Page 1

Operating Instructions

Sartorius CP|Gem

plus

Series

CPA, GCA and GPA Models

Electronic Micro-, Analytical and Precision Balances and Precious Metal Scales

98648-015-70

Page 2

Contents

Safety Precautions 3

Getting Started 5

Installation 6

Operation 15

Overview of Display and

Operating Elements 15

Basic Weighing Function 16

Below-Balance Weighing 18

Calibration and Adjustment 20

Configuration 25

Printing the Parameter Settings 25

Setting the Parameters

(Menu Codes) 26

Parameter Settings (Overview) 27

Setting IDs, Time, Date and

Display Brightness 32

Application Programs 35

Net-total Formulation 36

Counting 40

Reference Balance/Scale for Counting 40

Weighing in Percent 44

Animal Weighing/Averaging 47

Toggling between Weight Units 50

Generating a Printout 51

ISO/GLP-compliant Printout/Record 53

Interface Port 55

Data Input Format 59

Pin Assignment Charts 62

Cabling Diagram 63

Troubleshooting Guide 64

Preparing CPA2P.. Models for

Transport 65

Care and Maintenance 66

Instructions for Recycling 68

Overview 69

Specifications 69

Accessories (Options) 81

Declarations of Conformity 84

EC Type-approval Certificate 87

Plates and Markings 88

2

Page 3

Safety Precautions

Safety Instructions

§ Please read these operating instructions

carefully before using your balance

to prevent damage to the equipment.

!Do not use this equipment in hazardous

areas/locations.

!The balance housing may be opened

only by Sartorius service technicians

who have been trained at the factory.

!Make sure you disconnect the balance

from power before connecting or

disconnecting peripheral devices to or

from the balance.

!If you operate the equipment under

ambient conditions that require higher

safety standards, you must comply with

the installation regulations applicable

in your country.

When cleaning your balance, make

sure that no liquid enters the balance

housing; use only a slightly moistened

cloth to clean the balance.

Installation

!Make sure the voltage rating printed

on the AC adapter is identical to your

local line voltage.

– Proceed with extreme caution when

using pre-wired RS-232 connecting

cables, as the pin assignments may

not be compatible with Sartorius

equipment. Check all pin assignments

against the cabling diagrams and disconnect any lines that do not match.

!If there is visible damage to the equip-

ment or power cord, disconnect the

equipment from power and lock it in

a secure place to ensure that it cannot

be used for the time being.

– Connect only Sartorius accessories

and options, as these are optimally

designed for use with your balance.

The operator shall be responsible

for any modifications to Sartorius

equipment and for any connection

of cables or equipment not supplied

by Sartorius and must check and,

if necessary, correct these modifications

and connections. On request, Sartorius

will be happy to provide information on

operating specifications (in accordance

with the Standards for defined immunity

to interference).

$ Do not open the balance. If the seal

is broken, this will result in forfeiture

of all claims under the manufacturer's

warranty.

$ If you have any problems with your

balance, please contact your local

Sartorius office, dealer or service center.

3

Page 4

Equipment Supplied

The equipment supplied includes the

components listed below:

CPA2P, CPA2P-F

– Balance with display and control unit

– Kit of standard accessories

– AC adapter

– Dust cover

– Filter pan and lid (model CPA2P-F only)

– Spacer (model CPA2P-F only)

The kit of standard accessories contains

the following:

– Weighing pan

– Interior draft shield

– Hanger for below-balance weighing

– 1 brush

– 1 pair of forceps

– 1 piece of lint-free cloth

CPA Balances with a Readability of

< 0.1 mg; CPA…-DS, GCA Scales

–

Balance/scale with display and

control unit

– Electronics box (model CPA225D only)

– Draft shield with base plate

(not available for the CPA64-WDS)

– AC adapter

– Weighing pan

– Shield disk

– Centering plate (only for CPA…DS)

– In-use dust cover

– Gem tray (GCA scales only)

CPA Balances with a Readability of 1 mg

(except for the CPA…-DS models)

– Balance with display and control unit

– Draft shield with cover

– AC adapter

– Weighing pan

– Pan support

– Base plate

– In-use dust cover

CPA-Balances with a Readability of

0.01 g/0.1 g, GPA Scales

–

Balance/scale with display and

control unit

– AC adapter

– Weighing pan

– Gem tray (GPA scales only)

– In-use dust cover

CPA34001S, CPA34001P, CPA16001S,

CPA12001S, CPA34000

– Balance with display and control unit

– AC adapter

– Weighing pan

– In-use dust cover

4

Page 5

Getting Started

Storage and Shipping Conditions

– Do not expose the balance to

extreme temperatures, moisture, shocks,

blows or vibration.

Unpacking the Balance

§ After unpacking the equipment,

please check it immediately for any

external damage

$ If damage is evident, refer to the

instructions under “Safety Inspection"

in the chapter entitled “Care and

Maintenance."

$ Save the box and all parts of the

packaging for any future transport.

Disconnect all cables before packing

the balance for shipping!

Installation

Choose a location that is not subject

to the following negative influences:

– Heat (heater or direct sunlight)

– Drafts from open windows and doors

– Extreme vibrations during weighing

– Excessive moisture

Conditioning the Balance

Moisture in the air can condense on

the surfaces of a cold balance whenever

it is brought into a substantially warmer

place. If you transfer the balance to

a warmer area, make sure to condition it

for about 2 hours at room temperature,

leaving it unplugged from AC power.

Seal on Balances Verified for Use

in Legal Metrology in the EU*:

EU legislation requires that a control

seal be affixed to verified balances of

accuracy class K. The control seal

consists of a sticker with the “Sartorius"

logo. If the seal is broken, the verifi-

cation becomes null and void and the

balance must be re-verified.

* Including the Signatories of the Agree-

ment on the European Economic Area

5

Page 6

Installation

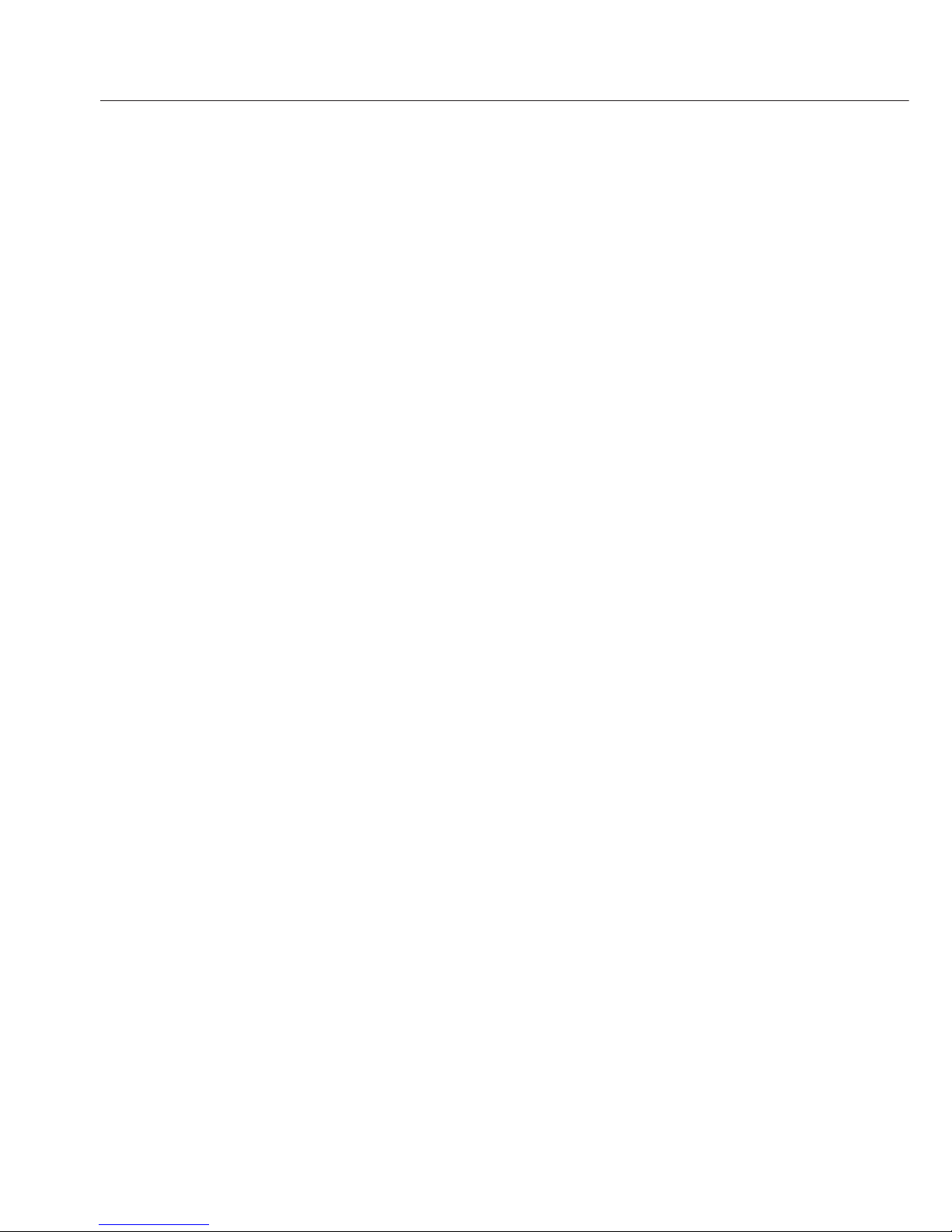

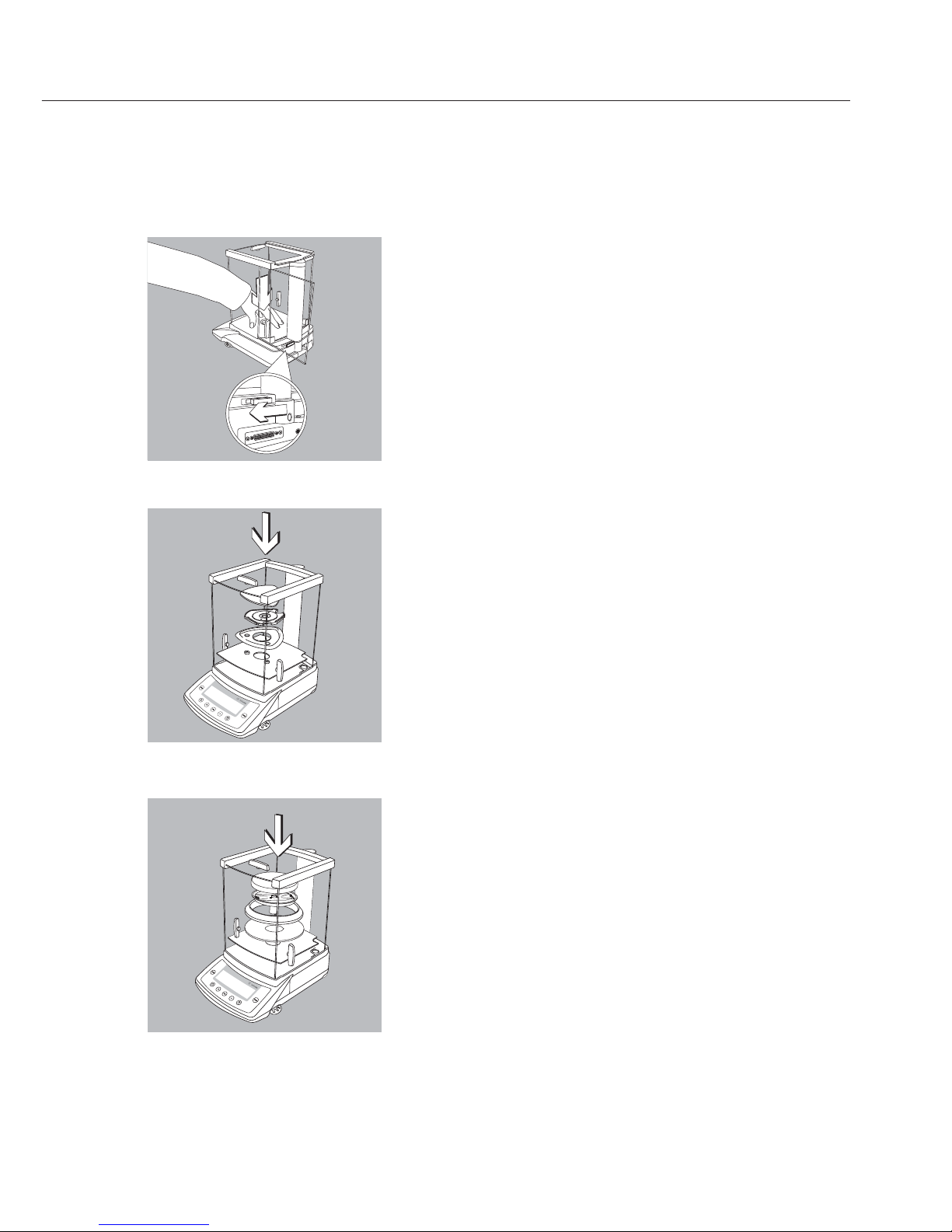

Model CPA2P

§ Remove the adhesive tape from the chamber doors

§ Place the components listed below inside the

chamber in the order given:

– Interior draft shield

– Weighing pan

Model CPA2P-F

1) Weighing filters of up to 125 mm d:

§ Lift the chamber lid gently and turn it to the

left or right

§ Place the components listed below inside

the chamber in the order given:

– Interior draft shield

– Filter pan

– Cover the sample (filter) with the lid

or

2) Weighing with the standard weighing pan

(20 mm d):

