Page 1

Operating Instructions | Betriebsanleitung | Mode d’emploi | Instrucciones de manejo |

Manuale d’uso | Instruções de Operação

Original Operating Instructions | Original-Betriebsanleitung | Mode d’emploi original |

Instrucciones de manejo originales | Manuale d’uso originale | Instruções de Operação Originais

Entris

BCE Model | Modelle BCE | Modèles BCE | Modelos BCE | Modelli BCE | Modelo BCE

Precision Balances | Präzisionswaagen | Balances de précision | Balanzas de precisión |

Bilance di precisione | Balanças de Precisão

®

1000059011

Page 2

English – page 3

Deutsch – Seite 45

Français – page 88

Español – página 131

Italiano – pagina 174

Português – página 217

Page 3

Contents

Contents

1 About these Instructions............................ 5

1.1 Scope......................................... 5

1.2 Other Applicable Documents .....................5

1.3 Target Groups.................................. 5

1.4 Symbols Used .................................. 5

1.4.1 Warnings in Operating Instructions ......... 5

1.4.2 Other Symbols........................... 5

2 Safety Instructions ................................. 6

2.1 Intended Use...................................6

2.2 Personnel Qualification.......................... 6

2.3 Significance of these Instructions .................6

2.4 Proper Working Order of the Device ............... 6

2.5 Symbols on the Device ..........................6

2.6 Electrical Equipment ............................7

2.6.1 Damage to the Electrical Equipment

of the Device............................ 7

2.6.2 Working on the Device’s Electrical

Equipment.............................. 7

2.6.3 Power Supply Unit and Power Supply Cable.. 7

2.7 Conduct in an Emergency........................ 7

2.8 Accessories and Spare Parts ......................7

2.9 Personal Protective Equipment ...................7

3 Device Description ................................. 8

3.1 Device Overview................................ 8

3.2 Device Connections ............................. 8

3.3 Conformity-Assessed Devices..................... 8

3.4 Symbols on the Device ..........................8

4 Operating Concept................................. 9

4.1 Operating Display in Weighing Mode ..............9

4.2 Menu and System Settings Display ................9

4.2.1 Buttons ...............................10

4.3 Displays in the Operating Display.................11

4.4 Menu Structure ...............................12

4.4.1 “Main Menu” Menu Structure.............12

4.4.2 “Toggle Between Weight Units”

Menu Structure ........................14

4.5 Navigating the Menus.......................... 14

5 Installation....................................... 14

5.1 Scope of Delivery.............................. 14

5.2 Selecting an Installation Site ....................14

5.3 Unpacking.................................... 15

5.4 Removing the Transport Lock ...................15

5.5 Assembling the Device..........................15

5.6 Acclimatizing the Device........................15

6 Getting Started................................... 16

6.1 Installing the Power Supply Unit .................16

6.1.1 Assembling the Power Supply Unit ........16

6.1.2 Dismantling the Power Plug Adapter....... 16

6.2 Connecting the Power Supply ...................16

7 System Settings................................... 16

7.1 Performing System Settings..................... 16

7.2 Setting the Calibration and Adjustment........... 17

7.2.1 Switching the isoCAL Function On or

Off (Only Model i-1x).................... 17

7.2.2 Setting Internal Calibration and

Adjustment (Only Model i-1x).............17

7.2.3 Setting the External Calibration and

Adjustment ............................17

7.3 Parameter List ................................18

7.3.1 “SETUP”/”BALANCE” Menu................18

7.3.2 “SETUP”/”GEN.SERV.” Menu...............19

7.3.3 “DEVICE”/”RS232” Menu .................20

7.3.4 “DEVICE”/”USB” Menu ...................20

7.3.5 “DEVICE”/”EXTRAS” Menu ................21

7.3.6 “DATA.OUT.”/”COM. SBI” Menu ............22

7.3.7 “DATA.OUT.”/”PRNT.PAR.” Menu ...........22

7.3.8 “DATA.OUT.”/”PC.DIREC.” Menu............23

7.3.9 “APPLIC.”/”WEIGH” Menu ................23

7.3.10 “APPLIC.”/”COUNT” Menu ................23

7.3.11 “APPLIC.”/”PERCENT” Menu............... 24

7.3.12 “APPLIC.”/”NET.TOT.” Menu ...............24

7.3.13 “APPLIC.”/”TOTAL” Menu .................24

7.3.14 “APPLIC.”/”ANIM.WG” Menu ..............24

7.3.15 “APPLIC.”/”CALC.” Menu..................24

7.3.16 “APPLIC.”/”DENSITY” Menu ...............25

7.3.17 “APPLIC.”/”STATIST.” Menu ...............25

7.3.18 “APPLIC.”/”PEAK.HLD.” Menu.............. 25

7.3.19 “APPLIC.”/”CHECK.WG.” Menu............. 25

7.3.20 “INPUT” Menu..........................26

7.3.21 “INFO” Menu ...........................26

7.3.22 “LANGUAG.” Menu ...................... 27

8 Operation ........................................ 27

8.1 Switching the Device On and Off.................27

8.2 Waiting for the Warm-up Time ..................27

8.3 Leveling the Device with a Level Indicator . . . . . . . . . 27

8.4 Overview of Calibration and Adjustment ..........27

8.5 Calibrating and Adjusting Device with

isoCAL Function (Only Model i-1x) ...............27

8.6 Calibrating and Adjusting the Device Internally

(Only Model i-1x)..............................28

8.7 Externally Calibrating and Adjusting the Device ....28

8.8 Printing Results of the Calibration and Adjustment

Process ......................................28

8.9 Weighing.....................................29

8.10 Setting or Changing an Application ..............29

8.11 Running Applications (Examples)................. 29

8.11.1 Executing the “Toggle Between

Weight Units” Function ..................29

8.11.2 Selecting Convertible Units and their

Decimal Places .........................29

8.11.3 Running the “Statistics” Application .......29

8.12 Printing Weighing Result with ID Marking .........30

Entris® BCE Operating Instructions 3

Page 4

Contents

9 Cleaning and Maintenance.........................30

9.1 Removing the Weighing Pan and Associated

Components ..................................30

9.2 Cleaning the Device............................ 30

9.3 Assembling the Weighing Pan and Associated

Components .................................30

9.4 Maintenance Schedule .........................30

9.5 Software Update ..............................30

10 Malfunctions ..................................... 31

10.1 Warning Messages .............................31

10.2 Troubleshooting ...............................32

11 Decommissioning .................................33

11.1 Decommission the Device .......................33

12 Transport ........................................33

12.1 Installing the Transport Lock ....................33

12.2 Transporting the Device ........................33

13 Storage and Shipping .............................33

13.1 Storage ......................................33

13.2 Returning the Device and Parts ..................33

14 Disposal..........................................34

14.1 Information on Decontamination ................34

14.2 Disposing of the Device and Parts ................34

14.2.1 Information on Disposal .................34

14.2.2 Disposal ...............................34

16 Accessories.......................................43

16.1 Balance Accessories ............................43

16.2 Printer and Accessories for Data Communication ...43

16.3 External Calibration and Adjustment Weights ......44

17 Sartorius Service..................................44

18 Conformity Documents ............................44

12.1 Transportsicherung montieren ...................76

15 Technical Data.................................... 35

15.1 Ambient Conditions............................ 35

15.2 Contamination Type, Overvoltage Category (Device). 35

15.3 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

15.3.1 Power Supply Device ....................35

15.3.2 Power Supply Unit ......................36

15.4 Electromagnetic Compatibility................... 36

15.5 Backup Battery................................36

15.6 Materials..................................... 36

15.7 Warm-up Time ................................37

15.8 Interfaces ....................................37

15.8.1 Specifications of the RS232 Interface . . . . . . 37

15.8.2 Specifications for the USB-C Interface .....37

15.9 Device Dimensions .............................37

15.10 Metrological Data............................. 38

15.10.1 Models BCE6202 | BCE4202 | BCE3202..... 38

15.10.2 Models BCE2202 | BCE1202 ..............39

15.10.3 Models BCE822 | BCE622 ................40

15.10.4 Models BCE8201 | BCE5201 | BCE2201..... 41

15.10.5 Models BCE8200 | BCE6200 ..............42

4 Entris® BCE Operating Instructions

Page 5

About these Instructions

1 About these Instructions

1.1 Scope

These instructions are part of the device. These instructions

apply to the device in the following versions:

Device Model

Entris® BCE

precision balance

with frame

draft shield,

readability

10 mg | 0.1 g | 1 g

1) Country-specific marking in model, x =

S Standard balances without country-specific

additions

SAR Standard balances with country-specific additions

for Argentina

SJP Standard balances with country-specific additions

for Japan

SKR Standard balances with country-specific additions

for South Korea

OBR Balances with approval for Brazil

OIN Balances with approval for India

OJP Balances with approval for Japan

ORU Balances with approval for Russia

CCN Balances with approval for China

CEU Conformity-assessed balances with EU type

examination certificate without country-specific

additions

CFR Conformity-assessed balances with EU type

examination certificate only for France

2) Model-typical marking in model

i-1x Devices with internal calibration and adjustment

function

1.2 Other Applicable Documents

In addition to these instructions, observe the following

documentation:

− Installation instructions for the accessories, e.g. printer

1) 2)

BCE622i-1x | BCE622-1x | BCE822i-1x |

BCE822-1x | BCE1202i-1x | BCE1202-1x |

BCE2201i-1x | BCE2201-1x | BCE2202i-1x |

BCE2202-1x | BCE3202i-1x | BCE3202-1x |

BCE4202i-1x | BCE4202-1x | BCE5201i-1x |

BCE5201-1x | BCE6200i-1x | BCE6200-1x |

BCE6202i-1x | BCE6202-1x | BCE8200i-1x |

BCE8200-1x | BCE8201i-1x | BCE8201-1x

1.3 Target Groups

These instructions are addressed to the following target groups.

The target groups must possess the specified knowledge.

Target group Knowledge and qualifications

User The user is familiar with the operation of the

device and the associated work processes.

They understand the hazards which may arise

when working with the device and know how

to prevent them.

They have been trained in the operation of

the device.

Operator The operator of the device is responsible for

ensuring compliance with workplace health

and safety regulations.

The operator must ensure that all persons

who work with the device have access to

the relevant information and are trained in

working with the device.

1.4 Symbols Used

1.4.1 Warnings in Operating Instructions

WARNING

Denotes a danger with the risk that death or severe injury may

result if it is not avoided.

CAUTION

Denotes a hazard that may result in moderate or minor injury

if it is not avoided.

NOTICE

Denotes a danger with the risk that property damage may

result if it is not avoided.

1.4.2 Other Symbols

t

y Result: Describes the result of the actions carried

[ ] Text inside brackets refers to control and display

[ ] Text inside brackets indicates status, warning, and

Required action: Describes actions which must be

carried out.

out.

items.

error messages.

Indicates information for legal metrology for

conformity-assessed (verified) devices. Conformityassessed devices are also referred to as “verified” in

these instructions.

