WCI5005-e03104

Service Manual

Sartorius Combics 1 | Combics 2

Models CIS1U | CIS2U | CISL1U | CISL2U

for Combics Indicators

and

Models CAPP.U-...-LU | CAPS.U-...-LU

for Combics Weighing Platforms

including Service Specifications

C

F

REF

O

K

2

Contents

Overview

04 Service Concept

04 General Information

05 When to Use Which Procedure

05 Combics Indicators

07 Overview of the Models

07 Auxiliary Service Tools and Equipment

08 Accompanying Literature

09 Operating Concept

09 Keys below the Display

10 Configuring the Combics

10 Purpose, Features

12 Function of the Keys when Configuring the Menu

12 Printing the Parameter Settings

13 Description of the Equipment

14 Function of the Service Keys and Switches

14 A. Menu Access Switch

14 B. SBI/BPI Key

15 Activating the BPI Mode

15 C. Boot Key

16 Activating the xBPI Protocol

17 Activating the Service Mode

17 Activating the Service Mode

19 Working in the Service Mode

19 Additional Menus in Service Mode

22 Menu Item 1-18:

Entering Calibration/Linearization Weights

22 1-18-1: External User-defined Calibration

Weight (Service Mode not Required)

23 1-18-2 1. Entering 1st Linearization Weight

24 Calibration/Adjustment Routines in Service Mode (General

Information)

25 Valid areas for Use

26 Zone “D”

27 Menu Line 1-9: Calibration/Adjustment Functions

28 1-9-1 External Calibration/Adjustment with Default

Weights

28 1-9-3 External Calibration/Adjustment with User-

defined Weights

30 1-9-5 Internal Linearization (Only for WP1 on COM1 or

UniCOM Ports)

30 1-9-7 External Linearization with User-defined Weights

33 1-9-8 Setting the Preload

34 1-9-9 Clearing the Preload

36 Adjustment without Weights

36 Menu Item 1-19:

Entering the Specifications of the Load Cell(s)

39 Menu Item 1-20: Entering the Geographical Latitude and

Altitude, or the Acceleration of Earth Gravity

40 Entering the Place of Adjustment with Subsequent

Adjustment (Example)

40 Menu Item 1-13: Zero at On

46 Configuring the A/D Converter of the Combics Indicator

(Service Mode)

46 Menu Item 11: A/D Converter Settings (Configuration:

Standard, Trade)

3

47 A/D Converter Configuration (General Information)

47 Notes on A/D Converter Configuration

48 Descriptions of the Individual Menu Items

49 Selecting the Weighing Range Structure

(Menu Item 11-3)

52 Menu Item 9-1: A/D Converter Configuration (Example:

Trade Configuration)

57 Menu Item 9-1: A/D Converter Configuration with Load

Cell(s) Connected (Example: Standard Configuration)

58 Loading the Standard Configuration

(if the Trade configuration is currently loaded)

62 Menu Item 1-19: Entering the Specifications of the Load

Cell(s)

64 Entering the Date of Service

65 Entering the Serial Number of the Combics Indicator

67 Entering the Model Designation of the Combics Indicator

68 Defining Transaction Numbers for Data Records (Weight

Values) which were stored in the Alibi Memory

69 Repairing the Combics Indicator

69 Replacing the Front Panel

70 Blank Display

70 Replacing the Power Cord

71 Replacing the Power PCB

72 Replacing the DC/DC Converter

73 Replacing the A/D Converter

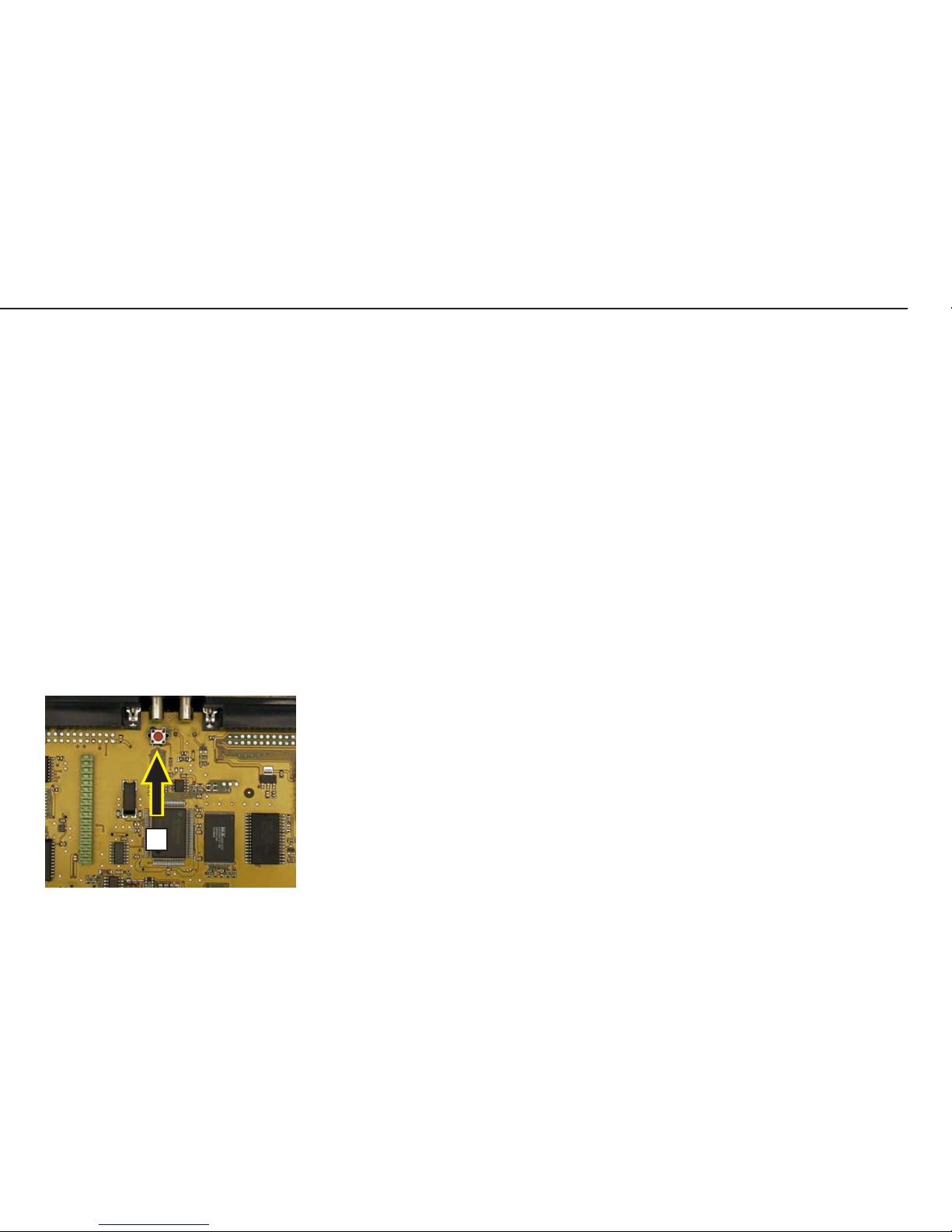

73 Quick-test of the A/D Converter

74 Replacing the Digital PCB

75 Checking the IP67 Protection

75 Torque Values for Cable Glands and Vent Valve

76 Adjusting the Weighing Platform

76 Adjusting the Off-center Load

76 Procedure (Example Illustrated on the Left)

77 Diagram: Determining the Adjustment Resistance

78 Off-center Load Adjustment: 0-ohm Resistors (Example)

79 Setting the Overload Stops

79 1. Weighing Platforms with 1 Load Cell: Steel

80 2. Weighing Platforms with 1 Load Cell: Stainless Steel

81 3. Weighing Platforms with 4 Load Cells: Steel

82 4. Weighing Platforms with 4 Load Cells: Stainless Steel

83 Repairing the Weighing Platforms

83 Replacing the Connecting Cable

84 Replacing Load Cells

85 Torque Values

86 Pin Assignments in the Junction Box

87 Replacing the Load Cell Foot

87 Color Codes of the Wiring for Weighing Platforms, Models

CAPS../CAPS..

88 Error Codes

90 The Combics Weighing Platforms

91 Type Designation

91 Complete Combics scale

92 Complete Combics stainless steel scale

93 Service Specifications

93 CAPP/CAPS1U-.....-LU

94 CAPP/CAPS4U-.....-LU

4

Overview

Service Concept

Prerequisites for performing maintenance and repair work on Sartorius Combics

scales requires considerable experience with both indicators and weighing platforms.

In case of defects, repairs are performed on site. Generally, the equipment is not

replaced.

General Information

– Do not connect or disconnect cables to or from the equipment; always disconnect the

power cable from the wall socket (mains supply) first!

– To ensure safety, an isolating transformer must be installed between the indicator and

the power supply before performing work that entails opening the Combics indicator

housing.

On Combics scales, check and adjust as necessary:

(The procedure is the same as for all scale and weighing platform models.)

– Repeatability (standard deviation)

– Off-center load

– Span

– Linearity

5

When to Use Which Procedure

Combics Indicators

Activate the service mode to perform all adjustments See page 17

Important: All adjustments required after repair work (such as

replacement of the A/D converter or the load cells) are

performed using the terminal.

The Sartocas service software is not required for these adjustments.

Using this software, however, can make some adjustments

unnecessary (see „Use Sartocas software“ below).

Activate the BPI mode to load a modified data record in the controller

of the A/D converter See page 15

Activate the xBPI protocal to perform calibration and adjustment, if necessary See page 16

using Sartocas

Use Sartocas software - to reactivate the SBI protocol by selecting the „Close“

command on the Combics terminal (or by restoring

factory defaults (menu line 9-1)

- to program a new A/D converter PCB with data read from the old PCB

The necessary adjustments and customer specific menu settings

are not necessary

6

Use PPLoader software to update the application software in the terminal

Drift, display

Inf 02 when starting an

adjustment routine to check the A/D converter (quick-test) See page 73

or with the strain-gauge simulator,

check load cell(s) with the load cell tester

Display blank (dark) Disconnect the equipment from the power supply and

disconnect all cables and wires from the subassemblies,

connect equipment to power again, connect subassemblies

in turn and measure voltages See pages 70-72

No communication with

connected equipment Check connections and data transfer parameters;

start internal test program; if necessary, replace

7

Overview of the Models

The hardware configuration consists of either a Combics 1 or 2 indicator and

Sartorius weighing platform(s), or a Combics 1 or 2 indicator and weighing

platform(s) (strain-gauge load cells) from another manufacturer.

Important: Mechanical and electrical service or repair work on the Combics scale requires

considerable experience, and for this reason should be performed only by

Sartorius technicians trained at the factory. Any attempt to perform repair work

can result in damage to the equipment.

Auxiliary Service Tools and Equipment

In addition to standard tools, you will need the following special tools to work on

the Combics scale:

Qty. Designation Order No.

1 Laptop

1 Sartocas service software, version 1.46 or later 6740-33

or

1 Psion Server version 4.10 or later

1 PPLoader software

1 Isolating transformer

1 Flintec LCT-01 load cell tester

1 Socket wrench, double hexagon, 10-32 mm,

“ square driver

1 Adapter for Allen screws, SW 5 - 17, ” square driver

8

Qty. Designation Order No.

