98648-010-90

Operating Instructions

Sartorius Combics Complete Scales

Models CH1NE | CH1NG | CW1P | CW1NP | CW1S | CW1FS | CW1NFS | CWINS | CW2P | CW2S | CW2FS

Combics complete scales are rugged

scales with indicators (Combics 1,

Combics 1 plus and Combics 2) for

the complex quality control tasks you

perform every day. They meet the

highest requirements placed on the

accuracy and reliability of weighing

results:

– in the food industry

– in the pharmaceutical industry

– in the chemical industry

– in the electronics and metal-working

industries

Combics complete scales are:

– Rugged and durable

(stainless steel housing)

– Easy to clean and disinfect

– Easy to operate, thanks to the following

features:

– large, backlit display segments

– large keys with positive click action

– Independent of the weighing

instrument location

– Equipped with a range of interfaces

for flexible use

– Password-protected from unauthorized

changes in parameters (optional)

Combics 1 plus speeds up your routine

procedures with:

– Input functions for tare values

through numeric keypad

– Option for 2 alphanumeric lines

to identify samples

– Connectivity for bar code scanner

to enter tare values or ID codes

Combics 2 indicators have the following

features:

– Built-in application programs:

– Counting

– Neutral measurement

– Weighing in percent

– Averaging

– Checkweighing

– Classification

– Net-total formulation

– Totalizing

– Automatic initialization when you

switch on the Combics

– Automatic taring when a load is placed

on the weighing instrument

– Optional remote control using an

external computer

Symbols

The following symbols are used in

these instructions:

§ indicates required steps

$ describes what happens after you

have performed a certain step

!indicates a hazard

Hotline:

For advice on the use of these

applications, just call or fax your local

Sartorius office. For the address, please

visit our Internet website at:

www.sartorius.com

2

Intended Use

Page

2 Intended Use

4 Warnings and Safety Precautions

5 General View of the Equipment

6 Getting Started

12 Operating Design

12 Weighing/Measurement

14 Configuration (Operating Menu)

15 Operation

15 Weighing W

23 Individual ID Codes

25 Calibration and Adjustment

27 Counting Z

31 Neutral Measurement Z nm

35 Checkweighing O

40 Classification O cl

45 Weighing in Percent %

49 Averaging (Animal Weighing) V

52 Net-total Formulation R

55 Totalizing Σ

59 Configuration

59 Operating Menu Overview

60 Setting the Language (Example)

61 Entering/Changing the Password (Example)

63 Operating Menu Overview (Parameters)

3

Contents

Page

79 Data Interfaces

81 Pin Assignment Charts

83 Installing the Interface Cable

84 Cabling Diagram

85 Synchronization

86 Configuring the Data Interface

as a COM Port

86 Data Input Format

87 Data Output Format

89 Configuring the Data Interface

as a Printer Port

89 Configuring Printouts

91 Sample Printouts

94 Error Codes

95 Care and Maintenance

95 Repairs

95 Cleaning

95 Safety Inspection

96 Recycling

97 Overview

97 Common Specifications

97 Model-specific Specifications

98 Type Designation

101 Dimensions (Scale Drawings)

103 Accessories

107 Declaration of Conformity

109 EC Type-approval Certificate

111 Plates and Markings

119 Index

Appendix:

General Password

Safety Information:

§ Please read these operating instructions

carefully before using your scale

to prevent damage to the equipment.

!Do not use this equipment in

hazardous areas.

!Use only standard cables that have

protective grounding conductors.

The protective conductor must not

be disconnected for any reason.

!Disconnect the scale from power before

connecting or disconnecting peripheral

devices.

!The scale may be opened only by

trained service technicians.

!If you operate the equipment under

ambient conditions subject to higher

safety standards, you must comply with

the applicable installation regulations.

!If there is visible damage to the

equipment or power cord, unplug the

equipment and make sure it cannot

be used for the time being.

!If you use electrical equipment in

installations and under ambient

conditions requiring higher safety

standards, you must comply with

the provisions as specified in the

applicable regulations for installation

in your country.

Installation:

– Proceed with extreme caution when

using pre-wired RS-232 connecting

cables from other manufacturers,

as the pin assignments may not be

compatible with Sartorius equipment.

Check all pin assignments against the

cabling diagrams and disconnect any

lines that are not assigned.

!Always wear gloves, safety boots and

protective clothing when lifting the

load plate with a vacuum lifting pad.

Danger of injury! This work may

be carried out only by authorized and

properly trained personnel.

– Weighing platforms with dimensions

larger than 1 x 1 m are provided with

suspension supports. Be careful not

to stand under the load when the

weighing platform/load plate is being

transported or lifted with a crane.

Always comply with the applicable

accident prevention regulations. Make

sure to avoid damaging the terminal

box and housing or the load cell during

transport.

– Connect only Sartorius accessories and

options, as these are optimally designed

for use with your Combics indicator.

The operator shall be solely responsible

for installation and testing of any

modifications to Sartorius equipment,

including connection of cables or

equipment not supplied by Sartorius.

Contact Sartorius for detailed operating

specifications in accordance with the

Standards for immunity to interference.

– Do not expose the indicator to

aggressive chemical vapors or to

extreme temperatures, moisture,

shocks, or vibration.

– Clean your Combics only in accordance

with the cleaning instructions (see “Care

and Maintenance”).

$ If you have any problems with your

Combics indicator, contact your local

Sartorius customer service center.

IP Rating:

– CW1P | CW1NP | CW2P | CH1NE

models are rated to IP44

(with option L1: IP65);

– CW1(F)S | CW1N(F)S | CH1NG |

CW2(F)S models are rated to IP67.

– The IP65/IP67 protection rating is

ensured only if the rubber gasket is

installed and all connections are

fastened securely (including the caps on

unused sockets). Weighing instruments

must be installed and tested by a

certified technician.

– If you install an interface port after

setting up your indicator, keep the

protective cap in a safe place for future

use. The cap protects the interface

connector from vapors, moisture and

dust or dirt.

Using the Equipment in Legal

Metrology in the EU*:

– When the indicator is connected to a

weighing instrument and the resulting

weighing instrument is to be verified,

make sure to observe the applicable

regulations regarding verification. When

connecting a Sartorius weighing instrument, please observe the “Guide to

Verification" on the enclosed CD and

the permitted weighing range as listed

in the Declaration of Conformity.

– EU legislation requires that a control

seal be affixed to the verified device.

The control seal consists of a sticker

with the “Sartorius" logo. This seal will

be irreparably damaged if you attempt

to remove it. If any of the verification

seals are damaged, make sure to observe

the national regulations and standards

applicable in your country in such cases.

In some countries, the verification will

become null and void and the equipment must be re-verified.

* Including the Signatories of the Agree-

ment on the European Economic Area

4

Warning and Safety Precautions

5

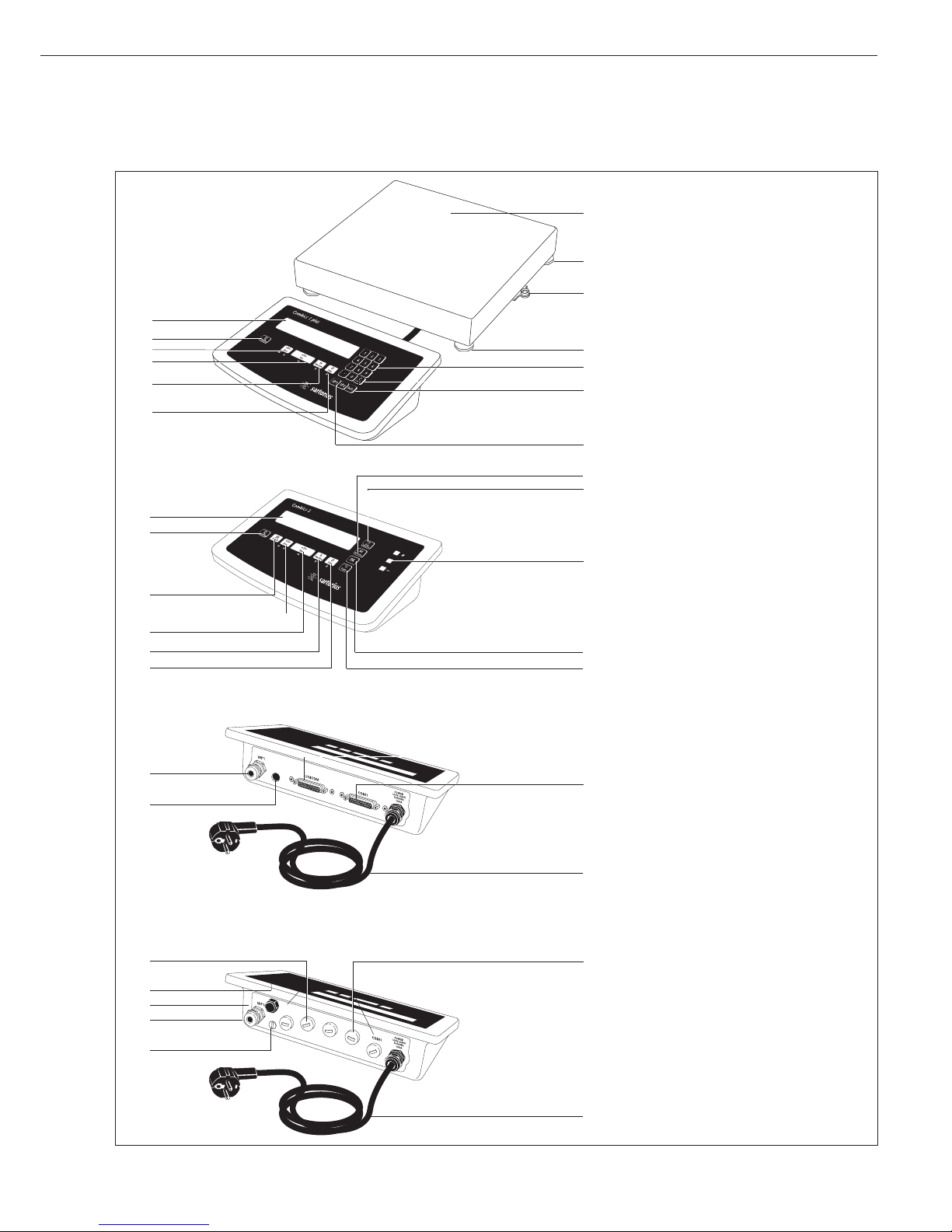

Display and Keypad:

1 Load plate

2 Leveling feet

3 Level indicator

4* Keypad for numeric input

5* “Clear” key (deletes ID codes and

tare input

6* “Info” key (shows ID codes and tare

input)

7* ID keys (for enteriing ID codes)

8 Data output

9 Gross/net; 2nd unit or 10 x higher

resolution (depending on the

settings)

10 Tare

11 Zero

12 On/off key

13 Display (for a detailed view, see

chapter entitled “Operating Design”

14 Select reference weight

(depending on the application)

15 “Clear” key

16 LEDs (for checkweighing and

classification)

17 Start application

18 Toggle to the application program |

application-specific information

19 Toggle to different weighing

platform

* Combics 1 plus only

General View of the Equipment

Combics 2

Rear view: Model: CW1P | CW1NP | CW2P

Rear view: Model:

CW1S | CW1NS | CW2S | CW1FS | CW1NFS | CW2FS | CH1NE | CH1NG

13

12

11

10

9

8

13

12

19

11

10

9

8

24

23

19

25

24

23

Combics 1|Combics 1 plus

Rear View

20

Second “UNICOM” interface port

for bar code scanner or external

rechargeable battery pack (Combics 2

only) (additional functions optional)

21 RS-232C “COM1” interface port

(standard)

22 Power cord with country-

specific plug

23 Menu access switch

(standard operating mode or

legal metrology mode)

24 Connector for weighing platform

25 Vent valve

1

2

3

2

4

5

6

7

14

15

16

17

18

20

21

22

21

22

6

The complete scale is available in

various versions. If you have ordered

special options, the indicator will be

supplied with these options premounted

at the factory.

Storage and Shipping Conditions

– Allowable storage temperature:

-10 ...+40°C (+14°F ... + 104°F)

– Unpackaged equipment may lose

its accuracy when exposed to strong

vibration. Excessive vibration may

compromise the safety of the

equipment.

– Do not expose the indicator

unnecessarily to extreme temperatures,

moisture, shocks, or vibration.

Unpacking

§ After unpacking the equipment,

please check it immediately for any

visible damage.

$ If you detect any damage, proceed

as directed in the chapter entitled

“Care and Maintenance” under “Safety

Inspection."

$ If you will need to ship the equipment

later, save all parts of the packaging

because only the original packaging

provides the best protection for

shipment.

$ Before shipping, be sure to disconnect

all cables to prevent damage.

Equipment Supplied

– Indicator

– Weighing platform

– Operating instructions (this manual)

– Special accessories listed on the bill of

delivery, if ordered

Getting Started

Installation Instructions

Choose a location that is not subject to

the following unfavorable conditions:

– Excessive temperatures (operating

temperature range: -10°C to +40°C;

+14°F to +104°F)

– Aggressive chemical vapors

– Excessive moisture (depends on

IP rating)

Conditioning the Indicator

Moisture in the air can condense on

cold surfaces whenever the equipment

is moved to a substantially warmer

place. To avoid the effects of condensa-

tion, condition the indicator for about

2 hours at room temperature, leaving it

unplugged from AC power.

Checking the Geographical Data

Entered for Use in Legal Metrology

Preparation

(see also the “Device Information”

menu items listed under “Operating

Menu Overview” in the chapter entitled

“Configuration”.)

