Page 1

SERVICE MANUAL

FILE NO.

Dual Camera

Contents

1. OUTLINE OF CIRCUIT DESCRIPTION ............................... 3

2. DISASSEMBLY ................................................................... 12

3. ELECTRICAL ADJUSTMENT ............................................. 18

4. USB STORAGE INFORMATION REGISTRATION ............ 25

5. TROUBLESHOOTING GUIDE............................................ 26

6. PARTS LIST........................................................................ 28

CIRCUIT DIAGRAMS & PRINTED WIRING BOARDS...........C1

RoHS

•This product does not contain any hazardous substances prohibited by the RoHS

Directive.

WARNING

•You are requested to use RoHS compliant parts for maintenance or repair.

•You are requested to use lead-free solder.

(This product has been manufactured using lead-free solder. Be sure to follow the

warning given on page 2 when carrying out repair work.)

VPC-FH1BK

(Product Code : 168 176 02)

(U.S.A.) (Canada) (Taiwan) (General)

VPC-FH1EXBK

(Product Code : 168 176 03)

(Europe) (U.K.) (South America)

(China) (Australia) (Hong Kong)

(Russia) (Middle East) (Africa)

(General) (Korea) (Taiwan)

VPC-FH1GXBK

(Product Code : 168 176 04)

(South America) (China)

(Australia) (Hong Kong)

(General) (Korea) (Taiwan)

VPC-FH1

(Product Code : 168 176 06)

(U.S.A.) (Canada) (Taiwan) (General)

VPC-FH1EX

(Product Code : 168 176 07)

(Europe) (U.K.) (South America)

(China) (Australia) (Hong Kong)

(Russia) (Middle East) (Africa)

(General) (Korea) (Taiwan)

VPC-FH1GX

(Product Code : 168 176 08)

(South America) (China)

(Australia) (Hong Kong)

(General) (Korea) (Taiwan)

CAUTION : Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the

manufacturer.

Discard used batteries according to the manufacturer’s instructions.

NOTE : 1. Parts order must contain model number, part number, and description.

2. Substitute parts may be supplied as the service parts.

3. N. S. P. : Not available as service parts.

Design and specification are subject to change without notice.

SG317/U, EX, GX, U2, EX2, GX2 (R)

REFERENCE No. SM5310779

Page 2

PRODUCT SAFETY NOTICE

The components designated by a symbol ( ! ) in this schematic diagram designates components whose value are of

special significance to product safety. Should any component designated by a symbol need to be replaced, use only the part

designated in the Parts List. Do not deviate from the resistance, wattage, and voltage ratings shown.

WARNING

Do not use solder containing lead.

This product has been manufactured using lead-free solder in

order to help preserve the environment.

Because of this, be sure to use lead-free solder when carrying

out repair work, and never use solder containing lead.

Lead-free solder has a melting point that is 30 - 40°C (86 104°F) higher than solder containing lead, and moreover it does

not contain lead which attaches easily to other metals. As a

result, it does not melt as easily as solder containing lead, and

soldering will be more difficult even if the temperature of the

soldering iron is increased.

The extra difficulty in soldering means that soldering time will

increase and damage to the components or the circuit board

may easily occur.

Because of this, you should use a soldering iron and solder

that satisfy the following conditions when carrying out repair

work.

Note:

If replacing existing solder containing lead with lead-free solder in the soldered parts of products that have been manufactured up until now, remove all of the existing solder at those

parts before applying the lead-free solder.

Soldering iron

Use a soldering iron which is 70 W or equivalent, and which

lets you adjust the tip temperature up to 450°C (842°F). It

should also have as good temperature recovery characteristics as possible.

Set the temperature to 350°C (662°F) or less for chip components, to 380°C (716°F) for lead wires and similar, and to 420°C

(788°F) when installing and removing shield plates.

The tip of the soldering iron should have a C-cut shape or a

driver shape so that it can contact the circuit board as flat or in

a line as much as possible.

Solder

Use solder with the metal content and composition ratio by

weight given in the table below. Do not use solders which do

not meet these conditions.

Metal content

Composition

ratio by weight

Lead-free solder is available for purchase as a service tool.

Use the following part number when ordering:

Part name: Lead-free solder with resin (0.5 mm dia., 500 g)

Part number: VJ8-0270

Tin (Sn) Silver (Ag)

96.5 %

3.0 %

Copper (Cu)

0.5 %

– 2 –

Page 3

OUTLINE OF CIRCUIT DESCRIPTION

1-1. CMOS CIRCUIT DESCRIPTION

1. IC Configuration

The CMOS peripheral circuit block basically consists of the

following ICs.

IC911 (IMX039LQR) CMOS imager

H driver, V driver, serial communication circuit built-in

CDS/PGA built-in Gain + 18 dB (step pitch 0.1 dB)

10 bit/12 bit A/D converter built-in

2. IC911 (CMOS)

[Structure]

The electric charges which are generated when each pixel is

optically converted are in turn converted into signal voltages

by the FD amplifier, and they are then transmitted by the builtin H driver and V driver. The signals are sampled and amplified by the CDS and PGA circuits at the point they are output,

and then they are AD converted and output. The output uses

the LVDS interface.

CMOS image sensor

Image size: diagonal 7.63 mm (1/2.3 type)

Pixels in total:

3632 (H) x 2832 (V) approx. 10.29 million pixels

Effective pixels:

-when using 1/2.3 type approx 9.29 million pixels:

3528 (H) x 2632 (V) approx. 9.29 million pixels

-when using 1/2.5 type approx 8.30 million pixels:

3336 (H) x 2488 (V) approx. 8.30 million pixels

-when using 1/2.9 type approx 5.56 million pixels:

3144 (H) x 1768 (V) approx. 5.56 million pixels

-when using 1/4.1 type approx 2.89 million pixels:

2160 (H) x 1336 (V) approx. 2.89 million pixels

Unit cell size: 1.75 µm (H) x 1.75 µm (V)

Optical black:

Horizontal (H) direction: Front 48 pixels, Rear 0 pixel

Vertical (V) direction: Front 4 pixels, Rear 0 pixel

– 3 –

Page 4

1-2. CP1 and VF1 CIRCUIT DESCRIPTION

1. Circuit Description

1-1. Digital clamp

The optical black section extracts averaged values from the

subsequent data to make the black level of the sensor output

data uniform for each line. The optical black section averaged

value for each line is taken as the sum of the value for the

previous line multiplied by the coefficient k and the value for

the current line multiplied by the coefficient k-1.

1-2. Signal processor

1. γ correction circuit

This circuit performs (gamma) correction in order to maintain

a linear relationship between the light input to the camera and

the light output from the picture screen.

2. Color generation circuit

This circuit converts the image sensor into RGB signals.

3. Matrix circuit

This circuit generates the Y signals, R-Y signals and B-Y signals from the RGB signals.

4. Horizontal and vertical aperture circuit

This circuit is used gemerate the aperture signal.

1-3. AE/AWB and AF computing circuit

The AE/AWB carries out computation based on a 64-segment

screen, and the AF carries out computations based on a 6segment screen.

1-4. SDRAM controller

This circuit outputs address, RAS, CAS and CLOCK data for

controlling the SDRAM. It also refreshes the SDRAM.

1-5. Communication control

1. SIO

This is the interface for the 8-bit microprocessor.

2. PIO/PWM/SIO for LCD

8-bit parallel input and output makes it possible to switch between individual input/output and PWM input/output.

2. Outline of Operation

When the shutter opens, the reset signals (ASIC and CPU)

and the serial signals (“take a picture” commands) from the 8bit microprocessor are input and operation starts. When the

TG/SG drives the image sensor, picture data is converted internally into a small-amplitude actuating signal, and is then

input to ASIC. The data that is input to the ASIC is input to the

SDRAM through digital clamp.

The AF, AE, AWB, shutter, and AGC value are computed from

this data, and obtain the optimum picture. The data which has

already been stored in the SDRAM is read by the CPU and

color generation is carried out. Each pixel is interpolated from

the surrounding data as being either R, G, and B primary color

data to produce R, G and B data. At this time, correction of the

lens distortion which is a characteristic of wide-angle lenses is

carried out. After AWB and γ processing are carried out, a matrix

is generated and aperture correction is carried out for the Y

signal, and the data is then compressed by JPEG and is then

written to card memory (SD card).

When played back on the LCD and monitor, data is transferred

from memery to the SDRAM, and the image is then elongated

so that it is displayed over the SDRAM display area.

3. LCD Block

The LCD display circuit is located on the CP1 board, and

consists of components such as a power circuit.

The signals from the ASIC are 8-bit digital signals, that is

input to the LCD directly. The 8-bit digital signals are converted to RGB signals inside the LCD driver circuit . This LCD

has a 3-wire serial, and functions such as the brightness and

image quality are controlled.

Because the LCD closes more as the difference in potential

between the VCOM (common polar voltage: AC) and the R,

G and B signals becomes greater, the display becomes darker;

if the difference in potential is smaller, the element opens and

the LCD become brighter.

In addition, the timing pulses for signals other than the video

signals are also input from the ASIC directory to the LCD.

1-6. TG/SG

Timing generated for image sensor control.

1-7. Digital encorder

It generates chroma signal from color difference signal.

– 4 –

Page 5

4. Lens drive block

4-1. Focus drive

The 16-bit serial data signals (LENS_SDI) and (LENS_SCLK

and LENS_EN) which are output from the ASIC (IC101) are

used to drive (FOCUS A +, FOCUS A -, FOCUS B + and FOCUS B -) by the motor driver IC (IC951), and are then used to

microstep-drive the stepping motor for focusing operation. Detection of the standard focusing positions is carried out by

means of the photointerruptor (F_SENSE) inside the lens block.

4-2. Zoom drive

The 16-bit serial data signals (LENS_SDI) and (LENS_SCLK

and LENS_EN) which are output from the ASIC (IC101) are

used to drive (ZOOM A +, ZOOM A -, ZOOM B + and ZOOM B

-) by the motor driver IC (IC951), and are then used to

microstep-drive the stepping motor for zooming operation. Detection of the standard zooming positions is carried out by

means of the photointerruptor (F_SENSE) inside the lens block.

4-3. ND filter

The 16-bit serial data signals (LENS_SDI) and (LENS_SCLK

and LENS_EN) which are output from the ASIC (IC101) are

used to drive (ND + and ND –) by the motor driver IC (IC951),

and then the ND filter is inserted into and removed from the

beam path.

4-3. Iris drive

The drive method is a galvanometer type without braking coil.

The output from the Hall sensor inside the lens is amplified by

the Hall amplifier circuit inside the IC951 lens drive IC, and the

difference between the current and target aperture determined

by the resulting output and the exposure amout (16 bit serial

signal (LENS_SDI) and (LENS_SCLK and LENS_EN)) output

from the ASIC (IC101) is input to the servo amplifier circuit

(IC951) to keep the aperture automatically controlled (DRIVE+

and DRIVE -) to the target aperture.

5. Video Clip Recording and Playback

5-1. Recording

The signal from the camera block is input to IC101 (ASIC). The

data that is input to the ASIC is input to SDRAM, and converts

this data to encoded MPEG4 data, after which it is written in

sequence onto the SD card as streaming data. At this time,

the audio signals that are input to the built-in microphone are

converted into digital data by the audio CODEC IC of IC182,

and they are then input to ASIC. The audio data is then encoded (AAC), and then it is written in sequence onto the SD

card together as streaming data with the image signals described above.

5-2. Playback

The data is read from the SD card, and the encoded data is

decoded into image data where it is displayed by the LCD or

on a TV monitor. At the same time, the audio data is also decoded, and is input to IC182 as digital data. D/A conversion is

carried out at IC182, and the sound is then output to the speaker

or to the LINE OUT terminal or the headphone.

6. Audio CODEC Circuit (IC182)

The audio signals from the microphone are converted into 16bit digital data. AD conversion is carried out at a maximum

sampling frequency of 48 kHz.

During audio playback, the 16-bit digital data is converted into

analog signals and these drive headphone through the speaker

or line out system and headphone amplifier. DA conversion is

carried out at a maximum sampling frequency of 48 kHz.

4-4. Shutter drive

Reverse voltage is applied to the above aperture drive coil to

operate the shutter. When the shutter operates, the SHUTTER

+ signal that is output from the ASIC (IC101) becomes high

(input to SHUTTER of IC951) and the shutter operates.

– 5 –

Page 6

1-3. PWA POWER CIRCUIT DESCRIPTION

1. Outline

This is the main power circuit, and is comprised of the following blocks.

Switching controller (IC501)

Digital 3.25 V power output (L5002)

Digital 1.8 V power output (L5003)

Digital 1.2 V power output (IC502, L5004)

LCD backlight system power output (Q5007, L5007)

Motor system 5.0 V power output (L5301)

CMOS digital 1.8 V power output (IC503, L5006)

Charge circuit (IC521)

2. Switching Controller (IC501)

This is the basic circuit which is necessary for controlling the

power supply for a PWM-type switching regulator, and is provided with seven built-in channels, only CH1 (motor system),

CH2 (digital 3.25 V), CH3 (digital 1.8 V) and CH7 (LCD backlight) are used.

Feedback from BOOST 5 V (CH1), VDD3 (CH2), VDD1.8

(CH3) and LCD backlight system (CH7) are received, and

the PWM duty is varied so that each one is maintained at the

correct voltage setting level.

Feedback for the backlight power (CH7) is provided to the

both ends voltage of registance so that regular current can

be controlled to be current that was setting.

2-1. Short-circuit protection circuit

If output is short-circuited for the length of time determined

by the condenser which is connected to Pin (A6) of IC501, all

output is turned off. To reset, momentarily set the control signal (P ON) to repeat control.

3. Digital 3.25 V Power Output

VDD3 is output. Feedback for the VDD3 is provided to the

swiching controller (Pin (F3) of IC501) so that PWM control

can be carried out.

4. Digital 1.8 V Power Output

VDD 1.8 is output. Feedback for the VDD 1.8 is provided to

the switching controller (Pin (C3) of IC501) so that PWM control to be carried out.

5. Digital 1.2 V Power Output

VDD 1.2 is output. Feedback for the VDD 1.2 is provided to

the switching controller (Pin (11) of IC502) so that PWM control to be carried out.

6. LCD Backlight Power Supply output

Regular current (15 mA) is being transmitted to LED for LCD

backlight. Feedback for the both ends voltage of registance

that is being positioned to in series LED are provided to the

switching controller (Pin (C4) of IC501) so that PWM control

to be carried out.

7. Motor System 5.0 V Power Output

BOOST 5 V is output. Feedback for the BOOST 5 V is provided to the (Pin (B7) of IC501) so that PWM control to be

carried out.

8. CMOS Digital 1.8 V Power Output

+1.8 V (D) is output.

9. Camera Charging Circuit

If the camera’s power is turned off, power save mode and

sleep mode setting while it is connected to the AC adaptor,

the battery will be recharged. In the above condition, a CTL

signal is sent from the microprocessor and recharging starts.

