Sartorius IS...-X Series, IS2CCE-SX, IS06BBE-SX, IS6CCE-HX, IS6CCE-SX Operating Instructions Manual

...Page 1

Operating Instructions

Sartorius Intec IS-X

Models IS06BBE-SX, IS2CCE-SX, IS6CCE-HX,

IS6CCE-SX, IS12CCE-SX, IS16EDE-HX, IS34EDE-HX, IS64EDESX, IS150IGG-HX, IS300IGG-HX and Verifiable Models

Weighing Platforms for Use in Hazardous Areas/Locations

98648-009-42

Page 2

Contents

Contents

2 Intended Use

3 Operating Limits

4 Tables of Specifications

9 Pin Assignment Chart

10 Troubleshooting Guide

11 Accessories (Options)

12 General View of the Equipment

15 Dimensions (Scale Drawings)

20 Declarations of Conformity

26 Certificates for Operation of the

Weighing Platform in

Hazardous Areas

Symbols

The following symbols are used in these

nstructions:

§ indicates required steps

$ indicates steps required only under

certain conditions

> describes what happens after you have

performed a certain step

– indicates an item in a list

! indicates a hazard

Make sure you observe the warning

and safety information in its entirety

during installation and operation, as

well as while performing maintenance

and repair work on the equipment. It is

important that all personnel using the

equipment understand this information,

and have access to it at all times.

The warning and safety information

is contained in the 11-language

installation manual included with the

equipment.

The warning and safety information

can be supplemented by the equipment

operator. Make sure all operating

personnel are informed of any additions

to these instructions.

Intended Use

The series IS...-.X models are precision

weighing platforms for weighing

samples in hazardous areas/locations.

Series IS...-.X equipment and connected

accessories are intended to be used

exclusively for weighing.

Instructions for installing the

equipment and putting it into

operation are contained in the enclosed

11-language installation manual.

Important Note:

The verifiable models („IS...-.XCE“) can

be verified for use as a scale only when

connected to a display and control unit,

indicator or terminal.

The following features make the

IS...-.X weighing platforms ideal for

use as inspection, measuring and test

instruments in quality management

systems:

– isoTEST calibration and adjustment

function

– ISO/GMP-compliant documentation

functions

IS...-.X weighing platforms save work

and speed up both simple and complex

routine procedures through the

following features:

– Ultrafast response times

– Connection to a PC in a PLC or other

control system

IS...-.X weighing platforms meet the

highest requirements placed on the

accuracy and reliability of weighing

results through the following features:

– Efficient filtering-out of vibration

– Stable and reproducible results

– Rugged, durable weighing system

– Weighing platform and accessories

approved for use in hazardous

areas/locations (see the table in the

11-language installation instructions)

All power supplies or AC adapters may

be connected only to an electrical

outlet (mains supply) with at least 90V

and no more than 264V (48 – 62 Hz).

Set up the explosion-protected IS...-

.X series weighing platform and

its accessories in accordance with

acknowledged technical regulations.

You must also comply with the national

laws and safety regulations of your

country.

Data Output

The weighing platform is equipped

with an RS-485 data interface (RS-232

available on request) which can be used

to connect any of the following:

– Printer*

– Peripheral device (such as a computer)*

– Universal remote switch

* connected through a Zener barrier

(see „Accessories“)

Hotline/Technical Advice

on Applications

Phone: +49 (0) 40/67960444

Fax: +49 (0) 40/67960474

E-mail: technical.support.hh

@sartorius-intec.com

2

Operating Instructions IS-X

Page 3

Operating Limits

Operating Limits

Overload Capacity

Thanks to the rugged construction of

Sartorius Intec weighing platforms, the

weighing system will not be damaged

if the maximum weighing capacity is

occasionally exceeded.

The table below lists the maximum

overload capacity of each weighing

platform model:

IS06BBE-SX.. IS2CCE-SX.. IS6CCE-SX..

IS6CCE-HX..

3 kg 12 kg 25 kg

IS16EDE-HX IS150IGG-HX,

IS34EDE-HX IS300IGG-HX

IS64EDE-SX

130 kg 600 kg

Shock Resistance

Even though Sartorius Intec weighing

platforms feature highly rugged

construction, there are some limits.

Avoid exposing the system to falling

objects, side impact, or shocks. The

weighing platform meets the mechanical

requirements of IEC 68 Part 2-27.

Notes on Integration into Conveyor

Systems

The weighing platform is suitable for

installation in conveyor systems. Make

sure to observe the following notes as

well as the equipment dimensions when

choosing components to be mounted

on your weighing platform

(see „Dimensions (Scale Drawings)“ in

this manual).

Any moving or rotating parts intended

to be permanently attached to the load

plate must be designed so that they

cannot affect the weighing results. For

example, rotating mechanisms must be

properly balanced.

The load plate must be clear on all

sides so that any parts or any dirt

that falls will not create a connection

between the weighing platform and

any permanently mounted preload

components.

Any cables or tubing between the

weighing platform and other equipment

must not apply any force to the

weighing platform. Make sure that

cables do not touch the load plate.

Special care must be taken to prevent

the build-up of static electricity

caused by moving parts (such as roller

conveyors).

Preload Range (Zero-setting Range)

The weight of components permanently

attached to the weighing platform is

known as the „preload.“ The preload

is electronically compensated up

to a defined value. Thus the entire

weighing capacity is available, and it

is possible to zero or calibrate/adjust

the weighing system (with external

weights). A preload heavier than the

defined value may result in a reduction

of the weighing capacity.

The maximum preload that can

be compensated depends on the

specification block configured (refer

to the tables of specifications below).

Components attached to the weighing

platform must be installed before the

weighing platform is connected to

power.

Configuring the Weighing Platform

The weighing platform can be

configured to meet individual

requirements, such as weighing in

international units, weighing in

unfavorable ambient conditions,

or external electronic processing

of weight values. This means the

final configuration of a unit can be

performed by the weighing equipment

dealer or the end user.

The weighing platform is adapted

for individual requirements using the

configuration menu in the connected

display and control unit or indicator.

The weighing platform can also be

configured using a connected

computer running the Sartorius Intec

configuration program

(see „Accessories“).

Options Available for

Weighing Range Configuration

SuperRange

This range divides the weighing

capacity of the platform into 50.000

intervals, an exceptionally high

resolution. The readability is identical

over the entire weighing range

(for example, 1 g).

SingleRange

The weighing range is divided into up

to 50.000 intervals. The readability is

identical over the entire weighing range

( for example, 10 g).

Multi-interval/DualRange

Intervals with adjusted

accuracy. These functions divide the

weighing capacity into as many 3

weighing ranges, each with a different

readability.

The weight readout is shown with

different levels of accuracy in each

range. The platform changes from one

range to another automatically when

the load on the platform is changed

(the readability in each range is listed in

the tables of specifications below).

Once the platform has been tared, the

highest possible resolution is available

even if the weighing platform is loaded.

The configuration options available

for each weighing platform are listed

below, in the section entitled „Tables of

Specifications.“

Operating Instructions IS-X

3

Page 4

Tables of Specifications

Tables of Specifications

Model IS06BBE-SX IS2CCE-SX IS6CCE-HX IS6CCE-SX IS12CCE-

SX

Readability g 0.001 0.01 0.01 0.1 0.1

.........