§ Press e to turn on the Combics

§ While all segments are lit, press )

> Appl is displayed

§ Select “Info”: Press k repeatedly;

press ) to confirm

§ Select “Device Specific Information”:

for WP1 or WP2: Press k repeatedly;

press ) to confirm

> Press k repeatedly to scroll through

the geographical data (data shown

depends on input before verification),

for example:

Latitude (in degrees): 51

4

Evalation (in meters): 513

5

or

Acceleration of gravity in m/s

–2

: 9.810

6

The scale can be used anywhere in

Germany if the geographical data is as

follows:

– Latitude: 51.00 degrees

Elevation: 513 meters

This data corresponds to the following

value:

Acceleration of gravity: 9.810 m/s

–2

These values are calculated for Germany

based on a mean value for the Earth’s

acceleration. The greater the precision

of the geographical data entered, the

greater the precision achieved with the

weighing instrument; the tolerance range,

however, is also restricted accordingly.

The tolerance ranges, for example

for a scale with 3000 e, are as follows:

– ±100 km for the latitude and

– ±200 m for the elevation above sea level.

!If used outside the specified zone, the

scale must be re-verified for use in legal

metrology. Please contact an authorized

service technician.

Seal on Indicators Verified for Use

in Legal Metrology in the EU*:

EU legislation requires that a control

seal be affixed to the verified device.

The control seal consists of a sticker

with the “Sartorius" logo. This seal will

be irreparably damaged if you attempt

to remove it. If the seal is broken, the

validity of the version becomes null

and void, and you must have your scale

re-verified.

* Including the Signatories of

the Agreement on the European

Economic Area

7

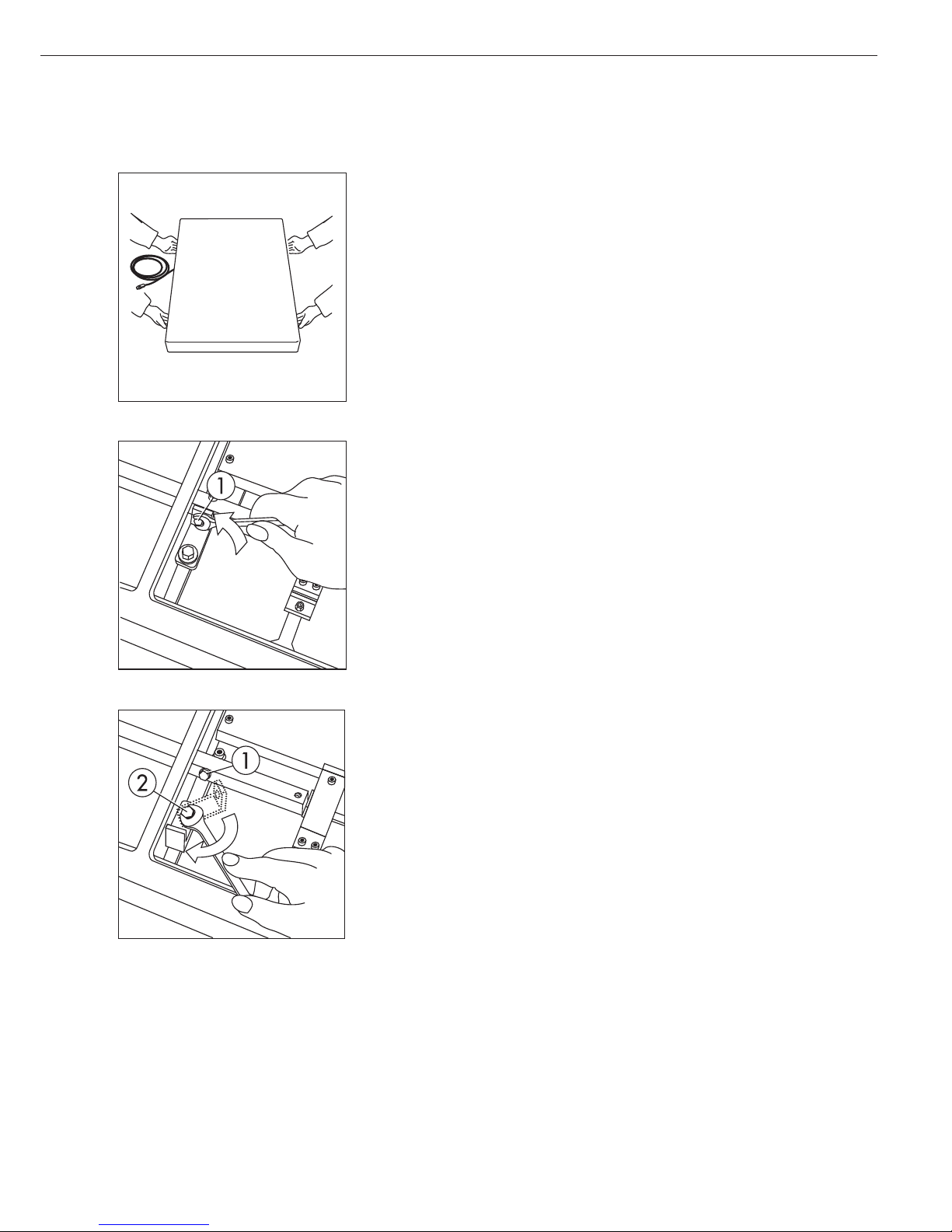

Unpacking the Platform

Important note:

These instructions apply to platforms that are 60 x 80 cm and larger.

§ Remove the weighing platform and weighing pan from the packaging.

§ When transporting or lifting the device, hold the unit on the longer sides and observe the

safety precautions (wear safety shoes and gloves if necessary).

§ Remove any plastic wrapping, packaging strips and styrofoam.

Removing the Transport Locking Device

§ Bring the scale to the location where it will be used and remove the weighing pan.

§ Loosen the transport locking device by removing screw 1.

§ Loosen screw 2, turn the fastening bracket by 180? and then tighten screw 2.

§ Tighten screw 1 again at the lever.

Important Note Regarding Transport of the Weighing Platform

!Be sure to refasten the transport locking device before transporting the weighing

platform.

Level the weighing platform at the weighing location using the adjustable feet so that the

air bubble is centered in the level indicator circle. Check that all four adjustable feet are

in contact with the surface.

The load must be equally distributed over all four leveling feet.

Connecting the Equipment to AC Power

§ Check the voltage rating and the plug design.

$ The scale is powered through the pre-installed power cord. The power supply is built

into the scale, which can be operated with a supply voltage of 100V to 240V.

Make sure that the voltage rating printed on the manufacturer´s ID label is identical to that

of your local line voltage. If the voltage specified on the label or the plug design of the

AC adapter does not match the rating or standard you use, please contact your Sartorius

office or dealer.

The power connection must be made in accordance with the regulations applicable in

your country.

§ To power a protective class 1 device, plug the power cord into an electrical outlet

(mains supply) that is properly installed with a protective grounding conductor

(protective earth = PE).

Safety Precautions

If your local AC output does not have a protective grounding conductor (protective earth),

have a certified electrician install equivalent protection according to your country’s valid

installation requirements. Make sure the protective grounding effect is not neutralized by

use of an extension cord that lacks a protective grounding conductor.

Connecting Electronic Peripheral Devices

§ Make absolutely sure to unplug the device from AC power before you connect or disconnect

a peripheral device (printer or PC) to or from the interface port.

Warmup Time

To deliver exact results, the device must warm up for at least 30 minutes after initial

connection to AC power or after a relatively long power outage. Only after this time will

the device have reached the required operating temperature.

Using Equipment Verified as Legal Measuring Instruments in the EU*:

$ Make sure to allow the equipment to warm up for at least 24 hours after initial connection

to AC power or after a relatively long power outage.

Connecting the External Rechargeable Battery Pack (Accessory: YRB10Z)

!Disconnect the equipment from AC power (unplug the AC adapter)

§ Installation

For model CW1P | CW1NP | CW2P: Connect a 25-pin D-SUB male connector (connecting

cable YCC02-RB01) to a second “UNICOM“ interface port

For model CW1(F)S | CW1N(F)S | CW2(F)S: see the section “Pin Assignment Chart”

(via connecting cable YCC02-RB02 or as option L2)

Operating

– Hours of operation: up to 40, depending on the weighing platform connected; without

options. The Combics will automatically switch to battery operation whenever there is a

power shortage or the power is cut off. Once the mains power supply is reinstated, the Combics will automatically switch back to normal operation.

Battery symbol

Battery fully charged:

Battery empty:

* including the Signatories of the Agreement on the European Economic Area

8

9

Connecting a Bar Code Scanner (Accessory: YBR02CISL)

!Disconnect the equipment from AC power (unplug the AC adapter)

$ Installation

For model CW1NP | CW2P:

– Connect a 25-pin D-SUB male connector (connecting cable YCC02-BR01) to a second

“UNICOM” interface port

– For bar code scanner and external rechargeable battery: please use T connector YTC01.

For model CW1N(F)S | CW2(F)S: see the section entitled “Pin Assignment Chart“

(via connecting cable YCC02-RB02 or as option M8)

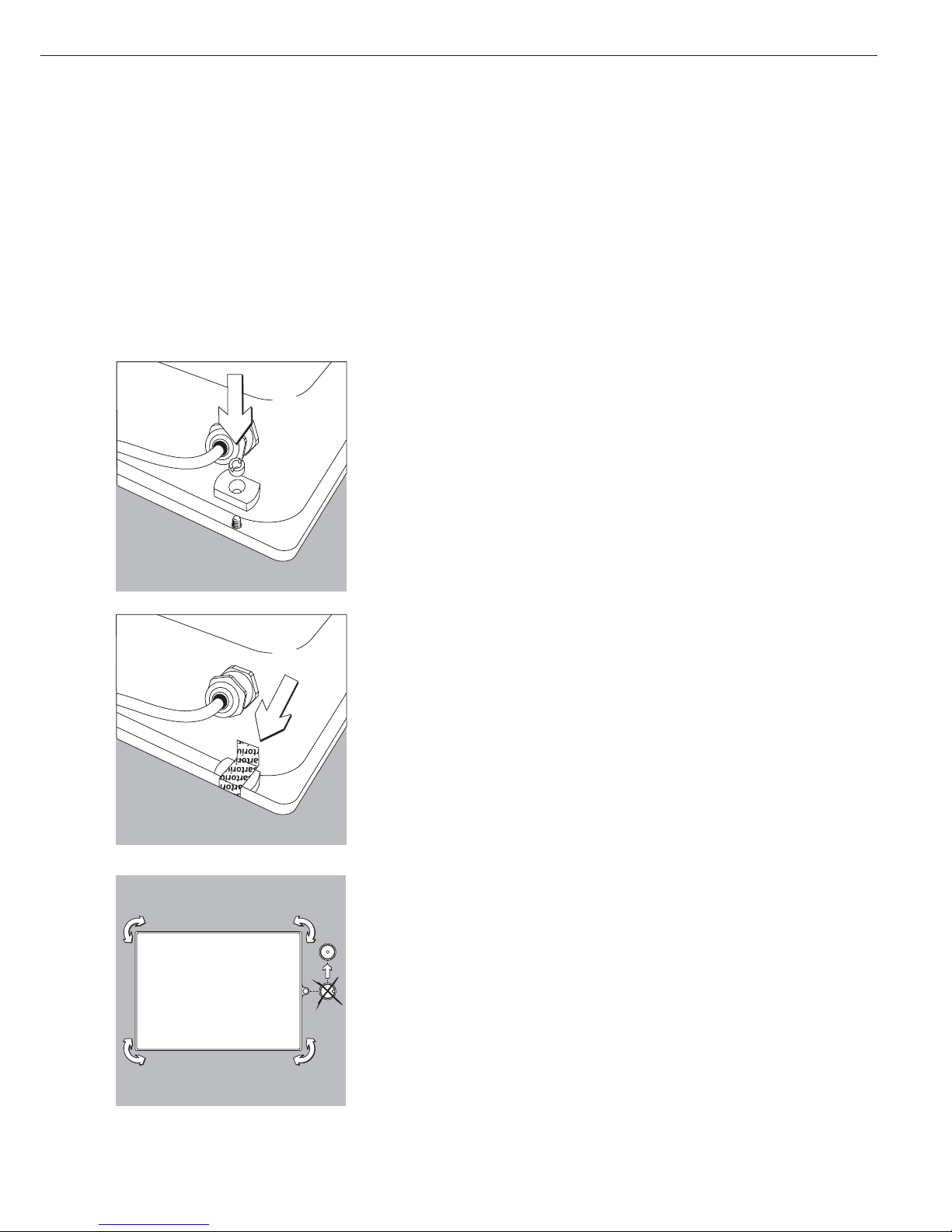

Installing the Verification Adapter for Use in Legal Metrology

(on verifiable models only)

