SAP BusinessObjects Production Business Guide

SAP BusinessObjects Production

Planning Rapid Mart XI 3.2, version for

SAP solutions - Business Guide

Version 12.2.2.0

October 2009

Copyright

Trademarks

© Copyright 2009 SAP AG. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or for any purpose

without the express permission of SAP AG. The information contained herein may be

changed without prior notice.

Some software products marketed by SAP AG and its distributors contain proprietary

software components of other software vendors.

All rights reserved. SAP, R/3, SAP NetWeaver, Duet, PartnerEdge, ByDesign, SAP Business

ByDesign, and other SAP products and services mentioned herein as well as their respective

logos are trademarks or registered trademarks of SAP AG in Germany and other countries.

Business Objects and the Business Objects logo, BusinessObjects, Crystal Reports, Crystal

Decisions, Web Intelligence, Xcelsius, and other Business Objects products and services

mentioned herein as well as their respective logos are trademarks or registered trademarks

of Business Objects S.A. in the United States and in other countries. Business Objects is an

SAP company.

All other product and service names mentioned are the trademarks of their respective

companies. Data contained in this document serves informational purposes only. National

product specifications may vary.

These materials are subject to change without notice. These materials are provided by SAP

AG and its affiliated companies ("SAP Group") for informational purposes only, without

representation or warranty of any kind, and SAP Group shall not be liable for errors or

omissions with respect to the materials. The only warranties for SAP Group products and

services are those that are set forth in the express warranty statements accompanying such

products and services, if any. Nothing herein should be construed as constituting an

additional warranty.

Contents

Chapter 1 Introduction 7

What is a Rapid Mart? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Rapid Marts packages accelerate Time to Value . . . . . . . . . . . . . . . . . 9

SAP BusinessObjects Rapid Marts packages architecture . . . . . . . . . 10

About this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 2 Overview 13

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

What is production planning? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

What you can do with this Rapid Mart . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Supported analyses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Related Rapid Marts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Sharing components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

The Rapid Mart schema . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Where the Rapid Mart fits in the production planning process . . . . . . . . . . 22

Chapter 3 Subject Areas 23

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Work Center section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Basic Data in a Work Center: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Integration of Work Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Rapid Mart data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Capacity section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Rapid Mart data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide 3

Contents

MRP results section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Rapid Mart data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Planned Order section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Rapid Mart data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Reservation section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Rapid Mart Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Routing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Rapid Mart data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Bills of Material (BOM) section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Rapid Mart data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Production Order section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Rapid Mart data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Production Operation section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Rapid Mart processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Rapid Mart data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Chapter 4 Reports 79

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Work Center Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Capacity Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

MRP Results Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Planned Order Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide

Contents

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Reservation Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Routing Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Bill Of Materials Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Production Order Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Production Operation Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Recommended Table Joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

SAP Master Data Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Data Discovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Data Auditing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Recommended table joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide 5

Contents

6 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide

Introduction

chapter

Introduction

1

What is a Rapid Mart?

What is a Rapid Mart?

SAP BusinessObjects Rapid Marts packages are blueprints for building data

marts with SAP BusinessObjects technology:

• Data Services

• Universe Designer

• Web Intelligence.

Rapid Marts packages deliver jump-start ETL (extract, transform & load)

mappings, schema, and initial reporting content, accelerating the deployment

of BI (business intelligence) for enterprise applications from SAP, PeopleSoft,

Oracle, and Siebel.

Each Rapid Mart is designed to address the reporting needs of a specific

business area (or department) like accounting, sales, or purchasing. A

component-based framework allows conducting analysis across these

selected business areas by combining different packages within the same

source application suite.

Rapid Marts focus on basic standard configuration of the enterprise

applications. They are country and industry neutral templates meant to be

easily modified and extended to suit customer specific application

implementation and reporting needs.

Rapid Marts incorporate best practices, and provide easily modifiable

templates. With Rapid Marts total development time of a data mart solution is

greatly reduced.

Each customer situation is different. You will probably encounter one or more

of these:

• Customizations you have made to SAP solutions the Rapid Mart does not

cover.

• Standard SAP solutions data fields important for your specific business,

but not included in the Rapid Mart templates.

• Optimization and performance challenges unique to your environment.

• Reporting requirements not covered within the Rapid Mart template

reports.

Rapid Marts are flexible templates that you can adjust to account for these

unique situations. It is expected that some customization and optimization will

be needed to suit your individual environment. Rapid Marts are not an

out-of-the-box solution.

8 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide

BI tools and analytic tools can access Rapid Mart data through SQL queries.

Rapid Marts can be implemented individually, or in any combination, to form a

single platform that delivers the infrastructure for your company’s internal and

external information needs. They can also serve as a staging area for

enterprise analytic applications.

Rapid Marts provide your business with an accelerated time to value through

rapid BI deployments because you can implement them quickly and easily

customize them to meet specific analytic requirements.

Rapid Marts packages accelerate Time to Value

Rapid Marts are packaged data solutions that you can quickly deploy to

address specific areas of business analysis.

Available Rapid Marts packages for SAP solutions include:

Financial Suite:

• SAP BusinessObjects General Ledger Rapid Mart, version for SAP

solutions

• SAP BusinessObjects Accounts Payable Rapid Mart, version for SAP

solutions

• SAP BusinessObjects Accounts Receivable Rapid Mart, version for SAP

solutions

• SAP BusinessObjects Cost Center Rapid Mart, version for SAP solutions

Operational Suite:

• SAP BusinessObjects Inventory Rapid Mart, version for SAP solutions

• SAP BusinessObjects Purchasing Rapid Mart, version for SAP solutions

• SAP BusinessObjects Sales Rapid Mart, version for SAP solutions

Manufacturing Suite:

• SAP BusinessObjects Plant Maintenance Rapid Mart, version for SAP

solutions

• SAP BusinessObjects Production Planning Rapid Mart, version for SAP

solutions

• SAP BusinessObjects Project Systems Rapid Mart, version for SAP

solutions

Human Capital Management (HCM) Suite:

• SAP BusinessObjects Human Resources Rapid Mart, version for SAP

solutions

Introduction

What is a Rapid Mart?

1

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide 9

Introduction

1

What is a Rapid Mart?

You can combine multiple Rapid Marts packages into a single environment to

build the foundation for your data warehouse or use them as a staging area

for business intelligence applications.

