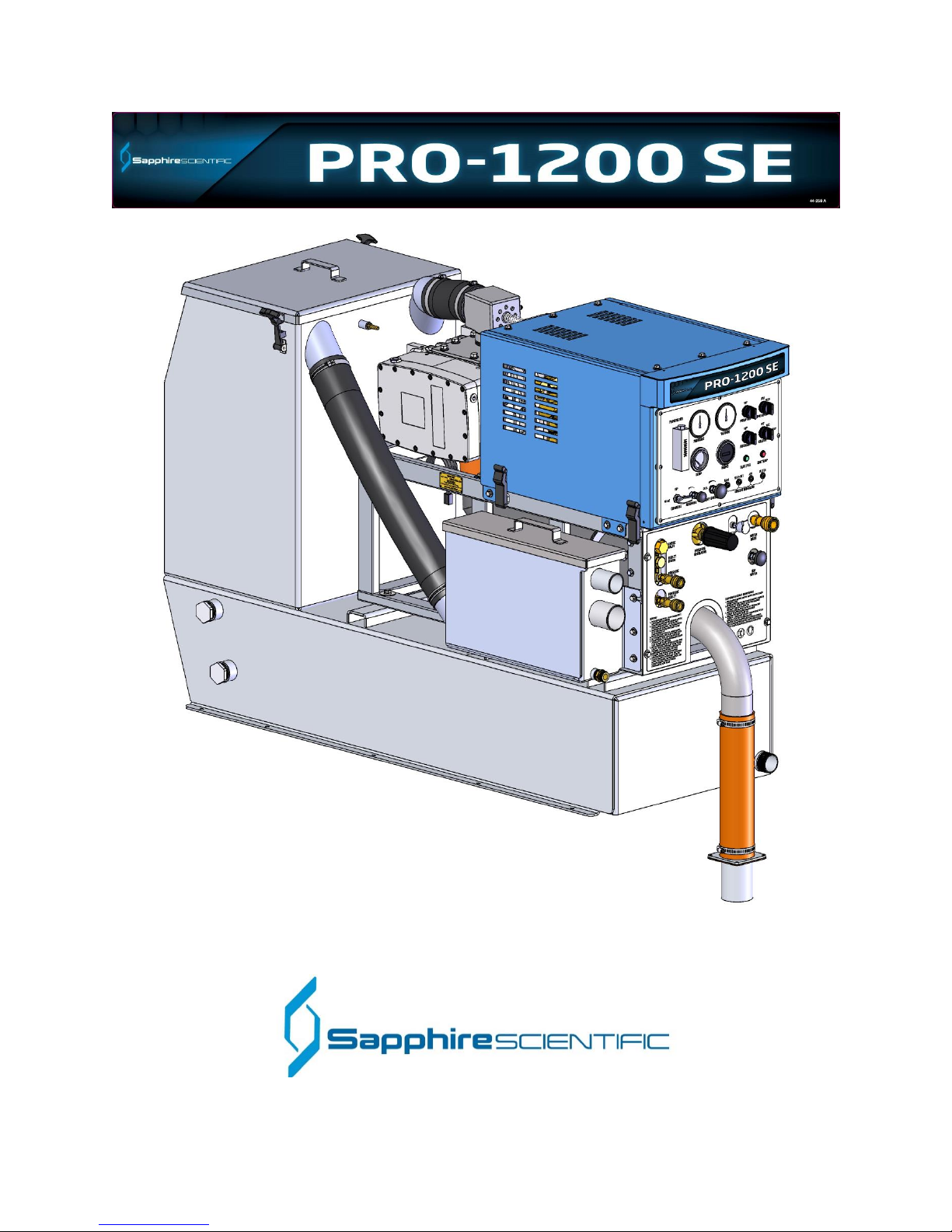

Sapphire Audio PRO-1200 SE Owner's Manual

OWNER’S MANUAL

2604 Liberator, Prescott, AZ 86301 1-866-445-3030

49-139, Rev A Sapphire Scientific Pro-1200 SE

This unit was manufactured by:

Sapphire Scientific

2604 Liberator

Prescott, AZ 86301

USA

! Do not alter or modify your Pro-

1200 SE in any way. Use only replacement parts

authorized by Sapphire Scientific. Modifications or use

of unapproved parts could create a hazard and will void

your warranty. Contact a Sapphire Scientific service

representative at 866-445-3030 for assistance.

This service and operations manual is

written specifically for the Pro-1200 SE

unit.

Published by Sapphire Scientific.

First Printing: April 2015

Printed in USA

Pro-1200 SE MANUAL

SAPPHIRE SCIENTIFIC P/N 49-139

REVISION A, APRIL 2015

The information contained in this document is subject to

change without notice and does not represent a

commitment on the part of Sapphire Scientific.

All rights reserved. Copyright 2014 by Sapphire

Scientific. No part of this work may be used or

reproduced in any form or means without the express

written consent and permission of Sapphire Scientific.

Congratulations on your purchase of the Pro-1200 SE direct-drive cleaning unit. This instruction and

parts manual is a guide for operating and servicing your Sapphire Scientific equipment.

Proper operation and service are necessary to ensure the outstanding performance of this unit. When

properly maintained, your truck-mount will have a long and trouble-free life.

The following service methods outlined in this manual are detailed in a manner that operation and

servicing may be performed properly and safely. Because service levels vary due to the skill of the

mechanic, tools and parts availability, ensure that prior to attempting any maintenance or repair, you

are familiar with the equipment and have all the proper tools to complete the task. Please call a

Sapphire Scientific service representative at 866-445-3030 for help with maintenance, repair and

warranty related questions.

The headings “WARNING” and “CAUTION” are utilized to warn you that steps must be taken to prevent

personal injury or damage to the equipment. Please make sure that you have read and understand

these instructions entirely before proceeding with the operation of this unit.

THIS UNIT MUST BE INSTALLED BY THE DEALER THAT YOU PURCHASED IT FROM IN ACCORDANCE

WITH THE SAPPHIRE SCIENTIFIC INSTALLATION PROCEDURES.

Be sure to fill out the warranty card online at: http://www.sapphirescientific.com

Page | I

49-139, Rev A Sapphire Scientific Pro-1200 SE

SAPPHIRE SCIENTIFIC LIMITED WARRANTY

Sapphire Scientific Pro-1200 SE

What Does This Warranty Cover?

This warranty covers the Sapphire Scientific Model Pro-1200 SE and is provided to the original purchaser only.

How Long Does This Warranty Last?

This warranty runs for:

Three (3) years from the date of installation on parts and labor (Excluding normal maintenance items.) Factory installed

original belts are covered for 500 hours. Water box, recovery tank and frame are covered for five years. All other

components including seals, o-rings and electrical components are covered for the entire two year warranty period.

What Sapphire Scientific Will Do:

If a defect in materials or workmanship occurs within the warranty period, Sapphire Scientific at its election will repair or

replace the defective part at no charge.

