Sartorius CW3P,CW3S,CW3FS,CH3E,CH3G,Combics 3 CW3P,Combics 3 CW3S,Combics 3 CW3FS,Combics 3 CH3E,Combics 3 CH3G Operating Instructions Manual

98648-011-25

Operating Instructions

Sartorius Combics 3

Models CW3P | CW3S | CW3FS | CH3E | CH3G

Complete Combics Scales

Combics 3 is a rugged, easy-to-use

complete scale for the complex quality

control tasks you perform every day:

– in the food industry

– in the pharmaceutical industry

– in the chemical industry

– in the electronics and metal-working

industries

The Combics 3 scales meet the highest

requirements placed on the accuracy

and reliability of weighing results, with:

– Rugged construction and long service

life (stainless steel housing)

– Easy operation, thanks to the following

features:

– large keys with positive click action

– alphanumeric keypad with ‘ABC’

input

– large, backlit, fully graphic-capable

dot-matrix display

– plain-text user guidance

– Easy to clean and disinfect

– Can be operated independently of the

weighing platform location

– Range of interfaces for flexible use

– Optional password-protection for

operating parameters

Combics 3 complete scales speed up

your routine procedures with:

– Fast response times

– Simple function for assigning up to

4 alphanumeric lines for identifying

weight values

– Connectivity for two weighing

platforms

– Automatic initialization when the scale

is switched on

– Automatic taring when a load is placed

on the weighing platform

– Optional remote control using an

external computer

Symbols

The following symbols are used in these

instructions:

§ indicates required steps

$ indicates steps required only under

certain conditions

> describes what happens after you have

performed a certain step

!indicates a hazard

Hotline:

For advice on the use of these

applications, just call of fax your local

Sartorius office. For the address, please

visit our Internet website at:

www.sartorius.com

2

Intended Use

2 Intended Use

3 Contents

4 Warning and Safety Information

5 Getting Started

5 Equipment Supplied

5 Installation Instructions

6 Transporting the Weighing Platform

7 Leveling the Weighing Platform

8 General View of the Equipment

9 Connecting the Combics to AC Power

9 Connecting the External Rechargeable

Battery Pack

10 Connecting a Bar Code Scanner

10 Installing the Verification Adapter for Use

in Legal Metrology

10 Operating Tolerances

11 Preload Range

12 Operating Design

12 Data Input

14 Data Output

17 Configuring the Combics

17 Setting the Language

18 Navigating in the Operating Menu

19 Defining Password Protection for the

Operating Menu

20 Printing the Parameter Settings

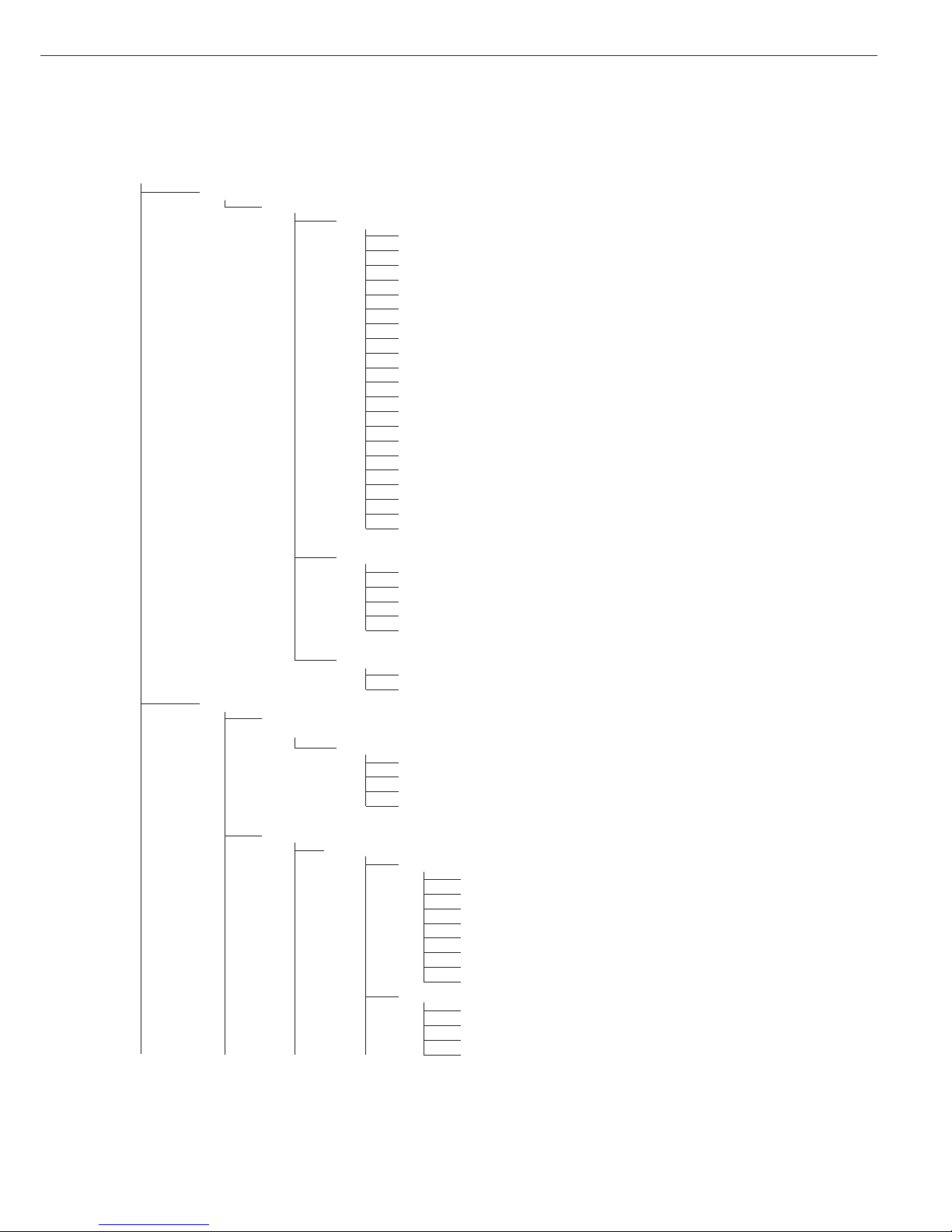

21 Operating Menu Overview (Parameters)

31 Operating the Combics

31 Weighing

32 Device Parameters

40 Data ID Codes

42 Calibration and Adjustment

45 Data Output Functions

47 Interface Port

49 Generating SBI Data Output

50 Configuring Printouts

52 Sample Printouts

55 Data Output Format

56 External Keyboard Functions

(PC Keyboard)

57 Data Input Format

58 Pin Assignment Charts

63 Cabling Diagram

3

Contents

64 Error Codes

65 Care and Maintenance

65 Service

65 Cleaning

65 Safety Inspection

66 Instructions for Recycling the Packaging

67 Overview

67 Common Specifications

67 Model-specific Specifications

68 Key to Model Designations

72 Dimensions (Scale Drawings)

74 Accessories

79 Declaration of Conformity

81 EC Type-approval Certificate

83 Plates and Markings

91 Index

Appendix

General Password

The Combics complies with the

European Council Directives as well

as international regulations and

standards for electrical equipment,

electromagnetic compatibility, and

the stipulated safety requirements.

§ To prevent damage to the equipment,

read these operating instructions

carefully before using your Combics

scale.

!Do not use this equipment in hazardous

areas/locations.

!The indicator may be opened only by

authorized service technicians who

have been trained by Sartorius and who

follow Sartorius’ standard operating

procedures for maintenance and repair

work.

!Make absolutely sure to unplug the

indicator from power before you

connect or disconnect any electronic

peripheral devices to or from the

interface port.

!If you use electrical equipment

in installations and under ambient

conditions requiring higher safety

standards, you must comply with the

provisions as specified in the applicable

regulations for installation in your

country.

– Warning When Using Pre-wired RS-232

Connecting Cables: RS-232 cables

purchased from other manufacturers

often have incorrect pin assignments

for use with Sartorius weighing systems.

Be sure to check the pin assignments

against the chart in this manual before

connecting the cable, and disconnect

any lines identified differently from

those specified by Sartorius.

– Use only extension cords that meet

the applicable standards and have

a protective grounding conductor.

– Disconnecting the ground conductor

is prohibited.

IP Protection:

– CW3P models are rated to IP44

(IP65 with Option L1)

– CW3S models are rated to IP67

– Note on installation:

The operator shall be responsible

for any modifications to Sartorius

equipment and must check and, if

necessary, correct these modifications.

On request, Sartorius will provide

information on the minimum operating

specifications (in accordance with the

standards for defined immunity to

interference).

$ If there is visible damage to the

equipment or power cord: unplug the

equipment and lock it in a secure place

to ensure that it cannot be used for

the time being

- Weighing platforms with dimensions

of 1+1 m or larger are provided with

suspension supports. Be careful not

to stand under the load when the

weighing platform/load plate is being

transported or lifted with a crane.

Always comply with the applicable

safety regulations. Make sure to avoid

damaging the terminal box or the

load cells during transport.

!Always wear gloves, safety boots and

protective clothing when lifting the load

plate with suction lifting equipment.

Warning: Danger of personal injury!

This work must be carried out by

authorized and properly trained

personnel.

– Connect only Sartorius accessories and

options, as these are optimally designed

for use with your Combics.

– Do not expose the indicator to

aggressive chemical vapors or to extreme

temperatures, moisture, shocks, or

vibration.

– Clean your Combics only in accordance

with the cleaning instructions (see “Care

and Maintenance”).

$ If you have any problems with your

Combics:

contact your local Sartorius office,

dealer or service center.

IP66/67 Protection Rating:

– The IP65/67 protection rating for the

indicator is ensured only if the rubber

gasket is installed and all connections

are fastened securely (including the

caps on unused sockets). Weighing

platforms and equipment must be

installed and tested by a certified

technician.

– If you install an interface port or battery

connector after setting up your

Combics, keep the protective cap(s) in

a safe place for protecting the interface

port or battery connector when not in

use, or prior to shipment. This will

protect the data interface or battery

connector from vapors, moisture and

dust or dirt.

Using the Equipment in Legal

Metrology:

– When the indicator is connected to

a weighing platform and the resulting

weighing instrument is to be verified,

make sure to observe the applicable

regulations regarding verification.

– If any of the verification seals are

damaged, make sure to observe the

national regulations and standards

applicable in your country in such cases.

In some countries, the equipment must

be re-verified.

4

Warning and Safety Information

The complete scale is available in

various versions. If you have ordered

special options, the scale is equipped

with the required features at the

factory.

Storage and Shipping Conditions

– Allowable storage temperature:

–10 ...+40°C (+14 to +104°F)

– Once the equipment has been removed

from the packaging, it may lose accuracy

if subjected to strong vibration.

Excessively strong vibration may

compromise the safety of the

equipment.

– Do not expose the indicator to

aggressive chemical vapors or to

extreme

temperatures, moisture, shocks,

or vibration.

Unpacking the Combics

§ After unpacking the equipment,

please check it immediately for any

visible damage.

$ If you detect any damage, proceed

as directed in the chapter entitled “Care

and Maintenance,” under “Safety

Inspection.”

$ It is a good idea to save the box and

all parts of the packaging until you have

successfully installed your equipment.

Only the original packaging provides the

best protection for shipment.

$ Before packing your equipment, unplug

all connected cables to prevent damage.

5

Getting Started

Equipment Supplied

– Indicator

– Weighing platform

– Operating instructions (this manual)

– Special accessories as listed on the bill

of delivery, if ordered

Installation Instructions

The scale is designed to provide

reliable results under normal ambient

conditions in the laboratory and in

industry. When choosing a location to

set up your scale, observe the following

so that you will be able to work with

added speed and accuracy:

– Avoid placing the scale in close

proximity to a heater or otherwise

exposing it to heat or direct sunlight.

– Protect the scale from drafts that come

from open windows or doors

– Avoid exposing the scale to extreme

vibrations during weighing.

– Protect the scale from aggressive

chemical vapors.

– Do not expose the scale to extreme

moisture over long periods.

Turn off the power if you do not need

to use the scale with other equipment.

Note:

This equipment has been tested and

found to comply with the limits for

a Class A digital device, pursuant to Part

15 of the FCC rules. These limits are

designed to provide reasonable

protection against harmful interference

when the equipment is operated in

a commercial environment.

This equipment generates, uses and

can radiate radio frequency energy and,

if not installed and used in accordance

with the instruction manual, may

cause harmful interference to radio

communications. Operation of this

equipment in a residential area is likely

to cause harmful interference in which

case the user will be required to correct

the interference at his own expense.

Changes or modifications not expressly

approved by Sartorius AG could void the

user’s authority to operate the

equipment.

Conditioning the Scale

Moisture in the air can condense on

the surface of a cold scale whenever it is

brought to a substantially warmer place.

If you transfer the scale to a warmer

area, make sure to condition it for

about 2 hours at room temperature,

leaving it unplugged from AC power.

Afterwards, if you keep the scale

connected to AC power, the constant

positive difference in temperature

between the inside of the scale and the

outside will practically rule out the

effects of moisture condensation.

Checking the Geographical Data

Entered for Use in Legal Metrology

Preparation

(See also the “Device Information”

menu items listed under “Operating

Menu Overview” in the chapter entitled

“Configuring the Combics”.)

§ Press e to turn on the Combics

§ Activate the Setup program:

Press the M key

> SETUP is displayed

§ Select “Device-specific information”:

Press the q soft key repeatedly;

press the O soft key to confirm

§ Specify WP1 or WP2 for the weighing

platform in question:

Press the q soft key repeatedly;

press the O soft key to confirm

> View geographical data (configured

prior to verification), for example:

Latitude (in degrees): 51

4

Elevation (in meters): 513

5

or

Gravitational acceleration

(in m/s

2

: 9.810

6

The scale can be used in legal metrology

anywhere in Germany if the

geographical data is as follows:

– Latitude: 51.00 degrees

– Elevation: 513 m

This data corresponds to the following

value:

Gravitational acceleration: 9.810 m/s

2

These values are calculated for Germany

based on a mean value for the Earth’s

acceleration. The greater the precision

of the geographical data entered, the

greater the precision achieved with the

weighing instrument; the tolerance

range, however, is restricted accordingly

(see above).

