Page 1

SERVICE MANUAL

FILE NO.

Digital Camera

Contents

1. OUTLINE OF CIRCUIT DESCRIPTION .................... 2

2. DISASSEMBLY ........................................................ 10

3. ELECTRICAL ADJUSTMENT .................................. 12

4. USB STORAGE INFORMATION

REGISTRATION ...................................................... 17

5. TROUBLESHOOTING GUIDE................................. 18

6. PARTS LIST............................................................. 19

CABINET AND CHASSIS PARTS 1 ........................ 19

CABINET AND CHASSIS PARTS 2 ........................ 20

ELECTRICAL PARTS .............................................. 21

PACKING MATERIALS............................................ 26

ACCESSORIES ....................................................... 26

AC ADAPTOR .......................................................... 26

CIRCUIT DIAGRAMS &

PRINTED WIRING BOARDS ...................................... C1

VPC-MZ3EX

(Product Code : 126 612 01)

(Europe)

(PAL General)

VPC-MZ3

(Product Code : 126 612 02)

(U.S.A.)

(Canada)

VPC-MZ3GX

(Product Code : 126 612 03)

(General)

VAR-G6U

(Product Code : 126 301 09)

(U.S.A.)

(Canada)

VAR-G6EX

(Product Code : 126 301 10)

(Europe)

(PAL General)

VAR-G6E

(Product Code : 126 301 11)

(U.K.)

PRODUCT SAFETY NOTICE

The components designated by a symbol ( ! ) in this schematic diagram designates components whose value are of

special significance to product safety. Should any component designated by a symbol need to be replaced, use only the part

designated in the Parts List. Do not deviate from the resistance, wattage, and voltage ratings shown.

CAUTION : Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Discard used batteries according to the manufacturer’s instructions.

NOTE : 1. Parts order must contain model number, part number, and description.

2. Substitute parts may be supplied as the service parts.

3. N. S. P. : Not available as service parts.

Design and specification are subject to change without notice.

SX612/EX, U, GX, SVA03/U, EX, E

REFERENCE No. SM5310441

Page 2

1. OUTLINE OF CIRCUIT DESCRIPTION

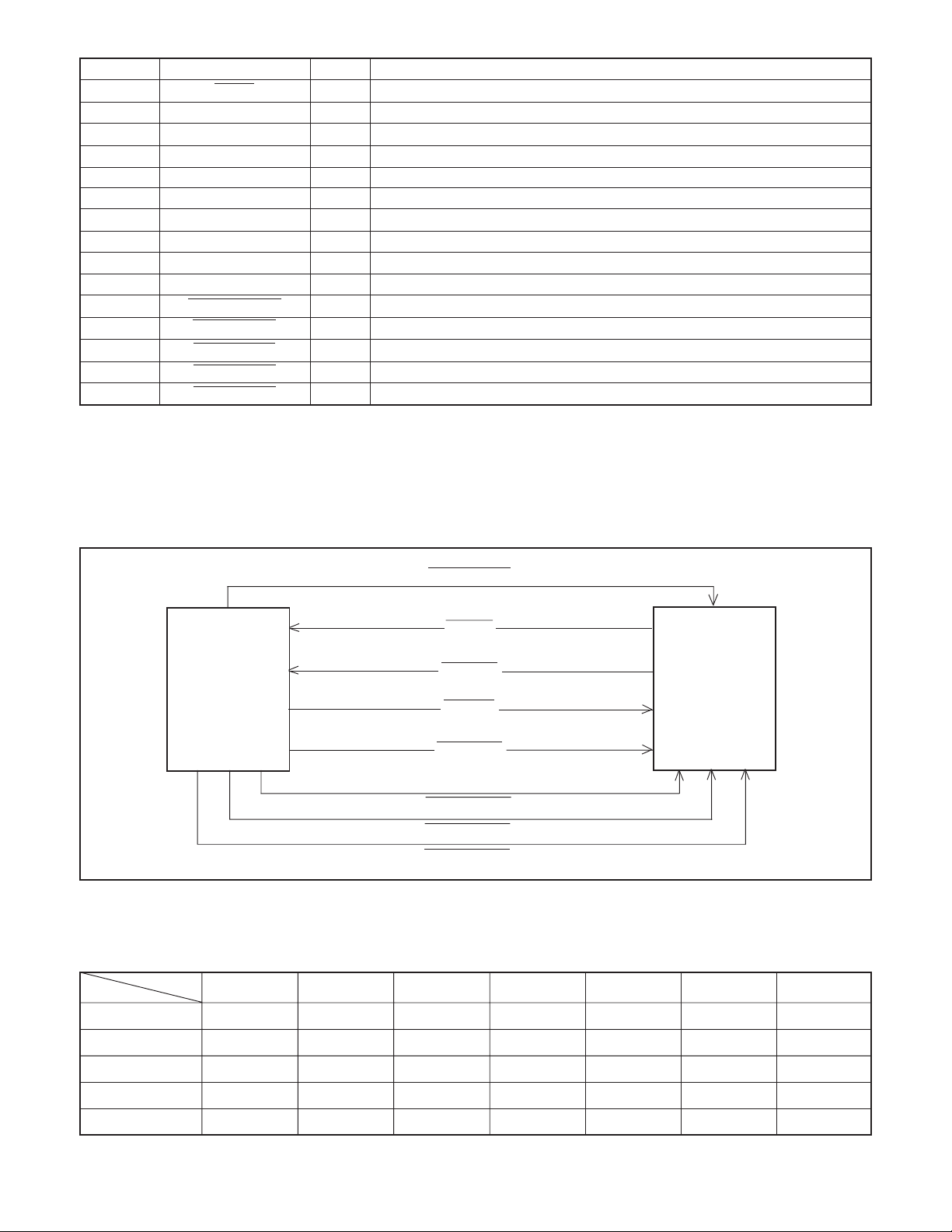

1-1. CA1 and A PART OF CA2 CIRCUIT

DESCRIPTIONS

Around CCD block

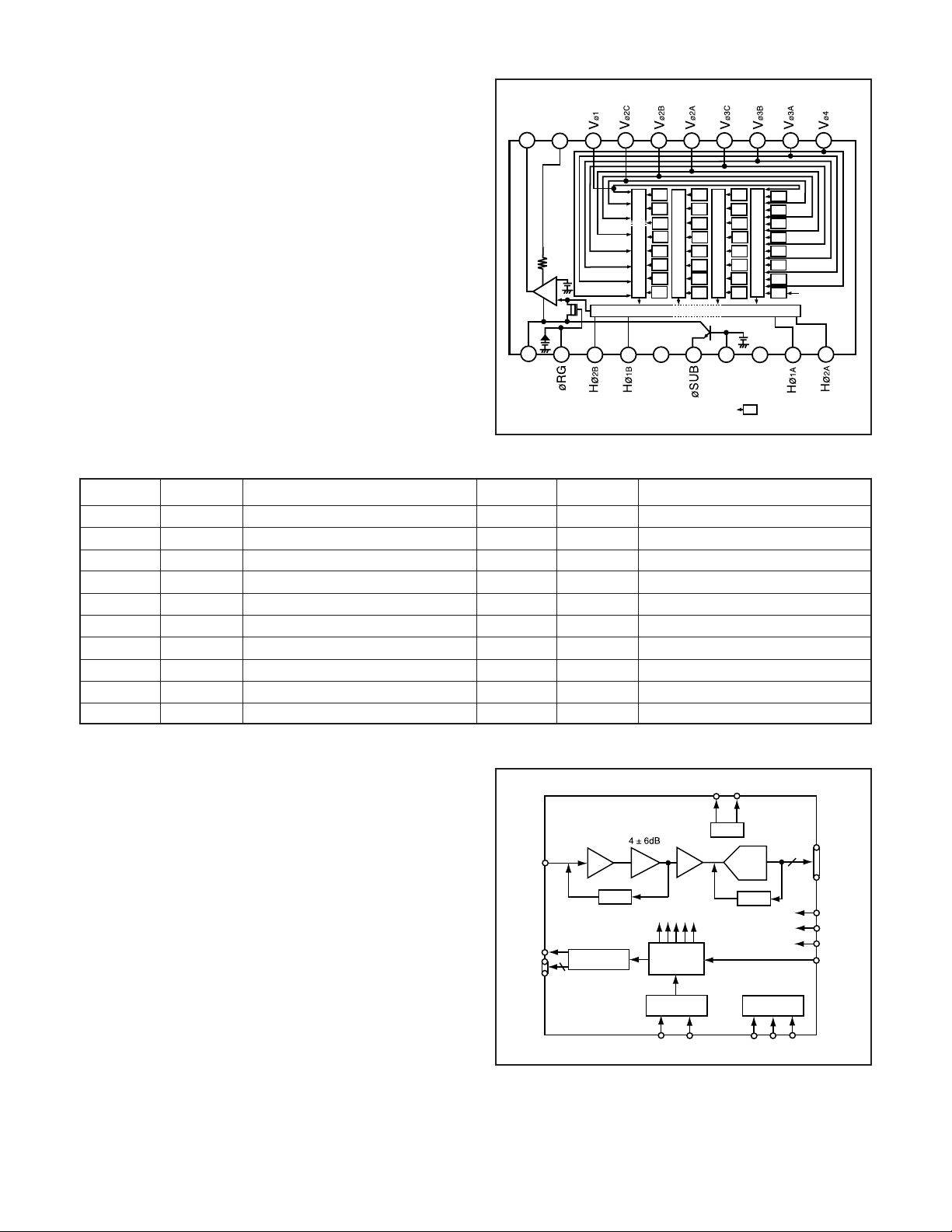

1. IC Configuration

CA1 board

IC901 (ICX274AQ) CCD imager

CA2 board

IC901 (H driver, CDS, AGC and A/D converter)

2. IC901 (CA1) (CCD imager)

[Structure]

Interline type CCD image sensor

Image size Diagonal 8.293 mm (1/1.8 type)

Pixels in total 1688 (H) x 1248 (V)

Recording pixels 1600 (H) x 1200 (V)

10

11

OUT

V

DD

V

GND

7

6

5

B

G

R

G

G

B

R

G

G

B

R

Vertical register

G

B

G

R

G

Horizontal register

15

16

GND

(Note) : Photo sensor

12

8

9

13

14

Fig. 1-1. CCD Block Diagram

17

3

4

G

R

G

R

G

R

G

R

18

L

V

SUB

C

1

2

B

G

B

G

B

G

B

G

(Note)

20

19

Pin No.

1

2

3

4

5

6

7

8

9

10

Symbol

4

Vø

Vø3A

Vø3B

Vø3C

Vø2A

Vø2B

Vø2C

Vø1

GND

V

OUT

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

GND

Signal output

Pin Description

Table 1-1. CCD Pin Description

3. IC904 (V Driver) and IC901 (CA2 board) (H driver)

An H driver and V driver are necessary in order to generate

the clocks (vertical transfer clock, horizontal transfer clock

and electronic shutter clock) which driver the CCD.

IC904 are V driver. In addition the XV1-XV4 signals which are

output from IC102 are the vertical transfer clocks, and the

XSG signal which is output from IC102 is superimposed onto

XV2 and XV3 at IC902 in order to generate a ternary pulse.

In addition, the XSUB signal which is output from IC102 is

used as the sweep pulse for the electronic shutter. A H driver

is inside IC901 (CA2 board), and H1A, H1B, H2A, H2B and

RG clock are generated at IC901 (CA2 board).

4. IC901 (CA2 board)

(CDS, AGC Circuit and A/D Converter)

The video signal which is output from the CCD is input to Pin

(29) of IC901 (CA2 board). There are inside the sampling hold

block, AGC block and A/D converter block.

The setting of sampling phase and AGC amplifier is carried

out by serial data at Pin (37) of IC911. The video signal is

carried out A/D converter, and is output by 10-bit.

Pin No.

11

12

13

14

15

16

17

18

19

20

CCDIN

RG

H1-H4

Symbol

V

DD

øRG

Hø

Hø1B

GND

øSUB

SUB

C

V

Hø1A

Hø2A

CDS

HORIZONTAL

4

DRIVERS

2B

L

CLAMP

Circuit power

Reset gate clock

Horizontal register transfer clock

Horizontal register transfer clock

GND

Substrate clock

Substrate bias

Protection transistor bias

Horizontal register transfer clock

Horizontal register transfer clock

PxGA

INTERNAL

PRECISION

GENERATOR

HD

2~36 dB

VGA

CLOCKS

TIMING

CORE

SYNC

VD

Pin Description

VRT

VREF

Fig. 1-2. IC901 Block Diagram

VRB

ADC

CLAMP

INTERNAL

REGISTERS

SL

SCK

12

SDATA

DOUT

CLPOB

CLPDM

PBLK

CLI

– 2 –

Page 3

1-2. CA2 CIRCUIT DESCRIPTION

1. Circuit Description

1-1. Scannning converter (Interlace converter)

This circuit uses the function of a 128-Mbit SDRAMs to convert the non-interlaced signal which is output from the CCD

into an interlaced signal for the video monitor.

1-2. Camera signal processor

This comprises circuits such as the digial clamp circuit, white

balance circuit, γ circuit, color signal generation circuit, matrix circuit and horizontal aperture circuit.

1. Digital clamp circuit

The optical black section of the CCD extracts 16-pixel averaged values from the subsequent data to make the black level

of the CCD output data uniform for each line. The 16-pixel

averaged value for each line is taken as the sum of the value

for the previous line multiplied by the coefficient k and the

value for the current line multiplied by the coefficient 1-k.

2. White balance circuit

This circuit controls the white balance by using the AWB judgement value computed by the CPU to control the gain for each

R, G and B pixel based on the CCD data which has been

read.

3. γ circuit

This circuit performs (gamma) correction in order to maintain

a linear relationship between the light input to the camera

and the light output from the picture screen.

4. Color generation circuit

This circuit converts the CCD data into RGB signals.

5. Matrix circuit

This circuit generates the Y signals, R-Y signals and B-Y signals from the RGB signals.

6. Horizontal aperture circuit

This circuit is used generate the aperture signal.

1-3. SDRAM controller

This circuit outputs address, RAS, CAS and AS data for controlling the SDRAM. It also refreshes the SDRAM.

1-4. PIO

The expansion parallel port can be used for functions such

as stroboscope control and LCD driver control.

1-8. Sound buffer

Audio memory

1-9. LCD driver

The 8-bit digital YUV signals which are input to the LCD driver

are converted to RGB signals, and the timing signal which is

necessary for LCD monitor display and the RGB signals are

then supplied to the LCD monitor.

1-10. LCD monitor

This is the image display device which displays the image

signals supplied from the LCD driver.

1-11. Memory card control

This reads data from the memory card and stores it in SDRAM,

and writes out the image data stored in SDRAM. In addition,

error correction is carried out when the data is read.

1-12. MJPEG compression

Still and continuous frame data is converted to JPEG format,

and movie images are compressed and expanded in MJPEG

format.

