Page 1

User Instructions

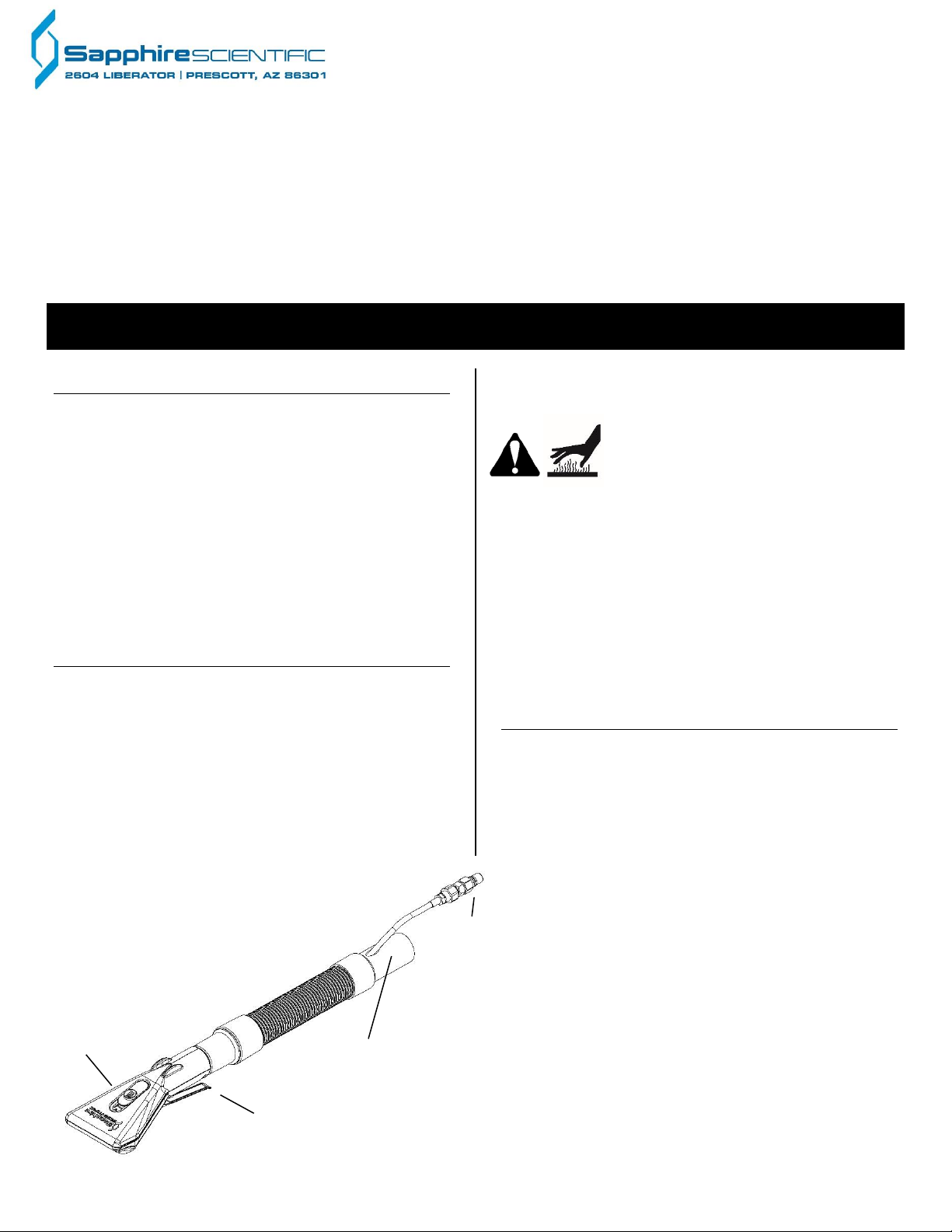

Rear vacuum hose cuff.

FIG. A: HEAD, VACUUM HOSE AND

SOLUTION LINE ASSEMBLY

Solution line

parts detail.

Vacuum

release slide

Solution trigger lever.

Upholstery Pro

Model F436-P

The Upholstery Pro cleaning tool provides deep, rapid penetration of cleaning solution and

simultaneous high volume extraction. Lightweight, easy to use, and adjustable for a wide range of

fabrics and soiling conditions, the Upholstery Pro produces cleaner, drier fabrics.

Patents: http://www.LBpatents.com

REA D A N D S A V E T H E S E I N S T R U C T I O N S

KEY FEATURES

Comfortable handle and highly flexible vacuum hose

provides relaxed balanced handling and substantially

reduces operator fatigue.

In-line solution strainer helps prevent clogging.

High pressure injector glide provides deep, even

penetration of solution into fabric surface.

Unique dual extraction slots permit full extraction in

both directions across fabric surfaces

Sliding vacuum release allows for precise vacuum

control on delicate fabrics.

Clear housing for easy monitoring of water flow, fabric

or carpet dryness, and cleaning effectiveness.

USING THE UPHOLSTERY PRO

1. Connect the rear quick-connect solution line to the

extractor solution line

2. Attach the rear hose coupling to the extractor vacuum

port.

3. Turn on extractor.

4. Squeeze the trigger lever to release the solution and

begin cleaning. The sliding trigger lock may be used

to hold the trigger valve in the open position.

quick-connect

coupling. See

Fig. D for

5. Use the vacuum release slide (Fig. A to adjust the

strength of the vacuum as needed.

