Sargent and Greenleaf 6120,6123 User Manual

Sargent and Greenleaf

Electronic Safe Lock Guide

Sargent and Greenleaf is a company dedicated to providing security. Not just a sense of

security, but real security designed to meet real-world needs. We offer mechanical locks that

deliver an unbeatable combination of quality and value. Electronic locks that take control to a

level never before possible. And exit devices that achieve the highest standard of safety. Since

1857, Sargent and Greenleaf has provided innovative security solutions to financial institutions,

businesses and governments across the globe. Today, we are a subsidiary of Stanley Security

Solutions, a growing division of Stanley Black & Decker.

Contents

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

6120 / 6123 Installation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

6120 Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6123 Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6123 Quick Reference Programming Guide . . . . . . . . . . . . . . . . . . . . . . . . . 20

6120 / 6123 Battery Changing Instructions—Two-Battery Keypad . . . . . . . . . . . .22

6120 / 6123 Battery Changing Instructions—One-Battery Keypad . . . . . . . . . . . . .24

6120 / 6123 Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6120 / 6123 Troubleshooting Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6120 / 6123 Management Reset Code Technical Bulletin. . . . . . . . . . . . . . . . . . 32

6120 / 6123 Commonly Asked Questions . . . . . . . . . . . . . . . . . . . . . . . . . . 33

A Brief History of Sargent & Greenleaf . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Product Overview

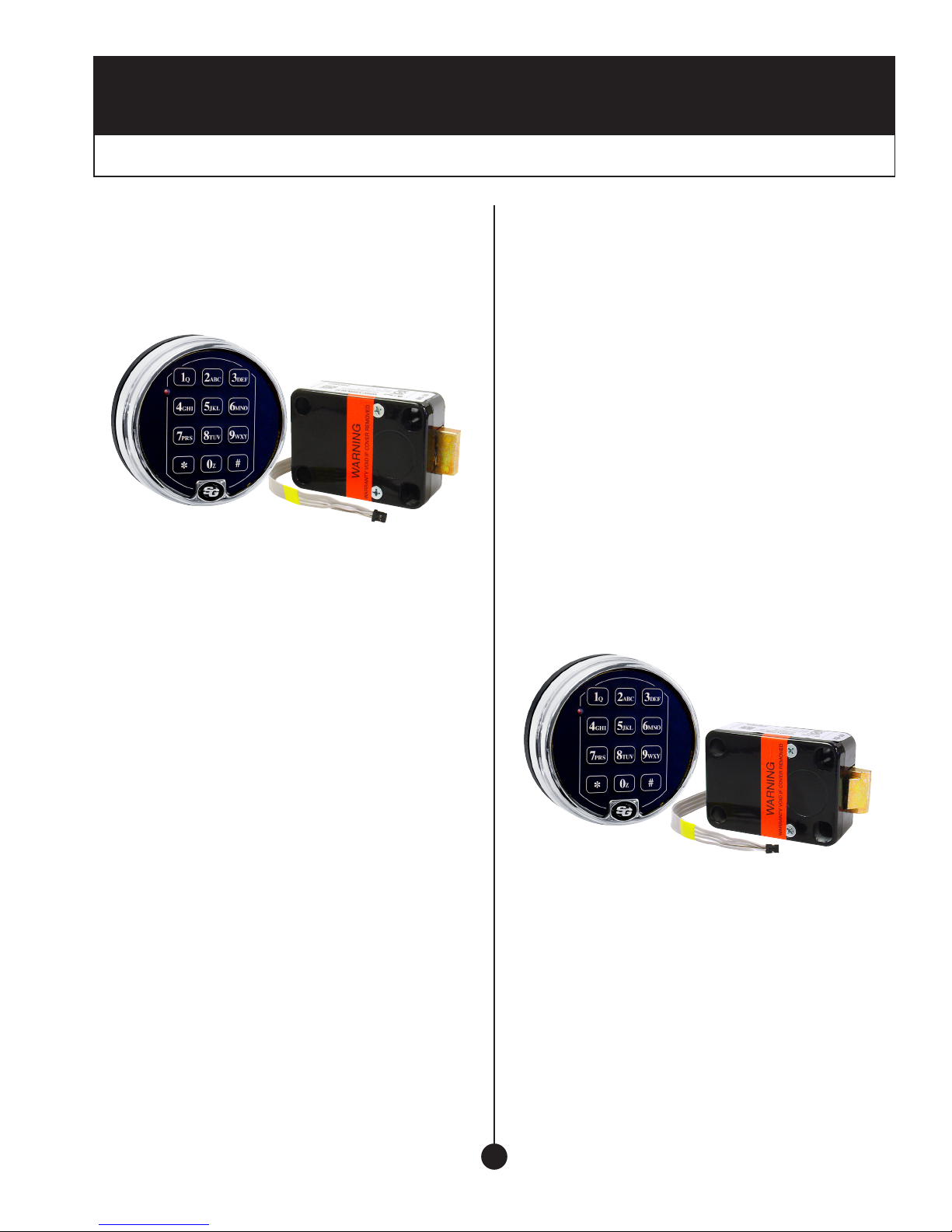

Models 6120 and 6123—Motorized Electronic Combination Locks

Added control And flexibility for greAter security

Sargent & Greenleaf safe locks have been protecting the assets

of banks, businesses, and governments for more than a century

and a half.

Features and Benefits:

• One-step operation—just enter the code and the lock

unlocks.

• Requires no turning of a dial to lock or unlock.

• Puts an end to the dangerous practice of “day locking” or

leaving the safe open.

• The 6120 gives you one master code and up to eight

independent user codes

• The 6123 gives you programmable time delay of up to ninetynine minutes with a variable opening window of two to nine

minutes.

