Sartorius Cubis MSU116P, Cubis MSU36P, Cubis MSU36S, Cubis MSU66S, Cubis MSU66P User Manual

Page 1

User Manual

Sartorius Cubis® Series

Electronic Semimicro Micro, Precision and Analytical Balances

MSU Models

Page 2

2 Cubis® MSU User Manual

Contents

Contents

Notes on Using This Manual...................... 3

Safety Instructions ........................... 4

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General View of the Equipment and Equipment

Supplied ................................... 6

Getting Started .............................. 11

Unpacking the Equipment .................... 11

Assembly .................................15

Installation Instructions ...................... 23

Power Connection .......................... 24

Anti-theft Locking Device..................... 26

Leveling.................................. 26

Switching On ..............................27

Removing the Retainer with the Display and

Control Unit............................... 28

Below-balance Weighing ..................... 33

Cable Opening of the Manual Analytical Balance

Draft Shield ................................. 36

Moving the Balance .......................... 37

Using the Balance ............................ 38

Turning the Balance On/Off ................... 38

Operating Design: Q-Guide.................... 38

Using the Display and Control Unit.............. 39

Setting the Language ........................40

Quick Guide: First Weighing ................... 40

Display in Operating Mode ...................41

Display in Setup Mode ....................... 42

Activating/Switching Users .................... 44

System Settings (Menu) ....................... 45

Leveling the Balance (Q-Level) ................. 46

Calibration/Adjustment Data ..................47

Configure Timer Controlled Actions .............48

Displaying Device Information ................. 50

Alibi Memory ..............................51

Device Parameters .......................... 54

Task Management ........................... 67

Using Applications with the Factory Settings....... 68

Creating New Tasks (Configuration) ............. 68

Configuring Printouts........................ 71

Combining Applications into One Task ........... 77

Executing Tasks ............................ 78

Weighing................................... 79

Mass Unit Conversion ......................... 80

SQmin Minimum Weighing ..................... 83

Individual Identifiers ..........................85

Density Determination......................... 88

Statistics ................................... 93

Calculation ................................. 96

Averaging ................................. 100

Formulation................................ 105

Weighing in Percent ......................... 109

Timer-controlled Functions .................... 112

Totalizing ................................. 114

DKD Measurement Uncertainty................. 116

Second Tare Memory (Preset Tare) .............. 118

Parts Counting ............................. 120

Checkweighing ............................. 124

Importing/Exporting Data ..................... 128

Calibration and Adjustment ................... 131

Calibration/Adjustment Using Internal

Calibration Weight .........................131

Calibration/Adjustment Using External

Calibration Weight .........................132

User Management .......................... 134

User Management ......................... 134

Creating User Profiles ....................... 134

Activating Users ........................... 137

Editing User Profiles........................ 138

Interfaces ................................. 140

USB Port (PC)............................. 141

PS2 Interfaces for Barcode Scanner or Keyboard . . . 142

Interfaces (RS-232) 25-pin and 9-pin ........... 143

Configuring Serial Ports ..................... 146

Bluetooth

®

Interface (COM C, Optional) ......... 149

Network Interface (Ethernet).................. 151

Data Output.............................. 156

Data Input ............................... 161

Updating the Software ....................... 166

Error and Status Messages .................... 168

GPL License ................................ 169

Care and Maintenance ....................... 170

Storage and Shipping ........................ 174

Disposal................................... 183

Technical Data.............................. 184

Balance Dimensions.......................... 197

Accessories ................................ 205

Declarations of Conformity .................... 207

EC Type-Approval Certificate .................. 209

Plates and Markings ......................... 211

Page 3

Cubis® MSU User Manual 3

Notes on Using this Manual

Notes on Using this Manual

t Please read this entire manual carefully and completely before using the device.

t Read the safety precautions carefully.

t This manual is part of the product. Keep it in a safe and easily accessible

location.

t If the manual should be lost or misplaced, please contact Sartorius for

a replacement or download the latest manual from our website:

www.sartorius.com

Symbols and Signs

The following symbols are used in this manual:

2

Warning symbol for various types of dangers.

These symbols are explained in more detail in Section “Safety Instructions.”

h

This symbol indicates useful information and tips.

This symbol indicates notes on use of the balance in legal metrology within

the scope of validity of Council Directive No. 2014/31/EU for instruments for which

the conformity assessment procedure has been carried out (Models MS...-.CE...).

H This symbol means that the USER key should be pressed.

D This symbol means that the TASK key should be pressed.

When individual functions are displayed, press the associated softkey.

t Indicates a required action

y Describes the result of an action

1.

If a procedure has multiple steps...

2. ... the steps are numbered consecutively.

– Indicates an item in a list

Page 4

4 Cubis® MSU User Manual

Safety Instructions

Safety Instructions

This device complies with European Council Directives as well as international regulations

and standards for electrical equipment, electromagnetic compatibility, and the stipulated

safety requirements. Improper use or handling can, however, result in damage and/or injury.

This device should only be operated by trained personnel.

Operators must read these installation instructions, particularly the safety information, and

must be familiar with the operation of the equipment. The operator is required to supplement these safety precautions as appropriate. The operating personnel must be provided

with the appropriate training.

The requirements pertaining to applicable installation regulations must be followed when

using electrical equipment in systems and environmental conditions with increased safety

requirements. Relevant laws, standards, regulations, guidelines and environmental protection laws valid in your country must be observed.

Always keep the equipment and balance freely accessible. Any installation work or balance

operation that does not conform to the instructions will result in forfeiture of all claims

under the manufacturer’s warranty.

Danger of Explosion!

1

Do not use this equipment in hazardous areas in which explosive materials are present.

Danger of Electrical Shock!

If the device is not used in accordance with the instructions, this can affect the product lia-

bility for the device.

2

Make sure that the voltage rating printed on the AC adapter is identical to your local

line voltage. The wall outlet must have a protective grounding conductor. The operating

instructions included with the AC adapter must be followed.

2

Do not switch on the equipment if the AC adapter or power cord are damaged.

If the balance itself, the AC adapter or any cables on the balance are damaged, disconnect

the equipment from the power supply and secure it so that it cannot be turned on.

2

Chemicals (e.g. gases or liquids) that can corrode and damage the inside or outside of the

balance, AC adapter, power cable or peripherals must be kept away from the equipment.

2

Do not operate the balance unless the housing and the display are undamaged and the

housing is closed so that inadvertent contact with parts inside the equipment is not possible. Make sure that no liquids penetrate the balance and do not allow conductive parts to

touch the balance.

2

Note on Installation:

The operator shall be solely responsible for any modifications to the equipment and for

connecting any cables or equipment not supplied by Sartorius.

Information on operational quality is available upon request from Sartorius.

You should only use peripherals and options supplied by Sartorius.

Page 5

Cubis® MSU User Manual 5

Safety Instructions

Note on cable quality:

CE conformity is only guaranteed with well shielded cables.

The shielding braid of the cable must be made of metal with at least 80% coverage and also

covered with metal foil as much as possible.

The shielding on both sides on the full metal or metalized connector casing, as well as on

the casing inlet, must be high-frequency compliant and have a flat design.

You can only turn off power to the device by pulling the plug or disconnecting the power

cord, or by unscrewing the four-pin plug at the DC supply cable for the balance.

Do not exert mechanical pressure on the display with sharp objects, as this will damage the

display. Liquid penetration can damage the electrical components.

Only use a lightly-moistened cloth for cleaning. See “Care and Maintenance” for cleaning

the device. Do not compromise the IP protection of the balance.

Do not open the balance housing. If the seal is broken, this will result in forfeiture of all

claims under the manufacturer’s warranty.

The device may only be opened by specialized personnel trained by Sartorius.

Disconnect the balance from the wall outlet prior to moving the device.

Avoid condensation damage to the device. When the balance is turned on, condensation

build-up is not possible. If the device is moved from a cool environment to a warm environment, you must allow the device to acclimatize for approx. 2 hours before connecting to the

power supply.

Hazards at the Place of Installation and During Operation

3

Avoid generating static electricity and establish equipotential bonding.

A 10 kOhm ground is used when connecting the balance to the power supply. Disconnecting the ground conductor is not permitted.

3

Exercise caution to avoid glass breakage.

There is a danger of lacerations or cuts caused by sharp edges on glass or metal (contact

springs), particularly when removing or replacing the glass draft shield panels; during cleaning;

if a glass sample container breaks, or when modifying the balance hardware configuration.

3

Models with a separate electronics module (e. g. MSU6.6/3.6/2.7), MSU225S/P

and MSU125P:

Do not mix up the electronics module.

Interchanging with, e. g. models of the ME/SE series will damage the device.

3

Make sure all equipment operators have received proper instructions when working with

hazardous or toxic materials.

Failure to follow correct handling procedures can result in breakage of parts or spillage of

liquids or other substances. Make sure the necessary protective clothing or equipment is

worn, such as protective gloves, clothing, eyewear.

All safety regulations applicable in the laboratory must be observed.

3

Exercise caution to avoid squeezing or crushing fingers when

– Operating the electronic draft shield

– Removing or installing the panels

– Adjusting the display

Do not expose the device to aggressive chemical vapors or to unnecessarily extreme tem-

peratures, moisture, shocks, or vibration.

The device should be set up in areas away from equipment or devices that have strong mag-

netic properties. Extreme electromagnetic fields from electrical lines should also be avoided.

Page 6

6 Cubis® MSU User Manual

Intended Use

Intended Use

Cubis® models are high-resolution balances. They were specially

developed for exact determination of material mass in liquid,

paste, powder or solid form.

Appropriate containers must be used for each type of sample

material.

Specific models cover specific weighing ranges: see

“Technical Data.”

Cubis® models are designed specially for use in research,

education and day-to-day laboratory tasks in science and

industry.

They are designed to be used exclusively indoors.

Cubis® models can be operated as standalone, connected to

a PC, or on a network.