WARNING: Quick-connect coupling

can become extremely hot during

use.

Tips for Use

Vacuum control. Use the vacuum release slide (Fig. A)

to control the strength of the vacuum when extracting

thin, delicate or lightweight fabrics.

For best results, use the Upholstery Pro with Legend

Brands cleaning chemicals.

For more information about cleaning with the Upholstery

Tool, visit LegendBrandsCleaning.com.

MAINTENANCE

Daily: Rinse the hand tool by running clean water

through the solution line.

Daily: Check the glide assembly (Fig. A) for steady,

even flow of solution through the injector nozzles. If any

of the injector ports appear clogged, use a small needle

to remove the obstruction, taking care not to damage the

glide. If the glide is scratched, gouged, snags on

carpets, or flows excessively, it may need to be

replaced (see “Servicing the glide,” below).

Replacement glide assemblies are available from

your distributor.

As needed: Lubricate the quick-connect

couplings (Fig. A) with a small amount of rust-

inhibiting oil such as LPS-3.

As needed: Lubricate trigger valve stem (Fig.

C) with a small amount of synthetic heavy duty

grease. To grease the stem, follow these steps.

1. Remove the trigger lever nut and bolt from the

trigger lever and remove lever.

2. Unscrew stem retention nut and lift out stem

07-02087B F436-P 1 Sapphire Scientific

assembly. Apply a small amount of grease to the

stem.

Page 2

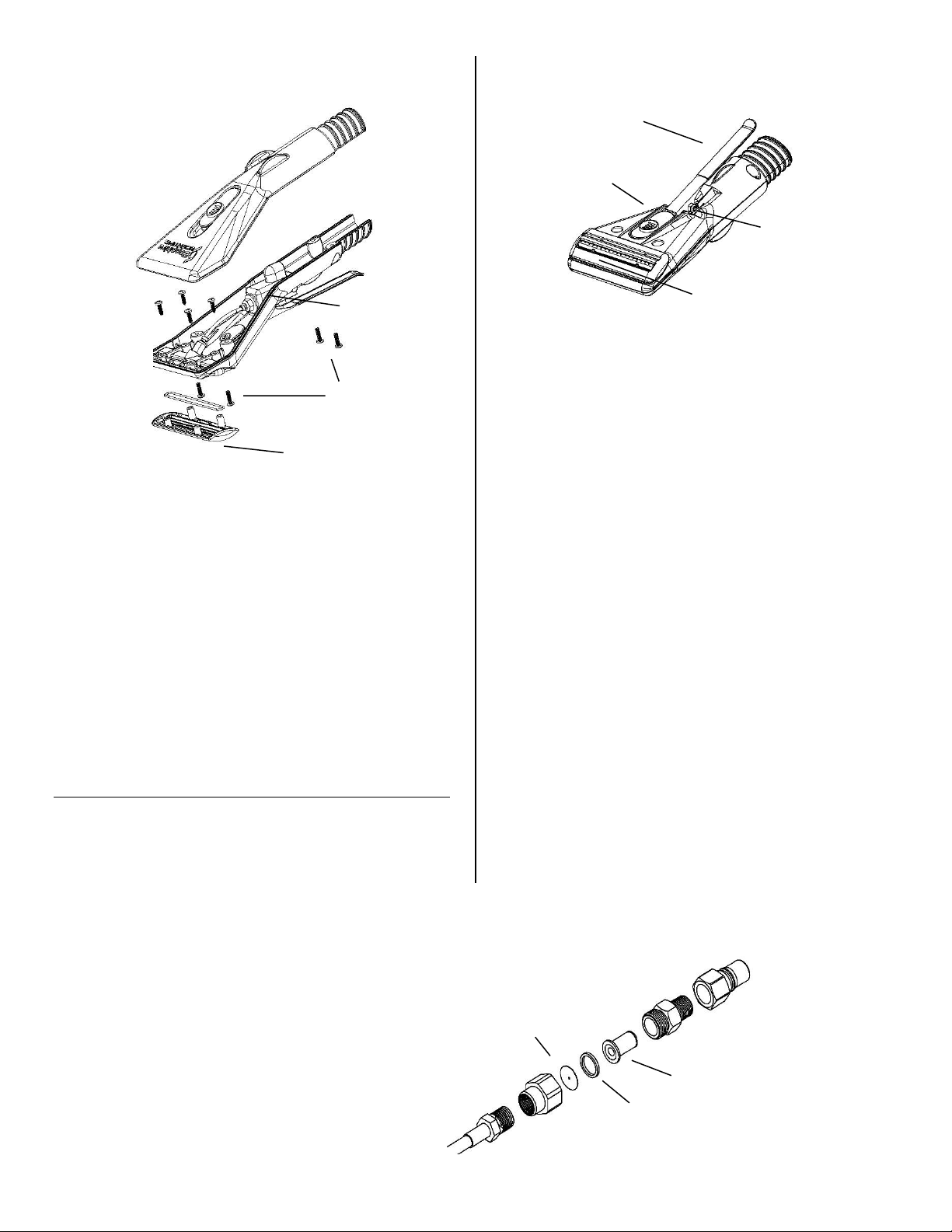

FIG. C: HEAD (BOTTOM VIEW)

Trigger lever

Glide

Trigger lever lock

Trigger lever

nut and bolt

Hex nut. Loosen here

Nylon washer

(03-01652)

Orifice

(03-01903)

Rear quickconnect coupling

Inline strainer

(03-01649)

FIG. D: SOLUTION LINE COUPLING ASSEMBLY

FIG. B: HEAD ASSEMBLY

Cover screws

(×4)

Glide and O-ring seal

(S13-01705)

Glide

screws (×4)

Trigger valve body

(13-01690)

Upper cover

Lower cover

(Inside

cover.)

