet on a

circuit different from that to which the receiver

is connected.

– Consult the dealer or an experienced radio/TV

technician for help.

Before you operate this equipment, check which

FCC class (Class A or Class B) it has according to

the Declaration of Conformity included. Be sure

to observe the information of this Declaration.

10

Connecting Electronic Peripheral Devices

● Make sure to unplug the balance from AC power

before you connect or disconnect a peripheral device

(printer or PC) to or from the interface port.

Warmup Time

To deliver exact results, the balance must warm up

as listed below after initial connection to AC power

or after a relatively long power outage.

– Model LE26P…: at least 4 hours

– All other precision and analytical models:

at least 30 minutes

Only after this time will the balance have reached

the required operating temperature.

Using Verified Balances in Legal Metrology:

$ Allow the equipment to warm up for at least

24 hours after initial connection to AC power.

Leveling the Balance

Purpose:

– To compensate for unevenness at the place of

installation

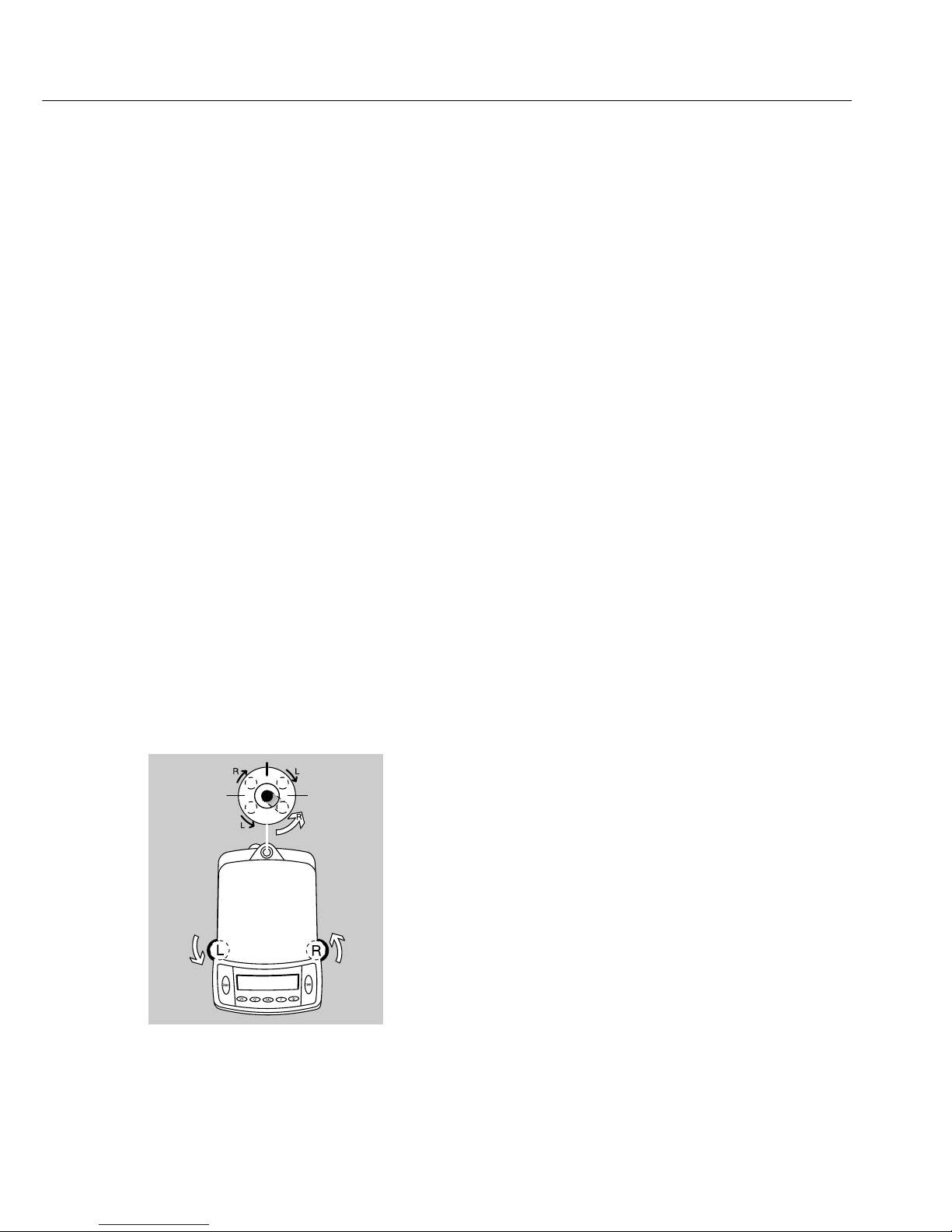

Leveling Balances with a Weighing Capacity

up to 10 kg

Only the 2 front feet are adjusted to level the

balance.