• The 6123 gives you one master code, one supervisor code,

five independent user codes, and one time delay override

code.

• The 6123 lets you choose from three different modes of

operation: single user, dual control, and supervisor/user.

• The 6123 lets you choose between single code time delay

override, dual code override, or no time delay override.

• The 6123 lets individual users change their own codes

without supervisory assistance.

• Automatically re-locks when you close the safe.

• Lets you change codes at any time with just a few touches of

the keypad.

• Protects from being opened or manipulated by repeated,

random code entry.

• Offers secure and reliable motor-driven lock bolt operation.

• Flexible interface capability — works with security systems,

time locks, alarm systems and CCTV.

• Allows for multiple users, while at the same time giving you

greater control over access.

• The 6120 has a built in programmable time delay of up to

nine minutes.

© Copyright 2011, Sargent & Greenleaf, Inc.

1

Product Overview

Models 6120 and 6123—Motorized Electronic Combination Locks

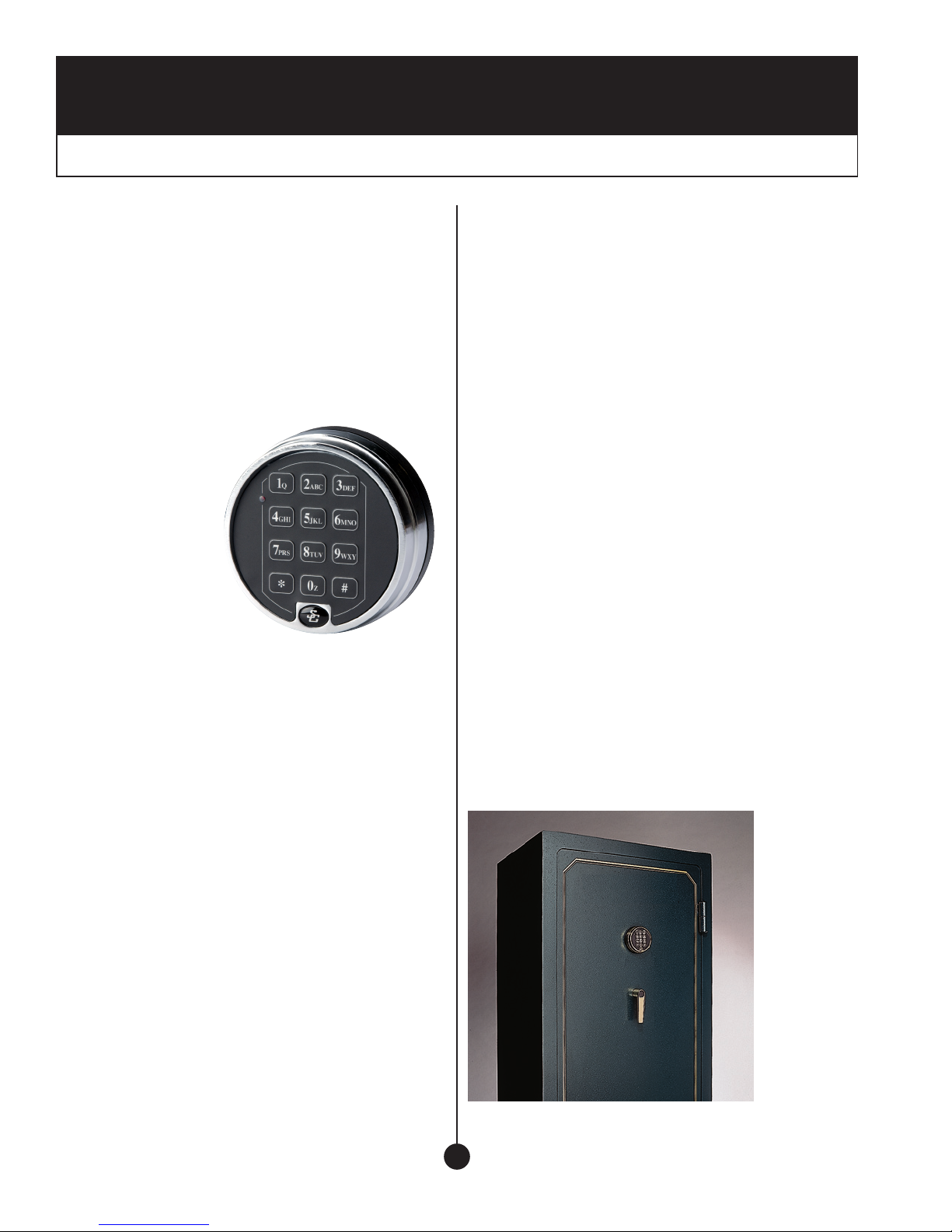

the secure, smArt wAy to protect your Assets.

Easy to use. Just enter your personal six-digit code and the

Comptronic lock automatically unlocks your safe door in one easy

step. It’s as simple as punching in a telephone number. There’s no

dial to turn.

Relocks automatically. There’s nothing to turn, and it re-locks

itself after 6 seconds. That’s because the bolt mechanism on

Comptronic locks is driven by an extremely reliable DC motor.

Easy to program. Every

Comptronic lock gives

you a choice of one

million six-digit codes.

Change them yourself

anytime. Programming is

easy and done through

the keypad. There is no

need for additional tools,

programming boxes, or

disassembly of your lock or safe.

Control access. The 6120 conveniently lets you assign up

to eight individual employee access codes. Perhaps more

importantly, you can delete and reprogram these codes at any

time with your Master Code, even if the code being deleted is

not known.

Protects against random dialing. With a million possible codes,

it’s unlikely a thief would ever have time to randomly enter

the right code, but why take a chance? Anytime four incorrect

codes are entered into the Comptronic 6120 or 6123, they

automatically shut down for five minutes.