General View of the Equipment and Equipment Supplied

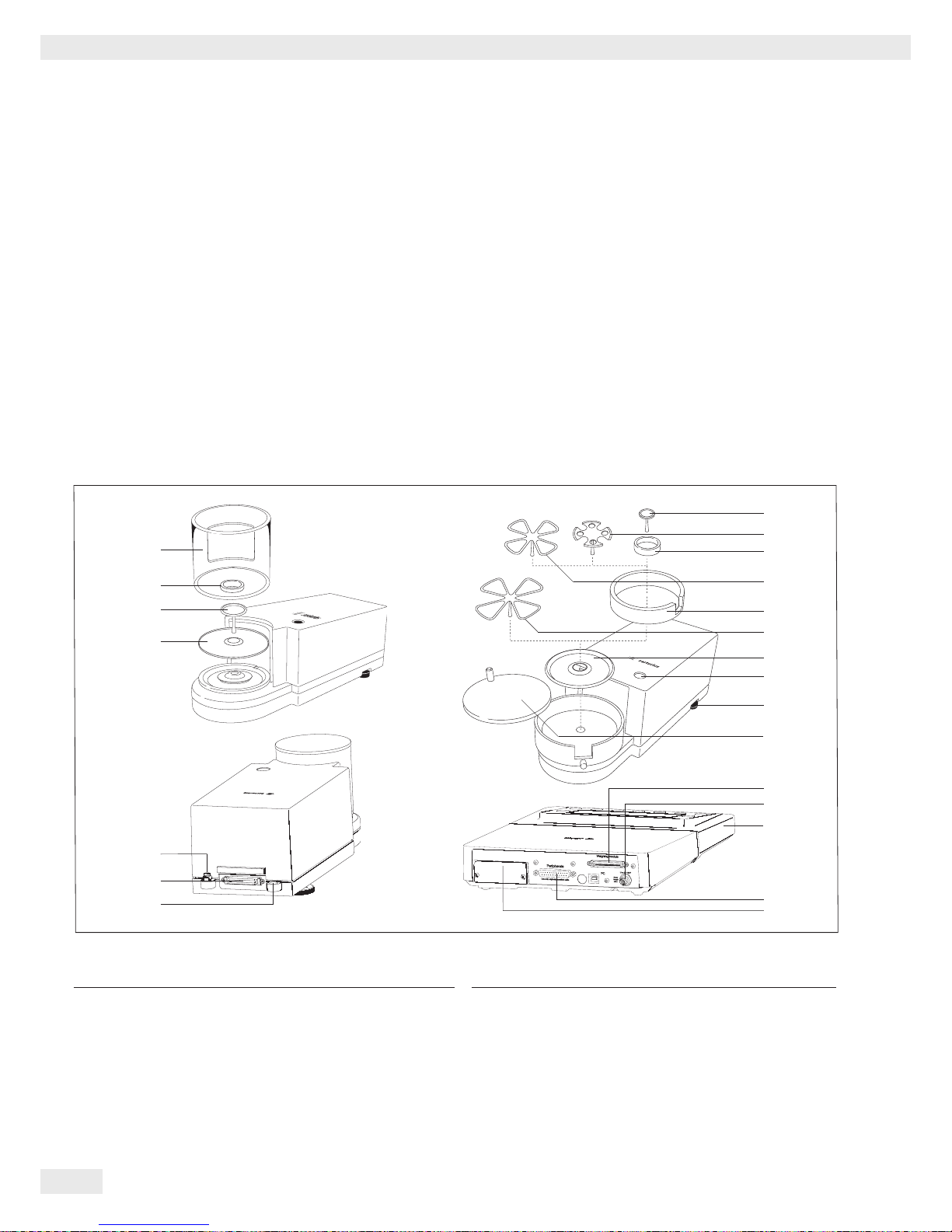

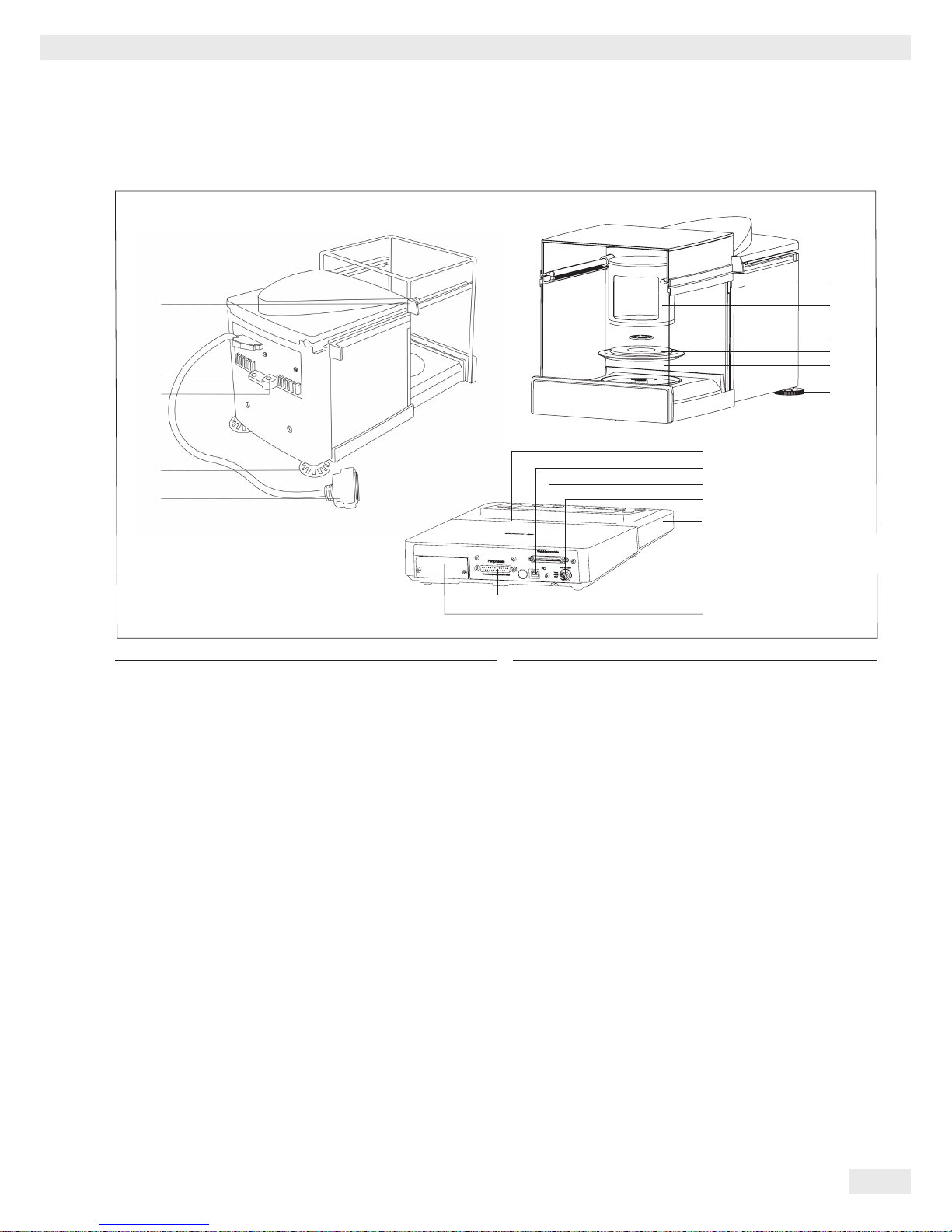

Microbalances: models MSU6.6S, MSU3.6P, MSU2.7S

Item Description

1 Weighing pan

2 Filter weighing pan d 50 mm

3 Internal draft shield (for MSU2.7S-F only)

4 Optional weighing pan d 75 mm

5 Shield disk

6 Optional weighing pan d 90 mm

7 Shield plate

8 Level indicator

9 Leveling foot

10 MSA2.7..model: socket

11 Draft shield cover

Item Description

12 Female connector for weigh cell

13 DC jack

14 Display and control unit

15 Serial communications port (PERIPHERALS)

16 Slot for optional interfaces

(e.g., 9-pin data output and PS2 or Bluetooth)

17 Lug for attaching antitheft locking device

18 Weigh cell connector - electronics module

19 Equipotential bonding conductor terminal

20 Draft shield

Not shown: AC adapter, USB cable

Use6

9719

87

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

7

1

3

19

Page 7

Cubis® MSU User Manual 7

General View of the Equipment and Equipment Supplied

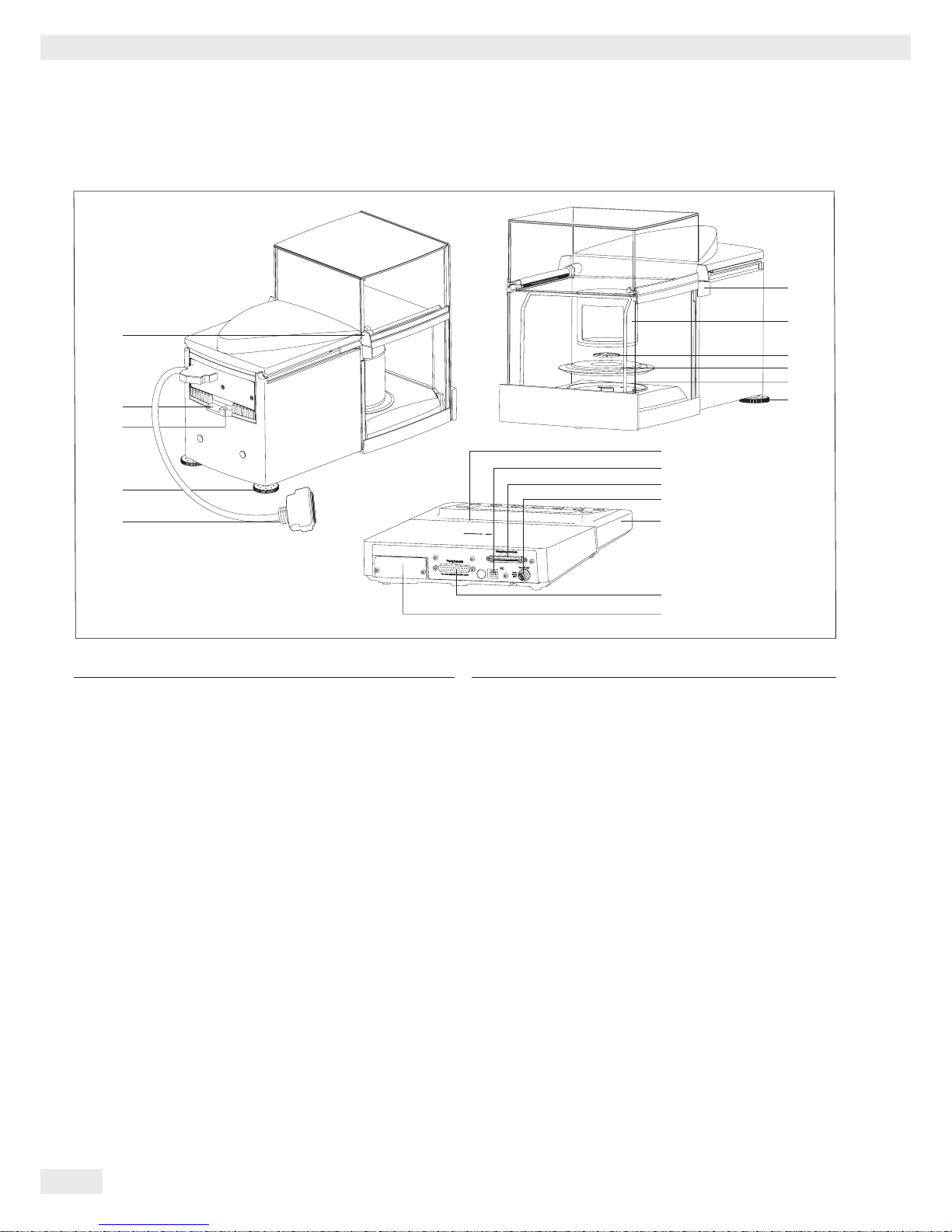

Models MSU66S, MSU66P, MSU36S, MSU36P

Item Description

1 Push handle/Handle

2 Inner draft shield

3 Weighing pan

4 Shield disc

5 Level indicator

6 Leveling foot

7 SD card slot

8 USB interface for PC connection

9 Weigh cell female connector

Item Description

10 DC jack

11 Display and control unit

12 Serial communications port (PERIPHERALS)

13 Slot for optional interface

(e. g. 9-pin data output and PS2 or Bluetooth)

14 Connection plug: Weigh cell – electronics module

15 Equipotential bonding conductor

16 Lug for attaching anti-theft locking device

Not shown: AC adapter, USB cable

1

16

15

6

14

Use6971

9

87

7

8

9

10

11

12

13

1

2

3

4

5

6

Page 8

8 Cubis® MSU User Manual

General View of the Equipment and Equipment Supplied

Model MSU116P

Item Description

1 Push handle/Handle

2 Inner draft shield

3 Weighing pan

4 Shield disc

5 Level indicator

6 Leveling foot

7 SD card slot

8 USB interface for PC connection

9 Weigh cell female connector

Item Description

10 DC jack

11 Display and control unit

12 Serial communications port (PERIPHERALS)

13 Slot for optional interface

(e. g. 9-pin data output and PS2 or Bluetooth)

14 Connection plug: Weigh cell – electronics module

15 Equipotential bonding conductor

16 Lug for attaching anti-theft locking device

Not shown: AC adapter, USB cable

1

16

15

6

14

U

se69719

87

7

8

9

10

11

12

13

1

2

3

4

5

6

Page 9

Cubis® MSU User Manual 9

General View of the Equipment and Equipment Supplied

General View of the Equipment

and Equipment Supplied

Analytical and precision balances with a weighing range of up to 15 kg

Item Description

1 Upper sliding draft shield panel/handle

2 Back panel

3 Weighing pan

4 Pan support (not for MSU225.../MSU125... models)

5 Shield plate

6 Pan retainer

7 Right sliding panel/handle

8 SD card slot

9 Leveling foot

10 Display

11 Display and control unit

12 Draft shield/Shield disk (only for models

with a readability of 1 mg and 10 mg)

13 Below-balance weighing port

(on the bottom of the balance)

14 Leveling foot

15 Level indicator

16 Power socket

17 Slot for attaching an anti-theft device

18 USB socket for a PC connection

19 Below-balance weighing hook

20 Slot for optional interfaces,

e.g., 9-pin data output and PS2 (as shown) or Bluetooth

21 Communication port (PERIPHERALS) for accessories

22 Menu access switch

23 Left sliding panel/handle

24 Ethernet interface

(on the bottom of the display and control unit)

25 Semi-microbalances: Female connector for weigh cell

26 Semi-microbalances: Electronics module

(for MSU225.../MSU125... models)

Not shown:

– AC adapter

– USB cable

– Operating instructions

10

11

23

3

4

5

5

6

6

13

13

11

11

14

14

6

12

12

4

3

3

15

16

17

18

19

20

21

22

4

25

26

15

17

20

21

22

1

2

3

4

5

6

7

9

8

24

Page 10

10 Cubis® MSU User Manual

General View of the Equipment and Equipment Supplied

General View of the Equipment and Equipment Supplied

Balances with a weighing range of 20 kg or more

1

3

4

5

7

2

6

Item Description

1 DC jack

2 Leveling foot

3 Level indicator

4 Serial communications port (PERIPHERALS)

Item Description

5 USB socket for a PC connection

6 Display and control unit

7 Weighing pan

Not shown: AC adapter, USB cable

Page 11

Cubis® MSU User Manual 11

Getting Started

Getting Started

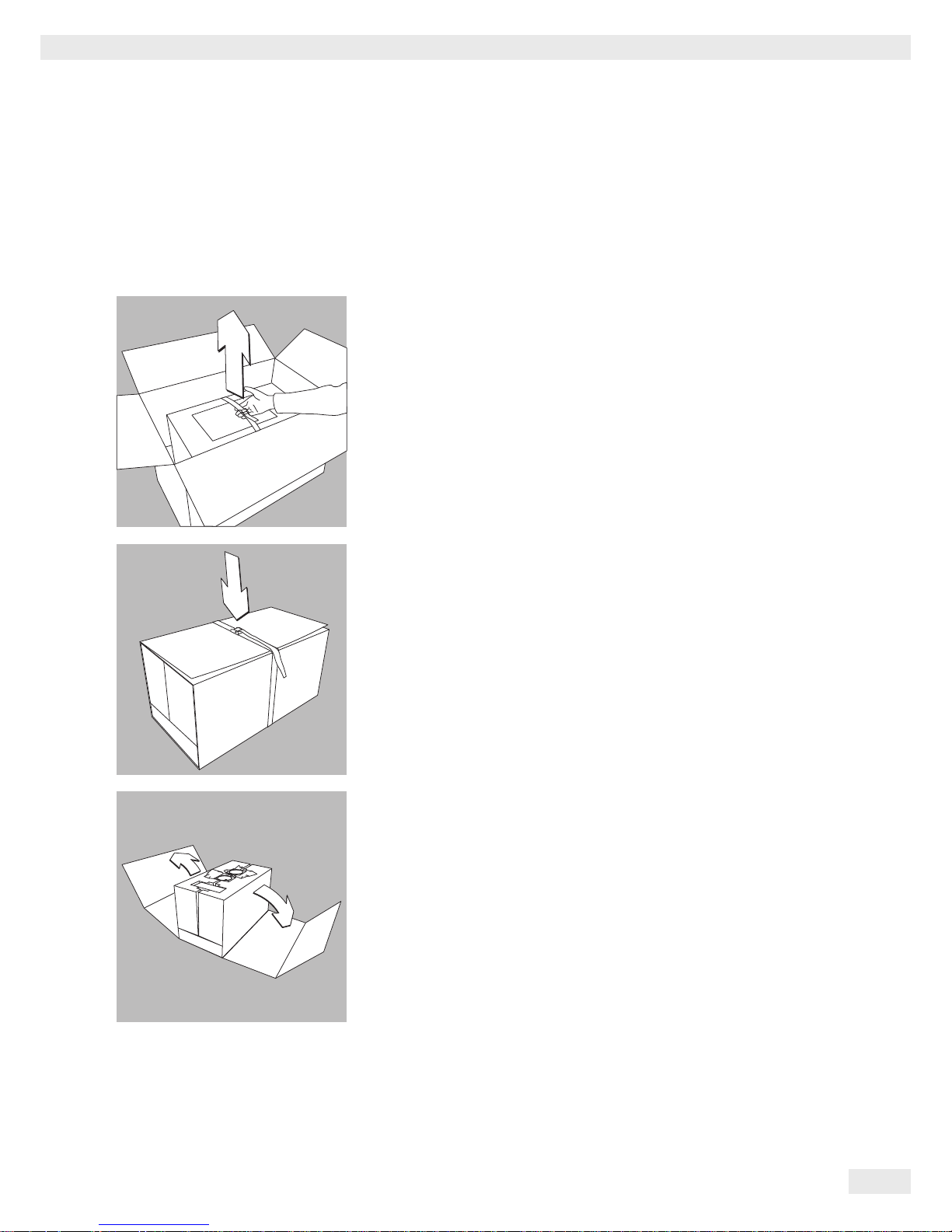

Unpacking

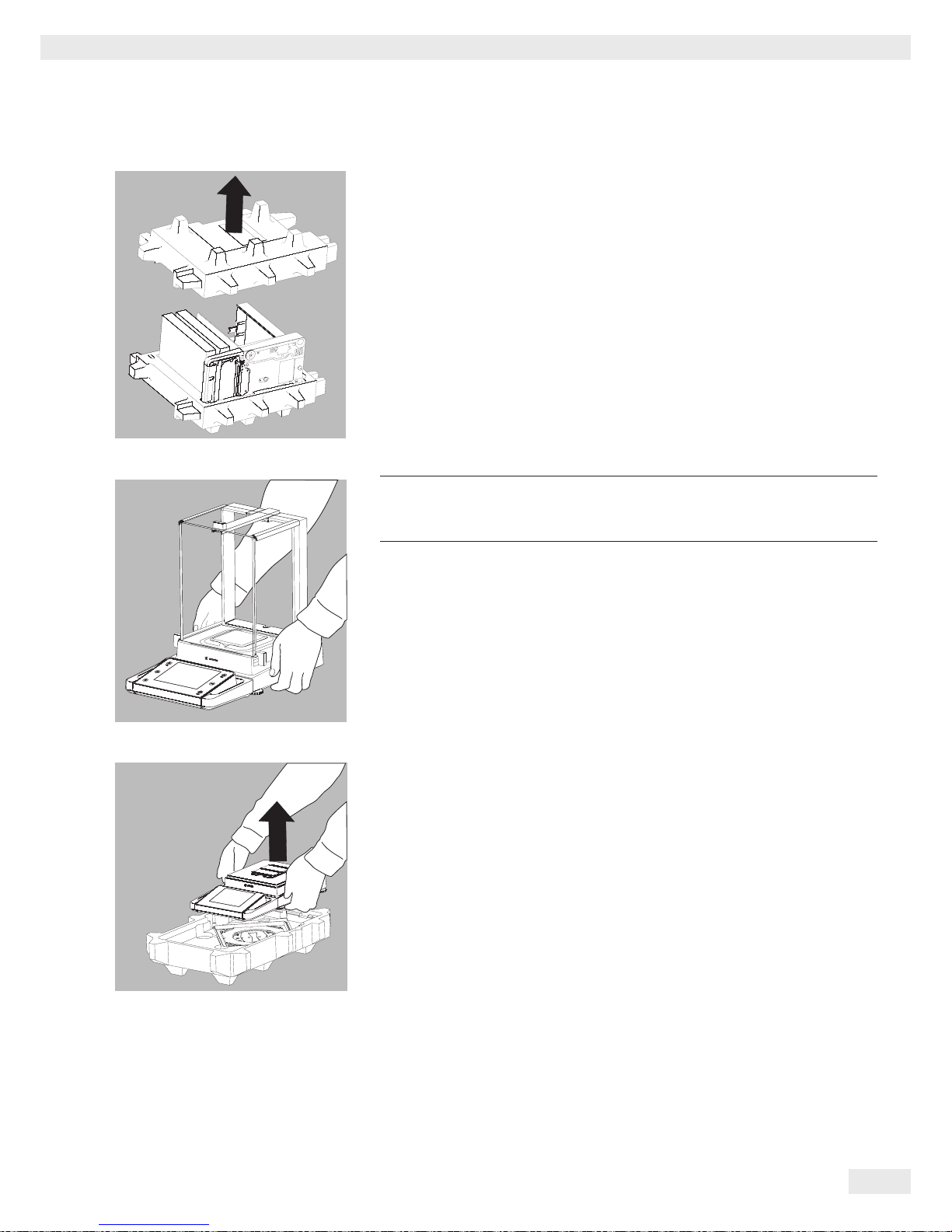

Models MSU116P, MSU66S, MSU66P, MSU36S, MSU36P:

t Lift the package containing the device out of the outer packaging by the strap.

t Loosen and remove the strap.

t Remove the cardboard sleeve.

Page 12

12 Cubis® MSU User Manual

Getting Started

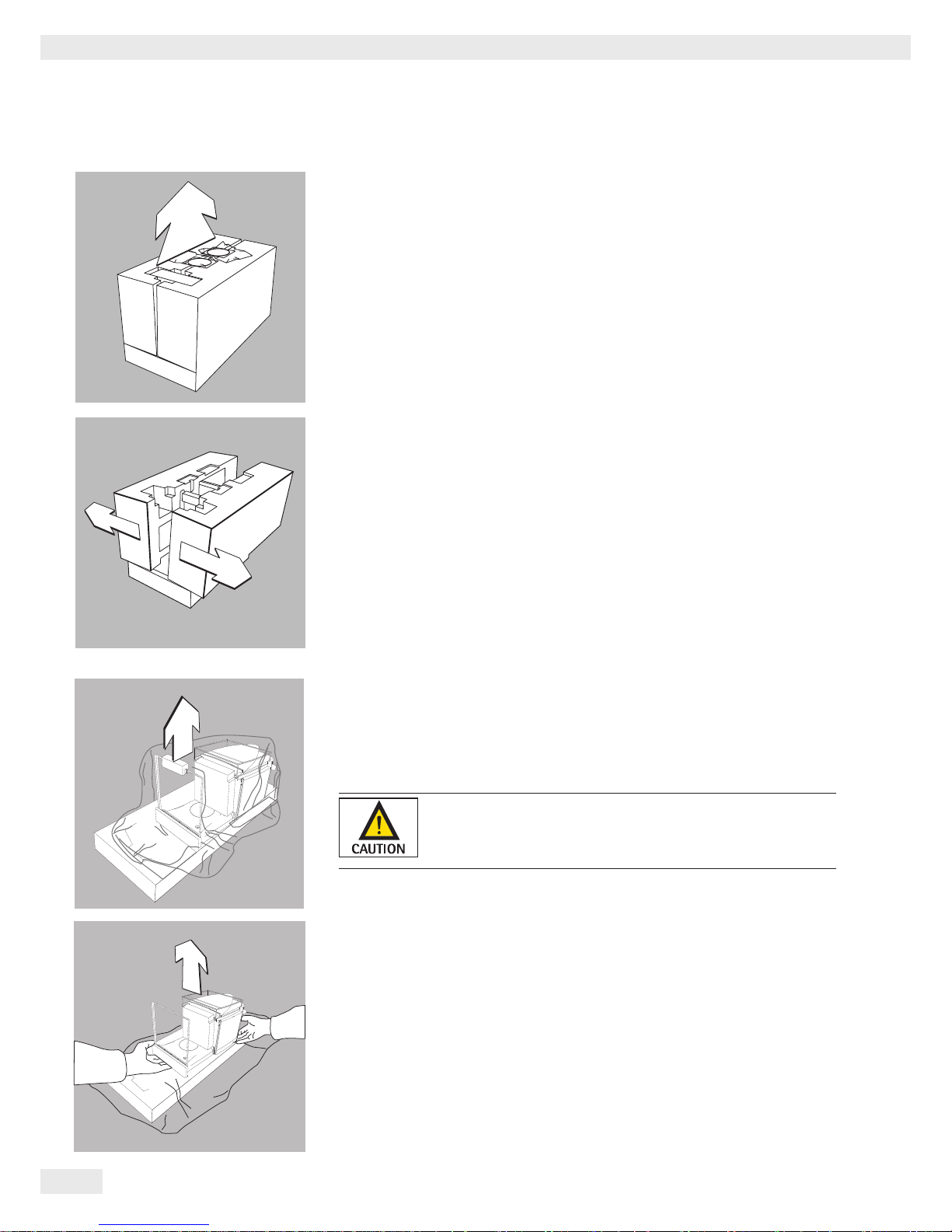

t Remove the following parts from the recessed spaces of the inner packaging:

− Weighing pan

− Shield plate

t Remove the lateral packaging paddings of the inner packaging by pulling out-

ward.

t Remove the retainer securing the front draft shield panel.

t Open the plastic wrapping.

Exercise caution to avoid glass breakage.

Never lift the device by the draft shield panels to remove

it from the packaging.

t Place one hand under the front panel and the other under the back of the

housing and lift the device out of the lower packaging padding.

Page 13

Cubis® MSU User Manual 13

Getting Started

Do not lift the device by the draft shield or the front panel since

this can result in damage.

t Place the device at the intended installation location.

t Open the draft shield doors.

t Remove the inner foam padding from the draft shield.

Save the box and all parts of the packaging in case it should

become necessary to transport the device. Only the original

packaging provides the best protection for shipment (see also

Shipping on page 36).

Before packing the device for shipping, unplug all connected

cables to prevent unnecessary damage.

Balance with the Analytical Draft Shield

t Open the packaging at the top.

t With both hands in the side impressions lift the balance, with the packaging,

out of the cardboard box.

Page 14

14 Cubis® MSU User Manual

Getting Started

t Place the packaging with the balance on the floor.

t Remove the top part of the packaging.

t Remove the packages (containing draft shield panels, weighing pan, pan sup-

port, AC adapter, etc.) from the lower packaging and place them to one side.

3

Caution! Exercise caution to avoid glass breakage.

Never lift the device by the draft shield panels to remove it from the

packaging.

t Use both hands to lift the balance out of the packaging.

t Place the balance on an even surface.

Balance with No Draft Shield

t Use both hands to remove the model without a draft shield from the packag-

ing.

t Remove the AC adapter and the balance parts from the packaging.

Page 15

Cubis® MSU User Manual 15

Getting Started

Assembly

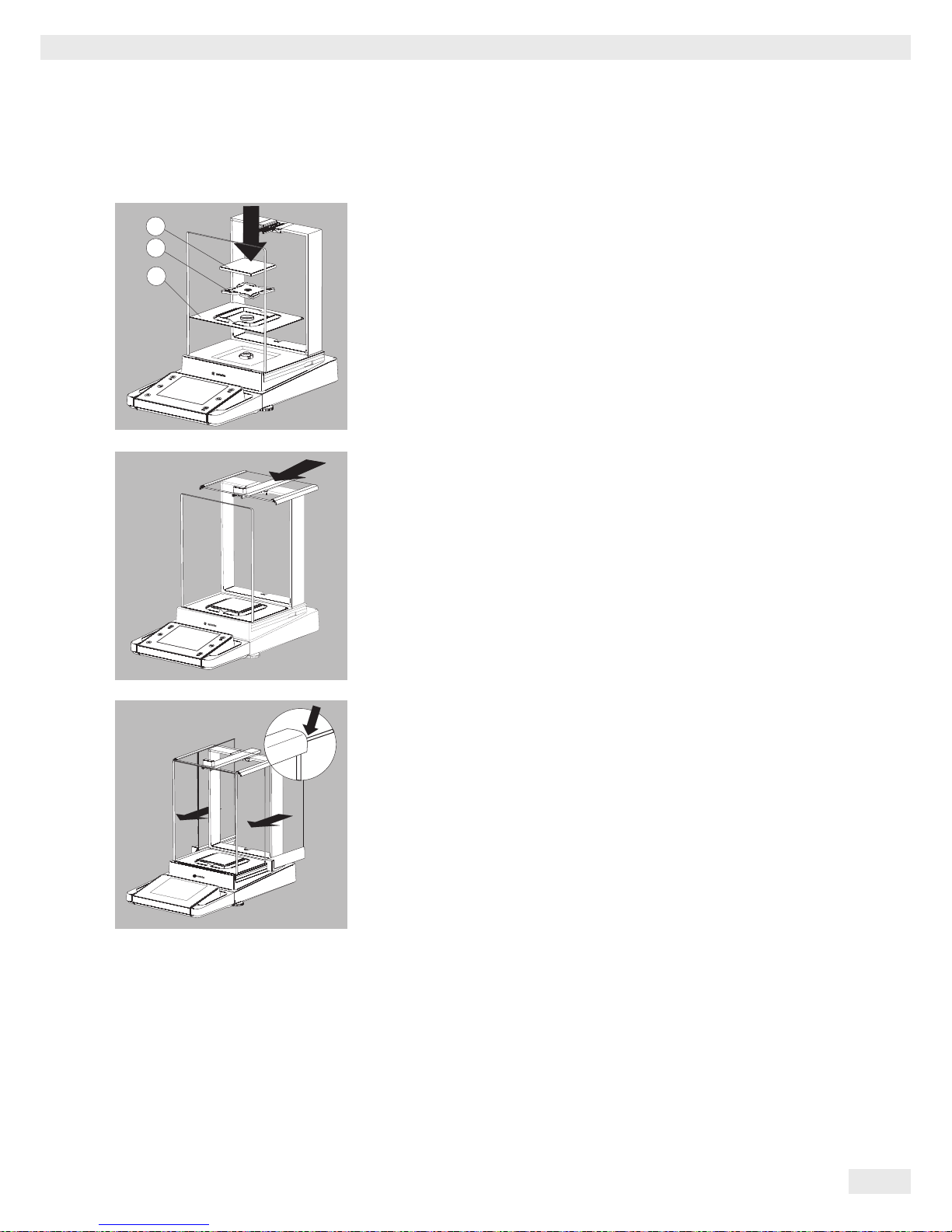

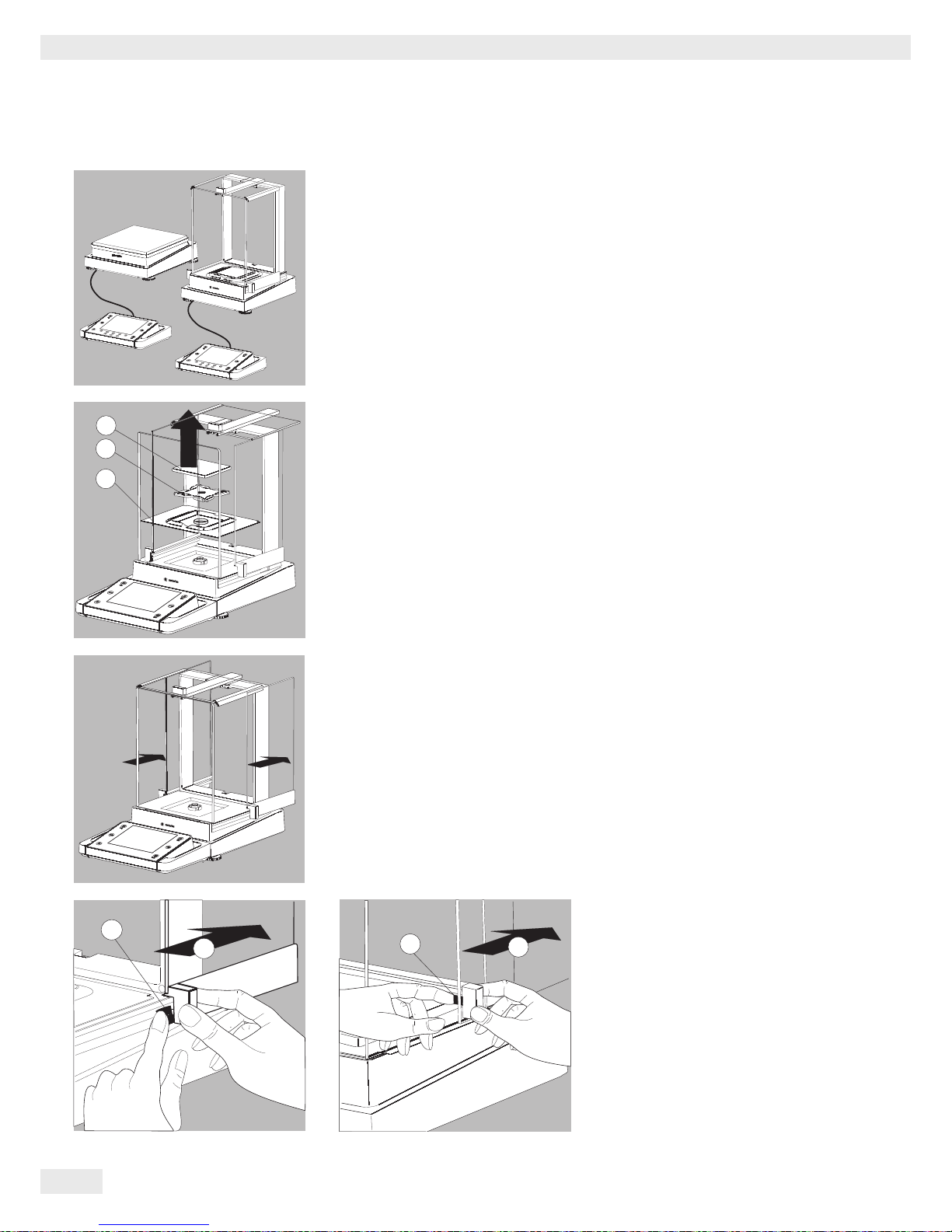

Installing the Analytical Draft Shield Labeled DA, DI, and DU

t Carefully fit parts onto the balance as shown in the picture.

