Sargent and Greenleaf 8550,8560 Installation And Combinatiion Changing Instructions

S

G

Installation and Combinatiion Changing Instructions

These instructions should be followed when installing Sargent

Caution: Lock mounting bedplate and dial ring mounting surfaces

must be parallel. Dial ring center line must be precisely aligned

8500 Series MP Safe Locks

Models 8550 (Group 1) and 8560 (Group 1R)

NOTE: READ COMPLETE INSTRUCTIONS BEFORE INSTALLATION

& Greenleaf 8500 Series locks.

with lock spindle center line (see Figure 3).

Locate exact position you want for the lock on the mounting

plate. Using the template on the last page of these

instructions, drill and tap four holes for the attaching

screws (1⁄4 X 20).

Using the template, drill a hole for the spindle through

the mounting plate. For applications requiring an optional

tube, the hole should be 13⁄16’’ diameter. For locks to be used

without tubes, the hole should be 1⁄2’’ diameter.

place as received from the factory.

INSTALLATION INSTRUCTIONS

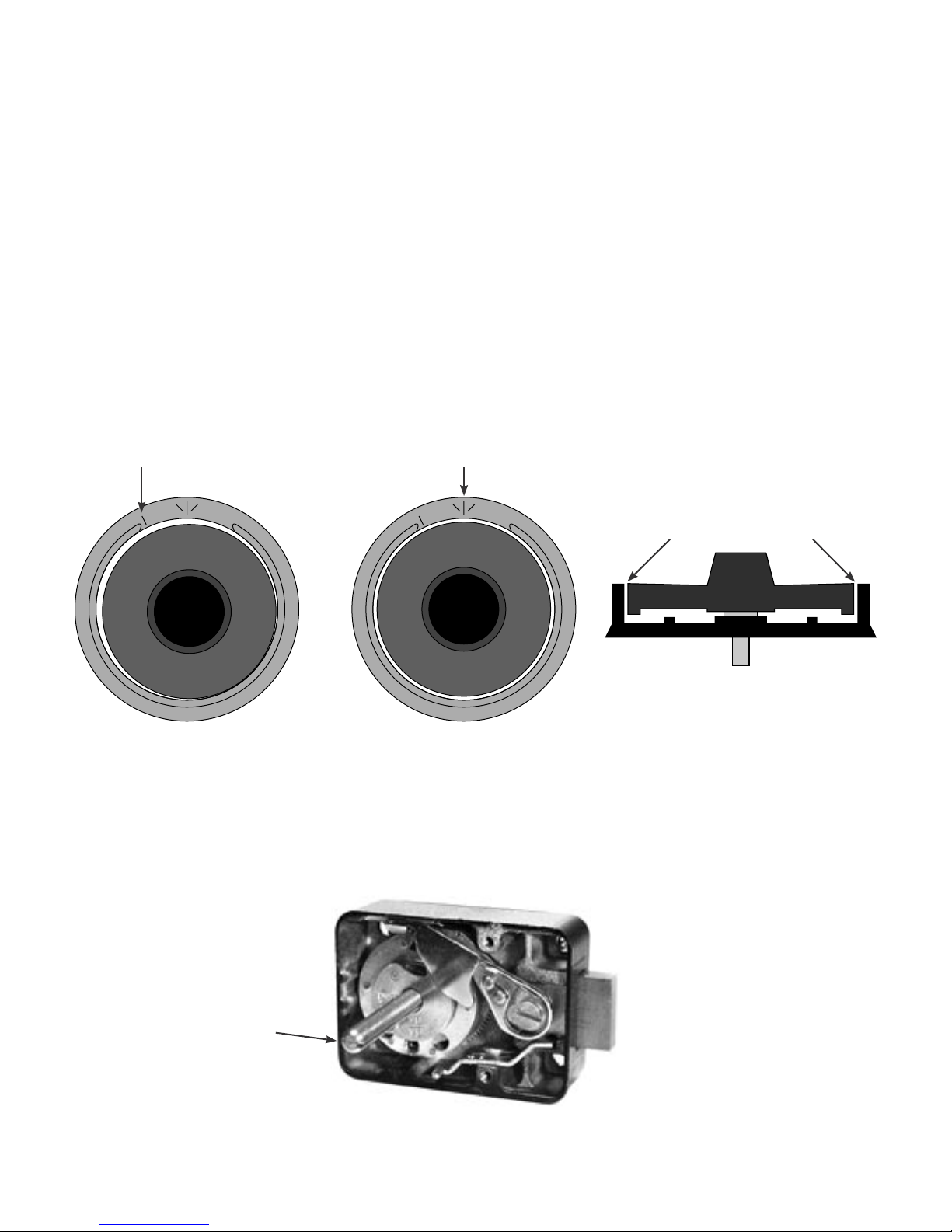

1. Remove the lock cover. Place the lock bolt in the extended position and the accelerator spring in the

loaded position (Figure 1). CAUTION: Do not remove the drive cam.

Accelerator Spring in Released Position Accelerator Spring in Loaded Position

Figure 1

MP Lock

Illustrations

Torque Adjusting Gear

Sargent & Greenleaf, Inc.

PO Box 930, Nicholasville, Kentucky 40356 USA

Phone (859) 885-9411

Phone (800) 826-7652

FAX (859) 887-2057

FAX (800) 634-4843

Copyright© 2002, Sargent & Greenleaf, Inc.

page 1

Sargent & Greenleaf S.A.

9, chemin du Croset

1024 Ecublens, Switzerland

Phone 41-21-691-9583

FAX 41-21-691-5349

Document 630-674

Revision 1.1 (7/7/03)

2. Mount the lock in place with four

1

X 20 attaching screws (provided).

⁄

4

3. Attach the dial ring by loosely installing the attaching screws to hold the dial ring in place for alignment.

The dial ring opening index should be at the 12 o’clock center position.

