Page 1

Operators Handbook

BAEDCU3 - Rev. 4.6 - 0504

D C U 3 - S y s t e m

Digital Measurement and Control System for Fermentors

Page 2

Page 3

Operators Handbook DCU3 – System

Introduction

BAEDCU3 - Rev. 4.6 - 0504

Introduction

Sartorius BBI Systems´ digital measurement and control system for fermentors, the DCU3 – system, is

available as stand-alone unit for operation of Sartorius BBI Systems´ laboratory scale fermentors and

as a rack version for the measurement and control cabinets of pilot plant fermentors. All information

given in the handbook refer to the operation of these fermentors, unless otherwise specified. Above

this the DCU3-system can be applied as universal measurement and control system for fermentor

automation and for customized general measurement and control tasks.

This „Operator's Handbook“ describes all standard functions available with the software version 4.6 of

the DCU3 - system. In general the range of functions implemented for a specific fermentor is smaller

than the range that this manual describes. The DCU system can be adapted to the different fermentor

types by means of the software configuration and fermentor specific features.

Besides the standard configurations the DCU3 - system can have customized configura-

tions, as required for special applications. The description of such configurations can be

added to this document or can be combined into a project-specific document.

Design, installation, start-up and use of the fermentor system are shown in the extra operating manual

of this unit. More detailed technical information on the hard- and software structure, the system installation, etc., is given in the extra „Technical Manual DCU3 - system“. If the DCU3 - system should be

used together with a host computer the corresponding protocol for communication is described in the

manual „DCU-Host Communication“. Both these manuals are available on request.

The digital control system DCU3 is one example of Sartorius BBI Systems´ product program of sophisticated fermentation and peripheral laboratory equipment. For further information about this device and

our complete product program please contact the

Sartorius BBI Systems GmbH

Schwarzenberger Weg 73-79

D - 34212 Melsungen

Tel.: +49 (0) 56 61 - 71 34 00, Fax: +49 (0) 56 61 - 71 37 02

e-mail: info@sartorius-bbi-systems.com

WebSite http://www.sartorius-bbi-systems.com

or your local representative of Sartorius BBI Systems GmbH or Sartorius AG.

Printed in Germany

© Sartorius BBI Systems GmbH. This document describes the device at the time of it s publication. Modification s

of the equiment and changes of the related documentation are preserved. No part of the documentation shall be

changed or duplicated or reprocessed for other purposes by third parties without our written permission.

Printed in Germany

Page 4

Operators Handbook DCU3 – System

Introduction

BAEDCU3 - Rev. 4.6 - 0504

Page 5

Operators Handbook DCU3 – System

Contents

BAEDCU3 - Rev. 4.6 - 0504

Contents Page

Introduction

1 Design and Function 1 - 1

2 Operating Behaviour

2.1 Switching „off“ and „on“ 2 - 1

2.2 Mains Failure 2 - 1

2.3 Shut Down Function 2 - 2

2.4 Interlocking Functions 2 - 2

3 Function Selection and Inputs

3.1 Operating Terminal 3 - 1

3.2 Inputs 3 - 7

4 Start-Menü „Main“

4.1 General Notes 4 - 1

4.2 Process Information Provided by the „Main“ Menu 4 - 1

5 Main Function „Calibration“

5.1 General Note 5 - 1

5.2 pH - Calibration 5 - 2

5.3 pO2 - Calibration 5 - 4

5.4 Redox - Calibration 5 - 5

5.5 Calibration of Turbidimetry Measurement 5 - 6

5.6 Totalizer for Pumps and Valves 5 - 8

5.7 Calibration of a Balance System 5 - 10

5.8 Flow Calibration 5 - 11

6 Main function „Control Loops“

6.1 Equipment and Functional Principles 6 - 1

6.2 Selection of Controller 6 - 2

6.3 Controller Operation in General 6 - 3

6.4 Parametrization of Controllers, in General 6 - 4

6.5 Temperature Controller 6 - 7

6.6 Stirrer Speed Controller 6 - 9

6.7 Airflow Controller 6 - 10

Page 6

Operators Handbook DCU3 – System

Contents

BAEDCU3 - Rev. 4.6 - 0504

6.8 pH - Control Function Operating as PID - Controller 6 - 11

6.9 pO2-Control Methods 6 - 12

6.10 pO2 - Cascade Controller with 3 Servo Controllers 6 - 12

6.11 pO2 - Cascade Controller with 4 Servo Controllers 6 - 16

6.12 pO2-Gasmix Controller / O2 – Enrichment 6 - 18

6.13 pO2 - Gasflow Ratio Controller 6 - 19

6.14 Oxygen (O2) – Enrichment Using 2 Massflow Controllers 6 - 22

6.15 Foam Controller 6 - 24

6.16 Dosing Pump Controller 6 - 26

6.17 Level Controller 6 - 27

6.18 Weight Controller 6 - 29

6.19 Pressure Controller 6 - 30

6.20 Gravimetric Dosing Controller 6 - 31

6.21 Setpoint Profiles 6 - 33

6.22 Timers 6 - 35

6.23 Alarm Limits of Process Values 6 - 37

6.24 Alarms of Digital Inputs 6 - 39

7 Main function „Batch Control“

7.1 General 7 - 1

7.2 Sequences 7 - 1

7.3 Process Time 7 - 5

8 Main Function „Recipes“

8.1 Overview 8 - 1

8.2 Recipe Selection 8 - 1

8.3 Controller Parameters in Recipes 8 - 3

8.4 Setpoint Profiles 8 - 4

8.5 Timers in Recipes 8 - 5

8.6 Process Value Alarms in Recipes 8 - 6

8.7 Digital Input Alarms 8 - 7

9 Main function „Maintenance“

9.1 Overview 9 - 1

9.2 Manual Operation in General 9 - 2

9.3 Manual Operation for Digital Inputs 9 - 2

9.4 Manual Operation for Digital Outputs 9 - 4

9.5 Manual Operation of Analog Inputs 9 - 6

Page 7

Operators Handbook DCU3 – System

Contents

BAEDCU3 - Rev. 4.6 - 0504

9.6 Manual Operation for Analog Outputs 9 - 8

9.7 Settings of Measurement Ranges 9 - 10

9.8 Connection of External Devices 9 - 11

9.9 Host Interface 9 - 12

9.10 Peripheral Interface 9 - 14

9.11 Balance Interface 9 - 15

9.12 System Settings 9 - 16

9.13 Service / Diagnostics 9 - 17

10 Main Function „Documentation“

10.1 Selection Menu 10 - 1

10.2 Report Printer 10 - 1

10.3 Recorder Configuration 10 - 3

11 Main Function „Password“ 11 - 1

12 Main Function „INFO“ 12 - 1

13 Alarms

13.1 Alarm Messages 13 - 1

13.2 Alarm Menu 13 - 2

14 Supplement

14.1 Alarms, Meanings and Remedial Measures (Troubleshooting) 14 - 1

14.2 Trouble Shooting for the DCU-System 14 - 5

14.3 Interlocking Functions 14 - 5

14.4 Abbreviations 14 - 6

14.5 Fermentor - Specific Adjustments of Balance Systems 14 - 8

14.6 Arrangement and Assignment Plans 14 - 9

14.7 Declaration of Conformity with EC-Directives, Standards and

Technical Specifications 14 - 9

Page 8

Operators Handbook DCU3 – System

Contents

BAEDCU3 - Rev. 4.6 - 0504

Page 9

Operators Handbook DCU3 – System

1., Design and Function

BAEDCU3 - Rev. 4.6 - 0504 1 - 1

1 DESIGN AND FUNCTION

The Digital Measurement and Control System DCU3 has been especially developed for the automation of fermentor systems. The hardware is based on an industrial 32 bit VME bus micro processor

system. All measurement and control functions are implemented in the software. The software is

stored on a PC-card, which can easily be replaced for extensions of the system by new versions.

For the fermentors of the BIOSTAT

®

series the Sartorius BBI Systems GmbH offers a broad range of

standard configurations of the DCU3 – system, which consider the features of the individual type of

fermentor. However, the extent of functions implemented for a delivered system will always depend on

the specifications of the customer, as agreed prior to ordering of the fermentor system. Therefore even

specific customized configurations are possible.

Standard functions are data acquisition, sensor calibration, alarm monitoring and control of operation

conditions. Additional software modules provide control of process conditions by changing parameters

depending on running time and state of the process. This includes setpoint profiles for controllers,

timer functions for pulsed actuators, dosing counters, etc. Complete sets of process parameters may

be predefined as recipes to allow performing of reproducible process sequences.

The DCU3 can be integrated into hierarchical automation systems via its remote interfaces. A host

computer system can be connected, such as the proven MFCS-Systems, for instance, providing functions like graphical visualization of processes, data acquisition and storage, process protocols, etc.

Page 10

Operators Handbook DCU3 – System

1., Design and Function

BAEDCU3 - Rev. 4.6 - 0504 1 - 2

Page 11

Operators Handbook DCU3 – System

2., Operating Behaviour

BAEDCU3 - Rev. 4.6 - 0504 2 - 1

2 OPERATING BEHAVIOUR

The DCU3 - system stores all parameters which are adjustable by the operator (setpoint, calibration

parameters, profiles, etc.) in a battery buffered memory. Hence these parameters are still available

when the DCU3 system is switched off and restarted again.

For enabling the outputs of the DCU3 - system and of several system functions, which directly act on

the fermentor system, 4 categories of switching-off or power failure, respectively, are differentiated:

1. Switching „off“ and „on“ using the mains switch at the front panel (see pos. 3 in fig. 1-1).

2. Shut down due to mains failure.

3. Emergency cut-off via the „SHUT-DOWN“-key at the operating terminal or using the mains

switch of the supply unit or cabinet of the fermentor (see BIOSTAT

®

MD, ED or BIOSTAT®

C-DCU3, UD, for instance).

4. Interlocking functions for system outputs.

2.1 Switching „off“ and „on“

The DCU3 - system is switched-on or off, respectively, via the mains switch on the front panel. After

being switched-on (again) the DCU3 will start at (return to) a defined state of operation:

All controllers are „off“, a ctuators are in rest position

All timers are „off“ (stopped )

No recip e loaded, no program (sterilization for example) active

2.2 Mains Failure

In the case of a (mains) power failure, after being restarted, the DCU3 - system continues its activities

as follows:

Controllers ru n on with the setpoint, which has been adjusted at the time of the power failure

Timers and setpoint profiles will be continued

Sequence s, such as sterilization programs, and recipes will be continued

The operator can set a maximum power failure time (FAILTIME) in the „maintenance“ menu. This is a

specific feature of the DCU3 - system. When the power failure lasts longer than the preset FAILTIME,

then the DCU3 - system behaves as if being switched-off with the mains switch, i.e. the system will be

shut down and set to a defined basic state.

After a power failure the system generates the message „Power Failure“, together with the time and

duration of the failure. If the maximum power failure time has expired (see „FAILTIME“), the system

displays the message „Pwf stop ferm“ with time and duration of the failure. See also the description of

the „Alarm messages“ in the supplement.

Page 12

Operators Handbook DCU3 – System

2., Operating Behaviour

BAEDCU3 - Rev. 4.6 - 0504 2 - 2

2.3 Shut Down Function

The shut down function can be released by :

Enabling the „SHUT DOWN“ key on the operating terminal and

Enabling the mains switch of the fermentor (located on the supply unit or cabine t).