§ Remove the nut located on the back of the indicator

§ Use the slotted screw to install the adapter plate

§ Affix the verification seal over the adapter

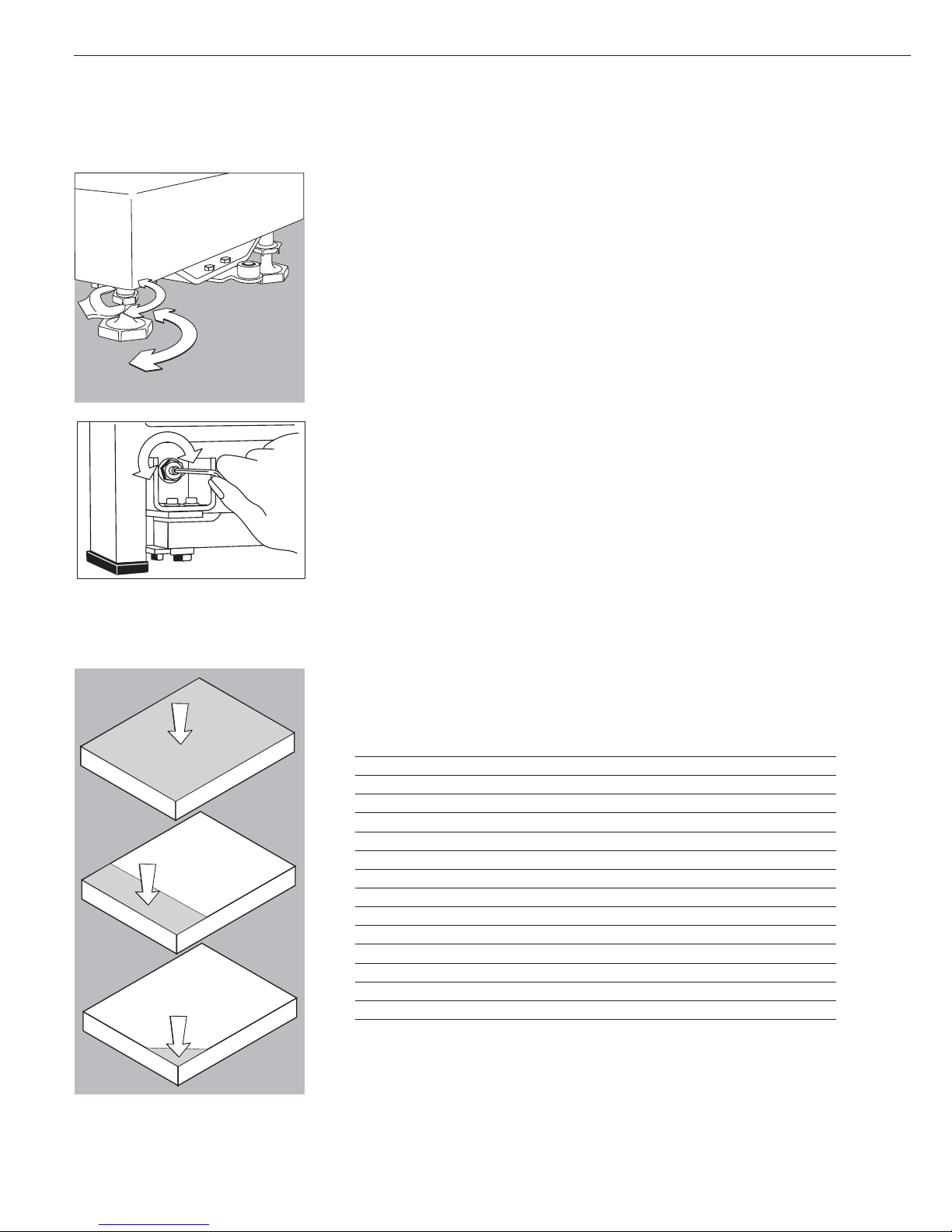

Leveling the Weighing Platform

Purpose:

– To compensate for uneven areas at the place of installation

– Make sure that the equipment is placed in a perfectly horizontal position for

consistently reproducible weighing results

Always re-level the weighing platform after changing the place of installation.

§ Remove the weighing pan.

§ Level the weighing platform using the four adjustable feet. Keep turning the feet

until the air bubble is centered in the level indicator circle.

§ Loosen the lock nuts on the leveling feet using an SW17 wrench.

§ Use an SW5 Allen wrench to extend or retract the leveling feet.

> Setting the adjustable feet:

Raise the weighing platform by extending the leveling feet (turning clockwise).

Lower the weighing platform by retracting the leveling feet

(turning counterclockwise).

§ After aligning the weighing platform, tighten the lock nuts against the platform frame.

> Small platforms (1 weighing cell): against the platform frame,

large platforms (4 weighing cells): against the platform foot.

§ Make sure that all the leveling feet are touching the surface.

The load must be equally distributed over all the leveling feet.

§ Once you have leveled the weighing platform, tighten the lock nuts.

§ Place the weighing pan back onto the weighing platform.

Operating Tolerances

Never exceed the maximum capacity of the weighing platforms.

The maximum loading capacities of the weighing platforms are listed in the table

below and depend on the position of the weight loaded on the platform (center, sides,

one-sided corner load):

Platform dimensions Center Side Corner

320 x 240 50 35 20

400 x 300 130 85 45

500 x 400 300 200 100

500 x 400 (P*) 600 400 200

650 x 500 (S**) 450 300 150

800 x 600 (P*) 1,200 800 400

800 x 600 (S**) 900 600 300

800 x 800 4,500 3,000 1,500

1000 x 800 4,500 3,000 1,500

1000 x 1000 4,500 3,000 1,500

1250 x 1000 4,500 3,000 1,500

1500 x 1250 4,500 3,000 1,500

1500 x 1500 4,500 3,000 1,500

2000 x 1500 4,500 3,000 1,500

* Steel

** Stainless steel

10

11

For CH*E models:

Platform dimensions Loading capacity (center) in kg

300 x 400 130

For CH*G models:

Platform dimensions Loading capacity (center) in kg

300 x 400 130

Platform dimensions Loading capacity (center) in kg

800 x 600 600

Shock Resistance

The weighing platform features a rugged construction, but you should not allow objects

to fall onto the weighing pan. Also avoid bumps to the side of the unit and shocks.

The weighing platform withstands the loads specified in standard DIN 1EC68, Part 2-27.

Important Note About Planning Structures for Attachment to the Weighing Platform

The weighing platform is suitable for installation in systems. The scale drawings should

be used as the basis for selecting any necessary structures to be affixed to the platform.

Use the YAS041S fastening set to secure the weighing platform.

Moving or rotating parts on the weighing pan must be designed so that they do not

influence the weighing results. For example, rotating parts must be balanced. The

weighing pan must have clearance on all sides to prevent any falling objects or dirt from

creating a connection between the weighing platform and any permanent structures.

Cables and hoses between the weighing platform and other devices must not exert any

force on the weighing platform. These cables must not touch the weighing pan.

When setting up systems in hazardous areas (zone 2 or 22), be sure to observe and

comply with the relevant regulations (e.g., EN60079-14).

Pay special attention that electrostatic charges resulting from moving parts

(e.g., conveyors) are avoided or discharged.

Preload Range (Zero-Point Range)

The weight of any structures that are permanently mounted on the weighing platform

constitutes the “preload.” The preload is electronically compensated in the weighing

platform so that the entire weighing range is available and so that the scale can be

zeroed or calibrated (using external weights).

Larger preloads will lead to a reduction of the weighing range. The weight on the scale

may not fall below the following weighing range values:

– At least 30 kg of the weighing range must remain for models CH*G-150 1G-H

– At least 60 kg of the weighing range must remain for models CH*G-300 1G-H

!You must always set the preload prior to verifying the scale for legal metrology.

All structures must be mounted on the weighing platform before it is connected to AC

power.

11

Keys

The operation of Combics 1, Combics 1

plus and Combics 2 involves just a few

keys. These keys have one function

during measurement and another

during configuration. Some of the keys

have one function when pressed briefly,

and another when held for longer than

2 seconds.

If a key is inactive, this is indicated as

follows when it is pressed:

– The error code “-------" is displayed

for 2 seconds. The display then returns

to the previous screen content.

– An acoustic signal (double-beep)

is emitted.

Weighing/Measurement

Input Through the Keypad

Keys below the Display

e On/off key

(in standby mode, off is displayed).

( – Press briefly:

Zero the instrument

– Press and hold (> 2 sec ):

Show the adjustment/

configuration counter

) – Tare the instrument

– Save numeric input as tare weight

(Combics 1 plus only)

– Press and hold (> 2 sec ):

Start calibration/adjustment

k Toggle the display between

(depends on configuration):

– first and second weight unit,

– gross and net values, or

– normal and 10-fold increased

display resolution

p – Press briefly: Print

– Press and hold (> 2 sec ):

Print GMP footer

n When two weighing instruments

are connected, this key toggles the

display between instruments

(Combics 2 only).

Keys to the Right of the Display on

Combics 1 plus

Keys for entering ID codes and tare values

1, 2, 3… 9, .

Numeric keypad for entering

values that are identified by the key

subsequently pressed (e.g., ) for

tare input or “ID" key for ID codes)

E Press to delete data (either ID code

or tare input, depending on subsequent key; e.g., ) for tare)

When pressed during numeric input:

deletes the last character entered

I Press to enter data (either ID code

or tare value, depending on subsequent key; e.g. )) for tare)

g, h

Press to store or view ID codes

(user-defined data to identify

weight values)

Keys to the Right of the Display on

Combics 2

These keys are used for operating

applications. Please refer to the individual application descriptions for details.

c Deletes initialization values or

totalizing memory, depending on

configuration.

r For modifying reference values.

O Store a value or start an

application program.

w Toggle between display modes

within an application program

Input Through the Digital Input Port

The indicator is equipped with a control

input (universal input port). You can

connect a hand switch or foot switch

to this port, if desired. Assign one

of the following functions to this port

in the operating menu:

– p key

– p (> 2 sec.)

– ) key

– ) key (> 2 sec.)

– k key

– n key

– O key

12

Operating Design

13

Operating Design

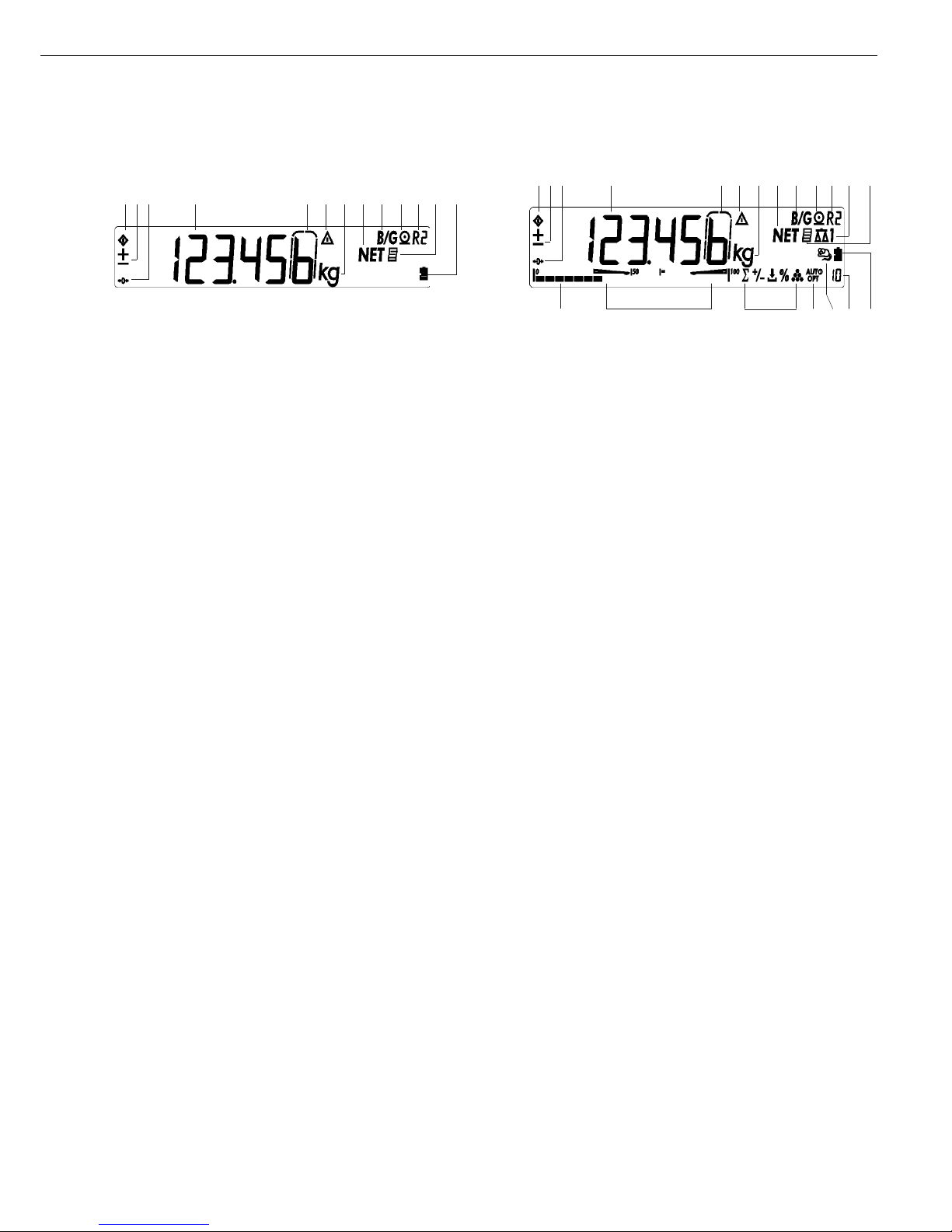

Display in Weighing Mode

The illustration above shows all of the

main display elements and symbols shown

during weighing.

1 Busy symbol; indicates that an

internal process is in progress

2 ± sign for the value displayed

3 Identifies “zero" as a weight value

(after the weighing instrument has

been zeroed)

4 Weight value or calculated value

(main display)

5 In legal metrology, on equipment

with e = d, the digit shown with

a border is not valid

6 Identification of calculated value

in the main display (value not valid

in legal metrology)

7 Weight unit of the value displayed

8 Net value in the main display

(when data is stored in tare memory)

9 Gross value in main display

(when data is stored in tare memory)

10 Printing in progress

11 Display of the range on multiple-

range instruments

12 GMP-compliant printing in progress

(Combics 1 plus and Combics 2 only)

13 Battery symbol showing status of

rechargeable battery (empty outline

indicates battery is drained)

14 Indicates active weighing instrument;

flashes to prompt calibration/

adjustment (Combics 2 only)

15 Bar graph (Combics 2 only)

– Shows how much of the available

weighing capacity is “used up" by

the current load, or

– Shows the measured value in

relation to a target value

(with the Checkweighing or

Classification application)

16 Symbols for Checkweighing and

classification (Combics 2 only)

17 Application symbols:

Totalizing, Checkweighing,

Classification, Net-total Formulation,

Weighing in Percent, Counting and

Neutral Measurement.

For details, please refer to the the

descriptions of the applications

(Combics 2 only).

