Sartorius IS 150 IGG-H, IS 300 IGG-H, IS 300 IGG-H0CE, IS 150 IGG-H0CE Installation And Operating Instructions Manual

Page 1

Installation and Operating Instructions

Sartorius

IS 150 IGG-H , IS 150 IGG-H0CE,

IS 300 IGG-H , IS 300 IGG-H0CE

Weighing Platforms

98648-006-06

98648-006-05

Sartorius

IS 150 IGG-H , IS 150 IGG-H0CE,

IS 300 IGG-H , IS 300 IGG-H0CE

Wägeplattformen

Aufstellungs- und Betriebsanleitung

Page 2

2

Installation Instructions

Contents

General Specifications .................................... 21

ID Label ............................................................. 22

Pin Assignment Chart RS-485 ....................... 23

Troubleshooting Guide .................................... 24

Care and Maintenance .................................... 25

Servicing ......................................................... 25

Cleaning ......................................................... 25

Safety Inspection .......................................... 26

Information on Recycling ............................ 26

TÜV Certificates ............................................... 27

Installation instructions .................................. 31

Legal Measuring Instrument .......................... 34

Preload .............................................................. 35

Approved Auxiliary Measuring Devices......... 36

Certificate ......................................................... 37

Declarations of Conformity ............................ 39

Plates and Markings ........................................ 42

A Service Offered by Sartoriusr ..................... 45

Accessories (Options) ...................................... 46

Certificate ......................................................... 51

Contents

General View of the Weighing Platform .........3

Notes .....................................................................4

Safety Instructions..............................................5

Installation Instructions .....................................6

Getting Started ...................................................7

Unpacking the Weighing Platform ................7

Removing the Transport Locking Devices .....7

Leveling the Weighing Platform ....................8

Connecting the Weighing Platform ..............9

Safety Precautions ........................................ 11

Warm-up Time .............................................. 12

Operating Limits ........................................... 12

Shock Resistance ........................................... 12

General Instructions ....................................... 13

Preload Range (Zero-Setting Range) ......... 13

Dimensions ........................................................ 14

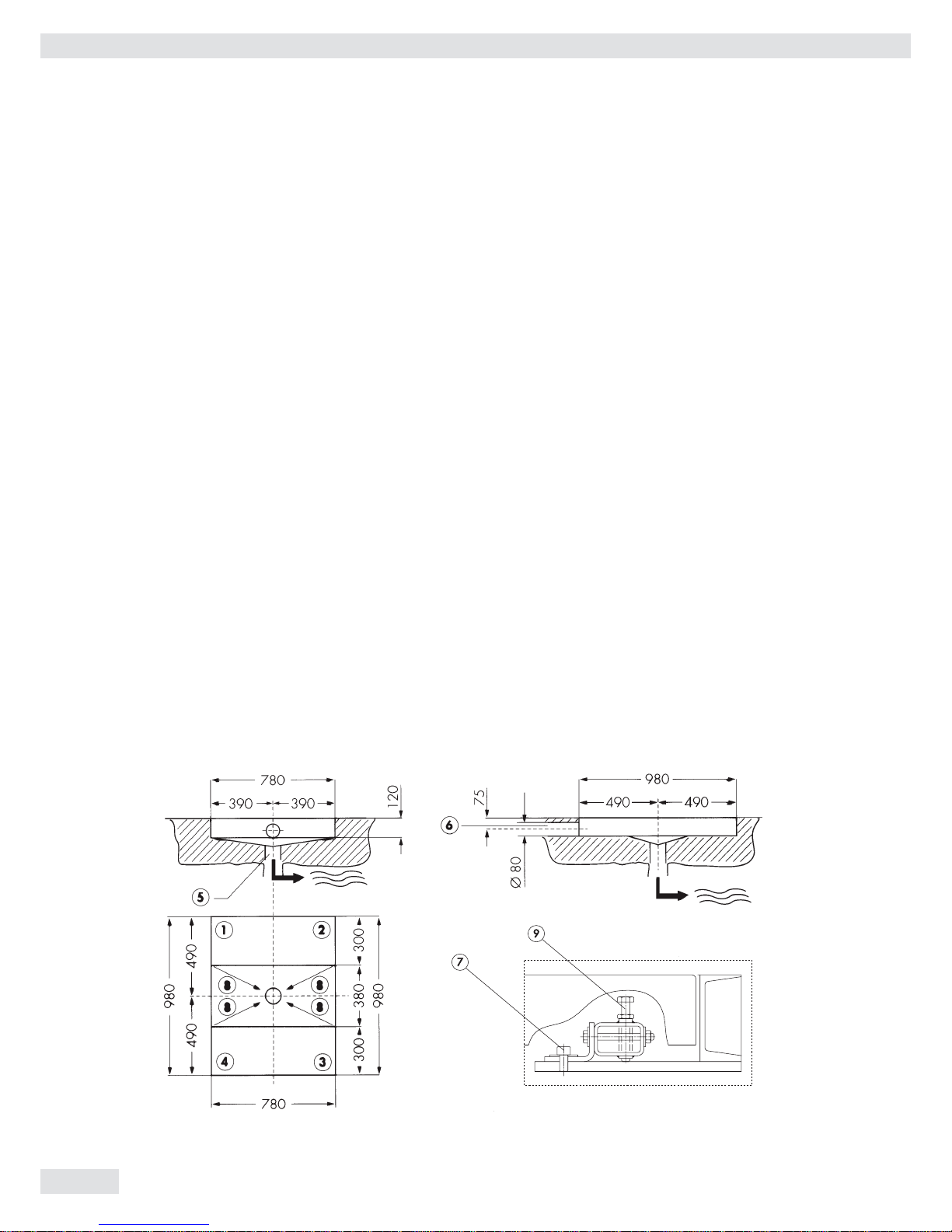

Pit Installation of the Weighing Platform ... 15

Installation of the Drive-on Ramp YAR ........ 17

Configuring the Weighing Platform ............. 18

Specifications Chart ........................................ 19

Page 3

Installation Instructions

3

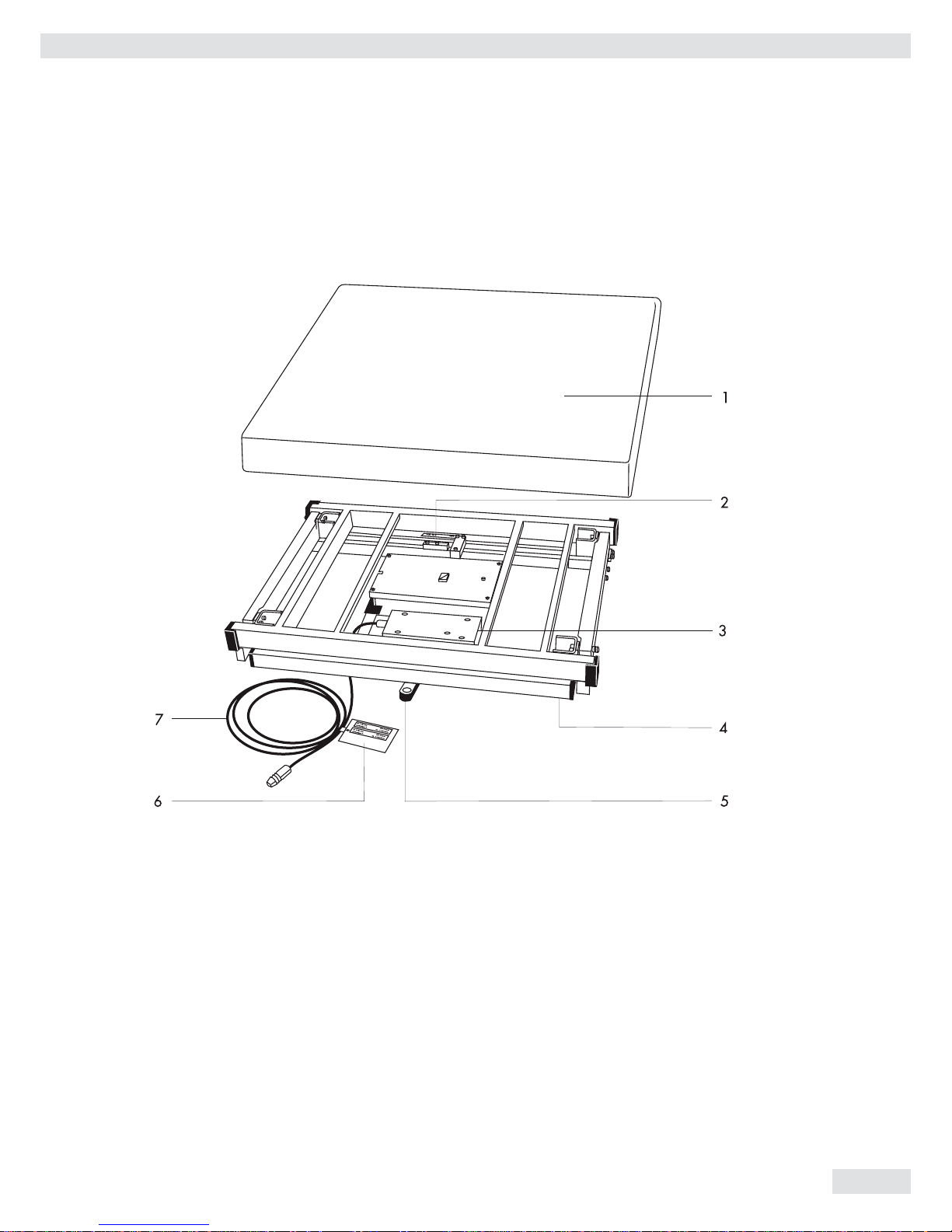

General View

General View of the Weighing Platform

No. Designation

1 Load plate

2 Manufacturer‘s label

3 Line voltage connector (optional)

4 Leveling feet

5 Level indicator

6 Tag plate for metrological ID label

7 Connecting cable

(interface port/power supply)

Page 4

4

Installation Instructions

Notes

With this Sartorius IS weighing platform, you have acquired a high-quality

weighing instrument that features advanced technology. As a rule, you will be

using this weighing platform as part of a modular weighing system.

Please read through these installation and operating instructions before

operating your new weighing platform.

Warranty

Do not miss out on the benefits of our full warranty. Please complete the

warranty registration card, indicating the date of installation, and return the card

to your Sartorius dealer or office.

