Sartorius IW2P1x-6ED-L,IW2P1x-15ED-L,IW2P1x-30ED-L,IW2P1x-150 series,IW2P1x-300GF-L,IW2P1x-60ED-L,IW2P1x-60FE-L Operating Instructions Manual

Operating Instructions | Betriebsanleitung | Mode d’emploi |

Istruzioni per l’uso | Manual de instrucciones

Sartorius Miras 2

IW Models | IW Modelle | Modèles IW | Modelli IW | Modelos IW

98648-018-73

2

Miras 2

English page 3

In cases involving questions of

interpretation, the German-language

version shall prevail.

Deutsch Seite 35

Im Auslegungsfall ist die

deutsche Sprache maßgeblich.

Français page 67

En cas de questions concernant

l’interprétation, la version

en langue allemande fera autorité.

Italiano pagina 99

In caso di interpretazione dubbia,

fa testo la versione in lingua tedesca.

Español página 131

En caso de interpretación,

la versión en lengua alemana

será determinante.

2

Miras 2

3

Contents

Description Page

Safety Precautions 4

Getting Started 7

General View of the Equipment 8

Setting Up the Scale 9

Operating Design 12

Descriptions of the Keys 15

Configuration (Setup Menu) 16

Application Programs 18

Counting 18

Check Weighing 19

Toggling between Weight Units 20

Calibration/Span Adjustment 21

SBI Interface Protocol Descriptions 23

RS-232 Interface Diagram 26

Print Formats 27

Error Codes 31

Care & Maintenance 32

Specifications 33

Accessories (Options) 33

C Marking 34

33

Contents

Contents

Description Page

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . 4

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . 7

General View of the Equipment . . . . . . . . . . . . . 8

Setting Up the Scale . . . . . . . . . . . . . . . . . . . . . 9

Operating Design . . . . . . . . . . . . . . . . . . . . . . . . 12

Descriptions of the Keys. . . . . . . . . . . . . . . . . . . 15

Configuration (Setup Menu) . . . . . . . . . . . . . . . 16

Application Programs. . . . . . . . . . . . . . . . . . . . . 18

Counting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Check Weighing . . . . . . . . . . . . . . . . . . . . . . . . . 19

Toggling between Weight Units. . . . . . . . . . . . . . 20

Calibration/Span Adjustment . . . . . . . . . . . . . . . 21

SBI Interface Protocol Descriptions . . . . . . . . . . 23

RS-232 Interface Diagram. . . . . . . . . . . . . . . . . 26

Print Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Care & Maintenance . . . . . . . . . . . . . . . . . . . . . 32

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Accessories (Options) . . . . . . . . . . . . . . . . . . . . . 33

C Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

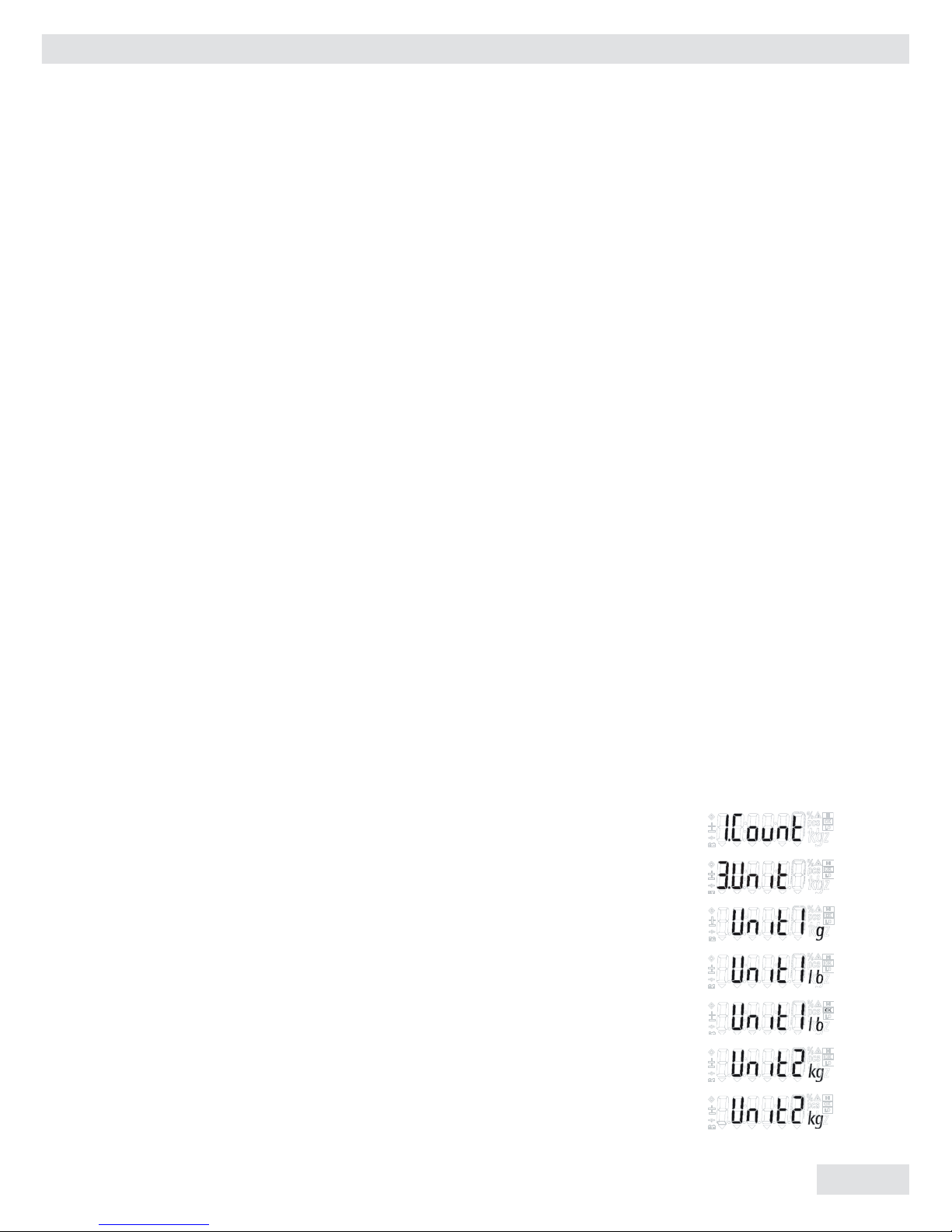

Select Weight Units

Step Key (or instruction) Display

Select application setup (Fn/Up) > 2 sec

Select “Toggling Weight Units” (Fn/Up) repeatedly

Confirm selection (Print/Enter)

Select weight unit 1 (Fn/Up)

Confirm weight unit 1 (Print/Enter)

Select weight unit 2 (Fn/Up)

Confirm weight unit 2 (Print/Enter)

4

Miras 2

Safety Precautions

4

Explanation of Symbols:

! Caution, risk of danger:

Read the accompanying text carefully.

The instrument is double-insulated.

Protective conductor terminal

Earth ground terminal

Safety tips, electrical protection class

! This instrument was built and tested in accordance with the safety regulations

for measuring and control instrumentation for protection class I (protective earth

connection) according to IEC 1010/ EN61010-1 or VDE 0411. The instrument was

delivered in safe condition. To maintain this condition and to ensure safe operation,

the operator must follow the instructions and warnings given in this documentation

Protective earth

! The connecting cable of the unit complies with the regulations in accordance with

VDE 0411 or EN61010. The mains plug must contain a protective earth conductor,

which must not be interrupted inside or outside this instrument (e.g. by using an

extension cable without protective earth). Before commissioning, acceptance of the

installation by a technically competent expert is required.

Measurement category

! This instrument is designed for measurement

category I, with a maximum of 8.5 V. To ensure safe operation do not use this

instrument for measurements within the measurement categories II, III or IV.

Miras 2

5

! Opening the instrument

CAUTION: DANGER TO LIFE!

– Working on the instrument when it is

switched on can be dangerous to life.

Disconnect the instrument from the

supply voltage! When removing covers

of parts by means of tools, live parts or

terminals may be exposed. Capacitors in

the unit may still be charged even after

disconnecting the unit from all voltage

sources.

– As the unit has no power switch, to

completely remove AC power from the

unit, disconnect the AC power cable

from the mains socket.

– Do not expose the scale unnecessarily to

aggressive chemical vapors or to

extreme temperatures,

moisture, shocks, or vibration.

– Avoid exposing the scale to static elec-

tricity; be sure to connect the equipotential bonding conductor to the junction box.

Repair and maintenance

– Repairs are subject to checking and can

be carried out only at Sartorius. In case

of defect or functional trouble, please

contact your local Sartorius dealer for

repair. When returning the instrument

for repair, an exact and complete fault

description must be supplied.

Only a trained technician aware of the

hazards involved may carry out maintenance work, during which the relevant

precautions must be taken.

Important note:

– Make sure that the construction of the

instrument is not altered to the detriment of safety. In particular, leakage

paths, air gaps (of live parts) and insu-

lating layers must not be reduced.

The manufacturer cannot be held

responsible for personal injury or damage caused by an instrument repaired

incorrectly by user or installer.

– Only authorized service technicians who

have been trained by Sartorius and who

follow Sartorius’s standard operating

procedures for maintenance and repair

may open the scale. If you see any indication that the scale cannot be operated

safely (for example, because of equipment damage), turn off the scale and

lock it in a secure place so that it cannot be used for the time being.