Entris® BCE Operating Instructions 5

Page 6

Safety Instructions

Figures on the Operating Display

The figures on the operating display of the device may deviate

from those in these instructions.

2 Safety Instructions

2.1 Intended Use

The device is a high-resolution balance, which can be used

indoors, e.g. in industrial areas. The device was developed for

the accurate determination of the mass of materials in liquid,

paste, powder, or solid form.

Appropriate containers must be used for loading each type of

material.

The device is exclusively designed for use according to these

instructions. Any further use beyond this is considered

improper.

If the device is not used properly: the protective systems of the

device may be impaired. This can lead to unforeseeable personal

injury or property damage.

Operating Conditions for the Device

Do not use the device in potentially explosive environments.

The device may only be used indoors.

The device may only be used with the equipment and under the

operating conditions described in the Technical Data section of

these instructions.

2.2 Personnel Qualification

If people who do not have sufficient knowledge on the safe

handling of the device carry out work on the device: Those

people may injure themselves or other people nearby.

t Ensure that all individuals working on the device possess

the necessary knowledge and qualifications (description see

Chapter “1.3 Target Groups”, page 5).

t If a particular qualification is indicated for the actions

described: Have these activities carried out by the required

target group.

t If no particular qualification is indicated for the actions

described: Have these activities carried out by the “user”

target group.

2.3 Significance of these Instructions

Failure to follow the instructions in this manual can have

serious consequences, e.g. exposure of individuals to electrical,

mechanical, or chemical hazards.

t Before working with the device: Read the instructions

carefully and completely.

t If these instructions are lost, request a replacement or

download the latest version from the Sartorius website

(www.sartorius.com).

t Ensure that the information contained in these instructions

is available to all individuals working on the device.

2.4 Proper Working Order of the Device

A damaged device or worn parts may lead to malfunctions or

cause hazards which are difficult to recognize.

Modifications to the Device

You may not modify or repair the device or make any technical

changes. Any retrofitting or technical changes to the device are

only permitted with prior written permission from Sartorius.

t Only operate the device when it is safe and in perfect

working order.

t In the event of damage to the housing, disconnect the

device from the power supply and prevent it from being

restarted.

t Do not open the device housing. Have any malfunctions or

damage repaired immediately by Sartorius Service.

t Comply with the maintenance intervals (for intervals and

maintenance work, see Chapter “9.2 Cleaning the Device”,

page 30).

2.5 Symbols on the Device

All symbols appearing on the device, such as warnings and

safety labels, must be legible.

t Do not conceal, remove, or modify the symbols.

t Replace the symbols if they become illegible.

6 Entris® BCE Operating Instructions

Page 7

Safety Instructions

2.6 Electrical Equipment

2.6.1 Damage to the Electrical Equipment of the Device

Damage to the device’s electrical equipment, e.g. damaged

insulation, can be life-threatening. There is a danger to life

from contact with live parts.

t If the electrical equipment of the device is defective, cut off

the power supply and contact Sartorius Service.

t Keep live parts away from moisture. Moisture can cause

short circuits.

2.6.2 Working on the Device’s Electrical Equipment

Only Sartorius Service personnel may work on or modify the

electrical equipment of the device. The device may only be

opened by Sartorius Service personnel.

2.6.3 Power Supply Unit and Power Supply Cable

Serious injury can result, e.g. from electric shocks, if an

unsuitable/inadequately dimensioned power cord or unsuitable

power supply unit is used.

t Only use the original power supply unit and original power

supply cable.

t If the power supply unit or power supply cable must be

replaced: Contact Sartorius Service. Do not repair or modify

the power supply unit or power cable.

2.9 Personal Protective Equipment

Personal protective equipment protects against risks arising

from the material being processed.

t If the workplace or the process in which the device is being

used requires personal protective equipment: Wear personal

protective equipment.

2.7 Conduct in an Emergency

If there is immediate danger of personal injury or equipment

damage, e.g., due to malfunctions or dangerous situations,

the device must be immediately taken out of operation.

t Disconnect the device from the power supply.

t Malfunctions should be remedied by Sartorius Service.

2.8 Accessories and Spare Parts

The use of unsuitable accessories and spare parts can affect the

functionality and safety of the device and have the following

consequences:

− Risk of injury to persons

− Damage to the device

− Device malfunctions

− Device failure

t Only use approved accessories and spare parts supplied by

Sartorius.

t Only use accessories and spare parts that are in proper

working order.

Entris® BCE Operating Instructions 7

Page 8

Device Description

3 Device Description

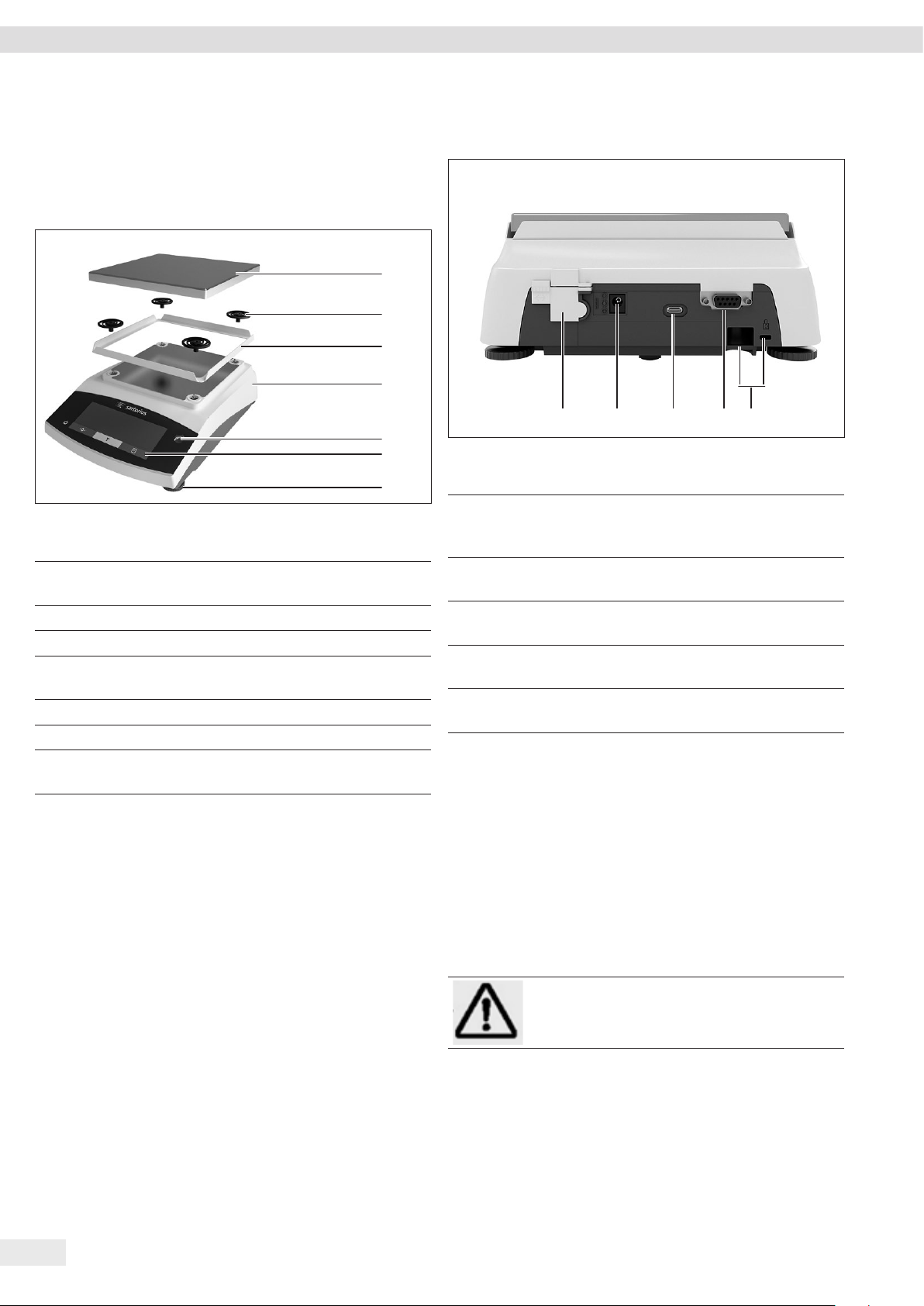

3.1 Device Overview

Fig. 1: Precision balance (front view)

Pos. Designation Description

1 Weighing pan For placing the sample on the

balance

2 Shock absorber

3 Frame draft shield

4 Manufacturer’s

ID label

5 Control unit

6 Level

7 Leveling foot Used to level the balance,

Not visible

manually adjustable

3.2 Device Connections

1

2

3

4

21 3 5

5

6

7

Fig. 2: Precision balance (rear view)

Pos. Designation Description

1 Menu access

switch

2 Power supply Connection for power supply to the

3 USB-C connection For the connection to a printer, PC,

4 RS232 connection 9-pin, for the connection to a

5 Slot For attaching an anti-theft device

Protects the device from changes

to the device settings. Is sealed for

conformity-assessed devices.

device

or a second display

printer, PC, or a second display

or a Kensington lock

4

3.3 Conformity-Assessed Devices

8 Entris® BCE Operating Instructions

Some settings of conformity-assessed models are protected

against user changes, e.g. external calibration for devices in

accuracy class II. This measure is intended to ensure the

suitability of the devices for use in legal metrology.

3.4 Symbols on the Device

Symbol Meaning

NOTICE! Read the operating

instructions.

