Page 1

WCP5001-e07104

Service Manual

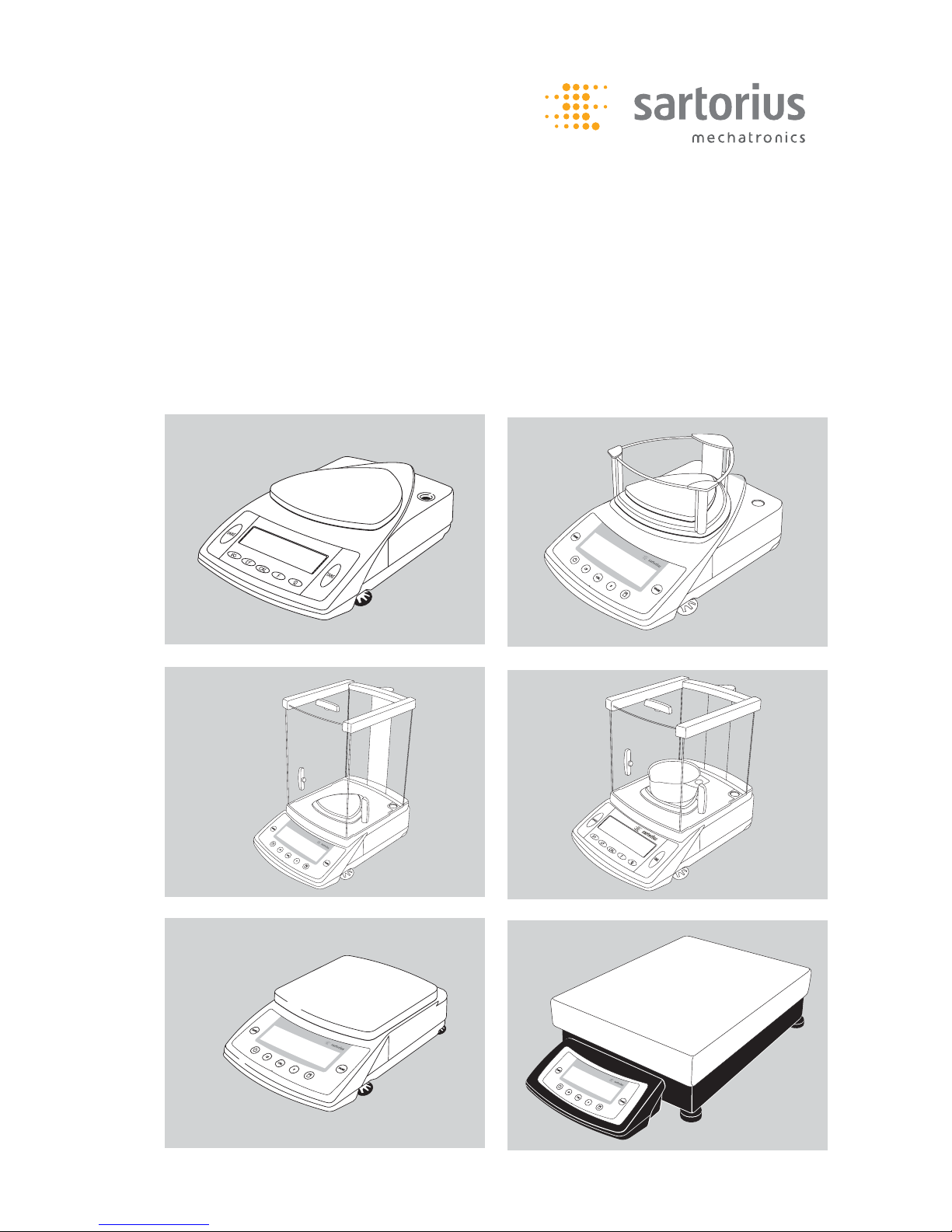

Sartorius Competence | Sartorius Gem

plus

CPA-, CP-, GC- und GP-Models

Electronic Semimicro-and Analytical Precision Balances and Precious Metal Scales

Including Service Specifi cations Sheets

Page 2

2 | Contents

Page

03 General Information

03 Fundamentals at a Glance

04 The Most Important Information at a Glance

04 Service Concept for the CP/GC/GP Scale/

Balances

04 General Notes

05-06 New Features Compared to the BP

06-07 Models with Special Weighing Systems

08 Auxiliary Service Tools, Equipment and Weights

08 Accompanying Literature

09 Handling and Operation

09 Function of the Keys

09 Displaying the Hardware and Software Versions

10 Function of the Service Switch and Access Lock

Switch

10 Access Lock Switch

11 Brief Instructions Balance/Scale Operating Menu

11-12 Accessing and Setting the Balance/Scale Opera-

ting Menu

13-14 Menu Code Settings(Rel BAC 13.44 Version)

15 Function of the BPI Switch

15 Activating the BPI Mode

16 Testing and Adjusting Balances/Scales with Strain

Gauge Systems

16 Testing and Adjustment Sequence on Balances/

Scales with Strain Gauge Systems

16 Checking the Overload Stop

16 Setting the Overload Stop

17 Zero-Point Offset Adjustment

17 1. Adjustment with a Digital Voltmeter

17 2. Adjustment using the Service Software

(Sartocas / Psion)

18 Checking the Repeatability (standard deviation)

18 Checking and Adjusting the Off-Center Loading

Error

18 Checking the Off-Center Loading Tolerances

19-20 Procedure for Adjusting the Off-Center Loading

Error (Strain Gauge)

21 Span Adjustment

21 External Adjustment

22 Adjusting Linearity

22 Adjusting External Linearity

23 Testing and Adjusting Balances/Scales with Double-

Lever Systems

23 Testing and Adjustment Sequence on Balances/

Scales with Double Lever Systems

23 Checking the Overload Stop

23 Checking the Repeatability (standard deviation)

24 Checking and Adjusting the Off-Center Loading

Error

24 Checking the Off-Center Loading Tolerances

25 Procedure for Adjusting the Off-Center Loading

Error (Double Lever Systems)

26 Span Adjustment

26 External Adjustment

27 Adjusting Linearity

27 Adjusting External Linearity

28 Balance/Scale with Monolithic Weigh Cells

28 Testing and Adjustment Sequence on Balances/Scales

with Monolithic Weigh Cells

28 Checking the Overload Stop

28 Checking the Repeatability (standard deviation)

29 Off-Center Loading Error

29 Checking and Adjusting the Off-Center Loading Error

29 Checking the Off-Center Loading Tolerances

29 Procedure for Adjusting the Off-Center Loading

Error (Monolithic Weigh Cells)

30 3-Point Adjustment

31 Span Adjustment

31 External Adjustment

31 Overwriting the Internal Calibration Weight

32 Internal Span Adjustment

33 Linearity

33 Checking the Linearity

33 Adjusting the Linearity

34 Overwriting the Internal Linearization Weight

35 Balances/Scales with Forked Lever Systems

35 Testing and Adjustment Sequence on Balances/Scales

with Forked Lever Systems

35 Checking the Overload Stop

35 Checking the Repeatability (standard deviation)

36 Off-Center Loading Error

36 Checking and Adjusting the Off-Center Loading

Tolerances

36 Procedure for Checking the Off-Center Loading

Tolerances

37 Procedure for Adjusting the Off-Center Loading

Error (Forked Lever Systems)

38 External Adjustment

39 Linearity

39 Checking the Linearity

39 Adjusting the Linearity

40-41 Error Codes

42-44 Calibration/Adjustment Data

Page 3

General Information | 3

Generals Information

Fundamentals at a Glance

We strongly recommend completing a service training course at

Sartorius before performing work on Sartorius weighing instruments.

Please do not attempt or permit any unauthorized repair work.

The following CP models will be/have been replaced by CPA models:

Standard models:

CP - Models = Nachfolger CPA CP - Models = Nachfolger CPA

CP64 = CPA64 CP124S = CPA124S

CP224S = CPA224S CP324S = CPA324S

CP225D = CPA225D CP34000 = CPA34000

CP4201 = CPA4201 CP6201 = CPA6201

CP8201 = CPA8201 CP12001S = CPA12001S

CP16001S = CPA16001S CP34001S = CPA34001S

CP34001S = CPA34001S CP622 = CPA622

CP2202S = CPA2202S CP3202S = CPA3202S

CP4202S = CPA4202S CP153 = CPA153

CP323S = CPA323S CP423S = CPA423S

Important Note: All CPA models have an overlay that is different from the one on CP

models (see page 9).

The analytical balances with model names CPA324S and CPA224S and

higher have a monolithic weigh cell.

stamp approved models: CP - Models = Nachfolger CPA CP - Models = Nachfolger CPA

CP124S-ACE = CPA124S-PCE CP12001S-0CE = CPA12001S-0CE

CP224S-PCE = CPA224S-PCE CP16001S-0CE = CPA16001S-0CE

CP64-0CE = CPA64-0CE CP34001S-0CE = CPA34001S-0CE

CP124S-0CE = CPA124S-0CE CP622-0CE = CPA2202S-0CE

CP224S-0CE = CPA224S-0CE CP2202S-0CE = CPA2202S-0CE

CP324S-0CE = CPA324S-0CE CP3202S-0CE = CPA3202S-0CE

CP225D-0CE = CPA225D-0CE CP4202S-0CE = CPA4202S-0CE

CP523S-PCE = CPA523S-PCE CP153-0CE = CPA223S

CP3202S-ACE

CP4202S-PCE

CP4202S-ACE = CPA4202S-PCE

CP34000-0CE = CPA34000-0CE

CP34001P-0CE = CPA34001P-0CE

CP2201-0CE = CPA2201-0CE

CP6201-0CE = CPA5201-0CE

CP8201-0CE = CPA8201-0CE

Page 4

4 |

Service Concept for CPA/CP/GC/GP Balances/Scales

Valid until further notice

- All calibration/adjustment work required for starting up operations and testing

must be carried out in accordance with the operation instructions.

- Quality defects.

o Immediately report all quality defects that may occur to the Quality

Assurance Department (WQM).

- Defective balances/scales

o Warranty.

• Within the first 6 months of installation, any defective balance/scale

covered by the warranty should be exchanged.

o Seal of warranty.

• If you have to remove the Seal of Warranty, please affix your control seal

with the Sartorius logo to the unit!

o In other cases, proceed according to the OAW135 (standard operating

procedure for returns for repairs).

• Defective weighing cells.

Proceed as described in the Service Concept for Weighing Cells, refer to

(Service Information Document 6.2001 / OAW135-2/3).

• Defective electronics.

These balances/scales along with an error record should be sent back to

the Central Mechanics Workshop (ZW) in Goettingen (OAW135-2).

• Other service situations can be dealt with on site, for example:

Broken draft shields; weighing pan can no longer be used;

replacing small parts, ... etc.

General Notes

Transport:

- Always turn off the CP/GC balance/scale first by pressing the e button and

then wait about 10 seconds before you pull the mains plug.

If the balance/scale with an internal calibration weight is currently running

in the calibration mode, the internal calibration weights are exposed. This can

cause the weighing system to be damaged during transport. By switching off the

balance/scale properly, they will be locked.

- Before you plug in or remove any connecting cables, always separate the balance/

scale from the power supply, as otherwise components can become destroyed.

