Sartorius Centrisart G-16,Centrisart G-16C Operating Manual

Translation of the original operating manual

sb

09/2015

Rev. 1.3 of 02/03/2017

G-16;Version; ; ;

Version

WZG6001-e150401

Operating Manual

Centrisart G-16

Laboratory centrifuge from serial no.

157603

98648-020-94

© Copyright by

Sartorius Lab Instruments GmbH & Co. KG

Weender Landstraße 94-108

37075 Göttingen

Germany

Phone: +49.551.308.0

Fax: +49.551.308.3289

www.sartorius.com

Table of contents

Version 09/2015, Rev. 1.3 of 02/03/2017

5

Translation of the original operating manual, WZG6001-e150401

1 General information ........................................................................................................................................... 9

1.1 Importance of the operating manual ...................................................................................................................... 9

1.2 Intended use .................................................................................................................................................................... 9

1.3 Warranty and liability .................................................................................................................................................. 9

1.4 Copyright ....................................................................................................................................................................... 10

1.5 Standards and regulations ........................................................................................................................................ 10

1.6 Scope of supply ............................................................................................................................................................ 10

2 Layout and mode of operation ....................................................................................................................... 11

2.1 Layout of the centrifuge ........................................................................................................................................... 11

2.1.1 Functional and operating elements ................................................................................................................ 11

2.1.2 Name plate ............................................................................................................................................................. 12

2.2 Mode of operation ...................................................................................................................................................... 13

2.2.1 Centrifugation principle ..................................................................................................................................... 13

2.2.2 Area of application ............................................................................................................................................... 13

2.2.2.1 Speed, radius, and relative centrifugal force ..................................................................................... 14

2.2.2.2 Density ........................................................................................................................................................... 14

3 Safety ................................................................................................................................................................ ... 15

3.1 Marking of the unit .................................................................................................................................................... 15

3.2 Explanation of the symbols and notes .................................................................................................................. 16

3.3 Responsibility of the operator ................................................................................................................................. 17

3.4 Operating personnel ................................................................................................................................................... 17

3.5 Informal safety instructions ..................................................................................................................................... 17

3.6 Safety instructions ...................................................................................................................................................... 18

3.6.1 Electrical safety ..................................................................................................................................................... 18

3.6.2 Mechanical safety ................................................................................................................................................. 18

3.6.3 Fire prevention ...................................................................................................................................................... 19

3.6.4 Chemical and biological safety ......................................................................................................................... 19

3.6.5 Safety instructions for centrifugation ........................................................................................................... 20

3.6.6 Resistance of plastics ........................................................................................................................................... 20

3.6.7 Service life of rotors and accessories .............................................................................................................. 20

3.7 Safety devices ............................................................................................................................................................... 21

3.7.1 Lid lock device ....................................................................................................................................................... 21

3.7.2 Standstill monitoring system ............................................................................................................................ 21

3.7.3 System check.......................................................................................................................................................... 21

3.7.4 Earth conductor check ........................................................................................................................................ 21

3.7.5 Imbalance monitoring system ........................................................................................................................... 21

3.7.6 Rotor monitoring system .................................................................................................................................... 21

3.8 Measures in the event of hazards and accidents ............................................................................................... 22

3.9 Remaining hazards ...................................................................................................................................................... 22

Table of contents

6

Version 09/2015, Rev. 1.3 of 02/03/2017

Translation of the original operating manual, WZG6001-e150401

4 Storage and transport ...................................................................................................................................... 23

4.1 Dimensions and weight .............................................................................................................................................. 23

4.2 Storage conditions ...................................................................................................................................................... 23

4.3 Notes on transport ...................................................................................................................................................... 23

4.4 Packaging ....................................................................................................................................................................... 24

4.5 Transport safety device .............................................................................................................................................. 24

5 Set-up and connection .................................................................................................................................... 25

5.1 Installation site ............................................................................................................................................................. 25

5.2 Power supply ................................................................................................................................................................. 25

5.2.1 Type of connection ............................................................................................................................................... 25

5.2.2 Customer-provided fuses ................................................................................................................................... 25

6 Using the centrifuge ......................................................................................................................................... 26

6.1 Initial start-up .............................................................................................................................................................. 26

6.2 Switching the centrifuge on .................................................................................................................................... 26

6.2.1 Opening and closing the lid ............................................................................................................................... 26

6.2.2 Installation of rotors and accessories ............................................................................................................. 27

6.2.2.1 Installation of the rotor ........................................................................................................................... 27

6.2.2.2 Installation of angle rotors with a hermetically sealed lid ............................................................ 27

6.2.2.3 Installation of accessories ........................................................................................................................ 28

6.2.2.4 Adapters ................................................................................................ ................................ ........................ 29

6.2.2.5 Tubes .............................................................................................................................................................. 29

6.3 Control system "Spincontrol L" ................................................................................................................................ 30

6.3.1 User interface ........................................................................................................................................................ 30

6.3.2 Manual mode ......................................................................................................................................................... 31

6.3.2.1 Starting a centrifugation run ................................................................................................................. 31

6.3.2.2 Interrupting a centrifugation run ......................................................................................................... 31

6.3.2.3 Interrupting a deceleration process ...................................................................................................... 31

6.3.2.4 Selection, display, and modification of data ..................................................................................... 31

6.3.2.5 Speed / relative centrifugal force (RCF) .............................................................................................. 32

6.3.2.6 Runtime ......................................................................................................................................................... 32

6.3.2.7 Rotor selection ................................................................................................................................ ............ 34

6.3.2.8 Acceleration and deceleration curves ................................ ................................................................ .. 35

6.3.2.9 Automatic lid opening function ("AutoOpen") ................................................................................. 35

6.3.2.10 Sound signal ("Buzzer") ............................................................................................................................ 36