– If you use suction lifting equipment to

lift the load plate, always wear gloves,

hard-toed safety boots and protective

clothing. Warning: This procedure can

cause personal injury! Only reliable

personnel who are qualified to perform

such work are allowed to use suction

lifting equipment.

– Always make sure the scale is discon-

nected from AC power before performing any installation,

cleaning, maintenance or repair work.

– Check the pin assignment if you use

cables purchased from a different manufacturer. Before connecting such a

cable to Sartorius equipment, check the

pin assignment on the corresponding

wiring diagram or chart and disconnect

any wires that are assigned differently

from those specified by Sartorius.

The operator shall be solely responsible

for any damage or injuries that may

occur when using cables not supplied

by Sartorius.

5

6

Miras 2

! Note:

– Do not use this equipment in hazardous areas.

– Make sure the voltage rating printed on the

power supply is identical to your local line

voltage.

– Use only commercially available batteries

(rechargeable or dry-cell battery). If you use

a rechargeable battery, use only 12 V 2.3AH.

– The scale is energized at all times unless you

disconnect the AC power and the battery.

– Exposure to excessive electromagnetic interfer-

ence can cause the readout value to change.

Once the disturbance has ceased, the instrument

can be used again in accordance with its intended purpose.

6

Miras 2

7

Getting Started

Storage and Shipping Conditions

Do not expose the scale to shocks,

vibrations, moisture or extreme temperatures.

Unpacking the Scale

After unpacking the scale, check it

immediately for any visible damage as

a result of rough handling during shipment.

Note:

– The display and control unit is attached

to the weighing platform via a cable.

– If you see any sign of damage, proceed

as directed in the chapter entitled “Care

and Maintenance,” under the section on

“Safety Inspection.”

– Save the box and all parts of the

packaging until you have successfully

installed your scale. Only the original

packaging provides the best protection

for shipment. Before packing your scale,

unplug all connected cables to prevent

damage.

Equipment Supplied

The equipment supplied includes the

components listed below:

– Scale with attached display and control

unit

– Load pan

– Installation and operating instructions

Installation Instructions

The Sartorius Miras scales are designed

to provide reliable weighing results

under normal ambient conditions. When

choosing a location to set up your scale,

observe the following so that you will

be able to work with added speed and

accuracy:

– Set up the scale on a stable, even sur-

face

– Avoid placing the scale in close proxim-

ity to a heater or otherwise exposing the

scale to heat or direct sunlight

– Protect the scale from drafts that come

from open windows or doors

– Avoid exposing the scale to extreme

vibrations during weighing

– Protect the scale from aggressive

chemical vapors

– Do not expose the scale to extreme

moisture over long periods

– Remove transport locking: see page 9

Conditioning the Scale

Moisture in the air can condense on

the surfaces of a cold scale whenever it

is brought into a substantially warmer

place. If you transfer the scale to a

warmer area, make sure to condition it

for about 2 hours at room temperature,

leaving it unplugged from AC power.

Afterwards, keep the scale continuously

connected to AC power.

77

8

Miras 2

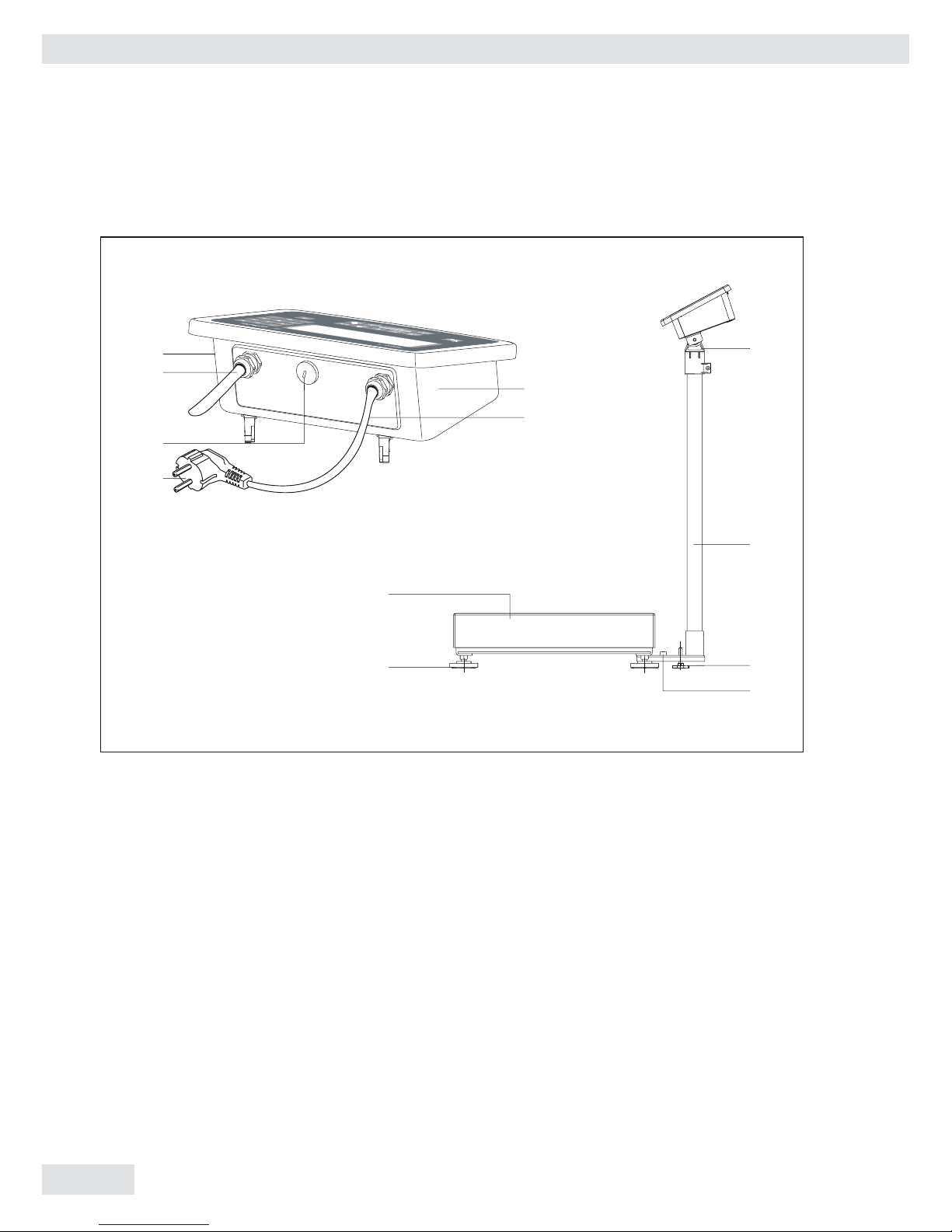

General View of the Equipment

1 Housing

2 Power cable

3 Display and control unit retainer

4 Display and control unit column

5 Column support foot

6 Level indicator (option)

7 Leveling feet

8 Stainless steel weighing pan

9 Power plug

10 Cable gland cover

(for optional RS-232 port outlet)

