Sartorius IS 150 IGG-H,IS 300 IGG-H,IS 300 IGG-H0CE,IS 150 IGG-H0CE,IS 150 IGG-H Installation And Operating Instructions Manual

Installation and Operating Instructions

Sartorius

IS 150 IGG-H , IS 150 IGG-H0CE,

IS 300 IGG-H , IS 300 IGG-H0CE

Weighing Platforms

98648-006-06

98648-006-05

Sartorius

IS 150 IGG-H , IS 150 IGG-H0CE,

IS 300 IGG-H , IS 300 IGG-H0CE

Wägeplattformen

Aufstellungs- und Betriebsanleitung

2

Installation Instructions

Contents

General Specifications .................................... 21

ID Label ............................................................. 22

Pin Assignment Chart RS-485 ....................... 23

Troubleshooting Guide .................................... 24

Care and Maintenance .................................... 25

Servicing ......................................................... 25

Cleaning ......................................................... 25

Safety Inspection .......................................... 26

Information on Recycling ............................ 26

TÜV Certificates ............................................... 27

Installation instructions .................................. 31

Legal Measuring Instrument .......................... 34

Preload .............................................................. 35

Approved Auxiliary Measuring Devices......... 36

Certificate ......................................................... 37

Declarations of Conformity ............................ 39

Plates and Markings ........................................ 42

A Service Offered by Sartoriusr ..................... 45

Accessories (Options) ...................................... 46

Certificate ......................................................... 51

Contents

General View of the Weighing Platform .........3

Notes .....................................................................4

Safety Instructions..............................................5

Installation Instructions .....................................6

Getting Started ...................................................7

Unpacking the Weighing Platform ................7

Removing the Transport Locking Devices .....7

Leveling the Weighing Platform ....................8

Connecting the Weighing Platform ..............9

Safety Precautions ........................................ 11

Warm-up Time .............................................. 12