1 Torque wrench, 10-120 Nm 14x18, stainless steel

1 Torque wrench, 60-320 Nm 14x18, stainless steel

1 Set of open-ended wrenches with sockets

1 Set of sockets, up to 30 mm (hexagonal, stainless steel)

2 Transport belt (to move load plates or weighing

platforms; available from specialist suppliers)

2 Ring lugs (stainless steel; for moving the load plates or

weighing platforms; available from specialist suppliers)

1 Set open-ended wrenches (spanners) (up to 24 mm, stainless steel)

1 Threaded rod, M 16x120, for lifting the weighing platform

(available from specialist supplier)

1 Testing device for checking IP66/67 protection (not yet defined)

1 Set of screwdrivers (slotted)

1 Set of screwdrivers (Phillips head )

1 Set of Allen wrenches

1 Digital voltmeter (Beckman) 6738-62

1 Strain gauge simulator 6740-74

1 RS-232/485 converter 6740-68

Accompanying Literature

Operating instructions for “Combics 1 | 2 Indicators“ WCI6004-e03081 98648-012-27

Operating instructions for “Painted or Stainless Steel Weighing Platforms“ WCA6004-e03081 98648-012-26

9

Operating Concept

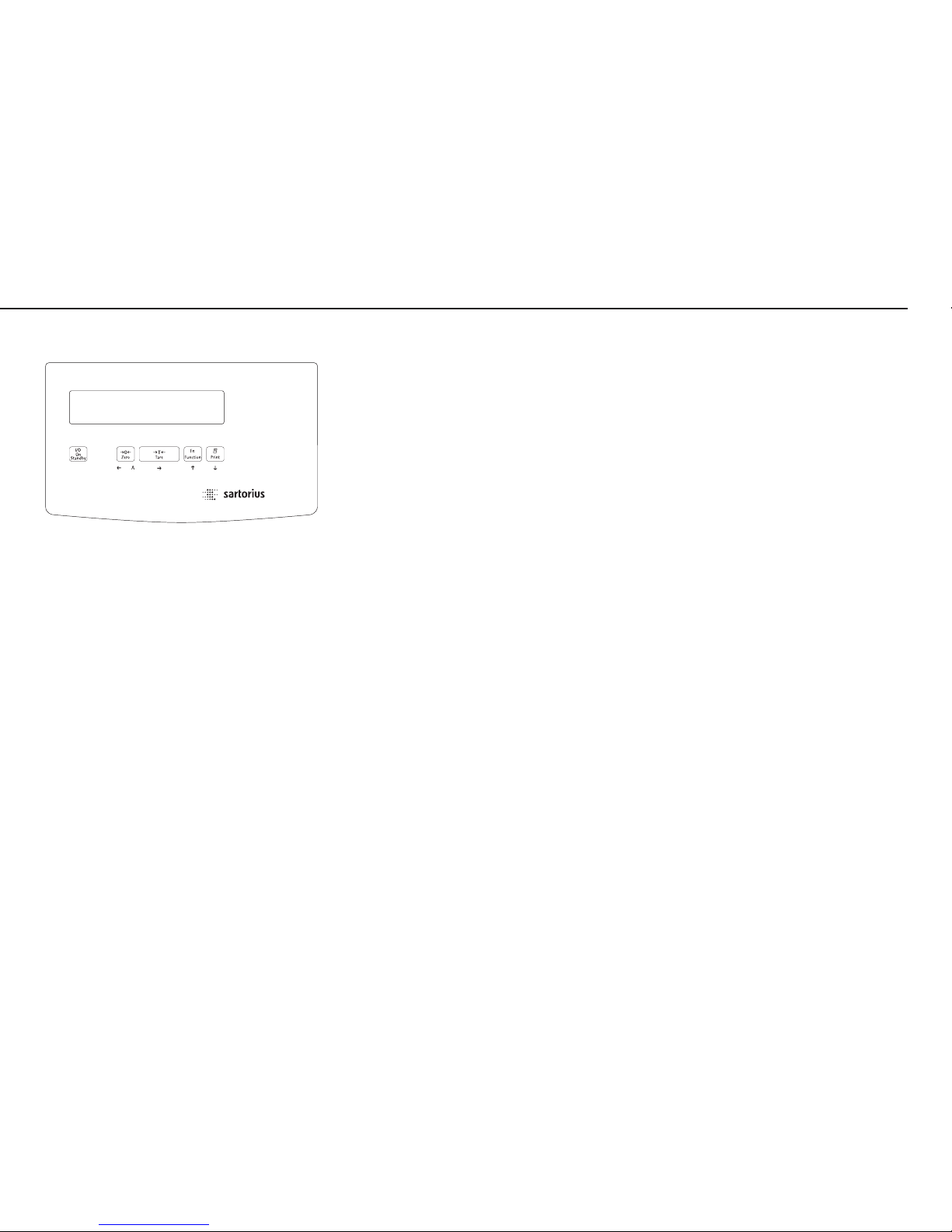

Keys below the Display

e On/off

(On) Turns the Combics on and off.

(Standby) Combics switched off displays

“off“.

n Toggle the display between

(Scale #) the weighing platforms

(Combics 2 only)

With two weighing platforms

connected, this key toggles

the display between the two

readouts.

( During weighing:

(Zero) Zero the scale

In the operating menu:

Closes active submenu and

returns to next higher menu

level and menu level (unless

the first menu level is already

shown)

During alphanumeric input

in the operating menu:

– Press briefly:

Activate character to the left

of the currently active

character

(with the first character

active: Exit the input mode

without saving changes)

– Press and hold (> 2 sec ):

Exit the input mode without

saving changes

) During weighing:

(Tare) – Press briefly:

Tare the scale

– Press and hold (> 2 sec ):

Calibration/adjustment

In the operating menu:

– Press briefly:

Display the next lower menu

level or

Select and store a menu item

– Press and hold (> 2 sec ):

Exit the operating menu

During alphanumeric input in the

operating menu:

– Press briefly:

Activate character/s to the

right of the currently active

character ®

(after the last character:

store input)

– Press and hold (> 2 sec ):

Store current input and display

the menu item

k During weighing:

(Function)Toggle (depends on operating

menu settings) between:

– first and second weight unit or

– gross and net or

– normal and 10-fold increased

display resolution

In the operating menu:

Show the next item on the

same menu level (scroll

through values in series)

Combics_1Folie_u.eps

Combics 1

10

During alphanumeric input

in the operating menu:

– Cursor in first position,

no characters entered yet:

Delete entire string and

enter “0“

– Change the displayed

character; scroll forward

(sequence: 0 through 9,

decimal point, minus

sign, Z through A, pace)

p During weighing:

(Print) – Press briefly:

Print

– Press and hold (> 2 sec ):

Print GMP footer

In the operating menu:

Print the menu settings

starting from the current

position; or print Info data

During alphanumeric input in

the operating menu:

– Cursor in first position, no

characters entered yet:

Delete entire string and

enter a space

– Change the displayed

character; scroll

backwards ÿ (sequence:

Space, A through Z,

minus sign, decimal

point, 9 through 0)

Note:

The sequence in which keys are

pressed in the following

descriptions (“Key sequence:“)

are given as examples only.

Other sequences are possible.

Configuring the Combics

Purpose

You can configure the Combics to

meet individual requirements by

entering user data and setting

selected parameters in the operating

menu. The operating menu is a

combination of text levels and

numeric codes.

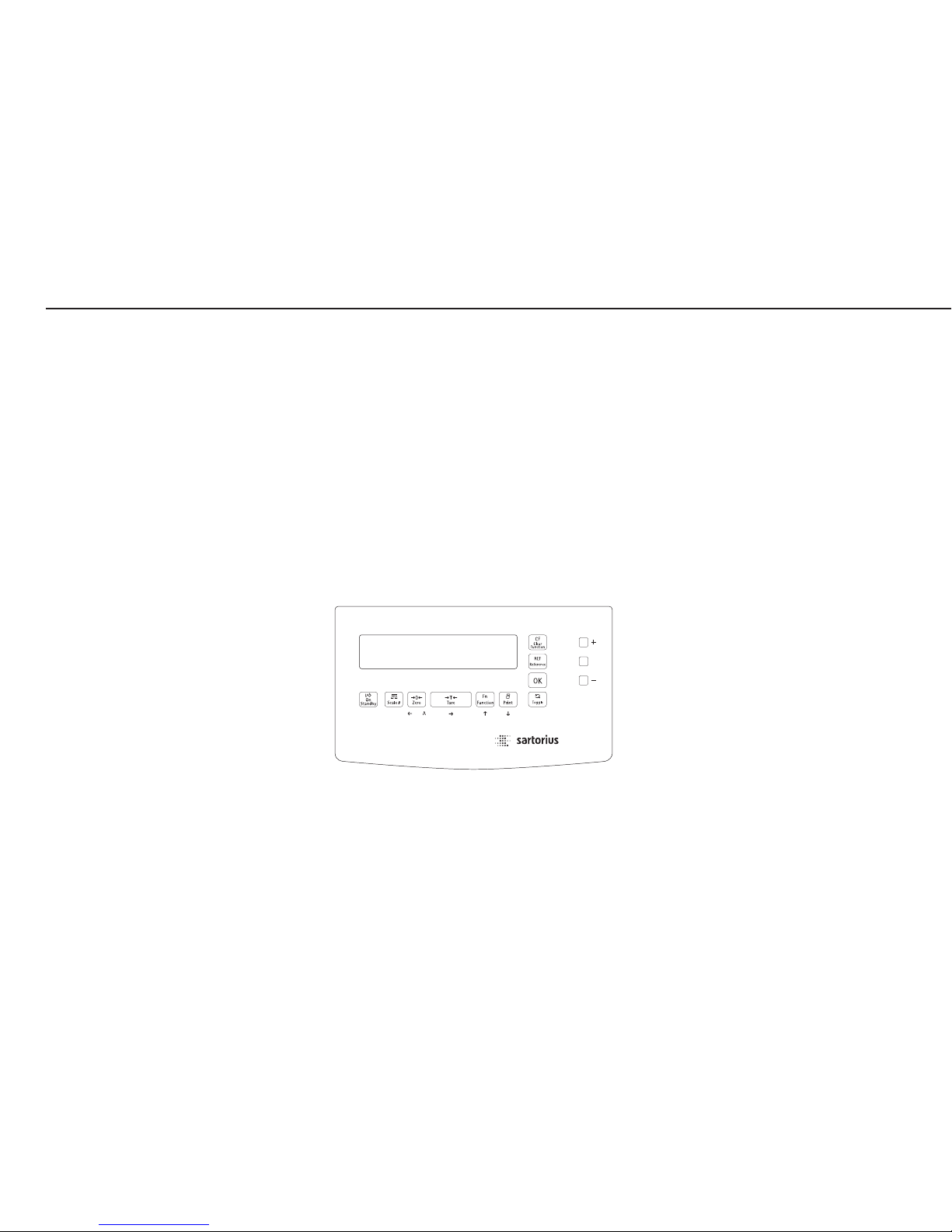

Features

The operating menu parameters are

divided into the following categories

1. Text-menu level

– Application programs »APPL«

– Key assignments k »fn-key«

– Device parameters »setup«

– Device information »InFo«

– Language for calibration and

adjustment printouts »LAnG«

Combics 2

Combics_2Folie_u.eps

11

You can display, enter or change the

following parameters:

In addition to basic weighing

functions, you can use the

Combics 2 to calculate and

display weighing data as follows:

– Counting

– Neutral measurement

– Averaging (animal weighing)

– Checkweighing

– Classification

– Weighing in percent

– Net-total formulation

– Totalizing

Function: Key assignment for k

»fn-key«

– Gross/net toggling

»gro net«

– Toggle between the 1st, 2nd and

3nd weight unit

(are eycled in the display)

»3. unit«

–

10-fold higher resolution

»Res 10«

– Device parameters »setup«

Device configuration, i.e.,

to meet individual requirements

by selecting predefined menu

parameters in the operating

menu. The device parameters

are combined in the following

groups :

– Weighing platform »wp1«

– Interfaces (COM1 and optional

UniCOM)

– Digital control line »ctrl in«

– Bar code scanner »barcode«

– Printer protocols »prtport«

– Extra Functions: Utilities

»utilit«.

– Timer »time«

– Date »date«

– Set user password »code«

– Display device information

»info« (serial number, etc.)

– Language for calibration and

adjustment records »lang«.

Select the language.

The rest of the menu

is language-independent.

12

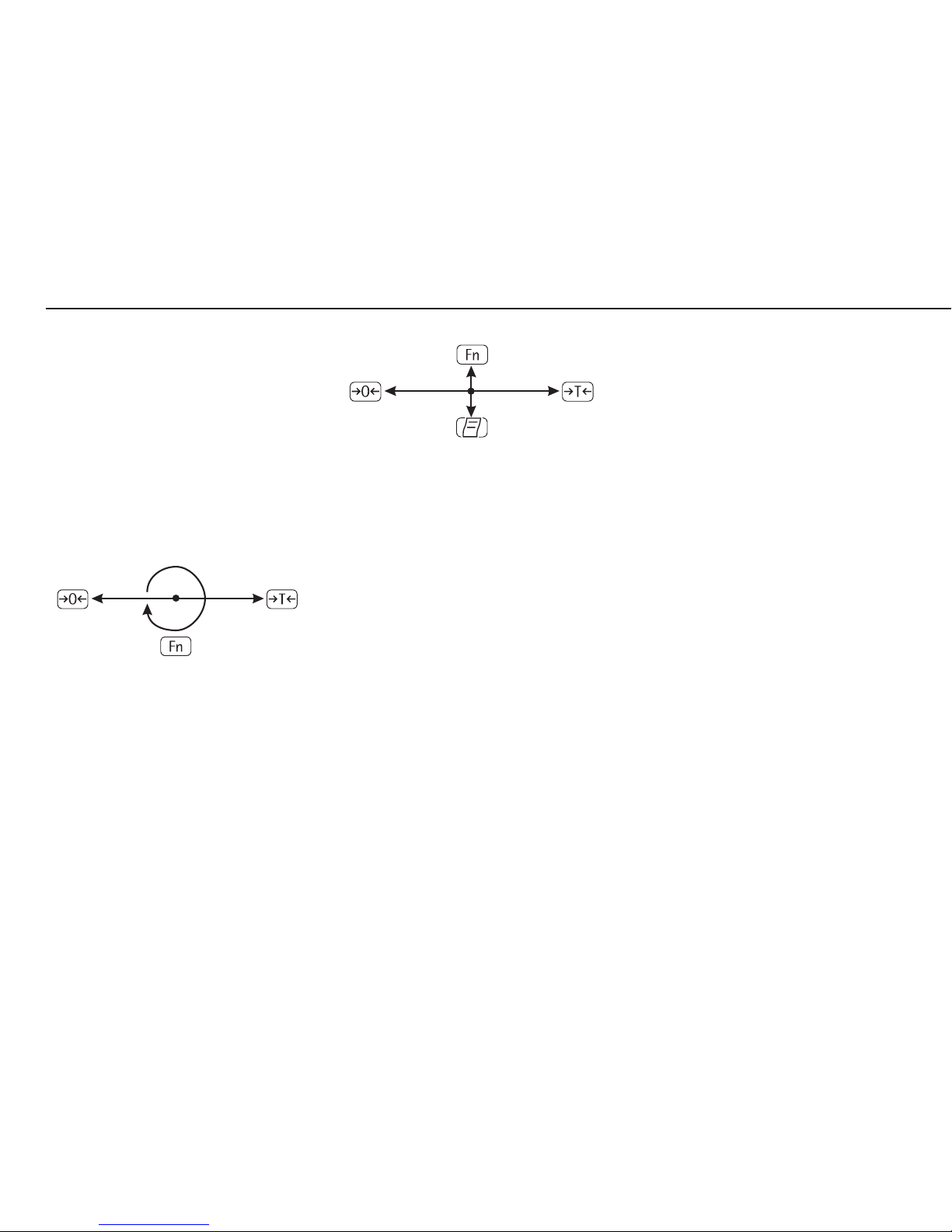

(Function)

(O) (Tare)

(Print)

– Scroll upwards (0, 1, 2, 3, etc.):

Press the k key

– Scroll downwards ¬ (A, B, C, etc.):

Press the p key

– Next position: Press the ) key

– Previous position: Press the (

key

– Exit input mode without saving

changes; with cursor in first

position: Press the ( key

– Exit the input mode without

saving changes:

Press and hold the ( key

(> 2 sec)

– To confirm your input: Press the

) key with the cursor 1 space

beyond the last position; or press

and hold (> 2 sec)

– Confirm currently active

character and move 1 position

Functions of the Keys when

Configuring the Menu

Open the operating menu:

Turn the Combics off and on

again by pressing e; while all

segments are displayed, press the

) key briefly.

