Page 1

1. OUTLINE OF CIRCUIT DESCRIPTION

1-1. CA-A CIRCUIT DESCRIPTIONS

Around CCD block

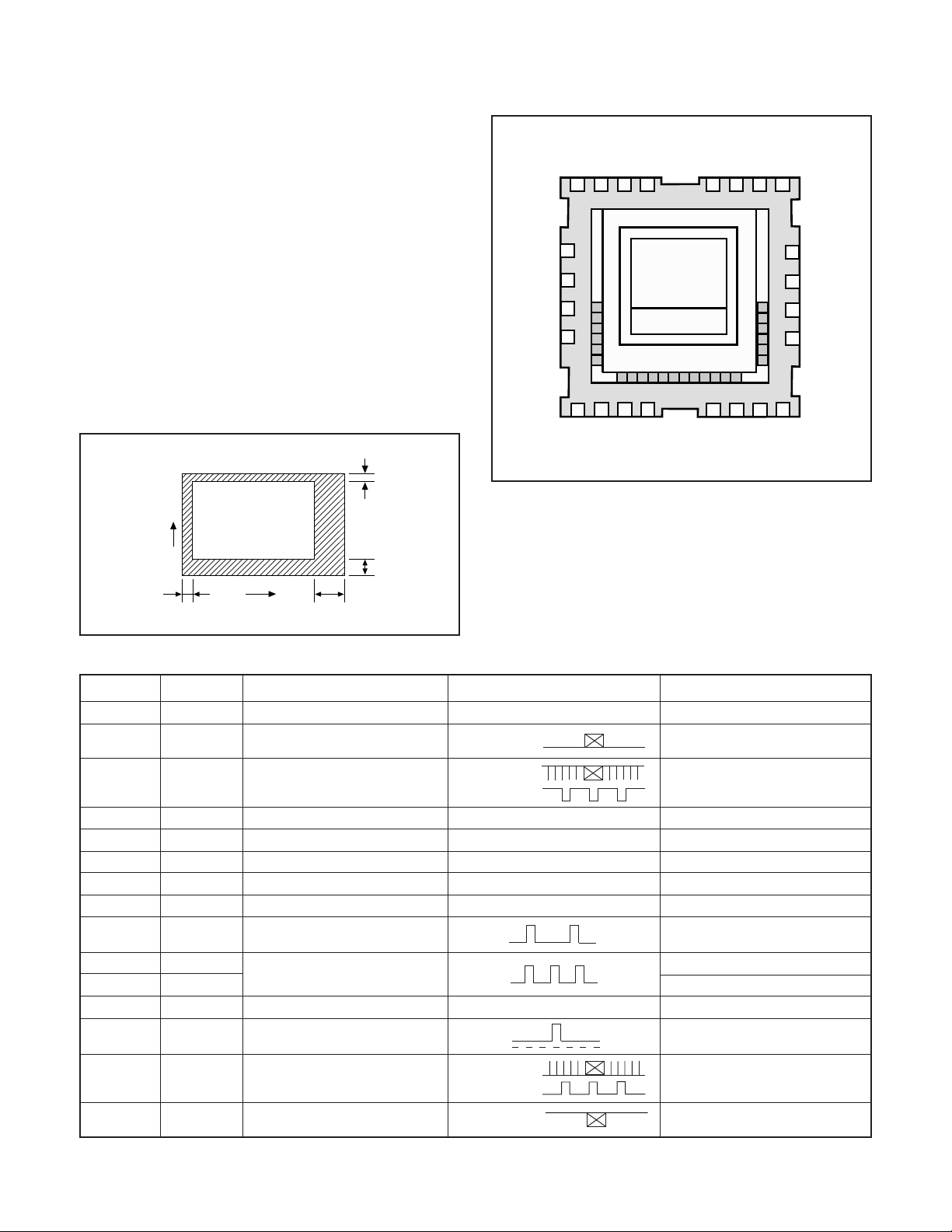

1. IC Configuration

IC903 (RJ24J1AA0PT) CCD imager

IC902 (TC74VHC04FTP) H driver

IC904 (LR366854) V driver

IC905 (AD9806KST) CDS, AGC, A/D converter

PI4

PI3

(NC)