Fits new and existing safes. You can request a Comptronic

6120 or 6123 for a new safe, or you can replace the lock on

your existing safe. And because it’s available in a variety of

attractive keypad finishes (including 24 karat gold), your

Comptronic lock will look as good on your safe as it works.

Over 8,000 openings between battery changes. Two

9-volt alkaline batteries are housed in the standard keypad

(S&G recommends Duracell®). When batteries get low, the

Comptronic’s audio signal changes pitch to let you know it’s

time for fresh ones. Your access codes remain unchanged while

you install new batteries.

The support of the industry leader. S&G is a leading global

manufacturer of high security safe combination locks, with the

broadest array of locks available. Our electronic locks have more

applications than all others. We provide excellence in all areas,

from our ISO 9001, U.L., and other worldwide certifications to

our experienced customer service staff. And, as with all our

products, we stand behind the 6120 and 6123 with one of the

best warranties in the industry.

The 6123 lets you assign a Supervisor Code, a time delay

override code, and up to five individual employee access codes.

Either the Master Code holder or Supervisor Code holder can

delete and reprogram these codes at any time, even if the

employee access code is unknown.

Time delay opening and control. No robber can afford to wait

for a safe to be opened. The Comptronic 6120 lets you program

an opening delay of up to nine minutes. The 6123 time delay

can be set up to ninety-nine minutes. Employees enter their

access code, wait the delay period, and re-enter their code to

open the safe.

2

© Copyright 2011, Sargent & Greenleaf, Inc.

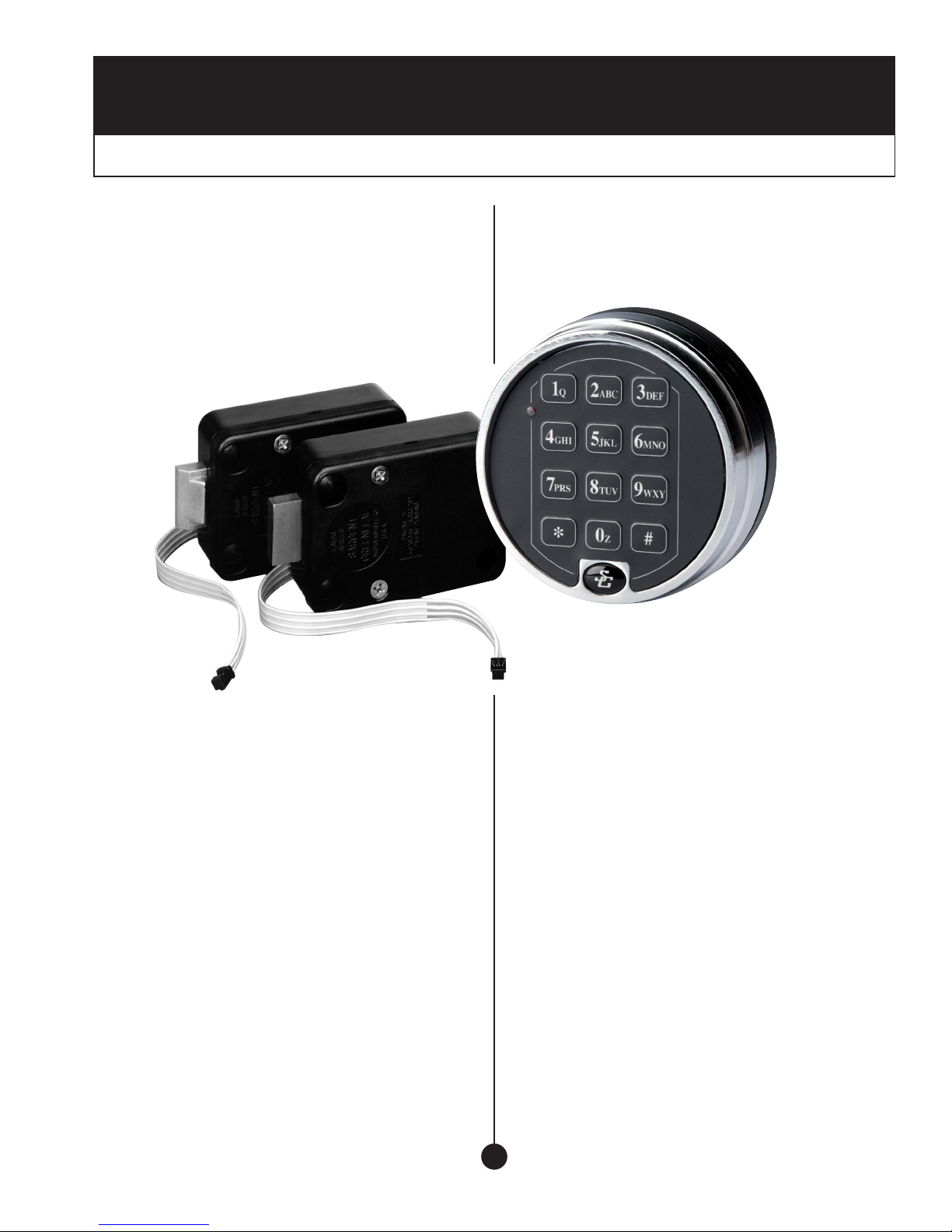

Installation Instructions

Models 6120 and 6123—Motorized Electronic Combination Locks

Sargent & Greenleaf 6120 series electronic locks combine ease

of operation with security. Advanced electronic circuit design

makes them easy to install, easy to open, and easy to change

codes. Follow these instructions carefully to get the best

possible performance from your lock.

