Sartorius IS16EDE-H, IS34EDE-H, IS64EDE-S, IS16EDE-H0CE, IS64EDE-H0CE Installation And Operating Instructions Manual

...

98648-010-27

Sartorius

IS16EDE-H, IS16EDE-H0CE, IS34EDE-H, IS34EDE-H0CE,

IS64EDE-H, IS64EDE-S, IS64EDE-H0CE

Weighing Platform for Display and Control Unit

for Standard Use or Verified for Use in Legal Metrology

Installation and Operating Instructions

Industrial

Weighing Technology

2

Contents

Page

General View of the Weighing Platform 3

Intended Use 4

Warranty 4

Storage and Shipping Conditions 4

Safety Instructions 4

Installation Instructions 5

Ambient Conditions 5

Conditioning the Weighing Platform 5

IP65 Protection 5

Getting Started 6

Setting Up the Weighing Platform 6

Leveling the Weighing Platform 6

Connecting the Weighing Platform 6

Separate Power Connection for

the Weighing Platform (Optional) 7

Safety Precautions 8

Fixed Power Connection 8

Warmup Time 9

Menu Access Switch 9

Operating Limits 9

Maximum Overload Capacity 9

Shock Resistance 9

General Instructions for Integration into

Conveyor Systems 10

Preload Range (Zero-setting Range) 10

Configuring the Weighing Platform 10

Specifications Charts 11

General Specifications 14

Selecting and Affixing the Respective

ID Label 15

Pin Assignment Chart for the

RS-485 Interface 15

Pin Assignments/Interface Connector 15

Troubleshooting Guide 16

Care and Maintenance 18

Service 18

Cleaning 18

Wet Environment 18

Corrosive Environment 18

Safety Inspection 18

Instructions for Recycling the Packaging 18

CE Marking 19

Declaration of Conformity 20

Using the Weighing Platform

in Legal Metrology 21

Components of a Verifiable

Weighing System 21

Page

Separate Testing and Verification

of Weighing System Components 21

Effect of the Preload on Verifiability 21

”EC Verification” - A Service Offered by

Sartorius 22

Subsequent Verifications within the

European Countries 22

EC Type Approval Certificate 23

Plates and Markings 26

Dimensions (Scale Drawings) 27

Accessories (Options) 28

3

1

2

3

4

5

6

8

9

7

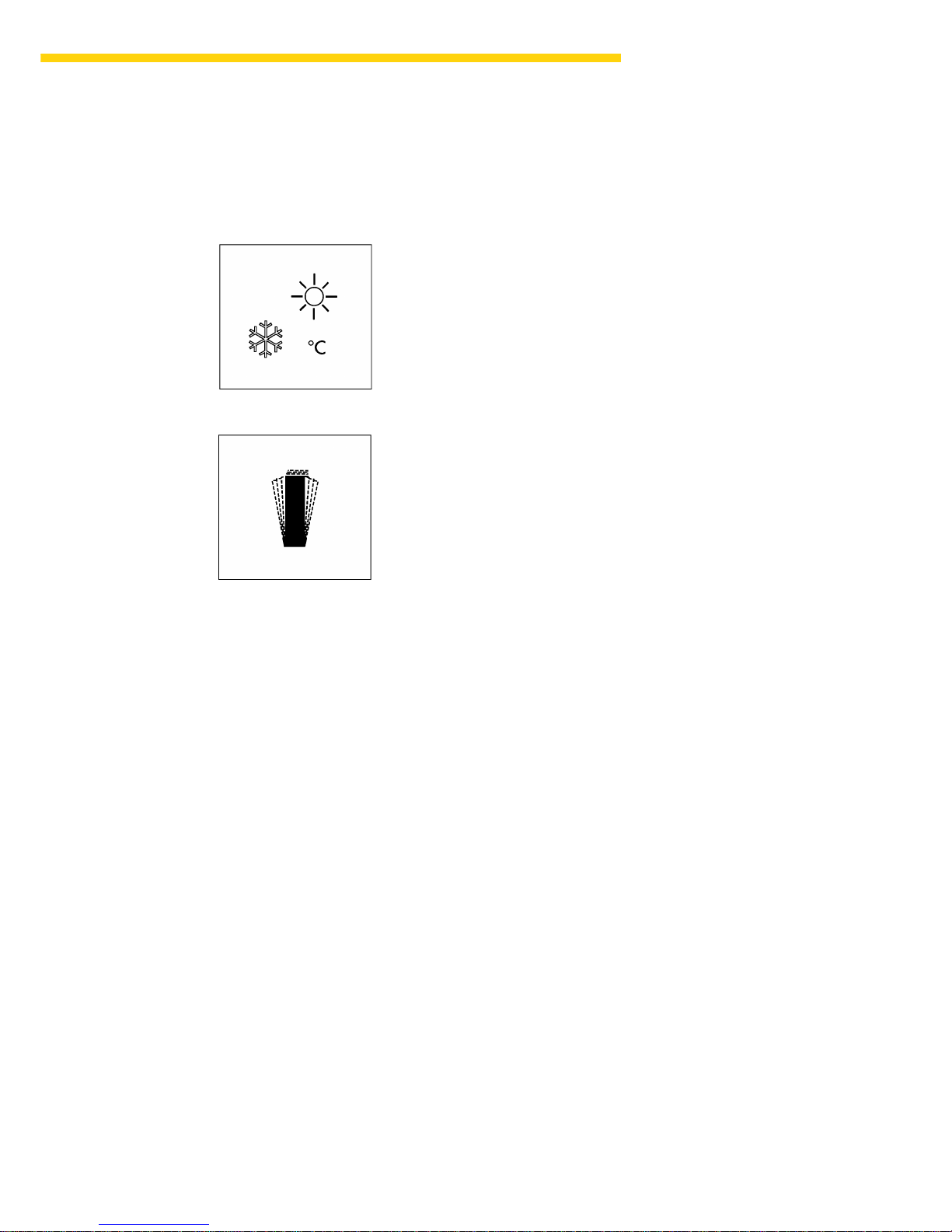

General View of the Weighing Platform

No. Designation No. Designation

1 Load plate 6 Connecting cable

2 Manufacturer’s label (interface port/power supply)

3 Metrological ID labels (only on weighing 7 Valve for barometric pressure compensation

platforms verifiable or verified for use in 8 Blank for power supply cable gland

legal metrology) (optional)

4 Leveling feet 9 Menu access switch (located behind the plug )

5 Level indicator

General View

4

Intended Use

This weighing platform is part of a modular system that consists of the

weighing module (weighing platform) and a display and control unit or isi

industrial terminal. The display and control unit comes with a separate

instruction manual. Before installing or operating your weighing equipment,

please read all instructions thoroughly.

Warranty

Do not miss out on the benefits of our full warranty. Please contact your

Sartorius office or dealer for further information. If available, complete the

warranty registration card, indicating the date of installation, and return it to

your Sartorius office or dealer.

Storage and Shipping Conditions

– Allowable storage temperature: – 10 °C to + 40°C

+ 14 °F to + 104 °F

– Allowable humidity during storage: 90% relative humidity

After unpacking the equipment, please check it immediately for any visible

damage. If you detect any damage, proceed as directed in the section

entitled “Safety Inspection.”