The tolerances ranges, for example

for a scale with 3000 e, are as follows:

– ± 100 for the latitude, and

– ± 200 for the elevation above sea level.

!If used outside the specified zone,

the scale must be re-verified for use in

legal metrology. Please contact an

authorized service technician.

Seal on Indicators Verified for Use

in Legal Metrology in the EU*

EU legislation requires that a control

seal be affixed to the verified device.

The control seal consists of a sticker

with the “Sartorius” logo. This seal will

be irreparably damaged if you attempt

to remove it. If the seal is broken, the

validity of the verification becomes null

and void, and you must have your scale

re-verified.

*

including the Signatories of the Agreement

on the European Economic Area

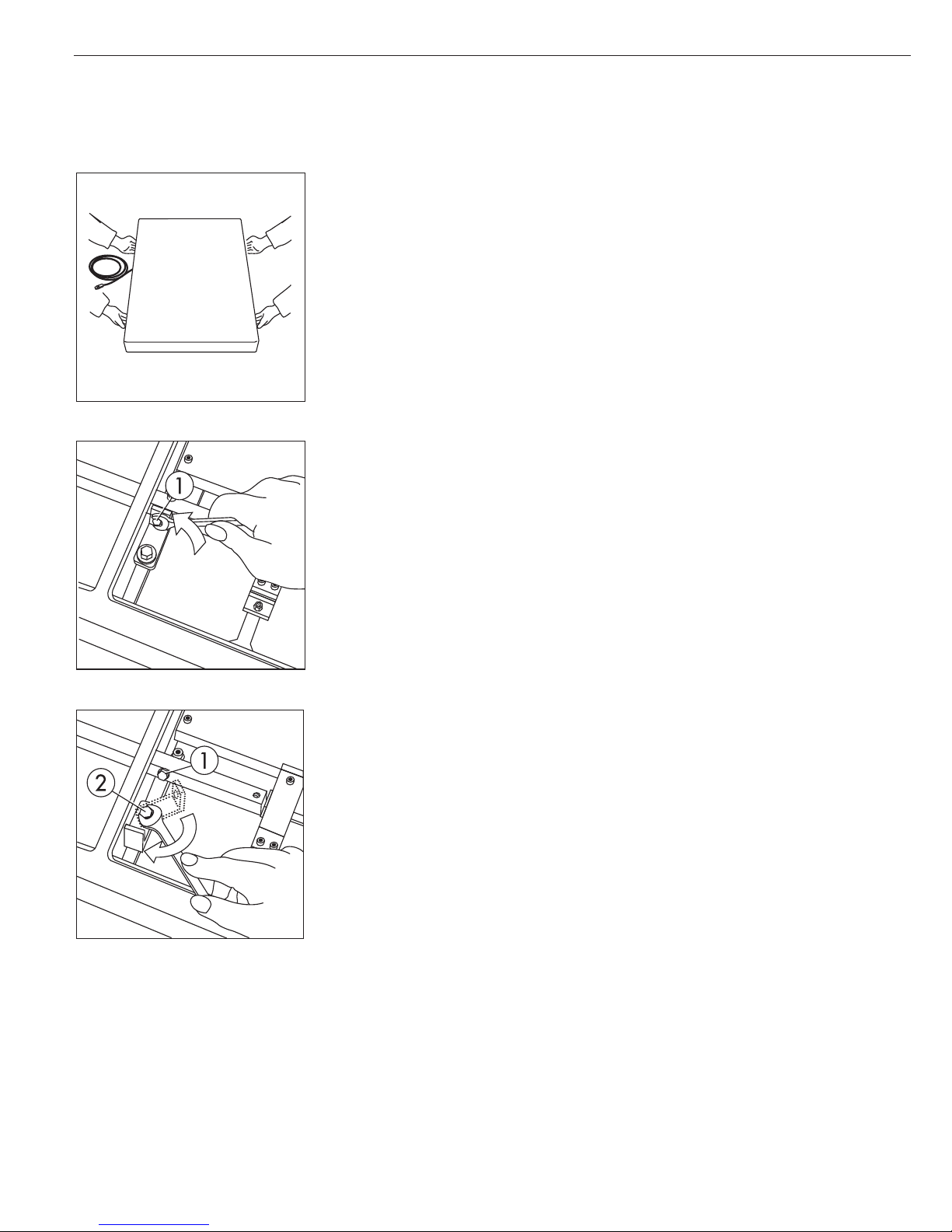

Unpacking the Platform

Important note:

These instructions apply to platforms that are 60 x 80 cm and larger.

§ Remove the weighing platform and weighing pan from the packaging.

§ When transporting or lifting the device, hold the unit on the longer sides and observe the

safety precautions (wear safety shoes and gloves if necessary).

§ Remove any plastic wrapping, packaging strips and styrofoam.

Removing the Transport Locking Device

§ Bring the scale to the location where it will be used and remove the weighing pan.

§ Loosen the transport locking device by removing screw 1.

§ Loosen screw 2, turn the fastening bracket by 180° and then tighten screw 2.

§ Tighten screw 1 again at the lever.

Important Note Regarding Transport of the Weighing Platform

!Be sure to refasten the transport locking device before transporting the weighing platform.

Level the weighing platform at the weighing location using the adjustable feet so that the

air bubble is centered in the level indicator circle. Check that all four adjustable feet are in

contact with the surface.

The load must be equally distributed over all four leveling feet.

6

7

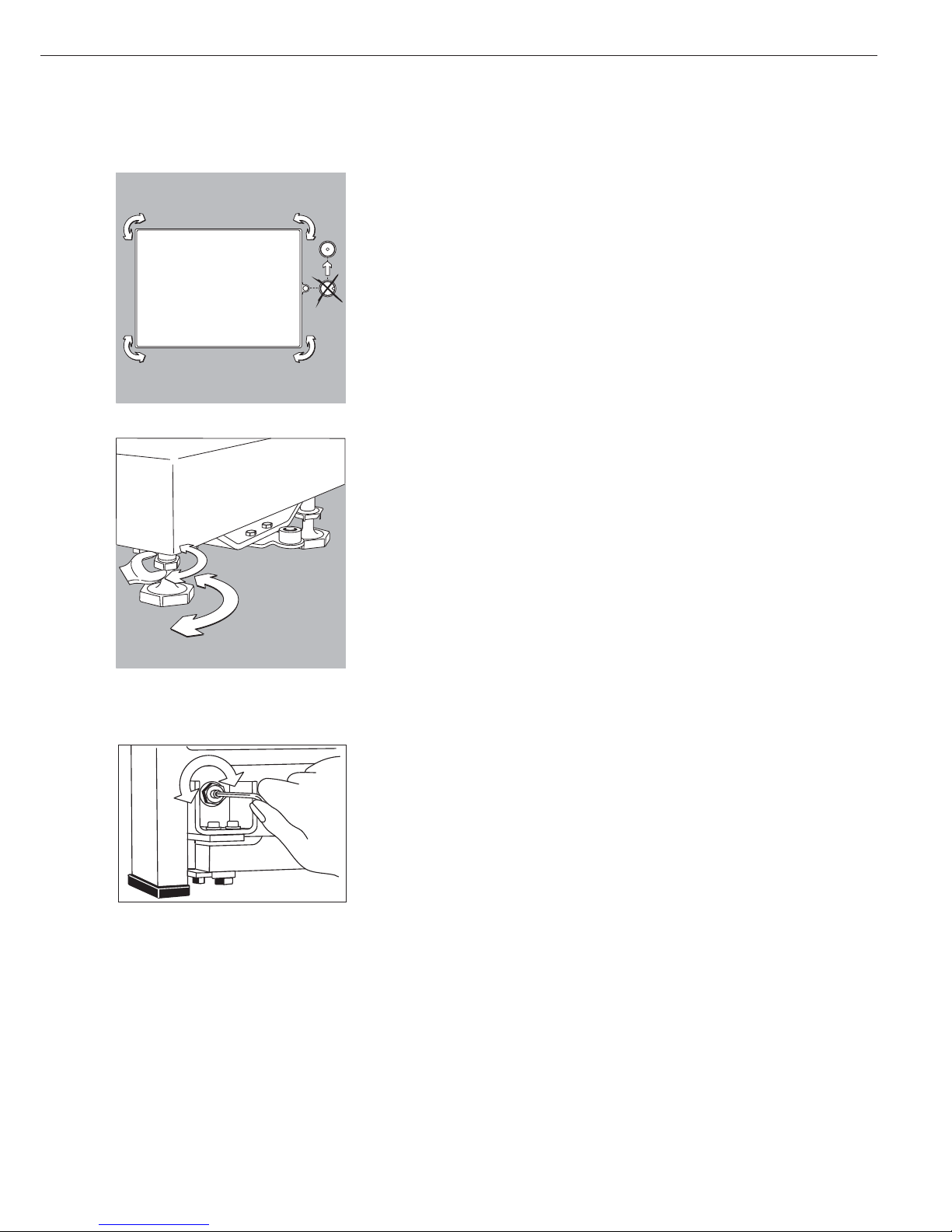

Leveling the Weighing Platform

Purpose:

– To compensate for uneven areas at the

place of installation

– To ensure that the equipment is placed

in a perfectly horizontal position for

consistently reproducible weighing

results

Always level the weighing platform

again any time after it has been moved

to a different location.

§ Level the weighing platform using the

four leveling feet. Turn the feet until

the air bubble is centered in the level

indicator.

§ Check to ensure that all four leveling

feet rest securely on the work surface.

> The load must be equally distributed

over all four feet

§ Loosen the lock nuts on the leveling

feet using a open-end wrench

(spanner).

> Adjusting the leveling feet:

To raise the weighing platform, extend

the leveling feet (turn clockwise).

To lower the weighing platform, retract

the leveling feet (turn ounterclockwise).

§ After leveling the weighing platform,

tighten the lock nuts as follows:

Small platforms (1 load cell): against the

platform frame

Large weighing platforms (4 load cells):

against the platform foot

§ Remove the load plate

§ Loosen the locknuts on the leveling feet

using a 17 mm open-end wrench

(spanner)

> Small platforms (1 load cell):

against the platform frame

Large weighing platforms (4 load cells):

against the platform foot

§ Extend or retract the leveling feet using

a 5 mm Allen wrench (key)

§ After leveling the weighing platform,

refasten the locknuts securely against

the platform frame

§ Replace the load plate

Checking the Geographical Data

Entered for Use in Legal Metrology

(for CW* Models Only):

Preparation

(See also the “Device Information”

menu items listed under “Operating

Menu Overview” in the chapter entitled

“Configuring the Combics”.)

§ Press e to turn on the Combics

§ Activate the Setup program:

Press the M key

> SETUP is displayed

§ Select “Device-specific information”:

Press the q soft key repeatedly;

press the O soft key to confirm

§ Specify WP1 or WP2 for the weighing

platform in question:

Press the q soft key repeatedly;

press the O soft key to confirm

> View geographical data (configured

prior to verification), for example:

Latitude (in degrees): 51

4

Elevation (in meters): 513

5

or

Gravitational acceleration

(in m/s

2

: 9.810

6

The scale can be used in legal metrology

anywhere in Germany if the

geographical data is as follows:

– Latitude: 51.00 degrees

– Elevation: 513 m

This data corresponds to the following

value:

– Gravitational acceleration: 9.810 m/s

2

These values are calculated for Germany

based on a mean value for the Earth’s

acceleration. The greater the precision

of the geographical data entered, the

greater the precision achieved with the

weighing instrument; the tolerance

range, however, is restricted accordingly

(see above).

The tolerances ranges, for example

for a scale with 3000 e, are as follows:

– ± 100 for the latitude, and

– ± 200 for the elevation above sea level.

!If used outside the specified zone,

the scale must be re-verified for use in

legal metrology. Please contact an

authorized service technician.

Indicators Verified for Use in Legal

Metrology in the EU*

EU legislation requires that a control

seal be affixed to the verified device.

The control seal consists of a sticker

with the “Sartorius” logo. This seal will

be irreparably damaged if you attempt

to remove it. If the seal is broken, the

validity of the verification becomes null

and void, and you must have your scale

re-verified.

* including the Signatories of the

Agreement on the European Economic

Area

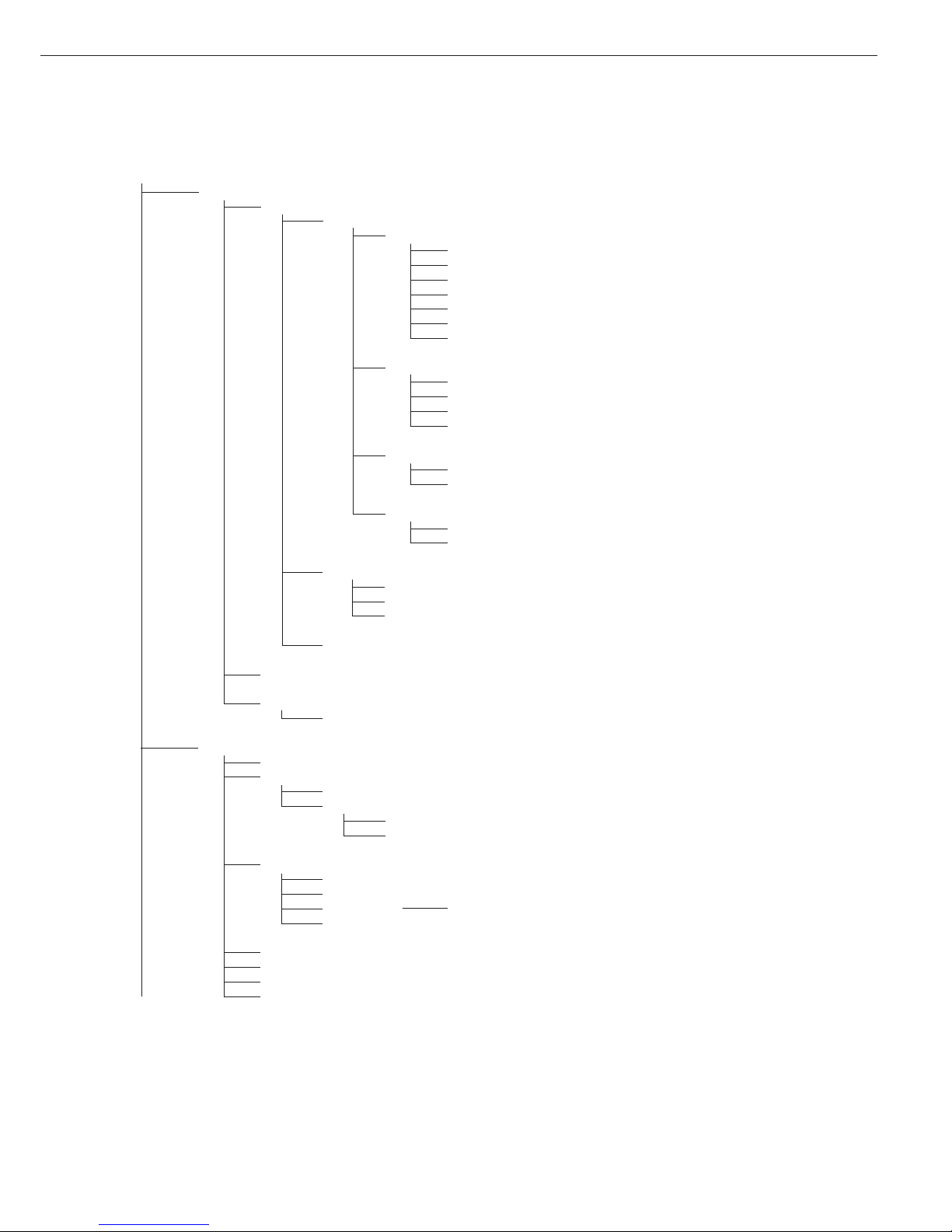

1 Load plate

2 Leveling feet

3 Level indicator

4 LEDs for checkweighing and

classification

5 Toggle to alphabetical input

6 Alphanumeric keypad

7 CF key (clear function)

8 Settings:

Access Setup program

9 Toggle to the application program |

application-specific information

10 Data output key

11 Gross/net; 2nd unit or 10x higher

resolution (depending on the

settings)