2. Outline of Operation

When the shutter opens, the reset signals, ZTEST0, ZTEST1,

ZTEST2 signals and the serial signals (“take a picture” commands) from the 8-bit microprocessor are input and record

operation starts. When the TG drives the CCD, picture data

passes through the A/D and is then input to the ASIC as 10bit data. This data then passes through the DCLP, AWB, shutter

and γ circuit, after which it is input to the SDRAM. The AWB,

shutter, γ, and AGC value are computed from this data, and

two exposures are made to obtain the optimum picture. The

data which has already been stored in the SDRAM is read by

the CPU and color generation is carried out. Each pixel is

interpolated from the surrounding data as being either R, G

or B primary color data to produce R, G and B data. At this

time, correction of the lens distortion which is a characteristic

of wide-angle lenses is carried out. Aperture correction is carried out, and in case of still picture the data is then compressed

by the JPEG method and in case of picture it is compressed

by MJPEG method and is written to compact flash card. When

the data is to be output to an external device, it is read JPEG

picture data from the compact flash card and output to PC via

the USB.

1-5. SIO (Serial control)

This is the interface for the 4-bit microprocessor.

1-6. USB control

This is comunicated PC with 12 Mbps.

1-7. TG, SG block

This is the timing generation circuit which generates the clocks

(vertical transfer clock and electronic shutter clock) which drive

the CCD.

– 3 –

Page 4

3. LCD Block

During EE, gamma conversion is carried out for the 10-bit

RGB data which is input from the A/D conversion block of the

CCD to the ASIC in order that the γ revised can be displayed

on the video. The YUV of 640 x 480 is then transferred to the

SVRAM.

The data which has accumulated in the SDRAM is converted

to digital YUV signal in conformity to ITUR-601 inside the ASIC

by SDRAM control circuit inside the ASIC, the data is sent to

the LCD driver IC and displayed the image to LCD panel.

If the shutter button is pressed in this condition, the 10-bit

data which is output from the A/D conversion block of the

CCD is sent to the SDRAM (DMA transfer), and is displayed

on the LCD as a freeze-frame image.

During playback, the JPEG image data which has accumulated in the compact flash card is converted to YUV signals.

In the same way as for EE, the data is then sent to the SDRAM,

converted to digital YUV signal in conformity to ITUR-601 inside the ASIC, the data is sent to the LCD driver IC and displayed the image to LCD panel.

The LCD driver is converted digital YUV signals to RGB signals from ASIC, and these RGB signals and the control signal which is output by the LCD driver are used to drive the

LCD panel. The RGB signals are 1H transposed so that no

DC component is present in the LCD element, and the two

horizontal shift register clocks drive the horizontal shift registers inside the LCD panel so that the 1H/1V transposed RGB

signals are applied to the LCD panel.

Because the LCD closes more as the difference in potential

between the VCOM (common polar voltage: AC drive) and

the R, G and B signals becomes greater, the display becomes

darker; if the difference in potential is smaller, the element

opens and the LCD become brighter. In addition, the brightness and contrast settings for the LCD can be varied by means

of the serial data from the ASIC.

– 4 –

Page 5

1-3. PW1 POWER CIRCUIT and LENS DRIVE

BLOCK DESCRIPTION

1. Outline

This is the main power circuit, and is comprised of the following blocks.

Switching power controller (IC501)

Analog and LCD system power output (Q5001, T5001)

Digital 1.85 V power output (Q5009, L5008)

Digital 3.35 V power output (Q5010, L5009)

Digital 3.35 V step-up power output (Q5011, L5010)

LED backlight power output (Q5012, L5011)

5 V system power output (Q5015, L5012)

2. Switching Controller

This is the basic circuit which is necessary for controlling the

power supply for a PWM-type switching regulator, and is provided with six built-in channels, only CH1 (analog and LCD

system power output), CH2 (digital 1.85 V system power output), CH3 (digital 3.35 V system power output), CH4 (digital

3.35 V step-up power output), CH5 (LED back light power

output) and CH6 (5 V system power output) are used. Feedback from 15.0 V (A) (CH1), 1.85 V (D) (CH2), 3.35 V (D)

(CH3), 4.7 V (L) (CH4), LED backlight output (CH5) and 5 V

(CH6) power supply outputs are received, and the PWM duty

is varied so that each one is maintained at the correct voltage

setting level.

2-1. Short-circuit Protection

If output is short-circuited for the length of time determined

by the condenser which is connected to Pin (37) of IC501, all

output is turned off. The control signal (P ON) are recontrolled

to restore output.

3. Analog and LCD System Power Output

15.0 V (A), -7.5 V (A) and 9.6 V (L) are output. Feedback for

the 15.0 V (A) is provided to the switching controller (Pin (40)

of IC501) so that PWM control can be carried out.

7. LED Backlight Power Output

A constant current flows to the backlight LEDs. Feedback for

the voltage of R5098 is provided to the power controller (Pin

(2) of IC501) so that PWM control can be carried out.

8. 5 V System Power Output

5 V is output. Feedback for the 5 V is provided to the swiching

controller (Pin (4) of IC501) so that PWM control can be carried out.

9. Lens drive block

9-1. Iris drive

When the drive signals (IRIS_A, IRIS_/A, IRIS_B and IRIS_/

B) which are output from the ASIC, the stepping motor is driven

by the driver (IC951), and are then used to drive the iris steps.

9-2. Focus drive

When the drive signals (FRSTB, FCW, FOEB and FCLK) which

are output from the ASIC, the focus stepping motor is sinewave driven by the micro-step motor driver (IC953). Detection

of the standard focusing positions is carried out by means of

the photointerruptor (FOCUS PI) inside the lens block.

9-3. Iris drive

The zoom DC motor drive signals (ZOOM_A and ZOOM_/A)

which are output from the ASIC are used to drive by the motor

driver (IC951). Detection of the zoom positions is carried out

by means of photointerruptor (ZOOM PI) inside the lens block.

9-4. Shutter drive

When the shutter drive signals (SHUT_A and SHUT_/A) which

are output from the ASIC, it is driven regular current by the

motor driver IC (IC951).

4. Digital 1.85 V Power Output

1.85 V (D) is output. Feedback for the 1.85 V (D) is provided

to the switching controller (Pins (43) of IC501) so that PWM

control can be carried out.

5. Digital 3.35 V Power Output

3.35 V (D) is output. Feedback for the 3.35 V (D) is provided

to the swiching controller (Pin (45) of IC501) so that PWM

control can be carried out.

6. Digital 3.35 V Step-up Power Output

4.7 V is output. Feedback for the 4.7 V is provided to the

swiching controller (Pin (47) of IC501) so that PWM control

can be carried out.

– 5 –

Page 6

1-4. ST1 STROBE CIRCUIT DESCRIPTION

1. Charging Circuit

When UNREG power is supplied to the charge circuit and the

CHG signal from SY1 board becomes High (3.3 V), the charging circuit starts operating and the main electorolytic capacitor is charged with high-voltage direct current.

However, when the CHG signal is Low (0 V), the charging

circuit does not operate.

1-1. Power switch

When the CHG signal switches to Hi, Q5407 turns ON and

the charging circuit starts operating.

1-2. Power supply filter

C5401 constitutes the power supply filter. They smooth out

ripples in the current which accompany the switching of the

oscillation transformer.

1-3. Oscillation circuit

This circuit generates an AC voltage (pulse) in order to increase the UNREG power supply voltage when drops in current occur. This circuit generates a drive pulse with a frequency

of approximately 50-100 kHz. Because self-excited light omission is used, the oscillation frequency changes according to

the drive conditions.

2. Light Emission Circuit

When RDY and TRIG signals are input from the ASIC expansion port, the stroboscope emits light.

2-1. Emission control circuit

When the RDY signal is input to the emission control circuit,

Q5409 switches on and preparation is made to let current

flow to the light emitting element. Moreover, when a STOP

signal is input, the stroboscope stops emitting light.

2-2. Trigger circuit

When a TRIG signal is input to the trigger circuit, D5405

switches on, a high-voltage pulse of several kilovolts is generated inside the trigger circuit, and this pulse is then applied

to the light emitting part.

2-3. Light emitting element

When the high-voltage pulse form the trigger circuit is applied to the light emitting part, currnet flows to the light emitting element and light is emitted.

Beware of electric shocks.

1-4. Oscillation transformer

The low-voltage alternating current which is generated by the

oscillation control circuit is converted to a high-voltage alternating current by the oscillation transformer.

1-5. Rectifier circuit

The high-voltage alternating current which is generated at

the secondary side of T5401 is rectified to produce a highvoltage direct current and is accumulated at electrolytic capacitor C5412.

1-6. Voltage monitoring circuit

This circuit is used to maintain the voltage accumulated at

C5412 at a constance level.

After the charging voltage is divided and converted to a lower

voltage by R5417, R5419 and R5420, it is output to the SY1

circuit board as the monitoring voltage VMONIT. When this

VMONIT voltage reaches a specified level at the SY1 circuit

board, the CHG signal is switched to Low and charging is

interrupted.

– 6 –

Page 7

1-5. SY1 CIRCUIT DESCRIPTION

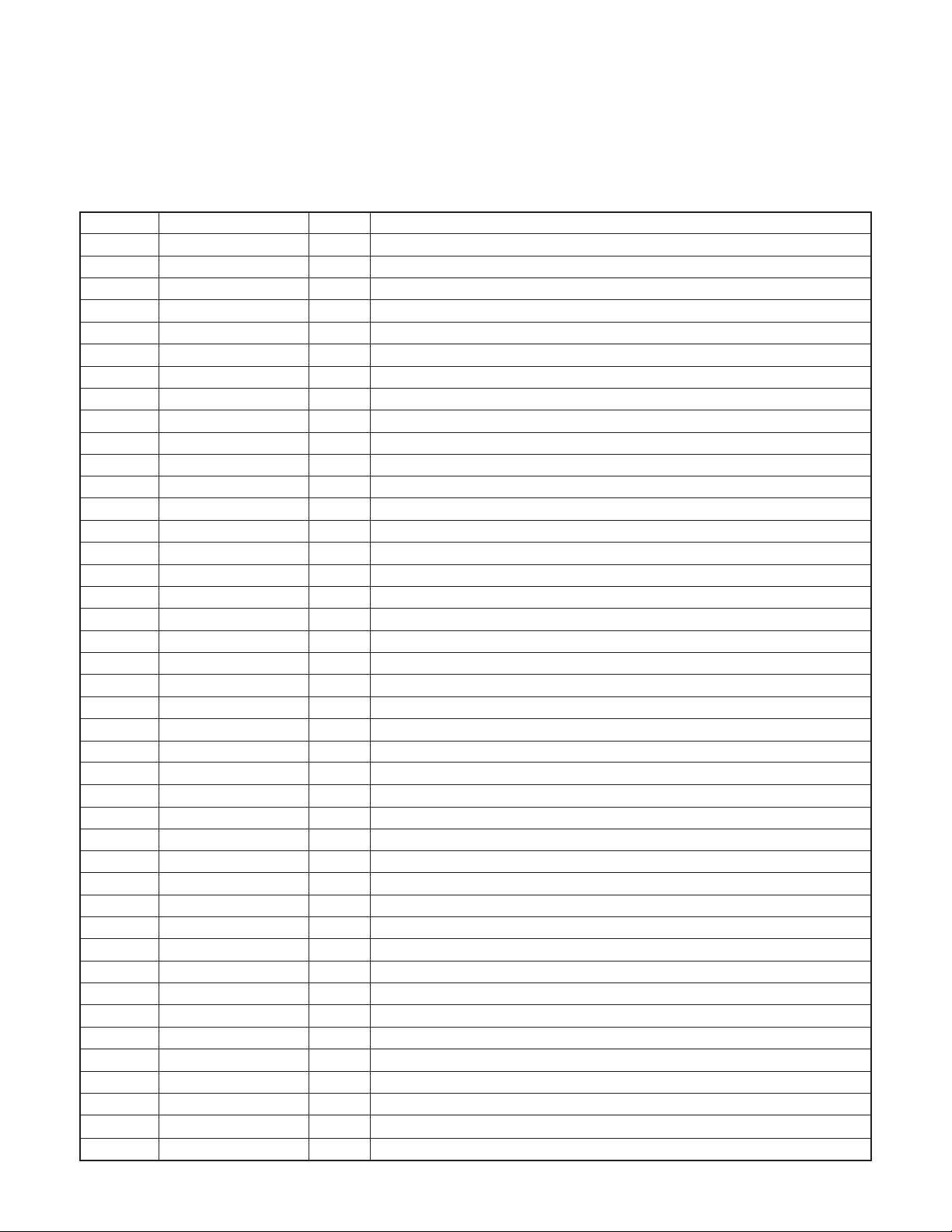

1. Configuration and Functions

For the overall configuration of the SY1 circuit board, refer to the block diagram. The SY1 circuit board centers around a 8-bit

microprocessor (IC301), and controls camera system condition (mode).

The 8-bit microprocessor handles the following functions.

1. Operation key input, 2. Clock control and backup, 3. Power ON/OFF, 4. Storobe charge control, 5. Signal input and output for

zoom and lens control.

Pin

1~4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24 VDD

25 AVSS

26~29 SCAN IN 3~0

30

31 NOT USED

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

STBY_LED (GREEN)

Signal

SCAN OUT 0~3

P ON

PA O N

LCD ON

BL_ON

VSS

VDD

SELF_LED

STBY_LED (RED)

AVREF_ON

SI

SO

SCK

PRG SI

PRG SO

PRG SCK

NOT USED

NOT USED

CHG ON

INT_TMP

CHG VOL

BATTERY

AVREF

AVDD

RESET

XCOUT

XCIN

IC

XOUT

XIN

VSS

BAT OFF

SREQ

SCAN IN6

INTP3

NOT USED

BOOT

I/O

O

O

O

O

O

O

O

O

O

O

I/O

O

I/O

O

O

O

I/O

Outline

Key matrix output

Digital power ON/OFF control H : ON

Analog power ON/OFF control H : ON

LCD power ON/OFF control H : ON

LCD backlight ON/OFF

-

-

I

I

-

-

-

-

I

I

-

I

I

-

-

I

I

I

I

-

I

I

I

I

-

GND

VDD

Self-timer LED control L : ON

Stand-by LED (green) control L : ON

Stand-by LED (red) control L : ON

A/D converter standard voltage control L : ON

Receiving data (from ASIC)

Sending data (to ASIC)

Communication clock (to ASIC)

Flash memory write receiving data

Flash memory write sending data

Flash memory write communication clock

-

-

Flash charge control H : ON

VDD

Analog GND

Key scan input

Internal temperature detection input (analog input)

-

Storobe charge voltage detection (analog input)

Battery voltage detection (analog input)

Analog standard voltage input terminal

A/D converter analog power terminal

Reset input

Clock oscillation terminal (32.768 kHz)

Clock oscillation terminal

Flash memory writing voltage

Main clock oscillation terminal (4MHz)

Main clock oscillation terminal

GND

Battery OFF detection

Serial communication requirement (from ASIC)