Weighing capacity g 620 2200 6200 6200 12,000

Max. overload capacity kg 3 12 12 25 25

Tare range (subtractive) g – 620 – 2200 – 6200 – 6200 – 12000

Preload (can be electronically g 93 110 – 1240 1200

compensated without reducing the weighing capacity)

Max. preload at start of isoTEST g 110 1300 5200 6400 10000

calibration/adjustment

(platform must be zeroed)

Repeatability <±g 0.001 0.01 0.01 0.05 0.05

Linearity <±g 0.002 0.02 0.02 0.1 0.2

Sensitivity drift within +10 to +30 °C <±/K 2 • 10

Response time (average) s 1.5 1.5 1.5 1 1

External calibration weight g 500 (E2) 2000 (F1) 5000 (E2) 5000 (F2) 5000 (F1)

(of at least accuracy class...)

Load plate dimensions mm Ø 130 218 x 200 218 x 200 218 x 200 218 x 200

Platform dimensions (W x D x H) mm 240x294x86 240x294x86 240x294x86 240x294x86 240x294x86

Net weight, approx. kg 7 7.3 8.4 7.3 7.3

Dust and water protection rating for the housing acc. to EN 60529 IP44

AC power source Power supply model YPS02-X or AC adapter model YPS02-Z (100-240V)

(must be connected by the weighing equipment dealer or a Sartorius Intec service tech-

nician)

Frequency Hz 48 – 62

Allowable ambient operating temperature 0 °C to +40 °C (273 °K to 313 °K; 32 °F to 104 °F)

Operating temperature range +10 °C to +30 °C (or 0 °C to +40 °C; depends on configuration)

Adaptation to ambient conditions By selection of 1 of 4 optimized filter levels

Display update (depends on filter level selected) 0.1 - 0.1 - 0.2 - 0.4 (normal output rate)

Power consumption Average: 25VA

Selectable weight units: Grams, kilograms, carats, pounds, ounces, Troy ounces, Hong Kong taels,

Singapore taels, Taiwanese taels, grains, pennyweights, milligrams, parts per

pound, Chinese taels, mommes, Austrian carats, tola, baht and mesghal

Built-in RS-485 interface (standard equipment; xBPI protocol):8 bits, odd parity; transmission rate: 9600 -

38,400 baud; half-duplex; convertible to RS-232 (SBI protocol): 7 bits, Parity: even,

odd, mark, space; transmission rates: 150 — 19,200 baud; 1 or 2 stop bits, software/

hardware handshake; factory settings: 1200 baud, odd parity, 1 stop bit, hardware

handshake with 2 characters after CTS

Model series Marking (ATEX) Use in IP rating Markings in acc. with FMRC Use in

Zone approval for USA and CSA

approval for Canada

IS.. BBE-.X.. 1, 2 (gas) IP 54 IS CL I, DIV 1, GR A,B,C,D, T4 Class I, Division 1 (gas)

IS.. CCE-.X.. 1, 2 (gas) IP 54 IS CL I, DIV 1, GR A,B,C,D, T4 Class I, Division 1 (gas)

IS… EDE-.X.. 1, 2 (gas) IP 65 IS CL I, DIV 1, GR A,B,C,D, T4 Class I, Division 1 (gas)

20, 21, 22 IP 65 IS CL II,III, DIV 1, GR E,F,G, T4 Class II,III Division 1

IS64EDE-HX.. 1, 2 (Gas) IP 44 IS CL I, DIV 1, GR A,B,C,D, T4

h II 2 G EEx ib IIC T4 CL l, ZONE 1 AEx ib IIC T4 Class I, Zone 1 (gas)

h II 2 G EEx ib IIC T4 CL l, ZONE 1 AEx ib IIC T4 Class I, Zone 1 (gas)

h II 2 G EEx ib IIC T4 CL l, ZONE 1 AEx ib IIC T4 Class I, Zone 1 (gas)

h II 1 D T135°C (dust) (dust+ fibers)

h II 2 G EEx ib IIC T4 CL l, ZONE 1 AEx ib IIC T4 Class I, Zone 1 (gas)

-6

2 • 10-6 2 • 10-6 4 • 10-6 4 • 10

Class I, Division 1 (gas)

-6

IS… IGG-HX 1, 2 (gas) IP 65 and IP67 IS CL I, DIV 1, GR A,B,C,D, T4 Class I, Division 1 (gas)

(dust) (dust + fibers)

h II 2 G EEx ib IIC T4 CL l, Zone 1 AEx ib IIC T4 Class I, Zone 1 (gas)

h II 1 D T135°C 20, 21, 22 IP 65 and IP 67 IS CL II,III, DIV 1, GR E,F,G, T4 Class II,III Division 1

* = factory setting

4

Operating Instructions IS-X

Page 5

Tables of Specifications

HX-Mode IS16EDE-HX IS34EDE-HX IS64EDE-SX IS64EDE-HX IS150IGG-HX IS300IGG-HX

Readability g 0,1 0,1 1 0,1 1 2

Weighing capacity kg 16 34 64 64 150 300

Max. overload capacity kg 130 130 130 130 600 600

Tare range (subtractive) kg – 16 – 34 – 64 -64 – 150 -300

Preload (can be electronically compensated kg 4 4 13 13 20 60

without reducing the weighing capacity)

Max. preload at start of kg ca. 19 ca. 21 ca. 45 45 – -

isoTEST calibration/adjustment

(platform must be zeroed)

Repeatability <±g 0,05 0,1 0,5 0,2 1 2

Linearity <±g 0,2 0,2 1 1 4 8

Sensitivity drift

within +10 to +30 °C <±/K 2 • 10

-6

2 • 10-6 3 • 10

-6

3 • 10

-6

2,5 • 10

-6

2,5 • 10

-6

Response time (average) s 1,5

External calibration weight kg 10 (F1) 10 (F1) 10 (F2) 10 (F1) 50 (F2) 50 (F2

(of at least accuracy class...)

Operating temperature range °C 10...30 10...30 0...40 0...40 0...40 0...40

Load plate dimensions mm 300 x 400 300 x 400 300 x 400 300 x 400 800x600 800x600

Net weight, approx. kg 16 16 16 16 70 70

Dust and water protection rating of the

housing acc. to EN 60529 IP65 IP65 IP65 IP44 IP67 IP67

AC power source Power supply model YPS02-X or AC adapter model YPS02-Z (100-240V) (must be

connected by the weighing equipment dealer or a Sartorius Intec service technician)

Frequency Hz 48 – 62

Allowable ambient operating temperature 0 °C to +40 °C (273 °K to 313 °K; 32 °F to 104 °F)

Operating temperature range +10 °C to +30 °C (or 0 °C to +40 °C; depends on configuration)

Adaptation to ambient conditions By selection of 1 of 4 optimized filter levels

Display update (depends on filter level selected) 0.1 - 0.1 - 0.2 - 0.4 (normal output rate)

Power consumption Average: 25VA

Selectable weight units: Grams, kilograms, carats, pounds, ounces, Troy ounces, Hong Kong taels,

Singapore taels, Taiwanese taels, grains, pennyweights, milligrams,

parts per pound, Chinese taels, mommes, Austrian carats, tola, baht and mesghal

Built-in RS-485 interface (standard equipment; xBPI protocol): 8 bits, odd parity, transmission rate:

9600 - 38,400 baud; half-duplex; convertible to RS-232 (SBI protocol): 7 bits,

Parity: even, odd, mark, space; transmission rates: 150 — 19,200 baud; 1 or 2

stop bits, software/ hardware handshake; factory settings:

1200 baud, odd parity, 1 stop bit, hardware handshake with 2 characters after CTS

* = factory setting

Operating Instructions IS-X

5

Page 6

Tables of Specifications

IS „-.XCE“ Series Verifiable Models

Model IS06 BBE-SXCE IS2 CCE-SXCE IS6 CCE-HXCE

Readability g 0.001 0.01 0.01

Weighing capacity g 620 2200 6200

Max. overload capacity kg 3 12 12

Tare range (subtractive) g – 620 – 2200 – 6200

Preload (can be electronically compensated) g 93 110 –

.........

without reducing the weighing capacity)

Max. preload at start of g 110 1300 5200

isoTEST calibration/adjustment

(weighing inst. must be zeroed)

Repeatability <±g 0.001 0.01 0.01

.........