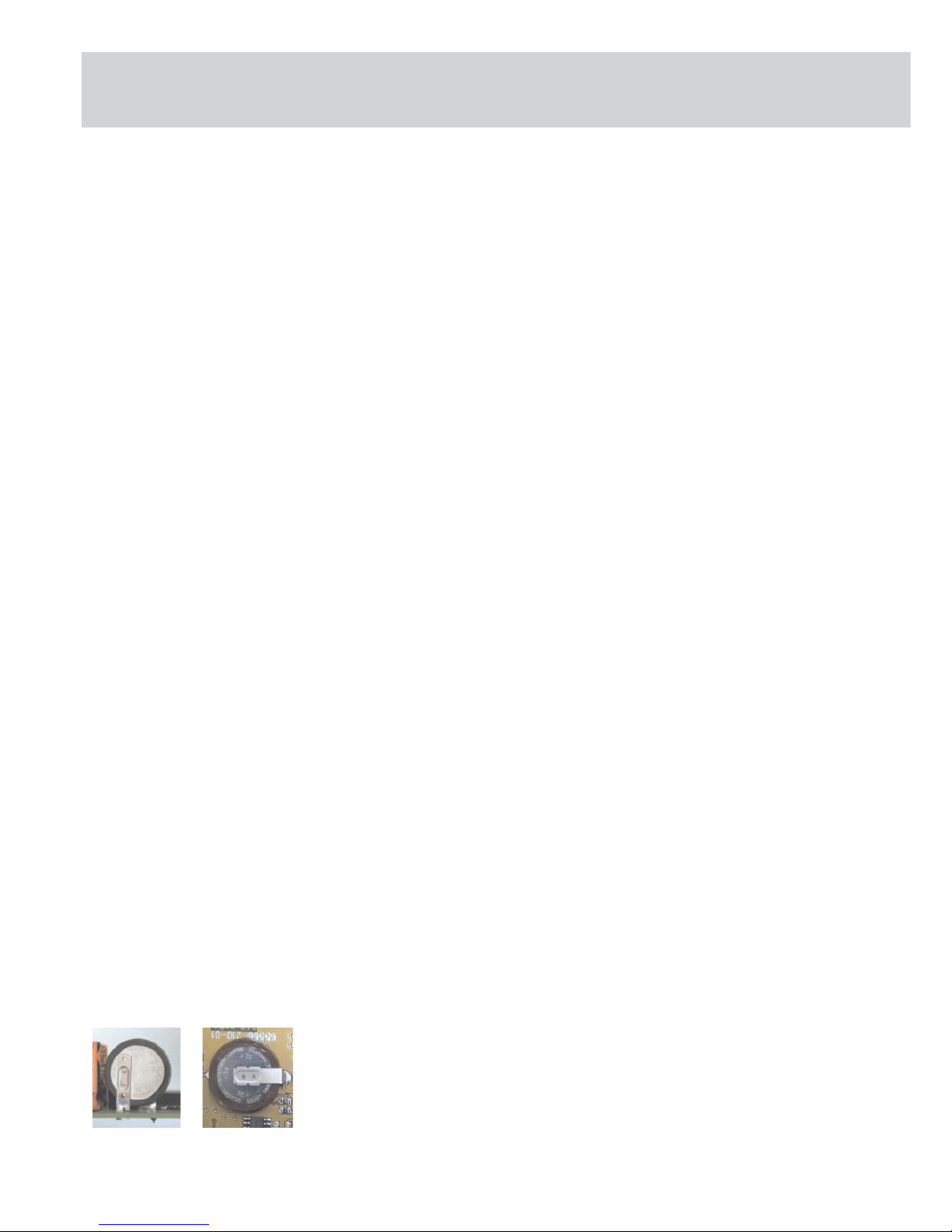

positioned How to change the battery:

upright fl at Important Note!

When exchanging the battery (if available), be sure that

- you use a new battery that is identical to the old one or equivalent to the

battery recommended by the manufacturer.

- the poles are correctly positioned when soldering in the battery.

Warning: If you use the wrong battery, this may result in an explosion.

Be sure to dispose of the defective battery properly according to your country‘s

environmental protection laws!

Generals Information

Aut_5007a.jpg

Aut_5006a.jpg

Page 5

| 5

New Features Compared to the BP: New, different housings (see Overview, Page 6)

Procedure: Checking the balance/scale 1. Check the repeatability

Balance/Scale with strain gauge system (standard deviation, see page 18)

Balance/Scale with double lever system (standard deviation, see page 23)

Balance/Scale with monolithic weigh cell (standard deviation, see page 28)

Balance/Scale with forked lever system (standard deviation, see page 35)

2. Checking the off-center loading error and adjust as required

Balance/Scale with strain gauge system (see page 18)

Balance/Scale with double lever system (see page 24)

Balance/Scale with monolithic weigh cell (see page 29)

Balance/Scale with forked lever system (see page 36-37)

3. Adjusting the sensitivity with internal calibration weight

Balance/Scale with monolithic weigh cell (see page 32)

4. Adjusting the sensitivity with external calibration weight

Balance/Scale with strain gauge system (see page 21)

Balance/Scale with double lever system (see page 26)

Balance/Scale with monolithic weigh cell (see page 31)

Determine the internal calibration weight as required (see page 31)

balance/scale with forked lever system (see page 38)

5. Adjusting the linearity is preferably performed using the sequential method, or

with calibrated weights,

Balance/Scale with strain gauge system (see page 22)

Balance/Scale with double lever system (see page 27)

Balance/Scale with monolithic weigh cell (see page 33)

Check the internal linearization weights as required (see page 34)

Balance/Scale with forked lever system (see page 39)

Activating the BPI Mode/ Perform only before working with the SARTOCAS Program or PSION; for calibration/

Deactivating write-protect adjustment. Linearization and programming a data record when exchanging the

main PCB.

Reset write-protect After working with the SARTOCAS program or PSION, always make sure to conclude

with the „Close“ function (returning the balance from BPI back to SBI mode),

otherwise write-protect is not set, and the balance/scale remains in the BPI mode

(see Page 11). If all else fails, reset the SBI mode by pressing menu reset (9-1°).

Exchanging the Main PCB When ordering replacement PCBs, always state the model and the serial number, that

is the only way that a new preprogrammed PCB set can be delivered.

Opening the housing - Unscrew the 1 (sealed) screw on the reverse side and slide the upper half of

the housing back.

- After reclosing the balance/scale, the service technician or service organization

must reaffi x another control seal!

Triangular weighing pan - Check the off-center loading error according to the OIML Recommendation R76,

see 4-point test (Pages 18; 24; 29)

- when carrying out adjustment/calibration work using the 3-point test (page 30)

Blue backlighting - Is adjustable and can be switched off

Service software - TradeCAS or SartoCAS starting with Version 1.44

Psion CAS Version 4.9 and later.

Do not use older software versions!

Adjusting the off-center load - On strain gauge, Angled lever and double lever systems perform by fi ling on

monolithic weigh cell with adjustment screws

Service Guide

Page 6

6 |

Models with Special Weighing Systems

Weighing systems - Strain gauge on low-resolution balances/scales,

Double lever system and forked lever system on high resolution precision balances

Monolithic weigh cells on analytical balances

Span adjustment - With external weights on precision balances not verifi ed for legal metrology

- With built-in weights on analytical balances and precision balances verifi ed for

legal metrology

Linearity - Is internally possible using (2 built-in weights) on analytical balances,

- On other models with external service software (CAS, PC/ PSION)

Menu locking - Menu access can be blocked by entering code (8-1-2) of the balance/scale

operating program

- The access lock switch is only functional on calibration models (calibration/

adjustment externally blocked)

BPI switch - (BPI = Binary Processor Interface) to prepare for working with CAS service

software, log out with „CLOSE“ function

- Or if all else fails by resetting the operating menu (9-1°)

Be careful, the factory settings are activated.

ERR 30 is also shown after pressing the p key, if the wrong interface cable

is used!

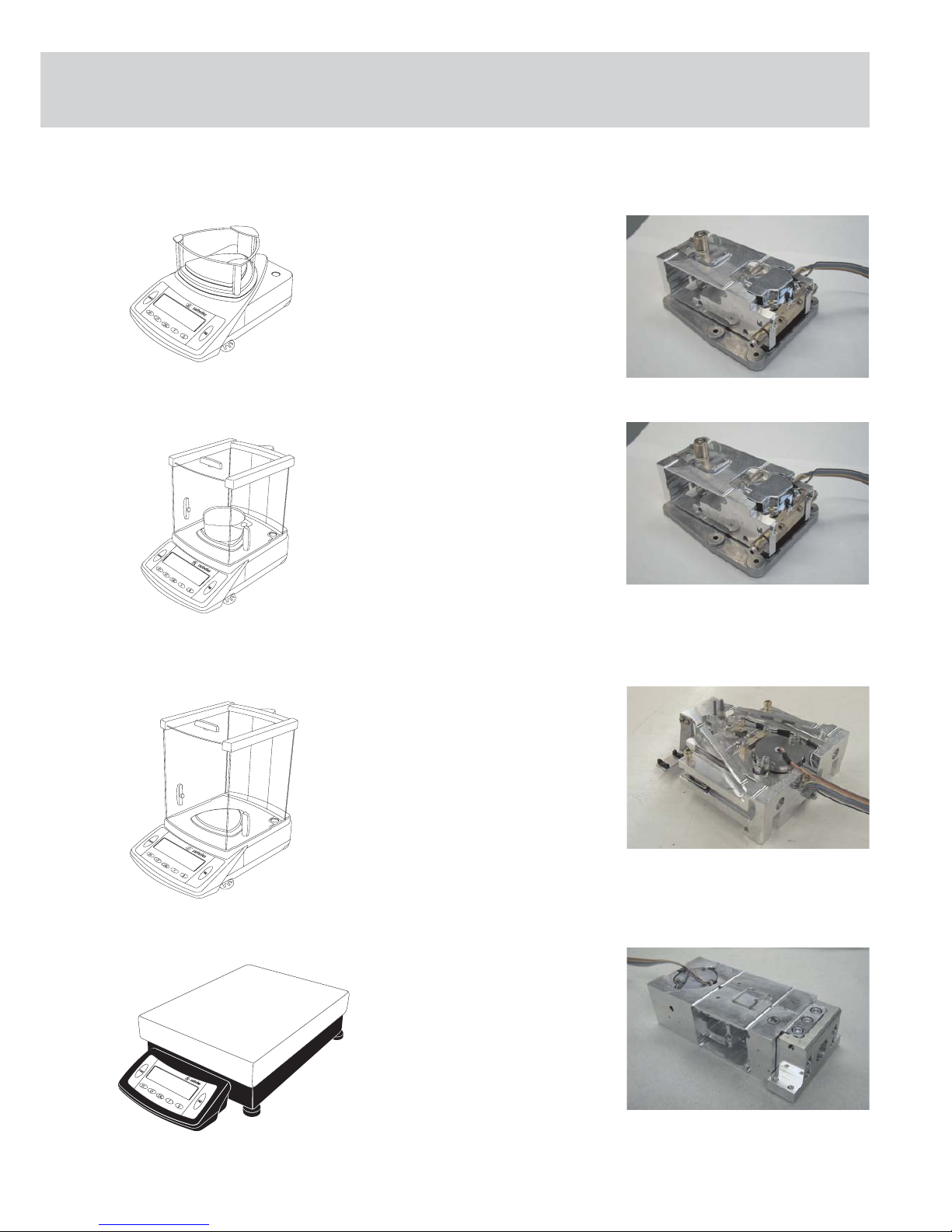

Models with Special Weighing Systems

Model 1

Weighing system: Strain gauge

(Strain gauge) (see right)

CP622

Model 2

Weighing system:

Strain gauge (see right)

CP8201, CP6201, CP4201, CP2201,

GP8201

Weighing system:

Angled lever (see below, right)

CP4202S, CP3202S, CP3202P,

CP2202S, GP5202, GP3202

CP_01b.eps

CP_01b.eps

CP_01.eps

Aut_4906.jpg

Aut_4910.jpg

Aut_4915.jpg

Page 7

| 7

Model 3

Weighing system:

Angled lever (see right)

CP423S, CP323S, CP323P, CP153

Model 3

Weighing system:

Angled lever (see right)

GC2502

Model 4

Weighing system:

Monolithic (see right)

CP225D, CP324S, CP224S, CP124S,

CP64, GC1603, GC803S, GC803P

Model 5

Weighing system:

Fork lever (see right)

CP34001S, CP34001P, CP34000,

CP16001S, CP12001S

CP2_11.eps

CP_06.eps

Aut_4920.jpg

Aut_5254.jpg

CP2_01.eps

CP2_02.eps

Aut_5259.jpg

Aut_5259.jpg

Page 8

8 |

Auxiliary Service Tools, Equipment and Weights

Caution: After removing the seal (warranty label) and fi nishing service work, reaffi x your

control seal with the Sartorius logo!