– 6 –

Page 7

1-4. ST1 STROBE CIRCUIT DESCRIPTION

1. Charging Circuit

When UNREG power is supplied to the charge circuit and the

CHG signal from microprocessor becomes High (3.3 V), the

charging circuit starts operating and the main electorolytic

capacitor is charged with high-voltage direct current.

However, when the CHG signal is Low (0 V), the charging

circuit does not operate.

1-1. Charge switch

When the CHG signal switches to Hi, IC541 starts charging

operation.

1-2. Power supply filter

C5401 constitutes the power supply filter. They smooth out

ripples in the current which accompany the switching of the

oscillation transformer.

1-3. Oscillation circuit

This circuit generates an AC voltage (pulse) in order to increase the UNREG power supply voltage when drops in current occur. This circuit generates a drive pulse with a frequency

of approximately 200-300 kHz, and drive the oscillation transformer.

2. Light Emission Circuit

When FLCTL signal is input from the ASIC, the stroboscope

emits light.

2-1. Emission control circuit

When the FLCLT signal is input to the emission control circuit, Q5402 switches on and preparation is made to the light

emitting. Moreover, when a FLCLT signal becomes Lo, the

stroboscope stops emitting light.

2-2. Trigger circuit

The Q5402 is turned ON by the FLCLT signal and light emission preparation is preformed. Simultaneously, high voltage

pulses of several kV are emitted from the trigger coil and applied to the light emitter.

2-3. Light emitting element

When the high-voltage pulse form the trigger circuit is applied to the light emitting part, currnet flows to the light emitting element and light is emitted.

Beware of electric shocks.

1-4. Oscillation transformer

The low-voltage alternating current which is generated by the

oscillation control circuit is converted to a high-voltage alternating current by the oscillation transformer.

1-5. Rectifier circuit

The high-voltage alternating current which is generated at

the secondary side of T5401 is rectified to produce a highvoltage direct current and is accumulated at electrolytic capacitor C5412.

1-6. Charge monitoring circuit

The functions programmed in the IC541 monitor oscillations

and estimate the charging voltage. If the voltage exceeds the

rated value, charging automatically stops. Then, the

ZCHG_DONE signal is changed to Lo output and a "charging

stopped" signal is sent to the microcomputer.

– 7 –

Page 8

1-5. SYA CIRCUIT DESCRIPTION

1. Configuration and Functions

For the overall configuration of the SYA block, refer to the block diagram. The SYA block centers around a 8-bit microprocessor

(IC301), and controls camera system condition (mode).

The 8-bit microprocessor handles the following functions.

1. Operation key input, 2. Clock control and backup, 3. Power ON/OFF, 4. Storobe charge control

Pin

1

2

3

4

5

6

7

8

9

10

11~14

15

16

17

18

19

20

21 SCAN_IN0

22 PANEL_OPEN

23 KEY 2nd

24

25 NOT USED

26

27

28

29

30 NOT USED

31 P ON

32 NOT USED

33

34

35

36

37

38

39

40

41 HINGE

42~44

45

46

47

Signal

ASIC_SCK

ZCARD

ZBACKUPCTL

CHG_CNT

HOT LINE

GREEN_LED

RED_LED

ST_CHG_ON

VDD2

VSS2

SCAN IN4~1

ZUSB_DET

HDMI_HPD

ZCHG_DONE

TIMEOUT

BAT_UTX

BAT_URX

USB_ON

TGVD

MRST

SW3.2ON

NOT USED

ZBOOT_COMREQ

ERR

VSS3

VDD3

RDSEL

CLK (SFW)

DATA0 (SFW)

DC_IN

SCAN OUT2~0

ZOOM_AD

NOT USED

ZAV_JACK

I/O

O

I

O

O

I

O

O

O

-

-

I

I

I

I

I

O

I

I

I

I

O

O

I

O

O

O

O-

O Digital system power start-up signal

O-

I/O

I

-

-

I

I

I

I

I

O

I

O

I

Serial communication clock output

Card detection

Backup battery charge control

Camera charge permission

Hot line request from ASIC

Switch unit LED (green)

Switch unit LED (red)

Strobo charge control

Power

Power

Keyscan input 4~1

USB power detection terminal

HDMI hot plug detection

Main condensor charge detection

Camera charge done detection

Battery power detection IC UART output

Battery power detection IC UART input

Keyscan input 0

Panel open detection

S2 key input

USB charge control

-

VSYNC monitoring

System reset

SW 3.2 V power control

-

BOOT signal input

Camera charge error detection

Power

Power

Debugger signal

Debugger signal

Debugger signal

DC jack insertion detection

Panel rotation detection

Keyscan output 2~0

Zoom key AD input

-

AV cable detection

Outline

See next page →

– 8 –

Page 9

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

BAT_TMP

BAT_OFF

ZSREQ

KEY_1st

IR_IN

ZRESET

XCIN

XCOUT

VSS1

XIN I

XOUT O -

VDD1

BATTERY

USB_HOST I USB host cable detection

INT_TEMP I

ASIC_SDI O

ASIC_SDO

I

I

I

I

I

I

I

O

-

-

I UNREG voltage detection

I

Table 5-1. 8-bit Microprocessor Port Specification

Battery temperature detection

Battery OFF detection signal input

Serial communication request signal

S1 key input

Remote controller input

Microprocessor reset input

32 k oscillation input

32 k oscillation output

Power

Power

Power

Camera temperature detection

Serial communication data output

Serial communication data input

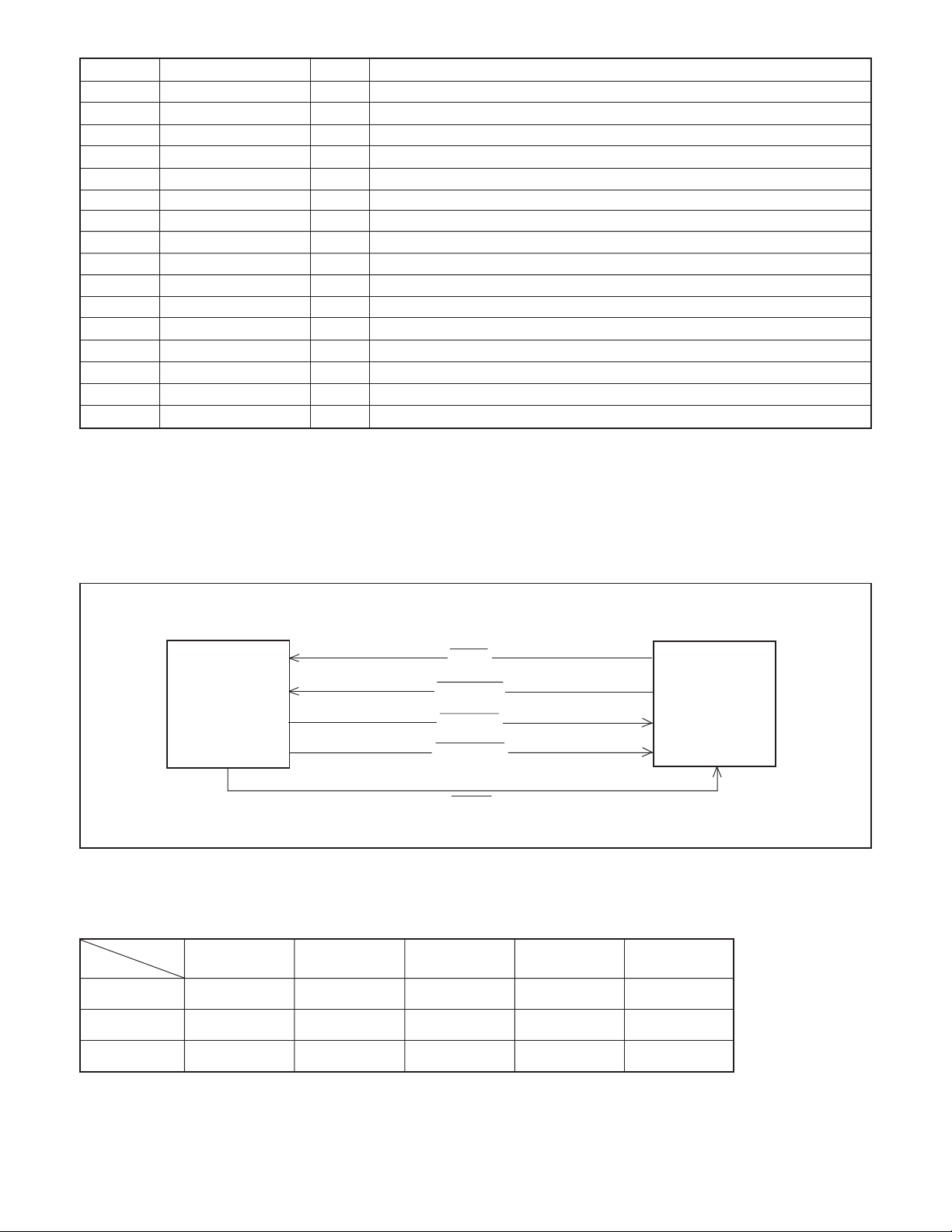

2. Internal Communication Bus

The SYA block carries out overall control of camera operation by detecting the input from the keyboard and the condition of the

camera circuits. The 8-bit microprocessor reads the signals from each sensor element as input data and outputs this data to the

camera circuits (ASIC) or to the LCD display device as operation mode setting data. Fig. 5-1 shows the internal communication

between the 8-bit microprocessor, ASIC and SPARC lite circuits.

SREQ

8-bit

Microprocessor

Fig. 5-1 Internal Bus Communication System

ASIC_SDO

ASIC_SDI

ASIC_SCK

MRST

3. Key Operaiton

For details of the key operation, refer to the instruction manual.

SCAN

SCAN

OUT

IN

0

1

2

0

UP

-

PW_TEST

123

DOWN

VREC

-

Table 5-2. Key Operation

LEFT

PLAY

TEST -

RIGHT

MENU

ASIC

4

SET

POWER

-

– 9 –

Page 10

4. Power Supply Control

The 8-bit microprocessor controls the power supply for the overall system.

The following is a description of how the power supply is turned on and off. When the battery is attached, a regulated 3.2 V

voltage is normally input to the 8-bit microprocessor (IC301) by IC302, so that clock counting and key scanning is carried out

even when the power switch is turned off, so that the camera can start up again. When the battery is removed, the 8-bit microprocessor operates in sleep mode using the backup lithum battery. At this time, the 8-bit microprocessor only carries out clock

counting, and waits in standby for the battery to be attached again. When a switch is operated, the 8-bit microprocessor supplies

power to the system as required.

The PON signal from the 8-bit microprocessor at pin (32) set to high, and then turns on the DC/DC converter. At this time, low

signal is output from pin (18) so that the ASIC is set to the reset condition. After, this pin set to high, and set to active condition.

When the power switch is turned off, the ASIC returns to the reset condition, all DC/DC converters are turned off and the power

supply to the whole system is halted.

ASIC,

memory

Power voltage

Power OFF

Power switch ON-

Auto power OFF

CAMERA

LCD monitor

Playback

Note) 4 MHz = Main clock operation, 32 kHz = Sub clock operation

3.3 V 1.8 V 1.2 V

OFF

OFF

ON

ON

Table 5-3. Camera Mode

CMOS

2.7 V (A) 1.8 V (D)

1.8 V (I/O)

OFF

OFF

ON

OFF

8 bit

CPU

3.2 V

(ALWAYS)