Linearity <±g 0.002 0.02 0.02

Sensitivity drift within +10 to +30 °C <±/k 2 • 10

Response time (average) s 1.5 1.5 1.5

External calibration weight g 500 (E2) 2000 (F1) 5000 (E2)

(of at least accuracy class...)

Accuracy class K K K

Type . BD BF BF

Verification scale interval g 0.01 0.1 0.1

Minimum capacity acc. to g 0.02 0.5 0.5

prepackage regulations*

Operating temperature range °C 10 to 30 (50 to 86°F) 10 to 30 (50 to 86°F) 10 to 30 (50 to 86°C)

Load plate dimensions mm Ø 130 218 x 200 218 x 200

Platform dimensions (WxDxH) mm 240x294x86 240x294x86 240x294x86

Net weight, approx. kg 7 7.3 8.4

Dust and water protection rating for the housing acc. to EN 60529 IP44

AC power source Power supply model YPS02-X or AC adapter model YPS02-Z (100-240V);

YRB02-Z (rechargeable battery), YPS02-XV24 (24V)

Frequency Hz 48 – 62

Adaptation to ambient conditions By selection of 1 of 4 optimized filter levels

Display update

(depends on filter level selected) 0.1 - 0.1 - 0.2 - 0.4 (normal output rate)

Power consumption Average: 25VA

Built-in RS-485 interface (standard equipment; xBPI protocol): 8 bits, odd parity,

transmission rate: 9600 - 38,400 baud; half-duplex; convertible to

RS-232 (SBI protocol): 7 bits, parity: even, odd, mark,

space; transmission rates: 150 — 19,200 baud; 1 or 2

stop bits, software/hardware handshake; factory settings:

1200 baud, odd parity, 1 stop bit, hardware handshake with 2 characters after CTS

-4

2 • 10-4 2 • 10-4

* = factory setting

6

Operating Instructions IS-X

Page 7

Tables of Specifications

Verifiable Models, IS Series IS16EDE-HXCE IS34EDE-HXCE IS64EDE-SXCE IS150IGG-HXCE IS300IGG-HXCE

Readability in g 0,1 0,1 1 1 20

Weighing capacity in kg 16 34 64** 150** 300**

Max. overload capacity in kg 130 130 130 600 600

Tare range (subtractive) in kg – 16 – 34 – 64 – 150 -300

Preload (can be electronically compensated in kg 4 4 13 20 20

without reducing the weighing capacity)

Max. preload at start of ca. 19 ca. 21 ca. 45 – -

isoTEST calibration/adjustment

(weighing inst. must be zeroed) in kg

Repeatability <±g 0,05 0,1 0,3 1 5

Linearity <±g 0,2 0,2 1 4 8

Sensitivity drift within

+10 to +30 °C <±/K 2 • 10-6 2 • 10-6 3 • 10

-6

2,5 • 10

-6

2,5 • 10

-6

Response time (average) s 1,5 1,5 1,5 1,5 1,5

External calibration weight g 10000 (F1) 10000 (F1) 10000 (F2) 50000 (F2) 100000(F2)

(of at least accuracy class...)

Accuracy class K K K K K

Type BF BF HC BF BF

Verification scale interval g 1 1 10 10 20

Minimum capacity acc. to g 5 5 50 50 100

prepackage regulations*

Mindestlast nach FPV g 150 150 - - Operating temperature range °C 10...30 10...30 10...30 10...30 10...30

(50 to 86°F) (50 to 86°F) (50 to 86°F) (50 to 86°F) (50 to 86°F)

Load plate dimensions mm 300 x 400 300 x 400 300 x 400 800x600 800x600

Net weight, approx kg 16 16 70 70 70

Dust and water protection rating of the

housing acc. to EN 60529 IP65 IP65 IP65 IP67 IP67

AC power source

Power supply model YPS02-X or AC adapter model YPS02-Z (100-240V); YRB02-Z (rechargeable battery), YPS02-XV24 (24V)

Frequency Hz 48 – 62

Adaptation to ambient conditions By selection of 1 of 4 optimized filter levels

Display update (depends on filter level selected) 0.1 - 0.1 - 0.2 - 0.4 (normal output rate)

Power consumption Average: 25VA

Built-in RS-485 interface (Standard equipment; xBPI protocol): 8 bits, odd parity,

transmission rate: 9600 - 38,400 baud; half-duplex; convertible to

RS-232 (SBI protocol): 7 bits, parity: even, odd, mark,

space; transmission rates: 150 — 19,200 baud; 1 or 2

stop bits, software/hardware handshake; factory settings:

1200 baud, odd parity, 1 stop bit, hardware handshake with 2 characters after CTS