● Retract the two rear feet (only on models with

a rectangular weighing pan).

● Turn the 2 front feet as shown in the diagram until

the air bubble is centered within the circle of the

level indicator.

> In most cases this will require several adjustment

steps.

● For weighing heavy samples: Extend the 2 rear feet

until they touch the surface on which the balance

rests (only on models with a rectangular weighing

pan).

11

12

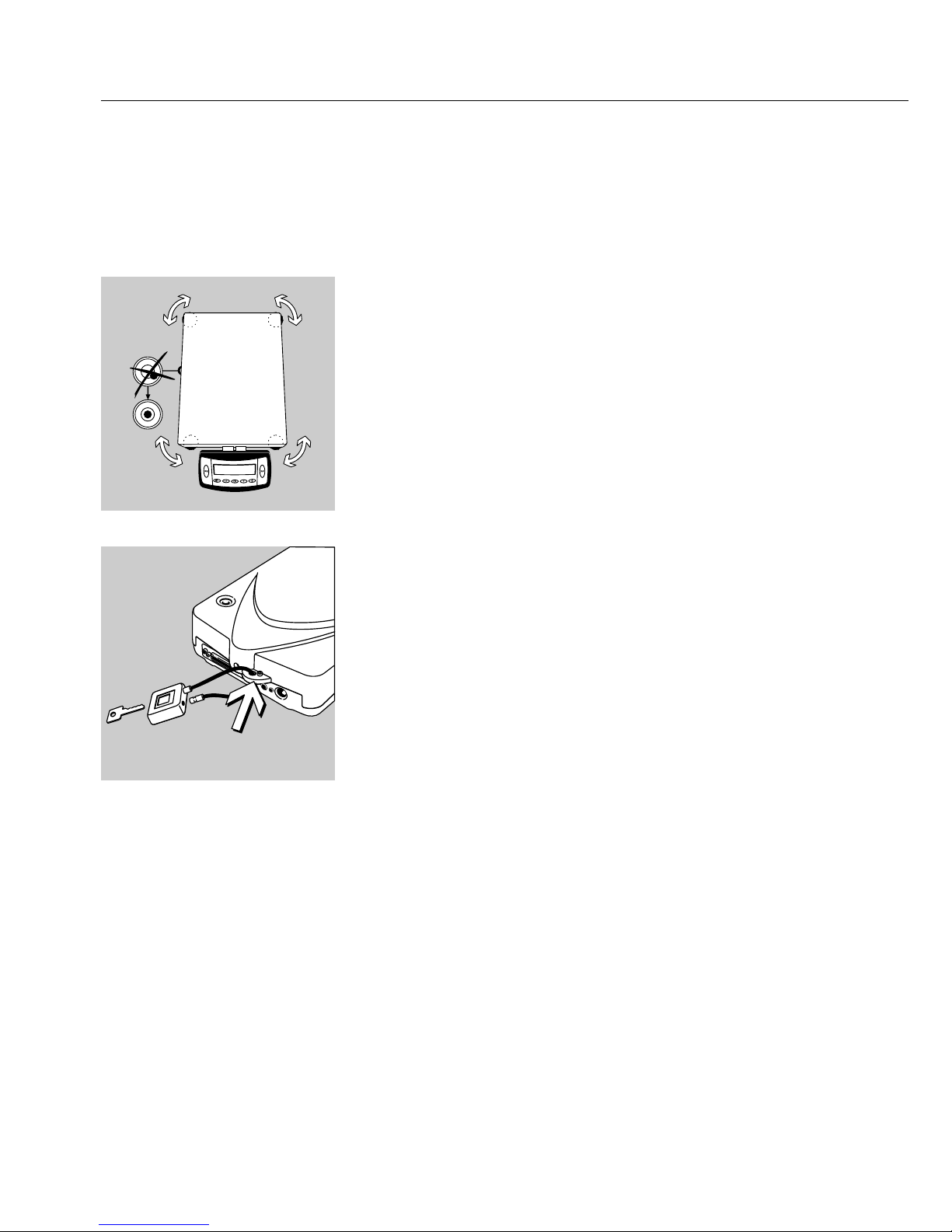

Leveling Balances with a Weighing Capacity

over 10 kg

● Adjust the leveling feet until the air bubble

is centered within the circle on the level indicator.