11 Load cell cable gland

12 Manufacturer’s ID tag

8

1

2

3

4

5

6

7

8

09

10

11

12

Miras 2

9

Setting Up the Scale

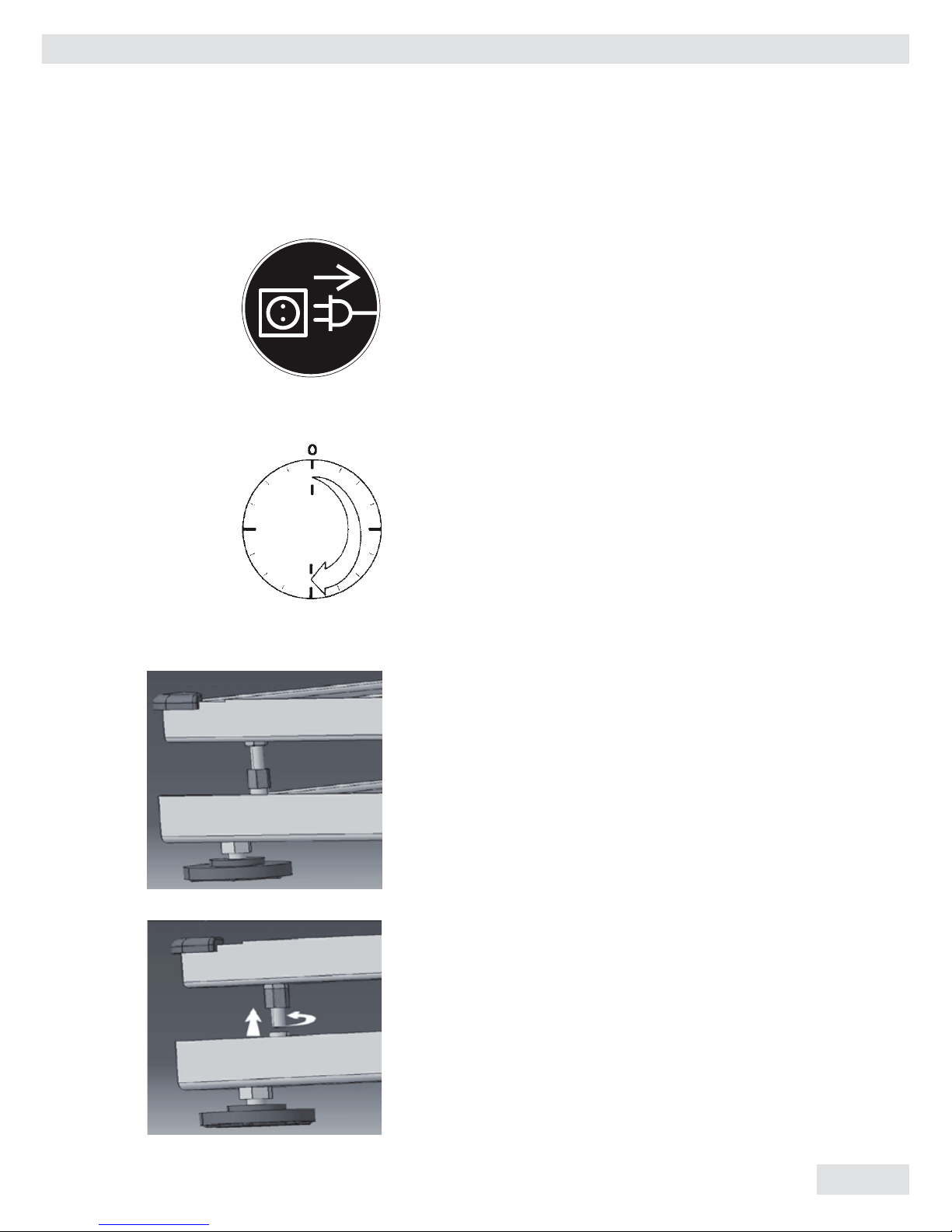

Connecting Electronic Peripheral Devices

§ Make absolutely sure to unplug the scale from AC

power or switch off (activate battery mode) before

you connect or disconnect a peripheral device (printer or PC) to or from the interface port.

Warm-up Time

To deliver exact results, the scale must warm up for

at least 30 minutes after

initial connection to AC power. Only after this time

will the scale have reached the required operating

temperature.

Transport Lock

– Under the metal frame structure there are four

safety overload protection pins (Note: not on all

platform models).

Before using the scale, rotate the nut (upwards) until

tight.

Place the load plate on the scale

9

10

Miras 2

Leveling the Scale

– Remove the load plate

– Using the 4 foot screws, level the scale so that the

air bubble is centered within the level indicator

– Check to ensure that all leveling feet rest securely on

the work surface

10

Miras 2

11

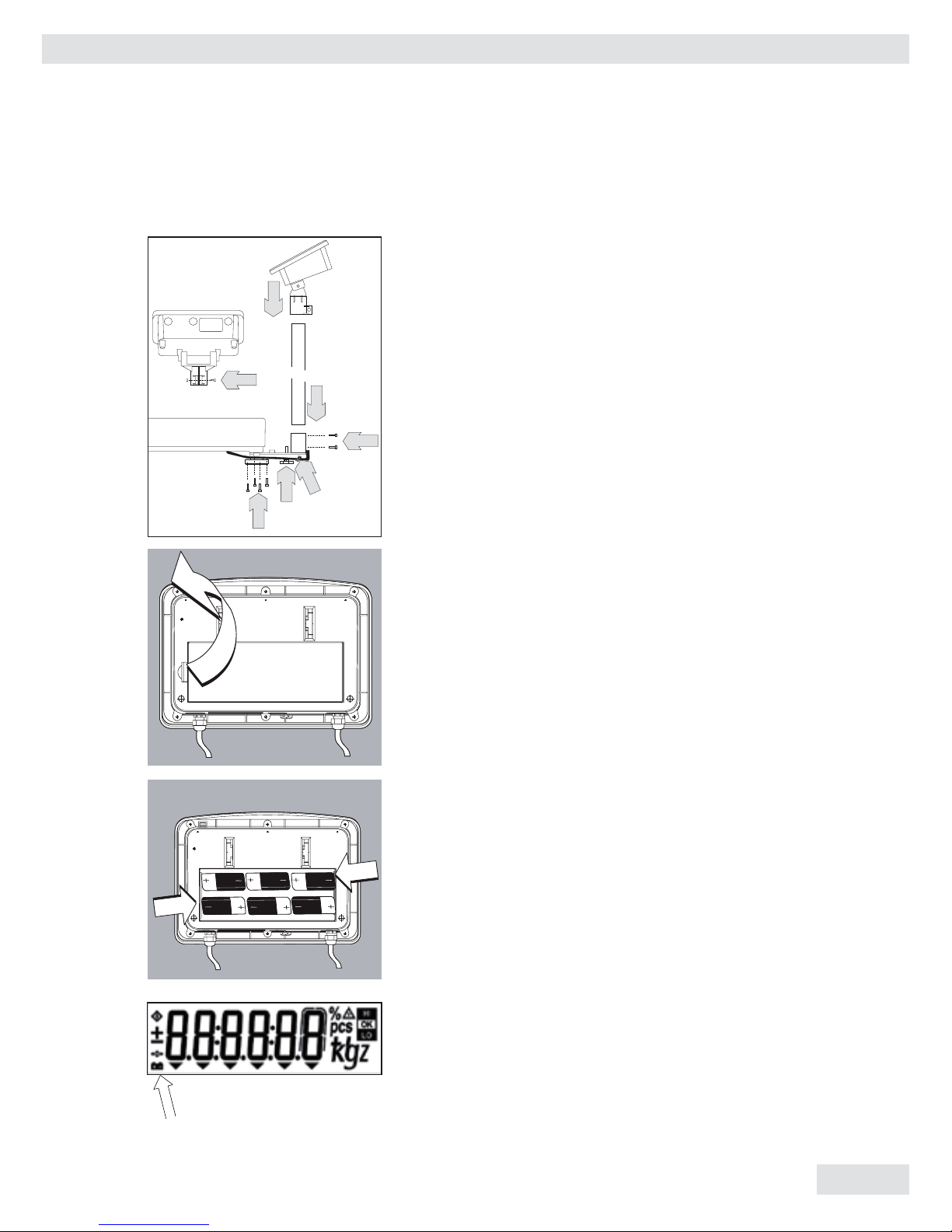

Assembly Procedure

1. Affix the column bracket with 4 screws

2. Install the column support leveling foot

3. Push the load cell cable into the column

4. Insert the column into the bracket holder

5. Affix the column with 2 screws

6. Insert the display and control unit retainer into the

column

7. Tighten the screw on the display and control unit

bracket

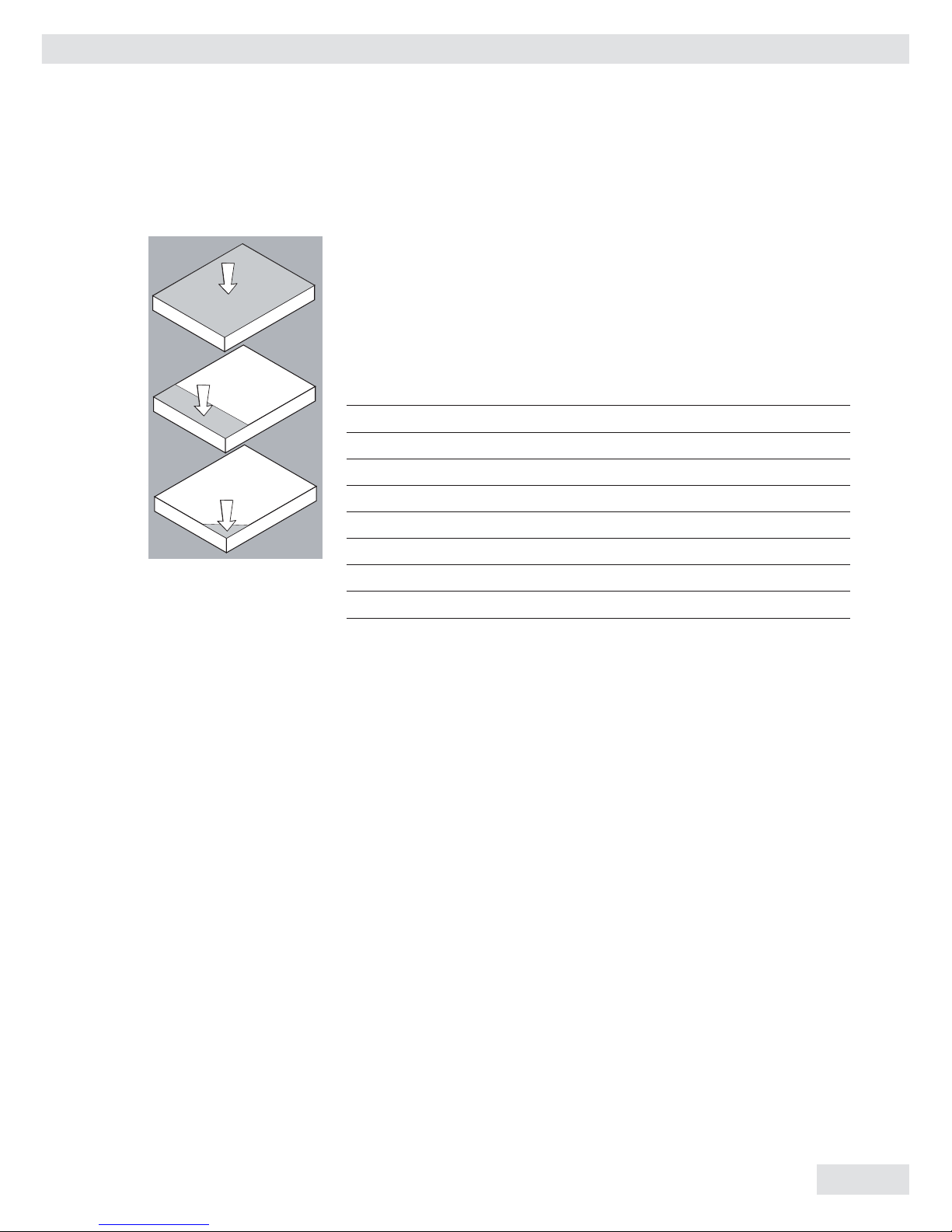

Battery-Powered Operation

To activate battery operation:

– Open the battery cover at the back of the Indicator.