Navigating in the operating

menu:

(On) (Tare)

(Function)

– Scroll :

Press the k key

– To the left ¬: Press (

– Change and store setting:

Press the ) key

– Exit the operating menu:

Press and hold the ) key (> 2

sec)

During alphanumeric input in

the operating menu:

to the right:

Press the ) key

– Move cursor 1 position to the left

Press the ( key

Printing the Parameter Settings

Generate a printout of the settings on

the current menu level:

Press the p key

> Printout (example)

The maximum width of this

printout is 20 characters.

--------------------

MENU

SETUP

WP1

------------------- 1

1.1

1.1.2

1.2.1

...

1.18

1.18.1

CAL.

10.000 kg

etc.

13

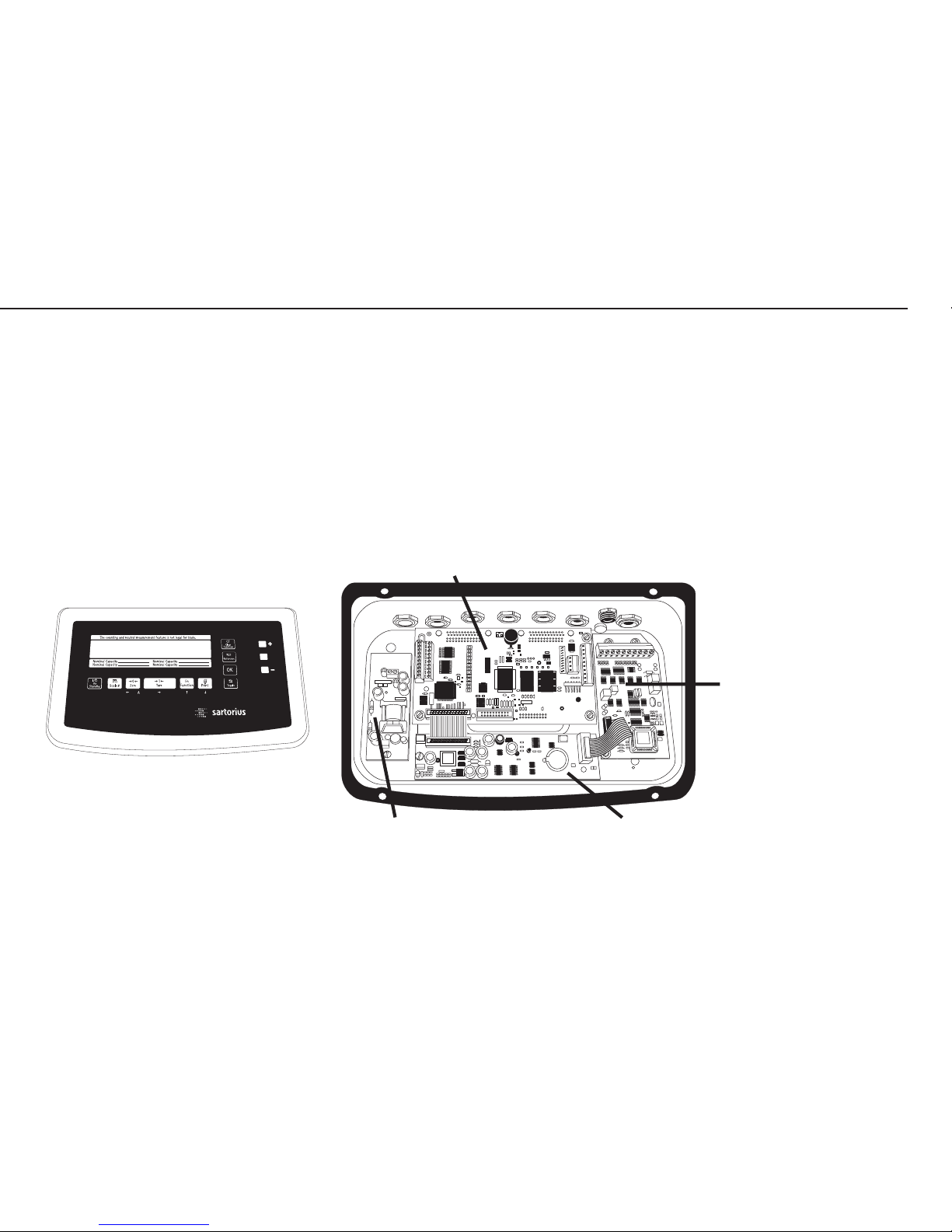

Description of the Equipment

The Combics scales from Sartorius are primarily used in industry. Because there are a number of hardware configurations

to choose from, Combics models are constructed according to customer requirements.

The Combics scale consists of:

– A choice of weighing platforms with capacities from 10 lbs to 10000 lbs (in stainless steel or steel) and indicators

The Combics 1 / 2 indicators consist of:

– Front panel with keypad and

digital display (Combics 2 has

additional keys and LEDs)

– Combics indicators

are equipped with either cable

glands or D-Sub 25

connectors.

Note: Additional electronic subassemblies are optional.

Digital PCB with application

processor, memory, RS-232 interfaces

Analog/digital converter

Power PCB

DC/DC converter

(Combics2 has a clock chip)

combics_15_klemmen.eps

Combics 2

14

Function of the Service Keys and Switches

A. Menu Access Switch

This switch must be open to work with the service software or configure the A/

D converter (e. g., “Trade” configuration). If the menu access switch is closed,

the error message “ACCESS SWITCH LOCKED” is displayed in the service program

and the indicator shows “L” (underload) or “H” (overload). In this case, the A/D

converter cannot be configured. If adjustment is necessary (span, linearity), the

“± 2%” window is active.

B. SBI/BPI Key

To use the Sartocas program (v 1.46 or later) or Psion server (v 4.10 or later).

the Combics indicator must be in BPI (binary processor interface) mode (for

example, to load a modified data record from the A/D converter into its

controller). This setting is valid for the COM1 port.

Note: To perform adjustment

only with the service software, the COM1

interface is set to the xBPI (eXtended Binary Processor Interface) protocol

and the laptop or Psion server connected to that port.

verriegelungs_schalter.eps

closed open

A

sbi_bpi_taster.jpg

B

15

Activating the BPI Mode

– Turn on the Combics.

– In weighing mode, press and hold the SBI/BPI key for approx.

5 seconds (the weight readout goes blank).

– Release the switch.

– Turn the Combics off and then on again.

– The Combics is now in BPI mode.

Important: Peripheral devices that communicate over the SBI (Sartorius Balance Interface)

protocol cannot be operated while the Combics is in BPI mode.

If you press the p key, only InF 30 is displayed.

To return the indicator to the SBI mode, either use the “Close” function in the

Sartocas service software or a Psion server (and then turn the Combics off and

back on again), or select the Menu Reset option (9 - 1 - 1) in the Combics

operating menu.

C. Boot Key

Activate this switch only if an attempt to program the application memory

with the PPLoader program fails (programming routine stops responding).

Procedure for making the PCB bootable:

– Disconnect the Combics from the main power.

– Press and hold the boot switch (approx. 3 sec.) while reconnecting the Combics

to power.

– Release the switch. After a brief period, the PCB is bootable again

(load application software again with the PPLoader program).

boot_taster.jpg

C

16

Activating the xBPI Protocol

Activate the xBPI protocol to perform adjustment with the service software

Sartocas software or Psion server without activating the BPI mode

through the SBI/BPI key.

Note: This menu item is accessible in the standard menu.

–Via Setup select the Device parameters menu item (for the COM1 port).

– Open the Device parameters menu and scroll down to the Interface

submenu.

– Open the Interface submenu and activate the xBPI menu item.

Note: Under xBPI a submenu is opened for assigning addresses, but this function is only

available when using xBPI with RS-485.