§ Lift the chamber lid gently and turn it to the

left or right

§ Place the components listed below inside

the chamber in the order given:

– Interior draft shield

– Spacer ring

– Weighing pan

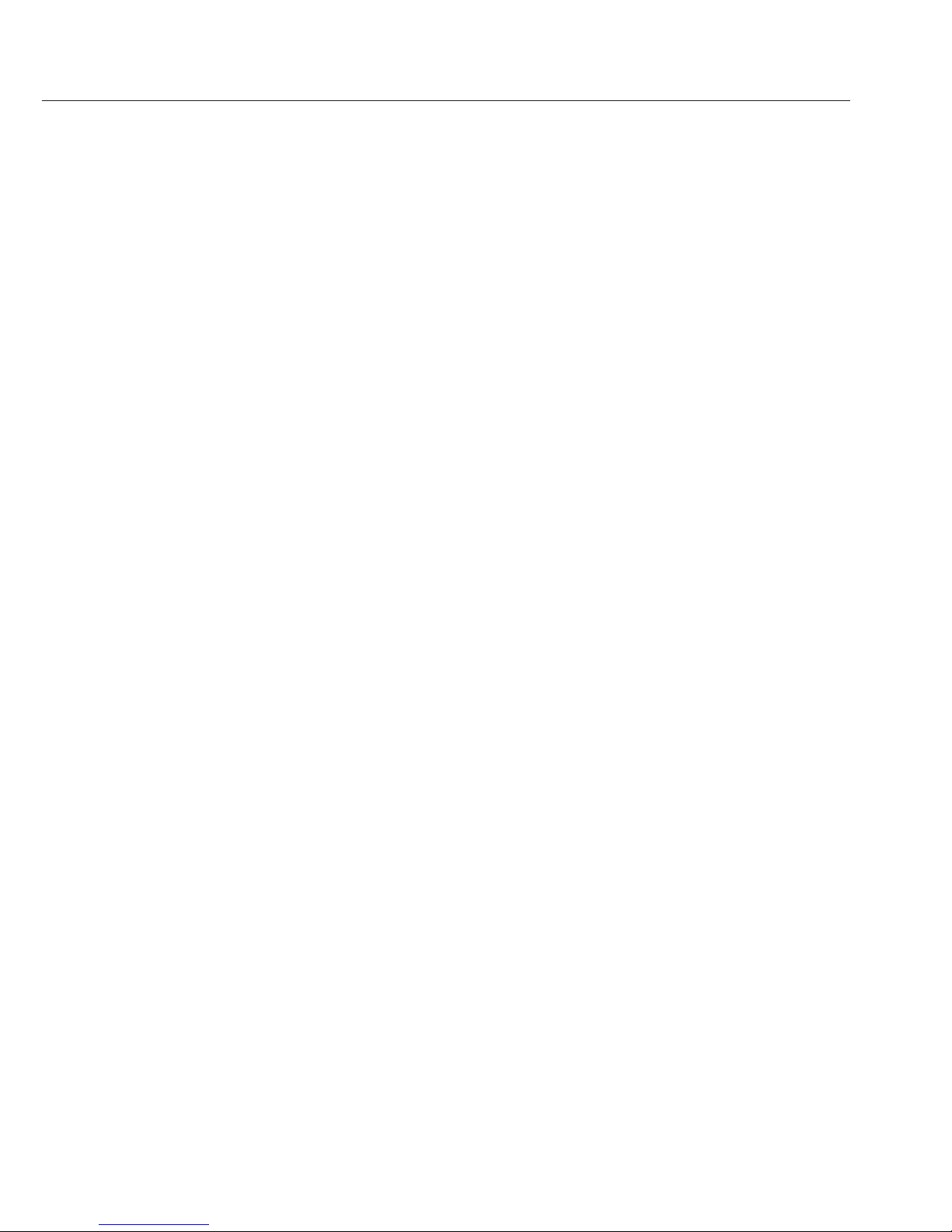

Balances with an Analytical Draft Shield

!Check the sliding lock device on the back of the

draft shield; make sure it is in the “open" position

(to the right).

§ Position the draft shield carefully on the balance

6

Page 7

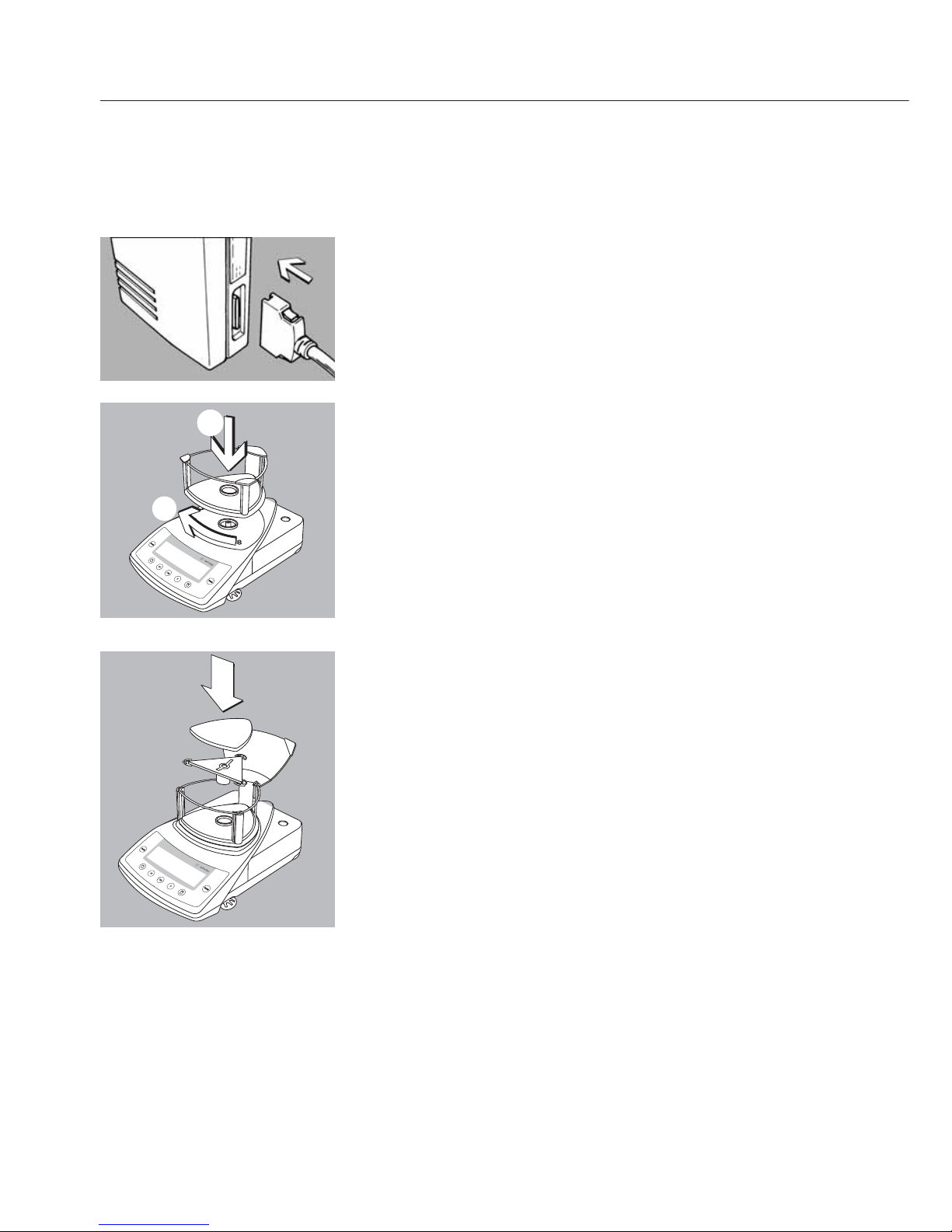

§ Secure the draft shield by pressing lightly on

the draft shield base and moving the sliding lock

device to the left

§ Place components inside the chamber in the

following order:

– Base plate

– Shield ring

– Pan support

– Weighing pan

– Gem tray (GCA scales only)

§ Place components inside the chamber in the

following order:

– Base plate

– Centering plate

– Shield ring

– Pan support

– Weighing pan

7

Round weighing pan shape

Triangular weighing pan shape

Page 8

Connecting Model CPA26P, CPA225D (-0CE)

to the Electronics Box

– Plug the male connector on the cable into the

female connector on the electronics box

!Do not exchange the balance or electronics box with

a component of a different balance!

Balances with a 3-Sided Draft Shield

§ Place draft shield on the balance with the cover

opening in front on the right

§ Turn the draft shield clockwise until it is firmly

in position

§ Place components inside the chamber in the

following order:

– Base plate

– Weighing pan receptor

– Weighing pan

$ To access the weighing chamber from the side,

remove side panels as desired

8

1

2

Page 9

9

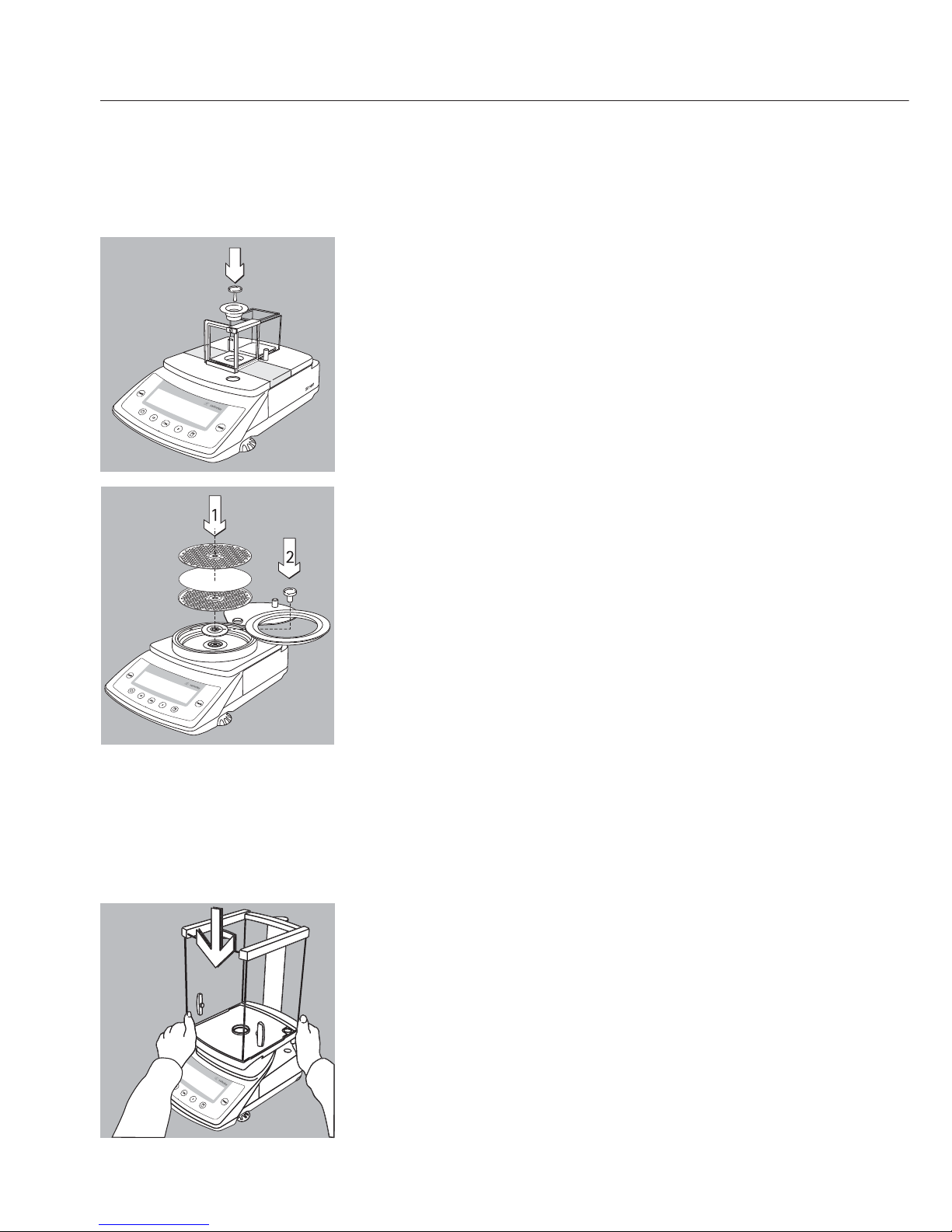

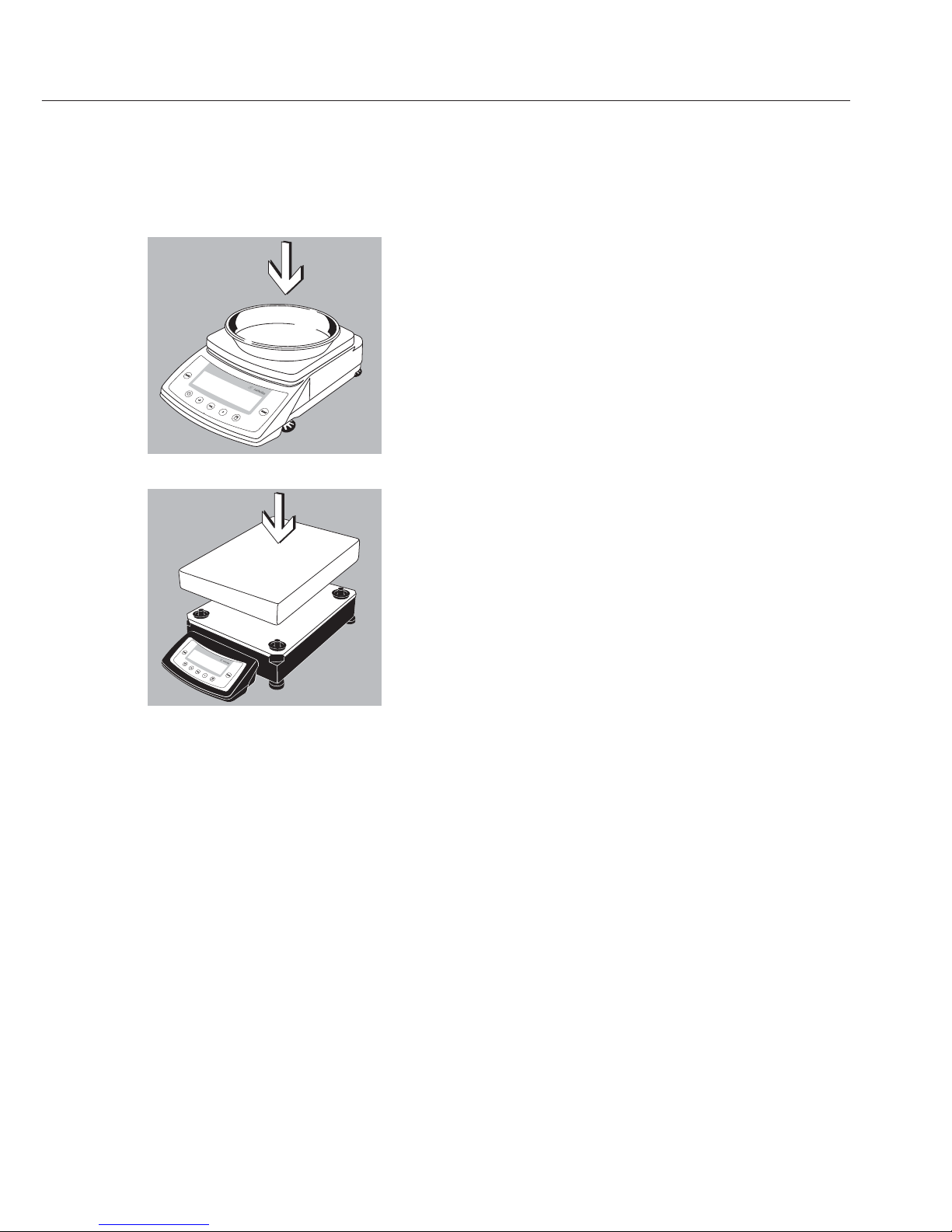

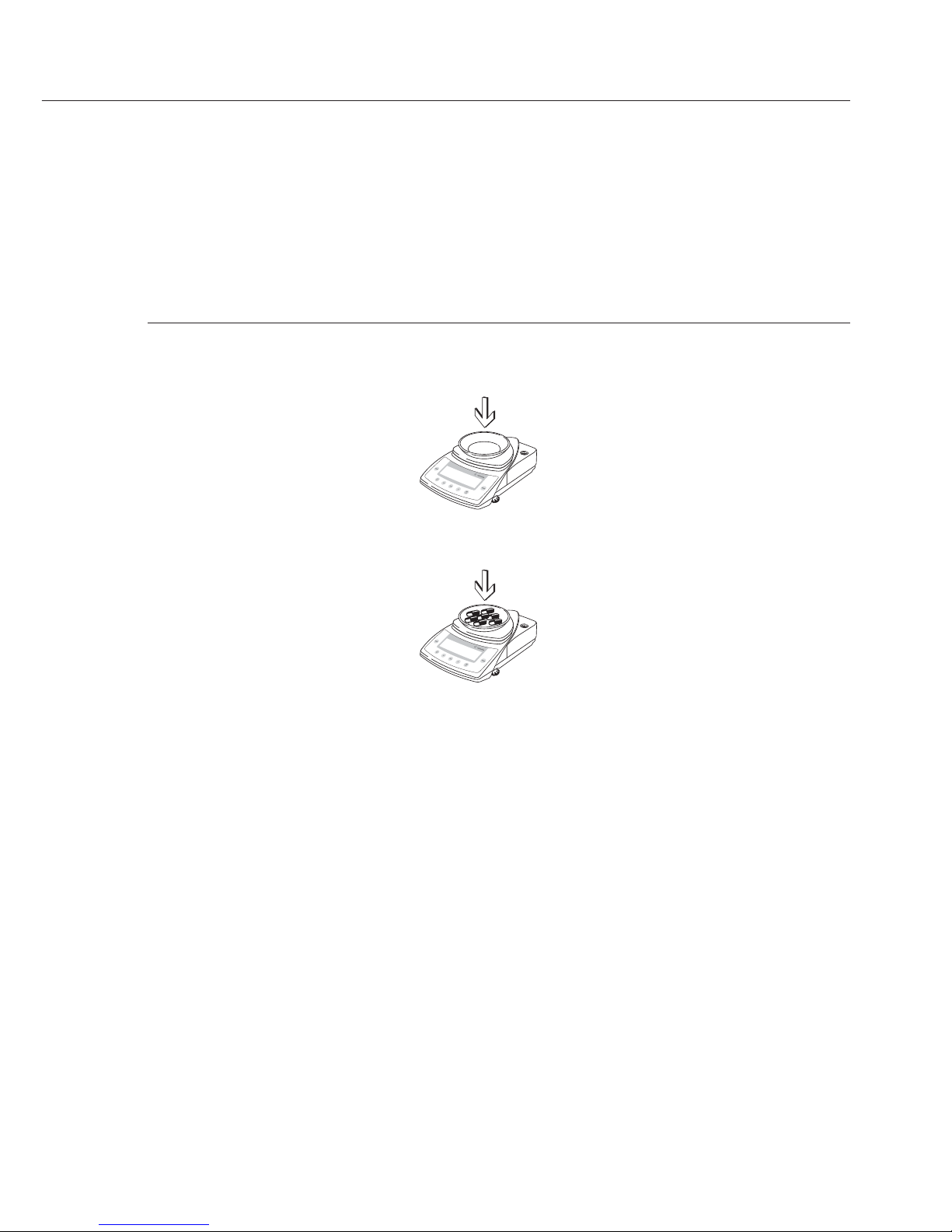

Balances/Scales with a Rectangular Weighing Pan

and a Weighing Capacity up to 10 kg

§ Place the components listed below on the

balance/scale in the order given:

– Weighing pan

– Gem tray (GPA scales only)

Balances with a Rectangular Weighing Pan and

a Weighing Capacity over 10 kg

§ Place the weighing pan on the balance

Page 10

10

Connecting the Balance to AC Power/

Safety Precautions

$ Use only original Sartorius equipment.

The AC adapter meets the requirements of IP20 in

accordance with EN 60529.

$ For AC adapters with higher protection ratings

or for an external rechargeable battery pack, please

see “Accessories."

CPA26P, CPA225D:

G Insert the right-angle plug from the AC adapter into

the jack on the electronics box.

All other balances with a weighing capacity

up to 10 kg:

G Insert the right-angle plug from the AC adapter

into the jack on the balance.

G Connect the AC adapter to an electrical outlet

(mains supply)

AC Adapter with Country-specific Power Cord

Some models come with separate country-specific

power cords for the AC adapter. In Europe, use only

original Sartorius AC adapter part no. 6971983.

§ Connect the angle plug to the balance/scale

§ Select the power cord for your area and connect it to

the AC adapter

§ Plug the power cord into the wall outlet (mains)

Connect the power cord to the AC adapter

(on balances with weighing capacities up to 10 kg)

$ Use an original Sartorius AC adapter with a wide input

voltage range (100 to 240 V~), order no. 6971966,

and replaceable power cord:

6900900 (Europe)

6900901 (US/CDN)

6971945 (UK)

6900905 (AUS)

6900902 (ZA)

Page 11

11

Balances with a Weighing Capacity over 10 kg:

G Insert the right-angle plug into the jack and

tighten the screw.

G Connect the AC adapter to an electrical outlet

(mains supply)

Safety Precautions

Plug-in AC Adapter:

The balance/scale is intended to be supplied by a

listed direct plug-in power unit marked “Class 2."

Universal AC Adapter 6971966:

The AC adapter rated to Class 1 can be plugged

into any wall outlet without additional safety

precautions.

The ground terminal is connected to the balance

housing, which can be additionally grounded

for operation. The data interface is also electrically

connected to the balance housing (ground).

Note:

This equipment has been tested and found to

comply with the limits pursuant to part 15 of FCC

Rules. These limits are designed to provide reason-

able protection against harmful interference. This

equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in

accordance with these instructions, may cause

harmful interference to radio communications.

For information on the specific limits and class

of this equipment, please refer to the Declaration

of Conformity. Depending on the particular class,

you are either required or requested to correct the

interference.

Page 12

If you have a Class A digital device, you need

to comply with the FCC statements as follows:

“Operation of this equipment in a residential area

is likely to cause harmful interference in which case

the user will be required to correct the interference

at his own expense.”

If you have a Class B digital device, please read and

follow the FCC information given below:

However, there is no guarantee that interference

will not occur in a particular installation. If this

equipment does cause harmful interference to radio

or television reception, which can be determined

by turning the equipment off and on, the user

is encouraged to try to correct the interference by

one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment

and receiver.

– Connect the equipment into an outlet on

a circuit different from that to which the receiver

is connected.

– Consult the dealer or an experienced radio/TV

technician for help.

Before you operate this equipment, check which

FCC class (Class A or Class B) it has according

to the Declaration of Conformity included. Be sure

to observe the information of this Declaration.

12

Page 13

Connecting Electronic Peripheral Devices

§ Make sure to unplug the balance from AC power

before you connect or disconnect a peripheral device

(printer or PC) to or from the interface port.

Warmup Time

To deliver exact results, the balance must warm up

as listed below after initial connection to AC power

or after a relatively long power outage.

– Model CPA2P…, CPA26P…: at least 4 hours

– All other precision and analytical models:

at least 30 minutes

Only after this time will the balance have reached

the required operating temperature.

Using Verified Balances in Legal Metrology:

$ Allow the equipment to warm up for at least

24 hours after initial connection to AC power.

Antitheft Locking Device on Balances with

a Weighing Capacity of up to 10 kg

G To secure the balance at the place of installation,

fasten a chain or a lock to the lug located on the

rear panel of the balance (order no.: LC1).

13

Page 14

14

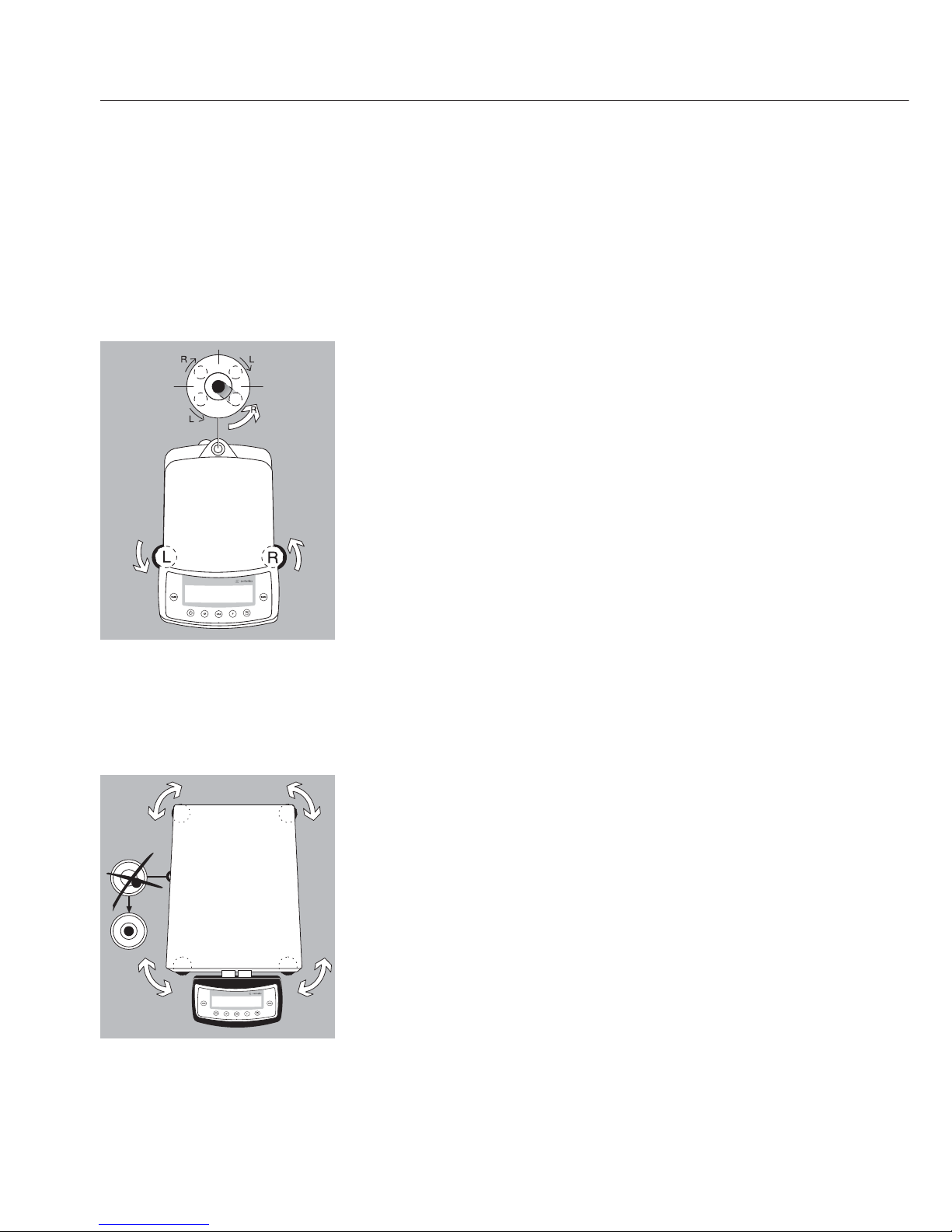

Leveling the Balance

Purpose:

– To compensate for unevenness at the place

of installation

Leveling Balances with a Weighing Capacity

of up to 10 kg

Only the 2 front feet are adjusted to level the

balance.

