INSTRUCTION MANUAL

CAPVEL-ICT

Capacitance Level Transmitter

Version 2.0

User Manual & Datasheet V 2.1

Contents

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Operating Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6 Capvel-BT Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

7 Capvel-ICT Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

8 Mechanical Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

9 Electrical Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

10 Measurement Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

11 Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

11.1 Tank Mounting Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

12 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

13 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

14 Error Display and Remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

15 Menu and Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

16 RS-485 Serial Commands for Communication with Capvel . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

17 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

18 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

19 Support Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

20 Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

List of Figures

1 Capvel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Tank Strapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

R

Sapcon Instruments Pvt.Ltd.

2

User Manual & Datasheet V 2.1

List of Tables

1 Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Electrical Specifcations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Measurement Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Error Display and Remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7 Percentage Level Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8 Configuring and Asking Sensor ID on Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Sapcon Instruments Pvt.Ltd.

R

3

Revision History

Revision Date Author(s) Description

1.0 18 Jan 2014 RND First Version Editing

1.1 25 Aug 2014 MRK Applications Revision

1.2 28 Jun 2015 RND Features Revision

1.3 10 Dec 2015 RND Specs Revision

1.4 23 Jul 2016 RND Specs Revision

2.0 08 Jan 2017 BRND Revised Format

2.1 17 Sep 2017 BRND Branding Revisions

1

User Manual & Datasheet V 2.1

1

• Copyright: All content on this document, such as text, graphics, logos and images is the property of Sapcon Instruments Pvt. Ltd.

The selection, arrangement and presentation of all materials on this document and the overall design of this document is the exclusive

property of Sapcon Instruments Pvt. Ltd.

• The images shown in this manual may differ from the actual instrument / housing in terms of dimensions, color and design. Please refer

to GA drawings for dimensional details.

• Values (of performance) described in this manual were obtained under ideal testing conditions. Hence, they may differ under industrial

environment and settings.

General Instructions

• Instrument shouldn’t block the material filling inlet.

• Secure the cover of housing tightly. Tighten the cable glands. For side mounting, the cable glands should point downwards.

• For side mounting, provide a baffle to prevent the material from falling on the probe.

• When handling forks, do not lift them using their tines. While using them with solids, ensure that material size is less than 10mm.

• Deforming the shape of the tines may interfere with the fork’s operating frequency.

• Make all electrical connections as instructed in the manual. Don’t power on the device before verifying the connections.

R

Sapcon Instruments Pvt.Ltd.