6.3.2.11 Program lock ("ProgLock") ....................................................................................................................... 36

6.3.2.12 Cycle display ("Cycles") ............................................................................................................................. 37

6.3.2.13 Input lock ..................................................................................................................................................... 38

6.3.3 Program mode ....................................................................................................................................................... 39

6.3.3.1 Saving a program ....................................................................................................................................... 39

6.3.3.2 Loading a program ..................................................................................................................................... 40

6.4 Switching the centrifuge off .................................................................................................................................... 40

Table of contents

Version 09/2015, Rev. 1.3 of 02/03/2017

7

Translation of the original operating manual, WZG6001-e150401

7 Malfunctions and error correction ................................................................................................................ 41

7.1 General malfunctions ................................................................................................................................................. 41

7.1.1 Emergency lid release ................................................................................................................................ .......... 42

7.2 Table of error codes .................................................................................................................................................... 43

7.3 Service contact ............................................................................................................................................................. 44

8 Maintenance and service ................................................................................................................................. 45

8.1 Maintenance ................................................................................................................................................................. 45

8.1.1 Centrifuge ............................................................................................................................................................... 45

8.1.2 Accessories .............................................................................................................................................................. 46

8.1.2.1 Plastic accessories ................................................................................................................................ ...... 47

8.1.3 Rotors, buckets and carriers .............................................................................................................................. 47

8.1.4 Load bearing bolts ................................................................................................................................................ 47

8.1.5 Glass breakage ....................................................................................................................................................... 48

8.2 Sterilisation and disinfection of the rotor chamber and accessories ........................................................... 48

8.2.1 Autoclaving ............................................................................................................................................................ 49

8.3 Service ............................................................................................................................................................................. 50

8.4 Return of defective units .......................................................................................................................................... 51

9 Disposal ................................................................................................................................................................ 52

10 Technical data .................................................................................................................................................... 53

10.1 Ambient conditions ..................................................................................................................................................... 54

11 Appendix .............................................................................................................................................................. 55

11.1 Range of accessories ................................................................................................................................................... 55

11.1.1 Maximum speed for tubes ................................................................................................................................. 56

11.1.2 Rotor radii ............................................................................................................................................................... 56

11.2 Speed-gravitational-field-diagram ........................................................................................................................ 57

11.3 Acceleration and deceleration curves .................................................................................................................... 58

11.4 Resistance data ............................................................................................................................................................. 61

11.5 EC declaration of conformity ................................................................................................................................... 65

12 Index ..................................................................................................................................................................... 67

Table of contents

8

Version 09/2015, Rev. 1.3 of 02/03/2017

Translation of the original operating manual, WZG6001-e150401

1 General information

Version 09/2015, Rev. 1.3 of 02/03/2017

9

Translation of the original operating manual, WZG6001-e150401

Pos: 1 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/010 Allgemeine Informationen/010 A llgemeine Informationen =========== ========================= @ 26\mod_1405318948131_ 68.docx @ 191680 @ 1 @ 1

1 General information

Pos: 2 /100 Sigma/100 BA Zentrifugen Sigma (Stan dardmodule)/010 Allgemeine Informationen/010 -0010 Stellenwert der Betriebsanleitung---------- --------------------------------------------- @ 26\mod _1405318949962_68.docx @ 191694 @ 2 @ 1

1.1 Importance of the operating manual

A fundamental requirement for the safe and trouble-free operation of the

centrifuge is to be familiar with the fundamental safety instructions and all

possible hazards.

The operating manual includes important information concerning the safe

operation of the centrifuge.

This operating manual and, in particular, the notes on safety and hazards must be

observed by all persons operating the centrifuge.

In addition, the local rules and regulations for the prevention of accidents must be

Pos: 3 /010 Universalmodule/ Leerzeile @ 0\mod_12021162445 00_0.docx @ 114 @ @ 1

Pos: 4 /100 Sigma/101 BA Zentrifugen Sartorius (Standardmodule)/010 Allgemeine Informationen/010 -0020 Bestimmungsgemäße Verwendung Sartorius - ------------------------------------------ @ 36 \mod_1431327167004_68.docx @ 262268 @ 2 @ 1

complied with.

1.2 Intended use

Centrifuges are power-driven machines that separate liquids from solid matter,

liquid mixtures, or solid mixtures by centrifugal force. They are solely intended for

this purpose. Any other use beyond this area of application is regarded as improper

use. Sartorius Lab Instruments GmbH & Co. KG cannot be held liable for any

damage resulting from such improper use.

The intended use also includes

observation of all the notes and instructions included in the operating manual

and

Pos: 5 /010 Universalmodule/ Leerzeile @ 0\mod_12021162445 00_0.docx @ 114 @ @ 1

Pos: 6 /100 Sigma/101 BA Zentrifugen Sartorius (Standardmodule)/010 Allgemeine Informationen/010 -0030 Gewährleistung und Haftung Sartorius --- ----------------------------------------------- @ 36 \mod_1435558416437_68.docx @ 266373 @ 2 @ 1

compliance with the care, cleaning, and maintenance instructions.

1.3 Warranty and liability

The warranty and liability are subject to our "General Terms and Conditions of

Business Relating to Goods and Services of Sartorius" that were distributed to the

operator upon the conclusion of the contract.

Warranty and liability claims are excluded if they are due to:

improper use.

non-compliance with the safety instructions and hazard warnings in the

operating manual.

Pos: 7 /010 Universalmodule/Seitenwechsel @ 0 \mod_1202116244312_0.docx @ 105 @ @ 1

improper installation, start-up, operation, or maintenance of the centrifuge.

