SAP BusinessObjects Production

Planning Rapid Mart XI 3.2, version for

SAP solutions - User Guide

Version 12.2.2.0

October 2009

Copyright

Trademarks

© Copyright 2009 SAP AG. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or for any purpose

without the express permission of SAP AG. The information contained herein may be

changed without prior notice.

Some software products marketed by SAP AG and its distributors contain proprietary

software components of other software vendors.

All rights reserved. SAP, R/3, SAP NetWeaver, Duet, PartnerEdge, ByDesign, SAP Business

ByDesign, and other SAP products and services mentioned herein as well as their respective

logos are trademarks or registered trademarks of SAP AG in Germany and other countries.

Business Objects and the Business Objects logo, BusinessObjects, Crystal Reports, Crystal

Decisions, Web Intelligence, Xcelsius, and other Business Objects products and services

mentioned herein as well as their respective logos are trademarks or registered trademarks

of Business Objects S.A. in the United States and in other countries. Business Objects is an

SAP company.

All other product and service names mentioned are the trademarks of their respective

companies. Data contained in this document serves informational purposes only. National

product specifications may vary.

These materials are subject to change without notice. These materials are provided by SAP

AG and its affiliated companies ("SAP Group") for informational purposes only, without

representation or warranty of any kind, and SAP Group shall not be liable for errors or

omissions with respect to the materials. The only warranties for SAP Group products and

services are those that are set forth in the express warranty statements accompanying such

products and services, if any. Nothing herein should be construed as constituting an

additional warranty.

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User

Guide

Contents

Chapter 1 Introduction 11

What is a Rapid Mart? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Rapid Marts packages accelerate Time to Value . . . . . . . . . . . . . . . . 13

SAP BusinessObjects Rapid Marts packages architecture . . . . . . . . . 14

About this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2 Overview 17

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

What is production planning? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

What you can do with this Rapid Mart . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Supported analyses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Related Rapid Marts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Sharing components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

The Rapid Mart schema . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Where the Rapid Mart fits in the production planning process . . . . . . . . . . 26

Chapter 3 Subject Areas 27

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Work Center section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Basic Data in a Work Center: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Integration of Work Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Rapid Mart data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Capacity section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 3

Contents

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Rapid Mart data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

MRP results section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Rapid Mart data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Planned Order section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Rapid Mart data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Reservation section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Rapid Mart Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Routing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Rapid Mart data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

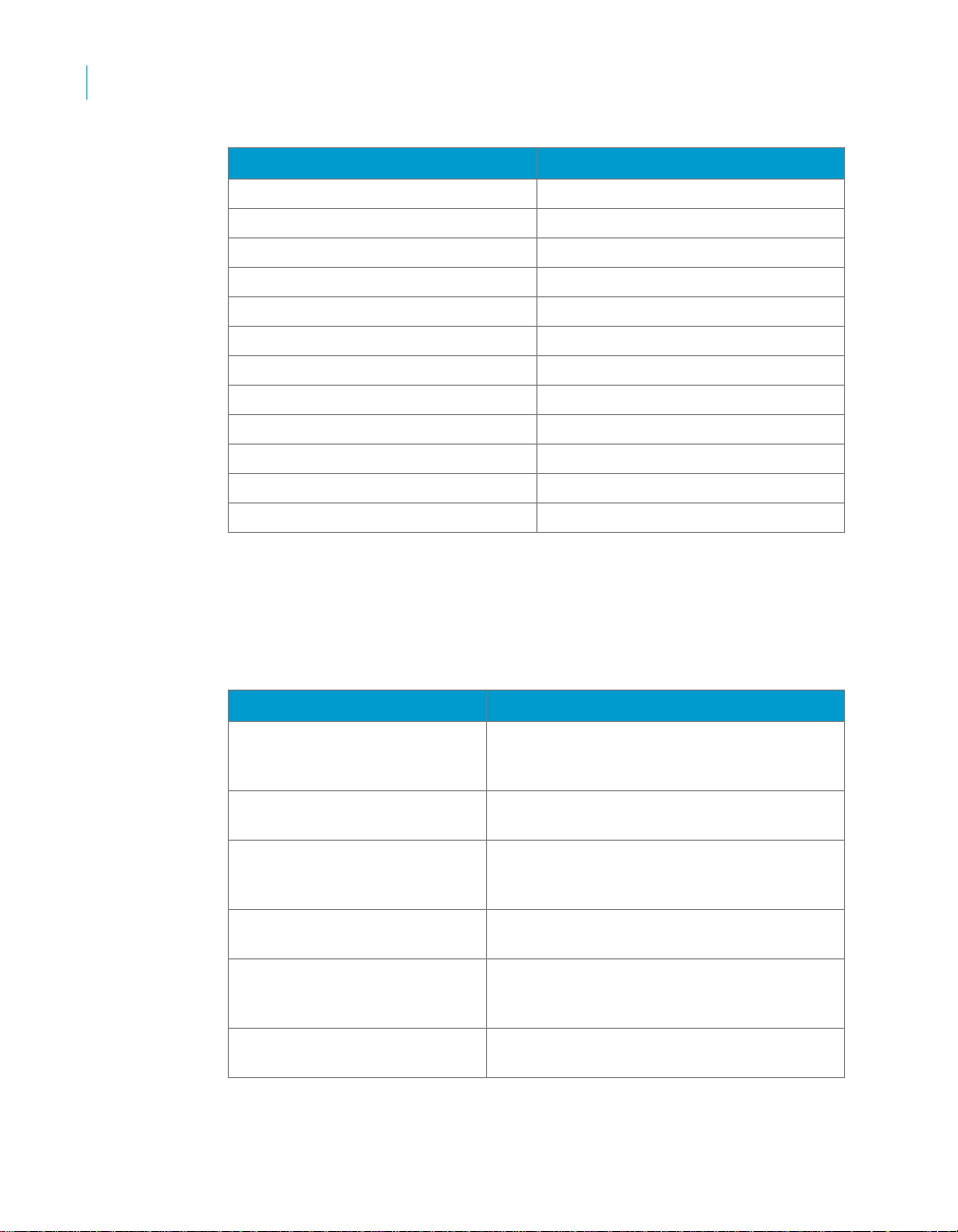

Bills of Material (BOM) section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Rapid Mart data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Production Order section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Rapid Mart data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Production Operation section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Rapid Mart data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Chapter 4 Reports 83

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Work Center Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Capacity Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

MRP Results Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

4 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Contents

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

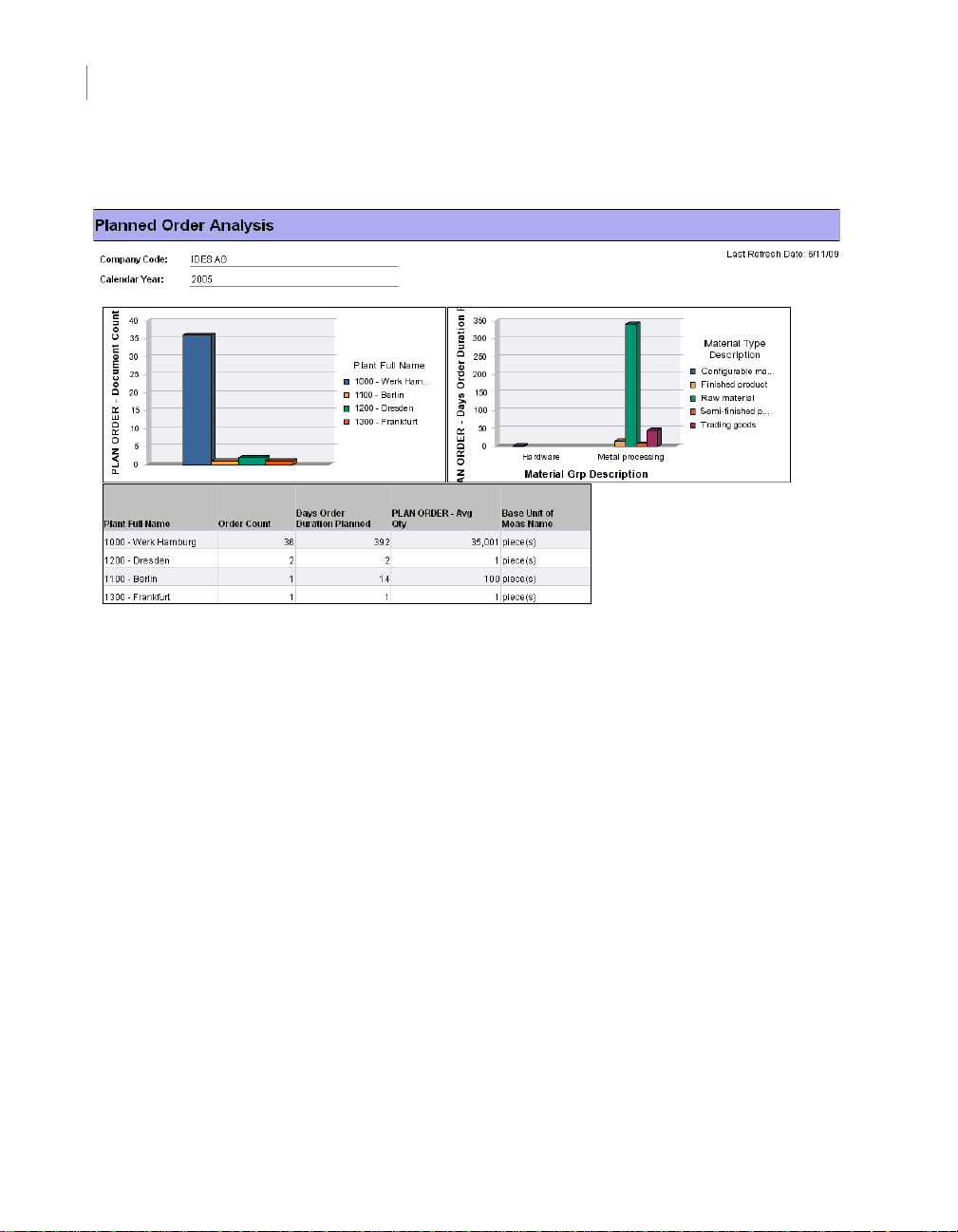

Planned Order Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Reservation Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Routing Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Bill Of Materials Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Production Order Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Production Operation Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

SAP Master Data Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Data Discovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Data Auditing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Recommended table joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Chapter 5 Universe 175

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Universe Design Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Universe Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Universe Table Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Join Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Hierarchies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Hierarchies Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 5

Contents

Geographic Hierarchies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Time Dimension and Fiscal Period Hierarchies . . . . . . . . . . . . . . . . .183

Material Product Hierarchy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

Horizontal & Vertical Hierarchies . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Hierarchy Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

Production Planning Specific Hierarchies . . . . . . . . . . . . . . . . . . . . . . . . .195

Accounting Hierarchies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

Additional Hierarchies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

SAP Production Planning Universe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .197

Universe Objects & Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .198

Common Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

Planned Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .214

Production Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .216

Production Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220

Reservation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Filters & Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Universe Validation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .226

SAP Capacity Planning and MRP Universe . . . . . . . . . . . . . . . . . . . . . . .228

Universe Objects & Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

Common Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .231

Capacity Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Capacity Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .244

MRP Result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Work Center Cost Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .249

Filters & Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Universe Validation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .254

SAP Production Routing and BOM Universe . . . . . . . . . . . . . . . . . . . . . .255

Universe Objects & Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .256

Common Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .258

Production BOM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .269

Production BOM Explosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .271

Routing BOM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .274

Routing Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

6 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Contents

Filters & Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Universe Validation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

SAP Master Data Universe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Universe Objects & Classes - Master Data . . . . . . . . . . . . . . . . . . . . 283

Universe Validation - Master Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Customizing the Universe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

Splitting the SAP Capacity Planning and MRP Universe . . . . . . . . . . 320

Chapter 6 Installing the Rapid Mart 323

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

System Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

Personnel Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

Rapid Mart product components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Preparing your environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Preparing Data Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Preparing Target Database Environment . . . . . . . . . . . . . . . . . . . . . 329

Preparing Source Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Preparing BusinessObjects Enterprise . . . . . . . . . . . . . . . . . . . . . . . 330

Performance Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

The Rapid Mart Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

Install the Rapid Mart Target Schema . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

Create Target Schema . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

Install the Data Services Job(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Renaming the Data Stores . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Import ATL File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

Adjusting the Data Stores . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

Using Auxiliary Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

Using ABAP Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

Final Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Installing Rapid Mart Reporting Content . . . . . . . . . . . . . . . . . . . . . . . . . 354

Import Wizard for Reporting Content BIAR File . . . . . . . . . . . . . . . . . 354

Creating Universe Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 7

Contents

Chapter 7 Using the Rapid Mart 373

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .374

Recovery framework . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .374

Data Services automatic recovery feature . . . . . . . . . . . . . . . . . . . . .374

Rapid Mart recovery framework . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

Execution status framework . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .376

The execution status table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .376

The execution status API . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .377

Executing a job with the Reset option . . . . . . . . . . . . . . . . . . . . . . . . . 378

Extraction, transformation and loading process . . . . . . . . . . . . . . . . . . . .378

Global Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .380

Global Variable Cross-Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380

Used in All Rapid Marts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .384

Used in 2 to 10 Rapid Marts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .387

Used in Only 1 Rapid Mart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

Setting Global Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .407

Executing the job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .411

Initial (First) Extraction and Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . 411

Incremental (Delta) Extraction and Load . . . . . . . . . . . . . . . . . . . . . . .412

Customizing the Rapid Mart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .414

Chapter 8 Technical Implementation 415

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .416

Work Center section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .416

Capacity section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 418

Capacity Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .421

Capacity Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .421

Routing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .422

Routing Line Fact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 425

Routing BOM Fact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .426

MRP Results section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .427

Initial (First) Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 429

Incremental (Delta) Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .430

8 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Contents

Planned Order section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

Initial (First) Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

Incremental (Delta) Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

Production Order section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 434

Initial (First) Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 438

Incremental (Delta) Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 439

Bill of Materials (BOM) section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 439

Production BOM Fact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 441

Production BOM Explosion Fact . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443

Reservation section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 445

Reservation Fact Load Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 448

Production Operation section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

Initial (First) Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Incremental (Delta) Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Dimensions with Incremental Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Routing Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 454

Routing Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 455

Optimization Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 455

Table Partitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 456

Data Transfer Transform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 457

Hierarchy Optimizations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 459

Dealing with NULL values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 461

Fact Table Stored Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 463

Fiscal Periods & Time Dim Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 464

Chapter 9 Documentation References 467

Data Services Documentation References . . . . . . . . . . . . . . . . . . . . . . . 468

BusinessObjects Enterprise Documentation References . . . . . . . . . . . . 468

Appendix A Rapid Mart Data Schema 471

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 9

Contents

10 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Introduction

chapter

Introduction

1

What is a Rapid Mart?