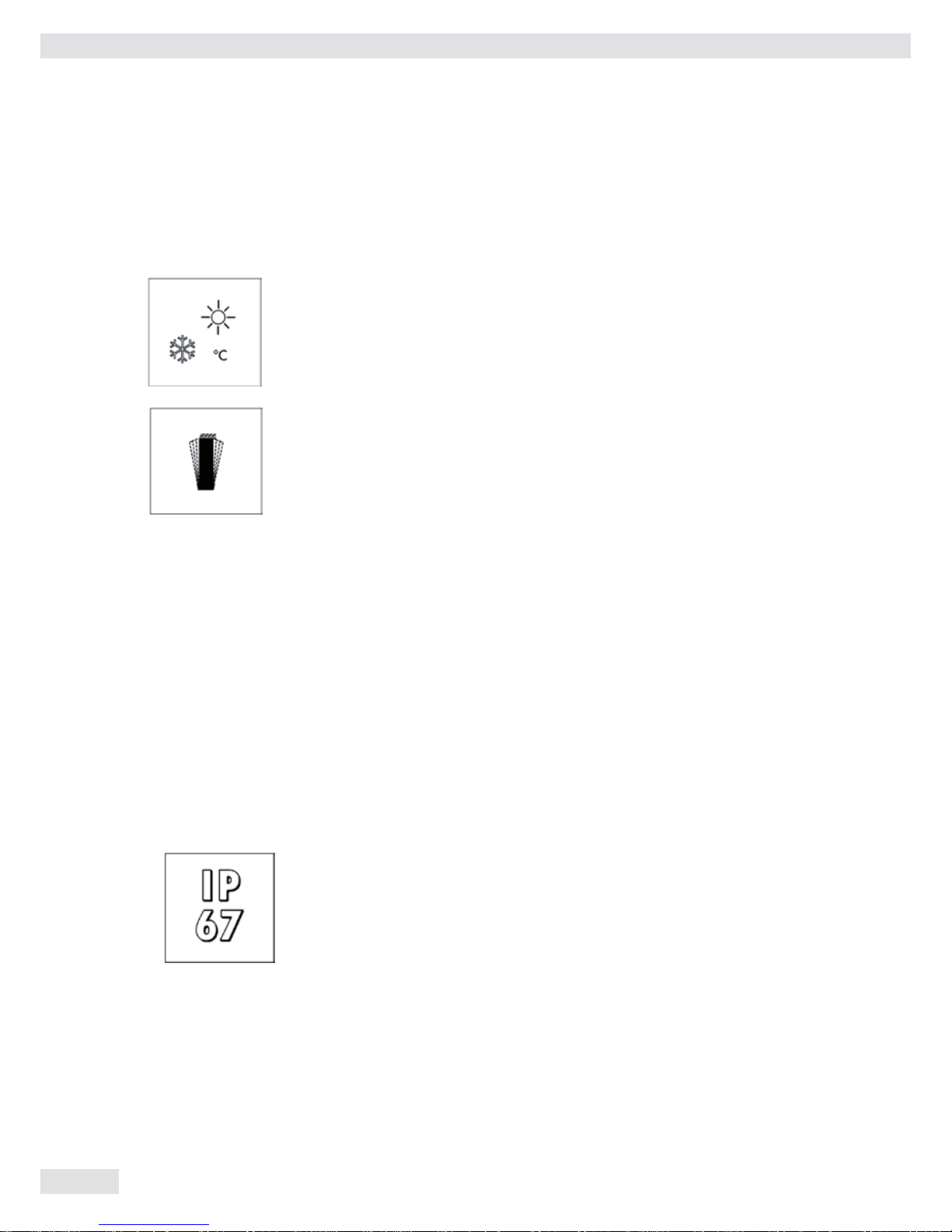

Storage and Shipping Conditions

Allowable storage temperature: – 10°C ... + 40°C

– 14°F ... + 104°F

Allowable storage humidity: 98% relative humidity at 40°C (104°F)

After unpacking the weighing platform, please check it immediately for any

visible damage. If you detect any damage, proceed as directed in the section

entitled „Safety Inspection.“

It is a good idea to save the box and all parts of the packaging until you have

successfully installed the weighing platform. If you need to ship the weighing

platform for any reason, be sure to unplug all connected cables to prevent

damage.

Page 5

Installation Instructions

5

Safety Instruction

Safety Instructions

The seals affixed to this equipment indicate that only authorized service technicians are

allowed to open the equipment and perform maintenance work so that safe and

trouble-free operation of the equipment is ensured and the warranty remains in

effect.

Before opening the weighing cell or A/D converter enclosure, make sure to unplug the

weighing platform from the power supply!

Instructions for Use in Hazardous Areas

Weighing platforms of the series ISI 150IGG-H… and IS300IGG-H comply with the

European Standards EN 50 021: 1999 and EN 5028-1-1-1 according to the

Statement of Conformity, No. TüV 01 ATEX 1739 X, including the 1st and 2nd

Supplements (see “TÜV Certificates”). Therefore, they are suitable for use in

Zones 2 and 22 hazardous areas. Their approval marking is:

h II 3 GD IP67 Eex nR II T6 T80°C

The type of explosion protection used in these weighing platforms involves protection of

the housing against penetration of potentially explosive vapor. For this purpose,

IP67 protection of the platform must be ensured when it is connected to the

power source. Opening the platform or disconnecting cables while the scale is

plugged into the power supply is strictly forbidden. Please read the installation

instructions in the Annex 35751-000-16-A4. To install the power supply, please

follow the installation instructions given in the section entitled “Connecting the

Weighing Platform” in “Getting Started.”

If you will be operating the platform outside the European Community in a Zone

2 hazardous area, you must comply with the national electrical code and

applicable safety regulations of your country. Please ask your local Sartorius

service technician, office or dealer for information on the currently valid

regulations applicable in your country.

The weighing platform may not be operated in Zone 0, 1, 20 or 21 hazardous areas, as it

does not have an EX approval certificate for these areas.

Any tampering with the weighing platform by anyone, other than installation of preload

devices, will result in forfeiture of all claims under the manufacturer‘s warranty.

Page 6

6

Installation Instructions

Installation Instructions

Installation Instructions

Sartorius dealers or service technicians, who have received special training, will help you

set up the weighing platform and show you how to operate it.

Ambient Conditions

Choose a suitable place to set up the weighing platform. Avoid exposing the weighing

platform to the following ambient conditions:

– Extreme heat radiation

– Extreme vibration

– Places that are difficult to access for cleaning and maintenance

Important Note

If you need to use the weighing platform in areas exposed to heavy traffic (e.g., fork-lift

trucks), you should install a protective frame, consisting of angular braces, around the

weighing platform. To calculate the dimensions for this protective frame, refer to the

section entitled „Dimensions (Scale Drawings).“

Conditioning the Weighing Platform

Do not expose the weighing platform to extreme moisture over long periods. Moisture

in the air can condense on the surfaces of a cold platform whenever it is brought to a

substantially warmer place. If you transfer the weighing platform to a warmer area,

make sure to condition it for about 2 hours at the new ambient temperature, leaving

it unplugged from the power supply. Afterwards, if you keep the weighing platform

connected to the power supply, the continuous positive difference between the

inside of the platform and the outside will practically rule out the effects of moisture

condensation.

IP67 Protection

In conformance with the IP67 protection rating, the weighing platform will remain

leaktight for 30 minutes if immersed at a depth of 1 meter (approx. 3 ft.).

The IP67 protection of the weighing platform is ensured only under the following

conditions:

– The weighing platform is maintained in the original factory condition

– The rubber seals of the weighing cell and the A/D converter are not perforated

– All cables are securely fastened in place by cable glands

– Both the weighing cell and the A/D converter enclosure are securely closed

Page 7

Installation Instructions

7

Getting Started

Unpacking the Weighing Platform

Important Note

To install the weighing platform in a pit, please observe the special requirements

given in the section „Pit Installation.“

Unpacking the Weighing Platform

- Remove the weighing platform and the load plate from the packaging

- To transport the weighing platform, lift it on both long sides

- Remove the plastic bags, packaging strips and foam material

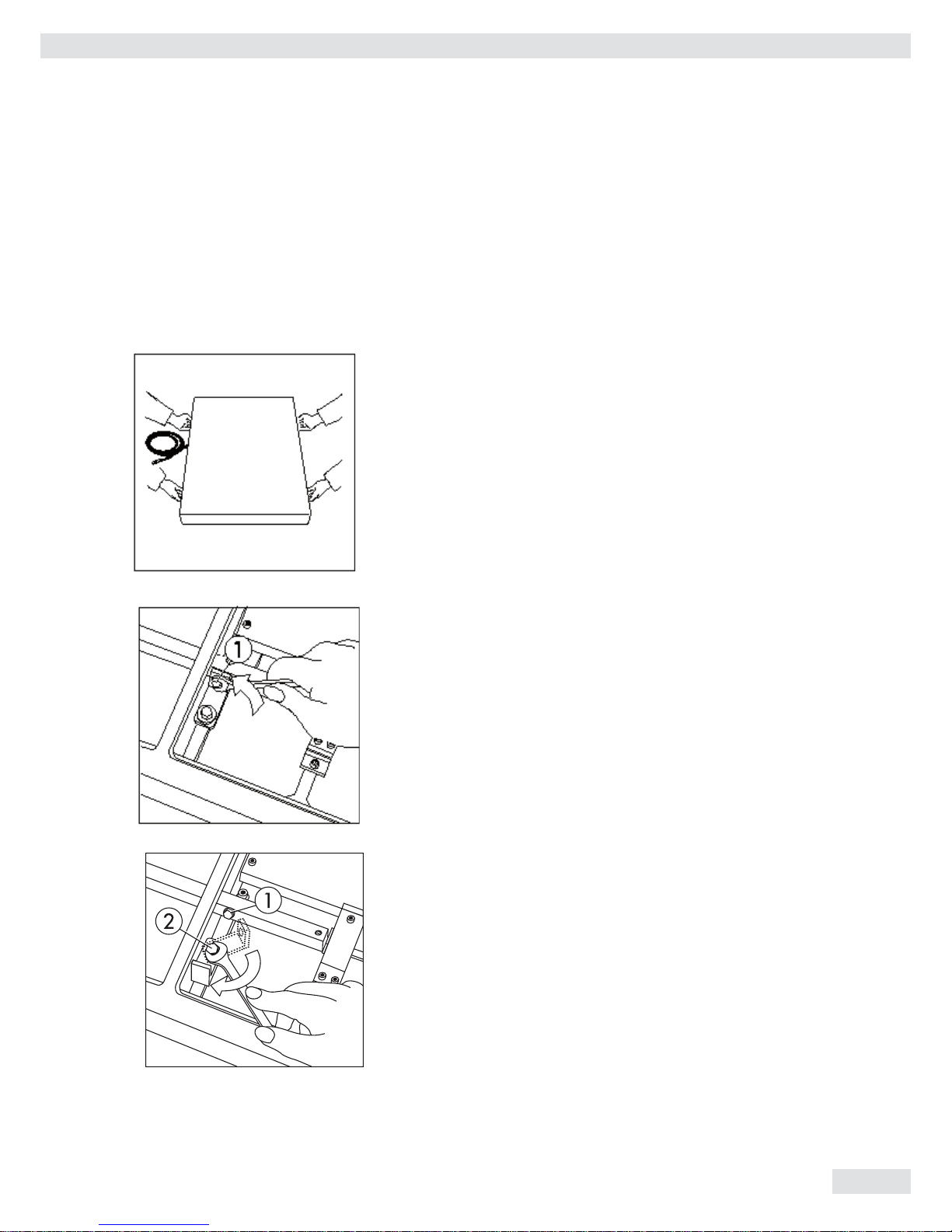

Removing the Transport Locking Devices

Set up the weighing platform in the vicinity of your work area and remove the

load plate.

