Operating Instructions

Sartorius Combics Series

Complete Scales Models CAW3P | CAW3S | CAH3

98648-018-49

Contents

Notes on Using this Manual 3

Warnings and Safety Precautions 4

Device Description 6

Intended Use 6

Overview of Equipment 7

Installation 8

Getting Started 12

Connecting Peripheral Devices or Another Platform 12

Connecting an IS Weighing Platform to a Combics 3 13

Connecting Peripheral Devices or a 2nd Weighing

Platform: Combics 3, Model CAW3S | CAH3 14

Interface Pin Assignment Chart COM1 15

Connecting a PC via Interface COM1 16

Interface Pin Assignment Chart COM2 17

Connecting a PC via Interface COM2 18

Interface Pin Assignment Chart PS2 19

Scale Configuration 21

Service Mode 21

Entering Adjustment and Linearization Weights 32

Function Allocation of the Allocation for the J Key

for Calibration/Adjustment 38

External Adjustment 39

Internal Calibration 43

Adjustment Without Weights 43

Function Allocation of the J Key for Linearization

and Setting/Deleting the Preload 46

External Linearization 47

Setting the Preload 50

Clearing the Preload 51

Operating Design 52

Weighing Operating Design 52

Menu Operating Design 58

Confi guration 59

Setup Overview (Parameters) 63

Operation 76

Weighing 76

Calibration, Adjustment 86

Internal Adjustment for CAH Models 90

SQmin Function 91

Data ID Codes 94

Data Interfaces 96

Confi guring the Data Interface as a COM Port 99

Data Input Format 101

Data Output Format 102

Confi guring the Data Interface as a Printer Port 106

Confi guring a Printout 107

GMP-compliant Printouts 108

Sample Printouts 109

Error Codes 115

Care and Maintenance 117

Service 117

Repairs 117

Cleaning 117

Safety Inspection 118

Disposal 119

Specifications 120

Balance Dimensions 123

Accessories 125

Documents List

1

28

Sartorius Services 128

Declaration of Conformity 129

EC Type-approval certifi cate 131

Test Certifi cate 132

Plates and Markings 133

Appendix: Guide to Verification

of Weighing Instruments 137

Explosion-risk area Zone 2 or 22 140

Appendix: Passwords 145

2 Operating Instructions Combics Complete Scales

Contents

Notes on Using this Manual

t Please read this entire manual carefully and completely before using the device.

t Read the safety precautions carefully.

t This manual is part of the product. Keep it in a safe and easily accessible

location.

t If the manual should be lost or misplaced, please contact Sartorius for a

replacement or download the latest manual from our website:

www.sartorius-mechatronics.com

Symbols and Signs

The following symbols are used in this manual:

2

Warning symbol for various types of dangers.

These symbols are explained in more detail in Section “Safety Instructions.“

h

This symbol indicates useful information and tips.

This symbol indicates notes on use in legal metrology within the scope of validity

of Council Directive No. 90/384/EEC, replaced by 2009/23/EC

(models MS...-.CE...).

e, 1, This and similar symbols mean that the respective key should be pressed.

T T ..., This means that this key must be pressed more than once.

t Indicates a required action

y Describes the result of an action

1. If a procedure has multiple steps...

2. ... the steps are numbered consecutively.

– Indicates an item in a list

h

Technical advice/hotline:

Phone: +49.551.308.4440

Fax: +49.551.308.4449

Operating Instructions Combics Complete Scales 3

Notes on Using this Manual

Warnings and Safety Precautions

Combics indicators comply with the European Council Directives as well as

international regulations and standards for electrical equipment, electromagnetic

compatibility, and the stipulated safety requirements. Improper use or handling can,

however, result in damage and/or injury.

t Read these operating instructions carefully before use.

This will prevent damage to the equipment.

3

The protective conductor must not be disconnected for any reason. Use only

standard cables that have protective grounding conductors.

3

If there is visible damage to the equipment or power cord: unplug the equipment

and secure it against further use.

3

Make absolutely sure to unplug the indicator from power before you connect or

disconnect any electronic peripheral devices to or from the interface port.

3

The device should only be opened by personnel trained in accordance with Sartorius

guidelines.

3

If you use electrical equipment in installations and under ambient conditions

requiring higher safety standards, you must comply with the provisions as specifi ed

in the applicable regulations for installation in your country.

3

The operator shall be responsible for any modifi cations to the equipment and for

any connections of cables or equipment not supplied by Sartorius and must check

and, if necessary, correct these modifi cations and connections.

Information on operational quality is available upon request from Sartorius (in line

with norms pertaining to immunity).

3

Do not expose the equipment to aggressive chemical vapors or to unnecessarily

extreme temperatures, moisture, shocks, or vibration.

3

Only clean the device as stipulated in the cleaning instructions: Refer to the

“Care and Maintenance“ chapter.

3

The display value can be affected by extreme electromagnetic infl uences. Once the

disturbance has ceased, the instrument can be used again in accordance with its

intended purpose.

Danger of Explosion!

1

Do not use this equipment in hazardous areas.

4 Operating Instructions Combics Complete Scales

Warnings and Safety Precautions

Installation

3

Warning when using pre-wired RS-232 connecting cables: RS-232 cables purchased

from other manufacturers often have pin assignments that are incompatible with

Sartorius products. Be sure to check the pin assignments against the chart in this

manual before connecting the cable, and disconnect any lines identifi ed differently

from those specifi ed by Sartorius.

3

Connect only Sartorius accessories and options, as these are optimally designed for

use with your device. Therefore, do not use any proprietary solutions. The operator

shall be solely responsible for installation and testing of any modifi cations to

Sartorius equipment, including connection of cables or equipment not supplied

by Sartorius. Information on operational quality (in line with norms pertaining to

immunity) is available on request.

t If you have any problems with your device, contact your local Sartorius offi ce,

dealer or service center.

IP Protection Rating

IP Rating – All models are rated to IP44 (with option L1: IP65)

– CAWxS models are rated to IP67.

– CAH1E* models: platform IP65, indicator IP69K.

– CAH1G* models: platform IP67, indicator IP69K.

– CAWxS models are rated to IP69K with the “I69“ option.

– Complete scales with secured protective caps must be installed and tested by a

certifi ed technician.

– If you install an interface port or battery connection after setting up your

indicator, keep the protective cap in a safe place for future use. The cap protects

the interface connector from vapors, moisture and dust or dirt.

Use in Legal Metrology

– When the indicator is connected to a weighing platform and this equipment is

to be verifi ed, ensure that the applicable regulations regarding verifi cation are

observed.

– When connecting Sartorius weighing platforms, observe the “Guide to

Verifi cation of Weighing Instruments“ and the Declaration of Conformity with

the list of permitted weighing ranges.

– A sticker with the “Sartorius“ logo was affi xed to the indicator as a control seal

following verifi cation. This seal will be irreparably damaged if you attempt to

remove it. This will nullify the verifi cation‘s validity. In this case, re-verifi cation

would be required in compliance with all relevant national regulations and laws.

Operating Instructions Combics Complete Scales 5

Warnings and Safety Precautions

Device Description

Combics complete scales:

– Are robust and durable, thanks to their stainless steel housing

– Are easy to clean and disinfect

– Are easy to operate, thanks to the following features:

– Large, backlit, fully graphical dot-matrix display

– Large keys with positive click action

– Can be operated independently of the weighing platform location

– Have a range of interfaces for fl exible use

– Have optional password protection for operating parameters

Combics 3 speeds up your routine procedures with:

– Integrated programs for applications (some can be combined):

– Counting

– Neutral Measurement

– Averaging (animal weighing)

– Weighing in percent

– Checkweighing

– Classifi cation

– Totalizing

– Net-total Formulation

– Automatic initialization when the scale is switched on

– Fast response times

– Automatic taring when a load is placed on the weighing platform

– Designation of weight values with up to 4 lines of alphanumeric text

– Can be controlled via two external computers using various protocols

– Barcode scanner connection option for entering tare value or IDs (6 units)

– Possibility to input tare values via the number block

– LED for measurement range identifi cation

– Connection option for a second weighing platform

– Alibi Memory

– Internal rechargeable battery

– Product data memory

– Confi gurable printout

– FlexPrint

Intended use

The Combics 3 is a robust complete scale for daily production and quality control in

industrial applications. Any other use beyond this is considered improper.

6 Operating Instructions Combics Complete Scales

Device Description

General View of the Equipment

Platform

1 Level indicator

2 Load plate

3 Leveling feet

Indicator

4 10 digit keypad for entering alphanumeric values

5 LEDs (for checkweighing and classifi cation)

6 Display (for details, see “Operating Design“ chapter)

7 Additional function keys (see “Operating Design“)

8 General function keys: Zero, Tare, Switch function, Adjustment/

Calibration, Print/Data output

(see “Operating Design“)

9 Toggle between weighing platforms (WP)

10 On/Off

Rear view of indicator:

11 “UNICOM“

Optional:

– RS-232|RS-485 or 422 interface, e.g. for:

– PC connection

– Printer connection

– Digital I/O

– 4 to 20 mA

– Profi bus DP

– Ethernet TCP/IP|ModBus TCP

12 RS-232 interface “COM1“

e.g. for:

– PC connection

– Printer connection

– Digital input

– Stop light output

13 “PS2“ e.g. for:

– Keyboard connection

– Barcode scanner connection

14 Power cord with country-specifi c plug

15 Input for menu access switch (standard or legal-for-trade mode)

for WP 1

16 Weighing platform WP 1 connection

for analog scales,

optional for “xBPI“|“SBI“ scales

17 Weighing platform WP 2 connection,

optional for analog scales or “xBPI“|“SBI“ scales

18 Input for menu access switch (standard or legal-for-trade mode)

for WP 2

19 RS-232 interface “COM2“

e.g. for:

– PC connection

– Printer connection

20 Vent valve: 1.5 Nm

Operating Instructions Combics Complete Scales 7

Device Description

CAW3S | CAH3

11

19

17

18

16

15

12

14

20

P

S

2

CAW3P

19

18

17

16

15

11

14

12

13

10

1

2

3

4

5

6

7

8

9

Installation

Installation

When a Combics indicator is ordered with special equipment, the desired options

come pre-loaded from the factory.

Storage and Shipping Conditions

3

Once the equipment has been removed from the packaging, it may lose accuracy if

subjected to strong vibration.

3

If the load plate is lifted using a vacuum lifting pad, gloves, safety shoes and safety

gear must be worn. Risk of injury!

This work may only be carried out by reliable and authorized personnel.

3

Suspension points are provided for weighing platforms with an overall size of

1 + 1 m or larger. Do not step under the load during weighing platform/load plate

transport or when lifting. Corresponding accident prevention regulations must be

followed.

Do not damage the clamp boxes and load receptors during transport.

– Do not expose the equipment to unnecessarily extreme temperatures, moisture,

shocks, blows or vibration.

– Permissible storage temperature: –10°C to +40°C

Installation Location

Avoid adverse infl uences at the place of installation:

– Extreme temperatures (operating temperature: –10°C to +40°C)

– Aggressive chemical vapors

– Extreme moisture (according to IP protection class)

Unpacking

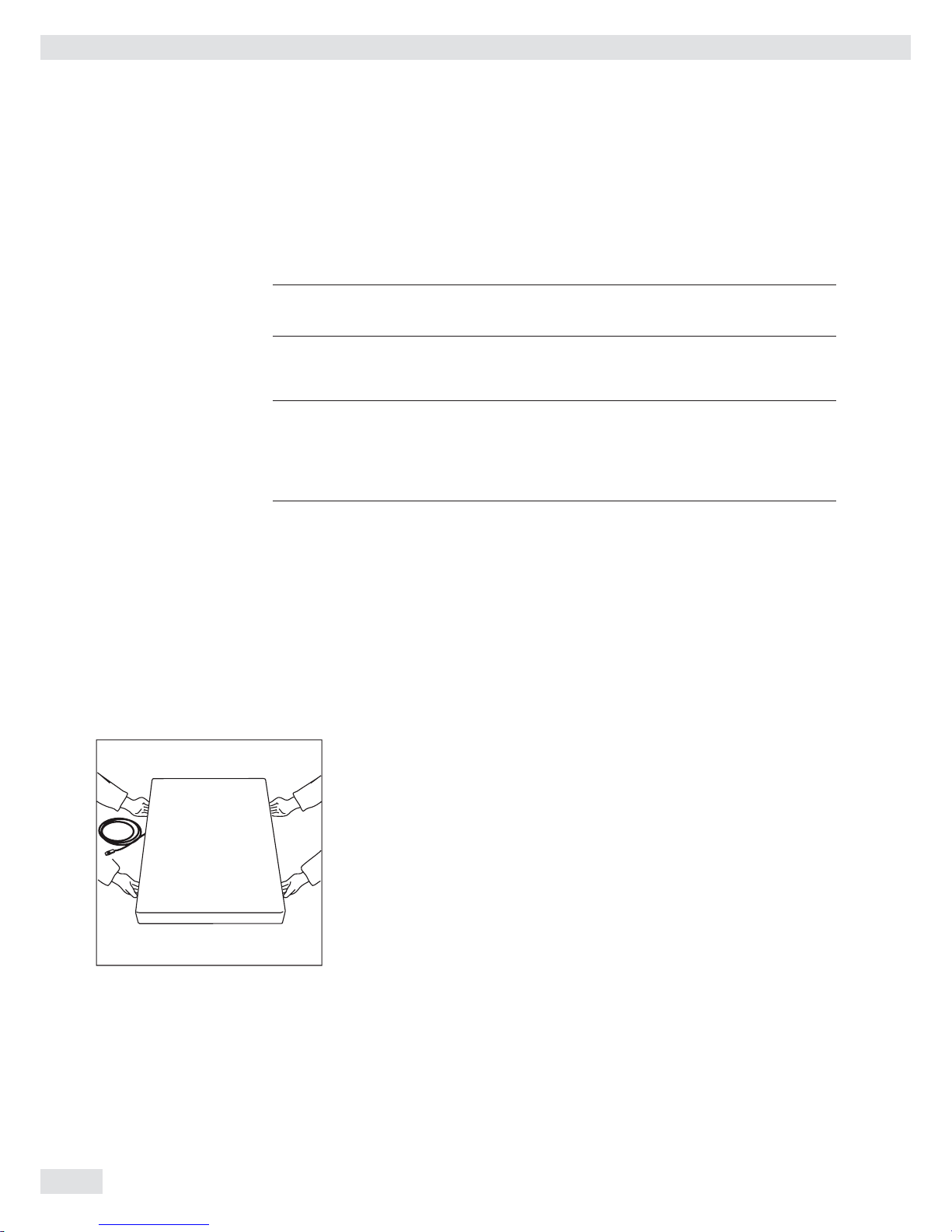

For devices with a platform size of 60 x 80 cm or larger:

t Protective gear must be worn (safety shoes and if required, gloves)

t Always lift on the side walls when lifting or transporting the weighing platform.

t After unpacking the device, check it for any visible damage as a result of rough

handling during shipment.

y If you detect any damage, proceed as directed in the chapter entitled “Care and

Maintenance“ under “Safety Inspection.“

t Save the original packaging for any future transport.