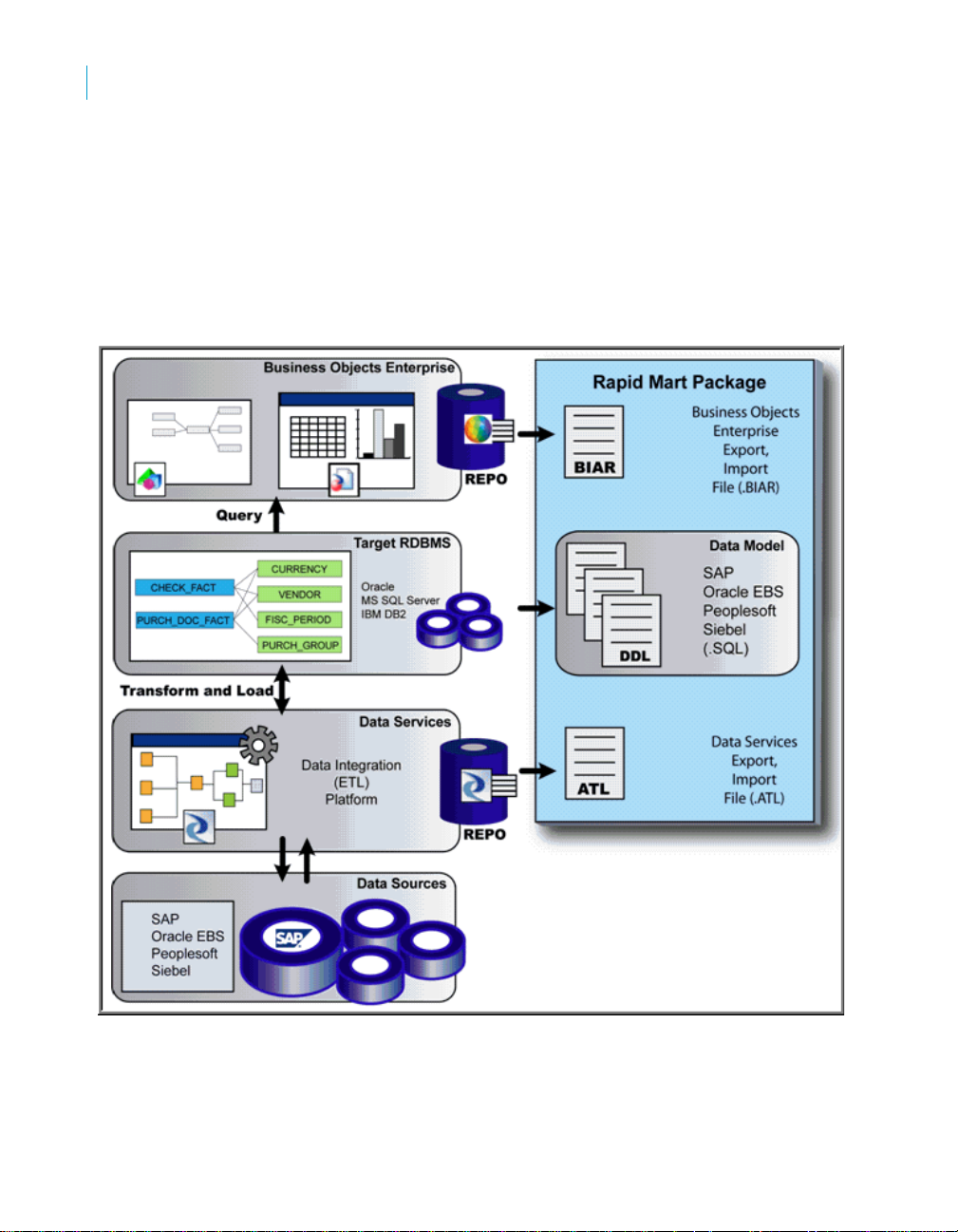

SAP BusinessObjects Rapid Marts packages architecture

Rapid Marts architecture is driven by SAP BusinessObjects technology.

Rapid Mart Architecture:

Rapid Marts packages include the following components:

10 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide

Introduction

About this document

• Data Movement Jobs - packaged source-to-target mappings and data

transformations. Each job is designed to perform initial and incremental

data movement;

• Data Model & Schema - set of data mart database objects designed with

dimensional data modeling approach. Rapid Marts packages for SAP

solutions has a single integrated data model. The schema are available

for Oracle, SQL Server IBM DB2, and Teradata;

• Semantic Layer (Universes) - SAP BusinessObjects metadata packages

for efficient query generation. There can be one or more universes per

Rapid Mart. Each universe is developed using Rapid Marts design

principles to ensure compatibility, code readability, and component

re-use. In addition, there is one Master universe for

development/maintenance of multiple use objects (like Customer,

Material, Currency, etc.);

• Reports (Samples) - set of 15-20 Web Intelligence reports per Rapid

Mart. They represent answers to mostly asked business questions (for

example, in the SAP BusinessObjects Sales Rapid Mart, version for SAP

solutions - 'What is the monthly Revenue trend by Division for this

year?'). The reports are developed using Rapid Mart color/layout

templates. Reports are examples of Web Intelligence best practice

development (trends, listing, guided analysis, roll ups and downs, etc.).

1

About this document

This document describes the SAP BusinessObjects Production Planning

Rapid Mart, version for SAP solutions. This document contains information for

a variety of users—information that helps you understand the use of the

Rapid Mart, the data in the Rapid Mart, the reports you can create with the

Rapid Mart, and how to use and update the Rapid Mart.

This document contains the following chapters:

• Chapter 2: Overview — Describes the business problems you can solve

and the types of analyses you can do with this Rapid Mart

• Chapter 3: Subject Areas — Contains detailed information about each

section in the Rapid Mart, including the processes each section captures

• Chapter 4: Reports — Provides examples of reports you can produce

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide 11

Introduction

1

About this document

12 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide

Overview

chapter

Overview

2

Overview

Overview

This chapter describes the business problems you can solve with the SAP

BusinessObjects Production Planning Rapid Mart, version for SAP solutions

and the types of analyses you can do with this Rapid Mart. The information in

this chapter is useful for those who want a business-level overview of the

Rapid Mart and its benefits.

This chapter discusses the following topics:

• What is production planning?

• What you can do with this Rapid Mart

• Supported analyses

• Related Rapid Marts

• The Rapid Mart schema

• Where the Rapid Mart fits in the production planning process

What is production planning?

Within SAP solutions, the process of production planning and control (PP)

determines what to produce, how much to produce, and when to produce it.