12 Tare key

13 Zero key

14 Toggle to different weighing

platform

15 On/off key

16 Function keys

17 Graphic-capable dot-matrix display

Rear View

18 COM2 | UniCOM interface

19 COM1: RS-232 interface

20 Power cord with country-specific

plug

21 Menu access switch (standard

operating mode or legal metrology

mode)

22 Connector for weighing platform

23 Vent valve; torque: 1.5 Nm

8

General View of the Equipment

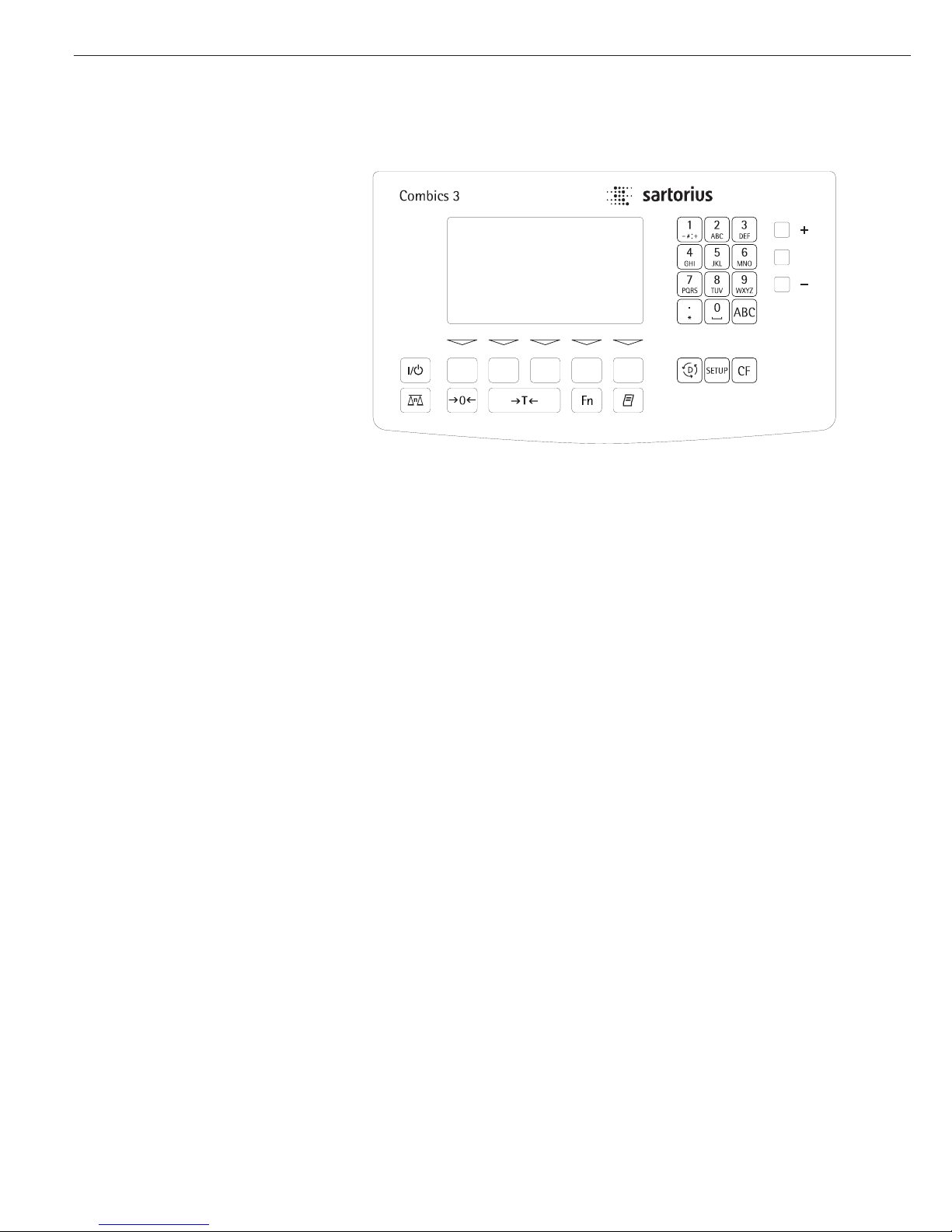

Combics 3

Rear view: CW3P models

Rear view: CW3S | CW3FS | CH3E | CH3G

17

16

15

14

13

12

11

10

22

21

18

23

22

21

1

2

3

2

4

5

6

7

8

9

18

19

20

19

20

Connecting the Combics to AC Power

§ Check the voltage rating and the plug design.

$ The scale is powered through the pre-installed power cord. The power supply is built in

to the scale, which can be operated with a supply voltage of 100V to 240V.

Make sure that the voltage rating printed on the manufacturer’s ID label is identical to

that of your local line voltage. If the voltage specified on the label or the plug design of

the AC adapter do not match the rating or standard you use, please contact your Sartorius

office or dealer.

The power connection must be made in accordance with the regulations applicable in

your country.

§ To power a protective class 1 device, plug the power cord into an electrical outlet (mains

supply) that is properly installed with a protective grounding conductor (protective earth

= PE).

Safety Precautions

If you use an electrical outlet that does not have a protective grounding conductor

(protective earth), make sure to have a certified electrician install equivalent protection

according to the installation requirements valid in your country. Make sure the protective

grounding effect is not neutralized by use of an extension cord that lacks a protective

grounding conductor.

Connecting Electronic Peripheral Devices

§ Make absolutely sure to unplug the scale from AC power before you connect or

disconnect a peripheral device (printer or PC) to or from the interface port.

Warmup Time

To deliver exact results, the scale must warm up for at least 30 minutes after initial

connection to AC power or after a relatively long power outage. Only after this time will

the scale have reached the required operating temperature.

Using Equipment Verified as Legal Measuring Instruments in the EU*

$ Make sure to allow the equipment to warm up for at least 24 hours after initial

connection to AC power or after a relatively long power outage.

Connecting the External Rechargeable Battery Pack (Accessory YRB10Z)

!Disconnect the equipment from AC power (unplug the AC adapter)

§ Installation

CW3P models: Connect a 25-pin D-Sub male connector (connecting cable YCC02-RB01)

to the COM2 port

CW3.S models: Please see “Pin Assignment Charts” in this manual

(implemented via the YCC02-RB02 connecting cable or as Option L2)

Operation

– Hours of operation: up to 40, depending on the weighing platform connected; without

options. The Combics automatically switches to battery operation whenever there is a

power shortage or the power is cutoff. Once the mains power supply is restored, the

Combics automatically switches back to normal operation.

Battery symbol

Battery fully loaded:

Battery empty:

* including the Signatories of the Agreement on the European Economic Area

9

Connecting a Bar Code Scanner (Accessory YBR02CISL)

!Disconnect the equipment from AC power (unplug the AC adapter)

§ Installation

For model CW3P:

– Connect a 25-pin D-Sub male connector to the COM 2 (UniCOM) port

– To connect both a bar code scanner and an external rechargeable battery, please use the YTC01 T-connector.

For model CW3S: please see “Pin Assignment Charts” in this manual (implemented via the YCC02-BR02 connecting cable or as Option M8)

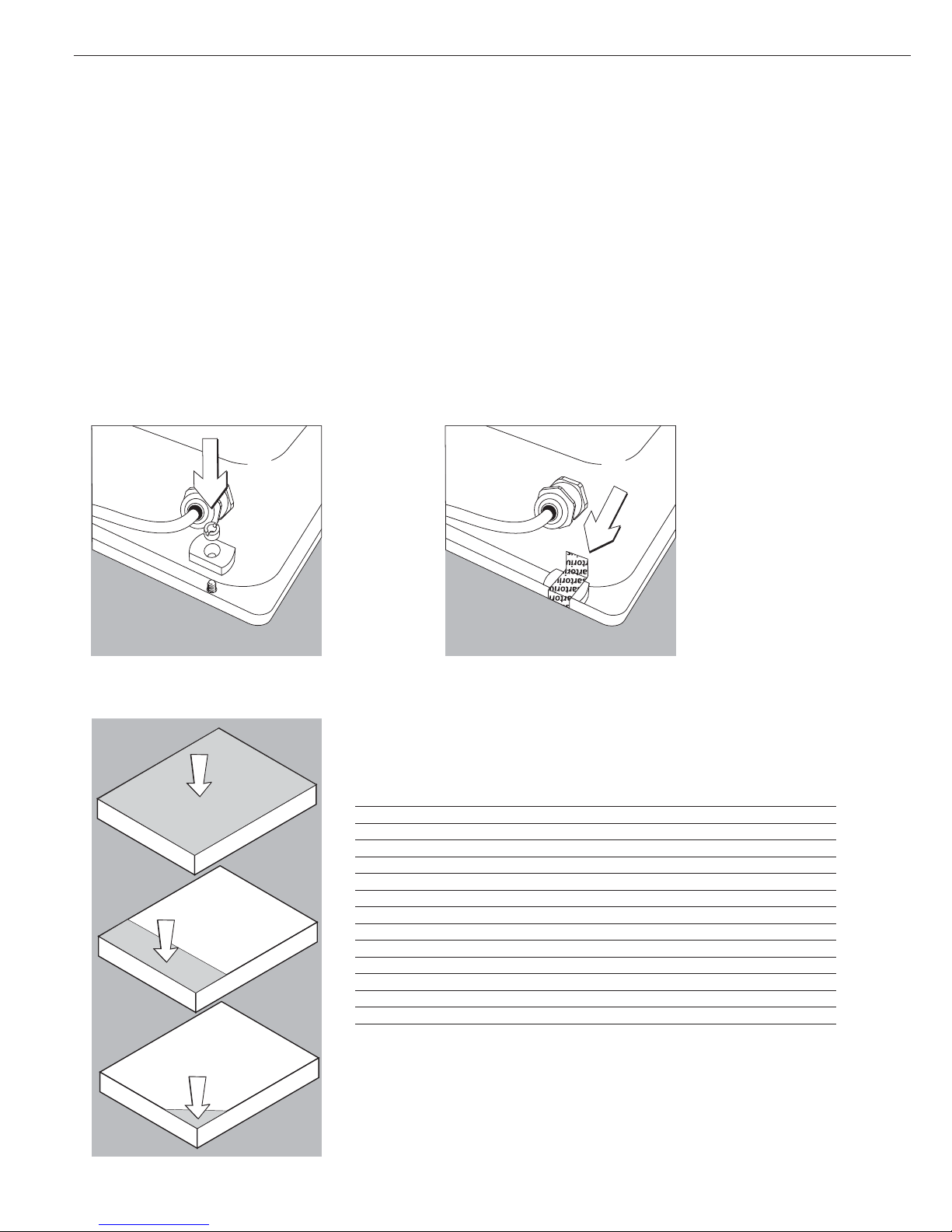

Installing the Verification Adapter for Use in Legal Metrology (on verifiable models only)

§ Remove the nut located on the back of the indicator

§ Use the slotted screw to install the adapter plate § Affix the verification seal over the adapter

10

Operating Tolerances

Never exceed the maximum capacity of the weighing platform.

The maximum loading capacities of the weighing platforms are listed

in the table below, and depend on the position of the load on the platform:

Platform size Center Side Corner

320 + 240 50 35 20

400 + 300 130 85 45

500 + 400 300 200 100

500 + 400 (P*) 600 400 200

650 + 500 (S**) 450 300 150

800 + 600 (P*) 1200 800 400

800 + 600 (S**) 900 600 300

800 + 800 4500 3000 1500

1000 + 800 4500 3000 1500

1000 + 1000 4500 3000 1500

1250 + 1000 4500 3000 1500

1500 + 1250 4500 3000 1500

1500 + 1500 4500 3000 1500

2000 + 1500 4500 3000 1500

* Steel

** Stainless Steel

11

For CH3E models:

Platform dimensions: 300 x 400 Loading capacity (center) in kg: 130

For CH3G models:

Platform dimensions: 560 x 450 Loading capacity (center) in kg: 130

Platform dimensions: 800 x 600 Loading capacity (center) in kg: 600

Shock Resistance

The weighing platform features a rugged construction, but you should not allow objects

to fall onto the weighing pan. Also avoid bumps to the side of the unit and shocks.

The weighing platform withstands the loads specified in standard DIN 1EC68, Part 2-27.

Important Note About Planning Structures for Attachment to the Weighing Platform

The weighing platform is suitable for installation in systems. The scale drawings should

be used as the basis for selecting any necessary structures to be affixed to the platform.

