Operating Instructions

Controller for Automatic Mass Comparators

from Software Version 1.22

for

CC.......- L / CCE.......- L Model

98648-006-96

2

Contents

Page

Practical Use

3

Manual operation with cursor button 4

Getting Started

5

5

Configuring the Controller 5

Setting the Language 6

Setting the Time for Averaging 6

Setting the Date and Time 7

Setting the Number of A B B A Cycles 8

Setting the Number of Pre - Cycles 9

Setting the Delay time before taken values 10

Setting the Scale - Timeout 11

Setting the Results via AUX 11

Setting the Start delay 12

Operating the Controller

1

13

Manual Operation of the Load Alternator 13

Move Vertically 13

Raise to Upper Position 13

Move to Centring Position 14

Lower toward Mass Comparator 14

Move Horizontally 15

Starting the Mass Comparison

17

1)

without start delay time is setting 17

Select the procedure for mass comparison 17

Begin Measurement 18

Continuous Function 19

Starting the Mass Comparison

20

2)

when start delay time is setting 20

Select the procedure for mass comparison 20

The mass comparison start 22

Continuous Function 23

D

Data Interface ( Aux ) 24

Values only 24

Values and Times 25

Connecting cable to PC 25

Programming for external control from PC 26

Linking the PC to the control unit 26

External control commands 26

Vertical movements 26

Horizontal movements 26

Automatic weighing 27

Commands without movement 27

Error messages 27

T

Troubleshooting 28

Error messages 28

Maintenance 30

Replacing the Paper Roll 30

3

Practical Use

The CC.....-L / CCE…..-L controller regulates the load alternator function

sequences as well as the collection and evaluation of measured data.

The individual values measured are output automatically to the built-in

printer with the date and time of measurement and the calculated results.

A modern, touch-screen display shows all function sequences and also

serves as the user interface for operating the controller.

User guidance prompts in plain English will guide you through the simple

operation of the device.

You can choose the following languages:

- German

- English

- Spanish

- French

All of the function sequences are displayed and can be activated by pressing

the corresponding field on the right hand side of the touch screen e. g.

The number in this corresponding field is match marking to the number in

front of the function sequence.

The corresponding touch fields are not in the same line to the function

sequences on the touch screen.

Operators errors are virtually impossible!

The controller recognizes the position of the load alternator at all times; if

you select a function that cannot or should not be performed from a certain

position, an error message is displayed and the function is n

not

performed.

This prevents damage to the mass comparator that could otherwise have

been caused by operator error.

You can choose the following measurement sequences:

1 x A B B A - cycle

6 x A B B A - cycles

02 - 99 x A B B A - cycles

With the 4-position load alternator, you can compare:

- 2 weights: N - 2

- 4 weights: N - 1 / N - 2 / N - 3

- Combinations: N - 1 / 1 - 2 / N - 3 / 1 - 3 / N - 2 / 3 - 2

The reset key is to stop the measurement

also the emergency interrupt key.

As soon as you press the reset key, the load alternator is stopped and

remains in the position it was in when you pressed reset. Any measurement

sequence running at the time is stop.

The display indicates that the function was interrupted.

You can also press reset to stop a measurement sequence after you have

selected the continuous function.