18 Symbols for reference updating

(Combics 2 only)

– Auto: Depending on the weight

value, a reaction is triggered in

the application

– Opt: Automatic reference

updating has been performed

(Counting application)

19 Numeric display; e.g., shows

reference value (Combics 2 only)

Saving Data in

Weighing Mode

All of the application parameters

saved (e.g., reference values) remain

stored and are still available when

– you switch the Combics off and

then back on again

– you return to the originally selected

application from a second one

(for example, when you switch from

Averaging back to Counting, all parameters saved for Counting are available)

123 4 6 11 1271359810

123 4 6 11 1471259810

17 19 1316 17 18

15

Display during weighing/measurement Display during weighing/measurement

(Combics 1, Combics 1 plus) (example) (Combics 2) (example)

14

Configuration

(Operating Menu)

Navigation and input in the operating

menu are implemented using the keys

below the display (on Combics 1 plus,

numeric values can be entered using

the numeric keypad)

Opening the Menu

Press the e key to switch the Combics

off and then on again; while all segments

are displayed, press the ) key briefly.

Navigating the Menu

( Close the active submenu and return

to next higher menu level (“back")

) – Press briefly (< 2 sec):

Select and store a menu item

– Press and hold (> 2 sec ):

Exit the menu

k Show the next item on the

same menu level (the display scrolls

through all items in series)

p Print the menu settings starting

from the current position, or print

Info data

Alphanumeric Input in the Menu

( – Press briefly:

Activate character to the left of

the current character (when first

character is active: exit input

mode without saving changes)

– Press and hold (> 2 sec ):

Exit the input mode without

saving changes

) – Press briefly (< 2 sec):

Confirm currently active character

and move 1 position to the right

(after the last character: store

input)

– Press and hold (> 2 sec ):

Store current input and display

the menu item

k – Cursor in first position, no char-

acters entered yet: Delete charac-

ter(s) and enter 0

– Change the displayed character;

scroll forward (sequence: 0 to 9,

decimal point, minus sign, Z to A,

space)

p – Cursor in first position, no char-

acters entered yet: Delete entire

string and enter a space

– Change the displayed character;

scroll backwards (sequence:

Space, A to Z, minus sign,

decimal point, 9 to 0)

Numeric input in Combics 1 plus

operating menu:

Enter values (date and time, etc.) using

the 10-key numeric keypad

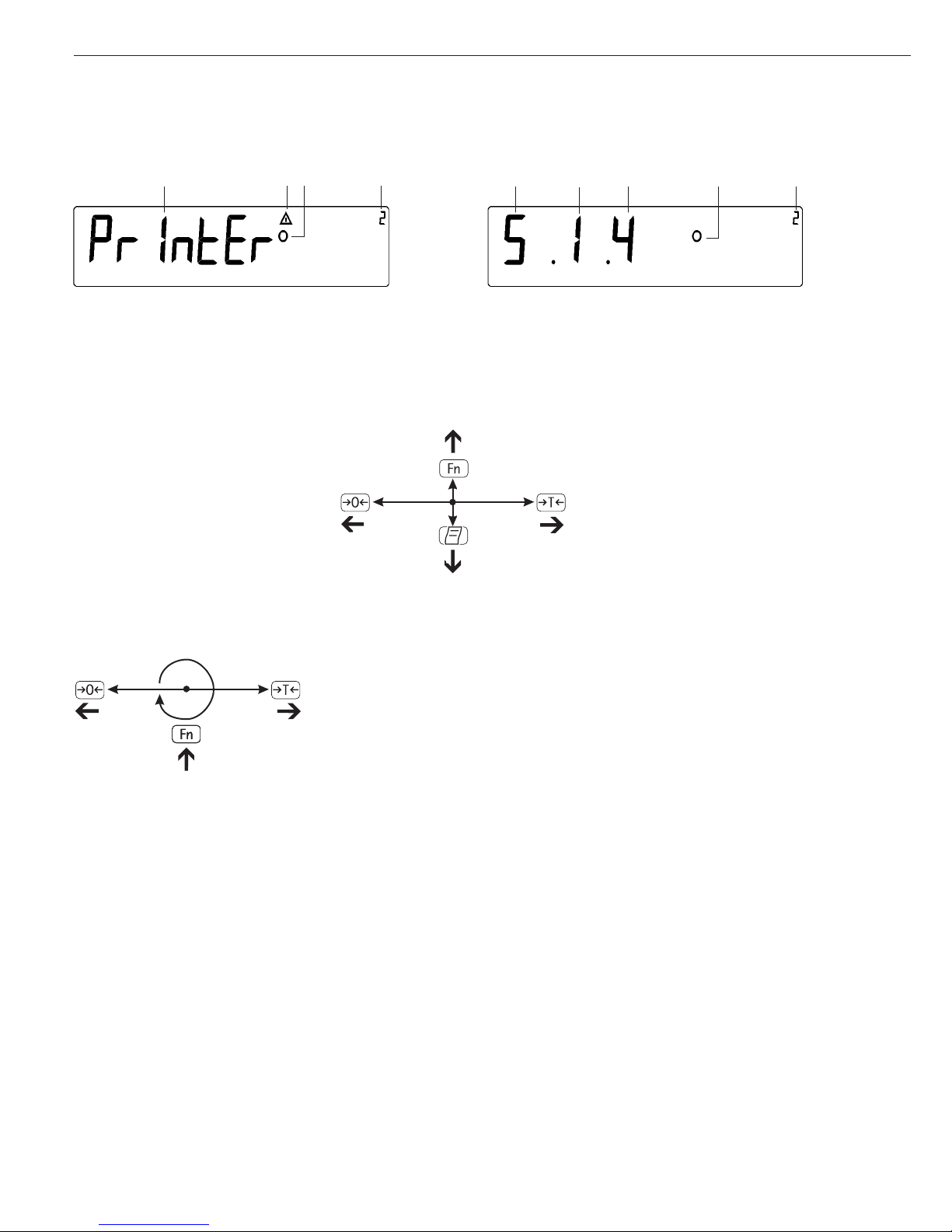

Display of Menu Settings

The illustration above shows all of the

main display elements and symbols shown

during menu configuration.

1 Selected menu item on text level

(e.g., “Printer" for configuring the

connected printer)

2 Indication that there are additional

submenus

3 Indication that this is the currently

active setting

4 Menu history (indicates the highest

menu level)

5 Highest level in numeric menu

6 Second level in numeric menu

7 Third level in numeric menu

Saving Data in Configuration Mode

The parameters selected in the operating

menu remain stored after you switch off

the Combics.

You can prevent unauthorized changes

in operating menu settings by requiring

password input for menu access.

1243

6

43

5 7

Display of menu settings: Text menu (example) Display of menu settings: Numeric menu (example)

15

Operation

Weighing W

The basic weighing function is available

at all times.

Features:

– Zero the weighing instrument

by pressing (

– Store the weight on the instrument

as tare by pressing )

– Tare container weight automatically

– Enter tare weight through bar code

scanner (Combics 1 plus and

Combics 2 only)

– Enter tare weight through numeric

keypad (Combics 1 plus only)

– Delete tare values by pressing 0

and ) or E and ) (Combics 1

plus only)

– Press k to toggle the display

between:

– Gross and net values,

– 1st and 2nd weight unit, or

– normal and 10-fold higher resolution

– Weighing with two weighing instru-

ments (Combics 2 only)

– Individual data ID codes with numeric

values for identifying weight values

(Combics 1 plus only)

– Print weight value:

– GMP-compliant printout

– Automatic printing

– Automatic data output

(see “Data Interfaces")

Automatic Taring (Menu Item 3.7)

When menu item 3.7.2 is active,

the first load placed on the weighing

instrument that exceeds the specified

minimum load is stored, at stability,

in the tare memory.

The weighing instrument returns to

the initial state when the load is less

than 50% of the minimum load.

Minimum Load for Automatic

Taring and Automatic Printing

(Menu Item 3.5)

You can choose from the following

settings for the minimum load:

1 digit (no minimum load)

2 digits

5 digits

10 digits

20 digits

50 digits

100 digits

200 digits

500 digits

1000 digits

The “digits" here refer to the intervals

in the connected weighing instrument.

If the interval of the connected instrument is 1 g, for example, and 1000 digits

are required, the minimum load is

1000 g (=1000 digits).

If the interval of the connected instrument is 5 g and the same number of

intervals is required as in the example

above, the minimum load is 5000 g.

Once the load on the weighing

instrument exceeds the specified minimum, the instrument is tared and/or a

printout is generated, if the operating

menu is configured for automatic taring

(menu item 3.7.2) and/or automatic

printing (menu item 7.13.2).

Automatic Printing (Menu Item 7.13)

When menu item 7.13.2 is active,

the first weight value that exceeds the

specified minimum load is printed.

If the menu code for automatic taring

is also active, the weighing instrument

is only tared when the minimum load

is exceeded; the value is not printed.

First Weighing Instrument Displayed

(Combics 2 only)

You can define which weighing instrument shows the first weight value when

you switch on the Combics, under

utilit (menu item 8.9).

Entering Tare Weight using

a Bar Code Scanner (Combics 1 plus

and Combics 2 only)

You can enter the tare value of a

container using a bar code scanner.

To do this, the “Store value as tare"

(tare) menu item must be selected

under “Setup > Bar code" in the

operating menu. In this case, the value

is stored as the tare automatically, without pressing the t key. The contents

of the tare memory are display in Info

mode (press and hold w).

Entering ID Codes using a Bar Code

Scanner (Combics 1 plus only)

You can use a bar code scanner to

enter ID codes.

To do this, the “Store value as ID1"

(id1) menu item must be selected

under “Setup > Bar code" in the

operating menu. In this case, the value

is stored as ID1 automatically, without

pressing the g key.

To store the second ID code, the h

key must be pressed.

To view the stored ID codes:

– Press I and g

– Press I and h

16

Calibration/Configuration

Counter on Standard

Weighing Instruments

Purpose

These two mutually independent

counters automatically keep track of

changes made in calibration/adjustment

parameters and in the operating menu.

Counter values are stored in an EEPROM, and remain stored during the

entire service life of this memory chip.

To view the current values in the

counter, press and hold the ( key

(longer than 2 sec). The readout shows

the “configuration counter" value for

3 seconds first (identified by “P").

Then the "calibration counter" value is

shown for 3 seconds (identified by “C").

The information display closes automatically after 6 seconds.

Features of the Calibration Counter:

– Limited to a count of 9999

– Counter set to “C 0000" when the

hardware is first put into operation

– Counter cannot be reset

– The counter value is updated (“1” is

added) automatically following:

– Successful calibration/adjustment

or linearization

– Changes in the user-defined cali-

bration/adjustment or linearization

weight (menu item 1.18)

– Changes in any of the following

parameters:

Function of the q key (menu item

1.9)

Zero-setting range (menu item 1.11)

Initial zero-setting range (menu item

1.12)

Resetting of the above parameters

to factory settings (menu item 9.1.1)

Features of the Configuration

Counter:

– Limited to a count of 9999

– Counter set to “P 0000" when the

hardware is first put into operation

– Counter cannot be reset

– The counter value is updated

(“1" is added) automatically following:

– Changes in the following

parameters:

Place of installation (menu item 1.1)

Application filter (menu item 1.2)

Stability range (menu item 1.3)

Taring (menu item 1.5)

Auto zero (menu item 1.6)

Weight unit 1 (menu item 1.7)

Weight unit 2 (menu item 3.1)

Weight unit 3 (menu item 3.3)

Resetting of the above parameters to

factory settings (menu item 9.1.1)

– Function of the k key changed

to or from 10-fold higher resolution

display

– Activation or deactivation of applica-

tion-dependent automatic taring

(menu item 3.7)

– Resetting of the application parame-

ters to factory settings (menu code

9.1.1)

Device parameters

Password

You can prevent unauthorized changes

in the device settings (“Setup") and

application settings (“Appl," Combics 2

only) by assigning a password under

“Setup > Code" (Code; see also the

chapter entitled “Configuration").

Acoustic Signal

An acoustic signal is emitted when

you press a key (active key: single beep;

inactive key: double-beep).

You can switch the acoustic signal off

or on under “Setup > Utilities" (Setup,

Utilit) (menu item 8.2).

Keys

In the Setup menu under “Utilit,"

you can block or release the keypad for

input (menu item 8.3).

Automatic Power-off

In the Setup menu under “Utilit"

you can configure the Combics to

shut down automatically following

a specified interval of no user activity

(menu item 8.7).

Display Backlighting

In the Setup menu under “Utilit"

you can choose from the following

settings for the display backlighting:

– On (8.8.1)

– Off (8.8.2)

– Shut off after the specified time

period has elapsed (8.8.3)

Timer Mode

In the Setup menu under “Utilit"

you can set the timer interval to

2, 4 or 10 minutes (menu item 8.9).