Please make sure that you use the proper tools and equipment and that the

balance/scale is set up on a solid, level surface and in a clean work area that is free

of vibrations and drafts.

PSION CAS Version 4.9 and later

Service software CAS for PC Version 1.44 or later 6740-33

and

RS232 connecting cable (25-Pin) 7357312

or

RS232 connecting cable (9-Pin) 7357314

Tool Kit Angled fi le 6740-80

In addition to your standard tools and equipment, you will need the following sets of

weights when working on Sartorius Competence balances/scales:

For Model Accuracy Weight Catalog No.:

CPxxxx-CPAxxxx class (OIML) in grams

CP64 E2 1x50 YCW4528

CP124S, GC803 S/P E2 1x100 YCW5128

CP323P, CP153 F1 1x100 YCW5138

CP225D, CP224S E2 1x200 YCW5228

CP324S, GC1603P E2 1x200+ YCW5228 +

1x100 YCW5128

CP423S, CP323S,

GC 2502 F1 1x200 YCW5238

CP622 F2 1x500 YCW5548

CP3202P, CP2202S F1 1x1000 YCW6138

CP4202S, CP3202S,

CP4201, CP2201,

GP3202 F1 1x2000 YCW6238

CP8201, GP8201,

CP6201 F1 1x5000 YCW6538

CP34001S, CP34001P,

CP16001S, CP12001S,

CP34000 F1 1x10000 YCW7138

Accompanying Literature

Operating Instructions Sartorius Competence/CP/CPA Series/Sartorius Gemplus Publication No: WCP6006-e05073

Auxiliary Service Tools, Equipment and Weights

Page 9

| 9

Handling and Operating the CP balances/scales

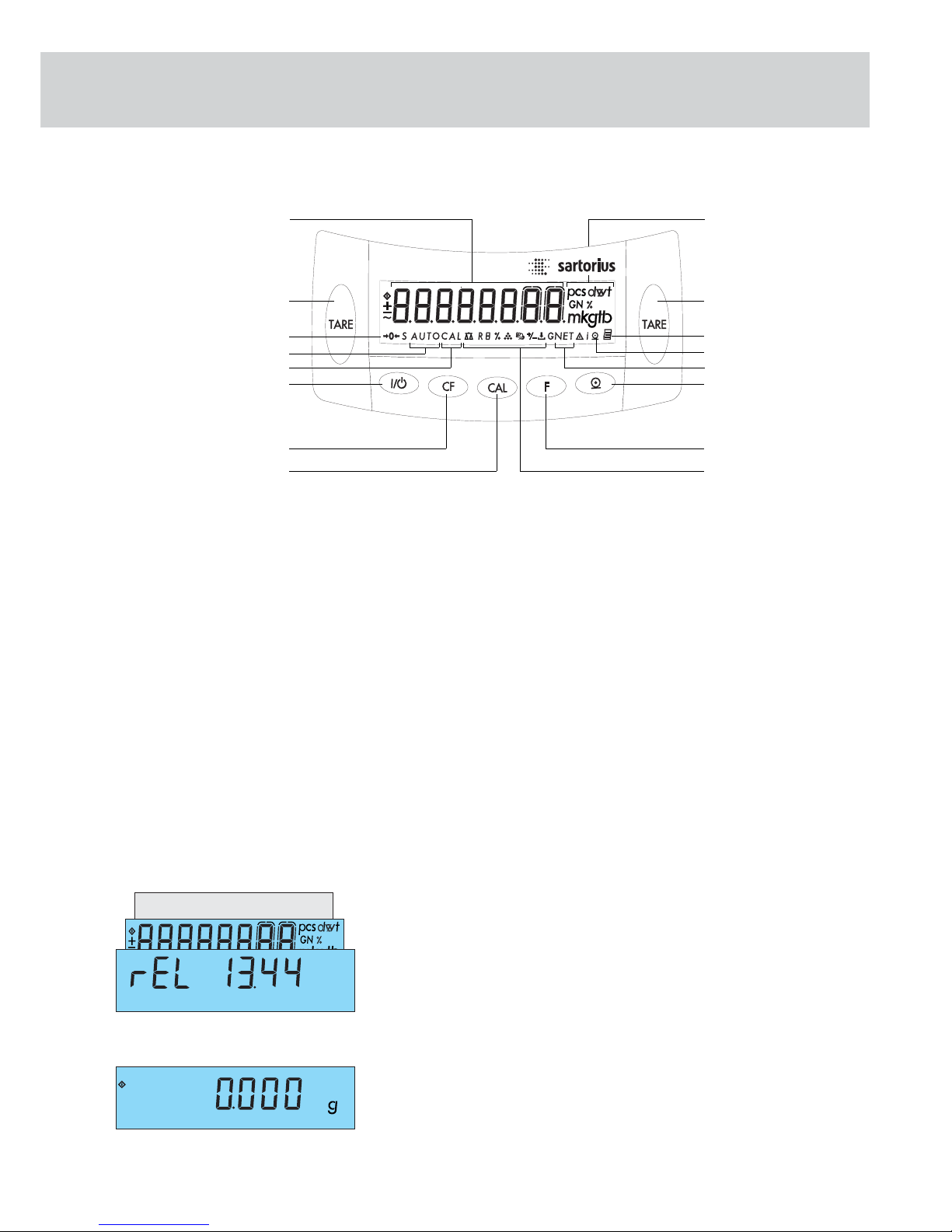

Function of the Keys

Position Description

1 Weighing unit

2 Taring

3 Pictograph for „GLP-compliant print-out active“

4 Pictograph for „Printing active“

5 Display: occupied memory in the net total applications

program

6 Data output (Print)

7 Function key:

activates selected applications program

8 Pictograms for the selected application

9 Activate calibration/adjustment mode

1*

2*

3*

4*

5*

710

11

12

13

15

2*

6*

14

Position Description

10 Clear Function

This key is used as an abort key:

- Deactivate applications program

- Interrupt calibration/adjustment mode

11 ON/OFF key:

Shuts the display on and off.

(The balance/scale may remain on -

depending on the factory setting.)

12 Display: Calibration/adjustment mode

13 Display: animal weighing with automatic start

14 Pictograph for stand-by operations or zero range

15 Weight display depending on the

selected basic unit

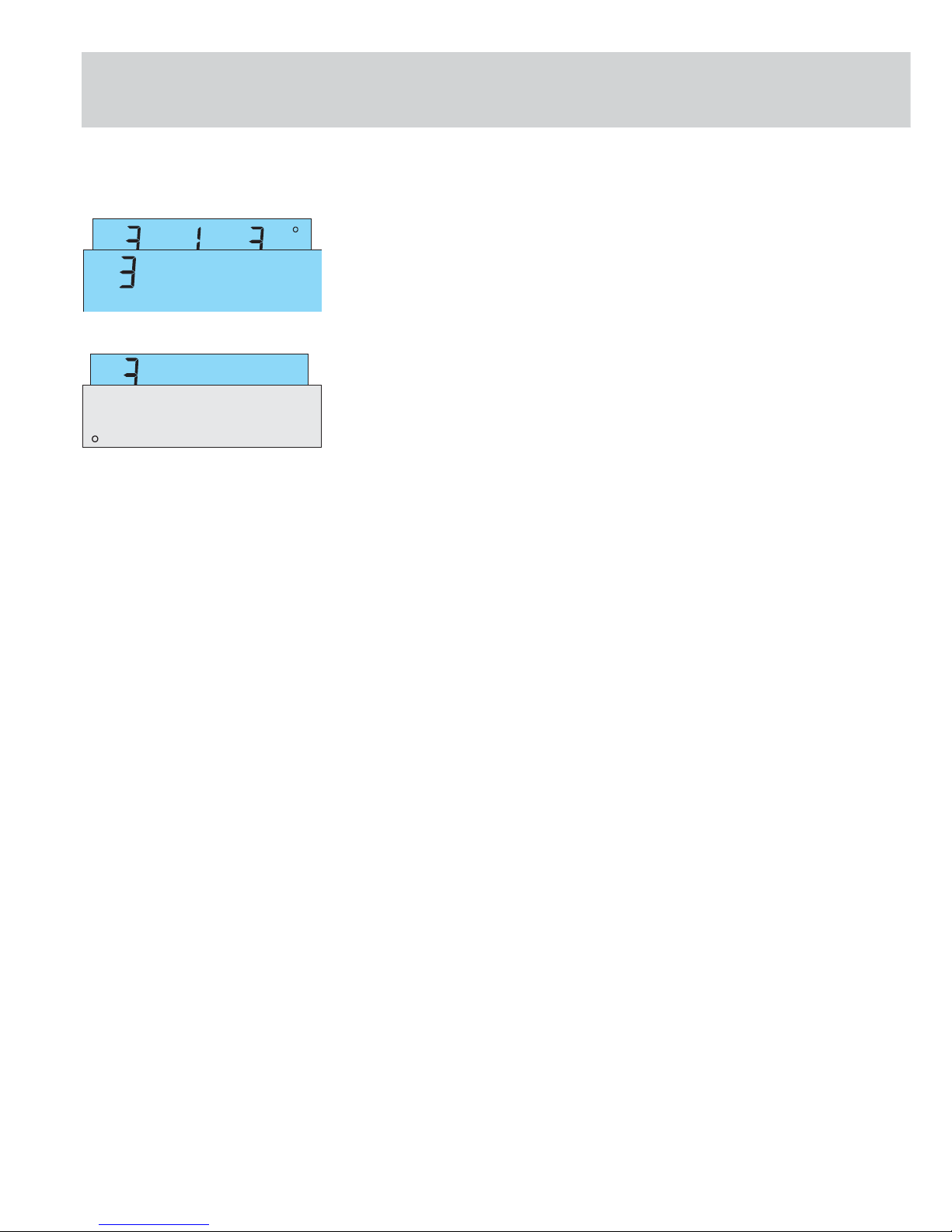

Displaying the Hardware and Software Versions

- Turn the balance/scale on and back off again with the e button.

- While all display segments are lit („Segment Test“), briefly press the p key,

the pattern shown to the left appears in the display.

- This remains displayed for around 3 sec.

- The first number shows the hardware generation; the last two numbers the

software version.

- The display then returns to the normal weight readout mode.

Anz_07-F.eps

Anz_00-F.eps

8

9

Page 10

10 |

Funktion Service-Switch

Aut_4106.ipg / CP_bpi_sch.eps

Aut_4106.ipg / CP_bpi_t_sch.eps

2

2

Access Lock Switch

The access lock switch (2) is located on the rear panel of the balance/scale.

On models CP622, CP4202S, CP3202S, CP3202P, CP2202S, GP5202, GP3202, CP8201,

CP6201, CP4201, CP2201, GP8201, CP423S, CP323S, CP323P, CP153, GC2502,

CP225D, CP324S, CP224S, CP124S, CP64, GC1603, GC803S, GC803P, the opening on

the left is intended for the access lock switch (2) (see fi gure on the left).

With the CP225D it´s in an external electronics box

On models CP34001S, CP34001P, CP34000, CP16001S, CP12001S, the opening on

the left is intended for the access lock switch (2) (see fi gure on the left).

Caution! Always leave the access lock switch (see left) in its left position. This switch

should only be operated on models verifi ed for use in legal metrology!