4

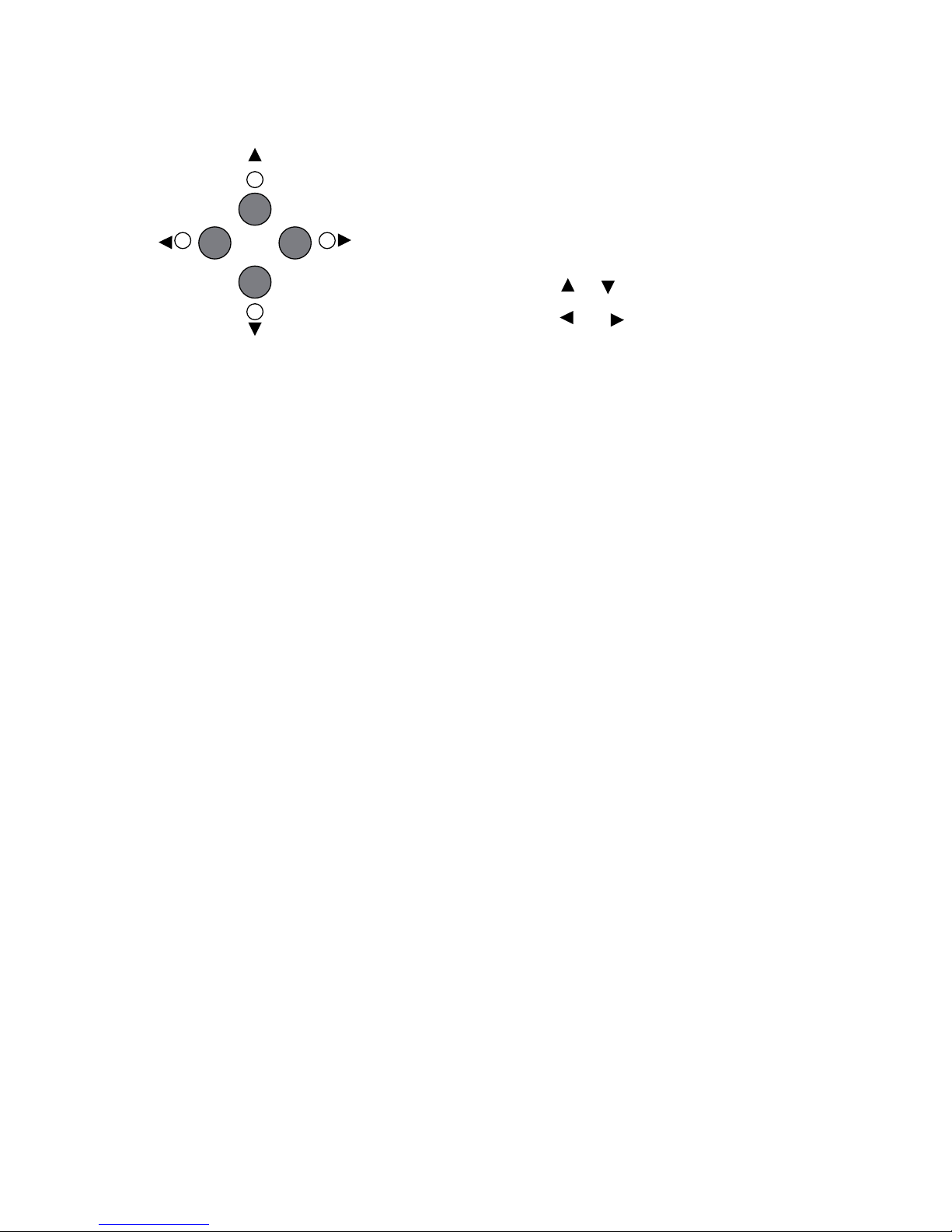

Manual operation with the cursor buttons

There are four cursor buttons on the front side.

With this cursor buttons you can easy operate the load alternator, in it’s

basic movements.

That means turning right and left, lifting or lowering the platform.

This is helpful for loading the platform from the front side and other

applications.

The cursor buttons are only active if the main menu appears on the display.

See page no. 5

Movement vertically:

Movement horizontally:

Four control light identify the current position and the activity of the load

alternator.

All lights on means that the platform is in the upper position.

Movement in all directions is possible.

A blinking control light identifies the actually operation relating to the

direction of movement.

A non active control light means that a movement in this direction is not

possible.

To start the movement by your choice, press the cursor button.

Horizontal movement:

- short press turn 90 degrees,

- long press (3 sec.) turn 180 degrees,

Vertical movement:

- short press move - from the top toward to centre, or

- from the centre to the lower position, or

- raise from the lower to the centre, or

- raise from the centre to the upper position

- long press move - direct from the upper to the lower,

- from the lower to the upper position.

Note:

Two control lights on the printer indicate the capacity of the paper

A green light means: enough paper

A red light means: paper roll come to end

If the paper roll in the printer runs out in the middle of a measuring

sequence, the printer switches off.

The individual values measured and the results calculated after the printer

shuts off are stored in memory.

For example: with 6 x A B B A selected, the memory can store data from up

to 6 complete measurements.

When the memory is full, this is indicated by a crossed-out printer symbol in

the display.

The load alternator continues according to the selected function sequence.

Subsequent measurement data are not stored.

To retain the data stored in memory:

- Do not interrupt the measurement sequence

- Do not press reset

- Do not turn off the controller

Place a new roll of paper in the printer (see "Maintenance")

The stored data are output to the printer.

5

Getting Started

Then the initial start up window is displayed.

Configuring the Controller

After you turn on the controller,

the Sartorius logo is displayed for

approx. 5 second.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

The continuous display in the upper

right corner shows:

- model no. of the connected comparator

- software version,

- language setting,

- date.

Press anywhere to access the main menu.

Initial System Start up

load the weights.

Press anywhere to access

the main menu.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1: Mass comparison Cycles

2: Move vertically

3: Move Horizontally

4: Configure

All settings is stored in the memory when you

turn off the controller.

To configure the device settings,

Press the numeric key "44"

for configuration.

1

2

3

4

6

The main configuration windows is displayed.

Setting the Language

The display returns to the main configuration

window

in the desired language.

Setting the Time for Averaging

Press the numeric key "11" to access the

language menu.

1: Language

2: Time for -

averaging ( 10 )

3: Date and time

4: More

Configurations..

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

Press the numeric key on the touchscreen that corresponds

to the desired language.

1: Deutsch

2: English

3: Español

4: Francais

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

The time for averaging is a period of time

during which measured values are transferred

to the controller continuously; i.e.,

each time a weight is placed on the mass

comparator and stabilizes.

The average calculated from these values is

output for further processing.

Press the numeric key "22" to access

the menu for setting the averaging time.

1: Language

2: Time for -

averaging ( 10 )

3: Date and time

4: More

Configuration..

1

2

3

4

6

21 3

4 5

7 8 9

1

2

3

4

7

The following setting windows is displayed.

The display returns to the main configuration

windows.

Setting the Date and Time

The following setting windows is displayed.

Set a time from 05 to 99 seconds

Then press

to confirm new settings, or

to cancel new settings

2: Time for

averaging

Please enter

the new value.

( 10 )

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

Press the numeric key "3

3

" to access the

menu for setting the date and time.

1: Language

2: Time for

averaging ( 10 )

3: Date and time

4: More

Configurations..

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

The procedure for setting the date and time is

self-explanatory.

Press the number on the touch-screen that

corresponds to the item you wish to set.