32KHz OFF

32KHz OFF

4 MHz ON

4 MHz ON

MONITOR

LCD

3.3 V

– 10 –

Page 11

MEMO

– 11 –

Page 12

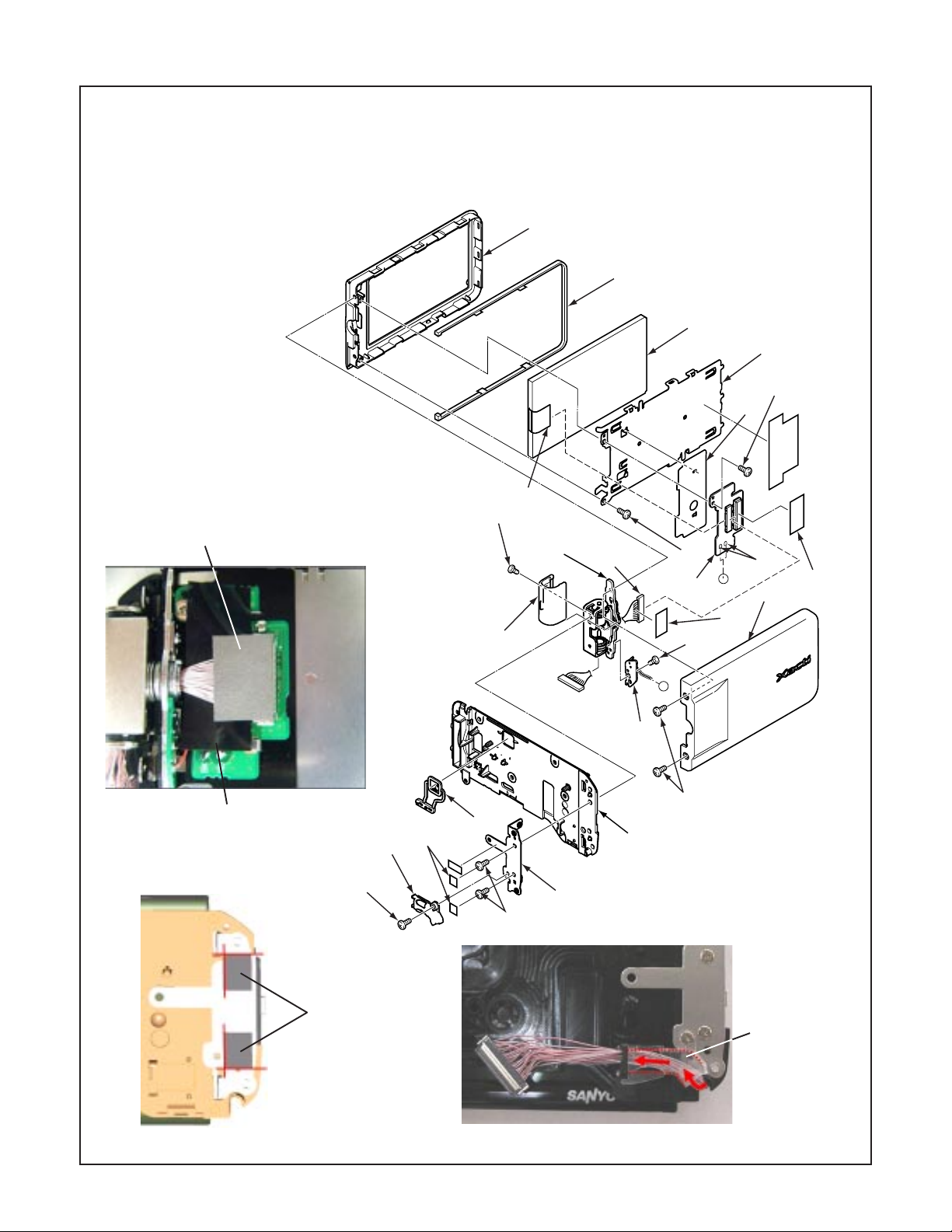

2. DISASSEMBLY

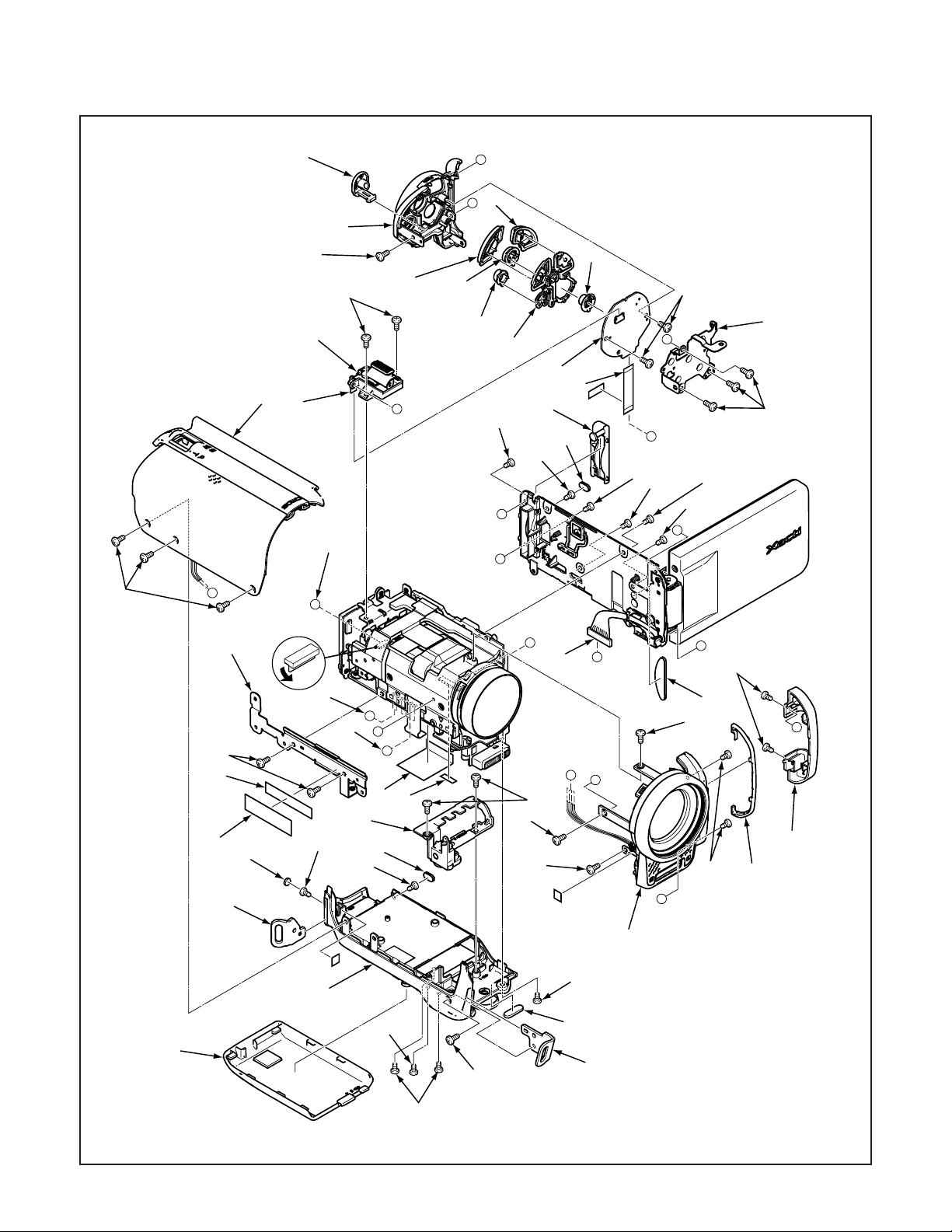

2-1. REMOVAL OF CABINET BOTTOM, CABINET TOP, CABINET BACK, TB4 BOARD AND CABINET FRONT

When assembling,

assemble order.

A → B

When assembling,

assemble order.

A → B

A

7

I

21

28

33

22

34

B

39

A

38

D

41

37

36

When assembling,

tighten the screws order.

a → b → c

31

30

F

b

A

27

B

40

23

32

35

F

26

24

3

J

c

a

29

19

24

56

D

25

J

A

20

57

E

43

42

45

15

46

13

18

14

44

B

17

6

I

47

3

H

B

G

48

16

49

H

a

G

B

54

b

53

c

55

A

9

C

5

4

54

52

51

C

When assembling,

tighten the screws order.

a → b → c

E

50

10

8

1

2

12

When assembling,

assemble order.

A → B

11

9

NOTE: Discharge a strobe capacitor with the

discharge jig (VJ8-0188) for electric shock prevention.

– 12 –

Page 13

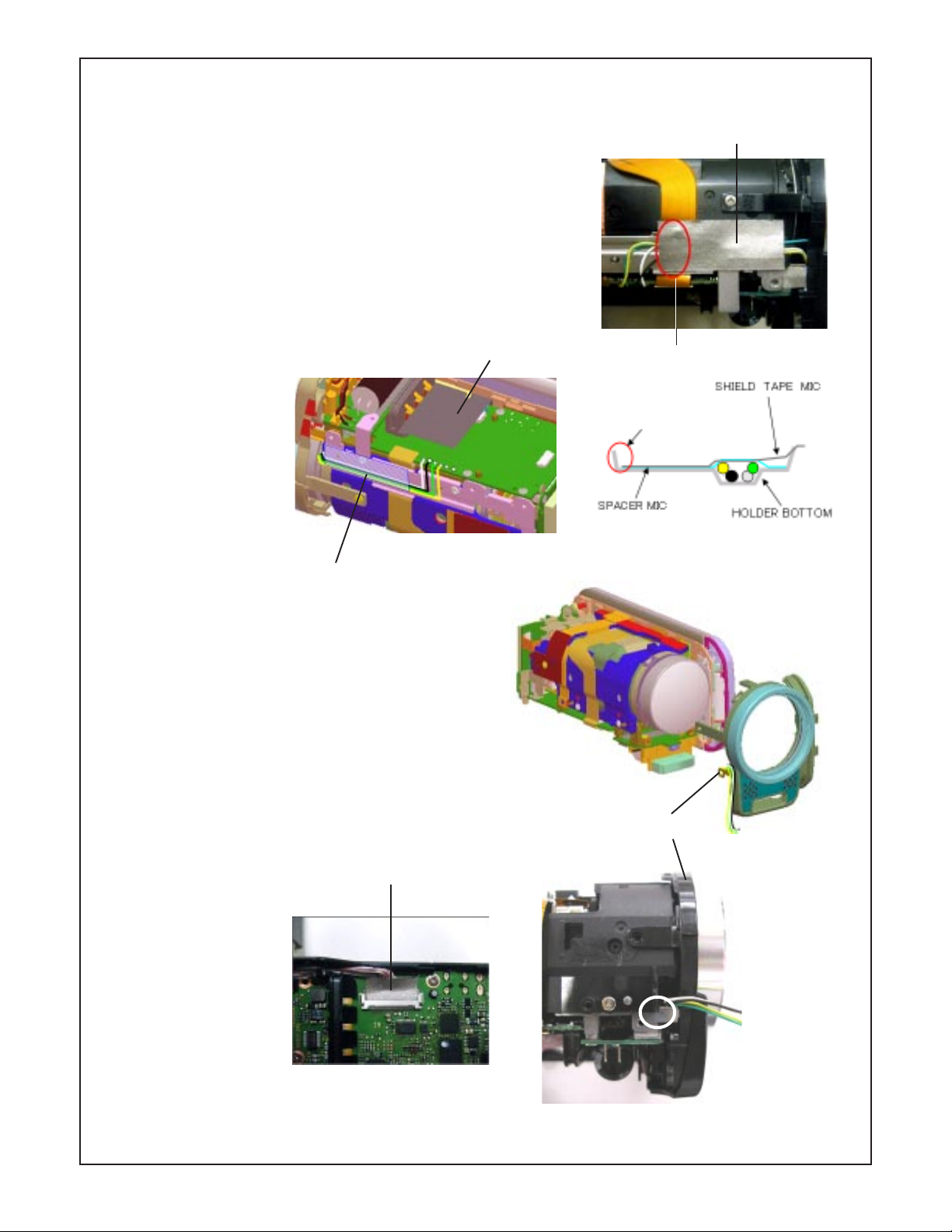

1. Cover battery

2. Spacer bottom

3. Spacer LCD

4. Spacer LCD front

5. Two screws 1.7 x 2

6. Screw 1.7 x 7

7. Three screws 1.7 x 3

8. Screw 1.7 x 3

50. Dec joint

51. Dec line joint

52. Two screws 1.7 x 4

53. Screw 1.7 x 3

54. Two screws 1.7 x 3

55. Compl, cabinet front

56. Screw 1.7 x 3

57. Screw 1.7 x 3

9. Three screws 1.7 x 4

10. Remove the cabi bottom from the main body.

11. Screw 1.7 x 3

12. Holder strap front

13. Spacer blind

14. Screw 1.7 x 3

15. Holder strap back

16. Two screws 1.7 x 4

17. Stand

18. Remove the solder.

19. Screw 1.7 x 3

20. Screw 1.7 x 3

21. Cabinet top

22. Screw 1.7 x 3

23. Two screws 1.7 x 3

43. Spacer mic

24. Two screws 1.7 x 3

25. Flexible pwb CP1 & TB4

26. Cover SD

27. Remove the cabinet back from the main body.

28. Cover DC

29. Three screws 1.7 x 4

30. Holder back

31. Two screws 1.7 x 4

32. TB4 board

33. FPC

34. Unit, zoom

35. Flexible pwb CP1 & TB4

36. Button select

37. Holder button bas

48. Sheild tape LCD CP1

38. Button menu

39. Button rec play

40. Button movie

41. Button shutter

42. Sheild tape mic

43. Spacer mic

44. Remove the solder.

45. Two screws 1.7 x 4

46. Holder bottom

47. Spacer shield wire

48. Sheild tape LCD CP1

49. Connector

47. Spacer shield wire

42. Sheild tape mic

Cross-section drawing

Do not run.

55. Compl, cabinet front

Note:

Do not tuck the

lead wires.