What is a Rapid Mart?

SAP BusinessObjects Rapid Marts packages are blueprints for building data

marts with SAP BusinessObjects technology:

• Data Services

• Universe Designer

• Web Intelligence.

Rapid Marts packages deliver jump-start ETL (extract, transform & load)

mappings, schema, and initial reporting content, accelerating the deployment

of BI (business intelligence) for enterprise applications from SAP, PeopleSoft,

Oracle, and Siebel.

Each Rapid Mart is designed to address the reporting needs of a specific

business area (or department) like accounting, sales, or purchasing. A

component-based framework allows conducting analysis across these

selected business areas by combining different packages within the same

source application suite.

Rapid Marts focus on basic standard configuration of the enterprise

applications. They are country and industry neutral templates meant to be

easily modified and extended to suit customer specific application

implementation and reporting needs.

Rapid Marts incorporate best practices, and provide easily modifiable

templates. With Rapid Marts total development time of a data mart solution is

greatly reduced.

Each customer situation is different. You will probably encounter one or more

of these:

• Customizations you have made to SAP solutions the Rapid Mart does not

cover.

• Standard SAP solutions data fields important for your specific business,

but not included in the Rapid Mart templates.

• Optimization and performance challenges unique to your environment.

• Reporting requirements not covered within the Rapid Mart template

reports.

Rapid Marts are flexible templates that you can adjust to account for these

unique situations. It is expected that some customization and optimization will

be needed to suit your individual environment. Rapid Marts are not an

out-of-the-box solution.

12 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

BI tools and analytic tools can access Rapid Mart data through SQL queries.

Rapid Marts can be implemented individually, or in any combination, to form a

single platform that delivers the infrastructure for your company’s internal and

external information needs. They can also serve as a staging area for

enterprise analytic applications.

Rapid Marts provide your business with an accelerated time to value through

rapid BI deployments because you can implement them quickly and easily

customize them to meet specific analytic requirements.

Rapid Marts packages accelerate Time to Value

Rapid Marts are packaged data solutions that you can quickly deploy to

address specific areas of business analysis.

Available Rapid Marts packages for SAP solutions include:

Financial Suite:

• SAP BusinessObjects General Ledger Rapid Mart, version for SAP

solutions

• SAP BusinessObjects Accounts Payable Rapid Mart, version for SAP

solutions

• SAP BusinessObjects Accounts Receivable Rapid Mart, version for SAP

solutions

• SAP BusinessObjects Cost Center Rapid Mart, version for SAP solutions

Operational Suite:

• SAP BusinessObjects Inventory Rapid Mart, version for SAP solutions

• SAP BusinessObjects Purchasing Rapid Mart, version for SAP solutions

• SAP BusinessObjects Sales Rapid Mart, version for SAP solutions

Manufacturing Suite:

• SAP BusinessObjects Plant Maintenance Rapid Mart, version for SAP

solutions

• SAP BusinessObjects Production Planning Rapid Mart, version for SAP

solutions

• SAP BusinessObjects Project Systems Rapid Mart, version for SAP

solutions

Human Capital Management (HCM) Suite:

• SAP BusinessObjects Human Resources Rapid Mart, version for SAP

solutions

Introduction

What is a Rapid Mart?

1

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 13

Introduction

1

What is a Rapid Mart?

You can combine multiple Rapid Marts packages into a single environment to

build the foundation for your data warehouse or use them as a staging area

for business intelligence applications.

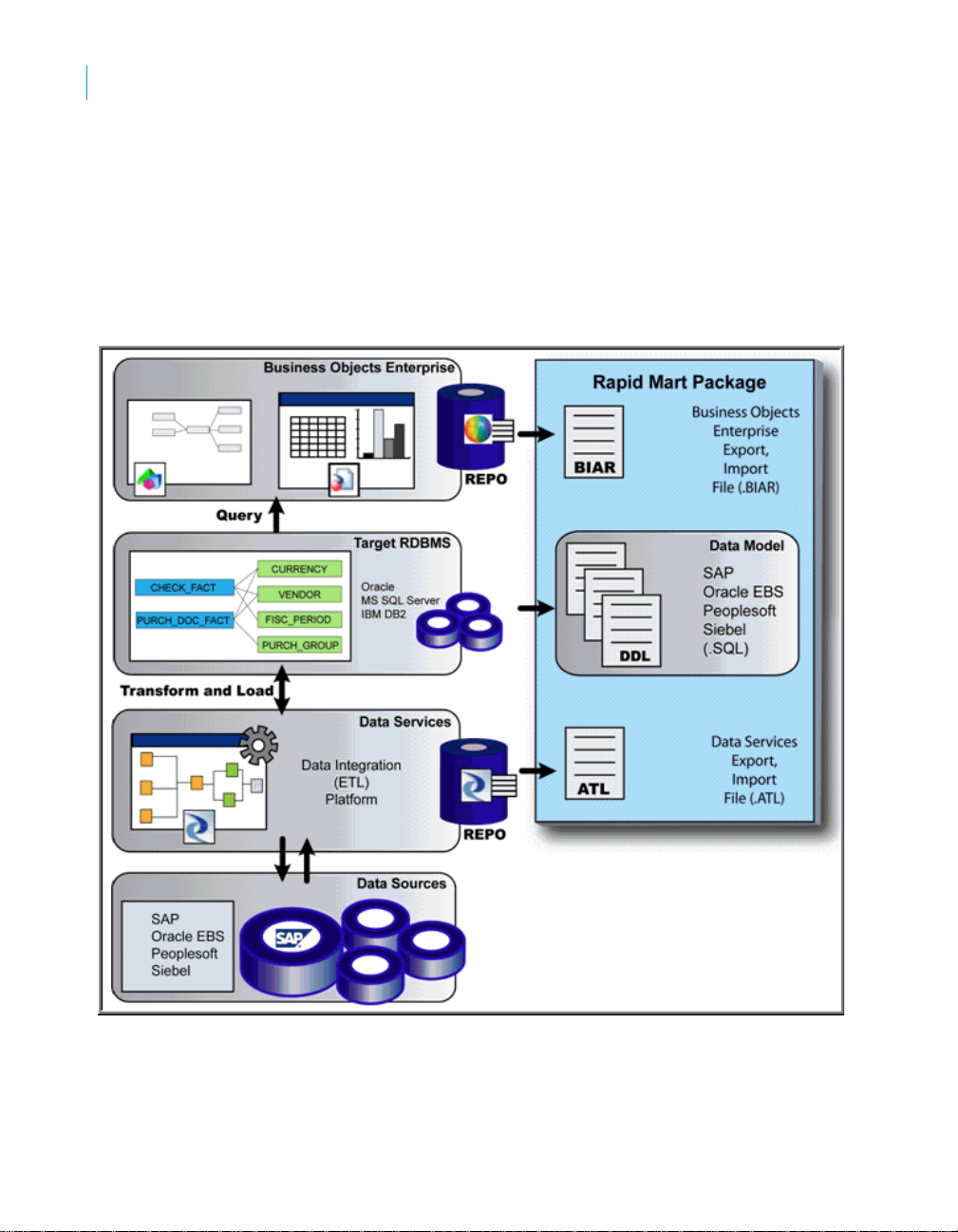

SAP BusinessObjects Rapid Marts packages architecture

Rapid Marts architecture is driven by SAP BusinessObjects technology.

Rapid Mart Architecture:

Rapid Marts packages include the following components:

14 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Introduction

About this document

• Data Movement Jobs - packaged source-to-target mappings and data

transformations. Each job is designed to perform initial and incremental

data movement;

• Data Model & Schema - set of dat a mart database objects designed with

dimensional data modeling approach. Rapid Marts packages for SAP

solutions has a single integrated data model. The schema are available

for Oracle, SQL Server IBM DB2, and Teradata;

• Semantic Layer (Universes) - SAP BusinessObjects metadata packages

for efficient query generation. There can be one or more universes per

Rapid Mart. Each universe is developed using Rapid Marts design

principles to ensure compatibility, code readability, and component

re-use. In addition, there is one Master universe for

development/maintenance of multiple use objects (like Customer,

Material, Currency, etc.);

• Reports (Samples) - set of 15-20 Web Intelligence reports per Rapid

Mart. They represent answers to mostly asked business questions (for

example, in the SAP BusinessObjects Sales Rapid Mart, version for SAP

solutions - 'What is the monthly Revenue trend by Division for this

year?'). The reports are developed using Rapid Mart color/layout

templates. Reports are examples of Web Intelligence best practice

development (trends, listing, guided analysis, roll ups and downs, etc.).

1

About this document

This document describes the SAP BusinessObjects Production Planning

Rapid Mart, version for SAP solutions. This document contains information for

a variety of users—information that helps you understand the use of the

Rapid Mart, the data in the Rapid Mart, the reports you can create with the

Rapid Mart, and how to use and update the Rapid Mart.

This document contains the following chapters:

• Chapter 2: Overview — Describes the business problems you can solve

and the types of analyses you can do with this Rapid Mart

• Chapter 3: Subject Areas — Contains detailed information about each

section in the Rapid Mart, including the processes each section captures

• Chapter 4: Reports — Provides examples of reports you can produce

• Chapter 5: Universe — Describes the SAP BusinessObjects Universes

upon which the reports are built.

• Chapter 6: Installing the Rapid Mart — Cont ains the information you need

to install the Rapid Mart

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 15

Introduction

1

About this document

• Chapter 7: Using the Rapid Mart — Describes how to execute the Rapid

Mart, including information about initializing variables and considerations

you need to make when customizing the Rapid Mart

• Chapter 8: Technical Implementation — Describes each section and the

work flows that run to load that section

• Chapter 9: Documentation References — Information about where to find

related to the Rapid Mart technical documentation on Data Services and

BusinessObjects Enterprise

• Appendix A: Rapid Mart Data Schema — Contains a detailed list of the

tables and views in the Rapid Mart

16 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Overview

chapter

Overview

2

Overview

Overview

This chapter describes the business problems you can solve with the SAP

BusinessObjects Production Planning Rapid Mart, version for SAP solutions

and the types of analyses you can do with this Rapid Mart. The information in

this chapter is useful for those who want a business-level overview of the

Rapid Mart and its benefits.

This chapter discusses the following topics:

• What is production planning?

• What you can do with this Rapid Mart

• Supported analyses

• Related Rapid Marts

• The Rapid Mart schema

• Where the Rapid Mart fits in the production planning process

What is production planning?