Proceed as follows with the red color-coded transport locking device:

- Remove screw 1

- Loosen screw 2 and turn the angular brace by 180°,

refasten screw 2

- Refasten screw 1 to the lever

Important Note on Transporting the Weighing Platform

Follow the above instructions in reverse order to replace the transporting locking

device when transporting the weighing platform.

Getting Started

Page 8

8

Installation Instructions

Getting Started

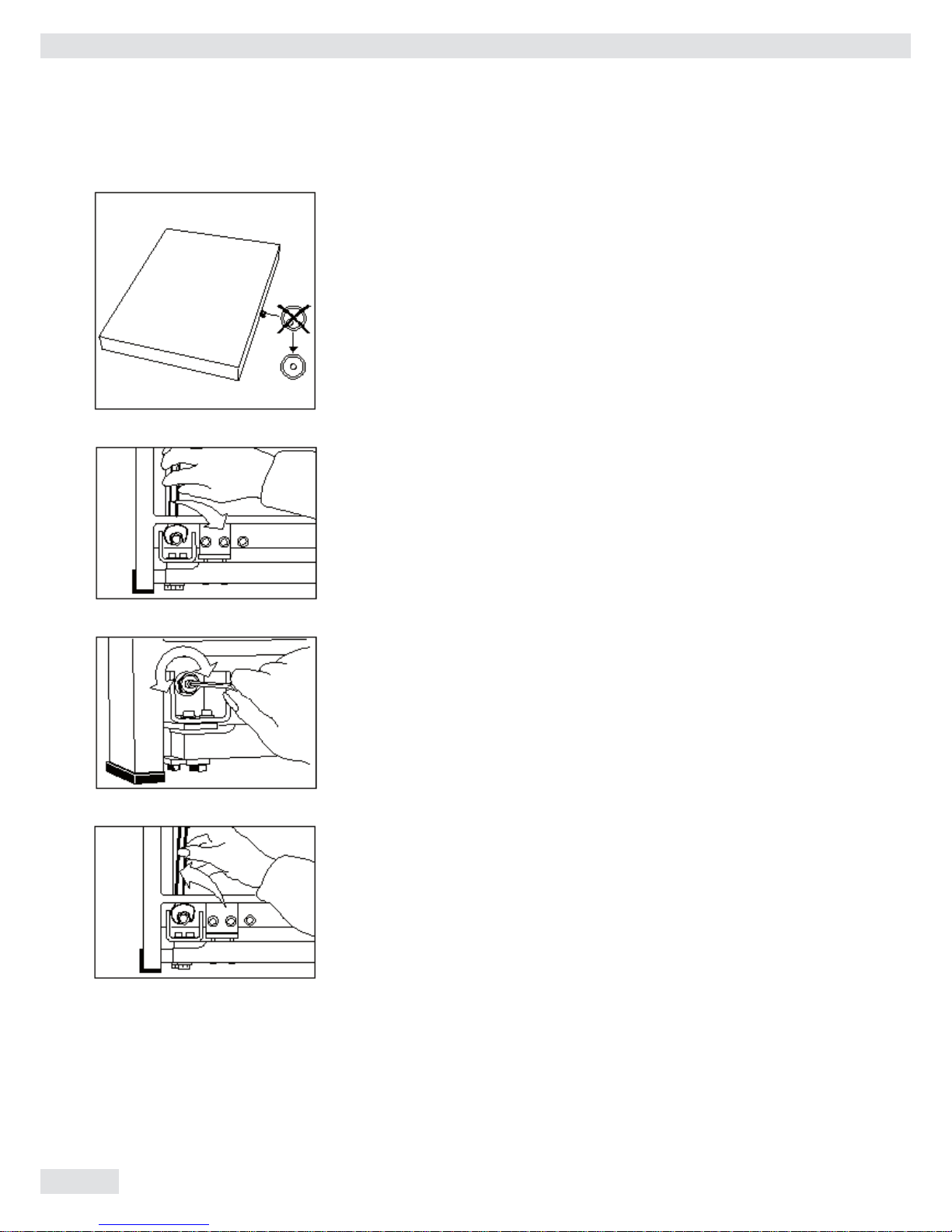

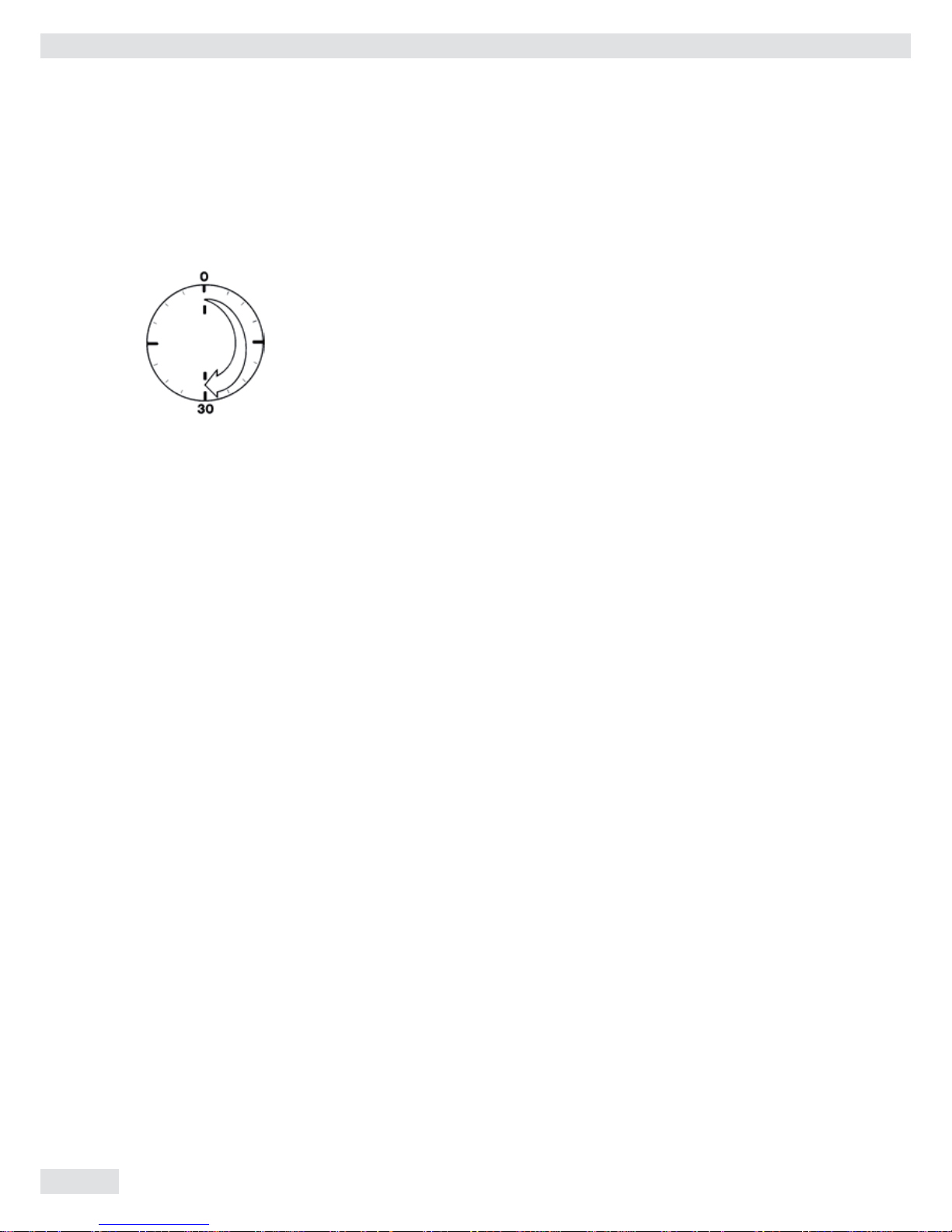

Leveling the Weighing Platform Using the Level Indicator

At the place of installation, level the weighing platform using the leveling feet

so that the air bubble is centered within the circle of the level indicator. Check

to ensure that all 4 leveling feet securely touch the surface and that they equally

support the weight of the platform.

- Remove the load plate

- Loosen the locknuts on the leveling feet using a 17 mm open-end wrench

(spanner)

- Extend or retract the leveling feet using a 5 mm Allen wrench (key)

- After leveling the weighing platform, refasten the locknuts securely against

the platform frame

- Replace the load plate

Page 9

Installation Instructions

9

Getting Started

Connecting the Weighing Platform

Before initially operating the scale, connect the following cables and completely

assemble the components listed below:

- interface cable to a Sartorius isi industrial terminal or a computer with special

software

- separate power cable for power supply via a Sartorius AC adapter

- components for conveyor systems

Make absolutely sure to unplug the weighing platform from the power supply

before you connect or disconnect any interface cables.

Please note that the person or company who connects any non-Sartoriusapproved indicating and control devices (e.g., a computer) or power supplies to

the weighing platform shall assume all risks and responsibilities associated with

this equipment.

Plug the connecting cable into the connector of a Sartorius isi industrial

terminal. Afterwards, hand-tighten the locking ring. The connecting cable is

6 meters long (approx. 20 feet). To order an extension cable or to customize a

cable to your requirements, refer to the list of accessories or contact Sartorius.