– 13 –

Page 14

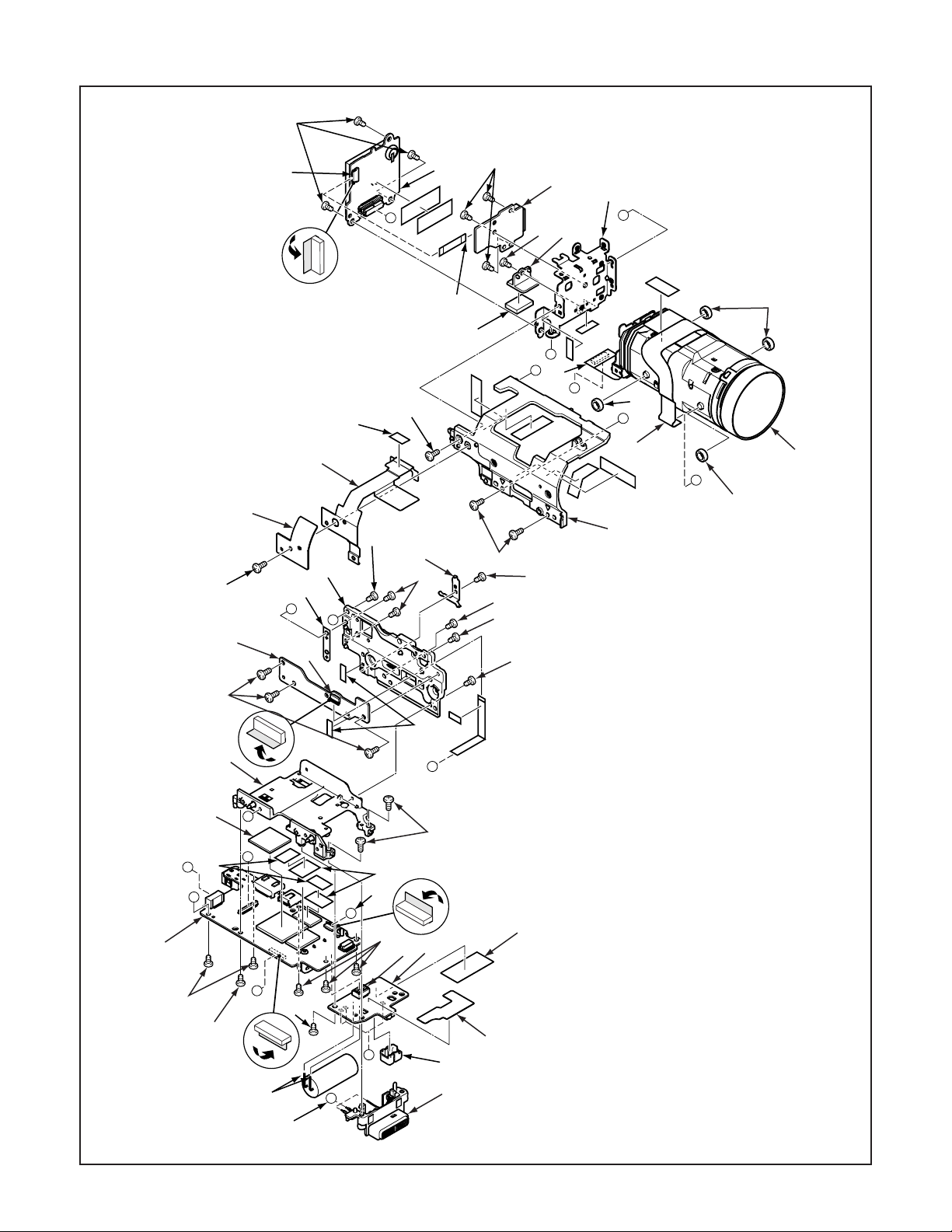

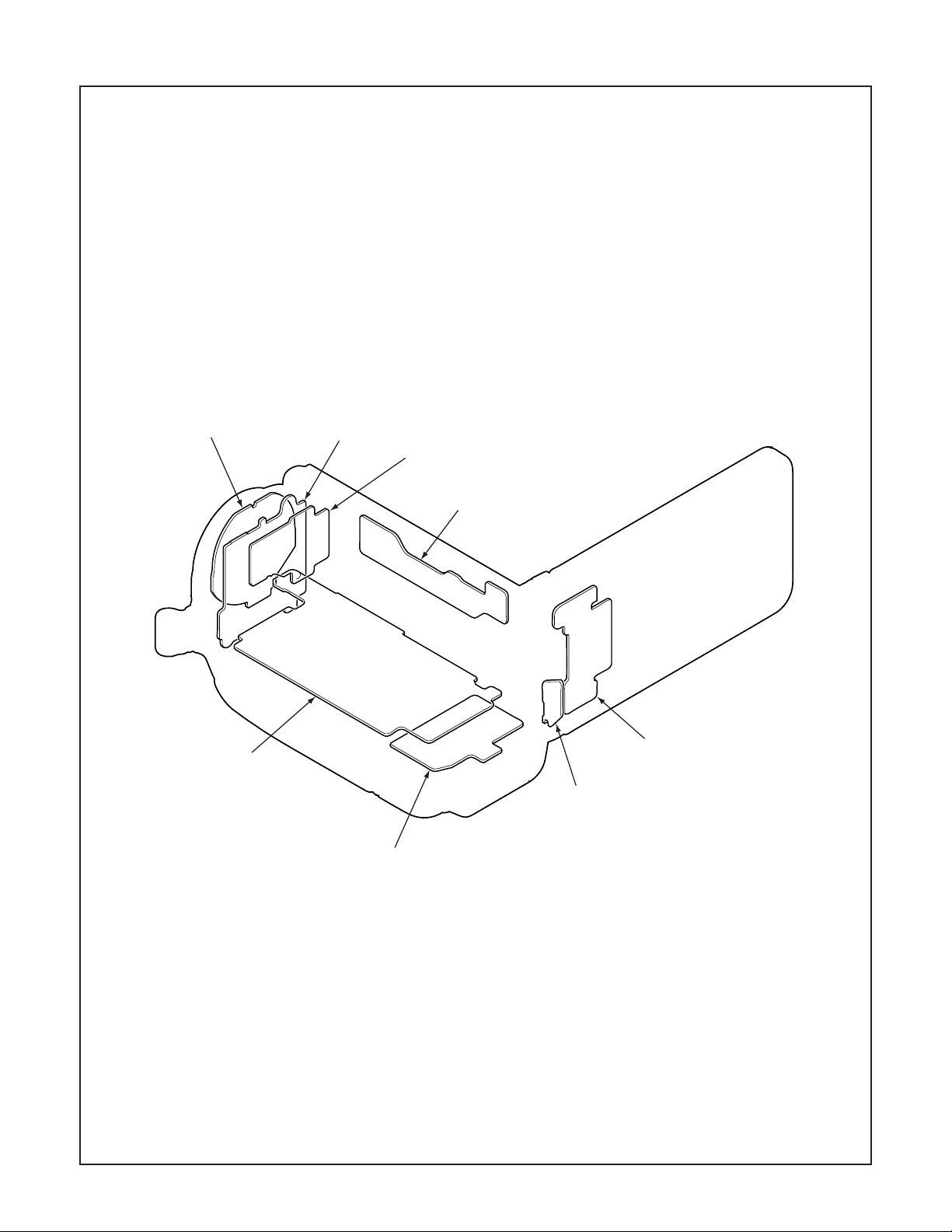

2-2. REMOVAL OF TB1 BOARD, TB5 BOARD, LENS, ST1 BOARD, CP1 BOARD AND TB3 BOARD

When assembling,

tighten the screws order.

a → b → c

When assembling,

tighten the screws order.

A → B

3

2

51

5

7

c

a

b

6

E

10

8

9

19

21

22

A

17

20

C

B

23

H

12

1

4

A

D

15

25

24, 26

F

B

25

16

49

A

38

52

14

46

a

B

18

B

11

45

47

14

a

47

40

13

E

42

C

b

43

39

50

48

When assembling,

tighten the screws order.

37

G

D

a → b

27

H

44

41

G

39

b

F

29

30

36

28

31

34

33

32

I

I

35

– 14 –

Page 15

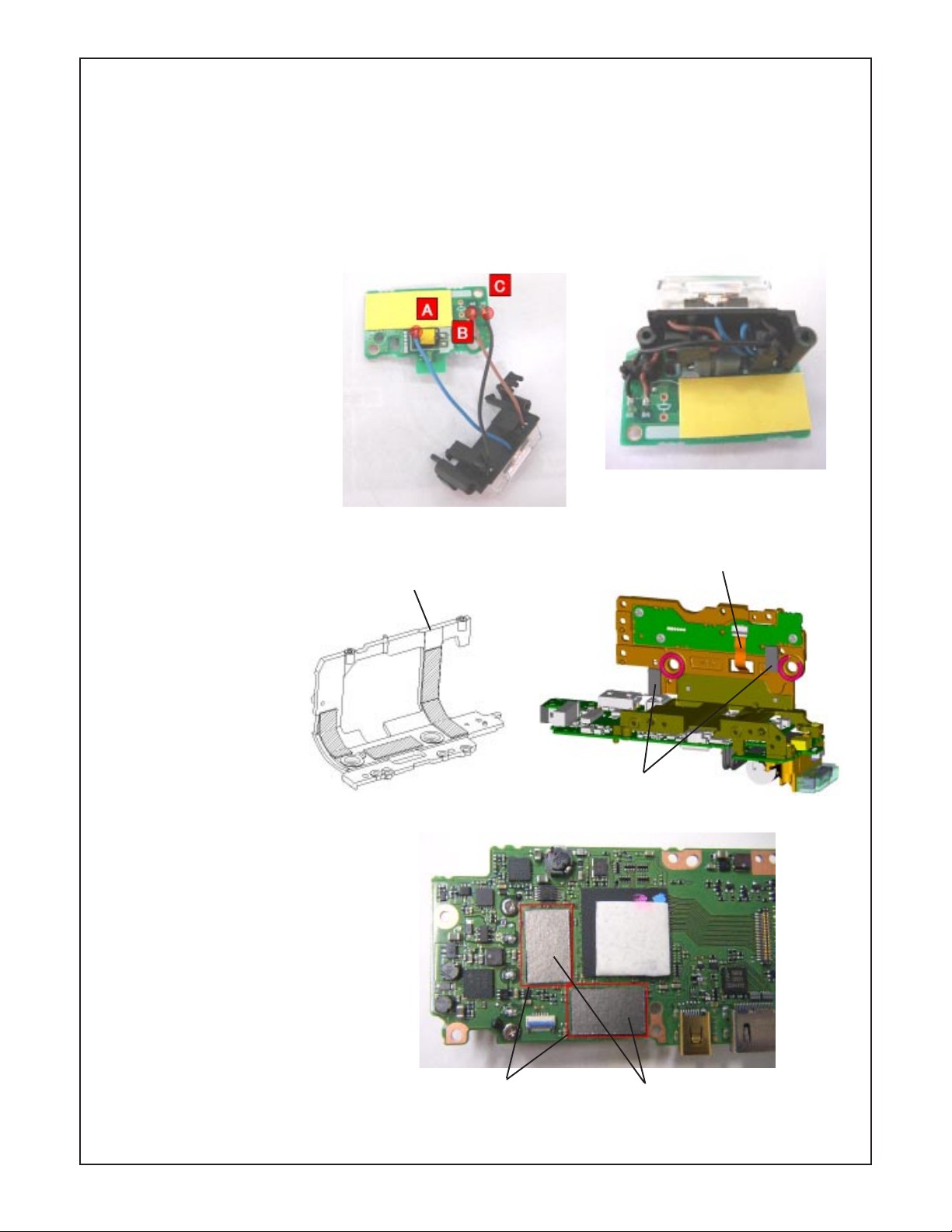

1. Shield tape VF1

2. Screw 1.7 x 3

3. Heat sink left

4. Heat sink tape top

5. Three screws 1.7 x 3

6. TB1 board

7. Flexible pwb TB1 & TB5

8. Three screws 1.7 x 2.5

9. TB5 board

10. Flexible pwb TB1 & TB5

11. Two screws 1.7 x 4

12. Screw 1.7 x 3

13. Two screws 1.7 x 3

14. Two screws 1.7 x 4

15. FPC

16. Holder lens chassis

17. Holder lens

18. Two screws 1.7 x 3

19. Holder TB1

20. Spacer CA

21. Screw 1.7 x 2.5

22. Holder CA

23. Connector

24. Remove the lens part.

25. Holder lens

26. Lens

27. Two screws 1.7 x 7

28. Screw 1.7 x 3

29. Connector

30. ST1 board

31. Spacer ST1

32. Remove the solder.

33. Assy, lamp

34. Cover triger

35. Remove the solder.

36. Spacer con ST1

37. Spacer lens right

38. Flexible pwb CP1 & TB3

39. Four screws 1.7 x 3

40. CP1 board

41. Flexible pwb CP1 & TB3

42. Heat sink rub ASIC

43. Sheild tape DDR

44. Spacer DDR

45. Screw 1.4 x 2

46. Earth jack

47. Two screws 1.7 x 3

48. Chassis bottom

49. Spacer holder TB1

50. Three screws 1.7 x 2.5

51. TB3 board

52. Chassis right

33. Assy lamp soldering order

16. Holder lens chassis

44. Spacer DDR

33. Assy lamp dressing method

38, 41. Flexible pwb CP1 & TB3

37. Spacer lens right

43. Sheild tape DDR

– 15 –

Page 16

2-3. REMOVAL OF TB2 BOARD, VF1 BOARD AND LCD

1. Screw 1.7 x 2

2. Screw 1.7 x 3

3. Holder wire

4. Spacer holder joint

5. Two screws 1.7 x 3

6. Holder joint

7. Cabinet right

8. Button power

9. Cover joint

10. Two screws 1.7 x 3

11. Cover LCD back

12. Dec line A

13. Sheild tape VF1

14. Connector

13. Sheild tape VF1

15. Spacer LCD FPC

16. Remove the solder.

17. Assy, joint

When assembling,

assemble order.

A → B

18. Screw 1.7 x 2

19. TB2 board

20. FPC

26

20

1

17

B

A

9

14

12

21. Two screws 1.7 x 3

22. VF1 board

23. Spacer pwb

24. Holder LCD

25. LCD

26. Cover LCD front

When assembling,

assemble order.

A → B

25

24

21

23

B

A

21

22

16

A

11

13

18

15

15. Spacer LCD FPC

4

3

2

4. Spacer holder joint

A

19

10

8

7

6

5

3. Holder wire

– 16 –

Page 17

2-4. BOARD LOCATION

TB4 board

CP1 board

TB1 board

TB5 board

TB3 board

VF1 board

TB2 board

ST1 board

– 17 –

Page 18

3. ELECTRICAL ADJUSTMENT

Firmware

QrCode

AWB

Focus

UV Matrix

R Bright

RGB Offset

Tint

B Bright

Gain

Phase

LCD

Calibration

Upload

PAF Cal.

LCD Type

H AFC Test

VCOMDC

VCOMPP

Cal Data

Cal Mode

OK

OK

EVF

USB storage

Get

Set

VID

Set

PID

Set

Serial

Set

Rev.

Set

Setting

Language

Video Mode

VCO

Factory Code

Hall Cal.

Backrush pulse :

Set

Get

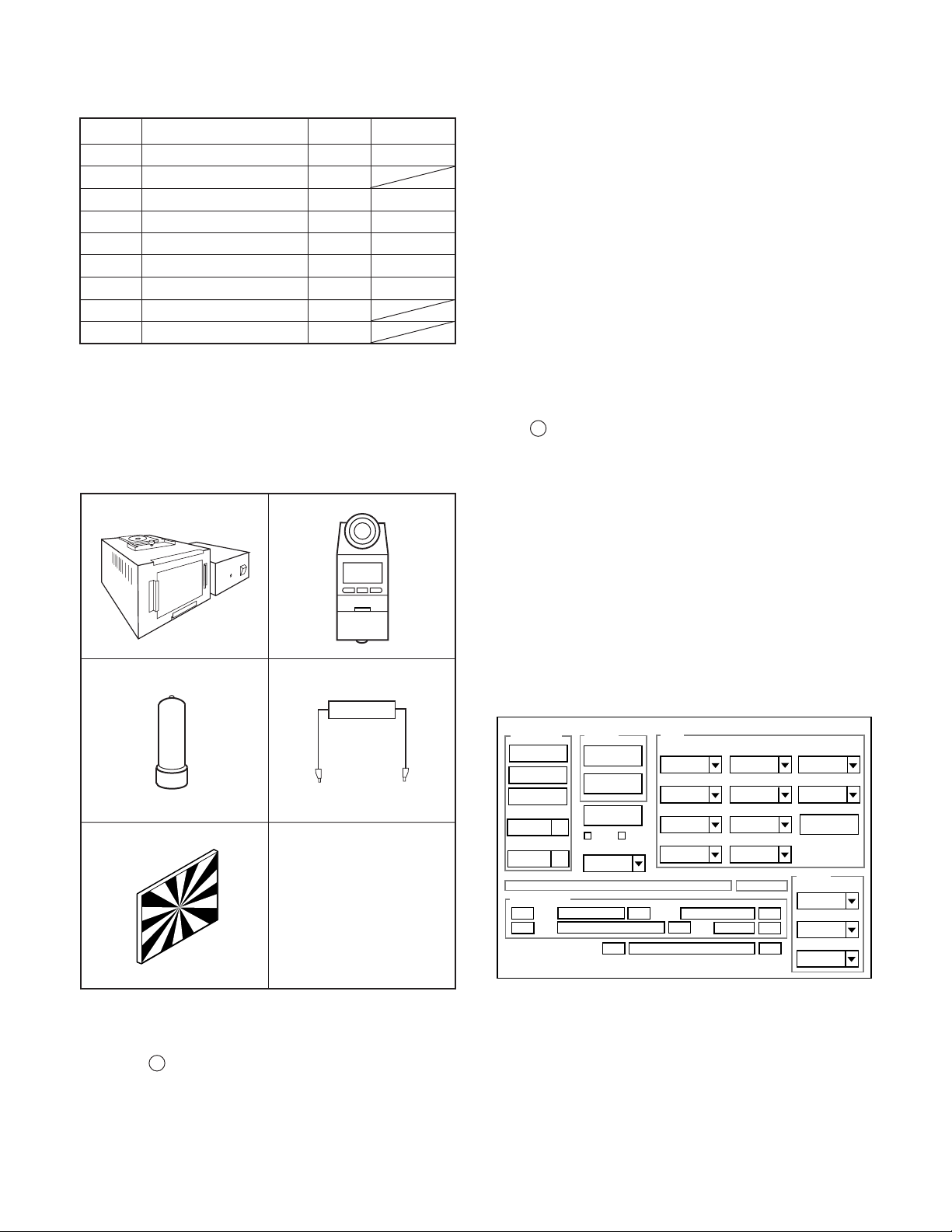

3-1. Table for Servicing Tools

Ref. No.

