Page 1

98648-006-98

Sartorius Basic

plus

Electronic Semi-micro-, Analytical

and Precision Balances

Installation and Operating Instructions

Page 2

Page 3

3

Page

General Views of the Balances 5

Warranty 12

Storage and Shipping Conditions 12

Installation Instructions 13

Ambient Conditions 13

Getting Started 15

Preparing the Weighing

Chamber/Balance 15

Connecting the Balance

to AC Power 16

Voltage Selection 17

Safety Precautions 17

Information on Radio Frequency

Interference 17

Connecting Electronic

Peripheral Devices 18

Information on Weighing Electrostatically Charged Samples 18

Leveling the Balance Using the

Level Indicator 19

Operating the Balance 20

Warmup Time 20

Turning the Display On and Off 20

Self-Test 20

Taring 21

Simple Weighing 21

Calibration/Adjustment 22

Internal Calibration 22

External Calibration 23

Calibration Test 24

Blocking the Calibration/

Adjustment Functions 24

Interface Port 24

Below-Balance Weighing 25

Fastening an Antitheft Locking Device

25

Page

Troubleshooting Guide 26

Care and Maintenance 27

Balance Operating Menu 28

Changing Menu Code Settings 28

Accessing the Menu 29

Undoing All Menu Code

Changes – Reset Function 30

Balance Operating Parameters 31

Adapting the Balance to

Ambient Conditions 31

Standard Weighing and

Filling Modes 31

Stability Range 31

Tare Parameter 32

Auto Zero Function 32

Adjustment, Calibration and

Linearization Functions Using CAL 32

Weighing Using Two

Weighing Units 33

Weight Units 33

Display Modes 34

Interface Parameter Settings 35

Utilities for Printouts or Data Transfer 36

Data Output Parameter 36

Auto Print 36

Data Output at Defined Intervals 36

Data ID Codes 37

Additional Functions 38

Menu Access Function 38

Blocking the Keys 38

Universal Switch for

Remote Control 39

Power-On Mode 39

Contents

Page 4

Page

Page

Application Programs 40

Tare Memory 40

Practical Example:

Tare – Net – Gross Weights 40

Practical Example: Net Total 41

Weighing in Percent 42

Practical Example: Determination

of the Residual Weight in Percent 44

Counting 45

Practical Example:

Counting Small Parts 46

Animal Weighing/Averaging 47

Animal Weighing in the

Automatic Start Mode 49

ISO/GLP-compliant Printout

or Record 50

Printout/Record for

Adjustment or Calibration and

Linearization Functions 51

Data Printout/Record

(ISO/GLP-compliant) 52

Data Printout/Record for

Application Programs 53

Interface Description 54

Pin Assignment Chart 66

Cabling Diagram 67

Specifications 68

Standard Features 68

EC Pattern Approval 76

Accessories (Options) 84

Declaration of Conformity 87

4

Page 5

5

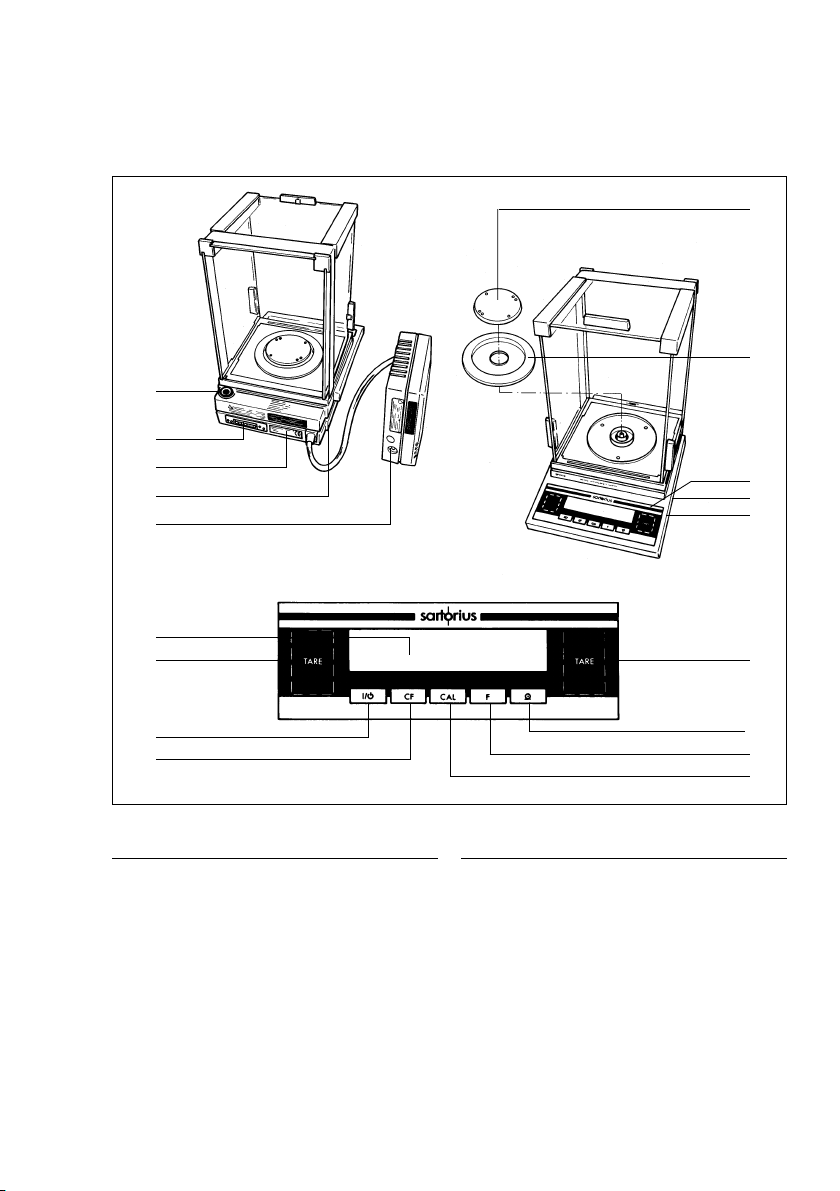

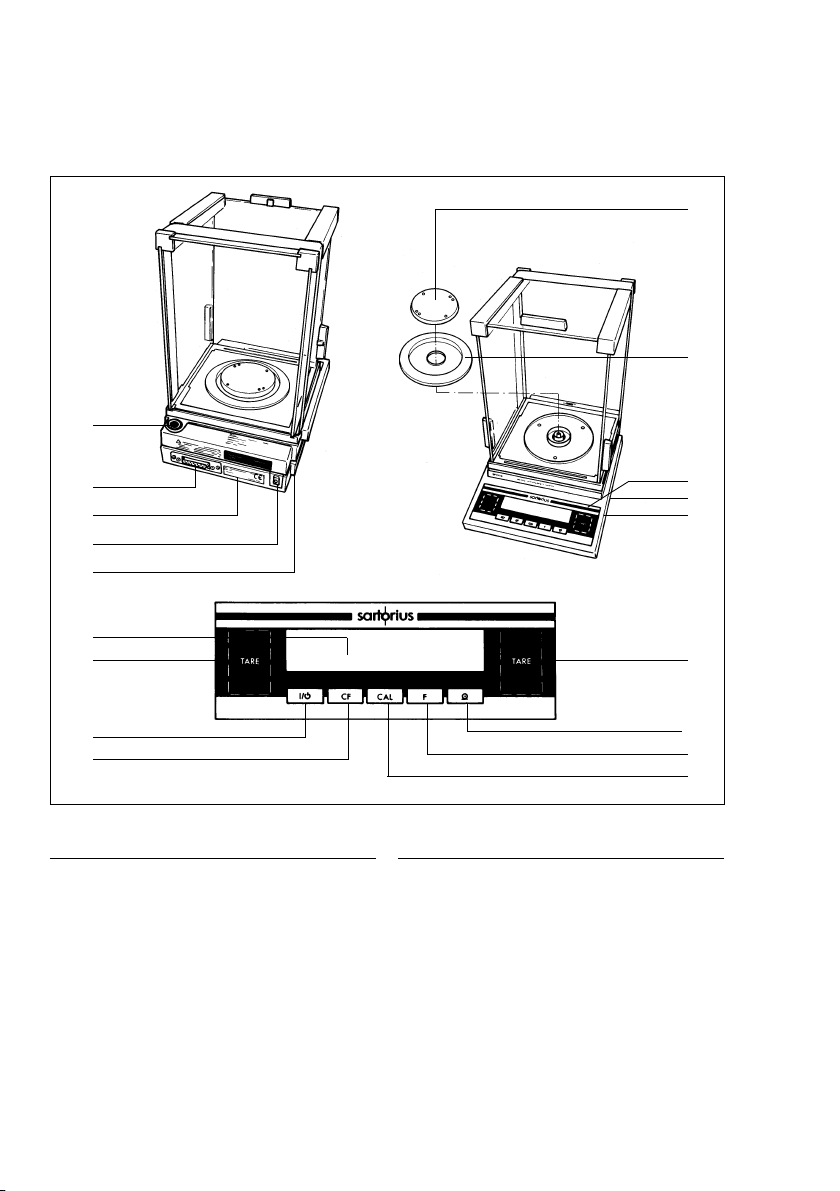

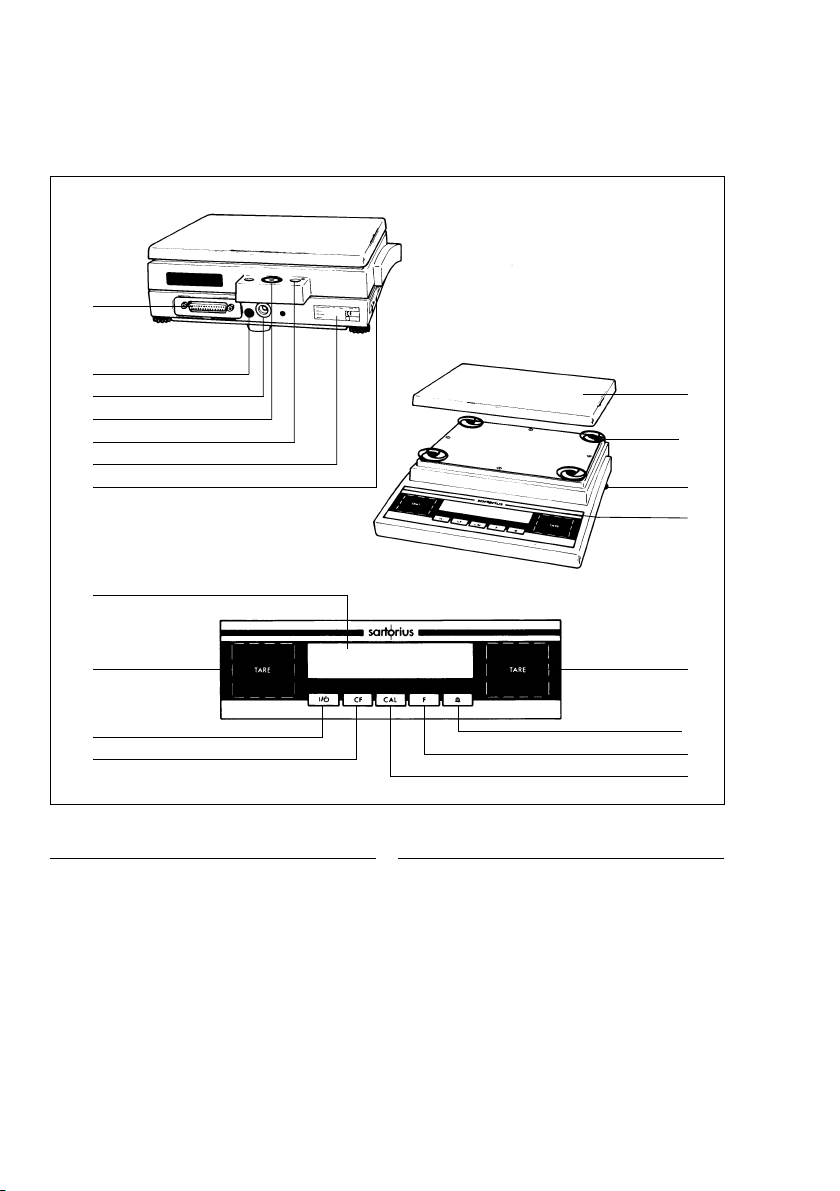

No. Designation Order no. for

replacement

1 Weighing pan 69 B20116

2 Shield disk 69 B20117

3 Metrological ID label

for verified balances approved

for use as legal measuring instruments

4 Menu access switch

5 Leveling foot 69 B20005

6 Zero-setting and tare keys t

7 Print key (data output) p

8 Function key v

9 Adjustment/calibration key q

10 CF key (clear function) c

11 On/off key e (standby)

No. Designation Order no. for

replacement

12 Weight display

13 DC jack

14 Verification ID label with metrological

data for verified balances approved

for use as legal measuring instruments

15 Manufacturer’s label with

the C mark of conformity

16 Data interface port

17 Level indicator

Not shown: Dust cover 69 60BP07

Caps and plugs (set) 69 B20009

BP 211D, BP 211D-0CE

12

6

11

10

6

8

9

7

17

16

15

14

13

2

1

4

3

5

Page 6

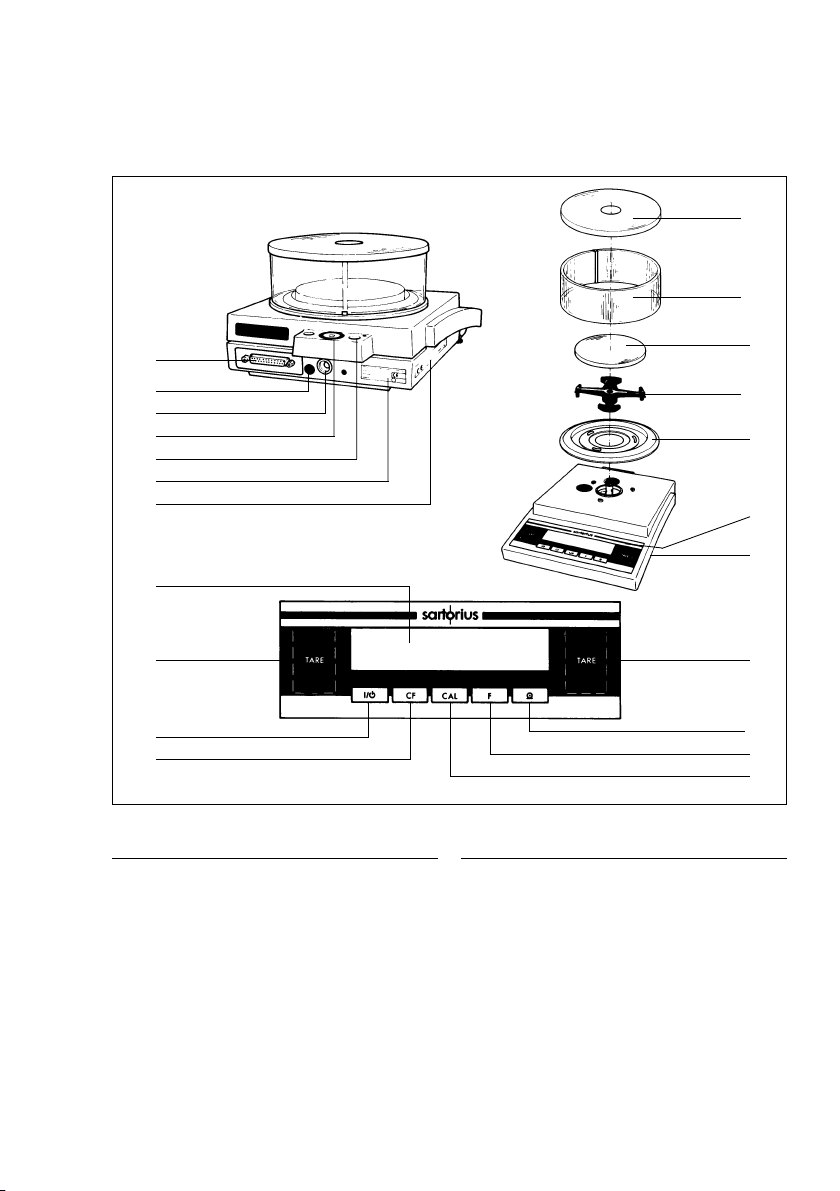

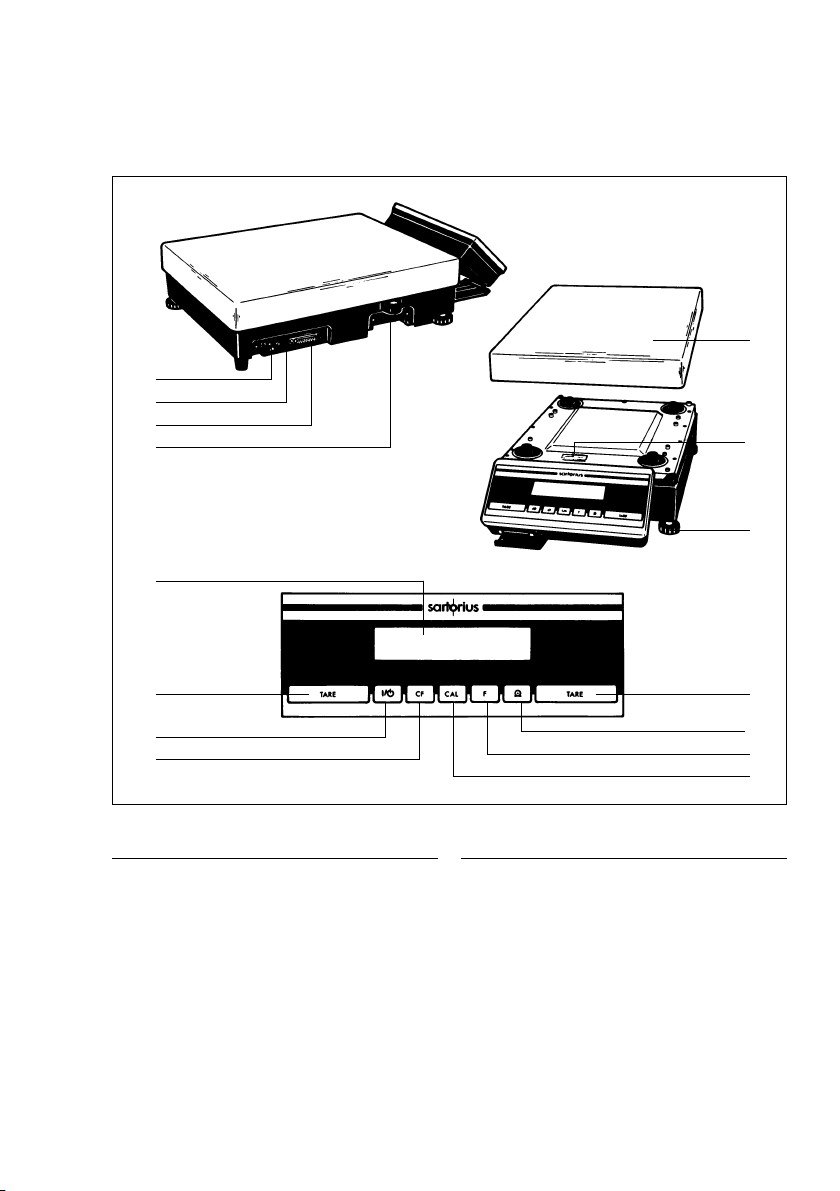

BP 301S,BP 221S,BP161P, BP121S, BP 61S, BP 301S-0CE,

BP 221S-0CE, BP161P-0CE,BP121S-0CE,BP 61S-0CE

17

1

2

16

15

14

13

12

6

11

10

No. Designation Order no. for

replacement

1 Weighing pan 69 B20116

2 Shield ring 69 B20117

3 Metrological ID label

for verified balances approved

for use as legal measuring instruments

4 Menu access switch

5 Leveling foot 69 B20005

6 Zero-setting and tare keys t

7 Print key (data output) p

8 Function key v

9 Adjustment/calibration key q

10 CF key (clear function) c

11 On/off key e (standby)

3

4

5

6

7

8

9

No. Designation Order no. for

replacement

12 Weight display

13 Verification ID label with metrological

data for verified balances approved

for use as legal measuring instruments

14 DC jack

15 Manufacturer’s label with

the C mark of conformity

16 Data interface port

17 Level indicator

Not shown: Dust cover 69 60BP07

Caps and plugs (set) 69 B20009

6

Page 7

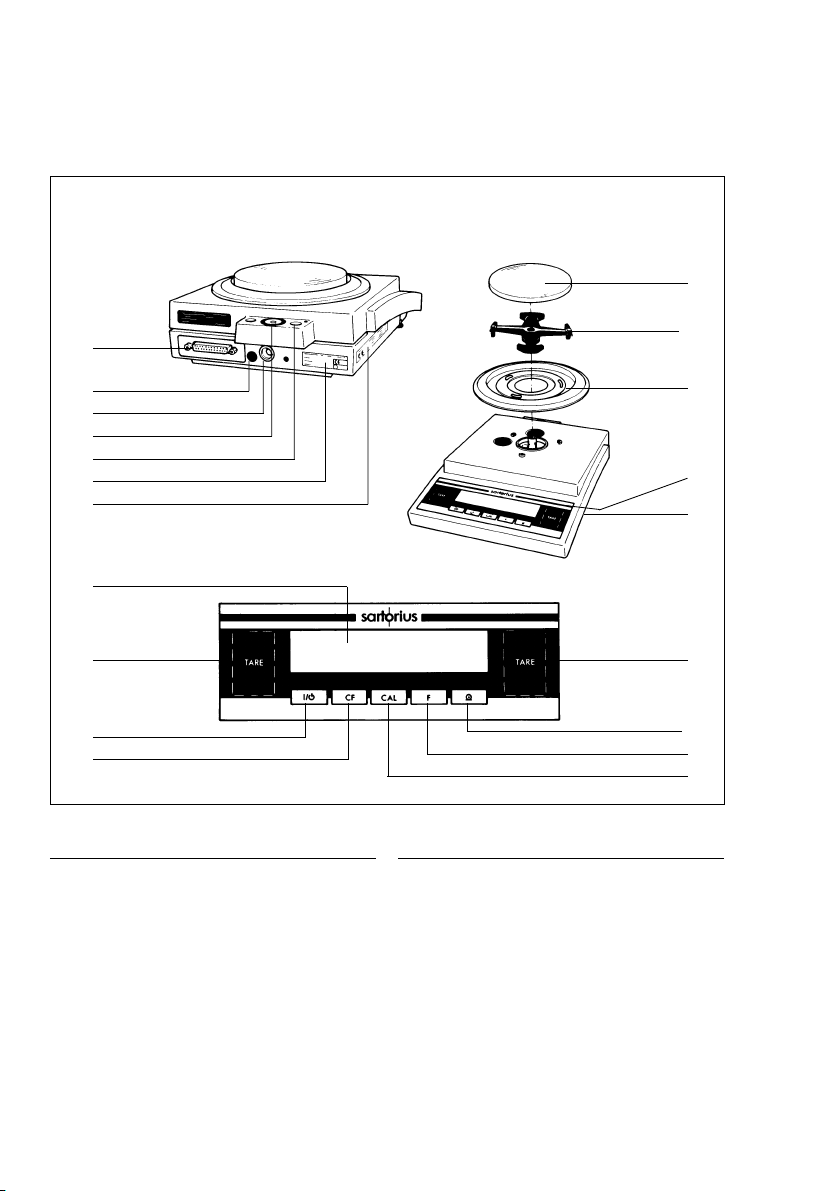

7

No. Designation Order no. for

replacement

1 Weighing pan 69 B20002

2 Shield ring 69 B20015

3 Metrological ID label

for verified balances approved

for use as legal measuring instruments

4 Menu access switch

5 Leveling foot 69 B20005

6 Zero-setting and tare keys t

7 Print key (data output) p

8 Function key v

9 Adjustment/calibration key q

10 CF key (clear function) c

11 On/off key e (standby)

12 Weight display

No. Designation Order no. for

replacement

13 Verification ID label with metrological

data for verified balances approved

for use as legal measuring instruments

14 DC jack

15 Manufacturer’s label with

the C mark of conformity

16 Data interface port

17 Level indicator

18 Lug for attaching an antitheft locking device

19 Draft shield cover 69 L22009

20 Glass draft shield cylinder 69 L22007

21 Pan support 69 B20011

Not shown: Caps and plugs (set) 69 B20009

BP 410 S,BP 310 S,BP 310 P,BP150,

BP 410 S-0CE,BP 310S-0CE, BP310 P-0CE, BP 150-0CE, BP 110-0CE

12

6

11

10

16

4

14

17

18

15

13

21

20

19

2

1

3

5

6

8

9

7

Page 8

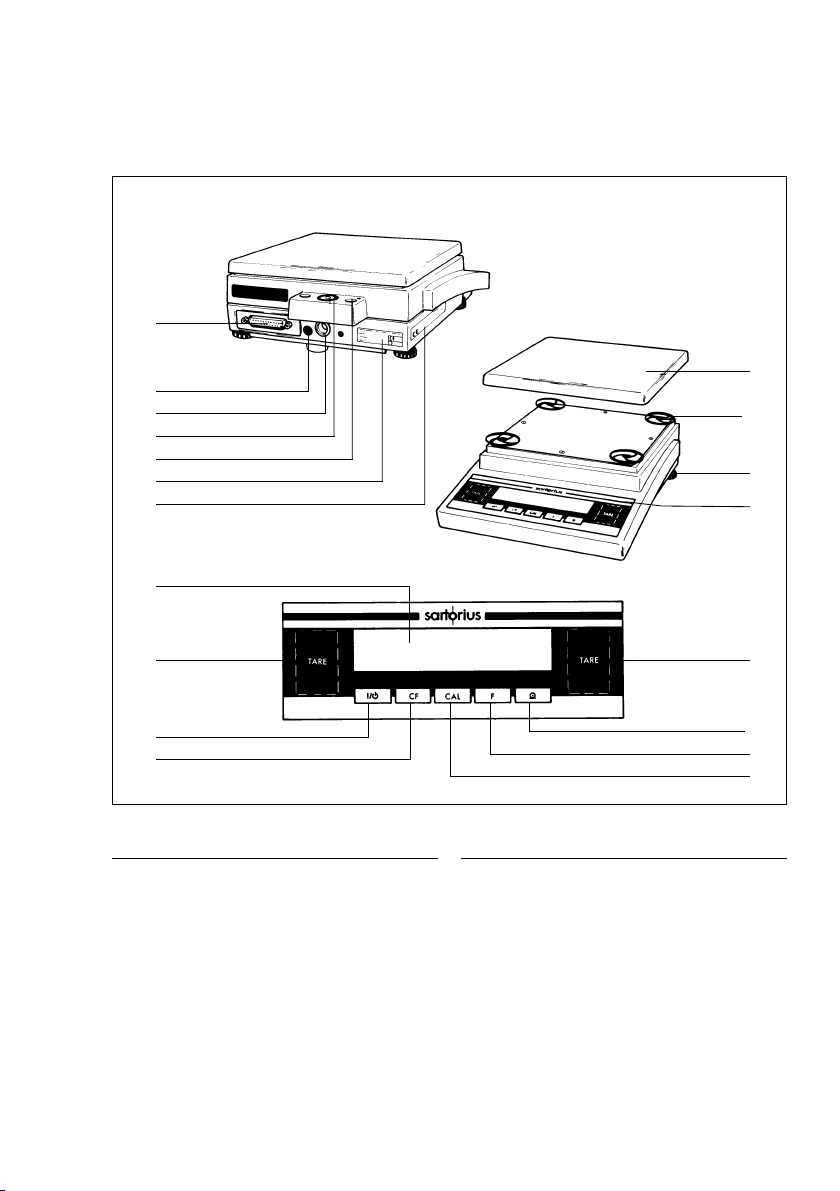

BP 610,BP410, BP 610-0CE

1

16

4

14

17

18

15

13

12

6

11

10

No. Designation Order no. for

replacement

1 Weighing pan 69 B20002

2 Shield ring 69 B20015

3 Metrological ID label

for verified balances approved

for use as legal measuring instruments

4 Menu access switch

5 Leveling foot 69 B20005

6 Zero-setting and tare keys t

7 Print key (data output) p

8 Function key v

9 Adjustment/calibration key q

10 CF key (clear function) c

11 On/off key e (standby)

12 Weight display

21

2

3

5

6

7

8

9

No. Designation Order no. for

replacement

13 Verification ID label with metrological

data for verified balances approved

for use as legal measuring instruments

14 DC jack

15 Manufacturer’s label with

the C mark of conformity

16 Data interface port

17 Level indicator

18 Lug for attaching an antitheft locking device

21 Pan support 69 B20011

Not shown: Caps and plugs (set) 69 B20009

8

Page 9

9

No. Designation Order no. for

replacement

1 Weighing pan 69 B20003

3 Metrological ID label

for verified balances approved

for use as legal measuring instruments

4 Menu access switch

5 Leveling foot 69 B20005

6 Zero-setting and tare keys t

7 Print key (data output) p

8 Function key v

9 Adjustment/calibration key q

10 CF key (clear function) c

11 On/off key e (standby)

12 Weight display

No. Designation Order no. for

replacement

13 Verification ID label with metrological

data for verified balances approved

for use as legal measuring instruments

14 DC jack

15 Manufacturer’s label with

the C mark of conformity

16 Data interface port

17 Level indicator