It is a good idea to save the box and all parts of the packaging until you

have successfully installed the equipment. Only the original packaging

provides the best protection for shipment. To prevent damage to the

equipment, unplug all cables before packing the equipment for shipping.

Safety Instructions

The equipment may be opened only by authorized service technicians who

have been trained by Sartorius and who perform repair or maintenance work

in accordance with Sartorius’ standard operating procedures.

– Always disconnect the equipment from power before performing

any repair work.

– Do not use the weighing platform in a hazardous area/location.

– Do not operate the equipment in environments exposed to potentially

explosive mixtures of ambient gases and dust.

– Any damage to the seals affixed to the equipment housing will result

in forfeiture of all claims under the manufacturer’s warranty.

Note:

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense. Changes or

modifications not expressly approved by Sartorius AG could void the user’s

authority to operate the equipment.

5

Installation Instructions

The equipment must be installed and put into operation by a trained Sartorius

dealer or service technician, who will also show you how to work with it.

Ambient Conditions

Choose a suitable place to set up the weighing platform. Avoid exposing the

weighing platform to the following ambient conditions:

– Extreme heat radiation

– Extreme vibration

– Aggressive chemical vapors

– Difficulty of access for maintenance and cleaning

Important:

If you need to use the weighing platform in an area exposed to heavy traffic

(e.g., fork-lift trucks), you should install a protective frame, consisting of

angular braces, around the weighing platform.

To calculate the dimensions for this protective frame, refer to the section

entitled “Dimensions (Scale Drawings).”

Conditioning the Weighing Platform

Do not expose the weighing platform to extreme moisture over long periods.

Moisture in the air can condense on the surfaces of a cold platform whenever

it is brought to a substantially warmer place. If you transfer the weighing

platform to a warmer area, make sure to condition it for about 2 hours at the

new ambient temperature, leaving it unplugged from the power supply.

Afterwards, if you keep the weighing platform connected to the power supply,

the continuous positive difference between the inside of the platform and the

outside will practically rule out the effects of moisture condensation.

IP65 Protection

In conformance with the IP65 protection rating, the weighing platform is dusttight (protection rating 6: resistant to penetration by dust particles, according

to particle size) and washdown-resistant (rating 5: resistant to splashes of

water, washdown-resistant).

IP65 protection is guaranteed only if:

– the seals were installed by a qualified technician, and

– the connecting cables and cable glands were installed and

connected by a qualified technician.

Installation Instructions

6

Getting Started

Setting Up the Weighing Platform

- Remove the weighing platform and load plate from the packaging

- Remove the foam material and manufacturer’s labels

- Place the load plate on the weighing platform

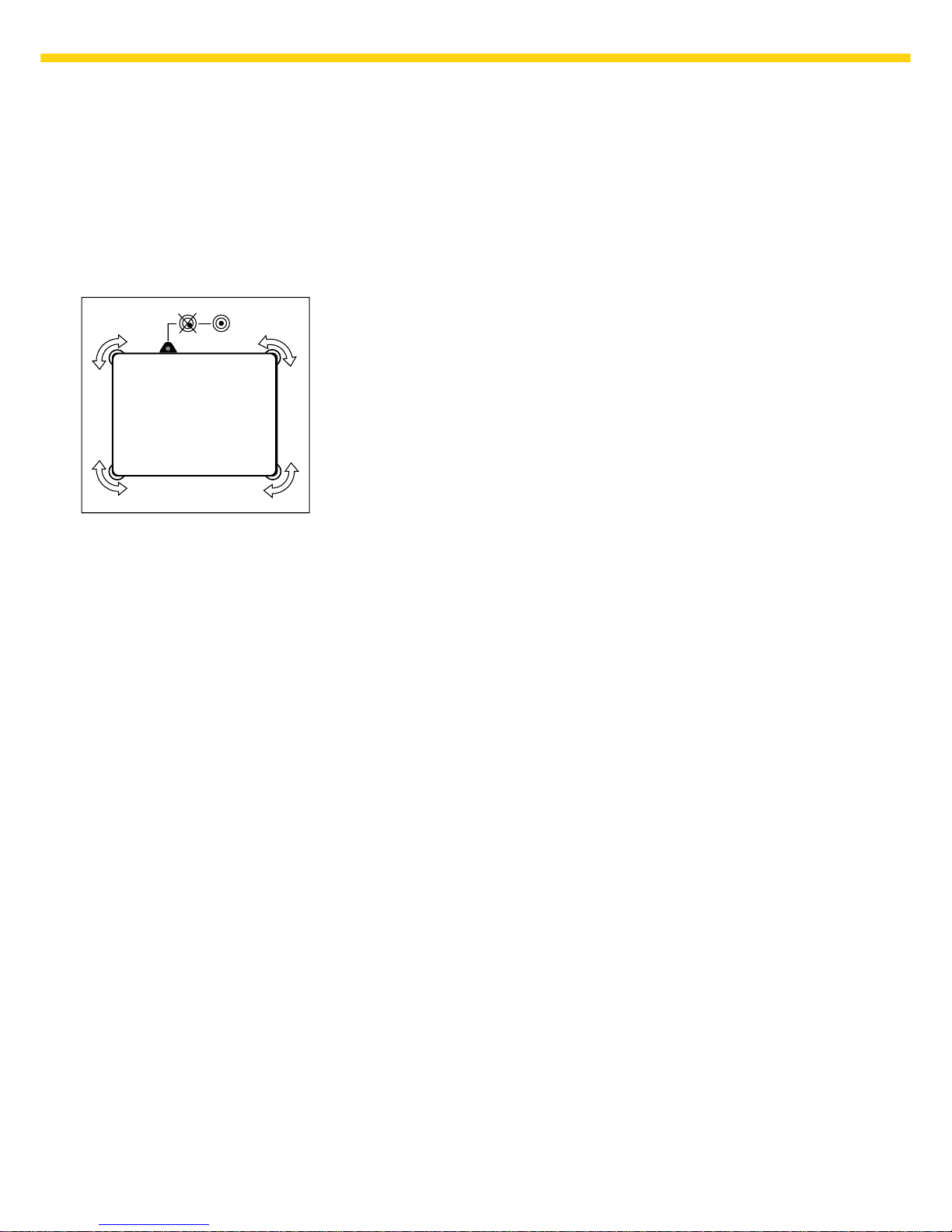

Leveling the Weighing Platform

Level the weighing platform at the place of installation using the leveling feet

(4) so that the air bubble is centered within the circle of the level indicator (5):

To raise the weighing platform, extend the leveling feet (turn clockwise).

To lower the weighing platform, retract the leveling feet (turn

counterclockwise).

Make sure all four feet are in contact with the surface on which the platform

stands.

Important:

- Do not perform any installation work while the equipment is connected to

power.

- Installation work that affects the IP65 protection rating must be performed

with extreme care.

- Always disconnect the equipment from power before connecting or

disconnecting the data cable.

- Failure to observe the instructions contained in this manual during

installation will result in forfeiture of all claims under the manufacturer’s

warranty.

Connecting the Weighing Platform

Please note that any person or company connecting a non-Sartorius-approved

display and control unit (such as a computer) or AC adapter to the weighing

platform shall assume all risks and responsibilities associated with this

equipment.