3 2 1 21

4

(NC)

(NC)

2324

(NC)

22

PI2

PI1

2. IC905 (CCD)

[Structure]

Frame transfer type CCD image sensor

Optical size 1/2.8 type

Effective pixels 1300 (H) x 980 (V)

Pixels in total 1353 (H) x 1006 (V)

Optical black

Horizontal (H) direction: left 2 pixels, right 51 pixels

Vertical (V) direction: upper 10 pixels, below 12 pixels

Dummy bit number Horizontal : 20 Vertical : 4

10

V

12

2

Fig. 1-1.Optical Black Location (Top View)

Pin No. Symbol

1, 2, 23, 24

NC

H

Pin Description

-

51

PS1

5

PS2

6

7

VPW

8

VOUT

9

Waveform

(LCC24

Top View)

10

11 12 16

PR

VSS

VDD

VRD

PH4

151413

PH1

Fig. 1-2. CCD Terminal Name

Voltage

PH2

20

19

18

17

PH3

PS3

PS4

NSUB

VOG

3, 4

5, 6

7

8

9

10

11

12

13, 15

14, 16

17

18

19, 20

PI3, PI4

PS1, PS2

PW

VOUT

VDD

VSS GND

VRD

PR

PH4, PH2

PH1, PH3

VOG

VSUB

PS4, PS3

21, 22 PI1, PI2

Image clock

Accumulation clock

P well

CCD output

Power

Reset drain

Reset gate

Horizontal register clock

CCD output gate

N substrate

Accumulation clock

Image clock

Table 1-1. CCD Pin Description

Frame shift

Frame shift

Line sending

Frame shift

Line sending

Frame shift

DC

DC

DC

DC

DC

DC

0~12 V

0~12 V

8 V