In the shut down state all outputs are switched over to their predefined safe state. Other active functions of controllers, timers, profiles, recipes and sterilization are not effected.

During the SHUT DOWN state you can change any of the active functions, as required.

If the SHUT DOWN state is enabled, the DCU3 - system displays the alarm message „Shut

Down DCU“ or „SHUT DOWN FERMENTOR“

Pressing the „SHUT DOWN“ key again or restarting the fermentor supply unit with the emergency

switch terminates the shut down function. Then all outputs of the DCU are reactivated.

2.4 Interlocking Functions

Interlocking functions trigger the outputs for functions which are important for operational safe ty, i.e.:

Fixed safety functions which cannot be changed by the user.

User-definable safety functions.

An interlocking function switches certain outputs of the DCU3 over into their predefined safety state.

However, this will not effect the course of controllers, timers, profiles, recipes and of the sterilization.

For details about specific functions see section „Interlocking functions“ in the supplement.

If the cause for release of an interlocking function is no longer present, the safety state of the corresponding output will be cancelled and the output returns into its operating state.

The safety state of an output is the same as the state during SHUT DOWN.

The state of the output displayed in the menu „MAINTENANCE, MANUAL OPERATION,

DIGITAL OUTPUTS“ and „ANALOG OUTPUTS“ is „lock“.

Page 13

Operators Handbook DCU3 – System

3., Function Selection and Inputs

BAEDCU3 - Rev. 4.6 - 0504 3 - 1

3 FUNCTION SELECTION AND INPUTS

3.1 Operating Terminal

The DCU3 - system has an especially developed touch screen terminal for display of all process parameters and for operation of the entire unit. This „touch terminal“ has integrated „touch keys“ where

the operator can select the menus and the related subfunctions, enter data and select and switch-over

the modes for fermentor operation. In general the terminal is operated simply by pressing the screen

at the position of the displayed keys.

The touch terminal is adjustable to provide an optimum angle of vision:

DCU-Tower :

BIOSTAT

®

B-DCU

1. Unscrew the locating screw of the support at the rear of the

terminal a little.

2. Push the terminal backward at its upper edge or pull until

the display can be read best. Tighten the screw again.

DCU3-System in table top housing:

BIOSTAT

®

MD-DCU3, Q-DCU-

3, C/CT-DCU3

1. Push the locking device on right hand of the terminal (see

push button 4 in fig. 1-1)

2. Pull the terminal at its lower edge or push backward, until

you achieve an angle where the display can be read best.

3. Release the locking device to fix the arrangement.

Rack version of DCU3 systems :

BIOSTAT

®

D-DCU3, customized

pilot- and production fermentors

The possible way of setting the angle depend s on the

mounting of the terminal in the rack.

3.1.1 Structure of the Touch Screen Display

Page 14

Operators Handbook DCU3 – System

3., Function Selection and Inputs

BAEDCU3 - Rev. 4.6 - 0504 3 - 2

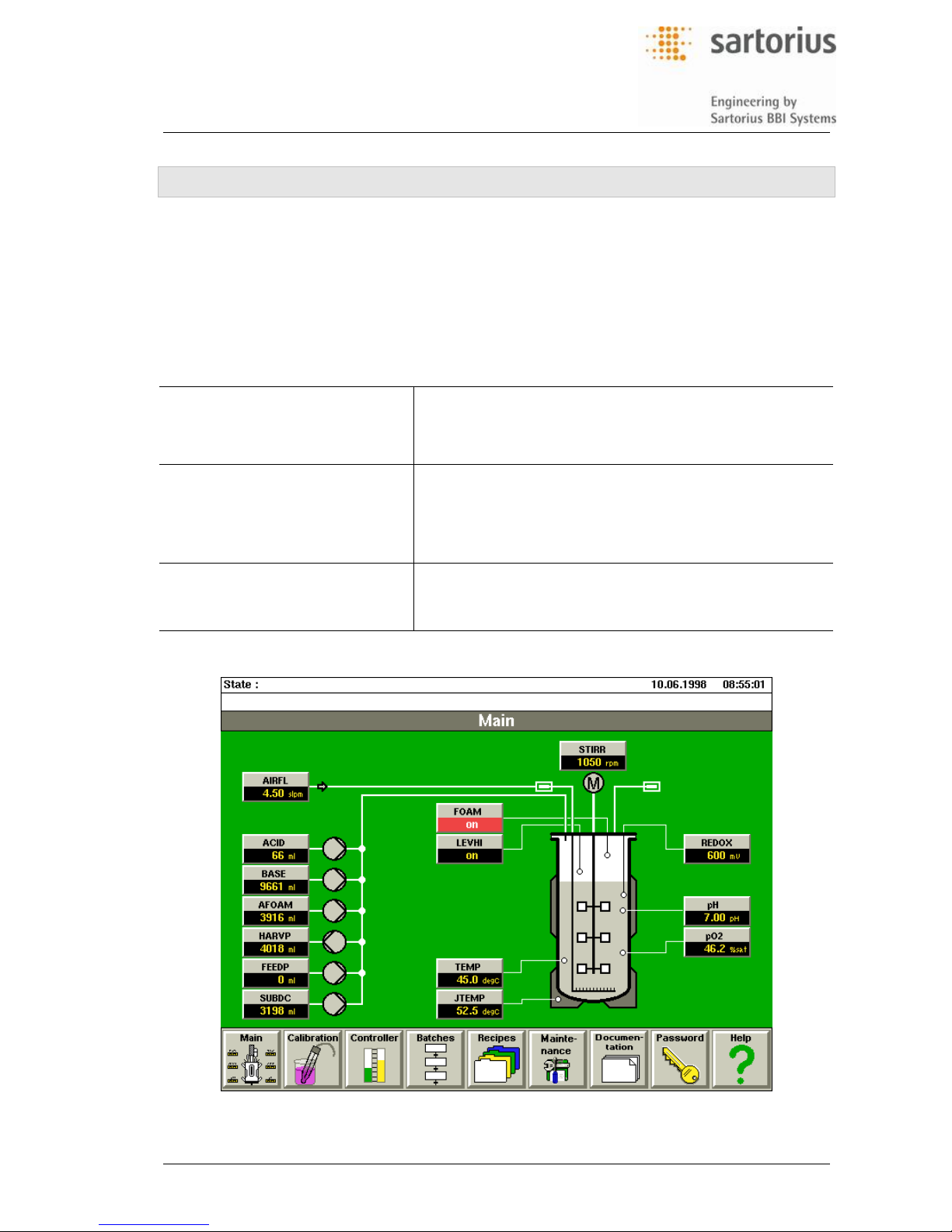

Structure of the Touch Screen Display, on the page above shown for the „Main“ menu:

1. line: Status line:

TAG Used for

hhhh:mm Display and Input of process time

Fermentation (etc.) Display of operating state. Possible displays are:

− Fermentation: System is in „Fermentation“ state

− Sequence: System runs a sequence

− Recipe 1..4: System runs a recipe (1..4)

18.01.00 14:03:11 Display of actual date and time in formate:

dd.mm.yyyy hh:mm:ss

2. line: Alarm line, display of alarms (showing the latest alarm)

3. line: name of active function in the workin g area

Workin g area: display of schematic setup of fermentor system and peripheral equipment;

– MAIN 2 : next „Main“-page

– the items displayed depend on the active function a nd can include symbols for devices,

process values, parameters, modes and settings;

– the displays of the items are designed as touch keys for direct access to submenus for

selecting functions and entering parameters.

Lowest line: Main function keys (also designed as touch-keys) for selection of submenus

and subfunctions, where parameters should be entered and operating modes should be set.

Page 15

Operators Handbook DCU3 – System

3., Function Selection and Inputs

BAEDCU3 - Rev. 4.6 - 0504 3 - 3

3.1.2 Function al Keys of the Working Area

For a selected function the lowest line of the working area can have additional touch keys, which are

especially assigned to this function and allow for direct access to the corresponding submenus.

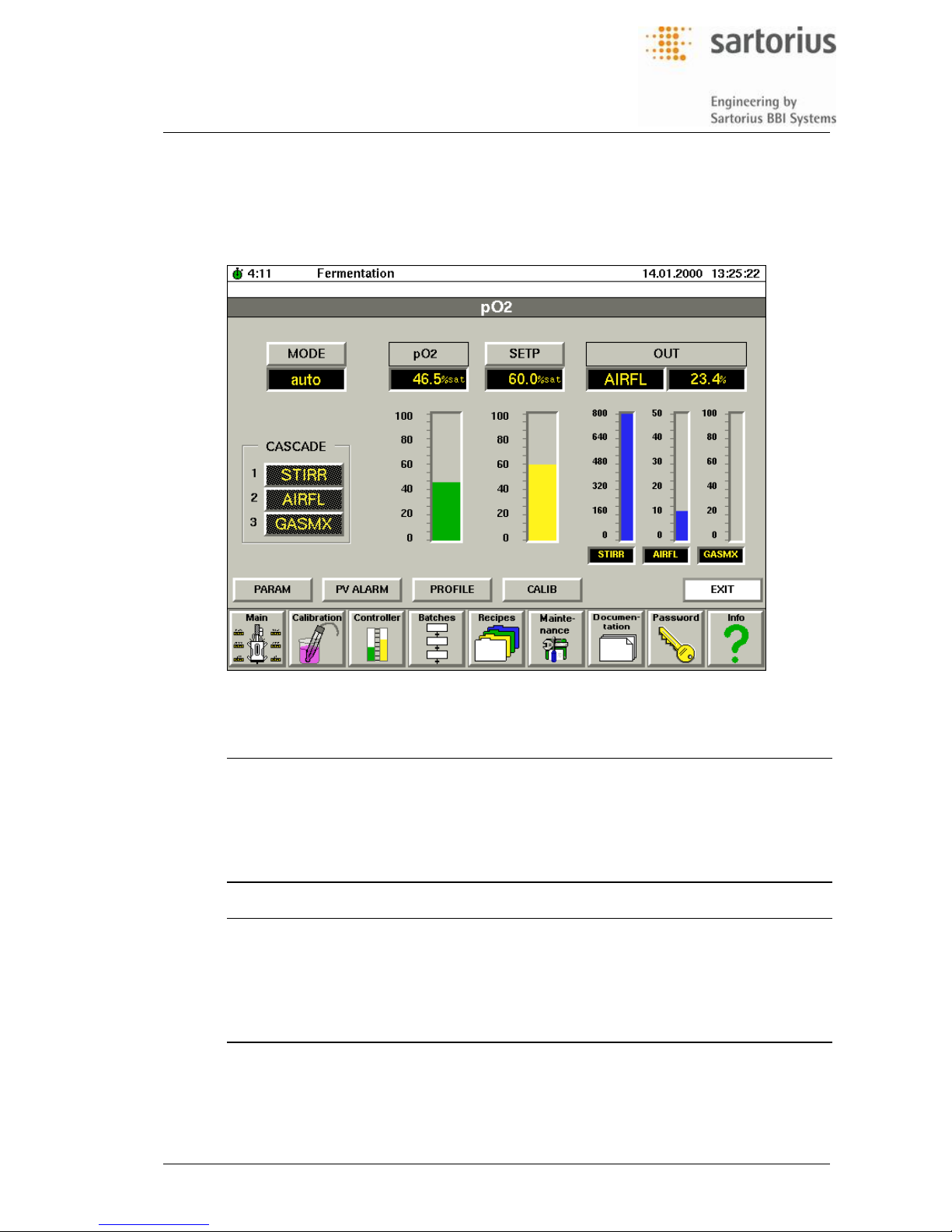

Example: Operating display of the pO

2

- controller with touch keys:

The following touch keys for function selection are available in the working area of the oper-

ating displays:

Selection key Function

Exit Closes the actual display

PARAM Request for display of related parameters

PV - Alarm Request for display of related process value alarms

PROFILE Request for display of related setpoint profiles

CALIB Request for display of related calibration function

Available keys not shown in this example are

CLOOP Selection of the related controller menu

CLOOPx Selection of additional controller displays

MAINx Request for display of related process overviews

TIMER Request for display of related timer functions

DI ALARM Request for display of related digital input alarms

Page 16

Operators Handbook DCU3 – System

3., Function Selection and Inputs

BAEDCU3 - Rev. 4.6 - 0504 3 - 4

3.1.3 Selection of Menus and Entering of Parameters

The operation of the DCU3 - system is organized systematically. Related tasks of fermentor operation

are combined in functional groups - the „main functions“ listed below. A main function can be directly

activated at any time during the running process from any submenu by pressing the corresponding

main function touch key at the screen.