1. Replace stem assembly and retighten retention nut.

Reattach trigger lever.

As needed: Clean the inline strainer (Fig. D) when

solution flow is visibly reduced. To clean the filter, loosen

the strainer assembly nut, and remove the strainer and

strainer washer. Rinse these items in clean water and

reassemble the strainer. It is not usually necessary to

replace the inline filter element. Be sure to include the

nylon washer when reassembling, and take care not to

over-tighten the strainer assembly nut.

To maintain appearance, wipe exterior surfaces with a

damp cloth.

SERVICING

The Upholstery Pro is designed to allow easy in-the-field

service to the glide and the trigger valve with basic hand

tools in just a few minutes. If replacement becomes

necessary, rebuild kits and replacement parts are

available from your Sapphire distributor or

from Sapphire Scientific at 800-932-3030.

Replacing the glide

Have on hand a Glide and O-ring

replacement kit (part no. S13-01705).

1. Remove the four cover screws (Fig. B)

and lift off the cover.

2. Remove the four glide screws (Fig. B)

and remove the glide and the O-ring seal.

Discard.

3. Install new O-ring into sealing edge of

new glide. Put new glide into head. Make

sure that the O-ring is in place.

4. Replace glide screws and tighten; then replace

cover and tighten with cover screws.

Servicing the trigger valve

If the trigger leaks or no longer releases sufficient

solution and you have determined that the glide is not

plugged or damaged (see “Check Glide Assembly,” p. 1)

the trigger may need service. Two repair options are

available.

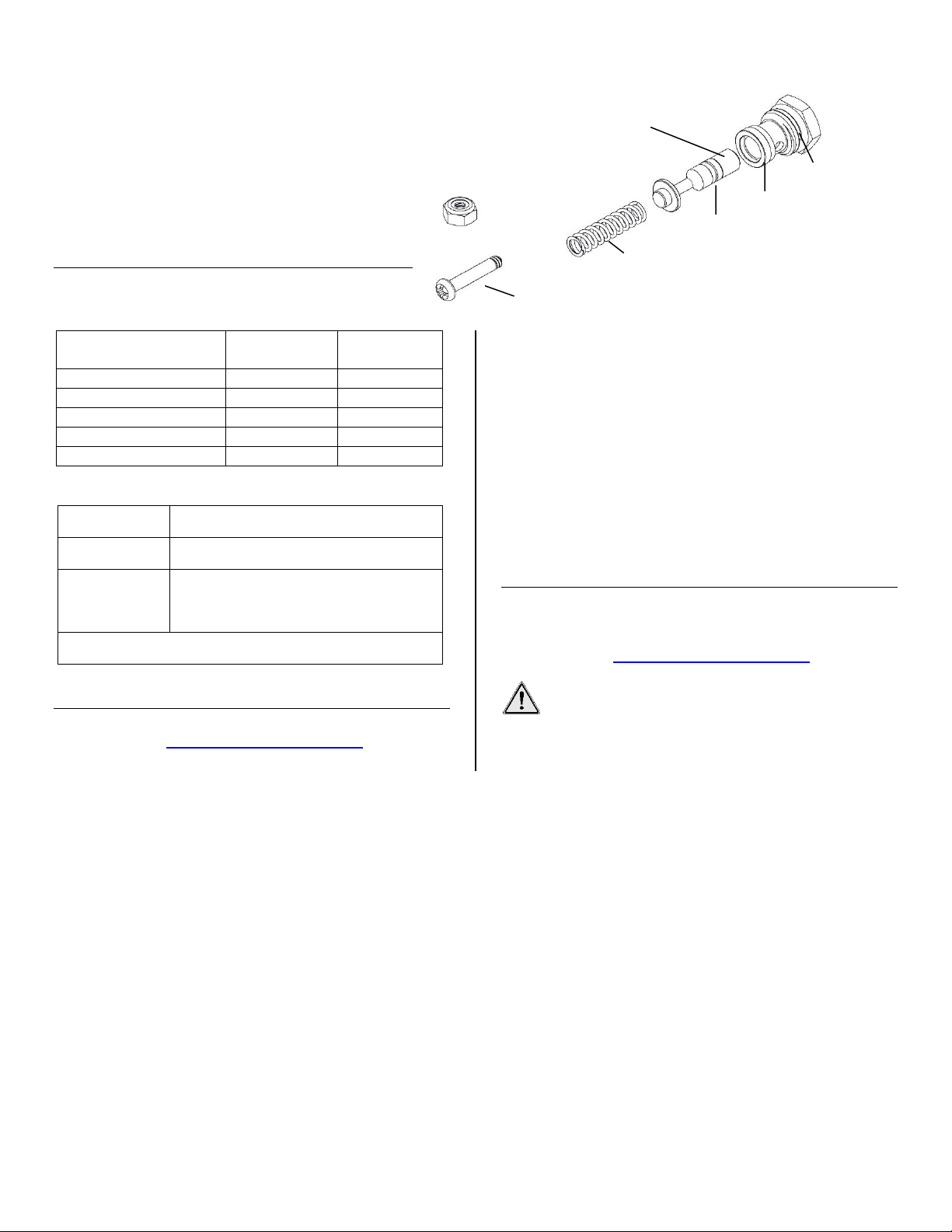

Option A: Rebuild the trigger valve.