Antitheft Locking Device on Balances

with a Weighing Capacity up to 10 kg

● To secure the balance at the place of installation,

fasten a chain or a lock to the lug located on the

rear panel of the balance.

13

Operation

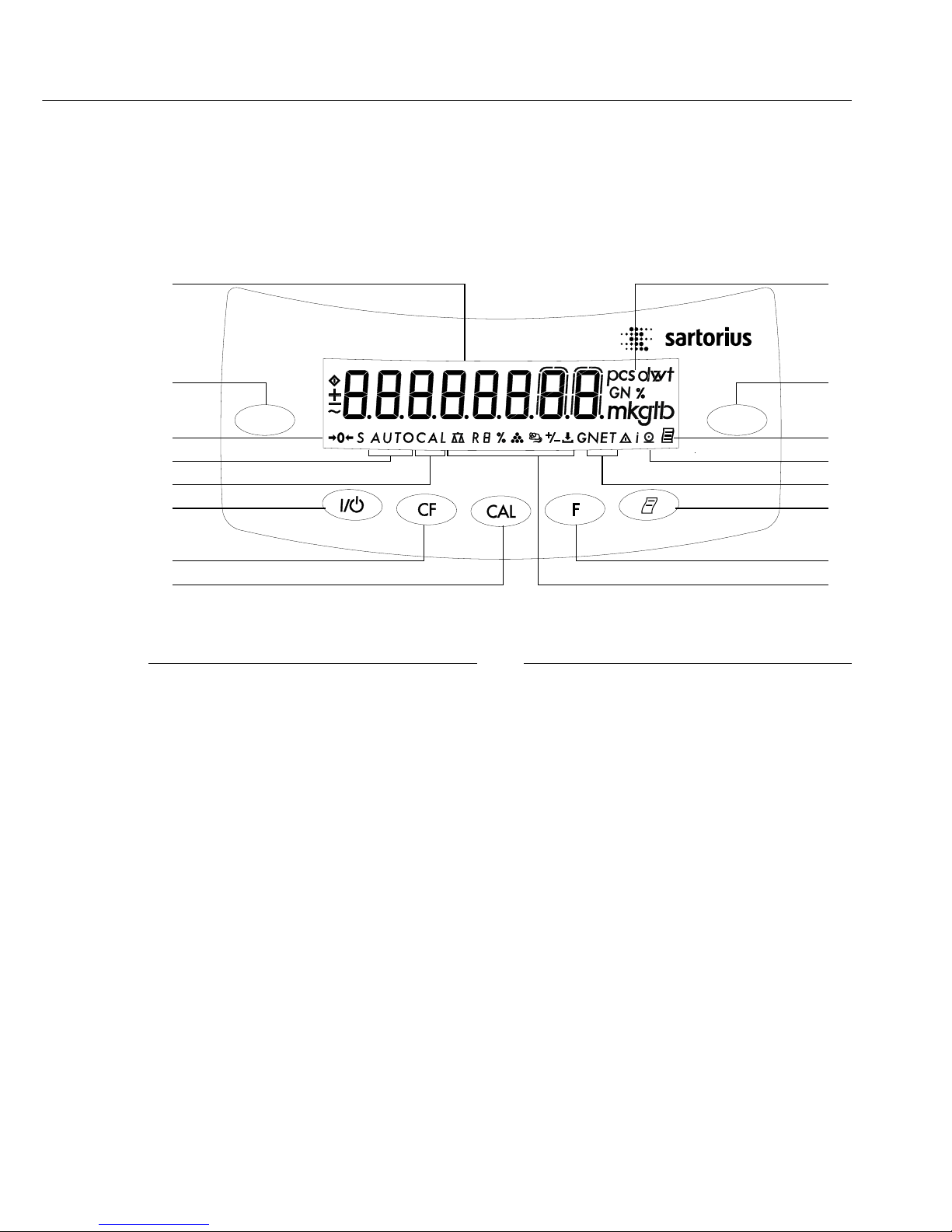

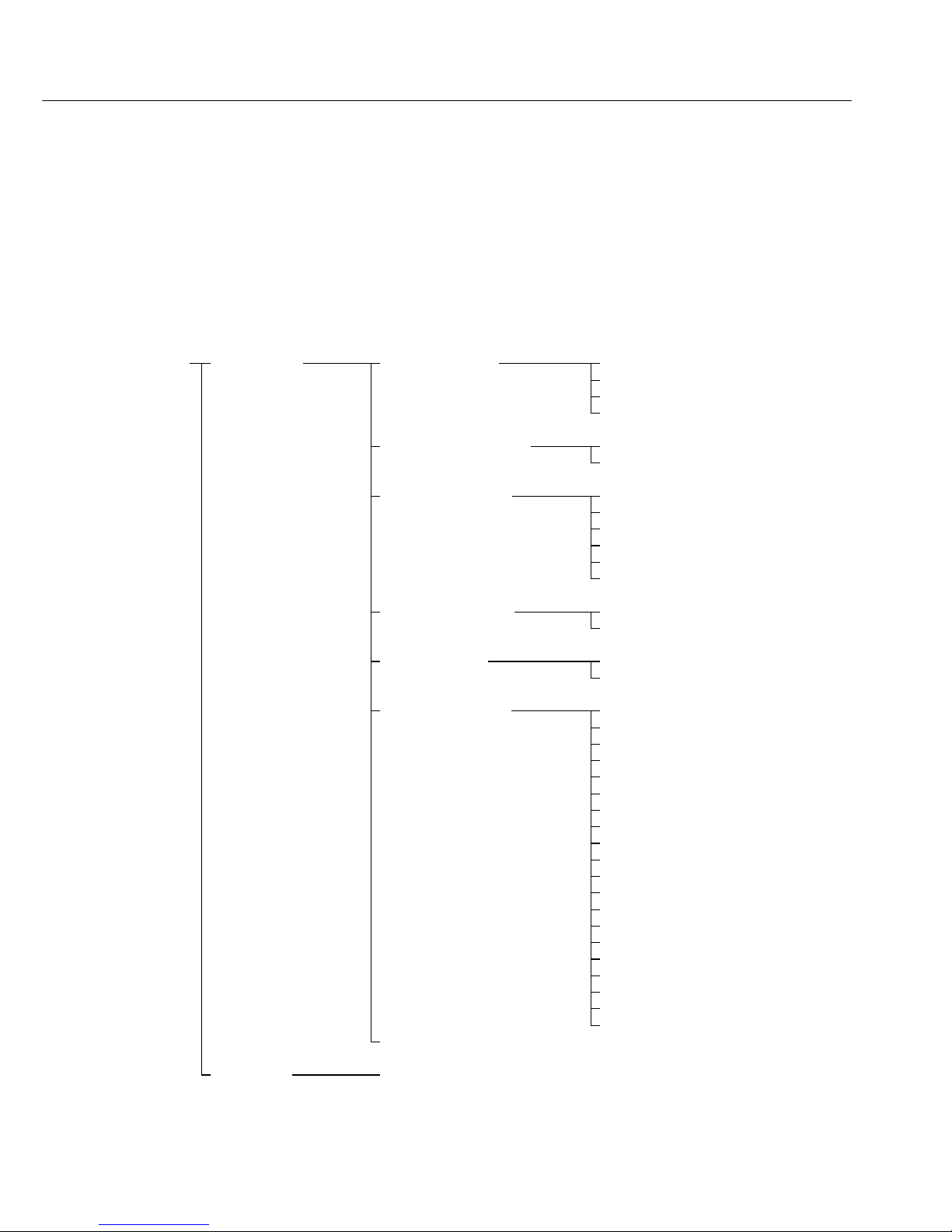

Overview of Display and Operating Elements

Position Designation

1 Weight units

2 Taring

3 Symbol: “GLP printing mode

active"

4 Symbol: “Printing mode active"

5 Display: Data in memory for

net-total formulation program

6 Data output: Press this key to

output readout values to the

built-in data interface.

7 Function key: Start application

program

8 Symbols for active application

9 Start calibration/adjustment rou-

tine Position

Position Designation

10 Delete (Clear Function)

This key is generally used to

cancel functions.