18 Lug for attaching an antitheft locking device

22 Shock absorber 69 B20006

Not shown: Caps and plugs (set) 69 B20009

BP 4100 S, BP 3100 S, BP 3100 P, BP2100 S,BP1200,BP 3100 S-0CE,

BP 4100 S-0CE, BP 3100 P-0CE, BP 2100 S-0CE,BP 2100-0CE, BP1200-0CE

12

6

11

10

16

4

14

17

18

15

13

1

5

22

3

6

8

9

7

Page 10

B P 810 0, B P 610 0, B P 410 0, B P 210 0, B P 8,

BP 8100-0CE, BP 6100-0CE, BP 8-0CE

16

4

14

17

18

15

13

12

6

11

10

No. Designation Order no. for

replacement

1 Weighing pan 69 B20004

3 Metrological ID label

for verified balances approved

for use as legal measuring instruments

4 Menu access switch

5 Leveling foot 69 B20005

6 Zero-setting and tare keys t

7 Print key (data output) p

8 Function key v

9 Adjustment/calibration key q

10 CF key (clear function) c

11 On/off key e (standby)

12 Weight display

1

22

5

3

6

7

8

9

No. Designation Order no. for

replacement

13 Verification ID label with metrological

data for verified balances approved

for use as legal measuring instruments

14 DC jack

15 Manufacturer’s label with

the C mark of conformity

16 Data interface port

17 Level indicator

18 Lug for attaching an antitheft locking device

22 Shock absorber 69 B20006

Not shown: Caps and plugs (set) 69 B20009

10

Page 11

11

No. Designation Order no. for

replacement

1 Weighing pan 69 LC0107

4 Menu access switch

5 Leveling foot 69 LC0092

6 Zero-setting and tare keys t

7 Print key (data output) p

8 Function key v

9 Adjustment/calibration key q

10 CF key (clear function) c

11 On/off key e (standby)

No. Designation Order no. for

replacement

12 Weight display

14 DC jack

15 Manufacturer’s label with

the C mark of conformity

16 Data interface port

17 Level indicator

Not shown:

Plug for menu access switch 69 I31113

BP16000 S, BP12000S,BP 34000P, BP34

12

6

11

10

14

4

16

17

1

5

15

6

8

9

7

Page 12

Please read through these installation and

operating instructions carefully before operating your

new balance.

Warranty

Do not miss out on the benefits of our full warranty.

Please complete the warranty registration card,

indicating the date of installation, and return the card

to your Sartorius office or dealer.

Storage and Shipping Conditions

Allowable storage temperature: +5°C …+40°C

+41°F…+104°F

In case there is any visible damage, proceed as

directed in the section entitled “Safety Inspection.”

Save the box and all parts of the packaging for any

future shipment of your balance as only the complete

original standard packaging ensures safe transport.

Before packing your balance, unplug all connected

cables to prevent damage.

Do not expose the balance unnecessarily to extreme

temperatures, moisture, shocks, blows or vibration.

12

Page 13

Installation Instructions

Ambient Conditions

When choosing a location to set up your balance,

observe the following:

– Set up the balance on a stable, even surface

(benchtop or floor), or place it on a wall console

(see “Accessories”)

– Avoid placing the balance in close proximity

to a heater or otherwise exposing the balance

to extreme heat or to direct sunlight

– Protect the balance from drafts that come

from open windows and doors

– Avoid exposing the balance to extreme vibrations

during weighing

– Protect the balance from aggressive

chemical vapors

– Do not operate the balance in a hazardous

area/location

Do not expose the balance to extreme moisture over

long periods. Moisture in the air can condense on

the surfaces of a cold balance whenever it is brought

to a substantially warmer place. If you transfer the

balance to a warmer area, make sure to condition it

for about 2 hours at room temperature, leaving it

unplugged from AC power. Afterwards, keep the

balance connected continuously to AC power.

13

Page 14

Using Verified Balances as Legal Measuring Instruments in the EU*

You must calibrate the balance at the place of installation before using it

as a legal measuring instrument (see the section entitled “Adjustment/

Calibration” starting on page 22).

This balance is not allowed to be used for weighing goods intended for direct

sale to the public. The type-approval certificate for verification applies only

to non-automatic weighing instruments. For balances of accuracy class k,

a thermometer and barometer are recommended for monitoring ambient

conditions. The temperature range indicated on the verification ID label must not

be exceeded during operation.

The balance must warm up for at least 24 hours after initial connection

to AC power.

* = including the Signatories of the Agreement on the European Economic Area

14

Page 15

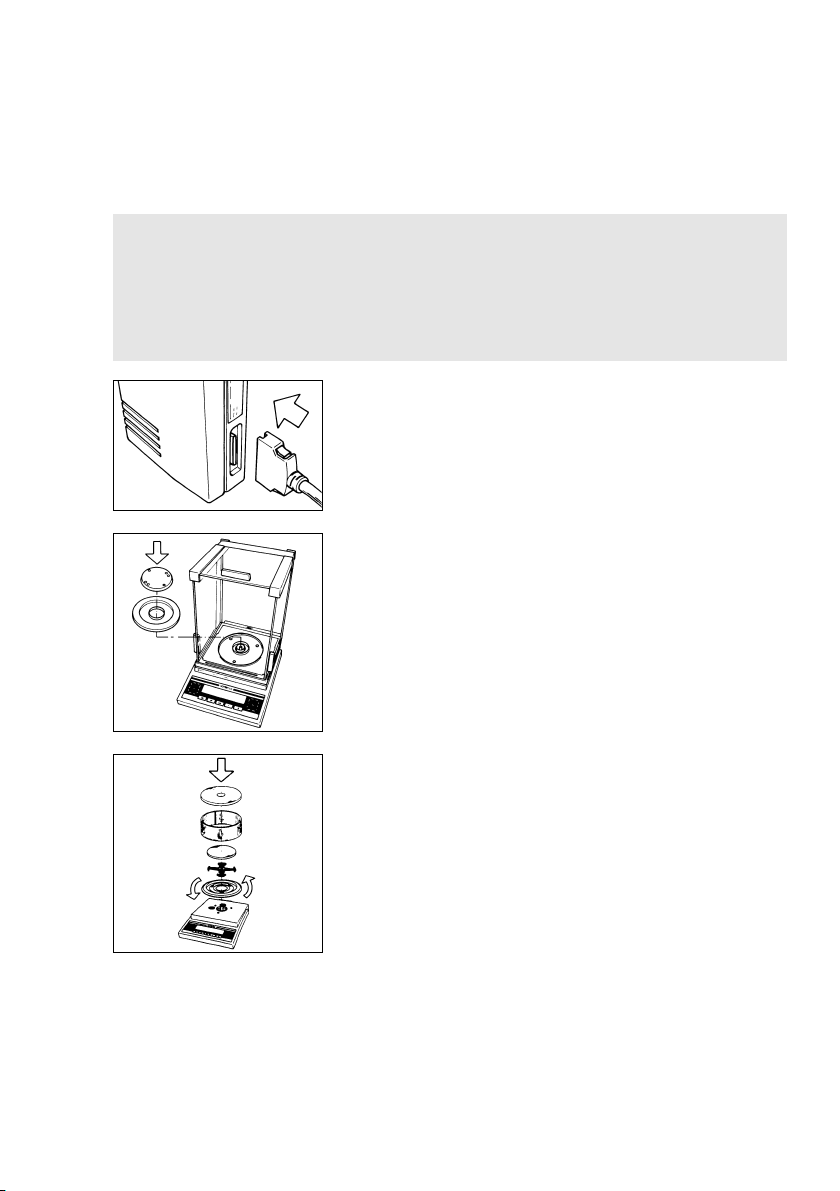

Getting Started

– Remove the plastic wrapping, adhesive tape and styrofoam from the balance.

Connecting the BP 211 D (-0CE) Balance

to the Electronics Box:

– Plug the cable into the socket of the electronics box.

Preparing the Weighing Chamber for Balances

with an Analytical Draft Shield Chamber

Place the components listed below inside the chamber

in the order given:

– Shield ring (2)

– Weighing pan (1)

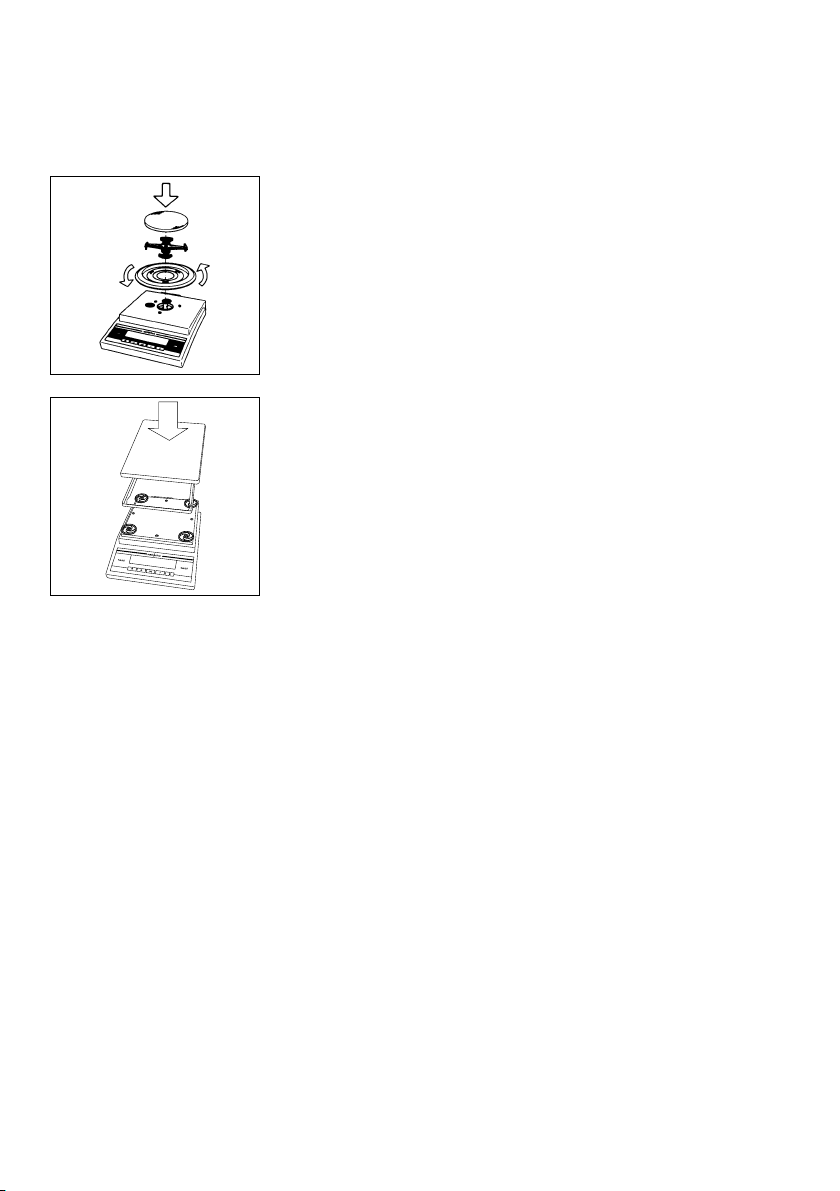

Preparing Balances with a Round Glass Draft Shield

– Place the shield disk (2) on the balance. Turn the disk

counterclockwise until it stops and is secured.