Main function Display, use

Main Graphic overview of the entire fermentor system showing the most important

process parameters and allowing for direct access to the related functions.

Calibration Calibration of sensors and pumps, taring of balance systems

Control Loops Operation of the controllers and related setpoint profiles and timers

Batch Control Operation of serial steps, batch processes, etc., such as sterilization runs

Recipes Operation of 4 recipes with preset controller parameters, setpoint profiles, tim-

ers and alarm parameters

Maintenance Manual access to inputs and outputs, measurement ranges of process values,

parameters of remote systems (such as host computers, balance systems) and

to the maintenance (service) functions

Documentation Operation of recorders and printers for documentation of the process

Info Information about the installed software / general notes

There are two possible methods to select a menu, step forward to a subfunction and enter parameters. As an example here are the possible methods for setpoint adjustment of the stirring speed:

Stepping through the menu tree as known from the former DCU1- and DCU2- systems:

1. Select the main function „Control Loops“ by pressing the touch key

2. Select the „Stirrer“ controller from the overview of controllers

3. Adjust the setpoint

Enabling the data entry function directly from the main menu. This is accomblished by object

(based) linking of the actual stirrer speed display in the main menu to the related controller

functions, i.e. „stirrer controller, setpoint profile and alarm limits“:

4. Press the „Stirrer“ - touch key in the working area of the main menu. The display directly

switches over to the menu of the stirrer controller.

5. Adjust the setpoint.

Page 17

Operators Handbook DCU3 – System

3., Function Selection and Inputs

BAEDCU3 - Rev. 4.6 - 0504 3 - 5

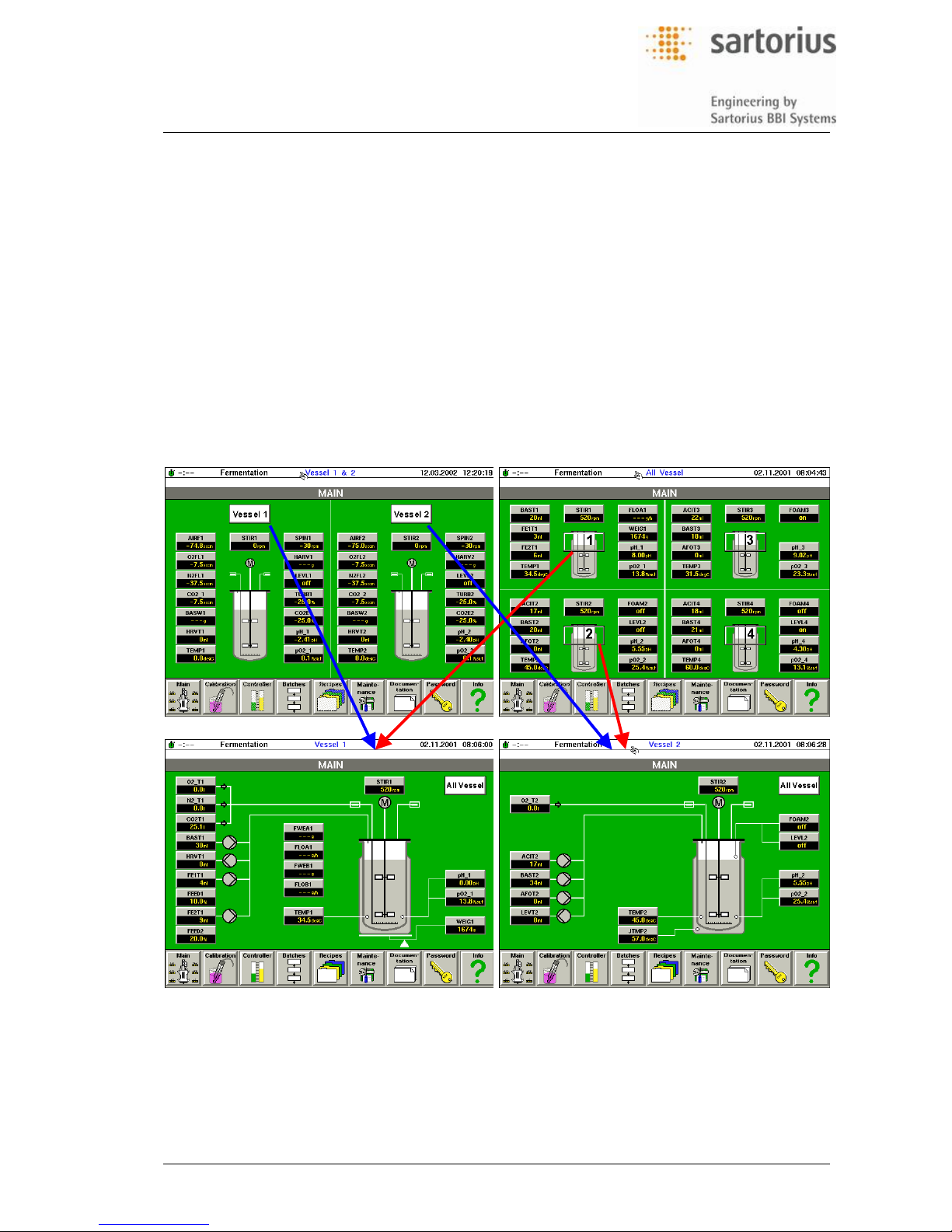

3.1.4 „Tou ch keys“ in the Menu „Main“

After switching on of the system the graphical overview in the menu „Main“ provides a schematic display of the main functional elements of the individual fermentor system, together with the most import

process parameters and the „touch keys“ for selection of the related functions:

Only for the single unit at fermentor systems with one culture vessel

As an overview of all subunits at fermentor systems with 2…4 culture vessels

At multible vessel fermentor systems the main menus of the subunits can be accessed as follows:

Via the touch key integrate d in the overview display showing the vessel no. of the subunit

(only for DCU3 systems available from about April 2002 on and as far as implemented).

Via the direct function key CHANGE UNIT

Menu „Main“: Direct access to the main menus of subunits at fermentors with 2..4 culture vessels:

Example: BIOSTAT

®

B-DCU twin Example: BIOSTAT® B-DCU quattro

The touch key „All vessel“ can be used to return to the overview display of all units.

The direct function key CHANGE UNIT cyclically switches over the displays of the main menus of all

units and the individual subunits:

All vessels v essel 1 vessel 2 (vessel 3, 4, if available) all vess els

Page 18

Operators Handbook DCU3 – System

3., Function Selection and Inputs

BAEDCU3 - Rev. 4.6 - 0504 3 - 6

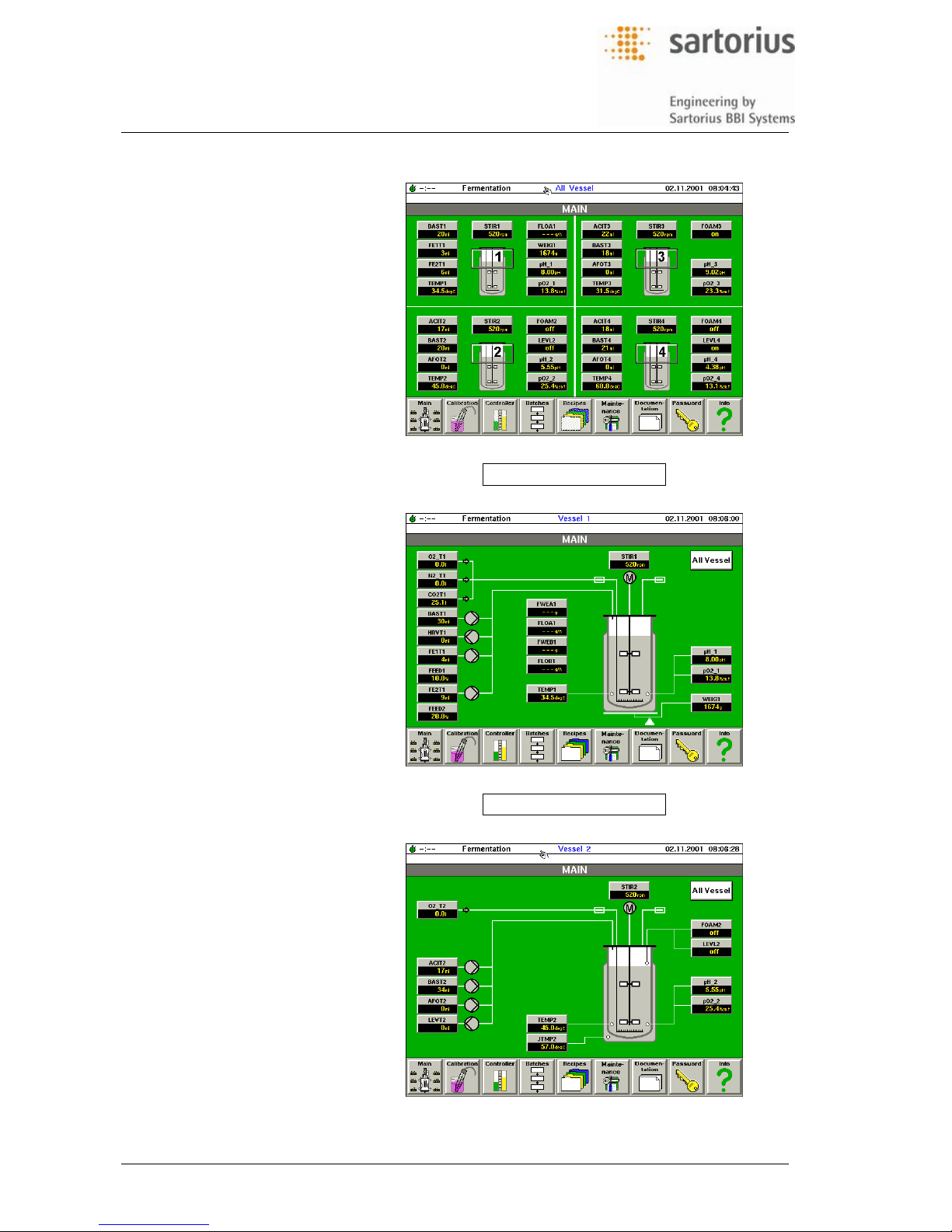

Switching over the main menu displays for 2…4 culture vessels via

direct function key CHANGE UNIT:

CHANGE UNIT

CHANGE UNIT

.....