Operating Limits ........................................... 12

Shock Resistance ........................................... 12

General Instructions ....................................... 13

Preload Range (Zero-Setting Range) ......... 13

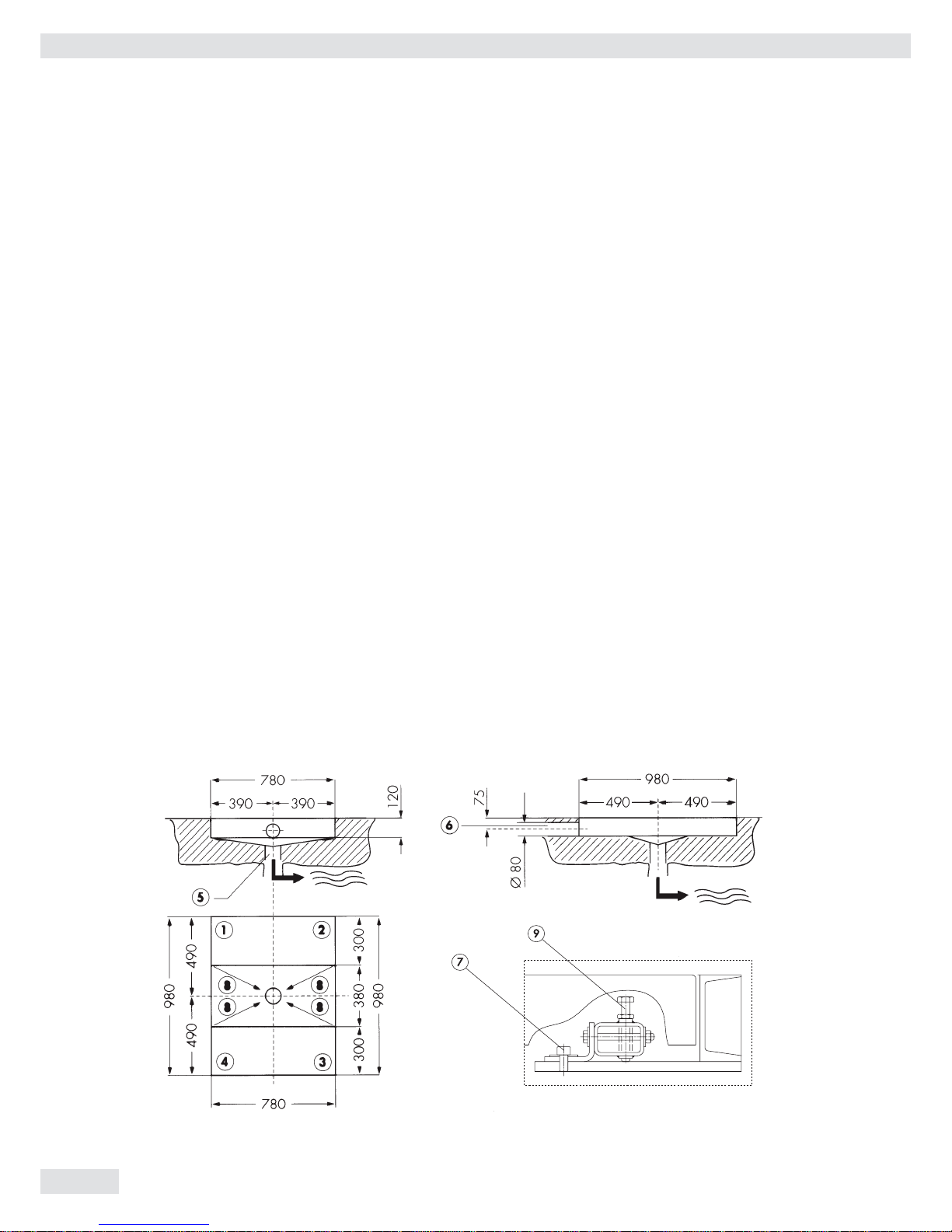

Dimensions ........................................................ 14

Pit Installation of the Weighing Platform ... 15

Installation of the Drive-on Ramp YAR ........ 17

Configuring the Weighing Platform ............. 18

Specifications Chart ........................................ 19

Installation Instructions

3

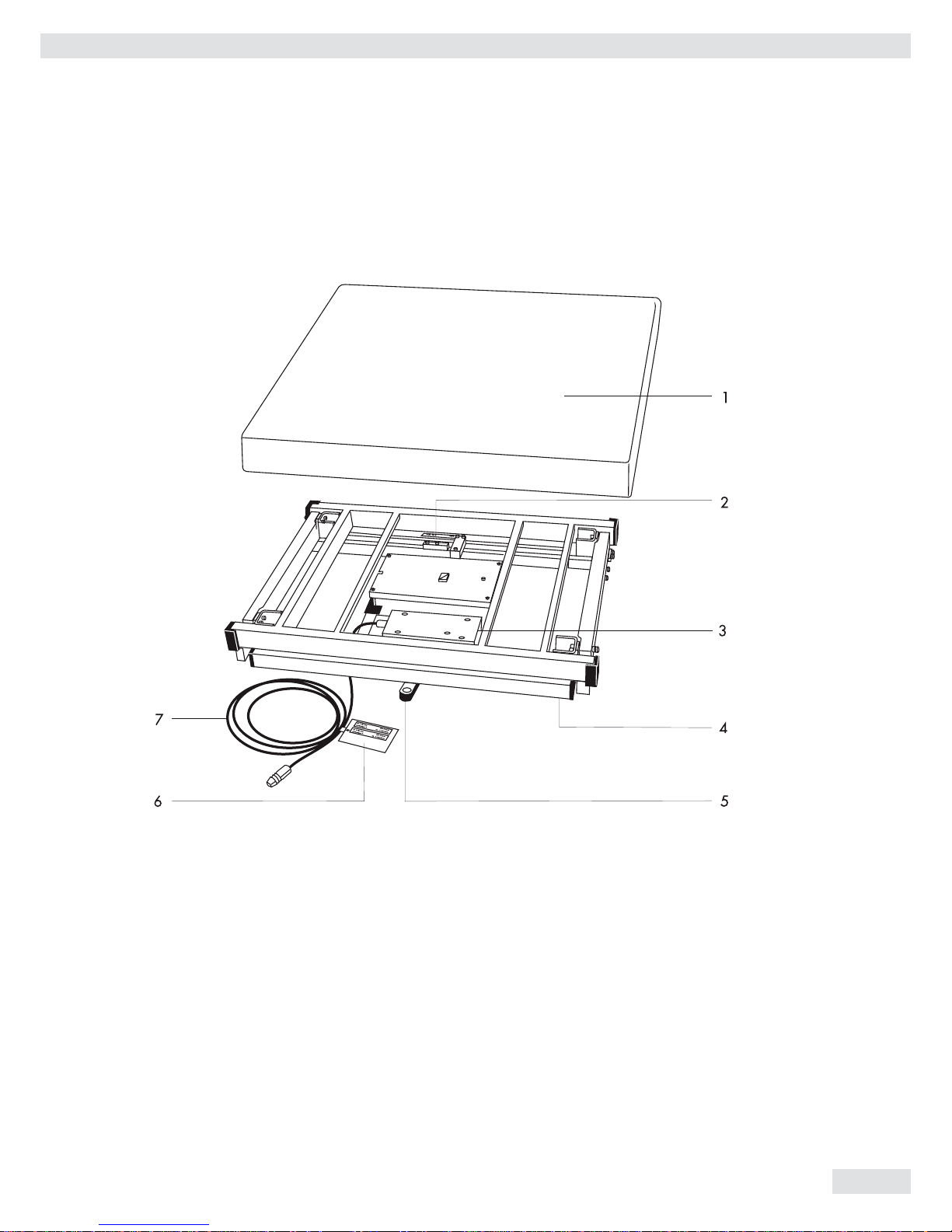

General View

General View of the Weighing Platform

No. Designation

1 Load plate

2 Manufacturer‘s label

3 Line voltage connector (optional)

4 Leveling feet

5 Level indicator

6 Tag plate for metrological ID label

7 Connecting cable

(interface port/power supply)

4

Installation Instructions

Notes

With this Sartorius IS weighing platform, you have acquired a high-quality

weighing instrument that features advanced technology. As a rule, you will be

using this weighing platform as part of a modular weighing system.

Please read through these installation and operating instructions before

operating your new weighing platform.

Warranty

Do not miss out on the benefits of our full warranty. Please complete the

warranty registration card, indicating the date of installation, and return the card

to your Sartorius dealer or office.

Storage and Shipping Conditions

Allowable storage temperature: – 10°C ... + 40°C

– 14°F ... + 104°F

Allowable storage humidity: 98% relative humidity at 40°C (104°F)

After unpacking the weighing platform, please check it immediately for any

visible damage. If you detect any damage, proceed as directed in the section

entitled „Safety Inspection.“

It is a good idea to save the box and all parts of the packaging until you have

successfully installed the weighing platform. If you need to ship the weighing

platform for any reason, be sure to unplug all connected cables to prevent

damage.

Installation Instructions

5

Safety Instruction

Safety Instructions

The seals affixed to this equipment indicate that only authorized service technicians are

allowed to open the equipment and perform maintenance work so that safe and

trouble-free operation of the equipment is ensured and the warranty remains in

effect.