1 General information

10

Version 09/2015, Rev. 1.3 of 02/03/2017

Translation of the original operating manual, WZG6001-e150401

1 connection cable

depending on the voltage variant

1 box spanner, size 10

(rotor fastening)

Part no. 69CE0009

1 tube of grease for load bearing

bolts

Part no. 69CE0006

Pos: 8 /100 Sigma/101 BA Zentrifugen Sartorius (Standardmodule)/010 Allgemeine Informationen/0 10-0040 Urheberrecht Sartorius-------------------- --------------------------------------------- @ 36 \mod_1431326565740_68.docx @ 262253 @ 2 @ 1

1.4 Copyright

The information and figures contained in these instructions correspond to the

version date specified below.

Sartorius reserves the right to make changes to the technology, features,

specifications and design of the equipment without notice.

Copyright notice:

This operating manual, including all of its components, is protected by copyright.

Any use beyond the limits of the copyright law is not permitted without our

approval.

This applies in particular to reprinting, translation and edition irrespective of the

Pos: 9 /010 Universalmodule/ Leerzeile @ 0\mod_12021162445 00_0.docx @ 114 @ @ 1

Pos: 10 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/010 Allgemeine Informationen/010 -0050 Normen und Vorschriften------------------- ----------------------------------- @ 26\mod_14053 18958202_68.docx @ 191765 @ 2 @ 1

type of media used.

1.5 Standards and regulations

EC declaration of conformity

Pos: 11 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 12 /100 Sigma/111 BA Zentrifugen Sart orius (Projekte)/Centrisart G-16/010 Allgemeine Informatione n/010-0060 Lieferumfang G-16 ------------ ------------------------------- @ 37\mod_143711292 6042_68.docx @ 272404 @ 2 @ 1

(see chapter 11.5 - "EC declaration of conformity")

1.6 Scope of supply

The centrifuge comprises:

Documentation:

Operating manual incl. EC declaration of conformity

(see chapter 11.5 - "EC declaration of conformity")

Accessories

Pos: 13 /010 Universalmodule/Abschnittswechsel @ 0\mod_1202124514062_0.docx @ 418 @ @ 1

Pos: 14 /010 Universalmodule/Seitenwechsel @ 0\mod_1202116244312_0.docx @ 105 @ @ 1

According to your order, our order confirmation, and your delivery note.

2 Layout and mode of operation

Version 09/2015, Rev. 1.3 of 02/03/2017

11

Translation of the original operating manual, WZG6001-e150401

1 Lid

2 User interface (see

chapter 6.3.1 - "User

interface")

3 Mains switch

4 Name plate

(see chapter 2.1.2 -

"Name plate")

5 Mains power input

6 Equipotential bonding

screw

Pos: 15 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/020 Aufbau und Wirkungsweise/020 A ufbau und Wirkungsweise======== ========================== @ 26\mod_1405318981820_ 68.docx @ 191779 @ 1 @ 1

2 Layout and mode of operation

Pos: 16 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/020 Aufbau und Wirkungsweise/020 -0010 Aufbau der Zentrifuge-------------------- -------------------------------- @ 26\mod_140531 8982945_68.docx @ 191793 @ 2 @ 1

2.1 Layout of the centrifuge

Pos: 17 /100 Sigma/111 BA Zentrifugen Sart orius (Projekte)/Centrisart G-16/020 Aufbau und Wirkungs weise/020-0010-0010 Funktions- und Bedieneleme nte G-16 @ 37\mod_1437112945932_68.docx @ 27242 0 @ 3 @ 1

2.1.1 Functional and operating elements

Pos: 18 /010 Universalmodule/Seitenwechsel @ 0\mod_1202116244312_0.docx @ 105 @ @ 1