1. Shield plate

2. Pan support (not for MSU225.../MSU125... models)

3. Weighing pan

t Slide the upper draft shield panel into the guide rails from the rear.

t Slide the left and right draft shield panels into the guide rails from the rear.

Make sure the panels are within the upper and lower guide rails.

t Slide the panels in until they engage.

1. Right draft shield panel

2. Left draft shield panel

y This completes the balance assembly.

2

1

3

Page 16

16 Cubis® MSU User Manual

Getting Started

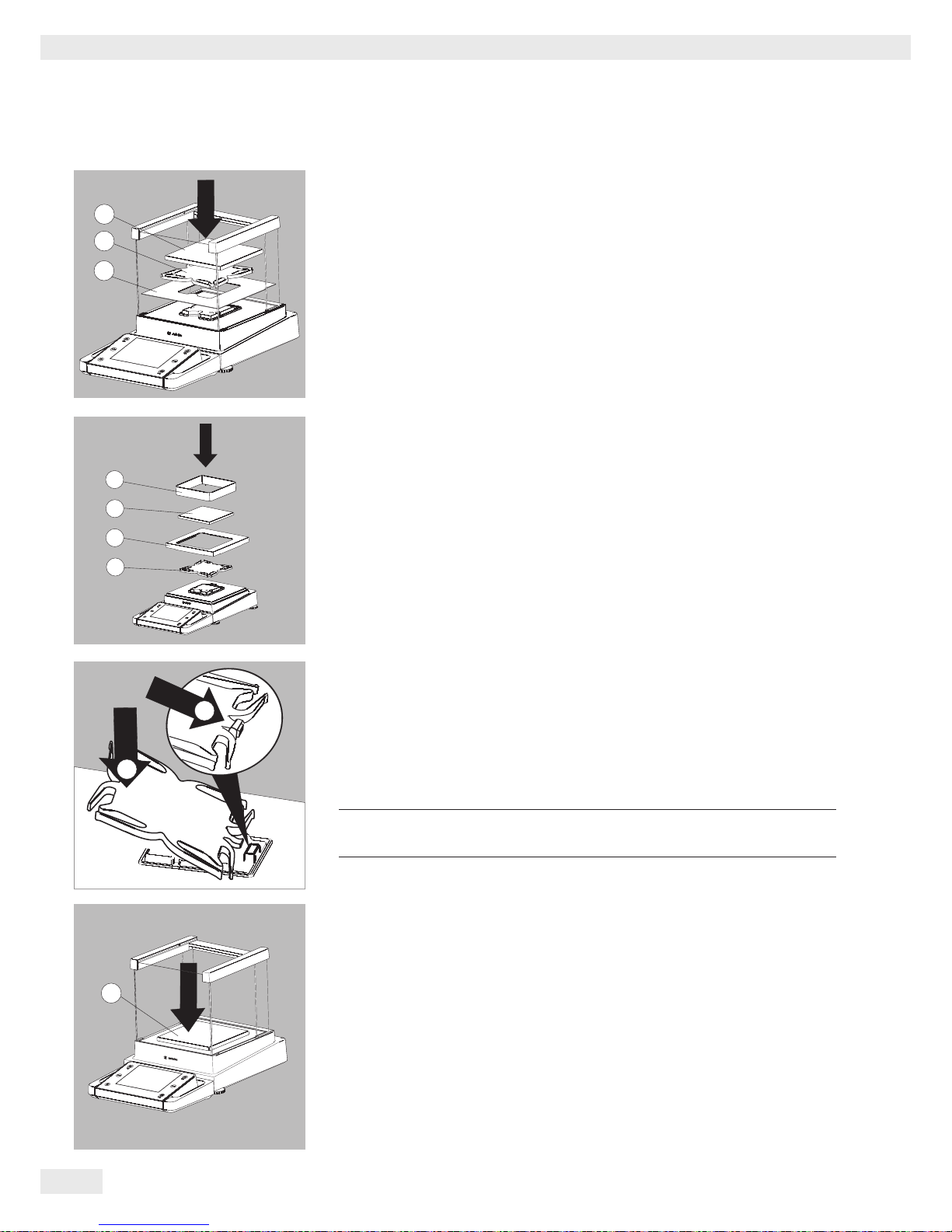

Installing the Draft Shield Labeled DE for Milligram Balances

t Carefully fit all parts as shown.

1. Shield plate

2. Pan support

3. Weighing pan

Assembly of Milligram Balances without Glass Draft Shield (DR Option)

t Fit all components listed below onto the balance in the order given:

1. Pan support (see also next section)

2. Shield plate

3. Weighing pan

4. Draft shield frame

t First insert the shield plate.

t Make sure the pin on the pan support is facing toward the front, and slide it

under the clip on the pan retainer.

1. Insert the pan support.

t After inserting the pan support, press it down against the shield plate so that it

lies flat.

3

Exercise caution to avoid pinching or crushing fingers.

2. Press down on the pan support

t Place the weighing pan (3) on the pan support.

2

1

3

1

2

3

4

3

2

1

3

1

2

3

4

2

1

3

Page 17

Cubis® MSU User Manual 17

Getting Started

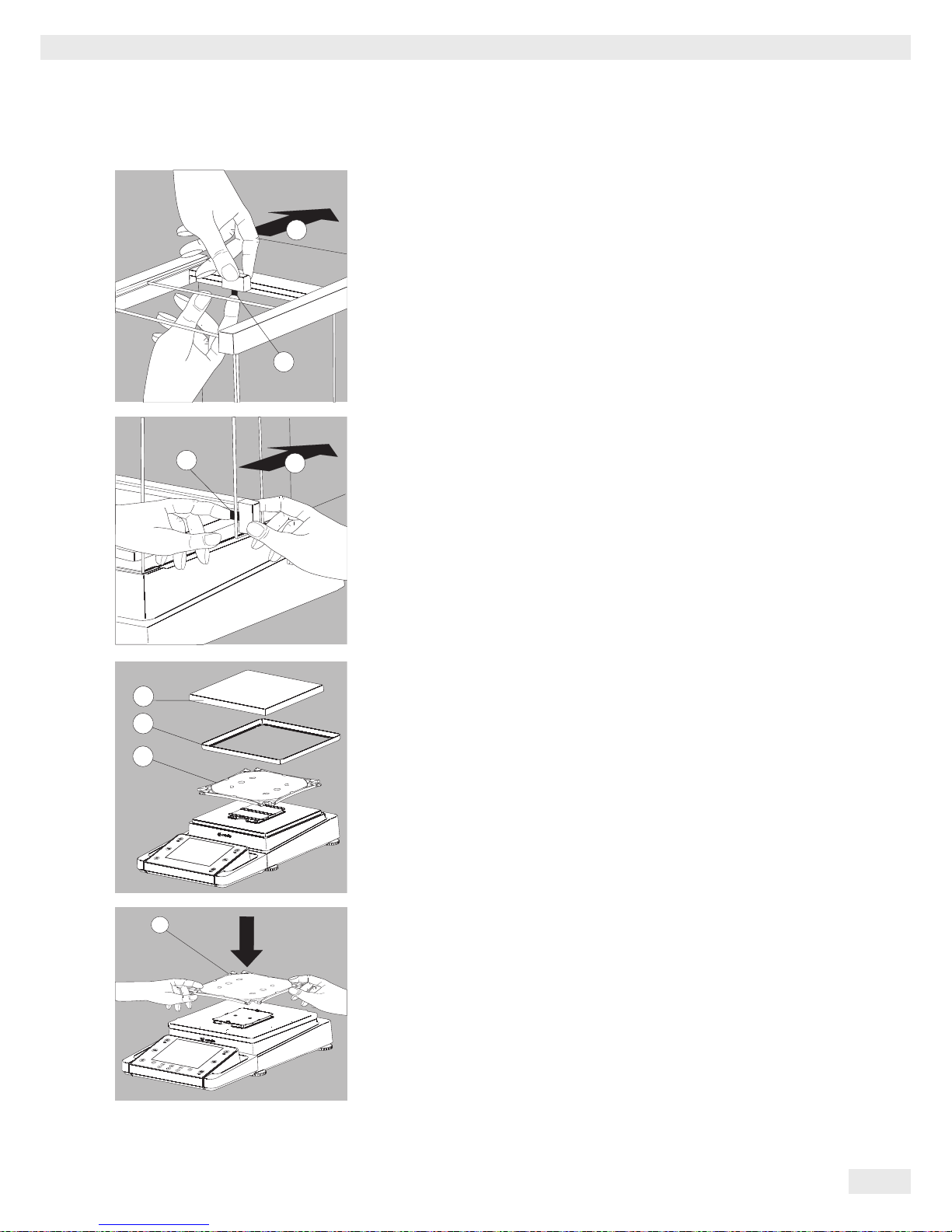

t Slide the upper draft shield panel into the guide rails from the rear while

pressing the locking tab.

t Slide the side draft shield panel into the guide rails from the rear while pressing

the locking tab.

y This completes the balance assembly.

t If necessary, remove the panel again:

1. Press on the locking tab

2. Remove the panel

t Place the panel in the storage slot at the back of the balance.

Assembling Precision Balances without a Draft Shield with a Weighing Range of

up to 15 kg

t Carefully insert all parts.

1. Pan support

2. Shield plate/Draft shield

3. Weighing pan

t Place the pan support (1) diagonally and press down lightly.

2

1

2

1

3

1

2

1

Page 18

18 Cubis® MSU User Manual

Getting Started

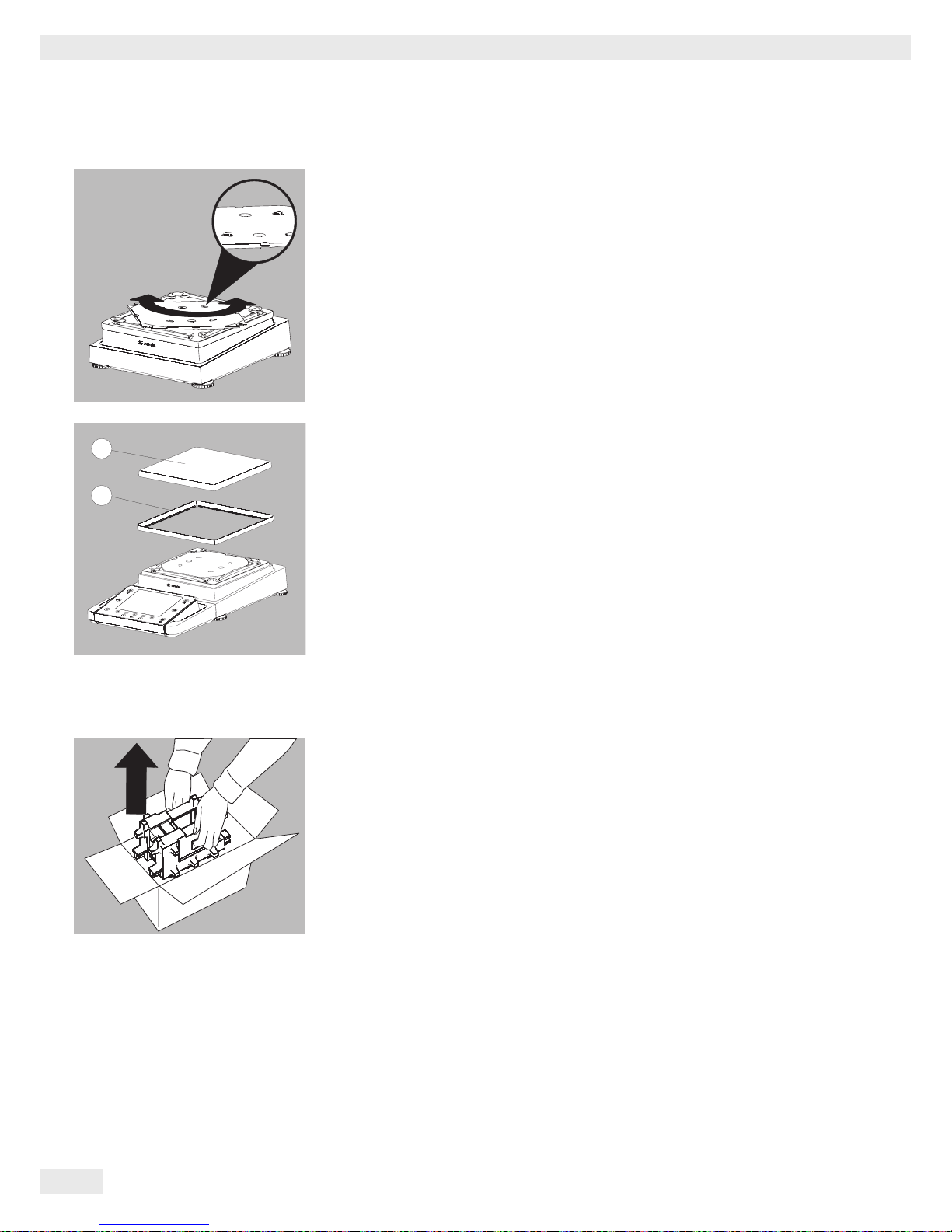

t Carefully turn the pan support clockwise until the two buttons engage.

The pan support is now attached.

t 2. Insert the shield plate/draft shield.

t 3. Place the weighing pan on the pan support

y This completes the balance assembly.

Balance with the Analytical Draft Shield

t Open the packaging at the top.

t With both hands in the side impressions lift the balance, with the packaging,

out of the cardboard box.

2

3

Page 19

Cubis® MSU User Manual 19

Getting Started

t Place the packaging with the balance on the floor.

t Remove the top part of the packaging.

t Remove the packages (containing draft shield panels, weighing pan, pan sup-

port, AC adapter, etc.) from the lower packaging and place them to one side.

3

Caution! Exercise caution to avoid glass breakage.

Never lift the equipment by the draft shield panels to remove it from the

packaging.

t Use both hands to lift the balance out of the packaging.

t Place the balance on an even surface.

Balance with No Draft Shield

t Use both hands to remove the model without a draft shield from the

packaging.

t Remove the AC adapter and the balance parts from the packaging.