Production quantities and scheduling are constrained by machine time, labor ,

material availability, and storage space. These resources are in turn

constrained by budget and other financial considerations. By balancing

resource constraints with demand and scheduling requirements, an effective

production plan optimizes factory lead times, improves customer delivery

performance, and reduces time consumed by work in progress (WIP).

Planning processes in SAP solutions generate time-based demands for

materials based on sales order planning, long term forecasts, stock

replenishment quantities, customer order requirements, backlog, safety stock

levels, and other anticipated sources of demand. The SAP solutions materials

requirements planning (PP-MRP) component combines lead time scheduling

information with independent and dependent requirements (based on bill of

materials) for a material and produces a production and procurement

proposal—a planning proposal—that satisfies current and projected demand

requirements.

The planning proposal that SAP solutions produces does not account for

material availability or work center capacity until a production order is created.

When creating a production order, SAP solutions explodes a bill of materials,

14 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide

What you can do with this Rapid Mart

creates requisitions for externally procured materials, selects a routing for

produced materials, reserves materials and resources, and calculates

capacity requirements for work centers.

What you can do with this Rapid Mart

The SAP BusinessObjects Production Planning Rapid Mart, version for SAP

solutions enables you to analyze the planning components that automate the

production process. The data that supports these planning

components—work centers, routings, planning strategies, bill of materials,

capacities, and MRP results—can provide insight into the production process

and help you improve and streamline both the planning process and the

actual production and procurement of goods and services.

The SAP BusinessObjects Production Planning Rapid Mart, version for SAP

solutions is made up of several components or sections. Each section

supports a subject related to planning analysis:

• Work center section — S tores data about work centers—the machines,

production lines, or labor pools capable of producing units of work as

output. The amount of work that a work center can produce during a

given time is its capacity . Basic work center data includes category (labor ,

machine, etc.), description, location (plant), and standard values for

queue times. This section also contains the work center hierarchy, which

allows you to roll up work center capacity to accumulate capacities at

various levels. This section also contains the work center assignment to

cost center.

• Capacity section— Stores standard shift times and operating times for

various capacity categories (machine, labor). Work centers have one or

more capacities, measured in terms of units of time, associated with

them. The combination of operating hours, utilization rate, and number of

capacities determines the standard available cap acity for the work center .

Additional capacity, called interval available capacity, might be available

for certain intervals of time. Capacity requirements generated by

production orders and planned orders using lead time scheduling are

also included in this section.

• Materials requirement planning (MRP) results section — Stores the

results tables from MRP and master production scheduling (MPS)

planning runs.

• Planned order section — Stores detailed routing and operation

information for planned orders. Planned Orders are transient in the SAP

solutions system (they are deleted once converted to a Production Order

Overview

2

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide 15

Overview

2

Supported analyses

or Purchase Requisition). The Rapid Mart can capture quasi complete

history of Planned Orders, (including those deleted) depending on how

often the Rapid Mart is refreshed.

• Reservation section — A request to the warehouse or stores to keep a

material ready for issue at a future date for a certain purpose. The

purpose of a reservation is to ensure that a material is available when

required. A material can be reserved for a cost center, a plant, or a

production order.

• Routing section — Stores routing information for production operations.

Manufactured goods require a routing to describe the steps required to

produce a quantity of output. Routings for a material are time-dependent

and may be lot size-dependent. This section contains a material-plant

level routing description including setup, processing, and teardown times

used for basic date scheduling. The routing header associated with each

material routing contains information on lot sizing, status, and usage. The

routing header links to a table containing the individual operations with

time parameters required for detailed scheduling of each stage of the

operation. An additional table contains a link between the routing and bill

of materials of the base material.

• Production BOM section — The Production Bill Of Materials (BOM)

Section of this Rapid Mart stores data that describes what materials are

used in planning production of a given material and the quantity needed

of each of its constituents. The BOM usage supported in this component

is production. BOM tables included are single level, BOM explosion with

quantities, and BOM explosion with materials-only for where-used

reporting.

• Production order section — Stores data about production orders.

When goods are required, planned orders are converted to production

orders. The production order specifies how much to produce, the routing,

the bill of material used to reserve, produce or procure dependent

materials, the scheduled and actual start and end dates, and the status of

the order.

• Production operation section — Operations are the activities to be

performed in the production process. They are a basis for determining

dates, capacity requirements, and costs. They enumerate the use of

materials, work centers, and quality checks during production.

Chapter 3: Subject Areas discusses each of these sections in more detail and

how to link them together for a complete analysis of production planning.

Supported analyses

16 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide

Overview

Supported analyses

The SAP BusinessObjects Production Planning Rapid Mart, version for SAP

solutions supports several types of analyses.