Follow the instructions displayed.

Press the numeric key "6

6

" to complete the

settings.

When you have completed the settings, the

display returns to the main configuration

window, see following.

1: Hours ( 10 )

2: Minutes ( 15 )

3: Day - ( 01 )

4: Month ( 07 )

5: Year ( 05 )

6: Set

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

X

1 2

65

3 4

1

2

3

4

3

21

4 5 6

7 8 9

X

0

8

The second configuration windows is displayed.

Setting the Number of A B B A Cycles

The following setting windows is displayed.

For more configuration:

Press the numeric key "44" to access to the

second configurations windows.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1: Language

2: Time for

averaging ( 10 )

3: Date and time

4: More

Configurations..

You can set the desired number of A B B A

cycles for a given measurement sequence.

The factory setting is 03 x A B B A.

To select a different number of ABBA - cycles,

Press the numeric key "1

1

" .

1: Set number of

A B B A - cycles ( 03 )

2: Set number of

Pre - Cycles ( 00 )

3: Delay time before

taken values ( 20 )

4: More

Configurations..

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

Set a number of cycles between 02 and 99.

Then press

to confirm new settings, or

to cancel new settings.

The display returns to the second configuration

window.

4: Set number of -

A B B A - cycles.

Please enter

the new value.

( 03 )

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1

2

3

4

X

1

2

3

4

1

2 3

4 5 6

7 8

0X

9

9

To optimize measuring sequences to meet the needs of the ambient conditions, the following settings are

required.

Setting the Number of Pre - Cycles

The following setting windows is displayed.

This setting enables user-definable A B B A cycles

to be performed immediately before the actual

measurement. We recommend that you use this

setting if, for instance, you plan to start a

measurement right after placing weights on the

load alternator platform.

The factory setting is 00.

To select a different number of Pre - cycles,

Press the numeric key "2

2

" .

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1: Set number of

A B B A - cycles ( 03 )

2: Set number of

Pre - Cycles ( 00 )

3: Delay time before

taken values ( 20 )

4: More

Configurations..

Set a number of cycles between 00 and 99.

Then press

to confirm new settings, or

to cancel new settings.

The display returns to the second configuration

window.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

2: Set number of

Pre - Cycles

Please enter

the new value.

( 00 )

1: Set number of

A B B A - cycles ( 03 )

2: Set number of

Pre - Cycles ( 00 )

3: Delay time before

taken values ( 20 )

4: More

Configurations..

C C 1 0 0 0 0 U - L

S o f t w a r e V 1..22

E n g l i s h

1 - J A N - 2010

X

2

3

4

1

1

2

3

4

1 32

5 6

8 9

4

7

0X

10

S

Setting the

Delay Time Before Taken Values (XX)

The following setting windows is displayed

A third configuration windows is displayed.

This setting defines a period of time before measured

values are transmitted after the mass comparator has been

loaded.

This time begins as soon as the mass comparator is loaded

and the load alternator motor

shuts off.

Because of, once the mass comparator has been

loaded and the stability symbol „g“ is displayed, the weight

value may drift slightly until the weight value is recognized

as a stable value in order to be transmitted.

This time may differ from location to location and must be

determined before performing the actual

measurement.

The factory setting is 20.

To select a different number of Delay time,

Press the numeric key "3

3

" .

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1: Set number of

A B B A - cycles ( 03 )

2: Set number of

Pre - Cycles ( 00 )

3: Delay time before

taken values ( 20 )

4: More

Configurations..

3: Delay time before

taken values

Please enter

the new value.

( 20 )

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

Set a number of time between 00 and 99 sec

Then press

to confirm new settings, or

to cancel new settings.

The display returns to the second configuration

window.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

For more configurations

Press the numeric key "4

4

" .

1: Set number of

A B B A - cycles ( 03 )

2: Set number of

Pre - Cycles ( 00 )

3: Delay time before

taken values ( 20 )

4: More

Configurations..

X

X

1 32

5

8

6

0

7

4

9

1

2

3

4

2

3

4

1

11

A fourth configuration windows is displayed.

Setting the Scale - Timeout

This setting defines the time at which a

measurement is to be automatically aborted in the

event of an error, for example,

if the stability symbol „g“ is n

not

displayed after

the mass comparator has been loaded.

This may happen if there is any interference due to

vibration transferred to the surface on which the

mass comparator rests, turbulent air currents or

changes in the climatic conditions.

Another source of this error is if the wrong

substitution weight (F2 key on the display panel

of the mass comparator) was selected for the weight

to be measured.

An additional source of this error is if the wrong

number of weights was selected in the menu

„Type of comparisons“

before beginning the measurement;

for example using 2 weights when 4 have actually

been selected or visa versa.

Scale - Timeout (

ON

) = waiting time 1 hour

Scale - Timeout (

OFF

) = waiting time infinity

To change between OON / O

OFF

press the numeric key “1

1

“.

Note:

After time out, the display will show this message:

„No correct value available!“

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1: Scale - Timeout ( OFF )

2: Results via AUX:

( values only )

3: Swap ¢ ² keys.

(OFF)

4: More

Configurations . .

Setting the Results via AUX

This setting defines the formats for receiving

measurements data on PC

(refer data interface page 19 and 20)

Results via AUX:

( v

values only

) = measurement values only

( v

values and times

) = measurement values with

To change between v

values only/values and times

press the numeric key “22“ .