Use only original Sartorius AC adapters.

The connecting cable is 3 meters long (approx. 10 feet). To order an

extension cable or a customized cable, refer to the list of accessories or

contact Sartorius.

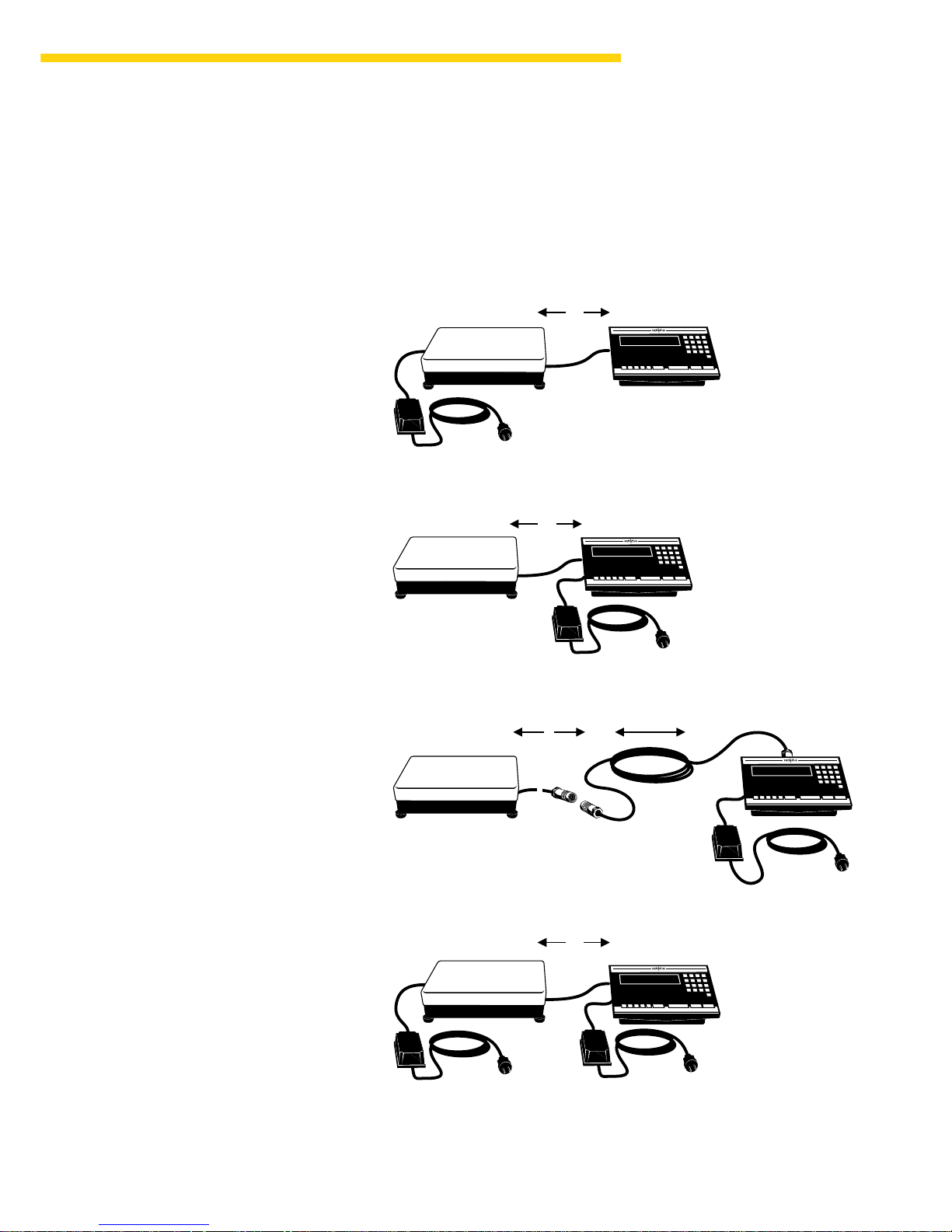

Cable Lengths:

Because you can choose whether to power the weighing platform via the

interface port of the display and control unit or using a separate AC adapter

(adapter kit required; must be installed by a Sartorius service technician),

some restrictions apply to the cable lengths permissible between components.

If you use a cable longer than 12 meters (∼ 40 feet) between the weighing

platform and the display and control unit, each of these components must be

powered by a separate AC adapter.

7

Separate Power Connection (Optional) for the Weighing Platform

An adapter kit must be installed by a Sartorius dealer or service technician to

connect the weighing platform separately to line current (mains supply). In

addition, this separate power connection is required if you interface the

weighing platform directly with a computer.

The following diagrams show the options for powering weighing platforms

and display and control units:

Connecting the industrial-grade ING2 AC adapter to the Sartorius isi

industrial terminal without an extension cord:

Connecting the industrial-grade ING2 AC adapter only to the isi industrial

terminal with an extension cord:

Connections using cables longer than 12 m (~40 ft):

max3m

max3m

Getting Started

3m 6m

300 m max.

8

The weighing platform is powered by the external industrial-grade ING 2 AC

adapter (see “Accessories”). Make sure that the voltage rating printed on this

unit is identical to your local line voltage. If the voltage specified on the label

or the plug design does not match the rating or standard you use, please

contact your local Sartorius office or dealer. To use a main feeder cable from

the ceiling or to mount a CEE plug, you will have to make arrangements

inside your facilities for installation of such cable equipment.

Use only original Sartorius AC adapters, identified by the Sartorius label. Use

of AC adapters from other manufacturers, even if these units have an

approval identification marking from a national testing laboratory, requires the

consent of a trained service technician.

For detailed information on further options for powering the equipment (e.g.,

using local low voltage), contact Sartorius AG headquarters in Germany or

one of the main offices based in your country.

The equipment must be connected to power in conformance with the

installation requirements of your country.

Safety Precautions

The Sartorius power supply rated to Industrial Class 2 (with safety extra-low

voltage emission (SELV)) can be plugged into any electrical outlet without

additional safety precautions. The ground or earth terminal is connected to

the platform housing, which can be additionally grounded, if required.

Install the power cable with adequate protection to prevent damage to the

cable.

Fixed Power Connection

If the power cable is permanently installed or secured so that it cannot be

unplugged, an emergency switch must be installed for disconnecting power to

the equipment. This emergency switch must be located near the weighing

platform and must be easily accessible. In addition, this switch must be

labeled as an emergency switch. All operators must be instructed in the use

of this switch.

Whenever possible, avoid wiring your weighing platform into networks that

carry a heavy load (such as a connection to a compressor or similar

equipment).

9

Warmup Time

To deliver exact results, the weighing platform must warm up for at least 30

minutes after initial connection to AC power or after a relatively long power

outage. Only after this time will the weighing platform have reached the

required operating temperature.

Preparing the Weighing Platform for Verification for Use in Legal Metrology

in the EU:* Allow the weighing platform to warm up for at least 24 hours

after initial connection to the power supply.