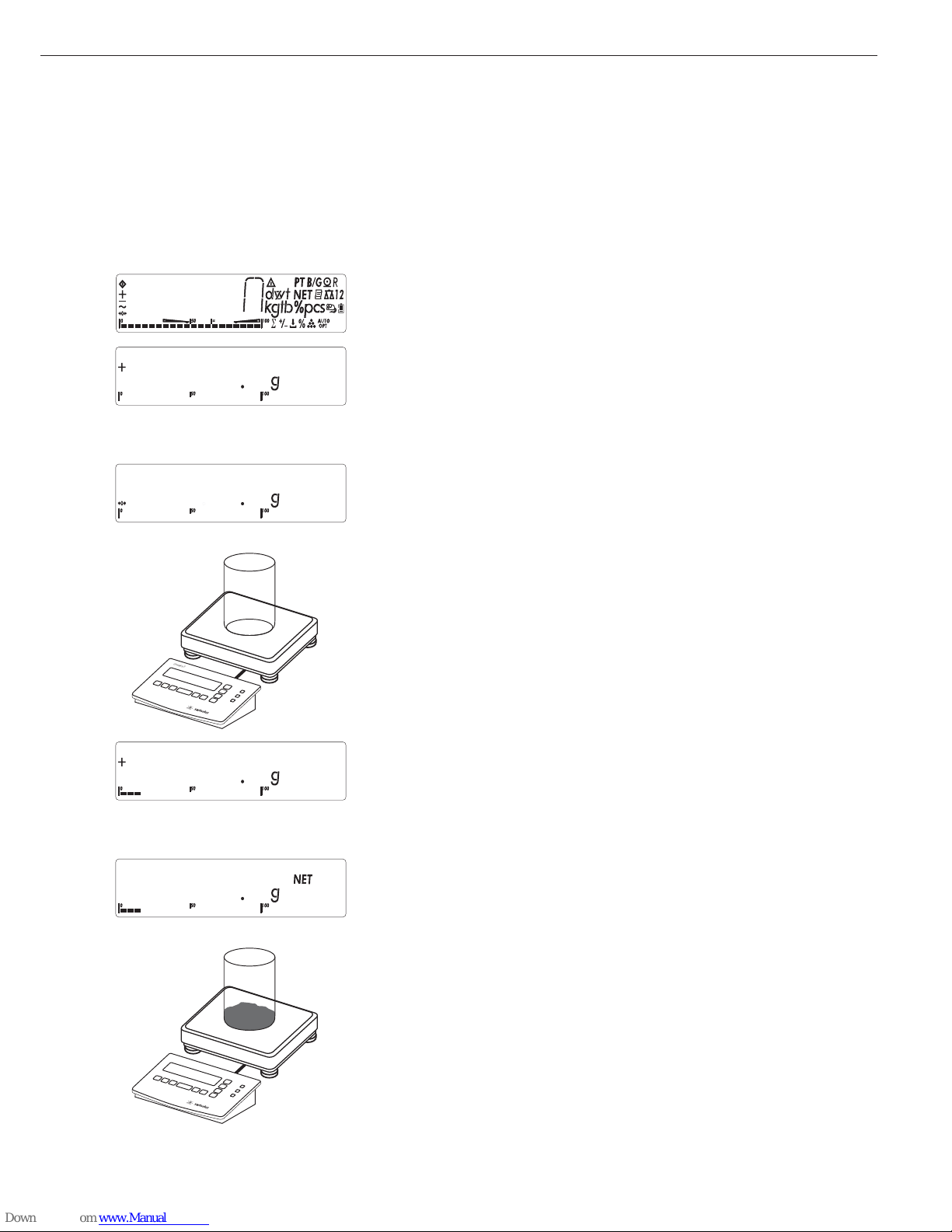

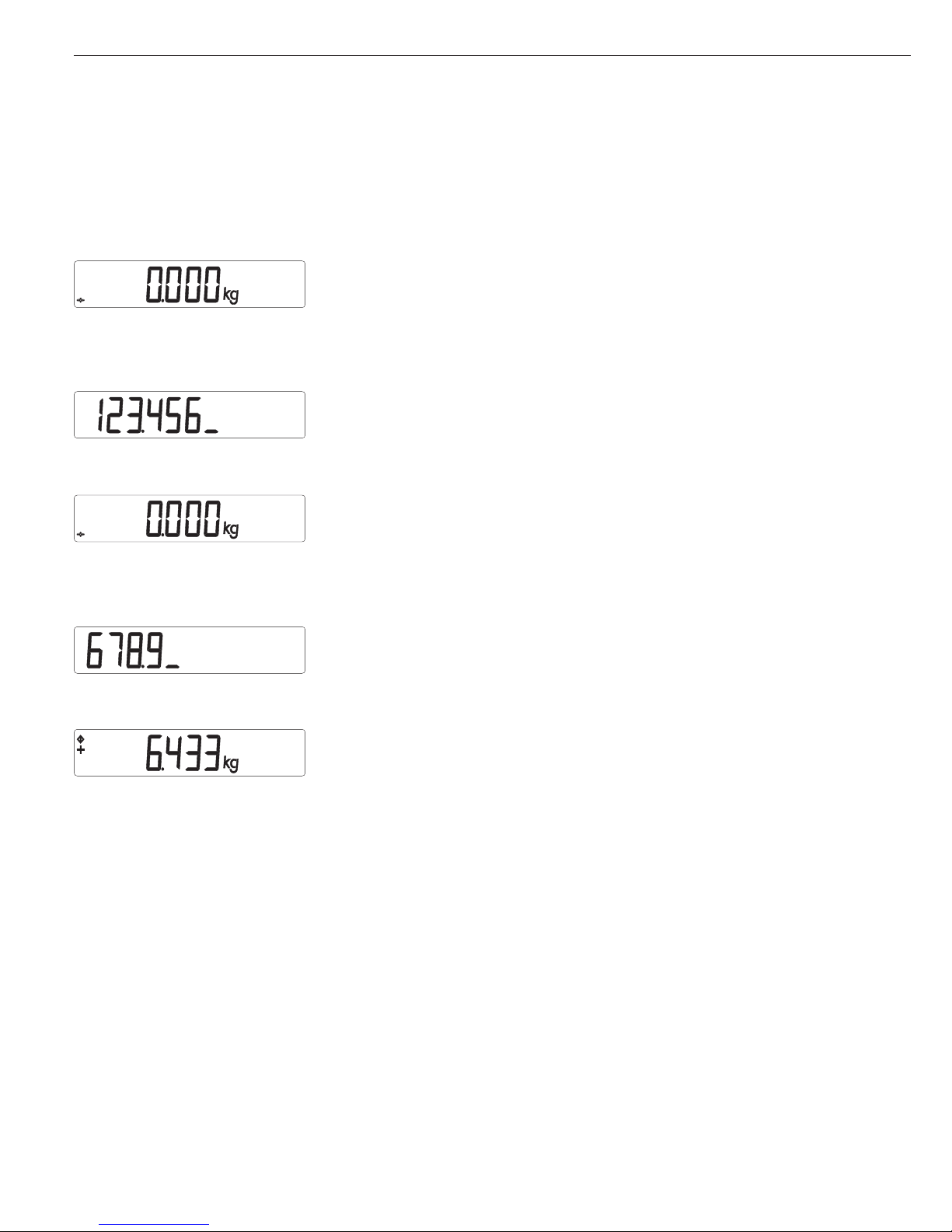

Example

Switch on the Combics, zero the weighing instrument, tare the container weight, place sample in container,

toggle display to gross weight, 2nd weight unit or 10-fold increased resolution

e Switch on the Combics

All display segments are shown for approx. 1 second (self-test)

Display with no load on weighing instrument

( Zero the weighing instrument

Display with no load on weighing instrument

Place container on weighing instrument

Container weight is displayed

) Tare the weighing instrument

Display with tared container on weighing instrument

Place sample in container (in this example, 120.2 g)

17

Operating

8

881

8888888

8

881

01

8

881

00

8

881

500

8

881

00

Combics 2

OK

REF

CF

Fn

0

T

n

-

Combics 2

OK

REF

CF

Fn

0

T

n

-

18

Display with tared weighing instrument and sample in container

k Toggle display; readout depends on your settings:

gross weight

(in this example, 50 g for container + 120.2 g substrate) or

display in 2nd weight unit (in this example, kg) or

display with 10-fold increased resolution

k Return to previous readout

(if 10-fold increased resolution is shown, display returns to previous readout

automatically after 10 seconds)

p Print results

ACE HARDWARE

GOETTINGEN

24.02.2002 15:10

--------------------

G# + 170.2 g

T + 50.0 g

N + 120.2 g

--------------------

8

881

1202

8

881

1702

8

881

12023

8

881

1202

19

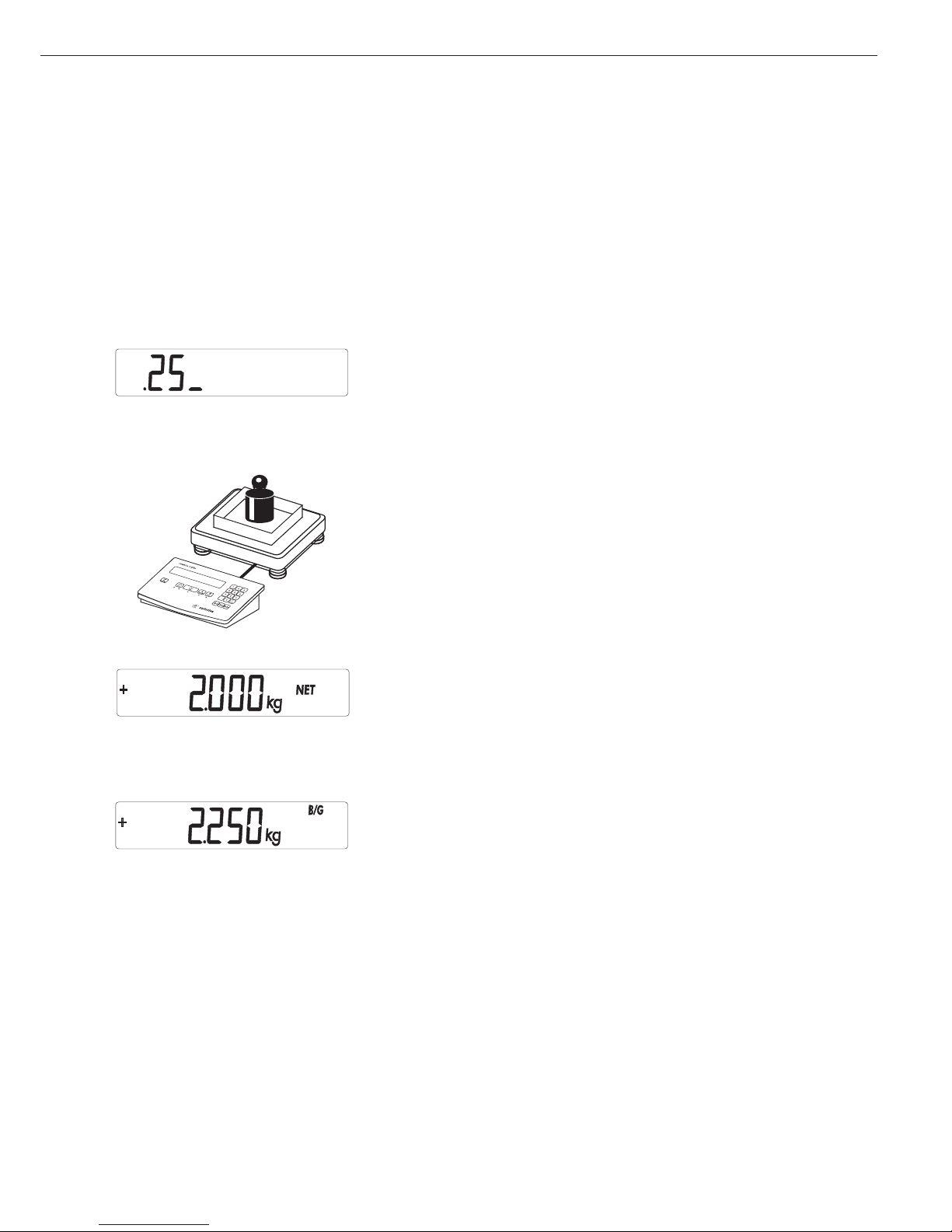

Example:

Combics 1 plus: Weighing with tare value entered using the numeric keypad; generate printout of results

e Switch on the Combics 1 plus

The automatic self-test runs. Once a readout is shown, Combics 1 plus is automatically

zeroed and ready to operate. With no load on the weighing instrument, you can zero the

instrument at any time by pressing (.

.25 Enter the tare weight in the current weight unit using the keypad

(in this example, 0.25 kg).

) Tare the weighing instrument

Place container with sample on the weighing instrument

Read the result

k Toggle the display from net to gross weight values. The display shows

the gross weight

(in this example, 0.250 kg for the container plus 2.000 kg for the sample)

Operating

20

Operating: CW1NP | CW1NS | CW1NFS | CH1NE

k Toggle to display of net value

p Print the results

---------------------- Start of GMP header (only if GMP-compliant printout is configured)

05.04.2004 10:09

Model CW1NP1-30ED-LOCE

Ser.no. 12345678

Vers. 1.0001.04.4

BVers. 01-33-01

---------------------- End of GMP header

ACE HARDWARE Header lines

GOETTINGEN

Batch no. 123456 ID code 1

Customer 6.789 ID code 2

05.04.2004 10:09

----------------------

G# + 2.250 kg

T + 0.000 kg

PT2 + 0.250 kg

N + 2.000 kg

----------------------

---------------------- GMP footer (only if GMP-compliant printout is configured)

05.04.2004 10:10

Name:

---------------------- End of GMP footer

E + ) Delete tare weight entered through the keypad

or

0 + )

21

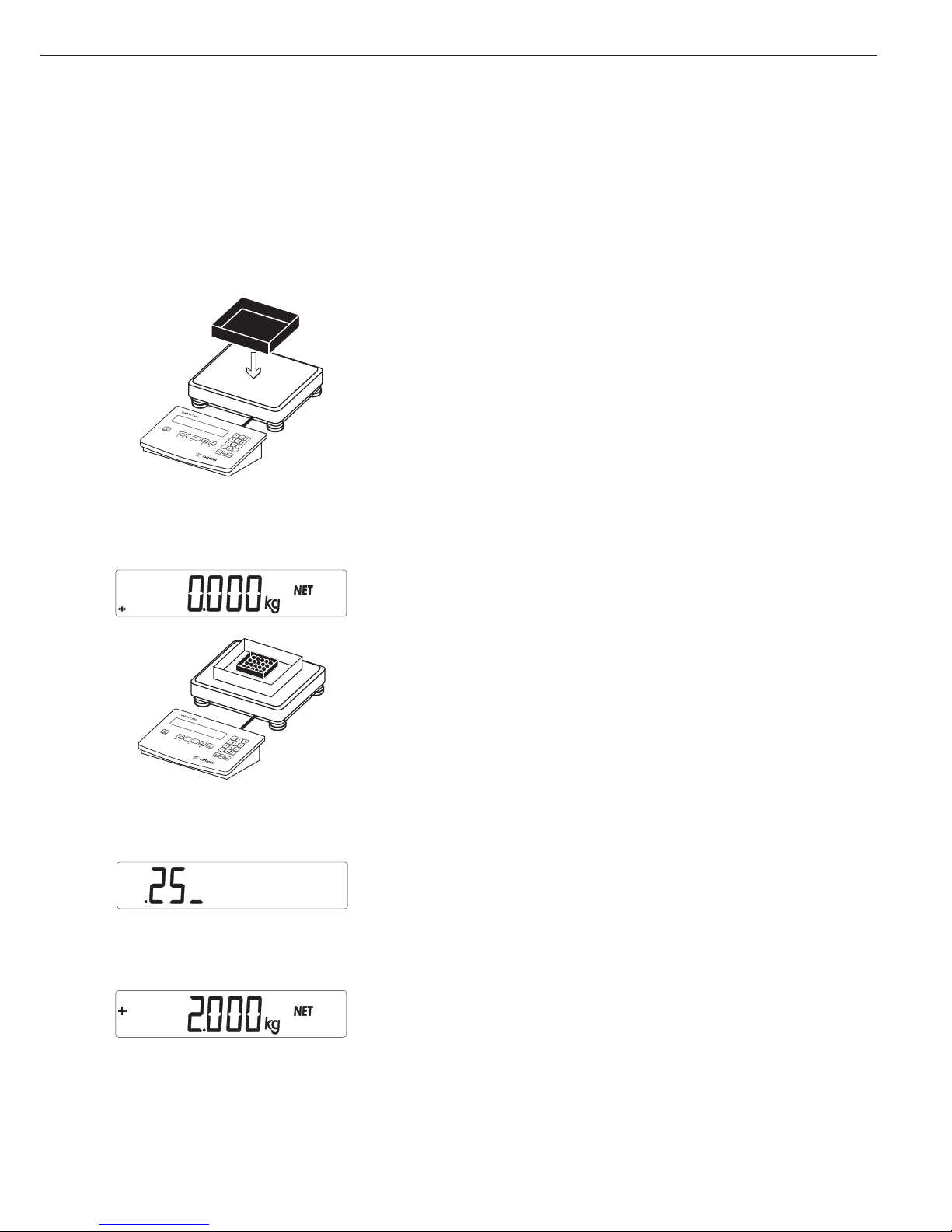

Example:

Combics 1 plus: Weighing with varying tare values; generate printout of results, delete tare values

e Switch on the Combics 1 plus

The automatic self-test runs. Once a readout is shown, the Combics is automatically

zeroed and ready to operate. With no load on the weighing instrument, you can zero the

instrument at any time by pressing (.