Before opening the weighing cell or A/D converter enclosure, make sure to unplug the

weighing platform from the power supply!

Instructions for Use in Hazardous Areas

Weighing platforms of the series ISI 150IGG-H… and IS300IGG-H comply with the

European Standards EN 50 021: 1999 and EN 5028-1-1-1 according to the

Statement of Conformity, No. TüV 01 ATEX 1739 X, including the 1st and 2nd

Supplements (see “TÜV Certificates”). Therefore, they are suitable for use in

Zones 2 and 22 hazardous areas. Their approval marking is:

h II 3 GD IP67 Eex nR II T6 T80°C

The type of explosion protection used in these weighing platforms involves protection of

the housing against penetration of potentially explosive vapor. For this purpose,

IP67 protection of the platform must be ensured when it is connected to the

power source. Opening the platform or disconnecting cables while the scale is

plugged into the power supply is strictly forbidden. Please read the installation

instructions in the Annex 35751-000-16-A4. To install the power supply, please

follow the installation instructions given in the section entitled “Connecting the

Weighing Platform” in “Getting Started.”

If you will be operating the platform outside the European Community in a Zone

2 hazardous area, you must comply with the national electrical code and

applicable safety regulations of your country. Please ask your local Sartorius

service technician, office or dealer for information on the currently valid

regulations applicable in your country.

The weighing platform may not be operated in Zone 0, 1, 20 or 21 hazardous areas, as it

does not have an EX approval certificate for these areas.

Any tampering with the weighing platform by anyone, other than installation of preload

devices, will result in forfeiture of all claims under the manufacturer‘s warranty.

6

Installation Instructions

Installation Instructions

Installation Instructions

Sartorius dealers or service technicians, who have received special training, will help you

set up the weighing platform and show you how to operate it.

Ambient Conditions

Choose a suitable place to set up the weighing platform. Avoid exposing the weighing

platform to the following ambient conditions:

– Extreme heat radiation

– Extreme vibration

– Places that are difficult to access for cleaning and maintenance

Important Note

If you need to use the weighing platform in areas exposed to heavy traffic (e.g., fork-lift

trucks), you should install a protective frame, consisting of angular braces, around the

weighing platform. To calculate the dimensions for this protective frame, refer to the

section entitled „Dimensions (Scale Drawings).“

Conditioning the Weighing Platform

Do not expose the weighing platform to extreme moisture over long periods. Moisture

in the air can condense on the surfaces of a cold platform whenever it is brought to a

substantially warmer place. If you transfer the weighing platform to a warmer area,

make sure to condition it for about 2 hours at the new ambient temperature, leaving

it unplugged from the power supply. Afterwards, if you keep the weighing platform

connected to the power supply, the continuous positive difference between the

inside of the platform and the outside will practically rule out the effects of moisture

condensation.

IP67 Protection

In conformance with the IP67 protection rating, the weighing platform will remain

leaktight for 30 minutes if immersed at a depth of 1 meter (approx. 3 ft.).

The IP67 protection of the weighing platform is ensured only under the following

conditions:

– The weighing platform is maintained in the original factory condition

– The rubber seals of the weighing cell and the A/D converter are not perforated

– All cables are securely fastened in place by cable glands

– Both the weighing cell and the A/D converter enclosure are securely closed

Installation Instructions

7

Getting Started

Unpacking the Weighing Platform

Important Note

To install the weighing platform in a pit, please observe the special requirements