What This Warranty Does Not Cover:

This warranty does not cover or apply to defects due directly or indirectly to misuse, abuse, disassembly, alteration,

corrosive chemicals, improper voltage, improper fuel, fire, flood, negligence, accident, improperly or incorrectly

performed maintenance or repair, or failure to perform necessary or recommended maintenance or repair (See your

Owner’s Manual) or if the use of this product is not in compliance with the instructions and specifications for its use. Thi s

warranty does not cover normal maintenance items such as air and oil filters, lubricants and tune up parts. Paint is not

covered. Water box, recovery tank and frame are covered for five years. All other components including seals, o-rings and

electrical components are covered for the entire two year warranty period. We limit all implied warranties to:

Three (3) years from the installation date on parts and labor. It is strongly recommended that this truck mount be used

with, and only with, Sapphire Scientific Chemicals and as directed by label instructions on chemical bottles.

OTHER THAN THE WARRANTIES PROVIDED HEREIN, SAPPHIRE SCIENTIFIC MAKES NO EXPRESS OR IMPLIED, ORAL OR

WRITTEN WARRANTIES WITH RESPECT TO THIS PRODUCT OR WORKMANSHIP AND ALL WARRANTIES IMPLIED BY LAW

INCLUDING ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED TO THE

DURATION OF THIS WARRANTY. Some states do not allow limitations on how long an implied warranty lasts, so the

above limitations may not apply to you. WE SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR

PROPERTY OR FOR INCIDENTAL, CONTINGENT, SPECIAL OR CONSEQUENTIAL DAMAGES ARISING FROM USE OF OUR

PRODUCTS. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

How Do I Get Service?

In order to be eligible for service under this warranty you MUST do the following: (a) fill out the warranty registration card

on-line within thirty (30) days of the installation of our product; (b) write or call a service representative at Sapphire

Scientific for a return material authorization (RMA); and (c) have the serial number available. Proof of proper maintenance

may be required before warranty is granted.

Contact us at:

Sapphire Scientific

2604 Liberator, Prescott, AZ 86301

Phone: 928-445-3030 / 866-445-3030

If Sapphire Scientific uncovers a defect we will repair or replace the product, at our election. Ground shipping and

transportation costs will be covered by the manufacturer. Returning defective parts to the manufacturer, if required, shall

be the responsibility of the purchaser. Warranty may be denied if defective parts are not returned within the allotted 30

days. If it is determined that there is no defect in the product, or that the defect resulted from causes not within the scope

of our warranty, then the product will be repaired or replaced only at your request and at your expense and you must

bear all shipping costs.

How Does State Law Apply?

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Page | II

49-139, Rev A Sapphire Scientific Pro-1200 SE

TABLE OF CONTENTS

SECTION ONE: GENERAL INFORMATION 1

CONTACT INFORMATION ...........................................................................2

WARNINGS AND CAUTIONS .......................................................................3

SPECIFICATIONS .........................................................................................8

INSTALLATION REQUIREMENTS ..................................................................9

RESPONSIBILITIES ......................................................................................9

RECEIVING YOUR PRO-1200 SE ...................................................................10

SECTION TWO: OPERATION 11

UNDERSTANDING THE SYSTEMS .................................................................12

PREPARATION AND OPERATION .................................................................17

FREEZE PROTECTION ..................................................................................29

SECTION THREE: SERVICE AND MAINTENANCE 31

MAINTENANCE AND SERVICE CHARTS ........................................................32

MAINTENANCE ..........................................................................................34

GENERAL SERVICE ADJUSTMENTS ...............................................................41

TROUBLESHOOTING ...................................................................................47

SECTION FOUR: PARTS AND ACCESSORIES 53

ILLUSTRATED PARTS LISTING ......................................................................54

WATER FLOW DIAGRAM ............................................................................85

ELECTRICAL DIAGRAM ................................................................................86

Page | III

SECTION ONE – GENERAL INFORMATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

SECTION ONE: GENERAL INFORMATION

CONTACT INFORMATION ........................................................................ 2

WARNINGS AND CAUTIONS .................................................................... 3

SPECIFICATIONS ..................................................................................... 8

TORQUE VALUES ...................................................................................................... 8

JET SIZING................................................................................................................. 8

INSTALLATION REQUIREMENTS .............................................................. 9

RESPONSIBILITIES ................................................................................... 9

TRAINING ................................................................................................................. 9

INSTALLATION .......................................................................................................... 9

RECEIVING YOUR PRO-1200 SE ............................................................... 10

ACCEPTANCE OF SHIPMENT .................................................................................... 10

EQUIPMENT LISTING ................................................................................................ 10

Page | 1

SECTION ONE – GENERAL INFORMATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

Serial Number:

Date of Purchase:

Purchased From (Distributor):

_______________________________________

CONTACT INFORMATION

For information about unit operation, maintenance or repair of your Sapphire Scientific equipment,

please contact your local distributor.

To locate a local distributor, please visit our web site: http://www.sapphirescientific.com/

North American Distributors:

http://www.sapphirescientific.com/SSX_DistributorListings_NorthAmerica.aspx

If you need to contact Sapphire Scientific directly, for questions regarding this manual, service questions

that cannot be resolved by your distributor, or other general information, please contact our service

department here:

Phone: 1-800-932-3030

Service Email: service@sapphirescientific.com

Please fill in the information below so that you will have it on hand when contacting your distributor or

Sapphire Scientific.

Page | 2

SECTION ONE – GENERAL INFORMATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

WARNINGS AND CAUTIONS

Sapphire Scientific uses this WARNING symbol throughout the manual to warn of the possibility of

physical injury or fatality. Please read all warnings carefully before operating the equipment.

Sapphire Scientific uses this CAUTION symbol throughout the manual to warn of the possibility of

damage to equipment or personal property.

Page | 3

SECTION ONE – GENERAL INFORMATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