A stem replacement kit (part no. 48-064) is available

from your Sapphire distributor. The parts included in this

kit are shown in Fig. E.

1. Remove the nut and bolt from the trigger lever and

remove the lever.

2. Unscrew stem retention nut and lift out stem

assembly.

3. Install the stem assembly and retighten the stem

retention nut.

4. Replace cover and reinstall trigger lever. Use the

new lock nut provided (Fig. E).

Option B: Replace the trigger valve assembly

A replacement trigger valve assembly (part no. 13-

01690) is available from your Sapphire distributor.

1. Remove the four cover screws (Fig. B) and lift off the

cover.

2. Depress the hose release ring on the solution outlet

tube and pull out the tube. Avoid kinking the tube.

to access strainer.

07-02087B F436-P 2 Sapphire Scientific

Page 3

Description

Drawing

reference

Replacement

part no.

Trigger and valve body

Fig. B

13-01690

Glide and O-ring seal

Fig. B

S13-01705

Strainer

Fig. D

03-01649

Orifice

Fig. D

03-01903

Nylon washer

Fig. D

03-01652

Model

Sapphire Scientific Upholstery Pro F436-P

Part no. 67-019 67-019-P

Dimensions

Head: 4 in. extraction width

Hose assembly: 10 ft.

Construction

Head: High performance copolyester.

Glide: Engineering thermoplastic

Hose assembly: High-flex vacuum hose

Fittings: Brass with high-temp seals

Specifications are subject to change without notice. Some values

may be approximate.

1. Stem retention nut

FIG. E: STEM REPLACEMENT KIT (48-064)

2. Stem.

apply grease

6. O-ring seal

5. Teflon seal

7. Extractor spring

3. Trigger lever lock nut

8. Shoulder screw

4. O-ring seal

3. Remove the solution outlet tube fitting from the

valve body.

4. Disconnect the solution inlet hose assembly

from the valve body.

5. Valve body and trigger will now drop free.

6. Insert new trigger valve assembly and reinstall

solution outlet tube and solution inlet hose

assembly.

7. Replace cover.

REPLACEMENT PARTS

The following replacement parts are available from

your Sapphire Scientific distributor:

SPECIFICATIONS

Periodically

Warranty registration

Visit LegendBrandsCleaning.com to register your

purchase. Registration allows us to better assist you with

using, maintaining or servicing your equipment, as well

as to contact you in case we have important safety

information concerning your Sapphire Scientific product.

If you determine service is required, have your

equipment model, serial number and original proof of

purchase available and call your distributor for

assistance with obtaining a return material authorization

(RMA).

WARRANTY

Warranty information is available from your Sapphire

Distributor or at LegendBrandsCleaning.com.

CONTACT

Sapphire Scientific

2604 Liberator

Prescott, AZ 86301

800-932-3030 LegendBrandsCleaning.com

WARNING: This product may expose you to

chemicals, including lead and phthalates, known

to the State of California to cause cancer, birth defects,

or other reproductive harm. For more information, go to

P65Warnings.ca.gov

07-02087B F436-P 3 Sapphire Scientific

Page 4

Boquilla de manguera

de aspiración trasera

FIG. A: CABEZAL, MANGUERA DE

TUBO DE SOLUCIÓN

Acoplamiento

detalle.

Regulador de

aspiración

Palanca del gatillo de

Instrucciones de uso

Upholstery Pro

Modelo F436-P

La Upholstery Pro es una herramienta de limpieza que garantiza una penetración rápida y profunda de la solución limpiadora

y una extracción de grandes cantidades de suciedad simultáneamente. La Upholstery Pro pesa poco, es fácil de usar y se

adapta a una amplia variedad de telas y distintos niveles de suciedad para así dejar las telas más limpias y secas.

Patentes: http://www.LBpatents.com

LEA Y GUARDE ESTAS INSTRUCCIONES

CARACTERÍSTICAS PRINCIPALES

Mango cómodo y manguera aspiradora muy flexible

que permite un manejo equilibrado y distendido del

aparato, y disminuye el cansancio del operador

considerablemente.

Filtro de solución interno que ayuda a prevenir

obstrucciones.

Deslizante inyector de alta presión que garantiza una

penetración profunda y pareja de la solución en la

superficie de la tela.

Ranuras de extracción duales que permiten la

extracción total en ambas direcciones a lo largo de la

superficie de tela.

Disparador de aspiración regulable que permite tener

un control preciso de la potencia de aspiración en

telas delicadas.

Unidad principal transparente que facilita el control del

flujo del agua, de la sequedad de la tela o alfombra y

de la eficacia de la limpieza.

USO DE LA UPHOLSTERY PRO

1. Conecte el tubo de solución trasero de fijación

rápida al tubo de solución del extractor.

2. Junte el acoplamiento de la manguera trasera con el

puerto de aspiración del extractor.

3. Encienda el extractor.

4. Apriete la palanca del gatillo para expulsar la solución

y comenzar a limpiar. La traba del gatillo deslizable

se puede utilizar para mantener la válvula con gatillo

abierta.