– Insert 1.5 V size D dry-cell batteries (not included)

into the battery compartment.

– The battery symbol is displayed when the unit is

operating on battery power.

– If the battery symbol flashes, the battery power is

weak.

Replace the batteries (if using dry-cell batteries).

11

4

5

7

6

1

2

3

12

Miras 2

Operating Design

The scales in the Miras series consist

of a weighing cell and a display and

control unit. In addition to the choice

of power supply or rechargeable maintenance-free lead acid battery or dry

battery.

The display and control unit is affixed

to the weighing platform. Operation of

the Miras scale is simple and uniform.

The Miras models include the features

like gross/net toggling, counting,

checkweighing & unit toggling.

Display

The display is divided into sections:

Busy Symbol, Plus/Minus Sign

If the symbol displayed here is a diamond b, this indicates that the scale

is performing a function (busy symbol).

A plus or minus sign (+ or –) refers to

the value displayed.

Measured Value

Shows the measured value

Basic Unit and Additional Information

– When the scale has stabilized, the

weight unit is displayed here (g, kg,..).

– The arrows below the weight indications

shows the weighing mode (gross/net)

and the application mode (counting,

checkweighing, or unit toggling) enabled, if any.

– The

!

symbol indicates the unit is

not in weighing mode (e.g.: calibration

mode, configuration mode, error mode)

12

Miras 2

13

Operating Limits

Never exceed the maximum capacity of the scale.

The maximum loading capacities of the scales in this series are

listed in the table below and depend on the position of the load

on platform:

Model Width Length Center* Side Corner

(mm) (mm) kg kg kg

IW2P1.–6ED… 300 4000 50 35 20

IW2P1.–15ED… 300 400 130 85 45

IW2P1.–30ED… 300 400 500 400 200

IW2P1.–60ED… 300 400 600 400 200

IW2P1.–60FE… 400 500 600 400 200

IW2P1.–150FE… 400 500 600 400 200

IW2P1U–150GF… 500 650 600 400 200

IW2P1.–300GF… 500 650 600 400 200

13

14

Miras 2

Scale connected to AC power:

On/Off Switch:

On: Scale is operational and display

shows function or mode that is in use

Off: Depends on menu setting (“4.

Standby option.”), scale is completely

off (no display and no internal circuitry)

or in standby (no display and internal

circuitry working).

Back Light:

Depends on menu setting (“2. Backlight”). Backlight is on/off.

Auto Power Off:

Not active.

Scale running on battery power:

On/Off Switch:

On: Scale is operational and the display

shows the function or mode that is in

use

Off: Completely off (no display and no

internal circuitry working)

Back Light:

Depends on menu setting (“2. Backlight”). Backlight is on/off. Backlight

goes off after 15 seconds if no operation is done (no key pressed/no weighing). Backlight comes back on whenever

a key (except on/off) is pressed or when

a load is placed on the scale.

Auto Power Off:

Depends on menu setting (“3. Auto

power off”); system power shuts down.

Time limit options for auto power in

setup menu are 5, 10 or 15 minutes,

or can be disabled.

14

Power Management Option

Miras 2

15

15

Descriptions of the Keys

1) On/Off

“On/off” function will depend on

different power supply conditions.

Use the setup menu for backlight

control and for auto power off.

In Main Mode

§ Off-Mode:

If standby active: Scale is in standby

mode, but there is no display visible

other than mode symbol (no backlight,

no display, no symbols)

If standby not active:

Scale is completely off

§ On-Mode:

Scale is in operation and the display

shows the function that is in use.

In this mode, auto power off function

is invalid.

In Battery Mode

§ Off-Mode: Scale is completely off.

§ On-Mode: Scale is in operation and the

display shows the function that is in use.

Backlight works based on setup menu

In this mode, auto power off function

is valid. After 5, 10 or 15 minutes, the

system shuts off when not in use in

accordance with the setup menu setting.

2) Zero/Arrow-Left (Zero/Left)

Weighing mode: Set scale to zero

Parameter mode: Shift position of digit

to the left

3) Tare/Arrow-Right (Tare/Right)

Weighing mode: Tare the scale

Parameter mode: Shift position of digit

to the right

4) Gross-Net/Arrow-Down (G/N/Down)

Weighing mode: Toggle weight unit

gross/net

Counting mode: Toggle weight unit

gross, net and pcs

Function mode: To scroll down menu

selection

Parameter mode: Reduce digit value by 1

5) Function/Arrow-Up (Fn/Up)

Weighing mode: Switch the scale from

normal weighing mode to application

setup mode

Function mode: Scroll up in menu

selection

Parameter mode:

Increase digit value by 1

6) Print/Enter (Print/Enter)

Weighing mode: Print key

Function mode: Scroll level up in menu

mode/confirm selected menu.

16

Miras 2

16

Configuration (Setup Menu)