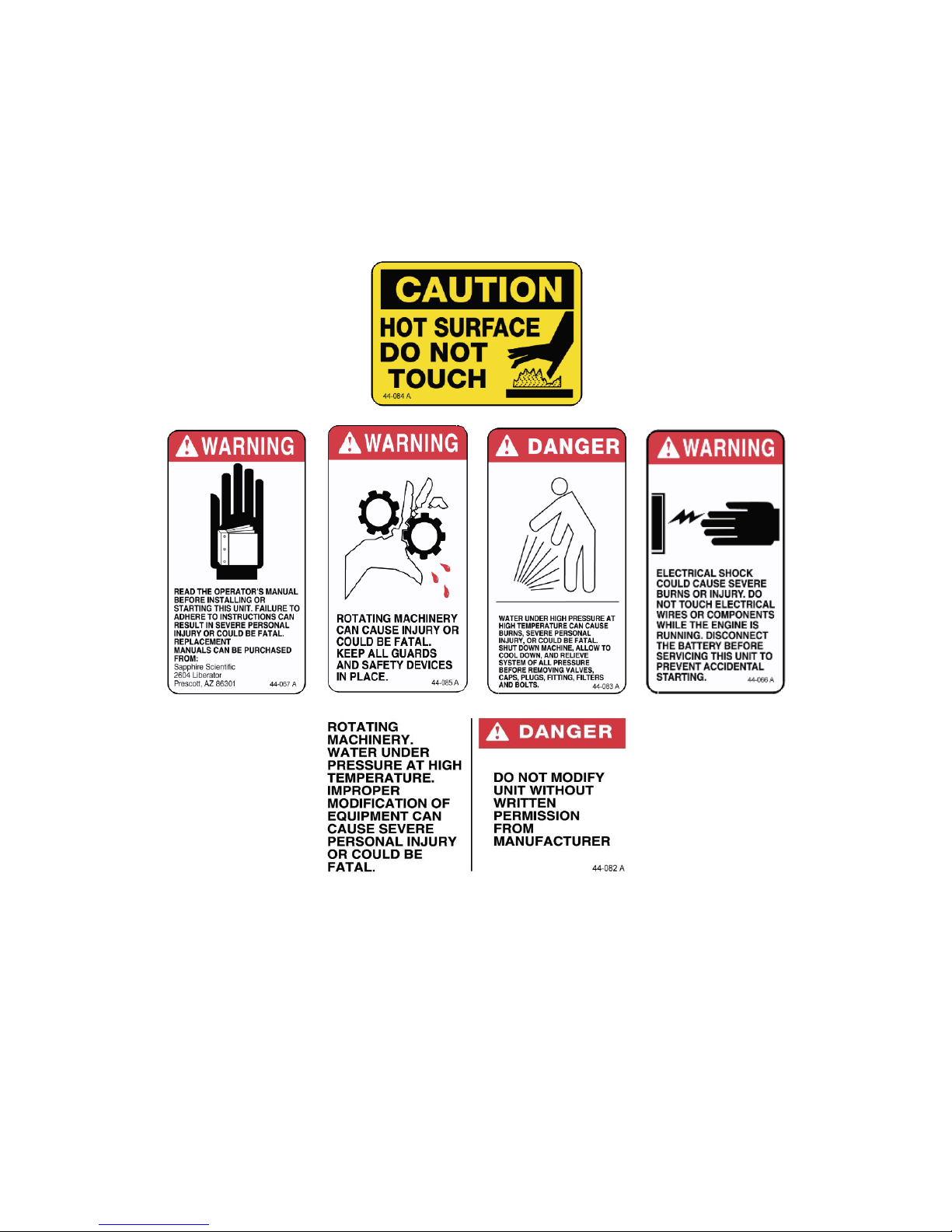

FOR YOUR SAFETY

The following warning labels are on your Pro-1200 SE console. These labels point out important

WARNINGS and CAUTIONS, which must be followed at ALL times. Failure to follow these warnings

could result in injury or fatality to yourself and/or others or property damage. Please follow these

instructions carefully! Do NOT remove these decals.

Page | 4

SECTION ONE – GENERAL INFORMATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

1. Read the operator’s manual before starting this unit.

Failure to adhere to instructions could result in severe personal injury or could be fatal.

2. Operate your vehicle and equipment in a well-ventilated area.

Exhaust fumes contain carbon monoxide, which is an odorless and

deadly poison that can cause severe injury or death. DO NOT run

the vehicle in an enclosed area. DO NOT operate this unit where

the vehicle exhaust may enter a building doorway, window, vent or

other opening.

3. DO NOT place hands, feet, hair, clothing or any body parts near rotating or moving parts.

Rotating machinery can cause severe injury or death.

4. NEVER operate this unit without belt and safety guards. High speed moving parts, such as belts

and pulleys should be avoided while the unit is running. Severe injury, fatality and/or damage

may result.

5. NEVER service a unit while it is running. High speed mechanical parts as well as high

temperature components and fluids may result in severe injury or fatality.

6. Blower and heat exchanger components, hoses and fittings will be extremely hot from

operation. To prevent severe burns, DO NOT touch these areas while the unit is running, or

shortly after the unit is shut off.

7. Water under pressure at can cause severe personal injury or fatality. Shut down unit, allow to

cool down, and relieve system of all pressure before removing caps, valves, plugs, fittings, filters

or hardware.

Page | 5

SECTION ONE – GENERAL INFORMATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

8. DO NOT smoke around the vehicle. Gas fumes could accumulate and ignite. Battery gasses are

extremely flammable. This will prevent possible explosions.

9. All high-pressure hoses must be rated at 250° F and 3000 PSI. Severe injuries may result from

improper hoses.

10. The Occupational and Health Administration (OSHA) recommends the use of hearing protection

when a technician is exposed to an average of 85 decibels (this is an average of exposure over

an 8 hour period). This equipment can produce 85 decibels at a distance of 10 feet. Please

check with your local state agencies to see if OSHA standards apply to your application.

11. This unit produces high pressure. Improper use could result in injury.

Page | 6

SECTION ONE – GENERAL INFORMATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

12. DO NOT damage the vehicle in any way during the installation. Avoid component or hose

contact with moving parts, hot surfaces, brake lines, fuel lines, catalytic converters, exhaust

pipes, mufflers, rotating parts or sharp objects.

13. DO NOT exceed your vehicles weight limit. This will prevent unsafe or hazardous driving

conditions.

14. Always keep your vehicle clean and orderly. Tools and accessories must be securely stowed

while driving the vehicle.

15. Ensure that you have received proper training and are familiar with the start-up and shut-down

procedures prior to operation.

16. DO NOT alter or modify your Pro-1200 SE in any way. Use only replacement parts authorized by

Sapphire Scientific. Modifications or use of unapproved parts could create a hazard and will void

your warranty. Contact a Sapphire Scientific service representative at 866-445-3030 for

assistance. This includes the use of any open ended hoses.

17. Failure to apply preventative measures towards freezing can result in system failure and loss of

warranty on affected parts. Parking the vehicle indoors will help against freezing, but should not

be the primary method of freeze protection.

Page | 7

SECTION ONE – GENERAL INFORMATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

Vehicle Engine Speed

1400 RPM (High Speed/No Load)

1200 RPM (Med Speed/No Load)

1000 RPM (Low Speed/No Load)

Water Pump (High)

1585 RPM

Water Pump Flow Rate

5.0 GPM

Water Pump Pressure (Max)

1200 PSI

Vacuum Pump (High)

3450 RPM

Vacuum Relief Valve

13 in. Hg

Waste Tank Capacity at Shut-Off

84 gallons

Console/Tank Weight (empty)

700 lbs.

Console/Tank Weight (full waste tank)

1400 lbs.

Pulley Hub (At drive shaft end)

15 ft./lbs. (180 in./lbs.)