Page 19

Operators Handbook DCU3 – System

3., Function Selection and Inputs

BAEDCU3 - Rev. 4.6 - 0504 3 - 7

3.1.5 Direct Function Keys

The direct function keys on right hand of the „Touch Terminal“ allow for direct access to the system:

SHUT DOWN : Pressingthis key sets all analog and digital outputs into a safe state. An active

SHUT DOWN state is indicated by lighting LED in the key. Repeatedly pressing the key

cancels (releases) the SHUT DOWN state and the system returns to its previous state.

ACK : If an alarm message occurs, a red LED in the ACK - key lights. Pressing the ACK - key then

enables the alarm menu on the display.

REM : Pressing the REMote control key allows for the transmission of data from the host to the

DCU system. Effective only if a host computer is connected to the DCU-system.

CHANGE UNIT : Switching-over of the operating terminal. Applicable for DCU3-system which are

prepared for controlling several fermentors/culture vessels.

3.2 Inputs

3.2.1 Numerical and Non-numerical Inputs

Example for entering numerical inputs, shown here for the temperature setpoint:

1. Press either the touch-key „Temp“ in the working area of the „main“ menu or the key “SETP”

in the menu TEMP Control Loop

A touch key pad fades in for data input.

2. Enter the new setpoint. For this consider the

permissible setpoint range, as indicated.

3. At erroneous inputs delete the entry with CANCEL and enter the correct numbers.

4. Confirm the input with the „Ok“-key.

5. The system closes automatically the touch key

pad. The new setpoint is displayed.

Input of operating mode, i.e. controller modes:

1. Press the touch key „MODE“;

a window with the selectable modes fades in.

2. Press the touch key of the intended mode, i.e.

„off“.

3. At selection of a wrong mode, delete with CANCEL and select again the correct mode

4. The selection window closes and the display

shows the new mode.

Page 20

Operators Handbook DCU3 – System

3., Function Selection and Inputs

BAEDCU3 - Rev. 4.6 - 0504 3 - 8

Input of text:

1. Enter the text with a max. number of letters

(Range).

2. At wrong inputs delete the entry using the „<-“

key or CANCEL.

3. Confirm the Entry with „Ok“. The system closes

the keypad and displays the text.

Selection boxes (slide r): The slider can be moved as follows:

1. Pressing the arrow key

2. Moving the white zone within the slider

3. Pressing the shaded zone at the relative position of the table, which should be accessed

Special Notes

What do touch keys indicate, whose label appears in black & white dithered („light“) letters?

If a controller´s mode is set to „auto“, for instance, the data entry for the controller output is

locked. This locking of an entry against inputs is indicated on the „OUT“ key. The letters

then are displayed in black & white dithering („light“).

3.2.2 Password - System

System settings and functions, that are restricted for use by authorized personnel only, are protected

by a password. Among others these are, for instance, the setting of controller parameters (such as

PID), the setting of interface parameters and the manual operating mode.

For more detailed information refer to section “Main function “Password””.

Page 21

Operators Handbook DCU3 – System

4., Start-Menü „Main“

BAEDCU3 - Rev. 4.6 - 0504 4 - 1

4 START-MENÜ „MAIN“

4.1 General Notes

The „Main“ menu is displayed after switching on the DCU3 - system. With the new „object-based“ display of entries and the direct selection of submenus and functions for data input and mode selection,

the main menu is the control center for operation during a fermentation run.

The schematic display of the culture vessel together with the connected peripheral assemblies, the

symbols for stirrers, pumps, totalizers, balance system and the location of the electrodes facilitates the

overview over the state of the process parameters. Above this it is the starting point for easy access to

the submenus and subfunctions for inputs and selections.

4.2 Process Information Provided by the „Main“ Menu

The main menu displays the process values together with schematics of the related component parts

of the fermentor system:

Measured values for pH, pO

2

, foam, etc.;

Inputs of external actuators, such a s motor control, massflow controller;

Processed values, such as dosing volumes of pumps, totalizers, calculated values of arith-

metic functions, etc.;

Signals of external device s connected to the DCU3 - system, such as a balance system;

The extent of displayed entries, process values and parameters depends on the configuration of the

DCU3 - system for the related fermentor system. The table on next page gives an overview on commononly applied tags and entries.

Page 22

Operators Handbook DCU3 – System

4., Start-Menü „Main“

BAEDCU3 - Rev. 4.6 - 0504 4 - 2

4.2.1 Alarms

If a process value exceeds its alarm limit or if a device is switched over to an alarm state the

backround color of the corresponding symbol changes to red (in this „laser-printed“ manual

shown light-grey, see example for the entry of foam measurement).

4.2.2 Invalid Process Values

If a process value is „invalid“ the display changes to „---„, see example „flow“:

4.2.3 Direct Function Keys and Headline Text at the Touch Display

Direct Fun ction keys on the touch display have the background colour grey/white.

Headline texts (background colour white) label indicate a correlation of the functions of the

subsequent keys

Page 23

Operators Handbook DCU3 – System

5., Main Function „Calibration“

BAEDCU3 - Rev. 4.6 - 0504 5 - 1

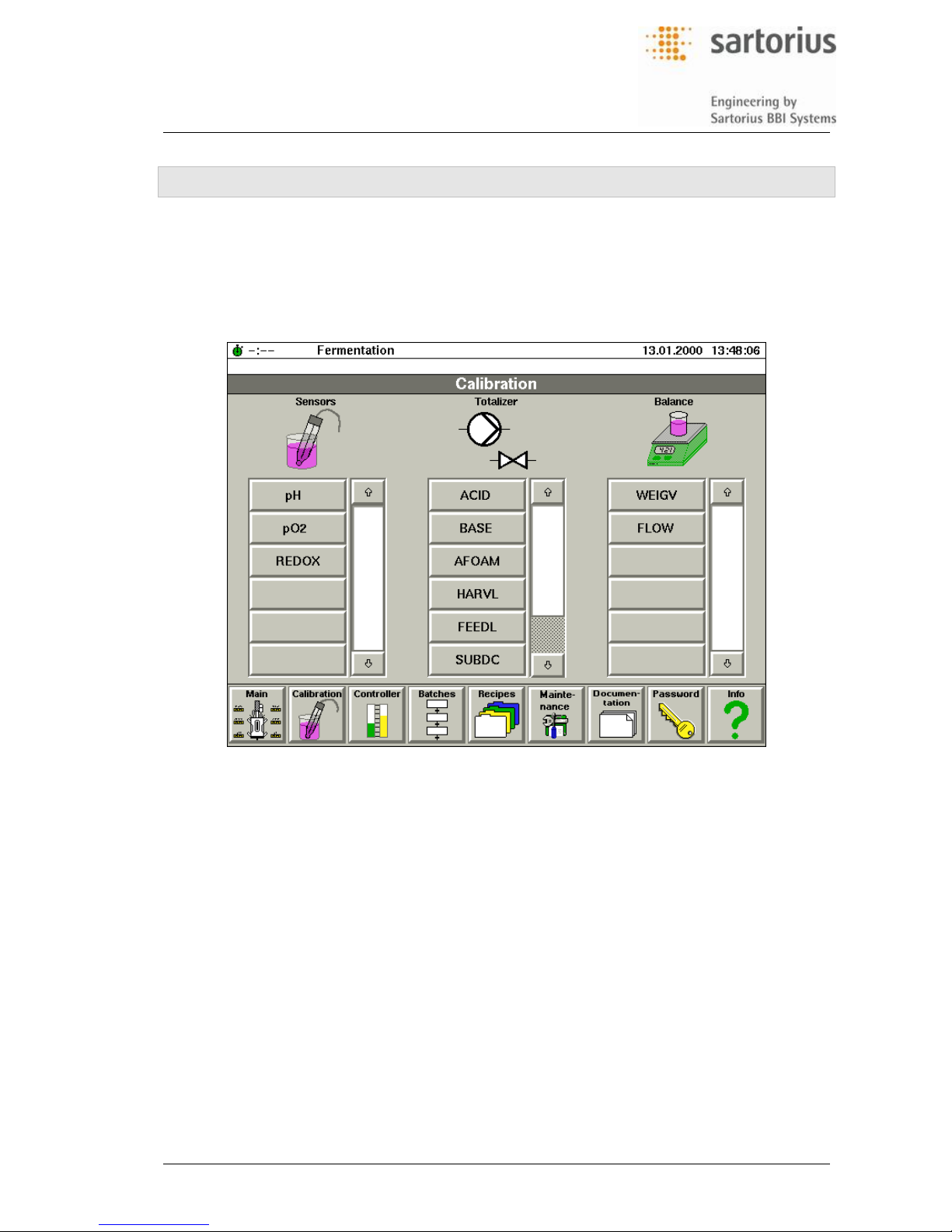

5 MAIN FUNCTION „CALIBRATION“

5.1 General Note

All calibration functions required for routine operation of the fermentor can be executed using the main

function „calibration“. You can select the following functions via the corresponding selection menu:

Selection menu „Calibration“:

The entries refer to the following functions:

– „Sensors“ : calibration of the electrodes using calibration buffers and standard conditions

– „Totalizer“ : calculation of the delivery of the addition agent pumps for dosing counters

– „Balance“ : the functions required for (pre)setting of balan ce systems, such as zero taring

and tare correction

You will enter all inputs at the touch terminal. Context based information displayed on the

terminal will guide you through the individual menus, telling you which inputs and selections

are required. The DCU3 - system automatically adapts the related (measured or calculated)

process values to the settings resulting from the calibration.

The calibration parameters will be stored when the DCU3 - system is switched off. Hence

the DCU3 - system will use these settings again for the calculation of parameters, when it is

restarted for continueing a process or for a new process, until the calibration is done again.

Page 24

Operators Handbook DCU3 – System

5., Main Function „Calibration“

BAEDCU3 - Rev. 4.6 - 0504 5 - 2

5.2 pH - Calibration

The pH electrode is calibrated by a two-point calibration using liquid buffers. The calibration is done

before the electrode is installed in the culture vessel. For details about preparing of the pH-electrode

and handling during calibration see the operating information delivered by the manufacturer. For details about mounting the electrode into the culture vessel, see the fermentor´s operating manual.

The calibration determines the „zero drift“ and „slope“ of the electrode. The measured pH-value is calculated from the electrode voltage using the Nernst equation, considering the „zero drift“, „slope“ and

„temperature“. During calibration the temperature is entered manually. For pH-measurement during

the process temperature effects are compensated via the measured temperature in the fermentor.

The impact of heat during the sterilization can cause a zero drift of the electrode. To compensate for

such effects the DCU3 - system allows to recalibrate the pH-electrode during the process. You can

measure the pH-value in a sample taken from the fermentor and enter this value into a corresponding

menu. The software recalculates the zero drift and displays the corrected „in-situ“ pH-value afterwards.

The operating display for the pH - electrode shows the pH value, the electrode voltage and the electrode parameters „zero drift“ and „slope“. Thus the functioning of the electrode can be easily checked.