Depending on the model (verifi able or standard), the switch has two functions.

1. To unlock the menu to change the menu code settings „ 1 9 2 „ the external

span adjustment on verifiable balances/scales.

External adjustments are generally possible on standard models. It is not neces-

sary to open or close the switch.

2. After the menu is activated „ 8 1 2 „ (read only parameter), it can be released

by moving the switch (2) read only (right position) or for changing the settings

(left position).

Note: On verifi ed models, span adjustment can be carried out with external weights

without the service software.

Procedure:

1. Open access lock switch

2. Activate menu „ 1 9 7 „

3. Press the q key

4. Adjust the balance/scale

5. Close access lock switch!!

Right

closed

Left

open

Page 11

| 11

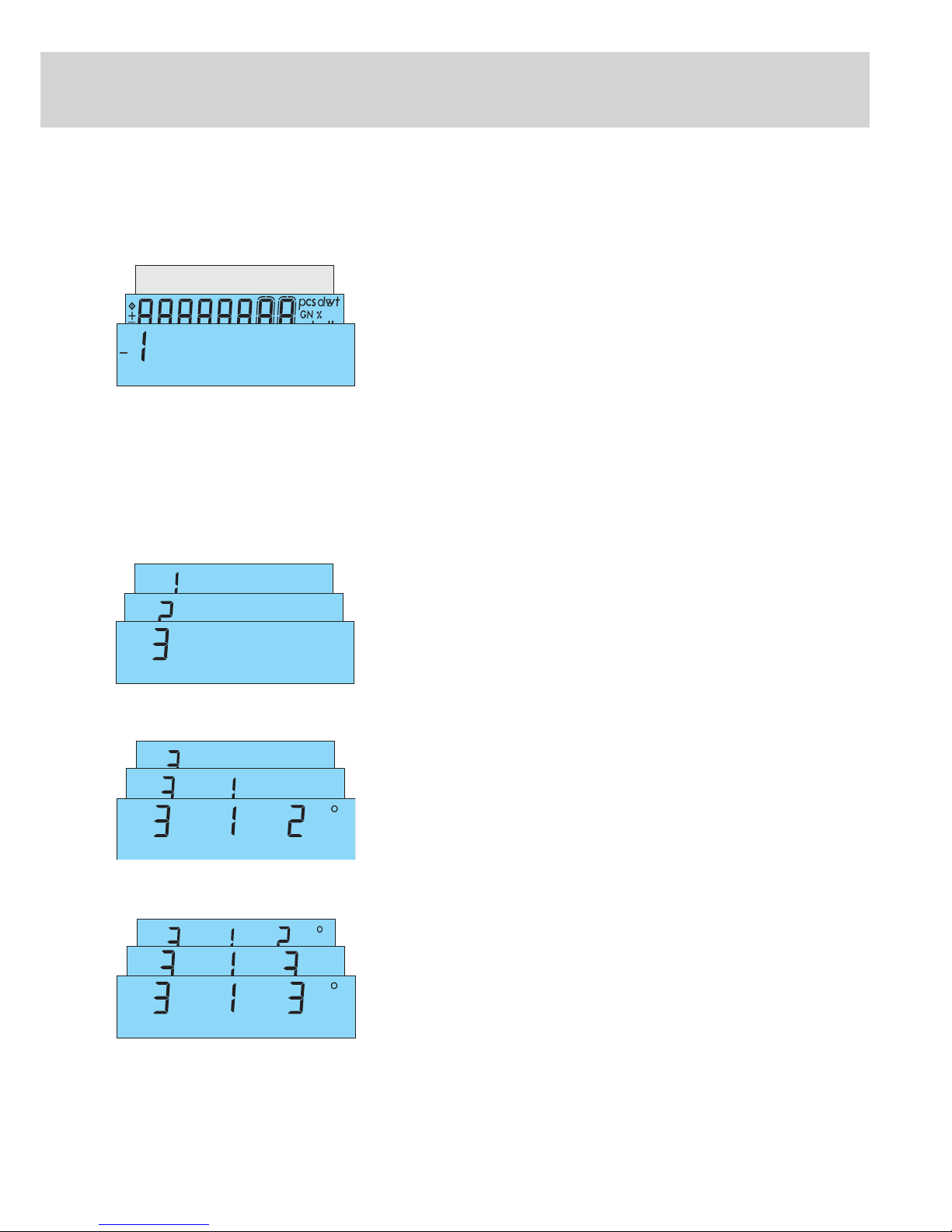

Accessing and Setting the Balance Operating Menu

Accessing the Menu Using the „e“ „t“ keys:

- Turn the balance/scale off and back on by pressing the e button.

- While all segments are displayed (Segment Test), briefly press t.

- „1“ is displayed.

Note:

If „ -1“ is displayed, this indicates that the operating menu is blocked by the menu

access switch (see fi gure on the left). Menu code setting „ 8 1 2 „ (read only

parameters) is activated.

To unlock the menu to change the menu code settings, move the menu access

switch to the left.

Move the switch back to the right after you have made your changes!

Selecting a Menu Code Setting Using the „q“ and „p“ Keys:

- Press q to select the desired number. Numbers increase by one each time

they are pressed and go from 9 back to 1 again (1, 2, 3 ... 8, 9, 1 ...).

- Press p to move from the first code number to the second and third numbers

(1st - 2nd - 3rd etc.). Numbers increase by one each time they are pressed and go

from 3 back to 1 again (1st - 2nd - 3rd - 1st etc.).

Changing and Storing a Setting with the „t“ Key:

- Briefly press one of the t keys to confirm desired setting. A „°“ appears after

the new setting, e.g. „3-1-3 °.“

- To store the setting, press one of the t keys for more than two seconds.

Anz_01-F.eps

Anz_02-F.eps

Balance Operating Menu

Anz_04-F.eps

Anz_03-F.eps

Page 12

12 |

Anz_05-F.eps

Anz_06-F.eps

Exiting the Menu Without Storing:

- To exit the menu, press p. This returns you to the first position in the

balance/scale operating menu.

- If you do not wish to store the changes, press the t key to deactivate this

menu item during the selection procedure or before storing by pressing e

(balance/scale is switched off).

Page 13

| 13

1 11 Weight Unit for Calibration Weight *

1 11 1 o Grams

1 11 2 Kilograms

1 11 3 Pounds

Menu 2 Application Programs

2 1 Program selection

2 1 1 o Weighing as the basic function

2 1 2 Toggle weight units (mass unit

conversion)

2 1 4 Counting

2 1 5 Weighing in percent

2 1 6 Net total formulation

2 1 7 Animal weighing / Averaging

Menu 3 Application Parameters

3 1 2nd Weight Unit

3 1 1 Grams (Display: o)*

3 1 2 o Grams (Display: g)

3 1 3 Kilograms

3 1 4 Carats

3 1 5 Pounds*

3 1 6 Ounces*

3 1 7 Troy ounces*

3 1 8 Hong Kong taels*

3 1 9 Singapore taels*

3 1 10 Taiwanese taels*

3 1 11 Grains*

3 1 12 Pennyweights*

3 1 13 Milligrams

3 1 14 Parts per pound*

3 1 15 Chinese taels*

3 1 16 Mommes*

3 1 17 Austrian carats*

3 1 18 Tola*

3 1 19 Baht*

3 1 20 Mesghal*

3 2 Range 2 Display Mode *

3 2 1 o All digits

3 2 5 Reduced by 1 digit

3 5 Resolution for Counting and Weighing in

Percent

3 5 1 Display accuracy (internal resolu

tion)

3 5 2 o Full accuracy

3 6 Decimal Places for Calculations

3 6 1 None

3 6 2 o Without one decimal place

3 6 3 Without two decimal places

3 6 4 Without three decimal places

3 7 Animal Actvity for Delaying Start until:

3 7 1 Stable conditions (calm)

3 7 2 o Normal

3 7 3 Unstable conditions (active)

3 8 Animal Weighing Will Start by

3 8 1 Manual mode

3 8 2 o Automatic mode

Menu 1 Weighing

1 1 Filter Selection

1 1 1 Very stable conditions

1 1 2 o Stable conditions

1 1 3 Unstable conditions

1 1 4 Very unstable conditions

1 2 Applications Filter

1 2 1 o Standard weighing mode

1 2 2 Manual fi lling mode

1 3 Stability Range

1 3 1 1/4 digit

1 3 2 1/2 digit

1 3 3 1 digit

1 3 4 o 2 digits

1 3 5 4 digits

1 3 6 8 digits*

1 5 Tare Parameter*

1 5 1 At any time

1 5 2 o Not until readout is stable

1 6 Auto Zero Function

1 6 1 o Auto Zero on

1 6 2 Auto Zero off

1 7 1st Weight Unit

1 7 1 Grams (Display: o)*

1 7 2 o Grams (Display: g)

1 7 3 Kilograms

1 7 4 Carats

1 7 5 Pounds*

1 7 6 Ounces*

1 7 7 Troy ounces*

1 7 8 Hong Kong taels*

1 7 9 Singapore taels*

1 7 10 Taiwanese taels*

1 7 11 Grains*

1 7 12 Pennyweights*

1 7 13 Milligrams

1 7 14 Parts per pound*

1 7 15 Chinese taels*

1 7 16 Momme*

1 7 17 Austrian carats*

1 7 18 Tola*

1 7 19 Baht*

1 7 20 Mesghal*

1 8 Range 1 Display Mode*

1 8 1 o All digits

1 8 5 Reduced by 1 digit*

1 9 q Calibration /Adjustment Function

1 9 1 o External calibration/adjustment

1

)

1 9 3 Internal calibration/adjustment 3)

1 9 5 External linearization 3)

1 9 6 Internal linearization/calibration 3)

1 9 7 q key blocked 4)

1 10 Calibration /Adjustment Sequence

1 10 1 o Calibrate, then auto adjust

1 10 2 Calibrate, then manual adjust

Menu Code Settings (Rel BAC 13.44 Version)

4)

If Access Switch is locked (otherwise extern Cal./adjustment)

Page 14

14 |

Menu 4 Application Parameters - Counting

4 1 Auto reference sample updating function

4 1 1 o Off

4 1 2 On

Menu 5 Data Interface

5 1 Baud rate

5 1 1 150 baud

5 1 2 300 baud

5 1 3 600 baud

5 1 4 o 1200 baud

5 1 5 2400 baud

5 1 6 4800 baud

5 1 7 9600 baud

5 1 8 19200 baud

5 2 Parity

5 2 1 Mark

5 2 2 Space

5 2 3 o Odd

5 2 4 Even

5 3 Number of Stop Bits

5 3 1 o 1 stop bit

5 3 2 2 stop bits

5 4 Handshake Mode

5 4 1 Software handshake

5 4 2 o Hardware handshake,

2 char. after CTS

5 4 3 Hardware handshake,

1 char. after CTS

Menu 6 Utilities for Printouts/ Basic Function Weig

hing

6 1 Manual/Auto print

6 1 1 Manual with p key

without stability

6 1 2 o Manual with p key

after stability

6 1 3 Manual with p key

at stability

6 1 4 Auto print without stability

6 1 5 Auto print at stability

6 1 6 Auto print when load changes 2)

6 2 Automatic Printing

6 2 1 Start/stop auto print using the

p key

6 2 2 o Auto print not stoppable

6 3 Time-Dependent Printouts at Defi ned Inter

vals

6 3 1 o 1 display update

6 3 2 2 display update

6 4 Automatic Taring after Each Printout

6 4 1 o Off

6 4 2 On

Menu 7 Print Application Programs

7 1 Print Application Parameter

7 1 1 Off

7 1 2 o On; all param.

7 1 3 On; only main parameters

7 2 Print Format

7 2 1 Raw data (16 char.)

7 2 2 o For other apps

(22 char.)