§ Retract the two rear feet (only on models with

a rectangular weighing pan).

§ Turn the 2 front feet as shown in the diagram

until the air bubble is centered within the circle of

the level indicator.

> In most cases this will require several adjustment

steps.

§ For weighing heavy samples: Extend the 2 rear

feet until they touch the surface on which the

balance rests (only on models with a rectangular

weighing pan).

Leveling Balances with a Weighing Capacity

of over 10 kg

§ Adjust the leveling feet until the air bubble

is centered within the circle on the level indicator.

Page 15

15

Operation

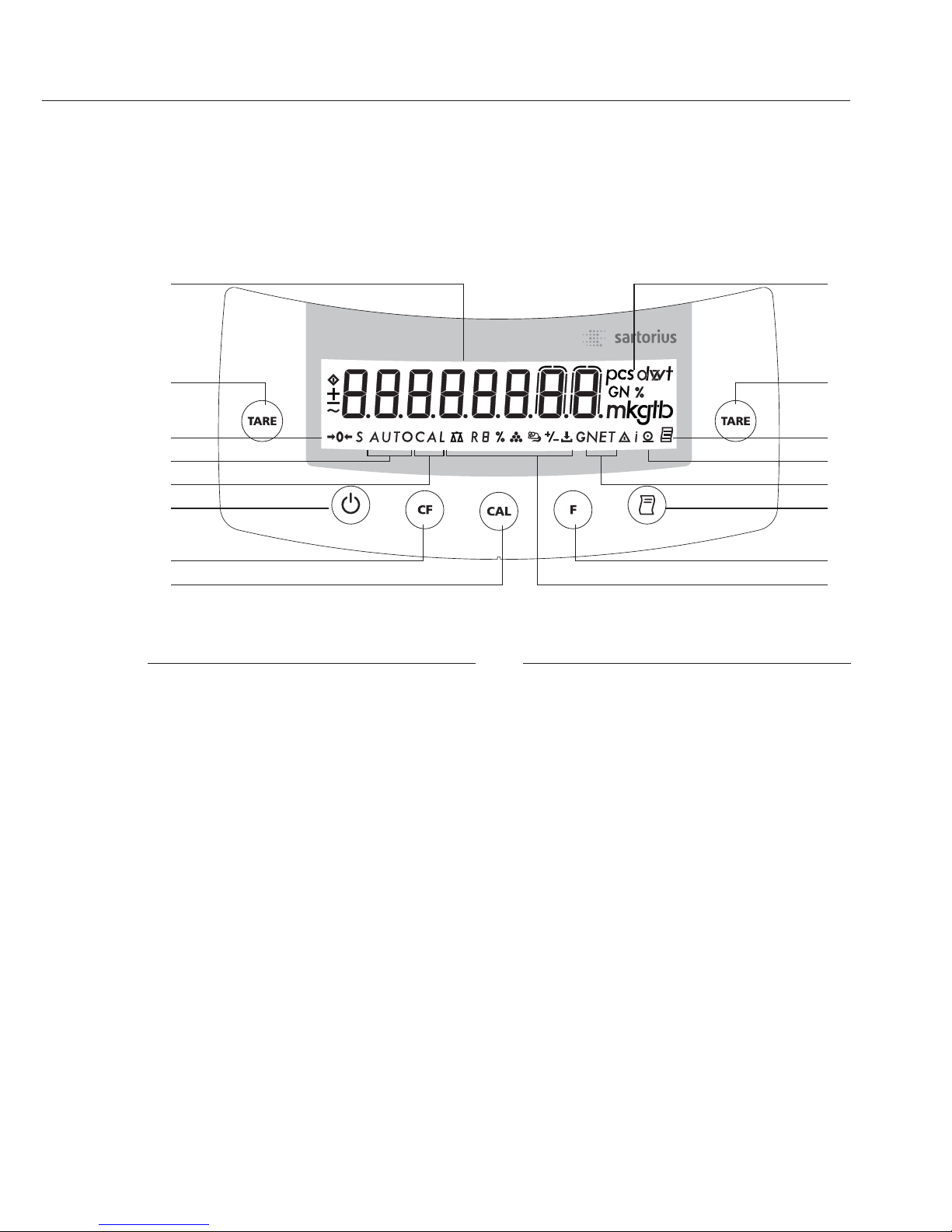

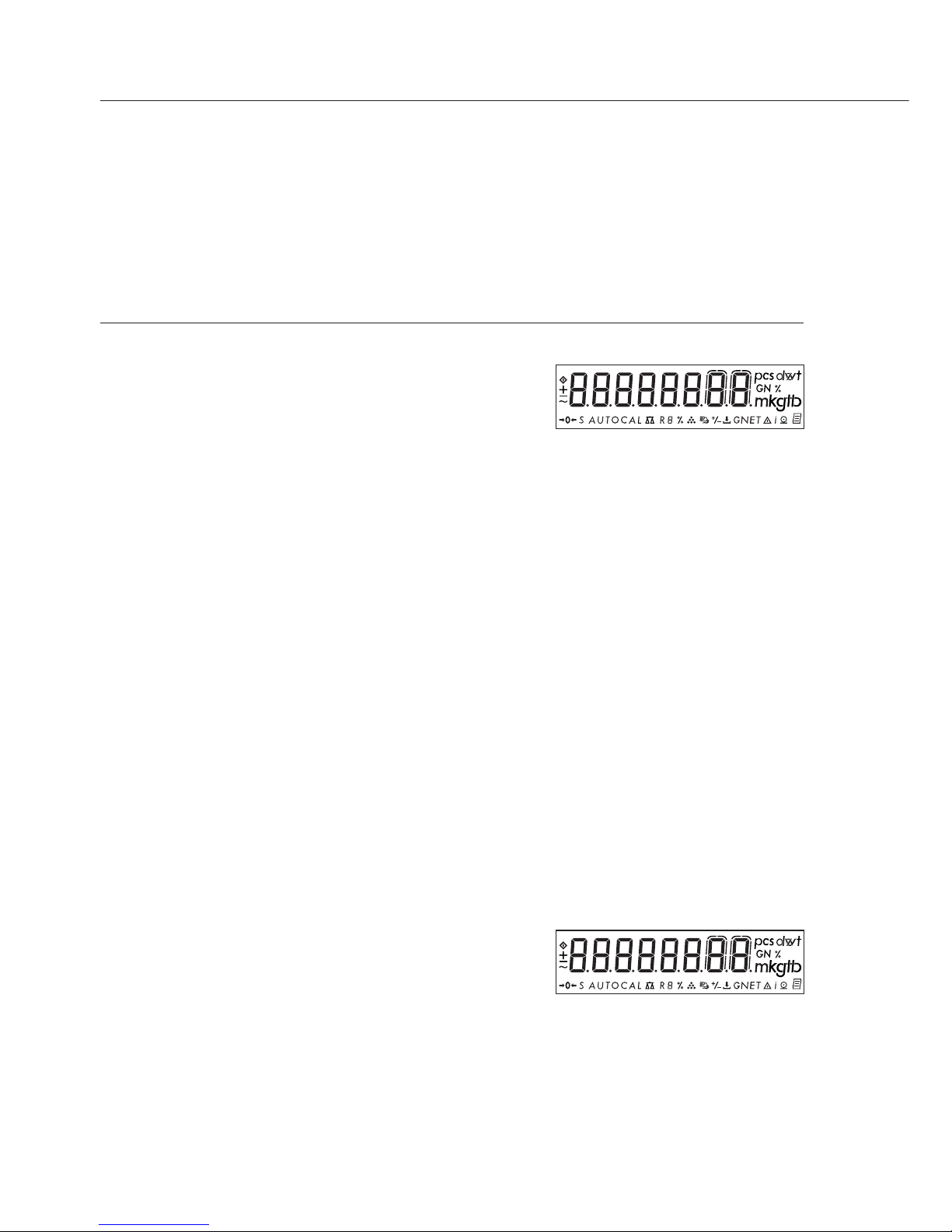

Overview of Display and Operating Elements

Position Designation

1 Weight units

2 Tare key

3 Symbol: “GLP printing mode

active"

4 Symbol: “Printing mode active"

5 Display: Data in memory for

net-total formulation program

6 Data output: Press this key

to output readout values to the

built-in data interface.

7 Function key:

Start application program

8 Symbols for active application

9 Start calibration/adjustment

routine

Position Designation

10 Delete (Clear Function)

This key is generally used to

cancel functions.

– Quit application program

– Cancel calibration/

adjustment routine

11 On/off

12 Display: Calibration/adjustment

function

13 Display: Animal weighing with

automatic start

14 Symbols for stand-by mode

or zero range

15 Weight value displayed in selected

weight unit

15 1

2 2

14 3

4

5

6

13

12

11

10

9

7

8

Page 16

Purpose

The basic weighing function can

be used alone or in combination with

an application program (counting,

weighing in percent, etc.).

Features

– Taring the balance

– Assigning IDs to weights (as needed)

– Printing weights

Using Verified Balances as Legal

Measuring Instruments in the EU*:

The type-approval certificate for verification applies only to non-automatic

weighing instruments. For automatic

operation with or without auxiliary

measuring devices, you must comply

with the regulations applicable to

the place of installation.

G Before using the balance as a legal

measuring instrument, calibrate and

adjust it at the place of use using the

built-in motorized calibration weight;

for details, see “Calibration and

Adjustment" in the next chapter.

$ The temperature range (°C) indicated

on the verification label may not be

exceeded during operation.

Example:

BD BL 200

+10°C to +30°C

0°C to +40°C isoCAL

K

* Including the Signatories of the Agree-

ment on the European Economic Area

Working with CPA2P, CPA26P…

Models:

Working with the microbalance

requires a steady hand and a smooth,

uninterrupted technique.

Use forceps or other suitable utensil to

place the sample on the weighing pan.

Perform a number of test measurements

before you begin weighing, to allow the

temperature inside the weighing chamber

to adjust to the ambient temperature

outside the chamber. Otherwise, if the

chamber door was closed for a longer

period of time prior to beginning

weighing, the sudden change in temperature inside the chamber when you

open the door might affect the weight

readout. This is why a series of test

measurements is recommended; the

repeated opening and closing of the

weighing chamber door, at the same

rate of speed as will be used during the

actual weighing sequence, will both

compensate this difference in temperature to some extent and help you

develop a smooth working rhythm.

Place the sample gently on the weighing

pan. The weight readout should stabilize

within 15 to 20 seconds. The degree of

precision attained increases in proportion as the weighing operations become

more consistent.

16

Basic Weighing Function

Page 17

17

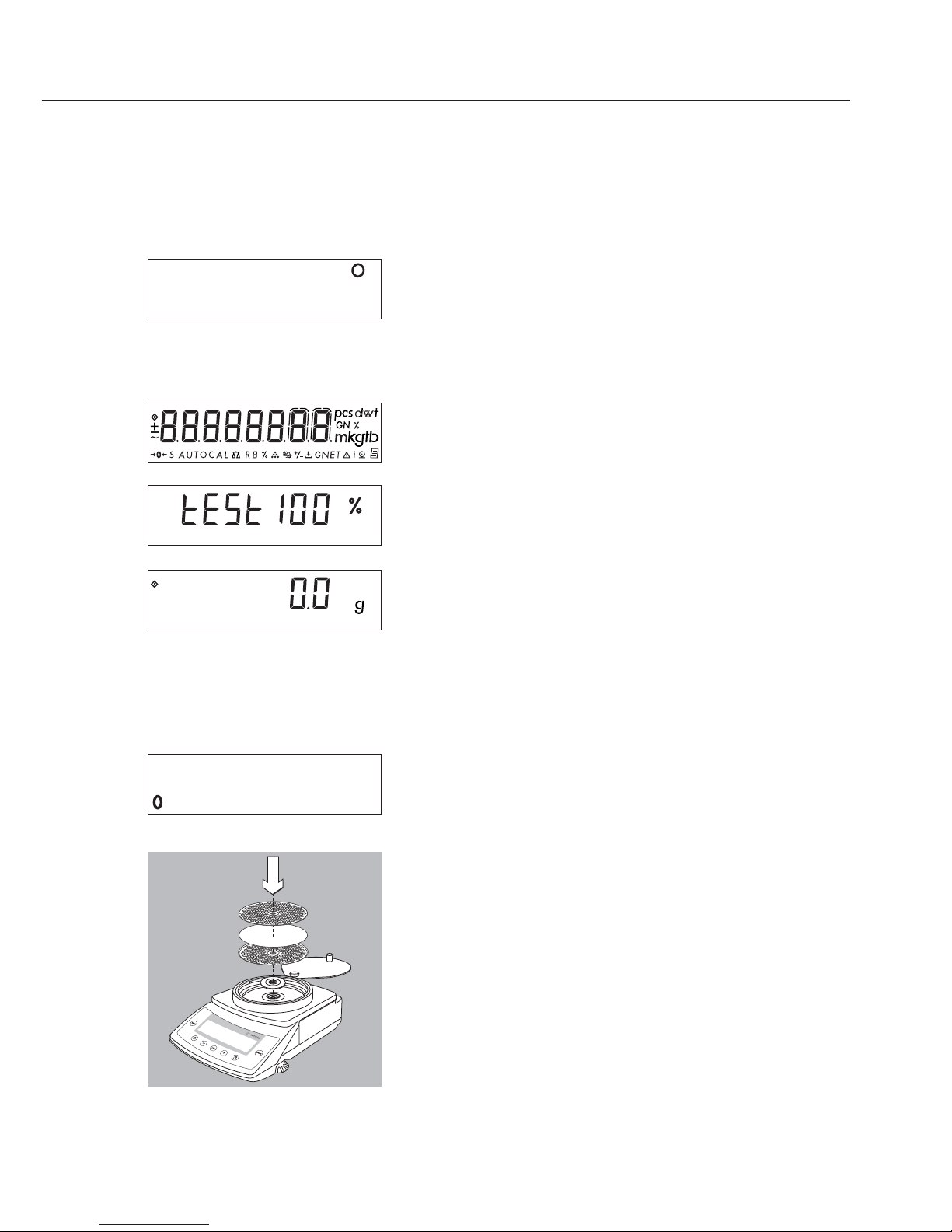

Preparation

A circle in the upper right-hand corner of the display

indicates that the balance was disconnected from

power. This symbol is shown, for example, the first

time the balance is put into operation, or after a

power outage.