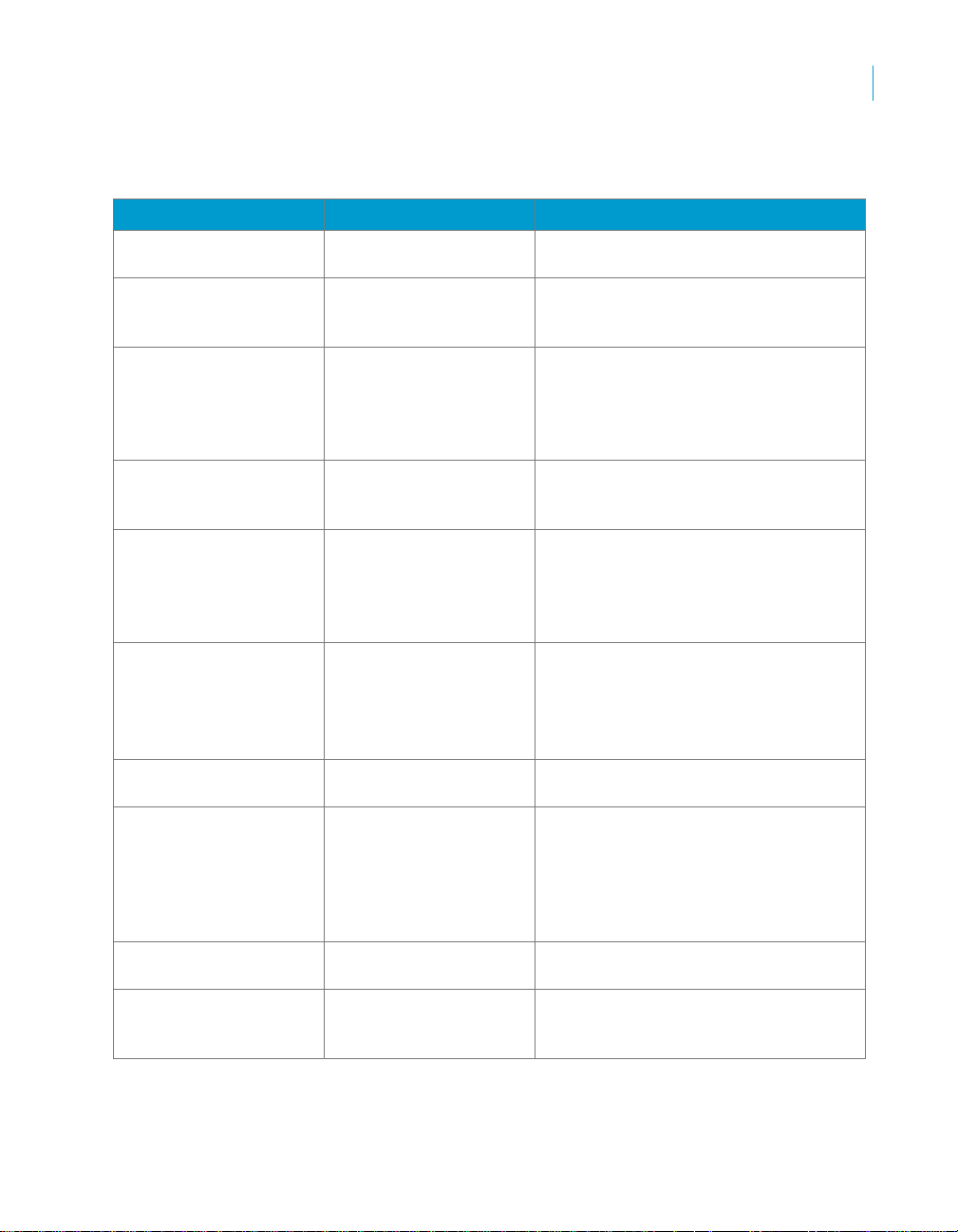

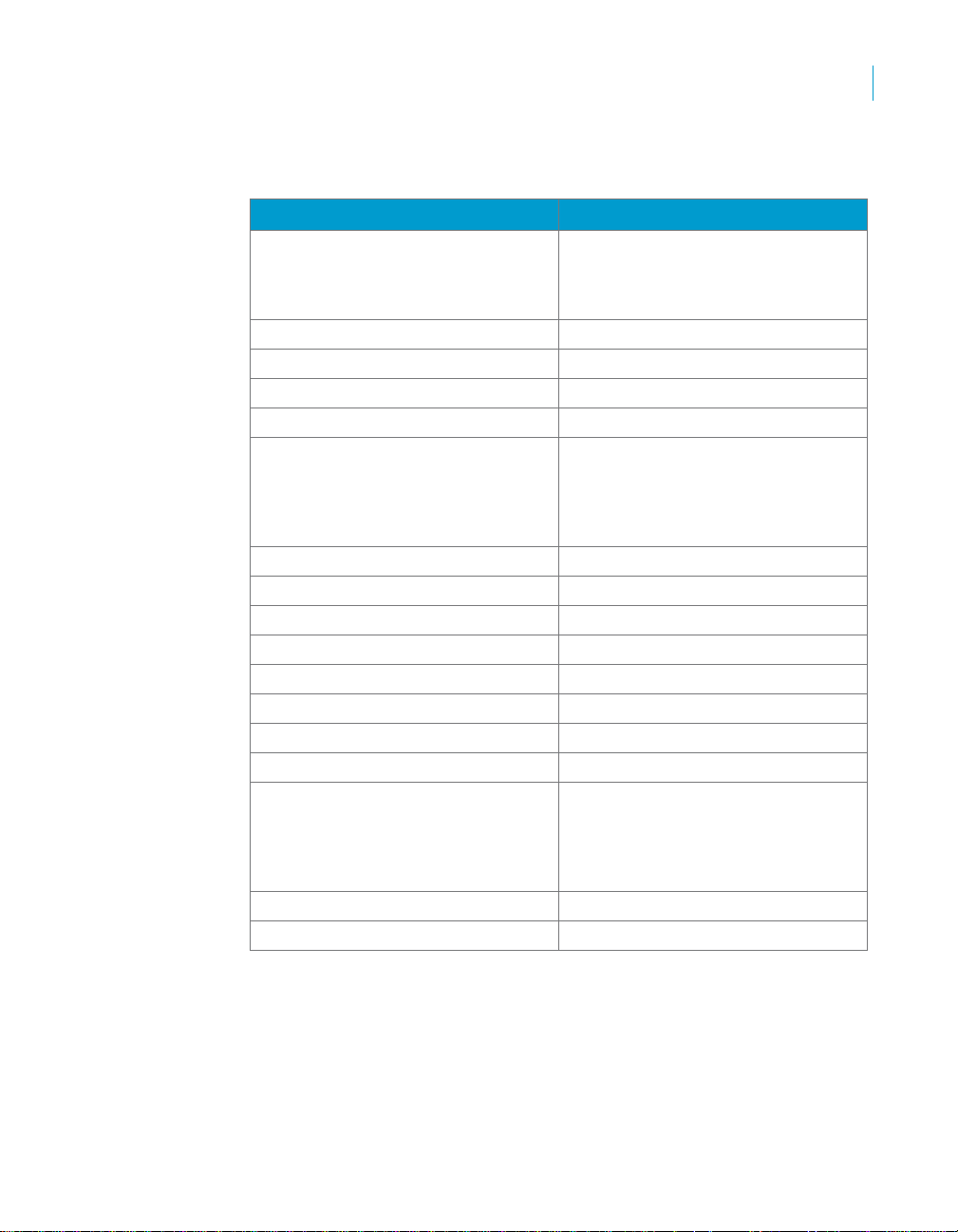

Business function Types of analysis Measures available in the Rapid Mart

Bill of material Explosion

Where-used

Routing explosion

Work center Hierarchy

Capacity planning

Cost analysis

Routing/operations Lead time

Where-used

MRP results MRP requirements list

Planned orders Pegged requirements

Planned versus actual

scheduling

• Report dependent requirements for

production bill of materials

• Single, top, and multi-level listings

of bills of materials where a

particular component is used

• Accumulation of operations required

to produce a multi-level material

displayed hierarchically by

aggregating the operation times of

BOM components

• Calculate accumulated work center

capacity using work center

hierarchies

• Evaluate standard work center

capacity and shifts. Assess the

need for alternative interval capacity

based on factory calendar and

percent utilization.