For corrections or control of all settings please

scroll by

pressing the numeric key “44“ , or

conclude the configurations by pressing the

Sartorius logo to access to the main menu.

1: Scale - Timeout ( OFF )

2: Results via AUX:

( values only )

3: Swap ¢ ² keys.

(OFF)

4: More

Configurations . .

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2012

1

2

3

4

1

2

3

4

12

The following setting windows is displayed.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 – J A N - 2010

Seting the start delay ( 000 )

This setting make it possible to start the

measurements after the deceleration time.

max. delay time : 256 Minute

This setting is very useful for the of acclimatization

of all weights in the same chamber.

To set or change the delay time,

Press the numeric key "1

1

"

1: Set start delay ( 000 )

2: -- --

3: -- --

4: More

configurations . .

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 – J A N - 2010

Set a number of time between 000 and 255 Minute

Then press

to confirm new settings, or

to cancel new settings.

The display returns to the fourth configuration

window.

For corrections or control of all settings please

scroll by

pressing the numeric key „44“, or

conclude the configurations by pressing the

Sartorius logo to access to the main menu.

The main window is displayed.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 – J A N - 2010

1: Set start delay ( 000 )

2: -- --

3: -- --

4: More

configurations . .

1: Set start delay

Please enter

the new value.

( 000 )

1

2

3

4

X

X

1 32

5

8

6

0

7

4

9

1

2

3

4

13

Operating the Controller

Manual Operation of the Load Alternator

E.g.: 1. To control the position of the weight

2. To adjust the mass comparator

3. After interrupting a measurement

Vertical Movement

R

Raise to Upper Position

The main menu is displayed.

If not, press the Sartorius logo.

Always begin with the "Move vertically" item.

Press the number key "2

2

" .

1: Mass comparison cycles

2: Move vertically

3: Move horizontally

4: Configure

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1: Raise load alternator

to upper position

2: Move load alternator

to centering position

3: Load load alternator

toward mass comparator

4: Move horizontally

When you select this function, the load

alternator goes through several position shifts

until it recognizes the initial raised position.

Always activate this function:

- after turning on the mass comparator,

- after canceling a measurement by pressing

reset, and

- before configuring the controller.

When the menu illustrated on the left is

displayed, press the number key "1

1

" .

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

The load alternator platform is raised into the

upper initial position.

If the platform is already in this position

when you select this function, it is lowered

slightly and then returned to this position.

"1

1: in progress

" is displayed while the platform

is in motion.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1: Raise load alternator

to upper position

2: Move load alternator

to centering position

3: Load load alternator

toward mass comparator

4: Move horizontally

1: in progress.

2

3

4

1

1

2

3

4

1

2

3

4

14

M

Move to Centering Position

Lower toward Mass Comparator

1: Raise load alternator

to upper position

2: Move load alternator

to centering position

3: Load load alternator

toward mass comparator

4: Move horizontally

2: in progress.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.20

E n g l i s h

1 - J u l - 2005

With this function, the load alternator

Platform is parked in on intermeditate

position as it is lowered.

You can perform a visual inspection at this

point.

Press the number key "2

2

" .

"2

2: in progress

" is displayed during this

procedure.

When you activate this function, the load

alternator platform is lowered toward the mass

comparator and the weight is placed on the

weighing pan.

Press the number key "3

3

" .

You can select this function immediately

following Function 1, if desired.

1: Raise load alternator

to upper position

2: Move load alternator

to centering position

3: Load load alternator

toward mass comparator

4: Move horizontally

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

When you press the "33" key, the message

"3: Please comfirm by reselecting function"

is displayed.

Press the number key again "33".

The load alternator platform is lowered toward to

the mass comparator.

1: Raise load alternator

to upper position

2: Move load alternator

to centering position

3: Load load alternator

toward mass comparator

4: Move horizontally

3: Please confirm by

Re-selectiong function.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1

2

3

4

1

2

3

4

1

2

3

4

15

When the load alternator platform is in the

upper position,

touch the Sartorius logo on the screen

to return to the main menu.

Horizontal Movement

When you press the "3

3

" key, another window is

opened.

1: Raise load alternator

to upper position

2: Move load alternator

to centering position

3: Load load alternator

toward mass comparator

4: Move horizontally

3: in progress.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

"3

3: in progress

" is displayed while the load

alternator is in motion.

After visual inspection or sensetivity adjustment of

the mass comparator,

return the load alternator platform

to the upper position.

Press the number key "1

1

" .

1: Mass Comparison cycles

2: Move vertically

3: Move horizontally

4: Configure

C C 1 0 0 0 0 U – L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N – 2010

You can only activate this function when the

load alternator is in the raised position.

(If necessary, you can ensure that this is the

case by selecting Function 2.)

Press the number key "3

3

" .

Press the number key that corresponds to the

desired function:

e.g., to rotate the alternator 180°,

press the number key "11" .

1: Turn 180° / Move to

next defined position

2: Turn 90°

3: Turn 90°

4: Move vertically

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1

2

3

4

1

2

3

4

1

2

3

4

14

Then press the Sartorius logo on the display

To return to the main menu

1: Turn 180° / Move to

next defined position

2: Turn 90°

3: Turn 90°

4: Move vertically

1: in progress.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

"1

1: in progress

" is displayed while the load

alternator is in motion.

Press the corresponding number key to activate

other functions as desired.