4

User Manual & Datasheet V 2.1

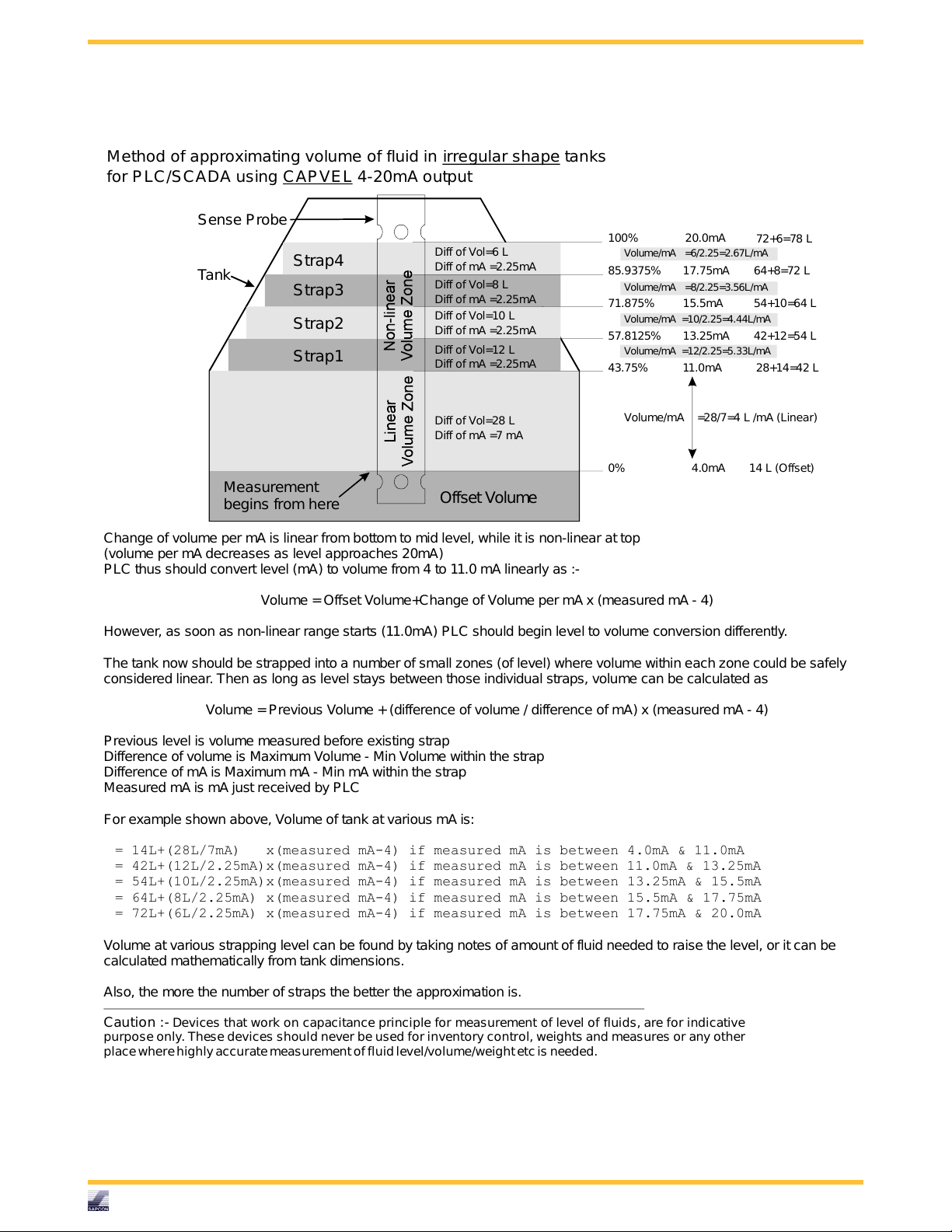

3-wire Single Supply O peration

mAmp

Maximum InternalR esistance of Indicator/PLC /Scanner

[(Sensor Supply - 4V) x 50] Ohm

Indicatoror

Scanner

orPLC

4-20mA

mAmp

MaximumInternal Resistanceof Indicator/PLC/Scanner

[(Loop S upply - 4V) x 50] O hm

Indicatoror

Scanner

orPLC

4-20mA

4-wire Dual Supply Operation ( Galvanic Isolated )

J umpers

( Towards ISO )

J umpers

( Towards LOOP )

I

S

O

L

A

T

I

O

N

1 Introduction

2 Operating Principle

CAPVEL is composed of specially developed capacitance change gauging circuit. It uses fast RISC based

processor to perform all the complicated jobs of evaluating the level out of the capacitance. This capacitance is

formed by the sense rod and the metallic container wall,

where containers are non-metallic or non-uniformly wide

or having turbulent fluid, a metallic stilling well is provided. The amount of capacitance is proportional to the

level of material between the sense rod and metallic wall

of stilling tube or container.

mA input or multimeter in 40 mA range or any-other

device that takes 4-20 mA signal as input.

4 Features

5 Applications

6 Capvel-BT Features

• User Interface : 2 DIP switches + 2 LED

• Output-1 : 4-20 mA, Galvanically Isolated

• Output-2 : Rs-485 Digital Data

7 Capvel-ICT Features

• User Interface : 4 Digit Display with 4 Keys + 2

LED

• Output-1 : 4-20 mA, Galvanically Isolated

• Output-2 : Rs-485 Digital Data

Figure 1: Capvel

3 System Description

CAPVEL is composed of cast aluminium housing,

supplied with suitable mounting arrangement viz.NPT,

BSP or Flanges and two metallic cable entries. An

external Earthing / Grounding terminal is also provided.

The sensing rod which is mostly Teflon coated. This

sensing rod can be replaced by flexible probe for some

applications. The stilling tube is also provided for

turbulent fluids, irregular width tanks, non-metallic

tanks or for fluids with low dielectric (e.g. diesel).