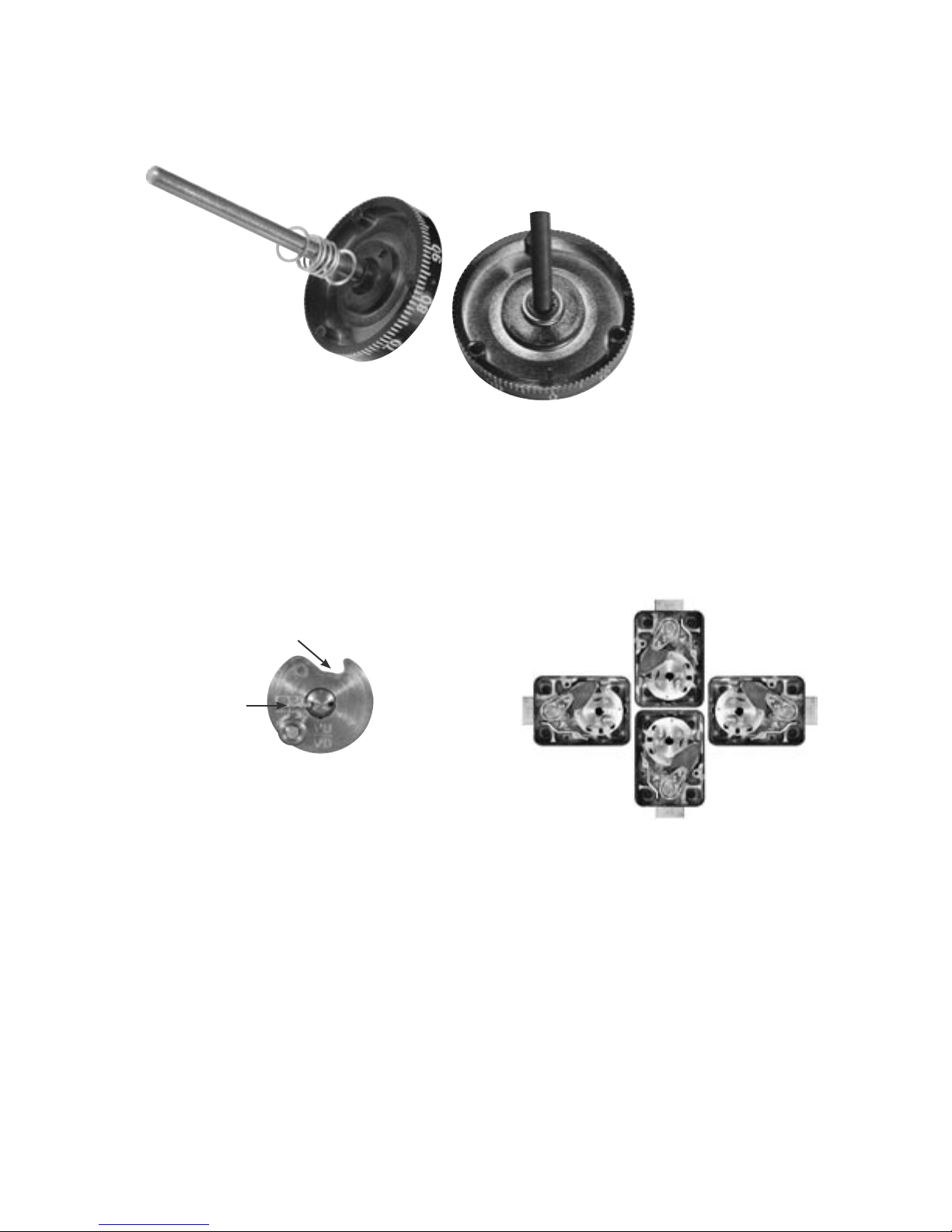

4. To install the dial, hold the drive cam in place with one hand and thread the dial/spindle assembly into

the cam until the dial comes to a stop against the surface of the dial ring.

Caution: When threading the dial into the cam, do not allow the cam to slide outward against the accelerator

spring. The accelerator spring can be easily damaged in this manner.

5. The alignment of the dial and ring is critical to the proper operation of the lock. Perfect alignment must

be obtained. The dial should be ush and centered with the surface of the dial ring for true centering

(Figure 2).

Figure 2

Changing Index Opening Index

Dial Edges

Flush with Ring

Misaligned Aligned

6. Measure the excess spindle that projects beyond the drive cam (Figure 3)

7. Remove the dial, cut off the excess spindle, and remove any burrs from the end. You may also nd that

the spindle threads more easily into the drive cam after cutting if the spindle end is beveled slightly.

Figure 3

Excess Spindle

page 2

8. Tighten the dial ring screws.

9. Place a at washer, the compression spring, and another at washer over the spindle and into the recess

at the dial hub (Figure 4).

Figure 4

10. Insert the dial into the lock, but remember that you should not allow the cam to slide outward against

the accelerator spring, possibly damaging it. Hold the drive cam in place, positioned for its gate to

receive the nose of the drop lever, and thread the dial into the cam until the dial stops.