Key scan input 6

-

-

Compulsion boot control

See next page →

– 7 –

Page 8

49 AV JACK

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

DC IN

CARD

BUZZER

SCAN OUT 4

SCAN IN 4

SCAN IN 5

SUB1

USB

LCD ON2 O

NTZPAL O NTSC/PAL switch H : NTSC

BACKUP_CNT

ASIC TEST 0

ASIC TEST 1

ASIC TEST 2

ASIC RESET

I

O DC jack/battery detection input (analog input) L : DC jack insertion

I

O

I

O

I

I/O

I

O

O ASIC reset control signal 0

O ASIC reset control signal 1

O

O

Table 5-1. 8-bit Microprocessor Port Specification

AV jack connection detection H : AV jack detection

CF card insertion detection L : Insertion

Buzzer beep tone output H : Pulse output

Key scan output 4

Key scan input 4

Key scan input 5

Communication line to main

USB connector detection L : USB detecion

LCD ON/OFF control 2 H : ON

Backup battery charge control L : Charge ON

ASIC reset control signal 2

ASIC reset singal

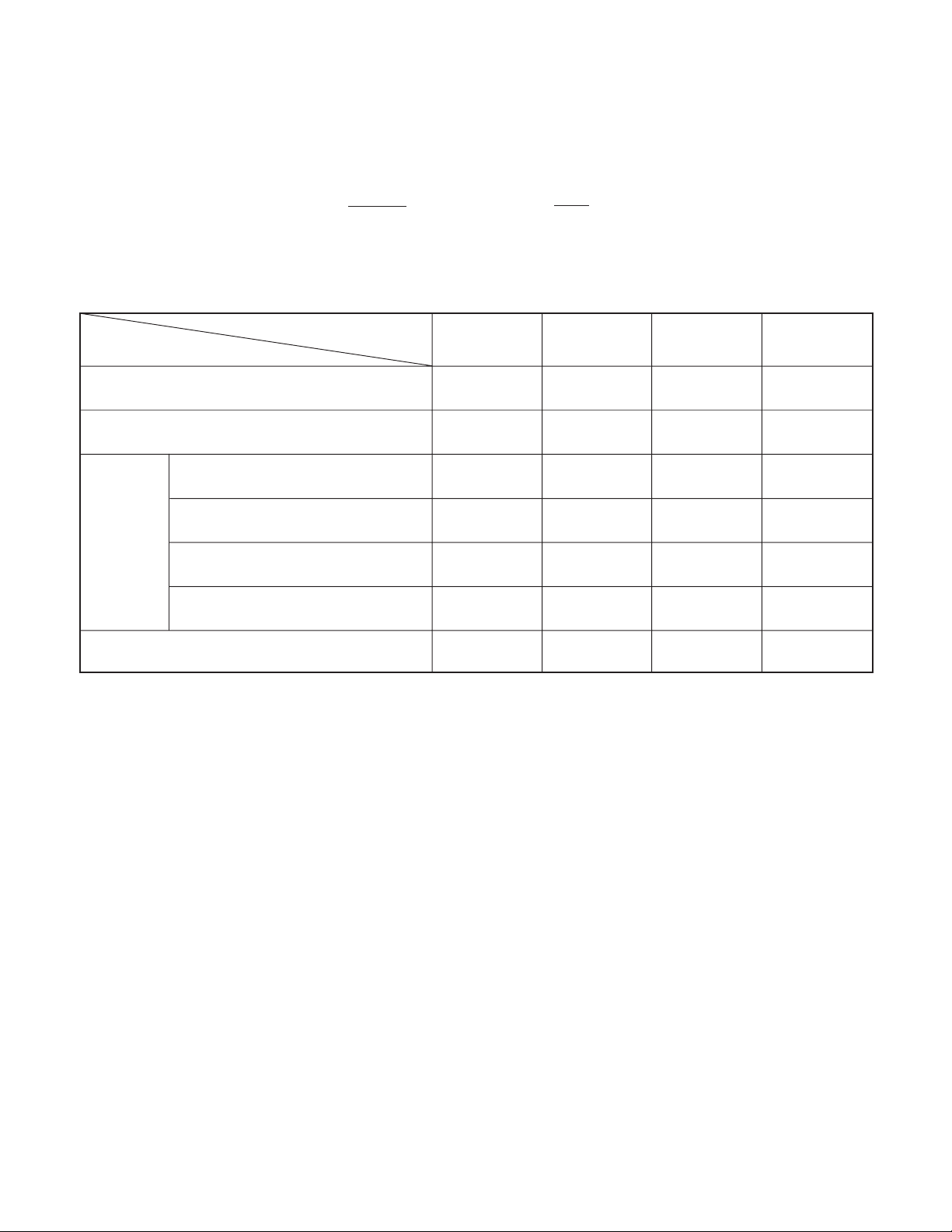

2. Internal Communication Bus

The SY1 circuit board carries out overall control of camera operation by detecting the input from the keyboard and the condition

of the camera circuits. The 8-bit microprocessor reads the signals from each sensor element as input data and outputs this data

to the camera circuits (ASIC) or to the LCD display device as operation mode setting data. Fig. 5-1 shows the internal communication between the 8-bit microprocessor, ASIC and SPARC lite circuits.

ASIC RESET

S. REQ

8-bit

Microprocessor

Fig. 5-1 Internal Bus Communication System

ASIC SO

ASIC SI

ASIC SCK

ASIC TEST 1

ASIC TEST 2

ASIC TEST 0

3. Key Operaiton

For details of the key operation, refer to the instruction manual.

SCAN

OUT

SCAN

IN

0

1

2

3

0

← LEFT

PLAY

-

WEB

-

1

↑ UP

VF

-

DC MODE

-4

2

↓ DOWN

LCD

TEST

SET UP

-

3

→ RIGHT

WIDE

FOCUS

VIDEO CLIP

SHOOTING

-

4

MENU

TELE

FLASH

SEQUENTIAL

SHOT

-

ASIC

5

SET

-

1st

STILL IMAGE

-

6

-

-

2nd

-

POWER ON

Table 5-2. Key Operation

– 8 –

Page 9

4. Power Supply Control

The 8-bit microprocessor controls the power supply for the overall system.

The following is a description of how the power supply is turned on and off. When the battery is attached, a regulated 3.2 V

voltage is normally input to the 8-bit microprocessor (IC301) by IC302, so that clock counting and key scanning is carried out

even when the power switch is turned off, so that the camera can start up again. When the battery is removed, the 8-bit microprocessor operates in sleep mode using the backup capacitor. At this time, the 8-bit microprocessor only carries out clock

counting, and waits in standby for the battery to be attached again. When a switch is operated, the 8-bit microprocessor supplies

power to the system as required.

The 8-bit microprocessor first sets both the P (A) ON signal at pin (6) and the P ON signal at pin (5) to high, and then turns on the

DC/DC converter. After this, low signals are output from pins (61), (62), (63) and (64) so that the ASIC is set to the reset condition.

After this these pins set to high, and set to active condition. If the LCD monitor is on, the LCD ON 2 signal at pin (58) set to high,

and the DC/DC converter for the LCD monitor is turned on. Once it is completed, the ASIC returns to the reset condition, all DC/

DC converters are turned off and the power supply to the whole system is halted.

ASIC,

memory

Power voltage

Power OFF

Power switch ON-

Auto power OFF

Shutter switch ON

CAMERA

Monitor OFF

LCD finder

Play back

Table 5-3. Camera Mode (Battery Operation)

Note) 4 MHz = Main clock operation, 32 kHz = Sub clock operation

3.3 V 1.8 V

OFF

OFF

ON

OFF

ON

ON

CCD

5 V (A)

+12 V etc.

OFF

OFF

ON → 2 OFF

OFF

ON

OFF

(ALWAYS)

5. 8-bit D/A circuit (Audio)

This circuit converts the audio signals (analog signals) from the microphone to 8-bit digital signals.

8 bit

CPU

3.2 V

32KHz OFF

4 MHz OFF

4 MHz OFF

4 MHz OFF

4 MHz ON

4 MHz ON

LCD

MONITOR

5 V (L)

+8.5 V etc.

6. 8-bit A/D circuit (Audio)

The audio signals which were converted to digial form by the 8-bit A/D circuit are temporarily to a sound buffer and then recorded

in the SSFDC card. During playback, the 8-bit D/A circuit converts these signals into analog audio signals.

– 9 –

Page 10

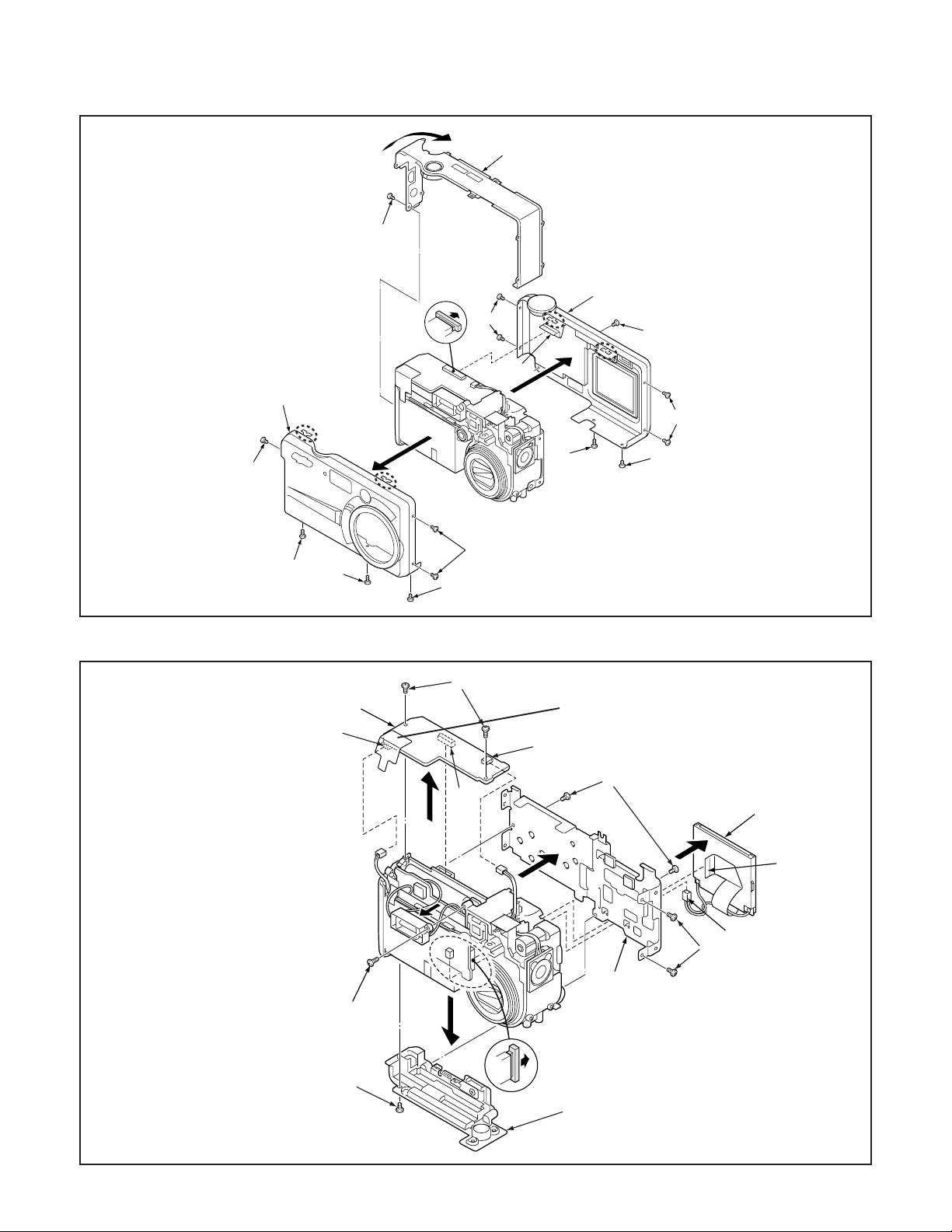

2. DISASSEMBLY

5

1

2

3

2

4

5

6

7

8

9

10

11

12

2-1. REMOVAL OF CABINET FRONT, CABINET BACK AND CABINET TOP

8

1. Six screws 1.7 x 2.5

2. Three screws 1.7 x 4

3. Four screws 1.7 x 2

4. Cabinet front

5. Cabinet back

6. FPC

7. Screw 1.7 x 2.5

8. Cabinet top

7

5

3

6

1

4

2

1

3

1

NOTE: Do not touch the holder cabi lock.

1

2

2

1

Because they change the shape

and get injured.

2-2. REMOVAL OF SY1 BOARD AND LCD

1. Two screws 1.7 x 3

2. Two connector

3. Connector

4. SY1 board

5. Four screws 1.7 x 3

6. Screw 1.7 x 3

7. Holder card

8. Holder monitor

9. FPC

10. Connector

11. LCD

12. Screw 1.7 x 4

NOTE: Attach the button buttery + side is

the bottom (Z3001 of SY1 board).

– 10 –

Page 11

2-3. REMOVAL OF PW1 BOARD, CA2 BOARD, ST1 BOARD AND CA1 BOARD

11

1. FPC

2. Screw 1.7 x 3

3. Screw 1.7 x 4

4. Holder battery

5. Connector

6. ST1 board

7. Three screws 1.7 x 3

8. FPC

9. Connector

10. PW1 board

11. Four screws 1.7 x 3

12. Holder terminal

13. CA2 board

14. Spacer CA1

15. Two screws 1.4 x 3.5

16. CA1 board

17. Three screws 1.7 x 4

18. Holder lens

10

2

7

4

3

6

12

9

1

8

5

17

11

13

14

2-4. BOARD LOCATION

18

15

16

17

SY1 board

ST1 board

PW1 board

CA2 board

CA1 board

– 11 –

Page 12

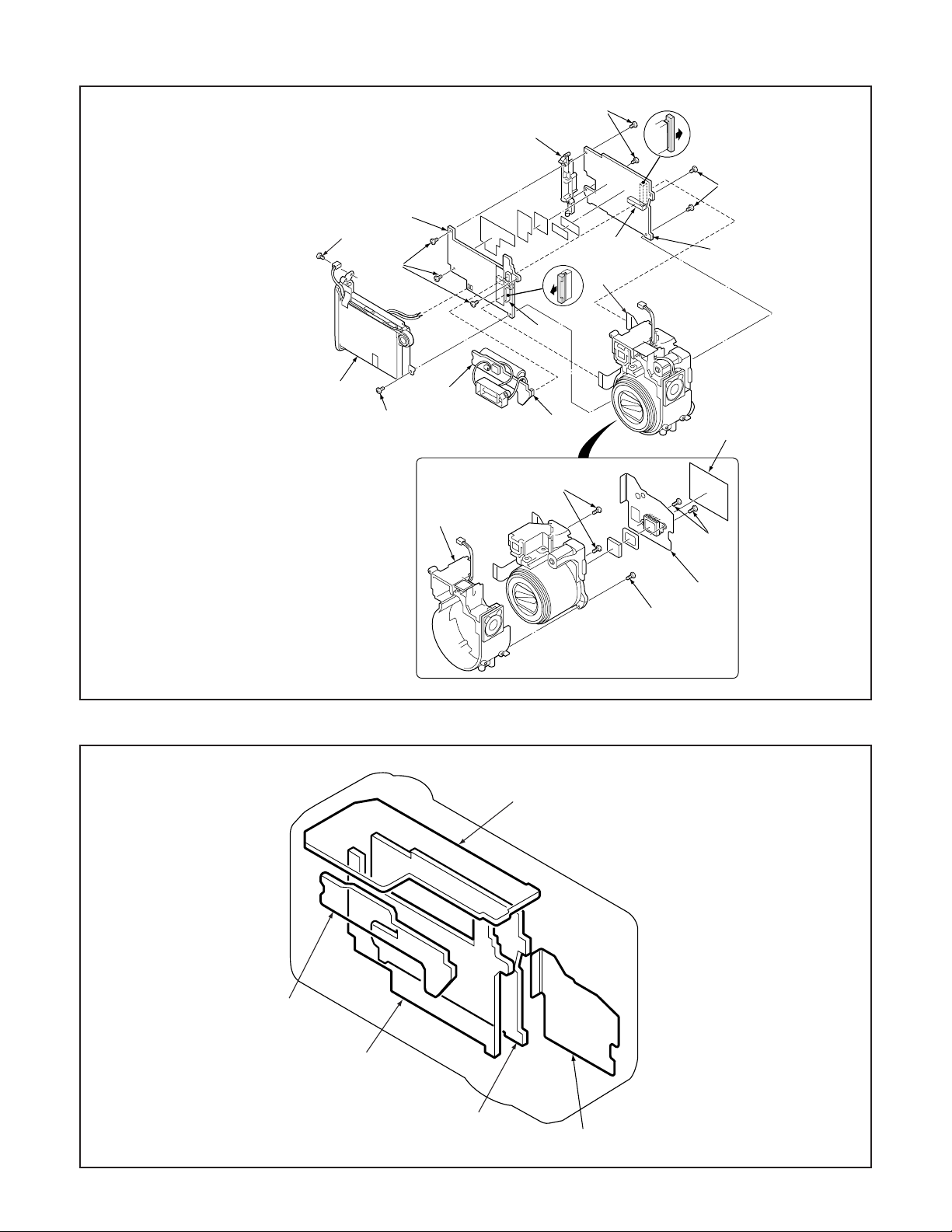

3. ELECTRICAL ADJUSTMENT

Firmware

Image

AWB

Focus

UV Matrix

RGB Odd

RGB Gain

Tint

RGB Even

VCOMDC

Phase

LCD

Calibration

Upload

Initialize

LCD Type

H AFC Test

VCOMPP(LOW)

VCOMPP(HI)

Cal Data

Cal Mode

OK

OK

EVF

USB storage

Get

Set

VID

Set

PID

Set

Serial

Set

Rev.

