Sapphire Audio SS-P 150,SS-P 500,SS-P 150H,SS-P 500H,SS-P 1200EX User Instructions

ARTWORK SPEC SHEET

Sapphire Portable Extractors Manual

SS-P 500, SS-P 500H, SS-P 1200EX

Part name

Part number

Declaration of conformity

n/a

Date of request

8/19/2010

Due date

ASAP

Requested by

Eric Bosell

Type of artwork

Manual

Reason for change

New product line

Material disposition

n/a

Vendor

TBD

Material

20# white

Finish

Book

Color

Black ink

Notes

Insert warranty text noted above into finished manual.

FINAL SIGN-OFF

This page should be completed and saved as the first page of final manual file (PDF or Word), then sent to

Marketing Manager for forwarding to Purchasing (for procurement) and Engineering (for controlled storage).

Product name

Covering models SS-P 150, SS-P 150H,

MANUAL

24-00265 Rev. A

Warranty text 49-055 Rev. A

Finished size 8½ × 11 in.

#1 Marketing Manager:

#2 Vendor Representative:

SS-P Portable Extractors

User Instructions

For SS-P 150, SS-P 150H, SS-P 500, SS-P 500H, and SS-P 1200EX models

SS-P Portable Extractors provide deep, rapid cleaning of carpets, upholstery and hard surfaces.

Heated models provide additional cleaning power. Lightweight, easy to use, and adjustable for a

wide range of carpet types and soiling conditions, the SS-P Extractors produce cleaner, drier

carpets and surfaces.

Patent Pending

READ AND SAVE THESE INSTRUCTIONS

Contents

Introduction

Warnings and cautions ......................................... p. 1

Key features .............................................................. 1

Product introduction .................................................. 2

Operating instructions

SS-P 150, SS-P 150H, SS-P500, SS-P 500H .......... 3

SS-P 1200EX ............................................................ 3

Maintenance (all units) .............................................. 4

Other information

Specifications ............................................................ 5

Warranty and registration ......................................... 5

Warnings: Risk of personal injury

Read these instructions before operating machine.

WARNING: Unplug machine before

servicing. Possbility of electrical shock.

WARNING: In heated units, solution line can

become extremely hot during use.

WARNING: Interior components may be hot

after operation. Let unit cool completely

before servicing.

WARNING: Do not operate machine unit in the

presence of flammable materials.

Cautions: Risk of property damage

CAUTION: Protect from freezing. Freezing may

damage internal components and will void warranty.

CAUTION: Do not use with water with over 3 grains

per gallon (51 miligrams per liter) of hardness. Use

with hard water could result in the formation of

mineral deposits inside pumps and fittings. Damage

caused by mineral deposits will void warranty.

CAUTION: Use only to extract liquids. Do not use as

a dry vacuum. Dust particles will damage the

vacuum motors. Damage caused by dry vacuumi ng

will void the warranty.

CAUTION: To prevent the growth of mold and

mildew inside the tanks, always drai n waste tank

completely and empty solution tank after use.

Key features

Compact: Smaller footprint than leading compet itors –

only 39.5H × 32L × 19.75W in. (100.3 × 81.2 × 50.2 cm).

Versatile: Sapphire portable extractors may be used

successfully with most professional wands and hand

tools. Use with 1½ in. vacuum wands, hoses and tools,

or adapt for use with 2 in. equipment (adaptor purchased

separately).

Lightweight: only 87–130 lbs. dry weight dependi ng on

model.

Easy to transport: Rugged molded handles are wellplaced for easy maneuverability. Molded grip poi nt

assures safe handling when lifting.

Integrated cord wrap provides secure cord storage.

Slim profile. Semi-pneumatic 10 in. diameter non-

marking wheels mounted in recessed wheel wel ls.

Durable: Rotomolded housing helps reduce

maintenance and provides quiet operation.

Integrated rotomolded standpipe resists breakage for

years of leak-free service.

24-00265 A 2010-08 1 Sapphire Scientific

FIG. 1: Front View

Control Panel

Vacuum

Recovery tank

Solution

Tank attachment

Recovery tank

cover

A

B

C

FIG. 2: Rear View

F

H

Dual power cords (heated models and 1200EX only)

inlet

line quickconnect

Quiet operation: Noise suppressor for quiet operatio n.

May be operated with single motor for reduc ed noise.