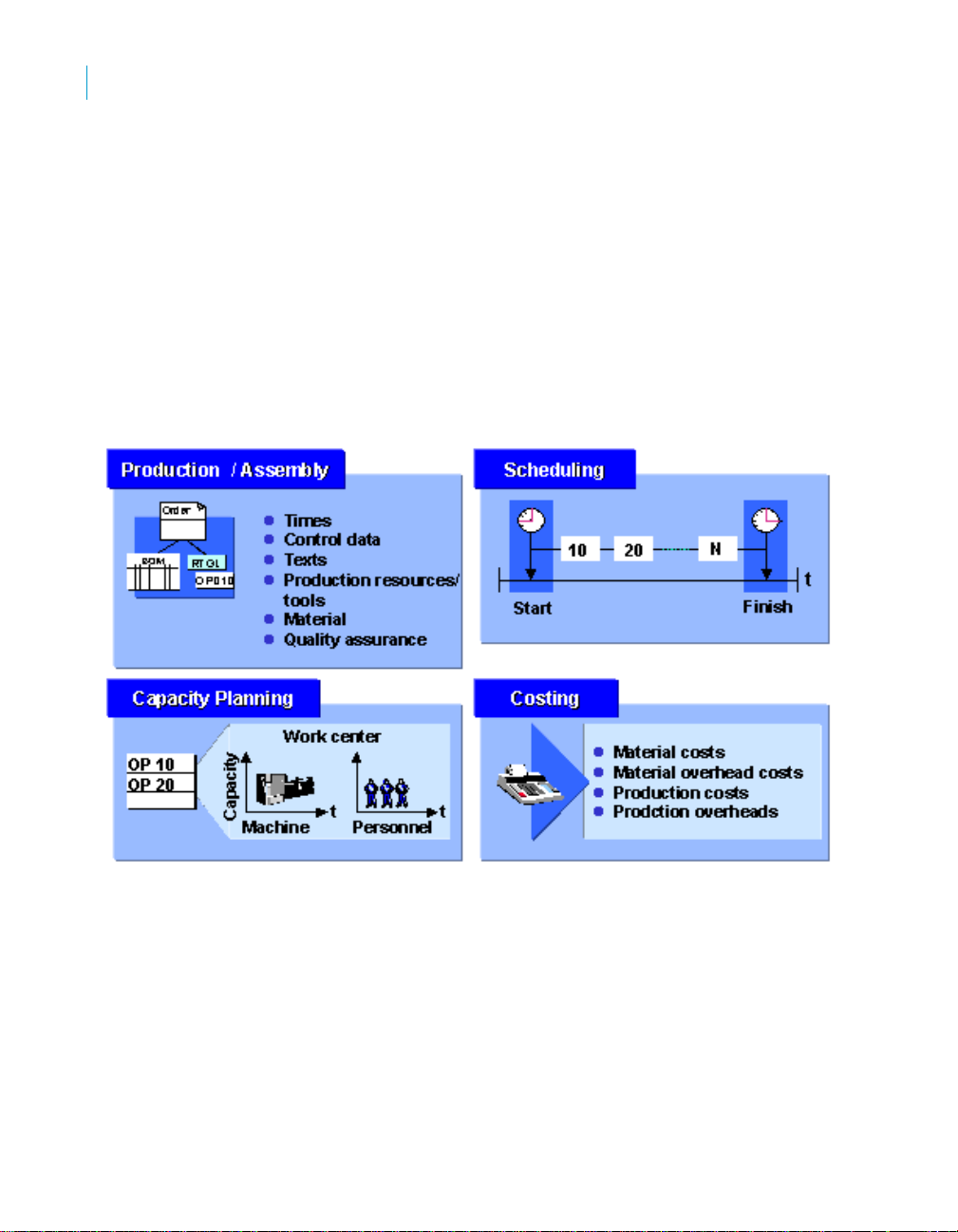

Within SAP solutions, the process of production planning and control (PP)

determines what to produce, how much to produce, and when to produce it.

Production quantities and scheduling are constrained by machine time, labor ,

material availability, and storage space. These resources are in turn

constrained by budget and other financial considerations. By balancing

resource constraints with demand and scheduling requirements, an effective

production plan optimizes factory lead times, improves customer delivery

performance, and reduces time consumed by work in progress (WIP).

Planning processes in SAP solutions generate time-based demands for

materials based on sales order planning, long term forecasts, stock

replenishment quantities, customer order requirements, backlog, safety stock

levels, and other anticipated sources of demand. The SAP solutions materials

requirements planning (PP-MRP) component combines lead time scheduling

information with independent and dependent requirements (based on bill of

materials) for a material and produces a production and procurement

proposal—a planning proposal—that satisfies current and projected demand

requirements.

The planning proposal that SAP solutions produces does not account for

material availability or work center capacity until a production order is created.

When creating a production order, SAP solutions explodes a bill of materials,

18 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

What you can do with this Rapid Mart

creates requisitions for externally procured materials, selects a routing for

produced materials, reserves materials and resources, and calculates

capacity requirements for work centers.

What you can do with this Rapid Mart

The SAP BusinessObjects Production Planning Rapid Mart, version for SAP

solutions enables you to analyze the planning components that automate the

production process. The data that supports these planning

components—work centers, routings, planning strategies, bill of materials,

capacities, and MRP results—can provide insight into the production process

and help you improve and streamline both the planning process and the

actual production and procurement of goods and services.

The SAP BusinessObjects Production Planning Rapid Mart, version for SAP

solutions is made up of several components or sections. Each section

supports a subject related to planning analysis:

• Work center section — Stores data about work centers—the machines,

production lines, or labor pools capable of producing units of work as

output. The amount of work that a work center can produce during a

given time is its capacity . Basic work center data includes category (labor ,

machine, etc.), description, location (plant), and standard values for

queue times. This section also contains the work center hierarchy, which

allows you to roll up work center capacity to accumulate capacities at

various levels. This section also contains the work center assignment to

cost center.

• Capacity section— Stores standard shift times and operating times for

various capacity categories (machine, labor). Work centers have one or

more capacities, measured in terms of units of time, associated with

them. The combination of operating hours, utilization rate, and number of

capacities determines the standard available cap acity for the work center .

Additional capacity, called interval available capacity, might be available

for certain intervals of time. Capacity requirements generated by

production orders and planned orders using lead time scheduling are

also included in this section.

• Materials requirement planning (MRP) results section — Stores the

results tables from MRP and master production scheduling (MPS)

planning runs.

• Planned order section — Stores detailed routing and operation

information for planned orders. Planned Orders are transient in the SAP

solutions system (they are deleted once converted to a Production Order

Overview

2

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 19

Overview

2

Supported analyses

or Purchase Requisition). The Rapid Mart can capture quasi complete

history of Planned Orders, (including those deleted) depending on how

often the Rapid Mart is refreshed.

• Reservation section — A request to the warehouse or stores to keep a

material ready for issue at a future date for a certain purpose. The

purpose of a reservation is to ensure that a material is available when

required. A material can be reserved for a cost center, a plant, or a

production order.

• Routing section — Stores routing information for production operations.

Manufactured goods require a routing to describe the steps required to

produce a quantity of output. Routings for a material are time-dependent

and may be lot size-dependent. This section contains a material-plant

level routing description including setup, processing, and teardown times

used for basic date scheduling. The routing header associated with each

material routing contains information on lot sizing, status, and usage. The

routing header links to a table containing the individual operations with

time parameters required for detailed scheduling of each stage of the

operation. An additional table contains a link between the routing and bill

of materials of the base material.

• Production BOM section — The Production Bill Of Materials (BOM)

Section of this Rapid Mart stores data that describes what materials are

used in planning production of a given material and the quantity needed

of each of its constituents. The BOM usage supported in this component

is production. BOM tables included are single level, BOM explosion with

quantities, and BOM explosion with materials-only for where-used

reporting.

• Production order section — Stores data about production orders.

When goods are required, planned orders are converted to production

orders. The production order specifies how much to produce, the routing,

the bill of material used to reserve, produce or procure dependent

materials, the scheduled and actual start and end dates, and the status of

the order.

• Production operation section — Operations are the activities to be

performed in the production process. They are a basis for determining

dates, capacity requirements, and costs. They enumerate the use of

materials, work centers, and quality checks during production.

Chapter 3: Subject Areas discusses each of these sections in more detail and

how to link them together for a complete analysis of production planning.

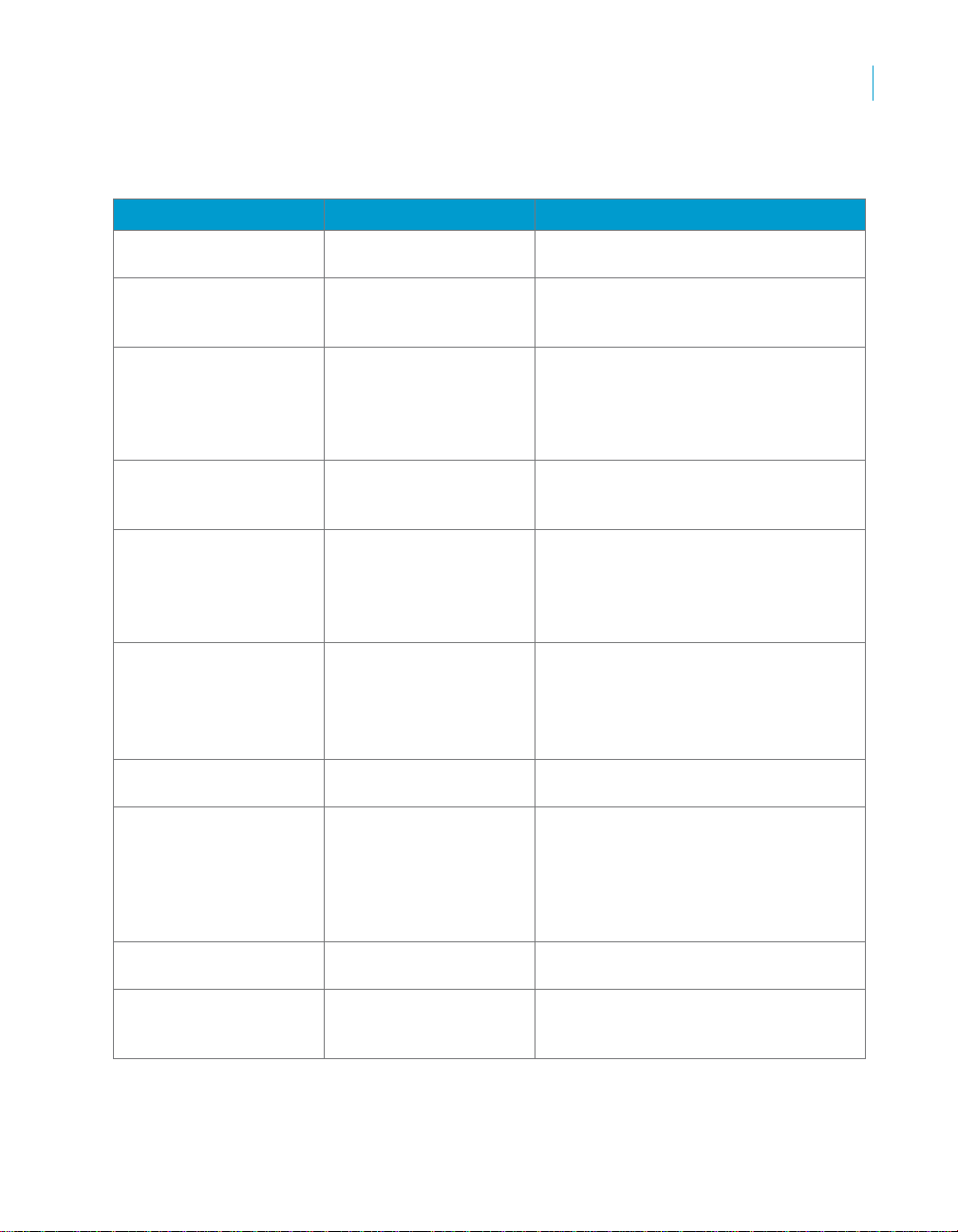

Supported analyses

20 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Overview

Supported analyses

The SAP BusinessObjects Production Planning Rapid Mart, version for SAP

solutions supports several types of analyses.

Business function Types of analysis Measures available in the Rapid Mart

Bill of material Explosion

Where-used

Routing explosion

Work center Hierarchy

Capacity planning

Cost analysis

Routing/operations Lead time

Where-used

MRP results MRP requirements list

Planned orders Pegged requirements

Planned versus actual

scheduling

• Report dependent requirements for

production bill of materials

• Single, top, and multi-level listings

of bills of materials where a

particular component is used

• Accumulation of operations required

to produce a multi-level material

displayed hierarchically by

aggregating the operation times of

BOM components

• Calculate accumulated work center

capacity using work center

hierarchies

• Evaluate standard work center

capacity and shifts. Assess the

need for alternative interval capacity

based on factory calendar and

percent utilization.

• Analysis of production costs by work

center (requires purchase of Cost

Analysis (CA) Rapid Mart)

• Report and aggregate

manufacturing lead time by activity

• Find materials using a routing or

routing using a material

• Report results of materials

requirements planning (MRP) and

master production scheduling

(MPS) planning runs, including

materials requirements at the time

of the planning run

• Planned capacity requirements by

sales order

• Compare planned operation start

times, finish times, and lead times

with actual

2

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 21

Overview

2

Related Rapid Marts

Business function Types of analysis Measures available in the Rapid Mart

Planned versus actual

yield

To support these analyses, the SAP BusinessObjects Production Planning

Rapid Mart, version for SAP solutions includes a number of dimension tables.

Reporting dimensions include material master data, planning data,

plant-specific material master data, error texts, capacity parameters formulas,

and production version, as well as time-related dimensions, such as factory

calendar, time buckets, and calendar year.

• Compare planned yield with actual

Related Rapid Marts

Each Rapid Mart is composed of multiple components. A component is a

stand-alone work flow that completes a particular task, such as loading a

specific dimension table. Components can contain other components. A

section is a set of components that address a particular business problem or

subject area. A section is itself a component.

Components of the SAP BusinessObjects Production Planning Rapid Mart,

version for SAP solutions are related to other SAP BusinessObjects Rapid

Mart components. For example:

• Inventory positions in the SAP BusinessObjects Inventory Rapid Mart,

version for SAP solutions.