given in the section „Pit Installation.“

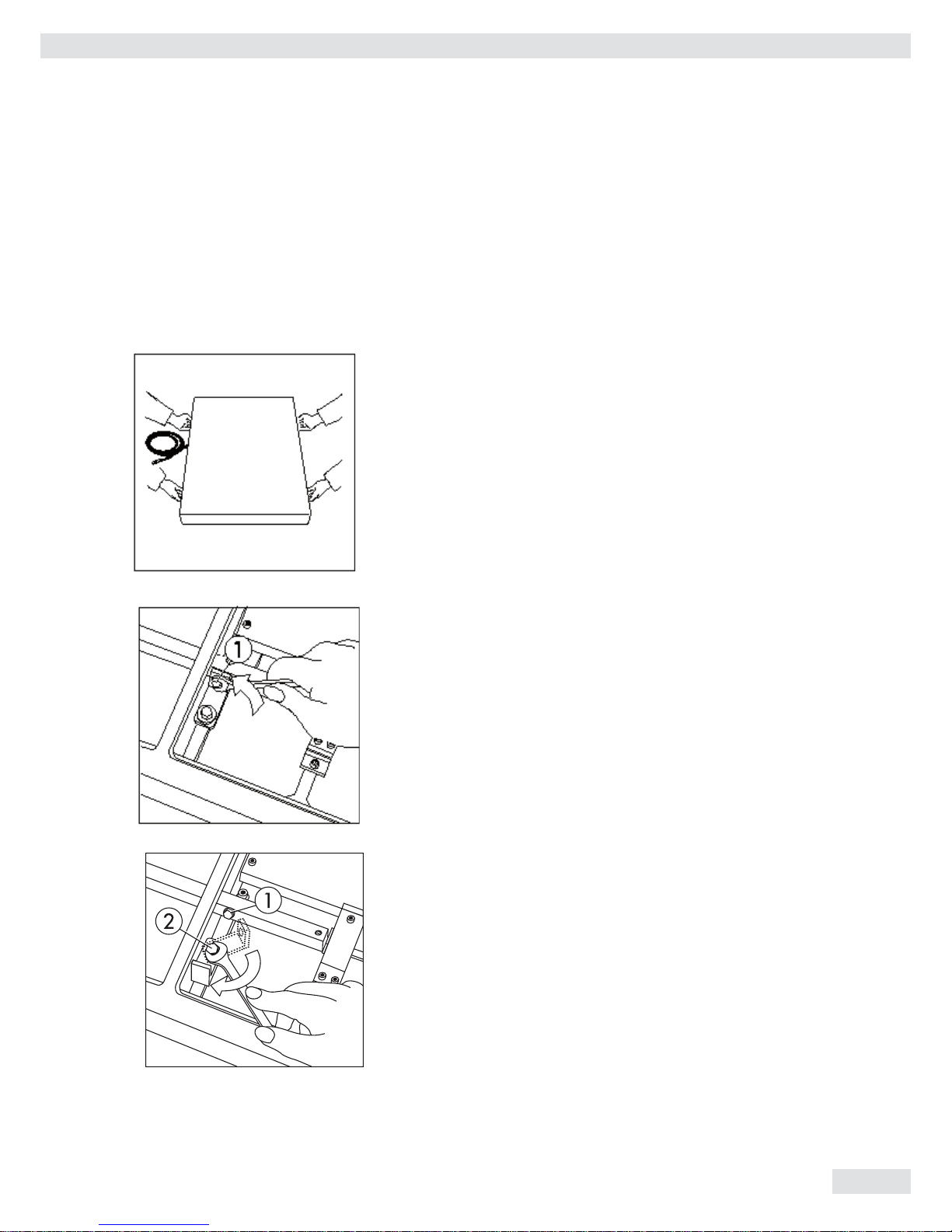

Unpacking the Weighing Platform

- Remove the weighing platform and the load plate from the packaging

- To transport the weighing platform, lift it on both long sides

- Remove the plastic bags, packaging strips and foam material

Removing the Transport Locking Devices

Set up the weighing platform in the vicinity of your work area and remove the

load plate.

Proceed as follows with the red color-coded transport locking device:

- Remove screw 1

- Loosen screw 2 and turn the angular brace by 180°,

refasten screw 2

- Refasten screw 1 to the lever

Important Note on Transporting the Weighing Platform

Follow the above instructions in reverse order to replace the transporting locking

device when transporting the weighing platform.

Getting Started

8

Installation Instructions

Getting Started

Leveling the Weighing Platform Using the Level Indicator

At the place of installation, level the weighing platform using the leveling feet

so that the air bubble is centered within the circle of the level indicator. Check

to ensure that all 4 leveling feet securely touch the surface and that they equally

support the weight of the platform.

- Remove the load plate

- Loosen the locknuts on the leveling feet using a 17 mm open-end wrench

(spanner)

- Extend or retract the leveling feet using a 5 mm Allen wrench (key)

- After leveling the weighing platform, refasten the locknuts securely against

the platform frame

- Replace the load plate

Installation Instructions

9

Getting Started

Connecting the Weighing Platform

Before initially operating the scale, connect the following cables and completely

assemble the components listed below:

- interface cable to a Sartorius isi industrial terminal or a computer with special

software

- separate power cable for power supply via a Sartorius AC adapter

- components for conveyor systems

Make absolutely sure to unplug the weighing platform from the power supply

before you connect or disconnect any interface cables.

Please note that the person or company who connects any non-Sartoriusapproved indicating and control devices (e.g., a computer) or power supplies to

the weighing platform shall assume all risks and responsibilities associated with

this equipment.

Plug the connecting cable into the connector of a Sartorius isi industrial

terminal. Afterwards, hand-tighten the locking ring. The connecting cable is

6 meters long (approx. 20 feet). To order an extension cable or to customize a

cable to your requirements, refer to the list of accessories or contact Sartorius.

Cable Lengths:

Since you can choose to power the weighing platform via the interface port of

the Sartorius isi industrial terminal or a separate power supply unit, there are a

few restrictions that apply to the cable lengths between these components.

If you use a cable that is longer than 12 meters (∼ 40 feet) between the weighing

platform and the Sartorius isi industrial terminal, each of these components must

be energized by a separate AC adapter.

Note on use in a Zone 11 hazardous area:

The industrial terminal must be mounted securely on a vertical surface so that

the connecting jacks face downwards.

Separate Power Connection for the Weighing Platform

Have your local Sartorius dealer or service technician connect the weighing

platform separately to line current (mains supply). This separate power

connection is required when you use cables that are longer than 12 meters or if

you interface the weighing platform directly with a computer.