– Quit application program

– Cancel calibration/adjustment

routine

11 On/off

12 Display: Calibration/adjustment

function

13 Display: Animal weighing with

automatic start

14 Symbols for stand-by mode or

zero range

15 Weight value displayed in selected

weight unit

Tare Tare

15 1

2 2

14 3

4

5

6

13

12

11

10

9

7

8

14

Purpose

The basic weighing function can be

used alone or in combination with

an application program (counting,

weighing in percent, etc.).

Features

– Taring the balance.

– Assigning IDs to weights (as needed).

– Printing weights.

Using Verified Balances as Legal

Measuring Instruments in the EU*:

The type-approval certificate for verification applies only to non-automatic

weighing instruments. For automatic

operation with or without auxiliary

measuring devices, you must comply

with the regulations applicable to the

place of installation.

● Before using the balance as a legal

measuring instrument, calibrate and

adjust it at the place of use using the

built-in motorized calibration weight;

for details, see “Calibration/Adjustment"

in this chapter.

$ The temperature range (°C) indicated

on the verification label may not be

exceeded during operation.

Example:

BD BL 200

+10°C to +30°C

0°C to +40°C isoCAL

K

* Including the Signatories of the Agree-

ment on the European Economic Area

Working with LE26P… Models:

Working with the microbalance requires a

steady hand and a smooth, uninterrupted

technique.

Use forceps or other suitable utensil to

place the sample on the weighing pan.

Perform a number of test measurements

before you begin weighing, to allow the

temperature inside the weighing chamber

to adjust to the ambient temperature

outside the chamber. Otherwise, if the

chamber door was closed for a longer

period of time prior to beginning weighing,

the sudden change in temperature inside

the chamber when you open the door

might affect the weight readout. This

is why a series of test measurements is

recommended; the repeated opening and

closing of the weighing chamber door,

at the same rate of speed as will be used

during the actual weighing sequence,

will both compensate this difference in

temperature to some extent and help you

develop a smooth working rhythm.

Place the sample gently on the weighing

pan. The weight readout should stabilize

within 15 to 20 seconds.

The degree of precision attained increases

in proportion as the weighing operations

become more homogenous.