* = factory setting

** = variable weight unit kg, t

Operating Instructions IS-X

7

Page 8

Pin Assignment Chart

Pin Assignment Chart

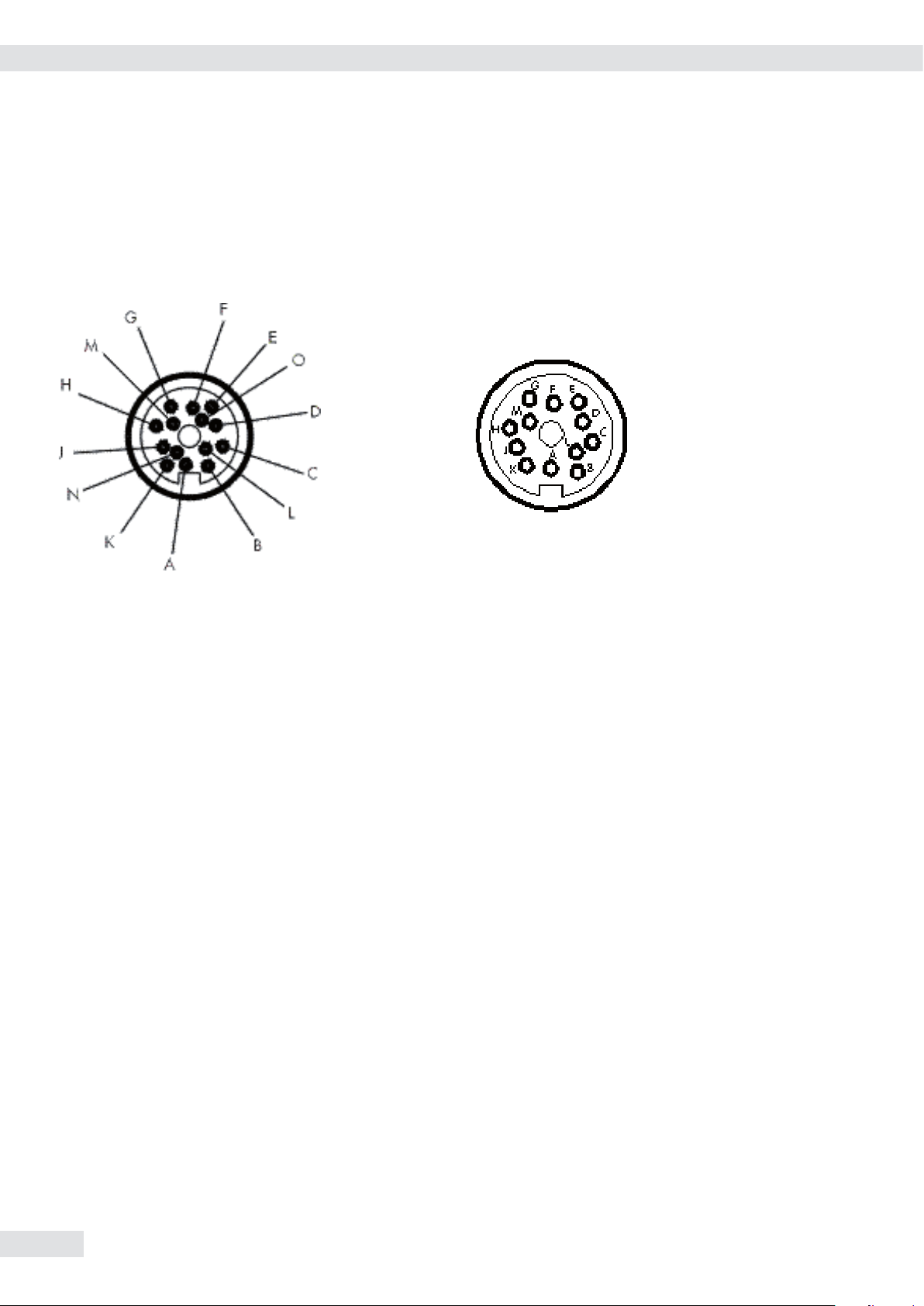

Female Interface Connector:

14-contact round female connector with screw lock hardware for cable gland

Pin Assignments

Platform: Zener barrier (output in safe area)

YDI01-Z, YDI02-Z, YDI03-Z:

14-pin 12-pin Signal RS-232

1

) Signal RS-485

Round male connector Barrier (SBI and xBPI) (xBPI)

G A Control output „heavier“ Control output „heavier“

K B Data output (TxD) RxD – TxD – N

J C Data input (RxD) RxD – TxD – P

N D Data terminal ready (DTR)

M E Signal GND Signal GND

F G

3

) Control output „lighter“ Control output „lighter“

A H Clear to send (CTS)

E J

3

) Control output „equal“ Control output „equal“

O – Universal switch 2) Universal switch 2)

D L

3

) Control output „set“ Control output „set“

Provide a low-resistance connection between shield and connector casing.

1

) RS-232-interface available on request

2

) Function: see „External Universal Remote Switch“ in the section entitled „Extra Functions.“

3

) YDI03-Z only

Important:

! Only electrical apparatus with a max. voltage Um f 250V may be connected to the Zener barrier. The Zener voltage UZ is 12V.

8

Operating Instructions IS-X

Page 9

Troubleshooting Guide

Troubleshooting Guide

Problem Possible cause(s) Solution

No segments are shown No AC power is available Check the AC power supply; con-

nect

on the display The power supply or AC adapter the power supply/AC adapter to power

is not connected

Device not used > 5 minutes Turn on the display and control

(now in stand-by mode) unit/indicator using the On/Off switch

Weight display shows “ H“ The load exceeds the weighing capacity Unload the weighing platform

Weight display The load plate is Place the load plate

shows “L“ or “ Err 54“ not in position on the platform

Weight display Data output not compatible Change the menu settings

shows “Err 01“ briefly with output format in device setup menu

Weight display One of the conditions for calibration Calibrate only when zero is dis-

played

shows “Err 02“ briefly was not met Zero the weighing platform

Load on weighing platform Unload the weighing platform

Weight display Calibration/adjustment could not Allow the scale to warm up and

then

shows “Err 03“ briefly be performed within repeat calibration/adjustment

the required time period

Error code “Err 08“ The load on the weighing platform Check whether your configuration

is too heavy to allow the platform to be zeroed meets the zero-setting point

requirements

Error code “Err 09“ Gross value < zero and weighing Zero the weighing platform

platform is unloaded, but cannot

be tared

Error code “Err 10“ Data in application tare memory Clear the application tare

when attempted to clear lower

tare memory

Error code “Err 12“ Attempt to write data in application Check configuration memory first

tare memory when blocked (menu item 2 2 x)

Value not permitted for Check value entered

manual tare input

Error code “Err 17“ Internal calibration/adjustment not possible Reduce preload or

because preload is too high Select a different configuration

Error code “Err 19“ The available weighing capacity Reduce preload or

is too low; max. capacity select a different configuration

reduced by high preload

The special code “A“ remains Press a key

on the display; none of the keys has

been pressed since the equipment

was switched on

The weight readout Unstable ambient conditions Set up the weighing platform

changes constantly (too much vibration, or the in a different area, or

weighing platform is exposed access the Setup menu to change

to a draft) device configuration

A foreign object is caught Remove the foreign object

between the load plate and

the weighing platform housing

The weight readout is The weighing platform has not been calibrated Perform calibration/adjustment

obviously wrong The platform was not tared before weighing Tare before weighing

If any other errors occur, please contact your local Sartorius Intec office or dealer or the Sartorius Intec Service Center.

Operating Instructions IS-X

9

Page 10

Accessories

Accessories (Options)

Order no.:

Power supply, flameproof, for use in hazardous area/location

100 - 240V EU YPS02-XDR

GB YPS02-XGR

USA/CDN YPS02-XKR

AC adapter for use outside the hazardous area/location

100 - 240V EU YPS02-ZDR

GB YPS02-ZGR

USA/CDN YPS02-ZKR

In the safe area (outside the hazardous area/location), accessories can be connected

through a Zener barrier.

Order no.:

Data output: RS-232 for IS-X YDO55IS-X

Data output: TTY/10mA for IS-X YDO01F-X

Zener barrier YDI01Z

(2 RS-485 data lines) for

connection in a bus network

Zener barrier YDI02Z

(4 RS-232 data lines)

Zener barrier YDI03Z

(4 RS-232 data lines

and 4 control lines)

Configuration program (on diskette) for IS-X weighing platform YAD01IS

(PC, DOC) without interface cable

Sartonet cable 6906926

Sartonet connection box 72583

Round plug-in connector 69Y03166

For customized cable solutions or accessories, please contact the Sartorius Intec.