5. Utilice el regulador de disparo de aspiración

(Fig. A) para ajustar la potencia de la aspiradora

según lo necesite.

ADVERTENCIA: El acoplamiento de

fijación rápida se puede calentar

mucho mientras se utiliza el aparato.

Consejos de uso

Control de la aspiradora. Utilice el regulador de

disparo de aspiración (Fig. A) para controlar la potencia

de la aspiradora cuando se utilice sobre telas finas,

delicadas y de poco peso.

Para optimizar los resultados, utilice la Upholstery Pro

con productos químicos de limpieza de Legend Brands.

Si desea obtener más información sobre el modo de uso

de la Upholstery, visite el sitio

LegendBrandsCleaning.com.

MANTENIMIENTO

A diario: Para enjuagar la herramienta manual, deje

correr agua limpia a través del tubo de solución.

A diario: Verifique el ensamblaje del

ABSORCIÓN Y ENSAMBLAJE DEL

del tubo de

solución de

fijación

rápida. Vaya

disparo de

07-02087B F436-P 4 Sapphire Scientific

a la Fig. D

para ver las

partes en

deslizante (Fig. A) para que el flujo de solución

expulsado por las boquillas del inyector sea

parejo y regular. Si alguno de los puertos del

inyector se obstruye, utilice una aguja pequeña

para remover la obstrucción, sin dañar el

deslizante. Si el deslizante se raya, se pica, se

engancha en las alfombras o expulsa la solución

Page 5

FIG. C: CABEZAL (VISTA INFERIOR)

Palanca del gatillo

Barra deslizante

Traba de la palanca del

gatillo

Tornillo y tuerca de la

Tuerca de cabeza

para acceder al filtro.

Arandela de nailon

(03-01652)

Orificio

(03-01903)

Acoplamiento

rápida

Filtro interno

(03-01649)

FIG. D: ENSAMBLAJE Y ACOPLAMIENTO DEL

TUBO DE SOLUCIÓN

FIG. B: ENSAMBLAJE DEL CABEZAL

Tornillos de la

cubierta (4)

Barra deslizante y

01705)

Tornillos del

Cuerpo de la

Cubierta

superior

Cubierta

inferior

palanca del gatillo

deslizante

(4)

(Cubierta

interna)

anillo obturador (S13-

válvula con gatillo

(13-01690)

excesivamente, es posible que necesite reemplazarlo

(lea la próxima sección “Sustitución del deslizante”). Los

repuestos del ensamblaje del deslizante se encuentran

a su disposición a través de su distribuidor.

Cuando sea necesario: Lubrique los acoplamientos

de fijación rápida (Fig. A) con un poco de aceite

inhibidor de oxidación como el LPS-3.

Cuando sea necesario: Lubrique el vástago de la

válvula con gatillo (Fig. C) con una pequeña cantidad

de grasa pesada sintética. Para engrasar el vástago,

siga estos pasos:

1. Retire la tuerca y el tornillo de la palanca del

gatillo y luego retire la palanca.

2. Desenrosque la tuerca de retención del vástago

y retírelo. Coloque una pequeña cantidad de

grasa en el vástago.

3. Vuelva a colocar el ensamblaje del vástago y

ajuste la tuerca de retención. Coloque la

palanca del gatillo nuevamente.

Cuando sea necesario: Limpie el filtro

interno (Fig. D) cuando vea que se redujo el

flujo de solución. Para limpiar el filtro,

desajuste la tuerca del ensamblaje del filtro y

remueva el filtro y la arandela del filtro.

Enjuague estos elementos con agua limpia y

vuelva a armar el filtro. En general, no es

necesario sustituir el filtro interno. Asegúrese

de colocar la arandela de nailon cuando lo

vuelva a armar y trate de no ajustar

excesivamente la tuerca del ensamblaje del

filtro.

Para mantener el aspecto del exterior del

aparato, límpielo con un paño húmedo.

SERVICIOS PARA EL MANTENIMIENTO

La Upholstery Pro está diseñada para facilitar el

mantenimiento del deslizante y la válvula con gatillo con

las herramientas manuales básicas dentro del área de

trabajo y en solo unos minutos. Si necesita sustituir

alguna pieza, los equipos de rearmado y las piezas de

repuesto se encuentran a su disposición a través de su

distribuidor de Sapphire o llamando al número de

teléfono de Sapphire Scientific: 800-932-3030.

Sustitución de la barra deslizante

Tenga a mano un equipo de sustitución de la barra

deslizante y el anillo obturador. (Pieza n.º S13-01705).

1. Retire los cuatro tornillos de la cubierta (Fig. B) y

separe la cubierta.

2. Retire los cuatro tornillos del deslizante (Fig. B) y

retire la barra deslizante y el anillo sellador.

Deséchelos.

3. Instale el nuevo anillo en el extremo de cierre de la

nueva barra deslizante. Coloque la nueva barra

deslizante en el cabezal. Asegúrese de que el

nuevo anillo obturador esté en su lugar.