Approx. 13 V

20 V

0 V

20 V

L=18 V, H=23 V

L=2.5 V, H=7.5 V

L=0 V, H=5 V

3.3 V

L=26 V, H=29 V

0~12 V

0~12 V

– 2 –

Page 2

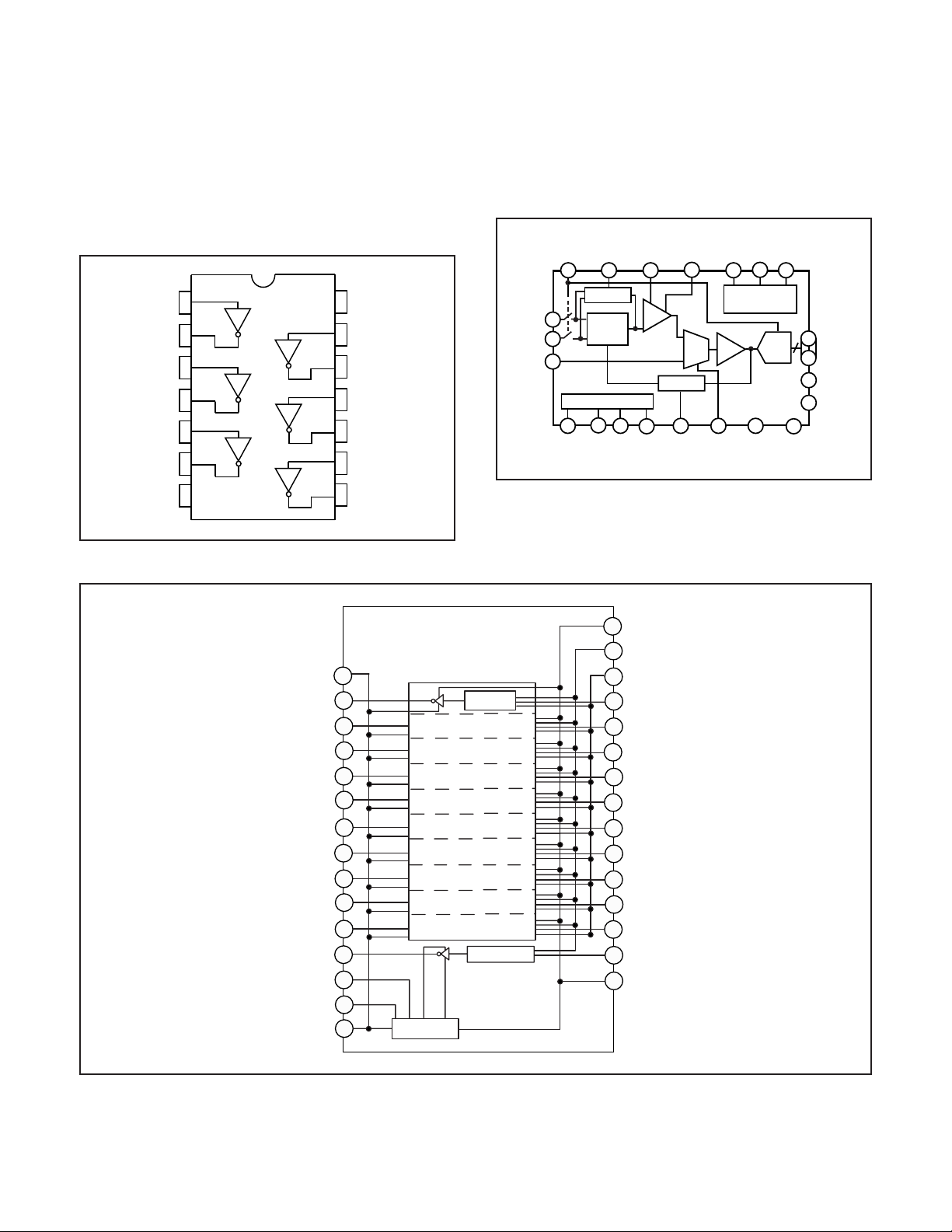

3. IC903 (H Driver) and IC902 (V Driver)

An H driver (IC903) and V driver (IC902) are necessary in

order to generate the clocks (vertical transfer clock, horizontal transfer clock and electronic shutter clock) which driver

the CCD.

IC902 is an inverter IC which drives the horizontal CCDs (H1

and H2). In addition the VREG 0~7, VXREG2 and VXREG3

signals which are output from IC102 are the vertical transfer

clocks. The clock is drived until peak value which necessary

CCD at IC902.

14

CC

1A

1Y

2A

2Y

3A

3Y

GND

1

2

3

4

5

6

7

V

13

6A

12

6Y

11

5A

10

5Y

4A

9

4Y

8

4. IC901 (CDS, AGC Circuit and A/D Converter)

The video signal which is output from the CCD is input to

Pins (26) and (27) of IC901. There are S/H blocks inside IC905

generated from the XSHP and XSHD pulses, and it is here

that CDS (correlated double sampling) is carried out.

After passing through the CDS circuit, the signal passes

through the AGC amplifier. It is A/C converted internally into

a 10-bit signal, and is then input to IC102.