* including the Signatories of the Agreement on the European Economic Area

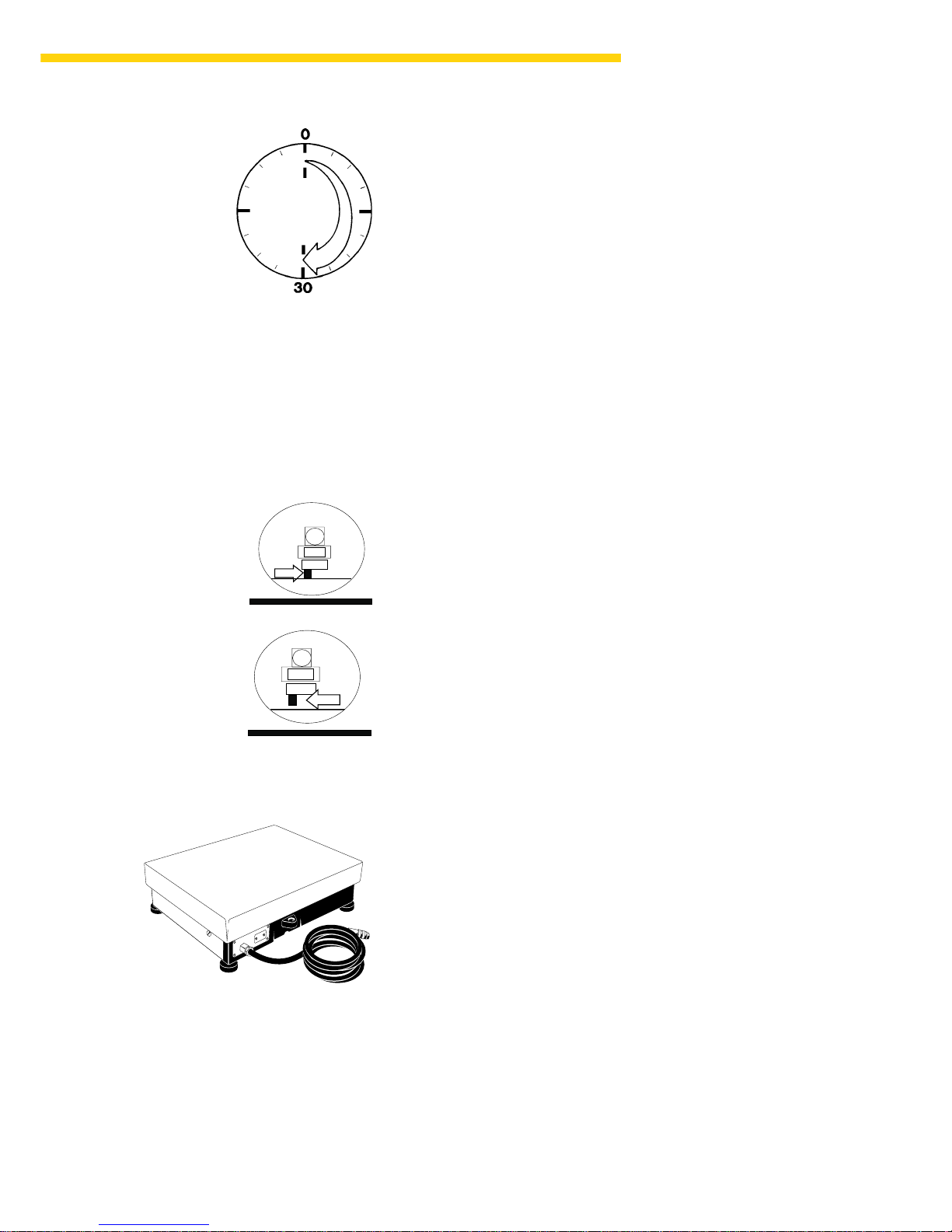

Menu Access Switch

Prior to Verification:

– All settings in the operating menu are accessible

(once the weighing platform has been verified for use in legal metrology,

menu items relevant to legal metrology are blocked)

– Select configuration settings from corresponding specifications group

(configuration cannot be changed after verification)

– Block the ‘write’ function for the xBPI interface

Function of the Menu Access Switch in Verification for Use in Legal

Metrology:

When the menu access switch (9) is open, weighing ranges can be

configured and calibration/adjustment can be performed, prior to

verification.

After Verification:

Move the menu access switch (9) to the left. Configuration settings relevant to

use of the weighing platform in legal metrology are no longer accessible.

Operating Limits

Maximum Overload Capacity

Because Sartorius weighing platforms are constructed to withstand rough

treatment in industrial environments, the platform will not be damaged if

occasionally loaded beyond the maximum weighing capacity.

The maximum overload capacity of this IS model is 130 kg.

Shock Resistance

Even though Sartorius weighing platforms feature highly rugged construction,

there are some limits. Avoid dropping objects from a considerable height

onto the weighing platform and do not expose the platform to strong side

impact. Sartorius weighing platforms are shock resistant in accordance with

the shock response spectrum defined in the IEC68 standard, Part 2-27.

Getting Started

10

General Instructions for Integration into

Conveyor Systems

The IS weighing platform is suitable for installation in conveyor systems. Follow

the general instructions given below and refer to the “Dimensions (Scale

Drawings)” to meet the requirements for such installation.

– Any moving or rotating parts intended to be permanently attached to the

load plate must be designed so that they cannot negatively affect the

accuracy of weighing results. For example, rotating mechanisms must be

properly balanced.

– The load plate must be clear on all sides so that any parts or any dirt that

falls will not create a connection between the weighing platform and any

permanently mounted preload components.

– Any cables or tubing between the weighing platform and other equipment

must not apply any force to the weighing platform. Make sure that

cables do not touch the load plate.

– Do not install the weighing platform in a conveyor system located in a

Zone 2 or 11 hazardous area/location.

Preload Range (Zero-setting Range)

The weight of components that are permanently installed on the weighing

platform is called “preload.” The weighing platform electrically compensates for

this preload so that the entire weighing range is available and the platform can

be zeroed and can also be calibrated/adjusted using external weights. Higher

preloads may result in a reduction in the maximum weighing capacity. The

maximum preload that can be compensated for depends on the specifications

configured (please see the “Specifications Chart”).

The preload must be set before the platform is verified for use in legal metrology.

The components for integration into a conveyor must be installed on the

weighing platform before you connect the platform to the power supply.

Configuring the Weighing Platform

If you have a standard-model weighing platform, you can adapt it for specific

requirements such as weighing in international weight units, use under

unfavorable ambient conditions, or further processing of weighing results, for

example. If your weighing platform is to be verified for use in legal metrology,

one weight unit must be selected before verification, and cannot be changed

after verification has been performed.

To configure settings in the weighing platform, access the operating menu in the

display and control unit. You can use either of the following as a display and

control unit with your IS weighing platform:

– Sartorius

isi

industrial terminal

– Computer with a special Sartorius configuration program (see

“Accessories”)

The configuration options for your weighing platform are listed in the

“Specifications Chart” on the following pages.

11

Specifications Charts

Access the configuration menu of the Sartorius industrial terminal or display and control unit of your choice. You need to set the appropriate codes

before verification of the platform as a legal measuring instrument. Please note that when you change the configuration, this may also change the

accuracy class besides the weighing capacity and the readability.