5.2.1 Operating Display

Tag Entry Displayed value or function, required input

pH pH Display of measured pH value,

input of pH-value measured in sample for recalibration

ELEC mV Display of measured electrode voltage (raw signal)

TCOMP Display “temperature compensation”

TEMP Display of temperature for temperature compensation

ZERO mV Display of zero drift

SLOPE mV/pH Display of slope

Start Calibration Enabling the calibration function

Start Recalibration Enabling the recalibration function (during the process)

Page 25

Operators Handbook DCU3 – System

5., Main Function „Calibration“

BAEDCU3 - Rev. 4.6 - 0504 5 - 3

Additional touch keys, tags and entries displayed depending on the selected function:

Tag Entry Displayed value or function, required input

TMPCO degC Input of temperature for manual temperature compensation

BUFFZ pH Input of pH-value of zero buffer

− note pH-value on the buffer bottle for the actual temperature

BUFFS pH Input of pH-value of slope buffer

− note pH-value on the buffer bottle for the actual temperature

5.2.2 Calibration

The pH - electrode is calibrated before installation into the culture vessel, e.g. prior to the sterilization.

Tip: Since the heat impact during the sterilization and chemical compounds of the culture me-

dium may effect the measurement characteristics of the electrode, it must be calibrated and

checked for proper function regularly (i.e. prior to any new fermentation run).

1. Start the calibration routine by pressing the „Start Calibration“ touch key.

2. Follow the instructions given in the related submenus.

5.2.3 Recalibration

Via these steps you can adapt the pH-measurement function to changing measuring char-

acteristics of the electrode, as it may be caused by heat impact during the sterilization or by

chemical reactions of the electrolyte with the culture medium, for instance:

1. Measure the actual pH-value in a sample taken from the running fermentation, using conventional pH-measuring techniques.

2. Start the calibration by pressing the „Start Recalibration“ touch key.

3. Follow the instructions given in the related submenus.

The DCU-system automatically recalculates the zero drift caused by the sterilization and

displays the corrected pH-value.

5.2.4 Special Notes

If necessary the values for „zero drift“ and „slope“ can also be entered directly in the corre-

sponding sections of the display.

The electrode has a restricted maximum lifetime which depends on the operating conditions

and the application. The electrode should be serviced or replaced, whenever the functional

check and the calibration indicate a malfunctioning.

The pH - electrode must be serviced or replaced if :

– the zero drift is beyond the range of -30 ...+30 mV

– the slope is beyond the range of 56...59 mV/pH

You'll find specific information about recommended service periods and estimated lifetime of

the electrode in the manufacturer´s documentation included in the delivery of the electrode.

Depending on the type of fermentor and the delivered pH-electrode, the operation and main-

tenance measures required for the electrode may differ from the information herein. You'll

find more detailed information about proper handling of the electrode during calibration and

installation into the culture vessel in the Operating Manual of the fermentor.

Page 26

Operators Handbook DCU3 – System

5., Main Function „Calibration“

BAEDCU3 - Rev. 4.6 - 0504 5 - 4

5.3 pO2 - Calibration

The pO2 - electrode is calibrated in terms of percentage oxygen saturation, „% pO2“. The calibration is

a two-position calibration. In a fermentor the oxygen-free culture medium is the zero reference and the

medium saturated with oxygen is the „100 % pO

2

“ - reference. The pO2-electrode is calibrated while it

is installed in the culture vessel and after the sterilization. Therefore the calibration considers possible

interferences resulting from heat impact or chemical effects during sterilization.

In in-situ sterilized culture vessels you can enter the current of the electrode measured at

the end of the sterilization cycle as zero reference of the electrode.

If it is impossible to measure the zero current before air is introduced, you can connect a ni-

trogen source to the air input and gas the vessel with oxygen-free nitrogen to replace the

oxygen dissolved in the medium.

The slope can be measured after gassing the medium with air (or gas mixtures containing

oxygen) at the operating conditions intended for the process. During the process the DCU system calculates the actual pO

2

considering the zero reference, slope and temperature.

The structure of the operating display for calibration of the pO

2

-electrode is nearly the same as for the

pH-calibration. See the display on your DCU - system for details or refer to the pH - calibration display.

The display shows the „pO

2

-saturation“ (% pO2), the actually measured electrode current, the actual

temperature and the zero and slope current together with the calibration conditions. This, in addition,

allows a simple function control of the pO

2

-electrode.

5.3.1 Calibration

5.3.1.1 Zero Calibration

1. Before starting the zero calibration: sterilize the vessel (i.e. run the sterilization cycle at insitu sterilizable fermentors) or

– connect a supply of oxygen-free nitrogen and ga s the medium until any dissolved oxygen

is exhausted.

2. Inititate the calibration of the electrode´s zero via „Start ZERO Calibration“. Follow the instructions given in the calibration menu.

If the displayed zero current (ZERO: ....) is not in the range of 0 ... +10 nA, the pO

2

-

electrode must be checked and serviced.

5.3.1.2 Calibration of Slope

1. Gas the medium with air (or the intended gas mixture containing oxygen) at the conditions

(flow rate, pressure, temperature) intended for optimum oxygen supply. A constant electrode current will indicate that the medium is saturated with oxygen.

2. Inititate the slope calibration via „Start SLOPE Calibration“ and follow the instructions given

in the calibration menu.

If the measured current re mains below 30 nA, the electrode must be checked and serviced.

5.3.2 Special Notes

At a first use or at any time the pO

2

-electrode has been disconnected from the amplifier for

more than 5 ... 10 min. it must be polarized. This polarization takes at least 6 h (the time will

be shorter, if the electrode is disconnected for only a few minutes). See information in the

Operating Manual of the fermentor or in the documentation delivered with the electrode.

If necessary the „Ze ro“ and „Slope“ can be entered manually into the corresponding fields.

Page 27

Operators Handbook DCU3 – System

5., Main Function „Calibration“

BAEDCU3 - Rev. 4.6 - 0504 5 - 5

5.4 Redox - Calibration

The Redox calibration is in fact a functional check. You will measure a calibration buffer and compare

the measured value with the reference indicated on the buffer bottle. If these values are different, the

Redox can be entered manually. The DCU - system then calculates a corresponding correction factor.

5.4.1 Operating Display

Tag Entry Displayed value or function, required input

REDOX mV Display of combined electrode voltage

CHECK mV Display of combined electrode voltage of last calibration

Start Check Electrode Enabling calibration of the Redox electrode

Additional touch keys, values and functions available in this display:

REFBU mV Enter reference voltage of redox buffer

5.4.2 Functional Check

The electrode function is checked before it is mounted into the culture vessel and therefore prior to the

sterilization. Since the heat impact of sterilization or chemical reactions with compounds of the culture

medium may effect the measuring characteristics of the electrode its function should be checked regularly, i.e. prior to any next use and, if wrong operation is suspected, after a fermentation run.

1. Place Redox electrode in a beaker filled with the reference buffer

2. Enable functional check via „Start check electrode“. Follow the instructions of the menu.

5.4.3 Special Notes

If the measured buffer Redox and the value on the buffer bottle deviate by more than 6 mV

(about 3%) the electrode must be serviced. See documentation delivered with the electrode.

Page 28

Operators Handbook DCU3 – System

5., Main Function „Calibration“

BAEDCU3 - Rev. 4.6 - 0504 5 - 6

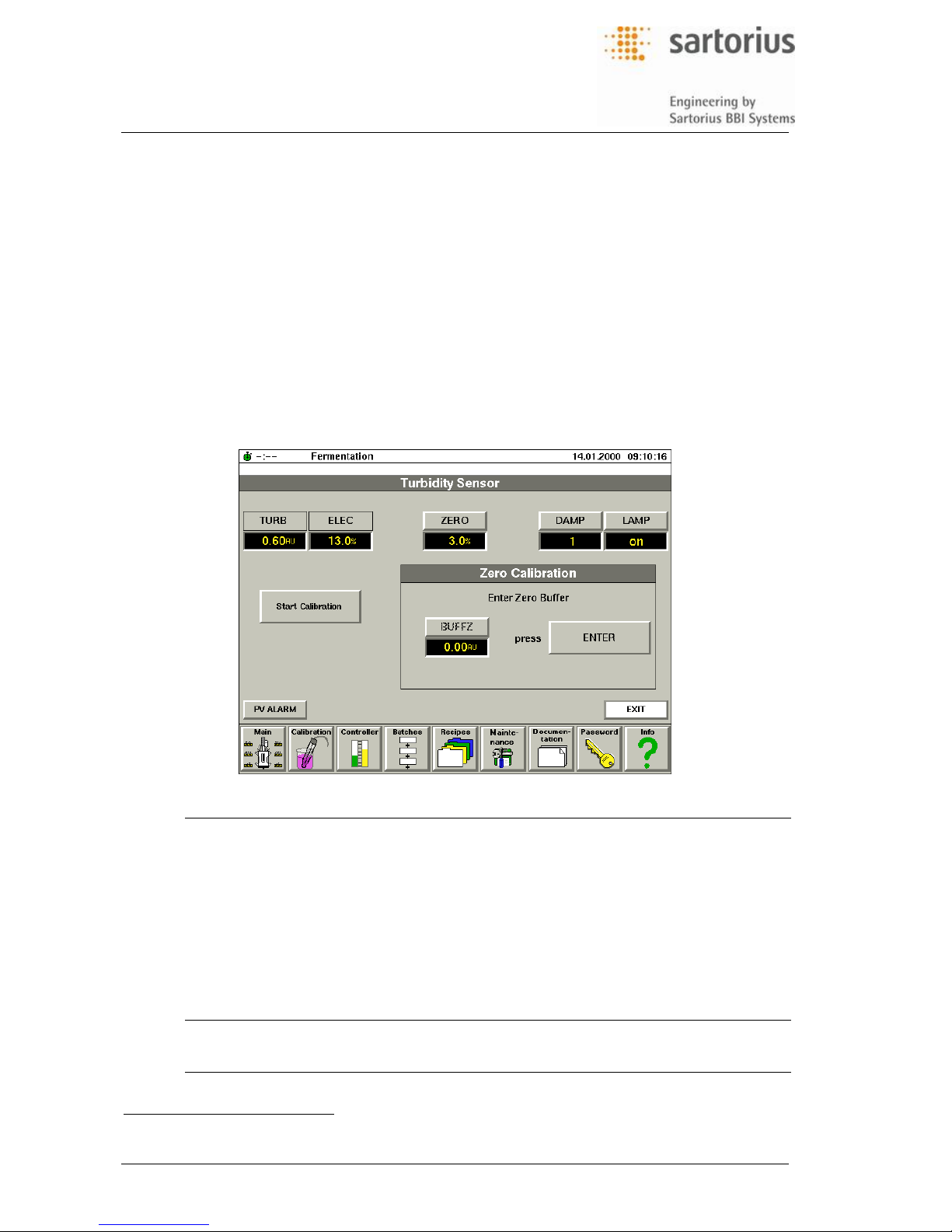

5.5 Calibration of Turbidimetry Measurement

Calibration of the turbimetry measurement probe is a „single-step“ procedure evalulating the „zero deviation“ of the sensor is. For this the sensor is placed into particle- and bubble-free deinonized water.

The system calculates the turbidimetry as the arithmetical mean of the value measured during a defined measuring time in terms of „absorption units, AU“. For calculation the system considers the zero

deviation and a selectable damping factor „DAMP”. To obtain stable turbidimetry measurements, the

damping factor „DAMP“ can be selected in 4 stages.

The operating display of the turbidimetry sensor includes the data field for absorption units (AU), the

percentage sensor raw signal [%] and the zero deviation against „0 AU“. This allows for an easy functional check of the sensor. The lamp contained in the turbidimetry sensor can be switched on and off

via the „Sensor Calibration“ - menu, see LAMP-entry

1)

.