Page 9

Operating Concept

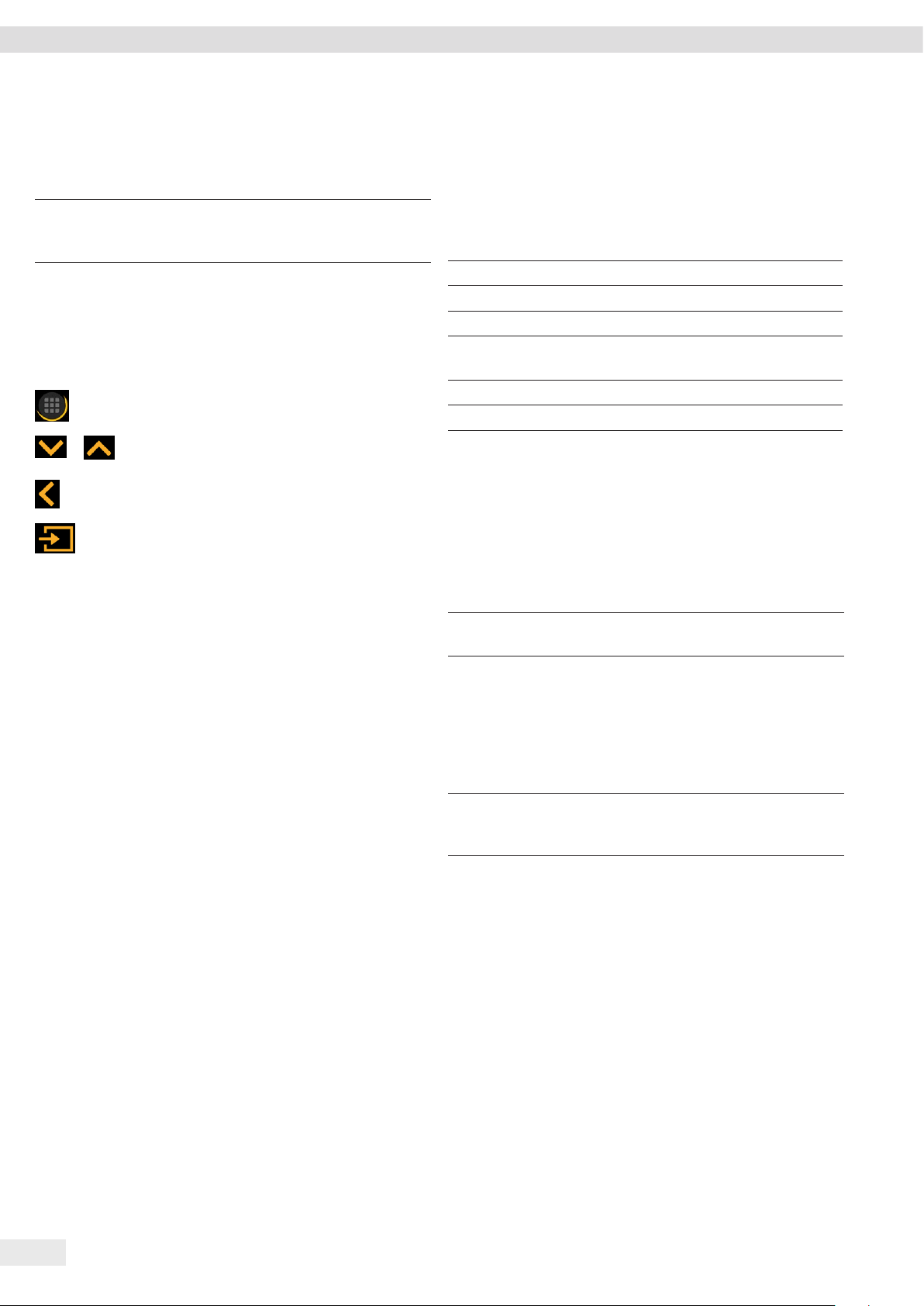

4 Operating Concept

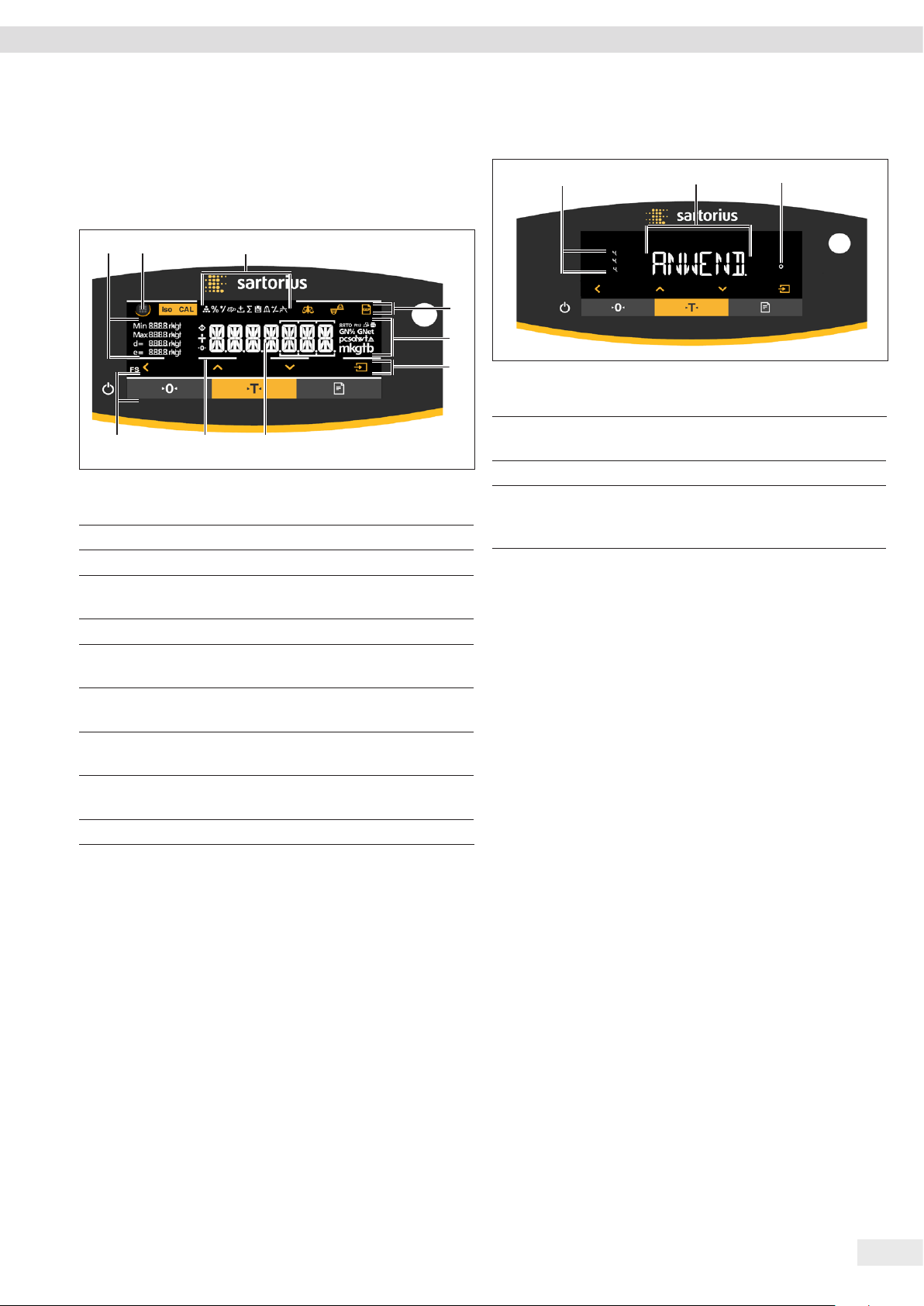

4.1 Operating Display in Weighing Mode

1

2

9

Fig. 3: Operating display in weighing mode (example)

Pos. Designation Description

1 Metrological data

2 Menu

3 Application

overview

4 Toolbar

5 Weighing unit Displays the selected unit,

6 Navigation bar For navigation in the menu and

7 Measurement

display

8 Visual touch

feedback

9 Toolbar

3

8

7

Displays the selected application

program during operation

e.g. grams, [g]

system settings

4.2 Menu and System Settings Display

1

4

5

6

Fig. 4: Menu and System Settings Display (example)

Pos. Designation Description

1 Menu or

parameter entry

2 [Selection] display

3 Menu level Shows the position of the

2

displayed menu or parameter

in up to 4 levels

3

Entris® BCE Operating Instructions 9

Page 10

Operating Concept

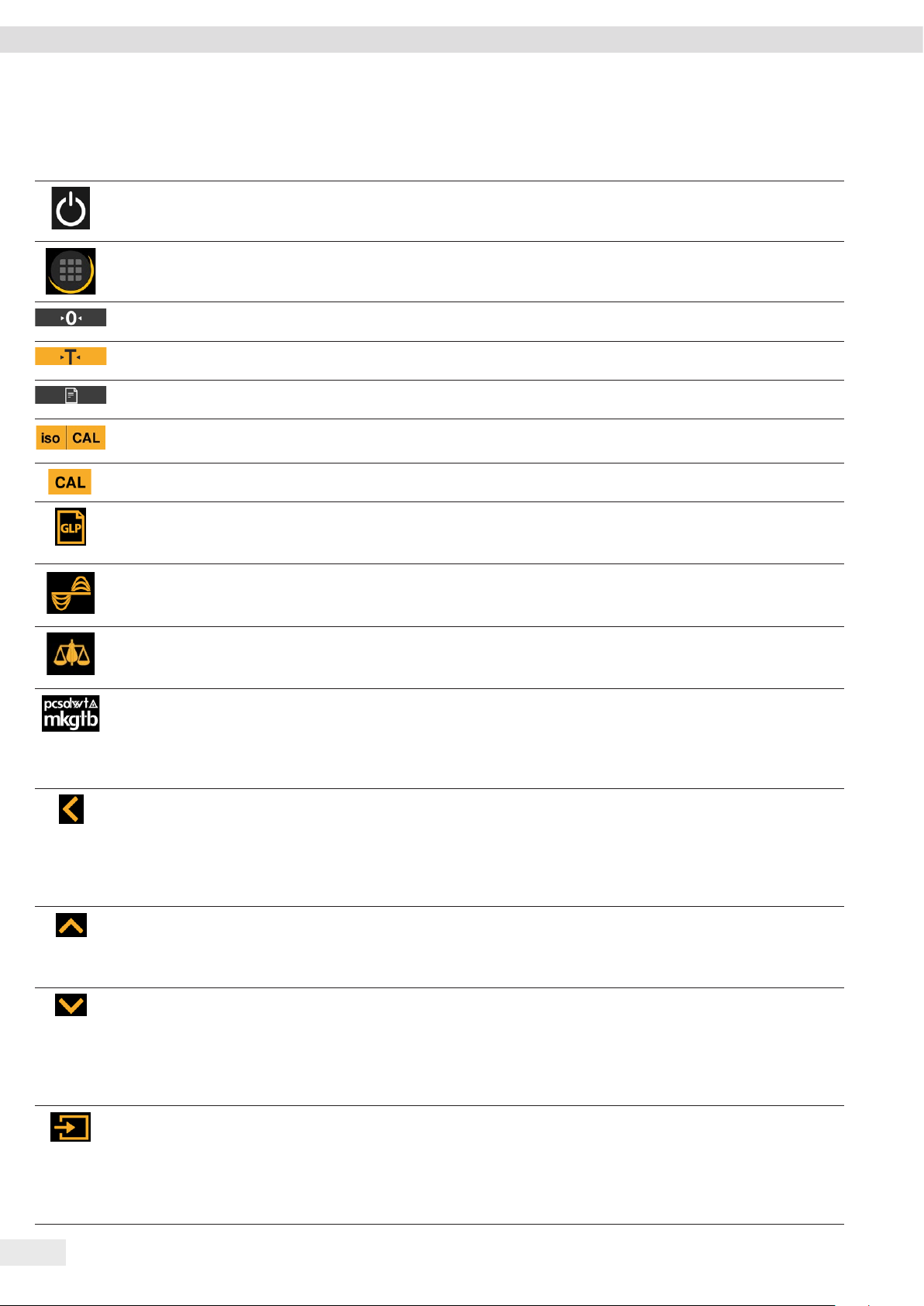

4.2.1 Buttons

Symbol Designation Description

[On/Off] button − When the button is pressed: Switches the operating display on.