• Modifications to the lock (including lock bolt attachments)

are not recommended, and will void the manufacturer’s

warranty.

mounting considerAtions

• Sargent & Greenleaf 6120 series Motorized Electronic

Combination Locks have been designed to use the same

mounting screw locations and occupy the same space as a

standard S&G 6730 mechanical lock. The 6120 series uses

standard mounting dimensions to simplify retrofit in safes

originally equipped with mechanical locks.

• The keypad base diameter is 4” (101,6 mm). This is slightly

greater than the diameter of standard S&G dial rings for

mechanical locks. The 6120 series keypad will cover any

scratches or paint blemishes left by the old lock.

© Copyright 2011, Sargent & Greenleaf, Inc.

• A minimum distance of .150” (3,8 mm) is required between

the end of the lock case containing the bolt and the safe’s

blocking bar or cam plate which is normally blocked by the

extended lock bolt. This is because the lock bolt may not be

retracted quite as far by older batteries as by fresh ones.

• You should install fresh alkaline batteries in the keypad and

connect the lock wiring cable to check the functions of the

lock prior to installation. Follow the procedures given in the

Operating Instructions. Avoid pressure to the end of the

lock bolt during these checks.

• Do not allow the safe’s blocking bar or cam plate

to depress the electronic lock’s bolt farther than it

retracts during normal motor operation. This can lead to

inconsistent lock operation.

3

Installation Instructions

Models 6120 and 6123—Motorized Electronic Combination Locks

instAllAtion notes

Although the 6120 series is easy to install, we recommend

the following procedures be performed only by an experienced

locksmith or safe technician. Your safe may incorporate

relocking devices that are attached to the combination lock.

Misalignment or detachment of these devices can result in a

lockout—a condition that makes it unlikely that the safe can be

opened without damage.

AdditionAl items you will need

The 6120 series requires two 9-volt alkaline batteries (not

included). We recommend fresh Duracell® batteries. Do not use

old or partially drained batteries in your lock. New batteries will

power your lock for approximately 8,000 openings when used

without the time delay feature.

Many installations can be performed with nothing more that

a medium Phillips screwdriver. If the manufacturer of your

safe has made external relock device attachments to the lock,

specialized tools and knowledge may be required.

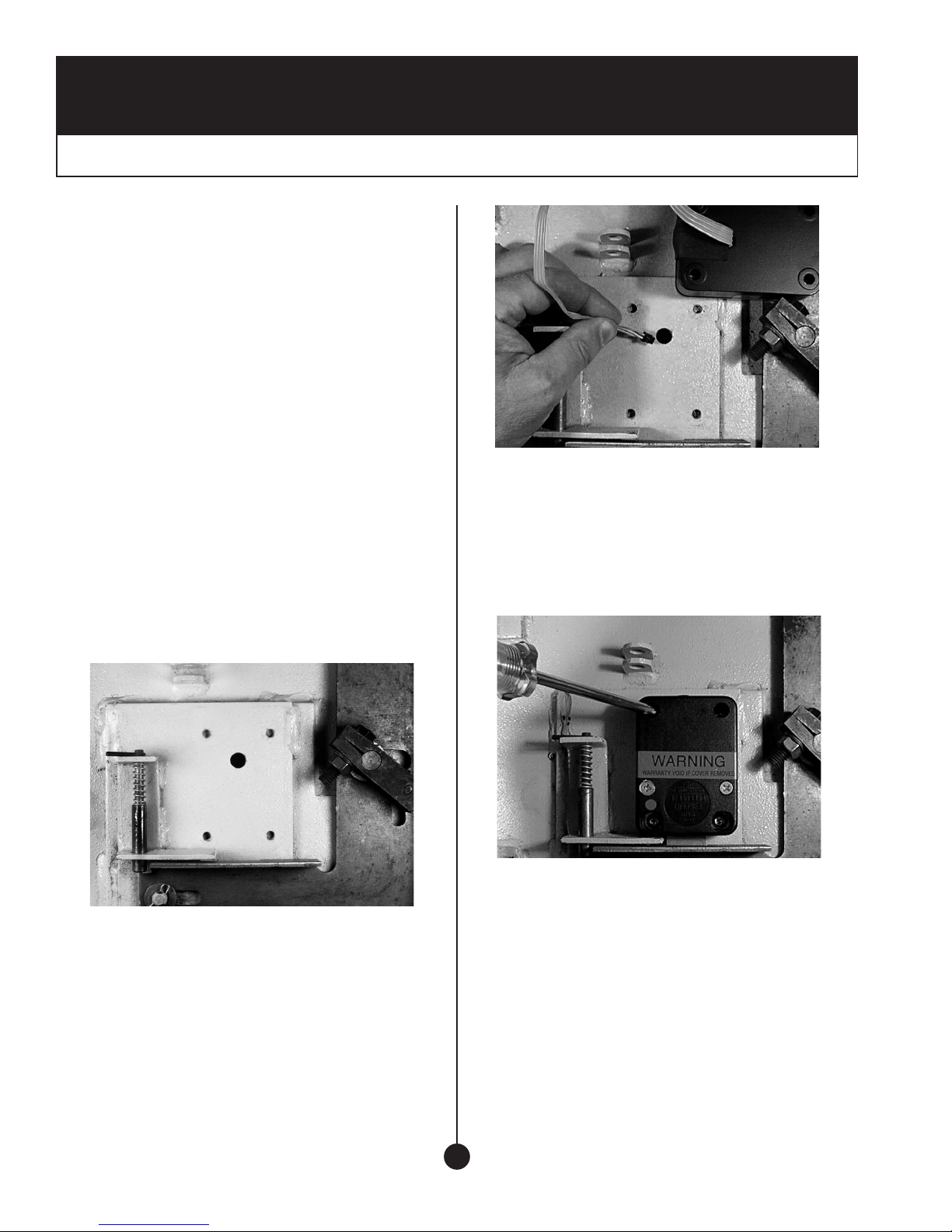

Step 2

Use a reamer or round file to remove any sharp edges from the

wire channel (spindle hole) that might damage the wire cable.