J-1

J-2

J-3

J-4

J-5

J-6

J-7

J-8

J-9

Name

Pattern box

Calibration software

Chroma meter

Spare lump (pattern box)

Discharge jig

Collimator

Spare lump (collimator)

Siemens star chart

ND2 filter

Number

1

1

1

1

1

1

1

1

1

Part code

VJ8-0190

VJ8-0192

VJ8-0191

VJ8-0188

VJ8-0260

VJ8-0282

3-3. Adjustment Items and Order

1. Lens Adjustment (Barcode Input)

2. Lens Adjustment (Infinity)

3. Lens Adjustment (1m)

4. Mecha Shutter Adjustment

5. WB Adjustment

6. CMOS White Point Defect Detect Adjustment

7. CMOS Black Point And White Point Defect Detect Adjust-

ment In Lighted

Note: If the lens, board and changing the part, it is necessary

to adjust again. Item 1-7 adjustments should be carried out in

sequence.

*Adjustment environment

Temperature: 25 ± 10 degrees, Humidity: 55 ± 25 %

Download the calibration software and the firmware

from the following URL.

http://www.digital-sanyo.com/overseas/service/

Place the DscCalDi.exe file, camapi32.dll file and

QrCodeInfo.dll file together into a folder of your

choice.

J-1 J-3

J-4

J-5

3-4. Setup

1. System requirements

Windows 2000 or XP or Vista

IBM R -compatible PC with pentium processor

USB port

40 MB RAM

Hard disk drive with at least 15 MB available

VGA or SVGA monitor with at least 256-color display

2. Pattern box

Turn on the switch and wait for 30 minutes for aging to take

place before using Color Pure. It is used after adjusting the

chroma meter (VJ8-0192) adjust color temperature to 3100 ±

20 K and luminosity to 900 ± 20 cd/m

the lump and its circumference are high temperature during

use and after power off for a while.

3. Computer screen during adjustment

2

. Be careful of handling

J-8

3-2. Equipment

1. AC adaptor

2. PC (IBM R -compatible PC, Windows 2000 or XP or Vista)

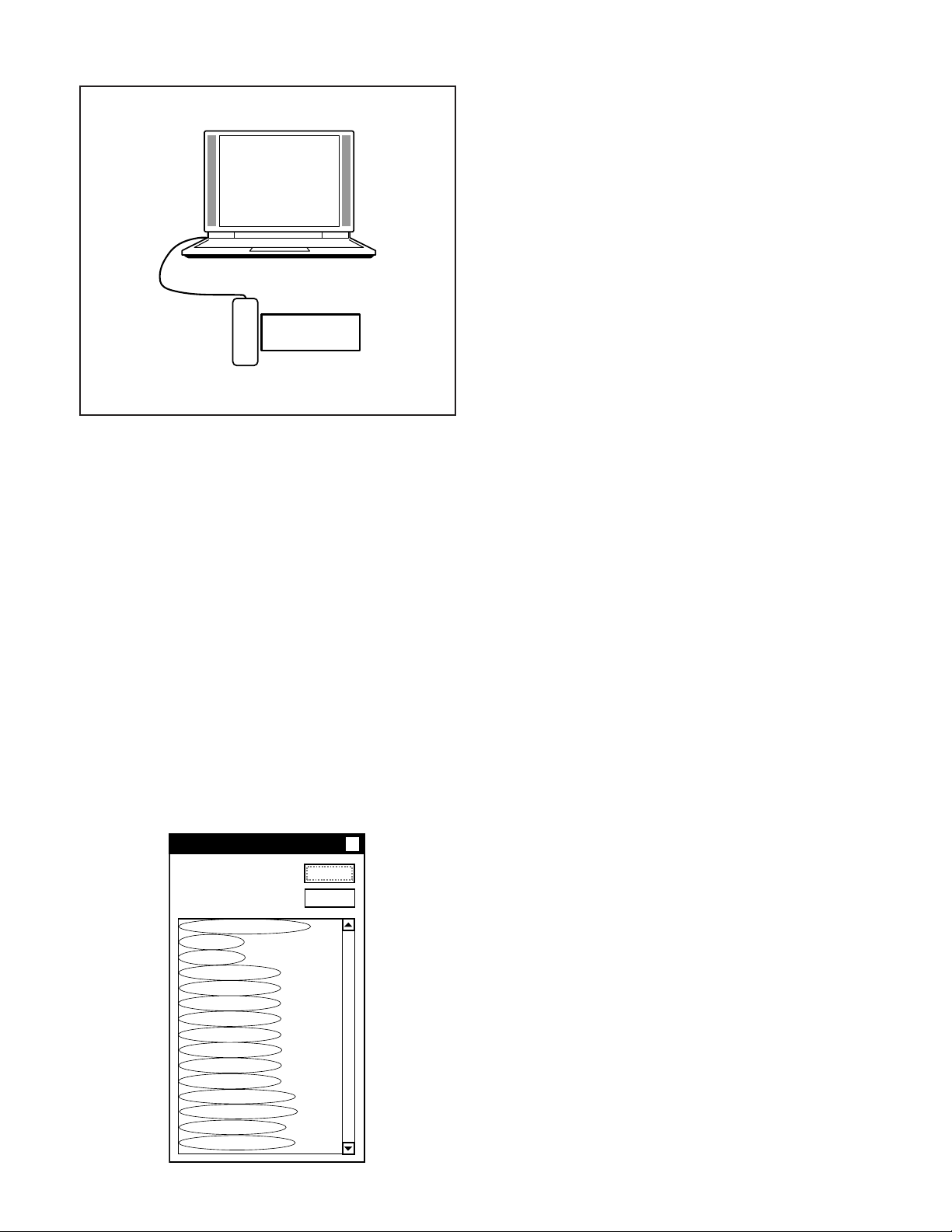

3-5. Connecting the camera to the computer

1. Use the supplied dedicated USB interface cable to connect

the camera to the computer.

2. Turn on the camera.

3. Choose the “COMPUTER”, and press the SET button.

Next, choose the “CARD READER”, and press the SET

button.

– 18 –

Page 19

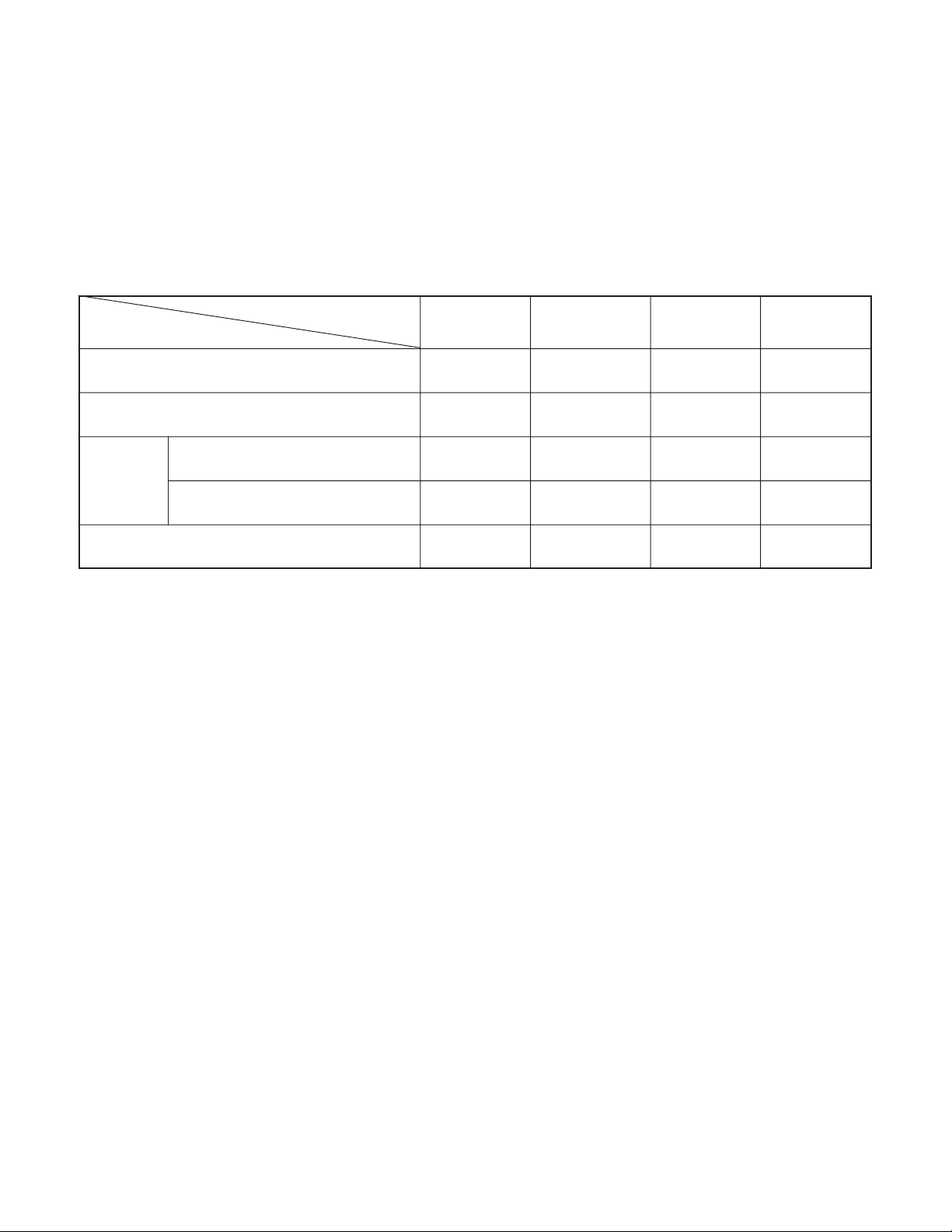

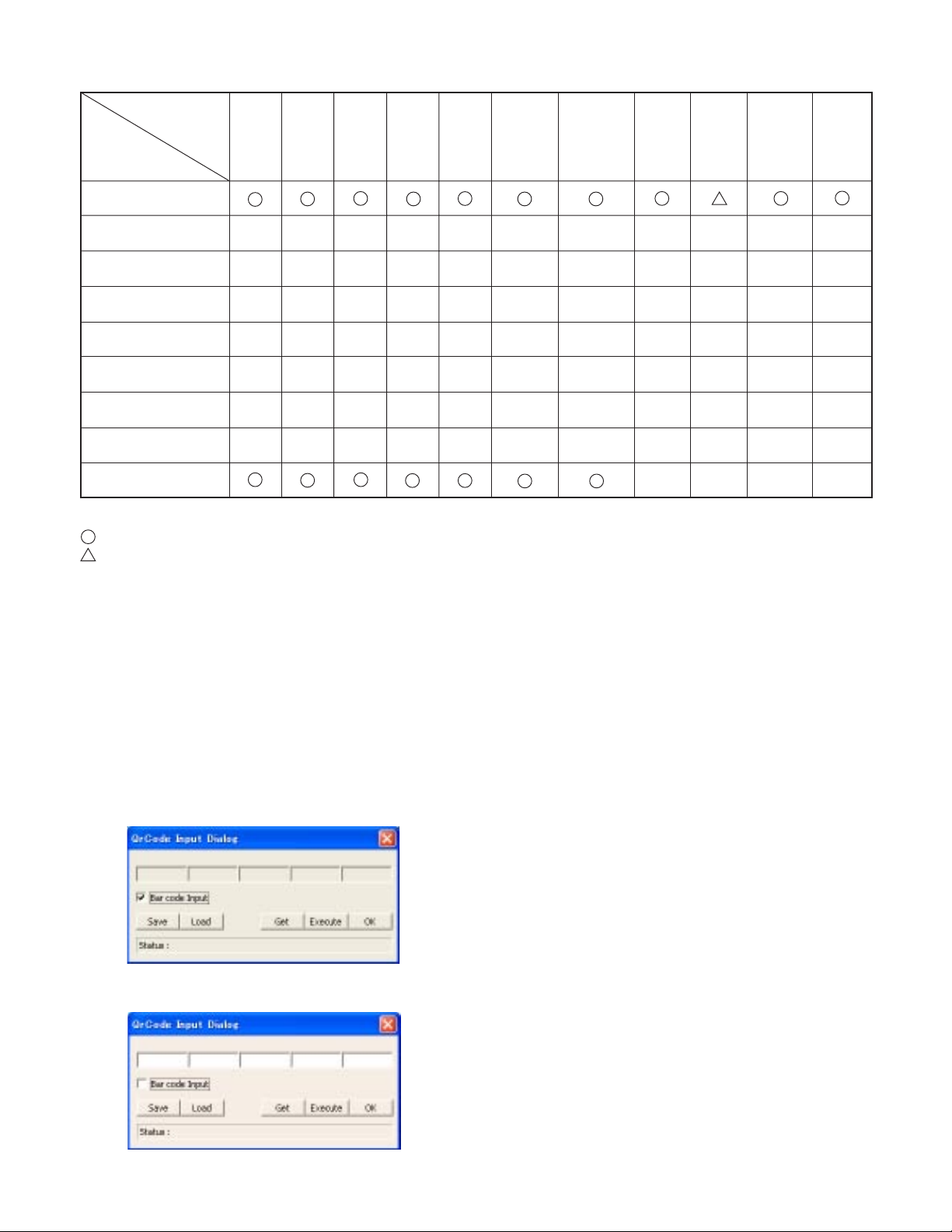

3-6. The adjustment item which in necessary in part exchange

Lens

Adjust-

ment

(Barcode

Input)

Lens

Adjust-

ment

(Infinity)

Lens

Adjust-

ment

(1 m)

Mecha

Shutter

Adjust-

ment

WB

Adjust-

ment

CMOS

White Point

Defect

Detect

Adjustment

CMOS Black

Point And

White Point

Defect Detect

Adjustment

In Lighted

Factory

Cord

Setting

Language

Setting

COMPL PWB CP1

COMPL PWB VF1

COMPL PWB ST1

COMPL PWB TB1

COMPL PWB TB2

COMPL PWB TB3

COMPL PWB TB4

COMPL PWB TB5

ASSY, FLEXIBLE

PWB CA1

: Be sure to carry out the necessary adjustments after replacing the unit.

: Adjustment is possible from the menu setting screen of the camera and by using the calibration software.

USB

storage

information

registration

Reset

Setting

3-7. Updating the firmware

Check the firmware version immediately after the CP1 board has been replaced. If an old version is being used, interference and errors in operation may also occur. If an old version is being used, update it with a newer version.

Refer to

3-8. Adjust Specifications

1. Lens Adjustment (Barcode Input)

Adjustment method:

1. Double-click on the DscCalDi.exe.

2. Click the “QrCode”.

3. QrCode Input Dialog display will be displayed.

4. Deselect Bar code Input.

3-13. Firmware uploading procedure. (Page 24)

5. Enter the alphanumeric characters which are underneath

the bar code which is included with the lens.

6. Click the Execute.

7. Click the OK.

Note: The five input boxes (numbered (1) (2) (3) (4) (5) in

order starting from the left) have the following limits on input.