Opening the threaded aluminium cover, an electronic

insert could be found. This is the electronic unit which

converts the level into 4-20 mA signal depending on the

calibration. The status LED is a bi-color LED that blinks

alternately in Red and Green to indicate instrument is in

process of converting the level to 4-20 mA signal. Two

DIP switches are provided to calibrate the 4 mA and

20 mA points. The calibration is easy and a complete

procedure is given in "Calibration" page. The two wires

connected at the back are pre-connected sensor wires

and should not be disturbed. Also while calibration try

to keep hands away from the wires of terminal 6 and 7.

Now referring to the "Connection Diagram", Capvel can

be wired in two possible combinations. Preferred one

is galvanically isolated, 4-wire combination where only

one source of power is available, 3-wire, non-isolated

combination can also be used. The converted level signal

can be sensed using a 4-20 mA indicator or PLC 4-20

• Output-3 : Controlling Devices connected with External Relay

Figure 2: Connection Diagram

Sapcon Instruments Pvt.Ltd.

R

5

User Manual & Datasheet V 2.1

8 Mechanical Specification

For Mechanical Specification please refer Table 1

PARAMETER VALUE

Housing Cast aluminium weather and Flame proof suitable for

mounting in hazardous area Gas Group IIA and IIB as per

IS-2148

Mounting

• Integral with sense rod or probe with SS /MS(plated)

• Screw - 1"/1 1/2" BSP/NPT (M)

• Flanged - (As per your order)

Cable Entry 2 X 1/2"/3/4" BSP/NPT, Brass

Gland type Double Compression Gland

Sensing Fully or Partially Teflon Coated Rod, Flexible Probe SS316

Stilling Tube Pipe, GI / SS

Overall Dimensions Please refer enclosed probe drawing

Table 1: Mechanical Specifications

9 Electrical Specification

For Electrical Specification please refer Table 2

PARAMETER VALUE

Mains

• Capvel-BT : 9V to 55V DC

• Capvel-ICT : 9V to 30V DC

Power Consumption

• Capvel-BT : Max. 0.5 watt @12 V

• Capvel-ICT : Max. 1 watt @12 V

Table 2: Electrical Specifcations

10 Measurement Specification

For Measurement Specification please refer Table 3

PARAMETER VALUE

Measurement Span 15 to 3000 pf above Zero

Response Time 0.5 to 5 secs.( Adjustable )

Accuracy +/- 1% FSL or better

Electronics Ambient Temp. 0◦C. to +60◦C

Fail-Safe Feature Reverse Calibratable (Low Level: 20 mA, High Level: 4

mA)

Table 3: Measurement Specifications

R

Sapcon Instruments Pvt.Ltd.

6

11 Installation Guidelines

Note:

During installation, all electrical connections must

be powered OFF and the fuel tank must be empty.

User Manual & Datasheet V 2.1

11.1

Tank Mounting Installation

Note:

It is recommanded that the tank must be empty

while following steps in this section.

12 Electrical Connections

13 Calibration

Sapcon Instruments Pvt.Ltd.