− If the button is held down: Switches the operating display off.

[Menu] button − When the button is pressed: The settings menu opens.

− If the button is held down: It switches to version display.

[Zero] button Zeroes the device.

[Tare] button Starts taring.

[Print] button Exports the readouts to the integrated data interfaces.

[isoCAL] button If the button is flashing: Starts the isoCAL function.

If the button is not flashing: Starts the set calibration and adjustment function.

[Adjust] button Starts the set calibration and adjustment function.

[GLP] button − Exits the GLP printout and starts printing the GLP footer.

− If the “Net-total”, “Totalizing”, or “Statistics” application is active: Prints and deletes the

saved values and exits the application.

[Ambient condition]

Switches between the ambient conditions “V.STABLE”, “STABLE”, UNSTABL.” and “V.UNSTBL.”.

button

[Application filter]

Switches between the “weighing” and “filling” application filters.

button

[Toggle between

weight units] button

If the “Toggle between weight units” function is active:

− If the button is held down: Accesses the “Toggle between weight units” function menu.

− When the button is pressed: Switches between the basic unit display and up to 4 other

units.

[Back] button − In the menu:

− When the button is pressed: Returns to the previous display.

− If the button is held down: Saves the menu settings.

− When entering digits: Selects the previous digit position.

− For an active application: Exits the application and deletes the set reference value.

[Up] button − In the menu: Scrolls through the menu levels or the available parameters.

− When entering digits: Increases the displayed value.

− In the main display of an active application: Switches to the display of the current weight

value/parameter.

[Down] button − In the menu: Scrolls through the menu levels or the available parameters.

− When entering digits: Decreases the displayed value.

− In the main display of an application that is not active: Accesses the display to set the

reference values.

− In the main display of an active application: Switches to the display of the current weight

value/parameter.

[Confirm] button − In the menu: Accesses the displayed menu level or confirms the displayed parameter.

− When entering digits: Selects the next digit position.

− In the main display of an application that is not active: Starts the application process and

saves the set reference value.

− In the main display of an active application: Adopts the next component or the next

parameter.

10 Entris® BCE Operating Instructions

Page 11

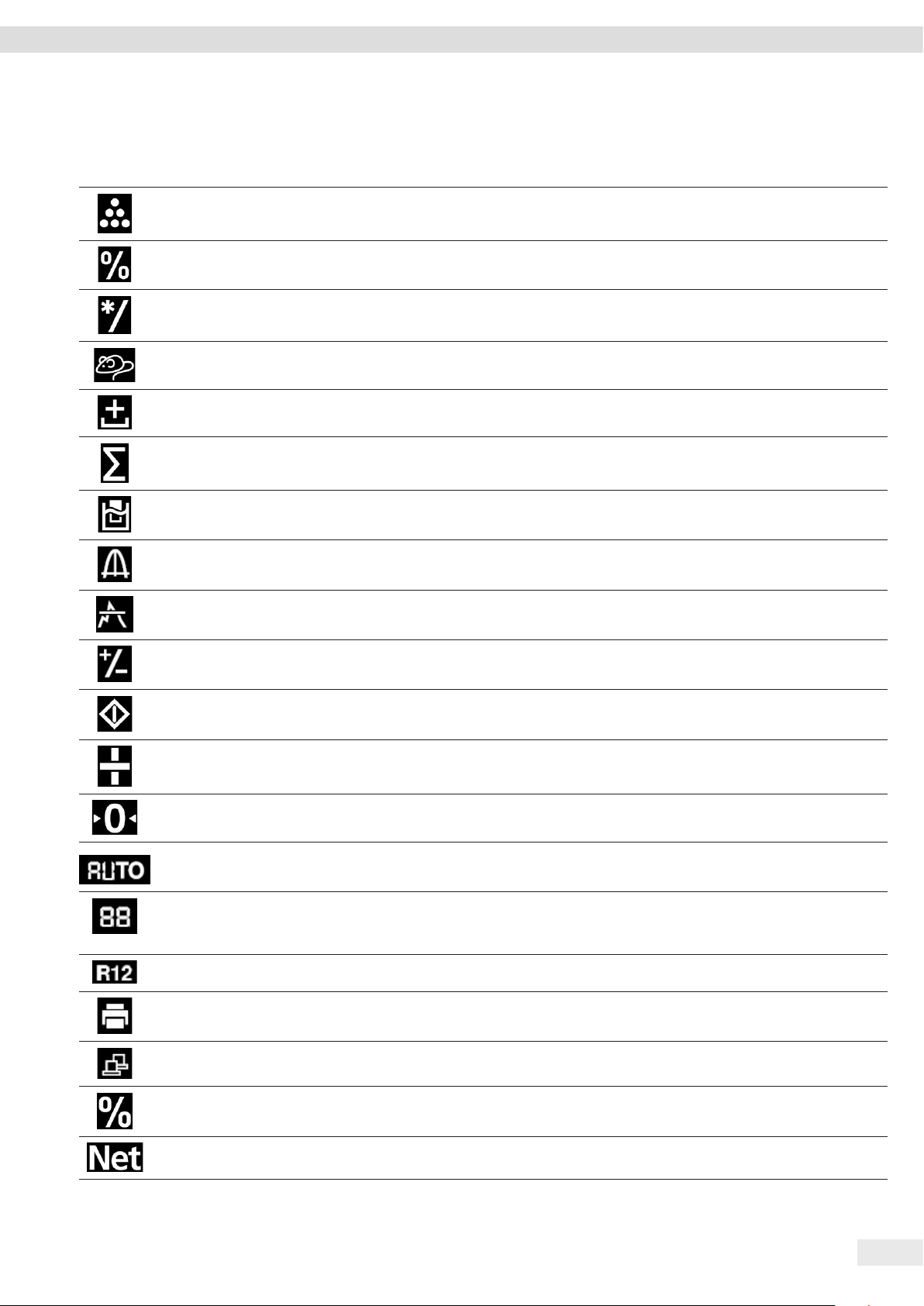

4.3 Displays in the Operating Display

Symbol Designation Description

[Counting] display Indicates that the “Counting” application is selected.

Operating Concept

[Weighing in percent]

display

[Calculation] display Indicates that the “Calculation” application is selected.

[Animal weighing]

display

[Net-total] display Indicates that the “Net-total” application is selected.

[Totalizing] display Indicates that the “Totalizing” application is selected.

[Density determination]

display

[Statistics] display Indicates that the “Statistics” application is selected.

[Peak hold] display Indicates that the “Peak hold” application is selected.

[Checkweighing] display Indicates that the “Checkweighing” application is selected.

[Busy] display Indicates that the device is processing a command.

Indicates that the “Weighing in percent” application is selected.

Indicates that the “Animal weighing” application is selected.

Indicates that the “Density determination” application is selected.

[Sign] display Indicates whether the value being displayed is positive or negative.

[Zero] display For some conformity-assessed devices: Indicates that the device has been zeroed.

[AUTO] display Indicates that the “Animal weighing” application starts automatically.

[Application help]

display

[R12] display Indicates the active range for multi-range balances.

[Printer] display − Indicates that a printer has been detected at the USB port.

[PC-Connect] display − Indicates that a PC or a second display has been detected at the USB port.

[Percent] display Indicates that a percentage value is being displayed.

[Net] display Indicates that a net value is being displayed.

− Indicates the number of components for “Totalizing”, “Net total”, and “Statistics”.

− Indicates the minimum limit “LL” and the maximum limit “HH” during

“Checkweighing”.

− Flashes if the data output is active.

− Flashes if the data connection is active.

Entris® BCE Operating Instructions 11

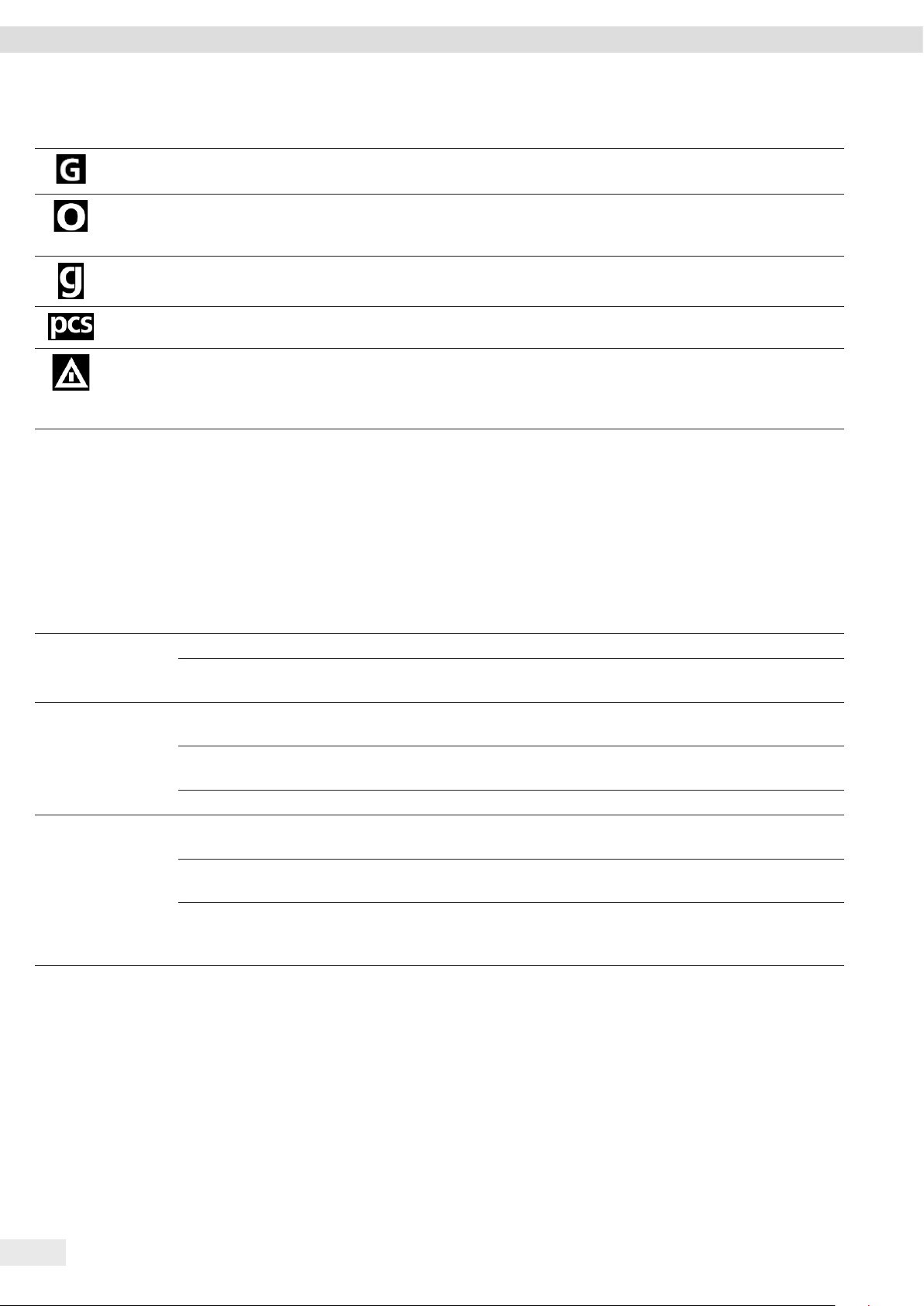

Page 12

Operating Concept

Symbol Designation Description

[Gross] display Indicates that a gross value is being displayed.