Unplug all connected cables before packing the equipment.

Checking Package Contents

– Indicator

– Weighing platform

– Operating instructions

– Options (special accessories) as listed on the bill of delivery

8 Operating Instructions Combics Complete Scales

Installation

CAH3 models: Remove transport locks

t Place the weighing platform at its installation location, remove the

weighing pan.

t Remove the transport lock: Remove screw 1

t Loosen screw 2.

t Turn the mounting bracket 180° and re-secure screw 2.

t Re-attach screw 1 to the lever

3

The transport lock must be re-installed before transporting the weighing platform.

Leveling the Weighing Platform

The weighing platform must be exactly level to ensure reproducible weighing results

every time. Therefore, the weighing platform must always be re-leveled after it has

been moved to a different location.

t Remove the weighing pan.

t Loosen the lock nuts using a wrench (SW17).

t Use a SW5 Allen key to screw the leveling feet in/out.

Turning the leveling feet clockwise lifts the weighing platform,

turning the leveling feet counterclockwise lowers the weighing platform.

Operating Instructions Combics Complete Scales 9

Installation

10 Operating Instructions Combics Complete Scales

t Align the weighing platform leveling feet so that air bubble is centered within

the circle of the level indicator.

t Check to ensure that all four leveling feet rest securely on the work surface.

y Each of the leveling feet must support an equal load.

t Re-fasten the lock nuts after leveling:

Small platforms (1 measuring cell) counter to the platform frame,

large platforms (4 measuring cells) counter to the platform foot.

t Place the weighing pan on the scale.

Operating Limits

You should not exceed the highest load for weighing platforms.

The highest capacity for the weighing platform is as follows depending on the load

used (center, side, one-sided corner load):

Platform size Center Side Corner

320 + 240 50 35 20

400 + 300 130 85 45

500 + 400 300 200 100

500 + 400 P* 600 400 200

650 + 500 S** 450 300 150

800 + 600 P* 1200 800 400

800 + 600 S** 900 600 300

800 + 800 4500 3000 1500

1000 + 800 4500 3000 1500

1000 + 1000 4500 3000 1500

1250 + 1000 4500 3000 1500

1500 + 1250 4500 3000 1500

1500 + 1500 4500 3000 1500

2000 + 1500 4500 3000 1500

* Steel

** Stainless steel

For CAH* models Platform size Supported load (center) in kg

400 + 300 130

560 + 450 130

800 + 600 600

Shock Resistance

The weighing platform has a robust design; however, falling weighing samples, side

impacts and shocks should be avoided. The weighing platform can withstand loads

specifi ed in the DIN standard IEC68 Part 2-27.

Notes on Planning Superstructures

3

Superstructures must be completely attached before the weighing platform is

connected to the power.

The weighing platform is designed for system integration. Scale drawings are the

basis for the selection of the required superstructures. The fi xing of model CAH*IG*

weighing platforms should be carried out using the YAS04IS fastening kit.

Moving or rotating parts on the weighing pan must be designed so that the

weighing results are not infl uenced. Rotating parts should be counterbalanced, for

example.

The weighing pan must be free on all sides so that there is no connection between

the weighing platform and fi xed parts due to falling parts or dirt. Cables and hoses

between the weighing platform and other devices may not exert any forces on the

weighing platform. These cables may not touch the weighing pan.

When setting up systems in hazardous areas (Zone 2 or 22), any relevant

specifi cations should be observed, e. g.: EN60079-14.

The design should ensure that moving parts do not cause electrostatic discharges

(e.g. roller conveyors).

Preload Range (Zero Set Range)

The weight of the superstructures that are attached to the weighing platform is

designated as a “preload.“ The preload is electronically compensated for in the

weighing platform so that the full weighing range remains available and thus

zeroing and/or adjustment (with external weights) is possible.

Greater preloads reduce the weighing capacity. You may not fall below the following

weighing range values:

– For CAH*E-16ED... and CAH*E-32ED... a min. 20 kg weighing range must be

maintained

– For CAH*E-64ED... and CAH*G-64FE... a min. 35 kg weighing range must be

maintained

– For CAH*G-150IG-H and CAH*G-300IG-H a min. 60 kg weighing range must be

maintained

The preload must always be set before verifi cation.

Acclimatizing the Device

Condensation can form on the surfaces of a cold device when it is brought into a

substantially warmer area.

t Allow the device to acclimatize for about 2 hours at room temperature, leaving

it unplugged from AC power.

Installation

Operating Instructions Combics Complete Scales 11

Getting Started

Steps 1.) Set up the weighing platform with the indicator.

2.) Level the weighing platform

3.) Connect peripheral devices, e.g. printer to the COM1 or UNICOM interface:

see Data Interfaces chapter starting on page 99

4.) Connecting the device to AC power

5.)

Carry out an alignment: for adjustment, see page 27, for linearization see page 24

Connecting Peripheral Devices or Another Weighing

Platform

An analog Sartorius platform (CAPP, CAPS) or an IS weighing platform is connected

at the factory to the Combics indicator WP1 input.

3

The load cell should be connected by a certifi ed technician who has received

specialized training from Sartorius. Any installation work that does not conform

to the instructions in this manual results in forfeiture of all claims under the

manufacturer’s warranty.

3

Peripheral devices should be connected by a certifi ed technician who has received

specialized training from Sartorius. Any installation work that does not conform

to the instructions in this manual results in forfeiture of all claims under the

manufacturer’s warranty.

3

Disconnect the equipment from the power supply before starting connection work.

t Place cables from peripheral devices next to the indicator.

CAW3S, CAH3 (IP69K) t Opening the Combics indicator:

Loosen the ten cap nuts on the front panel. Remove the front panel.

Installing Connection and Interface Cables

3

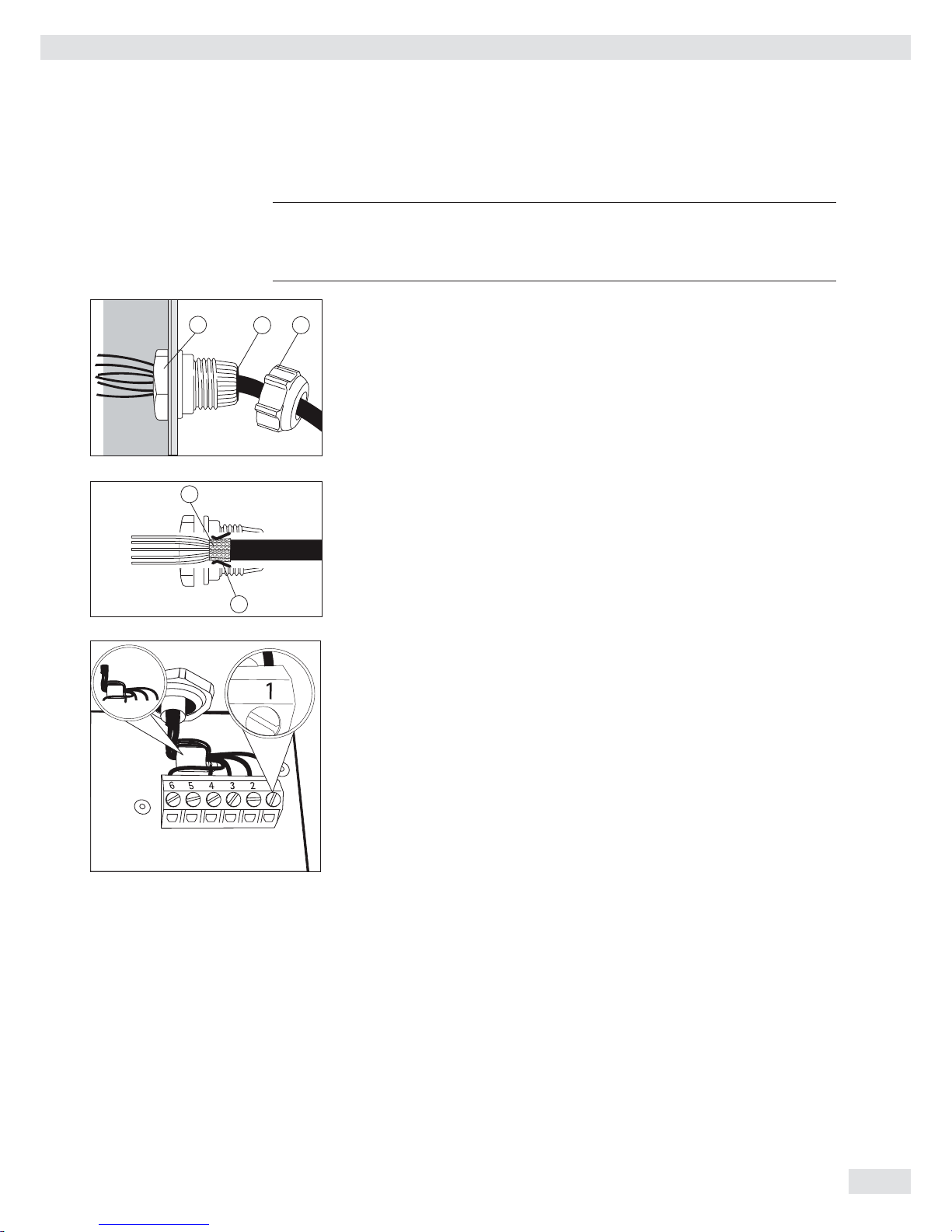

The cable gland (IP69K protection) is pre-mounted on the indicator. Please use

extreme caution when performing any work on the equipment that affects this

cable gland.

You must use a torque wrench. The torque for this cable gland is 5 Nm.

Preparing Cables

t Strip approx. 14 cm from the end of the cable.

t Shorten the shielding to approx. 2 cm and pull back over the insulation.

t Strip approximately 5 mm of the insulation from the wires of the connecting

cable and affi x ferrules to the wire ends.

Getting Started

12 Operating Instructions Combics Complete Scales

Attaching the Cable Entry

3

Please use extreme caution when performing any work on the equipment that

affects this cable gland.

You must use a torque wrench.

The torque for this cable gland is 5 Nm.

4

1

5

t Remove the protective cap from the bore hole on the indicator.

t Insert the included cable gland through the bore hole and secure from the inside

using the locknut (1).

2

3

t Insert the cable through the cable gland until the shielding (2) comes into

contact with the clamps (3). Tighten the screw-down nut (4) until the gasket (5)

inserted between the screw-down nut and cable forms a small beaded rim.

t Check the shielding and clamps.

t Securely connect the wires of the connecting cable in accordance with the

terminal assignments.

t After you close the housing again, use a pressure gauge to check the integrity of

the IP69K protection. For details, contact the Sartorius Service Center.

Connecting Cables

t Insert all cable wires through the ferrite case, wind them around the ferrite case

and then reinsert back through the ferrite case.

t Screw the wires tightly into the clamps.

See the following pages for terminal pin allocation

t Refer to the data sheet or operating instructions of the

weighing platform for details on the assignment of wire

colors/signals. Ensure any lines that are not assigned

are insulated correctly.

t When connecting a load receptor that uses 4-conductor technology (the cable

of the weighing platform to be connected only has 4 lines), connect clamp

pairs 1 and 2 (EXC+ und SENSE+), and 5 and 6 (SENSE- und EXC-) with a wire

jumper.

Connecting an IS Weighing Platform to a Combics 3

You can connect an IS weighing platform to WP2.

Features – IS weighing platforms process weighing data independently of the indicator.

– Internal adjustment option

– IS...-0CE models: have a separate approval number, printed on a tag that is

affi xed to the cable.