Cable Lengths:

Since you can choose to power the weighing platform via the interface port of

the Sartorius isi industrial terminal or a separate power supply unit, there are a

few restrictions that apply to the cable lengths between these components.

If you use a cable that is longer than 12 meters (∼ 40 feet) between the weighing

platform and the Sartorius isi industrial terminal, each of these components must

be energized by a separate AC adapter.

Note on use in a Zone 11 hazardous area:

The industrial terminal must be mounted securely on a vertical surface so that

the connecting jacks face downwards.

Separate Power Connection for the Weighing Platform

Have your local Sartorius dealer or service technician connect the weighing

platform separately to line current (mains supply). This separate power

connection is required when you use cables that are longer than 12 meters or if

you interface the weighing platform directly with a computer.

Page 10

10

Installation Instructions

Getting Started

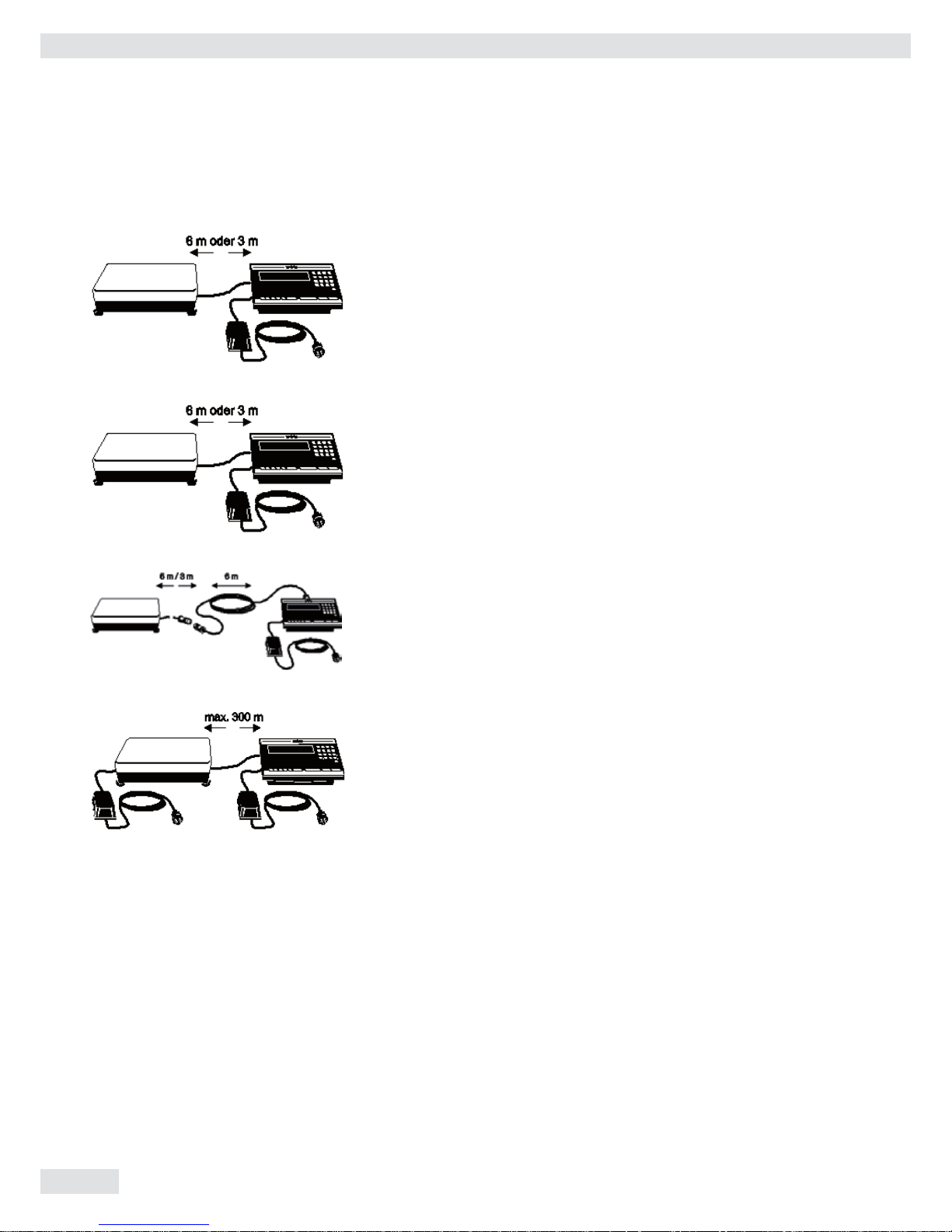

The following diagrams show the options for powering weighing platforms and

industrial terminals.

Cables for connecting the industrial-grade AC adapter, model ING2, to the

„IS“ weighing platform without an extension cord (using the YDO50IS (3m) or

YDO53IS (6m) data output port):

Cables for connecting the industrial-grade AC adapter, model ING2, to the isi

industrial terminal without an extension cord (using the YD050IS (3 m) or the

YD053IS (6 m) data output port):

Cables for connecting the industrial-grade AC adapter, model ING2, only to the

isi industrial terminal with an extension cord:

Connections for cables longer than 12 meters:

Page 11

Installation Instructions

11

Safety Precautions

Safety Precautions

The weighing platform is energized by an external industrial-grade AC adapter.

Make sure that the voltage rating printed on this unit is identical to your local

line voltage. If the voltage specified on the label or the plug design does not

match the rating or standard you use, please contact your local Sartorius dealer

or office. To use a main feeder cable from the ceiling or to mount a CEE plug,

you will have to make arrangements inside your facilities for installation of such

cable equipment.

Use only original Sartorius AC adapters/power supplies identified by the Sartorius

label. Use of AC adapters/power supplies from other manufacturers, even if these

units have an approval identification marking from a national testing laboratory,

requires the consent of an authorized Sartorius service technician.

For detailed information on further options for powering the weighing platform

(e.g., using local low voltage), contact Sartorius headquarters in Germany or one

of the main offices based in your country.

Hook up the weighing platform to the power supply in conformance with the

installation requirements of your country.

Safety Precautions:

A power supply rated to Industrial Class 2 can be plugged into any electrical

outlet without requiring any additional safety precautions. The ground or

earth terminal is connected to the platform housing, which can be additionally

grounded/earthed, if required.

Install the power cable for connection to an isi industrial terminal or a computer

with adequate protection so that the cable cannot get damaged.

Fixed Power Connection:

If the power cable is permanently installed or secured so that it cannot be

unplugged, the weighing platform must be able to be switched off by a suitable

emergency switch. This emergency switch must be installed near the weighing

platform and be within easy reach. In addition, this switch must be labeled as an

emergency switch. All operators must be shown how to operate this switch.

Operating the Weighing Platform in Zone 2 Hazardous Areas:

If you need to install the platform in Zone 2 hazardous areas, make sure

to comply with the applicable requirements of your country. Installation of

equipment in Zone 2 must be done by a certified technician.The female plug of

the power cable on the industrial-grade power supply must be secured to the

display unit of the weighing platform. The following requirements must be met

for the plug on the other end of the cable:

– either an explosion-protected plug must be installed;

– or the plug must be detached from the power cable and the power cable

permanently secured to a suitable junction box;.

– or the plug must be secured against accidental disconnection

(see Installation Instructions 35751-000-16 AN in this manual).

Connection to the Power Supply in a Zone 2 Hazardous Area:

Brown (live (L)) Blue (neutral (N))

Yellow/green (protective grounding conductor/protective earth)

Whenever possible, avoid wiring your weighing platform into networks that carry

a heavy electrical load (for instance, a compressor or similar equipment).

Page 12

12

Installation Instructions

Operating Limits

Warm-up Time

The weighing platform will need to warm up for at least 30 minutes after initial

connection to the power supply (or after a relatively long period without power

connection).

Preparing the Weighing Platform for Verification as a Legal Measuring

Instrument in the EU*:

After initially connecting the weighing platform to the power supply, (or after

a relatively long period outage), allow the platform to warm up for at least 24

hours.

*including the Signatories of the Agreement on the European Economic Area

Operating Limits

Maximum Overload Capacity

Sartorius weighing platforms are built so that occasionally loading them

beyond their maximum weighing capacity will not damage them in any way.

The maximum overload capacity of this IS model is 600 kg.

Shock Resistance

Even though Sartorius weighing platforms feature a highly rugged

construction, there are some limits. Avoid dropping objects from considerable

height on the weighing platform and do not expose it to strong side impact.

Sartorius weighing platforms withstand shock according to the shock

response spectrum defined in the IEC68 standard.

Page 13

Installation Instructions

13

General Instructions

General Instructions for Integration

into Conveyor Systems

The IS weighing platform is suitable for installation in conveyor systems.

Follow the general instructions given below and refer to the „Dimensions (Scale

Drawings)“ to meet the requirements for such installation. Secure the weighing

platform using the appropriate components from the set of fasteners, YAS04 IS.

Any moving or rotating parts intended to be permanently attached to the

load plate must be designed so that they cannot affect the weighing results.

Rotating mechanisms must be properly balanced, for example. In addition,

take care that the fittings do not collide with the parts of the scale platform

mechanism under the load plate. Make sure to remove the load plate from the

platform before drilling.

Any cables or tubing between the weighing platform and other equipment must

not apply any force to the weighing platform. Make sure that cables do not

touch the load plate.

If you install the weighing platform in conveyor systems in Zone 2 or 22

hazardous areas, you must comply with the applicable safety regulations (e.g.,

in Germany with VDE0165). Special precautions must be taken to prevent the

build-up of static electricity caused by moving parts (e.g., roller conveyors).

Preload Range (Zero-Setting Range)

The weight of components that are securely installed on the weighing platform

is called „preload.“ The weighing platform must electrically compensate for this

preload so that the entire weighing range is available and so that it is possible to

zero and adjust (calibrate using external weights) the platform. Higher preloads

may result in a reduction in the maximum weighing capacity.

The following weighing capacities must not be exceeded:

- for the IS 150 IGG--H, at least 30 kg weighing capacity must remain

- for the IS 300 IGG-H, at least 60 kg weighing capacity must remain

Note to Users in the EU *:

Always set the preload prior to verification.

The components for integration into a conveyor must already be installed on the

weighing platform before you connect the platform to the power supply.