Sapphire Scientific recommends that the total floor tool tip size be #4 or #6

SPECIFICATIONS

TORQUE VALUES

JET SIZING

Page | 8

SECTION ONE – GENERAL INFORMATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

INSTALLATION REQUIREMENTS

Prior to the installation of the unit, the vehicle that it will be installed in should be delivered to the

installer. It is the purchaser’s responsibility to ensure that the vehicle meets or exceeds payload

capacity for all equipment being installed.

The Pro-1200 SE Direct Drive unit weighs approximately 1400 lbs. with a full waste tank. If a water pond

is being installed, an additional 1100 lbs. needs to be included. Every accessory added will add weight.

Please adhere to the following recommendations prior to installing the unit:

1. The unit should NOT be installed in any motor vehicle rated at less than 3/4 ton capacity.

2. The combined weight of all equipment (with water weight) must not exceed the vehicle’s weight

limit.

3. Sapphire Scientific does not recommend using any type of flooring materials that absorb water.

This condition will result in rust and corrosion of the vehicle floor.

4. Insulation under rubber mats should be removed prior to installation of unit.

RESPONSIBILITIES

TRAINING

1. The sales representative you purchased your unit from is responsible for training you in the

operation, maintenance and safety precautions of your Pro-1200 SE unit.

2. It is the purchaser’s responsibility to become familiar with the entire Owner’s Manual, most

importantly all Warnings, Cautions and Notices.

3. It is the purchaser’s responsibility to review all warranty information.

INSTALLATION

1. The installer is responsible for correctly installing and properly securing equipment with proper

hardware and underside mounting plates.

2. Check the components and oil levels prior to starting the unit.

3. Check that all components appear to be operating normally.

4. Check all hoses and accessories for correct operation.

5. Check all tools/wands for correct operation.

Page | 9

SECTION ONE – GENERAL INFORMATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

Pro-1200 SE Console

Pro-1200 SE Sub-Mount Waste Tank

5 Gallon Chemical Tank

Center Console Assembly

Drive Shaft and Front End Kit

Angle, Tank Locator

Drive Shaft Rear Pulley, Hub & Belts

Floor Hose Manifold

Install Kit

Tube of Mystik® JT-6® No. 2 Grease

Right-Angle Grease Coupler

100’ of 2” Vacuum Hose

100’ of 1/4” Solution Hose

50’ of 1/2” Water Hose

3.2’ of 3-1/2” Black Vac Hose

Low Profile 12” Wide Wand

RECEIVING YOUR PRO-1200 SE SYSTEM

ACCEPTANCE OF SHIPMENT

Your Pro-1200 SE system was thoroughly tested, checked and inspected in its entirety prior to leaving

our manufacturing facility. When receiving your unit, please make the following acceptance check:

1. The unit should not show any signs of damage. If there is damage, notify the deliverer

immediately.

2. Carefully check your equipment. The Pro-1200 SE system should arrive with the following items

as well as any additional optional accessories you may have ordered:

EQUIPMENT LISTING

Page | 10

SECTION TWO – OPERATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

SECTION TWO: OPERATION

UNDERSTANDING THE SYSTEMS

WATER HEATING SYSTEM ........................................................................................ 12

WATER REQUIREMENTS .......................................................................................... 13

VACUUM SYSTEM .................................................................................................... 14

CHEMICAL SYSTEM................................................................................................... 16

CHEMICAL REQUIREMENTS ..................................................................................... 16

OPERATION

PREPARATION .......................................................................................................... 17