R

7

User Manual & Datasheet V 2.1

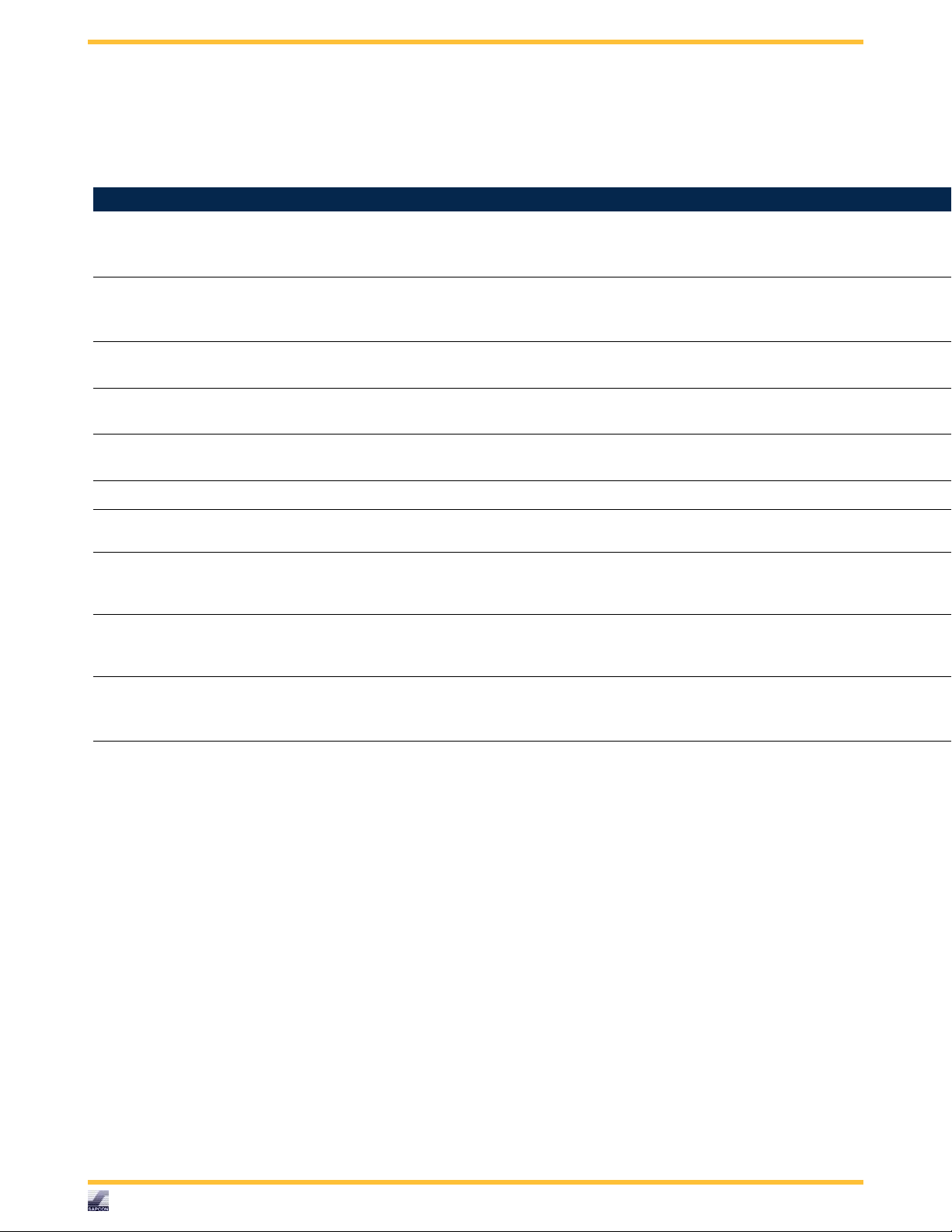

0% Level

100% Level

Fill the tank at Low Level

0% Level

100% Level

1

2

3

Lower C alibration has done !

1

Calibr ating L ower L evel

Pr ocedure of Calibration

When material is at 0% or 4mA level.

Now the S ensor is in RU N MODE again !

We can Calibrate 4mA and 20mA in any order according to our c hoice.

The order o f empty-fill or fill-empty is immaterial.

Calibr ating HIG H L evel

Upper Calibration has done !

DOWN

2

Press and Hold T his K ey

UP

For 3 Seconds

Wait for around 5 Seconds

3

Wait for around 5 Seconds

Press and Hold T his K ey

For 3 Seconds

Fill the tank at High Level

High-SCAL %

Low-SCA L%

Figure 3: Calibration

Sapcon Instruments Pvt.Ltd.