Place empty container on the weighing instrument

Tare the weighing instrument

)

Note: With the automatic tare function enabled, you do not need to press )

to tare the weighing instrument; the tare weight is stored automatically when you

place the container on the weighing instrument.

Wait until a zero value is displayed together with the NET symbol.

Place packaged sample in the container

.25 Enter the tare weight of the packaging in the current weight unit using the keypad

(in this example, 0.25 kg).

) Save the package weight. The package tare is added to the container tare.

Read off net weight

22

Operating: CW1NP | CW1NS | CW1NFS | CH1NE

p Print the results

G# + 6.433 kg

T + 4.183 kg

PT2 + 0.250 kg

N + 2.000 kg

--------------------

0 Enter a zero (“0") using the keypad

) Save the value entered. This deletes tare values; the display shows the gross value

p Print the results

G# + 6.433 kg

T + 0.000 kg

N + 6.433 kg

--------------------

23

Individual ID Codes

(Identifiers)

You can assign ID codes (such as product name, batch number, etc.) while

weighing, for identification of measured

values.

Features

– Assign up to two ID codes.

– Assign both a name and a value

for each ID code.

– The name is left-justified and the

value is right-justified on the printout.

If the entire code is too long for one

line, additional lines are printed.

– Enter ID code names in Setup under:

Setup: prtprot (printouts):

7.4.3 (ID1)

and

7.4.4 (ID2)

–

Enter up to 20 characters for the ID code

name. No more than 11 characters are

displayed during input; all 20 characters

are printed.

– Maximum length for values:

21 characters.

– Enter numeric values for ID codes

using the numeric keypad and press

g or h to save.

– To delete the last character entered

in the ID code value: Press E

To delete the entire ID code:

Press E and then g or h

– If both the name and value fields are

empty, no ID code is printed.

– Print ID codes: Refer to the Setup menu

for menu item numbers.

Data is output to COM1 menu item

7.7.x) or UniCOM (menu item 7.8.x).

– Show ID codes:

Press I and then g or h

– To store values entered using a bar code

scanner: Scan the value for ID1

Function Keys

g Store the input as

or value for first or

h second ID code.

E Delete the selected ID code value

I Display ID codes

Application Parameters: ID Codes

Setup

PrtProt Printouts

7.4. Input

ID code name

7.4.3 ID1

7.4.4 ID2

7.7 COM1: Configure

printout

7.7.6 ID1 and ID2

7.8 UniCOM:

Configure

printout

7.8.6 ID1 and ID2

24

Operating: CW1NP | CW1NS | CW1NFS | CH1NE

Example:

Entering ID code values.

Enter “123.456" and “678.9" as values for ID codes 1 and 2.

See “Entering the Password” in the chapter entitled “Configuration" for details on how to enter ID code names.

123. Enter value for ID code 1 (in this example, 123.456)

456

g

Confirm value for the first ID code

678 Enter value for ID code 2 (in this example, 678.9)

.9

h

Confirm the value for the second ID code

Place container with sample on the weighing instrument

p Print weight value (perform further weighing operations as desired, and print)

ID1 123.456 ID code 1

ID2 6.789 ID code 2

24.02.2003 10:09

-------------------Ser.no. 12345678

G# + 6.433 kg

T + 0.000 kg

N + 6.433 kg

Eg Delete ID code:

You can delete each ID code individually when the weighing series has been completed.

Eh

25

Operation

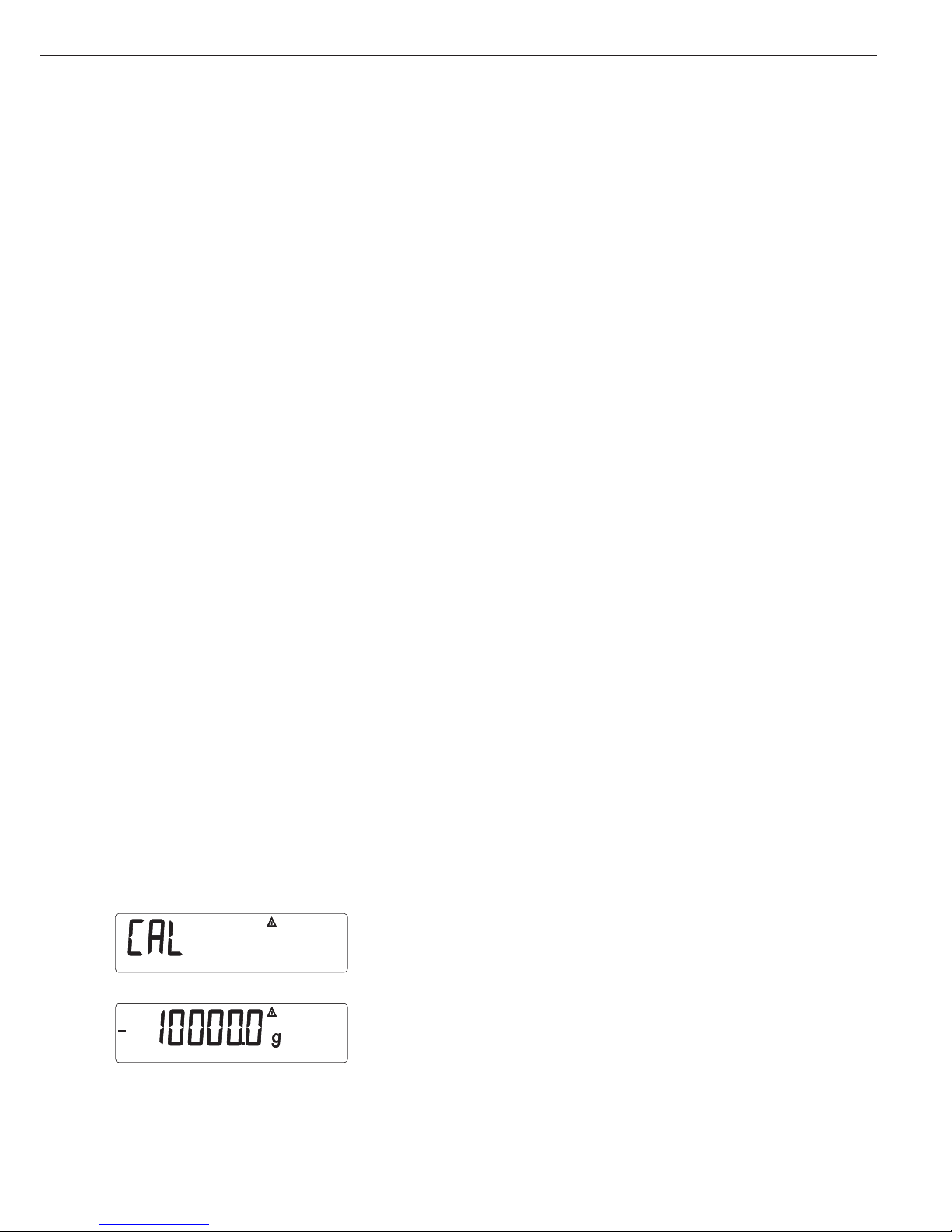

Example

External calibration and manual adjustment with default weights

Setup menu settings:

1.9.1; 1.10.2

( Unload and zero the weighing instrument

)> 2 sec Start calibration (e.g., when calibration prompt is flashing: W)

The following is displayed for 2 seconds

You are prompted to place the required weight on the weighing instrument

(e.g., 10 kg)

Calibration and Adjustment

Purpose

The accuracy of weighing results must

be carefully controlled. This is achieved

through calibration and adjustment.

Perform calibration to determine the

difference between the value displayed

and the actual weight on the weighing

instrument. Calibration does not entail

making any changes within the weighing

instrument.

The adjustment procedure actually eliminates the difference between the readout

and the actual weight, or reduces it to

a level within the permissible tolerance

limits.

Features

Which of the following features

are available depends on the weighing

instrument:

– External calibration/adjustment with

the default weight value or standard

weight (1.9.1) (not available on verified

instruments)

– External calibration/adjustment with

a user-defined weight (1.9.3) (not

available on verified instruments)

– Internal calibration/adjustment for

IS platform (1.9.4), WP2 only

– Block the ) key to prevent use of the

two functions described above (1.9.10)

– Calibrate first; then adjust automatically

(1.10.1) (not available on verified

instruments)

– Calibrate, then prompt for manual input

of adjustment command (1.10.2)

– Calibration prompt: flashing W symbol

(1.15.2). If more than one weighing

instrument is connected, the instrument

number is also displayed.

– Block external calibration/adjustment

(1.16.2)

CW Scales

– Display altitude and geographical

latitude or acceleration of gravity after

CAL is shown at the beginning of the

calibration procedure (menu item

8.12.2). These values are shown only if

they have been entered in the service

menu and activated.

For each of these parameters, the term

is displayed first (Altitud, Latitud

or Gravity) for 1 second, and then

the corresponding value is displayed

continuously until you press ).

Note

On verified weighing instruments, the

external calibration/adjustment function is available only when the menu

access switch is in the “open” position,

which entails breaking the verification

seal (refer to the chapter entitled

“Care and Maintenance"). The equipment must be re-verified after the seal

has been broken.

CH Scales

– Using a verified scale as a legal measur-

ing instrument:

Before using the scale as a legal measuring instrument, you must carry out an

internal calibration operation by selecting the “Internal Calibration” function

at the place of installation.

– To do so, press and hold the --- key.

During internal calibration, “CI” (for internal calibration) appears in the display.

Once the calibration procedure is complete,

a weight will be displayed automatically.

26

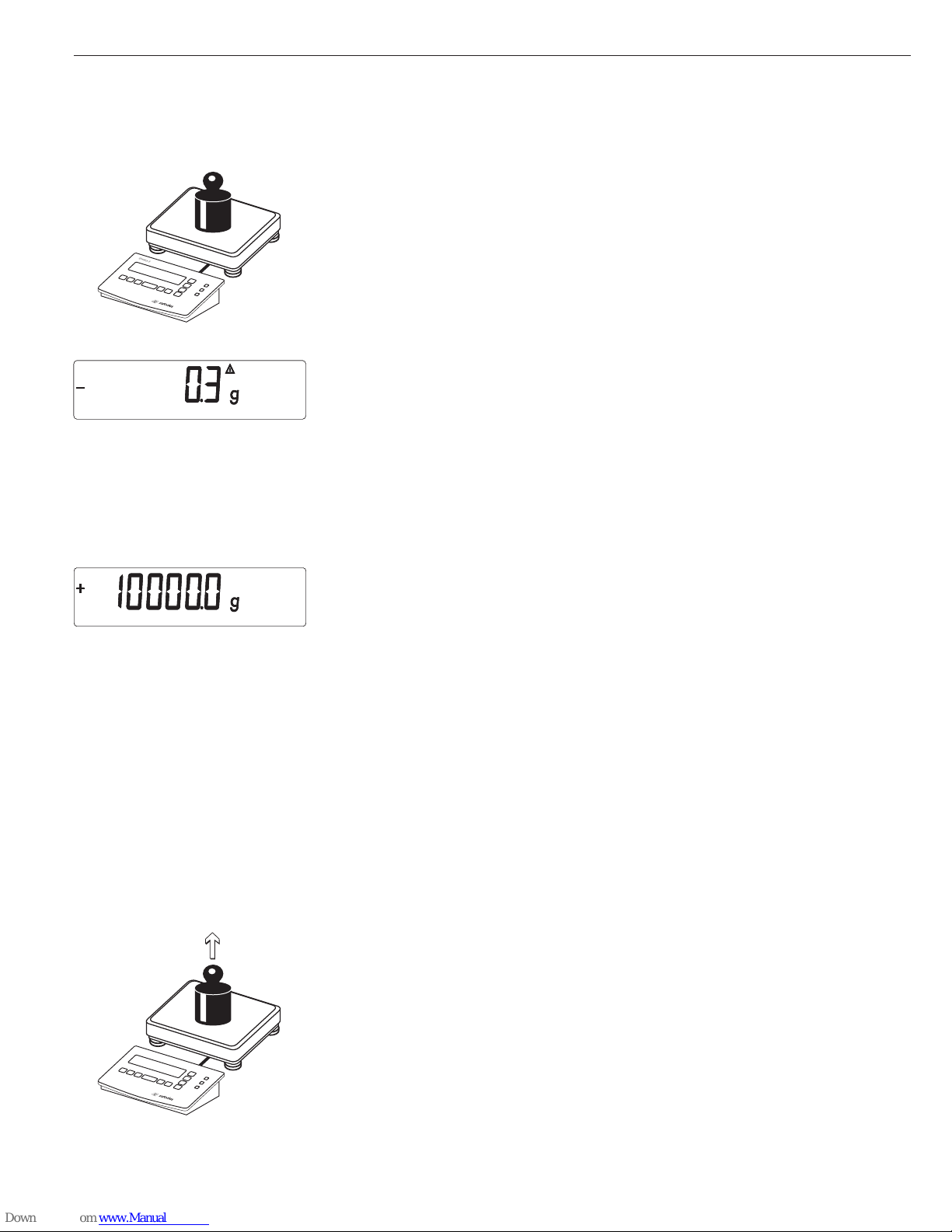

Position the calibration weight on the weighing instrument

The difference between the weight value and the true mass is displayed, with ± sign.