Fast access to parts: Clamshell design hinges open for

easy filter maintenance.

Fast, steady heat: Powerful 2000 watt in-line heat er on

select models (“H” designates heated models).

Convenient: Top-mounted switches are easy to reach

and feature protective caps.

outlet valve handle

screw. Unscrew to

open unit.

PRODUCT INTRODUCTION

All SS-P series portable extractors are equipped with a

control panel conveniently located at the top of the unit.

The rocker-style switches are fitted with protective

rubber caps. Heated units (designated with an “H” in t he

model name) are equipped with an additional swit ch to

control the heater.

Dual vacuum motors draw air and extracted moisture

through the vacuum hose into the recovery tank. Users

may select single motor mode (“VAC 1”) for quieter

operation or both motors (“VAC 1&2”) for maximum

vacuum.

24-00265 A 2010-06 2 Sapphire Scientific

D

H

A Cord and tool storage compartment

B Auto-fill coupling (1200EX only)

C Vacuum exhaust. Keep clear.

D Pressure gauge (500 and 1200EX models only)

E Auto Pumpout Switch

F Auto Pumpout coupling (1200EX only)

G Pressure regulator (500 and 1200EX models only)

Solution pumps deliver pressurized solution to the

cleaning tool. The model number indicates the

approximate maximum pressure in pounds per square

inch. Models designated 500 and 1200 are equipped

with an adjustable pressure regulator and a press ure

gauge.

Heated units include a 2000 watt inline soluti on heater.

Heated solution can boost the effectiveness of your

cleaning.

The SSP-1200EX includes Automatic Pumpout and

AutoFill features which automate the filling and emptying

procedures.