4. Vuelva a colocar los tornillos del deslizante y ajuste;

luego, coloque la cubierta y ajuste con los tornillos

de la cubierta.

trasero de fijación

hexagonal. Afloje aquí

07-02087B F436-P 5 Sapphire Scientific

Page 6

Descripción

Dibujo de

referencia

Número de

pieza de

repuesto

Cuerpo de válvula con

gatillo

Fig. B

13-01690

Barra deslizante y anillo

obturador

Fig. B

S13-01705

Filtro

Fig. D

03-01649

Orificio

Fig. D

03-01903

Arandela de nailon

Fig. D

03-01652

Modelo

Sapphire Scientific Upholstery Pro F436-P

Pieza n.º 67-019 67-019-P

Dimensiones

Cabezal: 4 pulgadas de ancho de extracción

Ensamblaje de manguera: 10 pies

Material de

construcción

Cabezal: resina de copolyester.

Deslizante: termoplástico de ingeniería

Ensamblaje de manguera: manguera de

absorción muy flexible

Sujetador: chapa con selladores resistentes a

altas temperaturas

Las especificaciones del producto están sujetas a cambios sin

aviso previo. Algunos valores pueden ser aproximados.

1. Tuerca de

retención del vástago

FIG. E: EQUIPO DE SUSTITUCIÓN DEL VÁSTAGO (48-064)

2. Vástago.

6. Anillo sellador

5. Anillo sellador de

teflón

7. Resorte del extractor

3. Tuerca de la

palanca del gatillo

8. Tornillo sellador

4. Anillo

sellador

Servicio de mantenimiento de la válvula con gatillo

Si usted ha determinado que el deslizante no está

obstruido o dañado (vaya a la sección “Verifique el

ensamblaje del deslizante”) y el gatillo pierde o ya no

expulsa suficiente solución, puede que el gatillo necesite

servicio. Hay dos opciones disponibles para la

reparación:

Opción A: Vuelva a armar la válvula con gatillo.

Un equipo de repuesto del vástago (pieza n.º 48-064) se

encuentra a su disposición a través de su distribuidor de

Sapphire. Las piezas incluidas en este equipo son las

que se pueden ver en la Fig. E.

1. Retire la tuerca y el tornillo de la palanca del gatillo y

retire la palanca.

2. Desenrosque la tuerca de retención y desarme el

ensamblaje del vástago.

3. Arme el ensamblaje del vástago y vuelva a ajustar la

tuerca de retención.

4. Vuelva a colocar la cubierta y rearme la palanca del

gatillo. Utilice la nueva tuerca de traba que se le

suministró (Fig. E).

Opción B: Sustituya el ensamblaje de la válvula con

gatillo.

Un repuesto del ensamblaje de la válvula con gatillo

(pieza n.º 13-01690) se encuentra a su disposición a

través de su distribuidor de Sapphire.

1. Retire los cuatro tornillos de la cubierta (Fig. B) y

luego retire la cubierta.

2. Presione el anillo de disparo de la manguera sobre

la salida del tubo de solución y extraiga el tubo.

Evite retorcer el tubo.

3. Retire el sujetador de la salida del tubo de solución

que se encuentra dentro del cuerpo de la válvula.

4. Desconecte el ensamblaje de la manguera de

entrada de solución del cuerpo de la válvula.

5. El gatillo y el cuerpo de la válvula ahora se soltarán.

6. Inserte el ensamblaje de la válvula con gatillo nuevo

y reinstale la salida del tubo de solución y el

ensamblaje de la manguera de entrada.

7. Vuelva a colocar la cubierta.

PIEZAS DE REPUESTO

Las siguientes piezas están a su disposición a través de

su distribuidor de Sapphire Scientific:

ESPECIFICACIONES DEL PRODUCTO

GARANTÍA

La información de la garantía se encuentra a su

disposición a través de su distribuidor de Sapphire o en

el sitio web LegendBrandsCleaning.com.

Registro de garantía

Visite LegendBrandsCleaning.com para registrar su

compra. El registro nos permite brindarle una mejor

asistencia para el uso, mantenimiento y servicio de su

equipo, y contactarlo en caso de que tengamos

información de seguridad importante con respecto a su

producto Sapphire Scientific. Si se requiere servicio,

tenga a su disposición el modelo de su equipo, el

número de serie y el comprobante de compra original, y

llame a su distribuidor para que lo ayude a obtener una

autorización para la devolución del material (Return

Material Authorization, RMA).

Coloque grasa

traba de la

07-02087B F436-P 6 Sapphire Scientific

periódicamente.

CONTACTO

Sapphire Scientific

2604 Liberator

Prescott, AZ 86301

800-932-3030 LegendBrandsCleaning.com

ADVERTENCIA:

Este producto puede exponerlo a usted a

sustancias químicas como el plomo y los ftalatos

que, según el estado de California, son causantes

de cáncer, defectos en el nacimiento y otros daños

reproductivos. Para obtener más información, visite

P65Warnings.ca.gov.

Page 7

Manchon du tuyau

d’aspiration arrière

Figure A : TÊTE, TUYAU D’ASPIRATION

ET ASSEMBLAGE DE LA CONDUITE DE

SOLUTION

Raccord de

Figure D.

Glissière de réglage

de l’aspiration

Levier de déclenchement de

la solution

Instructions d’utilisation

Upholstery Pro

Modèle : F436-P

L’outil de nettoyage Upholstery Pro permet une pénétration profonde et rapide de la solution de

nettoyage et une extraction simultanée d’un volume élevé. Léger, facile à utiliser et réglable pour une

large gamme de tissus et de conditions de saleté, l’appareil Upholstery Pro permet d’obtenir des tissus

plus propres et plus secs.