Fig. 1: Total view of the centrifuge

Fig. 2: Rear view of the centrifuge

2 Layout and mode of operation

12

Version 09/2015, Rev. 1.3 of 02/03/2017

Translation of the original operating manual, WZG6001-e150401

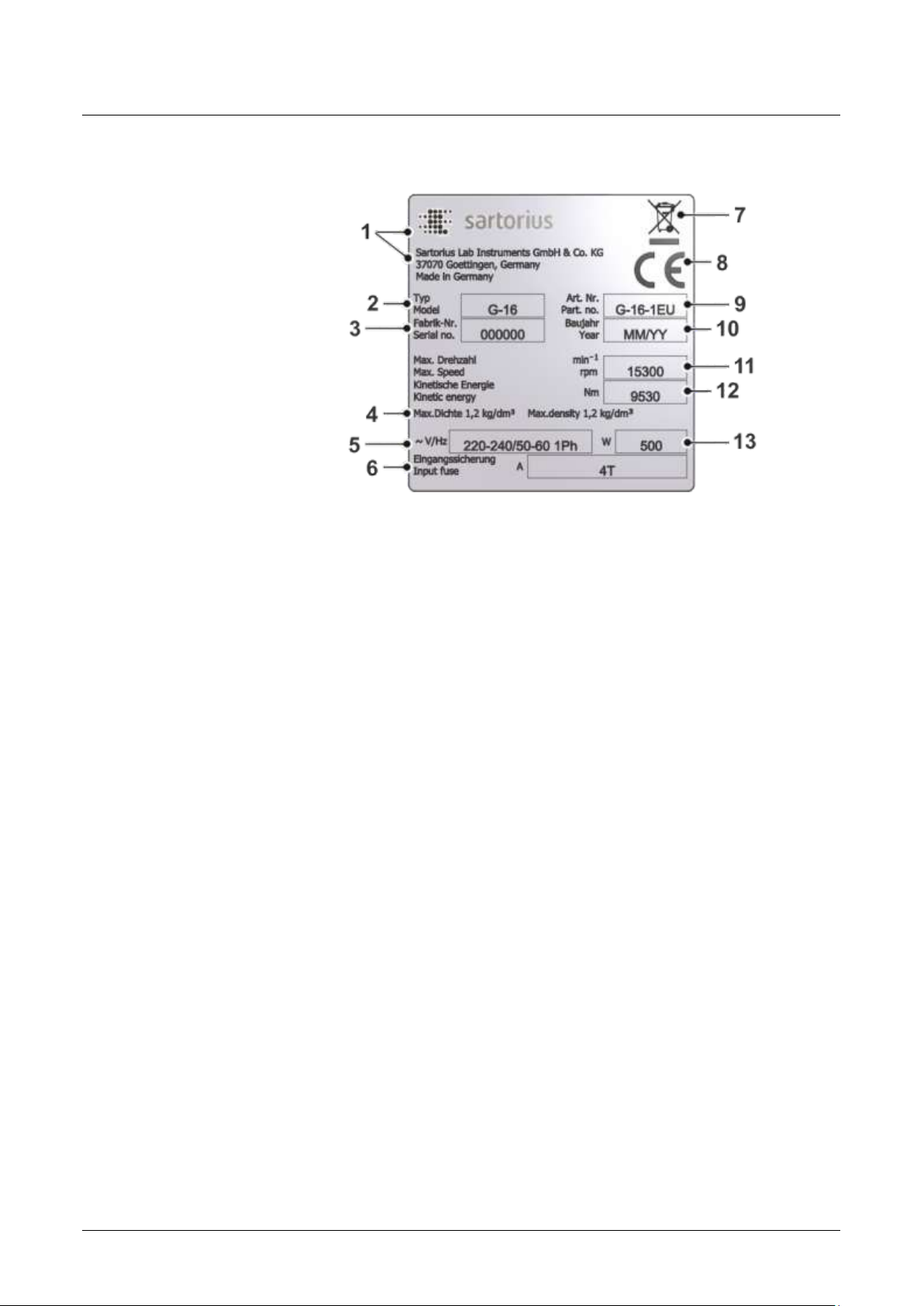

1 Manufacturer and

registered office

2 Type

3 Serial number

4 Max. density

5 Nominal voltage

6 Input fuse

7 Symbol for special

disposal (see chapter 9 -

"Disposal")

8 CE-mark in compliance

with the directive

2006/42/EG

9 Part number

10 Year of manufacture

11 Max. speed

12 Max. kinetic energy

13 Power consumption

Pos: 19 /100 Sigma/111 BA Zentrifugen Sart orius (Projekte)/Centrisart G-16/020 Aufbau und Wirkungs weise/020-0010-0020 Typenschild G-16 @ 37 \mod_1437112946469_68.docx @ 272435 @ 3 @ 1

2.1.2 Name plate

Pos: 20 /010 Universalmodule/Seitenwechsel @ 0\mod_1202116244312_0.docx @ 105 @ @ 1

Fig. 3: Example of a name plate

2 Layout and mode of operation

Version 09/2015, Rev. 1.3 of 02/03/2017

13

Translation of the original operating manual, WZG6001-e150401

Pos: 21 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/020 Aufbau und Wirkungsweise/020 -0020 Wirkungsweise--------------------------- ------------------------------- @ 26\mod_140531898 4194_68.docx @ 191807 @ 2 @ 1

2.2 Mode of operation

Pos: 22 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/020 Aufbau und Wirkungsweise/020 -0020-0010 Prinzip der Zentrifugation @ 26\mo d_1405318985448_68.docx @ 191821 @ 3 @ 1

2.2.1 Centrifugation principle

Pos: 23 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 24 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/020 Aufbau und Wirkungsweise/020 -0020-0020 Anwendungsbereich @ 26\mod_1405 318986763_68.docx @ 191835 @ 3 @ 1

Das

Centrifugation is a process for the separation of heterogeneous mixtures of

substances (suspensions, emulsions, or gas mixtures) into their components. The

mixture of substances, which rotates on a circular path, is subject to centripetal

acceleration that is several times greater than the gravitational acceleration.

Centrifuges use the mass inertia inside the rotor chamber for separating the

substances. Due to their higher inertia, particles or media with a higher density

travel outwards. In doing so, they displace the components with a lower density,

which in turn travel towards the centre.

The centripetal acceleration of an object inside a centrifuge, as the effect of

centripetal force, depends on the distance between the object and the axis of

rotation as well as on the angular velocity. It increases linearly as a function of the

distance with regard to the axis of rotation and quadratically as a function of the

angular velocity. The bigger the radius in the rotor chamber is and the higher the

speed is, the higher the centripetal acceleration is. However, the forces acting on

the rotor also increase.

2.2.2 Area of application

Depending on the area of application of the centrifuge and also on the particle

size, solids content, and volume throughput of the mixture of substances that is to

be centrifuged, there are different types of centrifuges.

The areas of application go from household use as a salad spinner or honey

separator up to specialised technical applications in the clinical, biological, or

biochemical context:

For numerous clinical examinations, cellular material must be separated from

the liquid to be analysed. The normal separation process can be sped up

considerably by using laboratory centrifuges.

In the metal-working industry, centrifuges are used for separating oil from

cream and low-fat milk.

Particularly big centrifuges are used in the sugar industry for separating the

syrup from the crystalline sugar.

Ultracentrifuges are predominantly used in biology and biochemistry in order

to isolate particles, e.g. viruses. They are specifically designed for high speeds up

Pos: 25 /010 Universalmodule/Seitenwechsel @ 0\mod_1202116244312_0.docx @ 105 @ @ 1

to 500,000 rpm. The rotor moves in a vacuum in order to avoid air friction.