• Account assignment by work center, controlling area, and activity along

with actual cost information for production orders in the SAP

BusinessObjects Cost Center Rapid Mart, version for SAP solutions.

• Purchase requisitions and purchase orders in the SAP BusinessObjects

Purchasing Rapid Mart, version for SAP solutions.

• Equipment maintenance scheduling by work center in the Plant

Maintenance Rapid Mart.

• Demand from sales documents in the SAP BusinessObjects Sales Rapid

Mart, version for SAP solutions.

Sharing components

The same components can be used in multiple Rapid Marts. For example, a

component that extracts information about materials bought, produced, and

sold is needed for a Rapid Mart that supports sales analysis and also for a

22 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Rapid Mart that supports inventory analysis. Work flows that extract star

schema “dimensions” are components. You can add a component to any

Rapid Mart using a simple import procedure.

A Data Services job can include multiple instances of a component. For

example, each section includes all the required dimension components.

Therefore, a job with several sections may include several instances of a

particular dimension component. Components are set to execute only once

within a job. This “execute once” feature ensures that shared components do

not cause duplicate data extraction from SAP solutions. For more information

about the “execute once” feature, see the Data Integrator/Data Services

Designer Guide.

Each of the sections listed in “What you can do with this Rapid Mart” on

page 19 are considered components. You can identify a component within a

Data Services job by a “C_” prefix before its name. For example, the

component that contains work centers and the associated reporting

dimensions is named C_WorkCenter_Section.

The Rapid Mart schema

The following diagrams show an overview of the SAP BusinessObjects

Production Planning Rapid Mart, version for SAP solutions components and

their relationships in Star Schema Format, and then the associated

hierarchies and auxiliary tables. As an overall picture, these diagrams are

challenging to understand. They are broken down into additional diagrams by

subject area in Chapter 3: Subject Areas.

Overview

The Rapid Mart schema

2

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 23

Overview

2

The Rapid Mart schema

Overview Star Schema (1 of 2):

24 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

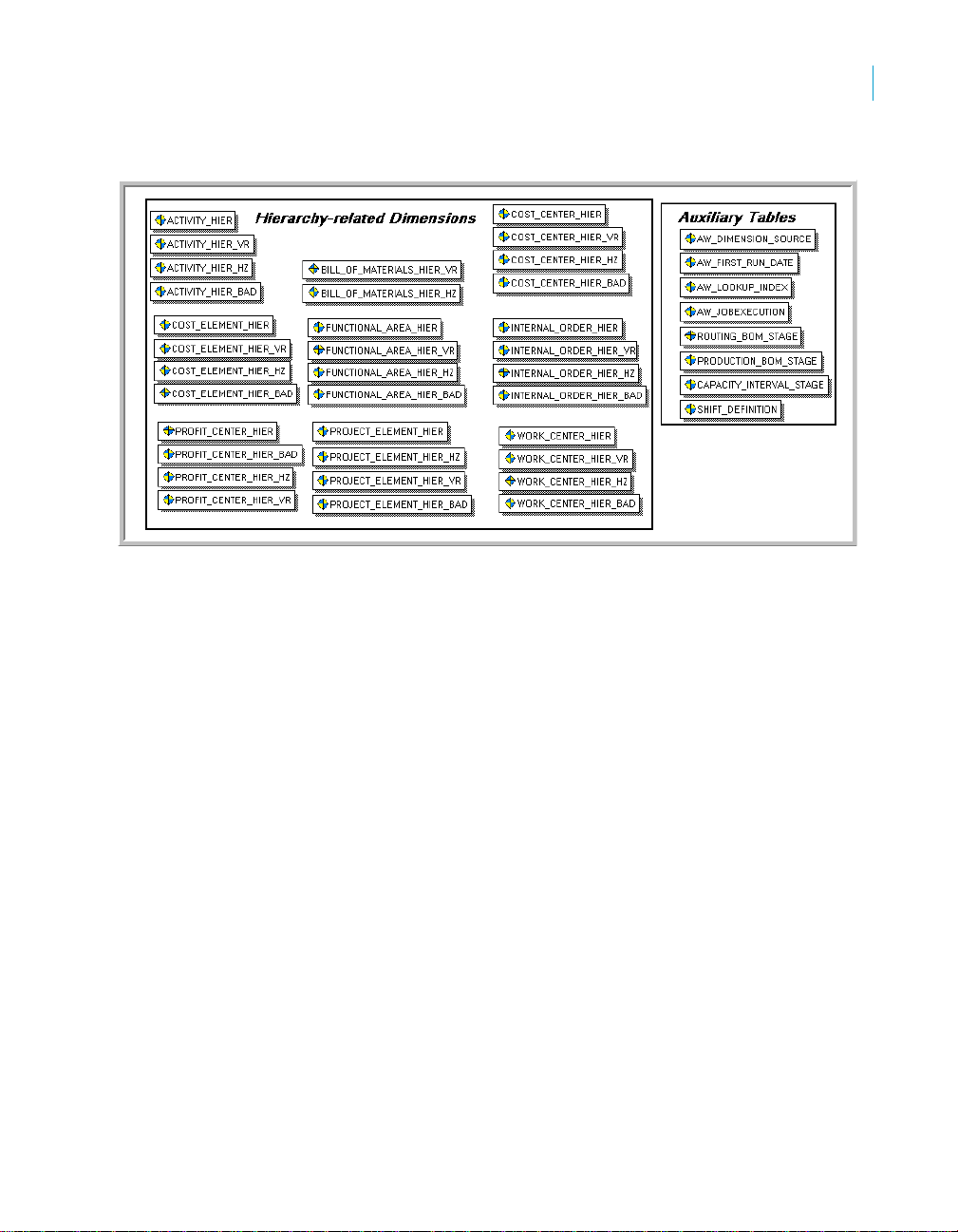

Overview Hierarchies and Auxiliary Tables:

Overview

The Rapid Mart schema

2

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 25

Overview

2

Where the Rapid Mart fits in the productio n planning process

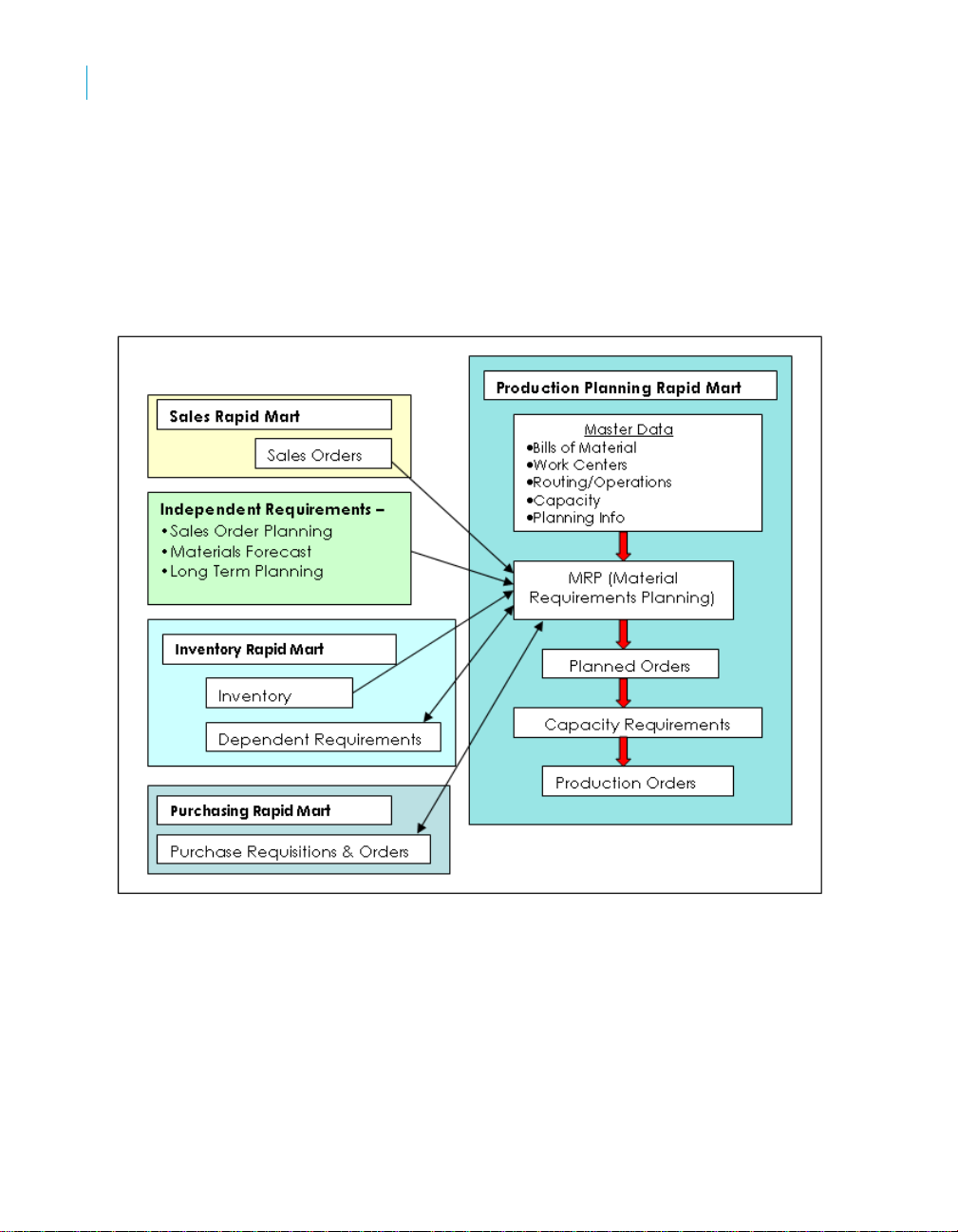

Where the Rapid Mart fits in the production

planning process

To create a comprehensive view of SAP solutions logistics modules, you can

combine the SAP BusinessObjects Production Planning Rapid Mart, version

for SAP solutions components with components from other Rapid Marts.

26 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Subject Areas

chapter

Subject Areas

3

Overview

Overview

Each section in the SAP BusinessObjects Production Planning Rapid Mart,

version for SAP solutions pertains to a particular subject area. This chapter

describes each section and the processes each section captures.

The information in this chapter is useful for readers who use the Rapid Mart to

design and support a real-time system, such as a Web application, and need

to understand the data in the Rapid Mart and how it relates to SAP solutions.

This chapter discusses:

• Work Center section

• Capacity section

• MRP results section

• Planned Order section

• Reservation section

• Routing section

• Bills of Material (BOM) section

• Production Order section

• Production Operation section

Work Center section

Production operations are carried out at a work center. In SAP solutions work

centers represent the following:

• Machines, machine groups

• Production lines

• Assembly work centers

• Employees, groups of employees

Work centers are used in task list (routing) operations and production orders.

Work centers contain the following types of information:

• Scheduling

Operating times and formulas are entered in the work center, so that the

duration of an operation can be calculated.

• Costing

Formulas are entered in the work center, so that the costs of an operation

can be calculated. A work center is also assigned to a cost center.

• Capacity planning

28 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Subject Areas

(Routings)

Work Center section

The available capacity and formulas for calculating capacity requirements

are entered in the work center.

• Simplifying operation maintenance

Various default values for operations can be entered in the work center.