Basic Weighing Function

15

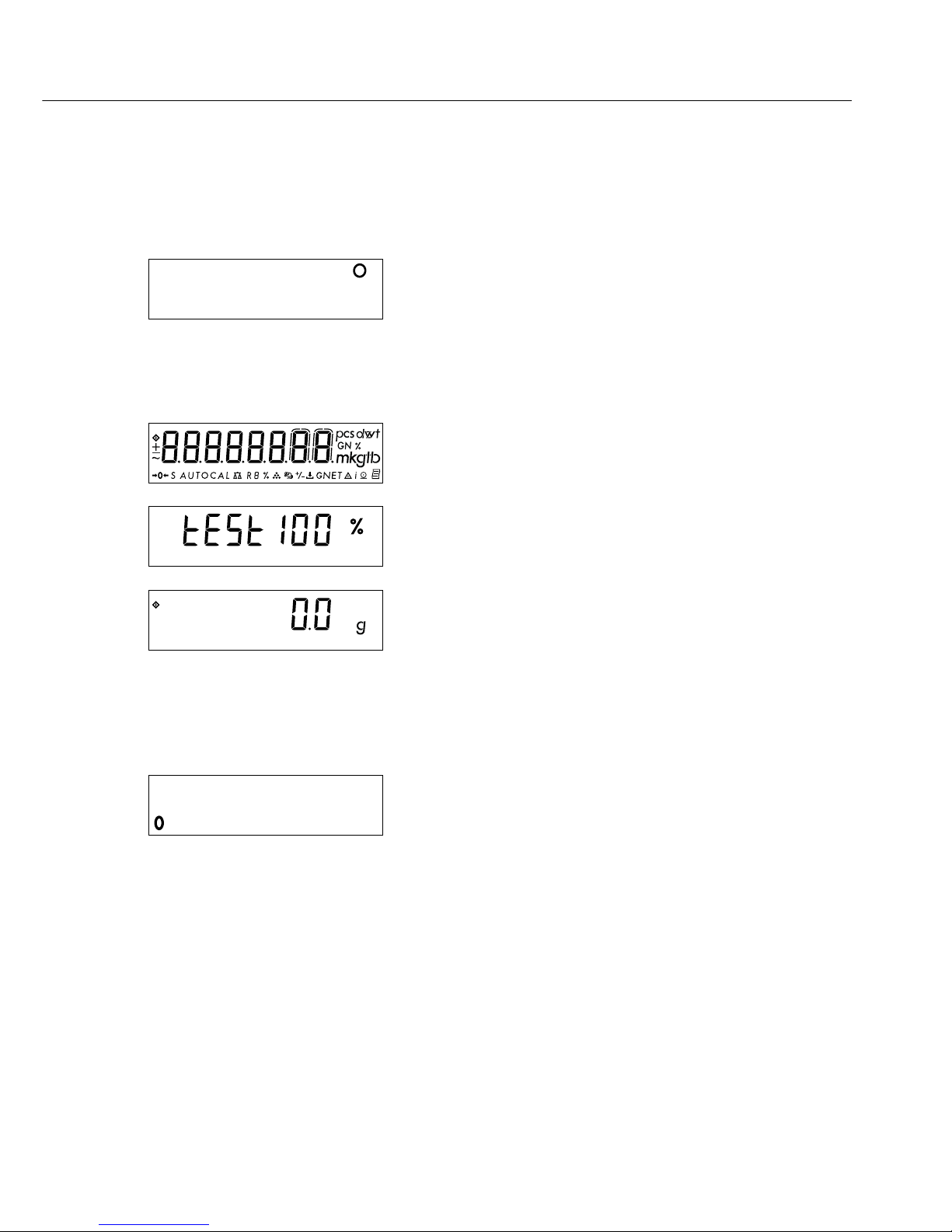

Preparation

A circle in the upper right-hand corner of the display

indicates that the balance was disconnected from

power.

This symbol is shown, for example, the first time

the balance is put into operation, or after a power

outage.

● Switch on the balance: Press e.

> All symbols on the display light up briefly.

> The balance performs a display test.

$ Tare the balance, if necessary: Press w

When you turn on the balance, the b symbol is

displayed until you press a key.

If the b symbol is displayed during operation,

this indicates that the processor is performing

a function and cannot receive further commands

at the moment.

Additional Functions

● Switching off the balance: Press e

A circle in the lower left-hand corner of the display

indicates that the balance has been switched off and

is in stand-by mode.

16

Below-Balance Weighing

A port for a below-balance weighing hanger

is located on the bottom of the balance (for models

with a weighing capacity of 12 kg or more, order the

hanger directly from Sartorius).

$ Below-balance weighing is not permitted in legal

metrology.

● Open cover plate on the bottom of the balance.

● Using the built-in hanger (1): Attach the sample

(e.g., using a suspension wire) to the hanger.

$ Bore hole (2): Carefully fasten the special hanger,

or order a hanger directly from Sartorius.

$ If necessary, install a shield for protection against

drafts.

2

17

Example

Simple Weighing

Step Key (or instruction) Display/Data Output

1. Switch on the balance. e

+ 0.0 g

Self-test is performed,

followed by automatic

initial tare function.

2. Place container on the balance

+ 11.5 g

(in this example, 11.5 g).

3. Tare the balance. w

+ 0.0 g

4. Place sample in container

+ 132.0 g

on balance (in this

example, 132 g).

6. Print weight. r

N + 132.0 g

18

Calibration and Adjustment

Purpose

Calibration is the determination of the

difference between the weight readout

and the true weight (mass) of a sample.

Calibration does not entail making any

changes within the balance.

Adjustment is the correction of any

difference between the measured value

displayed and the true weight (mass)

of the sample, or the reduction of the

difference to an allowable level within

the maximum permissible error limits.

Using Verified Balances as Legal

Measuring Instruments in the EU*:

Before using your balance as a legal

measuring instrument, you must perform “internal calibration" at the place

of installation after the warmup period.

Features

Calibration/adjustment can be

performed only when:

– there is no load on the balance,

– the balance is tared, and

– the internal signal is stable.

If these conditions are not met, an error

message is displayed (Err 02).

Adjustment can be performed

– automatically following calibration

(1 10 1), or

– manually, at operator discretion,

after calibration (1 10 2)

* Including the Signatories of the Agree-

ment on the European Economic Area

The weight displayed for the sample

on the balance must not differ from the

nominal weight by more than 2%.

You can use any of the following weight

units to calibrate/adjust the balance:

g, kg, lb (1 11 1 to 3, factory setting:

1 11 1)

You can block calibration/adjustment

of the balance as follows:

– Select menu code 1 9 7, and

– Close the menu access switch on the

back of the balance

– You can have calibration/adjustment

start automatically when a specified

time or temperature limit is reached

(isoCAL function; 1 15 3).