10

Installation Instructions

Getting Started

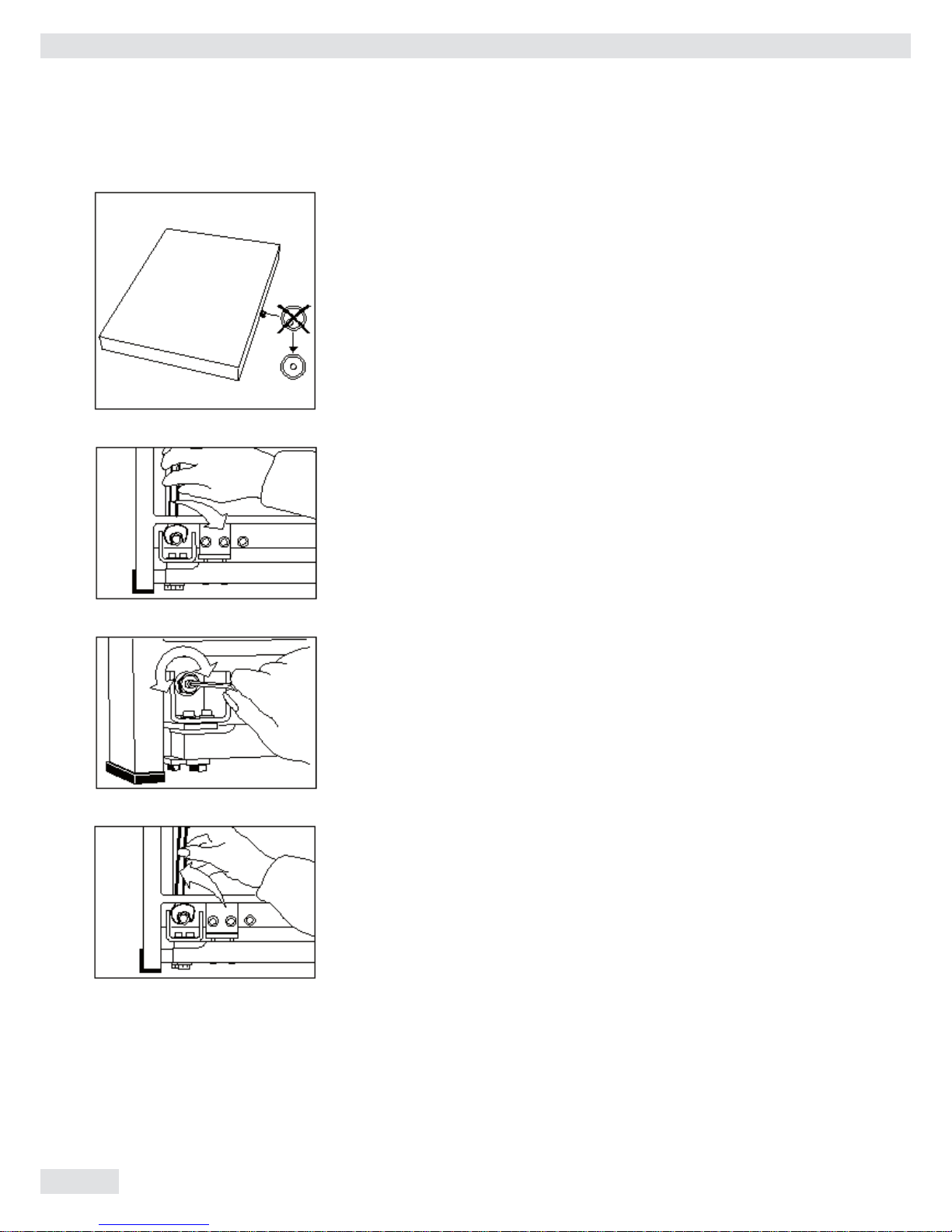

The following diagrams show the options for powering weighing platforms and

industrial terminals.

Cables for connecting the industrial-grade AC adapter, model ING2, to the

„IS“ weighing platform without an extension cord (using the YDO50IS (3m) or

YDO53IS (6m) data output port):

Cables for connecting the industrial-grade AC adapter, model ING2, to the isi

industrial terminal without an extension cord (using the YD050IS (3 m) or the

YD053IS (6 m) data output port):

Cables for connecting the industrial-grade AC adapter, model ING2, only to the

isi industrial terminal with an extension cord:

Connections for cables longer than 12 meters:

Installation Instructions

11

Safety Precautions

Safety Precautions

The weighing platform is energized by an external industrial-grade AC adapter.

Make sure that the voltage rating printed on this unit is identical to your local

line voltage. If the voltage specified on the label or the plug design does not

match the rating or standard you use, please contact your local Sartorius dealer

or office. To use a main feeder cable from the ceiling or to mount a CEE plug,

you will have to make arrangements inside your facilities for installation of such

cable equipment.

Use only original Sartorius AC adapters/power supplies identified by the Sartorius

label. Use of AC adapters/power supplies from other manufacturers, even if these

units have an approval identification marking from a national testing laboratory,

requires the consent of an authorized Sartorius service technician.

For detailed information on further options for powering the weighing platform

(e.g., using local low voltage), contact Sartorius headquarters in Germany or one

of the main offices based in your country.

Hook up the weighing platform to the power supply in conformance with the

installation requirements of your country.

Safety Precautions:

A power supply rated to Industrial Class 2 can be plugged into any electrical

outlet without requiring any additional safety precautions. The ground or

earth terminal is connected to the platform housing, which can be additionally

grounded/earthed, if required.

Install the power cable for connection to an isi industrial terminal or a computer

with adequate protection so that the cable cannot get damaged.

Fixed Power Connection:

If the power cable is permanently installed or secured so that it cannot be

unplugged, the weighing platform must be able to be switched off by a suitable

emergency switch. This emergency switch must be installed near the weighing

platform and be within easy reach. In addition, this switch must be labeled as an

emergency switch. All operators must be shown how to operate this switch.

Operating the Weighing Platform in Zone 2 Hazardous Areas:

If you need to install the platform in Zone 2 hazardous areas, make sure

to comply with the applicable requirements of your country. Installation of

equipment in Zone 2 must be done by a certified technician.The female plug of

the power cable on the industrial-grade power supply must be secured to the

display unit of the weighing platform. The following requirements must be met

for the plug on the other end of the cable:

– either an explosion-protected plug must be installed;

– or the plug must be detached from the power cable and the power cable

permanently secured to a suitable junction box;.

– or the plug must be secured against accidental disconnection

(see Installation Instructions 35751-000-16 AN in this manual).