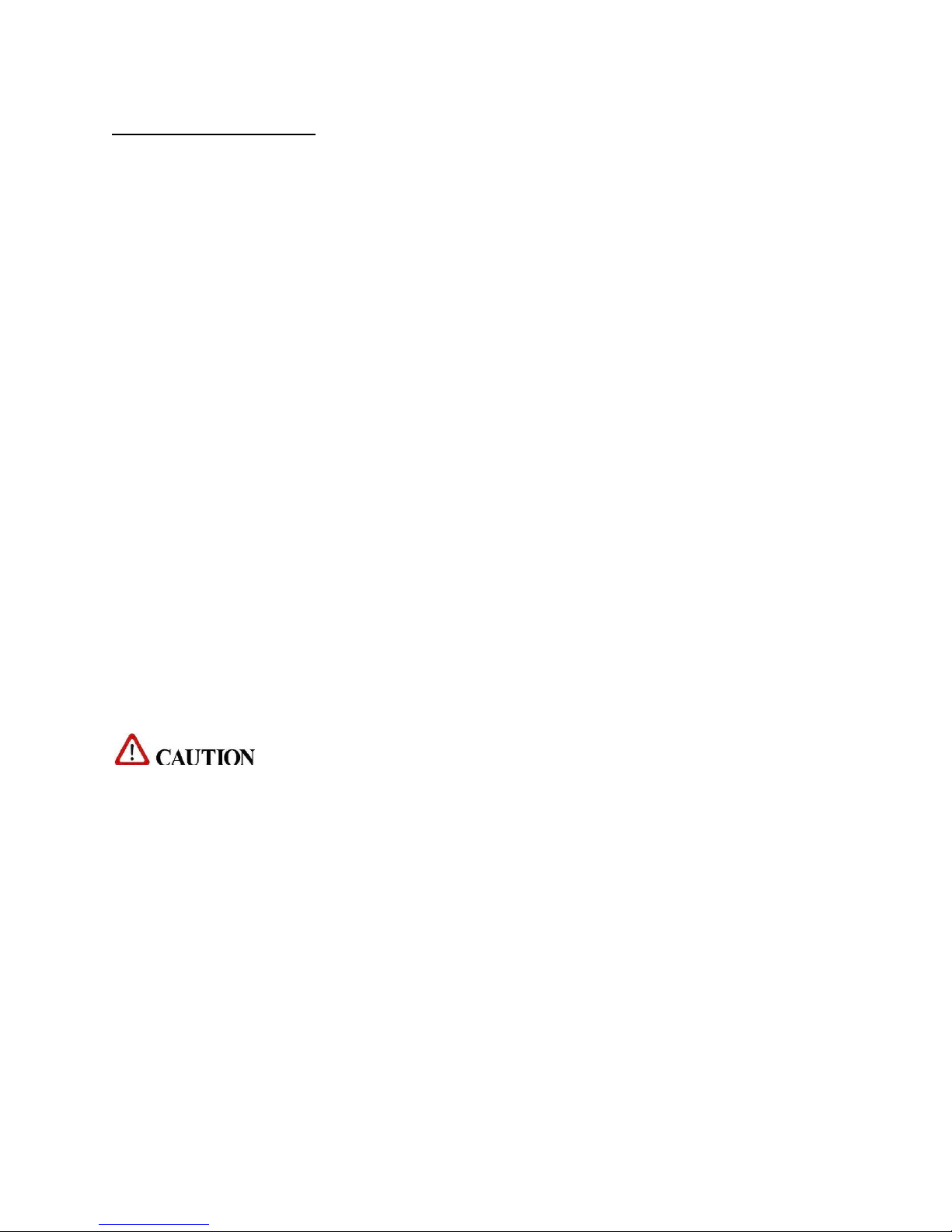

LOWER FRONT PANEL DIAGRAM ............................................................................. 19

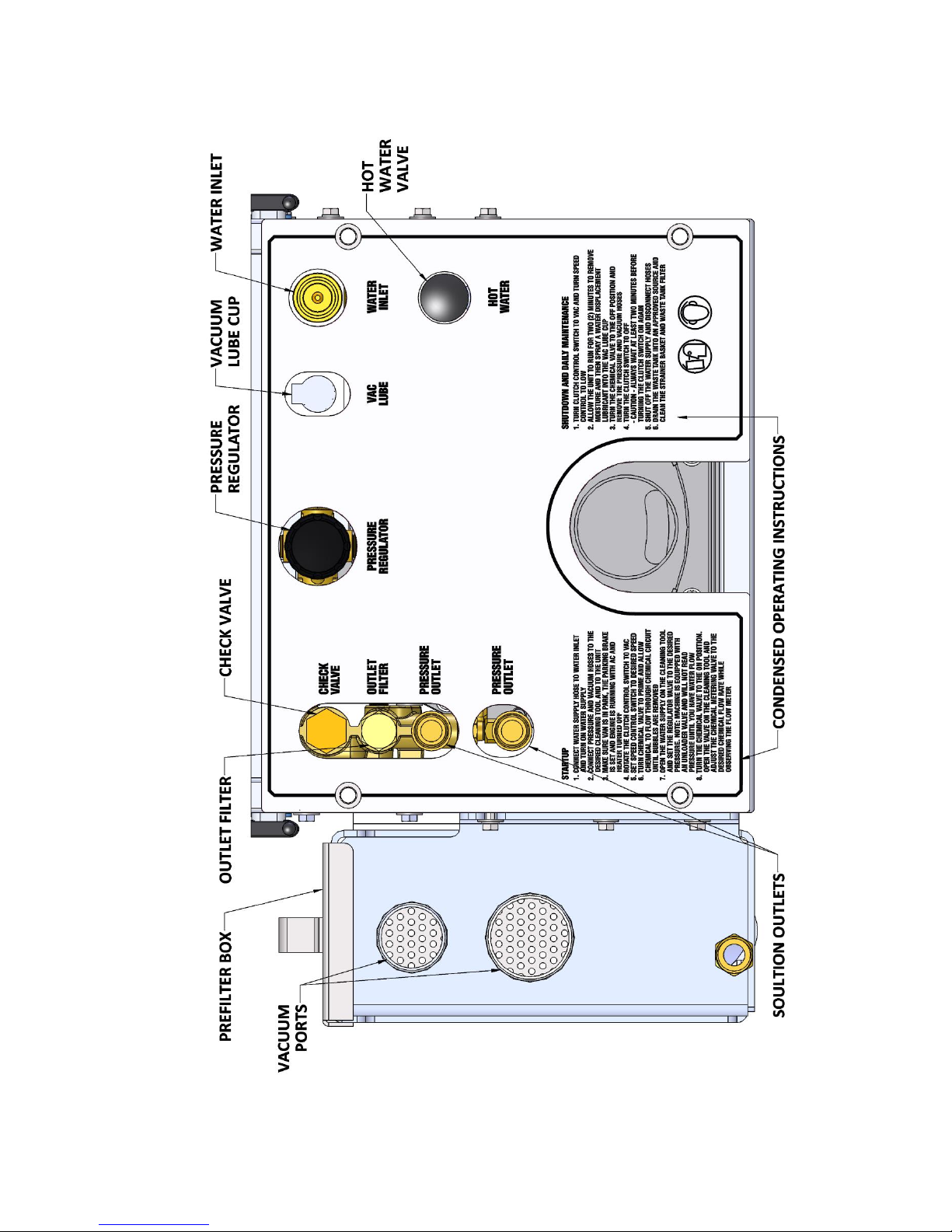

INSTRUMENT PANEL DIAGRAM ............................................................................... 20

STARTING THE UNIT ................................................................................................. 21

PRIMING THE CHEMICAL PUMP .............................................................................. 22

CHEMICALS .............................................................................................................. 22

AUTOMATIC WASTE PUMP ...................................................................................... 23

OPERATION .............................................................................................................. 24

CARPET CLEANING ................................................................................................... 24

UPHOLSTERY AND STAIR TOOL CLEANING .............................................................. 24

FLOOD RESTORATION / EXTRACTION ...................................................................... 25

DUAL-WAND OPERATION ........................................................................................ 25

GAUGE READINGS AND SETTINGS ........................................................................... 26

SHUT-DOWN AND DAILY MAINTANENCE ................................................................ 27

AUTOMATIC SHUT DOWNS...................................................................................... 28

FREEZE PROTECTION

WINTERIZING YOUR UNIT WITH ANTIFREEZE .......................................................... 29

REMOVING ANTIFREEZE FROM THE UNIT ............................................................... 30

Page | 11

SECTION TWO – OPERATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

UNDERSTANDING THE SYSTEMS

NOTE: Read and understand this section of the manual entirely before proceeding.

This portion of the manual divides the unit up into systems and describes how each system works. Prior

to proceeding into the operations and maintenance sections of this manual it is recommended that you

acquire a basic understanding of how the unit functions.