You can have calibration and adjustment

results documented as an ISO/GLP-

compliant printout; see page 47.

External Calibration in Verified

Balances of Accuracy Class K

– When the balance is used in legal

metrology, external calibration is

blocked by a seal over the menu access

switch.

19

Internal Calibration/Adjustment

The menu code setting 1 9 3

must be selected in the Setup menu.

Inside the balance housing is a motorized calibration weight which is applied

and removed automatically for internal

calibration.

● Activate calibration: Press q

> The built-in calibration weight

is applied automatically

> The balance is calibrated

> If “Calibrate, then auto adjust in one

operation" is selected in the Setup

menu, the balance is now adjusted

automatically.

> The internal calibration weight

is removed.

Calibration and Adjustment Sequence

In the Setup menu, you can configure

whether:

– calibration is always followed automati-

cally by adjustment (1 10 1; factory

setting), or

– you have the choice of ending the

sequence or starting adjustment after

calibration (1 10 2)

If no difference is determined between

nominal and actual weights, you can

end the calibration routine following

calibration.

Two keys are active at this point:

– q = start adjustment

– c = end the sequence

20

isoCAL:

Automatic Calibration and Adjustment

The menu code setting 1 15 3 must be

selected in the Setup menu.

– Temperature range with isoCAL:

0°C to +40°C

The “AUTOCAL" display automatically

begins flashing if the ambient temperature has changed in relation to the

temperature at the time of the last calibration/adjustment, or after a defined

time interval has elapsed.

The balance is telling you that it wants to

self-calibrate and adjust.

This adjustment prompt is activated

when:

– The change in temperature or the

elapsed time interval is greater than that

shown in the table below

– The load on the pan has not been

changed within the last 2 minutes

– The balance has not been operated within

the last 2 minutes

– The weight on the pan is no more than

2% of the maximum capacity of the

balance

– Then let the balance perform the

adjustment procedure

When these requirements are met,

the following symbols are displayed:

– C in the measured value line

– AUTOCAL flashes in the symbol display

In the Setup menu, you can configure the

balance to display the adjustment prompt

only, without performing

calibration/adjustment automatically

(menu code 1 15 2)

isoCAL Deactivated on Verified Balances:

The permitted operating temperature

range for balances used in applications

subject to legal metrology (legal for

trade) is restricted as follows:

– Balances of accuracy class k:

+15°C to 25°C (+59 to +77°F)

– Balances of accuracy class K:

+10°C to +30°C (+50 to 86°F)

Fully automatic adjustment is initiated under the following conditions:

Model When the After a time

temperature interval

changes by of

LE26P, LE225D, LE324S, LE244S 1.5 Kelvin 4 h

LE1003S, LE1003P, LE623S, LE623P, LE6202S,

LE5202S-DS, LE6202P, LE4202S 2 Kelvin 6 h

LE323S, LE2202S, LE34001P, LE34001S 4 Kelvin 12 h

LE5201, LE2201, LE10001, LE16001S 4 Kelvin 24 h

These values are also set in the corresponding verified balances (LE models with the -0CE

designation).

Internal Calibration

Step Key (or instruction) Display

1. Tare the balance. w

0.0 g

2. Start calibration. q

C

The internal weight is CAL

applied automatically.

3. The balance is calibrated –

0.2 g

(displayed only if menu CAL ± G

code 1 10 2 is set).

4. If the “Calibrate, then

Adjust*

auto adjust" setting is CAL

selected (1 10 1), the balance

is now adjusted automatically.

5. The calibration sequence is completed.

CC

CAL

6. The internal weight is removed.

0.0 g

* = displayed only if menu item 1 10 2 is selected.

21

22

External Calibration

Step Key (or instruction) Display

1. Tare the balance. w

0.0 g

2. Start calibration. q

+ 5000.0 g

CAL G

3. Apply the prompted calibration

weight (in this example, 5000 g).

4. The balance is calibrated – 0.2 g

(displayed only if menu CAL ± G

code 1 10 2 is set).

5. If the “Calibrate, then

Adjust

*

auto adjust" setting is CAL

selected (1 10 1), the balance

is now adjusted automatically.