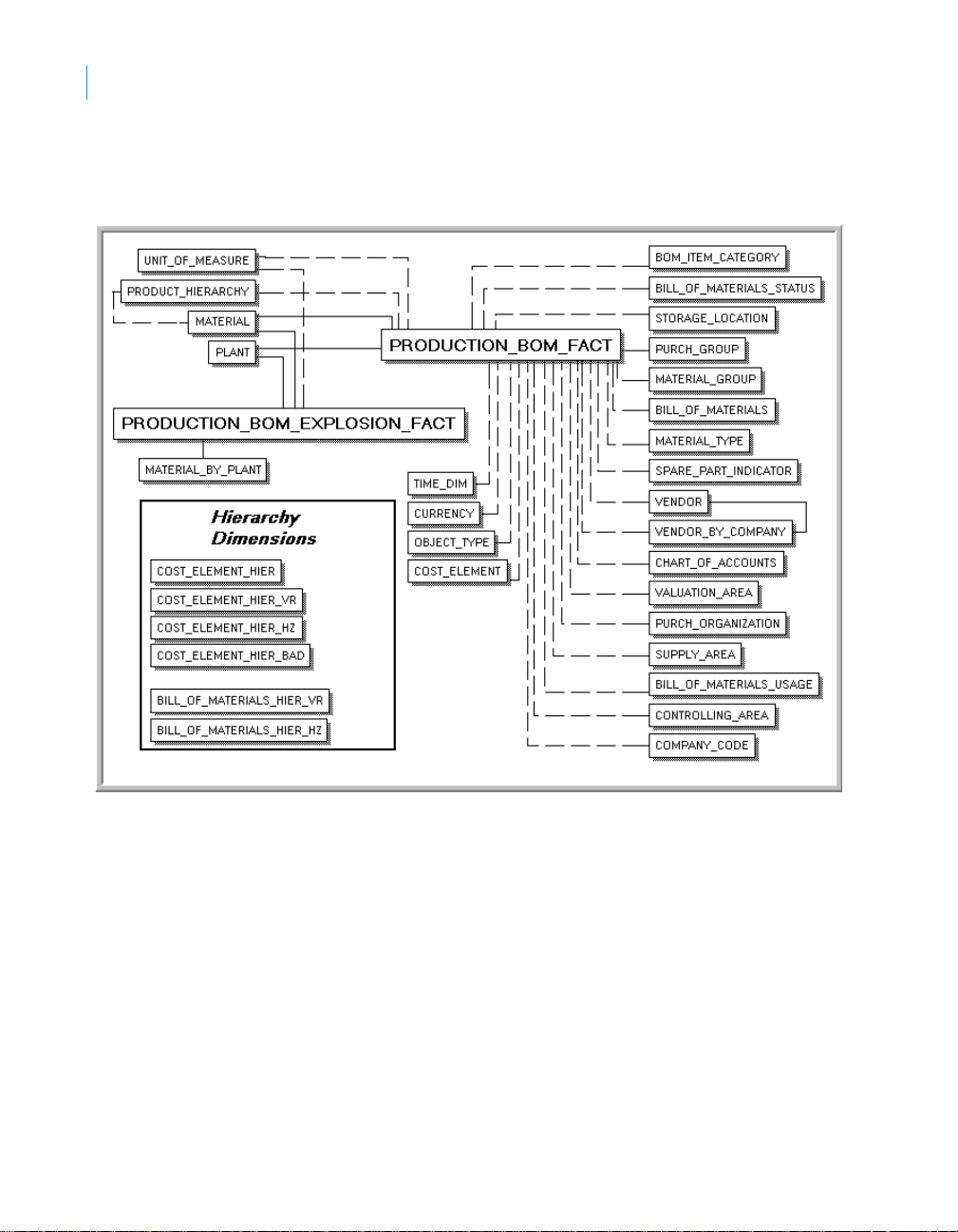

The following graphic illustrates the use of work center data.

3

A work center is created for a plant (a plant can have many work centers).

The work center category, which you define in Customizing the work center,

determines which data can be maintained in the work center.

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 29

Subject Areas

3

Work Center section

Basic Data in a Work Center:

• Assignments (to cost centers, etc.)

• Capacities

• Scheduling

• Default values

• Hierarchy

• Technical data

Integration of Work Centers

Task Lists (Routings)

Work centers are assigned to operations in task lists (routings). If you change

default values in a work center, the changes are effective in the task list if a

reference indicator has been set for the default value.

Work Center Hierarchies

Work centers can be arranged in hierarchies. These are important in capacity

planning. You use hierarchies to cumulate available capacities and capacity

requirements in a hierarchy work center.

Rapid Mart processing

The Rapid Mart extracts data from SAP solutions tables

• CRHD - Work Center Header

• CRCO - Assignment of Work Center to Cost Center

Data from these tables is used to populate target table

• WORKCENTER_COST_ASSIGN_FACT

The fact table contains descriptive information and basic data needed for

routing, costing, and capacity calculations.

30 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Subject Areas

Work Center section

The section captures the following dimensional attributes and their associated

dimension tables:

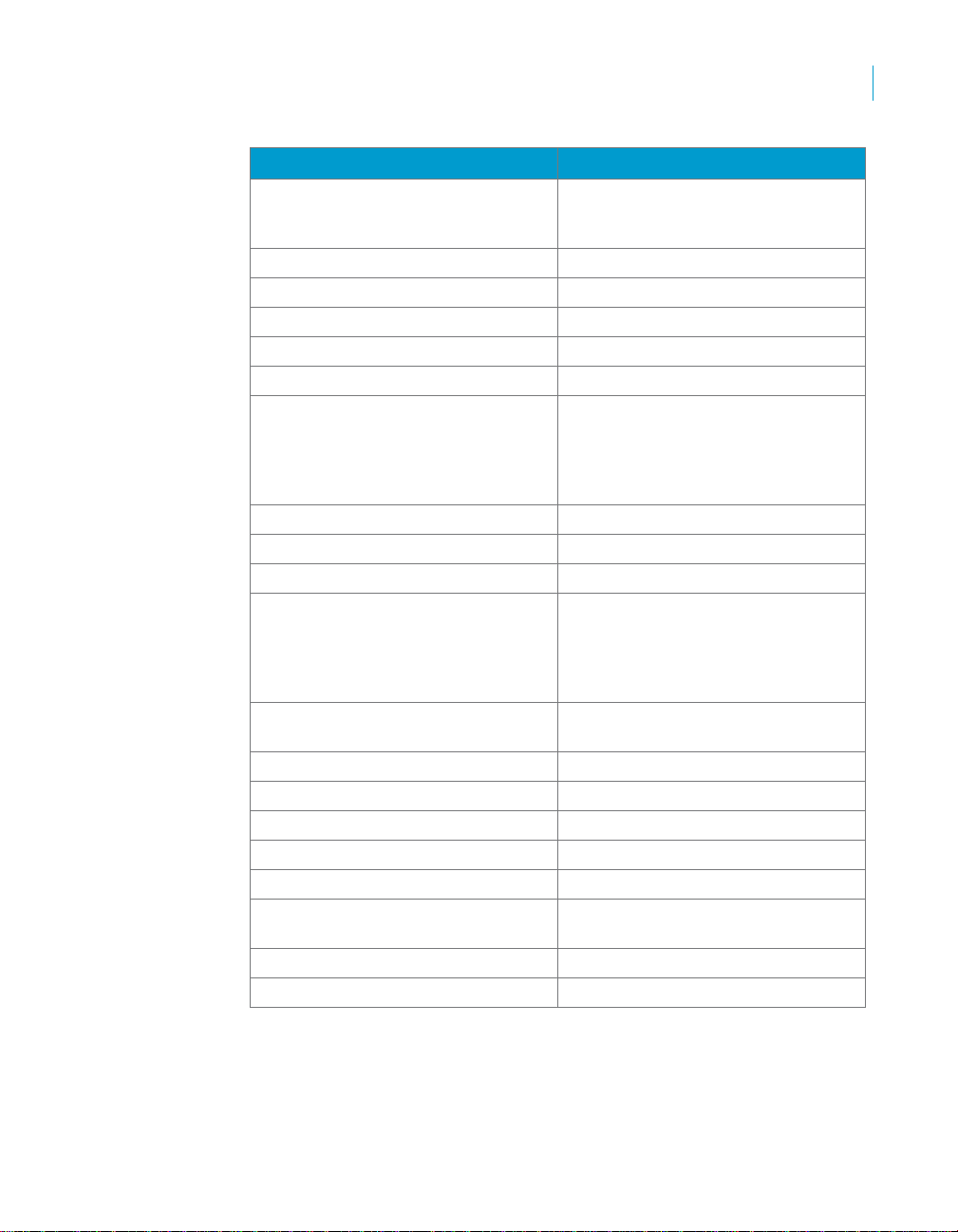

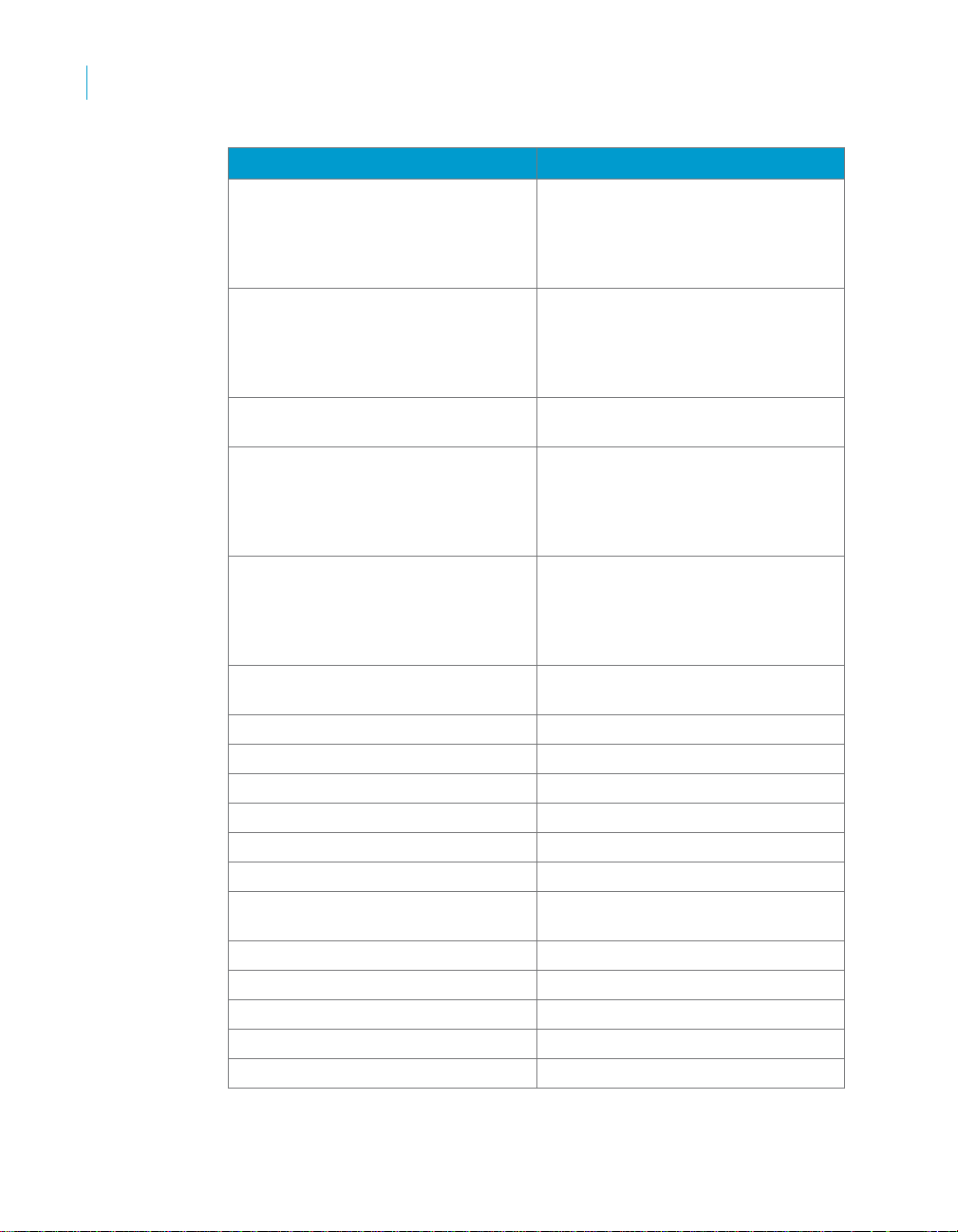

Attribute Name Dimension Tables

Activity & Hierarchy ACTIVITY, ACTIVITY_HIER,

ACTIVITY_HIER_HZ,

ACTIVITY_HIER_VR,

ACTIVITY_HIER_BAD

Chart of Accounts CHART_OF_ACCOUNTS

Company Code COMPANY_CODE

Control Key CONTROL_KEY

Controlling Area CONTROLLING_AREA

Cost Center & Hierarchy COST_CENTER,

COST_CENTER_HIER,

COST_CENTER_HIER_HZ,

COST_CENTER_HIER_VR,

COST_CENTER_HIER_BAD

Plant PLANT

Plant Location PLANT_LOCATION

Purchasing Organization PURCH_ORGANIZATION

Standard Text Key STANDARD_TEXT_KEY

Standard Value Key STANDARD_VALUE_KEY

Task List Usage TASK_LIST_USAGE

Time Dimension TIME_DIM

Valuation Area VALUATION_AREA

Work Center & Hierarchy WORK_CENTER,

WORK_CENTER_HIER,

WORK_CENTER_HIER_HZ,

WORK_CENTER_HIER_VR,

WORK_CENTER_HIER_BAD

Work Center Category WORK_CENTER_CATEGORY

Work Center Formula WORK_CENTER_FORMULA

3

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 31

Subject Areas

3

Work Center section

Fact Table Fields

A work center is master data information. Therefore, classic “measures”

(monetary and quantity values) are not found in the

WORKCENTER_COST_ASSIGN_FACT table. However, these fields are of

key importance:

Column Name Description

ACTIVITY_ID CRCO.LSTAR - Activity Type

CURRENT_FLAG “X” indicates record is currently in

effect

DAYS_VALID_ASSIGN Number of days assignment is valid

FORMULA_ID CRCO.FORML - Formula key for

costing

GROUP_USG_ID CRHD.PLANV - Key for task list

usage

LOCATN_ID CRHD.STAND - Work center location

PURCH_ORG_ID T001W.EKORG Purchasing

organization (lookup)

VALID_FROM_DATE Start date of validity period for this

record (calculated)

VALID_TO_DATE End date of validity period

(calculated)

WORK_CNTR_CATEG_ID CRHD.VERWE - Work center

category

32 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Rapid Mart data

The following diagram shows the tables in the work center section as a star

schema.