(1) can only contain numerical input from 0 to 2.

(2) can only contain numerical input from 0 to 2.

(3) can only contain numerical input from 1 to 2.

– 19 –

Page 20

2. Lens Adjustment (Infinity)

Camera

Collimator

Preparation:

POWER switch: ON

If using a ready-made collimator, set to infinity.

Note:

Do not vibrate during the adjustment.

If readjusting after it has already been adjusted, wait for 15

minutes or more for the unit to cool down first.

Adjustment method:

1. Set the camera so that it becomes center of the siemens

star chart in the collimator (zoom wide and tele).

(Set a distance of 0.5-1.0 cm between camera lens and

collimator lens. Do not touch the each lens.)

2. Set the camera so that it becomes center of the screen in

the collimator.

3. Double-click on the DscCalDi.exe.

4. Select “Infinity Cal.” on the LCD “Test”, and click the “Ye s ”.

5. Lens infinity adjustment value will appear on the screen.

6. Click the OK.

3. Lens Adjustment (1m) is carried out after this adjust-

ment.

Dsc Calibration

Infinity calibration :

AF_TEMP_AD_I: 480

PZ_BR: 2

AF_BR: 5

AF_I_WIDE: 69

AF_I_MID1: 257

AF_I_MID2: 126

AF_I_MID3: 213

AF_I_MID4: 203

AF_I_MID5: 187

AF_I_MID6: 121

AF_I_TELE: 195

FLAG_PZ_ADJ: 1

PZ_ADJ_INDEX: 0

IRIS_GAIN: -112

IRIS_OFFSET: -6

x

OK

Copy

Adjustment value determination is effectuated using below values.

The adjustment values fulfill the conditions below, they are determined as within specifications.

Adjustment value determination

AF_TEMP_AD_I: ATADI

ATADI: adjustment value of focus temperature A/D

(250<=ATADI<=893)

PZ_BR: PBR

PBR: adjustment value of zoom backrush pulse

(0<=PBR<=10)

AF_BR: ABR

ABR: adjustment value of focus backrush pulse

(0<=ABR<=10)

AF_I_WIDE: ZIW

ZIW: infinity adjustment value of focus at zoom position

wide (–300<=ZIW<=300)

AF_I_MID1: ZIM1

ZIM1: infinity adjustment value of focus at zoom position

middle1 (–300<=ZIM1<=300)

AF_I_MID2: ZIM2

ZIM2: infinity adjustment value of focus at zoom position

middle2 (–300<=ZIM2<=300)

AF_I_MID3: ZIM3

ZIM3: infinity adjustment value of focus at zoom position

middle3 (–300<=ZIM3<=300)

AF_I_MID4: ZIM4

ZIM4: infinity adjustment value of focus at zoom position

middle4 (–300<=ZIM4<=300)

AF_I_MID5: ZIM5

ZIM5: infinity adjustment value of focus at zoom position

middle5 (–300<=ZIM5<=300)

AF_I_MID6: ZIM6

ZIM6: infinity adjustment value of focus at zoom position

middle6 (–300<=ZIM6<=300)

AF_I_TELE: ZIT

ZIT: infinity adjustment value of focus at zoom position

tele (–250<=ZIT<=300)

FLAG_PZ_ADJ: FPZ

FPZ: flag of zoom barcode adjustment

(FPZ=1)

PZ_ADJ_INDEX: PZI

PZI: index of zoom barcode adjustment

(0<=PZI<=2)

IRIS_GAIN: g

g: adjustment value of gain (-128<=g<=127)

IRIS_OFFSET: o

o: adjustment value of offset (-128<=o<=127)

– 20 –

Page 21

3. Lens Adjustment (1m)

Camera

Preparation:

POWER switch: ON

Adjustment condition:

Siemens star chart (A3)

Fluorescent light illumination with no flicker

Illumination above the subject should be 700 lux ± 10%.

Note:

Do not vibrate during the adjustment.

If readjusting after it has already been adjusted, wait for 15

minutes or more for the unit to cool down first.

Adjustment method:

1. Set the siemens star chart 100 ± 0.5 cm from lens surface

so that it becomes center of the screen (zoom wide and

tele). Set the camera and the chart in a straight, and do not

put optical systems (mirror and conversion lens etc.)

2. Double-click on the DscCalDi.exe.

3. Click the “Focus”, and Click the “Yes ”.

4. Lens adjustment value will appear on the screen.

5. Click the OK.

100 0.5 cm

Siemens

star chart

Adjustment value determination

AF_TEMP_AD: ATAD

ATAD: adjustment value of focus temperature A/D

(250<=ATAD<=893)

AF_WIDE: ZW

ZW: adjustment value of focus at zoom position wide

(–300<=ZW<=300)

AF_MID1: ZM1

ZM1: adjustment value of focus at zoom position middle1

(–300<=ZM1<=300)

AF_MID2: ZM2

ZM2: adjustment value of focus at zoom position middle2

(–300<=ZM2<=300)

AF_MID3: ZM3

ZM3: adjustment value of focus at zoom position middle3

(–300<=ZM3<=300)

AF_MID4: ZM4

ZM4: adjustment value of focus at zoom position middle4

(–300<=ZM4<=300)

AF_MID5: ZM5

ZM5: adjustment value of focus at zoom position middle5

(–300<=ZM5<=300)

AF_MID6: ZM6

ZM6: adjustment value of focus at zoom position middle6

(–300<=ZM6<=300)

AF_TELE: ZT

ZT: adjustment value of focus at zoom position tele

(–250<=ZT<=300)

4. Mecha Shutter Adjustment

DscCalDi

Focus Result

x

!

AF_TEMP_AD: 453

AF_WIDE: 60

AF_MID1: -19

AF_MID2: -99

AF_MID3: -284

AF_MID4: -105

AF_MID5: -189

AF_MID6: -254

AF_TELE: 102

OK

Adjustment value determination is effectuated using below values.

The adjustment values fulfill the conditions below, they are determined as within specifications.

Camera

ND2 filter

Pattern box

(color viewer)

Preparation:

POWER switch: ON

Setting of pattern box:

Color temperature: 3100 ± 20 (K)

Luminance: 900 ± 20 (cd/m

2

)

Adjusting method:

1. Set a distance of 0.5-1.0 cm between the pattern box and

the camera. (Do not enter any light.)

2. Insert the ND2 filter between the camera lens and the pattern box.

– 21 –

Page 22

3. Double-click on the DscCalDi.exe.

4. Input “32” in the Cal Mode, and click Ok at the right side.

5. Click the OK.

6. Input “30” in the Cal Mode, and click Ok at the right side.

7. Click the OK.

5. WB Adjustment

Dsc Calibration

Cal Mode Results :

IRIS_LG: 12535

IRIS_LG_R1: 701

IRIS_LG_R2: 982

IR_TEMP_AD=345

IRIS_PWM1=200,166

IRIS_PWM2=143,119

IRIS_PWM3=108,98

IRIS_PWM4=89,82

IRIS_PWM5=77,72

IRIS_PWM6=68,65

OK

Copy

x

Dsc Calibration

Cal Mode Results :

MS=4580,100

MS_M=3706,3349

MS_C=2796,800

MS_C2=700,500

MS_C3=450,400

MS_C4=300,200

x

OK

Copy

Adjustment value determination is effectuated using the "MS",

“MS_M” , “ MS_C” , “MS_C2” , “ MS_C3” , “ MS_C4” ,

“IRIS_PWM1”, “IRIS_PWM2”, “IRIS_PWM3”, “IRIS_PWM4”,

“IRIS_PWM5” , “ IRIS_PWM6” , “ IR_TEMP_AD” and

“IRIS_LG_R2” values. If

MS = ms1, ms2

MS_M = ms3, ms4

MS_C = ms5, ms6

MS_C2 = ms7, ms8

MS_C3 = ms9, ms10

MS_C4 = ms11, ms12

IRIS_PWM1 = s1, s2

IRIS_PWM2 = s3, s4

IRIS_PWM3 = s5, s6

IRIS_PWM4 = s7, s8

IRIS_PWM5 = s9, s10

IRIS_PWM6 = s11, s12

IR_TEMP_AD = itad

IRIS_LG_R2 = iris_lg2

the adjustment values fulfill the conditions below, they are

determined as within specifications.

Adjustment value determination

2000<=ms1<=6500, 100<=ms2<=4100,

1800<=ms3<=5800, 1500<=ms4<=5500,

1000<=ms5<=5000, 800<=ms6<=4800,

700<=ms7<=4700, 500<=ms8<=4500,

450<=ms9<=4450, 400<=ms10<=4400,

300<=ms11<=4300, 200<=ms12<=4200

0<=s1<=255, 0<=s2<=255, 0<=s3<=255, 0<=s4<=255,

0<=s5<=255, 0<=s6<=255, 0<=s7<=255, 0<=s8<=255,

0<=s9<=255, 0<=s10<=255, 0<=s11<=255, 0<=s12<=255

ms2<ms12<ms11<ms10<ms9<ms8<ms7<ms6<ms5<ms4<ms3<ms1

s1>s2>s3>s4>s5>s6>s7>s8>s9>s10>s11>s12

250<=itad<=893

900<=iris_lg2<=1100

Adjustment values other than the above are irrelevant.

Camera

Pattern box

(color viewer)

Preparation:

POWER switch: ON

Setting of pattern box:

Color temperature: 3100 ± 20 (K)

Luminance: 900 ± 20 (cd/m

2

)

Adjusting method:

1. Set a distance of 0.5-1.0 cm between the pattern box and

the camera. (Do not enter any light.)

2. Double-click on the DscCalDi.exe.

3. Input “22” in the Cal Mode, and click Ok at the right side.

4. Click the OK.

5. Input “25” in the Cal Mode, and click Ok at the right side.

6. Click the OK.

Dsc Calibration

OK

Copy

Cal Mode Results:

WB=342,522,623

CHECK=129,127,127

Dsc Calibration

x

Cal Mode Results:

WB_ND=0,0,0

FLAG_FS_ADJ=17

CHECK_ND=129,129,0

Adjustment value determination is effectuated using the

“CHECK" and “CHECK_ND” values. If

CHECK= wc0, wc1, wc2

CHECK_ND= wnc0, wnc1, wnc2

the adjustment values fulfill the conditions below, they are determined as within specifications.

– 22 –

x

OK

Copy

Page 23

Adjustment value determination

wc0=128 ± 2, wc1=128 ± 2, wc2<=255

wnc0=128 ± 2, wnc1=128 ± 2, wnc2<=255

Adjustment values other than the above are irrelevant.

6. CMOS White Point Defect Detect Adjustment

Preparation:

POWER switch: ON

Adjustment method:

1. Double-click on the DscCalDi.exe.

2. Select “CCD Defect” on the LCD “Test”, and click the “Ye s ”.

3. After the adjustment is completed, OK will display.

4. Click the OK.

7. CMOS Black Point And White Point Defect Detect

Adjustment In Lighted

3-9. Factory Code Setting

1. Check the "Factory Code" display within the Setting group.

2. For U.S.A., Canada and NTSC general area

If "FC_SANYO_U" does not appear, click on the " " mark

located on the right of the "Factory Code" display BOX and

select "FC_SANYO_U".

3. For Europe and PAL general area

If "FC_SANYO_EX" does not appear, click on the " " mark

located on the right of the "Factory Code" display BOX and

select "FC_SANYO_EX".

3-10. Language Setting

1. Click on the " " mark located on the right of the

"Language" display BOX.

2. Select language. (Default is English.)

3. End "DscCal" and remove the camera before turning the

camera power OFF.

Camera

Pattern box

(color viewer)

Preparation:

POWER switch: ON

Setting of pattern box:

Color temperature: 3100 ± 20 (K)

Luminance: 900 ± 20 (cd/m

2

)

Adjusting method:

1. Set a distance of 0.5-1.0 cm between the pattern box and

the camera.

2. Double-click on the DscCalDi.exe.

3. Select “CCD Black” on the LCD “Test”, and click the “Ye s ”.

4. After the adjustment is completed, the number of defect

will appear.

5. Click the OK.

Calibration

AWB

Focus

UV Matrix

Cal Mode

Cal Data

USB storage

VID

Get

PID

Set

Backrush pulse :

OK

OK

Upload

Firmware

QrCode

PAF Cal.

EVF

LCD Type

Get

LCD

R Bright

RGB Offset

Tint

VCO

H AFC Test

Serial

Set

Set

Rev.

B Bright

Gain

Phase

Set

Set

Set

VCOMDC

VCOMPP

Hall Cal.

Setting

Language

Video Mode

Factory Code

3-11. Reset Setting

Carry out reset settings after replacing CP1 board.

1. Turn on the camera.

2. Set the NORMAL mode, and press the MENU button.

3. Choose the OPTION MENU 3.

4. Choose the RESET SETTINGS, and press the SET button.

5. Select RESET, and press the SET button.

3-12. The Compulsive boot starting method

1. Keep MENU button, SET button, and SHUTTER button depressed while switching on the power.

2. Connect the camera and the computer with USB cable.

– 23 –

Page 24

3-13. Firmware uploading procedure

1. Uploading the firmware should be carried out if the version

number (COMPL PWB XX-X) on the replacement circuit

board is lower than the version of the distributed firmware.

For XX-X, enter the name of the circuit board containing the

firmware.

2. The firmware is distributed by e-mail in self-extracting archive

format. Change the extension of the distributed file to .EXE

and save it in your preferred folder.

3. When you double-click the saved file, the firmware (binary

file) will be saved in the same folder.

4. The firmware must not be distributed without permission.

1. Overwriting firmware from the SD card

Preparation:

SD card: SD card with firmware rewritten into the root directory

Data: S317Nxxx.BIN (xxx: version)

Overwriting method:

1. Insert the above SD card.

2. Turn on the camera.

3. Set the NORMAL mode.

4. Press the MENU button.

5. Choose the OPTION MENU 3.

6. Choose the FORMAT.

7. Toggle the SET button to the left for 2 seconds. FIRMWARE

UPDATE will display.

8. Choose YES.

9. Press the SET button. Update is starting.

Note:

Do not turn off the camera’s power or remove the SD card

while the firmware is being updated.

The power will turn off after the update is complete.

2. Overwriting firmware from the calibration software

Preparation:

PC with overwriting firmware copied to the preferred folder in

the HD.

Data: S317Nxxx.BIN (xxx: version)

Overwriting method:

1. Connect the camera’s USB/AV terminal to the computer’

USB connector.

2. The USB Connection screen appears on the camera’s LCD

monitor. Choose the “COMPUTER”, and press the SET

button. Next, choose the “CARD READER”, and press the

SET button.

3. Double-click on the DscCalDi.exe.

4. Click the Firmware.

5. Choose the fimware file to use for overwriting, and click

the Yes.

6. Update is starting. The message will appear, and choose

OK.

7. After the update is complete, disconnect the USB cable

and turn the camera’s power off.