Page 20

20 Cubis® MSU User Manual

Getting Started

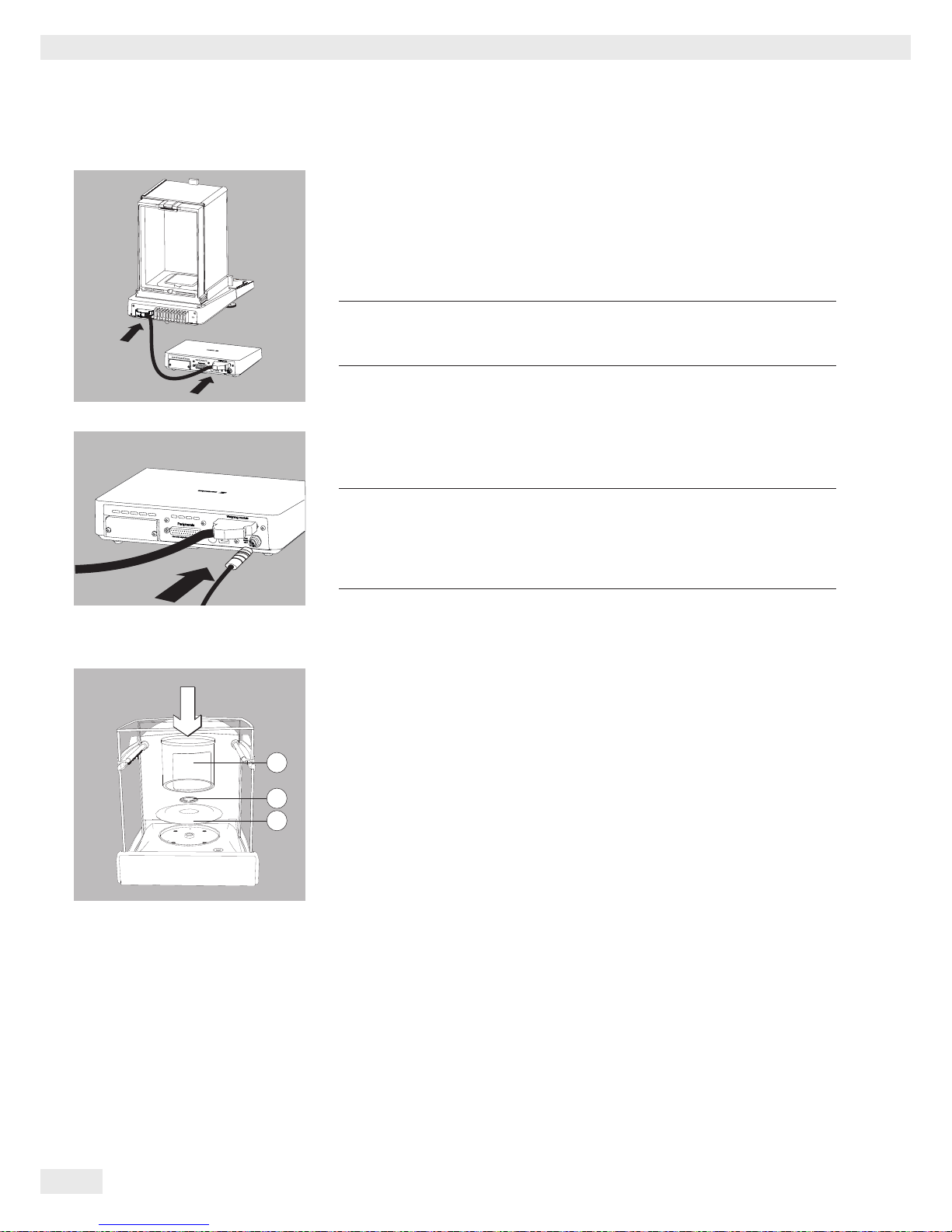

Models with an External Electronics Module: Connecting the Weigh Cell to the

Electronics Module

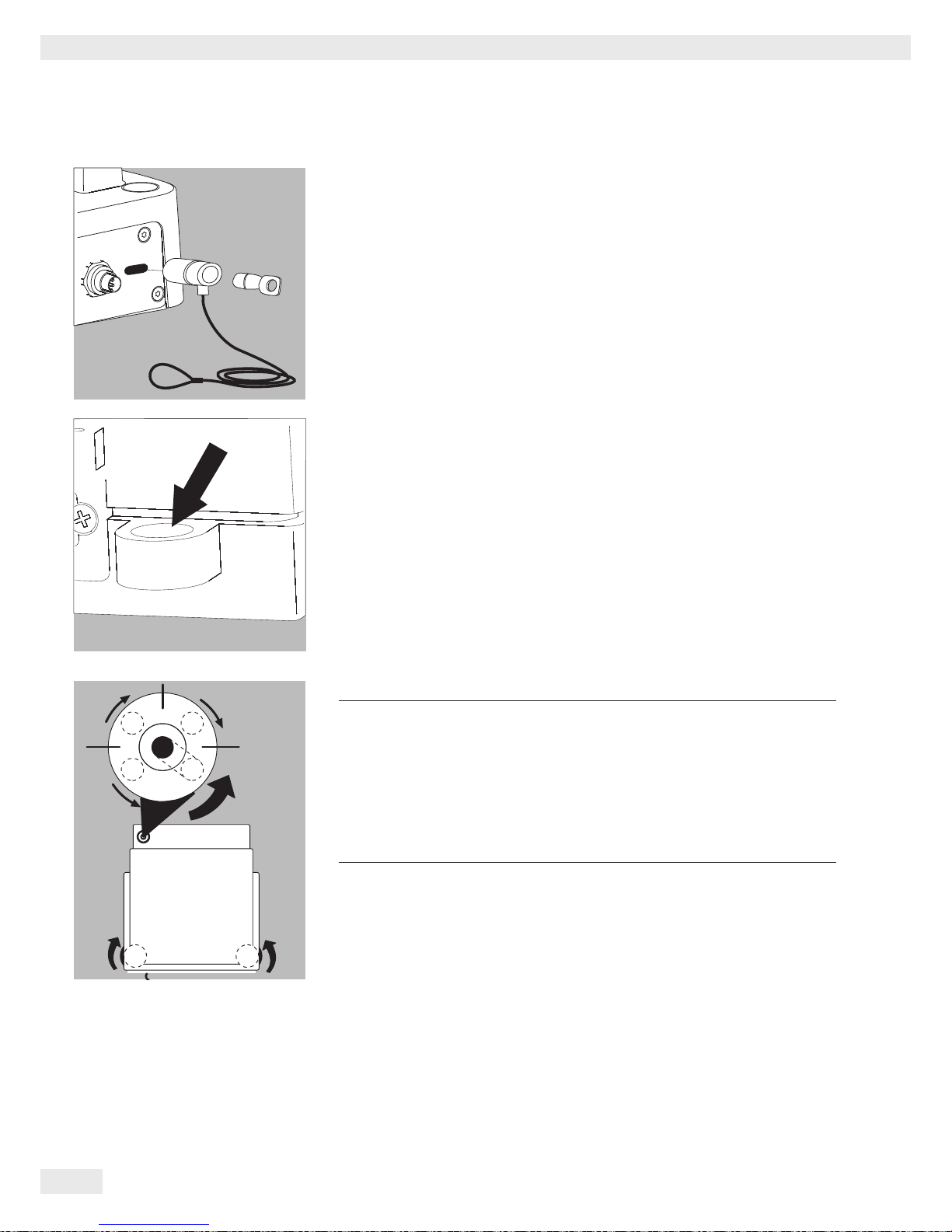

t Connect the weigh cell and electronics module using the connection cable:

Make sure that the connectors click into place so that both ends engage

correctly.

3

Check the plug contacts to ensure that the connection is correct.

There should be no tension on the connection cable, e.g. if pushed

directly against a wall.

t Connecting the Weigh Cell to the Evaluation Unit:

Make sure that the connector clicks into place so that the cable is engaged.

3

Models with a separate electronics module (e.g. MSU66/36/6.6/3.6/2.7,

MSU225S/P, MSU125P and MSU116P):

Do not mix up the eletronics module.

Interchanging with, e.g. models of the ME/SE series will damage the

device.

Models MSU66 and MSU36: Placing components into weighing chamber

t Insert the following components into the weighing chamber in the order given:

1. Shield disk

2. Weighing pan

3.

Internal draft shield

1

2

3

Page 21

Cubis® MSU User Manual 21

Getting Started

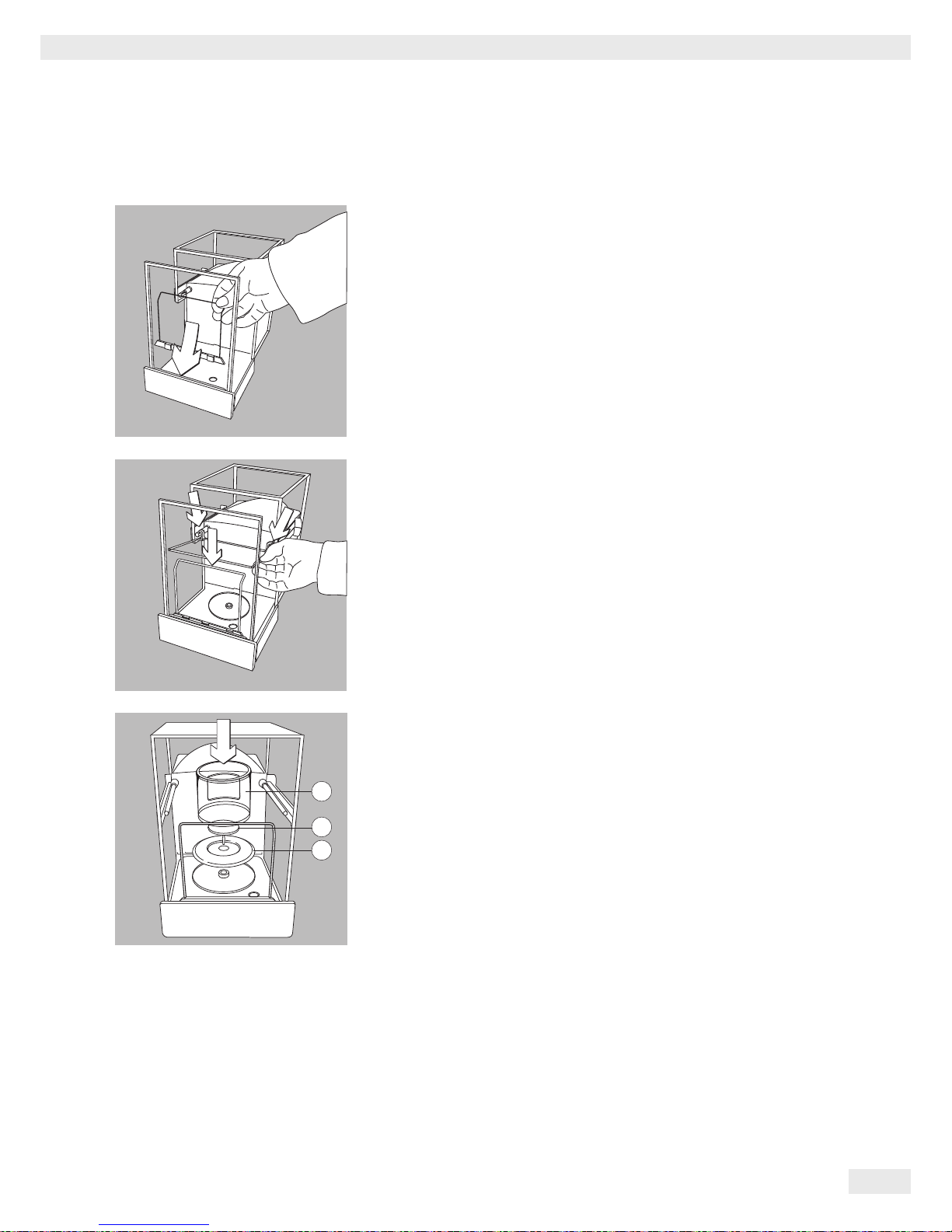

Model MSU116P: Placing components into the weighing chamber

t Position the support bracket directly behind the front panel.

t Position the glass panel in the retainers and place it at the back of the draft

shield.

t Place the components listed below inside the weighing chamber in the order

given:

1. Shield plate

2. Weighing

pan

3. Internal draft shield

1

2

3

Page 22

22 Cubis® MSU User Manual

Getting Started

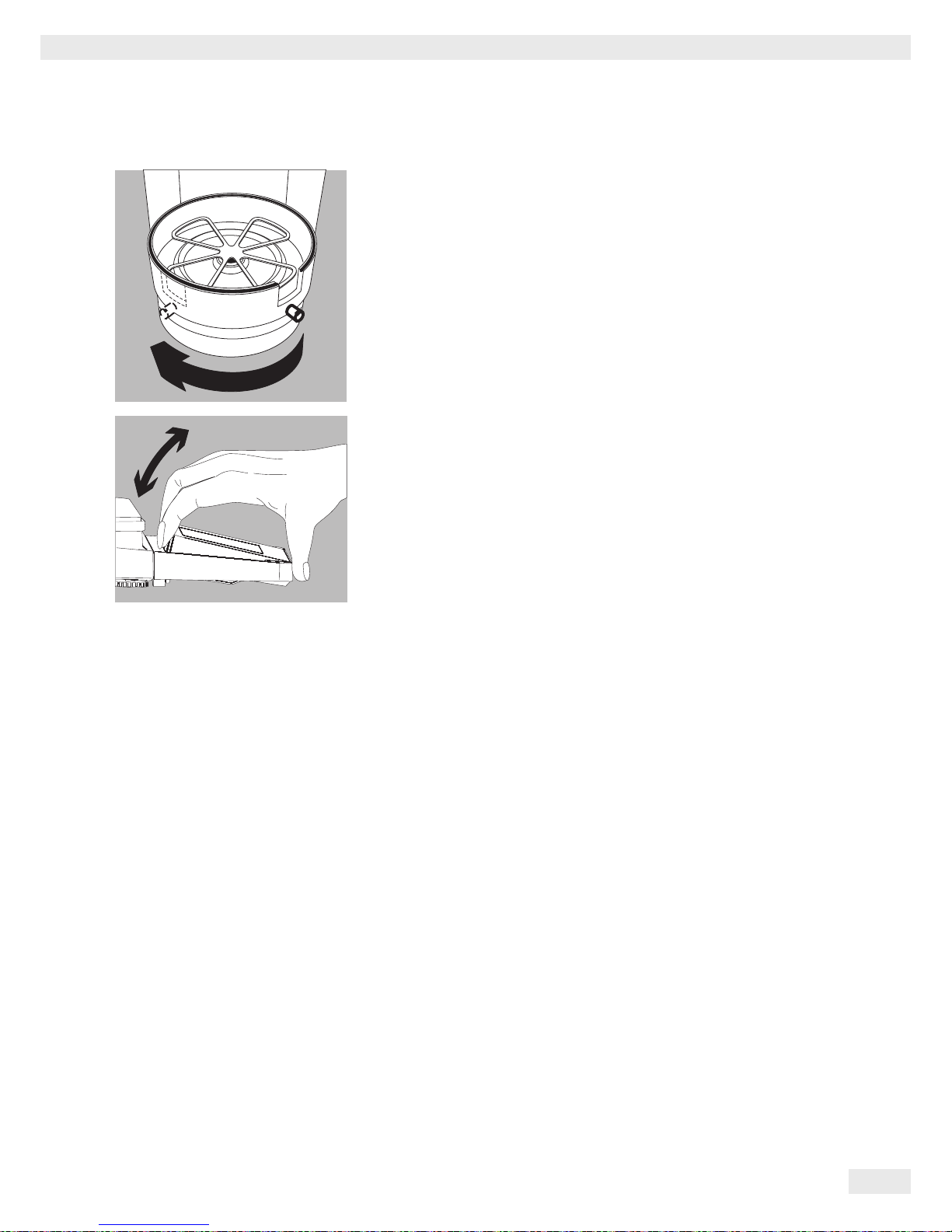

Models MSU6.6S/3.6P/2.7S: Placing Components on the Weigh Cell

t Place the following Parts in the order listed:

t 1. Shield plate

t 2. Shield plate

t 3. Weighing pan

Tip:

After inserting the weighing pan, turn it slightly to the left and right

while pressing it down lightly.

t 4. Internal draft shield (for SE2 only)

t 5. Draft shield: Center the hole over the pan (see arrows).