Place the components listed below on the balance

in the order given:

– Pan support (21)

– Weighing pan (1)

– Glass draft shield cylinder (20)

– Draft shield cover (19)

* = including the Signatories of the Agreement on the

European Economic Area

Control Seals on Verified Balances Approved for Use as Legal Measuring

Instruments in the EU*:

Legal regulations require the verified balance to be sealed. This control seal

consists of an adhesive label with the name “Sartorius” on it. This seal will

be irreparably damaged if you attempt to remove it. In this case, the validity of

the seal becomes void and you must have your balance re-verified.

15

Page 16

Preparing Balances with a Round Weighing Pan

– Place the shield disk (2) on the balance. Turn the disk

counterclockwise until it stops and is secured.

Place the components listed below on the balance

in the order given:

– Pan support (21)

– Weighing pan (1)

Preparing Balances with a Rectangular

Weighing Pan

Place the components listed below on the balance

in the order given:

– Pan shield (only for model BP4100 S-0CE or

the option YDS02BP)

– Weighing pan (1)

Connecting the Balance to AC Power

The balance is powered by an AC adapter. Make sure that the voltage rating

printed on this unit is identical to your local line voltage.

If the voltage specified on the label or the plug design of the AC adapter does

not match the rating or standard you use, please contact your dealer. The AC

adapters have IP 20 protection in accordance with DIN VDE 0470/EN 60529.

Important Note:

Use only original adapters. Use of AC adapters from other manufacturers, even if

these units have a registered approval rating from a national testing laboratory,

requires the consent of an authorized service technician. To operate the balance

using an external rechargeable battery pack or an industrial power supply (IP 65),

see “Accessories.”

16

Page 17

Plug the cord of the AC adapter into the balance

as follows:

– Use the DC jack (14) for balances with a weighing

capacity of <10 kg

– Use the DC jack (14) for balances with a weighing

capacity of ≥10 kg

Insert the right-angle plug into the jack as shown in the

diagram on the left; then tighten the screw.

Then insert the plug of the AC adapter into a wall outlet (mains).

Voltage Selection

(does not apply to balances with a weighing capacity of ≥12 kg)

You can select the voltage only if you use our portable power supply (6971172)

that has a European-type plug (rounded prongs).

Safety Precautions

The AC adapter rated to Class 2 can be plugged into any wall outlet without

requiring any additional safety precautions. The ground terminal is connected to

the balance housing, which can be additionally grounded for operation.

The data interface is also electrically connected to the balance housing (ground).

Information on Radio Frequency Interference

Note:

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

cause harmful interference, in which case the user will be required to correct the

interference at his own expense. Changes or modifications not expressly

approved by Sartorius AG could void the user’s authority to operate the equipment.

17

Page 18

Connecting Electronic Peripheral Devices

Make absolutely sure to unplug the balance from AC

power before you connect or disconnect a peripheral

device (printer or PC) to or from the interface port.

Adjusting the Display Unit on Balances with

a Weighing Capacity of ≥10 k g

Adjust the display unit to the position desired.

Information on Weighing Electrostatically Charged Samples

If static electricity from the sample or container

is interfering with the weighing procedure (causing

unstable readouts), use an antistatic pan instead of the

standard weighing pan when weighing on balances

with a readability of 0.1 mg (see “Accessories”).

18

Page 19

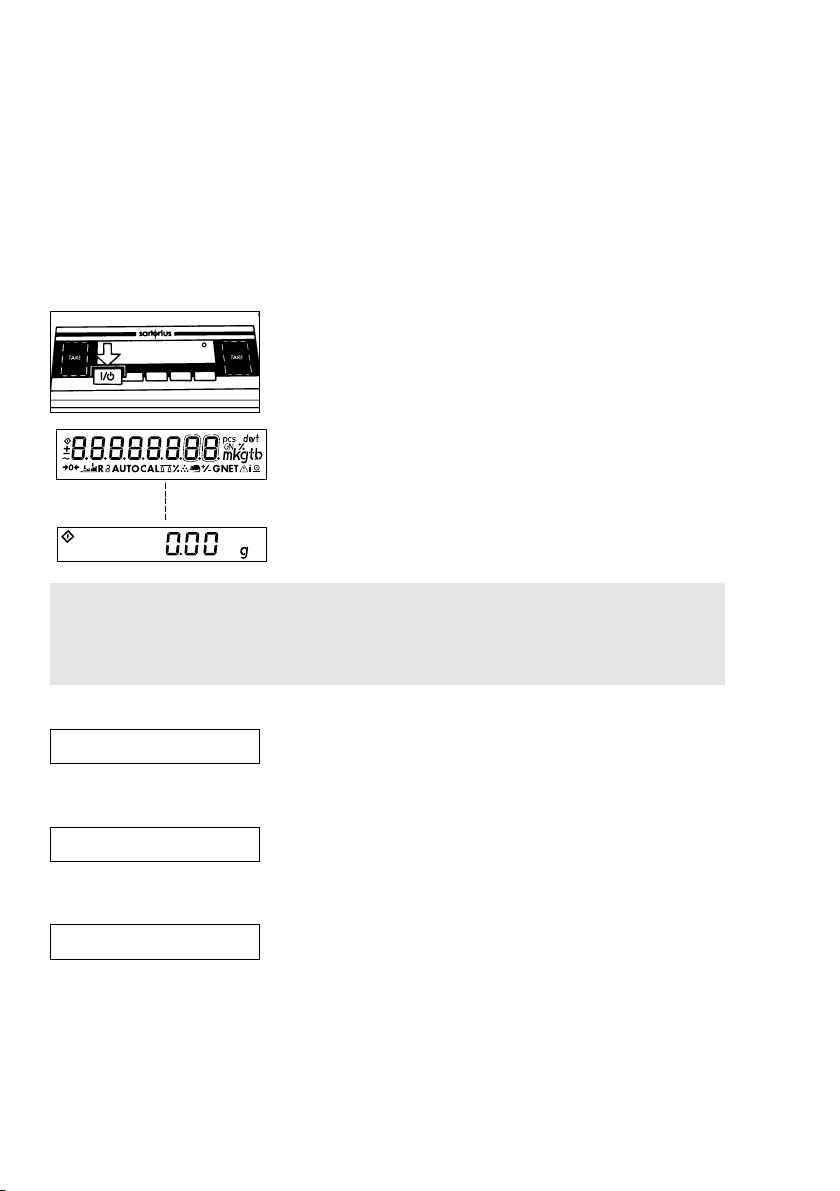

Leveling the Balance Using the Level Indicator

At the place of installation, level the balance using

the leveling feet (5) so that the air bubble is centered

within the circle of the level indicator (17).

For balances with a rectangular pan and a weighing

capacity of <10 kg:

Retract the two auxiliary feet located at the back

of the balance.

Use the level indicator as a guide to level the balance

as follows:

To lift the balance, extend the front leveling feet

(turn clockwise).

To lower the balance, retract the front leveling feet

(turn counterclockwise).

For balances with a rectangular pan and a weighing

capacity of <10 kg:

After rectracting the rear auxiliary feet, extend them

until they touch the surface on which the balance rests.

19

Page 20

Operating the Balance

Warmup Time

To deliver exact results, the balance must warm up for at least 30 minutes after

connection to AC power or after a power outage. Only after this time will the

balance have reached the required operating temperature.

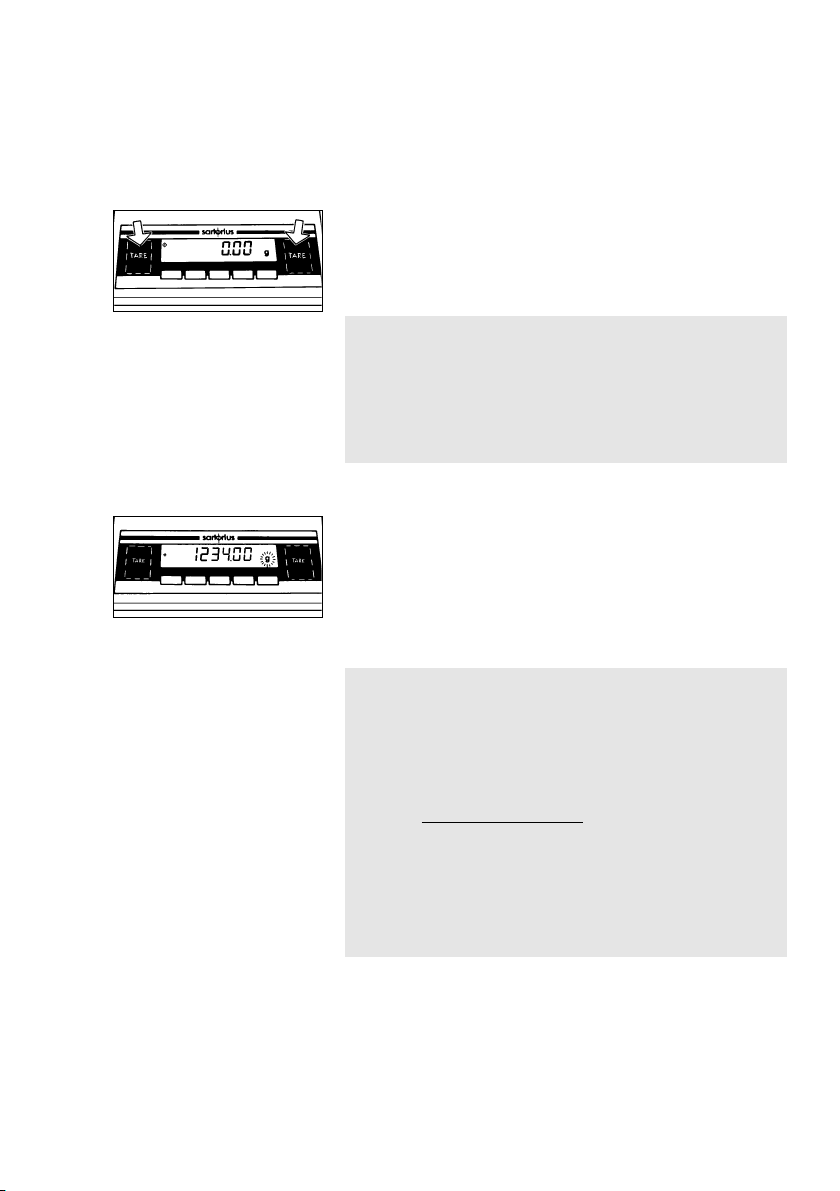

Turning the Display On and Off (Standby Mode)

Press the e key (11) to turn the display on and off.

Self-Test

After the balance has been turned on, an automatic

self-test of the balance’s electronic circuitry is

▼

Important Note Concerning Verified Balances Approved for Use as Legal

Measuring Instruments in the EU*:

The last digit on the display is bordered when the verification scale interval “e”

is greater than the scale interval “d.”

performed. At the end of the self-test, a zero readout

is displayed. This means that the balance is ready

to operate.

The display shows the following special codes for your information:

o

O displayed in the upper right corner stands for OFF

The balance was disconnected from AC power

(balance reconnected to AC power or power outage

longer than 3 seconds).

o

O displayed in the lower left corner means standby

The display has been turned off by the e key (11).

The balance is now in the ready-to-operate mode and

does not require warmup.

b

b means busy

Once you have turned on the balance, the b symbol

will be displayed until you press a key. During

operation, this symbol indicates that the balance

processor is still busy processing a function and will not

accept another command to perform any other

functions at this time.

* = including the Signatories of the Agreement on the European Economic Area

20

Page 21

Taring

A weight can be determined accurately only from

a defined zero point. Press one of the t keys (6)

to zero the weight display. You can tare within the

entire weighing range of the balance.

Simple Weighing (Weight Determination)

Place your sample on the weighing pan (1) to

determine the weight. Read off the weight indicated

on the display only after the weight unit “g”

or a different unit selected appears as the stability

symbol. You can find more information on the weight

units on page 33 under “Weight Units.”

* = including the Signatories of the Agreement on the

European Economic Area

Important Note Concerning Verified Balances

of Accuracy Class k

To avoid measuring errors, the respective air density

must be allowed for. The following formula is used to

calculate the mass of the sample:

1– ρL/8000 kg m

–3

m = n

w

1– ρL/ρ

m = mass of the sample

nw= weight readout

ρ

L

= air density during weighing

ρ = density of the sample

Important Note Concerning Verified Balances

Approved for Use as Legal Measuring Instruments

in the EU*:

The symbol n in the weight display (on the left)

shows that the balance is exactly tared to “Zero”

(±0.25 of a scale interval).

21

Page 22

Calibration/Adjustment

During calibration1), the span of the balance is adjusted to the changes in

ambient conditions.

You must adjust or calibrate your new balance at the place of installation after

each warmup period and before the first measurement. You must also re-adjust

or recalibrate your balance each time you set it up in a different area or when

ambient conditions change (especially the temperature). Verified balances

approved for use as legal measuring instruments must be adjusted/calibrated

at least once a day.

The balance offers you various adjustment and calibration functions. You can

select these functions by setting the appropriate menu codes. For more information,

refer to “Balance Operating Menu.”

You can interrupt any adjustment or calibration function by pressing c (10).

Using Verified Balances as Legal Measuring Instruments in the EU*:

Before using your balance as a legal measuring instrument, you must carry

out an “Internal Calibration” operation at the place of installation after the

warmup period.