5.5.1 Operating Display

Tag Entry Displayed value or function, required input

TURB AU Display of process value in 0...6 AU (Absorbing Units)

ELEC % Display of percentage raw signal of the sensor

ZERO % Display of zero deviation after calibration

LAMP

1)

On/off Display and selection of switching state of lamp in the sensor

DAMP 1 ... 4 Display and input of signal damping. The input signal is proc-

essed as the mean value of a floating reference window.

Damping factors base upon 4 selectable reference windows:

- step 1 = 6 s; step 2 = 12 s; step 3 = 30 s; step 4 = 60 s

Start Calibration Enabling the calibration routine

Additional touch keys, values and functions available in this display:

BUFFZ AU Display of zero solution

1)

Only Fundalux I – system, not applied with Fundalux II (available as option from 2004 on)

Page 29

Operators Handbook DCU3 – System

5., Main Function „Calibration“

BAEDCU3 - Rev. 4.6 - 0504 5 - 7

5.5.2 Calibration

For calibration of the turbidimetry sensor proceed as follows.

1. Start the calibration via „Start Calibration“

2. Follow the instructions of the calibration menu.

5.5.3 Special Notes

1. If the lamp

1)

is switched on, it will be kept in „on“-state when the DCU3 - system is switched

off and on again.

2. If required, the percentage zero deviation can directly be entered in the ZERO-entry.

Page 30

Operators Handbook DCU3 – System

5., Main Function „Calibration“

BAEDCU3 - Rev. 4.6 - 0504 5 - 8

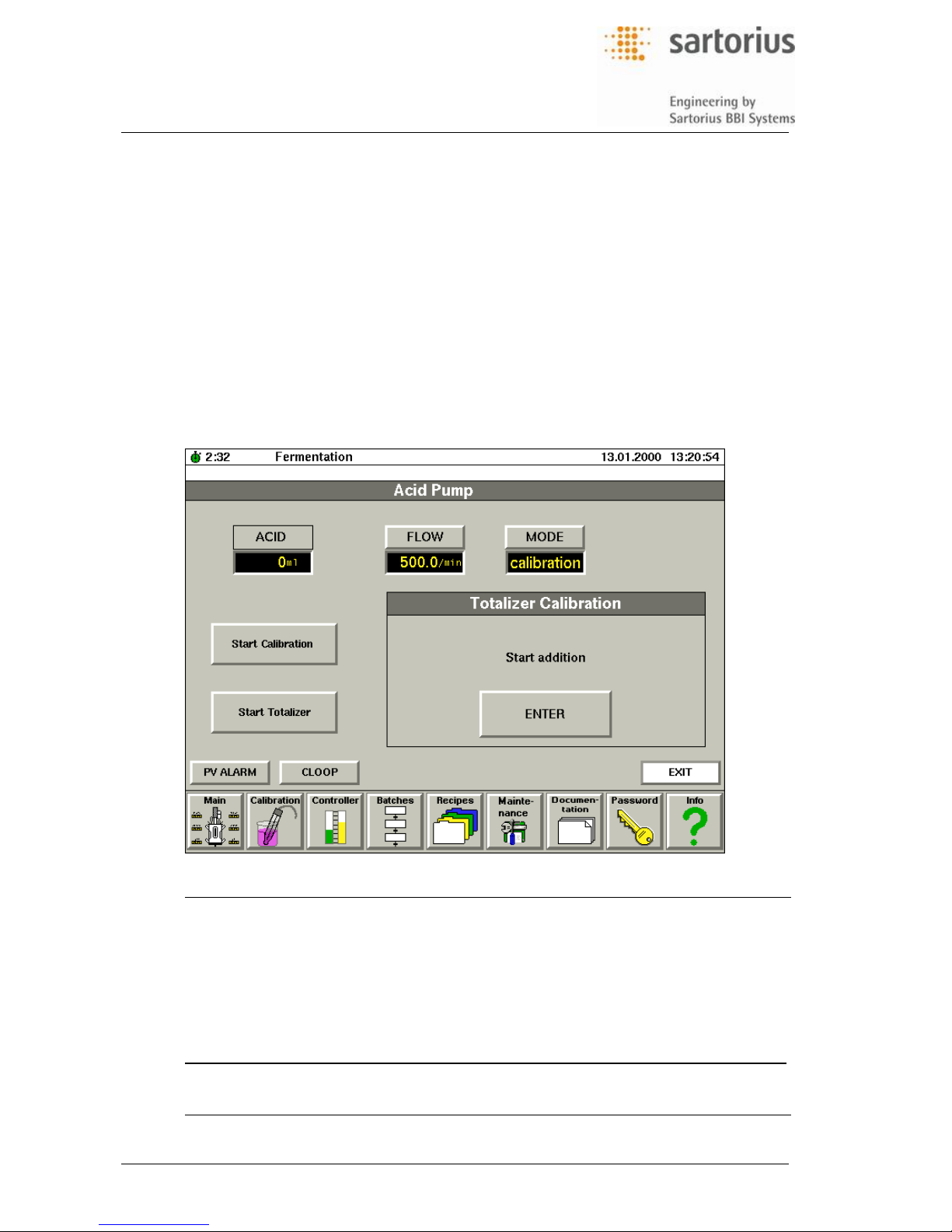

5.6 Totalizer for Pumps and Valves

For monitoring of the corrective agent consumption the dosing times of the pumps or of the dosing

valves are totalized and used as process values. The DCU3 - system converts the dosing times into

delivered volumes considering the specific flowrates of the pumps or of the dosing valves.

The dosing counters can be zeroed at any time via the operating display. If the specific flowrates are

known, you can enter them directly via the touch display. If the flowrates must be evaluated you can

use the „Calibration Totalizer“ function. Furthermore the flowrates can be calculated automatically during the calibration process from the measured running time and the entered delivery volume.

The standard configurations of the DCU-system include calibration routines and dosing counters for

acid, base, antifoam, feed, harvest and substrate. Since the calibration and dosing counter functions

are the same for all pumps and dosing valves, only those for the acid pumps will be described herein.

5.6.1 Operating Display

Tag Entry Displayed value or function, required input

ACID ml Display of delivered volume of liquid

FLOW ml/min Display of calculated delivery or input of either specific

pump delivery or valve flow, as far as known

Start Calibration Enabling the calibration

Reset Totalizer Resetting the dosing counter to zero

PV ALARM Enabling the alarm display

CLOOP Selection of the controller menu

Additional touch keys, values and functions available in this display::

VOLUME ml Input of volume delivered during calibration

Page 31

Operators Handbook DCU3 – System

5., Main Function „Calibration“

BAEDCU3 - Rev. 4.6 - 0504 5 - 9

5.6.2 Calibration of a Pump

For calibration allways use tubings of the same type and dimensions as for the delivery of

media during the process.

1. Place one end of the tubing into a beaker filled with water and the other end into a measuring beaker. Complete fill the tubing with water. For this you can manually activate the pump.

2. Start the calibration of the pump via „Start Calibration“.

3. Follow the instructions shown at in the DCU3 - display.

The DCU - system automatically calculates the flowrate considering the internally recorded

running time and measured delivery and displays the result in the entry „FLOW : x /min“).

5.6.3 Activation of the Dosing Counter

The dosing counter will automatically be started when the calibration of the pump is finished

and the corresponding controller is activated.

5.6.4 Special Notes

If already known, the delivery rate of the pump or of the dosing valve can be directly entered

into the FLOW - entry.

Page 32

Operators Handbook DCU3 – System

5., Main Function „Calibration“

BAEDCU3 - Rev. 4.6 - 0504 5 - 10

5.7 Calibration of a Balance System

The fermentor weight (the „vessel content“) can be measured by balance platforms or load cells (i.e.

optional accessories). They will be connected to the DCU3 via a strain gauge measuring amplifier.

The measurement amplifier is scaled to a gross weight output signal. The gross weight comprises the

empty vessel with the drive system, the individual vessel equipment and the vessel content (medium).

„Zero-taring“ using the calibration function is done by measuring the weight of the completely

equipped culture vessel without the culture medium and setting this weight as the „net weight“. However, tare correction is possible after changing the equipment of the culture vessel during a running

process. For this the net weight is stored and the tare weight will be adapted to the changing gross

weight.

5.7.1 Operating Display

Tag Entry Displayed value or function, required input

WEIGV kg display of net weight (WEIGH = GROSS - TARE)

GROSS kg display of gross weight

TARE kg display of tare weight

Start Taring Enabling the taring function

Start Hold Enabling the „hold“ function

PV ALARM Enabling the alarm display

CLOOP Selection of the controller menu

5.7.2 Calibration

1. For zero taring with the culture vessel being fully equipped, but without culture medium, start

the calibration with „Start taring“. Follow the instruction shown in the calibration menu.

2. If the culture vessel equipment is changed during the process, you can recalibrate the taring. Start the „Hold“ function for this and follow the instructions in the menü.

Page 33

Operators Handbook DCU3 – System

5., Main Function „Calibration“

BAEDCU3 - Rev. 4.6 - 0504 5 - 11

5.8 Flow Calibration

The dosing control function of the DCU3 - system operates with a remote balance system, which

measures the weight of the substrate. The balance system is connected to the DCU3 - system via a

serial interface. By default the actually measured weight will be transmitted to the DCU3 every five

seconds. The menu has an optional manual refilling function. This allows the use of low cost balance

systems which offer only small weight ranges.

Connecting a balance system via the serial interface also allows for measuring external weights. At an

existing FLOW-CALIBRATION menu one remote balance with serial interface can be connected to the

DCU3 without hardware extensions. One extension allows for up to 12 measurements.

The system calculates the volume delivered per time, the „massflow“, considering the actual weight

measured with the balance and the spent time. To minimize disturbances the calculation is based

upon a „dynamic calculation“ of the mean value. All values measured within a passed interval of either

1 min, 10 min or 60 min will be considered. The user can select this interval according to the process.

5.8.1 Operating Display

Tag Entry Displayed value or function, required input

FLOW kg/h Display of actual flow

WEIGF kg Display of net weight

Refill Enabling the refill function

Reset Flow Reset of the displayed flow (enable start with „0.00“)

CYCLE Input of calculation interval (cycle)

1

− interval of 1 minute

10

− interval of 10 minutes (recommend setting)

60

− interval of 60 minutes

PV ALARM Enabling the alarm display

CLOOP Selection of the controller menu

Page 34

Operators Handbook DCU3 – System

5., Main Function „Calibration“

BAEDCU3 - Rev. 4.6 - 0504 5 - 12

5.8.2 Special Notes

1. It is recommende to set a cycle interval of 10 minutes.

2. When selecting an interval of 10 or 60 minutes, respectively, the calculation and display of

the flowrate starts with the shortest interval and automatically switches over to the next

longer one. The flowrate of the initial phase is calculated from the shortest interval. This is

also true when a new setpoint is defined for the dosing controller.

The same is true for presetting a new setpoint of the dosing controller.

3. For manual refilling switch over to „Refill“-mode.

The automatic calculation of the actual flow will be stopped. The dosing controller continues

to act upon the last flow calculated. You can now refill the substrate storage vessel (bottle)

and tare the balance again. After switching over to „contr.“ mode the system starts with recalculation of the flow and continues dosing, now considering the actual values.