7 3 Auto Print Net Total Formulation / 2nd

Tare Memory

7 3 1 o Auto print last value N1

7 3 2 Auto print total T1

Menu 8 Extra Functions

8 1 Menu Access Function *

8 1 1 o Parameter settings alterable

8 1 2 Read only

8 2 Acoustic signal

8 2 1 o On

8 2 2 Off

8 3 Key Functions

8 3 1 o Accessible

8 3 2 Blocked

8 4 Universal Switch for Remote Control

8 4 1 o p

8 4 2 t

8 4 3 q

8 4 4 v

8 4 5 c

8 5 Power-On Mode

8 5 1 o Off/on/Stand-by

8 5 3 Stand-by/on

8 5 4 Auto on

8 8 Reference Weighing for Counting Small

Parts

8 8 1 o Off

8 8 2 On for QC scale

8 8 3 On for FB/FC/LA/LP scales

8 8 4 On for isi terminal

8 10 ISO/GLP-compliant Printout

8 10 1 o No ISO/GLP-compliant printout

8 10 2 Only for calibration/adjustment

8 10 3 Always on - all printouts

ISO/GLP-compliant

Menu 9 Reset Menu to Factory Settings

9 - 1 Restore

9 - 2 o Do not restore

Also resets SBI mode

Caution: Before resetting the menu, note down the menu settings

* = Not used for on balances/scales verifi ed for legal metrology.

1) = Not possible on balances/scales of accuracy class K verifi ed for legal

metrology

2) = Auto print, when weight changes > 10 d and

Stability: menu access switch < 5 d

3) = Only on models with internal r weight switch

o) = Model-dependent factory setting

Page 15

| 15

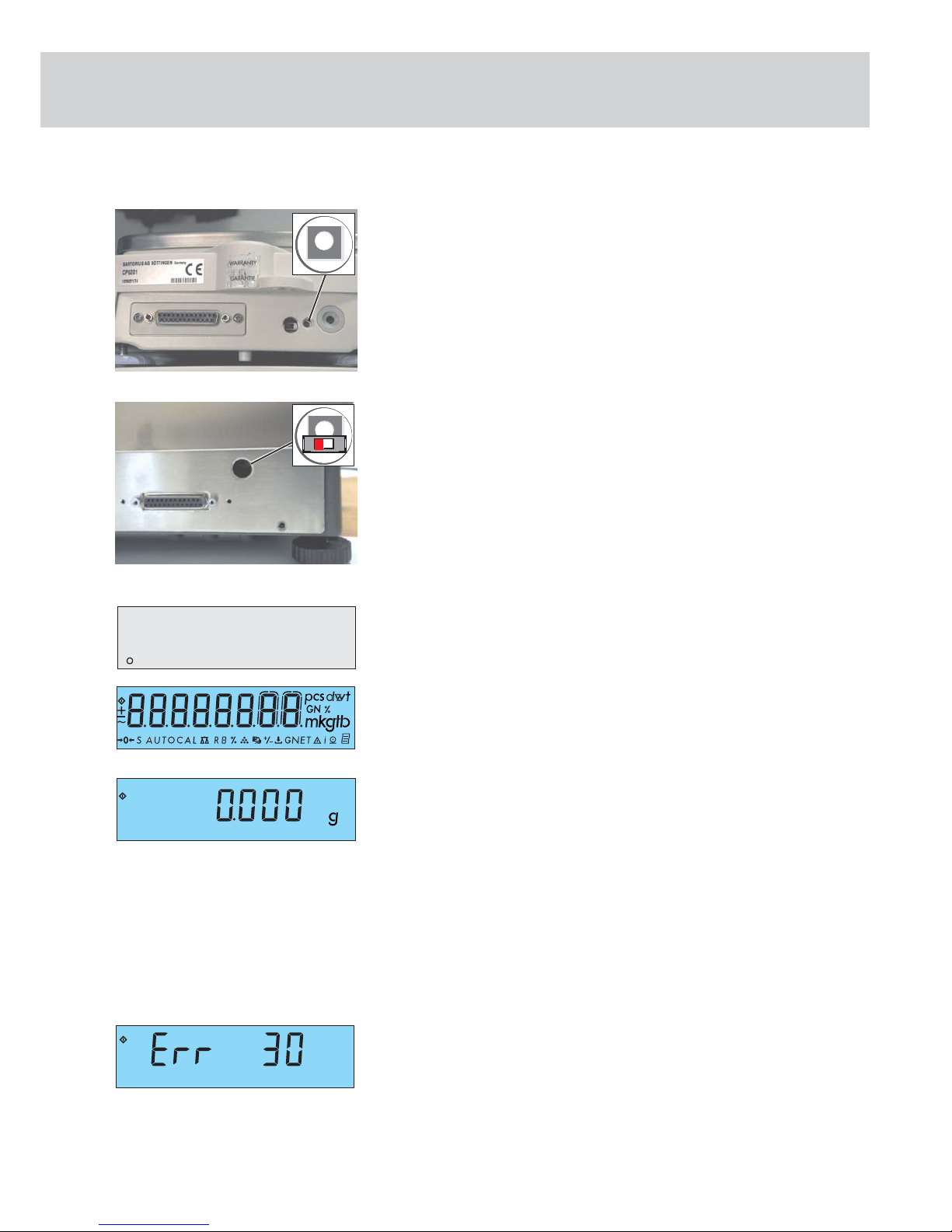

Activating the BPI Mode

The BPI switch (1) is used to prepare for working the service software and is located

on the rear panel.

On models CP622, CP4202S, CP3202S, CP3202P, CP2202S, GP5202, GP3202, CP8201,

CP6201, CP4201, CP2201, GP8201, CP423S, CP323S, CP323P, CP153, GC2502,

CP225D, CP324S, CP224S, CP124S, CP64, GC1603, GC803S, GC803P, the middle

opening is intended for the BPI switch (1) (see fi gure left).

With the CP225D it´s in an external electronics box

On models CP34001S, CP34001P, CP34000, CP16001S, CP12001S, on opening is

intended for the BPI switch (1) (see fi gure left).

Note:

To use the CAS programs (Version 1.44 and later) or the SARTORIUS MC1 Server

(version 4.9 and later and later), the balance/scale must be set to the BPI mode (=

Binary Processor Interface Mode) (e.g. for linearization /span adjustment or when

replacing the PCB).

- Turn on the balance/scale using the e key and wait for the segment test on the

balance/scale to run, i.e. until (e.g. CP423S) „ 0.000 g „ is displayed.

- Remove the capped plug from the rear panel of the balance, located to the left

of the DC jack (screw).

- The BPI switch is now accessible through the opening. Press the BPI switch once,

e.g. with a ball-point pen and hold it in:

- The weight readout in the display disappears (8-er-check it is executed).

- After about 3 seconds, the interface will be in the BPI mode.

- Release the BPI switch, the balance/scale now returns automatically to the

normal weight readout mode, but is still in the BPI Mode.

(Only SARTOCAS is functional).

- Insert the plug to close the opening on the back panel of the balance/scale.

- You can now use the balance/scale together with the SARTOCAS program

(version 1.44 and later) for PCs or the Psion server (version 4.9 and later) in

the BPI Mode.

Caution! After working in the BPI Mode, make sure to set the write-protect (with the

SARTOCAS program for SARTORIUS MC1 Server (Version 4.9 and later)), so that

the balance/scale returns to the standard data record output mode (SBI mode =

Sartorius Balance Interface).

If the balance/scale is in the BPI Mode (= Binary Processor Interface Mode) when you

press p key, the error code ERR 30 will be displayed!

You cannot run the standard peripheral devices until you set the balance/scale back

to the SBI mode!

Note: If necessary, it is possible to switch from SBI to BPI by activating the menu setting

»9 - 1« (menu reset).

Anz_00-F.eps

Anz_88-F.eps

Anz_OFF.eps

Aut_4106.ipg / CP_bpi_t.eps

Aut_4106.ipg / CP_bpi_t_sch.eps

1

1

Function Service BPI Switch

Anz_err30-F.eps

Page 16

16 |

B

A

Waagenplatte.tif

Überlast.tif

Testing and Adjustment Sequence on Balances/Scales with

Strain Gauge Systems

Preparations: Place the balance/scale on a solid, level surface that is free of vibration, e.g.

a stone table. Level the balance/scale using the level indicator. Turn the balance/

scale and allow it to warm up for about 30-60 minutes, depending on the model.

Calibrate/adjust the balance/scale on this place.

Note: Testing must be carried out according to the following Sartorius Standard Operating

Procedure for Testing WKD-037-02 and WKD-038-02. They are also equivalent to the

given adjustment data as described in this service manual.

You will need to check and, if necessary, adjust the following:

1. Overload stop

2. Zero point offset adjustment

3. Repeatability

4. Off-center loading error

5. Span adjustment

6. External linearity

Checking the Overload Stop

Note: Overload stops only need to be checked after replacing a strain gauge system.

Setting the Overload Stop

Setting the overload stops is only necessary in the case of mechanical damage or

after replacing the load cell!

After opening the balance/scale , screw off the load plate and remove it from the

weighing system.

If there is only one load plate, the two screws (A) have to be removed to obtain

access to the strain gauge.

Adjust the two overload stop screws (B) so that a distance of about 0.1 mm (paperthick) remains between the screws and the base plate when the maximum load plus

around 10% is placed on the balance/scale.

Caution: The overload stop screws (B) are not lock nuts. If ERR 02/03 appears during

adjustment work, make that the overload stop screws are at the proper setting.

Testing and Adjustment Sequence on Balances/Scales with Strain Gauge Systems

Page 17

| 17

The offset adjustment adapts the weighing system to the internal A/D converter.

You may need to adapt the A/D converter:

- after replacing the strain gauge measuring spring

- after replacing the main PCB

- when the sensitivity of the balance/scale cannot be adjusted (not even using the

service software) and error code „Err 02“ is displayed.

There are two ways of adapting the converter:

1. with a digital voltmeter

2. using the service software (SARTOCAS, PSION Server)

1. Adapting the A/D Converter using a Digital Voltmeter:

- Open balance/scale

- Reconnect balance/scale to mains power

- Unload the weighing pan, use a digital voltmeter to measure IC6 Pin 6 against

GND (see figure on the left)

Open the solder bridges and measure the ground at IC6 Pin 6. Depending on the

voltage displayed, open or close the solder bridges in accordance with the chart (see

next page). If the adjustment cannot be carried out through the solder bridges, an

adjustment resistance (R, see fi gure left) determined with a decade resistor can be set

when the solder bridges of the offset are open.

Caution! The converter output must be within the range of the between

-250 mV and -650 mV!

After replacing the main PCB, it may be necessary to transfer the existing

adjustment resistance (R) to the new PCB.

Umeas (V) J1 J2 J3

(solder bridges are open)

-0.212...+0.153 Closed Open Open

+0.153...+0.518 Open Closed Open

+0.518...+0.883 Closed Open Closed

+0.883...+1.249 Closed Closed Closed

2. Adapting the A/D Converter Using the Service Software (SARTOCAS /PSION):

- Activate the BPI Mode

- Use the service software in the „Diagnosis“ menu to check the output level

(modulation) of the A/D converter

Caution!

Opening or closing solder bridges (J1 - J3) must change the converter output to

within the range of 5% to 14%!

J3

J2

J1

R

Aut_5027.jpg

IC6 Pin6

GND

Aut_5027.jpg

R

Zero point offset adjustment

Page 18

18 |

Checking the Repeatability (Standard deviation)

- Select the test weight from the „Calibration/Adjustment Data Sheet“ (see pages

42-43).

- Unload the weighing pan and zero the balance/scale using the t key.

- Center the test weight on the weighing pan.

- Write down the weight displayed.

- Repeat the procedure five times.