[Selection] display In the menu: Identifies the selected parameter.

If the “Calculation” or “Density determination” application is active: Indicates that a

calculated value is being displayed.

[Unit symbol] display Indicates the set weight unit, e.g. [g] for “grams”.

[Quantity] Indicates that a quantity is being displayed.

[Invalid weight value]

display

− Indicates that the display does not contain a weight value, but is instead the

calculated result of an application, e.g. for the “Totalizing” application.

− For conformity-assessed devices: Indicates a fault. The cause of this fault is displayed

after pressing the [Change] key.

4.4 Menu Structure

4.4.1 “Main Menu” Menu Structure

t Navigating in menus (see Chapter 4.5, page 14).

Level 1 Level 2 Description

SETUP BALANCE Set the functions of the device.

GEN.SERV.

“General services”

DEVICE RS-232

“RS232, 9-pin”

USB

“USB-C”

EXTRAS Define the functions of the operating display.

DATA.OUT.

“Data output”

COM. SBI

“SBI communication”

PRNT.PAR.

“Printout settings”

PC.DIREC.

“Direct transfer of data

(PC)”

Reset the menu to factory settings.

Define the parameters for the COM interface.

Define the parameters for the USB interface.

Configure the automatic data output.

Perform the settings for the printout.

Define the output format for the data exchange between the balance and

the PC.

12 Entris® BCE Operating Instructions

Page 13

Operating Concept

Level 1 Level 2 Description

APPLIC.

“Applications”

WEIGH − Determine the weight value of a sample.

− Activate the functions for all applications.

COUNT Determine the number of parts that have approximately equal weight.

PERCENT

“Weighing in percent”

NET.TOT.

Determine the percentage share of a

sample based on a reference weight.

Carry out the weighing of components for a mixture.

“Net-total”

TOTAL

Add weights of independent weighing processes in a memory.

“Totalizing”

ANIMALW.

“Animal weighing”

CALC.

“Calculation”

DENSITY

Weigh unstable samples, e.g. animals. This program calculates the average of

several measurement cycles.

Calculate the weight using a multiplier or divisor, e.g. for determining the

weight per unit area of paper.

Determine the density of solid samples based on the buoyancy method.

“Density determination”

STATIST.

Save and statistically analyze weights and calculated values.

“Statistics”

CHECK.WG.

Check whether a weight value falls within the specified tolerances.

“Checkweighing”

PEAK.HLD.

Determine the maximum weight value of a sample (peak value).

“Peak Hold”

INPUT DEV.ID. Save the entered ID number for the device.

LOT ID Activate or deactivate the printout of a line for the LOT ID in the GLP

printout. It is possible to enter a LOT ID number or the LOT ID can be

manually entered in the line.

SPL. ID − Activate or deactivate the printout of a line for the SPL. ID in the GLP

printout.

− The entered ID number can be counted up or down with each sample.

DATE Set the date.

TIME Set the time.

PW. USER. Set the user password.

PW. SERV. Activate the service mode.

CAL. WT.

“Calibration weight”

Define the user-defined weight value for the calibration and adjustment

weight.

INTERVAL The SBI output rate can be set from 0 - 9999 seconds.

INFO

“Device information”

VER. NO.

“Version number”

SER. NO.

Display the software version number.

Display the device’s serial number.

“Serial number”

MODEL Display the device’s model ID.

BAC VER. Display the version of the BAC processor.

LANGUAGE Set the menu language of the operating display.

Entris® BCE Operating Instructions 13

Page 14

Installation

4.4.2 “Toggle Between Weight Units” Menu Structure

t Navigating in menus (see Chapter 4.5, page 14).

Level 1 Description

Unit 1 - unit 4 Define the displayed weight unit and the

resolution for the 1st to 4th convertible

unit.

4.5 Navigating the Menus

Procedure

t To open the main menu: Press the [Menu]

button.

t To display menu items or parameters of a

level: Press the [Up] or [Down] button.

t To return to the next higher menu level or

exit the menu: Press the [Back] button.

t To open a displayed menu level or a

displayed parameter: Press the [Confirm]

button.

5 Installation

5.1 Scope of Delivery

Item Quantity

Device 1

Pan support 1

Frame draft shield 1

Power supply unit with country-specific

AC adapters

Operating Instructions 1

Shock absorber 4

5.2 Selecting an Installation Site

Procedure

t Make sure that the following conditions are met at the

installation site:

Condition Features

Ambient

conditions

Setup surface − Stable, even surface with little vibration

Access to parts

relevant to

operation

− Suitability tested (ambient conditions

see Chapter 15.1, page 35)

− Sufficient space for the device (device

space requirements see Chapter “15.9

Device Dimensions”, page 37).

− Sufficient load bearing capacity for the

device (device weight see Chapter

“15.10 Metrological Data”, page 38).

Convenient and safe

1

14 Entris® BCE Operating Instructions

Page 15

Installation

5.3 Unpacking

Procedure

t Unpack the device.

t If the device is stored temporarily: Observe the storage

information (see Chapter 13.1, page 33).

t Keep all parts of the original packaging, e.g. to return the

device.

5.4 Removing the Transport Lock

Procedure

1

t Remove the transport locks (1)

and retain them for later use.

5.6 Acclimatizing the Device

When a cold device is brought into a warm environment:

The temperature difference can lead to condensation from

humidity in the device (moisture formation). Moisture in the

device can lead to malfunctions.

Procedure

t Allow the device to acclimatize for approx. 2 hours at the

installation site. The device must be disconnected from the

power supply beforehand.

5.5 Assembling the Device

Procedure

t Place the frame draft

3

2

1

shield (1) on the balance.

t Attach the shock absorbers (2).

t Place the weighing pan (3)

on top.

Entris® BCE Operating Instructions 15

Page 16

Getting Started

6 Getting Started

6.1 Installing the Power Supply Unit

6.1.1 Assembling the Power Supply Unit

Item number

on packaging

YEPS01-PS8 USA and Japan (US+JP), Europe and Russia

YEPS01-PS9 Argentina (AR), Brazil (BR), Korea (KR)

YEPS01-PS10 China (CN)

Procedure

t Push the power plug adapter as far as you can until it

clicks into place.

t Check whether the power plug adapter is securely locked

in place by pulling it gently.

y If the power plug adapter does not move: It is locked in

place.

Power supply unit YEPS01-15VOW with

connection cable and country-specific

power plug adapters (packed in PE bag

with printed country identification,

e.g. EU)

(EU+RU), Great Britain (UK), India (IN),

South Africa (ZA), Australia (AU), China (CN)

t Select the country-specific

power plug adapter. The

power plug adapter must be

suitable for use with the wall

outlet at the installation site.

t Insert the power plug adapter

into the power supply unit.

The grooved button must be

facing upwards.

6.2 Connecting the Power Supply

Procedure

t

WARNING Severe injuries caused by using defective

power supply cables! Check the power supply cable for

damage, e.g. cracks in the insulation.

t If required: Contact Sartorius Service.

t Check whether the country-specific power plug matches

the power connections at the installation site.

t If required: Replace the country-specific power plug

adapter.

t NOTICE Damage to the device due to excessive input

voltage! Check whether the voltage specifications on the

manufacturer’s ID label match those of the power supply

at the installation site.

t If the input voltage is too high: Do not connect the

device to the power supply.

t Contact Sartorius Service.

t Connect the right angle plug to the “Power Supply”

connection.

t Connect the mains plug to the wall outlet (mains voltage)

at the installation site.

y The [BOOTING] display appears in the operating display.

y The device performs a self-test.

7 System Settings

7.1 Performing System Settings

Default settings can be adjusted for the device and the

applications in order to align with the ambient conditions

and individual operating requirements.

The following settings are necessary to operate the device

together with connected components:

− Set up the communication of the connected devices

− Set up additional components

6.1.2 Dismantling the Power Plug Adapter

Procedure

t Press the grooved button

from above and pull back on

the power plug adapter.

t Push the power plug adapter

out of the power supply unit

and remove it.

16 Entris® BCE Operating Instructions

The following settings are recommended to set up the device:

− Set the menu language

− Set the date and time

− Set the calibration and adjustment

Procedure

t Press the [Menu] button.

t To adjust settings: Open the desired menu.

t Select and confirm the desired parameter (parameters,

see Chapter “7.3 Parameter List”, page 18).

t Exit the menu.

Page 17

System Settings

7.2 Setting the Calibration and Adjustment

7.2.1 Switching the isoCAL Function On or Off

(Only Model i-1x)

When using the isoCAL function, the device performs an

automatic time- and temperature-dependent internal

calibration and adjustment.

If this relates to a conformity-assessed device in

legal metrology: In some cases it is not possible to

switch off the isoCAL function.

Procedure

t Open the “SETUP”/”BALANCE” menu.

t To set the automatic start of the isoCAL function: Select the

“ON” calibration value for the “ISOCAL” parameter.

t To set the manual start of the isoCAL function: Select the

“Note” calibration value for the “ISOCAL” parameter.

t To switch off the isoCAL function: Select the “OFF”

calibration value for the “ISOCAL” parameter.

7.2.2 Setting Internal Calibration and Adjustment

(Only Model i-1x)

The following functions can be set for the internal calibration

and adjustment:

− Internal calibration with automatic start of the adjustment.

− Internal calibration with manual start of the adjustment.

Procedure

t Open the “SETUP”/”BALANCE” menu. Call up the “CAL.JUST.”

parameter and select the value “CAL.INT.”.

t If the calibration function needs to be set with subsequent

automatic adjustment: In the “SETUP”/”BALANCE” menu, for

the “CAL.SEQ.” parameter, select the “ADJUST” setting value.

t If the calibration function needs to be set without

subsequent automatic adjustment: In the

“SETUP”/”BALANCE” menu, for the “CAL.SEQ.” parameter,

select the “CAL./ADJ.” setting value.

7.2.3 Setting the External Calibration and Adjustment

The following functions can be set for the external calibration

and adjustment:

− External calibration with manual start of the adjustment.

If this relates to a conformity-assessed device in

legal metrology: External calibration and adjustment is not possible.

Procedure

t Open the “SETUP”/”BALANCE” menu.

t If the calibration function needs to be set with subsequent

automatic adjustment: Select the “ADJUST” calibration

value for the “CAL.SEQ.” parameter.

t If the calibration function needs to be set without

subsequent automatic adjustment: Select the “CAL-ADJUST”

calibration value for the “CAL.SEQ.” parameter.