2 Layout and mode of operation

14

Version 09/2015, Rev. 1.3 of 02/03/2017

Translation of the original operating manual, WZG6001-e150401

)/2,1( Rho

Pos: 26 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/020 Aufbau und Wirkungsweise/020 -0020-0020-0010 Drehzahl, Radius, Relative Zentrifugalbeschleunigung @ 26\mod_1405318988082_68. docx @ 191849 @ 4 @ 1

2.2.2.1 Speed, radius, and relative centrifugal force

The acceleration g, which the samples are subject to, can be increased by increasing

the radius in the rotor chamber and by increasing the speed. These three

parameters are interdependent and linked with each other via the following

formula:

Relative centrifugal force RCF = 11.18 x 10-6 x r x n2

r = radius in cm

n = speed in rpm

RCF without any dimension

If two values are entered, the third value is determined by way of the stated

formula. If, afterwards, the speed or the radius is changed, the resulting relative

centrifugal force will be recalculated automatically by the control unit. If the RCF is

changed, the speed will be adapted while the specified radius is maintained.

The speed-gravitational-field-diagram provides an overview of the relationship

between speed, radius, and RCF (see chapter 11.2 - "Speed-gravitational-field-

Pos: 27 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 28 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/020 Aufbau und Wirkungsweise/020 -0020-0020-0020 Dichte @ 26\mod_1405318989359_ 68.docx @ 191863 @ 4 @ 1

diagram").

2.2.2.2 Density

The laboratory centrifuge is suitable for the separation of constituents of different

densities in mixtures with a maximum density of 1.2 g/cm3. All information

concerning the speed of rotors and accessories refers to liquids with a density

corresponding to this specification. If the density is above this value, the maximum

permissible speed of the centrifuge must be reduced based on the following

formula:

n = n

Pos: 29 /010 Universalmodule/Abschnittswechsel @ 0\mod_1202124514062_0.docx @ 418 @ @ 1

Pos: 30 /010 Universalmodule/Seitenwechsel @ 0\mod_1202116244312_0.docx @ 105 @ @ 1

Rho = density in g/cm3

max

x

3 Safety

Version 09/2015, Rev. 1.3 of 02/03/2017

15

Translation of the original operating manual, WZG6001-e150401

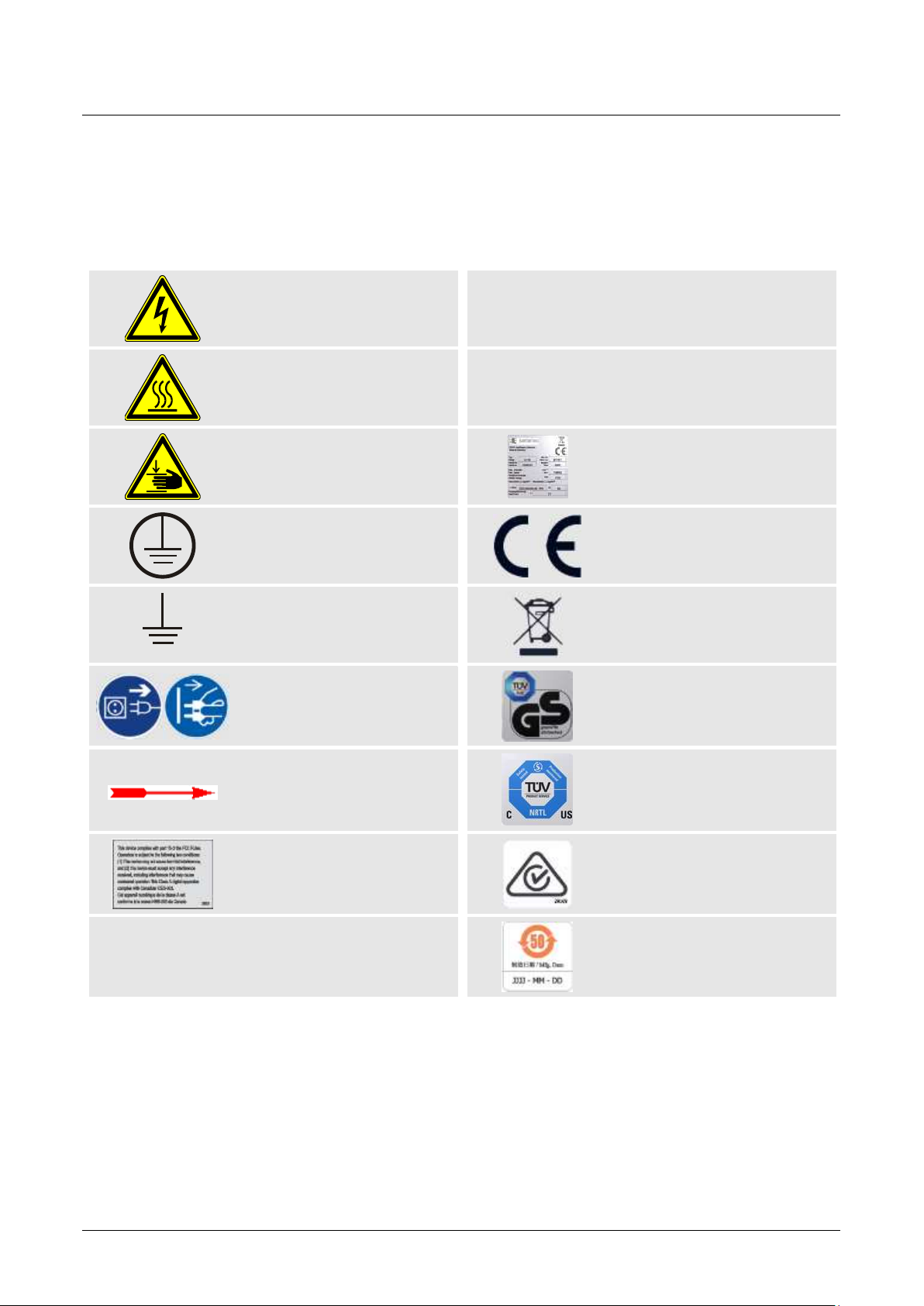

Dangerous voltage

I

On (Power)