Set

Setting

Language

Video Mode

VCO

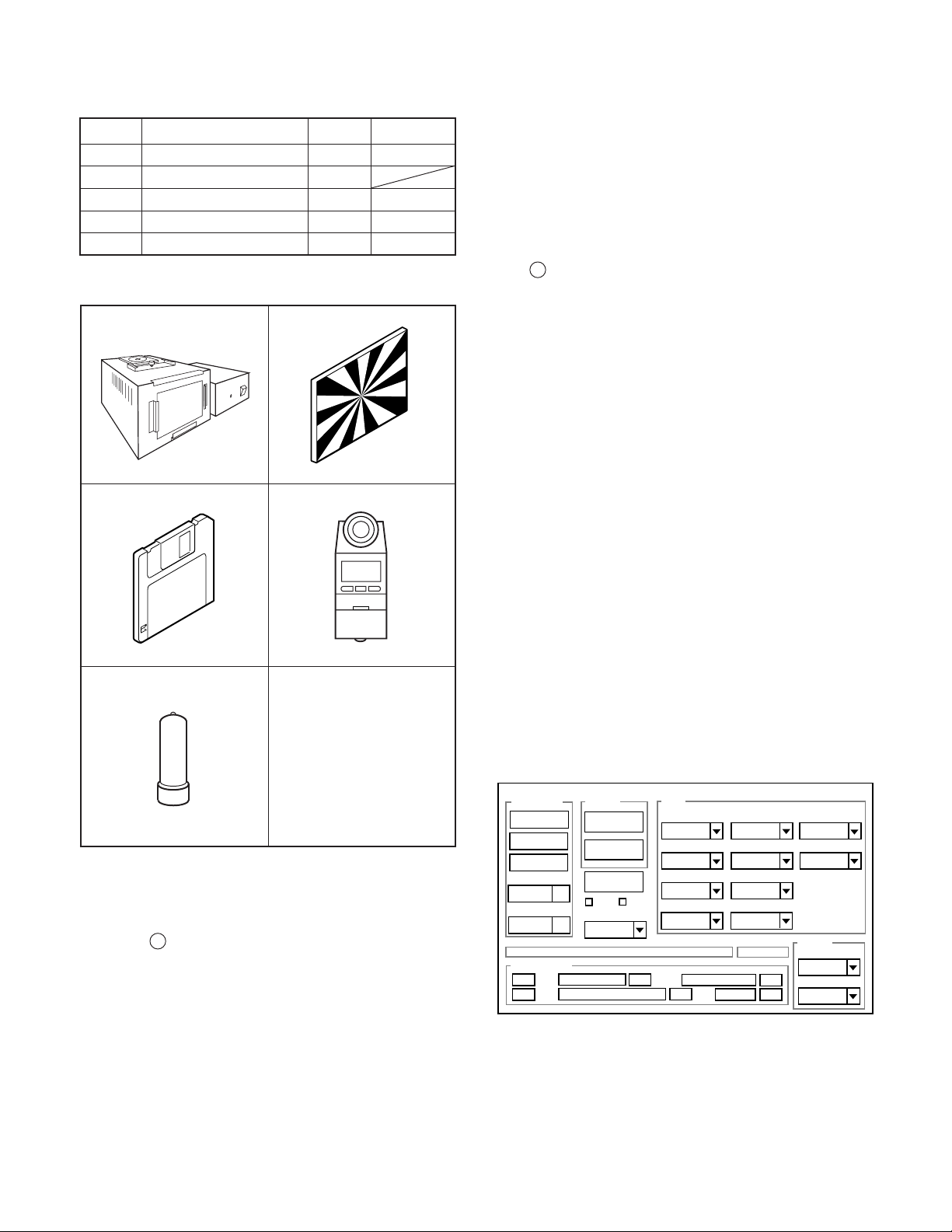

3-1. Table for Servicing Tools

1

1

1

1Chroma meter

1

Part code

VJ8-0190

VJ8-0193

VJ8-0192

VJ8-0191

Ref. No.

J-1

J-2

J-3

Name

Pattern box (color viewer)

Siemens star chart

Calibration software

Number

J-4

J-5

Spare lump

Note: J-1 Pattern box (color viewer) is 100 - 110 VAC only.

J-1 J-2

J-3

J-4

Note: If the lens, CCD and board in item 2-6, it is necessary

to adjust again. Item 2-6 adjustments other than these

should be carried out in sequence. For 5 and 6, carry

out adjustment after sufficient charging has taken place.

In case of carrying out adjustment item 3 and 4 after

adjusting item 5 and 6, adjust item 3 and 4 after turing

off the power.

3-4. Setup

1. System requirements

Windows 98 or Me or 2000 or XP

IBM R -compatible PC with pentium processor

CD-ROM drive

3.5-inch high-density diskette drive

USB port

40 MB RAM

Hard disk drive with at least 15 MB available

VGA or SVGA monitor with at least 256-color display

2. Installing calibration software

1. Insert the calibration software installation diskette into your

diskette drive.

2. Open the explorer.

3. Copy the DscCalDI_129 folder on the floppy disk in the FD

drive to a folder on the hard disk.

J-5

3-2. Equipment

1. Oscilloscope

2. Digital voltmeter

3. AC adaptor

4. PC (IBM R -compatible PC, Pentium processor, Window

98 or Me or 2000 or XP)

3-3. Adjustment Items and Order

1. IC501 Oscillation Frequency Adjustment

2. CCD VSUB Adjustment

3. AWB Adjustment

4. Lens Adjustment

5. CCD Defect Detect Adjustment

6. CCD Black Point Defect Detect Adjustment

7. LCD Panel Adjustment

7-1. LCD RGB Offset Adjustment

7-2. LCD Gain Adjustment

3. Installing USB driver

Install the USB driver with camera or connection kit for PC.

4. Pattern box (color viewer)

Turn on the switch and wait for 30 minutes for aging to take

place before using Color Pure. It is used after adjusting the

chroma meter (VJ8-0192) adjust color temperature to 3100 ±

20 K and luminosity to 900 ± 20 cd/m

2

. Be careful of handling

the lump and its circumference are high temperature during

use and after power off for a while.

5. Computer screen during adjustment

– 12 –

Page 13

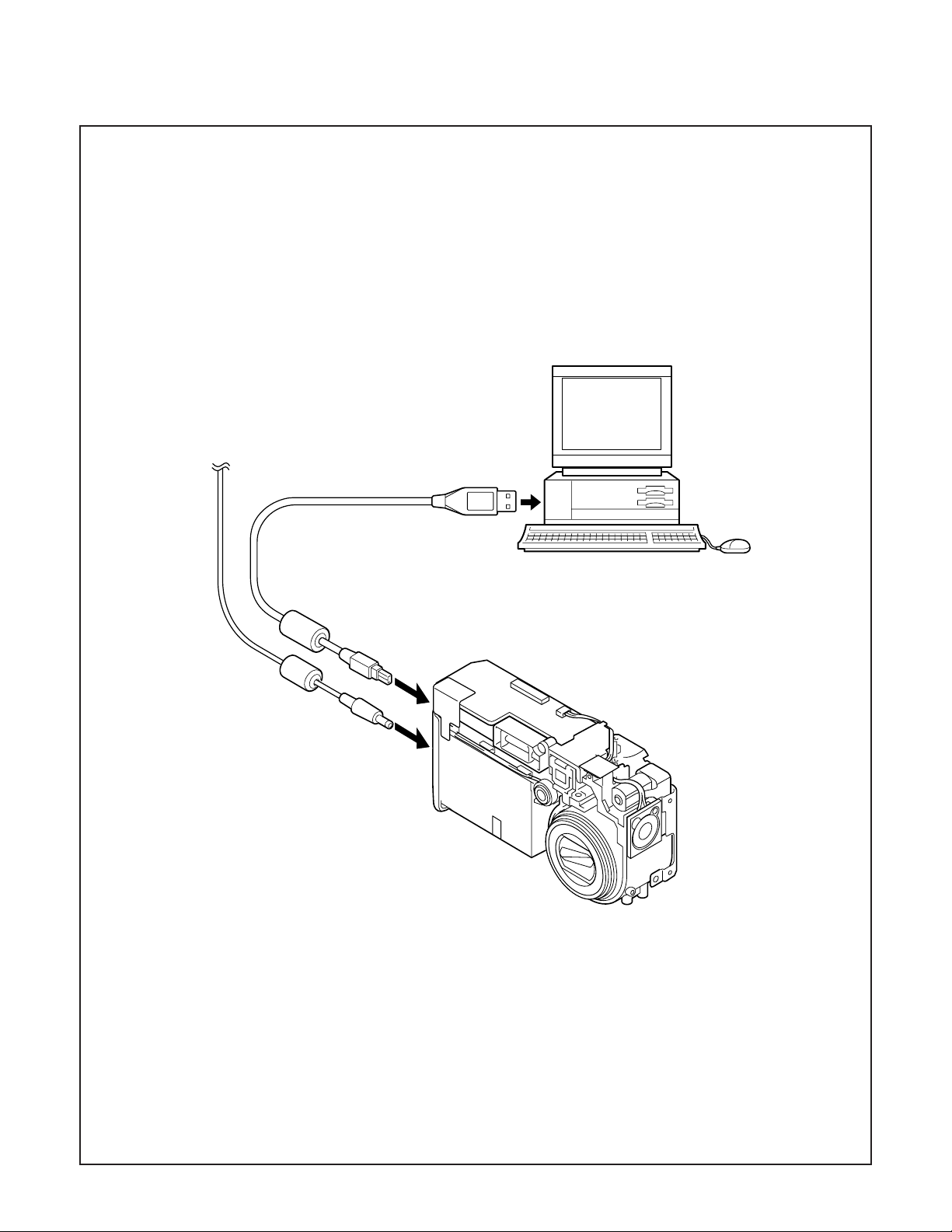

3-5. Connecting the camera to the computer

1. Line up the arrow on the cable connector with the notch on the camera's USB port. Insert the connector.

2. Locate a USB port on your computer.

To USB port

AC adaptor

USB cable

– 13 –

Page 14

3-6. Adjust Specifications

[PW1 board (Side B)]

CL526

VR501

Note:

1. When installing a new CCD, read the abbreviation described

on the rear side of CCD, and write it to the board.

2. If the CCD, each board and parts replaces, it is necessary

to adjust again.

Adjustment method:

1. Turn on the power. (Insert the DC jack.)

2. Shorten TP301 and TP302 of SY1 board with pushing S3003

(Flash sw).

3. Read the abbreviation display on the rear side of CCD.

Convert these to voltages using the table below.

For example, “h” → VSUB = 11.7 V

4. Adjust with VR921 so that the voltage of TP901 at VSUB

becomes the displayed voltage value ± 0.1 V.

Note:

1. Frequency adjustment is necessary to repair in the PW1

board and replace the parts. It is carried out with LCD

through screen display mode.

Preparation:

1. Carry out the frequency adjustment disconnecting cabinet

front, cabinet back, cabinet top and screws of holder battery. Side B of PW1 board can be seen.

2. Connect FPC of cabinet back to CN303.

3. Insert the compact flash.

4. Set the main switch to the camera mode.

5. Set the selector dial to the still image shooting mode.

6. Push the power switch, and comfirm that the through screen

from the CCD can be seen on the LCD.