R

8

User Manual & Datasheet V 2.1

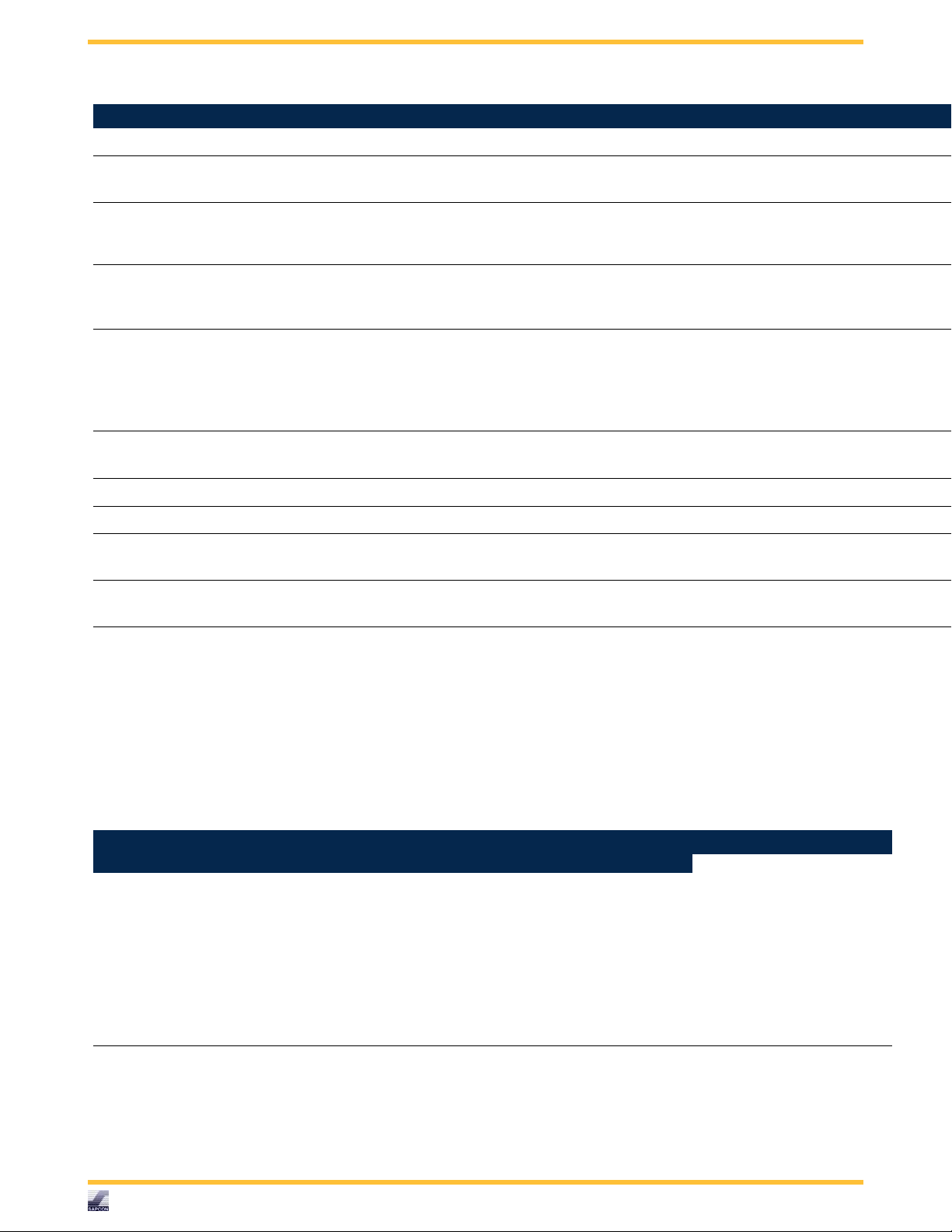

0%

43.75%

100%

4.0mA

11.0mA

20.0mA

14 L (Offset)

72+6=78 L

=28/7=4 L /mA (Linear)Volume/mA

Change of volume per mA is linear from bottomto mid level, while it is non-linear at top

(volume per mA decreases as level approaches 20mA)

PLC thus should convert level (mA) to volume from 4 to 11.0 mA linearly as :-

Volume =OffsetVolume+Change of Volume per mA x (measured mA - 4)

However, as soon as non-linear range starts (11.0mA) P LC should begin level to volume conversion differently.