Internal Calibration for Balances with a Built-in

Calibration Weight

22

Menu code selection: 1 9 3**

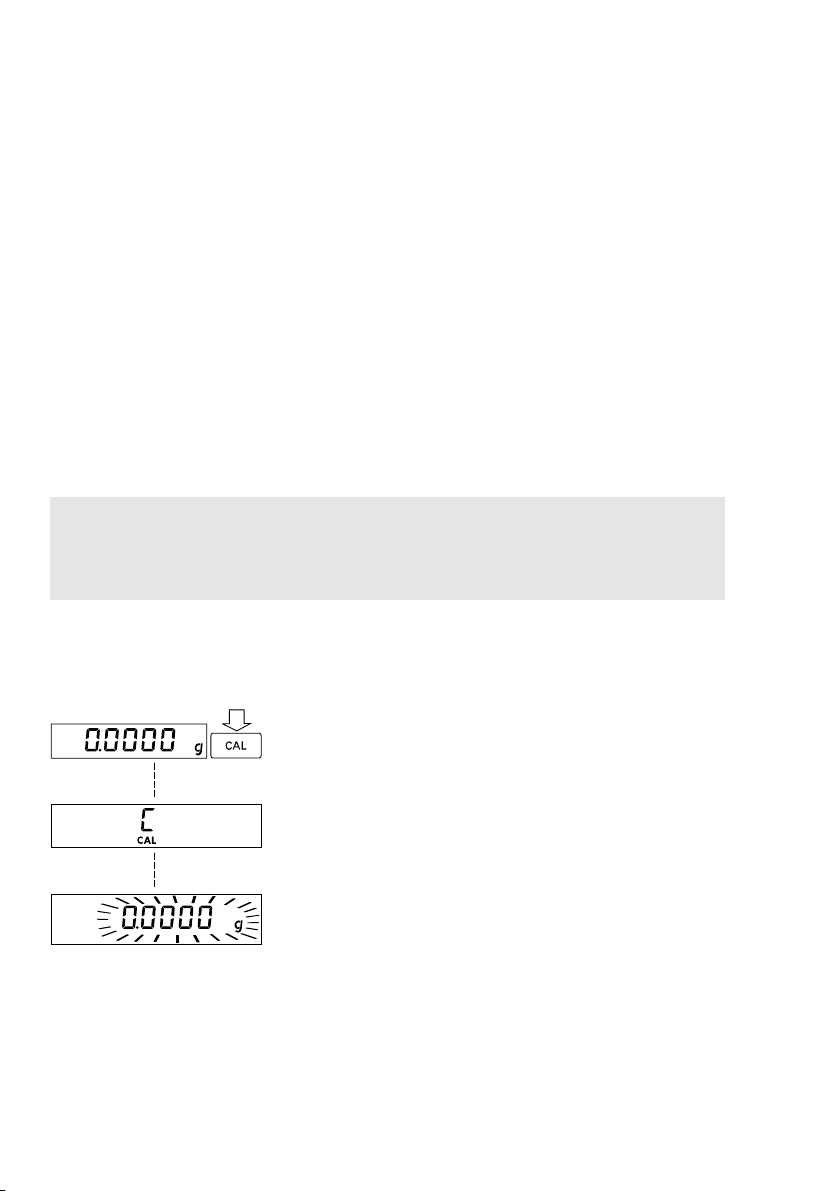

When the display shows a zero readout, press the

q key (9) to activate the calibration function.

▼

1

) “Calibration” technically means to determine

the difference between the balance readout and

the actual weight on the pan to determine the

▼

accuracy. Adjustment means to bring a balance

into the state of accuracy required for its use.

Therefore, “calibration,” as used in this manual,

actually means “adjustment.”

** = including the Signatories of the Agreement on

the European Economic Area

** = factory setting for standard balances with

a readability of ≤ 0.1mg and for verified

balances approved for use as legal measuring

instruments in Europe.

Page 23

The built-in calibration weight is internally applied

by servomotor and removed at the end of adjustment

or calibration.

If any interference affects the calibration procedure,

you may obtain a brief display of the error code

“Err 02.”

In this case, tare and press the q key again.

Important Note

! During calibration, the weighing pan must

be unloaded.

External Calibration**

Menu code selection – for standard balances: 1 9 1*

– for verified balances: 1 9 7

Use only calibration weights with nominal mass values

and tolerances equal to or better than the accuracy

class specified for your balance. You can find

an overview of the calibration weight sets under

“Accessories.”

Unlocking the Access Switch on Verified Balances

of Accuracy Class k:

– Remove the protective cap from the menu

access switch (4) on the rear panel of the computing

device.

– Move the menu access switch (4) in the direction

of the arrow.

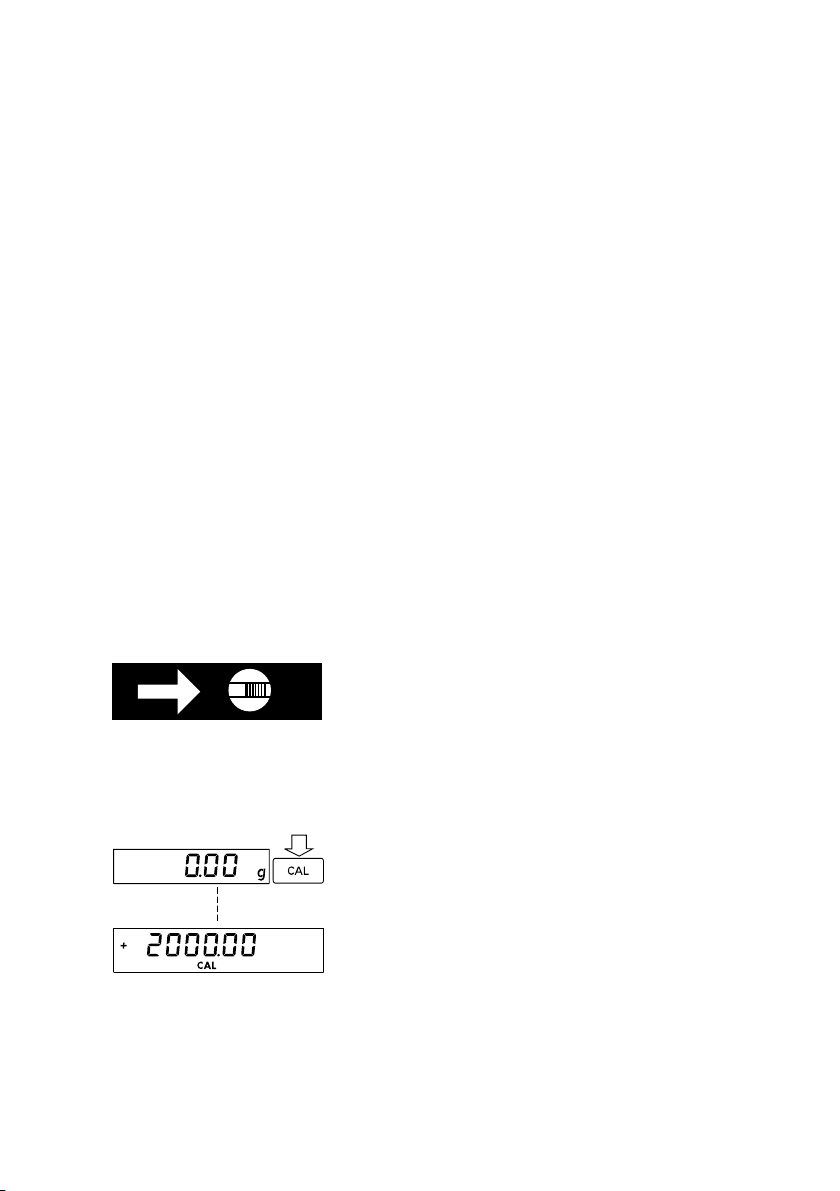

When a zero readout is displayed, press the q

key (9). This starts calibration. The calibration weight

in grams is then displayed.

Errors or interference at the start of the calibration

routine are indicated by the error code “Err 02.” If this

is the case, tare and press the q key again when

a zero readout appears.

** = factory setting on standard balances with

a readability of ≥1mg

** = not applicable to verified precision balances

of accuracy class K

23

▼

Page 24

Center the calibration weight on the weighing pan.

The balance then calibrates automatically.

At the end of calibration, the calibration weight

readout and the stability symbol “g” are displayed.

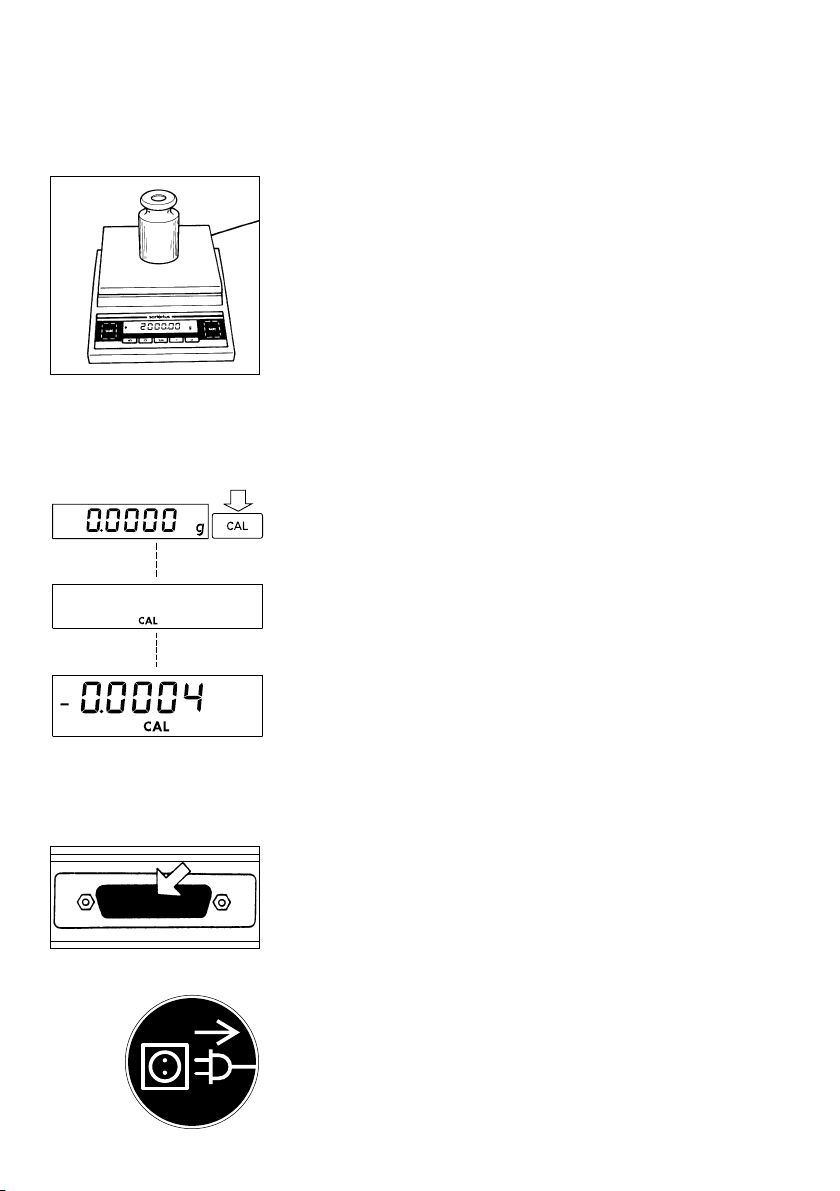

Calibration Test for Balances with a Built-in

Calibration Weight

Menu code selection: 1 9 4

When a zero readout is displayed, press the

q key (9). The built-in calibration weight is now

internally applied by servomotor. At the same

▼

time, CAL is displayed. After the display has

stabilized, the deviation of the current readout from the

target weight (in grams only) is indicated.

If external interference affects the calibration test, you

▼

may obtain a brief display of the error code “Err 02.”

In this case, tare; then press the q key again.

Blocking the Calibration/Adjustment Functions

You can block these functions by setting code 1 9 7

(when the menu access switch (4) is locked).

24

Interface Port

Depending on the balance model, unfasten or remove

the protective cap from the data interface port.

– Plug the connector into the interface port

– Secure the connector by tightening the screws

To print or output data, press the p key (7).

Important Note

Make absolutely sure to unplug the balance from AC

power before you connect or disconnect a peripheral

device (printer or PC) to or from the interface port.

For information about the data output parameters

and data ID codes, see page 36.

Page 25

Below-Balance Weighing

A port for a below-balance weighing hanger is located

on the bottom of the balance (for balances with

a weighing capacity of ≥10 kg, see “Accessories”).

For Balances with an Analytical Draft

Shield Chamber:

To hook a sample on the hanger, open the belowbalance port by turning the cover plate.

For Precision Balances (Weighing Capacity

of <10 kg):

To open the below-balance port, remove the cover

plate from the bottom of the balance.

Now you can attach a sample using a suspension

wire, for example. Common applications for belowbalance weighing include density determination

and immersing a sample in a special atmosphere

(medium for reaction).

Important Note

When you use the below-balance weighing hanger,

you must install a shield for protection against drafts.

Fastening an Antitheft Locking Device**

To fasten an antitheft locking device, use the lug (18)

located on the rear panel of the balance.

** = including the Signatories of the Agreement on the

European Economic Area

** = not on BP 211 D, BP 301S, BP 221S,

BP 161 P, BP 121 S, BP 61S (-0CE), BP 16000 S,

BP 12000 S, BP 34000 P, BP 34

Important Note Concerning Verified Balances

Approved for Use as Legal Measuring Instruments

in the EU*:

The below-balance weighing port may not

be opened or used when an approved balance is

being operated as a legal measuring instrument.