Work Centers:

Subject Areas

Work Center section

3

With the tables in this section you can analyze Work Centers along several

dimensions:

• Activity & Hierarchy

• Chart of Accounts

• Company Code

• Control Key

• Controlling Area

• Cost Center & Hierarchy

• Plant

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 33

Subject Areas

3

Capacity section

• Plant Location

• Purchasing Organization

• Standard Text Key

• Standard Value Key

• Task List Usage

• Time Dimension

• Valuation Area

• Work Center & Hierarchy

• Work Center Category

• Work Center Formula

Note: As Work Center Cost Assignment is a cross-reference fact table, both

work centers and cost centers appear as dimensions with their associated

hierarchies.

Typical queries for this section include:

• What Activities are associated with this work center?

• Which Work Centers are associated with each plant?

• What Cost Centers are associated with my work centers today vs. a year

ago?

Capacity section

The capacity section stores available capacity information by work center,

available interval capacity by date, and capacity requirements for planned

orders.

Work center capacities measure the amount of work output that a work center

can produce during a period of time. Capacity categories subdivide capacity

into types, such as machine, labor, or electrical output. More than one

capacity category can exist at a work center.

Capacities have standard operating times based on shift lengths, break times,

number of individual capacities, and percentage utilization rates. Additional

data items include the formulas and parameters used when calculating the

amount of capacity required for an operation during order scheduling and

capacity planning. Intervals of available capacity can be used to

accommodate deviations from standard available capacities. These intervals

are identified by a version and are delimited with beginning and ending

effective dates.

34 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Capacity planning uses planned order start dates and other work center

scheduling information to calculate capacity requirements for each operation

in the order. The operation capacity requirements consist of the sum of the

time required to set up, process, and teardown after each operation.

Comparison of required capacity to available capacity may necessitate

changes to planned orders before production begins.

Rapid Mart processing

in the Rapid Mart, Capacity Intervals and Capacity Requirements are two

separate fact tables.

Capacity Intervals

Capacity Intervals are sourced from these SAP solutions tables

• KAZY - Interval of Available Capacity

• TC36T - Available Capacity Descriptive Texts

• TC37A - Shift Definitions

• KAPA - Shift Parameters For Available Capacity

• KAKO - Capacity Header Segment

Data from these tables is used to populate target database tables:

• CAPACITY_INTERVAL_STAGE - from KAZY and TC36T. we use the

Data Services Effective Date transform to generate the Valid From Date

not available in the SAP solutions source tables.

• SHIFT_DEFINITION - from TC37A. This table defines the valid periods

(date ranges) of work shifts, and the hours of operation within those

validity periods

• CAPACITY_INTERVAL_FACT - from CAPACITY_INTERVAL_STAGE,

SHIFT_DEFINITION, KAKO, and KAPA

CAPACITY_INTERVAL_STAGE and SHIFT_DEFINITION are intermediate

staging tables, not used for reporting in the Rapid Mart universe (semantic

layer).

The final step of the load process outer-joins CAP ACITY_INTER VAL_STAGE

with data extracted from KAPA and KAKO tables (using

CAPACITY_INTERVAL_STAGE as the outer source). This ensures that all

capacity records are represented in the target table, regardless if intervals

have been defined for them or not. The SHIFT_DEFINITION table is used as

a lookup to determine validity dates and operating hours.

Subject Areas

Capacity section

3

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 35

Subject Areas

3

Capacity section

The calculation of shift start times, end times, hours of availability are

calculated for either Standard Available Capacity or Non-Standard Available

Capacity.

Capacity Requirements

Capacity Requirements are sourced from these SAP solutions tables

• KBKO - Header Record for Capacity Requirements

• KBED - Capacity Requirements Records

Data from these tables is used to populate target database table:

• CAPACITY_REQUIREMENT_FACT- contains results of capacity

Dimensional Attributes

The section captures the following dimensional attributes and their associated

dimension tables

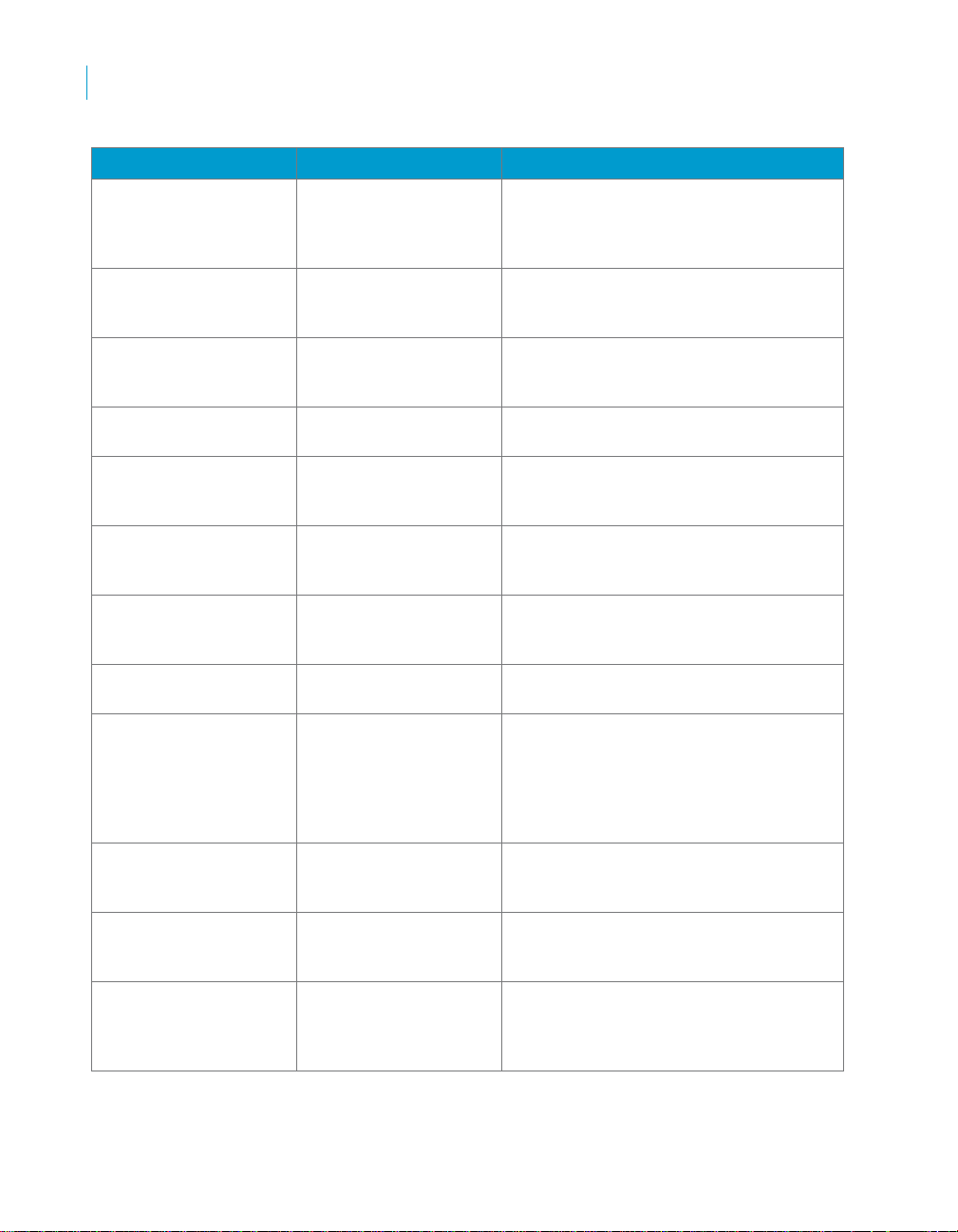

Attribute Name Dimension Tables

Capacity CAPACITY

Capacity By Work Center CAPACITY_BY_WORK_CENTER

Capacity Category CAPACITY_CATEGORY

Capacity Object Type CAPACITY_OBJECT_TYPE

Capacity Planning Group CAPACITY_PLANNING_GROUP

Company Code COMPANY_CODE

Controlling Area CONTROLLING_AREA

Internal Order & Hierarchy INTERNAL_ORDER,

Object Number Type OBJECT_NUMBER_TYPE

Object Status OBJECT_STATUS,

Order Operation ORDER_OPERATION

Plant PLANT

Purchasing Organization PURCH_ORGANIZATION

Routing ROUTING

planning when a routing is included in a planned order or a production

order.

INTERNAL_ORDER_HIER,

INTERNAL_ORDER_HIER_HZ,

INTERNAL_ORDER_HIER_VR,

INTERNAL_ORDER_HIER_BAD

OBJECT_STATUS_HZ

36 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Attribute Name Dimension Tables

Routing Operation ROUTING_OPERATION

Routing Sequence ROUTING_SEQUENCE

Scheduling Error SCHEDULING_ERROR

Scheduling Type SCHEDULING_TYPE

Task List Type (Routing Type) TASK_LIST_TYPE

Time Dimension TIME_DIM

Unit Of Measure UNIT_OF_MEASURE

Valuation Area VALUATION_AREA

Work Center Category WORK_CENTER_CATEGORY

Work Center & Hierarchy WORK_CENTER,

Fact Table Fields

Important measures for Capacity Intervals and Requirements are time

oriented, and mostly presented in days, hours, minutes, etc.

Subject Areas

Capacity section

WORK_CENTER_HIER,

WORK_CENTER_HIER_HZ,

WORK_CENTER_HIER_VR,

WORK_CENTER_HIER_BAD

3

Table Name Column Name Description

CAPACITY_INTERVAL_

FACT

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 37

DAYS_INTERVAL_CYCLE KAZY.ANZTG - Number of days in interval cycle of

HOURS_AVAIL KAPA.KAPAZ -Interval available capacity in hours

HOURS_BREAK KAKO.PAUSE - Cumulative break time in Hours

HOURS_OPRTN KAPA.EINZT - Operating time in hours

NUM_CAPACITY_INDIVID KAPA.ANZHL - Number of individual capacities

PRCNT_UTILIZATN_RATE KAPA.NGRAD - Capacity utilization rate (percent)