*including the Signatories of the Agreement on the European Economic Area

Page 14

14

Installation Instructions

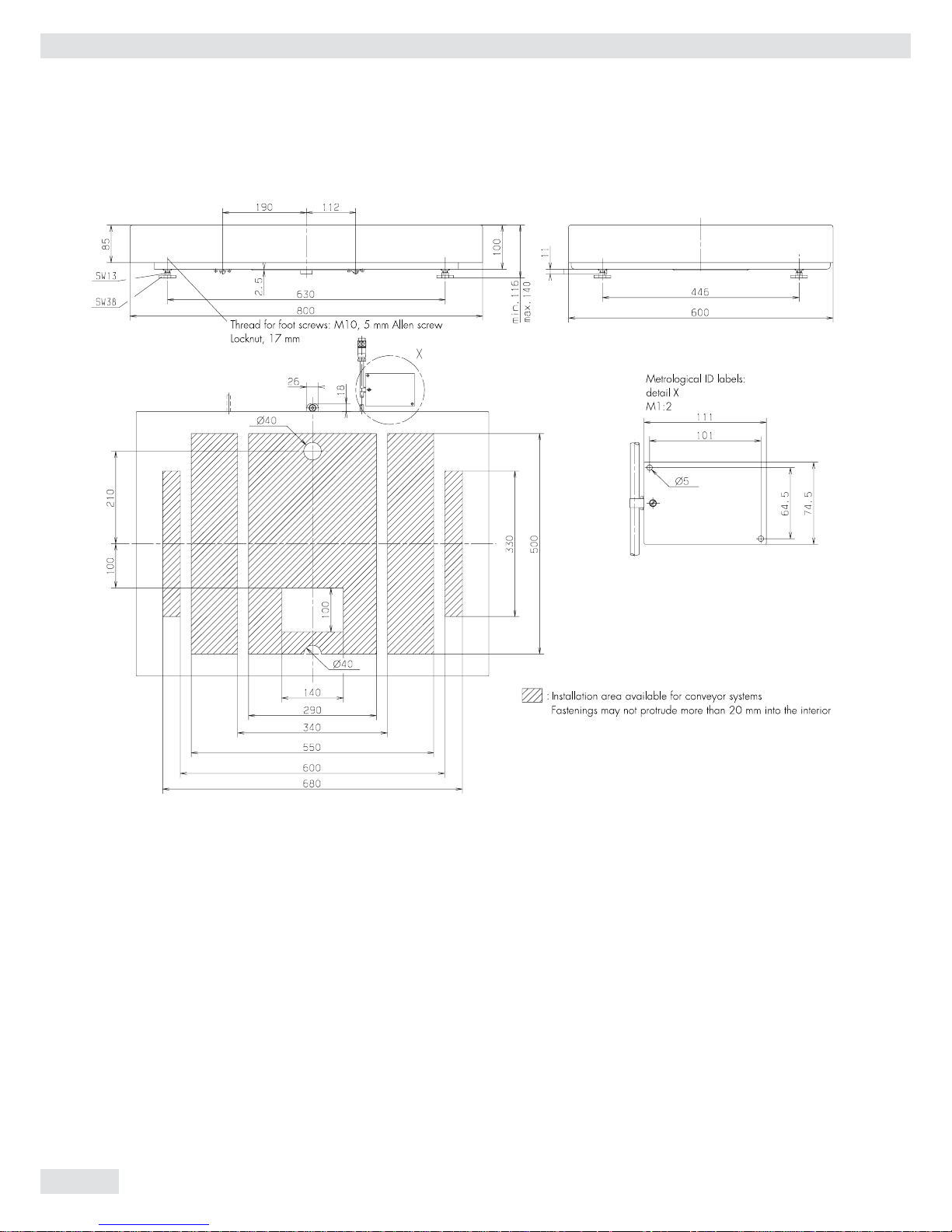

Dimensions

Dimensions (Scale Drawings)

Dimensions in millimeters

Page 15

Installation Instructions

15

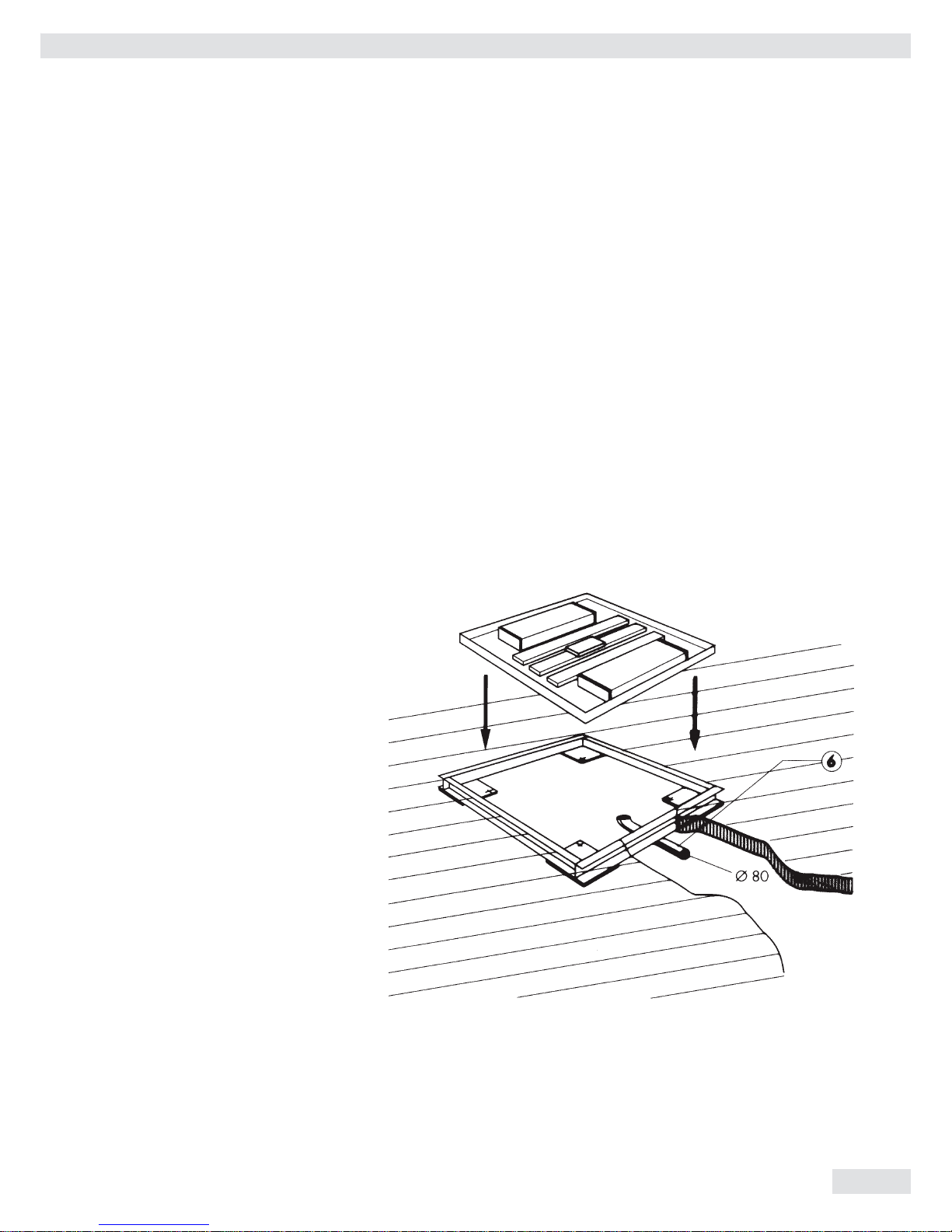

Pit Installation of the Weighing Platform

Pit Installation of the Weighing Platform

Preparation

Choose the appropriate pit frame from the list of accessories.

Note to Users in the EU*

If necessary, the weighing platform can be installed into the pit prior to

initial verification. If a verified weighing platform has been installed, it must

be subsequently verified in compliance with the applicable regulations of your

country.

Depending on the size of your weighing platform, excavate the area where

the platform is to be installed according to the diagrams on the following

page. You must connect a drainage system (5) if the weighing platform

will be operated in a wet area. In this case, slope the floor of the pit (8) at

a minimum of 5% toward the drain point. Position a tube (6) with a min.

diameter of 80 mm from a central point of the pit to the location of the

display in order route the signal cable. This will protect the cable, as required.

* including the Signatories of the Agreement on the European Economic Area

Page 16

16

Installation Instructions

Installation of a Pit Frame

Installation of a Pit Frame

- Remove the screws (7), washers and the metal plates of the pit frame

- Place tape over the threads of the pit frame

- Lower the frame into the pit

- Ensure that the contact areas of the pit frame (1), (2), (3) and (4) are completely level

- The pit frame must carry at least half the maximum weighing capacity of the platform

on each side

- Adjust the height by placing thin metal plates (7) underneath the pit frame. Back fill

with concrete and allow area to dry.

Positioning and Connecting the Weighing Platforms (Your Sartorius Service Technician

Will Help You )

- Remove the load plate, the level indicator and leveling feet

- Take the 4 hexagon bolts, M 10x70, from the set of fasteners, YAS 04 IS, attach the

locknuts to them and screw them into the threads for the leveling feet (foot screws).

Tighten the bolts.

- Remove the transport locking devices as described on page 7.

- Loosely attach the 4 angular braces to the frame of the weighing platform using the

screws (7) and washers from the set of fasteners.

- Push the connecting cable through the tube (6) and lower the weighing platform into

the pit frame.

- Loosely attach the angular braces to the pit frame using the screws of the pit frame.

- Center the weighing platform with respect to the pit frame.

- Adjust the height of the weighing platform with the 4 hexagon bolts (9), M 10x70. Fix

the screws with the locknuts and tighten the screws of the angular braces.

- Refit the load plate.

- Use the handles provided in the set of fasteners to remove the load plate.

Pit Construction Diagrams:

Page 17

Installation Instructions

17

Installation of the Drive-on Ramp YAR 10 IS

Installation of the Drive-on Ramp YAR 10 IS

To install the drive-on ramp, YAR 10 IS, use the angular braces and screws

provided. Proceed as shown in the diagrams below.

Loosely attach the angular braces (2) onto the frame of the weighing platform

using the hexagon bolts M8x80 (1), nuts and washers.

Place the side elements of the ramp on the bolts of the angular braces. Adjust

the height of the weighing platform from the ramp using the leveling feet and

securely tighten the fastening screws of the angular braces.