Connection to the Power Supply in a Zone 2 Hazardous Area:

Brown (live (L)) Blue (neutral (N))

Yellow/green (protective grounding conductor/protective earth)

Whenever possible, avoid wiring your weighing platform into networks that carry

a heavy electrical load (for instance, a compressor or similar equipment).

12

Installation Instructions

Operating Limits

Warm-up Time

The weighing platform will need to warm up for at least 30 minutes after initial

connection to the power supply (or after a relatively long period without power

connection).

Preparing the Weighing Platform for Verification as a Legal Measuring

Instrument in the EU*:

After initially connecting the weighing platform to the power supply, (or after

a relatively long period outage), allow the platform to warm up for at least 24

hours.

*including the Signatories of the Agreement on the European Economic Area

Operating Limits

Maximum Overload Capacity

Sartorius weighing platforms are built so that occasionally loading them

beyond their maximum weighing capacity will not damage them in any way.

The maximum overload capacity of this IS model is 600 kg.

Shock Resistance

Even though Sartorius weighing platforms feature a highly rugged

construction, there are some limits. Avoid dropping objects from considerable

height on the weighing platform and do not expose it to strong side impact.

Sartorius weighing platforms withstand shock according to the shock

response spectrum defined in the IEC68 standard.

Installation Instructions

13

General Instructions

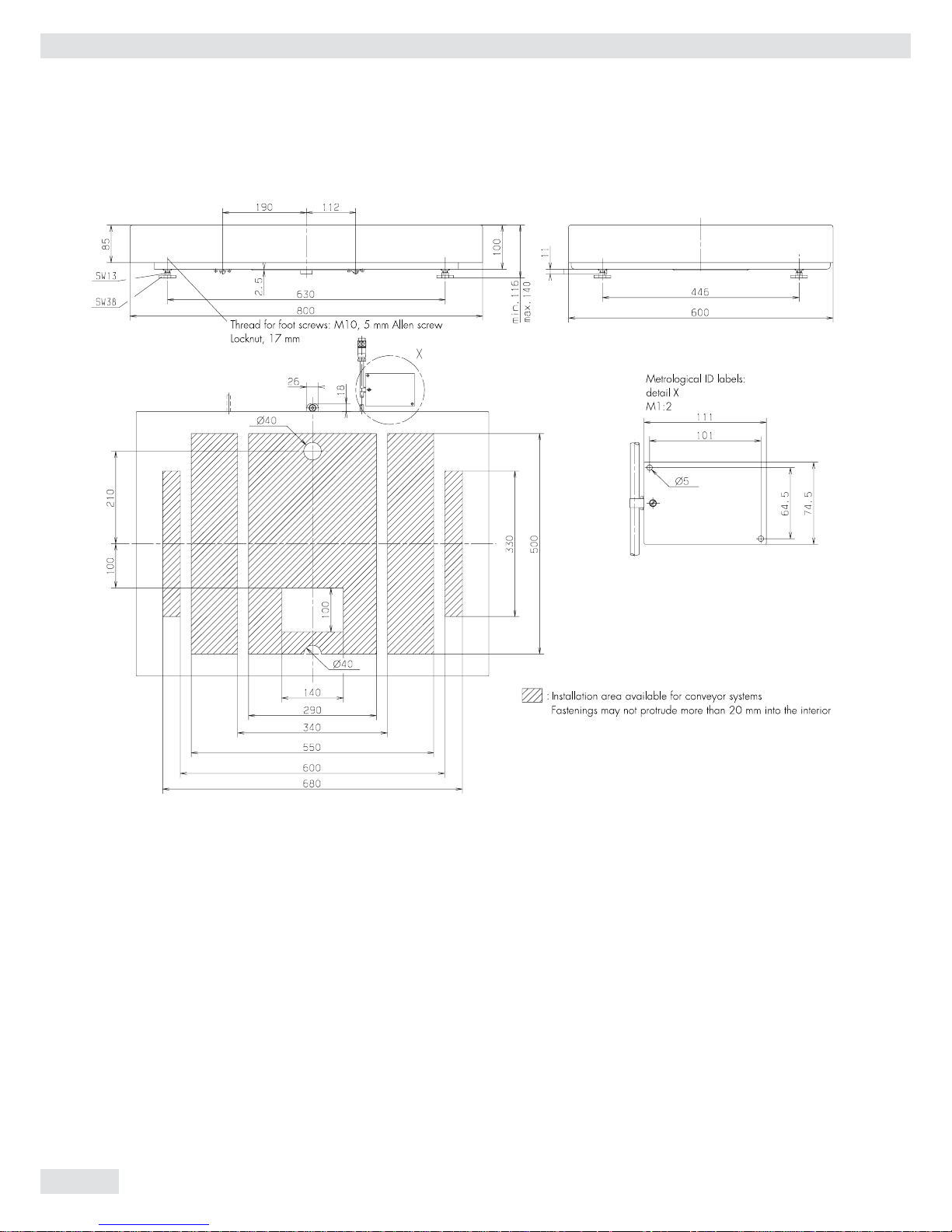

General Instructions for Integration

into Conveyor Systems

The IS weighing platform is suitable for installation in conveyor systems.

Follow the general instructions given below and refer to the „Dimensions (Scale

Drawings)“ to meet the requirements for such installation. Secure the weighing

platform using the appropriate components from the set of fasteners, YAS04 IS.

Any moving or rotating parts intended to be permanently attached to the

load plate must be designed so that they cannot affect the weighing results.

Rotating mechanisms must be properly balanced, for example. In addition,

take care that the fittings do not collide with the parts of the scale platform

mechanism under the load plate. Make sure to remove the load plate from the

platform before drilling.