STD_CAPACITY_FLAG KAZY.KKOPF - Standard capacity is valid for this

SURROGATE_DOC_ID Alternate key generated in the Rapid Mart for reporting

WORK_DAYS_FLAG KAPA.FABTG - Indicator: Workdays

available capacity

interval

purposes

Subject Areas

3

Capacity section

Table Name Column Name Description

CAPACITY_REQUIREM

ENT_FACT

HOURS_OPRTN_DURTN_

ACTL

HOURS_OPRTN_DURTN_

EARLY

HOURS_OPRTN_DURTN_

LATE

HOURS_OPRTN_DURTN_

SCHED

HOURS_SCHED_TTL Sum of setup time, processing time and teardown time

MINS_OPRTN_DURTN_ACTLCalculated Operation Duration in Min - based on

MINS_OPRTN_DURTN_EA

RLY

MINS_OPRTN_DURTN_LATECalculated Operation Duration in Min - based on

MINS_OPRTN_DURTN_SC

HED

MINS_SCHED_PRCSS KBED.KBEASOLL - Scheduled cap. requirements for

MINS_SCHED_SETUP KBED.KRUESOLL - Scheduled cap. requirements for

MINS_SCHED_TEARDWN KBED.KABRSOLL - Scheduled cap. requirements for

MINS_SCHED_TTL Sum of setup time, processing time and teardown time

QTY_OPRTN KBED.MGVRG- Operation quantity pr oduced

Calculated Operation Duration in Hours- based on

Actual Start date time

Calculated Operation Duration in Hours- based on

Earliest Start date time

Calculated Operation Duration in Hours- based on

Latest Start date time

Calculated Operation Duration in Hours- based on

Scheduled Start date time

in Hours

Actual Start date time

Calculated Operation Duration in Min - based on

Earliest Start date time

Latest Start date time

Calculated Operation Duration in Min - based on

Scheduled Start date time

the op. segment "processing converted to minutes

the op. segment "setup" converted to minutes

the op. segment teardown converted to minutes

in minutes

38 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

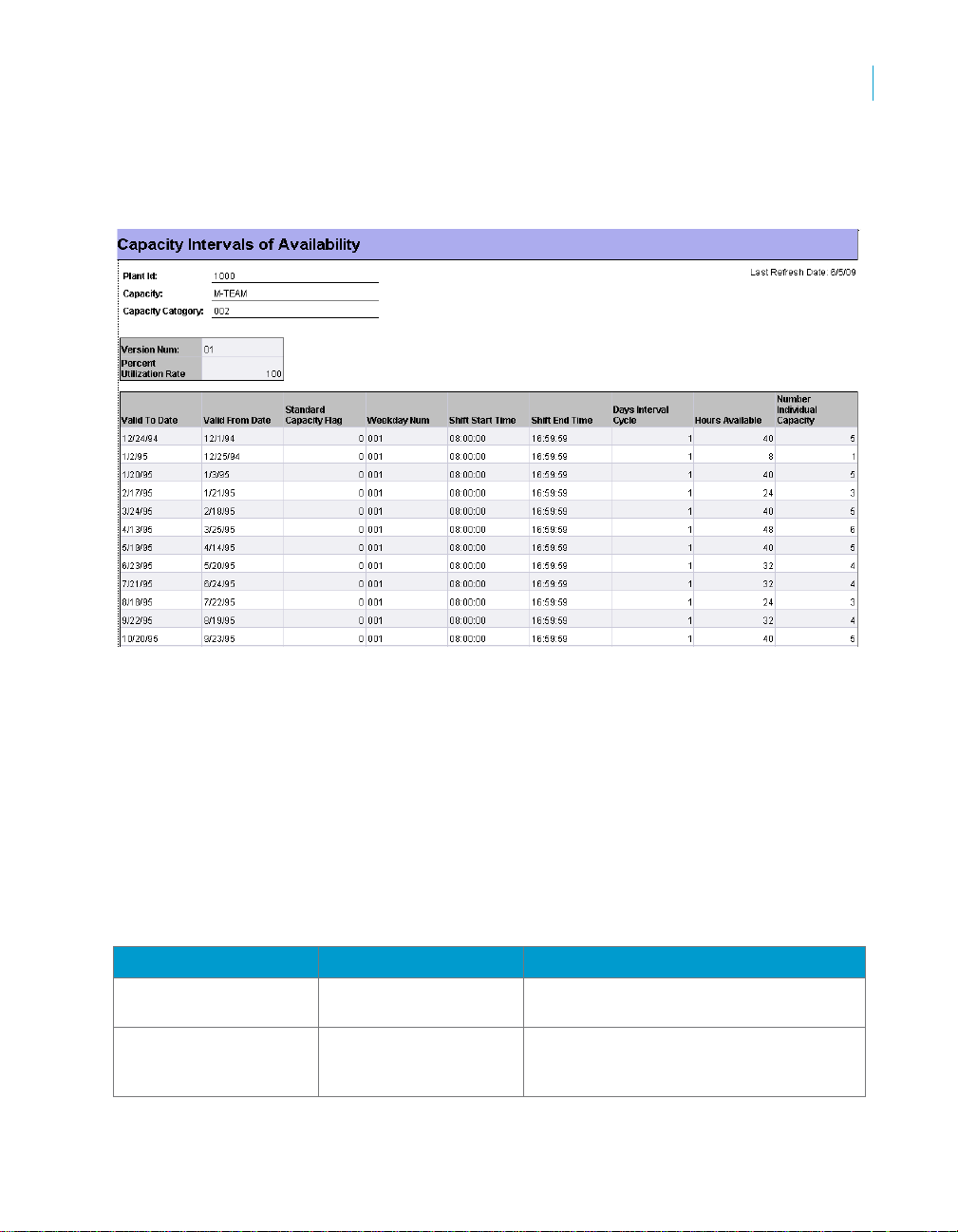

Rapid Mart data

The following diagrams show the tables in the Capacity section as a star

schema.

Capacity Intervals

Subject Areas

Capacity section

3

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 39

Subject Areas

3

Capacity section

Capacity Requirements

With the tables in this section you can analyze Work Centers along several

dimensions:

• Capacity

• Capacity By Work Center

• Capacity Category

• Capacity Object Type

• Capacity Planning Group

• Company Code

• Controlling Area

• Internal Order & Hierarchy

• Object Number Type

• Object Status

• Order Operation

• Plant

• Purchasing Organization

• Routing

• Routing Operation

40 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Subject Areas

MRP results section

• Routing Sequence

• Scheduling Error

• Scheduling Type

• Task List Type (Routing Type)

• Time Dimension

• Unit Of Measure

• Valuation Area

• Work Center Category

• Work Center & Hierarchy

Typical queries for this section include:

• What are capacity requirements by work center by weekly or monthly

time buckets?

• What are the sum individual capacities by work center according to work

center hierarchy?

• How productive are Capacity Intervals scheduled around holidays as

compared to regular intervals?

• Which are the top 10 routing operations in terms of actual operation

hours?

3

MRP results section

The MRP results section stores the results tables from material requirements

planning (MRP) and master production scheduling (MPS) planning runs.

Material requirements planning (MRP) combines production master data with

demand forecasts, sales orders, and material availability to arrive at a plan for

how much material to procure through production, purchase requisition, stock

transfer, or other means. Depending on user inputs, the bill of materials may

be exploded as well to generate requirements lists for dependent materials.

The MRP requirements list contains the amount of stock on hand, the

demands by requirement date, planned order quantities, procurement

quantities, scrap output, and exception warnings indicating errors.

The MRP process generates rough-cut capacity requirements if the

scheduling type selected at planning time is type 2 (lead time scheduling and

capacity planning).

The MRP results table also includes materials planned using master

production scheduling (MPS) strategies.

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 41

Subject Areas

3

MRP results section

Rapid Mart processing

MRP results can be stored in either clustered or transparent MRP detail

tables in SAP solutions. The Rapid Mart selects from both tables to ensure a n

accurate representation of MRP results.

The source tables in SAP solutions are:

• MDKP - Header Data for MRP Document

• MDTB - MRP Details (transparent)

• MDTC - Aggregated MRP table items (clustered)

The target table in the Rapid Mart is:

• MRP_RESULT_FACT

The clustered MDTC table is accessed via a Custom ABAP transform called

MRPCluster.

You can choose to maintain only the last set of MRP results or to accumulate

them over time. If you choose to preserve old results during incremental

loads, you should periodically clean the MRP_RESULT_FACT table so that

performance is not adversely affected.

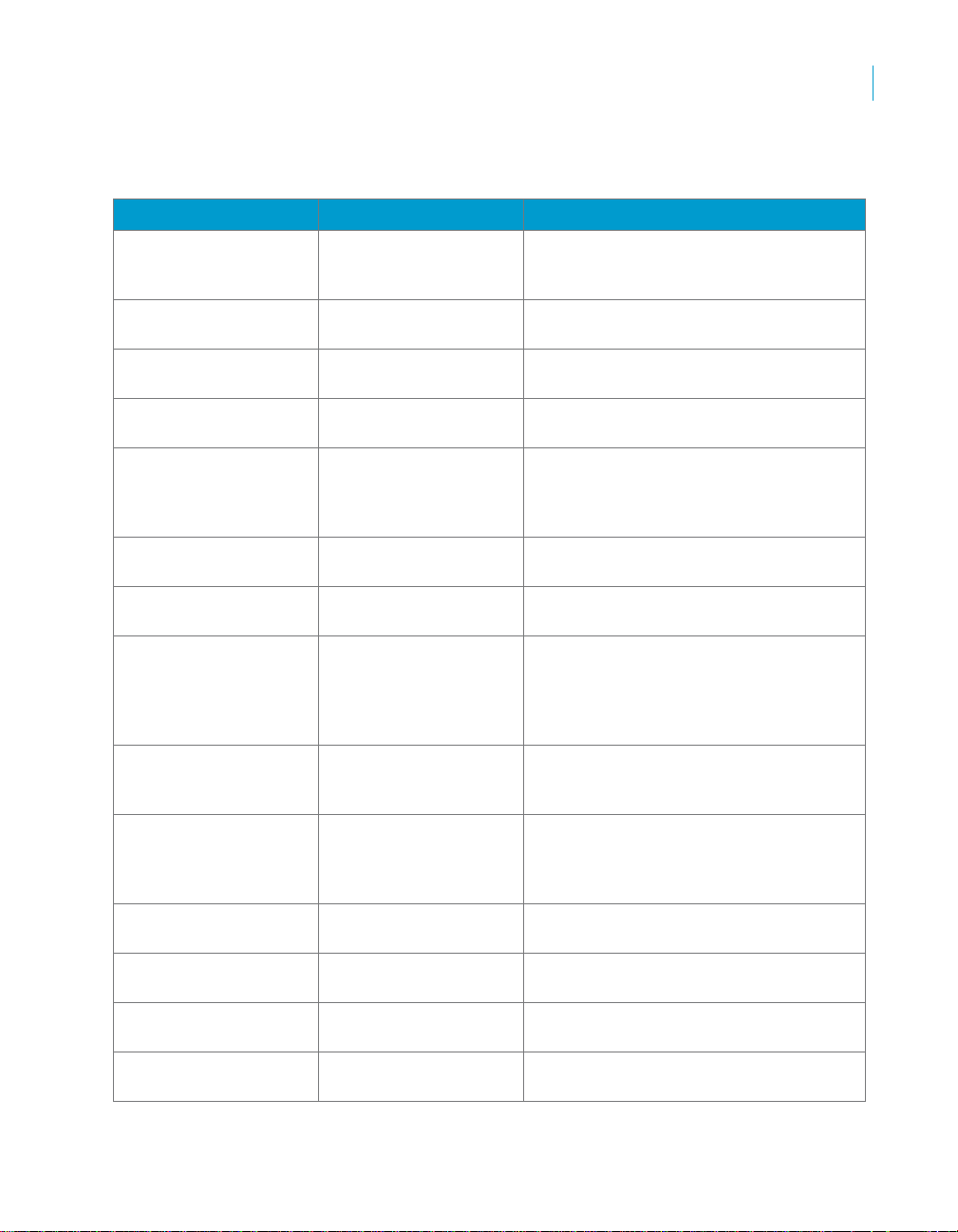

The section captures the following dimensional attributes and their associated

dimension tables:

Attribute Name Dimension Tables

Company Code COMPANY_CODE

Controlling Area CONTROLLING_AREA

Exception Text EXCEPTION_TEXT

Material & Product Hierarchy MATERIAL,

PRODUCT_HIERARCHY

Material By Plant MATERIAL_BY_PLANT

Material Group MATERIAL_GROUP

Material Type MATERIAL_TYPE

MRP Controller MRP_CONTROLLER

MRP Element Type MRP_ELEMENT_TYPE

MRP Group MRP_GROUP

MRP Lot Size MRP_LOT_SIZE

MRP Profile MRP_PROFILE

MRP Type MRP_TYPE

Plant PLANT

42 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Attribute Name Dimension Tables

Procurement Type PROCUREMENT_TYPE

Purchasing Group PURCH_GROUP

Purchasing Organization PURCH_ORGANIZATION

Storage Location STORAGE_LOCATION

Time Dimension TIME_DIM

Unit Of Measure UNIT_OF_MEASURE

Valuation Area VALUATION_AREA

Fact Table Fields

Important measures for MRP Results are both quantity and time oriented, and

presented in base unit of measure and days.

Column Name Description

DAYS_GR_PROCESS MDTB.WEBAZ - Goods receipt processing

DAYS_RECPT_COVERAGE MDKP.BERW2 - Receipt range of coverage

DAYS_STOCK_COVERAGE MDKP.BERW1 - Stock coverage without

QTY_MRP MDTB.MNG01 - Quantity received or

QTY_SCRAP MDTB.MNG02 - Variable scrap quantity

QTY_SHORTAGE MDTB.MNG03 - Shortage quantity

QTY_STOCK_EXCESS MDTB.RDMNG - Excess stock quantity

time in days

receipts

quantity required

Subject Areas

MRP results section

3

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 43

Subject Areas

3

MRP results section

Rapid Mart data

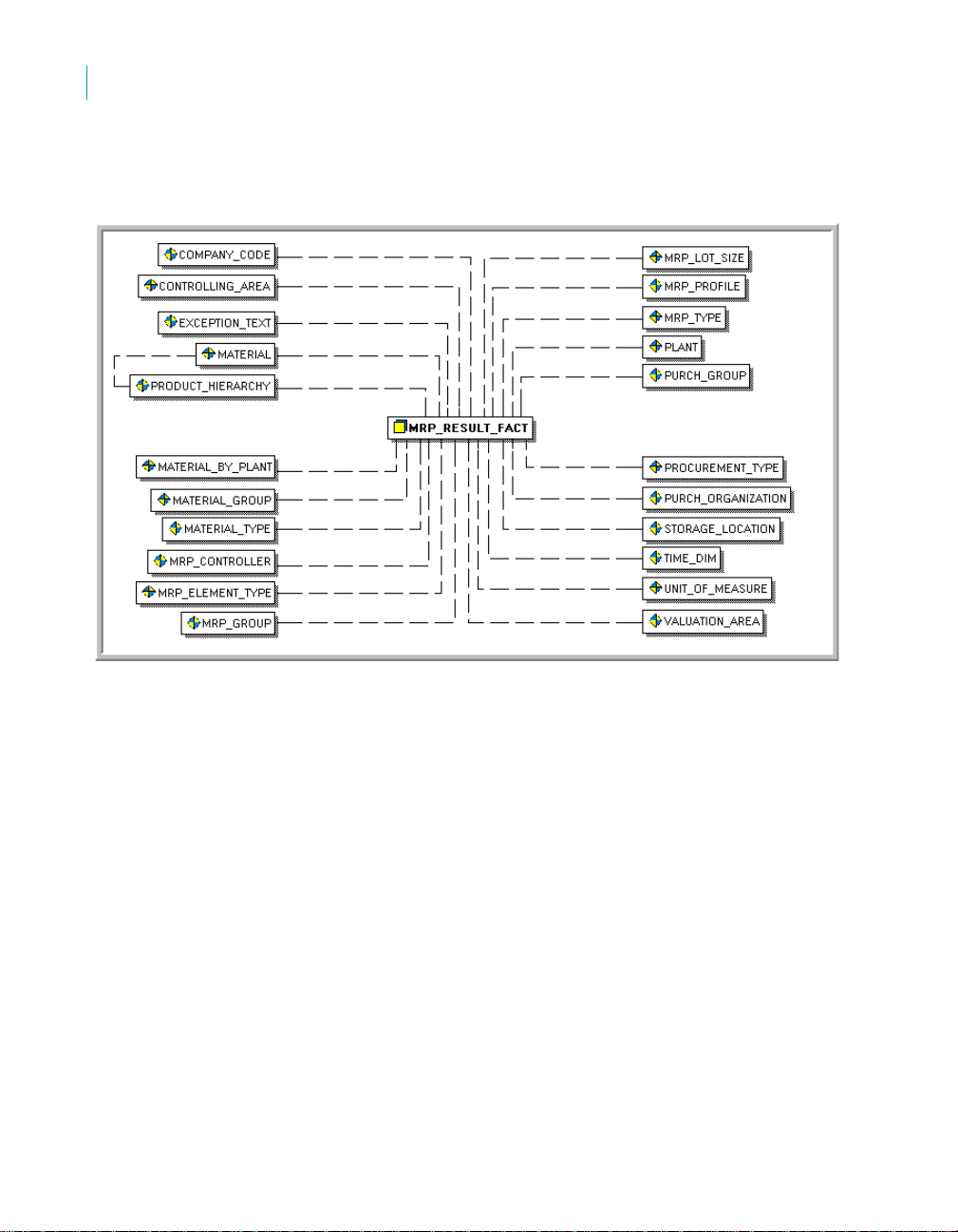

The following diagram shows the tables in the MRP results section.