Anbau der Auffahrrampe YAR 10 IS

Für den Anbau verwenden Sie die im Lieferumfang enthaltenen Winkel und

Schrauben. Verfahren Sie entsprechend untenstehender Zeichnung.

Die Winkel (2) am Rahmen der Wägeplattform mit den Sechskantschrauben

M8x80 (1), Muttern und Scheiben lose anschrauben.

Die Auffahrrampe wird auf die Bolzen der Winkel aufgelegt. Danach die Höhe

der Wägeplattform zur Rampe mit den Stellfüßen ausrichten und die

Befestigungsschrauben der Winkel festziehen.

Page 18

18

Installation Instructions

Configuring the Weighing Platform

Configuring the Weighing Platform

You can adapt the weighing platform to meet your specific requirements – e.g.,

metrological specifications, for weighing in international weight units – and to

perform optimally under various ambient conditions as well as process weighing

data. For this reason, final configuration of your Sartorius Modular Technology

equipment is possible only at your dealer’s or your particular facilities.

To adapt your weighing platform, access the configuration menu of the

equipment listed below:

- Sartorius isi industrial terminal

- Computer with a special Sartorius configuration program (see the

“Accessories”)

Options for Defining the Weighing Range Structure

SuperRange

This weighing range features exceptionally high resolution; i.e., the weighing

range is subdivided into more than 50,000 digits.

SingleRange

The weighing range is subdivided into 50,000 digits maximum.

Multi-Interval

Weighing ranges with multiple levels of accuracy

The multi-interval function divides the weighing range into 3 ranges, for

example. Each one has a different readability.

In the various ranges, the readability automatically adjusts when the readout

for the weight on the load plate changes (see the “Specifications Chart” for the

particular readability of each range).

After you have pressed the tare key, you will obtain the highest possible

resolution, even when an object is on the load plate of the weighing platform.

You will find the configuration options for your weighing platform in the

“Specifications Charts” on the following pages.

Page 19

Installation Instructions

19

Specifications Charts

Specifications Charts

Access the configuration menu of the Sartorius isi industrial terminal to set the code for the group of specifications of your

choice. Please note that when you change the configuration, this may also change the preload range besides the weigh-ing

capacity and the readability. Select the appropriate ID label and affix it to the weighing platform. For direc-tions, refer to the

section entitled “Selecting and Affixing the Respective ID Label.” A verifiable scale consists of a weighing platform (weighing

module) and a display and control unit. The scale has the type designation HCBF with isoTEST:

IS 150 IGG-H0CE

1) With relatively high preloads, the maximum capacity is reduced by 1-kg intervals

2) Up to a max. preload of 120 kg

3) Council Directive 90/384/EEC on non-automatic weighing instruments used in the EU and the Signatories of the Agreement on the European Economic Area

The weighing platform has a built-in calibration weight. Should external calibration be necessary, you will need one of the

following weights:

– Readability of 1 g: 50 kg, accuracy class F1

– Readability of 10 g or more: 50 kg, accuracy class M1

* factory setting

Specifications Charts

Access the configuration menu of the conected Sartorius terminal to set the code for the group of specifications of your

choice. Please note that when you change the configuration, this may also change the preload range besides the weigh-

ing capacity and the readability. Select the appropriate ID label and affix it to the weighing platform. For direc-tions,

refer to the section entitled "Selecting and Affixing the Respective ID Label." A verifiable scale consists of a weighing

platform (weighing module) and a display and control unit. The scale has the type designation with isoTEST HC BF or

SARTOCOWAT with HCBF : IS 150 IGG-H0CE

Weighing range structure SuperRange SingleRange Multi-Interval

Weighing range Standard Configurable

Maximum capacity, Max kg

150 61 31 150

Readability g

1 1 1 0 ... 30 kg 10

30 ... 60 kg 20

60 ...150 kg 50

Zero tracking ± 2% kg

± 3 ± 1.22 ± 0.62 ± 3

Initial zero-setting range kg

±10 ±10 ±10 ±10

Preload (electronic)

1

) kg

30 120 150 30

ISO test function 2) yes yes yes yes

Metrological specifications:

Accuracy class g

KK

–

l

Verification scale interval g 10 10 – 10/20/50

Minimum capacity, Min, g

acc. to CD³)

50 50 – 200

Temperature range °C 0 ... +40

Select particular group of

specifications

(use code)::

Spec. grp.1*

(10 3 1)

Spec. grp.2

(10 3 2)

Spec. grp.3

(10 3 3)

Spec. grp.4

(10 3 4)

Weighing range structure SingleRange

Weighing range

Configurable

Maximum capacity, Max kg

150 150 61 31

Readability g 20 50 20 10

Zero tracking ± 2% kg

± 3 ± 3 ±1.22 ± 0.62

Initial zero-setting range kg

±10 ±10 ±10 ±10

Preload (electronic)

1

) kg

30 30 120 150

ISO test function ²) yes yes yes yes

Metrological specifications:

Accuracy class

l l l l

Verification scale interval g 20 50 20 10

Minimum capacity, Min, g

acc. to CD³)

400 1,000 400 200

Temperature range °C

0 ... +40

Select particular group of

specifications

(use code):

Spec.grp.5

(10 3 6)

Spec. grp.6

(10 3 7)

Spec. grp.7

(10 3 8)

Spec. grp.8

(10 3 9)

Page 20

20

Installation Instructions

Specifications Charts

IS 300 IGG-H0CE

1) With relatively high preloads, the maximum capacity is reduced by 1-kg intervals

2) Up to a max. preload of 120 kg

3) Council Directive 90/384/EEC on non-automatic weighing instruments used in the EU and the Signatories of the

Agreement on the European Economic Area

The weighing platform has a built-in calibration weight.

Should external calibration be necessary, you will need one of the following calibration weights:

– Readability of 1 g: 50 kg, accuracy class F1

– Readability of10 g or more: 50 kg, accuracy class M1

* factory setting

IS 300 IGG-H0CE

Weighing range structure SuperRange SingleRange Multi-Interval

Weighing range Standard Configurable

Maximum capacity, Max kg

300 61 31 150

Readability g

2 1 1 0 ... 30 kg 10

30 ... 60 kg 20

60 ...150 kg 50

Zero tracking ± 2% kg

± 6 ± 1.22 ± 0.62 ± 3

Initial zero-setting range kg

±10 ±10 ±10 ±10

Preload (electronic)

1

) kg

60 120 150 30

ISO test function 2) yes yes yes yes

Metrological specifications:

Accuracy class g – –

l l

Verification scale interval g 10 10 – 10/20/50

Minimum capacity, Min, g

acc. to CD³)

50 50 – 200

Temperature range °C 0 ... +40

Select particular group of

specifications

(use code)::

Spec. grp.1*

(10 3 1)

Spec. grp.2

(10 3 2)

Spec. grp.3

(10 3 3)

Spec. grp.4

(10 3 4)

Weighing range structure SingleRange

Weighing range

Configurable

Maximum capacity, Max kg

300 300 151 61

Readability g 50 100 50 20

Zero tracking ± 2% kg

± 6 ± 6 ± 3.02 ± 1.22

Initial zero-setting range kg

±10 ±10 ±10 ±10

Preload (electronic)

1

) kg

60 60 209 299

ISO test function ²) yes yes yes yes

Metrological specifications:

Accuracy class

l l l l

Verification scale interval g 50 100 50 20

Minimum capacity, Min, g

acc. to CD³)

1,000 2,000 1,000 400

Temperature range °C

0 ... +40

Select particular group of

specifications

(use code)::

Spec.grp.6

(10 3 6)

Spec. grp.7

(10 3 7)

Spec. grp.8

(10 3 8)

Spec. grp.9

(10 3 9)

Page 21

Installation Instructions

21

General Specifications

General Specifications

(for Use in Standard Applications Not Subject to Legal Metrology)

* = Weight unit can also used in legal metrology

** = Menu setting “data output speed for converter” is five times faster

*** = The TÜV is the German Association for Technical Safety and Inspection

General Specifications

(for Use in Standard Applications Not Subject to Legal Metrology)

Model

IS 150 IGG-H IS 300 IGG-H

Readability g 1 2

Standard deviation g <± 1 < ± 2

Linearity g < ± 4 < ± 8

Response time (average) s < 1.5 < 1.5

Fastest response time

(constant relative accuracy)

s <1 <1

Adaptation to ambient conditions

and application requirements

By selection of 1 of 4 optimized filter levels

Data output speed

(depends on the filter level

selected)

s 0.1 - 0.1 - 0.2 - 0.4 (normal output speed)**

Dust and water protection rating IP 67, dust-tight and water-proof subject to defined conditions

(certified by TÜV*** in accordance with VDE 0470/EN60529)

Suitable for use in hazardous

areas

Zone 2 and 11

Overload capacity kg 600

Net weight (without "isi" terminal)

approx.

kg 70

Power requirements (optional) via A/C adapter, model ING2, 230 VAC or 115 VAC (to be connected

by your dealer or a Sartorius service technician only)

Frequency Hz 48 – 63

Power consumption

(with isi10,20,30 connected to

an A/C adapter, model ING2)

VA 34: maximum, 18: average

(only weighing platform

connected to an A/C adapter,

model ING2)

VA 10: average

Selectable weight units g*, kg* , ct, oz, ozt, tlh, tlt, GN, dwt, mg, /lb, tlc, mom, K, tol, bat,

MS, tons

Automatic zero-tracking function

(can be turned off by menu

code)

Standard feature

Built-in interface RS-485 (standard, XBPI protocol): 8-bit; odd parity;

transmission rates: 9,600...38,400; half-duplex

optional for RS-232 (SBI protocol): 7-bit; parity: even, mark, odd, space;

transmission rates: 150...19,200 baud;

1 or 2 stop bits, software /hardware handshake;

factory setting: 1,200 baud; odd parity; 1 stop bit; hardware handshake

with two characters after "CTS"

Page 22

22

Installation Instructions

ID Label

Selecting and Attaching ID Plates

The ID plate is to be selected and attached according to the specification block (configuration of scales) and the display and

control unit (terminal). For details of how to position the ID plate on the scales or tag holder, refer to the instructions in

"Plates and Markings".

If display and control units (terminals) of

type T

A, models CAIS1, CAISL1, CAIS2, CAISL2, CAIS3, CAISL3 are being used,

EC Type Approval Certificate No. T

7899, type SARTOCOWAT is applicable.