1: Mass Comparison cycles

2: Move vertically

3: Move horizontally

4: Configure

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

The main menu is displayed.

1

2

3

4

1

2

3

4

17

Starting a Measurement

1)

without start delay time is setting

Before placing a weight on the load alternator platform, make sure that the load alternator is in the initial raised

position. See the section entitled "Vertical Movement."

Center the reference and test weights within the marking on the load alternator platform. Always position the

reference weight on the "N."

Before beginning the measurement, the reference weight must be in position, on the "N" on the load alternator

platform, above the weighing system.

See the section entitled "Horizontal Movement."

S

Select the procedure for mass comparison

Select the "Mass comparison cycles" item from

the main menu. To do this

Press the number key "11".

1: Mass comparison cycles

2: Move vertically

3: Move horizontally

4: Configure

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1: 1 A B B A - cycle

2: 6 A B B A - cycles

3: User-defined number

of A B B A - cycles ( 03 )

4: Mass comparison method

When the start menu window opens, select

the "Mass comparison method" item f

first

.

Press the number key "44".

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1: Mass comparison

of two weights

2: Mass comparison

of four weights

3: All 6 comparisons

(N-1 / 1-2 / N-3 / 1-3 / N-2 / 3-2)

4 Mass comparison cycles

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N – 2010

Select the desired method of mass comparison:

e.g.:

1: Mass comparison of two weights

Press the number key "11" .

1

2

3

4

1

2

3

4

1

2

3

4

18

Press the number key "4

4

"

to return to the start menu.

Begin Measurement

Press the "2

2

" key again to start the measurement

Start the selected measurement sequence,

or cancel this input if you wish to select

a different number of cycles by pressing

another number key,

or press the Sartorius logo to return to the

main menu.

"1

1: in progress

"

is short displayed when you press

this key.

1: Mass comparison

of two weights

2: Mass comparison

of four weights

3: All 6 comparisons

(N-1 / 1-2 / N-3 / 1-3 / N-2 / 3-2)

4: Mass comparison cycles

1: in progress.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

When the start menu is displayed, press the

number key that corresponds to the desired

number of cycles to start the measurement

procedure:

e.g.:

to select 6 A B B A cycles,

press the number key"2

2

" .

The message

2: Please confirm by re-selecting function

is displayed.

1: 1 A B B A - cycle

2: 6 A B B A - cycles

3: User-defined number

of A B B A - cycles ( 03 )

4: Mass comparison method

2: Please confirm by

r

re-selecting function.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1: 1 A B B A - cycle

2: 6 A B B A - cycles

3: User-defined number

of A B B A - cycles ( 03 )

4: Mass comparison method

2: in progress.

To start the selected measurement sequence:

Press the number key once more "22".

"2

2: in progress

" is displayed.

1

2

3

4

1

2

3

4

1

2

3

4

19

The measurement procedure starts

The printer begins by printing the current time

and date, the mass comparator model

designation, the number of A B B A cycles

and the number of weights.

The load alternator begins by centering the

weights. The first weight to be tested is centered

first.

With 2 weights, this is the weight in position 2.

The load alternator platform rotates 180°

that the weight in position 2 is above the mass

comparator, then begins centering the weight.

The weight is placed on the weighing pan and

centered by the Centermatic 2 times, in regular

cycles.

The procedure is then repeated using the

reference weight.

One ABBA - cycles end the centering procedure.

Continuous Function

With the continuous function option, you can

repeat complete measurement cycles

continuously.

To stop the continuous function,

press the reset key.

Note:

Do n

not

press the reset key while the load

alternator platform is in motion!

Starting the Continuous Function

Start the measurement sequence as described

above.

When the

"2

2: Please confirm by reselecting function

"

message is displayed,

press the number key "22"

and hold it until the message

2: in progress. Continuous function!

is displayed.

The measurement sequence then starts.

Press reset key to stop a measurement sequence

.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1: 1 A B B A - cycle

2: 6 A B B A - cycles

3: User-defined number

of A B B A - cycles ( 03 )

4: Mass comparison method

2: in progress.

Continuous function!

1

2

3

4

20

Starting the Mass Comparison

2)

when the start delay time is setting, setting: see on page 12”

make sure that the load alternator is in the initial raised position, before placing a weight on the load alternator

platform,. See the section entitled "Vertical Movement."

Center the reference and test weights within the marking on the load alternator platform.

Always position the reference weight on position mark "N."

Before start the mass comparison,

The load alternator platform, with the reference weight on the position "N" must be in position above the weighing

system pan.

See the section entitled "Horizontal Movement."

S

Select the procedure for mass comparison

Select the "Mass comparison cycles" item from

the main menu.

Press the number key "11" .

1: Mass comparison cycles

2: Move vertically

3: Move horizontally

4: Configure

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

A new window will displayed. select :

start the mass comparison “without start delay time”

Press the number key "1

1

"

follow the section entitled:

starting the mass comparisson without start delay time

start the mass comparison with setting start delay time,

Press the number key "2

2

"

and follow the next step below

Press the number key "3

3

"

to change the start delay time.

Please choos

start option:

1: At once

2: After 30 minutes

3: Set start delay

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

The start menu window will displayed.

If you have press the number key "2

2

"

Select the "Mass comparison method" item f

first

.

Press the number key "4

4

" .