25

Page 26

Troubleshooting Guide

Problem Causes Solution

No segments – No AC power – Check the AC power

appear on the is available supply

weight display (13) – The AC adapter is not – Plug in the AC adapter

plugged in

No segments – The surface on which the – Make sure that the ambient

appear on the weight balance rests is not stable conditions are stable

display after – The balance has not – Prevent vibrations from

calibration/adjustment yet internally stabilized affecting the surface on

which the balance rests

– Close the draft shield

The weight display – The load exceeds the – Unload the balance

shows “H” capacity of the balance

The weight display – The weighing pan (1) – Position the pan

shows “L” is not in place

or “Err 54”

“Err 235”on the – Cable not connected – Plug in the cable correctly

BP 211 D (-0CE) properly

– Electronics box taken from – Make sure components are

another balance model appropriately connected

The weight readout – Too much vibration, – Access the menu to select

changes constantly or the balance is the correct code for

exposed to a draft the weighing environment

– The draft shield is – Close the draft shield

not completely closed

– A foreign object is – Remove the foreign object

caught between the pan

and the balance housing

– The below-balance – Close the port for below-

weighing port is open balance weighing

– The sample does not have

a stable weight (absorbs

moisture or evaporates)

– The sample is

electrostically charged

The weight readout – The balance has – Calibrate the balance

is obviously wrong not been calibrated (see page 22)

– The balance was not – Tare before weighing

tared before weighing

26

Page 27

Care and Maintenance

Servicing

Regular servicing of your balance by a Sartorius

technician will ensure its continued weighing

accuracy. Sartorius can offer you service contracts

with your choice of regular maintenance intervals

ranging from1month to 2 years.

Cleaning

Before cleaning the balance, unplug the AC adapter

from the wall outlet (mains supply).

Please do not use any aggressive cleaning agents

(solvents or similar agents). Instead, use a piece of

cloth which has been wet with a mild detergent (soap).

Make sure that no liquid enters the balance housing.

After cleaning, wipe down the balance with a soft,

dry piece of cloth.

Carefully remove any sample residue/spilled powder

by using a brush or a hand-held vacuum cleaner.

Make sure that no liquid or dust enters the crevice

surrounding the pan adapter.

Safety Inspection

If there is any indication that safe operation of the

balance with the AC adapter is no longer warranted,

turn off the power and disconnect the equipment

from AC power immediately. Lock the equipment in

a secure place to ensure that it cannot be used for the

time being.

Safe operation of the balance with the AC adapter

is no longer ensured when

– there is visible damage to the AC adapter

– the AC adapter no longer functions properly

– the AC adapter has been stored for a relatively long

period under unfavorable conditions

In this case, notify your nearest Sartorius Service

Center Unit. Only service technicians who are

authorized by Sartorius and who have access to the

required maintenance manuals are allowed to perform

maintenance and repairwork on the equipment.

27

Page 28

Balance Operating Menu

In the operating menu, you can define how your

balance will adapt to ambient conditions and also

how it will work to meet your special requirements.

Changing Menu Code Settings

To select specific functions, you will need to set the

respective menu codes.

The keys have special functions for setting

menu codes:

q (9) = Increases a number by one with each

press (the numbers change in cycles)

t (6) = Confirms and stores a code setting; and

exits the menu

p (7) = Moves to the next of the three numbers

of a code (1st-2nd-3rd-1st, etc.)

The code for “automatic power-on” is 8 5 4.

28

Page 29

Accessing the Menu (Example: Code 8 5 4)

– Press e to turn off the balance.

– Turn the balance back on. While all segments are

displayed, briefly hold down t.

– For standard balances, if “-” is displayed next

to the left-hand number, proceed as follows to unlock

the menu:

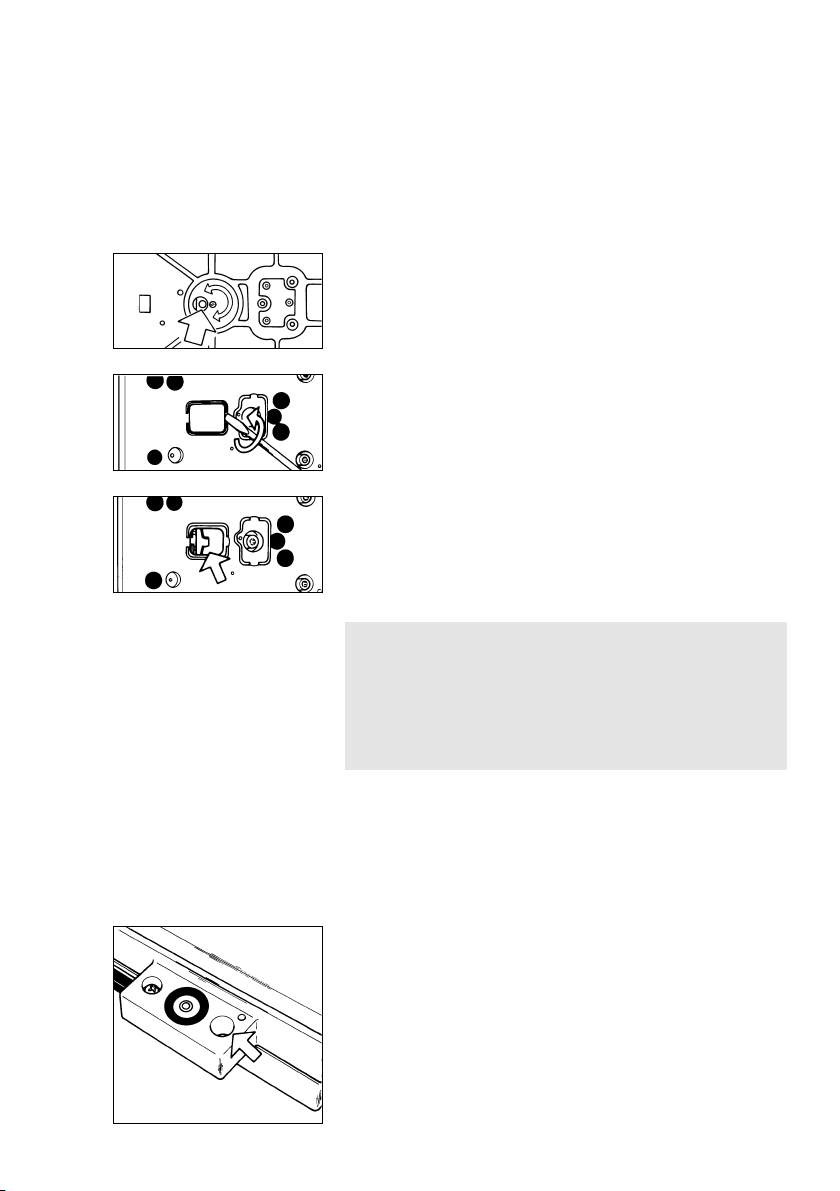

– For balances with a weighing capacity of <10 kg,

remove the protective cap and move the menu

access switch (4)

in the direction of the arrow.

– For balances with a weighing capacity of ≥10 kg,

remove the larger-threaded cap located on the right

next to the DC jack and move the menu access

switch (4) in the direction of the arrows.

– Press q several times until “8” appears.

– Press p until the 2nd number of the code appears.

– Press q until “5” appears.

– Press p until the 3rd number appears (when

you move to the third number, the previously set

menu code will appear).

– Press q to select “4.”

– Confirming a Menu Code Setting

Press a t key to confirm the code you have just set

(this is indicated by the “o” after the code).

– To store the new menu code setting, press one

of the t keys for more than 2 seconds!

29

▼

▼

▼

▼

▼

▼

▼

▼

Page 30

The current code setting in the balance operating menu

is identified by a small, superscript “

o

” after the last

number. When you access the operating menu, the

previously set code will be displayed after you have

selected the right-hand number, which means the entire

menu code setting will be displayed. This makes it

easy for you to check the previously set menu codes.

If you would like to change several menu code

settings, you do not have to press a t key after each

change to exit the balance operating menu.

You can also confirm individual settings.

Important Note Concerning Standard Balances:

Please do not forget to relock the balance operating

menu to avoid inadvertent changes to the settings.

The symbol “–” indicates that the menu is locked.

Important Note Concerning Verified Balances

Approved for Use as Legal Measuring Instruments

in the EU*:

The balance operating menu on verified balances

cannot be locked with the menu access switch

(“–” not displayed).

Exiting the Menu without Storing Code Changes

Changes to the code settings are not stored if you turn

off the balance by pressing e while selecting the

code numbers or before pressing t to save a setting.

Undoing All Menu Code Changes – Reset Function

The reset function lets you undo all menu code

changes, which means that you will obtain the original

factory-set menu codes identified by an “*.” To use

this function, select code 9 – – 1o. See the previous

page for information on confirming and storing

a menu code setting.

30

Reset function Code

On 9 – – 1

Off 9 – – 2

* including the Signatories of the Agreement on the

European Economic Area

Page 31

Balance Operating Parameters

Adapting the Balance to Ambient Conditions

The balance can be adapted to the prevailing ambient conditions at the place

of installation.

Code

Very stable conditions 1 1 1*

Stable conditions 1 1 2*

Unstable conditions 1 1 3

Very unstable conditions 1 1 4

Standard Weighing Mode – Manual Filling Mode

You can optimally adapt your balance to meet either of these requirements.

In the manual filling mode, the display compensates for fluctuations of the load on

the balance, giving you especially fast and stable readouts.

Code

Standard weighing mode 1 2 1*

Manual filling mode 1 2 2

Stability Range

The stability symbol will remain displayed in the case

of a weight variation +/– Code

0.25 digit 1 3 1

0.5 digit 1 3 2*

1 digit1) 133

2 digits1) 134*

4 digits1) 135

8 digits1)2) 136

* = factory setting; depends on the balance model in some cases

1

) = not applicable to the BP 8-0CE and BP 2100-0CE

2

) = not applicable to the verified balances approved for use as legal measuring

instruments in the EU

31

Page 32

Tare Parameter

You can define when the balance will perform the taring operation:

Code**

At any time 1 5 1

Not until the readout is stable 1 5 2*

Auto Zero Function

When this zero-tracking function is activated, any slight changes off the zero

readout are automatically tared.

Code

Auto Zero on 1 6 1*

Auto Zero off 1 6 2

Adjustment/Calibration and Linearization Functions Using CAL

Internal Linearization applicable only to the BP 211 D, 301S (-0CE)

Code

External calibration 1 9 1*/**

Internal calibration for balances with a built-in

automatic calibration function 1 9 3*

Calibration test for balances with a built-in

automatic calibration function 1 9 4

Internal linearization with automatic calibration 1 9 6

Adjustment/calibration functions blocked 1 9 7

Important Note Concerning Verified Balances Approved for Use as Legal

Measuring Instruments in the EU:

For verified balances of accuracy class K, the menu access switch is adjusted

to lock the “External Linearization” function after verification, and a control seal is

affixed to the balance to lock the menu access switch.

** = factory setting; depends on the balance model in some cases

** = setting not applicable to verified balances of accuracy class K

32

Page 33

Weighing Using Two Weighing Units

The v key (8) lets you toggle back and forth between two weight units.

The 2nd unit is identified by the display symbol “R1.”

Code

v key blocked 2 1 1*

Mass unit conversion by toggling 2 1 2

General View – Weight Units

Symbol/Conversion factor Code

1 g = 1st level 2nd level R1

Grams (o)** o 1. 1 7 1 3 1 1

Grams g 1. 1 7 2* 3 1 2*

Kilograms1) kg 0.001 1 7 3* 3 1 3*

Carats** ct 5. 1 7 4 3 1 4

Pounds** lb 0.0022046226 1 7 5 3 1 5

Ounces** oz 0.035273962 1 7 6 3 1 6

Troy ounces** ozt 0.032150747 1 7 7 3 1 7

Hong Kong taels** tl (thl)3) 0.02671725 1 7 8 3 1 8

Singapore taels** tl (ths)3) 0.02646063 1 7 9 3 1 9

Taiwanese taels** tl (tht)3) 0.02666666 1 7 10 3 1 10

Grains** GN 15.43235835 1 7 11 3 1 11

Pennyweights** dwt 0.643014931 1 7 12 3 1 12

Milligrams2) mg 1000. 1 7 13 3 1 13*

Parts per pound** o (/lb)3) 1.1287667712 1 7 14 3 1 14

Chinese taels** tl (thlc)3) 0.02645547175 1 7 15 3 1 15

Mommes** m (mom)3) 0.2667 1 7 16 3 1 16

Carats** k (K)3) 5. 1 717 3 117

Tola** t (tol)3) 0.0857333381 1 7 18 3 1 18

Baht** b (bat)3) 0.06578947436 1 7 19 3 1 19

Mesghal** m (MS)3) 0.217 1 7 20 3 1 20

** = factory setting; depends on the balance model in some cases

** = not applicable to verif. balances approved for use as legal meas. instruments

1

) = not applicable to verified balances of accuracy class k

2

) = not applicable to verified balances of accuracy class K

3

) = unit symbols output via the data interface

33

Page 34

Display Modes

You can select the display mode that best meets your individual accuracy

requirements (last numeral). The display increments possible are as follows:

1, 2, 5, 10, 20, 50, etc.

Starting with the basic increments of a weight unit, the display accuracy can

be reduced by as many as three levels so that you will obtain a faster readout with

a reduced display accuracy. The display accuracy is reduced proportionally to

the selected basic increment of a weight unit. To make this concept easier

to understand, the three levels are designated as “rounding factors” in the tables

summarizing the various menu code settings.