- The repeatability is calculated from the 6 weighing operations as follows:

(Max. value displayed - Min. value displayed) / 3

- Compare the calculated value with the given tolerance.

- If the calculated value is not within the given tolerance, it may be due to one

of the following reasons:

- The weighing system needs to be cleaned

- Mechanical parts are in the weighing system

- Bent / defective bending elements

Checking and Adjusting the Off-Center Loading Error

Caution: Larger errors in the off-center loading error affect the repeatability of the

weighing system!

The OIML Guideline R76-1 describes the tests for off-center loading tolerances for

square, round and even triangular weighing pans. Therefore, the test weight should

be placed on every 1/4 of the weighing pan surface.

The positions for placing test weights in triangular weighing pans are indicated in

the fi gures to the left.

Please refer to the sketches to the left to establish the testing points for checking

the off-center loading tolerances.

The markings should help you place the test weights in their proper positions.

Checking the Off-Center Loading Tolerances

Note: Select the test weights from the „Calibration/Adjustment Data Sheet (see

pages 42-43).

CP Balances/Scales with Rectangular Weighing Pans

Models: CP622

- Place the test weight on position 1 on the weighing pan and zero the balance/

scale by pressing the t key.

- In the order given, place the test weight in the position 2, 3, 4 and 5 as indicated

and write down the readout at stability, including the plus/minus signs.

- If the off-center loading error is too large, adjust the balance so that the offcenter loading error is within the tolerances specified.

CP Balances/Scales with Square Weighing Pans

Models: CP8201, CP6201, CP4201, CP2201, GP8201

- Compare the test weights with the tolerances listed in the „Calibration/

Adjustment Data Sheet (see pages 42-43).

- If the off-center loading error is too large, adjust the balance so that the offcenter loading error is within the tolerances specified.

Eck_re_1.eps

Eck_dr_2.eps

Front

5

2

1

3

4

Front

Eck_re_3.eps

Eck_dr_3.eps

Front

Front

5

2

1

4

3

Repeatability / Off-Center Loading

Page 19

| 19

Procedure for Adjusting the Off-Center Loading Error (Strain Gauge)

Note: After calibration/adjustment of the off-center loading error, you must check the

span and linearity and adjust as required.

On models CP2201, CP4201, CP6201, CP8201, GP8201, the off-center loading error

should be adjusted by careful fi ling at appropriately thin places.

First, remove the weighing support. On subsequent models, this adjustment can be

carried out through the long holes in the weighing pan support with an angled

round fi le. It is then no longer necessary to remove the weighing pan support.

- Carry out the adjustment by careful filing at the positions described.

- Only file negative errors, preferably at the upper thin sites

- To avoid distorting the adjustment results on models with a higher resolution

(60000 - 75000 increments), wait a few seconds after filing so that the thin

sites can „cool down.“

- After each adjustment, recheck the off-center loading error, as the force parallelogram of the measuring spring will also change the error in the non-adjusted

corners

- Check the off-center loading error once more after a longer period of time

1. Adjusting the Off-Center Loading Error: Front - Back

Negative error in the front:

(Captions: Weighing pan, right, left, front, back)

- File the edges of the upper thin site evenly on the left and right, moving inwards.

Small, inwardly tapering surfaces areas will be produced at the thin site „A“

Negative error in the back:

- File the edges of the upper thin site evenly on the left and right, moving inwards.

Small, inwardly tapering surfaces areas will be produced at the thin site „B“

back

right

loadplate

front

left

dms3ae.eps

dms3be.eps

A

B

back

right

loadplate

left

front

Page 20

20 |

back

right

loadplate

front

left

back

right

loadplate

front

left

2. Adjusting the Off-Center Loading Error: Right - Left

Negative error on the right:

- File the edges of the upper thin sites evenly on the front and back, moving

inwards. Small, inwardly tapering surfaces areas will be produced at the thin

sites „C“

Negative error on the left:

- File the edges of the upper thin sites evenly on the front and/or back, moving

inwards. Small, inwardly tapering surfaces areas will be produced at the thin

sites „D“

dms3ce.eps

dms3de.eps

D

C

Page 21

| 21

External Adjustment

Note: Before carrying out calibration/adjustment work, allow the balance/scale

to warm up (between 30 min. and 24h, depending on the model)!

The external calibration/adjustment can be performed in various ways.

Only use calibrated weights!

1. As described in this manual

2. or using the Sartorius MC1 Server (version 4.9 or later) or the SARTOCAS

program for PCs and laptops).

- Make sure that the balance/scale operating menu is set to the code „1 9 1 external calibration/adjustment accessible“ (see pages 13-14 „Operating Menu

Settings“) or „1 9 7 - external adjustment/calibration/", the Access Lock Switch

has to be closed.

- If necessary, tare the balance/scale by pressing the t key. Press q to

activate the calibration/adjustment routine.

- The calibration weight required is displayed, (depending on the model, e.g.

CP4201).

Caution! The balance/scale only accepts a weight that is within a tolerance range of

approx. 2% of the nominal value. Errors exceeding this tolerance range can only

be corrected using the SARTORIUS MC1 Server Software.

- Center the required weight (e.g. 2000g/F2) on the weighing pan and close the

draft shield.

- After the calibration weight has been stored, the balance will return to the

weighing mode.

– Menu »1 10 2 Calibration/Adjustment« calibration weight value will be displayed

first, then press q key.

Anz_14-F.eps

Anz_25-F.eps

Anz_26-F.eps

Waags_Just.eps

Front

Span adjustment

Page 22

22 |

Adjusting External Linearity

Checking the Linearity

Note: The linearity must be checked according to the Standard Operating Procedure

WKD-038.

- Check the linearity of the balance/scale for the entire weighing range in 4-g

steps.

- Compare the values displayed with the tolerance ranges given in the „Table of

Calibration/Adjustment Data“ on pages 42-43.

- If the errors exceed the permissible tolerance ranges, the linearity must be

adjusted.

Adjusting the Linearity

Caution! You can adjust the linearity on CP balances/scales only using the SARTORIUS MC1

Server Software (Version 4.9 and later) or with the SARTOCAS program.

- Activate the BPI mode (see page 15).

- Adjust the linearity with the SARTORIUS MC1 Server (version 4.9 and later) or

with the SARTOCAS program for PCs and laptops.

(Please see the program description for instructions on this automatic proce-

dure!).

Adjusting Linearity

Page 23

| 23

Testing and Adjustment Sequence on Balances/Scales with Double

Lever Systems

Preparations: Place the balance/scale on a solid, level surface that is free of vibration, e.g.

a stone table. Level the balance/scale using the level indicator. Turn the balance/

scale and allow it to warm up for about 30-60 minutes, depending on the model.

Calibrate/adjust the balance/scale on this place.

Note: Testing must be carried out according to the following Sartorius Standard Operating

Procedure for Testing WKD-037-02 and WKD-038-02. They are also the equivalent of

the given adjustment data as described in this service manual.

You will need to check and, if necessary, adjust the following:

1. Overload stop

2. Repeatability

3. Off-center loading error

4. Span adjustment

5. External linearity

Checking the Overload Stop

Note: Overload stops no longer need to be checked on double lever systems.

Setting the Overload Stop

It is no longer necessary to set the overload stops. They are factory set and adjusted.

Checking the Repeatability (Standard deviation)

- Select the test weight from the „Adjustment Datasheet (see Page 42-43).

- Unload the weighing pan and zero the balance/scale using the t key.

- Center the test weight on the weighing pan.

- Write down the weight displayed.

- Repeat the procedure five times.

- The repeatability is calculated from the 6 weighing operations as follows:

(Max. value displayed - Min. value displayed) / 3

- Compare the calculated value with the given tolerance.

- If the calculated value is not within the given tolerance, it may be due to one

of the following reasons:

- The weighing system needs to be cleaned

- Mechanical parts are in the weighing system

- Bent / defective bending elements

Testing and Adjustment Sequence on Balances/Scales with Double Lever

Eck_re_3.eps

Eck_dr_3.eps

Front

Front

Page 24

24 |

Checking and Adjusting the Off-Center Loading Error

Caution: Larger errors in the off-center loading error affect the repeatability of the

weighing system!

The OIML Guideline R76-1 describes the tests for off-center loading tolerances for

square, round and even triangular weighing pans. Therefore, the test weight should

be placed on every 1/4 of the weighing pan surface.

The positions for placing test weights in triangular weighing pans are indicated in

the fi gures to the left.

Please refer to the sketches to the left to establish the testing points for checking

the off-center loading tolerances.

The markings should help you place the test weights in their proper positions.

Checking the Off-Center Loading Tolerances

Note: The data for the test weight and the tolerance are listed in the „Adjustment

Datasheet (see Page 42-43).

CP Balances/Scales with Draft Shields and Triangular Weighing Pans

Models: CP423S, CP323S, CP323P, CP153, GC2502

- Place the test weight on position 1 on the weighing pan and zero the balance/

scale by pressing the t key.

- In the order given, place the test weight in the position 2, 3, 4 and 5 as indicated

and write down the readout at stability, including the plus/minus signs.

- If the off-center loading error is too large, adjust the balance so that the offcenter loading error is within the tolerances specified.

CP Balances/Scales with Square Weighing Pan

Models: CP4202S, CP3202S, CP3202P, CP2202S, CP5202, GP3202

- Compare the off-center loading errors with the tolerances listed in the („Adjustment Datasheet“ see Page 42-43).

- If the off-center loading error is too large, adjust the balance so that the offcenter loading error is within the tolerances specified.

5

2

1

4

3

Eck_re_2.eps

Eck_dr_wh1.eps

Front

5

2

1

3

4

Front

Checking Off-Center Loading

Page 25

| 25

Procedure for Adjusting the Off-Center Loading Error (Double Lever System)

Note: After calibration/adjustment of the off-center loading error, you must check the span

and linearity and adjust as required.

On models CP4202S, CP3202S, CP3202P, CP2202S, GP5202, GP3202,

CP153, CP323S, CP323P, CP423S, GC2502, the off-center loading error should be

adjusted by careful fi ling at appropriately thin places on the upper guide. To avoid

distorting the adjustment, wait a few seconds after fi ling so that the thin sites can

„cool down“.

Caution! After carefully removing the housing, adjust the off-center loading error only at

the thin sites in the back using an angled fi le.

Check the off-center loading error and adjust the largest error fi rst by carefully

fi ling at these points (see fi gures on the left and below).

The errors measured (see the section „Off-Center Loading Error) refer to the position

of the systems in the balance/scale.

Position of the Systems in the Balance/Scale

Off-center loading error:

Back-Left-Top Back-Left-Bottom Back-Right-Bottom Back-Right-Top

Filing positions: Filing positions: Filing positions: Filing positions:

Back-Right- Back-Right Back-Right-Top Back-Right-Bottom

and and or or

Left-Top Left-Bottom Back-Left-Bottom Back-Left-Top

Top

Bottem

Back

Front

Side view of the system

CP1d.tif

winkh.tif

CP_ecklj1.tif

CP_ecklj2.tif

front view

Adjusting Off-Center Loading

front view

front view

Page 26

26 |

Anz_14-F.eps

Anz_27-F.eps

Anz_28-F.eps

Span Adjustment

Waags_Just.eps

Front

External Adjustment

Note: Before carrying out calibration/adjustment work, allow the balance/scale to warm

up properly!

The external calibration/adjustment can be performed in various ways.

Only use calibrated weights!

1. As described in this manual,

2. or using the Sartorius MC1 Server (Version 4.4) or later) or the SARTOCAS

program for PCs and laptops).

- Make sure that the balance/scale operating menu is set to the code „1 9 1 e external calibration/adjustment accessible“ (see Page 13-14 „ Operating Menu

Settings“) or „1 9 7 - external adjustment/calibration/", the Access Lock Switch

has to be closed.