• Analysis of production costs by work

center (requires purchase of Cost

Analysis (CA) Rapid Mart)

• Report and aggregate

manufacturing lead time by activity

• Find materials using a routing or

routing using a material

• Report results of materials

requirements planning (MRP) and

master production scheduling

(MPS) planning runs, including

materials requirements at the time

of the planning run

• Planned capacity requirements by

sales order

• Compare planned operation start

times, finish times, and lead times

with actual

2

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide 17

Overview

2

Related Rapid Marts

Business function Types of analysis Measures available in the Rapid Mart

Planned versus actual

yield

To support these analyses, the SAP BusinessObjects Production Planning

Rapid Mart, version for SAP solutions includes a number of dimension tables.

Reporting dimensions include material master data, planning data,

plant-specific material master data, error texts, capacity parameters formulas,

and production version, as well as time-related dimensions, such as factory

calendar, time buckets, and calendar year.

• Compare planned yield with actual

Related Rapid Marts

Each Rapid Mart is composed of multiple components. A component is a

stand-alone work flow that completes a particular task, such as loading a

specific dimension table. Components can contain other components. A

section is a set of components that address a particular business problem or

subject area. A section is itself a component.

Components of the SAP BusinessObjects Production Planning Rapid Mart,

version for SAP solutions are related to other SAP BusinessObjects Rapid

Mart components. For example:

• Inventory positions in the SAP BusinessObjects Inventory Rapid Mart,

version for SAP solutions.

• Account assignment by work center, controlling area, and activity along

with actual cost information for production orders in the SAP

BusinessObjects Cost Center Rapid Mart, version for SAP solutions.

• Purchase requisitions and purchase orders in the SAP BusinessObjects

Purchasing Rapid Mart, version for SAP solutions.

• Equipment maintenance scheduling by work center in the Plant

Maintenance Rapid Mart.

• Demand from sales documents in the SAP BusinessObjects Sales Rapid

Mart, version for SAP solutions.

Sharing components

The same components can be used in multiple Rapid Marts. For example, a

component that extracts information about materials bought, produced, and

sold is needed for a Rapid Mart that supports sales analysis and also for a

18 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide

Rapid Mart that supports inventory analysis. Work flows that extract star

schema “dimensions” are components. You can add a component to any

Rapid Mart using a simple import procedure.

A Data Services job can include multiple instances of a component. For

example, each section includes all the required dimension components.

Therefore, a job with several sections may include several instances of a

particular dimension component. Components are set to execute only once

within a job. This “execute once” feature ensures that shared components do

not cause duplicate data extraction from SAP solutions. For more information

about the “execute once” feature, see the Data Integrator/Data Services

Designer Guide.

Each of the sections listed in “What you can do with this Rapid Mart” on

page 15 are considered components. You can identify a component within a

Data Services job by a “C_” prefix before its name. For example, the

component that contains work centers and the associated reporting

dimensions is named C_WorkCenter_Section.