SHD ADCCLK

22

21

GENERATOR

16

TIMING

A/D

AD9802

3341

ACVDD

ADVDD

43

10

2

DOUT

11

DRVDD

12

DVDD

17

PIN

DIN

ADCIN

PBLK

CLPDM SHP

CLAMP

27

26

CDS

29

2319

PGA

36

CLAMP

REFERENCE

48

37 20

CMLEVEL

VRT

47

VTB

STBY CLPOB

18

Fig. 1-5. IC901 Block Diagram

30

MUX S/H

ADCMODE

Fig. 1-3. IC903 Block Diagram

GND

1

OUT_1

2

OUT_2

3

OUT_3

4

OUT_4

5

OUT_5

6

OUT_6

7

OUT_7

8

OUT_8

9

OUT_9

10

OUT_10

OUT_NSUB

CAP5V

CAPNS

GND

11

12

13

14

15

Power circuit

OCNT circuit

DUTY circuit

OCNT circuit

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

VDD

OCNT

DUTY

IN_1

IN_2

IN_3

IN_4

IN_5

IN_6

IN_7

IN_8

IN_9

IN_10

IN_NSUB

VDD

Fig. 1-4. IC902 Block Diagram

– 3 –

Page 3

5. Transfer of Electric Charge by the Horizontal CCD

The transfer system for the horizontal CCD emplays a 4-phase drive method.

The electric charges sent to the final stage of the horizontal CCD are transferred to the floating diffusion (FD), as shown in Fig.

1-6. PR is turned on by the timing in (1), and the floating diffusion is charged to the potential of RD.

The PR is turned off by the timing in (2). In this condition, the floating diffusion is floated at high impedance.

The H2 potential becomes shallow by the timing in (3), and the electric charge now moves to the floating diffusion.

Here, the electric charges are converted into voltages at the rate of V = Q/C by the equivalent capacitance C of the floating

diffusion. PR is then turned on again by the timing in (1) when the H2 potential becomes deep.

Thus, the potential of the floating diffusion changes in proportion to the quantity of transferred electric charge, and becomes

CCD output after being received by the source follower. The equivalent circuit for the output circuit is shown in Fig. 1-7.

Reset gate pulse

Direction of transfer

(1)

(2)

(3)

PR

PR

PR

OG

H2

H1 H4 H3 H2 H1 H4 H3

(1)(2)

FDRD

H3

H4

OG

H2

H1 H4 H3 H2 H1 H4 H3

H1

FDRD

H2

PR

OG

H2

H1 H4 H3 H2 H1 H4 H3

FDRD

CCD OUT

(3)

Fig. 1-6. Horizontal Transfer of CCD Imager and Extraction of Signal Voltage

6. Lens drive block

6-1. Shutter drive

The regulator (IC952) drives by P ON signal which is output

20 V Pre-charge drain bias (PD)

from the power control IC (IC501) is drived, and then power is

supplied to iris shutter drive IC (IC951). The drive signal

(GPIO4, GPIO5, GPIO6, GPIO7) which is output from the

ASIC (IC102) is drived the iris shutter drive IC (IC951), and

the iris shutter spring is open and closed.

H Register

Electric

charge

Floating diffusion gate is

floated at a high impedance.

C is charged

equivalently

Voltage output

Fig. 1-7. Theory of Signal Extraction Operation

– 4 –

Page 4

1-2. CA-B CIRCUIT DESCRIPTION

1. Circuit description

1-1. PTG

This is program timing generator. Generates the timing signal

that is needed in order to drive the FT-CCD sensor.

1-2. FCP

The FCP receives the output data from the FT-CCD sensor

via the PTG, and then carries out various processing operations on the data (such as gamma correction and white

banance).

1-3. ITP

The ITP is a pixel conversion processor. It carries out various

processing operations (such as contour emphasis and chroma)

on the image data that is input from the FCP or from memory,

and then stores the processed data in memory.

1-4. CPU

This is 32 bit RISC CPU.

1-5. Memory controller

This is controlled SDRAM, flash ROM and CF card etc.

1-6. Video player

Outputs the RGB signals that are needed to control the graphic

overlay function and to drive the LCD.

1-7. GPIO

This is a multipurpose I/O. (It can be used as an input/output

port.)

1-8. COM port

This is communication block. Supports USB communication.

2. Outline of Operation

When the shutter opens, detect the 8-bit microprocessor and

transmit to record operation starts.

When the PTG drives the FT-CCD, picture data passes

through the A/D and is then input to the ASIC as 10-bit data.

This data then sends FCP, after which it is carried out various

processing operations on the data (such as gamma correction and white balance). The data is then sent to the ITP where

processing such as contour emphasis and chroma are carried out, after which it is temporarily stored in the SDRAM.