Run the connector through the wire channel. Gently pull the

connector and all excess cable to the outside of the safe. Make

sure the cable is not crimped or stressed at any point.

instAllAtion

Step 1

Remove the existing lock (if present). The mounting plate should

be smooth and flat, with 1⁄4-20 mounting screw holes. The wire

channel (spindle hole) must have a diameter of at least 5⁄16”.

The 6120 series can be mounted right-hand, left-hand, verticalup, or vertical-down without any modifications or adjustments.

Step 3

Once you’ve made sure the wire cable is not crimped or in

contact with any sharp surface, attach the lock to the safe’s

mounting plate. Use the four 1⁄4-20 (or metric M6) screws

provided. Tighten securely, attaching the lock firmly to the plate.

The lock incorporates a bolt-through cover that allows mounting

with the cover in place. Removing the cover voids the warranty.

4

© Copyright 2011, Sargent & Greenleaf, Inc.

Installation Instructions

Models 6120 and 6123—Motorized Electronic Combination Locks

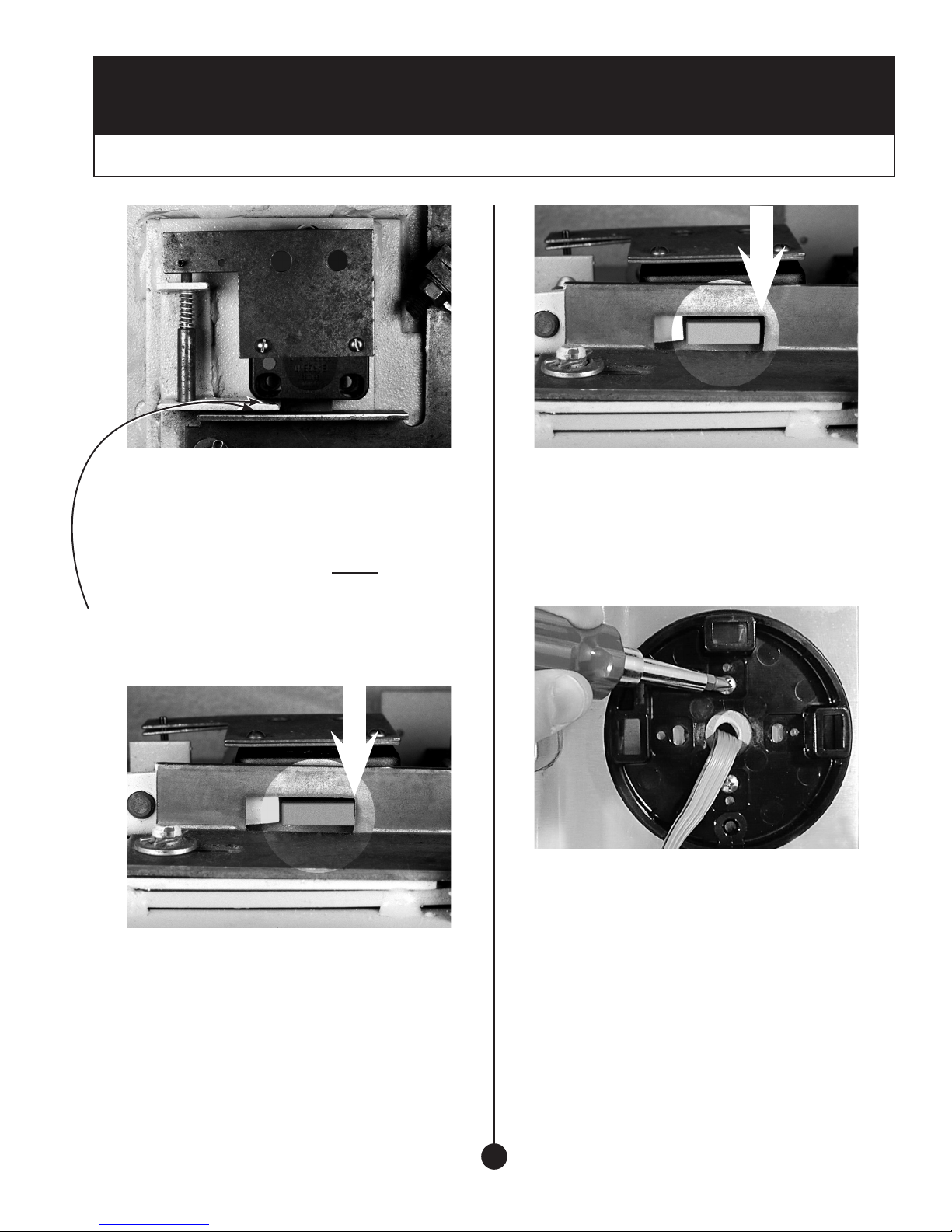

C L E A RA NC E

Step 4 (FOR SAFES WITH RELOCK DEVICES)

This is an installation that requires attachment of the safe

manufacturer’s relock device plate to the lock cover using the

cover screws. If your situation is similar, be sure the thickness

of the relock device plate(s) is not great enough to prevent the

screws from engaging the lock case by at least four threads. If

necessary, use longer 8-32 machine screws to insure proper fit.

The photo also illustrates a required space of at least .150” (3,8

mm) between the end of the lock body and the blocking bar of

the safe’s boltwork.

B I ND

Step 5

Make sure that the lock bolt does not bind against the safe’s

boltwork. 6120 series locks are sensitive to bolt end and side

pressure. The safe’s blocking bar or cam must not depress the

lock’s bolt farther than it retracts under normal motor operation.