The Rapid Mart schema

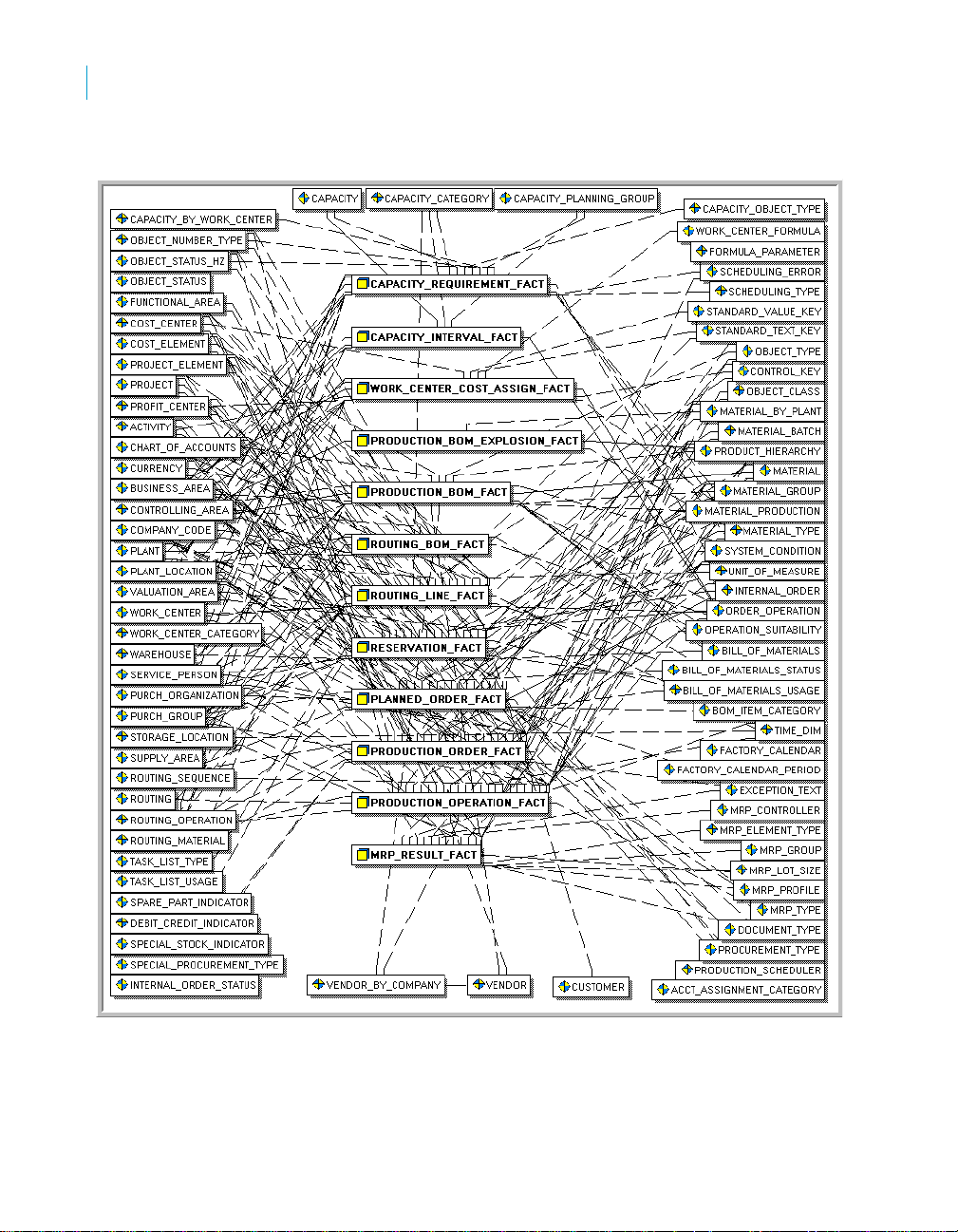

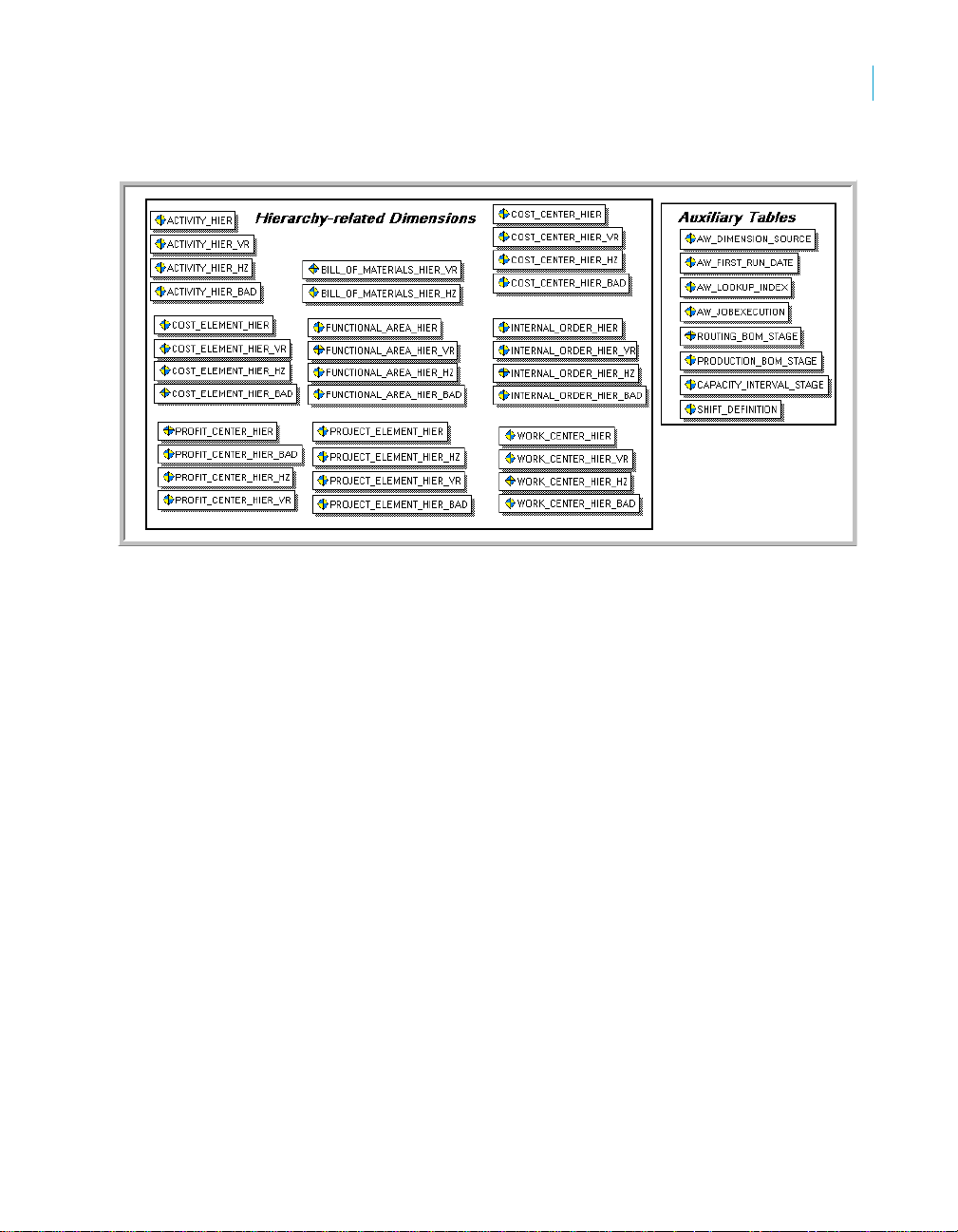

The following diagrams show an overview of the SAP BusinessObjects

Production Planning Rapid Mart, version for SAP solutions components and

their relationships in Star Schema Format, and then the associated

hierarchies and auxiliary tables. As an overall picture, these diagrams are

challenging to understand. They are broken down into additional diagrams by

subject area in Chapter 3: Subject Areas.

Overview

The Rapid Mart schema

2

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide 19

Overview

2

The Rapid Mart schema

Overview Star Schema (1 of 2):

20 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide

Overview Hierarchies and Auxiliary Tables:

Overview

The Rapid Mart schema

2

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide 21

Overview

2

Where the Rapid Mart fits in the productio n planning process

Where the Rapid Mart fits in the production

planning process

To create a comprehensive view of SAP solutions logistics modules, you can

combine the SAP BusinessObjects Production Planning Rapid Mart, version

for SAP solutions components with components from other Rapid Marts.

22 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide

Subject Areas

chapter

Subject Areas

3

Overview

Overview

Each section in the SAP BusinessObjects Production Planning Rapid Mart,

version for SAP solutions pertains to a particular subject area. This chapter

describes each section and the processes each section captures.

The information in this chapter is useful for readers who use the Rapid Mart to

design and support a real-time system, such as a Web application, and need

to understand the data in the Rapid Mart and how it relates to SAP solutions.