Display_xbpi.eps

17

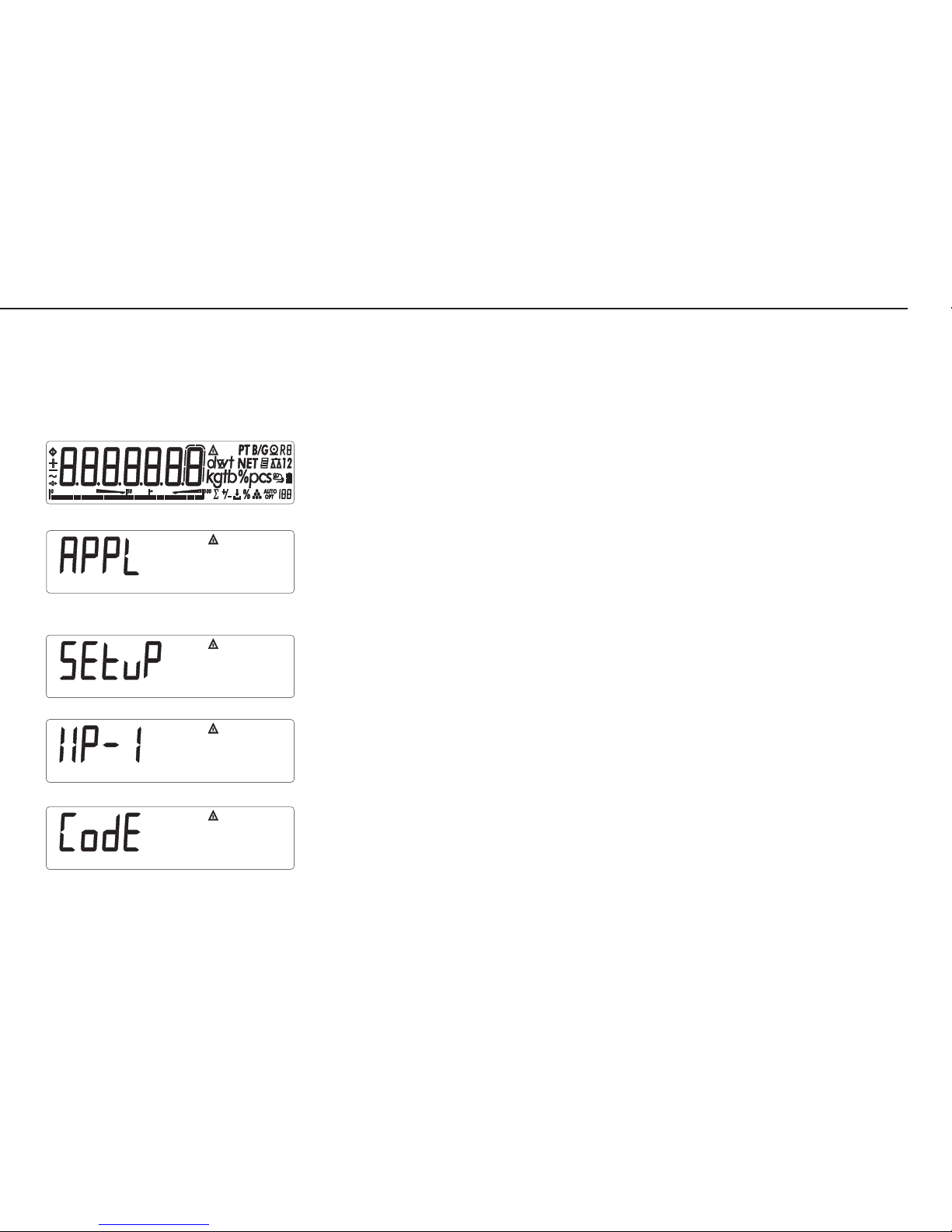

Activating the Service Mode

Activating the Service Mode

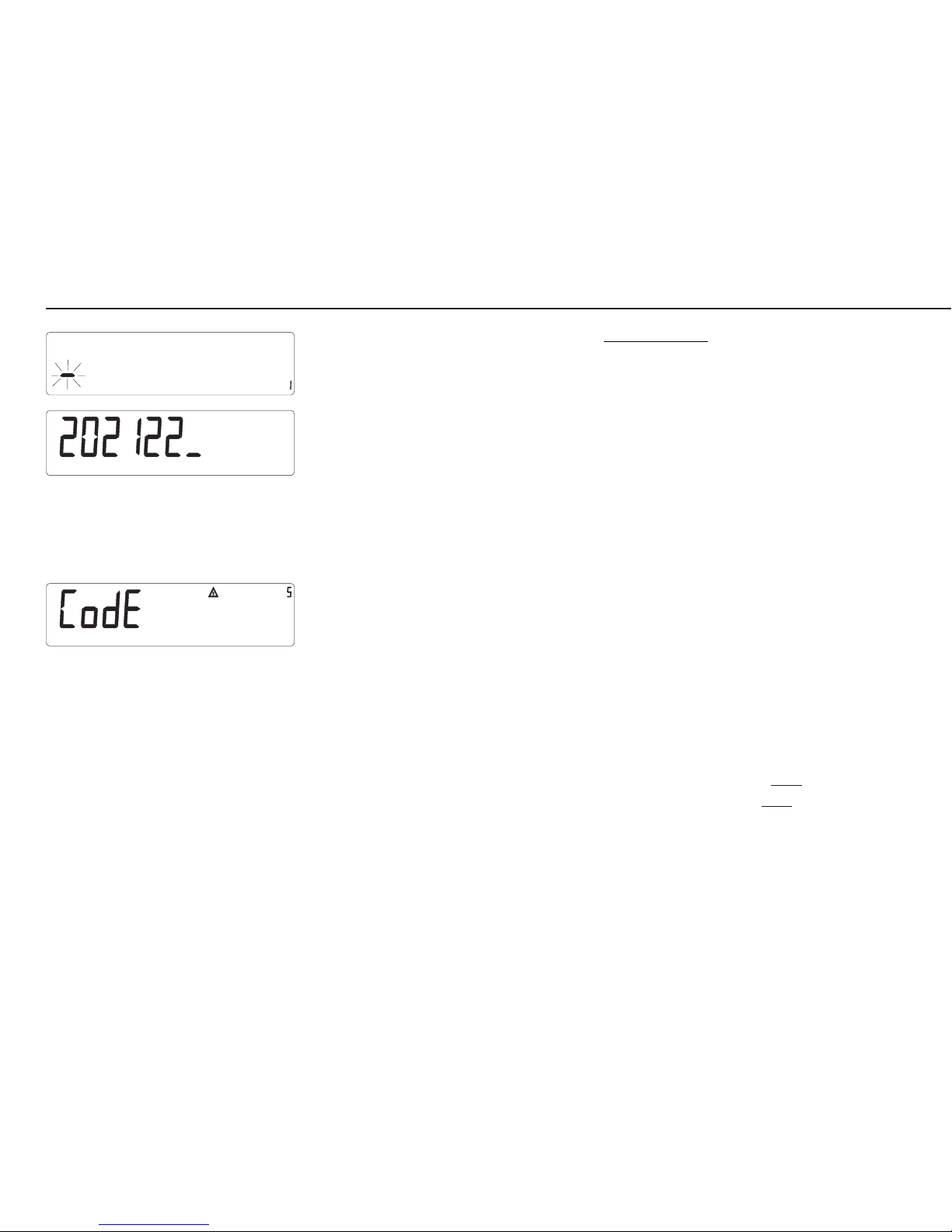

– Turn off the Combics (key: e).

– Turn on the Combics (key: e) and briefly press the ) key while all

segments are displayed.

The display shows APPL.

– Press the k key to scroll to the Setup item.

– Press the ) key; WP-1 is displayed.

– Press the k key to scroll to the CodE item.

setup.eps

display.eps

appl.eps

display_wp1.eps

code.eps

18

– Press the ) key; the display shows only a flashing cursor.

– Press k to select “2” and then press ) to confirm; the cursor jumps to the

second position; now you can enter the next number. Repeat this procedure

with the appropriate numbers to enter the service password (202122).

Note: If you find that one of the numbers is wrong, press ( to go back to that digit

and change it; then press the ) key repeatedly to return to the sixth digit

(the 2 flashes).

– After entering the last digit, press ) (< 2 sec.) and ( ( (in that order)

to activate the service mode. Setup appears in the display.

A “S” in the upper right-hand corner of the display indicates that the service

mode is active.

To cancel the password input process before it is finished, press ( repeatedly

until CodE is displayed.

Note: The service mode can be deactivated only by turning the off the Combics indicator.

Important: When the service mode is active (password 202122), you can only view the

customer password. The customer password can be deleted only by entering

the general password (40414243) or the customers password.

d_vore12.eps

202122.eps

code_s.eps

19

Working in the Service Mode

Note: When performing maintenance on an existing system, the service mode must be

activated to perform linearization, to set or clear the preload, and to enter the

date of service.

Additional Menus in Service Mode

In the Text Menu (“Setup”) Under the “Date” (DATE) and “Password” (CodE) menu items:

– Date of service S-DATE

– Memory number MEM-NO

– Indicator serial number SER-NO

– Model designation ModEL

In the numeric menu: The Setup menu for WP1 (WP-1) and the COM1 (COM1) and

UniCOM (UNICOM) ports is extended by the following items for

configuring weighing platforms WP1 (WP-1) and WP2 (WP-2):

1-9 Calibration/adjustment functions:

1-9-1: Ext. calibration/adjustment with default weight

(service mode not required)

1-9-3: Ext. calibration/adjustment with user-defined weight

(service mode not required)

1-9-5: Internal linearization (only for WP2 on COM1 and UniCOM ports)

1-9-7: External linearization with user-defined weights

1-9-8: Set preload

1-9-9: Clear preload

1-9-10: Key blocked (service mode not required)

20

Note: After necessary adjustments, install the suitable

adjustment routine for the customer.

1-18 Enter the calibration and linearization weights

1-18-1: Enter adjustment weight

1-18-2: Enter linearization weight 1

1-18-3: Enter linearization weight 2

1-18-4: Enter linearization weight 3

1-18-5: Enter linearization weight 4

1-19 Calibration without weights (by entering the

specifications of the load cell(s)):

1-19-1: Nominal load

1-19-2: Resolution

1-19-3: Sensitivity in mV/V for cell 1 (or mean derived

from all load cells)

1-19-4: Sensitivity in mV/V for cell 2

1-19-5: Sensitivity in mV/V for cell 3

1-19-6: Sensitivity in mV/V for cell 4

When multiple cells are connected, either the

individual values are entered under items

1-19-3 to 1-19-6, or the mean derived from all

load cells is entered under 1-19-3.

1-19-7: Store values entered for 1-19

1-20 Place of adjustment (geographical latitude

and altitude or, alternatively, the acceleration

of gravity at the place of installation):

1-20-1: Latitude in degrees

1-20-2: Altitude in meters above sea level

1-20-3: Acceleration of gravity

1-20-4: Store values entered for 1-20

8-12 Geographical data is displayed before every

span adjustment

9-1 Restore factory settings / Reset menu

9-1-3: Load “Standard” configuration

9-1-4: Load “Trade” configuration

9-1-10: Load default setting and delete

all Parameters

11 A/D Converter Settings:

11-1 Accuracy classes:

11-1-4: Accuracy class l

11-2 1. Weight unit (copy from menu subset 1-7):

11-2-1: long ton

11-2-2: Grams

11-2-3: Kilograms

...

11-2-21: Tons

21

11-3 Weighing range:

11-3-1: Single-range scale

11-3-2: Multiple-range scale

11-3-3: Multi-interval scale

11-4 Metrological data for single-range scale:

11-4-1: Scale interval d

11-4-2: Verification scale interval e

11-4-3: Minimum load

11-4-4: Maximum load

11-5 Metrological data for multi-interval scale:

11-5-1: Scale interval d

11-5-2: Verification scale interval e

11-5-3: Minimum load

11-5-4: Range 1

11-5-5: Range 2

11-5-6: Range 3

11-5-7: Maximum load

11-6 Metrological data for multiple-range scale:

11-6-1: Scale interval d

11-6-2: Verification scale interval e

11-6-3: Minimum load

11-6-4: Range 1

11-6-5: Range 2

11-6-6: Range 3

11-6-7: Maximum load

11-7 Available weight units:

11-7-1: User-defined unit

11-7-2: Grams

11-7-3: Kilograms

...

11-7-5: lb

...

11-7-21: Tons

11-8 Calibration/adjustment unit:

11-8-1: User-defined unit

11-8-2: Grams

11-8-3: Kilograms

...

11-8-5: lb

...

11-8-21: Tons

11-10 Store A/D converter configuration:

11-10-1: Store

11-10-2: Do not store

22

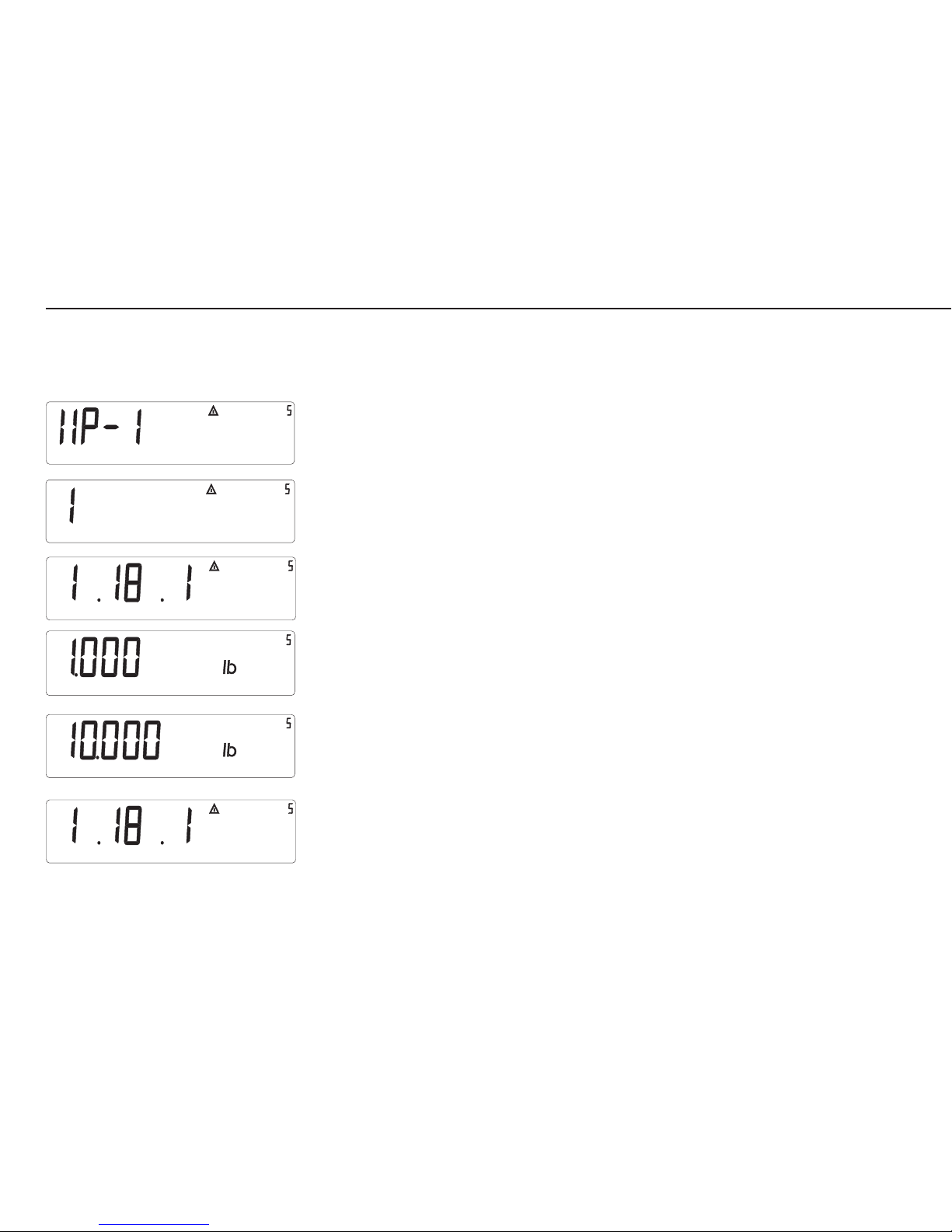

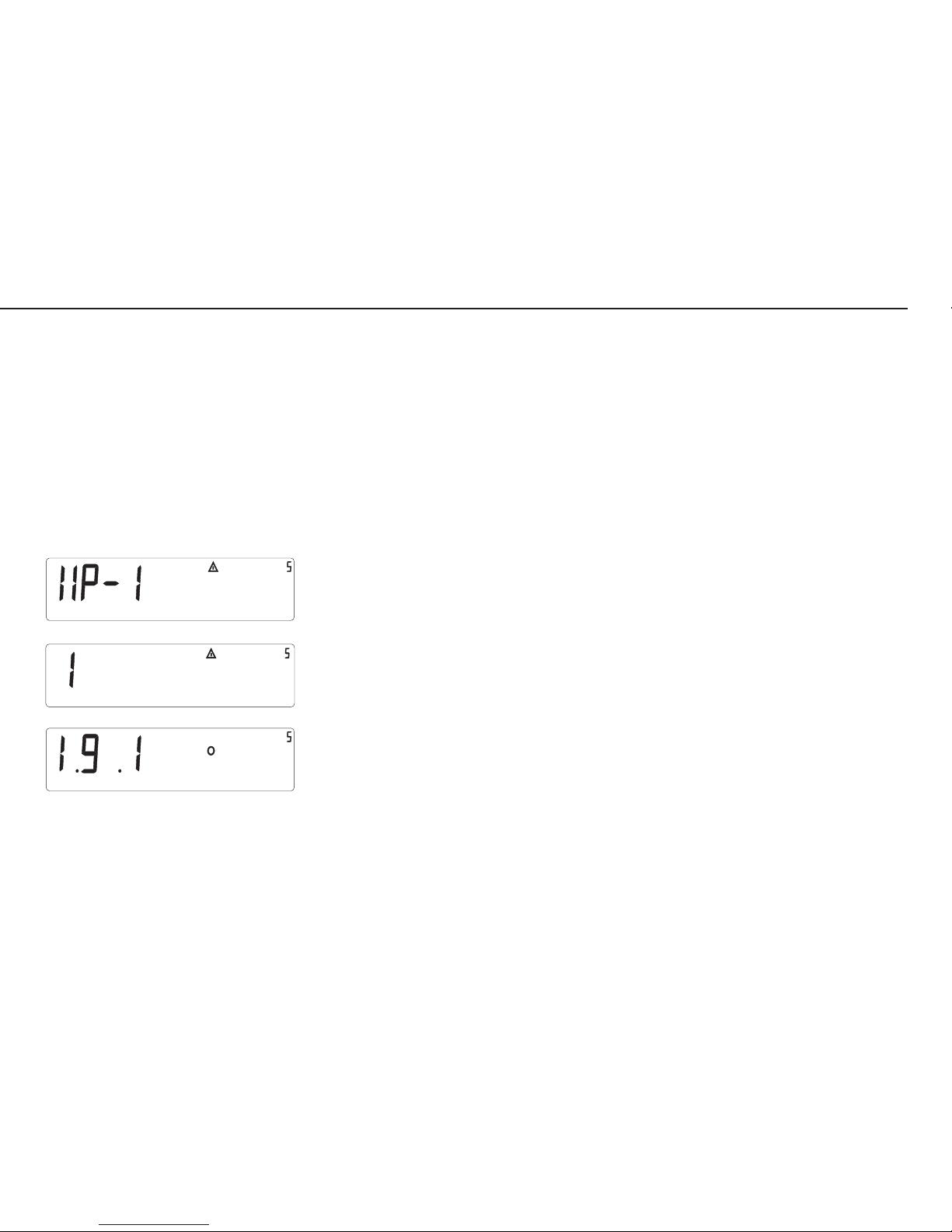

display_wps1_serv.eps

display_serv_01.eps

menu_1181.eps

user1Ib.eps

user2Ib.eps

menu_1181.eps

Menu Item 1-18: Entering Calibration/Linearization Weights

1-18-1: External User-defined Calibration Weight (Service Mode not Required)

– Activate the service mode (see page 16).

– Select weighing platform “WP1”.

– Press the ) key to open the numeric menu.

– Select menu item 1-18-1 (external user-defined weight) by pressing k )

repeatedly.

– Activate input mode for the user-defined weight (press ) briefly).

The first digit flashes.

– Enter the user-defined weight (in this example: 10,000 lb) (key sequence:

) k ) p ) ) ) k )). The last number entered flashes.

– Press the ) key again to store the user-defined weight; the menu jumps back

to 1-18-1.

– To exit the service mode, press and hold the ) key for longer than 2 seconds.

23

1-18-2: 1. Entering Linearization Weight

– Scroll to menu item 1-18-2 (press k repeatedly).

Note: The service mode must be active.

– Activate the input mode for the first linearization weight (press the ) key

briefly). The first number flashes.

– 1. Enter the linearization weight (in this example: 2,500 lb) (key sequence:

3 x k, ) p ) 6 x k, ) k ) k). The last number entered

flashes.

– Press and hold the ) key (> 2 sec.) to store the value for the first

linearization weight. The menu jumps back to item 1-18-2.

– Follow the above steps for menu items 1-18-3, 1-18-4, and 1-18-5 to enter

values for the second, third and fourth linearization weights as well.

Enter “0” instead of a weight value for unused linearization points.

– At the end of input, the display must show menu item 1-18-5.

– To exit the service mode, press and hold the ) key for longer than 2 seconds.

menu_1182.eps

user1Ib.eps

userl2Ib.eps

menu_1182.eps

menu_1185.eps

24

Calibration/Adjustment Routines in Service Mode (General Information)

There are three ways to adjust the span:

– Using external weights

– By entering the specifications of the load cell(s) (sensitivity in mV/V)

– By entering geographical data (latitude and altitude of the place of use) or by

entering the acceleration of gravity (at the place of use)

Span adjustment with external weights always takes precedence.

What does this mean when performing service work?

If a weighing system is used in a location other than that for which it was

originally intended (i.e., the geographical data at the new place of use does not

match the entered at Sartorius AG in Goettingen, Germany), the scale span can be

adjusted by using external weights or by entering the specifications of the load

cell(s). In this case, the geographical data entered for the original place of use is

no longer valid. The same applies for span adjustment performed after any repair

work on the weighing system.

Once you store the geographical data or acceleration of gravity at the place of use

and subsequently perform span adjustment using weights, the scale is correctly

programmed and adjusted.

You can now enter the geographical data of the new place of use to adapt the

scale for use at that location.

25

If the acceleration of gravity has been entered, this data takes precedence over

any

geographical data (latitude and altitude) previously entered.

Valid Locations for Use

Once the exact geographical data or the acceleration of gravity has been entered

and subsequent span adjustment performed, a scale with a resolution of 3000

digits can be used within a tolerance zone of ±100 km from the latitude entered

and ±200 m from the altitude.

The same applies when the acceleration of gravity is entered.

The following values are entered when the Combics scale is adjusted

in Goettingen, Germany:

– Latitude: 51.53 degrees (= 51° 32’)

– Altitude: 151 m

– or the corresponding acceleration of gravity, 9.811590 m/s-2

The greater the precision of the geographical data entered, the greater the

precision achieved with the weighing instrument; the tolerance range, however,

is restricted accordingly (see above).

26

Zone “D”

For a complete scale used in the Federal Republic of Germany, the following data

can be entered for scales with a resolution of 3000 digits at the place of span

adjustment:

– Latitude: 51.00 degrees

– Altitude: 513 m

– or the corresponding acceleration of gravity, 9.810 m/s

-2

The area of use valid for this scale is designated “Zone D” (valid only in Germany).

27

Menu Item 1-9: Calibration/Adjustment Functions

Note: When using a verified weighing platform, open the cover plate on the left side

of the back of the indicator and move the menu access switch to the right

(“accessible”; see page 14).

– Activate the service mode (see page 17).

1-9-1: External Calibration/Adjustment with Default Weights

– Select weighing platform »WP1«.

– Press the ) key to open the numeric menu.

– Select menu item 1-9-1 (external calibration/adjustment with default weights)

(key sequence:

) several times k )) and confirm () key briefly).

When this menu setting is active, you can exit the Service mode by turning the

Combics indicator off and then on again.

display_wps1_serv.eps

display_serv_01.eps

menu_191.eps

28

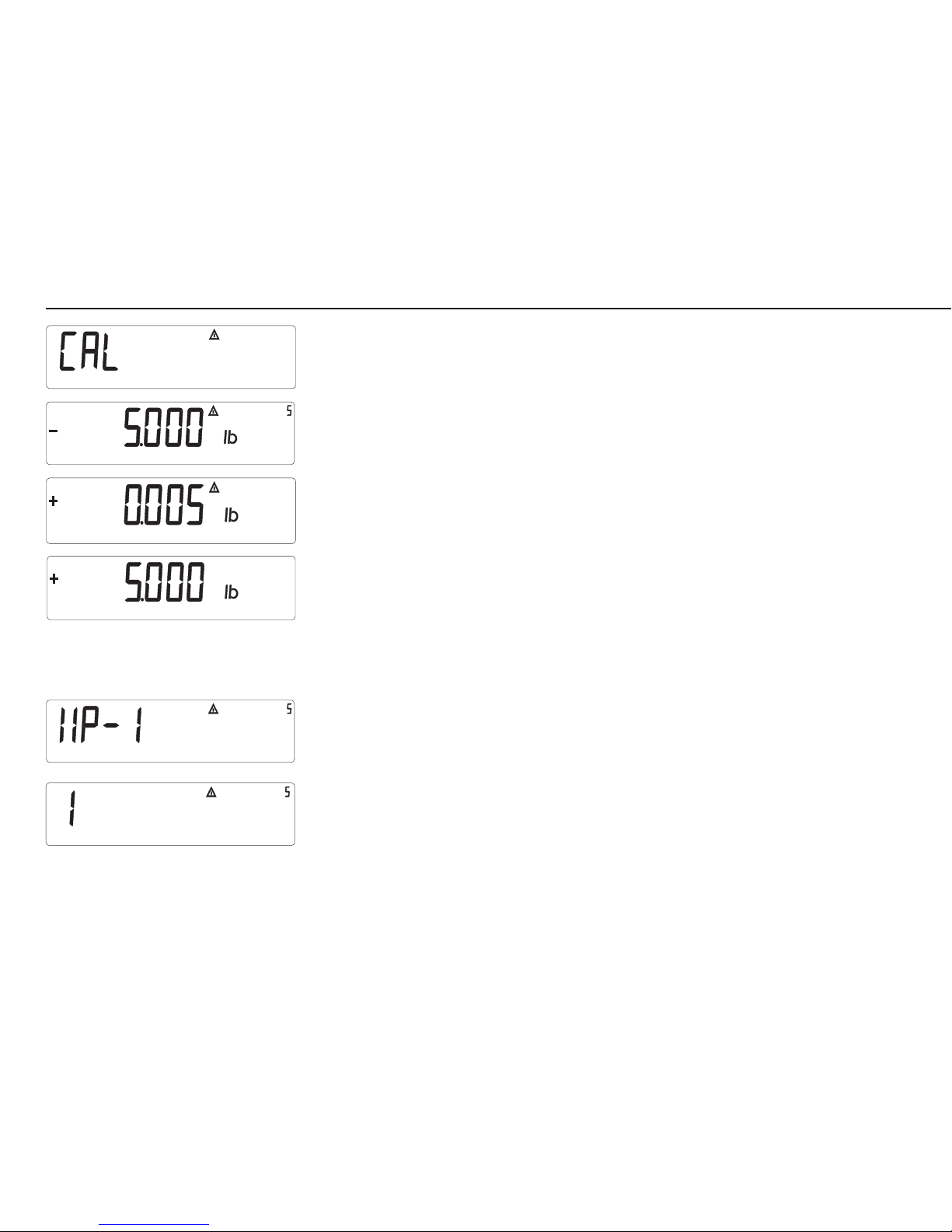

display_cal.eps

5lb.eps

display_serv_01lb.eps

5.0lb.eps

display_wps1_serv.eps

display_serv_01.eps

– After taring or zeroing the scale, press and hold the ) key until Cal is

displayed.

If menu item 8-12-2 is active, the geographical data is displayed before the

calibration weight is prompted. Confirm each of the values shown by pressing

the ) key to continue with the calibration routine.

– After approx. 2 seconds the calibration weight required is shown on the display.

– Place the prompted weight on the scale. After a brief pause, the difference

between the current value and the last is displayed (calibration).

– Press the ( key to stop the calibration/adjustment routine.

– Press the ) key to start the adjustment.

1-9-3 External Calibration/Adjustment with User-defined Weights

– Select weighing platform »WP1«.

– Press the ) key to open the numeric menu.

29

– Press ), then, several times, k ) to select menu item 1-9-3, “External

calibration/adjustment with user-defined weights” and confirm by pressing )

briefly.

– Press ( to jump to the first columns of the numeric menu.

– Press ) to store the selected menu item.

– Turn the Combics indicator off and then on again to exit the Service mode.

– After taring or zeroing the scale, press and hold the ) key until Cal is

displayed.

If menu item 8-12-2 is active, the geographical data is displayed before the

calibration weight is prompted. Confirm each of the values shown by pressing

the ) key to continue with the calibration routine.

– After approx. 2 seconds the calibration weight (user-defined weight) required

is shown on the display. Select menu item “1-18-1” to enter the user-defined

weight.

– Place the prompted weight on the scale. After a brief pause, the difference

between the current value and the last span adjustment is displayed

(calibration).

– Press the ( key to stop the calibration/adjustment routine.

– Press the ) key to start the adjustment.