Code

Display mode 1st level 2nd level R1

Highest possible accuracy 1 8 1* 3 2 1*

Last numeral blanked when load changes1) 182 322

Rounding factor 2** 1 8 3 3 2 3

Rounding factor 5** 1 8 4 3 2 4

Rounding factor 10** (last numeral off) 1 8 5 3 2 5

** = factory setting

** = not applicable to verified balances approved for use as legal measuring

instruments in the EU

1

) = applicable only to verified balances approved for use as legal measuring

instruments in the EU

34

Page 35

Interface Parameter Settings

Baud Rate Code

150 baud 5 1 1

300 baud 5 1 2

600 baud 5 1 3

1,200 baud 5 1 4*

2,400 baud 5 1 5

4,800 baud 5 1 6

9,600 baud 5 1 7

19,200 baud 5 1 8

Parity Code

Mark 5 2 1

Space 5 2 2

Odd 5 2 3*

Even 5 2 4

Number of Stop Bits Code

1 stop bit 5 3 1*

2 stop bits 5 3 2

Handshake Mode Code

Software handshake 5 4 1

Hardware handshake with 2 characters after CTS 5 4 2*

Hardware handshake with 1 character after CTS 5 4 3

*= factory setting

35

Page 36

Utilities for Printouts or Data Transfer

Sartorius balances come standard with an interface. You can plug a Sartorius

printer or a computer into this interface port. In addition, you can choose to have

data output from your balance to this on-line device either automatically or by

pressing the p key.

The balance operating menu lets you define the various parameters for data output.

Information on the data formats and for interfacing a computer or a different

peripheral device are available on request.

Data Output Parameter

This parameter is coupled with the stability parameter

Print on request = data is output only when the p key is pressed or a software

command is received

Auto print = continuous, automatic data output

Code

Print on request regardless of stability 6 1 1

Print on request after stability, with storage of the function 6 1 2*

Print on request at stability, without storage of the function 6 1 3

Auto print regardless of stability 6 1 4

Auto print at stability 6 1 5

Auto Print

You can stop and start automatic data output (auto print function) by pressing

the p key.

Code

Start/stop auto print using the p key 6 2 1

Auto print not stoppable 6 2 2*

Data Output at Defined Intervals

The menu code for “2 display updates” must be set if you connect the remote

display to the balance.

Auto print interval Code

1 display update 6 3 1*

2 display updates 6 3 2

* = factory setting

36

Page 37

Automatic Taring after Data Output (Print on Request)

This convenient setting lets you checkweigh a series of samples or products

without having to unload the balance after each weighing operation.

– the sample remains on the pan after the weight readout has been printed

or transferred to an on-line computer

– the balance is tared automatically after the weight readout has been printed

or transferred to an on-line computer

– you simply load the next sample or part

Code

Data output without automatic taring 6 4 1*

Data output with automatic taring 6 4 2

Automatic Output of the Application Parameters

After completing an application started by pressing the v key, you can have the

application parameters and results printed out or transferred to an on-line computer.

Code

Off 711*

On 712

Data ID Codes

To help you identify weights, piece counts, percentages, etc., a code letter is

printed or displayed in front of these values. For example, an “N” printed

or displayed in front of a weight value identifies it as a net weight. If you set the

code for “without data ID code,” only net weights, results in percent and

counting results will be output. You will find the data ID codes for a particular

application program listed in the corresponding description.

The ID code increases the data output format for each weight readout

from 16 to 22 characters.

ID code for data output Code

Without 7 2 1*

With 7 2 2

* = factory setting

37

Page 38

Automatic Output of the Tare Memory Data

If you have selected the application program “tare memory” (2 1 6), you can have

your choice of values output by pressing the v key:

Code

Last net value (individual value N1) 7 3 1*

Tare memory data (total T1) 7 3 2

Additional Functions

Menu Access Switch Function on Standard Balances

You can define the function of the menu access switch by setting the code for the

balance operating menu to “accessible.” The balance operating menu will then be

accessible at all times, which means that you can change the menu codes at any

time regardless of the setting of the menu access switch.

Access to the balance operating menu Code

Accessible 8 1 1

Depends on the setting of the menu access switch 8 1 2*

Menu Access Switch Function on Verified Balances

The balance operating menu can also be changed when the balance is being

used as a legal measuring instrument. Codes that are not permitted for operation

of the balance as a legal measuring instrument are blocked and cannot be

selected. For balances of accuracy class K, the menu access switch is adjusted

to lock the “External Calibration” function after verification. To do this, the switch

must be moved to the left. A control seal is affixed to the balance to lock the

menu access switch. Unauthorized attempts to remove this seal will irreversibly

damage it. If you break the seal, the validity of the verification will become

void, and you must have your balance re-verified.

Blocking the Keys

You can block all keys on the balance (except for e).

Key functions Code

Accessible 8 3 1*

Blocked 8 3 2

* = factory setting

38

Page 39

Universal Switch for Remote Control

You can connect an external universal switch to the interface port of your balance

for remote control of the functions listed below.

Functions Code

Print p 841*

Tare t 842

Adjust/calibrate/linearize (using q) 843

v key 8 4 4

c key 8 4 5

Power-On Mode

Depending on your requirements, you can change the power-on mode

of your balance.

The factory setting is: (power) off –> on <–> standby.

In this default setting, when you press the e key (11) to turn off the display, the

balance will remain in the standby mode. This means that it will be ready

to operate without requiring any warmup when you turn the display back on.

In the setting “Toggle between on and standby,” the balance will automatically

turn on again after it has been temporarily disconnected from AC power

or a power failure has occurred.

In the setting “Automatic power-on,” the balance will automatically turn on again

after it has been temporarily disconnected from AC power, the e key has

been

pressed, or after a power failure has occurred. In this setting, you cannot

use the

e key to turn off the balance. If your balance is connected to a central

power supply that is switched off overnight, the balance will turn on automatically

the next day as soon as the power supply is switched on again.

Power-on mode Code

(Power) off –> on <–> standby 8 5 1*

On <–> standby 8 5 3

Automatic power-on 8 5 4

* = factory setting

39

Page 40

Application Programs

In addition to the functions implemented for weighing, Sartorius Basic

offer you a variety of application programs.

To select an application program or a specific function, set the appropriate

code in the menu. The procedure for setting menu codes is described in detail

starting on page 28.

Using Verified Balances as Legal Measuring Instruments in the EU*:

All application programs can be selected on balances used as legal measuring

instruments. Non-metric values are indicated as follows:

Percent = %; Piece count (counting) = pcs; Computed value = o

plus

balances

Tare Memory

Tare Memory Code 2 1 6

Symbol displayed when a value is stored: NET

Press the v key (8) to store the tare weight. The balance is now automatically

tared so you can weigh again starting with a zero readout.

Practical Example: Tare – Net – Gross Weights

Menu code settings used in the example:

Function Code

Tare memory 2 1 6

Automatic output

of all parameters 7 1 2

With data ID code 7 2 2

Print tare memory 7 3 2

As an alternative, you can select

this automatic output parameter:

Print net value 7 3 1**

** = including the Signatories of the Agreement on the European Economic Area

** = factory setting

40

Page 41

Application: Obtaining printouts of tare, net and gross weights or outputting these

data to a computer

Step/Key Readout Data Output/Printout

c, t

0.00 g

Place container on pan +

22.65 g

v

0.00 g

NET

T1 + 22.65 g

Fill container with sample;

press p +

250.24 g

NET

N1 + 250.24 g

c, p +

272.89 g

N + 272.89 g

The data ID codes mean:

T1 + 22.65 g tare weight stored in the memory (weight value)

N1 + 250.24 g net weight when tare weight is stored

N + 272.89 g gross weight = tare + net

Practical Example: Net Total

Menu code settings used in the example:

Function Code

Tare memory 2 1 6

Automatic data output 7 1 2

With data ID code 7 2 2

Printout of individual

components/tare weights 7 3 1*

* = factory setting

As an alternative, you can select

this output parameter:

Printout of the net total

weight/total tare weight 7 3 2

41

Page 42

Application: Simple compounding and formulating of several components

with additive storage, automatic taring and outputting of the

component weights

Step/Key Readout Data Output/Printout

Place container on pan +

c, t

Weigh in 1st component; +

s

tore: v

Weigh in 2nd component; +

s

tore: v

Weigh in and store additional

components: v

Finish weighing in

components; output

total weight: c, p +

The data ID codes mean:

N1 + 60.33 g component weight (net individual weight)

N + 272.89 g total components weighed in (net total weight)

22.65 g

0.00 g

4.61 g

0.00 g

NET

60.33 g

0.00 g

NET

xxx.xx g

NET

272.89 g

N1 + 4.61 g

N1 + 60.33 g

N1 + xxx.xx g

N + 272.89 g

Weighing in Percent

Weighing in Percent Code 2 1 5

Symbol displayed: %

This application program enables you to obtain weight readouts in percent which

are in proportion to a reference weight. The reference weight readout is stored

as a menu-defined percentage (factory setting: 100%). After treating the sample,

place it on the weighing pan and read off the weight in percent.

42

Page 43

Changing the Reference Percentage

You can change the reference percentage in cycles. Choose from the following

settings: 5, 10, 20, 50 and 100.

To activate the Hold down v (8) for more than 2 seconds until

change function: “rEF 100 %” appears on the display

To change the setting: Briefly press v

To store the percentage: Hold down v for more than 2 seconds to store

this value permanently (in the non-volatile memory)

after you turn off the power

This setting is not canceled by the reset code 9 – – 1°!

Storage Parameter for the Reference Weight/Value

The reference weight/value is stored… Code

with full accuracy according to the internal resolution 3 5 1*

according to the display accuracy 3 5 2

When you exit the reference storage mode, “Err 22” may briefly be displayed.

This means that the new reference value has been stored.

Toggling between the Readout in Percent (%) and Weight (g)

After placing the sample on the weighing pan, you can toggle between the

readout in percent and the respective weight readout in grams by pressing

the v key after you have stored the reference value. To clear the readout in

percent, use the c key.

Display Parameter for Readouts in Percent

The following display parameters can be set for readouts in percent:

The readout in percent is displayed… Code

without a decimal place 3 6 1

with one decimal place 3 6 2*

with two decimal places 3 6 3*

with three decimal places 3 6 4

If the weight stored is too light to be displayed, the number of decimal places

is automatically decreased.

* = factory setting; depends on the balance model in some cases

43

Page 44

Practical Example: Determination of the Residual Weight in Percent

Menu code settings used in the example:

Function Code

Weighing in percent 2 1 5

Ref. % and weight 7 1 2

With data ID code 7 2 2

Application: Quick determination of the dry weight of a sample

Step/Key Readout Data Output/Printout

Place container on pan +

c, t

Add prepared sample +

to container; v +

For moisture analysis,

press t at this point

Remove container; dry sample

Reweigh sample in container +

p +

Press c to clear

residual weight readout and

reference value +

p +

The data ID codes mean:

pRef + 100 % reference percentage

Wxx% + 4.61 g net reference weight xx%

Prc + 72.5 % calculated percentage

N + 3.34 g net residual weight

22.65 g

0.00 g

4.61 g

100.0 %

0.0 %

xx.x %

72.5 %

72.5 %

3.34 g

3.34 g

nRef + 100 %

Wxx% + 4.61 g

Prc + 72.5 %

N + 3.34 g

44

Page 45

Counting

Counting Code 2 1 4

Symbol displayed: P

The counting program allows automatic conversion of weights into piece counts

based on a reference sample weight. A weight readout is stored as a reference

sample quantity (factory setting: 10 pcs = pieces). When you turn on the balance,

the reference sample quantity will be displayed as “rEF 10 pcs” before you enter

the piece count.

Displaying the Reference Sample Quantity

You can have the reference sample quantity (pcs) setting displayed by pressing

the v key when the balance is unloaded.

Changing the Reference Sample Quantity

You can change the reference sample quantity in cycles. Choose from the

following settings: 5,10, 20, 50 and 100.

To activate the Hold down v (8) for more than 2 seconds until

change function: “rEF…pcs” appears on the display

To change the setting: Briefly press v

To store the quantity: Hold down v for more than 2 seconds to store

this quantity permanently (in the non-volatile memory)

after you turn off the power

This setting is not canceled by the reset code 9 – – 1°!

Storage Parameter for the Reference Sample Weight

The reference weight is stored… Code

with full accuracy according to the internal resolution 3 5 1*

according to the display accuracy 3 5 2

When you exit the reference storage mode, “Err 22” may briefly be displayed.

This means that the new reference value has been stored.

Toggling between the Piece Count (pcs) and Weight (g)

After placing the sample on the weighing pan, you can toggle between the piece

count and the respective weight readout by pressing the v key.

*= factory setting

45

Page 46

Practical Example: Counting Small Parts

Menu code settings used in the example:

Function Code

Counting 2 1 4

Ref. qty. and ref. weight 7 1 2

With data ID code 7 2 2

Application: Counting bulk quantities of items with the same weight

Step/Key Readout Data Output/Printout

Place container on pan +

c, t

Add 10 counted parts

Press v to confirm reference rEF

sample quantity +

Fill container with desired

quantity of parts

(without counting them) +

p +

Press c to clear the

weight readout and

the reference value +

p +

The data ID codes mean:

nRef + 10 pcs reference sample quantity (piece count)

wRef + 5.6546 g reference weight

Qnt + 500 pcs calculated piece count

N + 2827.35 g net weight

22.65 gcs

0.00 gcs

5.6546 gcs

+

2827.35 gcs

2827.35 gcs

10 pcs

10 pcs

500 pcs

500 pcs

nRef + 10 pcs

wRef + 5.6546 g

Qnt + 500 pcs

N + 2827.35 g

46

Page 47

Animal Weighing/Averaging

Animal Weighing/Averaging Code 2 1 7

Symbol displayed: m

Use this program to determine the weights of live animals or weights under

unstable ambient conditions. In this program, the balance calculates the weight as

the average of a selectable number of individual weighing operations.