G Switch on the balance: Press (E)

> All symbols on the display light up briefly.

> The balance performs a display test.

$ Tare the balance, if necessary: Press (TARE)

When you turn on the balance, the b symbol is

displayed until you press a key.

If the b symbol is displayed during operation,

this indicates that the processor is performing

a function and cannot receive further commands

at the moment.

Additional Functions

G Switching off the balance: Press (E)

A circle in the lower left-hand corner of the display

indicates that the balance has been switched off and

is in stand-by mode.

Filter Weighing with Model CPA2P-F

The CPA2P-F filter microbalance comes with

a filter pan that has a utilizable diameter of 125 mm

as standard equipment. Place the filter on the pan

and close the lid.

Page 18

18

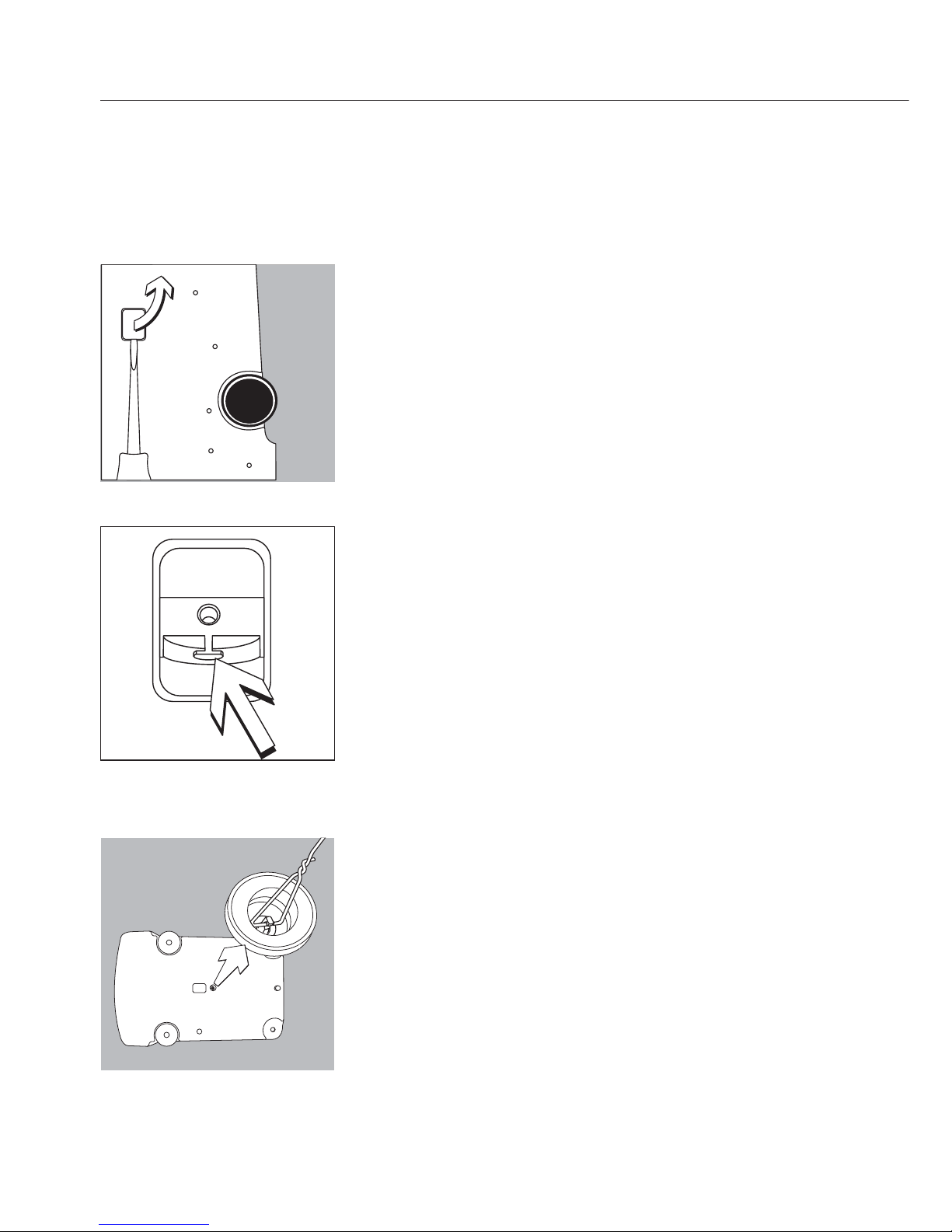

Below-Balance Weighing

A port for a below-balance weighing hanger

is located on the bottom of the balance (for models

with a weighing capacity of 12 kg or more, see

chapter on “Accessories.”

$ Below-balance weighing is not permitted in

legal metrology.

G Open cover plate on the bottom of the balance.

G Using the built-in hanger 1: Attach the sample

(e.g., using a suspension wire) to the hanger.

$ If necessary, install a shield for protection against

drafts.

G Remove the brass screw

G Suspend the below-balance weighing hook

supplied from the hanger

G If necessary, install a shield for protection against

drafts

1

Microbalance CPA2P..:

Analytical and precision balances:

Page 19

19

Example

Simple Weighing

Step Key (or instruction) Display/Data Output

1. Switch on the balance. (E)

+ 0.0 g

Self-test is performed,

followed by automatic

initial tare function.

2. Place container on the balance

+ 11.5 g

(in this example, 11.5 g).

3. Tare the balance. (TARE)

+ 0.0 g

4. Place sample in container

+ 132.0 g

on balance

(in this example, 132 g).

6. Print weight. (A)

N + 132.0 g

Page 20

20

Calibration and Adjustment

Purpose

Calibration is the determination of the

difference between the weight readout

and the true weight (mass) of a sample.

Calibration does not entail making any

changes within the balance.

Adjustment is the correction of any

difference between the measured value

displayed and the true weight (mass)

of the sample, or the reduction of the

difference to an allowable level within

the maximum permissible error limits.

Using Verified Balances as Legal

Measuring Instruments in the EU*:

Before using your balance as a legal

measuring instrument, you must perform

“internal calibration/adjustment" at the

place of installation after the warmup

period.

Features

Calibration/adjustment can be performed

only when:

– there is no load on the balance,

– the balance is tared, and

– the internal signal is stable.

If these conditions are not met,

an error message is displayed (Err 02).

Adjustment can be performed

– automatically following calibration

(1 10 1) or

– manually, at operator discretion,

after calibration (1 10 2)

* Including the Signatories of the Agree-

ment on the European Economic Area

– The weight displayed for the sample

on the balance must not differ from the

nominal weight by more than 2%.

– You can use any of the following

weight units to calibrate/adjust the

balance: g, kg, lb

(1 11 1 to 3, factory setting: 1 11 1)

You can block calibration/adjustment

of the balance as follows:

– Select menu code1 9 7, or

– Close the menu access switch on the

back of the balance

– You can have calibration/adjustment

start automatically when a specified

time or temperature limit is reached

(isoCAL function; 1 15 3).

– You can have calibration and

adjustment results documented as

an ISO/GLP-compliant printout;

see the chapter on ISO/GLP-compliant

Printout/Record.

External Calibration/Adjustment

in Verified Balances of Accuracy

Class K

– When the balance is used in legal

metrology, external calibration/adjust-

ment is blocked by a seal over the menu

access switch.

Page 21

21

Internal Calibration/Adjustment

The menu code setting 1 9 3

must be selected in the Setup menu.

Inside the balance housing is a

motorized calibration weight which

is applied and removed automatically

for internal calibration.

G Activate calibration: Press (CAL)

> The built-in calibration weight is

applied automatically.

> The balance is calibrated.

> If “Calibrate, then auto adjust in one

operation" is selected in the Setup

menu, the balance is now adjusted

automatically.

> The internal calibration weight is

removed.

! Important note for calibration/adjust-

ment of the CPA2P-F model: position

the cover before calibration/adjustment

Calibration and Adjustment Sequence

In the Setup menu, you can configure

whether:

– Calibration is always followed auto-

matically by adjustment (1 10 1; factory

setting), or

– You have the choice of ending the

sequence or starting adjustment after

calibration (1 10 2)

If no difference is determined between

nominal and actual weights, you can

end the calibration/adjustment routine

following calibration.

Two keys are active at this point:

– (CAL) = start calibration/adjustment

– (CF) = end the sequence

Page 22

22

isoCAL*:

Automatic Calibration and Adjustment

The menu code setting 1 15 3 must be

selected in the Setup menu.

– Temperature range with isoCAL:

0°C to +40°C

The “AUTOCAL" display automatically

begins flashing if the ambient temperature

has changed in relation to the temperature at the time of the last calibration/

adjustment, or after a defined time interval has elapsed. The balance is telling you

that it wants to self-calibrate and adjust.

This adjustment prompt is activated when:

– The change in temperature or the elapsed

time interval is greater than that shown in

the table below

– The load on the pan has not been

changed within the last 2 minutes

– The balance has not been operated within

the last 2 minutes

– The weight on the pan is no more than 2%

of the maximum capacity of the balance

*= CPA64-WDS models:

factory setting isoCAL off (Code 1 15 1)

When these requirements are met,

the following symbols are displayed:

– C in the measured value line

– AUTOCAL flashes in the symbol display

In the Setup menu, you can configure

the balance to display the adjustment

prompt only, without performing

calibration/adjustment automatically

(menu code 1 15 2).

! Important note for calibration/adjust-

ment of the CPA2P-F model: position

the cover before calibration/adjustment.

This is necessary to enable automatic

calibration (isoCAL) to take place.

isoCAL Deactivated on Verified

Balances:

The permitted operating temperature

range for balances used in applications

subject to legal metrology (legal for

trade) is restricted as follows:

– Balances of accuracy class k:

+15°C to 25°C (+59 to +77°F)

– Balances of accuracy class K:

+10°C to +30°C (+50 to 86°F)

Fully automatic adjustment is initiated under the following conditions:

Model When the After a time

temperature interval of

changes by

CPA2P, CPA2P-F, CPA26P, CPA225D, CPA324S, CPA224S,

CPA124S, CPA64, CPA1003S, CPA1003P, GCA1603, GCA803 1.5 Kelvin 4 hours

CPA623S, CPA423S, CPA6202S, CPA5202S-DS, CPA6202P,

CPA4202S, CPA523S-PCE, GPA5202, GPA3202 2 Kelvin 6 hours

CPA323S, CPA2202S…, CPA34001P, CPA34001S,

CPA223S, CPA3202S, GCA2502 4 Kelvin 12 hours

CPA5201, CPA2201-0CE, CPA10001, CPA16001S

CPA12001S, CPA34000, CPA8201 4 Kelvin 24 hours

These values are also set in the corresponding verified balances

(CPA…-0CE/-PCE models with the -0CE designation).

Page 23

23

Internal Calibration

Step Key (or instruction) Display

1. Zero the balance. (TARE)

0.0 g

CPA2P-F model:

Either position the standard pan

(8 g) or the filter pan (5 g) along

with the cover (3 g) beforehand.

2. Start calibration. (CAL)

C

The internal weight is CAL

applied automatically.

3. The balance is calibrated

– 0.2 g

(displayed only if menu CAL ± G

code 1 10 2 is set).

4. If the “Calibrate, then auto

Adjust*

adjust" setting is selected CAL

(1 10 1), the balance is

now adjusted automatically.

5. The calibration sequence

CC

is completed. CAL

6. The internal weight is removed.

0.0 g

* = Adjust displayed only if menu item 1 10 2 is selected.

Page 24

24

External Calibration

Settings:

Calibration/adjustment mode: External calibration/adjustment (menu code 1 9 1)

The weight required for calibration/adjustment is defined in the factory settings

(see “Specifications").

Step Key (or instruction) Display

1. Zero the balance. (TARE)

0.0 g

2. Start calibration. (CAL)

+ 5000.0 g

CAL G

3. Apply the prompted calibration

weight (in this example, 5000 g).

4. The balance is calibrated

– 0.2 g

(displayed only if menu CAL ± G

code 1 10 2 is set).