In case of still picture the data is then compressed by the

JPEG method and in case of picture it is compressed by

MJPEG method and is written to compact flash card.

3. LCD Block

RGB signals corresponding to the LCD driver are output from

the ASIC (video player). The LCD driver converts the RGB

signals that are output from the ASIC to a signal level that is

appropriate for the LCD monitor. These RGB signals and the

control signal which is output by the LCD driver are used to

drive the LCD panel.

The RGB signals are 1H transposed so that no DC component is present in the LCD element, and the two horizontal

shift register clocks drive the horizontal shift registers inside

the LCD panel so that the 1H transposed RGB signals are

applied to the LCD panel.

Because the LCD closes more as the difference in potential

between the VCOM (common polar voltage: fixed at DC) and

the R, G and B signals becomes greater, the display becomes

darker; if the difference in potential is smaller, the element

opens and the LCD become brighter. In addition, the brightness and contrast settings for the LCD can be varied by means

of the serial data from the ASIC.

1-9. Serial communication

This is the interface for the 8-bit microprocessor.

1-10. LCD driver

The RGB output signals that are output from the ASIC are

converted to a signal level that is appropriate for the LCD monitor.

1-11. LCD monitor

This is the image display device which displays the image

signals supplied from the LCD driver.

– 5 –

Page 5

1-3. CP1 POWER CIRCUIT DESCRIPTION

1. Outline

This is the main power circuit, and is comprised of the following blocks.

Switching controller (IC501)

Digital 5 V and analog system power output (T5001, Q5001)

Digital 2.5 V system power supply (Q5007)

Digital 3.4 V system power supply (Q5018)

LCD system power supply (Q5008, T5002)

Backlight power supply output (Q5013)

Inverter output (T5003, Q5017)

2. Switching Controller (IC501)

This is the basic circuit which is necessary for controlling the

power supply for a PWM-type switching regulator, and is provided with five built-in channels, only CH2 (digital 5 V, analog

system), CH4 (LCD system), CH3 (digital 2.5 V), CH1 (digital

3.4 V) and CH5 (backlight system) are used. Feedback from

5 V (D) (CH2), 2.5 V (D) (CH3) , 12.4 V (L) (CH4), 3.4 V (D)

(CH1) and 7 V (L) (CH5) power supply outputs are received,

and the PWM duty is varied so that each one is maintained at

the correct voltage setting level.

2-1. Short-circuit protection circuit

If output is short-circuited for the length of time determined

by the condenser which is connected to Pin (29) of IC501, all

output is turned off. The control signal (P ON) are recontrolled

to restore output.

3. Digital 3.4 V Power Output

3.4 V (D) is output. Feedback is sent to pin (41) of the switching controller (IC501) for PWM control to be carried out.

4. Digital 5 V and Analog System Power Output

5.1 V (D) , 26.4 V (A), 20 V (A), 13 V (A) and 5.1 V (A) are

output. Feedback for the 5.1 V (D) is provided to the switching controller (Pins (35) of IC501) so that PWM control can

be carried out.

5. Digital 2.5 V System Power Output

2.5 V (D) is output. Feedback is provided to the swiching controller (Pin (23) of IC501) so that PWM control can be carried

out.

6. LCD System Power Output

12.4 V (L) is output. Feedback for the 12.4 V (L) is provided

to the switching controller (Pins (22) of IC501) so that PWM

control can be carried out.

7. Backlight Power Supply output

7.0 V (L) is output. Feedback is sent to pin (17) of the switching controller (IC501) for PWM control to be carried out.

8. Inverter Output

The backlight uses a flat picture tube. When INV CLK is input, Q5017 carries out switching operations, so that T5003 is

energized and a high-voltage pulse is generated between pins

(3) and (4) of T5003. This high-voltage pulse is applied to the

backlight to make it illuminate.

– 6 –

Loading...

Loading...