Check to make sure this doesn’t happen when the safe handle

is moved to retract the door bolts (unlock the safe).

Step 6

The boltwork bind has been relieved by removing a small

amount of material from the right side of the boltwork opening.

When the safe’s boltwork is fully thrown to the locked position,

there is air space on all sides of the electronic lock’s bolt.

Step 7

Run the connector and wire cable through the center hole of the

mounting base. Then use the included 8-32 machine screws

to attach the base to the safe door. The attaching screw holes

will line up with those used for any standard S&G dial ring

(excluding R132 key locking dial rings).

This photograph shows boltwork in the locked position which

places pressure on the side of the lock bolt. This could prevent

the lock from opening properly.

© Copyright 2011, Sargent & Greenleaf, Inc.

5

Installation Instructions

Models 6120 and 6123—Motorized Electronic Combination Locks

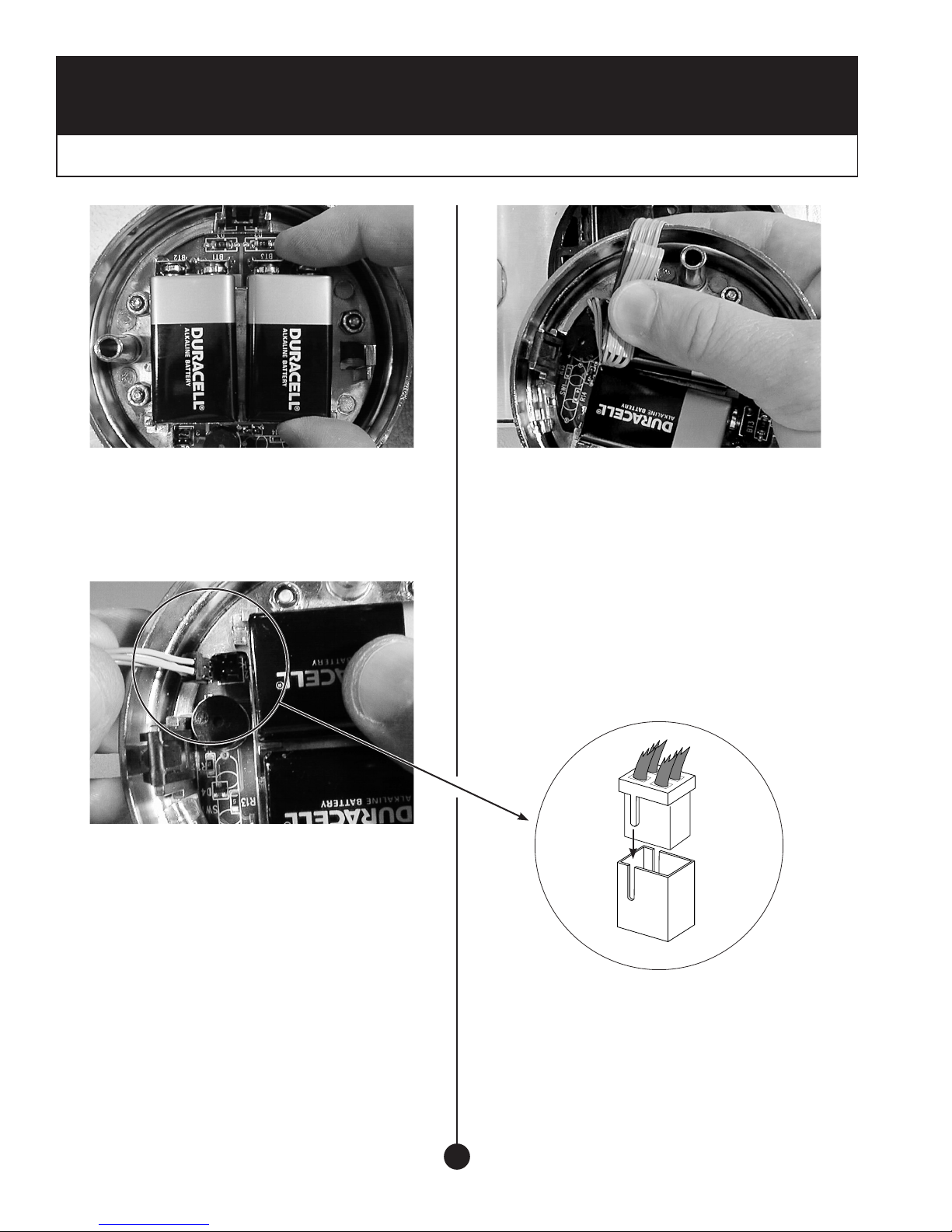

Step 8

Install a new 9-volt alkaline battery in each of the keypad’s

battery holders (Duracell® is recommended). Support the top of

each holder as the battery is inserted. This will prevent bending

or breaking the holder.

Step 9

The wire cable connector is shaped so that it will fit into the

circuit board receptacle only when aligned correctly. Insert the

connector into its receptacle in the keypad housing. If it does

not slide easily into place, do not force it. This means you need

to turn it 180º before attempting to insert it again.

Step 10

Make a loose coil of the excess wire cable. Hold the coil

away from the spring clips that will secure the keypad to the

mounting base.

A

L

I

G

N

R

I

D

G

E

W

T

O

L

S

H

T

I

6

© Copyright 2011, Sargent & Greenleaf, Inc.

Installation Instructions

Models 6120 and 6123—Motorized Electronic Combination Locks

Step 11

Place the keypad over the base. Make sure the wire cable is still

clear of the spring clips, then push the keypad firmly onto the

base. It should snap into place.