5. If the “Calibrate, then auto

Adjust

*

adjust" setting is selected CAL

(1 10 1), the balance is now

adjusted automatically.

6. The calibration/adjustment

CC

sequence is completed. CAL

7. After calibration/adjustment, the

+ 5000.0 g

weight is displayed with weight unit.

8. Remove the calibration weight.

0.0 g

* Adjust shown only if menu code 1 10 2 is set.

Important note: Afterwards, do not perform internal calibration/adjustment again.

Page 25

25

Configuration

Purpose

To adapt the balance to individual

requirements by choosing from

parameters options in the Setup menu.

Features

To open the Setup menu, switch the

balance off and then on again by

pressing (E). While all segments are lit,

press (TARE) briefly.

Scroll upward ↑:

Press (CAL)

Scroll to the right →:

Press (A)

Confirm input:

Press (TARE)

Save settings and exit menu:

Press and hold (TARE) (> 2 sec.)

G Printing the Parameter Settings

– At the 3

rd

menu level (lowest level;

see also the next page): Press and hold

(A) (> 2 sec.).

> Printout (Example)

Menu711

– At the 2nd menu level:

Press and hold (A) (> 2 sec.).

> Printout (Example)

Menu711

Menu721

Menu731

– All current menu settings are printed

when the 1

st

menu level (highest level)

is displayed: Press and hold (A)

(> 2 sec.).

Page 26

26

Setting the Parameters (Menu Codes)

Example: Adapting the balance to “very unstable" ambient conditions (menu code 1 1 4).

Step Key (or instruction) Display

1. Switch off the balance. (E)

2. Switch the balance on; (E)

while all segments

are displayed: (TARE) briefly

1

$ Scroll upward within a (CAL) 2

menu level; after the last repeatedly ...

menu code, the first

9

code is displayed again. 1

3. Select menu level 2 (A) 1 1

(scroll to the right).

4. Select menu level 3 (A)

1 1 2

o

(scroll to the right).

5. Menu level 3: (CAL)

Scroll until the desired repeatedly

1 1 4

number is shown.

6. Confirm change; (TARE)

1 1 4

o

“o” on display indicates

active setting.

$ Return to higher menu level (A)

1

(from the third level).

$ Set other codes as desired. (A), (CAL)

7. Save changes and exit Press and hold

the menu (TARE) (> 2 sec.)

or

$ Exit menu without saving

changes. (E)

Page 27

27

Parameter Settings (Overview)

o Factory setting

√ User-defined setting

Setup 1 Weighing 1 1 Adapt filter 111 Very stable conditions

112 o Stable conditions

113 Unstable conditions

114 Very unstable conditions

1 2 Application filter 121 o Final readout

122 Filling mode

1 3 Stability range 131 4 digit

The stability symbol is 132 1 digit

displayed when the 133 1 digit

value is stable within 134 o 2 digits

this number of digits. 135 4 digits

136 8 digits*

1 5 Tare function* 151 Without stability

152 o After stability

1 6 Auto zero 161oOn

162 Off

1 7 Weight unit 1 171 Grams (display: o)*

172 o Grams (display: g)

173 Kilograms

1

)

174 Carats

175 Pounds*

176 Ounces*

177 Troy ounces*

178 Hong Kong taels*

179 Singapore taels*

1710 Taiwanese taels*

1711 Grains*

1712 Pennyweights*

1713 Milligrams

2

)

1714 Parts per pound*

1715 Chinese taels*

1716 Mommes*

1717 Austrian carats*

1718 Tola*

1719 Baht*

1720 Mesghal*

1 8 see next page

2 through 9 see following pages

* = Not available in balances verified for use in legal metrology

1

) = Not available for models with a readability < 0.1 mg

2

) = Not available for verified balances of accuracy class K

Menu level 1

Menu level 2

Menu level 3

Factory setting

Menu item

Page 28

Menu 1 Weighing 1 1 through 1 7 see previous page

1 8 Display accuracy 1 * 181 o All digits

185 Reduced by 1 digit*

1 9 (CAL) key function 191 External cal./adj.

1

)

193 o Internal cal./adj.

196 CPA225D model:

Internal linearization

197 (CAL) key blocked

1 10 Calibration/ 1101 o Calibrate, then auto adjust

adjustment sequence in one operation

1102 Calibrate, then manual

adjust

1 11 Weight unit for 1111 o Grams

calibration weight * 1112 Kilograms

1113 Pounds

1 15 isoCAL function 1151 Off

2

)

1152 Only adjustment prompt

1153oOn

2 Application 2 1 Program selection 211 o Weighing

programs 212 Toggle weight units

214 Counting

215 Weighing in percent

3

)

216 Net-total formulation

217 Animal weighing

3

)

3 through 9 see next page

* = Setting cannot be changed on verified balances

1

) = Not available for verified balances of accuracy class K

2

) = Factory setting for CPA64-WDS

3

) = Not available for CPA…-PCE models

28

Menu level 1

Menu level 2

Menu level 3

Factory setting

Menu item

Page 29

29

Menu 1 through 2 see previous page

3 Application 3 1 Weight unit 2 311 Grams (display: o)*

parameters 312 o Gramm (Anzeige: g)

313 Kilograms

1

)

314 Carats

315 Pounds*

316 Ounces*

317 Troy ounces*

318 Hong Kong taels*

319 Singapore taels*

3110 Taiwanese taels*

3111 Grains*

3112 Pennyweights*

3113 Milligrams

2

)

3114 Parts per pound*

3115 Chinese taels*

3116 Mommes*

3117 Austrian carats*

3118 Tola*

3119 Baht*

3120 Mesghal*

3 2 Display accuracy 2* 321 o All digits

325 Reduced by 1 digit

3 5 Storage parameter 351 Internal resolution

for Counting and

Weighing in Percent 352 o Display accuracy with

higher stability

3 6 Decimal places for 361 None

calculations 362 o 1 decimal place

363 2 decimal places

364 3 decimal places

3 7 Animal activity 371 Calm

372 o Normal

373 Strong vibration

3 8 Start Animal weighing 381 Manual start

382 o Automatic start

4 Application 4 1 Autom. reference 411 o Off

parameters sample updating 412On

Counting

5 through 9 see next page

* = Setting cannot be changed on verified balances

1

) = Not available for models with a readability < 0.1 mg

2

) = Not available for verified balances of accuracy class K

Menu level 1

Menu level 2

Menu level 3

Factory setting

Menu item

Page 30

Menu 1 through 3 see previous page

5 Data interface 5 1 Baud rate 511 150 baud

512 300 baud

513 600 baud

514 o 1,200 baud

515 2,400 baud

516 4,800 baud

517 9,600 baud

518 19,200 baud

5 2 Parity 521 Mark

522 Space

523 o Odd

524 Even

5 3 Number of stop bits 531 o 1 stop bit

532 2 stop bits

5 4 Handshake mode 541 Software

542 o Hardware,

2 char. after CTS

543 Hardware,

1 char. after CTS

5 5 Communication mode 551 SBI (ASCII)

1

)

552 o Universal printer

6 Print for 6 1 Manual/auto/mode 611 Manual without stability

weighing with (A) key

612 o Manual after stability

with (A) key

613 Manual at stability

with (A) key

614 Automatic without stability

615 Automatic at stability

616 Automatic when load

is changed

1

)

6 2 Stop automatic 621 Manual with (A) key

printing 622 o Not stoppable

6 3 Time-dependent 631 o 1 display update

autom. printing 632 2 display updates

6 4 Tare the balance 641 o Off

after ind. printout 642On

7 through 9 see next page

1

) = Note concerning balances verified for legal metrology:

In the “SBI” setting, the non-verified digit indicated is not automatically identified.

Be sure to take the steps or make the settings on the auxiliary device so that these digits are properly identified.

See also the “Interface Port” chapter.

2

) = Auto print when load change is > 10 d and stability is reached: no printout until residual difference in load

value is < 5 d

30

Menu level 1

Menu level 2

Menu level 3

Factory setting

Menu item

Page 31

31

Menu 1 through 6 see previous page

7 Printing with 7 1 Print 711 Off

application application 712 o On; all parameters

programs parameters 713 On; main

parameters only

7 2 Line format 721 For raw data

of printout (16 characters)

722 o For other apps.

(22 characters)

7 3 Printout with 731 o Autom. printout

Net-total of last net value

program 732 Autom. printout

of tare value

8 Extra 8 1 Menu* 811 o Parameter settings

functions alterable

812 Parameters “read only"

8 2 Acoustic signal 821oOn

822 Off

8 3 Keypad 831 o Accessible

832 Blocked

8 4 External switch 841o(A) key

function 842 (TARE) key

843 (CAL) key

844 (F) key

845 (CF) key

8 5 Power-on mode 851 o Off/on/standby

for balance 853 Standby/on

854 Auto on

8 8 Reference balance 881 o Off

for Counting 882 On for QC scale

883 On for FB /FC /LA /LP

balances/scales

884 On for isi terminal

8 10 ISO/GLP-compliant 8101 o No ISO/GLP printout

printout 8102 For calibration/adjustment only

8103 Always on

9 Reset menu 9 – Factory settings 9 – 1 Restore

9 – 2 Do not restore

*= Setting cannot be changed on verified balances

Menu level 1

Menu level 2

Menu level 3

Factory setting

Menu item

Page 32

Setting IDs, Time, Date

and Display Brightness

Purpose

Configuring measurement environment parameters

for ISO/GLP-compliant data records.

Setting date and time (for ISO/GLP-compliant

records only).

Adapting display to ambient lighting conditions.

Features

– Enter up to 8 characters to identify a measurement

series. Permissible characters include the numbers

0 through 9 and the dash or minus sign (“–").

A dash is output as a space on printouts. Leading

zeroes are not output.

– Date and time at beginning and end of ISO/GLP-

printouts.

– Display brightness 1):

0 = off; levels of brightness: 1 through 9

Key functions during configuration:

Activate input of IDs, time and date:

Switch the balance off and then on again by

pressing (E); while all segments are displayed,

press the (F) key briefly

Scroll upward ↑: Press (CAL)

Scroll to the right →: Press (A)

Confirm input and toggle between IDs,

time and date: Press (TARE)

Save settings and exit menu:

Press and hold (TARE) (> 2 sec.)

1

) No display backlighting on models CPA2P…,

CPA26P(-0CE) and CPA225D(-0CE)

32

Page 33

33

Example: Setting the time, date and display brightness

Step Key (or instruction) Display

1. Switch off the balance. (E)

2. Switch the balance on; (E)

while all segments

are displayed: (F) briefly

--------

$ To move the cursor within (A) --------

ID number: repeatedly

$ ITo set or change ID: (CAL)

-3------

repeatedly

3. Confirm ID and activate (TARE)

H10.14.11

time setting.

4. Select 24-hour clock (“H") or

112-hour clock (“P"). (CAL)

H10.14.19

5. Toggle between hours, (A) H10.15.19

minutes, seconds and 12-hour

or 24-hour time mode.

6. Synchronize seconds with

a reference clock. (CAL)

H10.15.00

7. Confirm time and activate date. (TARE) 29.jan.01

8. Set date (CAL) repeatedly,

“Day," (A)

01.jan.01

“Month," and, (CAL) repeatedly

(A)

22.apr.01

if desired, “Year." (CAL) repeatedly

Confirm date and activate

display brightness. (TARE)

22.apr.01

Page 34

34

Step Key (or instruction) Display

9. Set display brightness. (CAL) repeatedly

lamp 7

10. Save changes and exit Press and hold

the menu (TARE) (2 sec.)

or

$ Exit menu without

saving changes. (E)

Page 35

35

Application Programs

Function Keys

(F) key: Start application program/

store component

(F) key Toggle between component

press and weight and total weight

hold for (net-total formulation);

2 seconds change reference quantity

(counting), reference percentage

(weighing in percent) or number

of measurements (animal weighing)

(CF) key: End application program; delete

Using Verified Balances as Legal Measuring

Instruments in the EU*:

All application programs can be selected on balances

used as legal measuring instruments.

Calculated values are alternately indicated with the

following symbols:

– Percent = %

– Piece count (Counting) = pcs

– Computed value = o, G

* Including the Signatories of the Agreement

on the European Economic Area

Page 36

Net-total Formulation

Menu code: 2 1 6 *

Display symbol: R

Purpose

With this application program you can weigh in

different components up to a defined total.

Features

– Weigh up to 99 components from “0" to a defined

total component weight.

– Store component weights (“Store xx comp."), with

– display zeroed automatically after value is stored,

and

– automatic printout

– Clear component memory following cancellation

of the weighing sequence [by pressing (CF)] and

printout of the total weight.

– Toggling between component weight and total

weight by pressing and holding (F) (2 sec.).

– Printout of the total of the individual component

weights (T COMP)

* = Factory setting on CPA…-PCE models

36

Page 37

37

Preparation

Set parameters for net-total formulation:

§ Set parameters for automatic printout when

component stored

2 Application programs

2 1 Program selection

2 1 6 * Net-total

7 Print for application

7 1 Print application parameters

7 1 1 Off

7 1 2 ο On; all parameters

7 1 3 On; main parameters only

7 3 Printout of net-total formulation data

7 3 1 ο Autom. print of last net value

7 3 2 Autom. print of tare value

ο = Factory setting

* = Factory setting on CPA…-PCE models

Printout of Net-total Formulation Data

COMP2 + 278.1 g: Second component

T COMP+ 2117.5 g : Sum of components

T1 + 1821.5 g : Tare weight (2

nd

tare memory)

N1 + 278.1 g: Net weight = Gross – tare

2

nd

tare memory

N + 2099.6 g: Net weight = Gross – tare

Page 38

Example: Counting parts into a container

Settings: Application program: Net-total formulation 2 1 6;

Print application parameters: On, print all 7 1 2; Automatic printout of last net value 7 3 1

Step Key (or instruction) Display/Data output

1. Place empty container

+ 65.0 g

on the balance.