The tank now should be strapped into a number of small zones (of level) where volume within each zone could be safely

considered linear. Then as long as level stays between those individual straps, volume can be calculated as

Volume =Previous Volume +(difference of volume / difference of mA) x (measured mA - 4)

Previous level is volume measured before existing strap

Difference of volume is Maximum Volume - Min Volume within the strap

Difference of mA is Maximum mA - Min mA within the s trap

Measured mA is mA just received by P LC

For example shown above, Volume of tank at various mA is:

= 14L+(28L/7mA) x(measured mA-4) if measured mA is between 4.0mA & 11.0mA

11.0mA & 13.25mA

= 54L+(10L/2.25mA)x(measured mA-4) if measured mA is between 13.25mA & 15.5mA

= 64L+(8L/2.25mA) x(measured mA-4) if measured mA is between 15.5mA & 17.75mA

= 72L+(6L/2.25mA) x(measured mA-4) if measured mA is between 17.75mA & 20.0mA

= 42L+(12L/2.25mA)x(measured mA-4) if measured mA is between

Volume at various strapping level can be found by taking notes of amount of fluid needed to raise the level, or it can be

calculated mathematically from tank dimensions.

Also, the more the number of straps the better the approximation is.

Strap1

Strap2

Strap3

Strap4

Offset Volume

57.8125%

71.875%

85.9375%

28+14=42 L

Diff of mA =2.25mA

Diff of Vol=12 L

Diff of mA =2.25mA

Diff of Vol=10 L

Diff of mA =2.25mA

Diff of Vol=8 L

Diff of mA =2.25mA

Diff of Vol=6 L

13.25mA

15.5mA

17.75mA

42+12=54 L

54+10=64 L

64+8=72 L

Volume/mA =12/2.25=5.33L/mA

Volume/mA =10/2.25=4.44L/mA

Volume/mA =8/2.25=3.56L/mA

Volume/mA =6/2.25=2.67L/mA

Diff of mA =7 mA

Diff of Vol=28 L

Measurement

begins from here

Tank

Sense P robe

Method of approximating volume of fluid in tanks

for P LC/SC ADA using 4-20mA output

irregular shape

CAP VEL

Caution :- Devices that work on capacitance principle for measurement of level of fluids, are for indicative

purpose only. These devices should never be used for inventory control, weights and measures or any other

placewhere highly accuratemeasurementof fluid level/volume/weightetc is needed.

Figure 4: Tank Strapping

Sapcon Instruments Pvt.Ltd.

R

9

User Manual & Datasheet V 2.1

14 Error Display and Remedy

For Error Display and Remedy please refer Table 4

CODE ERROR DISPLAY ERROR DESCRIPTION TROUBLESHOOTING

1 PrOP Probes are OPEN circuited Check the probes with

multimeter

2 PrSC Probes are SHORT cir-

cuited

3 ECAL Calibration Error Calibration is wrong,

4 PrHI Over Capacitance Tank and probe dimen-

5 PrLO Under Capacitance Tank and probe dimen-

6 RFOP Internal reference got open

circuited

7 RFSC Internal reference got short

circuited

8 RFHI Internal reference satu-

rated

9 RFLO Internal reference negligi-

ble

10 OSC Oscillations stopped Internal fault in sensor

Check the probes with

multimeter

Please recalibrate correctly

sions are not matched

sions are not matched

Internal fault in sensor

Internal fault in sensor

Internal fault in sensor

Internal fault in sensor

Table 4: Error Display and Remedy

Sapcon Instruments Pvt.Ltd.

R

10

User Manual & Datasheet V 2.1

15 Menu and Description

For Menu please refer Table 5 and 6

MENU SUB MENU CHANGE DESCRIPTION REMARK

rLdr (Relay Drive) r. FS FS. H <>FS. L Fail Safe Selection

FS.H/ FS.L:Fail Safe

High/Low

rLdr (Relay Drive) r.oPt o.Ind<>o.PUM Control Action Selection

Ind : Individual, PUM :

Pump

rLdr (Relay Drive) r. SP S.000<>S.100 Set point Only in Indi-

vidual Controlling

rLdr (Relay Drive) r.SPH h.001<>h.100 Higher Set point Only in

Pump Controlling

rLdr (Relay Drive) r.SPL L.000 <>L.099 Lower Set point Only in

Pump Controlling

SPH must be higher

than SPL

SPH must be higher

than SPL

rLdr (Relay Drive) r.Cd C.000 <>C.100 Cover Delay in Seconds

rLdr (Relay Drive) r.Ud U.000 <>U.100 Uncover Delay in Sec-

onds

SCAL (Scal Factor) SC.-H H.020<>H.100 Higher SCALE LEVEL SCAL-HIGH must be

20% or more Higher

than SCAL-LOW

SCAL (Scal Factor) SC.-L L.000<>L.080 Lower SCALE LEVEL SCAL-HIGH must be

20% or more Higher

than SCAL-LOW

dISP(Display) d.PER<>d.AmP Display Options PER

: Percentage, AmP :

mAmp

Table 5: Menu

Sapcon Instruments Pvt.Ltd.