Any cables or tubing between the weighing platform and other equipment must

not apply any force to the weighing platform. Make sure that cables do not

touch the load plate.

If you install the weighing platform in conveyor systems in Zone 2 or 22

hazardous areas, you must comply with the applicable safety regulations (e.g.,

in Germany with VDE0165). Special precautions must be taken to prevent the

build-up of static electricity caused by moving parts (e.g., roller conveyors).

Preload Range (Zero-Setting Range)

The weight of components that are securely installed on the weighing platform

is called „preload.“ The weighing platform must electrically compensate for this

preload so that the entire weighing range is available and so that it is possible to

zero and adjust (calibrate using external weights) the platform. Higher preloads

may result in a reduction in the maximum weighing capacity.

The following weighing capacities must not be exceeded:

- for the IS 150 IGG--H, at least 30 kg weighing capacity must remain

- for the IS 300 IGG-H, at least 60 kg weighing capacity must remain

Note to Users in the EU *:

Always set the preload prior to verification.

The components for integration into a conveyor must already be installed on the

weighing platform before you connect the platform to the power supply.

*including the Signatories of the Agreement on the European Economic Area

14

Installation Instructions

Dimensions

Dimensions (Scale Drawings)

Dimensions in millimeters

Installation Instructions

15

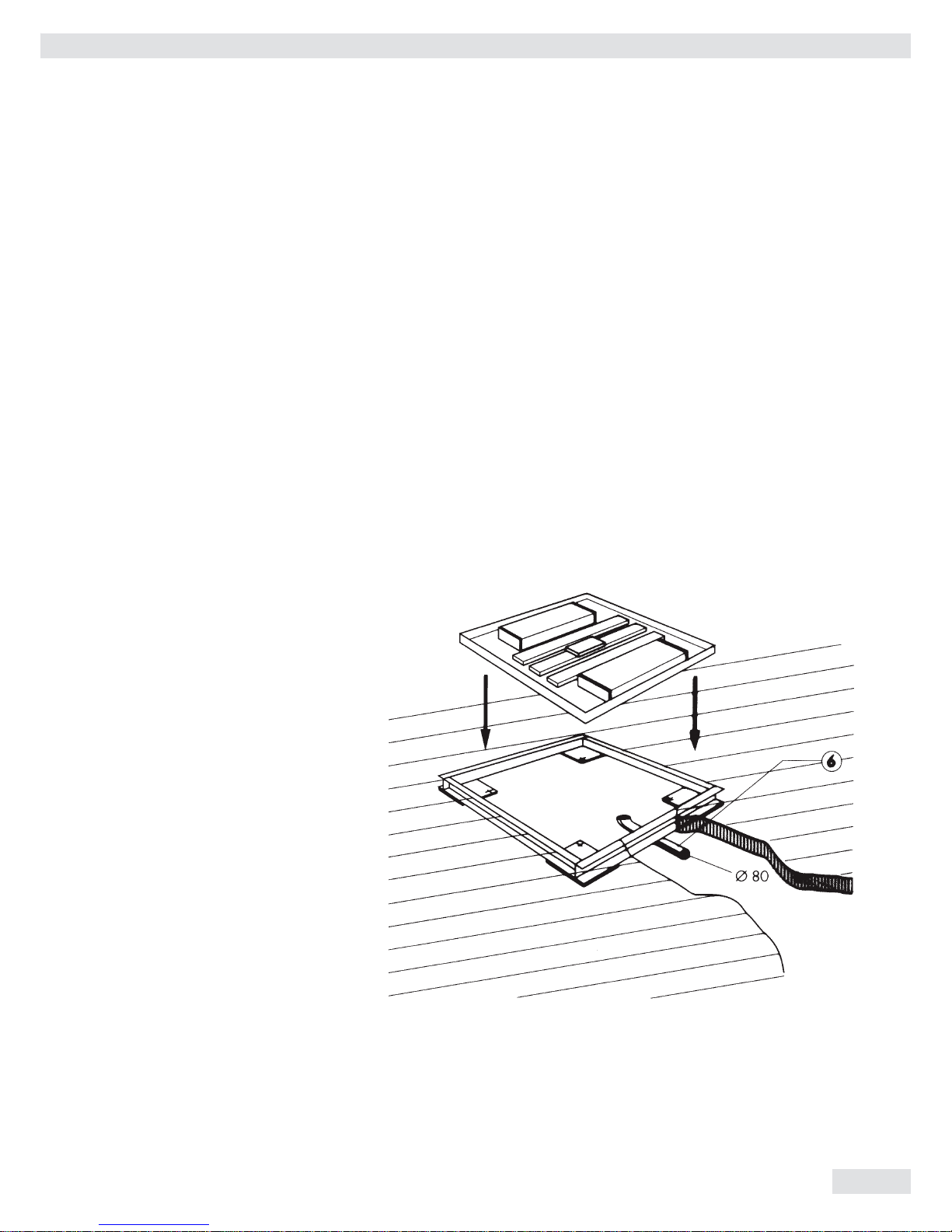

Pit Installation of the Weighing Platform

Pit Installation of the Weighing Platform

Preparation

Choose the appropriate pit frame from the list of accessories.

Note to Users in the EU*

If necessary, the weighing platform can be installed into the pit prior to

initial verification. If a verified weighing platform has been installed, it must

be subsequently verified in compliance with the applicable regulations of your

country.