Setting the Weight Value for the External Weight

A preset weight value or a user-defined weight value can be set

for the external weight.

Procedure

t If the preset weight value needs to be used: In the

“SETUP”/”BALANCE” menu, for the “CAL./ADJ.” parameter,

select the “EXT.CAL.” setting value.

t If a user-defined weight value needs to be set:

t In the “INPUT” menu, select the “CAL.WT.” setting value.

t Enter the desired weight value and press the [Confirm]

button.

t To use the user-defined weight value for the next

calibration: In the “SETUP”/”BALANCE” menu, for the

“CAL./ADJ.” parameter, select the “E.CAL.USR” setting

value.

Entris® BCE Operating Instructions 17

Page 18

System Settings

7.3 Parameter List

7.3.1 “SETUP”/”BALANCE” Menu

Parameter Setting values Explanation

AMBIENT V.STABLE Sets the ambient conditions to “very stable”: Activates a fast change in the weight values in

the event of a load change with a high output rate.

Recommended for the following work environment:

− Very stable table near the wall

− Closed and calm room

STABLE* Sets the ambient conditions to “stable”. Recommended for the following work environment:

− Stable table

− Slight movement in the room

− Slight draft

UNSTABL. Sets the ambient conditions to “unstable”: Activates the delayed change in weight values with

a reduced output rate. Recommended for the following work environment:

− Simple office desk

− Room with moving machinery or personnel

− Slight air movement

V.UNSTBL. Sets the ambient conditions to “very unstable”: Activates a significantly delayed change in the

weight values and long wait for stability with a further reduction in the output rate.

Recommended for the following work environment:

− Noticeable and slow floor vibrations

− Noticeable building vibrations

− Weighed goods moved

− Very strong air movements

APP FILT. FINAL.RD.* Activates a filter that enables a fast change in the display for very fast load changes.

Display changes with minimal load changes (in the digit range) occur more slowly.

FILLING Activates a filter that enables a very fast change in the display with minimal load changes,

e.g. when filling containers.

STABIL. V. ACC. Sets the stability to “very accurate”.

ACC.* Sets the stability to “accurate”.

FAST Sets the stability to “fast”.

ZER./TAR. W/O STB. If the button is pressed: The function of the [Zero] or [Tare] button is executed immediately.

W/ STAB.* The function of the [Zero] or [Tare] button is only executed after stability is achieved.

AUTOZER. ON* Activates automatic zeroing. The display is automatically set to zero in case of a deviation of

0 less than (X).

OFF Deactivates automatic zeroing. Zeroing must be triggered with the [Zero] button.

* Factory setting

18 Entris® BCE Operating Instructions

Page 19

System Settings

Parameter Setting values Explanation

UNIT GRAM*,

KILOGR., CARAT,

− The device displays the weight in the selected unit.

− The availability of units depends on national legislation and is therefore country-specific.

POUND,OUNCE,

TROY.OZ.,

HKTAEL,

SNGTAEL,

TWNTAEL,

GRAINS,

PENNYWT.,

MILLIGR., PART./

LB, TL./CHINA,

MOMMES,

AUSTR.CT, TOLA,

BAHT,

MESGHAL,

NEWTON

DISP.DIG. ALL* “Show all decimal places”: All decimal places are shown in the display. The setting change is

not available on conformity-assessed devices.

LP.ON.OFF “Reduced by 1 decimal place for load change”: The last decimal place on the display is switched

off until stability is achieved.

MINUS 1 “Last decimal place off”: The last decimal place is switched off.

CAL./ADJ. EXT.CAL. The [Adjust] button starts an external calibration and adjustment process with the preset

calibration weight.

E.CAL.USR. The [Adjust] button starts an external calibration and adjustment process with the user-

defined calibration weight value.

INT.CAL.* The [Adjust] button starts an internal calibration and adjustment process.

CAL.SEQ. ADJUST* The adjustment starts automatically after the calibration.

CAL.-ADJ. The adjustment must be started or exited manually after calibration with the [Confirm] button.

ON Z/T ON* Activates the initial taring/zeroing. The device is tared or zeroed after it is switched on.

OFF Deactivates the initial taring/zeroing: After it is switched on, the device shows the same value

as before it was last switched off.

ISOCAL OFF Switches the isoCAL function off.

NOTE If the balance needs to be calibrated: The [isoCAL] button flashes. The isoCAL function must be

manually triggered with the [Adjust] button.

ON* Activates the isoCAL function. The device is automatically adjusted as soon as a trigger starts

the isoCAL function.

EXT.CAL. UNLOCKED* Activates the external calibration/adjustment function under [CAL./ADJ.].

LOCKED Deactivates the external calibration/adjustment function under [CAL./ADJ.].

* Factory setting

7.3.2 “SETUP”/”GEN.SERV.” Menu

Parameter Setting values Explanation

MENU.RES. YES Resets the system settings to the factory default settings.

NO* Deactivates the option of resetting the device menu.

* Factory setting

Entris® BCE Operating Instructions 19

Page 20

System Settings

7.3.3 “DEVICE”/”RS232” Menu

Parameter Setting values Explanations

DAT.REC. XBPI Extended range of commands to control numerous balance functions with binary protocol for

direct communication with the device.

SBI* Enables SBI communication. The data is output to a PC or control unit. Enables the use of ESC

commands from a PC to control the basic balance functions with ASCII protocol.

REM.DISP. Enables data output on another display.

BARCODE Allows for the connection of an approved barcode scanner.

YDP20 Sets the standard settings of YDP20 printers.

YDP30 Sets the standard settings of YDP30 printers.

OFF Deactivates the automatic data output.

BAUD 600, 1200,

Sets the baud rate to the selected value.

2400, 4800,

9600*, 19200,

38400, 57600,

115200

PARITY ODD* Applies an odd parity.

EVEN Applies an even parity.

NONE Does not apply a parity.

STOPBIT 1 BIT* Sets the number of stop bits to 1.

2 BITS Sets the number of stop bits to 2.

HANDSHK. SFTWARE Sets the handshake protocol to software handshake.

HRDWARE* Sets the handshake protocol to hardware handshake.

NONE Does not set a handshake protocol.

DATABIT 7 BITS Sets the number of data bits to 7.

8 BITS* Sets the number of data bits to 8.

* Factory setting

7.3.4 “DEVICE”/”USB” Menu

Parameter Setting values Explanations

DAT.REC.** XBPI Extended range of commands to control numerous balance functions with binary protocol for

direct communication with the device.

SBI* Enables SBI communication. The data is output to a PC or control unit. Enables the use of

ESC commands from a PC to control the basic balance functions with ASCII protocol.

REM.DISP. Enables data output on another display.

PC.SPREA. Enables data output to a spreadsheet program via a direct PC connection.

YDP20 Sets the standard settings of YDP20 printers.

YDP30 Sets the standard settings of YDP30 printers.

PC.TEXT The balance transmits the data via keyboard command to the currently opened application on

the PC in text format.

OFF Deactivates the data output.

* Factory setting

** Are blocked if “PRINTER” or “REM.DISP.” are displayed under “DEV.USED”

20 Entris® BCE Operating Instructions

Page 21

System Settings

Parameter Setting values Explanations

BAUD** 600, 1200,

Sets the baud rate to the selected value.

2400, 4800,

9600*, 19200,

38400, 57600,

115200

PARITY** ODD* Applies an odd parity.

EVEN Applies an even parity.

NONE Does not apply a parity.

STOPBIT** 1 BIT* Sets the number of stop bits to 1.

2 BITS Sets the number of stop bits to 2.

HANDSHK.** SFTWARE Sets the handshake protocol to software handshake.

HARDW. Sets the handshake protocol to hardware handshake.

NONE* Does not set a handshake protocol.

DATABIT** 7 BITS Sets the number of data bits to 7.

8 BITS* Sets the number of data bits to 8.

DEV.USED NONE*,

Indicates which connection is detected at the USB port.

PRINTER, VIRT.

COM, PC HOST,

REM.DISP.

* Factory setting

** Are blocked if “PRINTER” or “REM.DISP.” are displayed under “DEV.USED”

7.3.5 “DEVICE”/”EXTRAS” Menu

Parameter Setting values Explanation

MENU EDITABL.* Activates write access. The menu parameters can be changed.

RD.ONLY Activates read access. The menu parameters cannot be changed.

SIGNAL OFF Switches the acoustic signal off.

ON* Switches the acoustic signal on.

KEYS UNLOCKED* Deactivates the button lock.

LOCKED Activates the button lock.

EXT.KEYB.

PRINT Assigns the print function to the external key.

CAL. Assigns the calibration and adjustment function selected under [CAL./ADJ.] to the external

key.

CF Assigns the [Back] function to the external key.

ENTER Assigns the [Confirm] function to the external key.

ZERO Assigns the [Zero] function to the external key.

TARE Assigns the [Tare] function to the external key.

APP Assigns the [From] function to the external key. The function is triggered for an application

that is not active.

GLP END Assigns the [GLP] function to the external key.

NONE* No function is assigned to the external key.

ON MODE

ON/STDB.* The [On/Off] button switches between on/standby with time.

ON/OFF The [On/Off] button switches between on/standby without time..

AUTO ON Changes the function of the [On/Off] button: The device no longer switches off or to standby

mode, instead it starts a boot process.

* Factory setting

Entris® BCE Operating Instructions 21

Page 22

System Settings

Parameter Setting values Explanation

LIGHT

OFF Deactivates the lighting on the operating display.

ON* Activates the lighting on the operating display.

* Factory setting

7.3.6 “DATA.OUT.”/”COM. SBI” Menu

Parameter Setting values Explanations

COM. OUTP. IND.NO* Activates the manual data output without stability.

IND.AFTR Activates the manual data output after stability.

AUTO.W/O Activates the automatic data output without stability.

AUTO W/ Activates the automatic data output after stability.

STOP.AUT. OFF* Deactivates the option to abort the automatic data output.

ON The automatic data output is aborted by pressing the [Print] button or a software command.

AUTO.CYCL. EACH VAL* Starts the automatic data output with a cycle after each value.

AFTER 2 Starts the automatic data output with a cycle after every 2nd value.

INTERV. The output rate can be set from 0 - 9999 seconds under “INPUT/INTERV.”.

FORMAT 22 CHARS* The data output provides 22 characters per line (16 characters for the measured value and

6 characters for identifiers).

16 CHARS The data output provides 16 characters per line for the measured value.

EXTR.LIN. The data output provides an additional line with the date, time, and weight value.

AUTO.TAR. OFF* Deactivates automatic taring after data output.

ON The device automatically tares after data output.

* Factory setting

7.3.7 “DATA.OUT.”/”PRNT.PAR.” Menu

Parameter Setting values Explanation

ACTIVAT. MAN. NO Manual without stability: The print process can be started manually at any time.

MAN.AFTR* Manual after stability: After pressing the [Print] button, the print command is only executed

once stability is achieved.