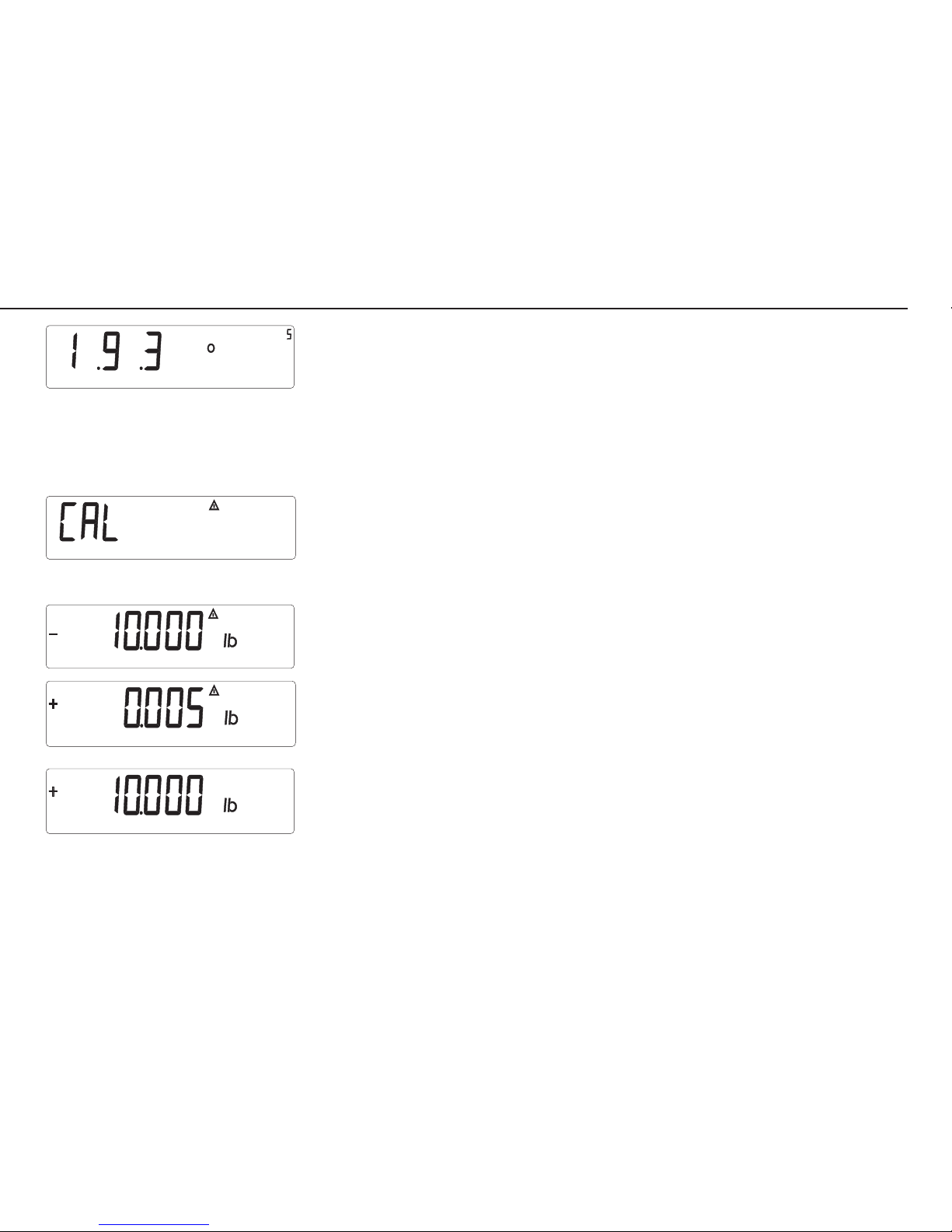

display_cal.eps

10Ib.eps

display_serv_01Ib.eps

10Ibw.eps

menu_193.eps

30

display_serv_01.eps

menu_197.eps

1-9-5 Internal Linearization (Only for WP1 on COM1 or UniCOM Ports)

1-9-7 External Linearization with User-defined Weights

– Activate the service mode (see page 17).

– Select weighing platform »WP1«.

– Press the ) key to open the numeric menu.

– Select menu item 1-9-7 (External linearization with user-defined weight) (key

sequence: ), then, several times, k )) and confirm by pressing )

briefly.

– Press and hold the ) key to store the selected menu items and return the

Combics indicator to the weighing mode.

When this menu setting is already active, you can exit the Service mode by

turning the Combics indicator off and then on again.

– After taring or zeroing the scale, press and hold the ) key until Lin is

displayed.

Display_WP1_Serv.eps

display_lin.eps

31

– After approx. 2 seconds the first linearization weight (user-defined weight)

is shown on the display. Select menu items 1-18-2 through 1-18-5 to enter the

linearization weights.

– Place the prompted weight on the scale. After a brief pause, the difference

between the current value and the last adjustment is displayed (calibration).

– Press the ( key to stop the calibration/adjustment routine.

– Press the ) key to store the value for the first linearization weight;

the second linearization weight is prompted.

– Place the prompted weight on the scale. After a brief pause, the difference

between the current value and the last adjustment is displayed (calibration).

– Press the ) key to store the value for the second linearization weight;

the third linearization weight is prompted.

– Place the prompted weight on the scale. After a brief pause, the difference

between the current value and the last adjustment is displayed (calibration).

2.5Ib.eps

display_serv_02Ib.eps

display_5Ib.eps

display_serv_03lb.eps

7.5Ib.eps

display_serv_04lb.eps

32

– Press the ) key to store the value for the third linearization weight;

the fourth linearization weight is prompted.

– Place the prompted weight on the scale. After a brief pause, the difference

between the current value and the last adjustment is displayed (calibration).

– Press the ) key to store the value for the fourth linearization weight.

The scale now prompts a requires the zero point (remove all weights from the

load plate).

– Once the zero point is stored, the Combics automatically returns to the

weighing mode.

10Ib.eps

display_serv_06Ib.eps

0kg.eps

display_serv_03lb.eps

33

1-9-8 Setting the Preload

Note: When using a verified weighing platform, open the cover plate on the left side

of the back of the indicator and move the menu access switch to the right

(“accessible”; see page 14).

– Activate the service mode (see page 17).

– Select weighing platform »WP1«.

– Press the ) key to open the numeric menu.

– Select menu item 1-9-8 (Set preload) (key sequence: ), then, several times,

k )) and confirm by pressing ) briefly.

– Press and hold the ) key to store the selected menu items and return the

Combics indicator to the weighing mode.

– Press )) to tare the Combics indicator, or press ( to zero it.

If you tare the indicator, “NET” might be displayed.

– Place the preload on the scale.

display_wp1_serv.eps

display_serv_01.eps

menu_198.eps

0lb_o.eps

vorl1.eps

34

– Press ) until SEt VOR is displayed.

– Release the ) key; after a brief pause, the Combics indicator automatically

returns to the weighing mode.

1-9-9 Clearing the Preload

Note: When using a verified weighing platform, open the cover plate on the left side

of the back of the indicator and move the menu access switch to the right

(“accessible”; see page 14).

– Activate the service mode (see page 17).

– Select weighing platform »WP1«.

– Press the ) key to open the numeric menu.

– Select menu item 1-9-9 (Clear preload) (key sequence: ), then, several times,

k )) and confirm by pressing ) briefly.

– Press and hold the ) key to store the selected menu items and return the

Combics indicator to the weighing mode.

vorl2.eps

0lb_o.eps

display_serv_01.eps

display_wps1_serv.eps

vorl3.eps

35

– Remove the preload weight from the scale. A weight value with a preceding

“minus” sign is displayed (for example, -0.335 lb).

– Press ) until CLr VOR is displayed.

– Release the ) key; the preload is cleared and, after a brief pause, the Combics

indicator automatically returns to the weighing mode.

Display_-0335lb.eps

vorl5.eps

0lb_o.eps

36

Adjustment without Weights

Menu Item 1-19: Entering the Specifications of the Load Cell(s)

– Activate the service mode (see page 17).

– Select weighing platform »WP1«.

– Press the ) key to open the numeric menu.

– Press the ) key, then, several times, k repeatedly and then ) again to

open menu item 1-19, “Calibration without weights”; then select item 1-19-1,

“Nominal capacity”.

– Press ) again to activate menu item 1-19-1.

– Enter the nominal capacity of the load cell(s) (e.g., 30.00 lb).

The nominal capacity has to match the maximum load set under menu item

11-4-4.

Note: If a weighing platform has more than one load cell, multiply the nominal capacity

accordingly. Example: The weighing platform consists of 4 load cells, each of them

has a capacity of 30 kg.

In this case, the nominal capacity (= maximum load) equals 4 x 30 kg, or 120 kg.

display_wps1_serv.eps

display_serv_01.eps

display_serv_01191.eps

display_mxl30Ib.eps

37

– To store the setting, press and hold the ) key (> 2 sec).

– Select menu item1-19-2 (key sequence: k, )).

– Enter the resolution (lowest scale interval d) (e.g., 0.01 kg). This value has to

match that stored under menu item 11-4-1 (or 11-5-1 or 11-6-1).

– To store the setting, press and hold the ) key (> 2 sec).

– Select menu item1-19-3 (key sequence: k, )).

Enter the sensitivity of the load cell in mV/V (usually listed in the load cell

specification sheets). If a weighing platform consists of more than one load cell,

enter here the sensitivity of load cell 1.

Example: The sensitivity of the load cell is 1.9440 mV/V.

– To store the setting, press and hold the ) key (> 2 sec).

Note: If a weighing platform consists of more than one load cell, enter the sensitivity

values for the other cells (up to 4) under menu items 1-19-4 (for load cell 2)

through 1-19-6 (for load cell 4) and confirm each value (k ) keys).

If the platform has less than four load cells, enter “0.000” under the unused menu

items.

display_schrittw_001Ib.eps

display_wze19440.eps

38

– Press k and ) to select menu item 1-19-7,

Store parameters set in menu item 1-19.

– Press ) ( ( to store the load cell specifications entered; the menu

automatically jumps back to the first menu page.

– Exit the operating menu and return to the weighing mode.

display_serv_01197.eps

display_serv_01.eps

39

Menu Item 1-20: Entering the Geographical Latitude and Altitude,

or the Acceleration of Gravity

When you activate menu item 1-20-1, the value 99999.99 is displayed; under

1-20-2, is 9999999 displayed too. Otherwise, if values have already been entered

for geographical latitude and altitude, then 0.000000 is displayed under menu

item 1-20-3.

During calibration, the Combics show will whether and which gravimetric data

(geographical latitude and altitude, or acceleration of gravity) is used, if the menu

item 8-12-2 is activated.

If latitude and altitude are used, the display shows “Altitude” for 2 seconds when

the calibration procedure is started (CAL), followed by the configured elevation

above sea level in meters. Press ) to confirm this information. Next, the display

shows “LATITUDE” for 2 seconds, followed by the value set for the geographical

latitude (in degrees). Press ) to confirm this information. The calibration

weight is now prompted. If the acceleration of gravity is given rather than the

geographical latitude and elevation, the display shows “GRAVITY” for 2 seconds

(after “CAL”), followed by the value entered for the local acceleration of gravity.

Press ) to confirm this information.

However, if the calibration weight is prompted as soon as the “CAL” display goes

out, this means whether the correction of the calibration factor has been

deactivated nor the menu item 8-12-2 is activated; in other words, neither the

geographical latitude and altitude nor the acceleration of gravity have been

entered under menu line 1-20.

40

Entering the Place of Adjustment with Subsequent Adjustment (Example)

– Activate the service mode (see page 17).

– Press ) to select weighing platform »WP1«.

– Press the ) key to open the numeric menu. The first menu page is displayed.

– Open menu line 1-20, “Place of adjustment”, by pressing k and ).

Menu item 1-20-1 (latitude) is displayed.

If the geographical latitude and altitude of the place of installation are known,

enter this data under menu items 1-20-1 (latitude) and 1-20-2 (altitude).

If you wish to use the acceleration of gravity at the place of installation for the

basis of adjustment rather than these two parameters, enter this value under

menu item 1-20-3.

Important: A value entered for acceleration of gravity takes precedence over the

combination of geographical latitude and altitude.

display_serv_01201.eps

display_wp1_serv.eps

display_serv_01.eps

41

Example: Entering geographical latitude and elevation:

Select menu item 1-20-1 (latitude) (press )).

In the example shown here, the most recently entered parameter was the value for

the acceleration of gravity (menu item 1-20-3). For this reason, the input fields

for menu items 1-20-1 and 1-20-2 are filled with 999…

In the example shown here, the geographical latitude of Goettingen, Germany,

was the value entered most recently. This value is the reference value, for which

no correction of the span adjustment was made with respect to the place of

installation, assuming that “151” (elevation in meters above sea level) has been

entered under menu item 1-20-2.

Enter the geographical latitude of the place of installation (or the reference

value 51.53) as a positive decimal number (convert angular minutes to decimal

places). Press ) to confirm your input.

– Select menu item 1-20-2 (“Elevation at the place of installation”) (key

sequence: ) k )).

The input field is filled with 999…, because the last value entered in menu line

1-20 was the acceleration of gravity (menu item 1-20-3).

display_999.eps

display_5153.eps

display_999.eps

42

– Enter a value for the local elevation at the place of installation in meters above

sea level (reference value: 151) (key sequence: ) k k).