Filter Balances (models MSU6.6S-F/2.7S-F): Placing Components on the

Weigh Cell

t Place the components on the weigh cell in the order given:

t 1. Model MSU2.7S-F: Connector

t 2. Shield plate

t 3. Internal draft shield

t 4. Filter weighing pan d 50 mm or weighing pan

(optional filter weighing pan d 75 mm or d 90 mm)

Note: After inserting the pan, turn it slightly to the left and right,

while pressing it down lightly.

t 5. Draft shield cover

! Notice

Turn the balance off and then on again after replacing the pan during

operation.

Setting up a filter weighing pan for left-handed users:

t Remove the draft shield cover

t Unscrew the pin and move from the right to the left side

3

2

4

5

1

MSU6.6S/3.6P/2.7S:

MSU6.6S-F/2.7S-F:

Page 23

Cubis® MSU User Manual 23

Getting Started

t Turn draft shield parts approx. 90 degrees to the left (loosen knurled screw).

Setting the Angle for the Display and Control Unit

The angle of the display unit can be adjusted by the user in order to ensure optimal

readability of the weight values on the display at all times.

t The display and control unit can be tilted as desired.

Choosing a Location

t Selecting the right setup location:

– Set up the device on a stable, even surface that is not exposed to vibrations

(e.g., weighing stone).

– Place the device in a location with enough free space around it so that

excessive heat cannot build up.

– Maintain free access to the device at all times.

– The balance may only be used in closed spaces and at a max. height above

sea level (see, chapter Techn. Data, “Ambient conditions”).

Choose a location that is not subject to the following negative influences:

– Heat (heater or direct sunlight)

– Drafts from open windows, AC systems, and doors

– Extreme vibrations during measurement

– Extreme humidity

For further information, please refer to the “Proper handling of analytical balances

and microbalances” document.

Page 24

24 Cubis® MSU User Manual

Getting Started

Acclimatization

Condensation from humidity can form on the surfaces of a cold device when it is

brought into a substantially warmer area.

Allow the device to acclimatize for about two hours at room temperature, leaving it

unplugged from the power supply.

Carefully read all warnings and safety precautions in the respective section of this

manual.

Power Connection

t Check the voltage rating and plug design.

– Make sure that the voltage rating printed on the manufacturer’s ID label is

identical to that of your local mains voltage.

– If the stated supply voltage or the plug design of the power cord does not

comply with your country’s standard, please inform the nearest Sartorius

representative or your dealer.

– The power must be connected in accordance with the regulations applicable in

your country.

– In order to connect the equipment to the power supply (protection class 1),

use a suitable, correctly installed wall outlet with a protective grounding

conductor (PE) and a fuse of a maximum of 16A.

– Only use original Sartorius AC adapters.

Analytical and precision balances:

1. Plug the DC supply cable of the AC adapter into the power socket of the

balance and tighten the threaded fitting.

°C

1

Page 25

Cubis® MSU User Manual 25

Getting Started

Balances with a readability of ) 0.01 mg

1. Plug the DC supply cable of the AC adapter into the power socket of the

electronics module and tighten the threaded fitting.

2. Plug the power cord into the AC adapter.

3. Insert the AC adapter plug into the wall outlet.

y The balance is now ready to use.

Safety Precautions

The output line of the adapter has a terminal (GND) connected to the metal

housing of the balance. The data port is also galvanically linked to the balance

housing (GND).

Connecting Electronic Devices (Peripherals)

t Make absolutely sure that the device is unplugged from the power supply

before connecting/disconnecting any peripheral device (printer, scanner, PC)

to or from the data port.

3

A device connected to the power supply should never be opened.

2

Page 26

26 Cubis® MSU User Manual

Getting Started

Anti-Theft Locking Device (Accessory)

Balances with a readability of ) 0.01 mg:

t An anti-theft locking device can be installed to the back of the balance if

required.

Balances with a readability of ) 1 μg:

To fasten the anti-theft locking device, use the lug located on the back of the

weigh cell.

Leveling

h

Leveling the balance compensates for slant or unevenness at the

place of installation. The scale must be perfectly horizontal to ensure

consistent, reproducible weighing results. All models are equipped with

an electronic tilt angle detection feature. If the balance is not level, a

warning message appears on the display.

Push-button automatic leveling is available on models with motorized

leveling feet. For models with manual leveling feet, please follow the

instructions on the display.

Leveling the Balance Manually

y The scale is leveled using both front leveling feet.

t Screw in both back leveling feet (only for models with back leveling feet).

t Turn the front leveling feet as shown in the illustration until the air bubble is

centered within the circle of the level indicator.

y Normally, several leveling steps are required

t Turn both back leveling feet until they touch the setup surface (only for models

with back leveling feet).

R

L

L

L

R

R

Page 27

Cubis® MSU User Manual 27

Getting Started

Switching On

t Turn on the device via the A key. The following appears on the display:

y You can now follow the brief instructions to configure further necessary

balance settings before beginning weighing operations.

Warm-up Time

y To deliver precise results as per the Specifications, the balance must warm up

for at least 30 minutes after initial connection to the power supply. Only then

will the device have reached the required operating temperature.

When a verified balance used in legal metrology (legal-for-trade

applications) is connected to the power, it must warm up for at least

two hours before operation.

12

6

93

2

Page 28

28 Cubis® MSU User Manual

Getting Started

Modifying the Balance

Setting Up the Display and Control Unit at the Place of Use

The display and control unit can be removed for all models to enable the operator

to customize the work space.

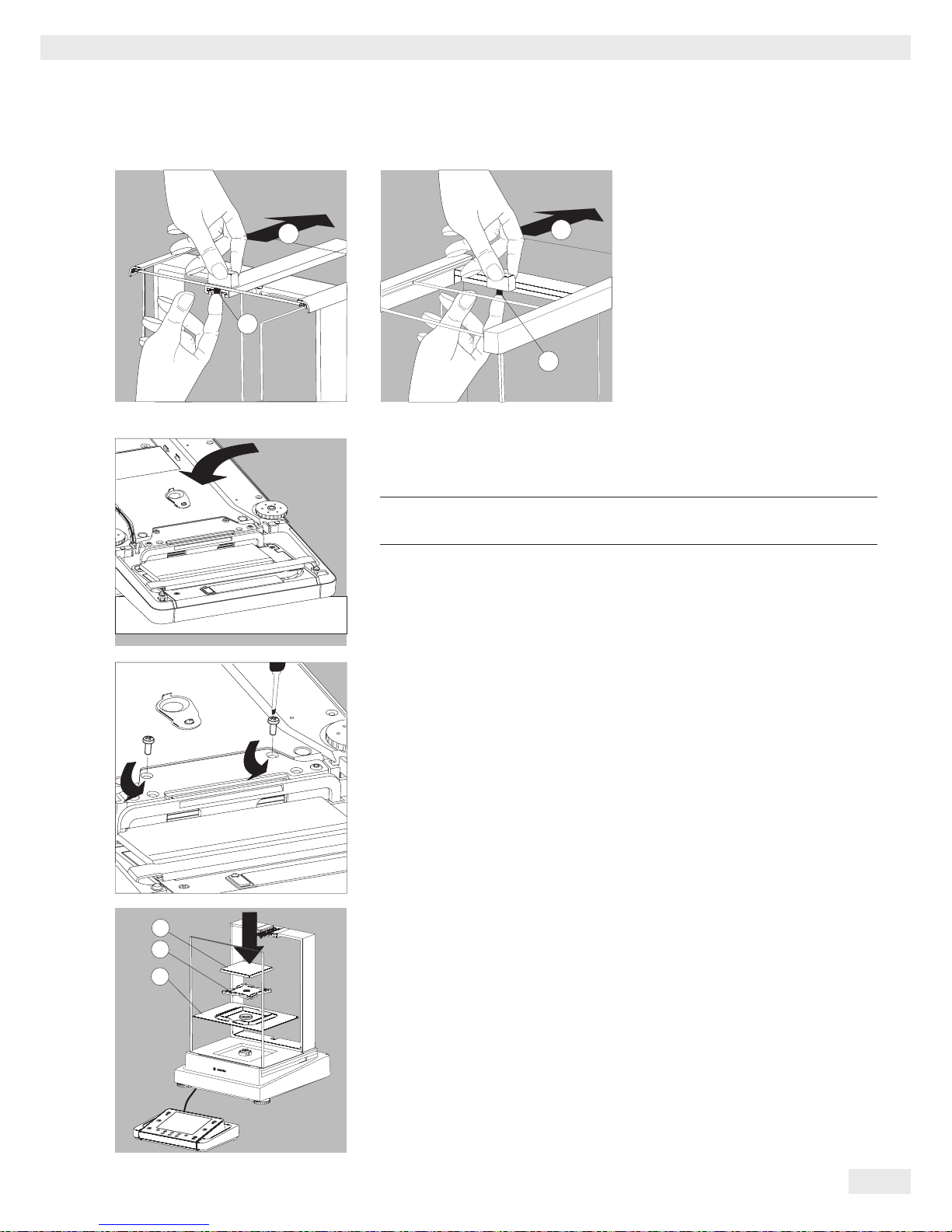

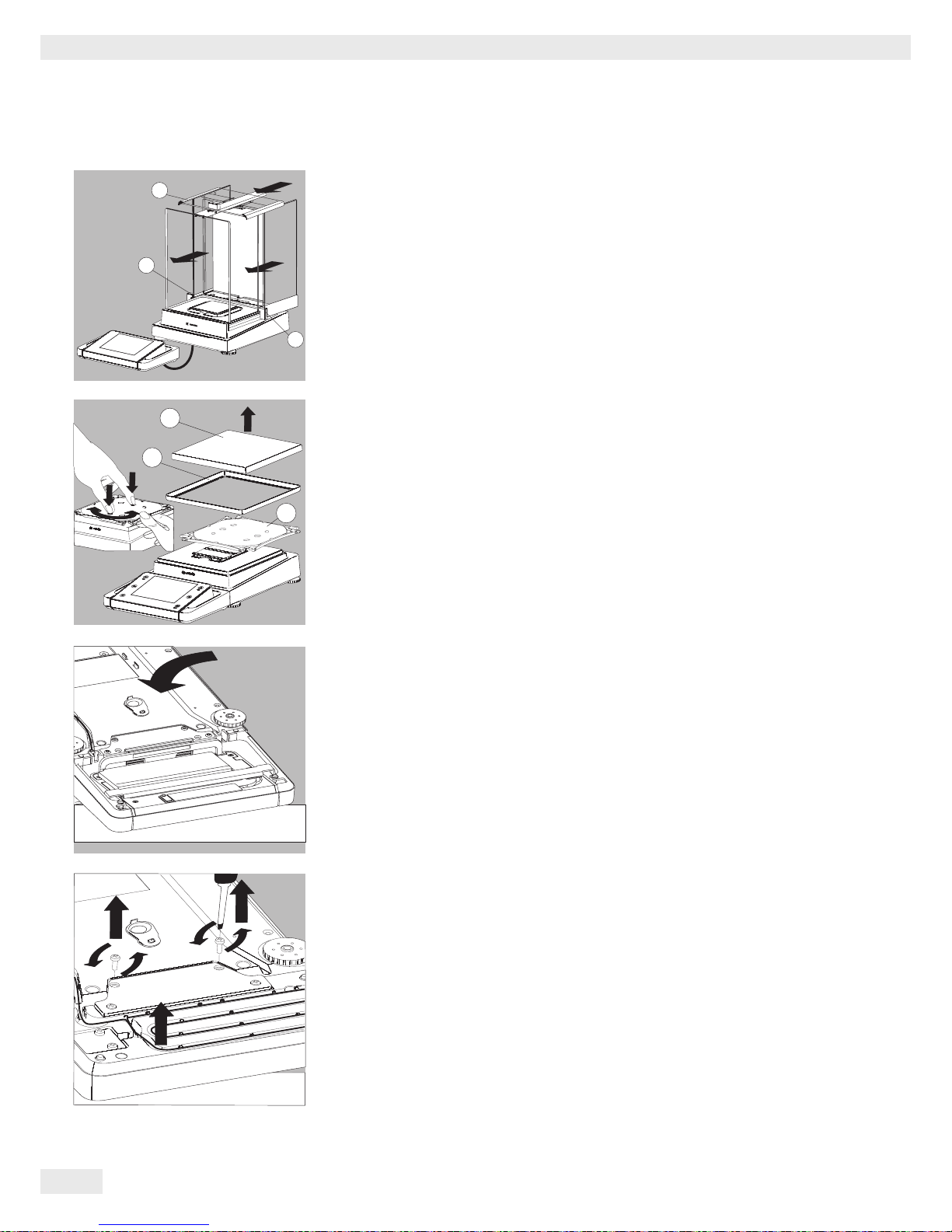

Removing the Retainer with the Display and Control Unit

Analytical balances:

t Remove all items (such as weights) from the draft shield.

t Carefully remove all parts as shown in the illustration.

1. Weighing pan

2. Pan support (not for models MSU225.../MSU125...)

3. Shield plate/Draft shield

t Keep all parts in a safe place.

t Remove the panels (right and left).

Models with the analytical draft shield:

1. Press on the locking tab

2. Remove the panel

Models with the milligram draft shield:

1. Press on the locking tab

2. Remove the panel

t Keep all parts in a safe place.

2

1

3

2

1

2

1

Page 29

Cubis® MSU User Manual 29

Getting Started

t Remove the upper draft shield

panel.

Models with the analytical draft shield

(left illustration):

1. Press on the locking tab

2. Remove the panel

Models with the milligram draft shield

(right figure):

1. Press on the locking tab

2. Remove the panel

t Keep all parts in a safe place.

t Turn over the balance and place on a soft surface.

3

Exercise caution to avoid breaking the glass on models with a draft shield.

t Use a 2.5 mm Allen wrench to remove the two screws from the display and

control unit retainer bracket.

t Remove the display and re-insert both screws back into their holes.

t Lengthen the cable and position the display and control unit as desired.

t Turn the balance over and place it on an even surface.

t Carefully place all parts on the balance.

1. Shield plate/Draft shield

2. Pan support (not for models MSU225.../MSU125...)

3. Weighing pan

2

1

2

1

2

1

3

Page 30

30 Cubis® MSU User Manual

Getting Started

t Replace the upper and side shield panels.

1. Upper draft shield panel

2. Right draft shield panel

3. Left draft shield panel

Removing the Display and Control Unit from Precision Balances without a Draft

Shield with a Weighing Range of up to 15 kg

t Carefully remove all parts as shown in the illustration.