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1: 1 A B B A - cycle

2: 6 A B B A - cycles

3: User-defined number

of A B B A - cycles ( 03 )

4: Mass comparison method

1

2

3

4

1

2

3

1

2

3

4

21

1: Mass comparison

of two weights

2: Mass comparison

of four weights

3: All 6 comparisons

(N-1 / 1-2 / N-3 / 1-3 / N-2 / 3-2)

4: Mass comparison cycles

1: in progress.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

Select the desired method of mass comparison:

e.g.:

1: Mass comparison of two weights

Press the number key "1

1

" .

"1

1: in progress

" is s

short

displayed

Press the number key "4

4

" to return to the

start menu.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

When the start menu is displayed, press the

number key that corresponds to the desired

number of cycles to start the mass comparison

procedure:

e.g.:

6 A B B A cycles,

press the number key "2

2

" .

The message

2: Please confirm by re-selecting function

is displayed.

1: 1 A B B A - cycle

2: 6 A B B A - cycles

3: User-defined number

of A B B A - cycles ( 03 )

4: Mass comparison method

1: 1 A B B A - cycle

2: 6 A B B A - cycles

3: User-defined number

of A B B A - cycles ( 03 )

4: Mass comparison method

2: Please confirm by

re-selecting function.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1

2

3

4

1

2

3

4

1

2

3

4

Confirm the selected mass comparison sequence,

or cancel by press another number key,

or press the Sartorius logo to return to the

main menu.

Confirm the selected mass comparison sequence,

press the number key "2

2

" again

to start the measurement .

22

1: 1 A B B A - cycle

2: 6 A B B A - cycles

3: User-defined number

of A B B A - cycles ( 03 )

2: Mass comparison

o

of two weights

i

in progress.

30

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

A number will displayed in the window.

e. g. 3

30

This number,

identicate the setting start delay time, in minute

The time cont down to “

“0”

before

the mass comparison procedure start automatically

The mass comparison starts

The printer begins by printing the current time and date, the

mass comparator model designation,

the number of A B B A cycles

and the number of weights.

The load alternator begins by centering the weights.

The first weight to be tested will centered first.

as following:

e.g. 2 weights on the load alternator.

The Testweight is on position 2.

The load alternator platform rotates 180° so that the weight

of position 2 is above the mass comparator pan.

The centering begins.

The weight will loaded and unloaded two times on the

weighing pan. The Centermatic center the weight in the

center position.

The load alternator platform rotates 180° back so that the

weight of position N is above the mass comparator pan

The same procedure for centering N start.

One ABBA - cycles end the centering procedure.

1

2

3

4

23

Continuous Function

With the continuous function option, you can

repeat complete measurement cycles

continuously.

to stop the continuous function.

Press the reset key

Note:

Do n

not

press the reset key while the load

alternator platform is in motion!

Starting the Continuous Function

Start the measurement sequence as described

above.

When the

"2

2: Please confirm by reselecting function

"

message is displayed,

press the number key "22" and hold it until the message

2: in progress. Continuous function!

is displayed.

The mass comparison starts.

Press the reset key

to stop the continous function

,

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1: 1 A B B A - cycle

2: 6 A B B A - cycles

3: User-defined number

of A B B A - cycles ( 03 )

4: Mass comparison method

2: in progress.

Continuous function!

1

2

3

4

24

Data Interface ( Aux )

General:

The individual measurements printed out during the measurement process are also available as an ASCII string at the

data interface (Aux) and can be received by the PC for further processing,

The measurements are always output in a couple of a combined data string.

Two different formats selectable. (refer configurations page 5 and results via AUX on page 11).

Results via AUX:

1. ( v

values only

) = data output of measurements values only

2. ( v

values and time

) = data output of measurements values with numbers of ABBA - cycles and time.

Values only

The measurements are always output in a couple of a combined data string comprising the measurements A and B oor

B and A (separated by a space).

The number of characters to be transferred is always 22.

The data output is as follows:

Measurement A, 1 space, measurement B and CR (carriage return n

no

CR/LF).

A line feed signal (LF) must be generated each time after data is received from the PC so that the next measured

values to be received appear in a new line. Otherwise, the new values will overwrite the former values.

Data output example: CCE1000S-L

Measurement A: - 0.000123, Measurement B: - 0.000456

Data string:

- 0 . 0 0 0 1 2 3 - 0 . 0 0 0 4 5 6 CR

1 2 3 4 5 6 7 8 9 10 11 12 13 1 4 15 16 17 18 19 20 21 22

1 ± sign for measurement A (one space if sign is + )

2 - 10 measurement value A with decimal point

11 space

12 ± sign for measurement B (one space if sign is + )

13 - 21 measurement value B with decimal point

22 carriage return

The Data string is 22 characters long and to partition as follows.

11 character = measurement A (B)

11 character = measurement B (A)

An example for receiving data on PC from the mass comparator and sorted in an excel file.

P

PC receive:

P

PC

Comparator measurement:

measurement A measurement B generated:

1. Measurement AA: 0,000 123, BB: 0,000 456 0

0,000123 0,000456

LF

2. Measurement B: 0,000 459, A: 0,000 126 0

0,000126 0,000459

LF

3. Measurement A

A

: 0,000 125, BB: 0,000 457 0

0,000125 0,000457

LF

4. Measurement B: 0,000 459, A: 0,000 124 0

0,000124 0,000459

LF

5. A

A

: BB:

25

values and times

This means that the data string consists of the transaction counter (number of the ABBA cycle),

time of value A, value A, time of value B and value B, or these data for B and A, respectively.