1. IC501 Oscillation Frequency Adjustment

Measuring Point

Measuring Equipment

ADJ. Location

ADJ. Value

Adjustment method:

1. Adjust with VR501 to 496 ± 1 kHz.

CL526

Frequency counter

VR501

496 ± 1 kHz

VSUB abbreviation

Voltage

C

10.7

N

12.7

1

8.9

D

10.9E11.1

P

12.9

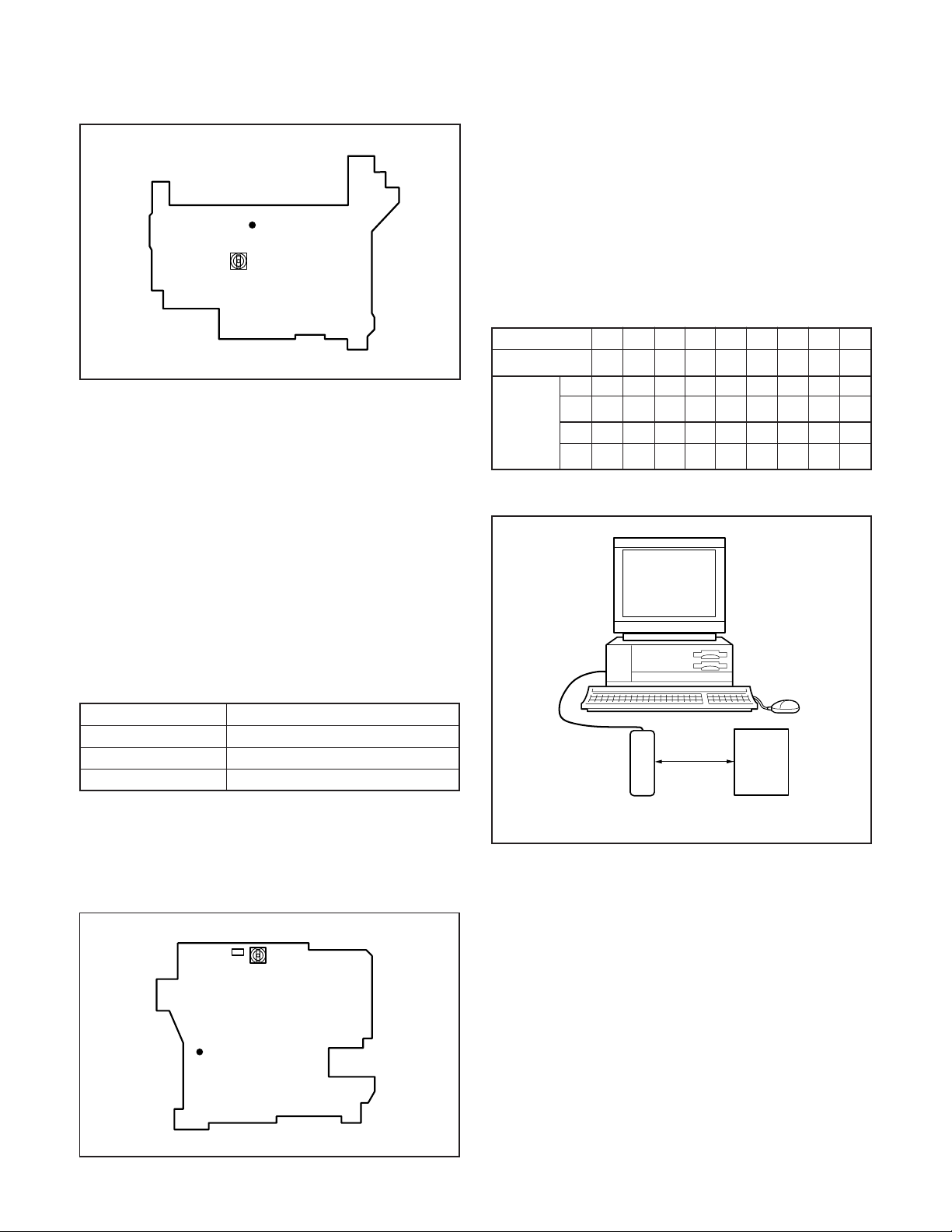

3. AWB Adjustment

Camera

2

9.139.349.5

f

11.5

11.3

R

S

13.5

13.3

13.1

0~18 cm

6

9.779.9810.1

G

H

11.7

U

V

13.7

Pattern box

(color viewer)

J

11.9

W

13.9

K

12.1

X

14.1

9

10.3

L

12.3

Y

14.3

A

10.5

m

12.5

Z

14.5

2. CCD VSUB Adjustment

[CA2 board (Side A)]

TP901

CL136(G)

VR501

Preparation:

POWER switch: ON

Adjusting method:

1. When setting the camera in place, set it to an angle so that

nothing appears in any part of the color viewer except the

white section. (Do not enter any light.)

2. Double-click on the DscCalDi129.

3. Click the AWB, and click the Yes.

4. AWB adjustment value will appear on the screen.

5. Click the OK.

– 14 –

Page 15

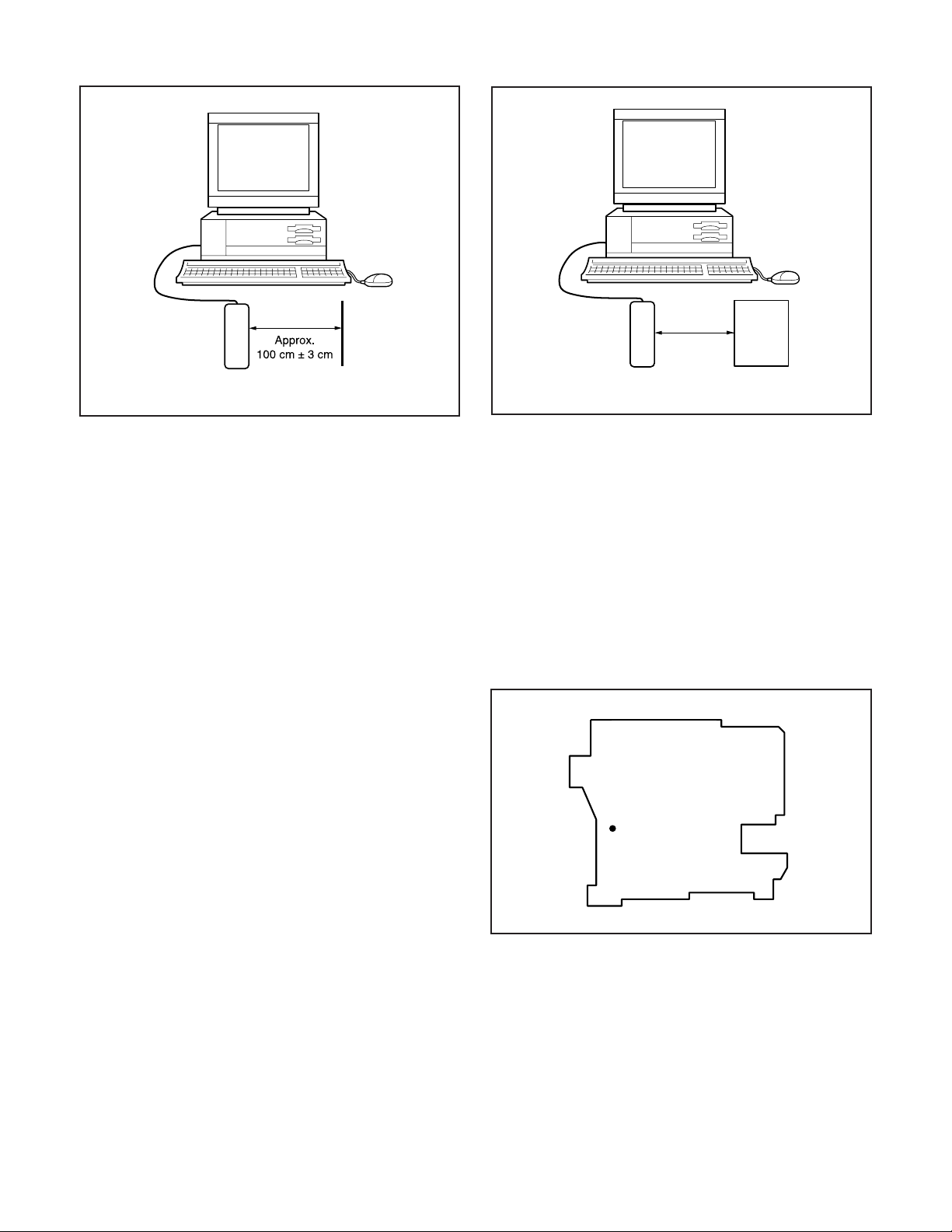

4. Lens Adjustment

6. CCD Black Point Defect Detect Adjustment

Camera

Siemens

star chart

Preparation:

POWER switch: ON

Adjustment condition:

More than A3 size siemens star chart

Fluorescent light illumination with no flicker

Illumination above the subject should be 400 lux ± 10 %.

Adjustment method:

1. Set the siemens star chart 100 cm ± 3 cm so that it becomes center of the screen.

2. Double-click on the DscCalDi129.

3. Click the Focus, and click the Yes.

4. Lens adjustment value will appear on the screen.

5. Click the OK.

5. CCD Defect Detect Adjustment

Preparation:

POWER switch: ON (Set the camera mode.)

Adjustment method:

1. Double-click on the DscCalDi129.

2. Select “CCD Defect” on the LCD “Test”, and click the “Ye s ”.

3. After the adjustment is completed, OK will display.

4. Click the OK.

Camera

0~18 cm

Pattern box

(color viewer)

Preparation:

POWER switch: ON

Adjusting method:

1. When setting the camera in place, set it to an angle so that

nothing appears in any part of the color viewer except the

white section. (Do not enter any light.)

2. Double-click on the DscCalDi129.

3. Select “CCD Black” on the LCD “Test”, and click the “Ye s ”.

4. After the adjustment is completed, the number of defect will

appear.

7. LCD Panel Adjustment

[CA2 board (Side A)]

TP901

VR501

CL136(G)

7-1. LCD RGB Offset Adjustment

Preparation:

POWER switch: ON

Adjusting method:

1. Double-click on the DscCalDi129.

2. Adjust LCD “RGB Odd” so that the amplitude of the CL136

waveform is 0.95 V ± 0.05 V.

3. Adjust LCD “RGB Even” so that the amplitude of the CL136

waveform is 4.55 V ± 0.05 V.

– 15 –

Page 16

4.55 ±

0.05 V

0.95 ± 0.05 V

CL136 waveform

7-2. LCD Gain Adjustment

Adjusting method:

1. Adjust LCD “RGB Gain” so that the amplitude of the CL136

waveform is 1.55 V ± 0.1 Vp-p.

Note:

7-1. LCD RGB Offset adjustment should always be carried

out first.

1.55 V

± 0.1 Vp-p

CL136 waveform

– 16 –

Page 17

4. USB STORAGE INFORMATION

REGISTRATION

USB storage data is important for when the camera is connected to a computer via a USB connection.

If there are any errors in the USB storage data, or if it has not

been saved, the USB specification conditions will not be satisfied, so always check and save the USB storage data.

Preparation:

POWER switch: ON

Adjustment method:

1. Connect the camera to a computer. (Refer to 3-5. Connecting the camera to the computer on the page 13.)

2. Double-click on the DscCalDi129.

3. Click on the Get button in the USB storage window and

check the USB storage data.

VID: SANYO

PID: VPC-MZ3 or VPC-MZ3EX

Serial:

Rev. : 1.00

4. Check the “Serial” in the above USB storage data. If the

displayed value is different from the serial number printed

on the base of the camera, enter the number on the base

of the camera. Then click the Set button.

5. Next, check VID, PID and Rev. entries in the USB storage

data. If any of them are different from the values in 3. above,

make the changes and then click the corresponding Set

button.

Calibration

AWB

Focus

UV Matrix

Cal Mode

Cal Data

USB storage

VID

Get

PID

Set

OK

OK

Upload

Firmware

Image

Initialize

EVF

LCD Type

LCD

RGB Odd

RGB Gain

Tint

VCO

H AFC Test

Serial

Set

Set

Rev.

RGB Even

VCOMDC

Phase

Set

Set

VCOMPP(LOW)

VCOMPP(HI)

Setting

Language

Video Mode

– 17 –

Page 18

5. TROUBLESHOOTING GUIDE

POWER LOSS INOPERTIVE

PUSH MAIN SW

IC301-45 (SCAN IN 6)

PULSE INPUT

YES

IC302-7 4.7 V

(BOOST 4.7 V)

HIGH

IC301-10

(VDD)

HIGH

IC301-36

(RESET)

HIGH

IC301-43

(BAT OFF)

HIGH

IC301-40

OSCILLATION

YES

IC301-37

OSCILLATION

YES

NO

CHECK CN303-3

LOW

CHECK PW1, IC952

LOW

LOW

CHECK IC302, R3004

LOW

NO

NO

CHECK R3003

CHECK X3001

CHECK X3002

CHECK IC302

TAKING INOPERATIVE

PUSH SHUTTER

BUTTON

IC301-55, 45

(SCAN IN 5, 6)

PULSE INPUT

YES

CN301-18, 15

(P ON, P(A) ON)

HIGH

SERIAL

COMMUNICATION

OK

CHECK CA2

NO

LOW

NG

CHECK S3001,

D3012, D3013,

R3038, R3037

CHECK IC301,

RB302, PW1

CHECK

IC301, CA2

CHECK IC301

NO PICTURE

CHECK CLK

OSCILLATION X1101,

IC111, R1101

YES

SD CLK

OSCILLATION

R1103

OK

IC102-62, 63

IC301-15, 16

OK

CHECK SOLDERING

OF MEMORY PIN

MAIN CLOCK FOR SYSTEM OPERATION

NO

NO OPERATION IF ABSENT

CHECK X1101 OSCILLATOR, R1101 AND IC111

SD RAM (IC103) MOVEMENT CLOCK

NG

NO READ PROGRAM FROM IC121 IF ABSENT

CHECK IC102, IC103

INCORRECT HAND

NG

SHAKING 8-BIT CPU

CHECK EACH INTERFACE

– 18 –

Page 19

6. PARTS LIST

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

CABINET & CHASSIS PARTS 1

1 636 066 8195 RING-SX612/J

2 636 066 8867 ASSY,CABI FRONT-SX612/J

3 636 066 6993 BADGE SANYO-SX612/J

4 636 066 7174 SHAFT CARD-SX612/J

5 636 066 7044 COVER CARD-SX612/J

6 636 067 8095 SPRING COVER CF-SX612/J

7 636 066 7129 HOLDER CARD-SX612/J

8 636 066 7143 KNOB CARD-SX612/J

9 636 066 7181 SLIDE CARD-SX612/J

10 636 067 8088 SPRING SLIDE CF-SX612/J

11 645 056 6448 PAD(L=5)

12 636 066 5361 HOLDER MONITOR-SX612/J

13 636 067 8026 SPACER HOL MONITOR-SX612

14 636 067 8071 SPACER CV MONITOR B-SX612

15 636 067 8019 SPACER CV MONITOR A-SX612

16 636 067 7333 ASSY,WIRE LCD SX612 (N.S.P.)

17 645 054 8864 LCD(AL127ALXD0)

18 636 066 5477 SPACER MONTOR-SX612/J

19 645 054 4071 UNIT,CONTROL PANEL-SX612

20 636 067 7968 ADHESIVE TAPE UNIT B-612

21 636 067 7951 ADHESIVE TAPE UNIT A-612

22 636 066 5354 DEC CARD ACCESS-SX612/J

23 636 066 5279 ASSY,CABINET BACK-SX612/J

24 636 068 1927 SPACER CABI BACK-SX612/J

25 636 066 5347 DEC MONITOR-SX612/J

26 636 066 5439 REFLECTOR VF-SX612/J

27 636 066 5330 COVER EYE-SX612/J

28 636 066 8898 ASSY,CABI TOP-SX612/J

29 636 066 7082 HOLDER STRAP-SX612/J

30 411 000 9403 RING E 2

101 412 065 1203 SPECIAL SCREW-1.7X2.5

102 412 065 1104 SPECIAAL SCREW-1.7X4

103 412 065 3405 SPECIAL SCREW-1.4X1.7

104 412 063 6101 SPECIAL SCREW-1.7X3.0

105 412 065 1401 SPECIAL SCREW-1.4X2.5

106 411 177 8407 SCR S-TPG PAN PCS 1.7X3

107 412 065 4006 SPECIAL SCREW-1.4X2

108 412 065 1302 SPECIAL SCREW-1.7X2

N.S.P.: Not available as service parts.