This chapter discusses:

• Work Center section

• Capacity section

• MRP results section

• Planned Order section

• Reservation section

• Routing section

• Bills of Material (BOM) section

• Production Order section

• Production Operation section

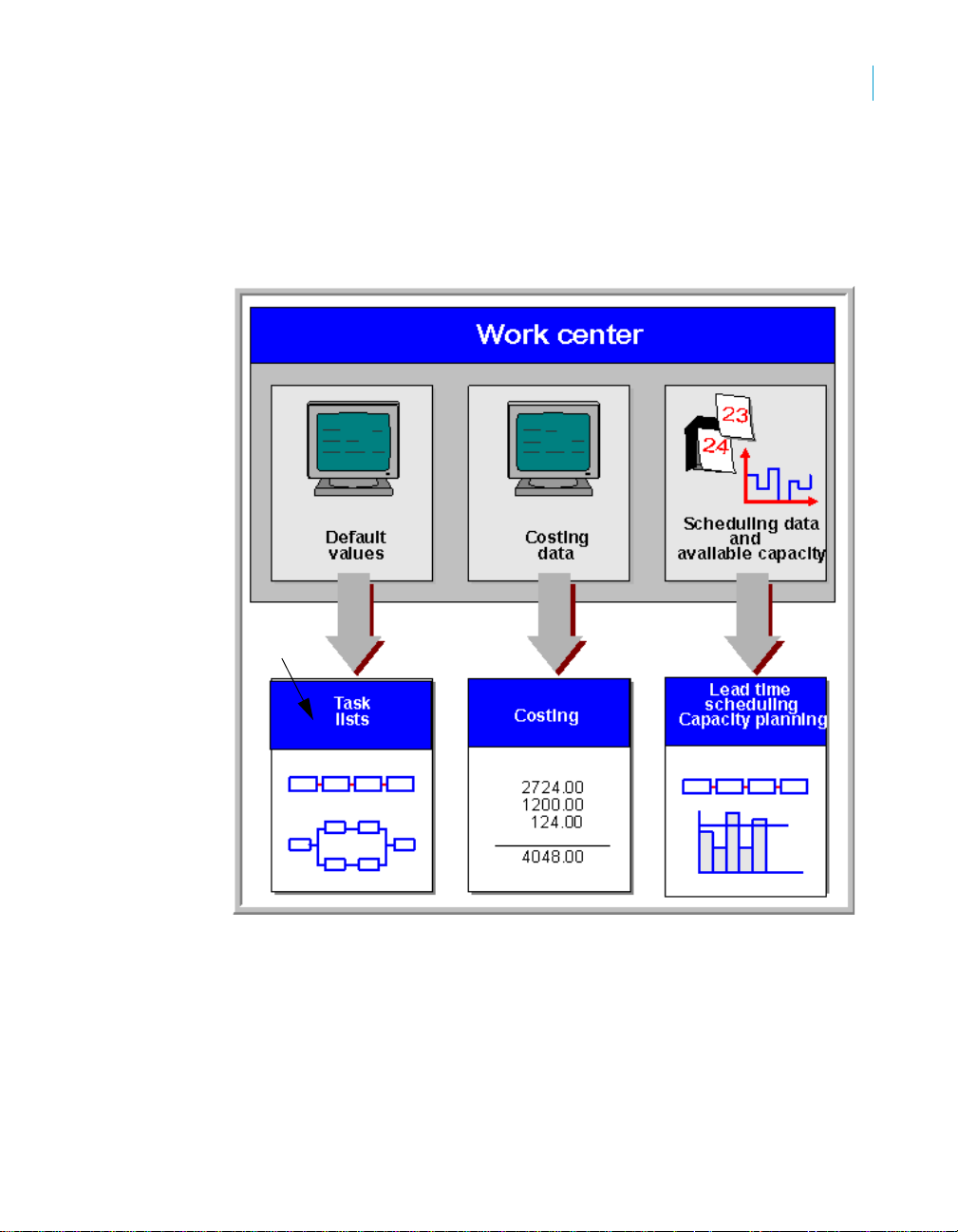

Work Center section

Production operations are carried out at a work center. In SAP solutions work

centers represent the following:

• Machines, machine groups

• Production lines

• Assembly work centers

• Employees, groups of employees

Work centers are used in task list (routing) operations and production orders.

Work centers contain the following types of information:

• Scheduling

Operating times and formulas are entered in the work center, so that the

duration of an operation can be calculated.

• Costing

Formulas are entered in the work center, so that the costs of an operation

can be calculated. A work center is also assigned to a cost center.

• Capacity planning

24 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide

Subject Areas

(Routings)

Work Center section

The available capacity and formulas for calculating capacity requirements

are entered in the work center.

• Simplifying operation maintenance

Various default values for operations can be entered in the work center.

The following graphic illustrates the use of work center data.

3

A work center is created for a plant (a plant can have many work centers).

The work center category, which you define in Customizing the work center,

determines which data can be maintained in the work center.

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide 25

Subject Areas

3

Work Center section

Basic Data in a Work Center:

• Assignments (to cost centers, etc.)

• Capacities

• Scheduling

• Default values

• Hierarchy

• Technical data

Integration of Work Centers

Task Lists (Routings)

Work centers are assigned to operations in task lists (routings). If you change

default values in a work center, the changes are effective in the task list if a

reference indicator has been set for the default value.

Work Center Hierarchies

Work centers can be arranged in hierarchies. These are important in capacity

planning. You use hierarchies to cumulate available capacities and capacity

requirements in a hierarchy work center.

Rapid Mart processing

The Rapid Mart extracts data from SAP solutions tables

• CRHD - Work Center Header

• CRCO - Assignment of Work Center to Cost Center

Data from these tables is used to populate target table

• WORKCENTER_COST_ASSIGN_FACT

The fact table contains descriptive information and basic data needed for

routing, costing, and capacity calculations.