10

Operating Instructions IS-X

Page 11

General View of the Equipment

2

3

4

6

8

10

11

1

5

7

9

3

6

10

11

7

12

9

8

IS06BBE-SX

General View of the Equipment

IS2CCE-SX, IS6CCE-HX, IS6CCE-SX, IS12CCE-SX

Pos. Designation

1 Draft shield cover

2 Glass draft shield

3 Load plate

4 Pan support

5 Shield ring

6 Lug for attaching an antitheft locking device

7 Leveling foot

8 DC jack

9 Data interface (RS-485)

10 Menu access switch (under protective threaded cap)

11 Level indicator

12 Pan draft shield (models IS2CCE-SX, S6CCE-HX only)

Operating Instructions IS-X

11

Page 12

General View of the Equipment

IS16EDE-HX, IS34EDE-HX, IS64EDE-SX

Pos. Designation

1 Level indicator

2 DC jack

3 Data interface (RS-485)

4 Leveling feet

5 Weighing platform

6 Load plate

12

Operating Instructions IS-X

Page 13

IS150IGG-HX, IS300IGG-HX

1

3

2

4

5

7

6

General View of the Equipment

Pos. Designation

1 Load plate

2 Manufacturer’s ID label

3 DC jack (optional)

4 Leveling feet

5 Level indicator

6 DC jack

7 Data interface (RS-485)

Operating Instructions IS-X

13

Page 14

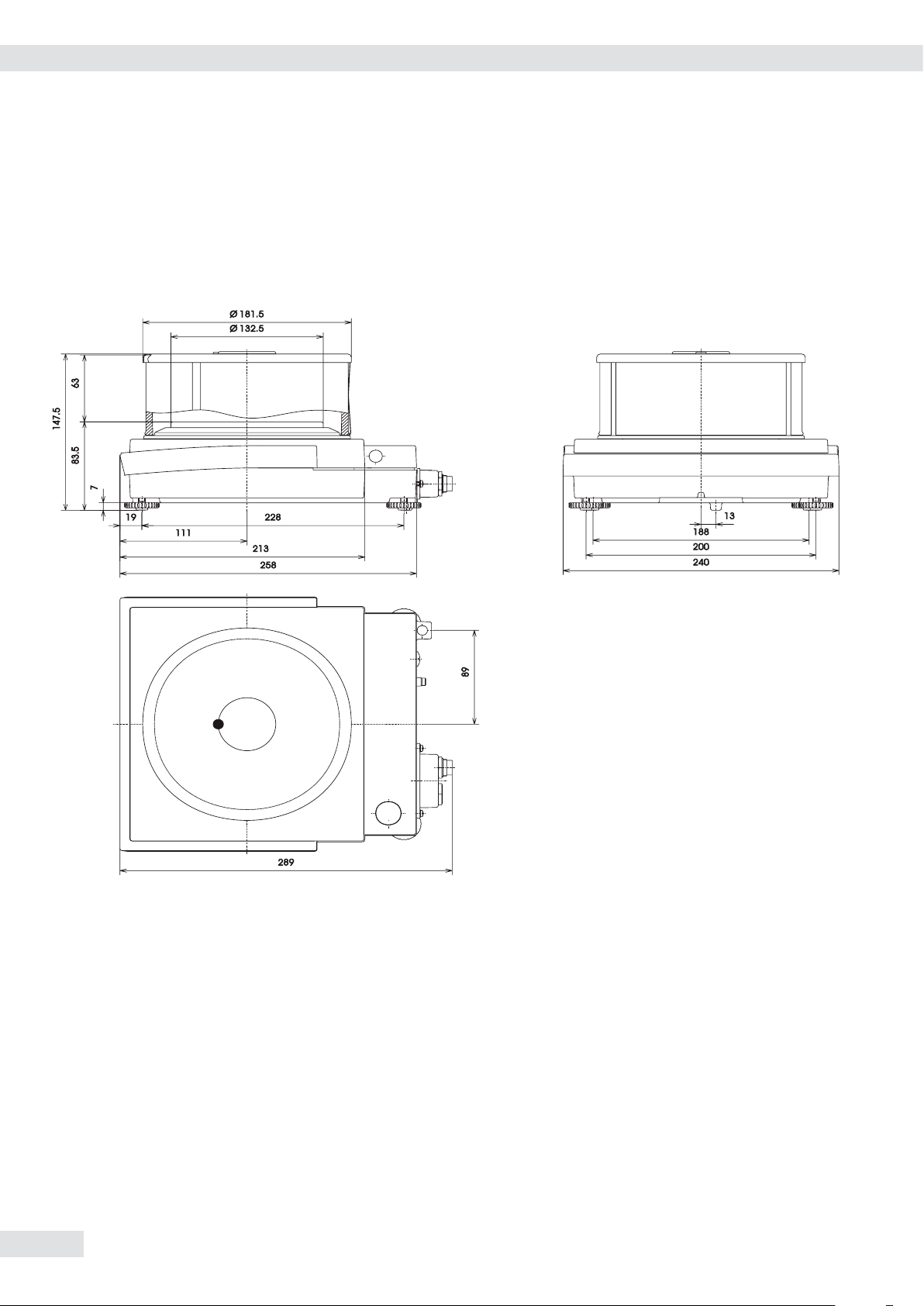

Dimensions

Dimensions (Scale Drawings)

IS06BBE-SX

All dimensions given in millimeters

14

Operating Instructions IS-X

Page 15

IS2CCE-SX, IS6CCE-HX

Dimensions

All dimensions given in millimeters

Operating Instructions IS-X

15

Page 16

Dimensions

IS6CCE-SX, IS12CCE-SX

All dimensions given in millimeters

16

Operating Instructions IS-X

Page 17

IS16EDE-HX, IS34EDE-HX, IS34EDE-HX, IS64EDE-SX

Dimensions

All dimensions given in millimeters

Operating Instructions IS-X

17

Page 18

Dimensions

All dimensions given in millimeters

EC Verification“ - A Service Offered by Sartorius Intec

Our service technicians authorized to perform the verification of your weighing instruments that are acceptable for legal metrological

verification can inspect and verify the metrological specifications at the place of installation within the Member States of the European Union

and the Signatories of the Agreement on the European Economic Area.

Subsequent Verifications within the European Countries

The validity of the verification will become void in accordance with the national regulations of the country in which the weighing instrument

is used. For information on verification and legal regulations currently applicable in your country, and to obtain names of the persons to

contact, please contact your local Sartorius Intec office, dealer or service center.

18

Operating Instructions IS-X

Page 19

Certificates

Operating Instructions IS-X

19

Page 20

Certificates

20

Operating Instructions IS-X

Page 21

Certificates

Operating Instructions IS-X

21

Page 22

Certificates

22

Operating Instructions IS-X

Page 23

Type of weighing instrument: iso-TEST Types of weighing modules: BD BF, BF BF, HA BD, HC BF

EC Type-approval D97-09-018 + Test certificates D09-96.30, D09-95.18

or

Type of weighing instrument: SARTOCOWAT Types of weighing modules: BD BF, BF BF, HA BD, HC BF

PPIS030511e EC Type-approval T7899 + Test certificates D09-96.30, D09-95.18

S

S

unlocked

locked

locked

unlocked

For variants for use in hazardous areas

Recognizable at a “-XCE“ in the model name

S

Plates and Markings – IS... -.CE + Terminals

Note: Protective seals of the indicating and operator terminal see belonging manuals.

(nur bei Typ SARTOCOWAT)

(only at type SARTOCOWAT)

P

S

K

M

S

P

locked

unlocked

S

Type BD BF

S

M

K

K

M

Type BF BF

K

M

Connects to the terminal no.

alternative

Connects to the terminal no.

(only at type SARTOCOWAT)

Plates and Markings

Operating Instructions IS-X

23

Page 24

Plates and Markings

Type of weighing instrument: iso-TEST Types of weighing modules: BD BF, BF BF, HA BD, HC BF

EC Type-approval D97-09-018 + Test certificates D09-96.30, D09-95.18

or

Type of weighing instrument: SARTOCOWAT Types of weighing modules: BD BF, BF BF, HA BD, HC BF

PPIS030511e EC Type-approval T7899 + Test certificates D09-96.30, D09-95.18

unlocked

S

S

S

SSS

locked

For variants for use in hazardous areas

Recognizable at a “-XCE“ in the model name

unlocked

locked

(only at type SARTOCOWAT)

(only at type SARTOCOWAT)

K

Descriptive plate with CE-conformity mark

M

Mark for EC verification (green metrology sticker)

S Protective seal

T

Plate with model designation

P

Menu access switch

S

S

S

Type HA BD

Connects to the terminal no.

S

K

M

Type HC BF

weighing pan

Connects to the terminal no.