2. Tare the balance. (TARE)

0.0 g

3. Add first component.

+ 120,5 g

4. Store component data. (F)

0.0 g

NET

COMP1 + 120.5 g

5. Add next component. + 70,5 g

6. Store component data. (F)

0.0 g

NET

COMP2 + 70.5 g

7. Weigh in further components Repeat steps

as desired. 5 and 6.

8. Continue filling to target press and hold (F)

+ 191,0 g

(view total). (2 sec.) G

38

Page 39

39

Step Key (or instruction) Display/Data output

9. Add last component.

+ 203,5 g

G

10. Store component data. (F)

0.0 g

NET

COMP 3+ 12.5 g

11. Display total weight. (CF) + 203,5 g

T COMP+ 203.5 g

Page 40

Counting

40

Menu code: 2 1 4

Display symbol: Z

Purpose

With the Counting program you can

determine the number of parts that

each have approximately equal weight.

To do this, a known number of parts

(the reference sample quantity) is

weighed first, and the individual piece

weight (reference weight) is calculated

from this result. Thus the number

of parts subsequently placed on the

balance can be determined from

their weight.

Features

– The minimum load is equal to one digit,

defined according to the resolution of

the active weight unit.

– Press and hold the (F) key (2 seconds) to

set the reference sample quantity.

– Configure the resolution used when

reference sample quantity is stored and

piece counts are calculated.

– Optional automatic output of the piece

count and average piece weight to the

data interface port when the menu

code 7 1 2 (print application parameters) is set.

– Long-term storage of the last reference

sample quantity “nRef" entered.

– Toggling between piece count and

weight by pressing (F).

Function Keys

(F):

Begin determination of piece weight

> Application program initialized with

predefined reference sample quantity.

(CF):

End application program; clear

initialization data

Changing the reference sample

quantity:

§ Press and hold (F) (2 sec.)

> Current reference sample quantity

is displayed.

$ Press (F) briefly to change the value;

press repeatedly until the desired reference sample quantity is displayed.

Quantities to choose from: 1, 2, 5, 10,

20, 50, 100.

§ Store setting in long-term memory:

Press and hold (F).

Page 41

41

Reference Sample Updating

Automatic reference sample updating

optimizes the counting accuracy.

You can activate or deactivate this

function in the Setup menu.

When this function is active, automatic

reference sample updating is performed

when the criteria of the factory-set

parameters are met.

> The abbreviation opt, for “optimizing,"

is displayed briefly with the new

reference sample quantity.

Reference Balance/Scale

(Counting with two balances/scales)

Purpose:

Use of a reference balance/scale affords

higher precision in counting large

amounts of parts. The CPA balance is

used to determine the reference weight.

The following weighing instruments or

terminals can be used for sample

weighing in conjunction with a refer-

ence balance/scale:

– For a QC scale: set menu code 8 8 2

– For an FB/FC/LA/LP balance/scale:

set menu code 8 8 3

– For an isi terminal:

set menu code 8 8 4

§ Please order the required connecting

cables directly from Sartorius.

The following settings must have

the same configurations in both bal-

ances/scales:

– Counting program

– Weight units

– Settings in the CPA balance:

Menu codes 7 1 2 and 7 2 2

– All data interface parameters:

– Baud rate

– Parity

– Number of stop bits

– Handshake mode

Transferring the Reference Value from

the CPA Reference Balance:

– Press the (F) key

> The reference value is passed to the

counting balance/scale

Counting Balance/Scale:

$ Refer to the operating manual of

the particular weighing instrument for

further instructions

Page 42

42

Preparation

Set parameters for the Counting program:

$ Select the application program in the Setup menu

§ Set the following parameters:

2 Application programs

2 1 Program selection

2 1 4 Counting

3 Application parameters

3 5 Storage parameter

3 5 1 Standard resolution

(internal resolution)

3 5 2 ο 10 + higher resolution

4 Application parameters for Counting

4 1 Autom. ref. sample updating

4 1 1 ο Off

4 1 2 On

8 Extra functions

8 8 Reference balance/scale

8 8 1 ο Off

8 8 2 On for QC scales

8 8 3 On for FB-/FC-/LA-/LP models

8 8 4 On for isi terminals

ο = Factory setting

Printout: Counting

nRef + 10 : Reference sample quantity

wRef + 21.14 g : Reference weight

Qnt + 500 pcs : Calculated quantity

Page 43

43

Example: Counting parts of equal weight

Settings:

Menu: Counting program (menu code 2 1 4)

Step Key (or instruction) Display/Data output

1. Place empty container

+ 22.6 g

on the balance/scale.

2. Tare the balance. (TARE)

0.0 g

3. Add reference sample quantity

to container

(in this example: 10 pcs).

4. Initialize the balance. (F)

ref 10 (briefly)

+ 2.14 g

+ 10 pcs

nRef + 10 pcs

wRef + 2.14 g

5. Add uncounted parts + 500 pcs

as desired.

6. Print piece count, if desired. (A)

Qnt + 500 pcs

7. Display weight. (F) + 1070.0 g

8. Display piece count. (F)

+ 500 pcs

9. Unload the balance.

– 0 pcs

10. Repeat as necessary,

starting from Step 5.

11. Delete reference

sample quantity (CF)

0.0 g

Page 44

44

Weighing in Percent

– Long-term storage of the last reference

percentage “pRef” entered.

– Toggling between percentage and

weight by pressing (F).

Function Keys

(F):

Begin calculation of percentage

> Current weight value stored as

reference weight “Wxx%” to be

loaded at initialization.

(CF):

End application program;

clear initialization data

Changing the reference percentage:

§ Press and hold (F) (2 sec.)

> Current reference percentage is

displayed.

$ Press (F) briefly to change the value;

press repeatedly until the desired

reference percentage is displayed.

Quantities to choose from: 1, 2, 5, 10,

20, 50, 100.

§ Store setting in long-term memory:

Press and hold (F).

Menu code: 2 1 5 *

Display symbol: %

Purpose

This application program allows you to

obtain weight readouts in percent which

are in proportion to a reference weight.

Features

– The minimum load is equal to one digit,

defined according to the resolution of

the active weight unit.

– Press and hold the (F) key (2 seconds)

to set the reference percentage

– Storage parameter (rounding-off factor)

for storing the reference weight

to calculate the percentage can be

configured.

– Configuration of decimal places dis-

played with a percentage.

– Optional automatic output of the

reference weight “Wxx%” and reference

percentage to the data interface port

when the menu code 7 1 2 (print

application parameters) is set.

* = not available for CPA…-PCE models

Page 45

45

Preparation

Set parameters for the Weighing in

Percent program:

$ Select the application program in the

Setup menu

§ Set the following parameters:

2 Application programs

2 1 Program selection

2 1 5 Weighing in percent*

3 Application parameters

3 5 Storage parameter

3 5 1 ο Standard resolution

(internal resolution)

3 5 2 10+ higher resolution

3 6 Decimal places for calc.

3 6 1 None

3 6 2 ο 1 decimal place

3 6 3 2 decimal places

3 6 4 3 decimal places

ο = Factory setting

* = Not in CPA…-PCE models

Printout: Weighing in Percent

pRef + 100 % : Reference percentage

Wxx% + 111.6 g : Reference weight net xx%

Prc + 94.7 %: Calculated percentage

Page 46

Example: Determining residual weight in percent

Settings:

Menu: Weighing in percent program (menu code 2 1 5),

Print application parameters: On; all parameters (menu code 7 1 2),

Reference percentage: ref 100% (Code )

Step Key (or instruction) Display/Data output

1. Place empty container

+ 22.6 g

on balance

2. Tare the balance. (TARE)

0.0 g

3. Place sample equal to 100%

of reference percentage on the

balance (in this example:

111.6 g).

4. Initialize the balance. (F)

ref 100 (briefly)

+ 111.6 g

+ 100.0 %

pRef + 100 %

Wxx% + 111.6 g

5. Remove container; e.g., to

treat sample (in this example,

the sample is now dried).

6. Place container with sample

+ 94.9 %

on the balance again

(after treatment).

7. Optional: print percentage. (A)

Prc + 94.9 %

8. Display residual weight and (CF) + 105.9 g

delete reference value.

9. Optional: print net (A)

N + 105.9 g

residual weight.

46

Page 47

47

Animal Weighing/Averaging

Menu code: Code 2 1 7 *

Display symbol: V

Purpose

Use this program to determine the

weights of unstable samples (e.g., live

animals) or to determine weights under

unstable ambient conditions. With this

program, the balance calculates the

weight as the average of a defined

number of individual weighing operations (also referred to as “subweighing

operations").

Features

– Animal weighing started manually

or automatically

– Minimum load threshold for starting

animal weighing:

– for automatic start:

100 display intervals

– for manual start:

50 display intervals

– Automatic start:

Begin the averaging operation by

pressing (F). “AUTO” is displayed

during weighing to indicate that

the following values will be averaged

automatically.

Animal activity: Averaging begins

automatically once two subweights are

measured within a predefined tolerance

range (calm = 2%, normal = 5%,

active = 20%).

– Number of weighing operations for

calculation of an average mDef can be

set before the beginning of each series.

* = not available for CPA…-PCE models

– Number of remaining weighing

operations in the current series is shown

during weighing.

– Arithmetic average displayed as a result

in the pre-set weight unit (identified by

G). The V symbol flashes during this

time.

– Toggling between weighed and

calculated results by pressing (F)

(after initialization)

– Unload threshold is one-half of the

minimum load.

– Balance/scale returns to the basic

weighing mode when unloaded;

i.e., when the load is below the unload

threshold

Function Keys

(F):

Activate animal weighing program

(CF):

End application program; delete result;

interrupt measuring operation.

Changing the number of subweighing

operations:

§ Press and hold (F) (2 sec.)

> Current number of subweighing

operations is displayed.

$ Press (F) briefly to change the value;

press repeatedly until the desired

number is displayed.

Quantities to choose from: 5, 10, 20,

50, 100.

§ Store setting in long-term memory:

Press and hold (F).

Page 48

48

Preparation

Set parameters for the

Animal Weighing program:

$ Select the application program

in the Setup menu

§ Set the following parameters:

2 Application programs

2 1 Program selection

2 1 7 Animal weighing*

3 Application parameters

3 7 Animal activity

3 7 1 Calm (2% of the

animal/object)

3 7 2 ο Normal (5% of the

animal/object)

3 7 3 Strong vibration (20%

of the animal/object)

3 8 Start

3 8 1 Manual

3 8 2 ο Automatic

ο = Factory setting

* = Not in CPA…-PCE models

Printout: Animal Weighing

mDef 20 : Number of subweighing operations

x-Net + 401.1 g: Calculated average

Page 49

Example: Determining animal weight with automatic start of 20 subweighing operations

Settings:

Menu: Animal weighing program (menu code 2 1 7),

Print application parameters: On; all parameters (menu code 7 1 2)

Step Key (or instruction) Display/Data output

1. Switch on the balance. (E)

2. Place animal weighing bowl

+ 22.6 g

on the balance.

3. Tare the balance. (TARE)

0.0 g

4. Place the first animal Weight value fluctuates due

in bowl. to animal activity.

5. Start automatic animal (F)

888

weighing. The balance delays 20

starting the subweighing 19

operation until successive 18

subweights lie within the ...

range defined.

1

6. After 20 subweighing operations + 410.1 g G

the arithmetic average “x-Net" mDef 20

is displayed. x-Net + 410.1 g

7. Unload the balance. 0.0 g

8. Weigh next animal (if applicable).

Next weighing series begins

automatically.

49

Page 50

Toggling between Weight Units

Menu code: 2 1 2

With this application program you can switch the display of a weight value back and

forth between two weight units.

Configure the “Toggle Weight Units" application in the Setup menu:

see “Configuration" Menu code: 2.1. 2

(Factory setting on GCA and GPA models)

Menu code Unit Conversion Display PrintWeight unit 1 Weight unit 2 out

1 7 1 3 1 1 ο Grams 1) 1.00000000000 o o

1 7 2 ο 3 1 2 ο Grams 2) 1.00000000000 g g

1 7 3 3 1 3 Kilograms 3) 0.00100000000 kg kg

1 7 4 ο 3 1 4 Carats 5.00000000000 ct ct

1 7 5 3 1 5 Pounds* 0.00220462260 lb lb

1 7 6 3 1 6 Ounces* 0.03527396200 oz oz

1 7 7 3 1 7 ο Troy ounces* 0.03215074700 ozt ozt

1 7 8 3 1 8 Hong Kong taels* 0.02671725000 tl tlh

1 7 9 3 1 9 Singapore taels* 0.02645544638 tl tls

1 7 10 3 1 10 Taiwanese taels* 0.02666666000 tl tlt

1 7 11 3 1 11 Grains* 15.4323583500 GN GN

1 7 12 3 1 12 Pennyweights* 0.64301493100 dwt dwt

1 7 13 3 1 13 ο Milligrams 4) 1000.00000000 mg mg

1 7 14 3 1 14 Parts per pound* 1.12876677120 o /lb

1 7 15 3 1 15 Chinese taels* 0.02645547175 tl tlc

1 7 16 3 1 16 Mommes* 0.26670000000 m mom

1 7 17 3 1 17 Austrian carats* 5.00000000000 K K

1 7 18 3 1 18 Tola* 0.08573333810 t tol

1 7 19 3 1 19 Baht* 0.06578947437 b bat

1 7 20 3 1 20 Mesghal* 0.21700000000 m MS

o = Factory setting, depends on model

* = Not available in verified balances

1

) = GPA5202/GPA3202: readability with Taiwanese taels reduced by one decimal place

2

) = GCA1603P, GCA803S: readability 0.0002 g; GCA2502: readability 0.001 g

3

) = Not available in the CPA64-0CE

4

) = Not available in verified balances/scales of accuracy class K

Function

G Press (F) to toggle between weight unit 1 and weight unit 2

50

Page 51

Generating a Printout

51

Purpose

You can generate printouts that include

weights, other measured values and

identification codes for documentation

purposes. You can format the printout

to meet individual requirements.