INTERV. The output rate can be set from 0 - 9999 seconds under “INPUT/INTERV.”.

AUTO.LC Automatically at load change: The print process starts after every load change.

FORMAT 22 CHARS* The printer output prints 22 characters per line (16 characters for the measured values and

6 characters for identifiers)

EXTR.LIN. The printer output prints an additional line with the date, time, and weight value.

PRT.INIT. OFF Deactivates the output of the application parameters.

ALL* The print command prints all parameters.

MAIN.PAR. The print command only prints the main parameters.

GLP OFF* Deactivates the GLP printout.

CAL./ADJ. Activates the GLP printout for all calibration and adjustment processes.

ALWAYS The GLP printout is always switched on. All printouts contain a GLP header and a GLP footer.

TAR./PRT. OFF* Deactivates automatic taring after printer output.

ON Automatically tares the device after every printout.

* Factory setting

22 Entris® BCE Operating Instructions

Page 23

System Settings

Parameter Setting values Explanation

TIME 24H* Sets the time to 24-hour mode.

12H − Sets the time to 12-hour mode (AM/PM).

− Is blocked for ISO format.

DATE DD.MMM.YY* Sets the date display format to DD.MMM.YY

MMM.DD.YY Sets the date display format to MMM.DD.YY

YY.MM.DD − Sets the date display format to ISO FORMAT YYYY-MM-DD.

− Sets the time to 24-hour mode.

* Factory setting

7.3.8 “DATA.OUT.”/”PC.DIREC.” Menu

Parameter Setting values Explanations

DEC.SEP. POINT* Sets a point as a decimal separator.

COMMA Sets a comma as a decimal separator.

OUT.FORM. TXT+NUM.* Exports text and numbers.

ONLY.NUM. Only exports numbers.

* Factory setting

7.3.9 “APPLIC.”/”WEIGH” Menu

Parameter Setting values Explanation

UNIT ON* Activates the “Toggle between weight units” touch function.

OFF Deactivates the “Toggle between weight units” touch function.

RECALL ON Activates the saving of the last stable weight value not equal to 0.

OFF* Deactivates saving.

APP FILT. ON* Activates the “Application filter” touch function.

OFF Deactivates the “Application filter” touch function.

AMBIENT ON* Activates the “Ambient conditions” touch function.

OFF Deactivates the “Ambient conditions” touch function.

* Factory setting

7.3.10 “APPLIC.”/”COUNT” Menu

Parameter Setting values Explanation

RESOLUT. DISP.ACC.* Sets the resolution to “display resolution”. The “Counting” application is started with the

displayed value.

10-FOLD Sets the resolution to 10-times more accurate than “display resolution”.

100-FOLD Sets the resolution to 100-times more accurate than “display resolution”.

REF.UPDT. OFF* Deactivates automatic reference sample updating.

AUTO Activates the automatic reference sample updating.

* Factory setting

Entris® BCE Operating Instructions 23

Page 24

System Settings

7.3.11 “APPLIC.”/”PERCENT” Menu

Parameter Setting values Explanation

DEC.PLCS NONE The result of the “Weighing in Percent” application is displayed without decimal places.

1 DEC.PL.* The result of the “Weighing in Percent” application is displayed to 1 decimal place.

2 DEC.PL. The result of the “Weighing in Percent” application is displayed to 2 decimal places.

3 DEC.PL. The result of the “Weighing in Percent” application is displayed to 3 decimal places.

* Factory setting

7.3.12 “APPLIC.”/”NET.TOT.” Menu

Parameter Setting values Explanation

PRT.COMP. OFF Deactivates the component printout.

ON* Activates the component printout.

* Factory setting

7.3.13 “APPLIC.”/”TOTAL” Menu

Parameter Setting values Explanation

PRT.COMP. OFF Deactivates the component printout.

ON* Activates the component printout.

* Factory setting

7.3.14 “APPLIC.”/”ANIM.WG” Menu

Parameter Setting values Explanation

ACTIVIT. CALM Sets the intensity of the “Animal activity” to “calm”. Recommended for minor movements of

the sample, e.g. caused by placement on the weighing pan.

MEDIUM* Sets the intensity of the “Animal activity” to “medium”. Recommended for medium movements

of the sample, e.g. caused by placement on the weighing pan.

V.ACTIVE Sets the intensity of the “Animal activity” to “very active”. Recommended for very active

movements of the sample, e.g. caused by placement on the weighing pan.

START MANUAL The “Animal weighing” application must be manually selected in the start screen.

AUTO* Sets the trigger to start the “Animal weighing” application to “automatic”.

* Factory setting

7.3.15 “APPLIC.”/”CALC.” Menu

Parameter Setting values Explanation

METHOD MUL.* Specifies multiplication as the method of calculation for the “Calculation” application.

DIV. Specifies division as the method of calculation for the “Calculation” application.

* Factory setting

24 Entris® BCE Operating Instructions

Page 25

System Settings

Parameter Setting values Explanation

DEC.PLCS NONE The result of the “Calculation” application is displayed without decimal places.

1 DEC.PL.* The result of the “Calculation” application is displayed to 1 decimal place.

2 DEC.PL. The result of the “Calculation” application is displayed to 2 decimal places.

3 DEC.PL. The result of the “Calculation” application is displayed to 3 decimal places.

* Factory setting

7.3.16 “APPLIC.”/”DENSITY” Menu

Parameter Setting values Explanation

DEC.PLCS NONE The result of the “Density determination” application is displayed without decimal places.

1 DEC.PL.* The result of the “Density determination” application is displayed to 1 decimal place.

2 DEC.PL. The result of the “Density determination” application is displayed to 2 decimal places.

3 DEC.PL. The result of the “Density determination” application is displayed to 3 decimal places.

* Factory setting

7.3.17 “APPLIC.”/”STATIST.” Menu

Parameter Setting values Explanation

PRT.COMP. OFF Deactivates the component printout.

ON* Activates the component printout.

TAR.STAT. OFF* Deactivates automatic taring after the components are saved.

ON Activates automatic taring after the components are saved.

* Factory setting

7.3.18 “APPLIC.”/”PEAK.HLD.” Menu

Parameter Setting values Explanation

APPLY AT STAB.* Peak values are applied when there is stability.

W/O STB. Peak values are applied without stability.

* Factory setting

7.3.19 “APPLIC.”/”CHECK.WG.” Menu

Parameter Setting values Explanation

INPUT MANUAL* The min/max limits are entered manually.

WG.VALUE The entry of the min/max limits is carried out by applying the weight value.

AUTO.PRT. OFF* The automatic printing is switched off.

ON With automatic printing, all values are exported.

OK ONLY With automatic printing, only values that are within the control range are exported.

NOT OK With automatic printing, only values that are outside the control range are exported.

* Factory setting

Entris® BCE Operating Instructions 25

Page 26

System Settings

7.3.20 “INPUT” Menu

Parameter Setting values Setting values Explanation

DEV. ID Max 14

Saves the entered ID number for the device.

characters 09-0,

A-Z, - , empty

LOT ID PRINT ON Activates the output of the lot ID number during GLP output.

OFF* Deactivates the output of the lot ID number during GLP output.

CONTENT** Max 14

Content of the LOT ID.

characters 09-0,

empty

SPL. ID PRINT ON Activates the output of the SPL. ID number during GLP output.

OFF* Deactivates the output of the SPL. ID number during GLP output.

START**** Max 14

Start value of the SPL. ID.

characters 09-0,

A-Z, - , empty

MODE** COUNT.UP* The SPL. ID number is counted up on each printout.

COUNT.DN The SPL. ID number is counted down on each printout.

SCAN*** The SPL. ID number is read in by the barcode scanner. Printing then occurs

automatically.

DATE Saves the entered date.

TIME Saves the entered time.

PW. USER Max 7

Saves the entered user password.

characters 09-0,

A-Z, - , empty

PW. DEL.**** YES Deletes the entered password.

NO* Does not delete the entered password.

PW. SERV. Max 7

Activates service mode.

characters 09-0,

A-Z, - , empty

CAL.WT. Changes the calibration weight for the adjustment or calibration process with

the user-defined weight value.

INTERV. The SBI output rate can be set from 0 - 9999 seconds.

* Factory setting

** Only visible if “PRINT”/”ON” is selected

*** Only possible if “BARCODE” is selected (see Chapter “7.3.3 “DEVICE”/”RS232” Menu”, page 20)

**** Only visible if “SPL. ID”/”MODE”/”SCAN” is not selected. Only visible if the user password is available.

7.3.21 “INFO” Menu

Parameter Setting values Explanation

VER. NO. Displays the version number of the control module.

SER. NO. Displays the serial number of the device.

Model Displays the type designation of the device.

BAC VER. Displays the version number of the weight sensor.

* Factory setting

26 Entris® BCE Operating Instructions

Page 27

Operation

7.3.22 “LANGUAG.” Menu

Parameter Setting values Explanation

Language ENGLISH,

DEUTSCH,

FRANC.

ITAL., ESPANOL,

PORTUG.,

РYССKИИ,

POLSKI

* Factory setting

Defines the menu language.

8 Operation

8.1 Switching the Device On and Off

Requirements

The device is connected to the power supply.

Procedure

t

CAUTION Pointed or sharp-edged objects may damage

the operating display!

t Only touch the operating display with your fingertips.

t To switch the device on: Press the [On/Off] button.

t To switch the device off: Press and hold the [On/Off]

button.

8.3 Leveling the Device with a Level Indicator

Unevenness at the installation site of the device may result in

incorrect weighing results. Leveling balances out unevenness at

the installation site.

Procedure

t Unscrew the rear leveling

feet, until they touch the

setup surface.

y The support foot (1) is not in

contact with the setup

surface.

t To level the device: Bring the

air bubble of the level

1

t Check that the device is standing on 4 leveling feet and

the support foot (1) is not in contact with the setup

surface.

indicator into the middle of

the circular marking. To do so,

turn the leveling feet to the

left or right.

8.4 Overview of Calibration and Adjustment

During calibration, a calibration weight is used to determine

the deviation of the displayed value from the actual value.

The subsequent adjustment eliminates this deviation.

We recommend regular calibration and adjustment:

8.2 Waiting for the Warm-up Time

In order to provide accurate weighing results, the device

must have reached the necessary operating temperature.

The operating temperature is reached after the warm-up time.

The warm-up time starts when the device is switched on.

Procedure

t Switch on the device.

t Wait until the operating temperature is reached (warm-up

time see Chapter “15.7 Warm-up Time”, page 37).

If a weighing process is carried out on a conformityassessed device during the warm-up time:

The weight value is marked as invalid.

− Daily, every time the device is switched on

− After every leveling

− After changing the ambient conditions (temperature,

humidity, or air pressure)

− After setting the device up at a new installation site

8.5 Calibrating and Adjusting Device with

isoCAL Function (Only Model i-1x)

Triggers for the automatic start of the isoCAL function are:

− The ambient temperature has changed since the last

adjustment process.