29

101

101

30

28

19

12

21

108

107

20

106

23

11

20

18

22

13

102

24

14

106

101

15

25

106

26

27

101

108

17

16

3

2

102

SX612/J Parts List-1

9

103

10

105

101

104

6

102

1

101

4

5

8

7

19

Page 20

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

CABINET & CHASSIS PARTS 2

31 636 066 9079 COMPL,REFLECTOR-SX612

32 636 068 0265 COVER TRIGER-SX612/J

33 636 066 4616 COMPL PWB,ST-1

34 636 066 5415 HOLDER LENS-SX612/J

35 636 066 5460 SPACER SPEAKER BACK-612/J

36 636 066 5446 SPACER SPEAKER BACK2-612J

37 645 055 1802 SPEAKER,8

38 636 066 5453 SPACER SPEAKER FRONT-612J

39 636 067 8057 SPACER HOLDER LENS-SX612

40 645 055 2243 LENS(ASSY),SZA4318

41 645 054 9960 OPTICAL FILTER

42 636 066 9505 SPACER

43 636 068 9848 COMPL,CA-1 SV-SX612

44 636 067 8033 SPACER CA1-SX612/J

45 636 067 8040 SPACER HOLDER BATT-SX612

46 636 064 8753 HOLDER MIC-SX212/J

47 645 055 1819 MICROPHONE

48 636 066 7099 HOLDER BATT F-SX612/J

49 636 066 8065 SPRING BATT EJECT-SX612/J

50 636 066 7105 HOLDER BATT B-SX612/J

51 636 066 7211 TERMINAL BATTERY A-612/J

52 636 066 7198 SPRING LEVER BATT-SX612/J

53 636 066 8577 LABEL CAUTION BATT-SX612

54 636 066 7150 LEVER BATT LOCK-SX612/J

55 636 066 7037 COVER BATT-SX612/J

56 636 066 7075 HOLDER P COVER-SX612/J

57 636 066 7167 SHAFT BATT-SX612/J

58 636 066 4609 COMPL PWB,PW-1

59 636 066 7136 HOLDER TERMINAL-SX612/J

60 636 066 4579 COMPL PWB,CA-2

61 636 067 8064 SPACER BACKUP-SX612/J

62 636 066 4593 COMPL PWB,SY-1

106 411 177 8407 SCR S-TPG PAN PCS 1.7X3

109 636 068 9848 COMPL PWB,CA-1 SV-SX612

110 411 181 8707 SCR S-TPG PAN PCS 1.4X3.5

N.S.P.: Not available as service parts.

106

61

62

106

55

46

56

47

57

106

45

32

33

54

53

106

48

106

52

49

58

109

59

50

106

51

39

40

60

109

106

106

44

43

110

110

42

41

109

SX612/J Parts List-2

109

31

34

35

36

37

38

20

Page 21

ELECTRICAL PARTS

Note:

1. Materials of Capacitors and Resistors are abbreviated as follows ;

Resistors Capacitors

MT-FILM Metallized Film Resistor MT-POLYEST Metallized Polyester Capacitor

MT-GLAZE Metallized Glaze Resistor MT-COMPO Metallized Composite Capacitor

OXIDE-MT Oxide Metallized Film Resistor TA-SOLD Tantalum Solid Capacitor

2. Tolerance of Capacitor (10pF over) and Resistor are noted with follow symboles.

F ............1% G ............2% J ............5% K ............10%

M ..........20% N ..........30% Z ..........+80% ~ -20%

3. Capacitors

µ

FP : pF

U :

4. Inductors

µ

H MH : mH

UH :

5. N.S.P. : Not available as service parts.

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

COMPL,CA-1 SV-SX612

636 068 9848

C9001 403 157 1904 CERAMIC 10P D 50V

C9002 403 314 5905 CERAMIC 0.47U K 16V

C9003 403 314 5905 CERAMIC 0.47U K 16V

C9004 403 314 5905 CERAMIC 0.47U K 16V

C9005 403 314 5905 CERAMIC 0.47U K 16V

C9014 403 338 4403 CERAMIC 0.1U K 16V

C9016 403 283 6309 CERAMIC 1U Z 10V

C9017 403 333 3708 CERAMIC 10U M 10V

C9019 403 338 4403 CERAMIC 0.1U K 16V

C9020 403 332 8209 CERAMIC 10U M 16V

C9021 403 332 8209 CERAMIC 10U M 16V

C9022 403 320 5500 CERAMIC 1U Z 25V

Q9002 405 153 6709 TR 2SC3931-D

R9015 401 105 7503 MT-GLAZE 82K JA 1/16W

R9020 401 105 0405 MT-GLAZE 100 JA 1/16W

R9021 401 105 4106 MT-GALZE 3.3K JA 1/16W

R9022 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

409 529 5907 IC ICX274AQF-C (N.S.P.)

636 066 5422 MOUNTING,LENS (N.S.P.)

(CAPACITORS)

(SEMICONDUCTOR)

(RESISTORS)

(MISCELLANEOUS)

COMPL PWB,CA-2

636 066 4579

C1001 403 345 3802 TA-SOLID 22U M 4V

C1002 403 346 2309 CERAMIC 0.1U K 10V

C1004 403 346 2309 CERAMIC 0.1U K 10V

C1005 403 346 2309 CERAMIC 0.1U K 10V

C1006 403 345 3802 TA-SOLID 22U M 4V

C1007 403 343 3101 CERAMIC 1U K 6.3V

C1008 403 346 2309 CERAMIC 0.1U K 10V

C1009 403 369 0306 CERAMIC 1U Z 4V

C1010 403 345 3802 TA-SOLID 22U M 4V

C1011 403 346 2309 CERAMIC 0.1U K 10V

C1012 403 346 2309 CERAMIC 0.1U K 10V

C1015 403 345 4205 TA-SOLID 47U M 6.3V

C1016 403 311 3409 CERAMIC 0.01U K 16V

C1017 403 311 3409 CERAMIC 0.01U K 16V

C1019 403 311 3409 CERAMIC 0.01U K 16V

C1021 403 311 3409 CERAMIC 0.01U K 16V

C1023 403 311 3409 CERAMIC 0.01U K 16V

C1025 403 346 2309 CERAMIC 0.1U K 10V

C1027 403 346 2309 CERAMIC 0.1U K 10V

C1028 403 329 6508 TA-SOLID 10U M 6.3V

C1029 403 345 3802 TA-SOLID 22U M 4V

C1031 403 346 2309 CERAMIC 0.1U K 10V

(CAPACITORS)

AL-SOLID Aluminum Solid Capacitor

NP-ELECT Non-Polarized Electrolytic Capacitor

OS-SOLID Aluminum Solid Capacitors with Organic

Semiconductive Electrolytic Capacitor

DL-ELECT Double Layered Electrolytic Capacitor

C1032 403 311 3409 CERAMIC 0.01U K 16V

C1033 403 311 3409 CERAMIC 0.01U K 16V

C1034 403 346 2309 CERAMIC 0.1U K 10V

C1035 403 346 2309 CERAMIC 0.1U K 10V

C1036 403 311 3409 CERAMIC 0.01U K 16V

C1037 403 311 3409 CERAMIC 0.01U K 16V

C1038 403 311 3409 CERAMIC 0.01U K 16V

C1039 403 311 3409 CERAMIC 0.01U K 16V

C1040 403 346 2309 CERAMIC 0.1U K 10V

C1041 403 346 2309 CERAMIC 0.1U K 10V

C1042 403 311 3409 CERAMIC 0.01U K 16V

C1043 403 311 3409 CERAMIC 0.01U K 16V

C1044 403 346 2309 CERAMIC 0.1U K 10V

C1045 403 346 2309 CERAMIC 0.1U K 10V

C1046 403 311 3409 CERAMIC 0.01U K 16V

C1047 403 369 0306 CERAMIC 1U Z 4V

C1048 403 369 0306 CERAMIC 1U Z 4V

C1050 403 346 2309 CERAMIC 0.1U K 10V

C1052 403 346 2309 CERAMIC 0.1U K 10V

C1053 403 311 4505 CERAMIC 1000P K 50V

C1054 403 311 4505 CERAMIC 1000P K 50V

C1055 403 311 4505 CERAMIC 1000P K 50V

C1056 403 311 4505 CERAMIC 1000P K 50V

C1057 403 329 6508 TA-SOLID 10U M 6.3V

C1101 403 343 3101 CERAMIC 1U K 6.3V

C1102 403 311 3409 CERAMIC 0.01U K 16V

C1113 403 346 2309 CERAMIC 0.1U K 10V

C1201 403 346 2309 CERAMIC 0.1U K 10V

C1302 403 343 3101 CERAMIC 1U K 6.3V

C1401 403 312 6805 CERAMIC 0.1U Z 16V

C1402 403 312 6805 CERAMIC 0.1U Z 16V

C1404 403 312 6805 CERAMIC 0.1U Z 16V

C1405 403 329 6508 TA-SOLID 10U M 6.3V

C1406 403 312 6805 CERAMIC 0.1U Z 16V

C1501 403 311 5007 CERAMIC 33P J 50V

C1502 403 369 0306 CERAMIC 1U Z 4V

C1503 403 343 3101 CERAMIC 1U K 6.3V

C1504 403 345 3802 TA-SOLID 22U M 4V

C1505 403 345 4205 TA-SOLID 47U M 6.3V

C1506 403 343 3101 CERAMIC 1U K 6.3V

C1507 403 311 7506 CERAMIC 22P J 50V

C1701 403 346 2309 CERAMIC 0.1U K 10V

C1702 403 369 0306 CERAMIC 1U Z 4V

C1703 403 369 0306 CERAMIC 1U Z 4V

C1704 403 343 3101 CERAMIC 1U K 6.3V

C1705 403 343 3101 CERAMIC 1U K 6.3V

C1706 403 346 2309 CERAMIC 0.1U K 10V

C1707 403 346 2309 CERAMIC 0.1U K 10V

C1708 403 343 3101 CERAMIC 1U K 6.3V

C1709 403 346 2309 CERAMIC 0.1U K 10V

C1710 403 346 2309 CERAMIC 0.1U K 10V

C1711 403 346 2309 CERAMIC 0.1U K 10V

C1712 403 369 0306 CERAMIC 1U Z 4V

C1713 403 311 3409 CERAMIC 0.01U K 16V

C1714 403 348 9108 CERAMIC 0.47U K 6.3V

21

Page 22

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

C1716 403 373 0804 CERAMIC 3.3U K 6.3V

C1717 403 346 2309 CERAMIC 0.1U K 10V

C1718 403 311 3409 CERAMIC 0.01U K 16V

C1719 403 346 2309 CERAMIC 0.1U K 10V

C1720 403 343 3101 CERAMIC 1U K 6.3V

C1721 403 343 3101 CERAMIC 1U K 6.3V

C1722 403 343 3101 CERAMIC 1U K 6.3V

C1728 403 329 6508 TA-SOLID 10U M 6.3V

C1729 403 329 6508 TA-SOLID 10U M 6.3V

C1730 403 343 3101 CERAMIC 1U K 6.3V

C1731 403 343 3101 CERAMIC 1U K 6.3V

C1732 403 338 4403 CERAMIC 0.1U K 16V

C1733 403 343 8700 CERAMIC 1U M 12V

C1734 403 379 0808 CERAMIC 1U M 16V

C2501 403 343 3101 CERAMIC 1U K 6.3V

C9001 403 320 5500 CERAMIC 1U Z 25V

C9002 403 312 6805 CERAMIC 0.1U Z 16V

C9003 403 283 6309 CERAMIC 1U Z 10V

C9004 403 311 7605 CERAMIC 2200P K 50V

C9005 403 283 6309 CERAMIC 1U Z 10V

C9006 403 311 3409 CERAMIC 0.01U K 16V

C9007 403 312 6805 CERAMIC 0.1U Z 16V

C9008 403 312 6805 CERAMIC 0.1U Z 16V

C9009 403 312 6805 CERAMIC 0.1U Z 16V

C9010 403 283 6309 CERAMIC 1U Z 10V

C9011 403 312 6805 CERAMIC 0.1U Z 16V

C9013 403 320 5500 CERAMIC 1U Z 25V

C9014 403 343 3101 CERAMIC 1U K 6.3V

C9016 403 346 2309 CERAMIC 0.1U K 10V

C9017 403 343 3101 CERAMIC 1U K 6.3V

C9018 403 311 3409 CERAMIC 0.01U K 16V

C9019 403 343 3101 CERAMIC 1U K 6.3V

C9020 403 343 3101 CERAMIC 1U K 6.3V

C9021 403 312 6805 CERAMIC 0.1U Z 16V

C9022 403 311 3409 CERAMIC 0.01U K 16V

C9023 403 346 2309 CERAMIC 0.1U K 10V

C9024 403 320 5500 CERAMIC 1U Z 25V

C9026 403 320 5302 CERAMIC 0.15U K 25V

C9027 403 346 2309 CERAMIC 0.1U K 10V

C9028 403 346 2309 CERAMIC 0.1U K 10V

C9029 403 346 2309 CERAMIC 0.1U K 10V

C9031 403 346 2309 CERAMIC 0.1U K 10V

C9032 403 345 4304 TA-SOLID 22U M 10V

C9033 403 346 2309 CERAMIC 0.1U K 10V

C9034 403 311 3409 CERAMIC 0.01U K 16V

C9035 403 346 2309 CERAMIC 0.1U K 10V

C9036 403 311 3409 CERAMIC 0.01U K 16V

C9037 403 345 4304 TA-SOLID 22U M 10V

C9038 403 346 2309 CERAMIC 0.1U K 10V

C9039 403 346 2309 CERAMIC 0.1U K 10V

C9040 403 352 7305 CERAMIC 4.7U K 6.3V

(DIODES)

D1501 407 109 4609 DIODE MA728

D1601 407 134 7408 DIODE MA141WK

OR 407 130 4401 DIODE DAN202U

D1701 407 206 6308 ZENER DIODE UDZS5.1B-TE17

D9001 407 113 5609 DIODE DSH015

OR 407 134 7200 DIODE MA141K

D9002 407 198 9905 DIODE MA727

D9003 407 198 9905 DIODE MA727

(INTEGRATED CIRCUITS)

IC102 410 458 2103 IC LC98700AF-UK8V (N.S.P)

IC103 409 530 5309 IC M2V28S50AWG-6 (N.S.P)

IC111 409 477 6803 IC IMISG587ETB

IC121 409 535 9906 IC 61201612C

IC144 409 517 9504 IC NC7WZ32K8X

OR 409 466 6104 IC TC7W32FK

IC145 409 395 5902 IC TC7SH00FU

IC146 409 524 0402 IC TC7MH245FK

IC147 409 524 0402 IC TC7MH245FK

IC148 409 482 0605 IC TC7MH244FK

IC149 409 482 0605 IC TC7MH244FK

IC151 409 528 6301 IC TK15465STB

IC171 409 530 5408 IC LC15005-EV

IC172 409 505 9400 IC TK11130CS

IC174 409 530 4500 IC TK11185CS

IC251 S 409 532 0203 IC LM62BIM3X

IC901 409 529 5808 IC AD9847AKST

IC902 409 505 9509 IC TK11131CS

IC903 409 530 5507 IC TC4S66FU

IC904 409 529 5204 IC CXD3440EN

OR 409 543 2807 IC CXD3440EN-1

IC953 409 301 5408 IC TC7S14FU(BRA)

(INDUCTORS)

L1002 645 021 1720 INDUCTOR,4.7U J

L1008 645 045 3274 FILTER,EMI 22000PF

L1009 645 045 3274 FILTER,EMI 22000PF

L1101 645 020 1912 INDUCTOR,240 OHM

L1501 645 035 7190 INDUCTOR,33U J

L1601 645 041 1953 INDUCTOR,100 OHM

L1702 645 035 7183 INDUCTOR,10U J

L9001 645 044 9000 FILTER,EMI 1000PF

L9002 645 020 1882 INDUCTOR,1800 OHM

(SEMICONDUCTORS)