ID plate for class

configurations

ID plate for class

configurations

If display and control units (terminals) of

type T

N, models CIS2, CSL2, CIS3, CISL3, type TN-X, model CISX3,

type T

N-Pro, model Combics Pro,

type i

si10, isi20, isi30, type YAC01LA, type YAC01LP, type YAC01FC, type YAC02FC,

PC with S

artorius Win Scale software

EC Type Approval Certificate No. D

97-09-018, type iso-TEST is applicable.

ID plate for class

configurations

ID plate for class

configurations

S

elect and Attach Plate Containing Metrological Data

Plates with the metrological data Max, Min e and d must also be attached near to the display.

Select the plate with the Max, Min e and d metrological data that is suitable for the configuration, cut along the dotted lines

and attach above the display.

The transparent protective film must be stuck over the plate containing the metrological data. The tamper-proof plate

containing the metrological data does n

ot need verification seals.

Examples of attached plates containing metrological data for the possible configurations.

Page 23

Installation Instructions

23

Pin Assignment Chart for the Interface RS-485

Pin Assignment Chart for the Interface RS-485

RS-485, 3-m Cable

Male Connector:

Type C091D, 12-pin round connector with threaded locking ring, Amphenol (IP67))

Pin Assignment

A RxD-TxD-N

B Not Connected

C Not Connected

D Not Connected

E Signal GND

F Menu Access Switch for Calibration/

Adjustment (routed externally)

G VCC (24V Power Supply)

H Not Connected

J GND (24V Power Supply)

K GND (24V Power Supply)

L RxD-TxD-P

M VCC (24V Power Supply)

Female Interface Connector (Recommended):

Type C091D, 12-pin, Amphenol (IP67)

Type of cable: AWG 24 specification

Be sure to follow the instructions given for connecting the weighing platform to

the power supply!

Page 24

24

Installation Instructions

Troubleshooting Guide

Troubleshooting Guide

(For Problems That You Can Fix Yourself)

Problem Possible Causes Solution

No segments appear on the

display

– No line current is available

– The AC adapter is not plugged in

– The weighing platform has been in the standby mode for

more than 5 minutes

– Check the power supply

– Plug the AC adapter into the platform

and into an electrical outlet

– Turn on the isi industrial terminal using the

on/off switch

The weight display shows “H” The load exceeds the capacity

of the weighing platform

Unload the weighing platform

The weight display shows

“L” or

“Err 54”

The load plate is not on the

weighing platform

Place the load plate on the platform

The weight display briefly

indicates “Err 01”

The weight unit selected requires more decimal places than

are available in the display

Select a different weight unit

The weight display briefly

indicates “Err 02”

One of the requirements for calibration/adjustment has not

been met (e.g., the weighing platform is still loaded)

Check the description of the operating menu/

instruction manual and recalibrate/readjust the

weighing platform

Unload the weighing platform

The weight display briefly

indicates “Err 03”

Calibration/adjustment was unable to be completed within

a specific time

Allow the equipment to warm up and

recalibrate/re-adjust

The error code “ERR 07” is

displayed

The last function you activated probably is not allowed for

weighing platforms used as

legal measuring instruments (legal-for-trade

Refer to the operating menu to check whether

this function is allowed for weighing platforms

used as legal measuring instruments

The error code “ERR 08” is

displayed

The load on the weighing platform is too heavy for the

platform to be zeroed

Check the “Specifications Chart” for the

configuration code you have selected

The error code “ERR 09” is

displayed

The gross weight value < zero and the weighing platform

is unloaded, but you cannot tare

Zero the weighing platform

The error code “ERR 10” is

displayed

The tare memories for your application are full, and you

tried to clear the lower-level tare memory

Clear the tare memories of your application

The error code “ERR 12” is

displayed

You tried to store a value in the tare memory for

applications, although this memory has been

blocked by menu code 2 2 x

Check the configuration

Check the value entered

The error code “ERR 17” is

displayed

Internal calibration is not possible because the preload

setting is too high

See “Setting the Preload” in the section on the

operating menu

The error code “ERR 19” is

displayed

The remaining weighing capacity available is too low

because the relatively high preload setting has reduced the

maximum capacity

See “Setting the Preload” in the section on the

operating menu

The special code »A« remains

displayed

None of the keys has been pressed since the weighing

platform was switched on

Press any key

The weight readout changes

constantly

Unstable environment (ambient conditions; e.g., too much

vibration or exposure to excessive drafts)

Set up the weighing platform in a different

area Access the “Devices” setup menu to adapt

the weighing platform to the particular

environment

The readout of the weighing

result is obviously wrong

The weighing platform has not been calibrated/ adjusted

The weighing platform was not tared before

weighing

Calibrate/ adjust the weighing platform

Tare before weighing

If any other errors occur, please contact your nearest Sartorius service center or your dealer.

Page 25

Installation Instructions

25

Care and Maintenance

Care and Maintenance

Servicing

Regular servicing by a Sartorius technician will extend the service life of your

weighing platform and ensure its continued weighing accuracy. Sartorius can

offer you service contracts, with your choice of regular maintenance intervals

ranging from 1 month to 2 years.

Cleaning

Before cleaning the weighing platform, unplug it from the power supply

(disconnect the AC adapter).

To clean the weighing platform when it has been exposed to dry ambient

conditions:

- Use a piece of cloth wet with a commercially available cleaning agent to wipe

down the weighing platform

To clean the weighing platform when it has been in a wet environment:

- Use a commercially available cleaning agent and a gentle, low-pressure jet of

water to hose down the platform afterwards

The weighing platform which has been tested according to EN 60529 and

found to comply with the IP67 protection standard, will remain leaktight for a

maximum of 30 minutes if immersed at a maximum depth of 1 meter (approx. 3

ft.).

However, pressurized water (e.g., strong jets of water using a hose or highpressure cleaning equipment) is not allowed to clean the IP67-protected

weighing platform.

Never use concentrated acids, bases, solvents or pure alcohol to clean the

weighing platform!

To clean the weighing platform exposed to a corrosive enviroment:

- Regularly remove all traces of corrosive substances from the platform

- Follow the manufacturer’s directions provided for the particular disinfectants

and cleaning agents you use to clean the weighing platform

Important Note:

If the water that you use to clean the weighing platform is too hot or cold,

the difference in temperature between the water and the platform can cause

condensation within the platform (according to EN 60529 on IP67 protection).

This condensation may cause the weighing platform to malfunction!

Page 26

26

Installation Instructions

Safety Inspection

Safety Inspection

If there is any indication that safe operation of the weighing platform is no

longer warranted, turn off the power and disconnect it from the power supply

immediately. Lock the equipment in a secure place to ensure that it cannot be

used for the time being.

Safe operation of the weighing platform with the power supply is no longer

ensured when

– there is visible damage to the power supply

– the power supply no longer functions properly

– the power supply has been stored for a relatively long period under

conditions that are different from those specified for “Storage and Shipping”

In this case, notify your nearest Sartorius Service Center or the International

Technical Support Unit based in Goettingen, Germany. Only service technicians

who are authorized by Sartorius and who have access to the required service

manuals are allowed to perform maintenance and repair work on the equipment.

Information on Recycling

To ensure safe shipment, your weighing platform has been packaged using

environmentally friendly materials. After successful installation of the platform,

you should return this packaging for recycling because it is a valuable source of

secondary raw material.

For information on recycling old weighing equipment, consult your municipal

waste disposal center or local recycling depot.

Page 27

Installation Instructions

27

Certificate

Page 28

28

Installation Instructions

Certificate

Page 29

Installation Instructions

29

Certificate

Page 30

30

Installation Instructions

Certificate

Page 31

Installation Instructions

31

Installation instructions

Page 32

32

Installation Instructions

Installation instructions

Page 33

Installation Instructions

33

Installation instructions

Page 34

34

Installation Instructions

Legal Measuring Instrument

Use of the Weighing Platform as a Legal

Measuring Instrument in the EU*

Components of a Legal Weighing

Your weighing platform is considered a modular device. Only when this device

is connected to a Sartorius isi industrial terminal and has been verifi ed in this

confi guration (a different confi guration can be specifi ed for initial verifi cation)

does it constitute an approved legal weighing instrument.

Therefore, a legal weighing instrument can consist of the following:

– a Sartorius isi industrial terminal + 1 to 3 IS weighing platforms

or

– a Sartorius isi industrial terminal + at least 1 weighing platform + up to 2

further EC- or nationally type-approved weighing instruments

As a weighing instrument, the weighing platform is not allowed to be used for

weighing goods intended for direct sale to the public. Since the platform’s

type-approval certifcate for verifi cation applies to non-automatic weighing

instruments only, you must comply with your country’s national regulations

that apply to the place of installation of your weighing instrument for automatic

operation with or without supplementary devices installed.

*including the Signatories of the Agreement on the European Economic Area

Page 35

Installation Instructions

35

Preload

Effect of the Preload on the Acceptability for

Verification in the EU*

Effect of the Preload on the Acceptability for Verification in the EU*

Only internal adjustment (calibration) is allowed for weighing instruments

verified as legal measuring instruments (refer to the operating instructions for

the particular isi industrial terminal you are using). Therefore, if you use your

weighing platform in a configuration for which you cannot use the ISO test

on account of the relatively high preload, the platform is not acceptable for

verification.

To have your weighing platform verified, you must change the preload setting

before verification only.

The legal basis permitting Sartorius to perform initial verification is constituted

by the following: 1) EC Council Directive No. 90/384/EEC on non-automatic

weighing instruments, which has been applicable within the harmonized Internal

Market of the European Union since 1 January 1993; and 2) the certificate

issued by the Metrology Department “Eichwesen” of the Landesverwaltungsamt

of Lower Saxony in Germany.

Before verification, the respective ID labels and metrology

sticker must be affixed to the area on the instrument(s) as

provided.

Page 36

36

Installation Instructions

Approved Auxiliary Measuring Devices

Approved Auxiliary Measuring Devices

When using the weighing platform as a legal measuring instrument in the EU,

you may connect to it only auxiliary measuring devices that have been approved

for legal metrology in accordance with the EC Type-Approval Certificate No.