– Please observe the conditions described in the manual for the weighing platform

you connect.

Getting Started

Operating Instructions Combics Complete Scales 13

14 Operating Instructions Combics Complete Scales

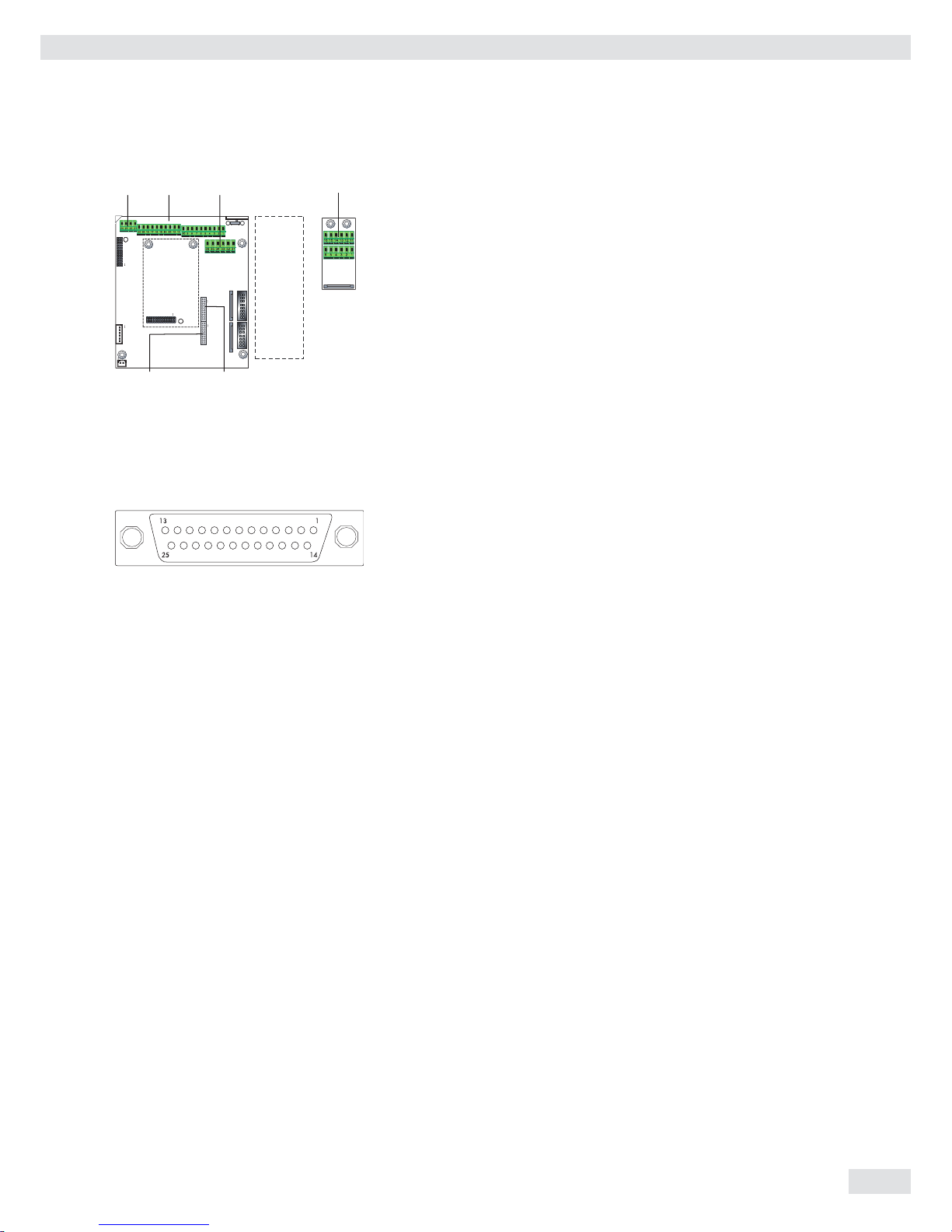

Getting Started

Connecting Peripheral Devices or a 2nd Weighing

Platform: Combics 3, Model type CAW3S | CAH3

PS2 COM1 COM2 A8

Keypad

LED + Display

Weighing platform

Interface 2

Digital PCB

COM1, COM2 and PS2 terminal assignments (applies to all PCBs)

PS2

1 LOAD_PRINTER 11 Clear to send (CTS) 21 5 V switched

2 RESET_OUT 12 Data terminal ready (DTR) 22 PS/2_data

3 GND 13 Data input (RXD) 23 PS/2_clock

4 GND 14 Data output (TXD) 24 GND

5 5V_OUT 15 GND COM2

6 5V switched 16 Universal In 31 CTS_COM2

7 GND 17 Control output: “lower“ 32 DTR_COM2

8 GND 18 Control output: “equal“ 33 RXD_COM2

9 n.c. 19 Control output: “heavier“ 34 TXD_COM2

10 LINE_OUT 20 Control output: “set“ 35 GND

36 GND

A8 terminal assignments

1 EXC+ Bridge supply voltage (+)

2 SENSE+ Sense (+) for bridge supply voltage

3 OUT+ Measuring voltage positive

4 OUT- Measuring voltage negative

5 SENSE- Sense (-) for bridge supply voltage

6 EXC- Bridge supply voltage (–)

Keys

LED + Display

A6/7

Tastatur

LED + Display

PS2 COM1 COM2

Interface PCB for RS-232/485 for IS weighing platform

(option A6/A7)

A6/7 terminal assignments

1 CTS 11 TxD/RxD+

2 DTR 12 TxD/RxD-

3 RxD 13 LINE_OUT

4 TxD 14 LINE_OUT

5 GND 15 GND

6 Adjustment Lock 16 GND

Keys

LED + Display

A20

Keypad

LED + Display

PS2 COM1 COM2

Weighing platform

Interface 1

Interface PCB for ADC 10.000e (option A20)

A20 terminal assignments

1 EXC+

2 SENSE+

3 OUT+

4 OUT-

5 SENSE-

6 EXC-

Keys

LED + Display

A62/72

KeypadLED + Display

PS2 COM1 COM2

Weighing platform

Interface 1

Interface PCB for RS-232/485 for IS weighing platform

(option A62/A72)

Interface PCB A6/7 and A62/72

1 CTS 11 TxD/RxD+

2 DTR 12 TxD/RxD-

3 RxD 13 LINE_OUT

4 TxD 14 LINE_OUT

5 GND 15 GND

6 Adjustment Lock 16 GND

Keys

LED + Display

Interface Pin Assignment Chart COM1

Model type CAW3P (IP44 protection)

COM1 female connectors:

25-pin D-Submini female connector (DB25S) with screw lock hardware for cable

gland

Recommended interface connector:

25-pin D-Submini (DB25) with shielded cable clamp assembly and shield plate

(Amp type 826 985-1C) and fastening screws (Amp type 164868-1)

COM1 pin assignments

Pin 1: Shield

Pin 2: Data output (TxD)

Pin 3: Data input (RxD)

Pin 4: GNO

Pin 5: Clear to send (CTS)

Pin 6: Not assigned

Pin 7: Internal ground (GND)

Pin 8: Internal ground (GND)

Pin 9: Not assigned

Pin 10: Not assigned

Pin 11: +12V for printer

Pin 12: RES_OUT\

Pin 13: +5 V switch

Pin 14: Internal ground (GND)

Pin 15: Universal switch

Pin 16: Control output: “lower“

Pin 17: Control output: “equal“

Pin 18: Control output: “heavier“

Pin 19: Control output: “set“

Pin 20: Data terminal ready (DTR)

Pin 21: Ground power supply (GND)

Pin 22: Not assigned

Pin 23: Not assigned

Pin 24: Power supply +15..25 V (peripherals)

Pin 25: +5 V

Operating Instructions Combics Complete Scales 15

Getting Started

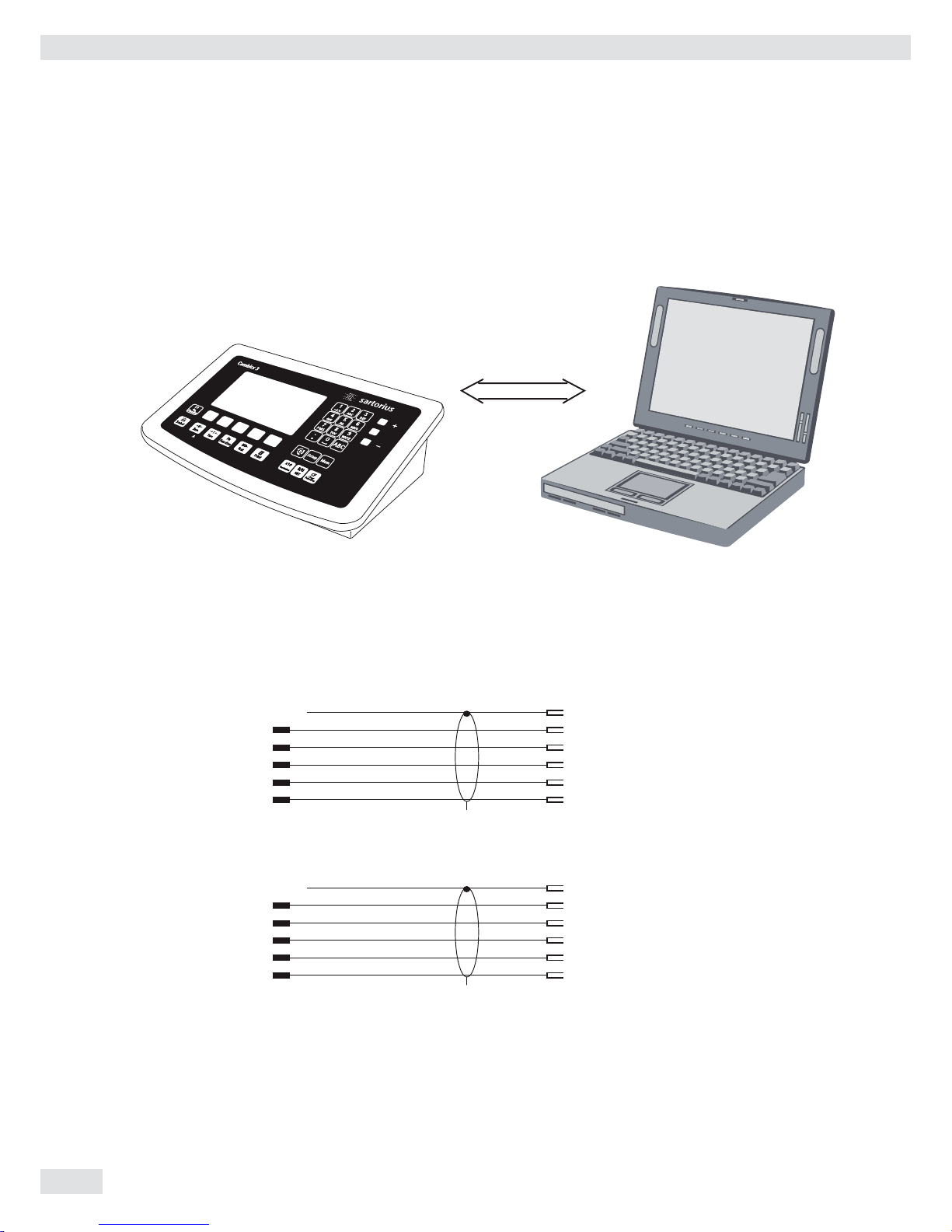

Connecting a PC via Interface COM1

Use the following cables to connect a PC to the indicator in accordance with the

RS-232C/V24 standard (max. cable length 15 m):

Model type CAW3P: connecting cable 7357312

Model type CAW3S | CAH3: connecting cable YCC02-D09F6

Pin assignment

Pin assignments for the cable from the indicator to an RS-232 PC interface (COM1).