Use the YAS041S fastening set to secure the weighing platform.

Moving or rotating parts on the weighing pan must be designed so that they do not

influence the weighing results. For example, rotating parts must be balanced. The

weighing pan must have clearance on all sides to prevent any falling objects or dirt from

creating a connection between the weighing platform and any permanent structures.

Cables and hoses between the weighing platform and other devices must not exert any

force on the weighing platform. These cables must not touch the weighing pan.

(For CW* models only):

When setting up systems in hazardous areas (zone 2 or 22), be sure to observe and

comply with the relevant regulations (e.g., EN60079-14).

Pay special attention that electrostatic charges resulting from moving parts

(e.g., conveyors) are avoided or discharged.

Preload Range (Zero-Point Range)

The weight of any structures that are permanently mounted on the weighing platform

constitutes the “preload.” The preload is electronically compensated in the weighing

platform so that the entire weighing range is available and so that the scale can be zeroed

or calibrated (using external weights).

Larger preloads will lead to a reduction of the weighing range. The weight on the scale

may not fall below the following weighing range values:

– At least 30 kg of the weighing range must remain for models CH3G-150 1G-H

– At least 60 kg of the weighing range must remain for models CH3G-300 1G-H

!You must always set the preload prior to verifying the scale for legal metrology.

All structures must be mounted on the weighing platform before it is connected to AC

power.

With Combics 3 you can

– collect weight values from two

weighing platforms

– use application programs to calculate

and display results

– assign codes to identify the samples

weighed

Before you begin, you need to configure

your Combics complete scale for your

requirements. This is achieved by

setting parameters in the operating

menu (for example, to configure a

connected printer). You can then begin

operation, with functions active for

storing and calculating weighing data.

The description of the operating design

is divided into the following sections:

– Data Input

– Display Modes

– Error Codes

– Data Output

– Saving Data

Data Input

There are a number of options for

entering data:

– Through the indicator keypad (e.g., with

the 0, 1, 2... 9 keys)

– Through the weighing platform (e.g.,

tare values)

– Through the digital input/output

interface

– Through the COM port

– Through a bar code scanner or external

keyboard

Keypad Input

Labeled Keys

These keys always have the function

indicated by the label, but the functions

might not be available at all times.

Whether a function is available at a

given time depends on the operating

state of the scale and the menu settings

active at that time. Some of the keys

have a second function, activated by

pressing and holding the key for longer

than 2 seconds.

e On/off key

Turn the Combics on and off or

switch it to the standby mode. In

standby mode, the display shows

OFF.

n Toggle the display between

connected weighing platforms.

With two weighing platforms

connected, this key toggles the

display between the two readouts.

( – Zero the scale

– Cancel a calibration/adjustment

procedure

) – Press briefly (< 2 sec):

Tare the weighing platform

– Press and hold (> 2 sec ):

Activate calibration/adjustment

k Toggles the display between:

– first and second weight unit, or

– gross and net values, or

– normal and 10-fold higher

resolution,

depending on your settings in the

operating menu.

p – Press briefly:

Print

– Press and hold:

Print GMP footer

D – Press and hold:

Toggle to info mode (only when

an initialized application is active)

M – Access to Setup program

– Exit the Setup program

c – Press briefly:

Quit application program, delete

input character

– Press and hold:

Delete entire input string

0, 1, 2... 9, .

Enter numbers, letters and other

characters

a Toggle between numeric and

alphabetic input

12

Operating Elements: Combics 3

Operating Design

13

Function Keys (Soft Keys)

The current function of a given soft key

is indicated in the last line on the display

(footer). Functions are indicated by

abbreviated texts or symbols .

Texts (Examples)

1st ID: Store the first ID line

ESC: Cancel input

Symbols in the footer:

oo: Return to initial state

o: Go one level higher

o: Show items under selected entry

Q: Move up one position in I/O window

q: Move down one position in

I/O window

l: Confirm selected parameter setting

F5 F4 F3

F2

F1

1st ID ESC

Numeric Input Through the Keypad

§ Enter numbers one digit at a time:

Press 0, 1, 2... 9 as needed

§ Store input:

Press the required key (e.g., press )

to store manual tare input)

$ Deleting a digit:

Press c briefly

$ Deleting entire input string:

Press and hold c (> 2 sec)

Text Input Through the Keypad

§ Press the a key

> ‘ABC’ is displayed

§ Press the key on which the desired letter

is printed repeatedly, until that letter

is displayed (please note that keys can

activate other characters in addition to

those shown on the key)

$ If the next letter or character you wish

to enter is activated by the same key as

the previous character, press the

l soft

key or wait 2 seconds before entering

the next character.

$ Entering a space: Press the 0 key

$ Entering punctuation or special

characters:

Press the 1 key or . key repeatedly

until the desired character is displayed,

and then press the

l soft key to insert

it in the string.

$ Deleting characters: Press c briefly

$ Deleting entire input string:

Press and hold c (> 2 sec)

$ Exit text input mode and return to

numeric input mode: Press the a key

> 123 is displayed

§ Store input:

Press the required soft key

(for example,

1st ID)

Input Through the Weighing Platform

You can store the weight on the

weighing platform; for example,

as a tare weight (press the ) key)

Input Through the Digital I/O Port

An input control line is available for

use with all application programs, for

connecting a remote hand switch or

foot switch. Configure this input line

in the Setup program, under

Device parameters Control input

to assign one of the following functions

to the remote switch:

–

Print key

– Print key - long

– Tare key

– Tare key - long

– Fn key

– WP toggle key

Input Through the COM Port

The Combics scale is equipped with

a simple ASCII interface (SBI ) for data

transfer. The functions are described

in detail in the chapter entitled

“Operating the Combics”, under

“Data Output Functions”.

14

Operating Design

Input Through a Bar Code Scanner or

External Keyboard

You can use a bar code scanner or a

keyboard to enter alphanumeric values

in the Combics. Generally, you can use

any bar code format that is compatible

with the scanner connected. Like values

entered through the keypad, barcode

and keyboard input is handled as:

– Weight values for tare memory

– Reference weight values for the

Counting, Neutral Measurement and

Weighing in Percent applications

– Numeric values

– Product identifiers

You can also configure your Combics 3

to activate a function when a particular

bar code is scanned, or to display the

value represented by the bar code

without initializing any function.

This feature is configured in the Setup

program, under:

Device parameters Bar code

Select Reference, Tare or ID1 to

use the value represented by the bar code

as a reference, tare or ID1 value.

Bar code values can include a designator

specifying that the value scanned is

designated as a tare value, for example, or

an ID4 value. If you select the menu

setting

Input without

activating function

, the

content of bar code is displayed but no

function is activated, regardless of the

designation. The next

key pressed determines which function is

to be activated (e.g., “Set tare value”).

If you select

Input, the value scanned

is displayed if it has no (recognizable)

designation assigned. In this case, no

function is activated. The next key

pressed determines which function is

to be activated.

If you select

External keyboard,

you can enter data through an external

keyboard; the data is handled in the same

manner as keypad input.

Display Modes

There are two display modes: one is used

during weighing and the other when

working with the operating menu (Setup

program).

Display Mode During Weighing

(Main Display)

This display is subdivided into nine

sections.

Lines for metrological data:

These lines show:

WP1/2 Active weighing platform

R1/2 Current weighing range of

the active weighing platform

(with multiple range scale

connected)

Max Upper limit of the weighing

range in the active weighing

platform

Min Lower limit of the weighing

range in the active weighing

platform (verified models only)

e Verification scale interval

the active weighing platform

(verified models only)

d Readability/index of the active

weighing platform

Application symbols:

This field shows a symbol indicating the

selected application program (e.g.,

A for

the Counting application). The other

symbols that can be shown here include:

S Printing mode active

T GMP printing mode active

Battery symbol:

A battery symbol is shown in this field

when the Combics 3 is operated with

a remote rechargeable battery: The

symbol is filled in when the battery is

fully charged; when the battery is empty,

only an outline is shown.

Lines for metrological data

Bar graph

Text lines

Soft key labels

Line for measured values

Plus/minus sign

Stability symbol

Battery symbol

Application symbol

Unit

Tare memory/

calculated value

Info/Status line

15

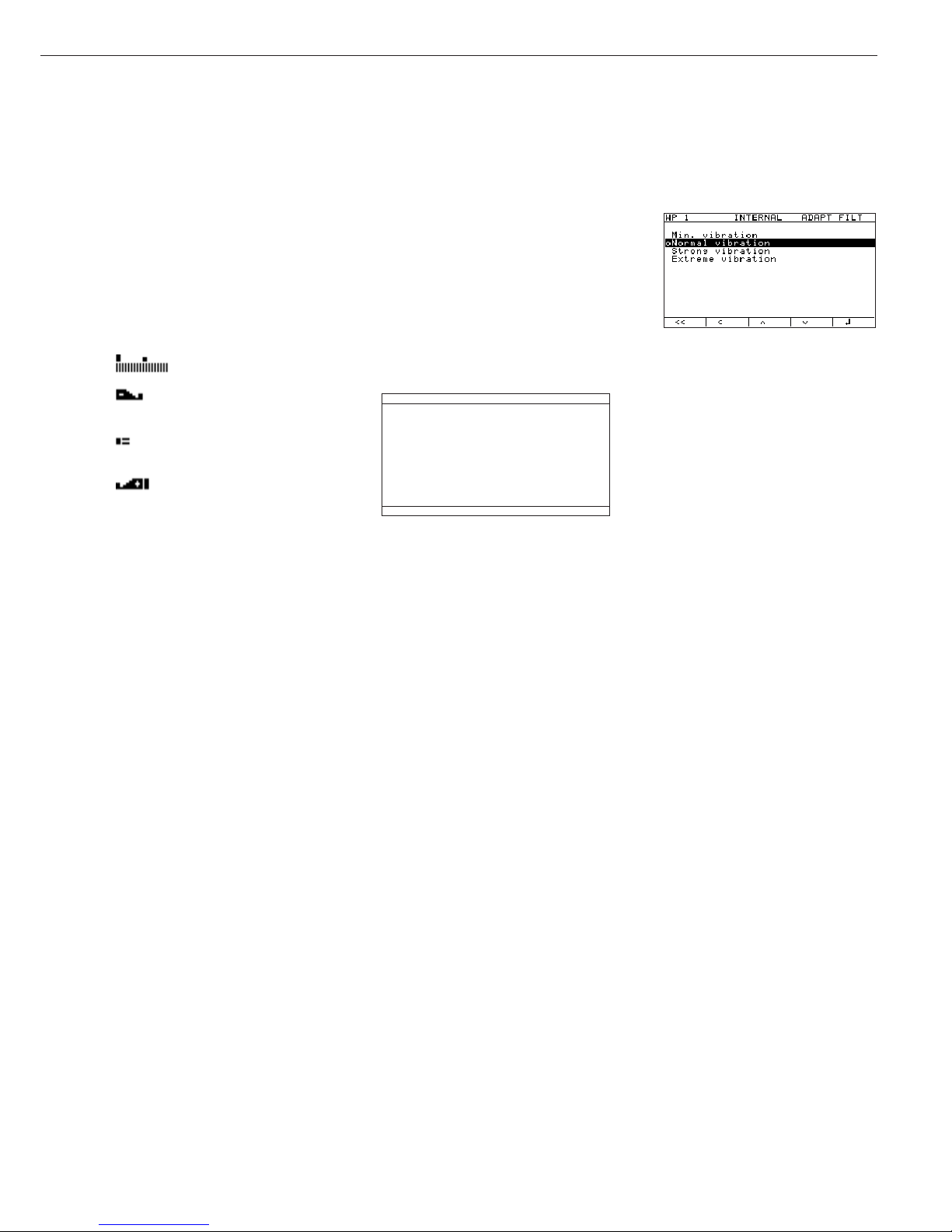

Bar graph:

The bar graph shows the percentage of the

weighing platform’s capacity that is “used

up” by the load on the scale (gross value).

When the Checkweighing application is

active, the tolerance limits are also shown

(calculated value). The following symbols

may be displayed here:

0% Lower limit

100% Upper limit

Bar graph with 10% markings

Minimum for the

Checkweighing application

Target for the Checkweighing

application

Maximum for the

Checkweighing application

Plus/minus sign:

This field shows either a plus or minus sign

(

+ or -) for weight values (or calculated

values), or the

o symbol when the

weighing platform is zeroed or tared.

Measured value/result line:

This field shows weight values, calculated

values and input characters.

Unit and stability:

When the weighing system reaches

stability, the weight unit or calculation

unit is displayed here.

Tare in memory, calculated values:

A symbol here indicates that a tare value

is stored or that the result is a calculated

value.

The following symbols may be displayed

here:

a Calculated value (cannot be

used in legal metrology)

NET Net value (gross weight

minus tare)

B/G Gross value (net value

plus tare)

Text lines:

The text lines show operator support

information, such as the name of the

active program, user guidance prompts,

etc.