1. Weighing pan

2. Shield plate/Draft shield

3. Pan support

t Keep all parts in a safe place.

t Turn over the balance and place it on a soft surface.

t Remove the two retaining screws.

t Remove the display and re-insert both screws back into their holes.

t Carefully pull the cable connected between the display and control unit from

the retainer.

3

2

1

2

1

3

Page 31

Cubis® MSU User Manual 31

Getting Started

t Determine the required cable length.

t Return the balance to an upright position and fit the parts onto the balance.

1. Attach the pan support

2. Shield disk (only for models with a readability of 10 mg)

3. Weighing pan

t Level the balance.

Removing the Display and Control Unit from Models with a Weighing Range of

20 kg or more

3

Remove the weighing pan before unscrewing the control unit, so that

the weighing pan does not fall and cause injury.

t Turn over the balance so that the pan side is facing down.

t Remove the two fixing screws using a screwdriver.

t Remove the control unit and re-insert both screws into their holes.

t Carefully remove the connection cable from its holder.

y

Longer connection cables should only be installed by a Sartorius technician.

2

1

3

Page 32

32 Cubis® MSU User Manual

Getting Started

Semi-microbalances: Attaching the Display and Control Unit to the Electronics

Module (MSU225..., MSU125... models)

The display and control unit can also be attached to the electronics module if

required for operation.

t Turn over the balance and place it on a soft surface.

Remove the connection cable from the cable channel:

t Remove two screws from beneath the weigh cell and detach the plate.

t Remove the connection cable plug.

t Then reattach the plate to the slot.

t Remove the display and control unit from the weigh cell:

Remove two retaining screws.

t Remove the display and control unit.

Page 33

Cubis® MSU User Manual 33

Getting Started

t Attach the display and control unit to the electronics module:

Reattach the two retaining screws.

Open the slot for the connection cable on the electronics module:

t Remove the screws from beneath the electronics module and detach the plate.

Connect the display and control unit to the electronics module:

t Plug in the connection cable.

t Then reattach the plate to the slot.

t Slide the cable that sticks out into the cable channel.

Preparing Below-balance Weighing

A port for a below-balance weighing hook is located on the bottom of the balance.

The below-balance weighing port may not be opened or used on

balances used for legal metrology.

Page 34

34 Cubis® MSU User Manual

Getting Started

Models MSU116P, MSU66S, MSU66P, MSU36S, MSU36P:

t Unscrew cover plate 3 from the bottom of the comparator

t Hang the container with the sample on the notched hook

t Install a draft shield if necessary

t Lift up weighing pan 1

t Unscrew hook 2

t Insert opposite end of hook 2 into port and refasten

t Place weighing pan 1 back on the device

Models MSU6.6S, MSU3.6P, MSU2.7S:

t Remove both screws from beneath the weigh cell and detach the cover plate.

t For example, attach a wire to sample and hang it on the notched hook.

h

Install a draft protection shield.

Analytical and Precision Balances with a Weighing Range of up to 15 kg:

1. Remove the hook for below-balance weighing from the bottom of the balance.

1

Page 35

Cubis® MSU User Manual 35

Getting Started

2. Push the cover of the below-balance weighing port to one side.

3. Carefully screw on the hook for below-balance weighing.

3

Do not screw it in too tightly,

as this could damage the thread or the balance.

h

Install a draft protection shield.

t Attach the sample (e.g., using a suspension wire) to the hook.

4.

When the below-balance weighing has been completed, unscrew the hook and

return it to the clip under the balance.

Balances with a Weighing Range of 20 kg or more:

t Use a suitable screwdriver to unscrew the cover plate from the bottom of the

mass comparator.

t Request the hook directly from Sartorius.

h

Install a draft protection shield.

Uninstalling Below-balance Weighing Equipment

t After uninstalling the below-balance weighing equipment, you must close the

opening again with the cover.

2

3

Page 36

36 Cubis® MSU User Manual

Getting Started

Using the Cable Opening of the Draft Shield

Models with an analytical draft shield have an opening for passing a cable

(for example, for a temperature sensor) through to the interior of the weighing

chamber.

1. Lift the locking tab on the rear panel of the analytical draft shield.

2. Lift the panel out of the draft shield.

t Turn the panel clockwise 180° so that the opening is at the bottom.

t Install the desired sensor.

t Insert the panel in the guide rail.

t Lift the locking tab and gently press the panel into position.

t Press the locking tab down and close it.

t You can now begin weighing.

Page 37

Cubis® MSU User Manual 37

Moving the Balance

Moving the Balance

Transporting the Device over Short Distances

3

Exercise caution to avoid glass breakage.

Never lift and carry the balance by its draft shield.

t Carry as shown in the illustration.

or

t Carry as shown in the illustration.

Storage and Shipping Conditions

–

Permitted storage and shipping temperature: -10 to +60°C

– Unpacked devices can lose their precision if subjected to extreme vibrations.

– Excessive vibrations may compromise the safety of the equipment.

Save the packaging for any future storage or shipment of the balance.

Only the original packaging provides optimum protection for the equipment.

– Follow all warnings and safety precautions.

– Chapter: “Storage and Shipping”

Page 38

38 Cubis® MSU User Manual

Using the Balance

Using the Balance

Turning the Balance On/Off

t Make sure the balance has been installed and put into operation in accordance

with the installation instructions.

A t Press the on/off key A on the control unit.

y The start screen appears briefly on the display, and then the user interface

appears.

h

On subsequent starts, the most recently active user profile and task are opened

(if at least one user profile has been set up).

t If prompted, level the balance (see Section “Leveling the Balance” for details).

A t To switch the balance to standby mode or turn it off, press the A key.

t Close the draft shield (if your model has one).

Operating Design: Q-Guide

Cubis® precision and analytical balances are controlled by application software with

interactive operator guidance. Once you open a menu or select an application, brief

instructions appear on the display to guide you through the menu or application

step-by-step. At each step along the way, the display shows only those options that

are relevant to your process; this helps prevent unnecessary “detours” and enables

you to reach your goal more quickly.

This type of user guidance is mostly intuitive. Although operation of the balance

is also mostly intuitive, this manual includes a section with very detailed, step-bystep instructions where you can learn about all of the available options

(see “Creating User Profiles” in Section “User Management”).

Basic Operational Structure

The most basic functions, weighing and taring, can be carried out as soon

as the balance is switched on. The application software is divided into three general

areas in which individual settings can be configured:

In Task Management (TASK), task profiles with specific applications, weighing settings, and printout settings can be configured.

User Management (USER) lets you set up user profiles with specific configura-

tion settings and user rights. You can also set up password protection to meet your

security requirements. Your balance can also be used without User Management.

Simple Weighing

D TASK

Task Management (from page 67)

Selecting and starting applications

Configured

at factory

Configured

by user

System Settings (from page 45)

Configuring applications

Configuring tasks

Creating user profiles

H USER

User Management (from page 134)

Selecting user profiles

Page 39

Cubis® MSU User Manual 39

Using the Balance

System Settings (MENU) contains all basic settings and parameters which are used

to operate the balance, affect the entire operation of the balance, and can also

be used for creating new tasks.

Wizard

You can choose between two display types in several menus:

The overview lists all parameters with their set options. You can select each individ-

ual option to change its setting.

When you activate the Wizard in the same menu, the program guides you step by

step: The individual parameters with their options are displayed in succession.

Using the Display and Control Unit

Control Keys (Softkeys):

D

TASK key: opens Task Management, in which applications can be selected and

tasks defined. While working in this menu, you can also use the TASK key to cancel

at any time and return to task overview.

H

USER key: opens User Management, in which user profiles can be selected and

user settings defined. While working in this menu, you can also use the USER key

to cancel at any time and return to user overview.

J

TARE keys – left and right: Zero and tare the balance.

If a balance verified for use in legal metrology is unloaded after taring:

A negative gross value marked with a warning symbol appears. To avoid

this: Apply the value of a container, e.g. using the application “Second

tare memory” (see section “Second tare memory (preset tare)”, page 121.

P

PRINT key: used to print the currently displayed measurement results

or a user-specific print-out

A

On/off key: used to turn on/off and switch to standby

-

Softkeys: used to activate the function displayed directly above them

qwe

Cursor softkeys: used for navigation on the display

O

Operating elements for electronic draft shield (optional)

Page 40

40 Cubis® MSU User Manual

Using the Balance

Adjusting the Display and Control Unit

The tilt angle of the display and control unit can be set as desired to enable optimal

readability for changing working conditions. The color and brightness of the display

can also be changed to match the illumination in the room.

(see “User Management” and “System Settings”).

SD Memory Card for Data Exchange

The display and control unit is equipped with a slot for an SD memory card where

you can import and export data (tasks, user profiles). Handling the memory card

is explained in Section Importing/Exporting Data.

Setting the Language

y The default language for the display is English.

t To change the language, select Menu and then Lang.

t Use the cursor softkeys to select the desired language.

y The display changes directly to the selected language.

t If you would like to select a language that was not included with the equip-

ment supplied but was later downloaded from the Cubis® website, you must

first import the language file (see Section “Importing/Exporting Data”).

y To display the downloaded language, select the last option in the language list

(“Reloadable language”) and then select the desired language.

Quick Guide: First Weighing

A t Press the on/off key A to turn on the balance.

t Close the draft shield (if your model has one).

J t Press the tare key J to tare the balance.

y The balance is tared, and the displayed value is zero.

t If required, open the draft shield and carefully place the sample on the weigh-

ing pan (in a suitable container if required).

t Close the draft shield (if your model has one).

t You can read the measured value as soon as the weight value stops changing

and the unit is displayed.

Page 41

Cubis® MSU User Manual 41

Using the Balance

Display

The display varies depending on whether the application software is in operating

mode or a menu is currently open (setup mode).

Display in Operating Mode

1 Function display: Current task (here: step 1 of 2)

2 Metrology line: Left: weighing capacity (max); right: d = readability (resolu-

tion) of the balance

3 Value range with current measurement value (the numeric value is displayed

in black numbers once the weighing system reaches stability; beforehand it is

shown in gray)

4 Status and warning messages (see below)

5 Task area with instructions on how to proceed

6 Functions which are currently available

7 User field: Display of current user, date, and time

8 For _.CE model balances verified for use as legal measuring instruments:

Display of weights that are not weight values, e. g., calculated values

and values < 0

9 Scaled display of measured value (percentage of weighing capacity utilization)

Status and Warning Messages

Tabs with the following messages may be displayed here:

isoCAL: isoCAL is active (extended temperature range)

isoCAL flashes: Calibration required

Level me! flashes: Balance is not level; leveling required

GLP: GLP print is active; header will be printed

[Maintenance] Maintenance: The next scheduled maintenance date has been reached.

SQmin: The entered SQmin value is permanently displayed

SQmin flashes: The weight value is less than the entered SQmin value

U or U* or PA: The selected DKD value (measurement uncertainty)

is currently displayed.

Ion: Ionizer in progress (only if your model has an ionizer)

1

2

3

5

6

7

8

9

4

Verified balances feature the

following additional displays:

In the line for metrological data:

Min Minimum weight

e Verification scale interval

In the value range:

o calculated values

k Values < 0 and other values

pcs Piece count

Page 42

42 Cubis® MSU User Manual

Using the Balance

Display in Setup Mode

1 Interactive area with instructions on how to proceed

2 Orientation line showing your current location

3 Working area with selectable options

4 Toolbar with the available buttons

5 Symbol indicating which menu (TASK, USER, or MENU) is currently open

6 Scroll bar to view entire selection area

Operating the Display Unit

3

Equipment may be damaged by objects with points or sharp edges

(e. g., ballpoint pens).

Use only your fingertips to operate the buttons and softkeys.

q e w The cursor softkeys can be used to navigate to any of the selectable functions

or settings on the display.

w When you reach the desired menu item, press w to confirm your selection.

Alternative selection: When only one out of multiple options is possible, select

the desired option and confirm with w.

Multiple selection: When several options are available, each option will have

a checkbox. To select or deselect an option, highlight it and then press w.

To continue to the next program step, select Next.

If the scroll bar appears on the right edge of the display, there are more options

than are shown on the display. Scroll down with the cursor keys to view all

of the selection options.

1

2

3

4

5

6

Page 43

Cubis® MSU User Manual 43

Using the Balance

Entering Text and Numbers

A keyboard will appear whenever you have to enter text and numbers.

A cursor appears in the entry line above the keyboard.

t Select the character you would like to insert using the cursor softkeys.

t To accept the character, confirm with Add.

y The character will appear in the entry line.

Press the shift softkey to switch the input mode between uppercase letters,

lowercase letters, numbers, and a complete set of special characters.

Press Add to confirm the selected character and add it to the text line.

The backspace key is used to delete the character to the left of the cursor.

The two arrow keys move the cursor one character to the left or right.

Press OK to exit input mode and save your entry.

Press Back to cancel input mode and go back one program step to the previous

screen.

Opening and closing the rotation draft shield (models MSU6.6S/3.6P/2.7S):

Defining the opening width:

t Touch DraftShld.

yThe settings for the opening angle are displayed.

t Check the settings and change as required.

O

Draft shield opens according to the opening angle setting.

Page 44

44 Cubis® MSU User Manual

Using the Balance

Activating/Switching Users

When the balance is in operating mode, the active user profile is displayed

in the user field at the top right of the screen. To activate another user profile,

open the User Management menu.

H t Press the USER key H.

y The user list is displayed. The user profile that is currently active is indicated

by an arrow.

t Select the user profile you would like to activate.

t Confirm your selection with w.

t If password protection is activated, enter your password.

y The program switches back to operating mode, with the selected user profile

activated.

Page 45

Cubis® MSU User Manual 45

System Settings (Menu)

System Settings (Menu)

This menu contains all balance settings relevant to the device. Basic settings can

be made here that immediately affect the device. Changed settings do not affect

previously defined tasks and user profiles.

h

All system settings are applied to all user profiles.

h

As long as a task is active and/or a user has been selected, several basic settings

cannot be changed. In order to change all settings, “Weighing” has to be selected

in operating mode and no user profile may be selected.

Not all functions/settings can be selected on balances used as legal measuring

instruments.

t To open System Settings, select Menu when the balance is in operating mode.

y The list of available system settings is displayed.

t Use the cursor softkeys to select the menu item for the settings you would like

to edit.

System settings are divided into the following menus:

– Level the balance

– Calibration/adjustment data

– Configure timer controlled actions

– Device information

– Device parameters

– Import/export data

– Service

You have already learned how to use the menus. In the following, only configuration options are described and explained.

Page 46

46 Cubis® MSU User Manual

System Settings (Menu)

Leveling the Balance (Q-Level)

It is essential for exact weighing results that the balance is absolutely level.

The front leveling feet can be used to level out small tilts in the floor. Depending

on the model, the balance is equipped with either motorized or manually operated

leveling feet.

An integrated sensor detects the alignment of the balance and triggers a warning

message when leveling is required. You can configure this warning message and the

automatic leveling function (see System Settings > Balance Parameters).

When the isoCAL function is activated, the isoCal trigger is set after manual

leveling. Balances with motorized leveling feet are leveled automatically prior to

each new calibration/adjustment.