Indicator side PC side

Model type CAW3P DSUB connector

25-pin D-Sub male connector 9-pin or 25-pin

1

Sgn GND 7 5 GND 7 GND

TxD 2 2 RxD 3 RxD

RxD 3 3 TxD 2 TxD

DTR 20 8 CTS 5 CTS

CTS 5 4 DTR 20 DTR

Model type CAW3S | CAH3

Open cable end DSUB connector

9-pin or 25-pin

Sgn GND 15 5 GND 7 GND

TxD 14 2 RxD 3 RxD

RxD 13 3 TxD 2 TxD

DTR 12 8 CTS 5 CTS

CTS 11 4 DTR 20 DTR

RS232

Getting Started

16 Operating Instructions Combics Complete Scales

Interface Pin Assignment Chart COM2

Model type CAW3P (IP44 protection)

COM1 female connectors:

25-pin D-Submini female connector (DB25S) with screw lock hardware for cable

gland

6

5

1

9

Recommended interface connector:

25-pin D-Submini (DB25) with shielded cable clamp assembly and shield plate

(Amp type 826 985-1C) and fastening screws (Amp type 164868-1)

COM1 pin assignments

Pin 1: Shield

Pin 2: Data output (TxD)

Pin 3: Data input (RxD)

Pin 4: GNO

Pin 5: Clear to send (CTS)

Pin 6: Not assigned

Pin 7: Internal ground (GND)

Pin 8: Internal ground (GND)

Pin 9: Not assigned

Pin 10: Not assigned

Pin 11: +12 V for printer

Pin 12: RES_OUT\

Pin 13: +5 V switch

Pin 14: Internal ground (GND)

Pin 15: Universal switch

Pin 16: Control output: “lower“

Pin 17: Control output: “equal“

Pin 18: Control output: “heavier“

Pin 19: Control output: “set“

Pin 20: Data terminal ready (DTR)

Pin 21: Ground power supply (GND)

Pin 22: Not assigned

Pin 23: Not assigned

Pin 24: Power supply +15..25 V (peripherals)

Pin 25: +5 V

Getting Started

Operating Instructions Combics Complete Scales 17

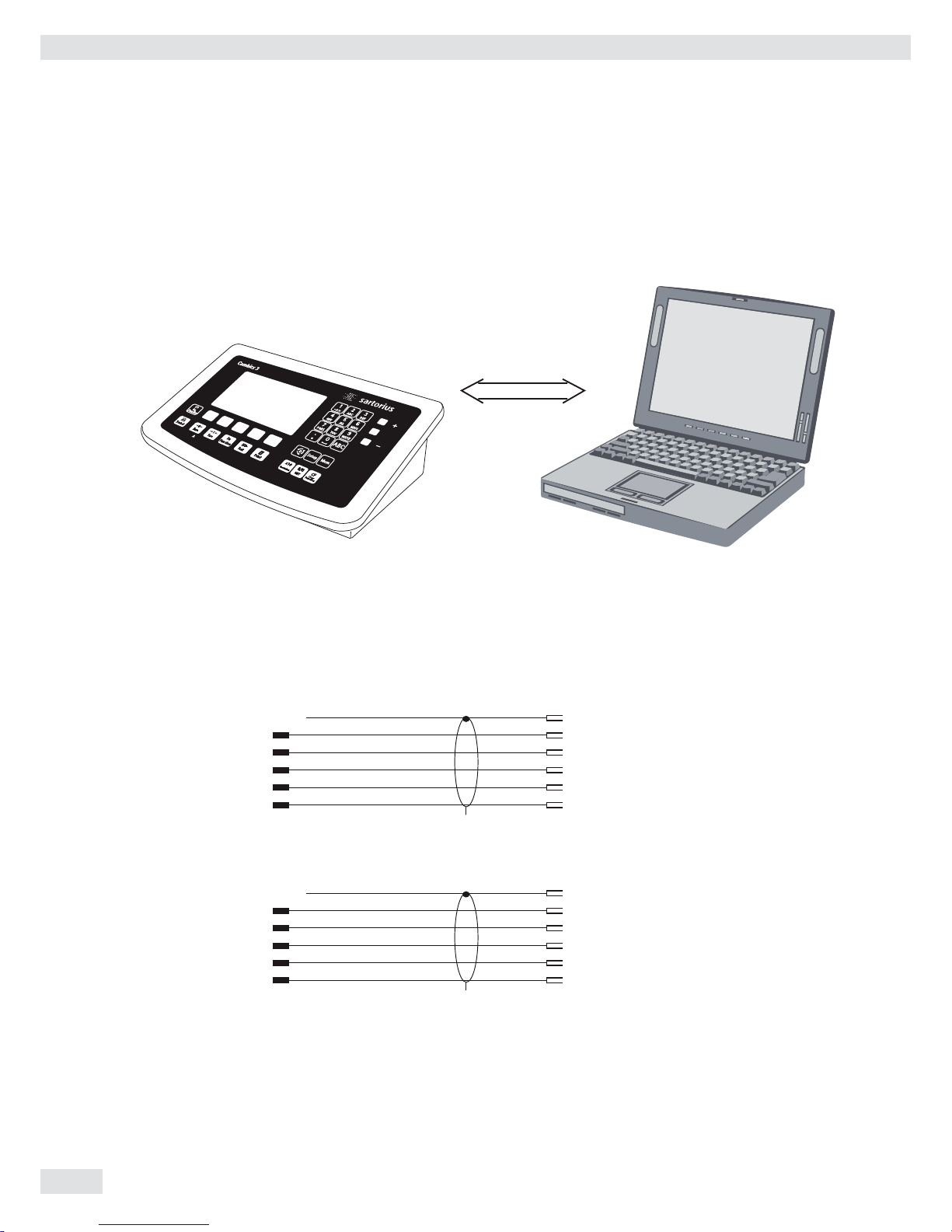

Connecting a PC via Interface COM2

Use the following cables to connect a PC to the indicator in accordance with the

RS-232C/V24 standard (max. cable length 15 m):

Model type CAW3P: connecting cable 7357312

Model type CAW3S | CAH3: connecting cable YCC02-D09F6

Pin assignment

Pin assignments for the cable from the indicator to an RS-232 PC interface (COM1).

Indicator side PC side

Model type CAW3P DSUB connector

25-pin D-Sub male connector 9-pin or 25-pin

1

Sgn GND 7 5 GND 7 GND

TxD 2 2 RxD 3 RxD

RxD 3 3 TxD 2 TxD

DTR 20 8 CTS 5 CTS

CTS 5 4 DTR 20 DTR

Model type CAW3S | CAH3

Open cable end DSUB connector

9-pin or 25-pin

Sgn GND 15 5 GND 7 GND

TxD 14 2 RxD 3 RxD

RxD 13 3 TxD 2 TxD

DTR 12 8 CTS 5 CTS

CTS 11 4 DTR 20 DTR

RS232

Getting Started

18 Operating Instructions Combics Complete Scales

3

1

4

2

6

5

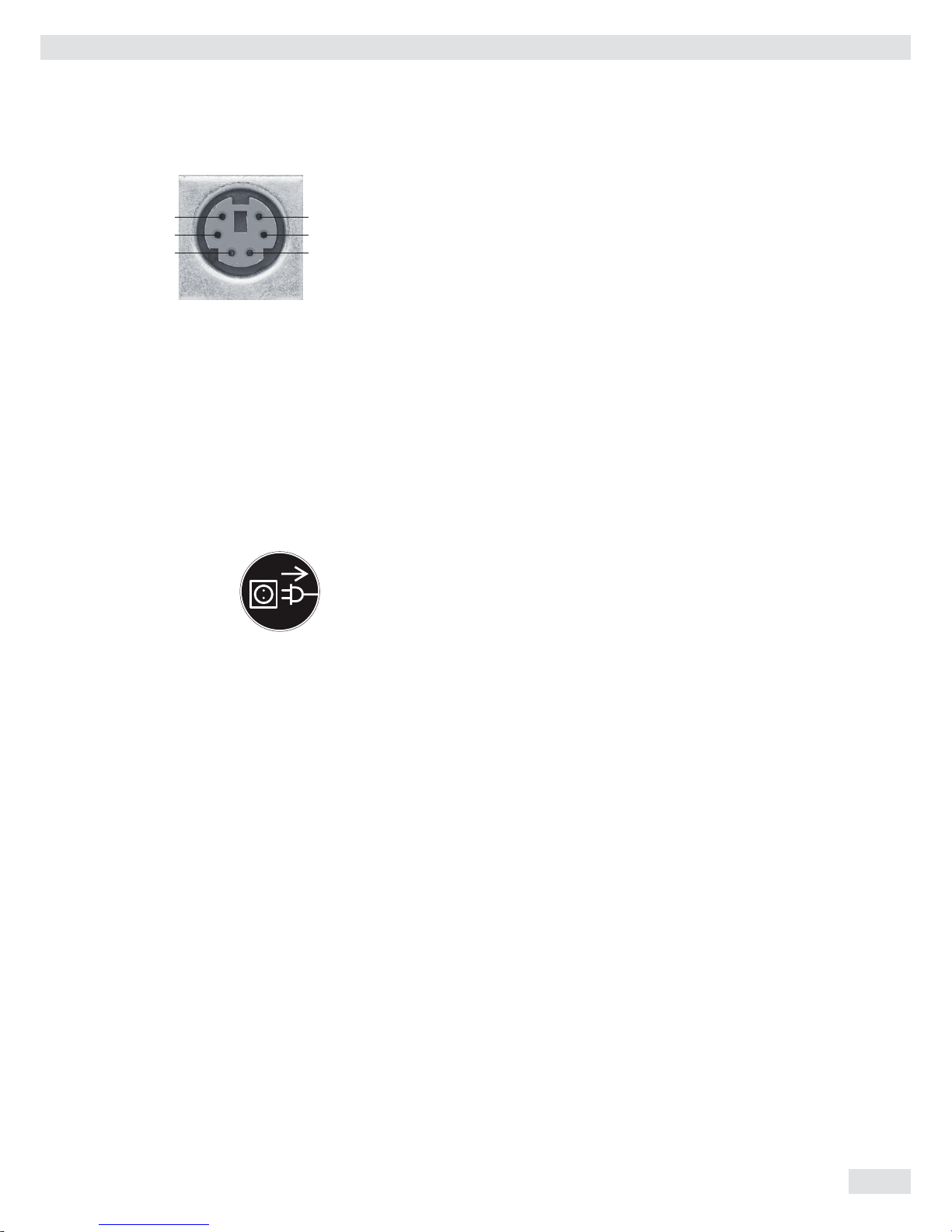

Interface Pin Assignment Chart PS2

Model type CAISL (IP44 protection)

PS2 female connector:

6-pin miniature socket PS2 (Mini-DIN)

Recommended interface connector:

6-pin miniature socket PS2 with integrated shielded cable clamp assembly

Pin assignment:

Pin 1: Keyboard data (data interface cable)

Pin 2: Not assigned

Pin 3: Internal ground (GND)

Pin 4: +5V switched

Pin 5: Keyboard clock

Pin 6: Not used

Connecting a Bar Code Scanner

Accessory YBR02CISL

t Disconnect the indicator from AC power (unplug the AC adapter)

For CAW3P models:

t Connect the barcode scanner via PS/2.

For CAW3S | CAH3 models:

t Pin assignment, see “Connecting Peripheral Devices“ (implemented via the

YCC02-BR02 connecting cable or as option M8) on page 14.

NOTE: This equipment has been tested and found to comply with the limits pursuant to part 15 of FCC Rules. These limits are designed to provide reasonable

protection against harmful interference. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with

these instructions, may cause harmful interference to radio communications. For

information on the specific limits and class of this equipment, please refer to the

Declaration of Conformity. Depending on the particular class, you are either required

or requested to correct the interference. If you have a Class A digital device, you

need to comply with the FCC statement as follows: “Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.“

Getting Started

Operating Instructions Combics Complete Scales 19

Closing the Combics Indicator

t Re-attach the front panel and secure it with the ten cap nuts ( 1Nm ).

Connecting the Device to AC Power

The indicator is powered through the pre-installed power cord. The power supply is

integrated into the indicator. The device can be operated with a supply voltage of

100 V to 240 V.

3

The power connection must be made in accordance with the regulations applicable

in your country.

The printed voltage rating (see type label) must match the voltage in the place of

installation. If the voltage specified on the label or the plug design of the AC adapter

do not match the rating or standard you use, please contact your Sartorius office or

dealer.

t Check the voltage rating and plug design.

t The device must be plugged into a properly installed wall outlet.

Protection Class 1 Device

t The device must be plugged into a properly installed wall outlet which has a

protective grounding conductor (PE).

Safety Precautions

3

If you use an electrical outlet that does not have a protective grounding conductor,

ensure that an equivalent protective conductor is installed by a certified electrician

(as specified in the applicable regulations for installation in your country).

The protective effect must not be negated by using an extension cord without a

protective grounding conductor.

Before using for the first time, any superstructure parts must be completely installed.

Avoid connecting the equipment to lines that have a heavy electrical load,

e.g. compressors, large machinery, etc.

Warm-up Time

To deliver exact results, the device must warm up for at least 30 minutes after

connection to AC power. Only after this time will the device have reached the

required operating temperature.

Using a Verified Device in Legal Metrology

Ensure that there is a warm-up time of at least 24 hours after connection to the

power supply.