Soft key labels:

This line shows the abbreviations or

symbols that indicate soft key functions

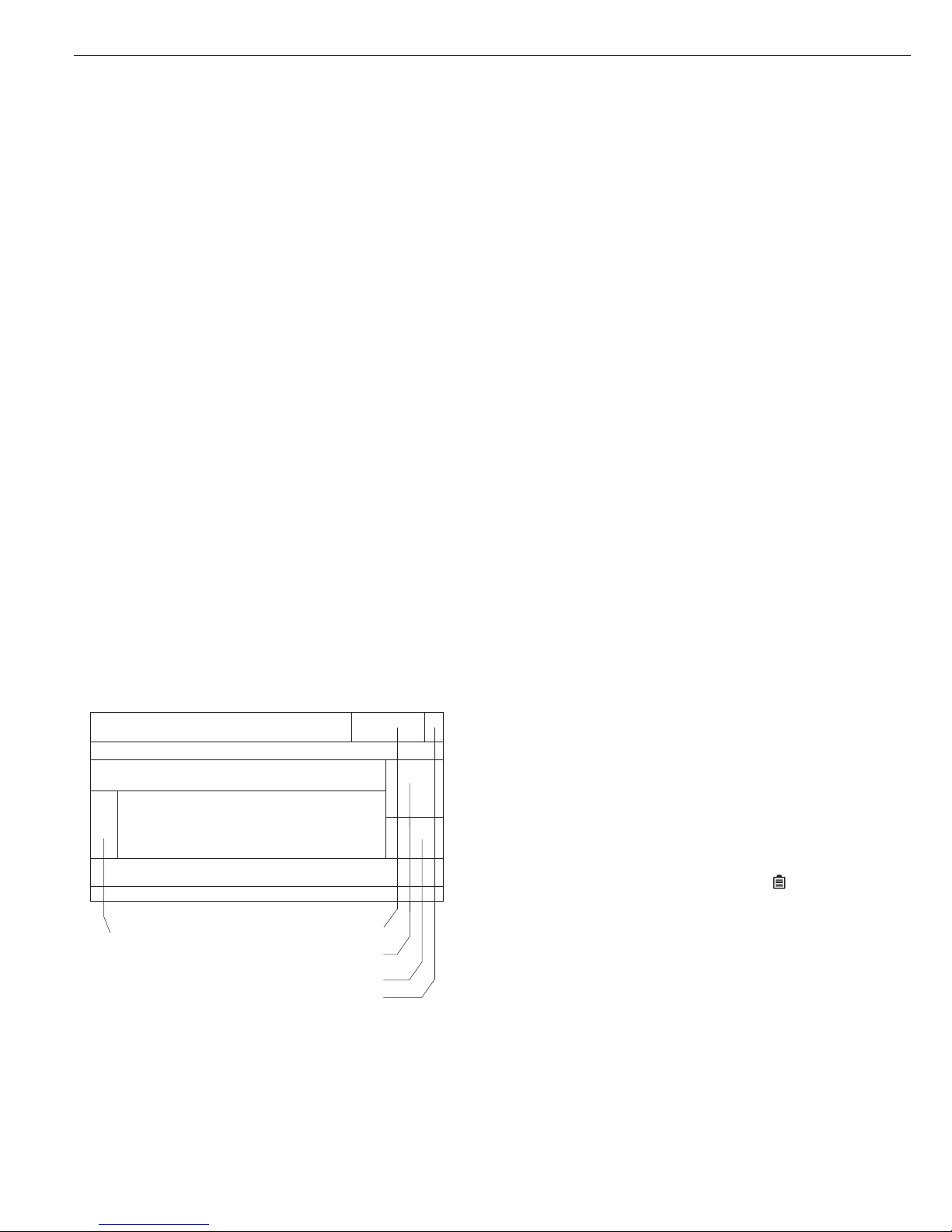

Display Mode for Configuration

and Information (Setup)

This display is divided into three sections.

Line for operating status:

The operating status line indicates

the function of the current screen page.

In the Setup program, this line shows

the “path” to the information displayed

Input and output window:

This section shows detailed information

(e.g., on the selected application) or a list

of options for selection. A selected item is

displayed inversely (white letters on a black

background). You can enter letters and

numbers in active fields here.

Soft key labels:

See the description above, under “Function

Keys (Soft Keys)” (page 11).

Status line

Input/output window

Soft key labels

Example: Setup: Device parameters:

WP-1: Internal: Adapt filter:

o This symbol indicates the currently

active menu setting

Setting parameters:

§ Press the Q or q soft key repeatedly

until the desired parameter is selected

(inverse display)

§ Confirm the setting: Press the l soft

key

§ Exit the Setup program: Press the

M key

Error Codes

– If a key is inactive, this is indicated as

follows:

– The error code “-” and/or

“

No function” is displayed for

2 seconds. The display then returns

to the previous screen content.

– An acoustic signal (double-beep)

is emitted.

– Temporary errors are indicated by

an error code, shown in the measured

value/result line for 2 seconds (for

example,

Inf 09).

– Fatal errors are indicated by an error

code displayed steadily in the measured

value/result line (for example,

Err

101

), until you turn the Combics off

and then on again (reset).

This process is the same for all

operating modes (weighing, application

programs and Setup program).

Error codes and messages are described

in detail in the chapter entitled “Error

Codes.”

16

Operating Design

Data Output

You can choose from four forms

of data output:

– Printer

– Digital input/output interface

– COM port

– LEDs

Printer

You can connect one or two strip

printers or one or two label printers

to the Combics. If you use a universal

printer or a model YDP02 or YDP03

printer, you can configure interface

parameters in the Setup program

(baud rate, stop bits, handshake

mode, data bits).

The printout can be formatted by the

user. The printout consists of two

user-definable header lines, up to four

lines identifying the weighing data,

one line for date and time, initialization

data (only when using applications),

serial number and results. For a strip

printer, universal printer or label printer,

you can also define whether a GMP

header and GMP footer (field for

operator signature) will be included

on the printout (GMP: Good

Manufacturing Practice).

These functions are described in detail

in the chapter entitled “Operating

the Combics”, under “Data Output

Functions.”

You can have printouts generated

at the press of a key, or automatically

(dependent on stability).

For the Totalizing and Net-total

applications, you can also configure

summarized printouts (results)

independent of individual or

component value printouts.

Press the p key to print the settings

of the current menu level on a strip

printer or a universal printer.

All submenus under the current menu

level are included on the printout.

Digital Input/Output Interface

The digital I/O interface is supported

by the Checkweighing and Classification

applications.

Checkweighing

Four data outputs transfer the following

information on the weight values:

“less than”, “equal to”, “greater than”

and “set” In the Setup menu, you can

configure whether the outputs are:

always on; activated when the scale

has stabilized; active only within the

checkweighing range; activated when

the scale has stabilized only if the

values are within the checkweighing

range, or off.

Classification

Four data outputs transfer information

on the class of the load (Class 1, 2, 3,

4 or 5) and whether the minimum load

is exceeded (Set). The user can define

whether the output lines are always

active, activated only at stability, or off.

For the Checkweighing and

Classification applications, you can use

the “Set” output to indicate:

– The scale(s) and the Combics 3 indicator

are ready to operate, or

– for Checkweighing: Set

– for Classification: Minimum load

exceeded

For all other applications, the “Set”

output indicates when the Combics 3

indicator is ready to operate.

COM Port

The Combics scale is equipped

with an SBI interface for data transfer.

You can define certain parameters for

this interface (generate printout,

time-dependent autoprint, ID codes).

See “Data Output Functions” in

the chapter entitled “Operating the

Combics” for a detailed description

of data output options.

LEDs

The Combics 3 has an integrated

checkweighing display consisting

of three LEDs, for use with the

Checkweighing and Classification

applications. These LEDs show the

relationship of the current weight

value to the tolerance limits in

Checkweighing; with the Classification

application, they indicate how the

weight value is classified.

Saving Data

The parameters you select in the

operating menu remain stored after

you turn off the Combics.

The Combics also stores all application

parameters (for example, reference

values). These parameters are

overwritten only when

– you turn the Combics off and then

back on again

– you return to the originally selected

application from a different one

(for example, if you switch from

Counting to Averaging, the values

previously stored for the Counting

application are restored)

You can restrict access to the Device

parameters menu in the Setup program

by assigning a password. The password

is configured in the Setup program,

under:

Device parameters Password

Purpose

You can configure the Combics 3 to meet

individual requirements by entering user

data and setting menu parameters in the

Setup program.

17

Configuring the Combics

Features

The operating menu parameters are

divided into the following categories

(highest menu level):

– Application parameters

– Fn key function

– Device parameters

– Device-specific information (

Info)

– Language

When you use the scale in legal

metrology, access to parameters

is restricted.

Factory setting

Parameters: The factory-set

configurations are identified by an “o”

in the list starting on the next page.

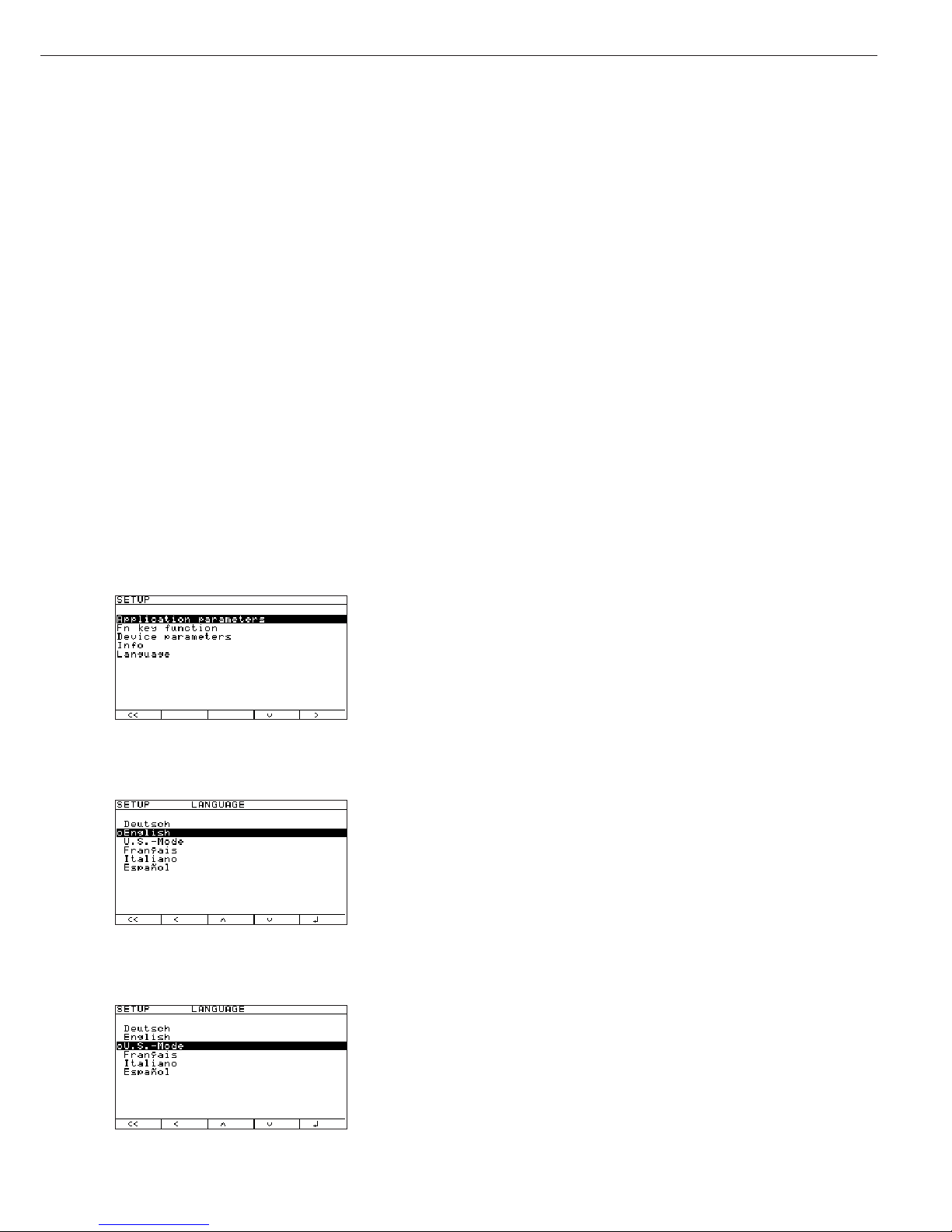

Setting the Language

You can choose from five languages

for the display of information:

– German

– English (factory setting)

– English with U.S. date/time format

– French

– Italian

– Spanish

Example: Selecting “U.S. Mode” for the Language

e Turn on the Combics

M Activate the Setup program

)

Soft key q (repeatedly), Select “Language”

Soft key O and confirm

Soft key Q, Select “U.S. Mode”

Soft key l Save the new setting

Soft key oo Exit the Setup menu

18

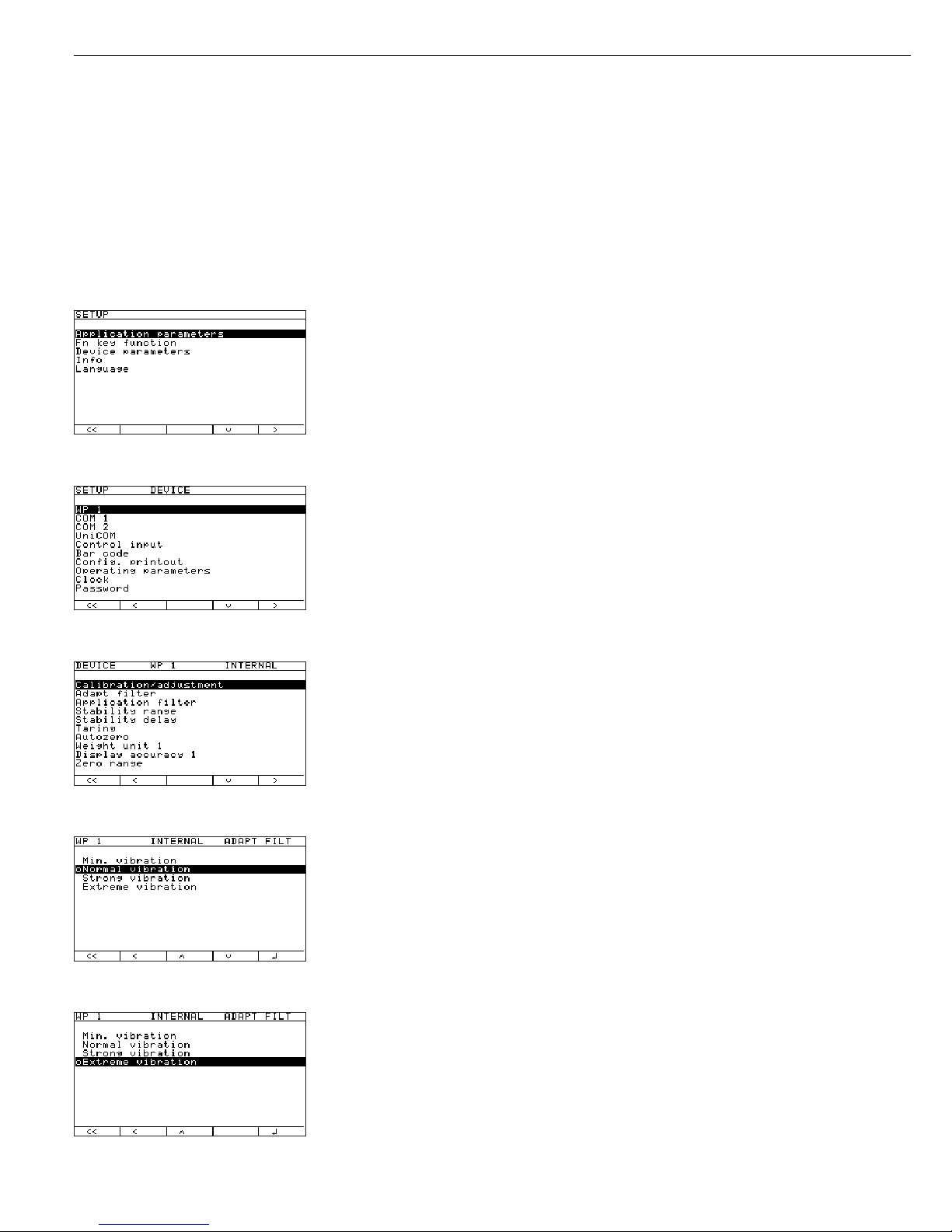

Navigating in the Operating Menu (Examples)