IS16EDE-H0CE (module, type BFBF/ together with the isi operator and indicating terminal (industrial terminal) or a PC with Sartorius software of

the type isoTEST), verifiable for use in legal metrology

IS16EDE-H0CE (type designation: modular instrument, type BF BF/modular instrument together with the isi industrial terminal or a PC with

Sartorius software), verifiable for use in legal metrology.

Specifications group Spec. gp.1* Spec. gp.2 Spec. gp.3 Spec. gp.4 Spec. gp.5 Spec. gp.6

(code): (10 3 1) (10 3 2) (10 3 3)5) (10 3 4)5) (10 3 5) (10 3 6)

Maximum capacity kg 16 6.1 3.1 12.1 16 12.1

Readability g 0.1 0.1 0.1 0.5 0 to 6 kg: 0.1 0 to 6 kg: 0.1

6 to 16 kg: 1 6 to 12.1 kg: 1

Weighing range Standard Configurable Configurable Configurable Configurable Configurable

Zero tracking±2% kg ±0.32 ±0.12 ±0.06 ±0.24 ±0.32 ±0.24

Initial zero-setting range kg ±1 ±1 ±1 ±1 ±1 ±1

Preload 1) kg 4 14 17 8 4 8

isoTEST function2) yes yes yes yes yes yes

Metrological specifications

Accuracy class kg KKStandard Standard KK

Minimum capacity

acc. to CD 3)g5 5––55

Minimum capacity

acc. to AWC4) g 150 150 ––150 150

Verification scale interval g 1 1 ––11

Temperature range °C +10 to +30 +10 to +30 +10 to +30 +10 to +30 +10 to +30 +10 to +30

1

) No reduction in the maximum capacity up to this preload; higher preloads reduce the maximum capacity in 0.1-kg steps

2

) The isoTEST function cannot be selected for preloads > approx. 18 kg

3

) CD = Council Directive 90/384/EEC on non-automatic weighing instruments used in the EU and the Signatories of the Agreement on the

European Economic Area

4

) AWC = average weight control based on the requirements of the German Regulations for Prepackaged Products

5

) Not allowed for use in legal metrology (legal for trade). A 10-kg calibration weight is required for external adjustment.

* = factory setting

IS16EDE-H0CE (module, type BFBF/ together with the isi operator and indicating terminal (industrial terminal) or a PC

with Sartorius software of the type isoTEST), verifiable for use in legal metrology

Specifications group Spec. gp.7 Spec. gp.8 Spec. gp.9 Spec. gp.10 Spec. gp.11 Spec. gp.12

(code): (10 3 7) (10 3 8) (10 3 9) (10 3 10) (10 3 11) (10 3 12)

Maximum capacity kg 16 16 12.1 16 6.1 3.1

Readability g 0 to 3 kg: 1 2 2 5 2 1

3 to 6 kg: 2

6 to 16 kg: 5

Weighing range Standard Configurable Configurable Configurable Configurable Configurable

Zero tracking±2% kg ±0.32 ±0.32 ±0.24 ±0.32 ±0.12 ±0.06

Initial zero-setting range kg ±1 ±1 ±1 ±1 ±1 ±1

Preload 1)kg44841417

isoTEST function2) yes yes yes yes yes yes

Metrological specifications

Accuracy class kg lllllStandard

Minimum capacity

acc. to CD 3) g 20 40 40 100 40 –

Minimum capacity

acc. to AWC4) g 150 500 500 2500 500 –

Verification scale interval g 1/2/5 2 2 5 2 –

Temperature range °C +10 to +40 +10 to +40 +10 to +40 +10 to +40 +10 to +40 +10 to +40

1

) No reduction in the maximum capacity up to this preload; higher preloads reduce the maximum capacity in 0.1-kg steps. You cannot set a

preload > 17 kg.

2

) The isoTEST function cannot be selected for preloads > approx. 18 kg

3

) CD = Council Directive 90/384/EEC on non-automatic weighing instruments used in the EU and the Signatories of the Agreement on the

European Economic Area

4

) AWC = average weight control based on the requirements of the German Regulations for Prepackaged Products

5

) Not allowed for use in legal metrology (legal for trade). A 10-kg calibration weight is required for external adjustment.

Specifications Chards

12

IS34EDE-H0CE (module, type BFBF/ together with the isi operator and indicating terminal (industrial terminal) or a PC

with Sartorius software of the type isoTEST), verifiable for use in legal metrology

Specifications group Spec. gp.1 Spec. gp.2* Spec. gp.3 Spec. gp.4 Spec. gp.5 Spec. gp.6

(code): (10 3 1) (10 3 2) (10 3 3) (10 3 4) (10 3 5) (10 3 6)

Maximum capacity kg 34 34 26.1 34 26.1 34

Readability g 0.1 0 to 6kg: 0.1 0 to 6kg: 0.1 1 1 0 to 6 kg 0.1

6 to 15kg: 0.2 6 to 15kg: 0.2 6 to 34 kg 1

15 to 34kg: 0.5 15 to 26.1kg: 0.5

Weighing range Standard Configurable Configurable Configurable Configurable Configurable

Zero tracking±2% kg ±0.68 ±0.68 ±0.52 ±0.68 ±0.52 ±0.68

Initial zero-setting range kg ±1 ±1 ±1 ±1 ±1 ±1

Preload 1)kg44124124

isoTEST function2) yes yes yes yes yes yes

Metrological specifications

Accuracy class kg KKKKKK

Minimum capacity

acc. to CD 3)g5 55 50505

Minimum capacity

acc. to AWC4) g 150 150 150 150 150 150

Verification scale interval g 1 1 1 1 1 1

Temperature range °C 10 to +30 +10 to +30 +10 to +30 +10 to +30 +10 to +30 +10 to +30

1

) No reduction in the maximum capacity up to this preload; higher preloads reduce the maximum capacity in 1-kg steps. You cannot set a

preload > approx. 31 kg.

2

) The isoTEST function cannot be selected for preloads > approx. 21 kg

3

) CD = Council Directive 90/384/EEC on non-automatic weighing instruments used in the EU and the Signatories of the Agreement on the

European Economic Area

4

) AWC = average weight control based on the requirements of the German Regulations for Prepackaged Products

5

) Not allowed for use in legal metrology (legal for trade). A 10-kg calibration weight is required for external adjustment.

* = factory setting

IS34EDE-H0CE module, type BFBF/ together with the isi operator and indicating terminal (industrial terminal) or a PC

with Sartorius software of the type isoTEST), verifiable for use in legal metrology

Specifications group Spec. gp.6 Spec. gp.7 Spec. gp.8 Spec. gp.9

(code): (10 3 6) (10 3 7) (10 3 8) (10 3 9)

Maximum capacity kg 34 26.1 34 26.1

Readability g 0 to 6 kg: 2 0 to 6 kg: 2 5 5

6 to 15 kg: 5 6 to 15 kg: 5

15 to 34 kg: 10 15 to 34 kg:10

Weighing range Configurable Configurable Configurable Configurable

Zero tracking±2% kg ±0.68 ±0.52 ±0.68 ±0.52

Initial zero-setting range kg ±1 ±1 ±1 ±1

Preload 1)kg412412

isoTEST function2) yes yes yes yes

Metrological specifications

Accuracy class kg llll

Minimum capacity acc. to CD 3) g 40 40 100 100

Minimum capacity acc. to AWC4) g 500 500 2500 2500

Verification scale interval g 2/5/10 2/5/10 5 5

Temperature range °C +10 to +40 +10 to +40 +10 to +40 +10 to +40

1

) No reduction in the maximum capacity up to this preload; higher preloads reduce the maximum capacity in 1-kg steps. You cannot set a

preload > approx.31 kg.