Q1301 405 167 0304 TR EMD3

Q1302 405 166 9506 TR EMH2

Q1303 405 166 9506 TR EMH2

Q1401 405 167 0304 TR EMD3

Q1501 405 166 9605 TR EMT1

Q1502 405 168 3908 TR EMZ1

Q1503 405 102 6705 TR 2SA1745-7

OR 405 102 8303 TR 2SA1745-6

Q1504 405 168 3700 TR DTC144EM

Q1601 405 168 3700 TR DTC144EM

Q1602 405 102 6705 TR 2SA1745-7

OR 405 102 8303 TR 2SA1745-6

Q1604 405 168 3700 TR DTC144EM

Q9001 405 102 5609 TR 2SD1819A-R

OR 405 092 4101 TR 2SC4081-R

Q9002 405 168 3700 TR DTC144EM

Q9511 405 168 9504 TR DTC115EM

Q9513 405 168 9504 TR DTC115EM

Q9514 405 164 2806 TR EMX1

(RESISTORS)

R1000 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

R1003 401 224 8801 MT-GLAZE 100 JA 1/16W

R1005 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1006 401 261 4903 MT-FILM 820 DU 1/16W

R1007 401 261 5108 MT-FILM 1.0K DU 1/16W

R1008 401 261 6402 MT-FILM 200 DU 1/16W

R1009 401 261 3906 MT-FILM 2.2K DU 1/16W

R1010 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1011 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1012 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1013 401 224 9006 MT-GLAZE 10K JA 1/16W

R1014 401 224 9006 MT-GLAZE 10K JA 1/16W

R1018 401 224 8801 MT-GLAZE 100 JA 1/16W

R1020 401 224 8801 MT-GLAZE 100 JA 1/16W

R1032 401 224 9006 MT-GLAZE 10K JA 1/16W

R1033 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1036 401 224 9006 MT-GLAZE 10K JA 1/16W

R1101 401 224 8801 MT-GLAZE 100 JA 1/16W

R1201 401 225 8107 MT-GLAZE 10 JA 1/16W

R1301 401 225 1405 MT-GLAZE 47K JA 1/16W

R1302 401 261 4507 MT-FILM 1.5K DU 1/16W

R1303 401 224 9006 MT-GLAZE 10K JA 1/16W

R1304 401 262 3608 MT-FILM 18 DD 1/16W

R1305 401 262 3608 MT-FILM 18 DD 1/16W

R1306 401 224 9006 MT-GLAZE 10K JA 1/16W

R1401 401 224 9006 MT-GLAZE 10K JA 1/16W

R1402 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1403 401 225 1405 MT-GLAZE 47K JA 1/16W

R1404 401 224 8900 MT-GLAZE 100K JA 1/16W

R1501 401 261 7102 MT-FILM 150 DU 1/16W

R1502 401 261 6501 MT-FILM 220 DU 1/16W

R1503 401 235 1402 MT-GALZE 1.2K JA 1/16W

R1504 401 225 3805 MT-GLAZE 1.5K JA 1/16W

R1505 401 261 6105 MT-FILM 390 DU 1/16W

R1506 401 261 5108 MT-FILM 1.0K DU 1/16W

R1507 401 261 5108 MT-FILM 1.0K DU 1/16W

R1508 401 261 4101 MT-FILM 2.7K DU 1/16W

R1509 401 225 2006 MT-GLAZE 680 JA 1/16W

R1510 401 226 5402 MT-GLAZE 56 JA 1/16W

R1511 401 261 9601 MT-FILM 68 DD 1/16W

R1512 401 224 9006 MT-GLAZE 10K JA 1/16W

R1513 401 224 8900 MT-GLAZE 100K JA 1/16W

22

Page 23

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

R1514 401 224 9303 MT-GLAZE 1K JA 1/16W

R1601 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1603 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R1604 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R1605 401 224 9303 MT-GLAZE 1K JA 1/16W

R1701 401 224 8900 MT-GLAZE 100K JA 1/16W

R1702 401 224 8900 MT-GLAZE 100K JA 1/16W

R1703 401 224 8900 MT-GLAZE 100K JA 1/16W

R1704 401 225 0606 MT-GLAZE 5.6K JA 1/16W

R1705 401 301 3507 MT-GLAZE 200 JA 1/16W

R1706 401 225 0606 MT-GLAZE 5.6K JA 1/16W

R1713 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1714 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1715 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1716 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1717 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1718 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R9001 401 224 8900 MT-GLAZE 100K JA 1/16W

R9002 401 261 5900 MT-FILM 330 DU 1/16W

R9003 401 261 3906 MT-FILM 2.2K DU 1/16W

R9004 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R9005 401 224 9006 MT-GLAZE 10K JA 1/16W

R9006 401 240 9004 MT-GLAZE 3.9 JA 1/16W

R9007 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R9013 401 224 9006 MT-GLAZE 10K JA 1/16W

R9014 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R9015 401 240 9202 MT-GLAZE 6.8 JA 1/16W

R9016 401 240 9202 MT-GLAZE 6.8 JA 1/16W

R9017 401 240 9202 MT-GLAZE 6.8 JA 1/16W

R9018 401 240 9202 MT-GLAZE 6.8 JA 1/16W

R9019 401 224 9006 MT-GLAZE 10K JA 1/16W

R9020 401 225 1801 MT-GLAZE 47 JA 1/16W

R9021 401 225 1801 MT-GLAZE 47 JA 1/16W

R9022 401 224 9006 MT-GLAZE 10K JA 1/16W

R9530 401 224 9006 MT-GLAZE 10K JA 1/16W

R9531 401 224 9006 MT-GLAZE 10K JA 1/16W

R9532 401 224 9006 MT-GLAZE 10K JA 1/16W

R9533 401 224 9006 MT-GLAZE 10K JA 1/16W

R9534 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R9535 401 225 0200 MT-GLAZE 3.3K JA 1/16W

R9536 401 225 1702 MT-GLAZE 39K JA 1/16W

R9537 401 225 0200 MT-GLAZE 3.3K JA 1/16W

R9538 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R9539 401 261 7508 MT-FILM 100K DD 1/16W

R9540 401 261 7508 MT-FILM 100K DD 1/16W

R9541 401 225 1405 MT-GLAZE 47K JA 1/16W

R9542 401 225 1405 MT-GLAZE 47K JA 1/16W

R9543 401 225 1405 MT-GLAZE 47K JA 1/16W

R9544 401 225 1405 MT-GLAZE 47K JA 1/16W

(R-NETWORKS)

RB101 645 037 4371 R-NETWORK 220X4 1/32W

RB102 645 037 4371 R-NETWORK 220X4 1/32W

RB141 645 028 0719 R-NETWORK 10KX4 1/32W

RB142 645 028 0719 R-NETWORK 10KX4 1/32W

RB171 645 037 0830 R-NETWORK 47X4 1/32W

RB901 645 037 0830 R-NETWORK 47X4 1/32W

RB902 645 037 0830 R-NETWORK 47X4 1/32W

(VARIABLE RESISTOR)

VR901 645 019 5150 VR,SEMI,10K S

(OSCILLATORS)

X1101 645 036 9865 OSC,CRYSTAL 14.31818MHZ

(CONNECTORS)

CN101 645 052 0556 PLUG,PWB-PWB 40P (N.S.P)

CN102 645 054 8819 SOCKET,PWB-PWB 60 (N.S.P)

CN141 645 056 6714 PLUG,CARD 50P (N.S.P)

CN171 645 033 1473 SOCKET,FFC 24P (N.S.P)

CN172 645 025 1320 PLUG,2P (N.S.P)

CN901 645 054 8802 SOCKET,FFC 31P (N.S.P)

(MISCELLANEOUS)

636 067 8408 SPACER SHIELD CF-SX612/J

636 068 1385 HEAT SINK RUBBER A-SX612 (IC102)

636 068 1392 HEAT SINK RUBBER B-SX612 (IC901)

636 068 1989 SHIELD TAPE ASSD-SX612/J (IC102,IC103)

636 068 1996 SHIELD TAPE ADC-SX612/J (IC901)

645 055 1970 HOLDER,CF(NORMAL)

COMPL PWB,PW-1

636 066 4609

(CAPACITORS)

C5001 403 338 4403 CERAMIC 0.1U K 16V

C5002 403 311 3409 CERAMIC 0.01U K 16V

C5003 403 346 2309 CERAMIC 0.1U K 10V

C5004 403 348 1300 CERAMIC 0.047U K 10V

C5005 403 375 7702 CERAMIC 0.068U K 16V

C5006 403 348 1300 CERAMIC 0.047U K 10V

C5007 403 346 2309 CERAMIC 0.1U K 10V

C5008 403 354 7808 CERAMIC 150P J 50V

C5009 403 343 3101 CERAMIC 1U K 6.3V

C5010 403 348 9108 CERAMIC 0.47U K 6.3V

C5011 403 317 1904 CERAMIC 6800P K 25V

C5012 403 311 7704 CERAMIC 4700P K 25V

C5013 403 311 7704 CERAMIC 4700P K 25V

C5014 403 311 3409 CERAMIC 0.01U K 16V

C5015 403 324 6305 CERAMIC 0.022U K 16V

C5016 403 343 3101 CERAMIC 1U K 6.3V

C5024 403 358 3202 CERAMIC 10U K 6.3V

C5025 403 343 3101 CERAMIC 1U K 6.3V

C5026 403 358 3202 CERAMIC 10U K 6.3V

C5027 403 311 3409 CERAMIC 0.01U K 16V

C5031 403 378 6009 CERAMIC 4.7U K 16V

C5032 403 379 3205 CERAMIC 2.2U K 16V

C5033 403 367 5402 CERAMIC 1U K 16V

C5034 403 332 8209 CERAMIC 10U M 16V

C5035 403 341 4803 CERAMIC 10U K 10V

C5037 403 325 0500 CERAMIC 2.2U K 16V

C5038 403 311 7605 CERAMIC 2200P K 50V

C5039 403 373 0804 CERAMIC 3.3U K 6.3V

C5040 403 358 3202 CERAMIC 10U K 6.3V

C5041 403 358 3202 CERAMIC 10U K 6.3V

C5042 403 367 6607 POS-SOLID 47U M 6.3V

C5043 403 311 7704 CERAMIC 4700P K 25V

C5045 403 343 3101 CERAMIC 1U K 6.3V

C5052 403 367 6607 POS-SOLID 47U M 6.3V

C5053 403 367 6607 POS-SOLID 47U M 6.3V

C5054 403 358 3202 CERAMIC 10U K 6.3V

C5055 403 311 7704 CERAMIC 4700P K 25V

C5056 403 358 3202 CERAMIC 10U K 6.3V

C5058 403 311 7605 CERAMIC 2200P K 50V

C5062 403 378 6009 CERAMIC 4.7U K 16V

C5063 403 340 6907 CERAMIC 1U K 16V

C5064 403 311 7704 CERAMIC 4700P K 25V

C5071 403 358 3202 CERAMIC 10U K 6.3V

C5072 403 358 3202 CERAMIC 10U K 6.3V

C5073 403 311 7704 CERAMIC 4700P K 25V

C5074 403 358 3202 CERAMIC 10U K 6.3V

C5075 403 373 0804 CERAMIC 3.3U K 6.3V

C5076 403 358 3202 CERAMIC 10U K 6.3V

C5077 403 358 3202 CERAMIC 10U K 6.3V

C5078 403 358 3202 CERAMIC 10U K 6.3V

C5079 403 372 3202 CERAMIC 22U M 6.3V

C5080 403 372 3202 CERAMIC 22U M 6.3V

C5086 403 343 3101 CERAMIC 1U K 6.3V

C5101 403 309 8706 CERAMIC 100P J 50V

C5102 403 309 8706 CERAMIC 100P J 50V

C9500 403 312 6805 CERAMIC 0.1U Z 16V

C9501 403 344 0505 CERAMIC 0.033U K 10V

C9502 403 344 0505 CERAMIC 0.033U K 10V

C9503 403 344 0505 CERAMIC 0.033U K 10V

C9504 403 344 0505 CERAMIC 0.033U K 10V

C9505 403 312 6805 CERAMIC 0.1U Z 16V

C9506 403 312 6805 CERAMIC 0.1U Z 16V

C9507 403 312 6805 CERAMIC 0.1U Z 16V

C9508 403 312 6805 CERAMIC 0.1U Z 16V

C9509 403 312 6805 CERAMIC 0.1U Z 16V

C9510 403 312 6805 CERAMIC 0.1U Z 16V

C9511 403 311 5007 CERAMIC 33P J 50V

C9512 403 311 4505 CERAMIC 1000P K 50V

C9513 403 311 4505 CERAMIC 1000P K 50V

C9514 403 312 6805 CERAMIC 0.1U Z 16V

C9515 403 312 6805 CERAMIC 0.1U Z 16V

C9517 403 367 9004 TA-SOLID 47U M 10V

C9518 403 311 7506 CERAMIC 22P J 50V

C9520 403 367 9004 TA-SOLID 47U M 10V

23

Page 24

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

C9521 403 367 9004 TA-SOLID 47U M 10V

C9522 403 312 6805 CERAMIC 0.1U Z 16V

(DIODES)

D5001 407 190 3703 DIODE RB050L-40-TE25

D5002 407 190 3703 DIODE RB050L-40-TE25

D5004 407 203 5809 DIODE F02J9

D5005 407 203 5809 DIODE F02J9

D5006 407 210 1900 DIODE 1SS400

D5007 407 223 2604 DIODE CRS06

D5008 407 223 2604 DIODE CRS06

D5009 407 210 5403 DIODE RB551V-30

D5011 407 201 2701 DIODE RB051L-40

D5012 407 187 8407 ZENER DIODE UDZ16B

D5013 407 162 8507 DIODE DAN222

D9507 407 201 2701 DIODE RB051L-40

(INTEGRATED CIRCUITS)

IC501 409 530 4609 IC FA7709R

IC502 409 301 5507 IC TC7S08FU

IC951 409 512 9806 IC LB8649FN

IC952 409 526 4002 IC XC9104D095M

IC953 409 532 0104 IC UPD168110MA-6A5

(JACK)

JK501 645 027 7030 SOCKET,DC

(INDUCTORS)

L1602 645 037 4340 INDUCTOR,1000 OHM

L1603 645 037 4340 INDUCTOR,1000 OHM

L1604 645 037 4340 INDUCTOR,1000 OHM

L5001 645 041 1977 INDUCTOR,330 OHM

L5002 645 041 1953 INDUCTOR,100 OHM

L5003 645 041 1953 INDUCTOR,100 OHM

L5004 645 037 1530 INDUCTOR,47U K

L5005 645 037 1530 INDUCTOR,47U K

L5006 645 037 1530 INDUCTOR,47U K

L5007 645 037 1523 INDUCTOR,10U K

L5008 645 055 8047 INDUCTOR,10U M

L5009 645 052 7432 INDUCTOR,10U M

L5010 645 036 7496 INDUCTOR,4.7U M

L5011 645 046 1941 INDUCTOR,10U M

L5012 645 046 1941 INDUCTOR,10U M

L5013 645 037 1530 INDUCTOR,47U K

L9501 645 052 7432 INDUCTOR,10U M

(FUSES)

PR501 423 029 3706 FUSE 32V 2.5A

PR502 423 028 0904 FUSE 32V 2A

PR503 423 028 0904 FUSE 32V 2A

PR504 423 028 1505 FUSE 32V 1A

PR505 423 029 3706 FUSE 32V 2.5A

(SEMICONDUCTORS)