Getting Started

20 Operating Instructions Combics Complete Scales

Configuring Weighing Platforms

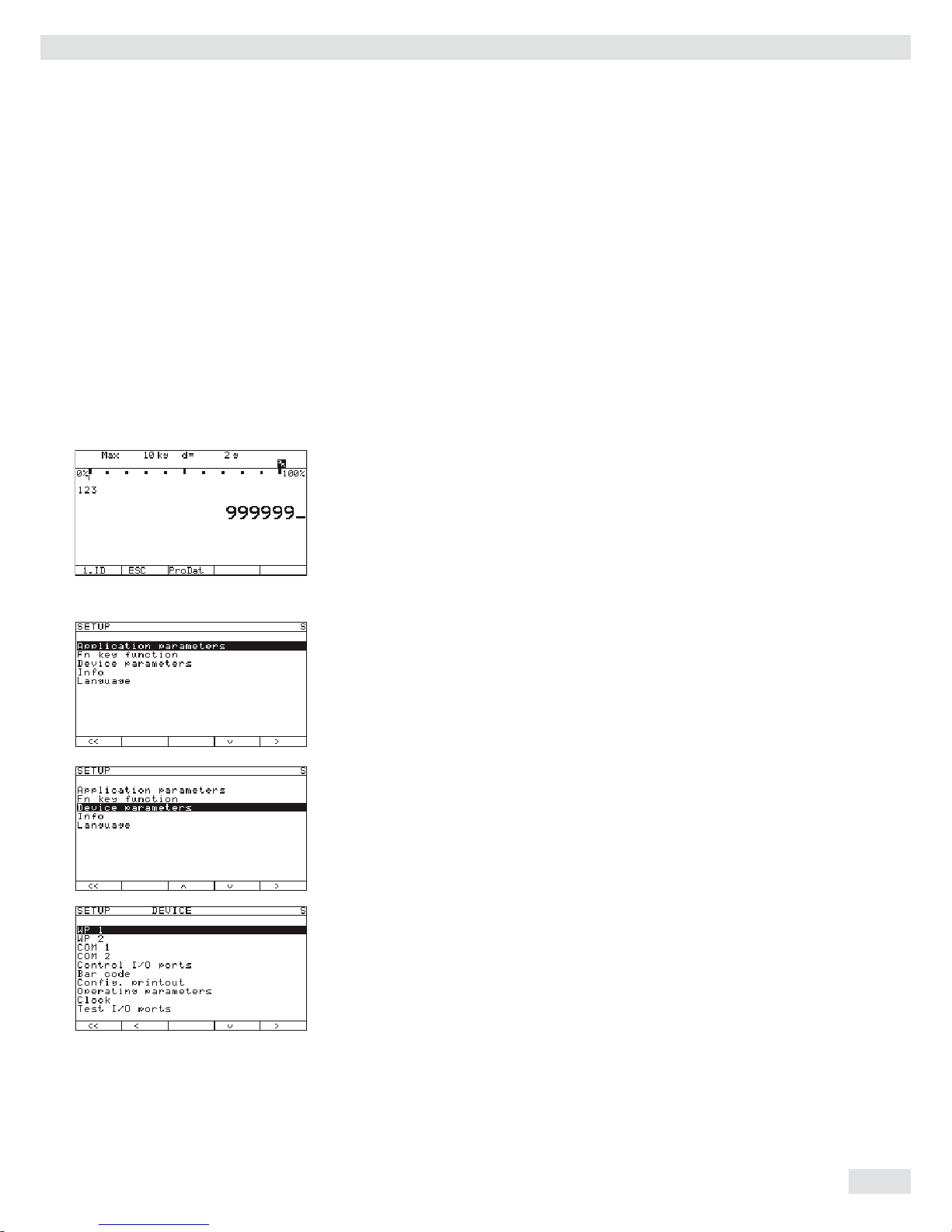

Service-Mode

Purpose The Service mode enables access to additional menu items in the Setup menu

which are not displayed when the Service mode is not active. The most important

calibration and adjustment work for the indicator and for the connected weighing

platform can be carried out in the Service menu, e.g. ADC configuration.

When the Service mode is active, an “S” is shown in the top right-hand corner of

the display. To deactivate the Service mode, restart the indicator (turn the indicator

off and back on again).

Activating the Service Mode

t Press e to turn on the device.

y When turned on the scale is in an application program.

t Enter the service password (see Appendix General User Password) and press

M to confirm.

y The device in now is Service mode. An “S“ appears in the top right-hand

corner of the display.

t Press the “q“ soft key several times to select the “Device

parameters

“ line.

t Press the “O“ soft key.

y The “Device“ submenu will open.

t Select and open the corresponding submenu. Repeat this procedure until the

desired menu item in the lowest menu level can be opened.

t View or change the menu item (confirm with “l“) and use “o“ to return to the

previous menu.

t Press M or “oo“ to exit the Setup menu.

Exiting Service Mode

Turn the device off and then on again to return to the normal application mode.

If you exit the Setup menu without changing settings by confirming with M or

the “oo“ soft key, the Service mode will remain active. Press the M key to

re-open the Setup menu.

Operating Instructions Combics Complete Scales 21

Configuring Weighing Platforms

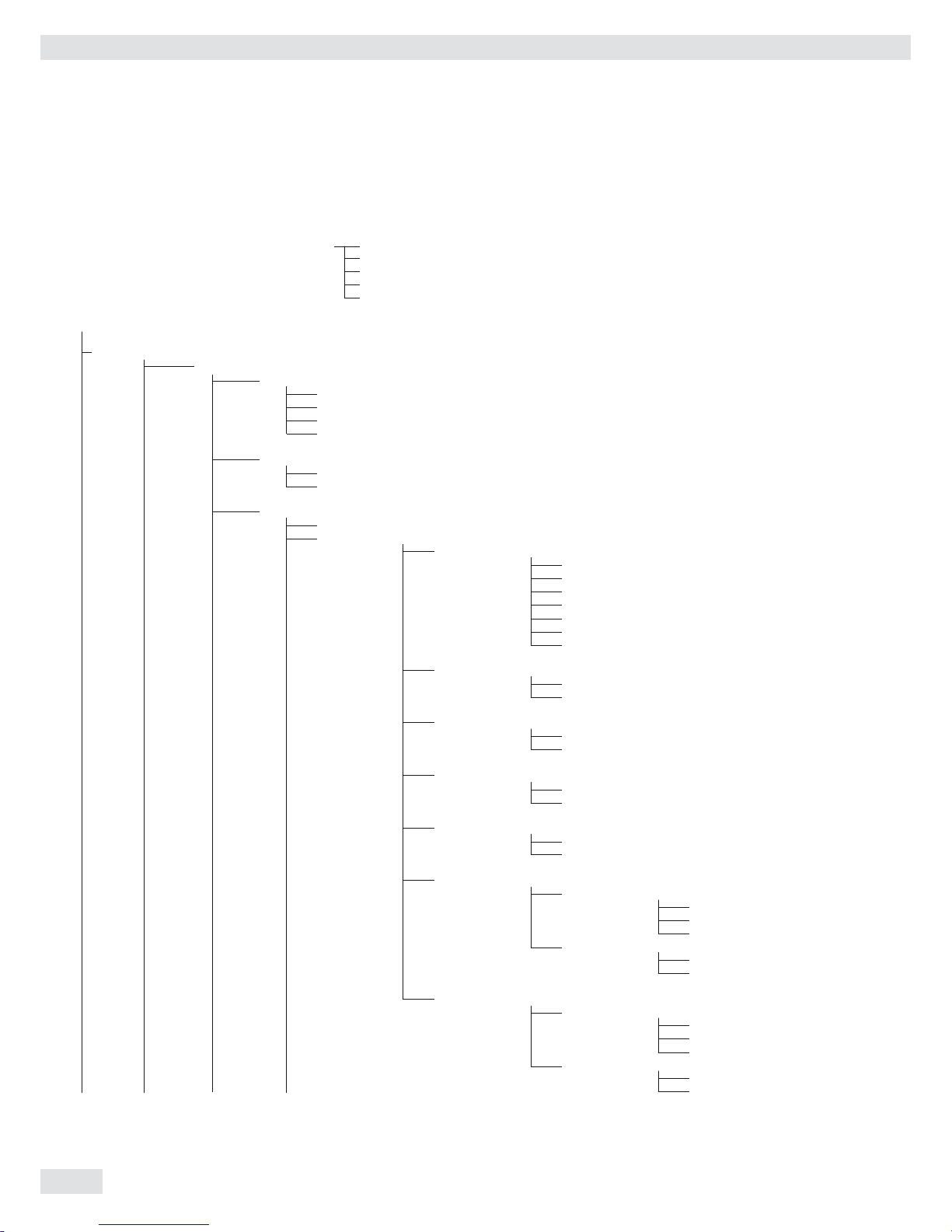

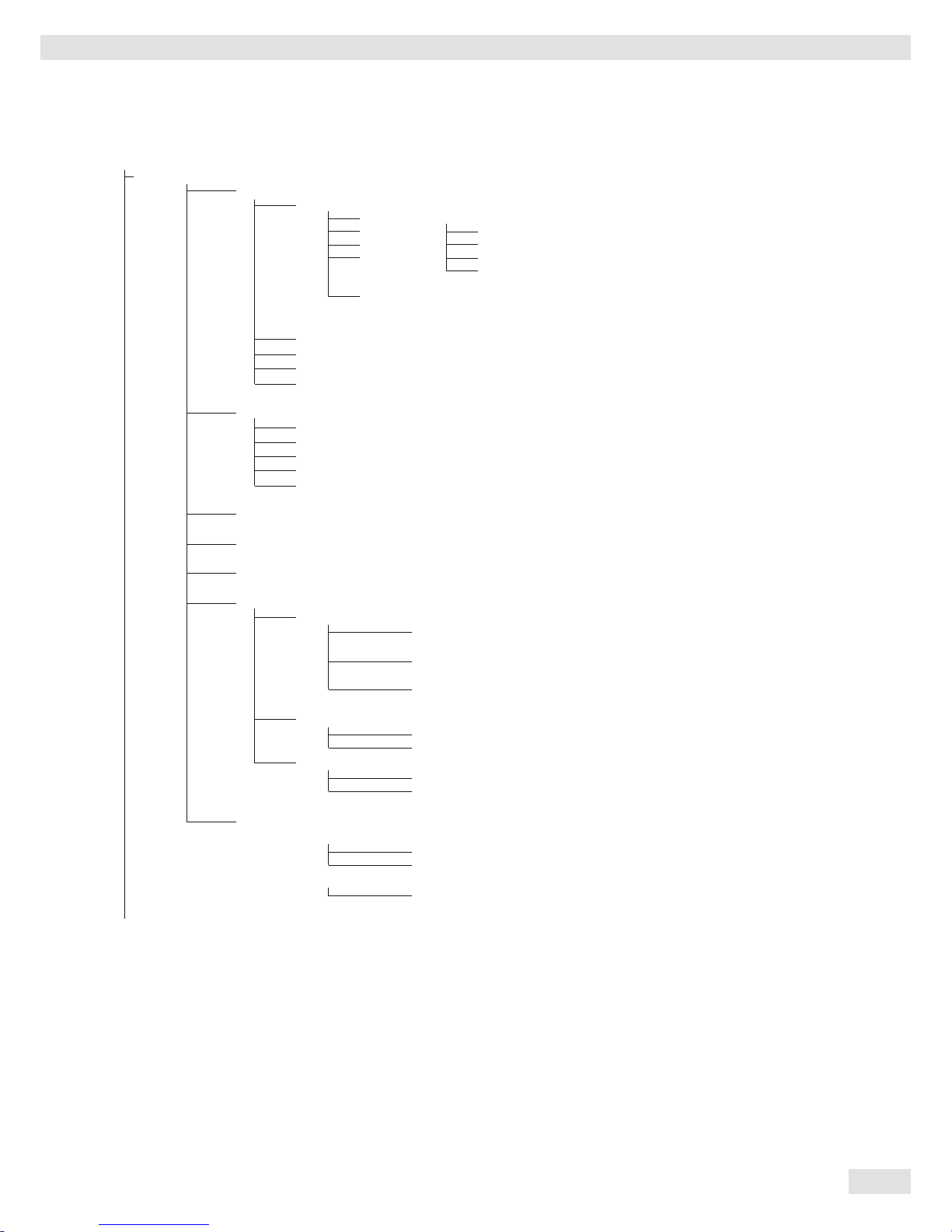

Overview of the Setup Menu in Service Mode

o = Factory setting

x = User-defi ned setting

Service password entry Setup Application parameters, please refer to the “Basic Application Programs” manual

Fn key “Setup Overview (Parameters)“

Device parameters

Info, see the “Setup Overview (Parameters)“ section

Language, see the “Setup Overview (Parameters)“ section

Setup access with service password

Device parameters

WP1

RS-232

1

)

SBI standard

SBI verifi able

o IS-232

ADC-232

RS-485 1)

o IS-485

ADC-485

Internal

ADC confi guration (see the “Setup Menu for ADC Confi guration“ section)

Calibration/Adjustment

CAL key function

o Ext. cal./adj.; factory-def. wt.

Ext. cal./adjust.; user-defi ned weight

Ext. lineariz.; factory-def. wts

Ext. lineariz.; user-def. wts

Set preload

Delete preload

Key blocked

Cal./adj. sequence

Cal. then auto adjust

o Cal. then manual adjust

isoCAL function 3)

o Off

Adjustment prompt

Activate external adjustment 2)

o Activated

Deactivated

Parameter for external weight

Cal./adj. weight:

Lin. weight 1...4:

Adjust without weights 2)

Input parameters

Nominal load:

Resolution:

Sensitivity 1…4:

Save parameters

Yes

o No

Geographical data 2)

Input parameters

Geographical latitude

Altitude

Gravitational acceleration

Save parameters

Yes

o No

1

) Equipment version: – then blocked internally

2

) Not available on devices verifi ed for use in legal metrology

3

) Only when operated with Sartorius IS weighing platforms or an external ADC

22 Operating Instructions Combics Complete Scales

Confi guring Weighing Platforms

Device Parameters

WP1

Internal

Calibration/Adjustment unit

Grams /g

Kilograms /kg

Tons /t

o Pounds /lb

Menu items “Adapt fi lter“ - “Factory settings: only bal. func,“

see the “Setup Overview (Parameters)“ section

Off

COM-1 (when the WP is assigned to this interface)

COM-2 (when the WP is assigned to this interface)

UNICOM (only if available)

WP2, see the “Setup Overview (Parameters)“ section

RS-232

1

) similar to “Internal“ menu for WP1

RS-485

1

) similar to “Internal“ menu for WP1

o Off

COM-1 similar to WP 1

COM-2 similar to WP 1

COM-1, see the “Setup Overview (Parameters)“ section

COM-2, see the “Setup Overview (Parameters)“ section

“Control I/O ports“ - “Terminal data,“ see the “Setup Overview (Parameters)“ section

SQmin

SQmin input

SQmin WP1

SQmin WP1 0.000 kg

SQmin WP2

SQmin WP2 0.000 kg

SQmin WP3

SQmin WP3 0.000 kg

Display

No

o Yes

GMP print

o No

Yes

Alibi memory

2

)

Clear alibi memory

Yes

o No

Alibi memory period

In days 90

1

) Equipment version: – then saved internally

2

) Only if alibi memory is available (option)

Operating Instructions Combics Complete Scales 23

Confi guring Weighing Platforms

Setup Menu for A/D Converter Configuration

Setup access in Service mode

WP1 – Internal – ADC confi guration

Standard confi guration Ranges Single-range mode Scale interval d

Max. cap.