With the tables in this section you can analyze Work Centers along several

dimensions:

• Company Code

• Controlling Area

• Exception Text

• Material & Product Hierarchy

• Material By Plant

• Material Group

• Material Type

• MRP Controller

• MRP Element Type

• MRP Group

• MRP Lot Size

• MRP Profile

• MRP Type

44 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Subject Areas

Planned Order section

• Plant

• Procurement Type

• Purchasing Group

• Purchasing Organization

• Storage Location

• Time Dimension

• Unit Of Measure

• Valuation Area

Typical queries for this section include:

• What is my planned scrap production for next month?

• What is the planned total quantity of purchase requisitions for next

month?

• List MRP requirements by requirement type.

• Which materials have the highest external procurement rate by quantity?

• Which plants have excess stock?

• Which materials consistently show a shortage by plant at the end of each

quarter?

3

Planned Order section

The planned order section extracts detailed information for planned orders.

Materials Requirements Planning results in planned orders that suggest the

amount of material to produce and when to produce it in order to meet the

demand requirements.

Conversion of a planned order to a production order creates orders for all the

material components needed to complete the planned order. Material

reservations are created if existing stocks will be used for components. A

routing and a bill of materials is required to create a planned order.

Planned orders that have been converted to production orders are removed

from the planned order table once the quantity to be produced is covered by

production orders. Only planned orders marked as convertible can be

converted to production orders.

The Rapid Mart facilitates maintaining a partial history of the planned orders

that have been removed. The Rapid Mart delta (incremental) load does not

delete Planned Orders that exist in the target table.

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 45

Subject Areas

3

Planned Order section

if a planned order is created and then subsequently converted to a production

order between Rapid Mart refreshes, the planned order will not appear in the

Rapid Mart target table as it was deleted in SAP solutions before it could be

captured by the Rapid Mart.

Additionally, a final set of changes to a planned order just before it is

converted (and deleted) may not be captured in the target Rapid Mart table.

Planned orders do not have creation or change dates associated with them.

Thus, there is no way to tell when a change or deletion of a planned order

occurs in SAP solutions.

The Rapid Mart does a full extract of all planned orders in either the first

(initial) load or delta (incremental) loads.

In an initial load, the planned order target table is truncated (all data deleted)

before data from SAP solutions is loaded.

In a delta load, no data is deleted in the target, and the Table Comparison

transform is used to add or updated existing records. Table Comparison does

not delete existing records in the target. Thus, the partial history detailed

above can be preserved.

Rapid Mart processing

Planned orders are sourced from SAP solutions table

• PLAF - Planned Orders

The data populates target table

• PLANNED_ORDER_FACT - Planned order details

The section captures the following dimensional attributes and their associated

dimension tables:

Attribute Name Dimension Tables

Account Assignment Category ACCT_ASSIGNMENT_CATEGORY

Bill Of Materials Status BILL_OF_MATERIALS_STATUS

Bill Of Materials Usage BILL_OF_MATERIALS_USAGE

Company Code COMPANY_CODE

Controlling Area CONTROLLING_AREA

Document Type DOCUMENT_TYPE &

DOCUMENT_CATEGORY

Material & Product Hierarchy MATERIAL &

PRODUCT_HIERARCHY

Material By Plant MATERIAL_BY_PLANT

46 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Subject Areas

Planned Order section

Attribute Name Dimension Tables

Material Group MATERIAL_GROUP

Production Material MATERIAL_PRODUCTION

Material Type MATERIAL_TYPE

MRP Controller MRP_CONTROLLER

Object Type OBJECT_TYPE

Plant PLANT

Procurement Type PROCUREMENT_TYPE

Production Scheduler PRODUCTION_SCHEDULER

Project PROJECT

Project Element & Hierarchy PROJECT_ELEMENT,

PROJECT_ELEMENT_HIER,

PROJECT_ELEMENT_HIER_HZ,

PROJECT_ELEMENT_HIER_VR,

PROJECT_ELEMENT_HIER_BAD

Purchasing Organization PURCH_ORGANIZATION

Routing ROUTING

Scheduling Error SCHEDULING_ERROR

Storage Location STORAGE_LOCATION

Task List Type TASK_LIST_TYPE

Time Dimension TIME_DIM

Unit Of Measure UNIT_OF_MEASURE

Valuation Area VALUATION_AREA

3

Fact Table Fields

Important measures for planned orders are both quantity and time oriented:

Column Name Description

DAYS_ORD_DURTN_PLAN Calculated Order to Completion time

in Days- based on Planned Start date

time

HOURS_ORD_DURTN_PLAN Calculated Order to Completion time

in Hours - based on Planned Start

date time

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 47

Subject Areas

3

Planned Order section

Rapid Mart data

Column Name Description

MINS_ORD_DURTN_PLAN Calculated Order to Completion time

in Min - based on Planned Start date

time

QTY_REDUCED PLAF.ABMNG - Reduced quantity in

the planned order

QTY_TTL PLAF.GSMNG - Total planned order

quantity

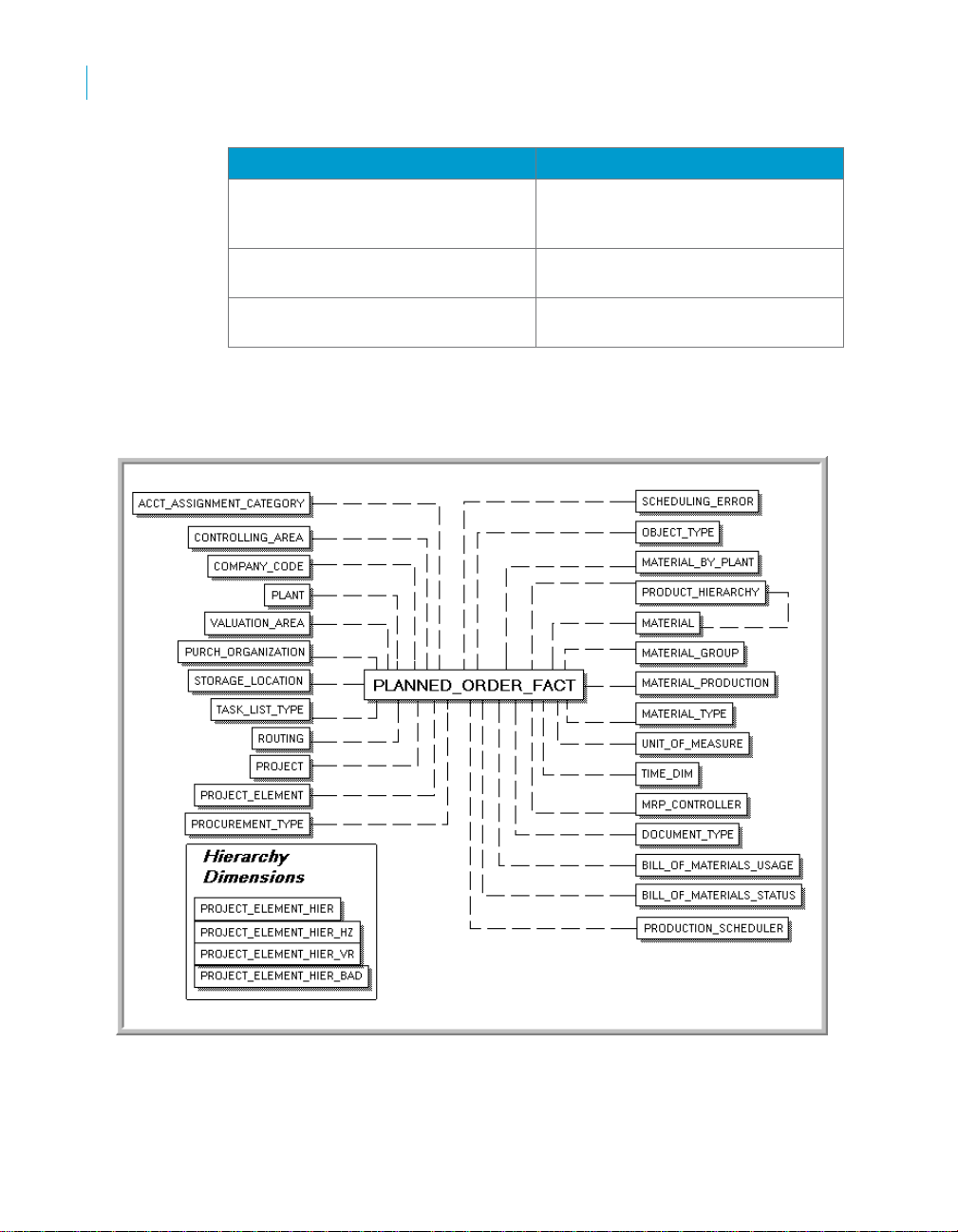

The following diagram shows the tables in the planned order section.

With the tables in this section you can analyze Planned Orders along several

dimensions:

48 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Subject Areas

Planned Order section

• Account Assignment Category

• Bill Of Materials Status

• Bill Of Materials Usage

• Company Code

• Controlling Area

• Document Type

• Material & Product Hierarchy

• Material By Plant

• Material Group

• Production Material

• Material Type

• MRP Controller

• Object Type

• Plant

• Procurement Type

• Production Scheduler

• Project

• Project Element & Hierarchy

• Purchasing Organization

• Routing

• Scheduling Error

• Storage Location

• Task List Type

• Time Dimension

• Unit Of Measure

• Valuation Area

Typical queries for this section include:

• Show planned production quantities by material, and by week

• Which MRP controllers have the most Planned Orders by month?

• What did this planned order looked like before it was deleted in SAP

solutions?

3

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide 49

Subject Areas

3

Reservation section

Reservation section

In SAP solutions, a reservation or dependent requirement is a request to the

warehouse to keep materials ready for use on a particular date. A reservation

ensures that a material is available when the material is needed. The MRP

process can make reservations automatically , or users can make reservations

manually. Any check on material availability must consider prior reservations

for the material. Reservations are allowed only if the material is available to

promise (ATP).

The reservation’s timing determines when goods issues (for consumption in a

production order, or for delivery in a sales order) are allowed for reserved

items. This may be manually overridden using the “movement allowed”

indicator. A goods issue appears in the material movements table and

references the reservation. At this point, SAP solutions reduces inventory by

the amount of the goods issue.

If the reservation is for a particular customer order, the sales order and sales

line item numbers are stored on the reservation. In this case, the goods issue

document in the material movements table also contains references to the

sales order. These fields provide a link to the sales and distribution functions

of the Sales Rapid Mart.

SAP solutions marks reservations as deleted when their retention periods

have been exceeded. Reservations marked deleted are not moved into the

Rapid Mart reservations table.

Rapid Mart processing

In the Rapid Mart, reservations are sourced from SAP solutions tables:

• RKPF - Document Header: Reservation

• RESB - Reservation/dependent requirements details

The target table in the Rapid Mart is:

• RESERVATION_FACT

The section captures the following dimensional attributes and their associated

dimension tables:

Attribute Name Dimension Tables

Acct Assignment Category ACCT_ASSIGNMENT_CATEGORY

Activity & Hierarchy ACTIVITY, ACTIVITY_HIER,

ACTIVITY_HIER_HZ,

ACTIVITY_HIER_VR,

ACTIVITY_HIER_BAD

50 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions User Guide

Subject Areas

Reservation section

Attribute Name Dimension Tables

Bill Of Materials & Hierarchy BILL_OF_MATERIALS,

BILL_OF_MATERIALS_HZ,

BILL_OF_MATERIALS_VR

BOM Item Category BOM_ITEM_CATEGORY

Business Area BUSINESS_AREA

Chart Of Accounts CHART_OF_ACCOUNTS

Company Code COMPANY_CODE

Controlling Area CONTROLLING_AREA

Cost Center & Hierarchy COST_CENTER,