Note: A negative value may be entered for local elevation; for example,

if the scale is installed in a mine.

– Press ) to confirm your input.

– Activate menu item 1-20-4 to store new data

(key sequence: ) k k).

Rather than the geographical latitude and local elevation of the place of

installation, you can enter a value for the acceleration of gravity at the place of

installation (menu item 1-20-3).

Example: Entering the acceleration of gravity place of installation.

– Select menu item 1-20-3 (acceleration of gravity) (key sequence: k k )).

Example: In the example shown here, the geographical latitude and local

altitude (menu items 1-20-1 and 1-20-2) were the last parameters

entered in menu line 1-20. Thus the input field for acceleration of

gravity is filled with 000…

In the example shown here, the most recently entered parameter

was the value for the acceleration of gravity at Goettingen, Germany

(menu item 1-20-3). This value is the reference value, which means

no correction of the span adjustment for the place of installation

is required.

display_000.eps

display_981.eps

display_151.eps

43

– Enter the acceleration of gravity at the place of installation (in ms-2 / or the

reference value: 9.811590). Press ) to confirm your input.

– Activate menu item 1-20-4 to store new data (key sequence: ) k).

The display shows “busy”, indicating that the parameters entered are being stored.

– Restart the scale: Turn the indicator off and then on again (key sequence: e

e, or press and hold the ) key (> 2 sec).

After the self-test of the display, the scale is ready to operate.

Note: Once the precise geographical data or acceleration of gravity has been entered, the

tolerance range is restricted (see page 23).

– After data has been entered as described above, the span must

be adjusted.

Example

Settings (changes in the factory settings required for this example):

Menu item 1-9-1: External calibration/adjustment with default weight;

Menu item 1-10-1: Calibration/adjustment in one operation;

Menu item 1-16-1: External calibration/adjustment/linearization

accessible.

display_busy.eps

display.eps

44

The parameters for altitude at the place of installation and geographical latitude

have been entered (menu items 1-20-1 and 1-20-2).

The display will show “ALTITUD” for 2 seconds, if the menu item 8-12-2 is activated.

The altitude at the place of installation is displayed in meters above sea level.

In the example shown here, the altitude of Goettingen, Germany (reference value)

is shown.

– Press the ) key to confirm the displayed value.

The display shows “LATITUD” for 2 seconds.

The geographical latitude of the place of installation is shown in degrees north

or degrees south.

In the example shown here, the altitude of Goettingen, Germany (reference value)

is shown.

– Press the ) key to confirm the displayed value.

– Place the prompted calibration weight on the scale (see page 25 for details on

calibration and adjustment).

or

display_latitud.eps

display_lat_5153.eps

10Ib.eps

display_altitud.eps

display_alt_151.eps

45

Instead of “ALTITUD” and “LATITUD”, “GRAVITY” is displayed for 2 seconds if the

acceleration of gravity (menu item 1-20-3) was entered rather than the elevation

and geographical latitude (menu items 1-20-1 and 1-20-2).

The value entered for the acceleration of gravity at the place of installation

is displayed (in m/s-2).

In the example shown here, the acceleration of gravity at Goettingen, Germany

(reference value) is shown.

This data is shown when menu item 8-12-2 is active.

– Press the ) key to confirm the displayed value.

– Place the prompted calibration weight on the scale (see page 25 for details on

calibration and adjustment).

display_gravity.eps

display_grav_981.eps

10Ib.eps

46

Configuring the A/D Converter in the Combics Indicator (Service Mode)

The A/D converter must be configured in the following cases:

– To adapt the existing configuration to customer requirements (for example,

to change the nominal capacity or the resolution).

– To adapt the Combics for use with any commercially available strain-gauge

load cell or analog Sartorius CAPP or CAPS weighing platform, when installing

a new system.

– After replacing the electronic A/D converter during repair work, also on

combics scales, when the Sartocas software is not used.

Menu Item 11: A/D Converter Settings (Configuration: Standard, Trade)

Note: Before the A/D converter can be configured, you need to load either the

“Standard” configuration or the “Trade” configuration, depending on customer

requirements.

– 9-1-3: Load “Standard” configuration

– 9-1-4: Load “Trade” configuration

47

Menu Item 11:

A/D Converter Configuration (General Information)

Note: Access is restricted by a special password.

Features With the menu access switch open, you can

configure most of the parameters affecting

the following specifications:

– Toggling between Standard and Trade configurations

(for use in legal metrology)

– Verification scale interval e

– Scale interval d

– Minimum load

– Maximum load

– Maximum load for a given range

– Verification scale interval e for a given range

– User-definable weight units

These parameters are not reset when you restore the

factory defaults in the operating menu.

Parameters not listed above are not affected by your

choice of Standard or Trade configuration; the same

restrictions apply as for Sartorius weighing instruments

which cannot be configured.

Note on A/D Converter Configuration

A/D converter configuration is performed using the

numeric menu (weighing platform 1).

Important: The A/D converter can be configured only in

the service mode.

The maximum load for each weighing range must be

entered in an appropriate weight unit. Select the desired

weight unit for operation under menu line 11-7, “Weight

units”. The maximum load for each range must be a value

that can be displayed in any available weight unit.

Weight units that are accessible (or blocked) for use as

Weight unit 1 are also available (or blocked) for use as

Weight unit 2. The weight unit used for the configuration

cannot be blocked.

Checking and Configuring the Equipment for Use in Legal

Metrology:

48

Following A/D converter configuration, write the

metrological data on a tag for all weighing ranges.

Afterwards, affix the enclosed protective acetate overlay

to the tag.

After completing calibration and adjustment, move the

menu access switch back to the “closed” position and then

turn the Combics indicator off and back on again to

activate the new configuration.

Open menu line 1-7 to make sure only the permitted

weight units are accessible.

Perform necessary routines for scales used in legal

metrology.

Descriptions of the Individual Menu Items

Menu Item 9-1-3 / 9-1-4:

Selecting and loading configuration data

Before selecting the menu item for A/D converter

configuration, check whether the weighing platform is

used in the standard operating mode (Standard

configuration) or in legal metrology (Trade configuration):

– Standard Configuration

(menu item 9-1-3)

or

– Trade Configuration

(menu item 9-1-4)

Menu Line 11-1 (Accuracy Class)

This menu line is not shown when the Standard

configuration is active.

When the Trade configuration is active (for verifiable or

verified weighing platforms), only menu item 11-1-4 is

shown.

Select the accuracy class appropriate for the weighing

platform connected. Which class is appropriate depends

on the load cell(s) installed.

In legal metrology, only classes l

(menu item 11-1-4) can be selected.

Press k to select the accuracy classes and ) to

confirm. A circle (o) after the menu code indicates the

active setting.

49

Selecting the Weighing Range Structure (Menu Item 11-3)

The capacity of the weighing platform can be divided into

multiple ranges. These settings are configured under menu

item 11-3:

Single-range Scale (11-3-1)

The entire weighing range is divided into scale intervals on

the basis of the lowest interval d and the maximum load.

In this case, the readability over the entire weighing range

is always the lowest scale interval d.

Multiple-range Scale (11-3-3)

A multiple-range scale has two weighing ranges.

When the maximum capacity of the lower range is

exceeded, the scale switches to the higher range (lower

resolution) and remains in that range. The scale can be

returned to the lower weighing range (higher resolution)

only by unloading the scale and then pressing the ( key.

Scale Interval d

The lowest scale interval d indicates the resolution of the

weighing instrument. The scale interval d can be entered

only in increments of 1, 2, 5, 10, 20, 50, etc. When working

on a verifiable or verified scale in accuracy class l, you

are not prompted to enter the lowest scale interval, as this

is equal to the verification scale interval e.

Verification Scale Interval e

The verification scale interval e indicates the resolution

of the weighing instrument in legal metrology.

When accuracy class l is active, this is equal to the scale

interval d. Thus with classes l, the lowest scale interval

d is not prompted.

50

Range 1, Range 2, Range 3

Here you can enter the limits for each of the weighing

ranges. When a limit is exceeded, the accuracy changes.

The following applies when entering range limits:

Range 1 < range 2 < range 3 < maximum capacity.

Thus the weighing capacity can be divided into 4 ranges.

The resolution changes in intervals of 1, 2, 5, 10, 20, 50,

etc. The lowest resolution is equal to the specified lowest

scale interval d. Set unused ranges to 0.

Maximum Capacity

The maximum capacity is the maximum load that may

be placed on the weighing instrument. If a heavier load

is placed on the platform, the display shows H.

The scale intervals are derived from the maximum load

and the lowest scale interval d. In legal metrology, the

number of intervals must not exceed 6000 e, or 3000 e per

range in a multi-interval scale. In standard operation, as

opposed to legal metrology, you can define a “SuperRange”

weighing instrument with more intervals.

For example, a maximum load of 60,000 lb with a lowest

scale interval d of 0.001 lb 60,000 scale intervals. These

parameters, however, may be influenced by physical

restrictions.

Available Weight Units (Menu Item 11-7)

With this function, you can make particular weight units

inaccessible during weighing. Available units are indicated

by a circle (o) on the display (more than one can be

selected).

Calibration/Adjustment Unit (Menu Item 11-8)

This setting defines the weight unit with which calibration

must be performed. The calibration unit remains the same,

even when a different weight unit is used during normal

weighing operation.

Calibration without Weights (Menu Item 1-19)

The values entered for nominal capacity (in lb; menu item

1-19-1; specification of the strain-gauge system),

resolution in kg; (menu item 1-19-2) and sensitivity in mV/

V menu item 1-19-3) are converted to internal quantities.

Once the A/D converter configuration data has been

stored, these parameters can no longer be read. For

weighing platforms with multiple load cells, enter the

sensitivities of the other load cells under menu items 119-4 (cell 2) through 1-19-6 (cell 4).

Select menu item 1-19-7 to store the data entered.

51

Important: Calibration without weights cannot be

performed on weighing instruments used in

legal metrology.

Storing Configuration Data (Menu Item 11-10)

Select menu item 11-10-1 to store the A/D converter

configuration data.

Once these parameters have been configured, the A/D

converter in conjunction with the load cell is defined as a

weighing instrument. The A/D converter, in conjunction

with the weighing platform, can now be used like any

standard weighing platform.

In addition, the weight unit must be defined and the

weighing platform adjusted (calibration/adjustment

and linearization must be performed). For a detailed

description of these procedures, see the chapter entitled

“Calibration/Adjustment in Service Mode”.

Important: After configuring the A/D converter

and adjusting the weighing instrument

(calibration/adjustment and linearization),

return the menu access switch to the

“closed” position (i.e. for use in legal

metrology). Turn the Combics indicator off

and then on again (key sequence: e e

to activate the new configuration.

Once the A/D converter configuration has been locked

(menu access switch closed), the indicator can no longer

be used to influence weighing results. The scope of

functions available in the weighing instrument is defined

by the A/D converter. Scale functions which can be

activated are, for example: weight readout, taring,

adjustment, reading tare value, saving/deleting tare values.

52

Menu Item 9-1:

A/D Converter Configuration (Example: Trade Configuration)

– Activate the service mode (see page 17).

– Press k repeatedly to select weighing platform »WP1«.

– Press the ) key to open the numeric menu. The first menu page is displayed.

– Open menu item 9-1 (Factory setting/Menu reset)

(key sequence: k k )).

Loading the Trade Configuration

– Select menu item 9-1-4 (Trade configuration) and confirm

(key sequence: ) k k)).

The selected configuration is loaded. »Busy« is displayed briefly.

Afterwards, the program returns to the display of menu item 9-1-2

(Restore factory defaults: »Off«; factory setting).

display_wp1_serv.eps

display_serv_01.eps

display_serv_91.eps

display_serv_914.eps

display_busy.eps

display_serv_912.eps

53

– Select menu page 11 (key sequence: ( ( k).

Note: If the Trade configuration is loaded, menu line 11-1 (for selecting

accuracy class) is displayed at this point.

Otherwise (Standard configuration), that menu line is skipped and 11-2

(weight unit 1) is displayed.

In this case, press k to open menu line 11-3.

– Press ) to confirm your selection.

– To use the weighing instrument in legal metrology (i.e., with the Trade

configuration loaded) press ) to enter the accuracy class:

– Select menu item 11-1-4 for accuracy class l.

– Press ) to confirm.

The configured menu item (in the picture here,

11-1-4 for accuracy class l) is marked by a circle (o).

display_serv_11.eps

display_serv_111.eps

display_serv_1114.eps

display_serv_1114w.eps

54

– Press the key sequence ( k k to open menu item 11-3 (Selecting the

weighing range structure).

– Press ) to confirm your selection.

In the example shown here, menu item 11-3-1 (Single-range scale) has been

selected.

– Press ( to return to menu item 11-3.

Note: Enter the scale interval, minimum load, range limits (multiple-range or multi-

interval scales only) and maximum capacity:

The menu line corresponding to the selected weighing range structure is displayed;

i.e.

– for single-range scale (menu item 11-3-1): in relation to menu item 11-4;

– for multiple-range scale (menu item 11-3-2): in relation to menu item 11-5;

– for multi-interval scale (menu item 11-3-3): in relation to menu item 11-6.