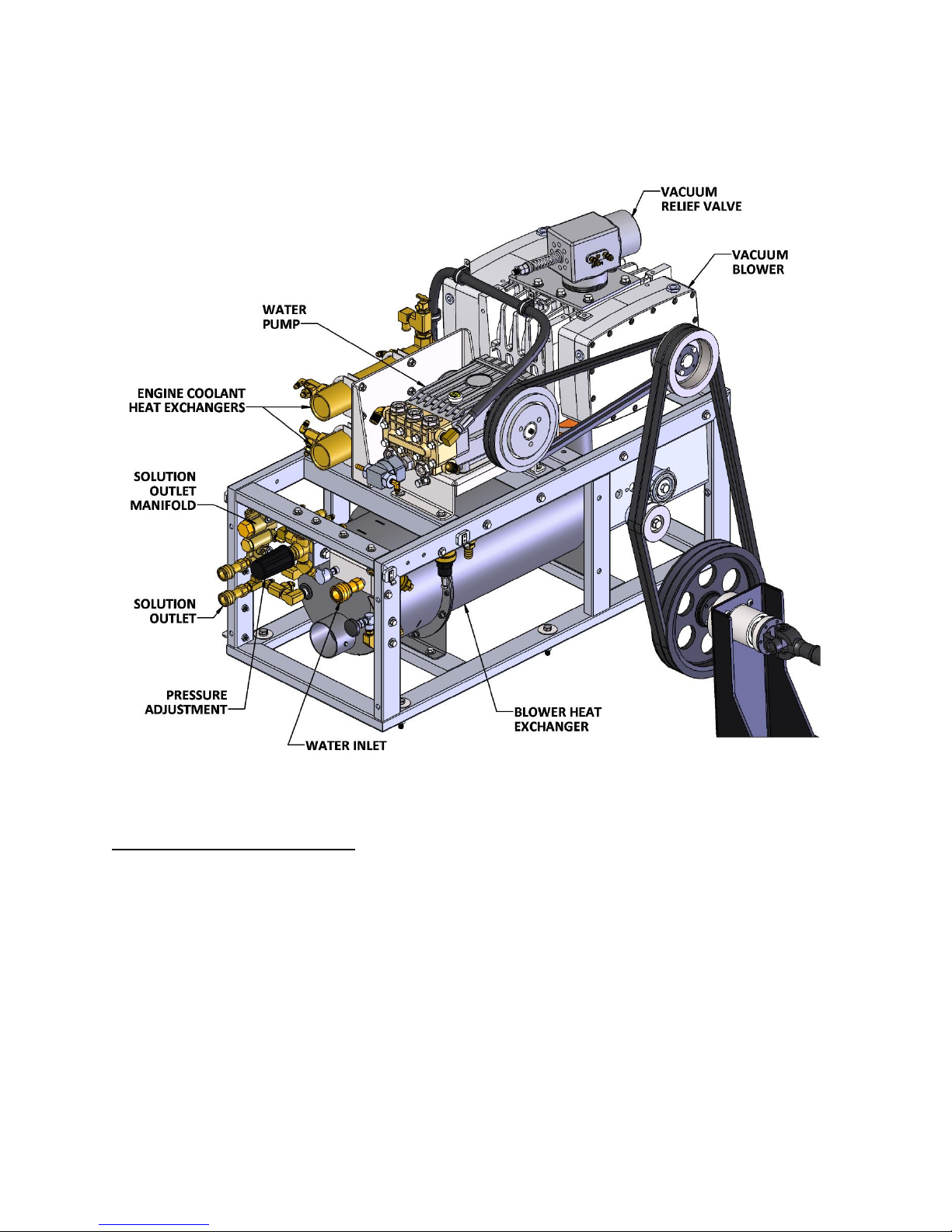

WATER HEATING SYSTEM

Water from the supply source (building hose bib or van fresh water tank with demand pump) enters the

console through the water inlet connection located on the upper right corner of the lower front panel.

The water flows through a “Y’ strainer and inlet pressure regulator, directly to the inlet side of the water

pump where it is pressurized. From here it flows through the coolant heat exchanger collecting the first

stage of heat from the van engine.

The water is routed through the blower heat exchanger where it is further heated by the blower exhaust

air passing over approximately 60 feet of finned tubing.

The hot water then flows through the solution outlet manifold that contains a strainer and check valve.

The chemical injection takes place inside the manifold.

The mixture of hot water and chemical then flows through the outlet of the manifold to the cleaning

tool.

Page | 12

SECTION TWO – OPERATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

WATER HEATING SYSTEM DIAGRAM

WATER REQUIREMENTS

Because hard water deposits will damage the plumbing and heat exchange systems on this unit,

Sapphire Scientific recommends that a high quality water softener be used in areas where the water

hardness exceeds 3-1/2 grains. If a water softener is used, it must have a flow capacity of at least 5 GPM

or greater, without any hose constrictions.

Page | 13

SECTION TWO – OPERATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

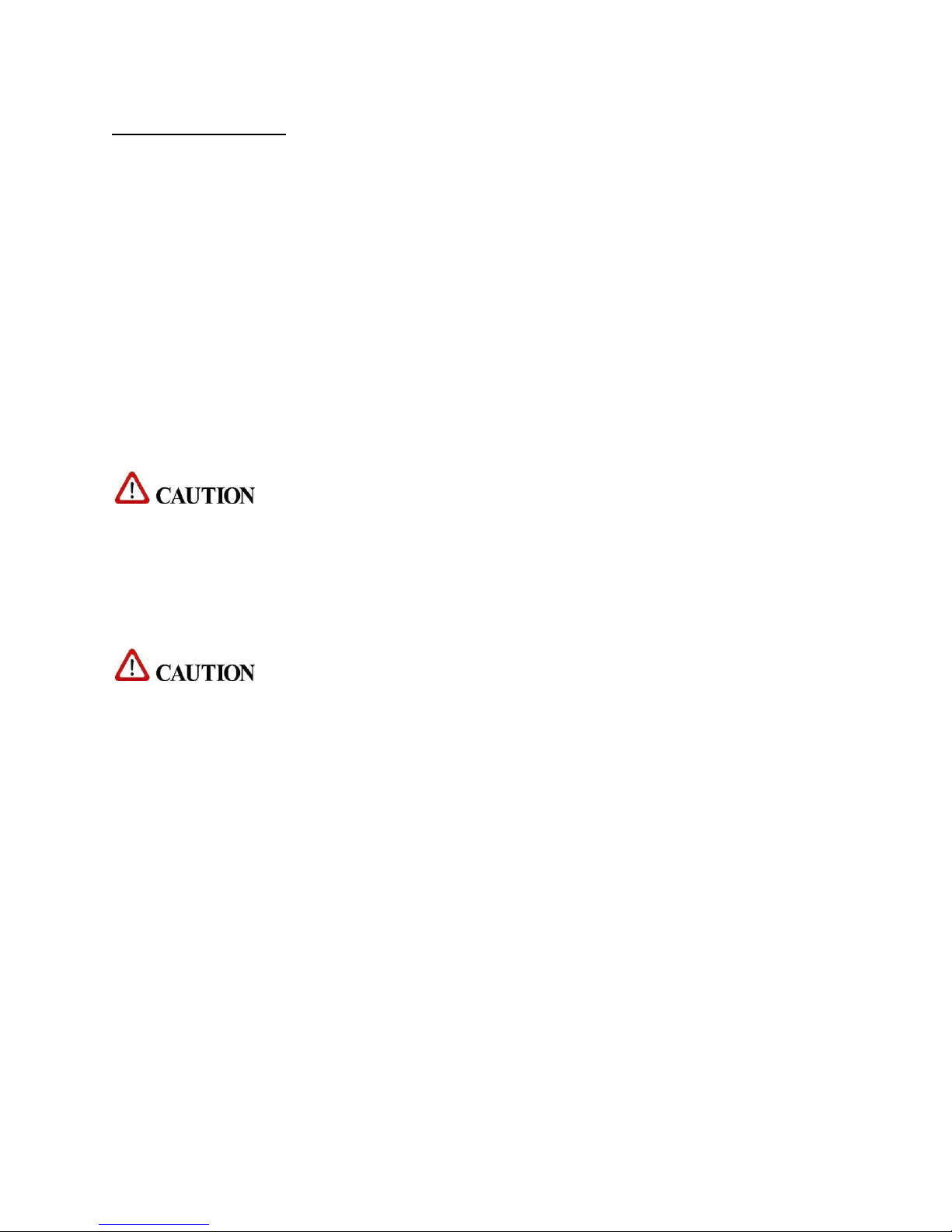

VACUUM SYSTEM

The van engine through an electric clutch and driveshaft turns the vacuum pump generating the

vacuum. The air is channeled into the top of the vacuum pump, compressed and discharged out the

opposite end, creating airflow. This airflow is used to do the work necessary for the extraction process.