2

) The isoTEST function cannot be selected for preloads > approx. 21 kg

3

) CD = Council Directive 90/384/EEC on non-automatic weighing instruments used in the EU and the Signatories of the Agreement on the

European Economic Area

4

) AWC = average weight control based on the requirements of the German Regulations for Prepackaged Products

5

) Not allowed for use in legal metrology (legal for trade). A 10-kg calibration weight is required for external adjustment.

* = factory setting

13

IS 64 EDE-H0CE (type designation: modular instrument, type BB BD/modular instrument together with a verifiable isi

industrial terminal of type BF BF 523).

Specifications group Spec. gp.1* Spec. gp.2 Spec. gp.3 Spec. gp.4

(code): (10 3 1) (10 3 2) (10 3 3)4) (10 3 4)4)

Maximum capacity kg 64 51 31 16

Readability g 1 1 1 1

Weighing range Standard Configurable Configurable Configurable

Zero tracking±2% kg ±1.3 ±1 ±0.6 ±0.3

Initial zero-setting range kg ±1.3 ±1.3 ±1.3 ±1.3

Preload 1)kg13264661

isoTEST function2) yes yes yes yes

Metrological specifications

Accuracy class kg KKStandard Standard

Minimum capacity

acc. to CD 3) g 50 50 ––

Minimum capacity

acc. to AWC4) g 10000 10000 ––

Verification scale interval g 10 10 ––

Temperature range °C 0 to +40 0 to +40 0 to +40 0 to +40

1

) No reduction in the maximum capacity up to this preload; higher preloads reduce the maximum capacity in 1-kg steps. You cannot set a

preload > approx.14 kg.

2

) The isoTEST function cannot be selected for preloads > approx. 36 kg

3

) CD = Council Directive 90/384/EEC on non-automatic weighing instruments used in the EU and the Signatories of the Agreement on the

European Economic Area

4

) AWC = average weight control based on the requirements of the German Regulations for Prepackaged Products

* = factory setting

IS 64 EDE-H0CEH0CE (module, type BF BF together with the isi operator and indicating terminal (industrial terminal) or

a PC with Sartorius software of the type isoTEST), verifiable for use in legal metrology

Specifications group Spec. gp.5 Spec. gp.6 Spec. gp.7 Spec. gp.8 Spec. gp.9

(code): (10 3 5) (10 3 6) (10 3 7) (10 3 8) (1039)

Maximum capacity kg 64 64 64 31 16

Readability g 0 to 15 kg: 5 10 20 10 5

15 to 30 kg:10

30 to 64 kg:20

Weighing range Configurable Configurable Configurable Configurable Configurable

Zero tracking±2% kg ±1.28 ±1.28 ±1.28 ±0.6 ±0.3

Initial zero-setting range kg ±1.3 ±1.3 ±1.3 ±1.3 ±1.3

Preload 1) kg1313134661

isoTEST function2) yes yes yes yes yes

Metrological specifications

Accuracy class kg lllll

Minimum capacity

acc. to CD 3) g 100 200 400 200 100

Minimum capacity

acc. to AWC4) g 2500 10000 15000 10000 2500

Verification scale interval g 5/10/20 10 20 10 5

Temperature range °C 0 to +40 0 to +40 0 to +40 0 to +40 0 to +40

1

) No reduction in the maximum capacity up to this preload; higher preloads reduce the maximum capacity in 1-kg steps. You cannot set a

preload > approx.14 kg.

2

) The isoTEST function cannot be selected for preloads > approx. 36 kg

3

) CD = Council Directive 90/384/EEC on non-automatic weighing instruments used in the EU and the Signatories of the Agreement on the

European Economic Area

4

) AWC = average weight control based on the requirements of the German Regulations for Prepackaged Products

* = factory setting

Specifications Chards

14

General Specifications

(applicable for use in standard applications, not in legal metrology)

Model IS 16 EDE-H IS 34 EDE-H IS 64 EDE-S IS64EDE-H

Maximum capacity kg 16 34 64 64

Readability g 0.1 0.1 1 0.1

Linearity g ≤±0.2 ≤±0.2 ≤±0.5 ≤±0.3

Repeatability g ≤±0.05 ≤±0.1 ≤±0.3 ≤±0.1

(standard deviation)

Response time (average) s <1.5 <1.5 <1 <1.5

Fastest response time (IQ) s <1 <1 <0.8 <0.8

Adaptation to ambient

conditions and application

requirements by selection of one of 4 optimized filter levels

Data output speed 0.1, 0.1, 0.2, 0.4 (normal data output speed)

(depends on filter level selected)

Dust and water protection rating IP65 IP65 IP65 IP44*

Net weight, approx. kg 15 15 15 15

Requirements for power

connection (optional) ING2 (TNG 220/115V)

Frequency Hz 48 - 63 48 - 63 48 - 63 48 - 63

Power consumption:

with isi 10,20,30 VA max. 34 max. 34 max. 34 max. 34

connected to ING2) average 10 average 10 average 10 average 10

Power consumption:

weighing platform only, VA average 2.5 average 2.5 average 2.5 average 2.5

connected to ING2

Selectable weight units g, kg, ct, oz, ozt, tlh, tlt, GN, dwt, mg, /lb, tlc, mom, K, tol, bat, MS

Allowable ambient °C +0 to +40 +0 to +40 +0 to +40 +0 to +40

temperature range (273 K - 313 K) (273 K - 313 K) (273 K - 313 K)(273 K - 313 K)

Allowable operating °C +10 to +30 +10 to +30 +10 to +30 +10 to +30

temperature range (283 K - 313 K) (283 K - 313 K) (273 K - 313 K)(273 K - 313 K)

Automatic zero tracking,

can be turned off by

menu code °C Standard feature Standard feature Standard featureStandard feature

Built-in interface, RS-485 (standard, xBPI protocol): 8 bits; odd parity; transmission speed: 9600–38,400 baud; half-duplex.

Convertible to RS-232 (SBI protocol): 7 bit; parity: even, mark, odd, space; transmission speed:

150–19,200 baud; 1 or 2 stop bits; software/hardware handshake.

Factory setting: 1200 baud; odd parity; 1 stop bit; hardware handshake with 2 characters after CTS

*) = IP 65 (special version available on request)

15

Selecting and Affixing the Respective ID Label

Select the respective metrology ID label according to the accuracy class of

your choice and affix it to the platform to be verified.

Pin Assignment Chart for the RS-485 Interface

Cable length: 3 m (approx. 10 ft.)

Male connector:

Type C091D, 12-pin round connector with threaded locking ring, Amphenol

(IP65)

A RxD-TxD-N

B Not connected

C Not connected

D Not connected

E Signal GND

F Menu access switch for calibration/adjustment

(routed externally)

G VCC (24V power supply)

H Not connected

J GND (24V power supply)

K GND (24V power supply)

L RxD-TxD-P

M VCC (24V power supply)

Pin Assignments/Interface Connector

(Recommended):

Type C091D, 12-pin, Amphenol (IP65)

Type of cable: AWG 24 specification

Be sure to follow the instructions above for connecting the weighing platform

to the power supply!