- If necessary, tare the balance/scale by pressing the t key. Press q to

activate the calibration/adjustment routine.

- The calibration weight required is displayed, (depending on the model, e.g.

CP4202S).

Caution! The balance/scale only accepts a weight that is within a tolerance range of

approx. 2% of the nominal value. Errors exceeding this tolerance range can only

be corrected using the SARTORIUS MC1 Server Software.

CP Balances/Scales with Draft Shields and Triangular Weighing Pans

Models: CP423S, CP323S, CP323P, CP153, GC2502

- Center the required weight (e.g. 200g/E2 depending on the model, e.g. CP423S)

on the weighing pan and close the draft shield.

- After the calibration weight has been stored, the balance will return to the

weighing mode.

– Menu »1 10 2 Calibration/Adjustment« calibration weight value will be displayed

first, then press q key.

CP Balances/Scales with Square Weighing Pan

Models: CP4202S, CP3202S, CP3202P, CP2202S, CP5202, GP3202

- Center the required weight (e.g. 2000g/E2 depending on the model, e.g.

CP4202S) on the weighing pan.

- After the calibration weight has been stored, the balance will return to the

weighing mode.

– Menu »1 10 2 Calibration/Adjustment« calibration weight value will be displayed

first, then press q key.

Eck_re_3.eps

Front

Page 27

| 27

Adjusting External Linearity

Checking the Linearity

Note: The linearity must be checked according to the Standard Operating Procedure

WKD-038.

- Check the linearity of the balance/scale for the entire weighing range in 4-g

steps.

- Compare the values displayed with the tolerance ranges given in the „Table of

Adjustment Data“ Page 42-43.

- If the errors exceed the permissible tolerance ranges, the linearity must be

adjusted.

Adjusting the Linearity

Caution! You can adjust the linearity on CP balances/scales only using the SARTORIUS MC1

Server Software (Version 4.9 and later) or with the SARTOCAS program.

- Activate the BPI mode (see Page 15).

- Adjust the linearity with the SARTORIUS MC1 Server (Version 4.9 and later) or

with the SARTOCAS program for PCs and laptops.

(Please see the program description for instructions on this automatic proce-

dure!).

Adjusting Linearity

Page 28

28 |

Testing and Adjustment Sequence on Balances/Scales with Monolithic Weighing

Systems

Preparations: Place the analytical balance on a solid, level surface that is free of vibration,

e.g. a stone table. Level the analytical balance using the level indicator. Turn the

balance/scale and allow it to warm up for about 4h-24h.

Note: Testing must be carried out according to the following Sartorius Standard Operating

Procedure for Testing WKD-037-02 and WKD-038-02. They are also the equivalent of

the given adjustment data as described in this service manual.

You will need to check and, if necessary, adjust the following:

1. Overload stop

2. Repeatability

3. Off-center loading error

4. Span adjustment

External span adjustment

Overwrite internal calibration weight

Internal span adjustment

5. Linearity

External linearization

Overwrite internal linearity weight

Checking the Overload Stop

Note: Overload stops no longer need to be checked monolithic weigh cells.

Setting the Overload Stop

It is no longer necessary to set the overload stops. They are factory set and adjusted.

Checking the Repeatability (Standard deviation)

- Select the test weight from the „Adjustment Datasheet (see Page 42-43).

- Unload the weighing pan and zero the balance/scale using the t key.

- Center the test weight on the weighing pan.

- Write down the weight displayed.

- Repeat the procedure five times.

- The repeatability is calculated from the 6 weighing operations as follows:

(Max. value displayed - Min. value displayed) / 3

- Compare the calculated value with the given tolerance.

If the calculated value is not within the given tolerance, it may be due to one

of the following reasons:

- The weighing system needs to be cleaned

- Mechanical parts are in the weighing system

- Bent / defective bending elements

Waags_Just.eps

Front

Balances/Scales with Monolithic Weighingssystems

Page 29

| 29

Checking and Adjusting the Off-Center Loading Error

Caution: Larger errors in the off-center loading error affect the repeatability of the

weighing system!

The OIML Guideline R76-1 describes the tests for off-center loading tolerances for

square, round and even triangular weighing pans. Therefore, the test weight should

be placed on every 1/4 of the weighing pan surface.

The positions for placing test weights in triangular weighing pans are indicated in

the fi gures to the left.

Please refer to the sketches to the left to establish the testing points for checking

the off-center loading tolerances.

The markings should help you place the test weights in their proper positions.

Checking the Off-Center Loading Tolerances

Note: The data for the test weight and the tolerance are listed in the „Adjustment

Datasheet (see Page 42-43).

CP Semimicro-Balances with Rectangular Weighing Pans

Models: CP225D, CP324S, CP224S, CP124S, CP64, GC1603, GC803S, GC803P

- Place the test weight on position 1 on the weighing pan and zero the balance/

scale by pressing the t key.

- In the order given, place the test weight in the position 2, 3, 4 and 5 as indicated

and write down the readout at stability, including the plus/minus signs.

- If the off-center loading error is too large, adjust the balance so that the offcenter loading error is within the tolerances specified.

Adjusting the Off-Center Loading Error (Monolithic System)

Off-center loading errors are determined by carrying out a 3-point adjustment.

The 3-point adjustment shows the greatest possible off-center loading error on the

balance/scale.

Note: You have to open the balance/scale for calibration/adjustment of the off-center

loading error.

- Remove the weighing pan and draft shield ring

- Open the draft shield cover and carefully remove the draft shield

- Remove the Seal of Warranty on the back panel of the balance/scale and the

loosen the thumbscrew (K)

- First, move the top part of the balance/scale to the back and then carefully

lift upwards

- Replace the weighing pan

Note: In the future, two openings in the top part of the balance/scale will make it

unnecessary to remove the housing.

open

closes

K

winds.jpg

5

2

3

4

5

2

3

4

1

Eck_dr_mo3.eps

Checking the Off-Center Loading

Page 30

30 |

3-Point Adjustment

- During calibration/adjustment of the off-center loading error, the system must

be covered over.

- To adjust the off-center loading error, change the settings of the off-center

load thumbscrews.

- Place the test weight in position A on the weighing pan and zero the balance/

scale by pressing t.

- In the order given, place the test weight in the position B and C and write down

the readout at stability

- Example: Position A tkey 0.0000 g

Position B + 0.0005 g

Position C - 0.0004 g

- Only adjust the side with the greatest error (in the amount), taking into account:

Negative errors

Turn the off-center load thumbscrews inwards (clockwise)

Positive errors

Turn off-center load thumbscrews outwards (counterclockwise)

- Adjust the thumbscrew by small turns and then recheck the off-center loading

error at positions A-C

- Repeat this procedure until the off-center loading error is within 3 points of

the tolerance range.

Note: After adjusting the off-center loading error, you must also check and, if necessary,

adjust the linearity and span on the balance/scale.

Caution! During assembly, be careful not to damage the internal data cable!

- Insert the upper part of the balance/scale (tilting it slightly) so that the two

retainers (under the keypad) lock into the two screws (in the front part of the

bottom of balance/scale)

- Slide the upper part of the balance/scale carefully to the front and then push

down gently

- Fasten the housing by tightening screw (K) and affix the Seal of Warranty

- Open the draft shield cover

- Place the draft shield on the balance/scale, align by eye, press down on the draft

shield gently from above and close the cover

- Replace the draft shield ring and weighing pan

open

closes

K

winds.jpg

A

B

C

Eck_dr_mo2.eps

AUT_5201.jpg

Page 31

| 31

External Adjustment

Note: The external calibration/adjustment can be performed in various ways.

Only use calibrated weights!

1. As described in this manual,

2. or using the Sartorius MC1 Server (Version 4.9 or later) or the SARTOCAS

program for PCs and laptops).

- Make sure that the balance/scale operating menu is set to the code „1 9 1 external calibration/adjustment accessible“ (see pages 13-14 „Operating Menu

Settings“) or „1 9 7 - external adjustment/calibration/", the Access Lock Switch

has to be closed.

- If necessary, tare the balance/scale by pressing the t key. Press q to

activate the calibration/adjustment routine.

- The calibration weight required is displayed, (depending on the model, e.g.

CP225D).

Caution! The balance/scale only accepts a weight that is within a tolerance range of

approx. 2% of the nominal value. Errors exceeding this tolerance range can only

be corrected using the SARTORIUS MC1 Server Software.

- Center the required weight (e.g. 200g/E1) on the weighing pan and close the

draft shield.

- After the calibration weight has been stored, the balance will return to the

weighing mode.

– Menu »1 10 2 Calibration/Adjustment« calibration weight value will be displayed

first, then press q key.

Overwriting the Internal Calibration Weight

Caution! The internal calibration weight on CP balances/scales should only be overwritten

using the PSION Server or the SARTOCAS program for PCs and laptops, since the

factory setting of the internal calibration weight is highly accurate. Only in the

case of emergency (e.g. no service software available) should you perform the

overwrite protection using the balance‘s overwrite program).

Important: Before carrying out the overwriting internal calibration weight, you must cor-

rectly adjust the span.

The balance/scale must warm up for at least 4 - 24 hours!

Note: There are various ways of overwriting the internal calibration weight on CP balances/

scales.

1. As described in this manual

2. or using the Sartorius MC1 Server (Version 4.9 or later) or the SARTOCAS

program for PCs and laptops).

Anz_14-F.eps

Anz_15-F.eps

Anz_16-F.eps

Waags_Just.eps

Front

Span Adjustment

Page 32

32 |

- Make sure that the balance/scale operating menu is set to the code „1 9 3 internal calibration/adjustment accessible „ (see Page 13-14 „ Operating Menu

Settings „).

- Slide the access lock switch to the left. It is accessible via an opening on the

back of the balance/scale.

- If you have done so already, perform external calibration/adjustment (see Page

31).

- Turn off the balance/scale by pressing e.

- Turn the balance/scale back on by pressing e and while simultaneously

holding down the q key until the readout shown on the left appears.

- Press the t key to tare the balance/scale; then press q to activate the

„overwrite internal calibration weight“ function.

- The built-in, motorized internal calibration weight is applied, then removed

automatically; the weight value is overwritten; and the balance/scale returns to

the normal weighing mode.

- Press the q key to check the external span adjustment once again.

Internal Span Adjustment

- Make sure that the menu code „1 9 3 - internal calibration/adjustment accessible“ is set (see Page 13 -14 Operating Menu Settings).

- Press the t key to tare the balance/scale; then press q to activate the

calibration/adjustment function..

- The built-in, motorized internal calibration weight is applied, then removed

automatically; the weight value is overwritten; and the balance/scale returns to

the normal weighing mode.

- Slide the access lock switch back to the right. Replace the capped plug to close

the opening.

Anz_09-F.eps

Anz_10-F.eps

Left

open

Right

closed

CP_bpi_sch.eps

Anz_19-F.eps

Anz_20-F.eps

Anz_09-F.eps

Anz_19-F.eps

Anz_20-F.eps

right

closed

CP_bpi_sch.eps

Page 33

| 33

Linearity

Checking the Linearity

Note: The linearity must be checked according to the Standard Operating Procedure

WKD-038.

- Check the linearity of the balance/scale for the entire weighing range in 50-g

steps.

- Compare the values displayed with the tolerance ranges given in the „Table of

Calibration/Adjustment Data“ on pages 42-43.

- If the errors exceed the permissible tolerance ranges, the linearity must be

adjusted.

Adjusting the Linearity

Caution! You can adjust the linearity on CP balances/scales only using the SARTORIUS MC1

Server Software (Version 4.9 and later) or with the SARTOCAS program.

- Activate the BPI mode (see page 15).

- Adjust the linearity with the SARTORIUS MC1 Server (Version 4.9 and later) or

with the SARTOCAS program (Version 1.44 or later) for PCs and laptops.