M

K

T

locked

T

unlocked

P

P

24

Operating Instructions IS-X

Page 25

In connection with Terminals types TN CIS2, CISL2, CIS3 or computer (CE) and

software Win Dcale (Do9-99.15)

Plates and Markings

Example of descriptive of the already veried weighing instrument

Example o plate with model designation - weighing module

IS64FEG-S0CE

IS64FEG-S0CE

Example o plate with model designation - terminal

In connection with Terminals types TA (CAIS1, CAISL1, CAIS2, CAISL2, CAIS3, CAISL3

Example of descriptive of the already veried weighing instrument

T

K

T

K

Example o plate with model designation - weighing module

IS6CCE-H0CE

IS6CCE-H0CE

Example o plate with model designation - terminal

CAIS3

CAIS3

Type of weighing instrument: isi-Test types of modules: BD BF, BF BF, HC BF,

HA BD, HC BF, EC Type-approval D97-09-18 + Prüfschein DO9-95-18

oder

Type of

weighing instrument: SARTOCOWAT types of modules BD BF, BF BF, HC

BF, HA BD, EC Type-approval T7899 + Prüfschein DO9-96-30, Do9-95-18

PPIS030511e/3

T

T

Operating Instructions IS-X

25

Page 26

Certicate

26

Operating Instructions IS-X

Page 27

Certificate

Operating Instructions IS-X

27

Page 28

Certificate

28

Operating Instructions IS-X

Page 29

Certificate

Operating Instructions IS-X

29

Page 30

Certificate

30

Operating Instructions IS-X

Page 31

Certificate

Operating Instructions IS-X

31

Page 32

Certificate

32

Operating Instructions IS-X

Page 33

Certificate

Operating Instructions IS-X

33

Page 34

Certificate

34

Operating Instructions IS-X

Page 35

Certificate

Operating Instructions IS-X

35

Page 36

Certificate

36

Operating Instructions IS-X

Page 37

Certificate

Operating Instructions IS-X

37

Page 38

Certificate

38

Operating Instructions IS-X

Page 39

Certificate

Operating Instructions IS-X

39

Page 40

Certificate

40

Operating Instructions IS-X

Page 41

Circuit: V1 V2 V3 V4

Li 0000

Uo 12.6 V 12.6 V 8.6 V 12.6V

Io 133 mA 133 mA 187 mA 150 mA

Po 1.46 W 1.46 W 1.51 W 1.68 W

Co 1µF 1µF 4 µF 1 µF

Lo 300µH 300 µH 300 µH 300 µH

Power supply

YPS02-Z.R

II (2) G

[EEx ib] IIC

II (1) D

Certificate

Non hazardous area

Sartorius cable: type LiYC-Y-CY 4 x 0,5²

(permanently installed on power supply; can be

Power supply

YPS02-X.R

II 2 G

Alternative

Connection

flexibly installed)

max. Length = 50 m

max. L

max. C

EEx d [ib] IIC T4

II 1 D T135°C

Circuit: V1 V2 V3 V4

Uo 12.6 V 12.6 V 8.6 V 12.6V

Io 133 mA 133 m A 187 mA 150 m A

Po 1.46 W 1.46 W 1.51 W 1.68 W

Co 1µF 1µF 4 µF 1 µF

Lo 300µH 300 µH 300 µH 300 µH

Barrier

YDI02-Z

YDI03-Z

II (2) G

[EEx ib] IIC

Circuit: RS-232

Uo 12 V 12 V

Io 82 mA 7.5 mA

Po 240 mW 22 m W

Co 1.41 µF 1.41 µF

Lo 5.5 mH 5.5 mH

Lo/Ro 144µH/ 1.5 mH/

= 8.4 µH

Cable

= 28.2 nF

Cable

Date

EX

12.02.02

Written by

Reviewed by

Released by

1)

12.02.02

12.02.02

Control signals (only for YDI03-Z)

Name

Klausgrete

Weitemeier

Klausgrete

IIC T4

Hazardous area

Compact scale

FC......-.X....

FCA......-.X....

Weighing platform

IS......-.X....

II 2 G EEx ib IIC T4

II 1 D T135°C (optional)

Circuit: V1 V2 V3 V4

Ui 12.6 V 12.6 V 8.6 V 12.6V

Ii 133 mA 133 mA 187 m A 150 mA

Pi 1.68 W 1.68 W 1.61 W 1.89 W

Ci 0 0 300 nF 100 nF

FC/FCA/IS......-.X.... /

1)

Power Supply

Verification of the

Intrinsic Safety

35520-099-61-A4

Sheet

Rev.

1

of

4

00

Non hazardous area

Cable: install as stationary

and protect ed equipment !

Maximum cable length 70m

for a 10-wire standard cable

with a maximum of 200 nF/

km and 1mH/k m.

The length of the installed

cable is defined as 20 m

because of the RS-232

specifications.

System appraisal

(see EC-Type Examination Certificate KEMA 02ATEX1108 X):

Co <= 125nF; Lo <= 100µH; Lo/Ro <= 33µH/

Data output

Uo 8,6 V

Io 23 mA

Po 50 mW

Co 6 µF

Lo 60 mH

Data output RS-232 Control signals

Ui 12.6 V 12.6V

Ii 85 mA 10 mA

Pi 270 mW 30 mW

Ci 3 nF 4 nF

Li 0 0

1)

(pins A/J/K/N and M)

EX

Written by

Reviewed by

Released by

1)

(pins C/D/E/F/G and M)

Name

Date

Klausgrete

12.02.02

Weitemeier

12.02.02

Klausgrete

12.02.02

IIC T4

T-connektor

YTE02-X

1)

actuated

switch

YPE05-X

1: per circuit

2: optionally used (passive wiring or switch only)

FC/FCA/IS......-.X.... /

2)

Foot

2)

RS-232 data output with control lines

II 2 G EEx ib IIC T4

II 1 D T135°C (optional)

Verification of the

Intrinsic Safety

35520-099-61-A4

Operating Instructions IS-X

Hazardous area

Compact scale

FC......-.X....

FCA......-.X....

Weighing platform

IS......-.X....

Sheet

Rev.

2

of

4

00

41

Page 42

Certificate

Barrier

YDI01-Z

II (2) G

[EEx ib] IIC

RS-485

Uo 12 V

Io 82 mA

Po 240 mW

Co 1.41 µF

Lo 5,5 mH

1)

Barrier

YDI03-Z

II (2) G

[EEx ib] IIC

Only control signals

(see sheet 2)

Non hazardous area

up to 7 f urther

units, which

have the same

type of RS-485

data output

connected to

this fieldbus

Cable: install as stationary and protected equipment !

For cables with a maximum of 125pF/m (wire versus wire):

Number of units Cable length Lo/Ro or Lo

in the hazardous area m µH/ µH/km

2 1000 61 400

4 1000 34 115

6 1000 22 46

8 1000 17 25

8 100 17 250

8 35 17 710

see also table in KEMA 02ATEX1108X, sheet 3/4

Converter

Data output RS-485 only (pins J/K)

Ui 12,6 V

Ii 810 mA

Pi 2.5 W

Ci 10 nF

Li 0

Uo 12.6V

Io 85 mA

Po 270mW

In accordance with the EC-T ype Examination Certificate

KEMA 01ATEX1099X the converter 725324 m ay be

connected to the FCT01-X.., but with reduced param eters:

Co = 620nF

Lo=2mH.

725324

[EEx ib] IIB

2)

Cable: install as stationary

and protected equipment !

Maximum cable length 70m

for a 10-wire s tandard cable

with a maximum of 200nF/

km and 1mH/k m.

IIC T4

Date

EX

12.02.02

Written by

Reviewed by

Released by

12.02.02

12.02.02

Name

Klausgrete

Weitemeier

Klausgrete

Data output;

only control signals

(see sheet 2)

T-connektor

YTE02-X

T-connektor

YTE02-X

Foot

actuated

3)

switch

YPE05-X

FC/FCA/IS......-.X.... /

Hazardous ar ea

Compact scale

3)

FC......-.X....

FCA......-.X....

Weighing platform

IS......-.X....

3)

II 2 G EEx ib IIC T4

II 1 D T135°C (optional)

1: per circuit

2: circuits combined

3: optionally used (passive wiring or switch only)

RS-485 data output and control signal outputs

Verification of the

Intrinsic Safety

35520-099-61-A4

Sheet

of

Rev.