Multi-interval mode Scale interval d

Range 1

Range 2

Range 3

Max. cap.

Multiple-range Scale interval d

mode Range 1

Range 2

Range 3

Max. cap.

Available units User-defi nable /o

Grams /g

Kilograms /kg

Carats /ct

...

Save parameters Yes

o No

o Verifi able Accuracy Class III/IIII

confi guration class

Ranges Single-range mode

D:

E:

Min. capacity:

Max. cap.:

Multi-interval mode

D:

E:

Min. capacity:

Range 1:

Range 2

Range 3:

Max. cap.:

Multi-interval mode

D:

E:

Min. capacity:

Range 1:

Range 2

Range 3:

Max. cap.:

Available units

User-defi nable /o

o Grams /g

o Kilograms /kg

...

Save parameters

Yes

o No

24 Operating Instructions Combics Complete Scales

Confi guring Weighing Platforms

Analog/Digital Converter (ADC)

Purpose Adjust the parameters of the analog/digital converter to the connected load cell or

weighing platform. After ADC confi guration, the ADC in connection with the load

sensor is defi ned as a scale.

3

Once the ADC confi guration has been locked, the indicator can no longer be used

to infl uence weighing results. The scope of functions available in the weighing

instrument is defi ned by the A/D converter. Weighing functions that can be

activated include reading weight values, taring, adjustment, reading the tare value,

saving/deleting the tare entry.

Setup Information – ADC confi guration is only possible when the menu access switch is open.

Re-close the menu access switch after ADC confi guration.

– Before ADC confi guration, you must fi rst set whether or not the weighing

platform will be used as a standard or verifi able weighing platform.

– ADC confi guration is carried out in the Service mode in the Setup menu under

“WP 1“ for the fi rst weighing platform and “WP 2“ for the second.

– Entries made in ADC confi guration will not be affected by a menu reset

(returning the setup parameters to their factory settings).

See also the overview in the “Setup Menu for A/D Converter Confi guration“ section.

Setting Parameters for ADC Configuration

Standard or Verifiable Configurations In ADC confi guration, you must fi rst select whether the weighing platform should

be confi gured as a standard or verifi able (for use in legal metrology) weighing

platform.

– Standard confi guration “Standard“

– Verifi able confi guration “Verifi able“

Select using the “Q“ or “q“ soft key. Press the “O“ soft key to confi rm the setting

and open the Confi guration menu.

Accuracy Class This menu item is not shown when the Standard confi guration is active. When

the Verifi able confi guration is active (for weighing platforms verifi ed or verifi able

for use in legal metrology), only Class l/m can be selected. Activate the

“Accuracy class“ menu item, select “Class III/IIII“ and

confi rm your selection using the “l“ soft key.

Ranges The capacity of the weighing platform can be divided into multiple ranges:

– “ Single-range mode“:

The entire weighing range is divided into scale intervals on the basis of the

lowest interval d and the maximum load.

– “ Multi-interval mode“:

The “Multi-interval mode” function divides the weighing capacity into as

many as four ranges, each with a different readability. Corresponding changes

take place automatically. Once the scale has been tared, the highest possible

resolution is available even if the weighing platform is loaded with a higher

weight. This is only permitted in the accuracy classes l/m for the verifi able

confi guration.

– “ Multiple-range mode“:

Multiple-range mode has two or three weighing ranges. When the range limit

is exceeded, the scale switches into the next highest weighing range (lower

resolution) and remains there. The scale can be returned to the lower weighing

range (higher resolution) only by pressing the ( key and then unloading the

scale.

Operating Instructions Combics Complete Scales 25

Confi guring Weighing Platforms

Select the desired confi guration using the “Q“ or “q“ soft key. Confi rm your

selection using the “O“ key. Make additional settings in the submenu: scale interval

d/verifi cation scale interval e, minimum load (Verifi able confi guration only),

range limits (Multi-interval or Multiple range mode only) and maximum capacity.

Confi rm using the “l“ soft key or cancel using “Esc.“

Scale Interval d Scale interval d indicates the resolution of the weighing instrument.

The scale interval d can be entered only in increments of 1, 2, 5, 10, 20, etc.

When using verifi able or verifi ed weighing platforms, the scale interval d is the same

as the verifi cation scale interval e.

Verification Scale Interval e The verifi cation scale interval e indicates the resolution of the weighing instrument

in legal metrology. The verifi cation scale interval e can be entered only in

increments of 1, 2, 5, 10, 20, etc. For weighing instruments of accuracy class l or

m, e = d. This is why the scale interval d does not need to be entered separately.

When “Standard confi guration” is used, this menu item is not displayed.

Minimum Capacity (Min. Cap.) When “Standard confi guration” is used, this menu item is not displayed. The

minimum load of the connected weighing platform is entered under this menu item.

The minimum load for scales of accuracy class l is 20 e and 10 e for class m.

Important Note: The function of the minimum load setting is to warn operators that below this

limit, the summation of tolerances might lead to signifi cant measurement errors. In

Germany, for example, initial weights below the minimum load are not allowed.

Maximum Capacity (Max. Cap.) The maximum capacity is the maximum load that may be placed on the weighing

instrument. When heavier weights are used the weighing instrument displays

overload “H.” The scale intervals of the weighing instrument are calculated using

the maximum load and the scale interval d (e.g. max. capacity = 15.000 kg, smallest

scale interval d = 0.005 kg yields 3000 scale intervals).

In legal metrology the total number of intervals must be no more than 3000 e, and

when using multi-interval scales there must not be more than 3000 e intervals per

range.

In standard operation, as opposed to legal metrology, you can defi ne a “Super

Range” weighing instrument of over 3000 intervals. These parameters, however,

may be infl uenced by physical restrictions.

Range 1, Range 2, Range 3 The range limits are entered for the individual ranges. The accuracy changes when

these limits are exceeded. The following applies when entering limits: range 1

< range 2 < range 3 < maximum capacity.

This means that the weighing range can be divided into a maximum of 4 ranges.

The resolution changes at intervals of 1, 2, 5, 10, 20 etc., where the lowest

resolution is the smallest scale interval entered. Set ranges that are not required for

use to zero.

Available Units With this function, you can make particular weight units (weight unit x, x=1, 2)

inaccessible during weighing. Available units are indicated by a * on the display

(more than one can be selected).

To enable or disable a unit, select the unit by pressing the “

Q“ or “q“ soft key, and

then press the “l“ soft key (toggle function).

Saving Parameters To save the ADC confi guration, use the “

O“ soft key to select “Yes“ and confi rm

with the “l“ soft key. The device software is reset, and the scale returns to the

normal weighing mode. To exit the menu without saving confi guration changes,

press the “o“ soft key.

Once these parameters have been confi gured, the A/D converter in conjunction with

the load cell(s) is defi ned as a weighing instrument. The A/D converter, in conjunc-

tion with the weighing platform, can now be used like any standard weighing

platform. In addition, the weight unit must be defi ned and the weighing platform

adjusted (calibration, adjustment and linearization must be performed). For a detailed

description of these procedures, see the “Adjustment in Service Mode“ section.

26 Operating Instructions Combics Complete Scales

Confi guring Weighing Platforms

Analog/Digital Converter (ADC) Configuration

Condition The weighing platform must already be connected.

Open the Menu Access Switch The menu access switch is located on the back of the indicator right next to the

weighing platform connection.

t Remove the cap.

t Slide the switch to the left (= “open“ position).

Activating the Service Mode t See “Service Mode“ on page 17.

Configuration t Select weighing platform “WP 1.“

t If the “Internal“ setting is not already activated (marked by “o“), select

the setting using the “Q“ or “q“ soft key and confi rm with “O.“

y The message “Function active“ appears briefl y. The “WP 1 internal“

menu will then open.

t Open the ADC Confi guration menu.

t Select the desired confi guration data record using the “Q“ or “q“ soft key:

“Standard“ or “Verifi able“ (verifi able confi guration).

The default setting depends on the data record.

t Open the menu for confi guring A/D converter parameters. In this example, the

menu for ADC confi guration of a weighing platform for use in legal metrology

is opened.

If “Standard“ was selected previously, then the “Accuracy

class

“ is not displayed.

t Open the fi rst menu item.

For a standard confi guration, the “Ranges“ menu item, for a verifi able

confi guration, the “Accuracy class“ menu item.

When the “Verifi able” confi guration is active, always select the “Accuracy

class

“ menu item fi rst.

t Set accuracy class l/m. The “o“ symbol should mark the setting, if required

confi rm using the “l“ soft key.

t Press the “o“ soft key to exit the menu item.

t Open the “Ranges“ menu item.

Operating Instructions Combics Complete Scales 27

Confi guring Weighing Platforms

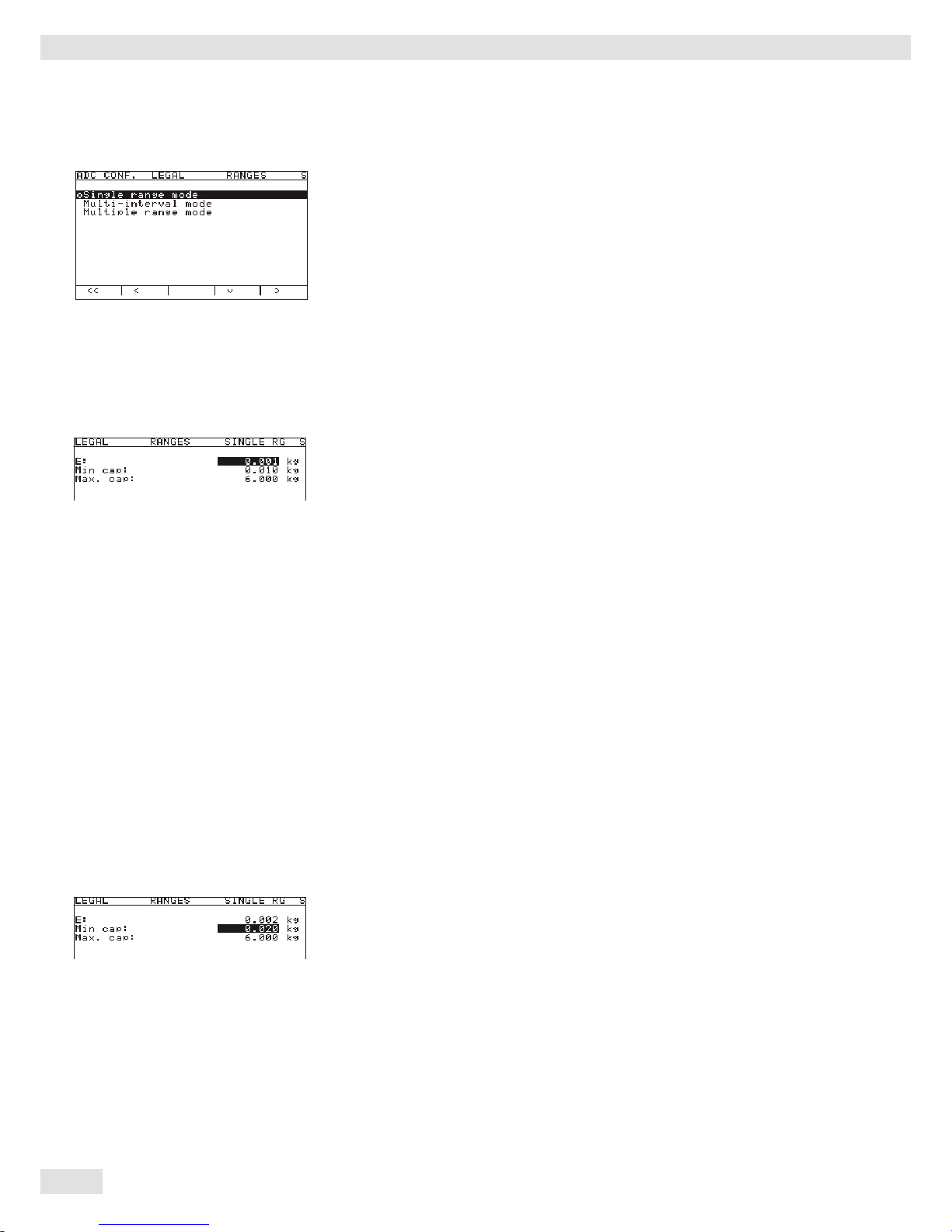

In the example shown here, “Single range mode“ has been selected

(marked by “o“).

t To select a different weighing range confi guration, use the “Q“ or “q“ soft key

to select the corresponding line and open the selected menu using the “O“ soft

key.

y The selected weighing range confi guration is now active. When you return

from the input menu for entering the weighing range parameters, the new

range confi guration is marked by a “o.“

For more information about range confi guration, please see “Setting Parameters for

ADC Confi guration.“

The default values displayed depend on the data record loaded and might have

to be changed. In the example shown here, the A/D confi guration is set with a

“Verifi able” data record in single-range mode.