Q5001 405 163 3606 TR CPH3409

Q5002 405 137 2000 TR 2SA1576A-R

Q5003 405 092 2107 TR 2SC4097-R

Q5004 405 165 1204 TR EMD2

Q5005 405 165 1105 TR EMH11

Q5006 405 157 1403 TR 2SA2018

Q5007 405 170 6409 TR DTA114YM

Q5008 405 115 5207 TR 2SC4617 R

Q5009 405 162 3706 TR CPH3313

Q5010 405 163 2302 TR CPH3307

Q5011 405 148 7100 TR CPH6401

Q5012 405 164 6408 TR MCH5803

Q5013 405 115 5108 TR 2SA1774 R

Q5014 405 169 4508 TR DTC114EM

Q5015 405 162 4000 TR CPH5803

Q5016 405 157 1403 TR 2SA2018

Q5017 405 168 3700 TR DTC144EM

Q5018 405 157 1403 TR 2SA2018

Q5019 405 169 4508 TR DTC114EM

Q5021 405 170 6409 TR DTA114YM

Q5022 405 168 3700 TR DTC144EM

Q9504 405 148 7100 TR CPH6401

Q9505 405 168 3700 TR DTC144EM

Q9506 405 162 4109 TR CPH6311

(RESISTORS)

R5001 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R5002 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5013 401 261 2602 MT-FILM 10K DU 1/16W

R5015 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R5016 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5017 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R5018 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5019 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R5020 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5021 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R5022 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5023 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5033 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5034 401 224 8900 MT-GLAZE 100K JA 1/16W

R5035 401 261 7805 MT-FILM 62K DD 1/16W

R5036 401 224 8900 MT-GLAZE 100K JA 1/16W

R5037 401 261 9304 MT-FILM 15K DD 1/16W

R5038 401 225 1702 MT-GLAZE 39K JA 1/16W

R5039 401 224 9006 MT-GLAZE 10K JA 1/16W

R5040 401 224 9303 MT-GLAZE 1K JA 1/16W

R5041 401 258 7009 MT-GLAZE 150K DC 1/16W

R5042 401 261 2602 MT-FILM 10K DU 1/16W

R5043 401 261 5900 MT-FILM 330 DU 1/16W

R5044 401 262 3400 MT-FILM 39 DD 1/16W

R5045 401 224 8900 MT-GLAZE 100K JA 1/16W

R5046 401 227 5609 MT-GLAZE 8.2K JA 1/16W

R5047 401 261 8703 MT-FILM 22K DD 1/16W

R5048 401 224 8900 MT-GLAZE 100K JA 1/16W

R5049 401 224 9006 MT-GLAZE 10K JA 1/16W

R5050 401 258 7009 MT-GLAZE 150K DC 1/16W

R5051 401 225 8008 MT-GLAZE 330 JA 1/16W

R5052 401 225 8008 MT-GLAZE 330 JA 1/16W

R5053 401 225 8008 MT-GLAZE 330 JA 1/16W

R5054 401 261 9304 MT-FILM 15K DD 1/16W

R5056 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R5057 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5061 401 225 0705 MT-GLAZE 56K JA 1/16W

R5062 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5063 401 224 9303 MT-GLAZE 1K JA 1/16W

R5064 401 261 9106 MT-FILM 12K DD 1/16W

R5066 401 261 2602 MT-FILM 10K DU 1/16W

R5067 401 261 3500 MT-FILM 3.9K DU 1/16W

R5068 401 261 6501 MT-FILM 220 DU 1/16W

R5071 401 225 0705 MT-GLAZE 56K JA 1/16W

R5072 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5073 401 224 9303 MT-GLAZE 1K JA 1/16W

R5074 401 261 9106 MT-FILM 12K DD 1/16W

R5076 401 261 2701 MT-FILM 4.7K DU 1/16W

R5077 401 261 6105 MT-FILM 390 DU 1/16W

R5078 401 262 3608 MT-FILM 18 DD 1/16W

R5081 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5082 401 224 9303 MT-GLAZE 1K JA 1/16W

R5083 401 261 8703 MT-FILM 22K DD 1/16W

R5084 401 261 2909 MT-FILM 5.6K DU 1/16W

R5085 401 261 5900 MT-FILM 330 DU 1/16W

R5086 401 262 3608 MT-FILM 18 DD 1/16W

R5091 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5092 401 224 8900 MT-GLAZE 100K JA 1/16W

R5093 401 284 3600 MT-GLAZE 16K JA 1/16W

R5094 401 237 2407 MT-GLAZE 270K JA 1/16W

R5095 401 224 9303 MT-GLAZE 1K JA 1/16W

R5096 401 224 9006 MT-GLAZE 10K JA 1/16W

R5097 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5098 401 261 9601 MT-FILM 68 DD 1/16W

R5101 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5102 401 224 8900 MT-GLAZE 100K JA 1/16W

R5103 401 224 9006 MT-GLAZE 10K JA 1/16W

R5104 401 224 9303 MT-GLAZE 1K JA 1/16W

R5105 401 261 8703 MT-FILM 22K DD 1/16W

R5106 401 261 2701 MT-FILM 4.7K DU 1/16W

R5107 401 261 5306 MT-FILM 470 DU 1/16W

R5108 401 262 3202 MT-FILM 33 DD 1/16W

R5112 401 224 8900 MT-GLAZE 100K JA 1/16W

R5113 401 224 9006 MT-GLAZE 10K JA 1/16W

R5115 401 237 2407 MT-GLAZE 270K JA 1/16W

R5120 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R5124 401 224 8900 MT-GLAZE 100K JA 1/16W

R5128 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5130 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R9501 401 293 8504 MT-FILM 0.68 FA 1/4W

R9503 401 261 8901 MT-FILM 27K DD 1/16W

R9504 401 261 8901 MT-FILM 27K DD 1/16W

R9505 401 261 2503 MT-FILME 9.1K DU 1/16W

24

Page 25

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

R9506 401 261 3302 MT-FILM 3.3K DU 1/16W

R9507 401 038 0008 MT-GLAZE 200 JA 1/10W

R9508 401 038 0008 MT-GLAZE 200 JA 1/10W

R9509 401 038 0008 MT-GLAZE 200 JA 1/10W

R9511 401 301 1701 MT-GLAZE 200K DC 1/16W

R9512 401 261 8505 MT-FILM 47K DD 1/16W

R9513 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R9514 401 304 2309 MT-FILM 6.8 FA 1/4W

R9515 401 304 2309 MT-FILM 6.8 FA 1/4W

R9519 401 105 6605 MT-GLAZE 6.8K JA 1/16W

R9520 401 105 6605 MT-GLAZE 6.8K JA 1/16W

R9522 401 224 9303 MT-GLAZE 1K JA 1/16W

R9523 401 224 8900 MT-GLAZE 100K JA 1/16W

(TRANSFORMER)

T5001 645 055 1024 TRANS,POWER,PULSE

(VARIABLE RESISTOR)

VR501 645 046 7844 VR,SEMI,2.2K S

(CONNECTORS)

CN105 645 054 4163 SOCKET,8P (N.S.P)

CN501 645 054 8789 PLUG,PWB-PWB 60P (N.S.P)

CN504 645 054 8796 SOCKET,FFC 21P (N.S.P)

CN506 645 054 8772 PLUG,PWB-PWB 20P (N.S.P)

(MISCELLANEOUS)

636 067 7999 SPACER PW1-SX612/J

636 068 1934 SPACER PW1A-SX612

COMPL PWB,SY-1

636 066 4593

(CAPACITORS)

C1801 403 343 3101 CERAMIC 1U K 6.3V

C1802 403 311 3409 CERAMIC 0.01U K 16V

C1803 403 312 6805 CERAMIC 0.1U Z 16V

C1804 403 312 6805 CERAMIC 0.1U Z 16V

C1805 403 346 2309 CERAMIC 0.1U K 10V

C1806 403 369 0306 CERAMIC 1U Z 4V

C1808 403 346 2309 CERAMIC 0.1U K 10V

C1809 403 329 6508 TA-SOLID 10U M 6.3V

C1810 403 343 3101 CERAMIC 1U K 6.3V

C1811 403 343 3101 CERAMIC 1U K 6.3V

C1812 403 343 3101 CERAMIC 1U K 6.3V

C1813 403 364 5306 CERAMIC 2.2U K 6.3V

C1814 403 343 3101 CERAMIC 1U K 6.3V

C1815 403 343 3101 CERAMIC 1U K 6.3V

C1816 403 343 3101 CERAMIC 1U K 6.3V

C1818 403 346 2309 CERAMIC 0.1U K 10V

C1819 403 346 2309 CERAMIC 0.1U K 10V

C1821 403 311 5601 CERAMIC 1500P K 50V

C1822 403 311 3409 CERAMIC 0.01U K 16V

C1823 403 312 6805 CERAMIC 0.1U Z 16V

C1825 403 369 0306 CERAMIC 1U Z 4V

C1827 403 343 3101 CERAMIC 1U K 6.3V

C1828 403 344 0505 CERAMIC 0.033U K 10V

C3002 403 369 0306 CERAMIC 1U Z 4V

C3003 403 312 6805 CERAMIC 0.1U Z 16V

C3004 403 312 6805 CERAMIC 0.1U Z 16V

C3005 403 312 6805 CERAMIC 0.1U Z 16V

C3006 403 368 7702 TA-SOLID 15U M 6.3V

C3007 403 369 0306 CERAMIC 1U Z 4V

C3008 403 312 6805 CERAMIC 0.1U Z 16V

C3010 403 311 7506 CERAMIC 22P J 50V

C3012 403 369 0306 CERAMIC 1U Z 4V

C3013 403 311 4505 CERAMIC 1000P K 50V

C3014 403 312 6805 CERAMIC 0.1U Z 16V

C3015 403 311 7506 CERAMIC 22P J 50V

C3016 403 312 6805 CERAMIC 0.1U Z 16V

(DIODES)

D1801 407 210 1900 DIODE 1SS400

D1802 407 210 1900 DIODE 1SS400

D3001 407 205 2806 DIODE RB520S-30

D3010 407 227 3102 DIODE EMP11

D3011 407 227 3102 DIODE EMP11

D3012 407 227 3102 DIODE EMP11

D3013 407 227 3201 DIODE EMN11

D3022 407 205 2707 LED SML-310LT

(INTEGRATED CIRCUITS)

IC181 409 526 6402 IC BH6410KN

IC182 409 505 9400 IC TK11130CS

IC183 409 432 2505 IC LMV321M7X

IC301 410 460 8803 IC UPD780022AGB-G09-8EU

OR 410 446 8308 IC UPD78F0034AGB-G09-8EU

IC302 409 383 1008 S-8423NFS

(SEMICONDUCTORS)

Q1802 405 168 4004 TR DTA114EM

Q1803 405 102 5609 TR 2SD1819A-R

OR 405 092 4101 TR 2SC4081-R

Q1804 405 168 3700 TR DTC144EM

Q3001 405 168 4004 TR DTA114EM

Q3002 405 115 6709 TR DTC123EE

Q3006 405 168 3809 TR DTA144EM

(RESISTORS)

R1801 401 261 9304 MT-FILM 15K DD 1/16W

R1802 401 225 0903 MT-GLAZE 82K JA 1/16W

R1803 401 225 9005 MT-GLAZE 470K JA 1/16W

R1804 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R1805 401 224 9808 MT-GLAZE 220K JA 1/16W

R1808 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1809 401 225 2105 MT-GLAZE 12K JA 1/16W

R1811 401 225 0705 MT-GLAZE 56K JA 1/16W

R1812 401 225 2105 MT-GLAZE 12K JA 1/16W

R1813 401 224 9501 MT-GLAZE 2.2K JA 1/16W

R1814 401 225 2105 MT-GLAZE 12K JA 1/16W

R1815 401 229 7205 MT-GLAZE 18K JA 1/16W

R1816 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1817 401 224 8900 MT-GLAZE 100K JA 1/16W

R1818 401 224 9006 MT-GLAZE 10K JA 1/16W

R1819 401 224 9006 MT-GLAZE 10K JA 1/16W

R3001 401 225 8503 MT-GLAZE 1.8K JA 1/16W

R3002 401 224 9303 MT-GLAZE 1K JA 1/16W

R3003 401 224 8900 MT-GLAZE 100K JA 1/16W

R3004 401 224 8900 MT-GLAZE 100K JA 1/16W

R3006 401 258 7009 MT-GLAZE 150K DC 1/16W

R3007 401 258 7009 MT-GLAZE 150K DC 1/16W

R3008 401 225 1405 MT-GLAZE 47K JA 1/16W

R3009 401 225 0408 MT-GLAZE 330K JA 1/16W

R3011 401 224 9006 MT-GLAZE 10K JA 1/16W

R3013 401 225 1405 MT-GLAZE 47K JA 1/16W

R3016 401 263 2303 MT-GLAZE 750 JA 1/16W

R3017 401 261 6501 MT-FILM 220 DU 1/16W

R3023 401 225 1405 MT-GLAZE 47K JA 1/16W

R3026 401 261 5306 MT-FILM 470 DU 1/16W

R3030 401 225 1405 MT-GLAZE 47K JA 1/16W

R3032 401 225 1405 MT-GLAZE 47K JA 1/16W

R3033 401 225 1405 MT-GLAZE 47K JA 1/16W

R3034 401 225 1405 MT-GLAZE 47K JA 1/16W

R3035 401 225 1405 MT-GLAZE 47K JA 1/16W

R3036 401 225 1405 MT-GLAZE 47K JA 1/16W

R3037 401 225 1405 MT-GLAZE 47K JA 1/16W

R3038 401 225 1405 MT-GLAZE 47K JA 1/16W

R3039 401 225 1405 MT-GLAZE 47K JA 1/16W

R3040 401 224 9006 MT-GLAZE 10K JA 1/16W

R3041 401 224 9006 MT-GLAZE 10K JA 1/16W

R3042 401 224 9006 MT-GLAZE 10K JA 1/16W

R3043 401 224 9006 MT-GLAZE 10K JA 1/16W

(R-NETWORK)

RB302 645 032 8886 R-NETWORK 47KX4 1/32W

(SWITCHES)

S3001 645 054 8857 SWITCH,PUSH 1P-2TX1

S3002 645 024 3851 SWITCH,PUSH

S3003 645 024 3851 SWITCH,PUSH

(OSCILLATORS)

X3001 645 046 1415 OSC,CERAMIC 4.00MHZ

X3002 645 048 3981 OSC,CRYSTAL 32.768KHZ

(BATTERY)

Z3001 645 051 6009 BATTERY,RECHARGE

(CONNECTORS)

CN181 645 037 7778 PLUG,2P (N.S.P)

CN182 645 037 7778 PLUG,2P (N.S.P)

CN301 645 045 8347 SOCKET,PWB-PWB 40(N.S.P)

CN303 645 052 6893 SOCKET,FPC 27P (N.S.P)

(MISCELLANEOUS)

636 066 6559 SPACER MICON-SX612/J

25

Page 26

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

Cord, Power

(VAR-G6U)

(VAR-G6E)

(VAR-G6EX)

N.S.P.

COMPL PWB,ST-1

636 066 4616

(CAPACITORS)

C5401 403 367 6607 POS-SOLID 47U M 6.3V

C5403 403 272 5603 CERAMIC 0.033U K 16V