D95-09-006:

– Electromechanical weighing instruments verified for legal metrology

– Hand or foot switches for activating the tare function and/or print function

– T-connector Model YTC01, Sartorius

– Interface converters Model Series 7253,

YCC 01- and YCO...,Sartorius

– Digital remote displays Models YRD12Z and

YRD13Z, Sartorius

– Printers Models YDP02-0D,YDP02-0CE,

Sartorius

– Industrial terminals of the isi series, used as display and control devices

– Checkweighing display with Model YRD 10Z, Sartorius

color-coded indicators (does not display weights or

other measured values)

– Bar code scanners

– Other printers and/or auxiliary measuring devices that are stated on an EC

Type-Approval Certificate for a Sartorius non-automatic weighing instrument,

or other printers and devices whose suitability for connection to weighing

instruments is confirmed by independently issued certificates or reports provided

by a Notified Body in the EU and the Signatories of the Agreement on the

European Economic Area.

For applications not subject to the regulations of legal metrology, any type of

auxiliary device can be connected to the weighing platform:

– D/A converter Model YDA01Z, Sartorius

– Additional printer, card reader, bar code scanner, remote display, modem, PC

device for data transfer to a central computer, or a similar device.

Information Concerning the EC Machinery Directive

Sartorius balances, scales and weighing platforms are not machines in the sense

of the EC Machinery Directive; however, as individual instruments they meet the

safety requirements of this Directive.

If Sartorius balances, scales and weighing platforms are installed in conveyor

systems, supplemented by auxiliary devices or equipment or otherwise modified,

responsibility for compliance with the EC Machinery Directive and other safety

requirements shall rest with the person who is responsible for the conveyor

system, equipment added and/or modification.

Page 37

Installation Instructions

37

Certificate

39

Page 38

38

Installation Instructions

Certificate

40

Page 39

Installation Instructions

39

Declarations of Conformity

Declarations of Conformity

Die C-Kennzeichnung auf Sartorius Geräten

The C Mark on Sartorius Equipment

In 1985, the Council of the European Community approved a resolution

concerning a new approach to the technical harmonization and standardization

of national regulations. The organization for monitoring compliance with the

directives and standards concerning C marking is governed in the individual EU

Member States through the implementation of the EC Directives adopted by the

respective national laws. As of December 1993, the scope of validity for all EC

Directives has been extended to the Member States of the European Union and

the Signatories of the Agreement on the European Economic Area.

Sartorius complies with the EC Directives and European Standards in order to

supply its customers with weighing instruments that feature the latest advanced

technology and provide many years of trouble-free service.

The C mark may be affixed only to weighing instruments and associated

equipment that comply with the applicable Directive(s):

Electromagnetic Compatibility

The equipment meets the requirements of the following Directive:

Council Directive 89/336/EEC “Electromagnetic Compatibility (EMC)”

This Directive regulates the use of equipment that can cause electromagnetic

interference or whose functioning can be influenced by such interference.

Applicable European Standards:

Limitation: EN 50081-1 Residential, commercial and

of emissions light industry

EN 50081-2 Industrial environment

Defined immunity EN 50082-1 Residential, commercial and

to interference light industry

EN 50082-2 Industrial environment

Important Note:

The operator shall be responsible for any modifications to Sartorius equipment

and for any connections of equipment not supplied by Sartorius and must check

and, if necessary, correct these modifications and connections. On request,

Sartorius will provide information on the minimum operating specifications

(in accordance with the Standards listed above for defined immunity to

interference).

Page 40

40

Installation Instructions

Declarations of Conformity

Additional Directive for Weighing Instruments Used in Legal Metrology:

Council Directive 90/384/EEC “Non-Automatic Weighing Instruments”

This Directive regulates mass determination in legal metrological applications,

e.g., in

– the manufacture of pharmaceuticals

– medicine and health care

– calculation of fees

– price calculation

For the respective Declaration of Type Conformity for weighing instruments that

have been verified by Sartorius for use as legal measuring instruments and that

have an EC Type-Approval Certificate, see page 37.

This Directive also regulates the performance of the EC verification by the

manufacturer, provided that an EC Type-Approval Certificate has been issued

and the manufacturer has been accredited by an officer of a Notified Body

registered at the Commission of the European Community for performing such

verification. On February 15, 1993, Sartorius was certified for performing

verification.

For information on the CE mark on Sartorius equipment and legal regulations

currently applicable in your country, and to obtain the names of the persons to

contact, pease ask your local Sartorius office, dealer or service center.

Page 41

Installation Instructions

41

Declarations of Conformity

Page 42

42

Installation Instructions

Plates and Markings

Page 43

Installation Instructions

43

Plates and Markings

Page 44

44

Installation Instructions

Plates and Markings

Page 45

Installation Instructions

45

A Service Offered by Sartorius

”EC Verification” - A Service Offered by Sartorius

Our service technicians authorized to perform the verifcation* of your weighing

instruments which are acceptable for legal metrological verification can inspect and

verify the metrological specifications at the place of installation within the Member

States of the European Union and the Signatories of the European Economic Area.

“New Installation” Service

Initial verification is covered in our “New Installation” service package. In addition to

initial verification, this package provides you with a series of important services which

will guarantee you optimal results in working with your weighing instrument:

– Installation

– Startup

– Inspection

– Training

– Initial verification

If you would like Sartorius to perform initial verification of your weighing

instrument, contact an authorized service representative. Please refer to the

Sartorius European Service Center Addresses on page 39.

Subsequent Verifications within the European Countries

The validity of the verification will become void in accordance with the national

regulations of the country in which the weighing instrument is used. For information

on verification and legal regulations currently applicable in your country, and to

obtain the names of the persons to contact, please contact your local Sartorius office,

dealer or service center as indicated on the following page.

* in accordance with the accreditation certificate issued to Sartorius

Page 46

46

Installation Instructions

Accessories

Accessories (Options)

Order No.:

Data interface port with 3-m cable (IP67, RS-485)

and 12-pin round connector YDO50IS

Data interface port with 3-m cable (IP67, RS-485)

and 12-pin round connector electrically

isolated YDO51IS

Data interface port with 3-m cable (IP67,

RS-232C/RS-423) and 12-pin round connector YDO52IS

Data interface port with 6-m cable (IP67, RS-485)

and 12-pin round connector (part of the standard

equipment supplied)) YDO53IS

Extension cable to connect an isi terminal

to a weighing platform; 12-pin round connector

to 12-contact round connector (IP65, 6 m) YCC 01-ISM6

Round female connector, IP65, 69 QC0011

type C091D, 12-contact, Amphenol

Round male connector, IP65, 69 QC0010

type C091D, 12-pin, Amphenol

Adapter cable, from round connector to PC, YCC 01-0017D2

25-pin D-Submini,

0.2 m long (YDO52IS required)

For ordering customized cables and accessories, contact

your local Sartorius office or dealer.

Page 47

Installation Instructions

47

Accessories

PC adapter cable, 25-pin D-Submini – 9-contact 6965619

D-Submini 0.25 m long (YDO 52 IS and YCC 01-0017D2

required)

Special menu access locking device, IP65 (for YAS 02 IS

legal metrology); for external positioning of the menu

access lock on weighing platforms built into systems.

If this device is used, a tag plate for ID labels is not

required.

Upgrade kit for DC power supply to YAS 03 IS

the weighing platform (without using an external

AC adapter or power supply; the AC adapter does not

come standard with this accessory) IP67 cable gland

(to be installed by an authorized service technician only)

Upgrade kit for DC power supply to YAS 03 IS

the weighing platform (without using an external

AC adapter or power supply; the AC adapter does

not come standard with this accessory) IP67 cable gland

(to be installed by an authorized service technician only)

External rechargeable battery pack; hours of

operation approx. 28 (YAS03IS required) YRB 06 Z

IP65 AC adapter, 3-m primary cable, 1.5-m secondary

cable; to be installed by an authorized

service technician only (YAS03IS required)

for 220 V 6971899

for 110 V 6971500

Adapter cable for connecting the weighing YRB 01 IS

platform to a 12-V car battery or to a separate

12-V power source using the terminal leads; cable length:

3.7 m (∼ 12 ft.); with integrated switch and fuse,

reverse battery polarity protection; to be installed, using

the YAS03IS, by an authorized service technician only

Roller conveyor, with 8 rollers (for the 800 x 600mm

IS weighing platform) Aluminum YRC01IGP

tainless steel YRC01IGS

Drive-on ramp (1,250 x 600 mm) YAR 10 IS

Pit frames – Stainless steel YEG 01 IP

– Painted YEG 04 IP

Set of fasteners for pit frame installation YAS 04 IS

For ordering customized cables and accessories, contact your local Sartorius

office or dealer.

PC adapter cable, 25-pin D-Submini – 9-contact 6965619

D-Submini 0.25 m long (YDO 52 IS and YCC 01-0017D2

required)

Special menu access locking device, IP65 (for YAS 02 IS

legal metrology); for external positioning of the menu

access lock on weighing platforms built into systems.

If this device is used, a tag plate for ID labels is not

required.

Upgrade kit for DC power supply to YAS 03 IS

the weighing platform (without using an external

AC adapter or power supply; the AC adapter does

not come standard with this accessory)

IP67 cable gland (to be installed by an authorized

service technician only)

External rechargeable battery pack; hours of

operation approx. 28 YRB 06 Z

(YAS03IS required)

IP65 AC adapter, 3-m primary cable,

1.5-m secondary cable; to be installed by an authorized

service technician only (YAS03IS required)

for 220 V 6971899

for 110 V 6971500

Adapter cable for connecting the weighing YRB 01 IS

platform to a 12-V car battery or to a separate

12-V power source using the terminal leads; cable length:

3.7 m (

∼ 12 ft.); with integrated switch and fuse,

reverse battery polarity protection; to be installed, using

the YAS03IS, by an authorized service technician only

Page 48

48

Installation Instructions

Certificate

Page 49

Installation Instructions

49

Page 50

50

Installation Instructions

Page 51

Installation Instructions

51

Page 52

Sartorius Industrial Scales GmbH & Co. KG

Leinetal 2

37120 Bovenden, Germany

Phone: +49.551.308.0

Fax: +49.551.309.83.190

www.sartorius.com

Copyright by Sartorius,

Goettingen, Germany.

No part of this publication may be reprinted

or translated in any form or by any means

without prior written permission from

Sartorius.

All rights reserved.

The status of the information, specifications

and illustrations in this manual is indicated

by the date given below. Sartorius

reserves the right to make changes to the

technology, features, specifications, and

design of the equipment without notice.

Date:

September 2013,

Sartorius Industrial Scales GmbH & Co. KG ,

Goettingen, Germany

Printed in Germany.

Gedruckt auf chlorfrei gebleichtem Papier

RS · KT

Publication No.: WIS6011-e13097

Loading...

Loading...