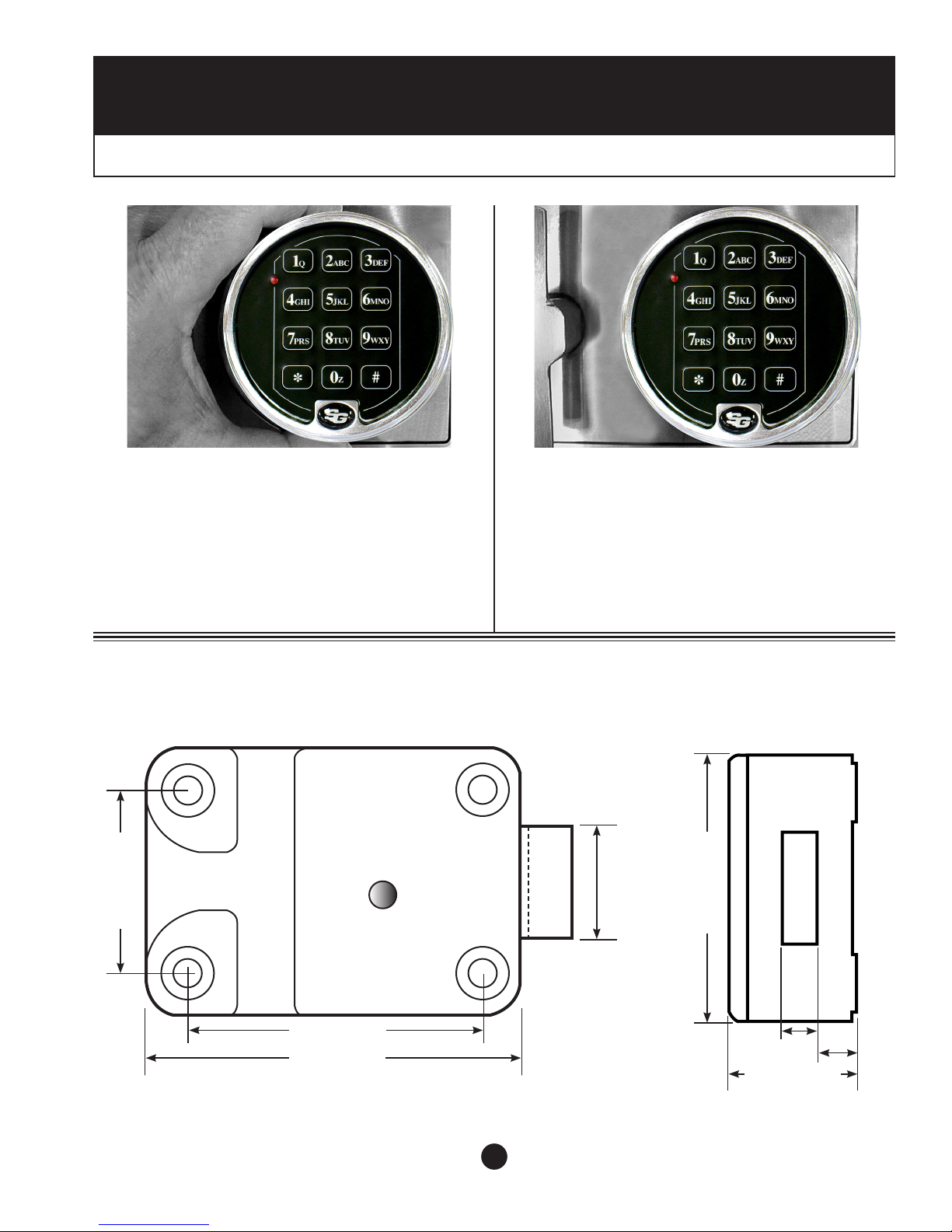

importAnt dimensions

Step 12

The installation is complete. Refer to your lock’s Operating

Instructions for opening, code changing, time delay, and battery

changing instructions.

Make sure your lock is fully operational before closing the safe

door for the first time.

1.624" (41,2 mm)

2.624" (66,6 mm)

3.320" (84,3 mm)

© Copyright 2011, Sargent & Greenleaf, Inc.

1.000" (25,4 mm)

7

2.400" (61,0 mm)

.312"

7,9 mm

.281"

7,1 mm

1.165" (29,6 mm)

Operating Instructions

Model 6120 —Motorized Electronic Combination Lock

The Sargent & Greenleaf Model 6120 combines ease of

operation with security. Its advanced electronic circuit

design makes it easy to open and easy to change codes.

Follow these instructions carefully to get the best

possible use from your lock.

introduction

• The Sargent & Greenleaf Model 6120 Motorized Electronic

Combination Lock is shipped from the factory with a factory

master code only. It is 1 2 3 4 5 6 #. This code is used to

open the lock and set or change all of its codes. If the safe

maker or your dealer sets a new master code, he will advise

you of the change. You should set the lock to your own,

unique master code immediately.

• The Model 6120 will always open on the master code. At your

discretion, it can also be set to accept up to eight different

user codes. The master code holder is responsible for

maintaining the number of active users programmed into

each lock. The master code is designated as code #1, and

the user codes (if set) are designated by user I.D. number 2,

3, 4, 5, 6, 7, 8, and 9. The user codes do not exist until they

are programmed into the lock.

• Each time a button is pressed and the lock accepts the

input, it emits a “chirp,” and the LED on the keypad lights

momentarily.

• All codes must contain six digits or six letters. Any digit or

letter can be used as many times as you wish. For instance,

the following codes (while not recommended) will operate the

lock: 5 5 5 5 5 5 # OR J J J J J J #

• All codes end with #. This signals the lock that you have

finished entering all digits of the code.