To configure the user interface of the scale to individual requirements

Step Key (or instruction) Display

1. Switch off the scale (On/Off)

2. Switch on the scale (On/Off)

3. While all the segments

are displayed: (Zero/Left) > 2 sec

Navigation in the Setup Menu

Key Function

(Print/Enter) Menu item: Confirm setting

(Fn/Up) Menu item: Scroll up

Digit input: Increase by 1

(G/N/Down) Menu item: Scroll down

Digit input: Reduce by 1

(Zero/Left) Digit input: Selection shift left

(Tare/Right) Digit input: Selection shift right

Miras 2

17

17

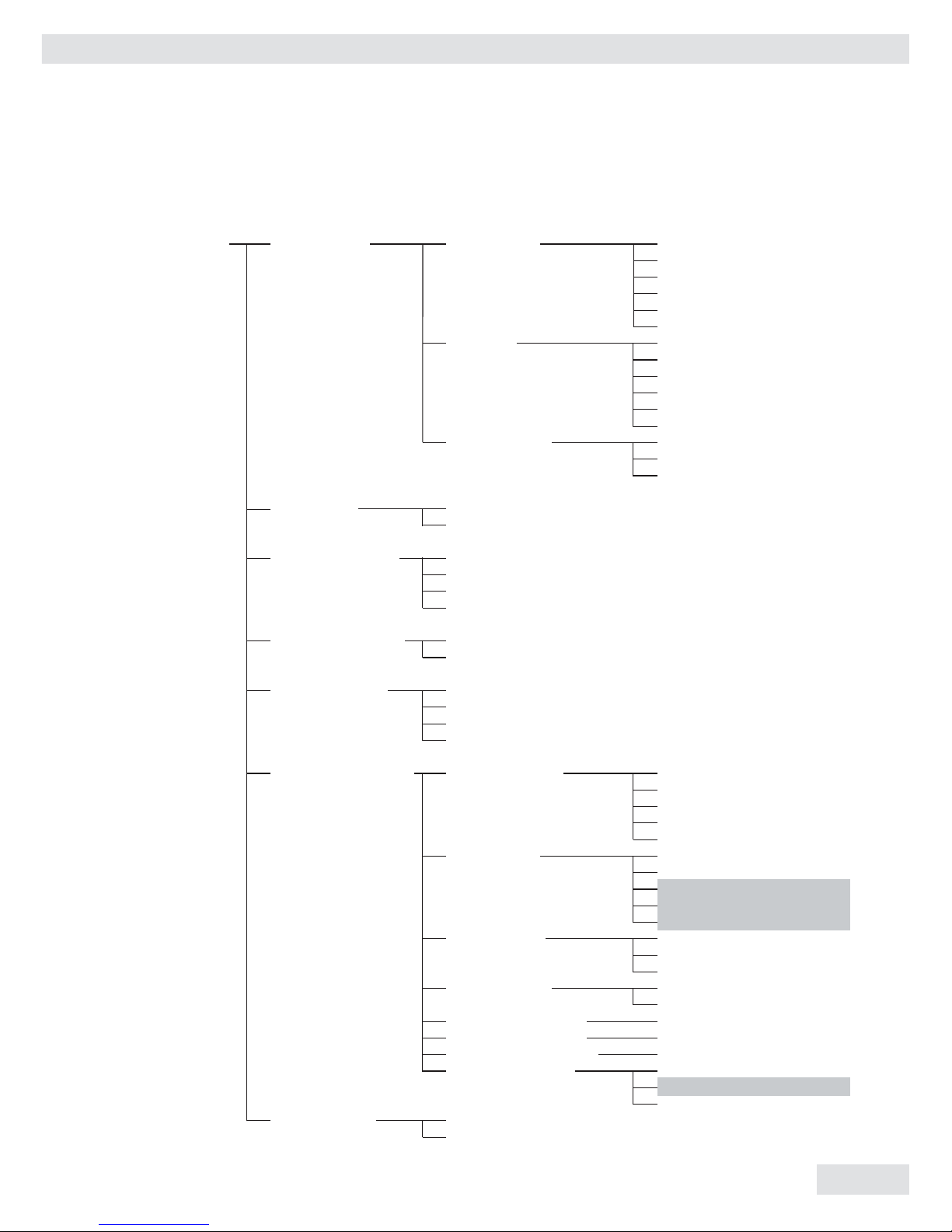

Setup Menu 1. Serial COM 1.1 Baud rate 1.1.1 600

1.1.2 1,200

1.1.3 2,400

1.1.4 4,800

1.1.5 9,600 •

1.1.6 19,200

1.2 Parity 1.2.1 7-bit-None

1.2.2 7-bit-Odd

1.2.3 7-bit-Even •

1.2.4 8-bit-None

1.2.5 8-bit-Odd

1.2.6 8-bit-Even

1.3 Print option 1.3.1 Short •

1.3.2 Long/block

1.3.3 Continuous

2. Backlight 2.1 On •

2.2 Off

3. Auto Power Off 3.1 No options •

3.2 5 Min.

3.3 10 Min.

3.4 15 Min.

4. Standby Options 4.1 On •

4.2 Off

5. Adapter Filter 5.1 Very stable conditions

5.2 Stable conditions •

5.3 Unstable conditions

5.4 Very unstable conditions

6. ADC Configuration 6.1 Decimal point 6.1.1 0

6.1.2 1

6.1.3 2

6.1.4 3

6.1.5 4

6.2 Basic unit 6.2.1 g

6.2.2 kg

6.2.3 lb • For some countries,

6.2.4 oz these units

6.2.5 t are disabled

6.3 Step width 6.3.1 1

6.3.2 2

6.3.3 5

6.4 e<>d frame 6.4.1 On

6.4.2 Off •

6.5 Adjust FSD (span) 6.5.1 (Enter FSD weight)

6.6 Calibration weight 6.6.1 (Enter CAL weight)

6.7 Linearisation weight 6.7.1 (Enter Lin weight)

6.8 Calibration unit 6.8.1 g

6.8.2 kg •

6.8.3 lb

7. Reset Menu 7.1 Do not restore

7.2 Restore

• = Factory setting

18

Miras 2

18

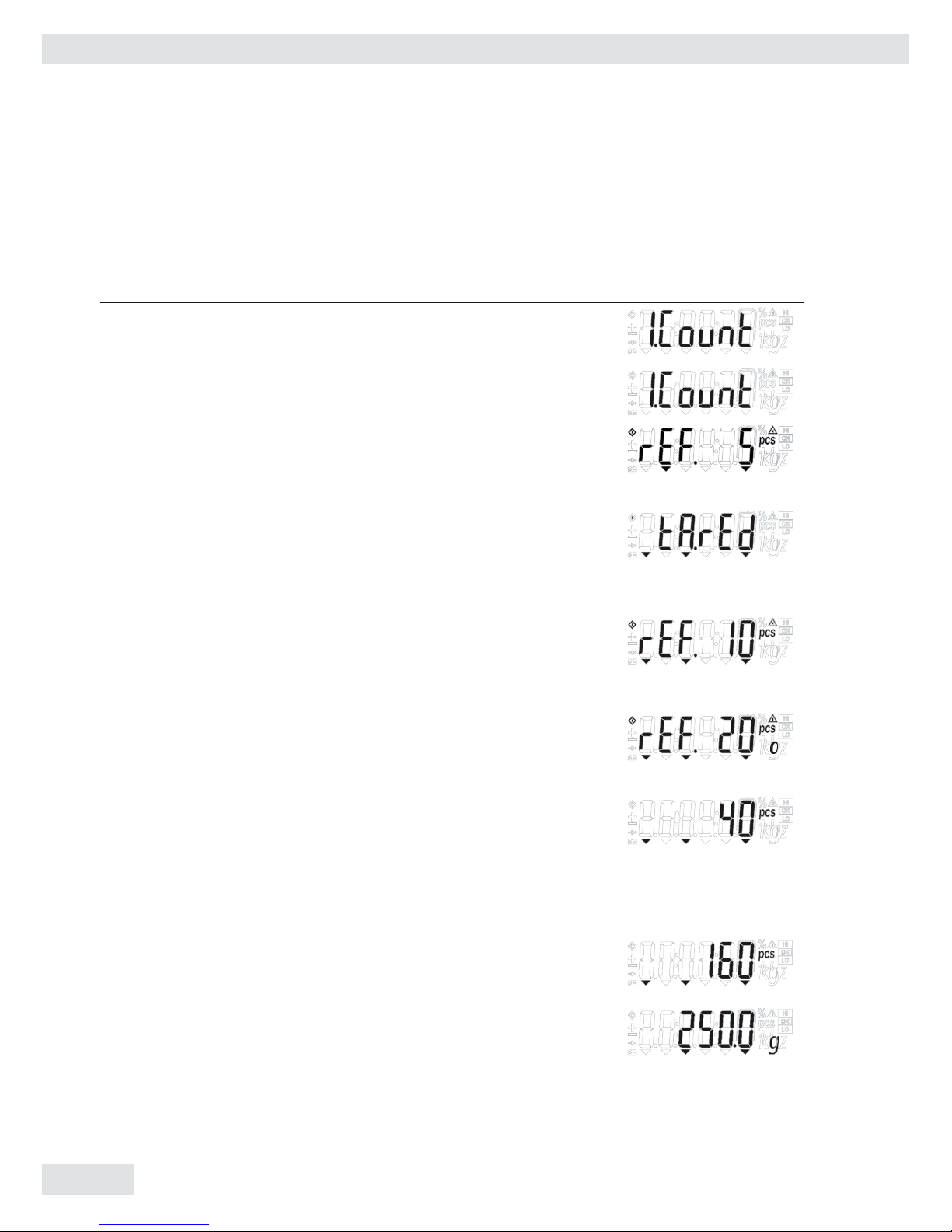

Application Programs

Counting

Step Key (or instruction) Display

a. Select application program (Fn/Up) > 2 sec

b. Select “Counting” (Fn/Up) or (G/N/Down)

repeatedly

c. Press Print/Enter. (Print/Enter)

Display shows reference piece

selection menu.

Counting is blinking.

d. Automatically the display

will show the reference pieces. (Tare/Right)

Place container and press Tare

if required (display “tared”).

e. Select reference sample quantity: (Fn/Up) or (G/N/Down)

5, 10, 20, 50 or 100, and put repeatedly

the reference on the scale.

(quantity flashes)

f. Press Print/Enter . Place reference sample on scale

Now “O” flashes. Automatic optimization is

active. (Print/Enter)

g. Place more reference samples

on scale (The number is

x+2 ~ 2x times the reference

pieces (x) selected in step e.)

When the sample is still, the

reference sample weight is calculated.

The flashing “O” goes out.

h. Place uncounted parts/samples

on the scale

i. Toggle between reference piece weight, (G/N/Down)

total weight, and total pieces.