Brevets : http://www.LBpatents.com

LIRE ET CONSERVER CES INSTRUCTIONS

CARACTÉRISTIQUES PRINCIPALES

La poignée confortable et le tuyau d’aspiration très

souple permettent une manipulation équilibrée et aisée

et une réduction importante de la fatigue de

l’utilisateur.

La crépine pour la solution aide à empêcher les

obturations.

Le patin à injecteur à haute pression permet une

pénétration rapide et homogène de la solution dans la

surface du tissu.

Deux fentes d’extraction uniques permettent une

extraction complète, dans les deux directions, à

travers la surface des tissus.

La glissière de réglage de l’aspiration permet un

contrôle d’aspiration précis pour les tissus délicats.

Boîtier transparent permettant une surveillance aisée

du débit d’eau, de l’assèchement du tissu ou du tapis

et de l’efficacité du nettoyage.

UTILISATION DE l’UPHOLSTERY PRO

1. Brancher la conduite de solution à connexion rapide

arrière à la conduite de solution de l’extracteur.

2. Relier le raccord de tuyau arrière à la sortie

d’aspiration de l’extracteur.

3. Mettre l’extracteur en marche.

4. Serrer le levier de déclenchement pour libérer la

solution et commencer le nettoyage. Le verrou de

déclenchement à glissière peut être utilisé pour

garder la vanne de déclenchement en position

ouverte.

5. Utiliser la glissière de réglage de l’aspiration

(Figure A) pour ajuster la puissance d’aspiration au

besoin.

ATTENTION : Le raccord de

connexion rapide peut devenir très

chaud lors de l’utilisation.

Conseils d’utilisation

Contrôle de l’aspiration. Utiliser la glissière de réglage

de l’aspiration (Figure A) pour contrôler la puissance de

l’aspiration lors de l’extraction sur des tissus fins,

délicats ou légers.

Pour obtenir de meilleurs résultats, utiliser l’appareil

Upholstery Pro avec des produits de nettoyage

Legend Brands.

Pour plus d’information sur le nettoyage à l’aide

connexion rapide

pour la conduite

de solution. Voir

des détails à la

de l’outil Upholstery, visiter

LegendBrandsCleaning.com.

MAINTENANCE

Quotidiennement : Rincer l’outil à main en

faisant couler de l’eau à travers la conduite de

solution.

Quotidiennement : Vérifier l’assemblage du

patin (Figure A) pour obtenir un débit constant et

stable de solution à travers les buses de

l’injecteur. Si toute sortie de l’injecteur semble

bouchée, utiliser une petite aiguille pour retirer

07-02087B F436-P 7 Sapphire Scientific

Page 8

Écrou hexagonal, le

à la crépine.

Rondelle en

(03-01652)

Orifice

(03-01903)

Raccord de

connexion rapide

Crépine interne

(03-01649)

FIG. D: SOLUTION LINE COUPLING ASSEMBLY

Figure B : ASSEMBLAGE DE LA TÊTE

Vis du

couvercle (×4)

Patin et joint torique

(S13-01705)

Vis du patin

du couvercle)

Corps de la vanne

(13-01690)

Couvercle

supérieur

Couvercle

inférieur

1. Écrou de rétention de la tige

Figure E : ENSEMBLE DE REMPLACEMENT

DE TIGE (48-064)

2. Tige. Appliquer

graisse ici.

6. Joint torique

5. Joint en téflon

7. Ressort de l’extracteur

3. Écrou de verrouillage du

levier de déclenchement

8. Vis à épaulement

4. Joint torique

(×4)

(à l’intérieur

l’obstruction, prendre soin de ne pas endommager le

patin. Si le patin est rayé, entaillé, s’accroche sur du

tapis, ou coule excessivement, il faut peut-être le

remplacer (voir « Entretien du patin », ci-après).

Des ensembles de remplacement du patin sont

disponibles auprès de votre distributeur.

de commande

Pour une belle apparence, essuyer les surfaces

externes avec un chiffon humide.

ENTRETIEN

L’appareil Upholstery Pro est conçu pour permettre un

entretien facile sur le terrain du patin et de la vanne de

déclenchement avec des outils à main de base, en

quelques minutes. Si le remplacement devient

nécessaire, des ensembles de réparation et des pièces

de rechange sont disponibles auprès de votre

distributeur Sapphire ou de Sapphire Scientific au

(800)932-3030.

Remplacement du patin

Se munir d’un ensemble de remplacement de patin et de

joint torique (no de pièce S13-01705).

1. Retirer les quatre vis du couvercle (Figure B) et

soulever le couvercle.

2. Retirer les quatre vis du patin (Figure B) et retirer le

patin et le joint torique. Les jeter.

3. Installer un nouveau joint torique dans le logement

d’étanchéité du nouveau patin. Placer le nouveau

patin dans la tête. S’assurer que le joint torique est

bien en place.

4. Replacer les vis du patin et les serrer; puis, replacer

le couvercle et le serrer à l’aide des vis du

couvercle.

Au besoin : Lubrifier les raccords de

connexion rapide (Figure A) avec une petite

quantité d’huile antirouille comme de la LPS-3.

Au besoin : Lubrifier la tige de la vanne de

déclenchement (Figure C) avec une petite

quantité de graisse synthétique longue durée.

Pour graisser la tige, suivre les étapes cidessous :

1. Retirer l’écrou et le boulon du levier de

déclenchement et retirer le levier.