3

4

00

42

Cable: install as stationary and

protected equipment. Maximum

length 600m for a standard

cable with a m aximum of

200nF/km and 1mH/k m.

Operating Instructions IS-X

IIC T4

TTY Data output

Ui 14.7 V 14.7 V

Ii 50 mA 130 mA (resistively limited)

Pi 265 mW 100 mW

Ci 0 0

Li 0 0

1: per circuit

1)

(pins G/K and D/F/J) (pins C/E and D/F/J)

Name

Date

EX

Written by

Reviewed by

Released by

12.02.02

12.02.02

12.02.02

Klausgrete

Weitemeier

Klausgrete

FC/FCA/IS......-.X.... /

10mA data output

Non hazardous area

Hazardous ar ea

Compact scale

FC......-.X....

FCA......-.X....

Weighing platform

IS......-.X....

II 2 G EEx ib IIC T4

II 1 D T135°C (optional)

Verification of the

Intrinsic Safety

35520-099-61-A4

Sheet

of

Rev.

4

4

00

Page 43

Certificate

Hazardous (Classified) Location

Class I, Division 1, Groups A,B,C,D

Class I, Zone 1, Groups IIA, IIB, IIC

SARTORIUS

FC......-.X...

Display Unit

4)

SARTORIUS

FC...BBE-.X.... or

IS...BBE-.X.... or

10)

FC...CCE-.X.... or

IS...CCE-.X....

.....EDE-.X....

+)

Weighing Module

Data Output

3)

5)

4)

SARTORIUS

Pedal Switch

YPE05-X

9)

SARTORIUS

T-Connector

YTE02-X

4)

SARTORIUS

Pedal Switch

YPE05-X

9)

SARTORIUS

T-Connector

YTE02-X

Hazardous (Classified) Location

Class I,II,III, Division 1,

Groups A,B,C,D,E,F,G

13)

SARTORIUS

Power Supply

YPS02-XKR

3)

7)

AC Supply

Canada: Group A is excluded!

OR

13)

SARTORIUS

Rechargeable

Battery Pack

YRB02-X

see

Control drawing

65656-001-07

Non-Hazardous Location

3)

9)

13)

9)

6)

SARTORIUS

Power Supply

YPS02-ZKR

AC Supply

Hazardous (Classified) or

Non-Hazardous Location

Any Approved / Certified

Universal Apparatus with

Entity Concept

parameters

YDI05-Z..

e.g.

(see note 5, 15)

7)

3)

2)

+: All FC..EDE-.X.., FCA..EDE-.X.., IS..EDE-.X..

with lower IP rating than IP65; see marking on the equipment !

Date

Written by

Reviewed by

Released by

2011-07-07

2011-07-07

2011-07-07

Name

Klausgrete

Klausgrete

Klausgrete

Title

Drawing

number

Control Drawing

33956-000-07-A4

Revision

04

Sheet

1

Operating Instructions IS-X

of

5

43

Page 44

Certificate

Hazardous (Classified) Location

Class I,II,III, Division 1, Groups A,B,C,D,E,F,G

Class I, Zone 1, Groups IIA, IIB, IIC

SARTORIUS

FC......-.X...

Display Unit

4)

SARTORIUS

FC...EDE-.X.... or

10)

IS...EDE-.X.... or

IS...IGG-.X....

3)

Weighing Module

Data Output

5)

4)

SARTORIUS

Pedal Switch

YPE05-X

9)

SARTORIUS

T-Connector

YTE02-X

4)

SARTORIUS

Pedal Switch

YPE05-X

9)

SARTORIUS

T-Connector

YTE02-X

Hazardous (Classified) Location

Class I,II,III, Division 1,

Groups A,B,C,D,E,F,G

13)

SARTORIUS

Power Supply

YPS02-XKR

3)

7)

AC Supply

Canada: Group A is excluded!

OR

13)

SARTORIUS

Rechargeable

Battery Pack

YRB02-X

see

Control drawing

65656-001-07

Non-Hazardous Location

9)

13)

SARTORIUS

Power Supply

YPS02-ZKR

9)

Hazardous (Classified) or

Non-Hazardous Location

3)

7)

AC Supply

44

Written by

Reviewed by

Released by

Operating Instructions IS-X

Date

2011-07-07

2011-07-07

2011-07-07

Name

Klausgrete

Klausgrete

Klausgrete

Title

Drawing

number

6)

Control Drawing

33956-000-07-A4

Any Approved / Certified

Universal Apparatus with

Entity Concept

parameters

YDI05-Z..

e.g.

(see note 5, 15)

Revision

04

Sheet

3)

2)

of

2

5

Page 45

Hazardous (Classified) Location

Class I,II,III, Division 1, Groups A,B,C,D,E,F,G

Class I, Zone 1, Groups IIA, IIB, IIC

SARTORIUS

FCA...EDE-.X....or

FCB...EDE-.X....or

3)

FCA...IGG-.X....

or

FCB...IGG-.X....

Weighing Module

Terminal YAC01FC-X or

Terminal YAC02FC-X or

Junction Box YAS06IS-X

Data Output (only for YAC0*FC-X)

4)

SARTORIUS

10)

3)

5)

+

OR

Hazardous (Classified) Location

Class I,II,III, Division 1,

Groups A,B,C,D,E,F,G

13)

SARTORIUS

Power Supply

YPS02-XKR

Canada: Group A is excluded!

13)

SARTORIUS

Rechargeable

Battery Pack

YRB02-X

Certificate

3)

7)

AC Supply

see

Control drawing

65656-001-07

I/O-Ports (only for YAC02FC-X)

14)

SARTORIUS

Pedal Switch

YPE05-X

SARTORIUS

Pedal Switch

YPE05-X

+: Only on Model YAC0*FC-X

Non-Hazardous Location

4)

9)

SARTORIUS

T-Connector

YTE02-X

9)

13)

SARTORIUS

Power Supply

YPS02-ZKR

3)

7)

AC Supply

4)

9)

SARTORIUS

T-Connector

YTE02-X

OR

9)

6)

Hazardous (Classified) or

Non-Hazardous Location

Any FApproved / Certified

Universal Apparatus with

Entity Concept

parameters

YDI05-Z..

e.g.

(see note 5, 15)

3)

2)

Date

Written by

Reviewed by

Released by

2011-07-07

2011-07-07

2011-07-07

Name

Klausgrete

Klausgrete

Klausgrete

Title

Drawing

number

Control Drawing

33956-000-07-A4

Revision

04

Sheet

3

Operating Instructions IS-X

of

5

45

Page 46

Certificate

ENTITY DATA FOR TERMINAL:

Data Output (Pos. 5) Input Parameters :

RS232 (combined circuits):

(Pin A/J/K/N/M): Ui = 12.6 V Ii = 340 mA * Pi = 1.08 W Ci = 2 nF Li = 15 µH

Ui = 25,2 V **

RS422 (combined circuits):

(Pin A/B/C/E/F/G/J/K/M/N): Ui = 7.5 V Ii = 500 mA * Pi = 900 mW Ci = 5.5 µF Li = 17 µH

RS485 (combined circuits):

(Pin J/K/L/M): Ui = 12.6 V Ii = 810 mA * Pi = 2.5 W Ci = 12 nF Li = 15 µH

Control Signals on RS232 or RS485 (per circuit):