j. Unload the scale

k. Counting application: Clear (Zero/Left) > 2 sec

Miras 2

19

19

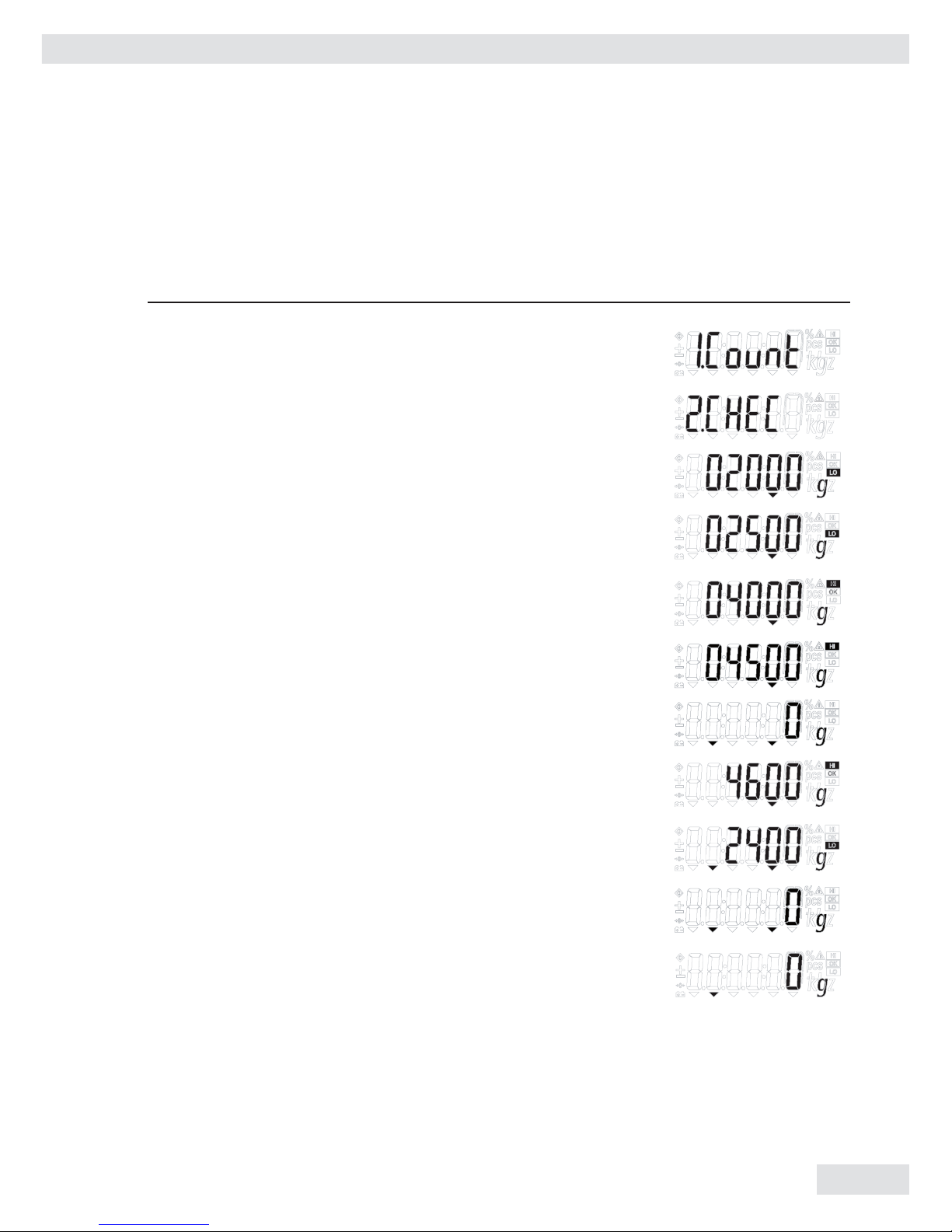

Check Weighing

Step Key (or instruction) Display

a. Select application program (Fn/Up) > 2 sec

b. Select “Checkweighing” (Fn/Up) or (G/N/Down)

repeatedly

c. Press Print/Enter to confirm. (Print/Enter)

“LO” flashes.

d. Set lower limit (Fn/Up) or (G/N/Down) and/or

(Zero/Left) or (Tare/Right)

e. Press Print/Enter to confirm (Print/Enter)

and save. “HI” flashes

f. Set upper limit, (G/N/Down) and/or

and then press Print/Enter. (Zero/Left) or (Tare/Right)

g. Press Print/Enter to confirm (Print/Enter)

and save.

h. Place the sample on the scale.

Display shows the difference

and HI/LO symbol

i. Unload the scale

j. Checkweighing application: Clear (Zero/Left) > 2 sec

20

Miras 2

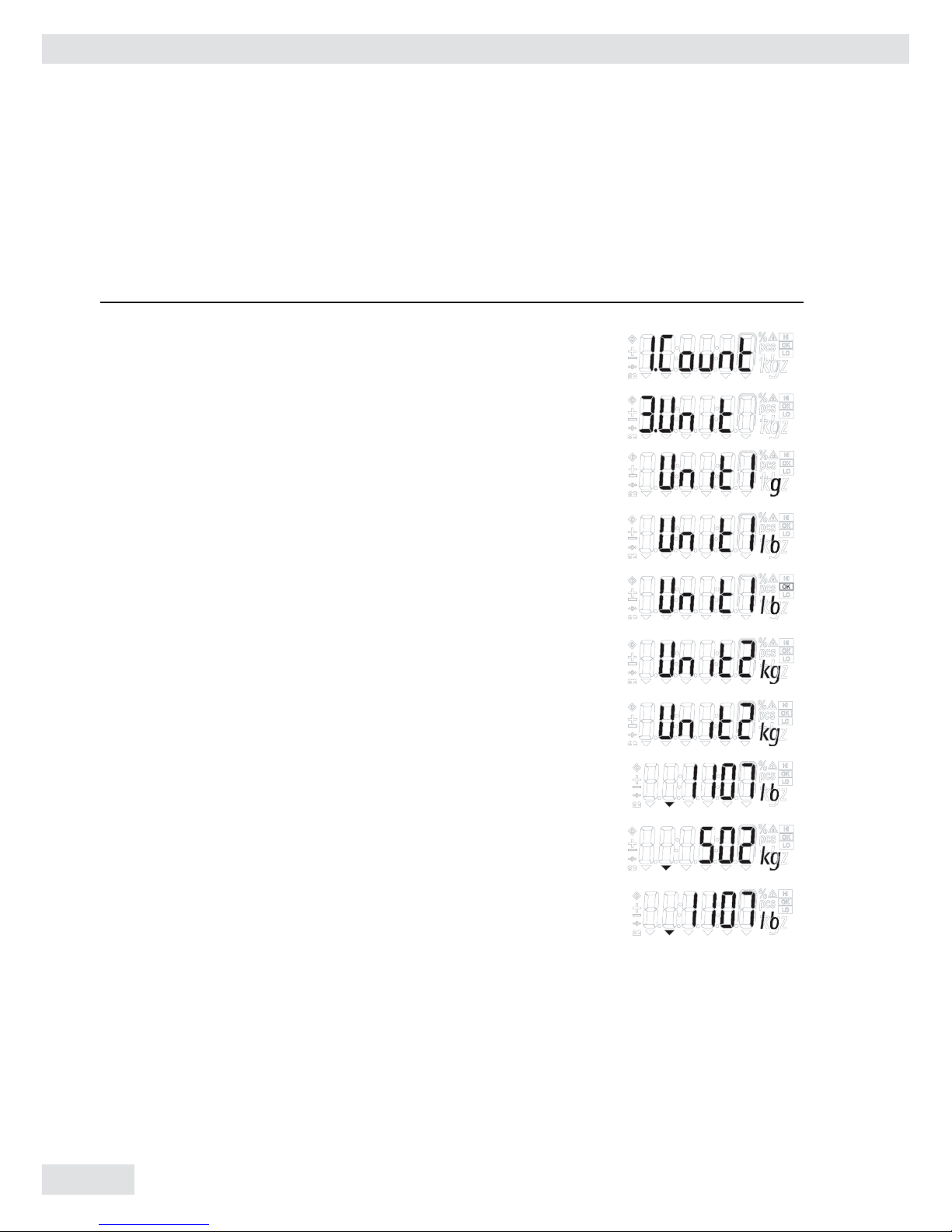

Toggling between Weight Units

Step Key (or instruction) Display

a. Select application program (Fn/Up) > 2 sec

b. Select “Toggling Weight Units” (Fn/Up)

repeatedly

c. Confirm selection (Print/Enter)

d. Select weight unit 1 (Fn/Up)

e. Confirm weight unit 1 (Print/Enter)

f. Select weight unit 2 (Fn/Up)

g. Confirm weight unit2 (Print/Enter)

h. Place sample on the scale

i. Toggle weight unit (Fn/Up)

j. Unit toggling application: (Zero/Left) > 2 sec

Clear (unit changes to basic

unit set)