Example: Adapting the Combics to ambient conditions at the place of installation; menu item: “Very unstable conditions”

for weighing platform WP1.

e Turn on the Combics

M Activate the Setup program

Soft key q, Select

Device parameters

Soft key O and confirm

Soft key O, Confirm weighing platform

WP-1 and then

Soft key O confirm

Internal

Soft key q, Select Adapt filter

Soft key O and confirm

2+ soft key q, Select

Very unstable

Soft key l and save

To continue: soft key o Change other menu settings if desired, or

Soft key oo Exit the Setup menu

19

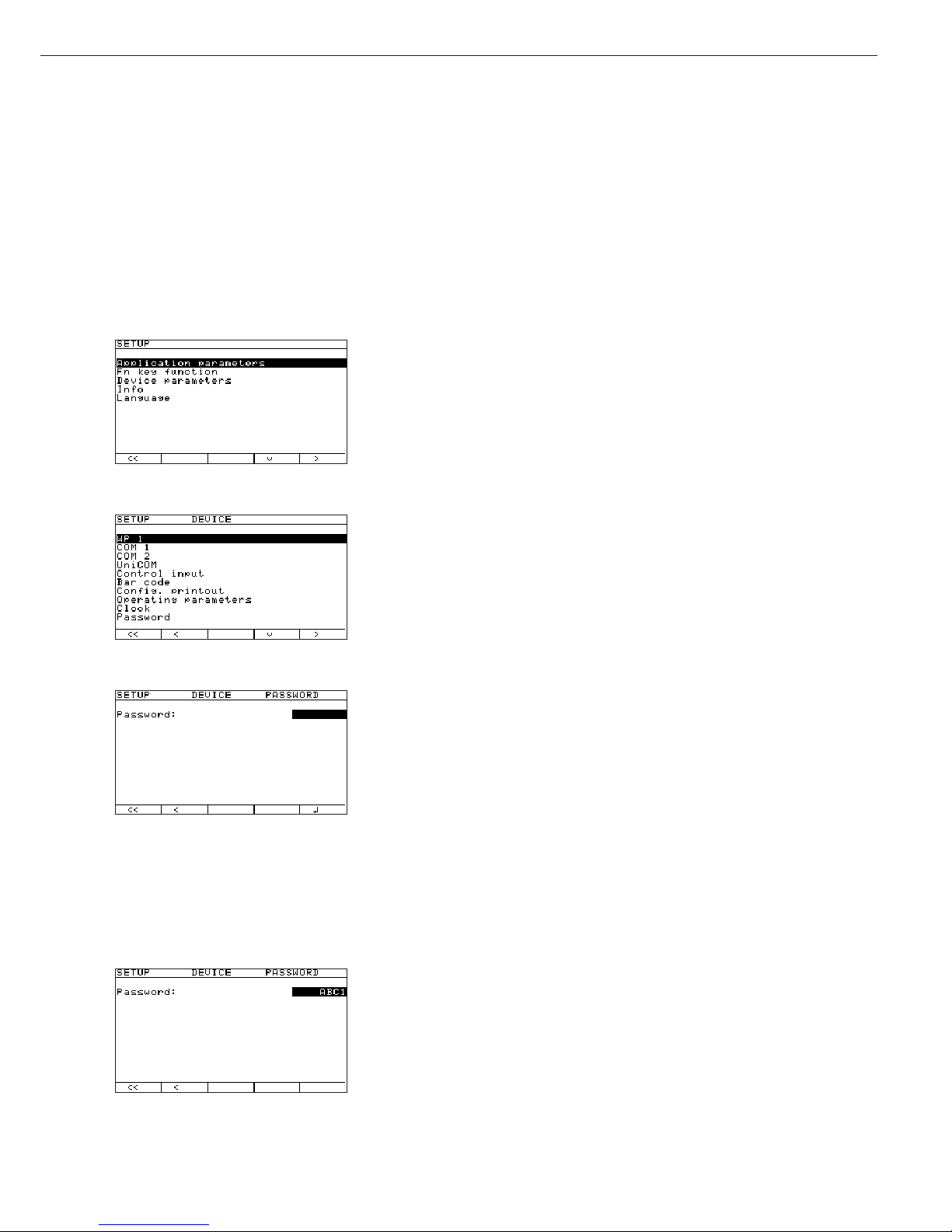

Defining Password Protection for the Operating Menu: Entering, Changing or Deleting a Password

You can define a password to protect the

Application parameters and Device parameters. To do this, enter a password

known only to authorized personnel. Without the password, only a few of the menu items can be accessed (k key, Info, language).

Example: Entering, changing or deleting the password “ABC1”

e Turn on the Combics

M Activate the Setup program

2+ soft key q, Select

Device parameters

Soft key O and confirm

Soft key q repeatedly, Select

Password

Soft key O and confirm

a, 2(ABC), Soft key l; Enter password: “ABC1” (max. 8 characters)

2+

2(ABC), Soft key l; Confirm input (wait 2 seconds or press l soft key)

3+

2(ABC), Soft key l; Confirm password

a, 1, Soft key l If necessary: delete password:

Press c and confirm with soft key l

To continue: soft key o Change other menu settings if desired, or

Soft key oo Exit the Setup menu

20

Printing Parameter Settings

To generate a printout of the settings

on the current menu level:

Press the p key

> Printout (example)

The maximum width of this printout

is 20 characters.

--------------------

12.01.2002 09:46

Model CW3P1-6ED-LCE

Ser.no. 12345678

Vers. 1.1010.10.2

BVers. 01-26-01

-------------------SETUP

DEVICE

--------------------

WP-1

Internal

COM1

Data communication

SBI

Baud rate

1200 baud

Parity

Odd

Number of stop b

1 stop bi

Handshake mode

Hardware 1 charact

Number of data b

7 bit

Data output

Printout, printer 1

Line format

For other apps. (22

characters)

COM2

Off

UNICOM

Off

Control input

Print key

Bar code

Reference val

Printout

Headers

Line 1:

Line 2:

ID codes

ID1:

123

ID2:

456

ID3:

ID3

ID4:

ID4

ISO/GLP/GMP

Off

Date/time

Date with time

Once at stability

Off

etc.