Vacuum ports on the tool being used, applied to the surface being cleaned, removes moisture, dirt and

spent chemicals. These elements are drawn back to the waste tank utilizing hoses and the force of air.

Particles of moisture and dirt are separated in the waste tank using a series of changes in direction and

velocity. The air is then filtered and rushes into the vacuum pump inlet.

The vacuum pump is also compressing the air drawn through it. Heat is generated as the air is

compressed. The hot discharge air goes through the blower heat exchanger and is discharged from the

console exhaust tube.

The vacuum pump speed is factory set to maximize vacuum pressure and provide sustained system life.

Do not alter the vacuum speed outside the recommended range shown in this manual. Doing so can

result in severe damage to the unit and voidance of warranty.

A level shut-off sensor (float switch) is located behind the console in the waste tank tower and will shut

down the unit before the tank is at full capacity. This protects the vacuum pump from water damage.

Waste tank level shut-off will not detect high foam levels. Foam entering the vacuum pump can cause

damage to the unit. The use of a quality defoamer is recommended.

A green indicator lamp will illuminate to alert the operator when the tank is full, the unit will shut down

and the waste water needs to be disposed of before the operation can continue.

IN ACCORDANCE WITH EPA, STATE AND LOCAL LAWS, DO NOT DISPOSE OF WASTE WATER INTO

GUTTERS, STORM DRAINS, STREAMS, RESERVOIRS OR ANY NON-COMPLIANT RECEPTICLE.

Always check local laws and regulations regarding “gray” water disposal. The penalties for non-

compliance can be serious.

Page | 14

SECTION TWO – OPERATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

VACUUM SYSTEM DIAGRAM

Page | 15

SECTION TWO – OPERATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

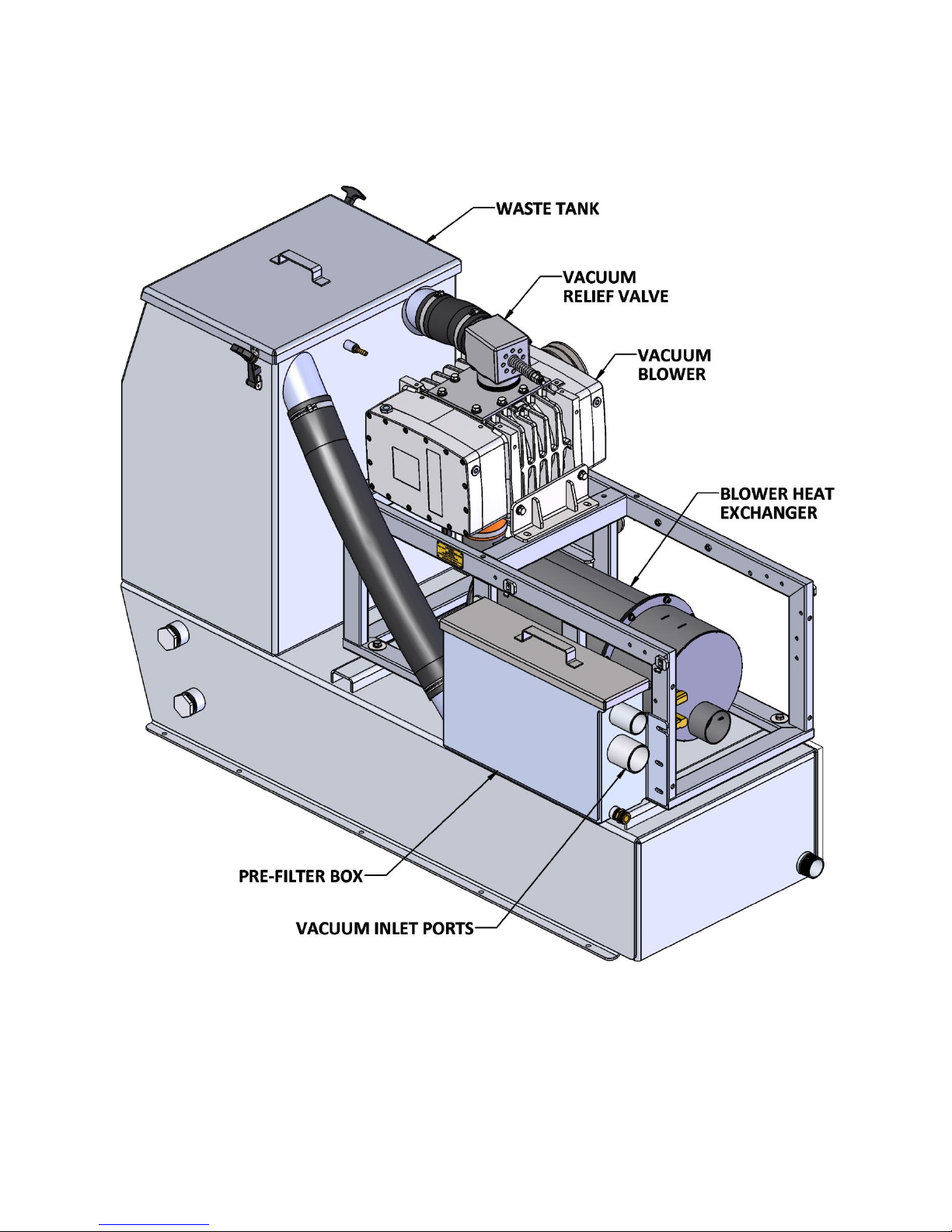

CHEMICAL SYSTEM

The chemicals are drawn from the chemical container through a strainer into the flow meter mounted

on the control panel. The flow meter indicates the rate of chemical flow in gallons per hour.

The chemicals then flow through the stainless steel chemical pump. The chemical is injected into a

three-way selector valve located on the front panel. This valve may be used to turn the chemical flow

ON, OFF or to PRIME the chemical pump.

When in the ON position, the chemicals then flow through the chemical metering valve to the solution

outlet. This valve controls the rate of flow to chemical into the cleaning solution, which is indicated on

the flow meter.

CHEMICAL REQUIREMENTS

The Sapphire Scientific Pro-1200 SE Direct-Drive unit’s unique last step chemical injection system can be

used with a variety of water diluted chemical compounds, either acidic or alkaline, depending on the

work to be performed. We recommend only using Chemspec brand of chemistry.

Page | 16

SECTION TWO – OPERATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

PREPARATION AND OPERATION

This section of the operator’s manual explains how to prepare, start, operate, shut down and maintain

your Pro-1200 SE direct-drive cleaning unit. The Pro-1200 SE unit is easy to operate, however only

trained operators should proceed.