− The interval time was exceeded (interval time, see Chapter

“15.7 Warm-up Time”, page 37).

If this relates to a conformity-assessed model:

The device has been disconnected from the power

supply since the last adjustment.

Entris® BCE Operating Instructions 27

Page 28

Operation

Requirements

− The automatic or manual start of the isoCal function is set

in the menu (see Chapter “7.2.1 Switching the isoCAL

Function On or Off (Only Model i-1x)”, page 17).

− The device is not located in the menu settings.

− The load on the weighing pan remains unchanged for

2 minutes.

− The load on the scales amounts to no more than 2% of the

maximum load.

− The device does not register an input for 2 minutes.

Procedure

t If the automatic start of the isoCAL function is triggered:

y The [isoCAL] button flashes in the operating display.

y The operating display shows “CAL.” for 19 seconds.

y If no load change or no operation takes place on the

device before the expiration of the time display:

The isoCAL function starts.

t If the manual start of the isoCAL function is triggered:

y The [isoCAL] button flashes in the operating display.

t Press the [isoCAL] button.

y The isoCAL function starts.

8.6 Calibrating and Adjusting the Device

Internally (Only Model i-1x)

Requirements

− The weighing pan is unloaded.

− The operating display shows a stable weight value.

− The internal calibration and adjustment function is set

(see Chapter “7.2.2 Setting Internal Calibration and

Adjustment (Only Model i-1x)”, page 17).

Procedure

t Press the [Zero] button.

t Press the [Adjust] button.

y The weight value is displayed.

t If the calibration function with subsequent automatic

adjustment is selected:

y The “CAL.RUN.” display appears in the operating display

during the process.

y The “CAL.END” display indicates the end of calibration.

t If the calibration function without subsequent automatic

adjustment is selected:

t Press the [Confirm] button.

y The calibration process starts.

y The “CAL.RUN.” display appears in the operating display

during the process.

y The calibration error is displayed.

t Press the [Confirm] button.

y The adjustment is performed.

y The “CAL.END” display indicates the end of calibration.

8.7 Externally Calibrating and Adjusting the

Device

Material Calibration and adjustment weight

Requirements

− The weighing pan is unloaded.

− The operating display shows a stable weight value.

− The external calibration and adjustment function is set

(see Chapter 7.2.3, page 17).

− The preset weight value for the adjustment weight or the

user-defined weight value for the adjustment weight is

selected (see Chapter 7.2.3, page 17).

Procedure

t Press the [Zero] button.

t Press the [Adjust] button.

t Place the indicated calibration and adjustment weight on

the balance.

y The weight value is displayed.

t If the calibration with subsequent automatic adjustment

function is selected and the calibration weight placed on

the device is within the specified limits:

y The adjustment process starts.

y If the “+” prefix was displayed: The applied weight is

too big.

y If the “-” prefix was displayed: The applied weight is

too small.

y The “CAL.END” message indicates the end of calibration.

t Remove the calibration weight.

t If the calibration without subsequent automatic adjustment

function is selected and the calibration weight placed on

the device is within the specified limits:

t Press the [Confirm] button.

y The adjustment process starts.

y If the “+” prefix was displayed: The applied weight is

too big.

y If the “-” prefix was displayed: The applied weight is

too small.

y The “CAL.END” message indicates the end of calibration.

t Remove the calibration weight.

8.8 Printing Results of the Calibration and

Adjustment Process

The results of the calibration and adjustment process can be

printed in a GLP printout.

Procedure

t Set the GLP printout in the menu (setting parameters,

see Chapter 7.3.7, page 22).

t Calibrate the device.

y Once the calibration is complete: The printing process starts.

28 Entris® BCE Operating Instructions

Page 29

Operation

8.9 Weighing

Requirements

− The device has been leveled.

− The device is calibrated and adjusted.

NOTICE

Chemicals may damage the device or accessories!

Chemicals can attack the device or the connected accessories

internally and externally. This may damage the device and

accessories.

t Use appropriate containers when weighing chemicals.

Procedure

t Zero the device. In order to do so, press the [Zero] button.

t If a container is being used for the sample:

t Tare the device. In order to do so, press the [Tare]

button.

t Place the sample in the container.

t If no container is used for the sample: Place the sample on

the weighing pan.

y The weight value is displayed depending on the selected

application program.

8.10 Setting or Changing an Application

Procedure

t In the “APPLIC.” menu, select an application, e.g. “STATIST.”

t Press the [Confirm] button.

t Exit the menu.

Procedure

t To switch the displayed weight unit during weighing or

before an application: Press the [Toggle between weight

units] button until the desired unit is displayed.

y The current weight value is displayed in the selected unit.

8.11.2 Selecting Convertible Units and their Decimal

Places

Procedure

t Press and hold down the [Toggle between weight units]

button.

t Select one of the parameters “Unit 1“ – “Unit 4” in the

submenu. To do so, press the [Confirm] button.

t Select the desired unit. To do so, press the [Confirm] button.

t Specify the decimal places for the selected unit. To do so,

press the [Confirm] button once again.

t Select the desired number of display digits. To do so, press

the [Confirm] button.

8.11.3 Running the “Statistics” Application

The “Statistics” application saves up to 99 weight values and

evaluates these statistically.

The following values are saved and exported:

− Number of components

− Mean value

− Standard deviation

− Variation coefficient

Sum of all values

− Lowest value (minimum)

− Highest value (maximum)

− Spread: Difference between maximum and minimum

8.11 Running Applications (Examples)

8.11.1 Executing the “Toggle Between Weight Units”

Function

The “Toggle between weight units” function enables a switch

between a maximum of four different units. The selected basic

unit is displayed every time the device is started (see “UNIT”,

Chapter “7.3.1 “SETUP”/”BALANCE” Menu”, page 18). The

units can be set during the weighing process and the decimal

places can be adjusted.

Requirements

The “Toggle between weight units” function is activated (see

Chapter “7.3.9 “APPLIC.”/”WEIGH” Menu”, page 23).

The weight value must be valid.

Requirements

− A printer or a PC is connected and configured.

− The “STATIST.” application is selected.

Procedure

t Place a sample on the weighing pan.

t To save the weight value: Press the [Confirm] button.

y The position of the saved value is displayed, e.g. “NO 1”.

y The recording of the statistics starts.

t Remove the sample on the weighing pan.

t To save the next value:

t Place a new sample on the weighing pan and press the

[Confirm] button.

t To switch between the display of the current weight value,

the number of saved components, and the calculated mean

in the results display: Press the [Up] or [Down] button.

t To delete all saved values: Press the [Back] button.

y The evaluation is printed and the active GLP print is ended.

t To print and exit the current statistics, and to delete the

saved values: Press the [GLP] button.

Entris® BCE Operating Instructions 29

Page 30

Cleaning and Maintenance

8.12 Printing Weighing Result with ID Marking

The device, the sample and a batch can be assigned an ID

number. The ID numbers are exported during GLP-compliant

printing.

Requirements

− The identity number is specified (see Chapter “7.3.20

“INPUT” Menu”, page 26).

− The printing of the lot ID line in the GLP printout is

activated in the menu (see Chapter “7.3.20 “INPUT” Menu”,

page 26).

− The “SPL. ID” output is activated in the menu.

− The GLP-compliant printout is activated (see Chapter “7.3.7

“DATA.OUT.”/”PRNT.PAR.” Menu”, page 22).

Procedure

t Start the printout. To do so, press the [Print] button.

y The GLP header is printed with the ID marking of the

LOT ID set in the menu and the current weight value.

y The [GLP] button appears in the operating display.

t Confirm the [PRINT] button.

y The SPL. ID and the current weight value are exported.

t Confirm the [PRINT] button.

y The SPL. ID and the current weight value are exported.

t To exit the GLP printout: Press the [GLP] button.

y The GLP footer is printed.

9.2 Cleaning the Device

NOTICE

Corrosion or damage to the device due to unsuitable

cleaning agents!

t Do not use corrosive, chloride-containing, or aggressive

cleaning agents.

t Do not use cleaning agents that contain abrasive

ingredients, e.g. scouring agents, steel wool.

t Do not use solvent-based cleaning agents.

t Only use suitable cleaning agents (materials see Chapter

“15.6 Materials”, page 36) and observe the product

information for the cleaning agent used.

Procedure

t NOTICE Malfunction or damage to the device due to the

ingress of moisture or dust!

t Only slightly moisten cleaning materials, such as cloths.

t Remove dust and powdery sample residue with a brush

or hand-held vacuum cleaner.

t Wipe the device and the associated components with a

slightly damp cloth. Use a mild soapy solution or a suitable

cleaning agent for more severe contaminations.

9.3 Assembling the Weighing Pan and

Associated Components

9 Cleaning and

Maintenance

9.1 Removing the Weighing Pan and

Associated Components

Requirements

− The device is switched off.

− The device is disconnected from the power supply.

Procedure

t Remove the weighing pan,

the shock absorbers and

the frame draft shield.

Procedure

t Assemble the weighing pan and the associated components

(see Chapter “5.5 Assembling the Device”, page 15).

t Connect the device to the power supply (see Chapter “6.2

Connecting the Power Supply”, page 16).

9.4 Maintenance Schedule

Interval Component Action

Regularly; depending on

the operating conditions

Device Contact Sartorius

Service.

9.5 Software Update

For a software update, contact Sartorius Service.

30 Entris® BCE Operating Instructions

Page 31

Malfunctions

10 Malfunctions

10.1 Warning Messages

Warning message Fault Cause Remedy Chapter, page

APP.ERR. The device has measured

an invalid weight value.

DIS.ERR. The value to be output

cannot be shown in the

operating display.

HIGH or ERR 55 The device is overloaded. The device’s maximum

LOW or ERR 54 The modulation of the

weighing converter

inside the device is too

low.

COMM.ERR. The device is not

receiving any weight

values.

PRT.ERR. The [Print] key is locked. The data interface for print

SYS.ERR. The system data is

faulty.

ERR 02 The device cannot be

calibrated when starting

the calibration function

due to a zero point

error.

ERR 10 Taring is not possible. The device cannot be

ERR 11 The weight value

cannot be saved in

the tare memory.

The applied weight is too low. Increase the applied weight to

The weight value is negative.

No sample has been placed

on the balance.

The data to be displayed is

not compatible with the set

display format.

weighing capacity has been

exceeded.

No weighing pan has been

placed on the balance.

A previously forgotten weight

was removed after starting

the device.

An error exists in the

weighing system or in

the device electronics.

No communication exists

between the control module

and the weigh cell.

output is set to xBPI mode.

A memory error exists in

the control module.

The device was not zeroed

before calibration.

The device is loaded. Remove the sample from the

manually tared because an

application program has the

tare memory reserved.

The weight value is negative

or “zero”.

more than the minimum load.

Place the sample on the balance.

Adjust the display settings in

the menu, e.g. resolution, unit,

decimal places.

Reduce the applied weight to

below the device’s maximum

weighing capacity.