During averaging, the number of remaining individual subweighing operations

is shown on the application display in a “countdown” mode.

Once all subweighing operations have been performed, the calculated mean

value is indicated as a stable readout on the weight display.

Manual or Automatic Start Mode

Depending on the menu code you select, animal weighing will be started

automatically or manually by pressing a key.

If you select the “automatic mode,” you will have to press v to start the program

for averaging the first weight. You can press c to interrupt a weight

measurement in progress at any time. In the “automatic mode,” the symbol

“AUTO” will be displayed during weight measurement. The result is locked into

the display. The ”m” symbol or “AUTO” flashes during this time. The readout will

stop flashing after you have unloaded the balance, and the next weight will

be displayed.

Animal weighing/averaging will start by Code

Manual mode 3 8 1

Automatic mode 3 8 2*

Once averaging has been completed, the program will stop until the balance is

unloaded to half the value (50 display increments) of the storage threshold.

* = factory setting

47

Page 48

Delayed Start Mode

A rule of thumb to go by for selecting the right setting to weigh animals is:

the more active an animal is, the greater the difference must be between two

successive subweights measured.

Depending on individual requirements, starting the averaging operation can be

delayed either in the automatic or manual mode until the animal you are weighing

has calmed down to a certain degree.

In this case, the start criterion is defined by the difference between two successive

subweights measured. If the animal moves, the start criterion is not met; therefore,

averaging will not start. Once the animal has calmed down, the program

checks whether two measured subweights are within the previously selected range.

If so, the actual averaging operation will be started.

Delay start until… Code

difference is slight 3 7 1

difference is average 3 7 2*

difference is considerable 3 7 3

During averaging, the number of subweighing operations left to perform is shown

on the weight display (countdown mode).

Changing the Number of Subweighing Operations

You can change the number of subweighing operations used to average

a weight. Change this number in cycles. You can choose from the following

settings: 5,10, 20, 50 and 100.

To activate the Hold down v (8) for more than 2 seconds until

change function: “rEF 10” appears on the display

To change the setting: Briefly press v

If you enter a wrong number, press c to clear it

To store the number: Hold down v for more than 2 seconds to store

this number permanently (in the non-volatile memory)

after you turn off the power

This setting is not canceled by the reset code 9 – – 1°!

* = factory setting

48

Page 49

Storage Threshold for the Automatic Start Mode

To obtain an added measure of reliability in the automatic mode, in order to

avoid an “incorrect start,” a weight value must correspond to a minimum load

of 100 display increments.

Practical Example: Animal Weighing in the Automatic Start Mode

Menu code settings used in the example:

Function Code

Animal weighing 2 1 7

Delay start until dif. is average 3 7 2*

Automatic start mode 3 8 2*

Automatic output

of all parameters 7 1 2

With data ID code 7 2 2

Application: Automatic weighing of animals based on10 subweighing operations

Step/Key Readout Data Output/Printout

Place animal weighing bowl

on balance

c, t

0.00 g

Place 1st animal in bowl

v

10 g

mdef + 10

465.20 g

x-Net + 465.20 g

Remove 1st animal

Place 2nd animal in bowl

10 g

mdef + 10

388.53 g

x-Net + 388.53 g

Repeat above steps

for all animals

The data ID codes mean:

mdef + 10 defined number of subweighing operations

x-Net + 401.18 g calculated average

* = factory setting

As an alternative, you can select

this output parameter:

Other delay start 3 7 x

Manual start mode 3 8 1

49

Page 50

ISO/GLP-compliant Printout or Record

Application:

Use of the balance as a test and measuring instrument in quality assurance

systems in compliance with the requirements of ISO, GLP, GMP and EN (European

Standards) in which proof of the balance’s accurate performance is required.

The balance can record all completed calibration or adjustment operations and

print out data in compliance with the requirements of Good Laboratory

Practice (GLP). The balance, interfaced with a data printer or a computer, creates

a document that records the date, time, serial number and model number,

making it possible to clearly trace data to the balance that generated it and the

time at which it was generated.

Select the ISO/GLP-compliant printout or record mode by setting the respective

code in the balance operating menu:

ISO/GLP-compliant printout/record mode Code

Off 8 10 1*

Only for adjustment/calibration and linearization functions 8 10 2

Always on (e.g., for adjustment/calibration and linearization

functions, application programs, weight readouts) 8 10 3

The following menu code setting must be selected in order to obtain an ISO/GLPcompliant printout/record:

With data ID code 7 2 2

Important Note

!

Operating the Balance with a Device That Has an ISO/GLP Printing

or Recording Capability

You can connect a special Sartorius Data Printer to Basic

ISO/GLP-compliant printouts

To generate ISO/GLP-compliant records with a computer, you will need

special software. For information on writing this software, please ask Sartorius for

a detailed description.

* = factory setting

50

ISO/GLP-compliant printouts/records will not be generated if the

factory setting, code 7 2 1, is selected. In addition, do not select the

“Auto print” data output parameter (code 6 14 or 6 15).

plus

balances for generating

(order no. YDP03-0CE).

Page 51

Printout/Record for Adjustment or Calibration and Linearization Functions

A printout or record is generated at the end of the following functions:

– all calibration, adjustment and linearization procedures

– calibration test

The printout can have the following lines:

-------------------MC1 - Sartorius : Balance family and manufacturer

Model BP211D : Balance model

S/N 040500048 : Serial number of the balance

ID : Space for entering the workstation or operator ID

-------------------Date : 21-Mar-97 : Current date

Start: 10:05:30 : Time at which the application started

Cal. : Extern : Calibration mode (in this case,

“external calibration”)

Set. : 200.00000 g : Calibration weight value

(only for “external calibration”)

End : 10:05:45 : End of application

Name : : Space for signature of the operator responsible

--------------------

Additional information for other calibration modes:

Cal. : Intern : Internal calibration

Stat.: Complete : Status comment for calibration or linearization

functions

Cal. : Test : Calibration test

Diff.:- 0.00004 g : Data measured during calibration test

51

Page 52

Data Printout/Record (ISO/GLP-compliant)

To have a data record printed out, perform the following:

– Press p to output the printout heading and the first value (after you have turned

on the balance or cleared a function by pressing c)

– Press p to output additional data

– To end printout generation and recording of data, press c

Generation of an ISO/GLP-compliant printout or record is also ended when

an adjustment or calibration operation is started.

The printout can have the following lines:

-------------------MC1 - Sartorius : Balance family and manufacturer

Model BP211D : Balance model

S/N 040500048 : Serial number of the balance

ID : Space for entering the workstation or operator ID

-------------------Date : 21-Mar-97 : Current date

Start: 11:00:30 : Time at which the application started

Ser. : : Space for entering a project number

N + 5.45390 g : Measured weights

N + 24.34586 g

N + 63.23450 g

End : 11:15:55 : End of application

Name : : Space for signature of the operator responsible

--------------------

52

Page 53

Data Printout/Record for Application Programs

For application programs, reference data (parameters) can be included

in the printout/record.

To have a data record printed out, perform the following:

– Press v to output the printout heading and reference data (the reference data

will be stored at the same time)

or

– Press p to output the printout heading and the first value

If you input and store new reference values while an ISO/GLP-compliant record is

being printed out, the new reference data will be output. If you enter different

data before generation of an ISO/GLP record has started, the printout heading

and the reference data will automatically be printed once you press p. Then the

measured value will be output.

– Press p to output weighing data

– Press c to end printout generation (generation of an ISO/GLP printout also

ends once an adjustment or calibration operation has been started)

– Then press c to clear the reference data for the application programs

The printout can have the following lines:

-------------------MC1 - Sartorius : Balance family and manufacturer

Model BP211D : Balance model

S/N 040500048 : Serial number of the balance

ID : Space for entering the workstation or operator ID

-------------------Date : 21-Mar-97 : Current date

Start: 14:04:12 : Time at which the application started

Ser. : : Space for entering a project number

nRef + 10 pcs : Reference data (in this case,“counting” –

see also page 45)

wRef + 0.13400 g

Qnt + 500 pcs : Measured values (in this case

“calculated piece count”)

:

:

End : 14:13:07 : End of application

Name : : Space for signature of the operator responsible

--------------------

53

Page 54

Interface Description

General Information

This description has been written for users who wish

to connect their Sartorius balance, which has a built-in

V24/V28-RS-232C(-S)*)/423 interface port

as a standard feature, to a computer or a different

peripheral device.

By using an on-line computer, you can change,

activate and monitor the functions of the balance.

In addition, an external universal switch for remote

control of various functions can be connected to the

data interface port on the balance.

If you interface an original Sartorius accessory

device, such as a Sartorius Data Printer or a similar

unit, with a balance that has the factory-set menu

codes, you do not need to change any settings.

Interfacing Devices with the Balance

Please note that the interface port is electrically

connected to the protective grounding conductor

(protective earth = PE) of the balance housing.

The cabling supplied as accessory components is

shielded and electrically connected on both

ends to the cases of the connectors. This electrical

connection may result in interference caused by

ground loops or by transient currents if you have

grounded the housing or connected the protective

grounding conductor for AC power. If necessary,

connect an equipotential bonding conductor

to the balance.

54

*) = Sartorius pin assignment

Page 55

General Specifications

Type of interface Serial point-to-point connector

Operating mode Asynchronous, full-duplex

Standard V28, RS-232C specification

Handshake*) 2-wire interface: via software (XON/XOFF)

4-wire interface: via hardware handshake lines with

Clear To Send (CTS) and Data Terminal Ready (DTR)

Transmission rates*) 150; 300; 600;1,200; 2,400; 4,800;

9,600;19,200 baud

Character coding 7-bit ASCII

Parity*) Mark, space, odd, even

Synchronization 1 start bit; 1 or 2 stop bits*)

Data output format*) 16 or 22 characters

of the balance

Character format*) – 1 start bit

– 7-bit ASCII

– 1 parity bit

– 1 or 2 stop bits

*) = can be changed by the user

55

Page 56

Data Output Formats

Depending on the menu code setting:

or 7 2 1 = without data ID code

or 7 2 2 = with data ID code

data will be output with either 16 (code 7 2 1) or 22 characters (code 7 2 2).

For data output of 22 characters, a 6-character ID precedes the 16 characters

reserved for the weight or other value.

Data Output Format with 16 Characters

Display segments that are not activated (“+” or “–” sign, leading zeros other than

zeros before the decimal point) are output as spaces.

The following data block format is output according to what is displayed

on the balance:

12345678910111213141516

+ ––––––––––––––––––––––––

******

10610510410310210110

0

0000000

**

––––––––––––––––––––––––

.......

–––––––––––––––––––––––– U U U

–10

5104103102101100

000000

******

* = space; U = unit

***

*

CR LF

56

Page 57

When data are output without decimals, the decimal point is suppressed (except

when a certain display mode is selected).

12345678910111213141516

Data output example: +72.55 g

12345678910111213141516

Characters:

1st Plus or minus sign or space

2nd Space

3rd–10th Weight with a decimal point, leading zeros = space

11th Space

12th–14th Unit symbol or space

15th Carriage return (CR)

16th Line feed (LF)

If the weighing system has not stabilized, no unit symbol will be output.

Unit symbols:

* * * No stability parameter G N* Grains

o * * Taiwanese taels (o) d w t Pennyweights

g * * Grams m g * Milligrams

k g * Kilograms / l b Parts per pound

c t * Carats t l c Chinese taels

l b * Pounds m o m Mommes

o z * Ounces K * * Austrian carats

o z t Troy ounces t o l Tola

t l h Hong Kong taels b a t Baht

t l s Singapore taels MS * Mesghal

t l t Taiwanese taels

* = space; U = unit

+

****

72.55*g

**

CR LF

+

******

–––––––––––––––––––––

***

***

10610510410310210110

0

*

CR LF

––––––––––––––––––––– U U U

– 000000

57

Page 58

Special Codes

Special codes are output only if the balance operating menu code 611, 614

or 615 is set (see the section entitled “Data Ouput Parameters”).

Special status-dependent codes

12345678910111213141516

******

The following status codes are output for “A B”:

* * : Tare H * : Overload

C * : Calibrate*) L * : Underload

– – : All numerals indicated in stable readout

Special error-dependent codes

12345678910111213141516

***

X = *, 0, 1or 2 as a one-place error code

Y Z = two-place error index code

ERR

AB

XYZ

*

******

****

CR LF

CR LF

* = space

*) = The displayed status code “C” will also be output when a print command

is received and if the balance has a built-in calibration weight

58

Page 59

Data Output with ID Code

When data with an ID code are output, the ID code consisting of 6 characters

precedes the data with the 16-character format.

During data output, all characters are shifted to the right by 6 places.

1s t

7th 22nd

character

S = Plus or minus sign

* = Space

x = Digit

U = Unit

. = Decimal point

C = Letter for an ID comment

CR = Carriage return

LF = Line feed

When special codes are output, the letters “Stat” for status code are assigned

to the1st through the 4th characters of the data string.

Status-dependent string:

1s t

7th 13th14th 22nd

character

A, B = status codes

Error-dependent string:

1s t

7th 10–12 th 14–16th 22nd

character

Stat

*****

ERR*XYZ

****

CR LF

Stat

********

AB

******

CR LF

C C C C C C S *x x x x x x x x *U U U CR LF

* * * * * * * * . . . . . . * * *

59

Page 60

Data Input Formats