Features

Printouts generated automatically or

manually (at the press of a key): weight

or calculated value is output.

Line format: Values printed with up

to 6 preceding characters for identification.

Print application parameters:

Printout of initialization values before

printing measurement results.

ISO/GLP-compliant printout:

Printout of ambient characteristics.

Printouts generated automatically

or by pressing (A), dependent on or

independent of stability.

You can have the following values

output automatically when using the

application programs if menu code

7 1 2 is configured (printout with data

ID codes):

– Net-total: Component or total weight

– Counting:

Reference sample quantity (nRef)

Reference weight for one piece (wRef)

– Weighing in percent:

Reference percentage (pRef)

Reference weight (Wxx%)

– Animal weighing/averaging:

Number of subweighing operations

(mDef)

Calculated average (x-Net)

Factory settings:

Print manual/automatic: Individual

printout dependent on stability:

Manual at stability (menu code: 6 1 2)

Line format:

Up to 6 characters at the beginning

of each line to identify the weight

or calculated value: Print net, tare, or

gross value, reference sample quantity,

or average piece weight with ID

(menu code 7 2 2).

Print application parameters:

Printout of one or more initialization

values for the active application

program: On (menu code 7 1 2)

ISO/GLP-compliant printout:

No ISO/GLP-compliant printout

(menu code 8 10 1)

Auto print:

Automatic printout of weight values:

No default setting; see print manual/

automatic (menu code 6 1 2)

Auto print cannot be interrupted by

pressing (A) (menu code 6 2 2).

Auto print after each display update

(menu code 6 3 1)

§ Setting menu codes for the printout:

see “Configuration"

Page 52

52

Printout without Data ID Codes: Examples

The value currently

+ 1530.0 g Weight in grams

displayed is printed (weight

+ 58.562 ozt Weight in Troy ounces

or calculated value with unit)

+ 253 pcs Piece count

+ 88.2 % Percentage

Printout with Data ID Codes:

The current value displayed

ID 12345678 Identification*

can be printed with a data

N + 153.0 g Current net weight

ID code of up to 6 characters

T1 + 23.4 g Value in 2nd tare memory

at the beginning of the line.

Qnt + 253 pcs Piece count

Prc + 88.23 % Percentage

* = on ISO/GLP records only

Print Application Parameters:

You can generate a print-

Comp7 + 278.1 g Net-total:

out of one or more of the 7

th

component weight

values configured for

T COMP+ 21.14 g Net-total: Total

initialization of an appli-

nRef + 10 Counting: Reference

cation as soon as you sample quantity

initialize the balance/scale.

wRef + 21.14 g Counting: Reference weight

Wxx% + 1200.0 g Weighing in percent:

Reference weight

Auto Print:

You can have the weight

N + 153.0 g Net weight

readout printed automatically.

Stat Display blank

Stat L Display underload

Stat H Display overload

Page 53

ISO/GLP-compliant Printout/Record

53

Features

You can have the parameters pertaining

to the ambient weighing conditions

printed before (GLP header) and after

(GLP footer) the values of a weighing

series. These parameters include:

GLP header:

– Date

– Time at beginning of measurement

– Balance manufacturer

– Balance model

– Balance serial number

– Software version number

– Identification number of the current

sampling operation

GLP footer:

– Date

– Time at end of measurement

– Field for operator signature

The record is output to a Sartorius data

printer or a computer.

Settings

G Setting menu codes for the printout

(see “Configuration"):

– ISO/GLP-compliant record after

calibration/adjustment only: menu

code 8 10 2; or ISO/GLP-compliant

record always on: menu code 8 10 3

– Line format for printout:

With data ID codes - 22 characters:

menu code 7 2 2

!No ISO/GLP-compliant record is output

if any of the following settings are

configured: menu code 6 1 4, 6 1 5,

6 1 6 (automatic printout) or 7 2 1

Function Keys

Press (A) to output header and first

measured value.

> Header is output the first time (A)

is pressed

Press (F) to include output header and

reference data on automatic printouts

when an application program is active

Close the application:

1) Output GLP footer:

Press (CF)

2) End application program:

Press (CF)

Page 54

54

The ISO/GLP-compliant printout can contain the following lines:

-------------------- Dotted line

17-Jan-2007 10:15 Date/time (beginning of measurement)

SARTORIUS AG Balance manufacturer

Mod. CPA10001 Balance model

Ser. no. 10105355 Balance serial number

Ver. no. 00-13-47 Software version

ID 2690 923 ID

-------------------- Dotted line

LID Measurement series no.

nRef + 10 pcs Counting: Reference sample quantity

wRef + 21.14 g Counting: Reference weight

Qnt + 235 pcs Counting result

Qnt + 567 pcs Counting result

-------------------- Dotted line

17-Jan-2007 10:20 Date/time (end of measurement)

Name: Field for operator signature

Blank line

-------------------- Dotted line

ISO/GLP-compliant printout for external calibration/adjustment:

-------------------- Dotted line

17-Jan-2007 10:30 Date/time (beginning of measurement)

SARTORIUS AG Balance manufacturer

Mod. CPA10001 Balance model

Ser. no. 10105355 Balance serial number

Ver. no. 00-13-47 Software version

ID 2690 923 ID

-------------------- Dotted line

Cal. Ext. Calibration/adjustment mode

Set + 5000.0 g Calibration weight

Diff. + 0.2 g Difference determined in calibration

Cal. Ext. Complete Confirmation of completed calibration procedure

Diff. + 0.0 g Difference from target following adjustment

-------------------- Dotted line

17-Jan-2007 10:32 Date/time (end of measurement)

Name: Field for operator signature

Blank line

-------------------- Dotted line

Page 55

Interface Port

55

Purpose

Your balance is equipped with an interface

port for connection to a computer or other

peripheral device.

You can connect a computer to change,

start and/or monitor the functions of the

balance and the application programs.

Features

Type of interface: Serial interface

Operating mode: Full duplex

Standard: RS-232

Transmission rates:

150, 300, 600, 1200, 2400, 4800, 9600

and 19,200 baud

Parity: Mark, space, odd, even

Character format:

1 start bit, 7-bit ASCII, parity,

1 or 2 stop bits

Handshake:

2-wire interface:

via software (XON/XOFF)

4-wire interface:

Hardware via handshake lines (CTS/DTR)

Operating mode: SBI

Data output format of the balance:

16 or 22 characters

Factory settings:

Transmission rate: 1200 baud (5 1 4)

Parity: Odd (5 2 3)

Stop bits: 1 stop bit (5 3 1)

Handshake: Hardware, 2 characters

after CTS (5 4 2)

Operating mode:

Standard Sartorius interface SBI (5 5 1)

Print manually/automatically:

Manual after stability (6 1 2)

Preparation

§ see “Pin Assignments" and

“Pin Assignment Chart"

Identification of Non-Verified Digits

Non-verified digits when “e#d”

are automatically identified on the

printout:

Select universal printer:

menu code 5 5 2.

Brackets are used to identify

non-verified digits.

Page 56

Output Format with 16 Characters

Display segments that are not activated are output as spaces.

The following characters can be output, depending on the characters displayed on the

balance:

Normal Operation

Position 12345678910111213141516

+ DDDDDD * UUUCRLF

or – ........ ***

or * ********

*: Space CR: Carriage return

D: Digit or letter LF: Line feed

U: Unit symbol

Special Codes

Position 12345678910111213141516

**********CRLF

or H *

or L *

or C *

*: Space H: Overload

C: Calibration/adjustment L: Underload

Error Codes

Position 12345678910111213141516

Err*###****CRLF

*: Space

# # #: Error code number

56

Page 57

Data output example: +123.56 g

Position 12345678910111213141516

+ 123. 56 g CRLF

+ 123.5[6]*g CRLF

Position 1: Plus or minus sign or space

Position 2: Space or brackets*

Positions 3–10: Weight with a decimal point; leading zeros = space

Position 11: Space or brackets*

Positions 12–14: Unit symbol or space

Position 15: Carriage return

Position 16: Line feed

Output Format with 22 Characters

When data is output with an ID code, the ID code (consisting of 6 characters) precedes

the 16-character string described above.

These 6 characters identify the subsequent value.

12345678910111213141516171819202122

IIIIII+*DDDDDDDD * UUUCRLF

*****– ........ ***

* ********

I: ID code character U: Unit symbol

1

)

*: Space CR: Carriage return

D: Digit or letter LF: Line feed

Example:

12345678910111213141516171819202122

N + 123.56 g CRLF

N + 123 . 5[6] g CRLF

1

) Depends on balance type; for example, not all units or characters are available on balances verified for use in legal

metrology.

*) Identification of non-verified digits:

Non-verified digits where e=d are identified by brackets (square) if you select the following setting:

Parameter settings: Communication mode: Universal printer (menu code 5 5 2); “SBI” menu setting

In the “SBI” setting (menu code 5 5 1), non-verified digits displayed are not automatically identified as such.

Be sure to take the steps or make the settings on the auxiliary device for this purpose.

57

Page 58

Special Codes

12345678910111213141516171819202122

Stat****************CRLF

H*

L*

*: Space H: Overload

L: Underload

Error Codes

12345678910111213141516171819202122

Stat*****Err*###****CRLF

*: Space # # #: Error code number

ID code

characters I Meaning

Stat Status

T1 Tare T1

N Net N

N1 Net N1

COMPxx Net-total: Component no.

T COMP Net-total: Total weighed in

Qnt Counting: Quantity

wRef Counting: Reference weight

nRef Counting: Reference sample quantity

Prc Weighing in percent: Percentage

Wxx% Weighing in percent: Reference weight

pRef Weighing in percent: Reference percentage

mDef Animal weighing: No. of measurements remaining

x-Net Animal weighing: Calculated average

58

Page 59

Data Input Format

You can connect a computer to your balance to send commands via the balance interface

port to control balance functions and applications.

The commands sent are control commands and may have different formats.

Each character must be transmitted according to the settings configured in the operating

menu for data transmission.

Format for Control Commands

Format 1: Esc ! CR LF

Format 2: Esc ! # _ CR LF

Esc: Escape CR: Carriage return (optional) ! #: Letters (characters) and numbers

!: Command LF: Line feed (optional) _: Underline

character

Command character Format 1:

! Meaning

K Weighing mode 1 (very stable conditions)

L Weighing mode 2 (stable conditions)

M Weighing mode 3 (unstable conditions)

N Weighing mode 4 (very unstable conditions)

O Block keys

P(A) key (print, auto print; activate or block)

R Unblock keys

S Restart/self-test

T (TARE) key

Z Internal calibration/adjustment

Command character Format 2:

!# Meaning

f0 Function key (F)

f1 Function key (CAL)

s3 (CF) key

x0 Perform internal calibration

x1 Print balance mode

x2 Print weigh cell serial number

59

Page 60

60

Synchronization

During data communication between the

balance and a connected device (computer),

messages consisting of ASCII characters are

transmitted via the interface. For error-free

data communication, the parameters for

baud rate, parity, handshake mode and

character format must be the same for both

units.

You can set these parameters in the

Setup menu so that they match those of

the connected device. You can also define

parameters in the balance to make data

output dependent on various conditions.

The conditions that can be configured are

listed in the descriptions of the application

programs.

If you do not connect a peripheral device

to the balance interface port, this will not

generate an error message.

Handshake

The balance interface (Sartorius Balance

Interface = SBI) has transmit and receive

buffers. You can define the handshake

parameter in the Setup menu:

– Hardware handshake (CTS/DTR)

– Software handshake (XON, XOFF)

Hardware Handshake

With a 4-wire interface, 1 more

character can be transmitted after CTS

(Clear to Send).

Page 61

61

Software Handshake

The software handshake is controlled via

XON and XOFF. When a device is switched

on, XON must be transmitted to enable

any connected device to communicate.

Data Output by Print Command

The print command can be transmitted

by pressing (A) or by a software command

(Esc P).

Automatic Data Output

In the “auto print" operating mode, data

is output to the interface port without

a print command. You can have data output automatically at defined print intervals,

with or without the stability parameter.

The length of a print interval depends on

the settings for “Adapting the filter"

(1 1 x) and “Time-dependent automatic

printing" (6 3 x).

If you select the auto print setting, data

will be transmitted immediately the

moment you turn on the balance. In the

operating menu, you can define whether

automatic printing can be stopped by

pressing (A).

Faster Output Speeds

If you require output speeds faster

than 10 Hz, please contact Sartorius for

information.

Page 62

Pin Assignment Charts

Female Interface Connector:

25-contact D-Submini (DB25S) with screw lock hardware

Male connector used (please use connectors with the same specifications):

25-pin D-Submini DB25S with integrated shielded cable clamp assembly