3

Note: The scale needs to be re-leveled and then adjusted each time its setup

location is changed.

When “Level me!” appears on the display, you must level the balance.

t Make sure that the weighing pan is empty.

t Select the option Level the balance from the menu.

Balance with Motorized Leveling Feet (Available for all models with a weighing

capacity of >61 g and <6200 g):

t To start the leveling function, select Next.

t Follow the instructions on the display.

Balance with Manually Operated Leveling Feet

t Follow the instructions on the display.

3

After each leveling routine, the balance must be calibrated/adjusted

(see Section “Calibration and Adjustment”).

Page 47

Cubis® MSU User Manual 47

System Settings (Menu)

Configuring Calibration/Adjustment

Settings are divided into the following submenus:

– Define calibration/adjustment functions

– Define external calibration weights

– Set fully autom. adjustment function isoCAL

t Configure the settings for all submenus.

t To save the settings, select Save.

h

Factory settings are marked with an asterisk (*).

Defining Calibration/Adjustment Functions

Cal./adj. key: Function: Block key / *Configure key selection menu / Select

fixed 1-key function

Cal./adj. selection menu: Select which calibration/adjustment functions

are listed when the Cal./adj. key is touched.

Cal./adj. sequence: Options: *Calibrate, then adjust automatically / Calibrate,

then adjust manually

Cal./adj. unit: Options: *Gram / Kilogram / Defined via data record

Defining External Calibration Weights

No. of ext. cal. weights: Enter the number.

Ext. cal. weight n: Enter the data for each calibration weight: weight value

(in grams), ID, certificate, validation

Configuring Fully Automatic Adjustment Function isoCAL

isoCAL: Define the function setting: Off / Show alert levels, manual start /

*On, automatic execution

isoCAL alert level: *isoCAL status field only / Alert message, repeating /

Error message, adjustment required

isoCAL temperature: Enter temperature difference (in Kelvin).

isoCAL interval time: Enter interval time in hours.

Page 48

48 Cubis® MSU User Manual

System Settings (Menu)

Configuring Timer Controlled Actions

You can program the following actions so that they run automatically at preset

times:

– Show message and execute command (see example below)

– Execute command

– Show message (e. g., a prompt as a reminder)

y The available actions are displayed. When you open this menu for the first time,

the list will be empty.

t Select Edit.

t To define a new timer controlled action, select Create.

Later you can also modify, copy, or delete each action here.

Example: You want the “Internal calibration/adjustment” function to run each

morning at 7:00 a.m. In addition, you want a message to be displayed.

t Select the desired action (e. g., “Show message and execute command”).

t Select the command you want to be executed (e. g., “Internal calibration/

adjustment”).

Page 49

Cubis® MSU User Manual 49

System Settings (Menu)

t Enter the text you want to be displayed when the action is being performed

(e. g., “Timer-controlled adjustment”).

t Enter the time when the action should be performed for the first time.

t Define the time interval at which you want the action to be repeated

(e. g., one day for daily occurrence).

t To start the action at the preset time, select Enable action.

Here you can disable the programmed action at any time and re-enable it later with

a new starting time.

y An overview of all settings for the action is displayed.

t Check and correct all settings as required.

t Select Next.

t Enter a name and a description for the action.

t To save the action, select Save.

Page 50

50 Cubis® MSU User Manual

System Settings (Menu)

y The programmed action is displayed in the list of actions.

You can edit them again at any time here.

Displaying Device Information

You can view various information here.

t Select the information that you want to view.

Displaying Basic Information

Here you can find all information about the manufacturer, model, serial number,

host name, and IP address used.

t To view the parameters for SQmin and DKD, select SQminDKD.

t To view the version of the balance, display and control unit, and application

software, select Version.

t To view the weighing ranges and digits (resolution), select Ranges.

Service Information/Hotline

Service contact information is displayed here along with the hotline number

and maintenance contract and interval information.

Calibration/Adjustment Log File

The log file is displayed here with the results of all calibration and adjustment

routines. The older entries are deleted by new entries on a rolling basis.

View Audit Trail

All changes to the menu, user profiles, and task profiles are logged in the audit

trail. These logs will include the following information: user, profile, parameter ID,

parameter, old and new setting. The older entries are deleted by new entries on a

rolling basis. The audit trail can be deactivated via Sartorius Service.

Page 51

Cubis® MSU User Manual 51

System Settings (Menu)

Alibi Memory

The alibi memory contains (stores) weighing results with date, time, and process

number. This takes place every time a print job is requested [e. g., by pressing

Print P]. Tare and input values are also saved. The alibi memory can therefore

be used as a replacement for a log printer.

The data memory has a ring buffer, meaning that the oldest data records can

be overwritten by new ones. The user can define a memory-time dependent

overwrite protection as well a storage period. Standard: 90 days, see Section

“Device Parameters.” The alibi memory can contain approximately 450,000 data

records; storage capacity depends on the size of each data record.

The alibi memory is verifiable. When the balance is calibrated, you must check that

the alibi memory is correctly functioning by saving some values.

If the alibi memory is being used in legal metrology (according to Council Directive

2014/31/EU), the following must be observed:

– Make sure that there is sufficient storage capacity. Responsibility for this lies

with the operator.

– The weighing results should be stored together with a unique ID code (e. g.,

number or date and time). This makes it possible for every weighing operation or weighing result to be easily assigned and verified if necessary. These ID

codes must be indicated on any receipts generated on peripheral devices.

– All the required tare and net values will be saved during data output.

– It must be possible for the contractual partners involved to be able to check

and verify the stored weighing results.

– Any continuously output weighing results that have not previously been stored

and have no identification codes may only be used for applications that are not

used in legal metrology

(e. g., batching, controlling, or similar). It is not permissible to circulate any

results lacking identification codes for applications used in legal metrology.

– Receipts can be prepared by a peripheral device not subject to legal verifica-

tion in accordance with the preamble to Annex I of Directive 2014/31/EU and

Section 7b (3) 2 of the German Verification Act.

These receipts must contain the following information:

– ID code for every weighing result,

– if used in Germany, a note stating that the weighing results can be com-

pared with the legally stored weighing results using their identification

codes.

You must first install and activate the alibi memory in order to use it (see Device

Parameters > Alibi Memory Configuration).

Searching for and Displaying Data in the Alibi Memory

You can search for data using various search criteria and view the storage capacity

of the alibi memory.

Page 52

52 Cubis® MSU User Manual

System Settings (Menu)

Searching for Data Records by Date

t Select the search function.

y An overview appears on the display.

t Limit the search by selecting the year, month, or day.

t Select Next.

y The desired records are displayed.

t Using the Prev. and Next buttons, you can view more data records from the

selected date.

Searching Data Records by Sequential Number (Data Record Number)

t Select the search function.

t Enter the number for the desired data record.

t Select OK.

Page 53

Cubis® MSU User Manual 53

System Settings (Menu)

y The desired data record appears on the display.

Viewing Information on the Alibi Memory and Available Memory Space

All important status information for the alibi memory is shown here. You can view

the percentage of memory space in use and an estimate of how many data records

can still be stored. The exact number depends on the size of each data record.

Page 54

54 Cubis® MSU User Manual

System Settings (Menu)

Device Parameters

Here you can update the software and change the following device settings.

Settings are applied to all user profiles.

– Configure balance parameters

– Configure data output

– Entering the Device ID

– Set date/time

– Configure display and control unit properties

– Touchscreen adjustment

– Ports

– Alibi memory

– Update software

– Software activation codes (e.g. for “Q-Apps” software options)

– Restoring factory settings

– Motorized draft shield (optional)

– Ionizer (optional)

Configuring Balance Parameters

h

Factory settings are marked with an asterisk (*).

General Weighing Settings

Here you can configure the default settings for general weighing functions.

These settings can be changed for a specific task whenever a new task is created.

h

These settings can only be changed when the balance is set to “Weighing”

in operating mode. If General weighing settings cannot be selected, use

the TASK D button to switch to Task Management and select Weighing.

In order to view detailed information about individual settings, select Info.

Adapt filter: The effects of unfavorable weighing conditions such as drafts or

vibration can be filtered out by adapting the balance filter (and thus its measuring

time) to suit ambient conditions. Options: Very stable conditions / *Stable conditions / Unstable conditions / Very unstable conditions

Application filter: Equalizes the load deviations on the display. Options:

*Final readout / Filling mode / Low filtering / Without filtering

Stability range: The stability indicator lights up when the weighing results are

constant within a set range. Options: Maximal accuracy / High accuracy / *Medium

accuracy / Fast / Very fast / Maximal fast

Stability delay: This setting compensates for slowly abating disturbances, such

as turbulence in the weighing chamber of an analytical balance). Options:

*Very short delay / Short delay / Median delay / Long delay

Zero/tare function: Conditions for performing the tare function.

Options: Without stability / *After stability / At stability

Automatic zeroing: When this option is turned on, the balance is tared auto-

matically when a set fraction of scale intervals per second changes from the display

zero point. Options: On / *Off

Basic unit: Weight unit to be used for this task. Options: Any available weight

unit — the default setting is in grams.

Display accuracy: A lower display accuracy results in a faster display.

Options: *All digits on / Last digit off

Zero/tare at power on: Automatic taring when the balance is switched on.

Options: *On / Off

Page 55

Cubis® MSU User Manual 55

System Settings (Menu)

Leveler Configuration (Q-Level)

You can configure the leveling function here.

Leveling Notice

Off, no indication: Leveling prompt is disabled.

Display status: As soon as leveling is required,

Level me! appears and flashes.

Alarm message, leveling required: As soon as leveling is required,

Level me! appears and flashes. If this notice is ignored, an alarm message appears

after five minutes. If this occurs, you can only continue working after the balance

has been leveled.

Automatic Leveling (Balances with Motorized Leveling Feet Only)

Switch off, start with key: Select Start to activate automatic leveling.

Switch on fully automatic: The balance is leveled automatically before every

calibration/adjustment routine.

t To save the settings, select Save.

Power On Mode

t Select the balance’s startup mode for when the balance is switched on or when

the on/off key A is pressed repeatedly.

Options: On/standby or Always on

t To save the settings, select Save.

Power Saving Mode

t Switch the power saving mode of the balance on or off.

Off, no function: Power saving mode is not in use.

Automatic shutoff after 2 minutes: The backlight on the display

and control unit switches off if the device is idle for two minutes.

t To save the settings, select

Save.

Restoring Factory Settings

You can reset all balance settings back to the default delivery status here

(after confirming the reset when prompted).

Page 56

56 Cubis® MSU User Manual

System Settings (Menu)

Configuring Data Output (Print Parameters)

Here you can configure all settings for printing and data output.

Several of these settings depend on the interface configuration

(see Section “Interfaces”).

h

Factory settings are marked with an asterisk (*).

In order to view detailed information about individual settings, select Info.

Printout interface: Options: COM port A, B, C (file/SD memory card), D and

print to file

Protocol: Options: Print / SBI / xBPI / Web services / SICS / Second display.

This setting cannot be changed here; it is defined when configuring the interfaces.

h

The parameters and settings that are displayed here depend on the configured

protocol.

GLP printing: When should ISO/GLP printing be allowed? Options:

*Off / For calibration/adjustment only / Always on.

Taring after printing: Automatic tare after print

command. Options: *Off / On

Print event: What event should trigger printing?

Options: *PRINT key / Starting a task / Initialization of an application / Application

result / Printing of component / Result from an application (evaluation of application) / End of task / Calibration/adjustment result

Print key elements: Which elements should be printed?

h

For further information, please refer to Configuring Printouts in Section

Interfaces.

Entering the Device ID

With these two IDs, you can expand the printer protocol.

t Select the input for both the IDs

t

Enter the desired value (text) for each identifier.

t To save settings, touch Save.

Associated input and output commands for data output:

See the chapter Interfaces: SBI Commands, page 164

Page 57

Cubis® MSU User Manual 57

System Settings (Menu)

Setting Date/Time

The date, time, and display format can be set here.

Under Date format:

t Select how the date is displayed and printed out.

− Standard: Language-dependent display format

− DD/MM/YYYY or DD.MM.YYYY: The date is displayed in the order of day,

month, and then year.

−

MM/DD/YYYY: The date is displayed in the order of month, day, and then year.

− YYYY-MM-DD: The date is displayed in the order of year, month and then day.

Under Time format:

t Select how the time is displayed and printed out.

− Standard: Language-dependent display format

− HH.MM.SS or HH:MM:SS: The time is displayed in 24-hour format.

− HH.MM.SS on: The time is displayed in 12-hour format. The hours before noon

are displayed with AM, and the hours after noon are displayed with PM.

Configuring Display and Control Unit Properties

The following properties of the display and control unit can be changed as neces-

sary: Language, Background color, Brightness, Acoustic signal.

These general properties are applied to all user profiles, are also used when no user

is logged in, and serve as a template when a new user profile is created.

Configuring Ports and Network Settings)

Here you can configure interfaces (serial ports and network) and settings for

the network.

Also settings for:

– Control inputs/outputs

– Print to file

– FTP server settings

A detailed description of the connection options and data interface ports can

be found in Section Interfaces.

Page 58

58 Cubis® MSU User Manual

System Settings (Menu)

Configuring Serial Ports

y The available ports are displayed.

t Select the port you want to configure.

t Configure all settings for this port.

t To save the settings, select Save.

Configuring Network Ports (Ethernet)

For more information on network operation, see “Network Interface” in Section

Interfaces.

t Select operating mode for the network interface.

No function / xBPI (expanded Sartorius communication / SBI (Sartorius standard

protocol) / Printer output / SICS protocol

t Select connection type.

Server or Client connection

t Configure the local TCP port.

t To save the settings, select Save.

Configuring Network (Ethernet)

t Define the settings for network operation.

The Hostname (device name — max. 24 characters) set here can be printed on logs.

The IP address can be entered and set as a default or obtained automatically.

t To save the settings, select Save.

Page 59

Cubis® MSU User Manual 59

System Settings (Menu)

Control Input/Output (e.g., for Remote Switch)

If you have connected a remote switch, for example, via the peripheral or optional

port, you can define its function here.

t Configure the setting for each port.

t Select the connected hardware device or control function.

h

During checkweighing, the control outputs have no function when set to:

– Foot switch YPE01RC

– Control inputs

t Configure the settings for the control inputs and outputs.

Options: Off, no function / TARE key / PRINT key / Cal./Adj. key /

Zeroing / Taring

t To save the settings, select Save.

Page 60

60 Cubis® MSU User Manual

System Settings (Menu)

Configuring “Print to file”

Purpose:

– Transferring a print file in TXT or CSV format to a SD card or FTP server.

– Viewing a print file directly in an Internet Browser.

t Select Off.

t Specify the file format.

Print to CSV file:

In addition to the SBI output (like in the TXT file), three additional columns are also

written to the file: ID, Value and Unit.

The 4 columns are separated by the “;” character. The “+” sign has also been removed

in the third column and the decimal point has been replaced by a decimal comma

(because of Excel).

t To specify the settings for the automatic or manual data transfer, touch Off.

y The data are deleted from the balance after the automatic or manual transfer