21

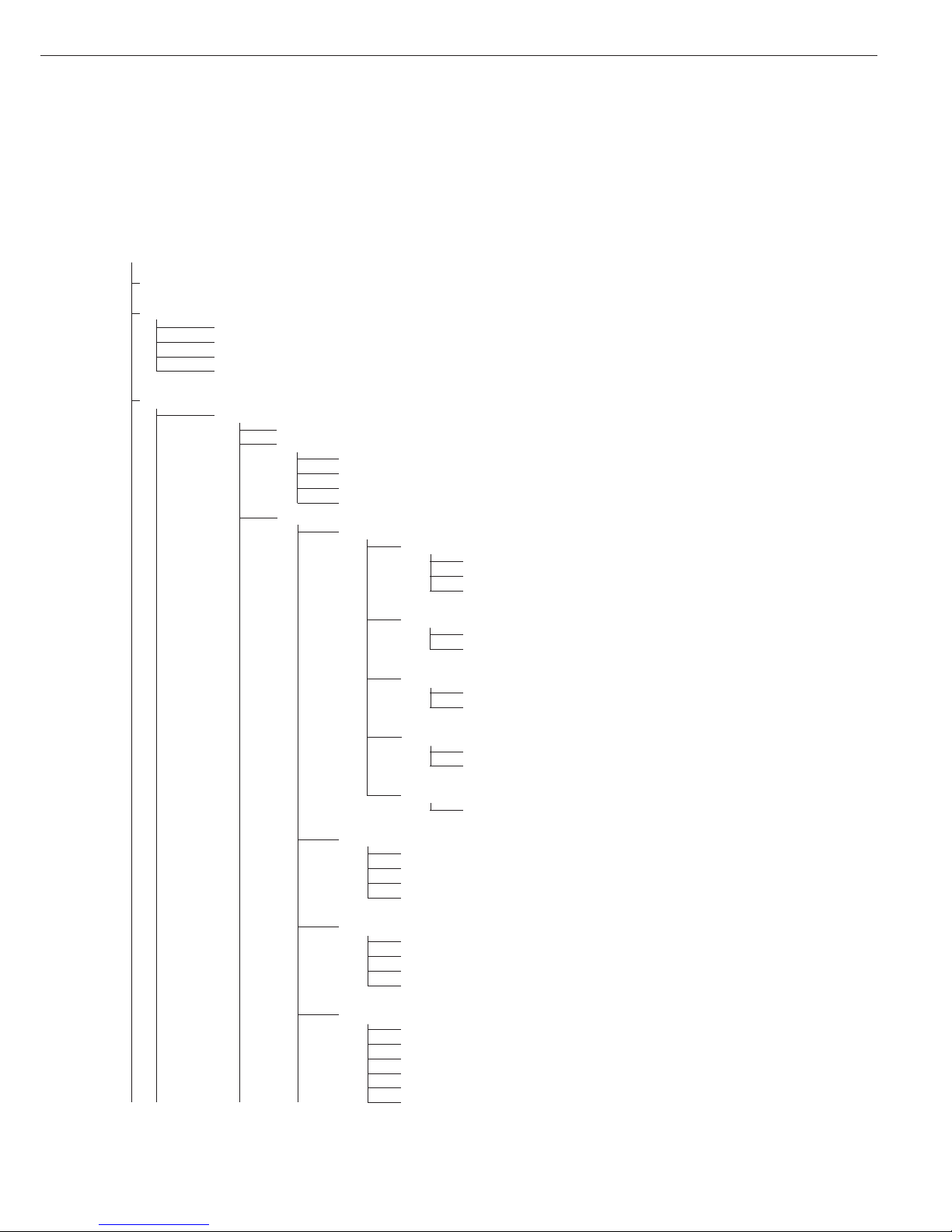

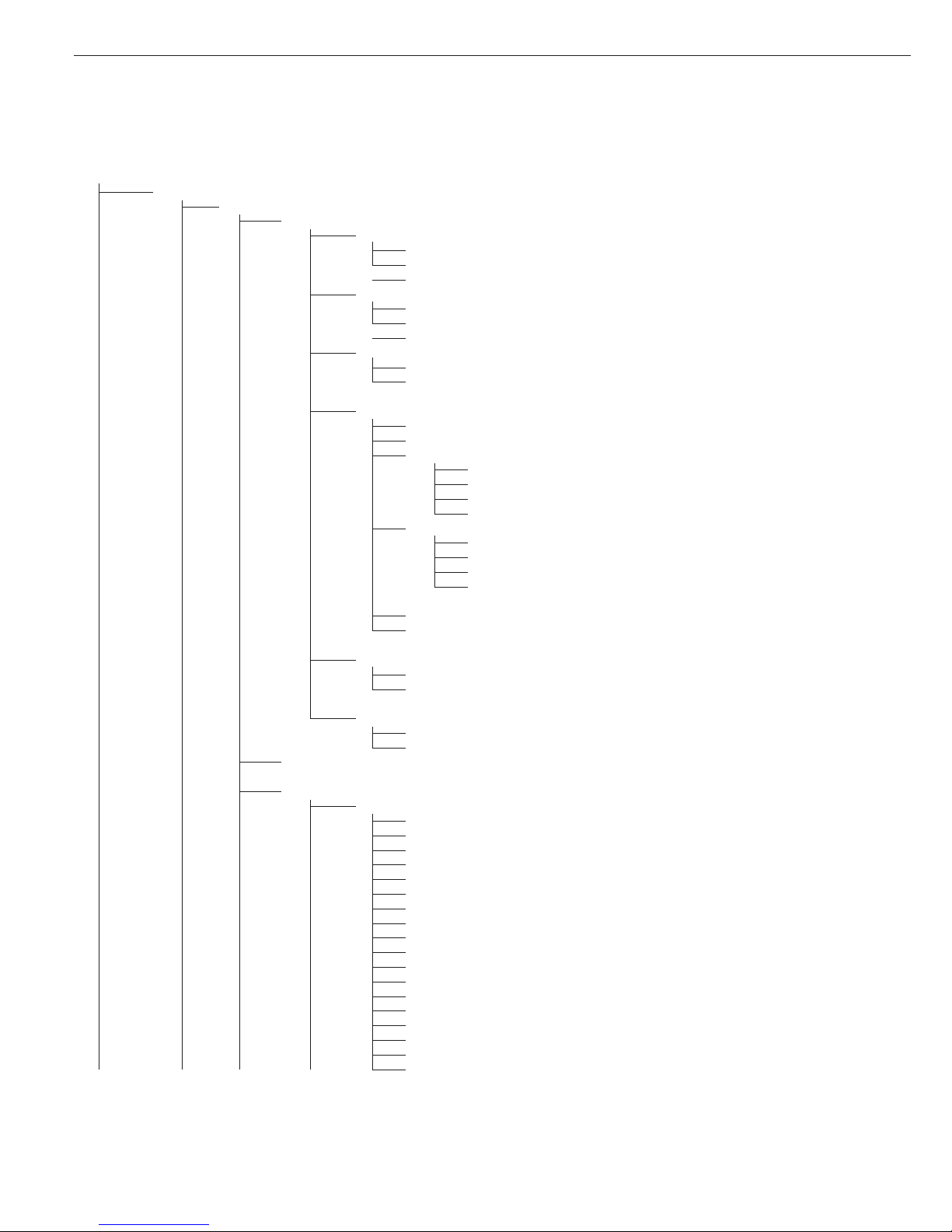

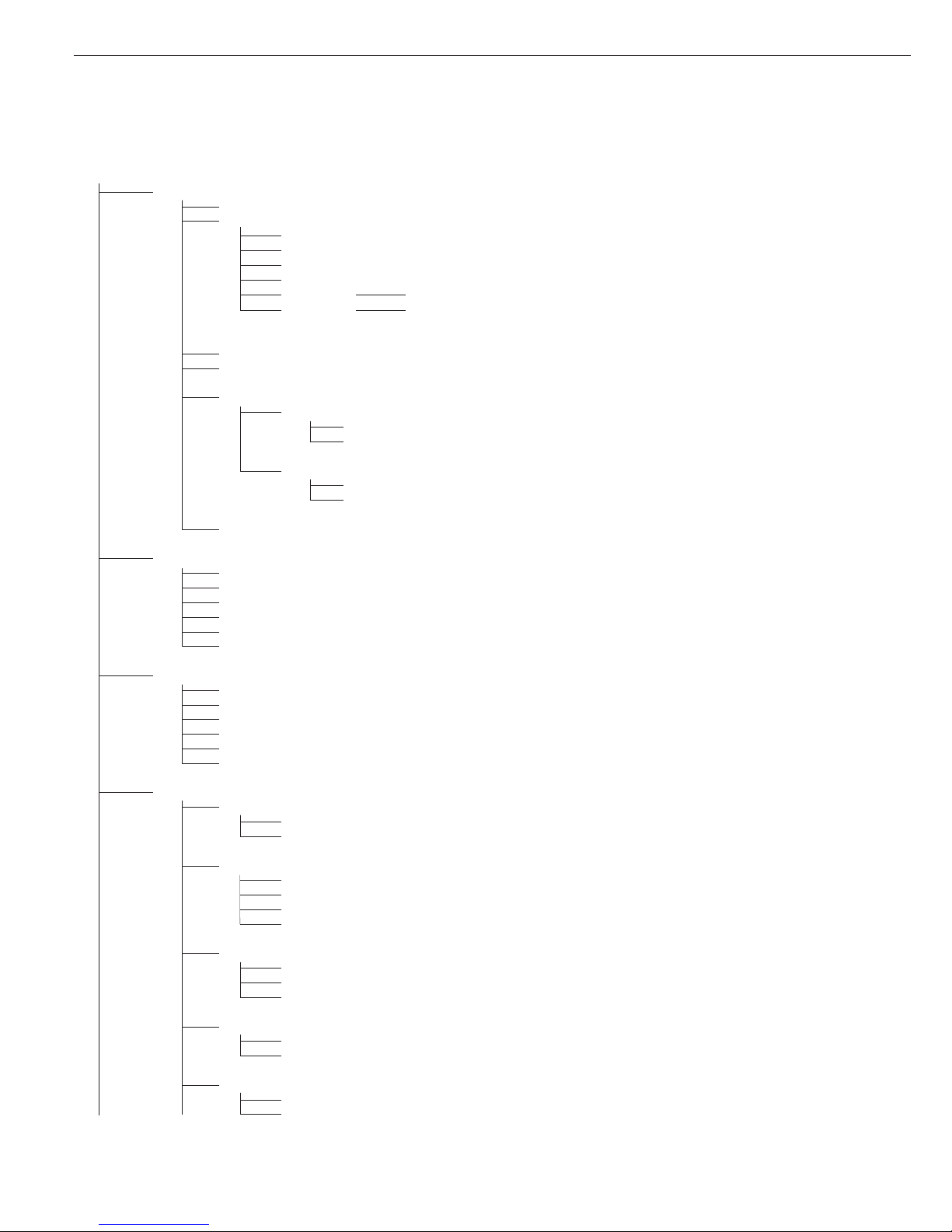

Operating Menu Overview (Parameters)

o = Factory setting

W User-defined setting

Setup

Application parameters: Please refer to the operating instructions for Combics 3 “Basic Application Programs”

Fn-key

Off

o Gross/net toggling

Toggle weight units

10 + higher resolution

Device Parameters

WP-1

Off

RS-232

1

)

SBI standard

SBI verifiable

o IS-232

ADC-232

Internal

Calibration/Adjustment

CAL Key Function

o Ext. cal./adjust.; default weight

Ext. cal./adjust.; weight can be selected

Key blocked

Calibration/Adjustment Sequence

Calibration with automatic adjustment

o Calibration with adjustment triggered manually

isoCAL Function

o Off

Adjustment prompt

External Calibration/Adjustment

2

)

o Accessible

Blocked

External Weight

Cal./adj. weight

Adapt Filter

Min. vibration

o Normal vibration

Strong vibration

Extreme vibration

Application Filter

o Final readout

Filling mode

Low filtering

W/o filtering

Stability Range

1/4 digit

1/2 digit

o 1 digit

2

)

2 digits

2

)

4 digits

2

)

8 digits

2

)

1

) = function will be made available in future

2

) = not available on scales verified for use in legal metrology

22

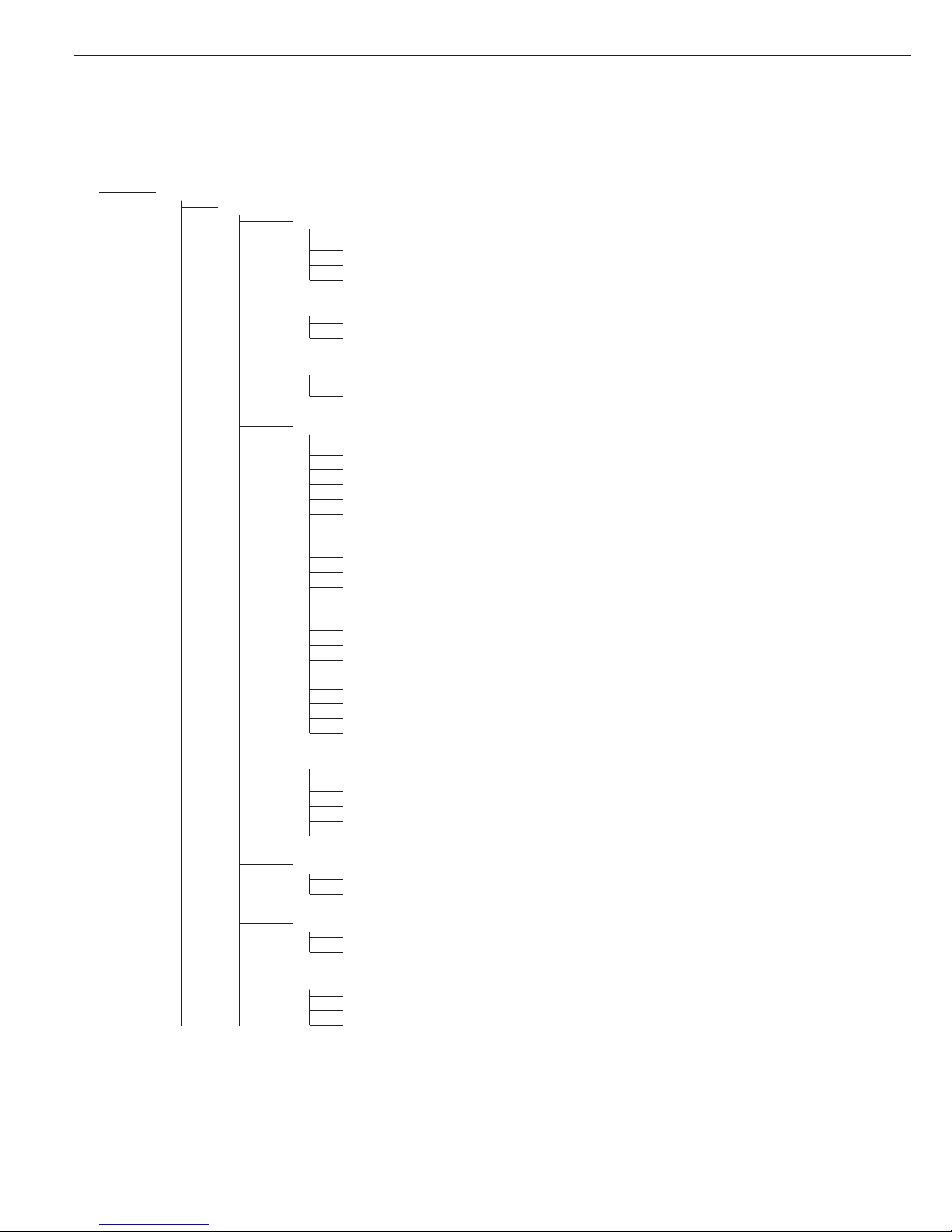

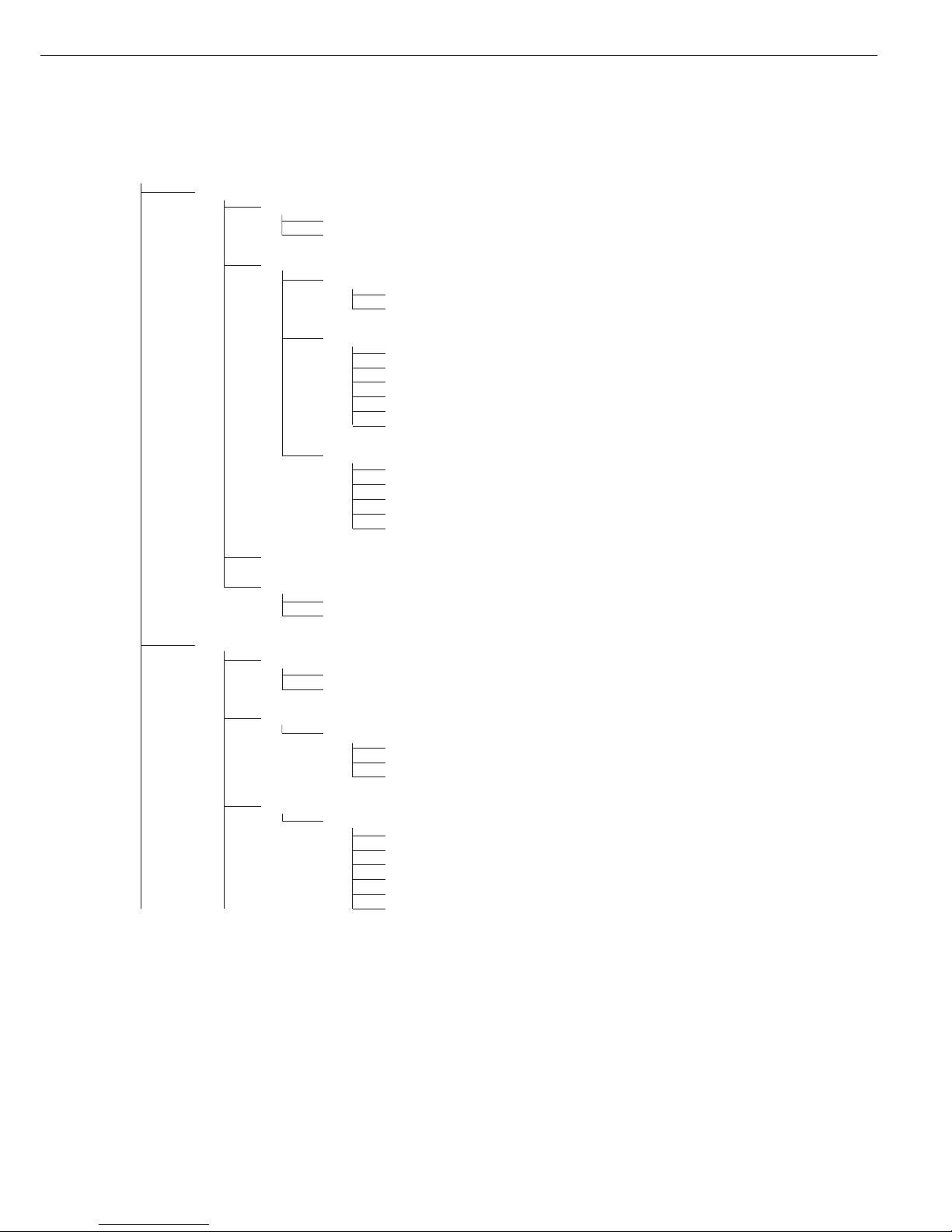

Device Parameters

WP-1

Internal

Stability Delay

No delay

o Short delay

Average delay

Long delay

Taring

1

)

Without stability

o After stability

Auto Zero

oOn

Off

Weight Unit 1

2

)

User-defined / o (factory setting: grams

1

)

Grams / g

o Kilograms / kg

Carats / ct

1

)

Pounds / lb

1

)

Ounces / oz

1

)

Troy ounces / ozt

1

)

Hong Kong taels / tlh

1

)

Singapore taels / tls

1

)

Taiwanese taels / tlt

1

)

Grains / GN

1

)

Pennyweights / dwt

1

)

Milligrams / mg

1

)

Parts per pound / lb

1

)

Chinese taels / tlc

1

)

Mommes / mom

1

)

Austrian carats / K

1

)

Tola / tol

1

)

Baht / bat

1

)

Mesghal / MS

1

)

Tons / t

Display Accuracy 1

o All digits

Reduced by 1 decimal place for load change

Index +1

1

)

Index +2

1

)

Reduced by 1 decimal place

1

)

Zero Range

1 percent/max. cap.

o 2 percent/max. cap.

Zero at Power On

2 percent/max. cap.

o 5 percent/max. cap.

