Sargent and Greenleaf 6126 Installation Instructions Manual

Installation Instructions

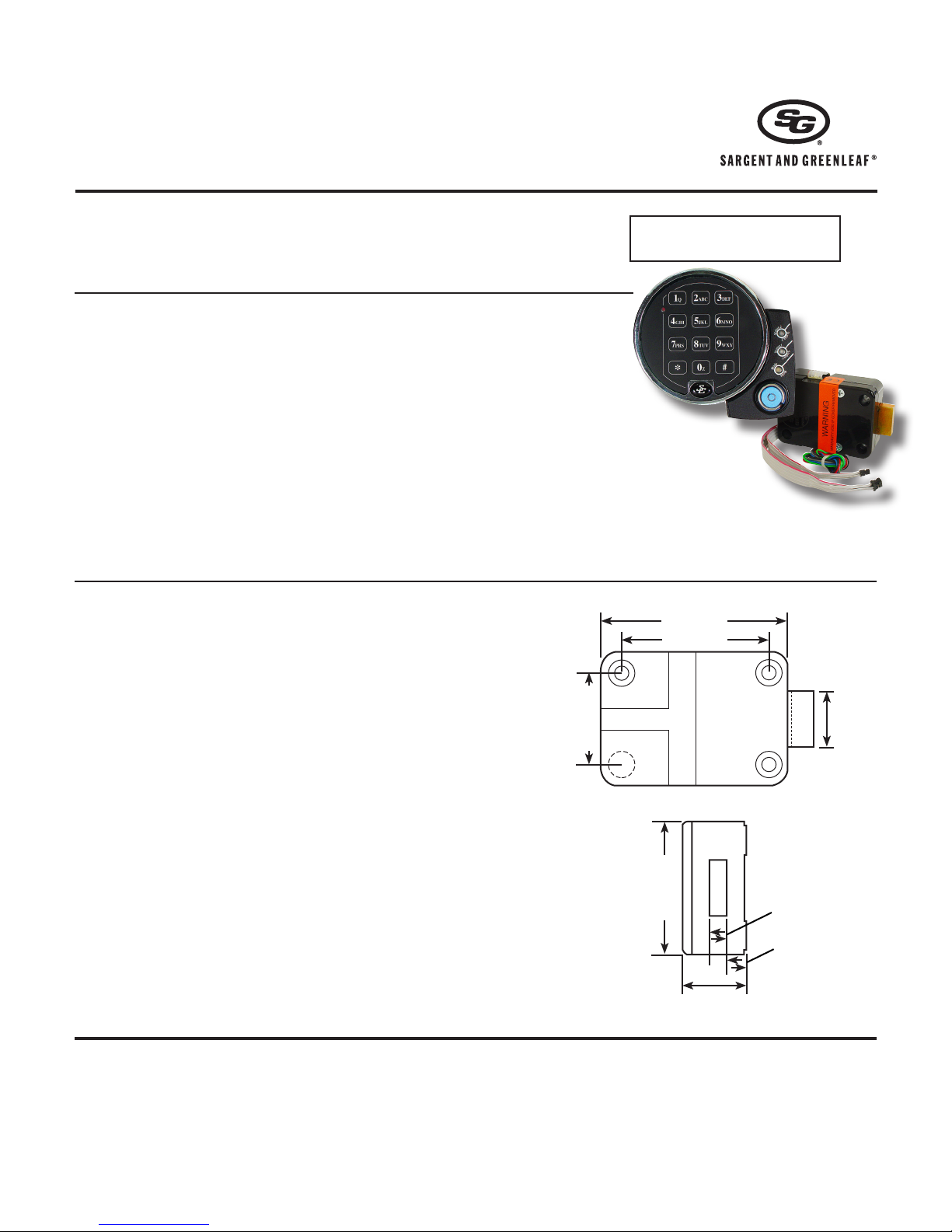

Model 6126 Audit Lock

Electronic Safe Lock

• Für Anweisungen auf Deutsch besuchen Sie bitte die folgende Website:

• Para obtener instrucciones en español, visite la siguiente página web:

• Pour obtenir les instructions en français, veuillez consulter le site ci-dessous:

• Per istruzioni in lingua italiana, visitare il sito web seguente:

• 如果要获取中文版的说明,请访问以下网址:

Mounting Considerations

• Sargent & Greenleaf 6100 series Motorized Electronic Combination Locks have

been designed to use the same mounting screw locations and occupy the same

space as most other S&G locks, both mechanical and electronic.

• Modifications to the lock (including lock bolt attachments) are not

recommended, and will void the your warranty.

• A minimum distance of .150" (3,8 mm) is required between the end of the lock

case containing the bolt and the closest approach of the safe’s blocking bar or

cam plate which is normally blocked by the extended lock bolt. Do not allow

the safe’s blocking bar or cam plate to depress the electronic lock’s bolt farther

than it retracts during normal motor operation. This can lead to inconsistent lock

operation.

• The 6100 series requires two 9-volt alkaline batteries (may or may not be included with your lock depending on the

specific kit ordered). We recommend fresh Duracell® batteries. Do not use old or partially drained batteries.

www.sargentandgreenleaf.com/

OPinstr.php

Attaching Screws: Use only the screws provided with the lock. Lock body mounting screws will be

either ¼-20 or M6, depending on the application. They must engage the mounting plate by at least

four full threads. Do not use lock washers or thread sealing compounds unless specifically directed to

do so in the full installation instructions.