• If you pause more than ten seconds between button presses

when entering a code, the lock will assume you do not want

to continue, and it will reset itself. To open the lock, begin

the code entry sequence again from the first step.

• If you realize you have pressed an incorrect button when

entering a code, press * or simply pause ten seconds or

more, then begin entering your code again.

• If four incorrect codes are entered in a row, the Model 6120

will shut down for a period of as long as fifteen minutes.*

This is a security feature. Pressing any button anytime during

the lockout period will reset the timer to its maximum penalty

time. Do not touch any keypad buttons for a period of fifteen

minutes, then enter any valid code to open the lock.

* Locks produced before mid 1997 shut down for fifteen minutes. Locks

produced after this shut down for five minutes.

8

© Copyright 2011, Sargent & Greenleaf, Inc.

Operating Instructions

Model 6120 —Motorized Electronic Combination Lock

to open the lock

Press the code digits or letters in order, followed by #. The lock

bolt will retract for six seconds, allowing you time to operate the

safe handle and open the door. Do not put any pressure on the

safe handle until after the code has been entered. The Model

6120 will lock automatically when the safe door is closed and

the handle is turned to the locked position.

Note: The Master Code Holder is responsible for maintaining

the number of active users programmed into each lock.

in cAse of trouble

If your lock should fail to open when a valid code is entered,

check for the following:

1. The boltwork of a safe can, under certain conditions, place

pressure on the side of the lock’s bolt. This is often caused

by something inside the safe pressing against the door or by

something caught between the safe door and its frame. When

this occurs, the lock will not operate properly. To relieve side

pressure on the lock bolt, move the safe’s handle to the fully

locked position, then re-enter a working code. The lock should

open after the pressure is removed.

2. If the lock “chirps” when keys are pressed, but it will not

open, the batteries may be drained to the point that they will

not operate the lock’s motor. Follow the battery replacement

procedure in this manual.

3. If the lock makes no sound when any of the keys are pressed,

dead batteries are likely to be the cause. Follow the battery

replacement procedure in this manual.

4. This item applies to the two-battery keypad only:

If the lock makes no sound when any of the keys are pressed,

but the batteries have been checked and found to be good,

a loose keypad connector may be the cause. Pull the keypad

away from the base as described in the battery changing

procedure. Check to make sure the wire connector is firmly

seated into its receptacle on the keypad circuit board. The

connector is designed so that it will only slide into the

receptacle when aligned correctly.

A

L

I

G

N

R

I

D

© Copyright 2011, Sargent & Greenleaf, Inc.

H

T

I

G

E

W

If all of the preceding remedies have been exhausted

T

O

L

S

and the lock still does not open, contact a qualified safe

technician in your area for professional service.

9

Operating Instructions

Model 6120 —Motorized Electronic Combination Lock

mrc — mAnAgement reset code

If a management reset code is used, it must be programmed into the

lock before the master code is changed for the first time. Once the

master code is changed, the lock cannot accept an MRC. Conversely,

once an MRC is programmed into a lock, it is always present. It

cannot be deleted or changed.

Some 6120 locks have factory installed management reset codes,

You cannot install a new MRC to replace an existing one.

The management reset code is used to regain control of a lock when

its master code is lost. When the MRC is employed, it deletes all

codes and changes the master code back to 1 2 3 4 5 6 #. See the

technical bulletin on page 32 for detailed information on how to set

and use a management reset code.

About chAnging codes

Always keep the safe door open when changing codes and

making other programming changes.

All code changing procedures begin by pressing SG* (the same

as 74*), followed by the existing six-digit master code and #.

The lock immediately chirps five times ( ). If the lock emits

a series of closely spaced chirps (nearly a continuous tone)

you’ve made a mistake and must start again.

to chAnge the mAster code (code #1)

Whenever # is pressed, the lock chirps to acknowledge the entry.

Wait for the chirps before proceeding. If a long series of closely

spaced chirps (almost a continuous tone) sounds when # is

pressed, the new code will not be accepted. Any existing user

code remains.

For instance, if you want to enable the #3 user code to open

the lock with a code of 4 4 6 6 3 3, you will use the following

procedure.

Press SG* (____) #

existing master code(7 4)

This same procedure would change any existing #3 user code to

4-4-6-6-3-3.

3 * 446633 #

new user code new user code

446633 #

to delete A user code

You may find that a particular user code which you have enabled

is no longer needed. It is a good security policy to remove any

unneeded codes. To do so, follow this procedure.

Press SG* (___) #

existing master code(7 4)

Whenever # is pressed, the lock chirps to acknowledge the entry.

Wait for the chirps before proceeding. If a long series of closely

spaced chirps (almost a continuous tone) sounds when # is

pressed, the user code will not be deleted.

(user I.D. 2 through 9) * #

#

Press SG* (___) #

existing master code new master code new master code(7 4)

Whenever # is pressed, the lock chirps to acknowledge the entry.

Wait for the chirps before proceeding. If a long series of closely

spaced chirps (almost a continuous tone) sounds when # is

pressed, the new master code will not be accepted—the old

code is retained.

1 * (___) #

(___) #

to enter or chAnge A user code (codes #2- #9)

Press SG* (___) #

(user I.D.) *(___) #

new user code new user codeexisting master code(7 4)

(___) #

In this procedure, the Model 6120 lock will not allow you to

inadvertently remove the master code.

security Advisory

If your lock is used many times a day (50 or more openings

daily), it is advisable to use as many different keys as possible

in your code number. Avoid using a key more than once whenever

possible. Check the keypad frequently for visible wear which

indicates which keys are being pressed for code entry. Change

the code to use different keys when wear is evident. If necessary,

have a qualified service technician replace the keypad.

10

© Copyright 2011, Sargent & Greenleaf, Inc.

Loading...

Loading...