11. Turn the dial counterclockwise until zero is aligned with the opening index of the dial ring, then turn

the dial one turn farther counterclockwise. When this is done, the proper spindle spline keyway and

drive cam spline keyway should be closely aligned (vertical-up—VU, right-hand—RH, etc.).

Figure 5

VU Mount

Gate

Spline Key

LH Mount

RH Mount

VD Mount

12. Insert the spline key with the tip toward the edge of the cam. Tap in lightly. Be very careful to avoid

striking the stainless steel roller that is attached to the top surface of the drive cam. With the spline

key inserted fully, the dial must turn freely with no rubbing or interference.

Note: Before installing the lock‘s cover, check for proper in and out travel of the dial to make sure the

accelerator spring operates correctly.

13. Turn the dial at least one complete revolution in either direction and then stop at zero. The accelerator

spring should now be in the loaded position.

14. Hold the cover in place on the lock and push the dial in at zero. Release the dial. Remove the

cover and check the position of the accelerator spring. It should be in the released position. If the

accelerator spring is not in the released position, the dial has not been backed out of the cam far

enough, and the condition must be corrected. Remove the spline key, hold the cam, and rotate the dial

one additional full turn counterclockwise. Install a new spline key and repeat steps 13 and 14.

page 3

Loading...

Loading...