External calibration Calibration record is printed, if adjustment was not performed and the process

Nom. + 10000.0 g was stopped by pressing (

Diff. - 0.3 g

--------------------

) Activate calibration/adjustment manually (press the ( key to cancel)

The calibration weight is displayed at the conclusion of calibration

-------------------- A GMP-compliant printout is generated

14.01.2002 13:00

Model CW2P1-30ED-LCE

Ser.no. 12345678

Vers. 1.1007.12.1

BVers. 01-25-01

-------------------External calibration

Nom. + 10000.0 g

Diff. - 0.3 g

External adjustment

Diff. + 0.0 g

--------------------

14.01.2002 13:02

Name:

--------------------

Unload the weighing instrument

Combics 2

OK

REF

CF

Fn

0

T

n

-

Combics 2

OK

REF

CF

Fn

0

T

n

-

27

Operating: CW2P | CW2P | CW1NFS | CW2FS

Counting Z

With the Counting application, you can

determine the number of parts that

each have approximately equal weight.

Features:

– Store the weight on the weighing

instrument as reference weight

– Enter reference weight using

a bar code scanner

– Enter tare weight using a bar code

scanner

– Automatic reference sample updating

(user-definable)

– Counting with two weighing

instruments

– Toggle the display between piece count

and weight by pressing w

– Info mode for display of average piece

weight and reference sample quantity

by pressing w (> 2 sec)

Before the quantity on the weighing

instrument can be calculated, the

average piece weight must be entered

in the application. There are 2 ways

to do this with the Combics:

– By placing the number of parts defined

as the reference sample quantity on

the weighing instrument and pressing

O to store the average piece weight.

The reference sample quantity

is shown in the numeric display, and

can be changed by pressing r.

How the reference weight is calculated

depends on the menu setting for resolution (3.9). Either the value is rounded

off in accordance with the display

resolution, or the display resolution is

increased 10-fold (+1 decimal place)

or 100-fold (+ 2 decimal places), or

maximum internal resolution is applied.

– By entering the reference piece

weight (i.e., the weight of one piece)

using a bar code scanner (menu setting:

“Setup> Bar code > Store value as

reference (ref)"). In this case, the value

is stored as a reference automatically,

without pressing the O key.

This value remains active in the

reference memory until you delete it by

pressing c, overwrite it or until you

select a different application. It also

remains in memory when you switch to

a different application program, or

switch off the Combics.

– Tare function:

1) If you store a tare (weight value) by

pressing the ) key, you can later

enter a tare value manually. The tare

value you enter is added to the stored

tare value.

Setting: menu code 3.25.1 (factory

default)

2) A tare value entered manually overwrites a stored tare value (weight value).

If you enter a tare value manually, a

tare value (weight value) stored later

overwrites the manually entered value.

Setting: menu code 3.25.2

Operating menu setting:

APPL : Z : 3.25.

Application Parameters: Counting

3. 5. Minimum Load for Automatic Taring and

Automatic Printing

3. 5. 1 * 1 digit

3. 5. 2 2 digits

3. 5. 3 5 digits

3. 5. 4 10 digits

3. 5. 5 20 digits

3. 5. 6 50 digits

3. 5. 7 100 digits

3. 5. 8 200 digits

3. 5. 9 500 digits

3. 5.10 1000 digits

3. 6. Minimum Load for Initialization

3. 6. 1 * 1 digit

3. 6. 2 2 digits

3. 6. 3 5 digits

3. 6. 4 10 digits

3. 6. 5 20 digits

3. 6. 6 50 digits

3. 6. 7 100 digits

3. 6. 8 200 digits

3. 6. 9 500 digits

3. 6.10 1000 digits

3. 7. Automatic Taring: 1st Weight Tared

3. 7. 1 * Off

3. 7. 2 On

3. 8. Start Application with Most

Recent Application Data

when Combics is Switched On

3. 8. 1 Automatic (on)

3. 8. 2 * Manual (off)

3. 9. Resolution for Calculation

of Reference Value

3. 9. 1 * Display resolution

3. 9. 2 Display resolution + 1

decimal place

3. 9. 3 Display resolution + 2

decimal places

3. 9. 4 Internal resolution

3.11 Storage Parameter

3.11. 1* At stability

3.11. 2 At increased stability

3.12. Reference Sample Updating

3.12. 1 Off

3.12. 3* Automatic

3.13. Reference Weighing Instrument

3.13. 1* No reference instrument selected

3.13. 2 WP1

3.13. 3 WP2

3.25. Tare function

3.25. 1* The tare value entered is added to

the stored tare value

3.25. 2 Overwritable tare value

28

Operating: CW2P | CW2P | CW1NFS | CW2FS

Storage Parameter

The reference weight is saved when

the weighing instrument has stabilized.

“Stability" is defined as the point at

which fluctuation of a measured value

lies within a defined tolerance range.

The narrower the tolerance range, the

more stable the weighing instrument

is at “stability." This setting is also

applied when you zero the weighing

instrument.

Under menu item 3.11 you can

determine whether the value is saved

“At stability" (normal tolerance range)

or “At increased stability" (narrower

tolerance range).

If you select “At increased stability,"

the average piece weight stored will

be more accurate and the results more

reproducible, but the response time

of the weighing instrument might be

longer.

Minimum Load for Initialization

The minimum load for initialization

is configured under menu item 3.6.

If the load exceeds this limit, the

weighing instrument can be initialized.

If the load is too light, the following

will occur when you try to save a value:

– The error code inf 29 is displayed

– A warning signal is emitted

(double-beep)

– The weighing instrument is not

initialized

– The preset reference sample quantity

is stored

Reference Sample Updating

In the Application settings under 3.12,

you can define whether the reference

sample is updated automatically.

Reference sample updating is performed

automatically only when the following

6 criteria are met:

1. Menu item 3.12.3 is active

2. The current piece exceeds the original

piece count by at least two

3. The current piece count is less

than twice the original piece count

(does not apply for the first update

if the piece count is entered using

a bar code scanner).

4. The current piece count is less

than 100.

5. The internally calculated piece count

(such as 17.24 pcs) differs by less

than ± 0.3 pcs from the whole number

(17 pcs in this example).

6. The weighing instrument is stable in

accordance with the defined stability

parameter.

When automatic reference sample

updating is active, the AUTO symbol is

displayed in addition to the Counting

symbol (Z). When the reference

sample has been updated,

OPT

is dis-

played below

AUTO

. During an updating operation, 0pt and the updated

piece count are displayed briefly in

the main display.

At the conclusion of reference sample

updating, a beep is sounded and

the new reference weight and reference

sample quantity are stored. Activate

the “Info" mode to view the reference

values (press and hold w > 2 sec).

Counting with

Two Weighing Instruments

You can use two weighing instruments

simultaneously with the Counting application. When using two instruments,

you can choose from the following

operating modes:

– Counting with two equivalent weighing

instruments

– Counting with one reference weighing

instrument and one counting platform

Counting with Two Equivalent

Weighing Instruments

Use this mode when samples of widely

varying weight are counted at one

workstation. Count the lighter-weight

pieces on one weighing instrument

and the heavier pieces on another.

When you press n to toggle from one

weighing instrument to the other, the

application is re-initialized.

You can define which of the two

weighing instruments is active in the

display when the Combics is switched

on (menu item 8.11). This is the first

weighing instrument active when you

switch on the Combics, regardless of

the setting for automatic initialization

of the Counting application.

Counting with One Reference Weighing

Instrument and One Counting Platform

In this mode, a high-resolution weighing

instrument with a relatively low maximum capacity is used as a reference

weighing instrument. The weighing

platform is used for weighing heavier

samples, and has a high capacity with

a relatively low resolution.

This way, you can both determine the

reference sample quantity very precisely

and count large amounts of parts,

without requiring an expensive highresolution, high-capacity weighing

platform.

Specify which weighing instrument

is the reference instrument under

menu item 3.13. The system toggles

automatically to the reference weighing

instrument for initialization (Ref

is displayed). Following initialization,

the system toggles to the counting

platform.

The system does not toggle automatically for automatic reference

sample updating; the update is based

on whichever instrument is active.

“Old” ref.

sample qty.

Pieces on

platform

Range for reference

sample updating

n n + 2 2 · n

29

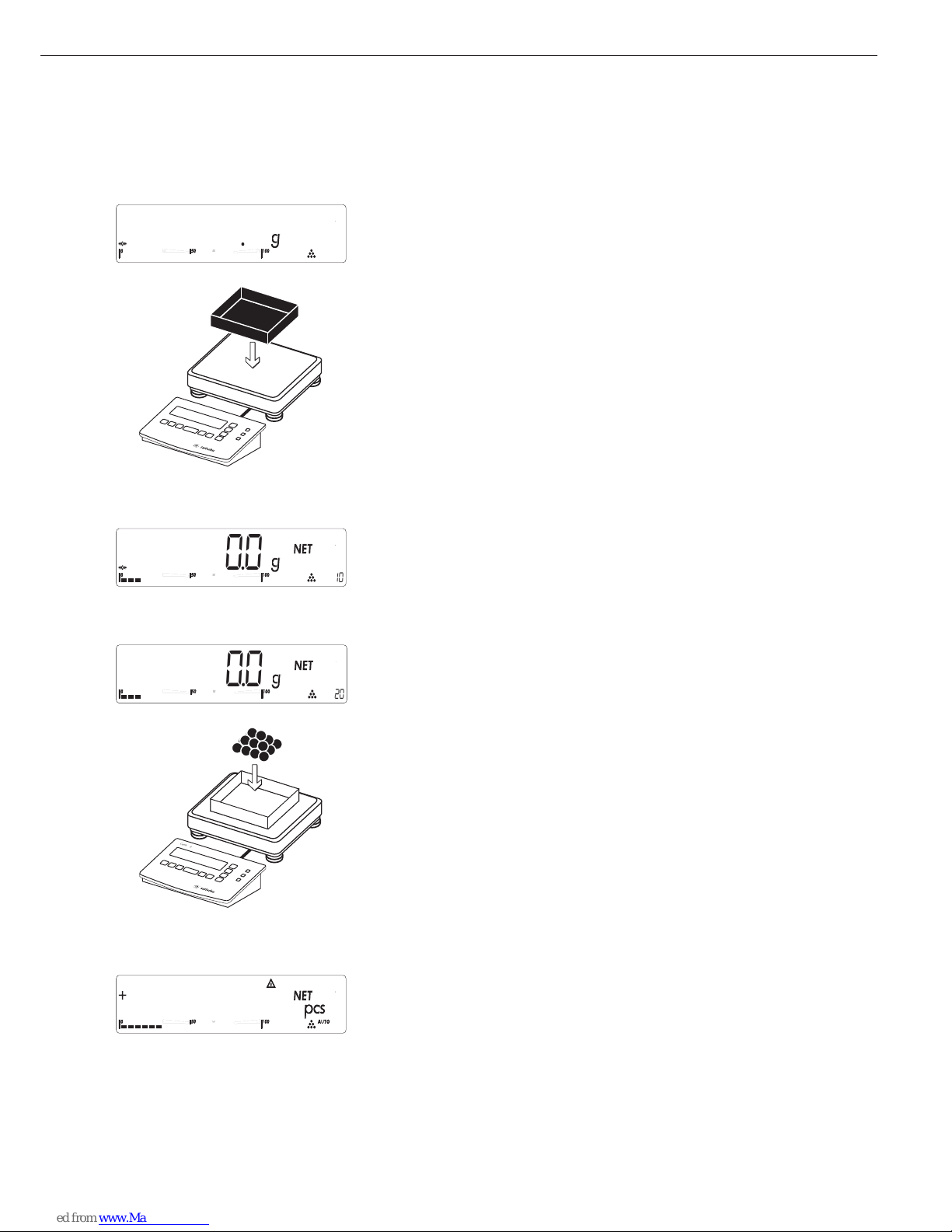

Example:

Place empty container on the weighing instrument

) Tare the weighing instrument

r(repeatedly, if necessary) Set the desired reference sample quantity (in this example, 20)

Place the corresponding number of pieces (20) in the container

OP Confirm reference sample weight

8

01

00

Combics 2

OK

REF

CF

Fn

0

T

n

-

8

01

00

8

02

00

Combics 2

OK

REF

CF

Fn

0

T

n

-

8

02

20

30

Operating: CW2P | CW2P | CW1NFS | CW2FS

Add more parts to the container (in this example, 18 pcs)

0pt is displayed if automatic reference sample updating is enabled

w Toggle the display from piece count to weight

w< 2 sec. Toggle to Info mode

Piece count is displayed

w Toggle to the next display mode

Reference sample quantity is displayed

w(> 2 sec) Return to weighing mode

p Print results

G# + 610.0 g

T + 200.0 g

N + 410.0 g

Qnt 38 pcs

--------------------

Combics 2

OK

REF

CF

Fn

0

T

n

-

8

02

38

8

02

0pt 38

31

Neutral Measurement Z nm

When the Neutral Measurement

application is selected, you can use your

weighing instrument to measure the

length, surface and volume of parts that

have roughly the same specific weight.