Single-range Mode t Select the individual input fi elds using the “

Q“ or “q“ soft key.

t For numeric input: use the 0 ... 9 keys and the . key (decimal point).

Make corrections using c.

t Confi rm using the “l“ soft key.

If other parameters follow the one just entered, the highlight bar is

automatically positioned on the next input fi eld.

To cancel numbers entered: press the “ESC“ soft key.

t Use the “

o“ soft key to go to the next menu level.

y This will apply all parameters.

t Press M or “oo“ to exit the Setup menu.

0 . 0 0 2

In the example shown here, a single-range scale in “Verifi able” confi guration

with a maximum capacity of 6.000 kg is modifi ed; the verifi cation scale interval

e is changed from 0.001 kg to 0.002 kg, in accordance with the maximum

permitted value of 3000 verifi cation scale intervals. Press the “l“ soft key to

confi rm the changed value.

The highlight bar is automatically positioned on the “Min. cap.“ fi eld.

The following values apply for the minimum load for verifi able scales:

– For class l: Min. cap. = 20 e

– For class m: Min. cap. = 10 e

A verifi cation scale interval that is changed, therefore, also affects the minimum load.

Changing the verifi cation scale interval “e“ is automatically applied to the “Min. cap.“

You can also change this value manually:

In the example, the minimum capacity must be increased to 0.04 kg for class l.

t Press the following keys in sequence: 0 . 0 4 0 and confi rm using

the “l.“

y The highlight bar is automatically positioned on the “Max. cap.“ fi eld.

t The value for the maximum capacity is not changed. For this example, the

input of parameters for single-range mode in the “Verifi able” confi guration is

now concluded.

t Use the “o“ soft key to go to the next menu level.

28 Operating Instructions Combics Complete Scales

Confi guring Weighing Platforms

Multi-interval Mode The illustration shows an example of the input menu opened for multi-interval

mode range confi guration. This example shows the parameters for a scale in

“Verifi able” confi guration, with 2 weighing ranges and a maximum capacity of

6.000 kg.

– Range 1: 0…3.000 kg with e1 = 0.001 kg

– Range 2: 3.002…6.000 kg with e2 = 0.002 kg

t Enter the verifi cation scale interval for Range 1 in the “

E“ input fi eld.

The minimum capacity for a class l scale must be set to 0.02 kg.

t Use the “o“ soft key to go to the next menu level.

y The active range confi guration is marked with “o.“

t Use the “o“ soft key to go back to the “Verifi able“ menu.

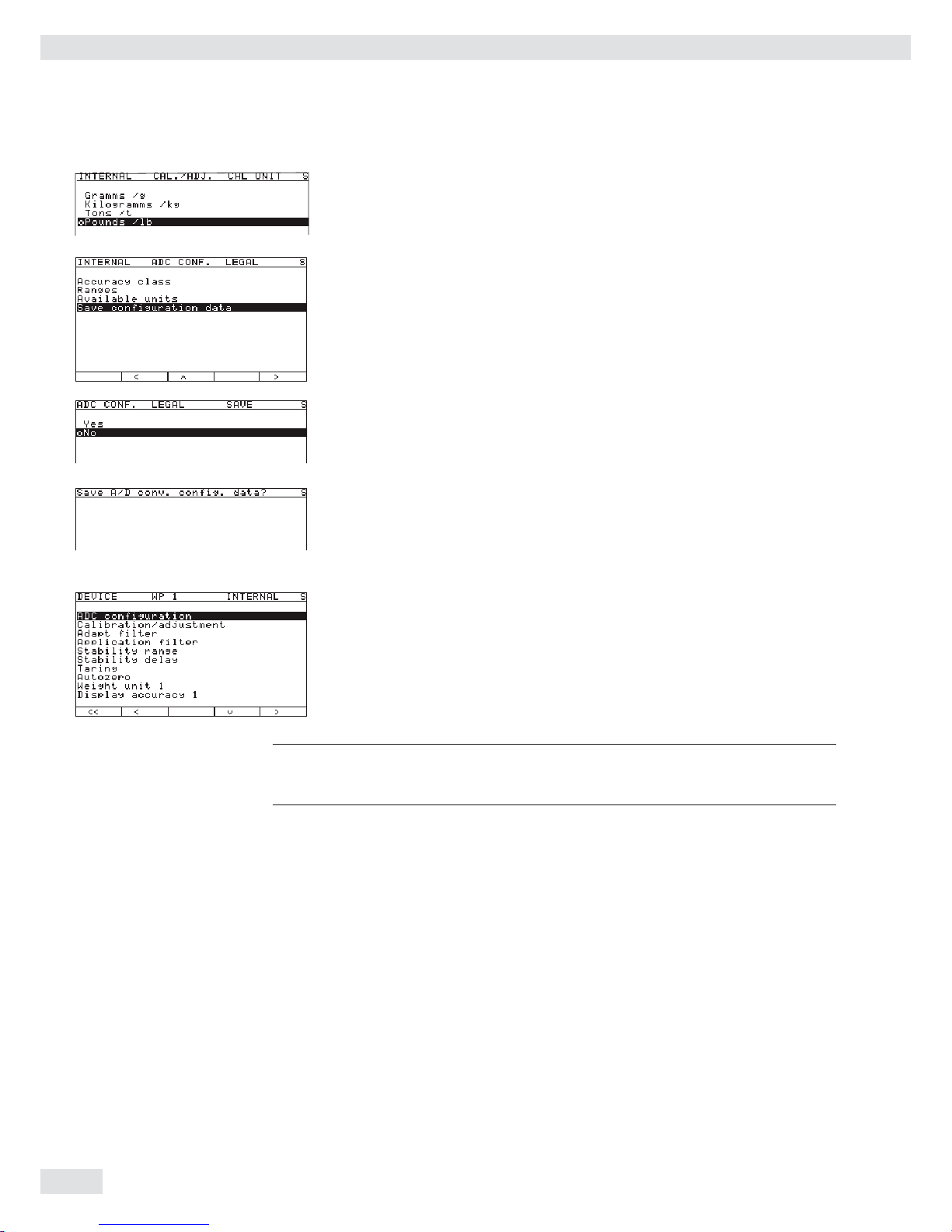

Selecting Units t Use the “q“ and “O“ soft key to open the “Available units“

menu item.

This menu lets you enable or disable the weight units available under “Weight

unit 1,“ “Weight unit 2“ and “Weight unit 3.“

t Select the respective unit using the “Q“ or “q“ soft key and confi rm using the

“l“ soft key.

In most cases, you will not need to change defi ned values.

Available weight units are marked by a *.

The weight unit used for confi guration of weighing ranges cannot be blocked.

t Use the “o“ soft key to go back to the “Internal“ menu.

t Use the “q“ and “O“ soft key to open the “Calibration/

adjustment

“ menu.

t Use the “q“ and “O“ soft key to open the “Calibration/

adjustment unit

“ menu item to defi ne the weight unit for

calibration and adjustment. In most cases, you will not need to change defi ned

values .

y All units are displayed in the menu that are activated in “Available

units

.“ The current setting is marked by a “o.“

Operating Instructions Combics Complete Scales 29

Confi guring Weighing Platforms

t To change the calibration/adjustment unit, select the unit using the “Q“ or “q“

soft key and confi rm using the “l“ soft key.

t Use the “o“ soft key to go back to the “Internal“ menu.

t Use the “Q“ soft key to select the “ADC confi guration“ menu item.

t Use the “O“ and “q“ soft key to select the “Save confi guration

data

“ menu item.

t To save the confi guration, use the “Q“ soft key to select “Yes“ and confi rm

using the “l“ soft key.

y The message “Function activated“ appears briefl y.

The program then returns automatically to the regular weighing mode.

To not save the confi guration:

t Press the “o“ soft key to exit the menu.

y The program returns to the next higher menu level.

To not save data:

t Press the “o“ soft key. The program returns to the WP1:Internal.

t Slide the menu access switch to the right (= “closed“ position) and reattach the

cap.

y The device is now in normal weighing mode.

h

Once ADC confi guration has been completed, an adjustment of the weighing

platform (calibration/adjustment and linearization) must be carried out (see

“Calibration/Adjustment without Weights“ and “External Linearization“).

30 Operating Instructions Combics Complete Scales

Confi guring Weighing Platforms

The displays depicted in the next two illustrations on the left show data from

a multi-interval scale confi gured as described above, or a similarly confi gured

multiple-range scale.

If the A/D converter was confi gured with a “Verifi able” data record, the lines for

display of metrological data (lines 1 and 2) show the data valid for use in legal

metrology.

The current range (e.g. R1) is displayed top left under the weighing point for

multiple-range scales.

ADC Configuration with Load Cell(s) Connected

Procedure: 1. Open the menu access switch, see “Analog/Digital Converter (ADC)

Confi guration.“

2. Activate the Service mode, see “Service Mode.“

3. Confi gure WP 1, see “Analog/Digital Converter (ADC) Confi guration.“

4. Set single-range mode, for example, see “Analog/Digital Converter (ADC)

Confi guration.“

5. Select the units, see “Analog/Digital Converter (ADC) Confi guration.“

6. Adjust without weights, see “Adjust without weights.“

7. Set/Delete the preload, see “Setting the Preload“ and “Deleting the Preload.“

Operating Instructions Combics Complete Scales 31

Confi guring Weighing Platforms

Entering Geographical Data for Use in Legal Metrology

Purpose Entering geographical data allows the external adjustment of weighing equipment

at a place (e.g. at the manufacturer or vendor‘s place of business) that is not the

same as the place of installation. If the weighing equipment is adjusted at the place

of installation, it is not necessary to enter geographical data.

The sensitivity of weighing equipment changes depending on the place of

installation as it is dependent on the on-site gravitational force – or, more precisely,

on gravitational acceleration. Saving geographical data makes it possible to change

the place of installation of the weighing equipment after external adjustment has

been carried out.

The adjustment of weighing equipment is valid at the place of installation and

within a specifi c tolerance zone. At 3000 e this zone extends ±100 km from the set

geographical latitude and ±200 m from the set elevation above sea level.

Installation Location in Germany An exception to this is the setting for “Germany (Zone D):” If during external

adjustment of weighing equipment within Germany the geographical data

– Geographical latitude: 51.00 degrees

– 513 m elevation above sea level

are entered, the weighing equipment can be used throughout Germany.

Gravitational acceleration for “Germany (Zone D)” is 9.810 m/s

2

. On delivery the

geographical data for “Germany (Zone D)” are entered in the output device.

It is recommended to use the geographical data settings for “Germany (Zone D)”

when adjusting and delivering the weighing equipment within Germany.

Entering exact geographical data will lead to a higher level of accuracy but will also

restrict the tolerance zone.

Setup Information – It is only possible to enter geographical data when the menu access switch is

open.

– When the Service mode is active, geographical data can be entered in the Setup

menu under “

WP 1“ for the fi rst weighing platform and “WP 2“ for the

second. Settings are made in the “Calibration/adjustment:

Geographical data: Input parameters

“ menu.

– You can enter either the “latitude“ (geographical latitude in degrees)

and “altitude“ (elevation in m above sea level) or the value for

gravitational acceleration “gravity.“

Gravitational acceleration takes precedence over the geographical latitude and

elevation of the location: If it has been entered, input fi elds for latitude and

elevation show the values “99999.99“ and “9999999“ respectively.

If only elevation and latitude have been entered, “0000000“ is displayed

for gravitational acceleration.

h

Then make sure that the geographical data for the adjustment location has been

entered correctly. If no external adjustment is carried out, enter the data for the

installation location. The data can be obtained from the relevant land registry or

Ordnance Survey.

32 Operating Instructions Combics Complete Scales

Confi guring Weighing Platforms

Procedure t Remove the cap.

t Slide the menu access switch to the left (= “open“ position).

If the device is part of a verifi ed weighing facility, this will only be possible if

the verifi cation seal is broken. The weighing equipment must then be verifi ed

again.

t Activate the Service mode, see “Service Mode.“

t Select weighing platform “WP 1“ in the “Device Parameters“

menu item.

t If the “Internal“ setting is not already activated (marked by “o“), select

the setting using the “Q“ or “q“ soft key and confi rm with “O.“

y The menu for the “WP-1 INTERNAL“ device parameters is displayed.

t Use the “Q“ or “q“ soft key to select and open the “CaCalibration/

adjustment

“ menu using “O.“

t Use the “Q“ or “q“ soft key to select and use “O“ to open the

“Geographical data“ menu.

t Use the “O“ soft key to confi rm “Input parameters.“

Entering Geographical Latitude and Elevation

t Use the “Q“ or “q“ soft key to select the corresponding input fi eld.

t Enter the number via the keypad and confi rm using the “l“ soft key.

y The next input fi eld is selected.