Recommended Attaching Screw Torque: 30 to 40 inch-pounds (33.9 to 45.2 dNm) for the lock body.

No more than 15 inch-pounds (1.695 Nm) for the keypad attaching screws.

Minimum Lock Cable (Spindle) Hole Diameter: 0.312" ( 7,9 mm )

Maximum Lock Cable (Spindle) Hole Diameter: 0.406" (10,3 mm)

Lock is Designed to Move: 0.0 lbs. (0 Newtons)

Lock Bolt Maximum Free Movement: 0.352" (8,95 mm) 0.109 inch outside the edge of the lock case

Maximum Bolt End Pressure: Lock is designed to withstand at least 225 lbs. (1000 Newtons)

Maximum Bolt Side Pressure : Safe and container boltwork or locking cam designs must never apply

more than 225 lbs. (1000 Newtons) of side pressure on the lock bolt.

Mounting Environment: The lock body is designed to be mounted inside a secure container. The

container must be constructed to offer protection against physical attack directed at the lock. The

amount of protection is dependent on the desired level of security for the system as a whole. Lock protection may include barrier materials, relock devices, thermal barriers, thermal relock components, or any

combination of these. Relock device attaching screws must NOT be longer than the depth of the tapped

attaching screw hole provided in the lock case. A minimum distance of .150 inch (3,8 mm) is recommended between the end of the lock case and the closest approach of the safe’s blocking bar or cam plate

(which is normally blocked by the extended lock bolt). Maintaining this clearance will allow the lock to

deliver optimum performance. The container should be constructed to prevent access to the combination

lock without the use of tools when the container door or drawer is left open.

Code Restrictions: Personal data that can be related to a code holder, such as a birth date, street number, or phone number, should not be used in creating a lock code. Avoid codes that can be easily guessed.

Note: Every installation of this product must comply with these requirements and those in the product installation instructions to qualify for the manufacturer’s warranty and to comply with EN1300 requirements.

1.624" (41,2mm)

3.320" (84,3mm)

2.624" (66,6mm)

2.400" (61,0mm)

1.165" (30mm)

Bolt extension:

Locked = .461"

(11,71mm)

Unlocked = .125"

(3,18mm)

1.000" (25,4mm)

.312"

7,9mm

.281"

7,1m m

Sargent & Greenleaf, Inc.

PO Box 930

Nicholasville, KY 40340-0930

Phone: (800)-826-7652 Fax: (800)-634-4843

Phone: (859)-885-9411 Fax: (859)-887-2057

Copyright© 2012, Sargent & Greenleaf, Inc.

page 1

Sargent & Greenleaf S.A.

9, Chemin du Croset

1024 Ecublens, Switzerland

Phone: +41-21 694 34 00

Fax: +41-21 694 34 09

Document 630-820

Revised 8/28/2013

Before You Install

Your 6126 Audit Lock was most likely shipped with the keypad and keypad extension connected to the lock cables to

allow for pre-installation testing. If your lock does not have cables already connected to the keypad and keypad extension, temporarily connect them now as shown in these instructions. You should install fresh batteries in the keypad

(S&G recommends Duracell® alkaline batteries) and check the function of the lock prior to installation by pressing

10101010# and observing the lock bolt retract, then extend 6 seconds later. After this check, disconnect the cables

from the extension base and keypad by pulling on the connectors (NOT on the cables themselves). The installer should

wear a properly grounded ESD wrist strap while working with lock cables and components to avoid ESD damage.

Step 1

Remove the existing lock (if present). The mounting plate should be smooth and

flat, with ¼-20 (M6) mounting screw holes. The wire channel (spindle hole) must

have a diameter of at least 0.312 inch (7,9 mm).

The 6100 series can be mounted right-hand, left-hand, vertical-up, or

vertical-down without any modifications or adjustments.

Step 2

Use a reamer or round file to remove any sharp edges from the wire channel

(spindle hole) that might damage the wire cable.

Gently pull the connectors to ease the cables through the hole. Pull 6" to 8" (15

to 20 cm) of cable to the front of the safe door. Later in the installation, excess

keypad extension cable will be pulled back inside the safe door. Make sure

cables are not crimped or stressed at any point.

Step 3

Using two of the ¼-20 (or M6) screws in the kit, loosely attach the lock body

to the safe’s mounting plate. This is just to hold it in place during cable

attachments to the keypad and keypad extension. Be very careful to avoid

crushing or crimping the cables. Note the black/red/green wire bundle. This is

for the bolt position indicator, a dry contact switch (200 VDC, 0.5 amp max.)

The black wire is common, the green wire completes a circuit to the black wire

when the lock bolt is retracted, and the red wire completes a circuit to the black

wire when the lock bolt is extended. The BPI can be used to trigger any switchactivated device.

Note the blue wire loop. This is the secure loop, a closed circuit that may be

used in applications requiring switches or other devices to signal the lock that

boltwork is thrown, the door is closed, or some other action has taken place. The

lock bolt will NOT extend if the circuit formed by the blue wire loop is open.

Both sets of wires should be bundled and placed where they will not interfere

with moving boltwork components if not used.

The lock incorporates a bolt-through cover that allows mounting with the cover in

place. Removing the cover voids the product warranty.

page 2

Loading...

Loading...