6. The calibration sequence is completed.

CC

CAL

7. After calibration/adjustment, the

+ 5000.0 g

weight is displayed with weight unit

8. Remove the calibration weight.

0.0 g

* Adjust shown only if menu code 1 10 2 is set.

Important note:

Afterwards, do not perform internal calibration/adjustment again.

Purpose

To adapt the balance to individual

requirements by choosing from parameters

options in the Setup menu.

Features

To open the Setup menu, switch the

balance off and then on again by pressing

e. While all segments are lit, press

w briefly.

Scroll upward ↑: Press q

Scroll to the right →: Press r

Confirm input: Press w

Save settings and exit menu:

Press and hold w (> 2 sec.)

● Printing the Parameter Settings

– At the 3rd menu level (lowest level;

see also the next page): Press and hold

r (> 2 sec.)

> Printout (Example)

Menu711

– At the 2nd menu level: Press and hold

r.

> Printout (Example)

Menu711

Menu721

Menu731

– All current menu settings are printed

when the 1st menu level (highest level)

is displayed:

Press and hold r.

23

Configuration

Setting the Parameters (Menu Codes)

Example: Adapting the balance to “very unstable" ambient conditions (menu code 1 1 4).

Step Key (or instruction) Display

1. Switch off the balance. e

2. Switch the balance on; e

while all segments

are displayed: w briefly

1

$ Scroll upward within a q 2

menu level; after the last repeatedly ...

menu code, the first

9

code is displayed again. 1

3. Select menu level 2 r 1 1

(scroll to the right).

4. Select menu level 3 r

1 1 2

o

(scroll to the right).

5. Menu level 3: q

Scroll until the desired repeatedly

1 1 4

number is shown.

6. Confirm change; “o" w

1 1 4

o

on display indicates

active setting.

$ Return to higher menu level r

1

(from the third level).

$ Set other codes as desired. r, q

7. Save changes and exit Press and

the menu hold w (> 2 sec.)

or

$ Exit menu without saving

changes. e

24

Parameter Settings (Overview)

o Factory setting

√ User-defined setting

Setup 1 Weighing 1 1 Adapt filter 111 Very stable conditions

112 o Stable conditions

113 Unstable conditions

114 Very unstable conditions

1 2 Application filter 121 o Final readout

122 Filling mode

1 3 Stability range 131 4 digit

The stability symbol is 132 1 digit

displayed when the 133 1 digit

value is stable within 134 o 2 digits

this number of digits. 135 4 digits

136 8 digits*

1 5 Tare function* 151 Without stability

152 o After stability

1 6 Auto zero 161oOn

162 Off

1 7 Weight unit 1 171 Grams (display: o)*

172 o Grams (display: g)

173 Kilograms

174 Carats

175 Pounds*

176 Ounces*

177 Troy ounces*

178 Hong Kong taels*

179 Singapore taels*

1710 Taiwanese taels*

1711 Grains*

1712 Pennyweights*

1713 Milligrams

1

)

1714 Parts per pound*

1715 Chinese taels*

1716 Mommes*

1717 Austrian carats*

1718 Tola*

1719 Baht*

1720 Mesghal*

1 8 see next page

2 through 9 see following pages

* = Not available in balances verified for use in legal metrology

1

) = Not available on verified balances of accuracy class K

25

M

enu level 1

M

enu level 2

M

enu level 3

Factory setting

M

enu item

Menu 1 Weighing 1 1 through 1 7 see previous page

1 8 Display accuracy 1 * 181 o All digits

185 Reduced by 1 digit*

1 9 q key function 191 External cal./adj.

1

)

193 o Internal cal./adj.

197 q key blocked

1 10 Calibration/ 110 1 o Calibrate, then auto adjust

adjustment sequence in one operation

110 2 Calibrate, then manual

adjust

1 11 Weight unit for 1111 o Grams

calibration weight * 1112 Kilograms

1113 Pounds

1 15 isoCAL function 1151 Off

1152 Only adjustment prompt

1153oOn

2 Application 2 1 Program selection 211 o Weighing

programs 212 Toggle weight units

214 Counting

215 Weighing in percent

216 Net-total formulation

217 Animal weighing

3 through 9 see next page

* = Setting cannot be changed on verified balances

1

) = Not available on verified balances of accuracy class K

26

M

enu level 1

M

enu level 2

M

enu level 3

Factory setting

M

enu item

Loading...

Loading...