The calculations of the differences and the final result does not belong to the output.

The controller ( control unit ) recognizes different numbers of characters for the measured values so that the data

string is correctly sorted with one setting on all automatic mass comparators model.

The Data string is 41 characters long and to partition as follows.

The partition of the data string is follows:

2 characters = number

1 characters = space

8 characters = time measurement A (B)

10 characters = measurement A (B)

1 characters = space

8 characters = time measurement B (A)

10 characters = measurement B (A)

1 characters = space

An example for receiving data on PC from the mass comparator and sorted in an excel file.

P

PC receive

: P

PC

Comparator measurement:

number measurement measurement

time A value A time B value B

generated:

1. Measurement A

A:

0,000456 BB: 0,000123 1

1 14:56:29 0,000123 14:58:22 0,000456

LF

2. Measurement B: 0,000456 A: 0,000126 1

15:02:09 0,000126 15:00:16 0,000456

LF

3. Measurement A

A:

0,000125 BB: 0,000457 2

2 15:04:02 0,000125 15:05:55 0,000457

LF

4. Measurement B: 0,000459 A: 0,000124 1

15:09:42 0,000124 15:07:49 0,000459

LF

5. Measurement A

A:

0,000128 BB: 0,000460

3 15:11:36 0,000128 15:13:29 0,000460

LF

6. Measurement B: A:

Connecting cable to PC

The two data protocols for the transfer require a semi duplex interface with transmit and

receiver lines.

As no handshake is required, the relevant handshake lines must be bridged.

IBM PC Control Unit

_____________________________________________________

female connector (9-pin) male connector (25-pin)

Shield ------------------------------------------- Shield

1 -- DCD -------

I

2 -- RXD -------I----------------------- TXD -- 2

3 -- TXD -------I----------------------- RXD -- 3

4 -- DTR -------o

5 -- GND -------I----------------------- GND -- 7

6 -- DSR -------o

8 -- CTS -------

I

24

Programming for external operation with PC

Introduction

The load alternator can be operated from a PC via the “AUX” port. Measurement procedures can be freely

programmed as required.

As the data protocol runs in 7 bit / ASCII format, any terminal program on the PC is suitable for testing the functions.

Interface parameters: 9600 Baud

EVEN Parity

1 start bit

7 data bits

1 stop bit

n

no

handshake, local echo must be switched off

Linking the PC to the control unit

Switch on the control unit of the load alternator.

Make sure that the main menu is displayed on the controller; if necessary key to the Sartorius logo.

To link the PC to the control unit, send a C

CR

( Carriage Return only nno CR/LF ) at intervals until the alternator responds

with ready for operation “?

??

”.

The control unit display will bring up the message “S

System controlled externally

”.

This message will remain on the display as long as the external control condition persists.

The built-in printer is disabled

.

On the PC monitor, two question marks “???” will be displayed indicating the system’s readiness to receive commands.

If further data (parameters, confirmations) are required, this will be indicated by the appearance of a single question

mark “?

?

”.

All command codes consist of a single letter or numeral. (No Carriage Return “CR” must be sent).

The alternator sends back the character it receives (echo) by way of confirmation.

Once the command has been executed, “?

??

” will be displayed on the screen.

External control commands

Vertical movements

“11“ Locating top starting position.

“33“ Lowering the centering position (middle position).

“44“ a) Lowering to mass comparator: If load changer centred.

Queries with “?“.

- “0“ confirms to lowering.

b) Locating centering position: If load changer in weighing position.

Executes command

immediately it is entered.

“DD“ (Down) Lowering to mass comparator. Executes command immediately

it is entered.

a) Lowering from the top starting position.

b) Lowering from the centering position.

Horizontal movements

“HH“ Rotate 180° clockwise.

“2

2

“ Rotate 180° counter-clockwise.

(CC50000S: Change the horizontal end position).

“99“ Rotate 90° clockwise.

(CC50000S: Change the horizontal end/centre position).

“NN“ Rotate 90° counter-clockwise.

27

Automatic weighing

“55“ 1 x A-B-B-A cycle.

Queries with “?“. - Confirms to start with “0“.

“66“ 6 x A-B-B-A cycles.

Queries with “?“. a) 1 x 6 x A-B-B-A : - Confirms to start with “0“.

b) Permanent function 6 x A-B-B-A :

- Enter “6

6

“ repeatedly.

Queries with “?“.

- Confirms to start with “0“.

“7

7

“ 3 - 99 x A-B-B-A cycles freely selectable.

Queries with “?“ Enter required number of A-B-B-A measurements.

Note!

The number is entered as “a single character” whose ASCII value

corresponds to the actual number required. (Enter in the terminal program: if

applicable, using ALT and number on the keypad).

- Executes command immediately it is entered.

Commands without

movement

“00“ (Zero) Set evaluation time in seconds 05 - 99.

Queries with “?“ Enter evaluation time.

Note!

The number is entered as “a single character” whose ASCII value

corresponds to the actual number required. (Enter in the terminal program: if

applicable, using ALT and number on the keypad).

“8

8

“ Compare mass of only 2 weights.

Entry necessary with only 2 weights before start.

“A

A

“ (All 6 comparisons) Mass comparison all 6 combinations.