20

Miras 2

21

21

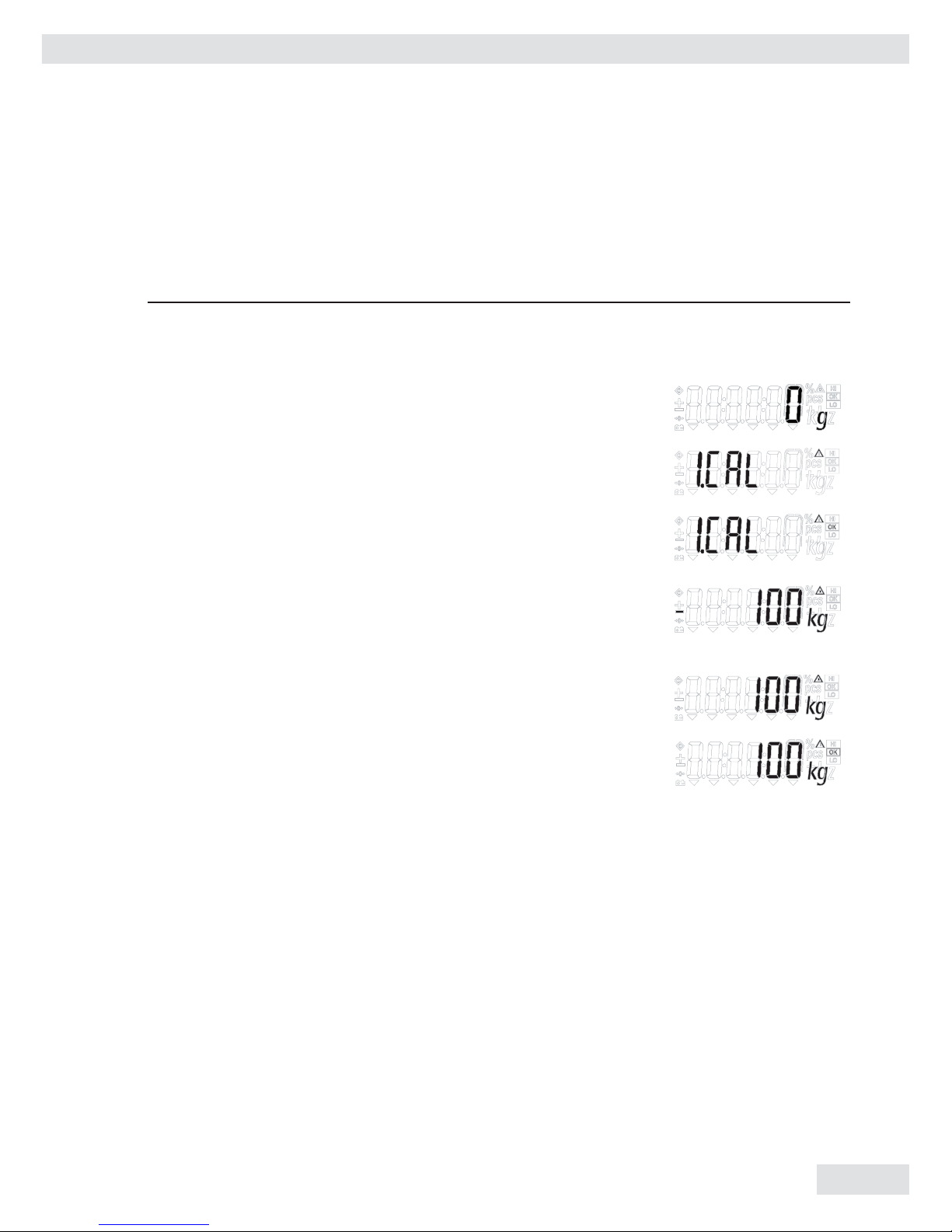

Calibration/Span Adjustment

Calibrate the Scale

Step Key (or instruction) Display

a. Switch on the scale (On/Off)

b. Zero the scale (Zero/Left)

c. Select calibration/linearization (Tare/Right) > 2 sec

mode

d. Select calibration (Fn/Up)

repeatedly

e. Confirm/start calibration. (Print/Enter)

After the zero point is stored,

the required calibration weight

is displayed

f. Place the required weight

on the scale

g. If the weight is applied within (Print/Enter)

the defined time limit and

tolerance, the “OK” symbol

is displayed.

Press “(Print/Enter)” to confirm

and save calibration.

(To exit calibration press

(Zero/Left) > 2 sec)

22

Miras 2

22

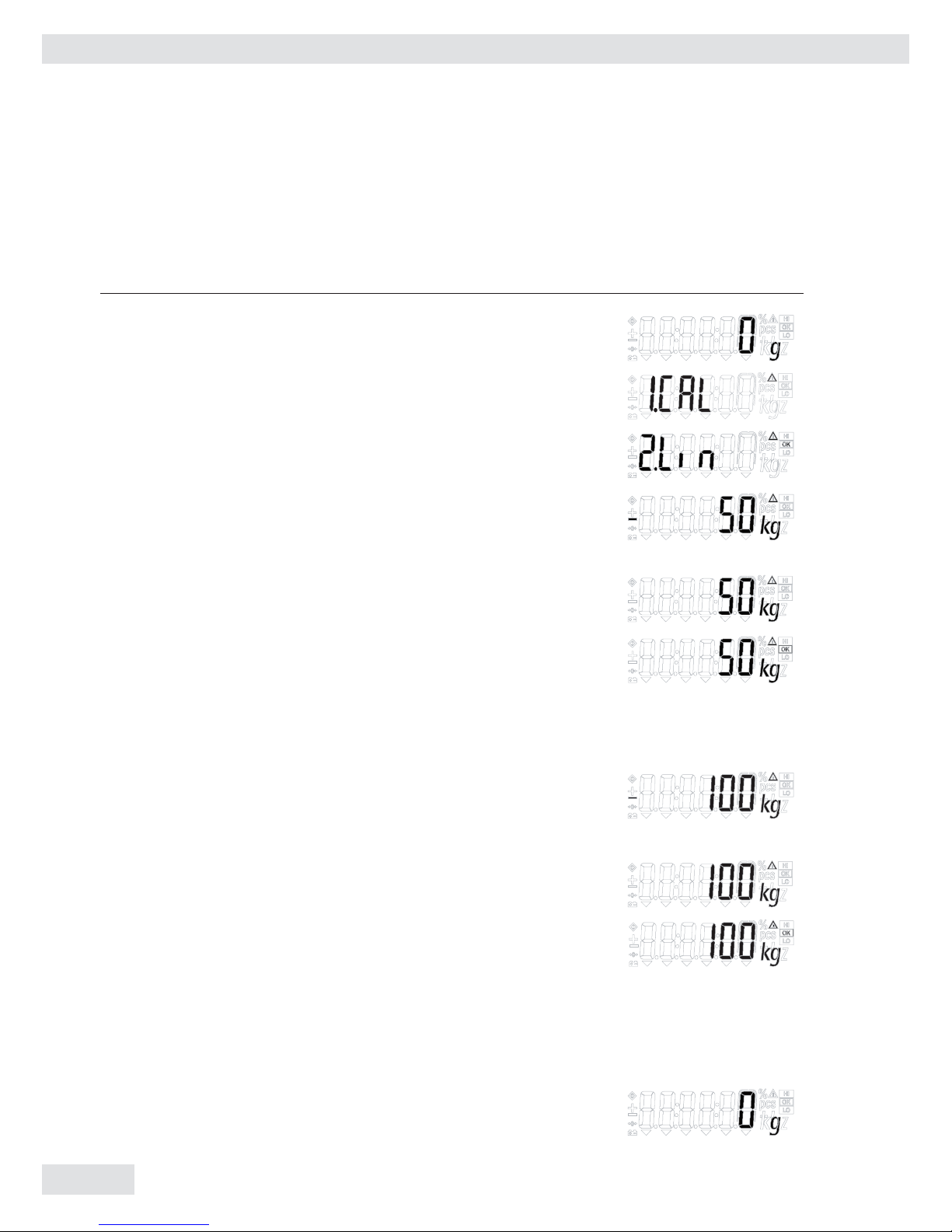

Linearize the Scale

Step Key (or instruction) Display

a. Switch on the scale (On/Off)

b. Zero the scale (Zero/Left)

c. Select calibration/linearization (Tare/Right) > 2 sec

mode

d. Select linearization (Fn/Up) or (G/N/Down)

repeatedly

e. Confirm/start linearization (Print/Enter)

After the zero point is stored,

the required linearization

weight is displayed.

f. Place the required weight on

the scale

g. If the weight is applied within (Print/Enter)

the defined time limit and tolerance,

the “OK” symbol is displayed.

Press “(Print/Enter)” to confirm

and save calibration. (To exit

linearization, press (Zero/Left) > 2 sec)

h. The next linearization weight

will be shown on the display

after confirmation of the

previous linearization weight.

i. Place the required weight

on the scale.

j. If the weight is applied within (Print/Enter)

the defined time limit and

tolerance, the “OK” symbol

is displayed. Press “(Print/Enter)”

to confirm and save calibration.

(To exit linearization,

press (Zero/Left) > 2 sec)

k. Remove the linearization weight

l. Linearization complete

Miras 2

23

SBI Interface Protocol Description

Output format with 22 characters

The following data block format is output:

I I I I I I V W W W W W W W W W U U U CR LF

I : ID W : Weight value

V : +/– sign U : Unit

ID Codes

S t a t Indicates a special weighing platform status, e.g., initialization, self-test,

adjustment/calibration

N Indicates net or gross value

N 1 Indicates net value with 1

st

tare memory assigned (not main tare)

N 2 Indicates net value with 2

nd

tare memory assigned (not main tare)

S / N Indicates equipment serial number

M o d e l Indicates equipment model

Plus/Minus Sign

+ Plus sign

– Minus sign

Space (i.e., no plus or minus sign; if weight value is 0 or if output does not include a

weighed value)

Unit No stable parameter.; no weighed value

g Grams

k g Kilograms

l b Pounds

o z Ounces

t Tons

Special Codes

The data block may contain special information.

Special status-dependent codes:

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

S1 S2 CR LF

The following status codes are output for “S1” and “S2”:

: Taring

C : Internal calibration

- - : All numerals shown in stable readout

H : Overload

L : Underload

23

24

Miras 2

Special Error-Dependent Codes:

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

E R R n n1 n2 CR LF

n – n3 contains an error code of up to 3 digits.

Data Input Formats

You can enter certain commands to control weighing platform functions through the SBI

interface.

As with data output, data is input as 7-bit ASCII characters; hardware and protocol configuration are identical to those for data output.

Formats:

ESC K CR LF

ESC K K1 – CR LF

ESC : Escape

K : Command character

K1 : 2

nd

command character (number)

- : Underline

CR : Carriage return

LF : Line feed

24

Miras 2

25

The CR and LF characters do not have to be transmitted in the data string.