Hot surface

0

Off (Power)

Caution! Risk of bruising

Name plate (see chapter 2.1.2

- "Name plate")

Protective earth (ground)

CE mark in compliance with

the directive 2006/42/EC

Earth (ground)

Do not dispose as part of

domestic waste

Unplug the mains plug

GS mark (tested safety; only

for Germany)

Arrow indicating the direction

of rotation

NRTL mark (only for the USA

and Canada)

Label concerning the FCC rules

(only for Canada)

RCM mark

(only for Australia)

China RoHS 2 mark

(only for China)

Pos: 31 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030 Sicherheit==== ============================= ====== @ 26\mod_1405319007254_68.docx @ 191877 @ 1 @ 1

3 Safety

Pos: 32 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 33 /100 Sigma/101 BA Zentrifugen Sart orius (Standardmodule)/030 Sicherheit/030-0011 Beschilderung des Geräts (D-16C, G-16, G-16C) Sartorius @ 37\mod_1436954887097_68.docx @ 269166 @ 2 @ 1

3.1 Marking of the unit

The following symbols are used for all types of centrifuges manufactured by Sartorius:

3 Safety

16

Version 09/2015, Rev. 1.3 of 02/03/2017

Translation of the original operating manual, WZG6001-e150401

NOTE

Safety indications on the centrifuge must be kept readable at all times. If

necessary, they must be replaced.

NOTE

Not all of the symbols/labels are used for this centrifuge type.

DANGER

This symbol stands for a direct hazard to the life and health of persons.

Non-observance of these symbols causes serious health problems up to lifeendangering injuries.

DANGER

This symbol stands for a direct hazard to the life and health of persons due to

electrical voltage.

Non-observance of these symbols causes serious health problems up to lifeendangering injuries.

WARNING

This symbol stands for a potential hazard to the life and health of persons.

Non-observance of these symbols can cause serious health problems up to lifeendangering injuries.

CAUTION

This symbol indicates a potentially hazardous situation

Non-observance of these notes can cause minor injuries or damage to property.

NOTE

This symbol indicates important information.

Pos: 34 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 35 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0020 Symbol- und Hinweiserklärungen @ 26\mod_14053190139 55_68.docx @ 191947 @ 2 @ 1

3.2 Explanation of the symbols and notes

In this operating manual, the following names and symbols to indicate hazards are

used:

Pos: 36 /010 Universalmodule/Seitenwechsel @ 0\mod_1202116244312_0.docx @ 105 @ @ 1

3 Safety

Version 09/2015, Rev. 1.3 of 02/03/2017

17

Translation of the original operating manual, WZG6001-e150401

Pos: 37 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0030 Verant wortung des Betreibers @ 26\mod_1405319015364_68.d ocx @ 191961 @ 2 @ 1

3.3 Responsibility of the operator

The operator is responsible for authorising only qualified personnel to work on the

centrifuge (see chapter 3.4 - "Operating personnel").

The areas of responsibility of the personnel concerning the operation, maintenance,

and care of the unit must be clearly defined.

The safety-conscious work of the personnel in compliance with the operating

manual and the relevant EC and national health and safety regulations as well as

with the accident prevention regulations must be checked at regular intervals (e.g.

every month).

Under the international rules for health and safety at work, the operator is obliged

to:

take measures in order to prevent all danger to life or health during work.

ensure that centrifuges are operated properly and entirely as intended (see

chapter 1.2 - "Intended use").

take protective measures against fire and explosion when working with

hazardous substances.

Pos: 38 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 39 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0040 Bedienper sonal @ 26\mod_1405319017634_68.docx @ 191989 @ 2 @ 1

take measures for the safe opening of centrifuges.

3.4 Operating personnel

Persons operating the unit must

be familiar with the fundamental regulations concerning workplace safety and

accident prevention

have read and understood this operating manual (and in particular the safety

Pos: 40 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 41 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0050 Informelle Sicherheitshinweise @ 26\mod_1405319019966_68. docx @ 192017 @ 2 @ 1

sections and warning notes) and confirmed this with their signature.

3.5 Informal safety instructions

This operating manual is a part of the product.

The operating manual must be kept at the location of use of the centrifuge.

Ensure that it is accessible at all times.

The operating manual must be handed over to any subsequent owner or

operator of the centrifuge.

Any changes made must be added to the operating manual.

In addition to the operating manual, the general and local rules and regulations

concerning the prevention of accidents and the protection of the environment

must also be supplied.

Safety and danger indications on the centrifuge must be kept readable at all

Pos: 42 /010 Universalmodule/Seitenwechsel @ 0\mod_1202116244312_0.docx @ 105 @ @ 1

times. If necessary, they must be replaced.

3 Safety

18

Version 09/2015, Rev. 1.3 of 02/03/2017

Translation of the original operating manual, WZG6001-e150401

DANGER

Ensure that the wall socket is properly wired and grounded.

Check that the mains voltage agrees with the nominal voltage listed on the

name plate.

Do not place vessels containing liquid on the centrifuge lid or within the safety

distance of 30 cm around the centrifuge. Spilled liquids may get into the

centrifuge and damage electrical or mechanical components.

Work on the power supply system must only be performed by certified

electricians.

Inspect the electrical equipment of the unit regularly. Defects such as loose or

burnt cables must be eliminated immediately.

WARNING

Do not open the lid when the rotor is in motion!

Do not reach into the rotor chamber when the rotor is in motion!

Do not use the centrifuge if it was installed incorrectly.

Do not use the centrifuge without panels.