Page 35

Operators Handbook DCU3 – System

6., Main function „Control Loops“

BAEDCU3 - Rev. 4.6 - 0504 6 - 1

6 MAIN FUNCTION „CONTROL LOOPS“

6.1 Equipment and Functional Principles

All control loops in the DCU3 - system are DDC controllers. They operate either as PID controllers,

setpoint controllers or on/off controllers and are adapted to the related control loops. Depending on the

actuator their output is either continuous or pulsewidth-modulated (pwm). Both single- and split-range

controls are possible. The controller structure (PID) can be parametrized, if necessary. Switching over

between the operating modes is carried out with bumpless transfer.

These modes can be selected:

Mode State of controller

off controller switched off with defined output

auto controller in operation

manual manual control of controller / actuator

profile time profile for setpoint

cascade servo controller in cascade control loop

In the controller display you can enter actual values, operating modes and controller outputs. Effective

ranges depend on the configuration implemented for a specific fermentor. The parametrization display

for adjustment of PID parameters, output limits and deadband is accessible via a password. In remote

operation setpoint and operating mode are specified by the host computer.

The extent of implemented controllers depend on the fermentor system and/or the individual

customized configuration. The controllers shown below can be implemented at present.

Temperature controller PID cascade controller, pwm-splitrange outputs for heating /

cooling

Stirrer controller Setpoint controller for external motor control

pH controller PID controller with pwm-split-range outputs for acid/base

pO

2

controller PID cascade controller for speed, airflow or pressure servo

controller (switchable)

pO

2

gasflow ratio controller Master controller for gasflow ratio controller

Gasflow ratio controller Ratio controller of two external massflow controllers

pO

2

Gasmix controller PID controller, with pwm continuous outputs for control of

N

2/O2

Airflow controller Setpoint controller for external massflow controller

Foam controller On/off controller for antifoam

Level controller On/off controller external harvest and/or feed pump

Feedpump controller Setpoint controller for external dosing pump

Pressure controller PID controller, continuous output pressure control valve

Weight controller PID controller, pwm-output for external harvest pump

Dosing controller PID controller for control of a external dosing pump

Note: Additional or alternate controller functions can be implemented into existing DCU-systems

lateron by changing the configuration, for instance. Above this, the software allows implementing of special control functions, if necessary.

Page 36

Operators Handbook DCU3 – System

6., Main function „Control Loops“

BAEDCU3 - Rev. 4.6 - 0504 6 - 2

6.2 Selection of Controller

6.2.1 Operating Display

Tag Entry Displayed value or function, required input

PV [PV] Display of actual process value, entry (= physical unit) depending on

process value

SETP [PV] input of setpoint, entry (= physical unit) depending on process value

MODE

input of controller mode

off

− master controller and servo controller switched off

auto

− master controller switched on, servo controller switched to „cascade“

manual

− manual access to controller output

prof

− timer profile for setpoint

TEMP, etc. selection of controller display

TIMER selection of timer for digital output

CLOOP selection of the controller menu

Page 37

Operators Handbook DCU3 – System

6., Main function „Control Loops“

BAEDCU3 - Rev. 4.6 - 0504 6 - 3

6.3 Controller Operation in General

In general the operation of the DDC-controller is almost the same. Operation in cludes the necessary

changes of the setpoints, of the controller modes and of the controller outputs. Additional controller

settings not required for routine operation, will be done via the parametrization functions.

6.3.1 Operating Display (Example for Temperature Controller)

Tag Entry Displayed value or function, required input

TEMP, etc [PV] Display of physical unit of actual value, such as „degC“ for TEMP,

„rpm“ for STIRR, „pH“ for pH-value, „% sat“ for O

2

saturation, etc.

SETP [PV] Input of setpoint in the physical unit of the process value, such as

„degC“ for TEMP, „rpm“ for STIRR, „pH“ for pH-value, etc.

MODE Input of controller mo de

off

− master controller and servo controller switched off

auto

− master controller on, servo controller switched to „cascade“ mode;

cascade

− servo controller operating in cascade mode (only some controlle rs)

profile

− timer profile for setpoint running (only some controllers)

manual

− manual access to controller output;

OUT % Display of controller output in [%]; inputs possible in mode „manual

PARAM Input of password for access to controller parameter

PV ALARM Enabling the alarm display

PROFILE request for setpoint profile

CALIB request for calibration function (only some controllers)

Page 38

Operators Handbook DCU3 – System

6., Main function „Control Loops“

BAEDCU3 - Rev. 4.6 - 0504 6 - 4

6.4 Parametrization of Controllers, in General

For optimum adaptation of the DDC controllers to the control loops of the fermentor, the operator can

change important control parameters of individual controllers via the parametrization displays:

MIN, MAX : Minimum and maximum limits for the controller output

DEADB : Deadband adjustment (only for PID controllers)

XP, TI, TD : PID-Parameter (only PID controllers)

The parametrization display combined with a controller display is only accessible by entering a password. On delivery a DCU3 - system is configured with such control parameters that ensure a stable

control of the fermentor system it is designed for. For details about the parameters preset in the factory see the corresponding table in the supplement or in the documentation delivered extra for customized configurations of the DCU3 – system.

Changing the preset control parameters is not necessary under normal use. An exception are control

loops which vary with the fermentation process, such as for pH- and pO

2

-control.

6.4.1 Output Limits

For setpoint controllers and PID controllers the controller outputs can be limited (MIN and MAX). Thus

unintended high actuator changes can be avoided and, for cascade controllers, the setpoint for the

servo controller can be limited.

The limits must be entered at MIN for the „minimum output“ and MAX for the „maximum

output“. All settings are in terms of [%].

For full contro ller output range the following limits must be entered:

– single controller output : MIN = 0%, MAX = 100 %

– splitrange controller output : MIN = -100 %, MAX = 100 %

6.4.2 Deadband

For PID controllers a deadband can be adjusted. If the control deviation is within this deadband the

controller output remains constant or is set to zero (specific feature of the pH controller). By means of

the deadband a more stable control with minimized actuator changes can be achieved for actual values which vary stochastically. Furthermore, this will avoid oscillating of the controller output for splitrange controller outputs (e.g. continuously alternating acid-alkali dosag e by the pH - controller).

The deadband is adjusted in the entry DEADB as percentage [%] of the measurement span

of the corresponding actual value. It is symmetrical to the adjusted setpoint.

example for pH controller: - measurement range pH = 2 - 12 pH

- measurement span 10 pH

- adjusted deadband ± 0.1 pH

- adjusted setpoint 6.0 pH

Then the pH-control is inac tive at an actual value of 5.9 pH - 6.1 pH

Page 39

Operators Handbook DCU3 – System

6., Main function „Control Loops“

BAEDCU3 - Rev. 4.6 - 0504 6 - 5

6.4.3 Operating Display

Tag Entry Displayed value or function, required input

MIN % Input of minimum output limit, representing the setpoint minimum for

the servo controller (0 ... 100 % = measuring range of process value)

MAX % Input of minimum output limit, representing the setpoint minimum for

the servo controller (0 ... 100 % = measuring range of process value)

DEADB [PV] Input of deadband; physical unit depending on process value

XP % Input of proportional range in [%] of the measuring range

(100 % = maximum measuring range of process value)

TI sec Input of reset time

TD sec Input of rate (delay) time

Process

Value

Selection of intended process value for control if double measurements

are applied

Page 40

Operators Handbook DCU3 – System

6., Main function „Control Loops“

BAEDCU3 - Rev. 4.6 - 0504 6 - 6

6.4.4 PID-Parameter

The PID - controllers can be optimized via the PID - parameters Xp, TI and TD in the corresponding

entries of the menu. The implemented digital controllers allow changes of the control behavior (P, PI,

PD, PID) and of the parameters during operation, which simplifies the optimization of the controllers.

Xp: Proportional ran ge in [%] of measurement range (P-section)

TI: Reset time in seconds (I-section)

TD: Rate time in seconds (D-section)

The control structure can be adjusted by setting the individual PID - parameters to zero :

– P-controller -> TI = 0, TD = 0

– PI-controller -> TD = 0

– PD-controller -> TI = 0

– PID-controller -> alle PID-Parameter defined.

6.4.5 PID Controller Optimization

An optimum adaptation of a PID - controller to its control loop requires detailed knowledge in control

theory. You may refer to any standard literature for proven adjustment rules (e.g. Ziegler Nichols).

Thus the following details are only general guidlines:

The D section (TD) should only be activated in the case of quite stable actual values. Oth-

erwise, if the actual values are varying stochastically the controller output will change considerably and fast. This will lead to an unstable control behavior.

As a general rule the TI : TD ratio should be 4 : 1.

In the case of a periodic oscillating control loop the following measures are recommended:

– increase Xp

– increase TI/TD

If the readjustm ent is too slow after setpoint jumps or if the actual value drifts, the following

measures are recommended:

– decrease Xp

– decrease TI/TD

Page 41

Operators Handbook DCU3 – System

6., Main function „Control Loops“

BAEDCU3 - Rev. 4.6 - 0504 6 - 7

6.5 Temperature Controller

The temperature is controlled via a cascade control with a master controller for the vessel temperature

and a servo controller for the jacket temperature. The output of the servo controller controls the steam

valve (or an electric heater) and the cooling valve in split-range operation via pulsewidth-modulated or

continuous outputs.

The master controller can be switched from PD-behavior at start-up to PID when approaching the setpoint, which minimizes overshooting. When the temperature controller is switched off, an additional

digital output switches off the circulation pump and the heating contactor in the fermentor.

The temperature control is operated via the displays for the master controller [TEMP] and the servo

controller [JTEMP]. However, since all operations for the servo controller are activated automatically,

the adjustment of setpoints and operating modes need only be carried out at the master controller.

6.5.1 Operating Display for Master Controller (Vessel Temperature)

For a description of the tags, the physical units or entries, the displayed value or function

and of the required inputs see the table in section 6.3, Controller Operation in General.

Page 42

Operators Handbook DCU3 – System

6., Main function „Control Loops“

BAEDCU3 - Rev. 4.6 - 0504 6 - 8

6.5.2 Operating Display for Servo Controller (Jacket Temperature)

For a description of the tags, the physical units or entries, the displayed value or function

and of the required inputs see the table in section 6.3, Controller Operation in General.

6.5.3 Operation

For routine adjustment of setpoint and operating mode only the master controller [TEMP]

must be operated. Direct manual adjustment of the heating and cooling system is possible

at the servo controller [JTEMP], when it is switched over into „manual“ mode.

For test purposes it is possible to split the cascade control and specify a setpoint for the

jacket temperature in „auto“ mode via the servo controller [JTEMP].

6.5.4 Special Notes

When the master controller is in „auto“ or „profile“ mode, the servo controller is automatically

switched over into „cascade“ mode. When the master controller is in „off“ mode, the servo

controller is also automatically switched to „off“ mode.

The servo controller cannot be operated with time profiles. A setpoint limit for the servo con-

troller can be parametrized via the MAX output limit of the master controller, for instance:

– BIOSTAT

®

MD: MAX = 63,3 [%] (corresponding to 95 °C, for prevention of excessive

jacket temperature during the process)

– BIOSTAT

®

ED and UD: MAX = 98,3 [%] (corresponding to 147 °C; for prevention of

overheating during sterilization)

For the default output limits of your fermentor system, see the configuration documentation

delivered extra. As a general guideline, the output limits for autoclaveable fermentors may

be preset like the BIOSTAT

®

MD, the limits for insitu-sterilizable fermentors may be preset

like the BIOSTAT

®

ED.