Control Commands

ESC P CR LF Print, auto print: initiate / stop

ESC T CR LF Zero/Tare – combination

ESC V CR LF Zero the weighing platform

ESC U CR LF Tare the weighing platform

ESC S CR LF Reset

ESC O CR LF Lock keyboard

ESC R CR LF Unlock keyboard

ESC x 1 _ CR LF Output model name

ESC x 2 _ CR LF Output serial number

Adaptation to Ambient Conditions

ESC K CR LF Very stable

ESC L CR LF Stable

ESC M CR LF Unstable

ESC N CR LF Very unstable

25

26

Miras 2

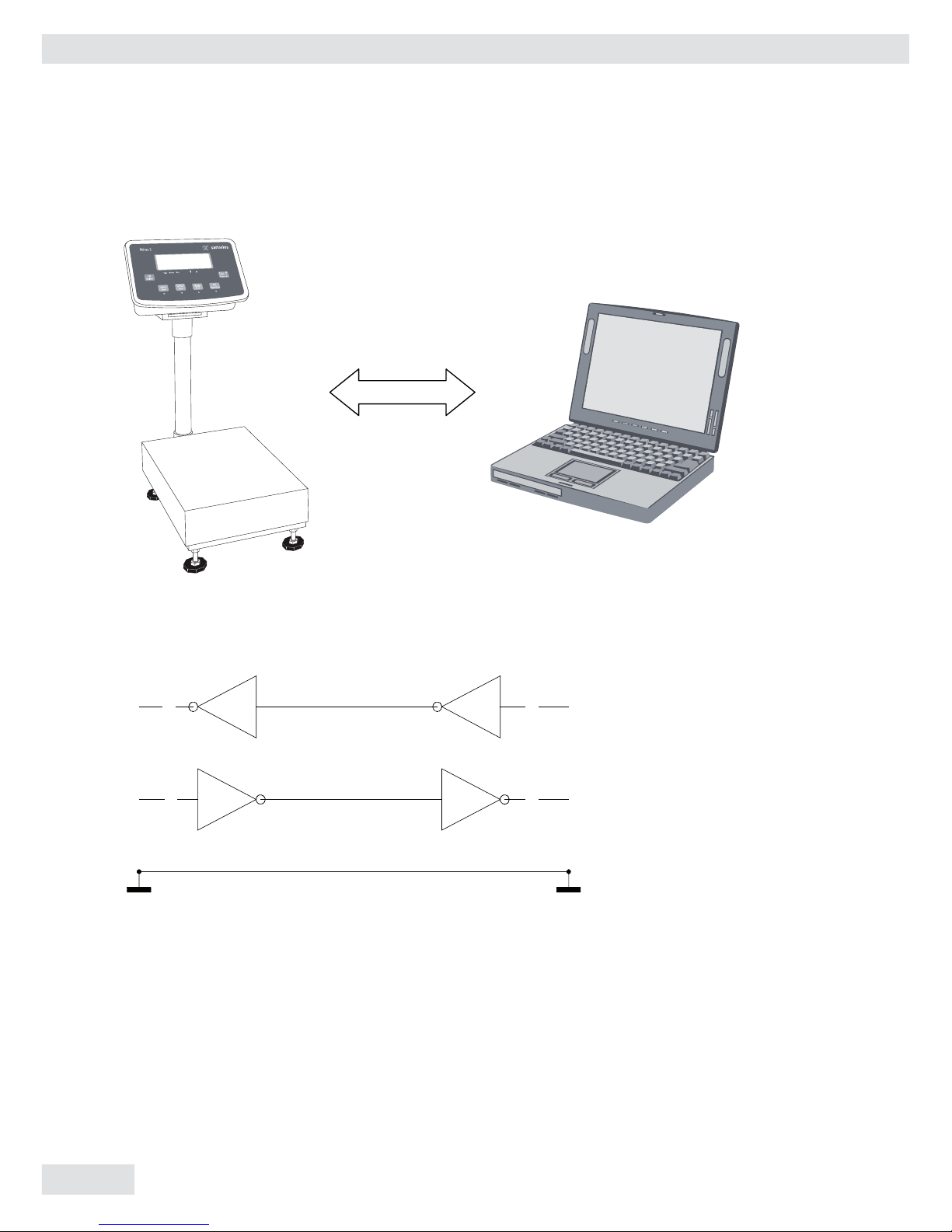

RS-232 Interface Diagram

Diagram for interfacing a computer or different peripheral device to the scale using

RS-232 cable length up to 15 m.

26

TXD RXD

1 3

GND

GND

TXDRXD

2 2

57

DB 25 DB 9

3

2

5

Miras 2

27

Print Formats

The print output can be configured for three modes: short mode (option 1.3.1), long/

block mode (option 1.3.2) and continuous mode (option 1.3.3). The SBI interface,

explained in the section above, is available in all modes. Sample print outputs are given

below for all three printing options in different weighing modes.

Note: To configure serial communication settings and print output options, please refer

to “Configuration (Setup menu)”.

Refer to “Application Programs” to configure the display and control unit for different

weighing modes.

2727

Printing Options

Mode of operation Short print Block print (long print) Continuous mode

Normal weighing

mode

Net weight Gross weight

(if tare is active)

Tare weight

(if tare is active)

Net weight

Gross weight

(if tare is not active)

or

Net weight

(if tare is active)

Counting mode Net weight

Pcs

Ref. weight

Gross weight

(if tare is active)

Tare weight

(if tare is active)

Net weight

Pcs

Ref. weight

Pcs (as default)

Pressing the Gross/Net key

switches

to:

Gross weight

(if tare is not active)

or

Net weight

(if tare is active)

Checkweighing

mode

Net weight

Chk OK/LO/HI

Gross weight

(if tare is active)

Tare weight

(if tare is active)

Net weight

Chk OK/LO/HI

LL (lower limit)

HH (upper limit)

Press key to toggle between:

Gross weight (with unit 1)

and

Gross weight (with unit 2)

28

Miras 2

a. Print Output: Expansion of Abbreviations

N Net weight

G Gross weight

T Tare weight (appears in block printing mode, if tare is not zero)

Chk. Checkweighing status (If checkweighing application is selected)

OK Ok (checkweighing mode, if the placed weight is in the range set)

HI High

LO Low

LL Lower limit (checkweighing)

HL Higher limit (checkweighing)

W.Ref. Reference weight (counting application)

Pcs Number of units on the pan

g Weight in grams

kg Weight in kilograms

+ Appears if the value is greater than or equal to zero

– Appears if the value is less than zero

28

Miras 2

29

b. Sample print outputs in different

applications

1. Short printing mode:

1.1 Normal weighing

G + 200 g

1.2 Counting

N + 400 g

Pcs 10 pcs

W.Ref.

40 g

1.3 Checkweighing

Ex 1: If the weight on the pan is <10%

of lower limit set.

N + 0 g

Chk.

Ex 2: If the weight on the pan < lower

limit set.

N +

100 g

Chk.

LO

Ex 3: If the weight on the pan is

between the set limits.

N + 200 g

Chk. OK

Ex 4: If the weight on the pan > upper

limit set.

N + 410 g

Chk. HI

1.4 Unit toggling

Ex 1: Before toggle key is pressed

G + 300 g

Ex 2 : After unit is toggled to

kilograms.

G + 0.300 kg

2. Block printing mode:

2.1 Normal weighing

Ex 1: If tare is zero

G + 200 g

Ex 2: If tare is not zero

G + 100 g

T + 50 g

N + 50 g

2.2 Counting mode

Ex 1: If tare is zero.

G + 400 g

Pcs

10 pcs

W.Ref.

40 g

Ex 2: If tare value is set.

G + 440 g

T + 400 g

N +

80 g

Pcs

2 pcs

W.Ref. 40 g

2.3 Checkweighing mode

Ex 1: If the weight on the pan is <10%

of lower limit set, with zero tare.

G + 0 g

Chk.

LL 200 g

HL 400 g

Ex 2: If the weight on the pan < lower

limit set, with zero tare.

G + 100 g

Chk. LO

LL

200 g

HL

400 g

Ex 3: If the weight on the pan is

between the set limits, with zero tare.

G + 200 g

Chk. OK

LL

200 g

HL

400 g

29

30

Miras 2

Ex 4: If the weight on the pan > upper

limit set.

G + 410 g

Chk. HI

LL 200 g

HL 400 g

Ex 5: If the weight on the pan is <10%

of lower limit set, with a set tare value.

G + 400 g

T + 400 g

N +

0 g

Chk.

LL 200 g

HL 400 g

Ex 6: If the weight on the pan < lower

limit set, with a set tare value.

G + 800 g

T + 400 g

N + 400 g

Chk. OK

LL

200 g

HL 400 g

Ex 7: If the weight on the pan > upper

limit set, with tare value set.

G + 810 g

T + 400 g

N + 410 g

Chk. HI

LL 200 g

HL 400 g

2.4 Unit toggling

Ex 1: Before toggle key is pressed.

G + 300 g

T + 200 g

N + 100 g

Ex 2 : After unit is toggled to kilograms.

G + 0.300 kg

T + 0.200 kg

N + 0.100 kg

3. Continuous printing mode

3.1 Normal weighing

Ex 1: If tare is not active

G + 200 g

Ex 2 : If tare value is present.

N + 200 g

3.2 Counting mode

default:

Pcs 2 Pcs

Ex 1: If tare is not active (G/N key)

G + 200 g

Ex 2 : If tare value is present. (G/N

key)

N + 200 g

3.3 Checkweighing

Ex 1: If tare is not active

G + 200 g

Ex 2 : If tare value is present.

N + 200 g

3.4 Unit toggling

Output 1: Before toggle key is pressed

G + 300 g

Output 2: After the unit is toggled to

kilograms.

G + 0.300 Kg

30