(Please see the program description for instructions on this procedure!).

Alternative manual procedure:

- When using the operating menu, make sure that the code „1 9 5 -external

linearization accessible“ is set (refer to page 13-14 „Operating Menu Settings“).

- Switch on the balance/scale using the e key.

- If necessary, press t to tare the balance/scale.

- Press the q key until the display on the left appears.

- Place the required weight on the weighing pan.

If the required weight is within ±2% of the tolerance range of the displayed

value the plus sign will go out. If not, the minus sign will appear. Errors that are

too large can be adjusted only with PSION or PC!

- Remove the weight and, if necessary, press the t key to tare the balance.

- Repeat this procedure until you are prompted to unload the balance.

- After the zero point value has been stored, the balance/scale will return to the

standard weighing mode.

Caution! After working in the BPI mode, make sure to set the write-protect again so that

the balance/scale returns to the standard data record output mode (SBI mode =

Sartorius Balance Interface) and peripheral devices can be connected.

Note: (SBI mode = Sartorius Balance Interface Mode)

(BPI mode = Binary Processor Interface Mode)

Anz_11-F.eps

Anz_10-F.eps

Anz_09-F.eps

Linearity

Page 34

34 |

Overwriting the Internal Linearization Weight

The factory setting of the internal linearization weights is highly accurate:

- If overwriting these weights is necessary, this indicates a mechanical or electrical

error!

- The balance/scale must be allowed to warm up (6 hours)!

Note: There are various ways of overwriting the internal calibration weight on CP balances/

scales.

1. As described in this manual

2. or using the Sartorius MC1 Server (Version 4.9 or later)

3. or with the SARTOCAS Program (Version 1.44 or later) for PCs and laptops.

- Make sure that the balance/scale operating menu is set to the code „1 9 6

-internal linearization accessible“ (see page 13-14 „Operating Menu Settings“).

- If you have not done so already, perform external linearization/adjustment.

- Slide the access lock switch to the right. It is accessible via an opening on the

back of the balance/scale.

- Turn the balance/scale back on by pressing e and then press the q key

until the readout shown on the left appears.

- Press the t key to tare the balance/scale; then press q to activate the

overwrite function.

- The built-in, motorized internal linearization weights are applied, then removed

automatically; the weight value is stored in the EEPROM of the processor; and

the balance/scale returns to the normal weighing mode.

- After completing the linearization routine, reset the code „1 9 6“ to „1 9 3“

and slide the access lock switch to the left (menu locked). Replace the capped

plug to close the opening.

Anz_10-F.eps

Anz_12-F.eps

right

closed

CP_bpi_sch.eps

Page 35

| 35

Testing and Adjustment Sequence on Balances/Scales with Forked

Lever Systems

Preparations: Place the balance/scale on a solid, level surface that is free of vibration, e.g.

a stone table. Level the balance/scale using the level indicator. Turn the balance/

scale and allow it to warm up for about 30-60 minutes, depending on the model.

Calibrate/adjust the balance/scale on this place.

Note: Testing must be carried out according to the following Sartorius Standard Operating

Procedure for Testing WKD-037-02. They are also equivalent to the given adjustment

data as described in this service manual.

You will need to check and, if necessary, adjust the following:

1. Overload stop

2. Repeatability

3. Off-center loading error

4. Span adjustment

5. External linearity

Checking the Overload Stops

Note: Overload stops no longer need to be checked on forked lever systems.

Setting the Overload Stops

The overload stops no longer need to be set. They are factory set and calibrated.

Checking the Repeatability (Standard Deviation)

- Select the test weight from the „Calibration/Adjustment Data Sheet“ (see pages

42-43).

- Unload the weighing pan and zero the balance/scale using the t key.

- Center the test weight on the weighing pan.

- Write down the weight displayed.

- Repeat the procedure five times.

- The repeatability is calculated from the 6 weighing operations as follows:

(Max. value displayed - Min. value displayed) / 3

- Compare the calculated value with the given tolerance.

- If the calculated value is not within the given tolerance, it may be due to one

of the following reasons:

- The weighing system needs to be cleaned

- Mechanical parts are in the weighing system

- Bent / defective bending elements

Balances/Scales with Forked Lever Systems

Eck_re_G3.eps

Page 36

36 |

Checking and Adjusting the Off-Center Loading Tolerances

Caution: Deviations in off-center loading tolerances affect the repeatability of the weig-

hing system!

The OIML Guideline R76-1 describes the tests for off-center loading tolerances for

square, round and even triangular weighing pans. Therefore, the test weight should

be placed on every 1/4 of the weighing pan surface.

The positions for placing test weights in triangular weighing pans are indicated in

the fi gures to the left.

Please refer to the sketches to the left to establish the testing points for checking

the off-center loading tolerances.

The markings should help you place the test weights in their proper positions.

Checking the Off-Center Loading Tolerances

Note: Select the test weight from the „Calibration/Adjustment Data Sheet (see pages

42-43).

CP balances/scales with square weighing pans (300x400mm)

Models: CP12001S, CP16001S, CP34000, GP34000P, CP34001S

- Place the test weight on position 1 on the weighing pan and zero the balance/

scale by pressing the t key.

- In the order given, place the test weight in the position 2, 3, 4 and 5 as indicated

and write down the readout at stability, including the plus/minus signs.

- If the off-center loading error is too large, adjust the balance so that the offcenter loading error is within the tolerances specified.

Eck_re_G2.eps

5

1

4

3

2

Checking the Off-Center Loading Tolerances

Page 37

| 37

Adjusting the Off-Center Loading Error

Off-center loading errors should be adjusted by careful fi ling at appropriately thin

places on the upper guide. To avoid distorting the adjustment, wait a few seconds

after fi ling so that the thin sites can „cool down.“

Caution! After carefully remove the housing, adjust the off-center loading error only at the

thin sites in the back and front using an angled fi le.

Check off-center loading error and adjust the largest error fi rst by carefully fi ling

(see fi gures).

The measured errors (see the section „Off-Center Loading Error“) refer to the system

positions in balance/scale!

Position of systems in the balance/scale

Off-center loading error:

Filing position: Filing position: Filing position: Filing position:

Back-Left Front-Right Front-Left Back-Right

Off-center loading error:

Filing positions: Filing positions: Filing positions: Filing positions:

Back Front Right Left

Right and left Right and left Front and Back Front and Back

Side view of the system

Back

Front

Front View

Back

Right

Front

Left

0

0

00

0

0

0

0

Front View

CP_eck-G1.epsCP_eck-G2.eps

CP_34000.eps

Gabel1.tif

Adjusting the Off-Center Loading Tolerances

Front View

Page 38

38 |

External Adjustment

Note: The external calibration/adjustment can be performed in various ways.

Only use calibrated weights!

1. As described in this manual,

2. or using the Sartorius MC1 Server (version 4.9 or later) or the SARTOCAS

program for PCs and laptops).

- Make sure that the balance/scale operating menu is set to the code „1 9 1 external calibration/adjustment accessible“ (see pages 13-14 „Operating Menu

Settings“) or „1 9 7 - external adjustment/calibration/", the Access Lock Switch

has to be closed.

- If necessary, tare the balance/scale by pressing the t key. Press q to

activate the calibration/adjustment routine.

- The calibration weight required is displayed, (depending on the model, e.g.

CP34001S).

Caution! The balance/scale only accepts a weight that is within a tolerance range of

approx. 2% of the nominal value. Errors exceeding this tolerance range can only

be corrected using the SARTORIUS MC1 Server Software.

- Center the required weight (e.g. 10 kg/F1) on the weighing pan and close the

draft shield.

- After the calibration weight has been stored, the balance will return to the

weighing mode.

– Menu »1 10 2 Calibration/Adjustment« calibration weight value will be displayed

first, then press q key.

Anz_14-F.eps

Anz_23-F.eps

Anz_24-F.eps

Eck_re_G3.eps

Span Adjustment

Page 39

| 39

Adjusting External Linearity

Checking the Linearity

Note: The linearity must be checked according to the Standard Operating Procedure

WKD-038.

- Check the linearity of the balance/scale for the entire weighing range in 4-g

steps.

- Compare the values displayed with the tolerance ranges given in the „Table of

Calibration/Adjustment Data“ on pages 42-43.

- If the errors exceed the permissible tolerance ranges, the linearity must be

adjusted.

Adjusting the Linearity

Caution! You can adjust the linearity on these balances/scales only using the SARTORIUS

MC1 Server Software (Version 4.9 and later) or with the SARTOCAS program

(Version 1.44 and later).

- Activate the BPI mode (see Page 15).

- Adjust the linearity with the SARTORIUS MC1 Server (Version 4.9 and later) or

with the SARTOCAS program for PCs and laptops.

(Please see the program description for instructions on this automatic proce-

dure!).

Linearity

Page 40

Error Code Explanation

Err 01 Display format overfl ow, i.e., the value to be output

cannot be shown on the display.

Err 02 Zero point error at the start of the calibration/

adjustment function; caused by operating error

(balance not tared, or still loaded), or stability was

not reached, or by a deviation of the zero point

(adjust the preload).

Err 06 Internal calibration weight defective or not present.

Err 10 “Tare” key is blocked, with data in the tare

2 memory. (only for the application “2nd tare

memory”)

Err 11 Invalid data; cannot be stored in the tare 2 memory.

Err 22 Reference value in the counting or weighing in per-

cent application not permissible; cannot be stored.

Err 30 The print key was pressed, or an external print com-

mand (“<ESC> P”) was given, while the balance was

in the BPI mode.

Err 50 Temperature compensation (TC) converter error;

value measured by the TC circuit exceeds the tolerance range.

Err 53 Temperature compensation (TC) converter not

functioning; no value transmitted to the balance

processor from the TC circuit.

Err 54 The balance converter value of the A/D converter is

below the lower limit; the value measured by the

A/D converter is too low, or no value is measured.

Err 55 The balance converter value of the A/D

converter is above the upper limit; the value

measured by the A/D converter is too high.

Remedial Measures

Reset the balance operating menu with menu

code »9 -- 1 «, “Accessing the Balance Menu.”

First make sure there was no operating error. If the

balance still cannot be calibrated/adjusted, you must

follow the procedure in “Adjusting the Preload”; then

perform “External Calibration/Adjustment.”

Check the calibration weight operating system and, if

necessary, exchange the main PCB. With balances

check the menu code settings. The codes »1 9 3 « and

»1 9 4 « should be blanked out, otherwise, overwrite

these codes with the SARTORIUS MC1Server 4.9.

The tare functions are interlocked; once the data

in the tare 2 memory has been deleted, the tare key

will be accessible again.

The display value you tried to store is negative. Check

the load on the balance (tare container).

The weight of the reference sample is too low, or the

displayed value is negative. Check the load on the balance

(reference sample).

Set the balance back to SBI; this can be done

using the SARTORIUS MC1 Server 4.9.

Perform TC compensation using the MC1 Server.

If this does not suffi ce, proceed as described under

» ERR 53 «.

Check the TC sensors, the main PCB and the

connectionbetween the two. If necessary, proceed as

directed in “Exchanging the Main PCB,” or replace the TC

sensors.

Check the weighing system, the main PCB and the

connection between the two. If necessary, proceed

as directed in “Exchanging the Main PCB,” or see

„Repairing the Weighing System.”

Check the weighing system, the main PCB and

the connection between the two. If necessary, proceed

as directed in “Exchanging the Main PCB.”

40 |

Error Messages

Page 41

Error Code Explanation

Err 220 ROM checksum error; the data in the internal ROM

of the balance processor (AOC) are incorrect.

Err 230 RAM read/write error; the data in the internal RAM

of the balance processor AOC is incorrect, or not

possible.

Err 237 EEPROM checksum error in the linearity range; the

balance has not yet been linearized, or the data in

the internal EEPROM of the balance processor AOC