(Pin C/D/E/F/G/M): Ui = 12.6 V Ii = 10 mA Pi = 30 mW Ci = 4 nF Li = 0

(Pin B/O) only for use in combination with simple apparatus: Ci = 4 nF Li = 0

TTY (Pin G/K andD/F/J): Ui = 14.7 V Ii = 50 mA Pi = 265 mW Ci = 2 nF Li = 15 µH

(Pin C/E and D/F/J): Ui = 14.7 V Ii = 130 mA Pi = 100 mW

Ci = 2 nFLi = 15 µH

The circuits may be connected to the converter Type 725324-1: Co = 620nF

Lo = 2mH

Data Output (Pos. 5) Output Parameters (combined circuits):

RS232 (combined circuits):

(Pin A/J/K/N/M): Uo = 12.6 V Io = 131 mA * Po = 411 mW Co = 1.15 µF Lo = 2 mH

RS422 (combined circuits):

(Pin A/B/C/E/F/G/J/K/M/N): Uo = 12.6 V Io = 180 mA * Po = 570 mW Co = 1.15 µF Lo = 0.7 mH

Lo/Ro = 62 µH/ohm

RS485 (combined circuits):

(Pin J/K/L/M): Uo = 12.6 V Io = 85 mA * Po = 270 mW Co = 1.15 µF Lo = 5 mH

Lo/Ro = 118 µH/ohm

Maximum length for a typical standard data cable:

RS232 limited by the RS232 standard to 25m ( 82 feet)

RS422 500 m (1,640 feet) for Group A,B,C,D and IIA, IIB, IIC; 1000 m (3,280 feet) for Group C, D and IIA, IIB

TTY 300 m (984 feet) for 1,200 bit/s; 150 m (492 feet) for 2,400 bit/s; 65 m (213 feet) for 4,800 bit/s;

30 m (98 feet) for 8,600 bit/s; 15 m (49 feet) for 19,200 bit/s; for Group A,B,C,D and IIA, IIB, IIC

RS485 up to 1000 m (3,280 feet)

with up to 8 Sartorius scales type FC/FCA/IS......-.X... or CIXS3-. or WZ......-X.. CW3X..-.... or FCT01-X..

when connected to Sartorius Interface Converter YDI05-Z.. or Barrier YDI01-Z.. or YDI02-Z..

the Barriers YDI0.-Z.. contain Z966 zener barriers from Pepperl & Fuchs.

Uo = 25,2 V ** Co = 107 nF **

46

Written by

Reviewed by

Released by

Operating Instructions IS-X

Date

2011-07-07

2011-07-07

2011-07-07

Name

Klausgrete

Klausgrete

Klausgrete

Title

Drawing

number

Control Drawing

33956-000-07-A4

Revision

04

Sheet

of

4

5

Page 47

1) In the USA: The installation must be in accordance with the National Electrical Code ®, NFPA 70, Article 504 or 505

and ANSI / ISA-RP 12.6.

In Canada: The installation must be in accordance with the Canadian Electrical Code ®, Part1, Section 18.

2) The apparatus must not be connected to any device that uses or generates in excess of 250Vrms or DC.

3) In the USA: The apparatus must be connected to a suitable ground electrode per National Electrical Code ®, NFPA

70, Article 504 or 505. The resistance of the ground pad must be less than 1 ohm.

In Canada: The apparatus must be connected to a suitable ground electrode per Canadian Electrical Code ®, Part

1. The resistance of the ground pad must be less than 1 ohm.

4) The cable to the terminal model YAC01LA-X00FC and to the T-Connector model YTE02-X must be protected

against damage.

5) The Entity Concept allows interconnection of intrinsically safe apparatus with associated apparatus not

specifically examined in combination as a system when the approved values of Voc, Isc and Pmax resp. Uo, Io, Po

of the associated apparatus are less than or equal to Vmax, Imax and Pmax resp. Ui, Ii, Pi of the intrinsically safe

apparatus and the approved values of Ca and La resp. Co and Lo of the associated apparatus are greater than Ci

and Li of the intrinsically safe apparatus plus all cable parameters.

6) In the USA: Optionally, the cable of any FMRC Approved Universal Apparatus with Entity Concept parameters (see

note 5) can be connected directly to the data output of the weighing module; this cable must be protected against

damage.

In Canada: Optionally, the cable of any CSA Certified Universal Apparatus with Entity Concept parameters (see

note 5) can be connected directly to the data output of the weighing module; this cable must be protected against

damage.

7) The apparatus must not be connected to any device that uses or generates in excess of 132Vrms or DC.

8) The cable to the terminal model YAC01FC-X or model YAC02FC-X needs not be protected against damage.

9) In the USA: These units are considered as non-certified simple apparatus. The levels as indicated for simple

apparatus in FMRC Class 3610 shall not be exceeded in this simple apparatus.

In Canada: These units are considered as non-certified simple apparatus. The temperature class of the apparatus

has to be determined. Per Levels generated in the simple apparatus as indicated in Table 3 of CAN/CSA-E79-11-

95.

When the parameters of the apparatus are not specified, based on the entity parameters of the weighing module

output the temperature class has to be determined and the capacitance and inductance of the interconnecting cable

may not exceed the Co and the Lo.

10) Connection by means of polarized connector.

11) Ambient temperature range: 0°C .... +40°C (32°F .... + 104°F)

12) WARNING: SUBSTITUTION OF COMPONENTS MAY IMPAIR INTRINSIC SAFETY.

AVERTISSEMENT: LA SUBSTITUTION DE COMPOSANTS PEUT COMPROMETTRE LA

SÉCURITÉ INTRINSÈQUE.

13) Connection by non interchangeable cable type LiYC-Y-CY 4 x 0.5; max length: 50m (164 ft).

14) The Entity Concept allows interconnection of intrinsically safe apparatus with associated apparatus not

specifically examined in combination as a system when the approved values of Voc, Isc and Pmax resp. Uo, Io, Po

of the associated apparatus are less than or equal to Vmax, Imax and Pmax resp. Ui, Ii, Pi of the intrinsically safe

apparatus and the approved values of Ca and La resp. Co and Lo of the associated apparatus are greater than Ci

and Li of the intrinsically safe apparatus plus all cable parameters.

The output circuits of the optional I/O of Type FCB must be connected to grounded shunt diode barriers; this ground

to be connected with the P.E. within the hazardous area.

15) The Sartorius Interface Converter YDI05-Z.. is approved/certified by FM for USA and Canada. See Certificate of

Compliance and Control Drawing number 65710-800-07-A4.

Furthermore Sartorius Barriers YDI01-Z.. and YDI02-Z.. may be used, which contain FM and CSA approved /

certified Z966 zener barriers from Pepperl & Fuchs.

16) WARNING: USE WET OR DAMP CLOTH TO CLEAN TO AVOID ELECTRIC STATIC DISCHARGE.

Certificate

Date

Written by

Reviewed by

Released by

2011-07-07

2011-07-07

2011-07-07

Name

Klausgrete

Klausgrete

Klausgrete

Title

Drawing

number

Control Drawing

33956-000-07-A4

Revision

04

Sheet

5

Operating Instructions IS-X

of

5

47

Page 48

Sartorius Industrial Scales GmbH & Co. KG

Leinetal 2

37120 Bovenden, Germany

Phone +49.551.309.83.0

Fax +49.551.309.83.190

www.sartorius-intec.com

Copyright by Sartorius Intec,

Goettingen, Germany.

No part of this publication may be reprinted or

translated in any form or by any means without

prior written permission from Sartorius Intec.

All rights reserved.

The status of the information, specifications

and illustrations in this manual is indicated

by the date given below. Sartorius Intec

reserves the right to make changes to the

technology, features, specifications, and design

of the equipment without notice.

Date:

April 2016, Sartorius Intec

Bovenden, Germany

Printed in Germany on paper that has been

bleached without any use of chlorine

RS ·KT

Publication No.:WIS6019-e16042

Loading...

Loading...