Specifications Chards

16

Troubleshooting Guide

Problem Possible Causes Solution

No segments appear on the No line current is available Check the power supply

display The AC adapter is not plugged Plug the AC adapter into

in the platform and into an

electrical outlet

The weighing platform has Turn on the display and

been in standby mode for control unit

more than 5 minutes

The weight display shows “H” The load exceeds the capacity Unload the weighing

of the weighing platform platform

The weight display shows “L” or The load plate is not on the Place the load plate on the

”Err 54" platform weighing platform

The weight display briefly The weight unit selected Change setting in the

indicates “Err 01” requires more decimal places “Devices” setup menu

than are available in the display of the display and control

unit

The weight display briefly One of the requirements for Possible solutions:

indicates “Err 02” calibration/adjustment has not - Zero the weighing

been met (e.g., platform.

the weighing platform is loaded) - Unload the weighing

platform

(Calibrate/ adjust the

weighing platform only

when a zero readout is

displayed)

The weight display briefly Calibration/adjustment could Allow the equipment to

indicates “Err 03” not be completed within a warm up and start

specific time calibration/adjustment

again

The error code “ERR 07” is The last function you activated To change the menu codes, displayed

is not allowed for weighing plat- contact your local dealer or

forms used in legal metrology service technician

(legal for trade)

The error code “ERR 08” is The load on the weighing Check the initial zero-setting displayed

platform is too heavy for the range for the configuration

platform to be zeroed code you have selected

from the “Specifications

Charts”, to determine

whether this range is correct

The error code “ERR 09” is The gross value is < zero and the Check the initial zero-setting displayed

platform is unloaded, but it is not range for the configuration

possible to tare the platform code you have selected

from the “Specifications

Charts”, to determine

whether this range is correct

17

The error code “ERR 10” is There are values stored in the tare Clear the tare memories for

displayed memories for your application, your application first, then

and you tried to clear the lower- clear the lower-level tare

level tare memory memory

The error code “ERR 12” is You tried to store a value in the Check the configuration

displayed tare memory for applications,

although this memory has been

blocked by menu code 2 2 x

You entered a numeric tare that Check the number you have

is not allowed entered and correct it, if

necessary

The error code “ERR 17” is Internal calibration is not Reduce the preload or

displayed possible because the preload select a different

setting is too high configuration code

The error code “ERR 19” is The remaining weighing Reduce the preload

displayed capacity available is too low

because the relatively high

preload setting has reduced the

maximum capacity

The special code “b” remains None of the keys has been Press any key

displayed pressed since the weighing

platform was switched on

The weight readout changes Unstable environment (ambient Set up the weighing

constantly conditions; e.g., too much platform in a different area

vibration or exposure to Access the “Devices” setup

excessive drafts) menu to adapt the

weighing platform to the

particular environment

A foreign object is caught Remove the foreign object

between the load plate and the

platform frame

The readout of the weighing The weighing platform was not Adjust/calibrate the

result is obviously wrong adjusted/calibrated before weighing platform

weighing

The weighing platform is not level Level the weighing platform

as described in the

instructions

If any other errors occur, please contact your local Sartorius dealer or Sartorius Service Center.

18

Care and Maintenance

Service

Regular servicing by a Sartorius technician will extend the service life of your

weighing platform and ensure its continued weighing accuracy. Sartorius can

offer you service contracts, with your choice of regular maintenance intervals

ranging from 6 months to 2 years.

Cleaning

Before cleaning the weighing platform, disconnect it from the power supply

(e.g., unplug the AC adapter).

To clean the weighing platform when it has been exposed to dry ambient

conditions:

– Use a piece of cloth dampened with a commercially available cleaning

agent to wipe down the weighing platform

Wet Environment:

To clean the weighing platform when it has been in a wet environment:

– Use a commercially available cleaning agent and hose down the platform

afterwards.

In conformance with the IP65 protection rating, the weighing platform is

washdown resistant.

However, the applicable standards (EN 60529 and, in Germany, DIN VDE

0470 T1) do not allow the use of pressurized water (such as strong jets of

water using a hose or high-pressure cleaning equipment). When spraying

down the weighing platform, avoid directing strong jets of water at the 4

silicone gaskets beneath the load plate so that they are not torn by the water

pressure.

Never use concentrated acids, bases, solvents or pure alcohol to clean the

weighing platform!

Corrosive Environment

To clean the weighing platform exposed to a corrosive environment:

– Regularly remove all traces of corrosive substances from the platform

– Follow the manufacturer’s directions provided for the disinfectants and

cleaning agents you use to clean the weighing platform

Important Note:

If the water that you use to clean the weighing platform is too hot or too cold,

the difference in temperature between the water and the platform can cause

condensation within the platform. This condensation may cause the weighing

platform to malfunction.

Safety Inspection

If there is any indication that safe operation of the weighing platform is no

longer warranted, turn off the power and disconnect it from the power supply

immediately. Lock the equipment is a secure place to ensure that it cannot be

used for the time being.

Safe operation of the weighing platform with the AC adapter is no longer

ensured when

– there is visible damage to the AC adapter

– the AC adapter no longer functions properly

– the AC adapter has been stored for a relatively long period under adverse

conditions

19

In this case, notify your nearest Sartorius Service Center or the International

Technical Support Unit based in Goettingen, Germany. Maintenance and

repair work may be performed only by authorized Sartorius service

technicians who have access to the required maintenance manuals and have

attended the relevant service training courses.

Instructions for Recycling the Packaging

Sartorius products are packaged to ensure safe shipment using

environmentally friendly materials. After successful installation of the

equipment, you should return this packaging for recycling. For information on

recycling options, including recycling of old weighing equipment, contact

your municipal waste disposal center or local recycling depot.

C Marking

The

CC

CC

C marking affixed to the equipment indicates that the equipment meets

the requirements of the following Directive(s):

Council Directive 89/336/EEC “Electromagnetic Compatibility (EMC)”

Applicable European Standards:

Limitation of emissions: EN 50081-1 Residential,

commercial and light industry

EN 50081-2 Industrial environment

Defined immunity

to interference: EN 50082-1 Residential,

commercial and light industry

EN 50082-2Industrial environment

Important Note:

The operator shall be responsible for any modifications to Sartorius equipment

(not permitted on equipment to be verified) and for any connections of cables

or equipment not supplied by Sartorius and must check and, if necessary,

correct these modifications and connections. On request, Sartorius will

provide information on the minimum operating specifications (in accordance

with the Standards listed above for defined immunity to interference).

Pursuant to the German Directive for the Implementation of Regulations for

Prevention of Accidents, “Elektrische Anlagen und Betriebsmittel (VBG 4)”

(electrical installations and equipment) of April 1986, it is hereby certified that

the equipment delivered has been manufactured and tested in compliance

with the following DIN/VDE regulations:

DIN IEC 348/VDE 0411

Safety requirements for electronic measuring apparatus

DIN IEC 380/VDE 0806

Safety of electrically energized office machines

DIN IEC 601/VDE 0750

Safety of medical electrical equipment

and with Article 73/23/EEC, European Community Low Voltage Directive of

19 February 1973.

When you use electrical equipment in installations and under ambient

conditions requiring higher safety standards, you must comply with the

provisions as specified in the applicable regulations for installation in your

country.