Tare/Zero at Power On

oOn

Off

Only zero at power on

1

) = not available on scales verified for use in legal metrology

2

) = depends on weighing platform model

23

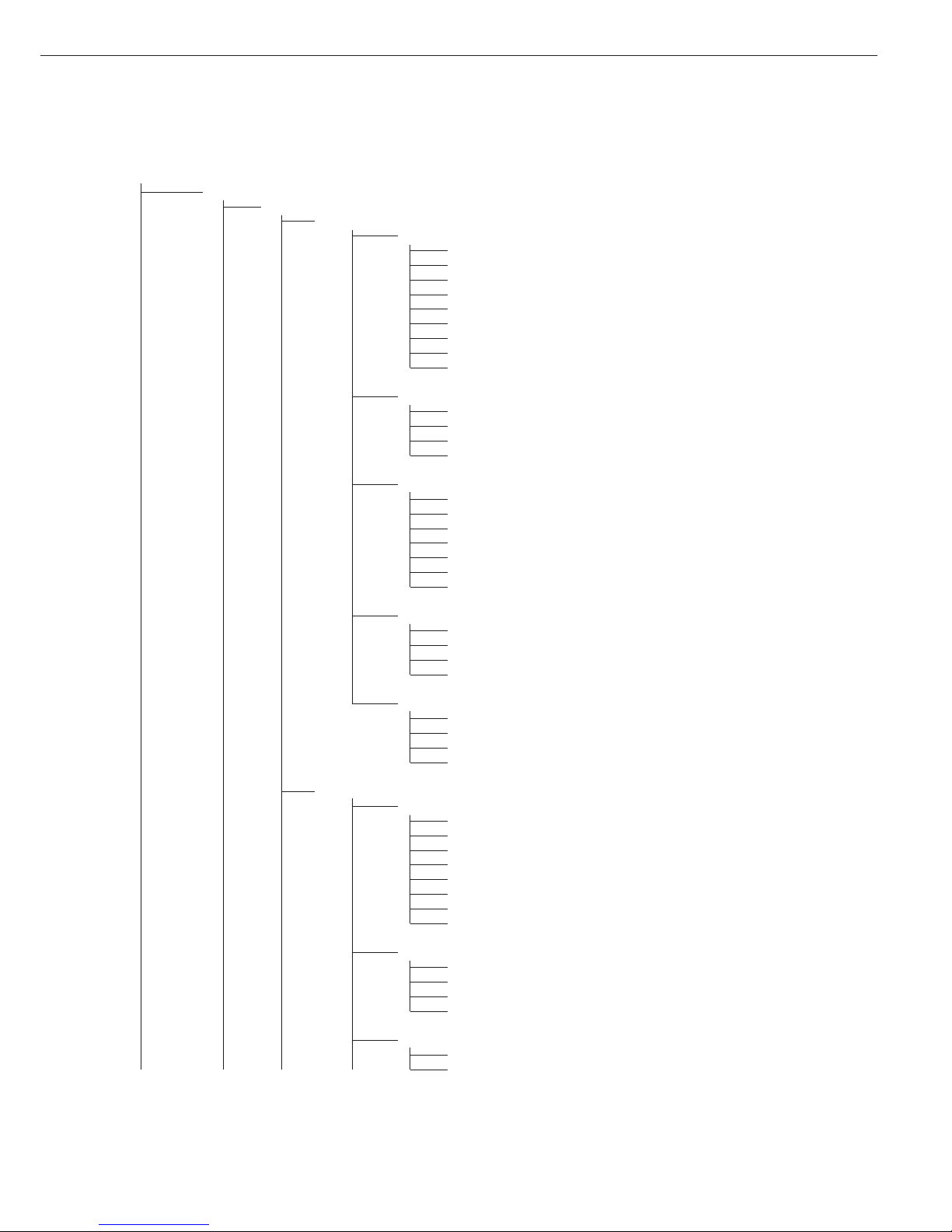

Device Parameters

WP-1

Internal

Weight Unit 2

2

)

User-defined / o (factory setting: grams

1

)

o Grams / g

Kilograms /kg

Carats / ct

1

)

Pounds / lb

1

)

Ounces / oz

1

)

Troy ounces / ozt

1

)

Hong Kong taels / tlh

1

)

Singapore taels / tls

1

)

Taiwanese taels / tlt

1

)

Grains / GN

1

)

Pennyweights / dwt

1

)

Milligrams / mg

1

)

Parts per pound / lb

1

)

Chinese taels / tlc

1

)

Mommes / mom

1

)

Austrian carats / K

1

)

Tola / tol

1

)

Baht / bat

1

)

Mesghal / MS

1

)

Tons / t

Display Accuracy 2

o All digits

Reduced by 1 decimal place for load change

Index +1

1

)

Index +2

1

)

Reduced by 1 decimal place

1

)

Factory Settings: Weighing Parameters

Yes

oNo

COM1

o Off

WP-2

o RS-232

SBI standard version (9600 baud)

SBI for legal metrology (9600 baud)

o IS-232

1

)

ADC-232

1

)

Data Communications

o SBI

Baud Rate

150 baud

300 baud

600 baud

o 1200 baud

2400 baud

4800 baud

9600 baud

19,200 baud

Parity

Space

3

)

o Odd

Even

None

4

)

1

) = not available on scales verified for use in legal metrology

2

) = depends on weighing platform model

3

) = not with 8 data bits

4

) = not with 7 data bits

24

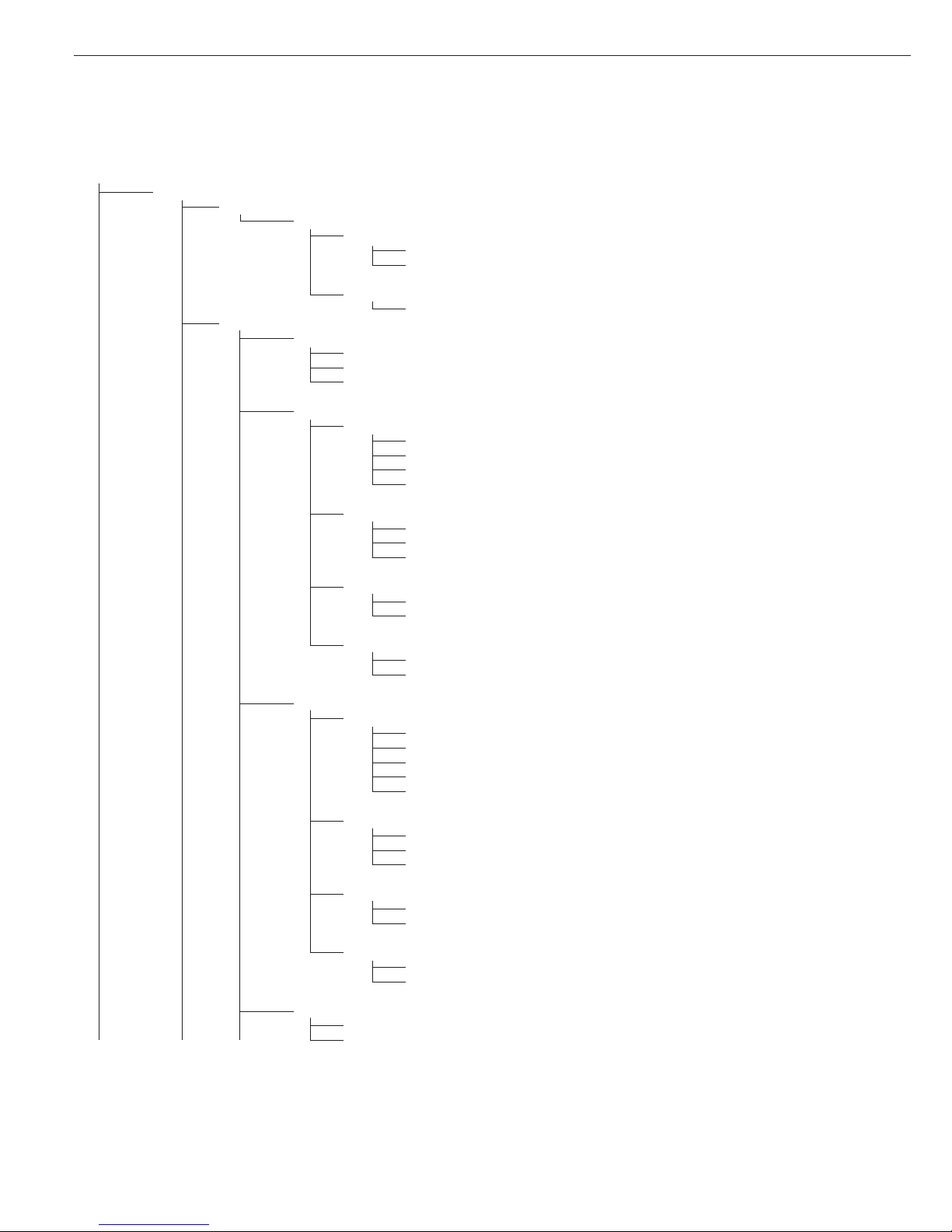

Device Parameters

COM1

Data Communications

o SBI

Number of Stop Bits

o 1 stop bit

2 stop bits

Handshake Mode

Software handshake

o Hardware, 1 character after CTS

Number of Data Bits

o 7 bits

8 bits

Data Output

On request, without stability

o On request, after stability

Automatic, without stability

o 1 display update

2 display updates

10 display updates

100 display updates

Automatic, at stability

o 1 display update

2 display updates

10 display updates

100 display updates

Printout, printer 1

Printout, printer 2

Line Format

For raw data (16 characters)

o For other apps. (22 characters)

Factory Settings

Yes

oNo

xBPI-232

MP8 (binary)

Application Program

MP8: 3-1-1

MP8: 3-1-2

MP8: 3-1-3

MP8: 3-1-4

MP8: 3-1-5

MP8: 3-1-6

MP8: 3-1-7

MP8: 3-1-8

MP8: 3-1-9

MP8: 3-2-1

MP8: 3-2-2

MP8: 3-2-3

MP8: 3-2-4

MP8: 3-2-5

MP8: 3-2-6

MP8: 3-2-7

MP8: 3-2-8

MP8: 3-2-9

25

Device Parameters

COM1

Data Communications

MP8

Application Program

MP8: 3-3-1

MP8: 3-3-2

MP8: 3-3-3

MP8: 3-3-4

MP8: 3-3-5

MP8: 3-3-6

MP8: 3-3-7

MP8: 3-3-8

MP8: 3-3-9

Program Code 2

o Code 2.1

Code 2.2

Code 2.3

Code 2.4

Baud Rate

150 baud

300 baud

600 baud

o 1200 baud

2400 baud

4800 baud

9600 baud

Parity

Mark

Space

o Odd

Even

Print in Weigh Mode

Manual without stability

o Manual with stability

Automatic without stability

Automatic at stability

SMA

Baud Rate

150 baud

300 baud

600 baud

1200 baud

2400 baud

4800 baud

o 9600 baud

19,200 baud

Parity

Space

1

)

Odd

Even

o None

2

)

Number of Stop Bits

o 1 stop bit

2 stop bits

1

) = not with 8 data bits

2

) = not with 7 data bits

26

Device Parameters

COM1

Data Communications

SMA

Handshake Mode

Software handshake

o Hardware, 1 character after CTS

Number of Data Bits

o 8 bits

Printer 1

1

)

YDP01IS

o Strip

Label

Label, manual form feed

YDP02

Baud Rate

o 1200 baud

2400 baud

4800 baud

9600 baud

Parity

Space

o Odd

Even

Number of Stop Bits

o 1 stop bit

2 stop bits

Handshake Mode

Software handshake

o Hardware, 1 character after CTS

YDP03

Baud Rate

o 1200 baud

2400 baud

4800 baud

9600 baud

19,200 baud

Parity

Space

oOdd

Even

Number of Stop Bits

o 1 stop bit

2 stop bits

Handshake Mode

Software handshake

o Hardware, 1 character after CTS

YDP02IS

o Strip

Label

1

) = max. 2 printers can be configured

27

Device Parameters

COM1

Printer 1

4

)

Universal

Baud Rate

150 baud

300 baud

600 baud

1200 baud

4800 baud

o 9600 baud

19,200 baud

Parity

Space

1

)

Odd

Even

o None

2

)

Number of Stop Bits

o 1 stop bit

2 stop bits

Handshake Mode

o Software handshake

Hardware, 1 character after CTS

o YDP04IS

o Strip

Label

Label, manual form feed

YAM01IS (external data logger)

Printer 2

4

) as for Printer 1

External Alibi Memory

o YAM01IS

COM2

Off

WP-2

RS-232: as for COM1

o RS-485

o IS-485

ADC-485

Data Communications

o SBI: as for COM1

xBPI-232: as for COM1

xBPI-485 Valid addresses: 0 to 31 inclusive; factory setting: 0

SMA: as for COM1

Printer 1:

4

) as for COM1

Printer 2:

4

) as for COM1

External Alibi Memory: as for COM1

External Multi-I/O Converter

3

)

1

) = not with 8 data bits

2

) = not with 7 data bits

3

) = function will be made available in future

4

) = max. 2 printers can be configured

28

Device Parameters

UniCOM (Optional Interface)

o Off

Data Communications: as for COM1, plus:

o SBI: as for COM1

xBPI-232: as for COM1

xBPI-485: as for COM2

SMA: as for COM1

Profibus Valid addresses: from 0 to 126 inclusive; factory setting: 126

Ethernet Optional: Ethernet (for details, see the “Combics UNICOM Interfaces”

installation instructions included in this manual)

Printer 1:

1

) as for COM1

Printer 2:

1

) as for COM1

Analog Output Port

Value Output

o Net value

Gross value

Error Signal

o High (20 mA)

Low (0/4 mA)

External Alibi Memory: as for COM1

Control Input (for Remote Switch)

o Print key p

Print key p - long

Tare key )

Tare key ) - long

Fn key k

WP toggle key n

Bar Code

o Reference value

Tare value

ID1

Data input

Input without activating a function

External keyboard

Printout

Headers

Line 1:

Line 2:

ID Codes

ID1:

ID2:

ID3:

ID4:

ISO/GLP/GMP-compliant Printout

o Off

For 1 application result

For several application results

Date/Time

o Date with time

Date only

Once at Stability

o Off

On

1

) = max. 2 printers can be configured

29

Device Parameters

Printout

FlexPrint

o Off

On

Printer 1

Number of Printouts

o 1 printout

2 printouts

Components/Individual Printout

o Headers 1, 2

o ID1, ... ID4

o Date and time

o Application ini data

o Scale ID (e.g., serial no.)

o Application result

Printout of Result/Total

o Headers 1, 2

o ID1 through ID4

o Date and time

o Scale ID (e.g., serial no.)

o Application result

Printer 2:

1

) as for Printer 1

Factory Settings

Yes

o No

Operating Parameters

Acoustic Signal

o On

Off

Keypad

Block Key Functions

o All keys unblocked

All blocked except Setup, I/O

Alphanumeric keys blocked

Display

Contrast

1

2

3

o4

5

6

1

) = max. 2 printers can be configured

Loading...

Loading...