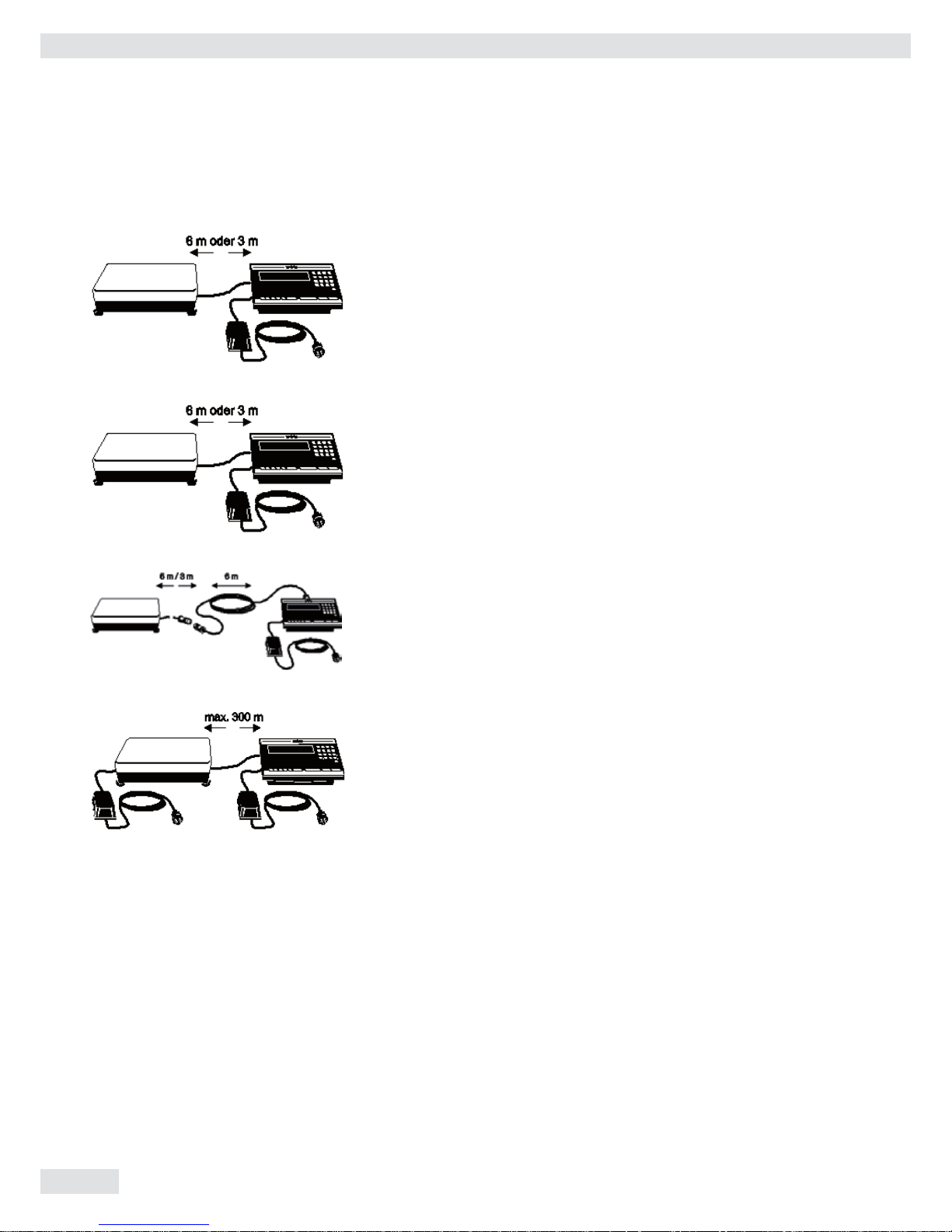

Depending on the size of your weighing platform, excavate the area where

the platform is to be installed according to the diagrams on the following

page. You must connect a drainage system (5) if the weighing platform

will be operated in a wet area. In this case, slope the floor of the pit (8) at

a minimum of 5% toward the drain point. Position a tube (6) with a min.

diameter of 80 mm from a central point of the pit to the location of the

display in order route the signal cable. This will protect the cable, as required.

* including the Signatories of the Agreement on the European Economic Area

16

Installation Instructions

Installation of a Pit Frame

Installation of a Pit Frame

- Remove the screws (7), washers and the metal plates of the pit frame

- Place tape over the threads of the pit frame

- Lower the frame into the pit

- Ensure that the contact areas of the pit frame (1), (2), (3) and (4) are completely level

- The pit frame must carry at least half the maximum weighing capacity of the platform

on each side

- Adjust the height by placing thin metal plates (7) underneath the pit frame. Back fill

with concrete and allow area to dry.

Positioning and Connecting the Weighing Platforms (Your Sartorius Service Technician

Will Help You )

- Remove the load plate, the level indicator and leveling feet

- Take the 4 hexagon bolts, M 10x70, from the set of fasteners, YAS 04 IS, attach the

locknuts to them and screw them into the threads for the leveling feet (foot screws).

Tighten the bolts.

- Remove the transport locking devices as described on page 7.

- Loosely attach the 4 angular braces to the frame of the weighing platform using the

screws (7) and washers from the set of fasteners.

- Push the connecting cable through the tube (6) and lower the weighing platform into

the pit frame.

- Loosely attach the angular braces to the pit frame using the screws of the pit frame.

- Center the weighing platform with respect to the pit frame.

- Adjust the height of the weighing platform with the 4 hexagon bolts (9), M 10x70. Fix

the screws with the locknuts and tighten the screws of the angular braces.

- Refit the load plate.

- Use the handles provided in the set of fasteners to remove the load plate.

Pit Construction Diagrams:

Loading...

Loading...