The

o

symbol is displayed as the weight

unit.

Features:

– Store the weight on the weighing

instrument as reference weight

– Enter reference weight using a bar code

scanner

– Enter tare weight using a bar code

scanner

– Toggle the display between weight

and calculated value by pressing w

– Info mode for display of reference

weight by pressing w (> 2 sec)

To calculate the result correctly, the

average weight of a reference quantity

must be known (in the example below,

the reference is 1 meter of electrical

cable). There are 2 ways to do this with

the Combics:

– By placing the number of parts defined

for the reference value on the weighing

instrument and pressing O to store

the average piece weight.

The reference value is shown in the

numeric display, and can be changed

by pressing r.

How the reference weight is calculated

depends on the menu setting for resolution (3.9). Either the value is rounded

off in accordance with the display

resolution, or the display resolution is

increased 10-fold (+1 decimal place) or

100-fold (+ 2 decimal places), or maximum internal resolution is applied.

– By entering the reference weight (i.e.,

the weight of one piece) using a bar

code scanner (menu setting: “Setup>

Bar code > Store value as reference

(ref)"). In this case, the value is stored

as a reference automatically, without

pressing the O key.

This value remains active in the reference

memory until you delete it by pressing

c, overwrite it or until you select

a different application. It also remains

stored after you switch off the Combics.

– Tare function:

1) If you store a tare (weight value) by

pressing the ) key, you can later

enter a tare value manually. The tare

value you enter is added to the stored

tare value.

Setting: menu code 3.25.1 (factory

default)

2) A tare value entered manually overwrites a stored tare value (weight value).

If you enter a tare value manually, a

tare value (weight value) stored later

overwrites the manually entered value.

Setting: menu code 3.25.2

Operating menu setting:

APPL : Z nm : 3.25.

Application Parameters: Neutral Measurement

3. 5. Minimum Load for Automatic Taring

and Automatic Printing

3. 5. 1 * 1 digit

3. 5. 2 2 digits

3. 5. 3 5 digits

3. 5. 4 10 digits

3. 5. 5 20 digits

3. 5. 6 50 digits

3. 5. 7 100 digits

3. 5. 8 200 digits

3. 5. 9 500 digits

3. 5.10 1000 digits

3. 6. Minimum Load for Initialization

3. 6. 1 * 1 digit

3. 6. 2 2 digits

3. 6. 3 5 digits

3. 6. 4 10 digits

3. 6. 5 20 digits

3. 6. 6 50 digits

3. 6. 7 100 digits

3. 6. 8 200 digits

3. 6. 9 500 digits

3. 6.10 1000 digits

3. 7. Automatic Taring:1st Weight Tared

3. 7. 1 * Off

3. 7. 2 On

3. 8. Start Application with Most Recent

Application Data when Combics

is Switched On

3. 8. 1 Automatic (on)

3. 8. 2 * Manual (off)

3. 9. Resolution for Calculation

of Reference Value

3. 9. 1 * Display resolution

3. 9. 2 Display resolution + 1

decimal place

3. 9. 3 Display resolution + 2

decimal places

3. 9. 4 Internal resolution

3.10. Decimal Places for Display of Results

3.10. 1 * None

3.10. 2 1 decimal place

3.10. 3 2 decimal places

3.10. 4 3 decimal places

3.11. Storage Parameter

3.11. 1* At stability

3.11. 2 At increased stability

3.13. Reference Weighing Instrument

3.13. 1* Off

3.13. 2 WP1

3.13. 3 WP2

3.25. Tare function

3.25. 1* The tare value entered is added to

the stored tare value

3.25. 2 Overwritable tare value

32

Operating: CW2P | CW2P | CW1NFS | CW2FS

Storage Parameter

The reference weight is saved when

the weighing instrument has stabilized.

“Stability" is defined as the point at

which fluctuation of a measured value

lies within a defined tolerance range.

The narrower the tolerance range, the

more stable the weighing instrument

is at “stability." This setting is also

applied when you zero the weighing

instrument.

Under menu item 3.11 you can

determine whether the value is saved

“At stability" (normal tolerance range)

or “At increased stability" (narrower

tolerance range).

If you select “At increased stability,"

the average piece weight stored will be

more accurate and the results more

reproducible, but the response time of

the weighing instrument might be

longer.

Decimal Places for Display of Results

In neutral measurement, not only whole

numbers but also decimal numbers

(for example, 1.25 o electrical cabling)

can be displayed. The number of decimal

places displayed in neutral measurement

is configured under menu item 3.10.

The measured result can be displayed

with 0, 1, 2 or 3 decimal places.

Minimum Load for Initialization

The minimum load for initialization

is configured under menu item 3.6.

If the load exceeds this limit, the

weighing instrument can be initialized.

If the load is too light, the following

will occur when you try to save a value:

– The error code inf 29 is displayed

– A warning signal is emitted

(double-beep)

– The weighing instrument is not

initialized

– The preset reference value is stored

Neutral Measurement with

Two Weighing Instruments

You can use two weighing instruments

simultaneously with the Neutral

Measure

ment application. When using

two instruments, you can choose from

the following operating modes:

– Neutral measurement with two

equivalent weighing instruments

– Neutral measurement with one

reference weighing instrument and

one measurement platform

Neutral Measurement with Two Equivalent Weighing Instruments

Use this mode when samples of widely

varying weight are measured at one

workstation. Measure the lighterweight pieces on one weighing instrument and the heavier pieces on another.

When you press n to toggle from one

weighing instrument to the other, the

application is re-initialized.

You can define which of the two

weighing instruments is active in the

display when the Combics is switched

on (menu item 8.11). This is the first

weighing instrument active when you

switch on the Combics, regardless of

the setting for automatic initialization

of the Neutral Measurement application.

Neutral Measurement with One

Reference Weighing Instrument and

One Measuring Platform

In this mode, a high-resolution weighing

instrument with a relatively low max-

imum

capacity is used as a reference

weighing instrument. The measuring

platform has a high capacity, but a relatively low resolution.

This allows you to both determine the

reference value with high resolution;

i.e., very precisely, and to measure large

samples, without requiring an expensive

high-resolution, high-capacity weighing

platform.

Specify which weighing instrument is

the reference instrument under menu

item 3.13. The system toggles automatically to the reference instrument for

initialization (Ref is shown in the main

display). Following initialization, the

system

toggles to the measuring platform.

33

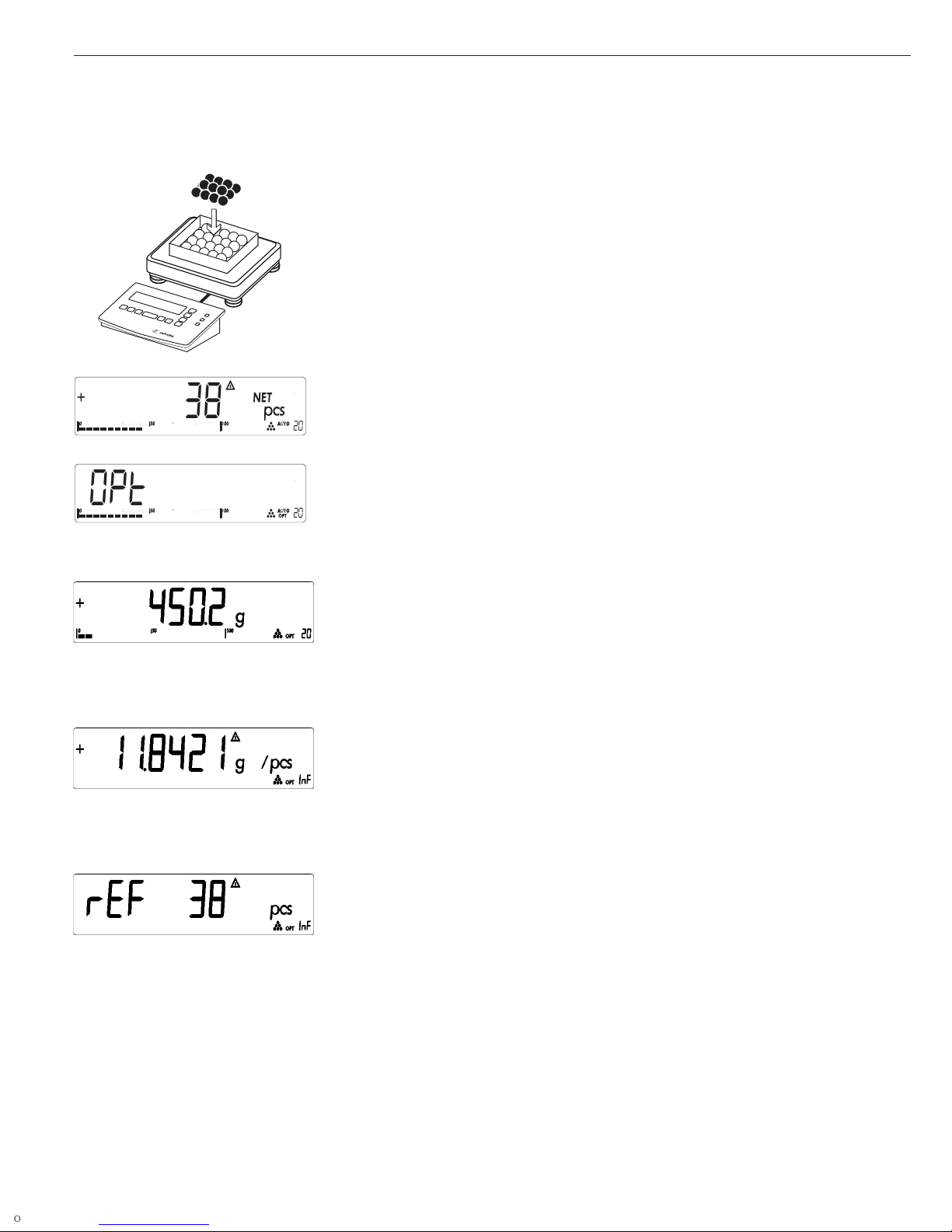

Example:

Determine the length of an amount of electrical cable after weighing in the defined reference unit value

Place empty container on the weighing instrument

) Tare the weighing instrument

r(repeatedly, if necessary) Set the desired reference value (in this example, 2)

Place a sample corresponding to the reference quantity in the container

(in this example, 2 meters of electrical cable)

O Confirm reference sample weight

Combics 2

OK

REF

CF

Fn

0

T

n

-

8

2

00

8

2

2

Combics 2

OK

REF

CF

Fn

0

T

n

-

8

1

00

8

1

00

34

Operating: CW2P | CW2P | CW1NFS | CW2FS

Remove the reference material and place the sample to be measured on the

weighing instrument (in this example, 8 meters of electrical cable

p Print results

G# + 734.1 g

T + 200.0 g

N + 534.1 g

Qnt 8 o

--------------------

8

2

8

Combics 2

OK

REF

CF

Fn

0

T

n

-

35

Checkweighing O

When the Checkweighing application is

selected, you can check whether sample

weights correspond to a specified target

weight; i.e., whether the weight on the

weighing instrument is within a given

tolerance range. The tolerance range

is defined by upper and lower limits.

The result is displayed in the main

indicator, in the bar graph and by colorcoded LEDs.

Features:

– The target value can be taken over

as a weighed value from a weighing

instrument, and the tolerance limits

are defined as a perceptual deviation

from the target value. The following

percentages can be selected as the

deviation: 0.1%, 0.2%, 0.5%, 1%, 1.5%,

2%, 3%, 5% or 10%.

– The target value, lower tolerance

limit (minimum) and upper tolerance

limit (maximum) can be taken over

as weighed values from the weighing

instrument.

– Target and tolerance limits checked

during input; values must conform to:

Upper limit > Target > Lower limit >

1 digit

– Checkweighing range: either 30%

to 170% of the target, or from 10%

to infinity

– Application started automatically

with most recent application data

when Combics switched on

– Automatic taring

– Automatic printing

– Toggle the display between weight

and tolerances limits by pressing w.

When tolerances are displayed, weights

exceeding the tolerance limits are

shown with “LL" (too low) or “HH"

(too high).

– Digital input/output interface

– Info mode for display of tolerance limits

by pressing w (> 2 sec)

Checkweighing entails comparing

the current weight value to a defined

target. The target value has a tolerance

range which can be entered either as

an absolute value or percentage (menu

item 4.5).

– Entering the tolerance range as

an absolute value (weighed value)

(menu item 4.5.1):

Start initialization by pressing O;

the middle segments of the bar graph

flash to prompt the placement of the

weight on the weighing instrument.

Place the weight on the instrument and

press O to store.

The bar graph segment for the lower

limit flashes to prompt the weight for

lower limit. Place the weight on

the weighing instrument and press

O to store.

The bar graph segment for the upper

limit flashes to prompt the weight for

upper limit. Place the weight on the

weighing instrument and press O to

store.

– Entering the tolerance range as

a percentage (menu item 4.5.2):

A value for the percentage is shown in

the numeric display (lower right-hand

corner) together with the “%" sign.

Press r to change the percentage

value (0.1%, 0.2%, 0.5%, 1%, 1.5%, 2%,

3%, 5%, 10%).

Start initialization by pressing O;

the middle segments of the bar graph

flash to prompt the placement of the

weight on the weighing instrument.

Place the weight on the instrument and

press O to store. To can change the

percentage value for the tolerance limits

again before the target value is stored,

press r.

Before the new initialization, the

previous initialization values must be

deleted by pressing c.

– Tare function:

1) If you store a tare (weight value) by

pressing the ) key, you can later

enter a tare value manually. The tare

value you enter is added to the stored

tare value.

Setting: menu code 3.25.1 (factory

default)

2) A tare value entered manually overwrites a stored tare value (weight value).

If you enter a tare value manually, a