Operate this unit and equipment only in a well-ventilated area. Exhaust fumes

contain carbon monoxide, which is an odorless and deadly poison that can cause severe injury or death.

DO NOT run this unit in an enclosed area. DO NOT operate this unit where the exhaust may enter a

building doorway, window, vent or any other opening.

VEHICLE PREPARATION

ENSURE THERE IS ADEQUATE FUEL

Check the fuel tank to ensure there is adequate fuel to complete the job and transport the vehicle. This

unit consumes approximately 2 US gallons of fuel per hour, depending on the speed setting.

CHECK VEHICLE SETTINGS

Park the vehicle in an a well-ventilated area, place automatic transmission in Park and set the

emergency brake. Make sure the heat and AC on the van are set to the OFF position.

VEHICLE WILL BE RUNNING

The vehicle must remain running and the accelerator and brake cannot be tampered with. If the vehicle

is to be left unattended, the doors should be locked and the hoses run through a security access door.

REMOVE TOOLS FROM THE VEHICLE

Remove any tools, accessories or hoses from the vehicle that you will require.

Do not park the vehicle on a lawn or close to shrubs, as heat from exhaust or water overflow may cause

damage.

Do not allow vacuum or solution hoses to rest against vehicle exhaust pipe. This can result in damage.

Do not operate machine with covers or guards removed.

Page | 17

SECTION TWO – OPERATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

UNIT PREPARATION

WATER SUPPLY CONNECTION

NOTE: Prior to connecting your water inlet hose to any supply faucet, flush out the faucet until the

water is free of any debris. Also, flush out any debris from your water inlet hose.

1. Connect the hose to the water supply faucet and flush out any debris from the faucet and hose.

2. Connect the hose to the water inlet fitting on the front of the unit. Activate the valve on the

water inlet to an open position.

3. Turn the water supply faucet on.

NOTE: Never use a waste pump outlet hose as a water inlet hose. Use only clean hoses for water supply.

CHECK YOUR DRAIN VALVES

Make sure the waste tank and pre-filter box drains are closed.

CONNECT SOLUTION HOSES

Before starting the unit, connect the high pressure solution hose(s) to the solution outlet connection(s)

at the front of the unit. Connect the cleaning tool(s) to the opposite end of the pressure hose(s).

CHECK YOUR CHEMICAL LEVELS

Check the chemical jug to make sure you have enough chemical mixed to finish the job. The hot water

valve on the lower front panel is intended to be used to add water to the chemical jug when the unit is

running.

CHECK FILTERS

Inspect the vacuum inlet filter and strainer basket in the waste tank. Inspect the strainer basket inside

the pre-filter box. See the Shut Down and Daily Maintenance section below for more information.

NEVER operate the unit with the waste tank air filter removed, damaged or not properly installed.

Page | 18

SECTION TWO – OPERATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

LOWER FRONT PANEL AND PREFILTER BOX

Page | 19

SECTION TWO – OPERATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

INSTRUMENT PANEL

Page | 20

SECTION TWO – OPERATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

STARTING THE UNIT

1. Make sure van is in Park, parking brake is set and heater and A/C are off. The accelerator pedal

or brake pedal cannot be engaged. Start the vehicle.

2. The engine must be running and idling at 1000 RPM.

3. The vehicle cannot sense motion.

4. Make sure the pressure hoses are connected properly and valves are open or closed as needed.

5. Connect the vacuum hose(s) to the vacuum inlet connection(s) on the pre-filter box. Connect

the opposite end of the vacuum hose(s) to the desired tool(s).

6. Set the clutch control switch to the desired operation. Use the vacuum position for water

recovery only or the pressure/vacuum position for cleaning operations.

7. Set the engine speed control switch to the desired operating speed.

NOTE: Water is under pressure, be sure that hoses are secured before turning the pump on.

8. Depress the cleaning tool trigger and observe the water pressure gauge reading. Set pressure to

450 PSI or as needed for the job being performed. To adjust the pressure, turn the unloader

handle clockwise to increase pressure and counterclockwise to decrease pressure.

NOTE: If the unit does not build water pressure after 5 seconds, check for adequate water supply. See

the troubleshooting section of this manual for more information.

9. Depress the cleaning tool trigger and read the face panel temperature gauge. Set the output

water temperature by adjusting the temperature control valve which is located on the

instrument panel. When the valve is closed, the temperature will be at maximum. Open the

valve to reduce temperature.

NOTE: Let the unit run for a few minutes with the vacuum inlets partially blocked off to warm up the

cleaning solution.

Page | 21

SECTION TWO – OPERATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

PRIMING THE CHEMICAL PUMP

NOTE: SAPPHIRE SCIENTIFIC recommends that the chemical pump be primed whenever the water

pump is turned on. This eliminates possible pressure fluctuations and damage to the chemical pump.

1. Turn the chemical selector valve located on the instrument panel to the PRIME position. The

chemical will then flow from the chemical container through the chemical prime tube into the

vacuum system.

2. Momentarily obstruct the vacuum port to create a load.

To reduce the risk of injury: NEVER obstruct a vacuum port with your hand or other body part. Keep

hair, loose clothing and all body parts away from vacuum port openings while unit is in operation.

3. When the chemical flows with no air bubbles, priming has been achieved.

4. Turn the chemical selector valve from PRIME to ON.

5. With the cleaning tool open, check the flow meter and adjust the chemical metering valve until

the desired rate of chemical flow is achieved.

NOTE: When inserting the chemical tube into the chemical container, ensure that it stays submerged, as

the chemical pump will not function if air is allowed to enter the inlet line.

CHEMICALS

CARPET CLEANING

Always use a good quality emulsifier which is recommended for use in truck mount equipment. Mix

emulsifier thoroughly in accordance with the manufacturer’s recommendations.

NOTE: Combining two or more chemicals, inadequately dissolving powders or using inferior quality

materials can cause sediment to build and clog your equipment. Serious damage can result from using

improper chemicals or mixtures.

UPHOLSTERY CLEANING

Use only chemicals recommended for wet cleaning of upholstery fabrics.

Page | 22

SECTION TWO – OPERATION

49-139, Rev A Sapphire Scientific Pro-1200 SE

AUTOMATIC WASTE PUMP

If your unit is equipped with an optional automatic waste pump:

1. Connect one end of the 5/8 in. or larger garden hose to the pump-out connection and the other end

to an acceptable waste disposal.

2. Turn the pump-out switch located on the front console control panel to the ON position. The waste

pump will now operate automatically throughout the cleaning period.

DO NOT use an outlet hose that is smaller than 5/8” I.D.

NEVER use a waste pump hose as a water inlet hose.

NEVER dispose of waste water in a storm drain, water way or on ground areas. Always dispose of

waste in accordance with Local, State and Federal laws.

Page | 23

Loading...

Loading...