R

11

User Manual & Datasheet V 2.1

MENU SUB MENU CHANGE DESCRIPTION REMARK

trbu (Turbulence) t.001 <>t.010 Turbulence Immunity

vts (Vehicle Mode) 1 = ON 0 = OFF Immunity to vehicle gen-

erated fluctuations

c. ID Id.00 <>id.99 Communication ID of

Sensor on RS-485 Network

Com (Communication

Settings)

Com (Communication

Settings)

Com(Communication

Settings)

othr o.LEN LE0.0 <>LE9.9 Probe Length in meters Only for optimization

othr o.PRF PR.1 <>PRF.9 Profile Only for optimization

InFo i.SEr 12345678 Serial No Factory Sated and Read

InFo i.dAt 12345678 Mfd. Date in DD-MM-

c.bAU b.00.3<>b.38.4 Communication Baud

Rate 9.6 x 1000 =

9600bps and so on

c.Flo F.CMd<>F.AUt Flow Control

• CMD : Send data

when Commanded

• AUT : Send Data

Automatically

c.dur d.001<>d.250 Auto Data Sending Du-

ration in Seconds

YY format

Only usefully in Vehicle

Tracking Systems

(Flow : AUT)

Only

Factory Sated and Read

Only

Table 6: Menu

16 RS-485 Serial Commands for Communication with Capvel

For RS-485 Serial Commands please refer Table 7

COMMAND DESCRIPTION

Level would be calculated

by dividing incoming five

digit number with 10.Please

note that:- Application Software must have to take care

of any possible errors during turn-on or off durations,

change in nature of service

material etc.

COMMAND TO BE

SEND TO SENSOR

<A,PER?>or

<B,PER?>or

<a,PER?>or

<z,PER?>or

<Z,PER?>

Table 7: Percentage Level Information

EXPECTED RESPONSE

FROM INSTRUMENT

<A,PER=01000,H>

<B,PER=01000,N>

<a,PER=00625,N>

<z,PER=00000,N>

<Z,PER=00000,L>

EXPLAINATION

100.0% (OVER)

100.0% (NORMAL)

62.5% (NORMAL)

0% (NORMAL)

0%(LOW)

Sapcon Instruments Pvt.Ltd.

R

12

User Manual & Datasheet V 2.1

COMMAND DESCRIPTION

Asking single letter ID of instrument on RS-485 network

Setting single letter ID

of instrument on RS-485

network.Example-setting id

as:- ’A’ (Capital A)

COMMAND TO BE

SEND TO SENSOR

<*,ID?> <A,ID?-A> Instrument is telling it’s ID

<*,ID=A> <A,OK> ID is taken by instrument

Table 8: Configuring and Asking Sensor ID on Network

EXPECTED RESPONSE

FROM INSTRUMENT

EXPLAINATION

and this is the acknowledgement from it

17 Settings

18 Maintenance

19 Support Training

20 Customer Support

Thank you for going through the instructions given in this manual. To further ease the process of installation and use,

we have developed special demo videos which are hosted on YouTube.

Sapcon’s YouTube channel, SAPCON INSTRUMENTS, lists all these videos: https://goo.gl/dnxfcz

Should you require further information regarding installation, use or working of the instrument, please don’t hesitate

to contact us. Kindly provide the following information at the time of contacting:

• Instrument Model and Serial Number

• Purchase Order Number and Date of Purchase

• Description of the query

• Your contact details

In an attempt to serve you better, we are open seven days a week (9:30am to 7:30pm). We are available at:

• www.sapconinstruments.com

• sales@sapcon.in

• +91-731-4757575

Sapcon Instruments Pvt.Ltd.

R

13

Loading...

Loading...