Only possible when 4 weights are used.

When required, entry before measurement starts.

“R

R

“ (READ) Take weight value from the mass comparator display.

Possible only when weighing is in progress and the weight is shown with the

stability symbol “g”.

The weight is transferred after a delay, determined by the evaluation time

entered.

Note!

The controller reports error and then stops the system if no correct weight

is available.

“V

V

“ (Version) indicates the comparator model and the software version.

Error messages

“NNA“ (not available) Function not available from current position.

“S

SE

“ (scale error) No correct weight available, control blocked.

“P

PE

“ (position error) No response from position switch: alternator blocked.

The measurements are sent to the PC as a couple of values an ASCII string.

The measurements “A” and “B” are separated by: a space (hexadecimal 20),

and end with: CR (hexadecimal 0D)

A line feed signal (LF) must be generated each time after data is received from the PC so that the next measured values

to be received appear in a new line. Otherwise, the new values sent will overwrite the former values.

28

Troubleshooting

Error message:

1: Function not possibile from this position!

Cause:

Solution:

If you press the

number key "1

1

" :

The load alternator platform is in the

centering or lowered position.

Move the platform to the initial raised

position. Press the

number key "2

2

" and then press the key "11"

while the submenu is displayed.

Error message:

3: Function not possible from this position!

Cause: Solution:

If you press the

number key "3

3

" :

The load alternator platform is in the

centering or lowered position.

Move the platform to the initial raised

position. Press the

number key "2

2

" and then press the key "11"

while the submenu is displayed.

1: Mass comparison cycles

2: Move vertically

3: Move horizontally

4: Configure

1: Function not possible

f

from this position!

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

1 Mass comparison cycles

2: Move vertically

3: Move horizontally

4: Configure

3: Function not possible

f

from this position!

1

2

3

4

1

2

3

4

29

Error message:

Cause: Solution:

After a measurement has begun:

The mass comparator has not been

turned on.

The controller is not connected to the

mass comparator.

The menu has not been configured for

data transfer.

You have started a measurement with

2 weights.

Turn on the mass comparator.

Connect the cable.

Check the menu settings in the mass

comparator.

Select the comparison method before

starting a measurement sequence. See

"Starting a Measurement."

During measurement:

Data is not transferred to the

controller because the display is not

stable; i.e., the stability symbol is not

displayed.

Check for and correct unfavorable

ambient conditions; e.g. vibrations,

drafts or air turbulence, extreme

temperature fluctuations.

Error message:

Cause: Solution:

After turning on the mass

comparator or during

measurement:

The load alternator platform is in the

centering or lowered position.

The power supply has been

interrupted.

The reset key was pressed.

Move the platform to the initial raised

position.

Restart measurement.

No correct value available!

Please check weights and

number loaded - then press

the reset button.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

Initial System Startup

Important! First raise

load alternator to

upper position, then

load the weights.

Press anywhere to access

the main menu.

C C 1 0 0 0 0 U - L

S o f t w a r e V 1.22

E n g l i s h

1 - J A N - 2010

30

Maintenance

Replacing the Paper Roll

Turn on the controller.

Lift up the printer cover .

Locate the small lever to the right of the paper transport roll and move it

towards the front.

Insert the start of the paper roll w

with the inside towards the front

into the

retainer behind the paper transport roll and move the lever back to its

original position.

The paper is drawn in automatically.

Press the grey push button to transport more paper, if is necessary.

Lift back the printer cover.

Order no.:

69 C 00034 (set of 5 roll thermo paper)

Note:

If the paper roll in the printer runs out in the middle of a measuring

sequence, the printer switches off. The individual values measured and the

results calculated after the printer shuts off are stored in memory.

With 6 x A B B A selected, for example, the memory can store data from up

to 6 complete measurement.

When the memory is full, this is indicated by a crossed-out printer symbol in

the display.

The load alternator continues according to the selected function sequence.

Subsequent measurement data are not stored.

To retain the data stored in memory:

- Do not interrupt the measurement sequence

- Do not press reset

- Do not turn off the controller

Place a new roll of paper in the printer as described above.

When you return the lever to its original position, the stored data are

printed automatically.

If the printer symbol was not yet displayed, the subsequent measured data

are printed automatically as before.

If the printer symbol is displayed, it remains displayed after the stored data

are printed. Subsequent data are neither printed nor stored in memory.

Press reset to cancel the measurement sequence. The printer symbol is no

longer displayed.

You can now start a new measurement.

Specifications subject to change without notice.

Printed in the EU on paper bleached

without chlorine.

HA_Controller for CC/CCE...-L · KT

Publication No.: WCC6014-e140405

Sartorius Lab Instruments GmbH & Co. KG

Weender Landstrasse 94–108

37075 Goettingen, Germany

Phone +49.551.308.0

Fax +49.551.308.3289

www.sartorius.com

Copyright by

Sartorius Lab Instruments GmbH & Co. KG,

Goettingen, Germany.

All rights reserved. No part of this

publication may be reprinted or translated

in any form or by any means without the

prior written permission of Sartorius.

The status of the information,

specifications and illustrations in this

manual is indicated by the date given

below. Sartorius reserves the right to

make changes to the technology, features,

specifications and design of the equipment

without notice.

Status:

April 2014,

Sartorius Lab Instruments GmbH & Co. KG,

Goettingen, Germany

Loading...

Loading...