Care and Maintenance

20

21

Use of the Weighing System in Legal Metrology

in the EU

Components of a Verifiable Weighing System

Your weighing platform is a modular device. The weighing system in which this

weighing platform is connected is verifiable for use in legal metrology only if

this platform is combined with a verifiable isi industrial terminal or with a PC

running Sartorius software (“Winscale”).

The weighing platform or weighing system may not be used for weighing

goods intended for direct sale to the public, and may not be used in legal

metrology prior to the initial verification.

The type-approval certificate for verification applies to non-automatic weighing

instruments and, in Germany, to automated weighing instruments used in noncontinuous weighing with or without control functions. Thus a verified weighing

system can consist of

– an isi industrial terminal + 1 to 3 IS weighing platforms

or

– an isi industrial terminal + at least one IS weighing platform + up to 2

additional weighing instrument that have undergone EU or national verification.

The weighing instrument may not be used for weighing goods intended for

direct sale to the public. The type-approval certificate for verification applies to

non-automatic weighing instruments only; for automatic operation with or

without auxiliary devices installed, you must comply with your country’s national

regulations applicable at the place of installation of your weighing instrument.

Separate Testing and Verification of the Weighing System Components

Initial verification can be performed separately on the isi industrial terminal and

the IS weighing platform.

Verification is valid, however, only after the two instruments are connected to

one another.

You can interchange tested and verified isi industrial terminals without having to

have the equipment re-tested and re-verified. The validity of the verification is

not affected.

Effect of the Preload on Verifiability

(The preload can be changed only prior to verification!)

Only internal adjustment (calibration) is allowed for weighing instruments

verified for use in legal metrology (see “Effect of the Preload on Internal

Calibration/Adjustment”).

The preload can be changed only prior to verification.

The legal basis permitting Sartorius to perform initial verification is constituted by

the following: 1) EC council directive no. 90/384/EEC on non-automatic

weighing instruments, which has been applicable within the harmonized Single

Market of the European Union since 1 January 1993; and 2) the certificate

issued by the Metrology Department “Eichwesen” of the Landesverwaltungsamt

(administrative offices) of Lower Saxony in Germany.

Declaration of Conformity

22

Approved Auxiliary Measuring Devices

If the weighing system is used in legal metrology, any auxiliary devices

connected must also be verifiable. Auxiliary devices that are metrologically

relevant, such as printers, remote display units, or the like, must have the

metrology label (black “M” on a green background). The auxiliary device

must be verified at the same time that the entire system is verified. In

Germany, if an auxiliary device is connected at a later date to a verified

system already in operation, the appropriate weights and measures office

must be notified; the auxiliary device may be used in legal metrology directly

following installation, however, provided that it is installed in accordance with

applicable regulations and that it bears the green metrology sticker referred to

above.

“EC Verification” - A Service Offered by Sartorius

Our service technicians authorized to perform the verification of your

weighing instruments that are acceptable for legal metrological verification

can inspect and verify the metrological specifications at the place of

installation within the Member States of the European Union and the

Signatories of the Agreement on the European Economic Area.

Subsequent Verifications within the European Countries

The validity of the verification will become void in accordance with the

national regulations of the country in which the weighing instrument is used.

For information on verification and legal regulations currently applicable in

your country, and to obtain the names of the persons to contact, please

contact your local Sartorius office, dealer or service center.

23

EC Type Approval Certificate

*

including the Signatories of the Agreement on the European Economic Area

Certificates

24

25

Certificates

26

Plates and Markings

27

300

265

35Ø

53

365

400

120.2

5353

Dimensions (Scale Drawings)

All dimensions given in millimeters

Plates and Markings

28

Accessories (Options)

Order No.:

Data interface port with 3-m cable (IP67, RS-485) YDO 59 IS

and round connector (electrically isolated)

Data interface port with 3-m cable (IP67, RS-232C/ YDO 58 IS

RS-423) and round connector (electrically

isolated)

Extension cable with round male and

female connectors (IP65, 6 m) YCC 01-ISM6

Round female connector, IP65, 69 QC0011

type C091D, 12-contact, Amphenol

Round male connector, IP65, 69 QC0010

type C091D, 12-pin, Amphenol

Adapter cable, from round connector to PC, YCC 01-0017D2

25-pin D-Submini; length: 0.25 m (approx. 10 in.)

(YDO58IS interface port required)

PC adapter cable, 25-pin D-Submini to 9-contact 69 65619

D-Submini; length: 0.2 m (approx. 8 in.) (YDO 52 IS

interface port and YCC 01-0017D2 adapter

cable required)

To order customized accessories or custom solutions, please contact the

Sartorius “Fast Factory”.

29

Order No.:

Stainless steel tag plate for metrological ID labels YAS 01 IS

(fastens to cable; required when weighing platform

is used for legal metrology in a weighing system)

Adapter kit for DC power supply to YAS 03 IS

the weighing platform (without using an external

AC adapter or power supply)

IP67 cable gland (to be installed by an authorized

service technician only)

External rechargeable battery pack; YRB 06 Z

hours of operation: approx. 28 (without isi

terminal) (YAS03IS adapter kit required)

IP65 AC adapter; 3-m primary cable,

1.5-m secondary cable; to be installed by an

authorized service technician only

(YAS03IS adapter kit required)

for 220 V 69 71899

for 110 V 69 71500

Adapter cable for connecting the weighing YRB 01 IS

platform to a 12-V car battery or to a separate 12-V

power source using the terminal leads; cable length:

3.7 m (approx. 12 ft.); with integrated switch and

fuse, reverse battery polarity protection; must be

installed by an authorized service technician using

the YAS03IS adapter kit.

Roller conveyor, with 7 rollers

Aluminum YRC 01 EDA

Stainless steel YRC 01 EDS

Calibration weight (1 · 10 kg, accuracy class F1) YCW 7138

(with weighing platforms verified for use in

legal metrology, the calibration weight is

used as a test weight only)

Configuration diskette for the IS weighing YAD 01 IS

platform (PC, DOS), without interface cable

Hanger for under-scale weighing 69EA0040

To order customized accessories or custom solutions,

please contact the Sartorius “Fast Factory”.

Accessories

Sartorius AG

37070 Goettingen, Germany

Weender Landstrasse 94 - 108, 37075 Goettingen, Germany

(+49/551) 308-0, (+49/551) 308-3289

Internet: http://www.sartorius.com

Copyright by Sartorius AG, Goettingen, Germany.

All rights reserved. No part of this publication

may be reprinted or translated in any form or by any means

without the prior written permission of Sartorius AG.

The status of the information, specifications and

illustrations in this manual is indicated by the date

given below. Sartorius AG reserves the right to

make changes to the technology, features,

specifications and design of the equipment

without notice.

Status: November 2001 Sartorius AG, Goettingen, Germany

Printed in Germany on paper that has been bleached without any use of chlorine · M.J. · KT

Publication No.: WIS6021-e01112

Loading...

Loading...