Do not use the centrifuge if the rotors and inserts show signs of corrosion or

other defects.

Only use the centrifuge with rotors and accessories that have been approved

by the manufacturer. In case of doubt, contact the manufacturer (see chapter

7.3 - "Service contact").

Do not hold your fingers between the lid and the housing when closing the lid.

Risk of crushing!

Defective lid relieving devices could cause the centrifuge lid to fall (contact

the service department, if necessary). Risk of crushing!

Do not hit or move the centrifuge during its operation.

Do not lean against or rest on the centrifuge during its operation.

Do not spin any substances that could damage the material of the rotors and

buckets of the centrifuge in any way. Highly corrosive substances, for example,

damage the material and affect the mechanical strength of the rotors and

buckets.

Stop the centrifuge immediately in the event of a malfunction. Eliminate the

malfunction (see chapter 7 - "Malfunctions and error correction") or inform

the service department of the manufacturer (see chapter 7.3 - "Service

contact").

Ensure that all repairs are performed only by authorised and specialised

personnel.

Pos: 43 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0060 Siche rheitshinweise--------------------------------------- ---------------------- @ 26\mod_1405319021480_68.do cx @ 192031 @ 2 @ 1

3.6 Safety instructions

Pos: 44 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0060-0010 E lektrische Sicherheit @ 26\mod_1405319022891_68. docx @ 192045 @ 3 @ 1

3.6.1 Electrical safety

To reduce the risk of electrical shock, the centrifuge uses a three-wire electrical

cord and plug to connect the equipment to earth-ground. To preserve this safety

Pos: 45 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 46 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0060-0020 Me chanische Sicherheit (außer 1-16/1-16K) @ 26\mod_ 1405319024314_68.docx @ 192059 @ 3 @ 1

feature:

3.6.2 Mechanical safety

In order to ensure the safe operation of the centrifuge, observe the following:

3 Safety

Version 09/2015, Rev. 1.3 of 02/03/2017

19

Translation of the original operating manual, WZG6001-e150401

WARNING

Prior to any start-up, check the centrifuge, rotor, and accessories for signs of

damage that can be discerned from the outside. Special attention must be paid

to all of the rubber parts (e.g. motor cover, lid seal, and adapters) in terms of

visible structural changes. Defective parts must be replaced immediately.

Open the centrifuge when it is not in use so that moisture can evaporate.

DANGER

Do not spin explosive or inflammable substances.

Do not use the centrifuge within hazardous locations.

DANGER

Infectious, toxic, pathogenic, and radioactive substances may only be used in

special, certified containment systems with a bio-seal in order to prevent the

material from being released.

Take suitable precautions for your own safety if there is a risk of toxic,

radioactive, or pathogenic contamination

Materials that chemically react with each other with a high level of energy are

prohibited.

WARNING

Keep informed about local measures to avoid harmful emissions (depending on

the substances to be centrifuged).

Protective clothing is not required for the operation of the centrifuge.

The materials to be centrifuged may, however, require special safety measures

(e.g. centrifugation of infectious, toxic, radioactive, or pathogenic substances).

Pos: 47 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 48 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0060-0030 Bra ndschutz thermische Sicherungen @ 26\mod_140531 9025698_68.docx @ 192073 @ 3 @ 1

3.6.3 Fire prevention

Pos: 49 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 50 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0060-0040 C hemische und biologische Sicherheit @ 26\mod_14053 19028141_68.docx @ 192101 @ 3 @ 1

3.6.4 Chemical and biological safety

If pathogenic, toxic, or radioactive samples are intended to be used in the

centrifuge, it is in the responsibility of the user to ensure that all necessary safety

regulations, guidelines, precautions, and practices are adhered to accordingly.

Pos: 51 /010 Universalmodule/Seitenwechsel @ 0\mod_1202116244312_0.docx @ 105 @ @ 1

3 Safety

20

Version 09/2015, Rev. 1.3 of 02/03/2017

Translation of the original operating manual, WZG6001-e150401

WARNING

Ensure that the centrifuge was set up properly (see chapter 5 - "Set-up and

connection").

Maintain a safety distance of at least 30 cm (12 inches) around the centrifuge.

Do not store any dangerous goods in the centrifuge area.

Do not stay in the safety area longer than what is absolutely necessary for the

operation of the centrifuge.

Only use the centrifuge with rotors and accessories that have been approved

by the manufacturer. We explicitly warn against the use of equipment of poor

quality. Breaking glass or bursting vessels can cause dangerous imbalances at

high speeds

Ensure that rotor and buckets are correctly fitted (see chapter 6.2.2.1 -

"Installation of the rotor").

Observe the instructions on the installation of accessories (see chapter 6.2.2.3 -

"Installation of accessories").

WARNING

The rotor must be loaded axial symmetrically at equal weights.

If liquids with a density > 1.2 g/cm3 are used, reduce the speed (see chapter

2.2.2.2 - "Density").

Do not use the centrifuge if the rotor is loaded asymmetrically.

Do not use the centrifuge with tubes that are excessively long.

NOTE

Refer to the resistance data (see chapter 11.4 - "Resistance data")!

WARNING

Perform regular checks (at least once per month) for safety reasons!

Pay special attention to changes, such as corrosion, cracks, material abrasion,

etc.

After 10 years, they must be inspected by the manufacturer.

After 50,000 cycles, the rotor must be scrapped for reasons of safety.

If other data concerning the service life are engraved on the rotor or bucket,

these data shall apply accordingly. For example, a bucket with the engraving

.

date 02/20 ruary 2020 at the latest.