E

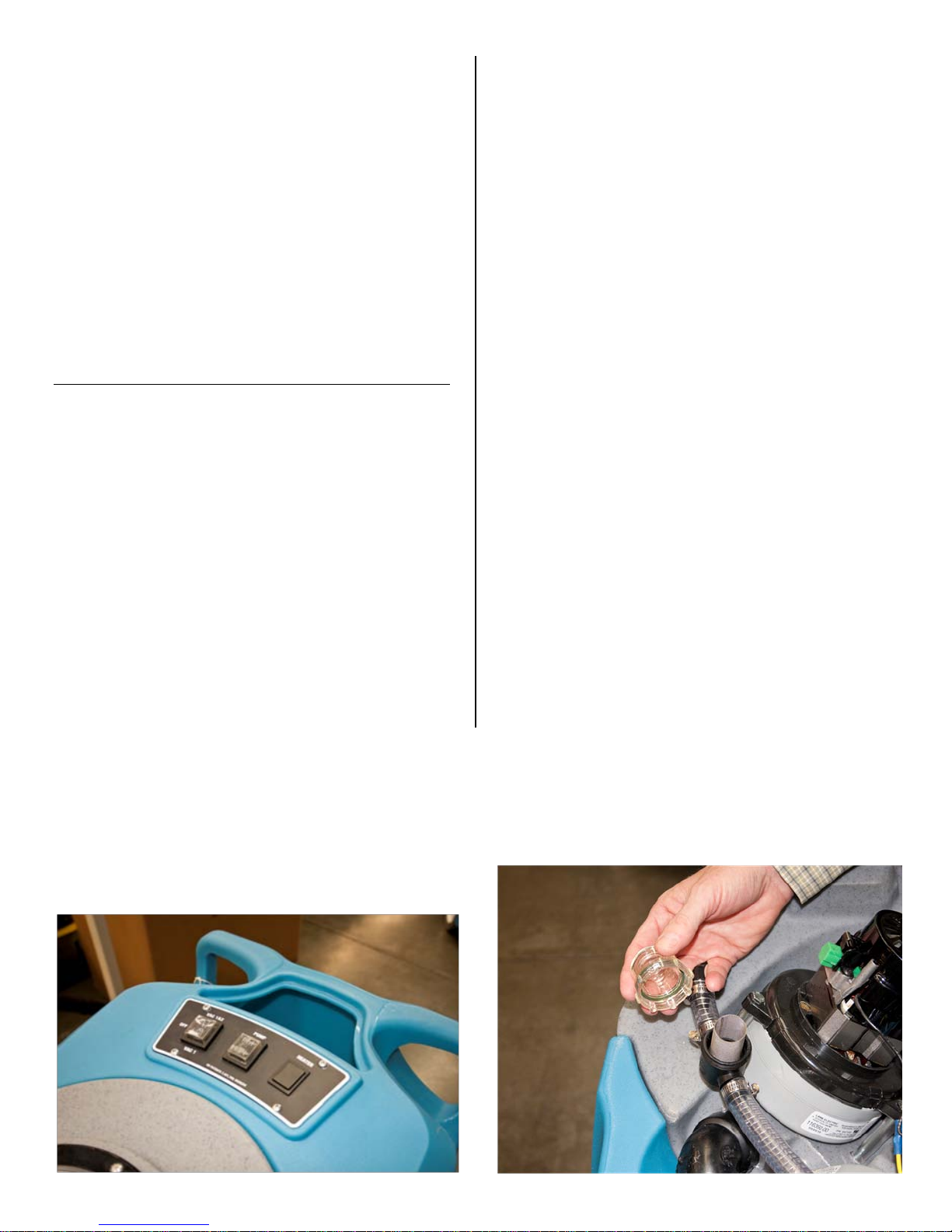

CONTROLS

ON THE CONTROL PANEL (see Fig. 3)

VAC 1 turns on one vacuum motor. This provides for

quieter operation and lower amp draw (about 8 amps).

VAC 1&2 turns on both vacuum motors. This provides

maximum vacuum power. Draws about 13.5 amp s.

Solution pump. Turns solution pump on and off.

Heat (heated units only). Turns on in-line solution

FIG. 4:

FIG. 3: Top Detail

Control

Cord

wrap

Solution

heater. Heated units are equipped with a second power

cord. Because the heating circuit draws about 17 amps,

the second power cord must be plugged in to a separ ate

electric power source rated for at least 20 amps.

OTHER CONTROLS

Pressure regulator (Fig. 2, G). 500 and 1200EX m odels

only. Turn clockwise to increase solution pressure; turn

counterclockwise to decrease solution pressure.

Auto pumpout switch (Fig. 2, E) 1200EX only. Switch

to on position to activate auto pumpout mode.

SS-P 150, SS-P 150H, SS-P 500 and

SS-P 500H OPERATING INSTRUCTIONS

1. Pre-mix cleaning solution with hot water in a

separate container. Pour mixed solution into the

solution tank of the machine.

IMPORTANT: When necessary use liquid defoamer

agent in the recovery tank to control foaming. Excess

foam in the recovery tank can allow moisture, ca rpet

fiber and other debris to be drawn through the vacuum

cutoff valve and cause damage to the vacuum motors.

Damage caused by moisture or debris will void the

product warranty. Follow defoamer manufacturer

instructions for proper application.

2. Connect vacuum and solution hoses to machine and

attach to extraction wand or hand tool.

3. Insert both plugs into separate 3-pin grounded

outlets. It is imperative that the cords are plugg ed

into separate circuits rated for at least 20 amps of

service. Keep cords clear of your cleaning path.

4. Switch vacuum control to VAC 1 or VAC 1&2

position.

5. Turn on solution pump.

6. If desired, turn on heater (H units only).

7. Begin cleaning. Refer to industry-approved

procedures.

8. Solution pressure may be adjusted with the pressure

regulator knob (Fig. 2, G). Monitor the pressure

gauge (if equipped) to ensure pressure is adequ ate.

CAUTION: When the recovery tank reaches capacity,

an automatic float valve blocks vacuum intake (see

Fig. 7) and the vacuum motors will make a high

pitched noise. When this occurs, the machine

should be turned off immediately to prevent damage

to the vacuum motors.

9. When the recovery tank is full, first turn the uni t off.

Pull up on the drain valve on the front of the

machine (Fig. 1) and empty the tank it into a suitable

container or drain. Be sure to close the valve again

securely before returning the unit to use.

10. When the job is complete, empty and rinse out the

solution tank thoroughly to prevent growth of harmful

bacteria. Turn on both vacuum motors and allow

them to run for 3–5 minutes to help eliminate any

moisture from the vacuum motors and assure long

vacuum life.

For maintenance instructions, see “Maintenance,” p. 4.

TIP: To empty the solution tank, remove the vacuum

hose from wand and extract the solution f rom solution

tank.

tank

panel

24-00265 A 2010-06 3 Sapphire Scientific

150

and 500 solution

filter location.

Rinse clean after

each use.

Loading...

Loading...