In this example, the geographical data are entered for the respective platform as a

value pair “Latitude“ and “Altitude.“ After this data was saved and the

scale returned to weighing mode, this pair of values is displayed again the next time

the display menu is opened. The input fi eld for gravitational acceleration is empty.

In this example, the value for gravitational acceleration is entered for the place of

installation. The fi elds “Latitude“ and “Altitude“ are invalid. The set

value is then re-displayed after it is saved and the input menu is re-opened. If you

exit the Setup menu and then open the Service mode, the set value for gravity is no

longer displayed.

Operating Instructions Combics Complete Scales 33

Confi guring Weighing Platforms

Entering Gravity

t Use the “Q“ or “q“ soft key to select the corresponding input fi eld.

t Enter gravity in m/s2 via the keypad and confi rm using the “l“ soft key.

Permissible value range:

9.700000 d < gravity 2 d < 9.900000

In the example shown here, the value for gravity has been changed.

The new value, 9.810000 m/s2 applies to the setting “Germany (Zone D).”

t Press the “o“ soft key to exit the Input menu.

t Use the “Q“ soft key to select the “Save parameters“ menu item.

t Use the “Q“ soft key to select “Yes“ and use the “l“ soft key to confi rm.

y The message “Data stored“ appears briefl y.

The program then returns to the “No“ display status.

t Press M or “oo“ to exit the Setup menu.

t Slide the menu access switch to the right (= “closed“ position) and reattach the

cap.

y The display goes out and the device restarts. Then weighing mode is active.

Adjusting Scales in Operating Mode

See also “Calibration and Adjustment“ in the chapter called “Operation“

t Open the Device parameters menu for the respective weighing platform,

(e.g. “WP 1:INTERNAL“).

– Open the “Calibration/adjustment“ submenu.

– „ CAL key function“ menu item:

Setting “Ext. cal./adj.: factory-def. wt.“

(factory setting).

– „ Cal/adj. sequence“ menu item:

Setting “Cal. then manual adj.“ (factory setting).

– „ Activate ext. adj.“ menu item

(not for a verifi able confi guration):

Setting “Activated“ (factory setting).

To display geographical data in the Device parameters menu, open the

“Operating parameters“ submenu.

Menu item “Display geogr. data > On“.

t Press ( to unload the scale.

34 Operating Instructions Combics Complete Scales

Confi guring Weighing Platforms

t Press J to start an external adjustment.

C.EXT.D

C.EXT.DEF.

y The display “C.EXT.D“ appears briefl y.

In the example, the altitude and latitude of the installation location are being entered.

Altitud

C.EXT.DEF.

y The display “Altitud“ appears briefl y.

y The altitude at the place of installation is displayed in meters above sea level - here, the

altitude for “Germany (Zone D).”

t Press J to confi rm the displayed value or press ( to cancel the adjustment.

Latitud

C.EXT.DEF.

y The display “Latitud“ appears briefl y.

y The geographical latitude of the place of installation is shown in degrees north or

degrees south - here the latitude setting for “Germany (Zone D).”

t Press J to confi rm the displayed value or press ( to cancel the adjustment.

y You are prompted to place the required weight on the platform (e.g.: 5.0 kg).

The subsequent steps for completing the calibration/adjustment are described in the

chapter entitled “Operation” under “Calibration and Adjustment.”

Operating Instructions Combics Complete Scales 35

Confi guring Weighing Platforms

If gravity is being entered instead of altitude and latitude, then “Gravity“ is

displayed for a brief time after “CAL.“

The entered value appears in m/s2, here for the “Germany (Zone D)“ setting.

t Press J to confi rm the displayed value or press ( to cancel the adjustment.

y You are prompted to place the required weight on the platform (e.g.: 5.0 kg).

The subsequent steps for completing the calibration/adjustment are described

in the chapter entitled “Operation” under “Calibration and Adjustment.“

t Slide the menu access switch to the right (= “closed“ position) and reattach the

cap.

y The display goes out and the device restarts. Then weighing mode is active.

If adjustment is carried out using a verifi able confi guration data record, the lines

for display of metrological data (lines 1 and 2) show the data valid for use in legal

metrology, if the menu access switch is closed. See also the chapter “Operation“,

“Confi guration for Use in Legal Metrology.“

36 Operating Instructions Combics Complete Scales

Confi guring Weighing Platforms

Entering Adjustment and Linearization Weights

Purpose Entering adjustment and linearization weights.

Procedure See also “Calibration and Adjustment“ in the chapter called “Operation“.

t Remove the cap.

t Slide the menu access switch to the left (= “open“ position).

t Activate the Service mode, see “Service Mode.“

t Select weighing platform “WP 1“ in the “Device Parameters“

menu item.

t If the “Internal“ setting is not already activated (marked by “o“), select

the setting using the “Q“ or “q“ soft key and confi rm with “O.“

y The menu for the “WP-1 INTERNAL“ device parameters is displayed.

t Use the “Q“ or “q“ soft key to select and open the “Calibration/

adjustment

“ menu using “O.“

t Use the “Q“ or “q“ soft key to select and use “O“ to open the “Parame-

ter for external weight

“ menu.

t The fi rst menu item “Cal/adj. wt.:“ (for selecting the user-defi ned

calibration weight), is also accessible without activating the Service mode.

The values for the linearization weights “Lin.-wt. 1“ to “Lin.-wt.

4

“ can, however, only be changed in the Service mode.

y The current values for the user-defi ned calibration weight and the

4 linearization weights are displayed.

In this example, the value for the external, user-defi ned adjustment weight is

changed to 6.000 kg.

t Press 6.000 and confi rm with the “l“ soft key.

y The “Lin.-wt. 1“ input fi eld is selected.

In this example, the value for linearization weight 1 is changed to 1.500 kg.

t Press 1.500 and confi rm with the “l“ soft key.

y The “Lin.-wt. 2“ input fi eld is selected.

t Enter or change all linearization weights in sequence as needed.

If you do not require all linearization positions, enter “0.000“ in the unused

fi elds to hide these lines in the display. Confi rm with the “l“ soft key after each

entry to move to the next input fi eld.

In the example shown here, four linearization weights have been entered

(1.5 kg, 3.0 kg, 4.5 kg and 6.0 kg).

When you close the input menu by pressing the “o“ soft key, the input values

are directly applied.

t Slide the menu access switch to the right (= “closed“ position) and reattach the

cap.

Operating Instructions Combics Complete Scales 37

Confi guring Weighing Platforms

Function Allocation of the allocation

for the J Key for Calibration/Adjustment

Purpose The J key is used for the calibration/adjustment function. Key settings can be

changed when the Service mode is activated:

Procedure t Remove the cap.

t Slide the menu access switch to the left (= “open“ position).

t Activate the Service mode, see “Service Mode.“

t Select weighing platform “WP 1“ in the “Device Parameters“

menu item.

t If the “Internal“ setting is not already activated (marked by “o“), select

the setting using the “Q“ or “q“ soft key and confi rm with “O.“

y The menu for the “WP-1 INTERNAL“ device parameters is displayed.

t Use the “Q“ or “q“ soft key to select and open the “Calibration/

adjustment

“ menu using “O.“

t Use the “O“ soft key to open the “Cal/adj. sequence“ menu.

t Use the “Q“ or “q“ soft key to select the “Cal. then manual

adj.

“ menu (factory setting) and confi rm with the “l“ soft key.

t Use the “o“ soft key to go to the next menu level.

t Use the “O“ soft key to open the “Activate ext. adj.“ menu.

t Use the “Q“ or “q“ soft key to select the “Activated“ menu item

(factory setting). Not for a verifi able confi guration.

t Geographical data is not displayed during calibration/adjustment (factory

setting).

To display geographical data in the Device parameters menu, open the

“Operating parameters“ submenu.

Menu item “Display geogr. data > On“.

38 Operating Instructions Combics Complete Scales

Confi guring Weighing Platforms

t Use the “O“ soft key to open the CAL key function“ menu.

y The “CAL key function“ submenu is displayed.

t Use the “Q“ or “q“ soft key to select the corresponding menu item and confi rm

with “l.“

y The menu item is marked by a circle “o.“

Note

The functions that can be confi gured in the “CAL key function“

submenu depends on the selected weighing platform and its confi guration data.

Functions that cannot be accessed are not displayed in the selection screen.

Important Note!

The function set in the “CAL key function“ menu is carried out in the

normal weighing mode because when you exit the Setup menu the Service mode is

deactivated. To perform the function on a digital weighing platform (such as an

IS platform), however, it must be carried out in Service mode.

t The procedure is as follows: after selecting the desired function and exiting

the Setup menu, reactivate Service mode again and then exit the Setup menu

immediately by pressing the M key or the “

oo“ soft key.

y The scale is now in Service mode without this being displayed.

t Trigger the previously set function using the J key.

C.EXT.D

C.EXT.DEF.

12

y The display shows “S_CAl:“ indicating that the scale is in Service mode.

t The corresponding menu item can be selected using the “Select“ soft key

and carried out using the J key.

t If you cancel the function using the ( key or by restarting the scale using

the e key, you will exit the Service mode.

External Calibration/Adjustment

with Factory-Defined Weight (Default Weight)

Configuration If not already selected (factory setting, marked by “o“ when active), select the

“CAL key function:Ext. cal./adj.; factory-

def. wt.

“ menu item (external adjustment with a factory-defi ned, standard

weight).

t Use the “Q“ or “q“ soft key to select this menu item and confi rm with “l.“

y The menu item is marked by a circle “o.“

Note:

The menu items “Ext. cal./adj.; factory-def. wt.“

(external adjustment with a factory-defi ned, standard weight), “Ext. cal./

adj.; user-defi ned wt.

“ (external adjustment with

a user-defi ned weight) and “Key blocked“ can also be accessed without

activating the Service mode.

Operating Instructions Combics Complete Scales 39

Confi guring Weighing Platforms

t Press e to turn off the device.

t Press e turn the device back on.

y The Sartorius logo is displayed briefl y, after which the device is in normal

weighing mode.

t Press ( to unload and zero the scale.

t Press J to start the external adjustment.

C.EXT.D

C.EXT.DEF.

y The display “C.EXT.D“ appears briefl y.

Note

If the display of geographical data (elevation and latitude or gravity) is activated,

this data is displayed and confi rmed each with a press of the J key (you can

cancel the calibration / adjustment process using the ( key).

See also “Entering Geographical Data for Use in Legal Metrology“ in this chapter.

Procedure y The target value of the required adjustment weight (5.000 kg in the example) is

displayed as a negative value.

t Place the required adjustment weight on the platform.

Note

If the calibration/adjustment sequence is set to automatic (“Calibration/

adjustment:Cal./adj. sequence:Cal., then auto

adjust

“ menu, see “Function Allocation of the allocation of the J Key for

Calibration/Adjustment“) and the adjustment weight consists of several pieces, then

they should be placed on the platform in series at short intervals.

When the weighing instrument has stabilized, the weight on the scale is accepted

as the calibration weight after a predefi ned interval, and the weighing instrument is

calibrated/adjusted with this weight.

The difference since the most recent span adjustment is not displayed; this value is

output only on GMP-compliant printouts.

y After a brief pause, the difference since the last span adjustment is displayed

(calibration).

Note

This display only appears for the “

Cal. then manual adj.“

setting (see previous note). If “Cal. then auto adj.“ is active, the

calibration/adjustment procedure cannot be cancelled.

To stop the procedure after calibration and before adjustment takes place, press the

( key (only if “Cal. then manual adj.“ is active).

t Press J to adjust the scale (only if “Cal. then manual adj.“

is active).

y At the conclusion of the calibration procedure, the calibration weight is

displayed as a positive value.

40 Operating Instructions Combics Complete Scales

Confi guring Weighing Platforms

--------------------

14.01.2010 13:50

Type CAW3P1-6DC-LCE

Ser.no. 12345678

Vers.no. 1.02.101110

BVers. 01-63-02

-------------------External calibration

Nom. + 5.000 kg

Diff. + 0.010 kg

External adjustment

Diff. + 0.000 kg

--------------------

14.01.2010 13:52

Name:

When calibration/adjustment is complete, the GMP-compliant printout shown on

the left is generated. If the adjustment procedure is canceled (only calibration is

performed), the last two lines, “External calibration” and “Diff. + 0.000 kg” are not

printed.

t Unload the scale.

t Press e to turn off the device.

t Press e turn the device back on.

y The Sartorius logo is displayed briefl y, after which the device is in normal

weighing mode.

3

If a serious operator error should occur during calibration (for example, if the menu

setting “Cal. then auto adj.“ is active and the wrong calibration

weight is placed on the scale), the scale might completely fail to stabilize, which

means it cannot show a zero point.

In this case, select the “

Adjust without weights“ menu and set the

mean sensitivity of the strain-gauge weighing beam to 2.0 mV/V.

Then re-adjust the scale.

See also “Adjust without weights.“

The zero point is only displayed for a verifi ed scale with d=e.

External Calibration/Adjustment

with a User-Defined Weight

Configuration Select the “CAL key function:Ext. cal./adj.; user-

def. wt.

“ menu item (external adjustment using a user-defi ned weight).

Note:

The menu items “Ext. cal./adj.; factory-def. wt.“

(external adjustment with a factory-defi ned, standard weight), “Ext. cal./

adj.; user-defi ned wt.

“ (external adjustment with a user-defi ned

weight) and “Key blocked“ can also be accessed without activating the