26 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide

Subject Areas

Work Center section

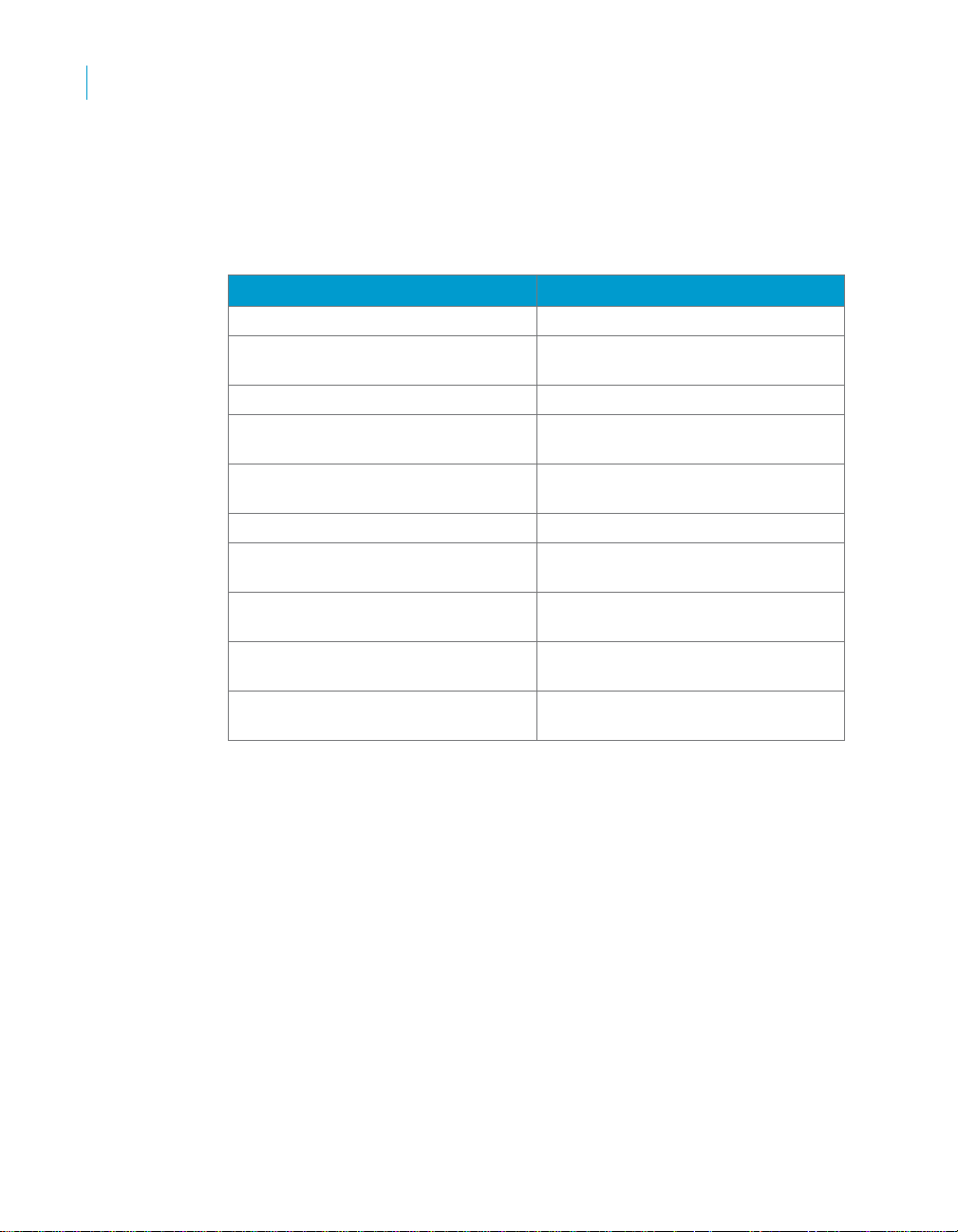

The section captures the following dimensional attributes and their associated

dimension tables:

Attribute Name Dimension Tables

Activity & Hierarchy ACTIVITY, ACTIVITY_HIER,

ACTIVITY_HIER_HZ,

ACTIVITY_HIER_VR,

ACTIVITY_HIER_BAD

Chart of Accounts CHART_OF_ACCOUNTS

Company Code COMPANY_CODE

Control Key CONTROL_KEY

Controlling Area CONTROLLING_AREA

Cost Center & Hierarchy COST_CENTER,

COST_CENTER_HIER,

COST_CENTER_HIER_HZ,

COST_CENTER_HIER_VR,

COST_CENTER_HIER_BAD

Plant PLANT

Plant Location PLANT_LOCATION

Purchasing Organization PURCH_ORGANIZATION

Standard Text Key STANDARD_TEXT_KEY

Standard Value Key STANDARD_VALUE_KEY

Task List Usage TASK_LIST_USAGE

Time Dimension TIME_DIM

Valuation Area VALUATION_AREA

Work Center & Hierarchy WORK_CENTER,

WORK_CENTER_HIER,

WORK_CENTER_HIER_HZ,

WORK_CENTER_HIER_VR,

WORK_CENTER_HIER_BAD

Work Center Category WORK_CENTER_CATEGORY

Work Center Formula WORK_CENTER_FORMULA

3

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide 27

Subject Areas

3

Work Center section

Fact Table Fields

A work center is master data information. Therefore, classic “measures”

(monetary and quantity values) are not found in the

WORKCENTER_COST_ASSIGN_FACT table. However, these fields are of

key importance:

Column Name Description

ACTIVITY_ID CRCO.LSTAR - Activity Type

CURRENT_FLAG “X” indicates record is currently in

effect

DAYS_VALID_ASSIGN Number of days assignment is valid

FORMULA_ID CRCO.FORML - Formula key for

costing

GROUP_USG_ID CRHD.PLANV - Key for task list

usage

LOCATN_ID CRHD.STAND - Work center location

PURCH_ORG_ID T001W.EKORG Purchasing

organization (lookup)

VALID_FROM_DATE Start date of validity period for this

record (calculated)

VALID_TO_DATE End date of validity period

(calculated)

WORK_CNTR_CATEG_ID CRHD.VERWE - Work center

category

28 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide

Rapid Mart data

The following diagram shows the tables in the work center section as a star

schema.

Work Centers:

Subject Areas

Work Center section

3

With the tables in this section you can analyze Work Centers along several

dimensions:

• Activity & Hierarchy

• Chart of Accounts

• Company Code

• Control Key

• Controlling Area

• Cost Center & Hierarchy

• Plant

SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide 29

Subject Areas

3

Capacity section

• Plant Location

• Purchasing Organization

• Standard Text Key

• Standard Value Key

• Task List Usage

• Time Dimension

• Valuation Area

• Work Center & Hierarchy

• Work Center Category

• Work Center Formula

Note: As Work Center Cost Assignment is a cross-reference fact table, both

work centers and cost centers appear as dimensions with their associated

hierarchies.

Typical queries for this section include:

• What Activities are associated with this work center?

• Which Work Centers are associated with each plant?

• What Cost Centers are associated with my work centers today vs. a year

ago?

Capacity section

The capacity section stores available capacity information by work center,

available interval capacity by date, and capacity requirements for planned

orders.

Work center capacities measure the amount of work output that a work center

can produce during a period of time. Capacity categories subdivide capacity

into types, such as machine, labor, or electrical output. More than one

capacity category can exist at a work center.

Capacities have standard operating times based on shift lengths, break times,

number of individual capacities, and percentage utilization rates. Additional

data items include the formulas and parameters used when calculating the

amount of capacity required for an operation during order scheduling and

capacity planning. Intervals of available capacity can be used to

accommodate deviations from standard available capacities. These intervals

are identified by a version and are delimited with beginning and ending

effective dates.

30 SAP BusinessObjects Production Planning Rapid Mart XI 3.2 for SAP solutions Business Guide

Loading...

Loading...