2. Dévisser l’écrou de rétention de la tige et

soulever l’ensemble de la tige. Déposer une

petite quantité de graisse sur la tige.

3. Remplacer l’ensemble de la tige et resserrer

l’écrou de rétention. Rattacher le levier de

déclenchement.

Au besoin : Nettoyer la crépine interne (Figure

D) lorsque le débit de solution est visiblement

réduit. Pour nettoyer le filtre, desserrer l’écrou de

l’ensemble de la crépine, et retirer la crépine ainsi

que sa rondelle. Rincer ces éléments dans de l’eau

propre et réinstaller la crépine. Il n’est

généralement pas nécessaire de remplacer

l’élément filtrant interne. Ne pas oublier d’inclure la

rondelle en nylon lors du remontage, et de

s’assurer de ne pas trop serrer l’écrou de

l’ensemble de la crépine.

desserrer pour accéder

nylon

régulièrement de la

07-02087B F436-P 8 Sapphire Scientific

Page 9

Description

Illustration de

référence

No de la pièce

de rechange

Déclencheur et corps de vanne

Figure B

13-01690

Patin et joint torique

Figure B

S13-01705

Crépine

Figure D

03-01649

Orifice

Figure D

03-01903

Rondelle en nylon

Figure D

03-01652

Modèle

Sapphire Scientific Upholstery Pro F436-P

No de pièce : 67-019 67-019-P

Dimensions

Tête : largeur d’extraction de 4 po

Assemblage du tuyau : 10 pi

Construction

Tête : De copolyster haute performance.

Patin : Thermoplastique d’ingénierie

Assemblage du tuyau : Tuyau d’aspiration

extrêmement flexible

Raccords : Laiton avec joints haute température

Ces spécifications peuvent être modifiées sans préavis. Certaines

valeurs peuvent être approximatives.

FIG. C: TÊTE (VUE DU DESSOUS)

Levier de

déclenchement

Patin

Verrou du levier de

déclenchement

Écrou et

de déclenche

Entretien de la vanne de déclenchement

Si le déclencheur fuit ou qu’il ne libère pas suffisamment

de solution et que vous avez déterminé que le patin

n’est pas obturé, ni endommagé (voir « Vérifier

l’assemblage du patin »), le déclencheur doit peut-être

être réparé. Deux options sont disponibles.

Option A : Réparer la vanne de déclenchement.

Un ensemble de remplacement de tige (no de pièce 48-

064) est disponible auprès de votre distributeur

Sapphire. Les pièces composant cet ensemble sont

illustrées à la Figure E.

1. Retirer l’écrou et le boulon du levier de

déclenchement et retirer le levier.

2. Dévisser l’écrou de rétention de la tige et soulever

l’ensemble de la tige.

3. Installer l’ensemble de la tige et resserrer l’écrou de

rétention de la tige.

4. Replacer le couvercle et rattacher le levier de

déclenchement. Utiliser le nouvel écrou de

verrouillage fourni (Figure E).

Option B : Remplacer l’ensemble de vanne de

déclenchement

Un ensemble de remplacement de vanne de

déclenchement (no de pièce 13-01690) est disponible

auprès de votre distributeur Sapphire.

1. Retirer les quatre vis du couvercle (Figure B) et

soulever le couvercle.

2. Appuyer sur l’anneau de libération du tuyau sur le

tube de sortie de la solution et tirer sur le tube pour

le retirer. Éviter d’entortiller le tube.

3. Retirer le raccord du tube de sortie de la solution du

corps de la vanne.

4. Débrancher l’ensemble du tuyau d’arrivée de la

solution du corps de la vanne.

5. Le corps de la vanne et le déclencheur peuvent

maintenant être retirés librement.

6. Insérer le nouvel ensemble de vanne de

déclenchement et rebrancher le tube de sortie de la

solution ainsi que l’ensemble du tuyau d’arrivée de

la solution.

7. Replacer le couvercle.

PIÈCES DE RECHANGE

Les pièces de rechange suivantes sont disponibles

auprès de votre distributeur Sapphire Scientific :

07-02087B F436-P 9 Sapphire Scientific

boulon du

levier

SPÉCIFICATIONS

GARANTIE

Des renseignements concernant la garantie sont

disponibles auprès de votre distributeur Sapphire ou sur

le site : LegendBrandsCleaning.com.

Enregistrement de la garantie

Visiter LegendBrandsCleaning.com pour enregistrer

votre achat. L’enregistrement nous permet de mieux

vous aider pour l’utilisation, l’entretien ou la réparation

de votre équipement, ainsi que pour communiquer avec

vous en cas de consignes de sécurité importantes

concernant votre produit Sapphire Scientific. Si vous

déterminez que des réparations sont nécessaires, ayez

en main le modèle, le numéro de série et la preuve

d’achat originale de votre équipement, et appelez votre

distributeur afin d’obtenir une autorisation de retour de

matériel (ARM).

CONTACT

Sapphire Scientific

2604 Liberator

Prescott, AZ 86301

(800) 932-3030 LegendBrandsCleaning.com

ATTENTION : Cet appareil peut vous exposer à

des produits chimiques, y compris du plomb et

des phtalates, qui selon l’État de Californie peuvent

causer des cancers, des malformations congénitales ou

d’autres anomalies de reproduction. Pour de plus

amples renseignements, visiter : P65Warnings.ca.gov

Loading...

Loading...