Note:

Do not turn off the camera’s power while the firmware is being updated.

– 24 –

Page 25

4. USB STORAGE INFORMATION REGISTRATION

USB storage data is important for when the camera is connected to a computer via a USB connection.

If there are any errors in the USB storage data, or if it has not

been saved, the USB specification conditions will not be satisfied, so always check and save the USB storage data.

Preparation:

POWER switch: ON

Adjustment method:

1. Connect the camera to a computer. (Refer to 3-5. Connecting the camera to the computer on the page 18.)

2. Double-click on the DscCalDi.exe.

3. Click on the Get button in the USB storage window and

check the USB storage data.

VID: SANYO

PID: FH1

Serial:

Rev. : 1.00

4. Check the “Serial” in the above USB storage data. If the

displayed value is different from the serial number printed

on the base of the camera, enter the number on the base

of the camera. Then click the Set button.

5. Next, check VID, PID and Rev. entries in the USB storage

data. If any of them are different from the values in 3. above,

make the changes and then click the corresponding Set

button.

Calibration

AWB

Focus

UV Matrix

Cal Mode

Cal Data

USB storage

VID

Get

PID

Set

Backrush pulse :

OK

OK

Upload

Firmware

QrCode

PAF Cal.

EVF

LCD Type

Get

LCD

R Bright

RGB Offset

Tint

VCO

H AFC Test

Serial

Set

Set

Rev.

B Bright

Gain

Phase

Set

Set

Set

VCOMDC

VCOMPP

Hall Cal.

Setting

Language

Video Mode

Factory Code

– 25 –

Page 26

5. TROUBLESHOOTING GUIDE

POWER LOSS INOPERTIVE

PUSH THE POWER

SW FOR A WHILE

IC301-43

(SCAN OUT1)

PULSE INPUT

NO

IC302-7 5.3 V

(BOOST 5.3 V)

YES

IC301-9, 35, 59

(VDD)

HIGH

IC301-53

(RESET)

HIGH

IC301-49

(BAT OFF)

HIGH

IC301-55

OSCILLATION

YES

YES

NO

LOW

LOW

LOW

NO

CHECK S3003

CHECK IC501

CHECK IC302

CHECK IC302, RB312

CHECK RB312

CHECK X3002

TAKING INOPERATIVE

PUSH SHUTTER

BUTTON

IC301-51, 23

(KEY_1st, KEY_2nd)

LEVEL INPUT

YES

IC501-F6 (PON)

IC503-4 (PAON2)

IC504-1 (PAON1)

HIGH

SERIAL

COMMUNICATION

OK

CHECK CP1 DMA

BLOCK

NO

LOW

CHECK IC301, IC101,

NG

CHECK SW UNIT

PWA BLOCK

CHECK IC301,

CP1 DMA BLOCK

CHECK IC301

NO PICTURE

X1102

CHECK

OSCILLATION

OK

IC301-64, 63

(ASIC_SO, ASIC_SI)

OK

CHECK SOLDERING

OF MEMORY

EACH PIN

NG

MAIN CLOCK FOR SYSTEM OPERATION

NO OPERATION IF ABSENT

INCORRECT HANDSHAKING

NG

BETWEEN 8-BIT CPU AND ASIC

CHECK EACH INTERFACE

– 26 –

Page 27

MEMO

– 27 –

Page 28

6. PARTS LIST (R)

LOCATION PARTS NO. DESCRIPTION

ACCESSORIES & PACKING MATERIALS

1 636 124 1403 STRAP BELT-SG314/U

2 636 125 0108 DISC,CD-ROM XSD G317 U(N.S.P.) ,

3 645 098 9612 BATTERY,RECHARGE,LI-ION

4 645 093 6180 CABLE,DSC A/V-SG211

5 645 099 3350 CABLE,DSC USB

OR 645 099 3367 CABLE,DSC USB

6 645 098 9117 CABLE,DSC COMPONENT-SG313

7 645 076 0235 CORD,POWER-1.5MK,

OR 645 098 8721 CORD,POWER-1.2MK,

7 645 084 0104 CORD,POWER-1.8MK,VPC-FH1BK,VPC-FH1

OR 645 098 8714 CORD,POWER-1.9MK,VPC-FH1BK,VPC-FH1

8 645 099 5835 ADAPTOR,AC-DC(BOX)

9 645 093 6746 REMOCON,INFRARED,WIHT COVER BATTERY

10 636 103 1783 STRAP CAP LENS-SG112/J

11 636 123 0414 ASSYL,CAP LENS-SG314

12 645 099 4029 CABLE,DSC USB HOST-SG313

13 645 094 6691 CORE,CLAMP,FOR HDMI(TV END)

14 645 095 3620 CORE,FERRITE,FOR HDMI(CAMERA END)

9051 636 124 5302 INSTRUCTION MANUAL,

9052 636 124 5319 INSTRUCTION MANUAL,

9053 636 124 5289 INSTRUCTION MANUAL,CAMERA SOFT GB,

9056 636 121 1925 INSTRUCTION MANUAL,Xacti library(English)

636 124 5890 CARTON INNER-SG317/EX,

636 124 5883 CARTON INNER-SG317/U,

636 077 8139 CUSHION SHEET-SX774/KRO

636 122 9326 REINFORCE PAD,A-SG314/J

636 119 2361 LABEL GOLD TEXT-SG218/GX2,

636 126 7595 LABEL GOLD MODEL-SG317/U2,

Xacti software,PDF instruction manual and

quick guide(English,French,German,Spanish,

Italian,Dutch,Portuguese,Russian,Turkish,Korean,

Traditional chinese,Simplified chinese

Note:Turkish is only a quick guide.)

VPC-FH1EXBK,VPC-FH1EX

VPC-FH1EXBK,VPC-FH1EX

SIMPLE MANUAL SHEET 8,QUICK GUIDE 8,

Dutch,English,French,German,Italian,

Russian,Spanish,Portuguese)

SIMPLE MANUAL SHEET 4, QUICK GUIDE 4,

Chinese (Simplified),Chinese (Traditional),

Korean,Turkish

CAMERA (English)

EXCEPT VPC-FH1BK,VPC-FH1

VPC-FH1BK,VPC-FH1

VPC-FH1,VPC-FH1EX,VPC-FH1GX

VPC-FH1,VPC-FH1EX,VPC-FH1GX

28

Page 29

1

2

3

4

7

8

5

9

6

10

11

12

13

14

29

Page 30

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

CABINET & CHASSIS PARTS 1

1 636 125 8289 LABEL CAUTION-SG217/U

2 636 125 6056 ASSY,CABI BOTTOM-SG317,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

2 636 125 6063 ASSY,CABI BOTTOM-SG317/J2,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

3 636 124 8297 ASSY,COVER BATTERY-SG317,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

3 636 124 8341 ASSY,COVER BATTERY-317J2,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

4 636 121 5442 STAND-SG314/J,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

4 636 124 8433 STAND-SG317/J2,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

5 636 121 5350 HOLDER STRAP FRONT-SG314

6 636 126 0633 SPACER BOTTOM-SG314/JO

7 636 127 5293 SPACER STRAP-SG317

8 636 121 5367 HOLDER STRAP BACK-SG314/J

9 636 125 8685 SPACER BLIND-SG314/J,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

9 636 125 8692 SPACER BLIND-SG317/J2,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

10 636 126 2439 SPACER LCD-SG314/J

11 636 127 4890 SHIELD TAPE MIC-SG317

12 636 122 9340 SPACER MIC-SG314/J

13 636 121 5428 HOLDER BOTTOM-SG314/J

14 636 126 0671 SPACER SHILD WIRE-SG314/J

15 636 127 4883 SHIELD TAPE LENS-SG317

16 636 124 7566 COMPL,CABINET FRONT-SG317,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

16 636 124 7665 COMPL,CABINET FRONT-SG317,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

17 636 121 8184 DEC LINE JOINT-SG317/J

18 636 121 8412 DEC JOINT-SG317/J,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

18 636 126 4006 DEC JOINT-SG317/J2,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

19 636 124 7634 COMPL,CABINET TOP-SG317,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

19 636 124 8150 COMPL,CABINET TOP-SG317,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

20 645 099 0168 UNIT,ZOOM-SG314/J

21 636 126 2446 SPACER LCD FRONT-SG314/J

22 636 121 4940 COVER SD-SG314/J

23 636 121 5381 HOLDER BACK-SG314/J

24 636 122 6356 FLEXIBLE PWB CP1&TB4SG314

25 636 127 5255 SHIELD TAPE SW1-SG317

26 636 122 6974 COMPL PWB,TB-4

27 636 121 4766 BUTTON SELECT-SG314/J,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

27 636 124 7986 BUTTON SELECT-SG317/J2,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

28 636 121 5916 HOLDER BUTTON BAS-SG314/J

29 636 121 4735 BUTTON MENU-SG314/J,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

29 636 124 7955 BUTTON MENU-SG317/J2,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

30 636 121 4773 BUTTON REC PLAY-SG314/J,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

30 636 124 7993 BUTTON REC PLAY-SG317/J2,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

31 636 121 4742 BUTTON SHUTTER-SG314/J,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

31 636 124 7962 BUTTON SHUTTER-SG317/J2,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

32 636 121 4759 BUTTON MOVIE-SG314/J,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

32 636 124 7979 BUTTON MOVIE-SG317/J2,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

33 636 124 7931 CABINET BACK-SG317/J,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

33 636 124 7948 CABINET BACK-SG317/J2,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

34 636 121 4964 COVER DC-SG314/J,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

34 636 124 8006 COVER DC-SG317/J2,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

101 411 178 9403 SCR S-TPG PAN PCS 1.7X4.0,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

101 411 193 2106 SCR S-TPG PAN PCS 1.7X4.0,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

102 411 175 5705 SCR PAN PCS 1.7X3,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

102 411 194 8206 SCR PAN PCS 1.7X3,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

103 412 078 7902 SPECIAL SCREW-1.7X3.0

104 411 218 4405 SCR S-TPG PAN PCS 1.7X7

105 411 178 6204 SCR PAN PCS 1.7X4

106 411 175 5705 SCR PAN PCS 1.7X3

107 411 177 9503 SCR S-TPG PAN PCS 1.7X3

108 411 194 8206 SCR PAN PCS 1.7X3

109 411 178 9403 SCR S-TPG PAN PCS 1.7X4.0

113 411 184 0005 SCR PAN PCS 1.7X2.0,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

113 411 194 8404 SCR PAN PCS 1.7X2.0,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

30

Page 31

34

33

D

102

102

19

20

106

106

32

A

30

29

28

31

27

109

F

26

10

24

109

108

23

106

109

E

C

108

22

25

F

106

D

A

113

21

SG317/J PARTS LIST 1

13

105

113

B

105

107

E

14

B

11

9

103

105

12

104

102

102

10

4

107

106

15

18

17

105

C

16

8

7

3

102

102

2

101

101

1

101

6

5

Cabinet 1

31

Page 32

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

CABINET & CHASSIS PARTS 2

25 636 127 5255 SHIELD TAPE SW1-SG317

35 636 121 5268 HOLDER WIRE-SG314/J

36 636 127 3152 SPACER HOLDER JOINT-SG314

37 636 127 4630 SHIELD TAPE HINJI-SG317

38 636 121 5411 HOLDER JOINT-SG314/J

39 636 121 4780 BUTTON POWER-SG314/J

40 636 121 8085 CABINET RIGHT-SG317/J

41 636 121 5336 ASSY,JOINT-SG314/J

42 636 106 6310 ASSY,SHIELD WIRE CP1-VF1

43 636 127 4586 SHIELD TAPE VF1-SG317

44 636 127 2667 ASSY,COVER LCD B SV-SG317,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

44 636 127 2681 ASSY,COVER LCD B SV-SG317,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

45 636 122 6950 COMPL PWB,TB-2

46 636 124 8181 COVER JOINT-SG317/J,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

46 636 124 8198 COVER JOINT-SG317/J2,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

47 645 099 2308 ASSY,LAMP-SG314

48 404 120 5400 ELECT 60U A 300V

49 636 068 0265 COVER TRIGER-SX612/J

50 636 126 0688 SPACER ST1-SG314/J

51 636 121 5251 SPACER CON ST1-SG314/J

52 636 122 6936 COMPL PWB,ST-1

53 636 127 4906 SHIELD TAPE LCD CP1-SG317

54 636 125 0856 COMPL PWB,CP-1 F/W

55 636 127 2421 SPACER DDR-SG317/J

56 636 127 2438 SHIELD TAPE DDR-SG317/J

57 636 121 5329 HEAT SINK RUB ASIC-SG314

58 636 121 5183 CHASSIS BOTTOM-SG314/J

59 636 122 6967 COMPL PWB,TB-3

60 636 121 5176 CHASSIS RIGHT-SG314/J

61 636 127 8478 SPACER LENS RIGHT-SG317/J

62 636 124 8488 EARTH JACK-SG317/J

63 636 124 7474 SPACER HOLDER TB1-SG317/J

64 636 127 4616 SPACER LCD FPC-SG317

65 636 122 6929 COMPL PWB,VF-1

66 636 121 5237 SPACER PWB-SG314/J

67 636 127 4609 SHIELD TAPE LCD-SG317

68 636 121 5404 HOLDER LCD-SG314/J

69 645 098 7229 LCD(990000412)

70 636 121 8177 DEC LINE A-SG317/J

71 636 127 2636 ASSY,COVER LCD F SV-SG317

72 636 121 8238 HOLDER LENS CHASSIS-SG317

73 636 127 4913 SPACER HOLDER LENS-SG317

74 636 124 7535 HEAT SINK LEFT-SG317/J

75 636 124 7559 HEAT SINK TAPE TOP-SG317

76 636 127 4586 SHIELD TAPE VF1-SG317

77 636 124 8679 ASSY,FPC CA1 SV-SG317

78 636 105 2207 HOLDER LENS-SG211/J

79 636 127 5156 SPACER LENS FPC-SG317/J

80 636 121 5374 HOLDER TB1-SG314/J

81 636 121 8245 HOLDER CA-SG317/J

82 636 121 5282 SPACER CA-SG314/J

83 636 122 6981 COMPL PWB,TB-5

84 636 124 7283 FLEXIBLE PWB TB1&TB5SG317

85 636 127 5279 SHIELD TAPE TB1-SG317

86 636 127 5286 SPACER TB1-SG317

87 636 122 6943 COMPL PWB,TB-1

88 636 127 4647 SHIELD TAPE PW-SG317

89 636 122 6349 FLEXIBLE PWB CP1&TB3SG314

102 411 175 5705 SCR PAN PCS 1.7X3,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

102 411 194 8206 SCR PAN PCS 1.7X3,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