Pos: 52 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0060-0050 Si cherheitshinweise zur Zentrifugation @ 26\mod_140531 9029632_68.docx @ 192115 @ 3 @ 1

3.6.5 Safety instructions for centrifugation

For safe operation, observe the following before starting the centrifuge:

Pos: 53 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 54 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0060-0060 Bes tändigkeit von Kunststoffen @ 26\mod_1405319 031161_68.docx @ 192129 @ 3 @ 1

3.6.6 Resistance of plastics

Chemical influences have a strong effect on the polymeric chains of plastics, and,

therefore, on their physical properties. Plastic parts can be damaged if solvents,

Pos: 55 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 56 /100 Sigma/101 BA Zentrifugen Sart orius (Standardmodule)/030 Sicherheit/030-0060-007 1 Lebensdauer Rotoren, Zubehör Sartorius ohne Ver weis @ 42\mod_1461918130583_68.docx @ 347506 @ 3 @ 1

acids, or alkaline solutions are used.

3.6.7 Service life of rotors and accessories

Pos: 57 /010 Universalmodule/Seitenwechsel @ 0\mod_1202116244312_0.docx @ 105 @ @ 1

The rotors and accessories have a limited service life.

3 Safety

Version 09/2015, Rev. 1.3 of 02/03/2017

21

Translation of the original operating manual, WZG6001-e150401

Pos: 58 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0070 Siche rheitseinrichtungen----------------------------------- ------ @ 27\mod_1405319034809_68.docx @ 192157 @ 2 @ 1

3.7 Safety devices

Pos: 59 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0070-0010 D eckelverriegelung @ 27\mod_1405319036321_68.do cx @ 192171 @ 3 @ 1

3.7.1 Lid lock device

Pos: 60 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 61 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0070-0020 St illstandsüberwachung @ 27\mod_1405319037803_68. docx @ 192185 @ 3 @ 1

3.7.2 Standstill monitoring system

Pos: 62 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 63 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0070-0031 Sy stemkontrolle Spincontrol L @ 27\mod_1405319040 423_68.docx @ 192213 @ 3 @ 1

3.7.3 System check

Pos: 64 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 65 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0070-0040 Sc hutzleiterprüfung Spincontrol L+S+Easy+Univers al @ 27\mod_1405319043129_68.docx @ 192241 @ 3 @ 1

The centrifuge can only be started when the lid is properly closed. The electrical

lock must be locked. The lid can only be opened when the rotor has stopped. If the

lid is opened by way of the emergency release system during operation, the

centrifuge will immediately switch off and decelerate brakeless. If the lid is open,

the drive is completely separated from the mains power supply, i.e. the centrifuge

cannot be started (see chapter 7.1.1 - "Emergency lid release").

Opening of the centrifuge lid is only possible if the rotor is at a standstill. This

standstill is checked by the microprocessor.

An internal system check monitors the data transfer and sensor signals with regard

to plausibility. The system continuously performs a self-check and identifies

malfunctions. Error messages are displayed as "Error" followed by a code number

(see chapter 7.2 - "Table of error codes").

3.7.4 Earth conductor check

For the earth conductor check, there is an equipotential bonding screw on the rear

panel of the centrifuge (see chapter 2.1.1 - "Functional and operating elements").

An earth conductor check can be carried out by authorized and specialized

personnel using a suitable measuring instrument. Please contact the service

Pos: 66 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 67 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0070-0051 Un wuchtüberwachung Spincontrol L+Easy+Univer sal @ 27\mod_1405319047031_68.docx @ 192283 @ 3 @ 1

department (see chapter 7.3 - "Service contact").

3.7.5 Imbalance monitoring system

The indication "Imbalance" in the rotor field and, in some cases, also a sound signal

indicate that the centrifuge is in the impermissible imbalance range.The drive will

Pos: 68 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 69 /100 Sigma/101 BA Zentrifugen Sart orius (Standardmodule)/030 Sicherheit/030-0070-007 0 Rotorüberwachung Sartorius @ 38\mod_1439880 024933_68.docx @ 276092 @ 3 @ 1

be switched off in the acceleration phase or during the run.

3.7.6 Rotor monitoring system

When a rotor number number is selected, the computer will automatically check

whether the entered speed or the entered gravitational field are permissible for the

Pos: 70 /010 Universalmodule/Seitenwechsel @ 0\mod_1202116244312_0.docx @ 105 @ @ 1

selected rotor.

3 Safety

22

Version 09/2015, Rev. 1.3 of 02/03/2017

Translation of the original operating manual, WZG6001-e150401

DANGER

If an emergency arises, switch off the centrifuge immediately!

If in doubt, call the emergency doctor!

Pos: 71 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0080 Verhalt en bei Gefahren und Unfällen @ 27\mod_140531905118 8_68.docx @ 192325 @ 2 @ 1

3.8 Measures in the event of hazards and accidents

Pos: 72 /010 Universalmodule/ Leerzeile @ 0\mod_1202116244 500_0.docx @ 114 @ @ 1

Pos: 73 /100 Sigma/100 BA Zentrifugen Sigma (Sta ndardmodule)/030 Sicherheit/030-0100 Restris iken @ 27\mod_1405319052885_68.docx @ 192339 @ 2 @ 1

3.9 Remaining hazards

The unit was built state- of- the- art and according to the accepted safety rules.

However, danger to life and limb of the operator, or of third parties, or

impairments of the unit or other material assets cannot be completely excluded

when the unit is being used.

Use the unit only for the purpose that it was originally intended for (see

chapter 1.2 - "Intended use").

Use the unit only if it is in a perfect running state.

Pos: 74 /010 Universalmodule/Abschnittswechsel @ 0\mod_1202124514062_0.docx @ 418 @ @ 1

Pos: 75 /010 Universalmodule/Seitenwechsel @ 0\mod_1202116244312_0.docx @ 105 @ @ 1

Immediately eliminate any problems that can affect safety.

Loading...

Loading...