Page 43

Operators Handbook DCU3 – System

6., Main function „Control Loops“

BAEDCU3 - Rev. 4.6 - 0504 6 - 9

6.6 Stirrer Speed Controller

The speed of the stirrer motor is controlled via an external, extra motor controller. You will adjust all

stirrer speed parameters at the DCU3 system. The control function of the DCU3 system works as a

setpoint controller and supplies the analog setpoint signal to the motor controller. Furthermore the

menu displays the stirrer speed signal delivered from the motor controller.

When the stirrer speed controller is switched to „off“, an additional digital output switches off the motor

contactor. If the fermentor is equipped with a pO

2

- controller the stirrer speed controller can be

switched as a servo controller in the pO

2

cascade control loop.

6.6.1 Operating Display

For a description of the tags, the physical units or entries, the displayed value or function

and of the required inputs see the table in section 6.3, Controller Operation in General.

6.6.2 Special Notes

In „manual“ mode, when entering the MIN/MAX output limits and entering data into OUT,

allways observe the permissible measuring range of the corresponding speed control:

– BIOSTAT

®

ED : 0 - 100 % = 0 - 1500 rpm

For further information on the permissible speed range of your fermentor check the preset

configuration of your DCU3 – system or refer to the configuration documentation of your fermentor system delivered extra.

Basic stirrer speed and/or maximum permitted speed during operation as a servo controller

in pO

2

cascade control are entered via the MIN/MAX output limits.

Page 44

Operators Handbook DCU3 – System

6., Main function „Control Loops“

BAEDCU3 - Rev. 4.6 - 0504 6 - 10

6.7 Airflow Controller

The airflow is controlled via an external massflow controller. The airflow control function of the DCU3 system works as a setpoint controller. It supplies the analog setpoint signals to the external massflow

controller . The menu at the DCU-system is used for entering the setpoints and display of the flowrate

signal coming from the massflow controller. For pO

2

control the airflow controller can be switched over

to be servo controller in the pO

2

cascade control loop.

6.7.1 Operating Display

For a description of the tags, the physical units or entries, the displayed value or function

and of the required inputs see the table in section 6.3, Controller Operation in General.

6.7.2 Special Notes

In „manual“ mode, when entering the MIN/MAX output limits and entering data into OUT,

allways observe the permissible measuring range of the corresponding airflow rate:

– BIOSTAT

®

ED : 0 - 100 % = 0 - 20 l / min

For further information on the permissible airflow range of your fermentor check the preset

configuration of your DCU3 – system or refer to the configuration documentation of your fermentor system delivered extra.

The basic airflow rate is entered via the MIN/MAX-output limits. If the airflow controller is

used as servo controller in the pO

2

cascade control, you can enter the maximum allowable

airflow rate here.

For standard laboratory scale fermentors the control valve of the external massflow control-

ler will be fully closed when the airflow controller is switched off.

When the pressure setpoint is rather high and the pressure controller is activated at this

time, the air supplied to the fermentor cannot be controlled up to its maximum aeration rate.

Page 45

Operators Handbook DCU3 – System

6., Main function „Control Loops“

BAEDCU3 - Rev. 4.6 - 0504 6 - 11

6.8 pH - Control Function Operating as PID - Controller

The pH - control function of the DCU system usually works in PID - behavior. The pH - control function

triggers the corrective agent pumps (or dosing valves) in split-range mode via two pulsewidthmodulated outputs. This allows a simultaneous control of both the acid and base pump (or valves).

As a special feature the acid and base control signals remain „off“ as long as the deviation

of the actual value lies within the parametrized dead band. This feature prevents unnecessary dosage of acid or base.

6.8.1 Operating Display

For a description of the tags, the physical units or entries, the displayed value or function

and of the required inputs see the table in section 6.3, Controller Operation in General.

6.8.2 Operating Information

For entering controller parameters in the parametrization menu see the section „Controller

Parametrization in General“ further above.

6.8.3 Special Notes

The dead ba nd is the percent span of the measuring range; it is symmetrical to the setpoint.

– Example: measuring range: 2 - 12 pH, span: 10 pH, DEADB: 0,1 pH, SETP: 7,0 pH

In this example the controller output is inactive in the range of 6.9 pH to 7.1 pH

When a gas mixing system is connected, the CO

2

valve is controlled via the negative output

signal of the pH controller (0 ... (-100) %)

If you select one of the operation modes „auto“, „profile“ or „manual“, the dosing counters

ACID and BASE will automatically be switched over to the „tlize“-mode.

Page 46

Operators Handbook DCU3 – System

6., Main function „Control Loops“

BAEDCU3 - Rev. 4.6 - 0504 6 - 12

6.9 pO2-Control Methods

Contrary to the other controls of fermentor systems (temperature, pH etc.) the pO2 - control is adapted

to the specific process requirements. For this the DCU3 - system comprises different pO

2

- controllers

that can be implemented according to the selected process. These control strategies can be realized:

pO

2

- cascade control with the following possible servo controllers:

– Stirrer

– Airflow (Massflow Controller)

– Substrate

– Pressure

– Gasmix (pulsed valves)

– Gasflow Ratio (two Massflow-Controllers with O

2

-enrichment)

The controller configuration can be especially matched to the fermentor system and process. Several

of the above controllers can be implemented. Besides the controllers mentioned above, customized

DCU configurations with other pO

2

- control strategies can be realized.

6.10 pO2 - Cascade Controller with 3 Servo Controllers

In the cascade system the pO2-controller is the master controller. Its output directly triggers the setpoint input of the servo controller.

Optionally a sequential mode can be selected for the pO

2

-cascade control. Then the pO2 - controller

triggers two or three servo controllers sequentially, in order of their priority. In the pO

2

- controller you

can define a specific „MIN/MAX“ range for the setpoint signal transmitted to each servo controller:

When the pO

2

control is switched on, at first the output of the pO2 controller operates the

setpoint input of the priority 1 - servo controller (CASC1). Optionally defined servo controllers 2 and 3 get the setpoint, which is defined as „MIN“ in the pO

2

controller.

At increase of O

2

-consumption, when the setpoint output of the 1st servo controller reaches

its „MAX“ limit, the output of the pO

2

controller is automatically switched over to the priority 2

- servo controller (CASC2). The user can adjust the delay time for switching-over, default

delay time is 5 minutes. Then the outputs are controlled as follows:

– servo controller 1: the predefined „MAX“ - output

– servo controller 2: controlled output of the pO

2

-controller

– servo controller 3: the predefined „MIN“ - output

After switching over to the 3rd servo controller, the outputs are controlled as follows:

– servo controller 1: the predefined „MAX“ - output

– servo controller 2: the predefined „MAX“ - output

– servo controller 3: controlled output of the pO

2

-controller

If the O

2

-consumption decreases the controller setting is switched back in reverse order.

Such a control strategy allows to keep the pO

2

value constant over prolonged periods of the process

without further manual intervention. The PID parameters for servo controllers of priority 1, 2 and 3 can

be adjusted independently of each other in order to allow maximum adaptation to the processdependent behavior of the control system.

Page 47

Operators Handbook DCU3 – System

6., Main function „Control Loops“

BAEDCU3 - Rev. 4.6 - 0504 6 - 13

6.10.1 Operating Display pO2 - Cascade Controller

For a description of the tags, the physical units or entries, the displayed value or function

and of the required inputs see the table in section 6.3, Controller Operation in General.

Additional functions of this Operating Display are the following:

Tag Entry Displayed value or function, required input

CASCADE Input of servo controller for sequential cascade control

STIRR

− stirrer speed controller

AIRFL

− airflow controller (if installed)

GASMIX

− gasmix controller

OUT [Controller] % Display of the controller output for the active servo controller

during sequential cascade control, with actual controller output

Page 48

Operators Handbook DCU3 – System

6., Main function „Control Loops“

BAEDCU3 - Rev. 4.6 - 0504 6 - 14

6.10.1.1 Parametrization Display pO2 - Cascade Controller with 3 Servo Controllers

Tag Entry Displayed value or function, required input

DEADB % Input of dead band in relation to measuring range (0 - 100 % sat)

Hyst. Time m:s Delay time for cascade switch over in [minutes:seconds]

Cascade [Controller] Display of the selected servo controller with its parameters

Minimum % Input of minimum output limit, considering the minimum setpoint

for servo controller (0 - 100 % = measuring range process valu e)

Maximum % Input of maximum output limit, i.e. the maximum setpoint for

servo controller (0 - 100 % = measuring range process value)

XP % Input of proportional range for servo controller [PARAM] in rela-

tion to measuring range

TI sec Input of reset time ifor servo controller [PARAM]

TD sec Input of rate time for servo controller [PARAM]

6.10.1.2 Operation of the Multistep Cascade Control

1. Assign the servo controllers to CASCADE, according to their intended priority.

2. Adjust the permitted minimum and maximum controller setpoint limits for the selected servo

controllers via their output limits MIN/MAX in the parametrization display of the pO

2

-

controller.

3. When the pO

2

-controller is switched on, the setpoint currently controlled by the pO2 control-

ler is indicated by „active“ on the display.

4. To achieve a reverse control, you can set the MIN->MAX limits correspondingly.

Page 49

Operators Handbook DCU3 – System

6., Main function „Control Loops“

BAEDCU3 - Rev. 4.6 - 0504 6 - 15

6.10.1.3 Special Notes

When the pO

2

controller is in „auto“ or „profile“ mode, the selected servo controllers are

automatically switched to „cascade“ mode.

When the pO

2

controller is in „off“ mode, the selected servo controllers are switched auto-

matically to „off“.

Switching over from servo controller 1 to servo controller 2, then to servo controller 3 (and

vice versa) only occurs when the output limit concerned is out of its range for the delay time

set in „HTIME“. After this delay period the switch-over condition will be checked again and

the controllers then be switched over only if the condition is still true. The delay time for

switching over can be set in the parametrization display of the pO

2

-controller.

The setpoint limits of servo controllers must be set by the master controller (pO

2

-controller).

A reverse switch-over sequence of one or more servo controllers (addition pumps, etc.) can

be achieved via reverse setting of the setpoint output limits (MIN > MAX).

The working range of the pO

2

- master controller is allways defined by the MIN/MAX-limits of

the corresponding servo controller.

Page 50

Operators Handbook DCU3 – System

6., Main function „Control Loops“

BAEDCU3 - Rev. 4.6 - 0504 6 - 16

6.11 pO2 - Cascade Controller with 4 Servo Controllers

This cascade controller operates in the same manner as the pO2 cascade controller with 3 servo controllers. The only difference is the fact, that 4 of the possible 4 servo controllers can be controlled.

6.11.1 Operating Display pO

2

- Cascade Controller with 4 Servo Controllers

For a description of the tags, the physical units or entries, the displayed value or function

and of the required inputs see the table in section 6.3, Controller Operation in General.

Additional functions of this Operating Display are the following:

Tag Entry Displayed value or function, required input

CASCADE Input of servo controller for sequential cascade control

STIRR

− stirrer speed controller

AIRFL

− Flow controller for air (if installed)

O2FL

− Flow controller for O2

PRESS

− Pressure controller

OUT [Controller]

%

Display of the controller output for the active servo controller during sequential cascade control, with actual controller output

Page 51