104 411 218 4405 SCR S-TPG PAN PCS 1.7X7

105 411 178 6204 SCR PAN PCS 1.7X4

106 411 175 5705 SCR PAN PCS 1.7X3

107 411 177 9503 SCR S-TPG PAN PCS 1.7X3

109 411 178 9403 SCR S-TPG PAN PCS 1.7X4.0

110 411 199 0601 SCR TIN 1.7X2,

VPC-FH1BK,VPC-FH1EXBK,VPC-FH1GXBK

110 411 199 0700 SCR TIN 1.7X2,

VPC-FH1,VPC-FH1EX,VPC-FH1GX

111 411 184 0005 SCR PAN PCS 1.7X2.0

112 411 181 2705 SCR PAN PCS-1.4X2

114 411 176 1003 SCR PAN PCS 1.7X2.5

32

Page 33

106

87

106

84

114

106

114

86

81

85

82

73

114

114

B

C

83

78

80

25

A

79

78

78

107

57

56

114

55

74

59

58

75

D

76

63

106

73

D

73

77

78

72

105

73

71

70

69

107

68

67

109

60

A

B

61

106

106

62

109

112

106

107

89

61

114

104

88

104

110

46

41

66

42

64

65

44

43

C

54

106

106

SG317/J PARTS LIST 1

53

106

48

111

55

56

106

52

49

47

50

51

106

39

35

40

36

37

33

106

36

106

38

45

111

102

102

Cabinet 2

Page 34

ELECTRICAL PARTS

Note:

1. Materials of Capacitors and Resistors are abbreviated as follows ;

Resistors Capacitors

MT-FILM Metallized Film Resistor MT-POLYEST Metallized Polyester Capacitor

MT-GLAZE Metallized Glaze Resistor MT-COMPO Metallized Composite Capacitor

OXIDE-MT Oxide Metallized Film Resistor TA-SOLID Tantalum Solid Capacitor

2. Tolerance of Capacitor (10pF over) and Resistor are noted with follow symboles.

F ............1% G ............2% J ............5% K ............10%

M ..........20% N ..........30% Z ..........+80% ~ -20%

3. Capacitors

U : µF P : pF

4. Inductors

UH : µH MH : mH

5. N.S.P. : Not available as service parts.

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

COMPL PWB,CP-1 F/W

636 125 0856

(VARISTORS)

VA101 308 050 0507 VARISTOR AVR-M1005C080MT

VA102 308 050 0507 VARISTOR AVR-M1005C080MT

VA131 308 050 1207 VARISTOR AVR-M1608C120MT

(SEMICONDUCTORS)

Q1001 305 181 4909 TR 2SK3541

Q1301 305 168 3703 TR DTC144EM

OR 305 216 1200 TR RN1104MFV

OR 305 172 4703 TR UNR32A3

Q1501 305 164 2809 TR EMX1

Q1502 305 172 8800 TR 2SC5658-R

OR 305 172 8909 TR 2SC5658-S

OR 305 186 7707 TR 2SC5609 00

Q1503 305 164 2809 TR EMX1

Q1504 305 172 8800 TR 2SC5658-R

OR 305 172 8909 TR 2SC5658-S

OR 305 186 7707 TR 2SC5609 00

Q1505 305 172 8800 TR 2SC5658-R

OR 305 172 8909 TR 2SC5658-S

OR 305 186 7707 TR 2SC5609 00

Q1506 305 172 8800 TR 2SC5658-R

OR 305 172 8909 TR 2SC5658-S

OR 305 186 7707 TR 2SC5609 00

Q1507 305 157 1406 TR 2SA2018

Q1508 305 157 1406 TR 2SA2018

Q1509 305 157 1406 TR 2SA2018

Q1902 405 218 3902 TR UP0431300

OR 305 167 0406 TR EMD12

OR 305 216 2108 TR RN4984FE

Q3001 305 210 5709 TR UP0KG8D

OR 305 217 3906 TR HN2E07JE

OR 305 200 9007 TR EML17

Q3003 405 218 3902 TR UP0431300

OR 305 167 0406 TR EMD12

OR 305 216 2108 TR RN4984FE

Q3005 305 186 7301 TR UP04213 00

OR 305 181 1205 TR NSBC144EDXV6T5

OR 305 173 4009 TR PEMH2

OR 305 166 9509 TR EMH2

Q5003 405 218 4701 TR SSM3J120TU

Q5004 305 181 4909 TR 2SK3541

Q5007 405 219 2706 TR MCH5835-E

Q5008 305 200 6006 TR UP03397

Q5009 305 184 6009 TR UP03396

Q5010 405 218 2707 TR UPA650TT-A

Q5011 405 218 2707 TR UPA650TT-A

Q5012 305 208 9702 TR SSM3J16TE

Q5013 305 181 4909 TR 2SK3541

AL-SOLID Aluminum Solid Capacitor

NP-ELECT Non-Polarized Electrolytic Capacitor

OS-SOLID Aluminum Solid Capacitors with Organic

Semiconductive Electrolytic Capacitor

DL-ELECT Double Layered Electrolytic Capacitor

POS-SOLID Polymerized Organic Semiconductor Capacitor

Q5014 305 169 4501 TR DTC114EM

OR 305 216 1101 TR RN1102MFV

OR 305 172 4604 TR UNR32A1

Q5015 305 168 3703 TR DTC144EM

OR 305 216 1200 TR RN1104MFV

OR 305 172 4703 TR UNR32A3

Q5016 305 181 4909 TR 2SK3541

Q5017 305 168 3703 TR DTC144EM

OR 305 216 1200 TR RN1104MFV

OR 305 172 4703 TR UNR32A3

Q5019 405 218 2707 TR UPA650TT-A

Q5020 305 181 4909 TR 2SK3541

Q5021 405 220 8308 TR MCH6428-E

Q5201 405 218 2707 TR UPA650TT-A

Q5202 305 206 7700 TR SI3473DV-E3

Q5203 405 218 2707 TR UPA650TT-A

Q5204 305 181 4909 TR 2SK3541

(INTEGRATED CIRCUITS)

IC101 409 696 4802 IC EV3HB,BGA (N.S.P)

IC102 410 671 3802 IC K4X51323PG-8GC8,BGA (N.S.P)

IC103 410 671 3802 IC K4X51323PG-8GC8,BGA (N.S.P)

IC104 309 635 9205 IC TC7MH273FK(EL,K)

IC111 409 694 3005 IC AK8128

IC121 409 695 1604 IC S29PL064J60BFI120#,BGA (N.S.P)

IC131 410 640 8005 IC S1R72V17B00A200,BGA (N.S.P)

IC132 309 488 5805 IC TC7WH32FK

IC181 309 650 3509 IC TK70630HC-G

IC182 409 697 3101 IC AK4649ECB-L,BGA (N.S.P)

IC191 410 671 2508 IC TDA9989BET/C1,518,BGA (N.S.P)

IC301 410 620 7202 IC LC87F2832AUFL64TBM-E,BGA (N.S.P)

IC302 309 611 7607 IC NJU7286ARB1

IC305 409 695 0102 IC MAX17022ETA+

IC501 410 667 4905 IC UPD168805FC-AN2-A,BGA (N.S.P)

IC502 409 686 6205 IC SC4624MLT,LLC (N.S.P)

IC503 409 695 6401 IC XC9235C18CE

IC504 409 695 6906 IC NJM2877F3-27

IC521 409 695 5800 IC MAX8601ETD+

IC951 410 676 4507 IC LC898200A-TBM-H,BGA (N.S.P)

IC952 409 685 5308 IC XC6221S04XG

(DIODES)

D1501 307 205 2809 DIODE RB520S-30

OR 307 221 0100 DIODE MA2SD24

D1901 407 261 8903 DIODE RB520S-30FJ

D5001 307 223 5509 DIODE MA2Z720

D5002 307 250 1802 DIODE RB496EA

D5003 307 248 0701 DIODE MA21D3800

D5007 307 250 0706 DIODE DRB060M-30

D5013 407 261 8903 DIODE RB520S-30FJ

D5014 407 261 8903 DIODE RB520S-30FJ

D5201 307 248 2408 ZENER DIODE EDZ7.5B

D5202 307 248 2408 ZENER DIODE EDZ7.5B

D5203 307 248 2408 ZENER DIODE EDZ7.5B

34

Page 35

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

D5204 307 248 0701 DIODE MA21D3800

D5301 307 248 0701 DIODE MA21D3800

(OSCILLATORS)

X1102 645 094 0170 OSC,CRYSTAL 48.00000MHZ

X1901 645 069 0075 OSC,CERAMIC 12.00MHZ

X3002 645 090 3298 OSC,CRYSTAL 32.768KHZ

(INDUCTORS)

L1001 645 094 0521 IMPEDANCE,33 OHM P

L1002 645 094 0521 IMPEDANCE,33 OHM P

L1003 945 061 7417 INDUCTOR,47U M

L1004 645 094 0521 IMPEDANCE,33 OHM P

L1005 945 053 5476 IMPEDANCE,240 OHM P

L1006 645 053 2276 IMPEDANCE,5 OHM P

L1301 645 095 6522 FILTER,EMI 90 OHM

L1302 945 066 4688 IMPEDANCE,30 OHM P

L1901 645 090 9719 IMPEDANCE,90 OHM M

L1902 645 090 9719 IMPEDANCE,90 OHM M

L5001 945 066 4688 IMPEDANCE,30 OHM P

L5002 645 068 7136 INDUCTOR,4.7U N

L5003 645 068 7136 INDUCTOR,4.7U N

L5004 645 098 4822 INDUCTOR,2.0U M

OR 645 086 2007 INDUCTOR,2.0U M

L5006 645 095 6508 INDUCTOR,4.7U N

L5007 645 095 6515 INDUCTOR,6.8U N

L5301 645 098 2118 INDUCTOR,4.7U M

OR 645 091 0043 INDUCTOR,4.7U M

(CAPACITORS)

CB301 403 467 3704 CERAMIC 1U K 6.3V

CB302 403 467 3704 CERAMIC 1U K 6.3V

CB303 303 391 4306 CERAMIC 0.1U K 16V

C1002 303 384 6508 CERAMIC 10U K 6.3V

C1004 303 276 1307 CERAMIC 1000P K 50V

C1005 303 384 6409 CERAMIC 4.7U K 6.3V

C1007 303 338 0309 CERAMIC 0.1U K 10V

C1008 303 338 0309 CERAMIC 0.1U K 10V

C1010 303 338 0309 CERAMIC 0.1U K 10V

C1011 303 338 0309 CERAMIC 0.1U K 10V

C1012 303 381 8109 CERAMIC 1U K 6.3V

C1013 303 381 8109 CERAMIC 1U K 6.3V

C1014 303 338 0309 CERAMIC 0.1U K 10V

C1016 303 338 0309 CERAMIC 0.1U K 10V

C1017 303 381 8109 CERAMIC 1U K 6.3V

C1019 303 381 8109 CERAMIC 1U K 6.3V

C1021 303 393 2607 CERAMIC 22U M 6.3V

C1022 303 338 0309 CERAMIC 0.1U K 10V

C1023 303 338 0309 CERAMIC 0.1U K 10V

C1024 303 384 6508 CERAMIC 10U K 6.3V

C1025 303 338 0309 CERAMIC 0.1U K 10V

C1026 303 338 0309 CERAMIC 0.1U K 10V

C1028 303 338 0309 CERAMIC 0.1U K 10V

C1030 303 338 0309 CERAMIC 0.1U K 10V

C1031 303 393 2607 CERAMIC 22U M 6.3V

C1032 303 381 8109 CERAMIC 1U K 6.3V

C1033 303 419 8903 CERAMIC 10U M 6.3V

C1034 303 419 8903 CERAMIC 10U M 6.3V

C1035 303 338 0309 CERAMIC 0.1U K 10V

C1036 303 276 1000 CERAMIC 0.01U K 16V

C1038 303 338 0309 CERAMIC 0.1U K 10V

C1040 303 338 0309 CERAMIC 0.1U K 10V

C1043 303 384 6409 CERAMIC 4.7U K 6.3V

C1044 303 419 8903 CERAMIC 10U M 6.3V

C1051 303 338 0309 CERAMIC 0.1U K 10V

C1052 303 338 0309 CERAMIC 0.1U K 10V

C1053 303 338 0309 CERAMIC 0.1U K 10V

C1057 303 338 0309 CERAMIC 0.1U K 10V

C1058 303 338 0309 CERAMIC 0.1U K 10V

C1063 303 338 0309 CERAMIC 0.1U K 10V

C1064 303 338 0309 CERAMIC 0.1U K 10V

C1065 303 338 0309 CERAMIC 0.1U K 10V

C1066 303 338 0309 CERAMIC 0.1U K 10V

C1067 303 338 0309 CERAMIC 0.1U K 10V

C1101 303 419 8903 CERAMIC 10U M 6.3V

C1121 303 311 7806 CERAMIC 8P D 50V

C1122 303 311 7806 CERAMIC 8P D 50V

C1201 303 338 0309 CERAMIC 0.1U K 10V

C1202 303 338 0309 CERAMIC 0.1U K 10V

C1301 303 381 8109 CERAMIC 1U K 6.3V

C1302 303 381 8109 CERAMIC 1U K 6.3V

C1303 303 381 8109 CERAMIC 1U K 6.3V

C1304 303 409 3406 CERAMIC 0.1U K 16V

C1305 303 338 0309 CERAMIC 0.1U K 10V

C1306 303 409 3406 CERAMIC 0.1U K 16V

C1307 303 276 1000 CERAMIC 0.01U K 16V

C1308 303 381 8109 CERAMIC 1U K 6.3V

C1309 303 381 8109 CERAMIC 1U K 6.3V

C1310 303 338 0309 CERAMIC 0.1U K 10V

C1311 303 433 1102 CERAMIC 1U K 10V

C1501 303 338 0309 CERAMIC 0.1U K 10V

C1801 303 338 0309 CERAMIC 0.1U K 10V

C1802 303 384 6409 CERAMIC 4.7U K 6.3V

C1804 303 338 0309 CERAMIC 0.1U K 10V

C1805 303 338 0309 CERAMIC 0.1U K 10V

C1806 303 381 8109 CERAMIC 1U K 6.3V

C1807 303 381 8109 CERAMIC 1U K 6.3V

C1808 303 381 8109 CERAMIC 1U K 6.3V

C1809 303 381 8109 CERAMIC 1U K 6.3V

C1810 303 439 8402 CERAMIC 2.2U K 6.3V

C1811 303 279 5005 CERAMIC 4700P K 25V

C1812 303 384 6409 CERAMIC 4.7U K 6.3V

C1818 303 338 0309 CERAMIC 0.1U K 10V

C1901 303 376 9401 CERAMIC 1U K 6.3V

C1902 303 376 9401 CERAMIC 1U K 6.3V

C1903 303 338 0309 CERAMIC 0.1U K 10V

C1904 303 276 2106 CERAMIC 3P C 50V

C1905 303 276 2106 CERAMIC 3P C 50V

C1906 303 338 0309 CERAMIC 0.1U K 10V