In each case, the menu lines for the other two weighing range structures are not

shown.

In this example, 11-3-1 (Single-range scale) has been selected.

Thus menu line 11-4 is opened automatically. Menu lines

11-5 and 11-6 are not available.

display_serv_113.eps

display_serv_1131w.eps

55

– The input field for the verification scale interval e is to open.

– If the Trade configuration is active, select menu item 11-4-2 (Verification scale

interval e) (key sequence: ( k k k )).

– Press the ) key again to open this item; 0.001 kg is displayed.

– Enter the value for e (for example, e = 0.1 lb) by pressing the key sequence )

) k ) ) p ) and store (press and hold ) > 2 sec).

When menu item 11-4-2 is opened again, the display shows 0.1 lb.

– Select menu item 11-4-3 (Minimum load) (key sequence: ( k).

– Press the ) key again to open this item; then enter the minimum load (key

sequence: k k k ) p ) k).

Example for accuracy class K: Minimum load = 20 x e = 2.0 lb

– To store the new setting, press and hold the ) key (> 2 sec).

display_serv_114.eps

display_serv_1142.eps

eiche1lb.eps

eiche2lb.eps

display_schrittw_01Ib.eps

display_serv_1143.eps

display_mnl20Ib.eps

56

– Press k to select menu item 11-4-4 (maximum load).

– Press ) again to open this menu item; then enter the maximum capacity (for

example 300.0 kg) (key sequence: k k k k ) k ) k )

p ) k). Enter “300” (it is not necessary to enter the decimal point and

the last “0”).

– To store the new setting, press and hold the ) key (> 2 sec).

Note: If “Multiple-range scale” or “Multi-interval scale” was selected during A/D

converter configuration rather than “Single-range scale”, then the range limits

must be entered under menu line 11-5 (multiple-range) or 11-6 (multi-interval).

Each of these menu lines has 3 items to choose from, for setting range limits

1, 2 and 3.

– Store the configuration data: Select menu line 11-10 (key sequence: ( (

k k k )).

The default setting is 11-10-2, “Do not store configuration”.

– Press k to select menu item 11-10-1 (Store configuration).

– To store the new settings, press and hold the ) key (> 2 sec).

Display_Serv_1144.eps

Display_Mxl30.eps

Display_Serv_11102.eps

Display_Serv_11101.eps

57

“Busy” is displayed briefly.

Afterwards, the Combics is re-started. The scale is in the normal weighing

mode.

Then adjust the weighing instrument and, if the Trade configuration is active,

return the menu access switch from the “accessible” to the “closed” position (see

page 12).

Menu Item 9-1: A/D Converter Configuration with Load Cell(s) Connected

(Example: Standard Configuration

– Activate the service mode (see page 17).

– Press ) repeatedly to select weighing platform »WP1«.

– Press the ) key to open the numeric menu. The first menu page is displayed.

– Open menu line 9-1 (Factory settings/Reset menu).

Display_busy.eps

Display.eps

Display_WP1_Serv.eps

Display_Serv_01.eps

58

Loading the Standard Configuration

(if the Trade configuration is currently loaded)

– Open menu item 9-1 (Standard configuration) and confirm (key sequence: k

k )).

– Select menu code 9-1-3 (key sequence: ) k) and press ) to store.

The selected configuration is loaded. “Busy” is displayed briefly.

Afterwards, the program returns to the display of menu item 9-1-2 (Restore

defaults: »Off«; factory setting).

– Open menu page 11 (key sequence: ( ( k).

Configuration: Enter the desired weighing range structure (single-range scale,

multiple-range scale, multi-interval scale), scale interval and maximum capacity

(with range limits, if necessary).

– Press ) k to select the weighing range structure (menu line 11-3).

Display_Serv_912.eps

Display_Serv_11.eps

Display_Serv_113.eps

display_serv_91.eps

Display_Serv_913.eps

Display_busy.eps

59

– Press ) to confirm your selection.

In the example shown here, menu item 11-3-1 (Single-range scale) has been

selected.

If desired, press k to change the weighing range structure:

11-3-2: Multiple-range scale; 11-2-3: Multi-interval scale.

– Press ( to return to menu line 11-3.

Note: Entering the scale interval, range limits (multiple-range or multi-interval scales

only) and maximum capacity:

The menu line corresponding to the selected weighing range structure

is displayed, i.e.,

– for single-range scale (menu item 11-3-1): in relation to menu item 11-4;

– for multiple-range scale (menu item 11-3-2): in relation to menu item 11-5;

– for multi-interval scale (menu item 11-3-3): in relation to menu item 11-6.

In each case, the menu lines for the other two weighing range structures are not

shown.

– When you activate menu code 11-3-1 (Single-range scale) (by pressing the key),

menu line 11-4 is opened automatically. In this case, menu lines 11-5 and 11-6

are not shown.

– Open menu item 11-4-1 to enter the scale interval d.

– Press ) to select the menu item.

Display_Serv_1131W.eps

Display_Serv_1141.eps

Display_Serv_114.eps

60

The scale interval d is shown, and a flashing digit indicates the cursor position.

You can change the digit that the cursor is on.

Move the cursor as needed to change other digits; in this manner, you can

change the number to the desired value.

– Defining the scale interval d for the weighing instrument:

If the currently active value (displayed; in this example, 0.001 lb) matches the

desired value, press and hold ) (> 2 sec) to confirm it.

– Otherwise, overwrite the value as desired (in this example, by entering 0.01 lb;

key sequence: k ) p ) k ) k k); then press and hold the

) (> 2 sec) to confirm.

After you store the data, the program jumps back to menu item 11-4-1.

– Press k to select menu line 11-4-4 (maximum load).

– Press ) to open the menu item.

Display_Serv_1141.eps

Display_Serv_1144.eps

display_schrittw_001Ib.eps

display_schrittw_0001Ib.eps

standard1Ib.eps

61

– Enter the desired maximum capacity (in this example, 30.0 kg; key sequence:

k k k k ) k ) p ) k) and then press and hold )

(> 2 sec) to store the value. Enter “30” (it is not necessary to enter the decimal

point and the last “0”).

After you store the data, the program jumps back to menu item 11-4-4.

Note: If “Multiple-range scale” or “Multi-interval scale” was selected during A/D

converter configuration rather than “Single-range scale”, then the range limits

must be entered under menu line 11-5 (multiple-range) or 11-6 (multi-interval).

Each of these menu lines has 3 items to choose (range limits 1, 2 and 3).

– Store the configuration data: Select menu line 11-10 (key sequence: ( k

k k

– Press ) to open menu item 11-10-2 (“Do not store configuration”)

(active setting).

– Press k to select menu item 11-10-1 (Store configuration).

Display_Serv_1144.eps

display_serv_1110.eps

Display_Serv_11102.eps

Display_Serv_11101.eps

standard1Ib.eps

62

Press ) to store the A/D converter configuration data.

“Busy” is displayed briefly; afterwards, the Combics is re-started.

After the self-test of the display, the scale is ready to operate.

Menu Item 1-19: Entering the Specifications of the Load Cell(s)

– Activate the service mode (see page 17).

– Select weighing platform »WP1«.

– Press the ) key to open the numeric menu.

– Press the ) key, then seveal times, k ) to open menu line 1-19,

“Calibration without weights”; then select item 1-19-1, “Nominal capacity”.

– Press ) again to activate menu item 1-19-1.

– Enter the nominal capacity of the load cell(s) (e.g., 30.00 kg).

The nominal capacity has to match the maximum load set under

menu item 11-4-4.

Display_Serv_01191.eps

display_mxl30Ib.eps

Display_busy.eps

Display_WP1_Serv.eps

Display_Serv_01.eps

63

Note: If a weighing platform has more than one load cell, multiply the nominal capacity

accordingly. Example: The weighing platform consists of 4 load cells, each of which

has a capacity of 30 kg. In this case, the nominal capacity (= maximum load)

equals 4 x 30 kg, or 120 kg.

– To store the setting, press and hold the ) key (> 2 sec).

– Select menu item1-19-2 (key sequence: k, )).

– Enter the resolution (lowest scale interval d) (e.g., 0.01 kg). This value has to

match that stored under menu item 11-4-1 (or 11-5-1 or 11-6-1).

– To store the setting, press and hold the ) key (> 2 sec).

– Open menu item 1-19-3 (key sequence: k )).

Enter the sensitivity of the load cell in mV/V (usually listed in the load cell

specification sheets). If a weighing platform consists of more than one load

cell, enter the sensitivity of load cell 1.

Example: The sensitivity of the load cell is 1.9440 mV/V.

– To store the setting, press and hold the ) key (> 2 sec).

Note: If a weighing platform consists of more than one load cell, enter the sensitivity

values for the other cells (up to 4) under menu items 1-19-4 (for load cell 2)

through 1-19-6 (for load cell 4) and confirm each value (k and ) keys).

If the platform has less than four load cells, enter “0.000” under the unused menu

items.

display_schrittw_001Ib.eps

Display_WZE19440.eps

64

– Press ) and then ) to select menu item 1-19-7,

(Store values for menu item 1-19).

– Press ) ( ( to store the load cell specifications entered; the menu

automatically jumps back to the first menu page.

– Press e twice; the indicator is now in weighing mode.

– Close the menu access switch (see page 14).

– Turn the Combics indicator off and then on again to activate the new

configuration.

Entering the Date of Service

After performing maintenance or repair, you can enter the date of the

next scheduled maintenance visit.

– Activate the service mode (see page 17).

– Press k repeatedly to scroll through the menu until the display

shows S-dAtE.

s-date.eps

Display_Serv_01197.eps

Display_Serv_01.eps

code_s.eps

65

– Press ) activate the input mode (the cursor flashes in the first position).

– Press the ) k p keys as needed to enter the next scheduled

maintenance date (for example, 25 Apr 03).

– Press and hold the ) key (with the cursor to the right of the last character)

to store the date; the display returns automatically to S-dAtE.

– Press e twice to return the Combics indicator to the weighing mode.

Entering the Serial Number of the Combics Indicator

After replacing the digital PCB, the serial number of the Combics

scale or Combics indicator must be written in memory.

– Activate the service mode (see page 17).

cursor.eps

s-date.eps

0lb_o.eps

s-date1.eps

code_s.eps

66

– Press k k k to scroll through the menu until the display shows Ser-

no.

– Press ) activate the input mode.

– Press the ) k p keys as needed to enter the serial number ( for

example, 13800012) of the existing weighing system.

Note: After you enter the last digit, the first digit is no longer displayed.

– Press and hold the ) key to store the serial number; the display returns

automatically to Ser-no.

– Press e twice to return the Combics indicator to the weighing mode.

0lb_o.eps

cursor.eps

ser-no1.eps

ser-no.eps

ser-no.eps

67

Entering the Model Designation of the Combics Indicator

After replacing the digital PCB, the model designation of the scale or

Combics indicator must be written in memory.

– Activate the service mode (see page 17).

– Press k k k k to scroll through the menu until the display shows

ModEL.

– Press ) activate the input mode (the cursor flashes in the first position).

– Press the ) k keys as needed to enter the model designation (for

example, CISL_1U of the weighing system.

– Press and hold the ) key (with the cursor to the right of the last character)

to store the model designation; the display returns automatically to ModEL.

– Press e twice to return the Combics indicator to the weighing mode.

cursor.eps

Display_CISLIU_.eps

model.eps

model.eps

code_s.eps

0lb_o.eps

68

Defining Transaction Numbers for Data Records (Weight Values)

which were stored in the Alibi Memory

– Activate the service mode (see page 17).

– Press k k to scroll through the menu until the display shows MEM-no.

– Press ) activate the input mode (the cursor flashes in the first position).

– Press the ) k keys as needed to enter the allocation number in the Alibi

memory.

– Press and hold the ) key (with the cursor to the right of the last character)

to store the allocation number; the display returns automatically to MEM-no.

– Press e twice to return the Combics indicator to the weighing mode.

code_s.eps

memory.eps

cursor.eps

memory1.eps

memory.eps

0lb_o.eps

69

Repairing the Combics Indicator

Important: An isolating transformer must be installed between the indicator and mains

before performing work that entails opening the Combics indicator housing.

To open the Combics indicator, remove the four nuts as shown in the illustration

on the left.

Note: After completing maintenance or repair work, check the seal between the

front panel and the housing body for damage and replace if necessary.

If the Combics indicator in question has an IP67 protection rating,

a special test procedure is used to check the IP67 protection after the

housing has been closed.

Replacing the Front Panel

In the case of a defective keypad overlay, keys, LEDs, or display, the entire front

panel must be replaced.

combics_10.eps

70

Blank Display

If the display is blank (dark), disconnect the equipment from mains, open the

housing and disconnect all cables and wires from the subassemblies.

Then connect the equipment to power again through an isolating transformer and

connect all subassemblies again, measuring the supply voltage in each case.

– The voltage at the power supply output (connector A; see page 71) is

15V ± 0.3 V direct current.

– The output voltages of the DC/DC converter are listed on page 72.

Replacing the Power Cable

– Disconnect the cable from the power source.

– After replacing the power cable, use a torque wrench to tighten the cable gland

to 3 Nm.

pg_netz.jpg

71

Replacing the Power PCB

– Disconnect the cable from the power source.